Patents

Literature

1791results about How to "Prevent jumping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

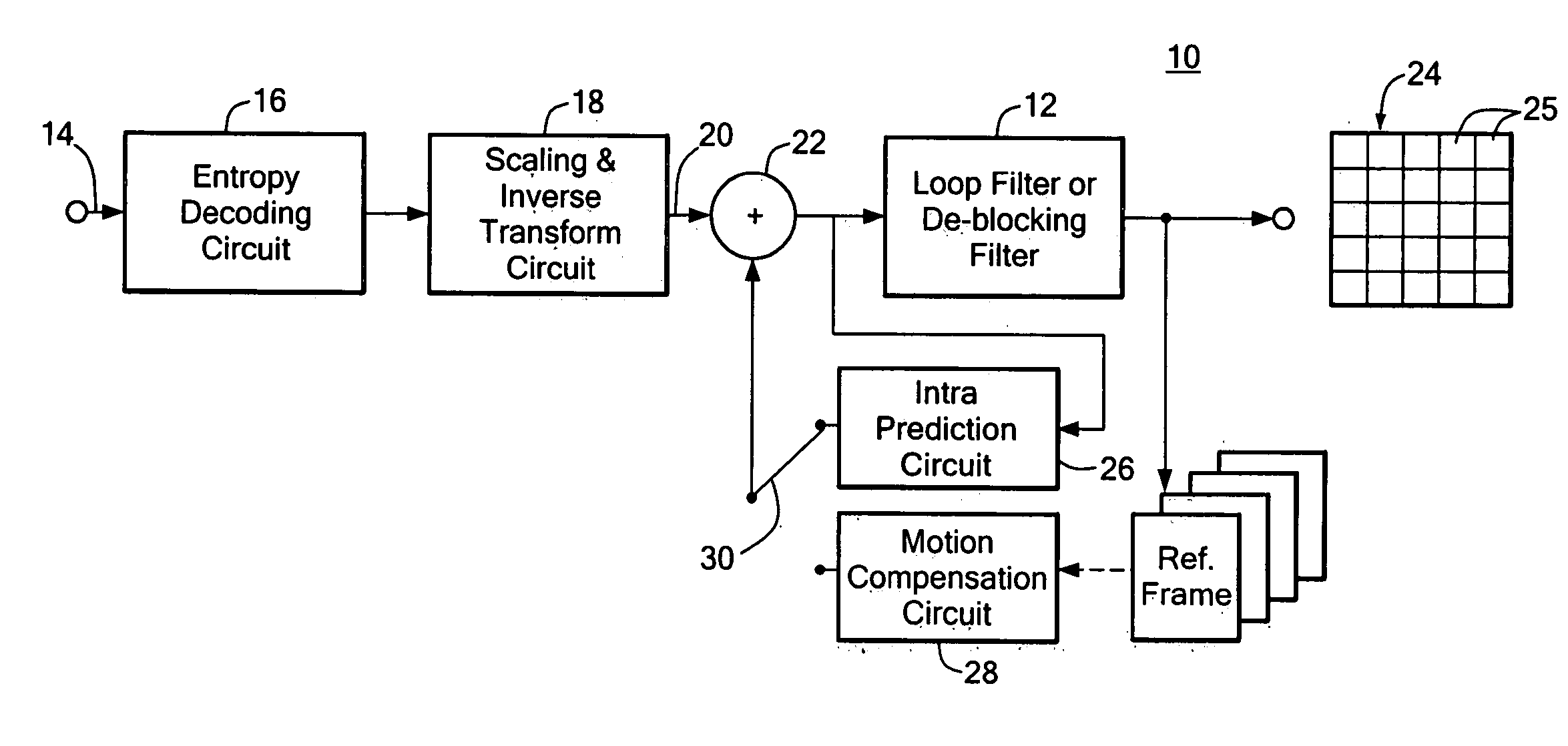

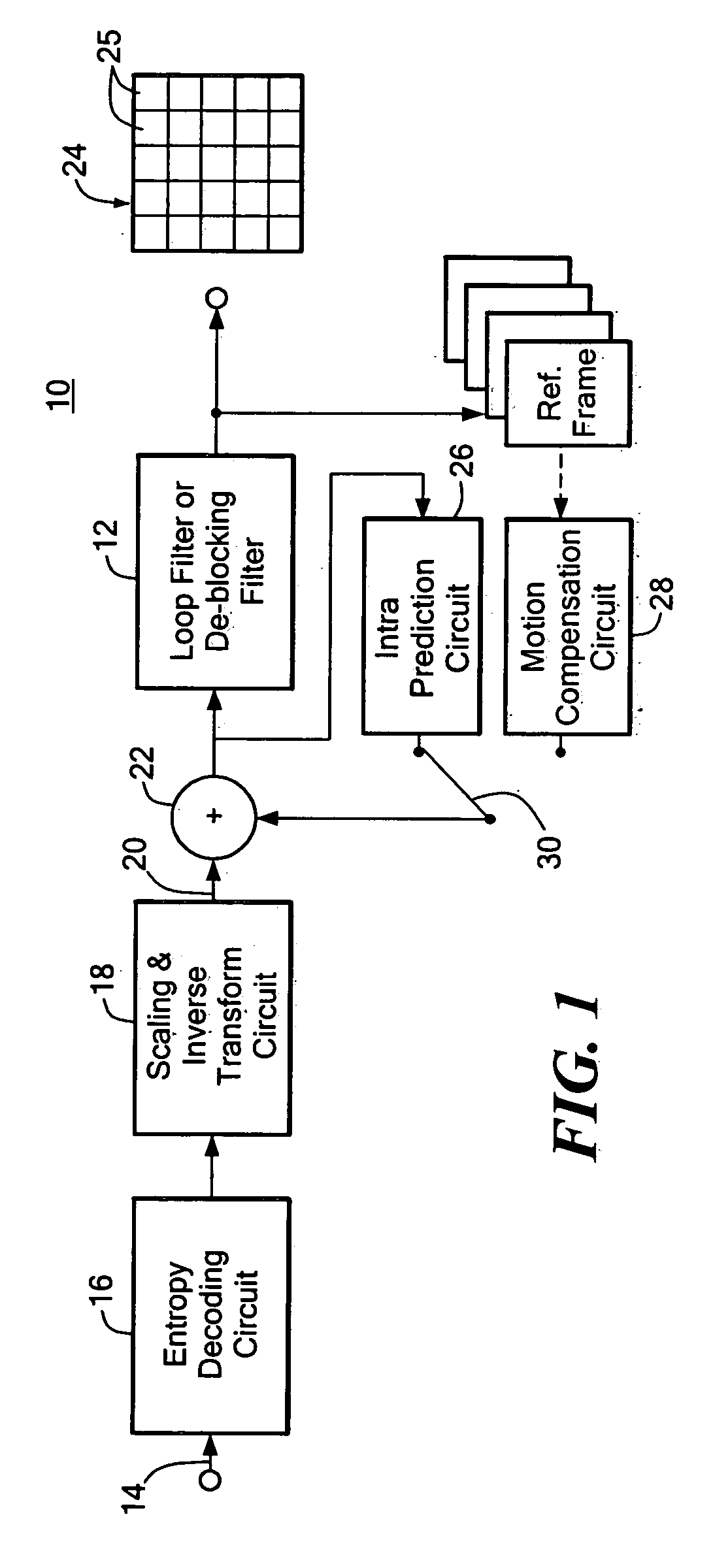

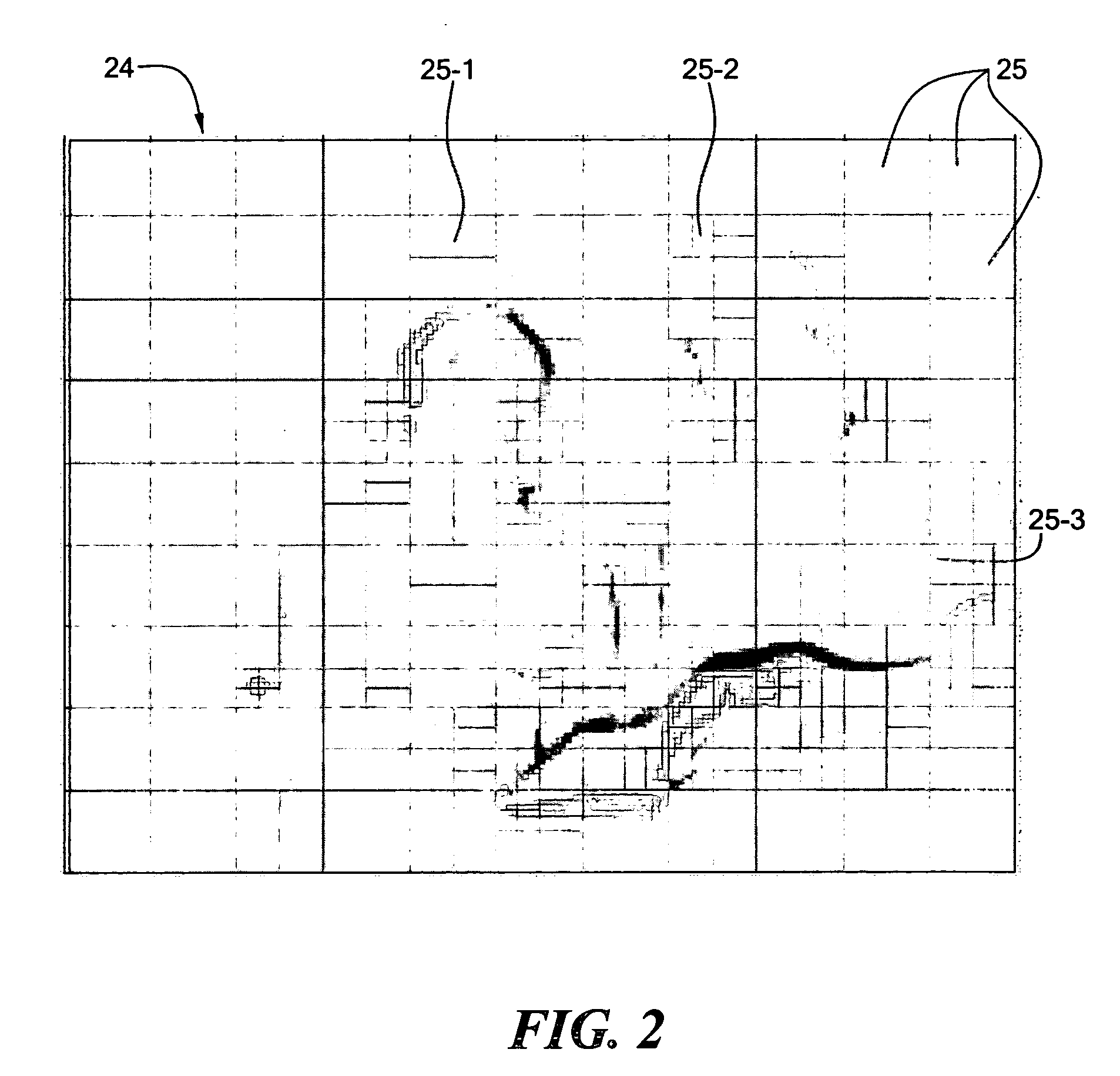

Method and apparatus for accelerating processing of a non-sequential instruction stream on a processor with multiple compute units

ActiveUS20060174236A1Speed up the processIncrease computing speedSoftware engineeringInstruction analysisData storingData store

Accelerating processing of a non-sequential instruction stream on a processor with multiple compute units by broadcasting to a plurality of compute units a generic instruction stream derived from a sequence of instructions; the generic instruction stream including an index section and a compute section; applying the index section to localized data stored in each compute unit to select one of a plurality of stored local parameter sets; and applying in each compute unit the selected set of parameters to the local data according to the compute section to produce each compute unit's localized solution to the generic instruction.

Owner:ANALOG DEVICES INC

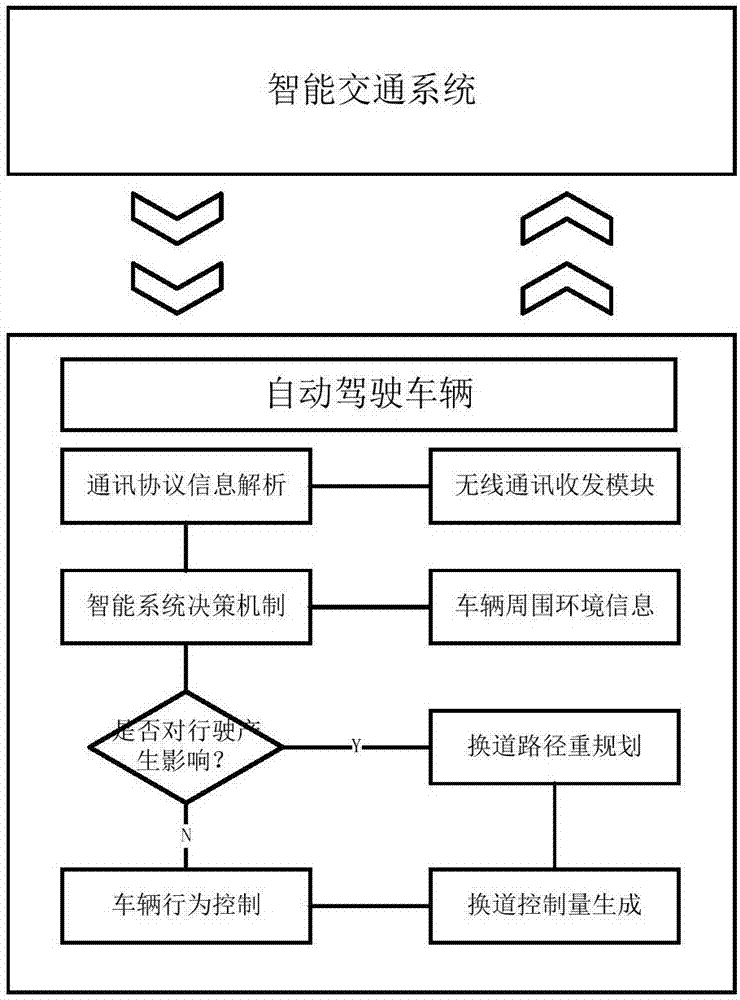

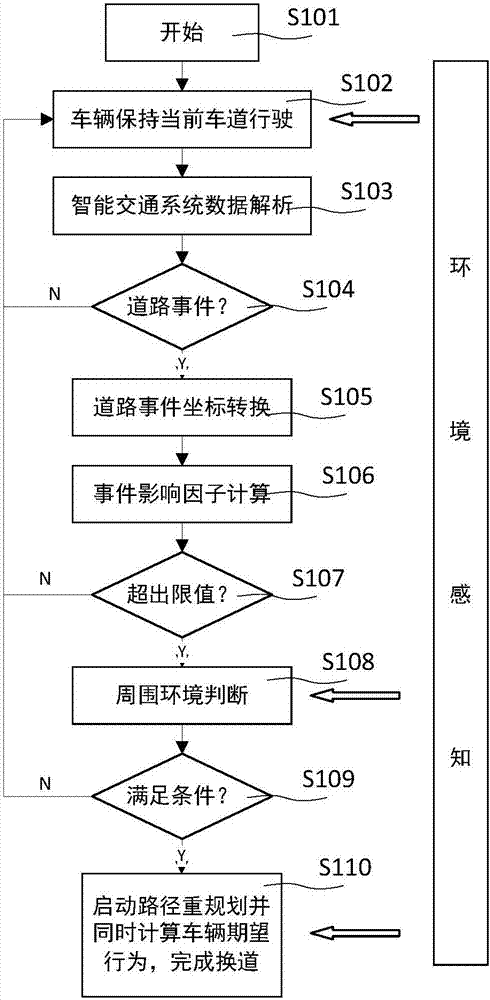

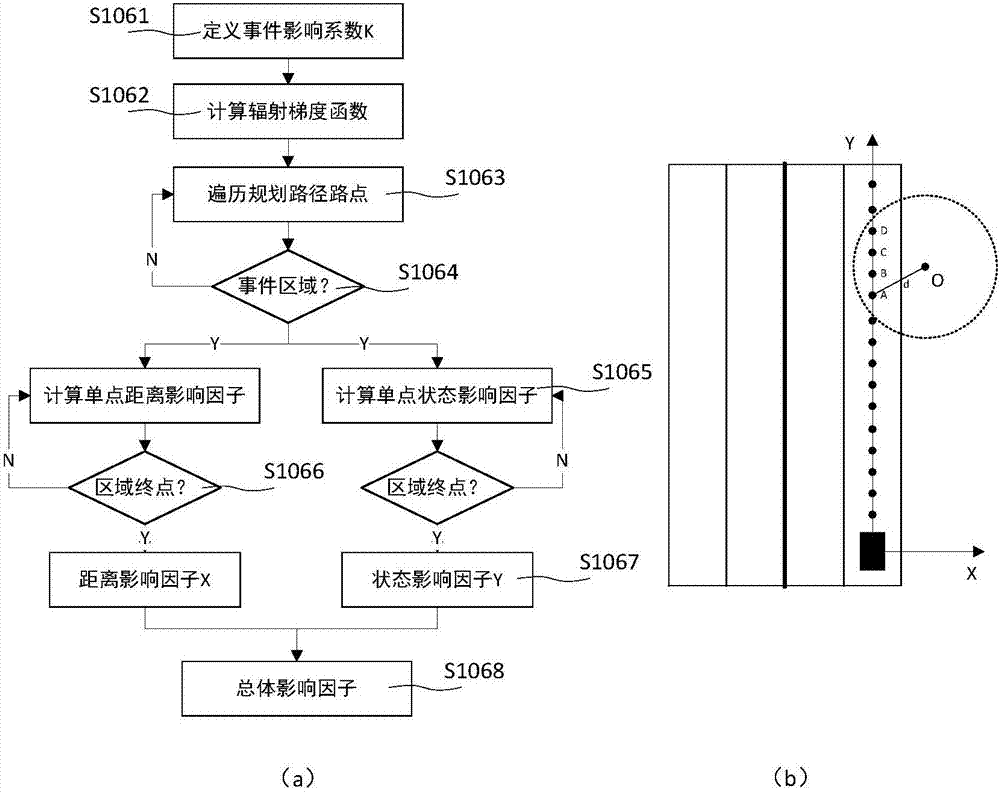

Intelligent traffic system-based intelligent vehicle lane changing decision-making method

ActiveCN106940933AIntelligent autonomous decision-making for changing lanesSmooth independent decision-making to change lanesArrangements for variable traffic instructionsAnti-collision systemsDecision takingBroadcast data

The invention relates to an intelligent traffic system-based intelligent vehicle lane changing decision-making method. The method comprises the following steps of firstly, parsing the received broadcast data of an intelligent traffic system by an intelligent driving system, and extracting the event information; secondly, completing the coordinate conversion of a road event by the intelligent driving system, and obtaining an event influence factor according to the event information; finally, according to the event overall influence factor and the judgment result that the current road environment allows the lane changing decision of a vehicle, allowing the lane changing path re-planning, simultaneously calculating the desired behavior of the vehicle and changing the lane of the vehicle. According to the technical scheme of the invention, according to the attribute of a road event ahead of the vehicle and the environmental information around the vehicle, the influence factor of the current vehicle driving road is calculated. Therefore, the necessity, the security and the reliability of the lane changing decision of an automatic driving vehicle are evaluated. Meanwhile, preparations are made in advance before the lane changing of the vehicle.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

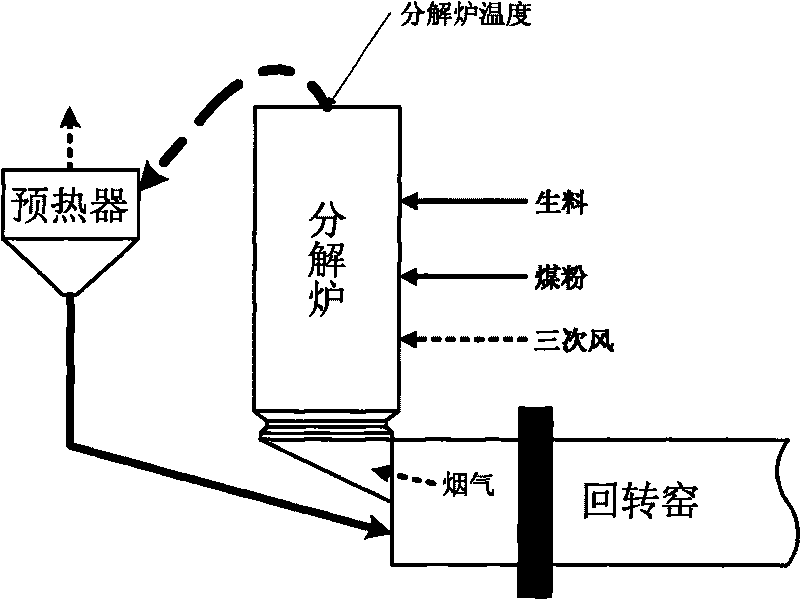

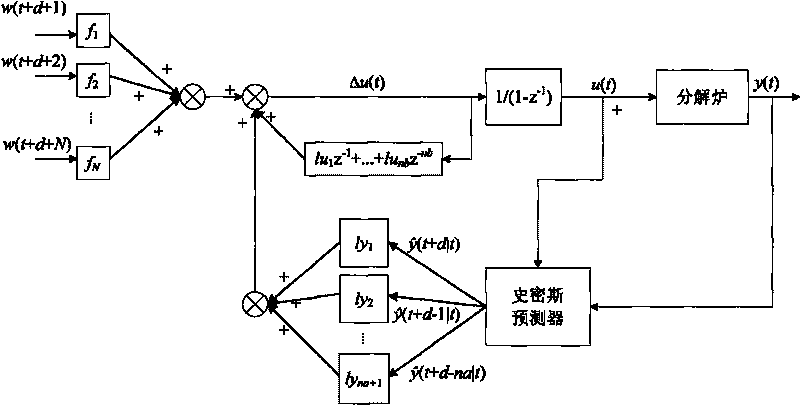

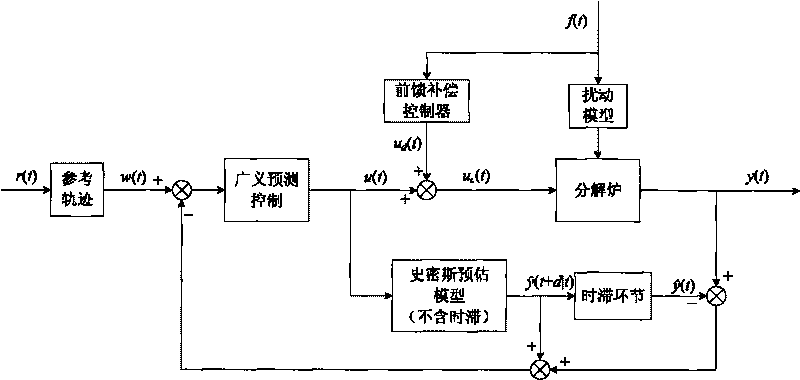

Cement decomposing furnace temperature control method based on constraint smith GPC

InactiveCN101751051AEasy to identifyFew adjustable parametersTemperature control using electric meansAdaptive controlFurnace temperaturePerformance index

The invention relates to a cement decomposing furnace temperature control method based on constraint smith GPC, which includes variable selection, model recognition, optimizing computation, constraint processing and feedforward compensation; the variable selection includes that: coal powder flow is selected as a control variable, raw flow is selected as the feedforward variable and the decomposing furnace temperature is selected as the controlled variable; the model recognition includes that: the model recognizer based on least square method and retardation time estimation time is adopted to obtain a pulse transfer function model; the optimizing computation includes that: the future output state is predicated and the reference track w of the output value is also set; a secondary performance index controller is adopted for the rolling optimization, the control increment Delta u of the current time is computed to obtain control action value u through addition; the constraint processing includes that: the control variable and controlled variable are respectively performed with constraint amplitude limiting processing; the feedforward compensation includes that: the dynamic compensation principle is utilized to compute the current time t added to the feedforward control action value ud. The invention has simple recognition process, less adjustable parameters, good tracking performance, strong robustness, effectively refrains the disturbance influence caused by raw material flow and prevents saltus step of the system variable.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

