Patents

Literature

68results about How to "Realize pipeline operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

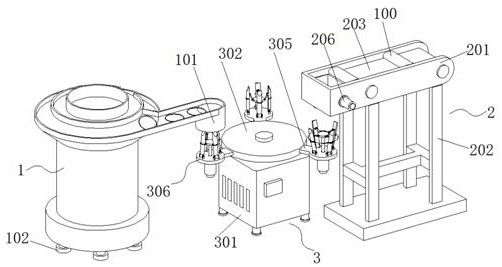

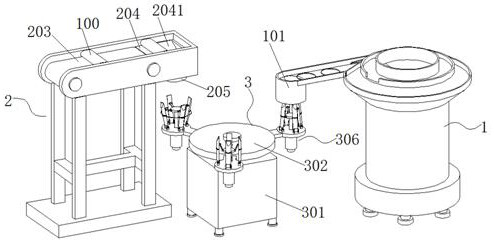

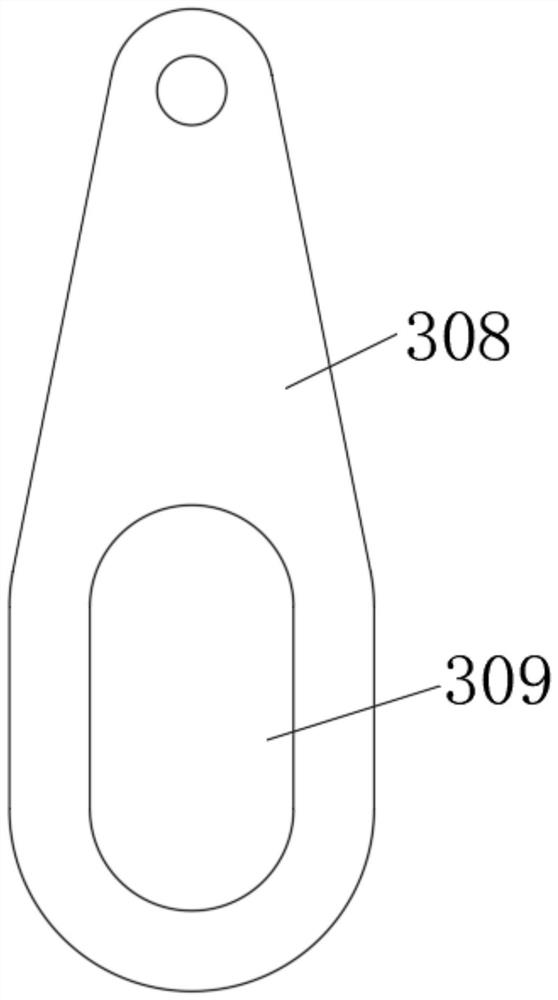

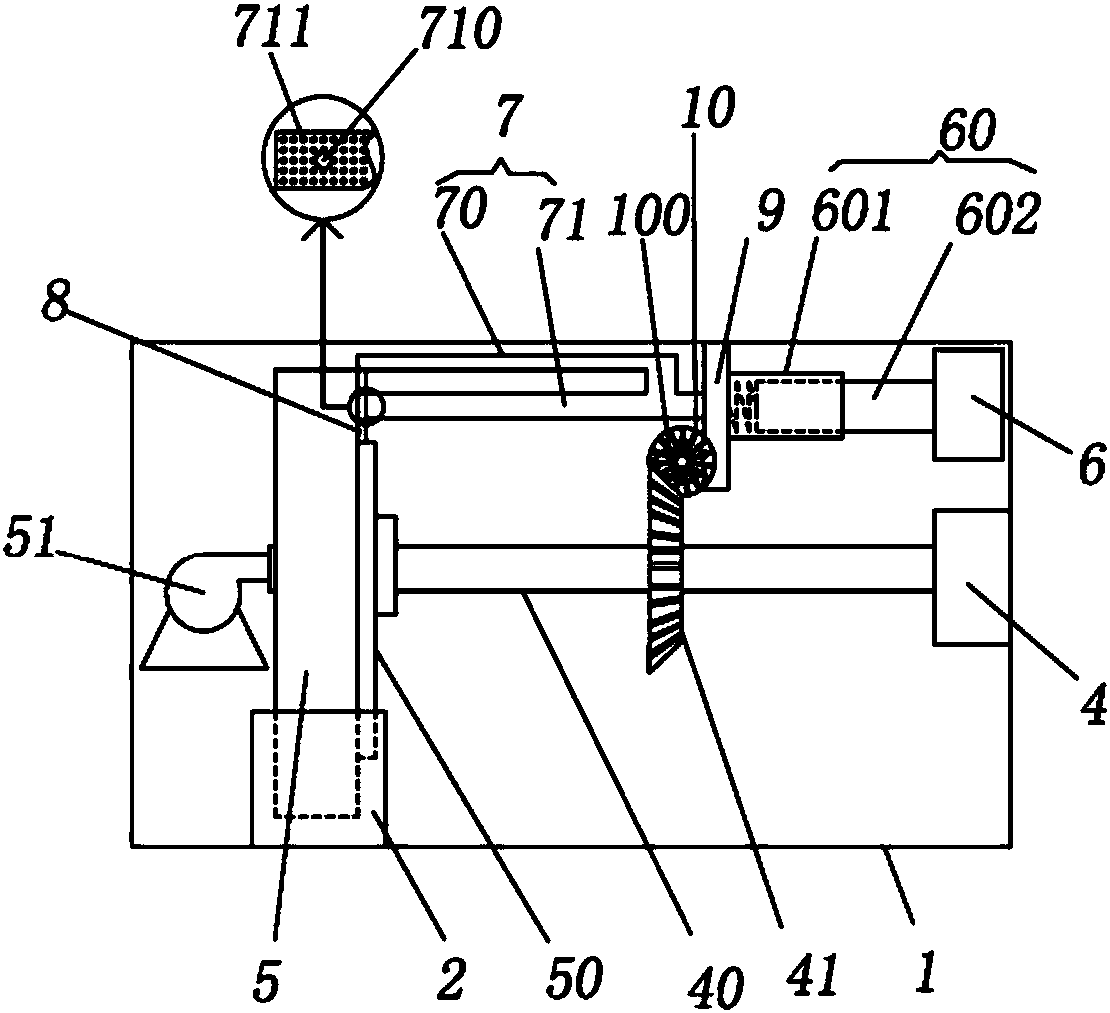

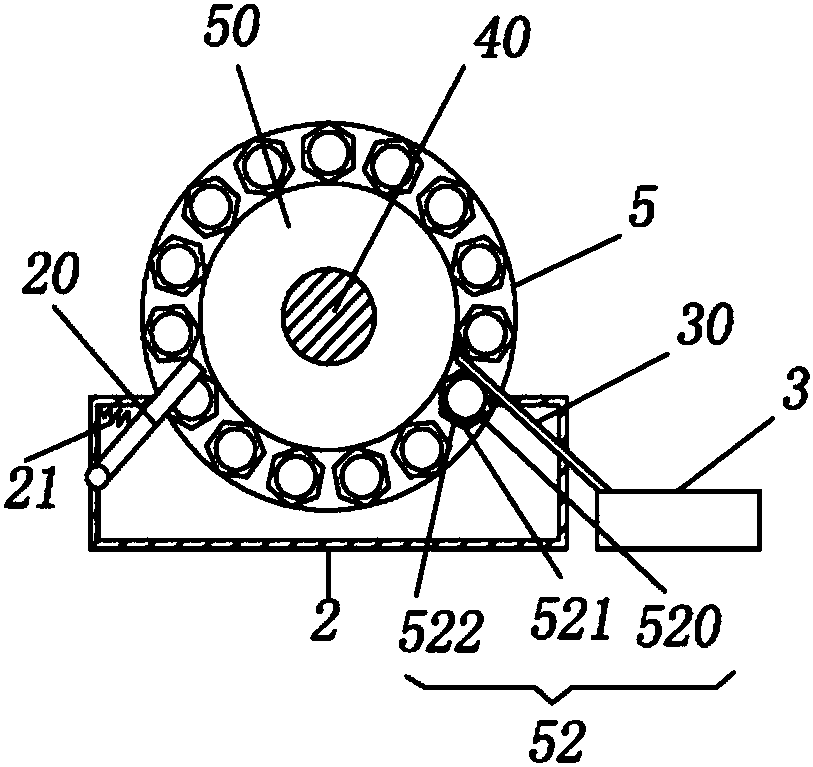

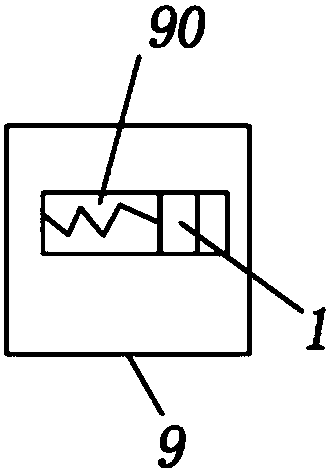

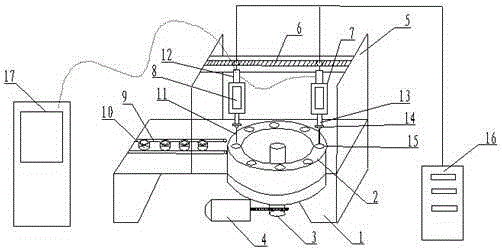

Automatic bundling equipment for plastic bag production

InactiveCN111605776AReduce laborRealize the effect of reducing staff and increasing efficiencyPaper article packagingBinding material applicationRubber ringElectric machinery

The invention relates to the technical field of plastic bag packaging equipment, and particularly discloses automatic bundling equipment for plastic bag production. The equipment comprises a rubber ring vibrating plate, a plastic bag discharging mechanism and a bundling device, wherein the bundling device is arranged between the rubber ring vibrating plate and the plastic bag discharging mechanism, the bundling device comprises a machine box, a turntable and a stepping motor, a PLC is arranged on the outer side surface of the machine box, the stepping motor is arranged inside the machine box,the upper end of an output shaft of the stepping motor is connected with a rotating rod through a coupler, the top end of the rotating rod penetrates through the top wall of the machine box and is connected with the circle center of the turntable, a plurality of connecting strips are uniformly connected to the circumferential surface of the turntable, and the outer end of each connecting strip isconnected with a rubber band bundling mechanism. According to the plastic bag bundling equipment, compared with the prior art, manual assistance is not needed to make rubber bands slip off in the process of bundling the folded plastic bags or the coiled plastic bags with the rubber bands, the labor amount of operators is reduced, and the effect of downsizing and increasing efficiency is achieved.

