Patents

Literature

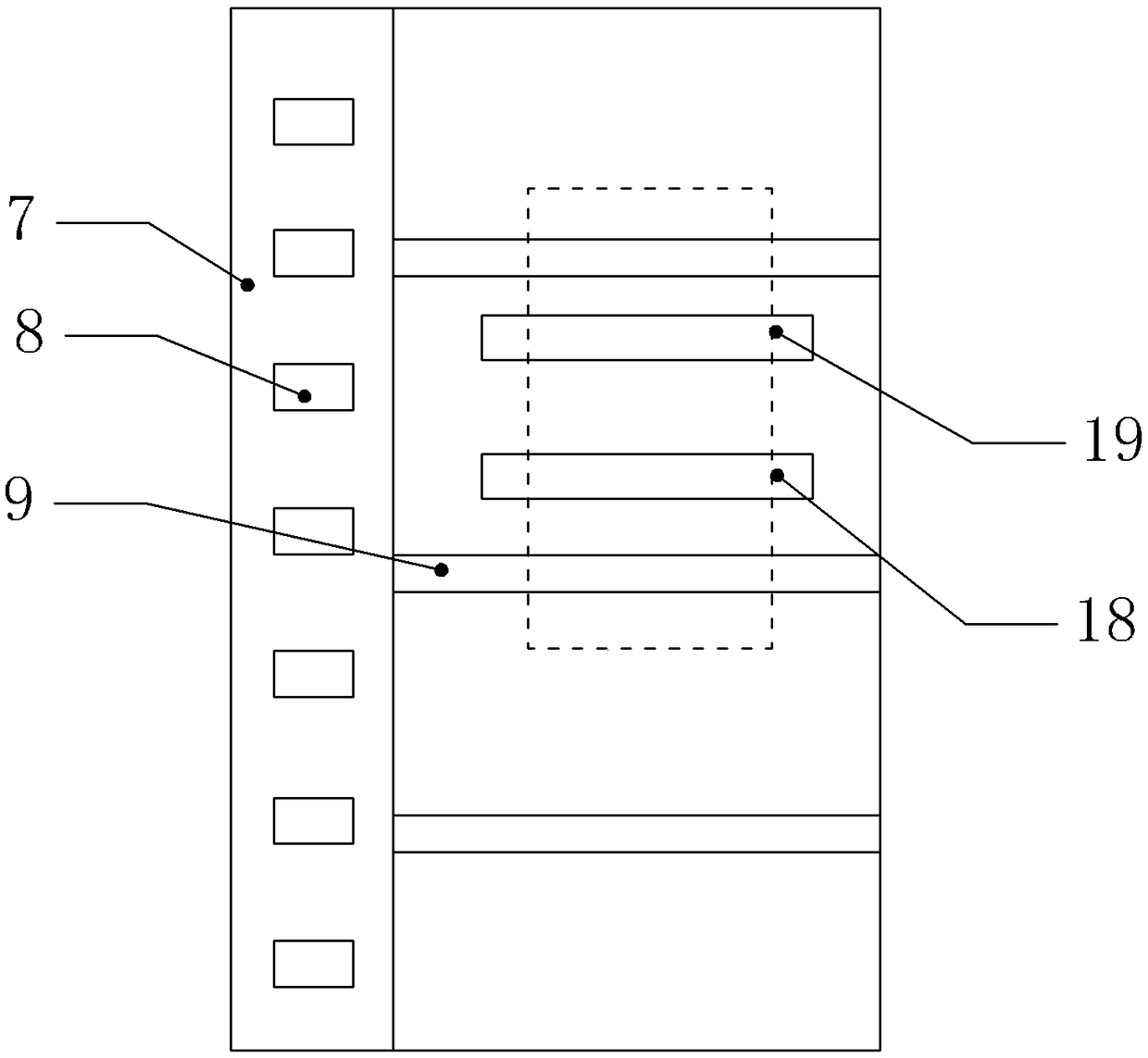

511results about How to "Has a guiding role" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

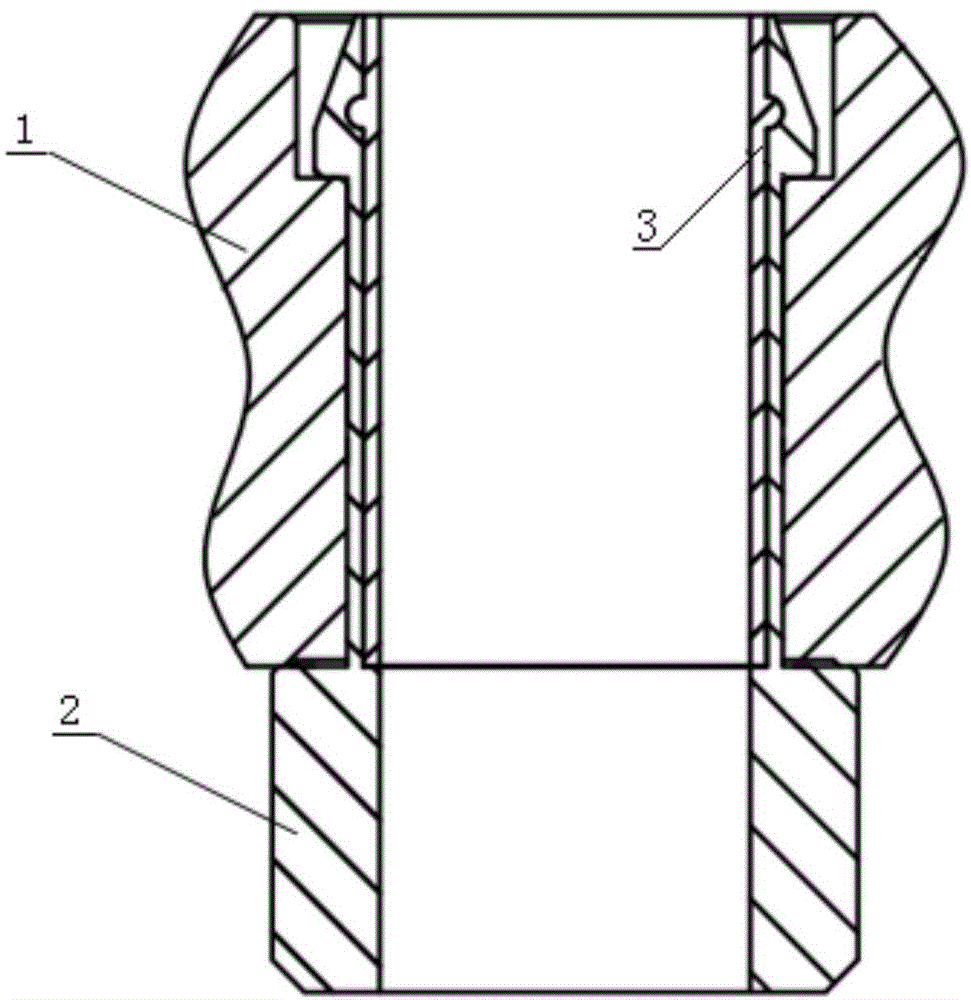

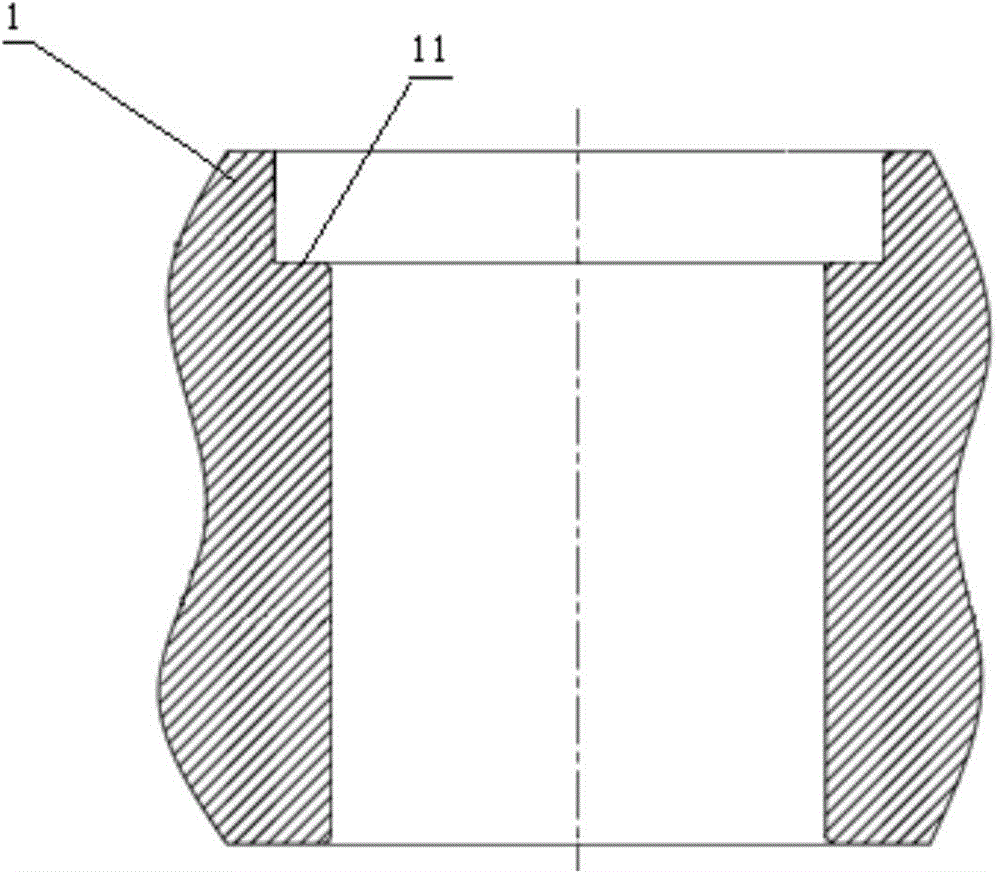

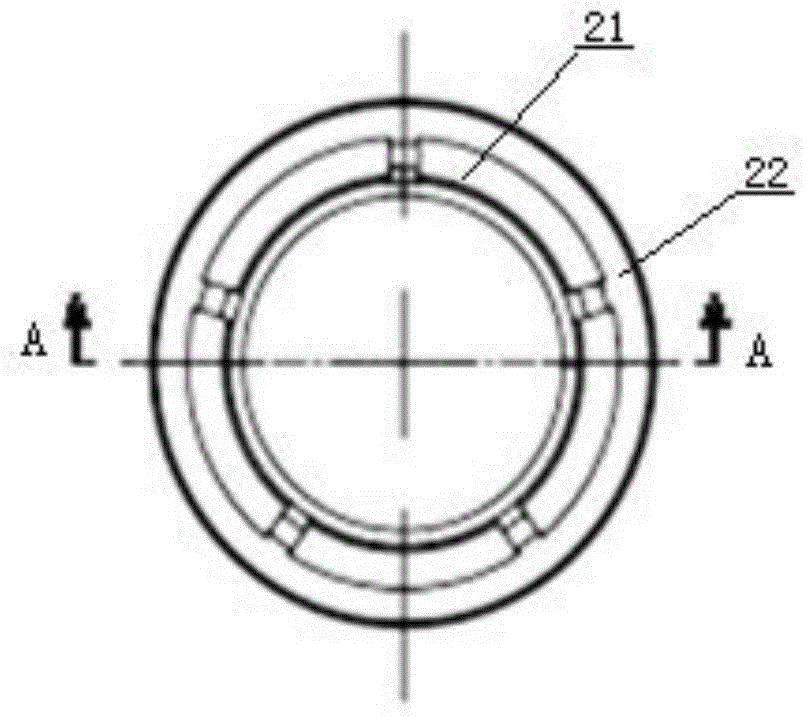

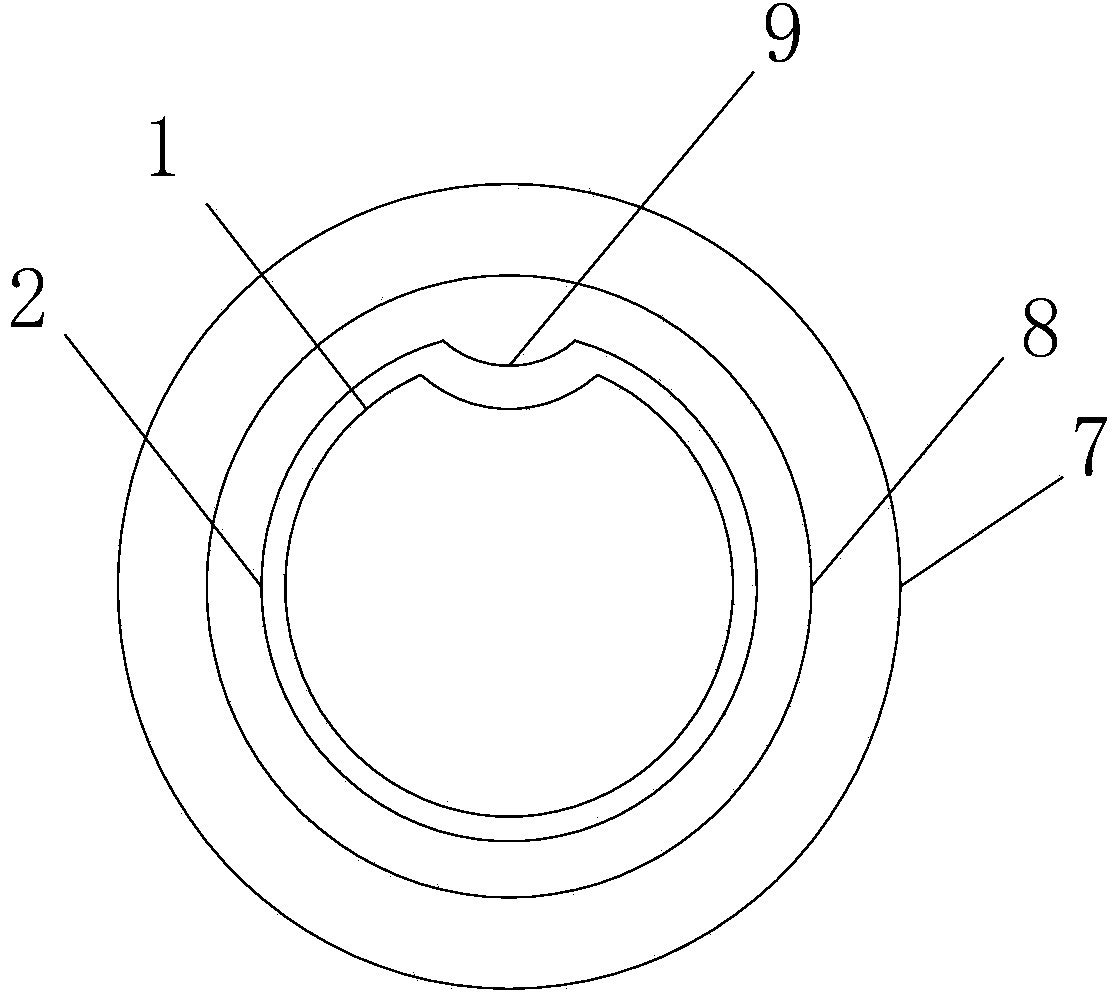

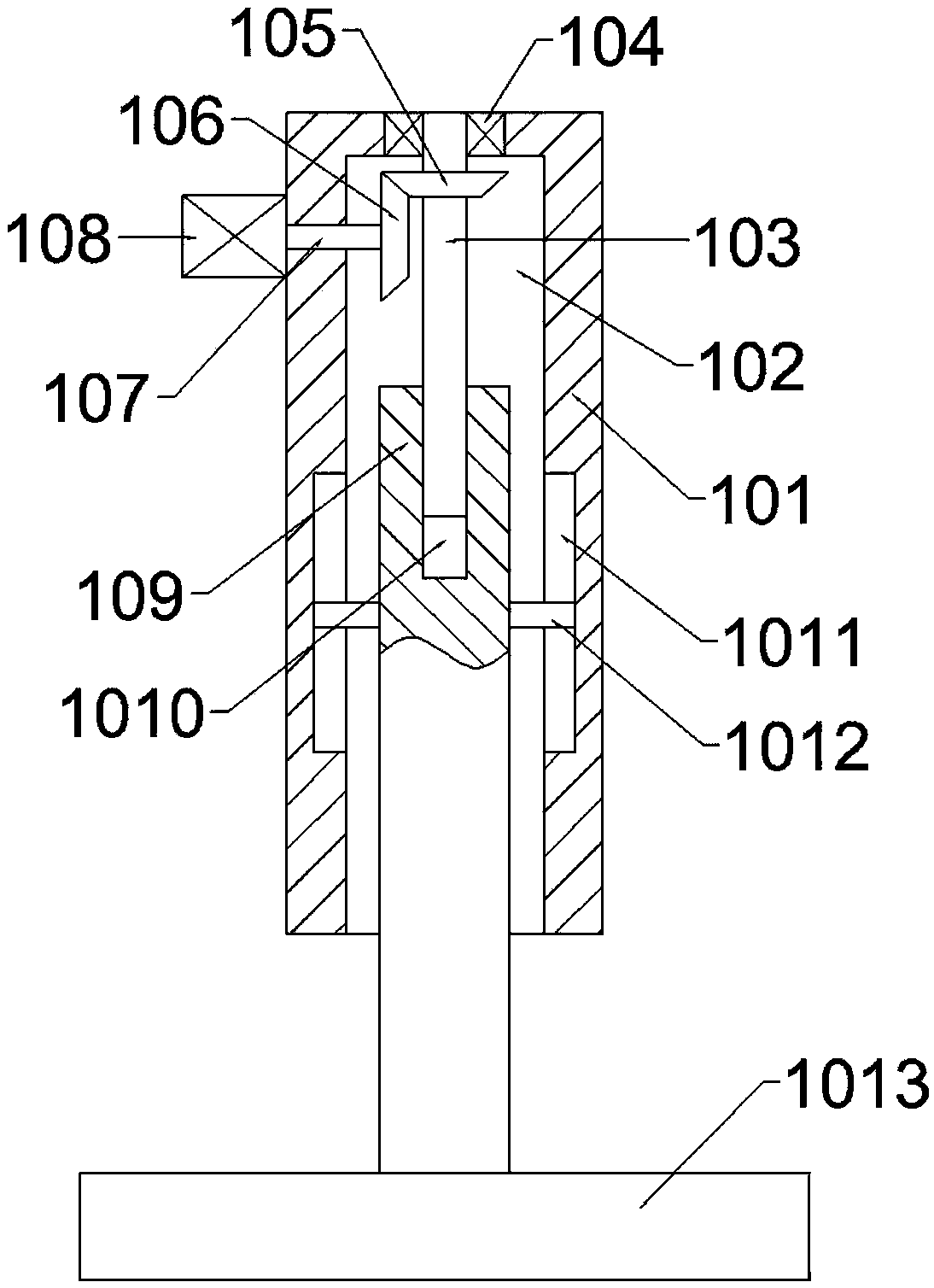

Detachable upper pipe seat and guide pipe connecting structure

ActiveCN104575629ARealize repeated installation and disassemblyHas a guiding roleNuclear energy generationRod connectionsEngineeringHooking

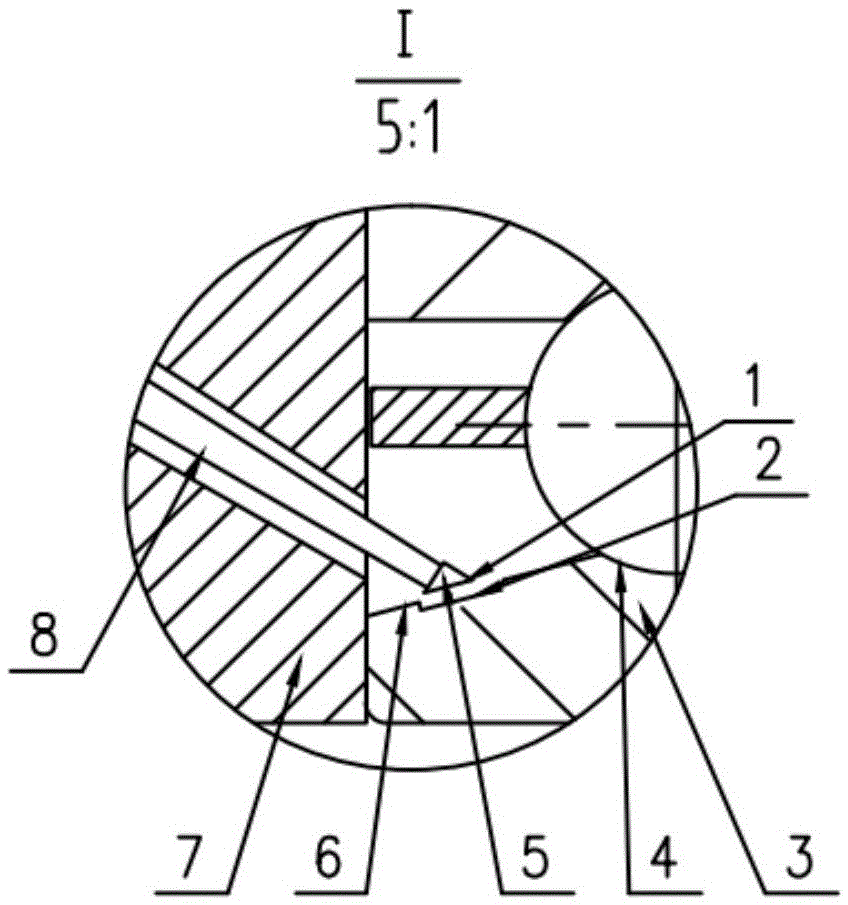

The invention provides a detachable upper pipe seat and guide pipe connecting structure which comprises an upper pipe seat, an elastic joint and a bracing pipe, wherein a guide pipe hole is formed in the upper pipe seat; the inner diameter of the upper part of the guide pipe hole is larger than the inner diameter of the lower part of the guide pipe hole so as to form a stepped surface; the elastic joint is of a tubular structure; the upper part of the elastic joint comprises at least two elastic fasteners; grooves are formed in the inner sides of the elastic fasteners along the peripheral direction; a lug boss is formed on the lower end of the elastic joint, is matched with the lower end surface of the guide pipe hole of the upper pipe seat and is used for limiting the upward motion of the elastic joint; the bracing pipe is of a tubular structure, a bulge is formed in the outer side of the upper part of the bracing pipe along the peripheral direction, and the bulge is embedded in the grooves of the elastic fasteners; and the bracing pipe is used for locking the elastic fasteners on the stepped surface of the guide pipe hole and limiting the downward motion of the elastic joint. According to the upper pipe seat and guide pipe connecting structure disclosed by the invention, the bracing pipe is taken out by using a hooking tool, and after the elastic joint is not supported, the elastic joint is pressed into the guide pipe hole, the upper pipe seat can be taken out, and the connecting structure can be repeatedly mounted and detached.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

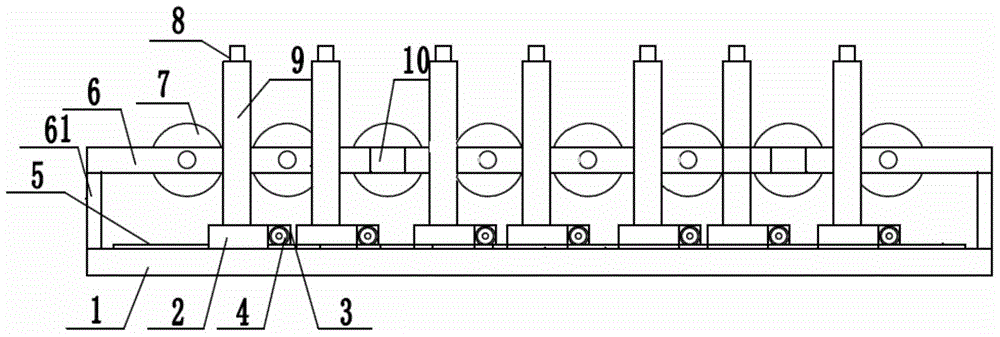

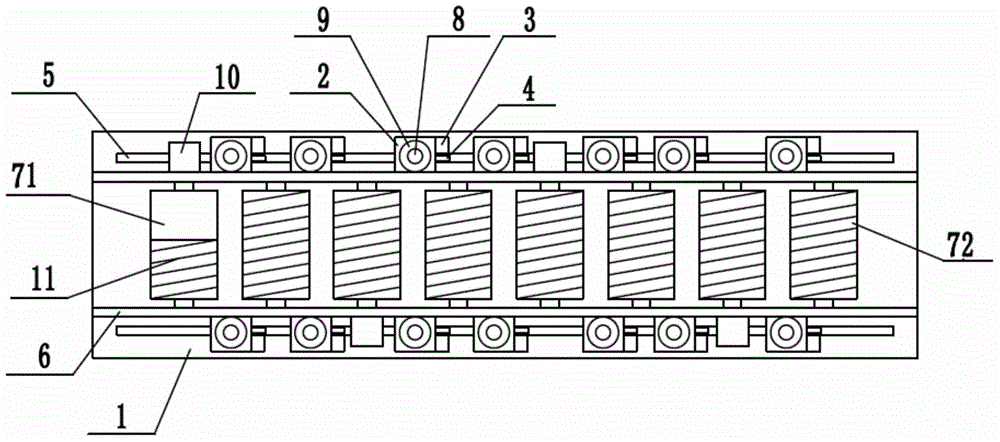

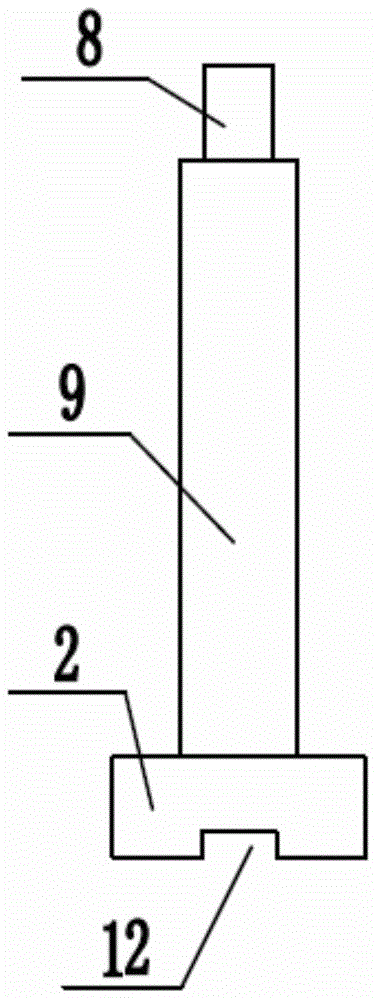

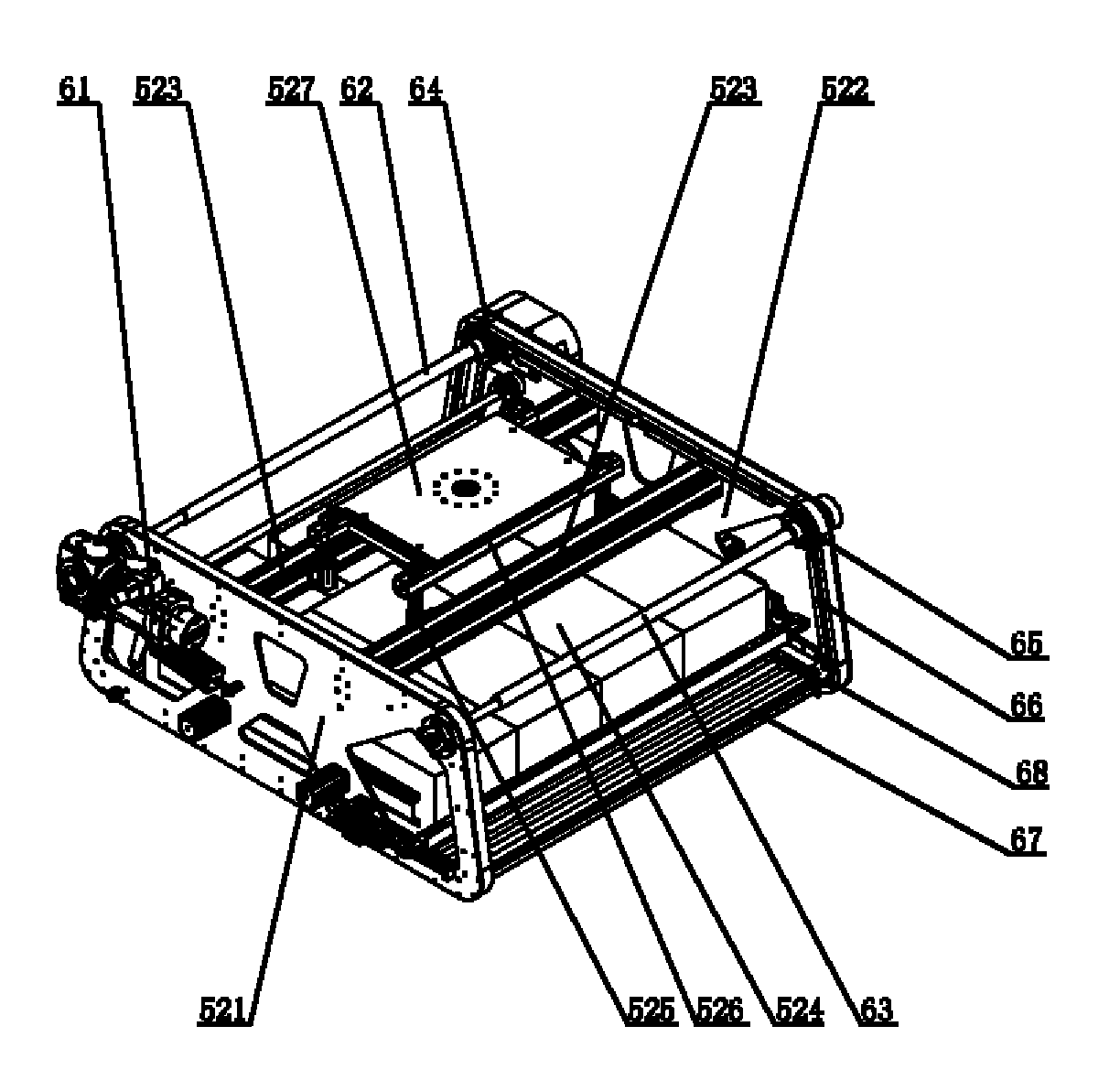

Steel plate conveying roller way of straightening machine

ActiveCN104401640AEasy to adjustGuaranteed uptimeRollersRoller-waysEngineeringMechanical engineering

The invention provides a steel plate conveying roller way of a straightening machine and belongs to the technical field of steel plate conveying devices. The steel plate conveying roller way of the straightening machine comprises a conveying base, two roller beam bodies which are symmetrically arranged on the upper end surface of the conveying base, two gear rack guide rails which are symmetrically arranged on the upper end surface of the conveying base and are disposed on the outer sides of the roller beam bodies, a plurality of sliding tables which are symmetrically arranged on the two gear rack guide rails, a plurality of connecting guide rods which are respectively, vertically and fixedly installed on the upper end surfaces of the sliding tables, and a plurality of conveying rollers of which connecting shafts at two ends are respectively arranged between the inner side surfaces of the two roller beam bodies, wherein the plurality of conveying rollers are driven through a first driving motor and are used for conveying a steel plate. The steel plate conveying roller way of the straightening machine has the advantages that the steel plate can be enabled to stably and effectively run on the conveying roller way of the straightening machine, the effect of steel plate conveying and guide is achieved, the steel plate is enabled to be conveyed to a designated position and the steel plate can be prevented from falling during conveying.

