Patents

Literature

51results about How to "Narrow melting range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

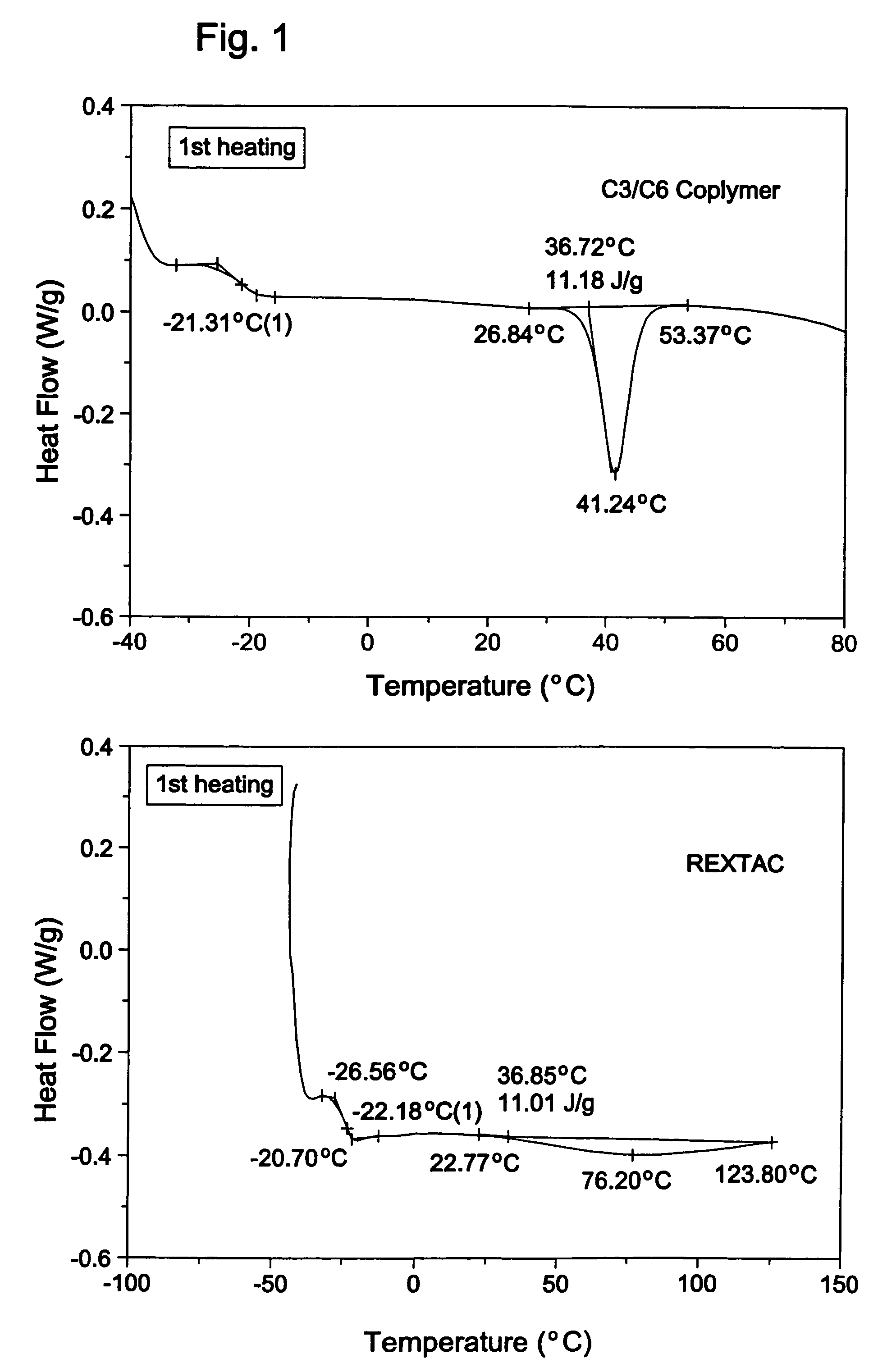

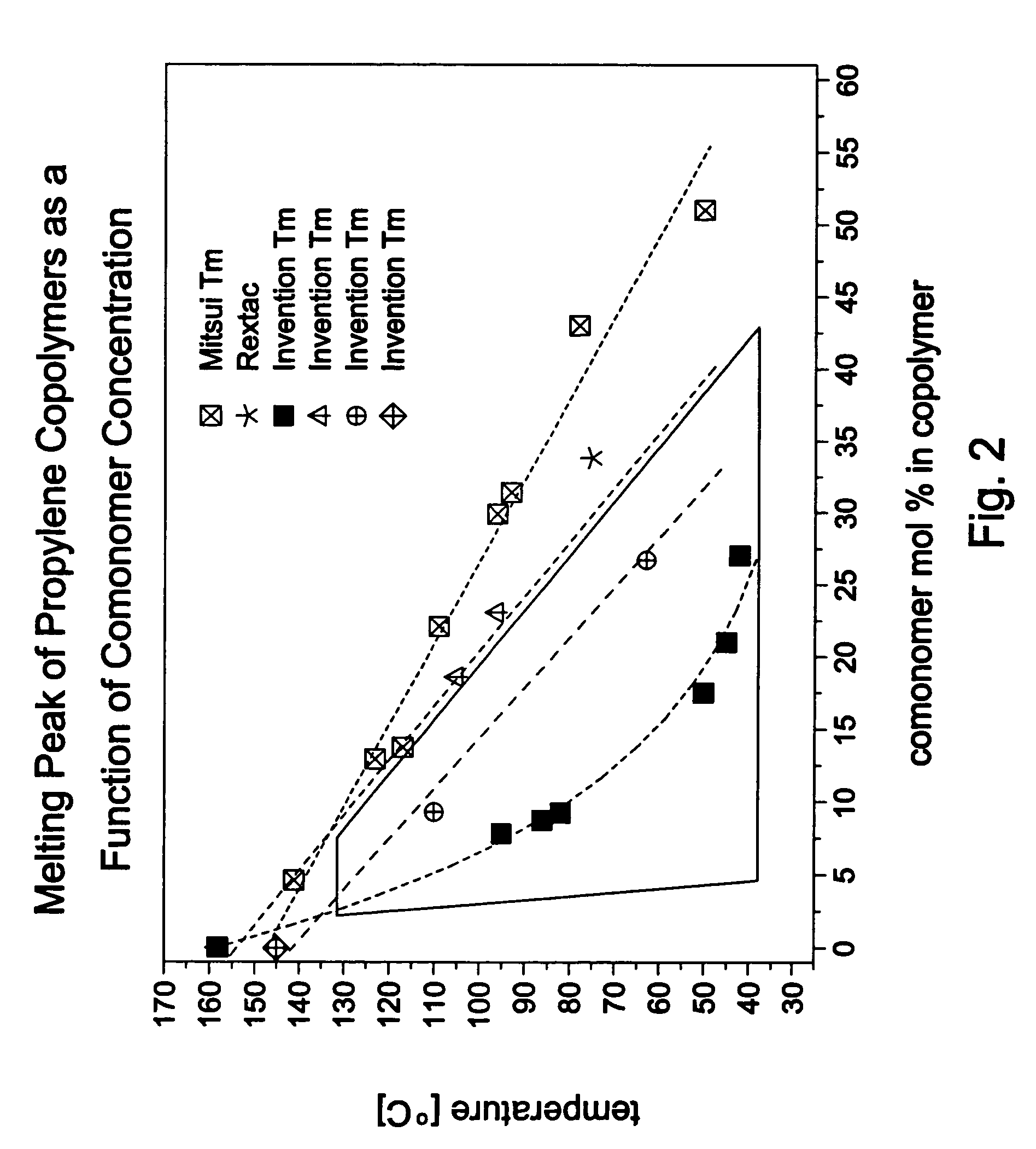

Adhesive alpha-olefin inter-polymers

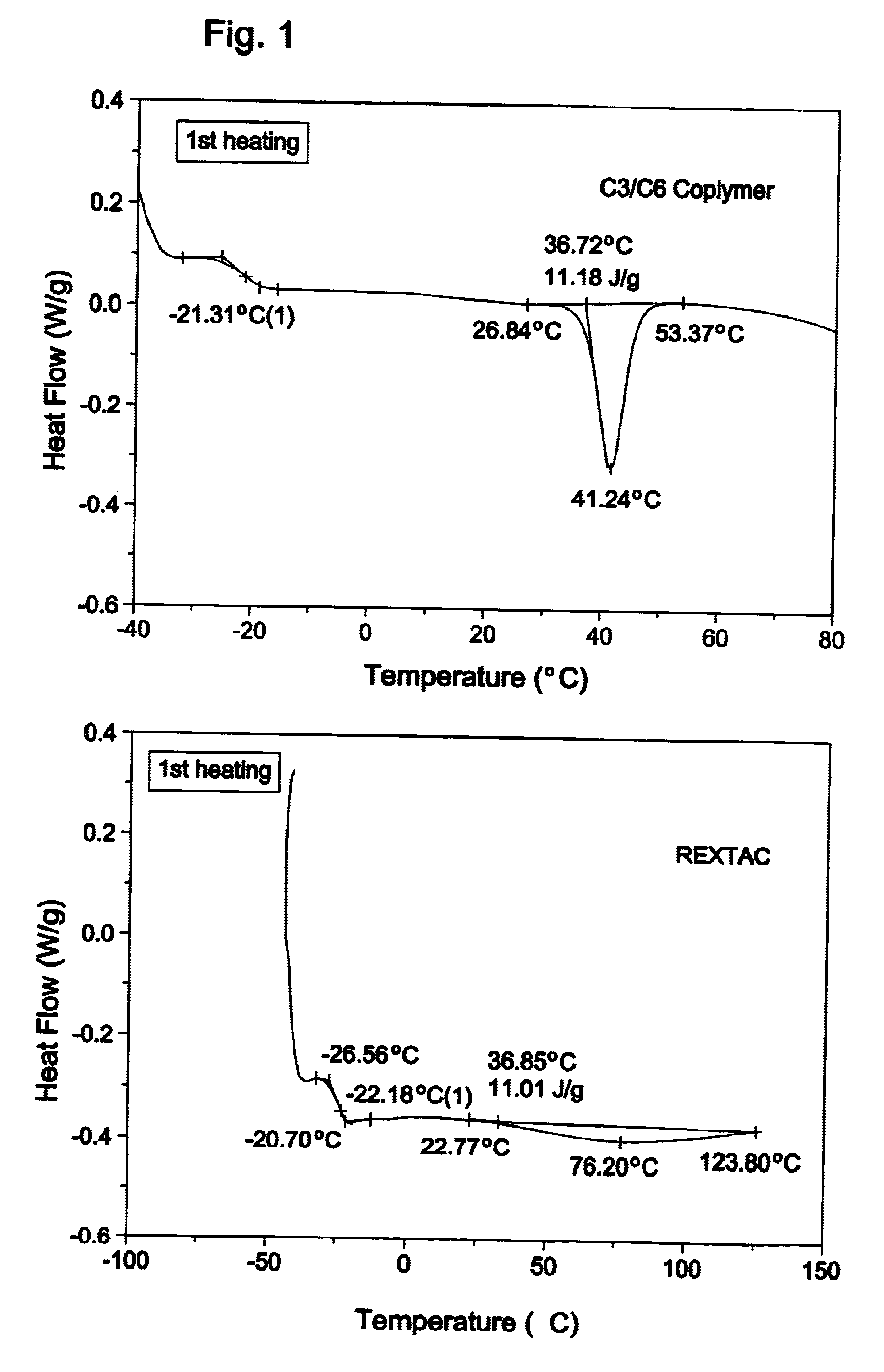

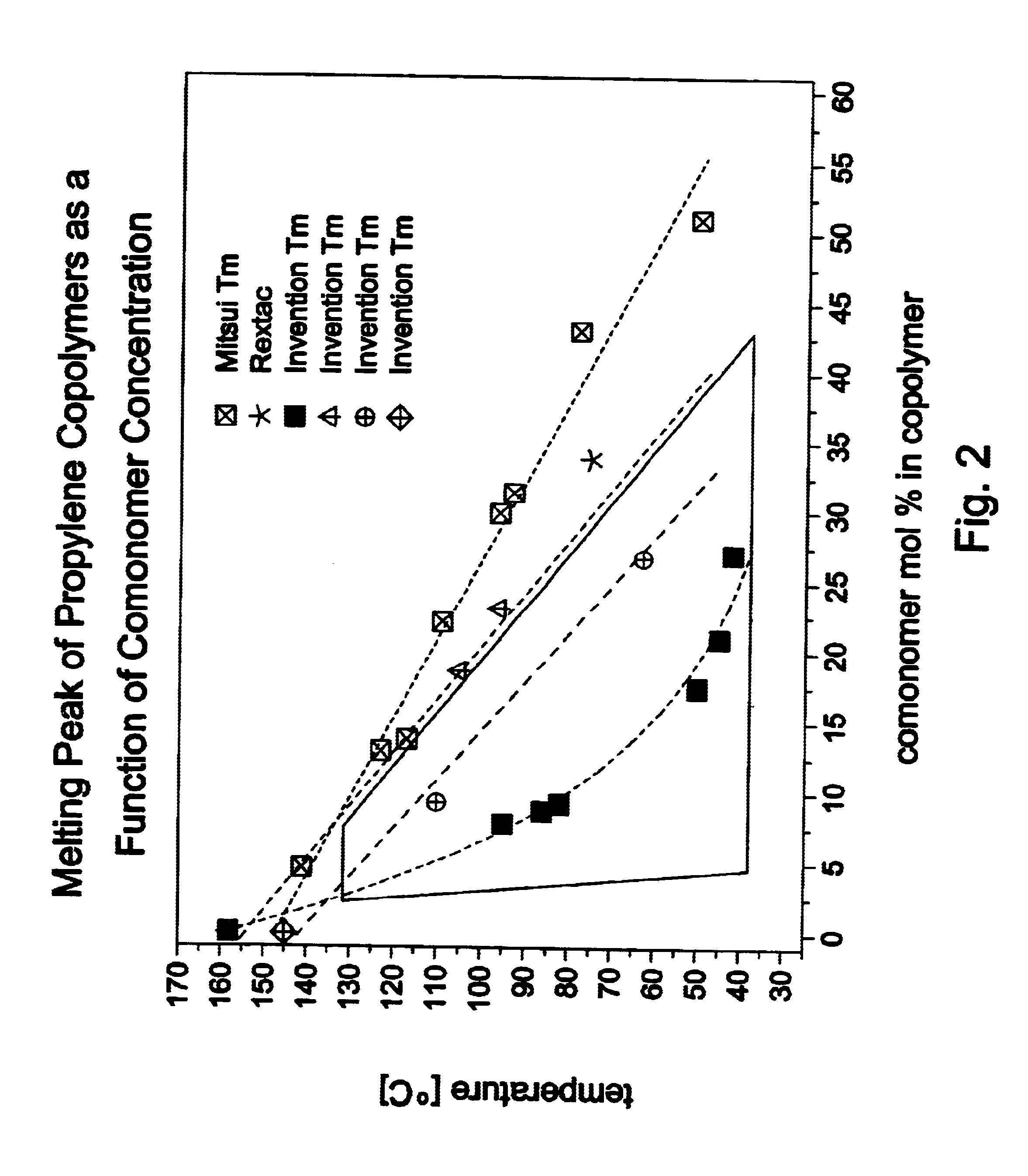

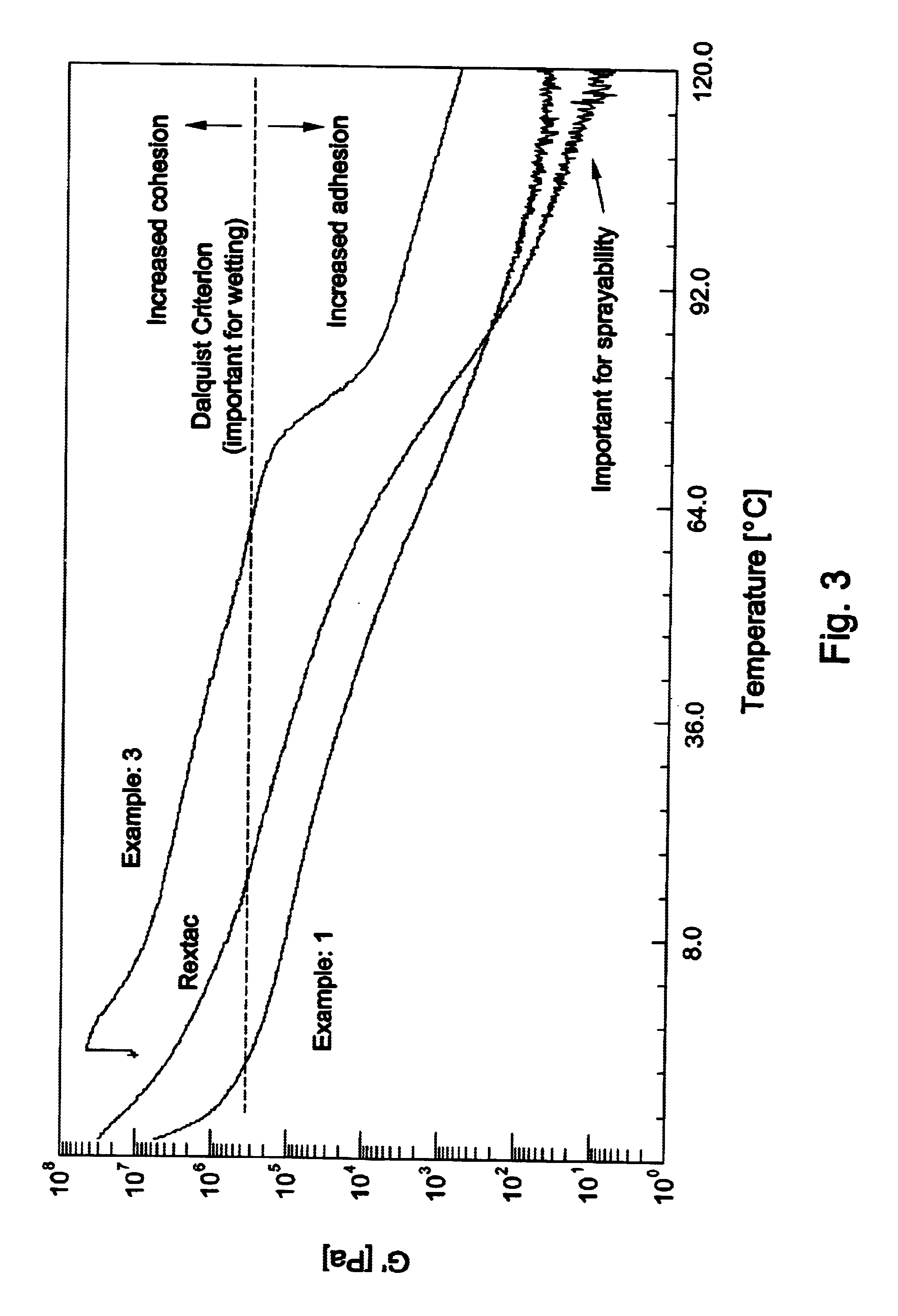

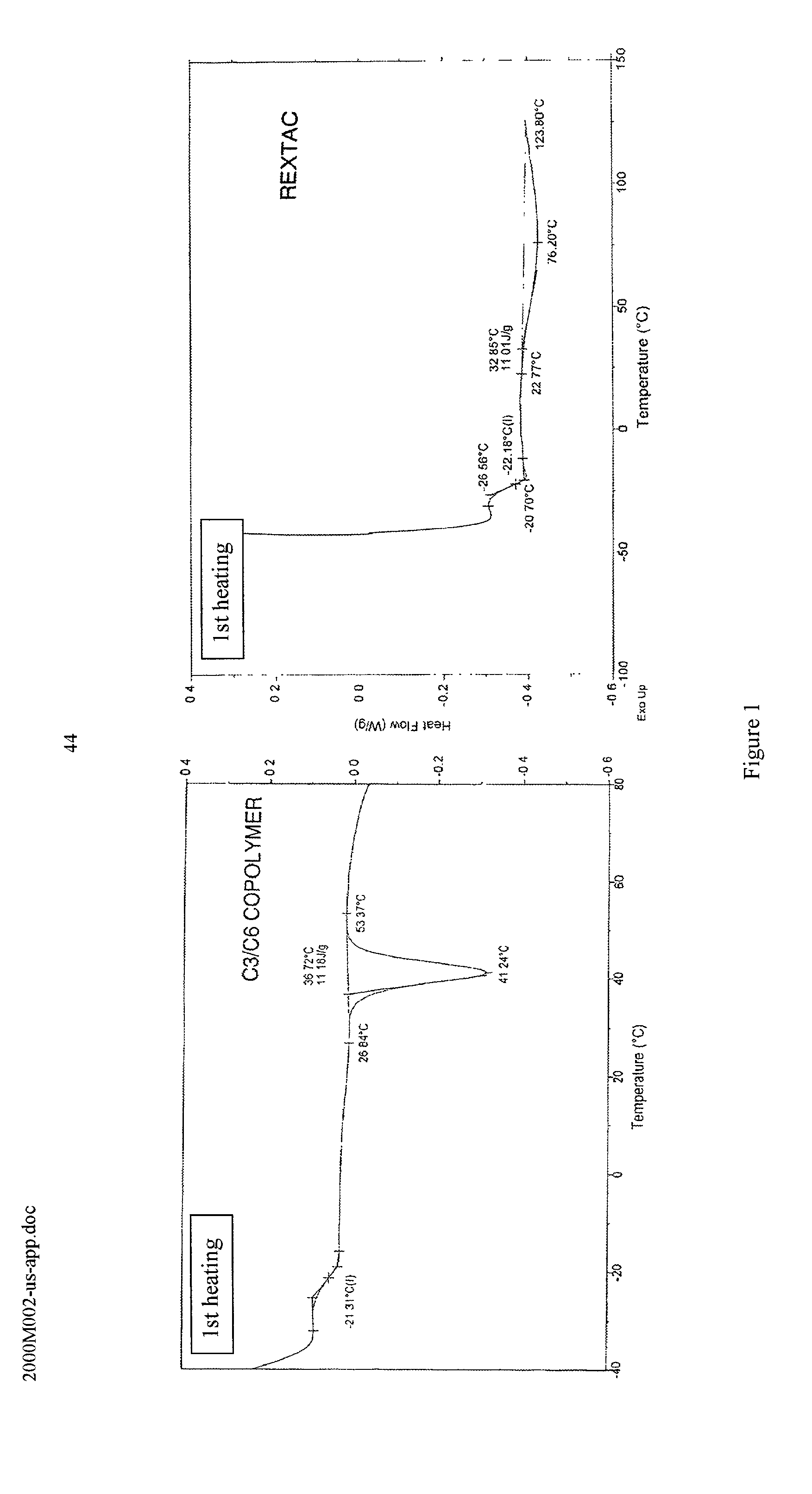

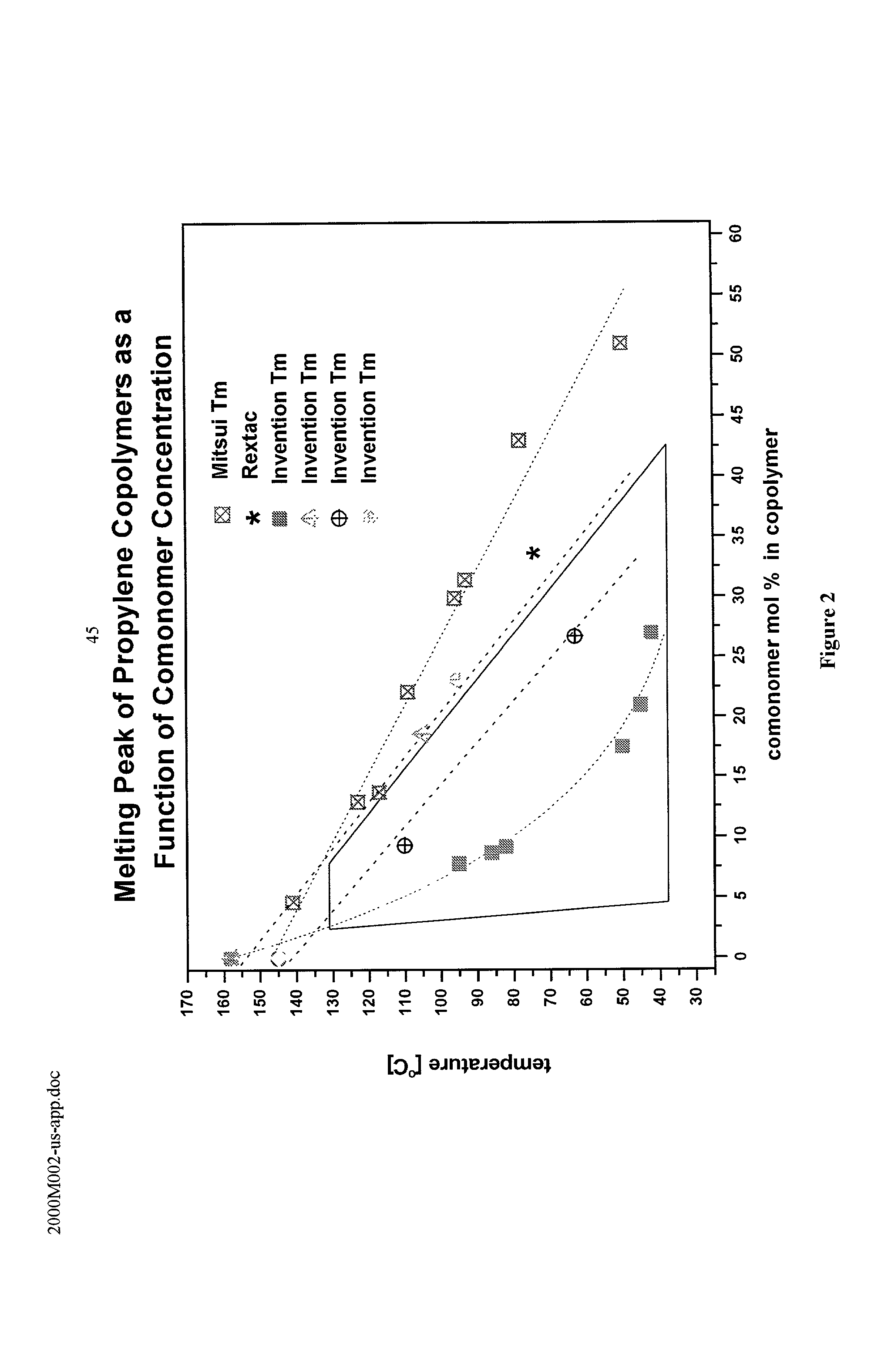

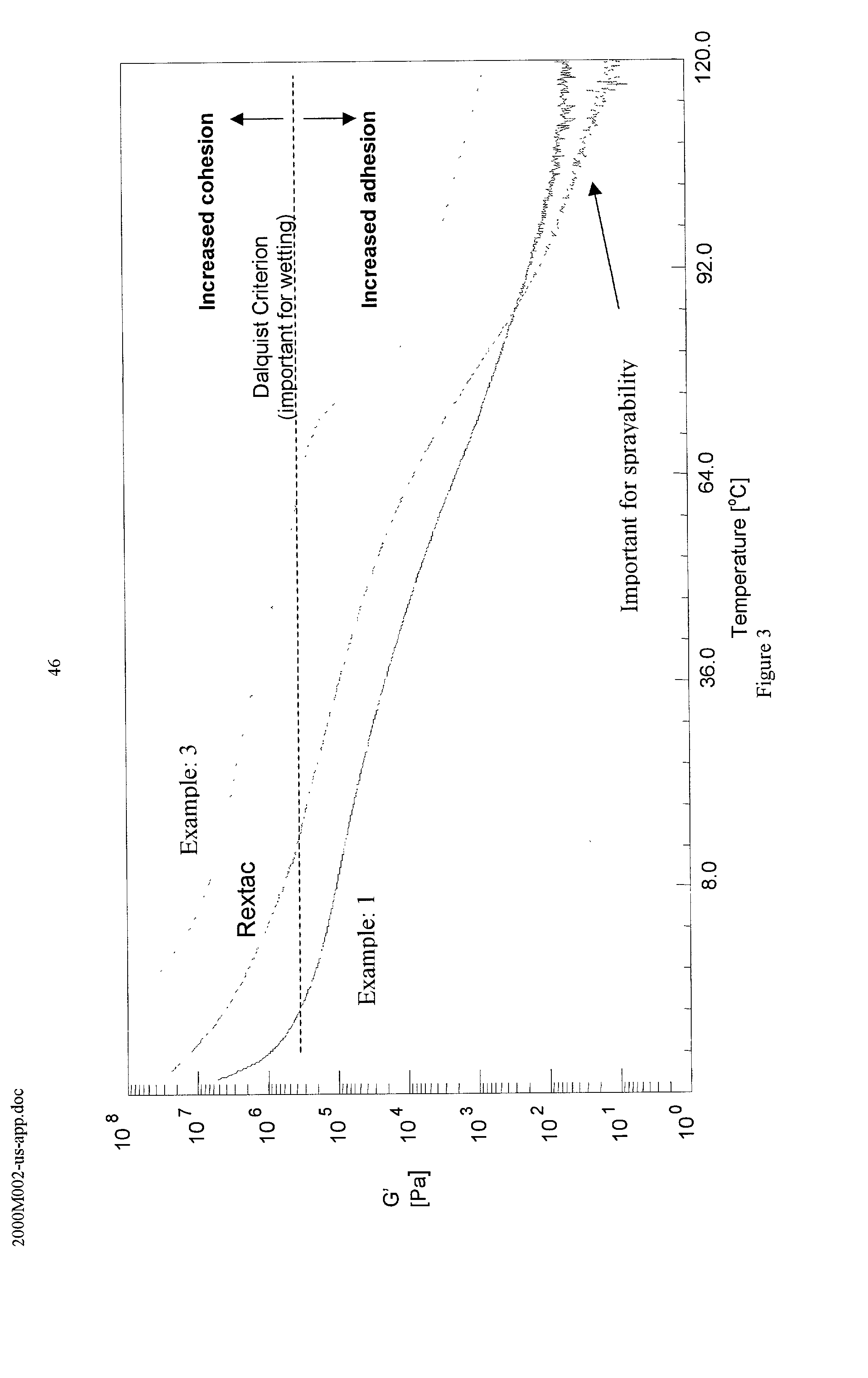

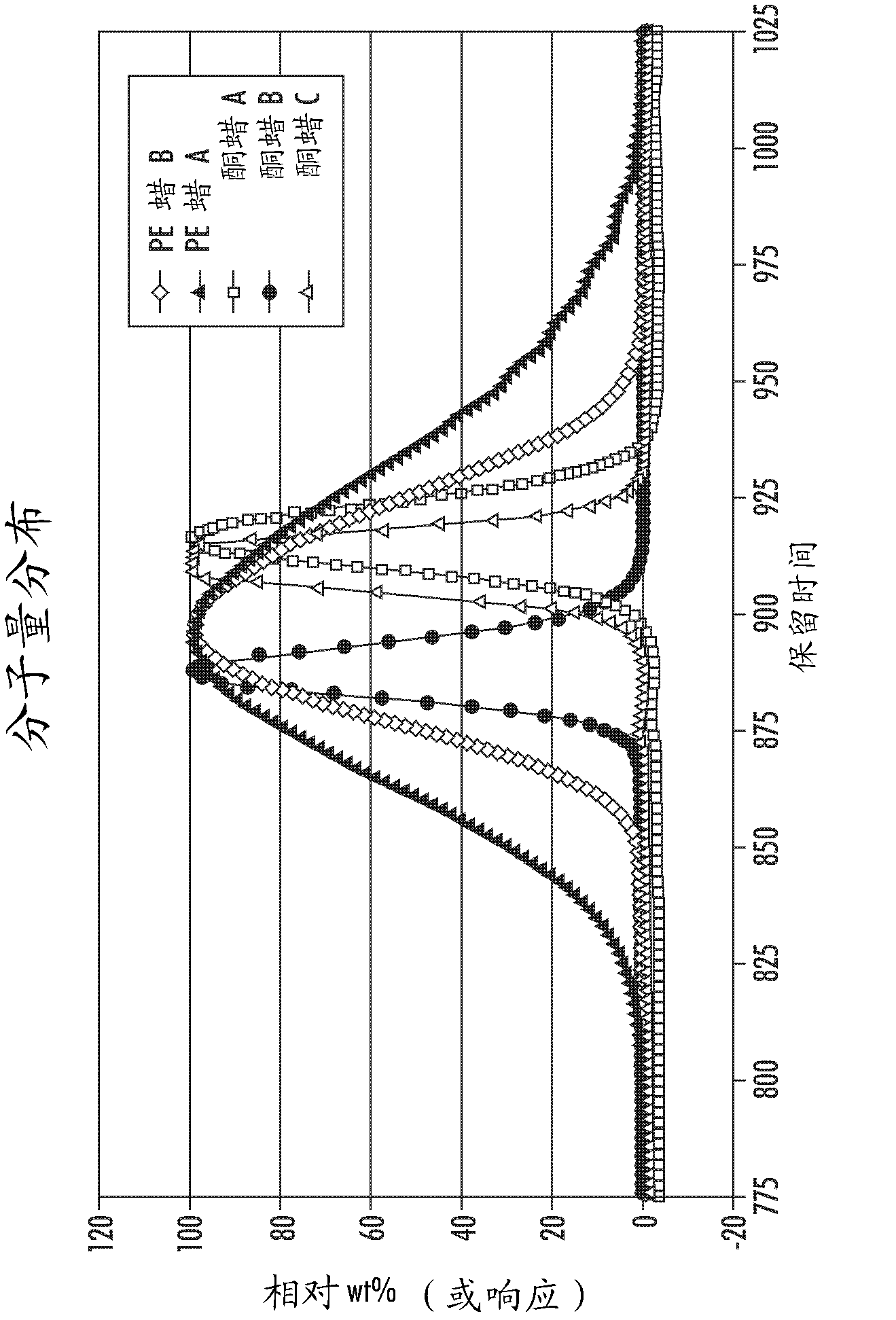

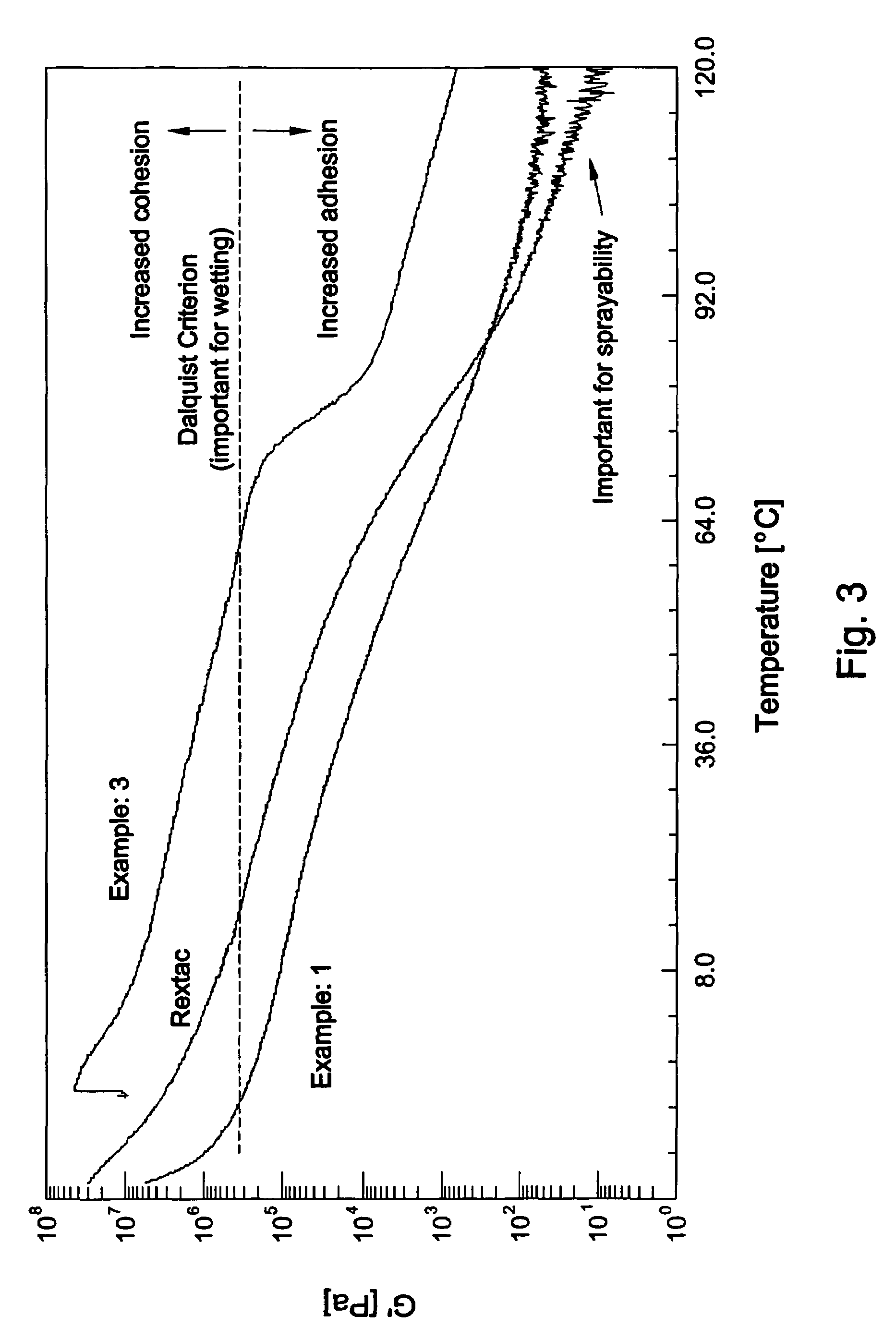

The invention relates to novel adhesive alpha-olefin inter-polymers which are largely amorphous and have a rheological behavior that makes them suitable for adhesive use, both without and with minimized amounts of tackifying resins. Specifically, the invention poly-alpha olefin inter-polymer may be composed of A) from 60 to 94 mol % of units derived from one alpha mono-olefin having from 3 to 6 carbon atoms and B) from 6 to 40 mol % of units derived from one or more other mono-olefins having from 4 to 10 carbon atoms and at least one carbon atom more than A); and C) optionally from 0 to 10 mol % of units derived from another copolymerizable unsaturated hydrocarbon, different from A) and B); the diad distribution of component A in the polymer as determined by <13>C NMR as described herein showing a ratio of experimentally determined diad distribution over the calculated Bernoullian diad distribution of less than 1.07; and the storage modulus G' of said polymer, determined upon cooling as described herein, intersecting a value of 3.10<5 >Pa at a temperature of less than 85° C. The invention also describes polymerization processes suitable for the manufacture of these adhesive alpha-olefin inter-polymers.

Owner:EXXONMOBIL CHEM PAT INC

Adhesive alpha-olefin inter-polymers

InactiveUS20020007033A1Minimize adverse interactionHigh activityWax adhesivesPolymer scienceUnsaturated hydrocarbon

The invention relates to novel adhesive alpha-olefin inter-polymers which are largely amorphous and have a Theological behavior that makes them suitable for adhesive use, both without and with minimzed amounts of tackifying resins. Specifically, the invention poly-alpha olefin inter-polymer may be composed of A) from 60 to 94 % of units derived from one alpha mono-olefin having from 3 to 6 carbon atoms and B) from 6 to 40 mol % of units derived from one or more other mono-olefins having from 4 to 10 carbon atoms and at least one carbon atom more than A); and C) optionally from 0 to 10 mol % of units derived from another copolymerizable unsaturated hydrocarbon, different from A) and B); the diad distribution of component A in the polymer as determined by 13C NMR as described herein showing a ratio of experimentally determined diad distribution over the calculated Bernoullian diad distribution of less than 1.07; and the storage modulus G' of said polymer, determined upon cooling as described herein, intersecting a value of 3.105 Pa at a temperature of less than 85 ° C. The invention also describes polymerization processes suitable for the manufacture of these adhesive alpha-olefin inter-polymers.