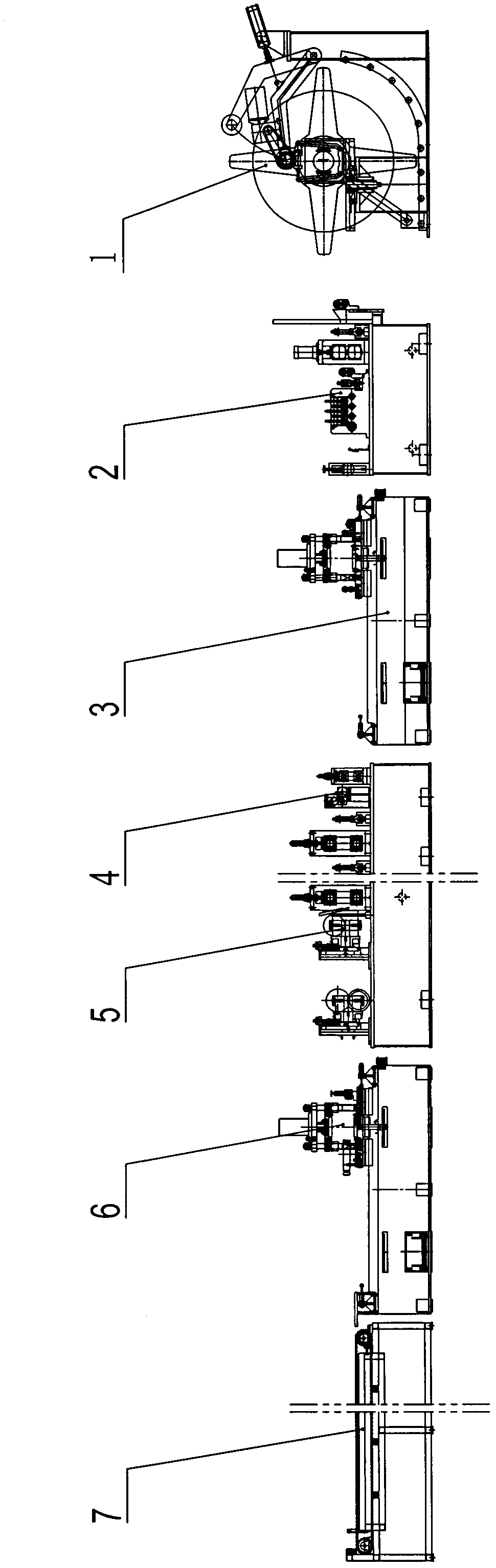

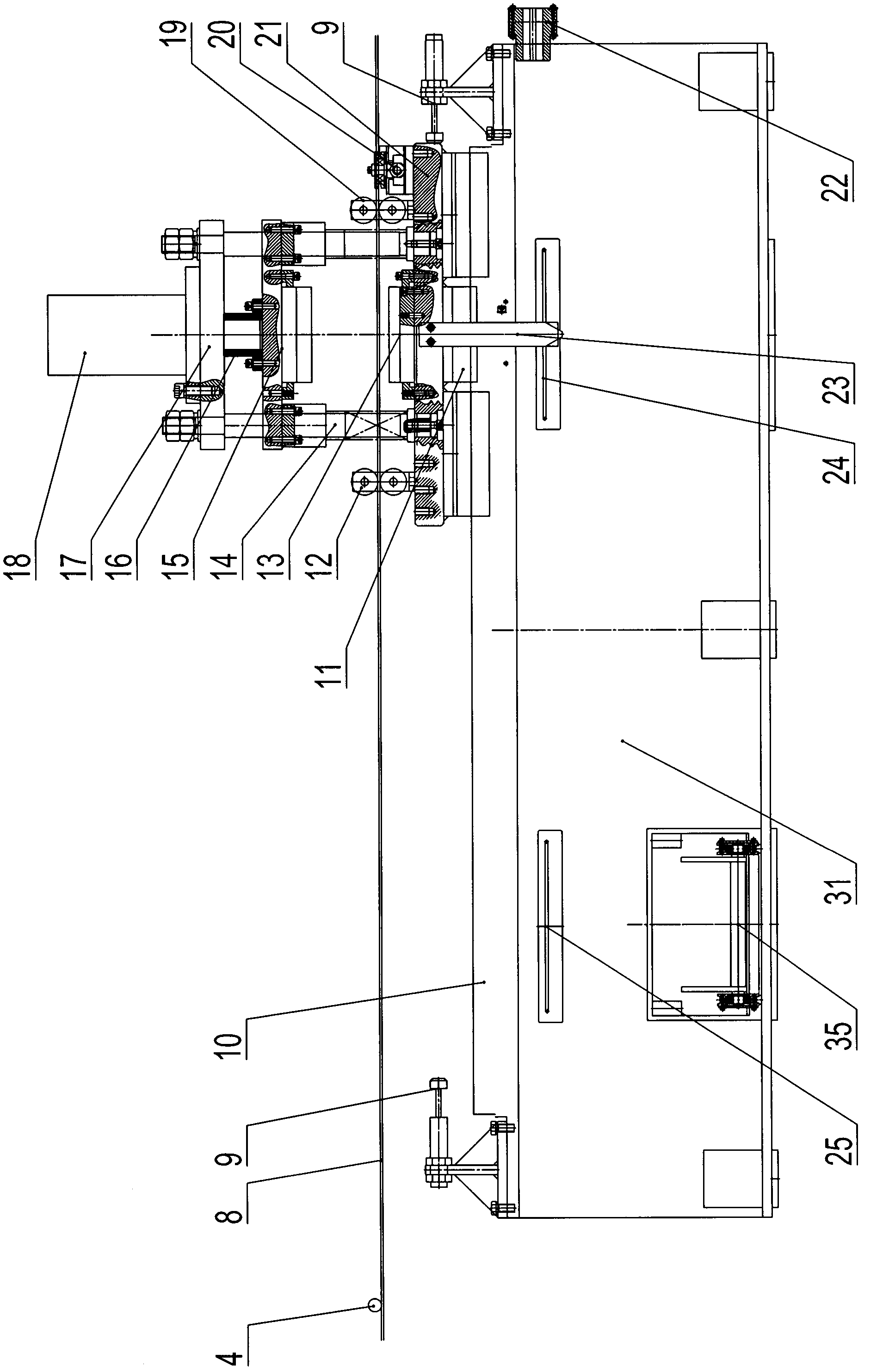

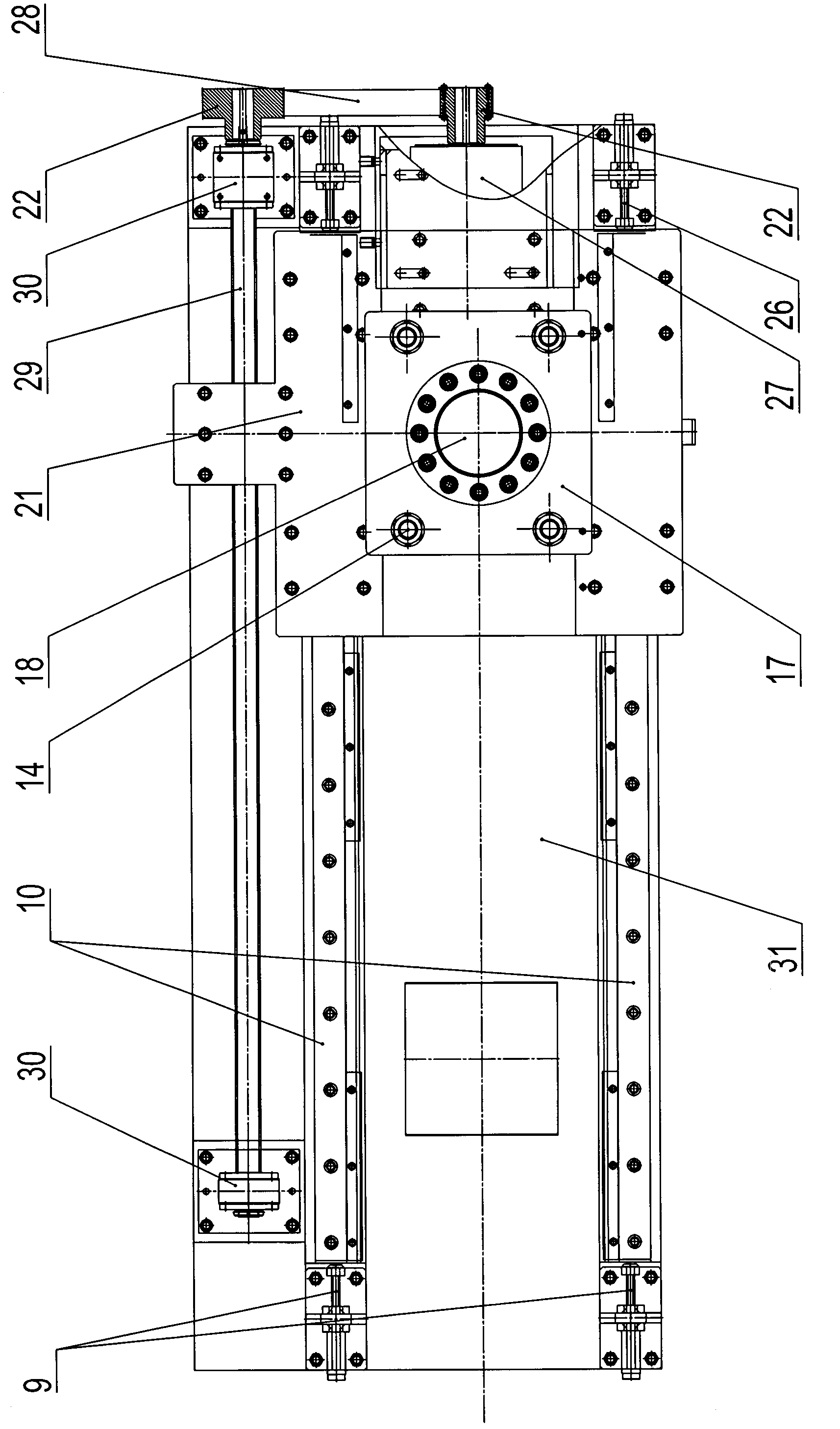

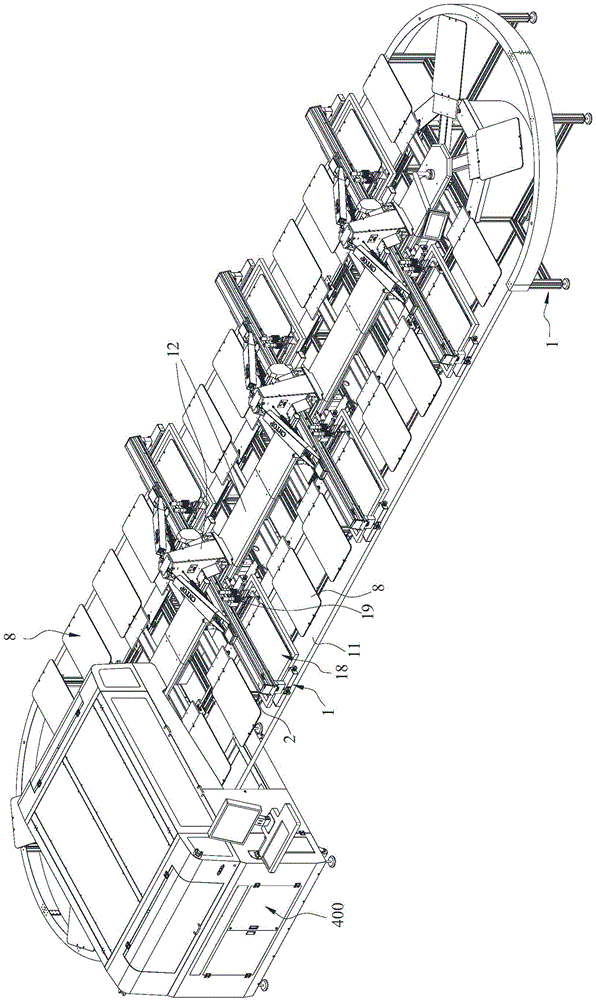

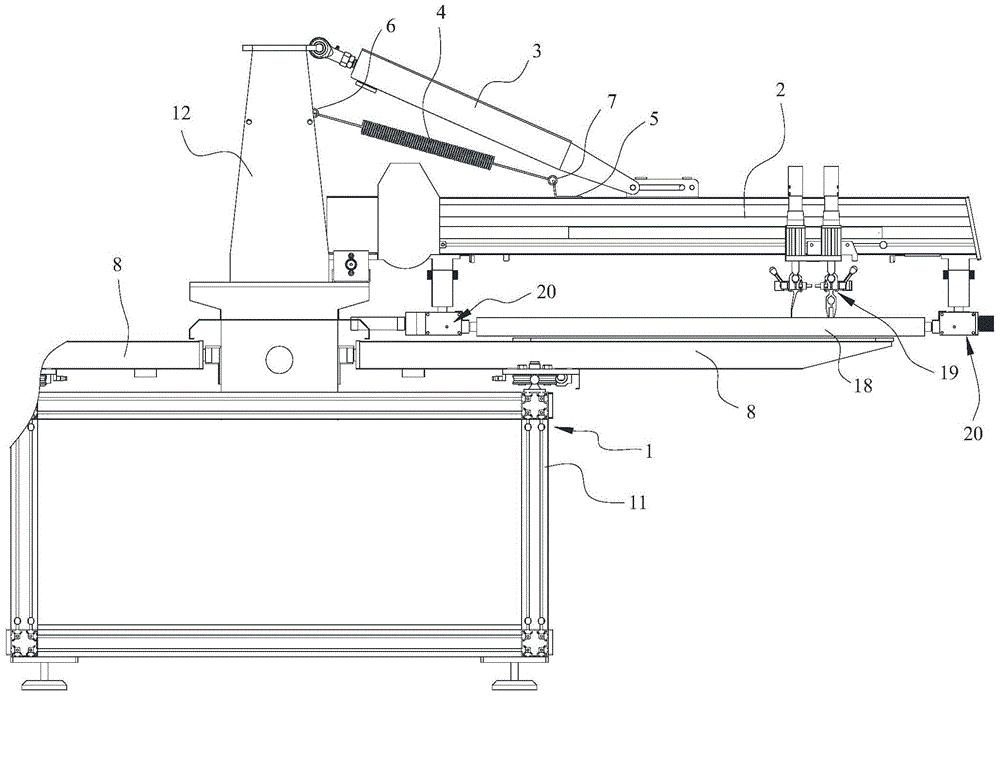

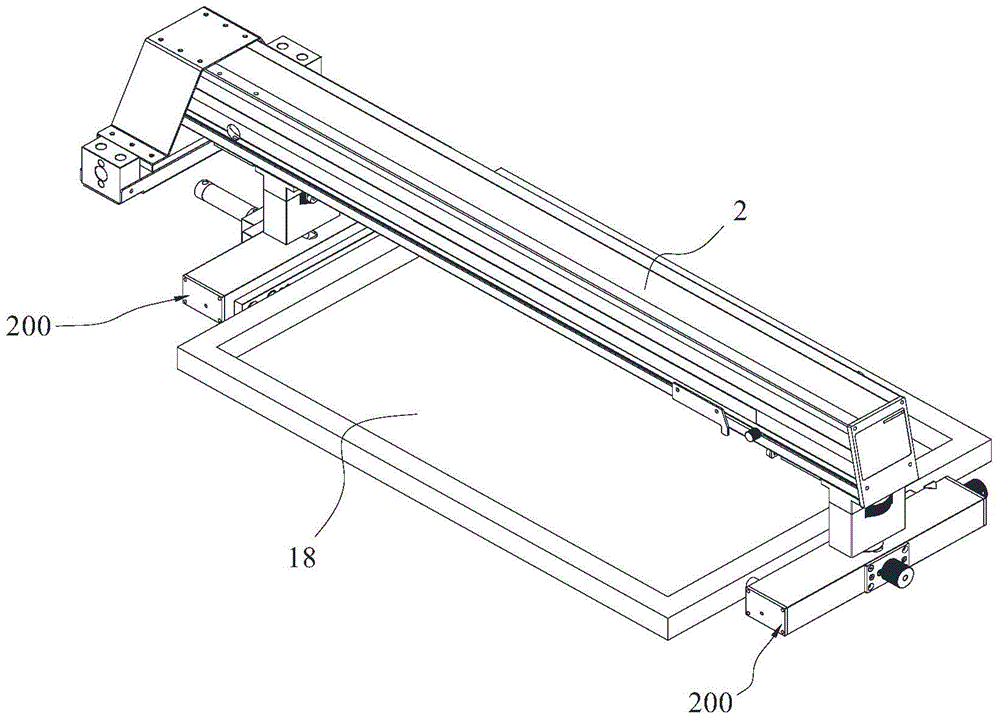

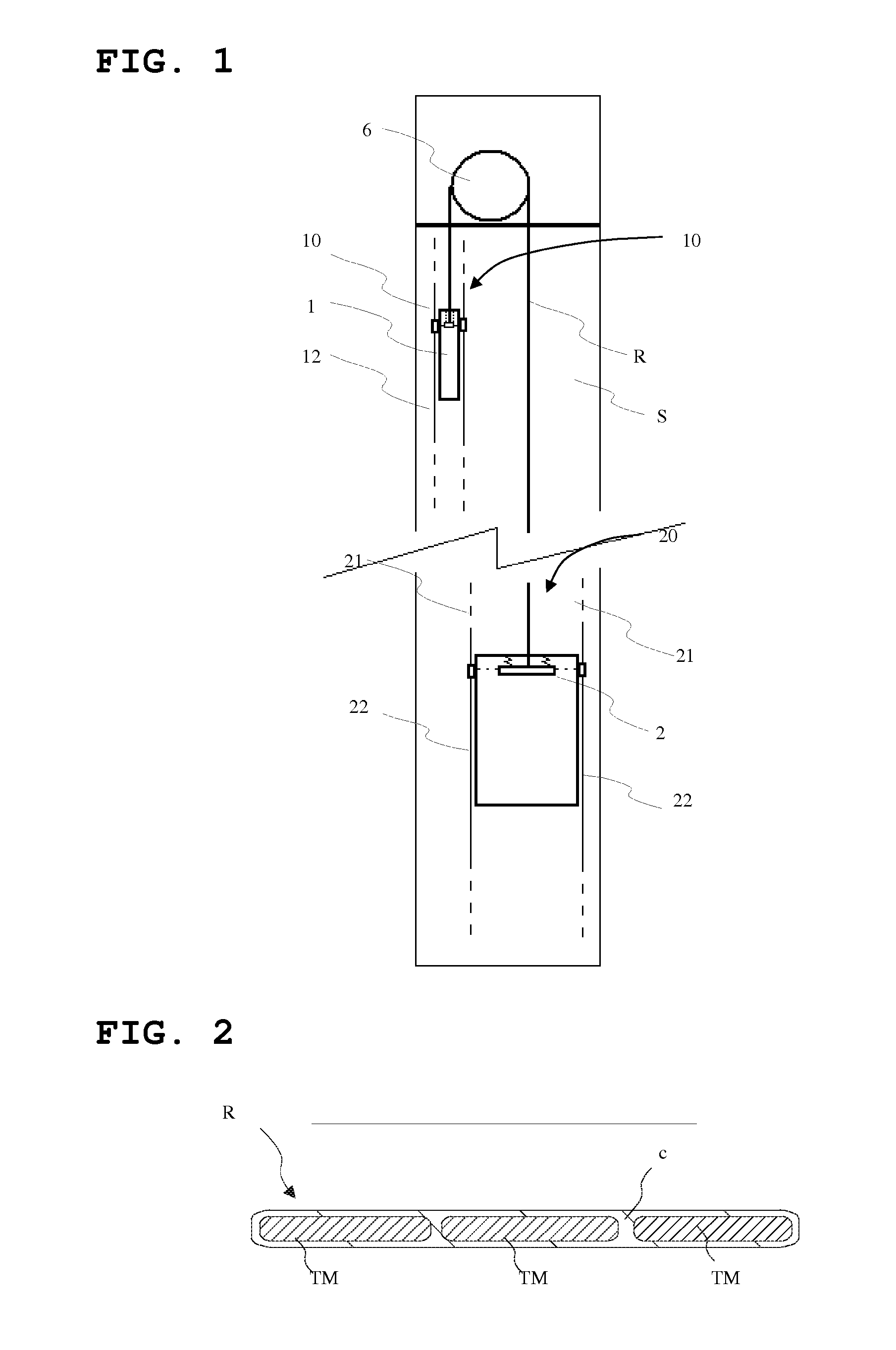

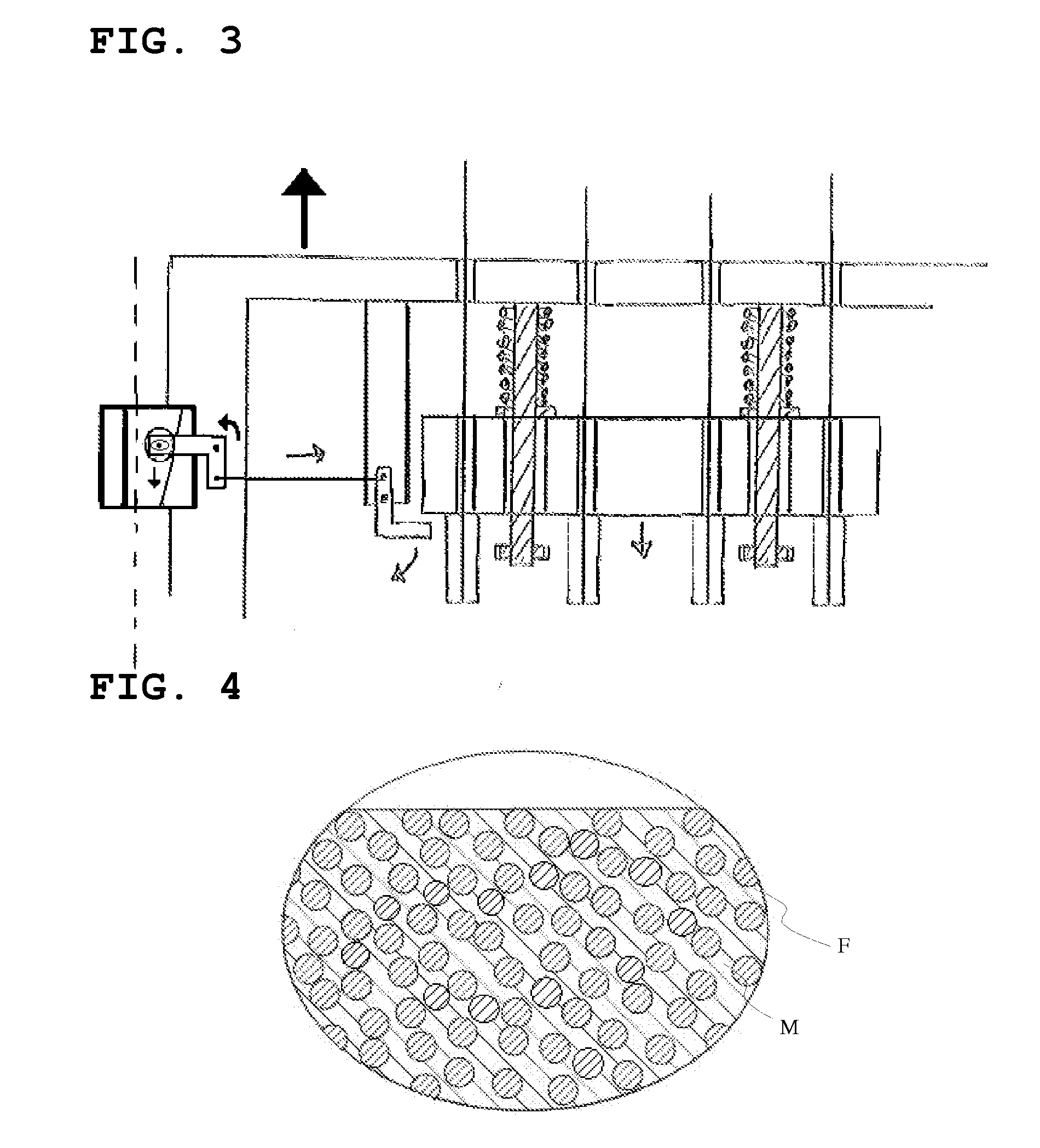

Roll forming processing method for online punching and production line

The invention relates to a roll forming processing method for online punching and a production line in the technical field of sheet roll forming. The method comprises the following steps of: emptying, leveling, punching, roll forming, cutting and blanking. The punching step comprises the following specific steps of: detecting a real-time displacement signal of the linear motion of a sheet; driving a punching mechanism to move at an accelerated speed according to the displacement signal and drive the sheet to a set punching position along the movement direction of the sheet; driving the punching mechanism to track the linear motion of a coiled sheet and keep moving synchronously with the sheet; in a process of keeping synchronous movement with the sheet, allowing the punching mechanism to punch a hole at the set position on the sheet; and returning the punching mechanism to an initial position. The invention also provides the production line for implementing the method. Punching is performed after a servo motor controlled by a programmable logic controller (PLC) drives a workbench to track the sheet. The processing method and the production line can improve sheet processing accuracy and increase sheet processing speed and can be used for molding, punching and processing sheets with fixedly shaped cross sections.

Owner:YANGZHOU NANYANG WELDING PIPE MOLD CO LTD

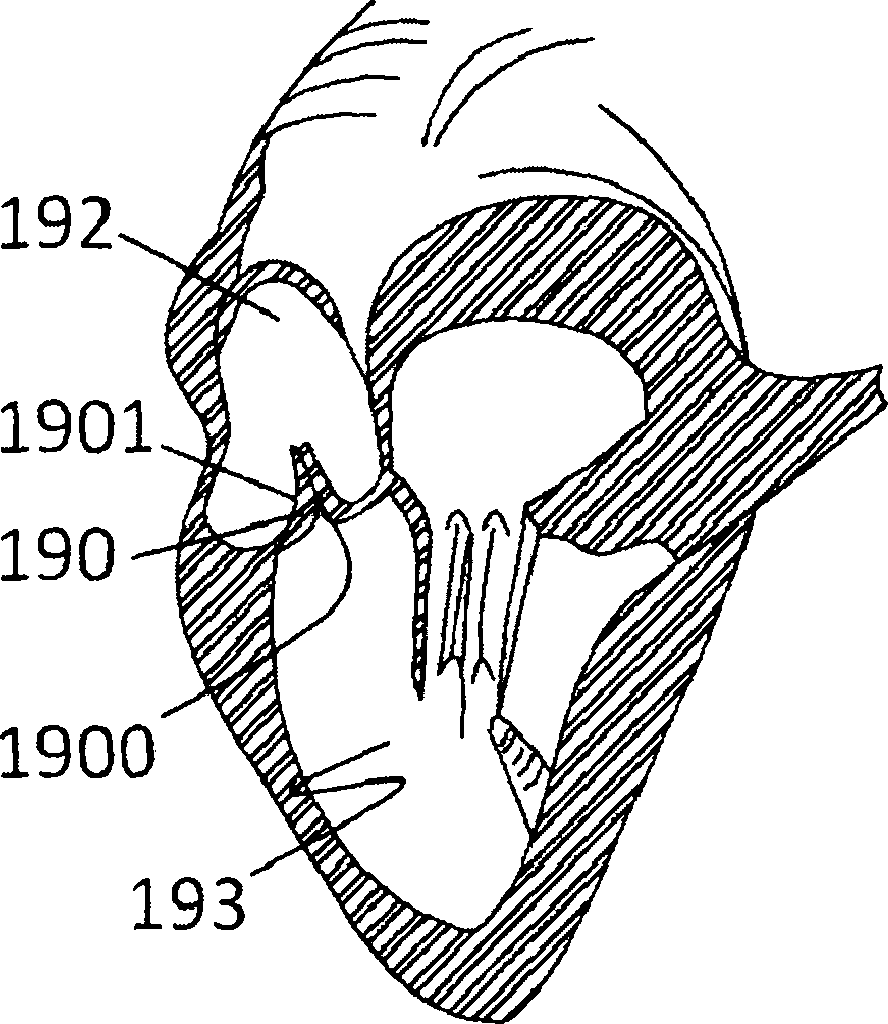

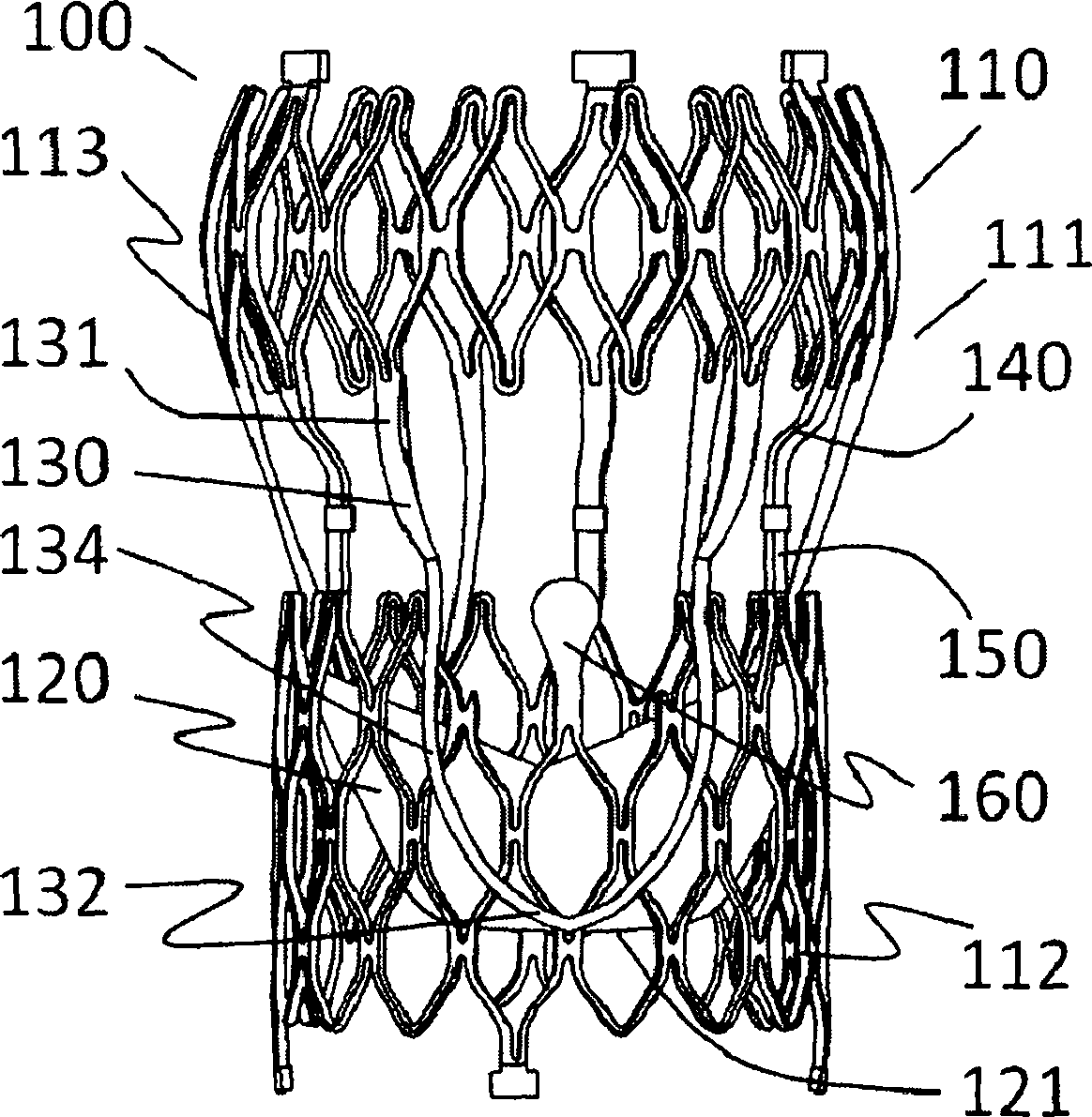

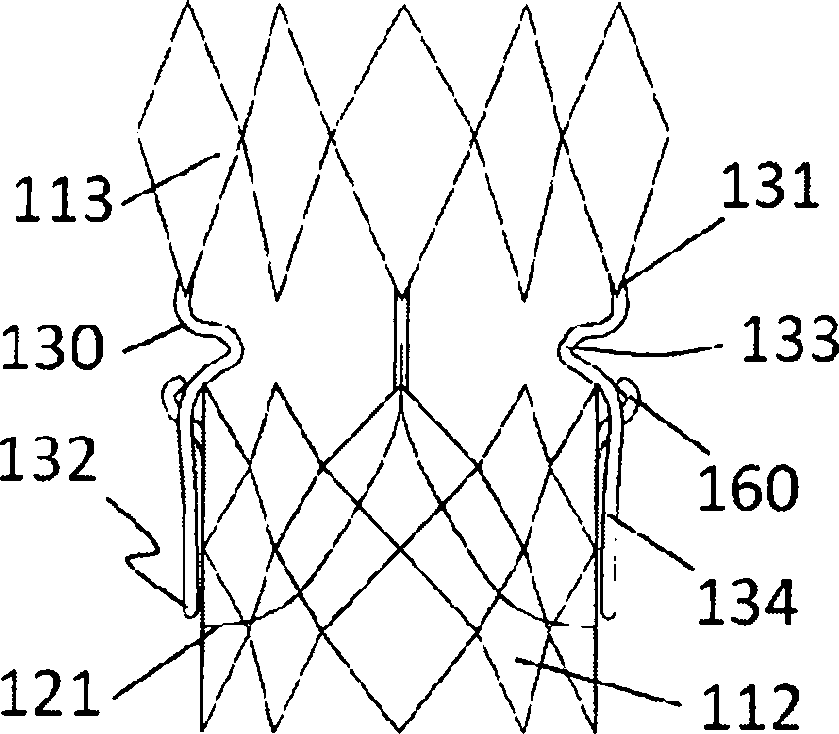

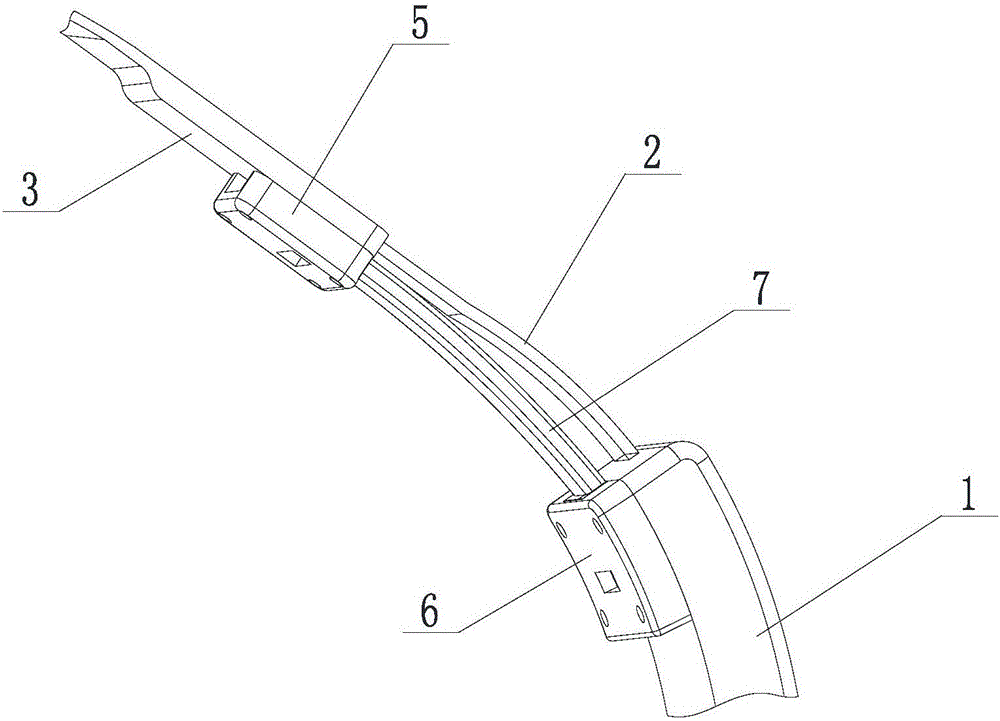

Artificial valve prosthesis with valve leaflet clamping device

The invention relates to artificial valve prosthesis with a valve leaflet clamping device. The manual valve prosthesis comprises a bracket and an artificial valve, wherein the bracket comprises an auxiliary support clamping section and a valve sewing section; the artificial valve is fixedly connected to the valve sewing section; the auxiliary support clamping section is composed of a support bracket, a valve leaflet clamping device and an upper connection fixing section; the leaflet clamping device, the support bracket and the upper connection fixing section are integrally cut; a lower connection fixing section matched with the upper connection fixing section is arranged on the valve sewing section; the bracket is embedded and connected with the lower connection fixing section into a whole through the upper connection fixing section; one part of the valve leaflet clamping device is overlapped with the valve sewing section; the overlapped part is tightly attached to the outer surface of the valve sewing section in a natural state; a bump which protrudes outwards along the radial direction is arranged on a skeleton structure of the valve sewing section in the overlapped region; and a bending section which bends towards the axis direction of the bracket along the radial direction of the bracket is arranged on the valve leaflet clamping device or the support bracket or the upper connection fixing section.