Owner:SHANDONG IRON & STEEL CO LTD

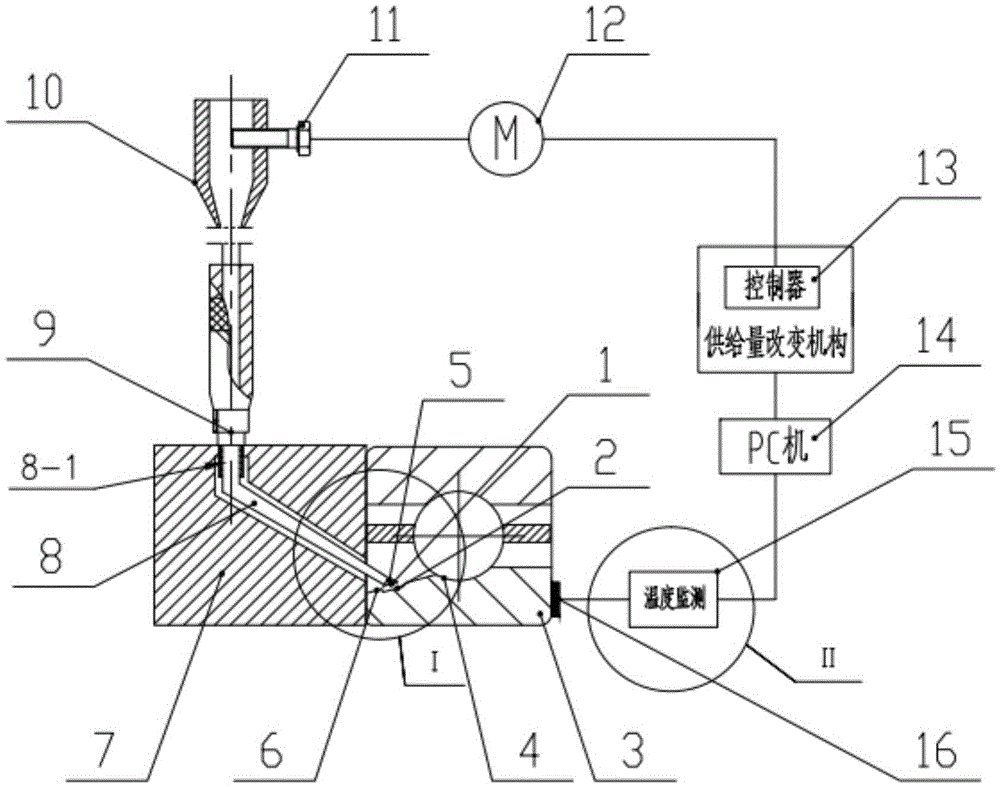

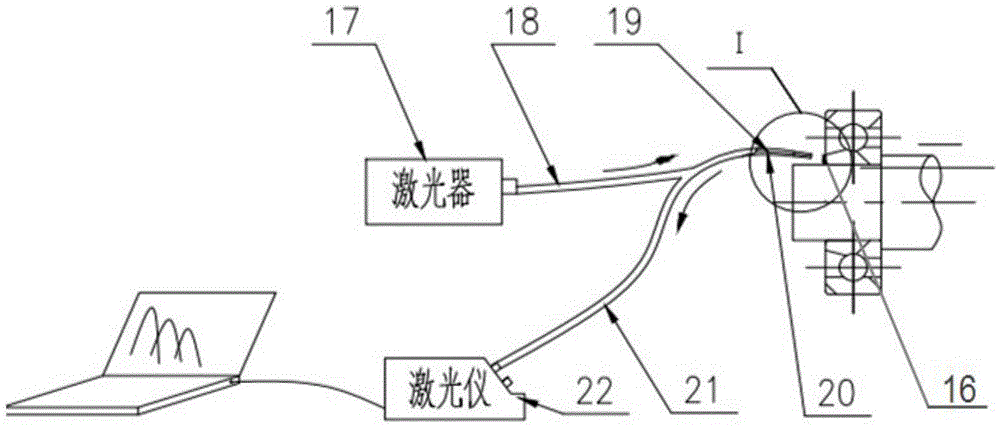

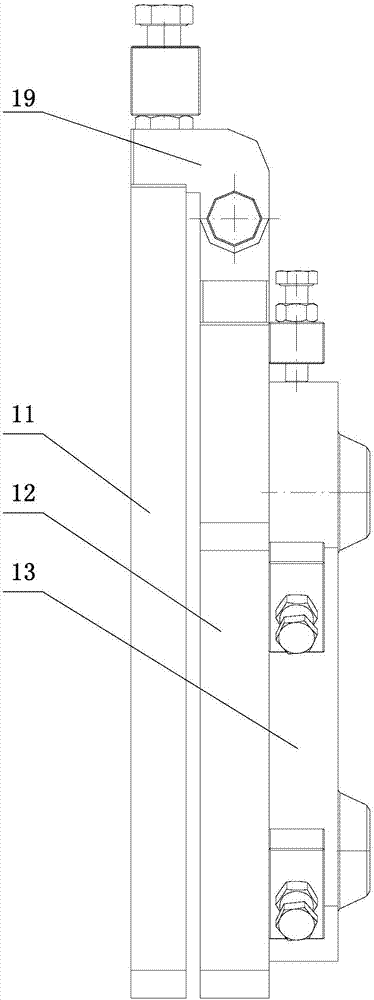

Device and method for adjusting lubrication state of bearing by monitoring temperature of inner ring

ActiveCN105627074AAccurate measurementRealize closed-loop controlBearing componentsLubrication elementsAuto regulationMonitoring temperature

The invention provides a device and method for adjusting the lubrication state of a bearing by monitoring the temperature of an inner ring. The temperature of the inner ring of the bearing is measured in a non-contact mode through a CdTe quantum dot, measurement data are transmitted to a controller, when the temperature change of the inner ring of the bearing is large, the controller drives a supply quantity change mechanism to adjust the position of an oil supply nut, and then the quantity of lubricating oil supplied by an oil supply mechanism is changed; when the temperature of the inner ring of the bearing exceeds a certain value, the stickiness of the lubricating oil is lowered, and good lubricating effect can be guaranteed by adjusting the distance between the lower end face of an oil supply nozzle and the inclined surface part of the outer diameter surface of the inner ring of the rolling bearing. According to the device and the method, the temperature of the inner ring is monitored on line, the supply quantity of the lubricating oil is automatically adjusted, the position of the oil supply nozzle is manually adjusted, the closed loop coupling influence of the lubricating property of the bearing and temperature rise of the inner ring of the bearing are considered, a mechanism for changing the gap between the oil injection nozzle and the inclined surface part of the outer diameter surface of the inner ring of the bearing is provided, and the effect is good in experiments.

Owner:XI AN JIAOTONG UNIV

Expandable processing device

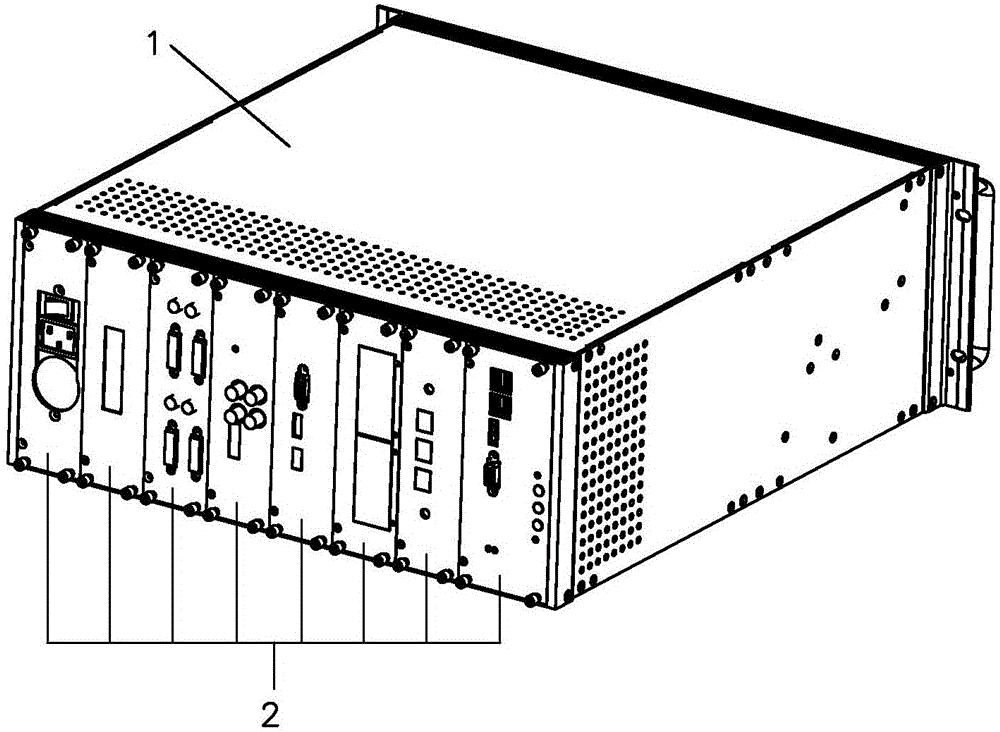

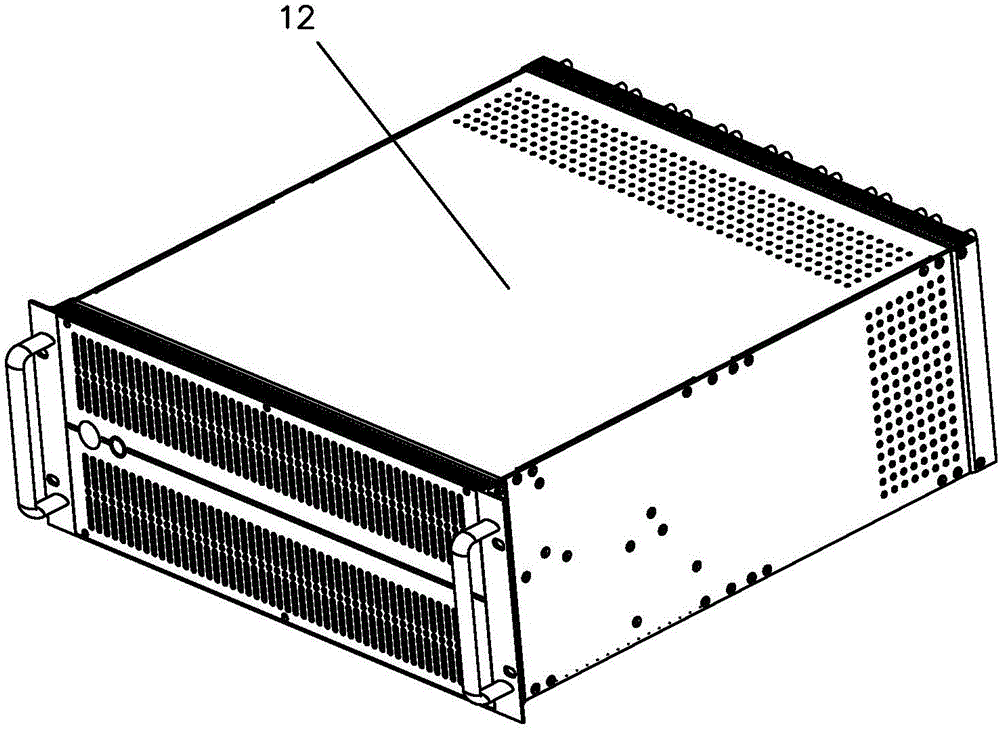

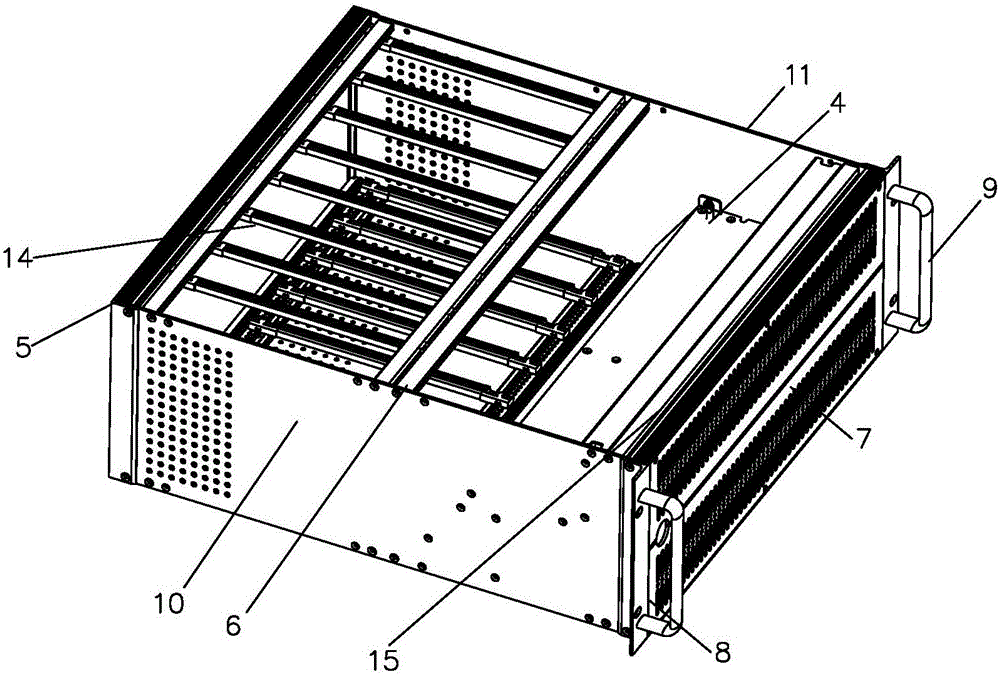

ActiveCN105975018AGood heat dissipationImprove heat dissipationDigital processing power distributionPhysicsEngineering

The invention relates to an expandable processing device. The expandable processing device comprises a case with an opening formed in the back. A plurality of first ventilation holes are formed in a front face plate of the case, a plurality of guiding rails arranged at intervals and correspondingly used for inserting different functional business modules are arranged in the case, the length direction of the guiding rails is perpendicular to the front face plate, a bus back plate functionally butting joint with the functional business modules is arranged between the guiding rails and the front face plate, a plurality of second ventilation holes are formed in the bus back plates, the bus back plate and the front face plate are arranged in parallel, an initiative heat dissipation assembly is arranged between the bus back plate and the front face plate and comprises a partition plate, air sucking fans for sucking air outside the case are arranged on the partition plate, and air blowing fans for blowing air into the case are arranged below the partition plate. By means of the guiding rails in the case, relative independence of installing space of the different functional business modules is achieved, electromagnetic interference between the functional business modules is reduced, heat dissipation can be achieved, and according to the front-feeding and front-discharging mode and the bottom-feeding and the top-discharging mode of the initiative heat dissipation assembly, it is guaranteed that devices inside the case can work within the wide temperature range.

Owner:ANHUI SUN CREATE ELECTRONICS

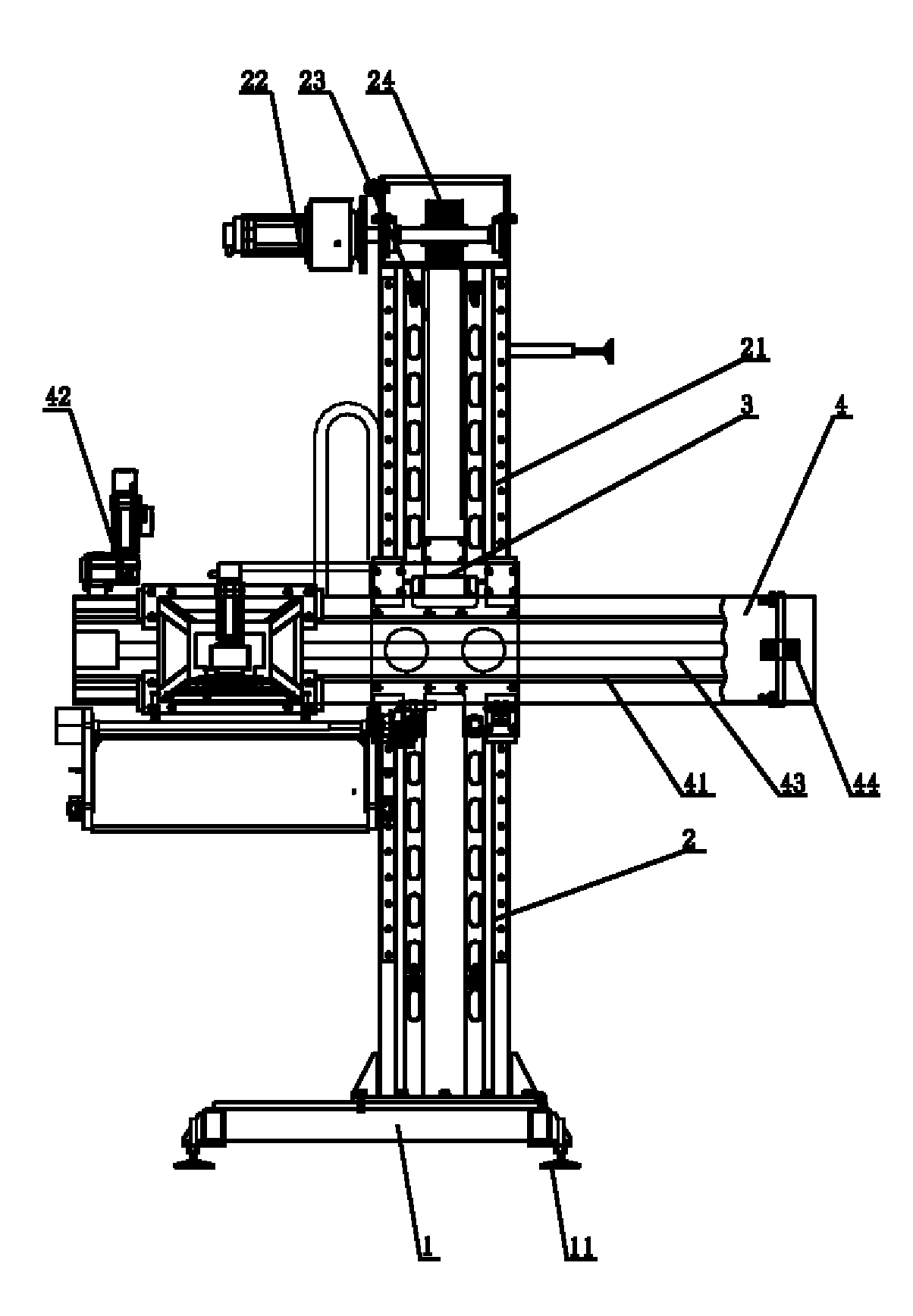

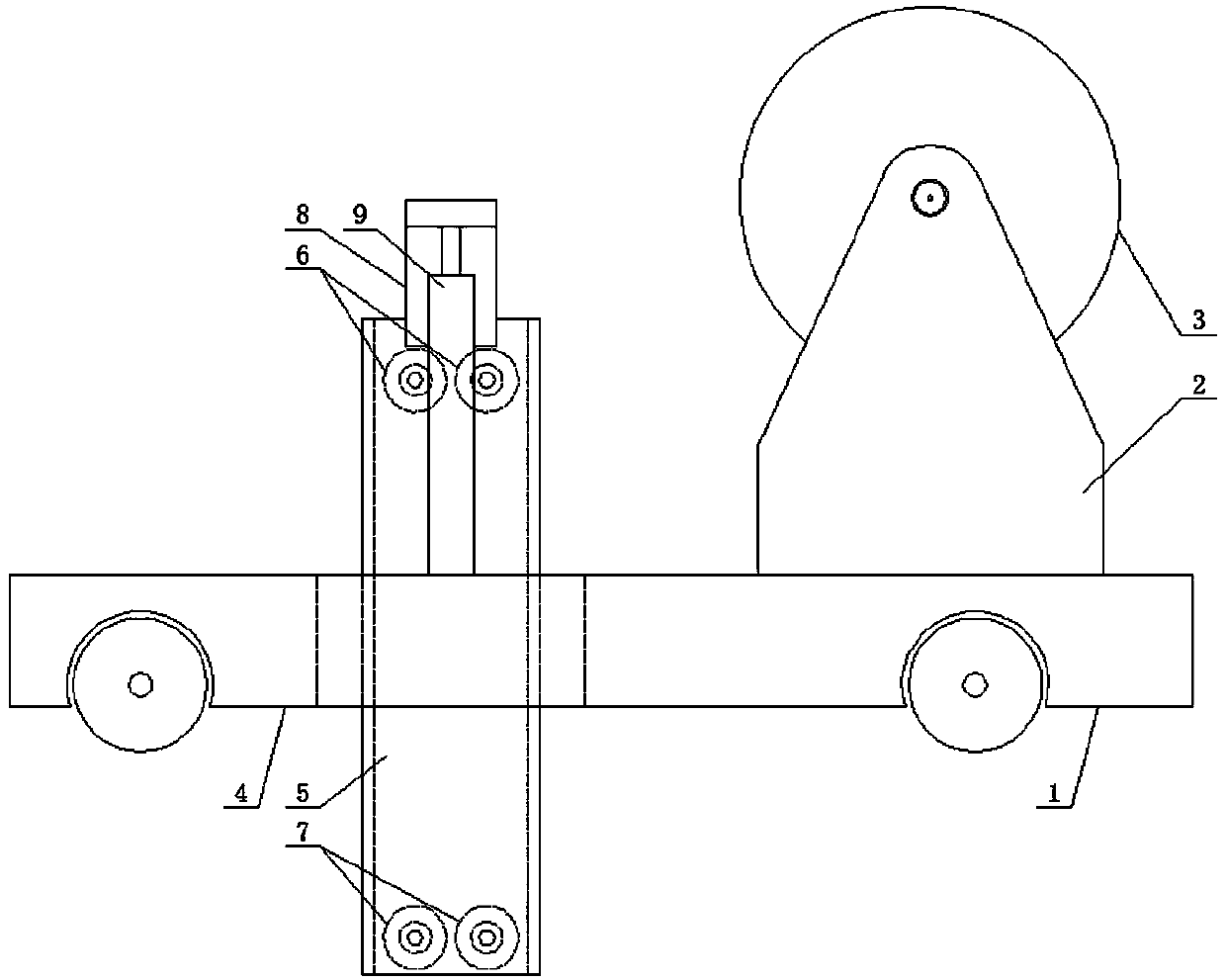

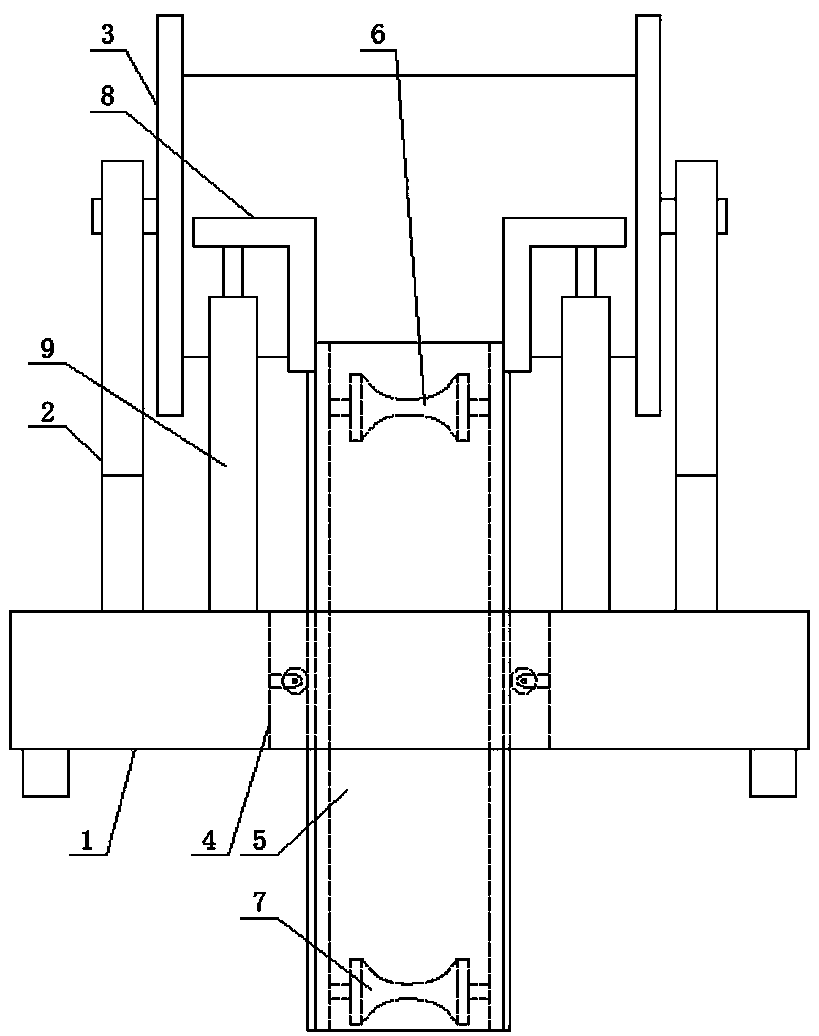

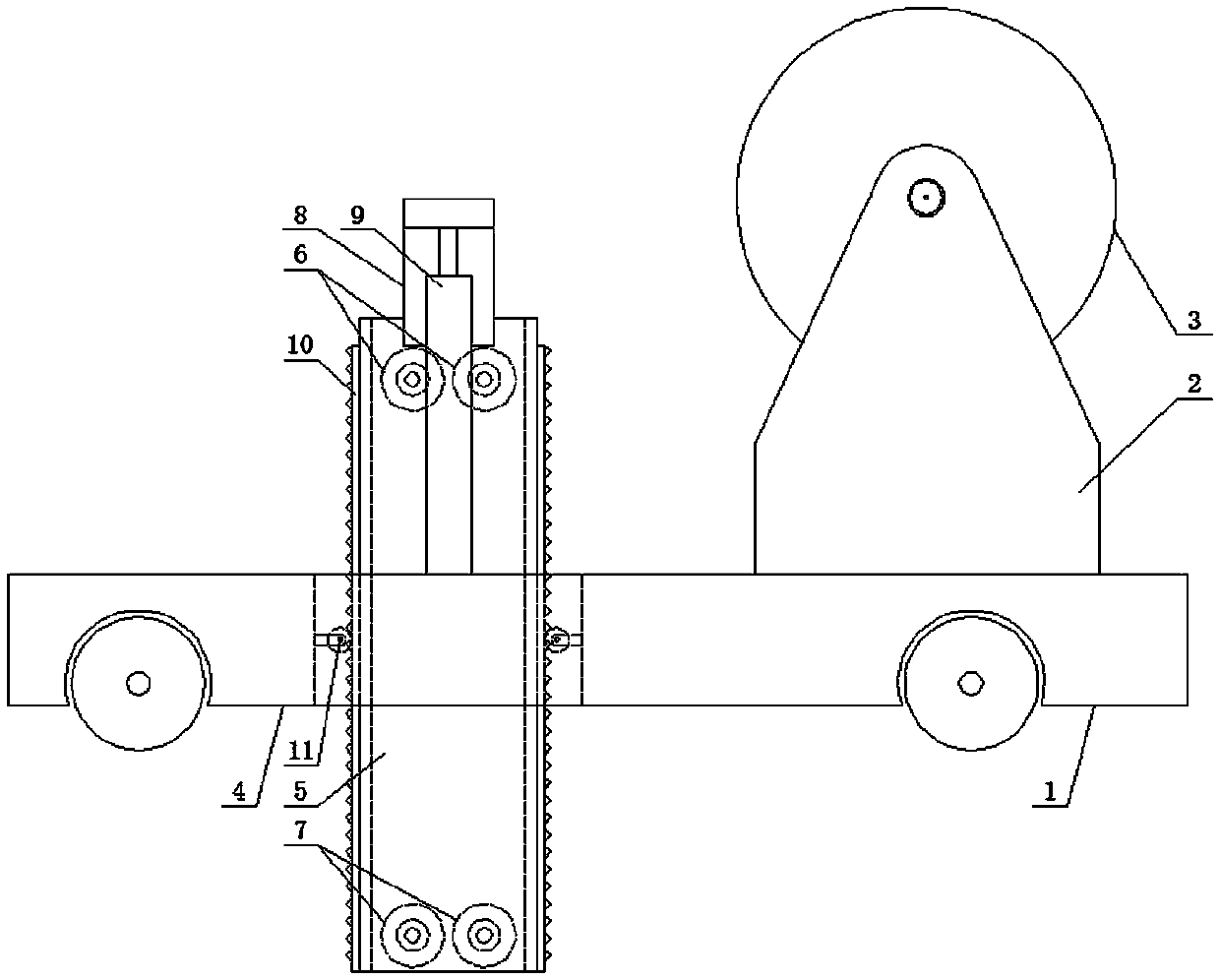

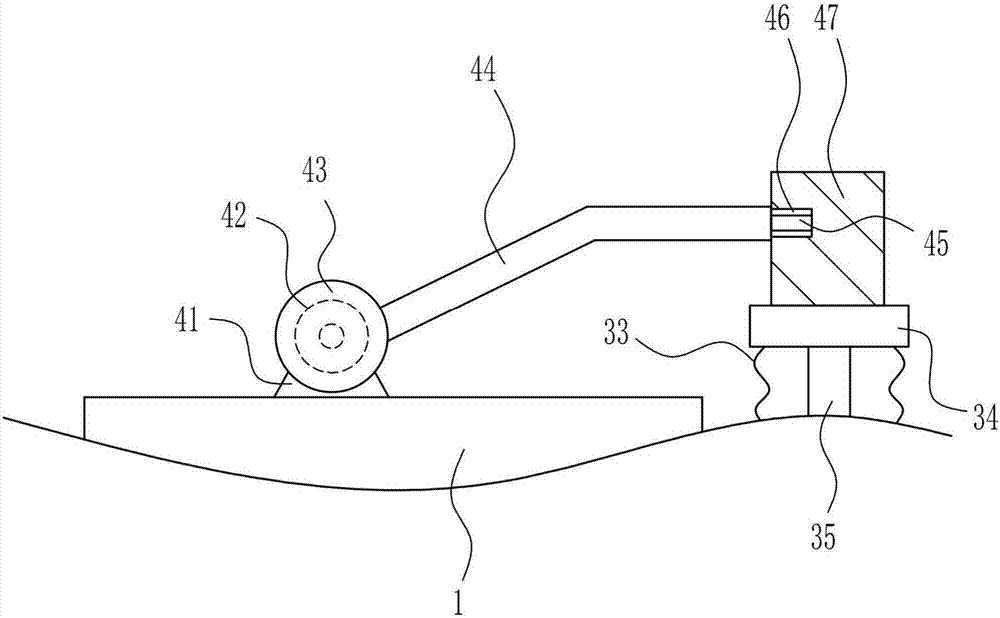

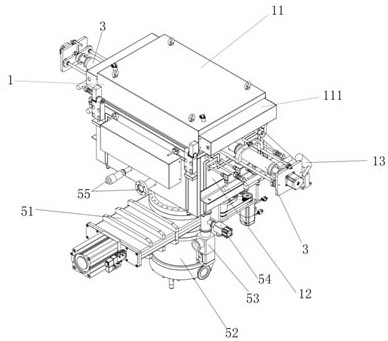

Single-arm stacker crane

InactiveCN101920851APrevent disengagementHas a guiding roleProgramme-controlled manipulatorStacking articlesIndustrial engineeringStacker

The invention discloses a single-arm stacker crane which comprises a base. A stand column is arranged on the base and is provided with a vertical first guide rail, a sliding block sliding along the first guide rail is arranged on the first guide rail, and a driving mechanism for driving the sidling block to move is arranged on the stand column; a beam is arranged on the sliding block and is provided with a horizontal second guide rail, the second guide rail is provided with a tong mechanism moving along the second guide rail, and a driving mechanism for driving the tong mechanism to move is arranged on the beam; and the tong mechanism comprises an extension arm, a tong frame, a third servo motor, a turntable and a rolling mechanism, one end of the extension arm is arranged on the second guide rail in a sliding way, the second servo motor is arranged on the extension end of the extension arm, the turntable is installed on the output shaft of the third servo motor, the tong frame is installed on the turntable, and the rolling mechanism is arranged on the tong frame. The single-arm stacker crane not only has simple structure and low cost, but also can change the direction of objects during stacking, thereby improving stacking stability.