Owner:BENGBU WEIGUANG PLASTIC PRODS

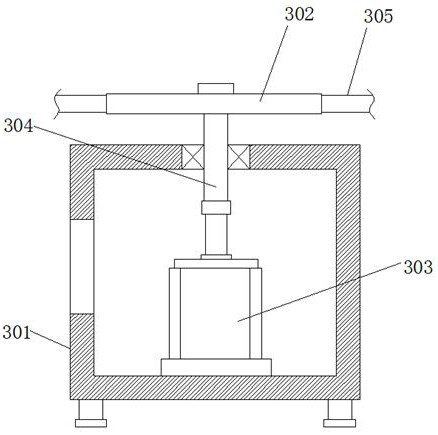

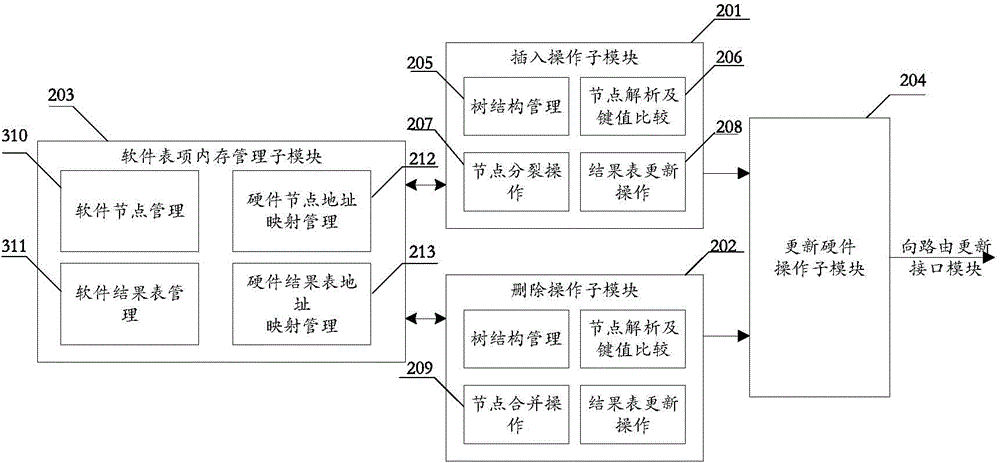

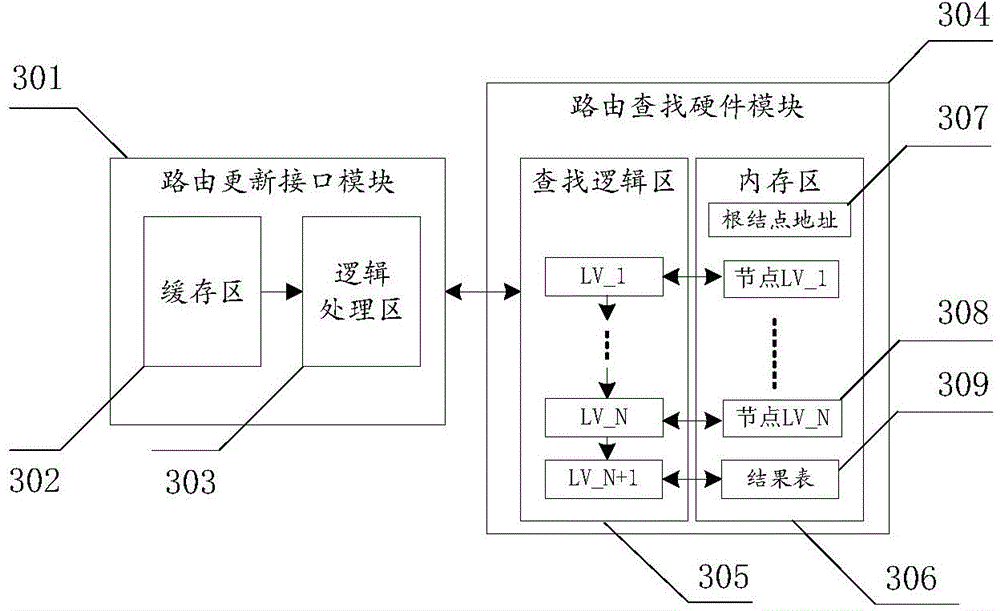

Routing lookup method, routing lookup device and method for constructing B-Tree tree structure

InactiveCN104426770AMeet high-performance lookup needsRealize pipeline operationResource allocationData switching networksData streamLongest prefix match