Owner:EXXONMOBIL CHEM PAT INC

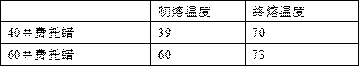

Middle-temperature sharp-quenching aluminum solder and method of producing the same

InactiveCN101134273AFlat surfaceGood workmanshipWelding/cutting media/materialsSoldering media6063 aluminium alloyMelt temperature

The present invention belongs to the field of aluminum and aluminum alloy connecting material, relates to aluminum brazing material, and is especially one kind of fast cooled Al-Si-Cu-Zn brazing material for brazing aluminum and aluminum alloy and its preparation process. The Al-Si-Cu-Zn brazing material consists of Si 5.0-12.5 wt%, Cu 15.0-30.0 wt%, Zn 2.5-7.5 wt%, Sr 0.001-0.5 wt% and Al for the rest. The Al-Si-Cu-Zn brazing material is prepared through one single roll and fast cooling process. It has melting temperature of 500-525 deg.c and brazing temperature of 530-570 deg.c, and is suitable for brazing aluminum and aluminum alloy with solidus temperature over 530 deg.c.

Owner:JIANGSU UNIV OF SCI & TECH

High-ductility environment friendly silver-saving medium-temperature brazing filler metal

ActiveCN101342644AReduce brittlenessHigh melting temperatureWelding/cutting media/materialsSoldering mediaCadmium CationFiller metal

The invention relates to a high plasticity environment protection silver-saving intermediate temperature solder in which an intermediate temperature solder is used to replace the silver copper zinc cadmium solder with high content of silver, and a processing technology thereof. Aiming at the defects of the prior silver solder which contains cadmium and lead such as the heavy pollution to environment, the hazard of the cadmium and lead to human body, large brittleness of solder alloy and high cost and so on, the purpose of the invention is to provide a cadmium-free and lead-free high plasticity environment protection silver-saving intermediate temperature solder with low cost, small brittleness of solder alloy, comparatively low melting temperature and comparatively small melting range. The high plasticity environment protection silver-saving intermediate temperature solder of the invention comprises Cu, Sn, P, Ni, Ag, Li and La; wherein, Li and Na are active microelements. The preparation steps of the high plasticity environment protection silver-saving intermediate temperature solder of the invention are that raw materials are weighted by formula; the solder alloy is refined into solder ingot castings which are made into filamentous solders by hot-pressing. The filamentous solder can be made into sizes of solder coiling wire, solder straight wire and solder welding ring.

Owner:浙江信和科技股份有限公司

Boracic Cu-P-based amorphous brazing filler metal and method for preparing same