Owner:广州市万世德智能装备科技有限公司

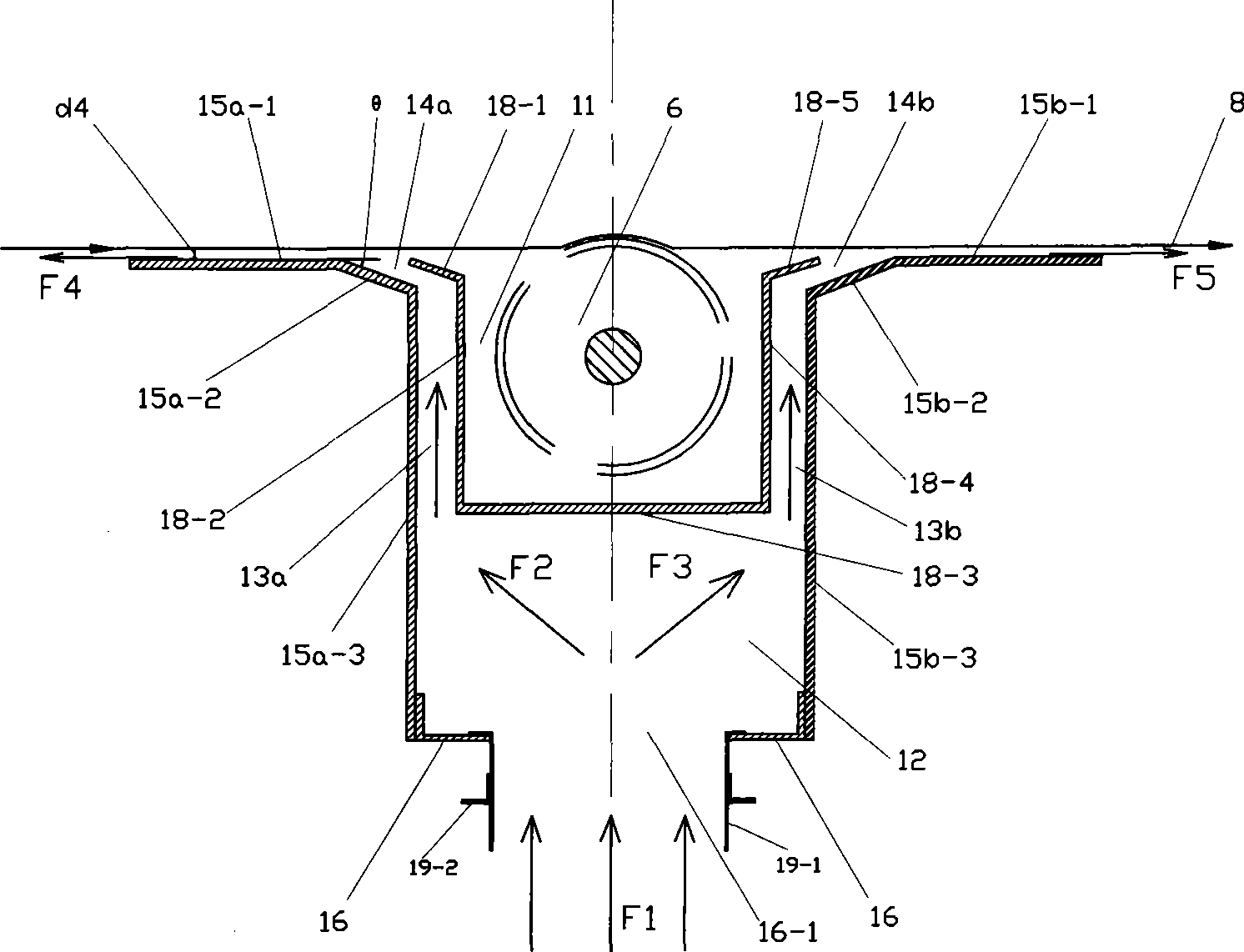

Air-flow type drying oven for drying coating layer of radiate material and blast nozzle parts thereof

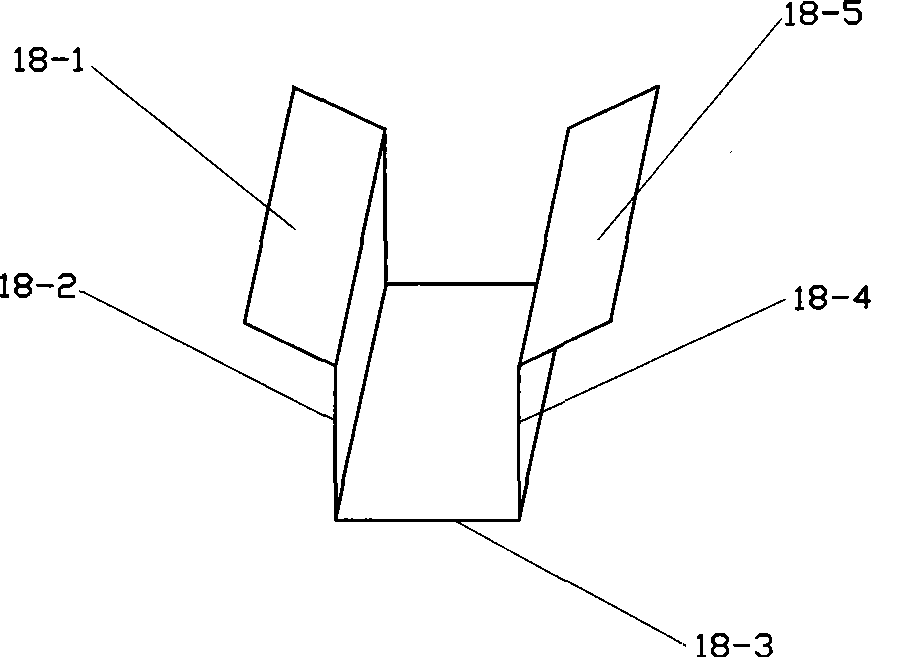

ActiveCN101417276AUniform heating on the surfaceIncrease the direct contact areaPretreated surfacesSpray nozzlesEngineeringAirflow

The invention discloses an air flow drying oven for drying the coating of a radiate material and a blast nozzle part thereof. The blast nozzle part is a case, the lower part of which is provided with an air inlet. The middle of the upper part of the case is provided with a guide roller groove, and the case is provided with an inner cavity at the lower part and a left air duct and a right air duct which are positioned at the left side and the right side of the upper part and directly communicated with the inner cavity. An air outlet of the left air duct is a left parallel air flow blast nozzle which inclines towards the left, and the air outlet of the right air duct is a right parallel air flow blast nozzle which inclines towards the right. When the blast nozzle part is used in the drying oven, the left and right blast nozzles accelerate the flow flowing to the left and right sides of the blast nozzle part, and a left horizontal supporting plate and a right horizontal supporting plate lead the air flow to form parallel wind which is parallel to the radiate material, thus increasing the direct contact area between the wind and the radiate material, leading the radiate material surface to be heated evenly and the heat exchange between the parallel hot wind and the radiate material to be more sufficient, improving the heat exchange efficiency and having better drying quality due to even heating.

Owner:CHANGZHOU YONGSHENG NEW MATERIALS EQUIP CO LTD

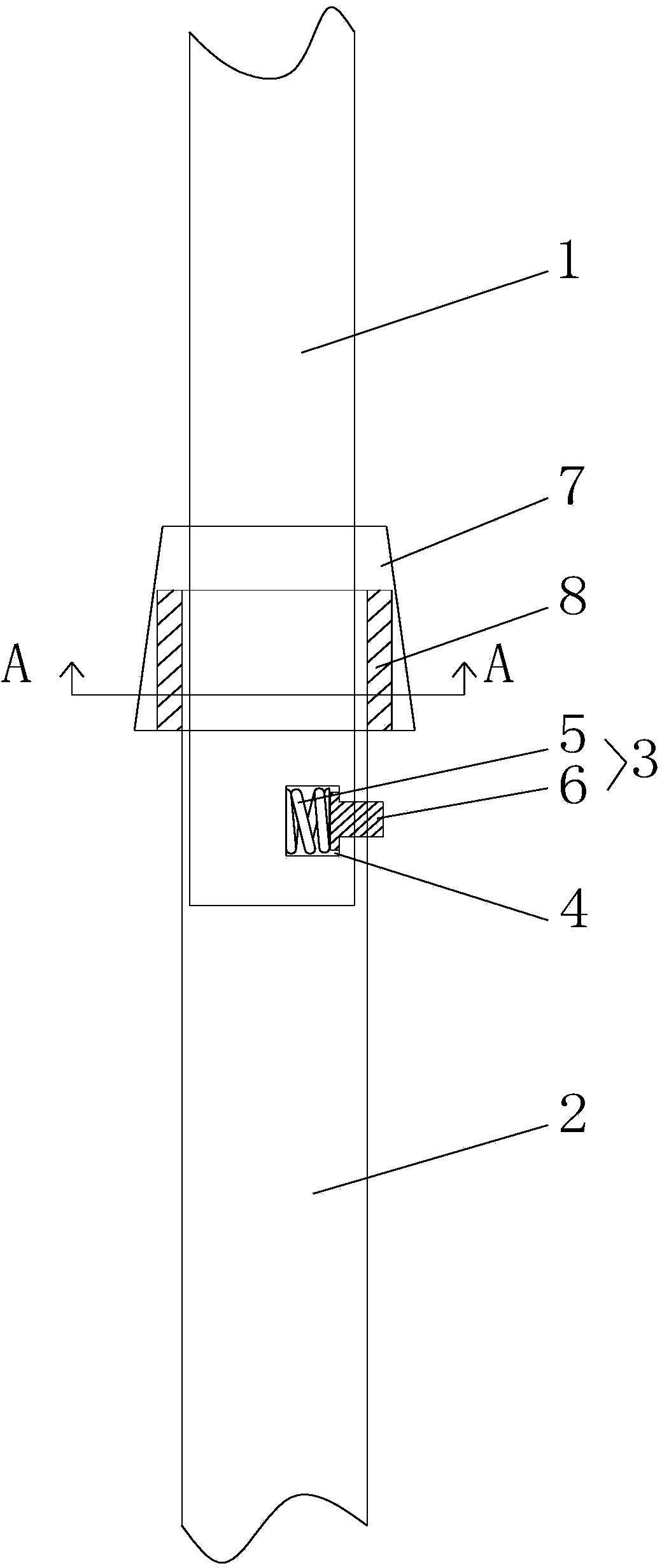

Telescopic frame for tent

InactiveCN104196319AHeight adjustablePrevent shrinkageTents/canopiesChinese charactersArchitectural engineering

The invention relates to a telescopic frame for a tent. The telescopic frame for the tent comprises a small-diameter rod, a large-diameter rod and a clamping connecting device, wherein the small-diameter rod and the large-diameter rod are connected through the clamping connecting device, a plurality of through holes are distributed in the large-diameter rod at equal intervals, the clamping connecting device is embedded in a groove in the small-diameter rod, and the groove is shaped like a Chinese character 'tu'. The multiple through holes are distributed in the large-diameter rod at equal intervals, the clamping connecting device is embedded in the groove in the small-diameter rod, a clamping connector of the clamping connecting device is clamped in the groove, and the height of the supporting frame is fixed. When adjustment is needed, the clamping connector is pressed, a spring is deformed, and the height of the telescopic frame is adjusted.

Owner:张琪

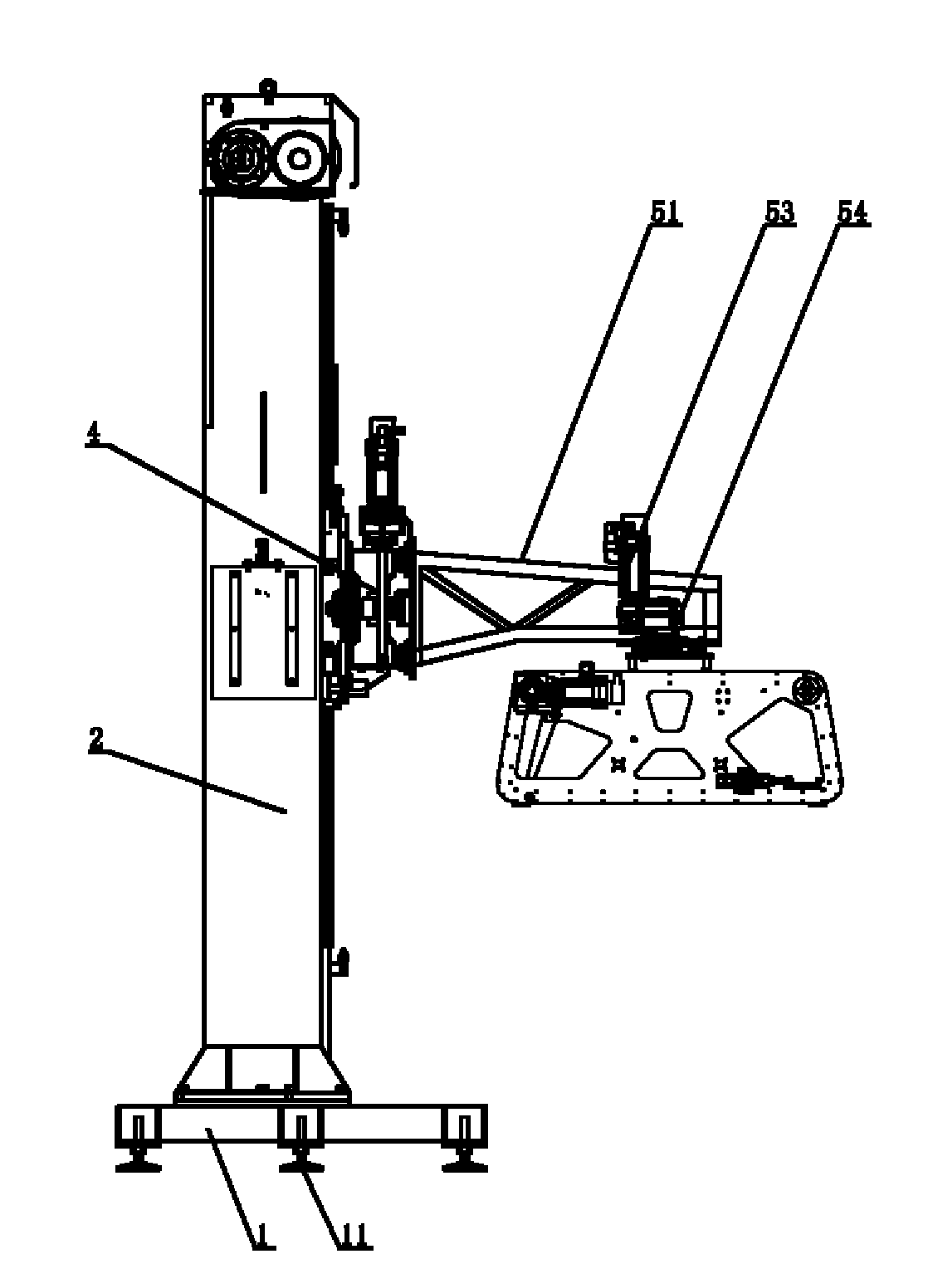

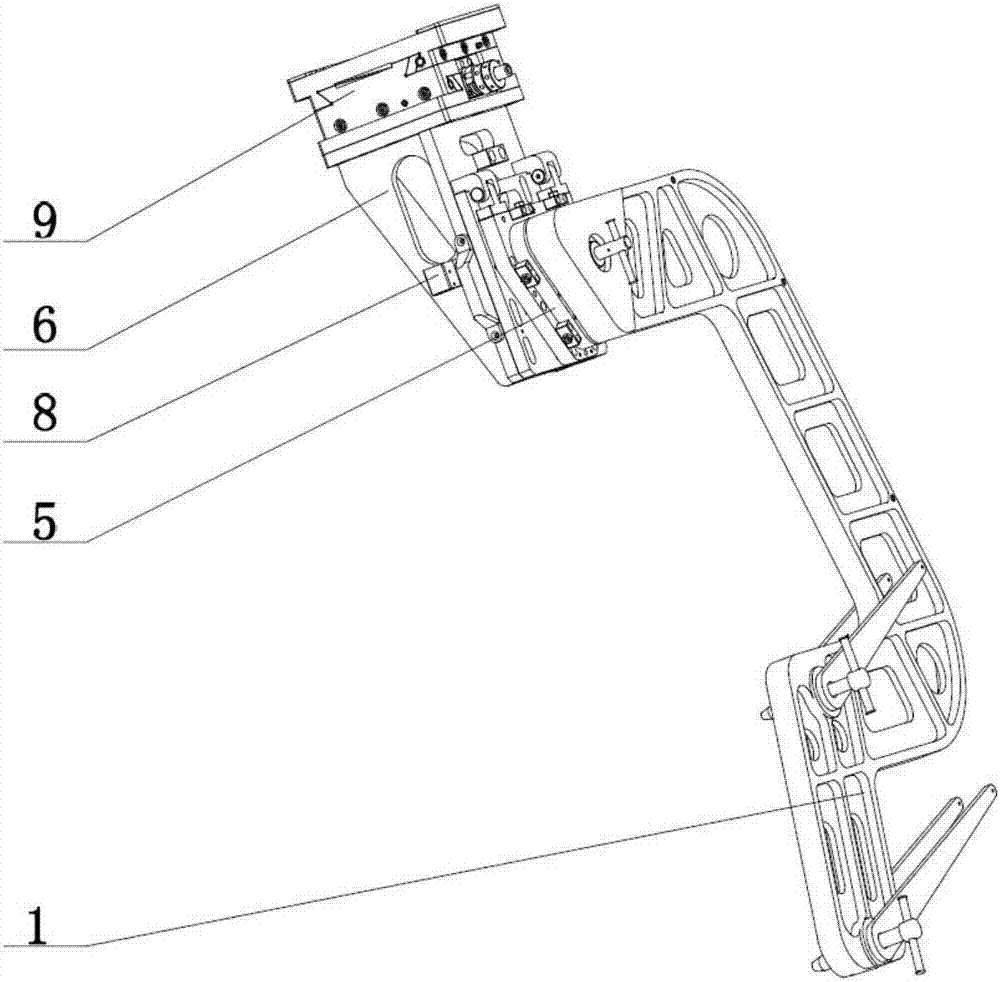

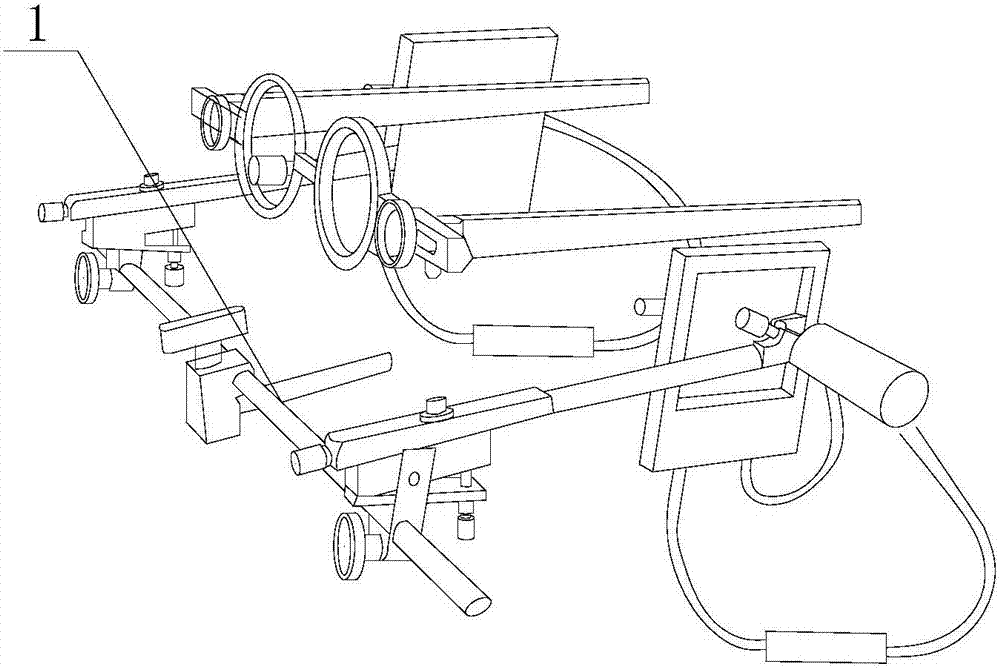

Positioning tool of aircraft wing box leading edge technological connector

The invention discloses a positioning tool of an aircraft wing box leading edge technological connector and belongs to the technical field of aircraft assembly. The positioning tool comprises a base unit, a support connected with the base unit and an intersection point positioning plate connected with the support. An adjusting unit is further arranged between the intersection point positioning plate and the support. The adjusting unit comprises a connecting plate, a first adjusting plate and a second adjusting plate. The connecting plate is connected with the support through a locking bolt, the first adjusting plate is rotatably connected with the connecting plate through a transverse rotary shaft, and the second adjusting plate is rotatably connected with the first adjusting plate through a longitudinal rotary shaft. Tapered bosses are evenly distributed on the second adjusting plate, tapered grooves matched with the tapered bosses are formed in the intersection point positioning plate, and the intersection point positioning plate penetrates through the second adjusting plate through a threaded positioning pin to be connected with the first adjusting plate. The intersection point positioning plate is provided with an interval spacer through the positioning pin. The positioning tool of the aircraft wing box leading edge technological connector is simple in structure and high in automatic degree.

