Patents

Literature

339 results about "Aromatic solvent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aromatic Solvent. Definition - What does Aromatic Solvent mean? An aromatic solvent is a solvent that contains an aromatic hydrocarbon such as naptha, toluene or xylene. Aromatic solvents are primarily used as solvents and diluents in various industrial fields.

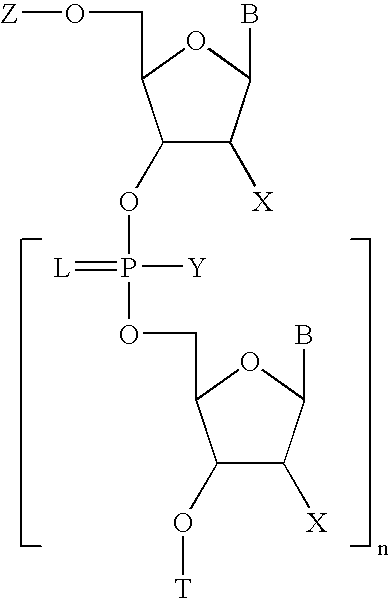

Methods for synthesis of oligonucleotides

Improved methods for synthesis of oligonucleotides and other phosphorus-linked oligomers are disclosed. The methods include the use of aromatic solvents, alkyl aromatic solvents, halogenated aromatic solvents, halogenated alkyl aromatic solvents, or aromatic ether solvents to achieve deprotection of protected hydroxyl groups.

Owner:IONIS PHARMA INC

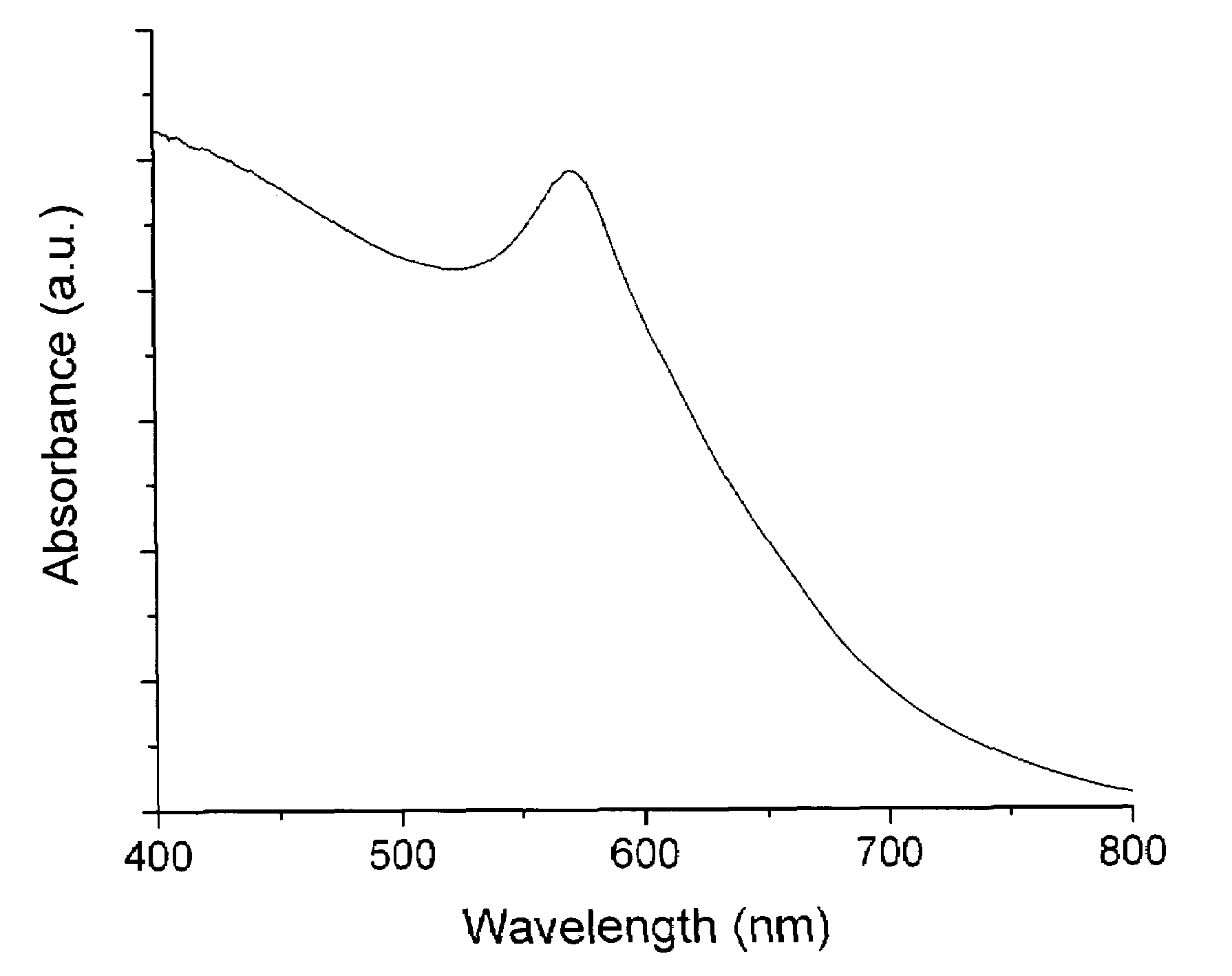

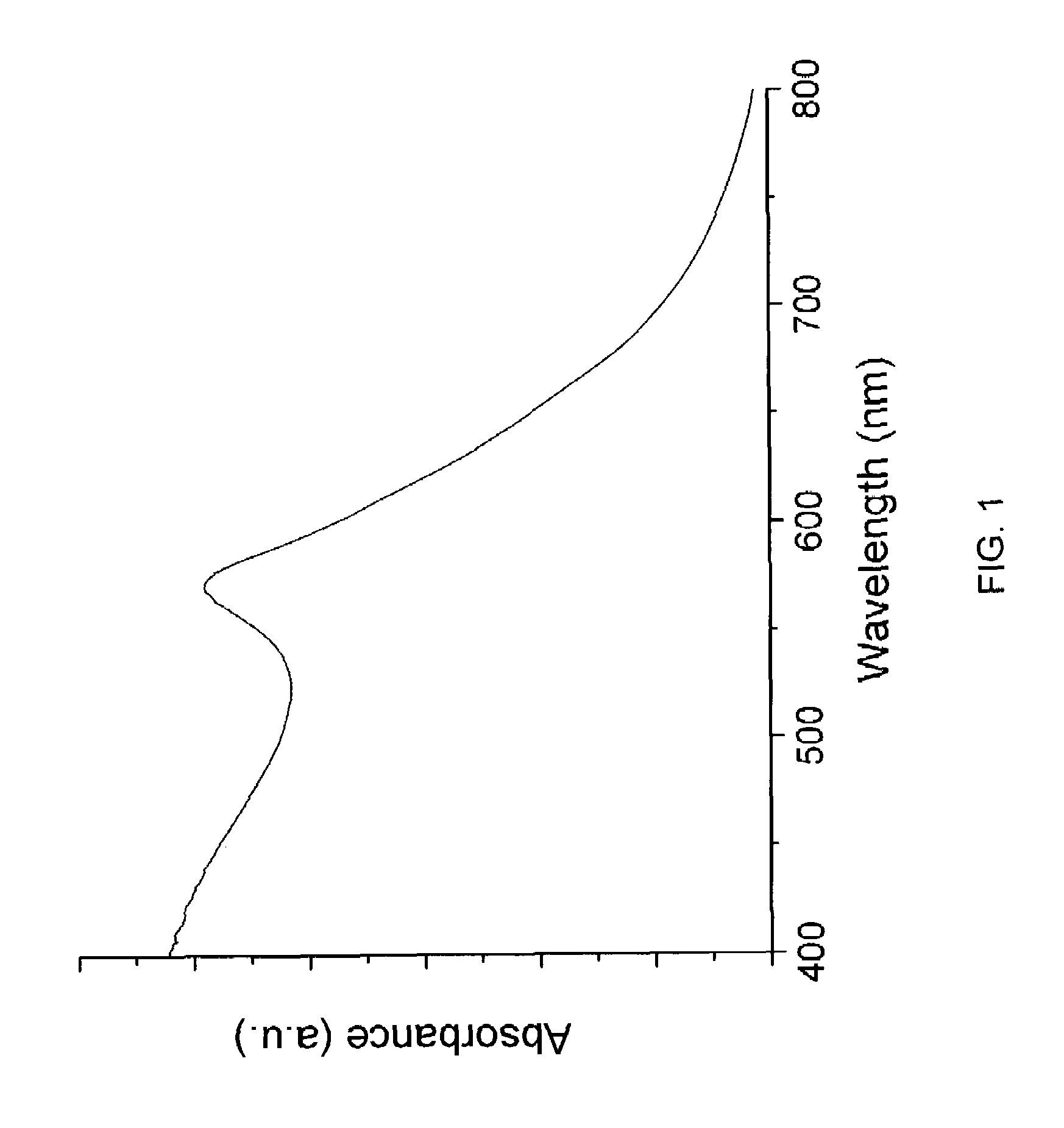

Synthesis metal nanoparticle

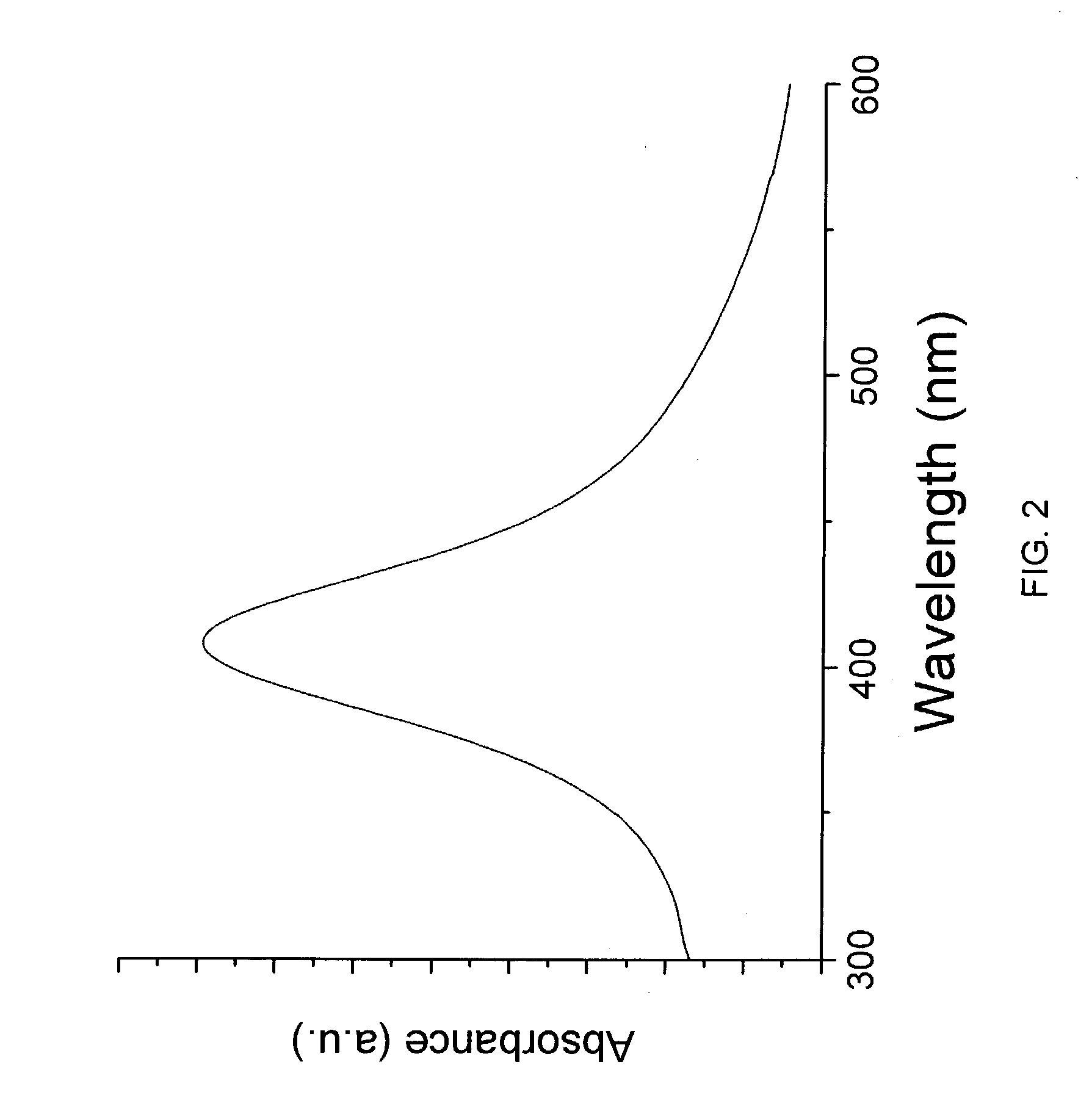

A method for providing an anhydrous route for the synthesis of amine capped coinage-metal (copper, silver, and gold) nanoparticles (NPs) using the coinage-metal mesityl (mesityl=C6H2(CH3)3-2,4,6) derivatives. In this method, a solution of (Cu(C6H2(CH3)3)5, (Ag(C6H2(CH3)3)4, or (Au(C6H2(CH3)3)5 is dissolved in a coordinating solvent, such as a primary, secondary, or tertiary amine; primary, secondary, or tertiary phosphine, or alkyl thiol, to produce a mesityl precursor solution. This solution is subsequently injected into an organic solvent that is heated to a temperature greater than approximately 100° C. After washing with an organic solvent, such as an alcohol (including methanol, ethanol, propanol, and higher molecular-weight alcohols), oxide free coinage NP are prepared that could be extracted with a solvent, such as an aromatic solvent (including, for example, toluene, benzene, and pyridine) or an alkane (including, for example, pentane, hexane, and heptane). Characterization by UV-Vis spectroscopy and transmission electron microscopy showed that the NPs were approximately 9.2±2.3 nm in size for Cu°, (no surface oxide present), approximately 8.5±1.1 nm Ag° spheres, and approximately 8–80 nm for Au°.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

Methods and compositions for on-line gas turbine cleaning

InactiveUS7185663B2Easy to cleanRestore powerInorganic/elemental detergent compounding agentsDetergent mixture composition preparationCombustion chamberAromatic solvent

Methods and compositions for on-line cleaning of internal surfaces of selected sections of a hydrocarbon fuel burning gas turbine and associated heat recovery equipment, during operation. Cleaning solutions containing graphite and / or molybdenum-based particles and oil soluble corrosion inhibitors, aromatic solvents, and surfactants are selectively introduced directly into the combustion chamber (combustor) of the gas turbine, into the fuel stream, water washing system, or the combustion air system (hot gas path). The cleaning process dislodges unwanted ash deposit buildup and, thereby restores the gas turbine to rated power. When introduced into the compressor section, the particles impinge on the metal surfaces, cleaning them prior to entering the hot gas section where the process may be repeated. They may also be carried through the exhaust to additionally clean attendant heat recovery equipment, if present.

