Patents

Literature

629results about "Ink ribbons" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

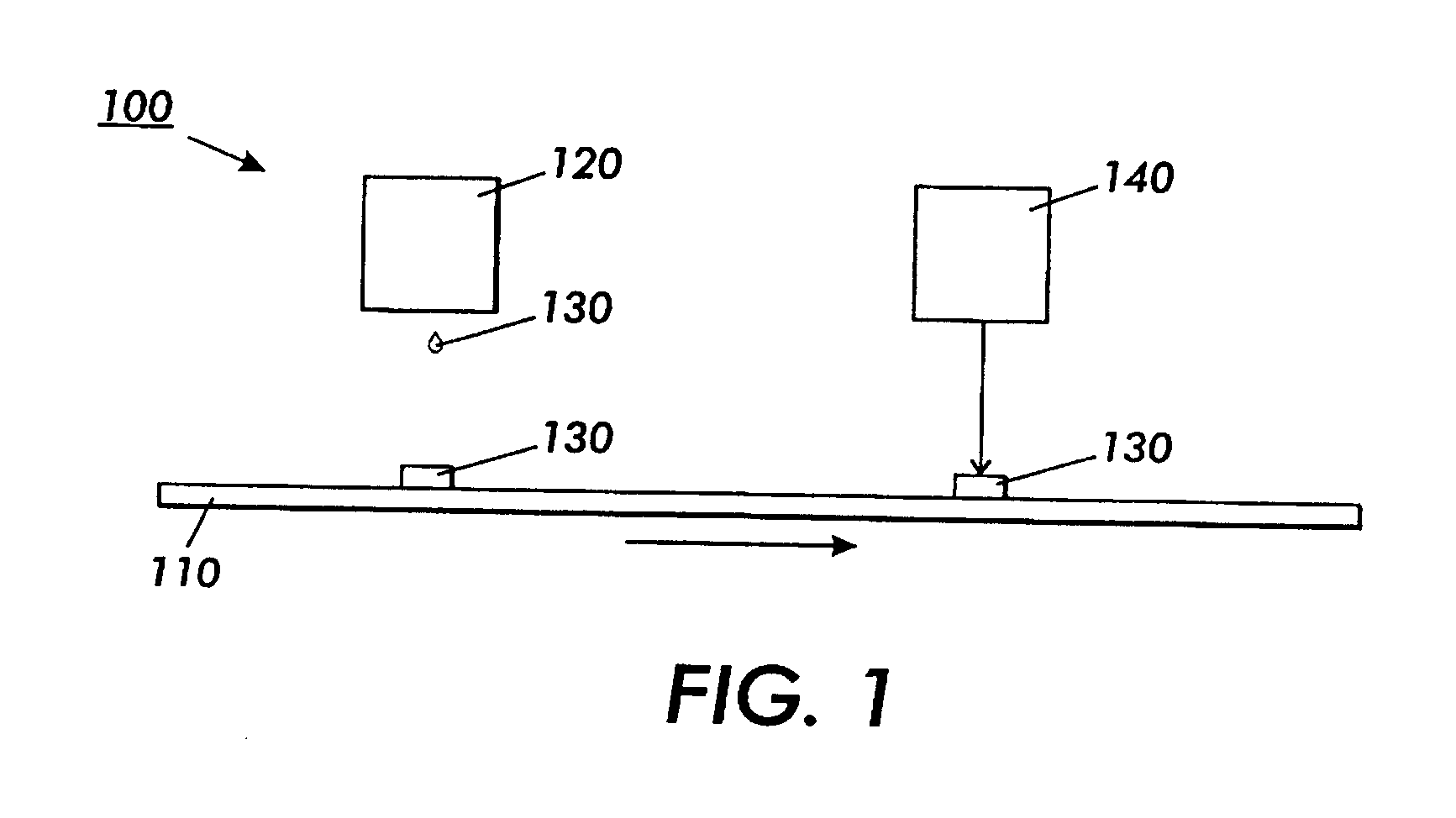

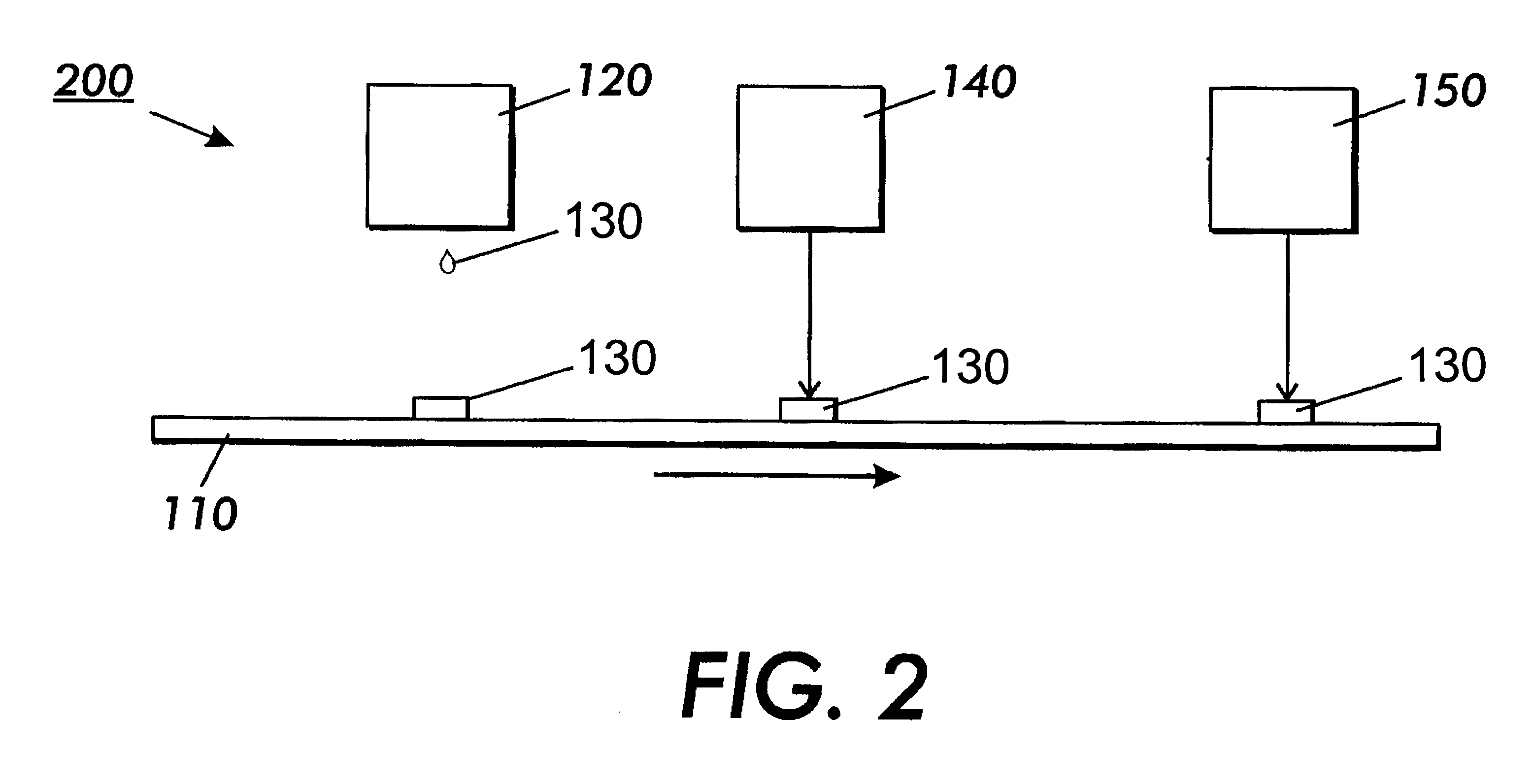

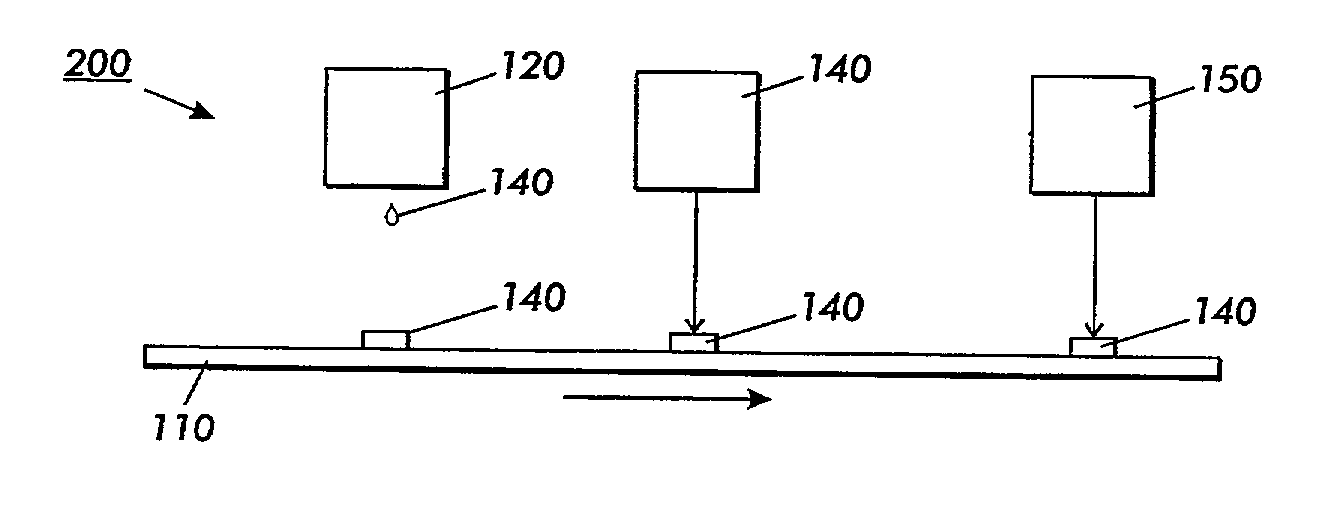

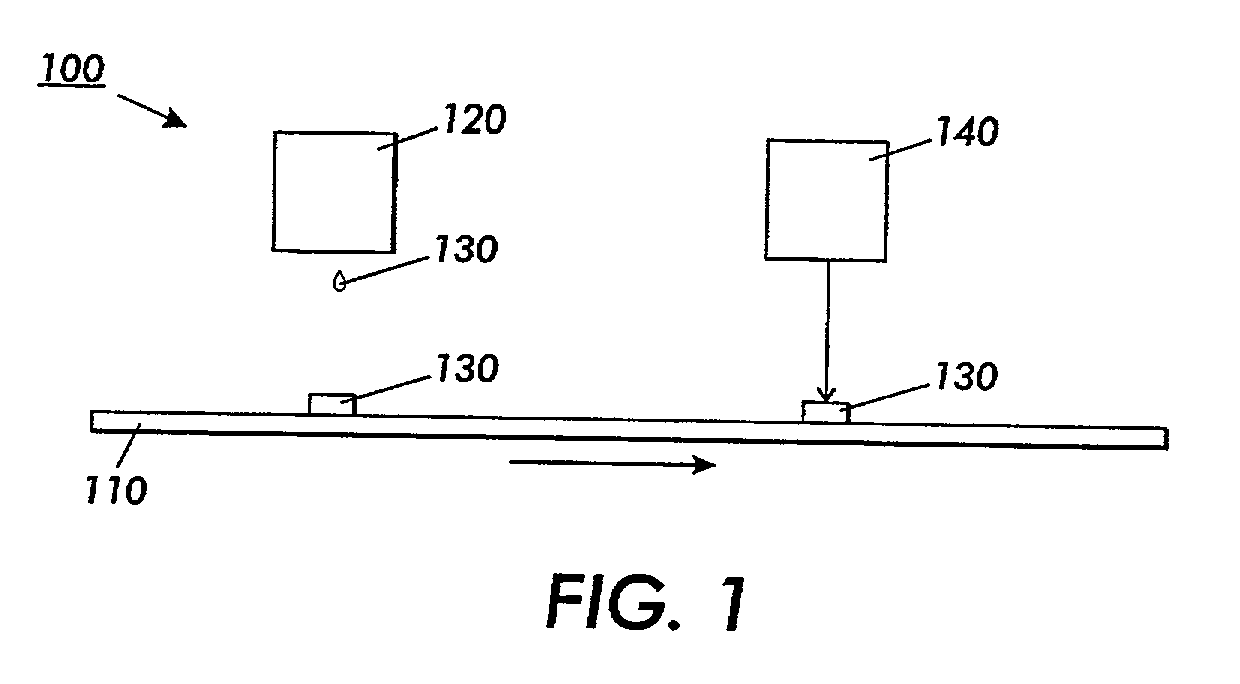

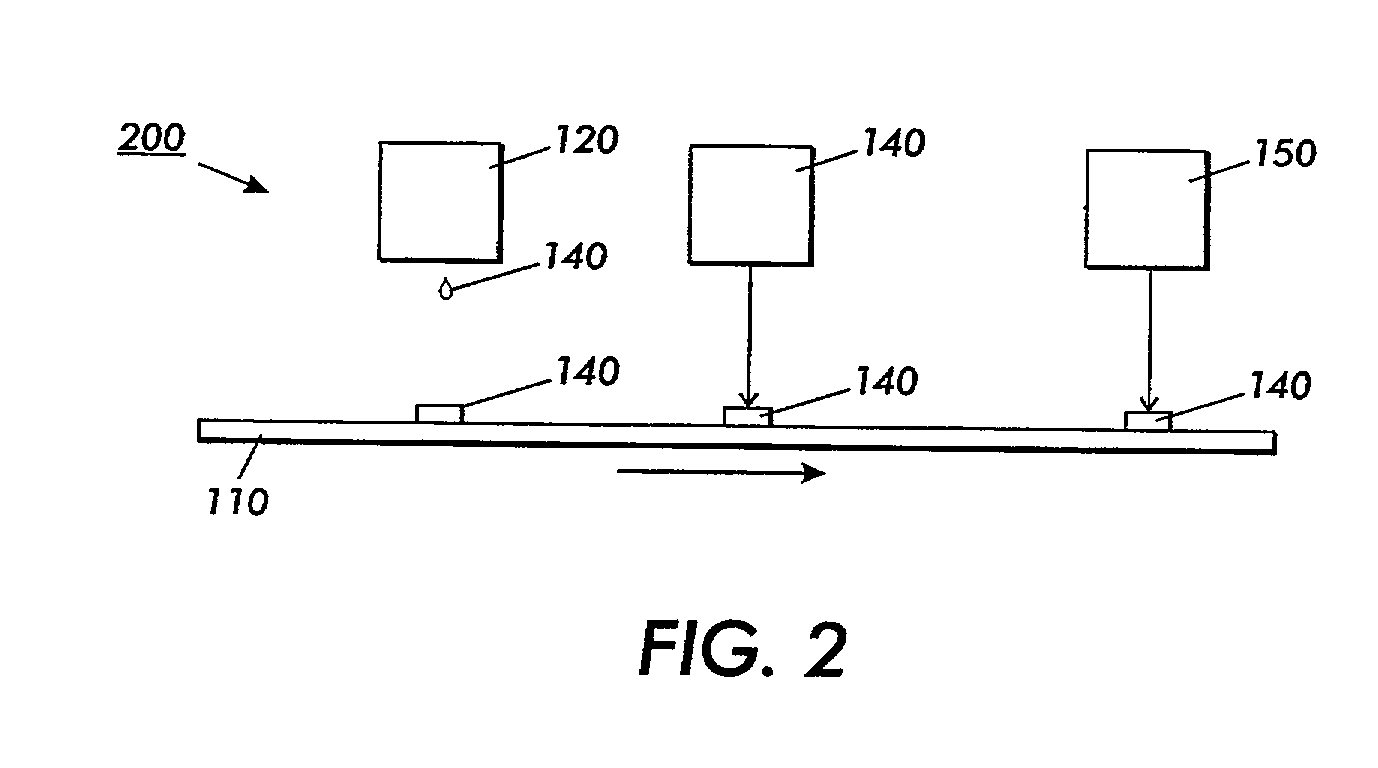

Systems and methods of printing with ultraviolet photosensitive resin-containing materials using light emitting devices

Method of printing with ultraviolet photosensitive resin-containing materials includes depositing at least one substance that includes an ultraviolet photosensitive resin on to a substrate, partially curing the substance by irradiating the substance with at least one ultraviolet light emitting device, and completely curing the substance. Substance curing system including a substrate, an applicator that deposits a substance that includes an ultraviolet photosensitive resin on to a substrate, and at least one ultraviolet light emitting device usable to irradiate the substance to partially cure and / or completely cure the substance.

Owner:XEROX CORP

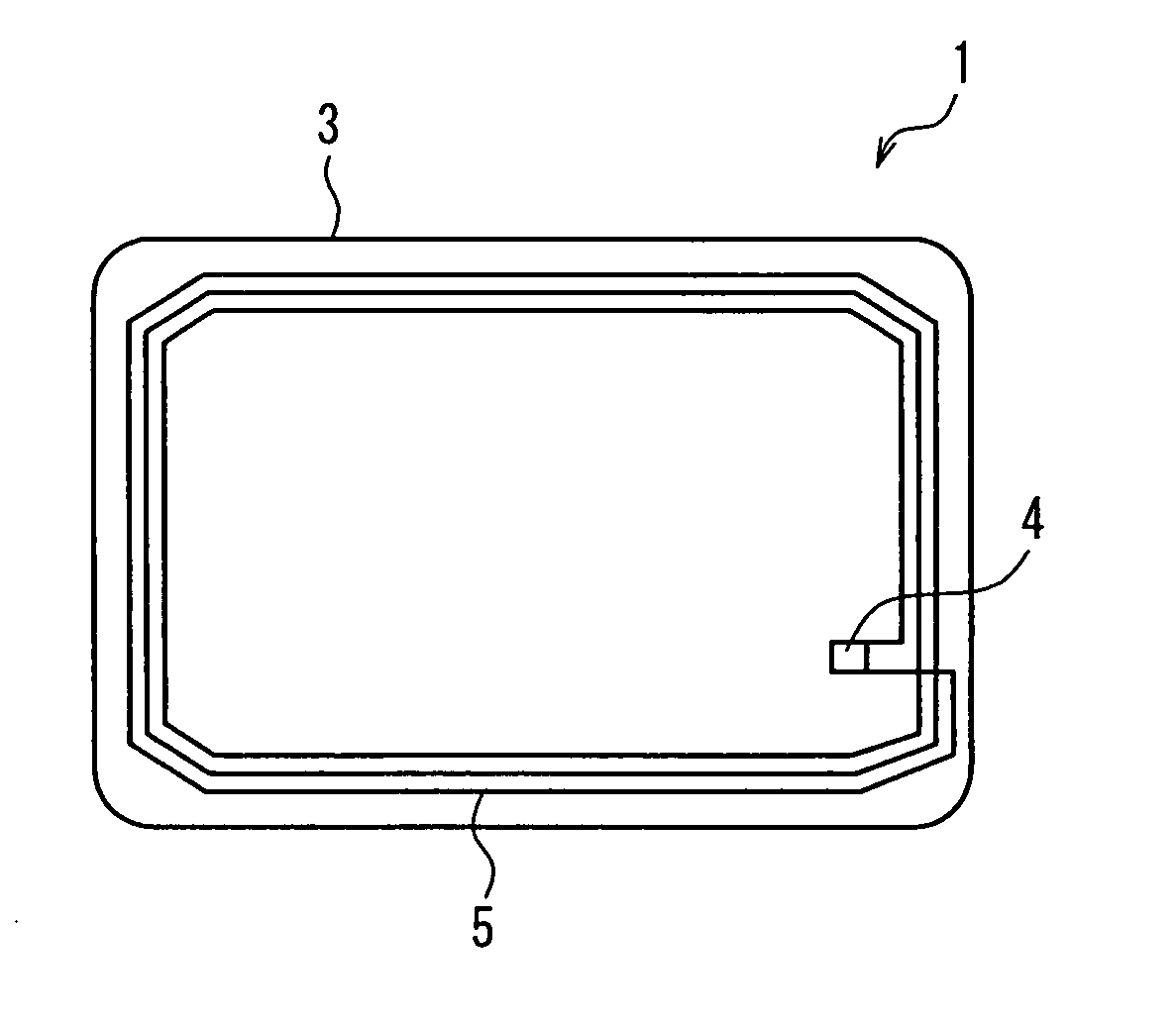

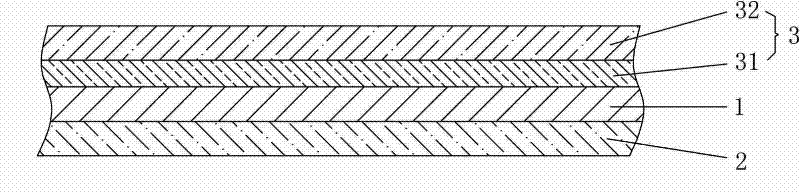

Magnetic sheet with stripe-arranged magnetic grains, RFID magnetic sheet, magnetic shielding sheet and method of manufacturing the same

InactiveUS20080070003A1Improve permeabilityEasy to manufactureInk ribbonsRecord information storageMagnetic shieldCondensed matter physics

