Patents

Literature

490results about "Crystallisation purification/separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for the production of particles or powders

In a novel process for the production of particles or powders, a substance or mixture of substances to be treated is provided in a pressure vessel. A highly compressible fluid is dissolved under pressure in the substance or mixture of substances provided until a solution containing 5% to 90% by weight of said highly compressible fluid has formed. The melting point of said highly compressible fluid is at least around 40 K lower than the melting point of the substance or mixture of substances to be treated. The solution obtained by dissolving said highly compressible fluid in the substance or mixture of substances provided is adjusted to a temperature of up to around 50 K above or below the melting point under atmospheric pressure of the substance or mixture of substances to be treated and is then rapidly decompressed by means of a decompression device in such a way that the temperature falls, downstream of the decompression device, below the solidification point of the substance or mixture of substances to be treated and essentially all of the highly compressible fluid turns gaseous, whereby particles of the substance or mixture of substances provided form. Subsequently, the particles which have formed are removed from the stream of decompressed highly compressible fluid.

Owner:WEIDNER ECKHARD +2

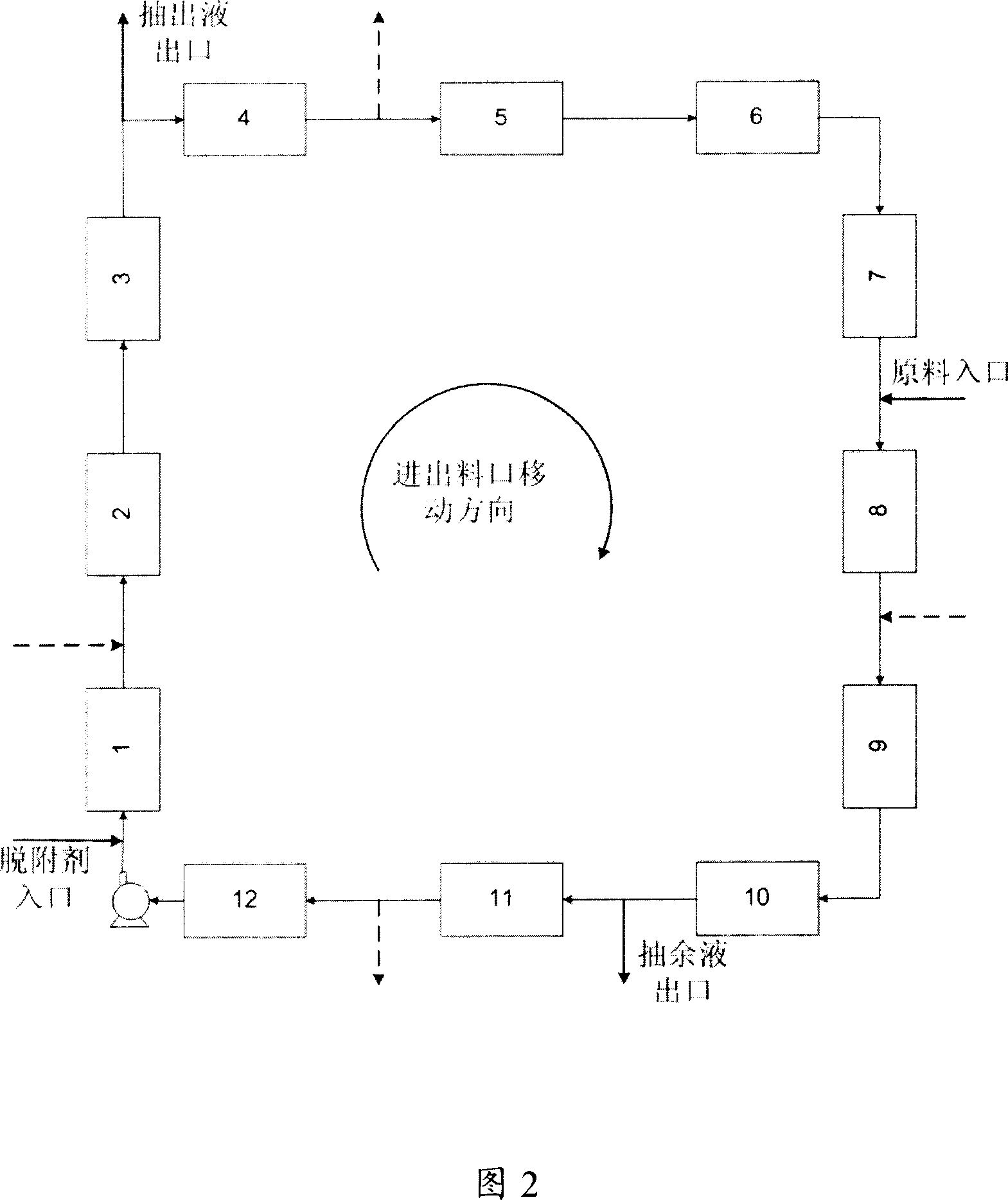

Adsorbent for adsorption stripping dimethyl benzene and its preparing process

InactiveCN1448213AImprove mass transfer efficiencyOther chemical processesAdsorption purification/separationAdhesiveSorbent

The adsorbent for adsorbing and separating paraxylene includes active adsorbing component in mass fraction 85-95 % and adhesive in mass fraction 5-15 %. The active adsorbing component is selected from BaX zeolite and BaKX zeolite, and the adhesive is selected from kaolin, silica and alumina, with the crystal grain size of X zeolite in the adsorbent being 0.5-1.0 micron. The adsorbent is suitable for adsorption and separation of paraxylene from C8 arene and has high adsorption selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Phenol removal in paraxylene recovery process

The invention is directed to purification of an aromatic hydrocarbon stream including selective removal of phenol from a process stream comprising aromatic hydrocarbon mixtures, especially aromatic hydrocarbon mixtures that contain higher-than-equilibrium paraxylene, by contact with suitable adsorbents, to provide a product stream having lower concentration of phenol than said process stream.

Owner:EXXONMOBIL CHEM PAT INC

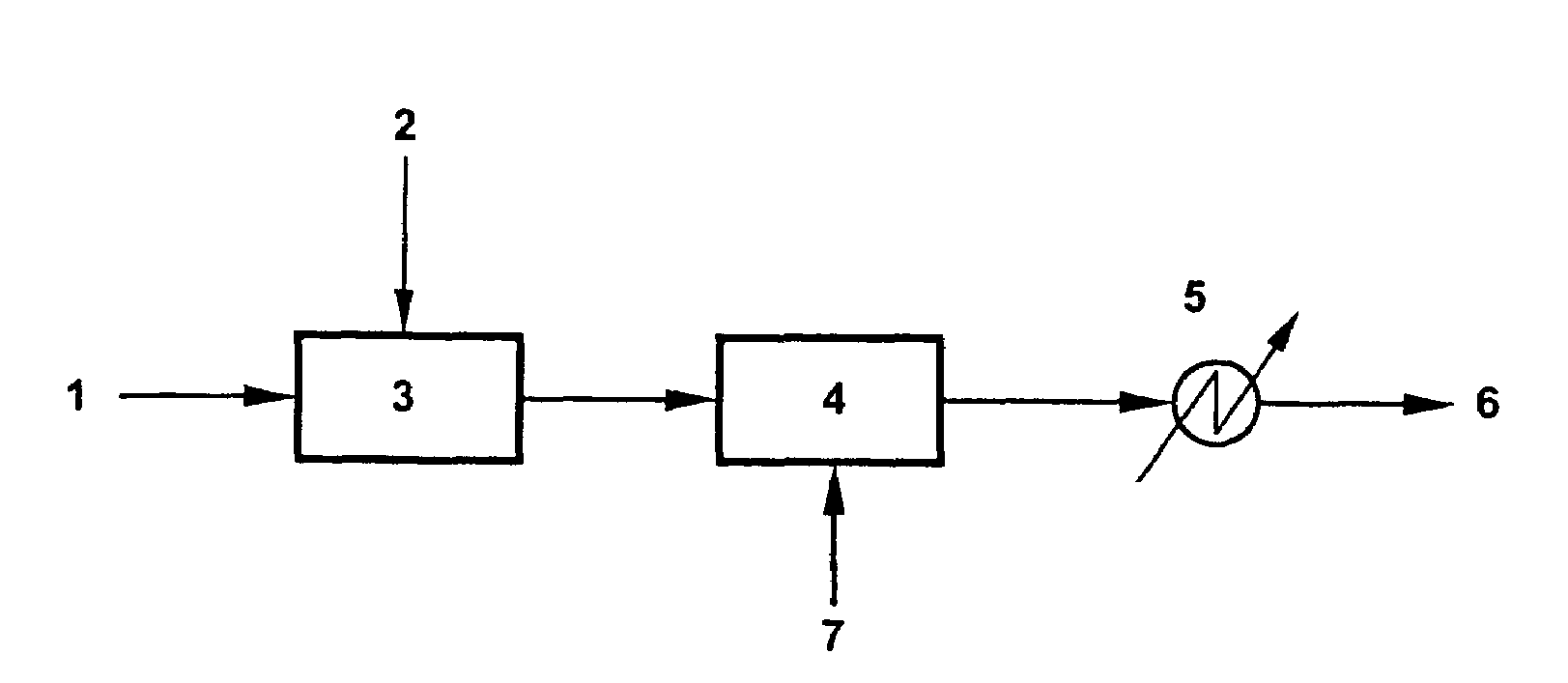

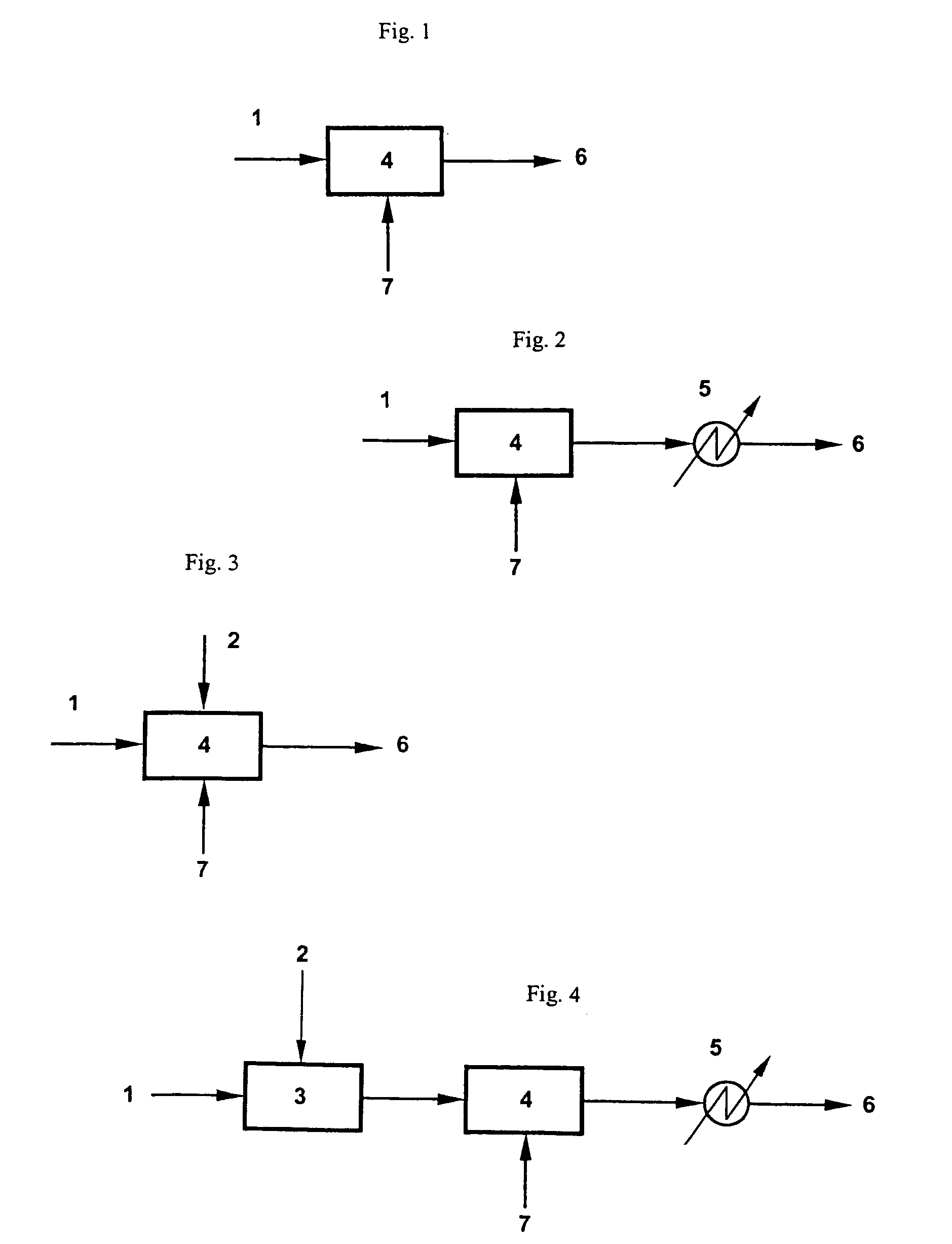

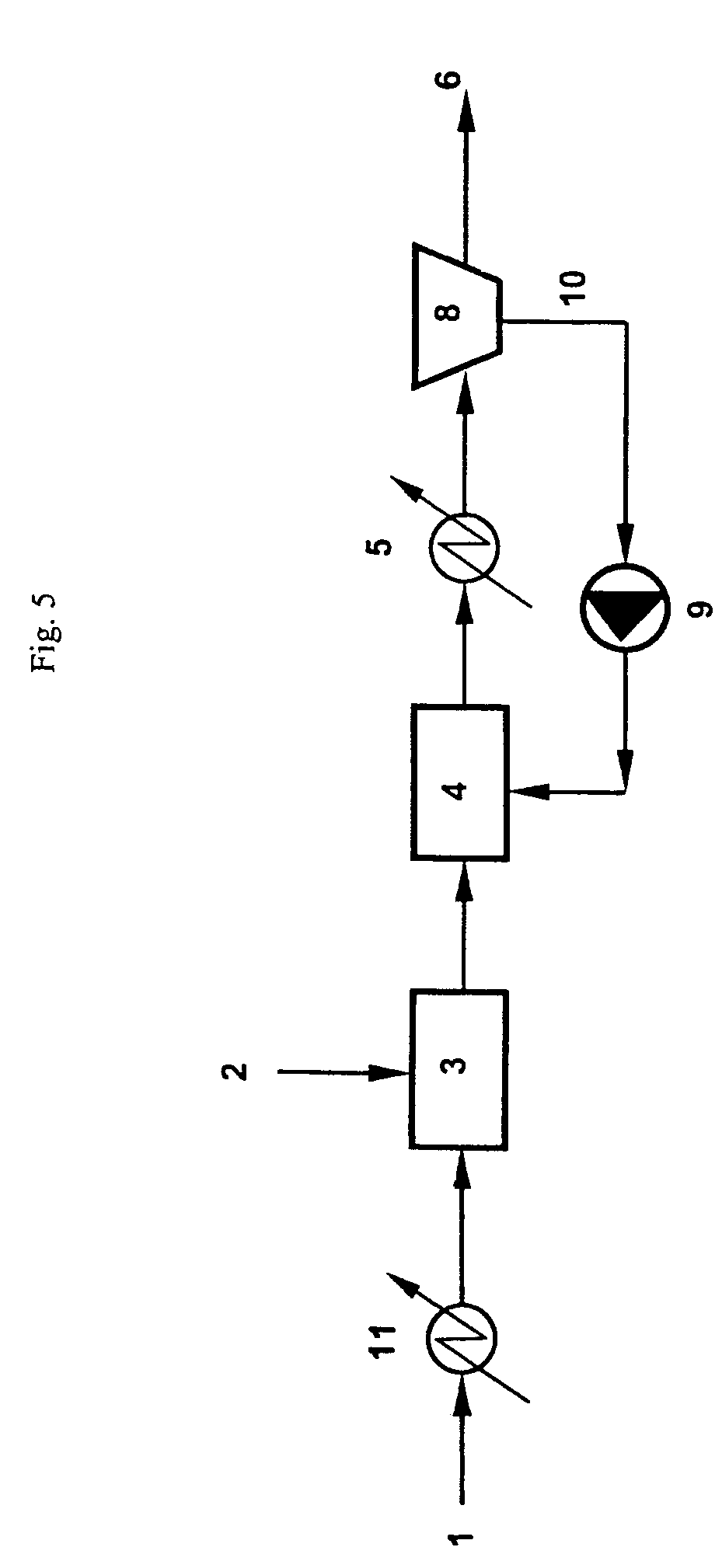

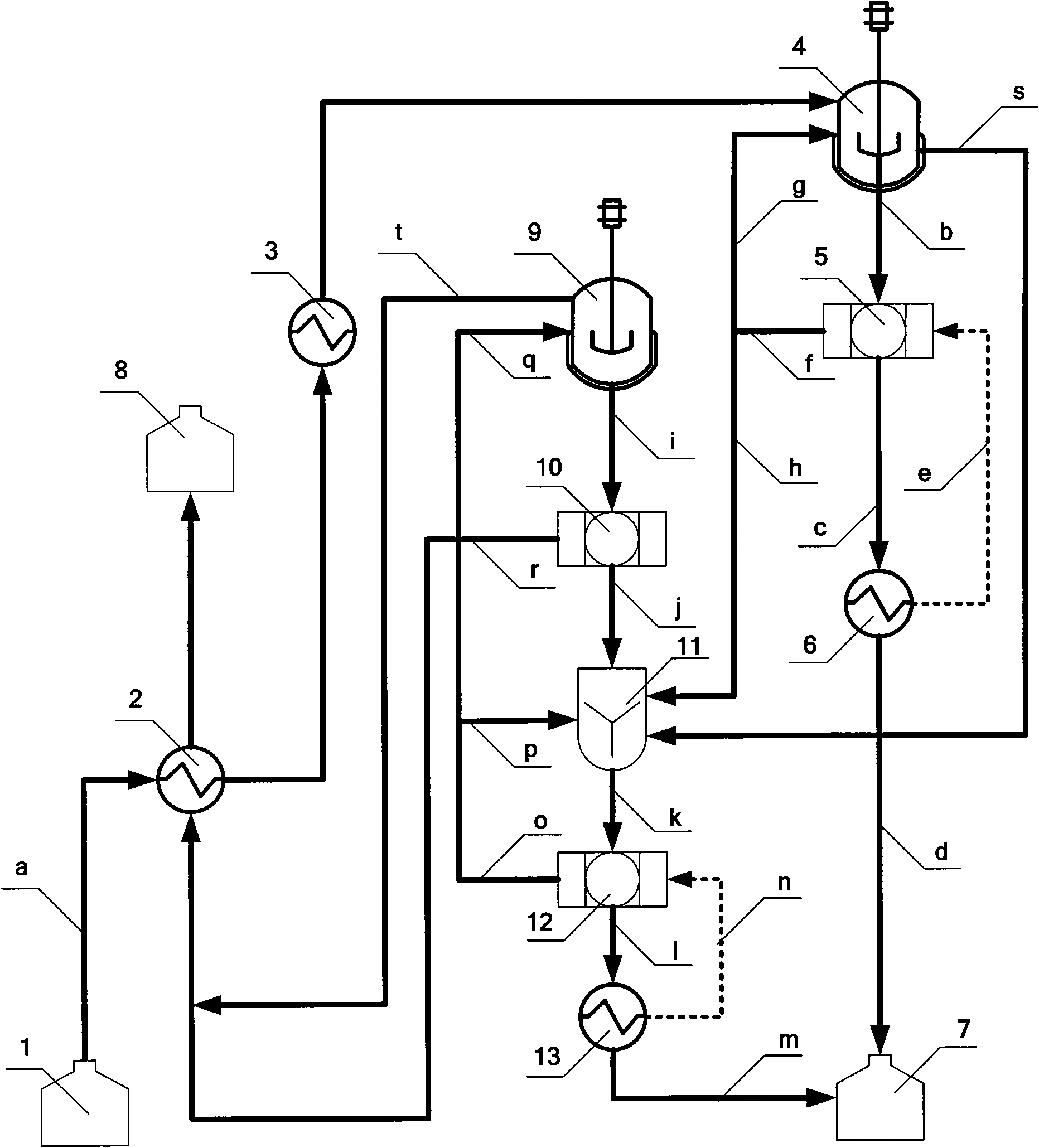

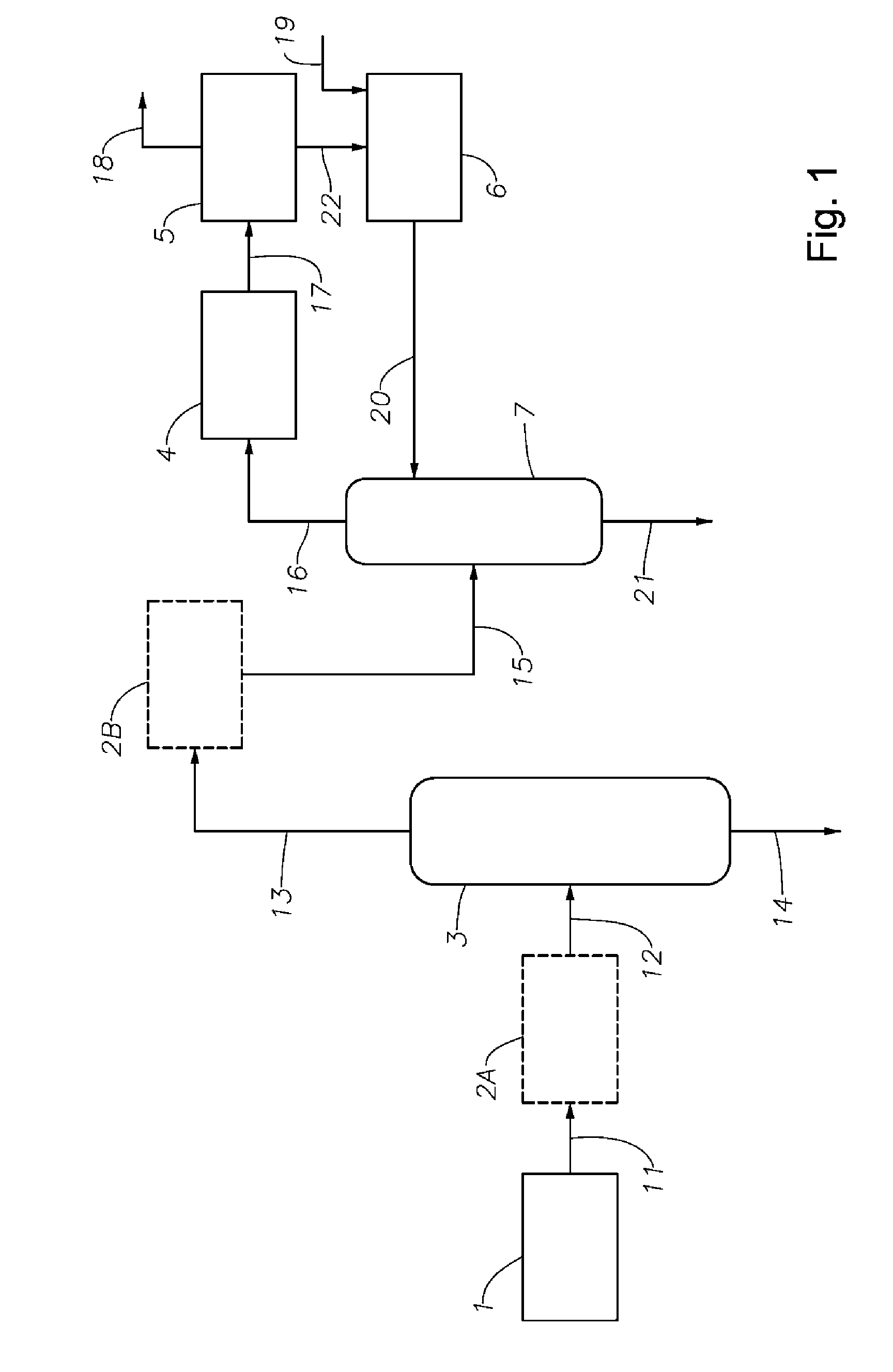

Method and system for transporting flows of fluid hydrocarbons containing wax, asphaltenes, and/or other precipitating solids

ActiveUS7261810B2Costly removalSimpler and steady operationRefining by heating/coolingWorking-up pitch/asphalt/bitumenWaxCrystallization temperature

