Patents

Literature

31results about How to "Avoid collisions and scratches" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

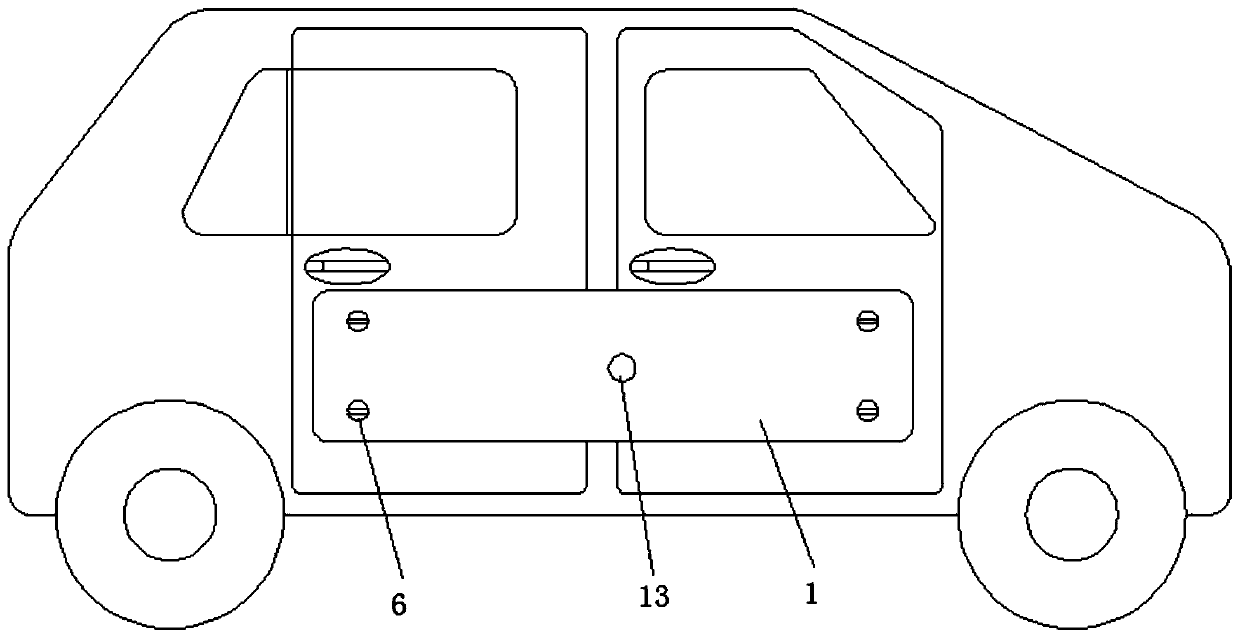

Vehicle, parking control method and device

InactiveCN109515432AImprove practicalityImprove applicabilityExternal condition input parametersParking spaceDrive motor

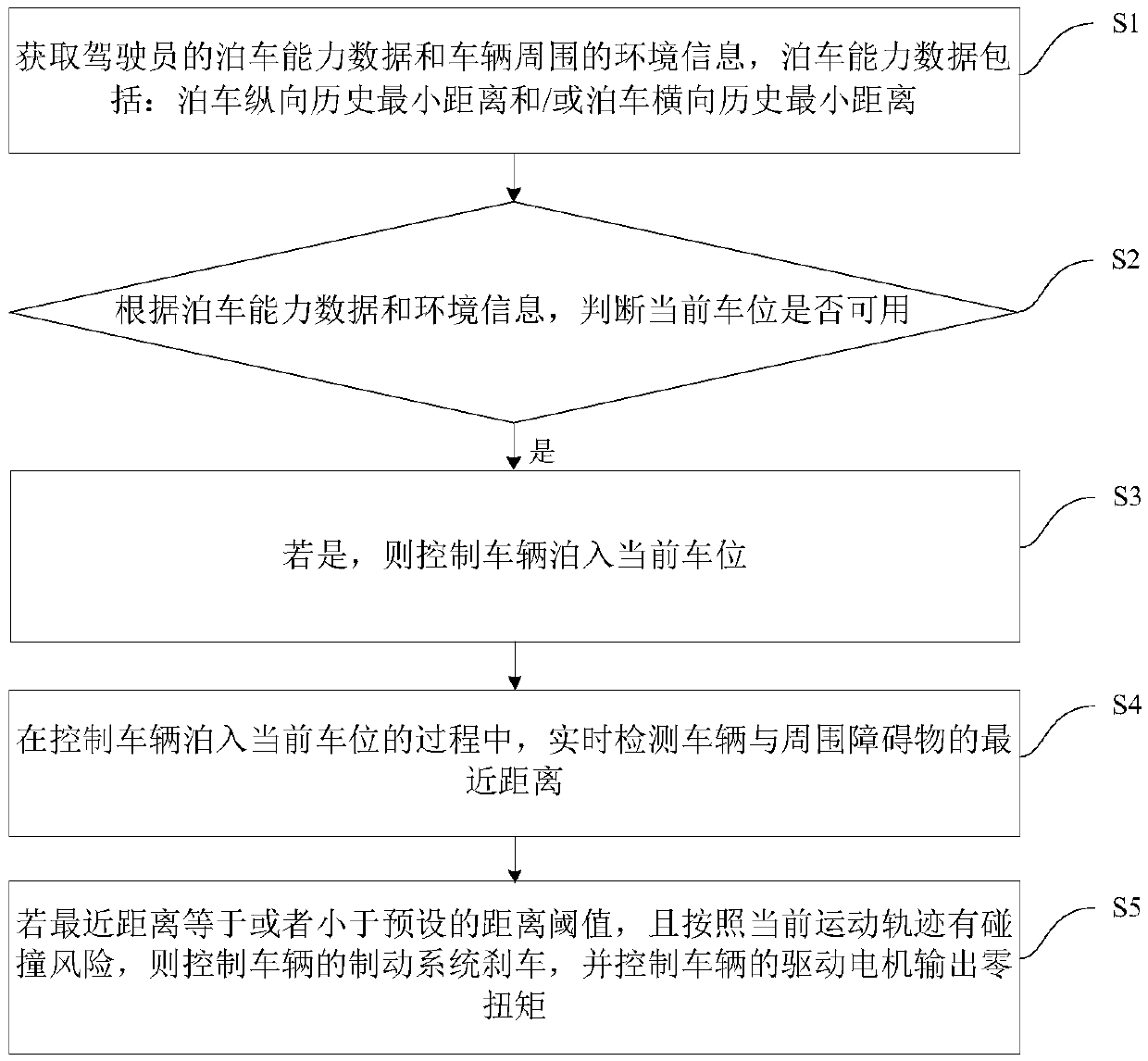

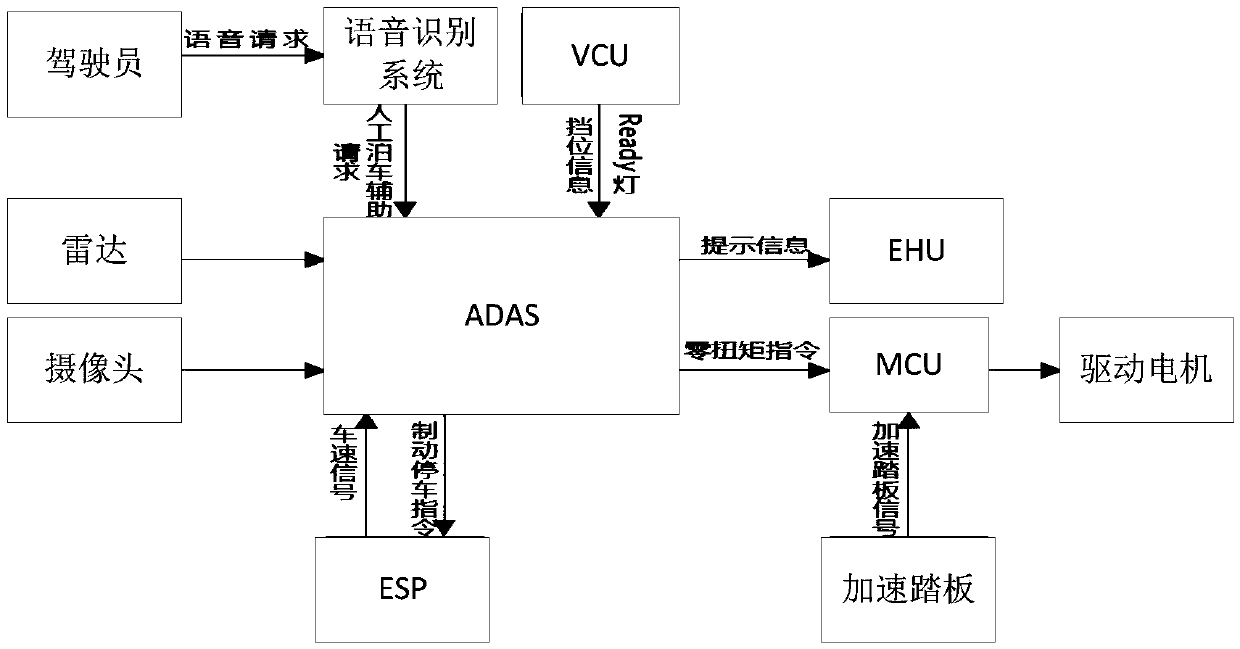

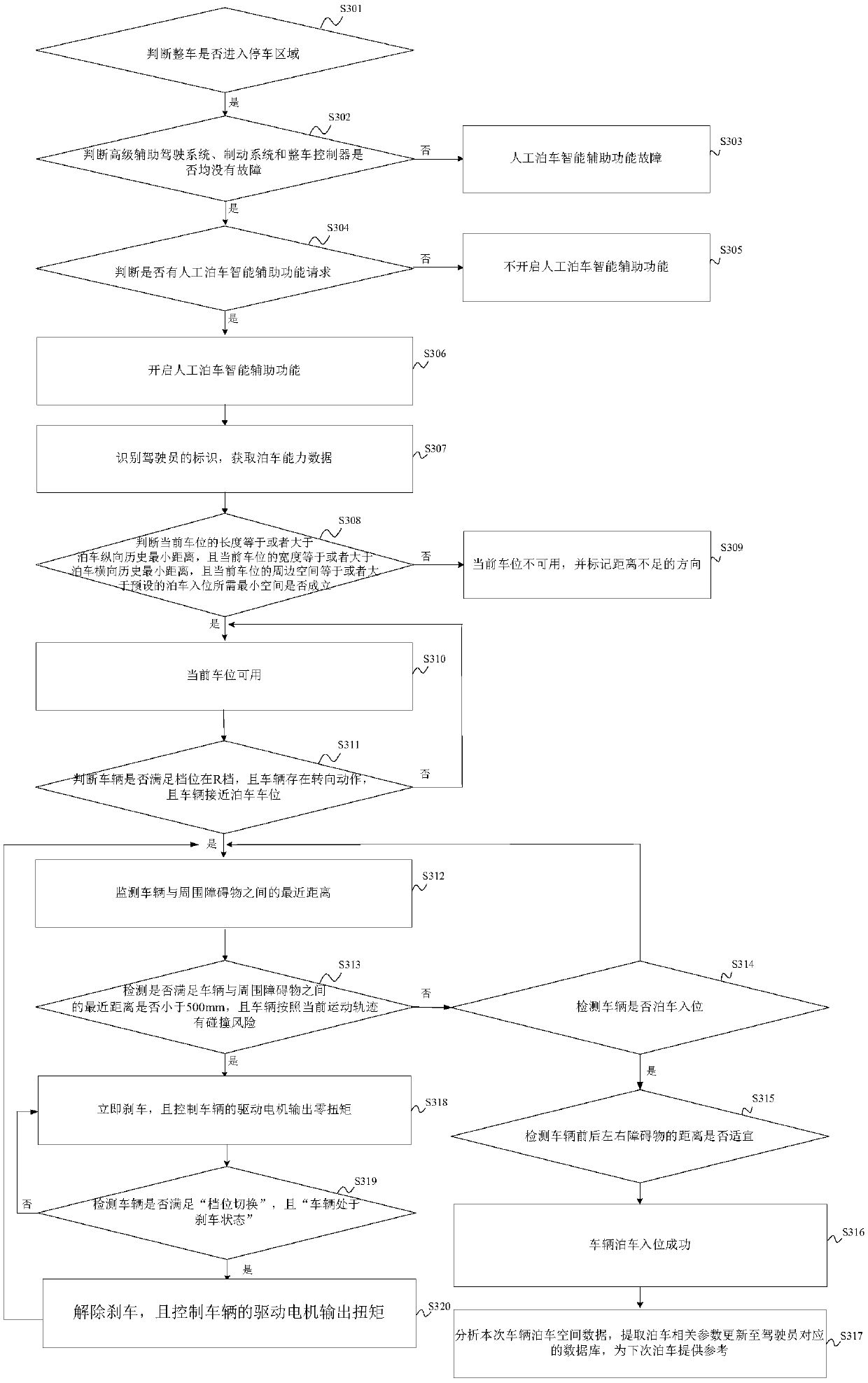

The invention discloses a vehicle, a parking control method and device. The method comprises the following steps of obtaining the parking capacity data of a driver and the environmental information around the vehicle, controlling the vehicle to be parked into the current parking space when the current parking space is available according to the parking capability data and the environmental information, detecting the nearest distance between the vehicle and the surrounding obstacles in the process of controlling the vehicle to be parked in the current parking space, controlling a braking systemof the vehicle for braking and controlling a drive motor of the vehicle to output 0 torque according to the fact that a collision risk exists in the current trajectory and if the nearest distance equal to or less than the preset distance threshold. According to the method, by detecting the nearest distance between the vehicle and the surrounding obstacles in real time, the vehicle running trajectory is predicted according to the vehicle body orientation, steering and gear so as to predict the collision cut risk, the braking system is controlled timely to take the braking measures and controla power system to disconnect the power output, the occurrence of the collision cut is effectively avoid, and the safety and practicability of the vehicle are greatly improved.

Owner:BEIJING ELECTRIC VEHICLE

Method for producing semi-tempered glass

ActiveCN102531365AProcess stabilityProcess energy savingGlass tempering apparatusToughened glassDouble stage

The invention relates to a method for producing semi-tempered glass. A double-stage cooling method is adopted in a cooling process of the method for producing the semi-tempered glass, namely secondary cooling is added on the basis of reservation of conventional primary cooling, so that the influence of abrupt change of wind pressure on the flatness of the glass is reduced in the cooling process, the semi-tempered glass with better flatness is obtained, and the effects of saving the cooling time, reducing the total energy-saving quantity of the semi-tempered glass to 10 percent of the prior art and promoting the flatness of the semi-tempered glass from 3 / 1,000 to 1 / 1,000 can be achieved.

