Patents

Literature

278 results about "Adding machine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An adding machine is a class of mechanical calculator, usually specialized for bookkeeping calculations. In the United States, the earliest adding machines were usually built to read in dollars and cents. Adding machines were ubiquitous office equipment until they were phased out in favor of calculators in the 1970s and by personal computers beginning in about 1985. The older adding machines were rarely seen in American office settings by the year 2000.

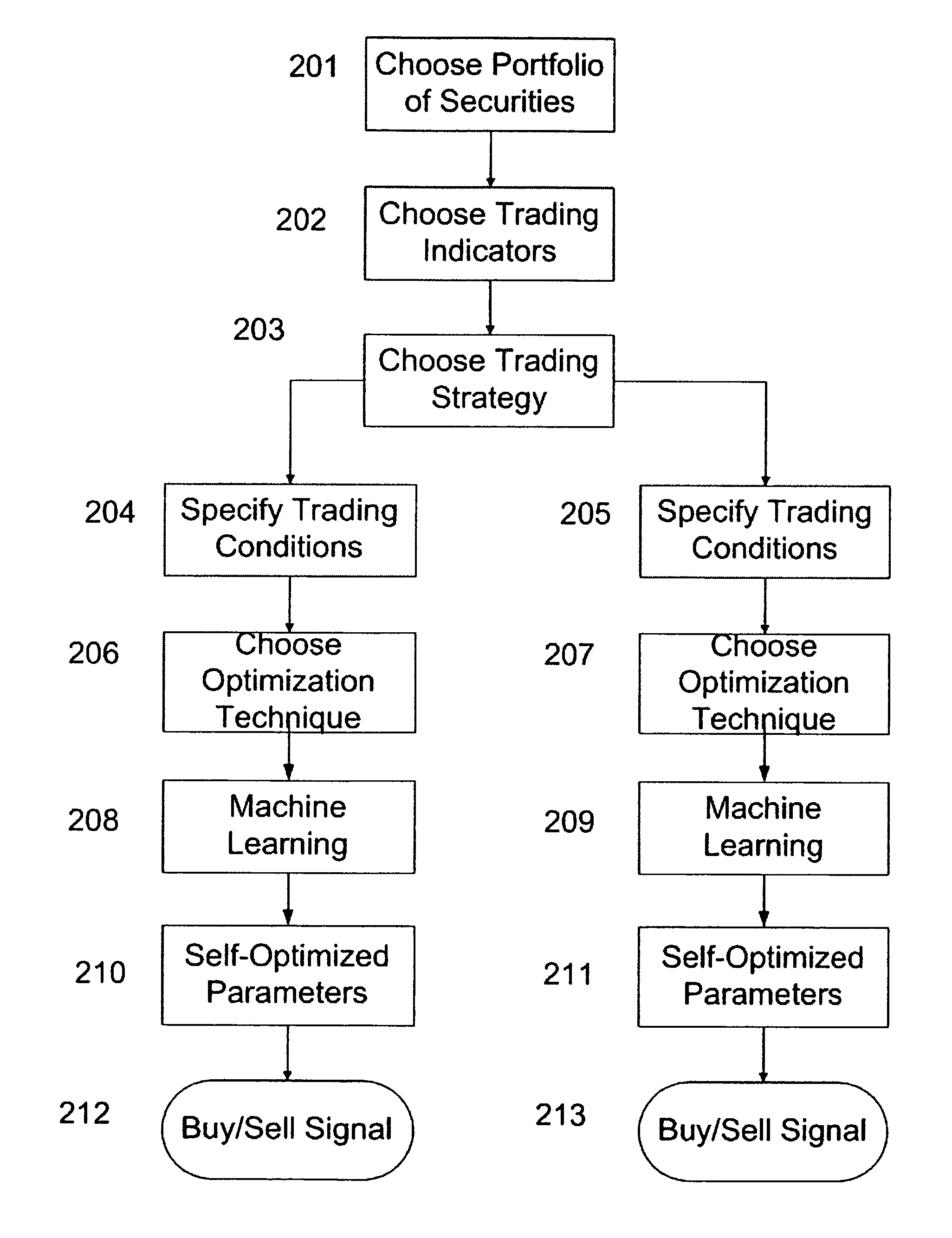

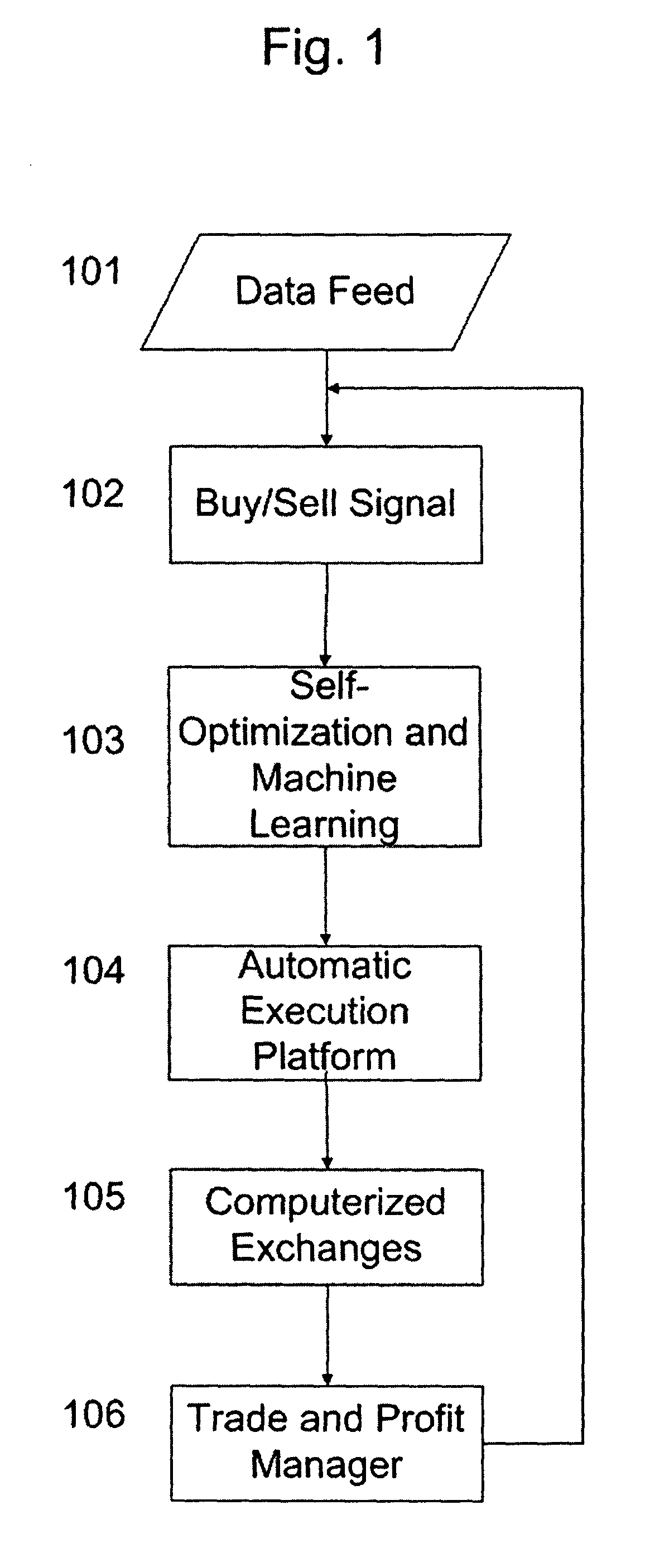

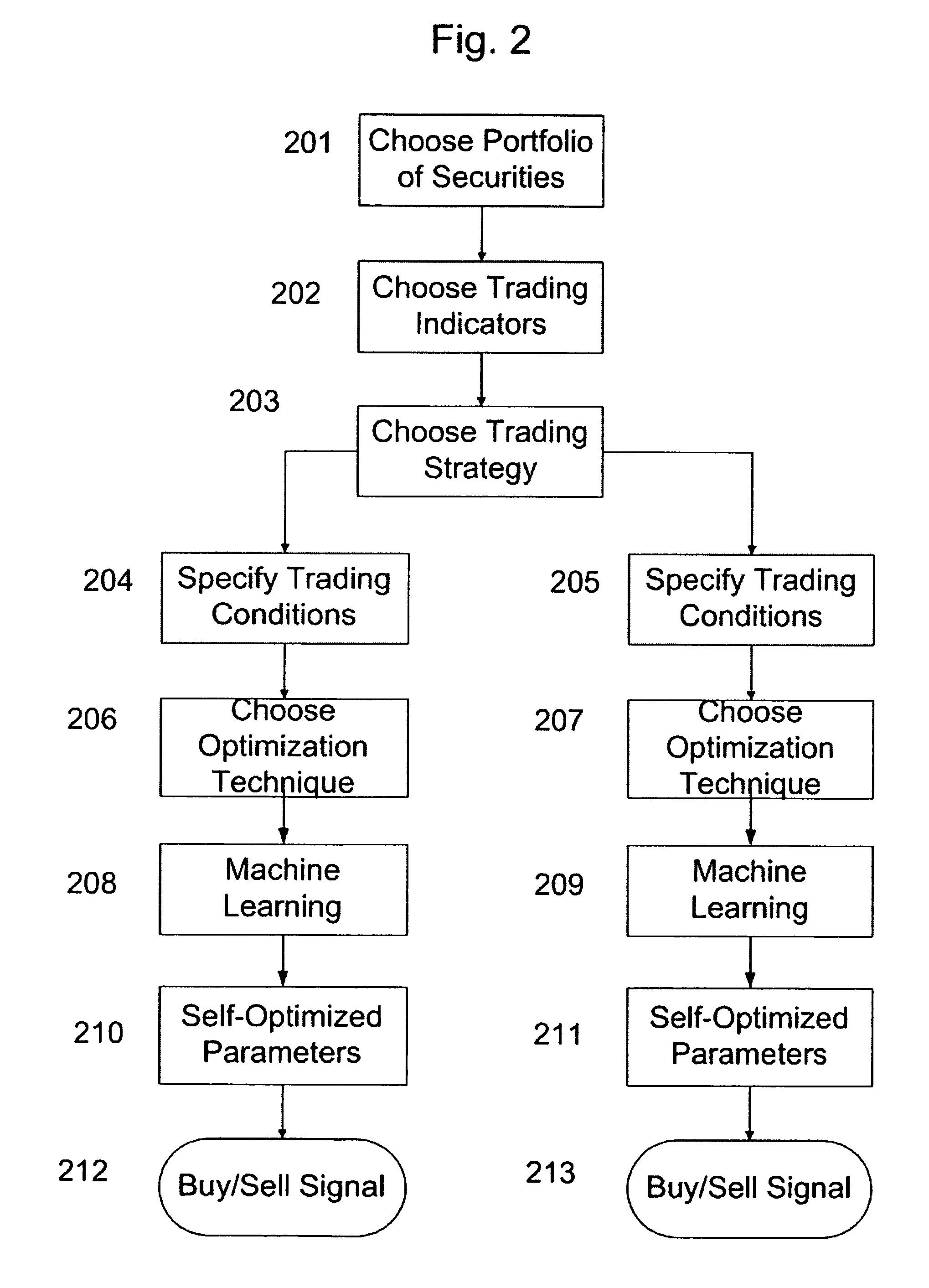

Machine learning automatic order transmission system for sending self-optimized trading signals

InactiveUS20050015323A1FinanceSpecial data processing applicationsData providerFinancial transaction

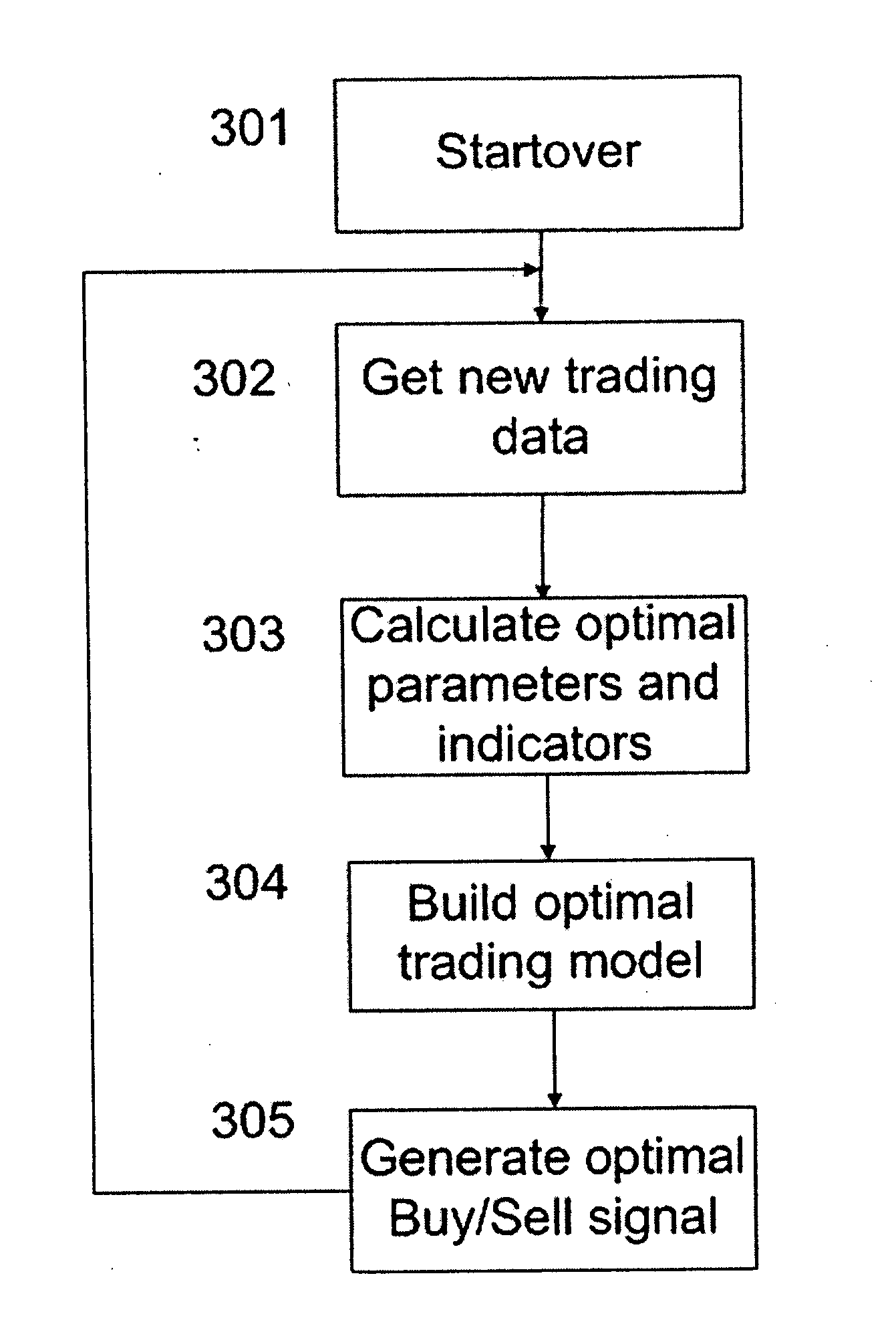

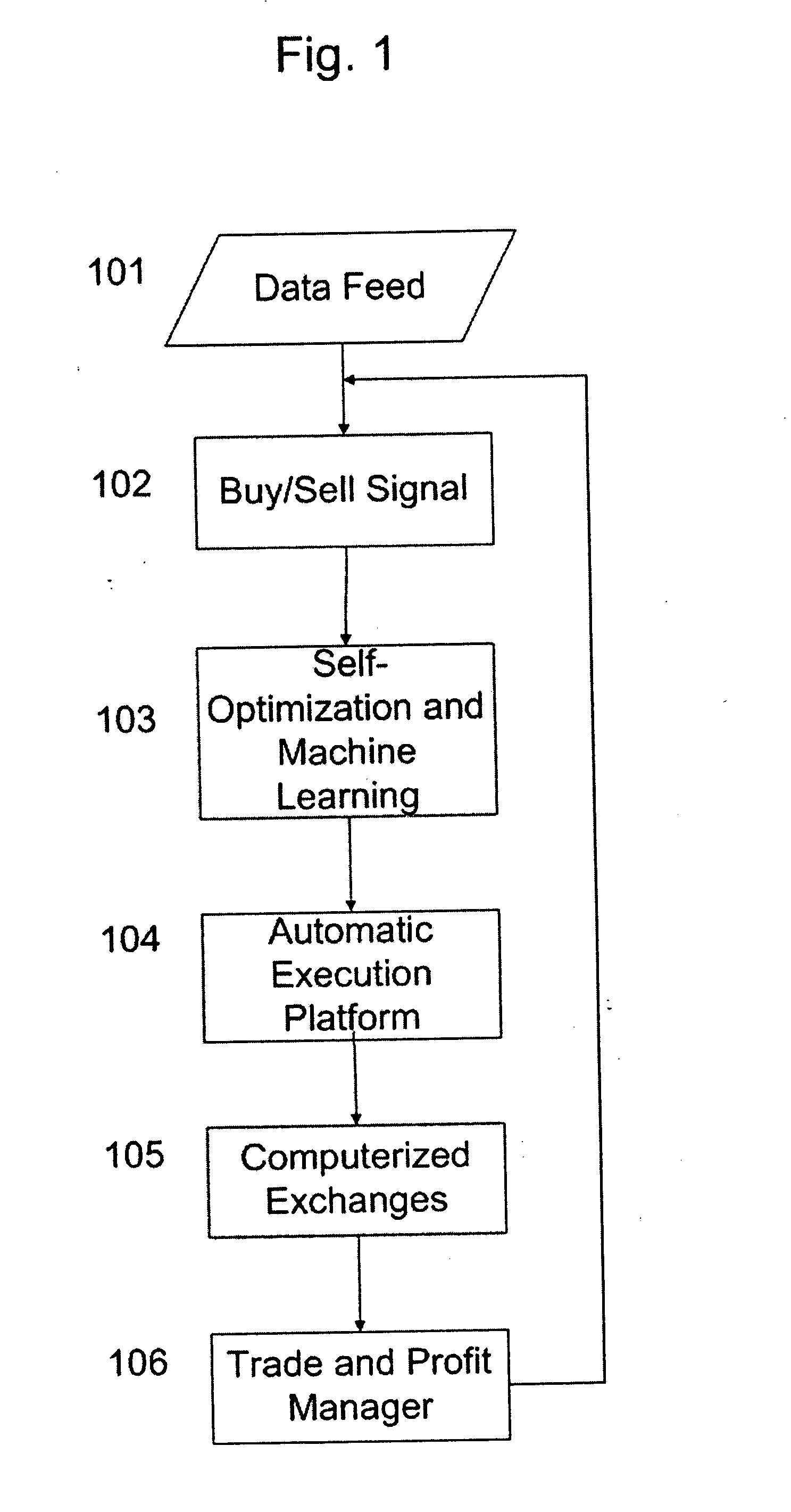

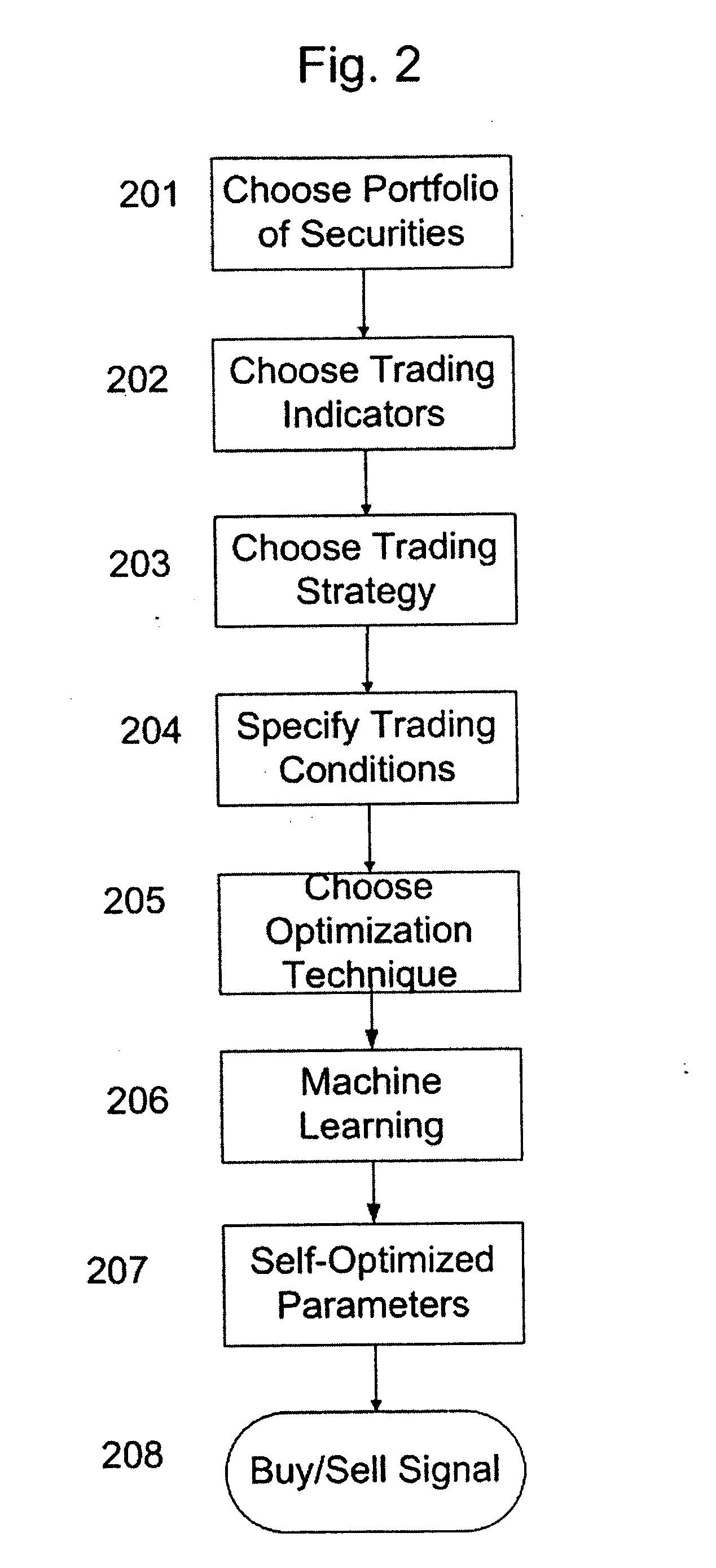

The invention is a Machine Learning system, method and computer program for automated transmission of Buy / Sell orders generated according to self-optimized trading parameters. Optimization could be performed according to every optimization method used. Perpetual real-time optimization (or self-optimization) of trading parameters adds Machine Learning feature to the invention. The invention provides a centralized trading system for the individual user or organization that wants to perform his trading automatically and completely without human intervention from receiving the data from the central server provider to real-time order execution in computerized financial markets. The disclosed system is integrated into a network of brokers, banks and other institutions trading on computerized markets. The system receives real-time market quotes information from a data provider remote server and uses it as an input for the defined trading strategies. These trading strategies generate Buy / Sell signals for a plurality of chosen market securities. The trading could be performed with previously optimized parameters or, alternatively, the optimization could be performed in real-time with trading strategy and its parameters being perpetually and automatically updated, and consequently the trading being performed with self-optimized parameters. The system further includes a module for storing specific order settings and risk / return information. Once execution criteria are satisfied, the order is sent for execution automatically. The system also includes a module for storing information relating to the Buy / Sell transactions and to the profit / loss accounting.

Owner:MAKOR ISSUES & RIGHTS

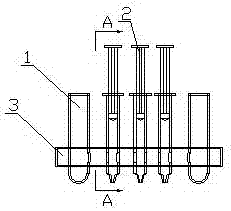

Process for producing fire-retardant high-tenacity terylene yarn

InactiveCN101545155AHigh strengthImprove flame retardant performanceFlame-proof filament manufactureMelt spinning methodsYarnPolyester

The invention relates to a process for producing a fire-retardant high-tenacity terylene yarn, which comprises the following steps: reforming equipment by using the prior industrial terylene yarn production line; adopting two sets of solid phase thickening devices; preparing high-viscosity polyester slices and high-viscosity fire-retardant master batches respectively, and thickening the high-viscosity polyester slices and the high-viscosity fire-retardant master batches, wherein the high-viscosity fire-retardant master batches are metered precisely according to certain proportion through a master batch adding machine and are mixed with the high-viscosity polyester slices, the optimal proportion of the two materials is controlled to be 12:88, so that the fire resistance and the tenacity are greatly improved; processing the two materials by a pin screw extruder, a meter and a spinneret plate; after slow cooling, lateral blowing and oiling, performing multi-stage hot-rolling stretching; and finally winding the two materials into spinning cakes on a winder. The process has the characteristics of simplicity, easy operation, high product tenacity, good fire resistance and the like.