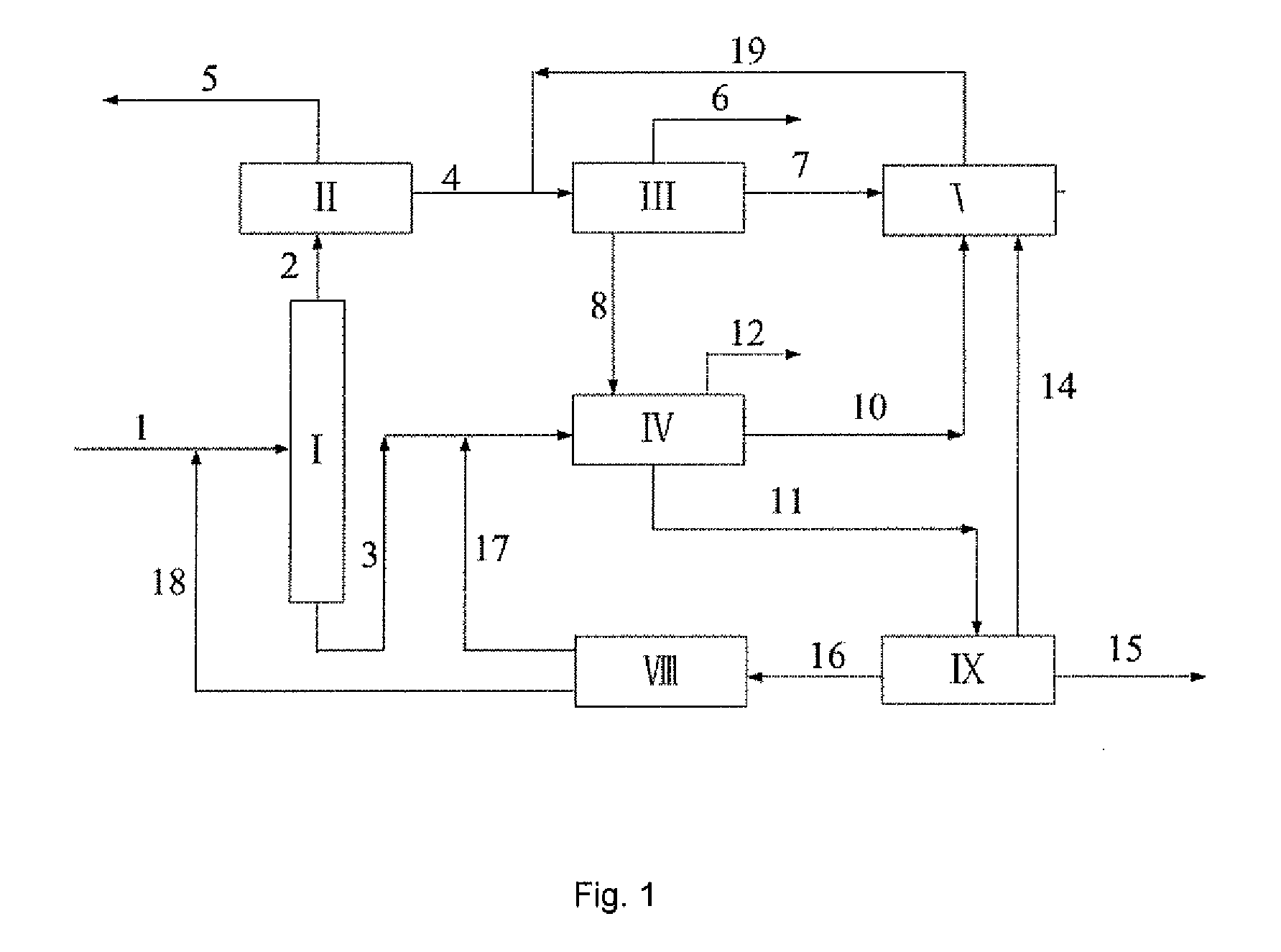

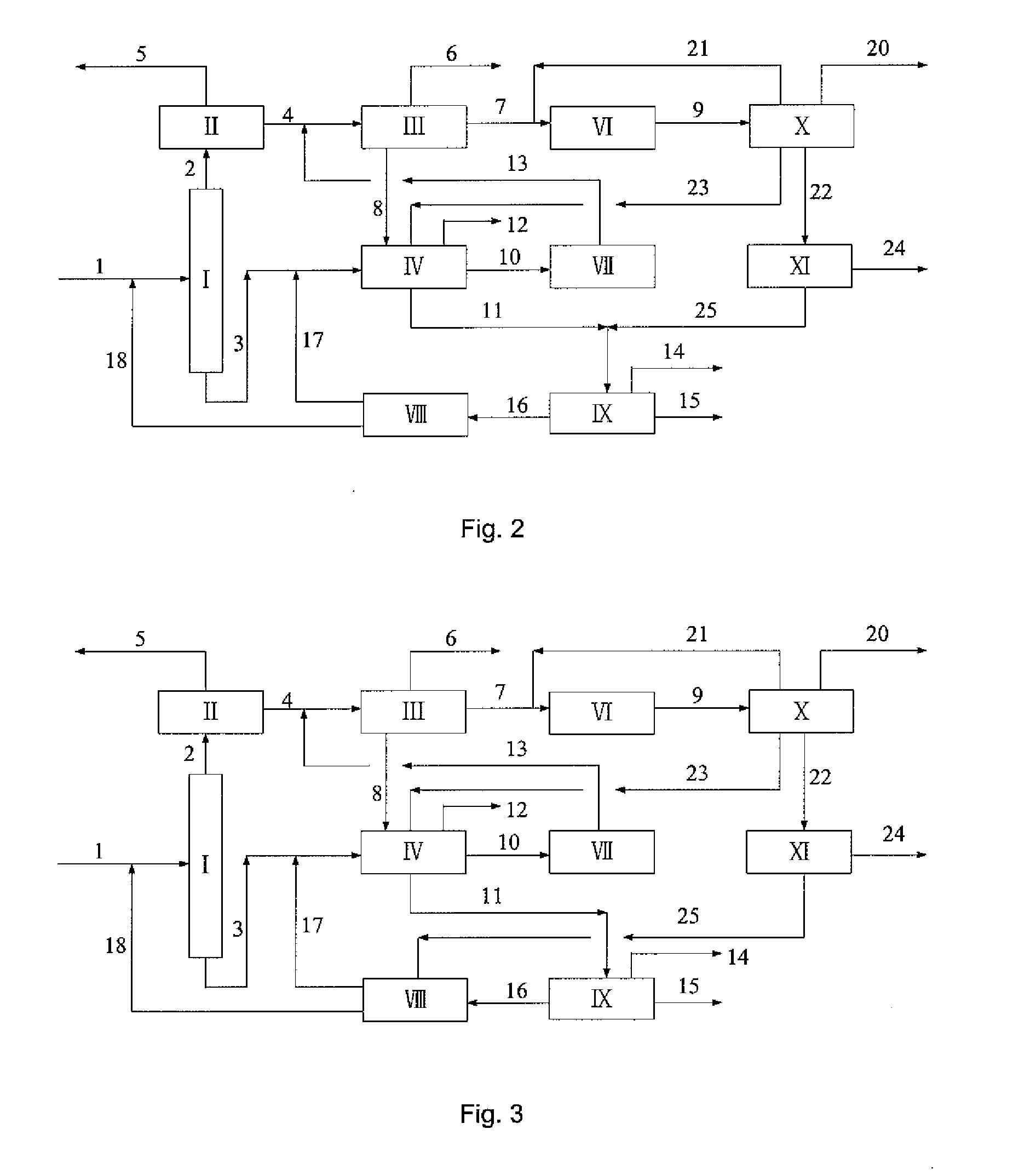

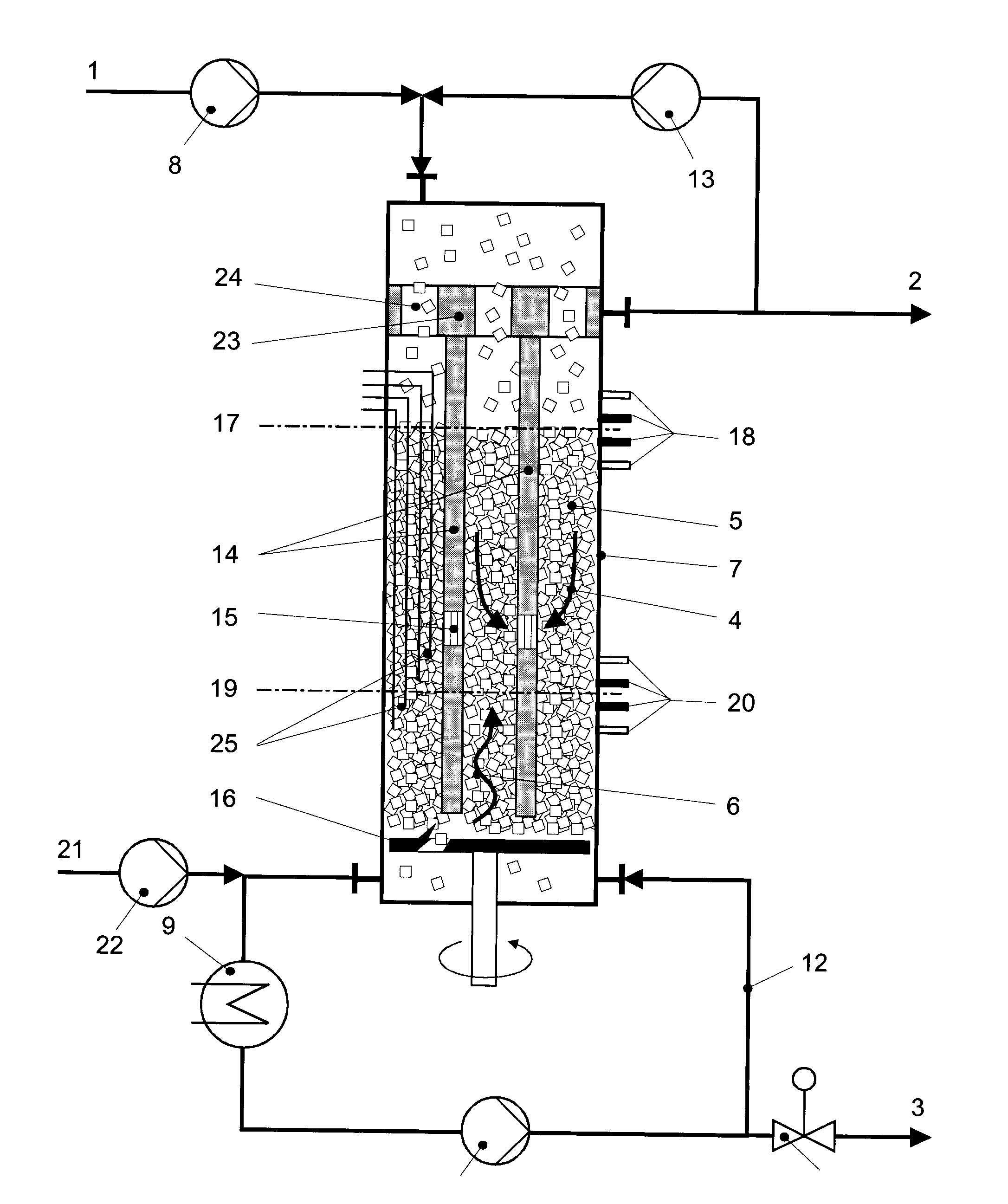

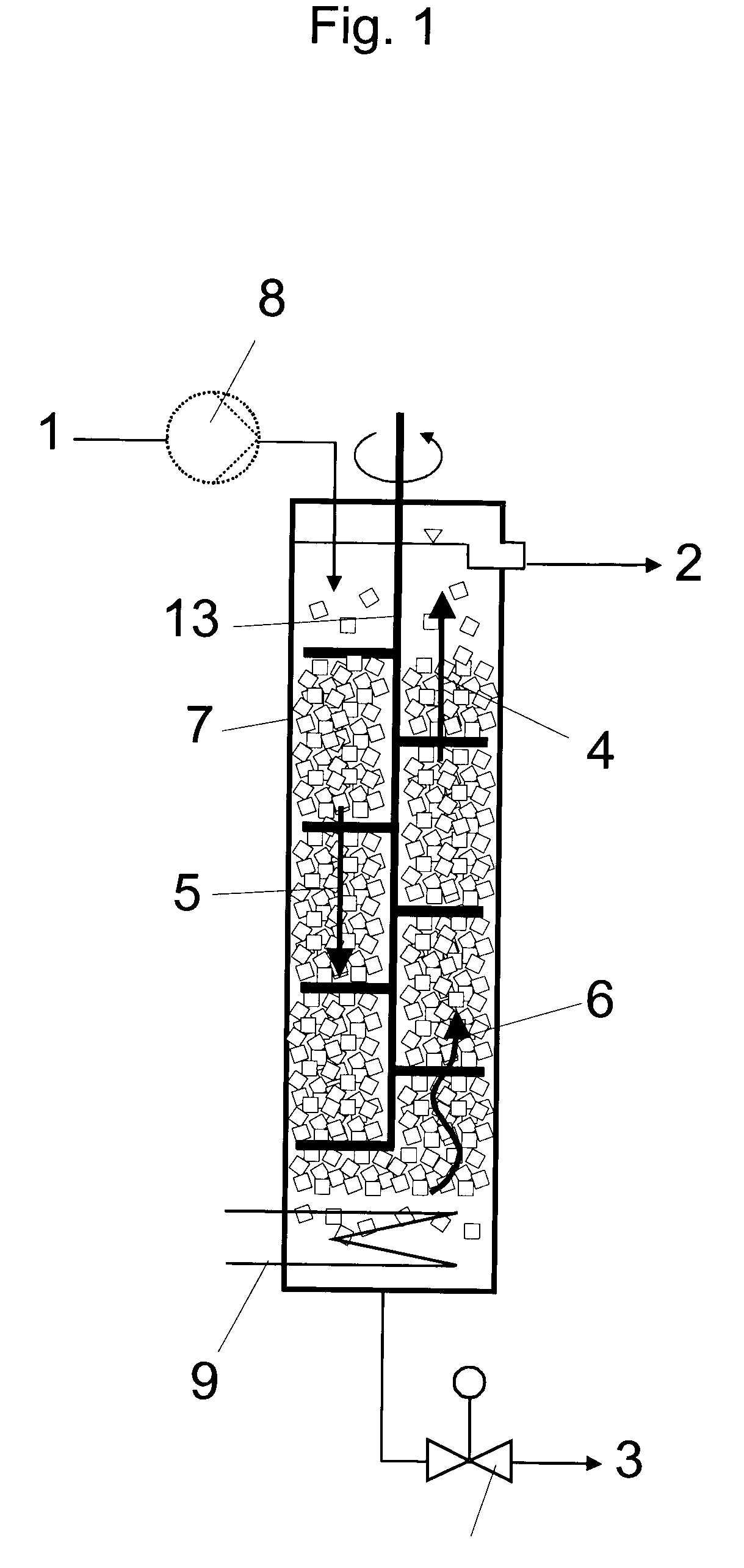

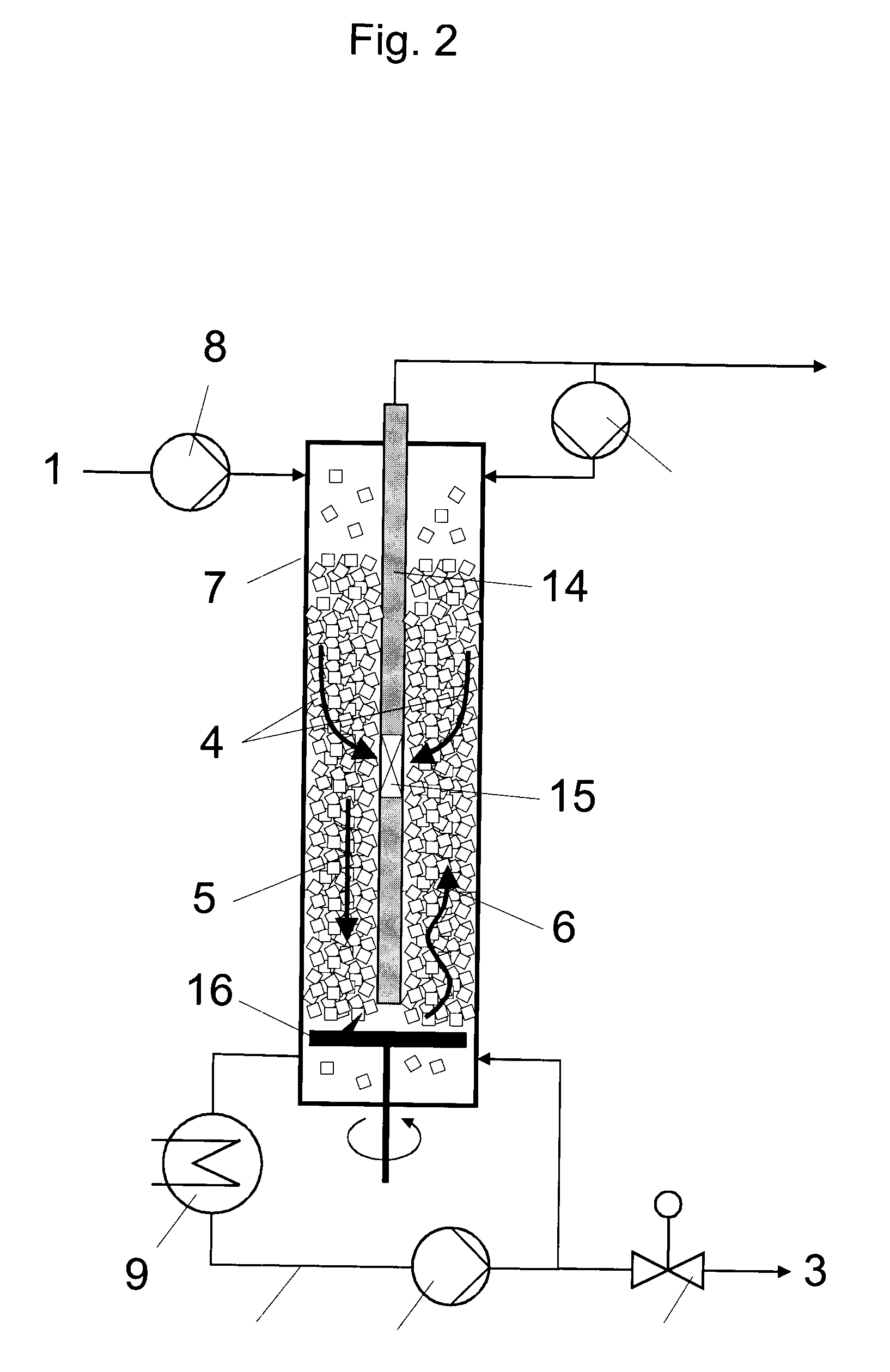

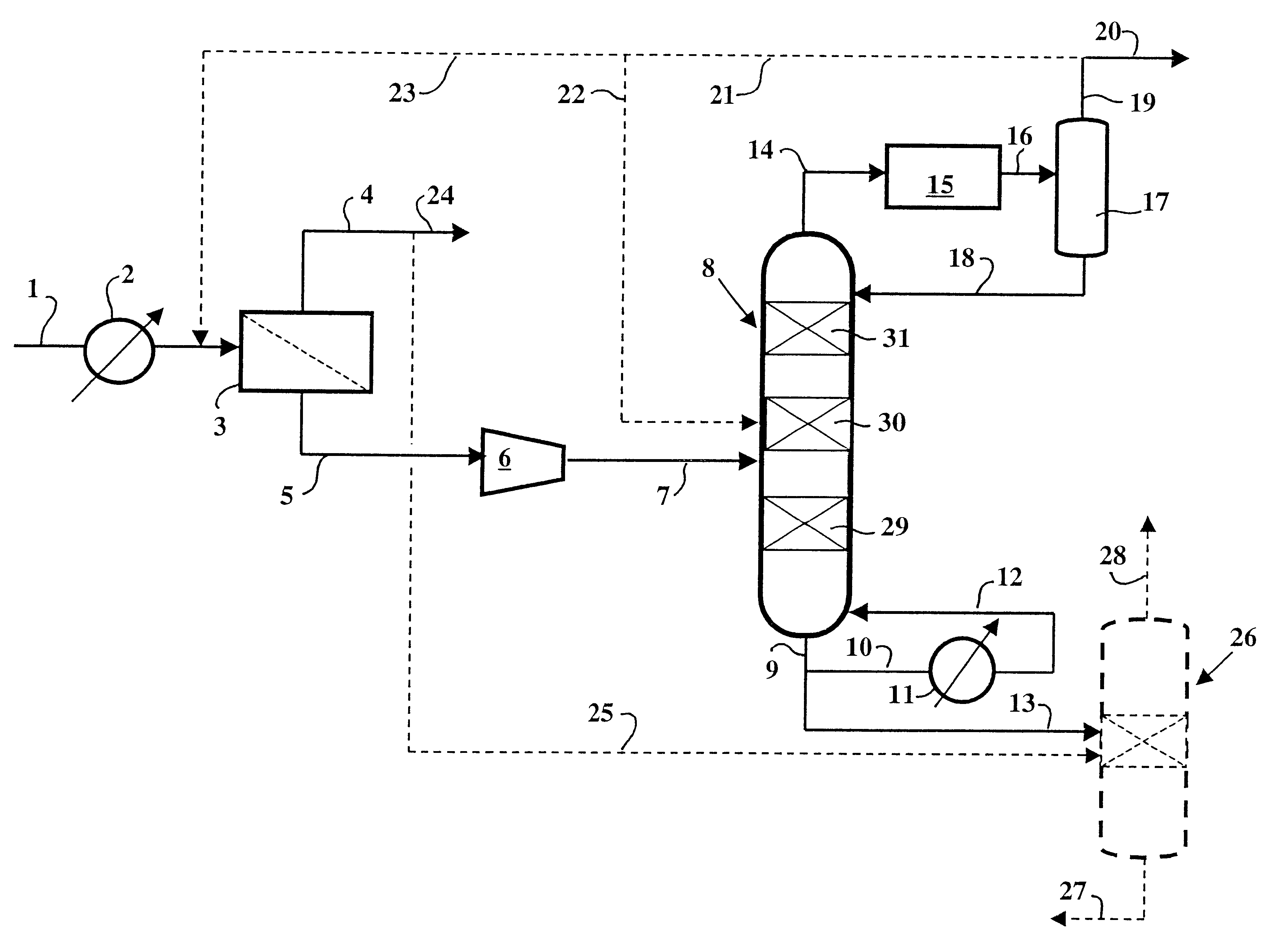

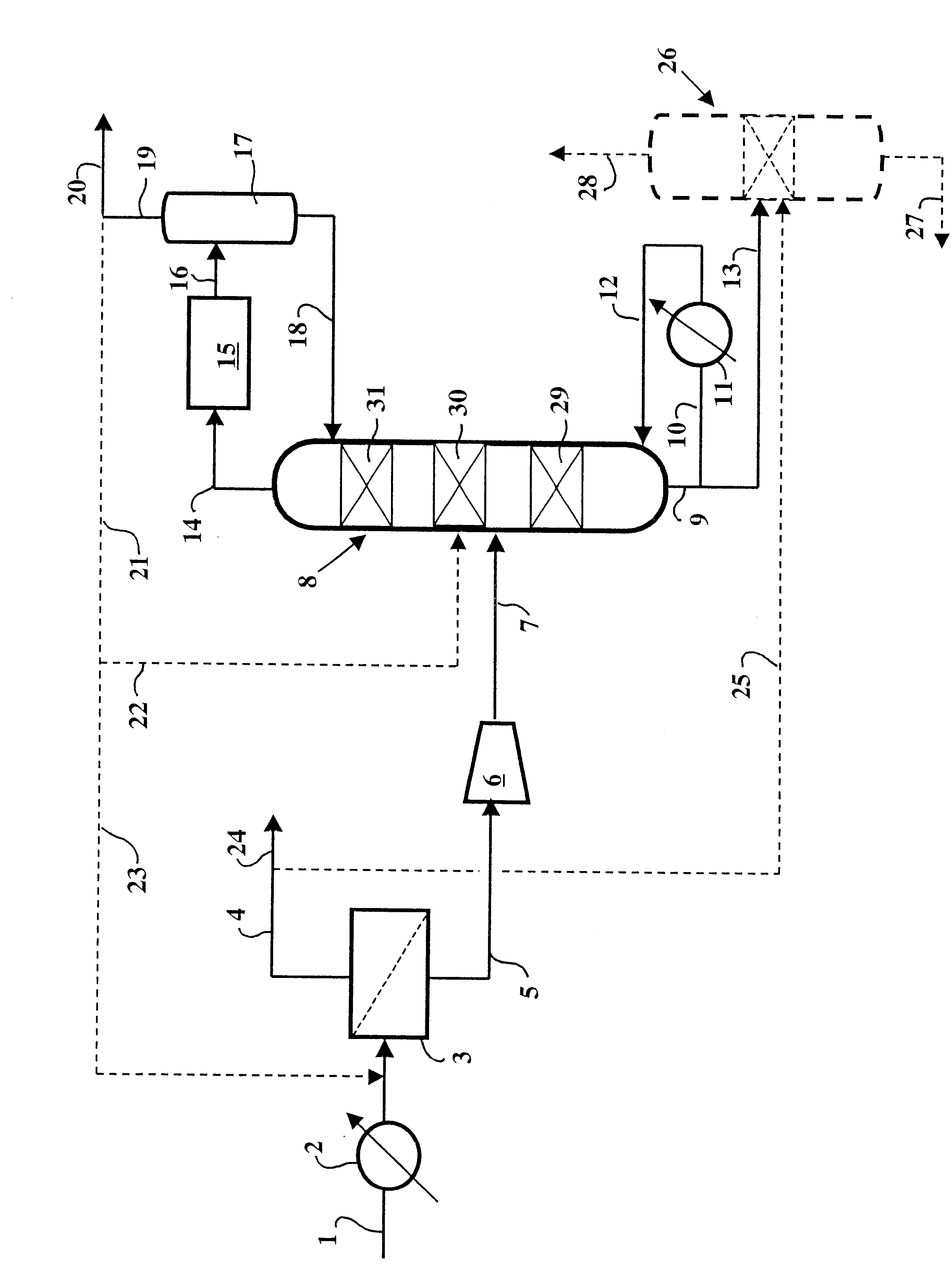

A method and a system for transporting a flow of fluid hydrocarbons containing wax and / or asphaltenes or any other precipitating solids through a treatment and transportation system including a pipeline are disclosed. The flow of fluid hydrocarbons is introduced into a reactor (4), where it is mixed with another fluid flow having a temperature below a crystallization temperature for the wax and / or asphaltenes or other solids and containing particles or crystals acting as nucleating and / or growth cores for the wax and / or asphaltenes or other solids, the mixing temperature providing precipitation of the wax and / or asphaltenes or other solids from the flow of fluid hydrocarbons, and the effluent flow of hydrocarbons and particles is conveyed from the reactor (4) to a pipeline (6) for transportation.

Owner:SINVENT AS +2

Solid-liquid separation process

ActiveUS8211319B2Efficient separationSemi-permeable membranesCrystallization separationHigh concentrationFiltration

A process for separating solids from liquids in a filtration zone defined by a higher concentration zone and a lower concentration zone separated by a filter. The process includes the steps of directing a slurry feed comprising a liquid and solids into the higher concentration zone, directing a displacement fluid to the higher concentration zone and passing at least a portion of the liquid through a filter to the filtrate zone, producing a filtrate.