Owner:ZTE CORP

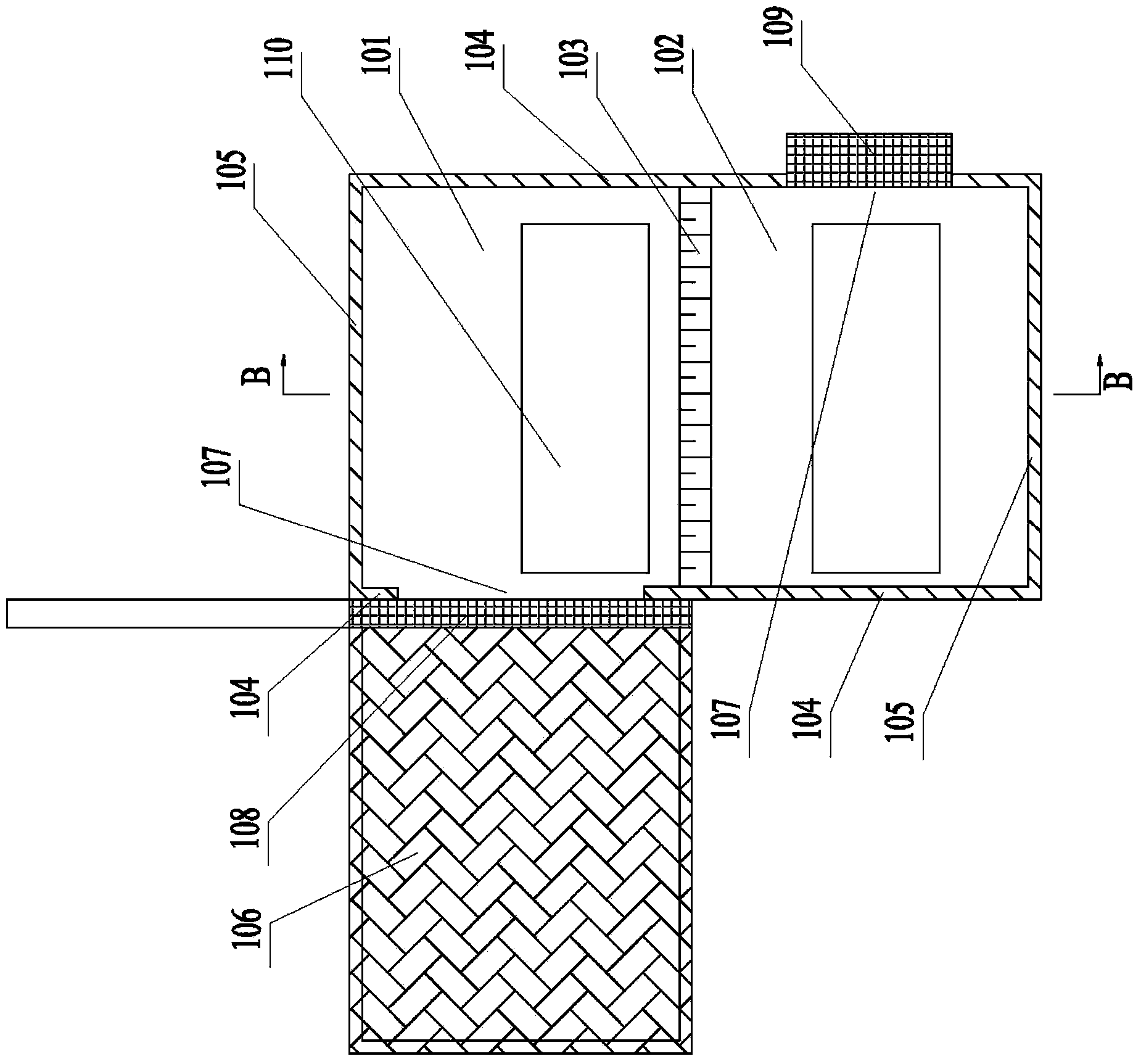

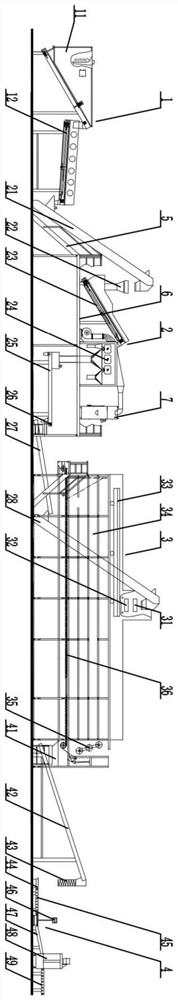

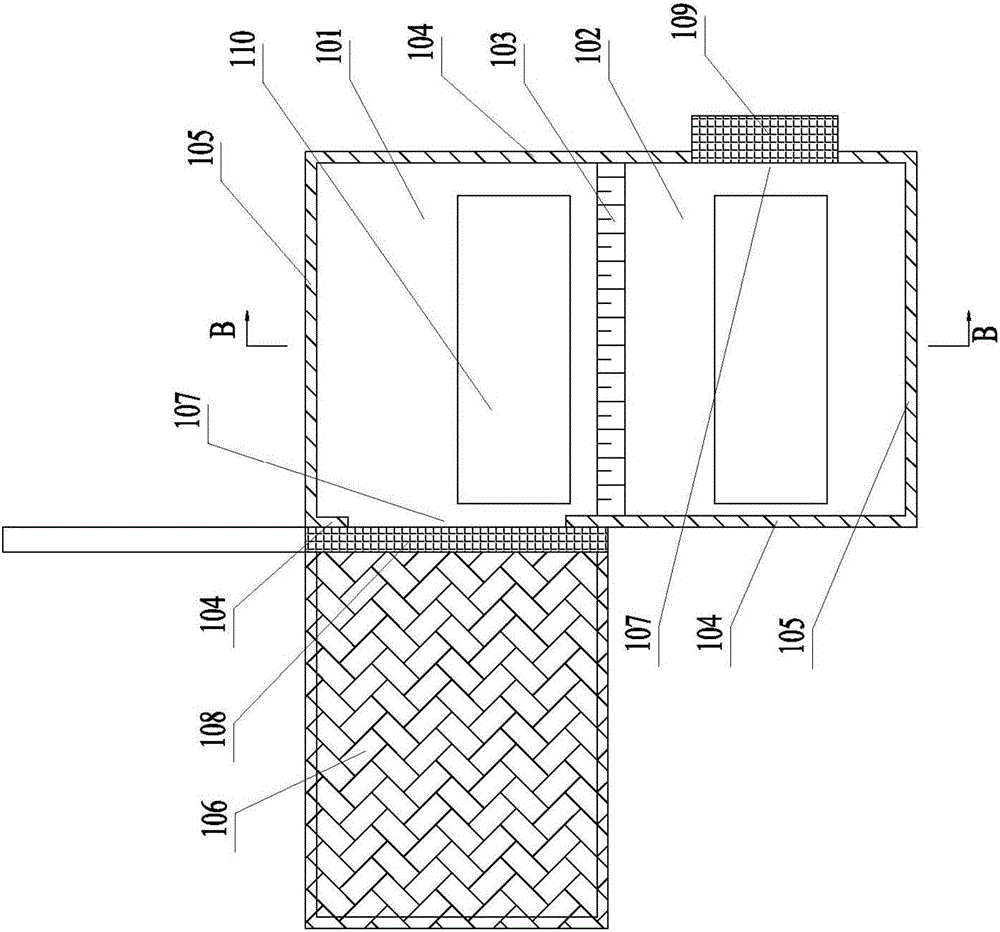

Deep and shallow dock combination for manufacturing and shipping large prefabricated components and assembly line working method

ActiveCN103669920ARealize pipeline operationShorten construction timeArtificial islandsUnderwater structuresMarine engineeringAssembly line

The invention relates to a working method for manufacturing large prefabricated components on a large scale in an assembly line manner and outfitting, lifting and shipping the large prefabricated components by the aid of a deep and shallow dock combination which comprises a shallow dock zone and a deep dock zone. The deep and shallow dock combination comprises a fence for stopping seawater from flowing into the deep and shallow dock combination. The shallow dock zone for primarily outfitting and lifting the large prefabricated components and the deep dock zone for secondarily outfitting and lifting the large prefabricated components are arranged in the fence; a shallow dock gate for opening and closing the shallow dock zone is arranged at one end of the fence, and a deep dock gate for opening and closing the deep dock zone is arranged at the other end of the fence. The working method has the advantages that large prefabricated component manufacturing, outfitting, lifting and shipping procedures can be carried out in an assembly line manner owing to the design of the shallow dock zone and the deep dock zone, accordingly, the construction time can be saved, and the construction progress can be accelerated.