Owner:LIQUID MINERALS GRP LTD

Alkaline earth metal containing precursor solutions

InactiveUS20090226612A1Anti-corrosive paintsLiquid/solution decomposition chemical coatingAlkaline earth metalBoiling point

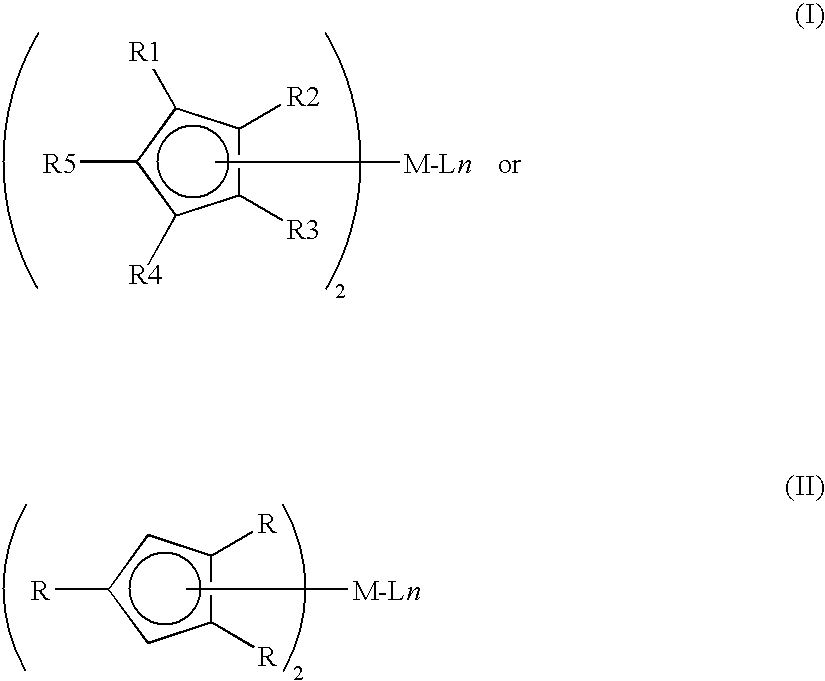

Methods and compositions for depositing a film on one or more substrates include providing a reactor with at least one substrate disposed in the reactor. A liquid precursor solution is provided, where the liquid precursor solution comprises a solid precursor and an aromatic solvent. The solid precursor has the general formula:M(RmCp)2Ln;wherein M is an alkaline earth metal, and each R is independently either H or a C1-C4 linear, branched, or cyclic alkyl group. L is a Lewis base; m is 2, 3, 4, or 5; and n is 0, 1, or 2. The aromatic solvent comprises at least one aromatic ring, and has a greater boiling point than the melting point of the solid precursor. The liquid precursor solution is vaporized to form a precursor solution vapor, and the vapor is introduced into the reactor. At least part of the vapor is deposited onto the substrate to form an alkaline earth metal containing film.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

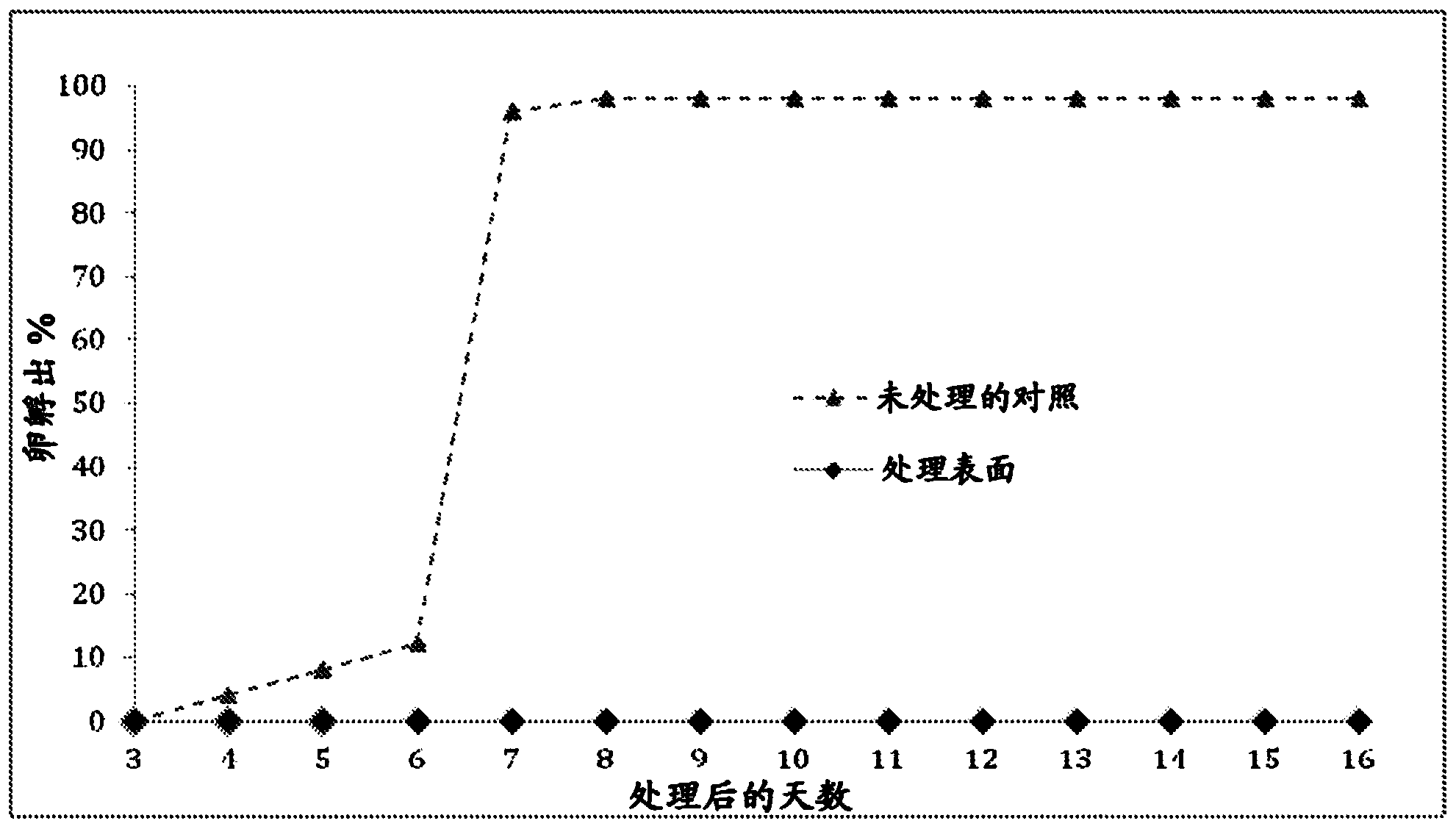

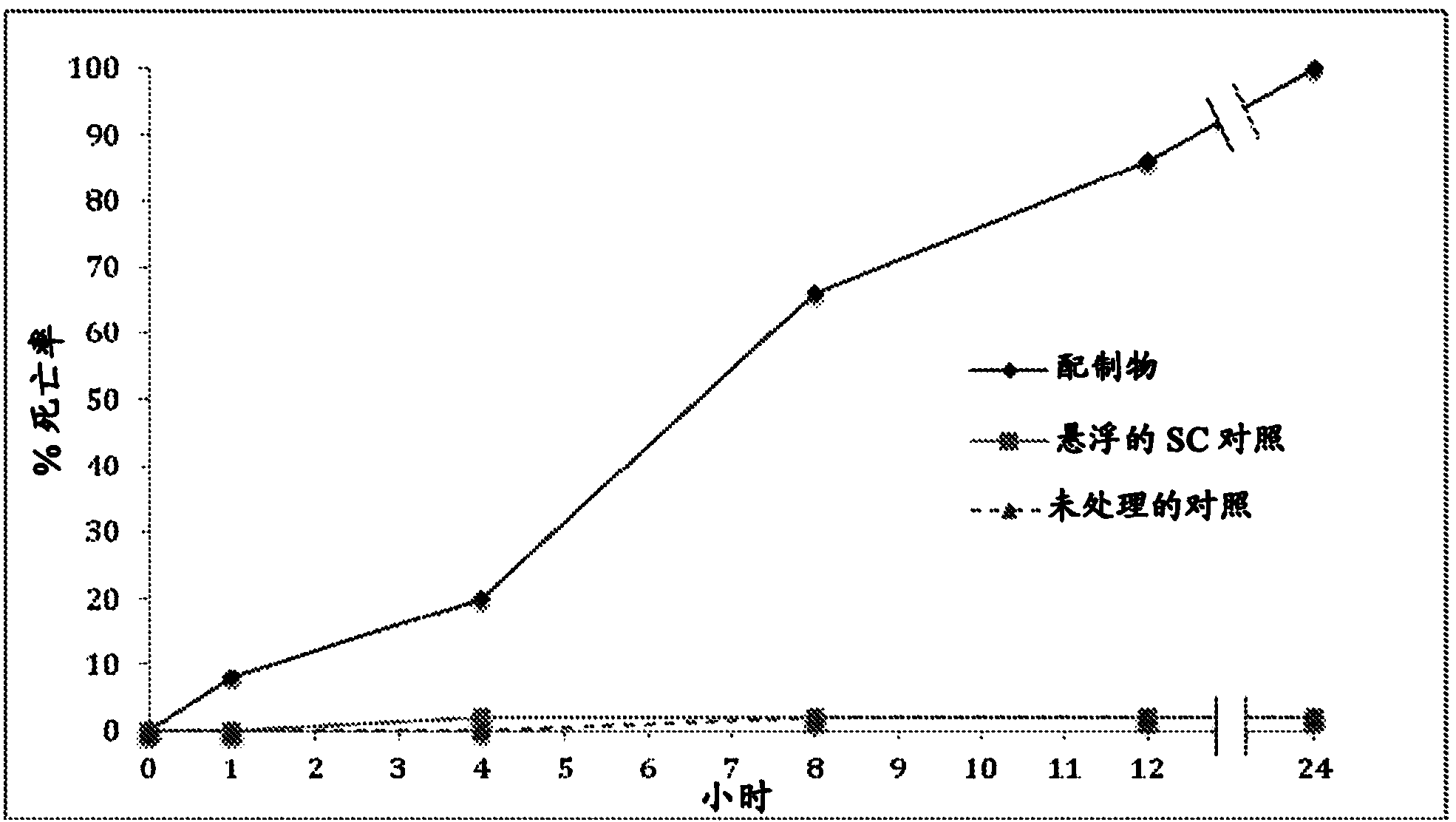

Pest control formulations and methods of making and using same

Compositions useful for controlling pests are disclosed. In some embodiments, the composition includes a pesticidal natural oil and a polar aromatic solvent. Methods of making and using the compositions are disclosed.

Owner:0903608 B C

Process for the preparation of liniear low molecular weight olefins by the oligomerization of ethylene

InactiveUS20020147375A1Reduce inactivation rateHigh yieldHydrocarbons from unsaturated hydrocarbon additionCatalystsAromatic solventAlpha-olefin

A process for the preparation of low molecular weight linear alpha olefins is disclosed. The process comprises oligomerising ethylene in an inert aliphatic or aromatic solvent in the presence of a catalyst comprising of a first component selected from zirconium alkoxide and zirconium aryloxide and a second component selected from alkyl aluminum halide and / or alkyl aluminum.

Owner:INDIAN PETROCHEMICALS CORPORATION LIMITED

Alcohol zircon flour coating for heavy castings and its production method

The invention relates to a paint used in large casting element and relative production, wherein said paint is alcohol-base zircon powder casting paint, which contains zircon at 62-75%, lithium-base at alta-mud 1-3%, deionized water at 1-3%, modified almasilate at 1-3%, nanometer clay at 0.15-0.8%, alumind at 0.020-0.08%, soluble polyester resin at 0.2-1.2%, polyvinyl butyral (PVB) at 0.1-0.8%, abietyl at 0.6-3%, industrial alcohol at 15-25%, alcohol isopropylicum at 1-5%, and aromatic solvent oil at 150#1-5%. The inventive product has high fire resistance, etc.

Owner:德阳立达化工有限公司

Hair styling compositions containing a combination of a propylphenylsilsesquioxane resin and a phenylsilsesquioxane resin

A process of styling hair involving applying onto the hair a composition containing: (a) at least one propylphenylsilsesquioxane resin comprising from about 30 to about 50 mole % of propyl siloxy units, based on the total mole % of siloxy units of the resin, and from about 50 to about 70 mole % of phenyl siloxy units, based on the total mole % of siloxy units of the resin; (b) at least one phenylsilsesquioxane resin; (c) at least one volatile solvent; and (d) optionally, at least one cosmetically-acceptable aromatic solvent.