InactiveCN101530952AAvoid difficultiesLower melting temperatureWelding/cutting media/materialsSoldering mediaWettingFiller metal

The invention discloses a boracic Cu-P-based amorphous brazing filler metal and a method for preparing the same, which belong to the technical field of the brazing of amorphous brazing filler metal and copper as well as copper alloy. The amorphous brazing filler metal comprises the following components in percentage by weight: 7.2 percent of P, 14.0 percent of Ni, 5.4 percent of Sn, 0.02 to 0.04 percent of B, 0.2 percent of Si, and the balance of Cu. The amorphous brazing filler metal is prepared by adopting a rapid solidification technique, and the prepared brazing filler metal has a bright and clean surface, two smooth sides and better toughness. The melting temperature of the amorphous brazing filler metal is between 602 and 663 DEG C and the brazing temperature is between 670 and 720 DEG C. The amorphous brazing filler metal is applicable to the brazing of the copper and the copper alloy, and applicable brazing process methods comprise flame brazing, furnace brazing, gas shield brazing, salt bath brazing, and the like. By adopting the amorphous brazing filler metal to perform flame brazing of red copper, the wetting property of the brazing filler metal is obviously better than the brazing filler metal with same components prepared by a conventional melting technique, and the shear strength of a brazed joint is more than 112 MPa.

Owner:JIANGSU UNIV OF SCI & TECH

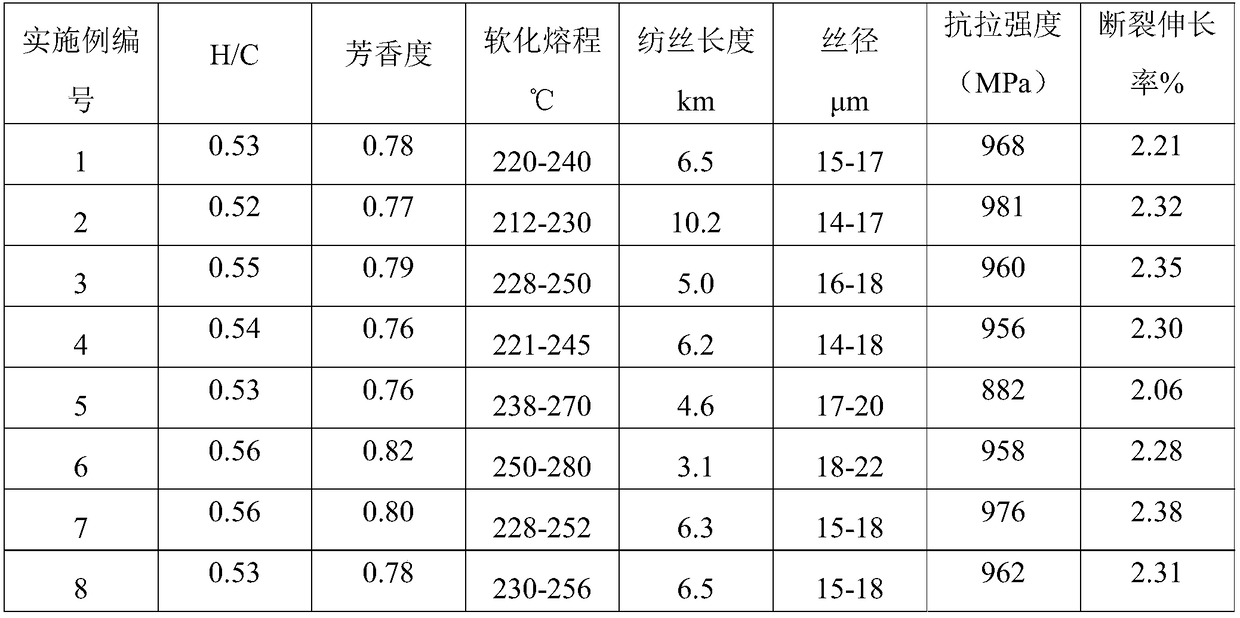

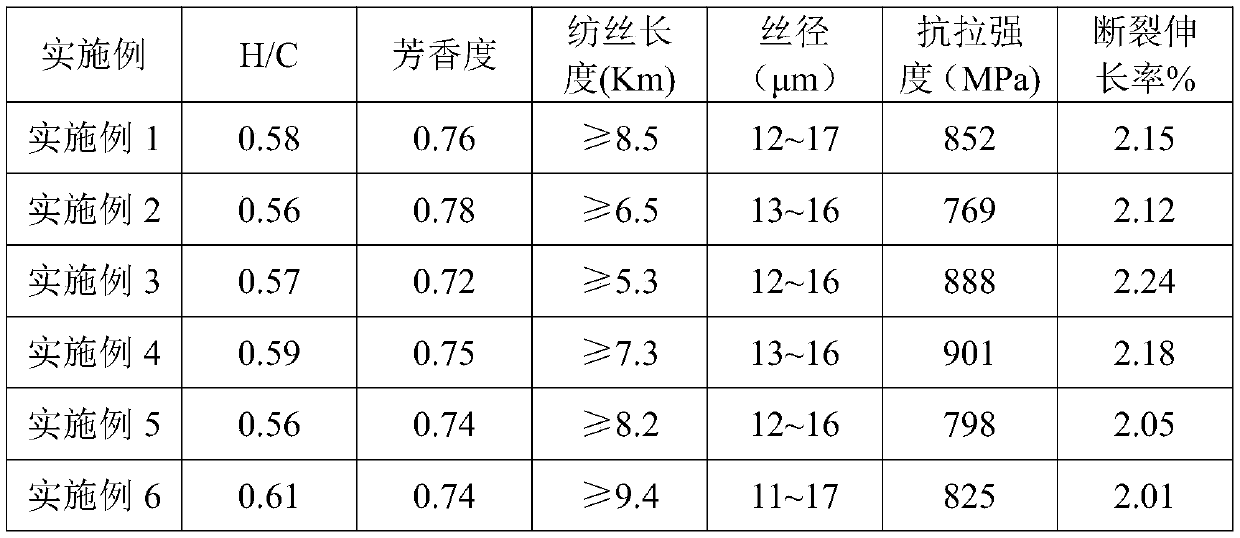

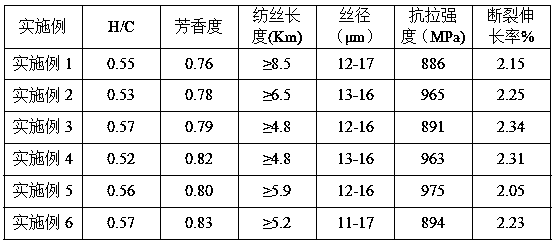

Method for preparing spinnable pitch from coal tar pitch

ActiveCN109181733AHigh yieldHigh overall yield (27-32%), softening pointWorking-up pitch/asphalt/bitumen by selective extractionWorking-up pitch/asphalt/bitumen by chemical meansFiltrationNitrogen

A method for preparing spinnable pitch from coal tar pitch comprises the following steps: crushing medium-low-temperature coal tar pitch to 20 meshes or below, performing extracting by using tetrahydrofuran, performing filtration to obtain a medium-low-temperature coal tar pitch soluble component, and recovering the tetrahydrofuran solvent from the soluble component to obtain refined pitch; and mixing the refined pitch with petrolatum, adding the obtained mixture into a reactor, introducing nitrogen under normal pressure, heating the reactor to 180-220 DEG C at a heating rate of 1-10 DEG C / min, switching to air, introducing the air into the reactor at a rate of 10-60 mL / min.g, heating the reactor to 280-350 DEG C at a heating rate of 1-10 DEG C / min, and allowing the obtained mixture to stay for 1-10 h to obtain the spinnable pitch. The method has the advantages of high yield, low price and moderate thermal polycondensation temperature.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