Owner:CCCC FHDI ENG

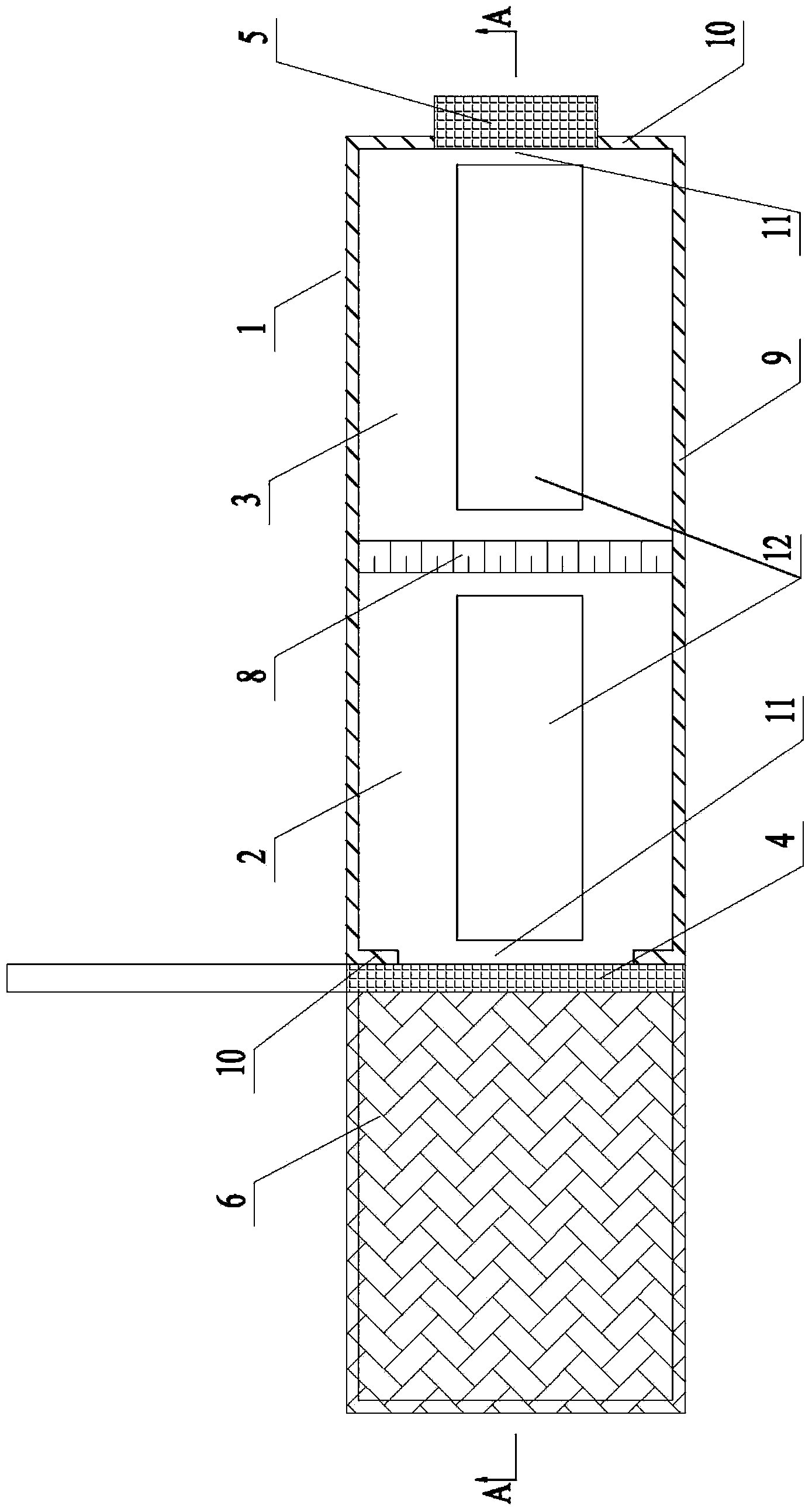

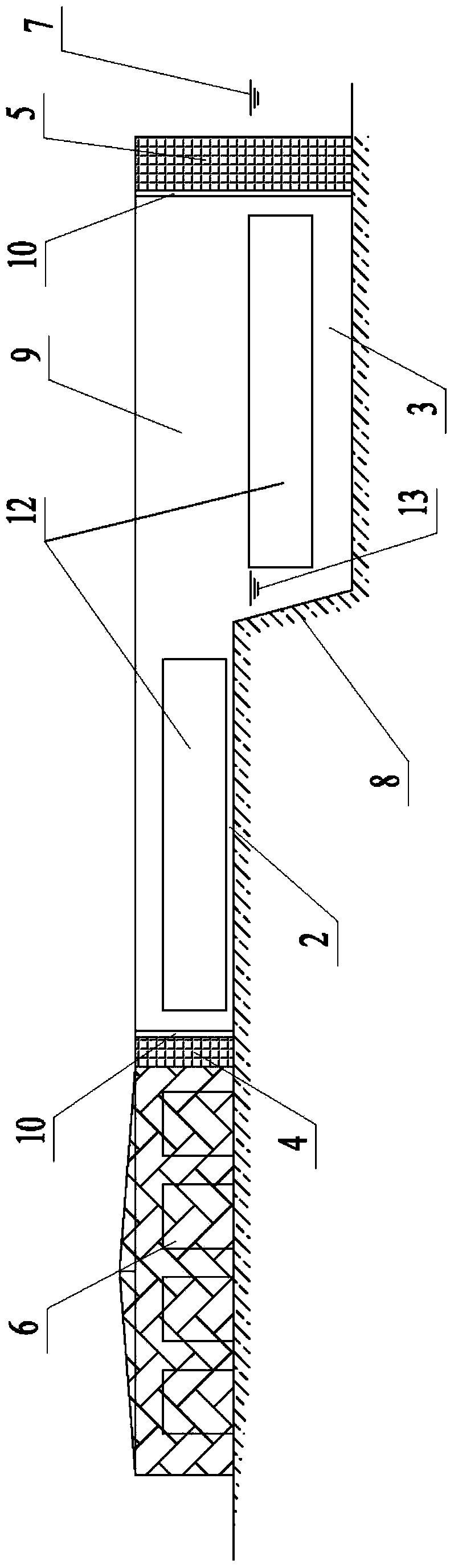

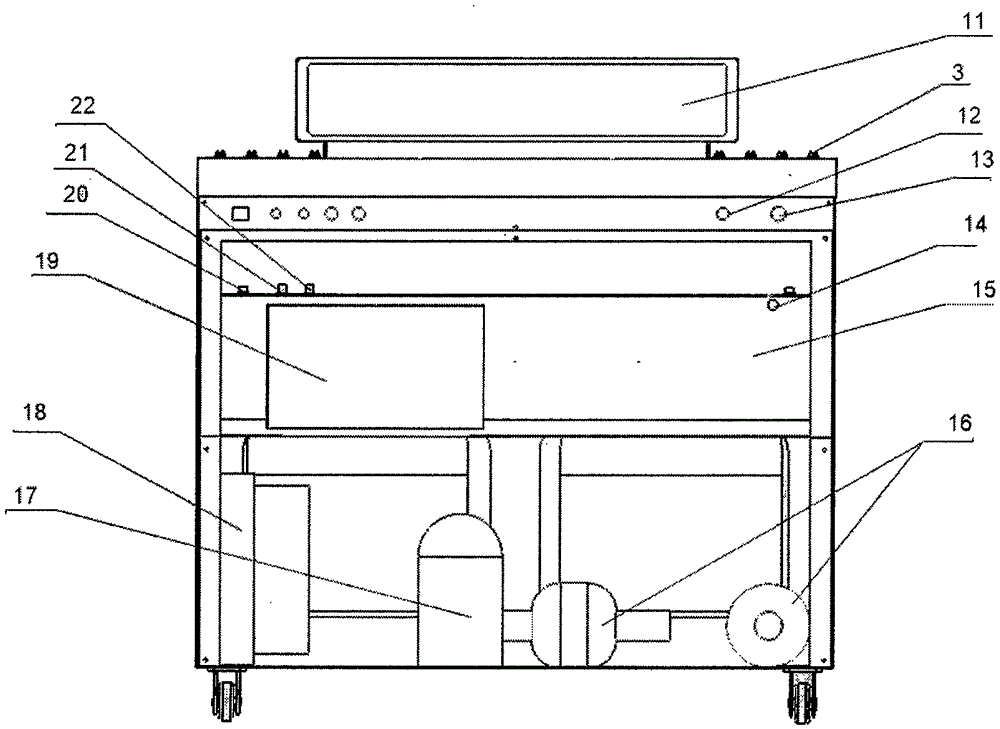

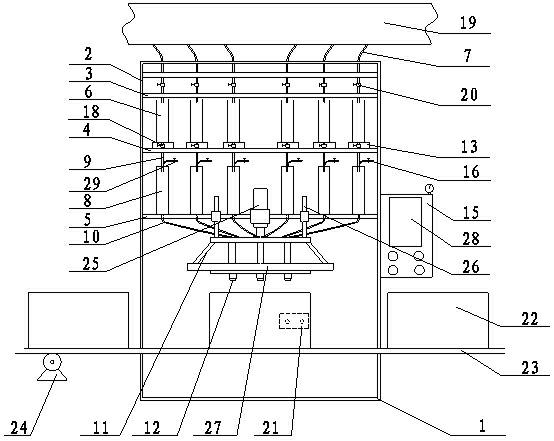

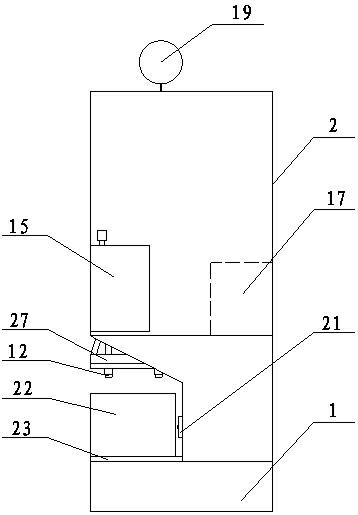

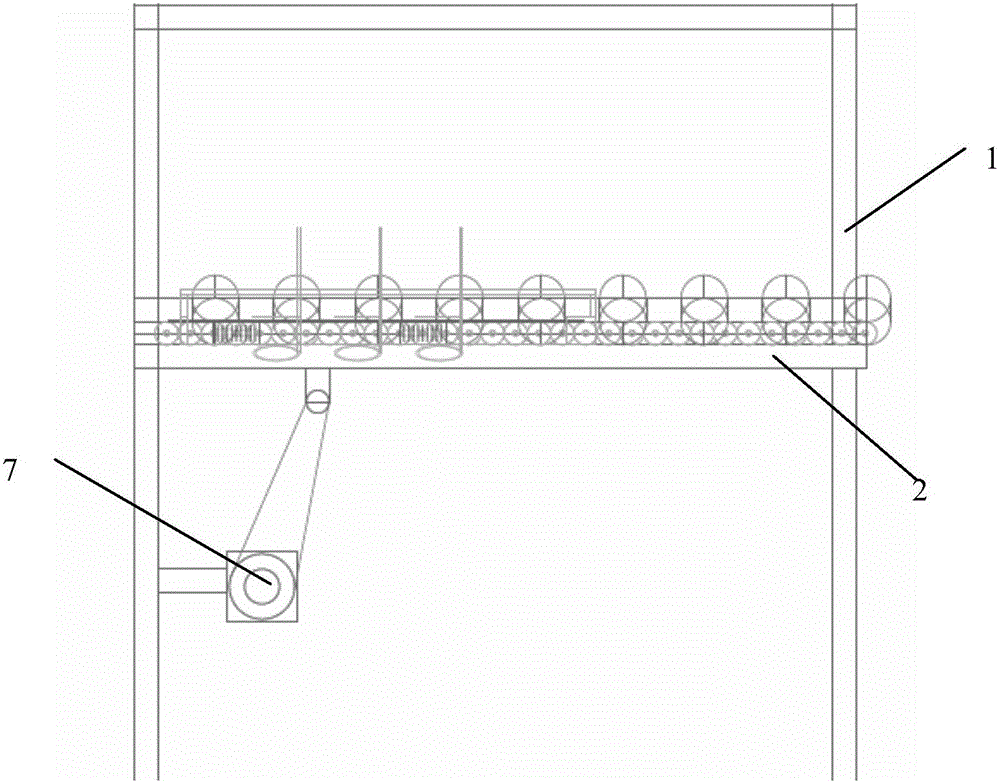

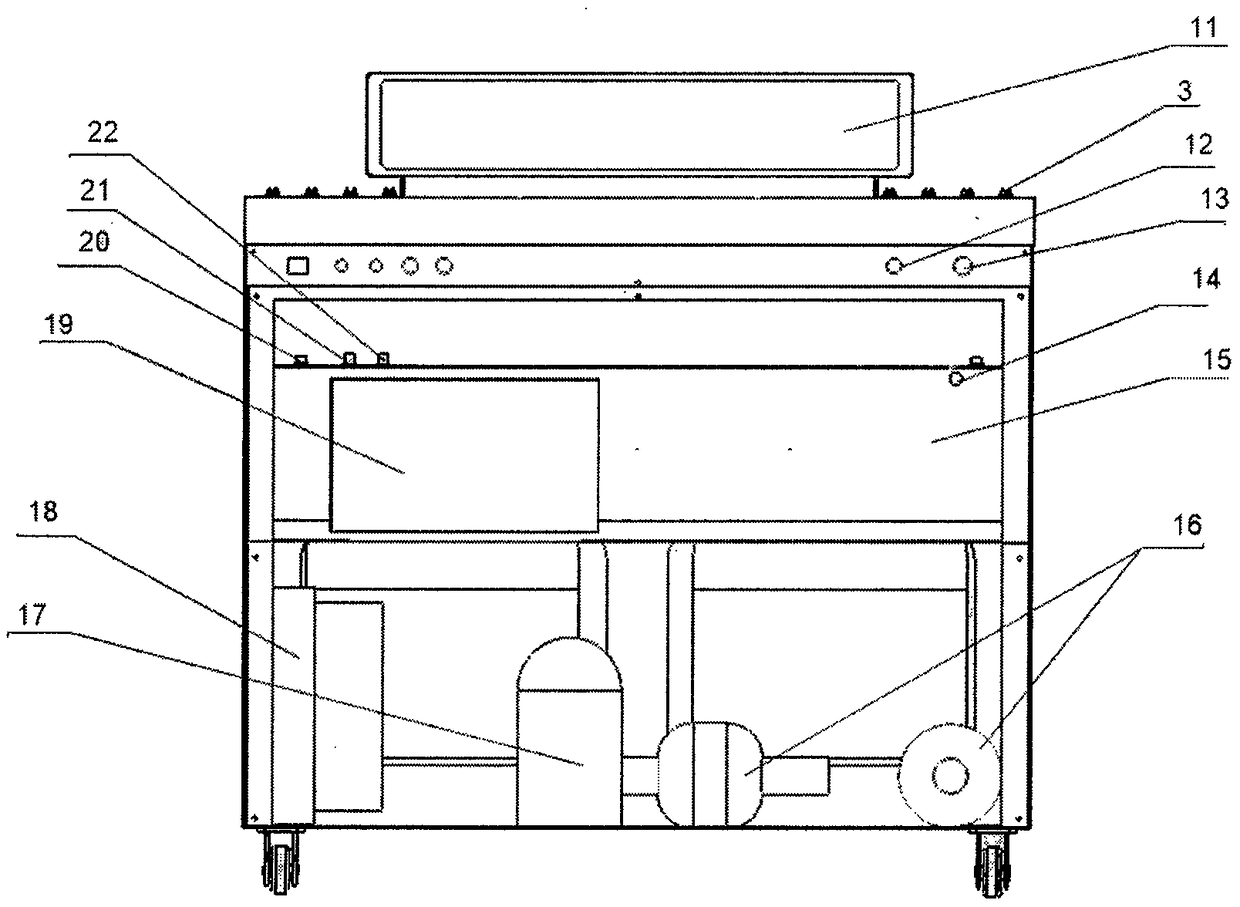

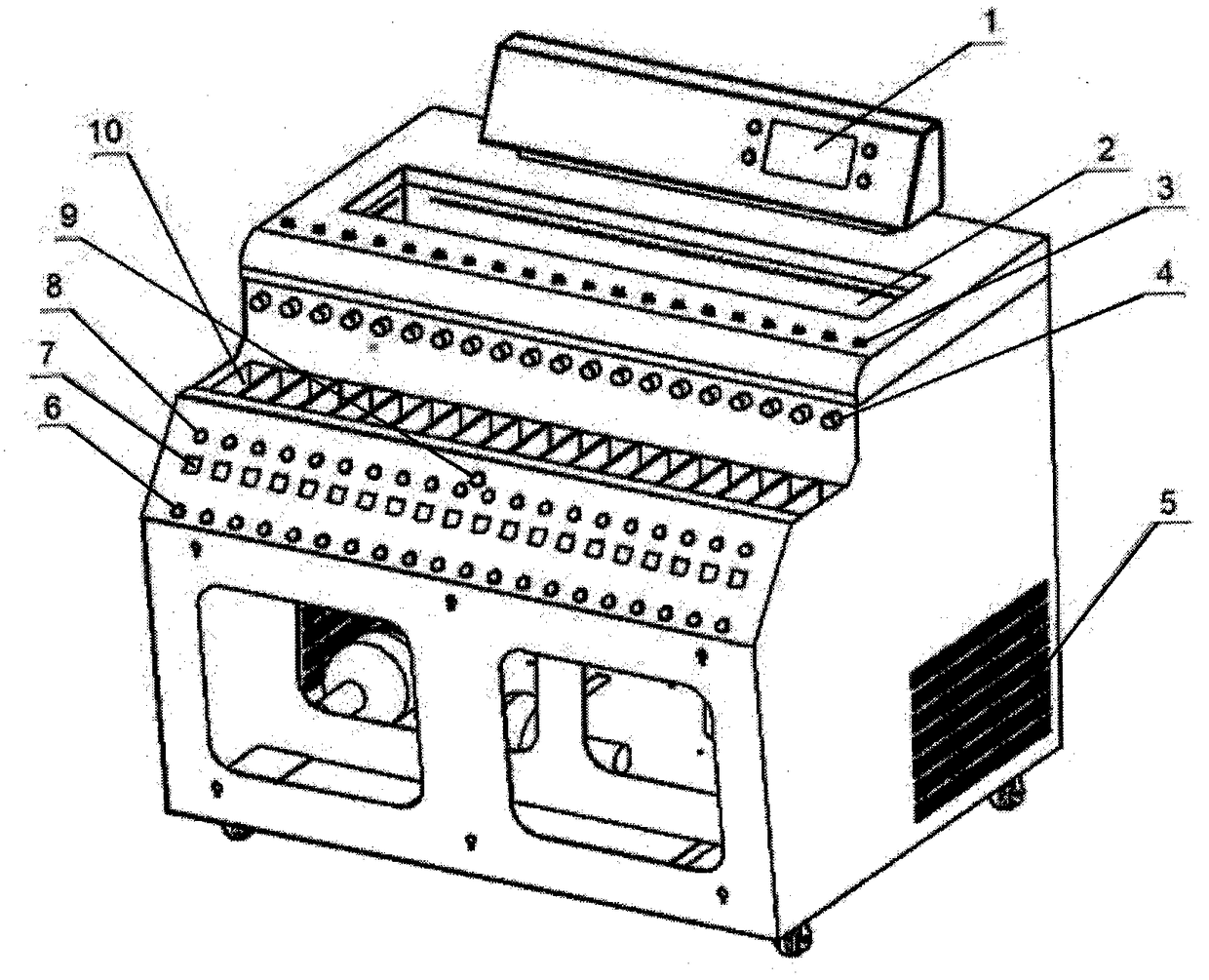

Cryoprecipitated antihemophilic factor preparation instrument and application method thereof

ActiveCN105399814AFast productionReduce lossFactor VIIPeptide preparation methodsWater circulationEngineering

The invention discloses a cryoprecipitated antihemophilic factor preparation instrument. The cryoprecipitated antihemophilic factor preparation instrument is characterized by being composed of three parts, i.e., a weight control part, a water temperature control and water circulation system part and a central control part, wherein the three parts are interconnected together, and the weight control part is divided into a weighing part and a control part. The cryoprecipitated antihemophilic factor preparation instrument disclosed by the invention not only can achieve the simultaneous batch preparation of cryoprecipitated antihemophilic factors, but also can implement single-bag operation, i.e., the implementation of batch preparation is not required, once a bag is completely prepared, the bag can be taken out, and then a next bag is put into the instrument to prepare, so that an effect of flow production is achieved, thereby greatly saving time.

Owner:佛山沃塘医疗科技有限公司

Acid adding machine for storage battery

The invention relates to an acid adding machine for a storage battery. The acid adding machine comprises a base, a machine body, a first platform, a second platform, a third platform, measuring cups, vacuum tubes and a lifting device, wherein the top of each measuring cup is provided with an acid adding branch tube; each measuring cup is communicated with a corresponding vacuum tube below the measuring cup through an acid conveying branch tube; the bottom of each vacuum tube is connected with a hose; and acid adding nozzles are formed at the bottom of the lifting device. The acid adding machine is characterized in that: the bottom of each measuring cup is provided with an electronic scale in which a hole for a corresponding acid conveying branch tube to pass through is formed; each electronic scale is electrically connected with a program control box arranged on one side of the machine body; each vacuum tube is connected with a vacuumizing hose; a vacuumizing pump is electrically connected with the program control box; and an acid adding valve is arranged on each acid conveying branch tube. The acid adding machine has the advantages that: the volume of acid liquor can be highly accurately measured with small errors, and can be automatically set, and the whole acid adding process can be automatically controlled.