Owner:LUOYANG NORTHGLASS TECH +2

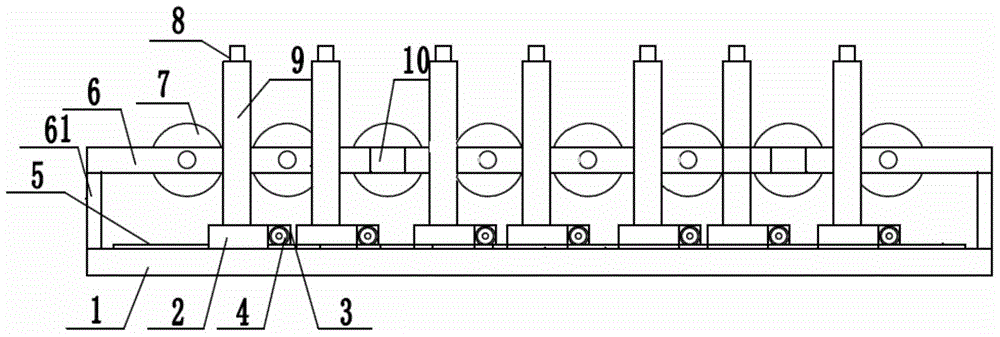

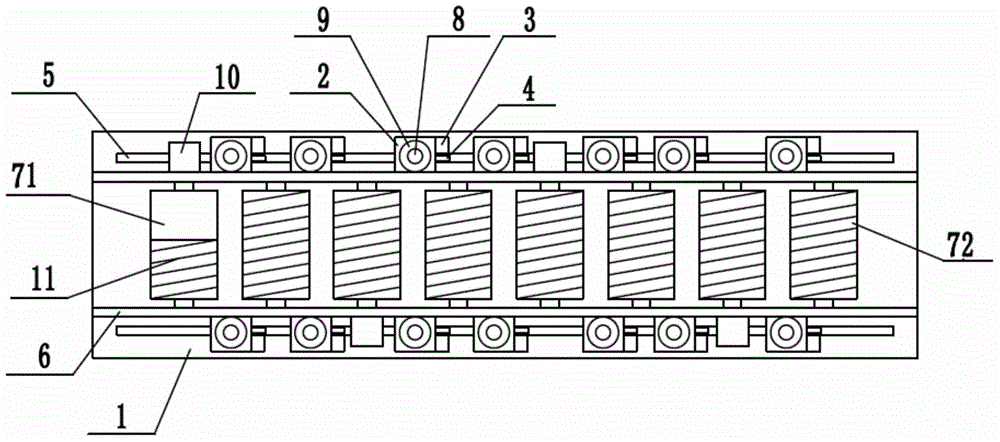

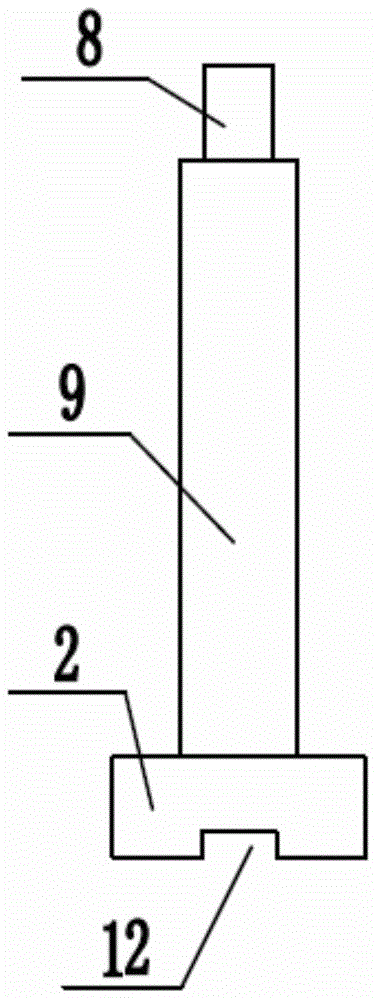

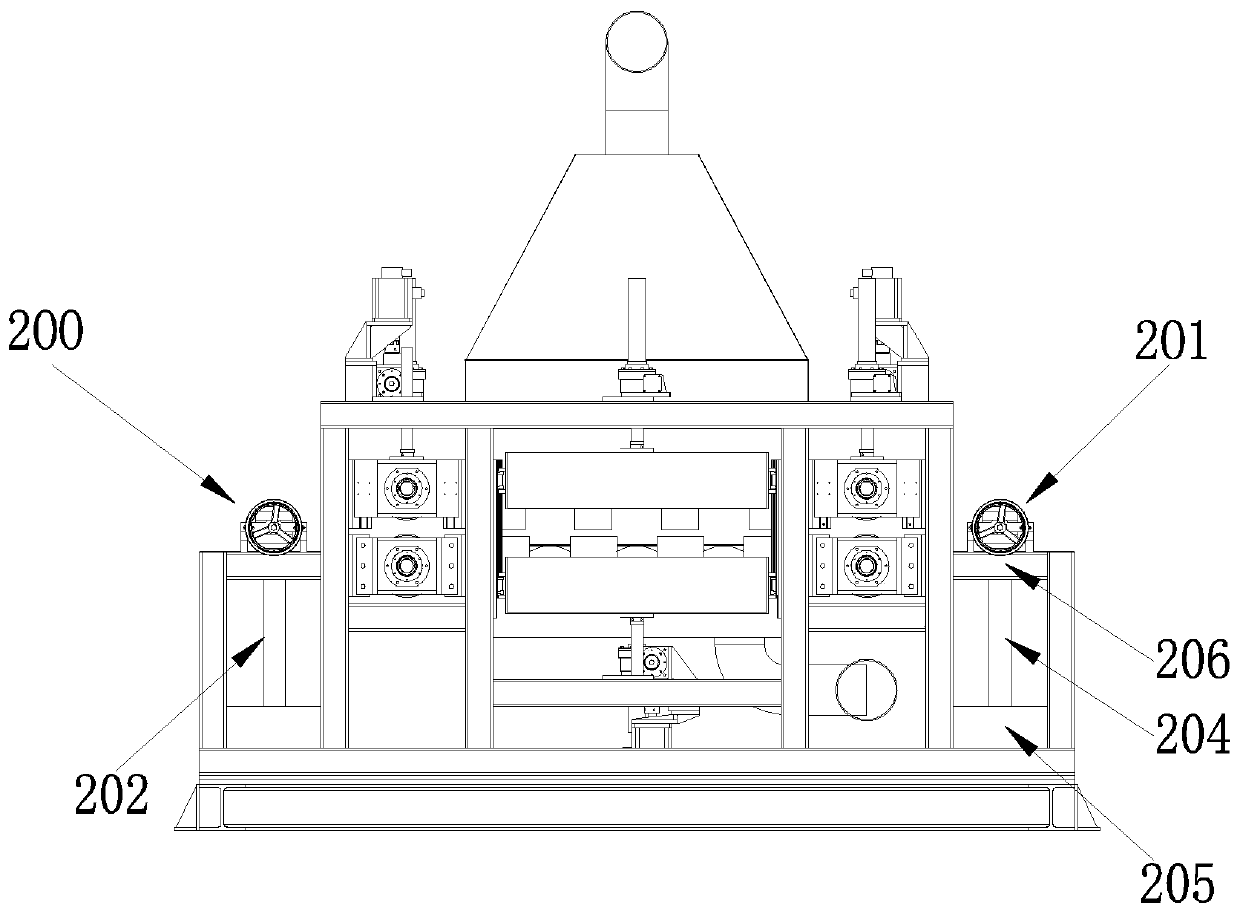

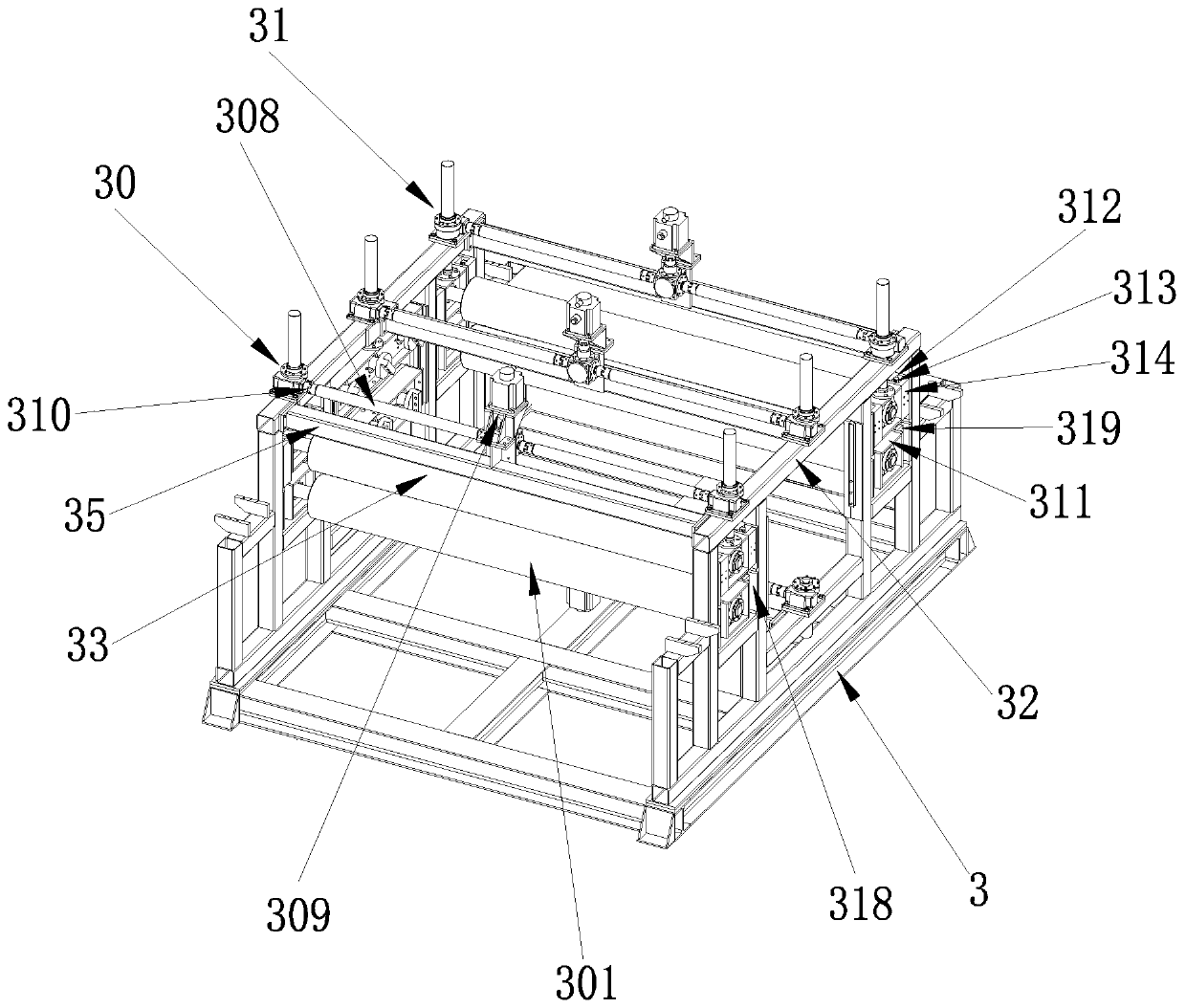

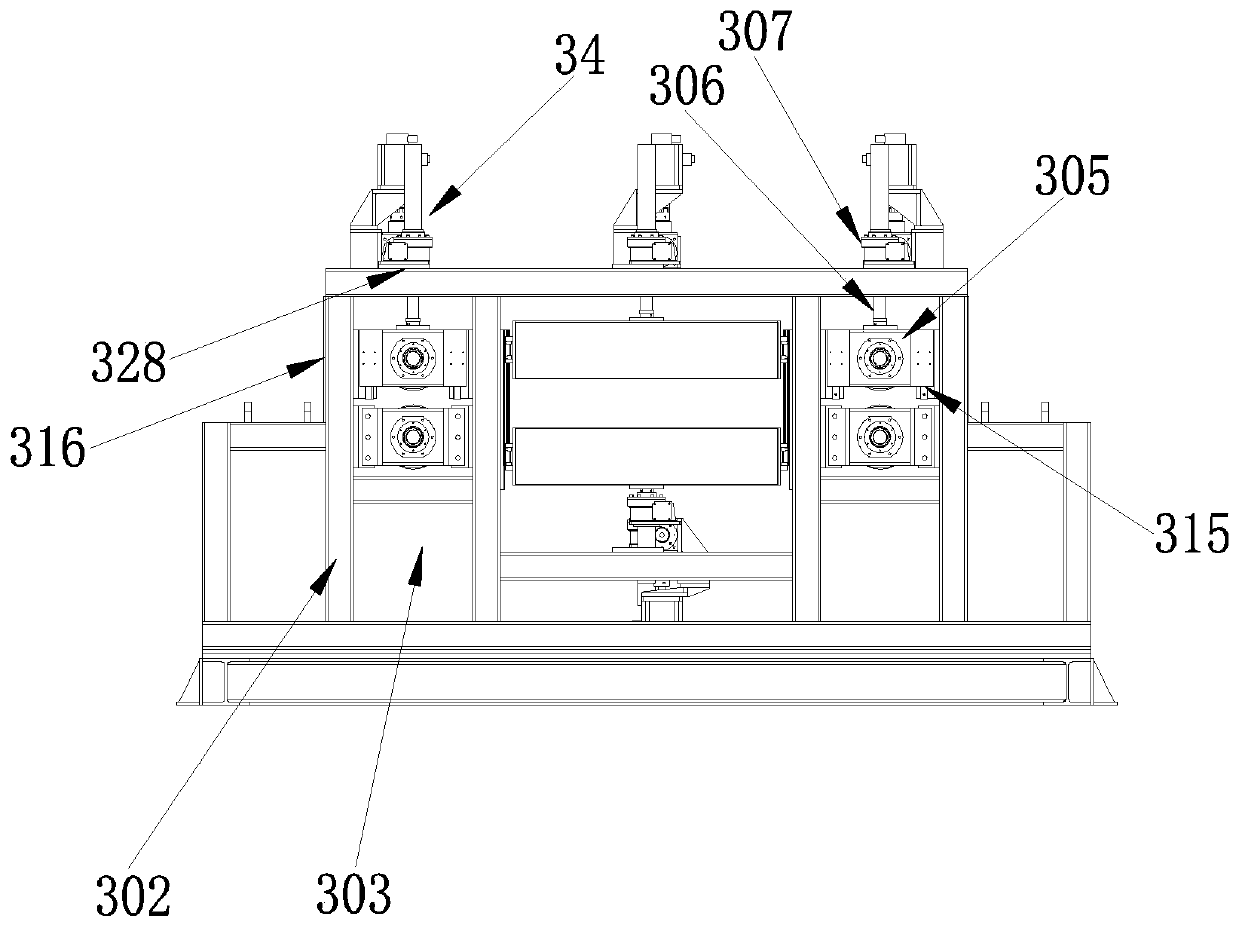

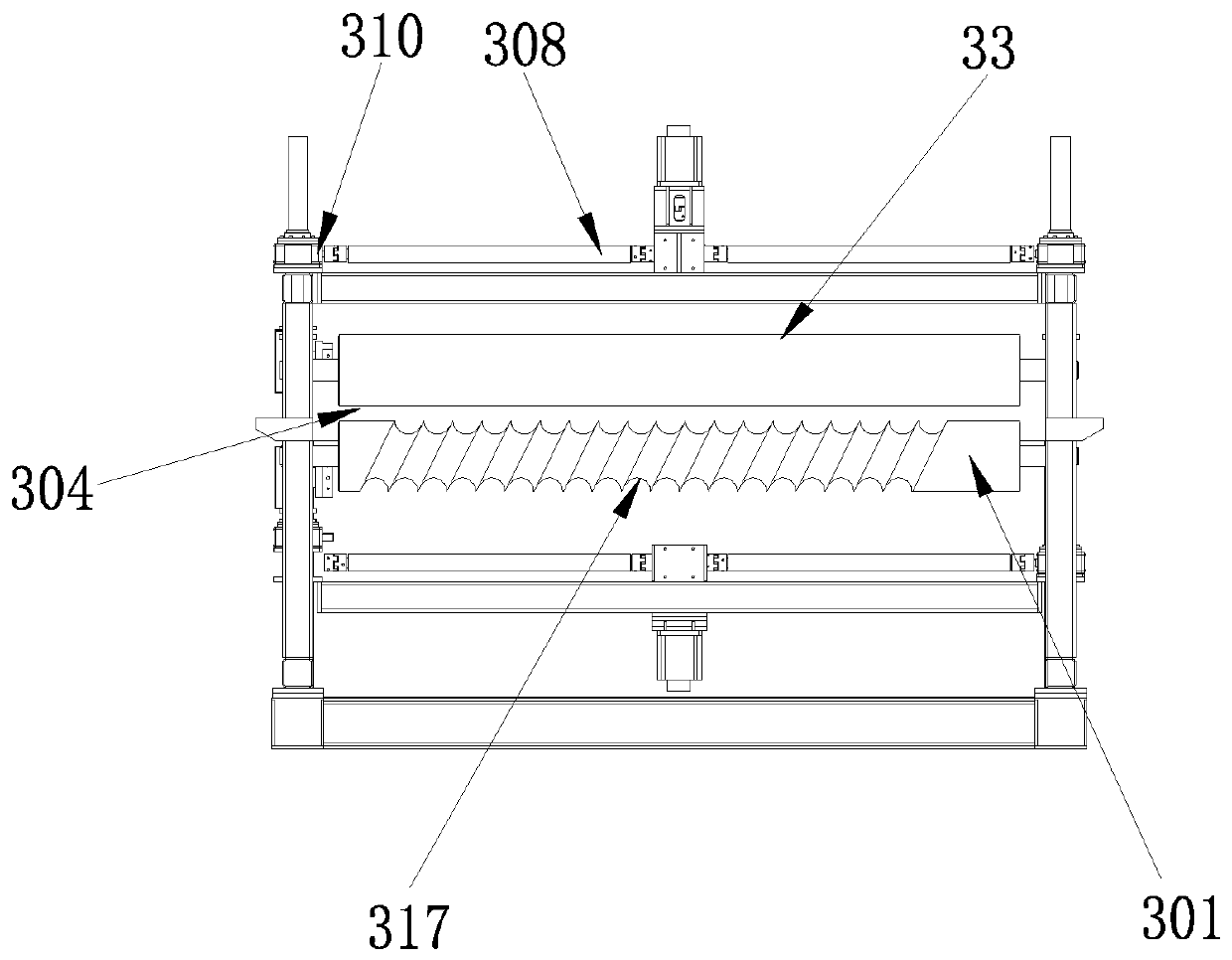

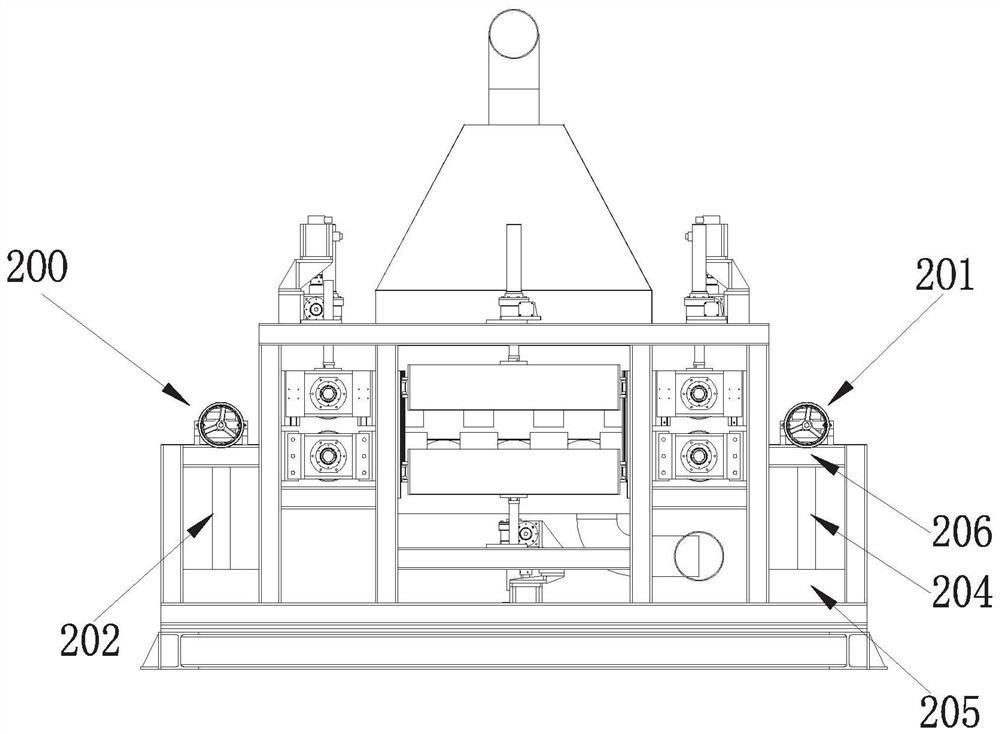

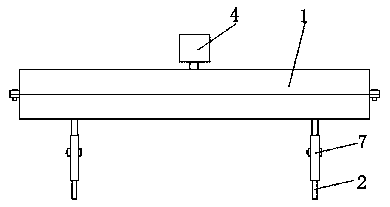

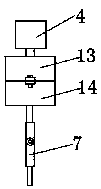

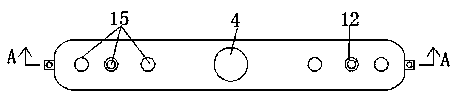

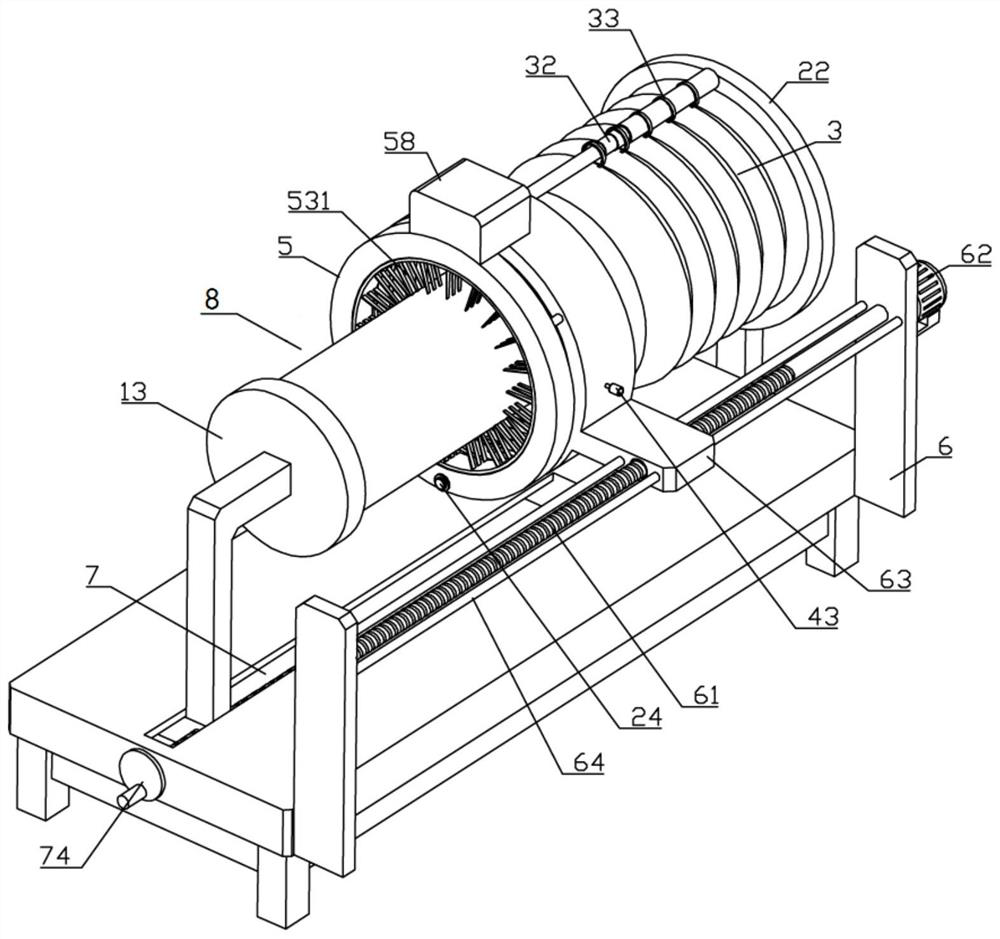

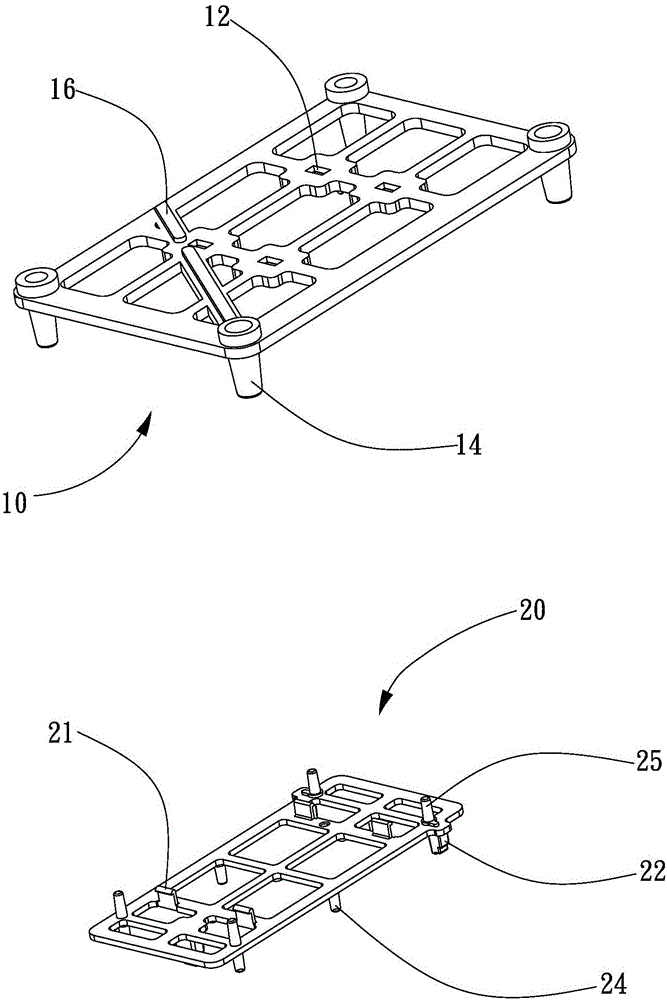

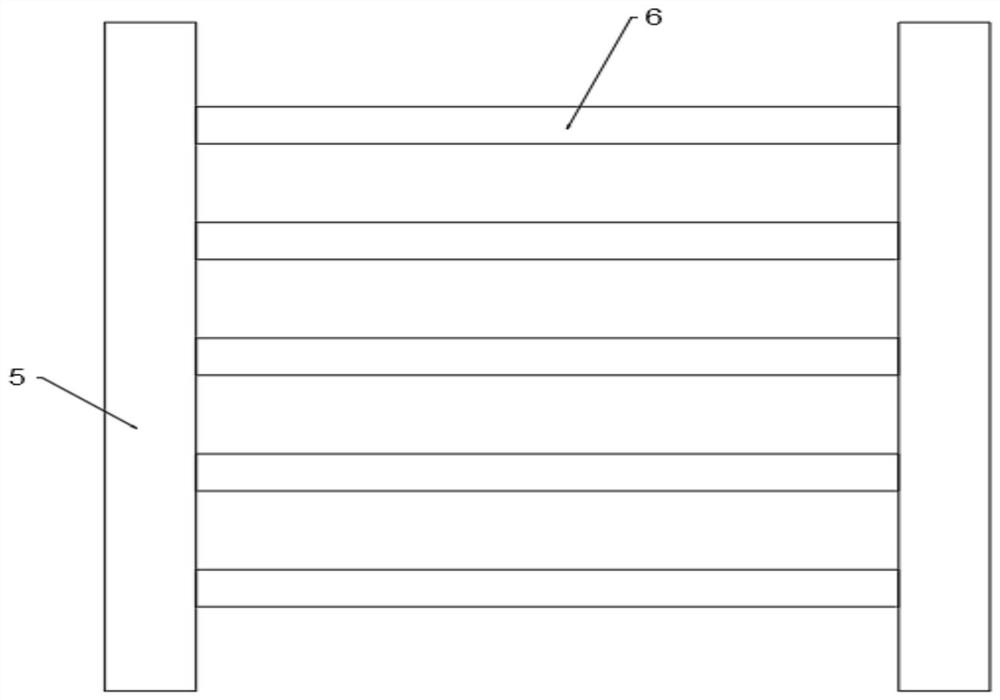

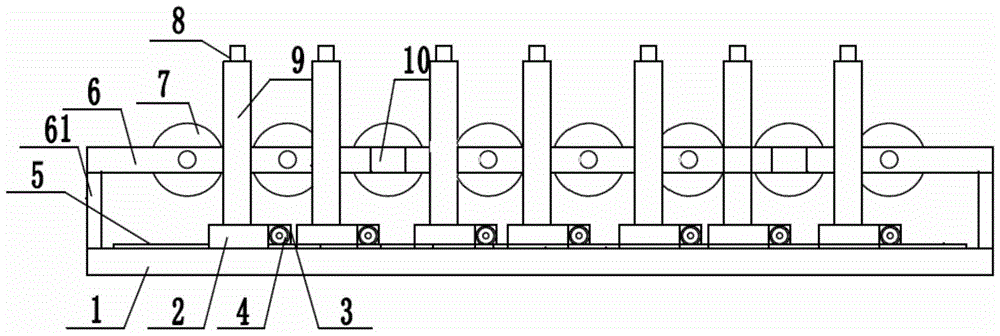

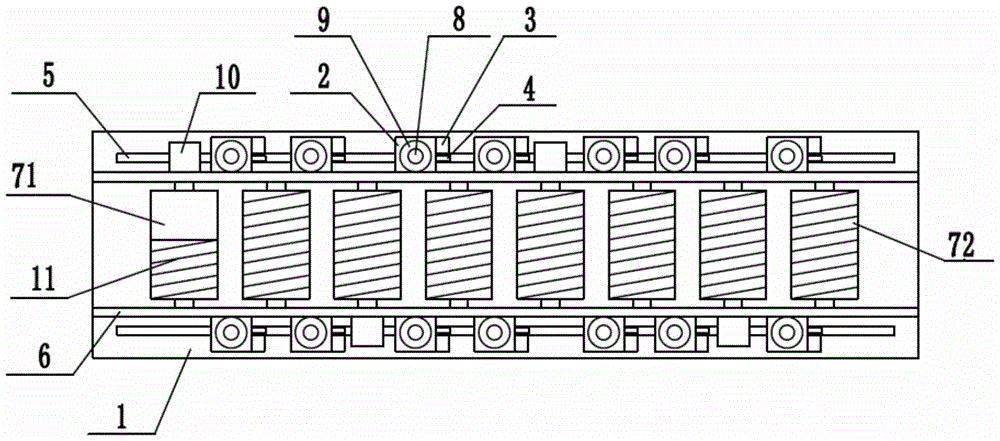

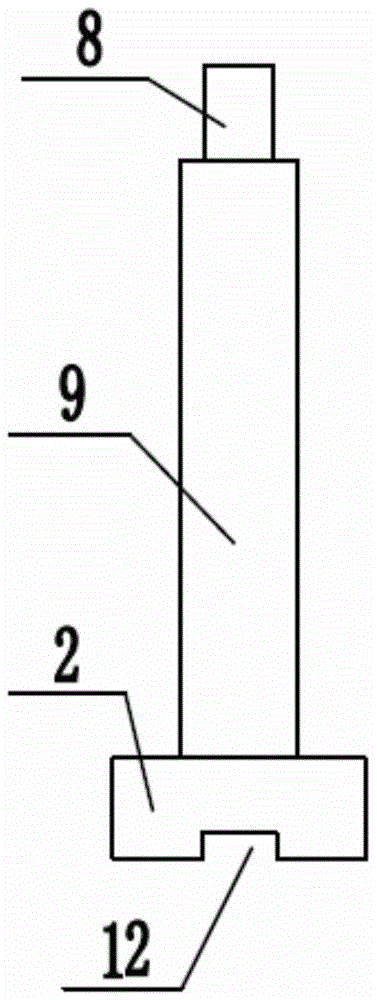

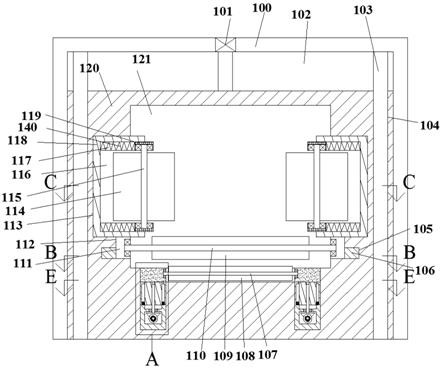

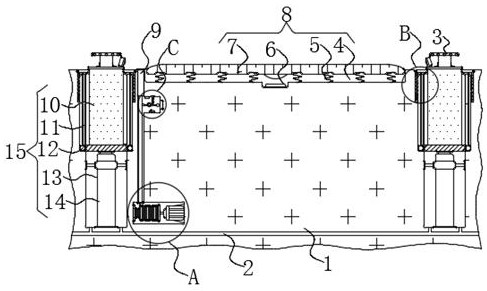

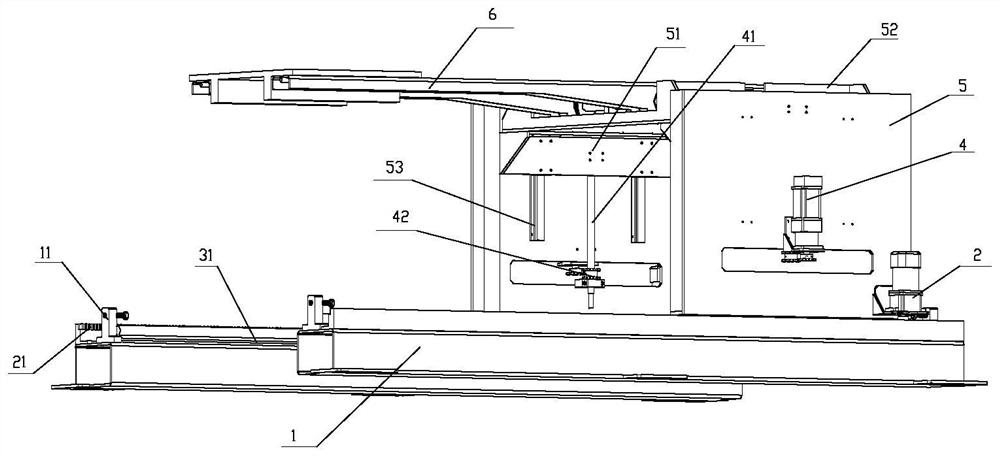

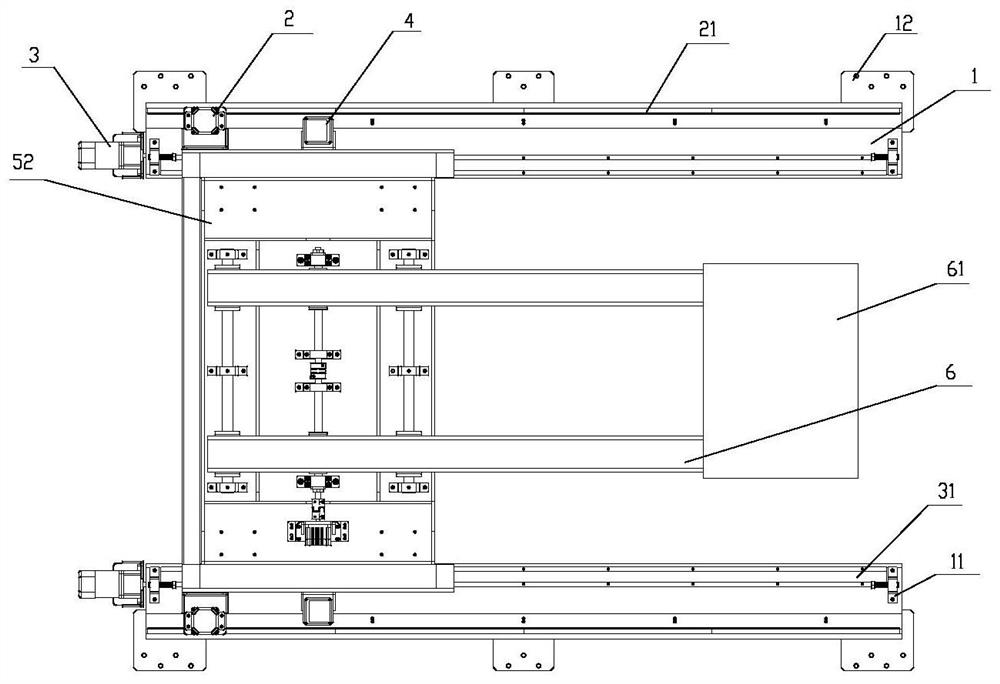

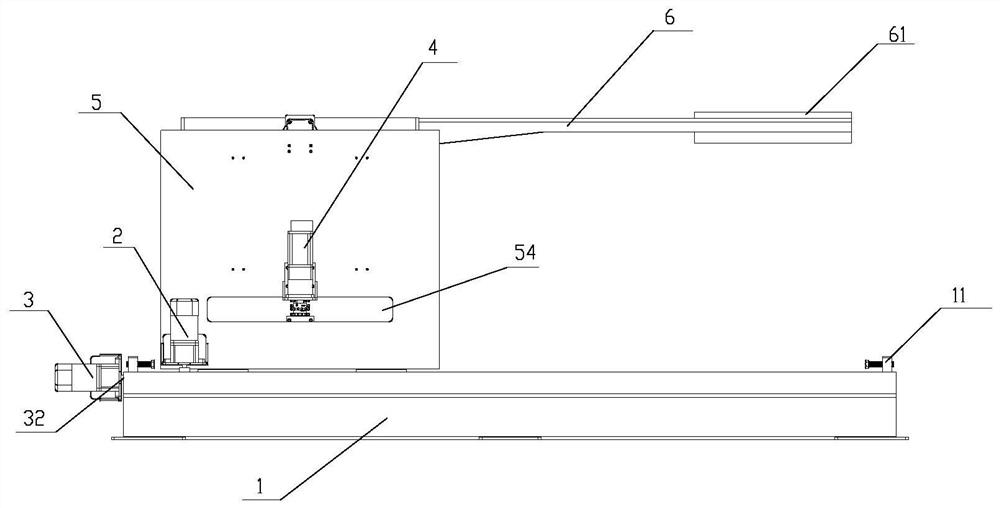

Steel plate conveying roller way of straightening machine

ActiveCN104401640AEasy to adjustGuaranteed uptimeRollersRoller-waysEngineeringMechanical engineering

The invention provides a steel plate conveying roller way of a straightening machine and belongs to the technical field of steel plate conveying devices. The steel plate conveying roller way of the straightening machine comprises a conveying base, two roller beam bodies which are symmetrically arranged on the upper end surface of the conveying base, two gear rack guide rails which are symmetrically arranged on the upper end surface of the conveying base and are disposed on the outer sides of the roller beam bodies, a plurality of sliding tables which are symmetrically arranged on the two gear rack guide rails, a plurality of connecting guide rods which are respectively, vertically and fixedly installed on the upper end surfaces of the sliding tables, and a plurality of conveying rollers of which connecting shafts at two ends are respectively arranged between the inner side surfaces of the two roller beam bodies, wherein the plurality of conveying rollers are driven through a first driving motor and are used for conveying a steel plate. The steel plate conveying roller way of the straightening machine has the advantages that the steel plate can be enabled to stably and effectively run on the conveying roller way of the straightening machine, the effect of steel plate conveying and guide is achieved, the steel plate is enabled to be conveyed to a designated position and the steel plate can be prevented from falling during conveying.

Owner:SHANDONG IRON & STEEL CO LTD

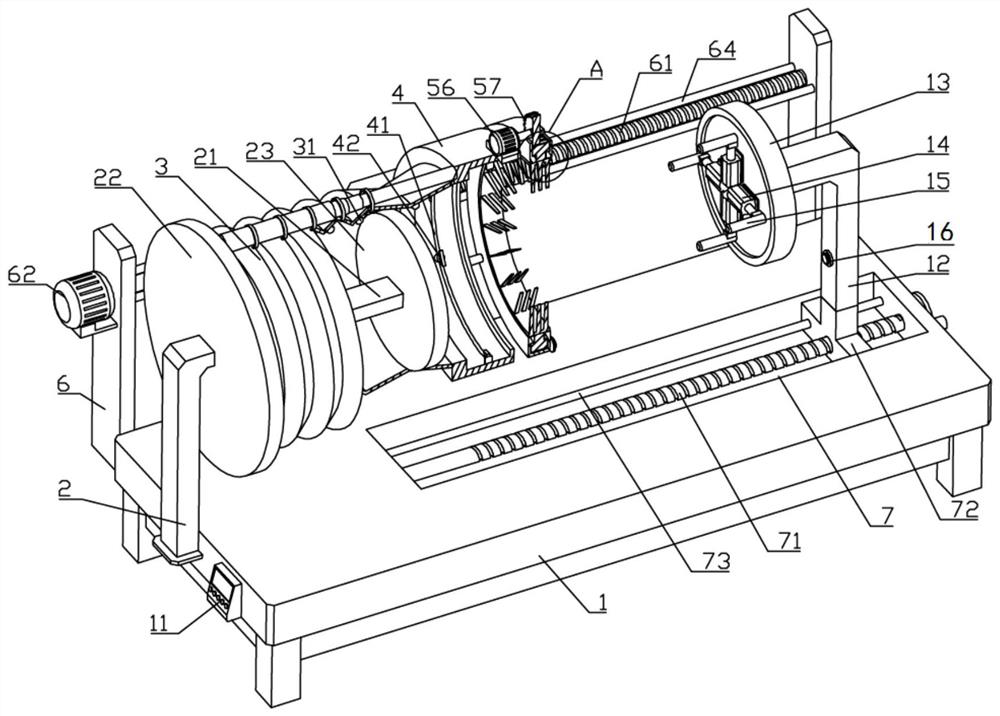

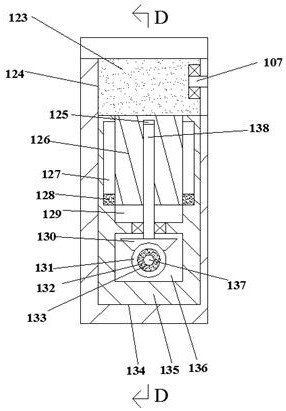

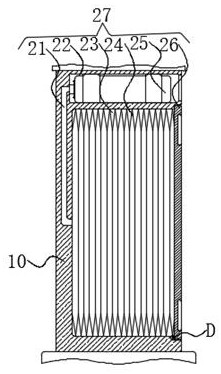

Steel plate rust removing mechanism

ActiveCN110900408AImprove stabilityWide range of useGrinding carriagesGrinding drivesSteel platesMaterial resources