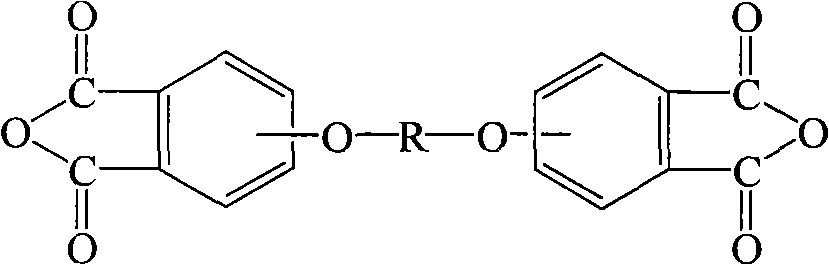

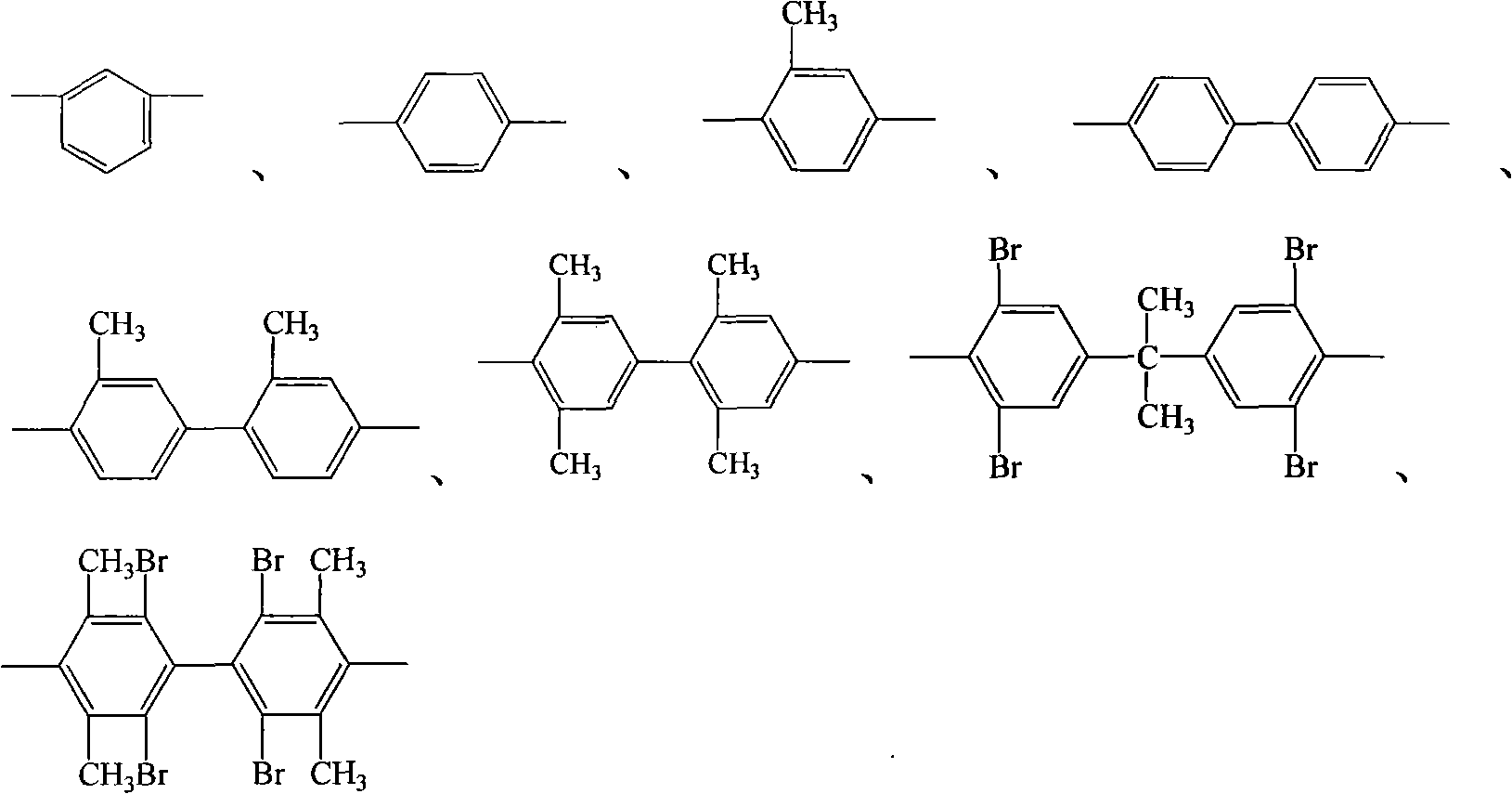

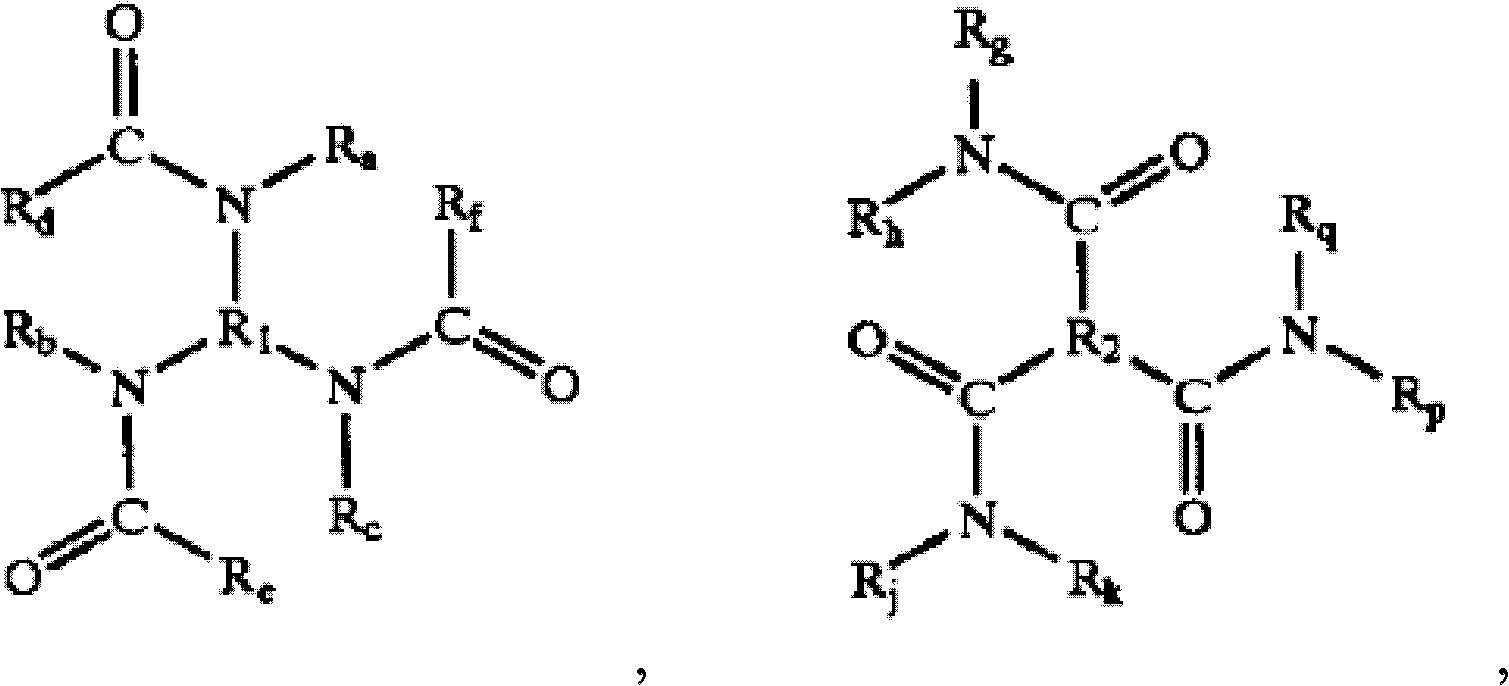

Process for producing aromatic diaether dianhydride monomer

The invention relates to a method for synthesizing a dianhydride monomer, in particular to a method for synthesizing an aromatic HQEDA monomer. The method adopts a 3(4) substituted phthalimide to prepare HQEDA and provides novel middle steps for preparing the HQEDA. The method comprises the following steps: preparing a 3 (4) substituted-N-alkyl (aryl) phthalimide from the 3(4) substituted phthalimide through Gabriel reaction principle or by adding a salifying agent and halocarbon into an apolar aprotic solvent to react; and using the prepared 3 (4) substituted-N-alkyl (aryl) phthalimide to prepare bis imide and the bis ether anhydride. The method has the advantages that raw materials are easily available, preparation method is simple and easy to operate, and the purity and yield of the prepared 3 (4) substituted-N-alkyl (aryl) phthalimide are obviously higher than that of the prior method.

Owner:NANJING UNIV OF TECH

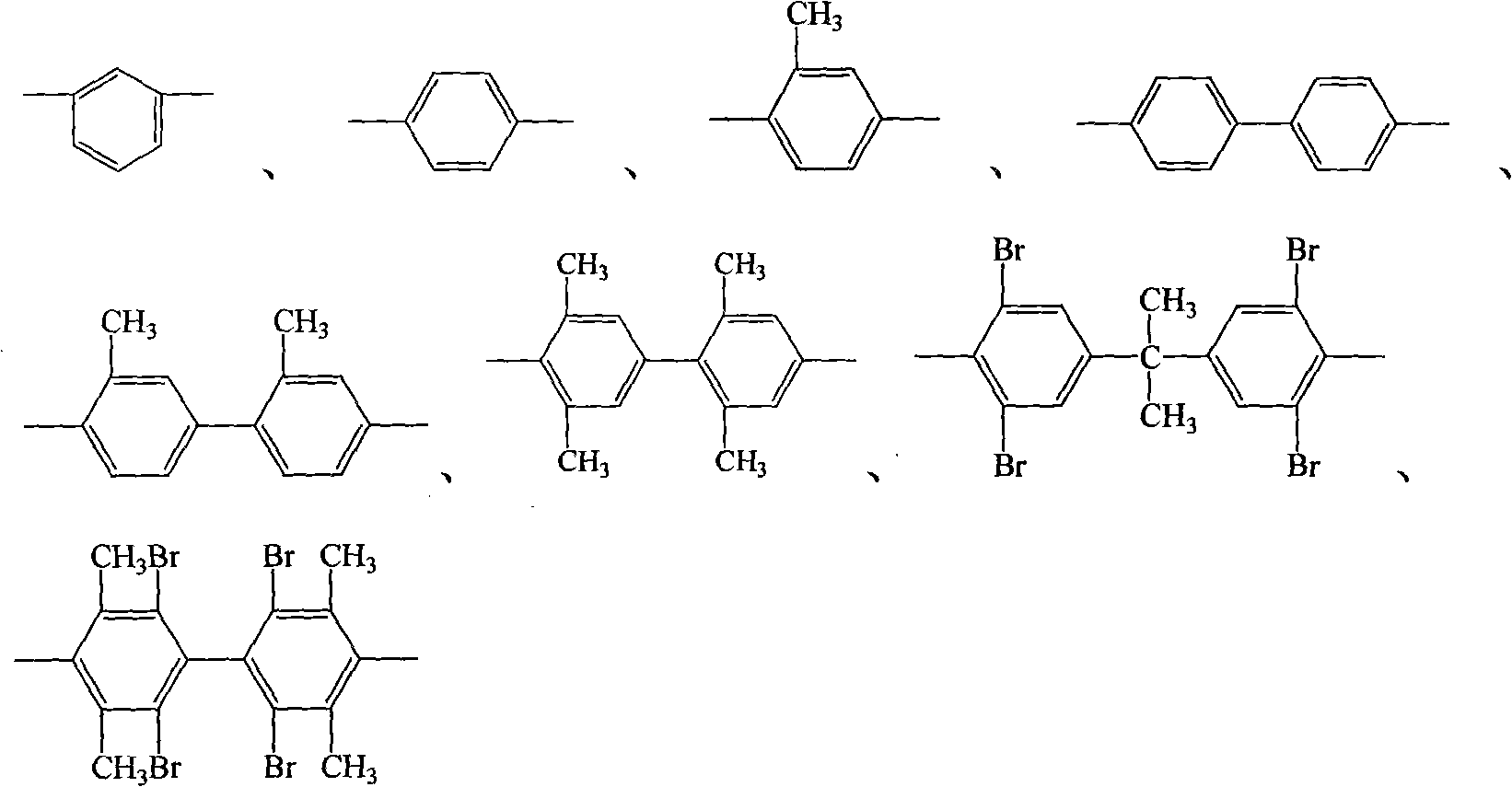

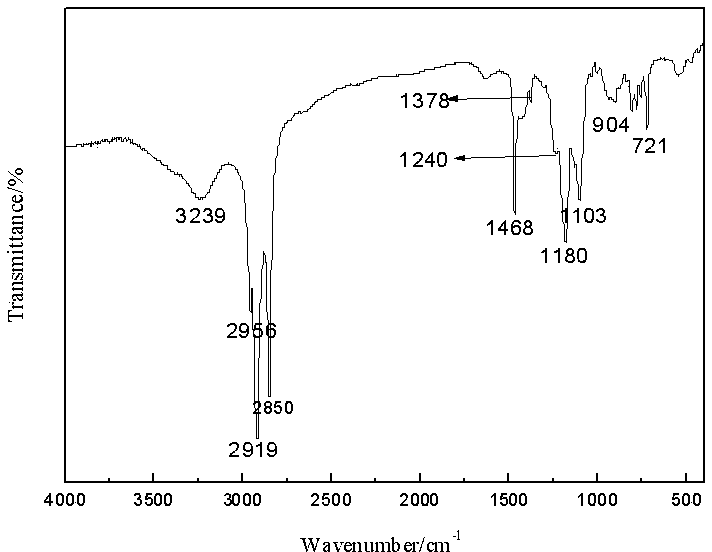

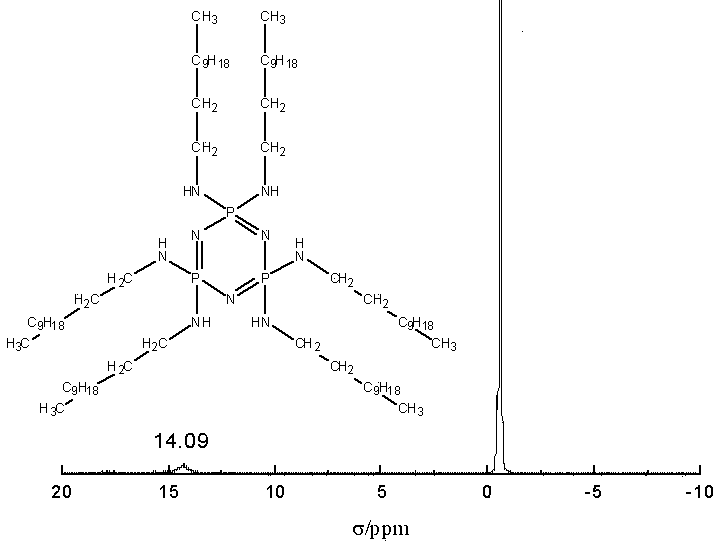

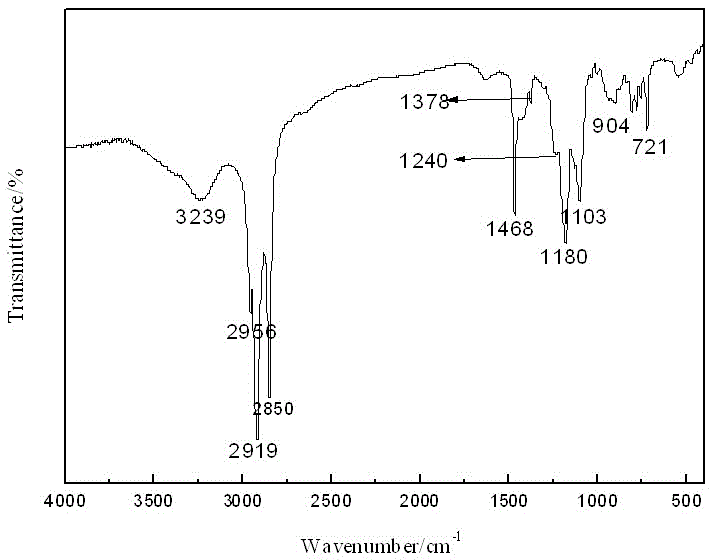

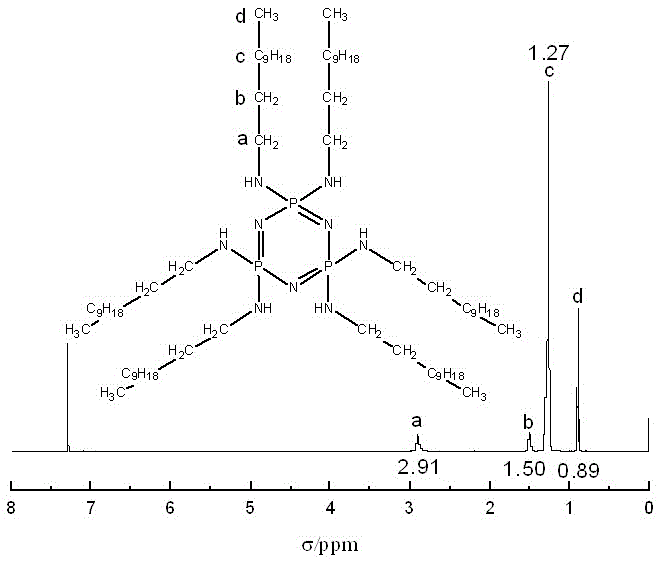

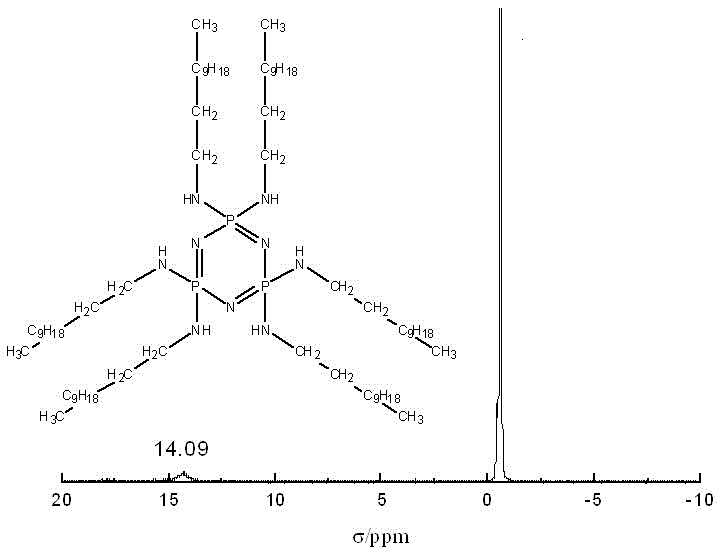

Phosphonitrile fire retardant and preparation method and application thereof

InactiveCN104292504ANarrow melting rangeHigh purityGroup 5/15 element organic compoundsChemical structureChemistry