Owner:PANASONIC CORP

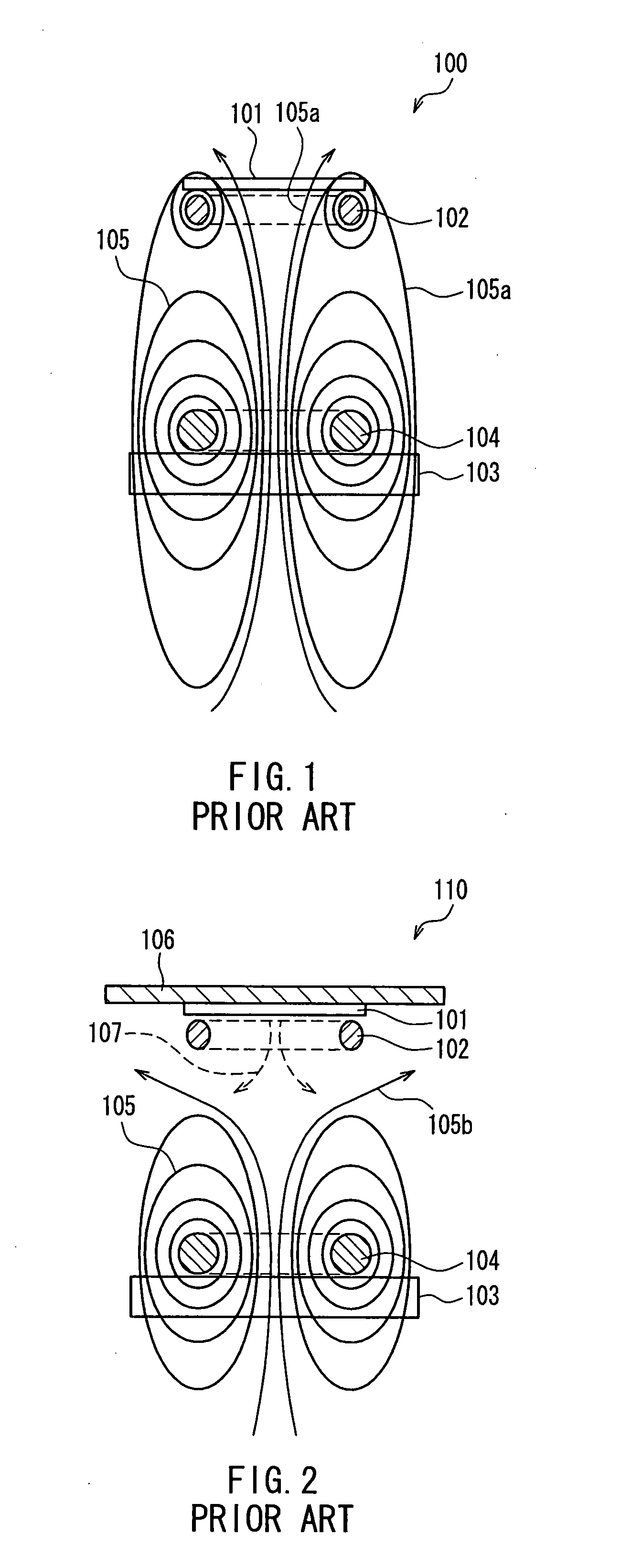

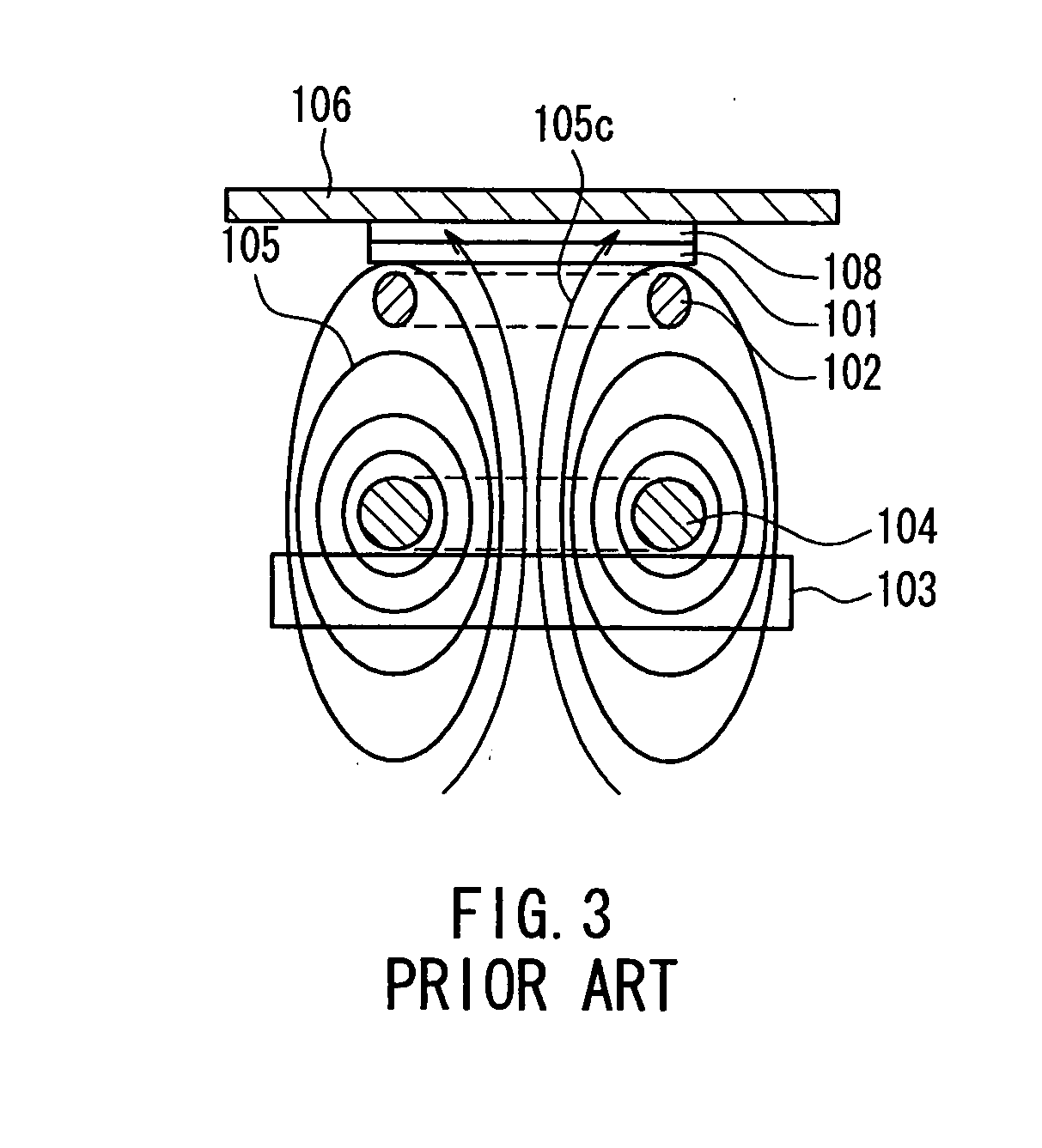

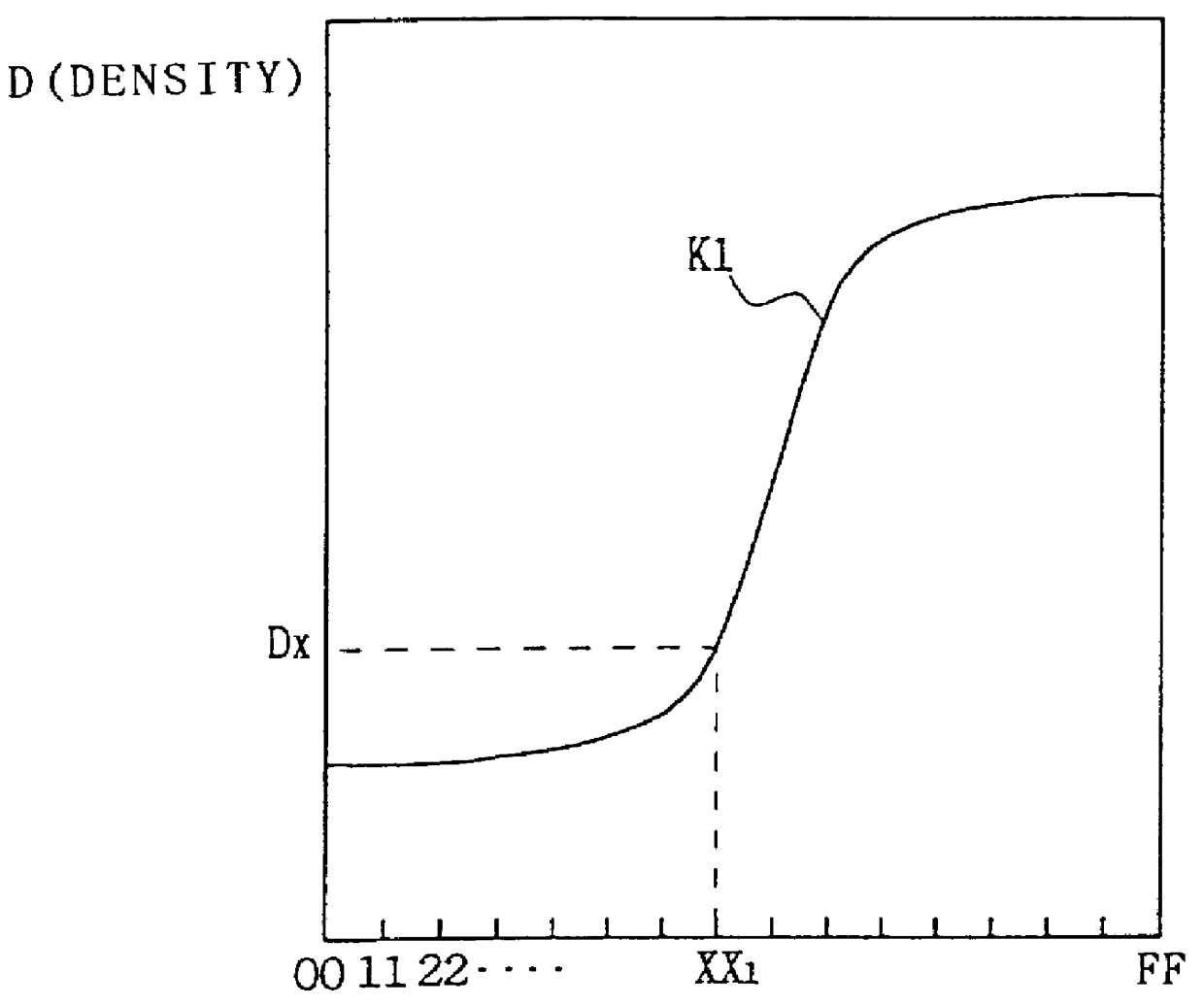

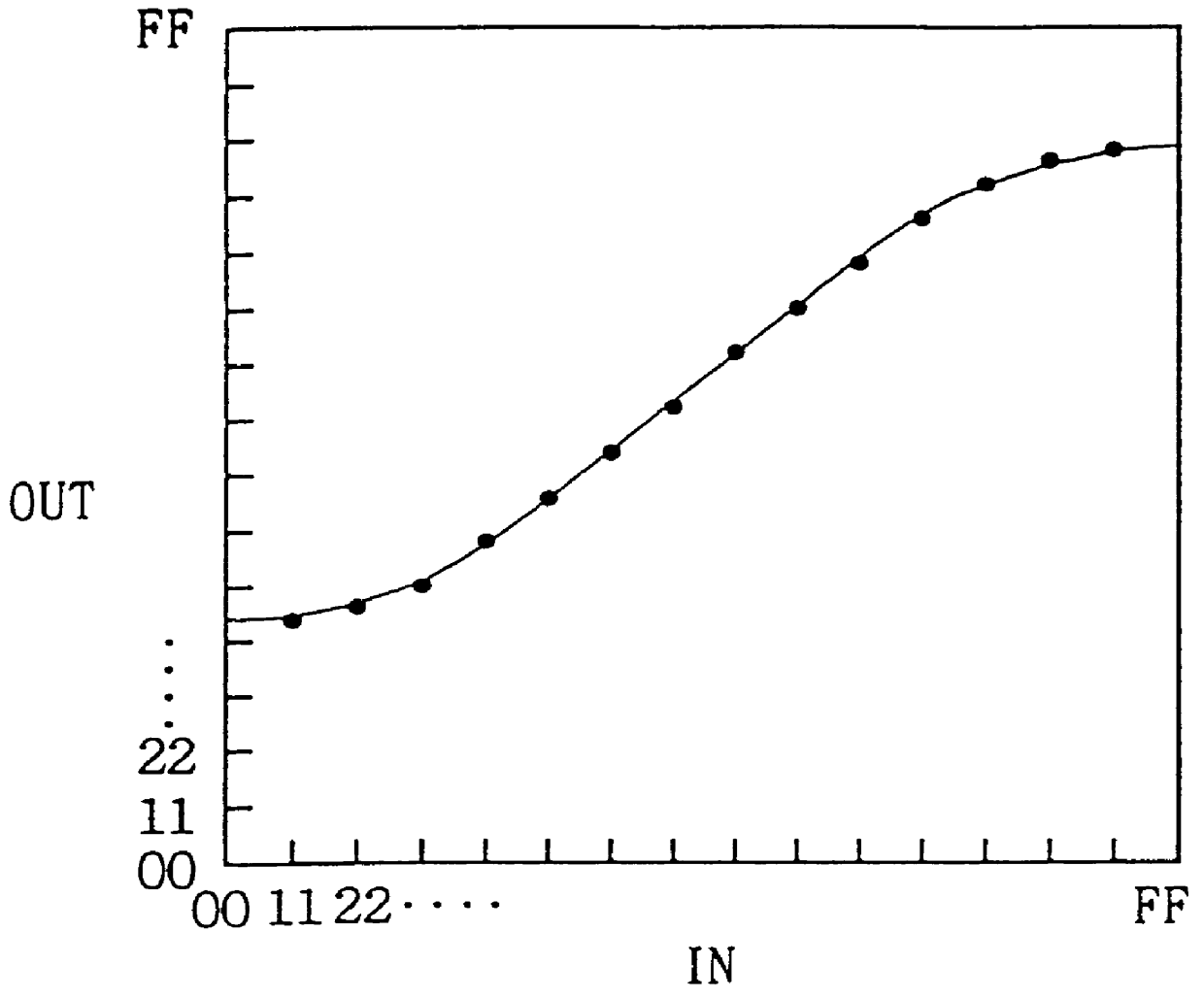

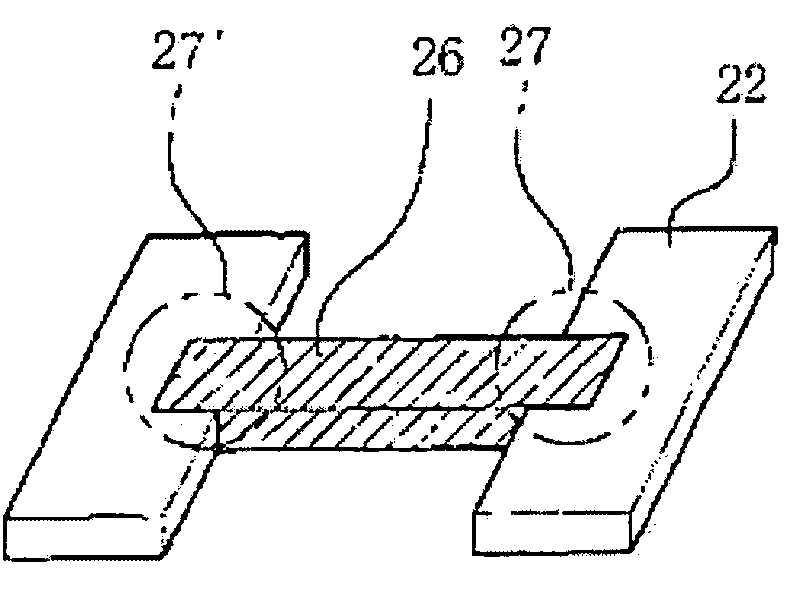

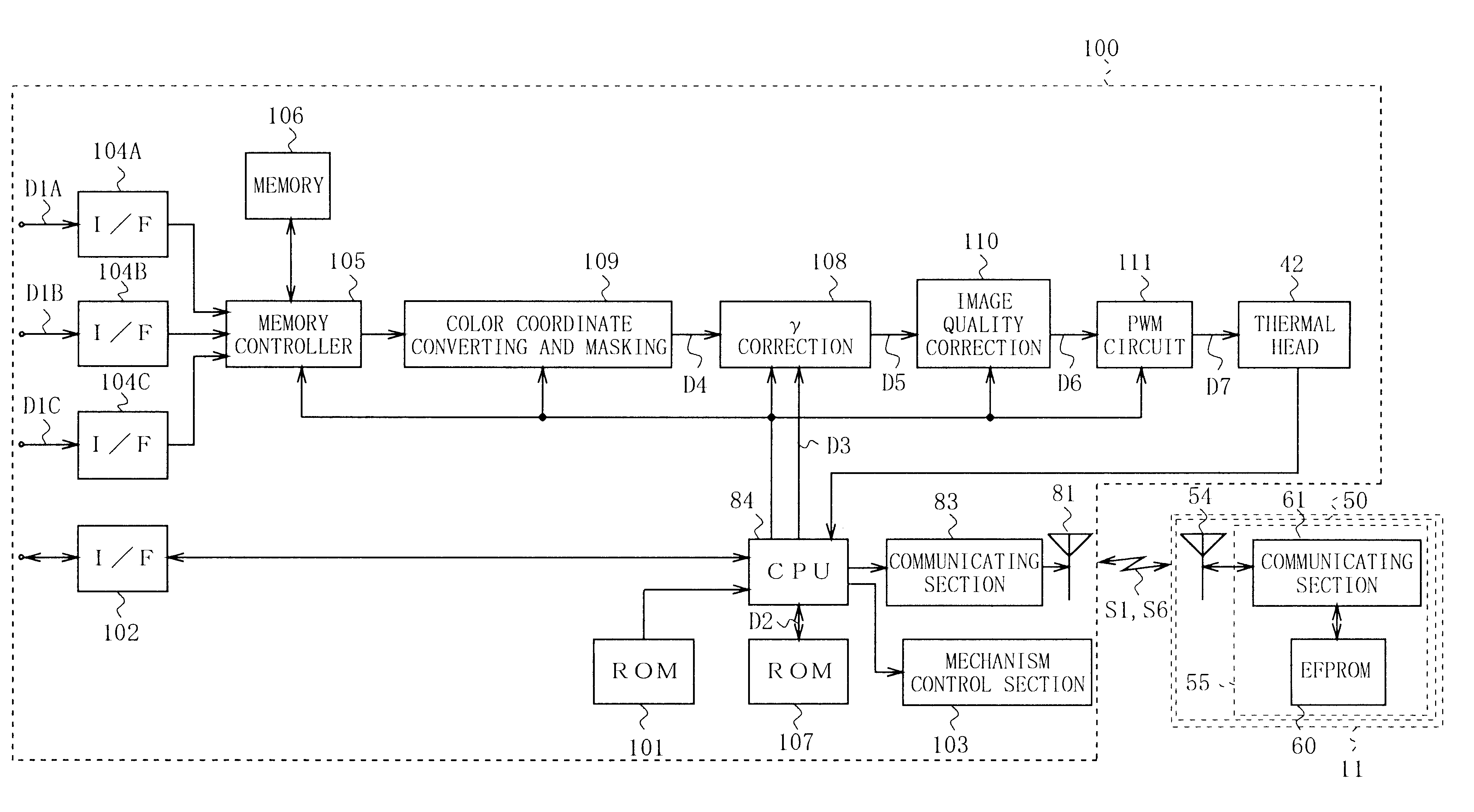

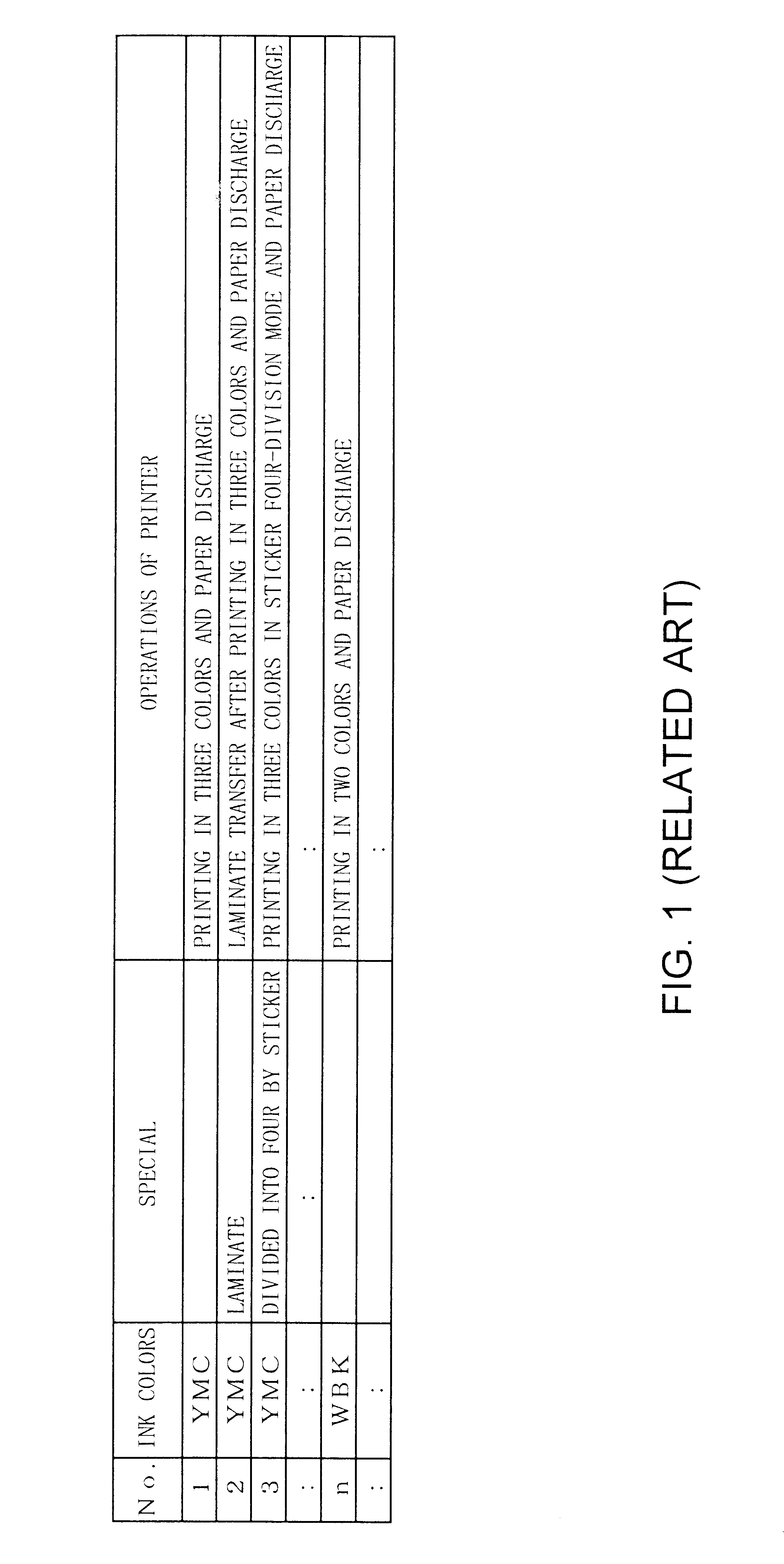

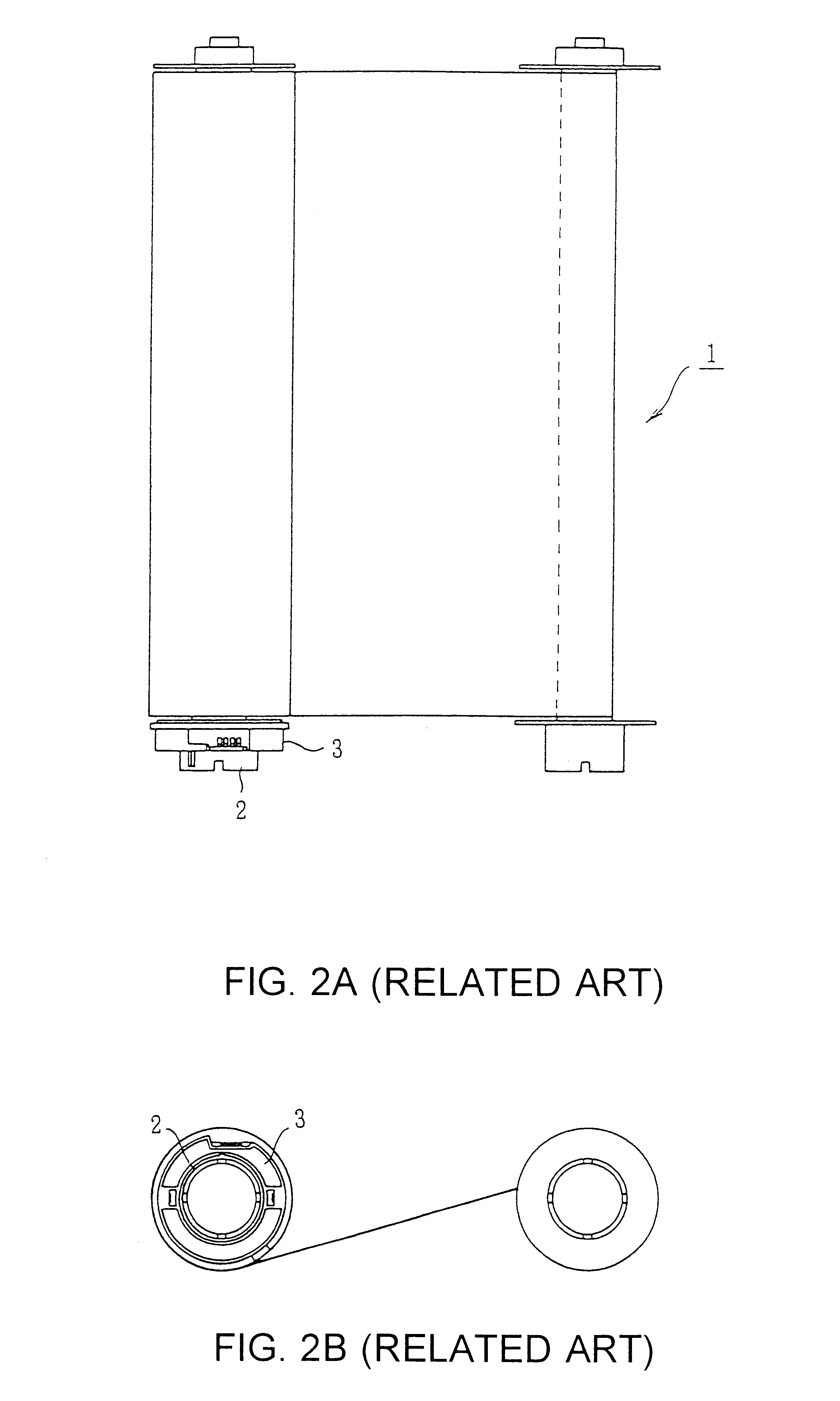

Printer device and printing method

InactiveUS6059469AEasy to optimizeProcess is performedPrinting mechanismsInk ribbonsCombined useEngineering

A printer device, and method, is disclosed which is used in conjunction with an ink ribbon assembly. The ink ribbon assembly includes an ink ribbon and a support. A storage device is integrated with the support. Data relating to the ink ribbon characteristics is stored in the storage device. The printer reads the data in the storage device and modifies the supplied print information ascending to the data stored in the ink ribbon assembly. Ink ribbon characteristic data can include production variance, ribbon type, and remaining ribbon data.

Owner:SONY CORP

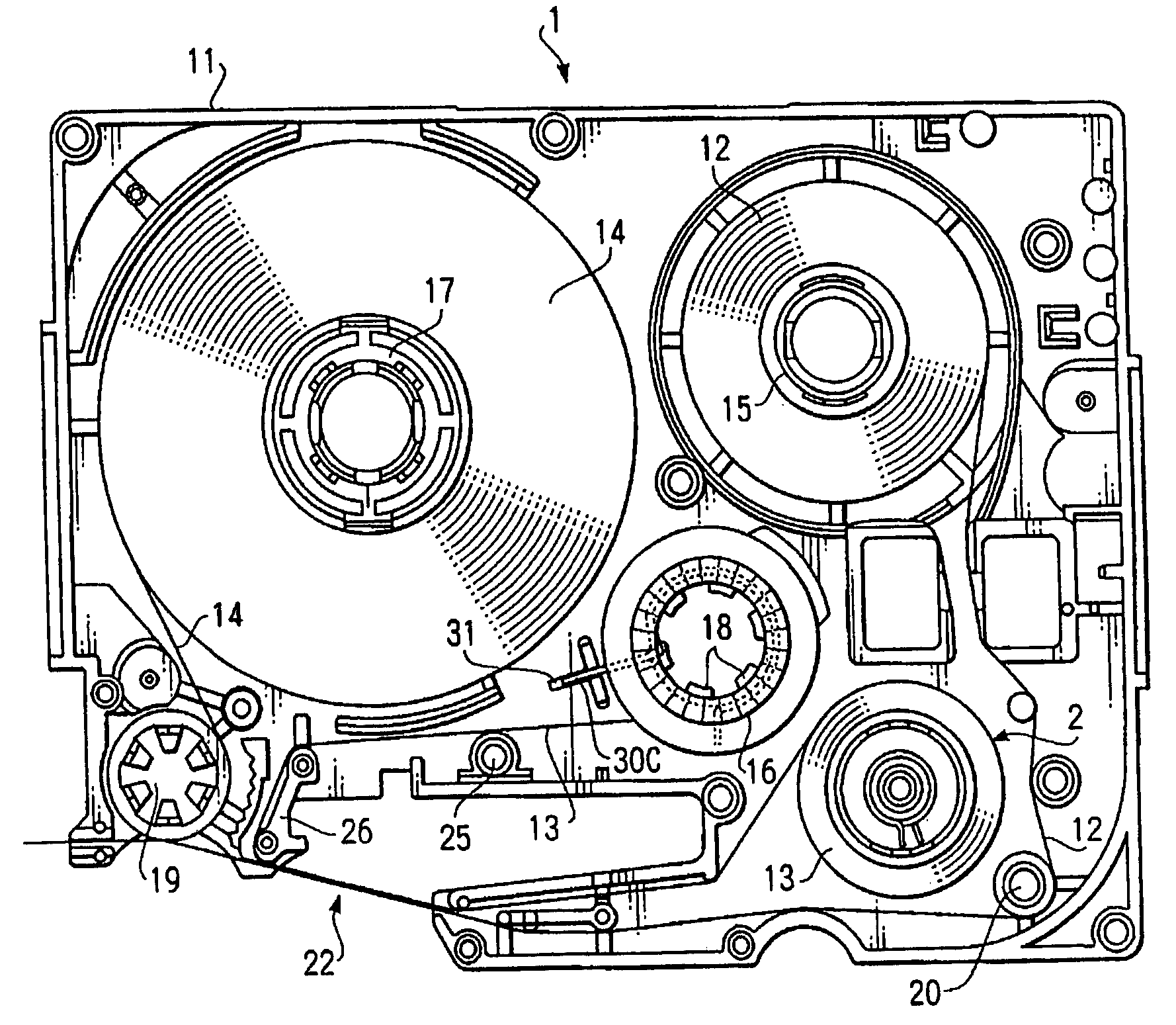

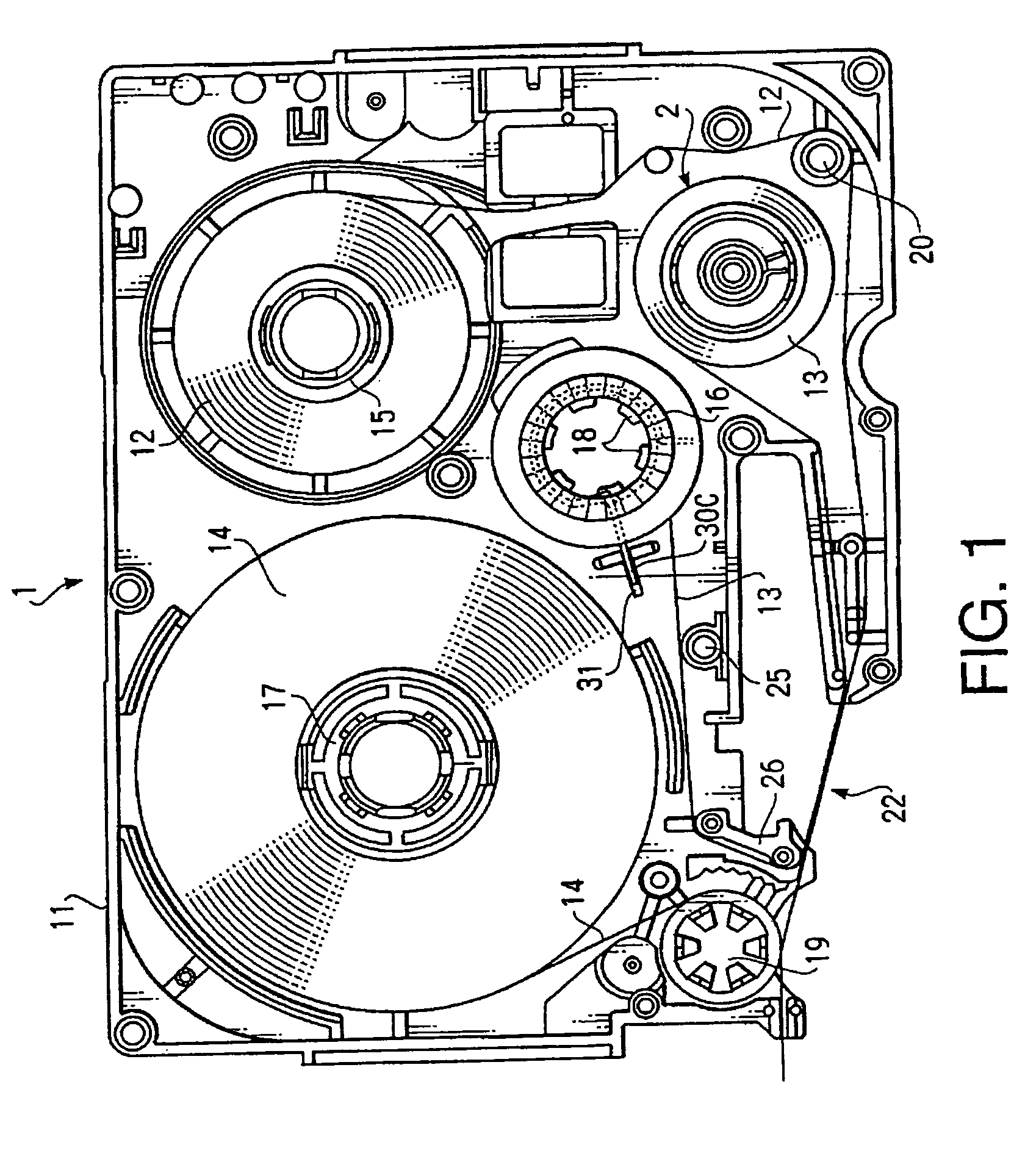

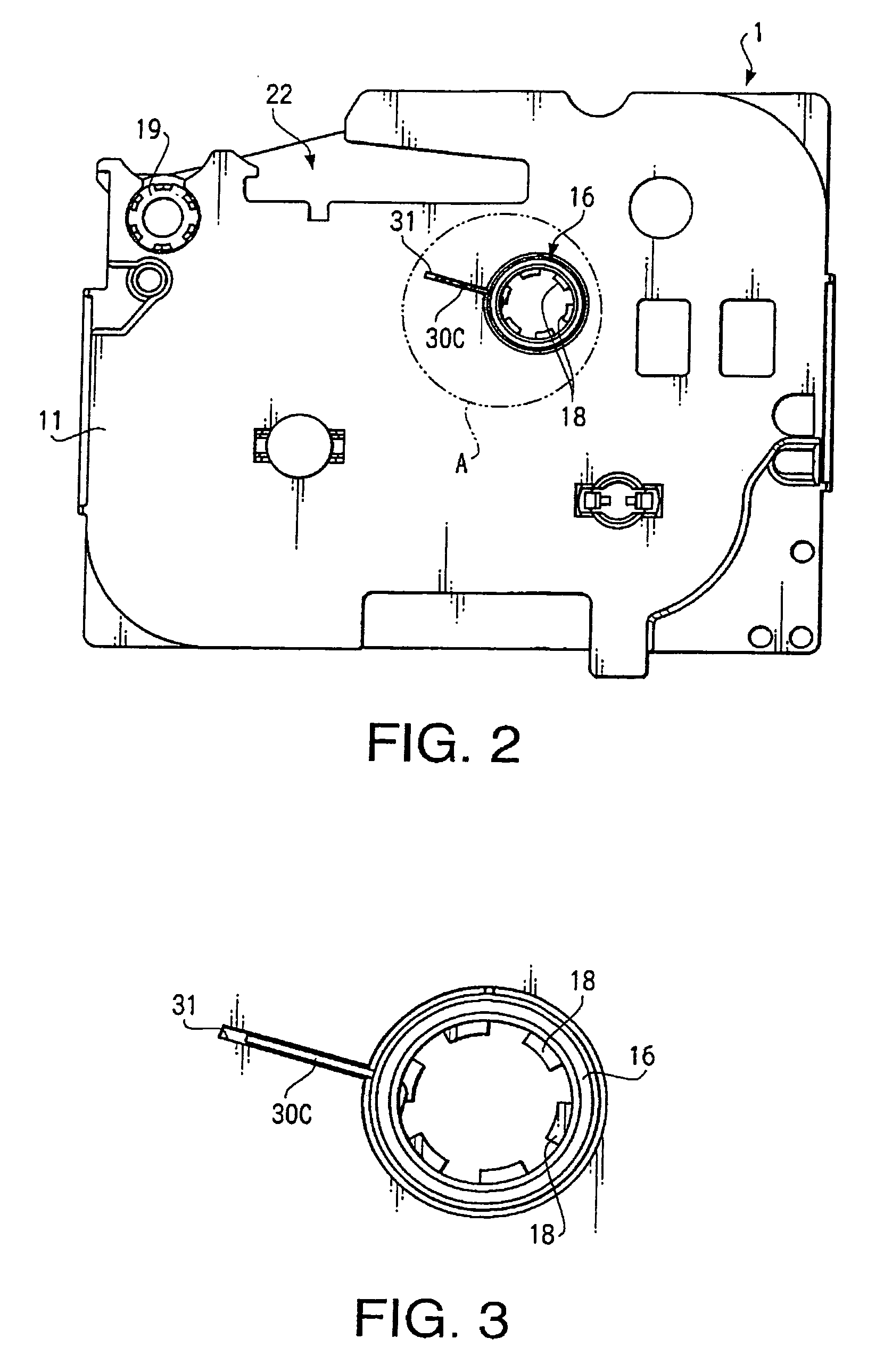

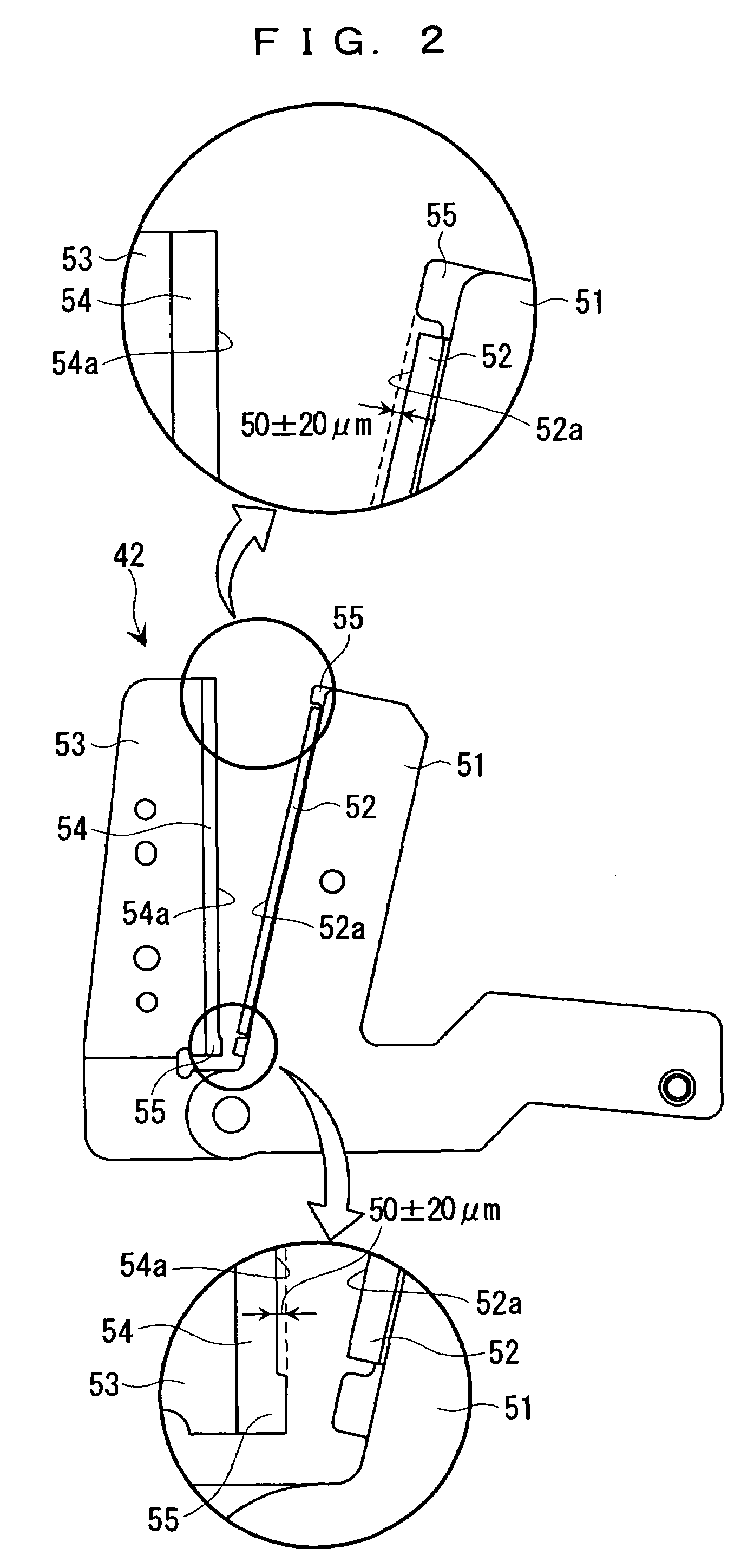

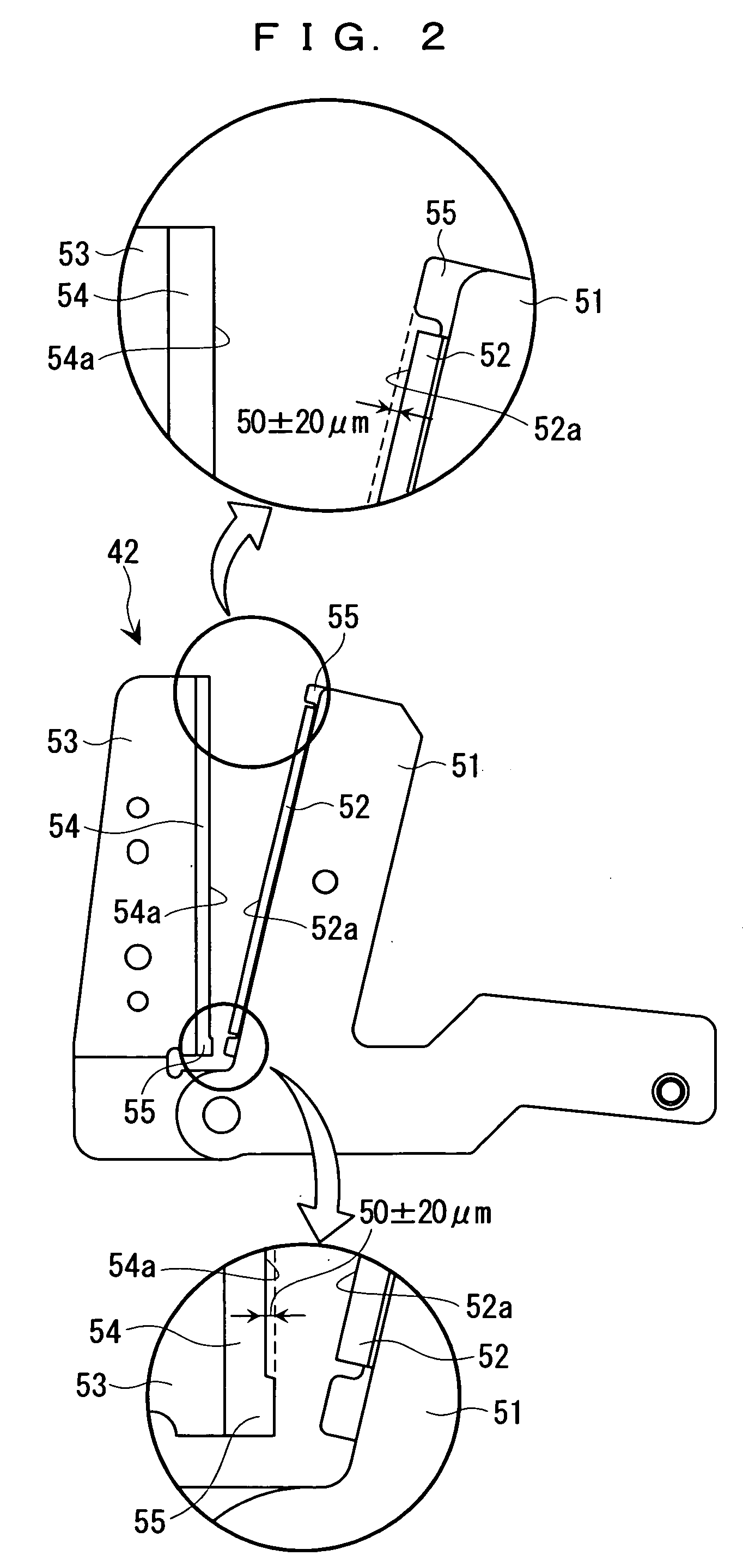

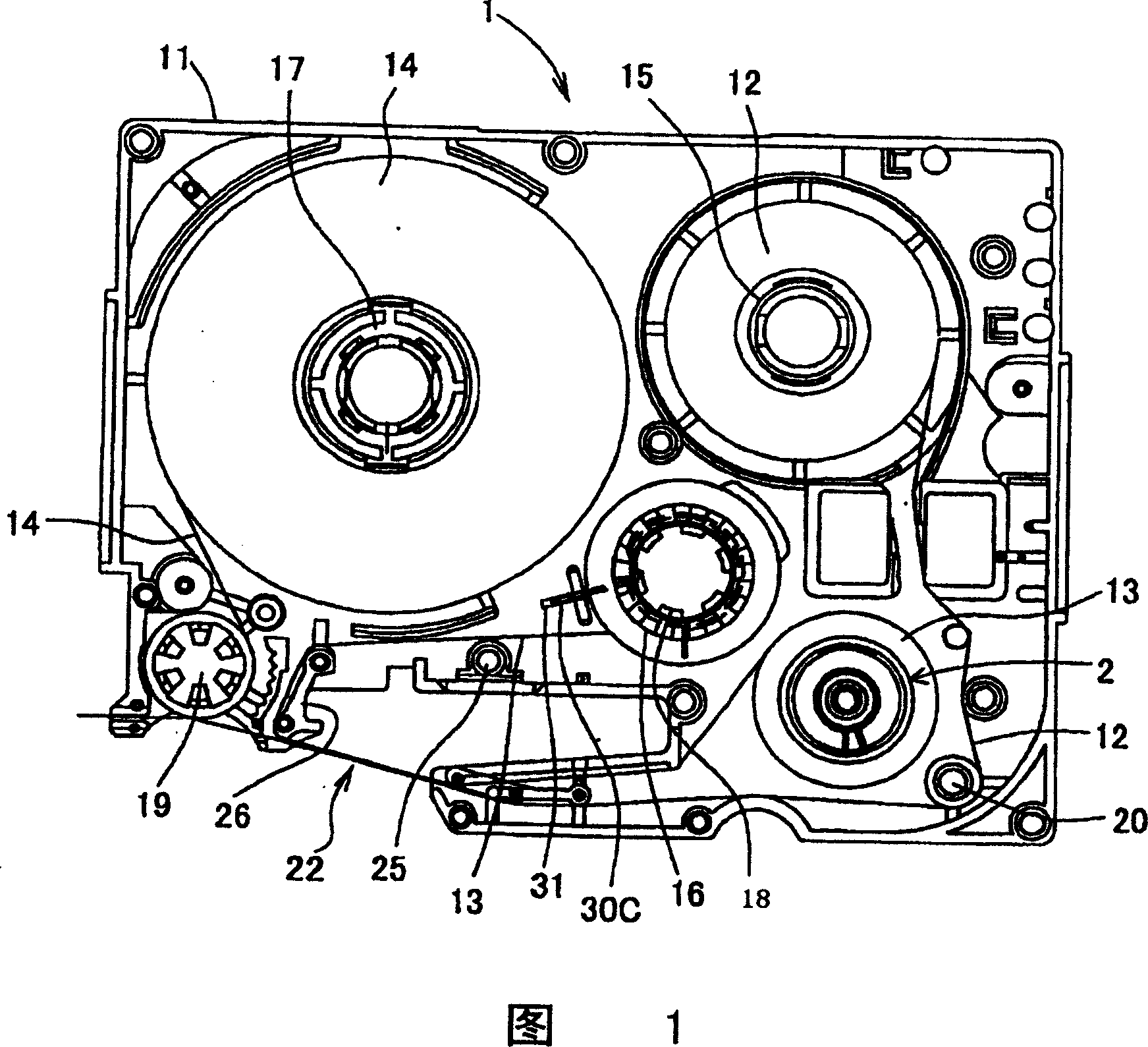

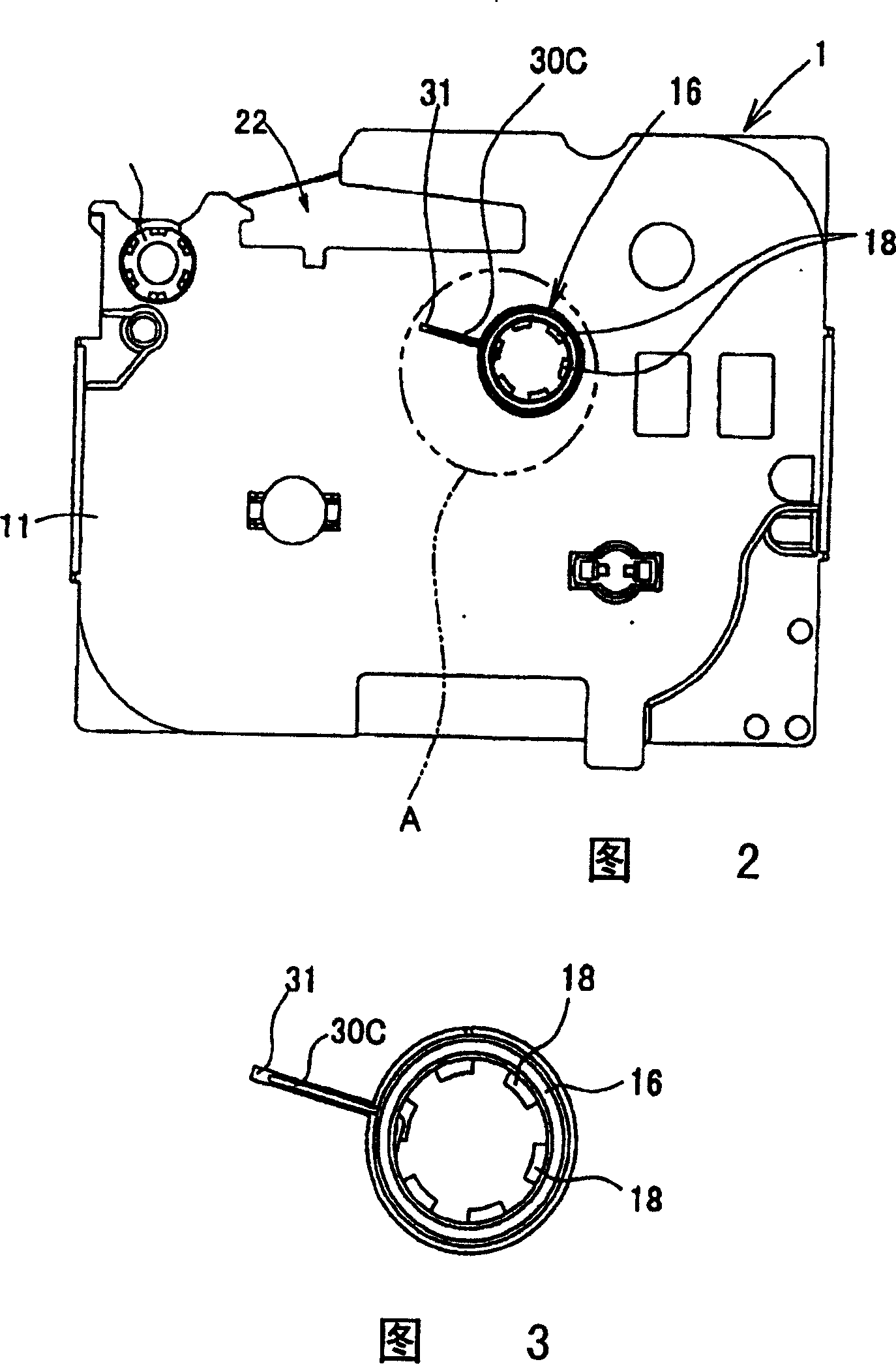

Ribbon cassette with ink ribbon slack prevention mechanism

ActiveUS7128483B2Smooth take-upPrevents slack in the ink ribbon from occurringInk ribbon cartridgesInk ribbonsEngineeringMechanical engineering

