Thermal transfer ribbon with night luminous function and preparation method thereof

A banner carbon ribbon and thermal transfer technology, applied in the field of thermal transfer banner carbon ribbon and its preparation, can solve the problems of limited exposure time, and can only be seen in places with continuous lighting at night, etc. Simple and efficient, good tinting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

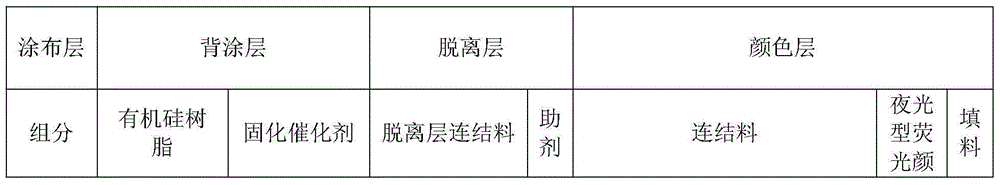

Embodiment 1

[0024] A thermal transfer banner ribbon with the function of glowing at night is composed of a tape base, a back coating and a heat transfer layer coated on both sides of the tape base, and the heat transfer layer is composed of a release layer and a color layer. The surface of one side of the tape base is successively a release layer and a color layer from inside to outside; the thickness of the tape base is 4 μm, the thickness of the back coating is 0.1 μm, the thickness of the color layer is 8 μm, and the thickness of the release layer is 4 μm.

[0025] In this embodiment, the preparation method of the thermal transfer banner carbon ribbon with night-time luminous function includes the following steps: a. Dilute and mix the silicone resin of the back coat with gasoline, add a curing catalyst 30 minutes before use, and mix evenly to form Back coating ink, coated on the surface of one side of the tape base, dried at 30°C to form a back coating, and enter the next process;

[...

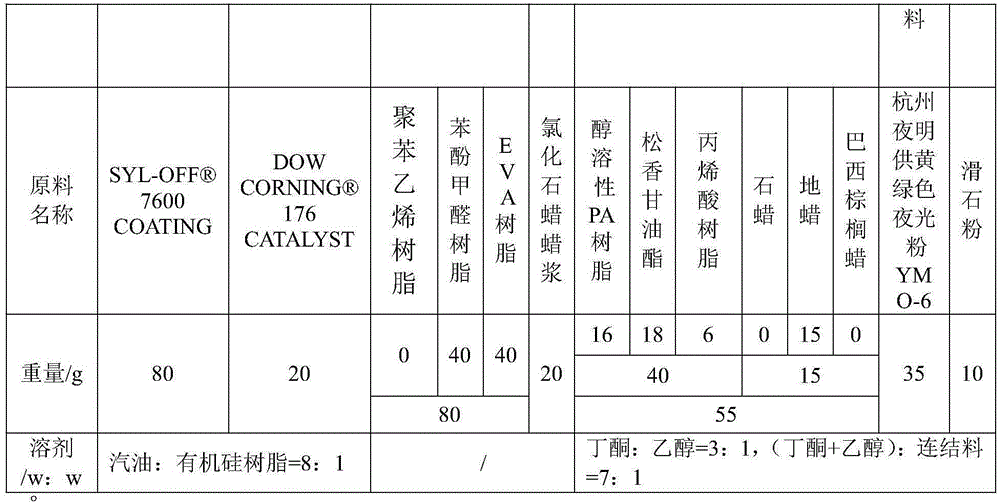

Embodiment 2

[0032] A thermal transfer banner ribbon with the function of glowing at night is composed of a tape base, a back coating and a heat transfer layer coated on both sides of the tape base, and the heat transfer layer is composed of a release layer and a color layer. The surface of one side of the tape base is successively a release layer and a color layer from inside to outside; the thickness of the tape base is 4.5 μm, the thickness of the back coating is 0.1 μm, the thickness of the color layer is 8 μm, and the thickness of the release layer is 5 μm.

[0033] In this embodiment, the preparation method of the thermal transfer banner carbon ribbon with night-time luminous function includes the following steps: a. Dilute and mix the silicone resin of the back coat with gasoline, add a curing catalyst 34 minutes before use and mix evenly to form Back coating ink, coated on the surface of one side of the tape base, dried at 31°C to form a back coating, and enter the next process;

...

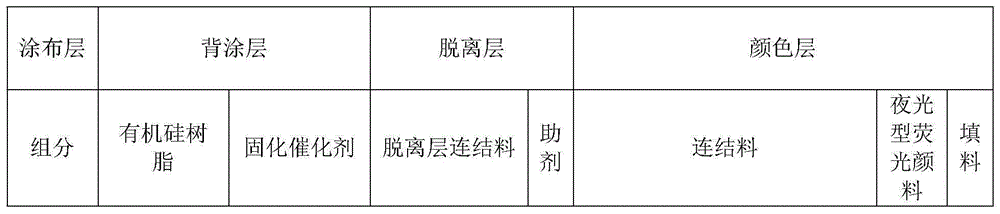

Embodiment 3

[0040] A thermal transfer banner ribbon with the function of glowing at night is composed of a tape base, a back coating and a heat transfer layer coated on both sides of the tape base, and the heat transfer layer is composed of a release layer and a color layer. The surface of one side of the tape base is successively a release layer and a color layer from inside to outside; the thickness of the tape base is 4.5 μm, the thickness of the back coating is 0.1 μm, the thickness of the color layer is 10 μm, and the thickness of the release layer is 4 μm.

[0041] In this embodiment, the preparation method of the thermal transfer banner carbon ribbon with night-time luminous function includes the following steps: a. Dilute and mix the silicone resin of the back coat with gasoline, add a curing catalyst 34 minutes before use and mix evenly to form Back coating ink, coated on the surface of one side of the tape base, dried at 31°C to form a back coating, and enter the next process;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com