The invention relates to a steel plate rust removing mechanism, which includes a fixing table, and a group consisting of a steel plate guiding device, a steel plate conveying and positioning device, asteel plate rust removing device, and a steel plate rust and dust removing device that are arranged on the fixing table. Steel ball brushes are distributed on the surfaces of a roller and a conveyingroller. The rust on both sides of the steel plate can be removed simultaneously, which greatly improves the rust removal efficiency of the steel plate. The steel ball brushes are spirally wound around the surfaces of the roller and the conveying roller, thereby not only cleaning the rust layer and the sticking substances on the surface of the steel plate, but also making the steel plate reach a certain surface quality requirement. The steel plate rust removing mechanism is not subject to sites, has high degree of automation, high efficiency of rust removal, is easy to maintain and install, saves manpower and material resources, and improves work efficiency.

Owner:ZHEJIANG CONSTR ENG GRP CO LTD

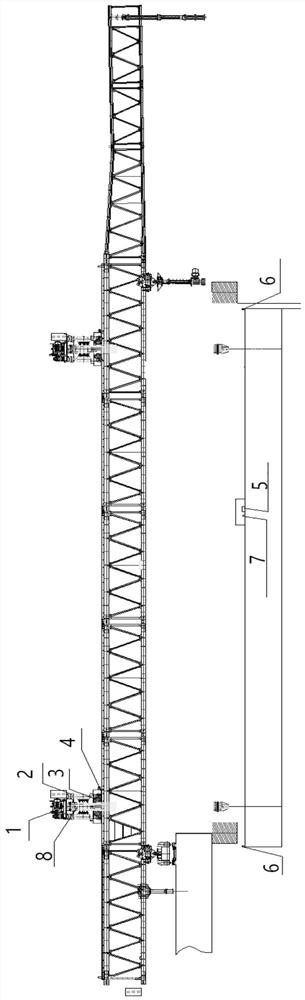

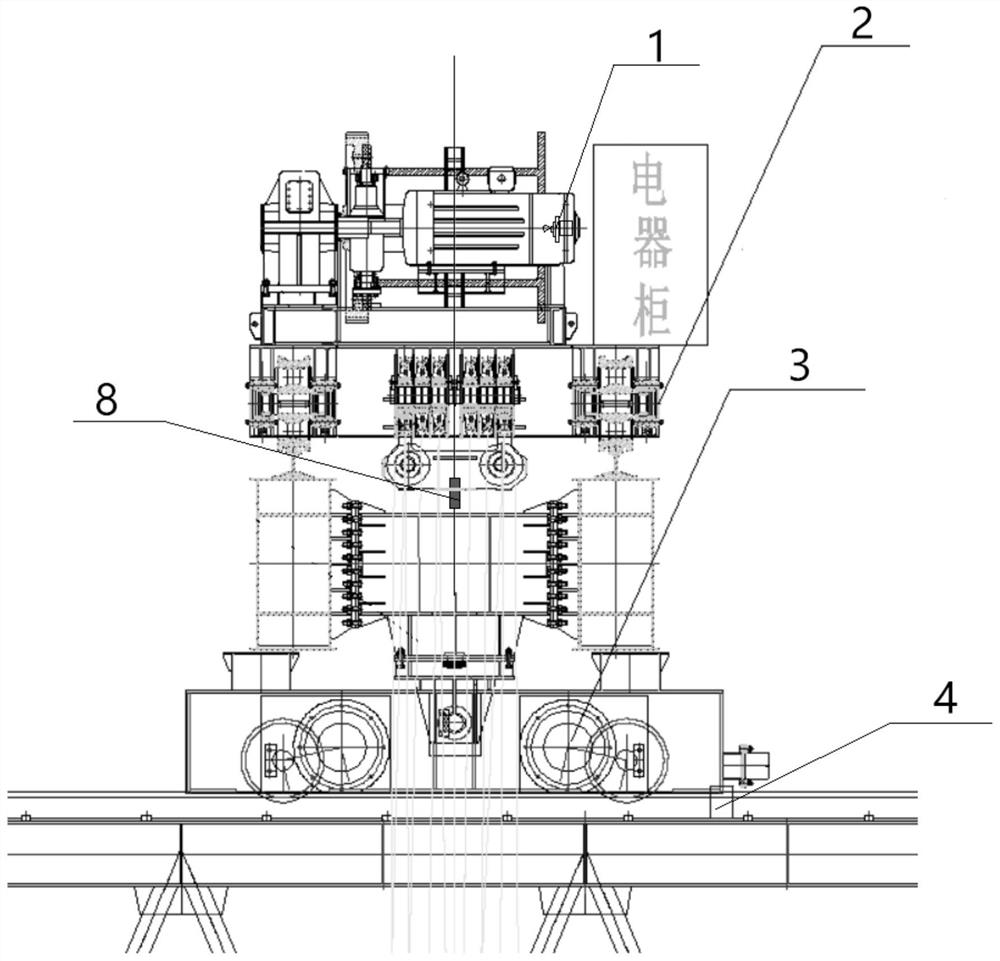

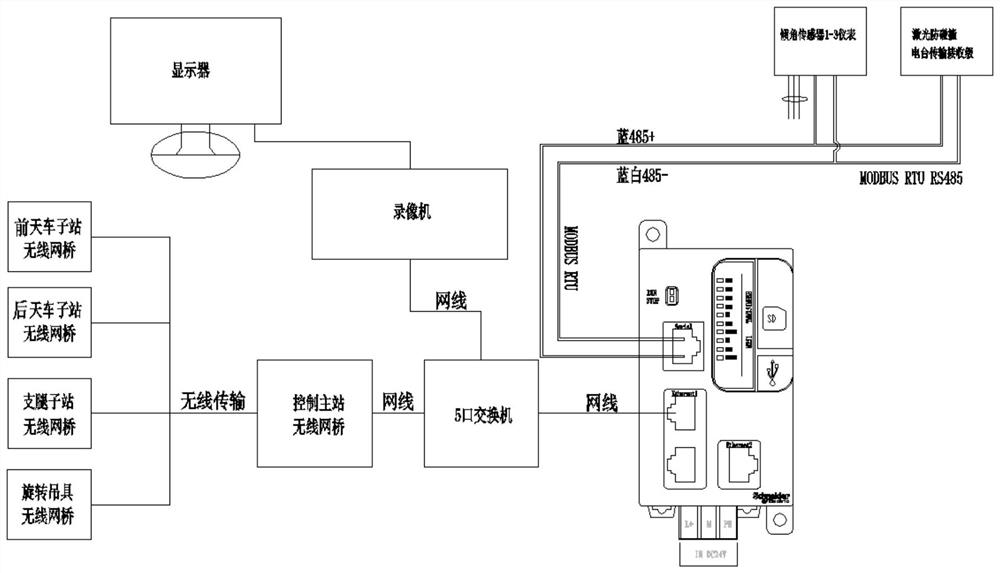

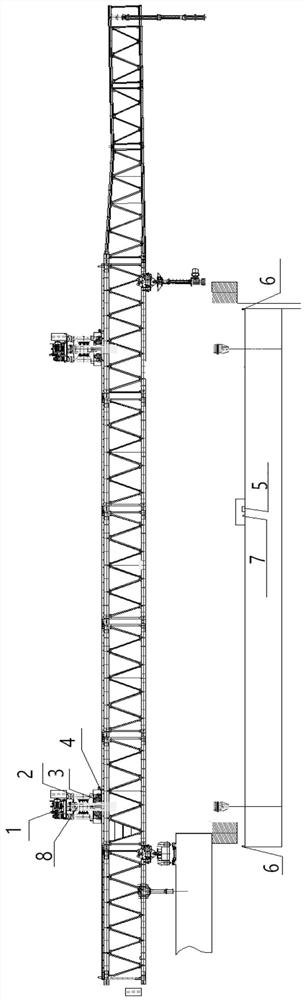

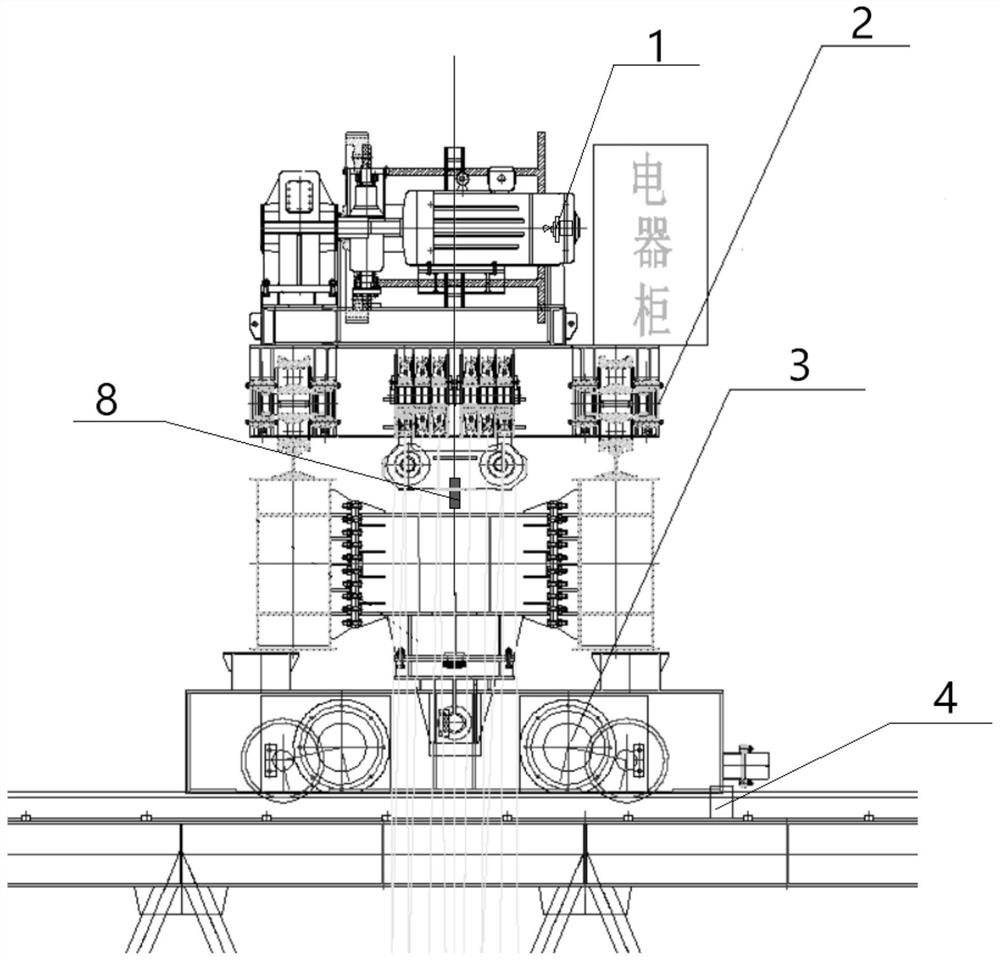

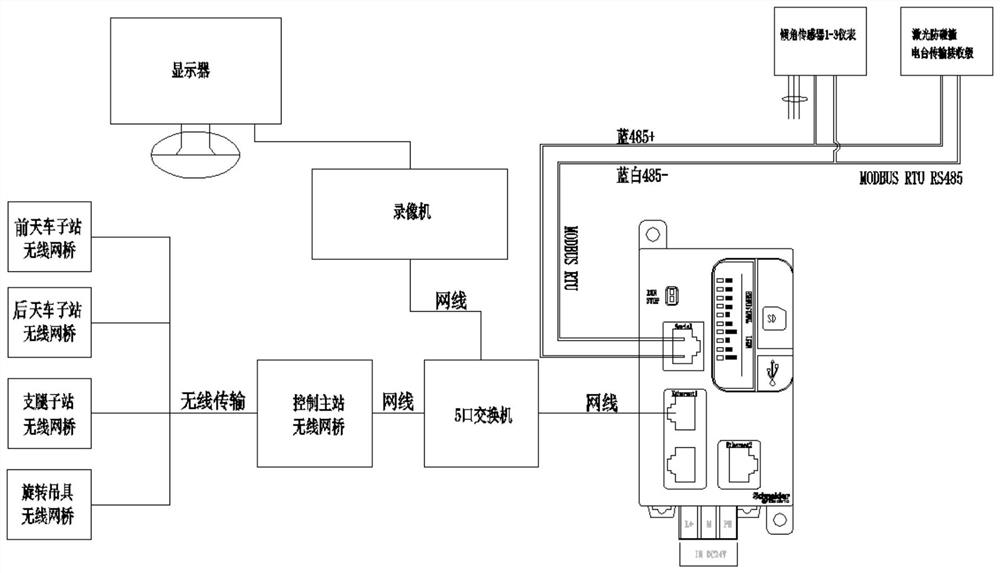

High-low crane automatic electrical control system and control method

ActiveCN112520582AKeep a safe distanceReduce labor costsBridge erection/assemblySafety gearWireless transmissionControl system

The invention provides a high-low crane automatic electrical control system and control method, and belongs to the technical field of electrical control. The high-low crane automatic electrical control system comprises a controller unit, a display unit, a sensor unit, a wireless transmission unit and a safety protection unit. The controller unit obtains the attitude of a box girder in hoisting according to an inclination angle sensor in the sensor unit, obtains the RTK space coordinate position of the head end and the tail end of the box girder according to a winch height encoder and a crown block stroke encoder, checks and resets the RTK position of a crown block in operation through an RFID position reader, calculates the RTK space coordinate position of the box girder and compares the RTK space coordinate position with a target value, the box girder is controlled to be lifted according to the difference value, automatic box girder lifting is achieved, the control precision is higher, the labor cost is reduced, and meanwhile the construction efficiency is improved; and the safety protection unit is used for guaranteeing that a certain safety distance is kept between the beam endand other objects, collision and scratching are prevented, the controller unit can control equipment to stop in time when an alarm is given, and construction safety is guaranteed.