Owner:陈晓美

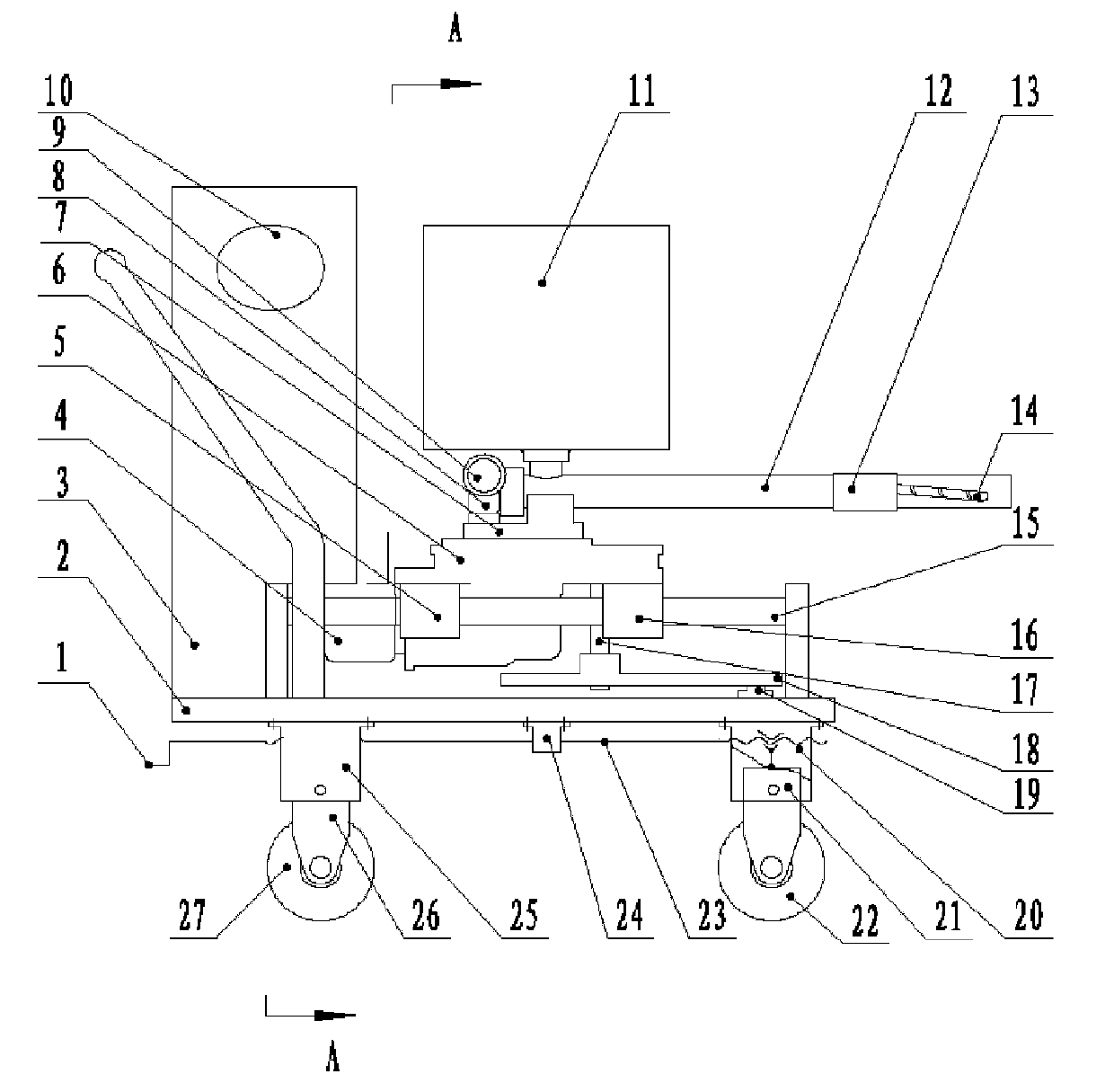

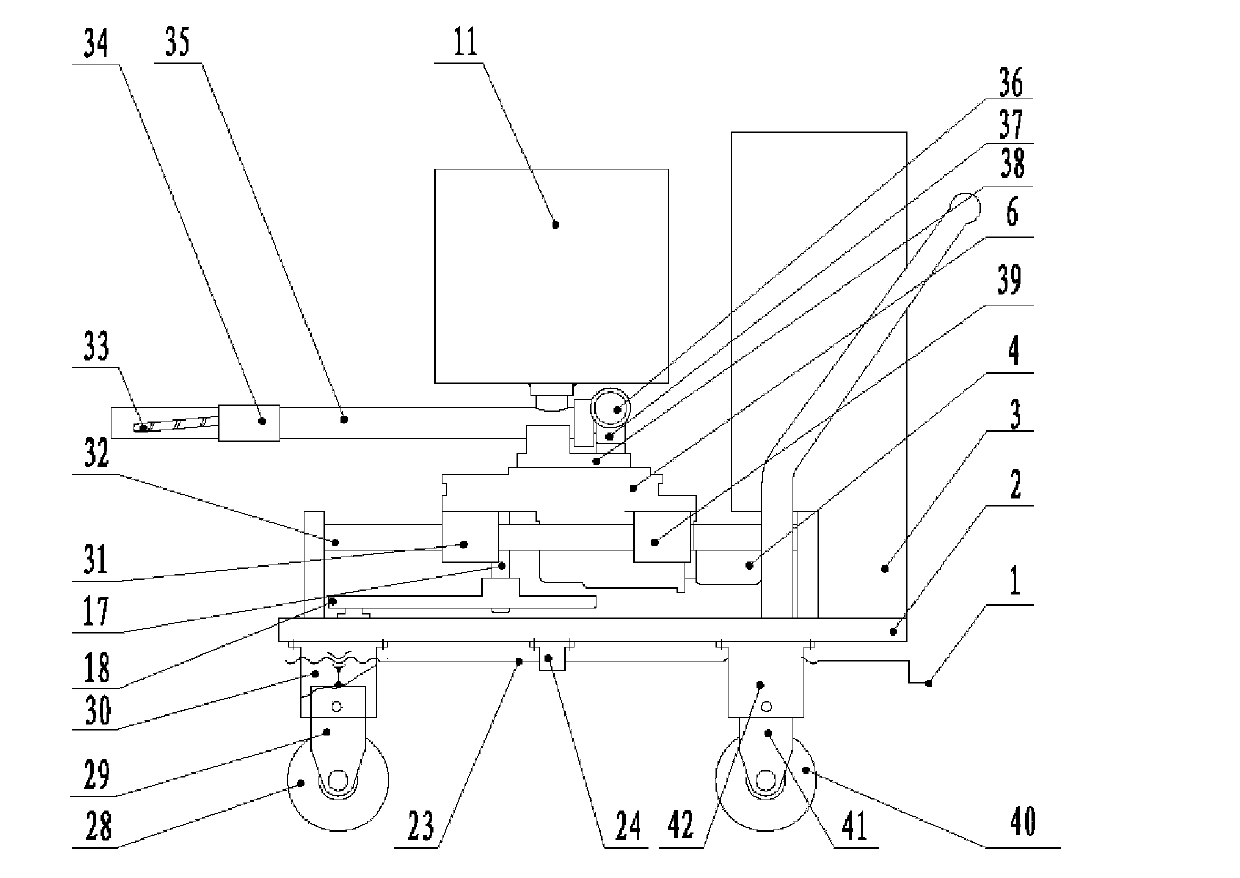

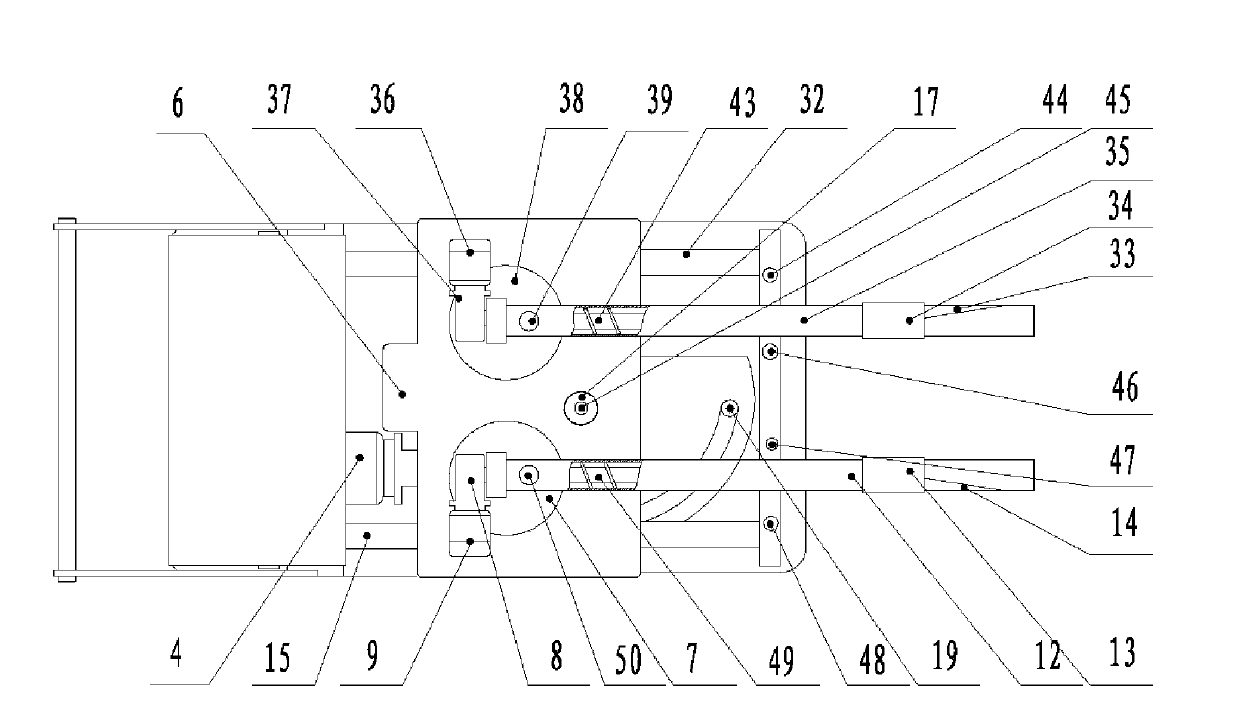

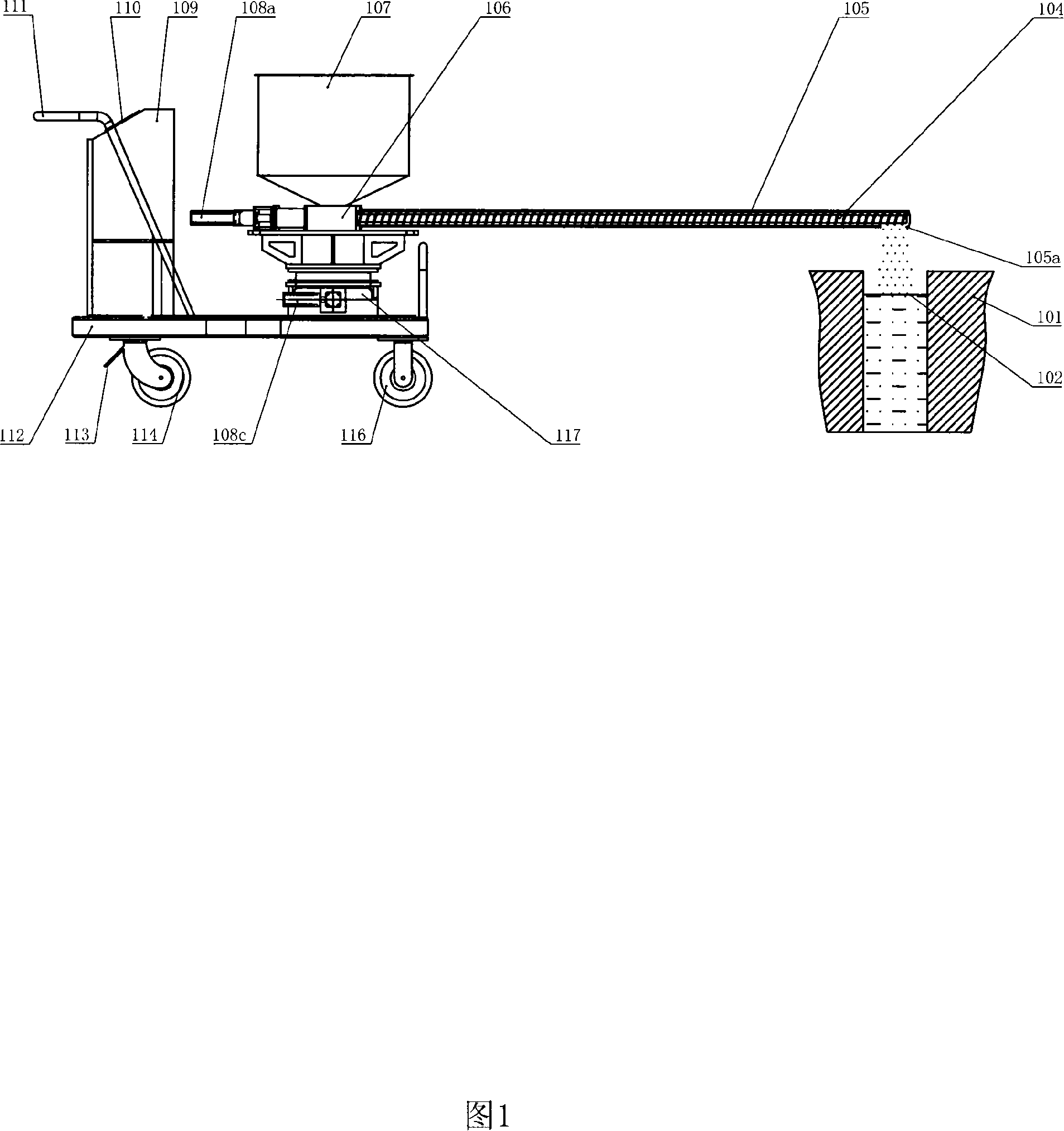

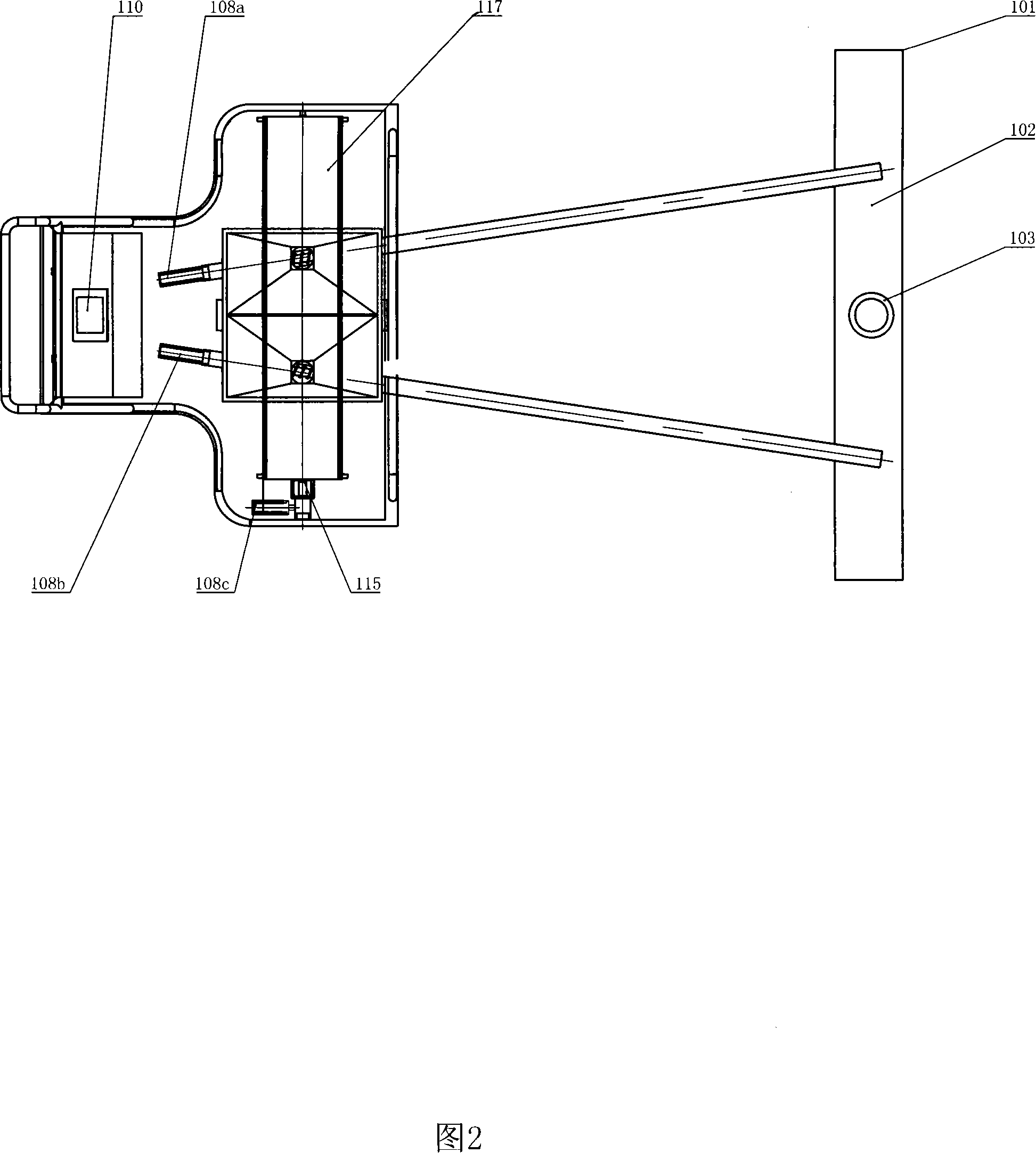

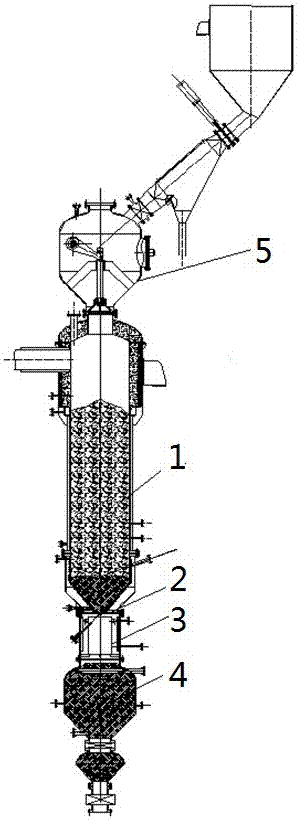

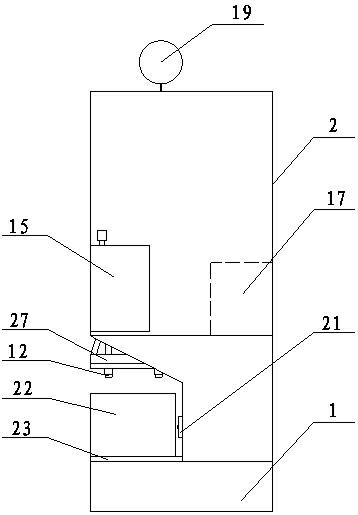

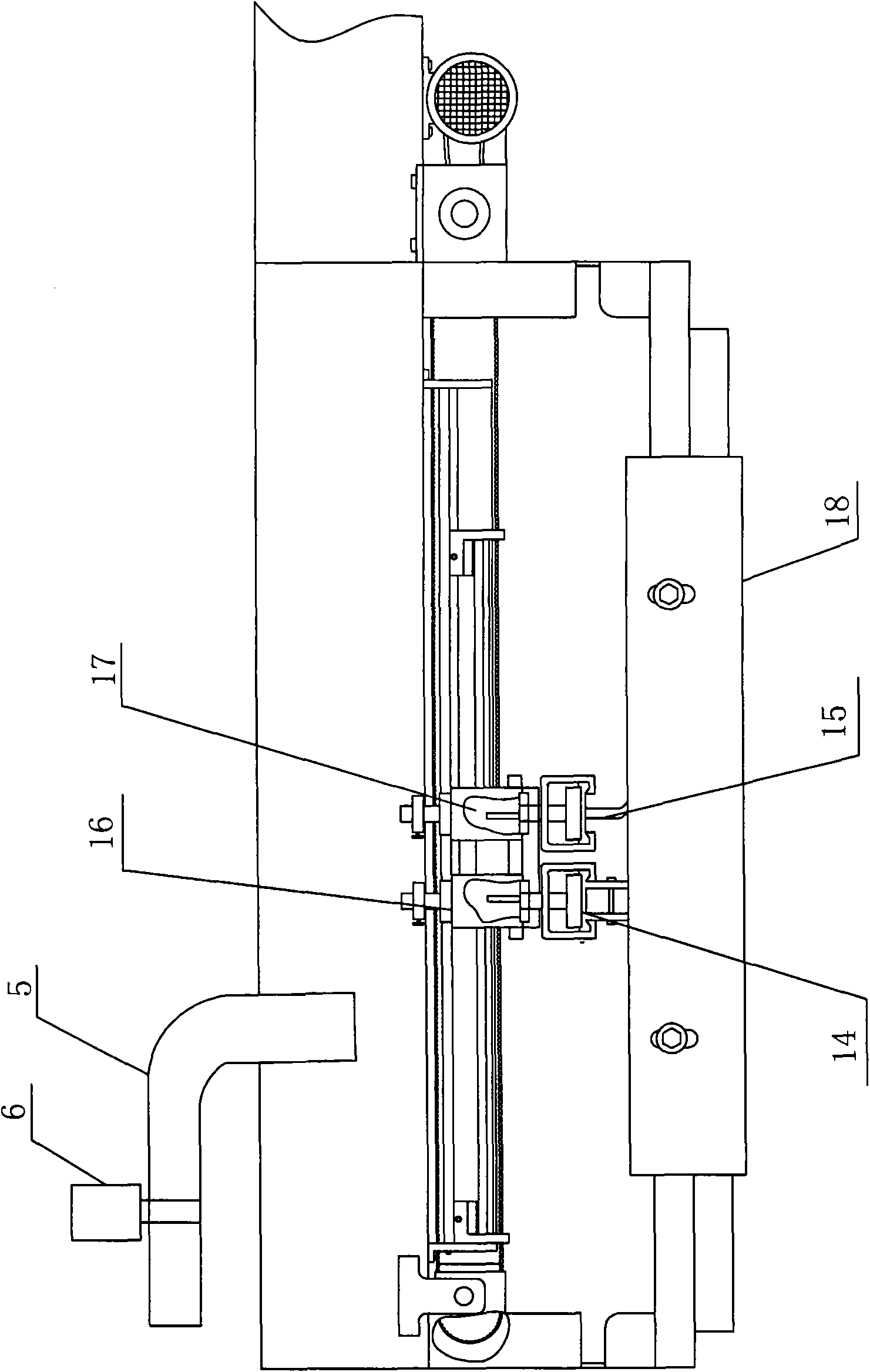

Double-barrelled automatic slag adding machine

The invention relates to a double-barrelled automatic slag adding machine. The technical scheme comprises that the slag adding machine comprises a frame, a slag adding system and an electric control system. The slag adding system is in the structure that: a vibrating motor (4) respectively drives two feed delivery pipe supporting discs (7 and 38) to rotate by virtue of two vibrating output shaftsof a third reduction box (6), namely a first feed delivery pipe (12) and a second feed delivery pipe (35) are driven to vibrate in the horizontal plane; and a translation compensation output shaft (17) of the third reduction box (6) drives a translation compensation cam (18) to rotate, thus the reciprocating linear motion of the slag adding system is realized. Two feed delivery motors (9 and 36) respectively drive a first feed delivery screw rod (49) and a second feed delivery screw rod (43) to rotate, thus a granular material is pushed towards the exit direction. The slag adding machine provided by the invention has the characteristics of compact structure, uniform slag addition, high degree of automation and wide application range and is simple in operation and applicable to automatic, continuous and uniform casting powder addition of a large-section crystallizer of which all the material spreading regions have the lengths in the range of 300-2500mm and the widths in the range of 0-300mm.