Owner:LOREAL SA

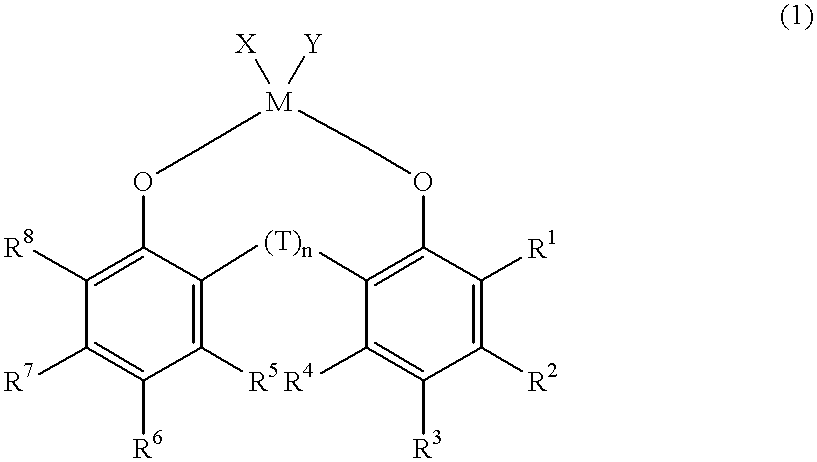

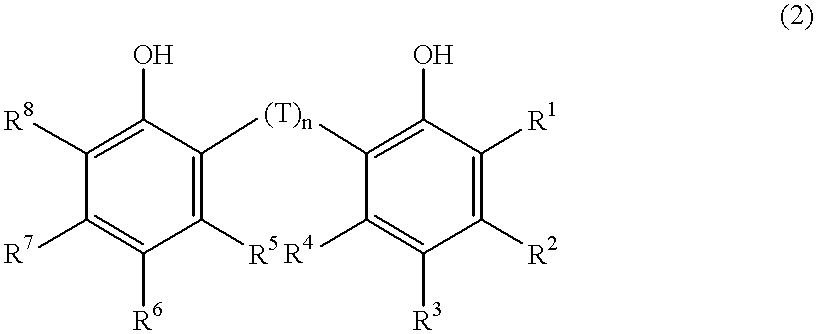

Olefin polymer, olefin polymerization catalyst and process for producing olefin polymer

InactiveUS6288192B1High molecular weightIncrease stickinessOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolymer scienceAromatic solvent

An olefin polymer selected from the group consisting of a 1-butene homopolymer, a copolymers of 1-butene with propylene and a copolymer of 1-butene with an alkenyl hydrocarbon having 5 or more carbon atoms, wherein said olefin polymer is an amorphous polymer having a polystyrene-reduced number average molecular weight of 200,000 and substantially not having a melting point, an olefin polymerization catalyst obtained by contacting a specific transition metal compound(A), an organoaluminumoxy compound (B) soluble in an aromatic solvent and water (C), and a process for producing said olefin polymer with said catalyst.

Owner:SUMITOMO CHEM CO LTD

Functional resin for paint and manufacture method thereof

ActiveCN101245132ALow viscosityLow viscosity high solid contentPolyester coatingsAromatic solventPolymer science

The invention discloses a functional coating resin which consists of 12-16 portions of bifunctional alcohol, 2-8 portions of multifunctional alcohol, 18-25 portions of bifunctional acid, 8-15 portions of bifunctional anhydride, 0.5-4.5 portions of multifunctional anhydride, 0.03-0.1 portion of catalyst, 24-30 portions of high boiling aromatic solvent and 3-6 portions of mixed ester. The preparation method of the functional coating resin is carried out by the steps according to the proportion: 12-16 portions of bifunctional alcohol, 2-8 portions of multifunctional alcohol, 18-25 portions of bifunctional acid, 8-15 portions of bifunctional anhydride, 0.5-4.5 portions of multifunctional anhydride, 0.3-0.1 portion of catalyst, the melting esterifiction, dehydration, high temperature polymerization are carried out by a gradual temperature-gradient method for 4 hours under 150-160 DEG C, 3 hours under 160-180 DEG C, 2 hours under 180-200 DEG C and 2 hours under 200-220 DEG C, reacting another 2-4 hours under 200-225 DEG C,24-30 portions of high boiling aromatic solvent is added and 3-6 portions of ester is mixed for dilution when the control requirements are achieved, thus obtaining the finished product. The functional coating resin is characterized by good workability, marresistance, thermal resistance and aging resistance, the product coating produced by matching the functional resin with pigments e.g. rutile titanium dioxide powder and phthalocyanine, amino resin and aids has excellent weatherability and mechanism character.

Owner:ZHEJIANG TIANNU GROUP PAINT MFG

Universal Synthetic Golf Club Cleaner and Protectant, Method and Product-by-Process to Clean, Protect Golf Club Faces and Rejuvenate Golf Clubs Grips

ActiveUS20110009301A1Reduce sidespinEasy to wipe cleanOrganic detergent compounding agentsAdditivesExperimental testingForeign matter

The club cleaner, conditioner and protectant comprises alpha-olefins, low-odor aromatic solvents; and at least one base oil selected from the base oil group consisting of Hydrolsomerized high base oils and HT Sever Hydro-cracked Base oils; as well as other (optional) ingredients. Also disclosed is a method for producing this product and related product-by-process. This product uses a formulated cleaning mixture to clean and restore the face of the club while rejuvenating the grips. The invention when sprayed on the clubface removes foreign materials and when wiped dry protects the face of the clubs from harsh stains, caused by soils, grass and chemicals related to fertilizers. In experimental testing, the invention increases drive distances by reducing sidespin and increasing backspin. The club is left with a factory-like finish making it easy to wipe clean of soiling. The invention when applied to the grips restores the surface to the new feel.

Owner:BESTLINE INT RESEACRH

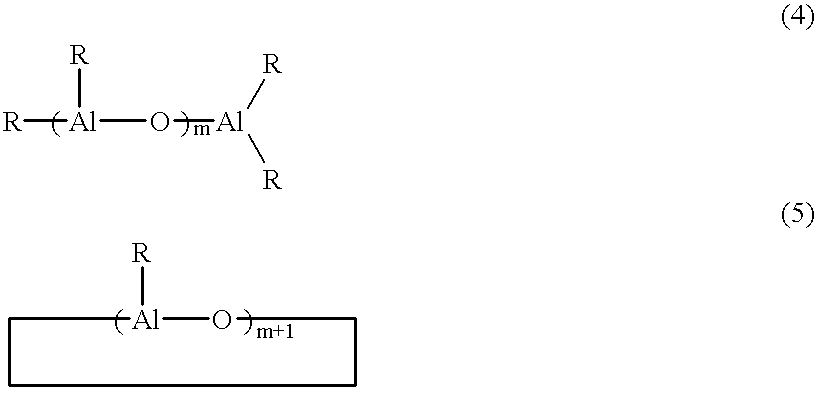

Ethylene oligomerization

InactiveUS20120101321A1Organic-compounds/hydrides/coordination-complexes catalystsHydrocarbons from unsaturated hydrocarbon additionAluminoxaneAromatic solvent

The oligomerization of ethylene using a chromium catalyst having a bridged diphosphine ligand can produce a selective product distribution (to predominantly hexene or predominantly octene / hexene) when activated with an aluminoxane. The oligomerization reaction also produces polymer by product—particularly when the aluminoxane is provided in a non-aromatic solvent. The present invention mitigates this problem.

Owner:NOVA CHEM (INT) SA

Lubricant composition and antioxidant composition

ActiveUS20110077181A1Sufficient long drain intervalIncrease the number ofTin organic compoundsLiquid carbonaceous fuelsAromatic solventMolybdenum compounds

The lubricating oil composition of the present invention comprises at least one species of aromatic constituent selected from the following (a1) to (a5):(a1) a lubricating base oil comprising a polycyclic aromatic content of 0.01% by mass or more based on the total amount of base oil(a2) a lubricating base oil comprising a total aromatic content of 20 to 100% by mass based on the total amount of base oil(a3) an aromatic solvent(a4) at least one species of polycyclic aromatic compound selected from alkyl naphthalene and compounds having three or more aromatic rings, and(a5) an aromatic compound having a nitrogen atom, an oxygen atom or a sulfur atom;and an organic molybdenum compound.