Owner:NINGBO JENSCARE BIOTECHNOLOGY CO LTD

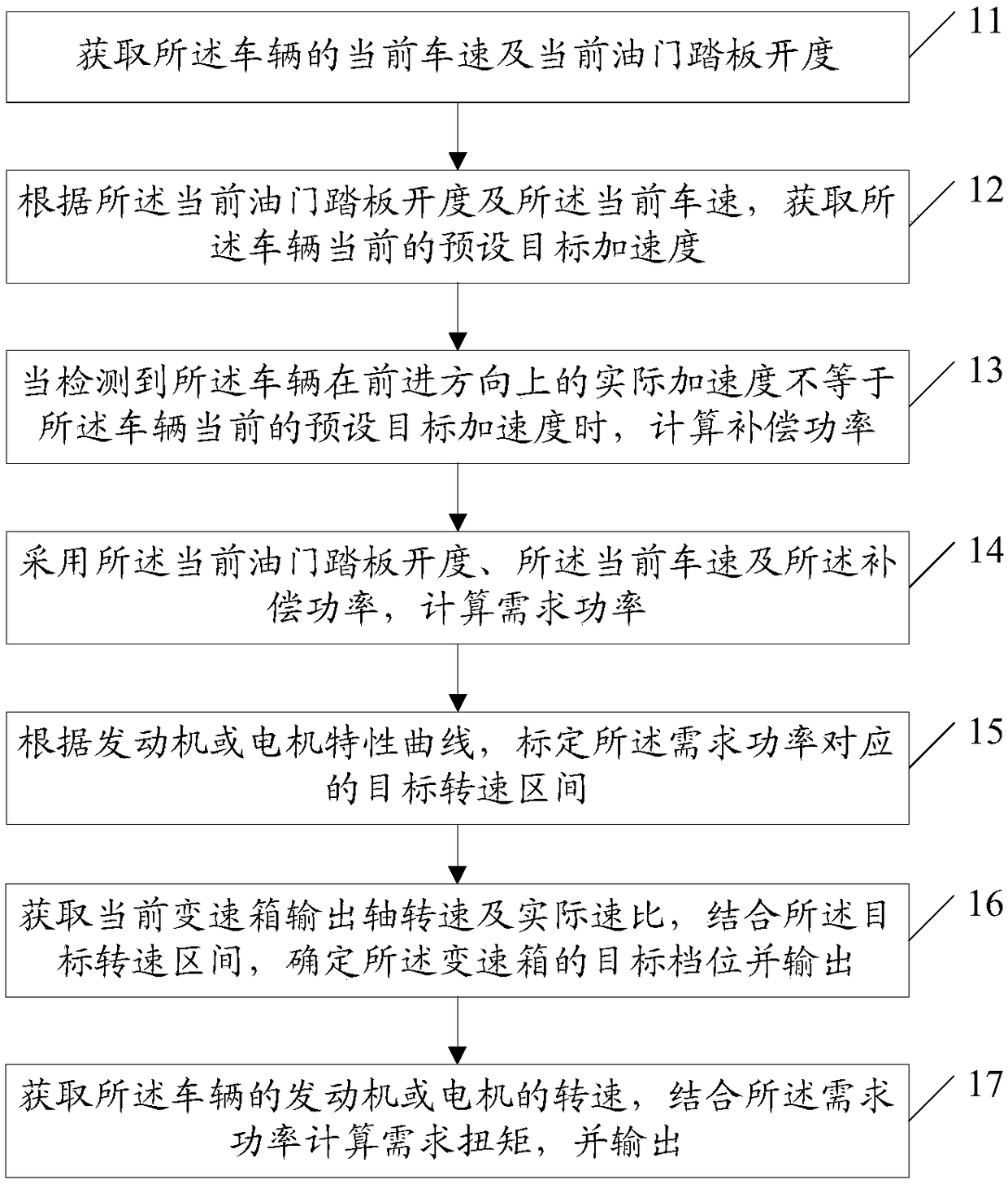

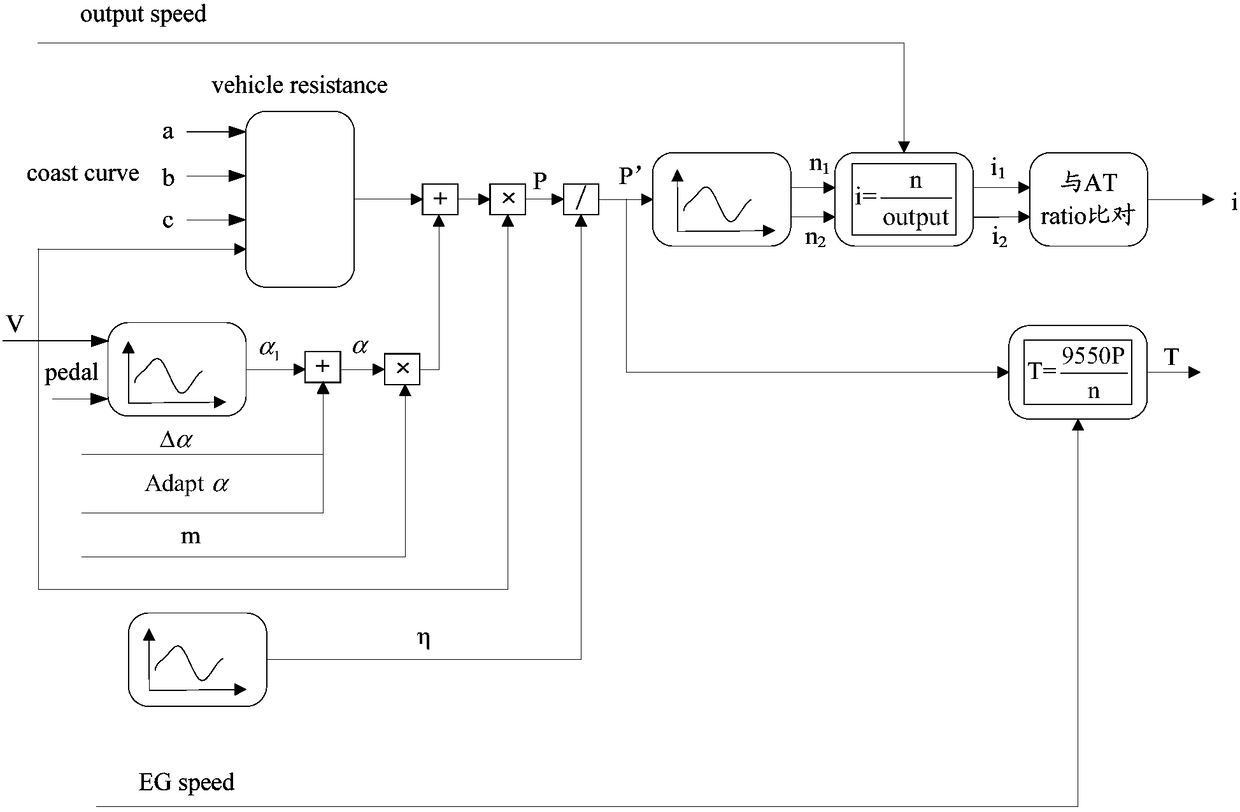

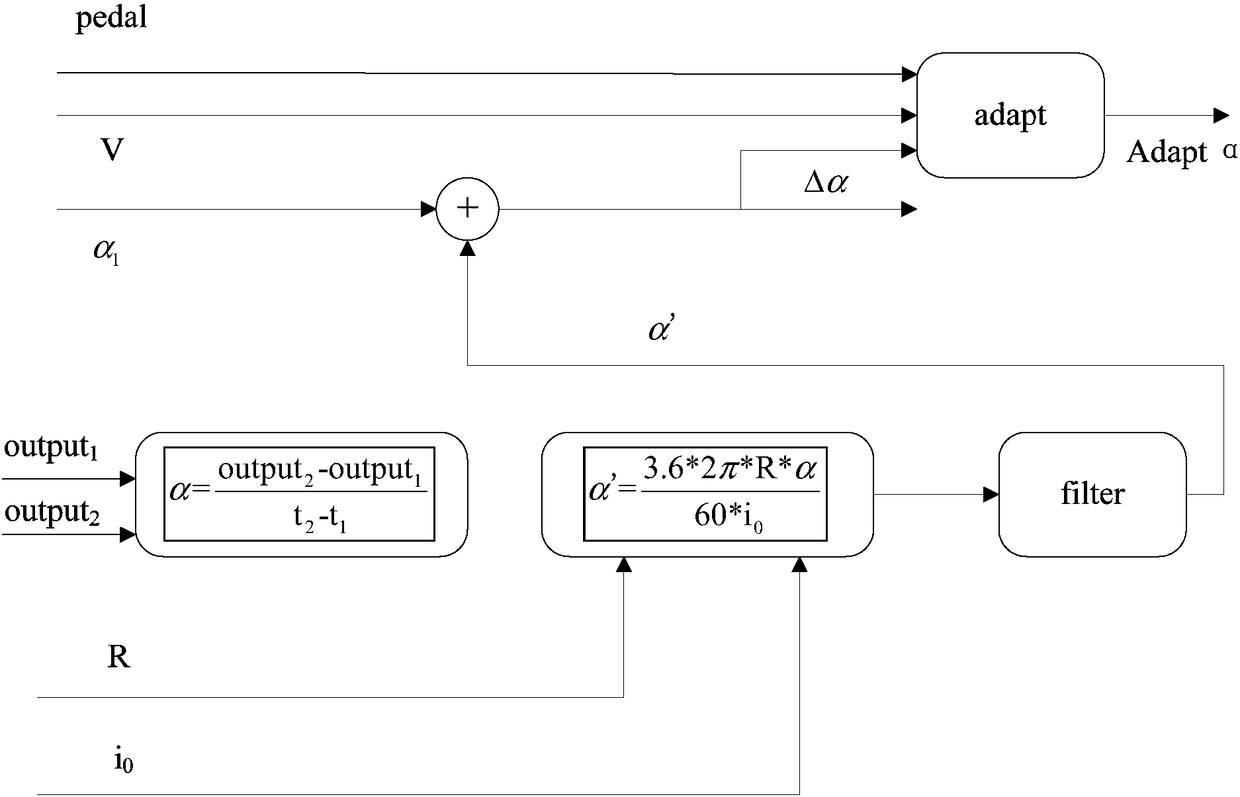

Vehicle power control method and device

ActiveCN109204310AImprove drivabilityImprove economyDriver input parametersElectric machinePower performance

A vehicle power control method and device are provided. The method comprises the following steps: obtaining the current accelerator pedal opening degree and the current vehicle speed of the vehicle; obtaining the current preset target acceleration of the vehicle according to the current accelerator pedal opening degree and the current vehicle speed; calculating a compensation power when detectingthat an actual acceleration of the vehicle in a forward direction is not equal to a current preset target acceleration of the vehicle; calculating a required power by using the current accelerator pedal opening, the current vehicle speed and the compensation power; calibrating a target speed interval corresponding to the required power according to a characteristic curve of an engine or an electric machine; obtaining a current transmission output shaft speed and an actual speed ratio, and combining the target speed interval, determining a target gear position of the transmission and outputtingthe target gear position; obtaining a rotational speed of an engine or an electric motor of the vehicle, calculating a required torque in combination with the required power, and outputting the required torque. By adopting the scheme, the economy and the power performance of the vehicle can be improved.

Owner:SAIC MOTOR

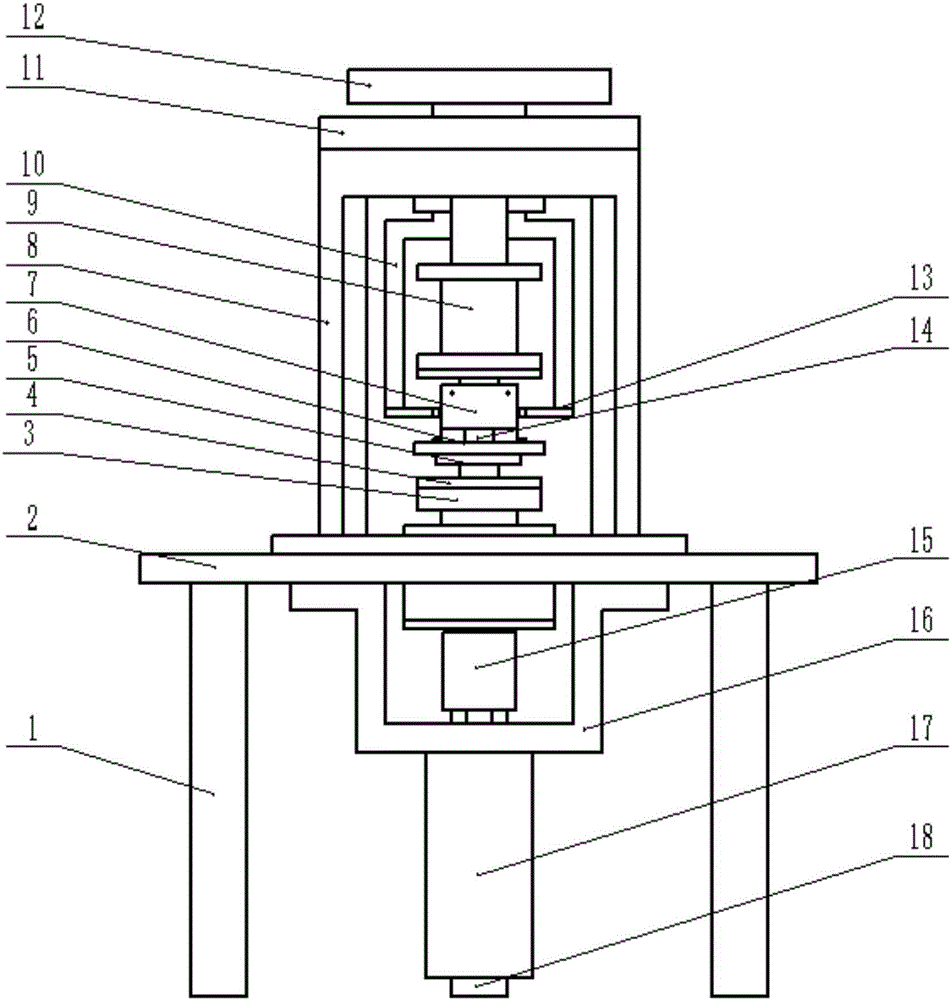

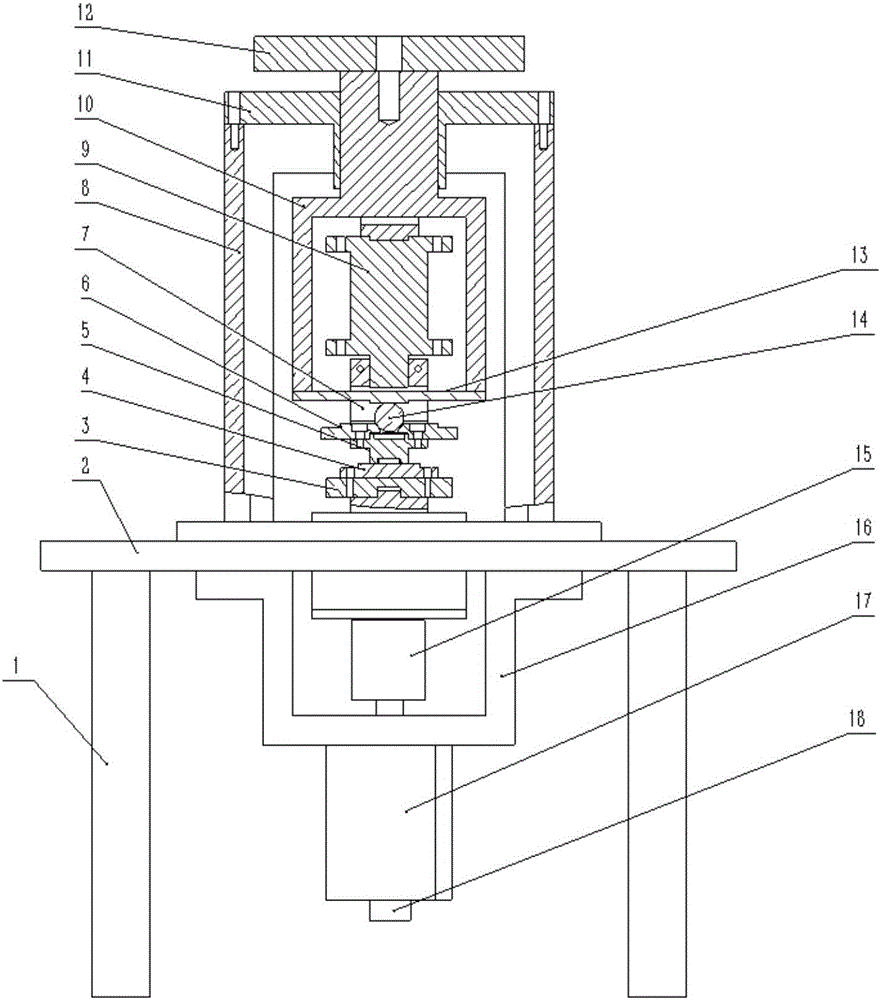

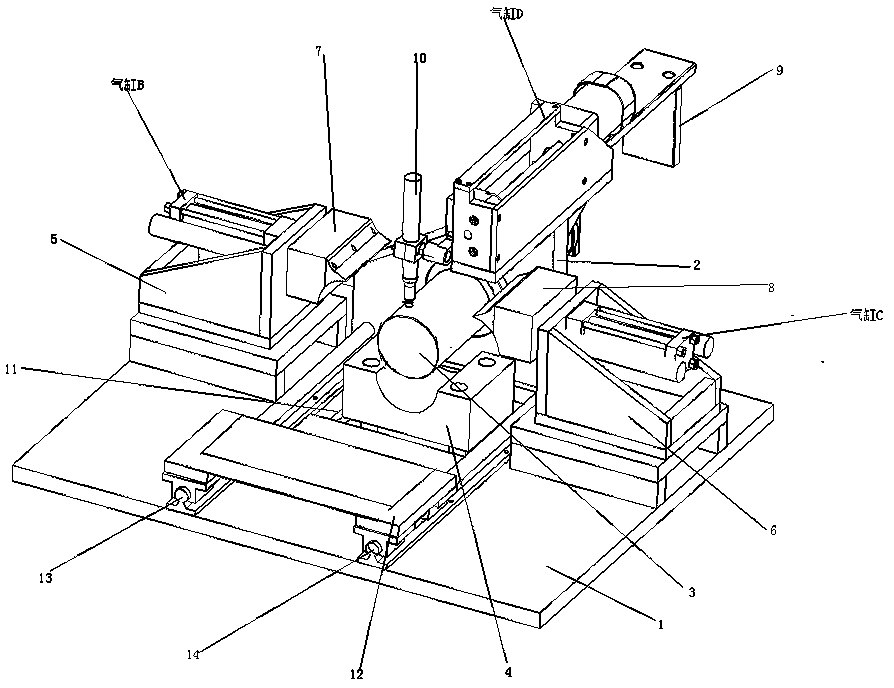

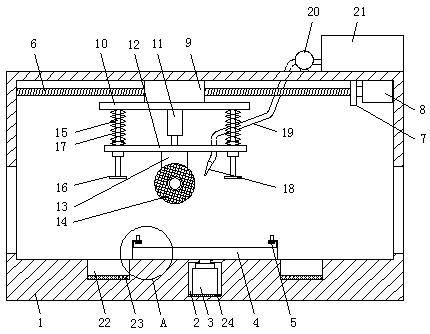

Surface-to-surface contact torsional fretting friction-wear testing system and control method thereof

ActiveCN107179254AAvoid results that affect test efficiencyGuaranteed stabilityInvestigating abrasion/wear resistanceFriction torqueWear testing

The invention discloses a surface-to-surface contact torsional fretting friction-wear testing system and a control method thereof. The testing system comprises a loading device, a positioning and clamping device, a friction pair, a driving device, a data acquisition device and a computer measurement and control system, wherein the loading device is used for applying positive pressure to the friction pair through a loading steel ball and keeping surface contact load in an operation process of the friction pair to be stable. A torque sensor, a driving motor signal and an angular displacement signal of the data acquisition device are connected with a computer data acquisition and control system; angular displacement amplitudes of a fretting friction pair are recorded and controlled and a change condition of a fretting friction torque is output in real time. The testing system and the control method thereof, provided by the invention, have the characteristics of convenience for operation, stable loads and relatively high angular displacement amplitude precision and can be used for reflecting torsional fretting friction-wear properties of an actual working condition better and the like; torsional fretting friction research under different loads, frequencies and angular displacement amplitudes can be carried out.

Owner:HUAZHONG UNIV OF SCI & TECH

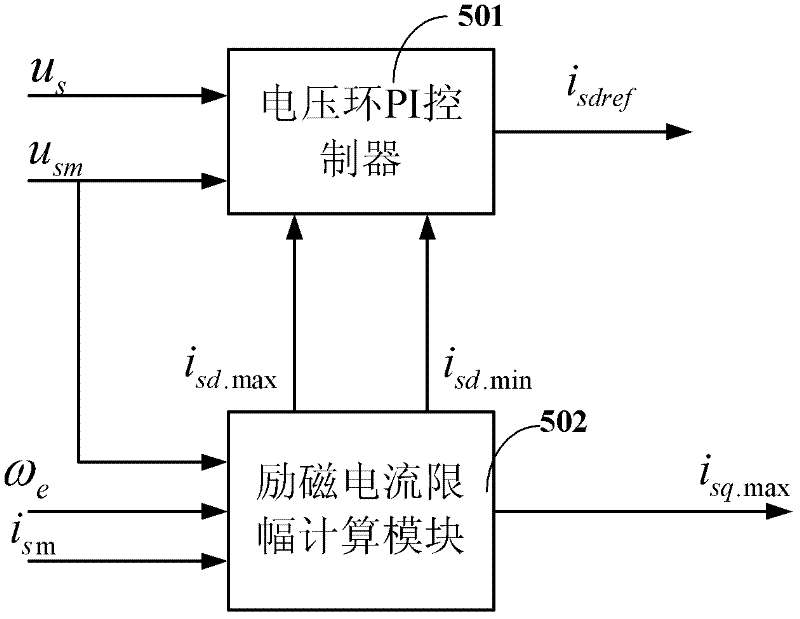

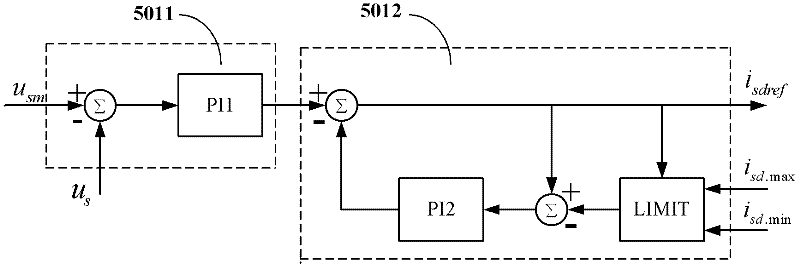

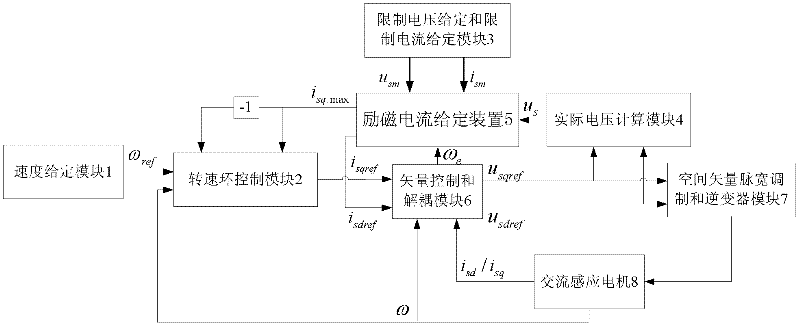

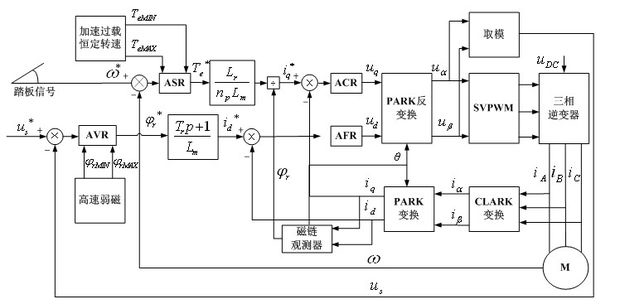

Exciting current given device of induction motor of electric vehicle

InactiveCN102403950AReduce back EMFReduce jitterElectronic commutation motor controlVector control systemsConstant powerVoltage vector

The invention discloses an exciting current given device for an induction motor of an electric vehicle. On the basis of the prior art, the exciting current given device is additionally provided with an exciting current limiting calculation module and a limiting PI (proportional integral) control module. When the induction motor normally runs, the calculated amplitude limiting maximum value (isd.Max) of the exciting current decreases along with the increase of the real synchronous speed omega e. The exciting current isdref of a voltage loop PI controller decreases under the condition of invariable maximum voltage vector (usm). Due to the decrease of the exciting current (isdref), the counter electromotive force of the induction machine decreases, therefore, under the condition of invariable busbar voltage uDC, the induction motor can rise to a higher rotating speed. In addition, according to the exciting current given device of the induction motor of the electric vehicle, the calculation of switching points among a constant torque area, a constant power area and a constant voltage area is eliminated, so that the level jump of output exciting currents caused by the inaccurate calculation of switching points can be effectively prevented, the given value of the exiting currents can vary stably, the joggling of the induction motor control caused by the level jump of the given valueof the exciting currents is reduced, and the safety of the induction motor control is improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Novel decorating machine

The invention discloses a novel decorating machine. The novel decorating machine comprises a table rack, a printing arm, a cylinder, an extension spring, an elastic table plate, a screen frame, a scraper, and a screen frame fixing device, wherein the table rack comprises a rack leg and a fixed arm fixed on the rack leg, the fixed arm is linear, the rack leg wounds the periphery of the fixed arm, one end of the printing arm is hinged to the lower portion of the fixed arm, a piston rod of the cylinder extends out of one end of a cylinder body of the cylinder to be hinged to the upper end of the fixed arm, the other end of the cylinder body of the cylinder is hinged to the middle of the printing arm and is in sliding match with the printing arm in the direction of the length of the printing arm, one end of the extension spring is connected with the middle of the fixed arm, the other end of the extension spring is connected with the printing arm through a sliding plate, the sliding plate is in sliding match with the printing arm, and the bottom of the elastic table plate is in sliding match with the rack leg. The novel decorating machine is capable of buffering the action performed by the cylinder to lift or press the printing arm, greatly reducing vibration by the aid of an elastic force produced by the elastic table plate, and improving register accuracy.

