Method for measuring fluorine gas content in fluorine-containing mixing gas through gas chromatography method

A gas chromatography and mixed gas technology, applied in the field of fluorine gas content measurement, can solve the problems of low detection limit, small error, difficult separation, etc., achieve high accuracy and solve the effect of fluorine resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

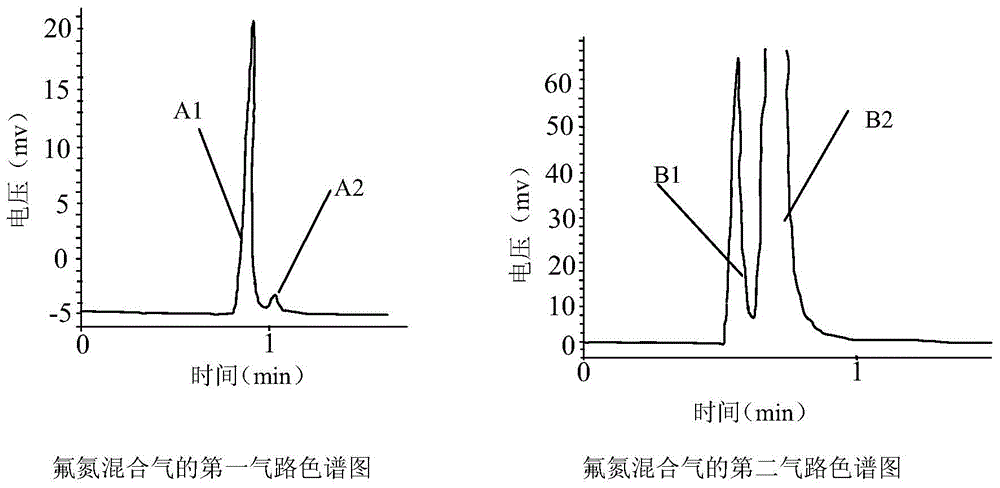

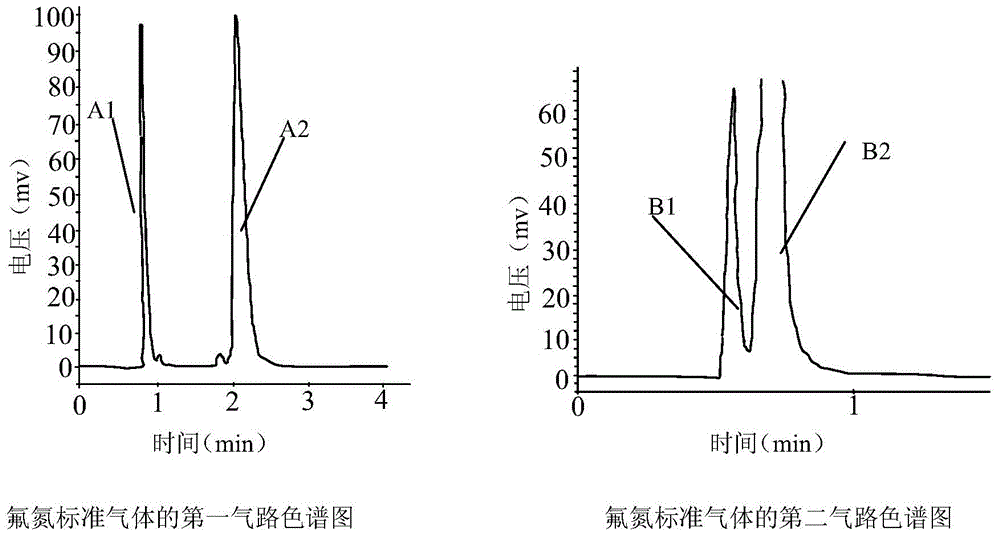

[0044] The mensuration of fluorine content in the fluorine-nitrogen mixed gas of embodiment 1

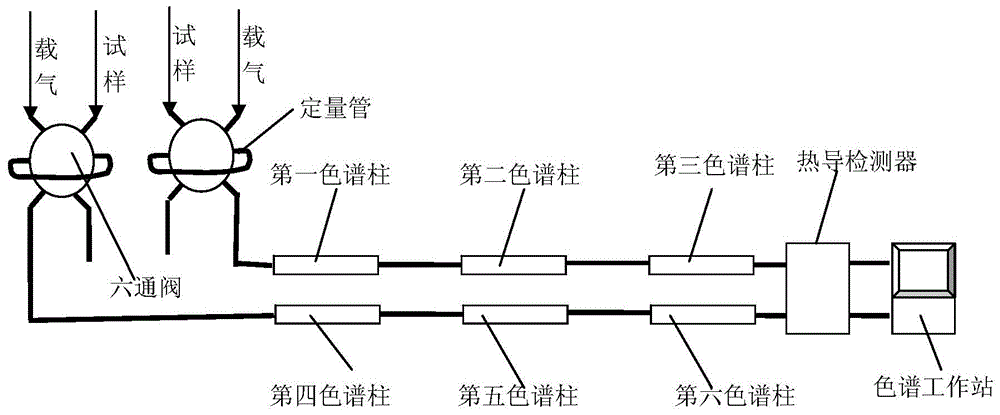

[0045] 1. The experimental conditions are:

[0046] Carrier gas: helium, purity 99.9%, flow rate 25ml / min

[0047] Carrier gas pressure: 150kpa

[0048] The first chromatographic column: Φ2mm×0.5m (inner diameter×height); filler: polytrifluorochloroethylene 60-80 mesh (permanent column)

[0049] Second chromatographic column: Φ2mm×1m (inner diameter×height) Packing agent: Potassium chloride (AR) 60-80 mesh (consumption column)

[0050] The third chromatographic column: Φ2mm×2m (inner diameter×height) filler: perfluoropolystyrene 40-60 mesh (permanent column)

[0051] Fourth chromatographic column: Φ2mm×0.5m (inner diameter×height); filler: polychlorotrifluoroethylene 60-80 mesh (permanent column)

[0052] The fifth chromatographic column: Φ2mm×1m (inner diameter×height) filler: silver powder (99.9) 40-60 mesh (consumption column)

[0053] Sixth chromatographic column: Φ2mm×1.5m...

Embodiment 2 6

[0076] The mensuration of fluorine content in the sulfur hexafluoride reaction gas of embodiment 2

[0077] 1. The experimental conditions are:

[0078] Carrier gas: helium, purity 99.9%, flow rate 30mL / min

[0079] Carrier gas pressure: 150kpa

[0080] The first chromatographic column: Φ2mm×0.5m (inner diameter×height); filler: polytrifluorochloroethylene 60-80 mesh (permanent column)

[0081] Second chromatographic column: Φ2mm×1m (inner diameter×height) Packing agent: Potassium chloride (AR) 60-80 mesh (consumption column)

[0082] The third chromatographic column: Φ2mm×2m (inner diameter×height) filler: perfluoropolystyrene 40-60 mesh (permanent column)

[0083] Fourth chromatographic column: Φ2mm×0.5m (inner diameter×height); filler: polychlorotrifluoroethylene 60-80 mesh (permanent column)

[0084] The fifth chromatographic column: Φ2mm×1m (inner diameter×height) filler: silver powder (99.9) 40-60 mesh (consumption column)

[0085] Sixth chromatographic column: Φ2mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com