Owner:NIPPON OIL CORP

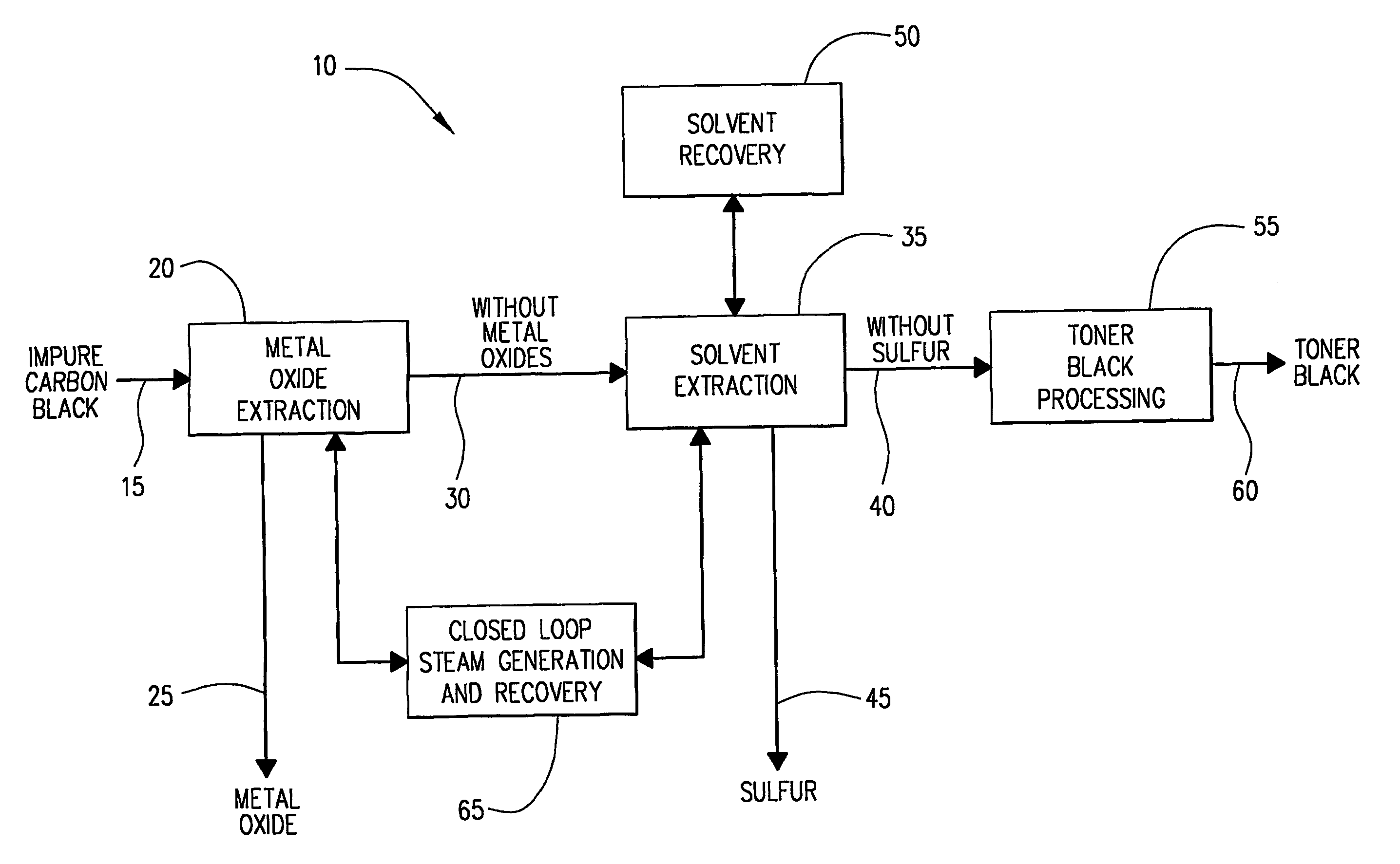

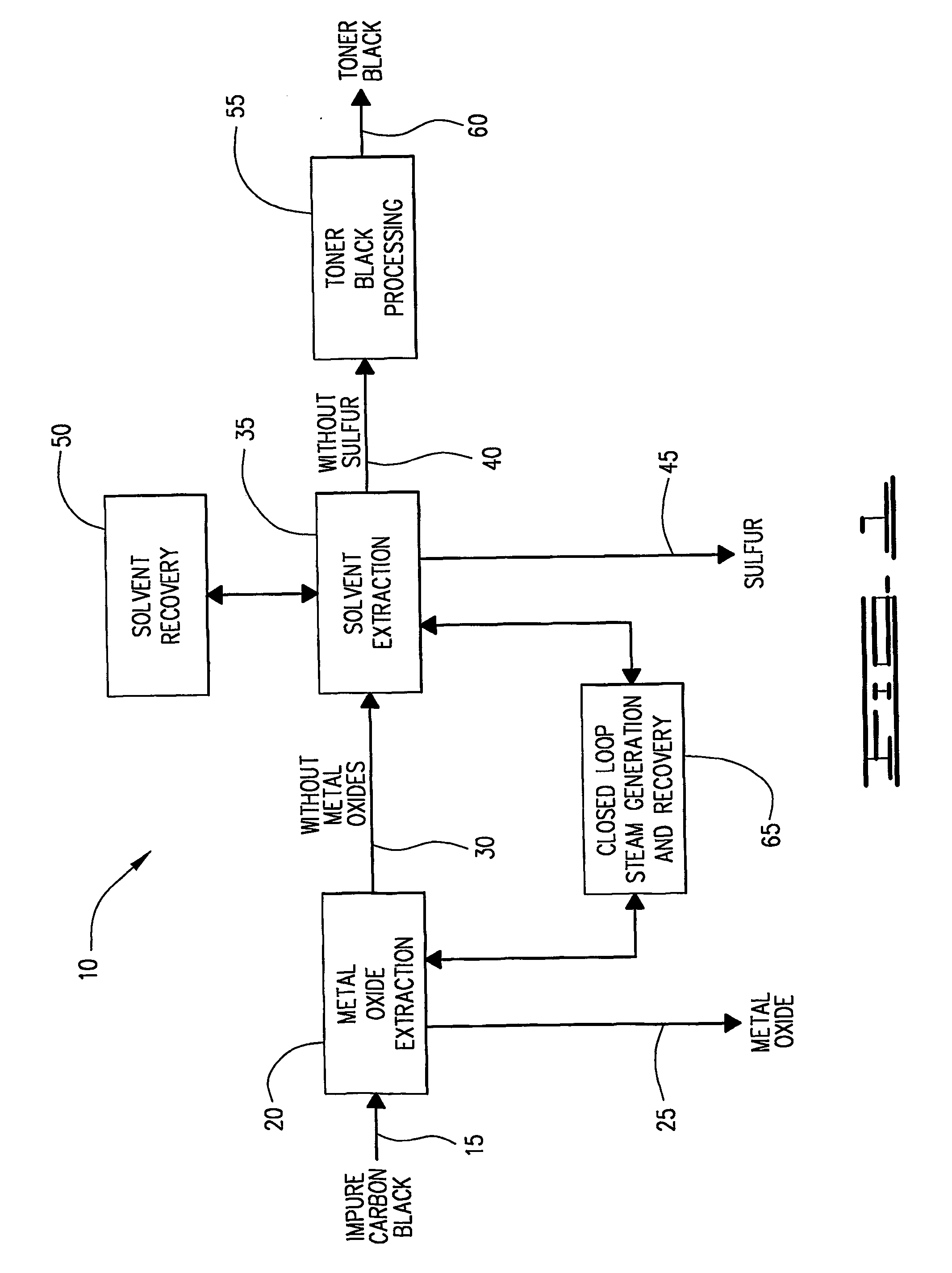

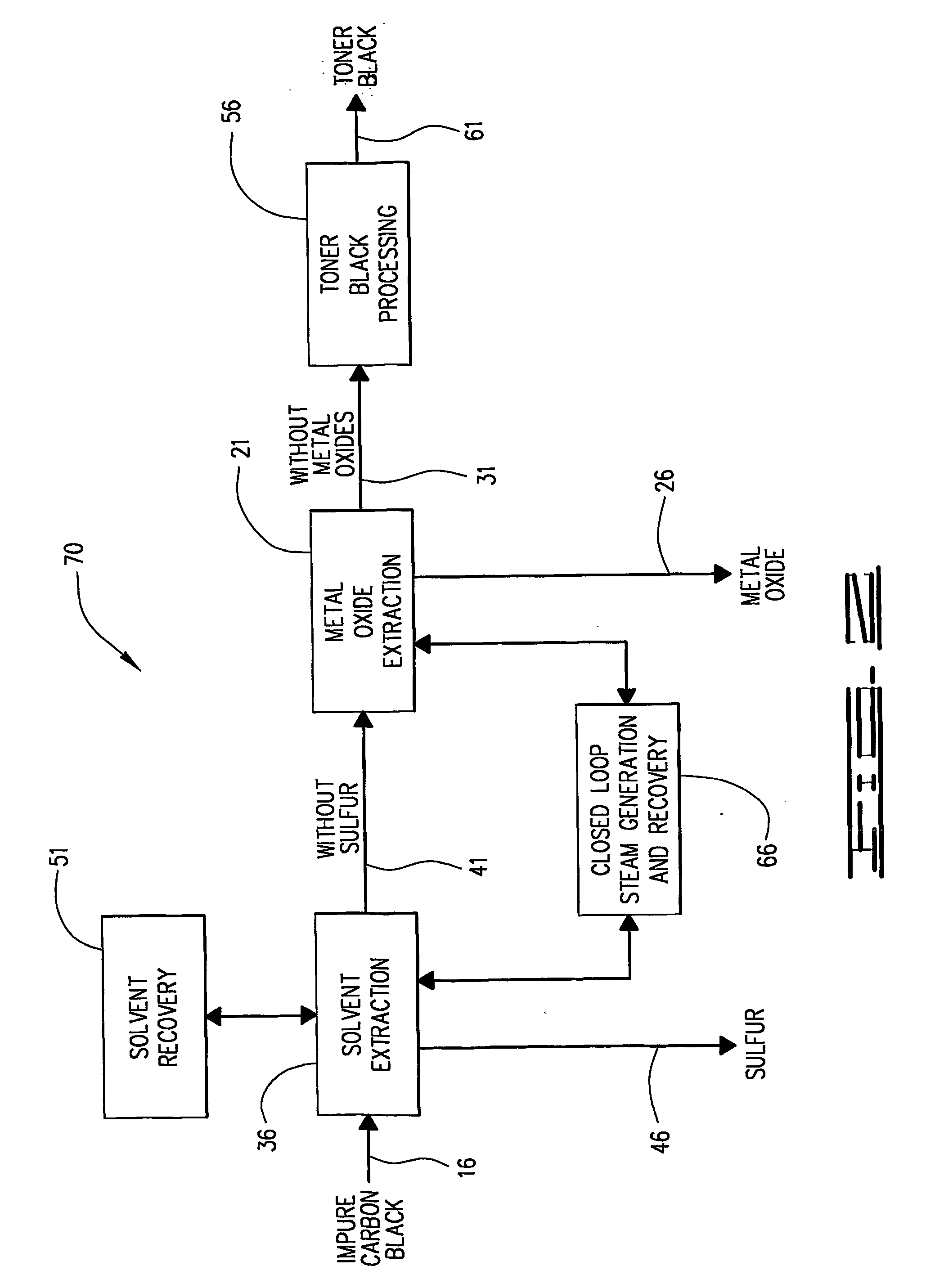

Apparatus and method for recovering carbon black from pyrolysis byproducts

ActiveUS20040047779A1Not to damageReduce riskPigmenting treatmentAlkali metal halidesAromatic solventSulfur

A system (10), process and apparatus are disclosed for purifying carbon black (15) containing sulfur and metal oxide impurities by digesting (20) the impure carbon black in an acid to extract the metal oxide (25). Sulfur (45) is then removed from the acid treated carbon black (30) by solvent extraction (35) with an organic aromatic solvent which is then recovered (50). The purified carbon black (40) is then suitable for use as a toner (60) by toner black processing (55).

Owner:FEDERAL RECYCLING TECH

Polyurethane matte white finish coat for non-benzene and odor-free furniture

ActiveCN102061123AFacilitated releaseReduce harmPolyurea/polyurethane coatingsCyclohexanoneAromatic solvent

The invention relates to polyurethane matte white finish coat for non-benzene and odor-free furniture, which consists of a main agent, a curing agent and a diluent, wherein the main agent comprises hydroxyl acrylic resin, titanium white, solvent, a defoaming agent, a flatting agent, an anti-settling agent, a dispersing agent and a flatting agent; the curing agent comprises a toluene diisocynate tripolymer, toluene diisocynate-trimethylolpropane addition product and butyl acetate; and the diluent comprises the butyl acetate, cyclohexanone and propylene glycol monomethyl acetate. By adopting the technical scheme, the polyurethane matte white finish coat has the advantages that: an obtained paint film has less residual solvent and is tasteless after 12 hours; a formula does not contain chemical substances harmful to body health of human beings, such as benzene, methylbenzene, dimethylbenzene, other aromatic solvents and derivatives, methanol, glycol ether ester solvents, halogenated hydrocarbon and the like, and the excellent decorative and protective effects of the conventional polyurethane (PU) dual-component furniture paint are reserved in the formula; and the polyurethane matte white finish coat is easy to construct and is applicable to various construction modes such as spraying, electrostatic spraying and brush coating.

Owner:上海展辰涂料有限公司

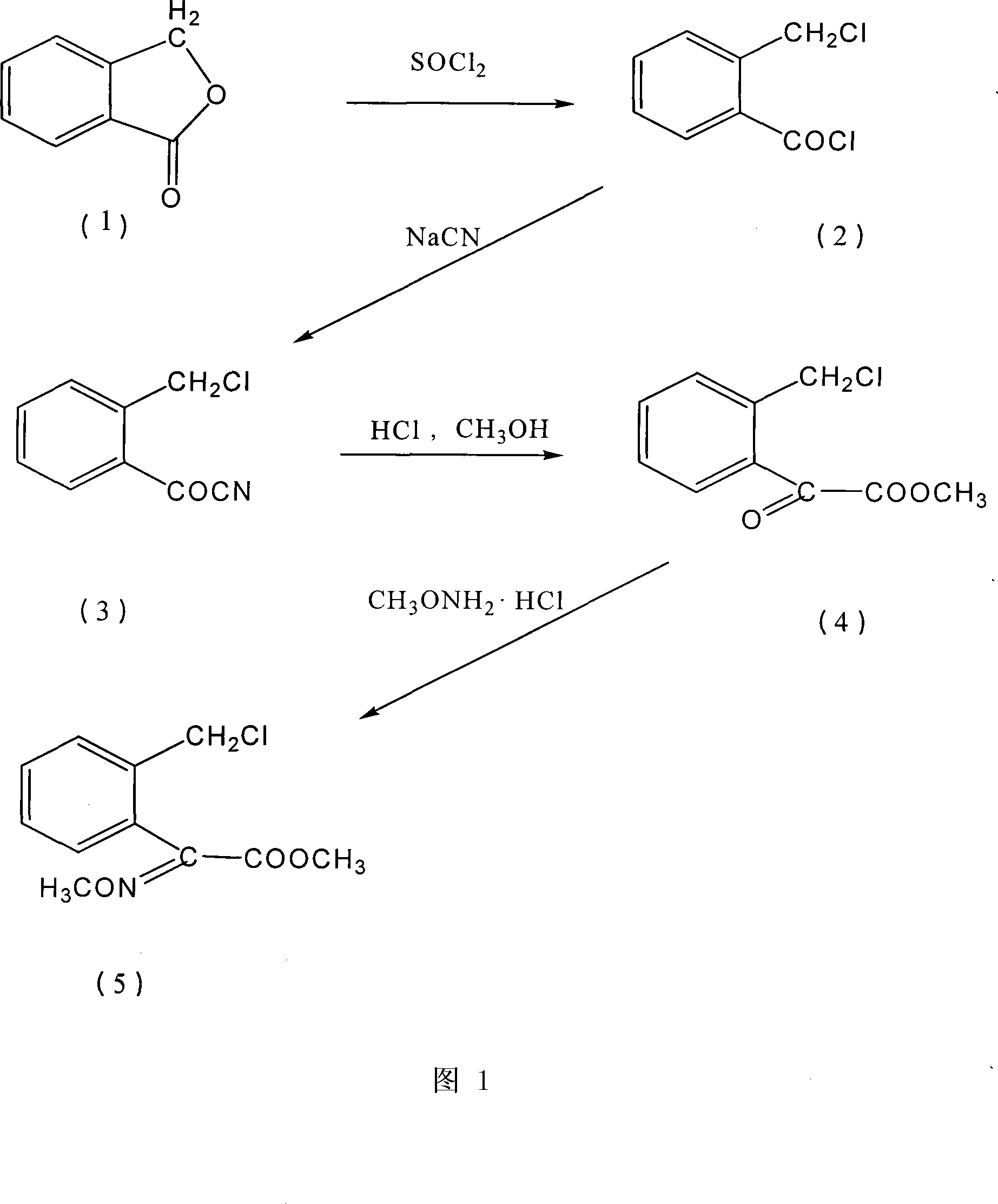

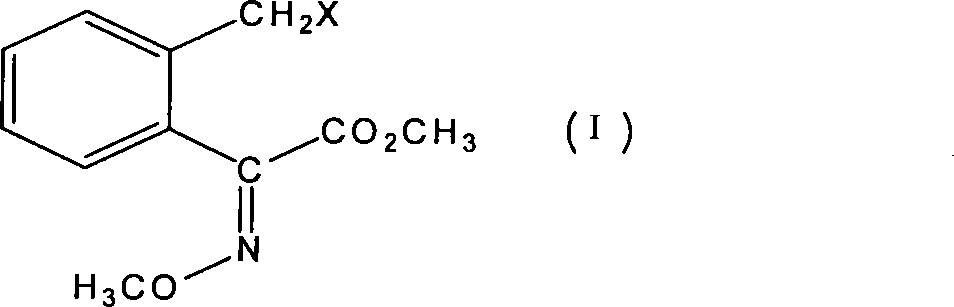

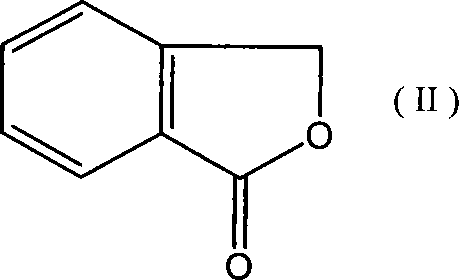

Method for preparing bactericidal agent intermediate (E)-2-(2'-chloromethyl)phenyl-2-methoxy imino methyl acetate

ActiveCN101139308AReduce energy consumptionReduce riskBiocideFungicidesPotassium cyanideProduction risk

The preparation method of the fungicide intermediate (E)-2-(2'-chloromethyl)-2-methicillin imino acetic methyl ester is: 1) the phenyl phthalate and the thionyl dihalide react with the influence of a catalyst; the catalyst is the Louis acid and phosphonic derivative; 2) the product of the first step and the alkali metal cyanide react with the influence of the organic solvent and phase transfer catalyst; the organic solvent is selected from the non-polar aromatic solvent or the halogen hydrocarbon; the phase transfer catalyst is selected from the halide of the four-level nitride or the ammonium salt; the alkali metal cyanide is selected from the sodium cyanide and potassium cyanide; 3) the products of the second step and the methanol react under the condition with the organic solvent and the chlorinated hydrogen; 4) the products of the third step and the methicillin amine hydrochloride under the condition with the organic solvent; thus, the target product can be got. The energy consumption and production risk of the present invention are obviously lowered; the relative collection rate is high; the safety in the production process is improved; and the present invention has no drawbacks such as the obstruction.