Owner:ZHEJIANG UNIV

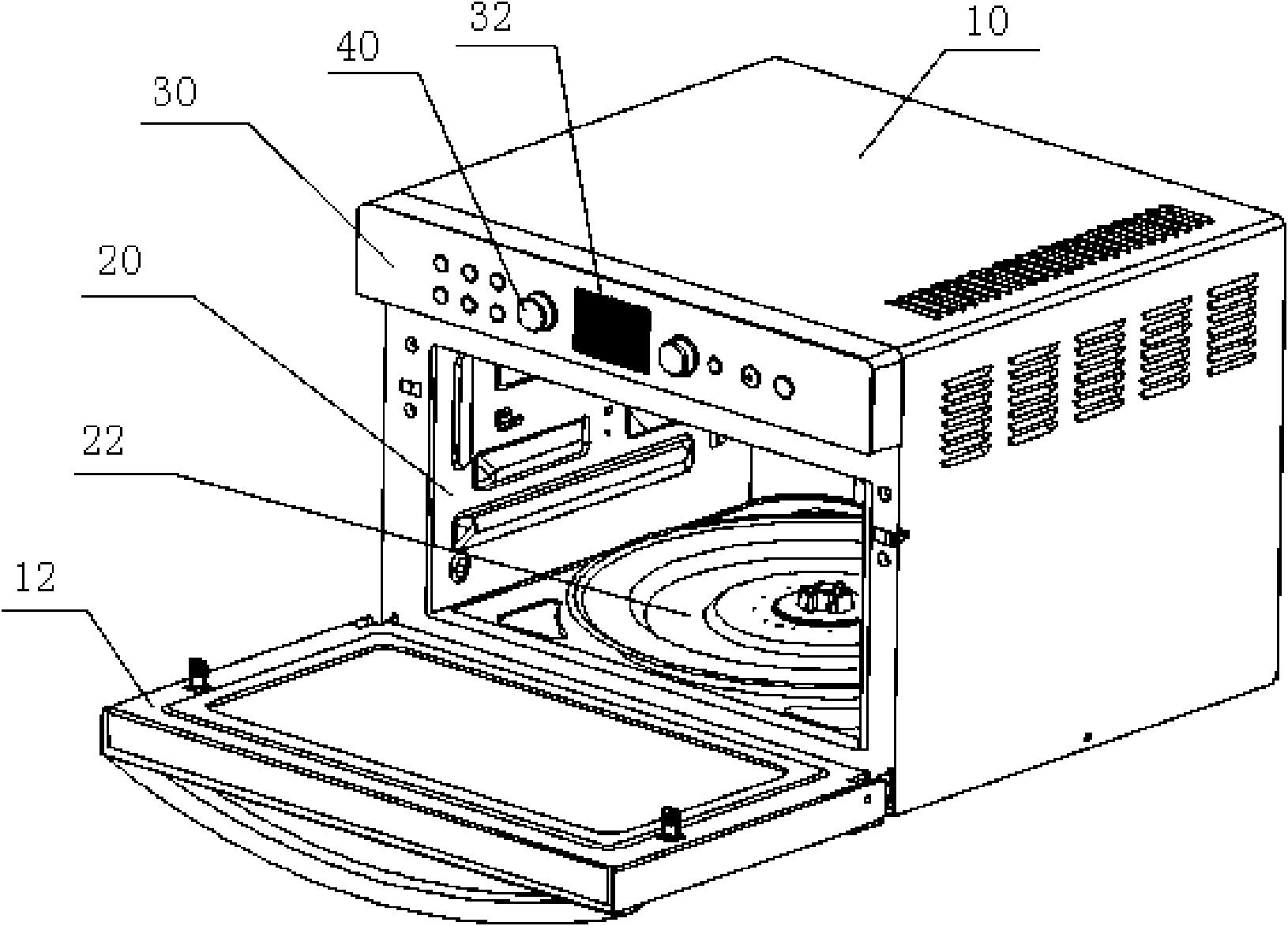

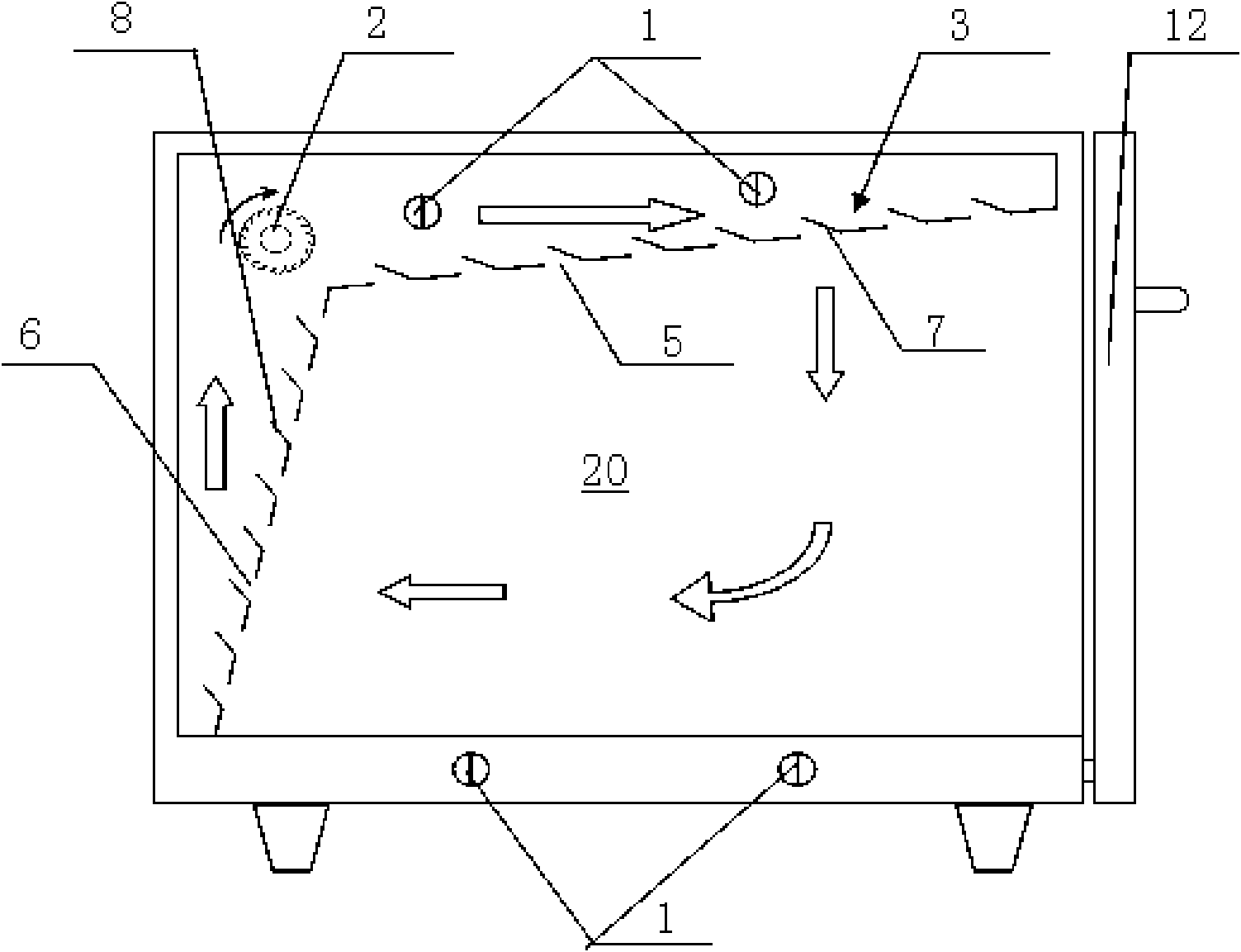

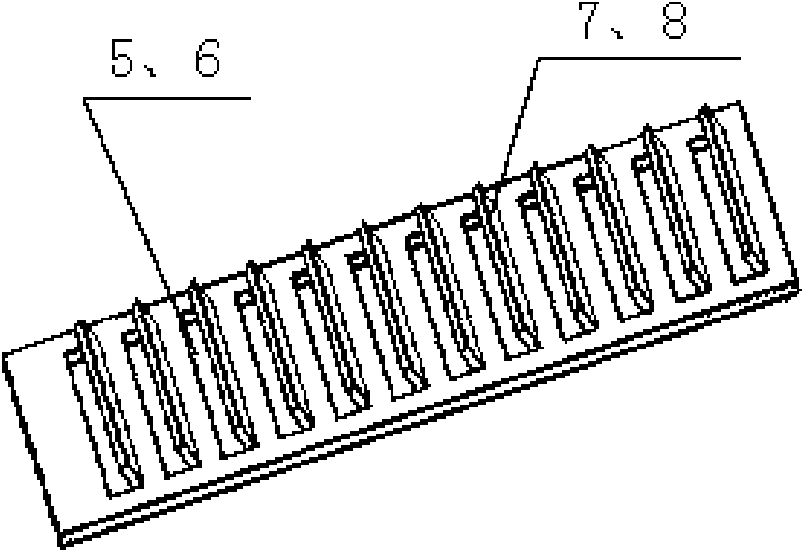

Cooking device internal hot air convection system using cross-flow fan

The invention relates to a cooking device internal hot air convection system using a cross-flow fan, which comprises a cooking cavity, a roasting tube arranged inside the cooking cavity, and a door for opening / closing the cooking cavity. A louver for spatially partitioning the roasting tube and the cooking cavity is also arranged inside the cooking cavity, a cross-flow fan parallel to the surface of the door is arranged on the inner side of the upper part of the cooking cavity, the louver is arranged at the top and the rear part of the cooking cavity and is positioned inside the space formed by the louver and the upper and the rear walls of the cooking cavity, an air inlet and an air outlet for air ventilation are formed on the surface of the louver, and the roasting tube is arranged between the air outlet and the cross-flow fan. According to the invention, the cross-flow fan replaces the centrifugal fan in the prior art, so that the hot air in the air cooking cabinet circularly flows; and the air outlet and an air return can guide the direction of the hot air, resulting in uniform flow of the hot air, good heat conduction effect and uniform heating of food.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

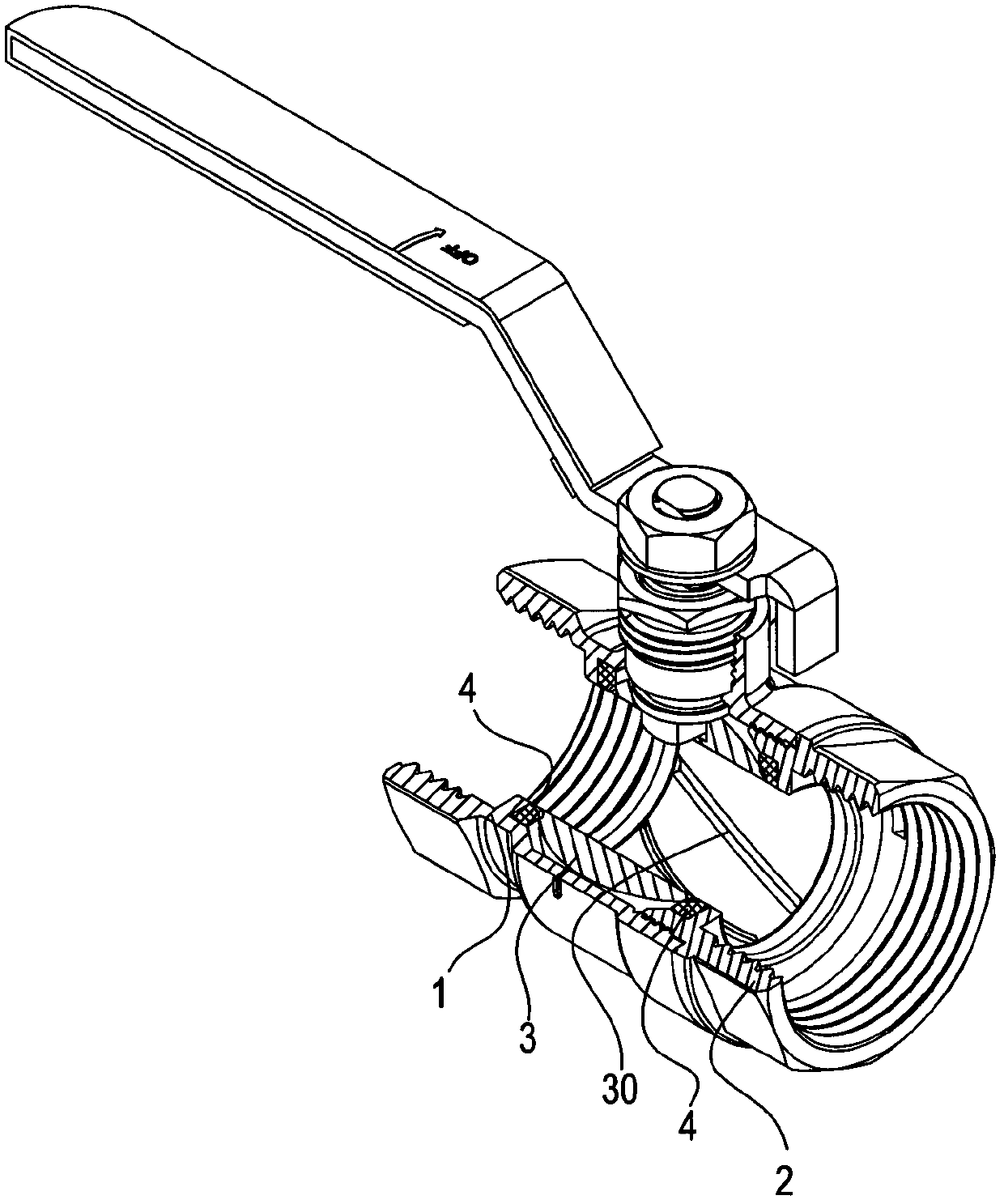

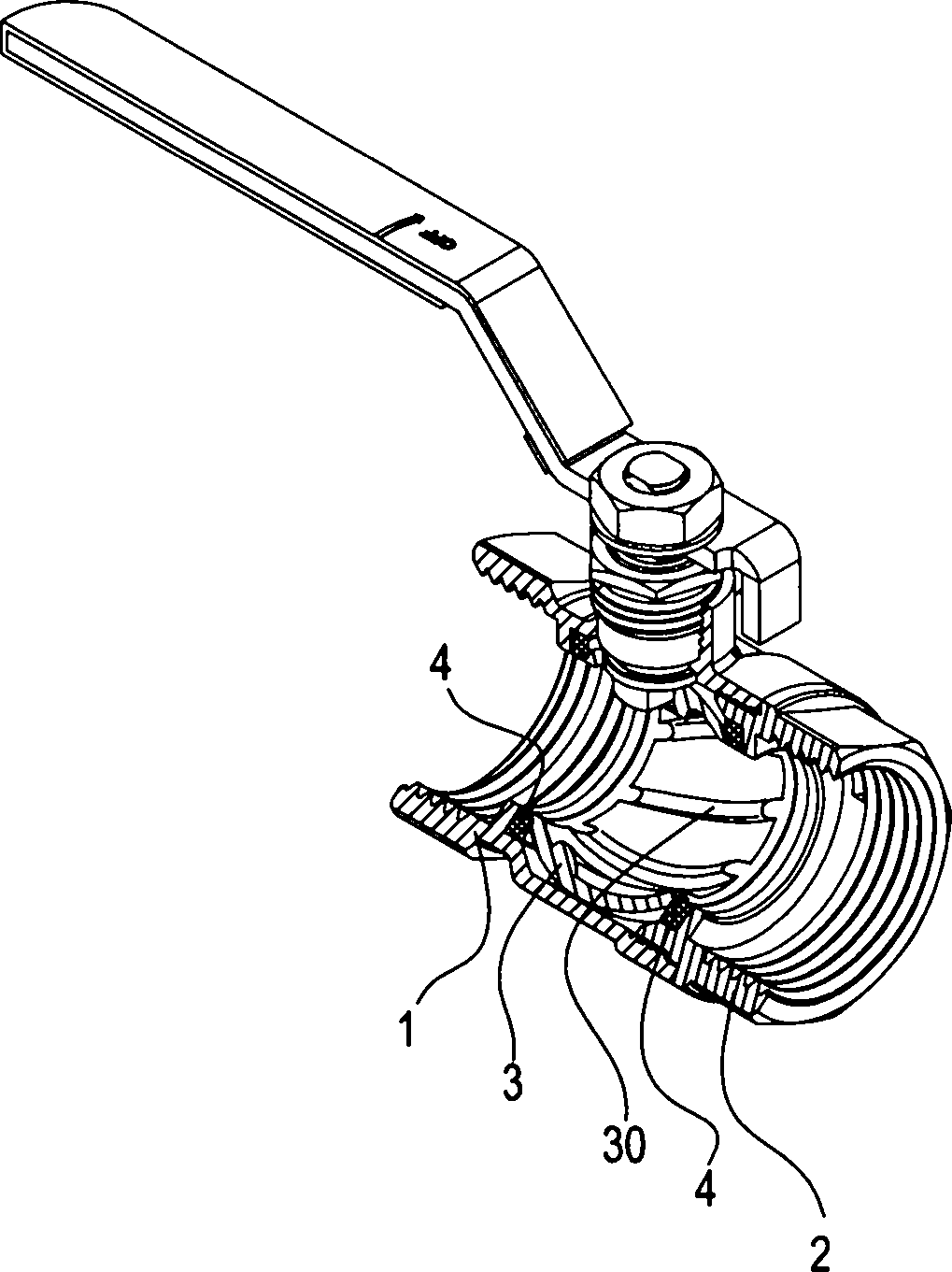

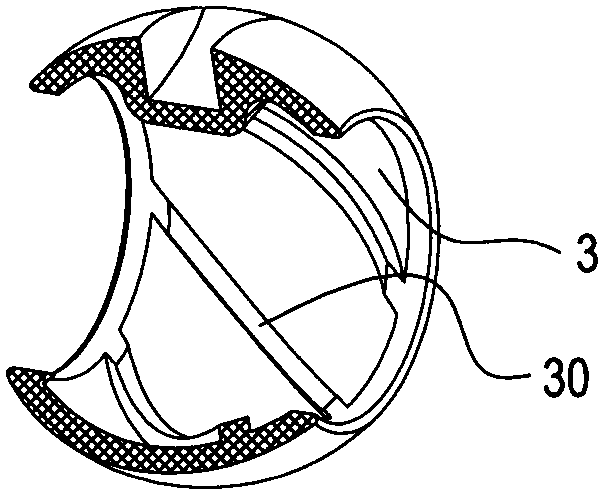

Ball valve with valve ball having spiral silencing function

ActiveCN104006213AReduce noiseReduce impact damagePlug valvesValve members for absorbing fluid energyAdditional valuesEngineering

The invention relates to a ball valve in the building water supply and drainage pipeline field. The ball valve comprises a ball valve body, a ball valve cap matched with the ball valve body and a valve ball arranged between the ball valve body and the ball valve cap, wherein the valve ball is clamped by sealing rings 4 at the two sides, more than one diversion rib is arranged on the inner wall of the valve ball, and an included angle between the diversion rib and the center line of the valve ball is in the range of 3-50 degrees. In the ball valve with the valve ball having a spiral silencing function, a fluid medium is guided via the spiral diversion rib on the valve ball, fluid impact is reduced, so that noise is reduced; and compared with the prior art, the ball valve has the advantages of simple structure, low processing difficulty and high practicability, can be applicable to normal and required building occasions, and has high product additional value and good market demand.

Owner:SPECIAL VALVE JIANGSU FLUID MASCH MFG CO LTD

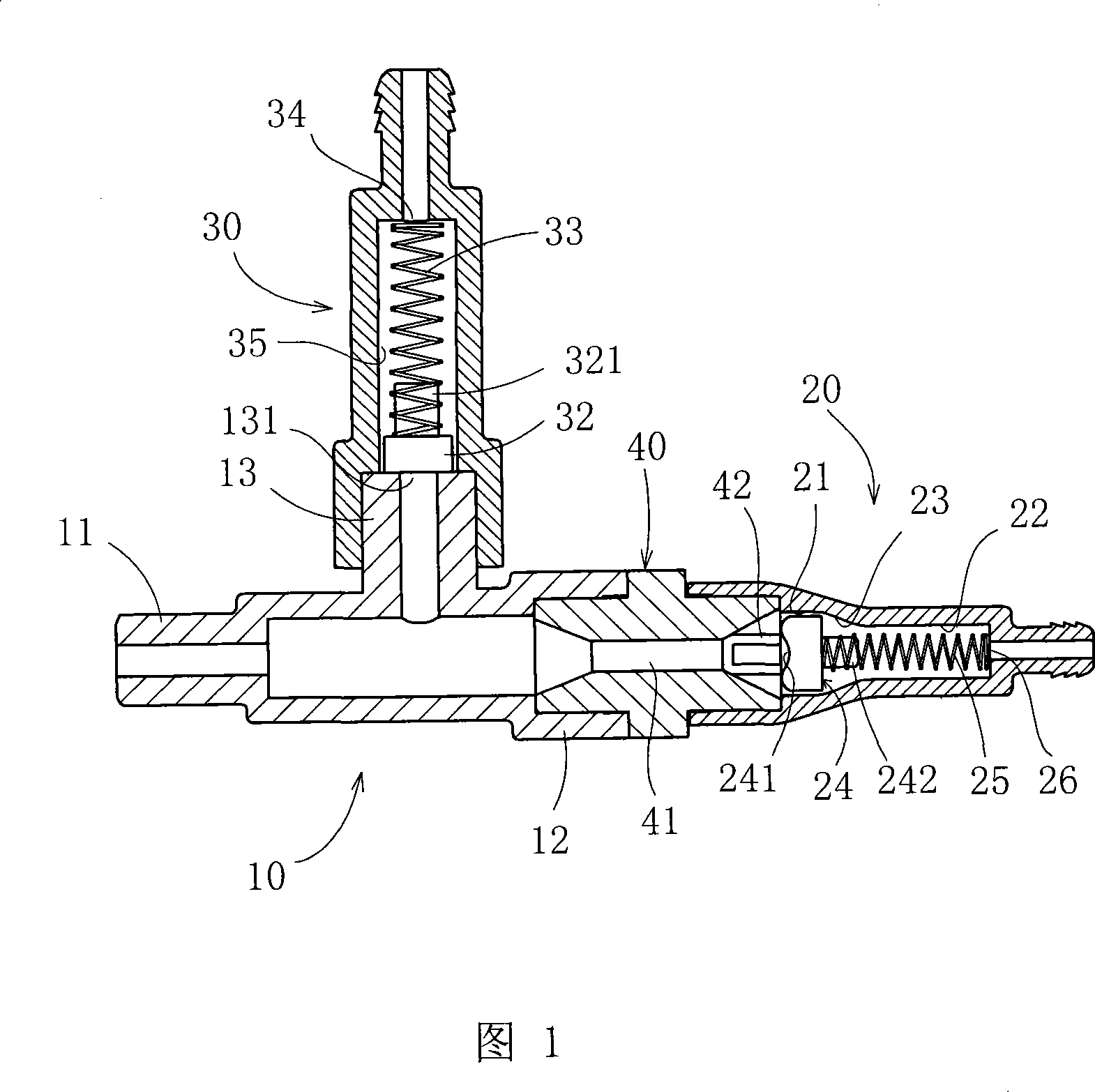

Pressure water valve

InactiveCN101074740ASimple structureEasy to implementEqualizing valvesMultiple way valvesDirect controlEngineering

A compressed water pump, including a T-type single sweep tee 10 with a water inlet, the first water outlet 11 and the second water outlet 12. There are a reducer 20 in 11 and a straight tube 30 in 12 and in the 20 and 30 there are closing plugs 24 & 32 and spring 25 & 33 . 24 & 25 can traverse move in the reducer and open or cap the water entryway. When water pressure is lower than pressure of 25, the inner water tube in the reducer is open; when water pressure is lower than pressure of 33, the inner water tube in the straight tube is closed; when water pressure is lower than pressure of two springs, water flows outlet from the opening reducer; when water pressure is higher than pressure of two springs, water flows outlet from the straight tube. This invention can control which water outlet open by changing water pressure.

Owner:陈达

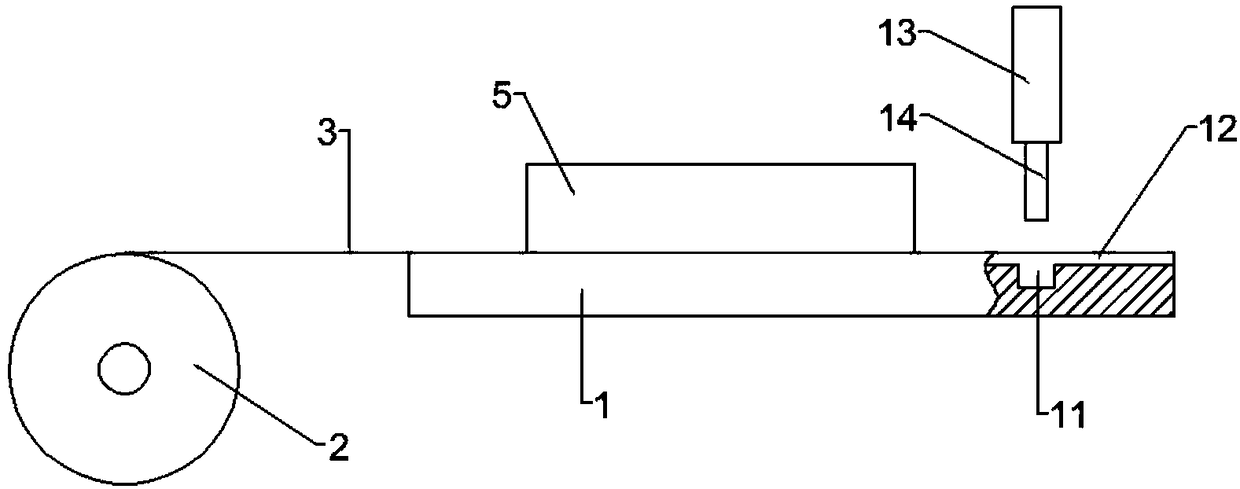

Copper wire cutting equipment having propelling function

The invention provides copper wire cutting equipment having a propelling function. The copper wire cutting equipment comprises a worktable and a wire unwinding roller; the upper surface of the worktable is provided with a guide groove; a copper wire is placed inside the guide groove; the left end of the copper wire is intertwined on the wire unwinding roller; the parts, positioned at the front andrear sides of the guide groove, of the worktable are symmetrically and fixedly connected with two mounting columns; each mounting column is in a cuboid shape and is provided with a moving groove; each moving groove is internally provided with a moving block; and each moving block is provided with a threaded through hole. The copper wire cutting equipment provided by the invention has the beneficial effects that the copper wire can move inside the guide groove; the guide groove plays a certain guiding role on the copper wire and can also be used for straightening the pre-bent copper wire; a second motor is used for driving a rotating shaft to rotate; the rotating shaft is used for driving a second bevel gear to rotate; the second bevel gear is used for driving a first bevel gear to rotate;the first bevel gear is used for driving a vertical threaded rod to rotate; an extending rod matched with the vertical threaded rod extends out of a groove so as to drive a clamping plate to clamp and fix the copper wire, and thus the copper wire can be conveniently driven to move.

Owner:HUIAN WEIKE ELECTRONICS TECH CO LTD

Temporomandibular joint deformity correction system and method for making personalized deformity correction device

InactiveCN107510511ANo changeGuide orthodontic treatmentOthrodonticsTemporomandibular jointSkull surface

The invention discloses a temporomandibular joint deformity correction system and a method for making a personalized deformity correction device. The method comprises 1, analyzing an occlusal function through an occlusion analysis system to determine an occlusion position, 2, preparing original upper and lower jaw models according to the occlusion analysis system and re-positioning an occlusion plate through patient wearing with the original upper and lower jaw models, 3, carrying out re-examination on the patient each month, 4, after re-examination, determining whether the occlusion position is correct and carrying out deformity correction, 5, stabilizing the occlusion position and carrying out a tooth arrangement test, and 6, producing the personalized deformity correction device according to the tooth arrangement model after the tooth arrangement test. Compared with the prior art, the system realizes personalized tooth arrangement through combination of an adjustable frame, function analysis and projective measurement analysis according to the patient's skull surface type, utilizes a covering material to precisely control the position of the occlusion position, prevents occlusion position change, evaluates the tooth movement amount in a visual state through 3D data scanning before and after tooth arrangement and provides good deformity correction treatment guidance for later treatment.