Owner:BP CORP NORTH AMERICA INC

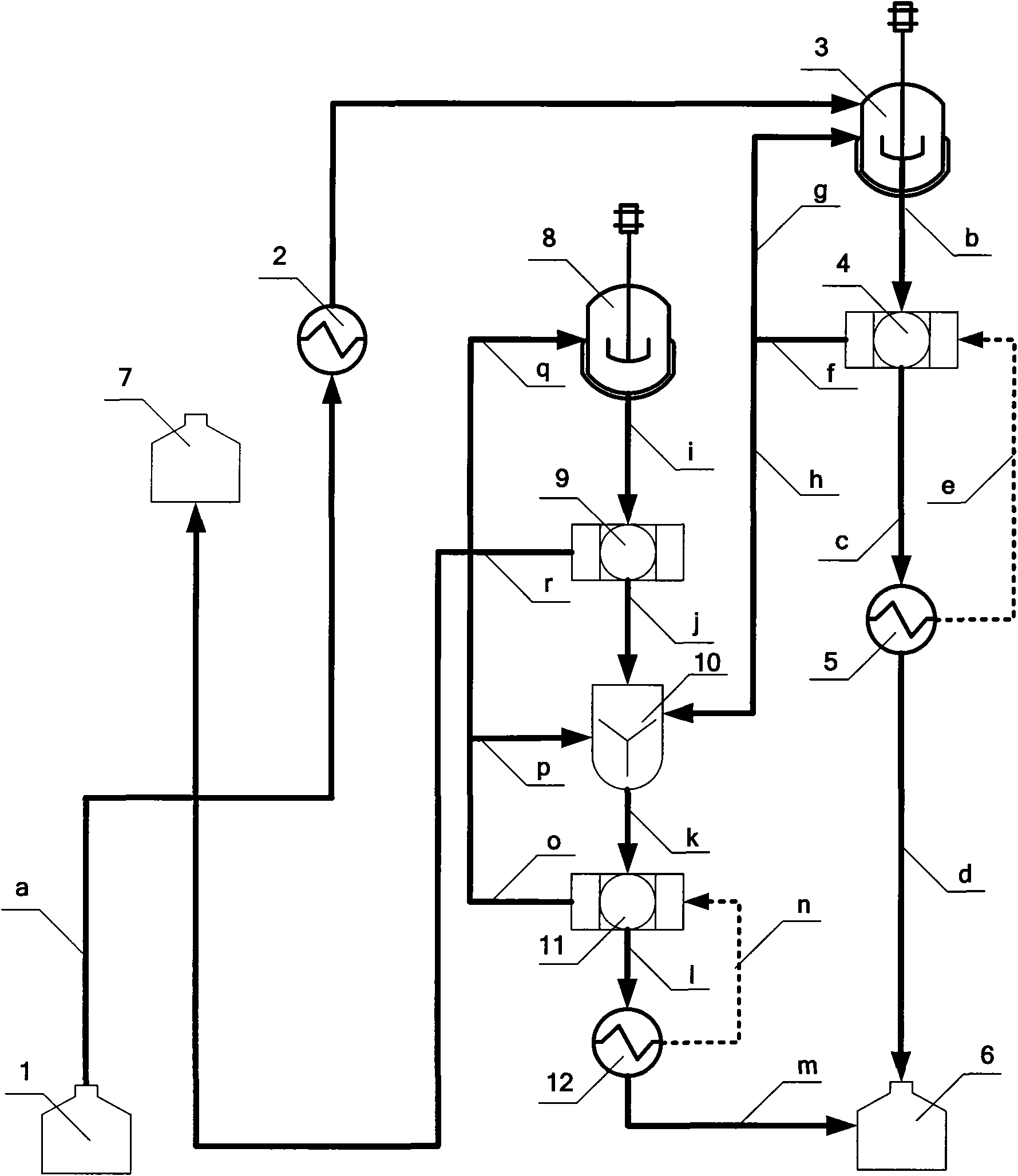

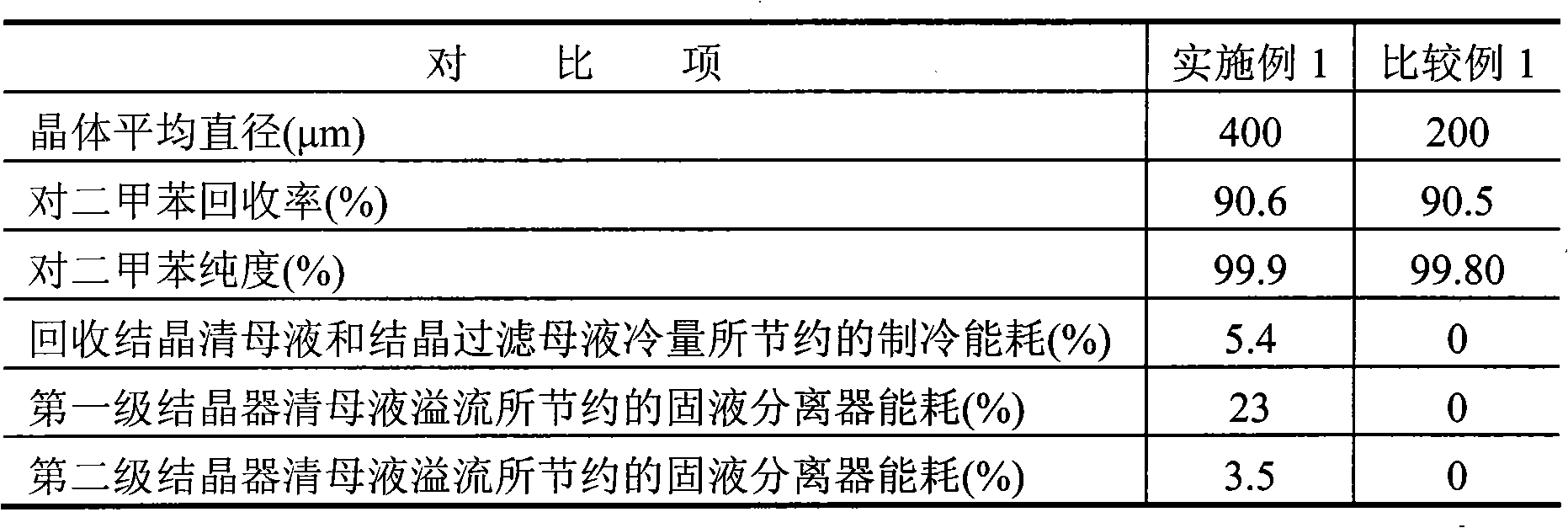

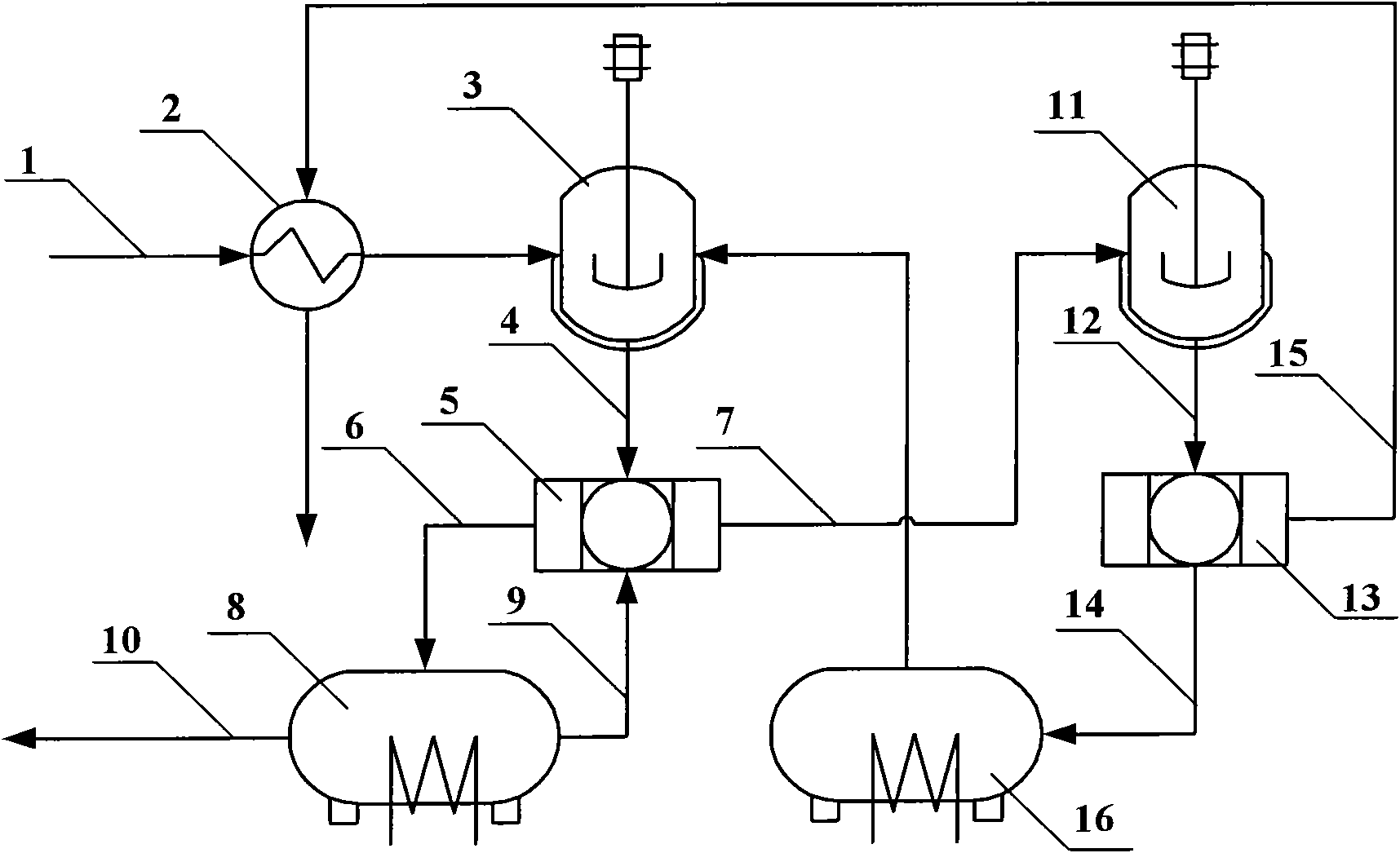

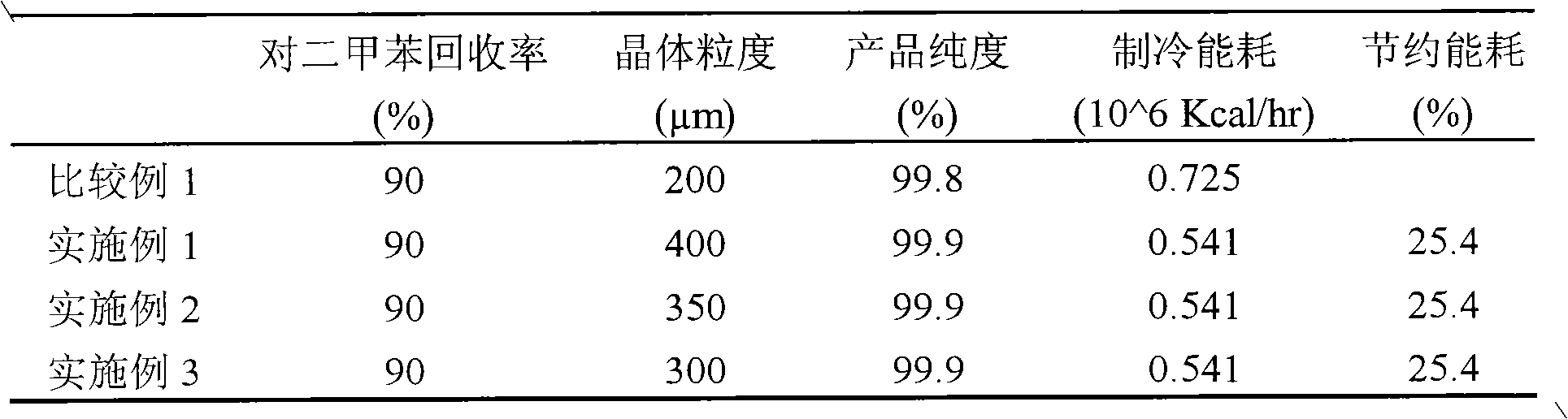

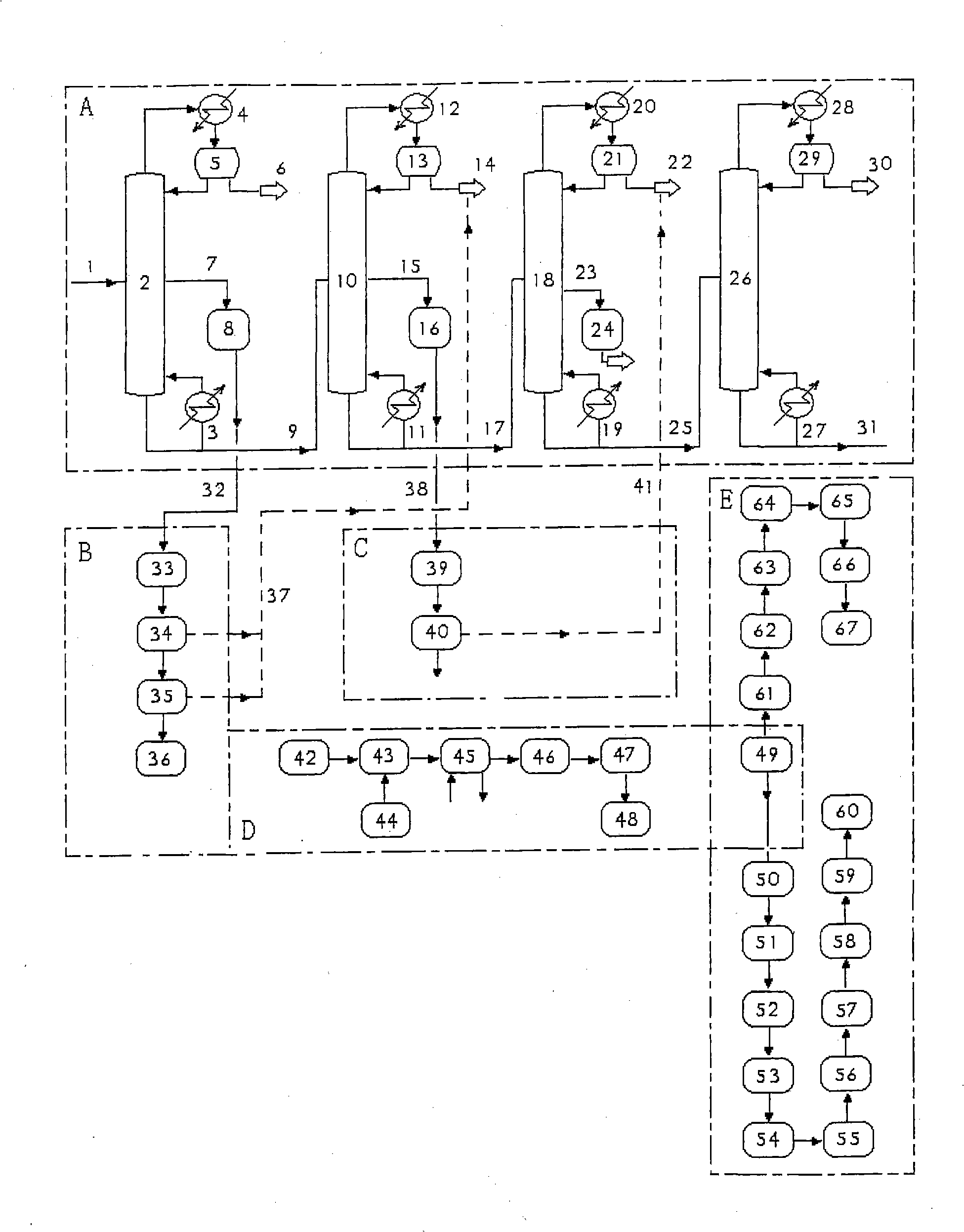

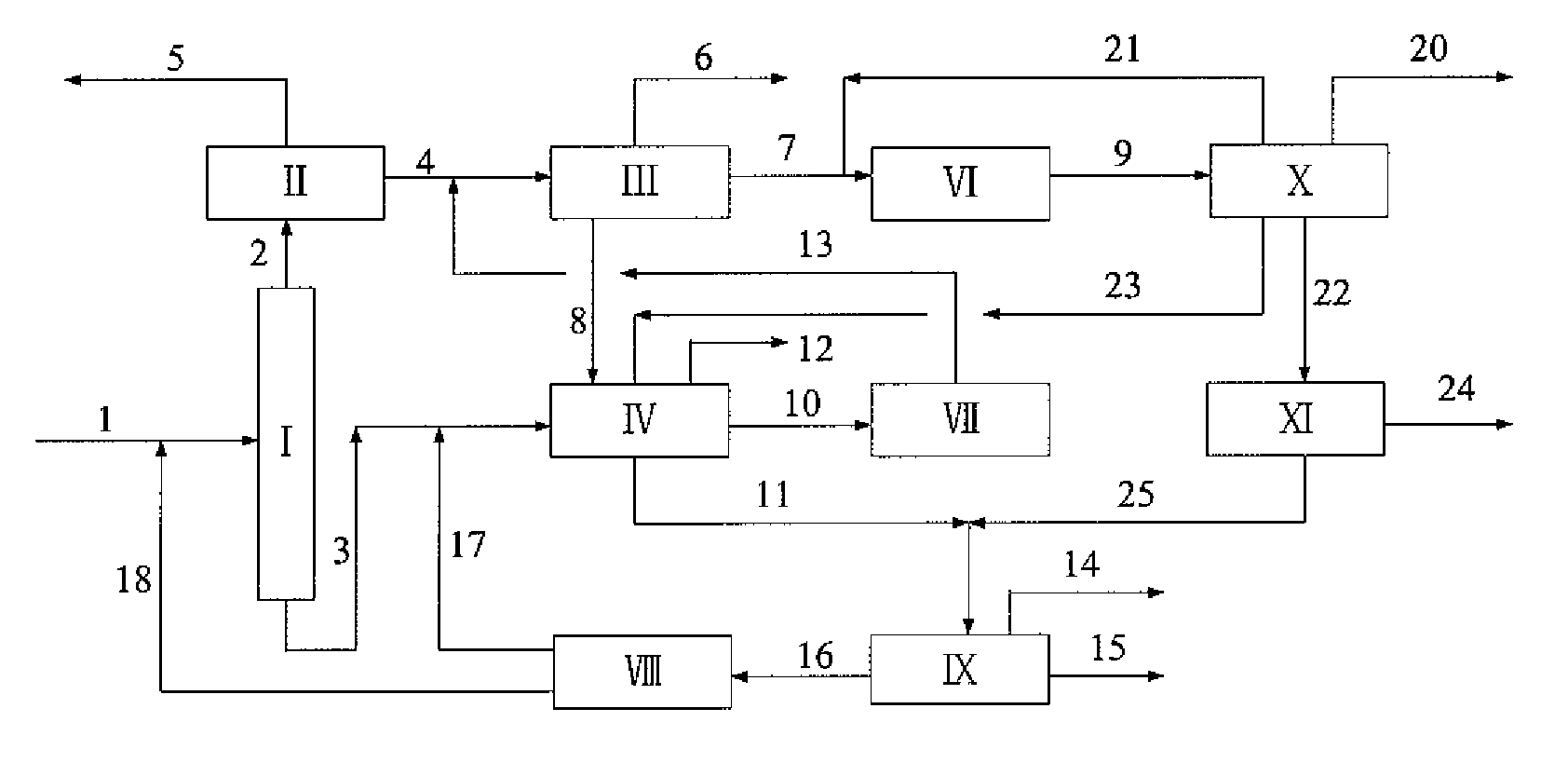

Method for preparing p-xylene by separating and crystallizing mixed xylenes

ActiveCN101941883AReduce energy consumptionReduce cooling energy consumptionHydrocarbonsCrystallisation purification/separationEnergy consumptionCrystallization

The invention relates to a method for preparing p-xylene by separating and crystallizing mixed xylenes, and mainly solves the problem of large energy consumption in a crystal separating process in the prior art. To well solve the problem, the invention adopts the following technical scheme of preparing the p-xylene by separating and crystallizing the mixed xylenes that: p-xylene crystal I and crystallization filtered stock I are obtained by crystallizing mixed xylenes in a primary crystallizer and separating crystal mush; the crystal I is melted by heat exchange, is partially returned to a first solid-liquid separator, and partially enters a product tank; the crystallization filtered stock I is separated into two streams, one stream returns to the crystallizer, and the other stream entersa pulping tank; one part of crystal mush in the primary crystallizer is cleared so as to obtain clear crystallization stock I which enters the pulping tank; p-xylene crystal II and crystallization filtered stock II are obtained by separating the crystal mush in a secondary crystallizer by a second solid-liquid separator; the crystal II enters the pulping tank, and separated after mixed heat exchange so as to obtain p-xylene crystal III and crystallization filtered stock III; the crystal III is melted by heat exchange, is partially returned to a third solid-liquid separator to be used as cleaning solution, and partially enters the product tank; the crystallization filtered stock II is separated into two streams, one stream returns to the secondary crystallizer, and the other stream enters the pulping tank; the crystallization filtered stock II and the mixed xylenes are subject to heat exchange and enter a stock tank; and the clear crystallization stock II and the mixed xylenes are subjected to heat exchange and enter the stock tank. The method can be used in p-xylene industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

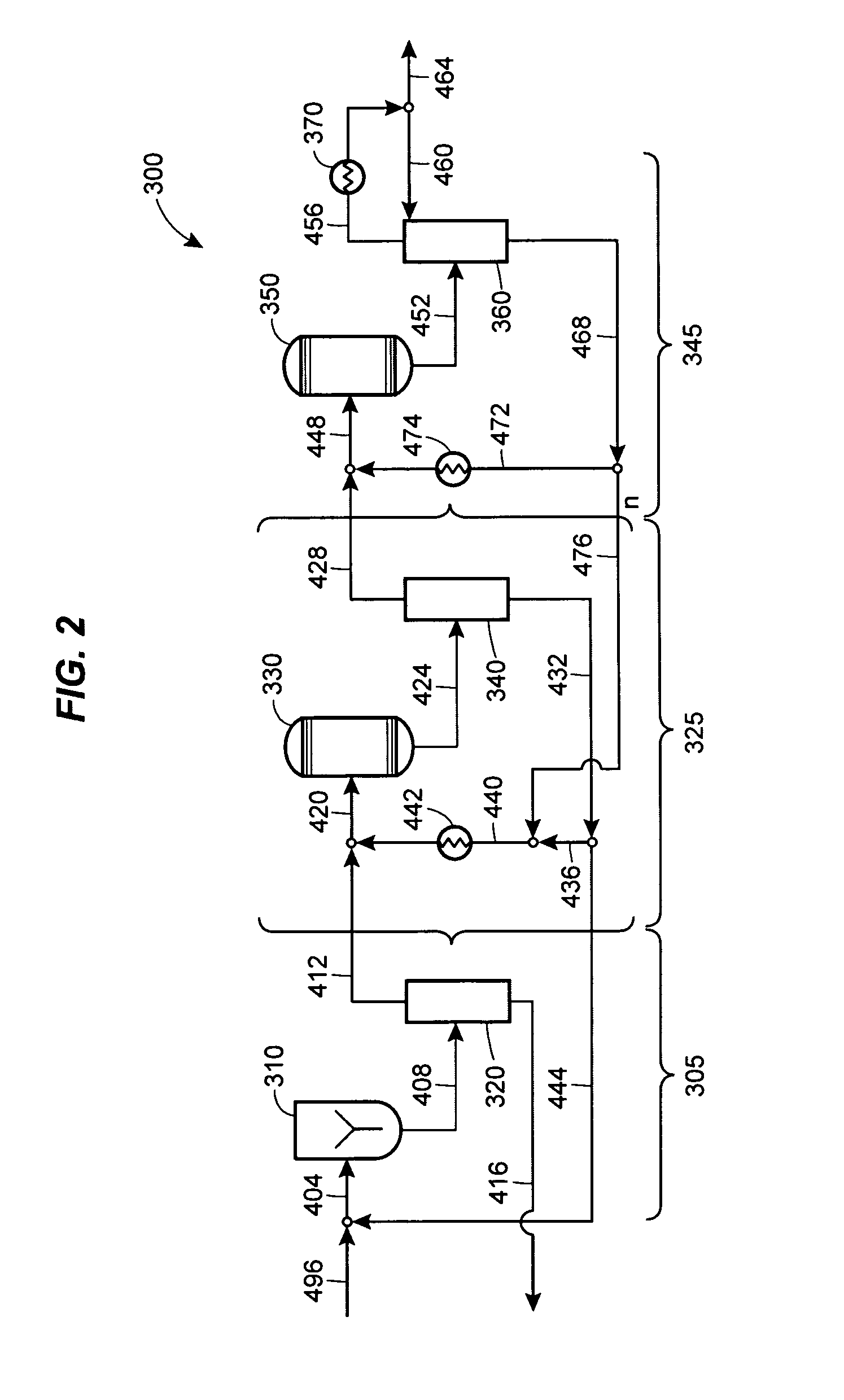

Apparatus and process for the separation of solids and liquids

A filter column apparatus comprising a filtration zone and a reslurry zone. These zones are separated by a barrier wall or are in substantial cooperation with each other. Also disclosed is a process for separating at least a portion of at least one substantially solid component from a solid-liquid stream comprising the substantially solid component and at least one substantially liquid component. Also disclosed is a process for forming a substantially solids containing packed bed. Also disclosed is a process for purifying paraxylene in a filtration zone.

Owner:BP CORP NORTH AMERICA INC

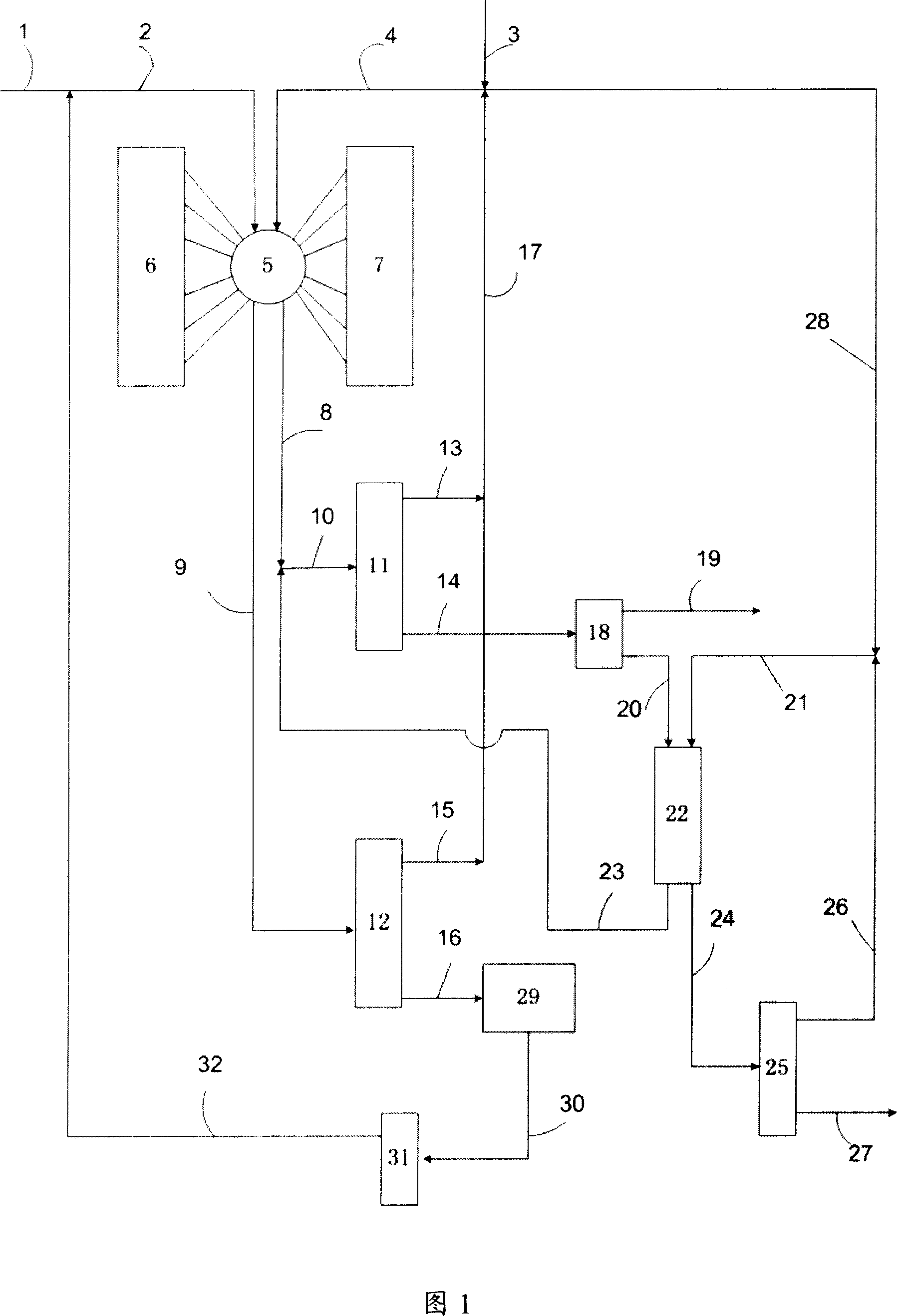

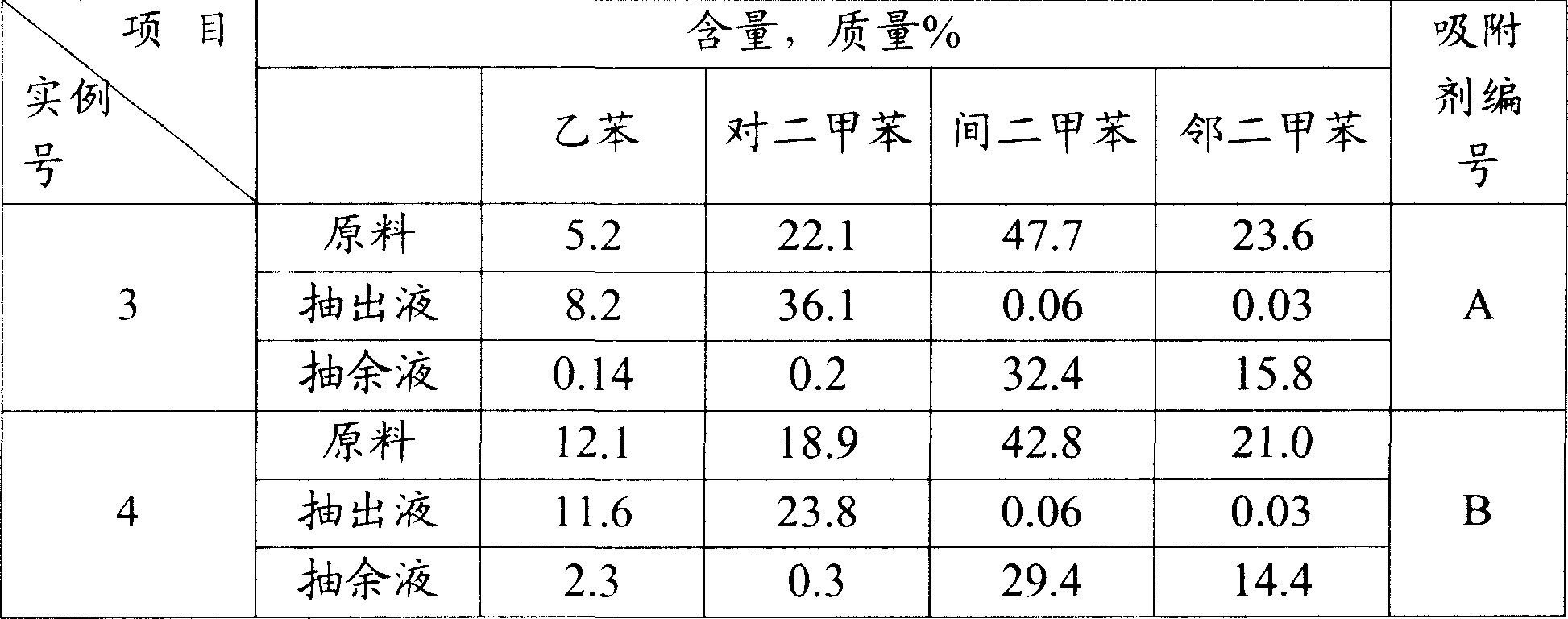

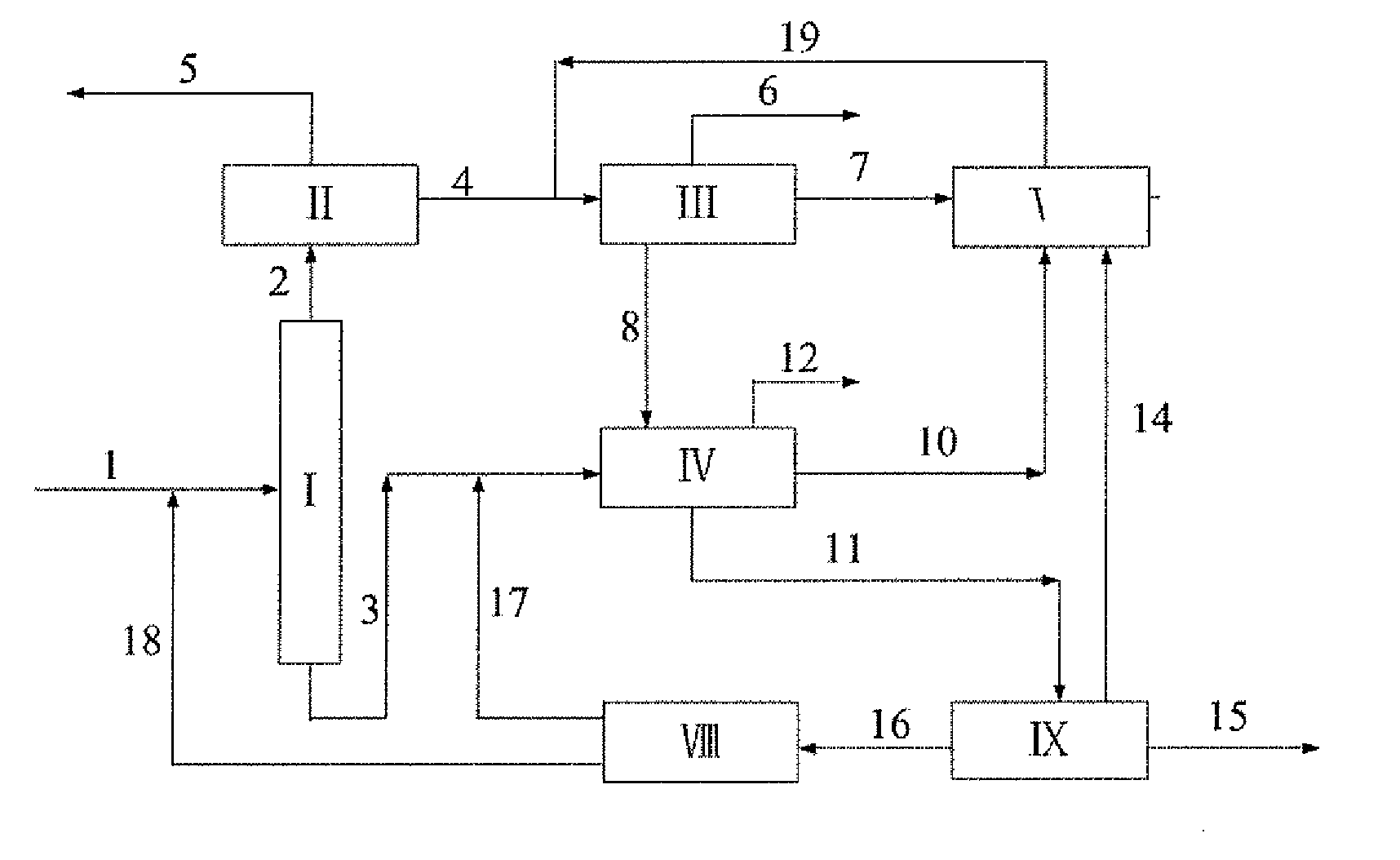

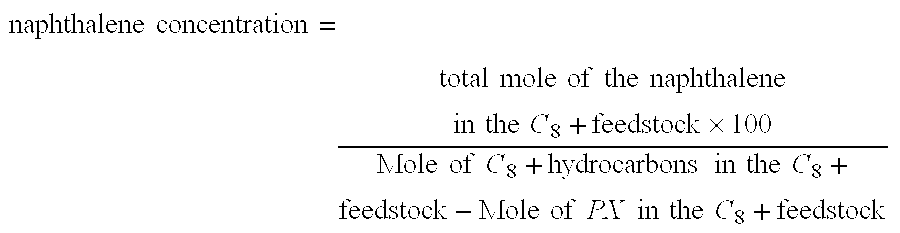

Method for adsorbing-crystal separation of paraxylene and ethylbenzene from C8 aromatic

ActiveCN101045671ALarge amount of processingHigh purityAdsorption purification/separationCrystallisation purification/separationO-XyleneIsomerization

An adsorbing-crystallizing process for separating p-xylene and ethylbenzene from C8 arylhydrocarbon includes such steps as adsorptive separation to obtain the first material flow containing ethylbenzene and p-xylene and the second material flow containing meta-xylene and o-xylene, crystallizing for separating p-xylene from the first material flow, and adsorbing for separating ethylbenzene from the residual mother liquid.