Owner:BROTHER KOGYO KK

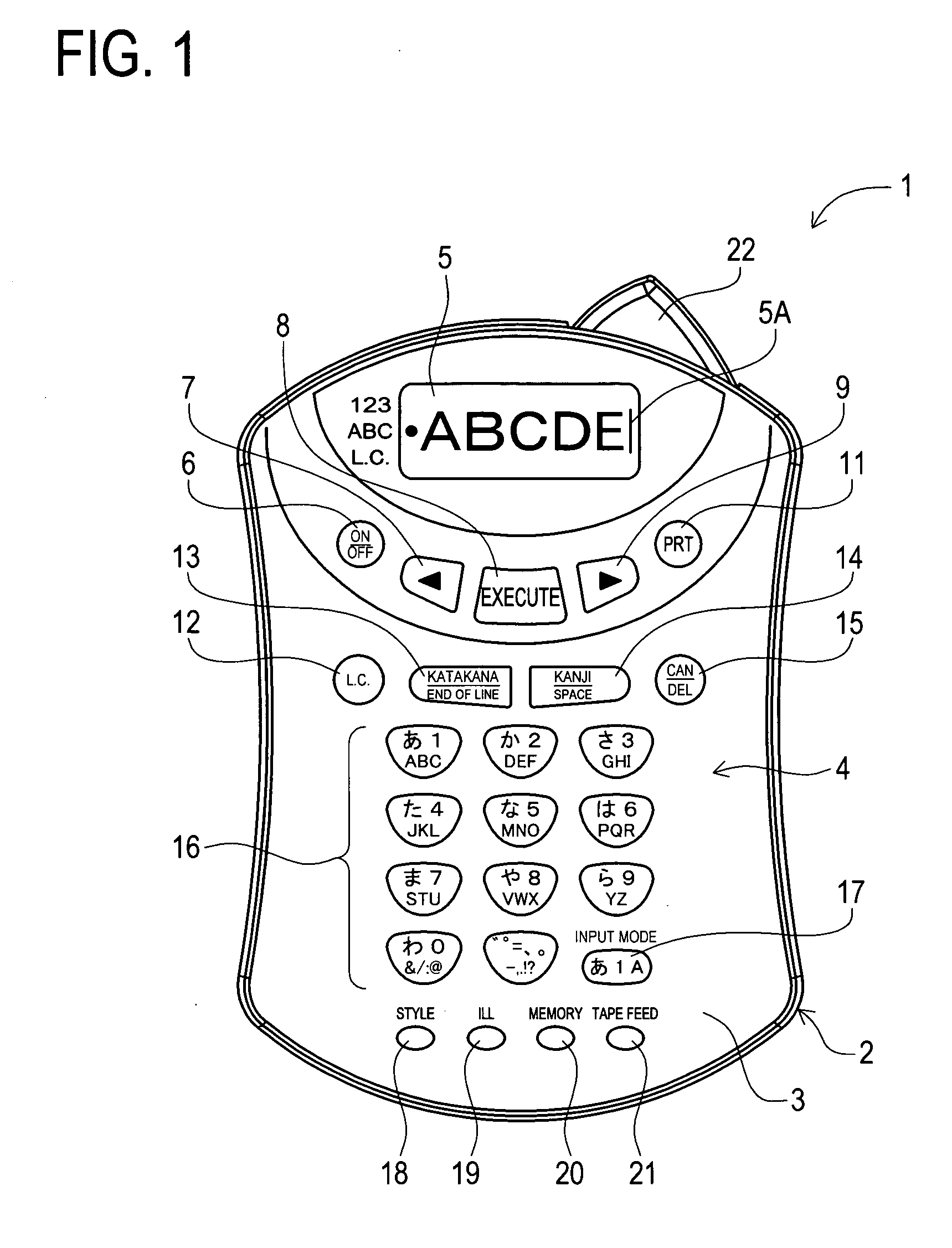

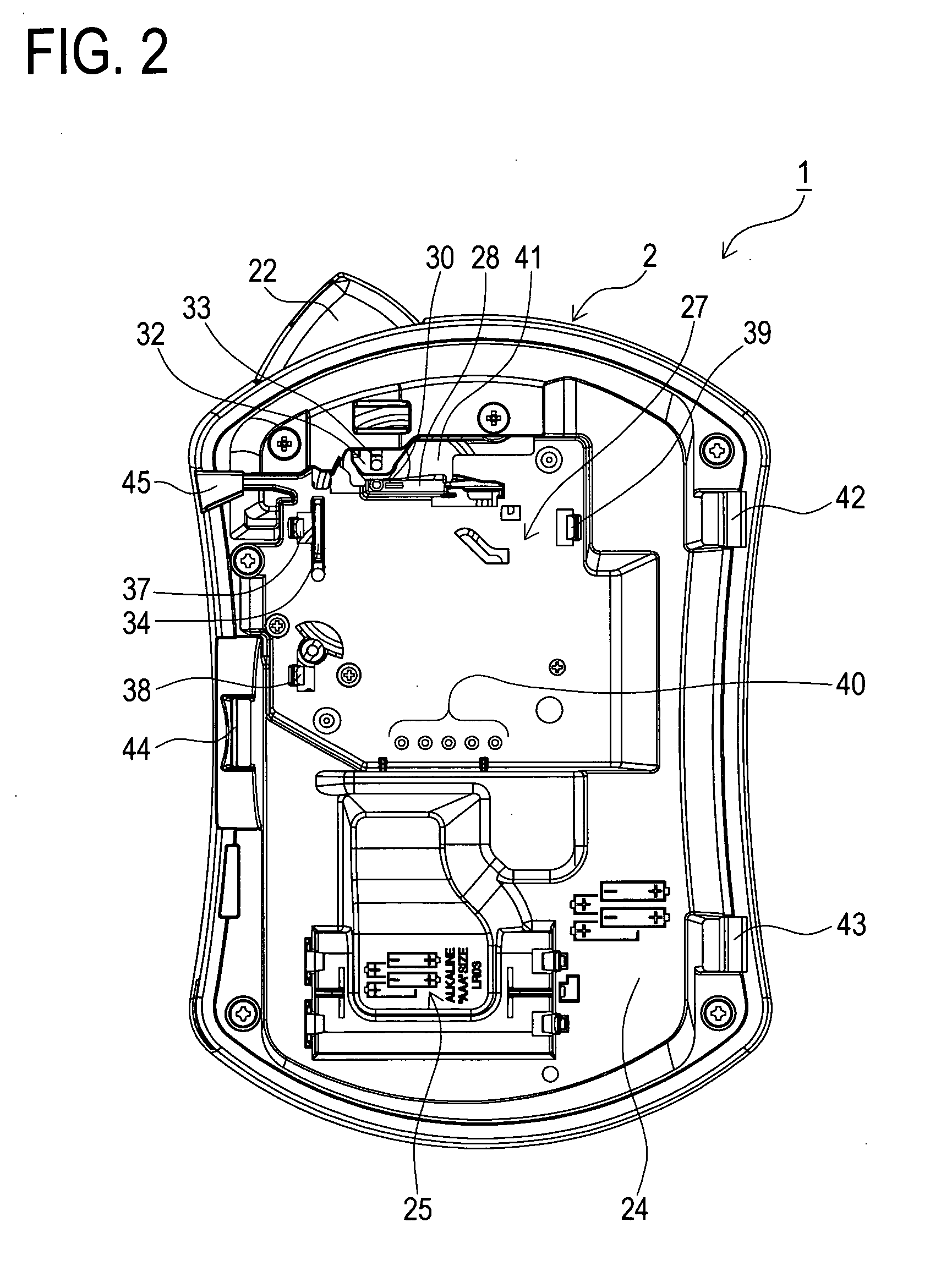

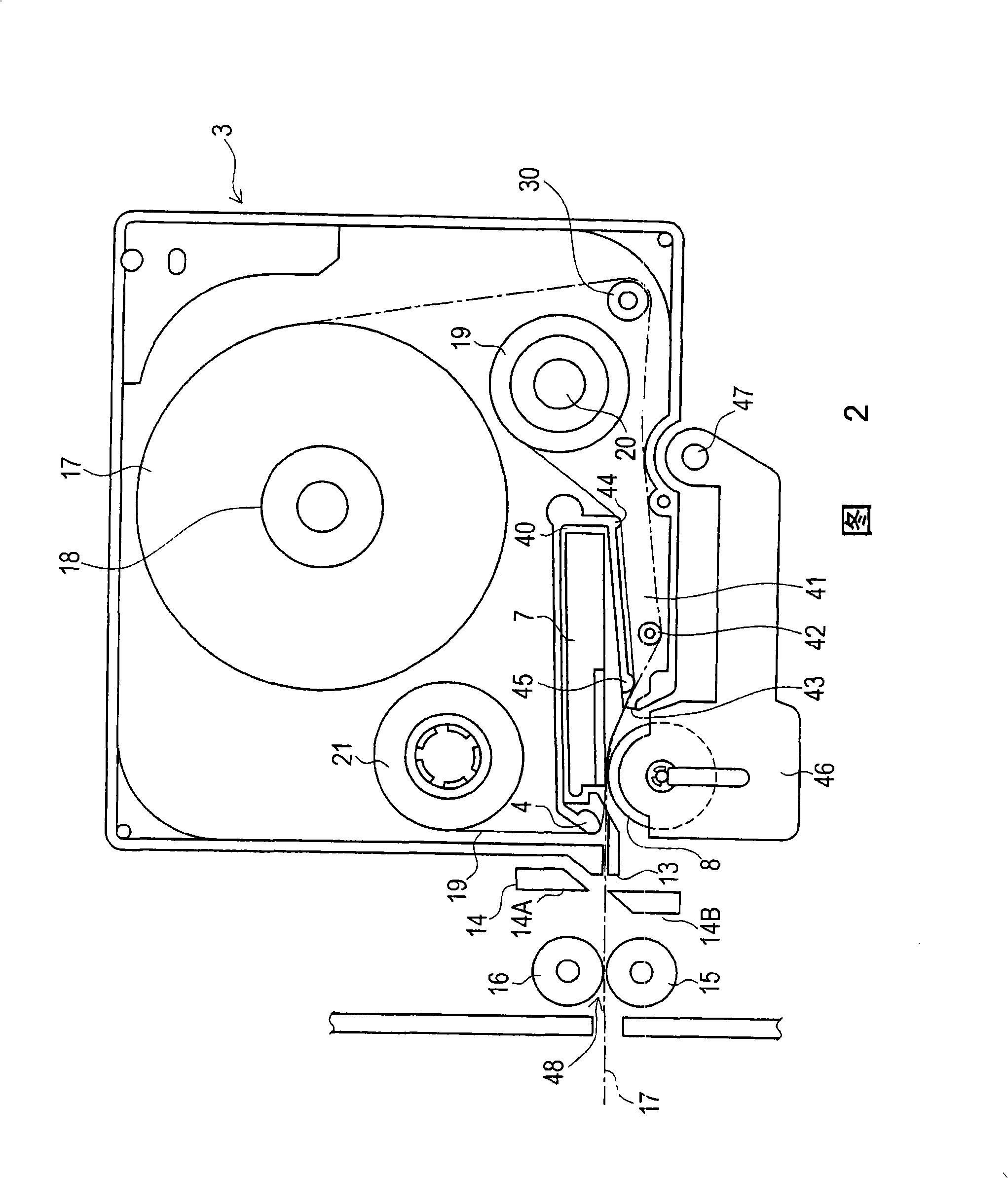

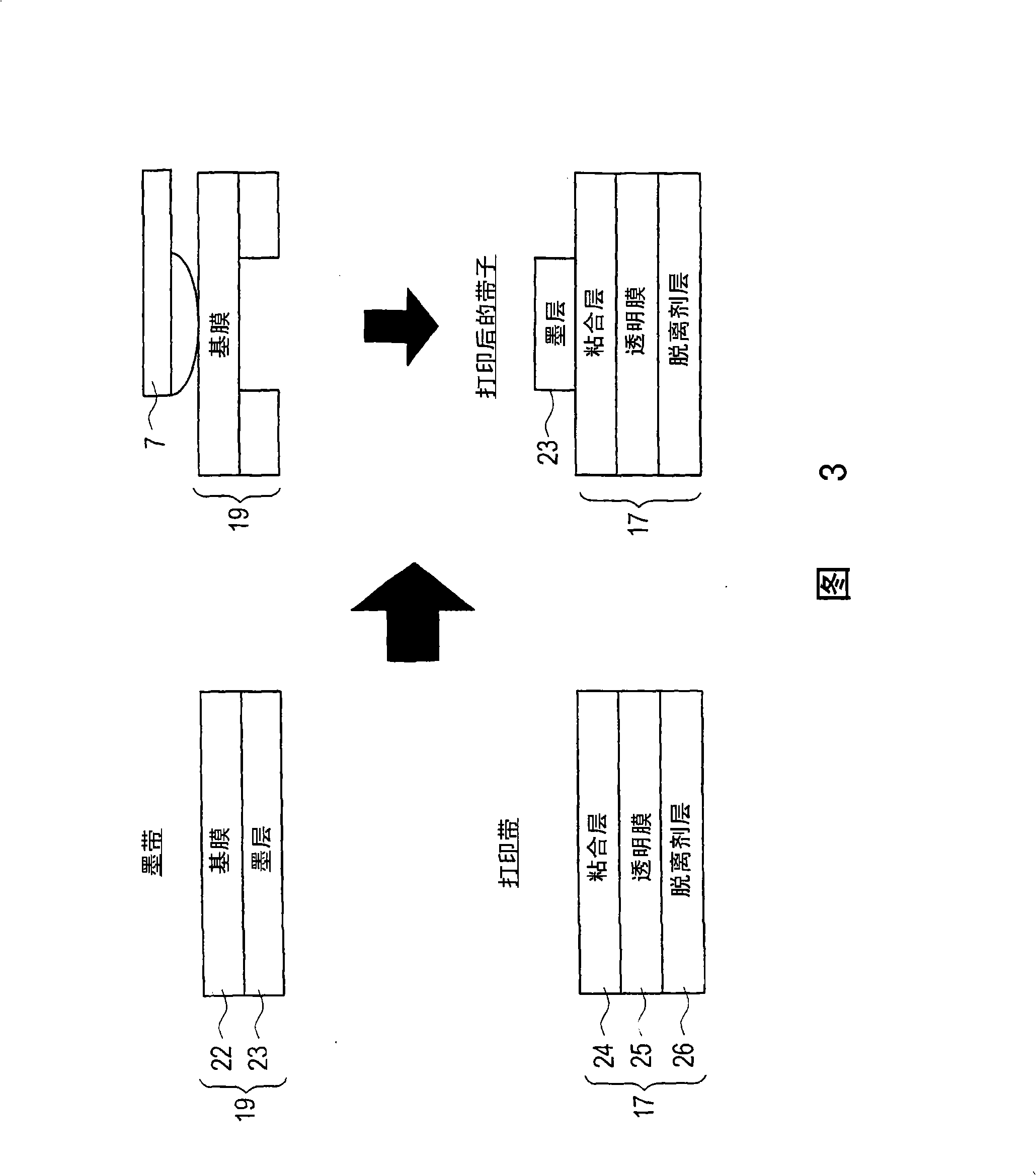

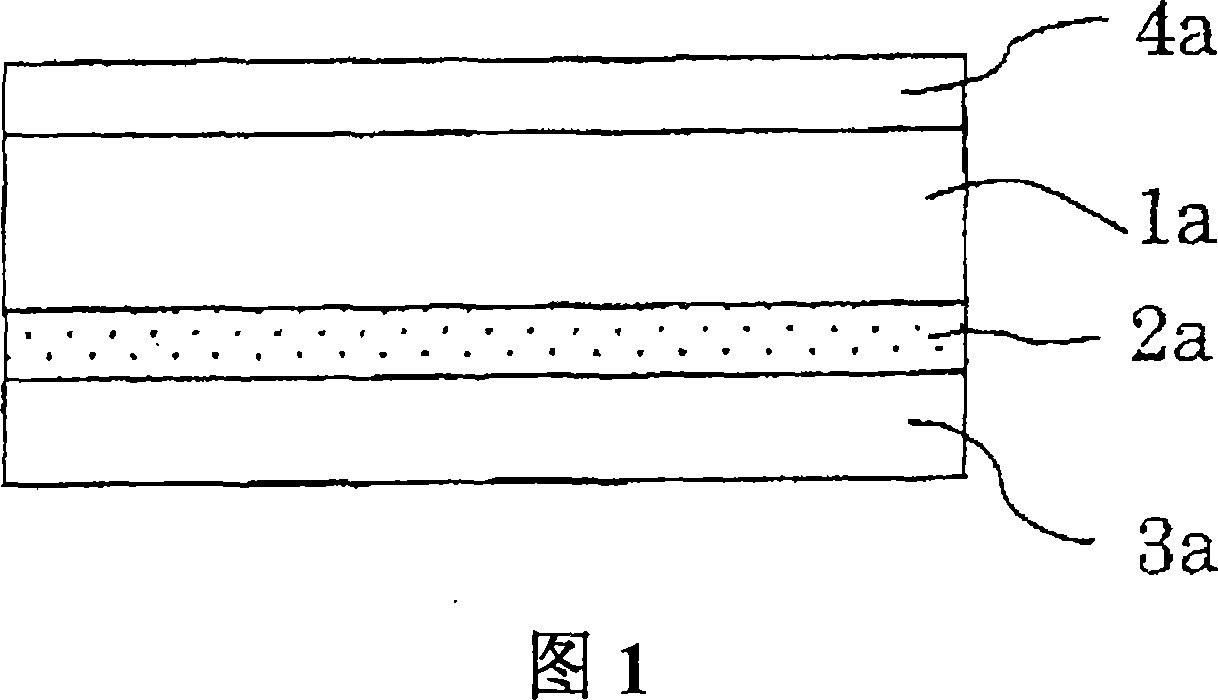

Lettering tape, tape cassette, tape printer

A lettering tape is formed having an integrated layered configuration in which a base layer, an ink layer, and an adhesive layer exhibiting adhesive properties when heated are sequentially stacked. When the lettering tape is selectively heated by a thermal head to form an image thereon, the heated portion of the ink layer onto which an image has been formed is adhered to the heated portion of the adhesive layer and simultaneously, the heated portion of the adhesive layer exhibits self-adhesive properties, thereby enabling transfer to the target transfer body.

Owner:BROTHER KOGYO KK

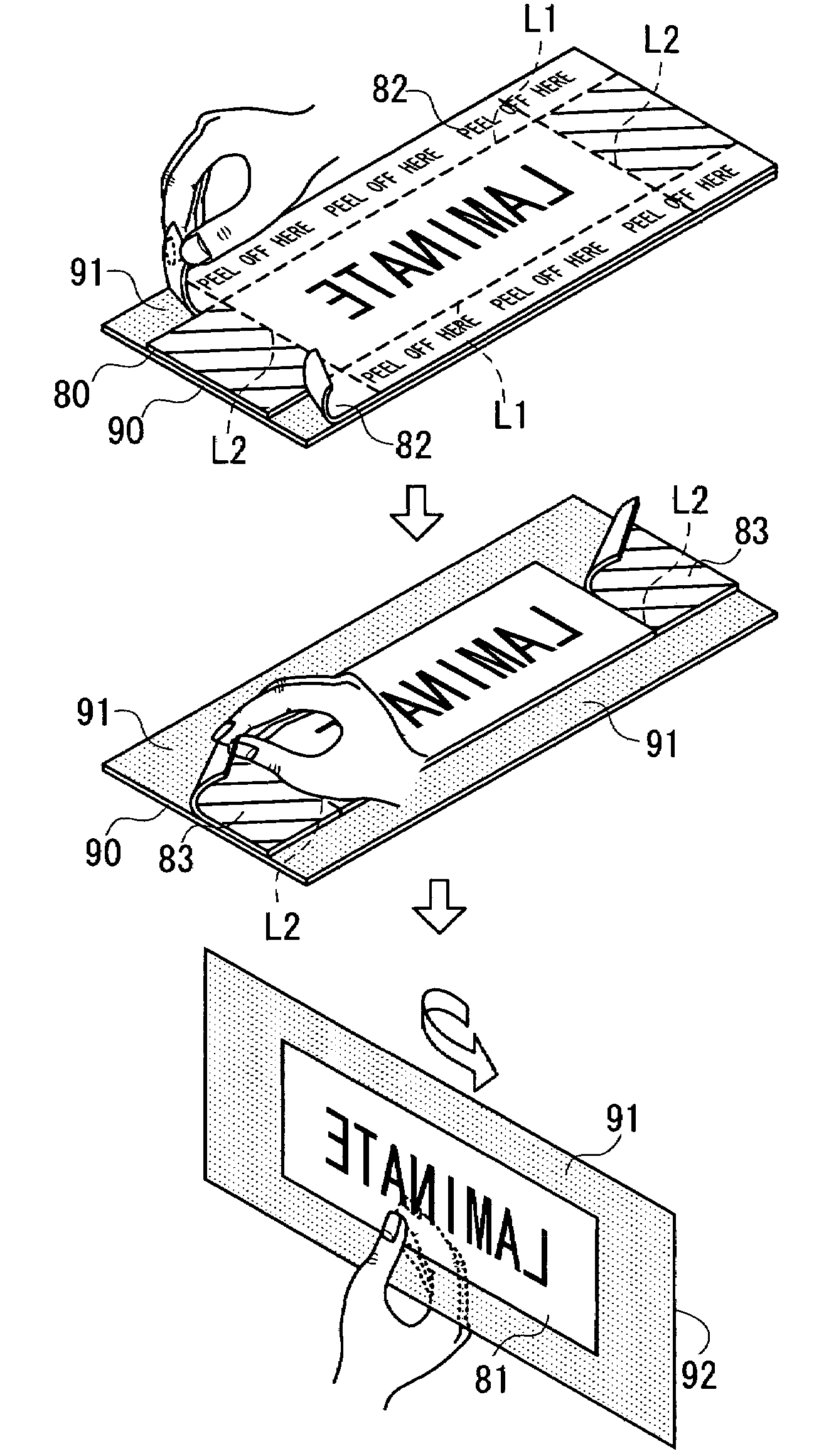

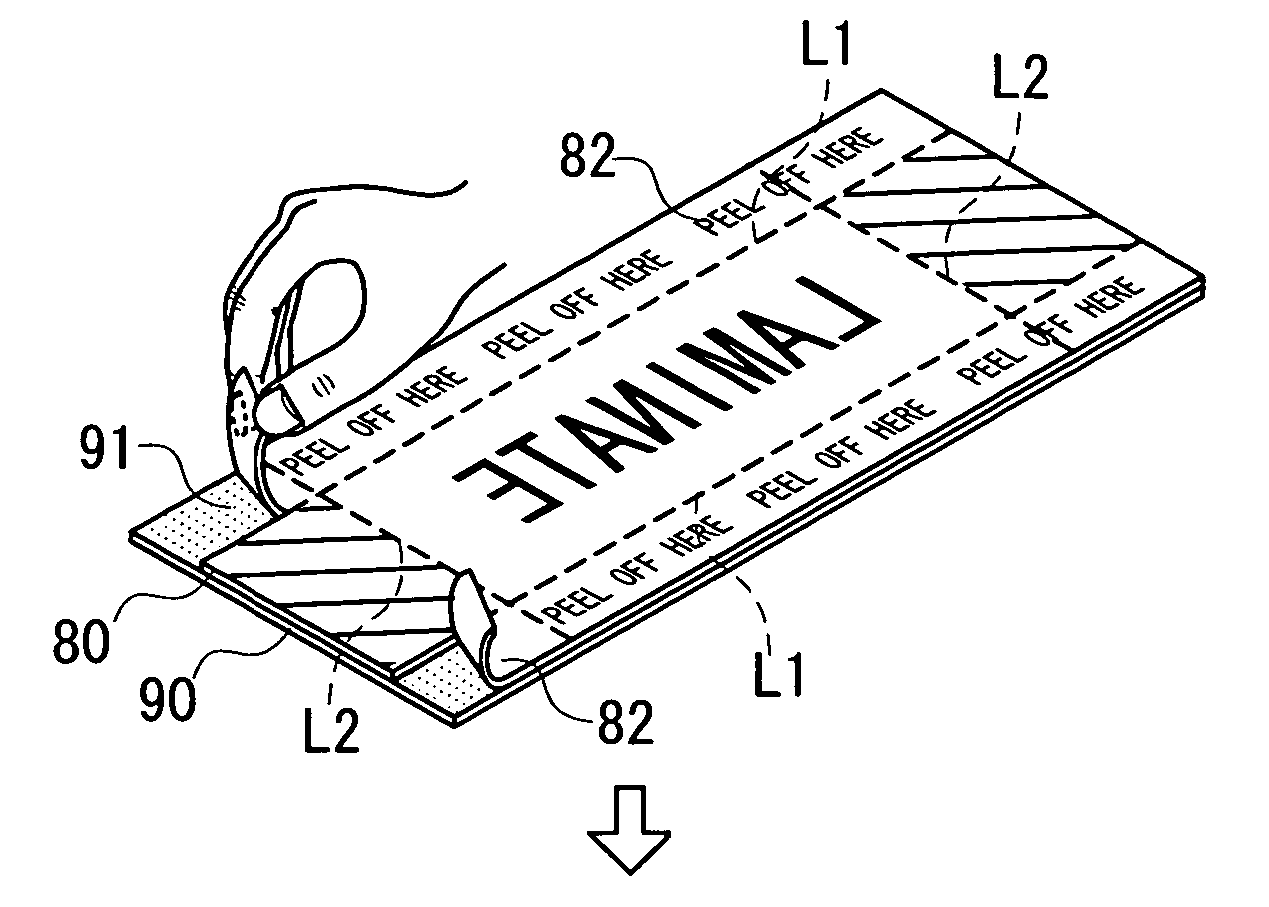

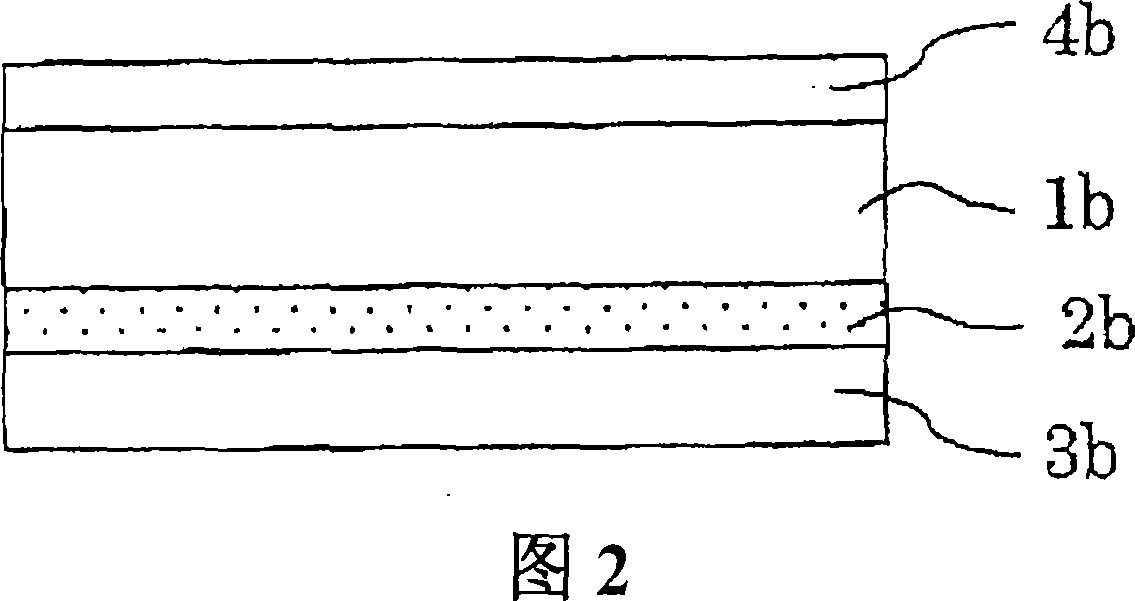

Printing tape, tape cartridge provided therewith, and tape printing apparatus

InactiveUS7357585B2Prevented from becoming easily peeled offRegion can be prevented smallInk ribbon cartridgesStampsElectrical and Electronics engineeringEngineering

A printing tape has a translucent recording-tape layer with a recording surface on a face thereof, and a translucent pseudo-laminating layer adhered to a back of the recording-tape layer. The pseudo-laminating layer has an adhesive-agent layer on a face thereof and a translucent tape layer on a back thereof. The recording-tape layer has a print-recording piece whose face serves as a printing region and a cut-off piece to be peeled off from the adhesive-agent layer. The print-recording piece is separated from the cut-off piece by a long-side cutting line formed in a longitudinal direction of the recording surface. By inverting both the recording-tape layer and the pseudo-laminating layer inside out for adhering to an object of adhesion after removing the cut-off piece, the pseudo-laminating layer serves as a laminate tape for the recording surface.

Owner:SEIKO EPSON CORP

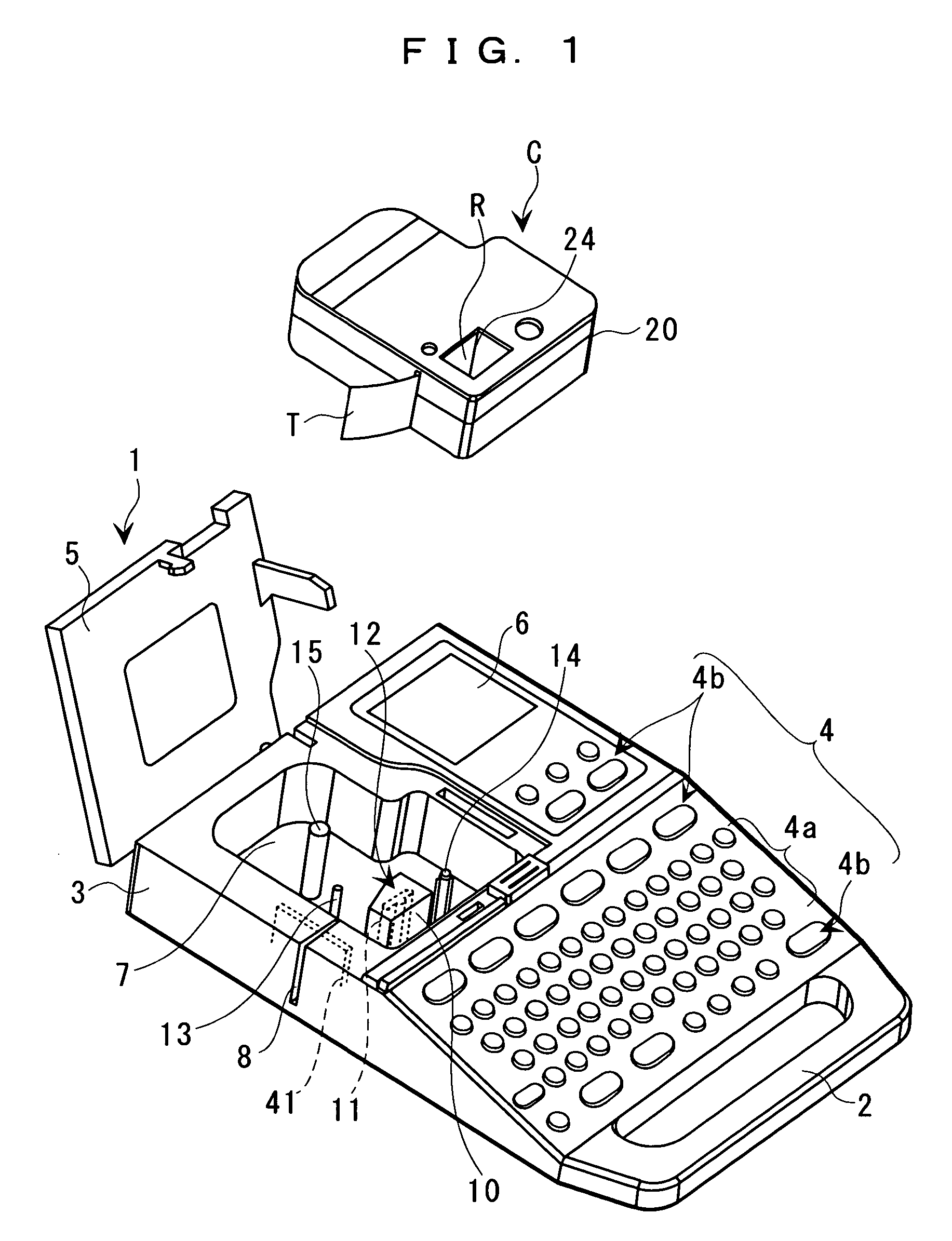

Tape cassette and tape printer

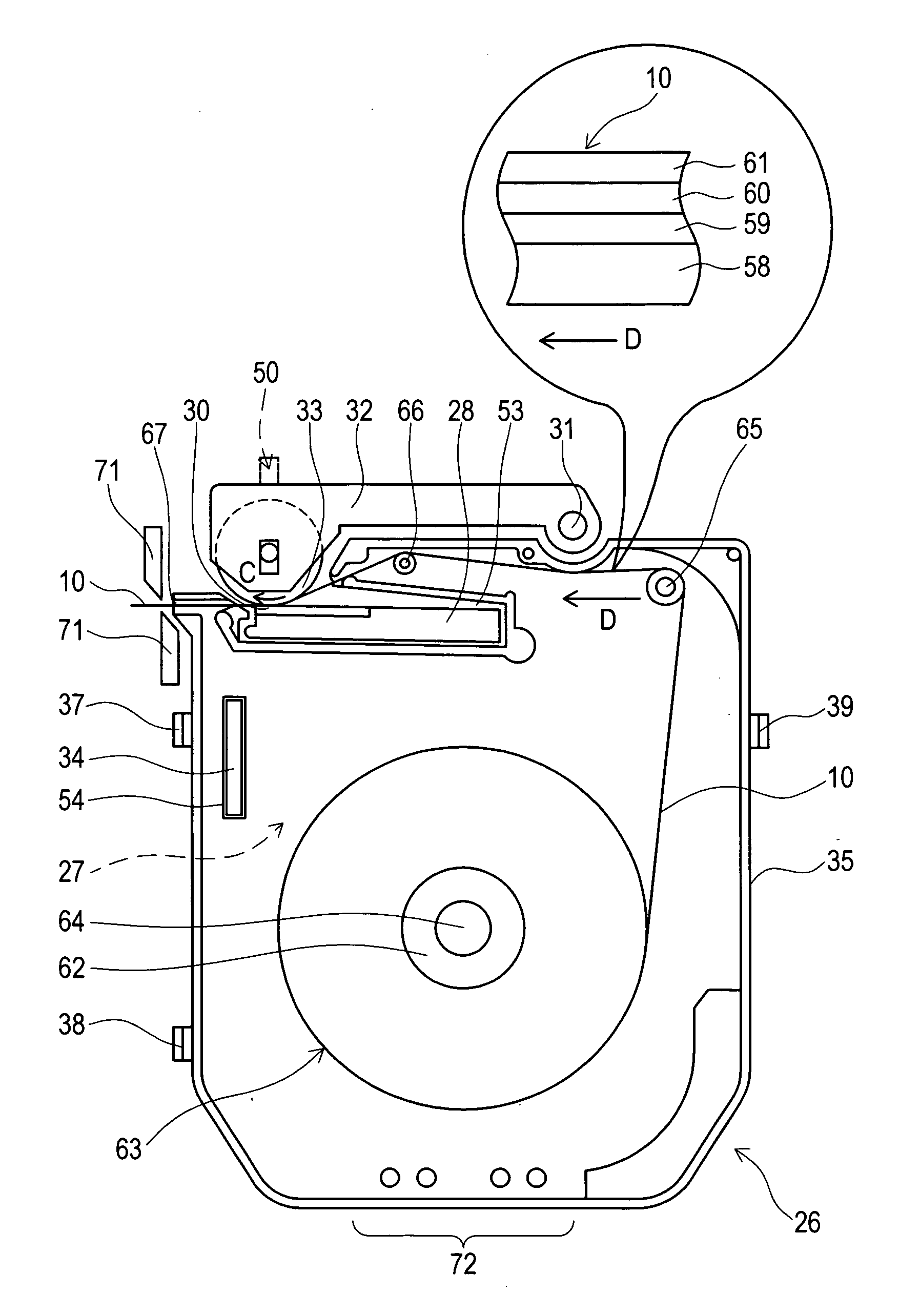

A tape cassette includes an ink ribbon provided with a base film coated with an ink layer thereon and a film tape provided with a transparent film with an adhesive layer formed on one surface thereof. When an adhesive layer of the film tape and the ink layer of the ink ribbon of the tape cassette into contact at a print position, the ink layer is adhered onto the adhesive layer on condition that the adhesive layer is heated to exhibit self-adhesive properties, and characters and the like are printed on the film tape. At a tape printing apparatus with the tape cassette mounted thereon, by arranging a cutter unit immediately downstream the thermal head, a post-printing tape is cut promptly after printing.