Owner:刘洋

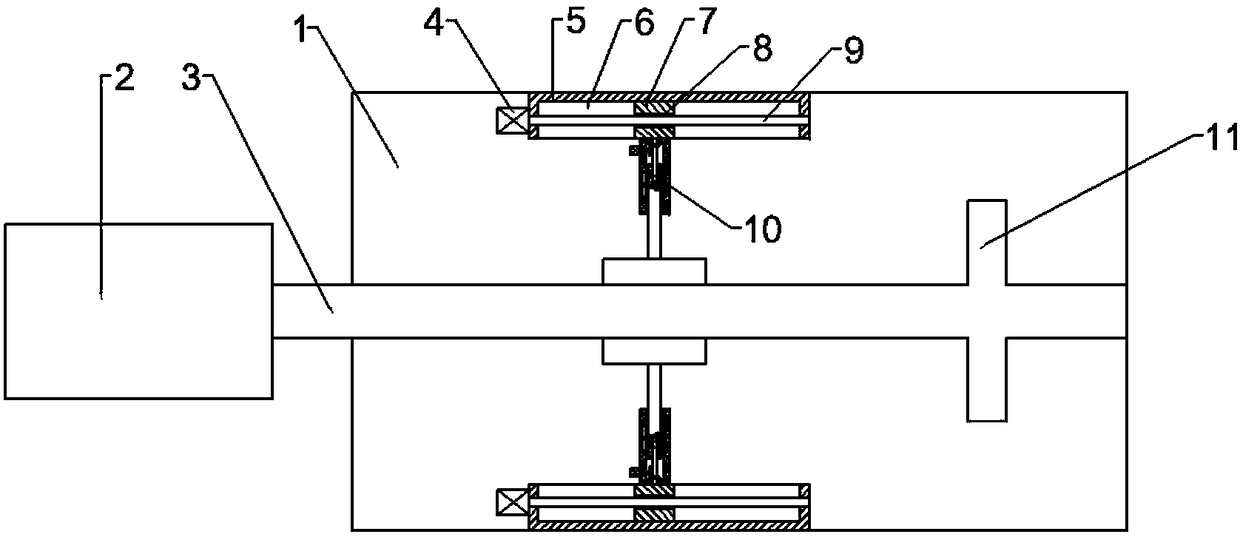

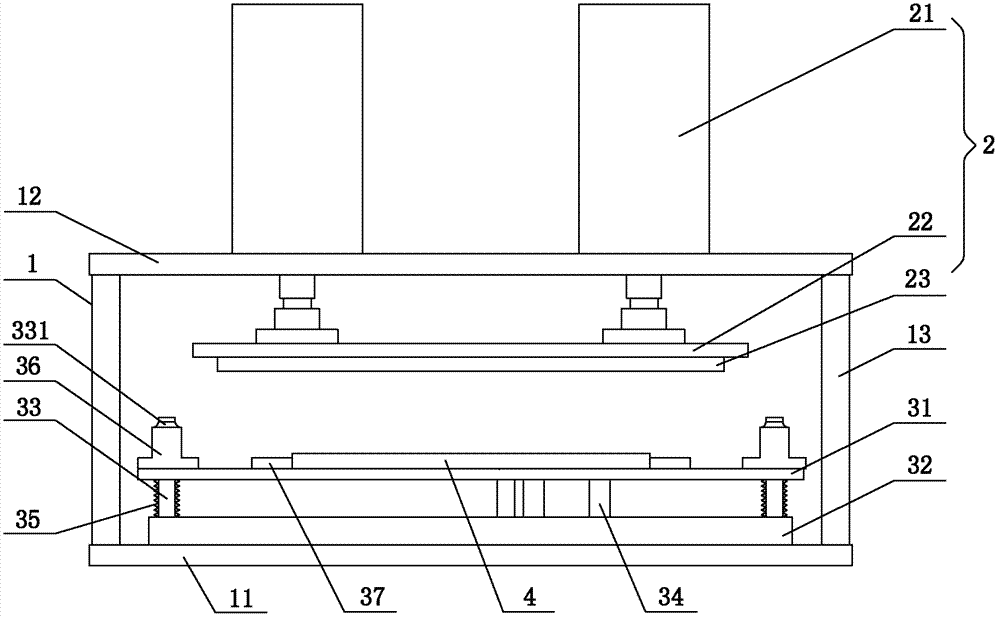

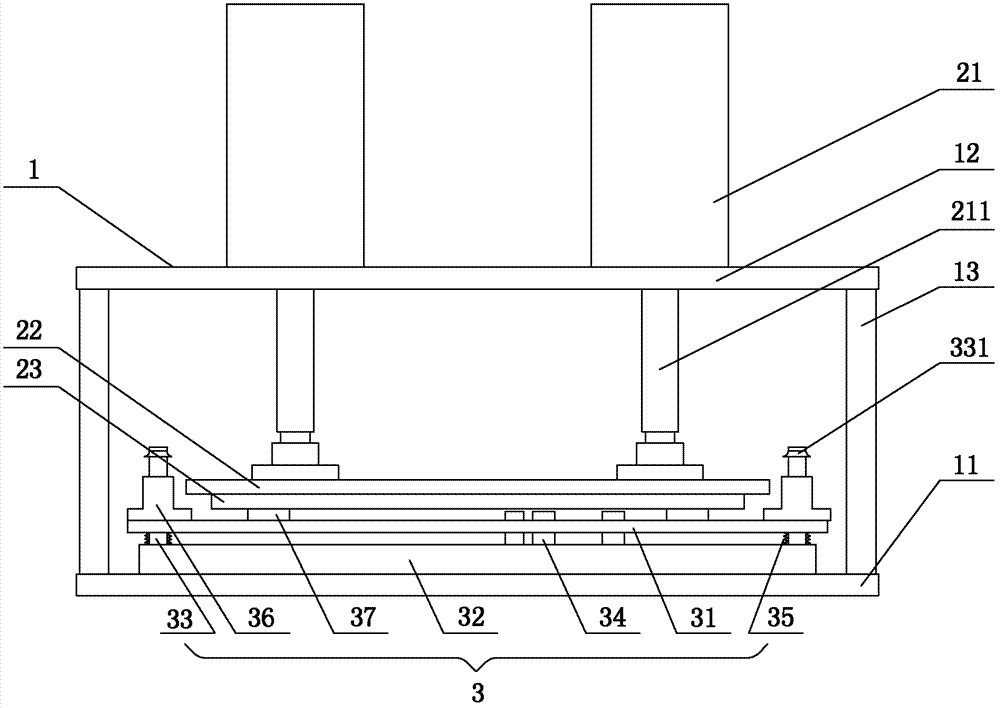

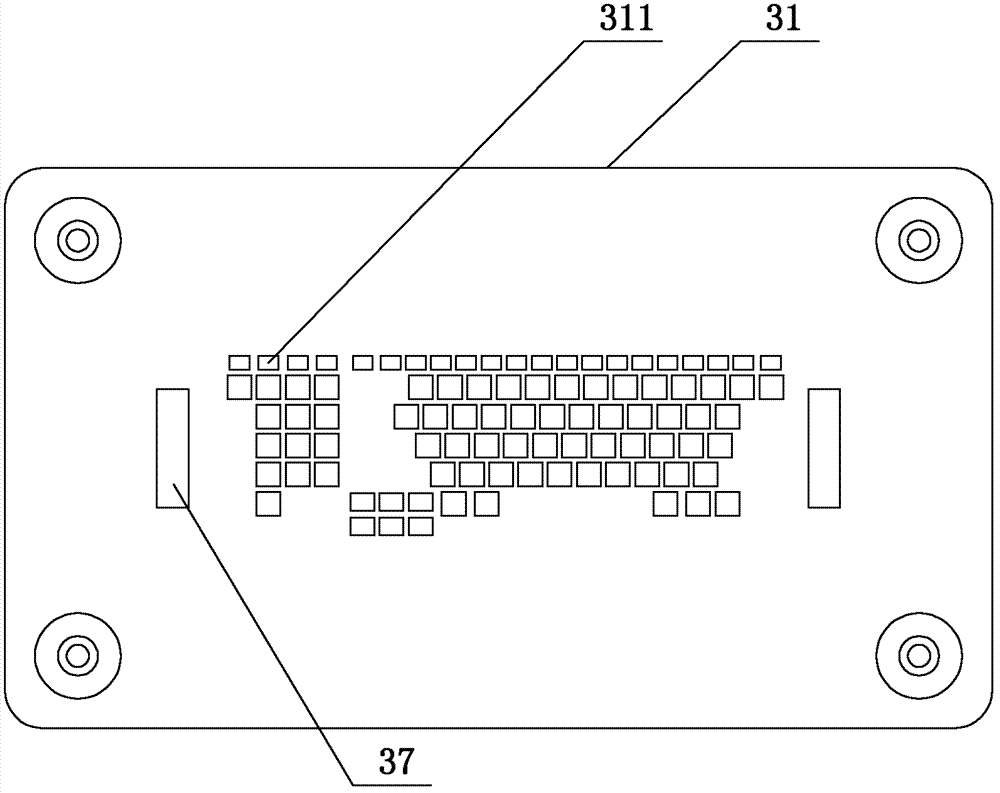

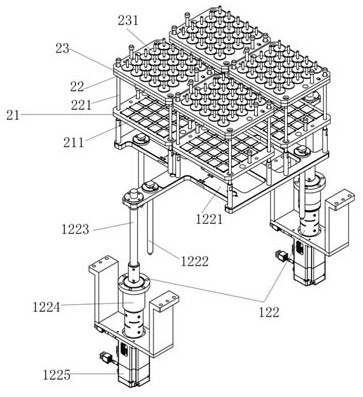

Semi-automatic keycap press

The invention relates to a semi-automatic keycap press, comprising a table supporting frame, a pushing module, an ejecting module and a keycap arranging mould disc, wherein the table supporting frame consists of a base plate, a top plate and four supporting columns; the pushing module is provided with an air cylinder, a pushing plate and a pressing plate; the air cylinder is arranged on the top plate, and a piston rod of the air cylinder extends out of the top plate; the pushing plate is connected with the lower end of the piston rod; the pressing plate is connected with the lower part of the pushing plate; the ejecting module is provided with an upper supporting plate, a lower supporting plate, four guide columns and a support column; the lower supporting plate is fixedly arranged on the base plate; the four guide columns are respectively arranged on four corners of the lower supporting plate; the upper supporting plate is provided with a through hole and is connected with the four guide columns in a sliding manner; a spring is respectively sleeved on the guide columns between the upper supporting plate and the lower supporting plate; the support column is arranged on the lower supporting plate below the through hole and corresponds to a keycap arranging slot on the keycap arranging mould disc; and the keycap arranging mould disc is detachably arranged between two mould disc locating blocks. The semi-automatic keycap press disclosed by the invention has the advantages of capabilities of reducing operation intensity of labors and improving operation efficiency.

Owner:QUNGUANG OPTOELECTRONICS SUZHOU

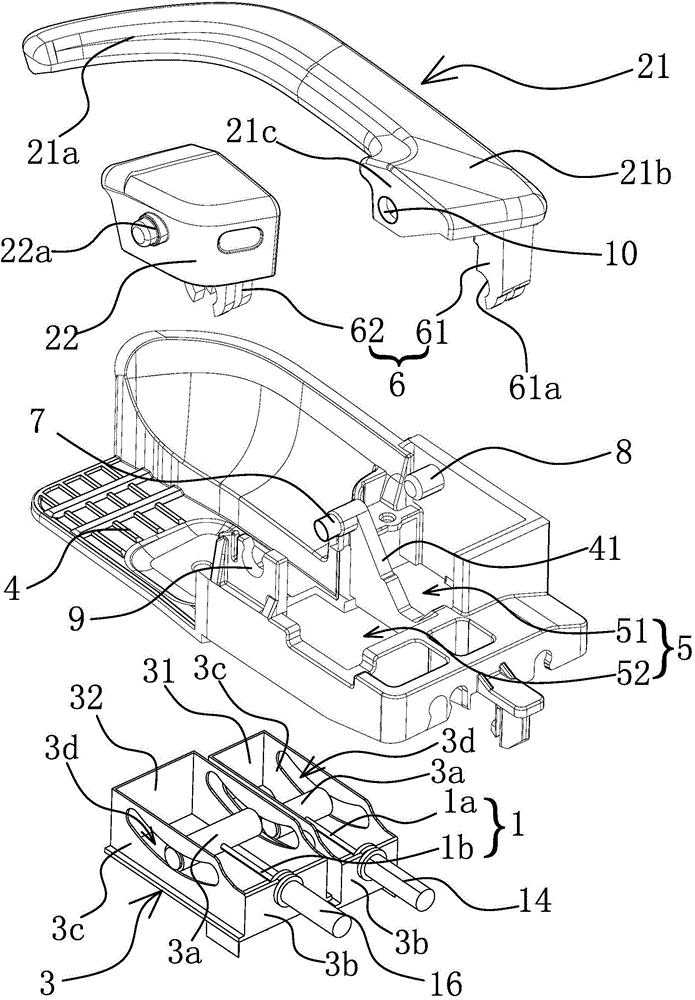

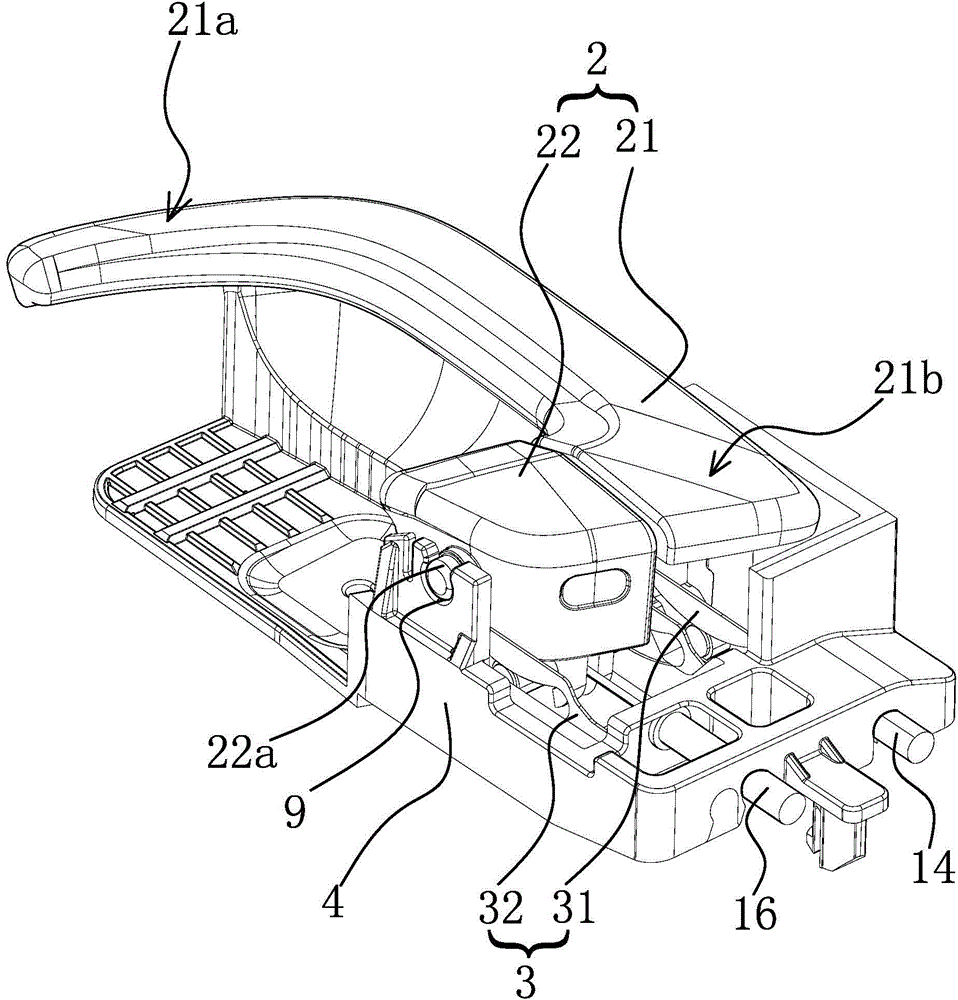

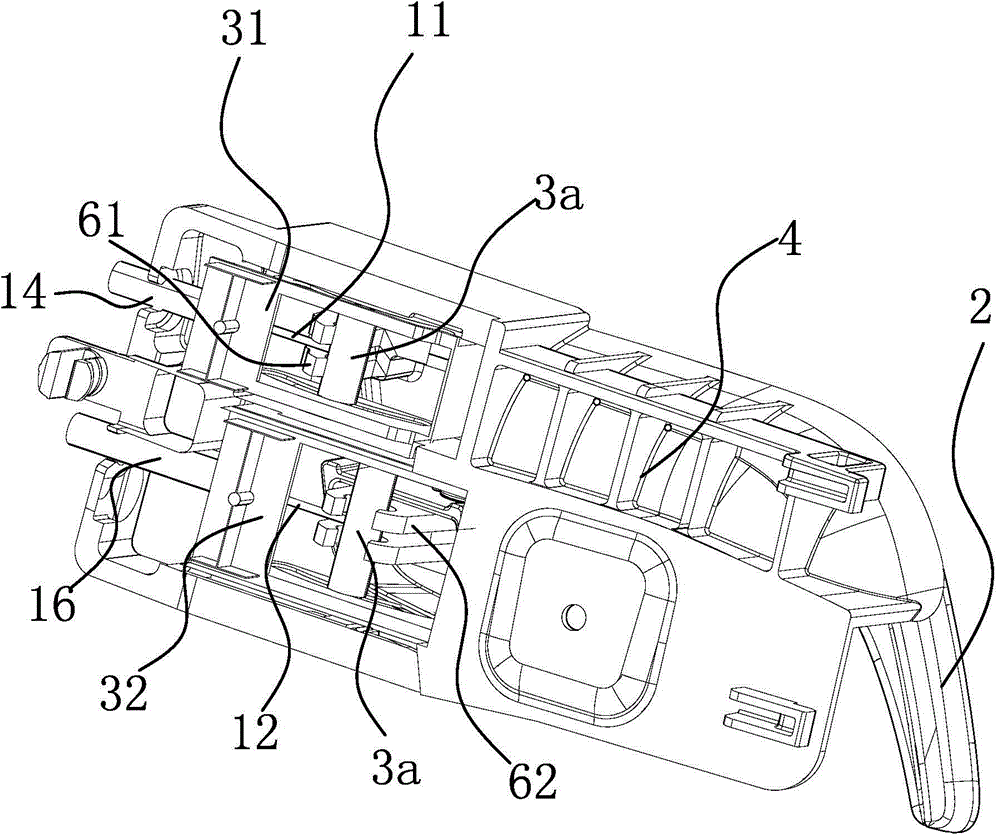

Mounting structure for automobile door lock

ActiveCN104631972ASimplify the installation processImprove assembly speed and accuracyVehicle locksCar doorDoor handle

The invention provides a mounting structure for an automobile door lock, and belongs to the technical field of automobiles. The mounting structure solves the problems that a door handle and door lock pull wires of an automobile cannot be assembled easily and time and labor are consumed in the prior art. The mounting structure for the automobile door lock comprises door lock pull wires, a door handle, a fixed base and a door guard board which is mounted on an automobile body. The door guard board is provided with a mounting cavity, the door handle is located on one side of the door guard board and hinged to the door guard board, and the other side, facing the door guard board, of the mounting cavity is opened. The fixed base is arranged in the mounting cavity, and the fixed base is provided with sliding columns in a sliding mode. The door handle is fixedly connected with a shifting piece which can drive the sliding columns to slide on the fixed base when the door handle is pulled, and one end of each door lock pull wire is connected to the corresponding sliding column. The mounting structure for the automobile door lock has the advantage of being convenient and fast to mount.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

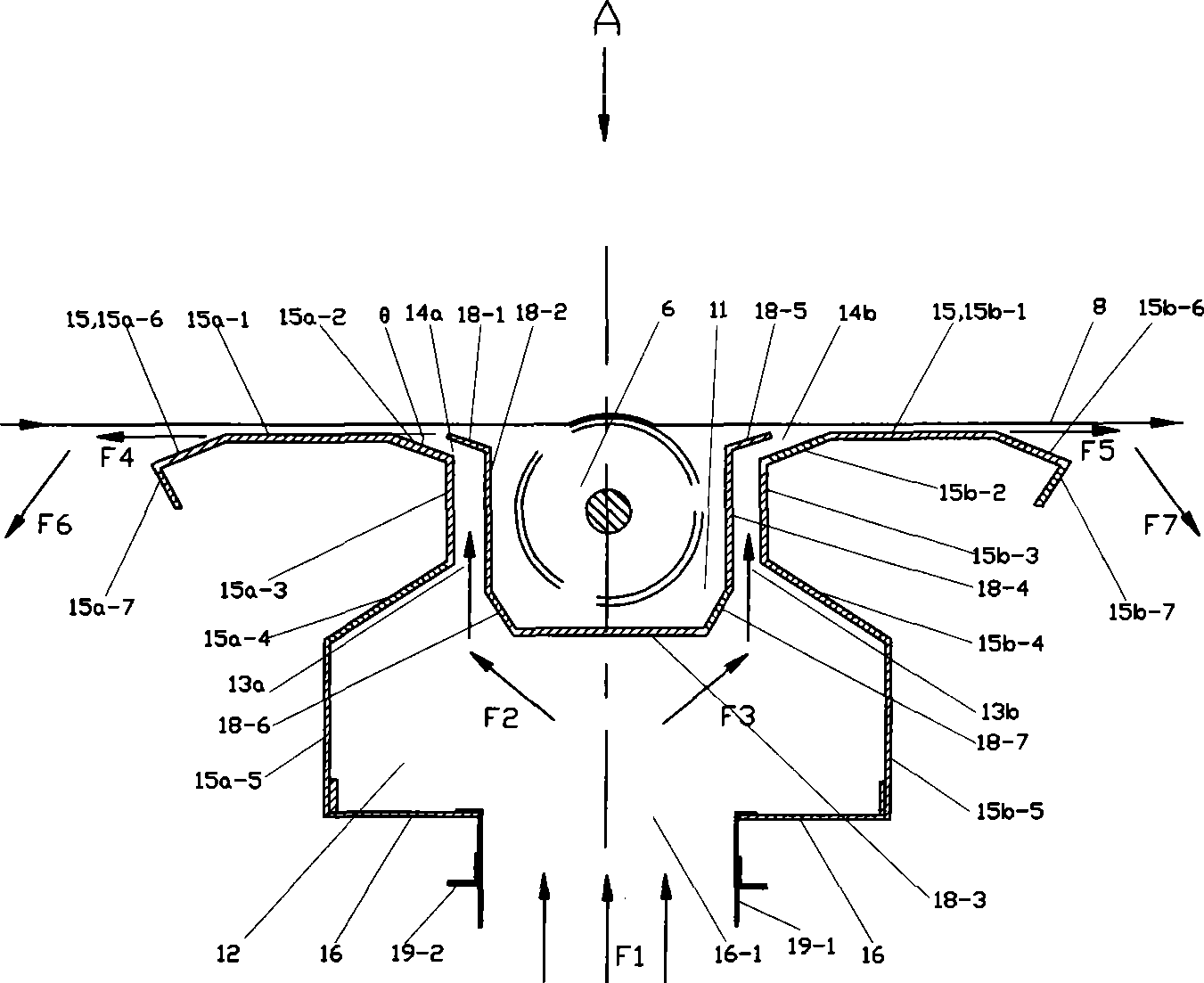

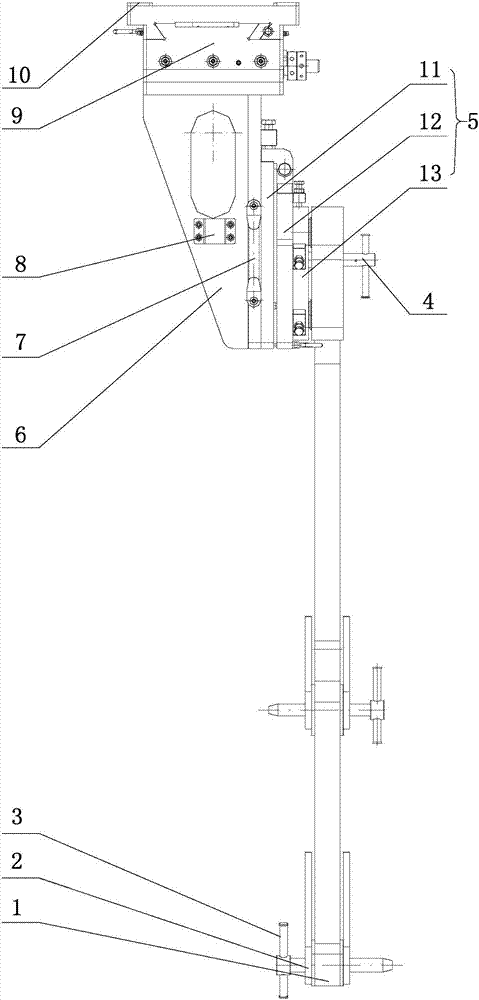

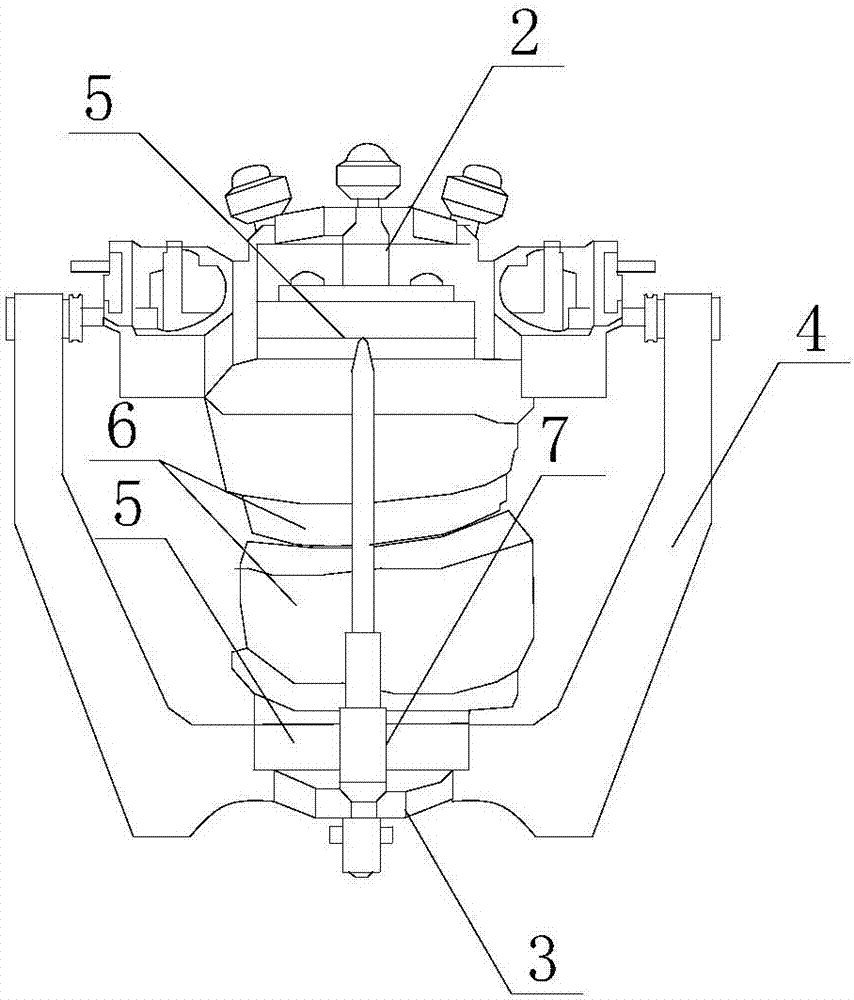

Pipe hammer system of percussion drill for rock-socketed inclined pile and impact construction method of rock-socketed inclined pile

ActiveCN104047542AHas a guiding roleEnsure consistencyBorehole drivesBulkheads/pilesEconomic benefitsDrill

The invention discloses a pipe hammer system of a percussion drill for a rock-socketed inclined pile and an impact construction method of the rock-socketed inclined pile. By utilizing the pipe hammer system of the percussion drill, the hammer clamping is greatly reduced, and a hammer body has a guide effect, so that the high efficiency of a plum blossom percussion drill and the guidance quality of an abrasion drill are provided, the requirement of impact energy is met, and meanwhile, a formed hole is guaranteed to be the same as or be close to the axis of a pile casing; the consistency of the axis of the hammer body and the axis of a pile foundation is well guaranteed in a construction process, so that the hole forming quality is greatly improved; the hole forming speed is greatly increased through casting an integrally-formed cast steel hammerhead; in comparison with the existing construction method of the rock-socketed inclined pile, the construction method of the rock-socketed inclined pile, which is designed by the invention, has the advantages of simple operation and low construction cost, each pile machine only needs five operators, the construction method has better economic benefit, the hole forming time is shortened, and the hole forming efficiency and the hole forming quality are greatly improved.