Owner:CHINA PETROLEUM & CHEM CORP +1

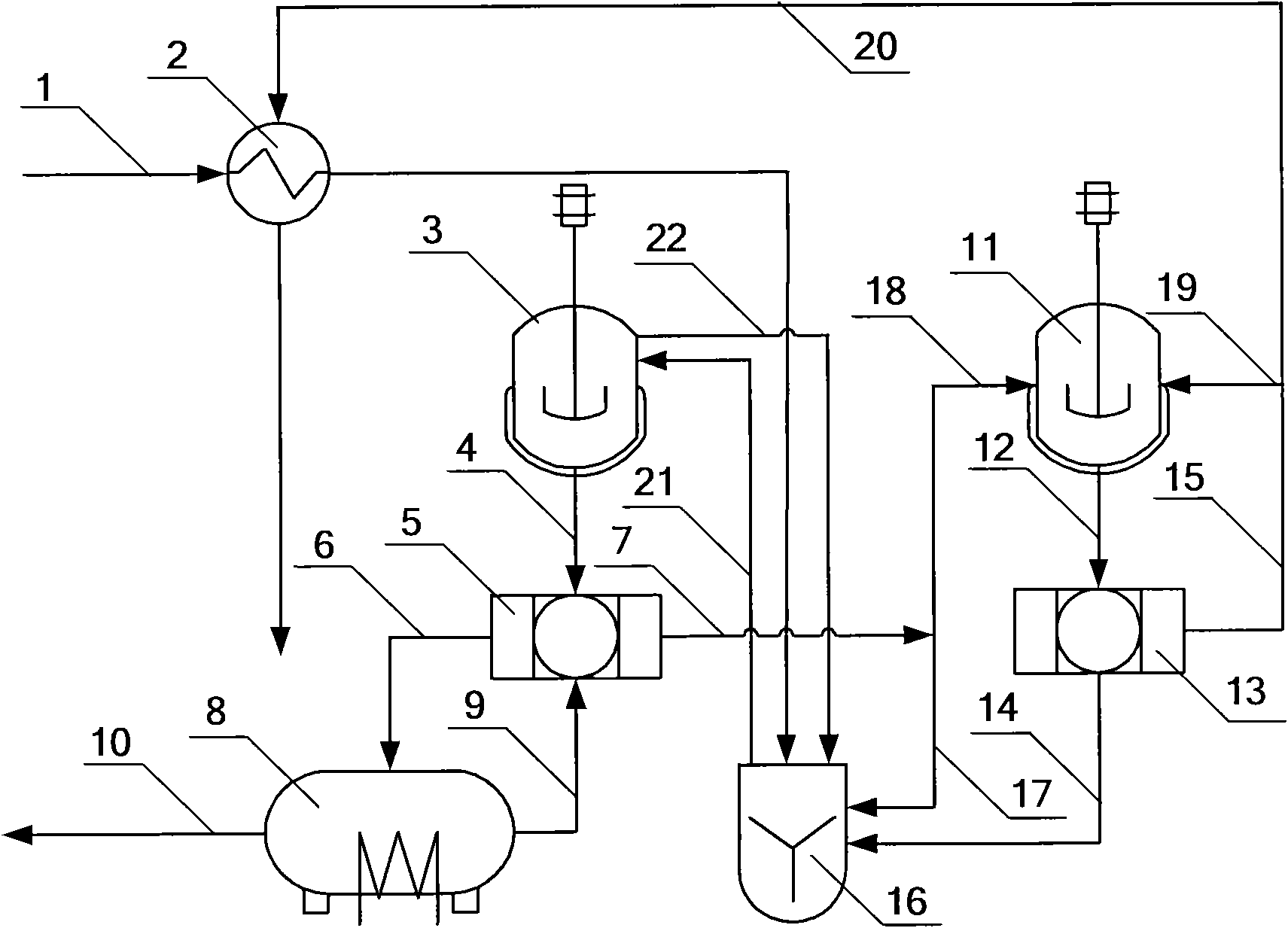

Crystallization method for p-xylene production

ActiveCN102372591AReduce cooling energy consumptionImprove technical effectCrystallisation purification/separationState of artEnergy consumption

The invention relates to a crystallization method for p-xylene production, and mainly aims to solve the problem of large energy consumption during crystallization separation in existing technologies. According to the method, a slurrying trough is arranged, and a p-xylene crystal obtained from a secondary crystallization process can be slurried so as to enter a first crystallizer, in which a clear mother solution enters the slurrying trough. The technical method of the invention well solves the above problem, and can be used for the industrial production of p-xylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