Owner:THE THIRD CONSTR OF CHINA CONSTR EIGHTH ENG BUREAU +1

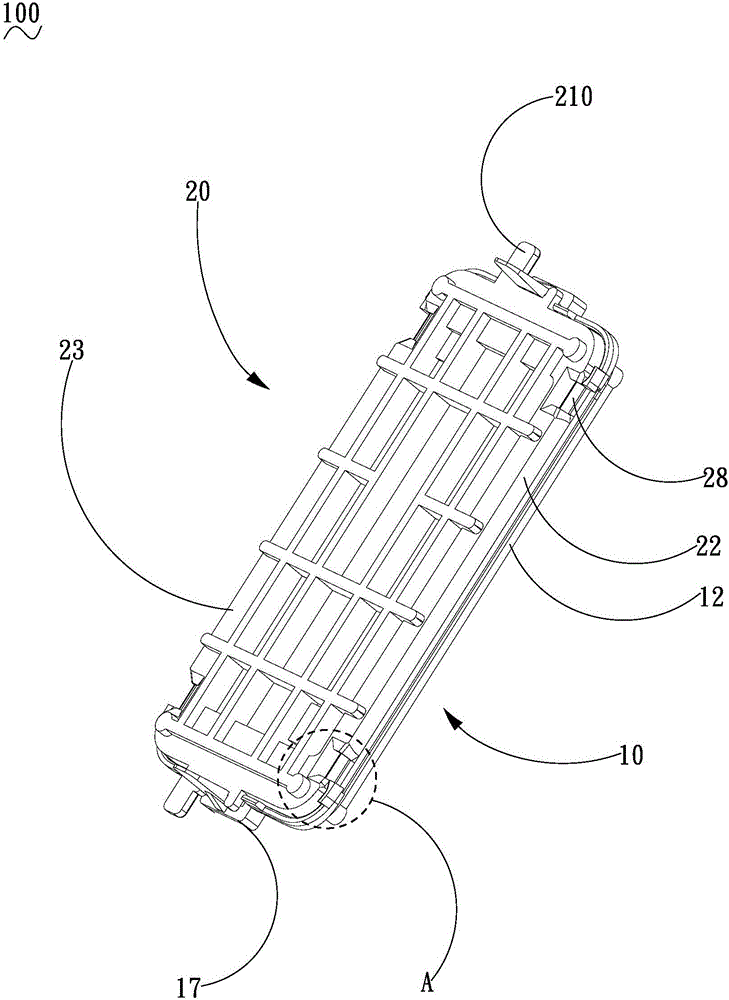

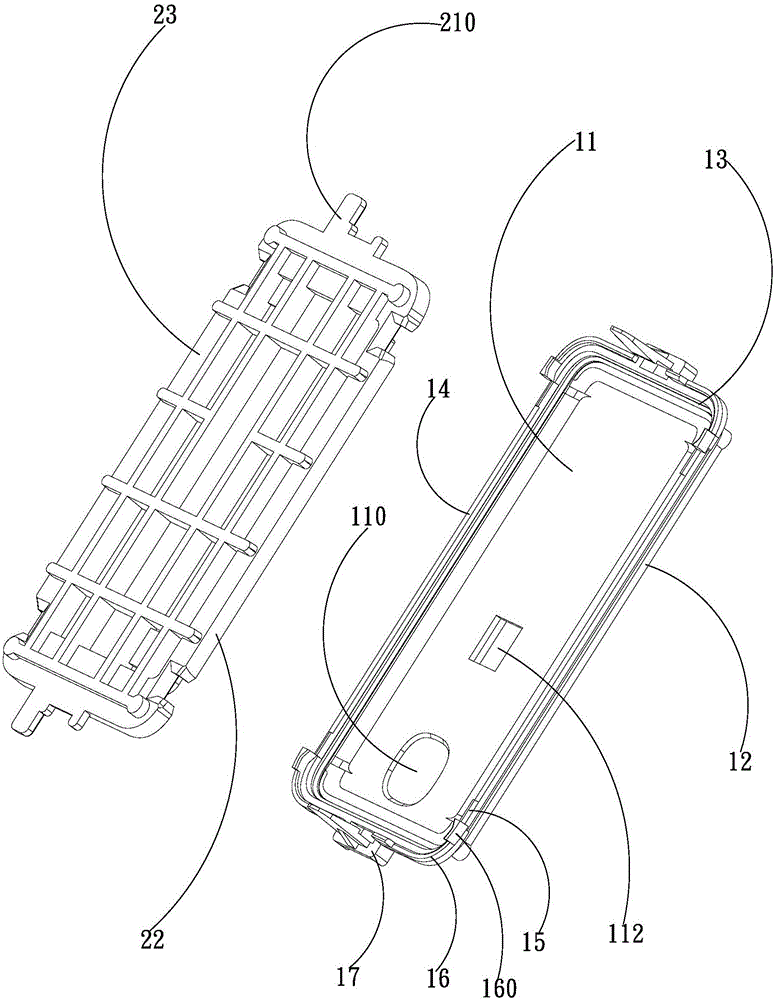

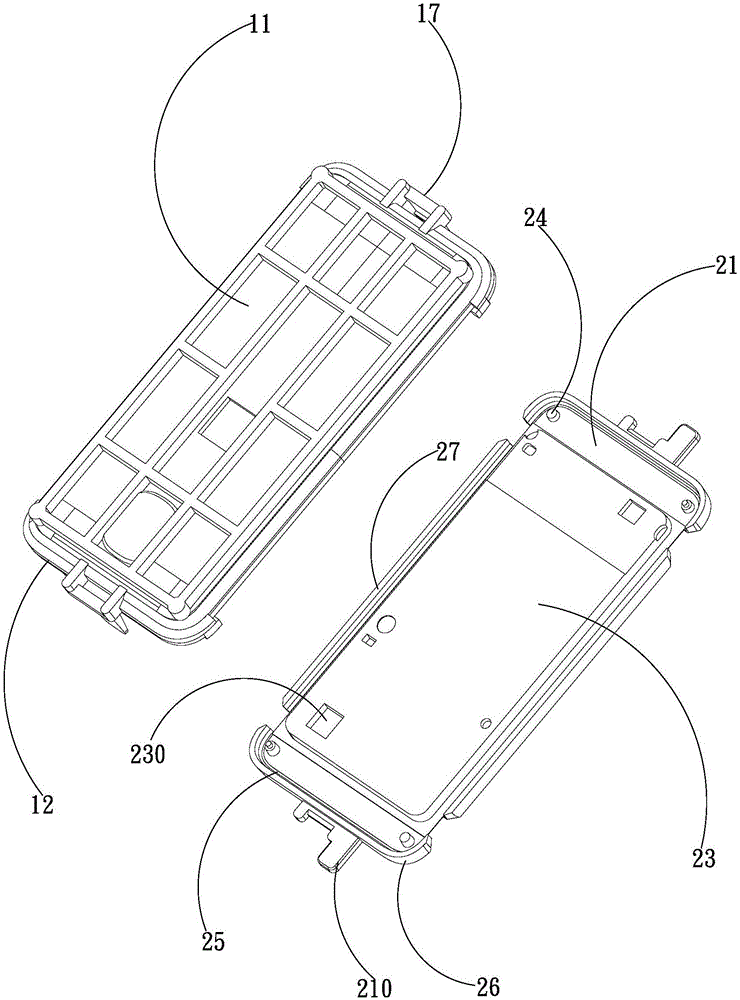

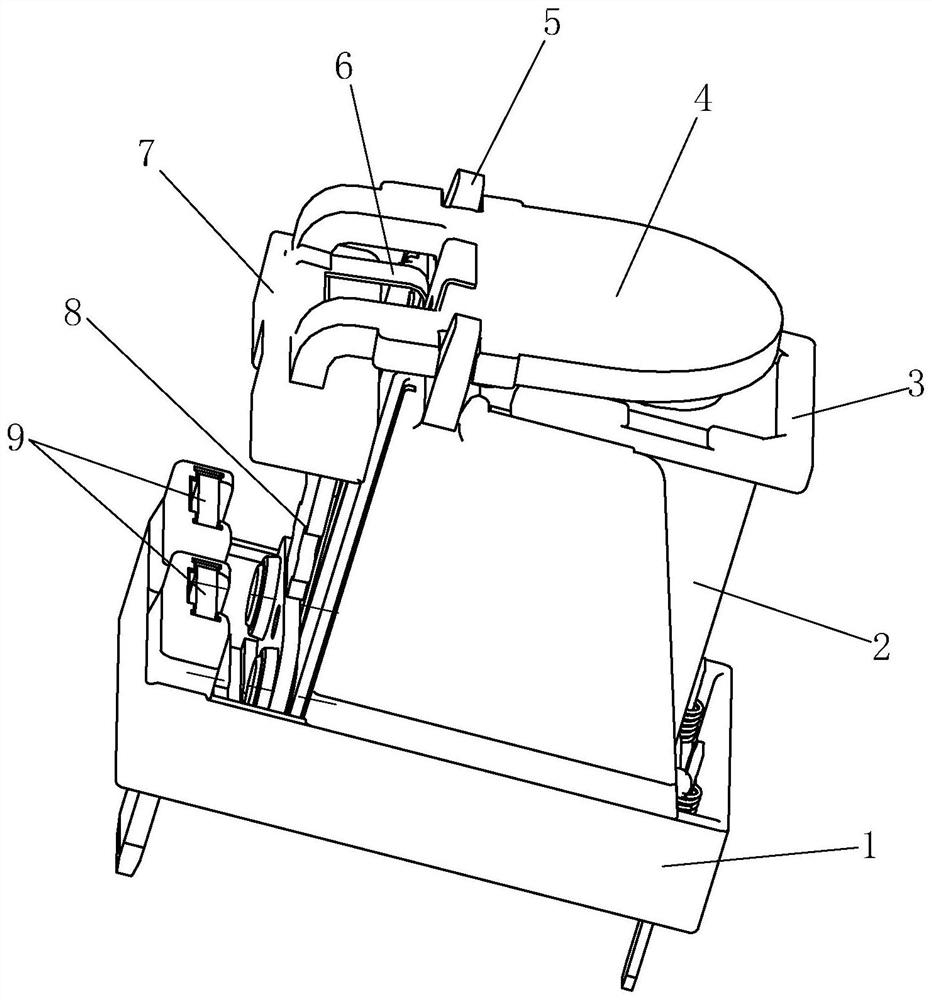

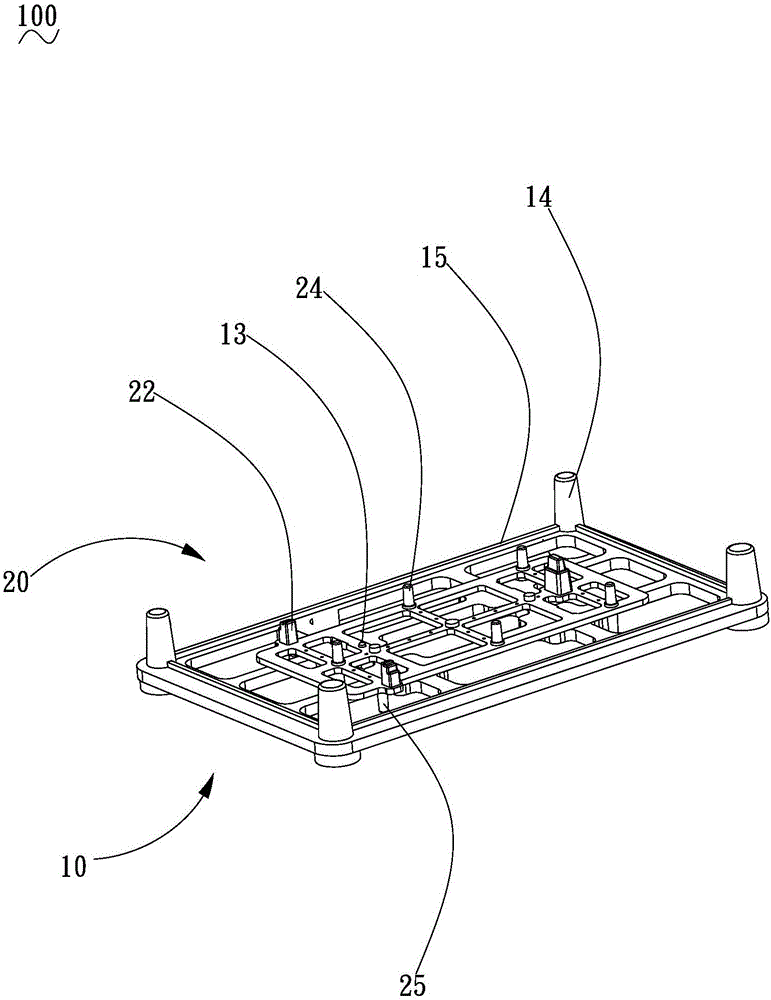

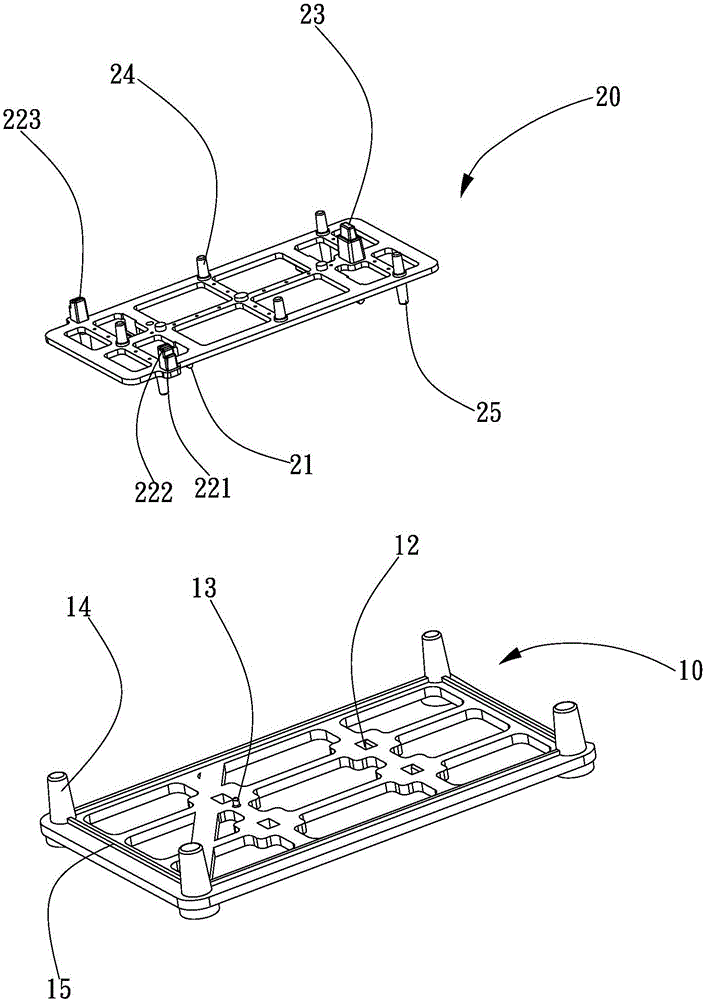

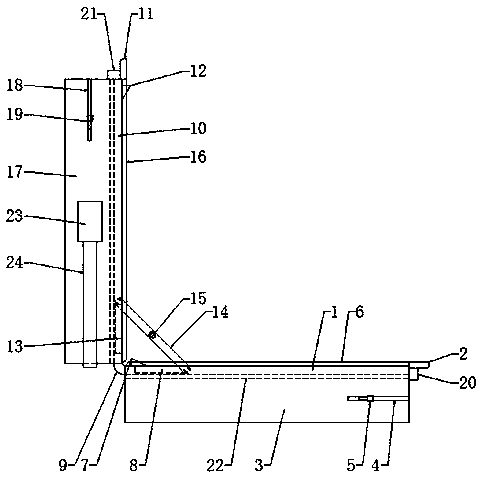

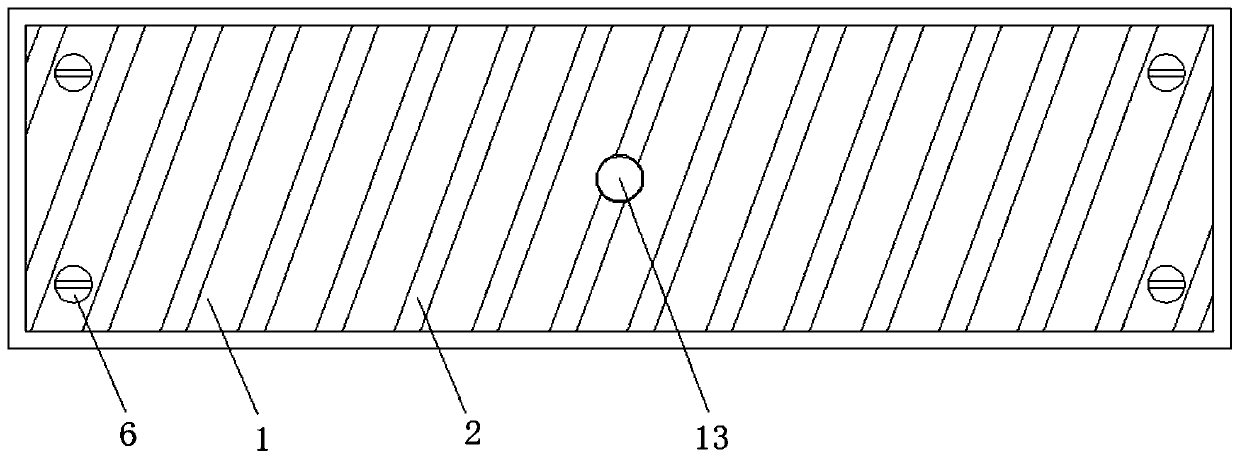

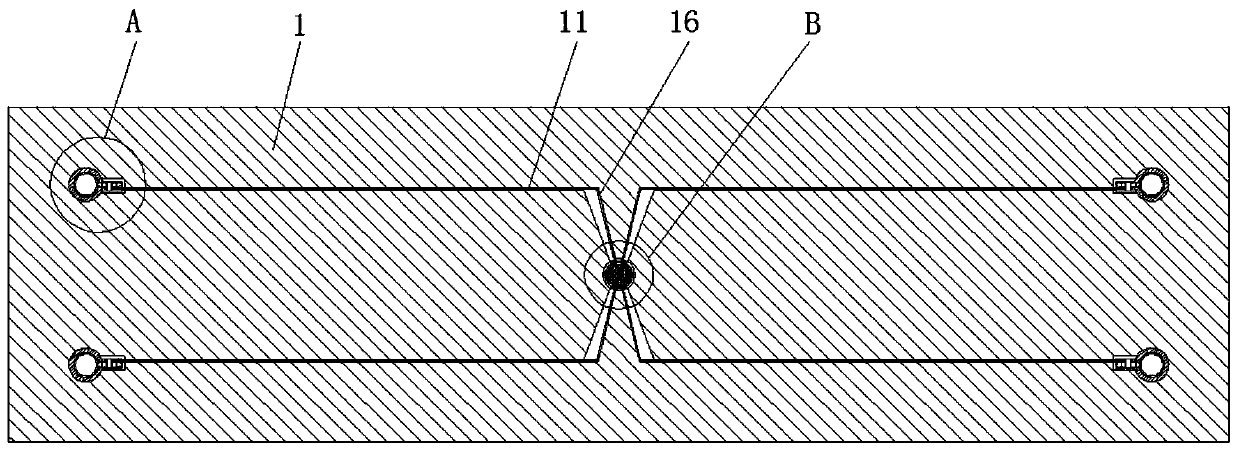

Spraying jig

ActiveCN106583124AAvoid collisions and scratchesReduce rework rateSpraying apparatusEngineeringSpecular surface

The invention relates to a spraying jig for carrying out partial spraying on a mobile phone shell. The spraying jig comprises a base plate and a cover plate, wherein the base plate comprises a base plate body and a side wall; the base plate body and the side wall are encircled to form an accommodating cavity; the accommodating cavity comprises a first groove; the first groove is formed along the circumferential edge of the base plate body to enable the base plate body to be separated from the specular surface at the lower part of the side edge of the mobile phone shell; the cover plate comprises a cover plate body and a shading part; a second groove is formed in the cover plate body; and the second groove is formed along the circumferential edge of the cover plate body to enable the cover plate body to be separated from the specular surface at the upper part of the side edge of the mobile phone shell. According to the spraying jig, the mobile phone shell is accommodated in the base plate and covered with the cover plate, so that exposed portions on the mobile phone shell can be sprayed; furthermore, the first groove is formed in the base plate, and the second groove is formed in the cover plate; and the first groove and the second groove enable the spraying jig to be separated from the specular surfaces on the side edge of the mobile phone shell, so that scratches of the specular surfaces due to collision between the spraying jig and the specular surfaces on the side edges of the mobile phone shell are avoided, and the rework rate of a product is reduced.