Owner:江苏海宝新能源有限公司

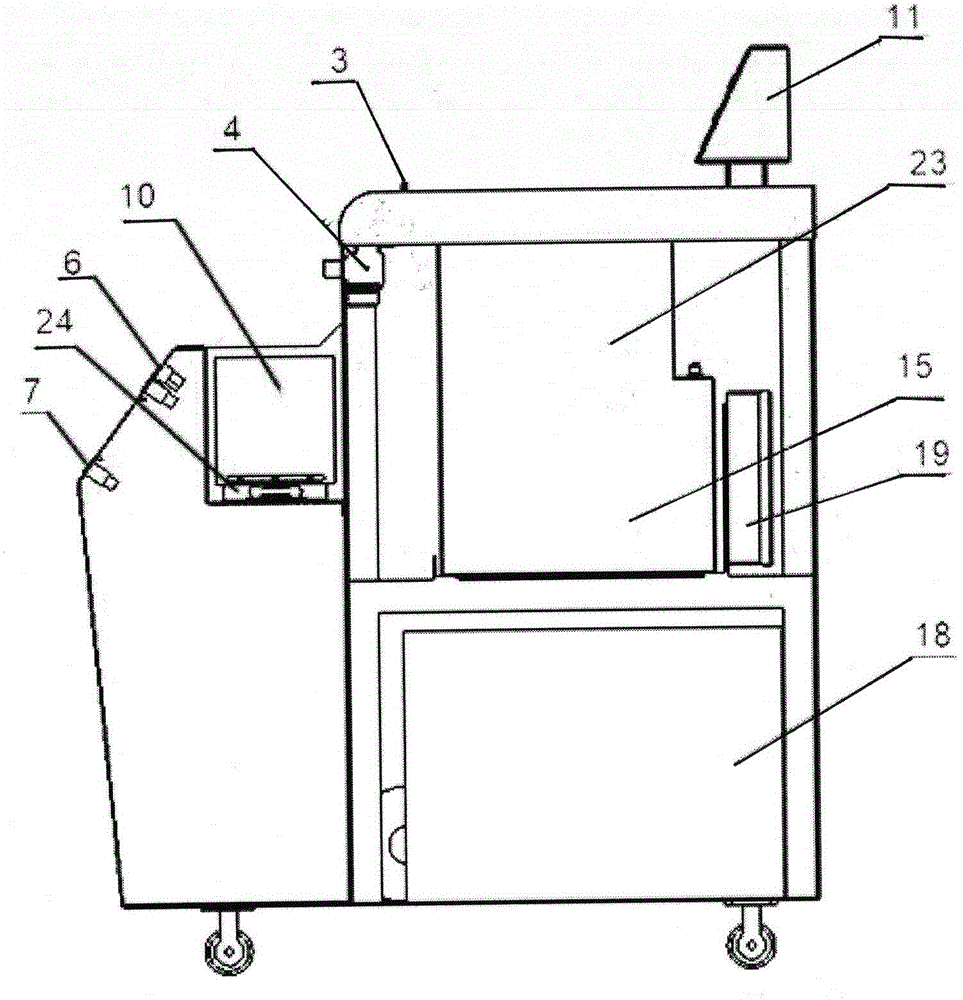

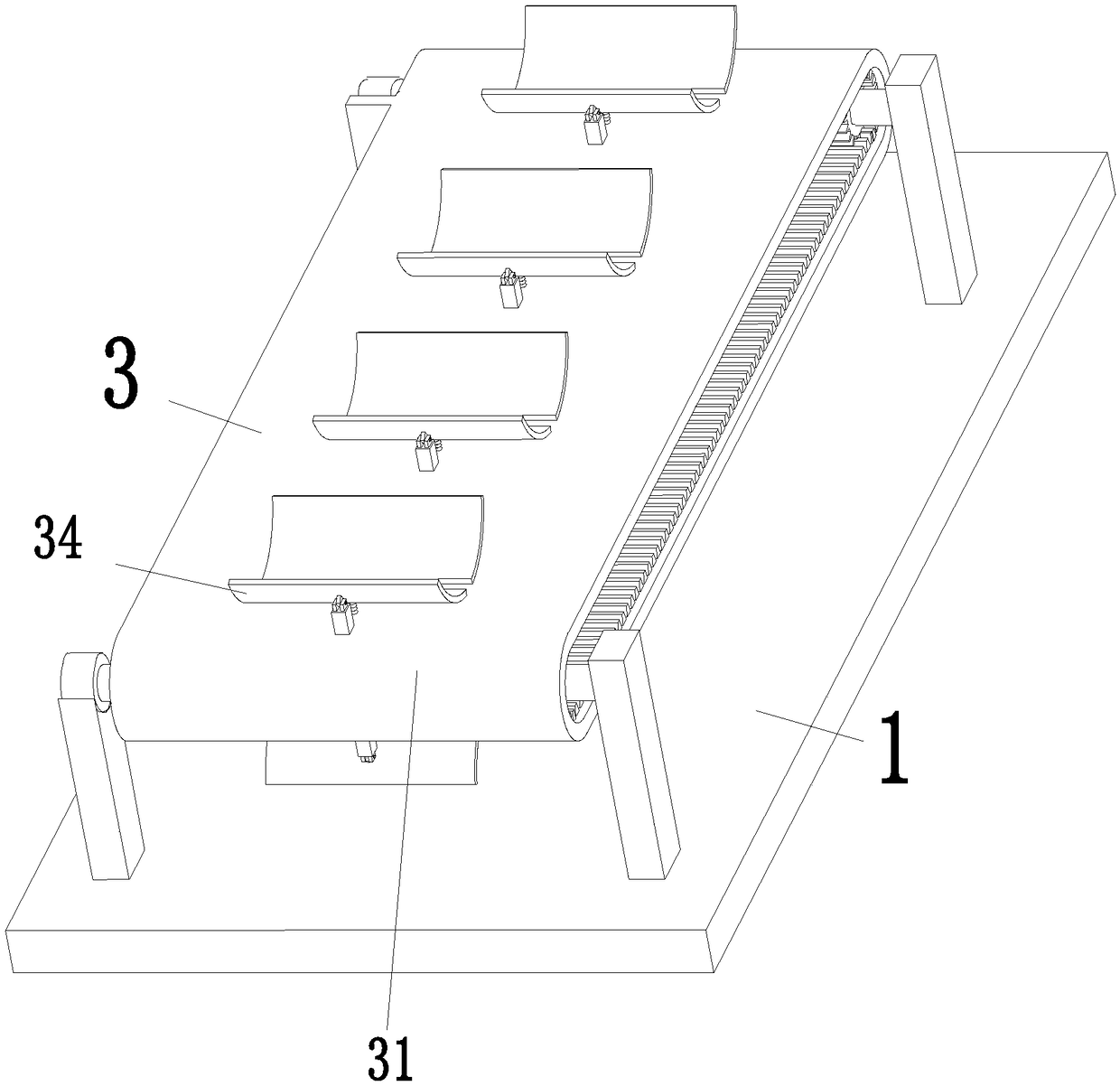

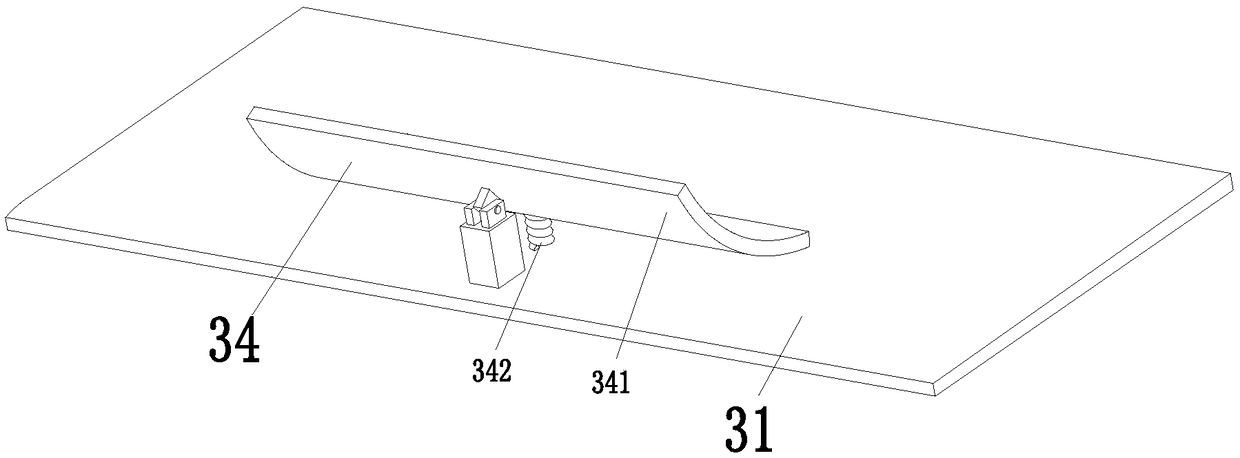

Online inspection and cleaning device of batteries

InactiveCN105775647ARealize pipeline operationRealize the goal of reducing manpower and increasing efficiencyDirt cleaningCleaning using toolsEngineeringAssembly line

The invention discloses an online inspection and cleaning device of batteries. The online inspection and cleaning device comprises a frame, a first conveying belt, a second conveying belt and an isolation hood, wherein the first conveying belt is arranged on an operating table of the frame and is used for bearing to-be-inspected batteries, the second conveying belt is used for bearing qualified batteries, the isolation hood is arranged on the tail end of the second conveying belt, an inlet and an outlet are correspondingly formed in the front and back parts of the isolation hood, at least one group of cleaning brush which is driven to rotate is correspondingly arranged in the ends, which are opposite to anodes and cathodes of the batteries, in the isolation hood, and the isolation hood is communicated with a vacuum device by virtue of a communicating pipe. According to the online inspection and cleaning device, a conveying belt type workbench is redesigned, and an online cleaning and dust removing device of the batteries is additionally arranged, so that the assembly line work can be realized, and the operations are completed by different operators according to different functions. The actual operation time and efficiency of different posts are measured, so that the number of operators of each post is reasonably arranged, the online cleaning and dust removing device is used for replacing manual operation, the purpose of increasing the efficiency by downsizing payrolls is realized, additionally, the previous and subsequent operation beats are balanced, the maximum efficiency is achieved, the scale production is facilitated, and the application range is wide.

Owner:TIANJIN LISHEN BATTERY

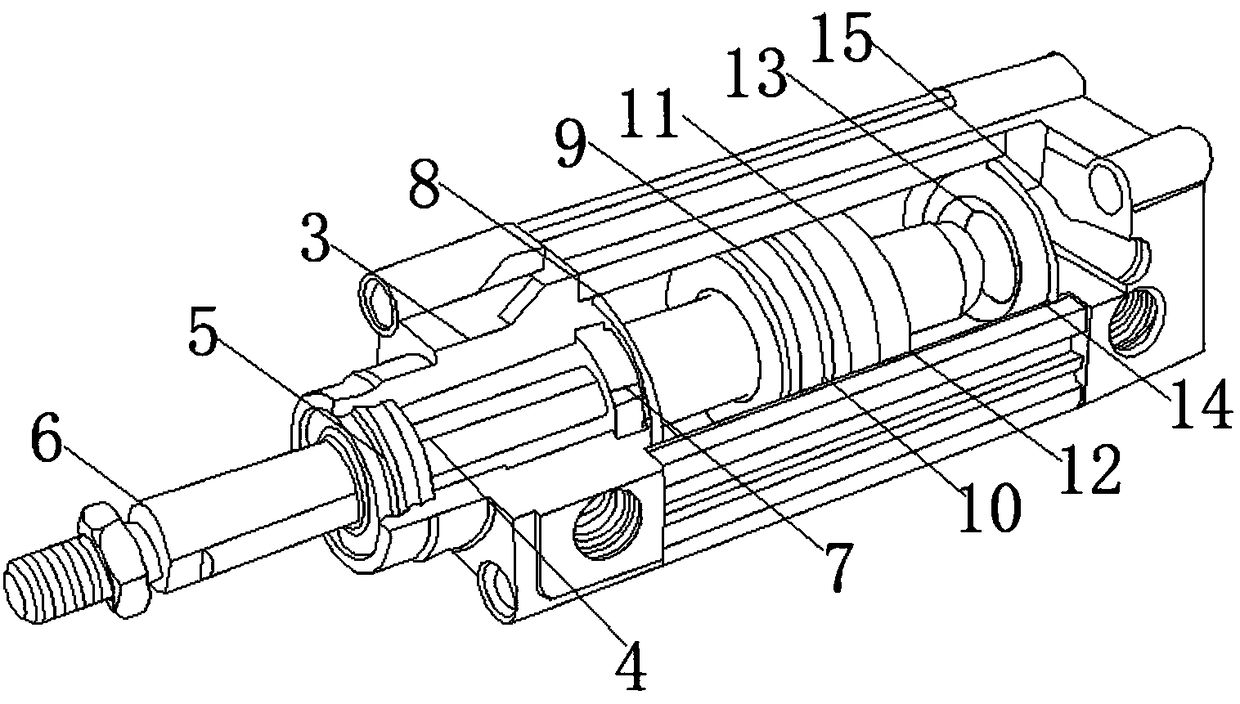

Automatic film tearing mechanism of manipulator

PendingCN108437605ALow costAvoid air bubblesLamination ancillary operationsLaminationPistonWear resistant

The invention discloses an automatic film tearing mechanism of a manipulator. The automatic film tearing mechanism of the manipulator comprises a base, wherein a mechanical column is fixedly mounted on the outer surface of one side of the upper end of the base; a film throwing lifting cylinder is fixedly mounted on the outer surface of the upper end of the mechanical column; a bearing is fixedly mounted in the center of the inside of the film throwing lifting cylinder; a plug rod sealing piece is fixedly mounted at the front end of the bearing; a plug rod is movably mounted in the center of the inner surface of the plug rod sealing piece; a buffer sealing ring is fixedly mounted on the outer surface of one side of the bearing; an end cap sealing ring is fixedly mounted on the outer surfaceof one side of the buffer sealing ring; a piston sealing piece is fixedly mounted on one side of the end cap sealing ring; a piston is fixedly mounted on one side of the piston sealing piece; a magnet is fixedly mounted on the outer surface of one side of the piston; and a wear-resistant ring is fixedly mounted on the outer surface of one side of the magnet. The film tearing mechanism is simple and practical, and is rapid and convenient, carrying films which are torn off are automatically collected in a waste box, a clamping end carries a film corner to finish film tearing, easily torn stickers are not required, and thus, costs are saved.