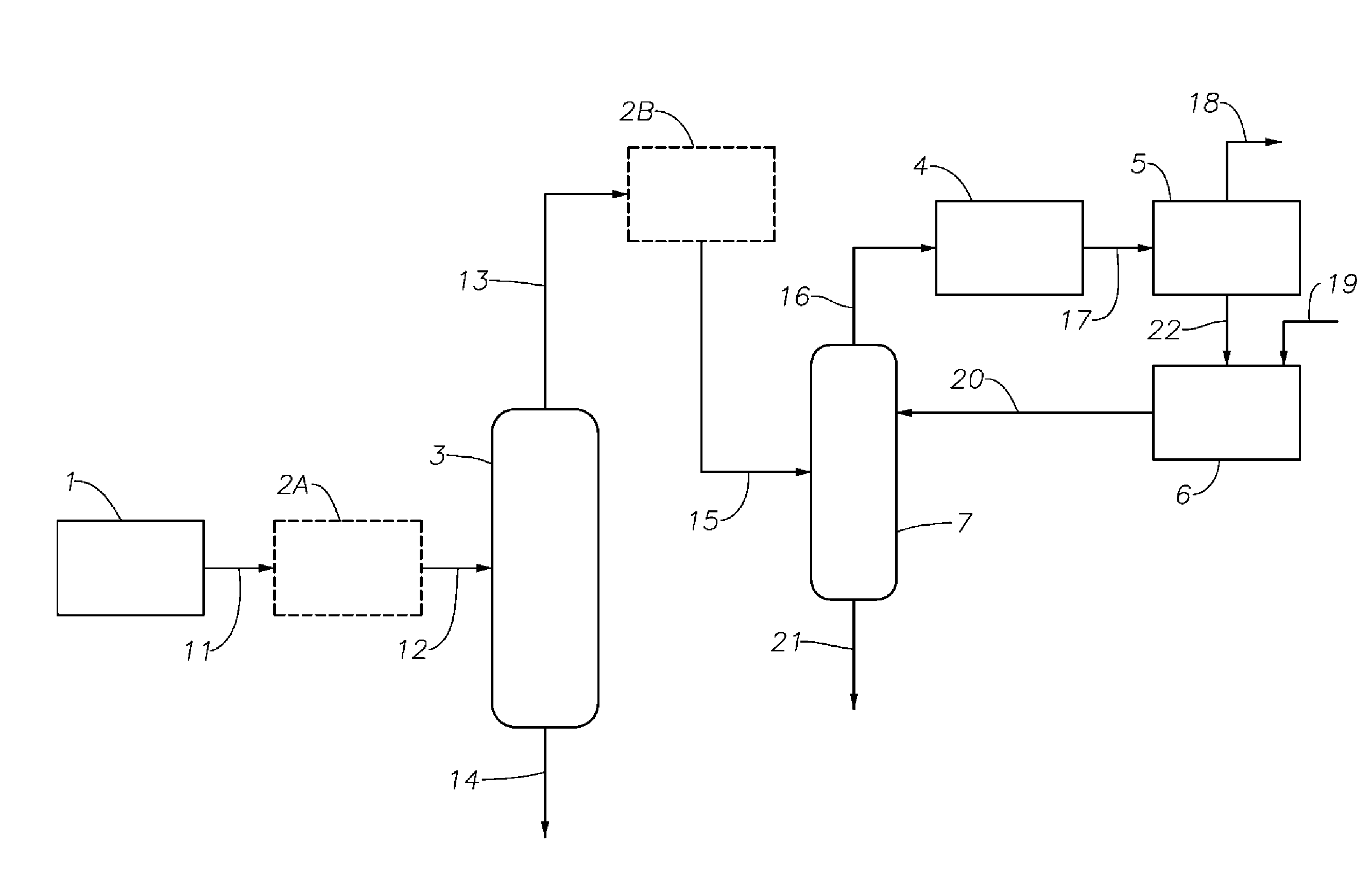

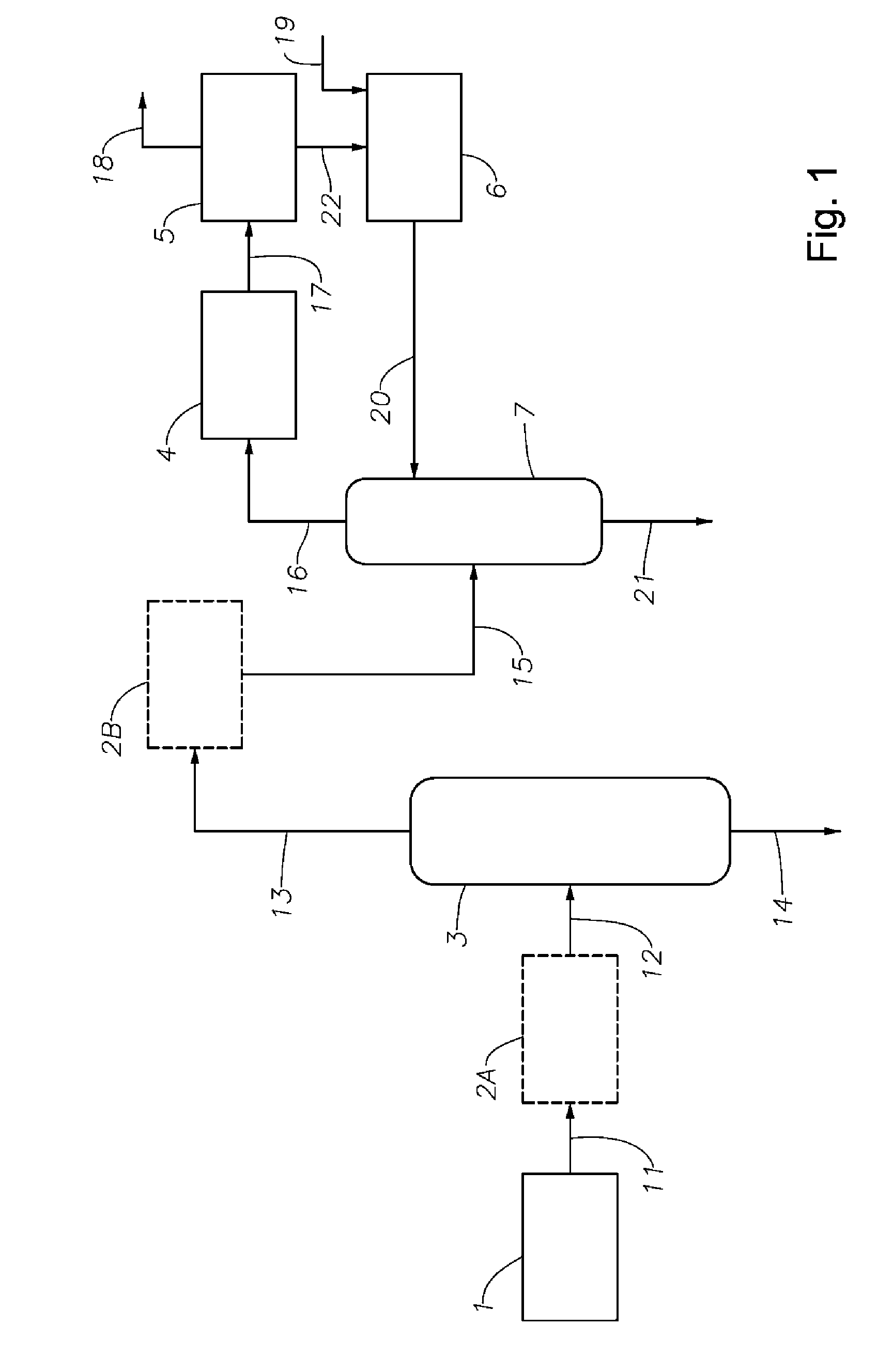

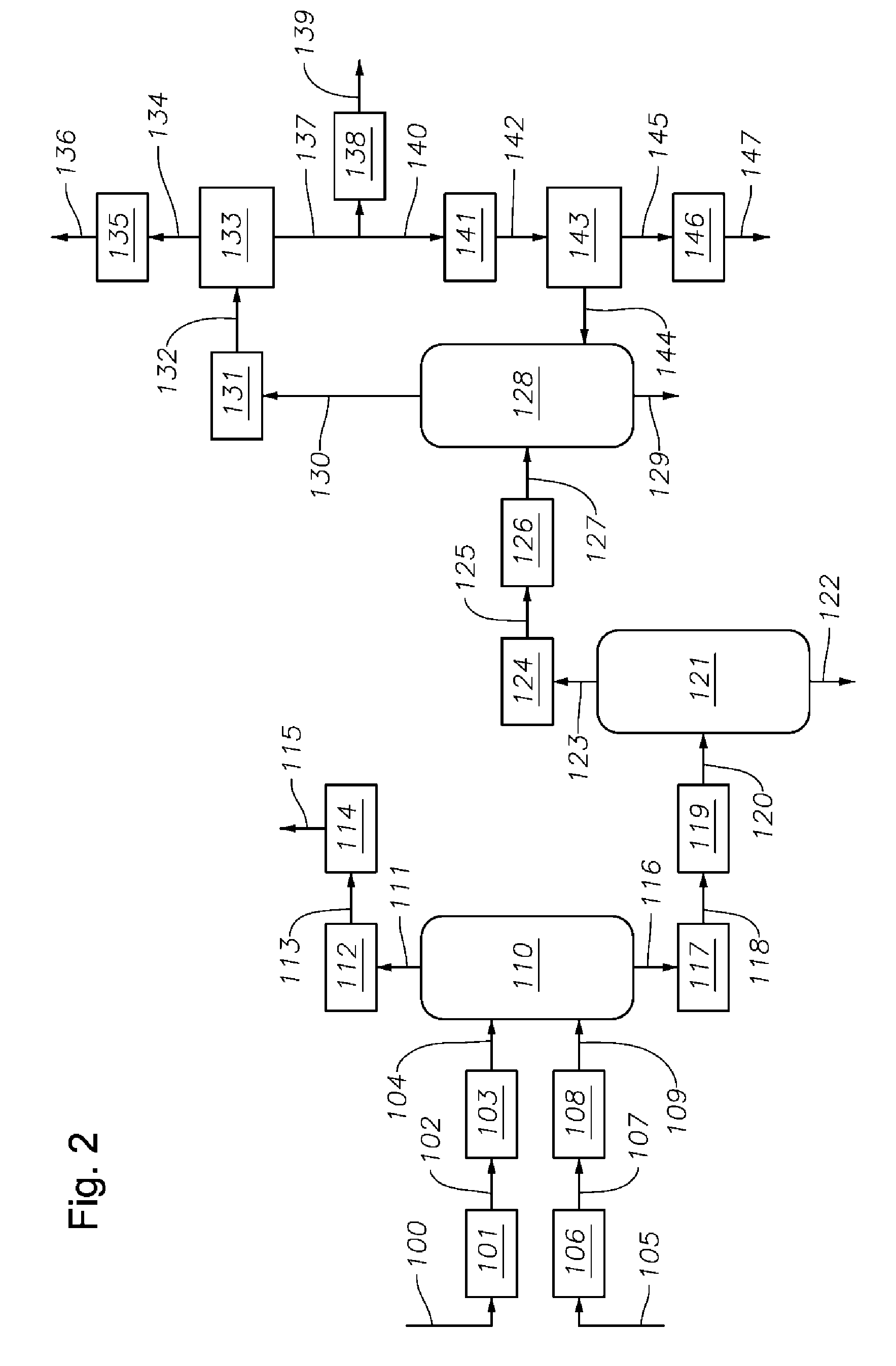

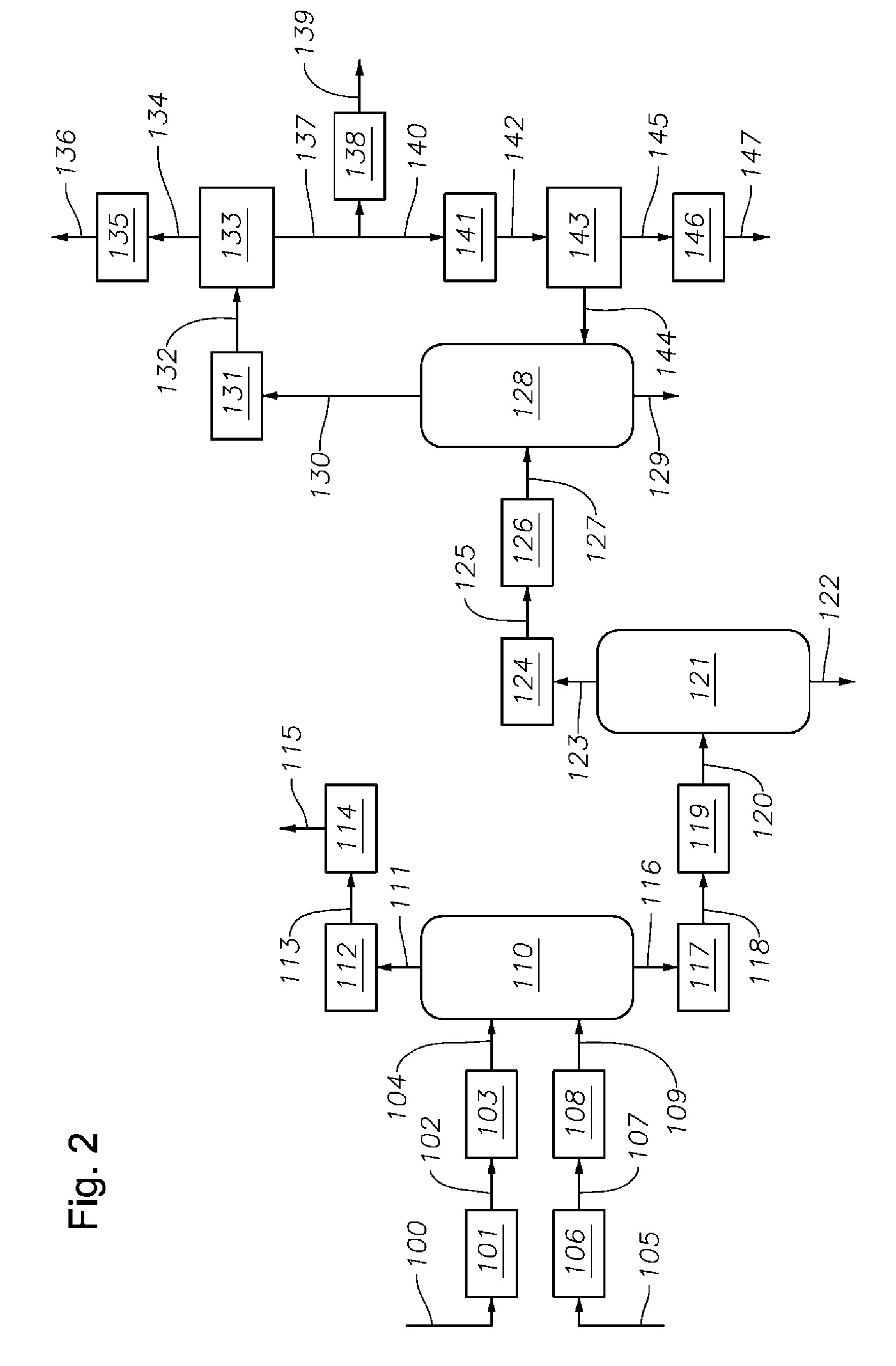

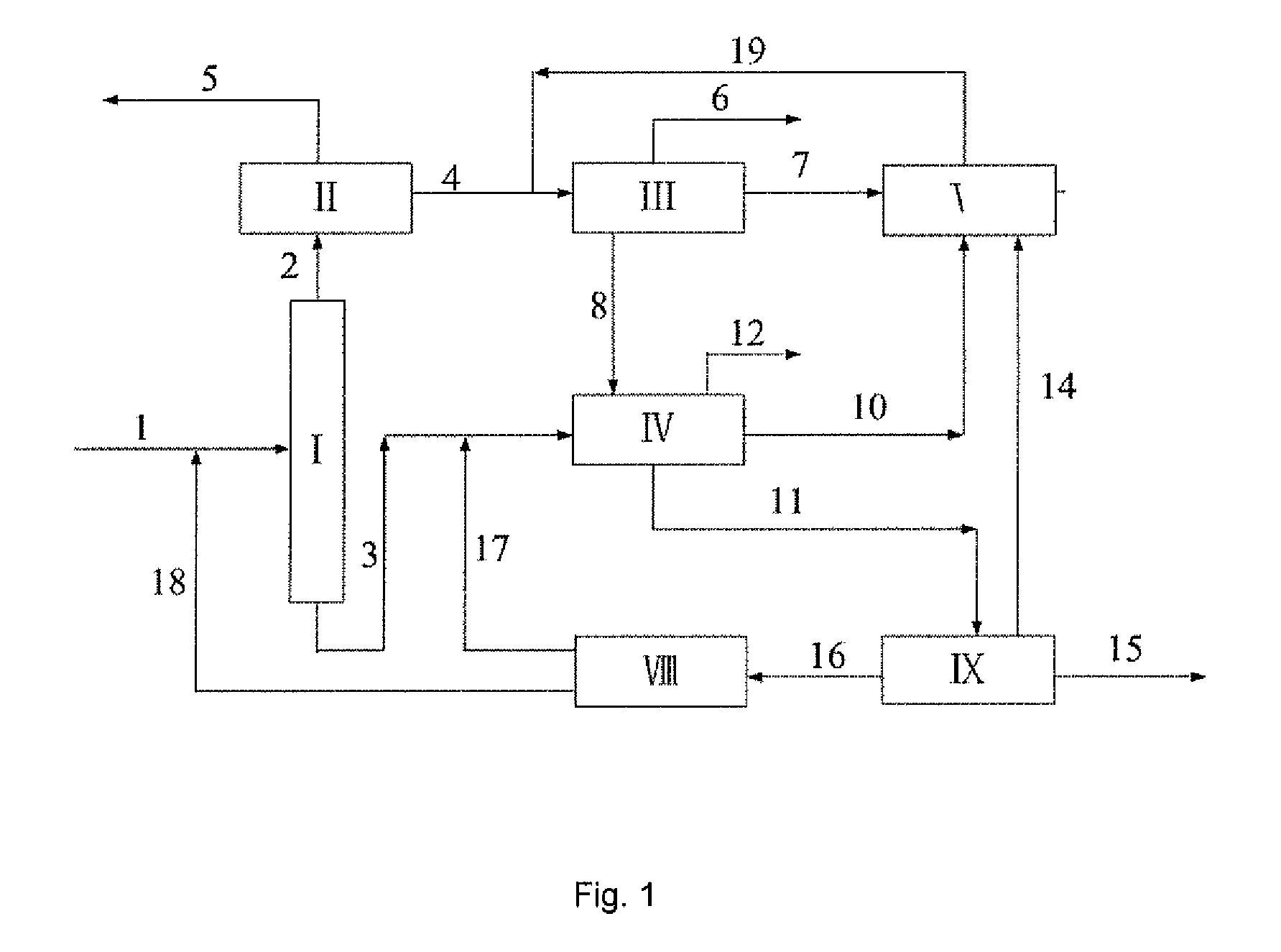

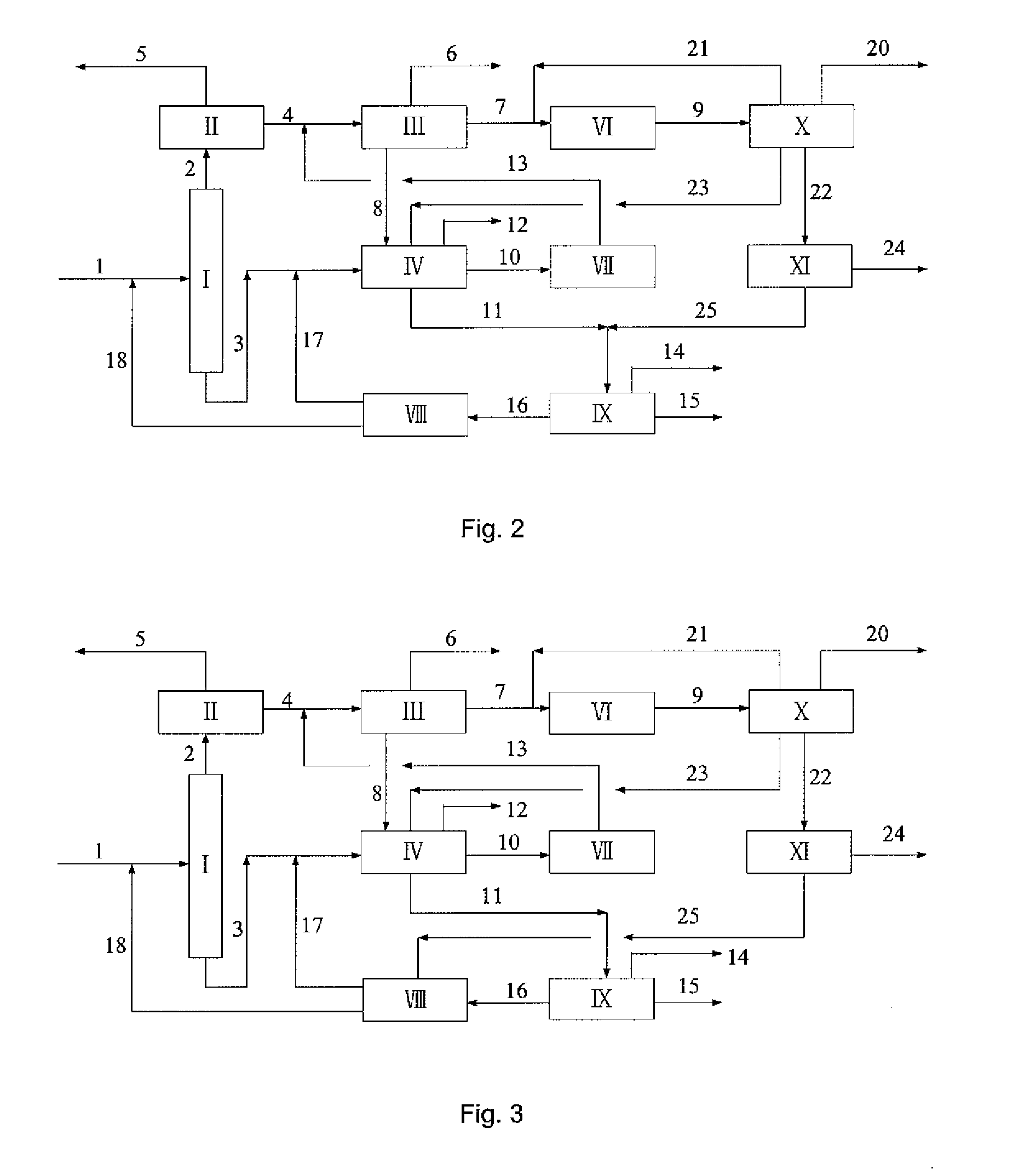

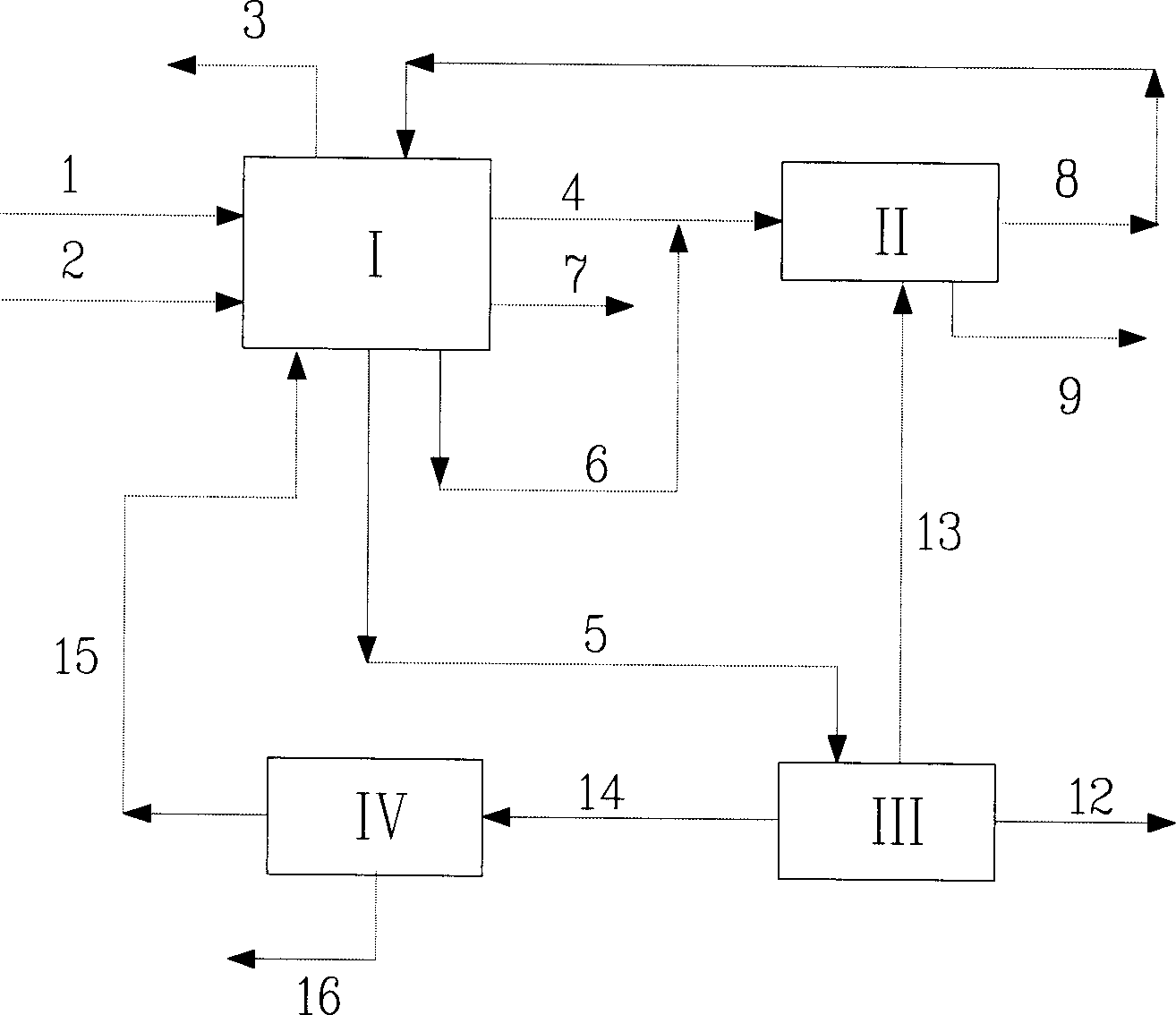

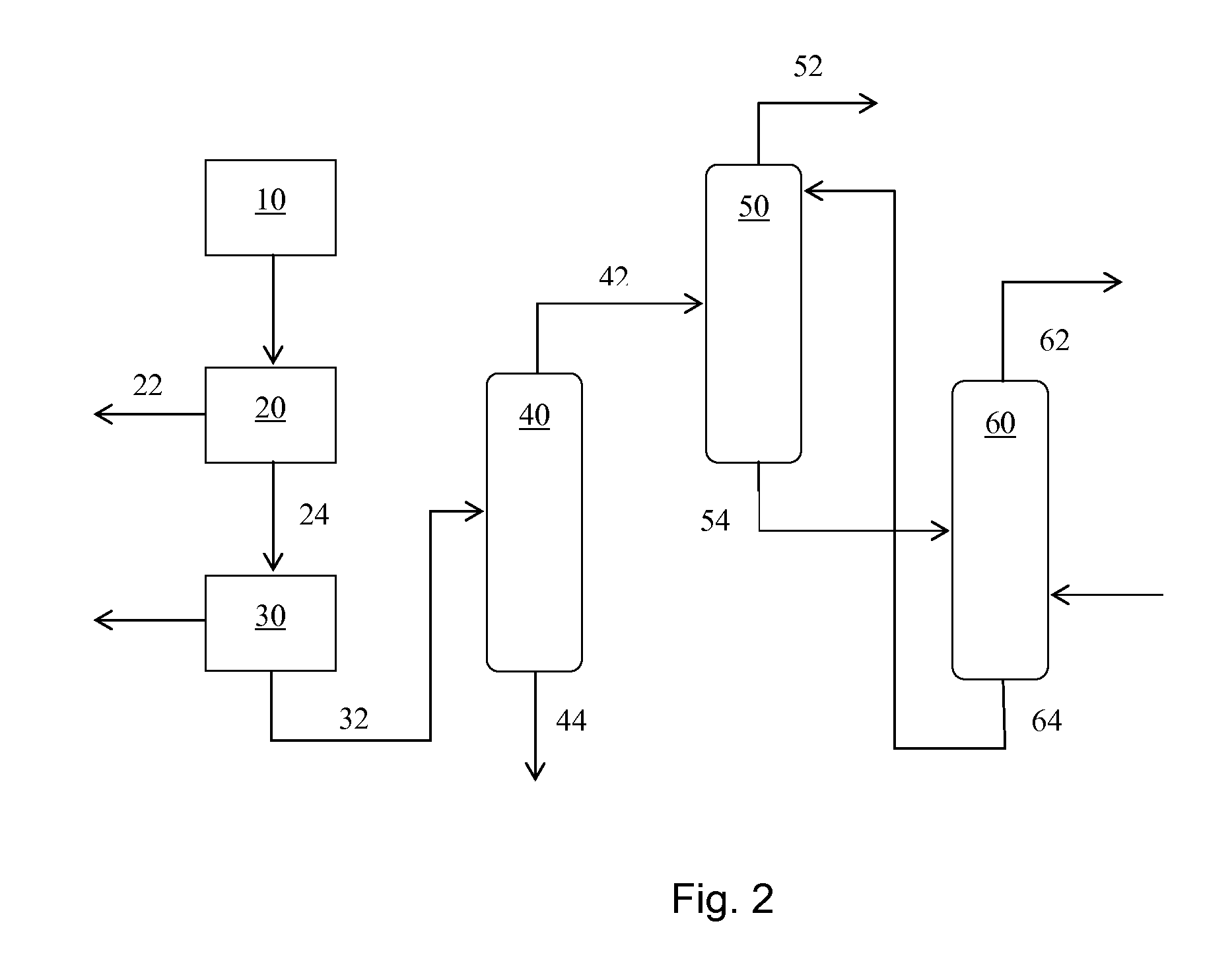

Integrated Process for the Production of P-Xylene

ActiveUS20100228066A1High energy consumptionImprove concentrationHydrocarbon by isomerisationMolecular sieve catalystsIsomerizationHydrogen

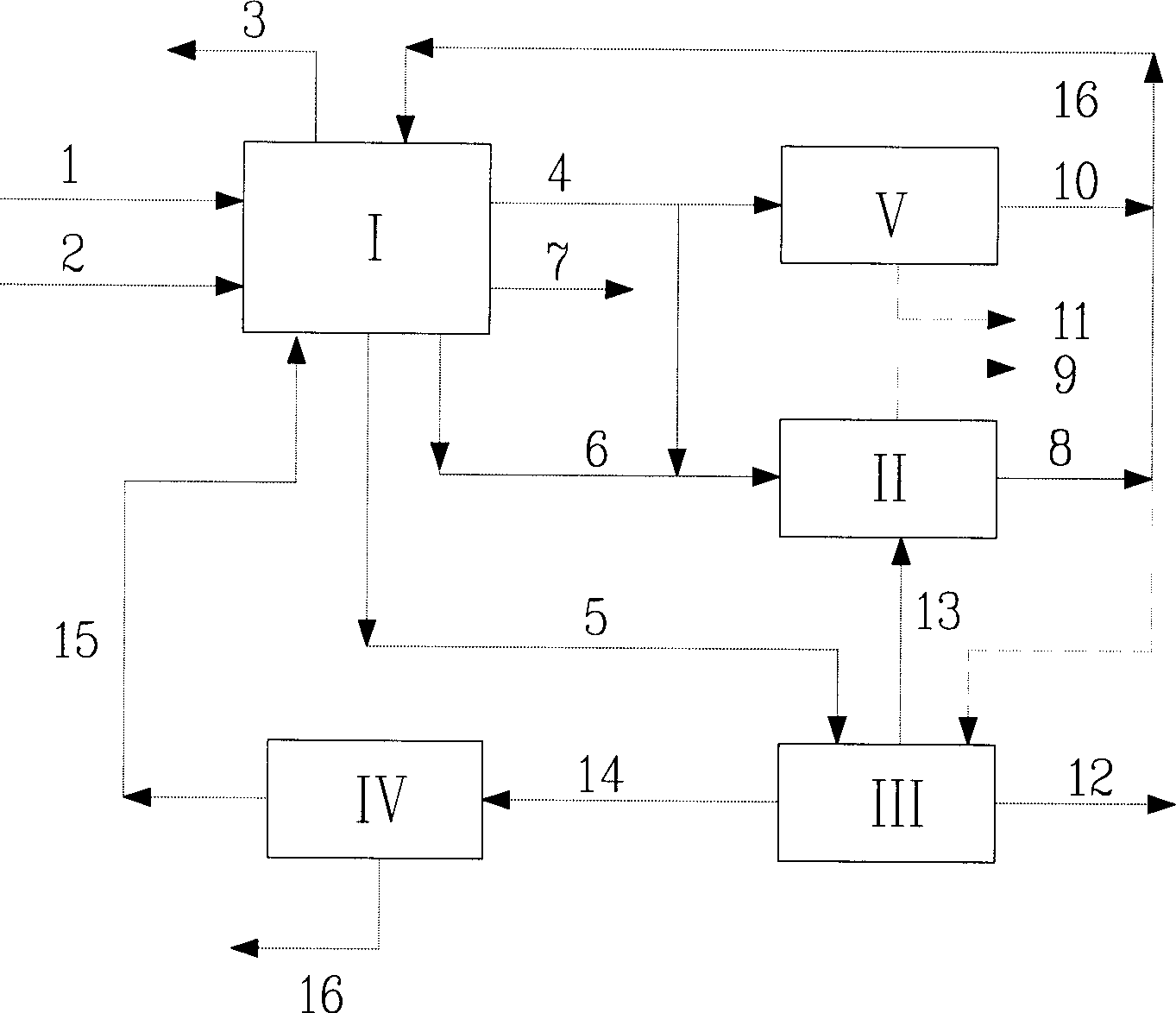

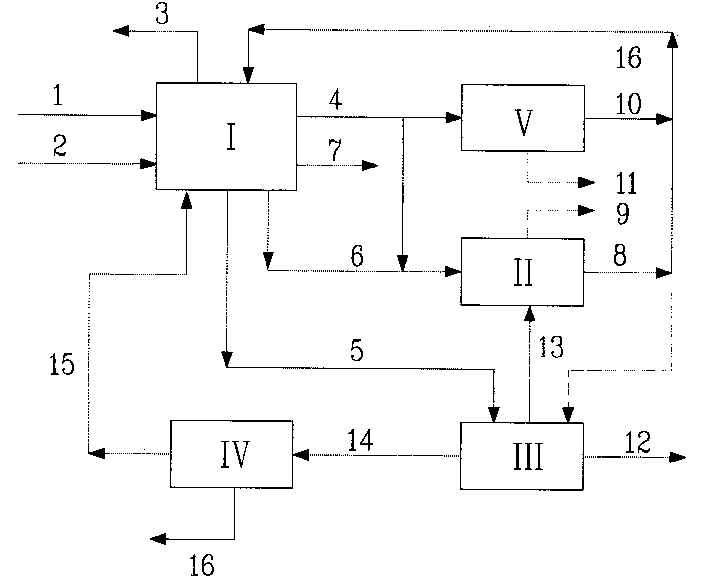

The present invention provides an integrated process for the production of p-xylene, comprising the steps of A) separating a mixed feedstock containing benzene, toluene, C8 aromatic hydrocarbons, C9 and higher aromatic hydrocarbons, and non-aromatic hydrocarbons from a reforming unit, to obtain a first benzene stream, a first toluene stream, a first C8 aromatic hydrocarbon stream, a stream of C9 and higher aromatic hydrocarbons, and a stream of non-aromatic hydrocarbons; B) feeding the stream of C9 and higher aromatic hydrocarbons from step A) to a C9 and higher aromatic hydrocarbon dealkylation unit, where dealkylation reaction occurs in the presence of hydrogen, and separating the reaction effluent to obtain a second benzene stream, a second toluene stream, and a second C8 aromatic hydrocarbon stream; C) feeding both the first toluene stream and the second toluene stream to a toluene selective disproportionation unit, where toluene selective disproportionation reaction occurs in the presence of hydrogen to produce a stream containing C8 aromatic hydrocarbons including p-xylene and benzene, which stream is separated to obtain a third C8 aromatic hydrocarbon stream, a third toluene stream, and a third benzene stream, with the third toluene stream being returned to an inlet of this unit; D) feeding both the first C8 aromatic hydrocarbon stream and the second C8 aromatic hydrocarbon stream to an adsorption separation unit, to obtain a first p-xylene product stream and a fifth C8 aromatic hydrocarbon stream, with the fifth C8 aromatic hydrocarbon stream being passed to an isomerization unit; E) feeding the third C8 aromatic hydrocarbon stream to a crystallization separation unit, to obtain a fourth C8 aromatic hydrocarbon stream and a second p-xylene product stream, with the fourth C8 aromatic hydrocarbon stream being passed to the adsorption separation unit or the isomerization unit; and F) feeding an effluent of the isomerization unit to an inlet of the adsorption separation unit.

Owner:CHINA PETROCHEMICAL CORP +1

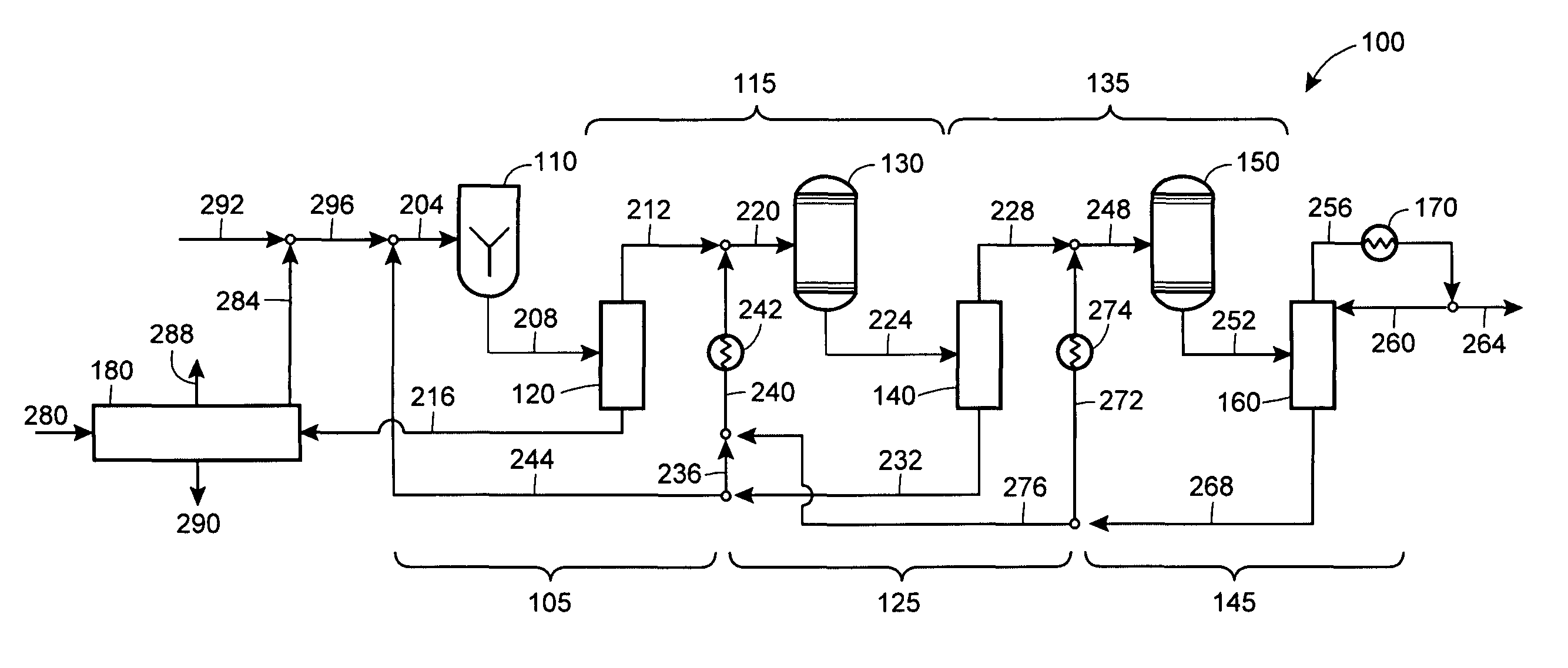

Process for the Production of Paraxylene

InactiveUS20120108868A1Weaken energyHydrocarbon by isomerisationDistillation purification/separationIsomerizationVapor phase

A process for the purification of aromatic feedstream to produce paraxylene is disclosed, including the separation of a C8+ aromatic feedstream into a steam comprising C8 aromatic species and a stream comprising C9+ aromatic species. After separation of PX from the C8 aromatic stream, a PX-depleted stream is separated and processed in a liquid phase isomerization unit and a vapor phase isomerization unit in parallel.