Owner:SHENZHEN CNTOP DIGITAL EQUIP CO LTD

Anti-break intelligent handset

InactiveCN105847471AStrong aestheticsSimple structureTelephone set constructionsPattern perceptionEngineering

The invention discloses an anti-break intelligent handset, comprising a body; a gravitational acceleration inductor arranged in the body and used for detecting acceleration when the handset is falling; and a display screen arranged on the right side of the body, wherein four corners of the body are movable corners in connection with compression springs, the movable corners are locked to the body through an electromagnetic switch, the outer contours of the movable corners locked to the body match the outer contour of the body, the electromagnetic switch is deblocked when the gravitational acceleration inductor detects that the handset falling acceleration is equal to or greater than gravitational acceleration g, and the compression springs drive the movable corners to extend out of the body. According to the invention, the movable corners matching the outer contour of the body are arranged, thereby avoiding influencing body associative perception when the movable corners are locked to the body; compared with the prior art, the body is more beautiful; besides, the movable angles and the compression springs are integrated; the structure is simpler and disassembly and assembly are more convenient.

Owner:LETV HLDG BEIJING CO LTD +1

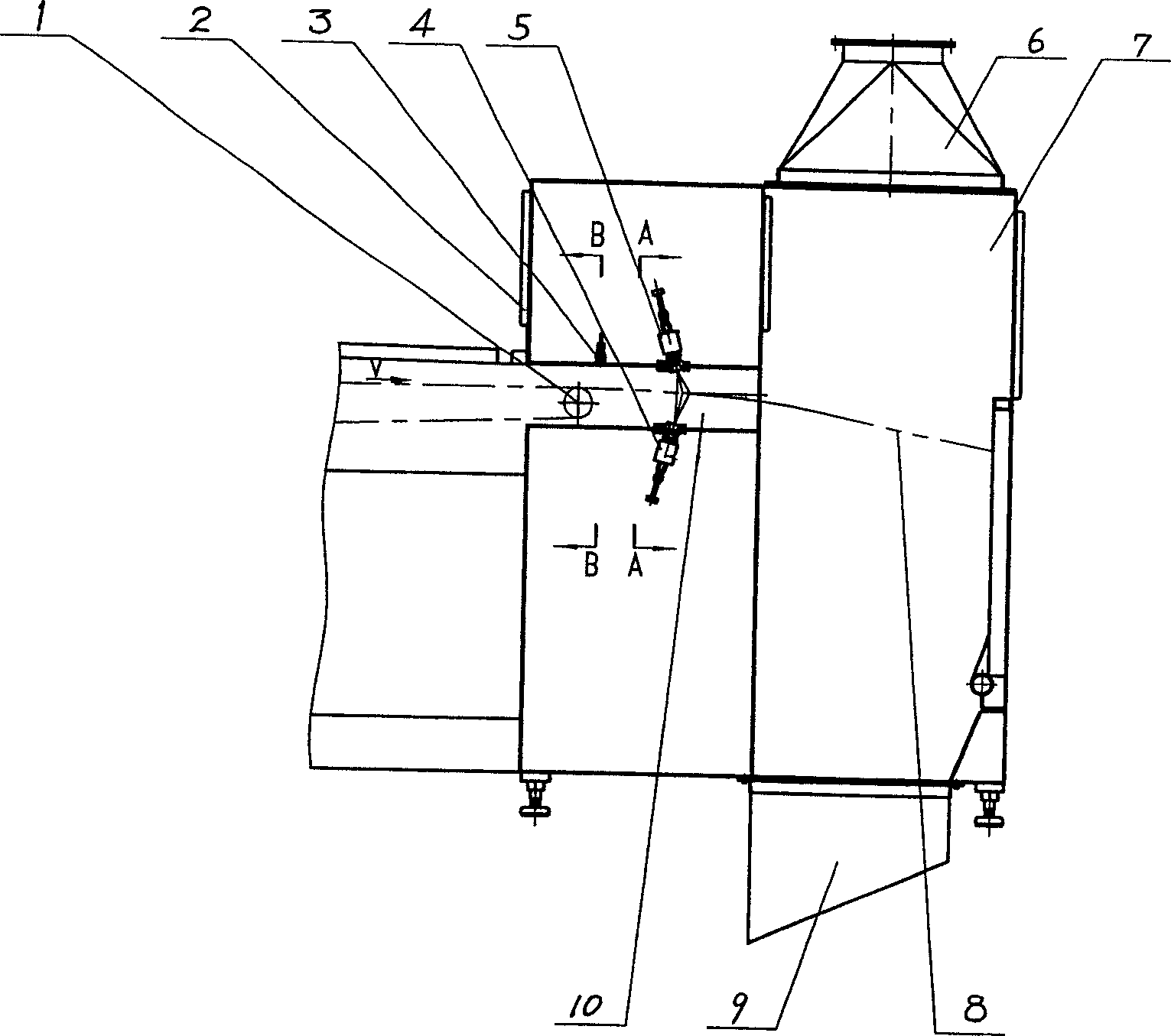

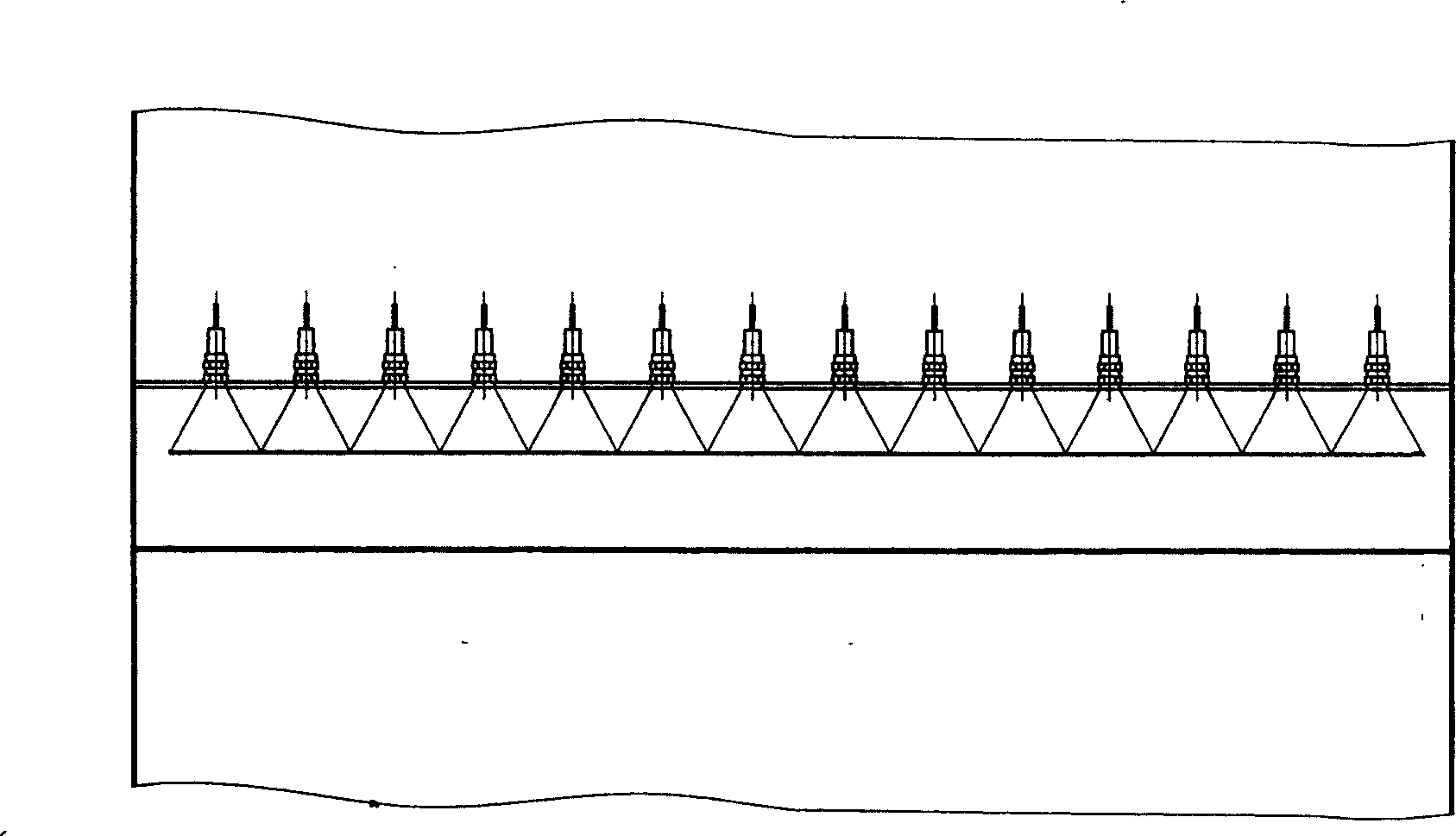

Method and apparatus for uniformly spraying liquid onto materials

ActiveCN1743083APrevent rollingPrevent jumpingLiquid surface applicatorsCoatingsEngineeringElectrical and Electronics engineering

The invented method utilizes a conveying appliance to throw-feed the spreact-thinned material into a charging machine, then uses a nozzle placed in the charging machine to spray the liquid material on the layer-like throw-fed material. Said invented equipment includes conveying machine, charging cabinet, material-falling cabinet, material channel, sensor and liquid material nozzle, etc.

Owner:YUNNAN KUNCHUAN TOBACCO EQUIP CO LTD

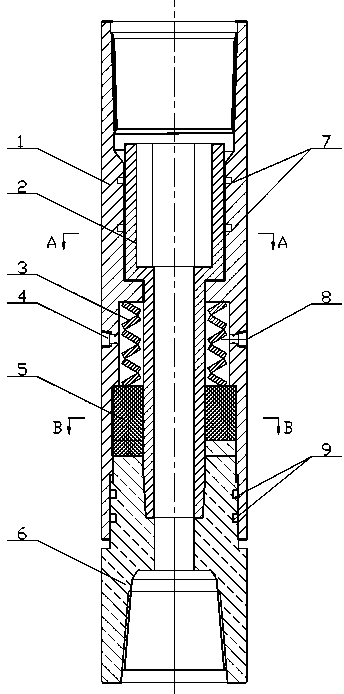

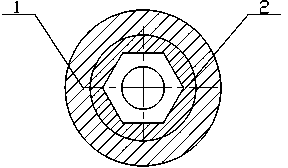

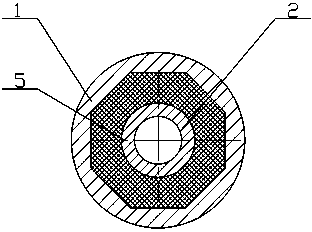

Rotating impact acceleration device and method of power drilling tool

The invention relates to a rotating impact acceleration device and a method of a power drilling tool. The device is characterized in that a rotor transmission shaft, a driving tooth-shaped impact hammer and a driven impact transmission joint are mounted at the inner side of a stator outer cylinder; the lower end of the rotor transmission shaft is in threaded connection with the driven impact transmission joint; the middle part of the rotor transmission shaft and the middle part of the stator outer cylinder are formed to a cylindrical cavity; an impact force accumulating spring is mounted in the cavity; the lower end of the impact force accumulating spring fits the driving tooth-shaped impact hammer; a tooth-shaped curved surface is arranged at the lower end of the driving tooth-shaped impact hammer, and is engaged with a tooth-shaped curved surface at the upper end of the driven impact transmission joint; the driven impact transmission joint is driven by the rotor transmission shaft to generate a rotating motion corresponding to the driving tooth-shaped impact hammer; and the driving tooth-shaped hammer and the impact force accumulating spring generate axial reciprocating impact on the driven impact transmission joint to realize the rotation and the impact. The device is simple in structure and shorter in length, and dose not influence the operations of the power drilling tool and a measuring tool while drilling.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Dynamic calibration method of electric automobile power battery SOC

InactiveCN108928245APrevent jumpingNo additional costElectric devicesElectrical testingPower batteryLithium-ion battery

The invention discloses a dynamic calibration method of an electric automobile lithium ion battery SOC. The method includes the following steps that an OCV-SOC list is obtained and stored through an open circuit voltage method, and vehicle standing threshold time is preset; if vehicle standing time is longer than the threshold time, the current single voltage of a vehicle is obtained, and if the vehicle standing time is shorter than or equal to the threshold time, a battery management system does not act; and the battery management system searches the OCV-SOC list according to the current single voltage for an SOC value needing to be calibrated, the current SOC value and the SOC value obtained through the search of the list are recorded, the SOC deviation between the current SOC value andthe SOC value obtained through the search of the list is calculated, and the battery management system uses an SOC algorithm with dynamic calibration for conducting dynamic calibration on the batterySOC. By the adoption of the dynamic calibration method of the SOC, the SOC deviation is recorded and not calibrated in the vehicle standing process according to the battery single voltage, a static error is complemented to the battery SOC in proportion in the vehicle operation process, the SOC jumping change caused by SOC static calibration is avoided, the client misunderstanding that large powerconsumption or electric quantity counterfeit happens in the vehicle standing process is avoided, and the method is only achieved through a software algorithm of the battery management system.

Owner:SICHUAN YEMA AUTOMATION CO LTD

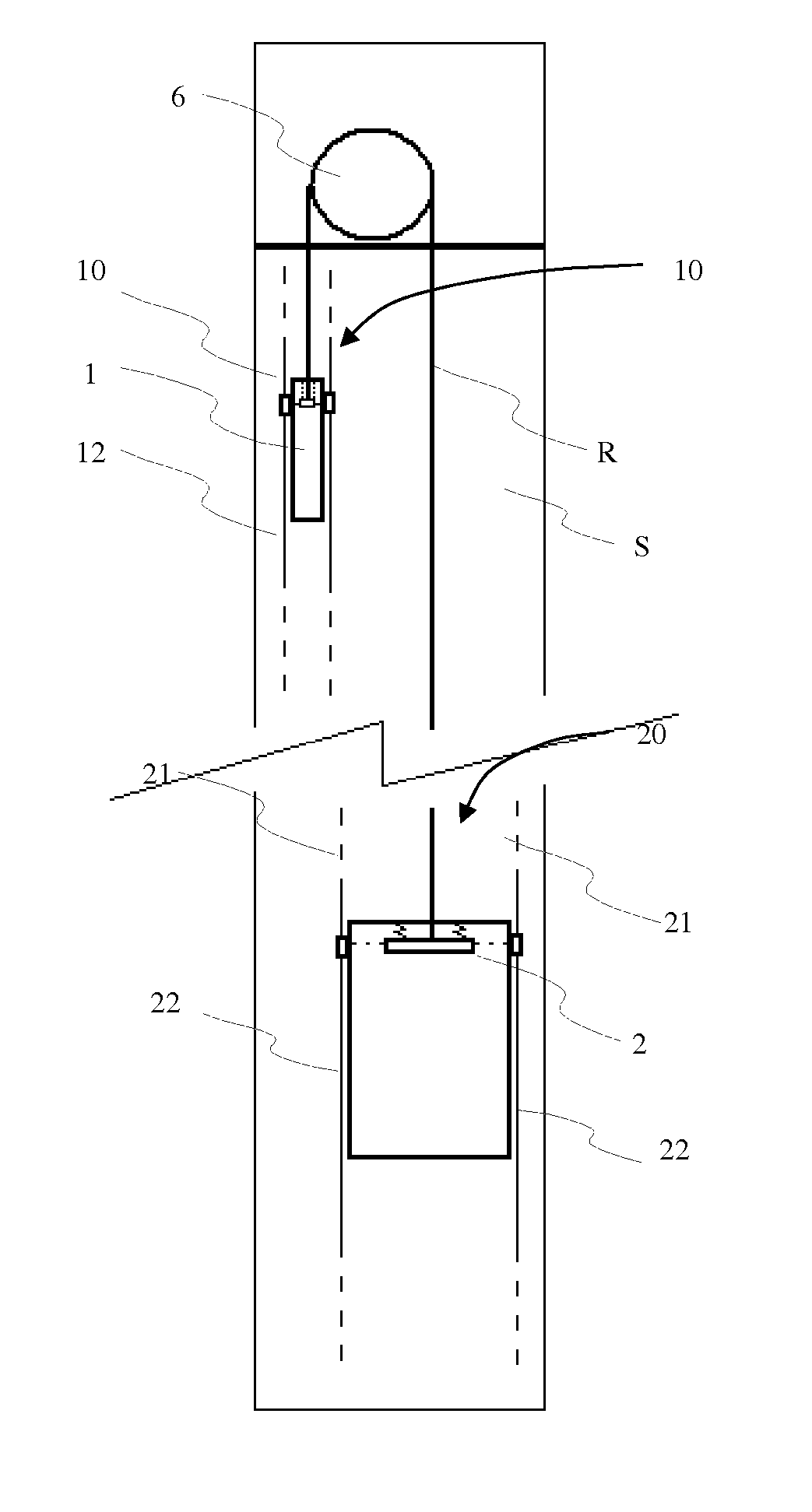

Elevator

InactiveUS20110266097A1Prevent jumpingPrevent subsidenceWoven fabricsElevatorsPulleyAutomotive engineering

Elevator, preferably a passenger elevator, which comprises an elevator car, and at least one hoisting rope for moving and supporting the elevator car, a traction sheave that acts on the hoisting rope, and a power source for rotating the traction sheave. The counterweight of the elevator comprises a brake for decelerating and / or preventing at least upward movement of the counterweight.

Owner:KONE CORP

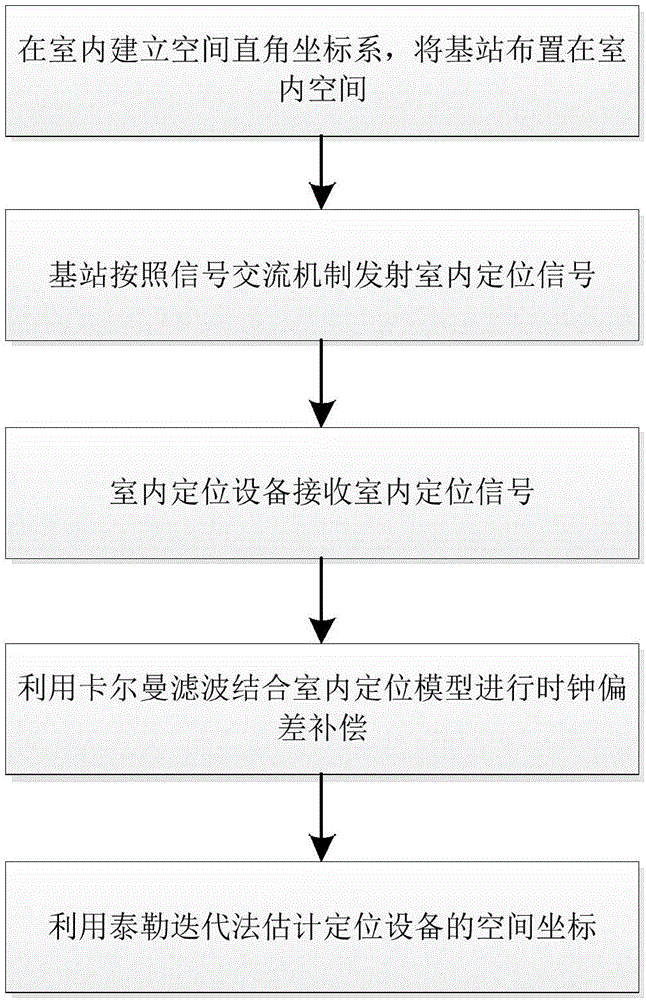

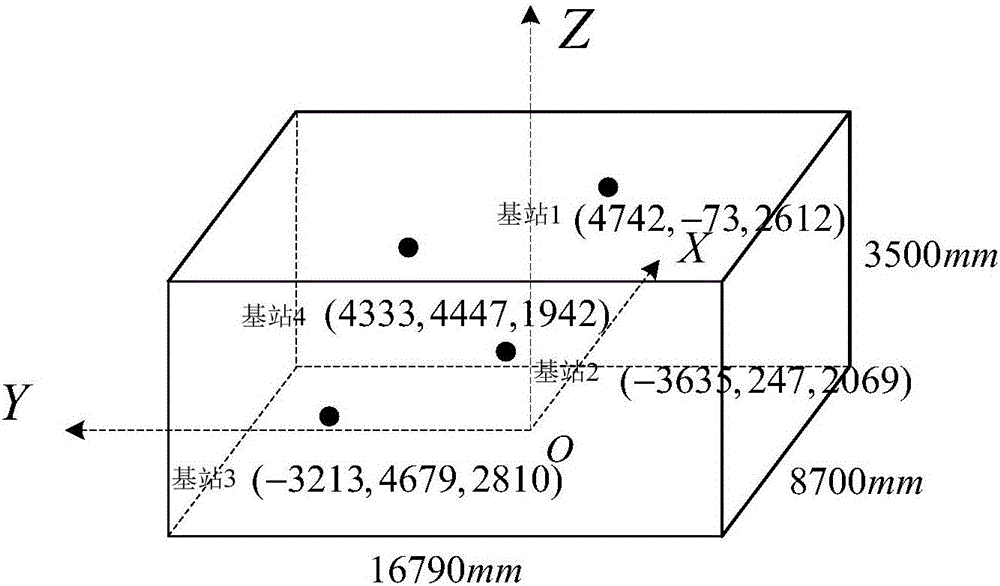

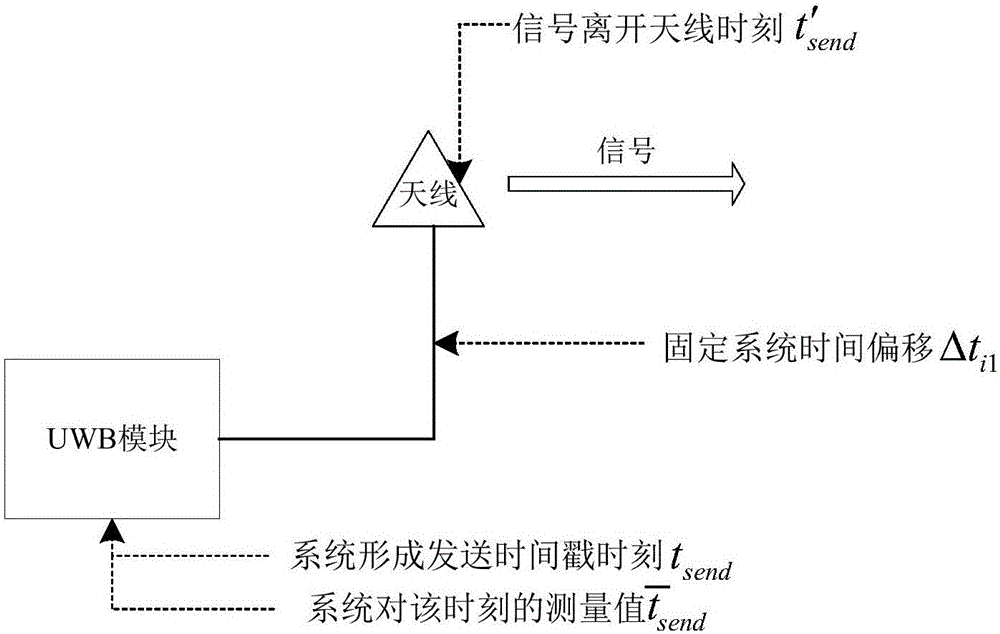

Ultra-wideband indoor positioning method

ActiveCN106793060AFlexible configurationImprove Clock Synchronization AccuracySynchronisation arrangementNavigational calculation instrumentsBroadbandIndoor positioning system

The invention provides an ultra-wideband indoor positioning method, which mainly solves the problems of low precision, limited user quantity, great time synchronous errors and the like of the existing ultra-wideband indoor positioning system. The method comprises the steps of firstly, building an indoor navigation coordinate system, and arranging a base station; secondly, sending a positioning signal by the base station according to a system signal communication mechanism, so that positioning equipment held by a user only passively receives a distance measuring signal from the base station; then, realizing clock synchronization on an algorithm by using a clock deviation compensation algorithm of a Kalman filtering algorithm; finally, solving the user coordinate by a Taylor iterative algorithm. The ultra-wideband indoor positioning method has the advantages that the goal of simultaneously realizing indoor three-dimensional accurate positioning of infinite positioning equipment can be achieved; an additional hardware network is not needed for realizing clock synchronization; the positioning equipment only receives a positioning signal but does not send the signal; the stable swinging can be realized between a sight distance scene and a non-sight distance scene.

