Steel plate conveying and positioning device

A positioning device, steel plate technology, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as inability to transport different types of steel plates, inability to implement steel plate transportation and noise reduction, and inability to reach designated locations, etc. Achieve the effect of improving stability and safety, improving use safety, sliding stability and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

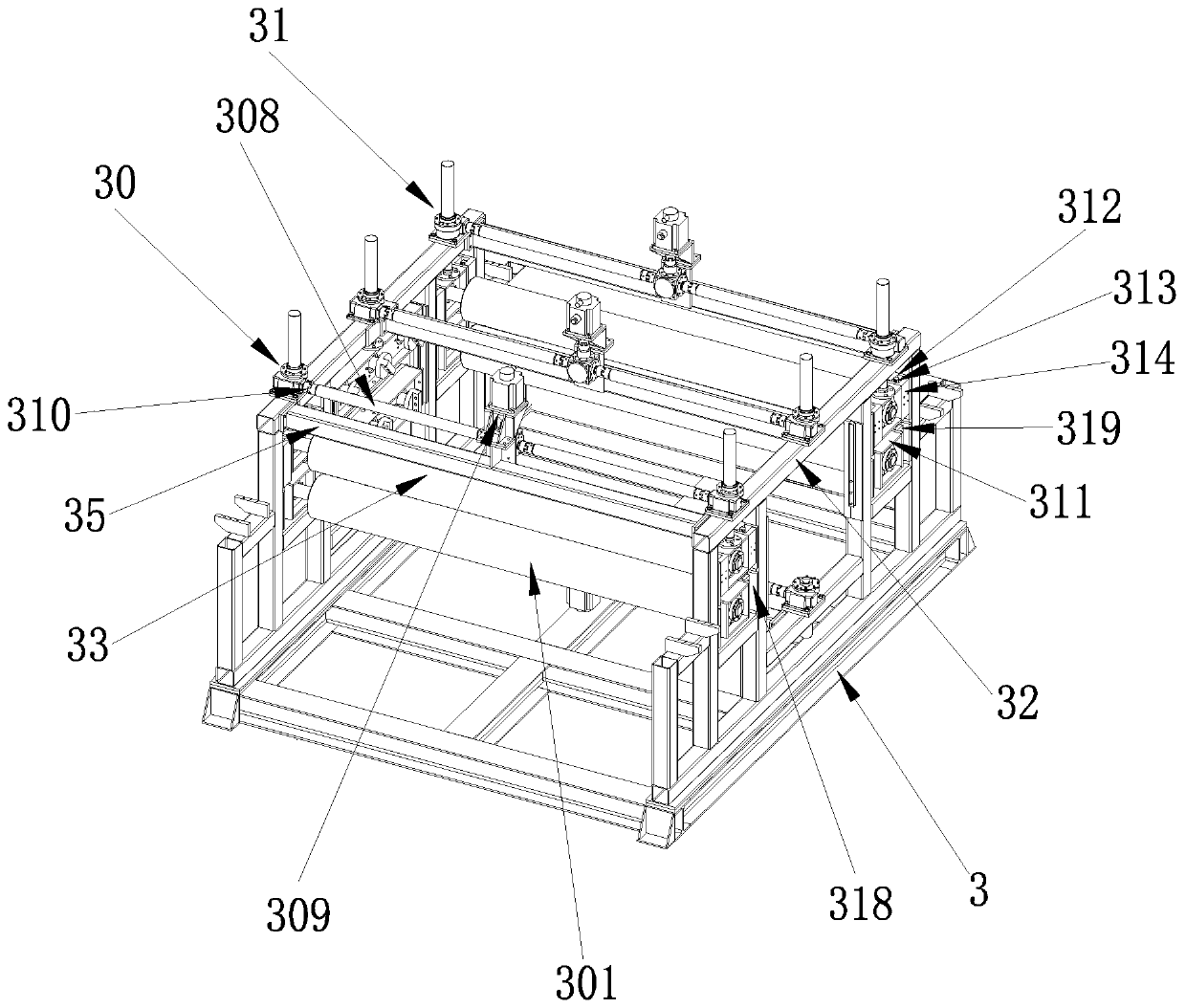

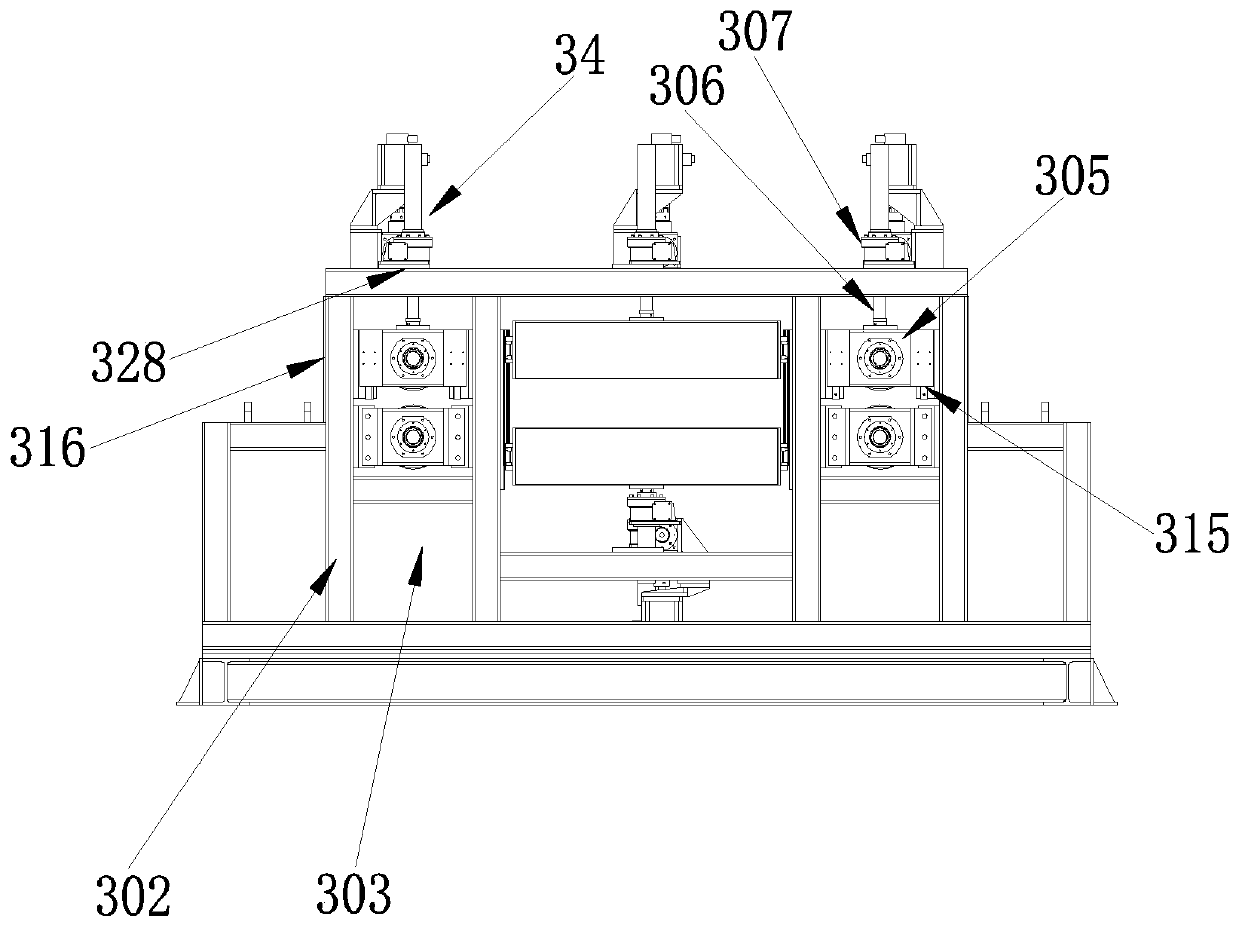