Owner:WUHAN UNIV OF SCI & TECH

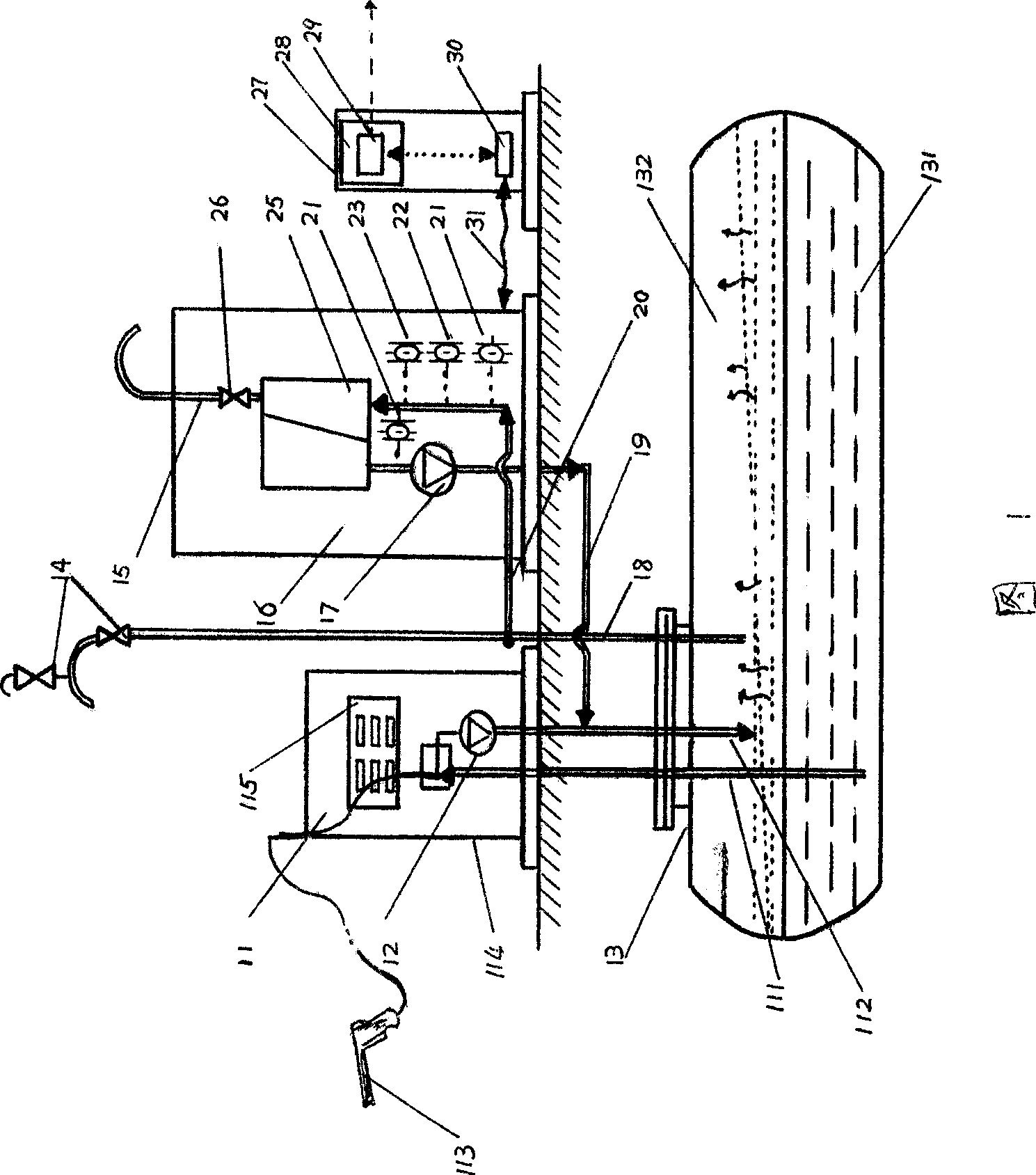

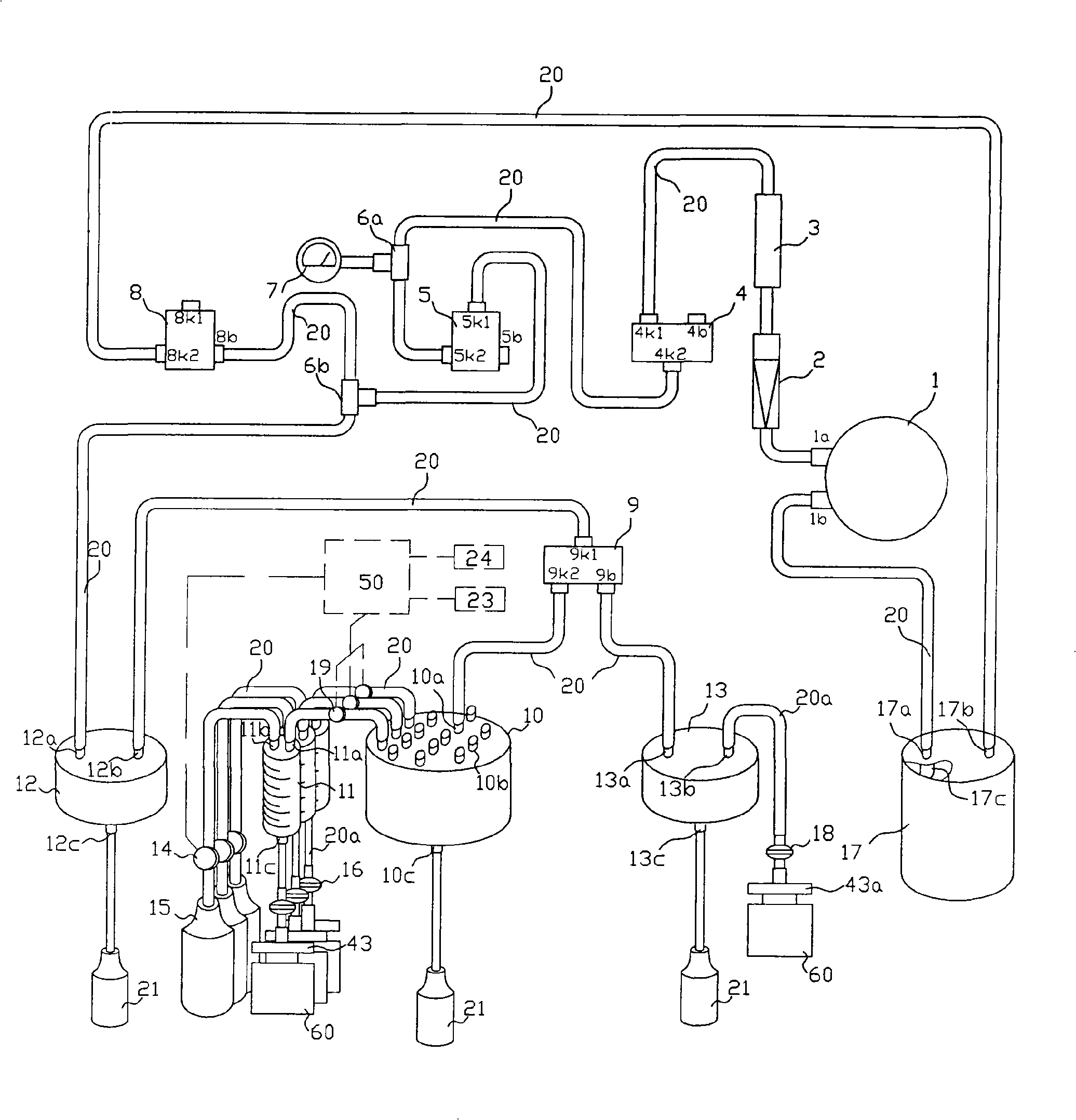

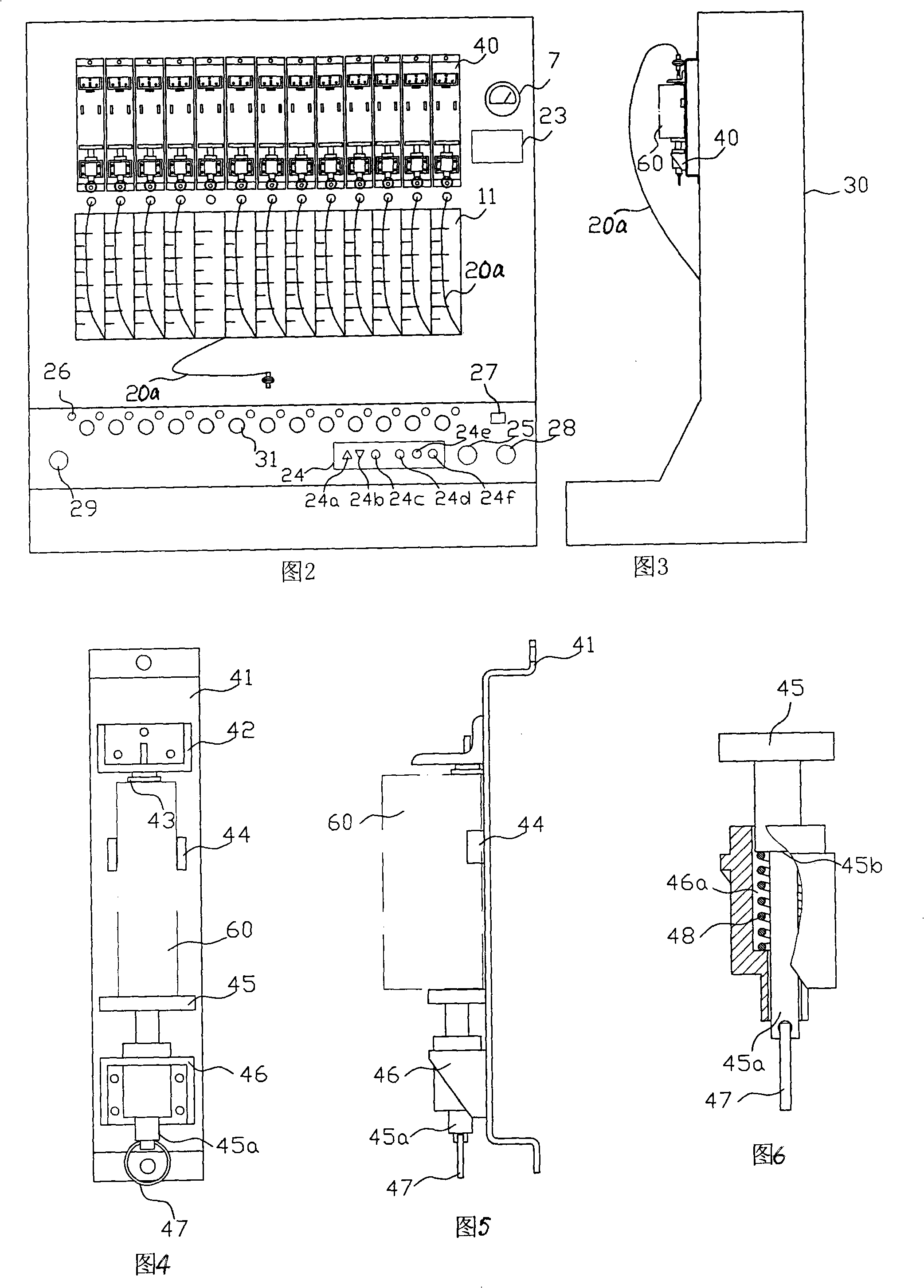

Oil-gas recovery processing method and system for gas station

InactiveCN101445214AReduce pollutionReduce riskDispersed particle separationLarge containersAutomatic controlProcess engineering

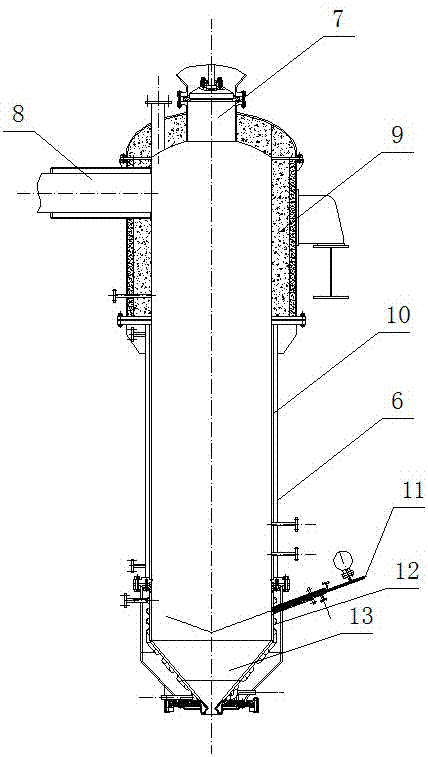

An oil-gas recovery processing method for a gas station and a system thereof mainly consist of an oil-gas recovery processing method and a system thereof, wherein, the oil-gas recovery processing method can be summed up as an intermittent operating process which consists of four periodic links and automatically controlled, that is, oil-gas collection, pumping by a vacuum pump, separating a membrane module to recovering and enriching the oil and the gas and discharging the tail gas; and the oil-gas recovery processing system comprises an oil adding machine (11), an underground oil tank (13), a main oil-gas recovering machine (16) and a control box (27); and the core part of the main oil-gas recovering machine (16) takes the membrane module (25) as a main body for separation and recovery. The method and the system can help save energy sources and protect environment, and the system has the advantages of simple and compact structure, less installation workload, and simple and easy use, maintenance and repair.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

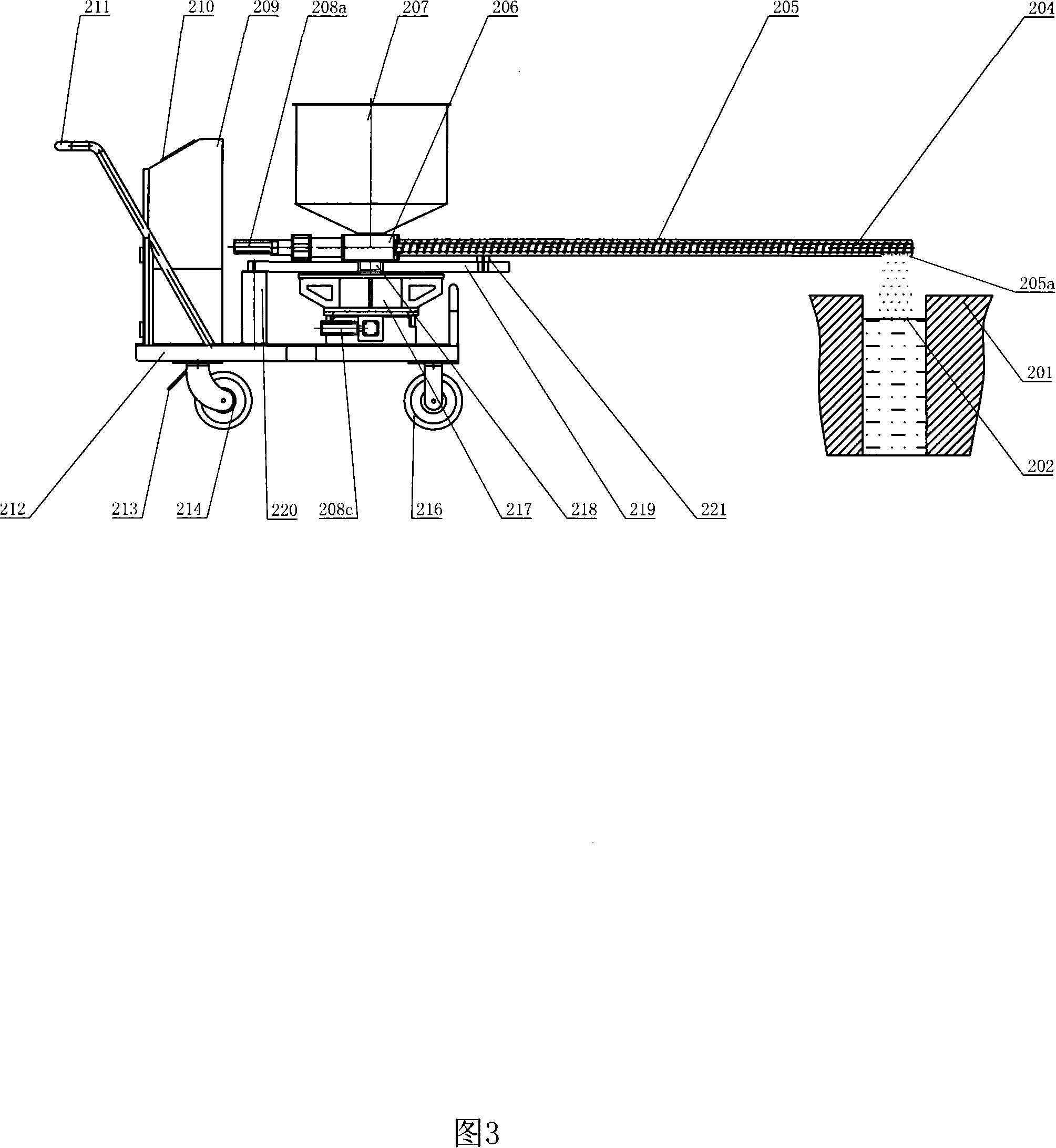

Mechanized production technique for producing Xiaoqu liquor with glutinous sorghum as raw material and device of spreading for cooling and mixing yeast thereof

The invention discloses a mechanized production technique for producing Xiaoqu liquor with glutinous sorghum as raw material, which comprises the following steps: firstly, putting the glutinous sorghum in hot water for soaking, and then putting the soaked grain in a spherical low-pressure distiller for primary distillation, secondary distillation and gelatinization; and spreading the gelatinized grain for cooling and mixing the same with a yeast, and then carrying out culture saccharification, low temperature fermentation and distillation to obtain the Xiaoqu liquor. The invention also discloses a device of spreading for cooling and mixing a yeast for use in the mechanized production technique, which is provided with stainless steel conveying chain plates, wherein the conveying chain plates are combined into a square form with the top end opened; the left conveying chain plate is sequentially provided with a conveying receiving hopper, a rice husk machine and a grain tipping machine from top to bottom; a machine of spreading for cooling and a wide-width quantitative yeast adding machine are arranged on the horizontal conveying chain plate from left to right; and two narrow-width quantitative yeast adding machines, two grain tipping machines and a saccharifying case feed hopper are arranged on the right conveying chain plate from bottom to top. The Xiaoqu liquor produced in the invention is low in fusel oil content and stable in quality, and has prominent Xiaoqu fen-flavor liquor style.

Owner:JING BRAND

Dynamical system for loadage of grinding body in cylinder type ball mill and application method of dynamical system

ActiveCN102600958AEasy loadingOptimizing the best loadGrain treatmentsDynamical optimizationProcess engineering

The invention discloses a method for detecting loadage of a grinding body in a cylinder type ball mill. The method can dynamically optimize the loadage of the grinding body according to an optimization object and obtain a non-load current or power and a knee current or power under optimal loadage of steel balls. During the follow-up running process, a procedure captures the knee current or power and the non-load current or power, estimates loss of the grinding body according to deviation, outputs an additive amount of the steel balls as required and add the steel balls through a ball adding machine according to the additive amount of the steel balls, so as to realize dynamically automatic addition of the grinding body. The dynamical system and the application method provided by the invention have the advantages that the optimal loadage of the grinding body can be optimized, so that the disadvantages that influence on production efficiency and product quality and loss of the steel balls due to excessive or too small loadage of the grinding body amount are avoided; the grinding body can be added scientifically, so that the disadvantages brought by addition in a fixed period and a fixed amount or in an irregular period and an irregular amount are avoided; and the labor intensity of workers can be reduced.

Owner:西安蓝海机械仪表成套有限责任公司

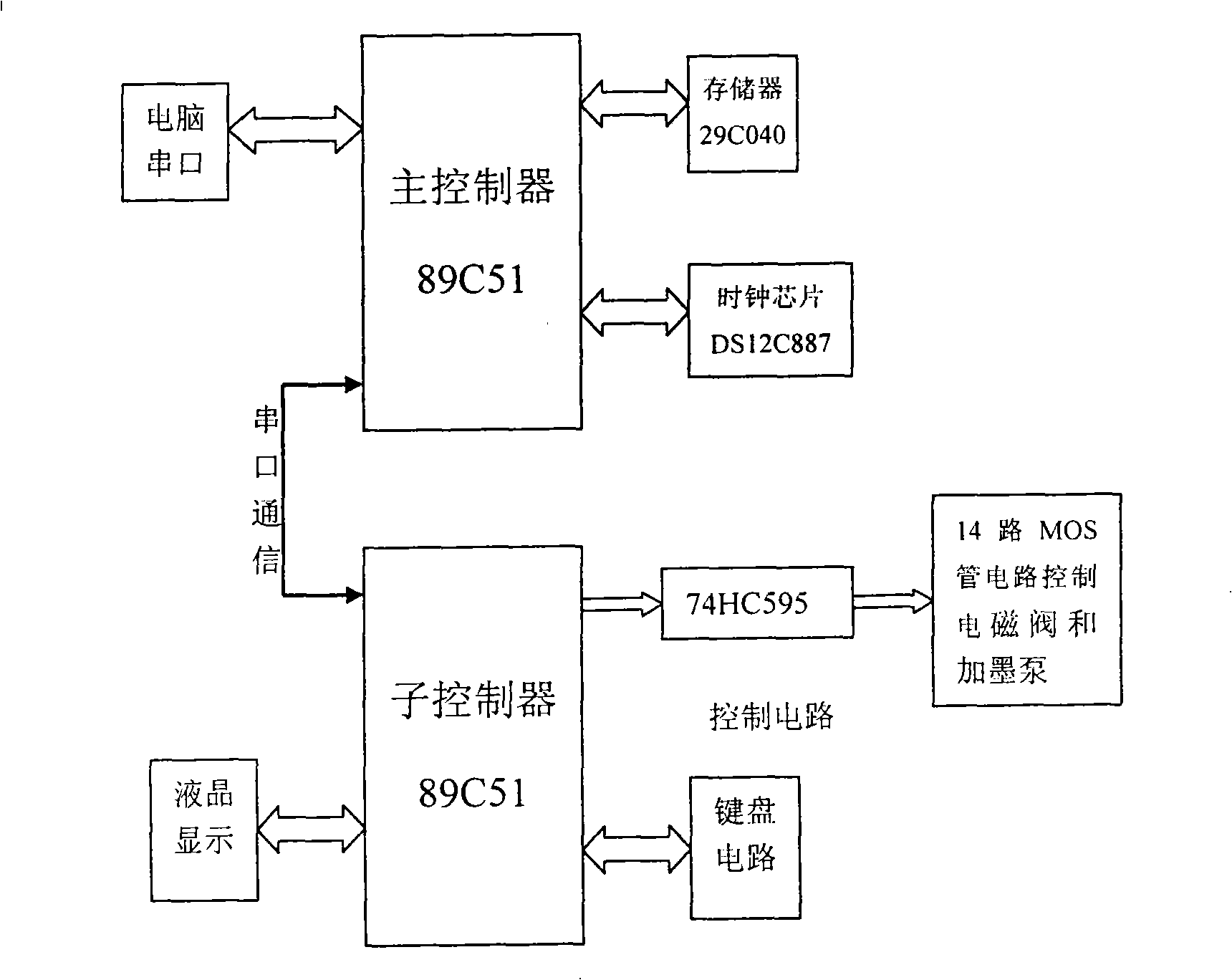

Large-section crystallizer automatic slag adding machine

The present invention relates to an automatic slag-adding device for large-section crystallizer. It is composed of slag hopper, spiral slag-adding pipe, locating buggy for carrying slag hopper, drive motor, controller and touch display screen. The movement of slag hopper on the locating buggy can implement uniform addition of slag for crystallizer. In the course of slag hopper movement the synchronous oscillation of said spiral slag-adding pipe also can be implemented. The controller can be used for automatically regulating slag-adding speed and range according to the crystallizer section, steel quality and billet-drawing speed. The touch display screen positioned on the locating buggy can be used for setting, modifying and displaying parameters of automatic slag-adding device.

Owner:田志恒

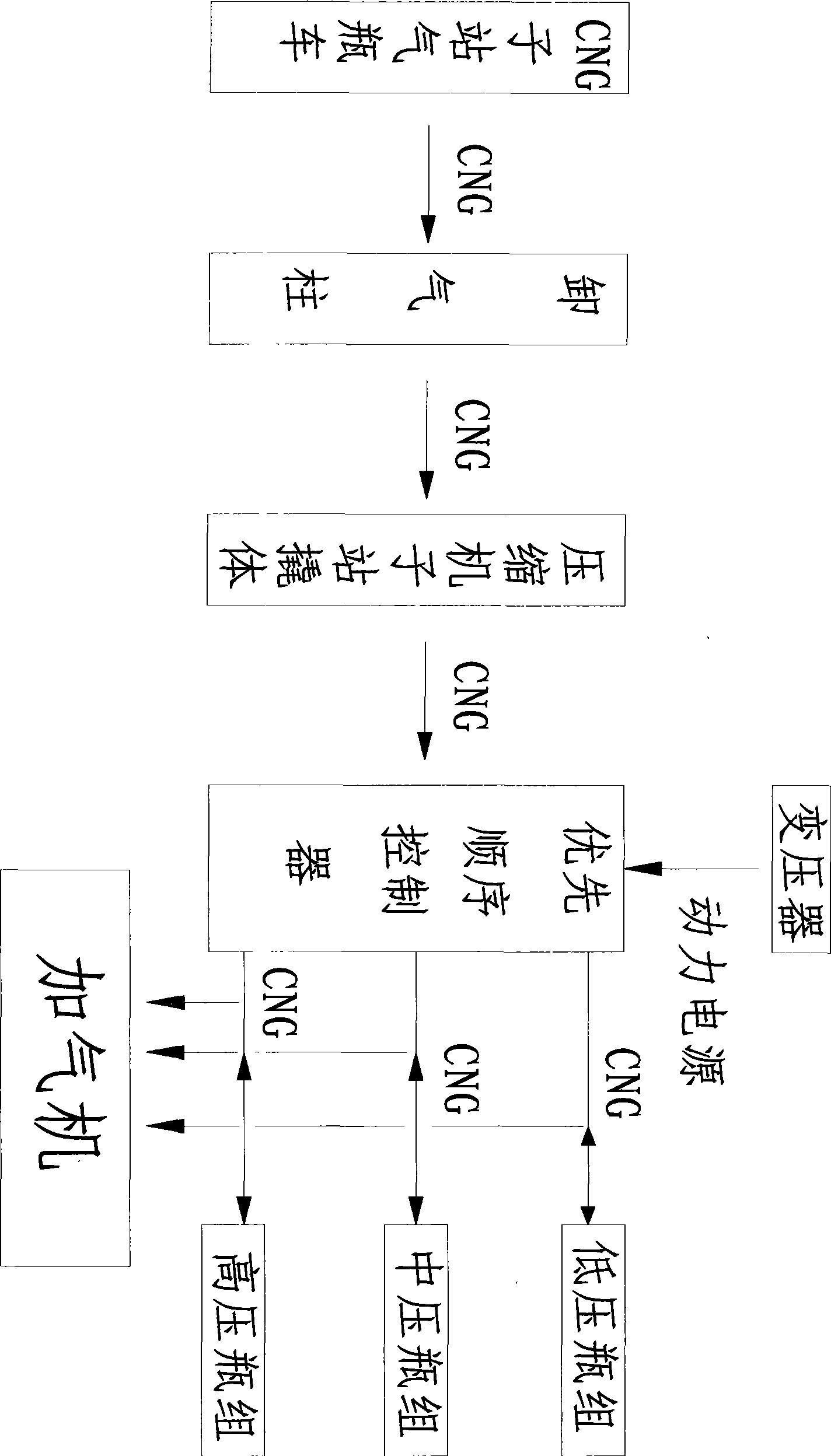

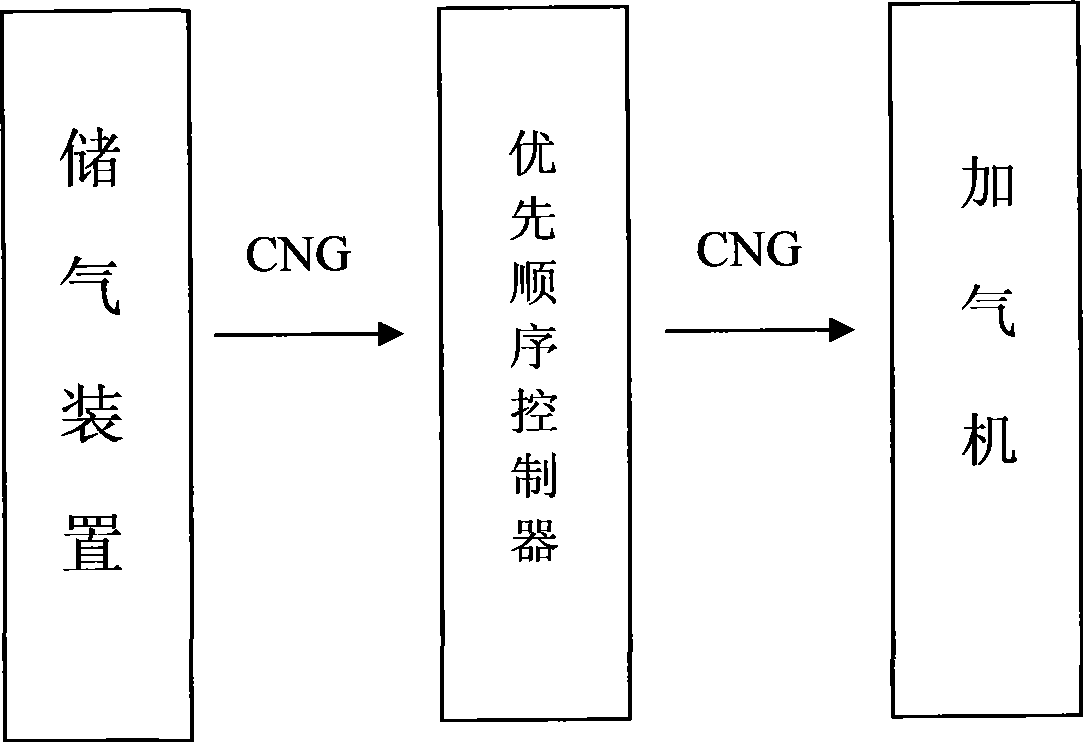

Secondary gas filling station

InactiveCN101509599ASimple structureSave peopleVessel mounting detailsFluid transferredCompressed natural gasGas cylinder

The invention relates to a brand-new branch gas station, only consisting of a gas adding machine, a priority sequence controller and a plurality of gas storage devices. The branch gas station has the technical characteristics that each gas storage device is composed of a plurality of gas tanks which are filled with high pressure compressed natural gas (CNG) of 25 MPa, the gas storage devices alternatively and cyclically provide high pressure CNG to form alternate recycle high pressure technology, solving the problem that the gas storage devices need a compressor or a hydraulic pump sell the remaining gas by pressurization, saving the massive equipment investment such as compressor, hydraulic pump, intra-station gas tank group and the like and easily standardizing the three major components: the gas adding machine, the priority sequence controller and the gas storage devices, being free from daily consumption such as power supply, mechanical wear and the like; in addition, the branch gas station is matched with a major gas station and pursues the technical road featuring L-CNG and is easily and rapidly replicated in cities throughout the country, thus enjoying the possibility of changing the backward situation at home where for the past dozens of years, CNG stations are hard to be integrated into a complete sales network.