Owner:JIANGSU GENGYUN CHEM CO LTD

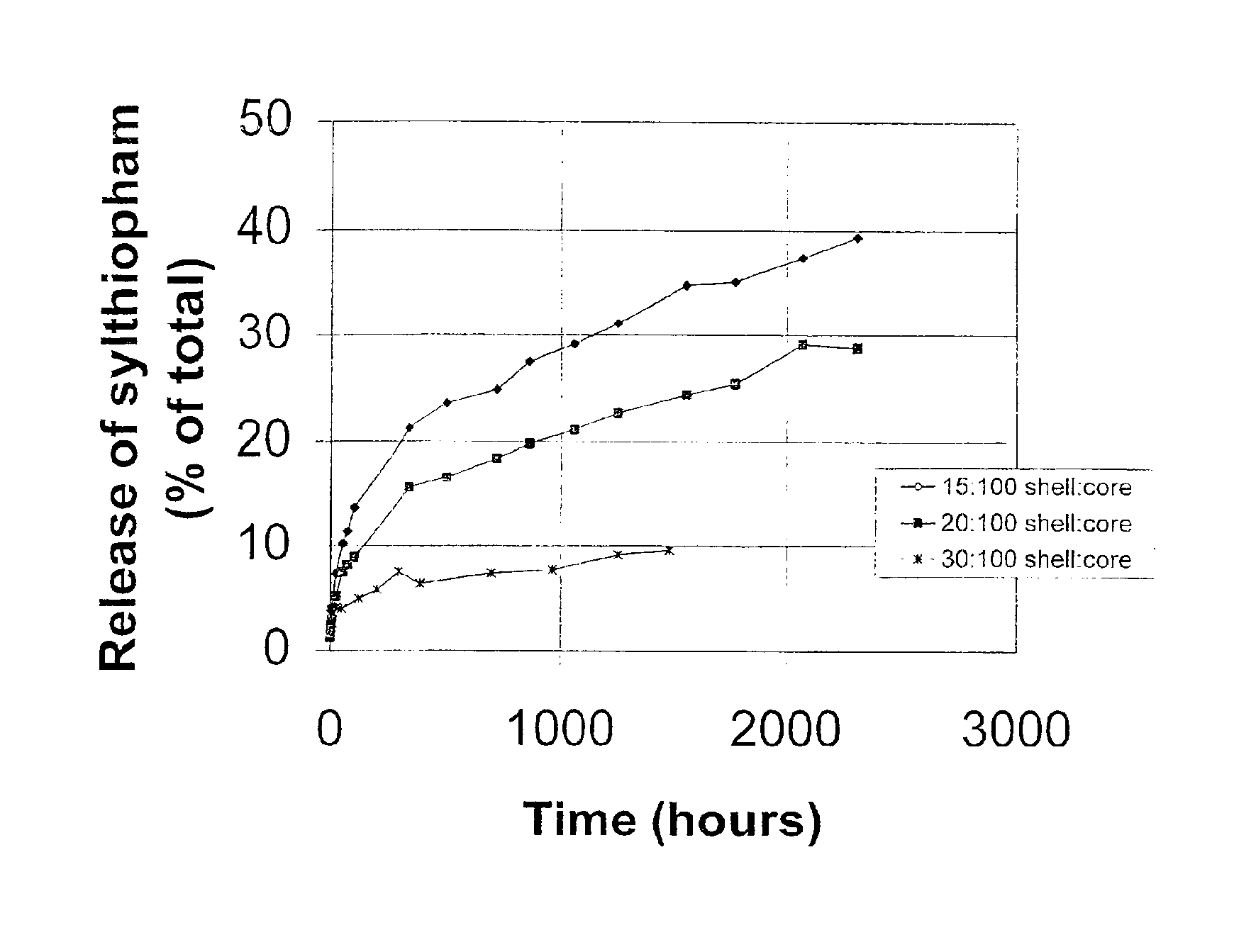

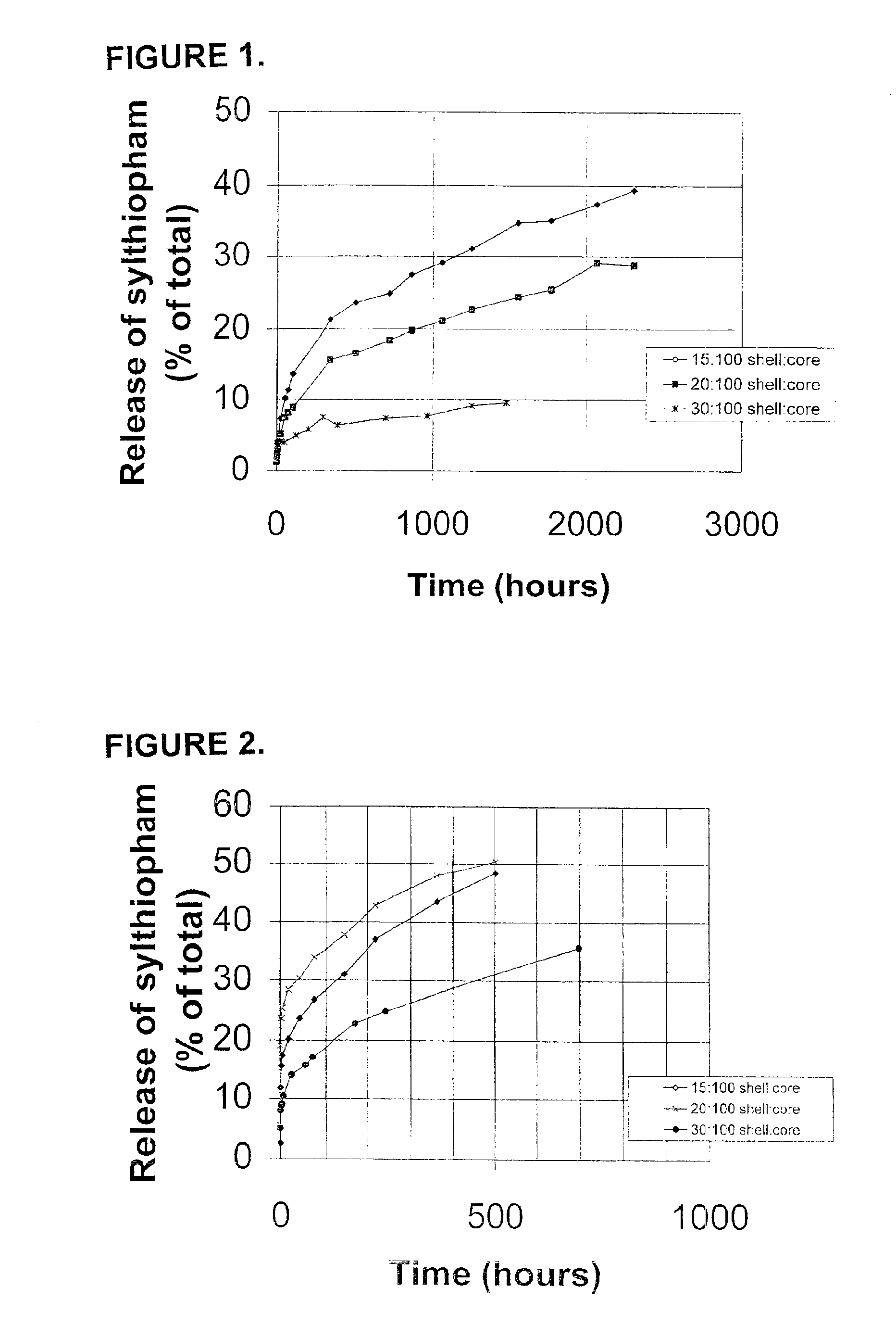

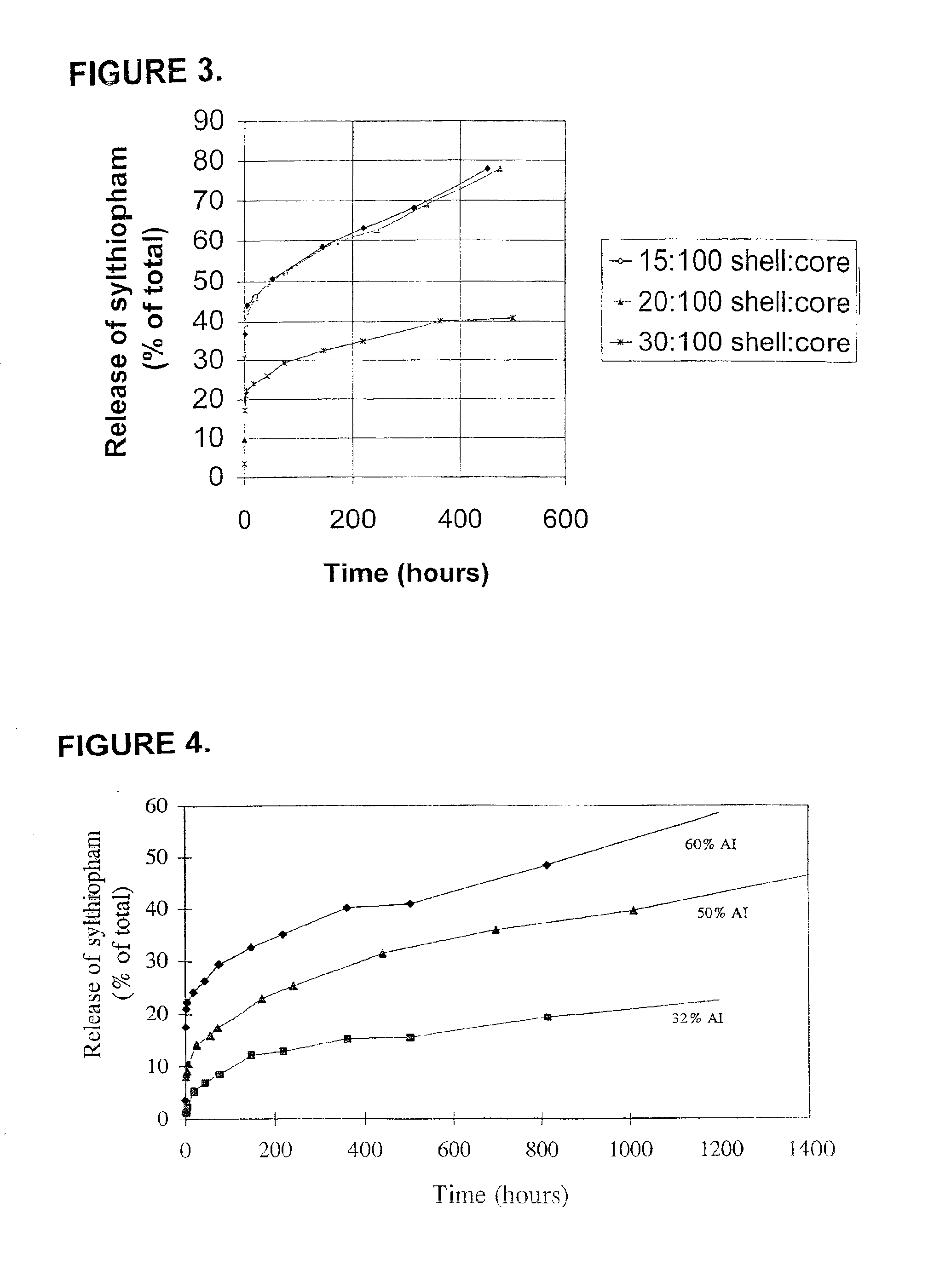

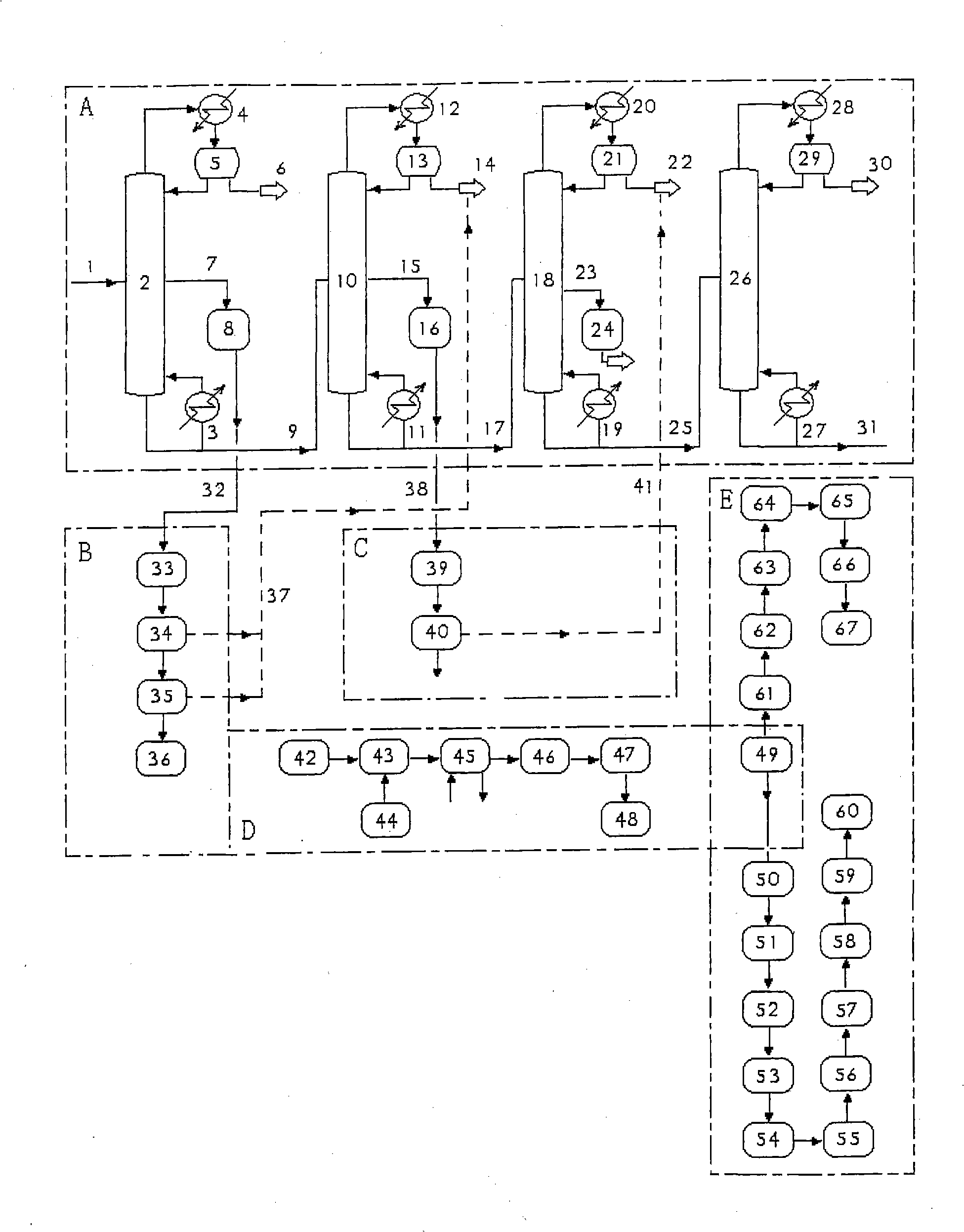

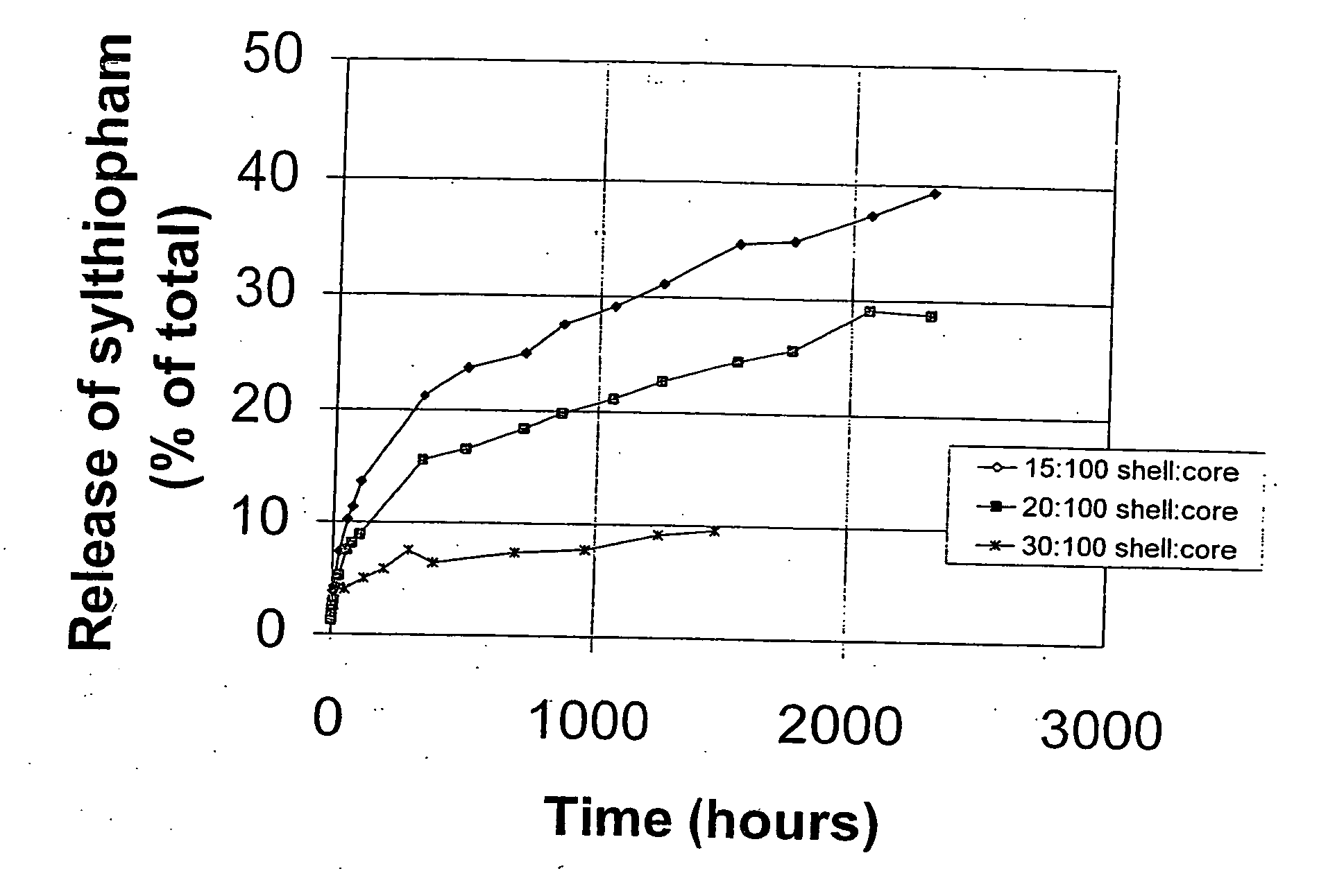