Owner:EXXONMOBIL CHEM PAT INC

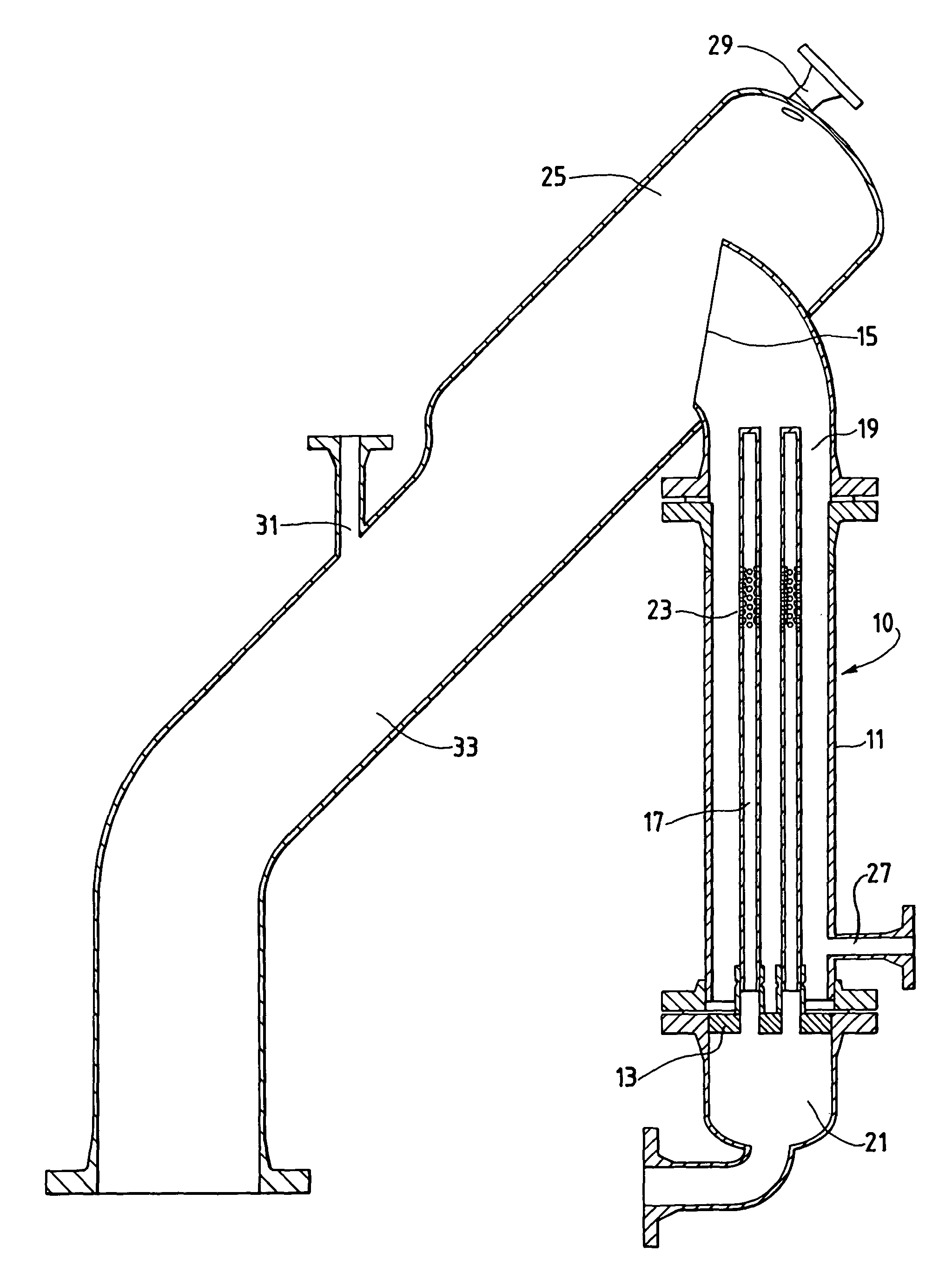

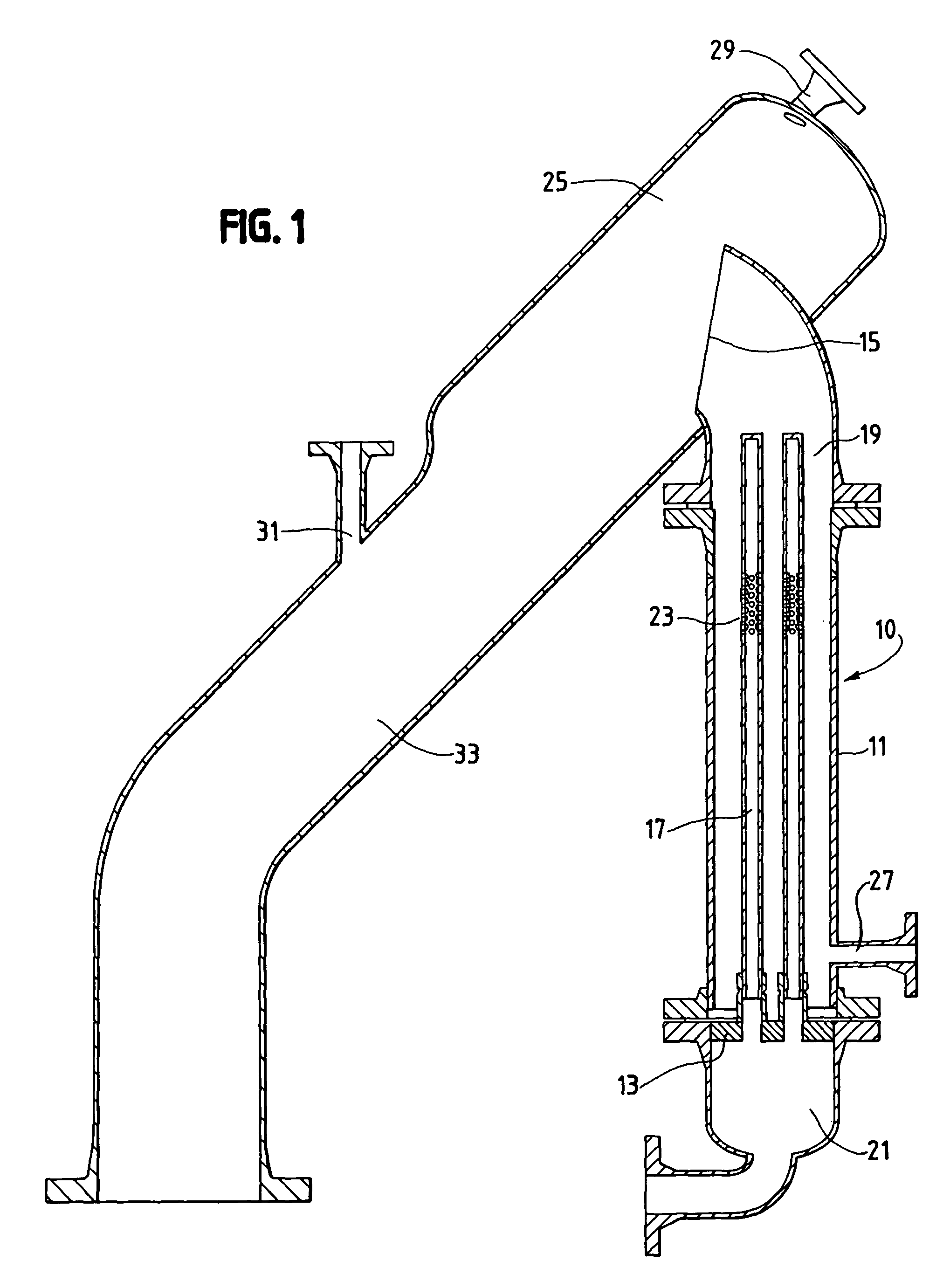

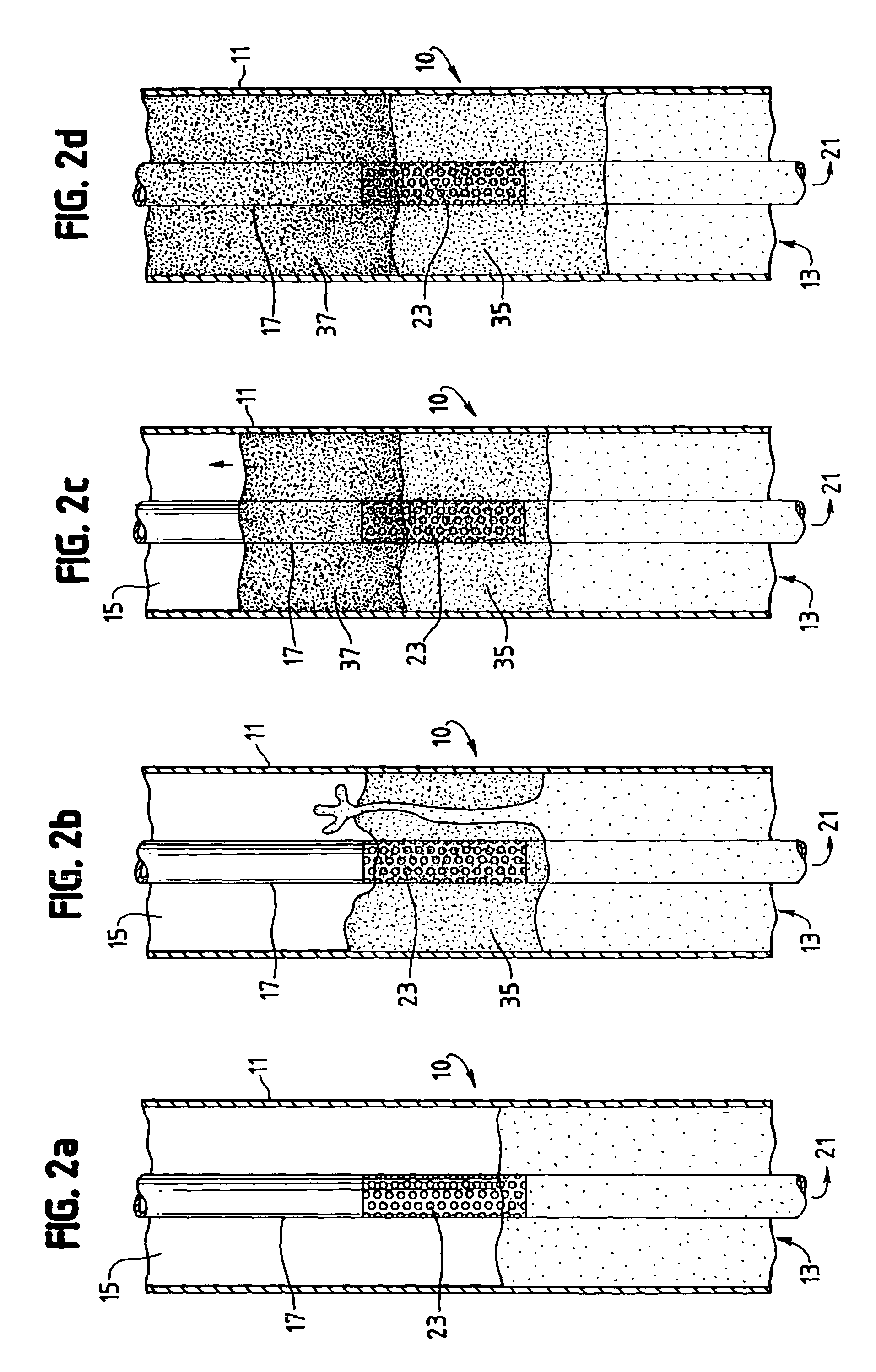

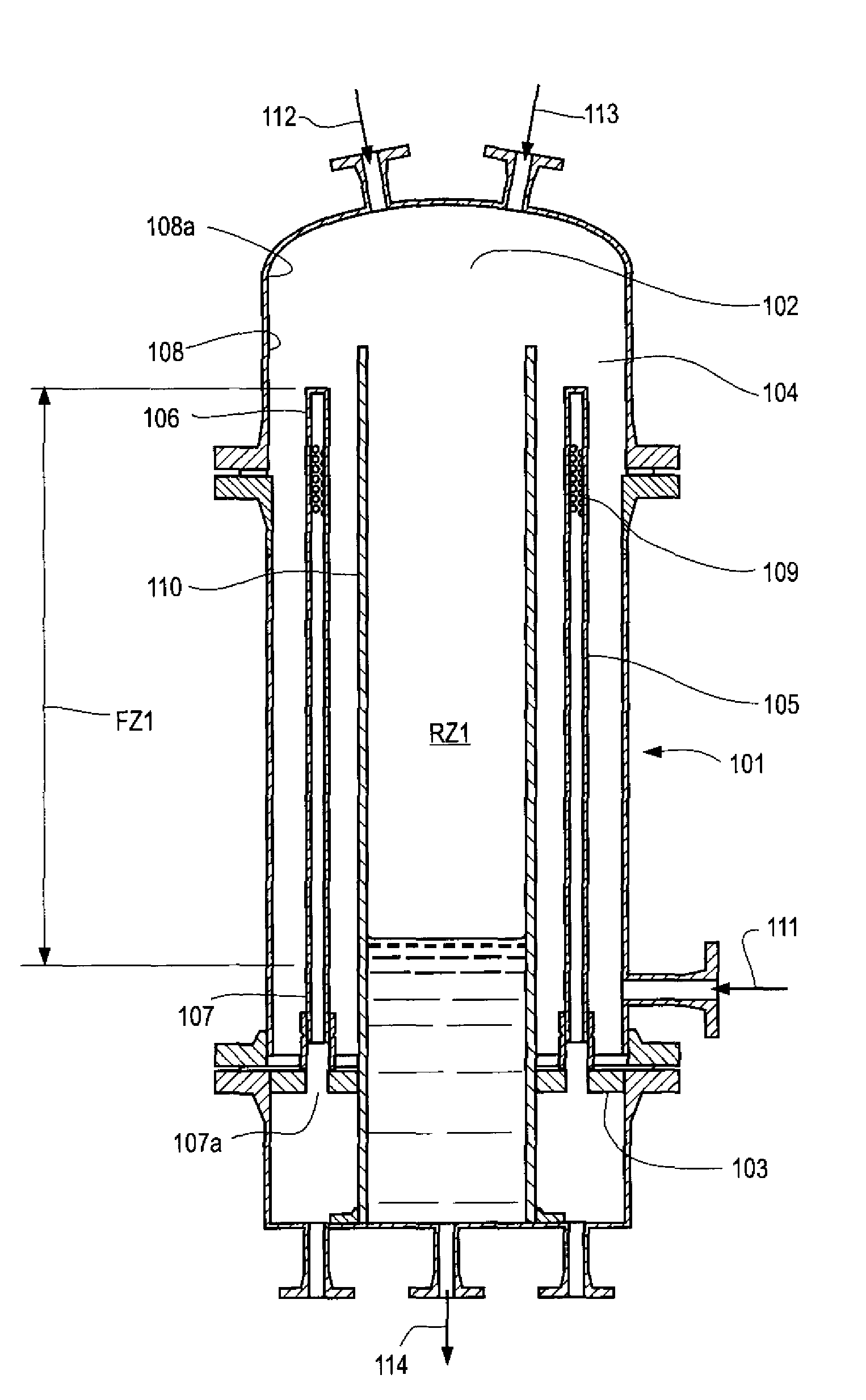

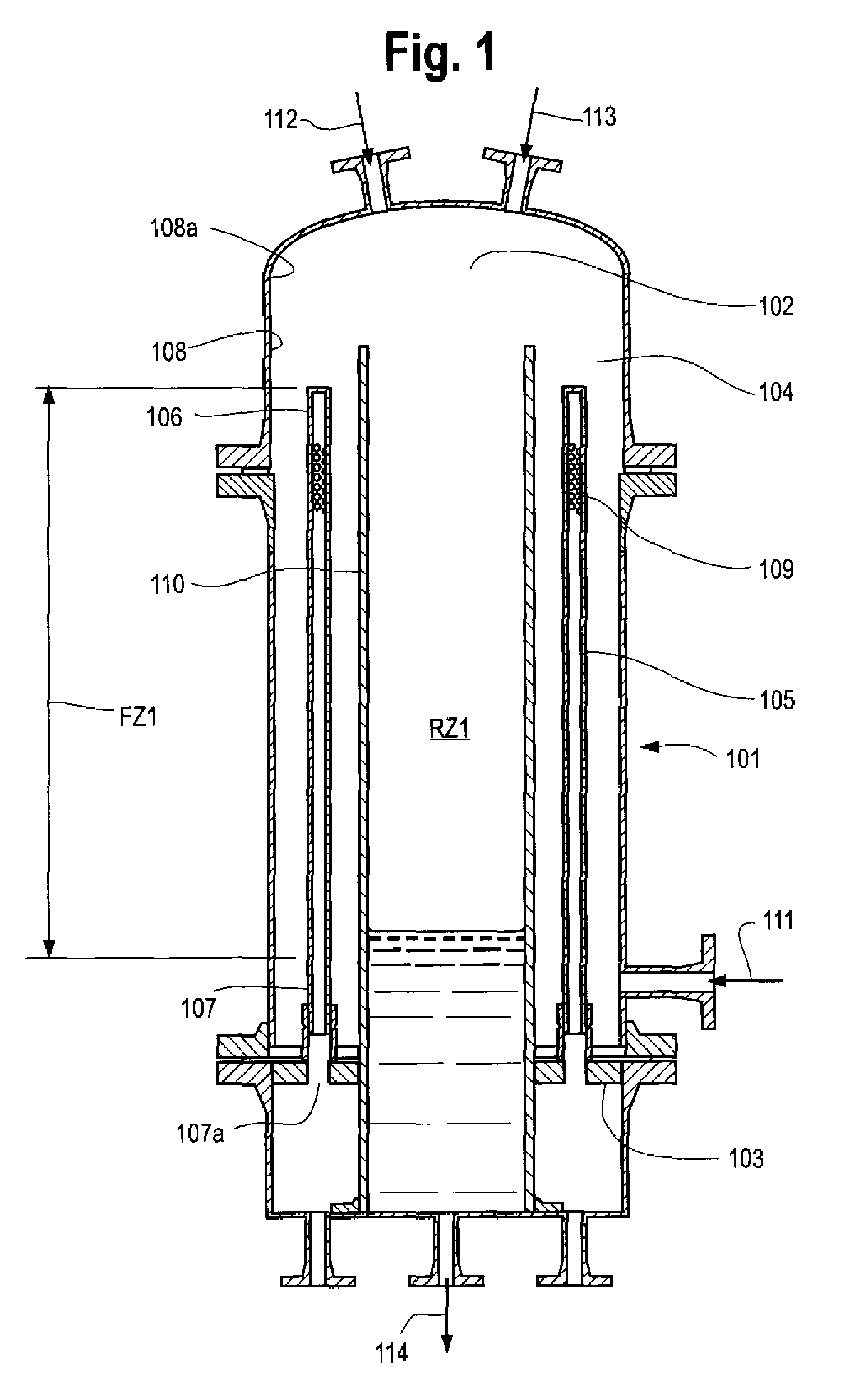

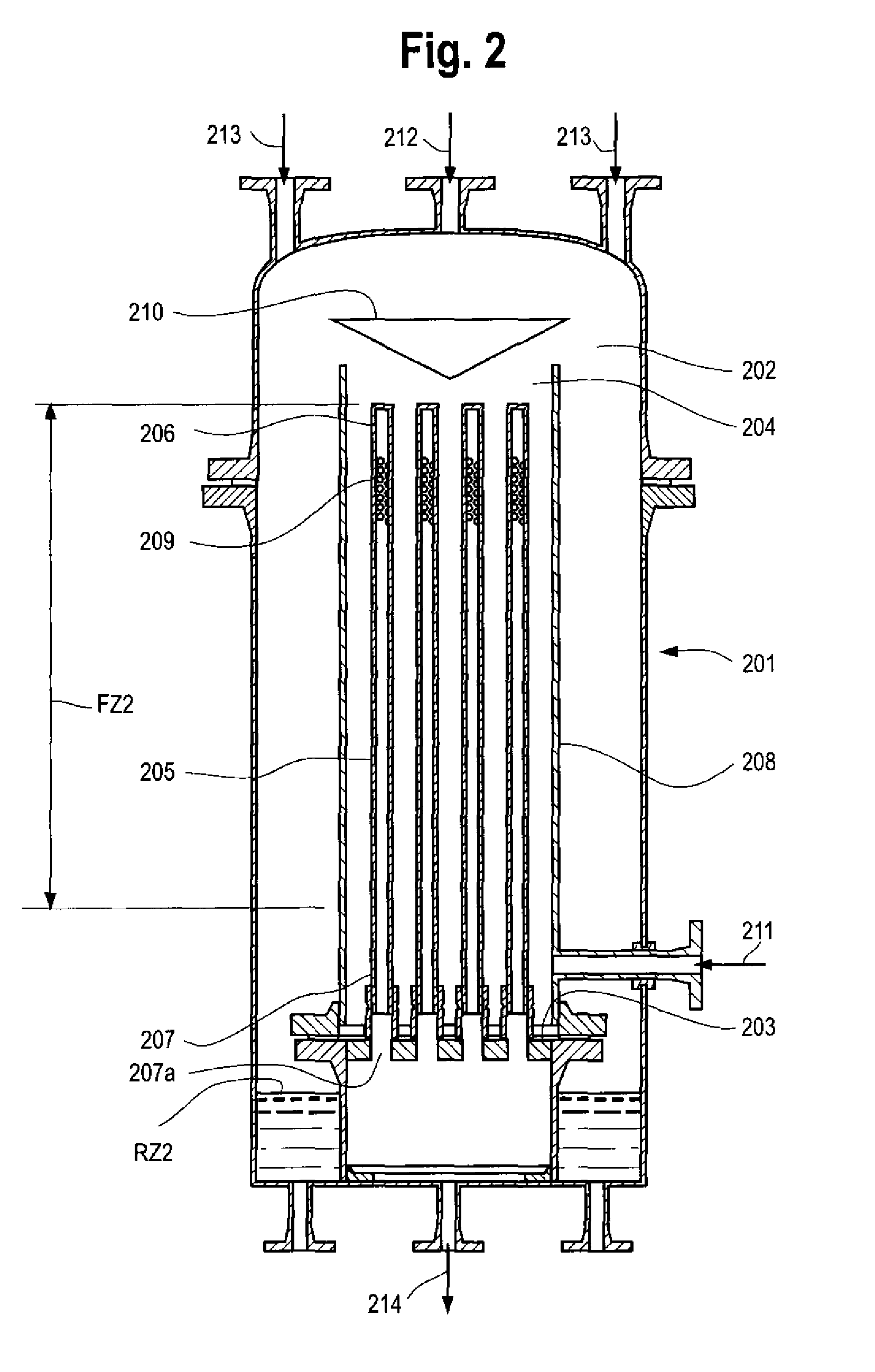

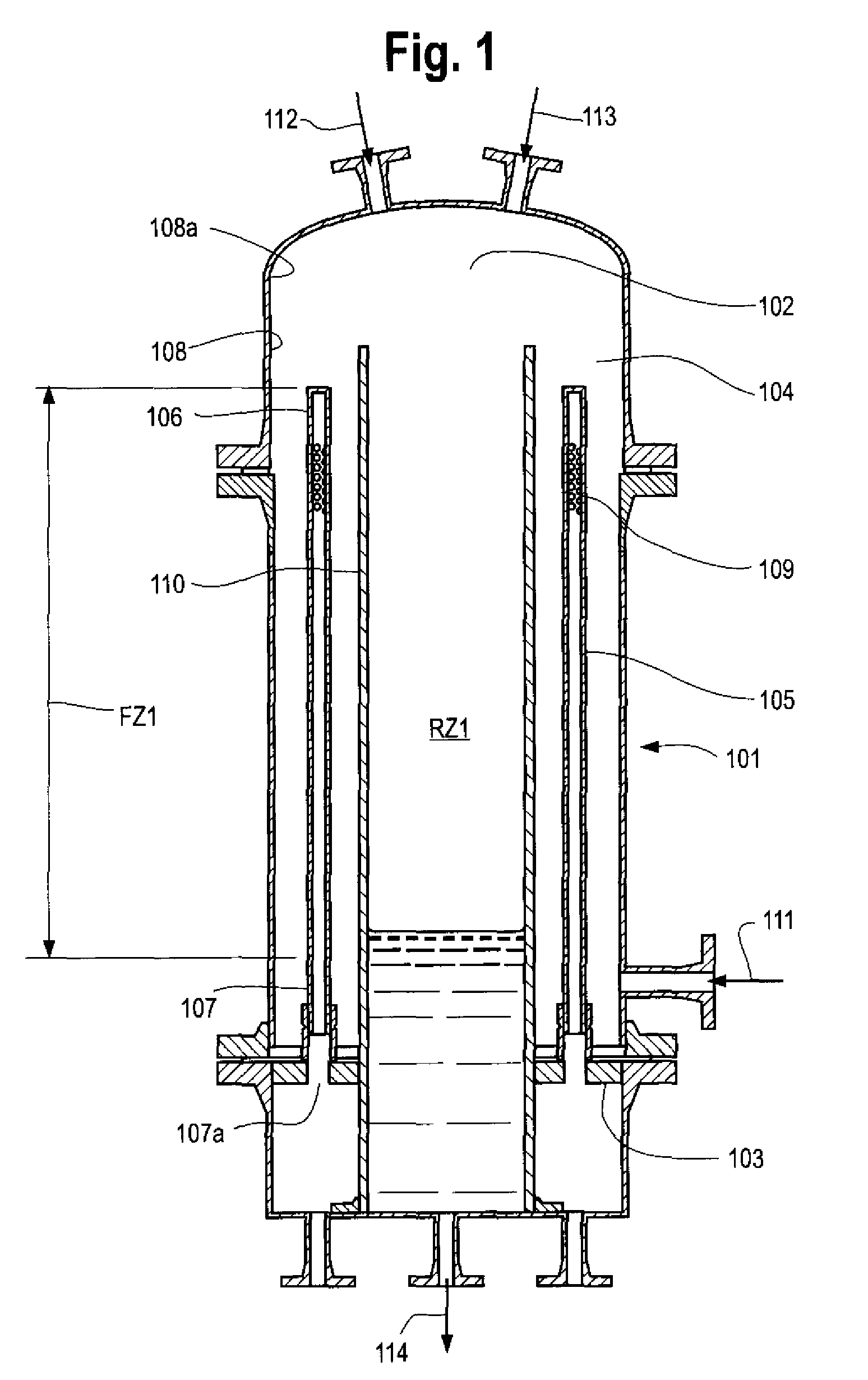

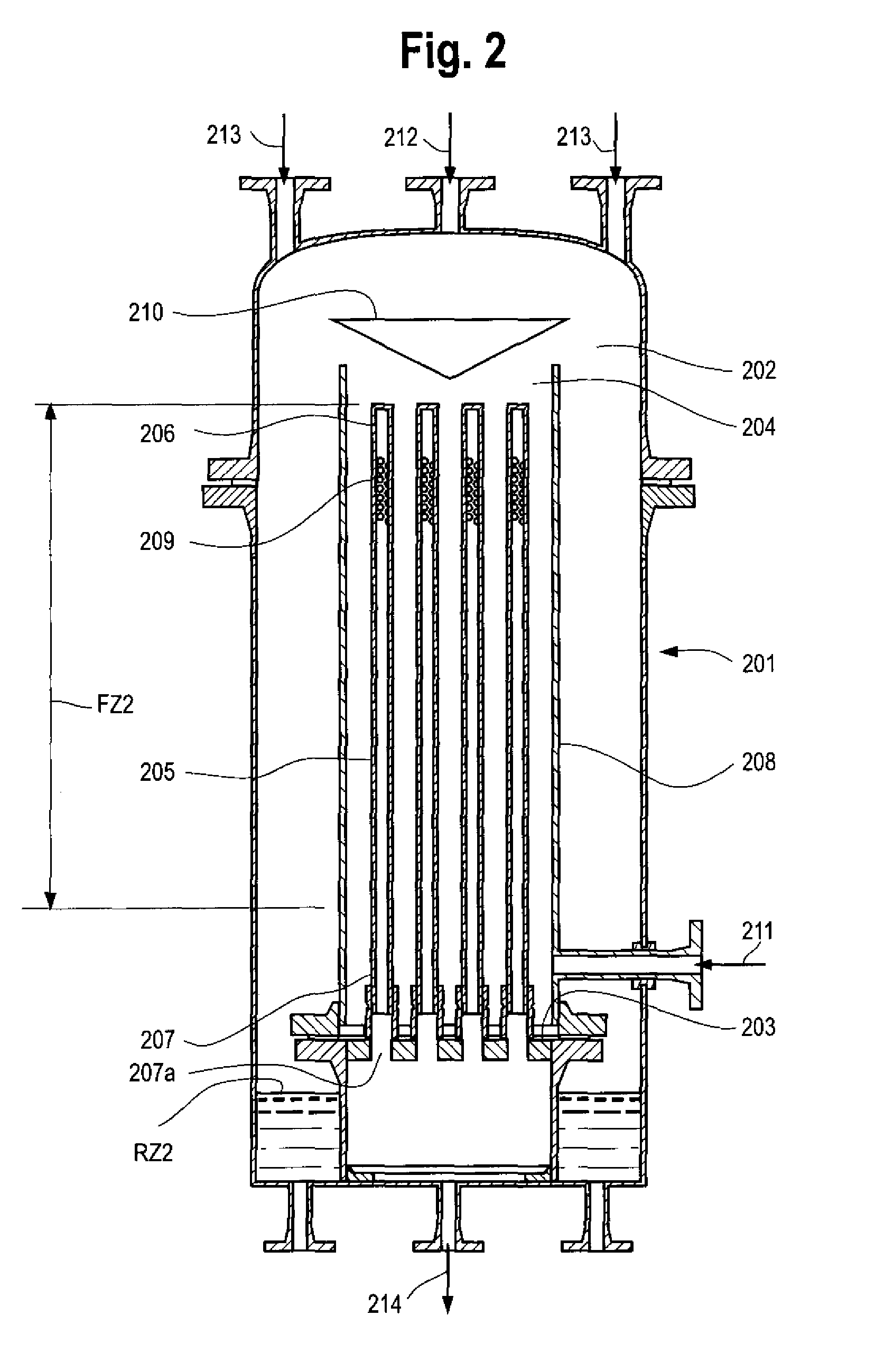

Process for purifying removal of acrylic acid, methacrylic acid, n-vinylpyrrolidone or p-xylene crystals from their suspension in mother liquor

ActiveUS20090018347A1Organic compounds purification/separation/stabilisationOrganic compound preparationHeat flowWater vapor

A process for purifying removal of acrylic acid, methacrylic acid, N-vinylpyrrolidone or p-xylene crystals from their suspension in mother liquor by means of a wash column with forced transport, whose shell of the process chamber is a metal wall, the wash column additionally being enveloped by a thermal insulation material having a water vapor barrier and a specific heat flow of >0.1 W / m2 and <10 W / m2 flowing into the process chamber through the metal wall of the wash column.

Owner:BASF AG

Process and apparatus for para-xylene production

Owner:EXXONMOBIL CHEM PAT INC

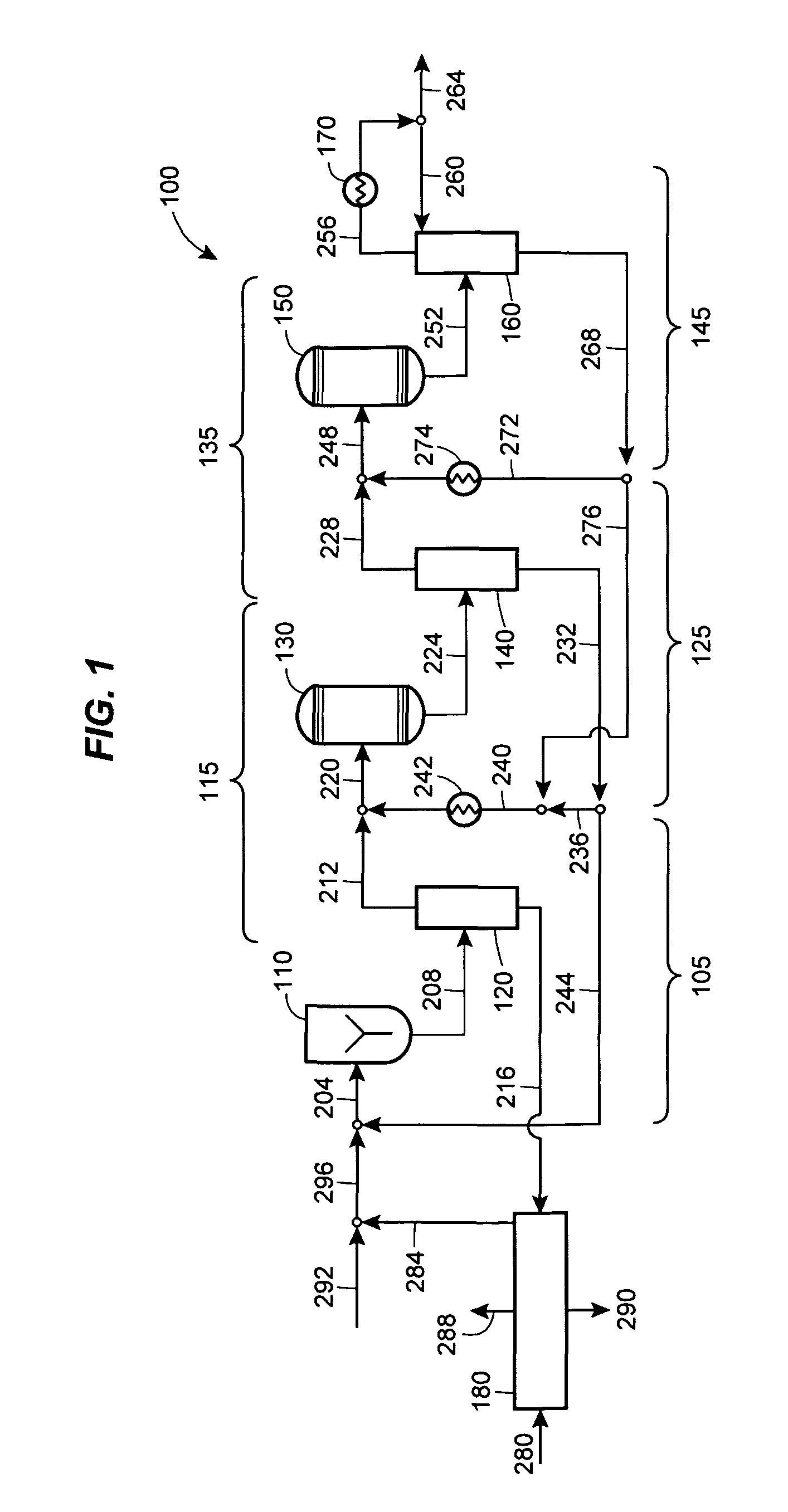

Melt-crystallization separation and purification process

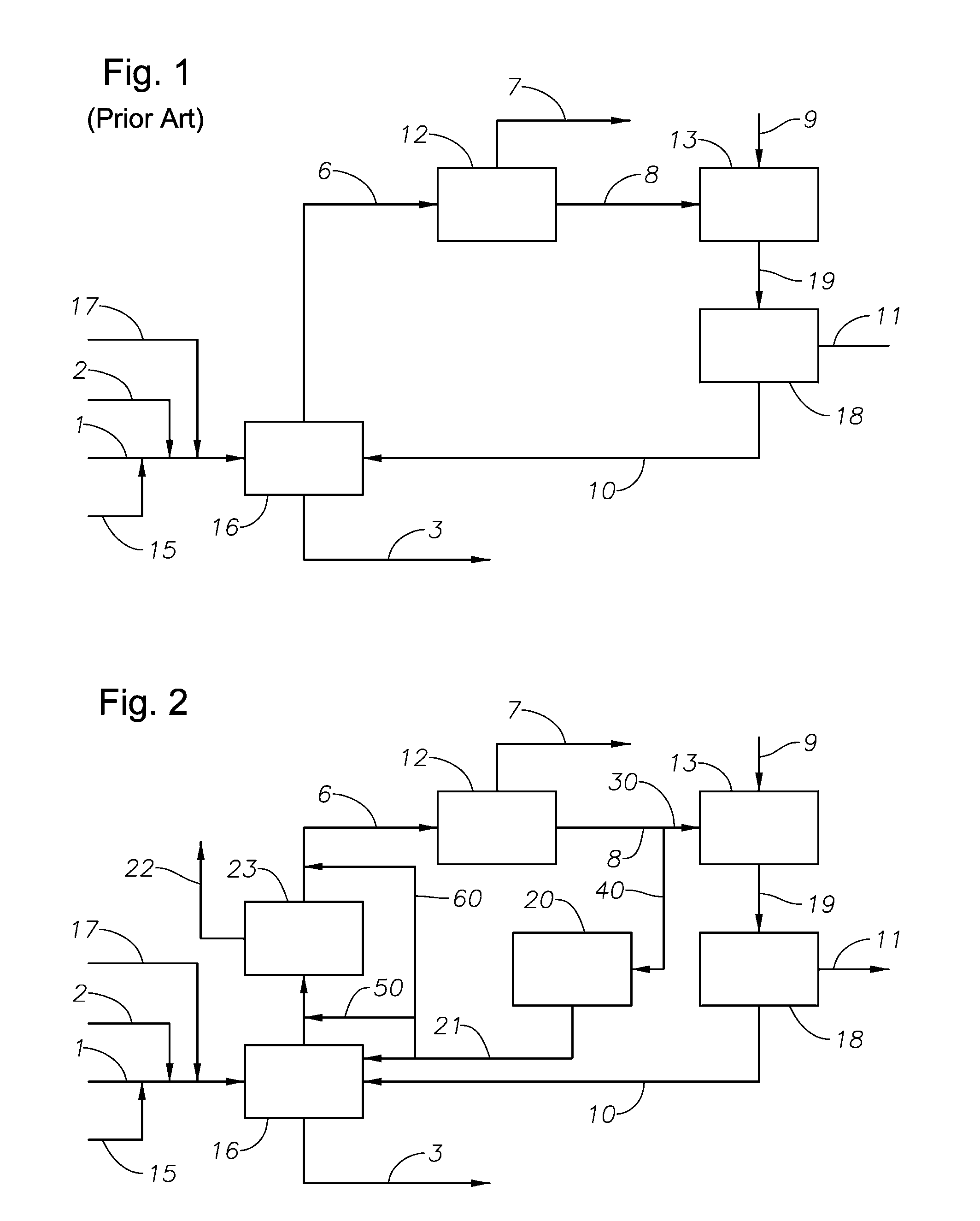

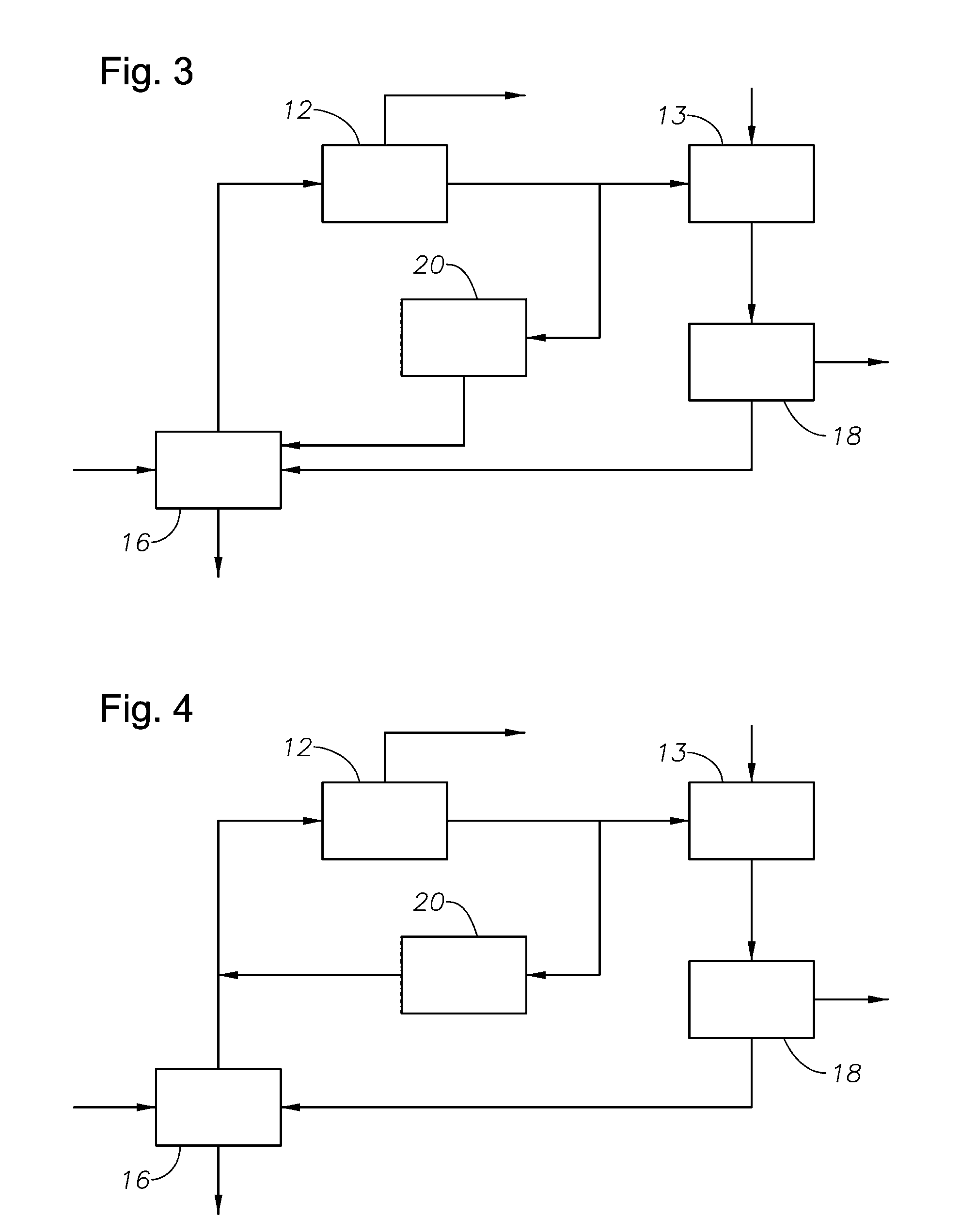

InactiveUS8530716B2Easy to operateImprove processing yieldRotary centrifugesSedimentation separationChemical reactorUnit operation

Processes for separating a solid from a solids-liquids slurry under conditions that prevent ingress of molecular oxygen are advantageous where the presence of molecular oxygen would otherwise reduce efficiencies, contribute to limited product yields, and potentially compromise safe operation of the process or downstream unit operations. Among the various embodiments disclosed herein, is a process utilizing filter columns as solid-liquid separators in combination with crystallization and reslurry unit operations to recover a product component from an initial feed mixture of miscible components. Embodiments of the disclosed processes may include the separation and purification of a product component using a crystallizer in series with a filter column followed by a chemical reactor, using a reslurry drum in series with a filter column, and using a combination of crystallizers and / or reslurry drums in series with at least one filter column. The use of filter columns in such processes is particularly attractive because these columns, when operated under the conditions disclosed herein, limit the undesirable ingress of molecular oxygen into the various process streams, and further improve process efficiencies related to both product component recovery and operating costs.