Owner:DONGGUAN CHANGYING PRECISION TECH CO LTD +1

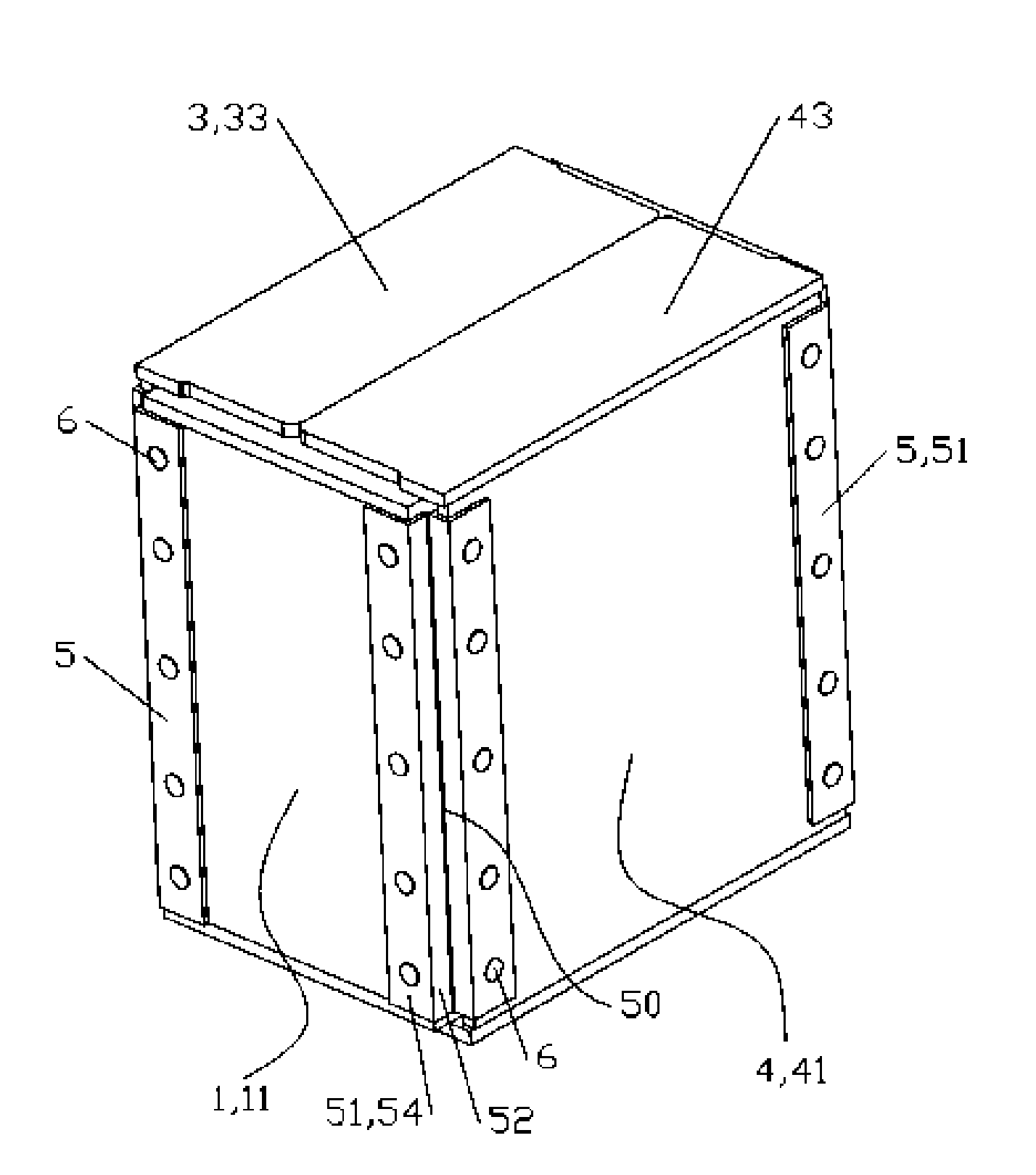

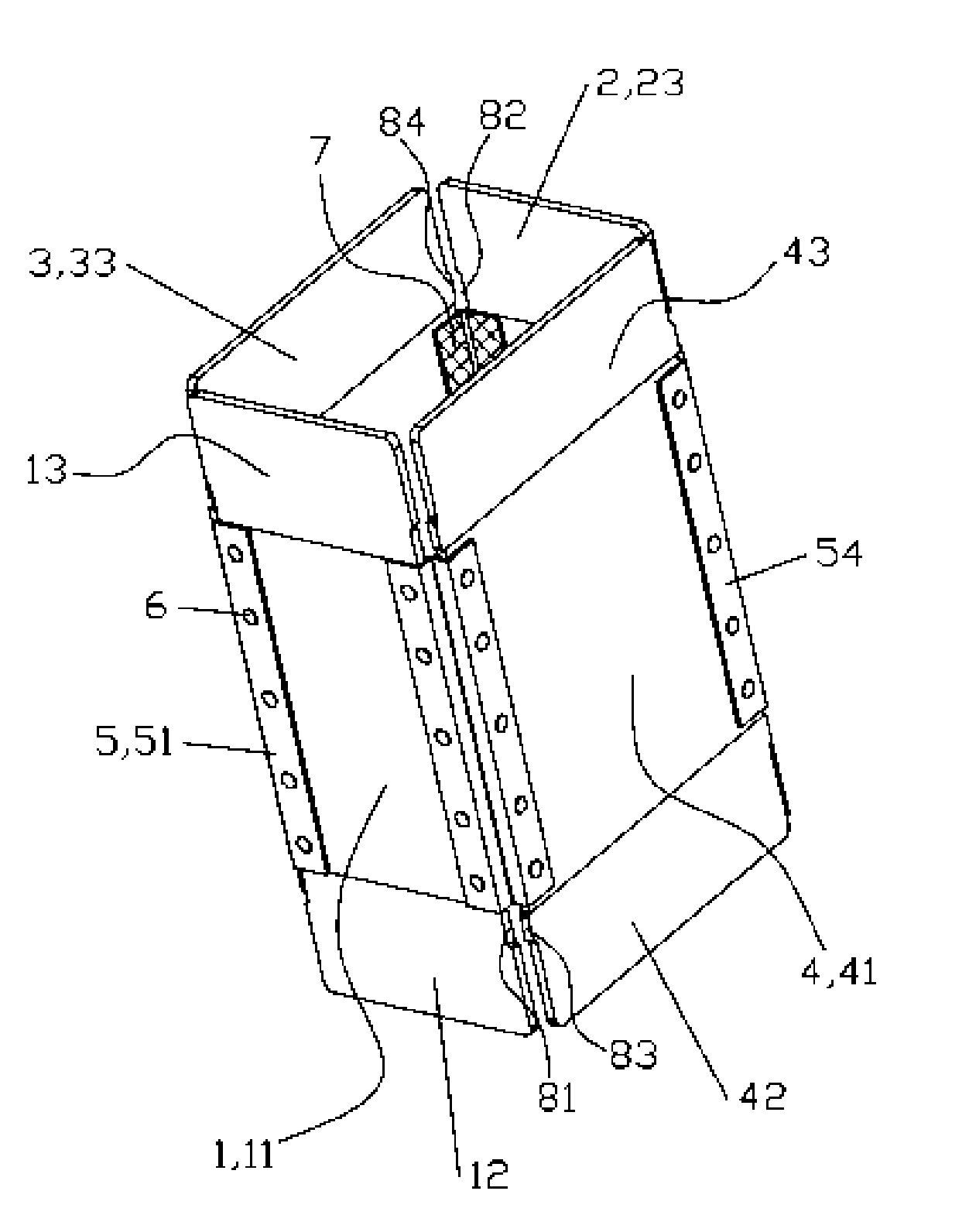

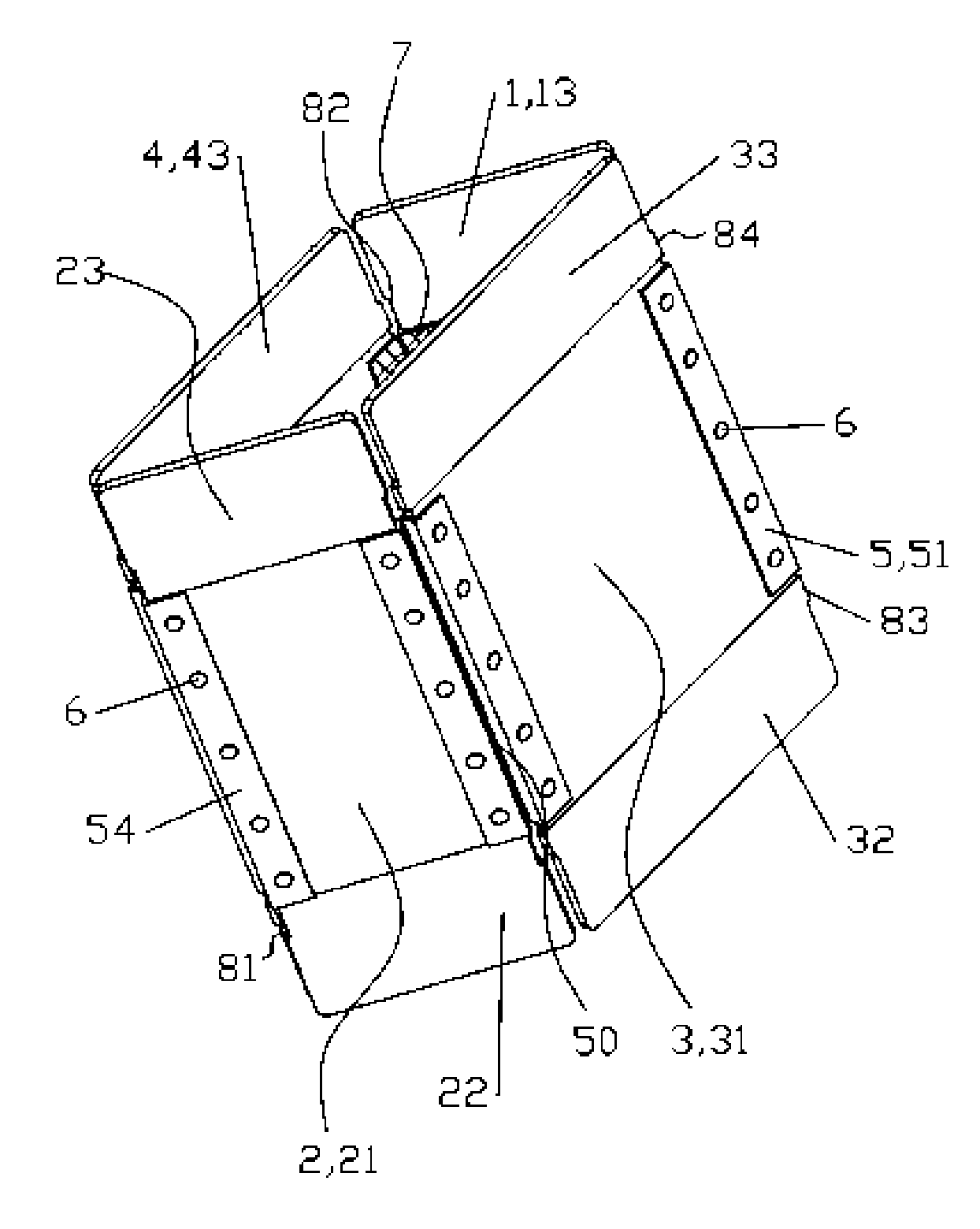

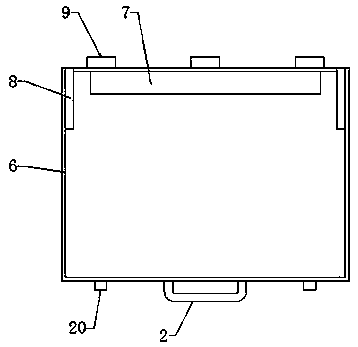

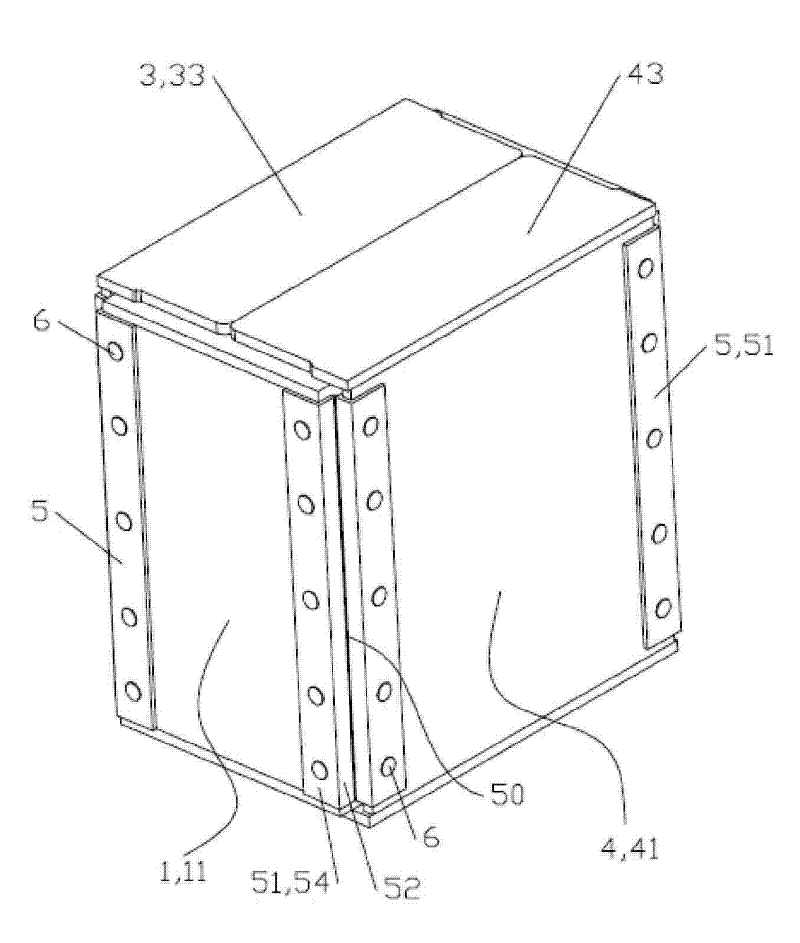

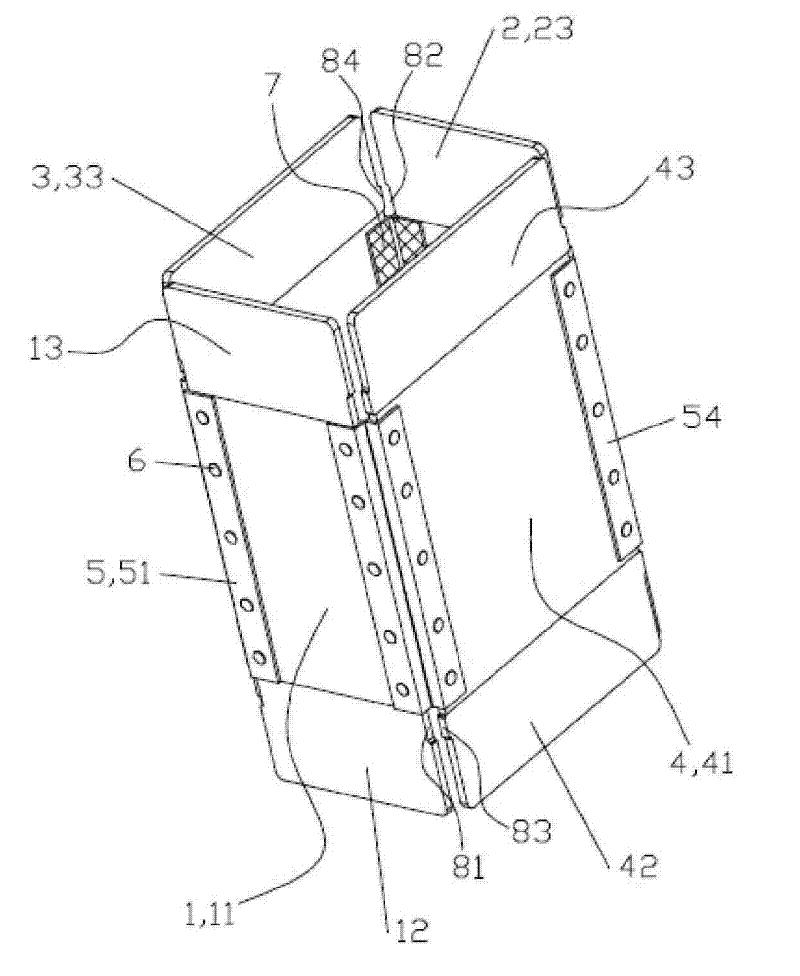

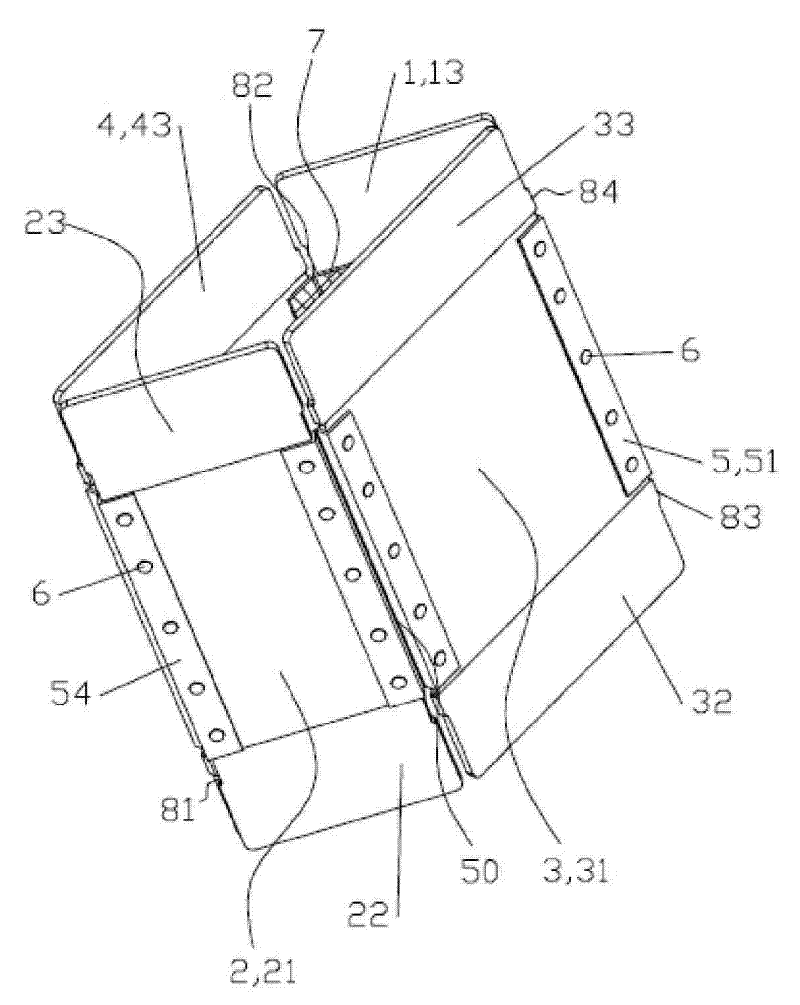

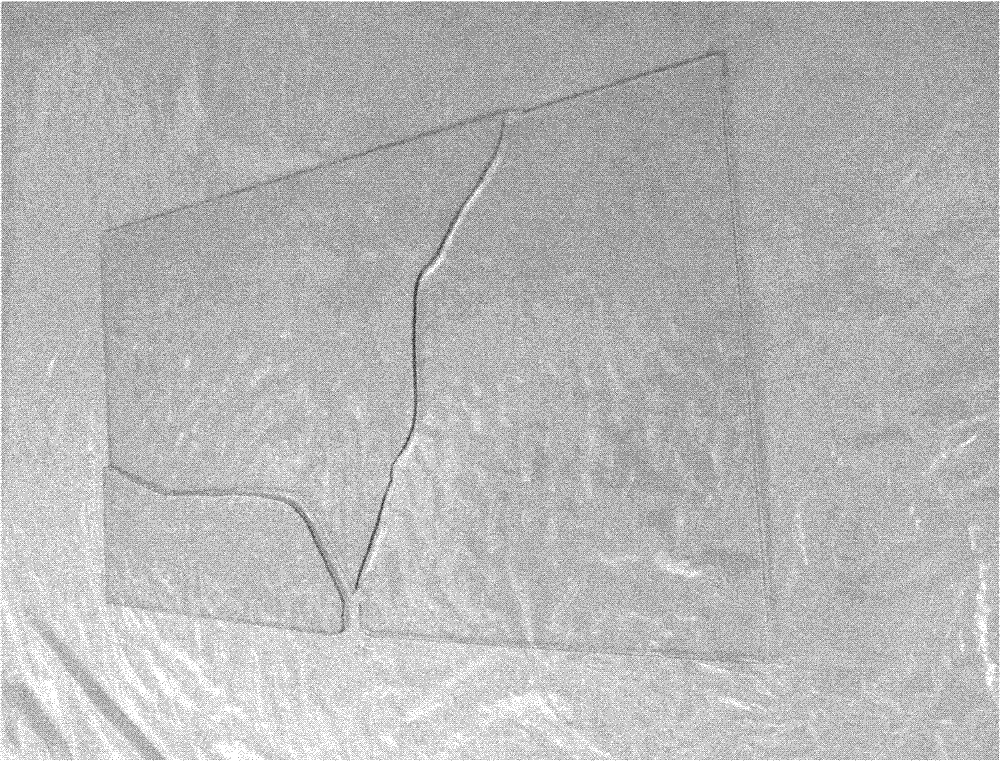

Folding type hollow plate reusable container

ActiveCN101665167ASimple structureEasy to foldPackage recyclingNon-removalbe lids/coversHinge angleEngineering

The invention discloses a folding type hollow plate reusable container, comprising a first plate, a second plate, a third plate, a fourth plate and four hinges, wherein the first plate, the second plate, the third plate and the fourth plate are all plastic hollow plates; the first plate and the second plate have same structure and are arranged in parallel from front to rear; the third plate and the fourth plate have same structure and are arranged in parallel from left to right; the four plates are stamped and bent so as to form a front plate, a rear plate, a left plate, a right plate, four top covers and four bottom covers; two sides of the front plate, the rear plate, the left plate and the right plate are respectively provided with three to eight rivet mounting holes, and the four hinges are also provided with corresponding rivet mounting holes; the first plate, the second plate, the third plate and the fourth plate are riveted and fixed by the four hinges and rivets, thus connecting together and forming a rectangular box body; and protecting strips made of PE cotton are attached on the parts of the four hinges in the box body and protect stored articles in the box from being collided and scratched. The folding type hollow plate container has simple structure, convenient folding and less occupied space.