The invention discloses a chemical structure of a phosphonitrile fire retardant, and discloses a preparation method of the phosphonitrile fire retardant. The method comprises the following steps: (a) dissolving phosphonitrilic chloride trimer and an acid-binding agent into an organic solvent, introducing N2 for protecting, stirring evenly to obtain a mixed solution, dropwise adding n-octylamine or lauryl amine to the mixed solution when stirring, carrying out reflux reaction at 50-80 DEG C for 9-12 hours after dropwise adding is ended, so as to obtain reaction liquid; and (b) cooling the reaction liquid, standing and separating a target product, and drying to obtain a phosphonitrile fire retardant. Meanwhile, the invention also discloses a composite material which is prepared from the prepared fire retardant added to EVA and is excellent in flame retardant property and mechanical performance. According to the novel phosphonitrile fire retardant developed by the method, the preparation method is simple and easy to operate; the prepared aliphatic amine-substituted phosphonitrile compound is narrow in melting range, high in purity and good in processability; and the composite material prepared by compounding with EVA can be widely used as a cable raw material.

Owner:HEBEI UNIVERSITY

Solid inks containing ketone waxes and branched amides

InactiveCN102533002AImprove solubilityReduce manufacturing costDuplicating/marking methodsInksWaxRoom temperature

Owner:XEROX CORP

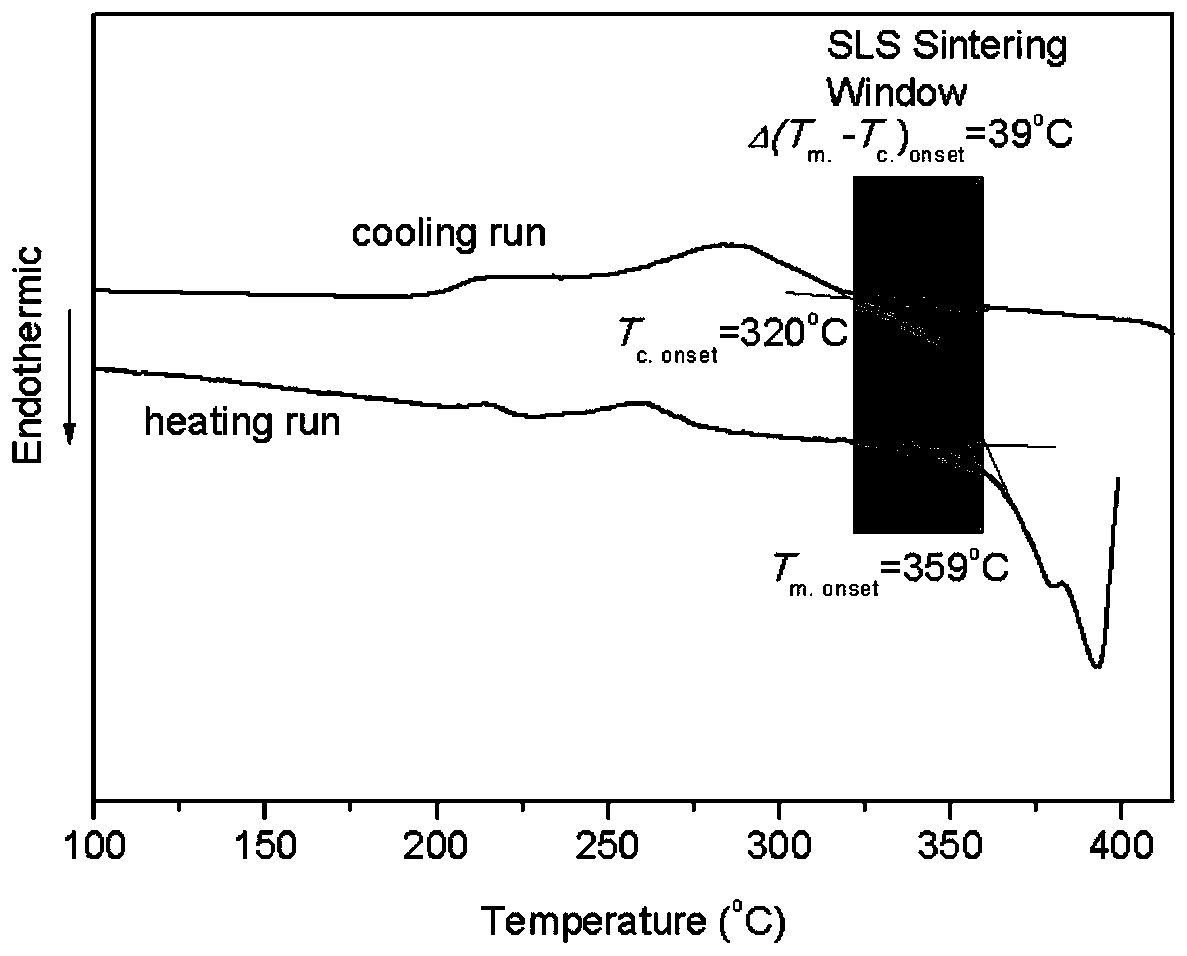

Selective laser sintering polyimide powder material and preparation and application methods thereof

ActiveCN109749442AReduce melt viscosityNarrow melting rangeAdditive manufacturing apparatusSelective laser sinteringAntioxidant

The invention relates to a laser sintering rapidly shaping powder material and preparation and application methods thereof, belongs to the field of rapidly shaping high-polymer materials and particularly relates to a selective laser sintering polyimide powder material and a preparation method thereof. The selective laser sintering polyimide powder material is composed of raw materials including, by weight part, 70-100 parts of crystalline polyimide resin, 0-30 parts of nanometer inorganic filler, 0.1-5 parts of polyphenylene sulfide resin and 0.1-3 parts of antioxidant. The selective laser sintering polyimide powder material can facilitate layering during a printing process; 3D (three-dimensional) products printed by the selective laser sintering polyimide powder material can be continuously applied at 330-380 DEG C.

Owner:宁波领科新材料科技有限公司

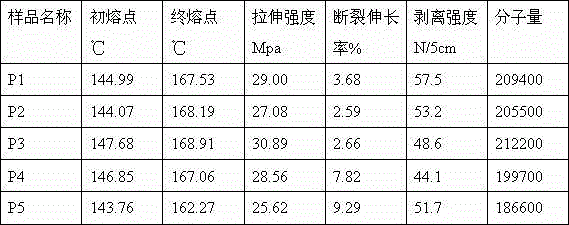

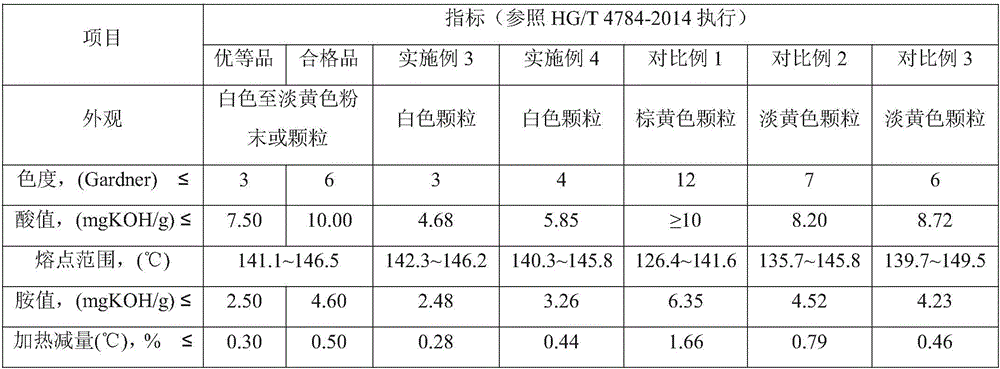

Preparing method for polyamide hot melt adhesive

The invention relates to a preparing method for polyamide hot melt adhesive, in particular to a preparing method for polyamide hot melt adhesive resistant to high temperature, high in melting point and narrow in melting range. According to the technical scheme, the preparing method is characterized in that two kinds of binary acid, the proportion and design of two kinds of diamine, caprolactam and monobasic acid are carefully selected, and the polyamide hot melt adhesive resistant to high temperature, high in melting point and narrow in melting range is obtained by a common method. The performance requirements of special field application are met, and the cost can be effectively lowered. The polyamide hot melt adhesive prepared through the preparing method can meet the requirement for adhering to automobile components and electronic components of which the working condition temperature reaches 140 DEG C.

Owner:SHANGHAI TIANYANG HOT MELT ADHESIVE CO LTD +2

Adhesive alpha-olefin inter-polymers

The invention relates to novel adhesive alpha-olefin inter-polymers which are largely amorphous and have a rheological behavior that makes them suitable for adhesive use, both without and with minimzed amounts of tackifying resins. Specifically, the invention poly-alpha olefin inter-polymer may be composed of A) from 60 to 94% of units derived from one alpha mono-olefin having from 3 to 6 carbon atoms and B) from 6 to 40 mol % of units derived from one or more other mono-olefins having from 4 to 10 carbon atoms and at least one carbon atom more than A); and C) optionally from 0 to 10 mol % of units derived from another copolymerizable unsaturated hydrocarbon, different from A) and B); the diad distribution of component A in the polymer as determined by 13C NMR as described herein showing a ratio of experimentally determined diad distribution over the calculated Bernoullian diad distribution of less than 1.07; and the storage modulus G′ of said polymer, determined upon cooling as described herein, intersecting a value of 3.105 Pa at a temperature of less than 85° C. The invention also describes polymerization processes suitable for the manufacture of these adhesive alpha-olefin inter-polymers.