Owner:沈军

Machine learning automatic order transmission system for sending self-optimized trading signals

A Multi-Channel Machine Learning system, method and computer program is for automated simultaneous transmission of a number of Buy / Sell orders generated according to differently self-optimized trading parameters for each independent trading strategy. Optimization could be performed according to every optimization method used. Perpetual real-time optimization (or self-optimization) of trading parameters adds Machine Learning feature to the invention and it is done independently for each trading strategy. A centralized trading system is provided for the individual user or organization that wants to perform his trading automatically and completely without human intervention from receiving the data from the central server provider to real-time order execution in computerized financial markets. The disclosed system is working based on an API / DSK programming tools and is integrated into a network of brokers, banks and other institutions trading on computerized markets, through a number of parallel working connection channels.

Owner:MAKOR ISSUES & RIGHTS

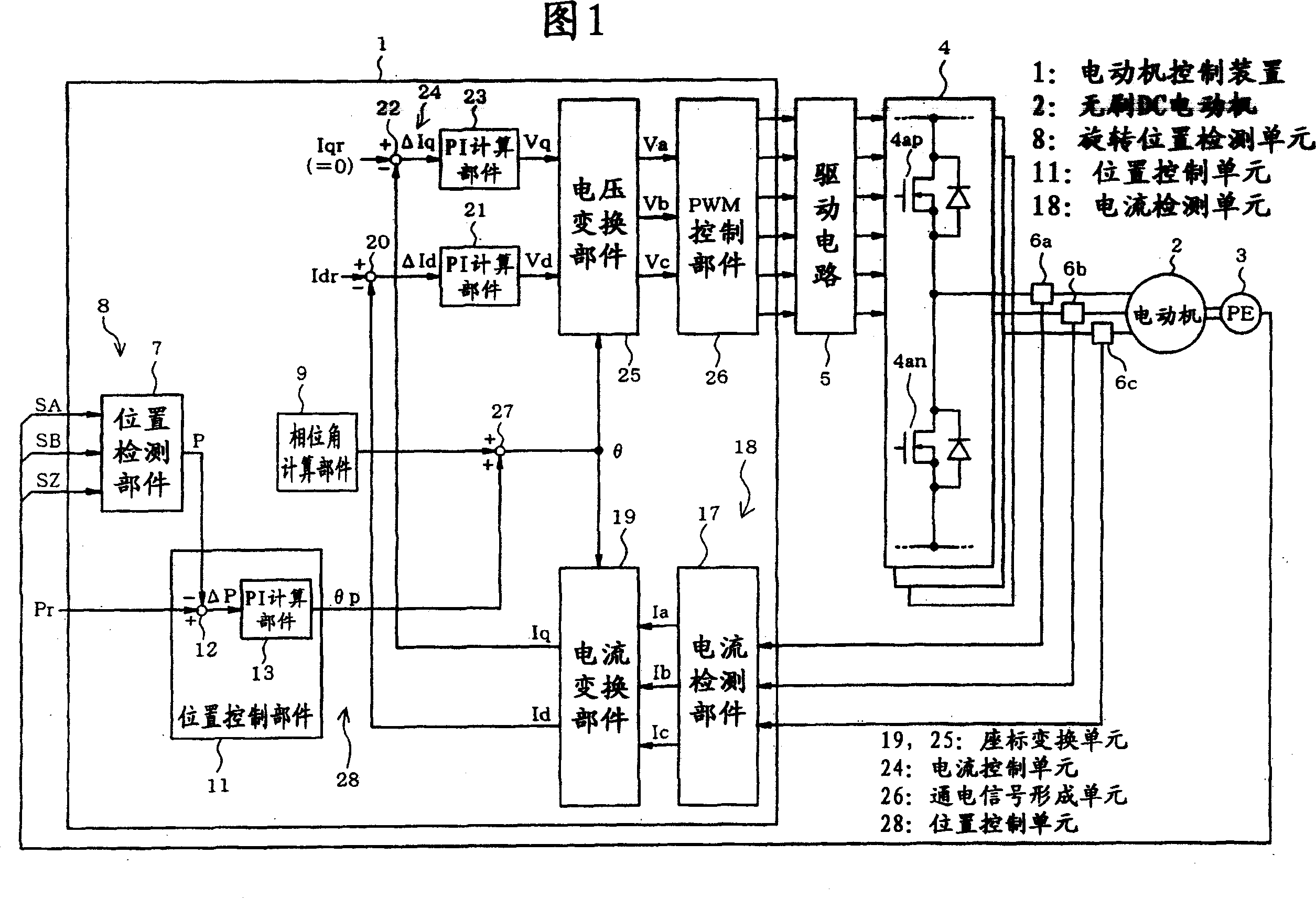

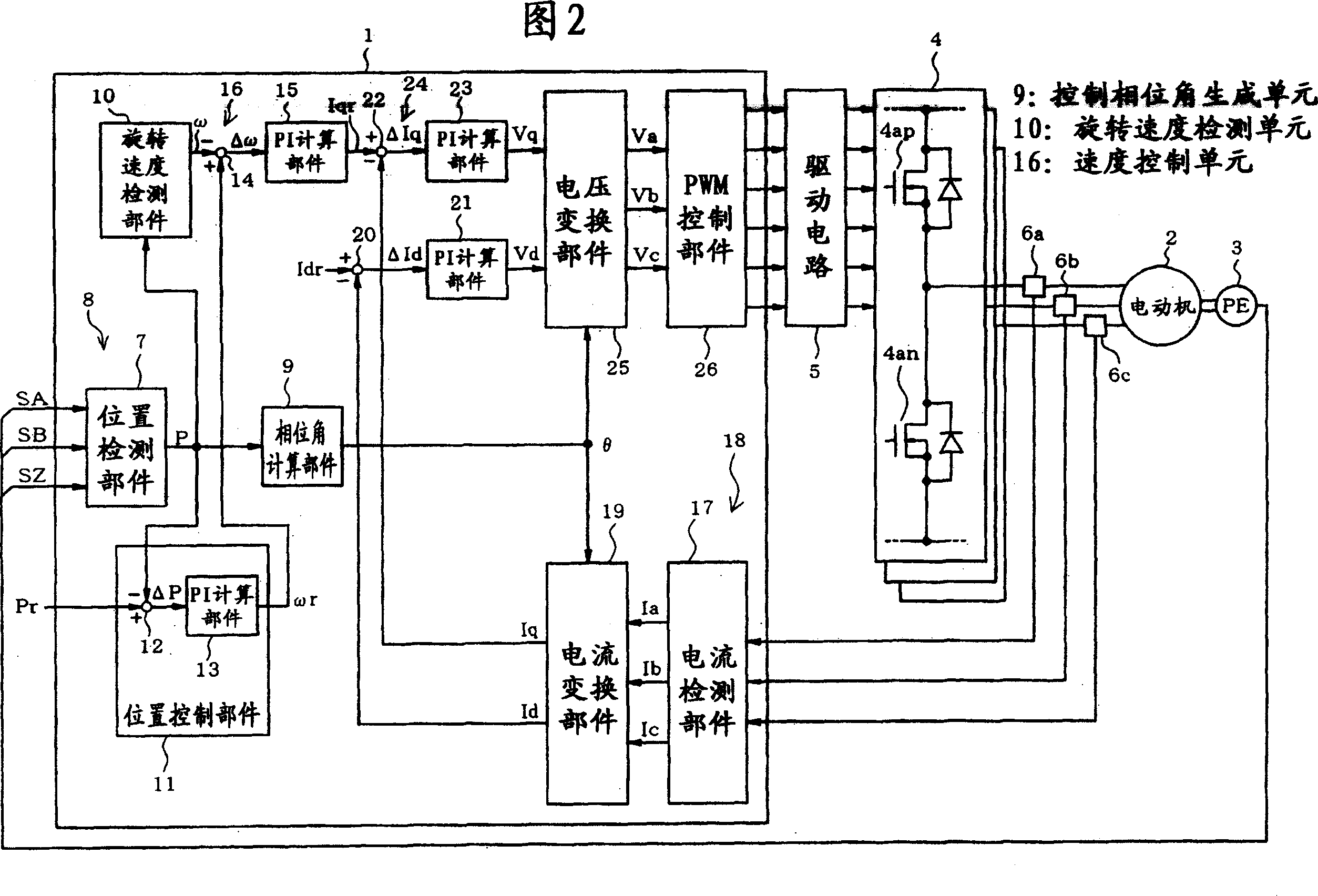

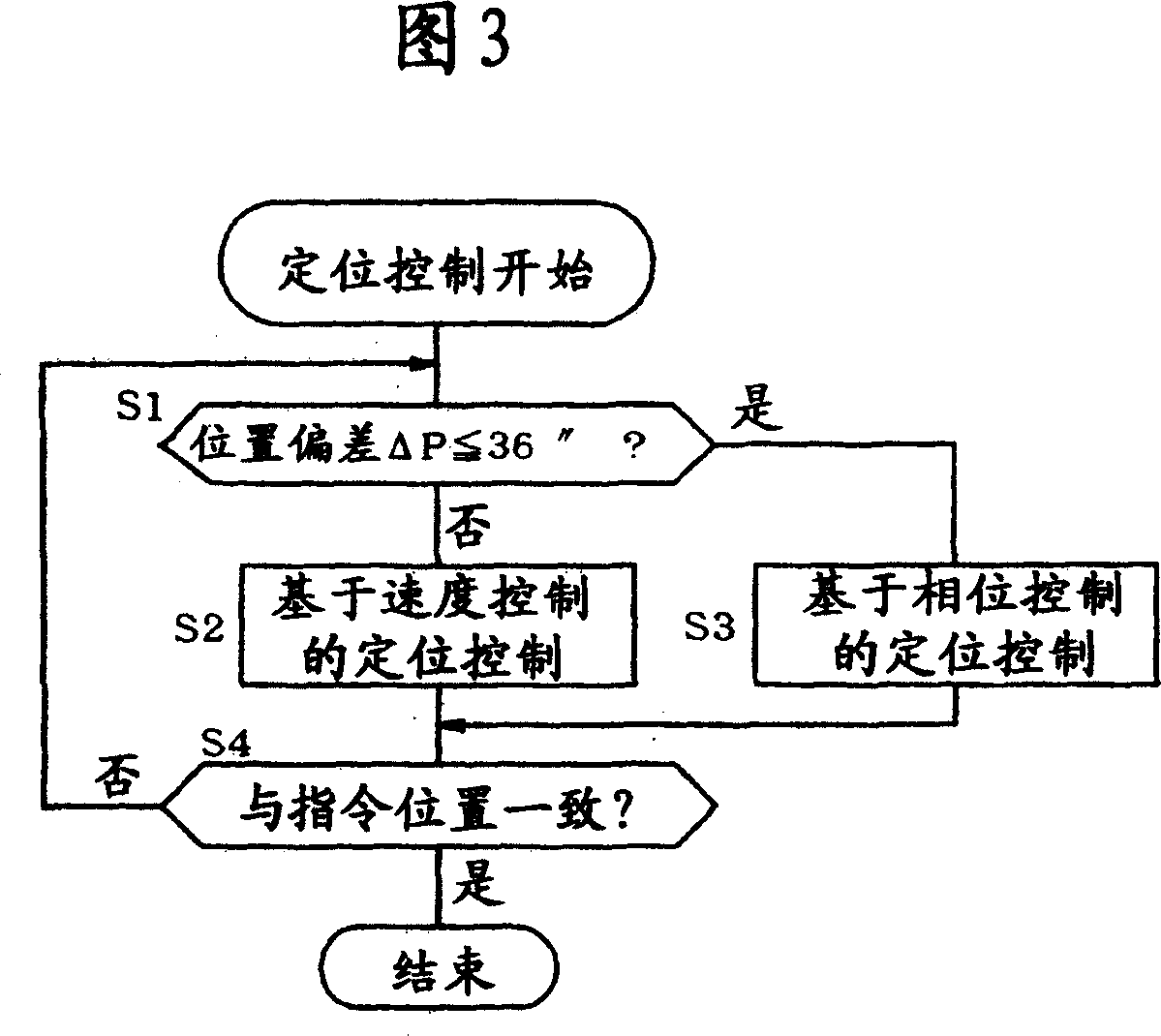

Motor control unit

InactiveCN101097438AHigh position resolutionVector control systemsSingle motor speed/torque controlMotor controlPhase control

A motor control unit of the present invention processes to high precision position. When the situation of position deviation (delta P) is more than the regulating value, to make speed feedback circulation be effective, and execute positioning control based on speed control. If the position deviation (delta P) is small than or equal to the regulating value, then to make speed feedback circulation be ineffective, and to execute positioning control based on phase control. On the base of phase control position control, to make statement q axis current (Iqr) is zero, and generate correction angle (theta p) by PI calculating component (13) based on the position deviation (delta p), to add phase angle (theta) while switching to the correction angle (theta P) using with adding machine (27). Current switching component (9) and voltage switching component (25) use corrected phase angle (theta) to process rotating coordinate switch.

Owner:KK TOSHIBA

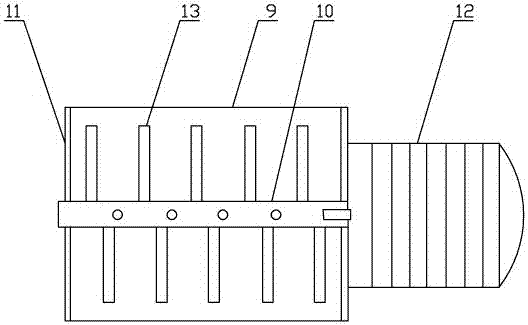

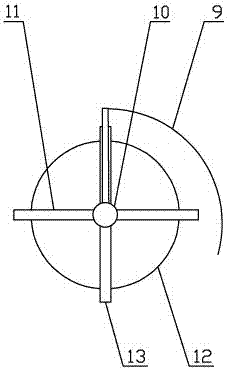

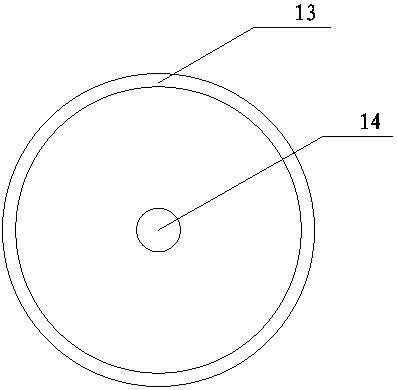

Automatic ball adding machine

ActiveCN103056002ASimple structureReduce manufacturing costGrain treatmentsFailure rateCircular disc

The invention designs a novel automatic ball adding machine which is suitable for adding balls into ball milling machines with various specifications, such as lattice-type ball mill, overflow type ball mill, semi-autogenous grinding ball mill, etc., and is accurate in ball adding amount, stable, and low in failure rate. The automatic ball adding machine provided by the invention comprises a ball adding barrel, a ball adding storehouse, a buffer area, a motor, a disc ball unloading machine and a ball uploading pipe. The automatic ball adding machine provided by the invention can effectively prevent occurrence of squeezing, stacking and blocking among the balls during a ball adding process, so that ball loading and unloading processes during a ball adding operation are quite smooth, and a ball adding number can be further calculated, thereby effectively improving ball adding efficiency. In addition, the ball adding machine is simple in structure, low in manufacture cost, convenient to maintain, and extremely low in failure rate, and is suitable for popularization and application in the ball adding process of the ball milling machines with various specifications.

Owner:NANJING MEISHAN METALLURGY DEV

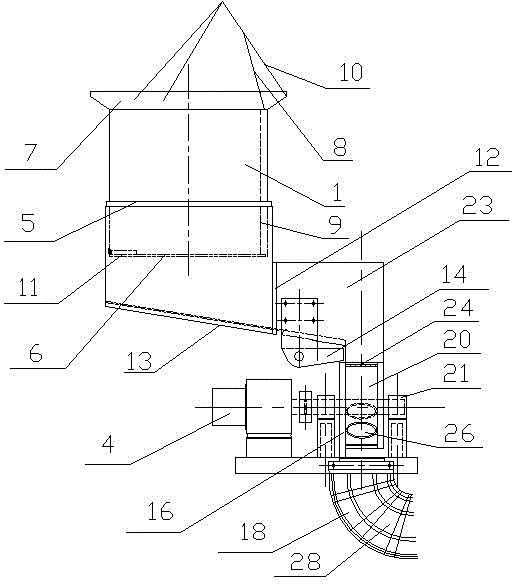

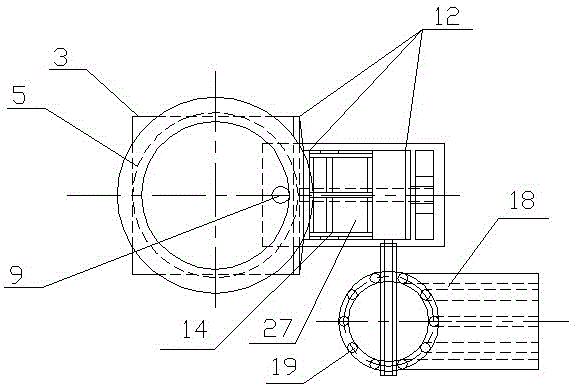

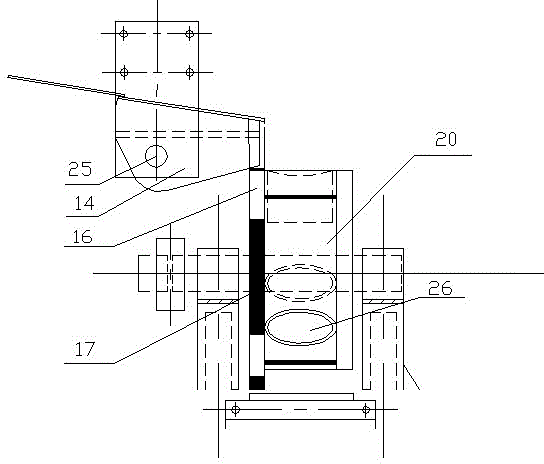

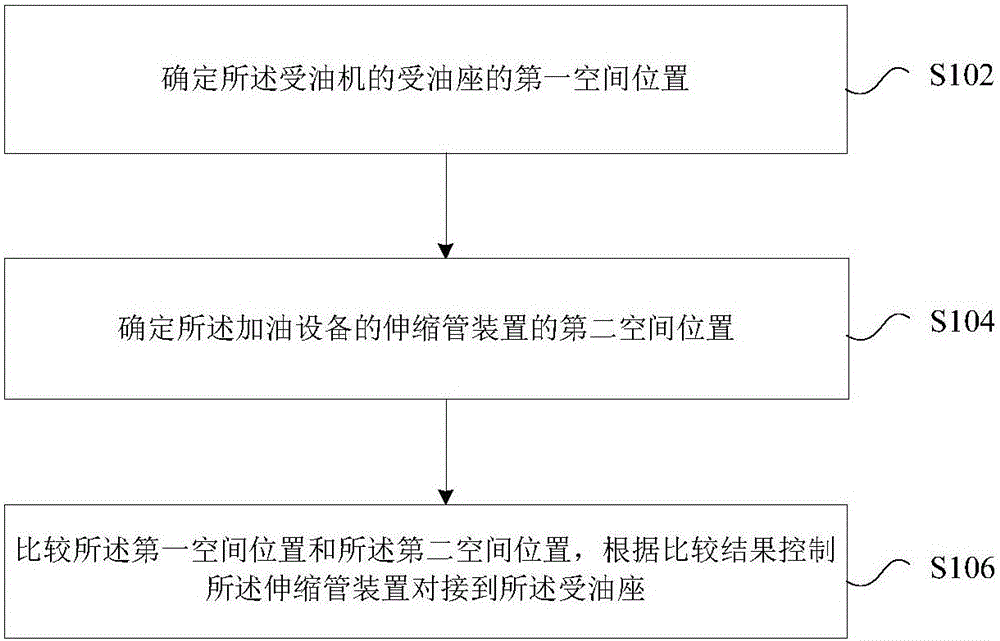

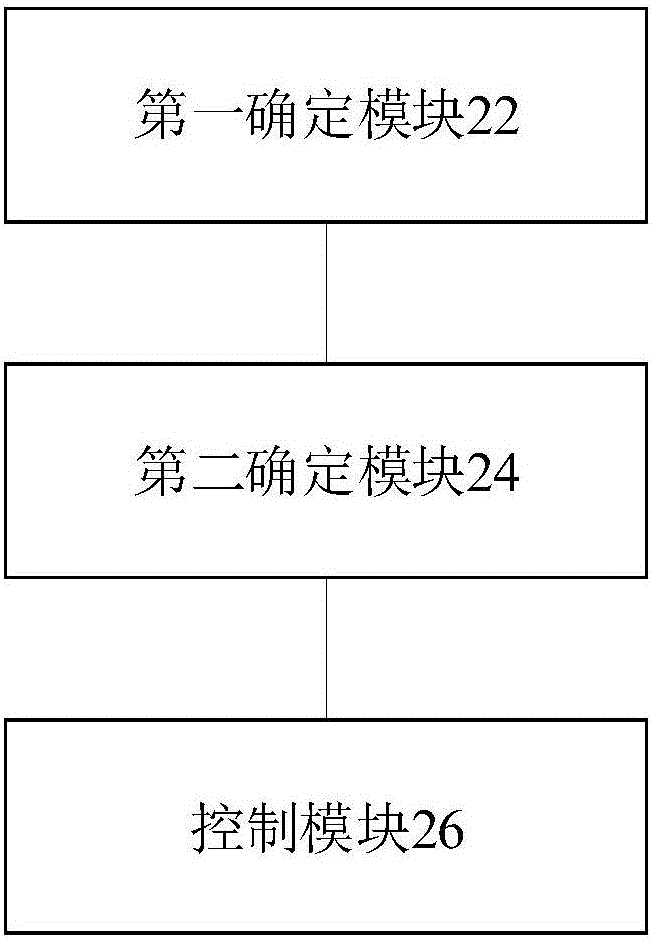

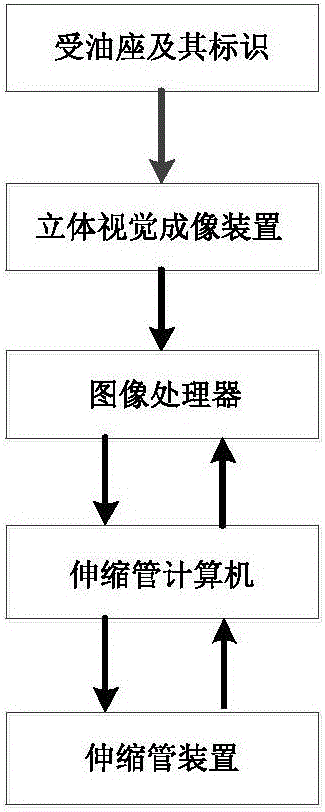

Control method and device for automatic butt joint of oil adding device and oil receiving machine

ActiveCN105084285AAutomatic reachSolve the problem of not being able to automatically refuel the oil receiverLiquid transferring devicesButt jointEngineering

The invention provides a control method for automatic butt joint of an oil adding device and an oil receiving machine. The method comprises the steps that the first space position of an oil receiving base of the oil receiving machine is determined; the second space position of a telescopic pipe device of the oil adding device is determined; the first space position and the second space position are compared, and the telescopic pipe device is controlled to be in butt joint to the oil receiving base according to the comparison result. By means of the control method, the problem that in the prior art, an oil adding device cannot automatically add oil to an oil receiving machine is solved, and accordingly the purpose of automatically adding oil to the oil receiving machine through the oil adding machine is achieved.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

Automatic ink loader for computer print cartridge and ink loading method

The invention relates to an automatic ink adding machine for a printing ink box and an ink adding method thereof. The automatic ink adding machine comprises a pipeline, a vacuum distributor, a vacuum valve, an ink measuring pipe, a residue pump can, a residual liquid can, a vacuum pump or compressor which are arranged in a casing, a vacuum watch, a residual ink pump connector, an ink injection connector, an ink box fixture which are arranged at the outside of the casing, an air-gas separator, an ink measuring pump, a display screen, a keyboard, a control unit and an electromagnetic valve including a negative ink injection valve, a first positive pressure valve, a second positive pressure valve and a residual ink pump valve. The automatic ink adding method comprises the following steps: 1. clamping the empty ink box to the fixture; 2. starting the vacuum pump; 3. opening the corresponding electromagnetic valve, and vacuumizing the ink measuring pipe and the ink box; 4. setting the ink application value; 5. opening the ink measuring ink pipe of the corresponding position and pumping the ink to the corresponding ink measuring pipe; 6. determining negative pressure ink adding or positive pressure ink adding and injecting the ink into the empty ink box. The machine and the method of the invention have the advantages of convenient clamping and high ink adding efficiency, thus facilitating the management of a plurality of ink adding chain stores, improving the ink adding speed of a soft ink bin and ensuring that the ink box with crazing can be reused.