Owner:CCCC SECOND HARBOR ENG +1

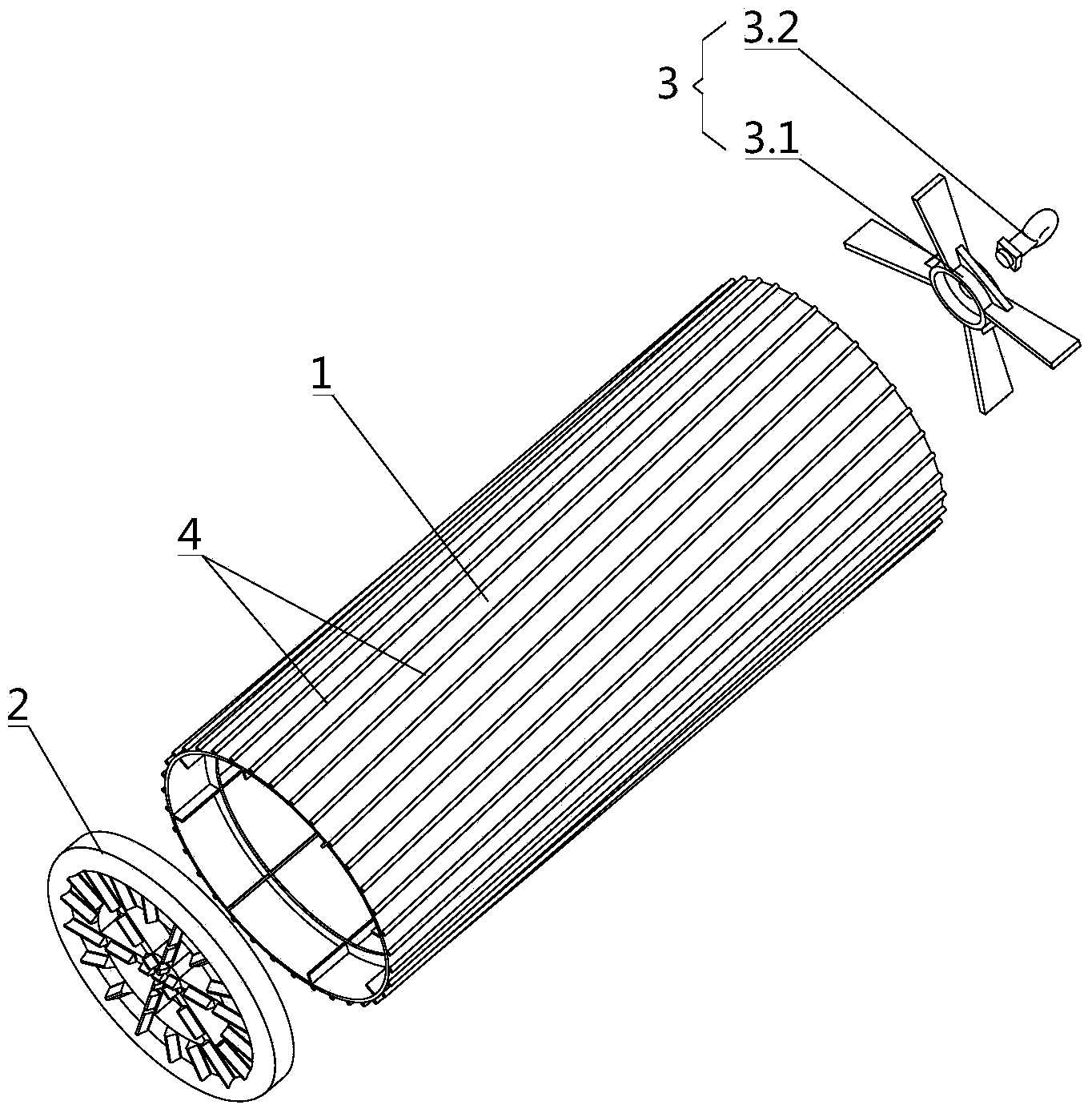

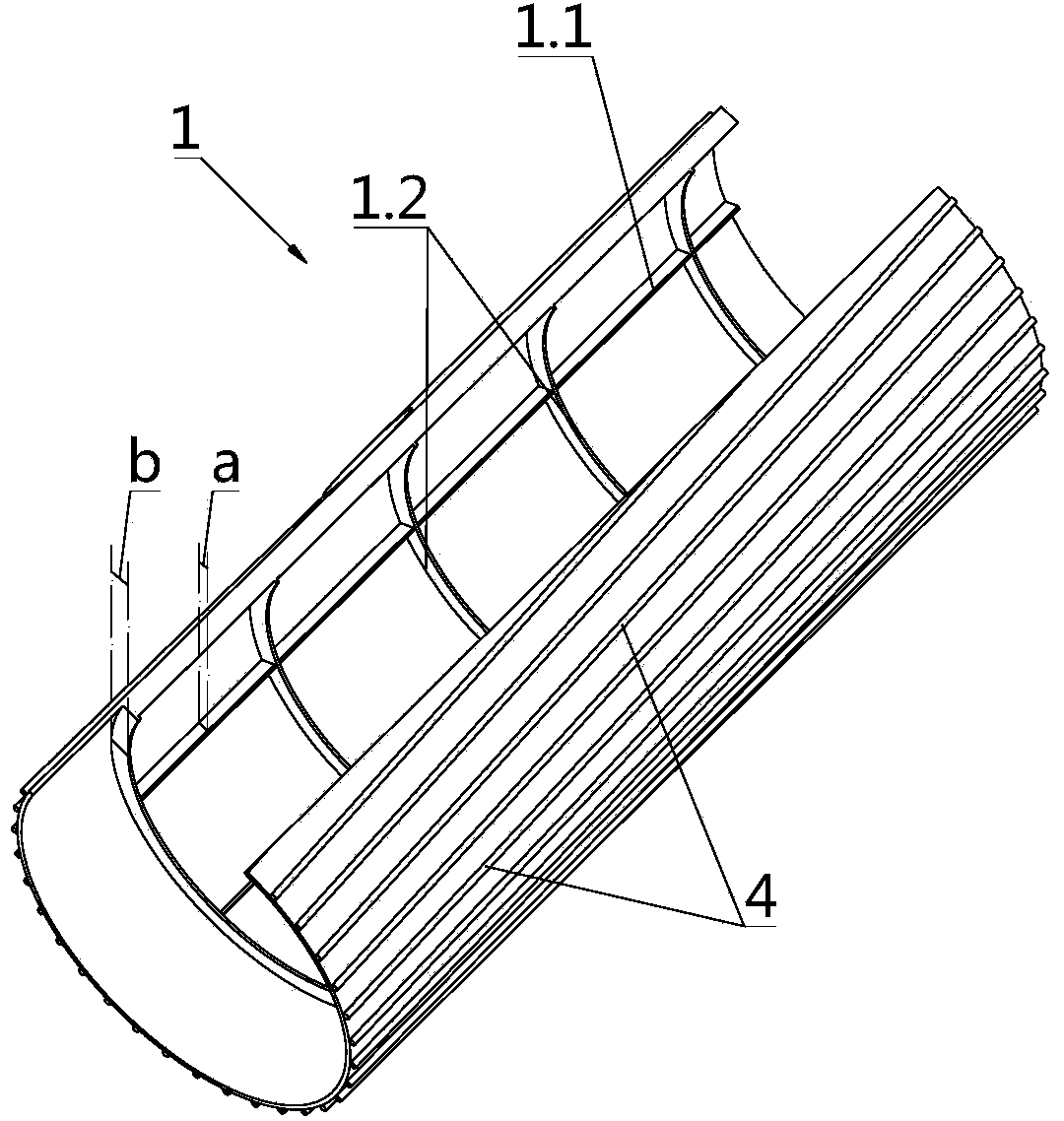

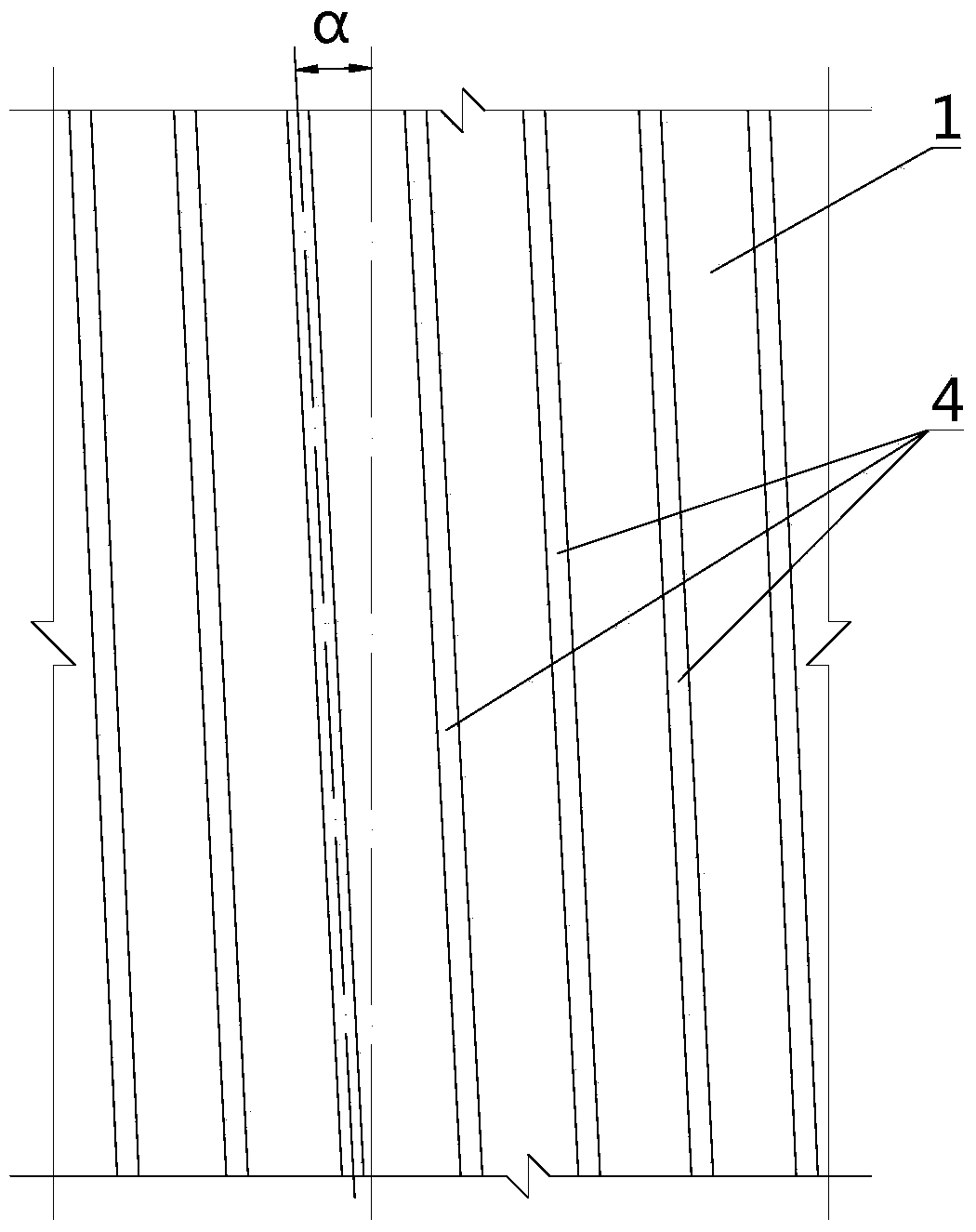

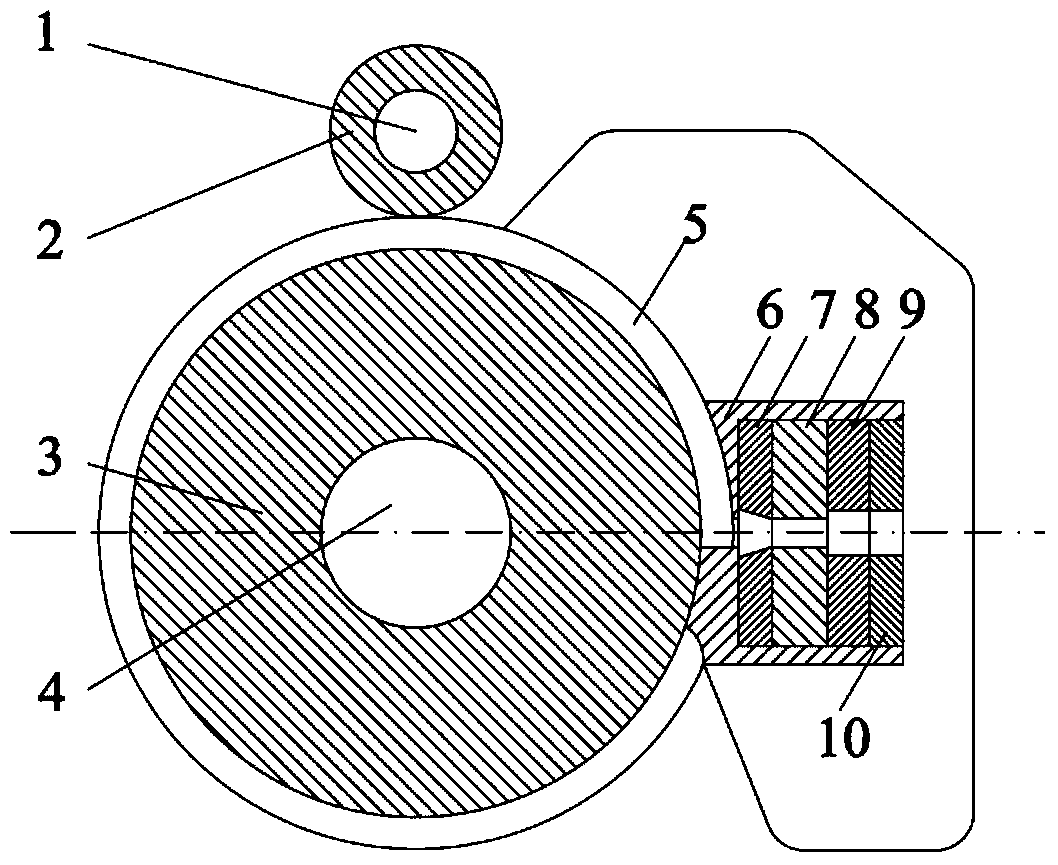

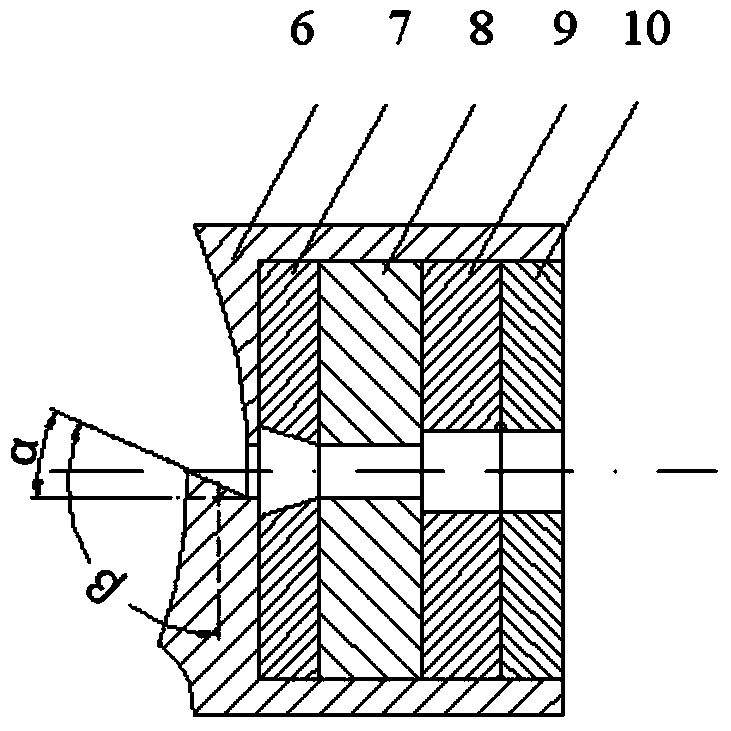

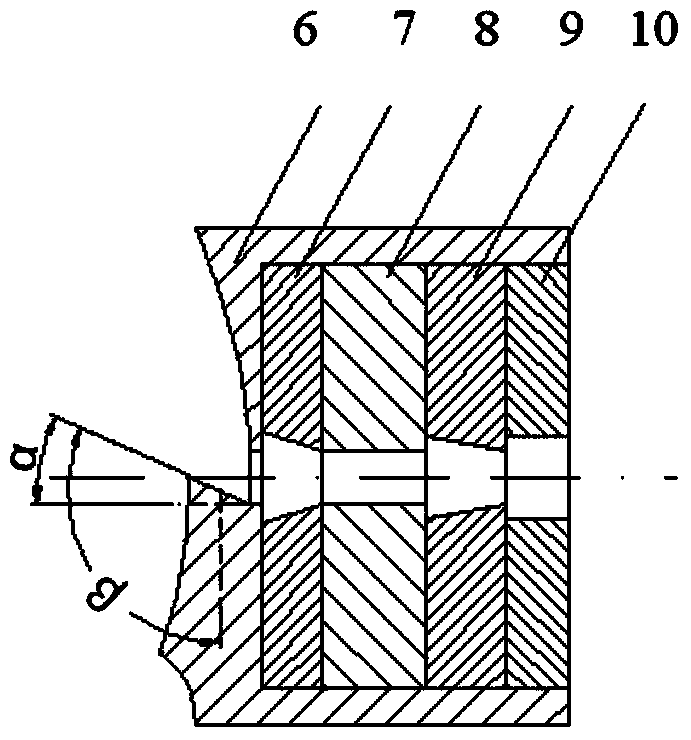

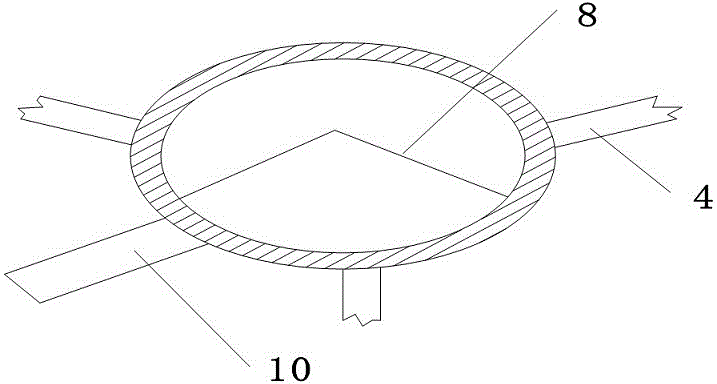

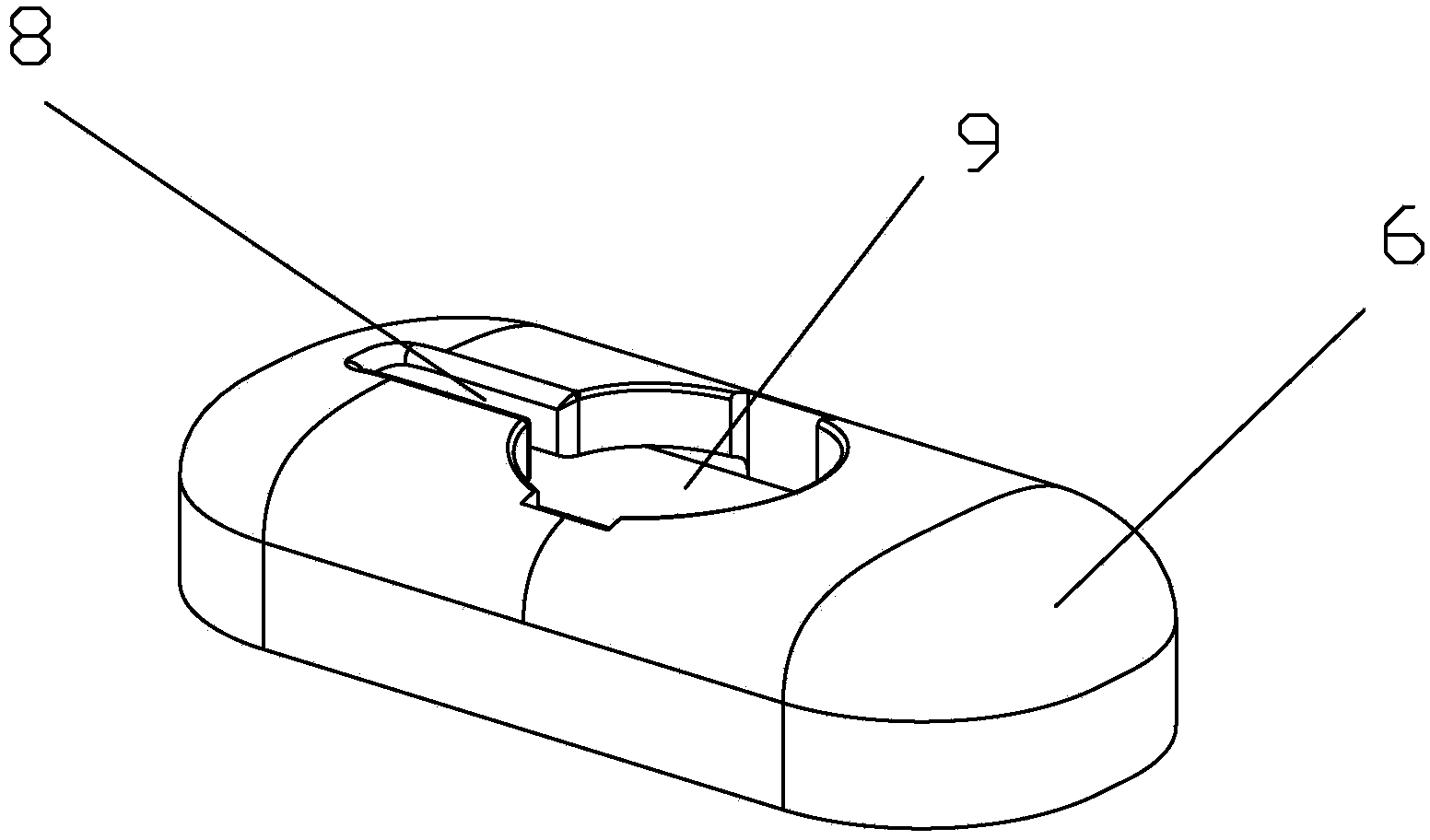

Continuous equal channel angular extrusion combination mould and extrusion method

ActiveCN103464501ASimple methodLow costExtrusion diesAgricultural engineeringEqual channel angular extrusion

The invention provides a continuous equal channel angular extrusion combination mould and an extrusion method. The combination die comprises a cavity (6) with a stock stopping block and a feeding opening, a mould (8) with a sizing strip hole, an inner mould cushion (7), an outer mould cushion (9) and a fastening device (10), wherein the inner mould cushion is located on the inner side of the mould; the outer mould cushion is located on the outer side of the mould; the fastening device is mounted outside the outer mould cushion; the inner mould cushion, the outer mould cushion and the fastening device are provided with inner holes; the feeding opening, the sizing strip hole and the inner holes of the inner mould cushion, the outer mould cushion and the fastening device are concentric; the inner hole of the inner mould cushion is a cone hole; the small-bore end of the cone hole is opposite to the sizing strip hole of the mould; the stock stopping block has a gradient; an angle alpha of the gradient is 0-45 degrees. The continuous equal channel angular extrusion combination mould is simple and practicable, low in cost and easy to maintain, is suitable for various metals, alloys and high polymers and is beneficial to the implementation of equal channel angular extrusion under a condition with different extrusion corners and different back pressures.

Owner:哈尔滨生材新材料科技发展有限公司

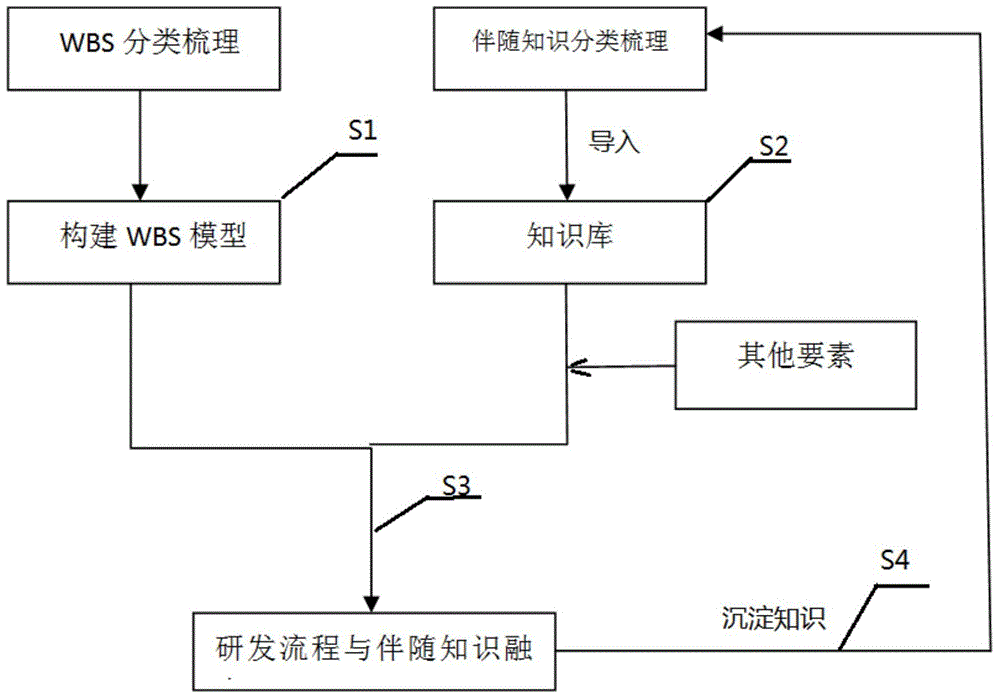

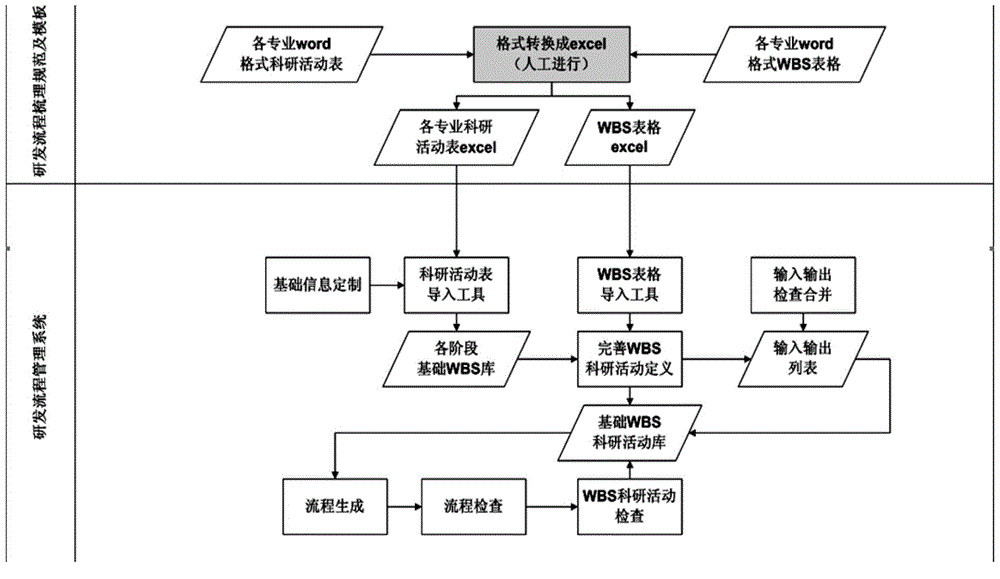

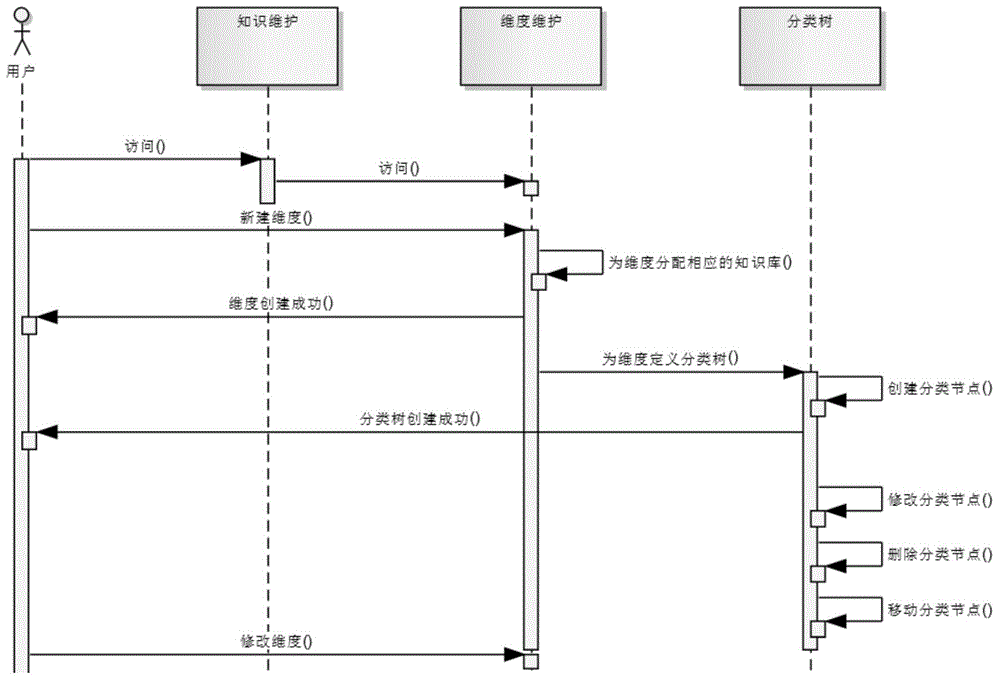

Aircraft research & development process and adjoint acknowledge combined method

InactiveCN104899401APromote accumulationImprove work efficiencySpecial data processing applicationsSoftware development processCombined method

The invention provides an aircraft research & development process and adjoint acknowledge combined method. According to the method, a WBS model is constructed for the aircraft research & development process, in other words, a process conforming to the model is formed based on a basic process according to a specific project, and then the model research work can be carried out; meanwhile, the adjoint acknowledge is sorted out and the sorted-out adjoint acknowledge is imported into a knowledge base; furthermore, the aircraft research & development process and the adjoint acknowledge are combined; in the project planning process, the correlated adjoint acknowledge can be searched; in the execution working process, the related adjoint acknowledge can be checked; the adjoint acknowledge is imported into the knowledge base by sorting out, and correlation-matched with the working unit of the WBS constructed in the research & development process; meanwhile, in the execution process, the occurring new adjoint acknowledge can be continuously imported into the WBS of the research & development process to form a virtuous circle. The aircraft research & development process and adjoint acknowledge combined method is advantageous for the accumulation of the acknowledge and has a guiding effect on the aircraft research & development process; as a result, the working efficiency in the aircraft research & development process can be effectively improved.

Owner:SHENYANG AIRCRAFT DESIGN INST AVIATION IND CORP OF CHINA

Carton indentation device

ActiveCN108928043AAccurate indentationGuaranteed indentation qualityBox making operationsPaper-makingDrive wheelCarton

The invention relates to the technical field of carton processing and discloses a carton indentation device which comprises a transmission mechanism, a convex block and a concave block, wherein the transmission mechanism comprises a driving wheel, a driven wheel and a conveyor belt; the conveyor belt comprises a propulsion part and a bearing part; the propulsion part comprises a connecting plate;a plurality of openings are formed in the connecting plate; the bearing part comprises a plurality of support rods; a fixed disc and a first sliding chute are arranged on one side of the propulsion part; a fixed rod is horizontally arranged between the driving wheel and the driven wheel; the concave block is fixedly connected onto the fixed rod; a first support roller is fixedly connected with theside, close to the fixed disc, of the fixed rod; and a second support roller is in sliding fit with the side, far away from the fixed disc, of the fixed rod. The carton indentation device can adjustthe distance between the two support rollers and the sunken width of an indentation and transmits corrugated boards discontinuously to enable the quality of the manufactured corrugated boards to be higher.