Owner:EXXONMOBIL CHEM PAT INC

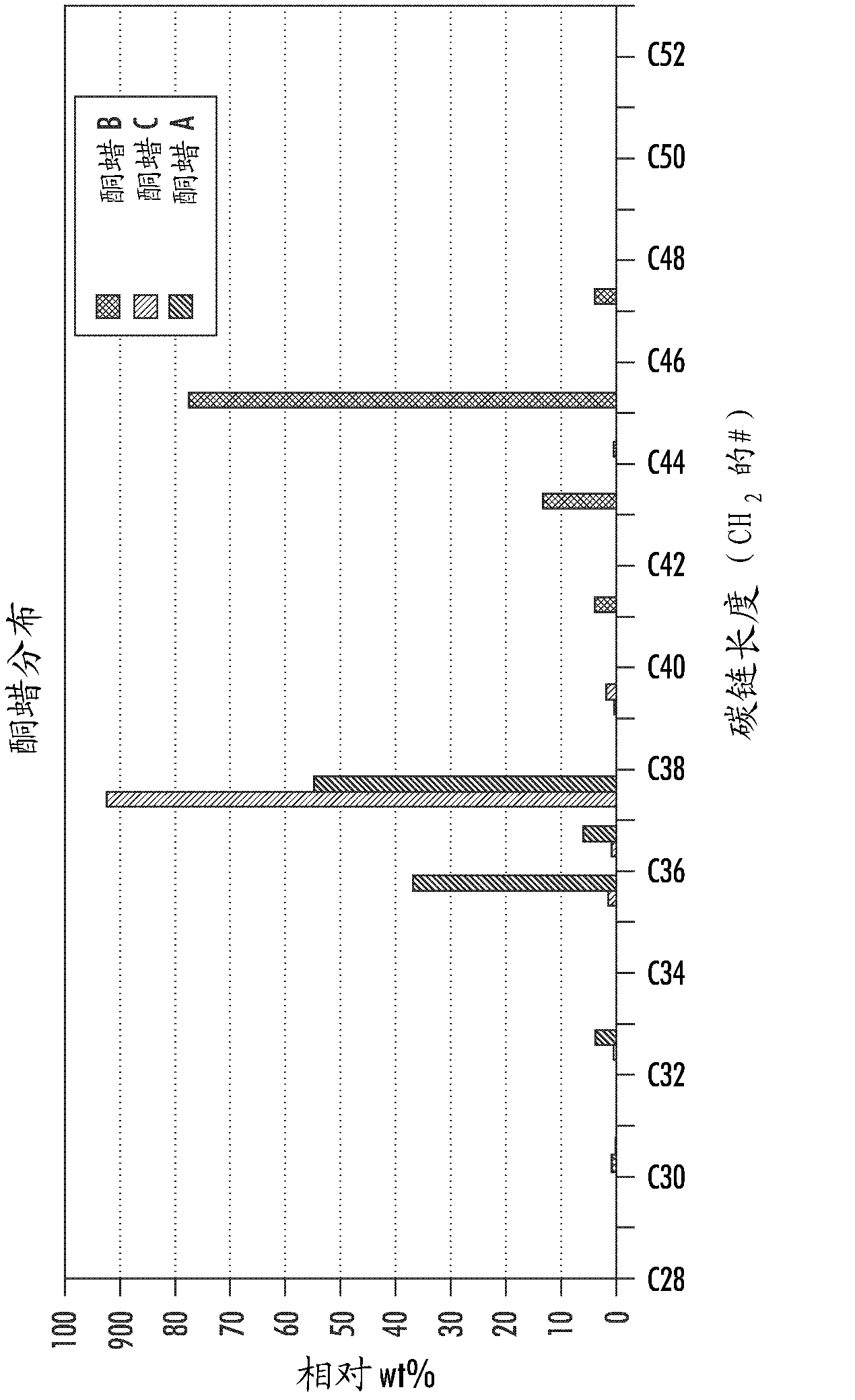

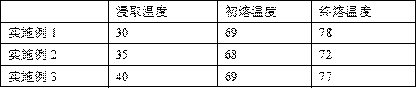

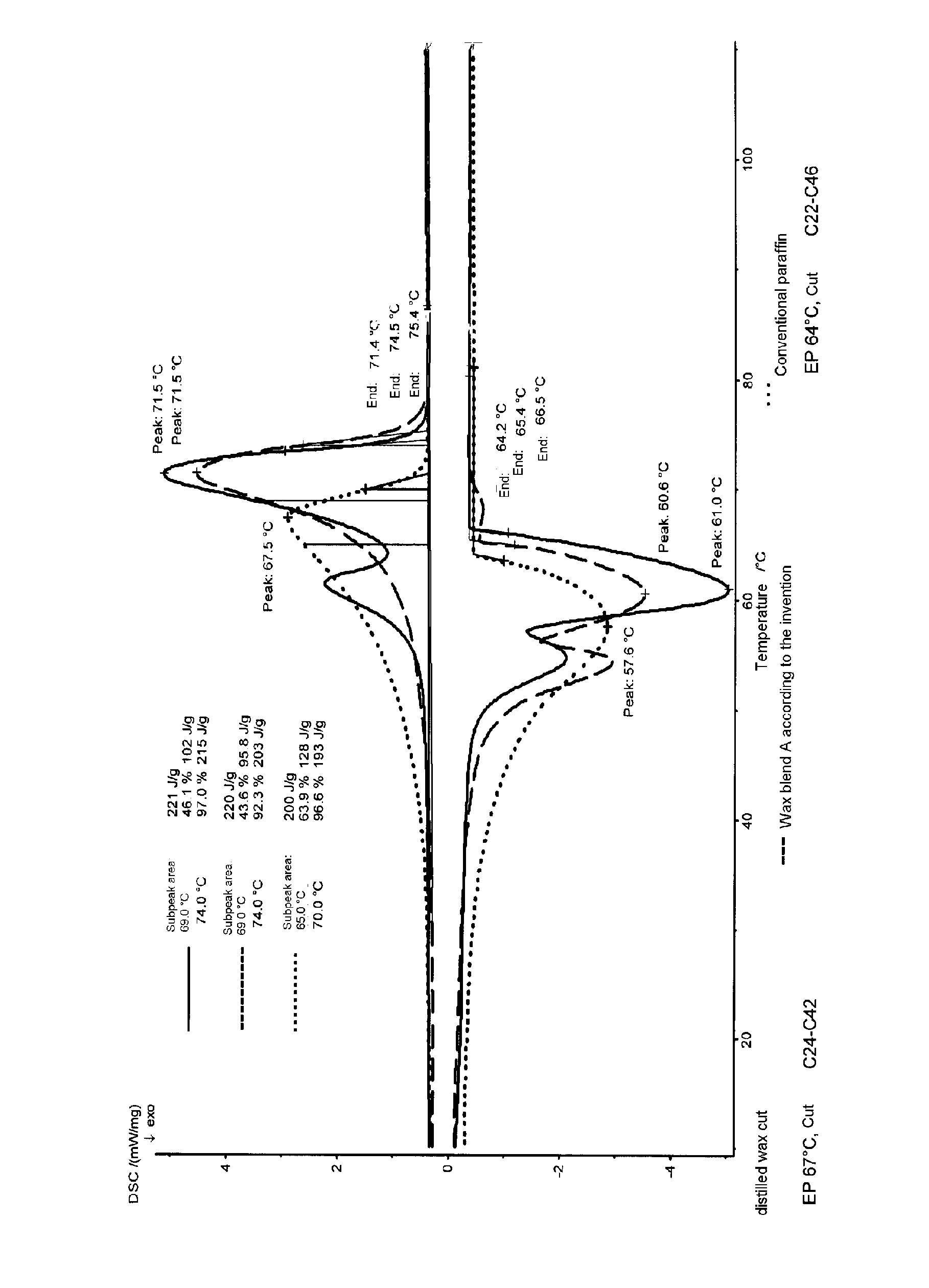

Granule-based wax sweating method

ActiveCN109810725AIncrease heat transfer areaIncreased flow poresPetroleum wax recoveryParaffin waxWarm water

A granule-based wax sweating method comprises the following steps: (1) filling water to the bottom part of a sweating device; (2) heating paraffin to a liquid state, adding sweating granules, and thenadding the mixture in the sweating device; (3) cooling the paraffin to be 10 to 20 DEG C lower than a melting point at the speed of 1 to 4 DEG C / h; (4) releasing the water, pumping warm water to a sweating tank, heating at the speed of 0.5 to 2 DEG C / h, and collecting the paraffin which can sweat at different melting points; (5) melting the paraffin after finishing heating, and enabling a moltenhigh-melting-point paraffin product to flow into an intermediate tank; (6) blowing residual sweating granules and the last one distillate in the sweating tank by using steam, filtering and separatingthe sweating granules and the distillate, and recycling the sweating granules. According to the granule-based wax sweating method disclosed by the invention, the compaction density of sweating raw materials is reduced, outflow of oil content and low-melting-point wax can be facilitated, the fluidity of sweating liquid is improved, and the separation effect is multiplied; meanwhile, the yield of asweating product is higher, a wax melting range is narrower, a wax product is concentrated in molecular weight, and the enthalpy value of a product is higher.

Owner:上海焦耳蜡业有限公司

Preparation method of vinyl distearamide

ActiveCN105777568AReduce chromaHigh purityOrganic compound preparationCarboxylic acid amides preparationEthylenediamineCompound a

The invention belongs to the technical field of chemical engineering and particularly relates to a preparation method of vinyl distearamide. The preparation method uses stearic acid and ethylenediamine as reacting raw materials, uses a composite antioxidant prepared by compounding an antioxidant 1076, an antioxidant DLTDP and an antioxidant T501 as a reacting antioxidant and uses a composite catalyst prepared by compounding a p-Toluene sulfonic acid / SAPO-34 supported solid acid catalyst and a phosphoric acid / SiO2-Al2O3 supported solid acid catalyst as a reaction catalyst. The preparation method of the vinyl distearamide is simple in process, no 'three wastes' emission is produced in the process of preparing the vinyl distearamide, the yield is high, and the prepared vinyl distearamide is high in purity, low in chromaticity and narrow in melting range.

Owner:GUANGZHOU CARDLO BIOCHEM TECH

Spinnable asphalt and preparation method thereof

InactiveCN111004641AHigh softening pointContinuous spinningWorking-up pitch/asphalt/bitumen by mixing fractionsSide chainSimple aromatic ring

The invention discloses spinnable asphalt and a preparation method thereof, wherein the spinnable asphalt comprises the following raw materials in parts by weight: 20-50 parts of medium and low temperature coal pitch-based refined asphalt and 50-80 parts of petroleum asphalt. The preparation method comprises the following steps: uniformly mixing 20-50 parts by weight of medium and low temperaturecoal pitch-based refined asphalt and 50-80 parts by weight of crushed petroleum asphalt, and putting the mixture into a reactor; and introducing inert gas into the reactor under normal pressure, heating to 370-450 DEG C at a speed of 2-9 DEG C / min, and reacting for 4-9 hours to obtain spinnable asphalt. According to the invention, high aromaticity is provided through refined asphalt, the aromaticcomponents and the asphaltene in petroleum asphalt are combined to provide a small amount of aromatic rings, and saturated components and colloid provide alkyl side chains and naphthenic structures, so that the high-quality spinnable asphalt having high softening point and narrow melting range and capable of continuously spinning can be obtained, the petroleum asphalt is used for replacing a modifier, and the preparation technological process of the spinnable asphalt can be simplified.

Owner:西安郎格飞博科技有限公司

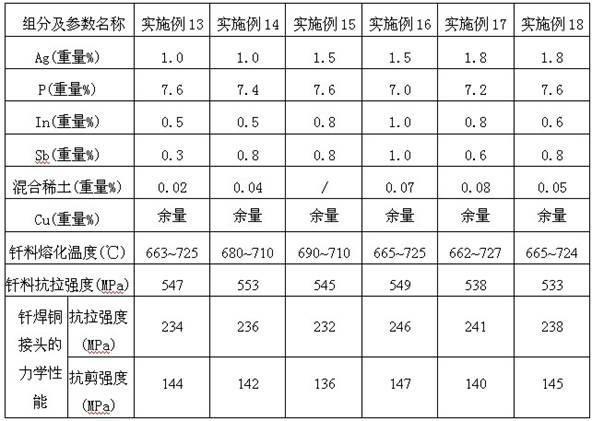

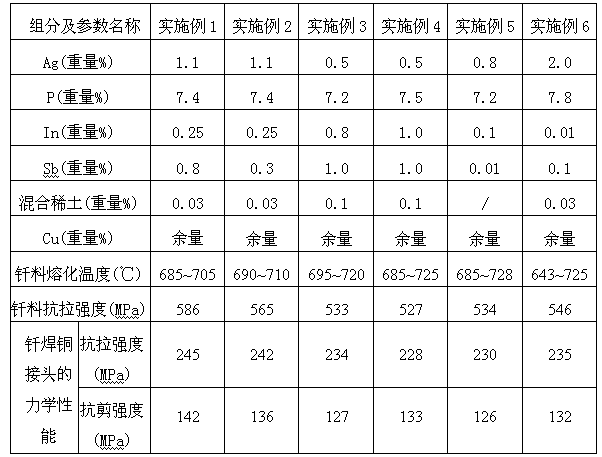

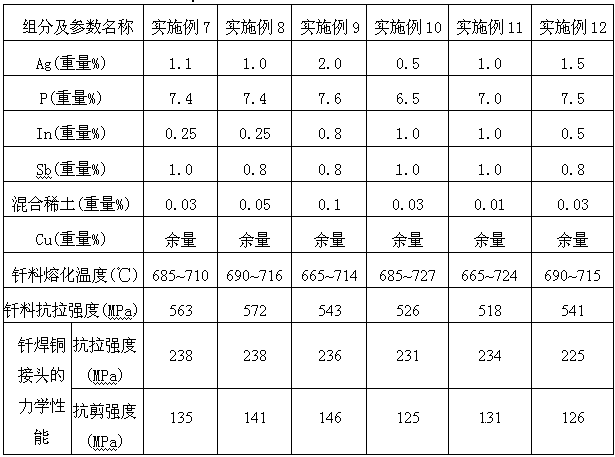

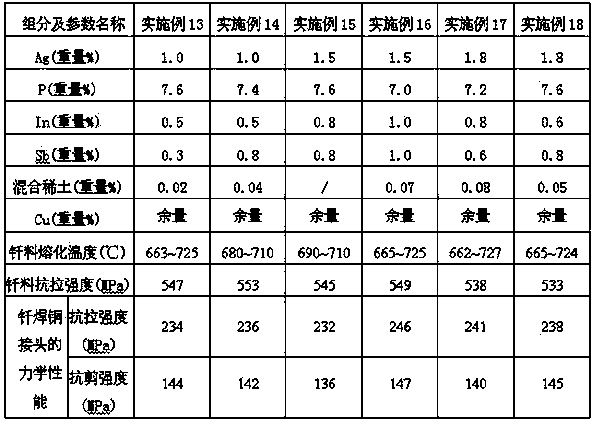

Indium-containing active copper-based solder

ActiveCN102689105AInhibit excessive productionImprove plasticityWelding/cutting media/materialsSoldering mediaElectromechanicsIndium

The invention relates to an indium-containing active copper-based solder, which is particularly suitable for soldering copper and copper alloy workpieces of heat exchangers, various valve bodies and the like, can be widely applied to soldering of industries of refrigeration, machinery, electromechanics, electrical appliances and the like and belongs to an intermediate temperature soldering material. The indium-containing active copper-based solder comprises the following components in percentage by weight: 0.5 to 2.0 percent of Ag, 6.0 to 7.8 percent of P, 0.01 to 1.0 percent of In, 0.01 to 1.0 percent of Sb and the balance of Cu. The indium-containing active copper-based solder has the advantages of reasonable formula design, high cost performance, low solder melting temperature, high wettability, high fluidity, high soldered joint mechanical strength and high soldering process performance.

Owner:HANGZHOU HUAGUANG ADVANCED WELDING MATERIALS CO LTD

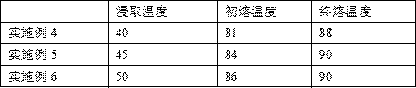

Method of increasing melting temperature of Fischer-Tropsch wax by leaching

InactiveCN108949231APerformance impactHigh melting temperatureMineral wax recovery/refiningWaxRaffinate

The invention discloses a method of increasing the melting temperature of Fischer-Tropsch wax by leaching. The method comprises the following steps: step one. enabling the granular Fischer-Tropsch waxhaving the particle size of 0.01 to 5mm to contact with a solvent, wherein the weight ratio of the solvent to the granular Fischer-Tropsch wax is 20 to 0.1, the leaching temperature is 30 to 230 DEGC, and the leaching time is 10 to 300 minutes; step two. removing the solvent which is mixed in the granular Fischer-Tropsch wax after leaching, and recovering the solvent to obtain the Fischer-Tropsch wax with the high melting temperature; step three. recovering the solvent in raffinate, and meanwhile obtaining the Fischer-Tropsch wax with the low melting temperature; and step four. recycling thesolvent obtained in the step two and the step three. The method has the advantages that the energy consumption is low, high temperature and high vacuum degree are not required, the adverse impact ofhigh temperature on the performance of the Fischer-Tropsch wax is avoided, the melting temperature of the Fischer-Tropsch wax is increased, the melting range is relatively narrow, the cutting is relatively fine, and the method can meet the diversified needs of the market, the production operation is flexible, and the yield is easy to adjust.

Owner:WUHAN POLYTECHNIC UNIVERSITY

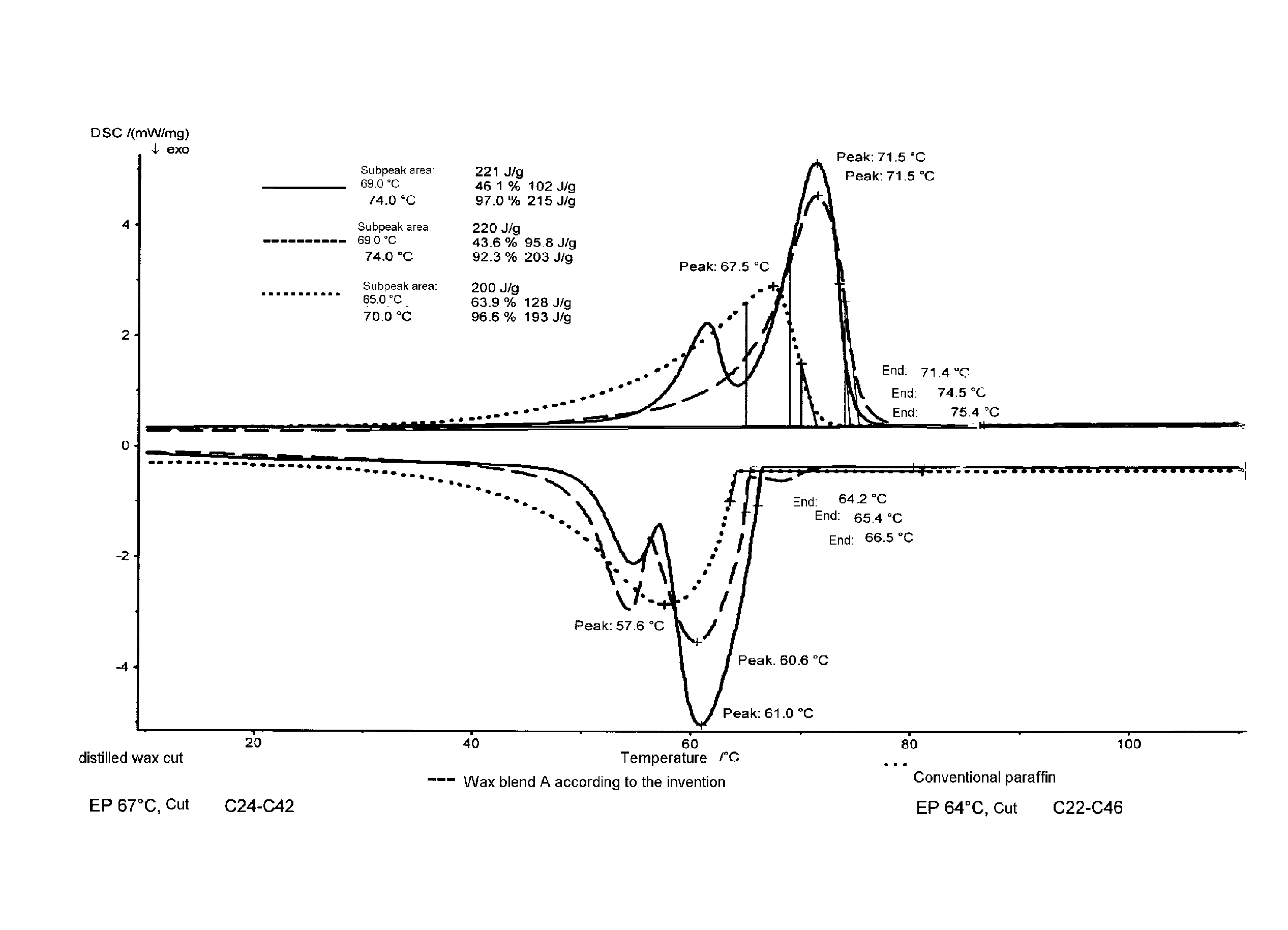

Wax blends containing long-chain hydrocarbons and alcohols, printing ink compositions and thermal transfer ribbons containing such wax blends, and use of the wax blends

The invention relates wax blends containing long-chain hydrocarbons and alcohols, to printing ink compositions and thermal transfer ribbons containing the wax blends, and to the use of said wax blends as additives in printing inks.

