Method and apparatus for uniformly spraying liquid onto materials

A technology of uniform spraying and feeding device, which is applied to the device and coating of the surface coating liquid, which can solve the problems of limited number of nozzles, spraying on the surface of the surface material, and difficulty in ensuring the uniformity of the material and liquid. tumbling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

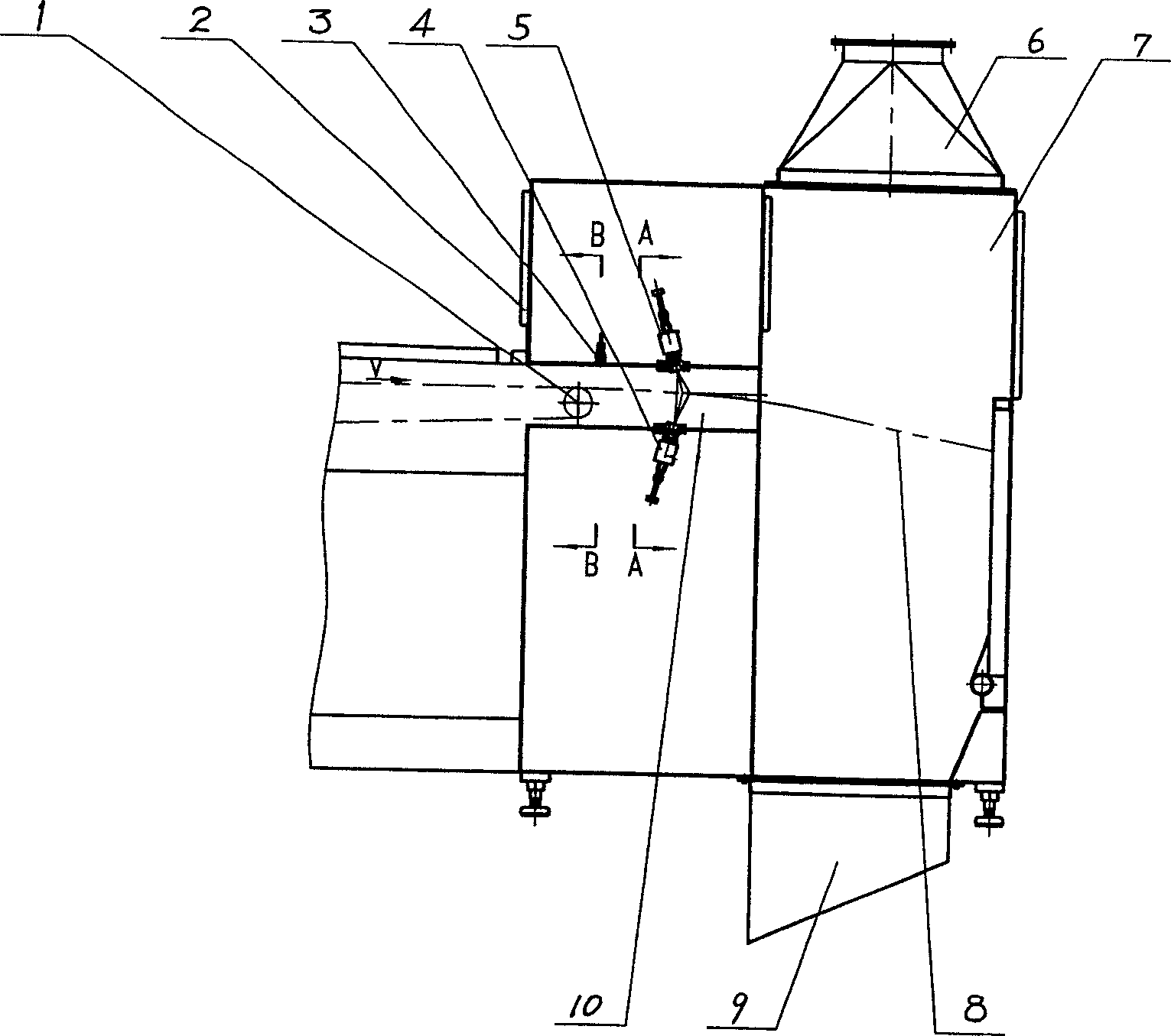

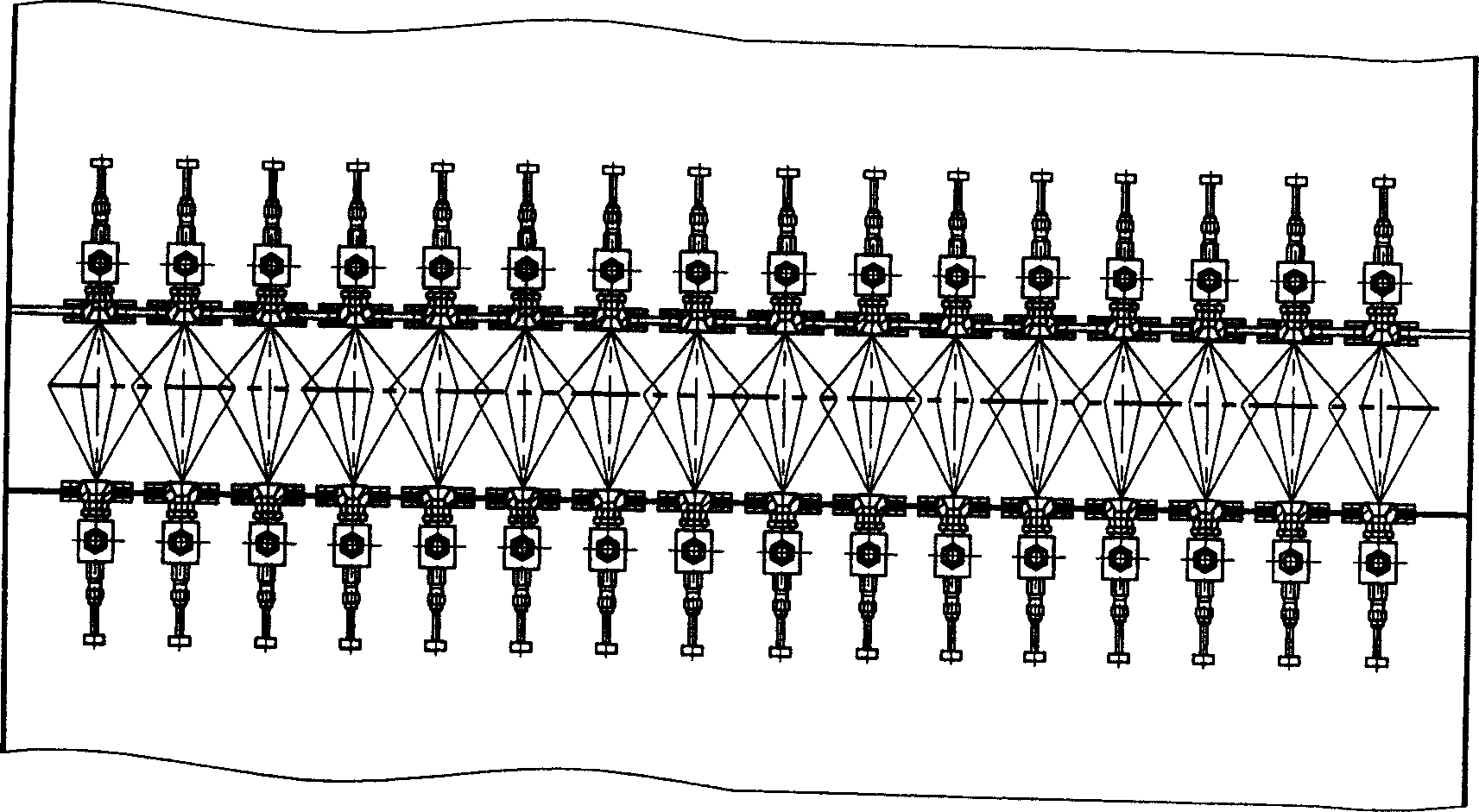

