Device and method for adjusting lubrication state of bearing by monitoring temperature of inner ring

A technology for inner rings and rolling bearings, which is applied to bearing components, shafts and bearings, lubricating parts, etc. It can solve the problems of non-adjustable clearance and the influence of rotational speed on the supply of lubricating oil, etc., and achieve good lubricating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation process of the present invention will be further explained below in conjunction with the accompanying drawings.

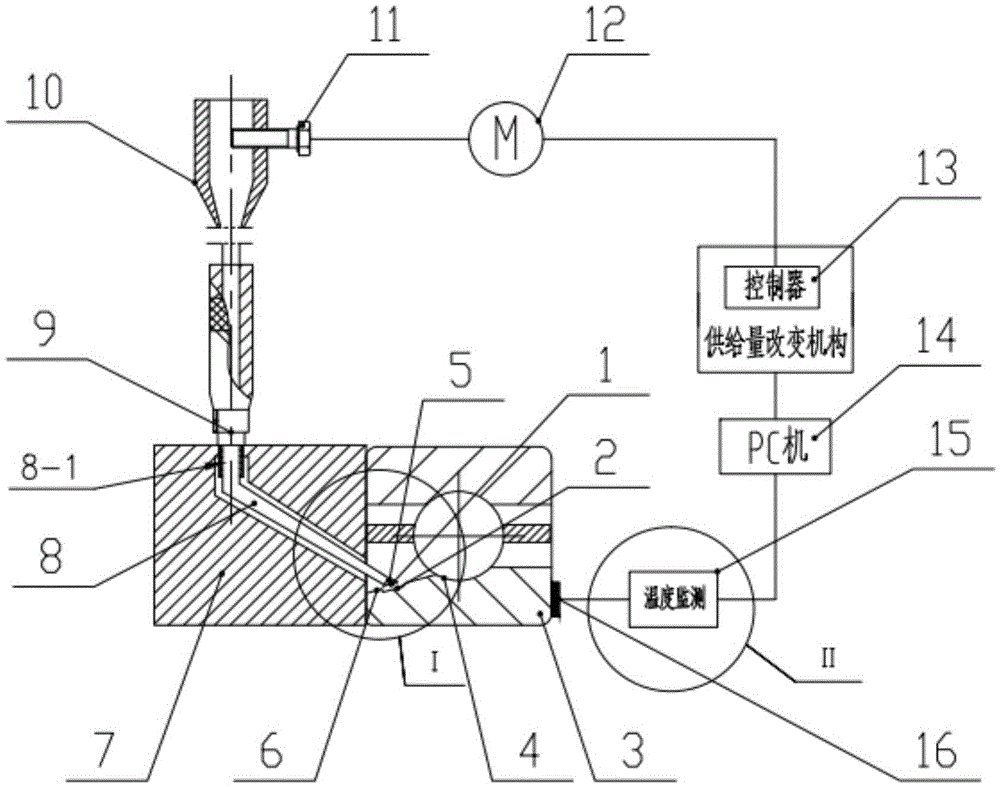

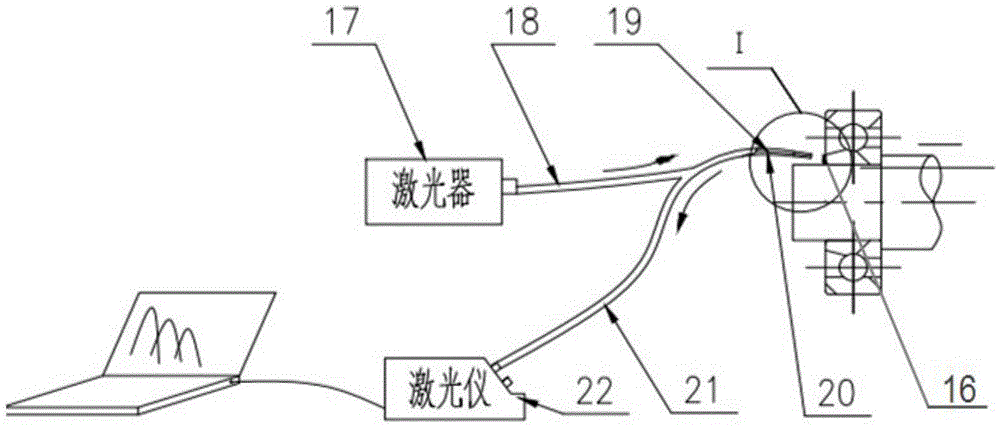

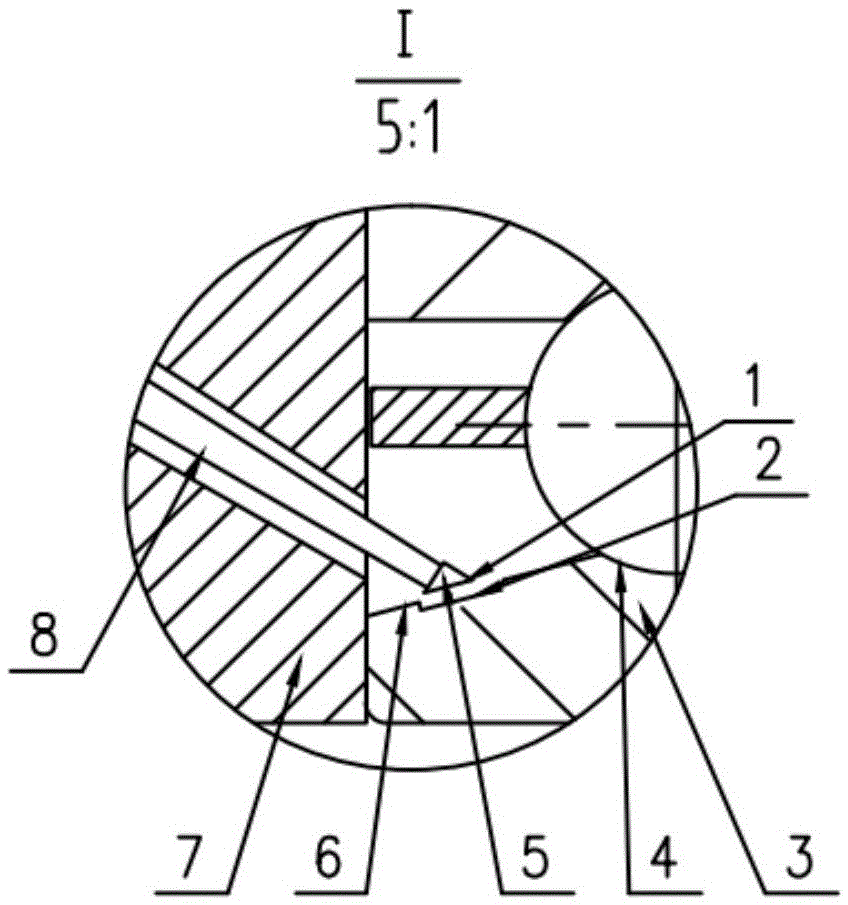

[0030] refer to figure 1 , a device for adjusting bearing lubrication performance by monitoring the temperature of the inner ring, including CdTe quantum dot colloid 16 uniformly attached to the end face 3 of the inner ring of the high-speed bearing, and the peak wavelength and temperature of the quantum dots have good linear stability ( like Figure 5 shown), using this linear relationship to predict the temperature change of the inner ring of the bearing by monitoring the change of the peak wavelength; refer to figure 2 , also includes a 400nm solid-state laser 17 and a spectrometer used in conjunction with the CdTe quantum dot colloid 16, the 400nm solid-state laser 17 is connected to the first probe 19 through the first optical fiber 18, the spectrometer 22 is connected to the second probe 20 through the second optical fiber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com