Owner:SASOL GERMANY GMBH

A kind of halogen-free flame-retardant EVA composite material

ActiveCN104311981BLow viscosityGood dispersionGroup 5/15 element organic compoundsPhosphateFatty amine

Owner:永清三利橡塑材料有限公司

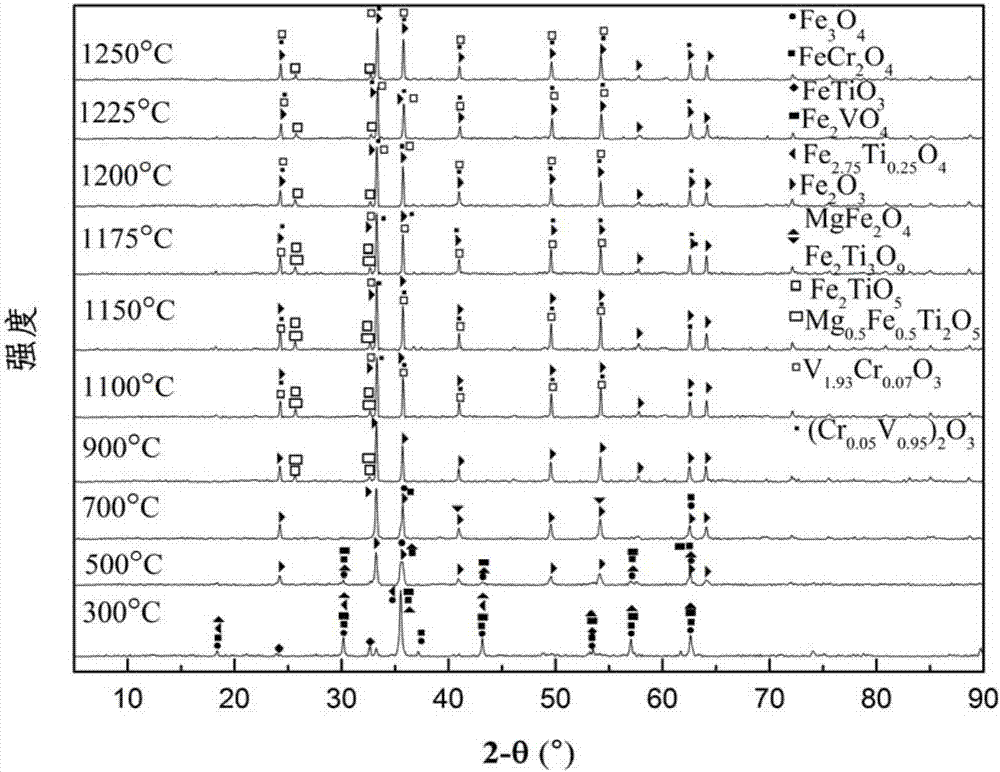

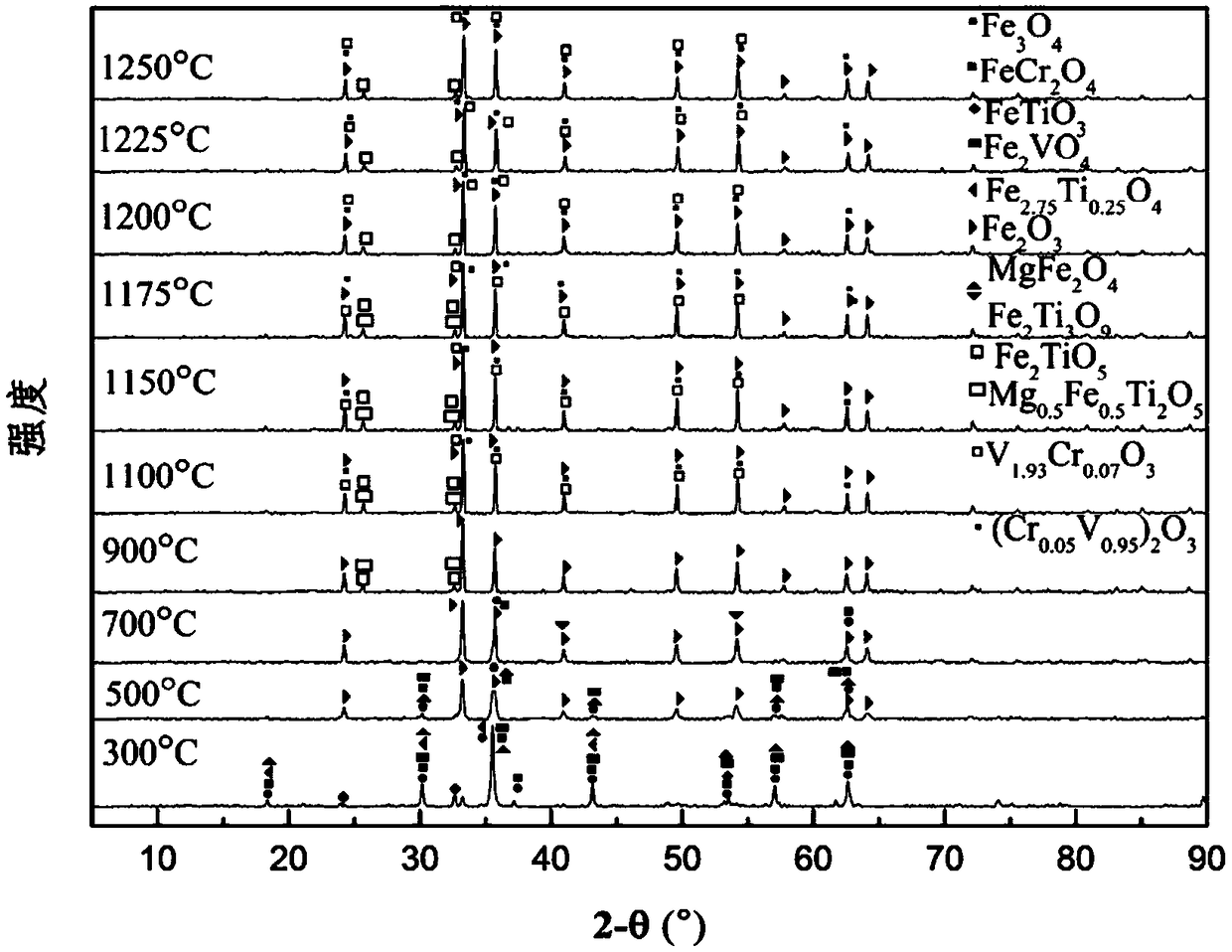

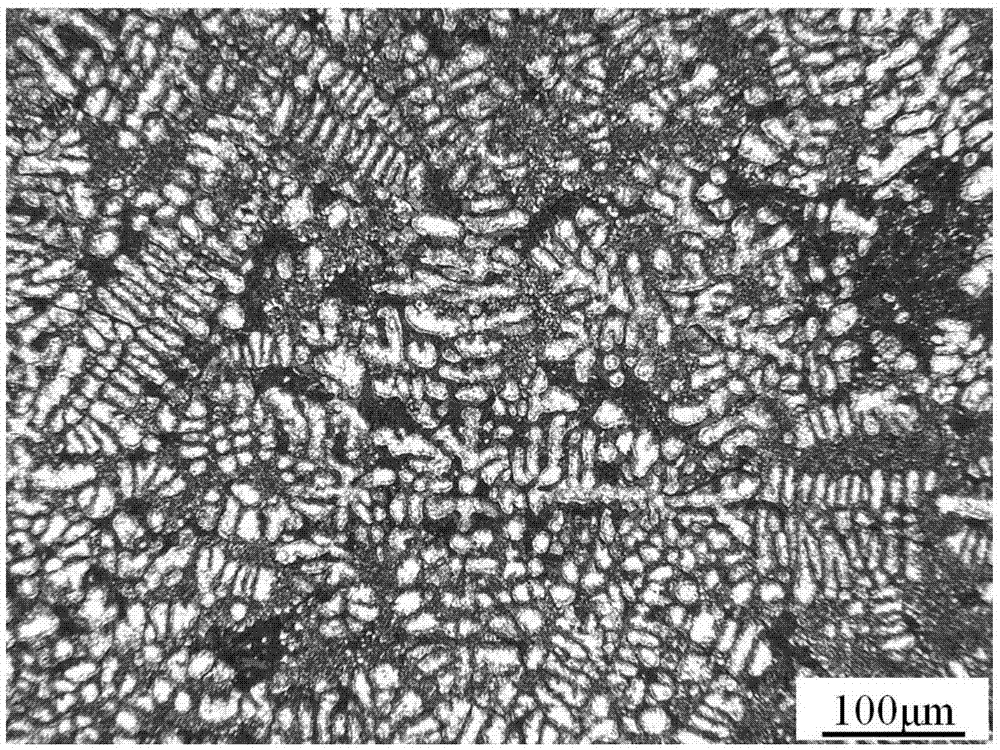

Method for preparing pellet by pre-treating high titanium type vanadium-titanium magnetite

The invention relates to a method for preparing a pellet by pre-treating high titanium type vanadium-titanium magnetite. The method comprises the following steps of carrying out fine ball milling pretreatment on the high titanium type vanadium-titanium magnetite by using an ore milling device, so as to enable the proportion of the particle size, which is less than 75 microns, of magnetite powder to be greater than 85 to 95 percent; drying, so as to enable the moisture of the high titanium type vanadium-titanium magnetite powder to be less than or equal to 1.3 percent; dry-mixing the dried magnetite powder and bentonite for 15min to 20min, and subsequently, spraying water, and wet-mixing for 15min to 20min; putting a wet-mixed raw material in a condition of 25 to 30 DEG C, braising the material for 25min to 35min, then putting into a pelletizer, and preparing a green pellet with a diameter of 10mm to 12.5mm; drying the green pellet; afterwards, roasting, and raising the temperature of the pellet to 800 to 900 DEG C according to a temperature rise rate of 10 to 12 DEG C per minute; afterwards, raising the temperature to 1,140 to 1,180 DEG C according to a temperature rise rate of 4 to 6 DEG C per minute, and roasting for 10min to 15min; subsequently, lowering the temperature according to a temperature fall rate of 5 to 8 DEG C per minute, taking out after the temperature is fallen to 300 DEG C, and carrying out air cooling. The method provided by the invention can be used for effectively improving the pelletizing performance and the pelletizing speed of the high titanium type vanadium-titanium magnetite, is used for enabling the strength of the green pellet to be best, moreover, is lower in roasting temperature and shorter in time, can be used for meeting the requirement of the compression strength of a mature pellet, and is used for obviously improving the production efficiency of the pellet of the high titanium type vanadium-titanium magnetite.

Owner:NORTHEASTERN UNIV LIAONING

A quenching solder for connecting cemented carbide and steel and its preparation method and connection method

InactiveCN102909489BLower melting temperatureEvenly meltedWelding/cutting media/materialsSoldering mediaCemented carbideUltimate tensile strength

The invention discloses a quenching solder for connecting hard alloy and steel as well as a preparation method and a connecting method of same. The quenching solder comprises the following components in percentage by weight: 28-33 percent of Ag, 18-20 percent of Zn, 1-8 percent of Ni, 5-9.5 percent of Mn, 3-6.5 percent of Co and 1-3 percent of Sn, and the balance of Cu. The preparation method of the quenching solder comprises the following steps: preparing the raw materials with the proportion into master alloy by adopting an electric arc melting method, continuously jetting a master alloy melt to the surface of a rotational cooling copper roller by using high-pressure argon to form a foil strip. A method for connecting the hard alloy and the steel by adopting the material comprises the following steps: carrying out surface treatment on the quenching solder, the hard alloy and the steel and then putting into a vacuum furnace by using a special fixture for brazing. The quenching solder has the advantages of low melting temperature, narrow melting interval, uniform solder melting and strong diffusivity of alloy elements; and through the connecting method, parts are wholly heated, the thermal stress is small, and the deformation can be controlled to a minimum limit, therefore, a stable and reliable joint can be obtained, and good joint strength is obtained.

Owner:JIANGSU UNIV OF SCI & TECH

Method for preparing spinnable asphalt through co-heating condensation polymerization of anhydride-modified coal asphalt and kerosene co-refining residues

ActiveCN110578188AHigh softening pointLess light componentsWorking-up pitch/asphalt/bitumen by chemical meansFibre chemical featuresKeroseneNitrogen gas

The invention discloses a method for preparing spinnable asphalt through co-heating condensation polymerization of anhydride-modified coal asphalt and kerosene co-refining residues. The method includes the steps of pulverizing kerosene co-refining residues and medium-and-low-temperature coal asphalt to reach the granularity of 20 mesh or below, extracting and filtering out soluble components through tetrahydrofuran, recovering a solvent to obtain asphaltene A and asphaltene B, mixing the asphaltene B with benzenetetracarboxylic anhydride and maleic anhydride, introducing nitrogen at normal pressure, raising the temperature to 350-450 DEG C at the temperature rise rate of 1-10 DEG C / min, keeping the temperature for 1-10 hours, lowering the temperature to the room temperature to obtain a solid product (substrate asphalt), mixing the substrate asphalt with the asphaltene A, introducing normal-pressure nitrogen, raising the temperature to 350-400 DEG C at the temperature rise rate of 1-10DEG C / min, keeping the temperature for 1-10 hours, and lowering the temperature to the room temperature to obtain the solid product (spinnable asphalt). The modified spinnable asphalt has the advantages of being moderate in softening point, short in softening and melting range and capable of continuously preparing asphalt fiber filaments through melting and spinning.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

A method for pretreating high-titanium vanadium-titanium magnetite to prepare pellets

The invention relates to a method for pretreating high-titanium vanadium-titanium magnetite to prepare pellets, which includes the following steps: using grinding equipment to perform fine ball milling pretreatment on high-titanium vanadium-titanium magnetite; drying; and drying the dried vanadium-titanium magnetite. Dry mix the mineral powder and bentonite, then spray water to wet mix; place the wet mixed raw materials at 25 to 30°C for simmering and then put them into a pelletizing machine to prepare green balls; dry the green balls; then roast them. The pellets are heated to 800-900°C; then, the temperature is raised to 1140-1180°C for roasting; then, the temperature is lowered to 300°C, then taken out and air-cooled. The method of the present invention effectively improves the ball-forming performance and ball-forming speed of high-titanium vanadium-titanium magnetite, so that the strength of green balls can be optimized, and the roasting temperature is low and the time is short, so that it can meet the requirements of compressive strength of cooked balls. The production efficiency of high-titanium vanadium-titanium magnetite pellets is significantly improved.

Owner:NORTHEASTERN UNIV LIAONING

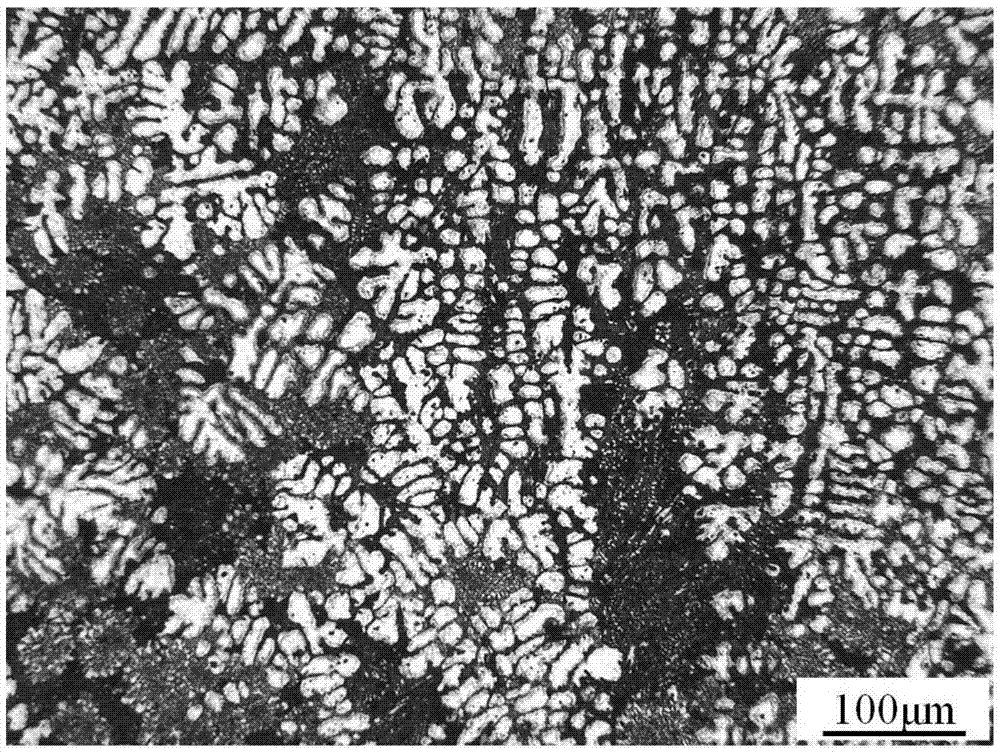

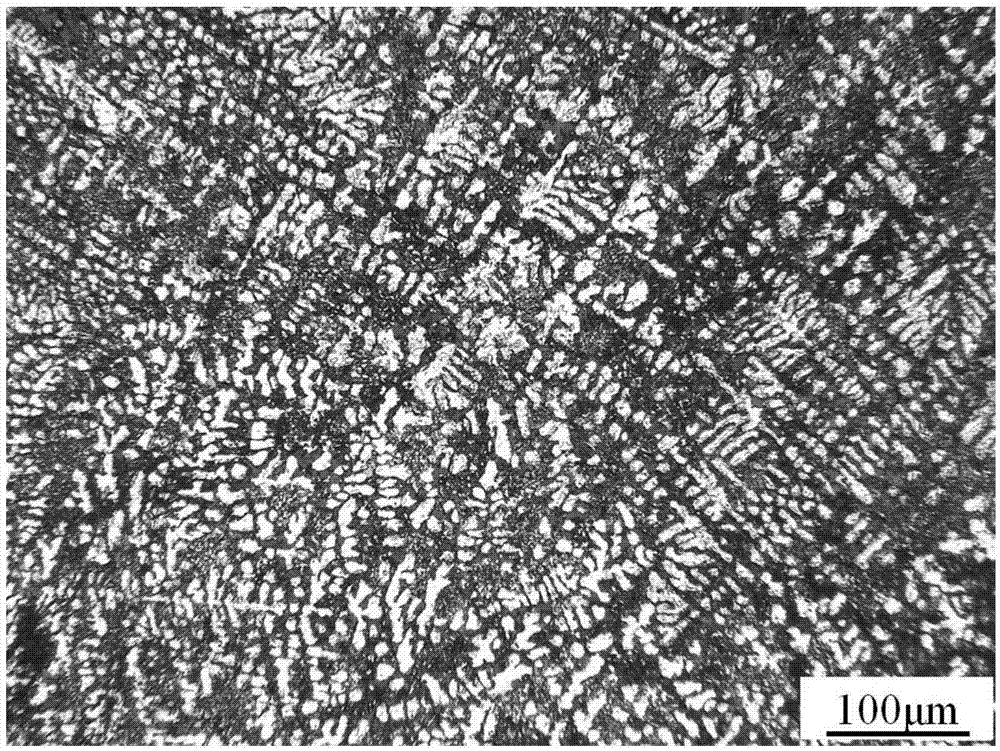

Medium temperature aluminum alloy brazing solder and preparing method thereof

InactiveCN105436739ALow melting pointNarrow melting rangeWelding/cutting media/materialsSoldering mediaMetallurgyBrazing