Owner:BROTHER KOGYO KK

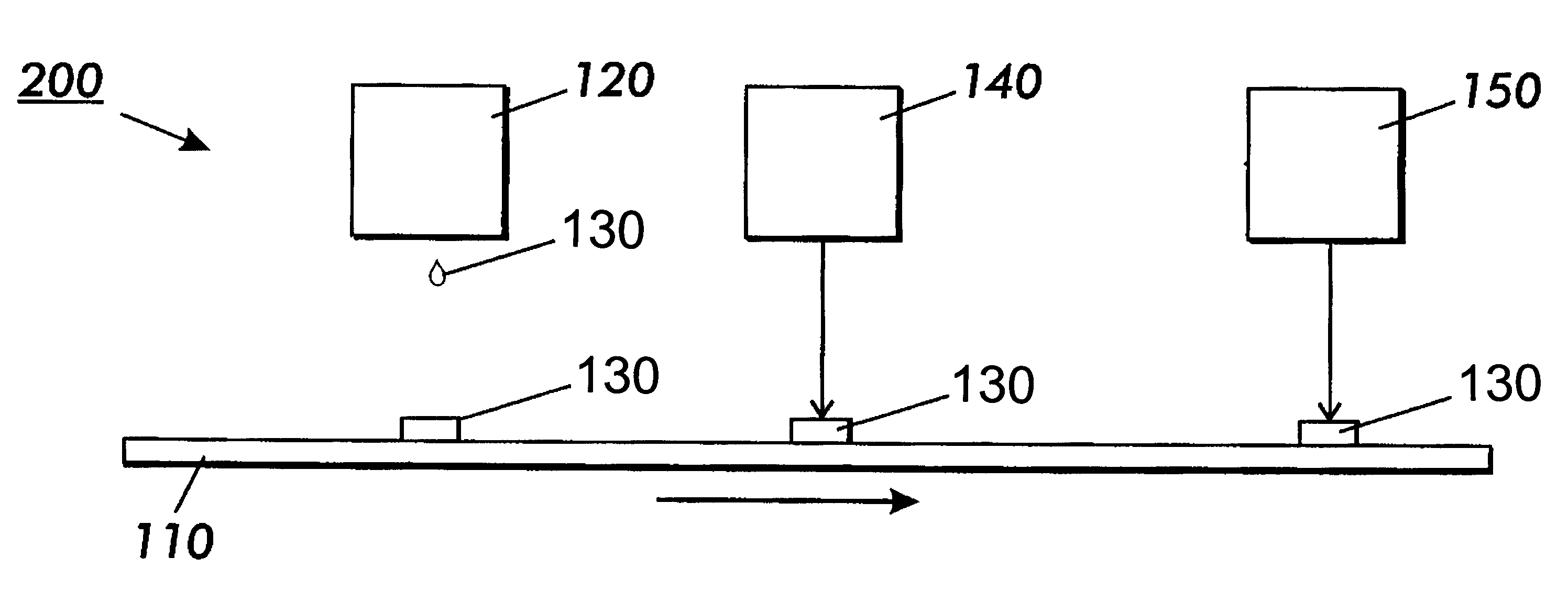

Systems and methods of printing with ultra violet photosensitive resin-containing materials using light emitting devices

Method of printing with ultraviolet photosensitive resin-containing materials includes depositing at least one substance that includes an ultraviolet photosensitive resin on to a substrate, partially curing the substance by irradiating the substance with at least one ultraviolet light emitting device, and completely curing the substance. Substance curing system including a substrate, an applicator that deposits a substance that includes an ultraviolet photosensitive resin on to a substrate, and at least one ultraviolet light emitting device usable to irradiate the substance to partially cure and / or completely cure the substance.