Owner:SHENZHEN NUOFENG OPTOELECTRONICS EQUIP

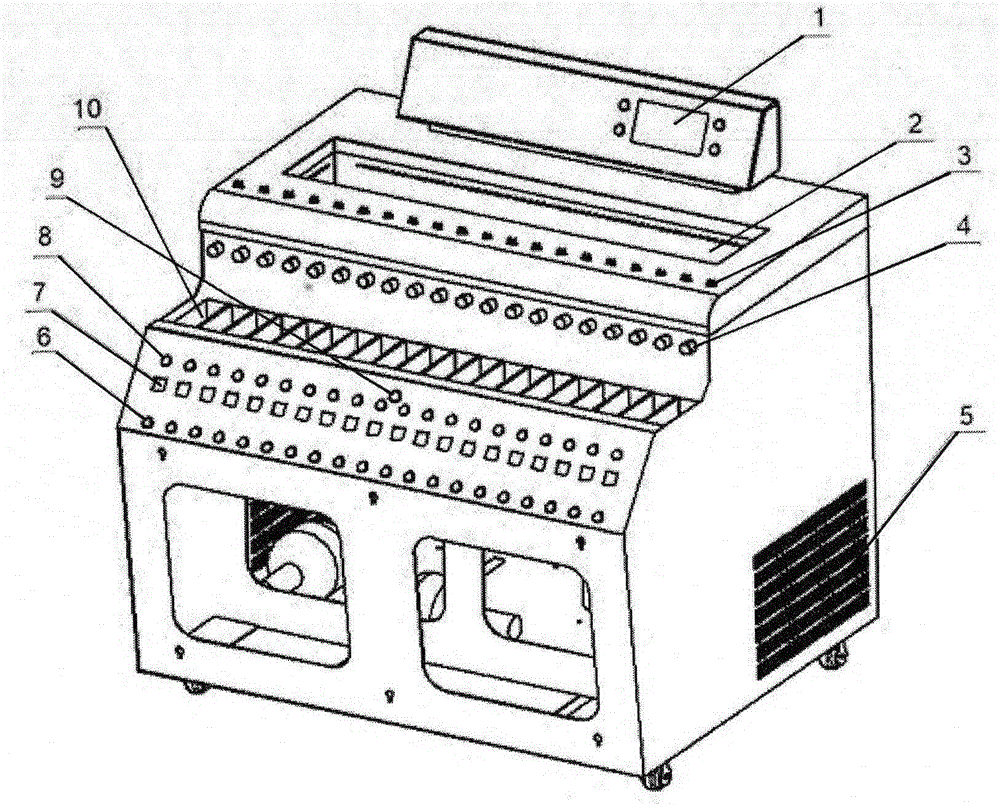

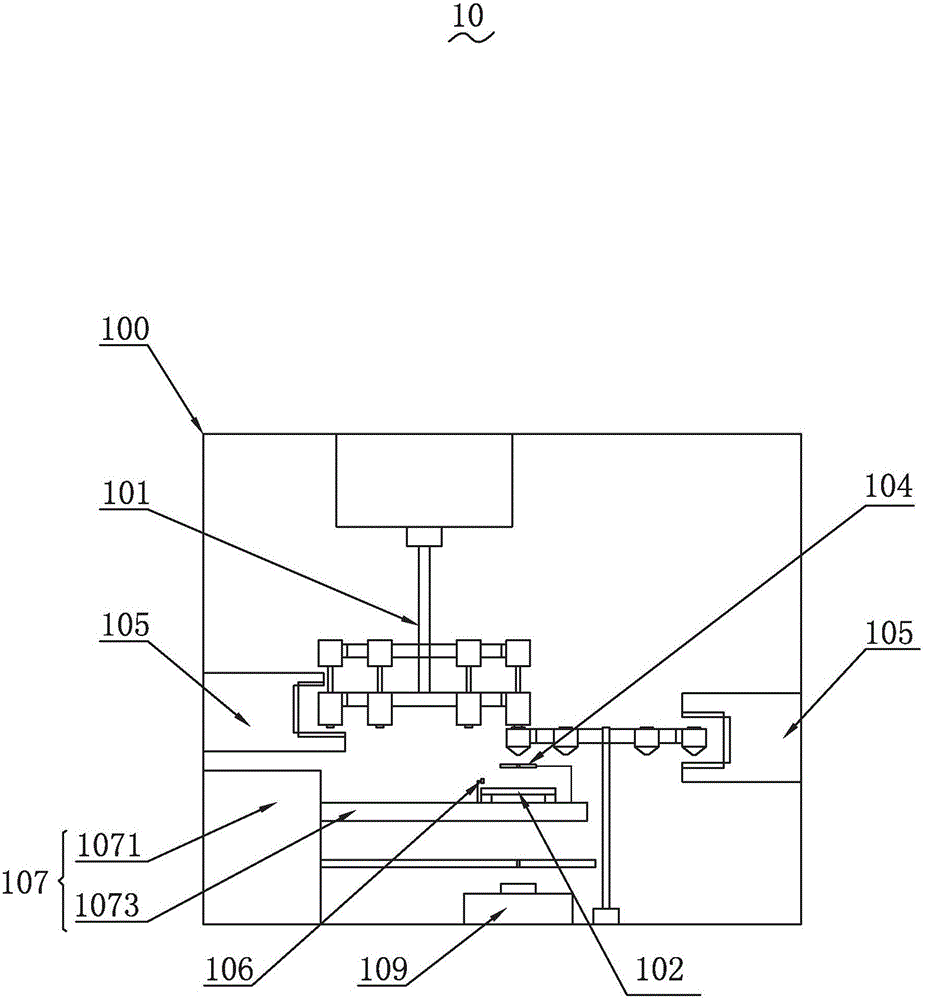

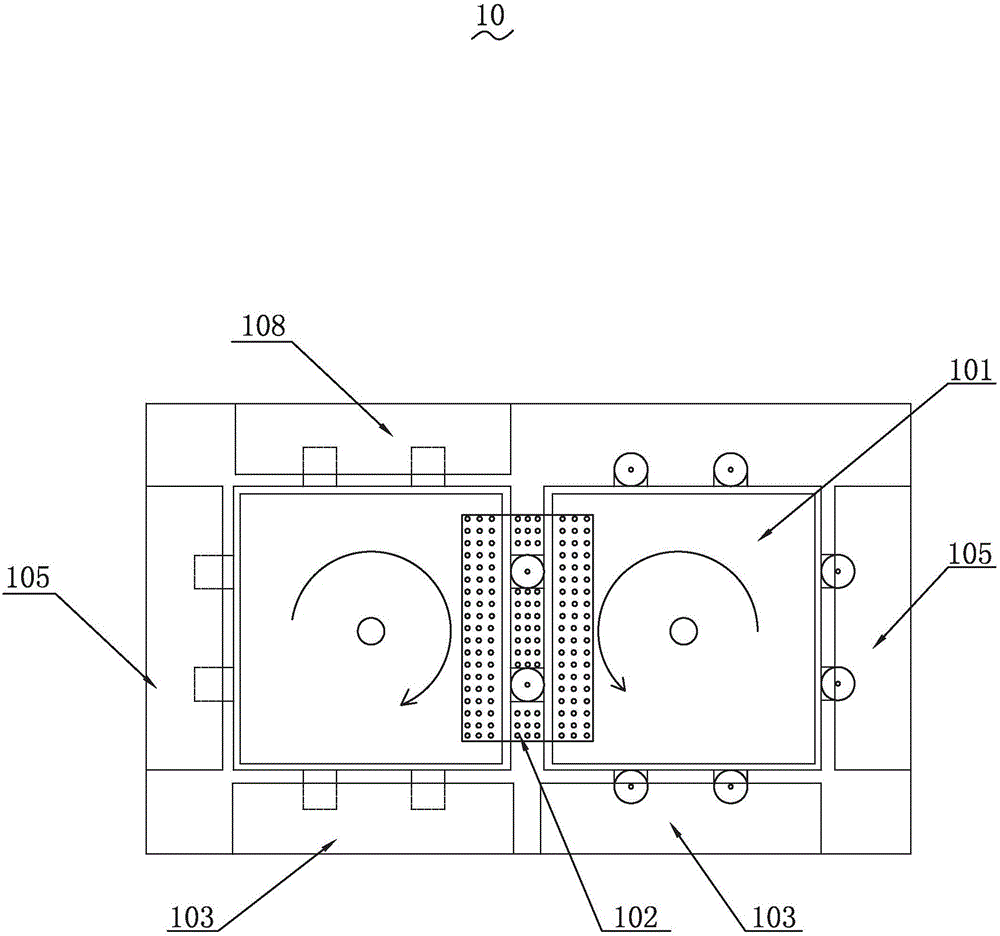

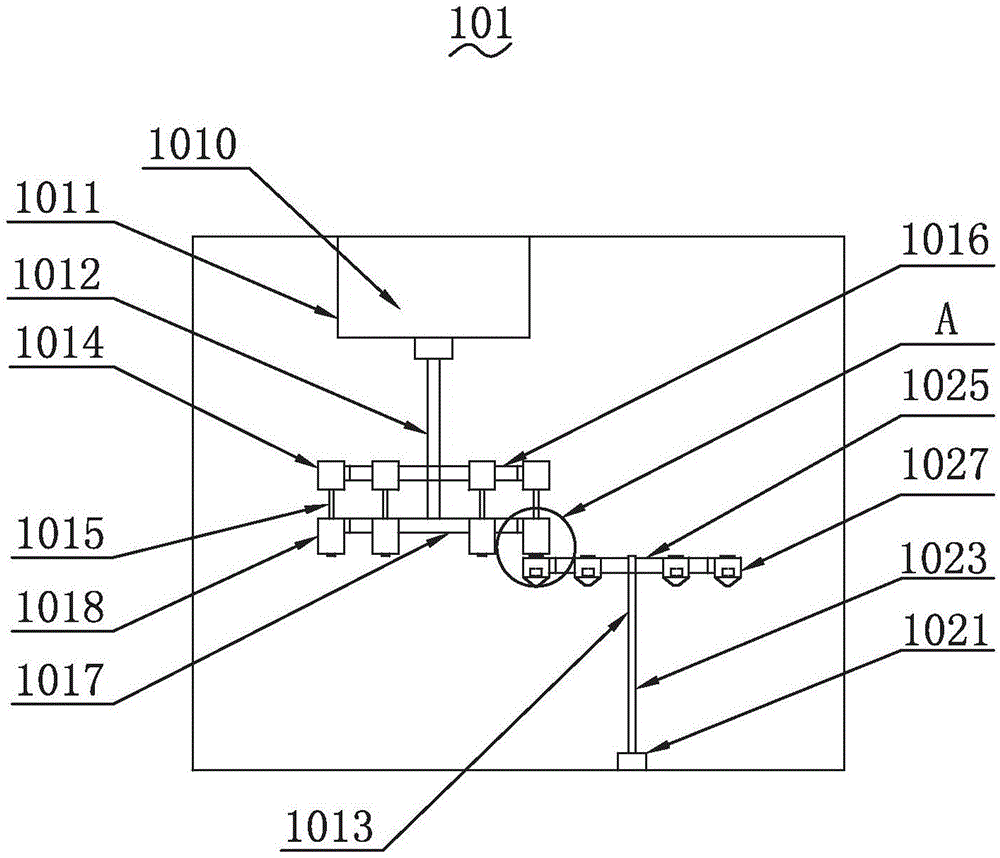

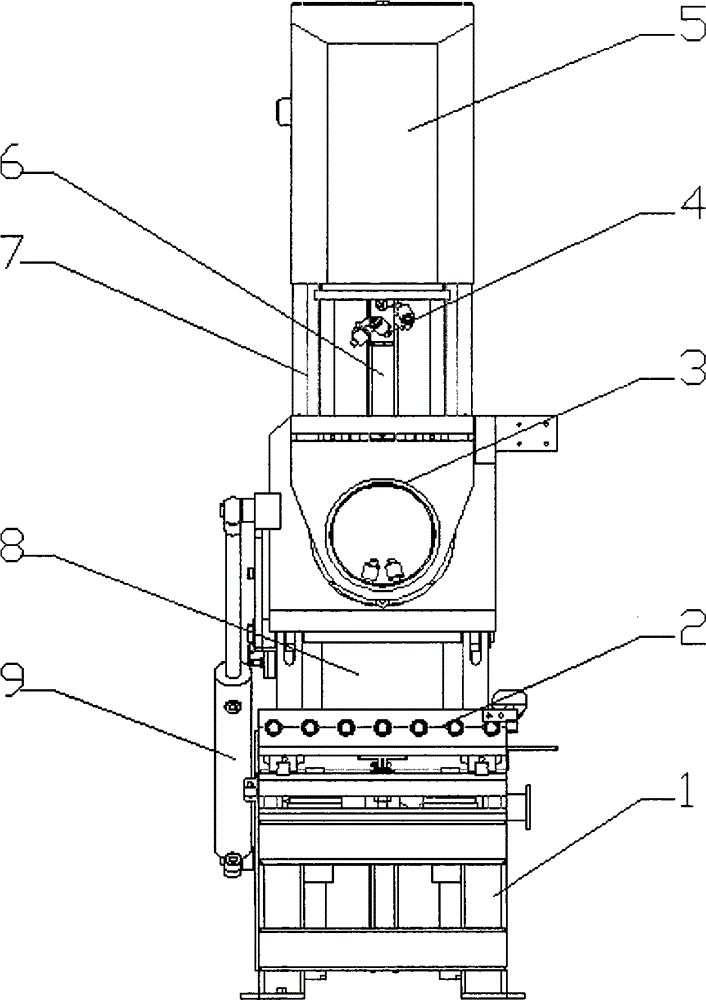

Assembly line type ultrahigh-pressure sterilizing equipment