Owner:BP CORP NORTH AMERICA INC

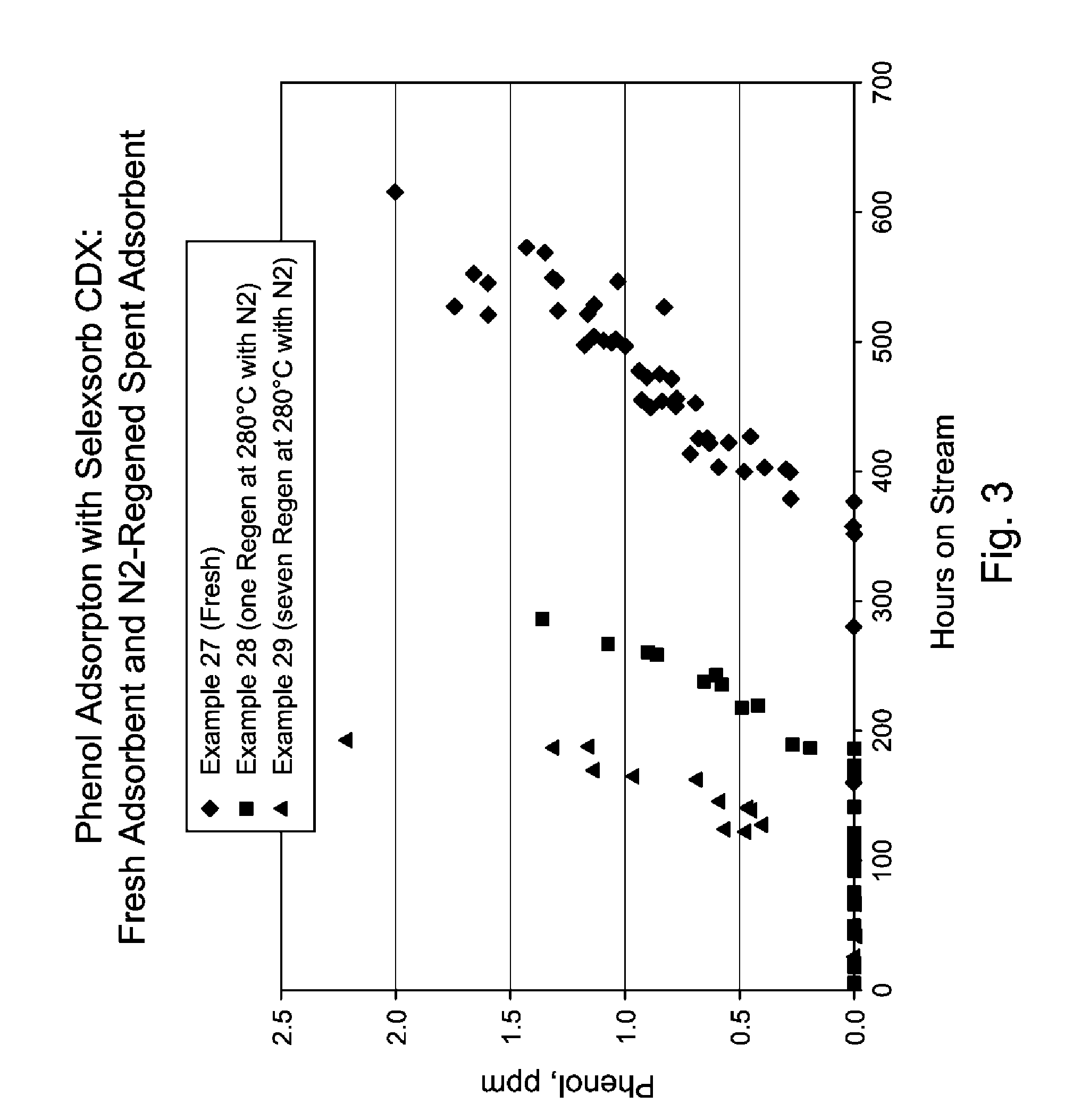

Phenol Removal in Paraxylene Recovery Process

ActiveUS20130324780A1Reduce concentrationHydrocarbon by isomerisationMolecular sieve catalystAromatic hydrocarbonPhenol

The invention is directed to purification of an aromatic hydrocarbon stream including selective removal of phenol from a process stream comprising aromatic hydrocarbon mixtures, especially aromatic hydrocarbon mixtures that contain higher-than-equilibrium paraxylene, by contact with suitable adsorbents, to provide a product stream having lower concentration of phenol than said process stream.

Owner:EXXONMOBIL CHEM PAT INC

Process for joint production of aromatic solvent, stone oil naphthalin and durene line products with C10 heavy aromatic raw material

ActiveCN101318874ATake advantage ofSave resourcesDistillation purification/separationCrystallisation purification/separationAromatic solventGas phase

The present invention discloses a method for jointly preparing a series of products of an aromatic solvent, petronaphthalene and durene from a C10 heavy aromatics material, belonging to the C10 heavy aromatics complex utilization technical field. The method comprises the following steps of: A) separating the C10 heavy aromatics material; B)refrigerating and crystallizing an enrichment solution of durene; C)refrigerating and crystallizing an enrichment solution of naphthalene; D) gas phase catalytically oxidizing durene; and E) preparing technical grade PMA, technical grade PMDA and electronic grade PMDA from a crude product. The method has the advantages that the method can carry out joint production to obtain the series of products of aromatic solvent, petronaphthalene and durene by the C10 heavy aromatics material so that the C10 heavy aromatics material obtains sufficient utilization, thereby contributing to resource economizing.

Owner:常熟华虞环境科技有限公司

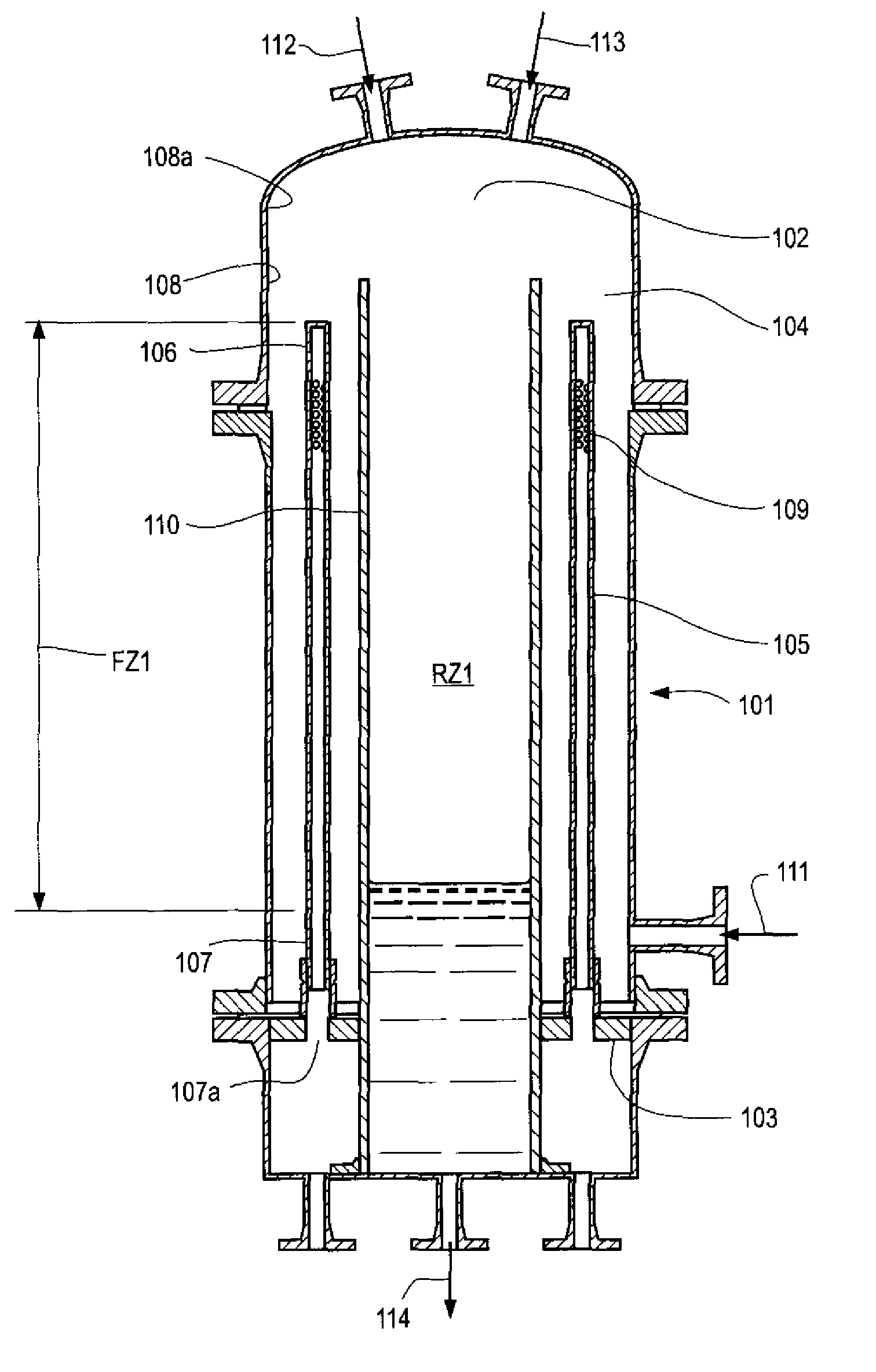

Apparatus and Process for the Separation of Solids and Liquids

A filter column apparatus comprising a filtration zone and a reslurry zone. These zones are separated by a barrier wall or are in substantial cooperation with each other. Also disclosed is a process for separating at least a portion of at least one substantially solid component from a solid-liquid stream comprising the substantially solid component and at least one substantially liquid component. Also disclosed is a process for forming a substantially solids containing packed bed. Also disclosed is a process for purifying paraxylene in a filtration zone.

Owner:BP CORP NORTH AMERICA INC

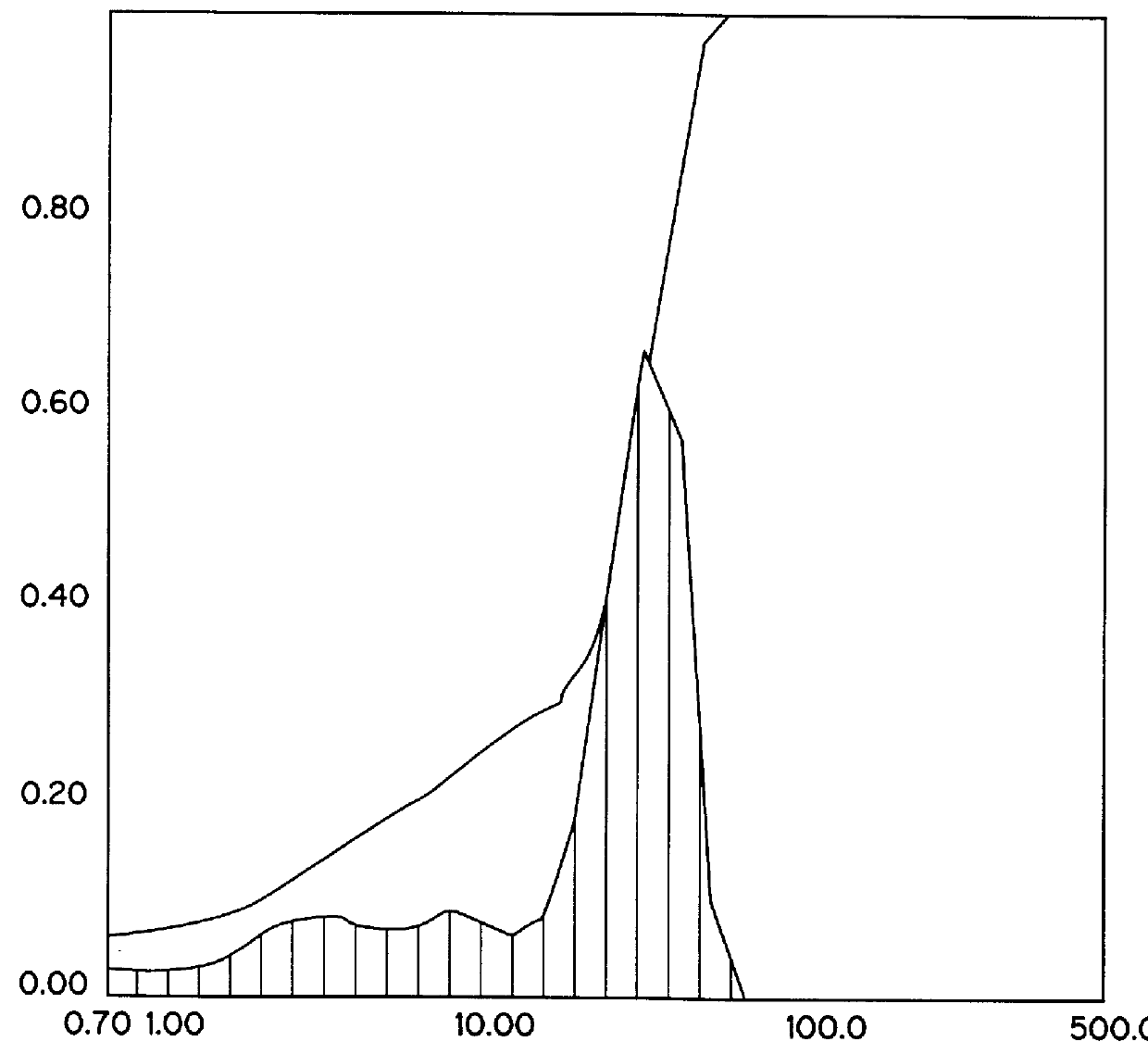

Narrow cut waxes and method of making

InactiveUS20090043140A1Narrow melting rangeHydrocarbon by hydrogenationLiquid hydrocarbon mixtures productionWaxCarbon number

A method of producing a wax composition having a constrained carbon number distribution and / or a narrow melting range is described. Additionally, hydrocarbon waxes and hydrocarbon wax compositions having a constrained carbon number distribution and / or melting point are described.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

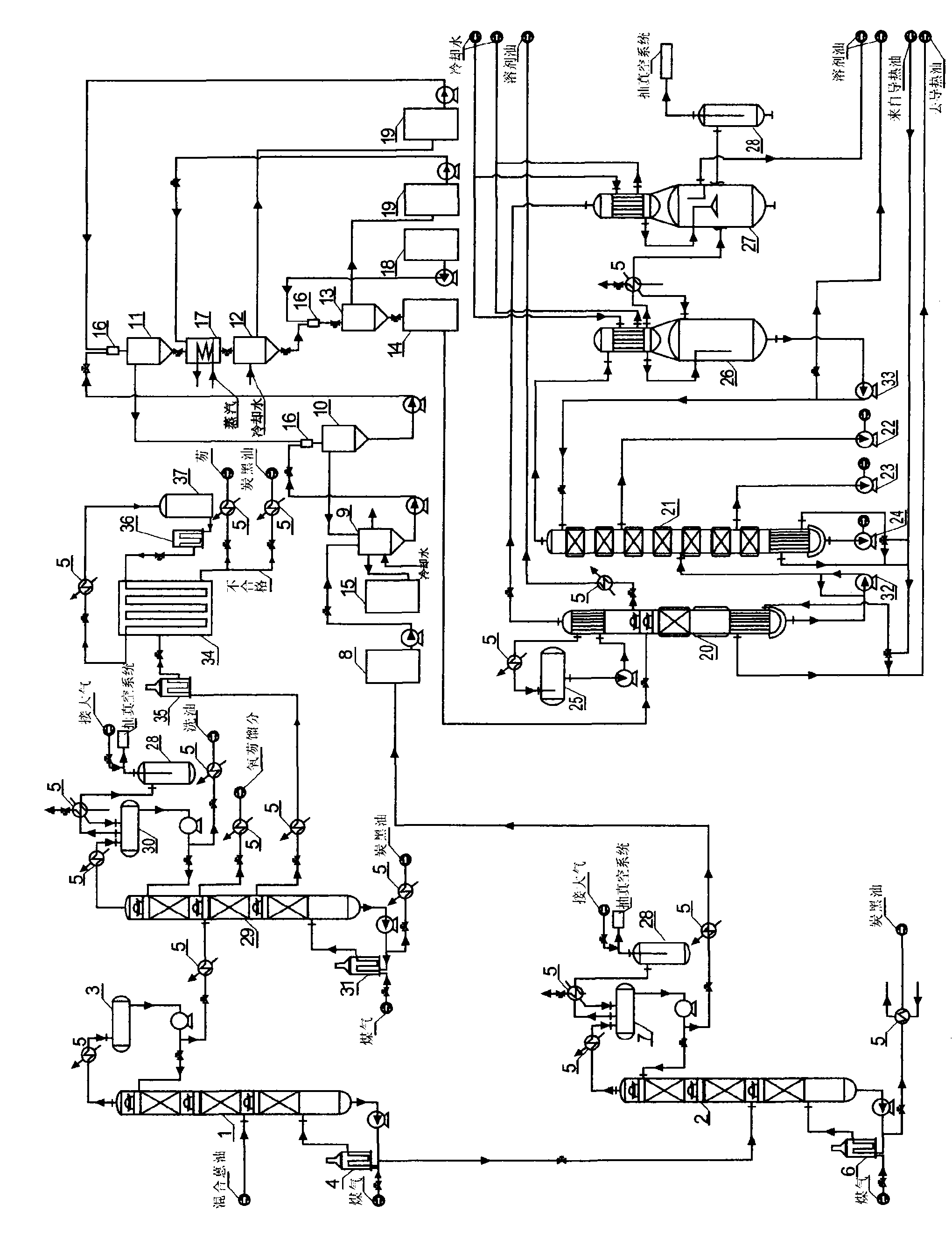

Method for extracting fluorene, anthracene and carbazole from mixed anthracene oil

ActiveCN101786935AImprove use valueStable jobDistillation purification/separationCrystallisation purification/separationAnthraceneCarbazole

The invention discloses a method for extracting fluorene, anthracene and carbazole from mixed anthracene oil, comprising the steps of mixed anthracene oil rectifying, fluorene static crystallization, semi-refined anthracene extraction from first anthracene oil, semi-refined anthracene rectifying for extracting refined anthracene and carbazole, i.e. carrying out three-tower separation on the mixedanthracene oil, extracting components such as wash oil fraction, first anthracene oil fraction, second anthracene oil fraction, and the like. A crystallization method is adopted to remove impurities in the anthracene fraction, and the product has high purity and high yield. The separation of the refined anthracene and the carbazole adopts efficient rectification under vacuum for extracting anthracene and the carbazole. The invention is a novel process flow organically combined by a plurality of process equipment, has the advantages of convenience, high efficiency and stable work, achieves thepurposes of extracting a plurality of precious industrial chemical raw materials such as fluorene, carbazole, refined anthracene, and the like from the mixed anthracene oil through a set of process, and greatly improves the utilization value of first anthracene oil fraction and second anthracene oil fraction in coal tar, wherein the integrated extraction rate of fluorene, anthracene and carbazolerespectively reach 66%, 62% and 55% relative to the mixed anthracene oil as raw materials. Moreover, the invention also has the advantages of high production automation degree, environmental friendliness, energy saving, emission reduction, and obvious social and economical benefit.

Owner:QUJING ZHONGYI SYNTHETIC CHEMICAL CO LTD

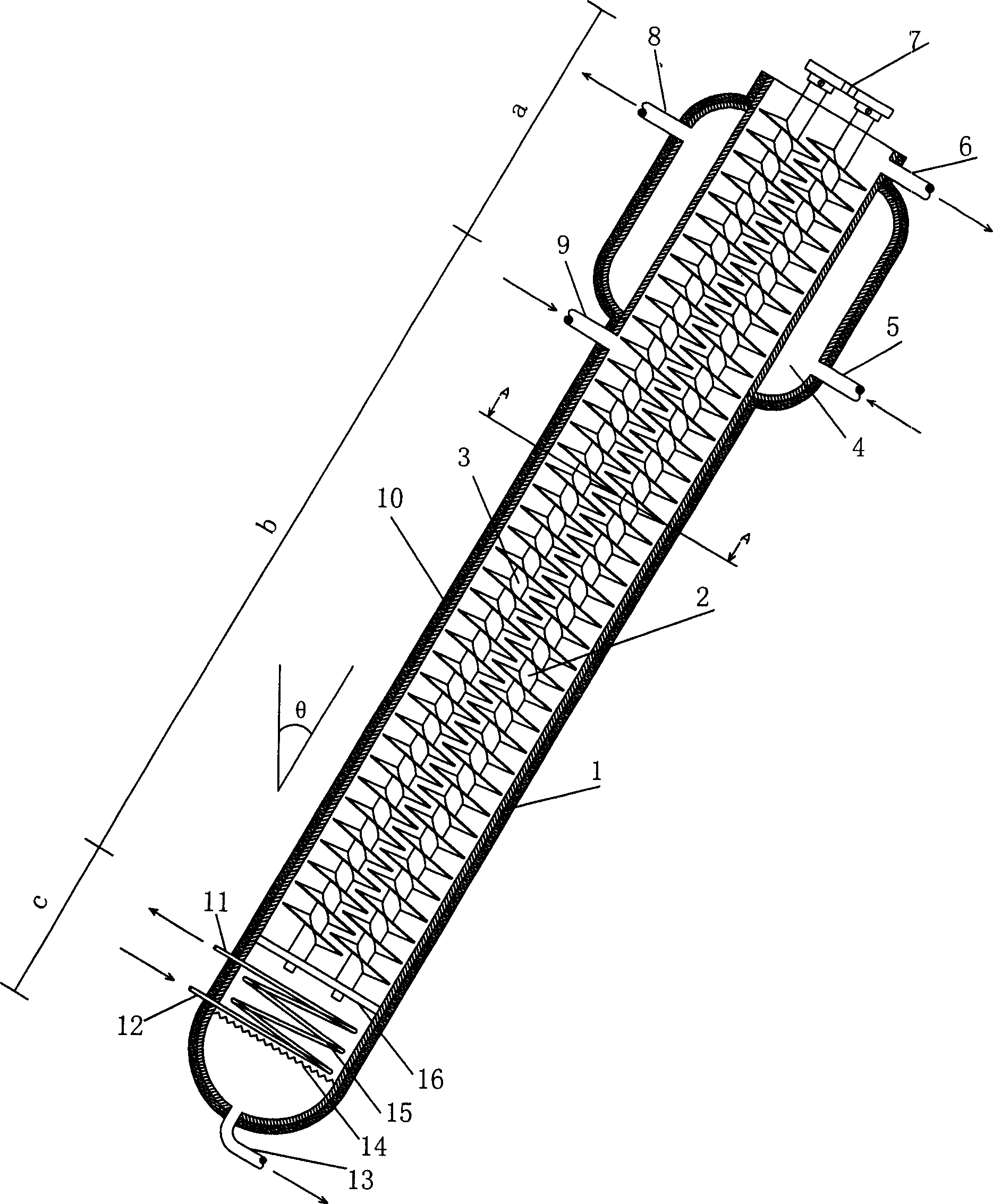

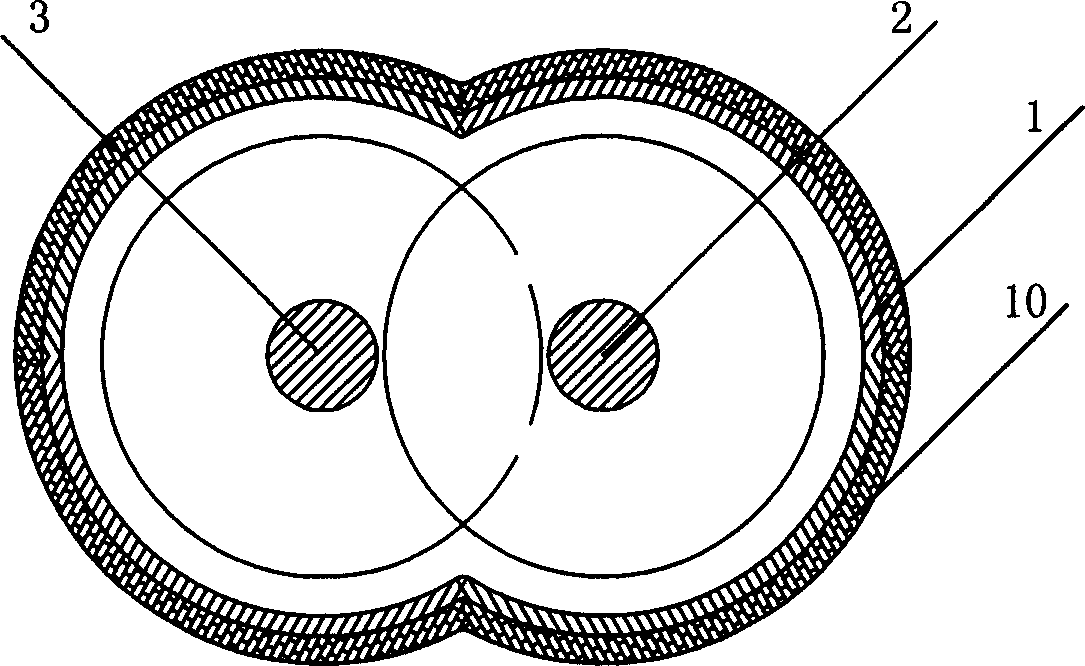

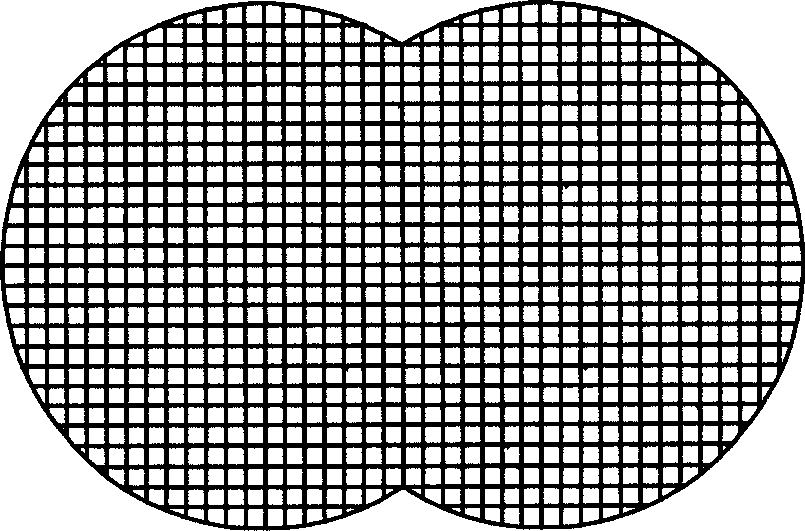

Equipment for preparing high pure organic matter by fusion-crystallization method

InactiveCN1792406AGuarantee continuous and stable operationReduce energy consumptionCrystallization separationCrystallisation purification/separationEngineeringOrganic matter

A device for preparing high-purity organic substance by fusion crystallizing method is a tower structure which is divided into upper cooling-crystallizing segment, middle separating-purifying segment and lower crystal fusing segment. Its tower body is inclined and is composed of casing consisting of intersected two cylinders, heater and parallel engaged two spiral stirrers.