Owner:XEROX CORP

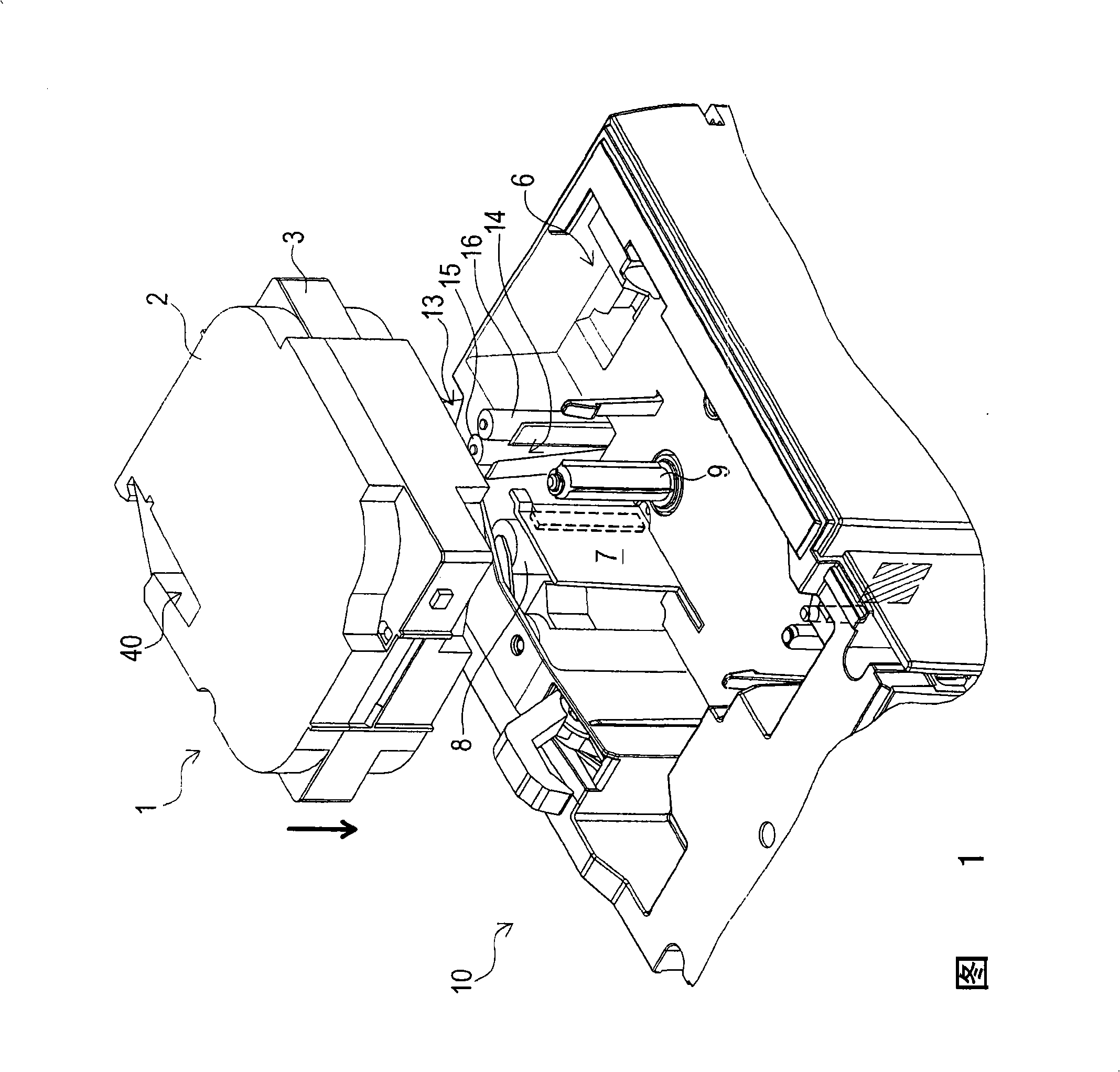

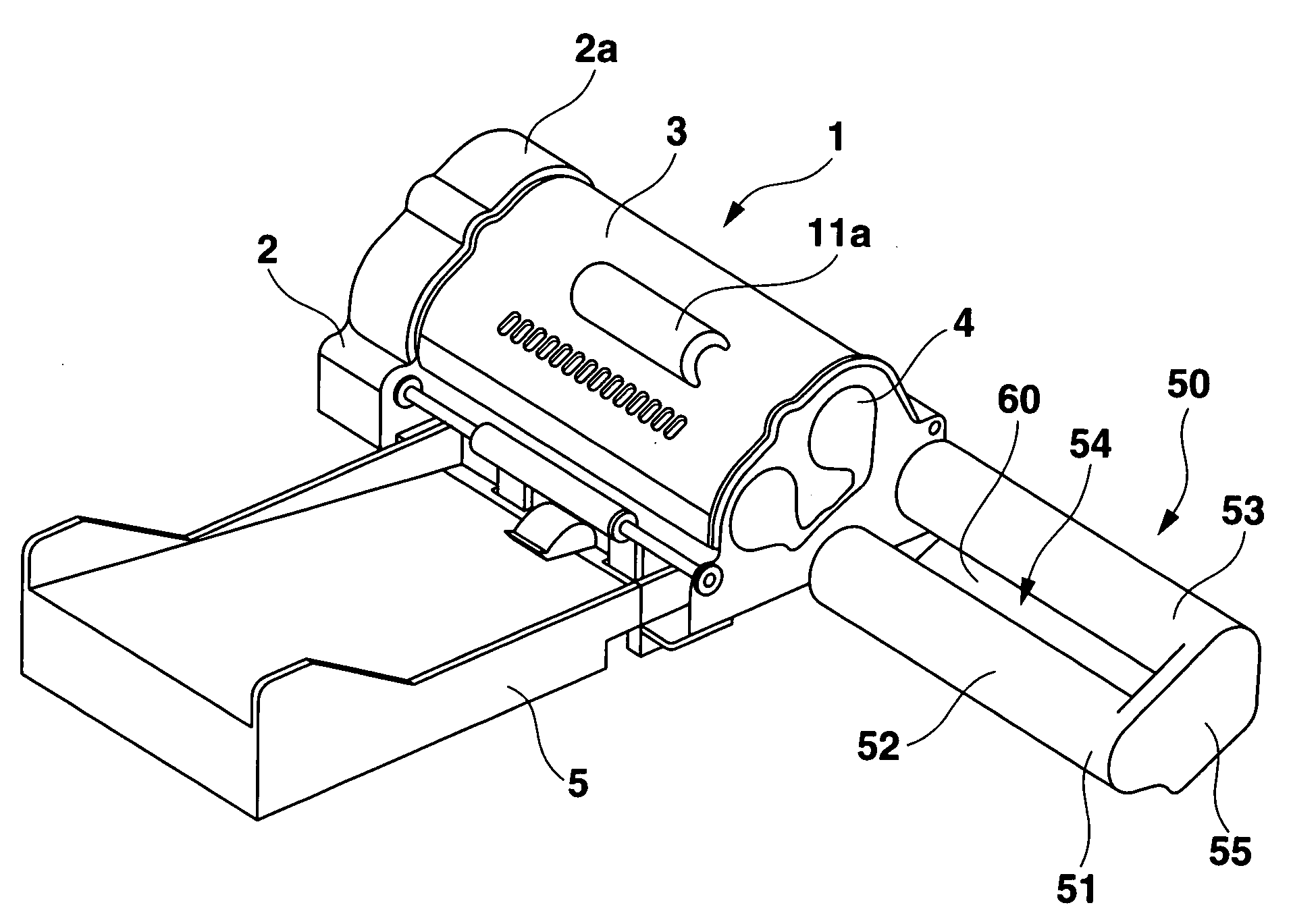

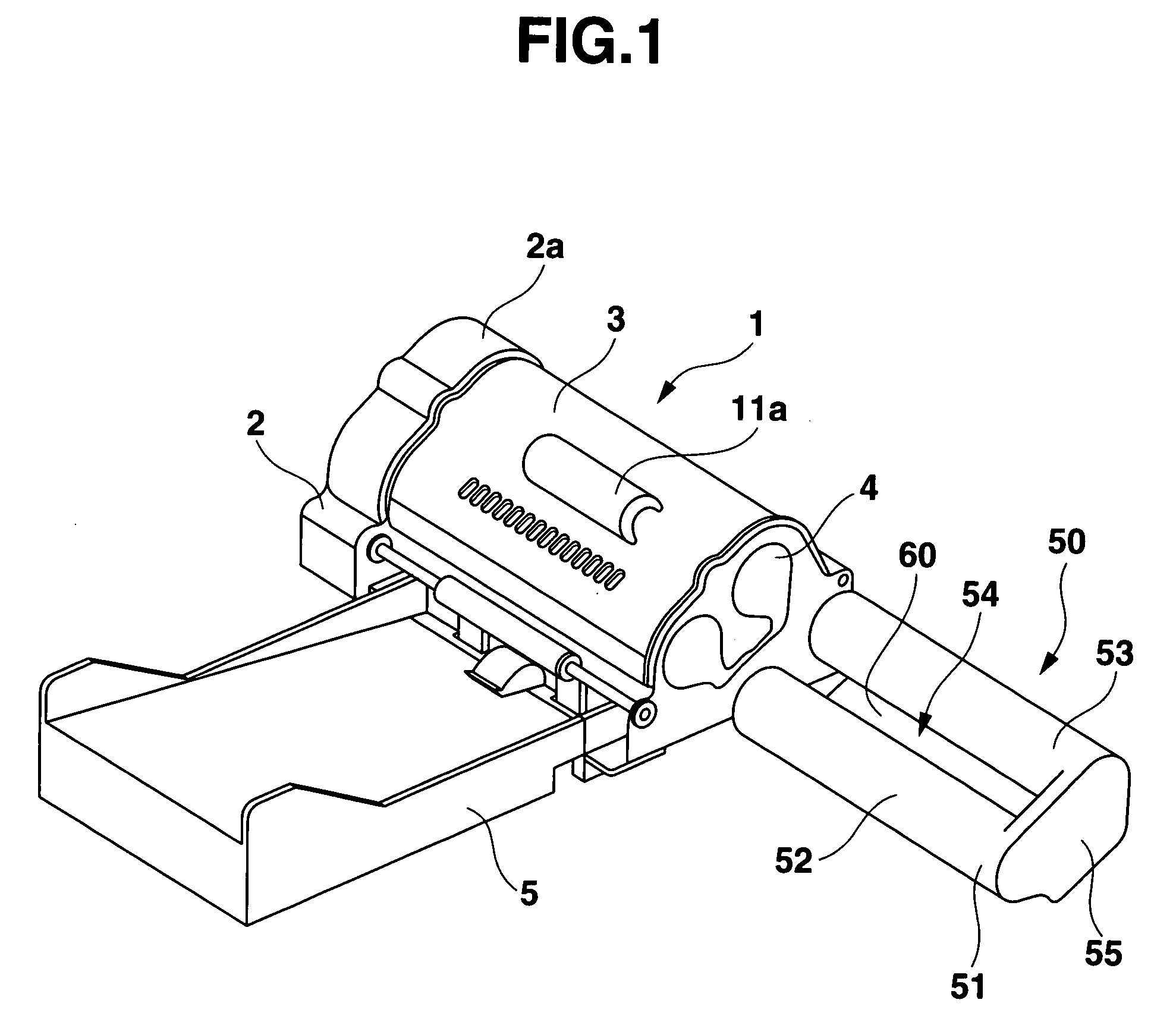

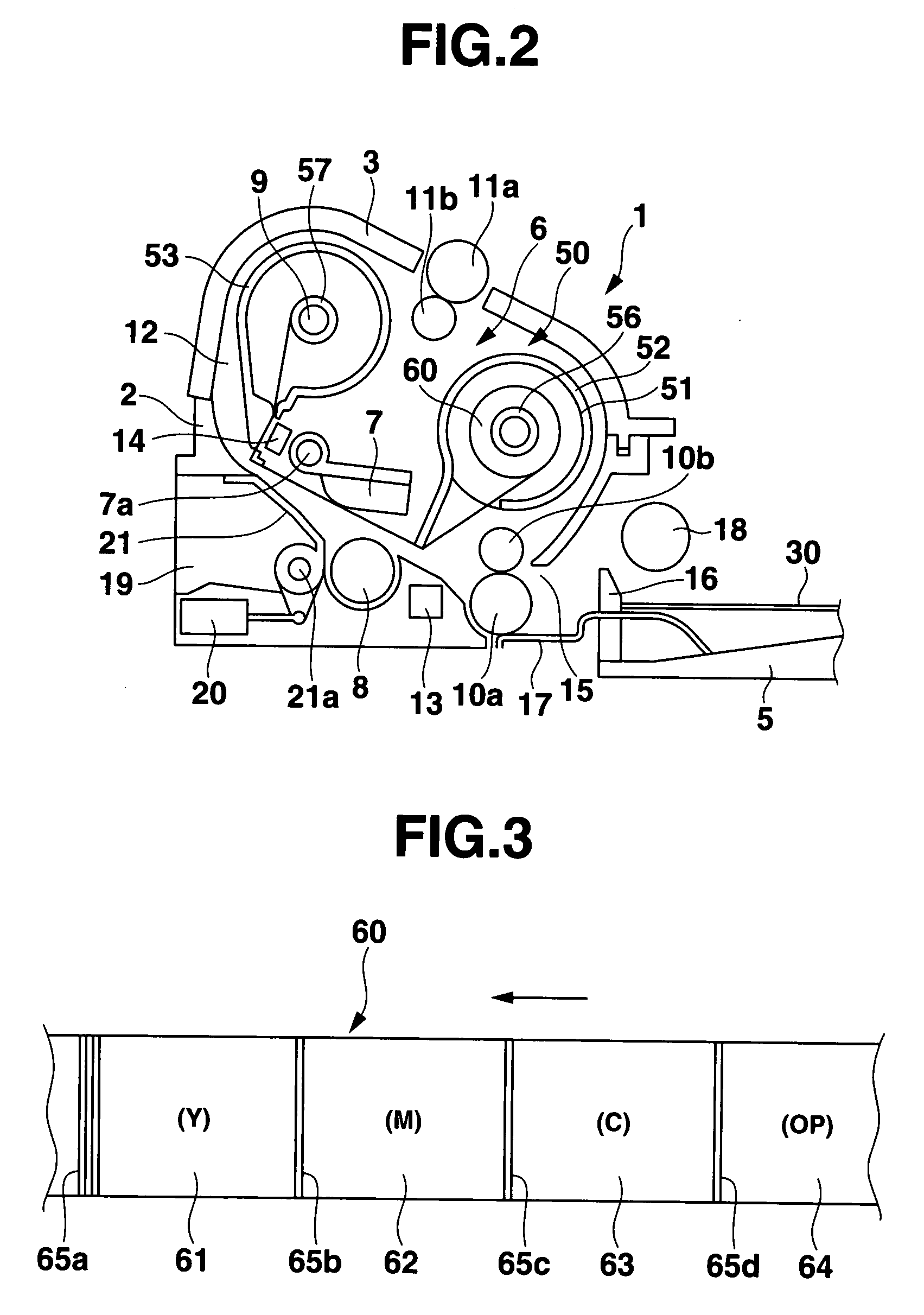

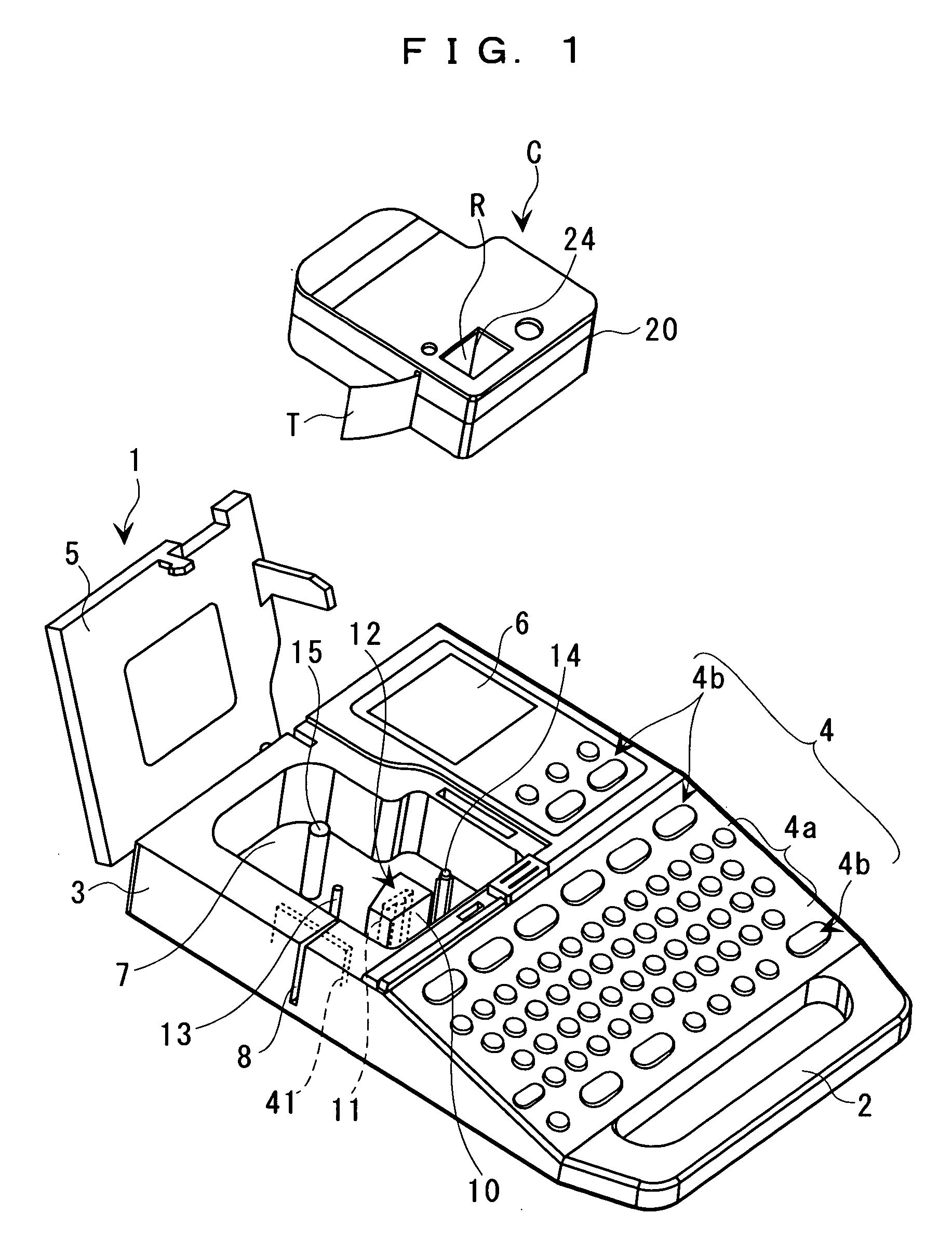

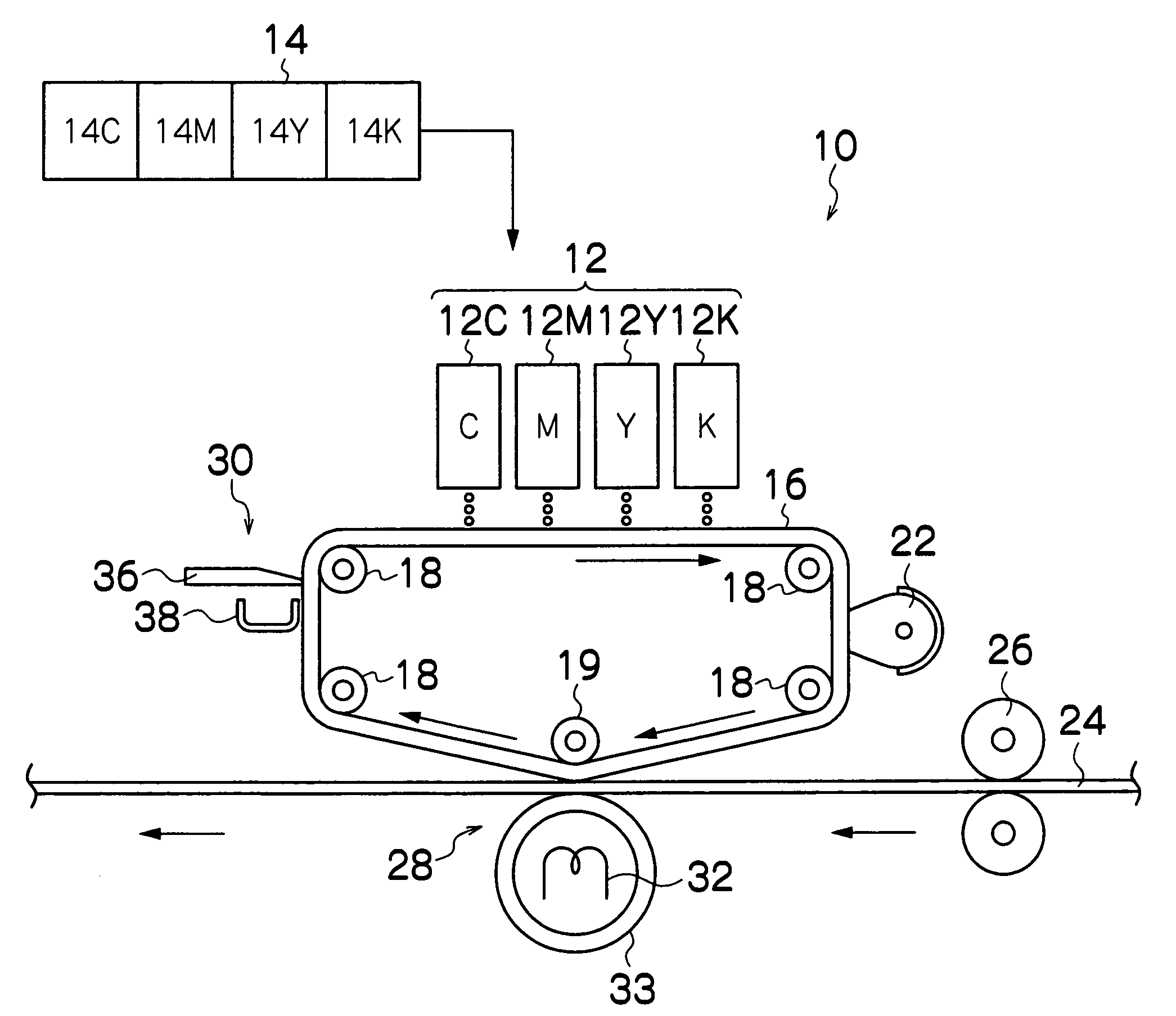

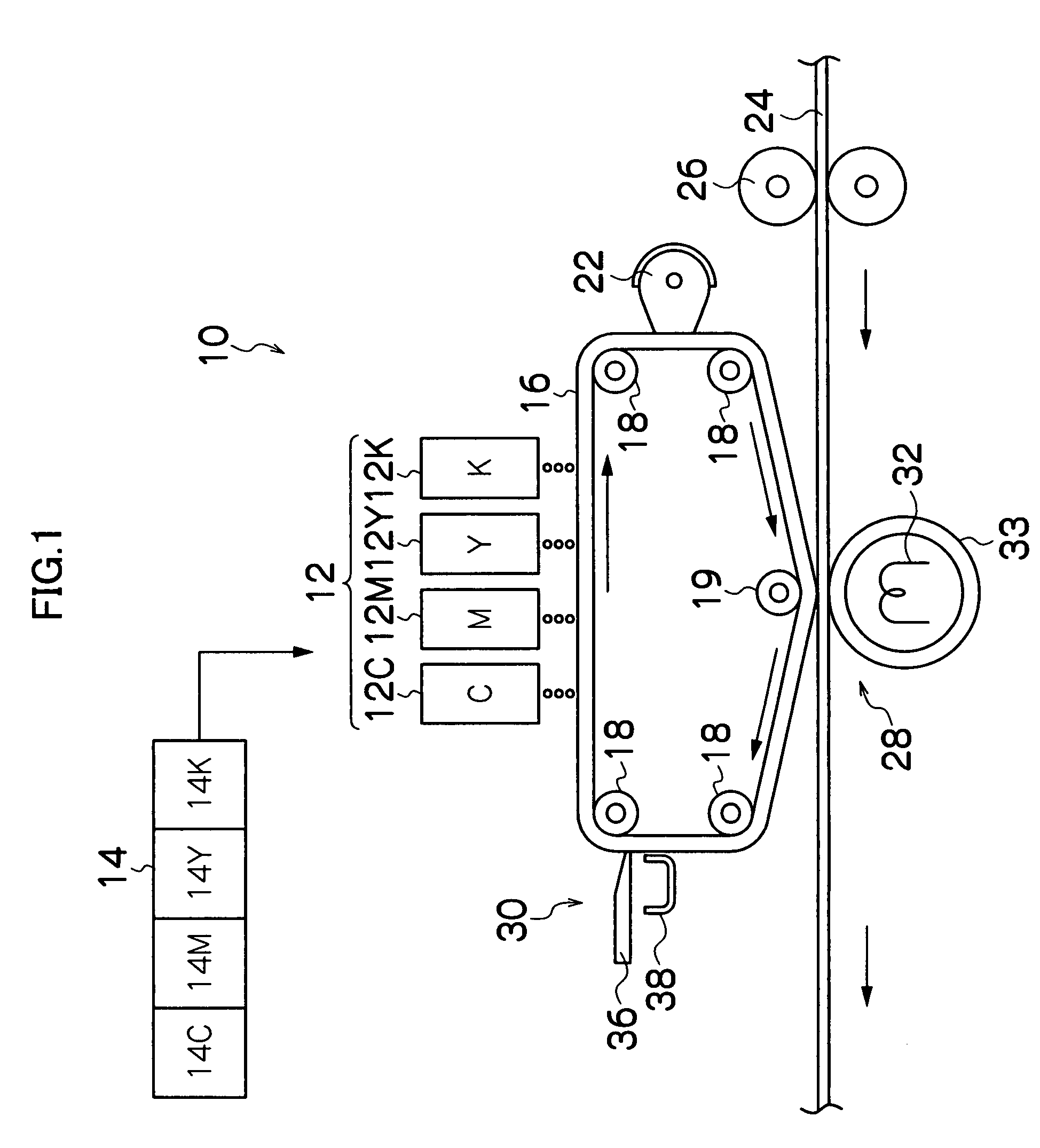

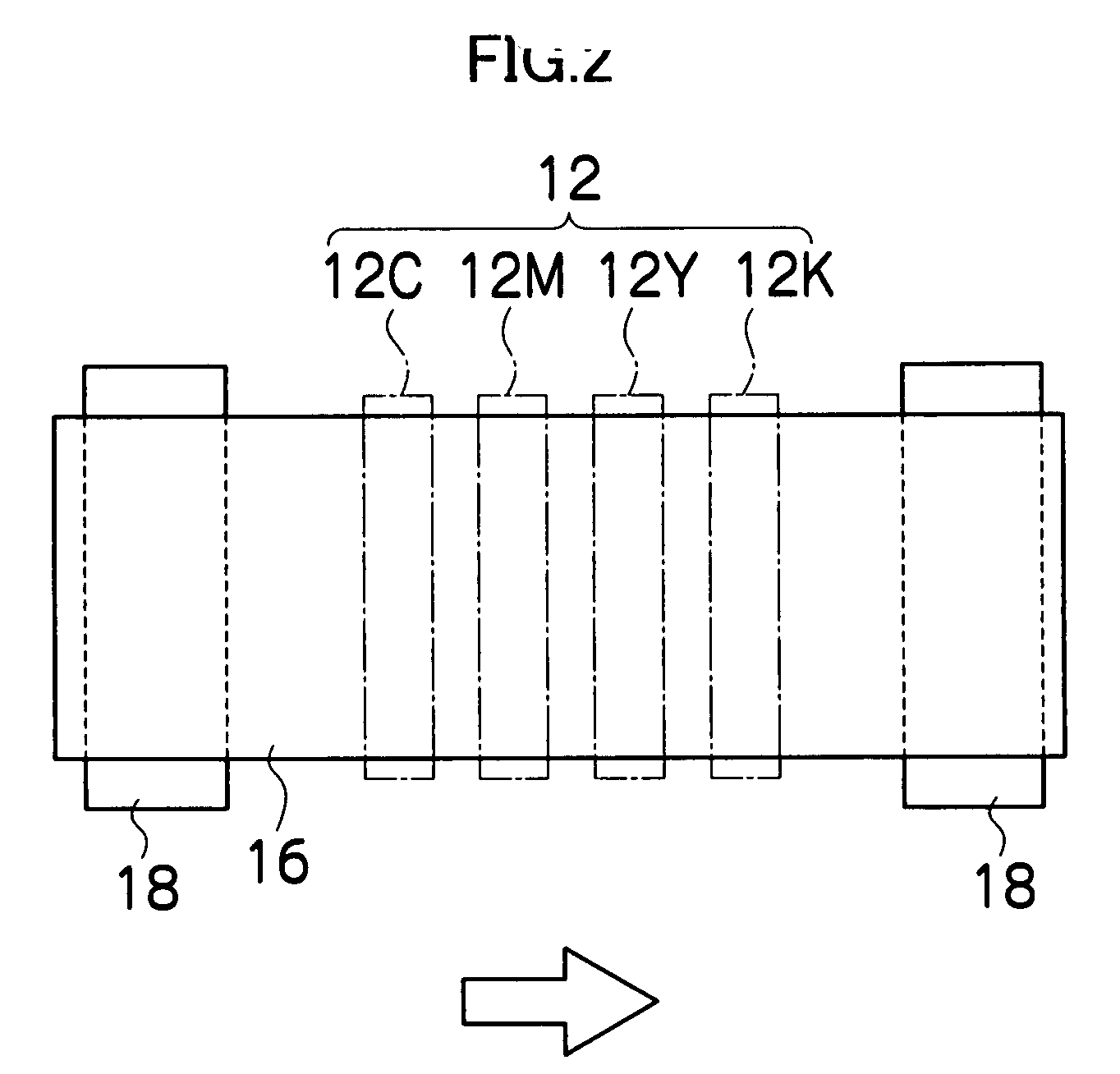

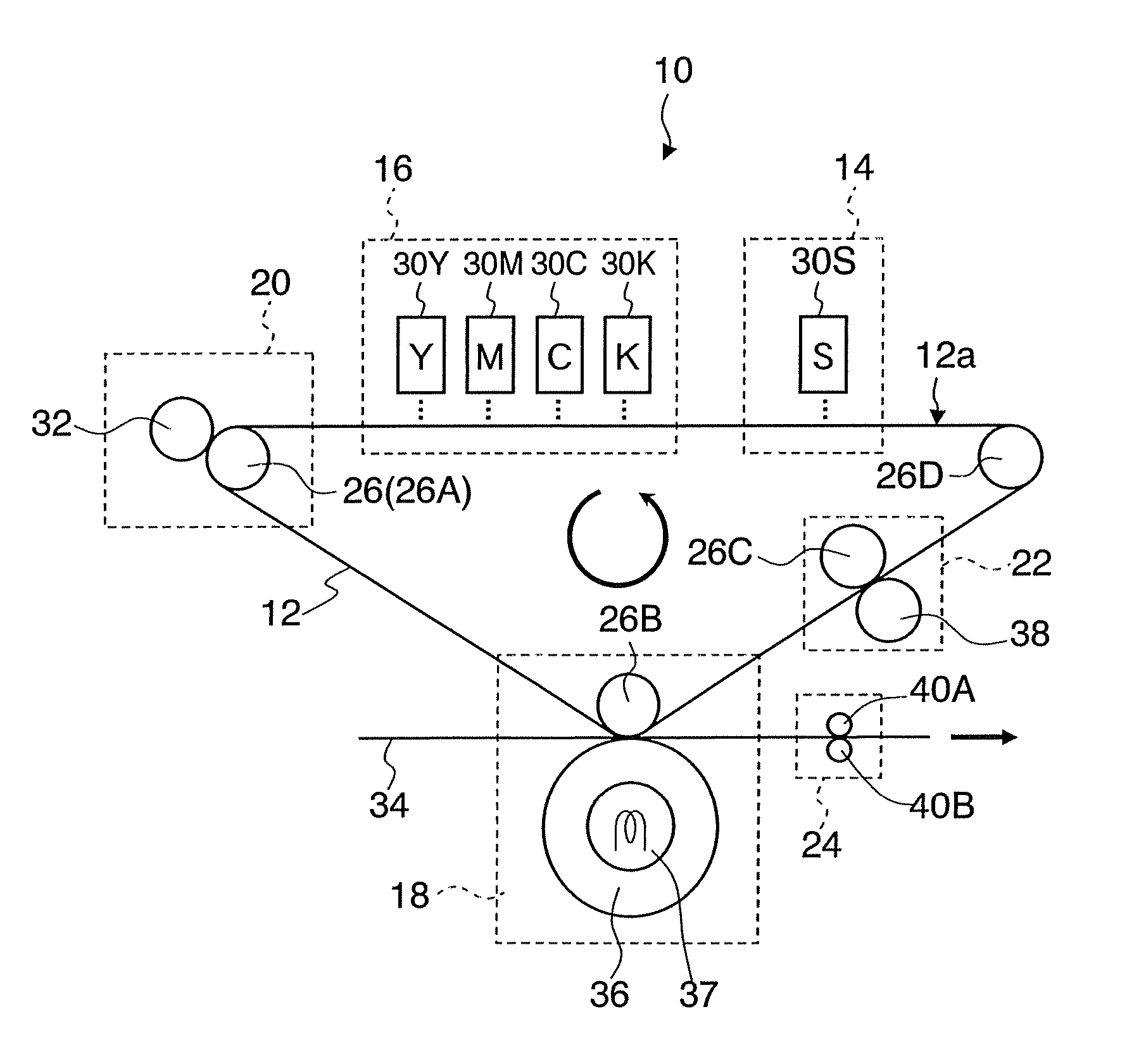

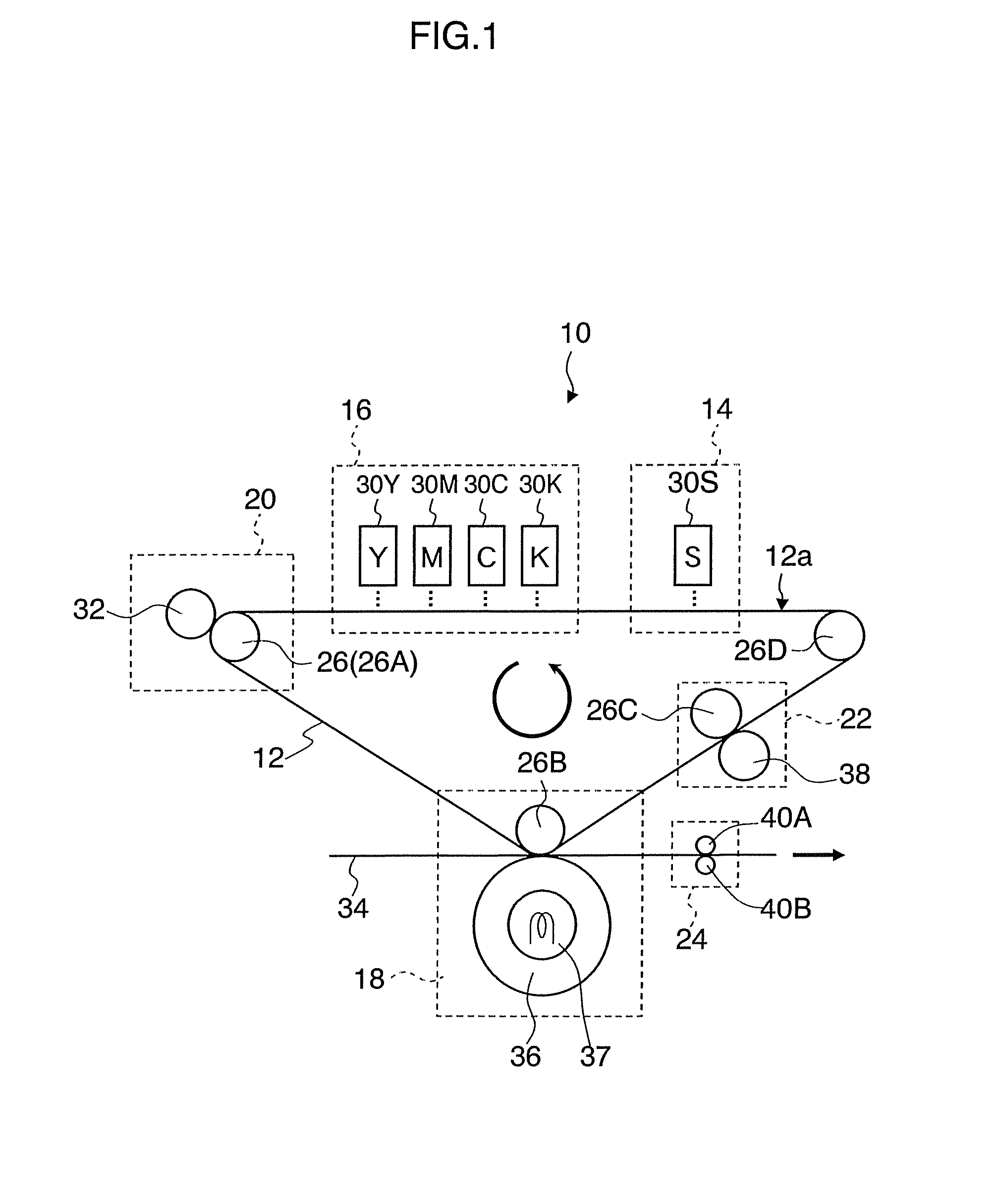

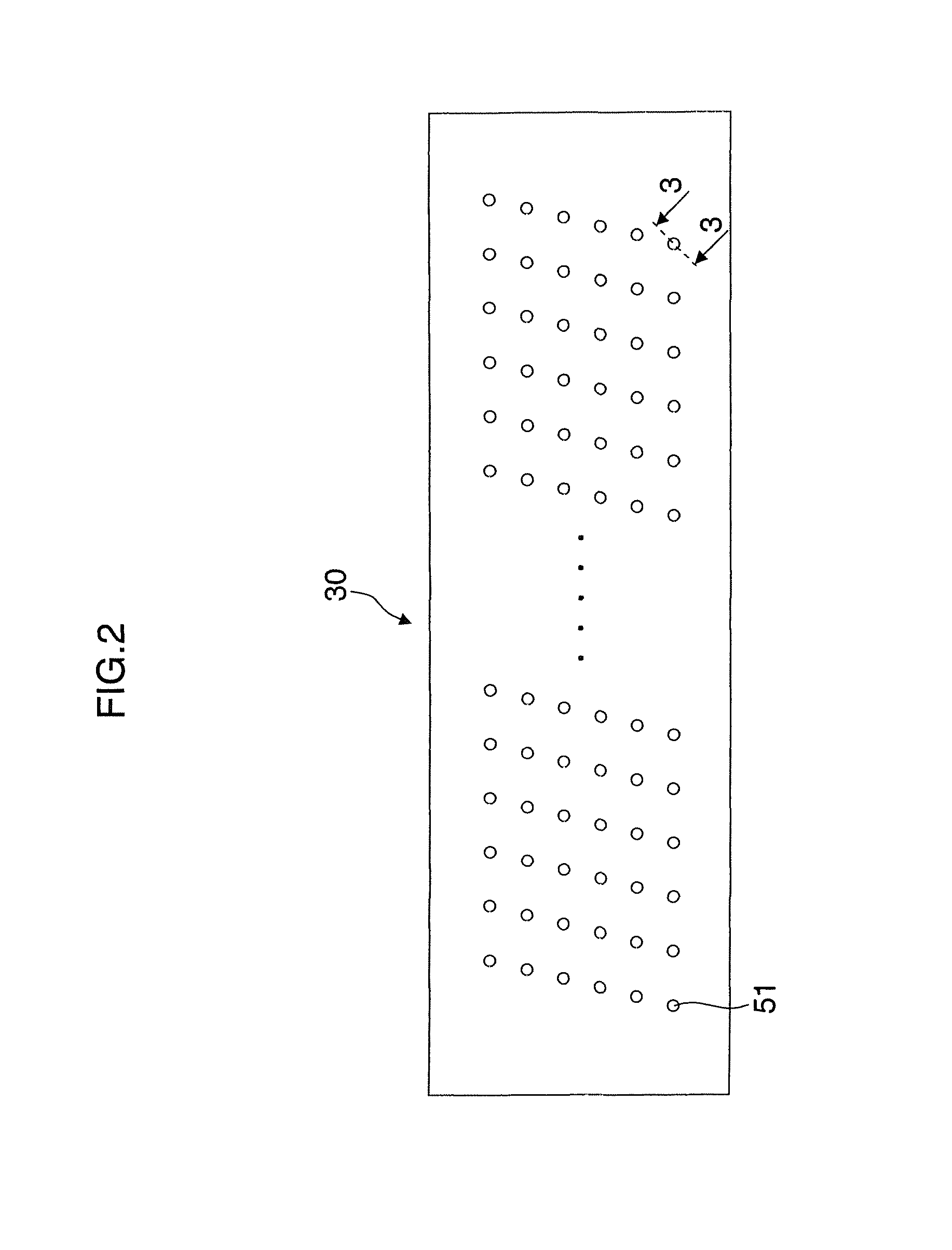

Printer

ActiveUS20080056793A1Small sizeEffectively availableRecording apparatusInk ribbonsColor imageEngineering

A size-reduced printer that conveys a recording sheet in a circulating manner along a ring-like conveyance path while printing a plurality of images on the recording sheet in different colors sequentially in a superimposed manner, thereby forming a full color image. When a ribbon cassette that contains a multi-color ink ribbon is loaded at a predetermined position within a printer housing, a ring-like conveyance path is formed between the ribbon cassette and the printer housing. While the thermal head is driven and the recording sheet is conveyed once in a circulating manner along the conveyance path, a one-color image is printed on a previous printed one-color image in a superimposed manner in a corresponding one of the different color inks of the multi-color ink ribbon, thereby forming a full color image fully.

Owner:CASIO COMPUTER CO LTD

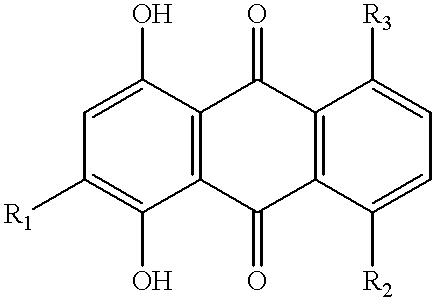

Thermal transfer recording system

InactiveUS6537410B2Improve performanceReduce volatilityInk ribbonsDecorative surface effectsAmorphous phaseCrystallization

There is described a thermal recording system which utilizes a donor element comprising a substrate and a thermal transfer material layer having a dye-containing phase which is amorphous and wherein the dye or dyes present in the amorphous phase form a continuous film. Imagewise heating of the medium transfers portions of the transfer layer to a receiver sheet, thus forming an image. The transfer layer may also include a non-dye phase comprising a thermal solvent. During the heating of the donor element, the crystalline thermal solvent melts and dissolves or liquefies at least a portion of the dye-containing phase, thereby lowering the temperature at which transfer of the transfer layer occurs.

Owner:INTELLECTUAL VENTURES I LLC

Printing tape, tape cartridge provided therewith, and tape printing apparatus

InactiveUS20060008608A1Prevented from becoming easily peeled offRegion can be prevented smallInk ribbon cartridgesStampsEngineeringElectrical and Electronics engineering

A printing tape has a translucent recording-tape layer with a recording surface on a face thereof, and a translucent pseudo-laminating layer adhered to a back of the recording-tape layer. The pseudo-laminating layer has an adhesive-agent layer on a face thereof and a translucent tape layer on a back thereof. The recording-tape layer has a print-recording piece whose face serves as a printing region and a cut-off piece to be peeled off from the adhesive-agent layer. The print-recording piece is separated from the cut-off piece by a long-side cutting line formed in a longitudinal direction of the recording surface. By inverting both the recording-tape layer and the pseudo-laminating layer inside out for adhering to an object of adhesion after removing the cut-off piece, the pseudo-laminating layer serves as a laminate tape for the recording surface.

Owner:SEIKO EPSON CORP

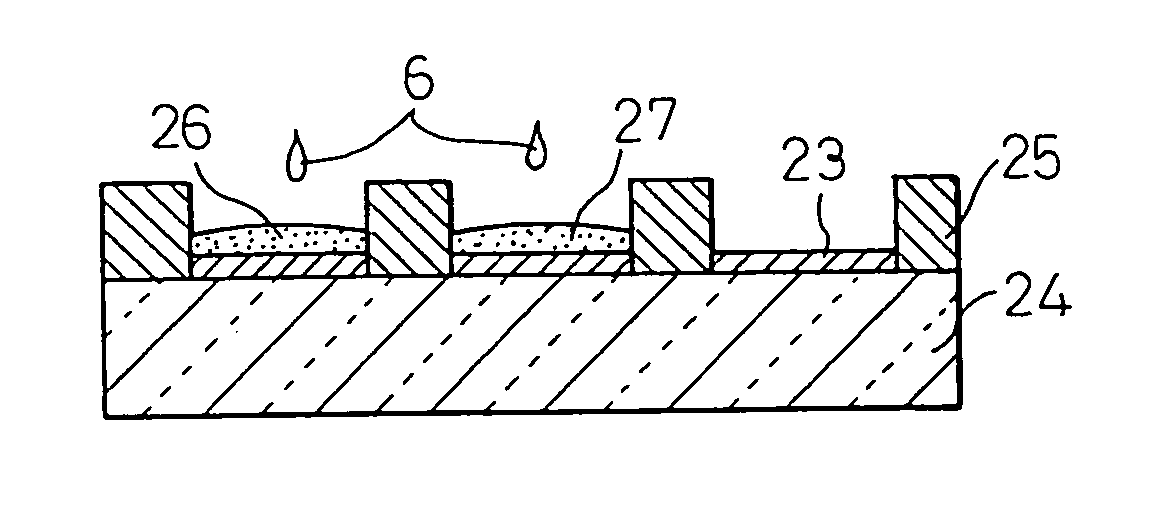

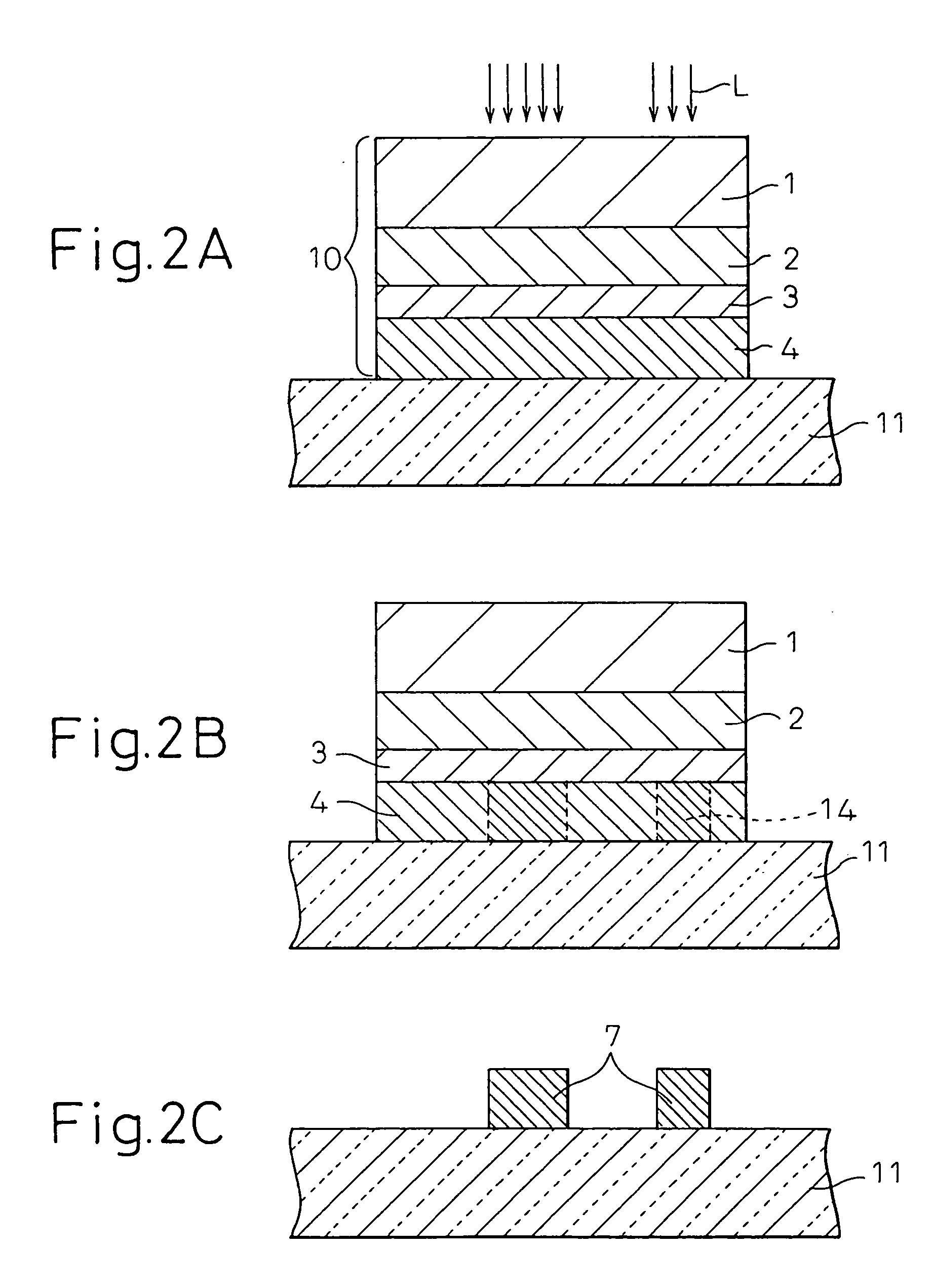

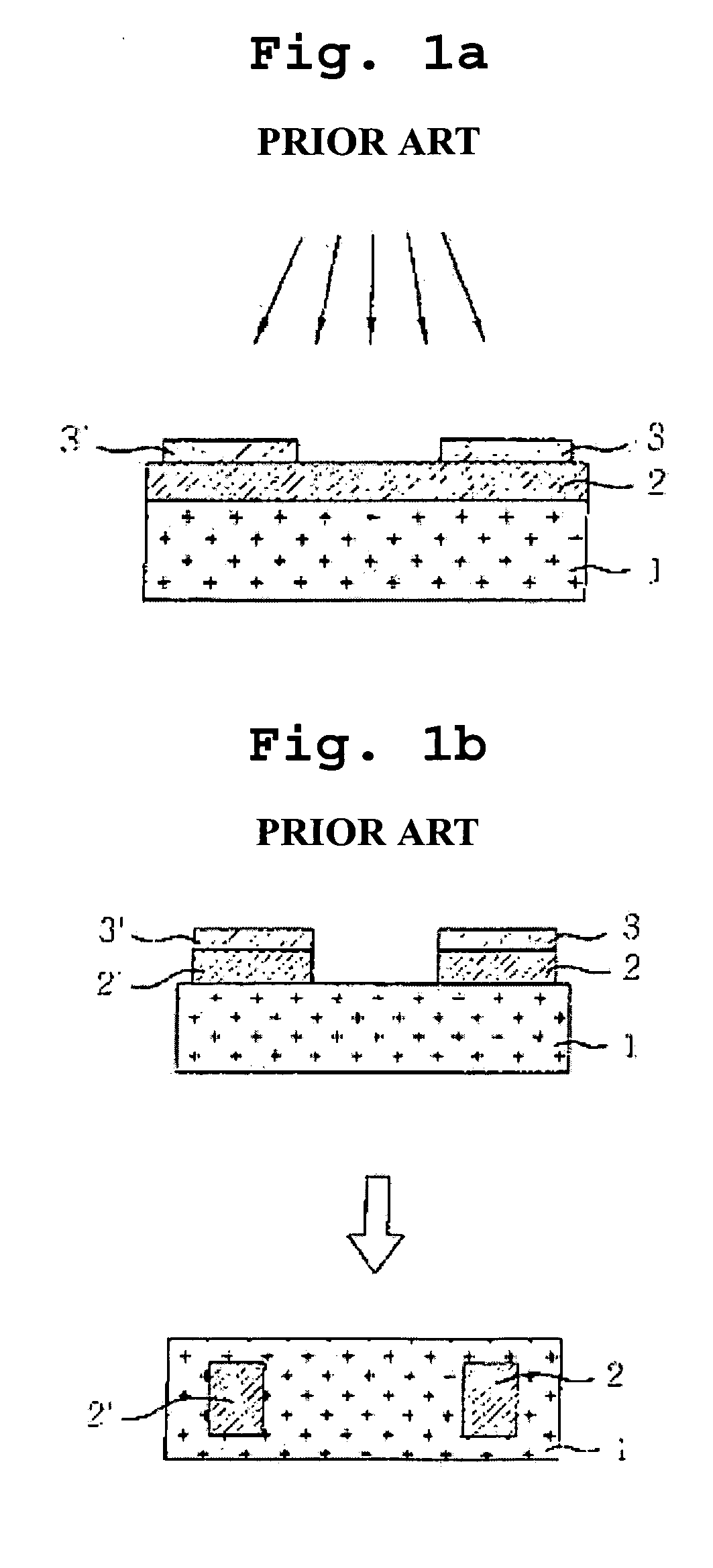

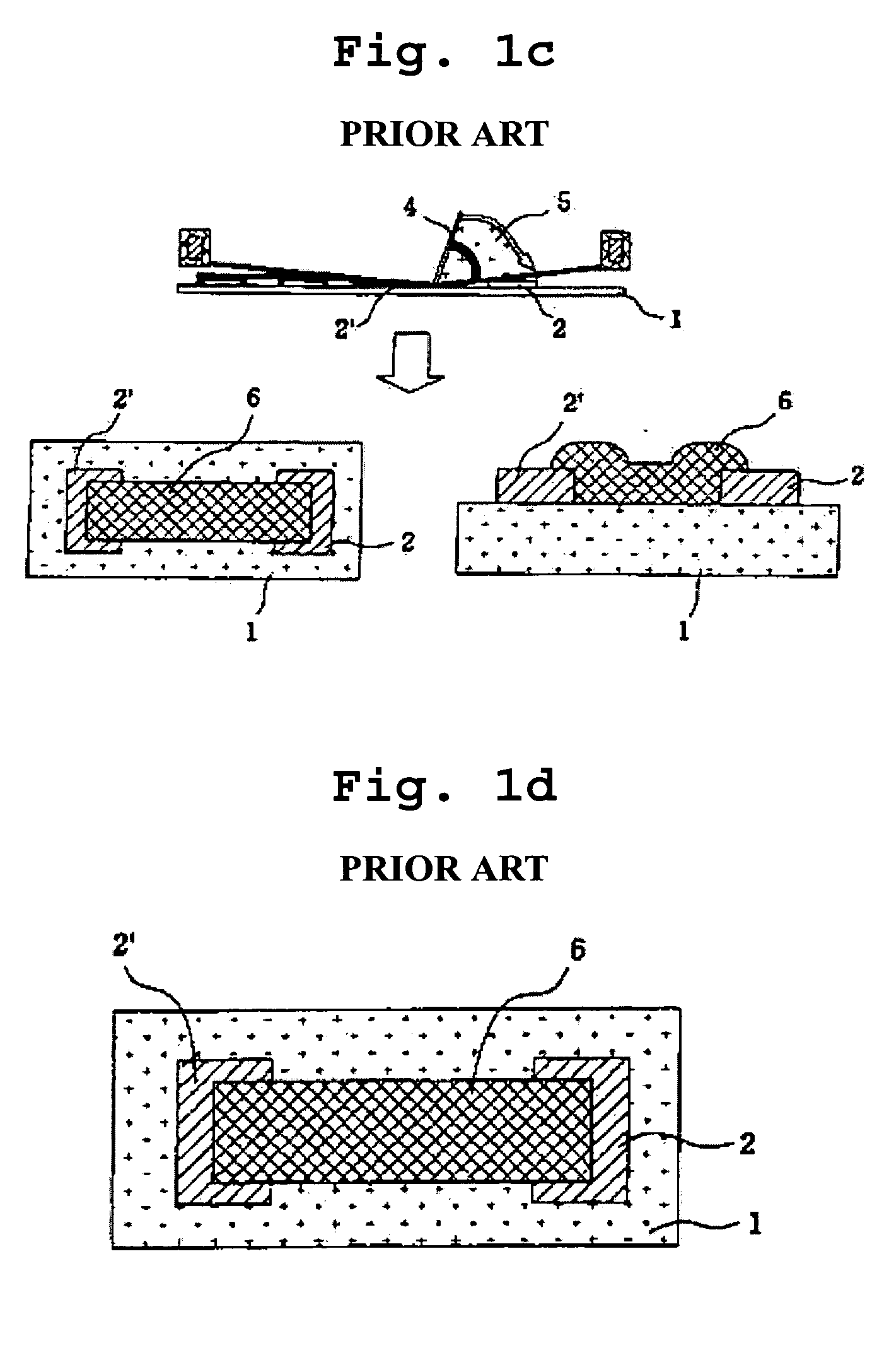

Donor sheet, color filter, organic EL element and method for producing them

InactiveUS20050157157A1Excellent ink repellencyReduce manufacturing stepsRecording apparatusInk ribbonsEngineeringSolvent

A donor sheet for transferring an image pattern to an image receiving element by a thermal imaging process using laser beam, comprising a base having formed in order on the base a light-to-heat conversion layer, and a transfer layer containing an image component which is melted by heating due to an action of the light-to-heat conversion layer and transferred to the image receiving element in a patterned form, in which the image component of the transfer layer contains an ink-repellent or solvent-repellent compound in an optimized amount. Using the donor sheet, it becomes possible to produce an separation member such as partition pattern and black matrix of a color filter by a shortened manufacturing step with ease and accuracy at high contrast, and can impart excellent ink repellency to the separation member.

Owner:3M INNOVATIVE PROPERTIES CO +1

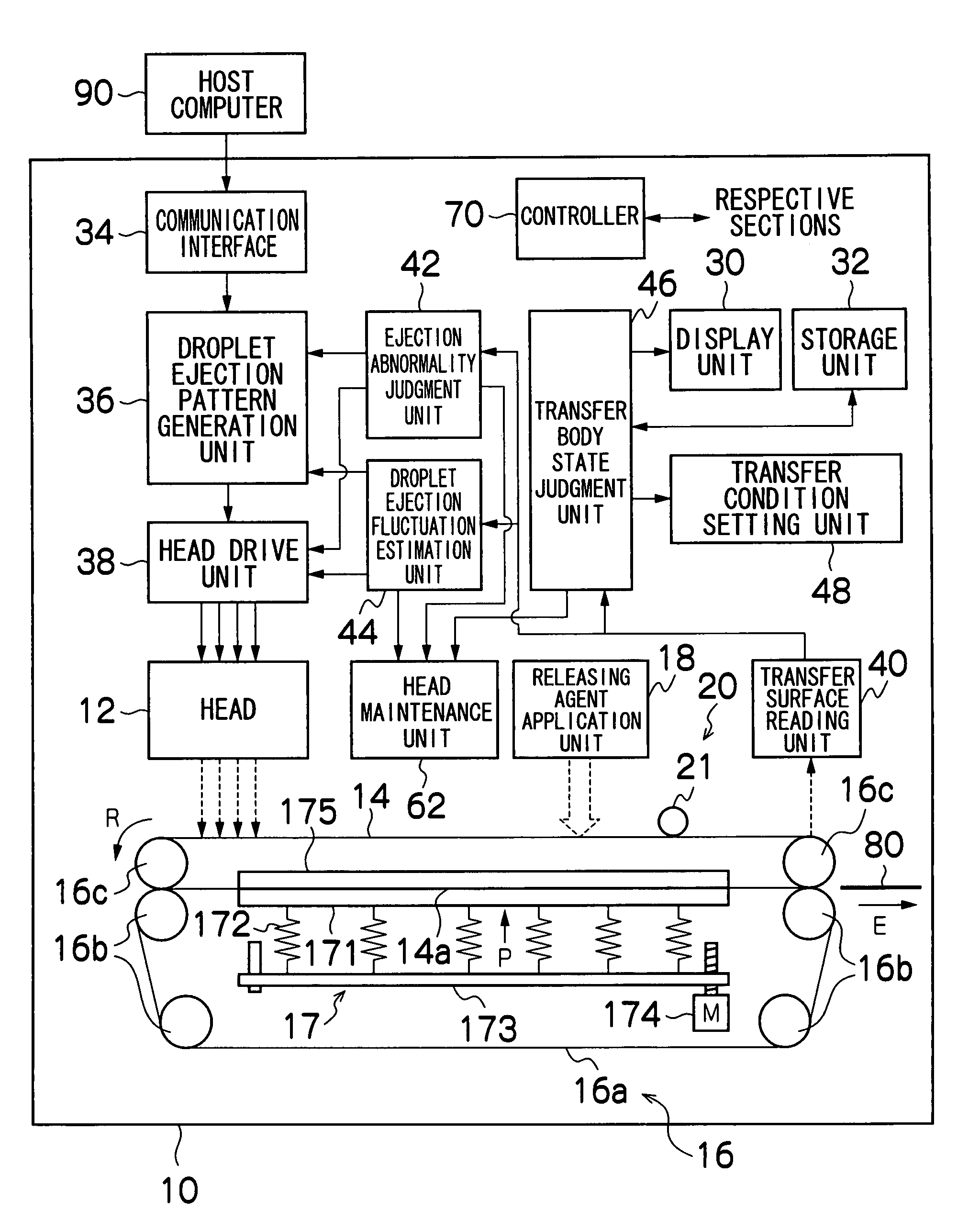

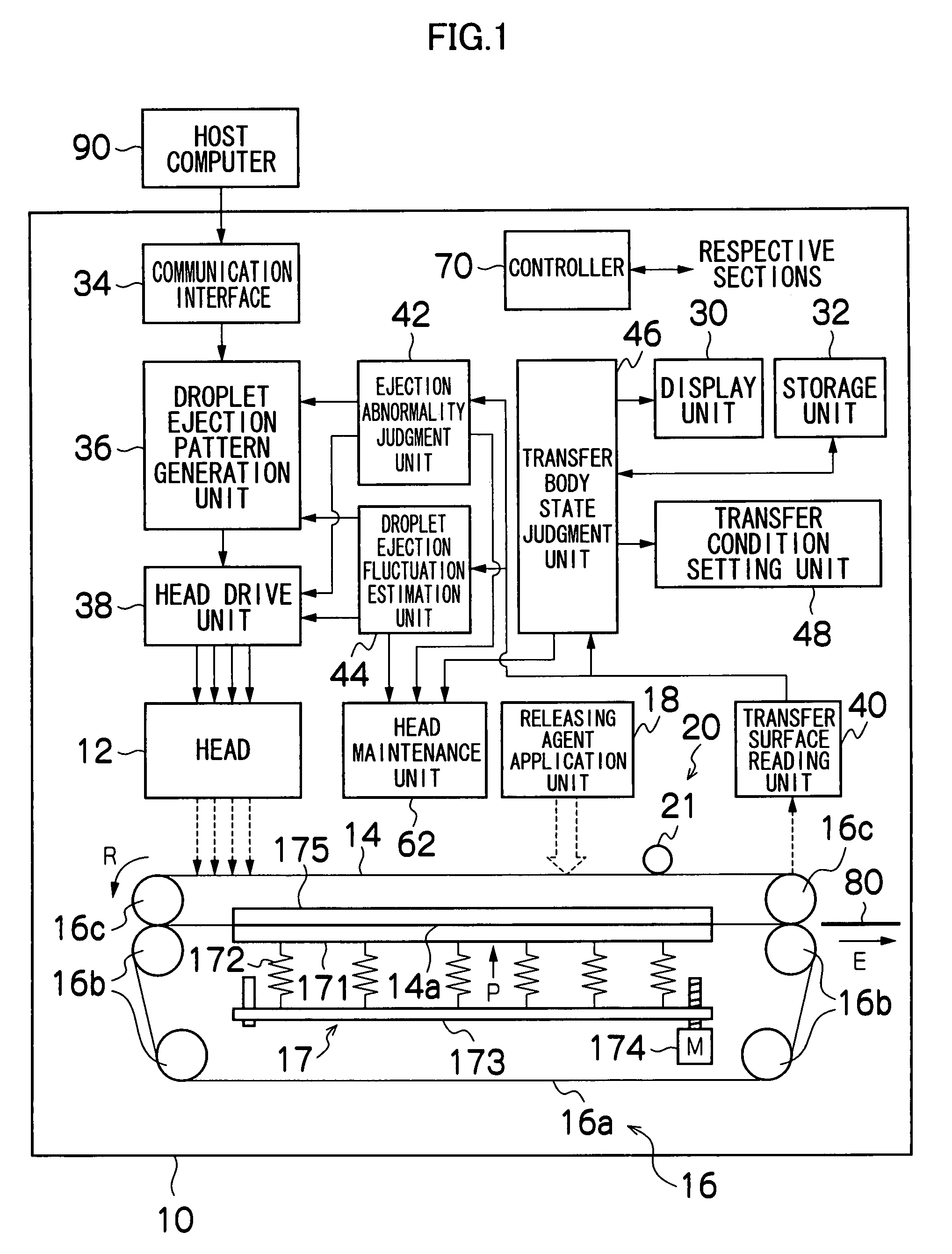

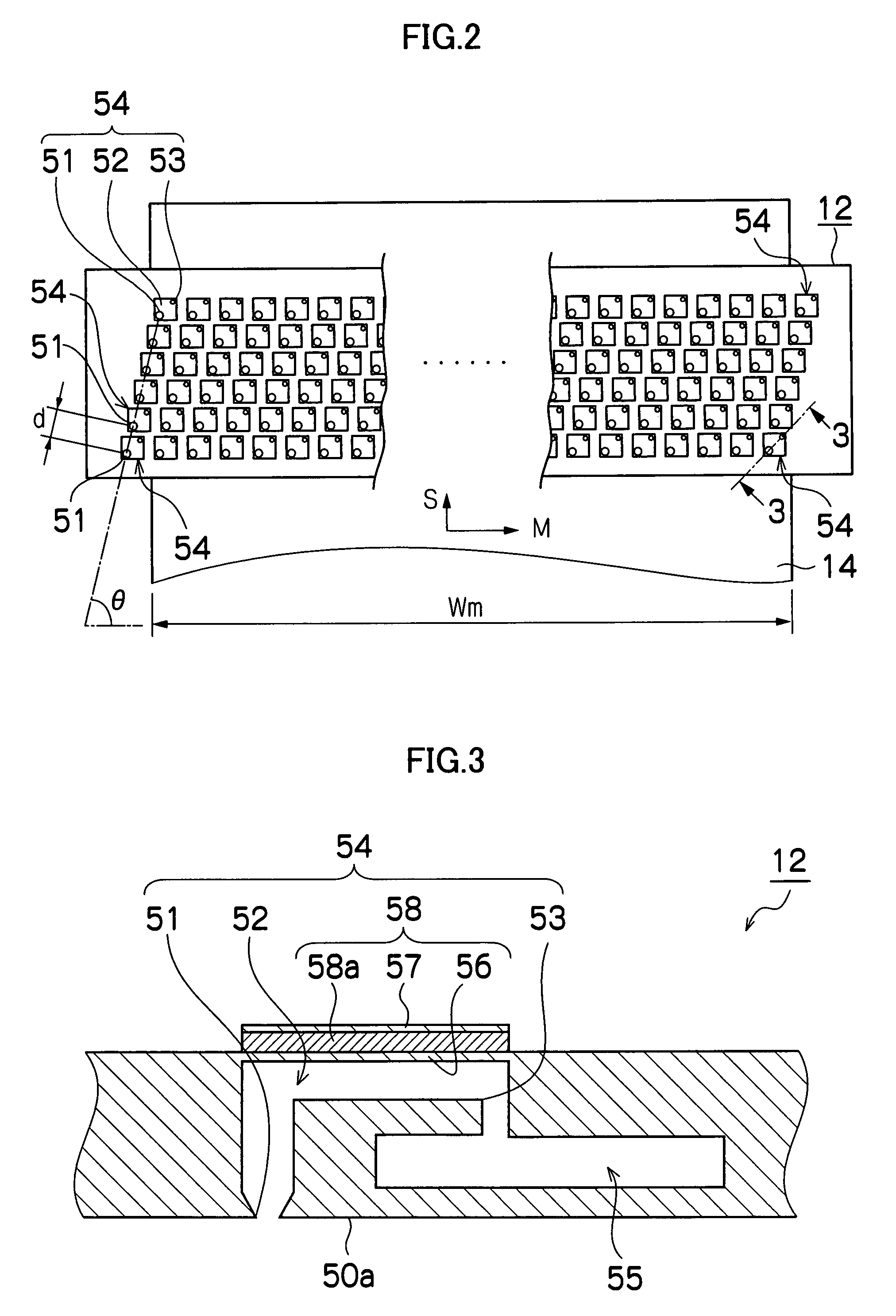

Inkjet recording method and apparatus

InactiveUS20080044587A1Reduce pile heightImprove transfer characteristicsRecording apparatusInk ribbonsPolymer scienceChemical compound

The inkjet recording method includes the steps of: applying a liquid on an intermediate transfer body, the liquid containing an energy-beam polymerizable compound and a coloring material, the energy-beam polymerizable compound being constituted of a monofunctional polymerizable compound of which percentage in the energy-beam polymerizable compound is not less than 99 wt % and not more than 100 wt %; radiating an energy beam on the liquid that has been applied on the intermediate transfer body, to produce a polymer of the liquid; and transferring the polymer on the intermediate transfer body to a recording medium by pressurizing and heating the polymer to a temperature not lower than a softening temperature of the polymer.

