Detachable upper pipe seat and guide pipe connecting structure

The technology of connecting structure and guide tube is applied in the field of connection structure of detachable upper tube seat and guide tube, which can solve the problems of difficult installation and disassembly, difficult thread connection processing, etc., and achieves improved connection strength, easy installation and disassembly operation, Anti-shake effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

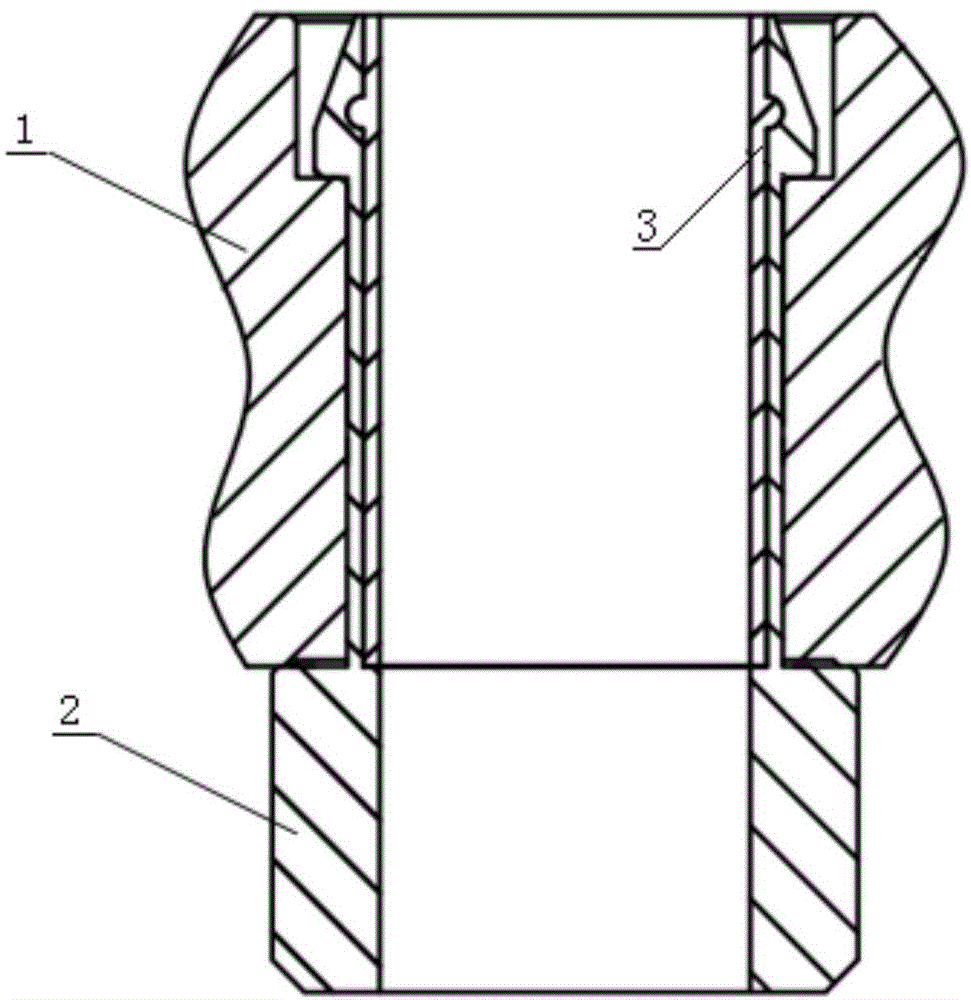

[0041] Such as figure 1 As shown, the connection structure between the upper tube base and the guide tube of an embodiment of the present invention includes an upper tube base 1, an elastic joint 2 and a tensioning tube 3;