Owner:SICHUAN UNIV

Integrated process for the production of P-xylene

ActiveUS8084657B2High energy consumptionLarge circulationHydrocarbon by isomerisationMolecular sieve catalystsIsomerizationAromatic hydrocarbon

Owner:CHINA PETROCHEMICAL CORP +1

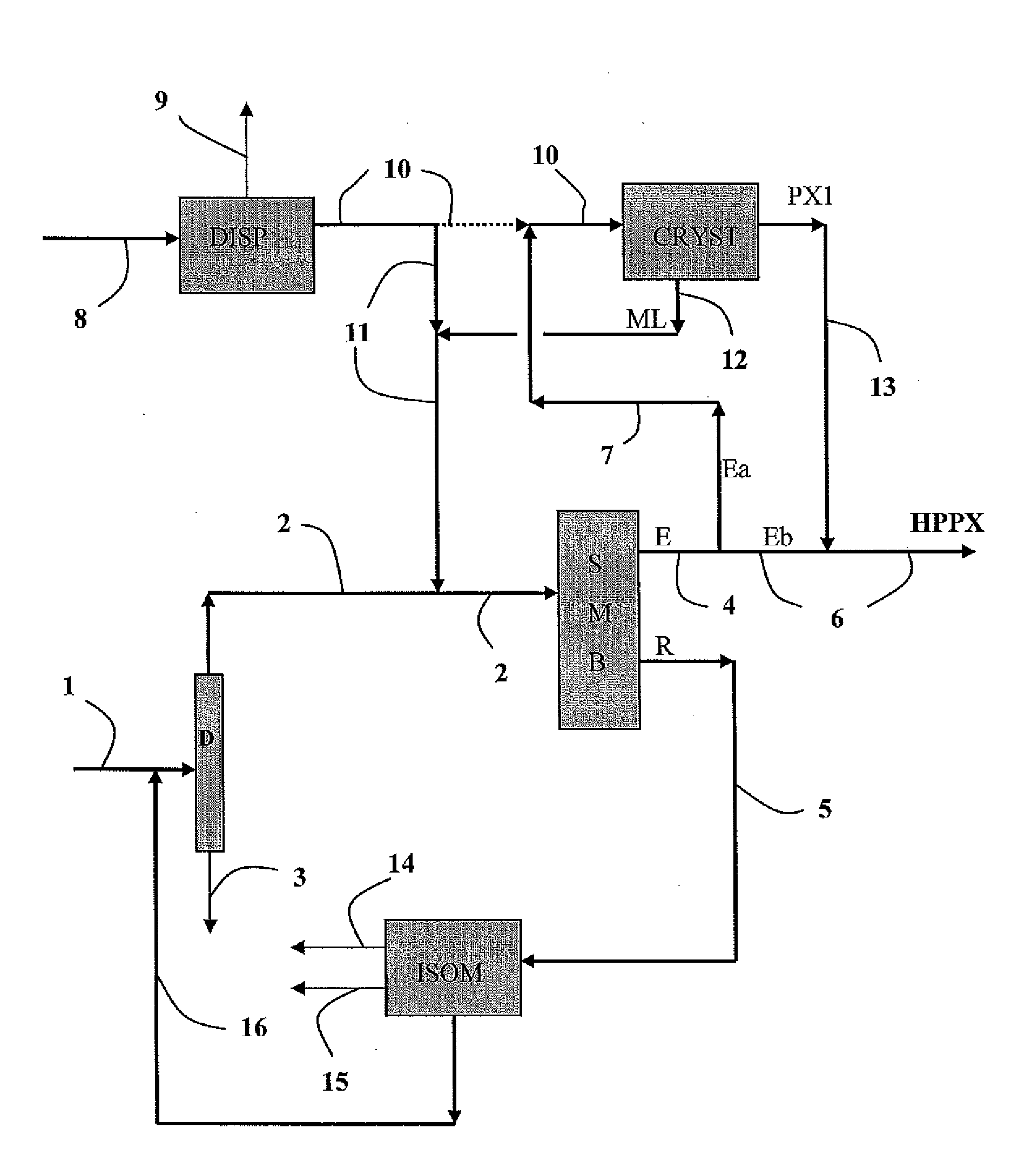

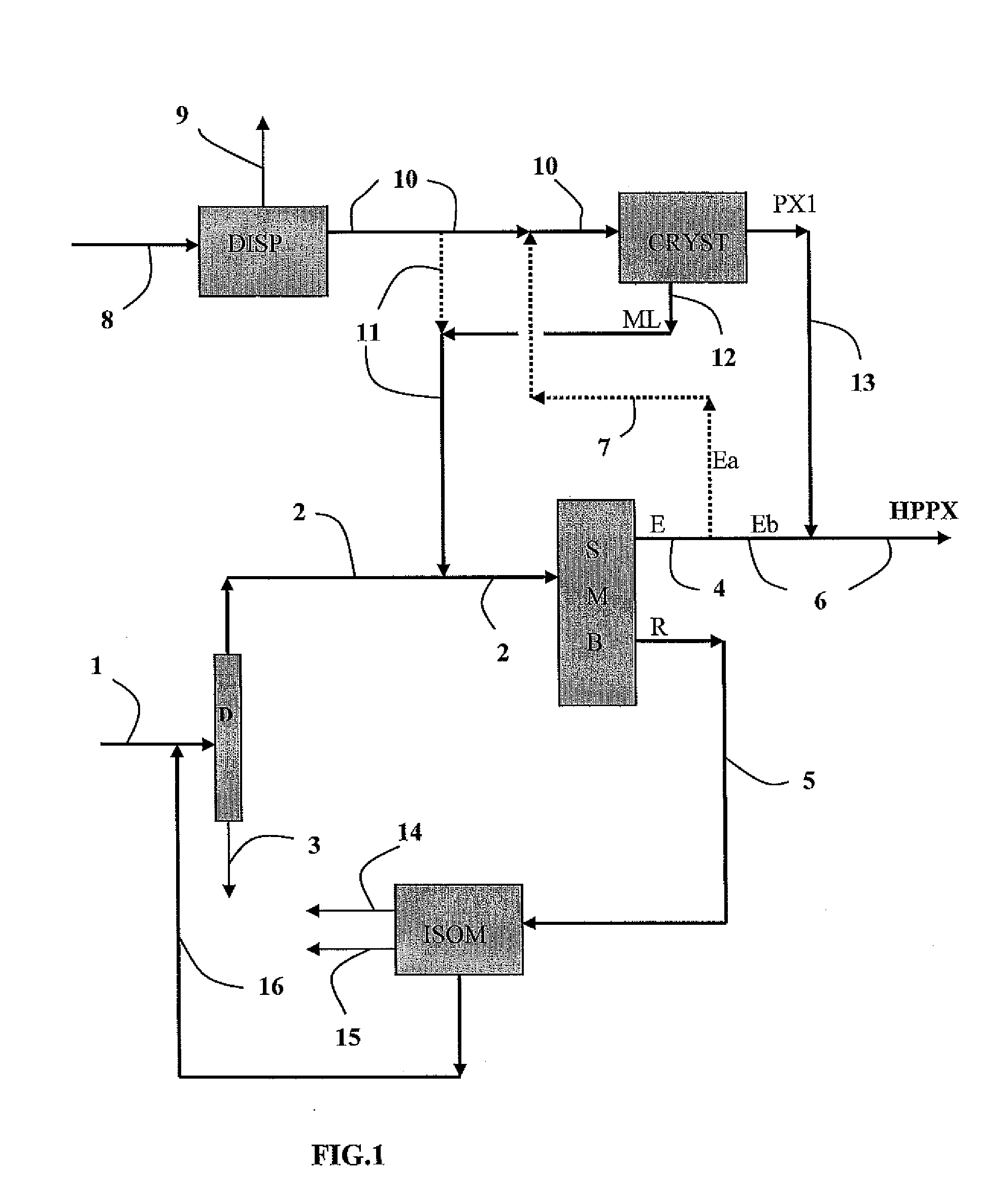

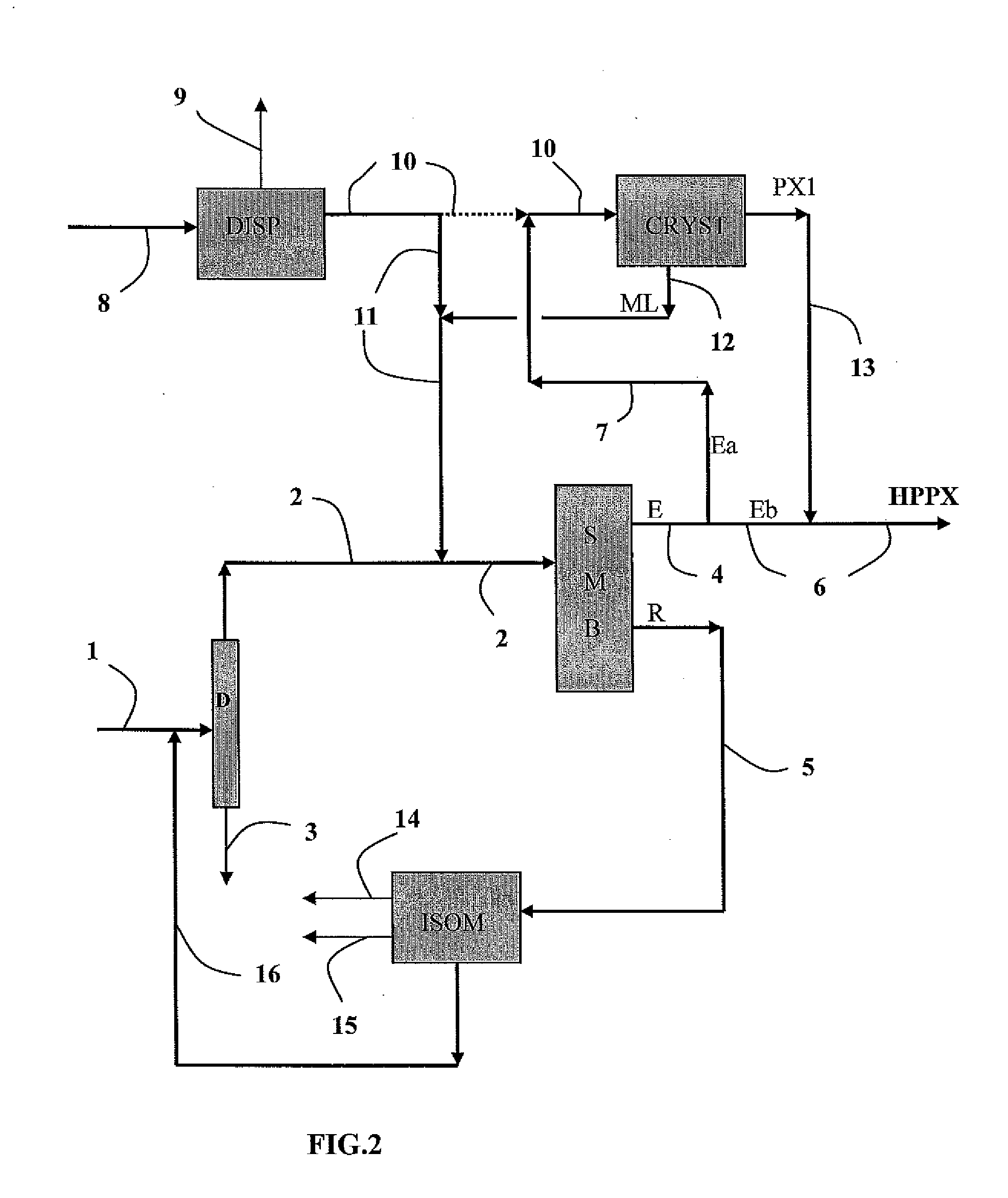

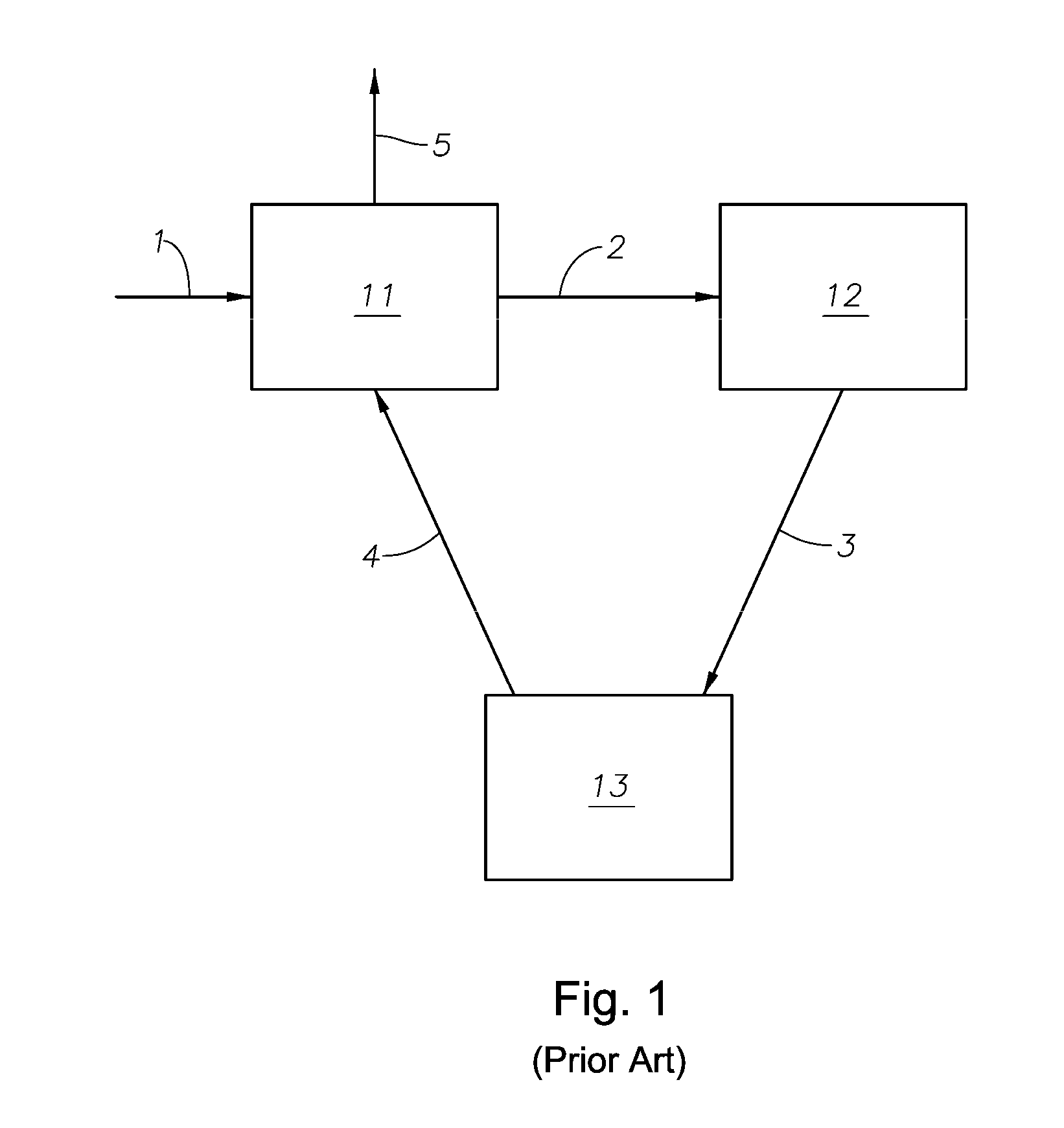

Method for combined production of paraxylene and benzene with improved productivity

ActiveUS20090069612A1Function increaseIncreases its supply flow rateHydrocarbon by isomerisationHydrocarbonsProduction rateSimulated moving bed

A process for the combined production of para-xylene and benzene comprises:separating a first feed, by adsorption in a simulated moving bed SMB, to produce an extract E rich in para-xylene and at least one raffinate R which is depleted in para-xylene;converting a secondary feed of toluene by selective disproportionation to produce benzene and xylenes;a) at the start of the cycle, producing a supplemental quantity of para-xylene in a crystallization unit supplied with the xylenes from the disproportionation;b) at the end of the cycle, when the adsorbant has aged:dividing the distilled extract E into a first fraction Ea and a complementary second fraction Eb;replacing the feed to the initial crystallization by the stream Ea;and recycling the xylenes from the disproportionation to the SMB.The invention enables para-xylene and benzene production to be maintained despite ageing of the SMB absorbent.

Owner:INST FR DU PETROLE

Process for the Purification of Paraxylene

ActiveUS20100261941A1Hydrocarbon by isomerisationMolecular sieve catalystsBiochemistryCrystallization

The proposed process uses crystallization technology to purify paraxylene simultaneously of large concentrations of C8 aromatics and also small concentrations of oxygenated species.

Owner:EXXONMOBIL CHEM PAT INC

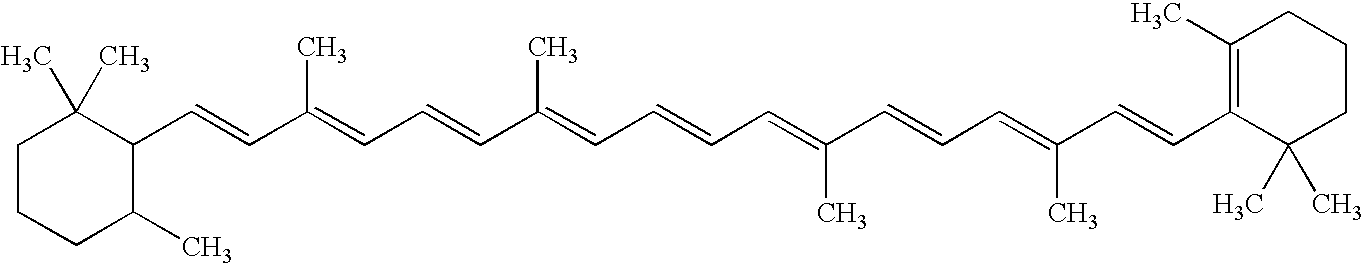

Method for the production of beta-carotene

InactiveUS20040067550A1Crystalline .beta.-carotene increases considerablyEnzymologyMicroorganism based processesBiotechnologyBeta-Carotene

The invention relates to a novel method for the production of beta-carotene from submerged cultures of mucoral fungi such as Blakeslea, Choanephora or Phycomyces by adding lectin to the culture medium and performing pH control once fermentation has started. The method involves beta-carotene recovery stage that makes it possible to simplify the process, optimize yields and increase purification of the product.

Owner:DSM IP ASSETS BV

Toluene selective disproportion and toluene and C9 and its above aromatic disproportion and alkyl transfusion method

InactiveCN1413968AReduce difficultyEliminate harsh requirementsHydrocarbon by isomerisationMolecular sieve catalystsHigh concentrationAlkyl transfer

The toluene is selectively disproportionated to obtain the mixed xylene containing high-concentration p-xylene. Then the C9 and C9+x arylhydrocarbon and toluene take part in disproportionation and alkyl transfer reaction to prepare benzene and thermodynamically balanced mixed xylene. The advantages are less circulation of arylhydrocarbon, low energy consumption, and low requirement to raw materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

Selective hydrogenation process comprising partial separation of hydrogen by a membrane upstream of a reactive column

InactiveUS6410811B2Hydrogen separation using solid contactHydrocarbon by hydrogenationHydrogenation processMembrane configuration

The process of the invention is a process for selective hydrogenation of a hydrocarbon feed containing hydrogen and C2+ hydrocarbons, characterized in that it comprises at least one step for separating a fraction of the hydrogen contained in the feed by means of a membrane (step a)) and a step for selective hydrogenation of the effluent from step a) in a reactive column (step b)).

Owner:INST FR DU PETROLE

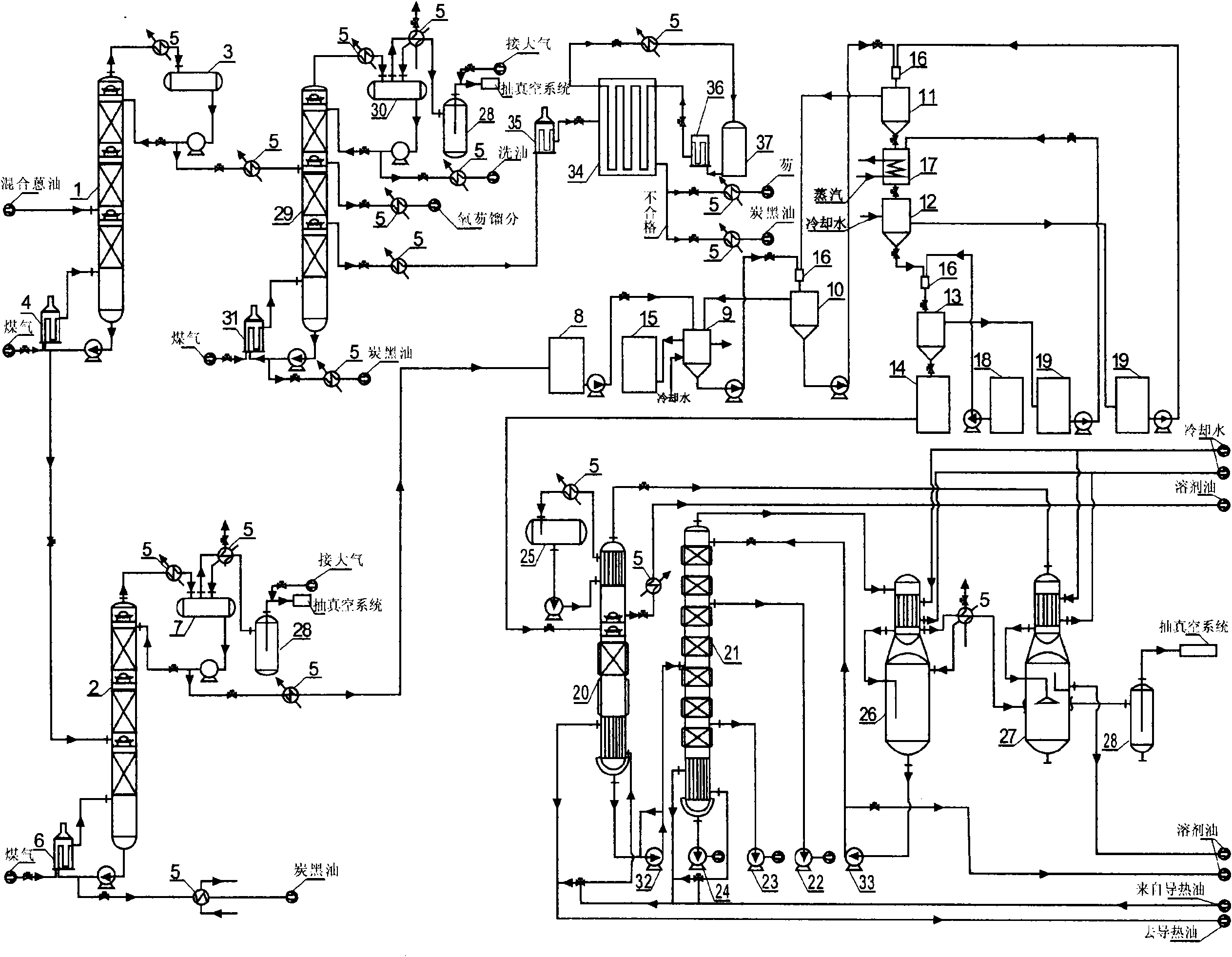

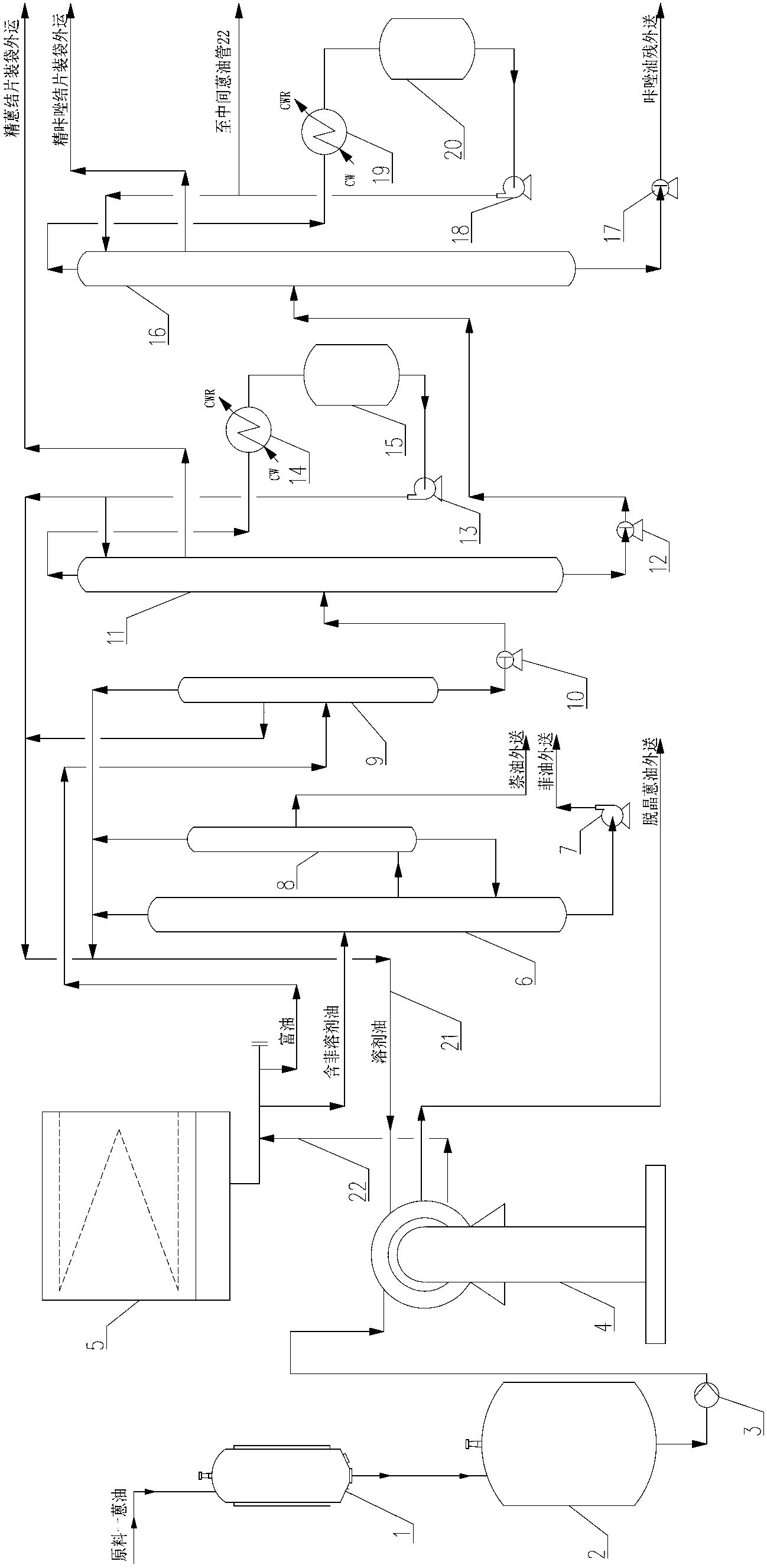

Method and device for producing refined anthracene, refined carbazole and phenanthrene product from raw material of monoanthracene oil

ActiveCN103232318ASuitable for the production of refined anthraceneReduce consumptionDistillation purification/separationHydrocarbonsAnthraceneCarbazole

The invention relates to a technical field of a coal tar deep-processing technology in a metallurgical coking industry, and especially relates to a method and a device used for producing refined anthracene, refined carbazole and phenanthrene products from a raw material of monoanthracene oil. The device comprises a stirring cooler, a slurry circulation tank, a centrifuge, a crystallization tank, a concentration tower, an anthracene tower, and a carbazole tower. The stirring cooler is sequentially technically connected with the slurry circulation tank, the centrifuge, and the crystallization tank. An oil-rich pipe of the crystallization tank is connected with a middle-section inlet in the concentration tower. A phenanthrene-containing solvent oil pipe of the crystallization tank is connected with a middle-section inlet of a solvent distillation tower. A phenanthrene oil product outlet is provided at the bottom of the solvent distillation tower. A refined anthracene product outlet is provided at a side line of the anthracene tower. A refined carbazole product outlet is provided at a side line of the carbazole tower. Compared with prior art, the method and device provided by the invention have the advantages that: (1) no extraction agent is needed in production; and with a three-step distillation process of the concentration tower, the anthracene tower, and the carbazole tower, three products of anthracene, carbazole and phenanthrene oil can be simultaneously obtained; and (2) advantages such as low solvent consumption, high product purity, low pollution, and capability of continuous operation are provided.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Preparing method for high-purity lycopene

InactiveCN1472183AHigh purityLow costCrystallisation purification/separationHydrocarbon solventsOrganic solvent

A process for preparing high-purity licopin includes such steps as dissolving the licopin oil resin in organic hydrocarbon solvent to obtain saturated solution at higher temp under protection of inertial gas, hot filtering, low-temp cooling while crystallizing, and filtering.

Owner:SHANGHAI JIAO TONG UNIV

Process for the purification of paraxylene

The proposed process uses crystallization technology to purify paraxylene simultaneously of large concentrations of C8 aromatics and also small concentrations of oxygenated species.

Owner:EXXONMOBIL CHEM PAT INC

Treatment of Off-Gas in the Production of Para-Xylene by the Methylation of Toluene and/or Benzene

A process for removing contaminants from an off-gas stream generated by the methylation of toluene and / or benzene by methanol to produce para-xylene. The treated off-gas stream, which contains C4− hydrocarbons, may be further processed in an olefins plant / process to yield valuable light alkanes and olefins.

Owner:EXXONMOBIL CHEM PAT INC

Popular searches

Liquefaction Granulation by liquid drop formation Flash distillation Glucose production Evaporation with vapour compression Peroxides/peroxyhydrates/peroxyacids/superoxides/ozonides Granular delivery Phosphorus preparation Chemical/physical/physico-chemical stationary reactors Hydrocarbon oils refining

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com