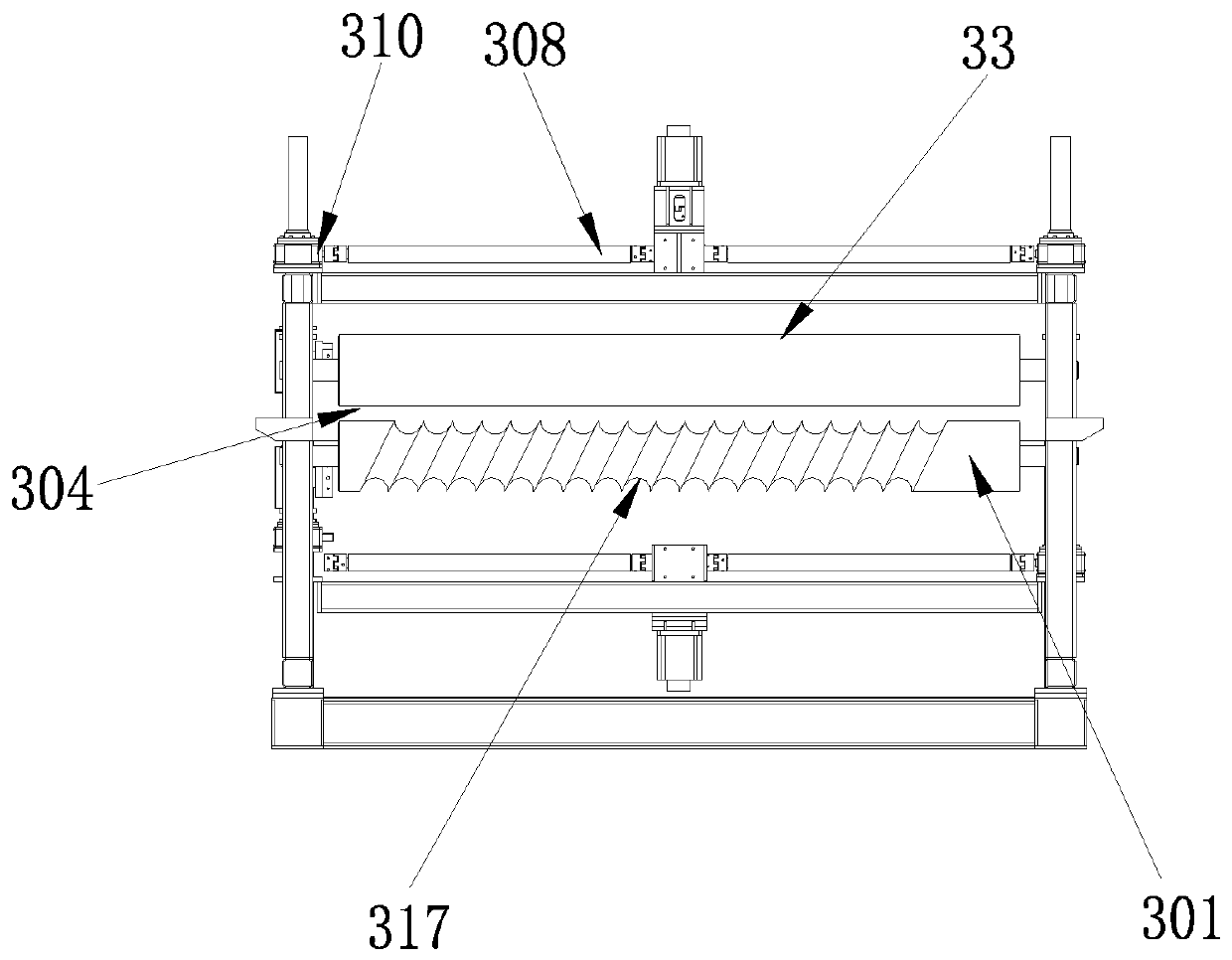

[0033] Embodiment 1: as Figure 1-3 As shown, a steel plate conveying and positioning device includes a base 3, a front positioning mechanism 30 and a rear positioning mechanism 31 fixed on the base 3 and arranged oppositely, and a horizontal bar 32 is fixed on the front positioning mechanism 30 and the rear positioning mechanism 31 and connecting rod 35; the front positioning mechanism 30 includes two support rods 302 symmetrically arranged with a delivery roller 301, and a guide groove 303 is formed between the two support rods 302, and the two ends of the delivery roller 301 are assembled in the guide groove 303. Driven by a driving motor, a pressure roller 33 is arranged on the conveying roller 301, and an adjustment mechanism 34 for adjusting the up and down movement of the pressure roller 33 is arranged on the conveying roller 301, and a passage 304 for steel plate conveying is formed between the pressure roller 33 and the conveying roller 301. Mechanism 34 drives pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com