Owner:遵义鸿达纸箱制品有限公司

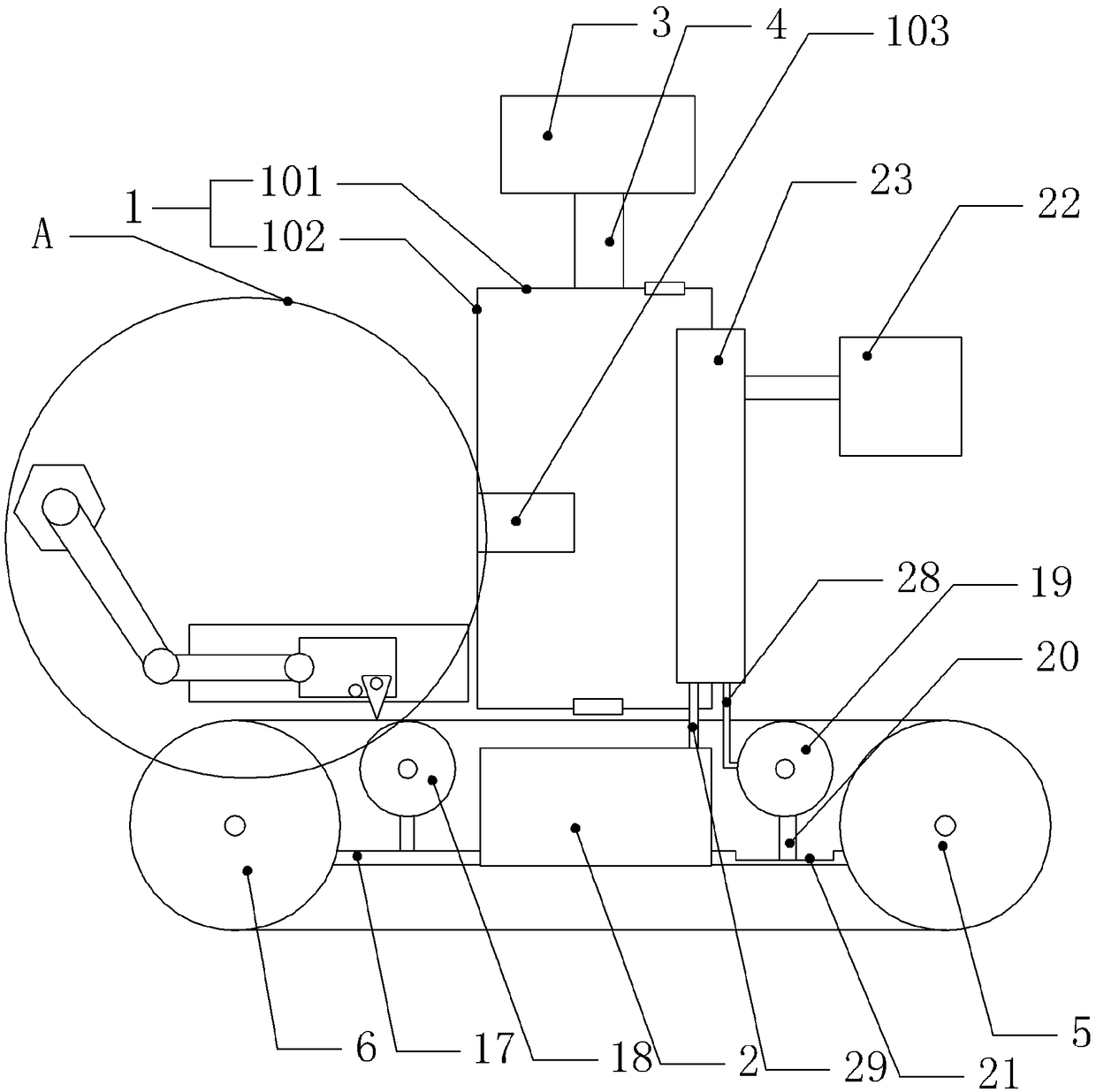

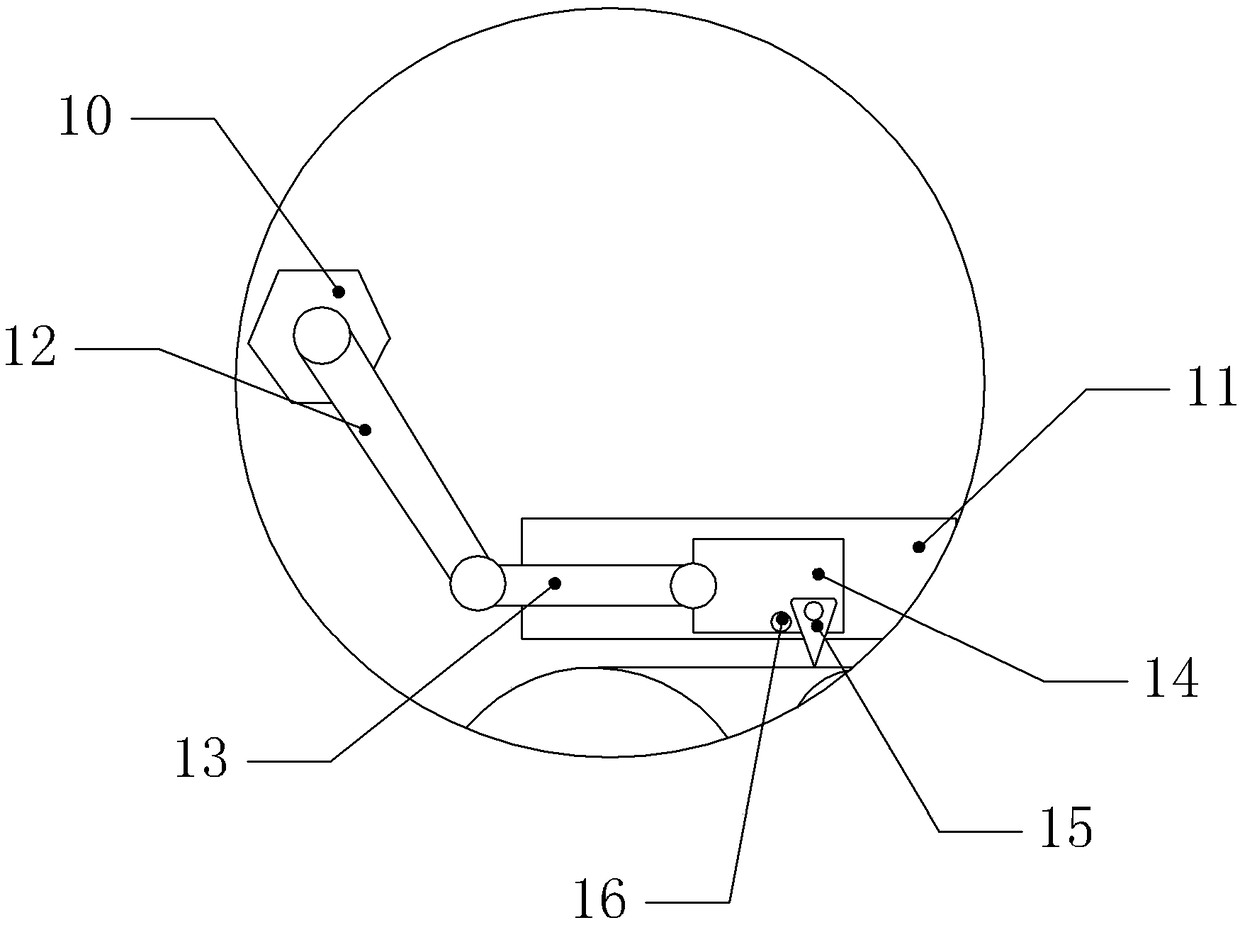

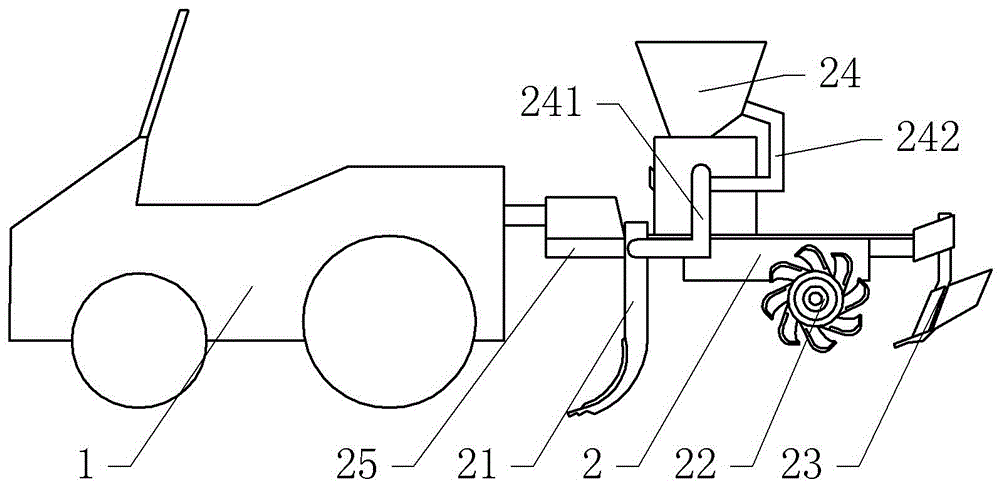

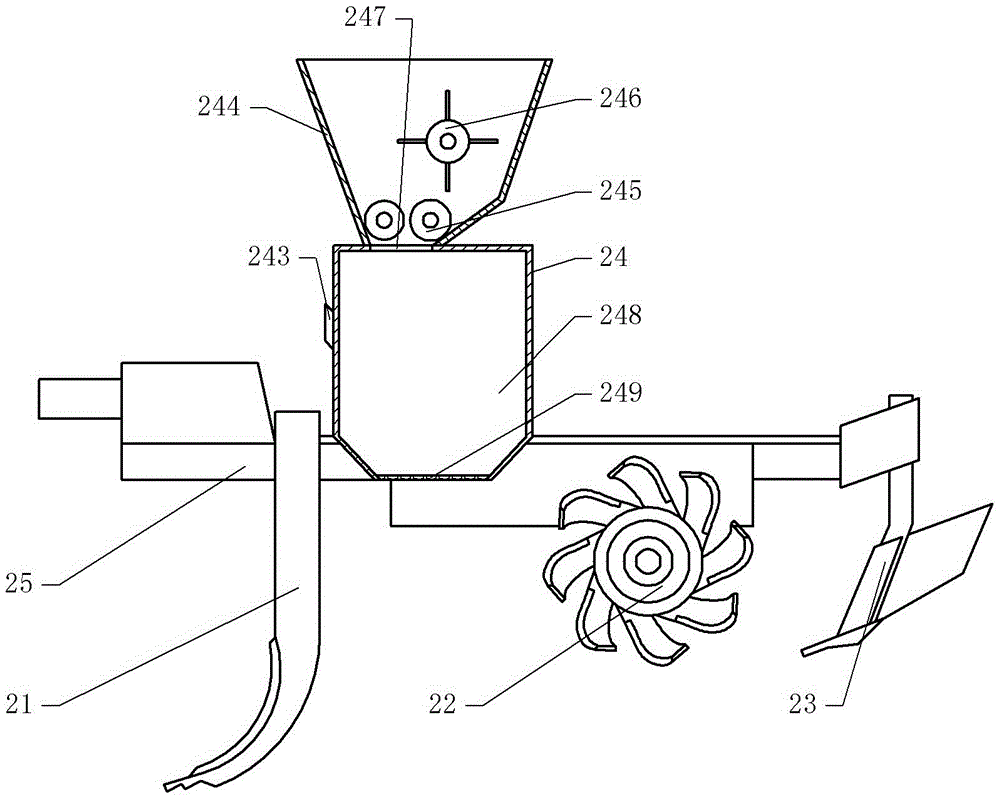

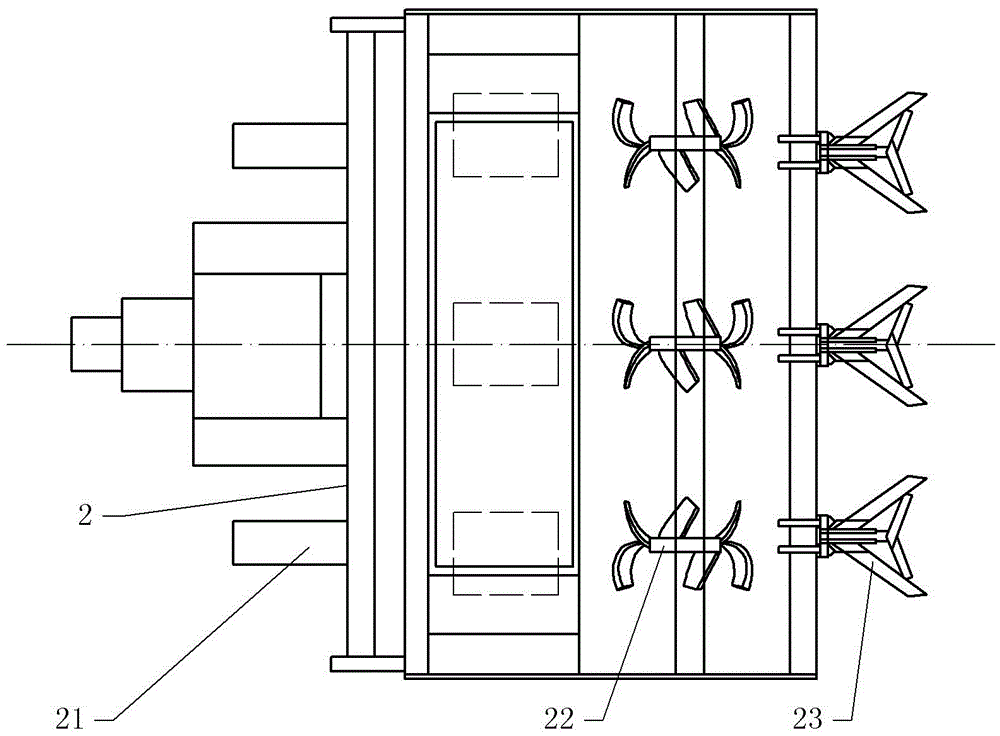

Straw burning and fertility improving machine

The invention discloses a straw burning and fertility improving machine, and relates to an agricultural machine. The straw burning and fertility improving machine comprises a walking system and a tilling system which move forwards together; the tilling system comprises a rack, a break shovel installed at the foremost end of the rack, a rotary tilling device and a ridging device, wherein the rotary tilling device and the ridging device are sequentially installed behind the break shovel; a straw burning device is further installed on the rack and comprises a burning chamber, a material inlet hopper, a feeding device and a smoke exhaust pipe; the burning chamber is provided with an air inlet and a feed opening, and multiple ash leakage holes are formed in the bottom of the burning chamber; the material inlet hopper and the feed opening are in butt joint, and the smoke exhaust pipe is communicated with the burning chamber; the break shovel is of a hollow structure and is provided with multiple smoke outlet holes, and the smoke exhaust pipe is communicated with the break shovel. According to the straw burning and fertility improving machine, straw burning can be achieved when tilling is conducted, and straw ash can be evenly scattered in soil; meanwhile, heat obtained during straw burning can be used for conducting sterilization and deinsectization on the soil, so that the use value of straw is improved, and the soil fertility loss is reduced.

Owner:CHONGQING YIFENG BIOLOGICAL FERTILIZER CO LTD

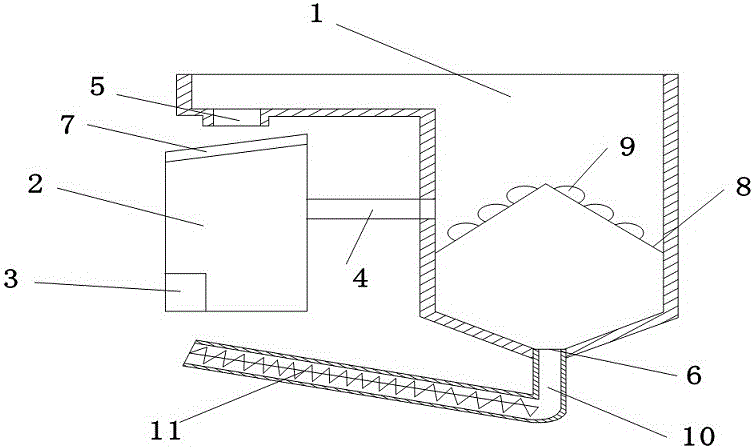

Underground cable laying device

ActiveCN109980579AIncrease labor intensityLaying efficiency is lowApparatus for laying cablesInsulation layerEngineering

The invention discloses an underground cable laying device. The underground cable laying device comprises a trailer body, wherein a pay-off rack is arranged on the front side of the upper part of thetrailer body, and the rear side of the upper part of the trailer body is provided with a guide mechanism for guiding the paying-off in a cable well; the guide mechanism comprises a rectangular via hole which is formed in the rear side of the upper part of the trailer body; a rectangular barrel is arranged in the rectangular via hole in a lifting mode; a pair of upper rolling wheels are rotationally arranged on the inner side of the upper opening of the rectangular barrel, a pair of lower rolling wheels are arranged on the inner side of the opening in the lower portion of the rectangular barrelin a rotating mode; a pair of inverted L-shaped push plates are symmetrically arranged on the left side and the right side of the upper end of the rectangular barrel; and a first automatic telescopicrod is arranged on the trailer body and located below the inverted L-shaped push plates in the vertical direction; the situation that the cable insulation layer is damaged due to the fact that the cable is not guided when the cable is laid in the underground cable well can be effectively solved, the extending depth of the guide mechanism can be adjusted according to the depth of the cable well, so that it is ensured that the cable cannot be directly rubbed with the lower edge of the cable well after entering the cable tunnel.

Owner:国网河南省电力公司社旗县供电公司

Eggshell membrane separating equipment with membrane removing function

InactiveCN106722369ALarge shrinkage ratioShattered completelyGrain treatmentsFood scienceEggshell membraneCylinder block

The invention discloses eggshell membrane separating equipment with a membrane removing function. The equipment comprises a cylinder block, wherein a membrane outlet is formed in the side wall of the top of the cylinder block, a shell outlet is formed in the bottom of the cylinder block, a water tank is arranged on one side of the cylinder block, a cooling device is arranged in the water tank, a plurality of water inlet pipes are arranged on one side of the water tank, a plurality of water inlets are formed in the side wall of the cylinder block, a pinnacle-shaped screen is arranged in the cylinder block, and a plurality of bumps are formed on the screen. According to the scheme, under the joint action of cooling water in many directions and the pinnacle-shaped screen, the membrane under the eggshell is easy to fall, the eggshell is fragile, and the eggshell membrane separating effect is relatively good.

Owner:CHONGQING CHANGSHOU DISTRICT BIAOGAN CHICKEN RAISING COOP

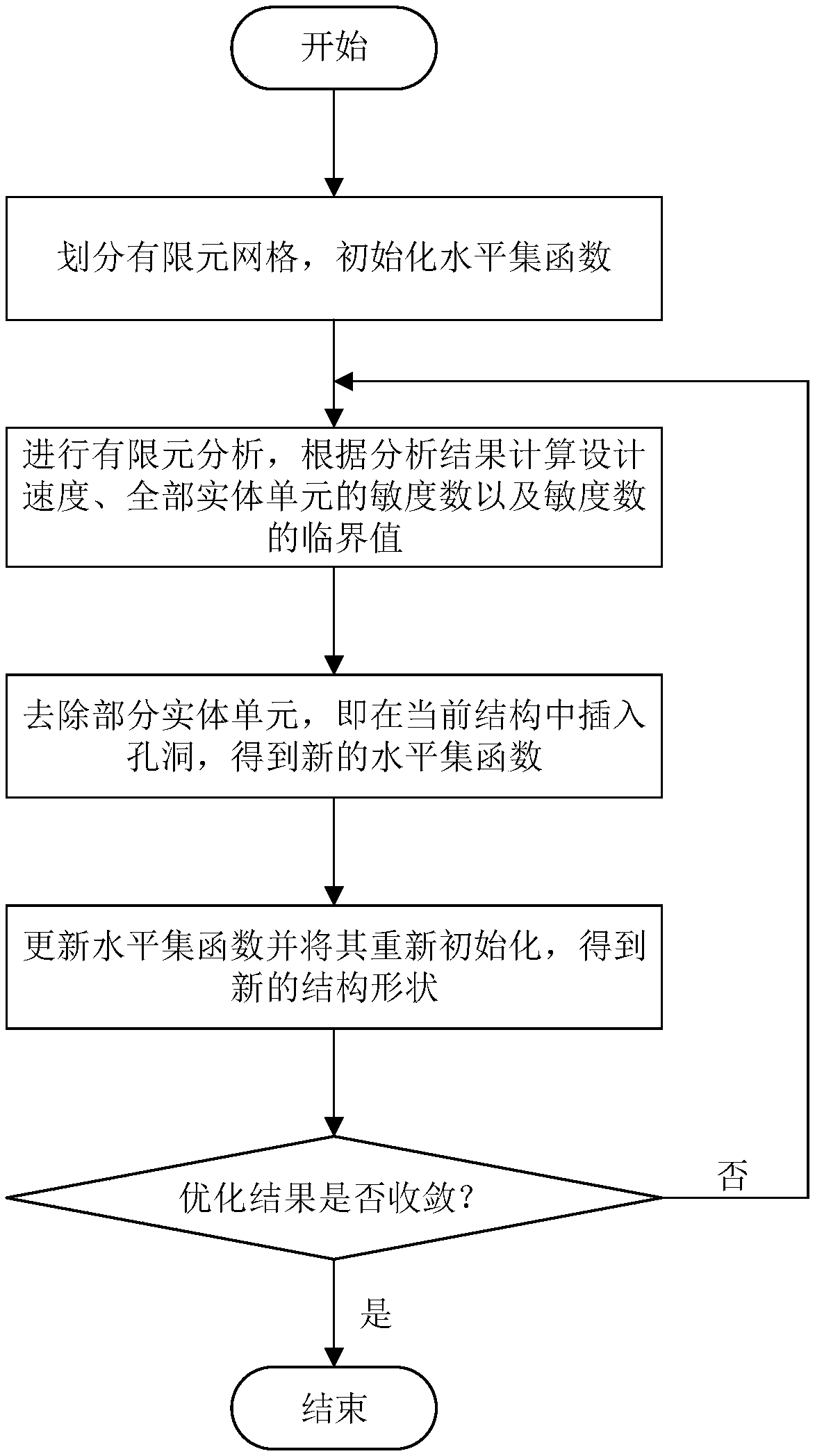

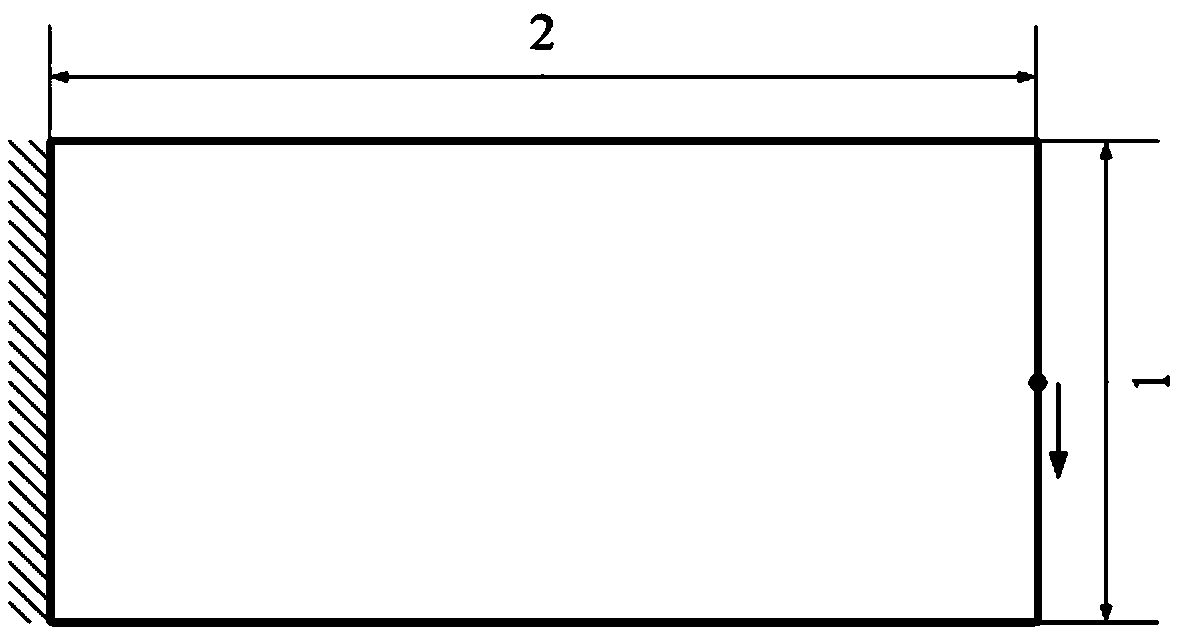

Improved level set topology optimization method for stable hole formation

ActiveCN109002614AAvoid dependencyImprove reliabilityDesign optimisation/simulationSpecial data processing applicationsSolid regionGrid cell

The invention belongs to the technical field of structural topology optimization, and discloses an improved level set topology optimization method for stable hole formation. The method includes: (a) dividing the finite element mesh into design domains, initially dividing the mesh into solid and cavity domains, and initially assigning values to the level set functions; (b) calculating a displacement vector in the design domain; (c) calculating the sensitivity of each grid cell in the velocity field and the physical region; (d) optimizing the initialized solid region, the cavity region and the level set function for the first time by using the sensitivity number; (e) using the velocity field to update the level set function of each grid cell in the entity and the cavity region respectively so as to redivide the entity region and the cavity region, thereby realizing the second optimization; (f) judging whether the result of the second optimization converges or not according to the flexibility and volume error. The invention overcomes the defect that the traditional level set topology optimization method cannot form holes in the structure, and solves the dependence of the optimizationproblem on the initial design, which is stable and effective.

Owner:HUAZHONG UNIV OF SCI & TECH

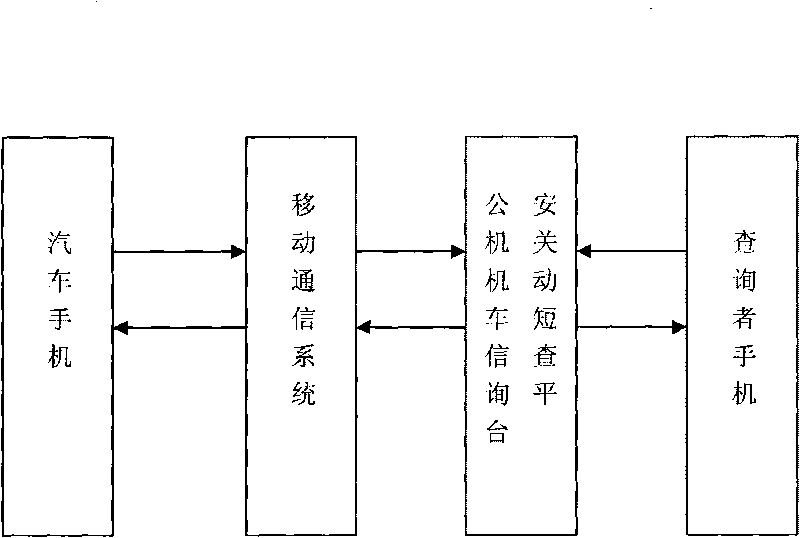

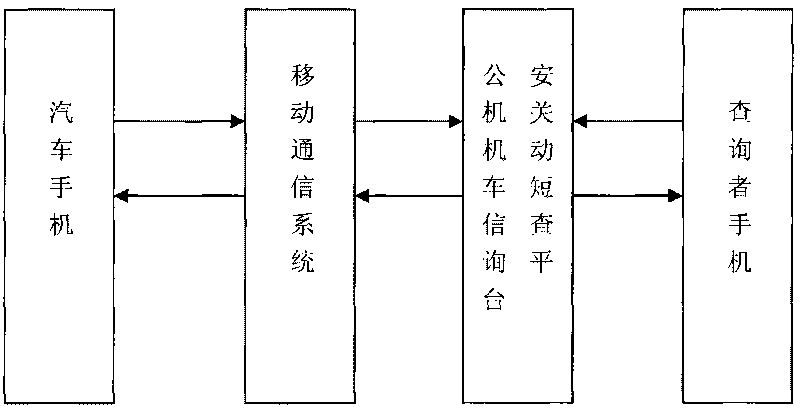

Motor vehicle network monitoring system

InactiveCN101710447AHitEasy to operateDetection of traffic movementWireless commuication servicesEngineeringInformation data

The invention relates to a system which fights against and prevents illegal criminal activities to motor vehicles and comprehensively monitors motor vehicles, in particular to a motor vehicle network monitoring system. The motor vehicle network monitoring system is composed of an automobile mobile phone, a mobile communication system and a public security monitoring system, wherein the mobile communication system transmits automobile mobile phone position information data to the public security monitoring system in time; an SIM is inserted into the automobile mobile phone and is matched with the data of the mobile communication system and the public security monitoring system; the motor vehicle network monitoring system fights against illegal vehicles, such as false license plate vehicles, slip license plate vehicles, hit and run vehicles and the like according to the authority and the no possibility of forging of the motor vehicle data collected by public security organs; in addition, citizens search the relative information of motor vehicles in the whole course, and the system has simple operation and does not need passwords and permission, so that all citizens can join.

Owner:杨青松

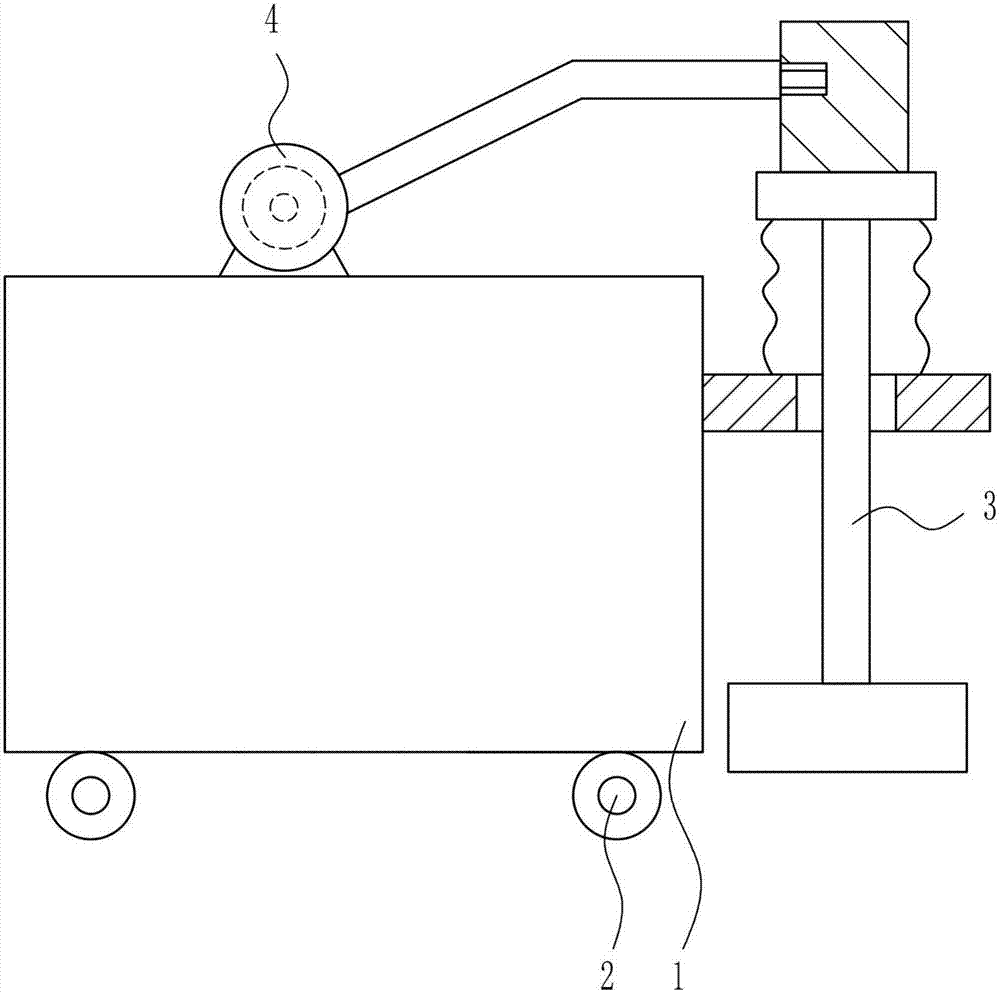

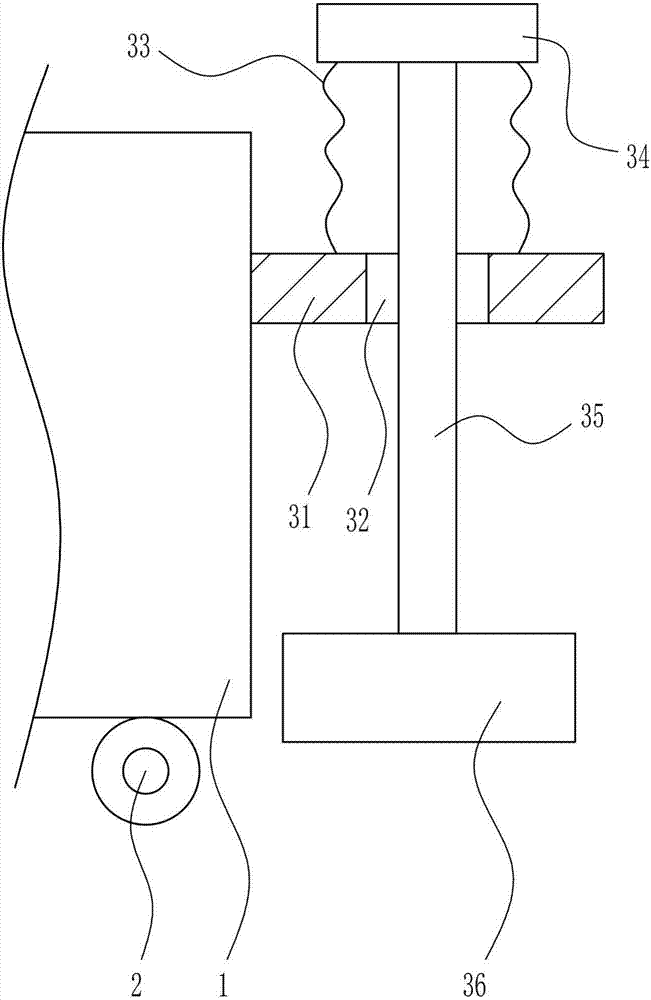

Flattening equipment for repairing small cracks of roads

The invention relates to flattening equipment and particularly relates to flattening equipment for repairing small cracks of roads. The technical problem to be solved by the invention is to provide the flattening equipment for repairing small cracks of roads, which is convenient in use and ideal in flattening. In order to solve the technical problems, the invention provides the flattening equipment for repairing small cracks of roads, comprising a vehicle body, wheels, a flattening device and a knocking device, wherein the wheels are arranged at the bottom of the vehicle body in a mode of bilateral symmetry, the flattening device is arranged at the right side of the vehicle body, and the knocking device is arranged at the top of the vehicle body. The knocking device drives the flattening device to move downward so as to flatten the pavement to be flattened; and when the pavement to be flattened is flattened, a fixed block is utilized for being in contact with the pavement.

