Acid adding machine for storage battery

A battery pack and acid dosing machine technology, which is applied to battery pack components, circuits, electrical components, etc., can solve problems affecting the performance and life of the battery pack, the range of use of the acid dosing machine, and the accuracy of acid measurement , to achieve the effect of small error, reduced emission and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

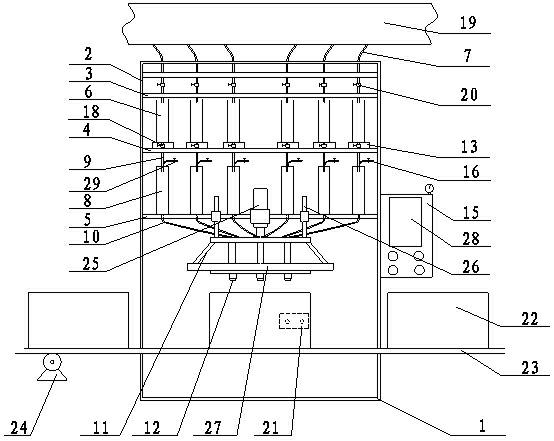

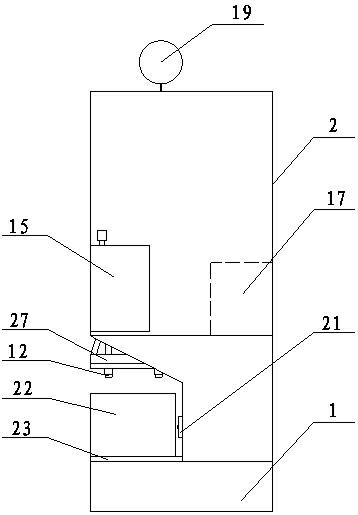

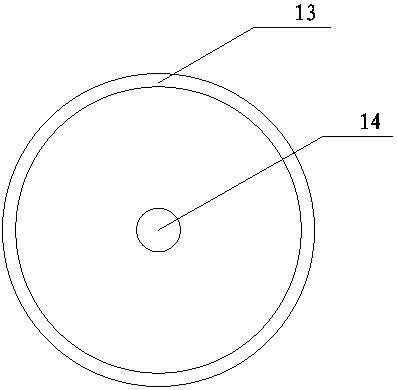

[0020] Such as Figure 1 to Figure 3 As shown, an acid adding machine for battery packs includes a base 1 and a body 2 fixed on the base 1 . Inside the body 2, a first platform 3, a second platform 4 and a third platform 5 are sequentially arranged from top to bottom, and six measuring cups 6 are evenly arranged between the first platform 3 and the second platform 4, and each The tops of the measuring cups 6 are all provided with an acid feed branch pipe 7 passing through the first platform, and the third platform 5 is provided with vacuum tubes 8 equal in number to the measuring cups 6 . Each measuring cup 6 is connected with the corresponding vacuum tube 8 below it through the acid delivery branch pipe 9, and the top of each acid delivery branch pipe 9 is sealed and connected with the bottom of the corresponding measuring cup 6, and the bottom end of each acid delivery branch pipe 9 is connected with the bottom of the acid delivery branch pipe 9. Corresponding to the top se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com