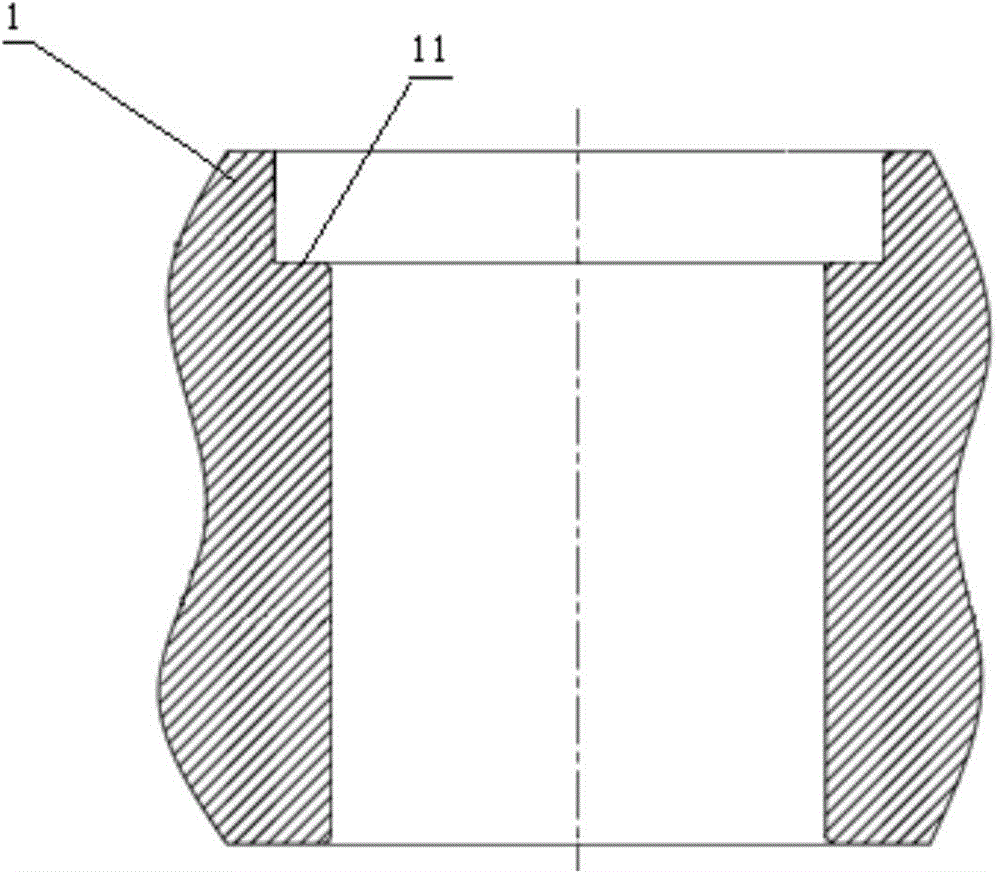

[0042] Such as figure 2 As shown, the upper pipe seat 1 is provided with a guide pipe hole, and the inner diameter of the upper part of the guide pipe hole is larger than the inner diameter of the lower part, forming a stepped surface 11;

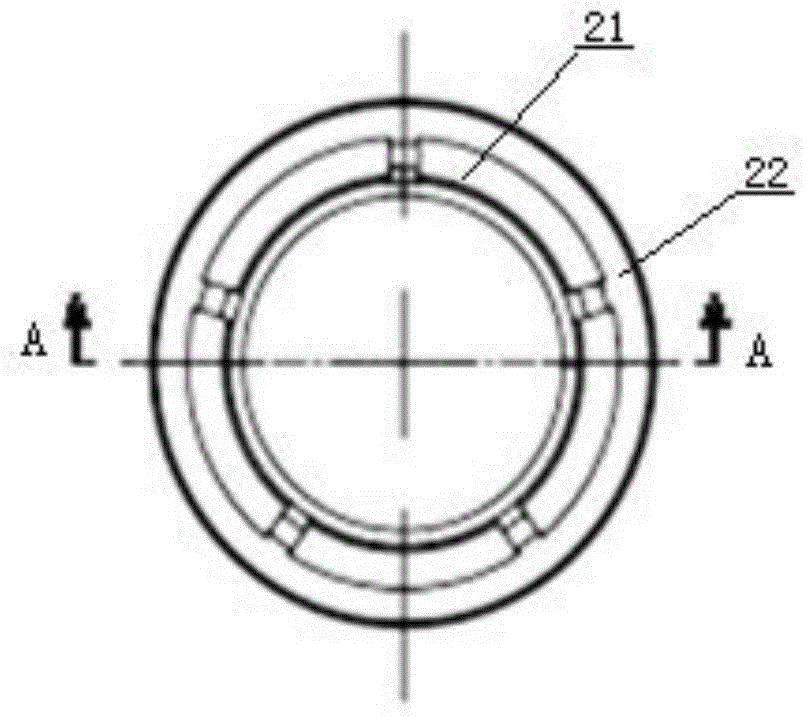

[0043] Such as image 3 , Figure 4 As shown, the elastic joint 2 is a tubular structure, and the upper part of the elastic joint includes at least two elastic buckles 21 . In this embodiment, the upper part of the elastic joint is processed into a petal shape and includes five elastic buckles 21 .

[0044] The uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com