Owner:FUJIFILM CORP

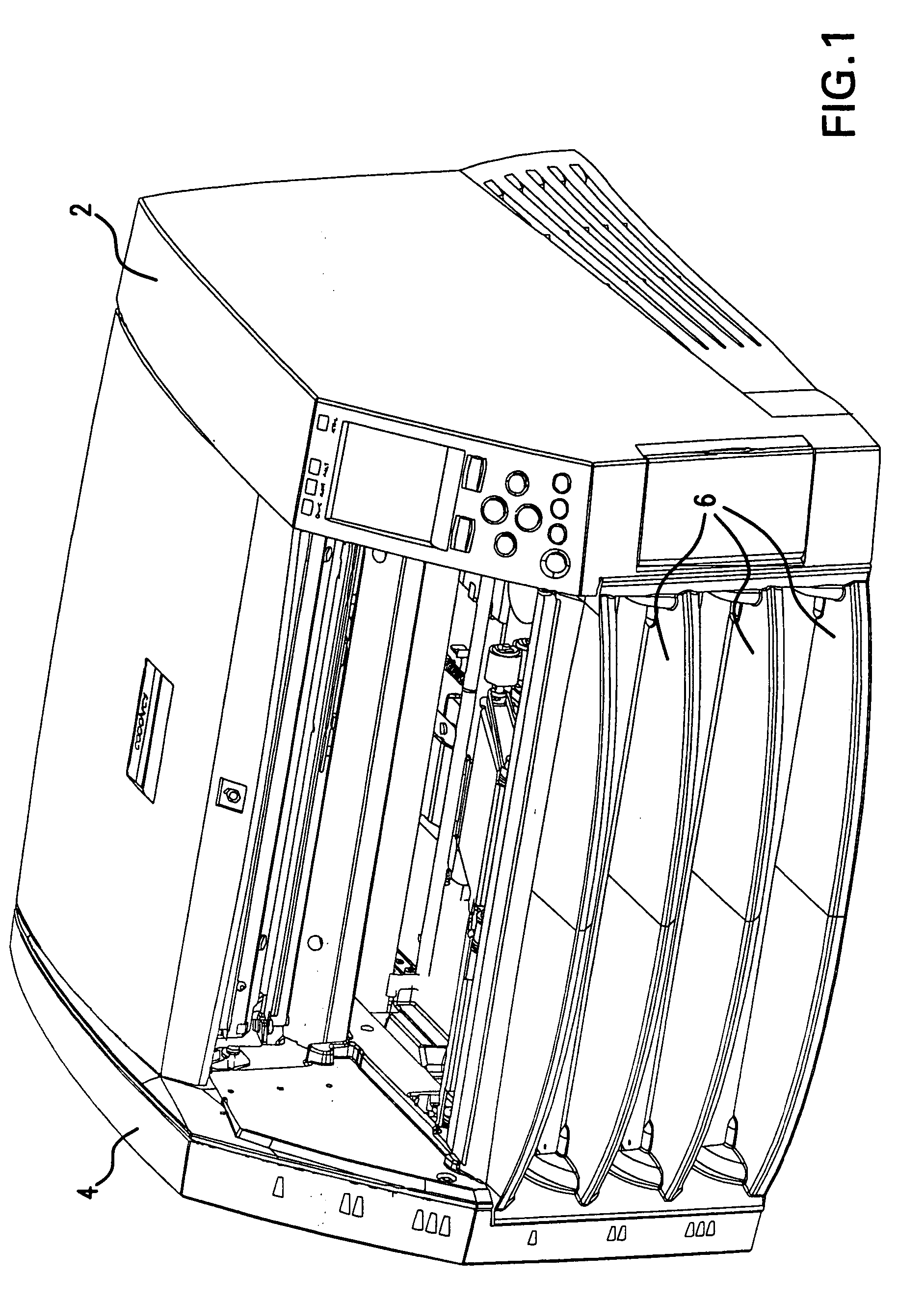

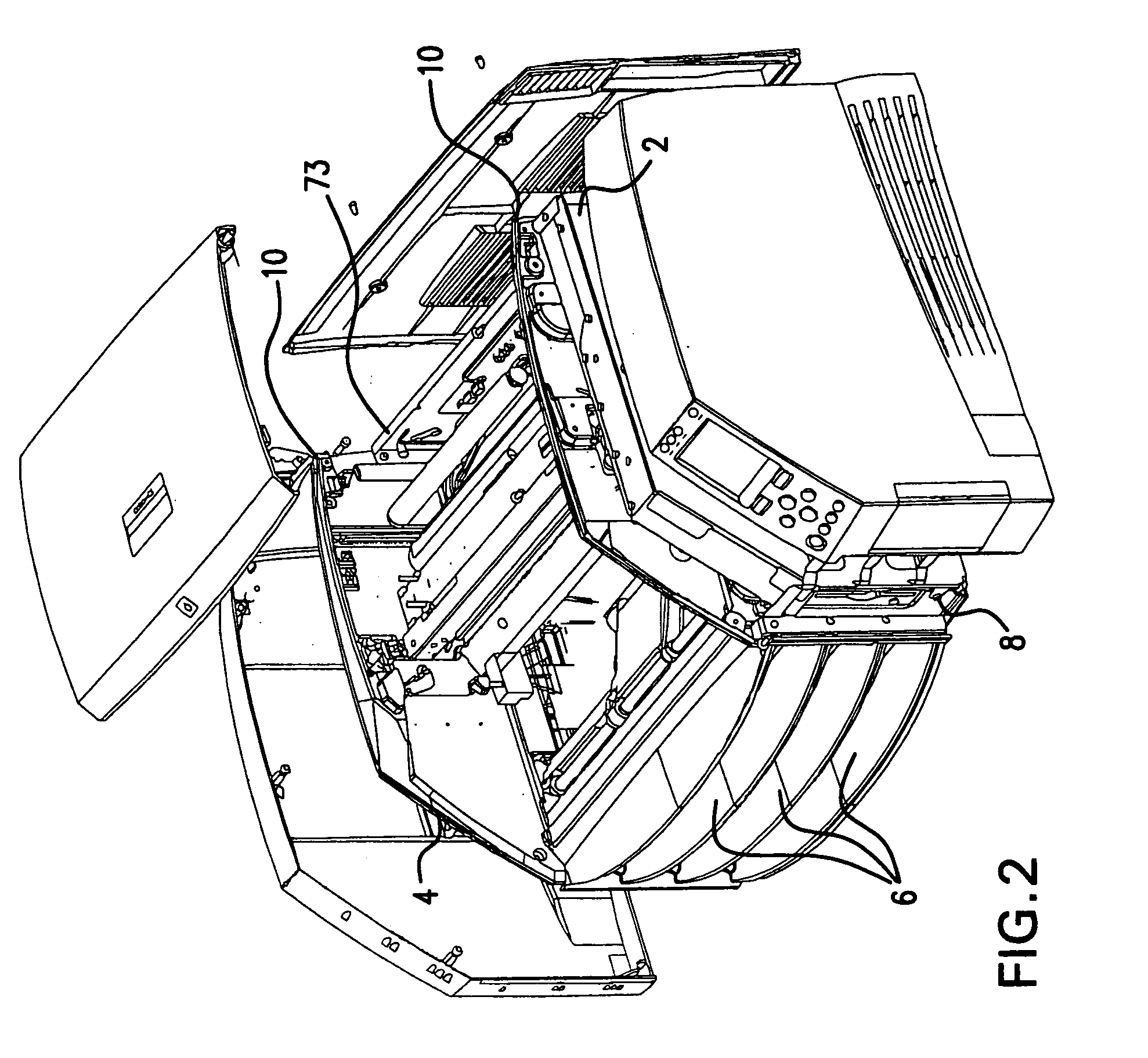

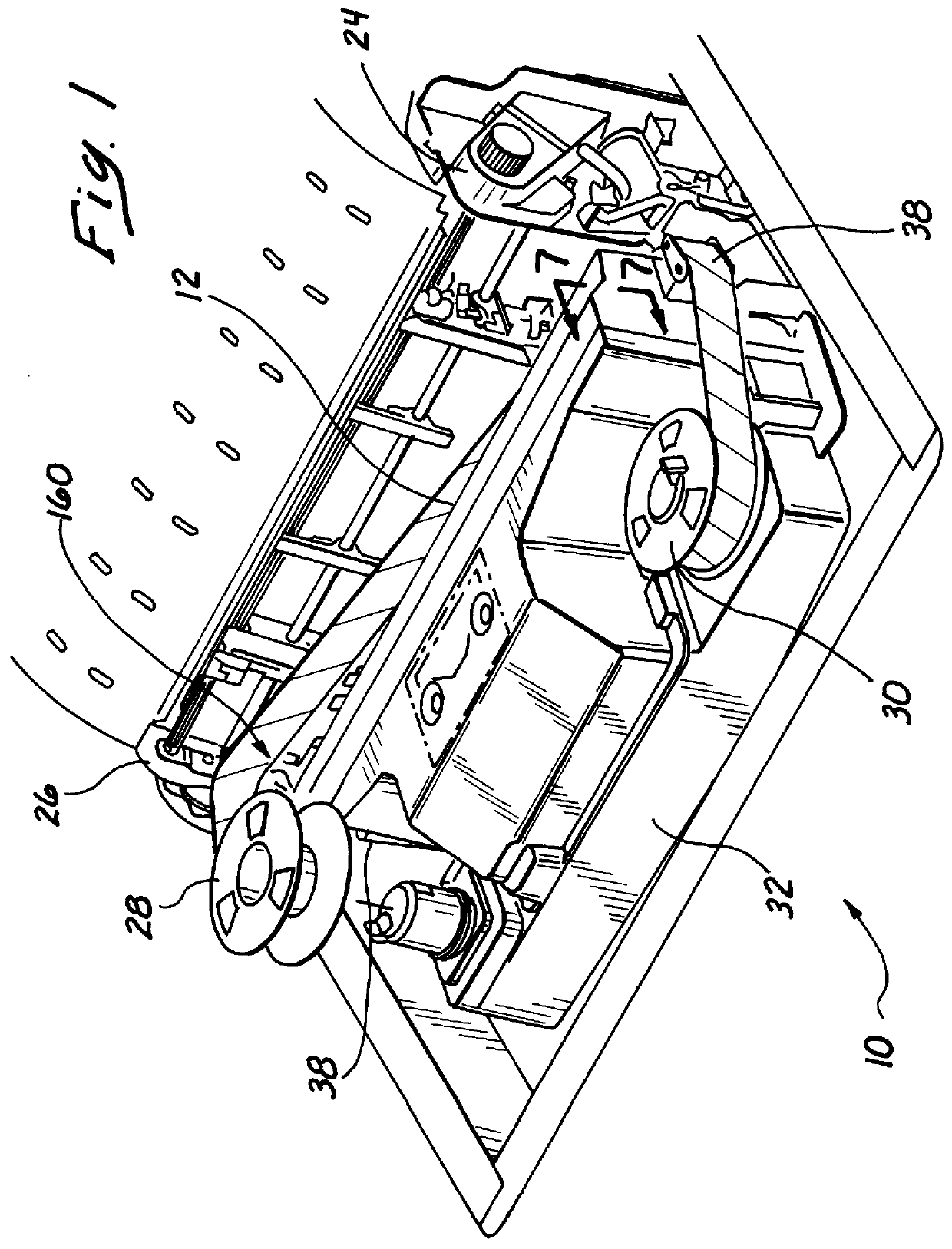

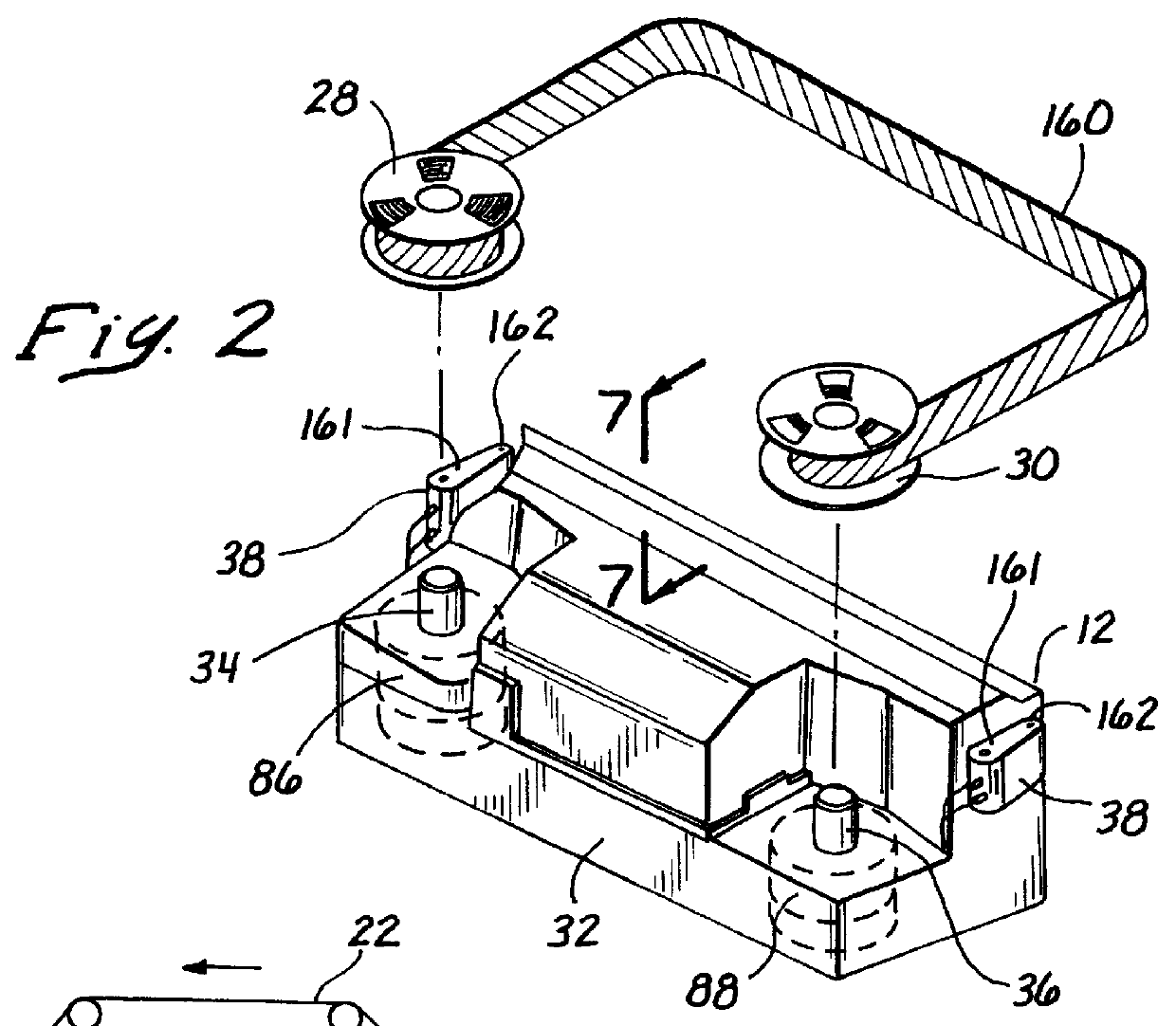

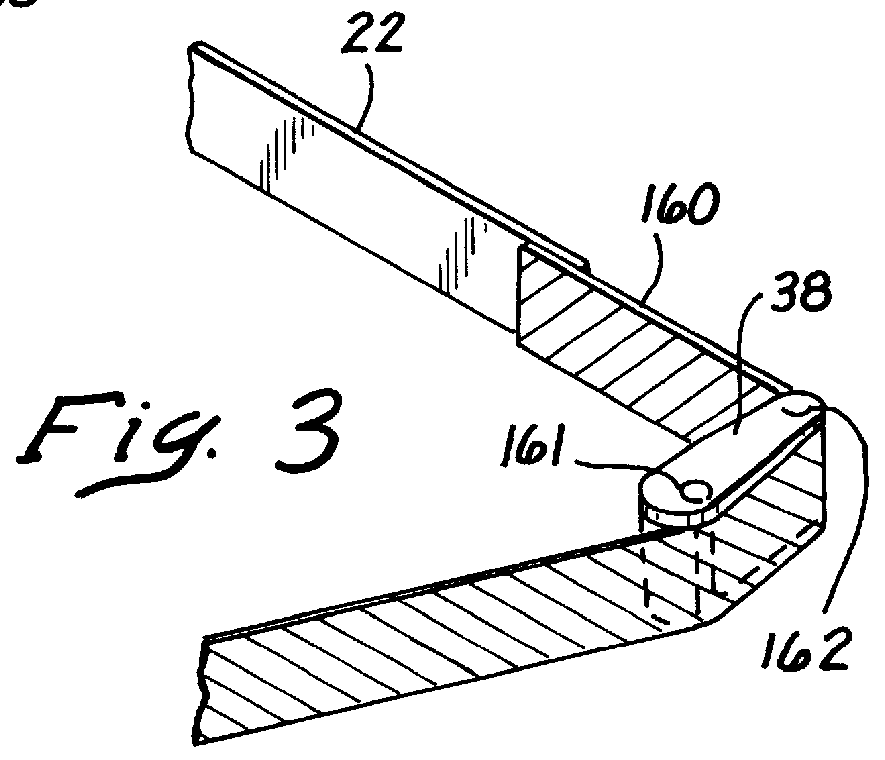

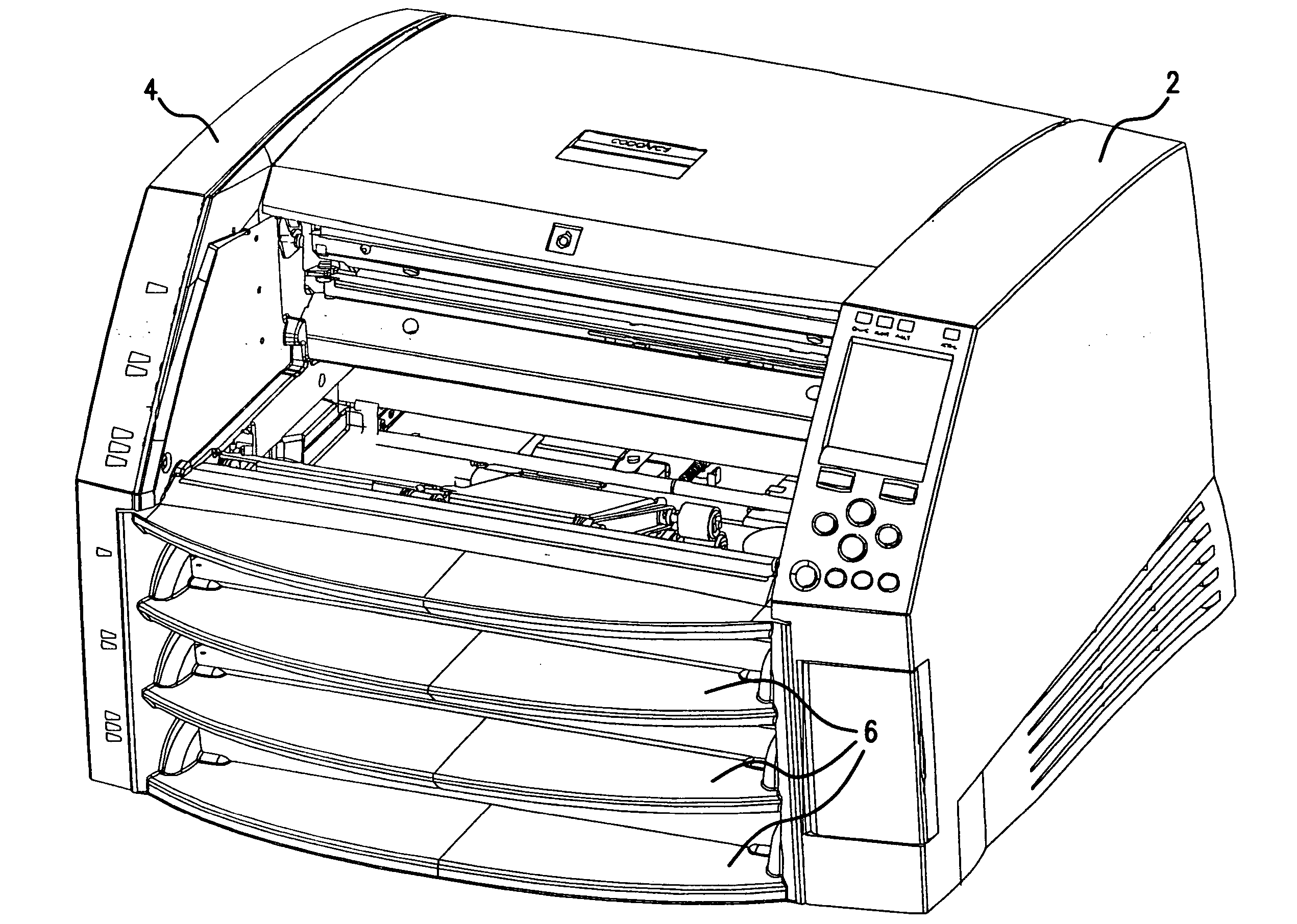

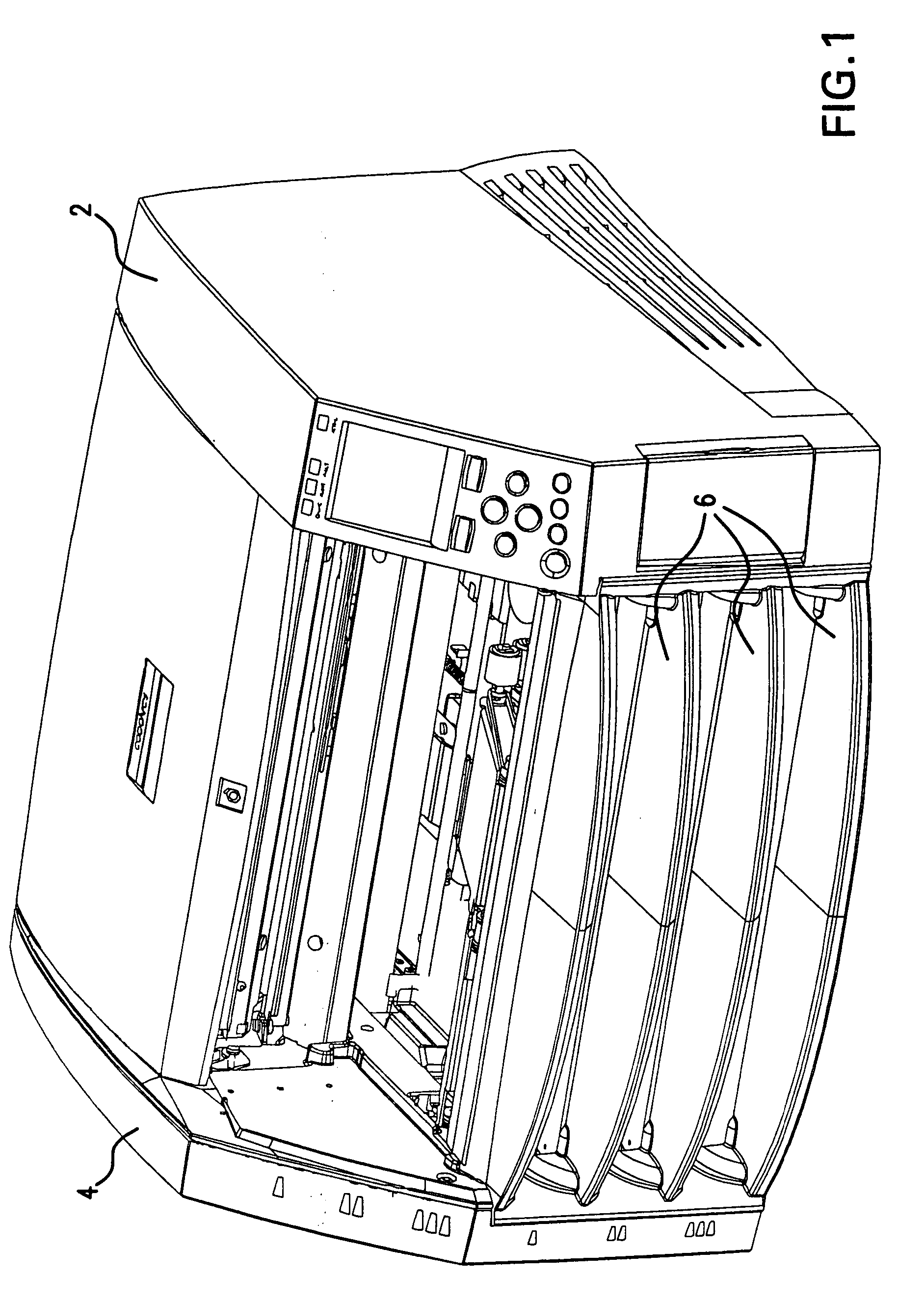

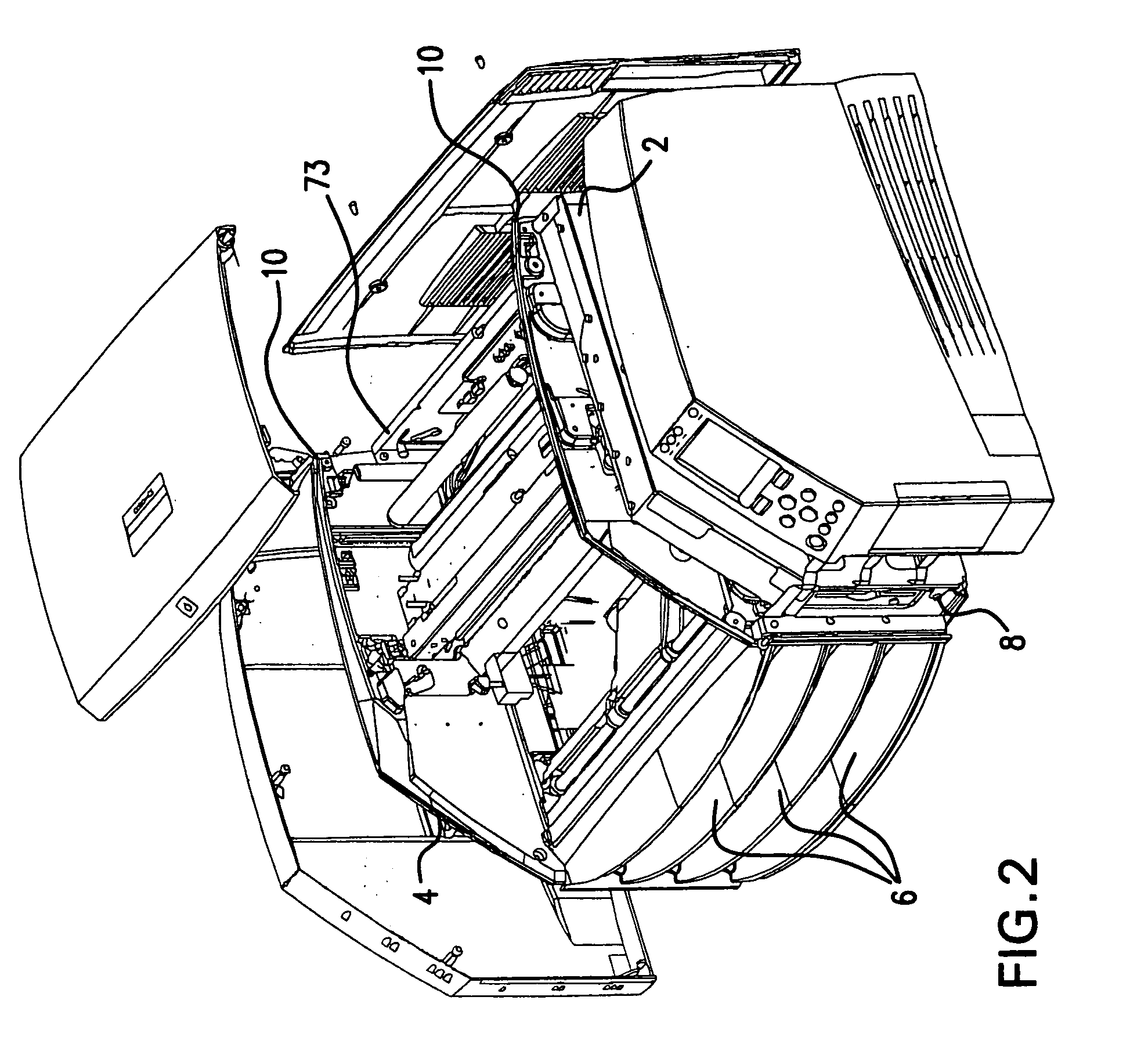

Multi-media printer including paper path sensors

A printer capable of transferring images to different types of media is disclosed. Media sheets of different sizes and types may be dispensed through a single input path to a print station including a printhead and a platen. The printhead is adapted for transferring images to media using either a direct thermal or dye diffusion process. A capstan roller, platen roller, picker assemblies and kicker assemblies are driven by a single motor, allowing for substantial cost and space savings. Other features are directed to improving the quality of images using the direct thermal and dye diffusion processes.

Owner:CODONICS

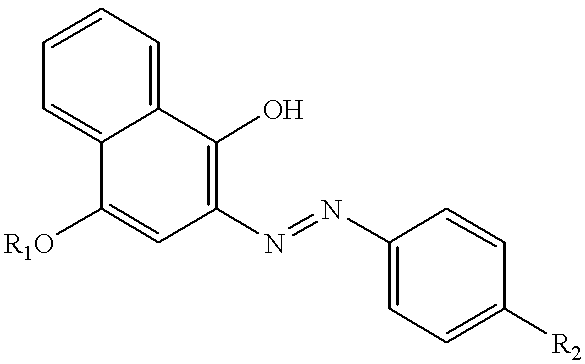

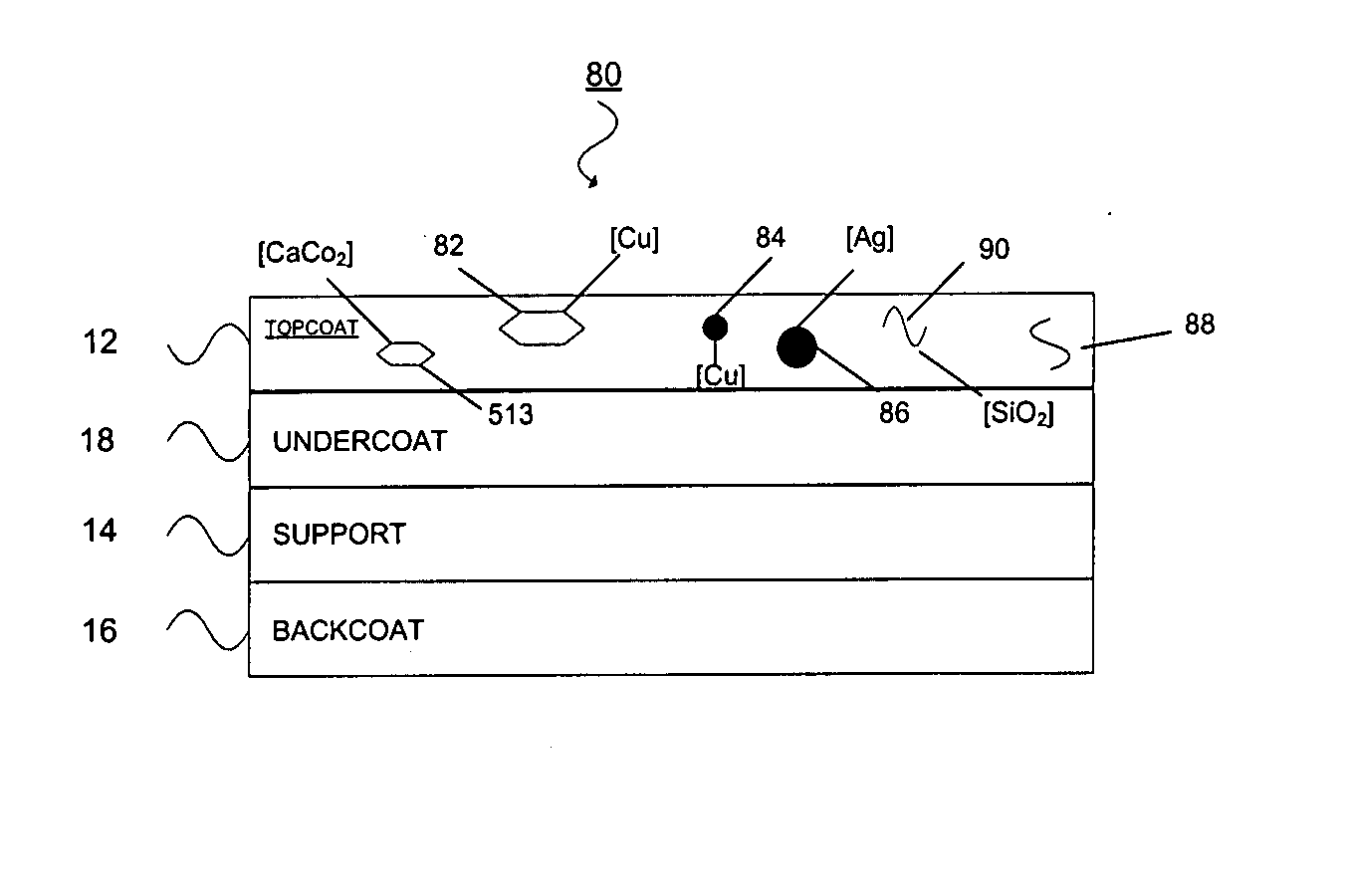

Thermal transfer ribbon

A thermal transfer printing medium that contains a thermal transfer layer which contains a first taggant and colorant, wherein: the first taggant comprises a fluorescent compound with an excitation wavelength selected from the group consisting of wavelengths of less than 400 nanometers, wavelengths of greater than 700 nanometers. When the thermal transfer layer is printed onto a white polyester substrate with a gloss of at least about 84, a surface smoothness Rz value of 1.2, and a reflective color represented by a chromaticity (a) of 1.91 and (b) of −6.79 and a lightness (L) of 95.63, when expressed by the CIE Lab color coordinate system, and when such printing utilizes a printing speed of 2.5 centimeters per second and a printing energy of 3.2 joules per square centimeter, a printed substrate with certain properties is produced. The printed substrate has a reflective color represented by a chromaticity (a) of from −15 to 15 and (b) from −18 to 18, and the printed substrate has a lightness (L) of less than about 35, when expressed by the CIE Lab color coordinate system. When the printed substrate is illuminated with light source that excites the first taggant with an excitation wavelength selected from the group consisting of wavelengths of less than 400 nanometers, wavelengths greater than 700 nanometers, the printed substrate produces a light fluorescence with a wavelength of from about 300 to about 700 nanometers.