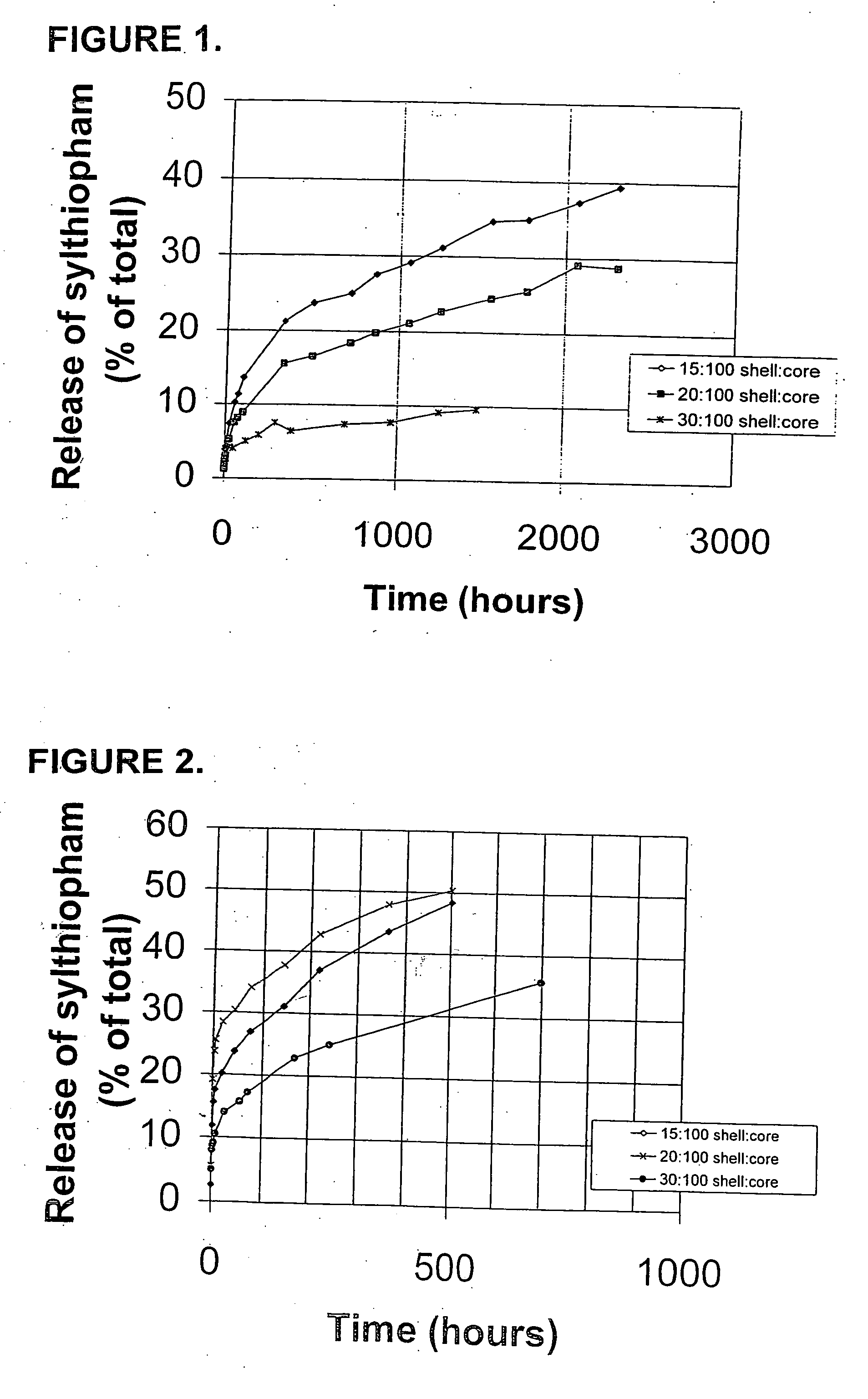

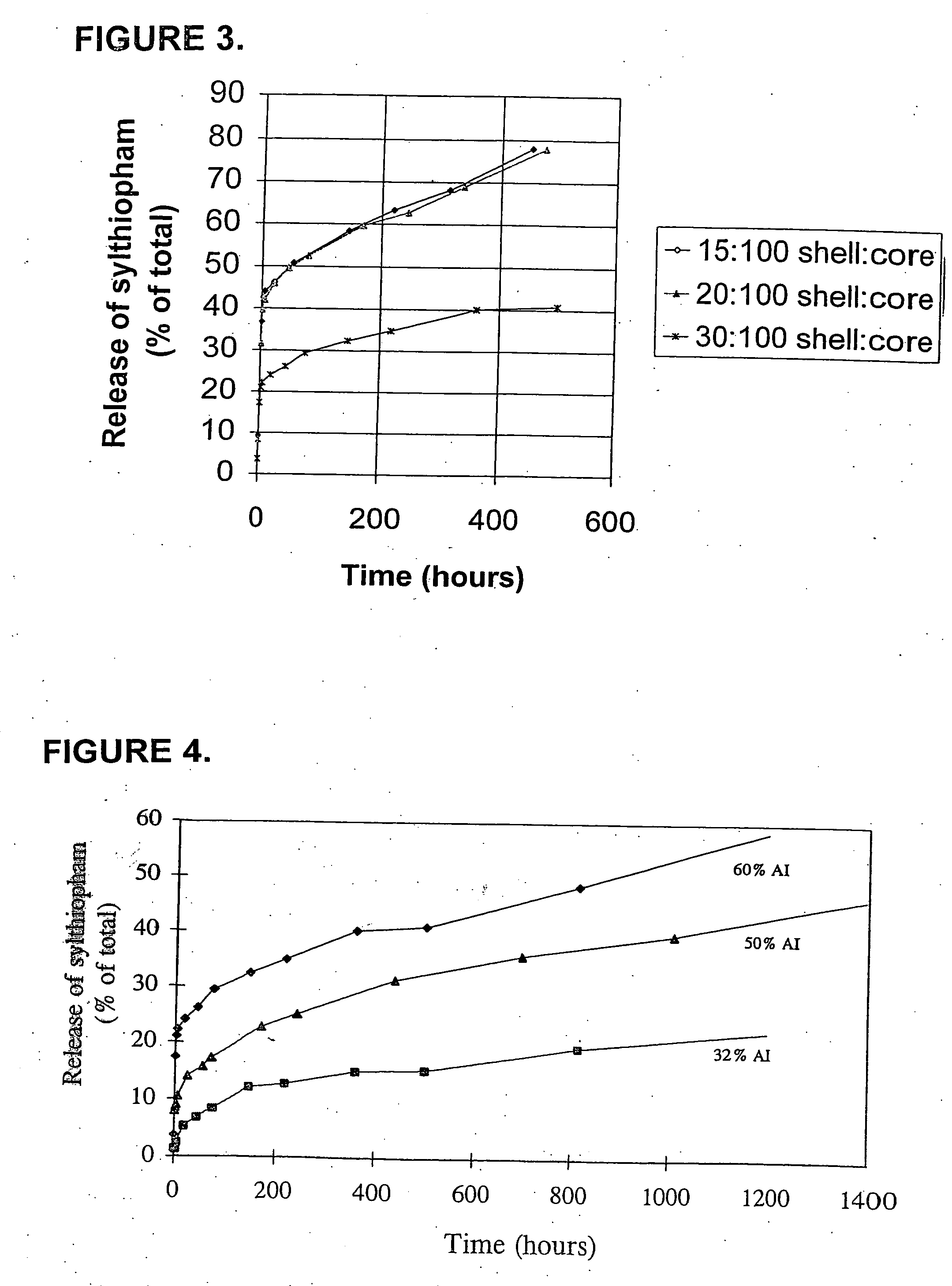

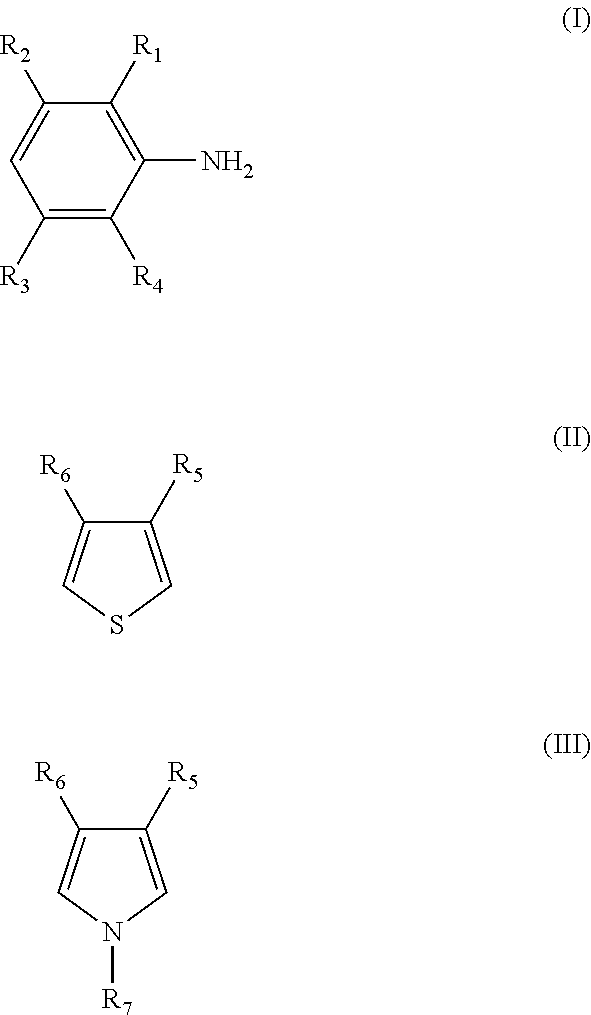

Method of microencapsulating an agricultural active having a high melting point and uses for such materials