Owner:HARBIN ENG UNIV

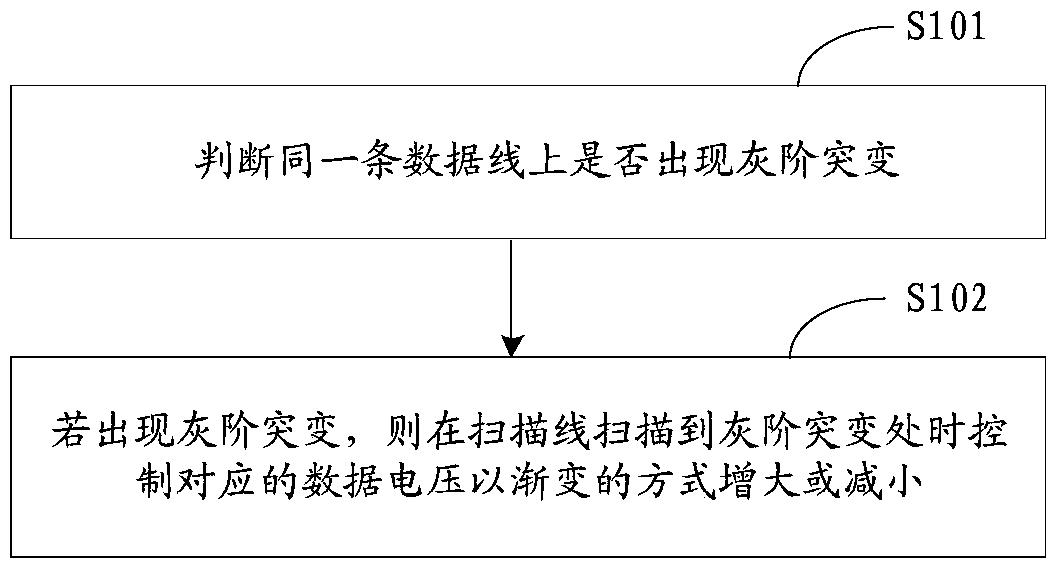

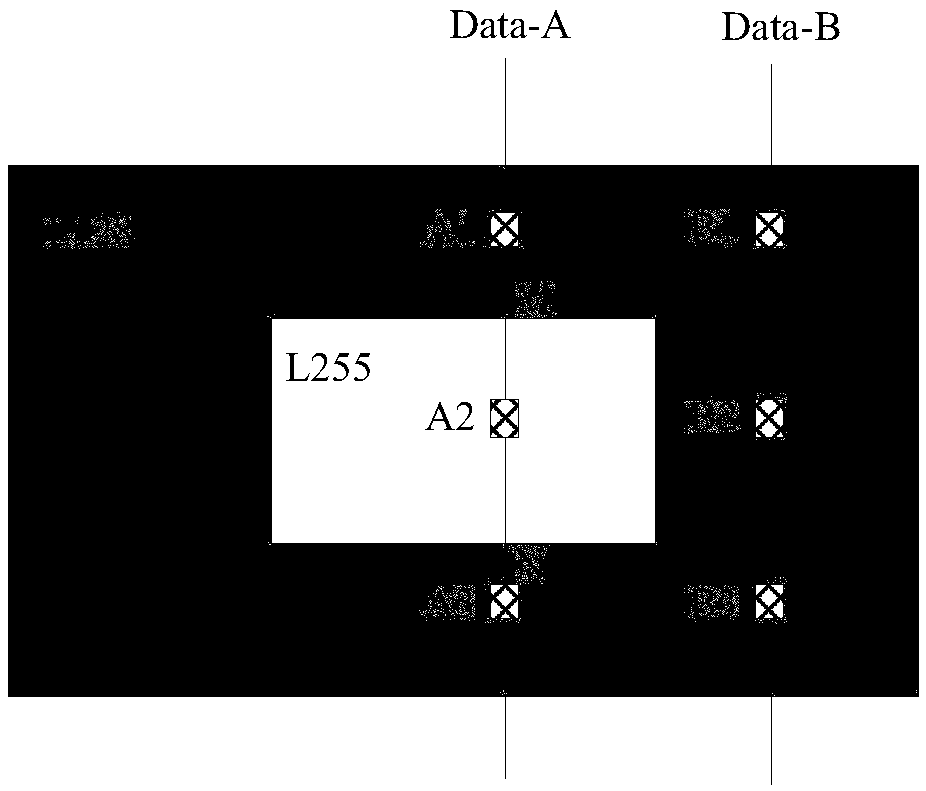

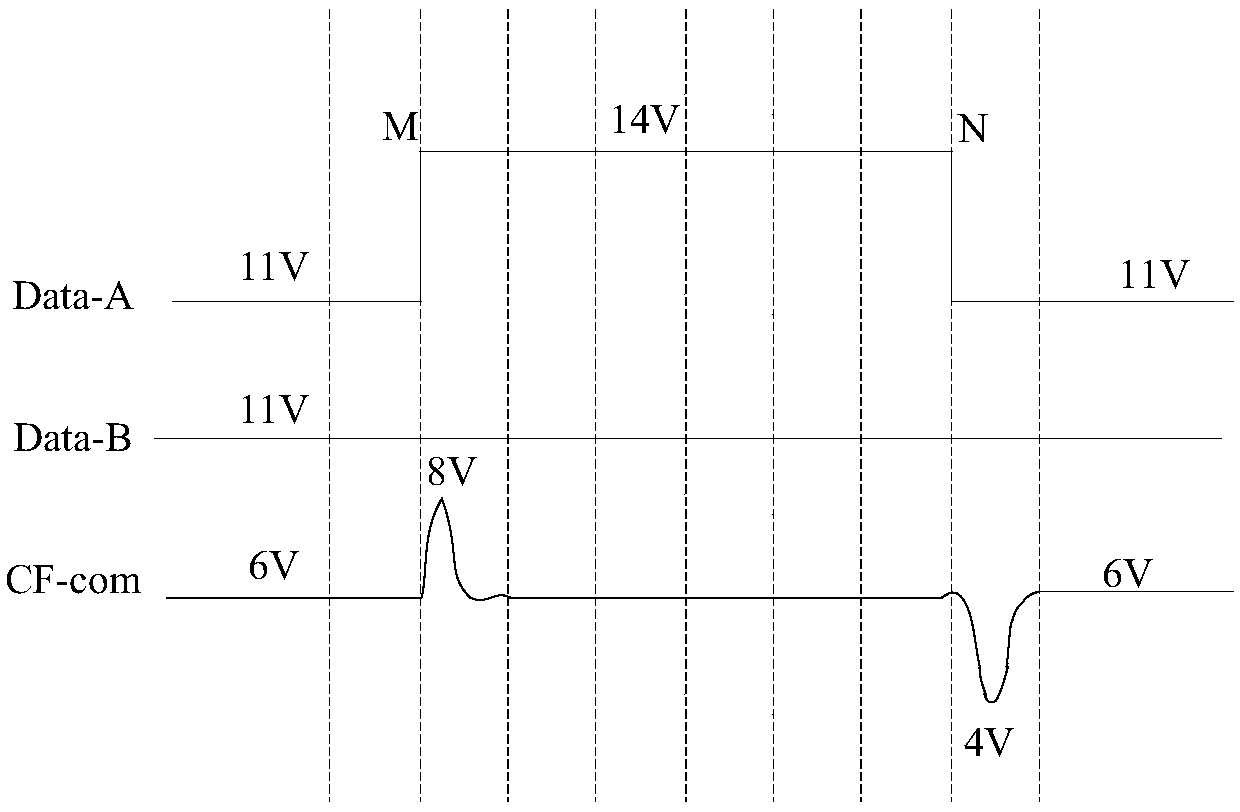

Display panel data voltage control method, display panel and display equipment

ActiveCN109147688AImprove display qualityPrevent jumpingStatic indicating devicesScale variationComputer science

The invention discloses a display panel data voltage control method, a display panel and display equipment, which relate to the technical field of display. The display panel data voltage control method comprises the steps of: determining whether gray-scale mutation occurs on the same data line, wherein the gray-scale mutation indicates that a gray-scale variation value between two adjacent pixel units on the same data line is greater than a preset threshold value; and controlling corresponding data voltage to increase or decrease when a scanning line scans a gray-scale mutation position if thegray-scale mutation occurs. By adopting the display panel data voltage control method, the horizontal crosstalk can be reduce or eliminates, and the panel display quality can be improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Sheet stacking apparatus

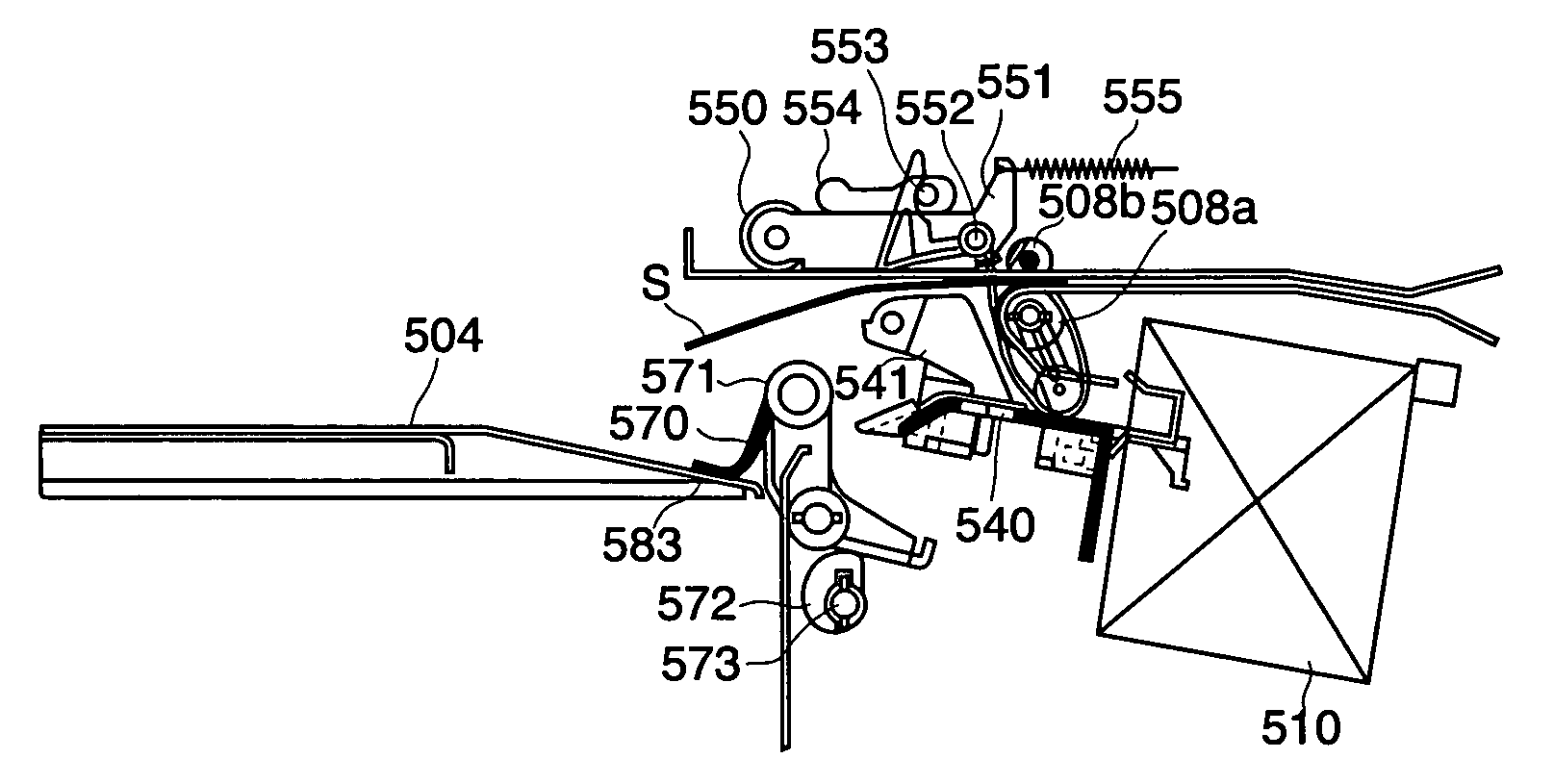

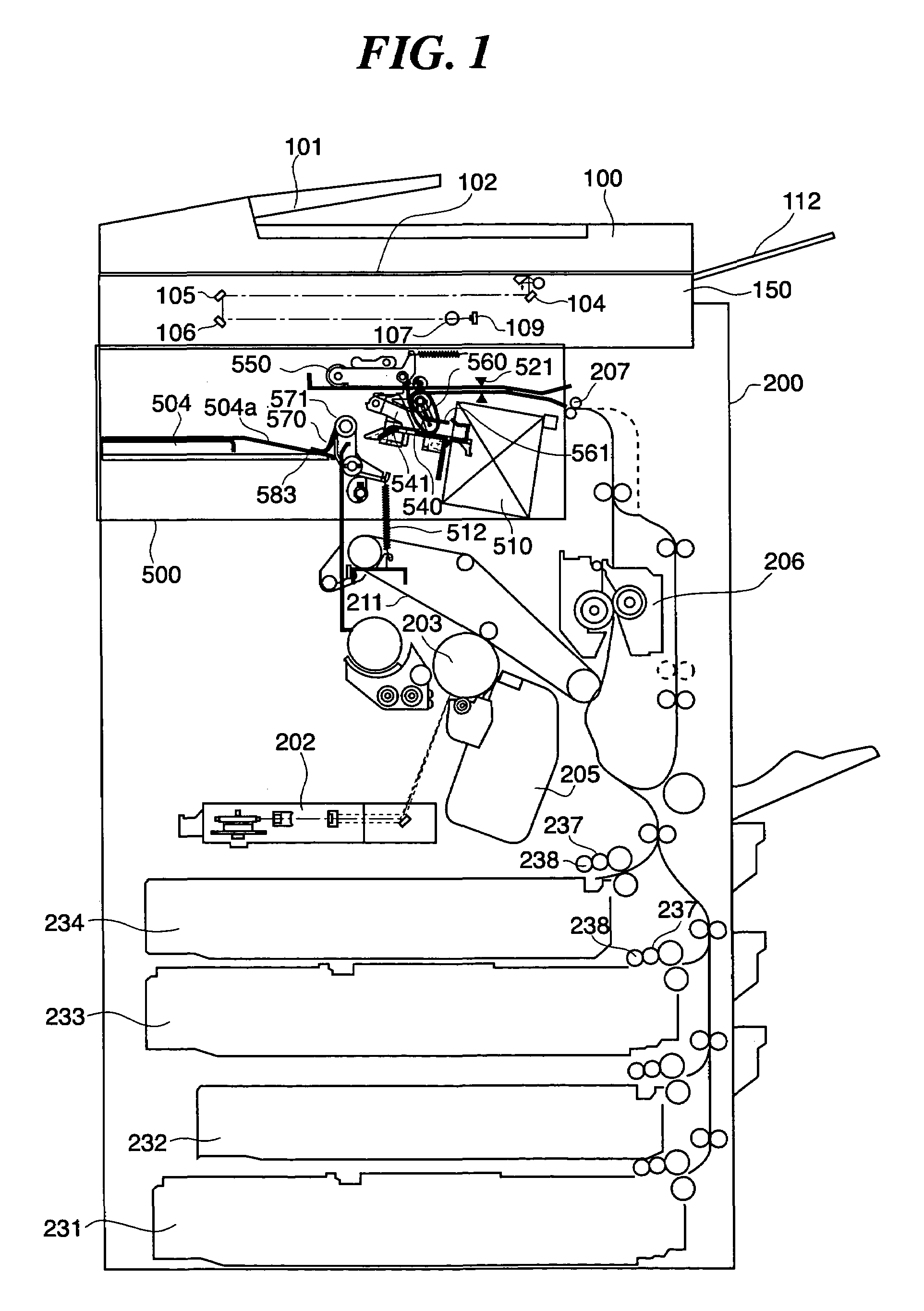

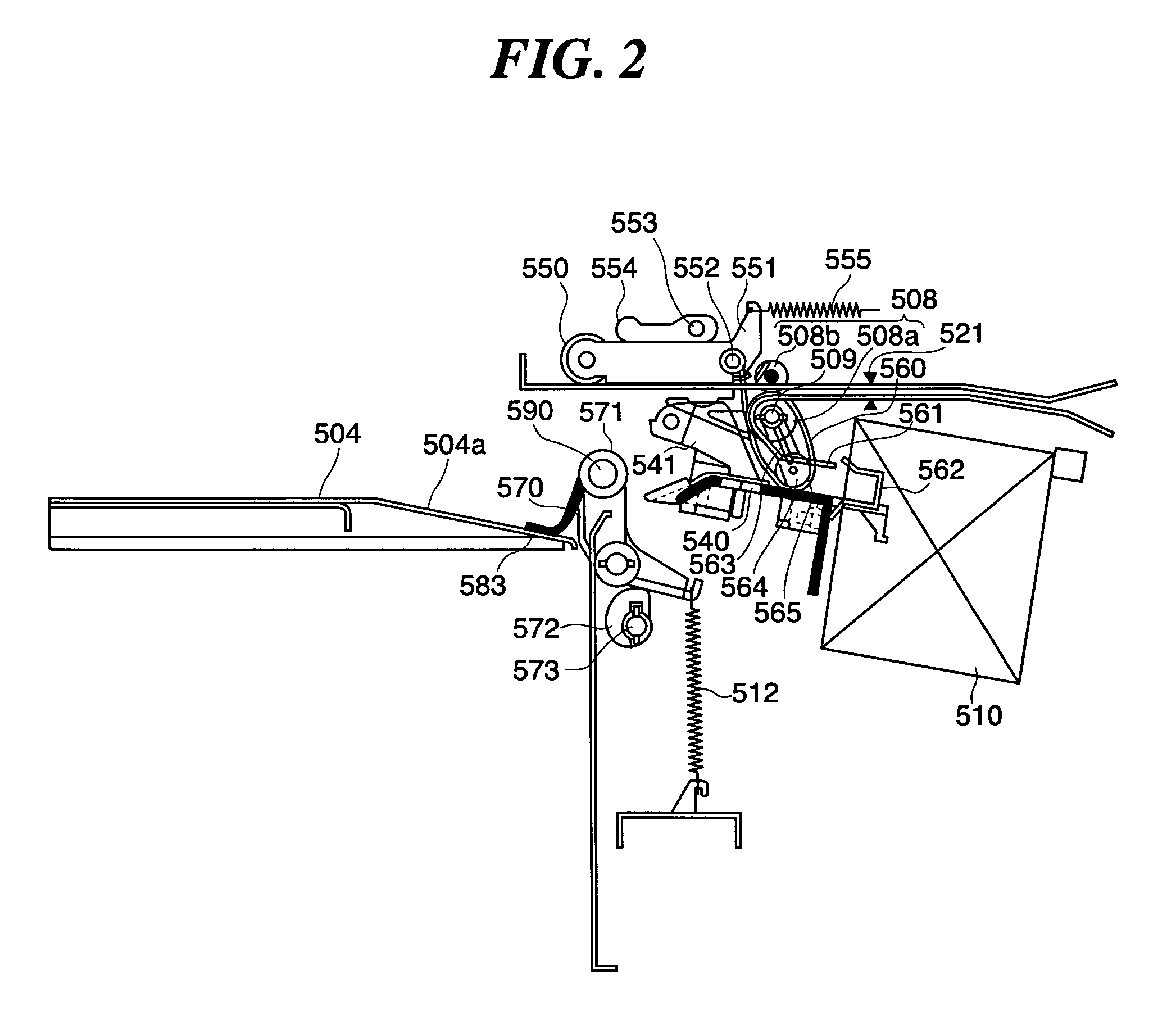

InactiveUS6962331B2Reliably sandwichingReliably catchingDigital data processing detailsFunction indicatorsEngineeringPaper sheet

A sheet stacking apparatus which is capable of reliably sandwiching or catching sheets, and also capable of providing control so as to ensure reliable conveyance of succeeding sheets during the catching operation. A stack tray is provided downstream of a processing tray that stacks sheets. A position on the stacking surface of the stack tray at which the leading end of a sheet having its trailing end passing a discharging section, which discharges sheets toward the processing tray, contacts the stacking surface is lower in level than the highest portion of the processing tray. A swinging arm that discharges the sheets stacked on the processing tray to the stack tray is capable of selectively assuming a catching state in which a sheet discharged to the processing tray is caught by the swinging arm, and a non-catching state in which a sheet discharged to the processing tray is not caught by the swinging arm. The swinging arm is controlled to assume the non-catching state when the discharging section starts discharging a sheet, and switch to the catching state before the trailing end of the sheet discharged by the discharging section passes the swinging arm.

Owner:CANON KK

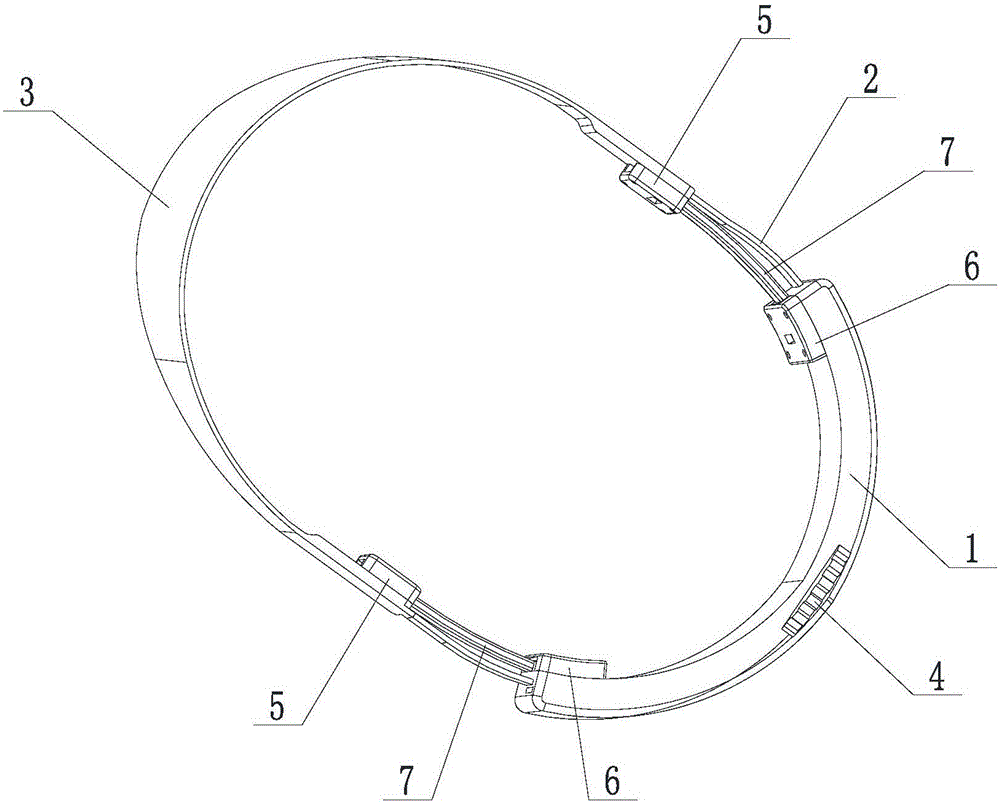

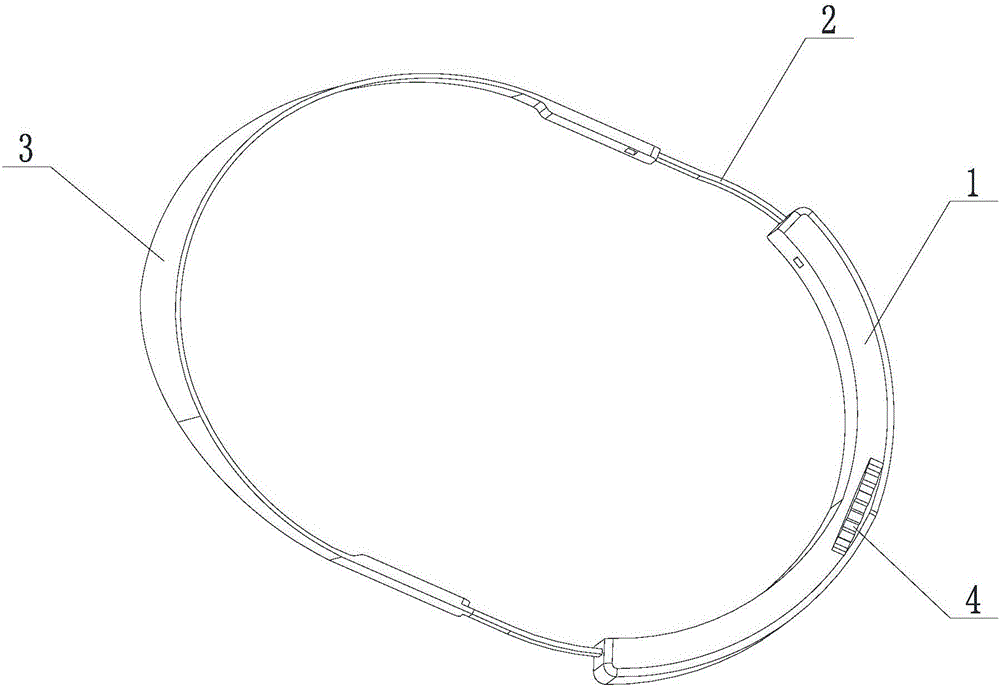

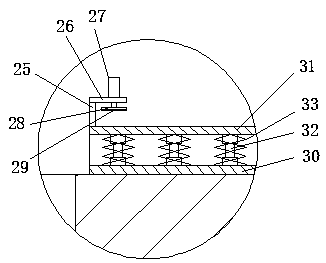

Head-mounted elastic auxiliary locking mechanism

The invention discloses a head-mounted elastic auxiliary locking mechanism, which is provided with a connecting band, wherein the rear part of the connecting band is provided with a rear shell, the rear shell is internally provided with a locking module, both ends of the connecting band are provided with a rack, the racks are inserted into the rear shell and meshed with the locking module, an elastic band is connected between the connecting band and the rear shell, the elastic band prevents meshing of the racks and the locking module from loosening when the locking module locks the racks, and the elastic band drives the racks to reset when the locking module unlocks the racks. In the invention, the connecting band is provided with the elastic band, and an elastic pulling force is provided among internal assemblies of the locking mechanism, so that a function of closely meshing and bounce preventing is realized on the one hand, and a function of automatic return is realized on the other hand.