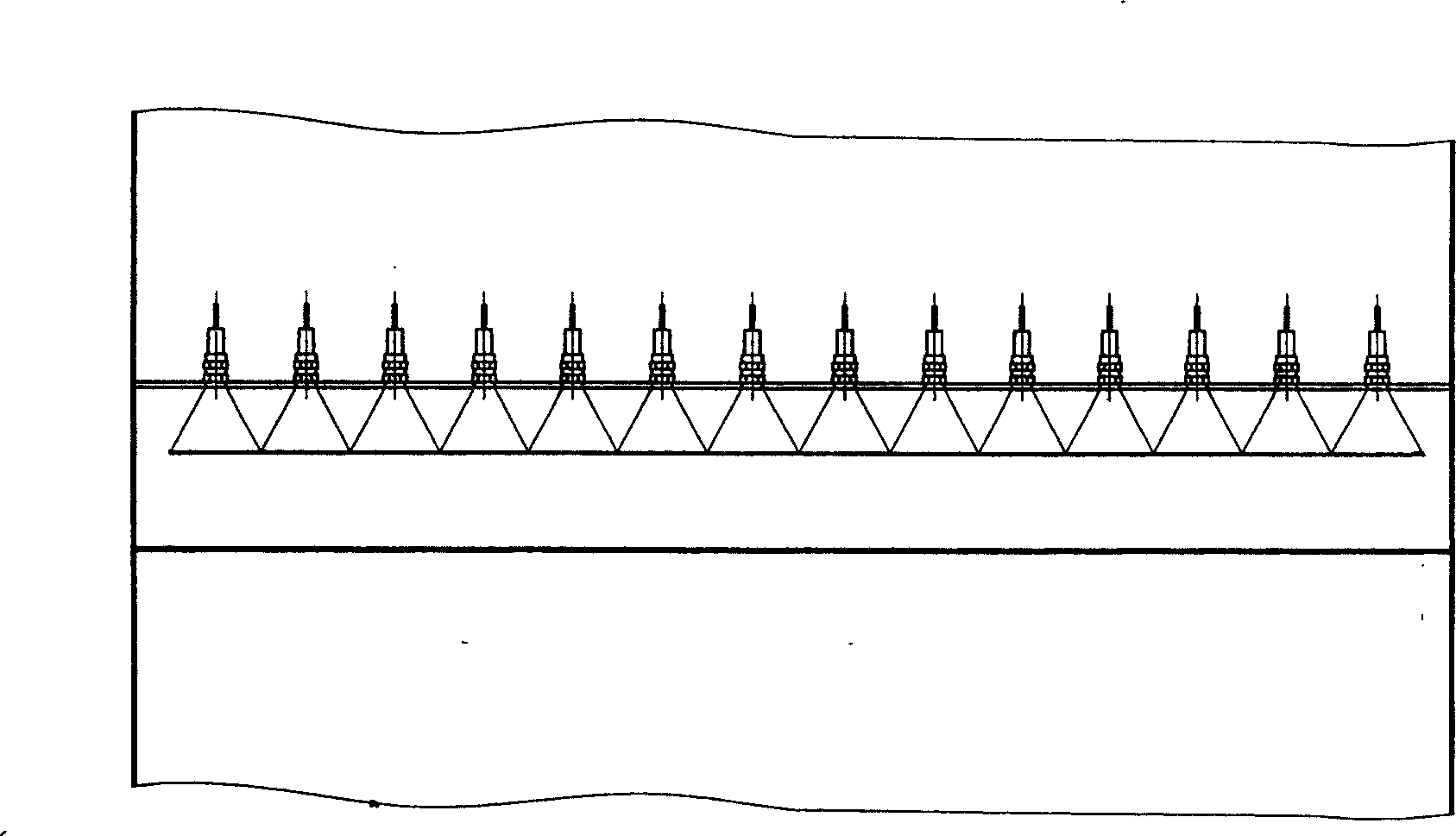

[0016] The method of the present invention adopts the conveying device to throw the thinned material into the feeding device, and sprays the material liquid on the layered material thrown in by the nozzle arranged in the feeding device. The device that realizes this method is as figure 1 As shown, it includes a conveyor 1, a feeding cabinet 2 and a blanking cabinet 7 arranged in sequence at the rear end of the conveyor, a material passage 10 is arranged in the feeding cabinet 2, the tail of the conveyor 1 extends into the material passage 10, and along the material passage 10 The sensor 3 and the feed liquid nozzle 5 are set. The sensor 3 and the feed liquid nozzle 5 can be arranged only above the material passage, or only below the material passage, and can also be arranged symmetrically above and below the material passage. In this embodiment, two groups of nozzles 4 and 5 are arranged symmetrically above and below the material channel. The sensors 3 and the feed liquid no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com