Owner:王浩

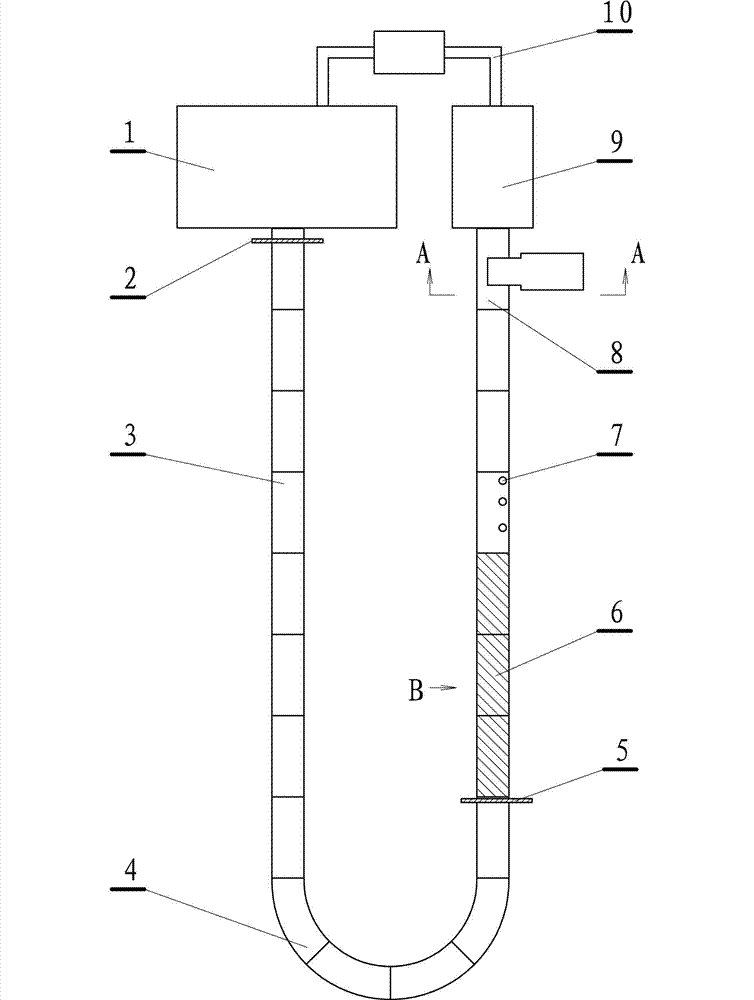

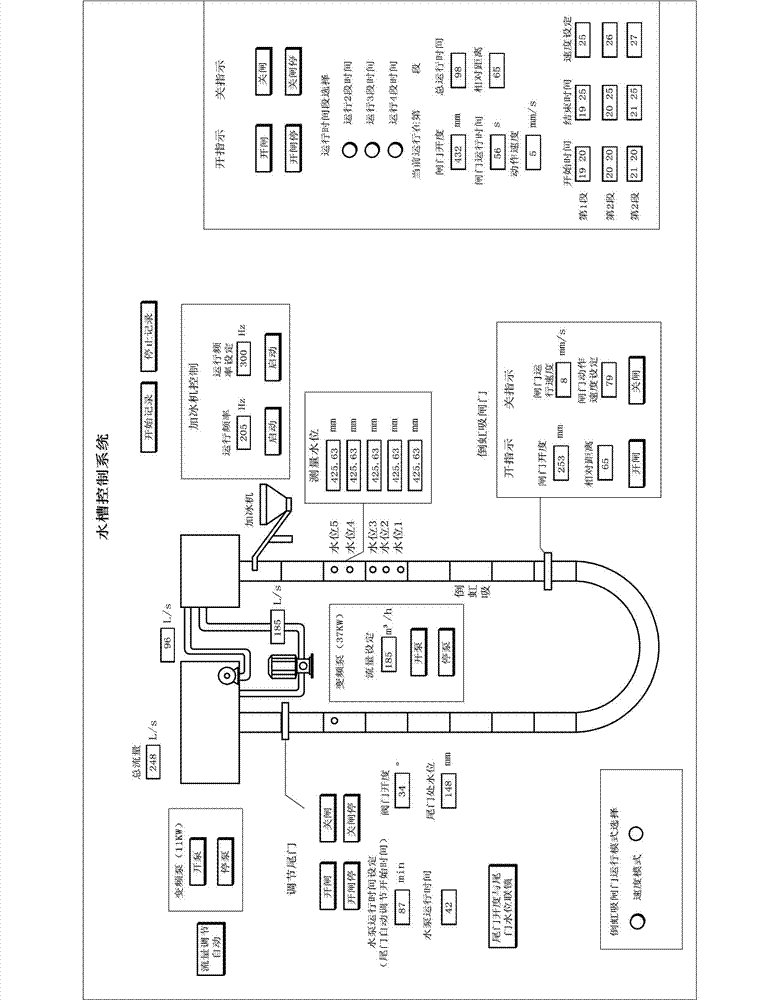

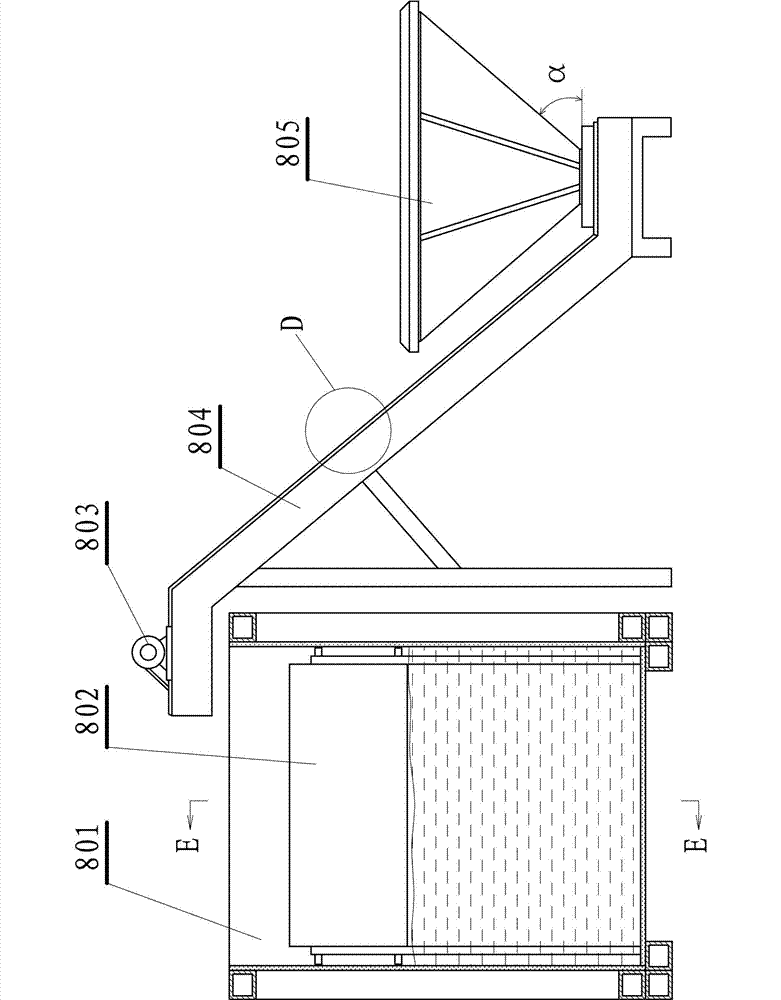

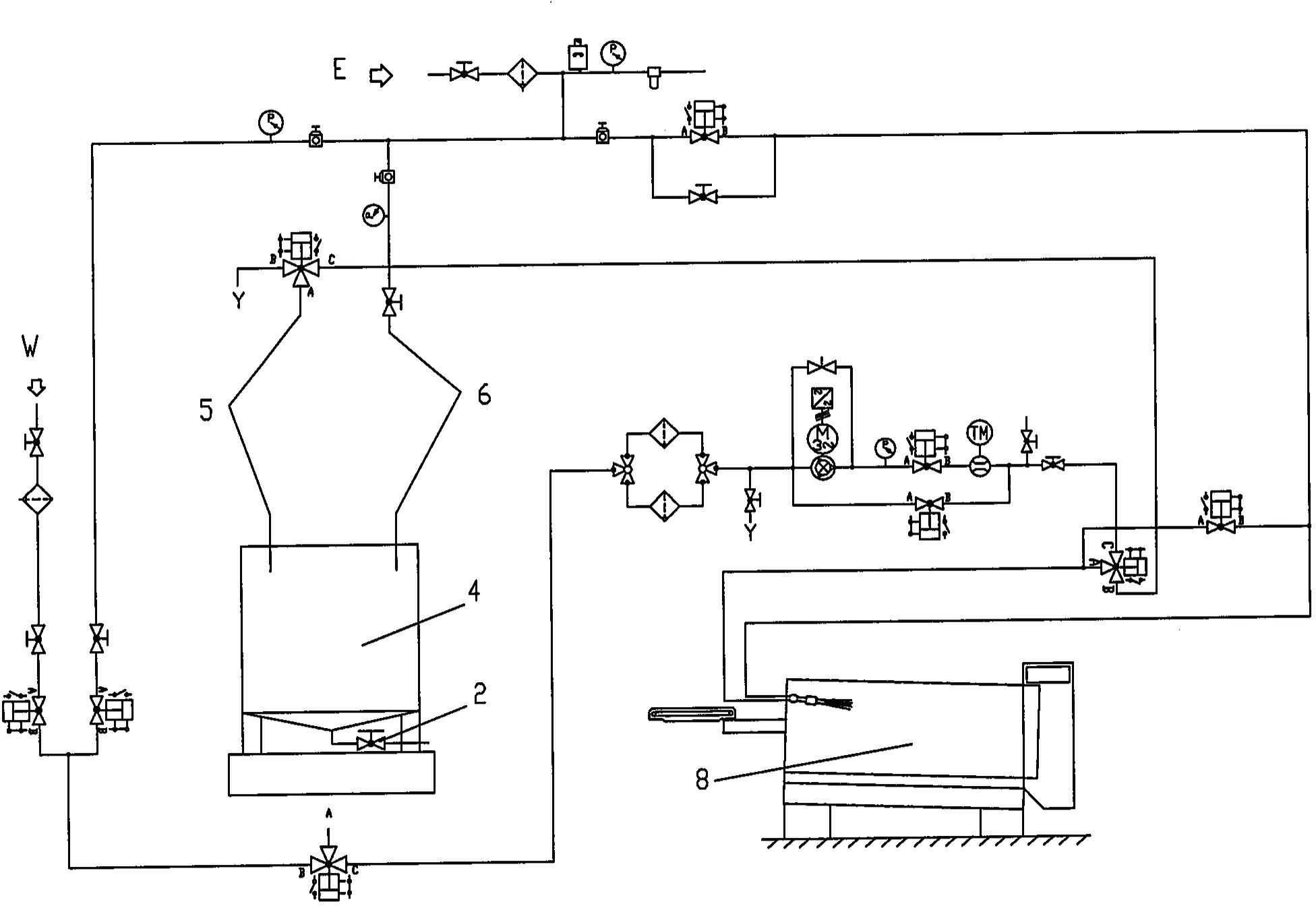

Ice-water coupling synthetic simulation platform and method

The invention relates to an ice-water coupling synthetic simulation platform and a method. The ice-water coupling synthetic simulation platform includes a source water tank and a return water tank, wherein the source water tank is detachably and sequentially connected with an ice adding groove section, two to three straight groove sections provided with water level sensors, an inverted siphon, a straight groove section, a U-shaped groove section, a plurality of straight groove sections and a return water tank to form a water tank, and an electric control tail door with the water level sensor is arranged on the straight groove section connected with the return water tank; and a water supply device, an automatic ice adding machine, an electric control inverted siphon gate, the electric control tail door and water level sensors are electrically connected with the controller. The application of the ice-water coupling synthetic simulation platform greatly reduces the manual operation of the ice-water coupling experiment, improves the accuracy of the experiment, accelerates the progress and speed of the experiment, which is significant to the emergency research, can save the losses of the lives and properties of the people under special circumstances, even saving the lives.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

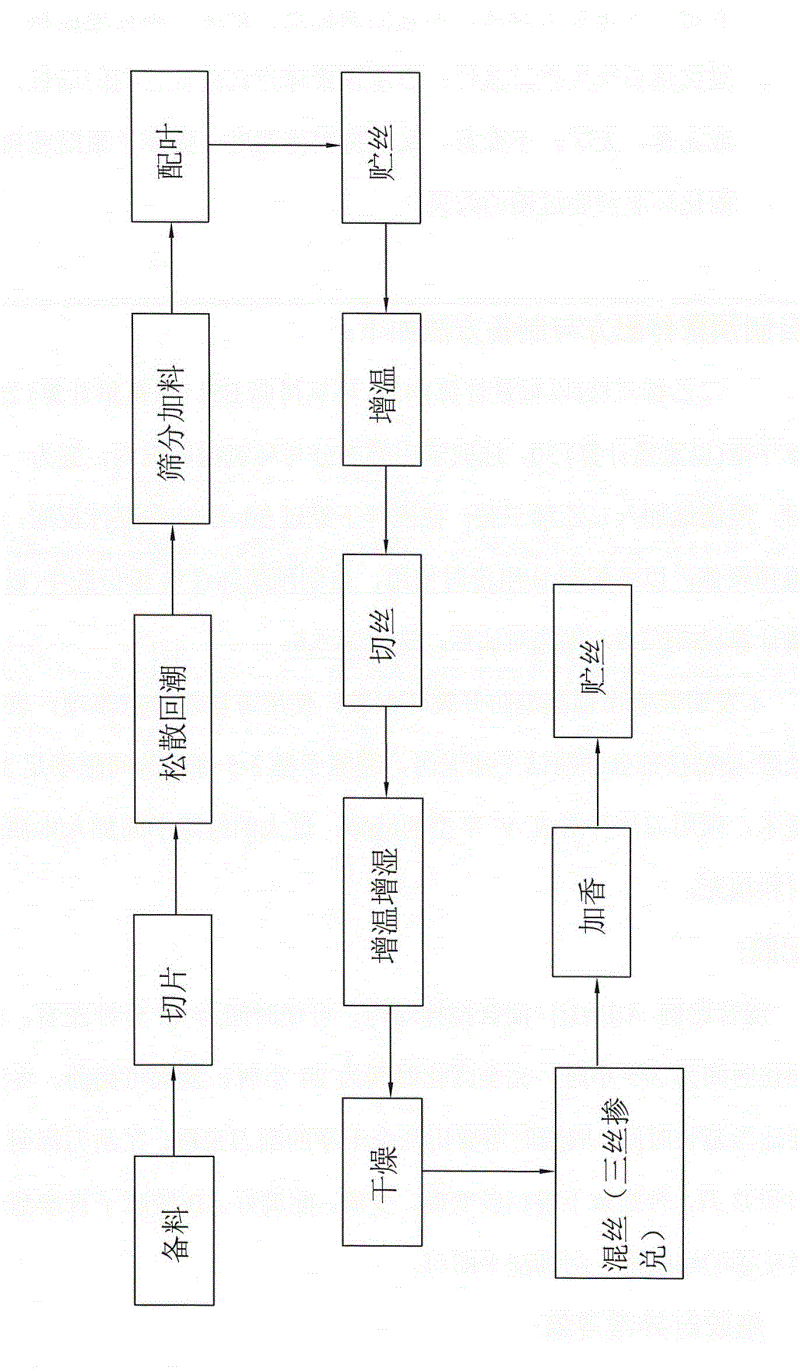

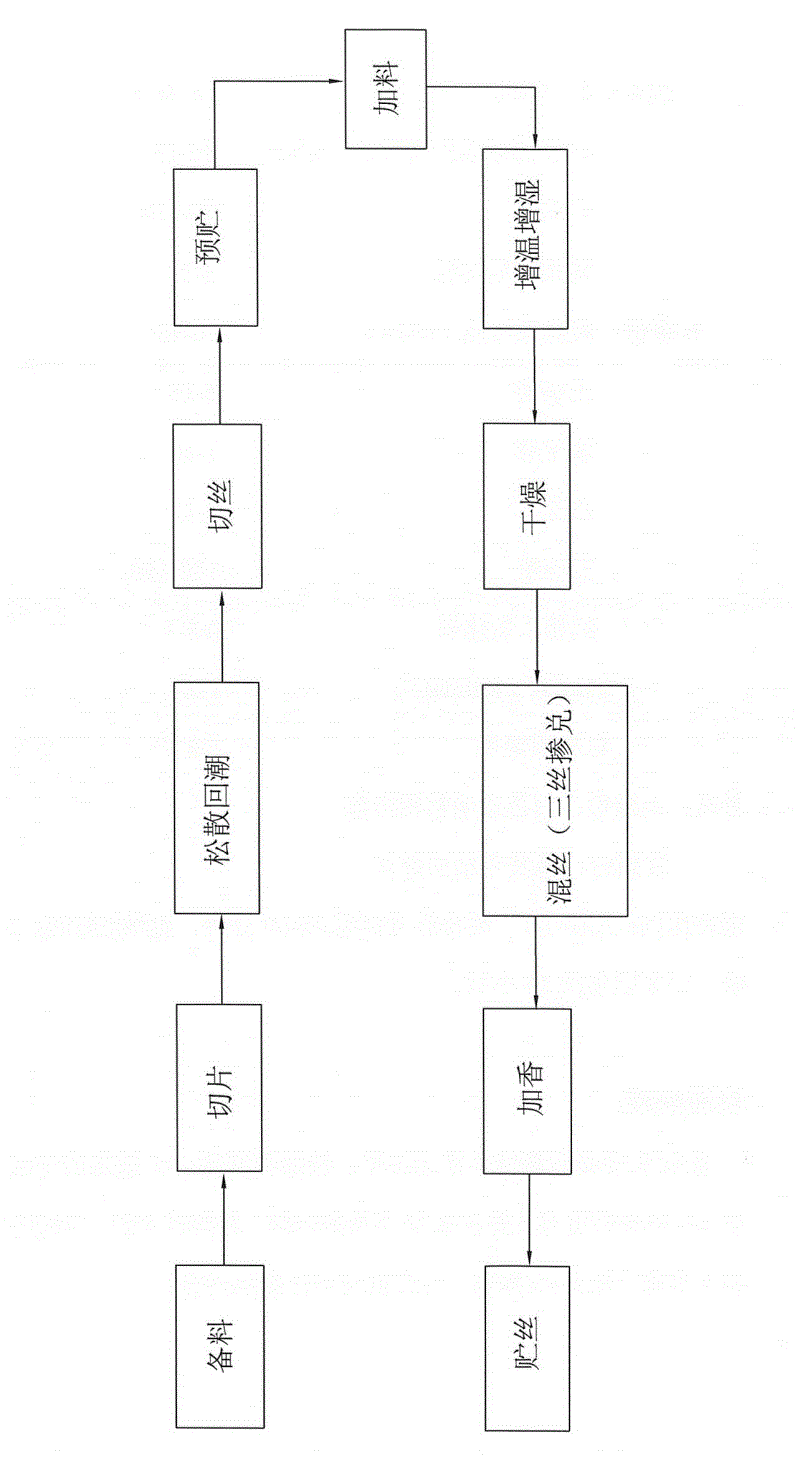

Tobacco shred processing and treating technology

InactiveCN102613679ASimple processSmooth processTobacco preparationTobacco treatmentEngineeringMoisture

The invention discloses a tobacco shred processing and treating technology, which comprises the following processing steps: firstly, slitting into slices: slitting a tobacco block with certain weight into a plurality of blocks; secondly, loosening and dampening: sending the slit flue-cured tobacco blocks into a loose dampening machine for warming and humidification, thus the flue-cured tobacco block is loosened into leaf slices; thirdly, slitting into shreds: sending the leaf slices after loosening and damping to a shred cutting machine for cutting shreds; fourthly, storing in advance: sending the split leaf shreds to a storage cabinet for storage, and balancing the moisture containing rate; fifthly, adding materials: sending the stored leaf shreds to a screening and material-adding machine and adding material liquids according to certain proportion so as to improve and enhance the sensory quality of shreds; sixthly, warming and humidifying the shreds: sending the shreds after material adding to a warming and humidifying machine for warming and humidification; and seventhly, sending the shreds after warming and humidification to a drying machine for drying treatment. The technology not only can meet the treatment requirement of the traditional processing technology, but also can effectively improve and enhance the physical quality and sensory quality of cigarettes, also the technology flow is more simple, direct and smooth, and the processing technology is more reasonable.

Owner:XIAMEN TOBACCO IND

Acid adding machine for storage battery

InactiveCN101667634AConvenient acid controlImprove acid addition efficiencyCell component detailsVacuum pumpingVacuum pump

The invention discloses an acid adding machine for storage batteries, comprising an acid injecting work station and a vacuum pumping work station, wherein the acid injecting work station is provided with an acid adding pump, a PLC control device and a second bedplate for placing a storage battery group, the acid adding pump injects acid fluid into the storage batteries which are placed on the second bedplate, and the PLC control device controls the second bedplate or the acid adding pump to move so as to ensure the acid adding pump to inject the acid fluid into a plurality of storage batteriesof the storage battery group; and the vacuum pumping work station is provided with a vacuum pump and a sealing device, the sealing device comprises a sealed space for containing the storage battery group after being added with acid, and the vacuum pump is communicated with the sealed space. By adopting the PLC control device to control the acid adding process of the battery group and vacuumize the whole battery group, the acid addition of a plurality of batteries can be finished simultaneously, thus increasing the acid adding efficiency; and by adopting a discharging pump with precise capacity, precise control of the acid adding amount is realized.