A method of producing a controlled release form of an agricultural active material includes the provision of an organic liquid composition in which the active is present, but where the liquid composition is free from aromatic solvents and is maintained below the normal melting point of the active. The liquid composition is formed into small droplets and the droplets are enclosed by a non-water soluble shell to provide microcapsules, the shell of which is designed to release the agricultural active at a pre-selected controlled rate when the microcapsule is exposed to natural environmental conditions. Controlled release forms of agricultural actives are also provided.

Owner:MONSANTO TECH LLC

Universal synthetic lubricant, method and product-by-process to replace the lost sulfur lubrication when using low-sulfur diesel fuels

A diesel fuel lubricant as a replacement for sulfur lubrication in Ultra-Low and Low Sulfur Diesel fuels, the process for producing said lubricant, and the method of using said lubricant. This lubricant comprises alpha-olefins; low odor aromatic solvents; and at least one a base oil selected from the base oil group consisting of hydroisomerized high base oils and HT Severe Hydro-cracked Base Oils; as well as other ingredients. Also disclosed is a method for producing this lubricant.

Owner:BESTLINE INT RESEACRH

Process for joint production of aromatic solvent, stone oil naphthalin and durene line products with C10 heavy aromatic raw material

ActiveCN101318874ATake advantage ofSave resourcesDistillation purification/separationCrystallisation purification/separationAromatic solventGas phase

The present invention discloses a method for jointly preparing a series of products of an aromatic solvent, petronaphthalene and durene from a C10 heavy aromatics material, belonging to the C10 heavy aromatics complex utilization technical field. The method comprises the following steps of: A) separating the C10 heavy aromatics material; B)refrigerating and crystallizing an enrichment solution of durene; C)refrigerating and crystallizing an enrichment solution of naphthalene; D) gas phase catalytically oxidizing durene; and E) preparing technical grade PMA, technical grade PMDA and electronic grade PMDA from a crude product. The method has the advantages that the method can carry out joint production to obtain the series of products of aromatic solvent, petronaphthalene and durene by the C10 heavy aromatics material so that the C10 heavy aromatics material obtains sufficient utilization, thereby contributing to resource economizing.

Owner:常熟华虞环境科技有限公司

Room temperature-curing environment-friendly anticorrosive coating for circuit board and preparation method thereof

InactiveCN103305106ASmall smellFast curingAnti-corrosive paintsPolyurea/polyurethane coatingsAromatic solventZircon

The invention discloses a room temperature-curing environment-friendly anticorrosive coating for a circuit board and a preparation method thereof. The anticorrosive coating is prepared through complex formulation of the following raw materials by mass: 50 to 90 parts of a polyurethane modified alkyd resin, 20 to 80 parts of an environment-friendly solvent, 0.01 to 2.0 parts of a main drier, i.e., cobalt naphthenate, 0.01 to 3.0 parts of a secondary drier A which is one or two selected from the group consisting of zinc isocaprylate and zinc naphthenate, 0.01 to 6.0 parts of a secondary drier B which is one or two selected from the group consisting of zircon isocaprylate and zirconium naphthenate, 0.1 to 3.0 parts of a fluorescent agent and 0.01 to 2 parts of a stabilizing agent. The tri-proof coating for the circuit board provided by the invention uses a plant extract as a resin source and is prepared through complex formulation of the resin, the environment-friendly solvent, corresponding metal driers and other auxiliary agents. The prepared coating does not contain aromatic solvents like xylene and ethylbenzene and has the advantages of little smell, a fast curing speed, good adhesion and excellent electrothermal performance.

Owner:DONGGUAN BAOHAN LIGHT IND TECH

Universal synthetic golf club cleaner and protectant, method and product-by-process to clean, protect golf club faces and rejuvenate golf clubs grips

ActiveUS8071522B2Reduce sidespinEasy to wipe cleanDetergent compounding agentsAdditivesForeign matterExperimental testing

The club cleaner, conditioner and protectant comprises alpha-olefins, low-odor aromatic solvents; and at least one base oil selected from the base oil group consisting of Hydroisomerized high base oils and HT Severe Hydro-cracked Base oils; as well as other (optional) ingredients. Also disclosed is a method for producing this product and related product-by-process. This product uses a formulated cleaning mixture to clean and restore the face of the club while rejuvenating the grips. The invention when sprayed on the clubface removes foreign materials and when wiped dry protects the face of the clubs from harsh stains, caused by soils, grass and chemicals related to fertilizers. In experimental testing, the invention increases drive distances by reducing sidespin and increasing backspin. The club is left with a factory-like finish making it easy to wipe clean of soiling. The invention when applied to the grips restores the surface to the new feel.

Owner:BESTLINE INT RESEACRH

Cosmetic compositions containing a propylphenylsilsesquioxane resin and a cosmetically-acceptable aromatic solvent

The present invention is directed to a cosmetic composition containing: (a) at least one propylphenylsilsesquioxane resin; (b) at least one cosmetically-acceptable aromatic solvent; (c) at least one colorant, and (d) optionally, at least one co-solvent, and wherein the composition is substantially free of volatile solvents. Also disclosed is a method of imparting lasting shine onto lips by contacting the lips with the above described composition.

Owner:LOREAL SA

Method of microencapsulating an agricultural active having a high melting point and uses for such materials

A method of producing a controlled release form of an agricultural active material includes the provision of an organic liquid composition in which the active is present, but where the liquid composition is free from aromatic solvents and is maintained below the normal melting point of the active. The liquid composition is formed into small droplets and the droplets are enclosed by a non-water soluble shell to provide microcapsules, the shell of which is designed to release the agricultural active at a pre-selected controlled rate when the microcapsule is exposed to natural environmental conditions. Controlled release forms of agricultural actives are also provided.

Owner:MONSANTO TECH LLC A BUSINESS ORGANIZED UNDER THE LAWS OF THE STATE OF DELAWARE

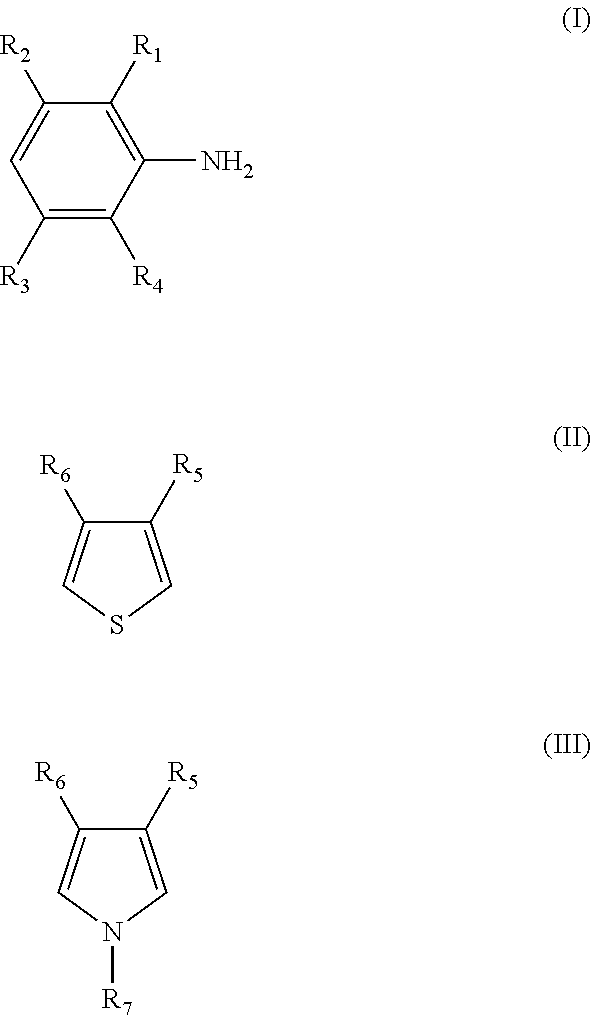

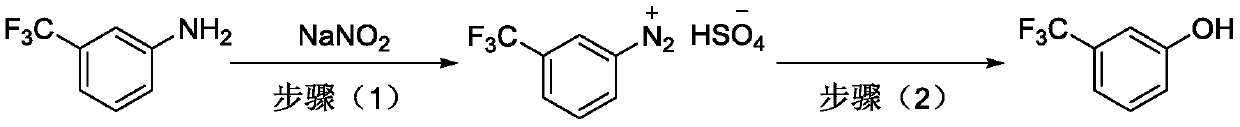

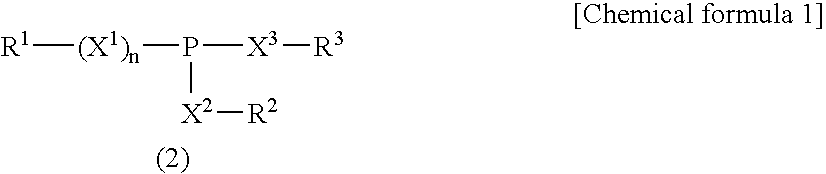

Composite conductive polymer composition, method of manufacturing the same, solution containing the composition, use of the composition

ActiveUS20110309308A1Easily formExcellent solvent solubilityHybrid capacitor electrodesCell electrodesChemistryKetone

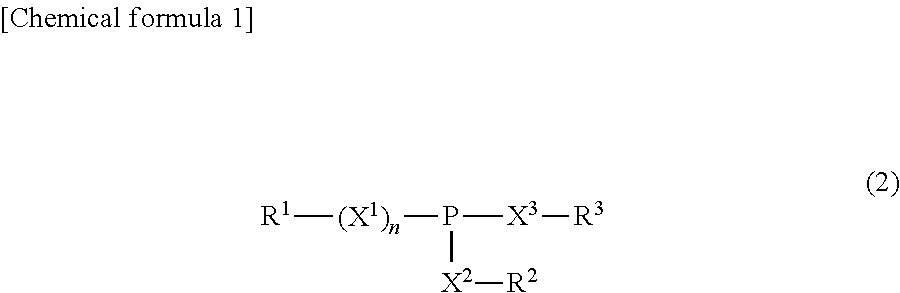

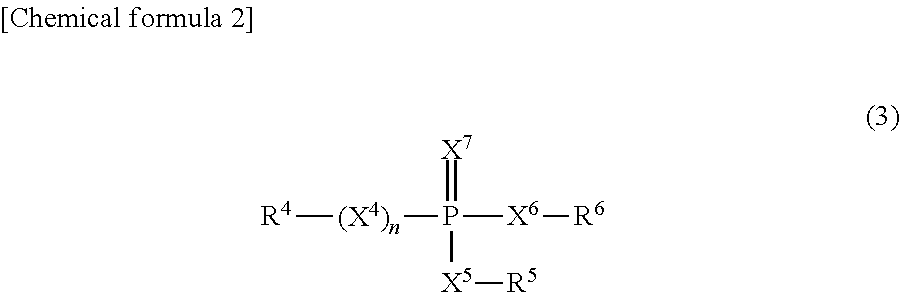

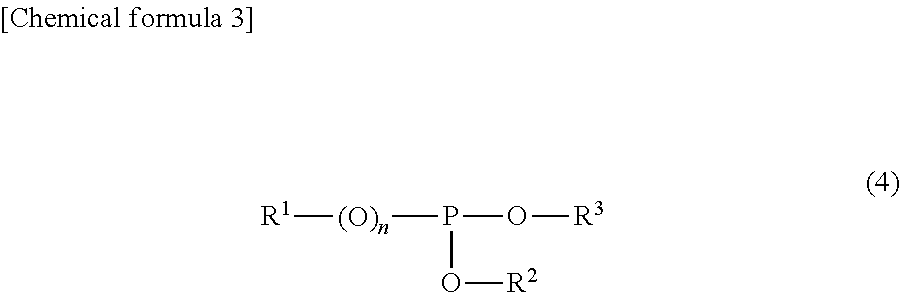

The purpose is to provide a technique which enables various kinds of conductive polymer composition to be dissolved in an organic solvent and to be used to form a conductive membrane on a target portion easily. Provided is a composite conductive polymer composition, a method of manufacturing the same, and a solution obtained by dissolving the composition in an aromatic solvent, ester-based solvent or ketone-based solvent. The composition is obtained by doping a π-conjugated polymer (β) with a polymer compound (A), wherein the polymer compound (A) is obtained from (a-1) a monomer having a sulfonic acid group and a polymerizable vinyl group in an amount of 20 to 60 mol %, (a-2) a polar monomer having a hydrophilic group and a polymerizable vinyl group in an amount of 20 to 60 mol %, and (a-3) another polymerizable monomer in an amount of 20 to 60 mol %, and the n-conjugated polymer (β) is obtained from a monomer compound selected from the formulas (I) to (III)in the formula (I) to (III), at least one of R1 to R4 represent an alkoxy group of C1 to C10, and the other groups represent H, an alkyl group of C1 to C10, or an alkoxy group of C1 to C10; at least one of R5 and R6 represent an alkoxy group of C1 to C10, and the other group represents H, an alkyl group or an alkoxy group of C1 to C10, or R5 and R6 jointly represent an alkylenedioxy group of C1 to C8; and R7 represents H, an alkyl group of C1 to C6, or an aromatic ring group.