Owner:JIANGSU HUASHENG PLASTIC

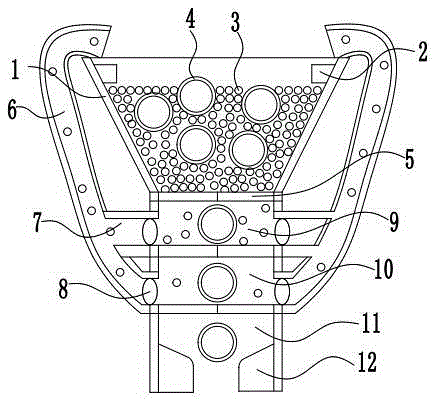

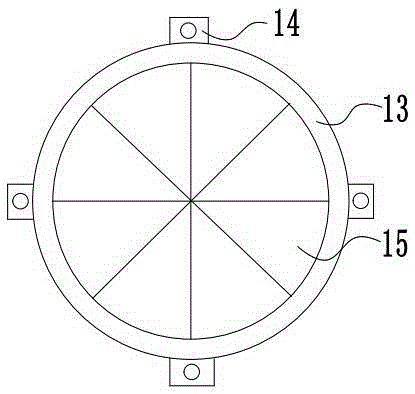

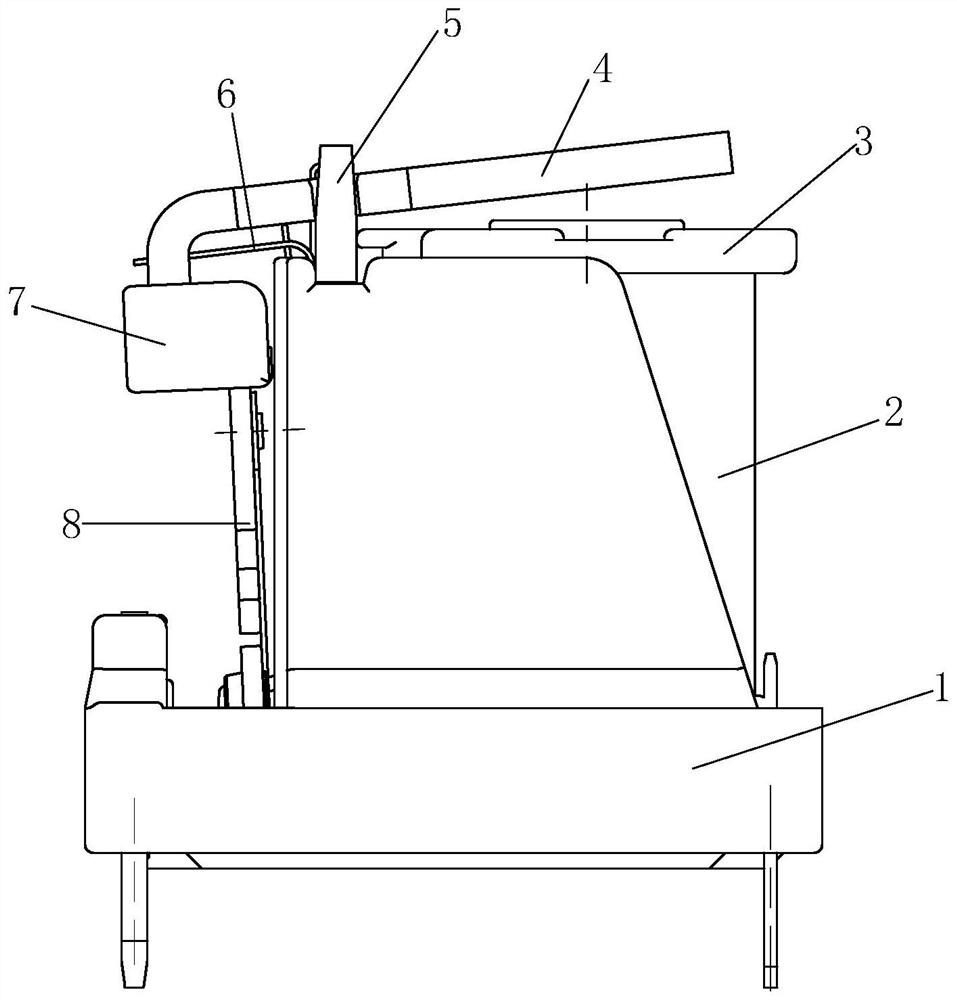

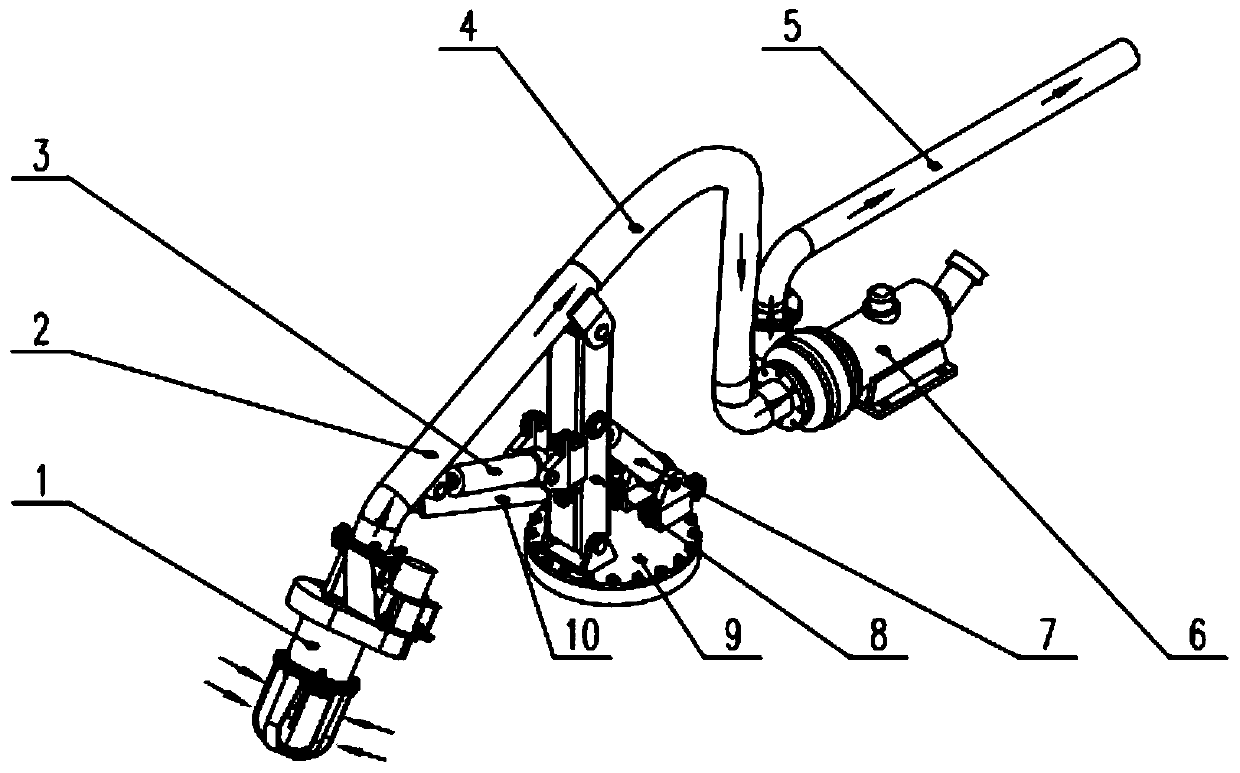

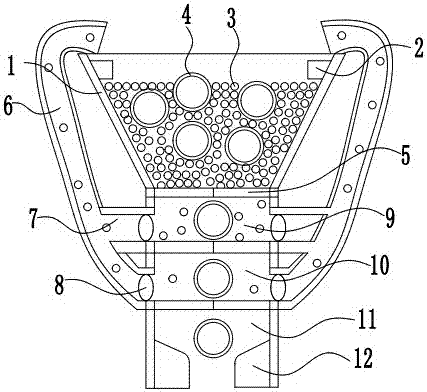

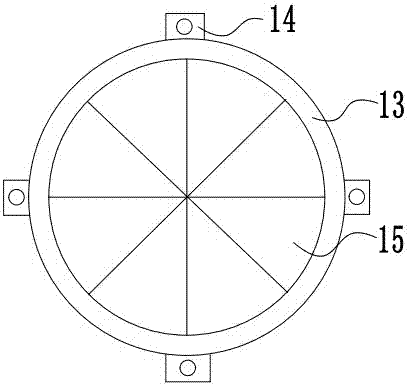

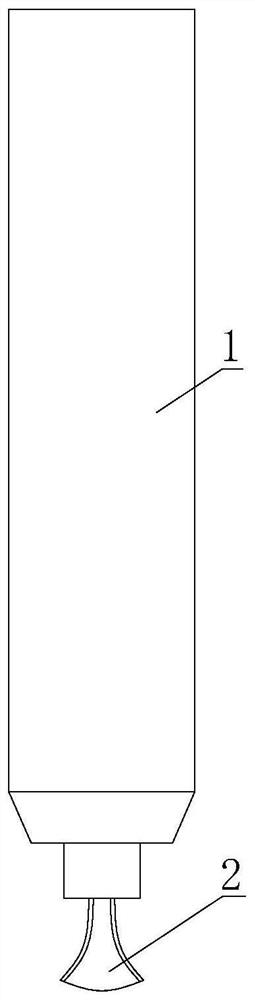

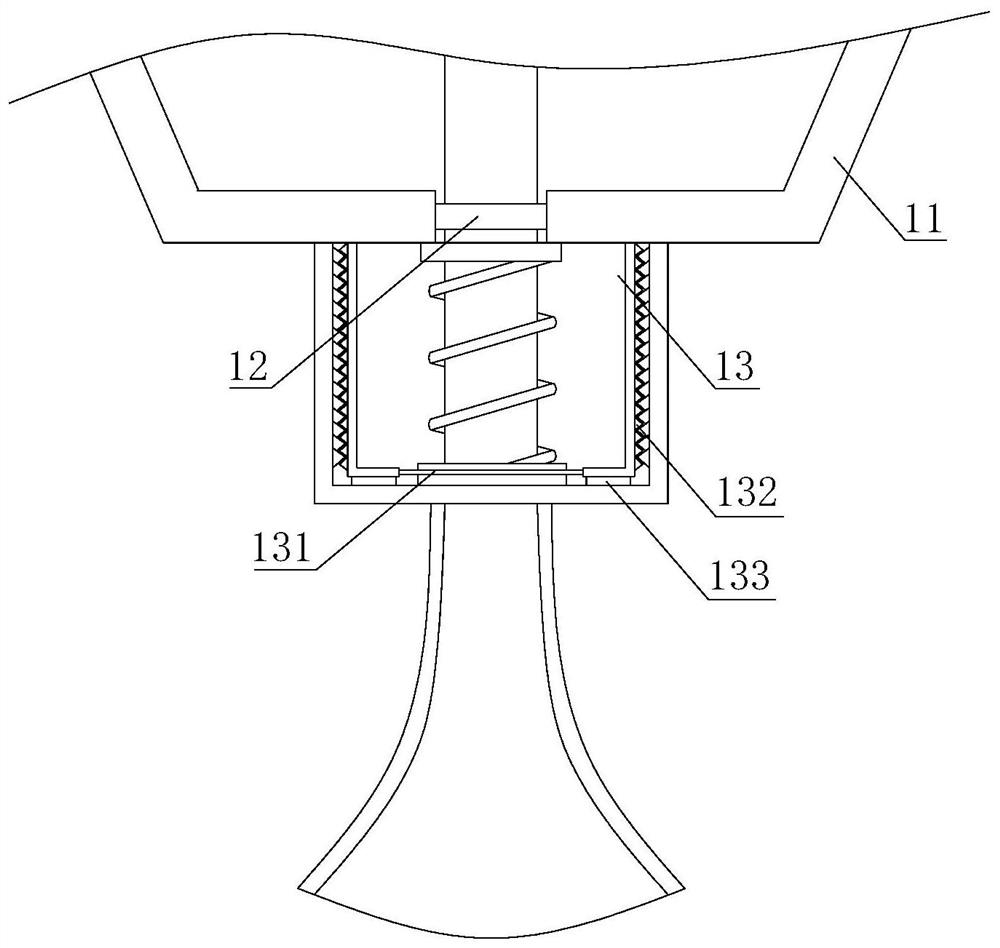

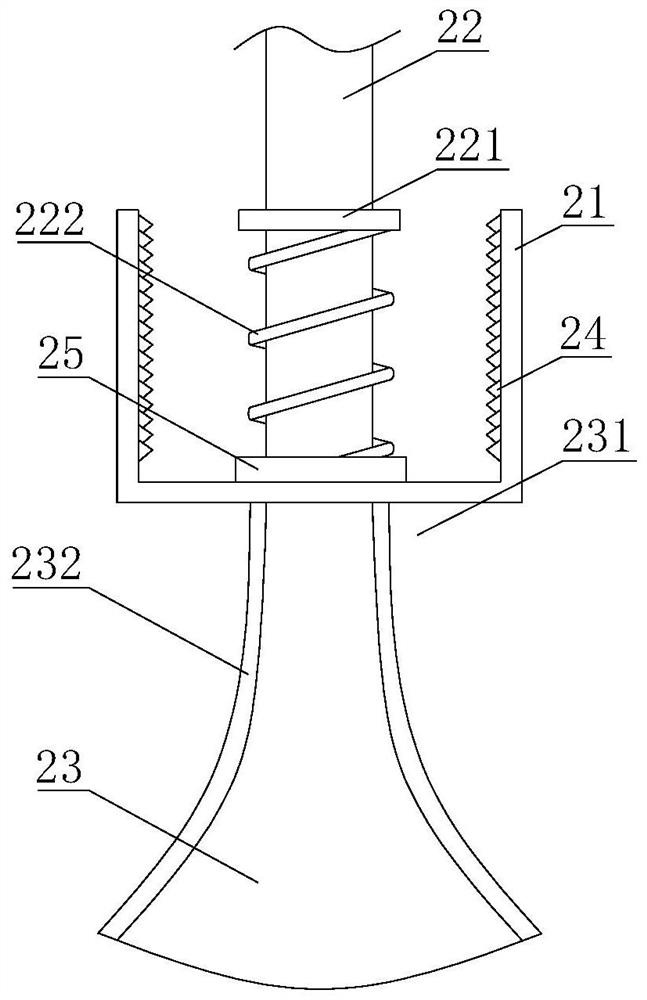

Hopper

ActiveCN105329565AAvoid collisionAvoid scratchesLarge containersConoidElectrical and Electronics engineering

The invention relates to a hopper, and particularly discloses a hopper used for conveying bearings. The hopper comprises a big-end-up conical charging barrel and a connecting pipe connected with the bottom end of the charging barrel; three screening plates are sequentially arranged in the connecting pipe from top to bottom and divide the connecting pipe into a first cavity, a second cavity and a third cavity from top to bottom; the top end of the first cavity and the bottom end of the charging barrel are isolated through one screening plate, and the bottom end of the third cavity is in an opening state; branch pipes are arranged on the lateral walls of the first cavity and the second cavity, and a draught fan is arranged in each branch pipe; the branch pipes are communicated with recycling pipes; outlets of the recycling pipes are located at the inlet of the charging barrel; a plurality of lubricating balls used for isolating the bearings are arranged in the charging barrel; the screening plates are hinged to the connecting pipe and can be reset automatically; an annular boss is arranged on the lateral wall of the third cavity, and a gap allowing only one bearing to pass through is formed in the middle of the boss. The hopper can independently convey the bearings and avoid the bearings from being scratched in the conveying process.

Owner:CHONGQING YUANCHUANG WHOLE LINE INTEGRATION

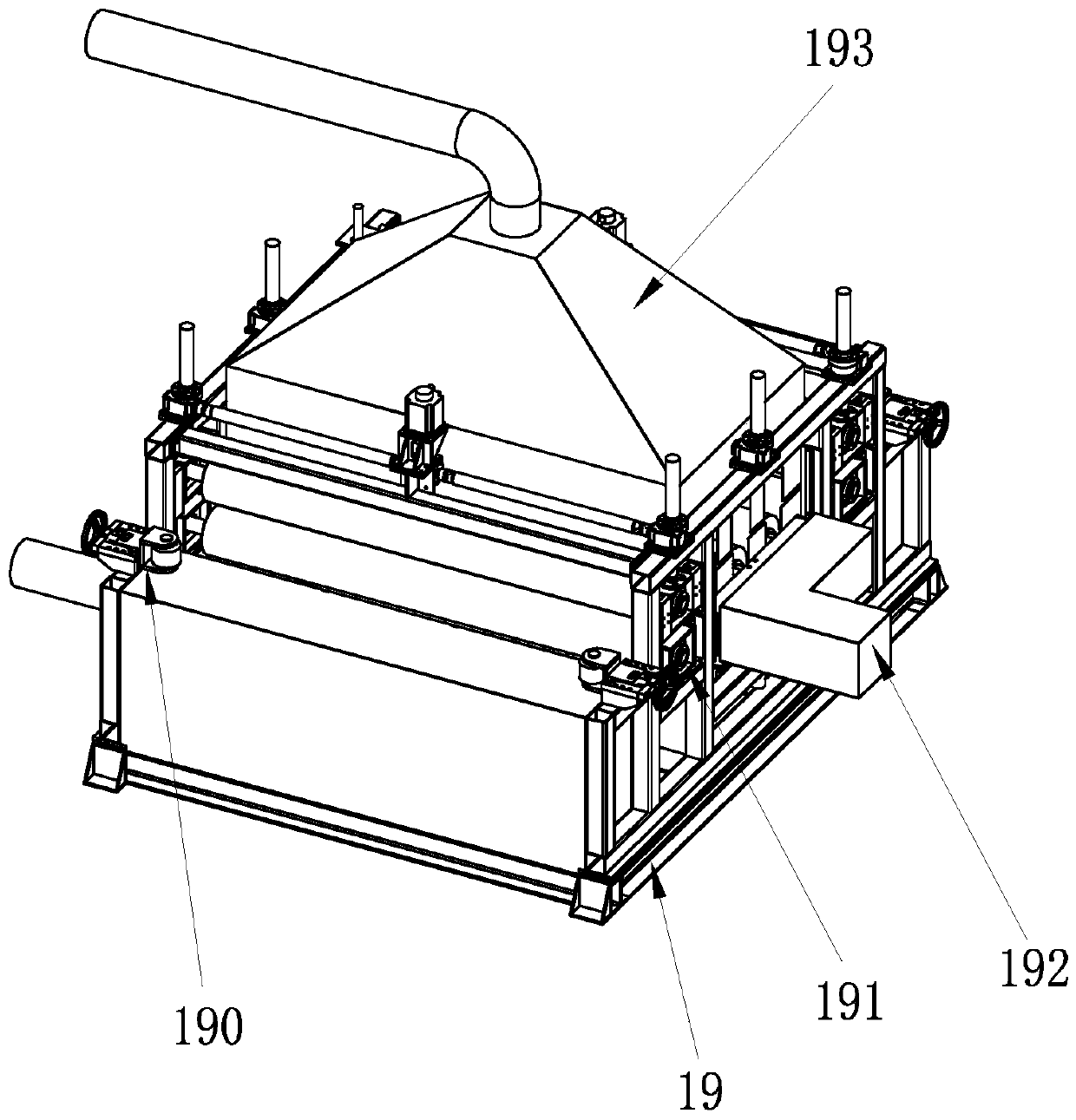

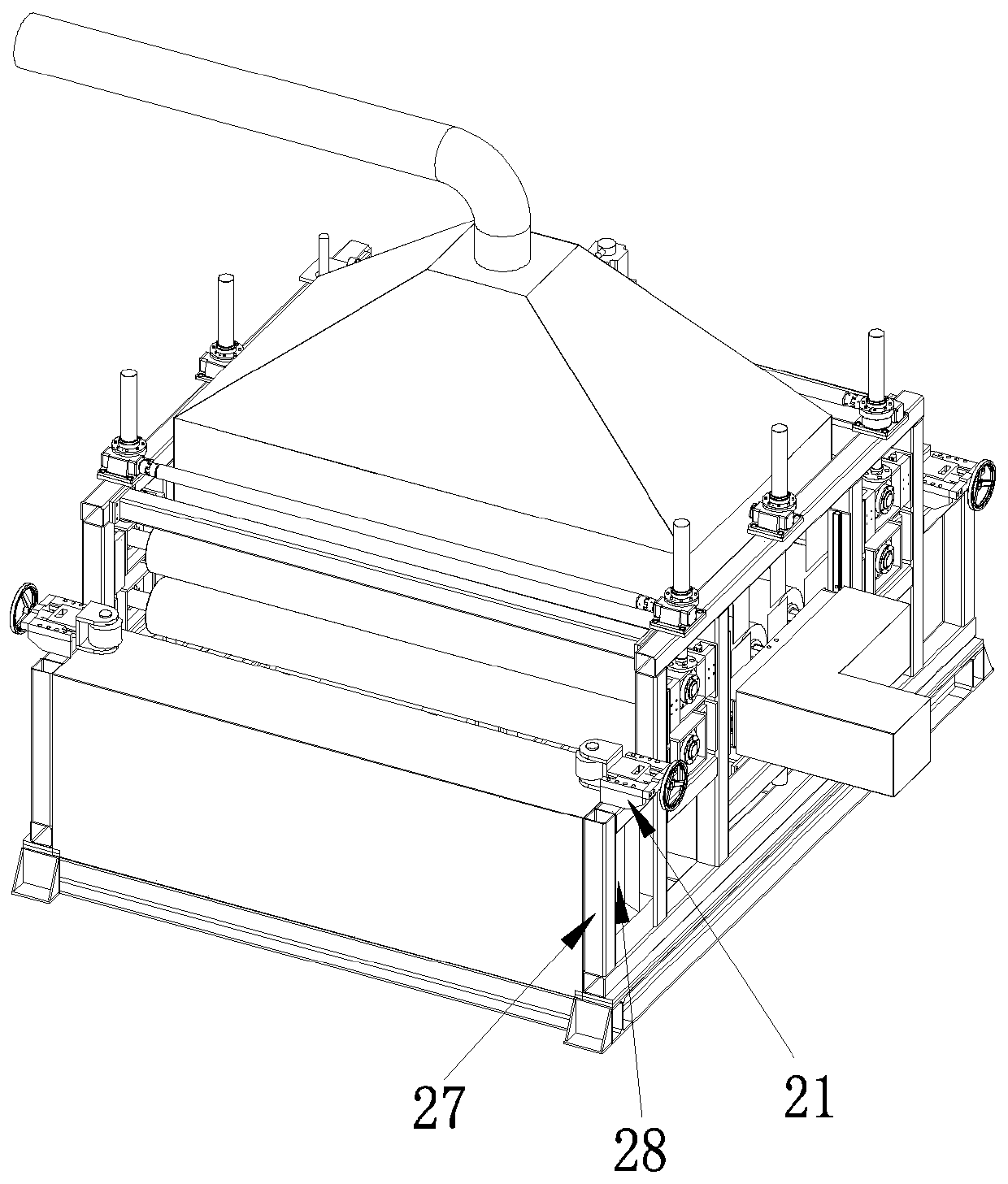

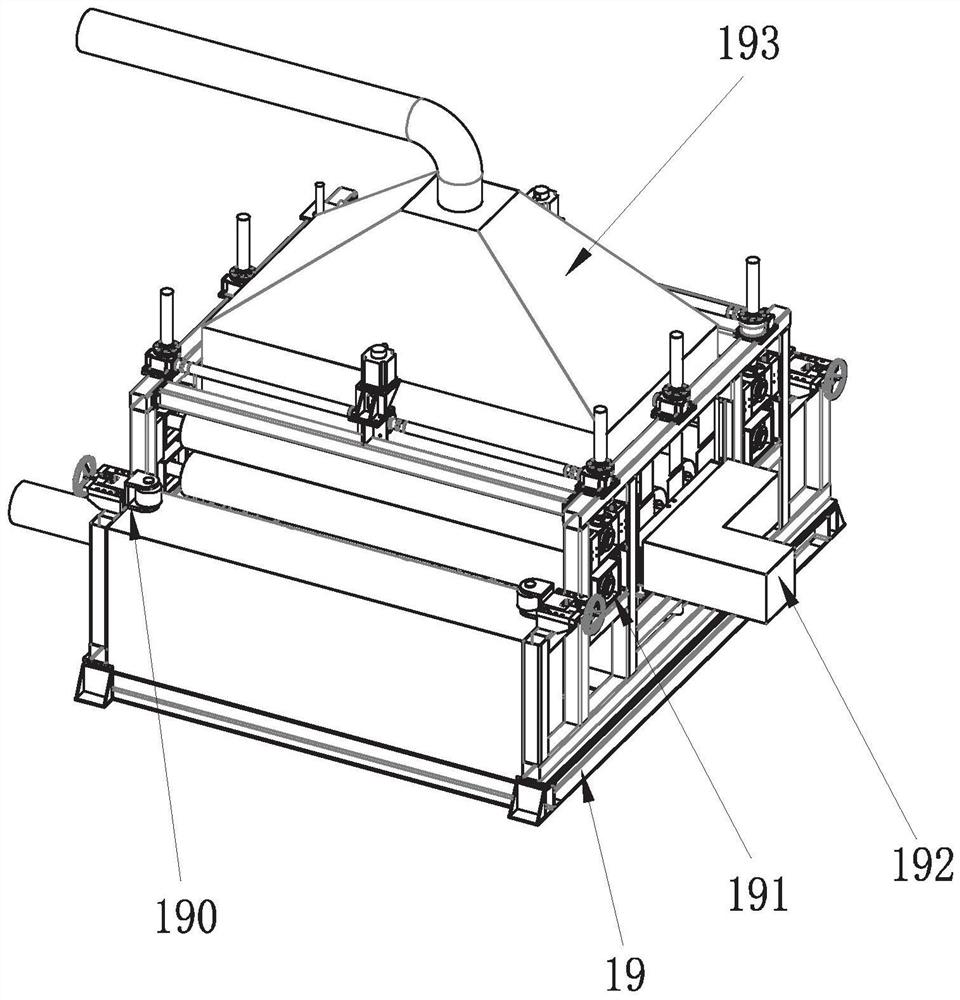

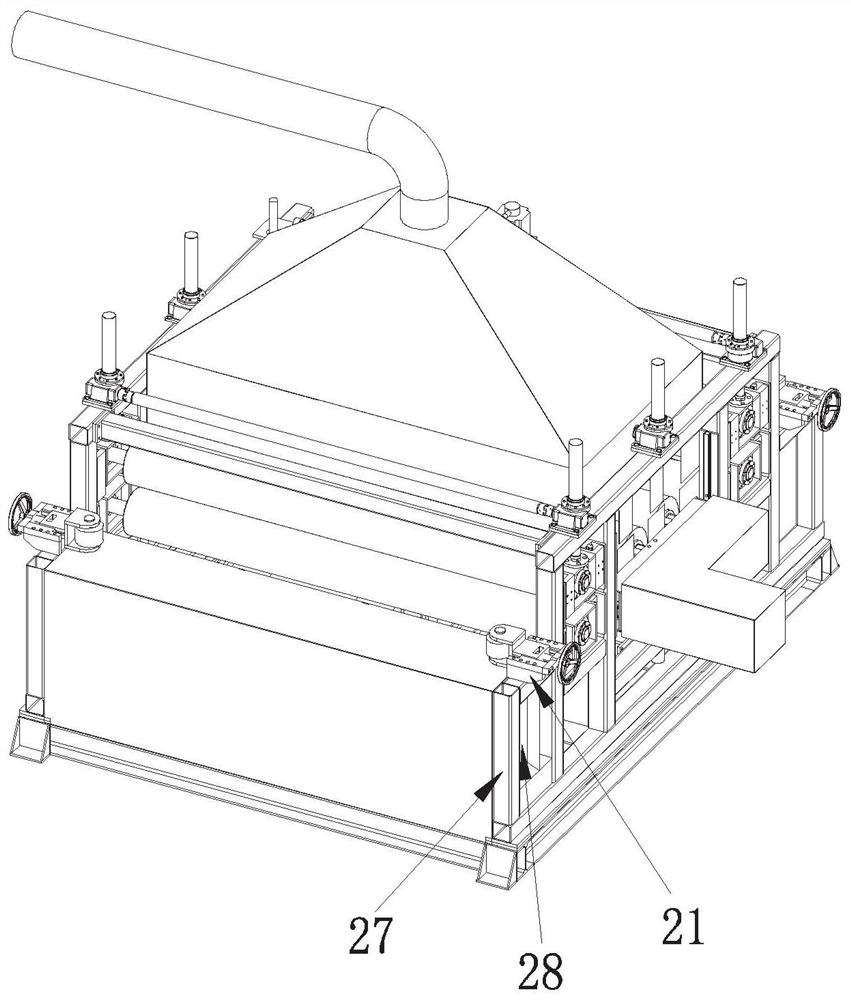

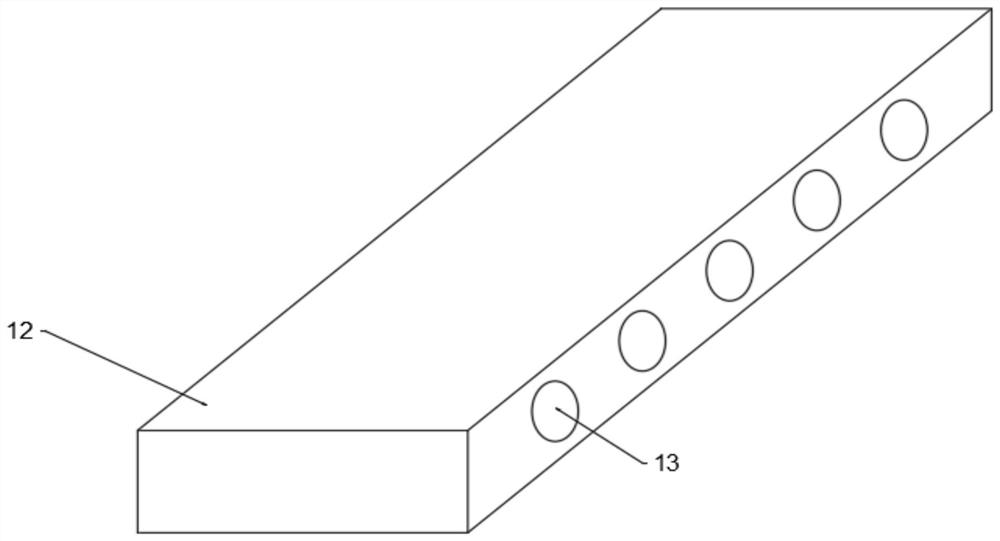

Steel plate conveying and positioning device

InactiveCN110921190AEasy to adjustPrevent ineffective operationConveyorsRollersElectric machineryEngineering