Owner:ZHAOQING LEOCH BATTERY TECH

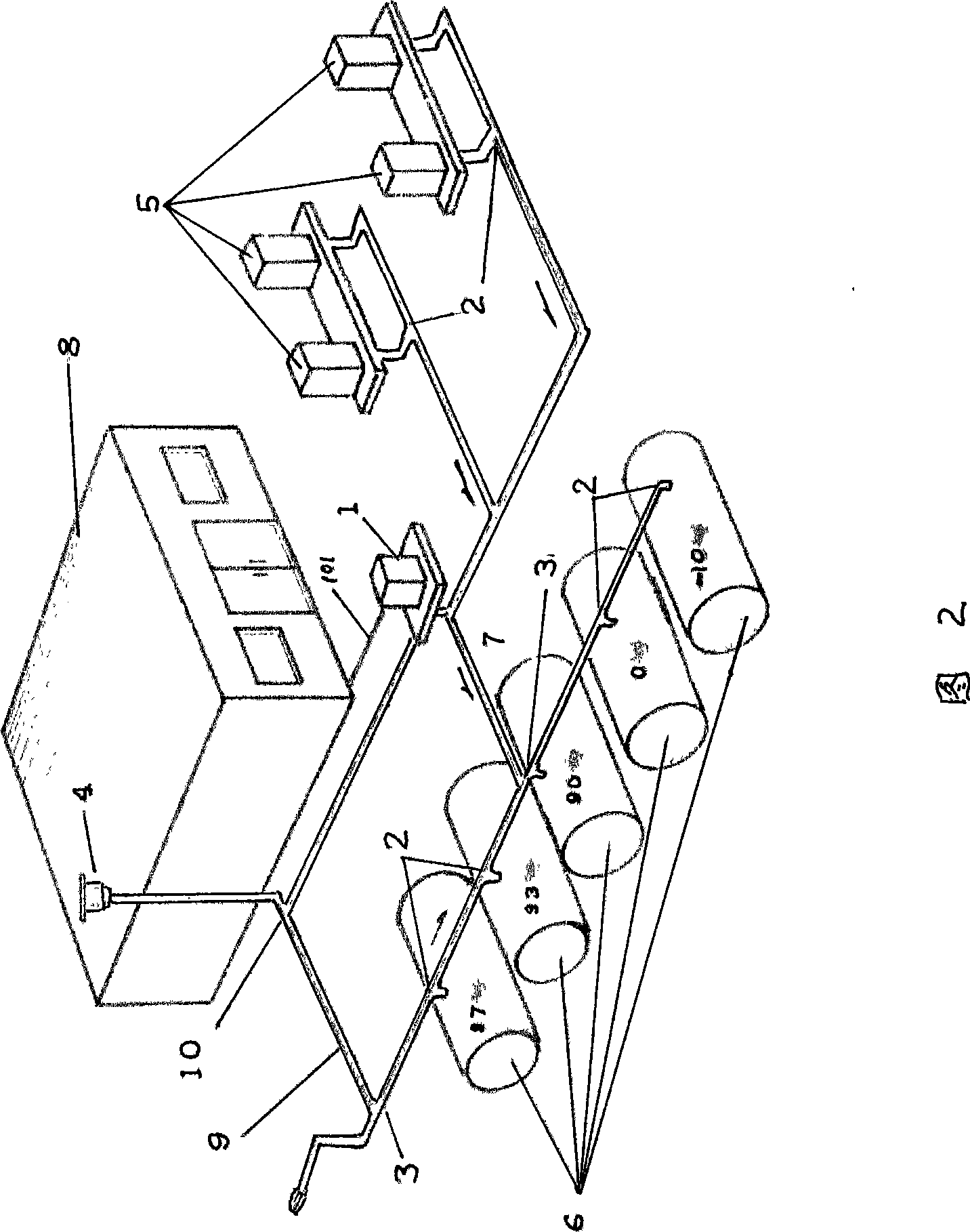

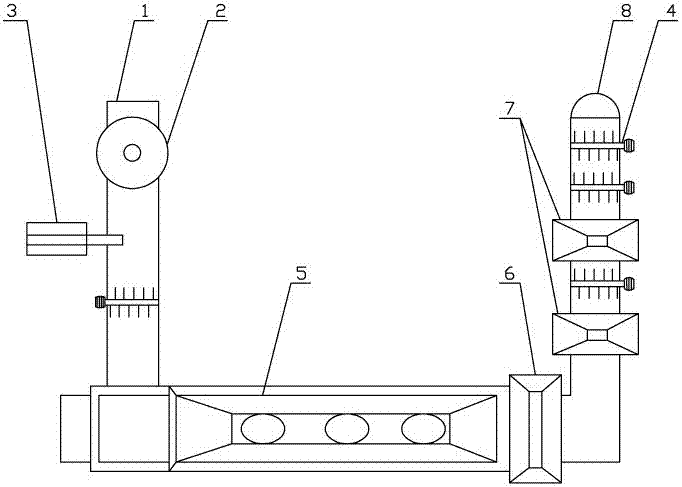

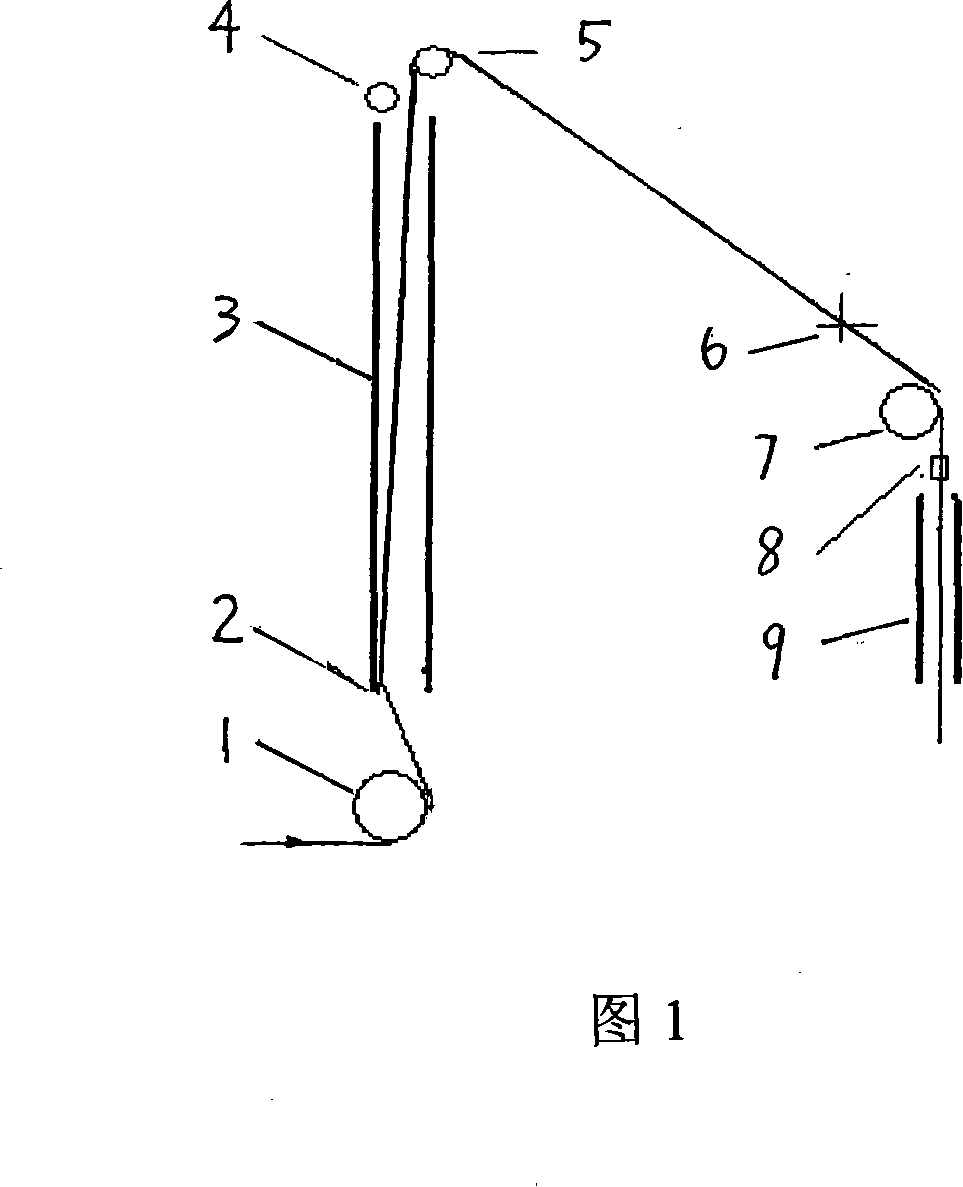

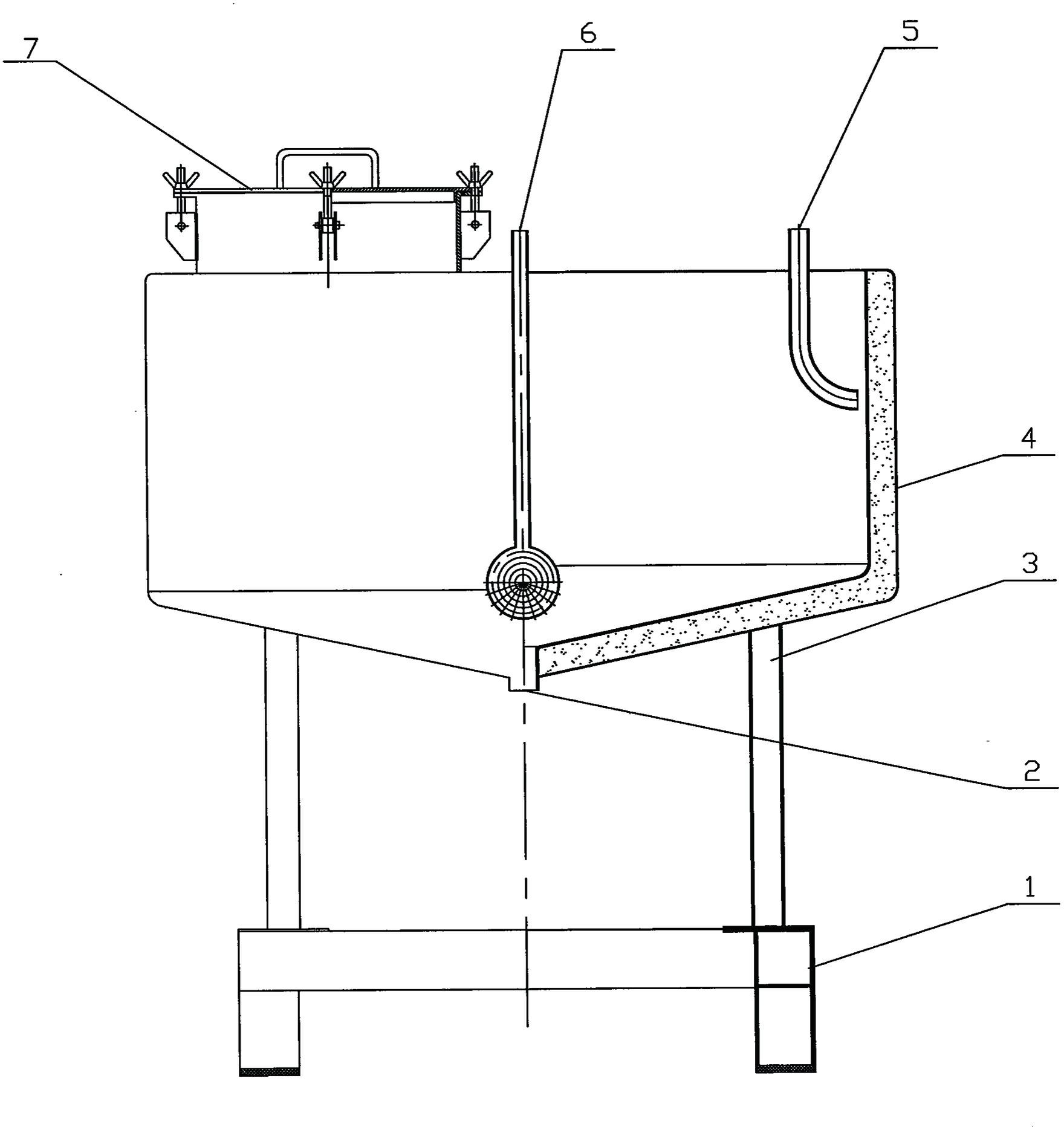

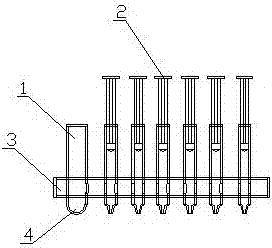

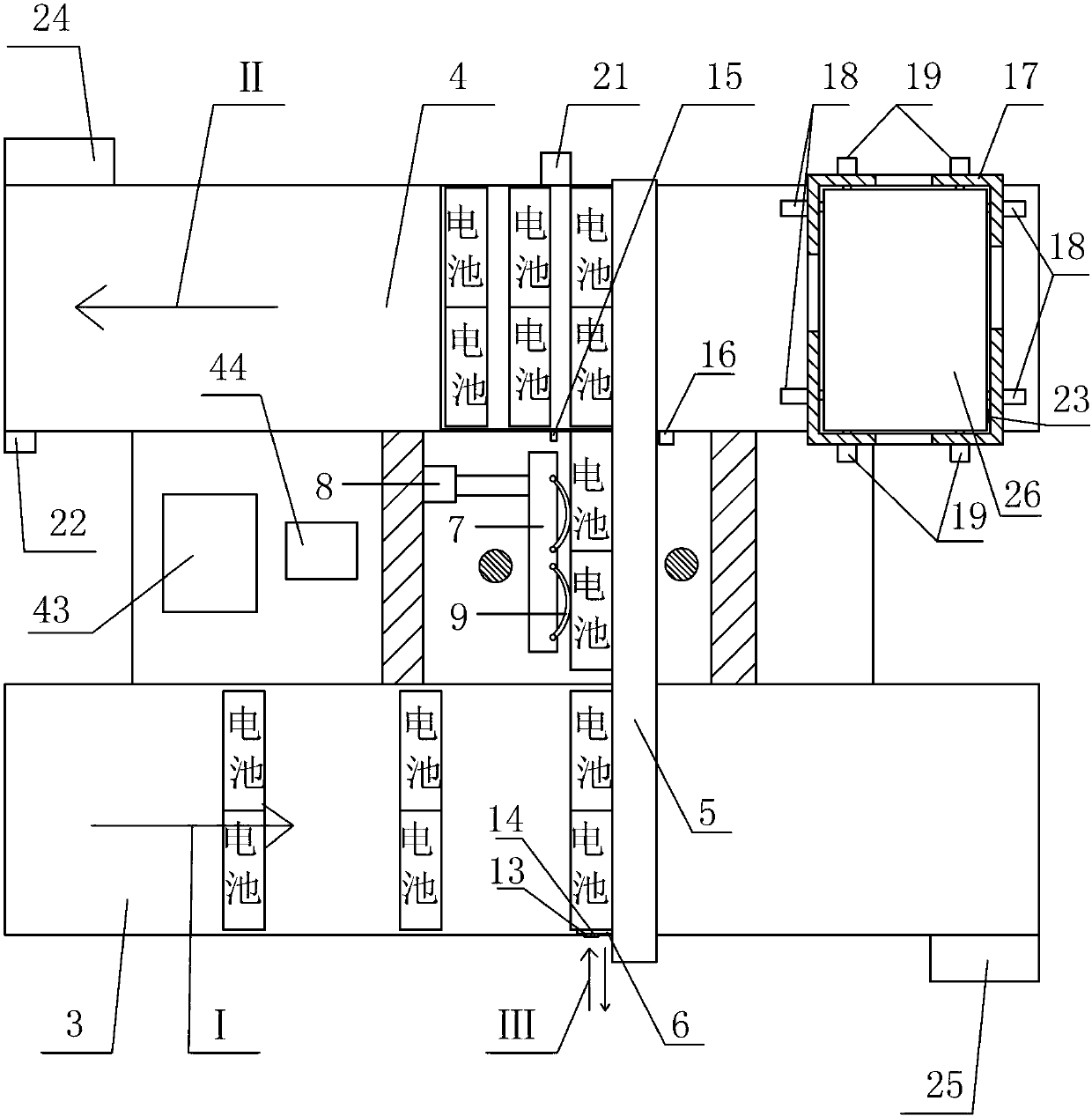

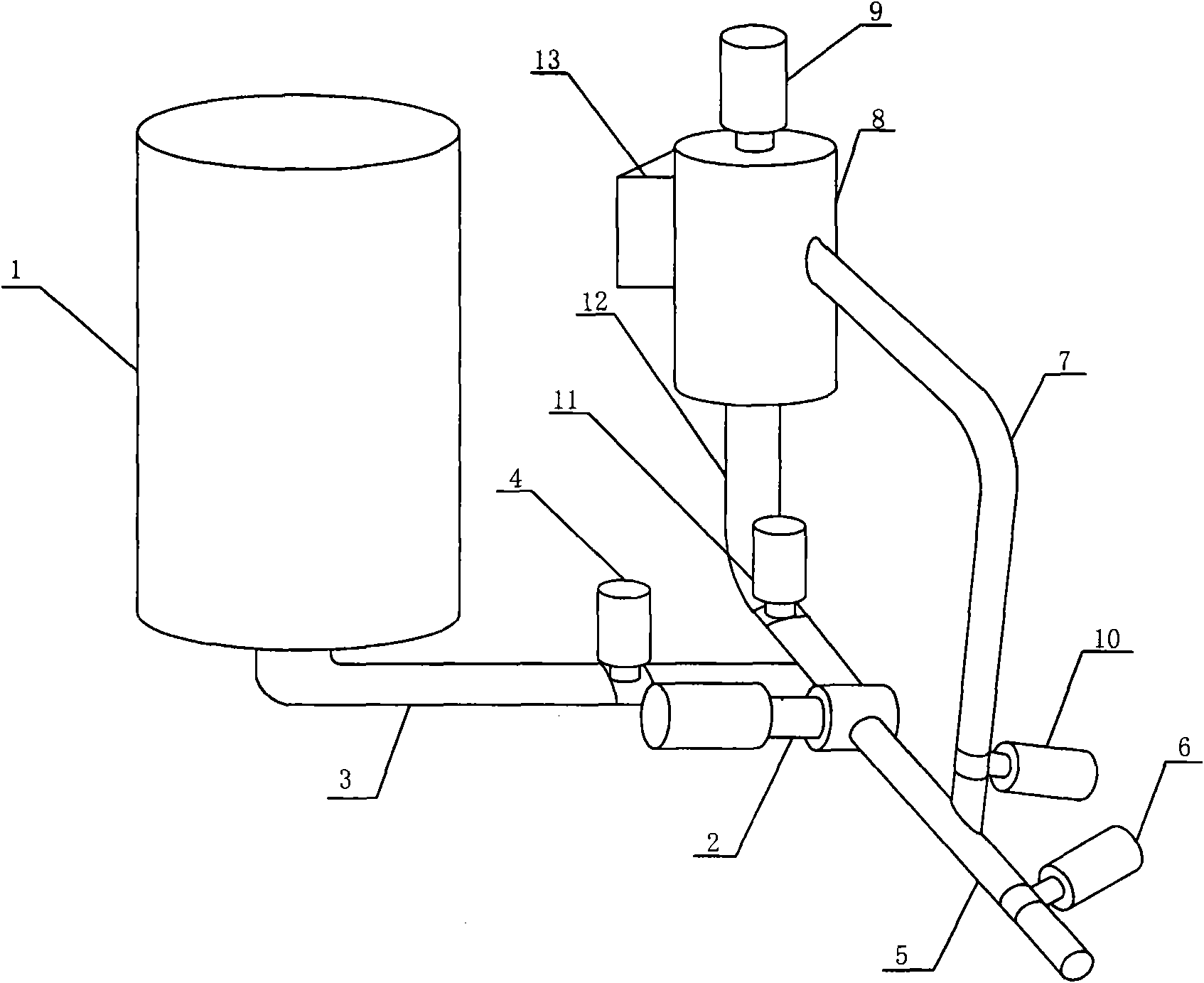

Technique for producing polyester filament yarn using false twisting distortion elasticizer

ActiveCN101250784AHigh fidelity requirementsGood hollownessTextiles and paperHot boxEconomic benefits

The invention relates to a process for manufacturing polyester fiber filament by using a false twisting deformation elastic-adding machine, which is characterized in that raw material strand silk which is from a roller (1) passes through an inlet silk guide (2), then directly passes through a hot box(3) and is heated by the mode of non-contact heating, then moves to a turning silk guide (5), (or passes through a twisting machine 6), then passes through a two-roller (7) and reaches to a network jet nozzle (8) and is manufactured to obtain fully drawn yarn FDY (or shape preserving performances with high requirements such as profile degree, degree of hollowness and the like) polyester fiber filament, The process has the advantages of without altering the device, simple process adjustment and the like, and the switching of the two product processes is flexible and convenient, and the process efficiently extends the using range of the false twisting deformation elastic-adding machine and has obvious economic benefits.

Owner:杭州逸暻化纤有限公司

Network protection software and method

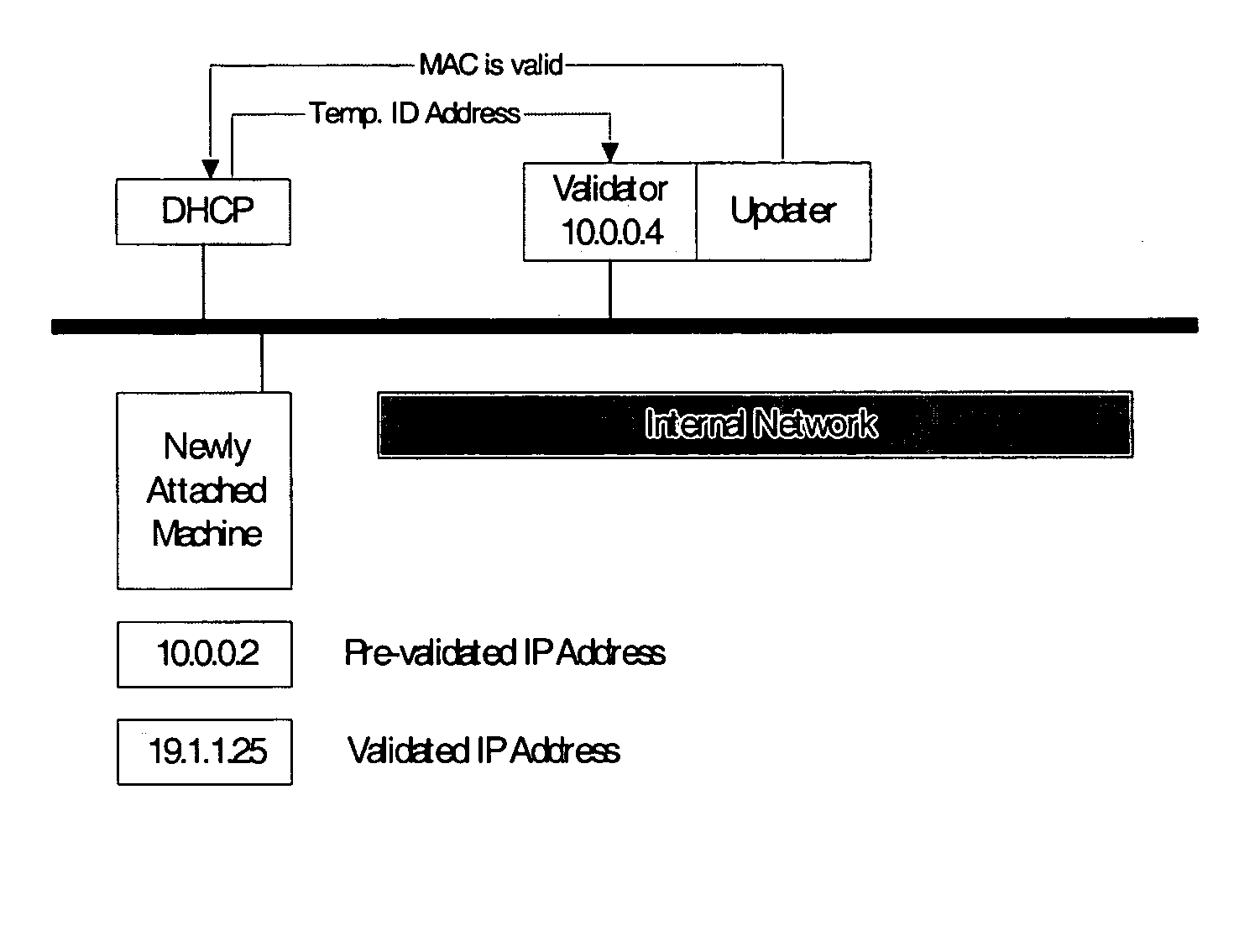

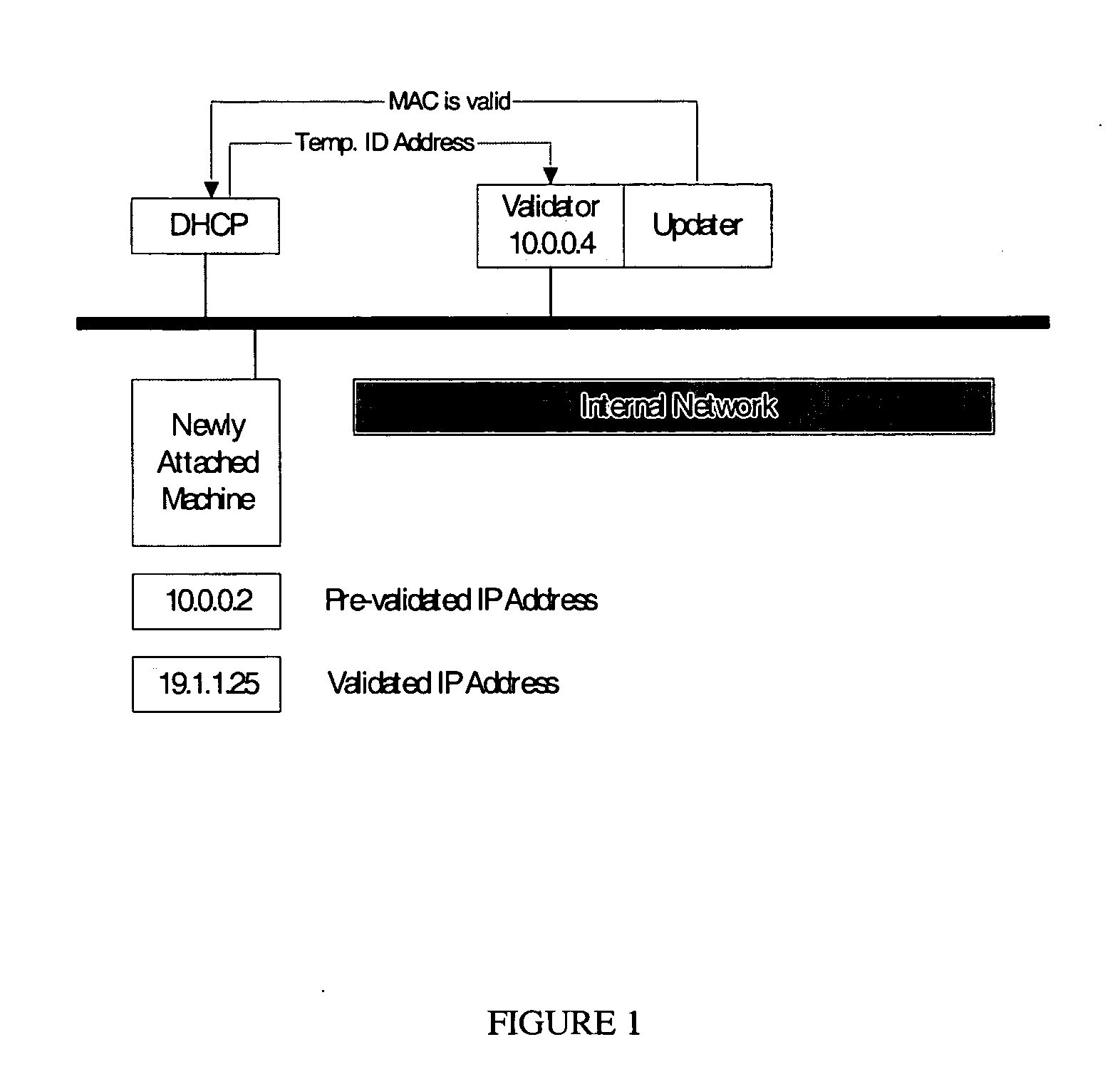

InactiveUS20050138431A1Digital data processing detailsMultiple digital computer combinationsOperational systemIp address

A software-based system allows immediate isolation of all IP traffic until a newly added machine has been qualified. In the preferred embodiment, this verification is carried out using a variety of mechanisms, optionally including a local agent, vulnerability scanning, and system fingerprinting. Any newly attached machine requesting an IP address is quarantined into a restricted address space until an authorization server validates that it is running a valid operating system at the appropriate patch levels, is not actively scanning or transmitting malicious data, has the proper virus software and engine, and is not vulnerable on known Trojan ports.

Owner:HARRISON JAY P

Mobile tobacco charging bucket with electronic tag and operating method for charging bucket

ActiveCN102415610AReduce lossTobacco preparationCo-operative working arrangementsSwitching timeCompressed air

The invention discloses a mobile tobacco charging bucket with an electronic tag. The tobacco charging bucket comprises a bucket body, bucket legs, a discharge quick joint, a fixed transport base plate, a return quick joint, a compressed air quick joint for stirring and a bucket cover. The tobacco charging bucket is characterized in that: the tobacco charging bucket is mobile, the bucket cover is opened when finished liquid is filled, and the bucket cover is connected with the discharge pipeline of a modulation bucket. When a spice is charged on site, the return quick joint is butted with a site charger or a return pipeline of a spice adding machine, the discharge quick joint is butted with the site charger or the charging or spice adding pipeline of the spice adding machine, and the compressed air quick joint for stirring is butted with a site compressed air pipeline. According to the mobile tobacco charging bucket used in an essence and spice modulation center and a site spice charging system, the switching time is furthest saved, adhesion of the spice in the pipeline is reduced, and the sanitary environment of a workshop is improved.