Owner:GEER TECH CO LTD

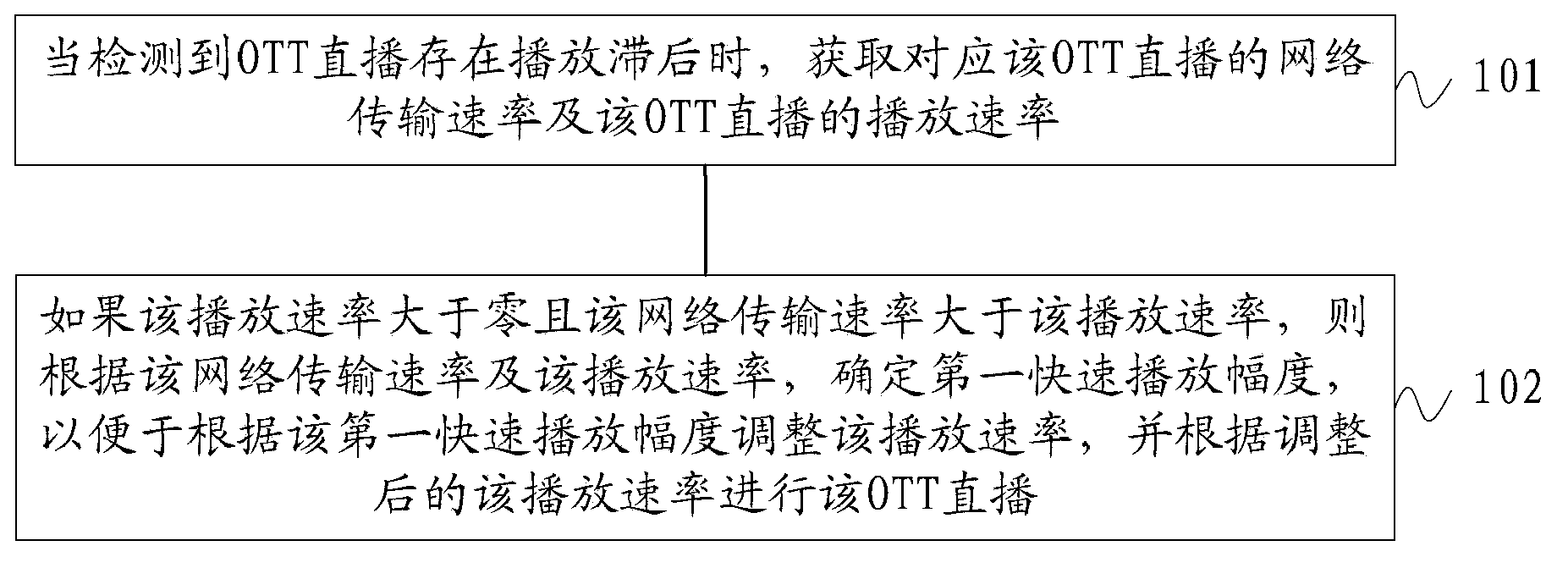

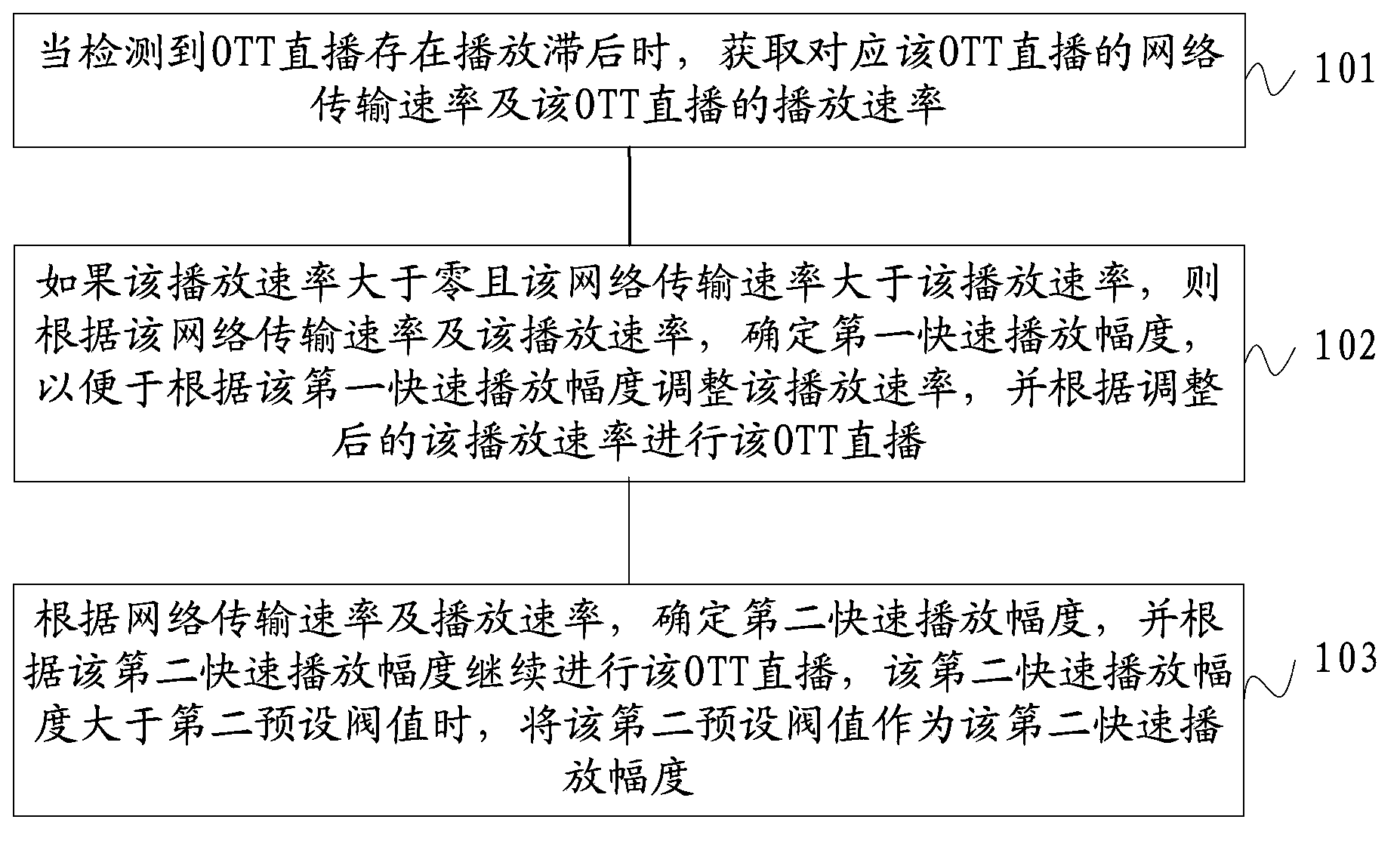

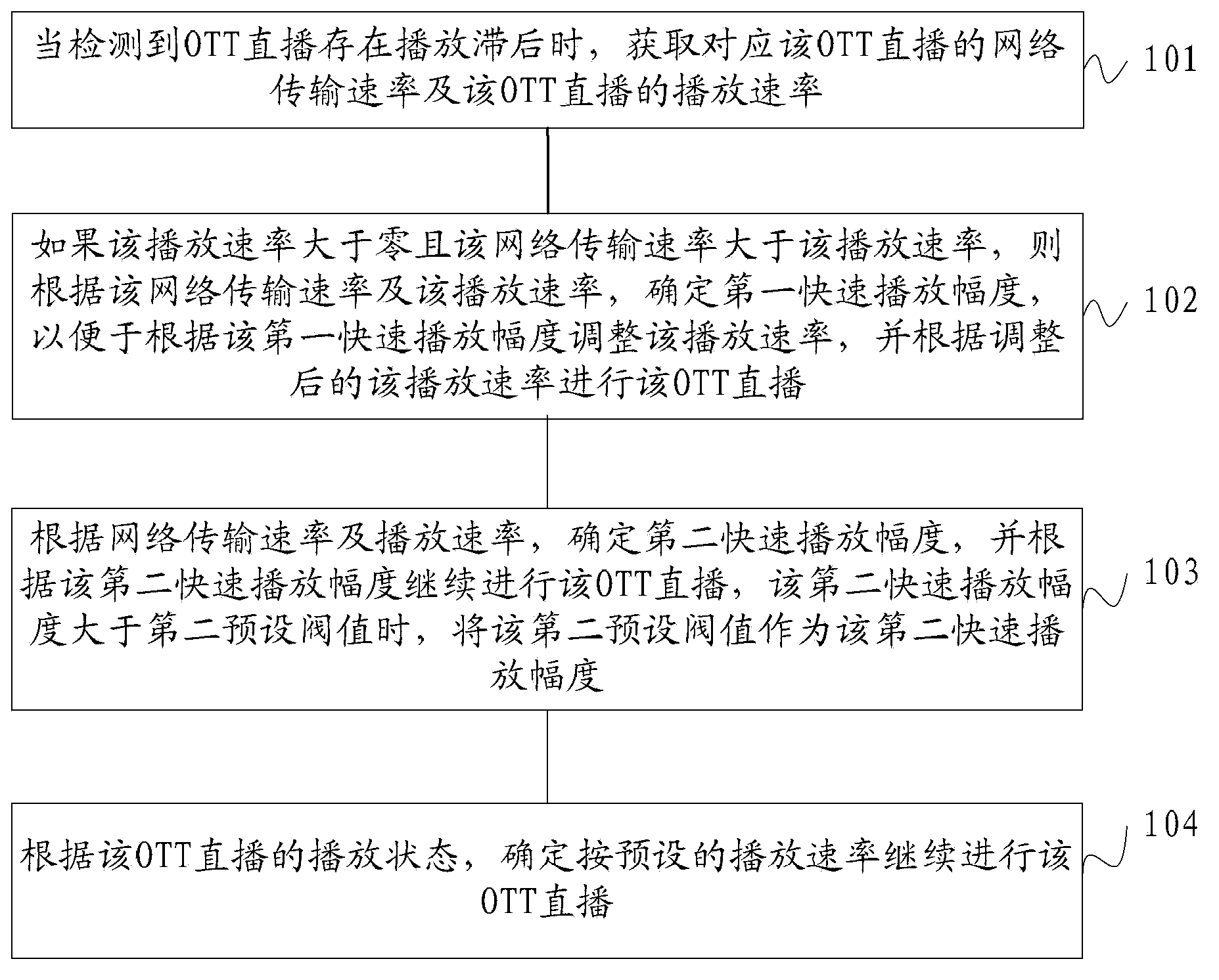

Method, device and system of OTT (Over The Top) live broadcast

ActiveCN104079955AResolve lagImprove continuitySelective content distributionThe InternetComputer science

An embodiment of the invention discloses a method, a device and a system of OTT (Over The Top) live broadcast for enhancing continuity of the OTT live broadcast so as to improve user experience. The method comprises the following steps of: when the OTT live broadcast is detected to have play lag, obtaining a network transmission rate corresponding to the OTT live broadcast and play speed of the OTT live broadcast; if the play speed is greater than zero and the network transmission rate is greater than the play speed, determining a first quick play range according to the network transmission rate and the play speed so as to facilitate adjusting the play speed according to the first quick play range and carrying out the OTT live broadcast according to the adjusted play speed. The embodiment of the invention is mainly applied to the field of Internet, the quick play range can be adjusted according to the network transmission rate and the play speed, the lag of the OTT live broadcast is repaired, jump of a content of the OTT live broadcast is avoided and the continuity of the OTT live broadcast is enhanced, so that the user experience is improved.

Owner:HUAWEI TECH CO LTD

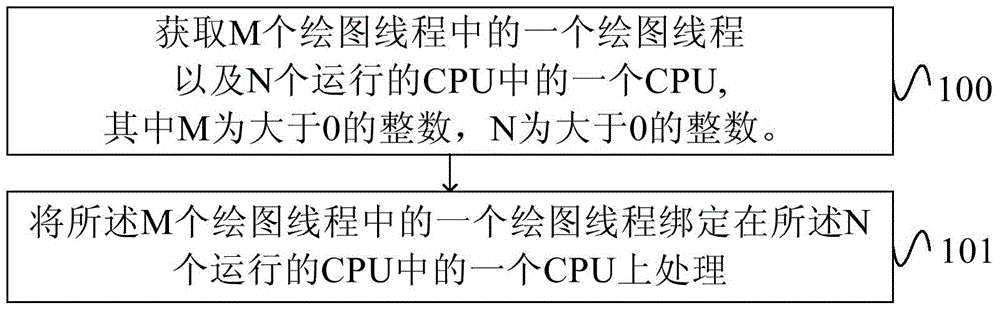

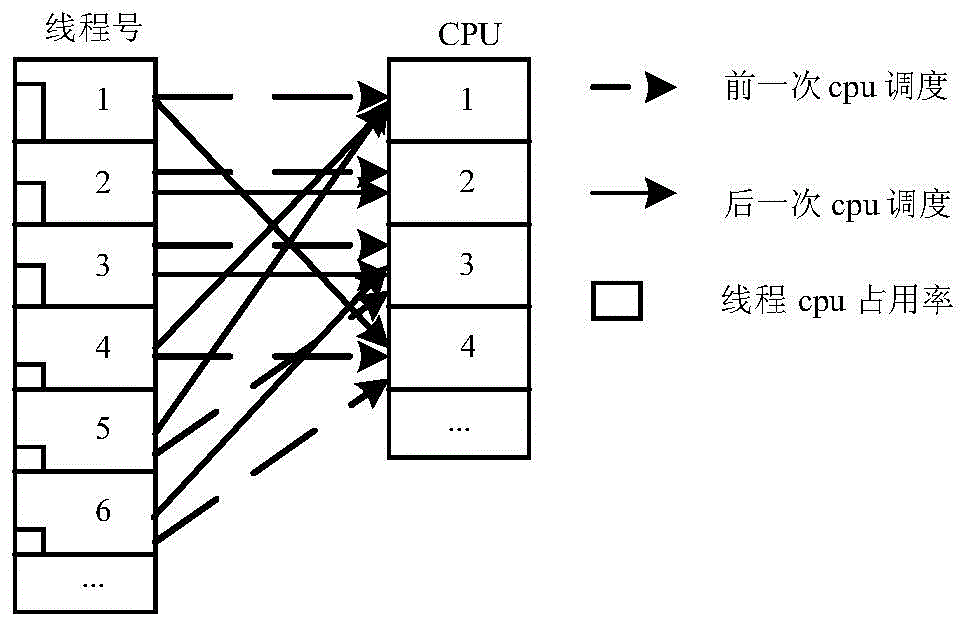

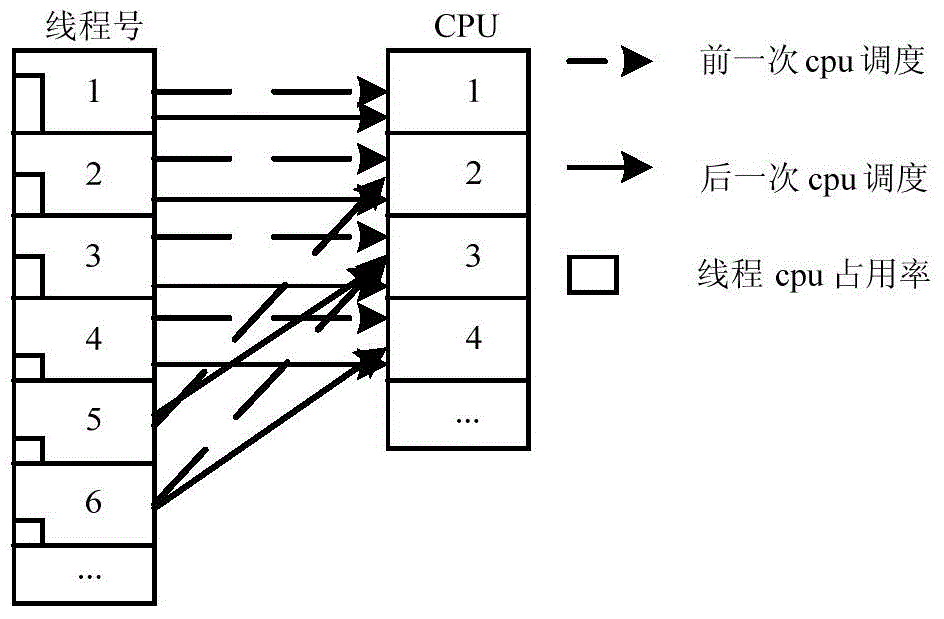

Scheduling method and device for multi central processing units (CPU)

InactiveCN104460934AReduce power consumptionPrevent jumpingProgram initiation/switchingPower supply for data processingParallel computingPower consumption

The invention provides a scheduling method and a device for multi central processing units (CPU). The scheduling method for multi central processing units (CPU) binds one drawing thread of M drawing threads to one central processing unit (CPU) of N running central processing units (CPU) by acquiring one drawing thread of the M drawing threads and one central processing unit of N running central processing units (CPU), wherein the M is an integer bigger than zero and the N is an integer bigger than zero. Under the premise that the system performance is not affected, resources of each central processing unit (CPU) are fully utilized and the power consumption of the multi-central processing unit (CPU) is reduced.

Owner:HUAWEI DEVICE CO LTD

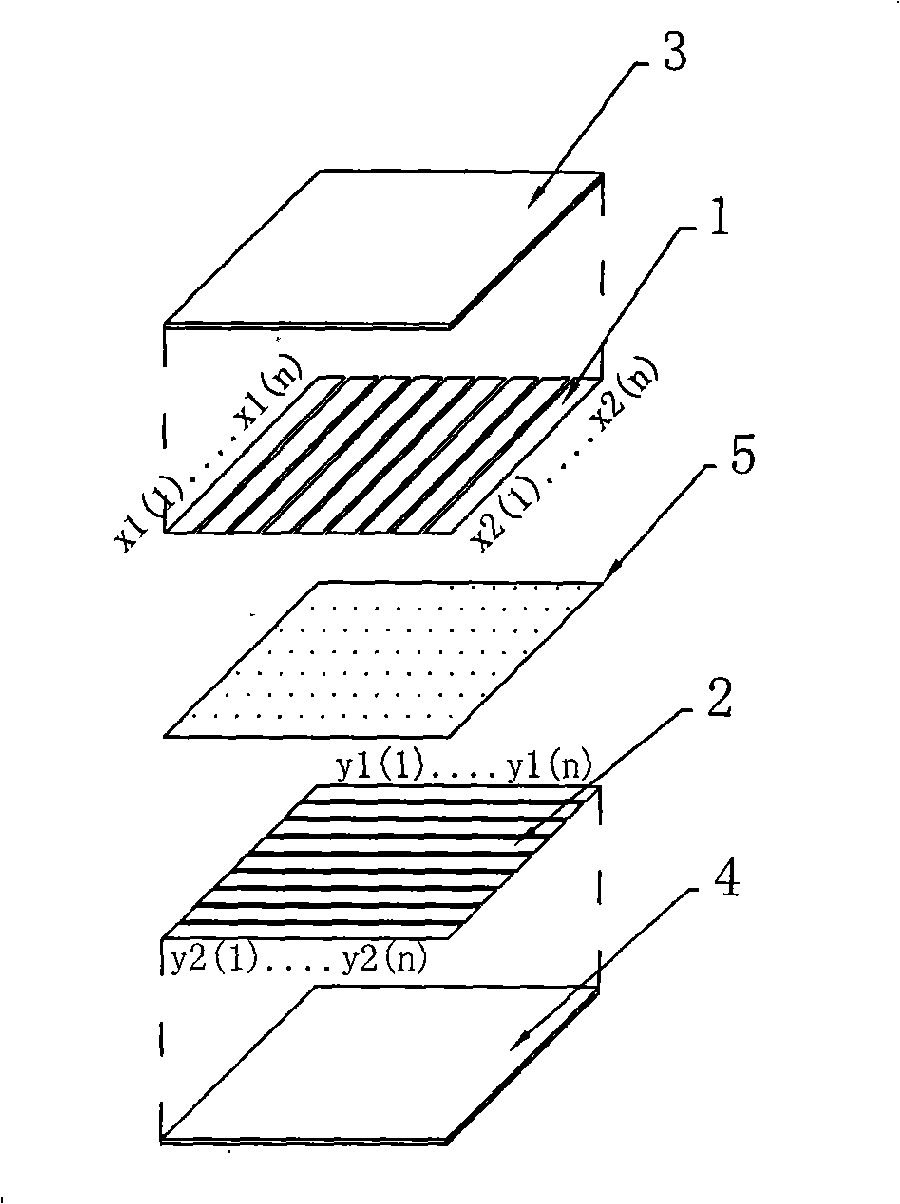

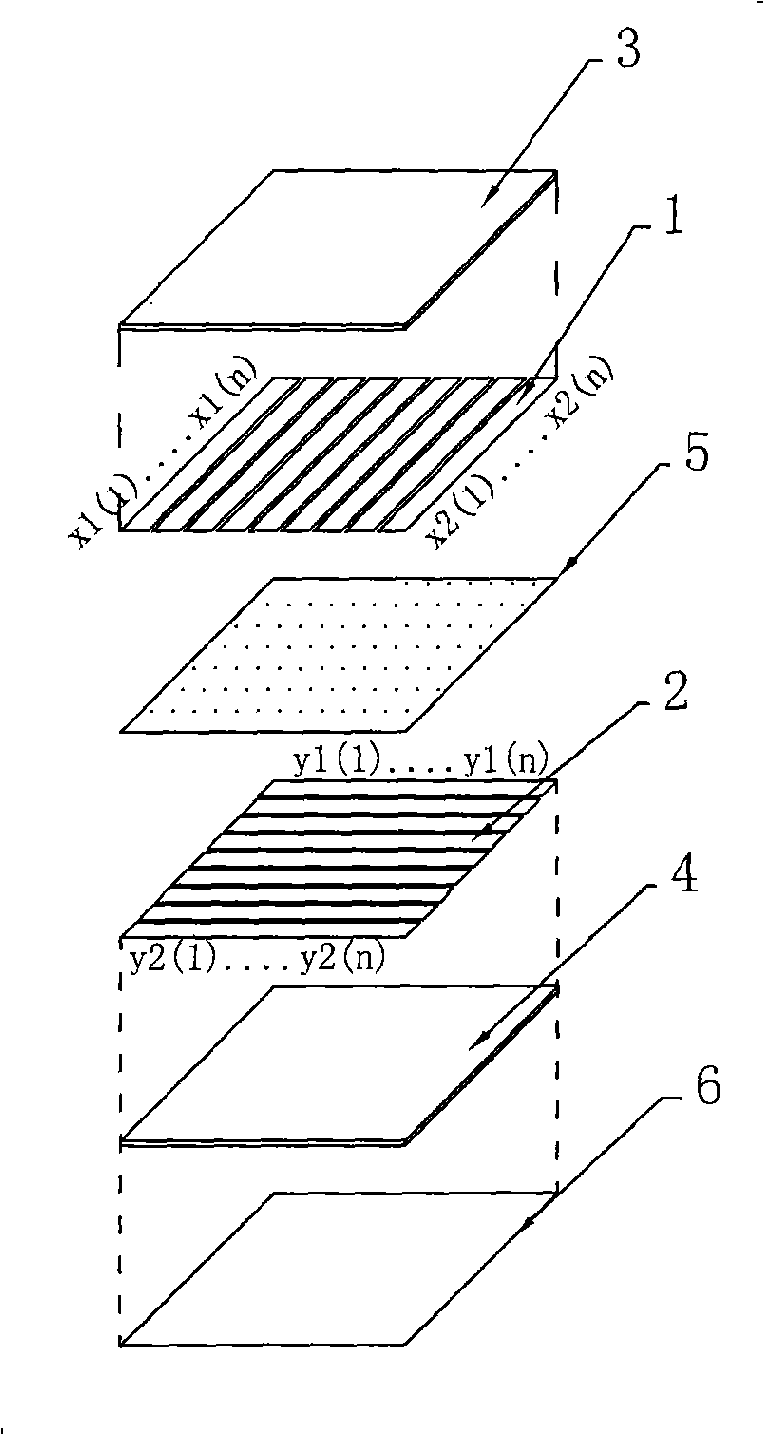

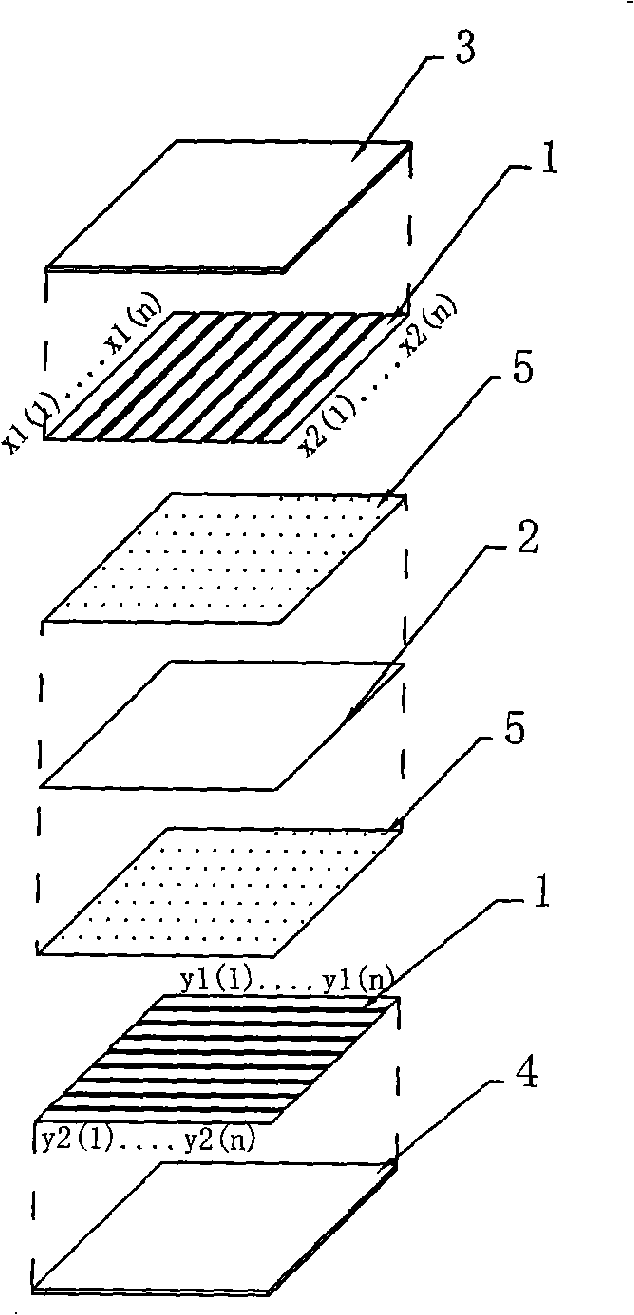

Electric resistance array touch screen

InactiveCN101339481AMulti-touch implementationDoes not produce false resultsInput/output processes for data processingElectrical resistance and conductanceTouchscreen

The invention discloses a resistor array touch screen. The touch screen body includes a detecting layer, a working layer, and a transparent insulation point layer between the detecting layer and the working layer. The detecting layer includes a transparent conductive film detecting layer, including a plurality of detecting units, wherein these detecting units are mutual independent and insulated, and each detecting unit forms a detecting electrode for determining touch points. The working layer includes a transparent conductive film resistor working layer matching with the detecting electrodes, and the transparent conductive film resistor working layer forms a resistor working unit. The invention realizes resistor array touch screen multi-point touching by different locating areas of different points in the resistor array touch screen multi-point touching determined by the different detecting electrodes, and supports single-point touch or multi-point touch concerning two or more points. The precise positions of detecting touch points in the detecting electrode area are detected by specific resistor characteristic signal detected by the detecting electrodes where the touch points locate, therefore the invention has precise positioning characteristic like common resistor touch screens.

Owner:GENERALTOUCH TECH

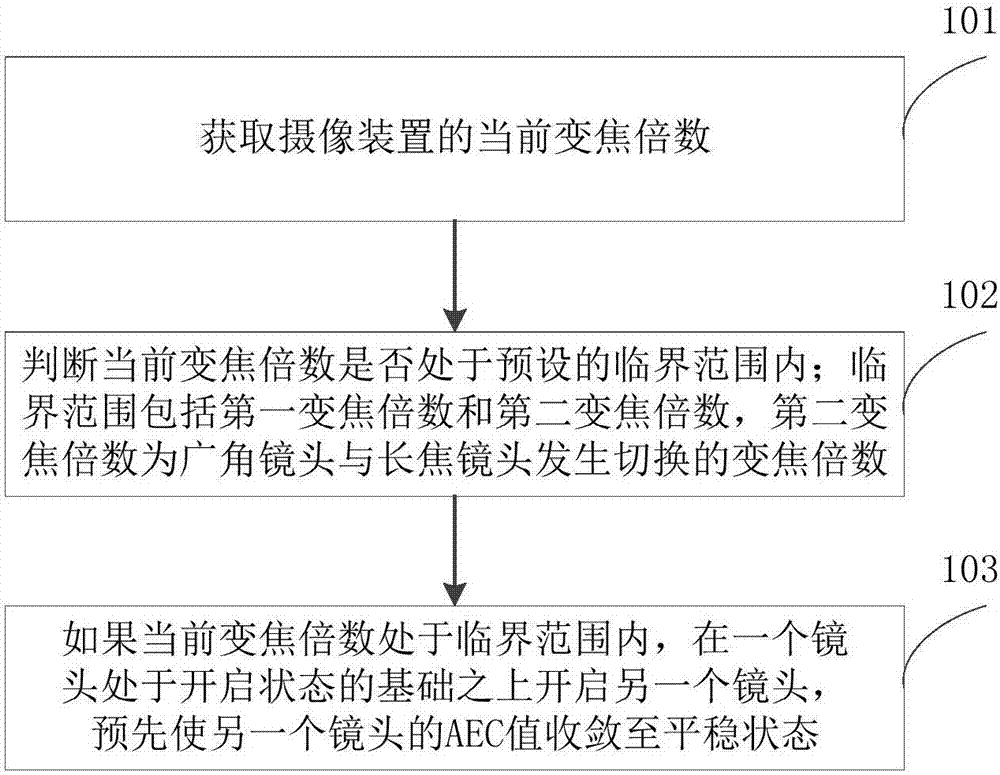

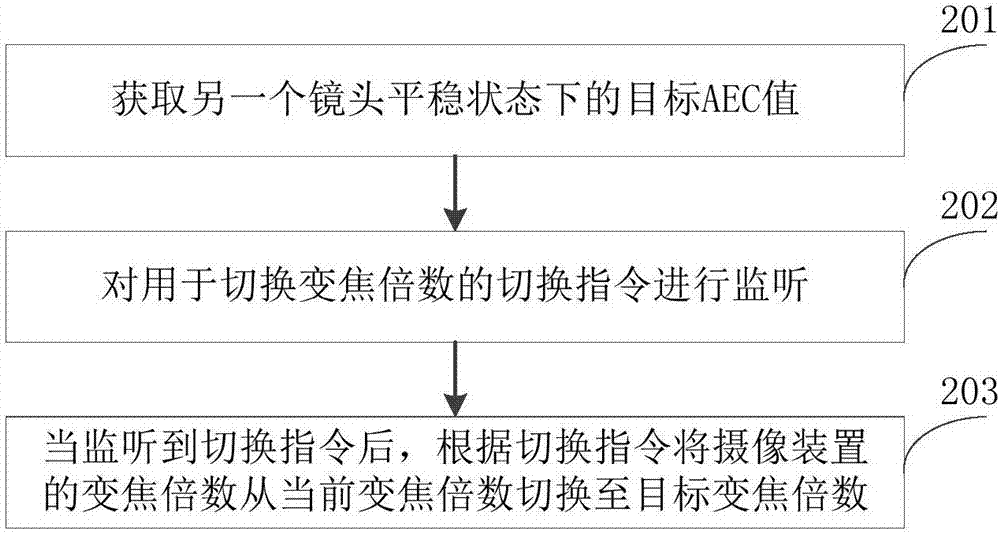

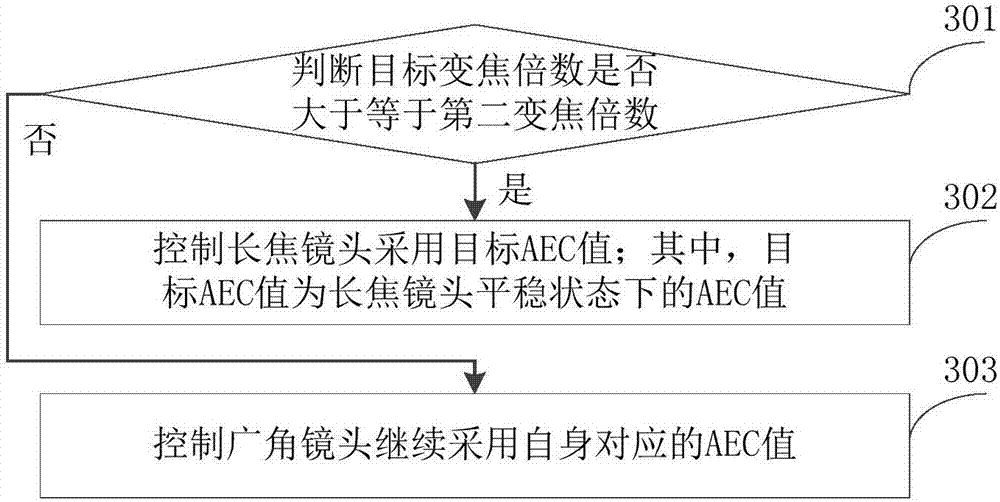

Method and device for inhibit AEC jumping and terminal equipment

ActiveCN107483808AImprove experienceImprove the shooting effectTelevision system detailsColor television detailsStable stateTelephoto lens

The invention provides a method and device for inhibit AEC jumping and terminal equipment. The method comprises the steps that the current zoom multiple of a camera device is acquired; whether or not the current zoom multiple is in a preset critical range is judged, wherein the critical range comprises the first zoom multiple and the second zoom multiple, and the second zoom multiple is the zoom multiple obtained when a wide-angle lens and a telephoto lens are switched; and if the current zoom multiple is in the critical range, another lens is opened on the basis that one lens is in an opened state, and an AEC value of another lens is converged to be in a stable state in advance. According to the method, due to the fact that the to-be-switched lens can be converged to be in the stable state in advance, the condition that the AEC brightness jumping problem is generated during lens switching is effectively avoided, and the shooting effect and the user experience are improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Metal plate rapid rounding and welding integrated device

PendingCN109604372AEasy to shapeNot easy to dentWelding/cutting auxillary devicesAuxillary welding devicesRoundingEngineering

The invention discloses a metal plate rapid rounding and welding integrated device. The device comprises a base, wherein a back plate is arranged at the rear end of the base, the device is characterized in that the back plate is fixedly provided with a sizing mold, a lower mold is arranged right below the sizing mold on the base in a up-down movable mode, a left upper mold support and a right upper mold support are arranged on the two sides of the lower mold in parallel, a left upper mold which can move leftwards and rightwards is arranged on the left upper mold support, the right upper mold support is provided with a right upper mold which can move leftwards and rightwards, a mold cavity of the left upper mold, a mold cavity of the right upper mold and a mold cavity of the lower mold arecombined to form a cylindrical mold cavity matched with the sizing mold; and a welding gun support is fixedly arranged behind the back plate, a welding gun is vertically arranged on the welding gun support, the welding gun can move back and forth, and the welding gun is located right above the sizing mold. According to the device, automatic rounding and automatic welding are achieved, the two procedures are continuously operated, the construction period is shortened, the labor and time cost is reduced, and the production efficiency is improved.