Owner:ZHEJIANG CONSTR ENG GRP CO LTD

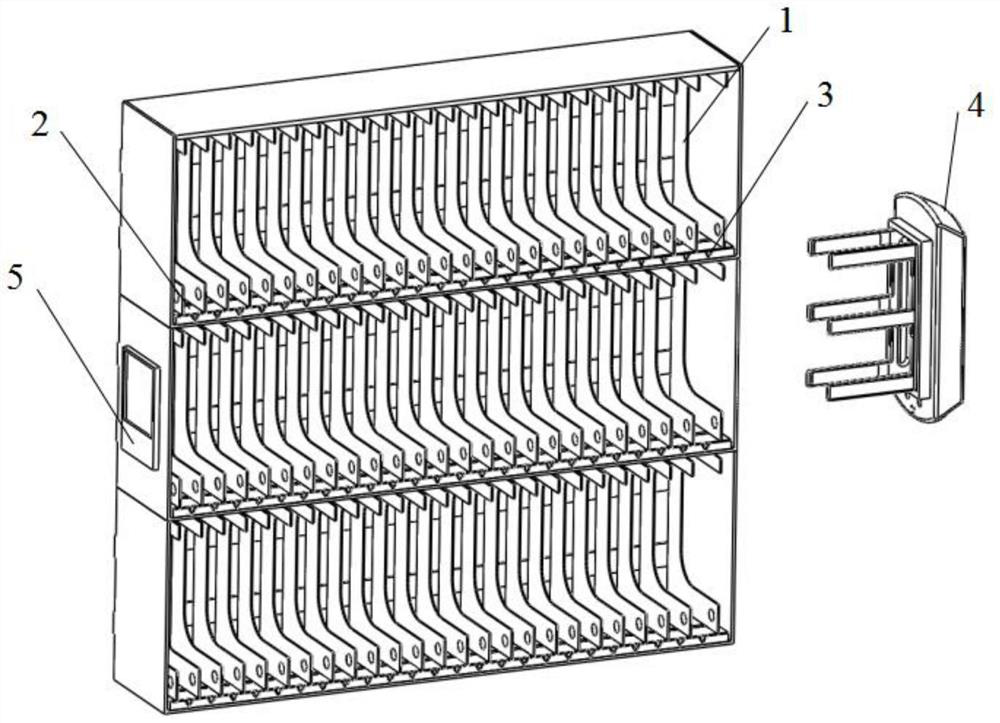

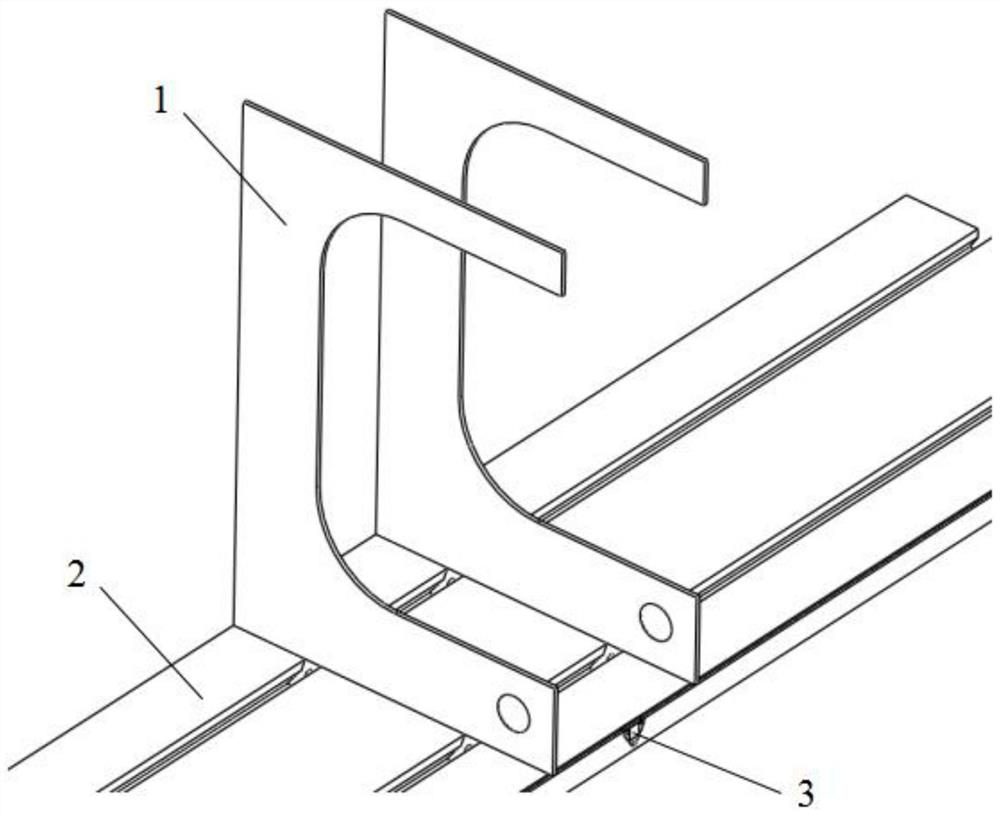

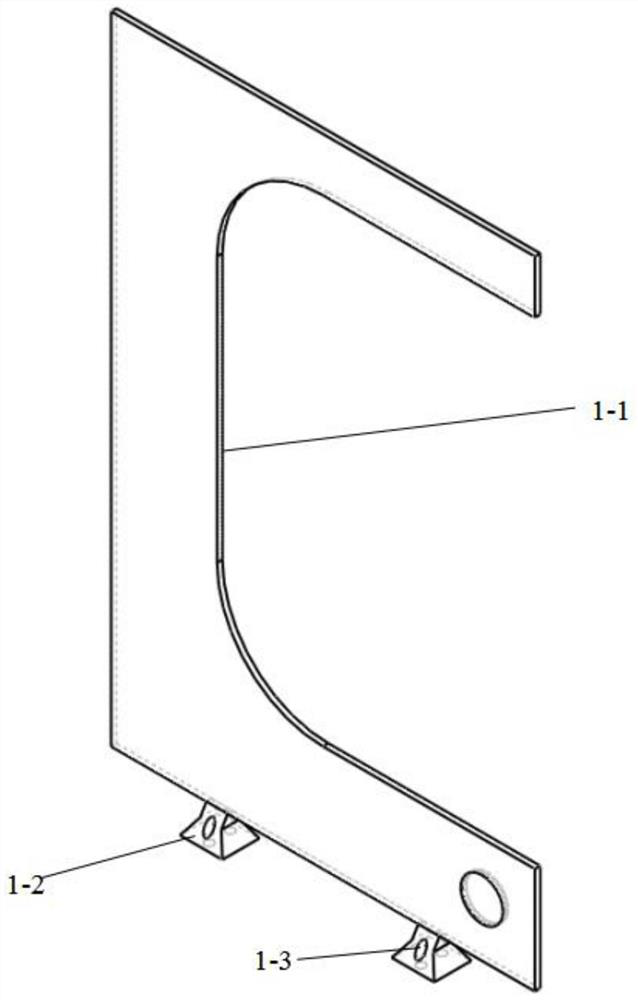

A book automatic access device and access method for library

ActiveCN111762487BEasy to grabEasy to manageGripping headsCash registersSoftware engineeringMechanical engineering

The invention discloses an automatic book access device for libraries, which includes a bookshelf and a mechanical gripper, the mechanical gripper is installed on a book distribution vehicle; inside the bookshelf, there are multiple layers at equal intervals from top to bottom The shelves are provided with a plurality of partitions parallel to each other along the horizontal direction on each shelf, and books are stored between adjacent partitions; a book management module and a book information module are also arranged on the bookshelves, so that The book management module is used for detecting, recording and displaying the absence of books on the bookshelf in real time; the book information module is used for storing the serial number information of books; The invention solves the problems of inaccurate book positions, different postures, and difficulties in automatic access in conventional libraries, realizes unique, adjustable, and data-based book positions on the bookshelf, and provides accurate feedback for book positions, thicknesses, and publications for the manipulator. information to ensure its automatic access to books.

Owner:武汉艾特创客科技有限公司

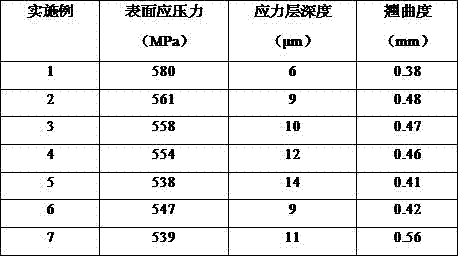

Manufacturing technology of semi-tempered glass

InactiveCN107056035AUniform mass distributionLow probability of self-explosionGlass tempering apparatusGlass productionSurface stressManufacturing technology

The invention discloses a manufacturing technology of semi-tempered glass. The manufacturing technology comprises the first step of preheating treatment of glass, wherein the glass to be treated is placed in a preheating furnace, and the glass which is subjected to preheating treatment is obtained through three stages of warming and heating; the second step of semi-tempered treatment, wherein the glass which is subjected to preheating treatment is sent into a toughening furnace, then warming is conducted to achieve semi-tempered treatment to obtain the glass which is subjected to semi-tempered treatment; the third step of rapid cooling treatment, wherein the glass which is subjected to semi-tempered treatment is sent into a quenching area, and rapid cooling is conducted at the wind pressure of 50-150 Pa for 3-8 min; the fourth step of annealing treatment, wherein the glass which is subjected to rapid cooling treatment is transferred to an annealing furnace with the temperature being 350-380 DEG C, and the temperature is lowered to 80-90 DEG C for 40-50 min to conduct annealing treatment, and then conducting cooling at the room temperature is conducted to obtain the semi-tempered glass. The manufacturing technology of the semi-tempered glass is flexible in operation, the manufactured semi-tempered glass is uniform in mass distribution, and flat and smooth, the probability of spontaneous explosion in a cooling process is low, the surface stress is strong, and the problems of edge breakage and warping cannot occur.

Owner:合肥钢骨玻璃制品有限公司

A mechanism for derusting steel plates

ActiveCN110900408BImplementation orientationPlay a guiding roleGrinding carriagesGrinding drivesMetallurgyDust control

The invention relates to a steel plate derusting mechanism, which includes a fixed platform, a steel plate guiding device arranged on the fixed platform, a steel plate conveying and positioning device, a steel plate derusting device and a steel plate derusting and dust removing device; Steel ball brushes are evenly distributed on the surface of the roller, and the steel plate can be derusted on both sides at the same time, which greatly improves the derusting efficiency of the steel plate; The rust layer and bonded matter also make the steel plate meet a certain surface quality requirement; the steel plate rust removal device is not limited by the site; the degree of automation is high, the efficiency of rust removal and cleaning is high, it is convenient for maintenance and loading and unloading, saving manpower and material resources, and improving work efficiency. efficiency.

Owner:ZHEJIANG CONSTR ENG GRP CO LTD

Planar screw synchronizer

InactiveCN110666499AAvoid collisions and scratchesManpower can be liberatedMetal working apparatusStructural engineeringMechanical engineering

The invention discloses a planar screw synchronizer comprising a shell. A drive assembly is arranged in the shell. The drive assembly is connected with two driven assemblies. Each driven assembly comprises a screwdriver bit. The planar screw synchronizer has the advantages that scratches and collisions can be avoided during part assembling or disassembling, and the work efficiency is high; the planar screw synchronizer is suitable for working conditions of screws at different distances, screws of different types and end covers in different shapes, and the application range is wide.

Owner:GUIZHOU HONGLIN MACHINERY

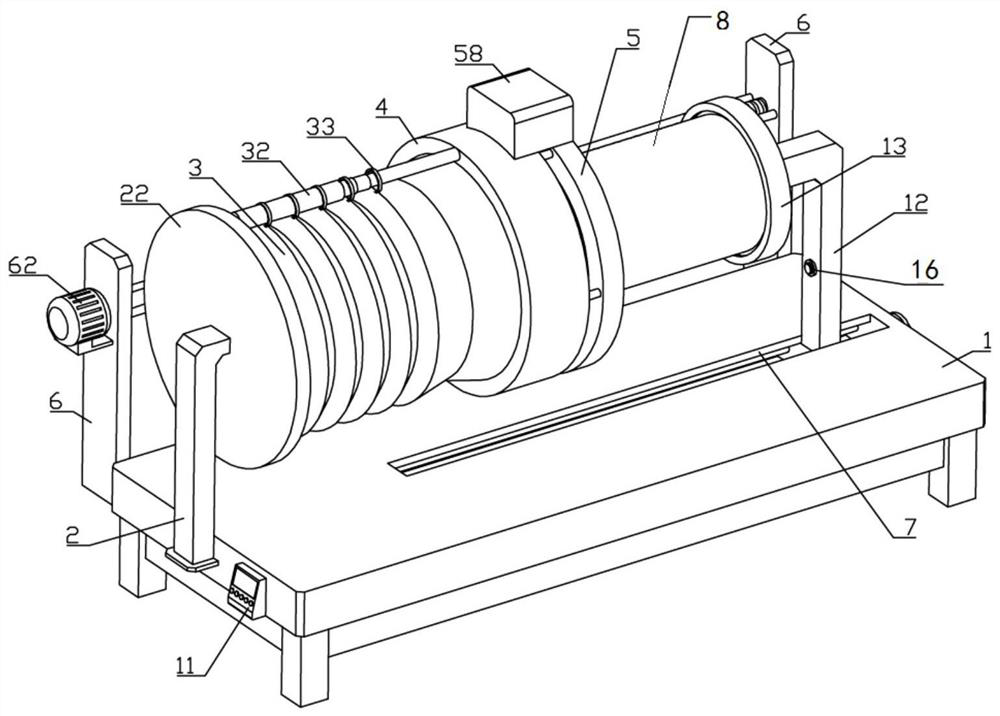

A spraying device for anti-corrosion coating on the outer layer of chemical pipelines

The invention discloses a spraying device for anti-corrosion coating on the outer layer of chemical pipelines, which can flexibly adjust the distance between the first support plate and the second support plate according to the length of the pipeline to be sprayed with anti-corrosion coating, thereby improving the ability of the spraying device to spray the pipeline It can evenly and effectively spray paint on the pipeline; through the cooperation of the telescopic bellows and the drying device, it can not only effectively protect the pipeline, but also quickly and effectively heat the paint on the surface of the pipeline to accelerate the curing of the paint , and there is no need to transfer the pipeline to the drying room for the second time, avoiding the collision and scratching of the pipeline coated with paint during the second transfer to the drying room, ensuring the integrity of the anti-corrosion coating layer on the outer surface of the pipeline, and improving the anti-corrosion coating layer of the pipeline Spraying processing efficiency; the spraying device of the present invention has a simple and reasonable structural design, high feasibility of preparation and implementation, and strong practicability.

Owner:江苏晨光涂料有限公司 +1

Dual-insulation electromagnetic relay

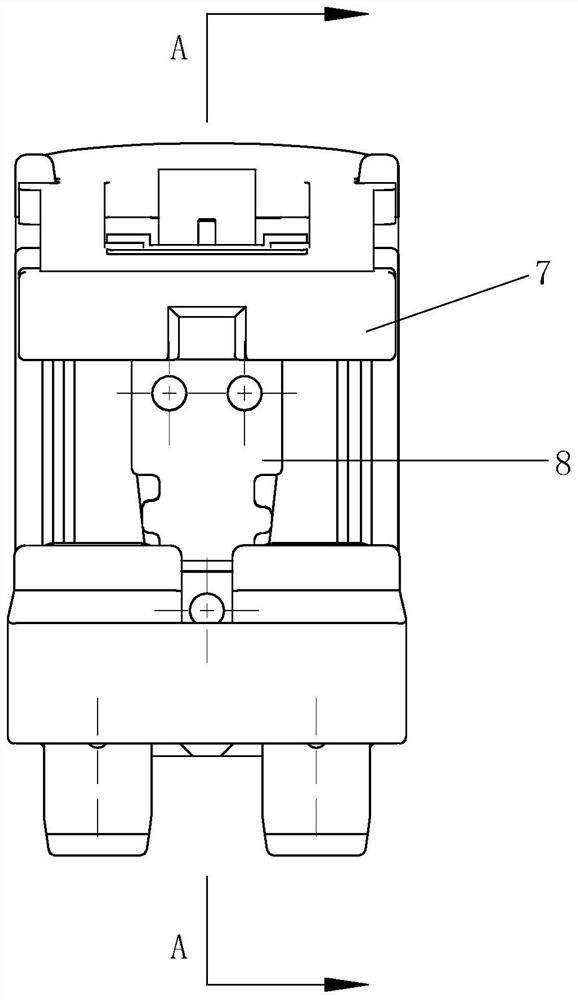

PendingCN111725026AHas the effect of double insulationMiniaturizationElectromagnetic relay detailsStructural engineeringContact system

The invention discloses a dual-insulation electromagnetic relay. The electromagnetic relay comprises a base, a magnetic circuit part and a contact part, wherein the contact part comprises a movable spring part and a static spring part, the magnetic circuit part comprises a yoke, an armature, an enameled wire and a coil rack, the coil rack is vertical, the yoke is provided with a vertical first edge matched with the outer side of the coil rack, the armature is matched with a knife edge of the first edge of the yoke, and a reset reed for resetting the armature is matched with the first edge of the yoke; the movable spring part is connected with the armature through an insulating part; the solid insulation distance between the contact part and the magnetic circuit part is greater than or equal to 2.0 mm; a first structure is arranged on the bottom face of the head of the coil frame, a second structure is arranged on the top face of the tail of the coil frame, and the first structure and the second structure are of a concave structure or a convex structure respectively and located between the enameled wire and the first edge of the yoke. According to the invention, a double-insulationeffect is achieved between the contact system and the magnetic circuit system, and the reinforced insulation requirement of IEC61810-1 / IEC60335-1 can be met.

Owner:ZHANGZHOU HONGFA ELECTROACOUSTIC CO LTD

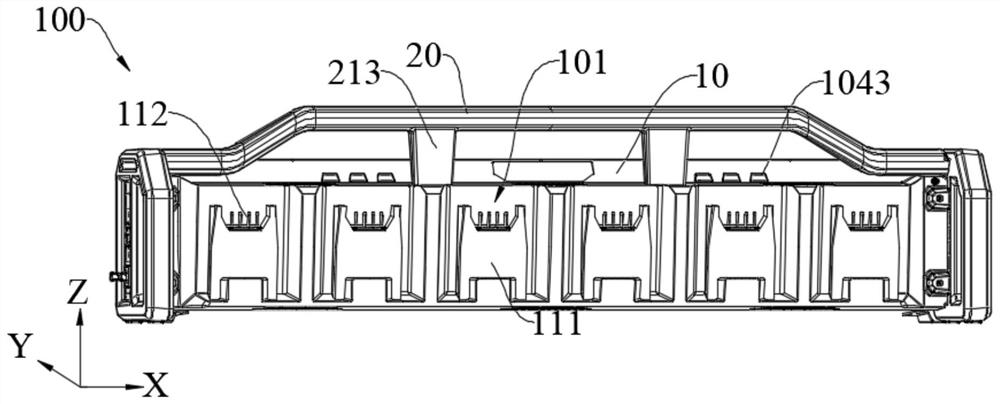

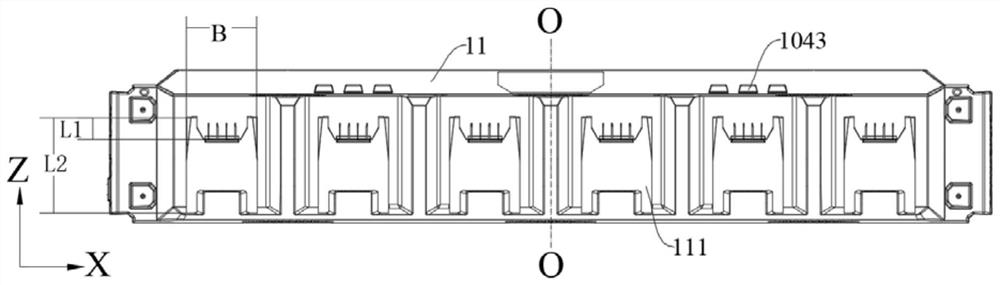

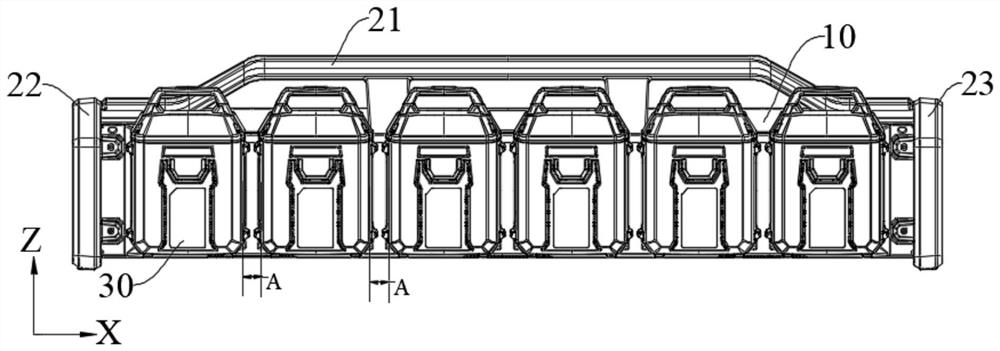

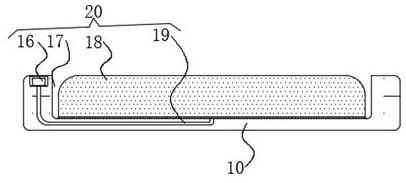

Multi-slot charger

PendingCN113905552AFair useImprove charging efficiencyBatteries circuit arrangementsCasings/cabinets/drawers detailsEngineeringStructural engineering

A multi-slot charger disclosed by the present invention can be vertically placed, horizontally placed or hung in a wall, and comprises a shell, and a lifting handle assembly which comprises auxiliary handles arranged at the two sides of the shell and a lifting handle arranged at the top of the shell. The auxiliary handles support the multi-slot charger when the multi-slot charger is vertically placed and / or horizontally placed; when the multi-slot charger is hung in the wall, the plurality of clamping slots can be formed in the shell, so that the multi-slot charger can be directly connected with the vertical wall; or a wall-hung fixing support can be installed on the shell, and the multi-slot charger can be fixed to the vertical wall through the wall-hung fixing support. The multi-slot charger provided by the invention can be placed in various different modes, so that different placement modes can be adopted in different use scenes, and the multi-slot charger can be used more reasonably.