Owner:SOKEN CHEM & ENG CO LTD

Method for directionally controlling the reaction of LiH and AlCl3 with catalyst to synthesize A1H3

The invention provides a method for directionally controlling the reaction of LiH and AlCl3 with a catalyst to synthesize A1H3, which relates to an AlH3 synthesis method. The technical problems that AlH3 made by the traditional AlH3 making method is unstable and requires high cost are solved. The method comprises the following steps of: 1. uniformly mixing anhydrous AlCl3, tertiary amine and an anhydrous aromatic solvent under anhydrous and anaerobic conditions to obtain a solution A; 2. uniformly mixing LiH and the anhydrous aromatic solvent under anhydrous and anaerobic conditions to obtaina solution B; 3. adding the solution B to the solution A, heating under anhydrous and anaerobic conditions for reaction, then standing and filtering to obtain filtrate; 4. removing the solvent in thefiltrate to obtain powder; and 5. vacuum drying to obtain AlH3. The method has low cost and is suitable for industrial production, and products produced with the method are stable. Made AlH3 can be used for making a high-energy solid propellant.

Owner:HARBIN INST OF TECH

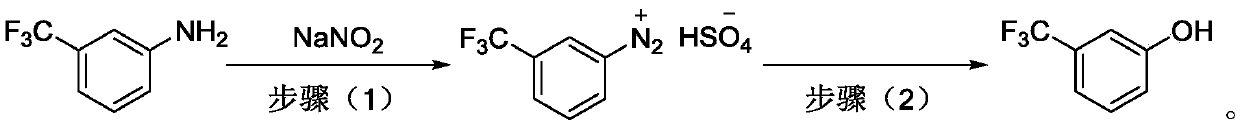

Preparation method of m-trifluoromethylphenol

ActiveCN110818533AIncrease concentrationIncrease temperatureOrganic chemistryOrganic compound preparationAromatic solventPhysical chemistry

Owner:ZHEJIANG WEIHUA NEW MATERIAL CO LTD

Preparation of fractionated novolak resins by a novel extraction technique

InactiveUS6121412APhotosensitive materialsSemiconductor/solid-state device manufacturingAlkanePolymer science

The present invention provides a method for producing a film forming, fractionated novolak resin, by: a) condensing formaldehyde with one or more phenolic compounds, and thereby producing a novolak resin; b) adding a photoresist solvent, and optionally a water-soluble organic polar solvent; c) feeding the mixture into a liquid / liquid centrifuge and feeding a C5-C8 alkane, water or aromatic hydrocarbon solvent into the liquid / liquid centrifuge at a ratio of optional water-soluble organic polar solvent and photoresist solvent to C5-C8 alkane, water or aromatic solvent, of from 5:1 to 0.5:1; d) rotating the liquid / liquid centrifuge containing the mixture at a speed of at least 500 rpm and thereby separating the mixture into two phases, collecting the two phases; e) optionally separating the lighter phase (L) into two second phases; f) removing residual C5-C8 alkane, water or aromatic hydrocarbon solvent from the heavier phase (H) from step d) and leaving the novolak resin dissolved in the photoresist solvent; A method is also provided for producing photoresist composition from such a fractionated novolak resin and for producing microelectronic devices using such a photoresist composition.

Owner:AZ ELECTRONICS MATERIALS USA CORP

Lubricant Composition and Antioxidant Composition

ActiveUS20080274922A1Rise in acid numberSufficient long drain intervalTin organic compoundsAdditivesAromatic solventAntioxidant

The lubricating oil composition of the present invention comprises at least one species of aromatic constituent selected from the following (a1) to (a5):(a1) a lubricating base oil comprising a polycyclic aromatic content of 0.01% by mass or more based on the total amount of base oil(a2) a lubricating base oil comprising a total aromatic content of 20 to 100% by mass based on the total amount of base oil(a3) an aromatic solvent(a4) at least one species of polycyclic aromatic compound selected from alkyl naphthalene and compounds having three or more aromatic rings, and(a5) an aromatic compound having a nitrogen atom, an oxygen atom or a sulfur atom;and an organic molybdenum compound.

Owner:NIPPON OIL CORP

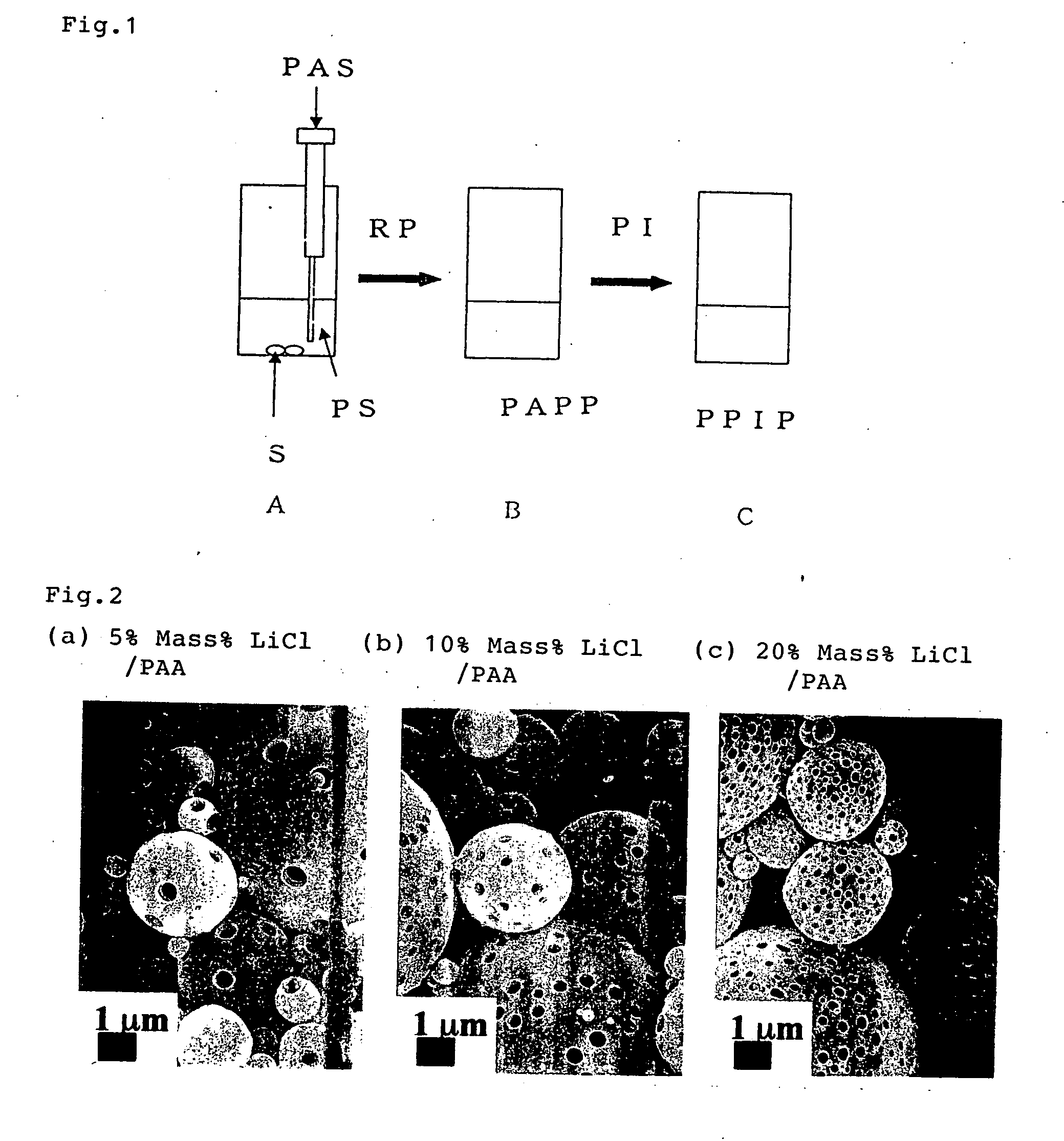

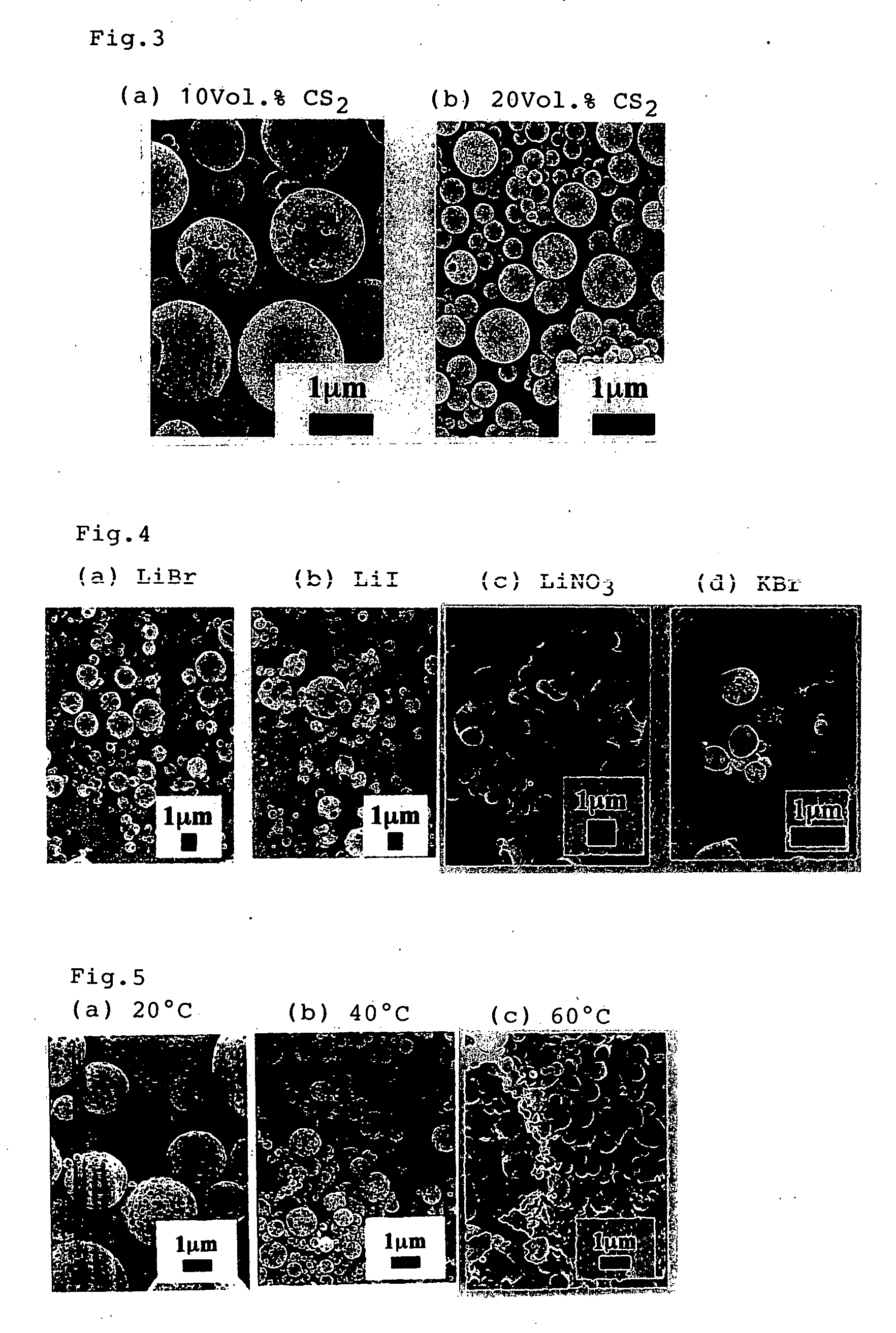

Process for producing fine porous polyimide particle

Owner:JAPAN SCI & TECH CORP

Silicone Resin Coating For Electronic Components

One-component, H-siloxane-containing addition-crosslinkable silicone resins, are prepared by charging a reactor with water and a solvent mixture of at least one aromatic solvent and at least one alkyl ester, adding a chlorosilane mixture containing an Si—H functional silane and a silane bearing an unsaturated hydrosilylatable group with stirring, the temperature not being above 50° C., separating an aqueous phase comprising a one-component, H-siloxane-containing addition-crosslinkable silicone resin, and washing the phase comprising the one-component, H-siloxane-containing addition-crosslinkable silicone resin in at least two washing steps to reduce residual HCl content, a final washing carried out using a 0.01%-1.0% strength aqueous solution of a base with a pH between 7.00-8.50, at a temperature of 20-50° C.

Owner:WACKER CHEM GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com