Owner:淮安茂华管业有限公司

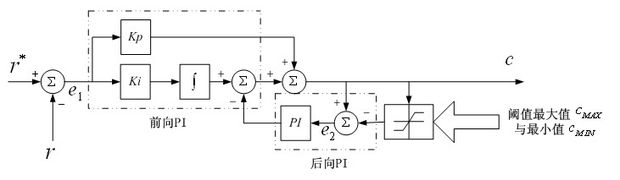

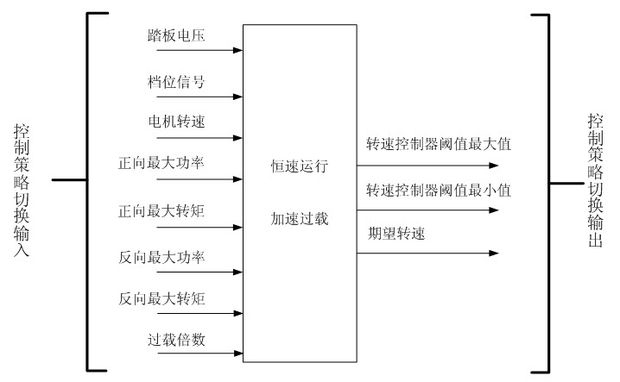

Flexible control system and method for alternating current asynchronous drive motor of electric vehicle

ActiveCN102403953ANo transitionPrevent jumpingElectronic commutation motor controlAC motor controlNew energyDrive motor

The invention relates to the intelligent control technique of new energy vehicles and particularly to a flexible control system and method for an alternating current asynchronous drive motor of an electric vehicle. The output end of an automatic speed regulator (ASR) and the output end of an automatic voltage regulator (AVR) are both connected with the input end of a reverse PI (Proportional Integral) controller, and the amplitude limiting threshold value of the reverse PI controller can be adjusted dynamically in real time; the input end of the reverse PI controller is connected to an amplitude limiting threshold operator; the maximal amplitude limiting threshold value or the minimal amplitude limiting threshold value of the ASR or the AVR is worked out by the amplitude limiting threshold operator and then is compared with the control quantity c of the controller, and the control quantity c is satisfied by treatment and adjustment of the reverse PI controller, so that the control quantity c can remain unchanged when the working condition of the electric vehicle is changed, a state changeover switch is avoided, the control structure is simple and clear, and the stability of the control effect is better.

Owner:DONGFANG ELECTRIC CORP LTD

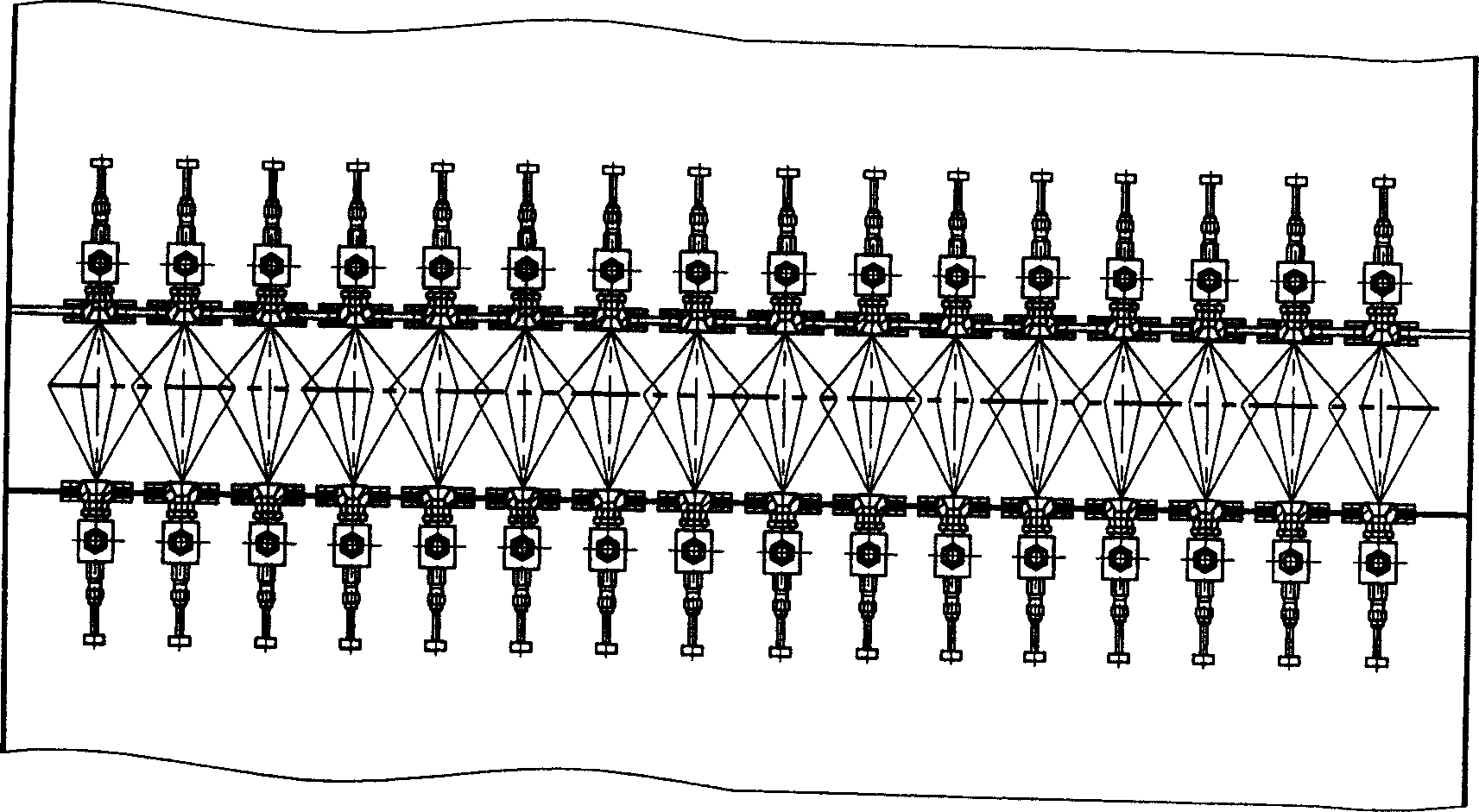

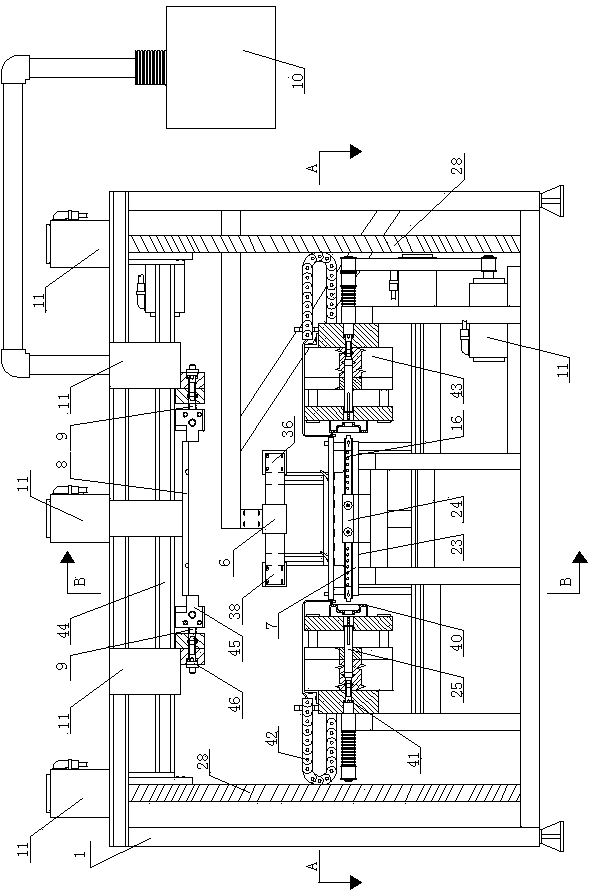

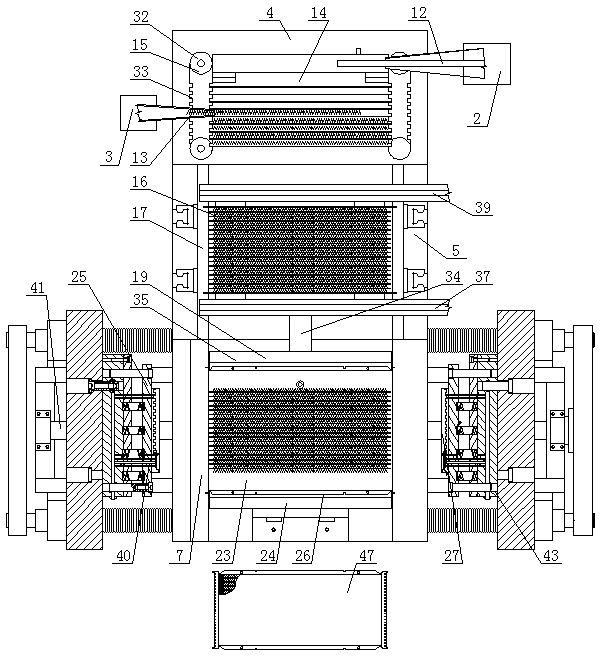

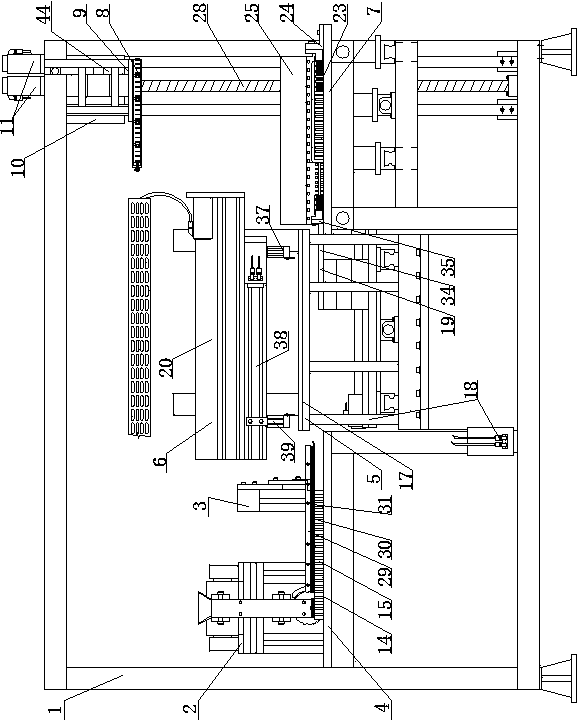

Numerical control assembly device for automobile radiator core production line

ActiveCN104259858ASave human effortImprove work efficiencyAssembly machinesNumerical controlProduction line

The invention discloses a numerical control assembly device for an automobile radiator core production line, belongs to a core assembly device, and aims to solve the problems of low efficiency and low precision existing in the prior art. According to the adopted technical scheme, the device comprises a rack, a radiating tube conveying device, a radiating belt turning and conveying device, a radiating tube and radiating belt automatic arrangement table, a core lifting conveying table, a front and rear manipulator assembly automatic operation mechanism, a radiator core assembly table, a core pressing device, a belt tidying device, a controller and a servo motor, wherein the radiating tube conveying device, the radiating belt turning and conveying device, the radiating tube and radiating belt automatic arrangement table, the core lifting conveying table, the front and rear manipulator assembly automatic operation mechanism, the radiator core assembly table, the core pressing device, the belt tidying device, the controller and the servo motor are arranged on the rack; the radiating tube and radiating belt automatic arrangement table, the core lifting conveying table and the radiator core assembly table are arranged on the rack from back to front in sequence; the radiating tube conveying device and the radiating belt turning and conveying device are positioned on the left and right sides of the radiating tube and radiating belt automatic arrangement table respectively; the front and rear manipulator assembly automatic operation mechanism is arranged above the core lifting conveying table; the core pressing device and the belt tidying device are positioned above the radiator core assembly table; the controller is adopted for control.

Owner:山东厚丰汽车散热器有限公司

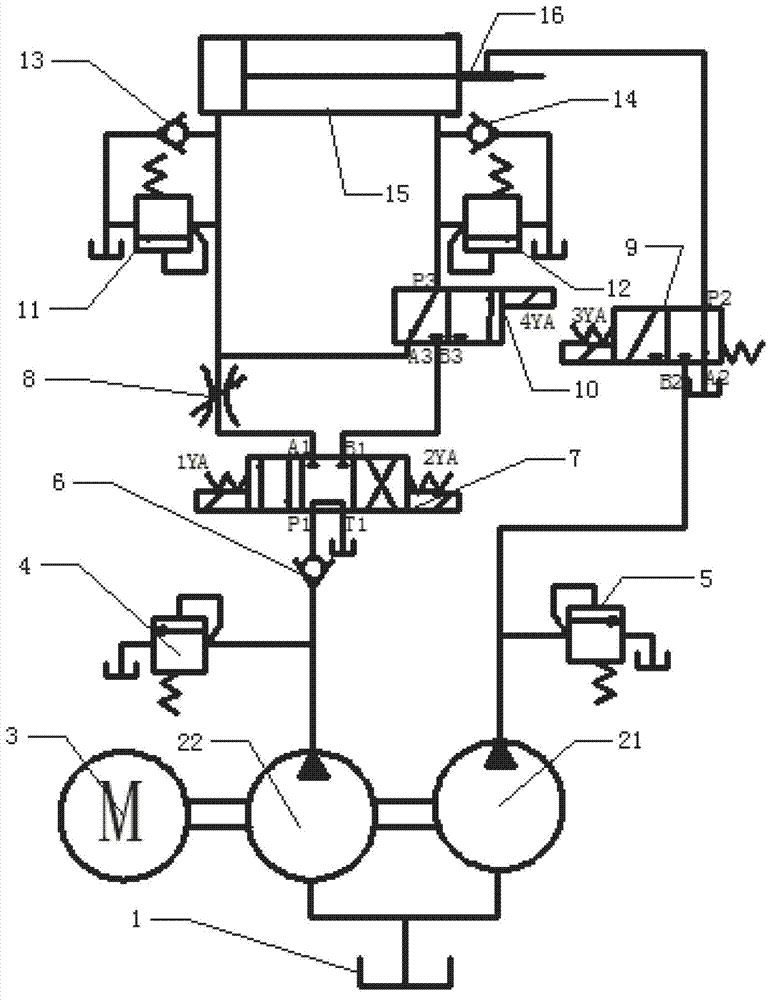

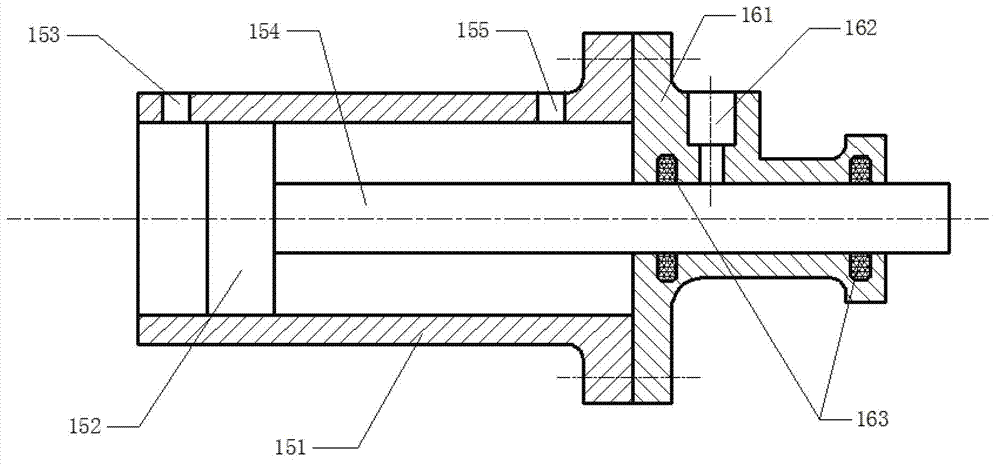

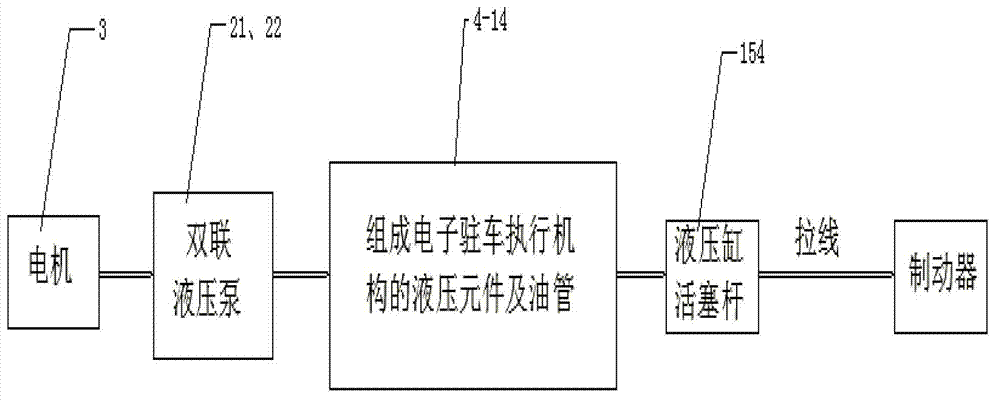

Hydraulically-controlled electronic parking executing mechanism

InactiveCN102729972AApplicable to a wide range of modelsPrevent jumpingBraking action transmissionLow noiseHydraulic cylinder

The invention discloses a hydraulically-controlled electronic parking executing mechanism, which comprises high-pressure and low-pressure pumps driven by using a motor in a duplex way, and a hydraulic cylinder, wherein the hydraulic cylinder comprises a cylinder body, a piston, a piston rod and a locking device; one end of the cylinder body is provided with an oil outlet, and the other end of the cylinder body is provided with an oil inlet; an unlocking oil port is formed at an elastic position on the locking device; the inlet of the high-pressure pump is connected with an oil tank; the port B2 of a first two-position three-way electromagnetic reversing valve is connected with the outlet of the high-pressure pump; the port P2 of the first two-position three-way electromagnetic reversing valve is connected with the unlocking oil port of the locking device; the inlet of the low-pressure pump is connected with the oil tank; the outlet of the low-pressure pump is connected with the port P1 of a three-position four-way electromagnetic reversing valve 7 through a first one-way valve; the inlet of a throttling valve is connected with the port A1 of the three-position four-way electromagnetic reversing valve, and the outlet of the throttling valve is connected with the oil inlet of the cylinder body, so that an oil inlet pipeline is formed; and the port B3 of a second two-position three-way electromagnetic reversing valve is connected with the port B1 of the three-position four-way electromagnetic reversing valve, and the port P3 of the second two-position three-way electromagnetic reversing valve is connected with the oil outlet of the cylinder body, so that an oil outlet pipeline is formed. A braking mechanism disclosed by the invention is suitable for wide vehicle types, and has continuous and stable power transmission, large and adjustable braking force, low wear and low noise.

Owner:NANJING UNIV OF SCI & TECH

Efficient polishing device used for metal casting machining and polishing method of efficient polishing device

InactiveCN110125754AReduce the impactAvoid influenceEdge grinding machinesGrinding drivesSlide plateEngineering

The invention discloses an efficient polishing device used for metal casting machining and a polishing method of the efficient polishing device. The efficient polishing device comprises a machine body. An installation cavity is formed in the bottom end of the machine body. A rotation motor is installed in the installation cavity. The output end of the rotation motor is fixedly connected with a work table. The work table is installed at the bottom end in the machine body in a rotating manner. Clamping devices which are symmetrically distributed are arranged on the left side and the right side of the top end of the work table. A lead screw, a stop piece and a slippage motor are sequentially arranged at the top end in the machine body from left to right. The left end of the lead screw is connected with the side wall in the machine body in a rotating manner, and the right end of the lead screw penetrates through the stop piece and is connected to the output end of the slippage motor. A slide block is installed on the lead screw. A slide plate is fixedly arranged at the bottom end of the slide block. A lifting cylinder is installed at the bottom end of the slide plate. By means of the efficient polishing device and the polishing method, castings can be conveniently polished, chippings can be collected during polishing, processing is facilitated, influences of vibration on the polishing effect during polishing are reduced, and the product quality is improved.

Owner:昆山鑫启盛精密配件有限公司

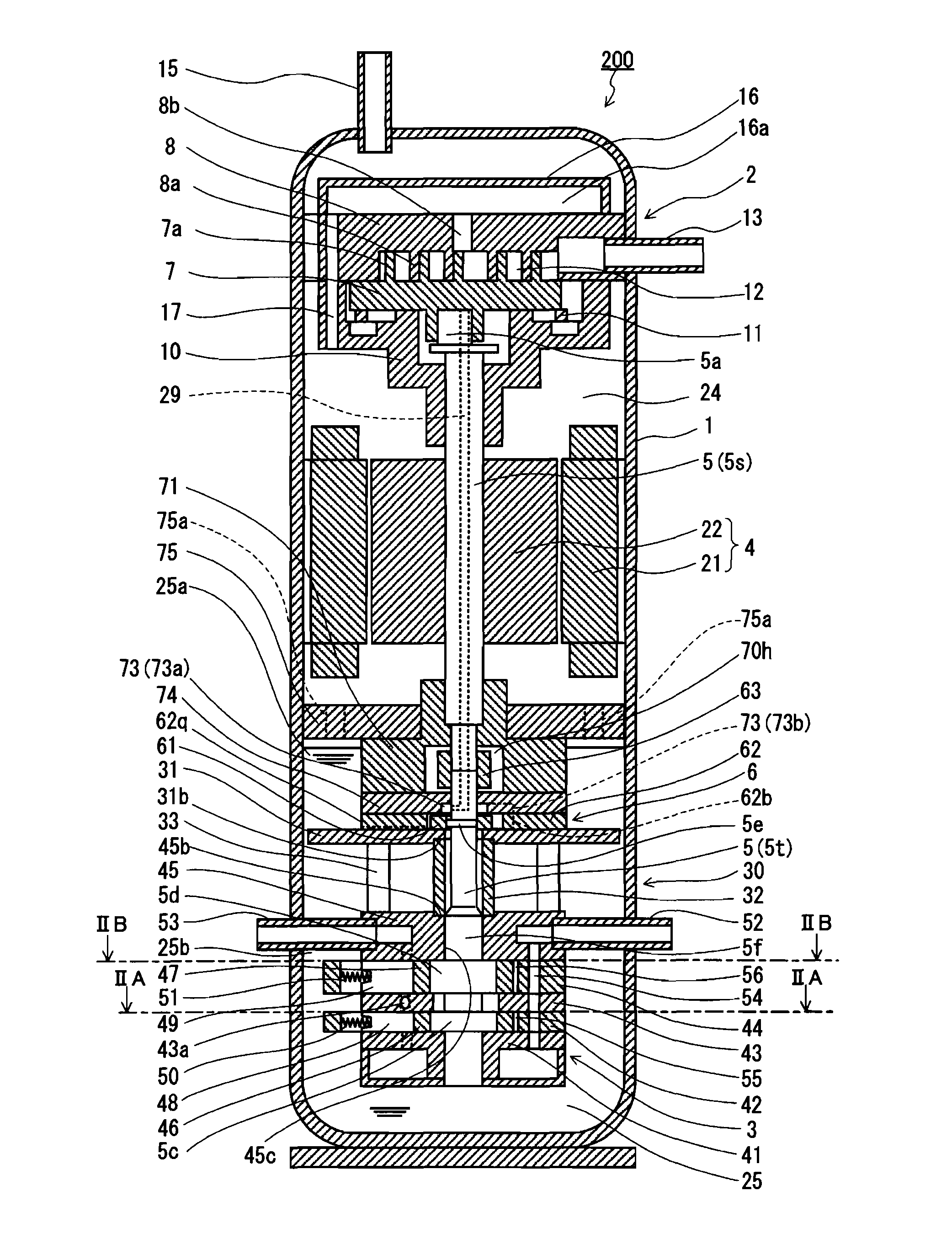

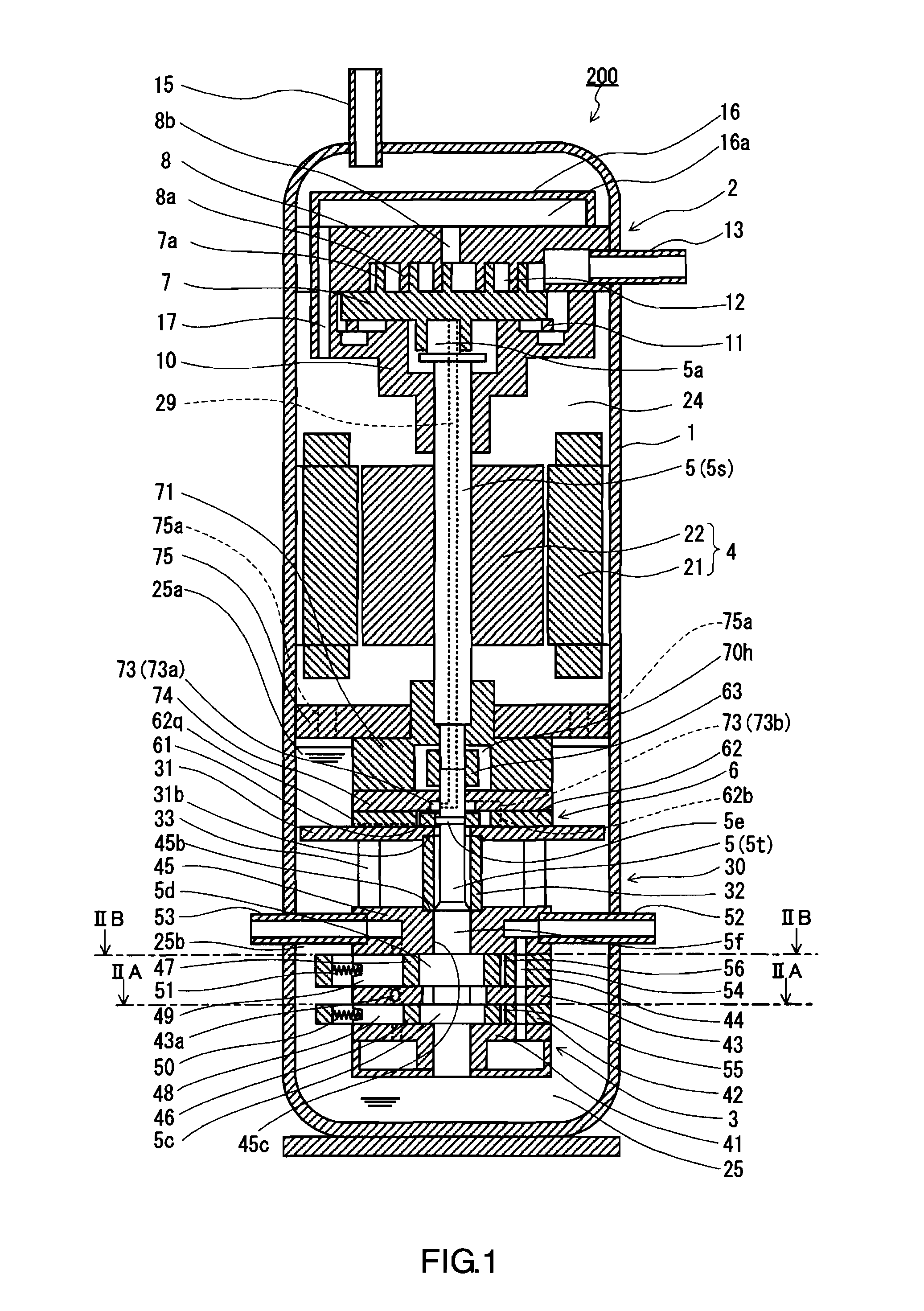

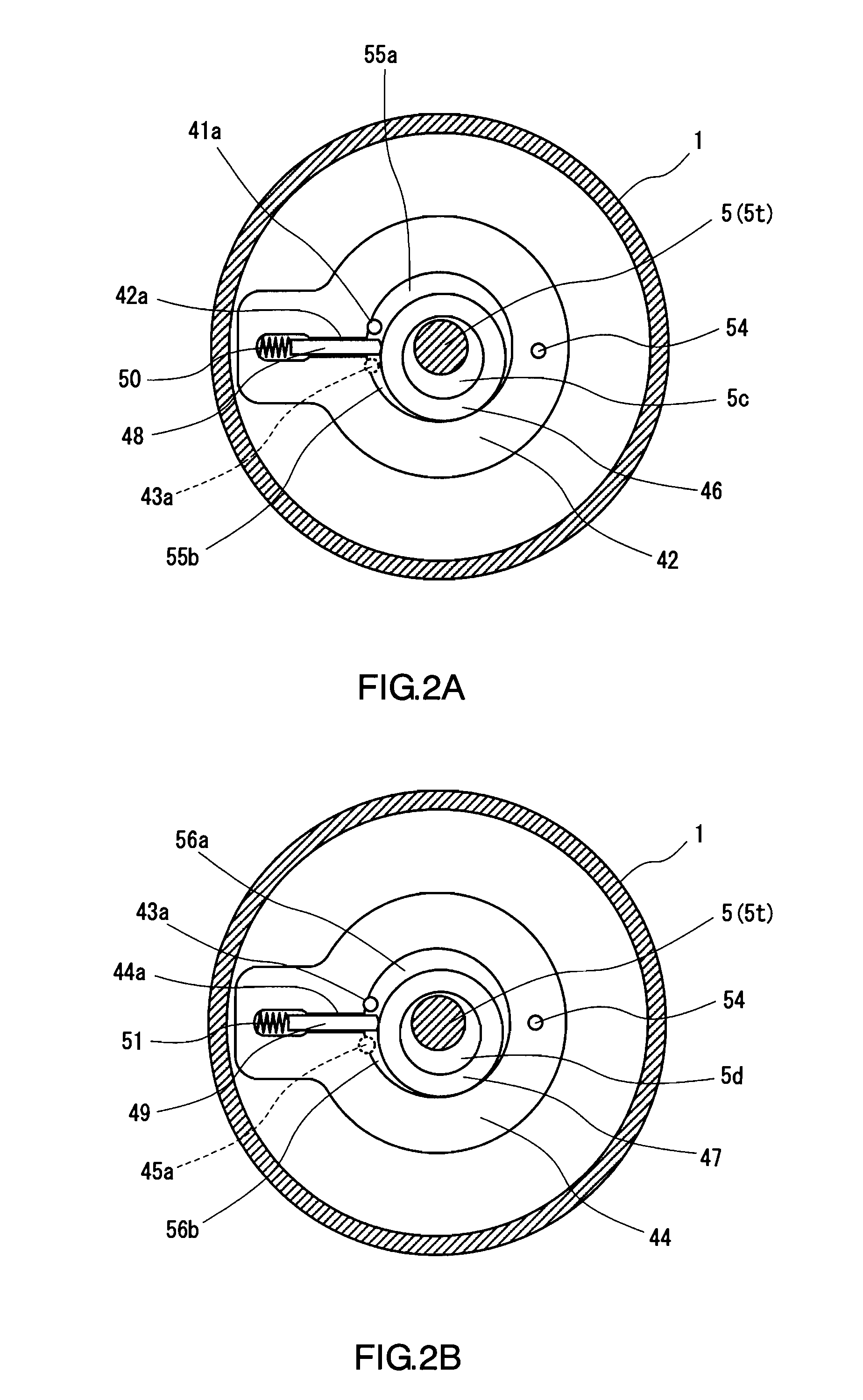

Expander-compressor unit

InactiveUS20100269536A1Raise countPrevent jumpingRotary/oscillating piston combinations for elastic fluidsDomestic cooling apparatusMechanical engineeringEngineering

An expander-compressor unit (200) includes a closed casing (1), a compression mechanism (2), an expansion mechanism (3), a shaft (5), and an oil pump (6). The shaft (5) includes an upper shaft (5s) provided with an upper eccentric portion (5a) for the compression mechanism (2), and a lower shaft (5t) provided with lower eccentric portions (5d and 5c) for the expansion mechanism (3) and an intermediate eccentric portion (5e) for the oil pump (6). The expansion mechanism (3) has an upper bearing member (45) for supporting a supported portion (5f) of the lower shaft (5t) located immediately above the lower eccentric portion (5d). The intermediate eccentric portion (5e) has a diameter equal to or less than that of the supported portion (5f).