Owner:XIAMEN TOBACCO IND

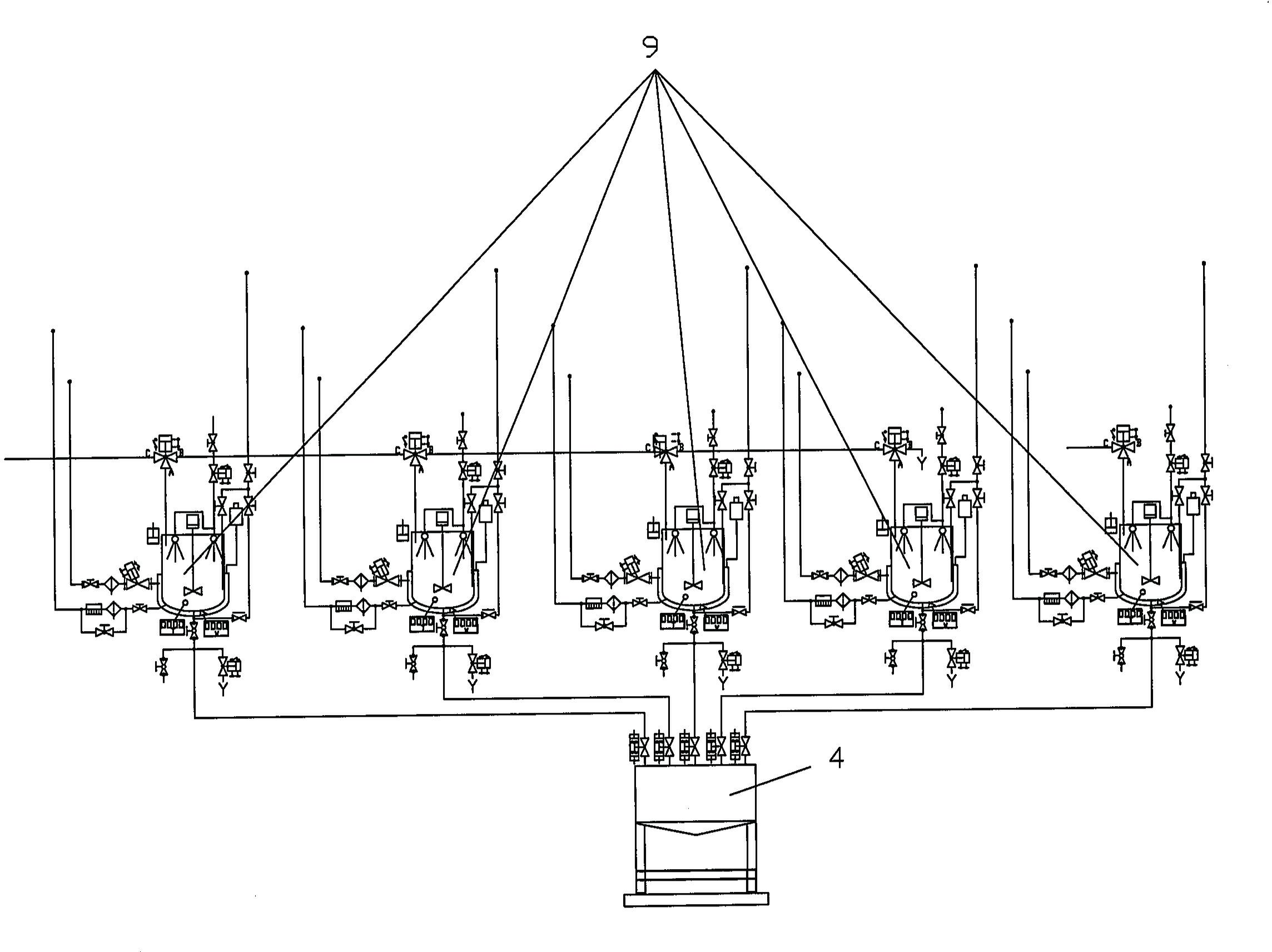

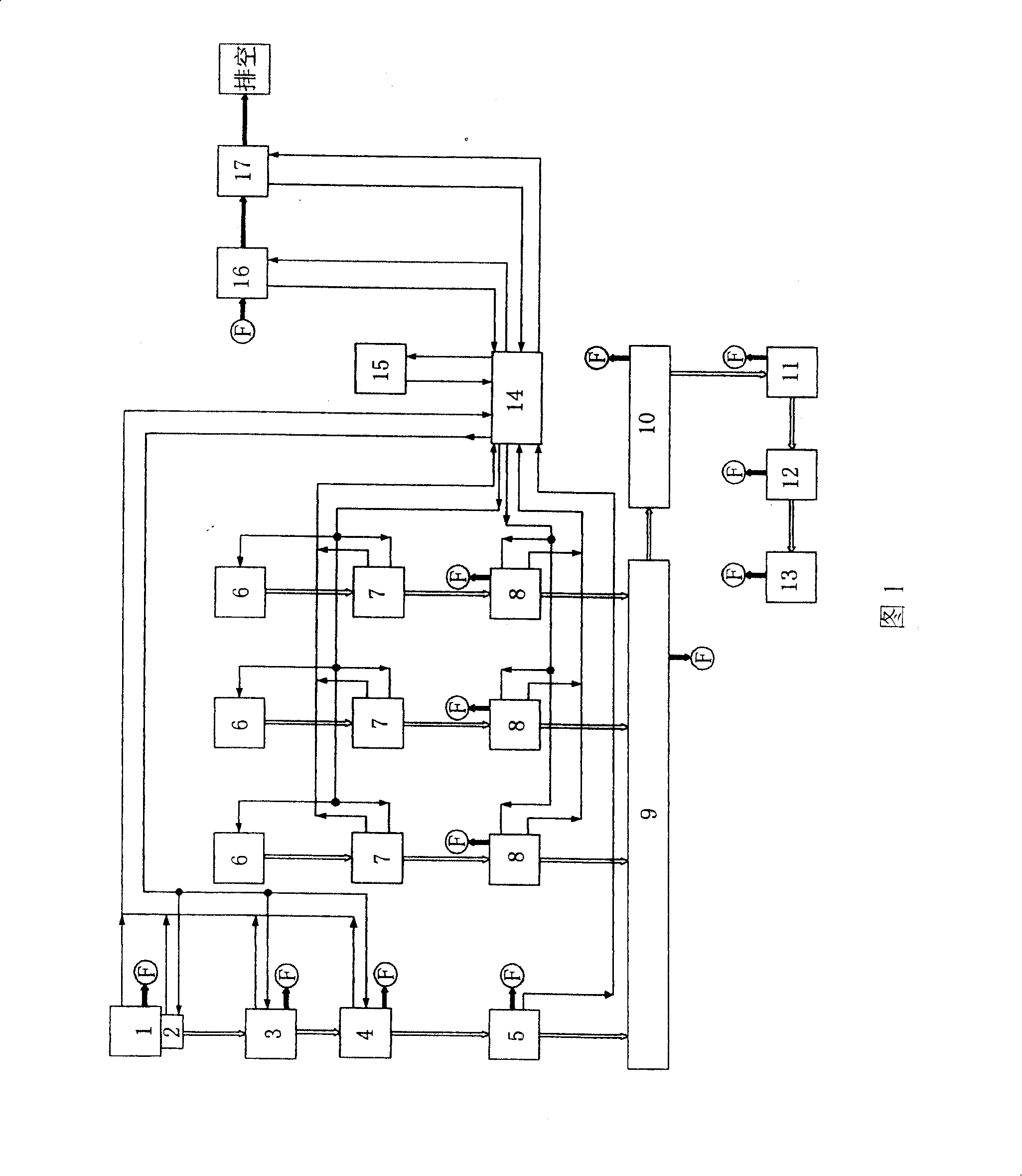

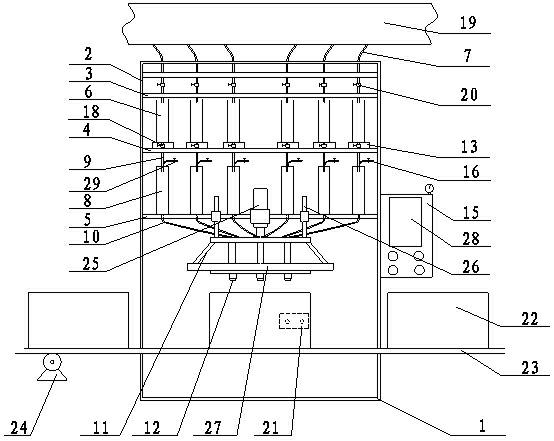

Novel full-automatic powder producing system

InactiveCN101172215APrevent leakagePrevent proliferationMixing methodsMixer accessoriesProduction lineEngineering

The invention discloses a novel full-automatic powder preparation system, which comprises a main material bin, a material feeding machine, an impulse type flow meter, a main material conveyor, an auxiliary material adding machine, an auxiliary material bin, a burden machine and a mixer and so on, a screening device is arranged between the material feeding machine and the main material conveyor, a decrement method weighing device is arranged between the auxiliary material bin and the auxiliary material adding machine, and a negative pressure source is also arranged to facilitate the whole system to operate in a negative pressure state. A central controller, a remote computer and a PLC device are arranged at a controlling part. The invention realizes the advance control of the auxiliary material flow, further ensures the accuracy, stability and consistency of the compounding ratio of the product ingredients, can meet the requirement of various products to the grain size to lead the production line to have the functions of one-button ordinal start, one-button ordinal stop and interlock of each production link. The powder leakage and diffusion in the process of material transporting, mixing and packaging and so on are prevented, the pollution to the surrounding environment is avoided, and the environmental protection is facilitated.

Owner:TIANJIN HI TECH IND PARK ZHONGHE WATERPROOF MATERIAL

Process-machine integral cultivation method for cultivating potatoes in northern dry land

InactiveCN104322238AChange the way of productionImprove ergonomicsPlant cultivationCultivating equipmentsSprayerInsect pest

The embodiment of the invention provides a process-machine integral cultivation method for cultivating potatoes in a northern dry land, and relates to the field of potato cultivation. Through adoption of the method, the benefit can be increased, and the cost can be saved. The method comprises: land selection; variety selection and potato seed treatment; fertilization; seeding: seeding by using a double-line potato planter integrating ditching, fertilization, seeding, suppression, film mulching and earthing; performing intertillage and ridging: performing mechanical intertillage and ridging twice: the first intertillage and ridging is performed during earth ejection of seedlings and comprises the steps of performing intertillage in furrows by adopting a rotary tillage earth adding machine, earthing up and pressing a film simultaneously, and adding 5 centimeters of earth, wherein the distance between a furrow and the ridge top is up to 12 centimeters, the ridge top is 50 centimeters in width, and the ridge bottom is 100 centimeters in width; spraying a soil enclosing weed killer by using a spray rod sprayer; the secondary cultivation and banking is performed by adopting a intertillage fertilizer distributor at the squaring stage of plants, wherein the ridging height is 5 centimeters, and potato seeds are 20 centimeters away from the earth surface; preventing and controlling plant diseases and insect pests; harvesting by using a machine.

Owner:HIGH LATITUDE CROPS INST TO SHANXI ACADEMY OF AGRI SCI

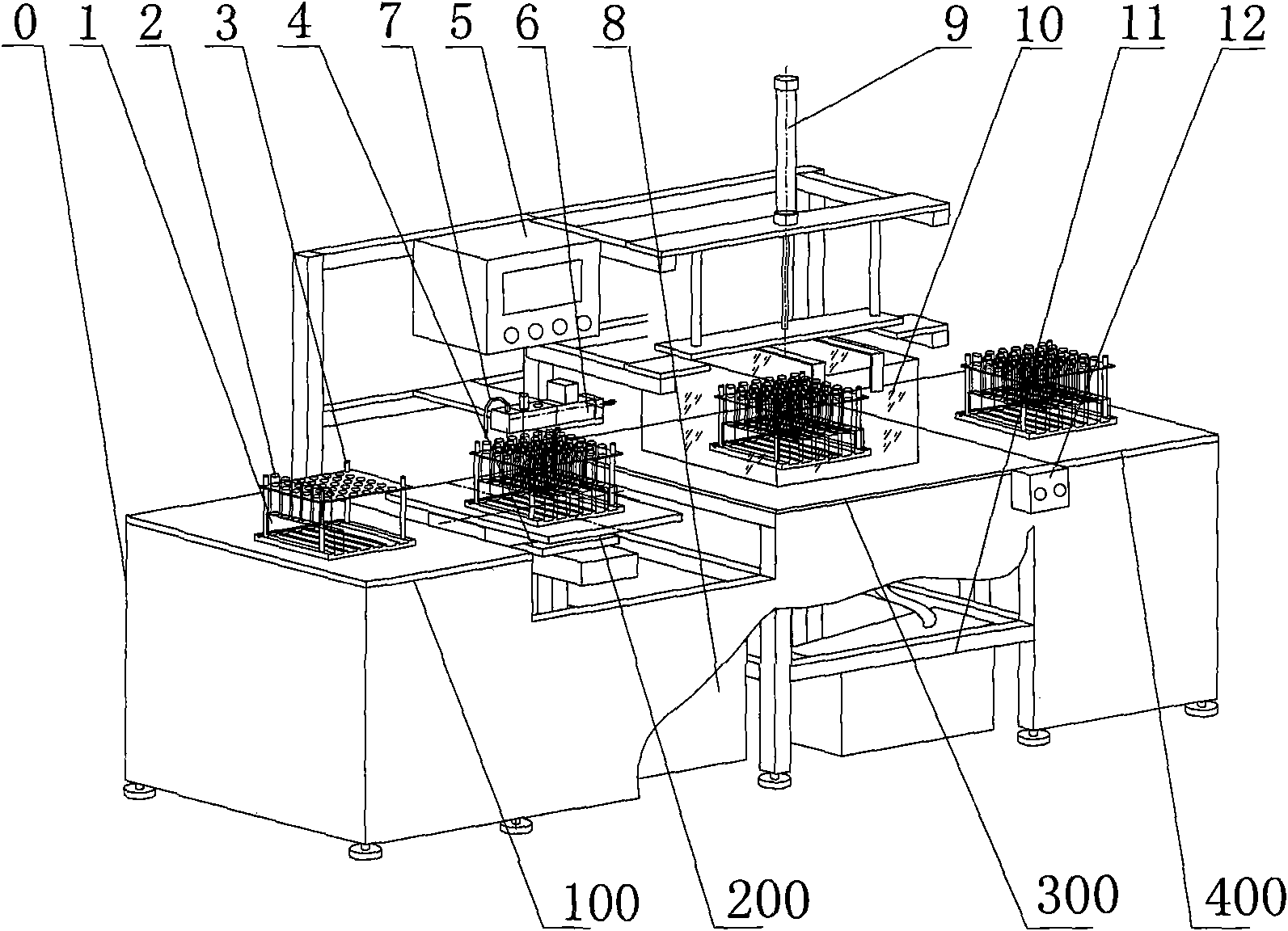

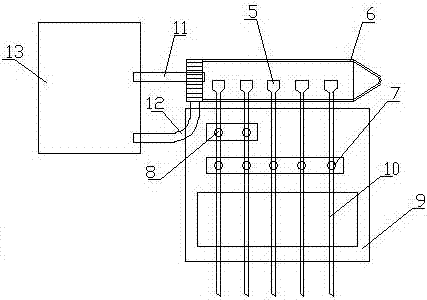

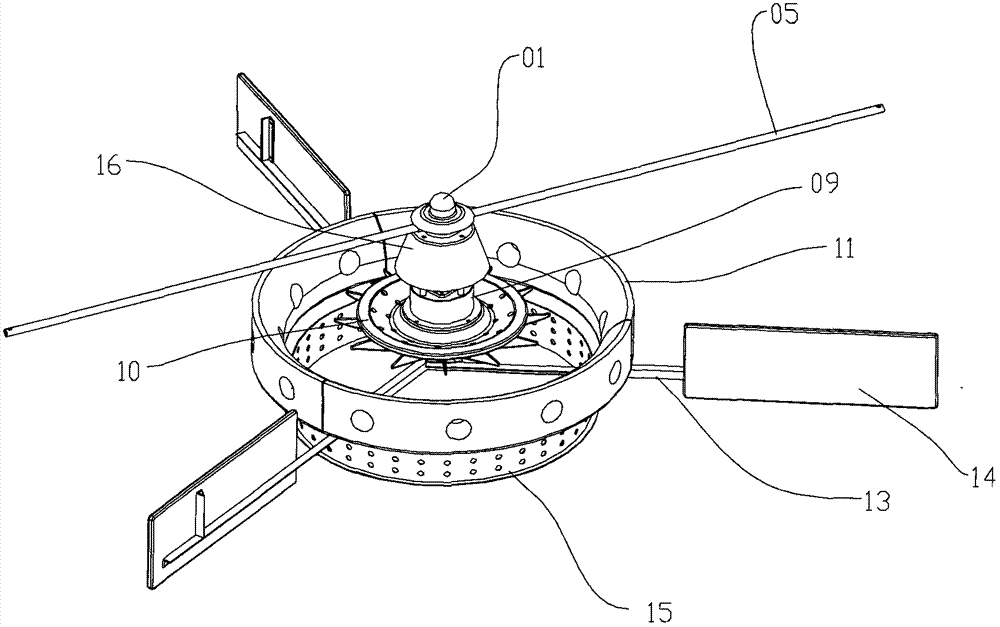

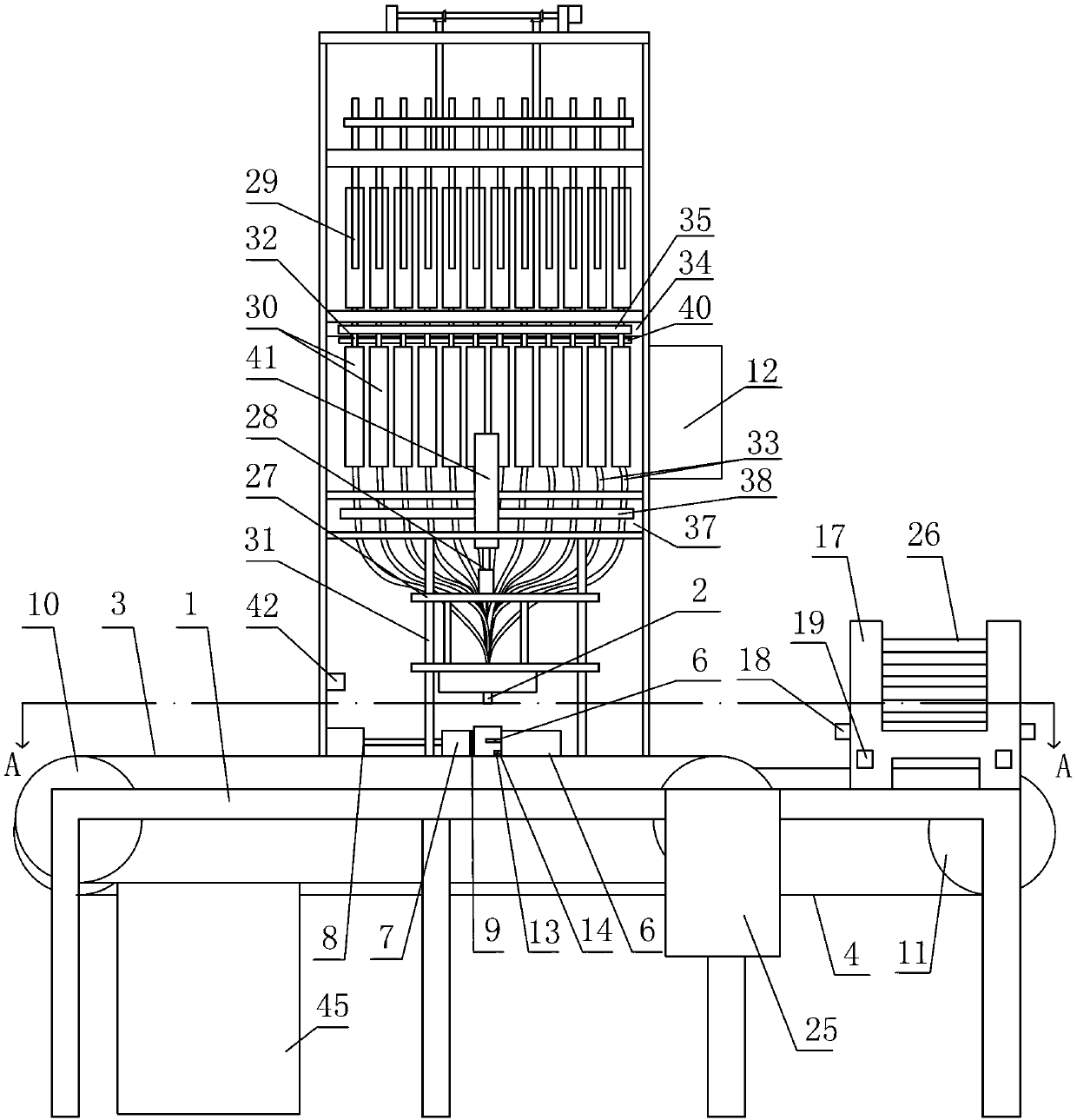

Cross-matching of blood, blood types A, B, O, and Rh D, and irregular antibody screening sample-adding machine

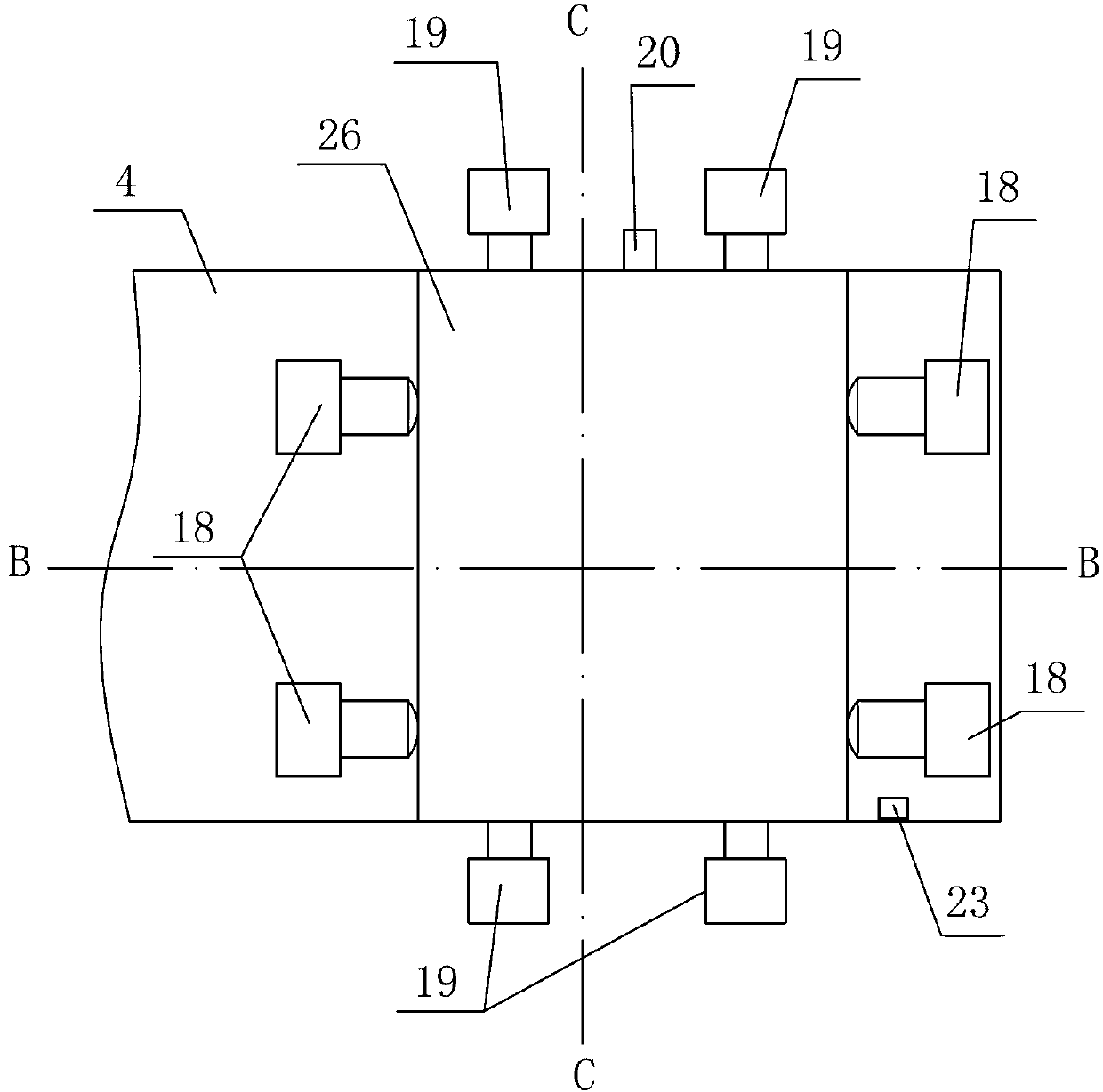

ActiveCN107247154AEasy to take pictures, scan filesSimple structureMaterial analysisGroup A - bloodBlood compatibility test

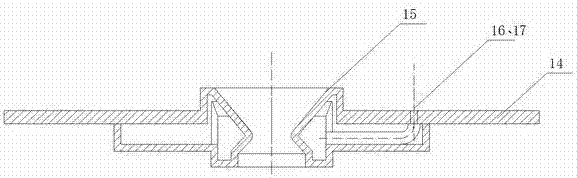

The invention relates to the technical field of medical experimental apparatus. Provided are cross-matching of blood, blood types A, B, O, and Rh D, and irregular antibody screening sample-adding machine. The screening sample-adding machine is provided with a distribution pipe with both ends sealed and characterized in that at least one injector is arranged side by side on the distribution pipe; needle parts of the injectors penetrating the distribution pipe are located at the lower end of the distribution pipe; radial through holes are arranged on the injectors inside the distribution pipe; a sample-adding pipe is arranged on the distribution pipe next to each injector; the sample-adding pipes are communicated with the injectors through the distribution pipe. The sample-adding machine solves the problems that sample-adding machines special for cross-matching of blood, blood types A, B, O, and Rh D, and irregular antibody screening experiments do not exist and it is complex, inefficient, and error-prone to operate with ordinary straw or dropper. cross-matching of blood, blood types A, B, O, and Rh D, and irregular antibody screening sample-adding machine are provided.