The invention discloses medium temperature aluminum alloy brazing solder and a preparing method thereof. The medium temperature aluminum alloy brazing solder comprises, by weight proportion, 0.5-3 parts of Mg, 3-25 parts of Cu, 1-2 parts of Al and 75-95 parts of a Si intermediate alloy. The preparing method comprises the steps of raw material taking, smelting and pouring. The solder has the beneficial effects of being low in melting point (lower than 550 DEG C), narrow in fusion zone and low in welding temperature; the good spreadability, the good gap filling performance, the good wettability and the good connector comprehensiveness are achieved; and the medium temperature aluminum alloy brazing solder is suitable for vacuum brazing.

Owner:GUIZHOU INST OF TECH

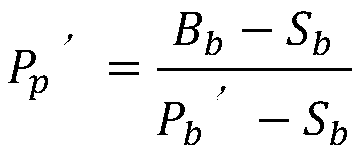

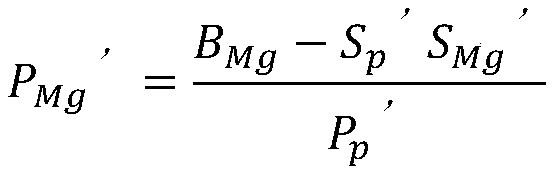

MgO optimal distribution method for iron-containing furnace charge of blast furnace

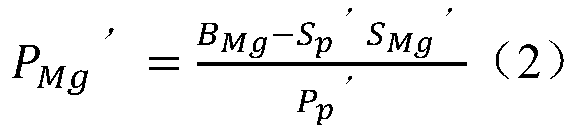

ActiveCN110982971ALarge span of soft melting zoneImprove smelting performanceSteel manufacturing process aspectsForecastingMaterials scienceBlast furnace

The invention relates to an MgO optimal distribution method for iron-containing furnace charge of a blast furnace. The method comprises the following steps: S1, determining that the MgO content SMg' of optimized sintered ore is less than or equal to 1.8% and the binary alkalinity (CaO / SiO2) Sb' is greater than or equal to 1.8; S2, determining that the MgO content of optimized pellets is 1.5%-2.0%and the binary alkalinity is less than or equal to 0.4, namely, PMg' is greater than or equal to 1.5% and less than or equal to 2.0%, Pb' is less than or equal to 0.4, and the charging proportion Pp'is less than or equal to 30%; S3, according to the binary alkalinity requirement Bb of the blast furnace comprehensive furnace charge and the binary alkalinity constraint condition of each iron-containing furnace charge, determining the charging proportion Pp' of the optimized pellets; S4, determining the MgO content PMg' of optimized pellets and the MgO content SMg' of optimized sintered ore according to the MgO content requirement BMg of blast furnace comprehensive furnace charge, the optimized iron-containing furnace charge proportions and the optimized iron-containing furnace charge MgO constraint conditions. The method has the advantages that the reduction degree of the comprehensive furnace charge is effectively improved, the soft melting temperature is reduced, the interval is narrowed, and the smelting performance is improved.

Owner:ANSTEEL GRP MINING CO LTD

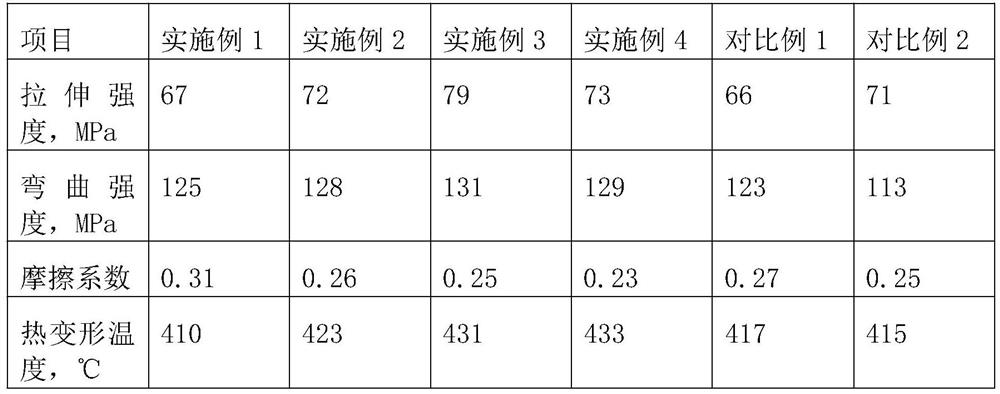

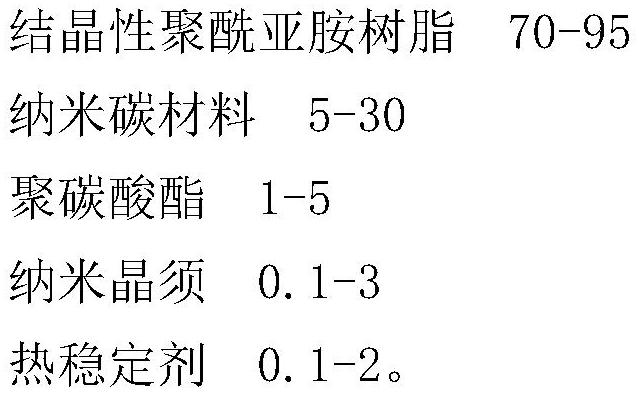

Polyimide composition and preparation method thereof

PendingCN114479454ANarrow melting rangeImprove mechanical propertiesAdditive manufacturing apparatusImidePolymer science

The invention provides a polyimide composition. The polyimide composition is prepared from 70 to 95 parts of crystalline polyimide resin, 5 to 30 parts of nano carbon material, 1 to 5 parts of polycarbonate, 0.1 to 3 parts of nano whisker and 0.1 to 2 parts of heat stabilizer. The defects that a polyimide material additive manufacturing product is large in shrinkage rate and high in porosity are overcome, and the method has wide application prospects in the field of additive manufacturing.

Owner:CHANGSHA ADVANCED MATERIALS IND RES INST CO LTD

Indium-containing active copper-based solder

ActiveCN102689105BInhibit excessive productionImprove plasticityWelding/cutting media/materialsSoldering mediaElectromechanicsIndium

The invention relates to an indium-containing active copper-based solder, which is particularly suitable for soldering copper and copper alloy workpieces of heat exchangers, various valve bodies and the like, can be widely applied to soldering of industries of refrigeration, machinery, electromechanics, electrical appliances and the like and belongs to an intermediate temperature soldering material. The indium-containing active copper-based solder comprises the following components in percentage by weight: 0.5 to 2.0 percent of Ag, 6.0 to 7.8 percent of P, 0.01 to 1.0 percent of In, 0.01 to 1.0 percent of Sb and the balance of Cu. The indium-containing active copper-based solder has the advantages of reasonable formula design, high cost performance, low solder melting temperature, high wettability, high fluidity, high soldered joint mechanical strength and high soldering process performance.

Owner:HANGZHOU HUAGUANG ADVANCED WELDING MATERIALS CO LTD

High-ductility environment friendly silver-saving medium-temperature brazing filler metal

ActiveCN101342644BReduce brittlenessHigh melting temperatureWelding/cutting media/materialsSoldering mediaFiller metalSilver copper

The invention relates to a high plasticity environment protection silver-saving intermediate temperature solder in which an intermediate temperature solder is used to replace the silver copper zinc cadmium solder with high content of silver, and a processing technology thereof. Aiming at the defects of the prior silver solder which contains cadmium and lead such as the heavy pollution to environment, the hazard of the cadmium and lead to human body, large brittleness of solder alloy and high cost and so on, the purpose of the invention is to provide a cadmium-free and lead-free high plasticity environment protection silver-saving intermediate temperature solder with low cost, small brittleness of solder alloy, comparatively low melting temperature and comparatively small melting range. The high plasticity environment protection silver-saving intermediate temperature solder of the invention comprises Cu, Sn, P, Ni, Ag, Li and La; wherein, Li and Na are active microelements. The preparation steps of the high plasticity environment protection silver-saving intermediate temperature solder of the invention are that raw materials are weighted by formula; the solder alloy is refined intosolder ingot castings which are made into filamentous solders by hot-pressing. The filamentous solder can be made into sizes of solder coiling wire, solder straight wire and solder welding ring.

Owner:浙江信和科技股份有限公司

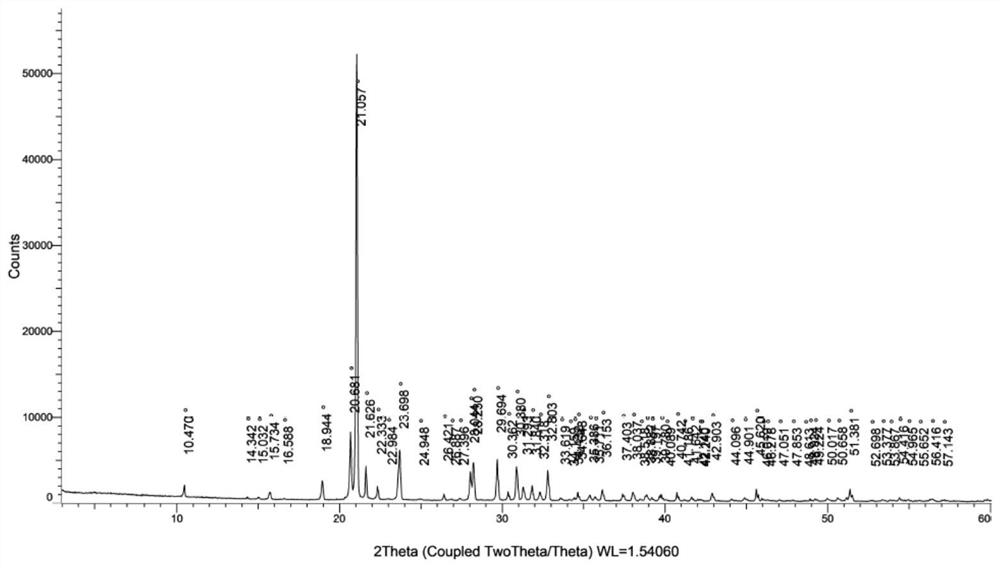

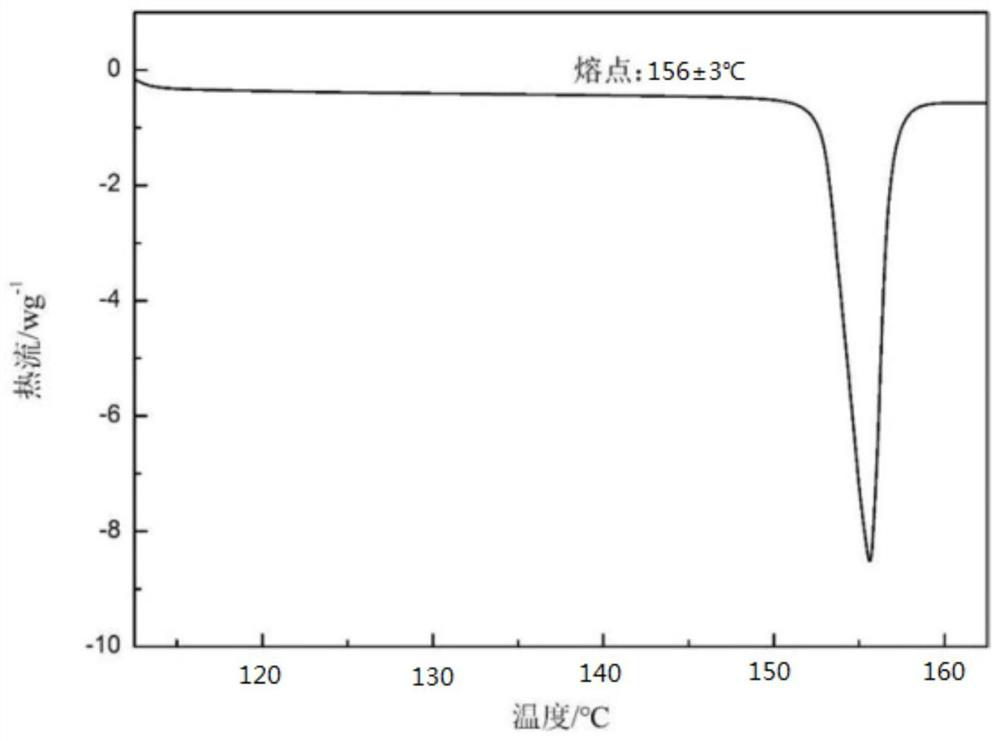

5-aminolevulinic acid hydrochloride crystal form and preparation method thereof

InactiveCN113149854ASimple and fast operationMild conditionsOrganic compound preparationOrganic chemistry methodsAminolevulinic Acid HydrochloridePhysical chemistry

The invention relates to the technical field of industrial crystallization, in particular to a 5-aminolevulinic acid hydrochloride crystal form and a preparation method thereof, and the preparation method comprises the following steps: adding a 5-aminolevulinic acid hydrochloride crude product into a specific solvent with the concentration of 0.3-0.8 g / ml, conducting dissolving and clarifying at room temperature, and conducting filtering to remove mechanical impurities so as to avoid interference on crystallization, then dropwise adding another specific solvent at room temperature, stopping dropwise adding after turbidity is generated, maintaining stirring and growing the crystal for 30 minutes or more, continuously dropwise adding a solvent with a specific multiple, separating out a large amount of crystals, conducting filtering, washing a filter cake, and conducting drying in vacuum to obtain the crystal of the 5-aminolevulinic acid hydrochloride crystal form. The product prepared by the method is a white crystal, has good solubility, short melting range and high purity, subsequent preparation of various preparations is facilitated, and a new crystal and a preparation method are provided for efficient utilization of 5-aminolevulinic acid hydrochloride.

Owner:海安艾拉新材料有限公司

Moderate temperature copper-based solder and preparation method thereof

ActiveCN102626837BLow melting pointHigh strengthWelding/cutting media/materialsSoldering mediaRare earthRoom temperature

A moderate temperature copper-based solder and a preparation method thereof relate to a solder and a preparation method thereof. According to the moderate temperature copper-based solder and the preparation method thereof, the technical problems that the current copper-based solder has great brittleness, cannot be processed into solder wires nor brazed with steel and stainless steel, and is more likely to generate poisonous zinc vapour are solved. The moderate temperature copper-based solder is prepared from Cu, Zn, Mn, Si, Sn, Ni, La and Ce. The method comprises the following steps of: 1, weighing materials, 2, preparing rare earth intermediate alloy; 3, smelting moderate temperature copper-based solder to obtain metal ingot; and 4, extruding the metal ingot to obtain the moderate temperature copper-based solder. The moderate temperature copper-based solder does not contain silver, Ga, In and other noble metal elements, so the preparation cost is low. The moderate temperature copper-based solder does not contain any poisonous elements, is safe and reliable to use and has high brazing mechanical property; and at room temperature, the moderate temperature copper-based solder can be applied to the brazing of steel, stainless steel and other black metals due to high mechanical property.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com