Owner:INT IMAGING MATERIALS

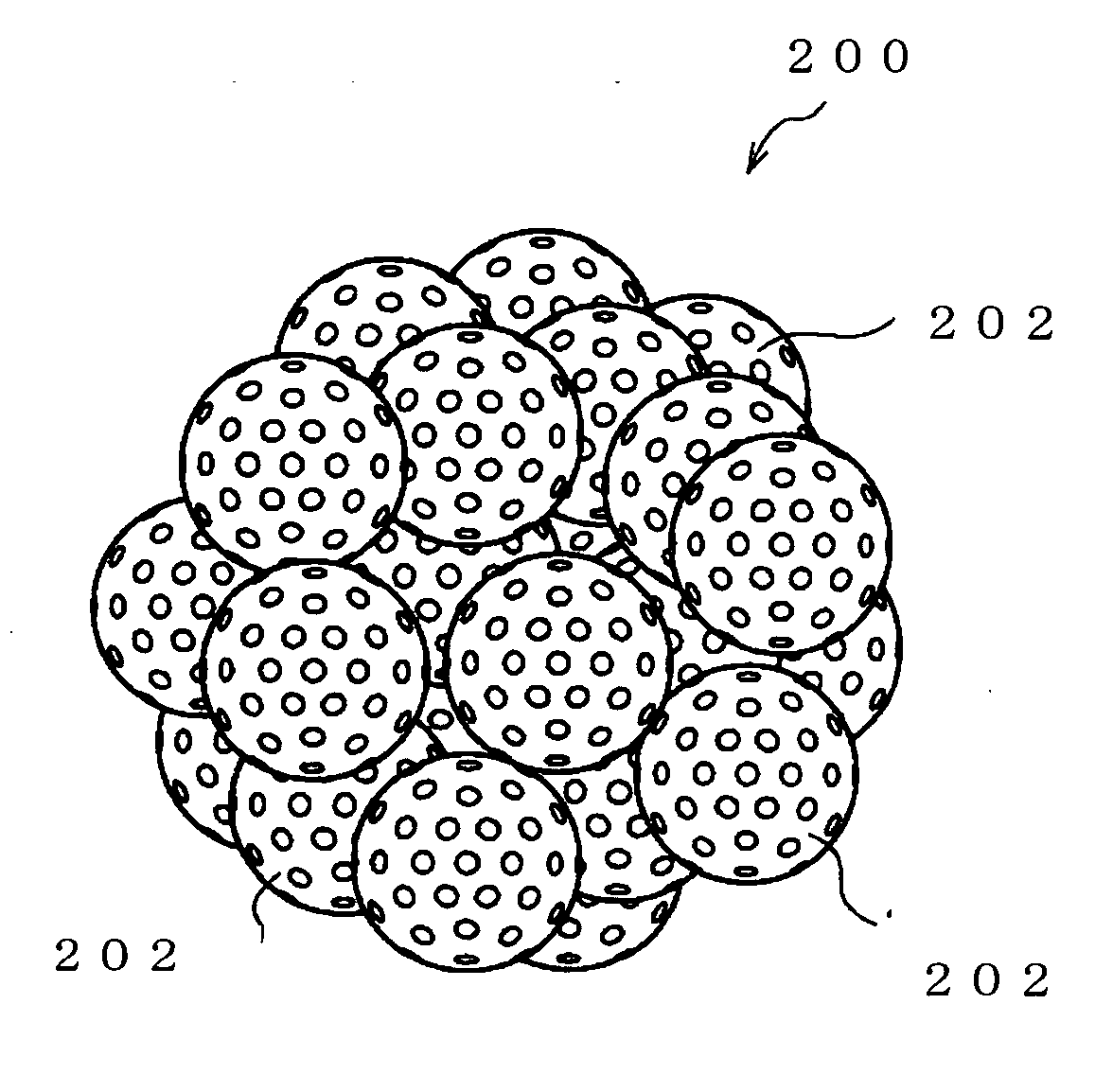

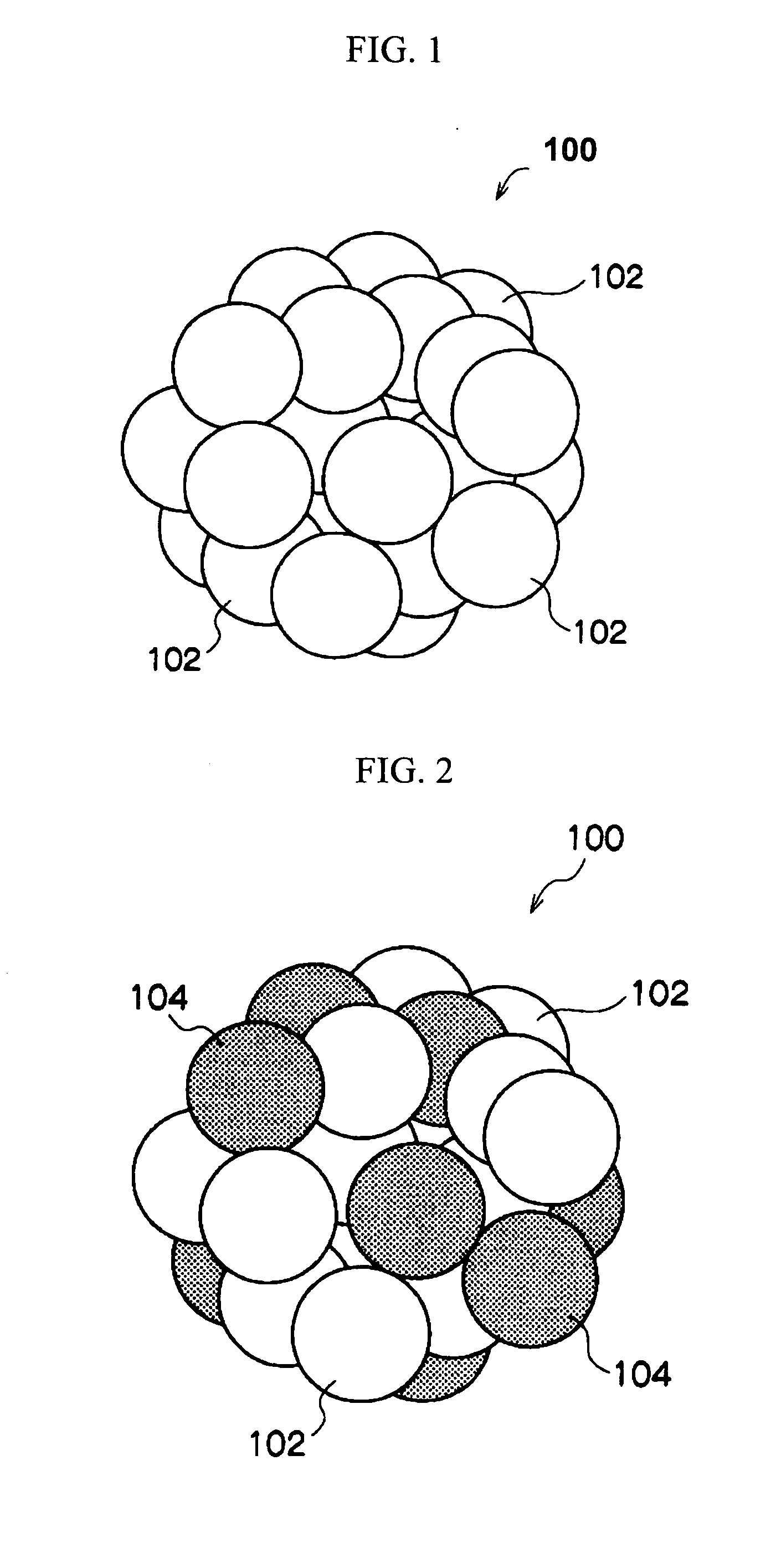

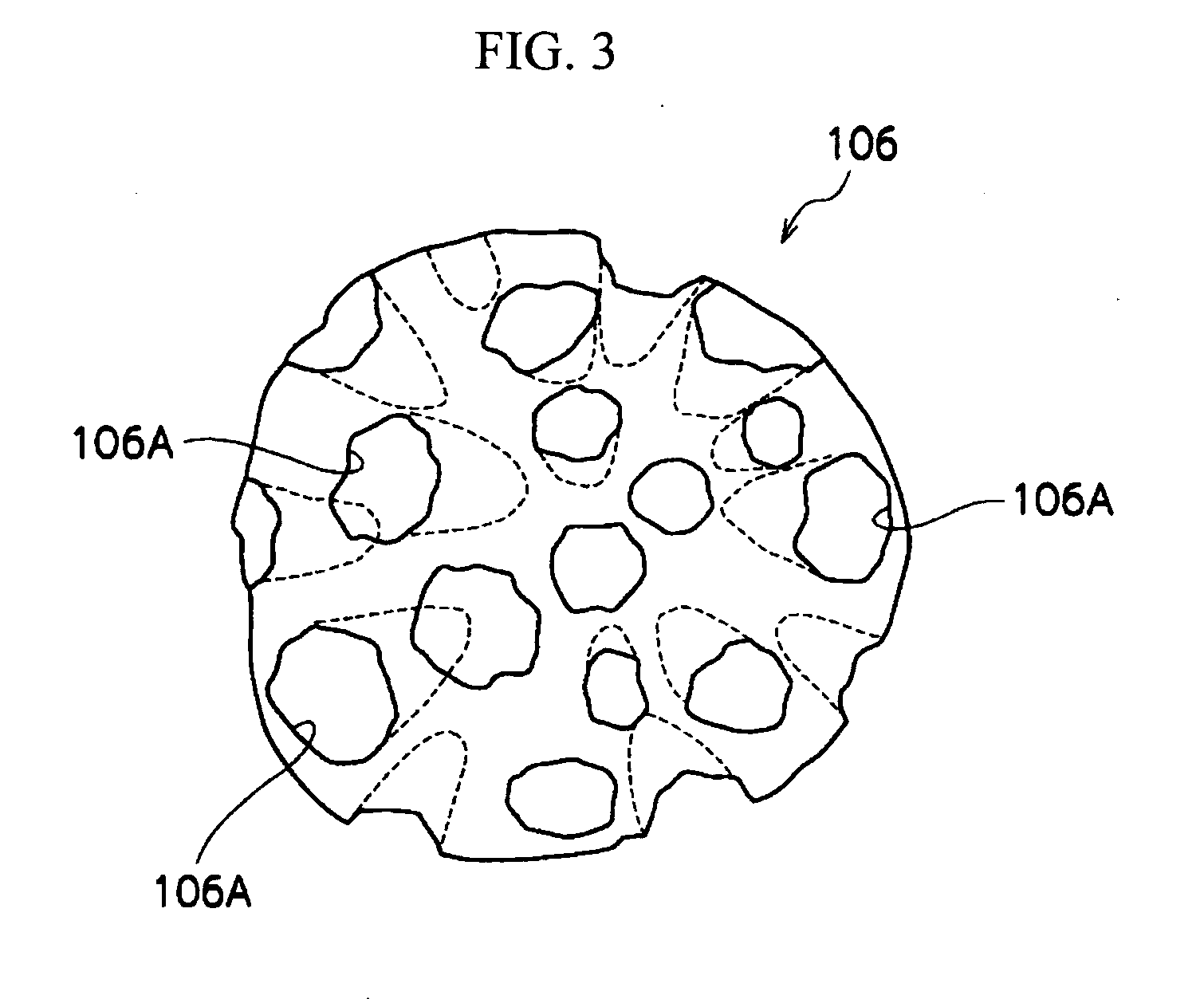

Ink receptive particles, marking materials system, ink receiving method, recording method, recording apparatus, and ink receptive particle storage cartridge

InactiveUS20060286315A1Improve image qualityIncrease speedRecording apparatusMaterial nanotechnologyEngineeringMaterial system

The present invention provides ink receptive particles, for receiving an ink containing a recording material, the ink receptive particles comprising trap structures for trapping at least a liquid component of the ink, and a liquid absorbing resin. Using the ink receptive particles, the invention also provides a marking materials system, an ink receiving method, a recording method, a recording apparatus, and an ink receptive particle storage cartridge.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Thermal transfer ribbon

A thermal transfer printing medium that contains a thermal transfer layer which contains a first taggant and colorant, wherein: the first taggant comprises a fluorescent compound with an excitation wavelength selected from the group consisting of wavelengths of less than 400 nanometers, wavelengths of greater than 700 nanometers. When the thermal transfer layer is printed onto a white polyester substrate with a gloss of at least about 84, a surface smoothness Rz value of 1.2, and a reflective color represented by a chromaticity (a) of 1.91 and (b) of −6.79 and a lightness (L) of 95.63, when expressed by the CIE Lab color coordinate system, and when such printing utilizes a printing speed of 2.5 centimeters per second and a printing energy of 3.2 joules per square centimeter, a printed substrate with certain properties is produced. The printed substrate has a reflective color represented by a chromaticity (a) of from −15 to 15 and (b) from −18 to 18, and the printed substrate has a lightness (L) of less than about 35, when expressed by the CIE Lab color coordinate system. When the printed substrate is illuminated with light source that excites the first taggant with an excitation wavelength selected from the group consisting of wavelengths of less than 400 nanometers, wavelengths greater than 700 nanometers, the printed substrate produces a light fluorescence with a wavelength of from about 300 to about 700 nanometers.

Owner:INT IMAGING MATERIALS

Image forming apparatus and method

InactiveUS7845788B2Image quality can be maintainedMaintain image qualityRecording apparatusInk ribbonsImage formationComputer science

Owner:FUJIFILM CORP

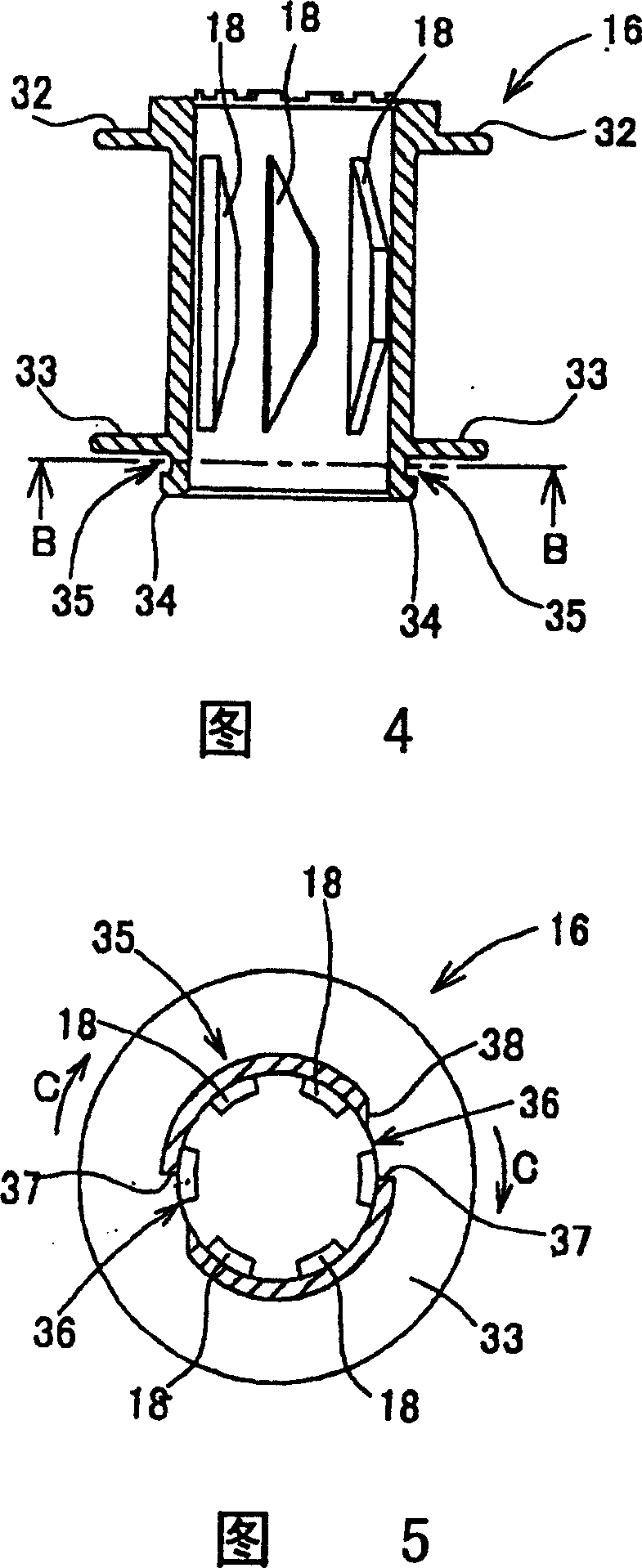

Robbon box with ribbon loose-proof mechanism

Owner:BROTHER KOGYO KK

Print ribbon feeder and detection system

A clean print ribbon feed system and method for a printer having a ribbon with two non-inked clean hands portions wound around a pair of spools is disclosed. Detection of the spool having greater angular velocity and lesser angular velocity determines the direction of feed. The spool having greater angular velocity winds and takes up the print ribbon. The non-inked portion can be formed as a conductive plastic and is initially wound on each spool. Detection of the non-inked portion of the ribbon takes place by two electrical contactors. The determination of the angular velocity of the spools determines the amount of print ribbon on one of the spools so that the spool having the lesser ribbon can be driven as a take-up spool to provide proper directional drive for winding the clean hands portion and the inked portion which follows.