Owner:PANASONIC CORP

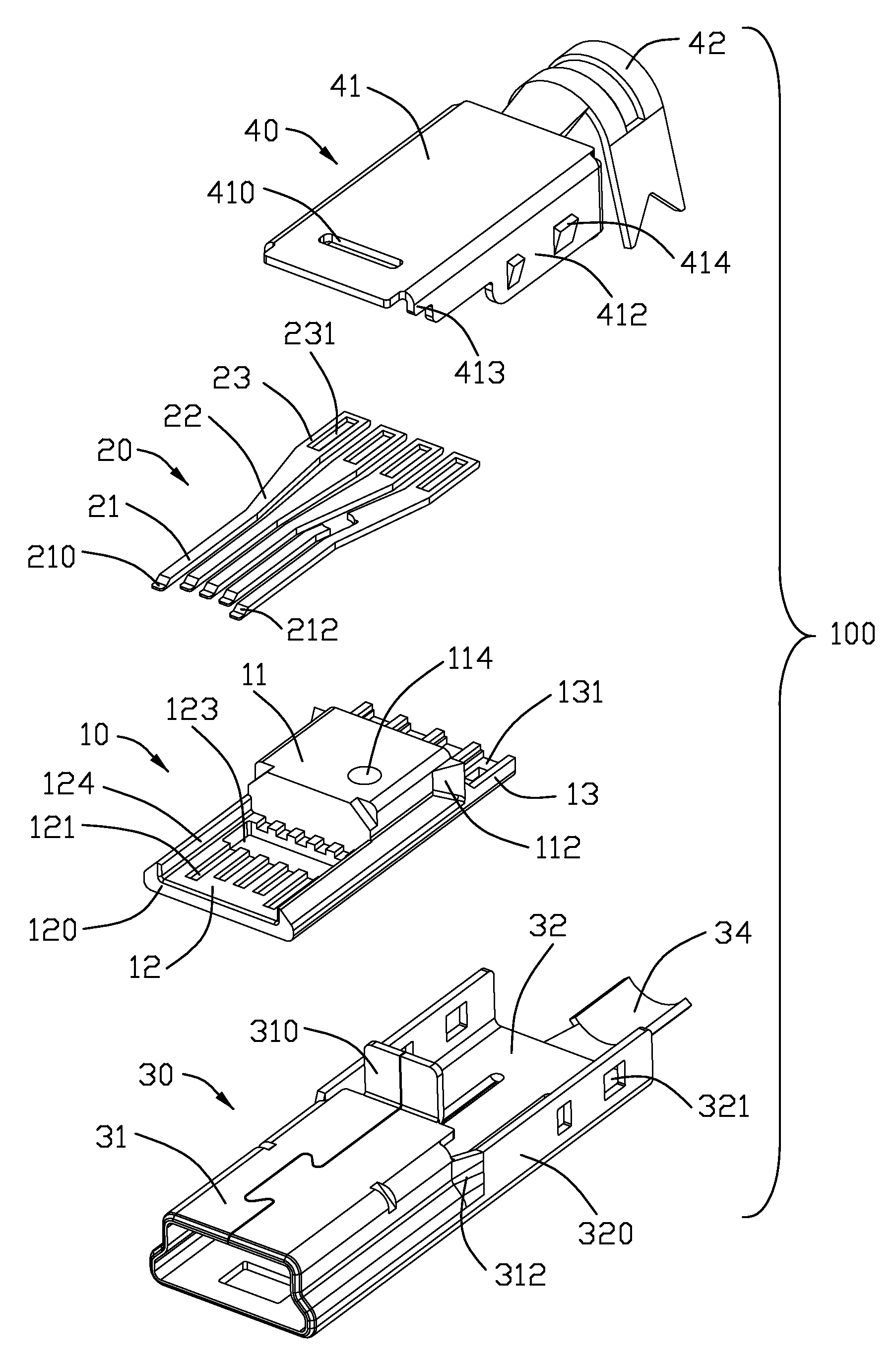

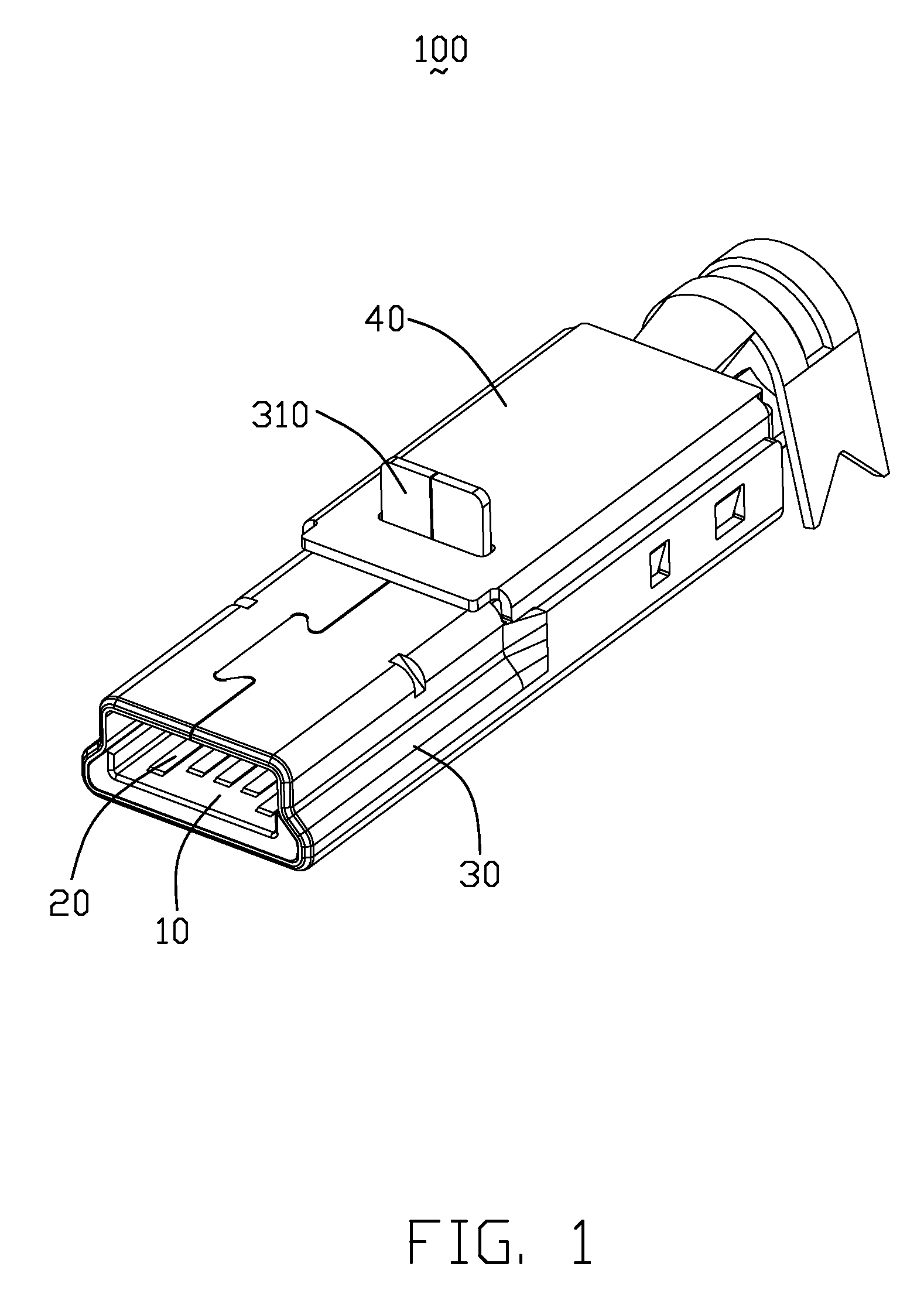

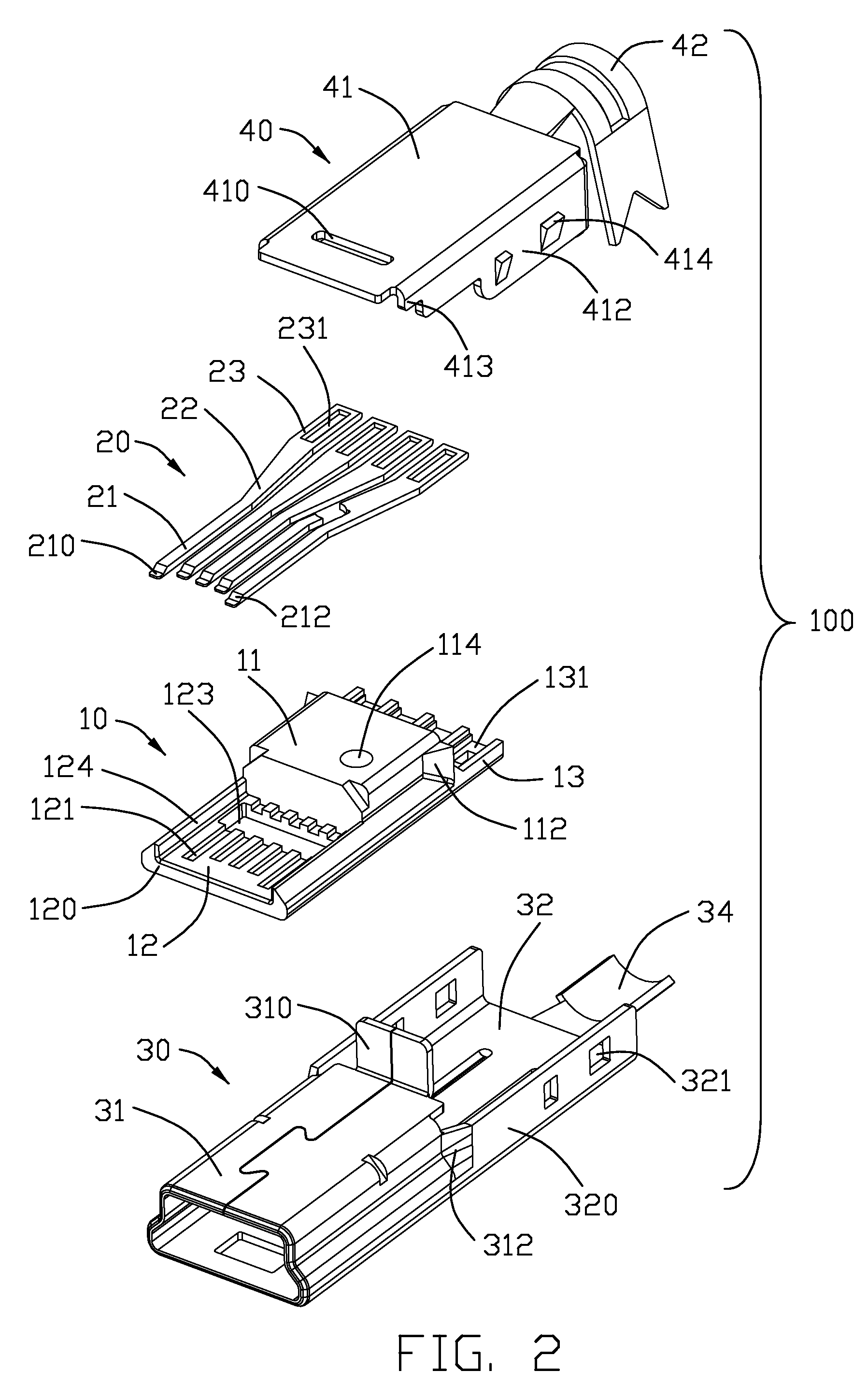

Electrical connector with improved contacts

InactiveUS7736190B2Prevent jumpingSmooth connectionElectric discharge tubesSoldered/welded conductive connectionsElectrical connectorMechanical engineering

An electrical connector (100) comprises an insulative housing (10), a shell encapsulating the insulative housing and a plurality of contacts (20) received in the housing abreast. The insulative housing defines a tongue (12), a plurality of passageways (121) and receiving grooves (131), the passageways extending to the tongue, the tongue has a stopping portion (126) in the front of each passageway. A cavity is defined below each stopping portion and communicated with the passageway. Each contact has a contacting portion (21) and a tail portion (23) wider than the contacting portion, the contacting portions are received in a corresponding passageways with the tail portions received in a corresponding receiving grooves. Each contacting portion defines a tab (210) protruding forwardly from a bottom surface thereof, the tab is received in the cavity and protected by the stopping portion (126); each tail portion is stamped downwards to form a notch (231) receiving wires and soldering with the wires.

Owner:HON HAI PRECISION IND CO LTD

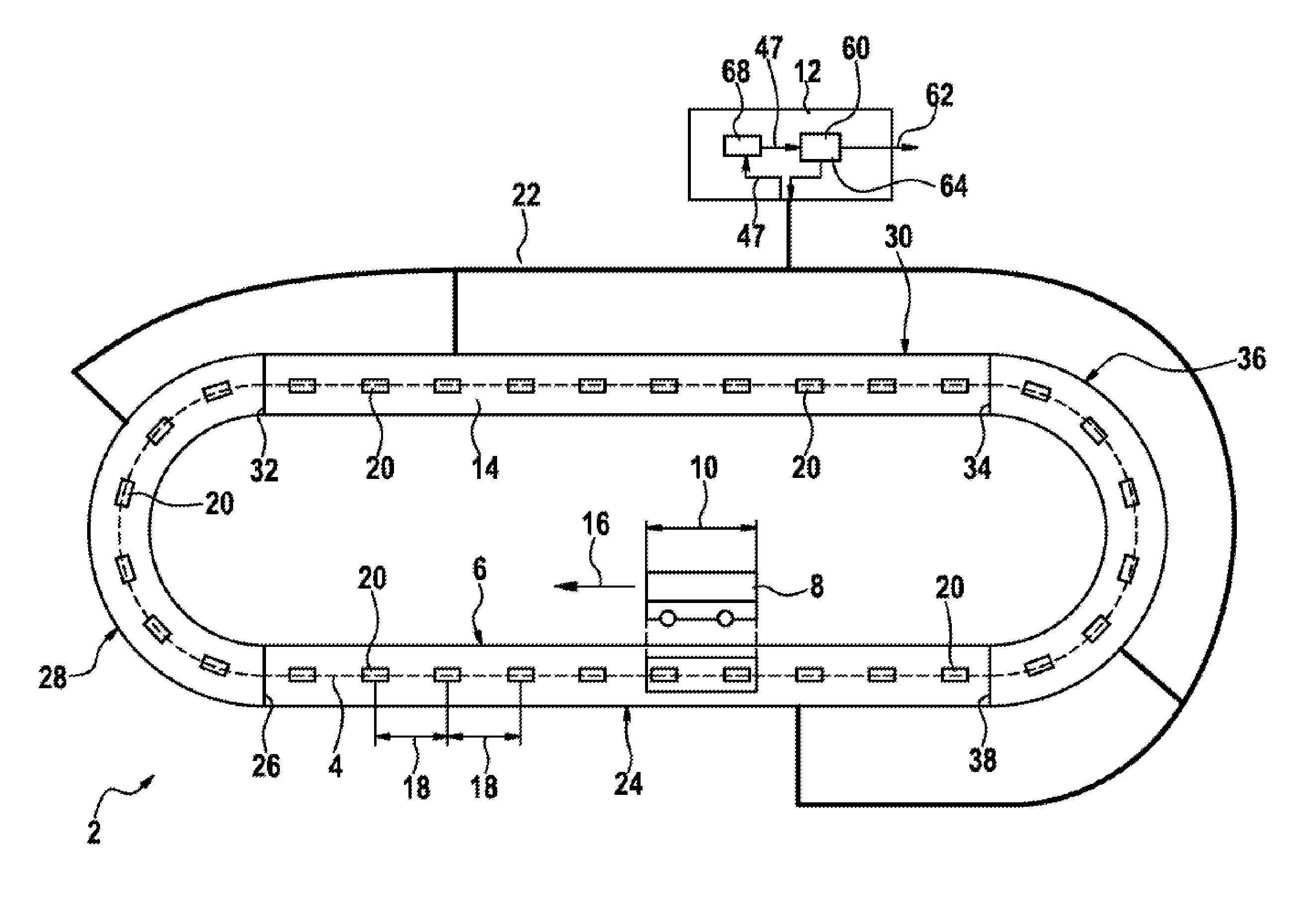

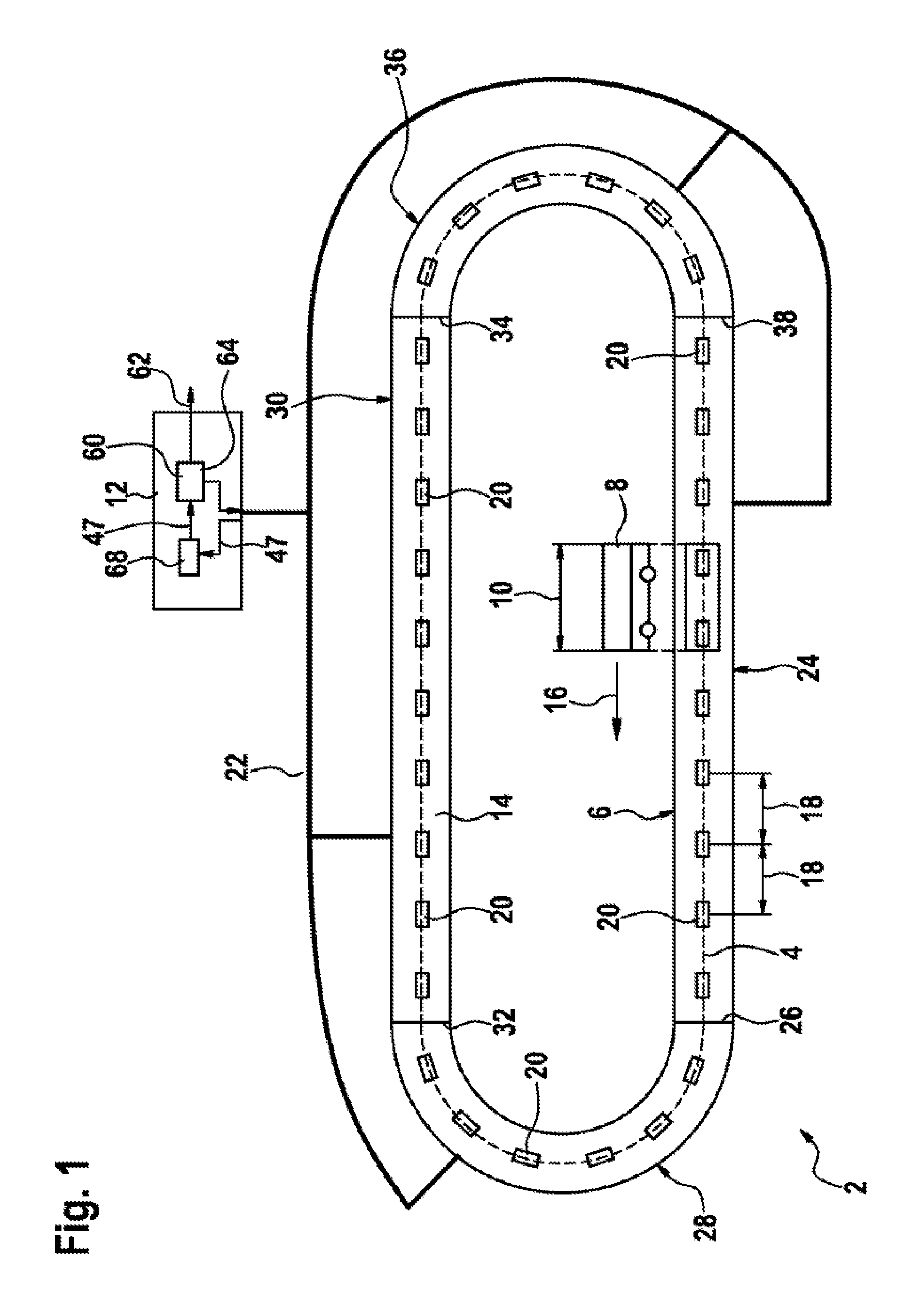

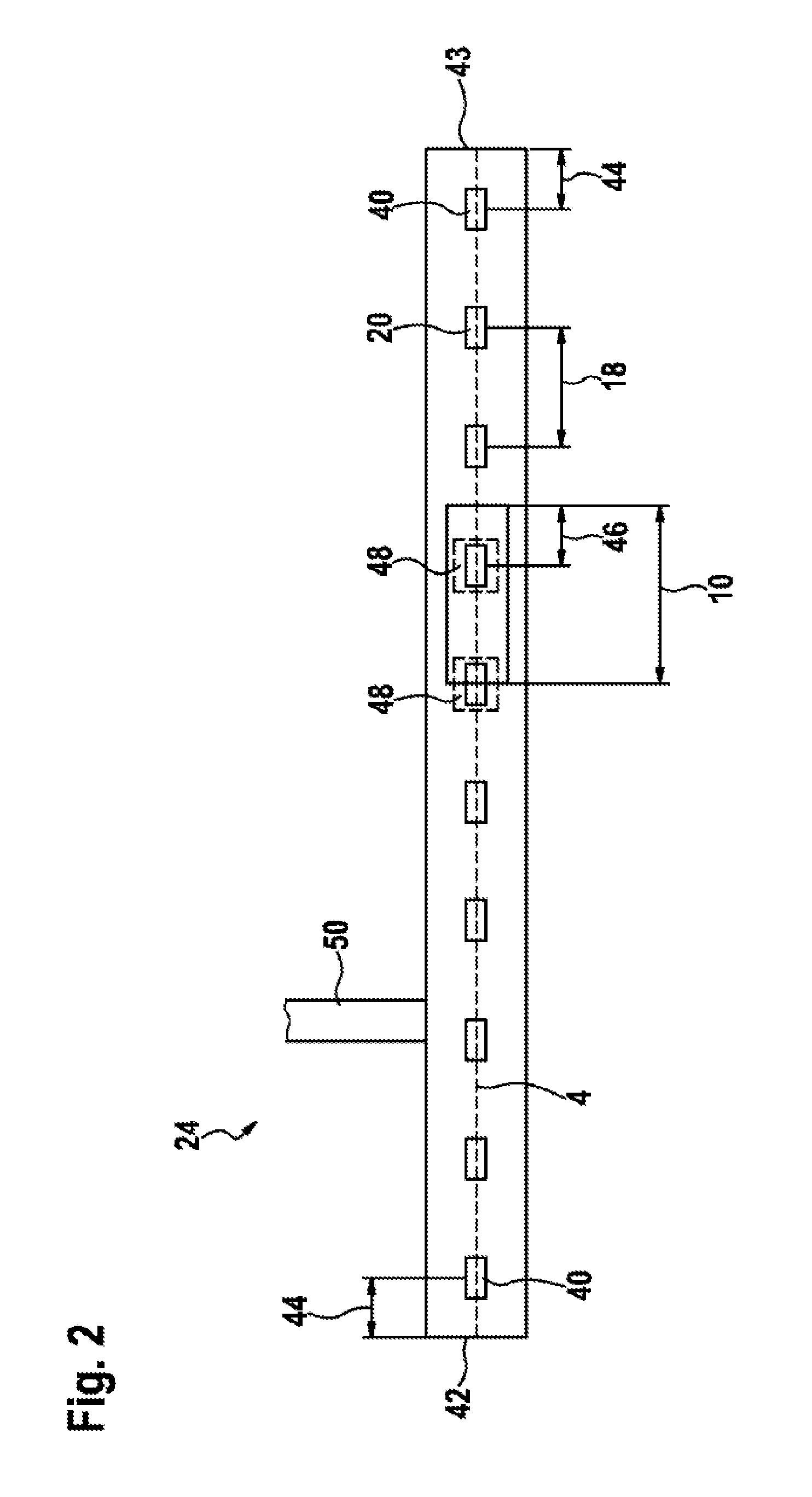

Incremental multi-position detection system for a revolving electromagnetic transfer system

InactiveUS20130037384A1More fail-safeCost-effective mannerControl devices for conveyorsConverting sensor outputTransfer systemEngineering

A transport apparatus (2) for conveying a product is disclosed. The transport apparatus (2) comprises a movable conveying element (8) which is intended to convey the product and has a pattern (52) which extends over a predetermined pattern length (66) in the direction of movement (16) of the conveying element (8) and has a multiplicity of travel increments (56, 58); a stationary, peripherally arranged running rail (6) which defines a running path (14) for the conveying element (8) and has a multiplicity of position sensors (20) on the running path (14), the distances (18) between which are shorter than the pattern length (66); and a measuring device (12) which is designed to determine an instantaneous position of the conveying element (8) on the running path (14), wherein, when the pattern enters and / or exits the measuring region (48) of a position sensor (20), the measuring device (12) determines the instantaneous position with respect to a reference position of the conveying element (8) on the running path (14), said reference position being derived from the position of the corresponding position sensor (20), monitors at least one of the position sensors (20), in the measuring region (48) of which the conveying element (8) is located, and increments or decrements the instantaneous position if a travel increment (56, 58) passes a position sensor (20) being monitored.

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com