Owner:刘大基

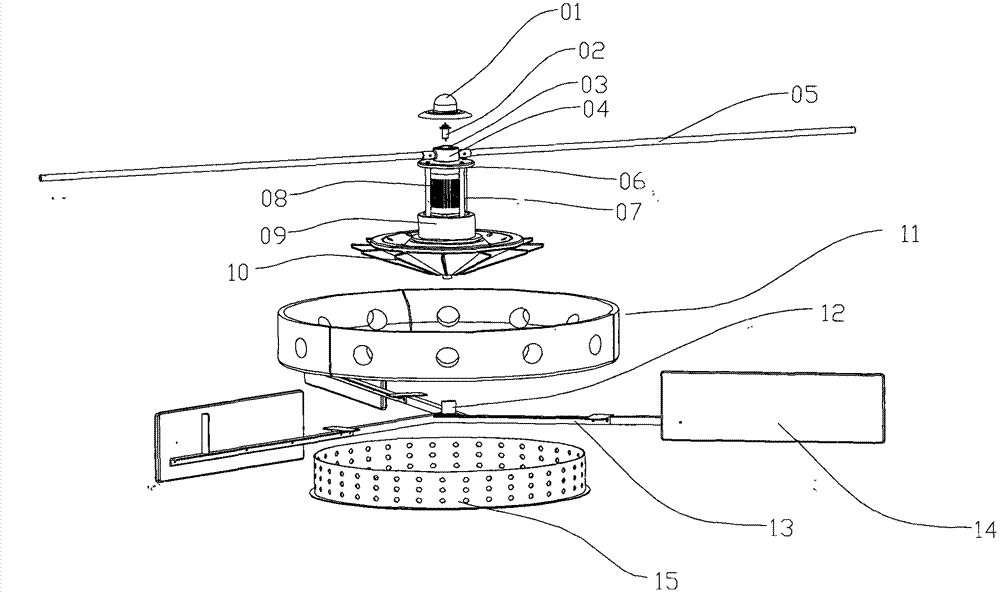

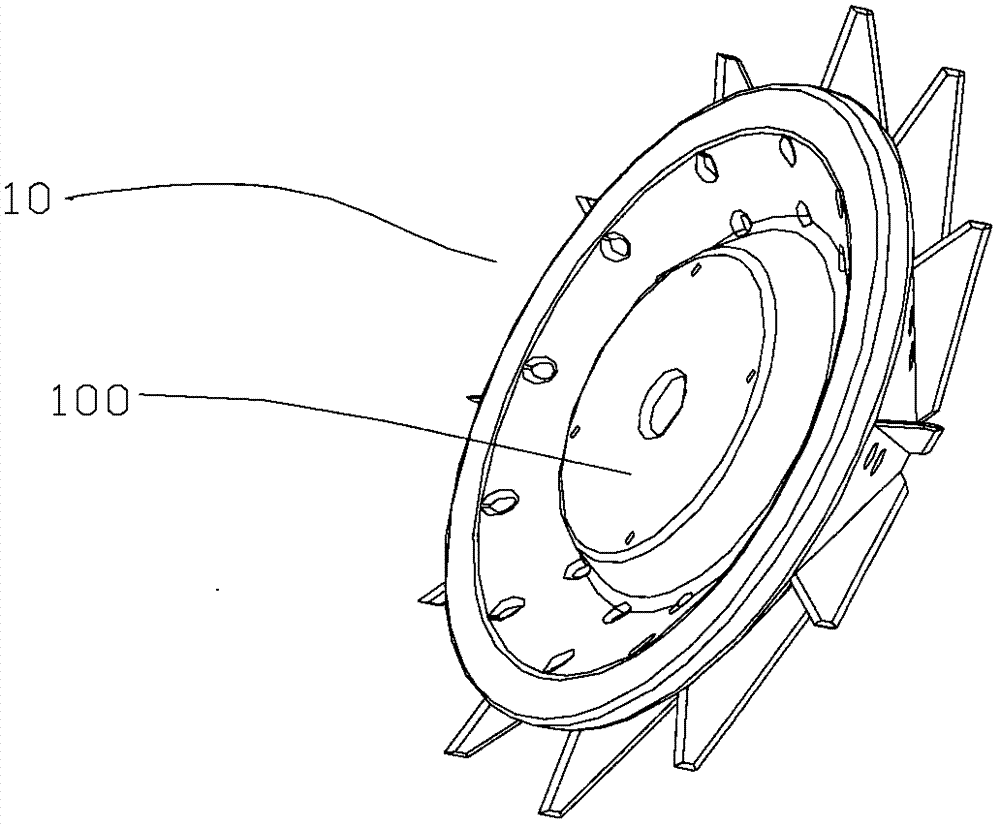

Water pushing and oxygen adding machine

ActiveCN103828758ALow costLess power consumptionPisciculture and aquariaEnvironmental engineeringOxygen

The invention discloses a water pushing and oxygen adding machine which comprises a driving device, a water pushing device, a water spacing ring, a machine supporting frame, an oxygen adding and water lifting wheel and a rotation fixing device. When the water pushing and oxygen adding machine works, the driving device drives the water pushing device to rotate slowly to produce running water ploughing water. Reverse torsion generated by the water pushing device is used for driving the oxygen adding and water lifting wheel to rotate at a high speed through the rotation fixing device, water is lifted, and aeration and oxygen dissolving are performed. The water with oxygen dissolved falls onto the water surface and is pushed to the periphery by the water pushing device, and oxygen can be evenly and rapidly added into the whole water body. The water spacing ring and the machine supporting frame are installed on the water pushing device and rotate along with the water pushing device. The water pushing and oxygen adding machine has the advantages that dozens of watt of power is enough for achieving the effect of fast adding oxygen and achieving running water, and the water pushing and oxygen adding machine has the advantages of being low in energy consumption, stable in operation and the like.

Owner:山东誉滕医疗器械有限公司

Novel fixed bed slag gasification reaction furnace and gas production method thereof

PendingCN107446628AImprove decomposition rateRaise the pyrolysis gasification reaction temperatureChemical industryGasification processes detailsCombustion chamberDecomposition

The invention belongs to the field of coal chemical industry and coke gasification, and relates to chemical engineering, chemical technology and chemical equipment technology, and particularly relates to a reaction furnace with fixed bed slag gasification, liquid slag removal and fractional gasification and a technology thereof. The reaction furnace comprises a gasifier furnace, a slag hole, a combustion chamber, a quench chamber and an automatic coke or coal adding machine. The invention provides the novel reaction furnace with the fixed bed slag gasification, liquid slag removal and fractional gasification which utilizes crushed coal (anthracite, bituminous coal and coke) as raw materials, and can operate under normal pressure to 0.09MPa pressure. The reaction furnace can improve the gasification temperature, carbon conversion rate and steam decomposition rate and cold coal efficiency, has a high content of effective gases, relatively simple operation and maintenance, and compact and reliable equipment, is less in investment, small in waste water quantity and safe and environmentally friendly, can convert into relatively clean water gas, and completely realizes localization.

Owner:江西昌昱实业有限公司

Acid adding machine for storage battery

The invention relates to an acid adding machine for a storage battery. The acid adding machine comprises a base, a machine body, a first platform, a second platform, a third platform, measuring cups, vacuum tubes and a lifting device, wherein the top of each measuring cup is provided with an acid adding branch tube; each measuring cup is communicated with a corresponding vacuum tube below the measuring cup through an acid conveying branch tube; the bottom of each vacuum tube is connected with a hose; and acid adding nozzles are formed at the bottom of the lifting device. The acid adding machine is characterized in that: the bottom of each measuring cup is provided with an electronic scale in which a hole for a corresponding acid conveying branch tube to pass through is formed; each electronic scale is electrically connected with a program control box arranged on one side of the machine body; each vacuum tube is connected with a vacuumizing hose; a vacuumizing pump is electrically connected with the program control box; and an acid adding valve is arranged on each acid conveying branch tube. The acid adding machine has the advantages that: the volume of acid liquor can be highly accurately measured with small errors, and can be automatically set, and the whole acid adding process can be automatically controlled.

Owner:江苏海宝新能源有限公司

Improved acid adding machine

InactiveCN103346285AOptimization requires a lot of laborConvenience to workCell component detailsEngineeringAutomation

The invention provides an improved acid adding machine. The improved acid adding machine comprises a machine body and an acid adding mechanism, wherein the acid adding mechanism comprises an acid filling head arranged on the machine body; a conveying belt I for conveying a battery to be subjected to acid filling and a conveying belt II for outputting the battery after acid filling is finished are arranged on the machine body; a pushing mechanism is arranged on the machine body and is used for pushing the battery to be subjected to acid filling on the machine body below the acid filling head and pushing the battery below the acid filling head after acid filling is finished to the conveying belt II; a fixing mechanism for clamping and positioning the battery to be subjected to acid filling is arranged on the machine body and positioned below the acid filling head; a tray frame which runs through up and down is arranged above the conveying belt II and on the machine body; an opening is formed in the bottom of the tray frame; a tray is placed on the tray frame and positioned over the opening; a tray placing mechanism is arranged on the tray frame and is used for fixing or loosening the tray relative to the tray frame to ensure that the tray falls from the opening to the conveying belt II. The conveying mechanism and the acid adding mechanism are reasonable in design and cooperate with each other well; the tray placing mechanism is provided, so the battery can be placed into the tray automatically and the automation degree is high.

Owner:CHANGXING ZHICHENG TIANSHOU ELECTRONICS FACTORY

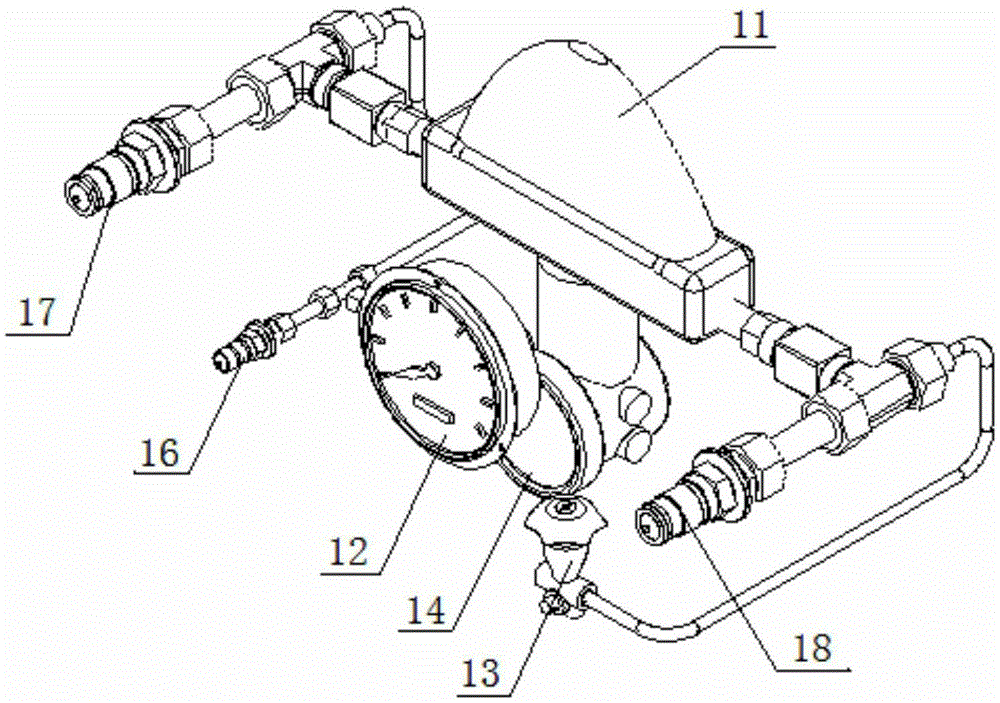

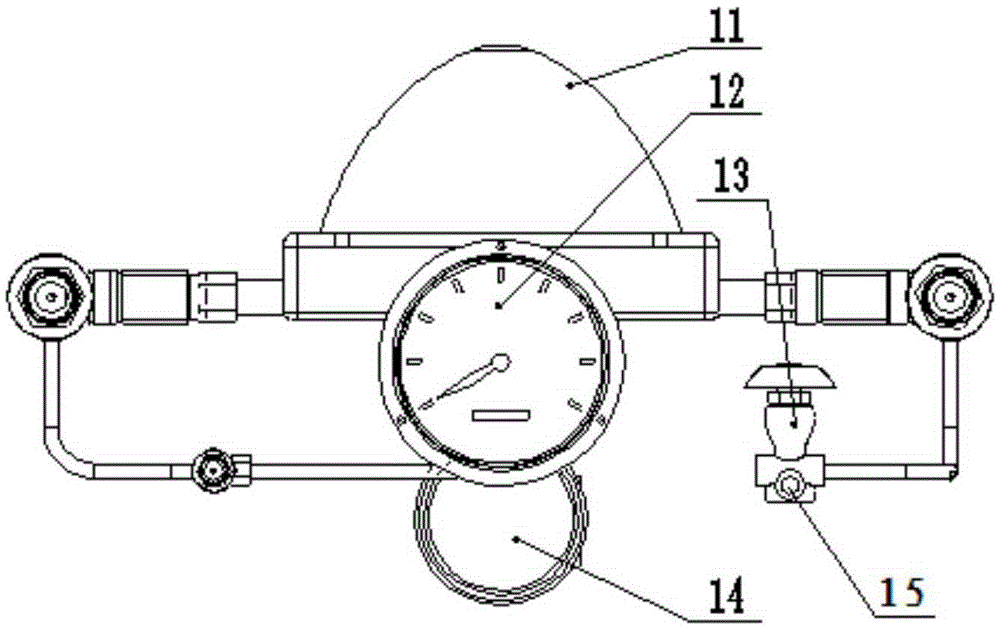

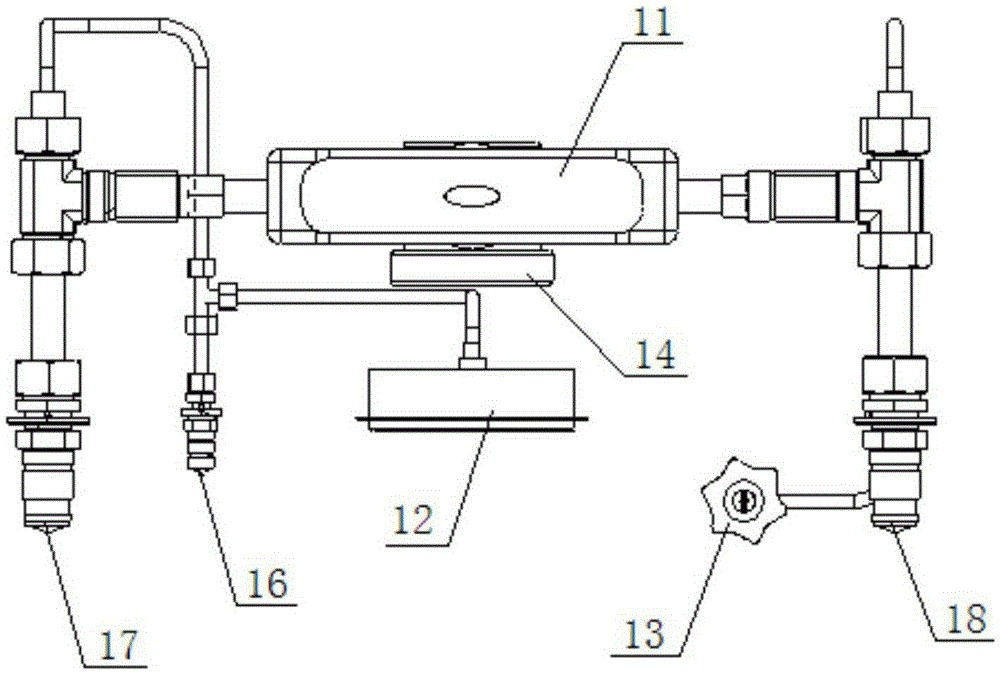

CNG field calibrating device, system and method

The invention relates to the technical field of natural gas metering, and discloses a CNG calibrating device. The CNG calibrating device comprises a flow sensor, a flow transmitter, a pressure gage, a gas adding machine detected gun connector, a stop valve and at least one gas receiving bottle opening. The flow sensor is connected with the flow transmitter. The gas adding machine detected gun connector is connected with the flow sensor through a pipeline. The stop valve is arranged on the pipeline. The gas receiving bottle openings are connected with the flow sensor and the pressure gage. The invention further discloses a CNG calibrating system and a field calibrating method. The CNG calibrating device is connected between a CNG adding machine and an automobile gas storage tank (or other gas storage tanks) in series, the device records the actual flow of gas adding of the gas adding machine, and calibration of the metering accuracy of the CNG adding machine is achieved accordingly.

Owner:CHONGQING INNOVATION MEASURE EQUIP

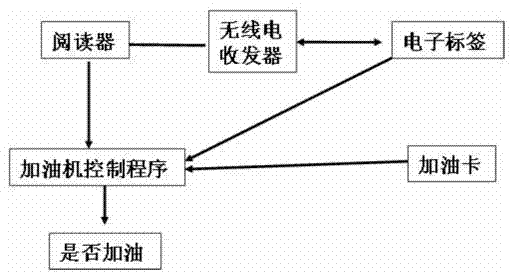

Oil filling card system based on electronic tag technology

InactiveCN103927614AEasy to manageVersatileCo-operative working arrangementsResourcesLicenseRadio-frequency identification

The invention belongs to application of RFID technology in oil filling card management, and relates to an oil filling card system based on the electronic tag technology. The oil filling card system based on the electronic tag technology is composed of an exclusive oil filling card, an electronic tag adhering to an automobile, a tag information reader in an oil adding machine and an oil adding machine control program. An internal chip of the oil filling card is labeled as an oil filling card based on the electronic tag technology, is implanted with exclusive information like the license plate number of the oil filled automobile, and is matched with the fixed automobile only. The license plate number of the corresponding automobile is also written into an inner chip of the electronic tag. When oil is poured into the automobile, the reader inside the oil filling machine collects the information of the tag on the oil filled automobile and transmits the information to the oil adding machine control program, the control program compares the label information with the oil filling card information, oil is poured into the automobile only when the automobile tag information is coincident with the oil filling card information, or the system does not provide oil, and accordingly the problem that an automobile of the non-limited license plate number illegally uses an oil filling card of an automobile of the limited license plate number for oil filling can be effectively solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Acid adding machine and acid adding system

The invention discloses an acid adding machine which comprises an acid storage device capable of metering acid liquor, and a fixed displacement pump used for pumping in acid liquor, as well as a bottom acid tank and a first conduit, wherein the fixed displacement pump is connected with the acid storage device, the bottom acid tank is arranged at the lower part of the acid storage device, and the bottom acid tank is connected with the acid storage device through the first conduit. The invention further discloses an acid adding system. According to the acid adding machine, the bottom acid tank is arranged at the lower part of the acid storage device, and acid pumped by the fixed displacement pump is collected into the bottom acid tank after being added to a lead-acid storage battery, so as to be sent back to an acid cooling machine, so that the acid adding temperature each time can be ensured within in a range easy to fill acid, the quality of the battery is ensured, a series of problems that the acid overflowing of the battery causes corrosion of terminals, insufficient added acid or lack of added acid quantity and heating and deformation of the battery caused thereby, and the capacity of the battery is insufficient, and the like can be solved, the production efficiency is improved, the damage and scrape of the battery can also be reduced, and the production cost is lowered.

Owner:ANHUI LEOCH POWER SUPPLY

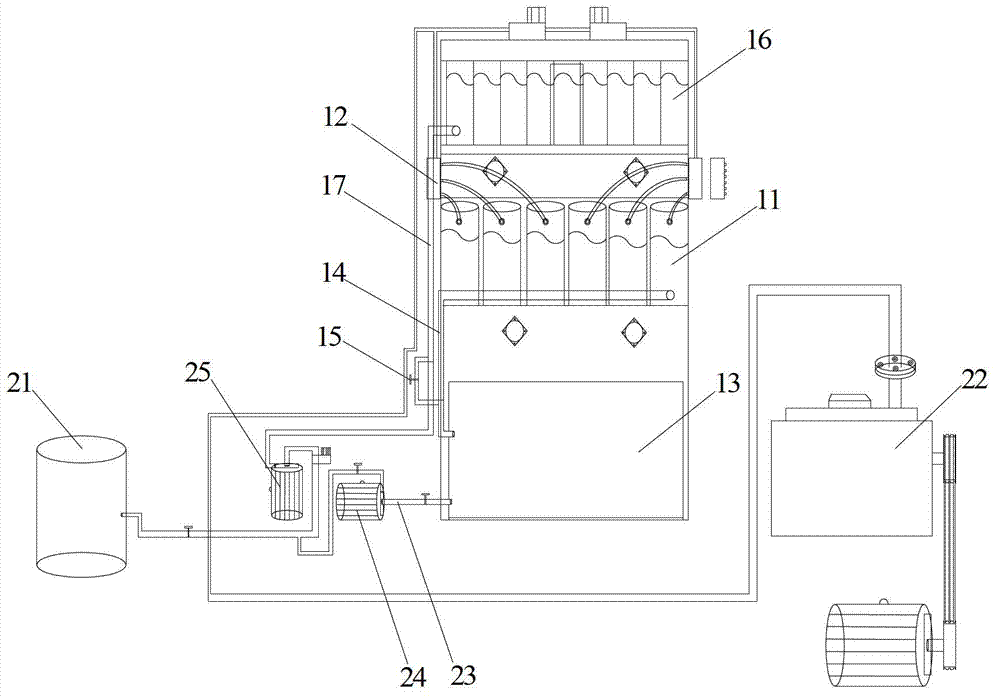

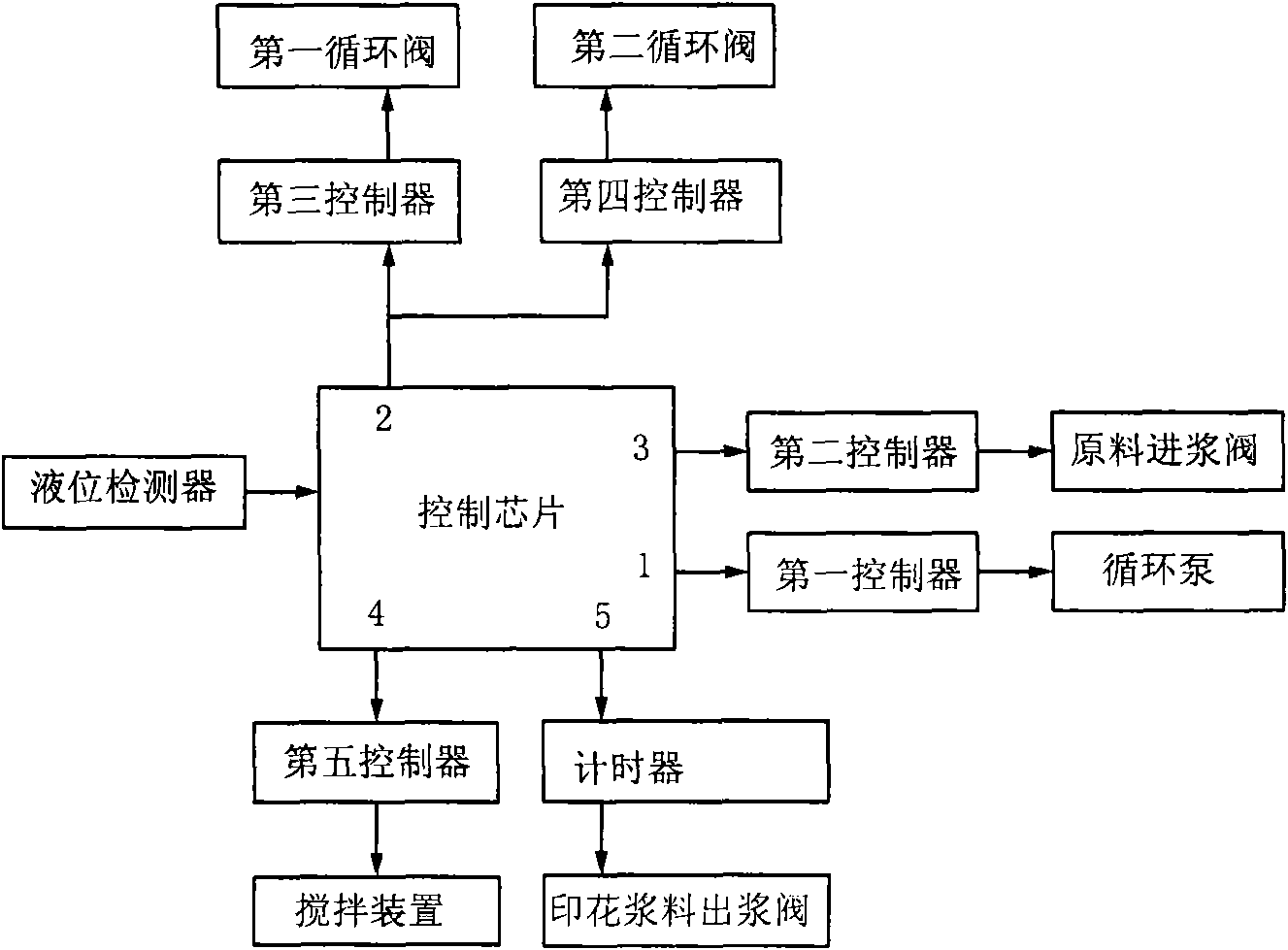

Fully automatic paste adding machine

InactiveCN101811390ASmall footprintReduce labor intensityScreen printersControl mannerFully automatic

The invention relates to a fully automatic paste adding machine for a decorating machine, which comprises a storage tank, a circulating pump, a stirring device and a control unit, wherein the storage tank is used for storing paste; a raw material paste outlet pipe is connected with the storage tank and the input port of the circulating pump; the output port of the circulating pump is connected with a printing paste output pipe; a paste inlet circulating pipe is arranged between the output port of the circulating pump and the stirring device; an interface part between the paste inlet circulating pipe and the output port of the circulating pump is positioned on the printing paste output pipe between the circulating pump and a printing paste outlet valve; a paste outlet circulating pipe is connected between the stirring device and the input port of the circulating pump; and an interface part between the raw material paste outlet pipe and the input port of the circulating pump is positioned on a paste outlet circulating pipe between a second circulating valve and the circulating pump. The invention has the beneficial effects that because the fully automatic control mode is adopted, operation of working personnel is not needed, thereby greatly reducing the labor intensity of the working personnel and saving the production cost.

Owner:常州杰盟鞋业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com