Owner:刘艳平

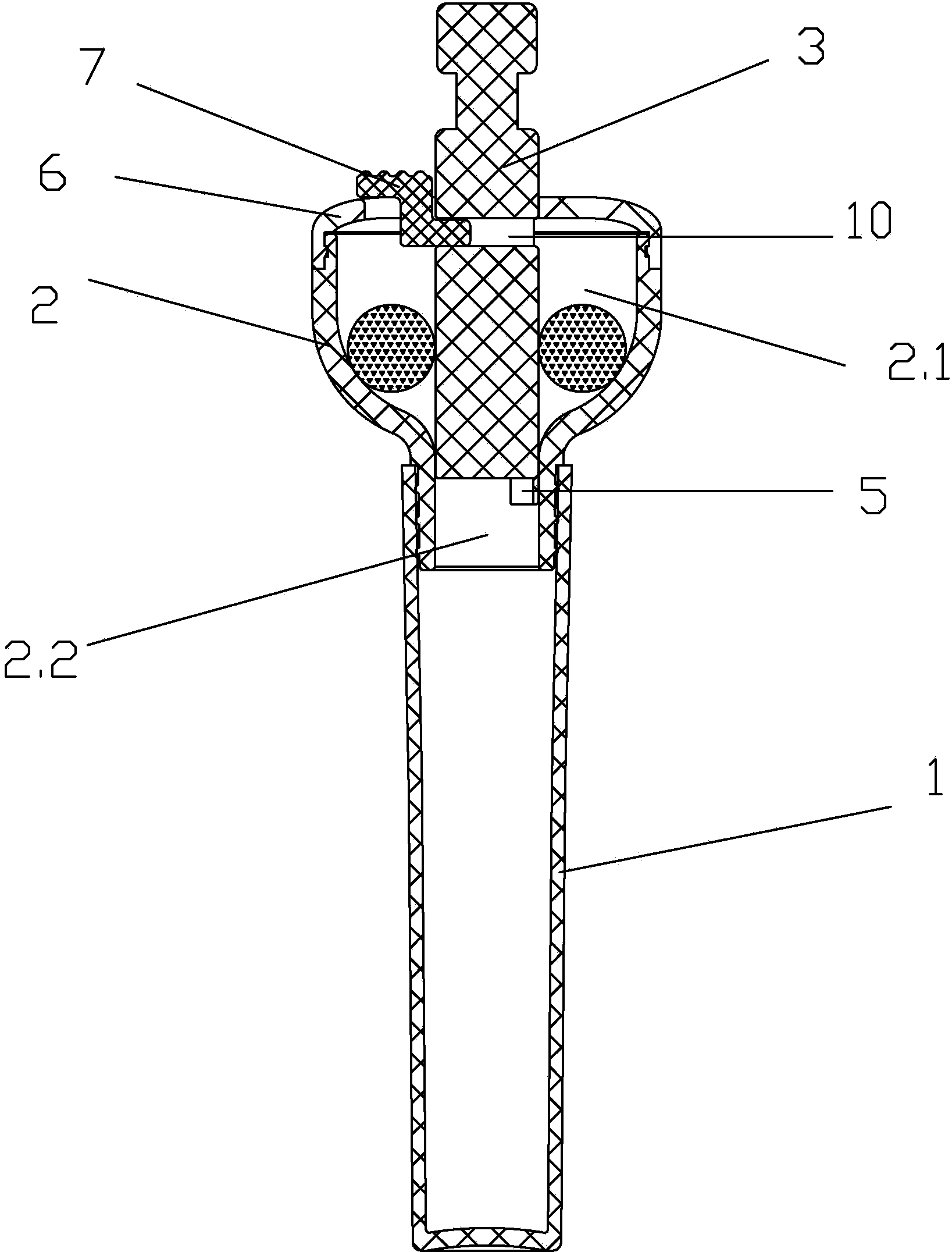

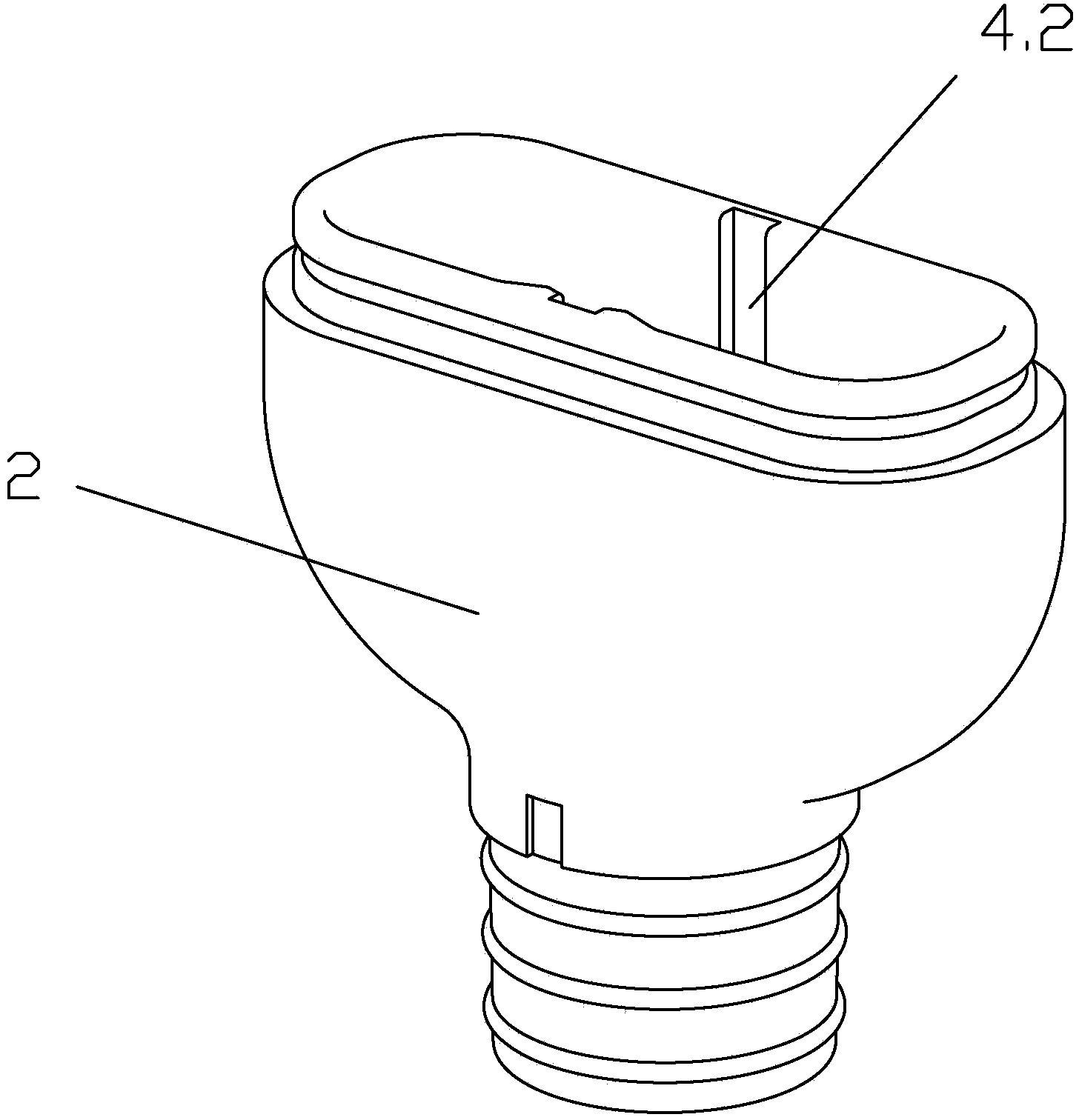

Multi-reagent colorimeter tube for portable colorimetric device

ActiveCN104374699AGuaranteed accuracyHas a guiding rolePreparing sample for investigationMaterial analysis by optical meansReagent bottleBiochemical engineering

The invention discloses a multi-reagent colorimeter tube for a portable colorimetric device. The multi-reagent colorimeter tube comprises a reaction cup (1) used for storing a first reagent and / or a to-be-detected sample, and a reagent bottle (2) used for storing at least one solid reagent, wherein openings are formed in the upper end of the reaction cup (1) and the lower end of the reagent bottle (2), and the upper end of the reaction cup (1) and the lower end of the reagent bottle (2) are in inserted connection with each other; a reagent bottle cover (6) is arranged on the upper part of the reagent bottle (2); a cavity (2.1) used for containing the solid reagents is formed in the reagent bottle (2); a feeding channel (2.2) is formed in the lower end of the cavity (2.1) and is communicated with the opening of the reaction cup (1); a reagent separation bar (3) through which the solid reagents are limited in the cavity (2.1) or drop into the reaction cup (1) by virtue of the feeding channel (2.2) is connected into the reagent bottle (2) in a sliding mode; and a through hole (9) through which the reagent separation bar (3) passes is formed in the reagent bottle cover (6).

Owner:宁波美康盛德生物科技有限公司

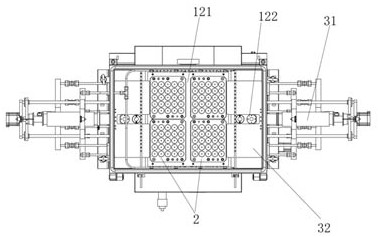

Multi-module packaging vacuum furnace for welding elements and using method thereof

ActiveCN112059352AAvoid OrientationHas a guiding roleHeating appliancesMetal working apparatusEngineeringPumping vacuum

The invention provides a multi-module packaging vacuum furnace for welding elements. The multi-module packaging vacuum furnace comprises a vacuum cavity, jigs, a lifting device, a movable baffle mechanism, a heating mechanism, a water cooling mechanism, a valve pump mechanism and a control device. The lifting device, the movable baffle mechanism, the heating mechanism, the water cooling mechanismand the valve pump mechanism are in communication connection with the control device. The invention further provides a using method of the vacuum furnace. The using method comprises the steps that themultiple layers of jigs are placed into a cavity body from bottom to top; the interior of the cavity body is vacuumized, and a baffle extends out to form a shielding state; when the vacuum degree inthe cavity body reaches the activation vacuum degree, a lower heating carrying table is heated to an activation temperature, the temperature is kept for a first time period, and after the cavity bodyis cooled to a safety temperature, the baffle is reset and returns to the reset state; the lifting device descends to the lowest point, a tube shell jig layer is tightly attached to a germanium windowjig layer, and heating is carried out to a welding temperature; and after welding is completed, the welded elements are taken down from the tube shell jig layer. According to the multi-module packaging vacuum furnace and the using method, the efficient function of multiple modules is realized.

Owner:北京仝志伟业科技有限公司

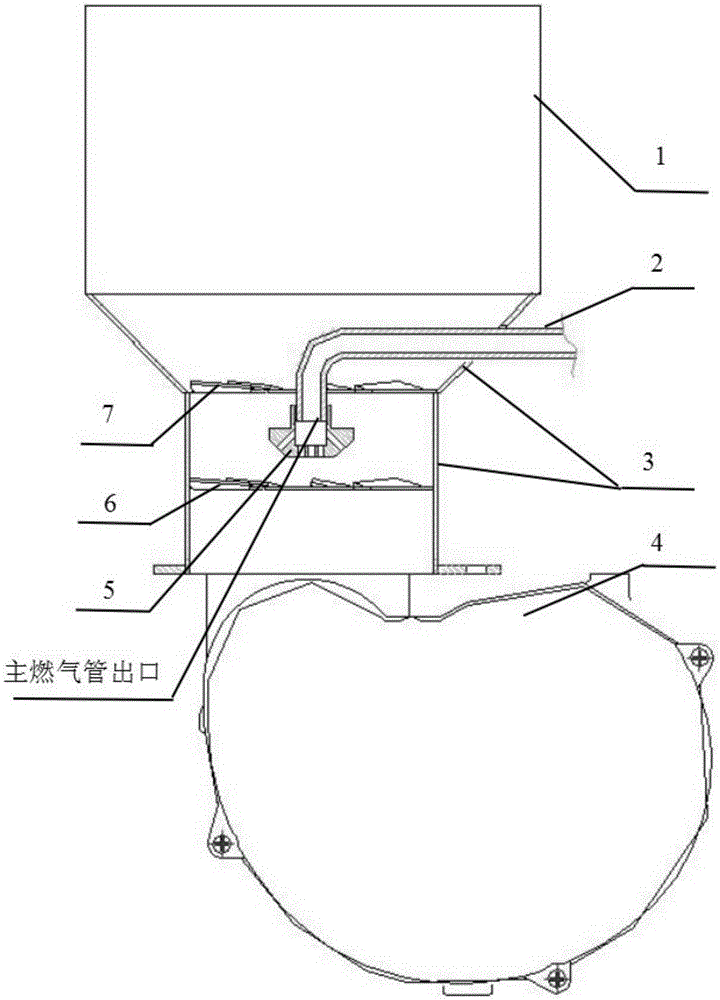

Forced mixing gas combustor

InactiveCN105402727AImprove blending effectImprove combustion efficiencyGaseous fuel burnerCombustorProcess engineering

Owner:YUNNAN AEROSPACE IND

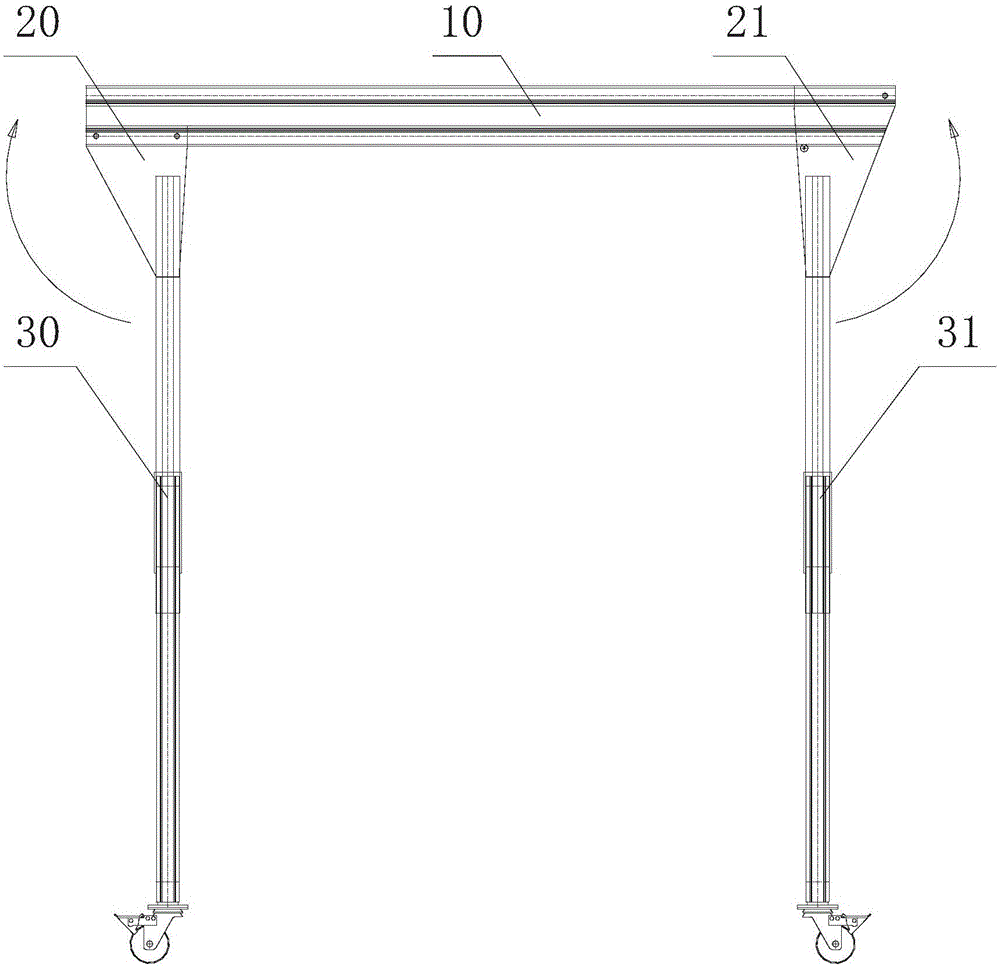

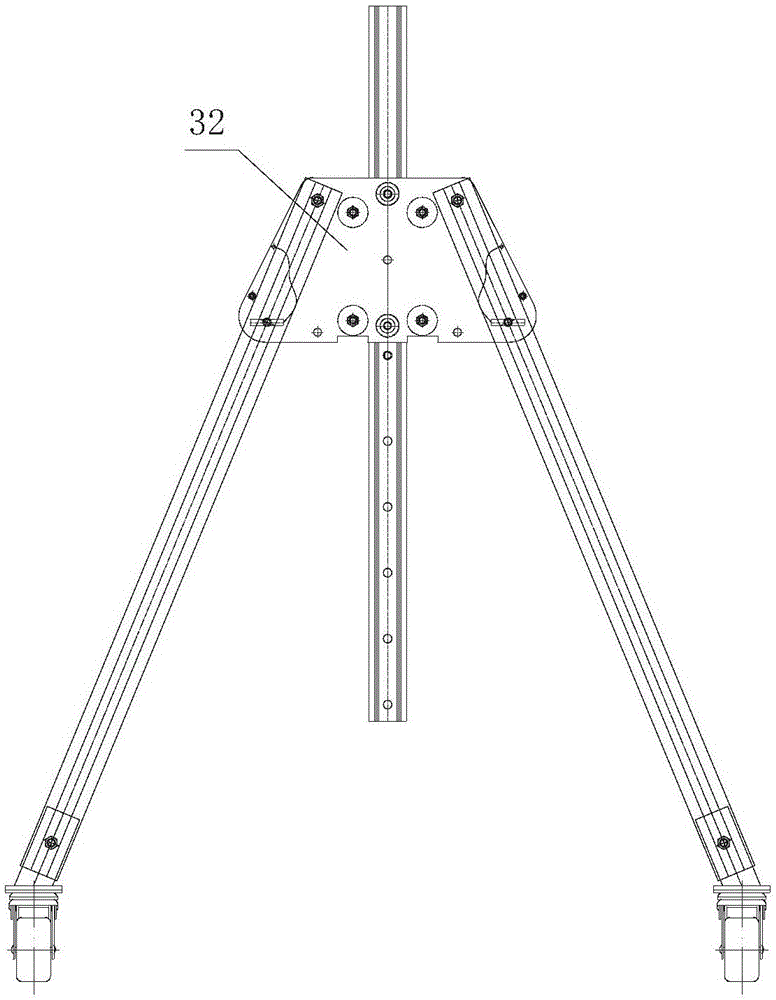

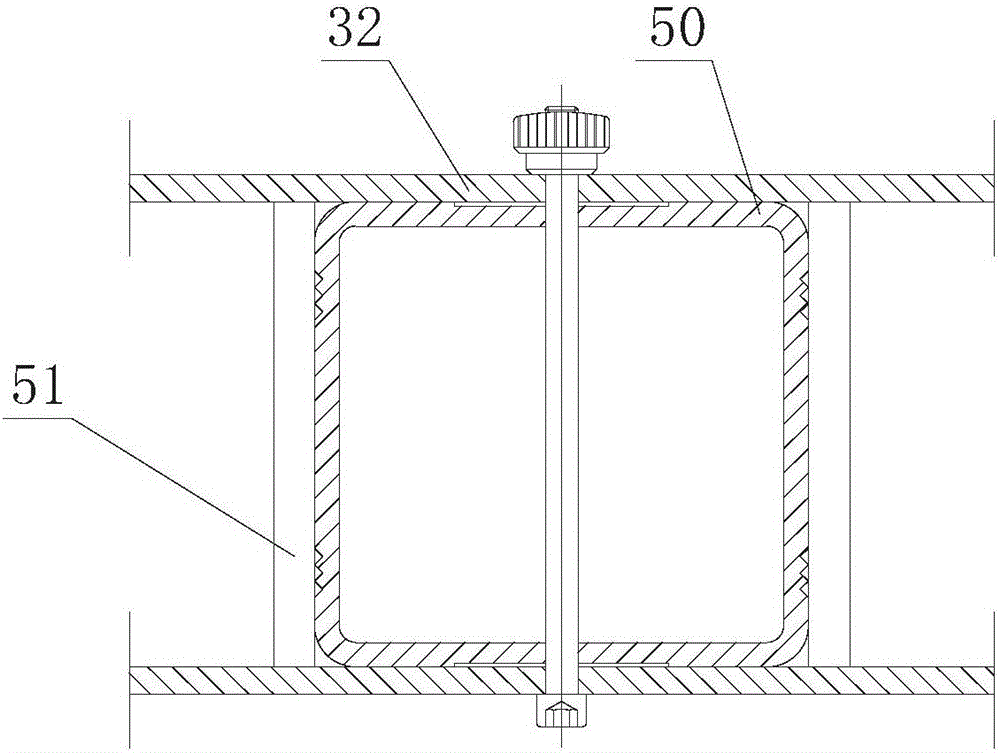

Foldable gantry hoisting device

ActiveCN106276626ASmall footprintEasy to install and removeLoad-engaging girdersBase supporting structuresStructural stabilityEngineering

The invention discloses a foldable gantry hoisting device. The device comprises a main girder, two movable connectors, columns and a plurality of bolt mechanisms, wherein the two movable connectors are arranged at the left end and the right end of the main girder respectively; the columns comprise a left column and a right column, each of the left column and the right column comprises an upper column, a column connector and two lower columns, the upper column is arranged on the corresponding movable connector, the column connector comprises two column connecting plates, a reinforcing element is arranged between the two column connecting plates, the two column connecting plates and the upper column are connected through fixing bolts, the fixing bolts penetrate the reinforcing element, and the tops of the two lower columns are movably arranged on the column connector; the plurality of bolt mechanisms are arranged between the main girder and the two movable connectors as well as between each column connector and the corresponding two lower columns. Compared with the prior art, the upper column and the corresponding two lower columns are arranged rotationally and fixed through the bolt mechanisms, unfolding and folding are convenient, and the occupied space is reduced; by means of the reinforcing elements, the column connectors are prevented from deformation, and the structural stability is improved.

Owner:科斯佩特智能装备(苏州)有限公司

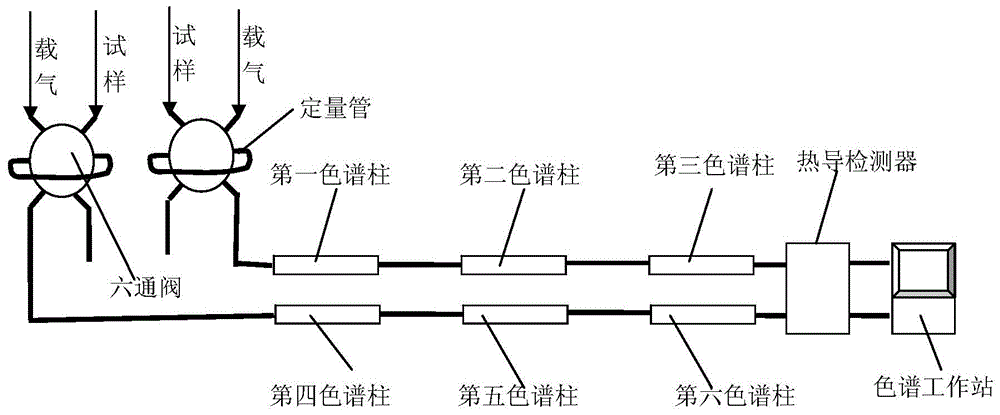

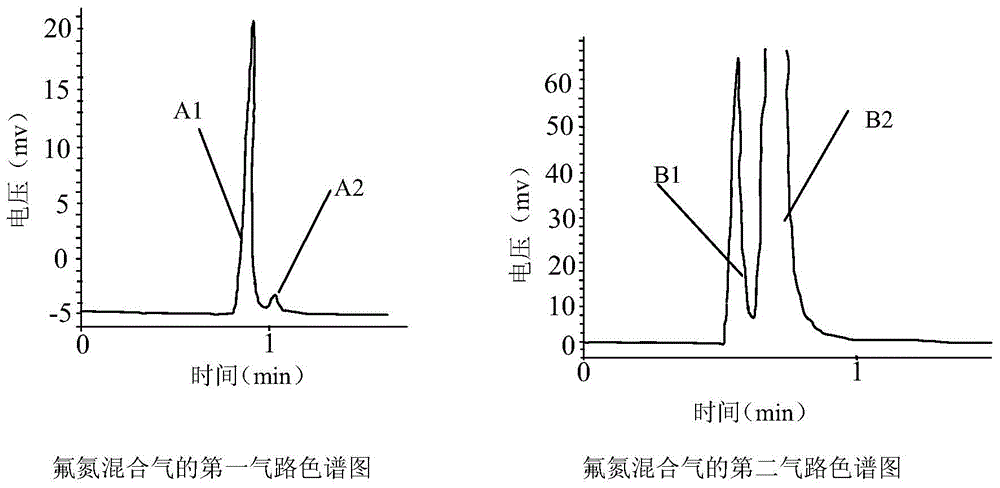

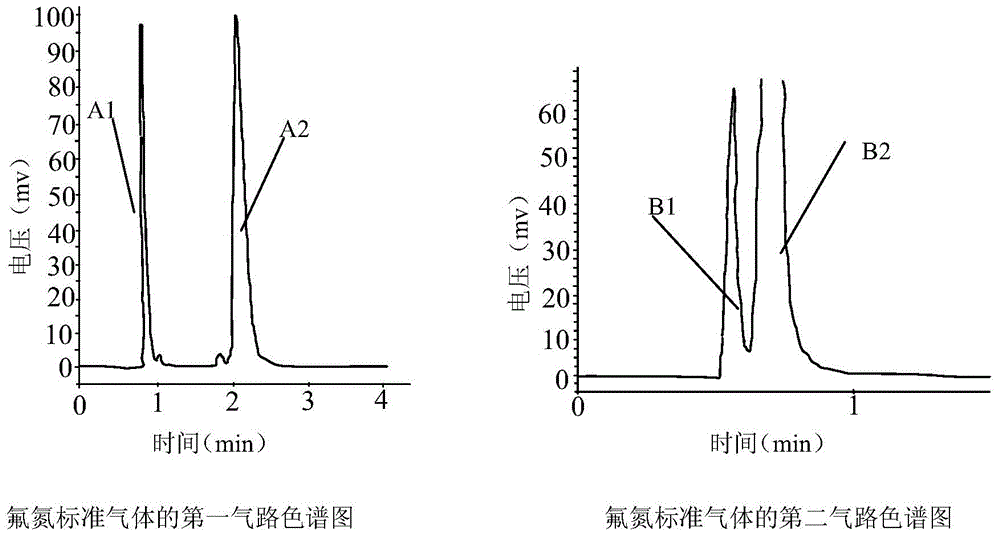

Method for measuring fluorine gas content in fluorine-containing mixing gas through gas chromatography method

ActiveCN104914172AImprove accuracyAdjust the running status in timeComponent separationProduct gasNitrogen gas

The present invention discloses a method for measuring the fluorine gas content in fluorine-containing mixing gas through a gas chromatography method. The method comprises that a fluorine-containing mixing gas sample passes through a chromatography instrument having two gas path systems to detect, wherein the first gas path detects the content of the mixed gas of oxygen gas, nitrogen gas and chlorine gas, and the second gas path system detects the oxygen gas content and the nitrogen gas content; and the measured content of the mixed gas of the oxygen gas, the nitrogen gas and the chlorine gas is subtracted by the oxygen gas content and the nitrogen gas content to obtain the chlorine gas content, ie., the fluorine gas content in the fluorine-containing mixing gas sample. The method has characteristics of simple operation, less error, and high accuracy.

Owner:FUJIAN YONGJING TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com