Owner:CHANGZHOU GLOBE CO LTD

A high and low crane automatic electrical control system and control method

ActiveCN112520582BKeep a safe distanceReduce labor costsBridge erection/assemblySafety gearWireless transmissionControl system

The invention provides an automatic electric control system and control method for high and low cranes, belonging to the technical field of electric control, including a controller unit, a display unit, a sensor unit, a wireless transmission unit and a safety protection unit. The controller unit obtains the attitude of the box girder during hoisting according to the inclination sensor in the sensor unit, obtains the RTK spatial coordinate position of the head and tail of the box girder according to the hoist height encoder and the crane stroke encoder, and checks and resets the sky through the RFID position reader. The RTK position of the vehicle during operation, calculate the RTK space coordinate position of the box girder and compare it with the target value, control the lifting of the box girder according to the difference, realize the automatic box girder hoisting, the control accuracy is higher, the labor cost is reduced, and the construction efficiency is improved at the same time ; The safety protection unit is used to ensure a certain safe distance between the beam end and other objects to prevent collisions and scratches. When an alarm occurs, the controller unit can control the equipment to stop in time to ensure construction safety.

Owner:THE THIRD CONSTR OF CHINA CONSTR EIGHTH ENG BUREAU +1

Tray

The invention relates to a tray for transporting mobile phone shells and tablet personal computer shells. The tray comprises a first tray and a second tray; a clamping groove is formed in the first tray; the second tray is provided with a clamping part, a bearing column and a camera clamping column; the clamping part has a barb; the bard penetrates through the clamping groove to buckle with the first tray; the bearing column is arranged at one end part of the second tray, and is used for butting against the mobile phone shells; and the camera clamping column is arranged at the other end part of the second tray, and is used for clamping with the mobile phone shells. As the second tray is fixed on the first tray, and the second tray is used for butting against the mobile phone shells, the mobile phone shells are synchronously suspended with the first tray and the second tray to prevent the collision scratch of highlight surfaces of the mobile phone shells. Further, the first tray and the second tray are machined by PC materials, so that the tray is used for such integral operations as cleaning, baking, packing and transfer of the mobile phone shells in the production process.

Owner:深圳市水佳鑫科技有限公司

Transfer device for machining

PendingCN112692805AAvoid collisions and scratchesEffective leapNon-rotating vibration suppressionWork tools storageEngineeringMachining

The invention discloses a transfer device for machining, which belongs to the technical field of machining and solves the problem that an existing transfer device for machining cannot be placed in a classified mode. The transfer device for machining is characterized by comprising a supporting plate, wherein a damping assembly is arranged at the bottom of the supporting plate, and a moving assembly is fixedly connected to the bottom of the damping assembly; a first placing plate is arranged above the supporting plate, supporting rods are symmetrically and vertically arranged above the first placing plate, second baffle plates are arranged in the middles of the supporting rods, a second placing plate is arranged on the outer sides of the supporting rods above the second baffle plates, a top plate is fixedly connected to the tops of the supporting rods, and a third placing plate is fixedly connected to the upper portion of the top plate. Parts are placed in a layered mode through the first placing plate, the second placing plate and the third placing plate, obstacles are conveniently crossed through the moving assembly, vibration borne by the device is weakened through the damping assembly, and thus, the transfer device has the advantages of being placed in a layered mode, flexible to move, effective in damping, simple, convenient to use and practical.

Owner:舒德祥

A steel plate conveying roller table for a straightening machine

The invention provides a steel plate conveying roller way of a straightening machine and belongs to the technical field of steel plate conveying devices. The steel plate conveying roller way of the straightening machine comprises a conveying base, two roller beam bodies which are symmetrically arranged on the upper end surface of the conveying base, two gear rack guide rails which are symmetrically arranged on the upper end surface of the conveying base and are disposed on the outer sides of the roller beam bodies, a plurality of sliding tables which are symmetrically arranged on the two gear rack guide rails, a plurality of connecting guide rods which are respectively, vertically and fixedly installed on the upper end surfaces of the sliding tables, and a plurality of conveying rollers of which connecting shafts at two ends are respectively arranged between the inner side surfaces of the two roller beam bodies, wherein the plurality of conveying rollers are driven through a first driving motor and are used for conveying a steel plate. The steel plate conveying roller way of the straightening machine has the advantages that the steel plate can be enabled to stably and effectively run on the conveying roller way of the straightening machine, the effect of steel plate conveying and guide is achieved, the steel plate is enabled to be conveyed to a designated position and the steel plate can be prevented from falling during conveying.

Owner:SHANDONG IRON & STEEL CO LTD

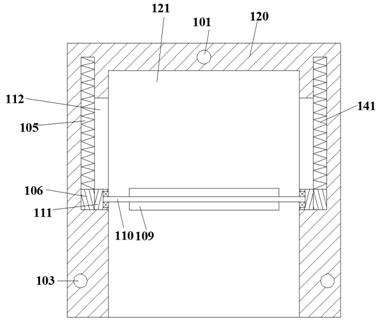

A parking guidance device

The invention discloses a parking space guiding device, which comprises a garage frame fixed on the ground, a lifting chamber with an opening facing forward is fixed in the garage frame, a vehicle frame is slid in the lifting cavity, and the vehicle There is a car cavity with an opening facing forward fixedly in the frame. The device of the present invention is simple in structure and easy to use. The device is provided with front and rear wheel restricting parts. By restricting the front and rear wheels at the same time, the three-dimensional garage will Even if the handbrake is slightly pulled by the driver, the car will not move and cause a collision, and this device is equipped with anti-scratch parts. When the front of the car or the body hits, the anti-scratch parts are equipped with a buffer mechanism and a sponge pad to absorb the car. The kinetic energy gives the driver sufficient time to stop the vehicle, reducing or even eliminating the occurrence of collisions and scratches.

Owner:英都科技(广州)有限公司

Portable animation design workbench

The invention discloses a portable animation design workbench. The workbench comprises a first platen, one side of the first platen is provided with a first handle, the bottom of the first platen is provided with a first bag, a first opening is formed in one side, close to the first handle, of the first bag, the first opening is closed by a first zipper, an inner edge of the top of the first platen is provided with a first buffer pressing strip, one side, away from the first handle, of the first platen is provided with a first fixing clamp, first placing slots are formed in the side, close tothe first fixing clamp, of the first platen symmetrically, one end, away from the first handle, of the first platen is provided with a plurality of hinges, the first platen is fixedly connected to a second platen disposed on the top of the first platen by the hinges, the top of the second platen is provided with a second handle, the first handle and the second handle are matched, and the upper portion of the side, near the first platen, of the second platen is provided with a second fixing clamp. The workbench has the advantages that drawings can be drawn at anytime and anywhere.

Owner:HEFEI AIWAN CARTOON CO LTD

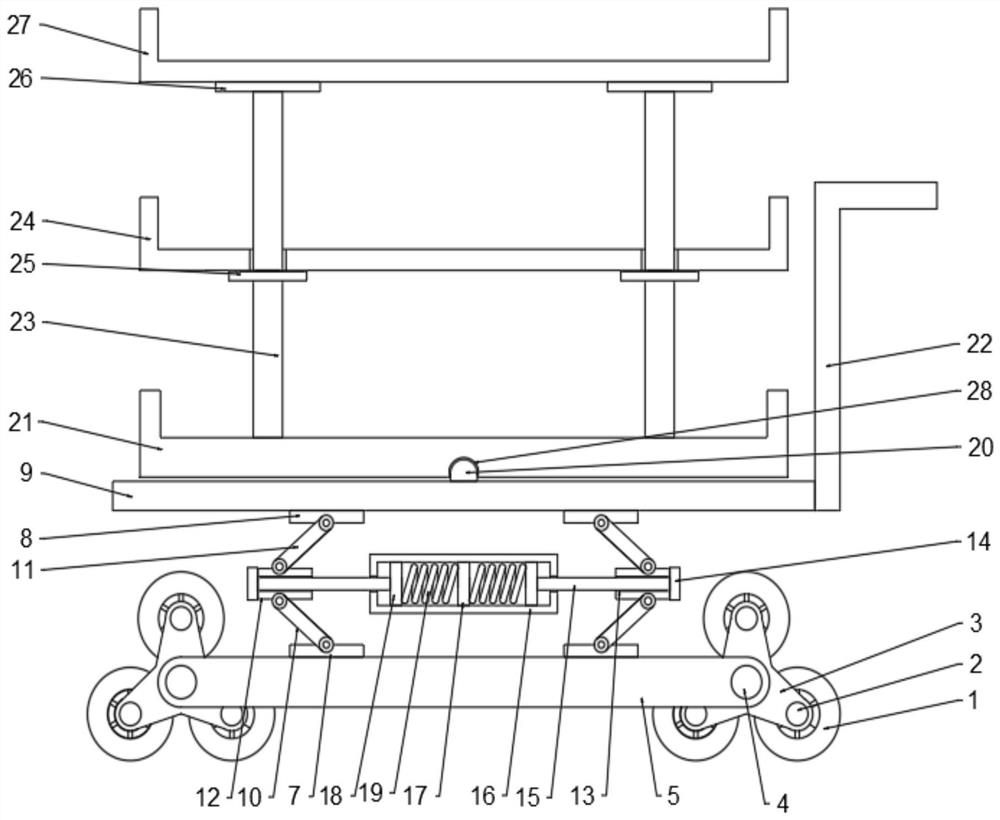

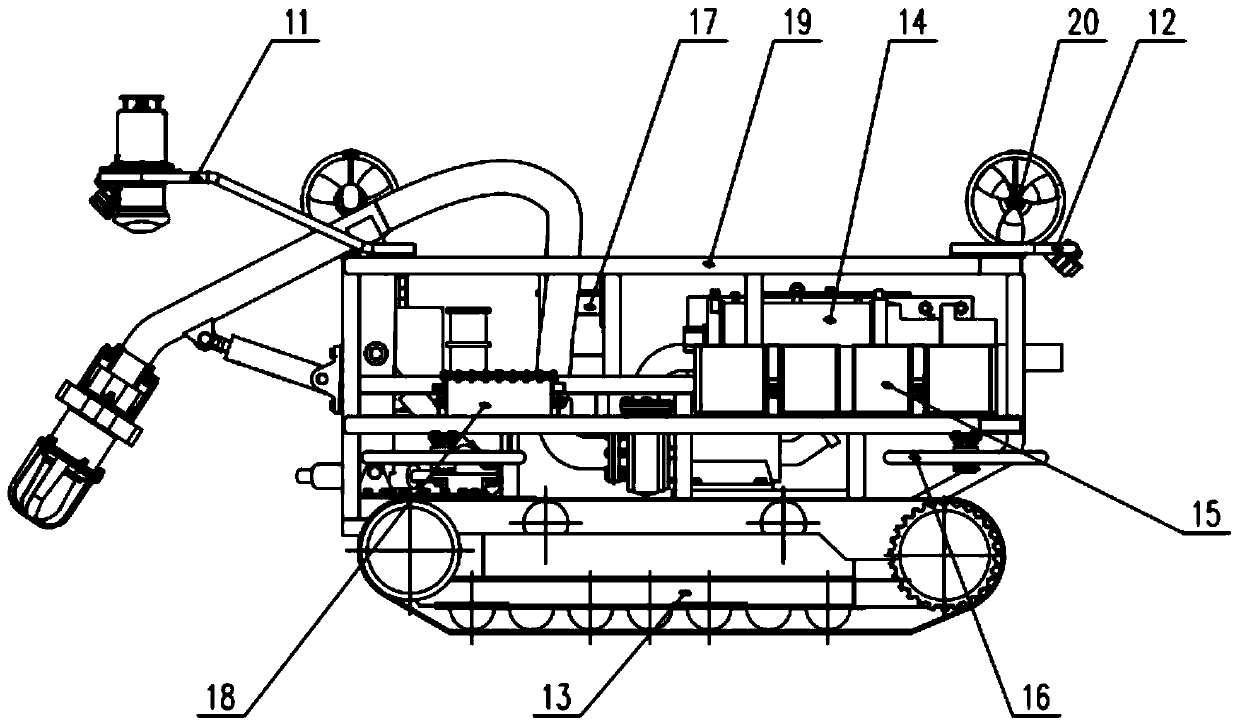

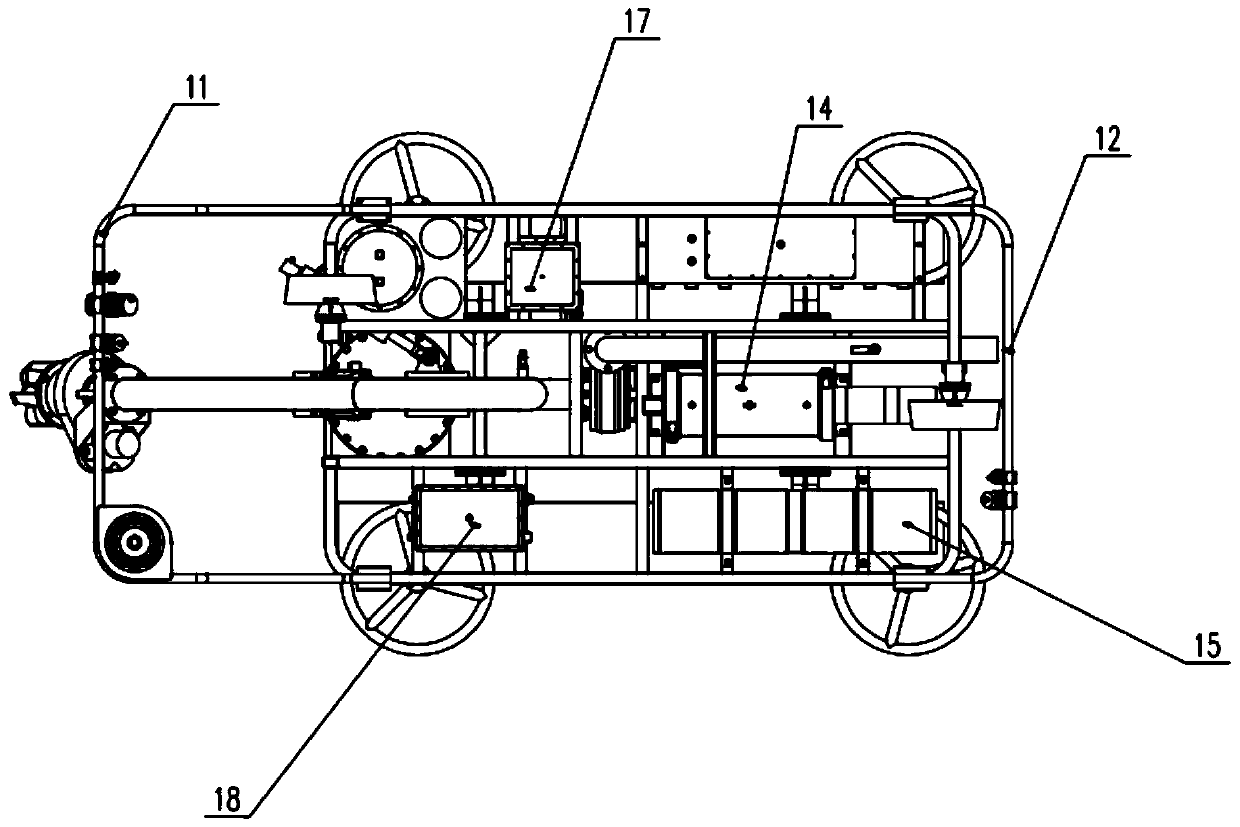

Dredging vehicle for deep water limited space

PendingCN111254999APlay a protective effectAvoid collisions and scratchesMeasurement devicesMechanical machines/dredgersHydraulic control unitMarine engineering

The invention discloses a dredging vehicle for a deep water limited space. The dredging vehicle comprises a vehicle body, a walking device, a conveying system, a dredging operation mechanism, space detection mechanisms and a monitoring and inspecting device, wherein the walking device, the conveying system, the dredging operation mechanism, the space detection mechanisms and the monitoring and inspecting device are mounted on the vehicle body, the dredging operation mechanism comprises a cut section head and a swinging mechanism for driving the cut section head to swing up and down and left and right, the conveying system comprises a connecting pipeline, a conveying pump and a conveying pipeline, one end of the connecting pipeline is connected with the cut section head, the other end of the connecting pipeline is connected with the input end of the conveying pump, the output end of the conveying pump is connected with the conveying pipeline, and the space detection mechanisms are mounted on the two sides of the vehicle body. According to the dredging vehicle, the dredging operation mechanism and the conveying system are installed on the vehicle body provided with the walking mechanism, and meanwhile, the vehicle body is further provided with a hydraulic power system, an electric control unit, a hydraulic control unit, a power control box, a front monitoring and inspecting assembly, a rear monitoring and inspecting assembly and the space detection mechanisms to form the dredging vehicle suitable for a deepwater limited space environment and capable of autonomous driving operation.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

a hopper

ActiveCN105329565BAvoid collisions and scratchesGuarantee normal productionLarge containersEngineeringConoid

Owner:CHONGQING YUANCHUANG WHOLE LINE INTEGRATION

Special-shaped ejector pin small hole waste discharge system

PendingCN112517938AAvoid collisions and scratchesEasy to disassemble and repairTailstocks/centresMaintainance and safety accessoriesProcess engineeringHardness

The invention discloses a special-shaped ejector pin small hole waste discharge system which comprises an extraction knife body and an ejector pin mechanism, wherein the size of a special-shaped ejector pin head is smaller than the diameter of an actual small hole by 5%, and after the special-shaped ejector pin head presses waste downwards, due to the fact that excavation grooves are formed in thetwo sides of the special-shaped ejector pin head, collision and scratching of edge materials of a product hole after rotating out are avoided; after a connecting sleeve is mounted at one end of a cylindrical protruding part, a rubber layer conducts buffering sealing on the connecting position of one end of the connecting sleeve and one end of the cylindrical protruding part; the rubber layer haslarge friction performance, so that the connecting position of the connecting sleeve and the cylindrical protruding part is attached more tightly; an SKD11 die steel layer is arranged on the surface of the special-shaped ejector pin head and the surface of the excavation grooves; the SKD11 die steel layer has good hardness and high toughness and is not prone to cracking; the abrasion resistance and corrosion resistance of the special-shaped ejector pin head can be enhanced through a smeared abrasion-resistant particle glue layer and a pvd nanometer abrasion-resistant coating, so that the special-shaped ejector pin head can be used for a long time, and the overall service life is prolonged.

Owner:成都冠佳科技有限公司

Smart city road auxiliary parking system

InactiveCN114333086AImprove stabilityPrevent breaking and tippingTicket-issuing apparatusIndication of parksing free spacesParking spaceStructural engineering

The invention discloses a smart city road auxiliary parking system which comprises a parking space surface, a triggering mechanism is arranged in the middle of the upper end of the parking space surface, vehicle distance positioning and separating mechanisms are arranged on the two sides of the upper end of the parking space surface, and supporting mechanisms are arranged at the upper ends of the two sides of each vehicle distance positioning and separating mechanism. When a positioning plate moves upwards, stable sliding blocks on the two sides are driven to move towards the upper ends of the interiors of stable sliding grooves, the stability of the positioning plate in the moving process is improved, and when the stable sliding blocks move upwards, a connecting rope is in a loose state, and a supporting block loses constraining force; the movable block, the movable supporting rod and the supporting block can be pushed to move upwards through the reset spring in an extruded state, the firmness of the positioning plate in the using process is improved through the movable supporting rod and the supporting block, and the situation that the positioning plate is toppled over and fractured due to impact in the using process is prevented.

Owner:黄湘珍

High-precision warehousing equipment based on ball screw transmission

ActiveCN112374009ASolve the problem of arrival position accuracyImprove efficiencyStorage devicesGear wheelBall screw

The invention provides high-precision warehousing equipment based on ball screw transmission. The high-precision warehousing equipment comprises a first driving motor, a second driving motor and a third driving motor. The first driving motor and the second driving motor are used for moving of the equipment in the horizontal direction. The third driving motor is used for moving of the equipment inthe vertical direction. The first driving motor conducts transmission in a gear and rack mode. The second driving motor and the third driving motor conduct transmission in a ball screw mode. Two parallel L-shaped supports are arranged on the upper surface of a supporting seat in the horizontal direction. A supporting plate in the vertical direction is further arranged on the supporting seat. According to the high-precision warehousing equipment, the problem of the arrival position precision of non-standard parts is solved, and meanwhile, the mechanical structure is further simplified, and moreimportantly, unmanned feeding and discharging operation can be achieved in warehousing of non-uniform specifications, and the warehousing operation efficiency is improved.

Owner:HUAIAN COLLEGE OF INFORMATION TECH

Folding type hollow plate reusable container

ActiveCN101665167BEasy to foldSimple structurePackage recyclingNon-removalbe lids/coversEngineeringRivet

The invention discloses a folding type hollow plate reusable container, comprising a first plate, a second plate, a third plate, a fourth plate and four hinges, wherein the first plate, the second plate, the third plate and the fourth plate are all plastic hollow plates; the first plate and the second plate have same structure and are arranged in parallel from front to rear; the third plate and the fourth plate have same structure and are arranged in parallel from left to right; the four plates are stamped and bent so as to form a front plate, a rear plate, a left plate, a right plate, four top covers and four bottom covers; two sides of the front plate, the rear plate, the left plate and the right plate are respectively provided with three to eight rivet mounting holes, and the four hinges are also provided with corresponding rivet mounting holes; the first plate, the second plate, the third plate and the fourth plate are riveted and fixed by the four hinges and rivets, thus connecting together and forming a rectangular box body; and protecting strips made of PE cotton are attached on the parts of the four hinges in the box body and protect stored articles in the box from being collided and scratched. The folding type hollow plate container has simple structure, convenient folding and less occupied space.

Owner:JIANGSU HUASHENG PLASTIC

Method for producing semi-tempered glass

ActiveCN102531365BProcess stabilityProcess energy savingGlass tempering apparatusToughened glassDouble stage

The invention relates to a method for producing semi-tempered glass. A double-stage cooling method is adopted in a cooling process of the method for producing the semi-tempered glass, namely secondary cooling is added on the basis of reservation of conventional primary cooling, so that the influence of abrupt change of wind pressure on the flatness of the glass is reduced in the cooling process, the semi-tempered glass with better flatness is obtained, and the effects of saving the cooling time, reducing the total energy-saving quantity of the semi-tempered glass to 10 percent of the prior art and promoting the flatness of the semi-tempered glass from 3 / 1,000 to 1 / 1,000 can be achieved.

Owner:LUOYANG NORTHGLASS TECH +2

Special safety protection device for automobile side protection

The invention provides a safety protection device special for automobile side face protection. The device comprises a base plate, buffer strips are arranged on the front face of the base plate. A magnetic tape and a rubber coating are arranged on the back surface of the base plate, fastening seats are fixedly inserted into four corners of the front surface of the base plate, supporting seats are fixedly connected to the fastening seats, a sleeve is fixedly inserted into the middle of the front surface of the base plate, a button is movably inserted into the sleeve, and four clamping plates arefixedly connected to the outer side of the button. The backing plate is adsorbed on a vehicle body through the magnetic tape, the rubber coating and the vacuum chuck; the side surface of the automobile is prevented from being collided and scratched by other automobiles or automobile doors; the automobile anti-theft device is simple in use and wide in application range, the movable block is clamped through the clamping plate, the threaded rod can rotate again only when the automobile door is pulled outwards, then the base plate can be detached, due to the fact that an automobile owner can lockthe automobile after parking, other people cannot detach the base plate, and the automobile anti-theft device is good in anti-theft performance and high in use safety.

Owner:陈嘉龙

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com