Owner:PRINTRONIX LLC

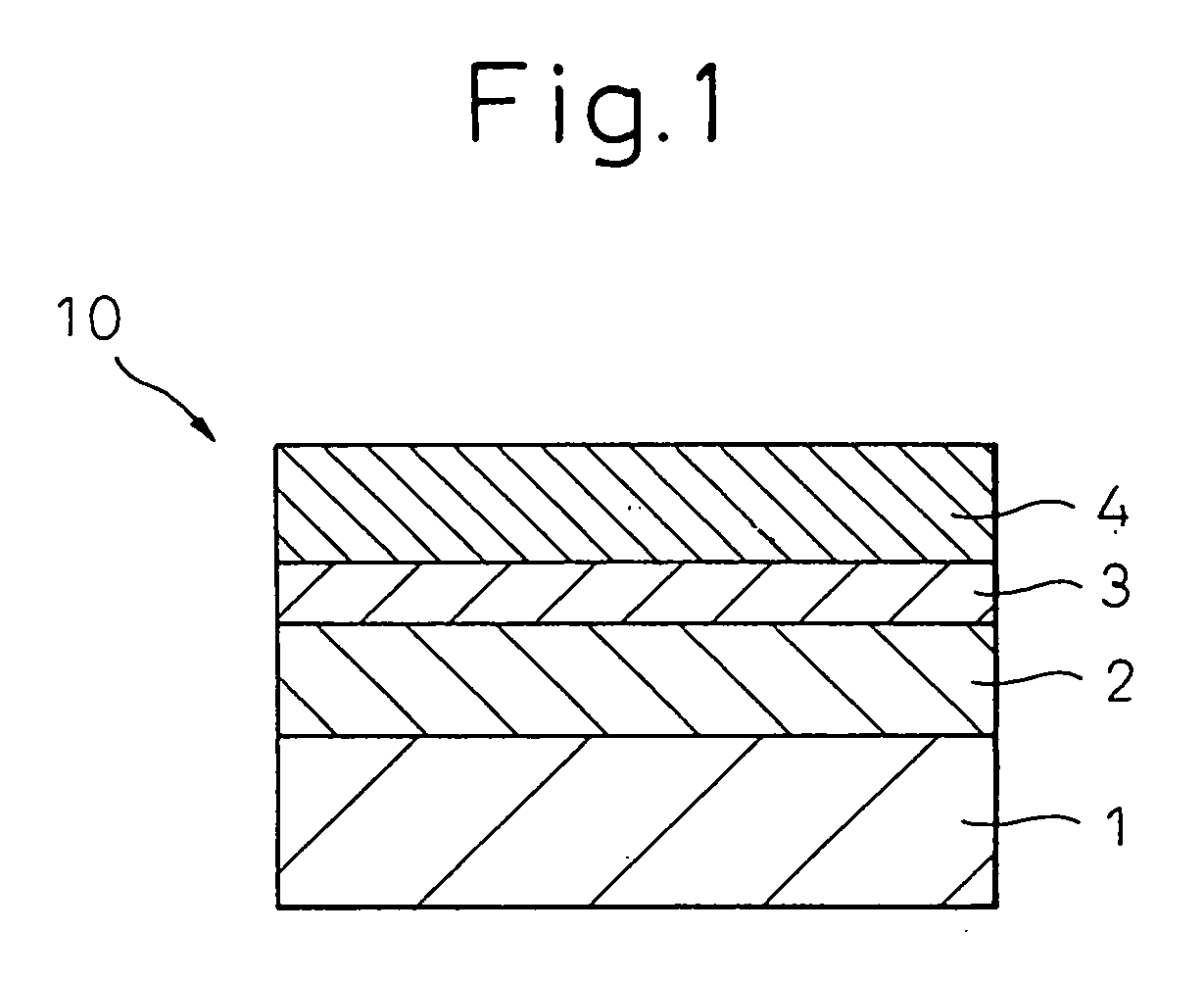

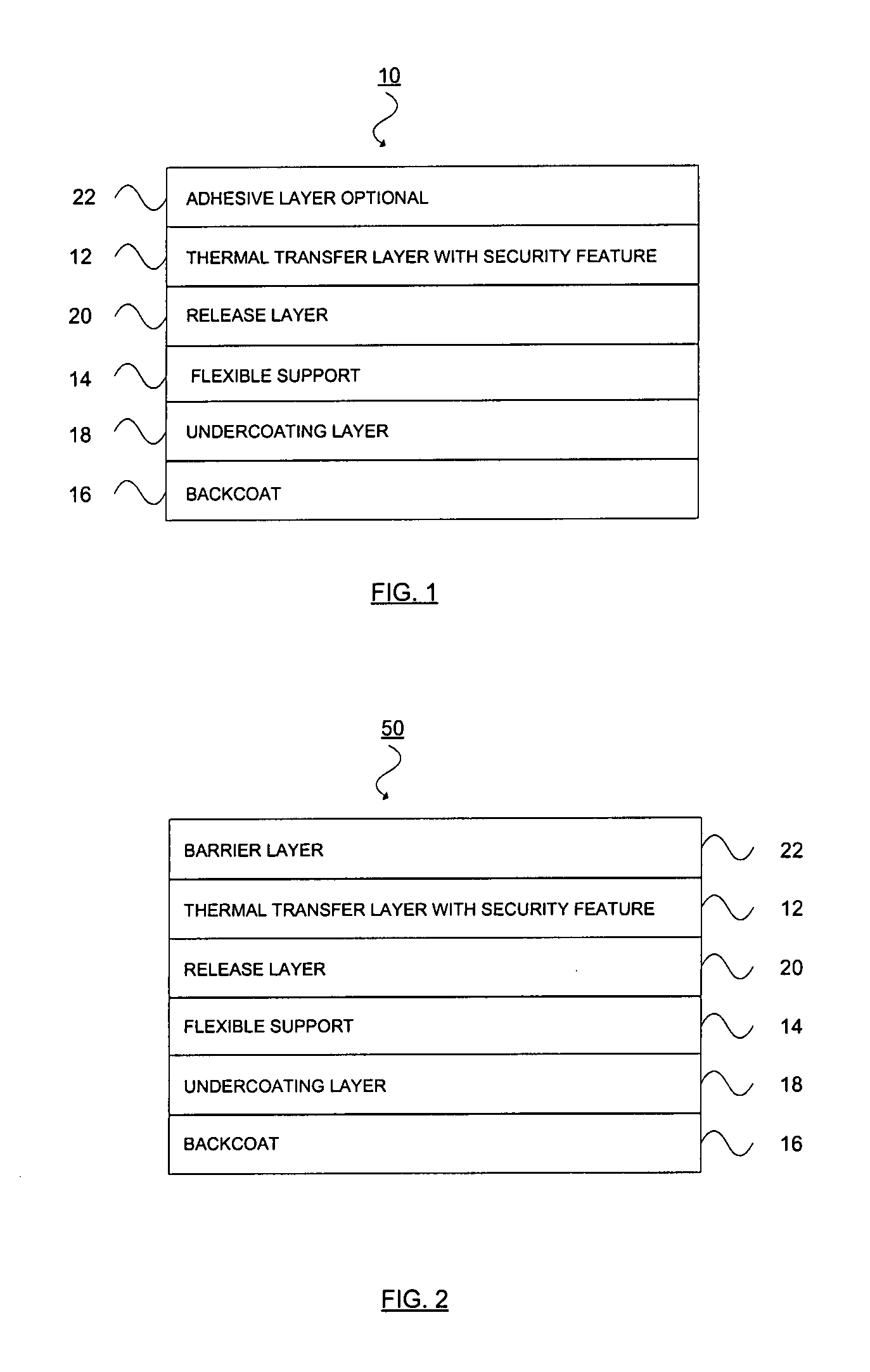

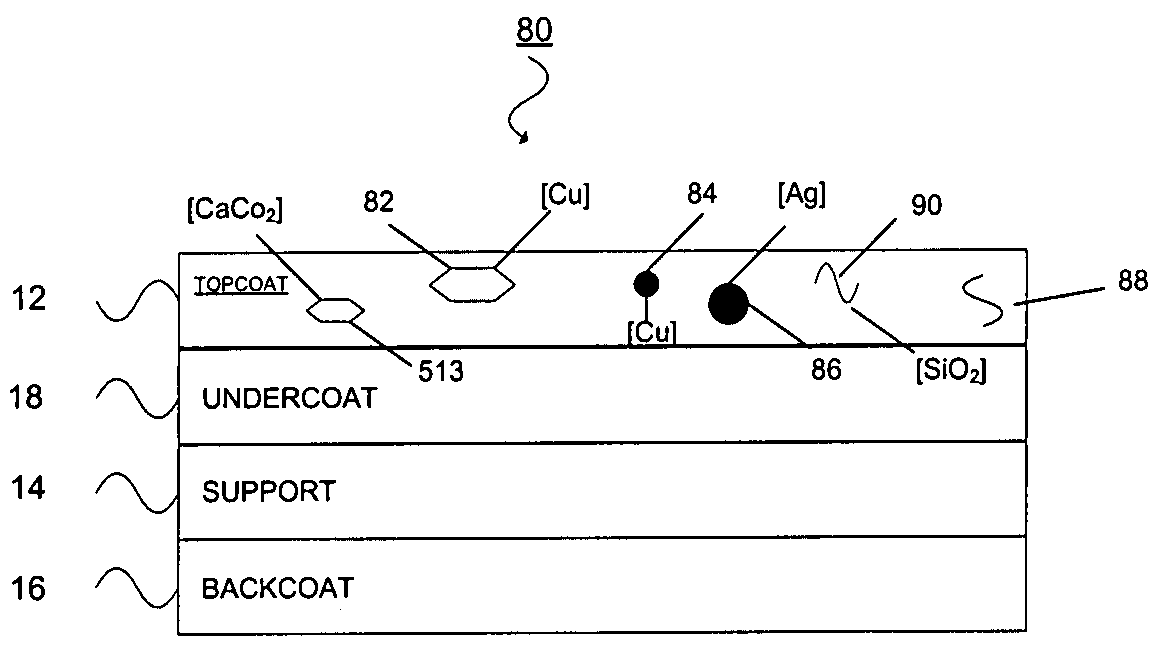

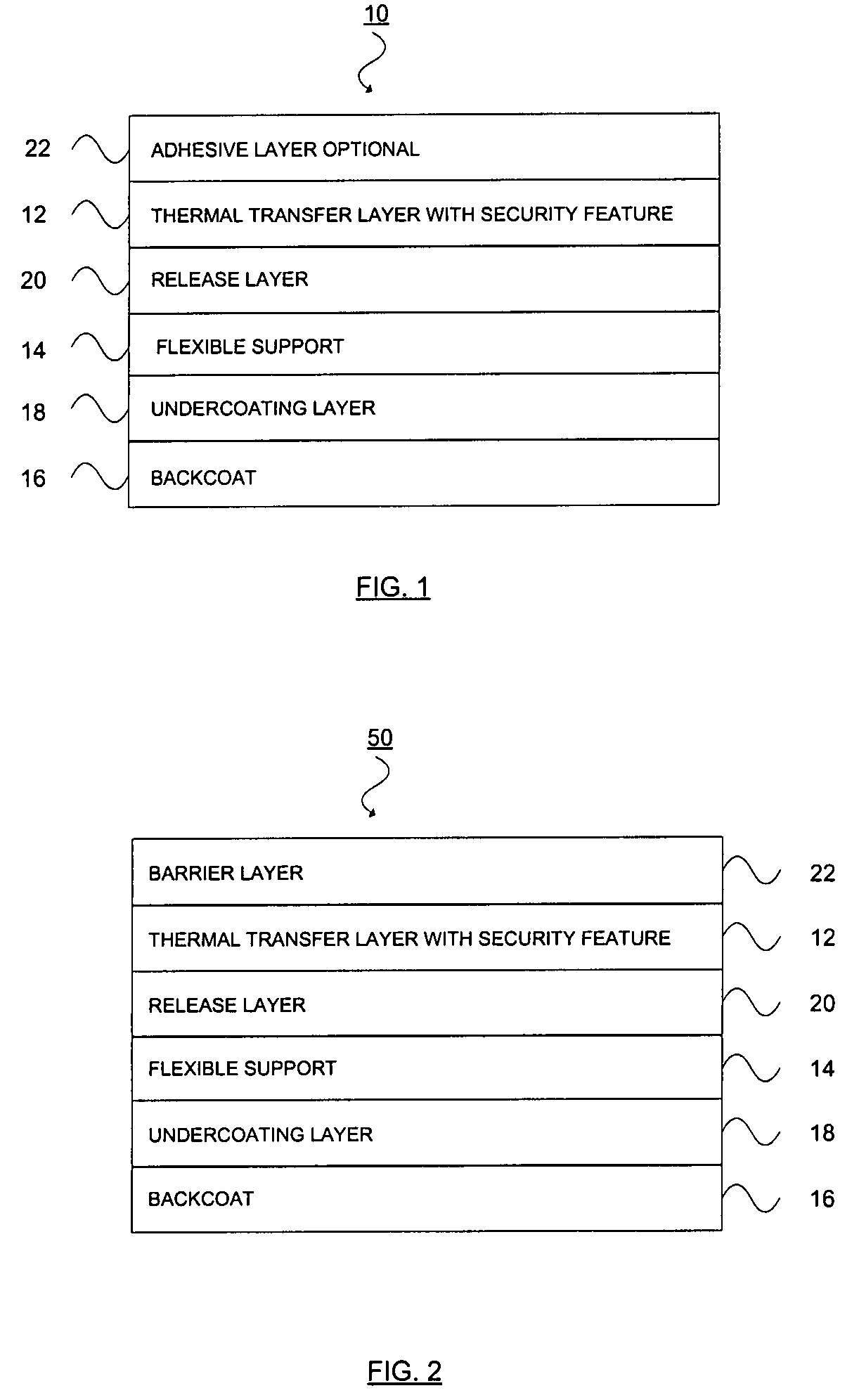

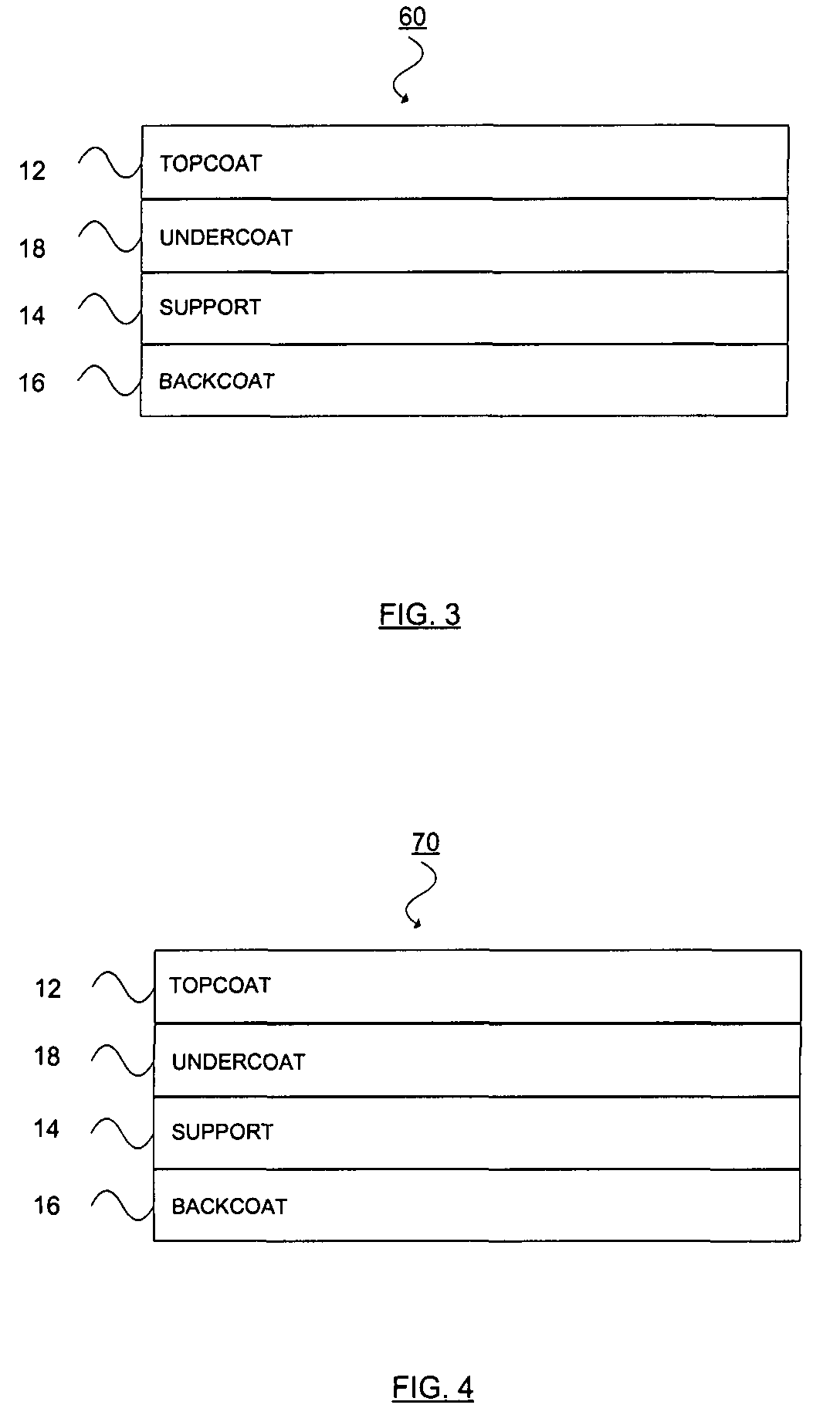

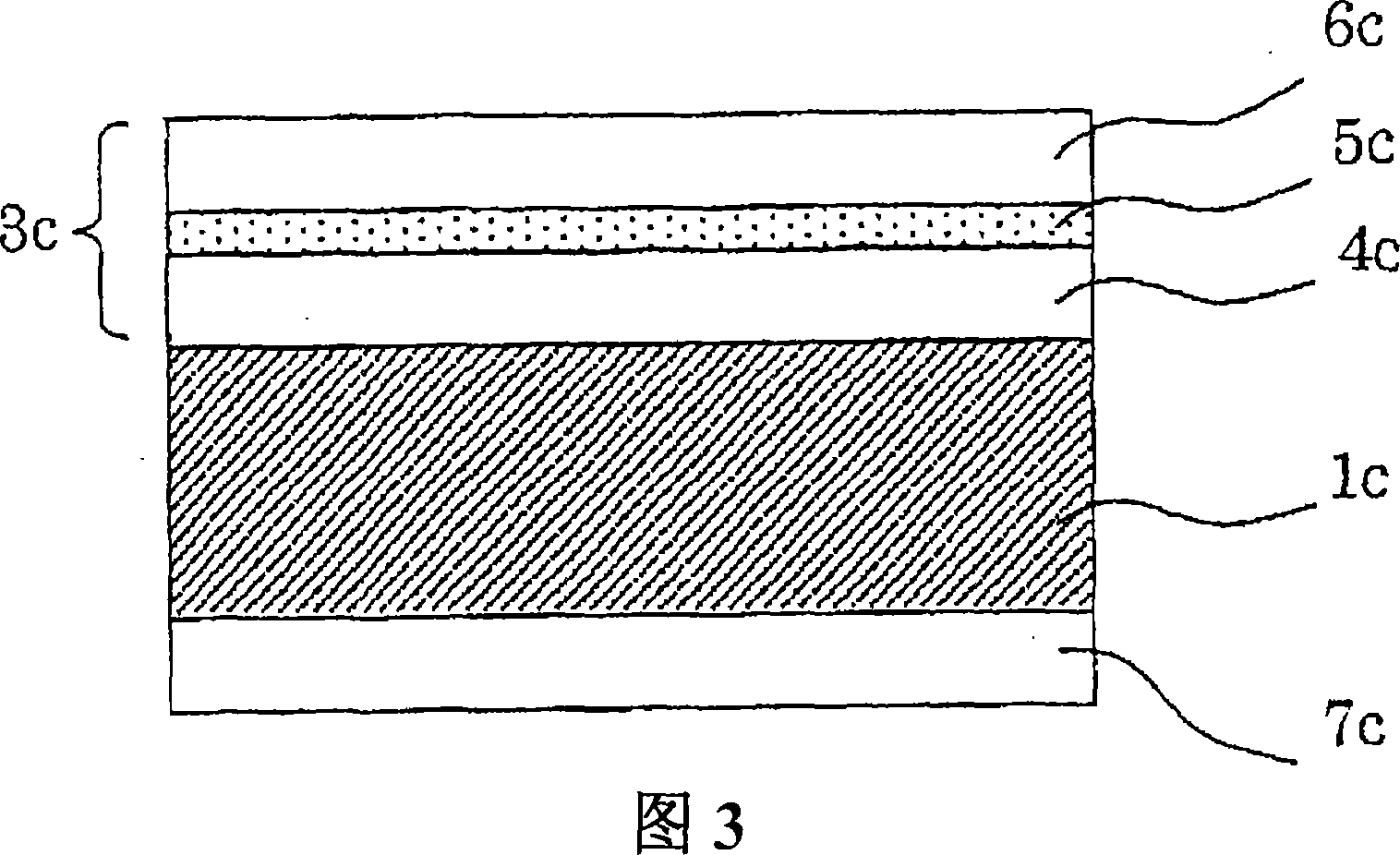

Thermal transfer sheet and protective layer transfer sheet

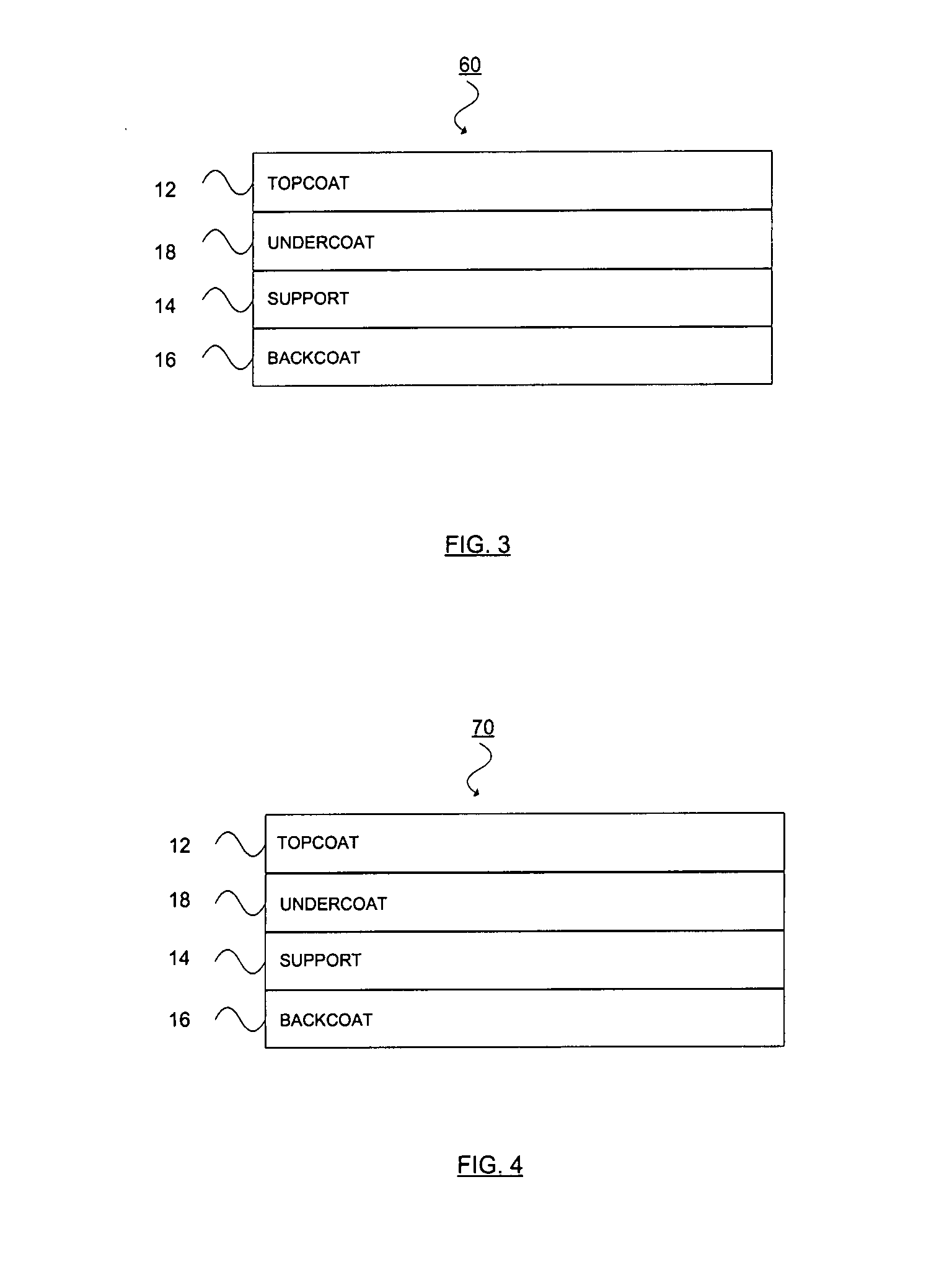

ActiveCN101048290AGood transferabilityImprove antistatic performanceInk ribbonsThermographyHigh densityPlasticizer

The invention provides a thermal transfer sheet and a protective layer transfer sheet. It is intended to provide a sheet of excellent transfer performance, in particular, a thermal transfer sheet that excels in transfer sensitivity and adhesion between base material and dye layer and that can be used in high-speed photographic printing with high transfer sensitivity, being capable of providing a photographic print of high density and high clearness, and a protective layer transfer sheet that excels in transfer performance, being markedly low in the generation of static electricity at the time of transfer. Further, it is intended to provide a photographic print that excels in antistatic performance, plasticizer resistance and transparency. There is provided a sheet with a base material, in particular, a thermal transfer sheet (I) comprising a laminate of, sequentially arranged, a base material, an underlayer and a dye layer, or a protective layer transfer sheet (II) comprising a base material and, detachably superimposed on at least part of the surface thereof, a protection transfer laminate including a conductive layer, characterized in that the underlayer and conductive layer are each one produced using colloidal inorganic pigment ultrafine particles.

Owner:DAI NIPPON PRINTING CO LTD

Method of producing printed circuit board with embedded resistor

InactiveUS20050175385A1Improve workabilityResistance value change remains constantSemiconductor/solid-state device detailsSolid-state devicesProduction rateScreen printing

Disclosed is a method of producing a printed circuit board (PCB) with an embedded resistor, in which a resistor with a desired shape and volume is precisely formed using a resistor paste so that resistance values according to a position of the PCB are uniform, thereby a laser trimming process is omitted or minimally utilized. The method has advantages in that a production time of the PCB is shortened and productivity is improved because an operation condition is rapidly set without being greatly affected by the position precision of a printing device. Other advantages of the method are that the resistor paste with a relatively uniform thickness is secured through a screen printing process, thereby easily forming the resistor and improving resistance tolerance.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

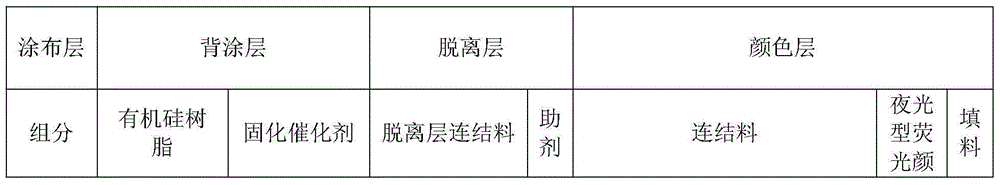

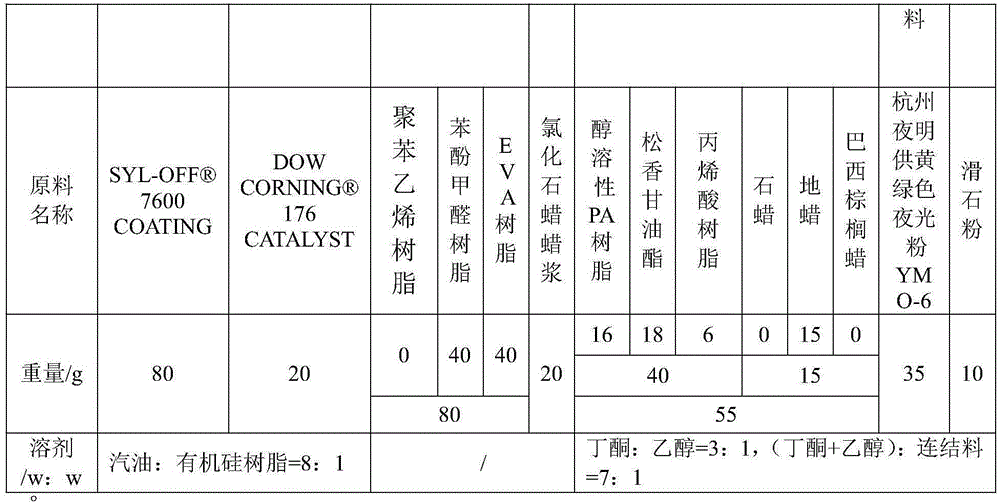

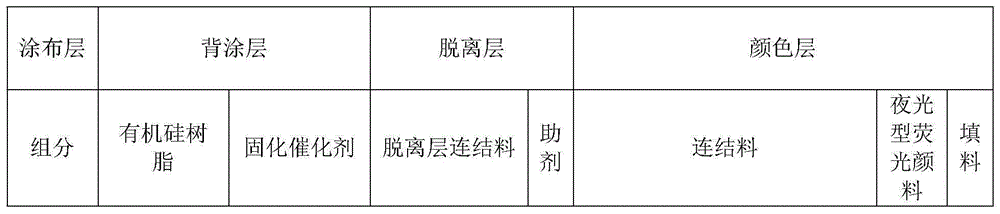

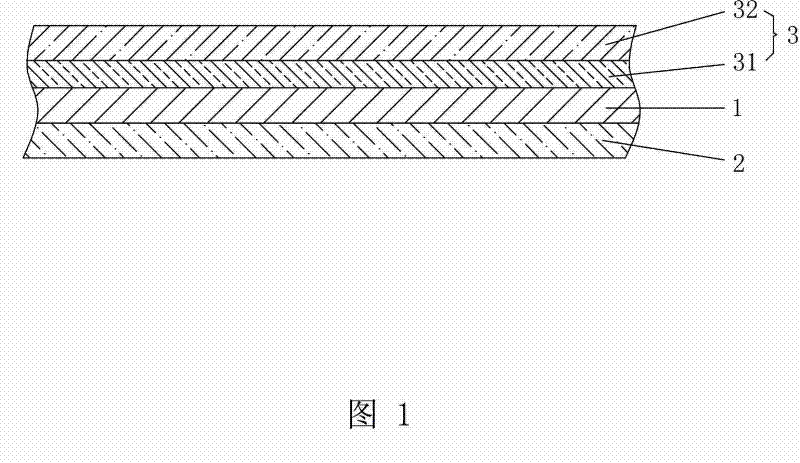

Thermal transfer ribbon with night luminous function and preparation method thereof

InactiveCN105058999AWith night light functionEasy to manufactureInk ribbonsLamination ancillary operationsWaxFluorescence

The invention relates to a thermal transfer ribbon with night luminous function and a preparation method thereof. The thermal transfer ribbon is formed by a ribbon base, a back coating and a thermal transfer printing layer, wherein the back coating and the thermal transfer printing layer are respectively coated on two sides of the ribbon base. The thermal transfer printing layer is formed by a separation layer and a color layer. A separation layer and a color layer are successively arranged from inside to outside on the surface of one side of the ribbon base. The color layer comprises, by weight, 40-60% of connection materials, 30-40% of night type fluorescence pigment and the balance fillers. The connection materials comprise following components: 20-40 parts by mass of resin and 10-35 parts by mass of wax. The thickness of the ribbon base is 4-5[mu]m. The thickness of the back coating is 0.1-0.5[mu]m. The thickness of the color layer is 8-15[mu]m. The thickness of the separation layer is 4-10[mu]m. In this way, scrolls can be simply and highly effectively made. The night type fluorescence pigment is used in the color layer, so the ribbon is highly adaptable especially at night, has strong tinctorial strength and is easier to use and personalized demands on scrolls are met.

Owner:ZHUOLI IMAGING TECH

Multi-media printer including paper path sensors

InactiveUS20050151823A1Cost-effective mannerEliminate needRecording apparatusInk ribbonsComputer printingEngineering

A printer capable of transferring images to different types of media is disclosed. Media sheets of different sizes and types may be dispensed through a single input path to a print station including a printhead and a platen. The printhead is adapted for transferring images to media using either a direct thermal or dye diffusion process. A capstan roller, platen roller, picker assemblies and kicker assemblies are driven by a single motor, allowing for substantial cost and space savings. Other features are directed to improving the quality of images using the direct thermal and dye diffusion processes.

Owner:CODONICS

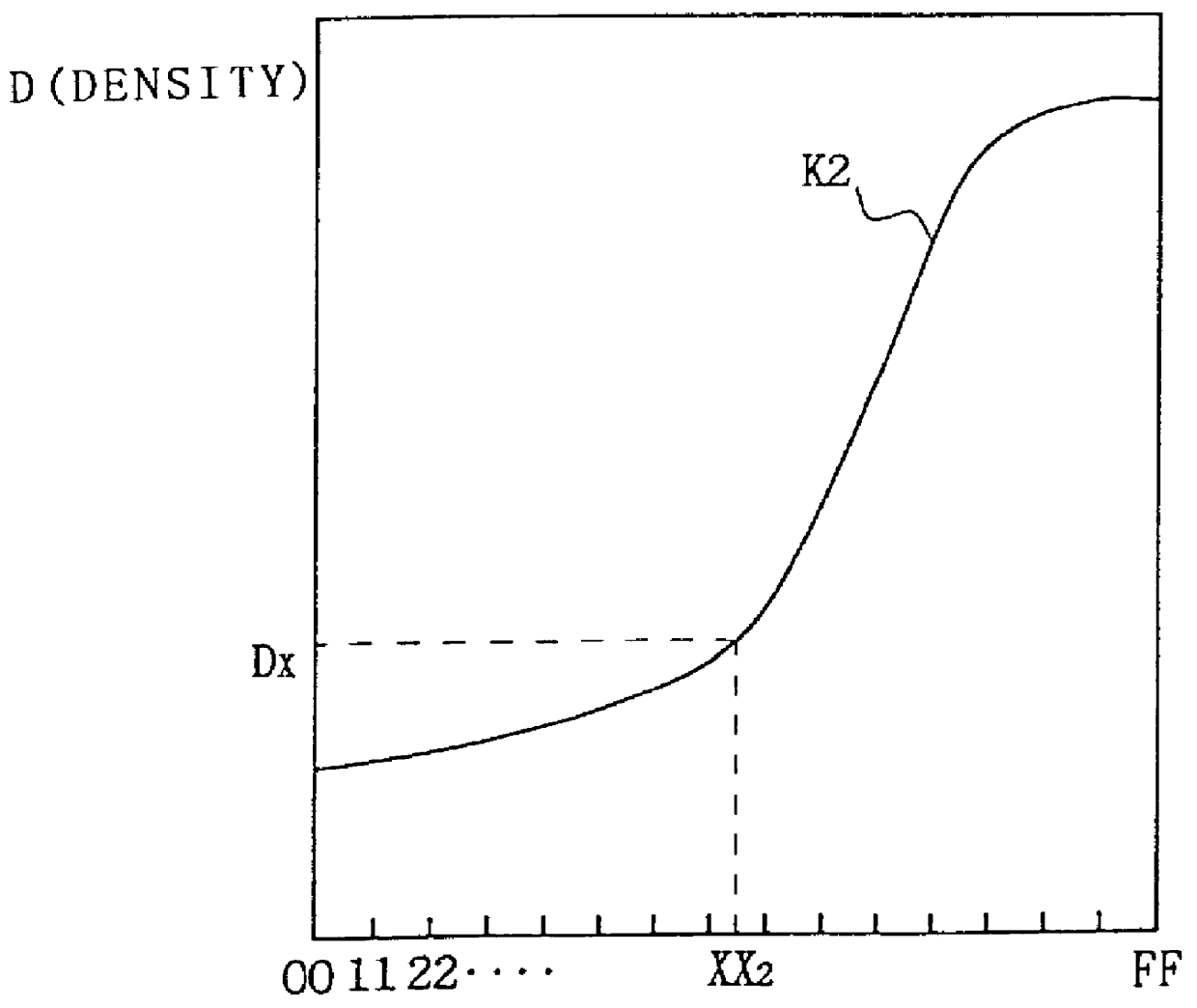

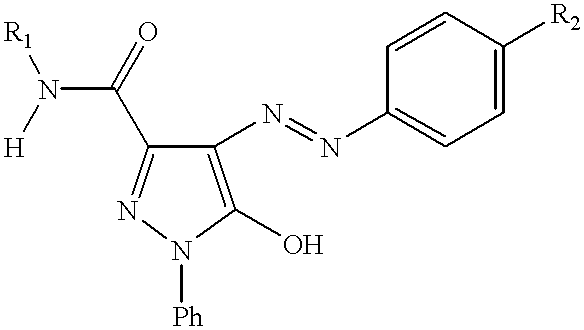

Printer system, printer apparatus, printing method, ink ribbon and printing medium

A printer system, a printer apparatus, a printing method, an ink ribbon and a printing medium that certainly and effectively prevent a quality of printed image from being degraded without causing trouble to a user. More concretely, the printing medium is provided with memory mechanisms and the memory mechanisms stores predetermined control data, the printer apparatus reads out the control data stored in the memory mechanisms by contactless communication and controls the photographic printing operation on the basis of the control data which is read out.

Owner:SONY CORP

Multi-layer thermal transfer ribbon and manufacturing method thereof

The invention relates to a multi-layer thermal transfer ribbon and a manufacturing method thereof, and the multi-layer thermal transfer ribbon comprises a membranous base band, a heat-resistant printing ink layer and a heat transfer printing ink layer, wherein the heat-resistant printing ink layer is coated on one side of the base band, the heat transfer printing ink layer is coated on the other side of the base band, the heat transfer printing ink layer comprises a stripping printing ink layer and an adhesive printing ink layer, the stripping printing ink layer is directly coated on the surface of the base band, the adhesive printing ink layer is coated on the stripping printing ink layer, printing ink in the striping printing ink layer is hot-melting type printing ink, and the printing ink in the adhesive printing ink layer is the hot-melting type printing ink or solvent type printing ink. The heat transfer printing ink layer of the multi-layer mixed-based ribbon can be easily completely stripped off the base band, and the great adhesive ability is realized on a smooth medium; in addition, the multi-layer thermal transfer ribbon further has the advantages of high resolution, clear printing, anti-friction property, moisture resistance, chemical corrosion resistance, environment friendliness and the like.

Owner:泉州市山水电脑耗材有限公司

Heat transfer printing color ribbon and its preparing method

InactiveCN1647941AHigh resolutionImprove bindingInk ribbonsDuplicating/marking methodsPolyesterAdhesive

The present invention relates to a kind of heat transfer printing color ribbon and its preparation process. The heat transfer printing color ribbon consists of base belt, ink layer and heat resistant back layer. The ink layer consists of adhesive, coloring agent and assistant, and the adhesive consists of two or more kinds one resin. The preparation process includes the following steps: dissolving resin in solvent to obtain 5-30 % concentration resin solution; mixing and dispersing resin solution, coloring agent and assistant to obtain ink layer coating liquid; and coating the ink layer coating liquid with a intaglio coating machine onto the film base belt with heat resistant back layer to obtain the heat transfer printing color ribbon. The preparation process is simple and low in cost, and the produced heat transfer printing color ribbon is suitable for heat transfer printing on polyester label.

Owner:CHINA LUCKY FILM CORP

Ink set and image forming apparatus and method

ActiveUS7876345B2Avoid uneven densityQuality improvementRecording apparatusInk ribbonsVolume averageWater soluble

The ink set includes: a first liquid which contains a coloring material, a polymer, and a dispersion medium composed of water and water-soluble solvent, the coloring material and the polymer being dispersed in the dispersion medium, the coloring material having properties such that when dispersed in an aqueous coloring material solution, a volume-average particle size of the coloring material is changed along with a pH change of the aqueous coloring material solution, the polymer having properties such that when dispersed in an aqueous polymer solution, a volume-average particle size of the polymer is changed along with a pH change of the aqueous polymer solution; and a second liquid which changes pH of the first liquid, wherein a condition of |α−β1|≧|α−β2| is satisfied, where α is pH of the first liquid before the first liquid is subjected to a pH change caused by the second liquid, β1 is pH of the aqueous coloring material solution at which the volume-average particle size of the coloring material reaches 1000 nm along with the pH change of the aqueous coloring material solution, and β2 is pH of the aqueous polymer solution at which the volume-average particle size of the polymer reaches 1000 nm along with the pH change of the aqueous polymer solution.

Owner:FUJIFILM CORP

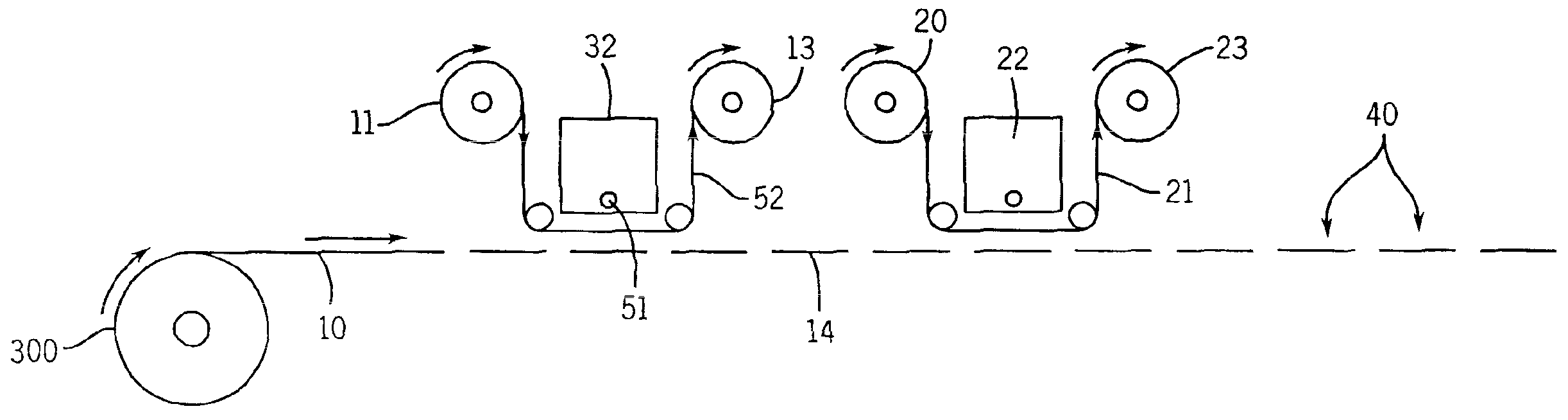

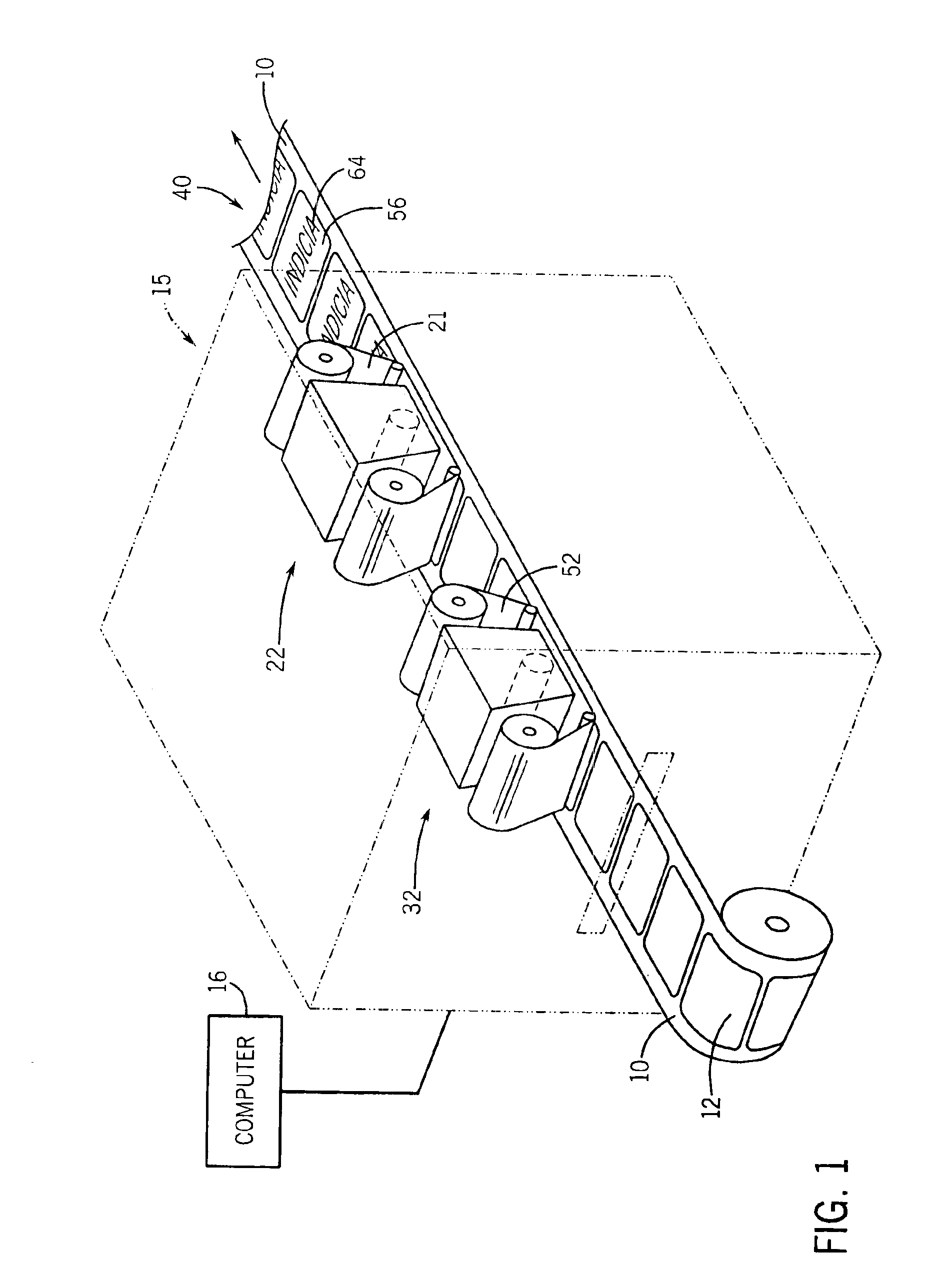

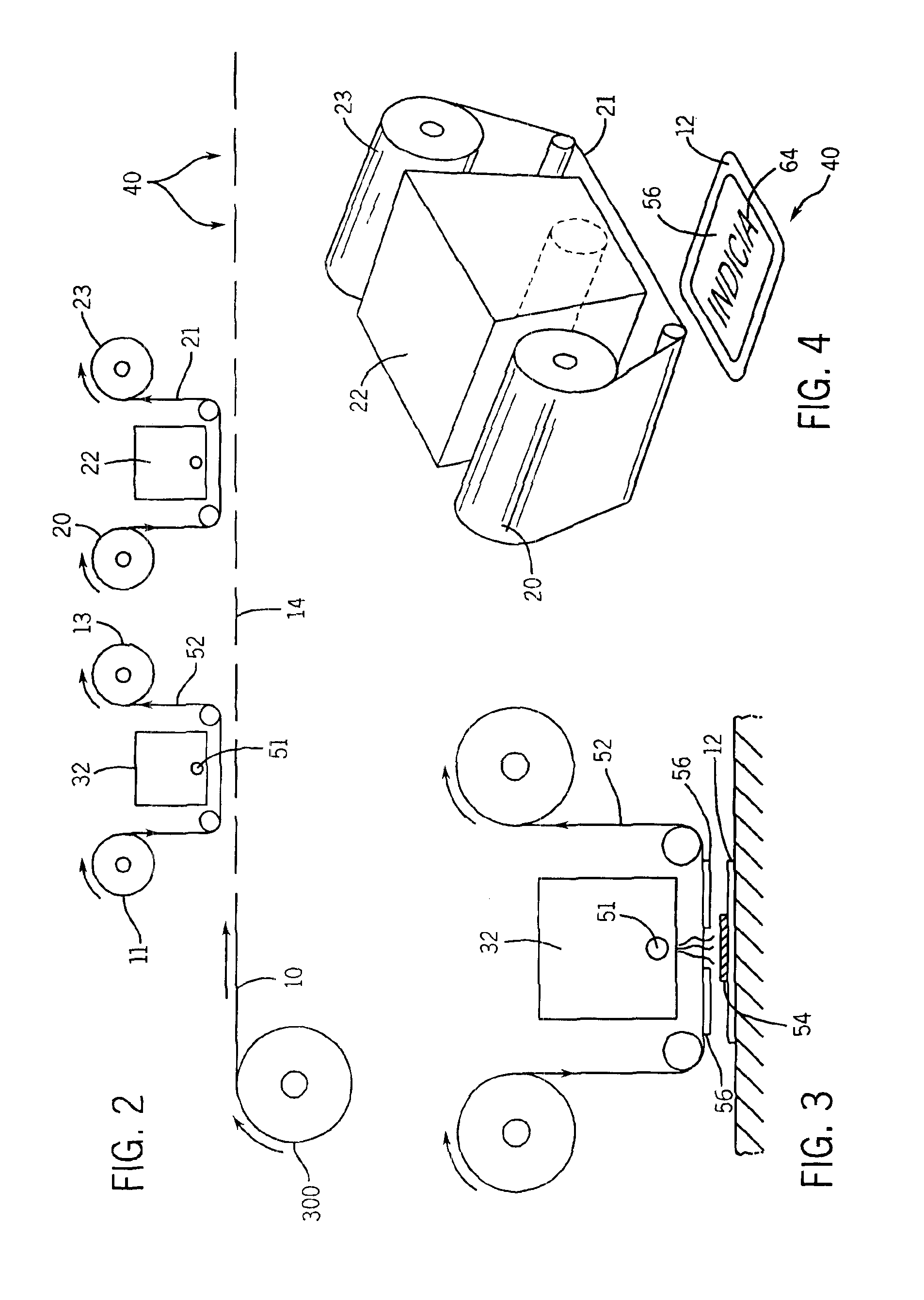

Method of printing, activating and issuing an activated time dependent label

InactiveUS6916130B1Eliminate the problemQuick assemblyRecording apparatusInk ribbonsBand shapeData information

A method for continuously producing a plurality of printed and activated time dependent labels. In one embodiment, the method comprises providing a web having a plurality of inked substrates thereon. Each substrate has a migrating ink pattern printed on a surface of the substrate. A transfer printer is provided that has a first ribbon means for applying a timing layer through which the migrating ink bleeds after a predetermined period of time. A second ribbon means is provided for printing variable data. The web of inked substrates is continuously fed through the printer, each inked substrate passing sequentially under the first ribbon means and then the second ribbon means. The first ribbon means is activated to apply the timing layer to a portion of the printed surface of each inked substrate thereunder to produce a coated substrate. The second ribbon means is activated to print the variable data information on each coated substrate thereunder, thus continuously producing a plurality of activated time dependent labels having variable data information printed thereon.In another embodiment for producing a plurality of printed and activated time dependent labels, the web having the plurality of inked substrates thereon is continuously fed through a transfer printer having a single ribbon means. The single ribbon means includes a first ribbon portion for applying a timing layer through which the migrating ink bleeds after a predetermined period of time, and a second ribbon portion for printing variable data. The web is continuously fed through the printer, wherein the first and second ribbon portions pass sequentially over each inked substrate. The first ribbon portion is activated to apply the timing layer to a portion of the printed surface of the inked substrate thereunder, to produce a coated substrate, and then the second ribbon portion is activated to print the coated substrate with the variable data information, thus continuously producing a plurality of activated time dependent labels having variable data information printed thereon.

Owner:BRADY WORLDWIDE INC

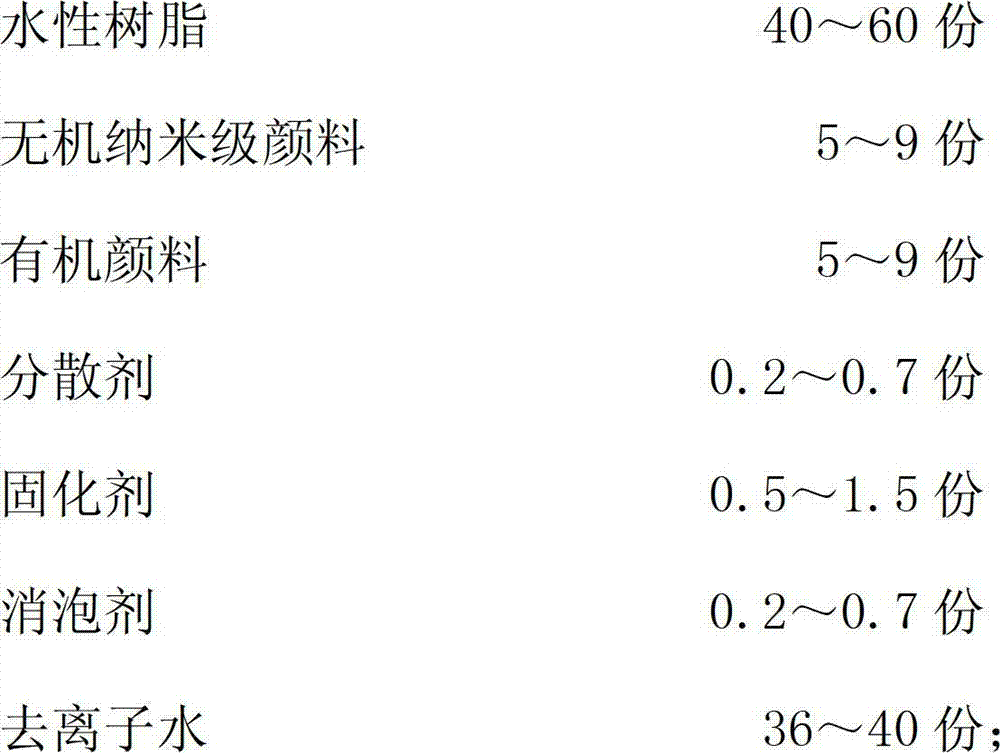

Thermal transfer ribbon and preparation method thereof

InactiveCN102785491AIncrease temperatureImprove heat resistanceInk ribbonsCoatingsWater basedPolyester

The invention discloses a thermal transfer ribbon which comprises an ink layer, a release agent layer, base material and a thermal resistant layer. The ink layer comprises water-dilutable resin, inorganic nanoscale pigment, organic pigment, dispersant, curing agent, deformer and deionized water. The release agent layer comprises organic silicone resin, water-based wax emulsion, talcum powder and deionized water. The base material includes polyester film and thermal-conductive silicone grease. The thermal resistant layer comprises perfluorocarbon, organic silicone resin and deionized water. The invention further discloses a preparation method for the thermal transfer ribbon. The preparation method includes steps of stirring, mixing, drying and the like. The thermal-conductive silicone grease is added to the base material polyester film, using temperature of the thermal transfer ribbon is increased, thermal resistance and adaptability of the thermal transfer ribbon are improved, and printing speed is increased. The thermal resistant layer is added to the thermal transfer ribbon, and accordingly performance of the thermal transfer ribbon is improved. The release layer is added, and accordingly the ink is easier to separate from the base, strippable level is high, printing effect is better, and writing is clearer. The deionized water is used as solvent, and accordingly production cost is reduced, and cost performance of the thermal transfer ribbon is better.

Owner:HUZHOU KAIEN COATING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com