InactiveCN105901468ARealize pipeline operationNo sterile manipulation requiredFood preservationUltra high pressure food processesUltra high pressureBiochemical engineering

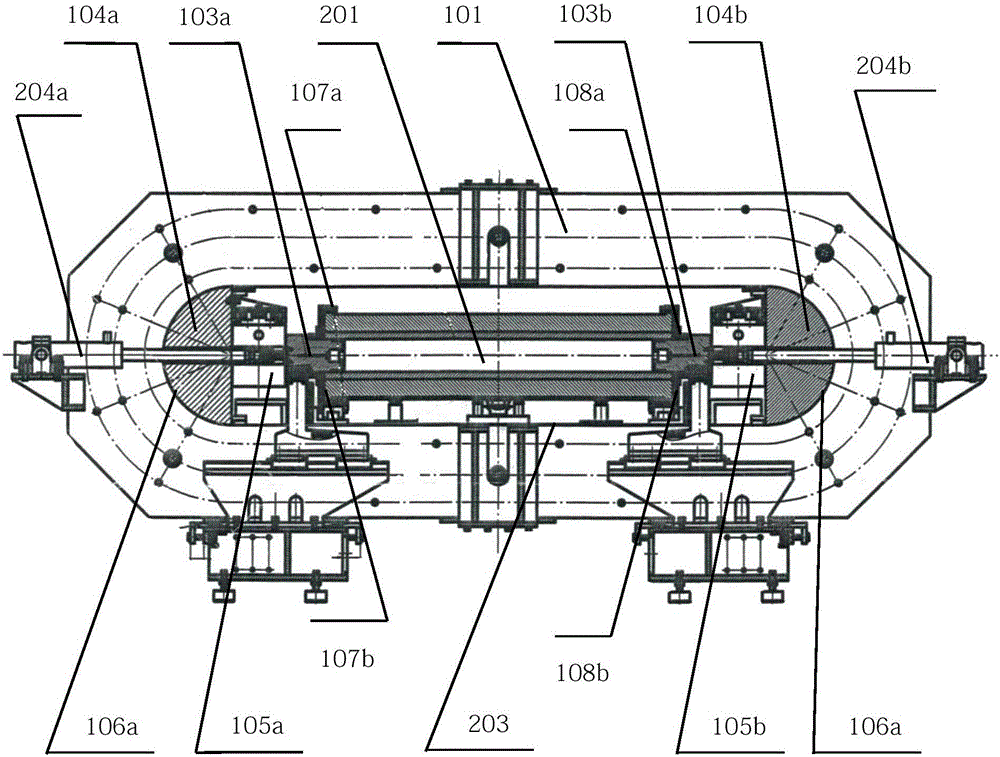

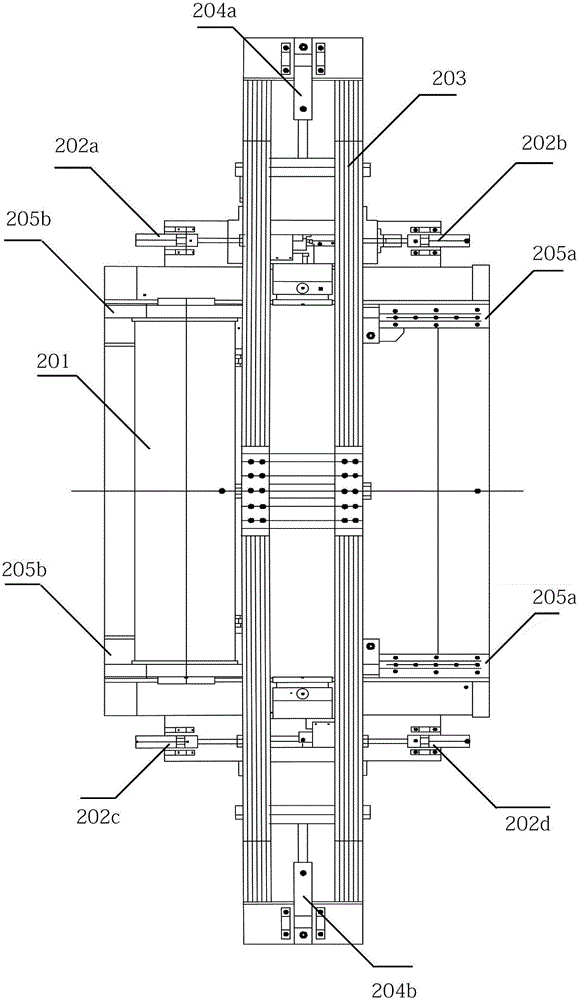

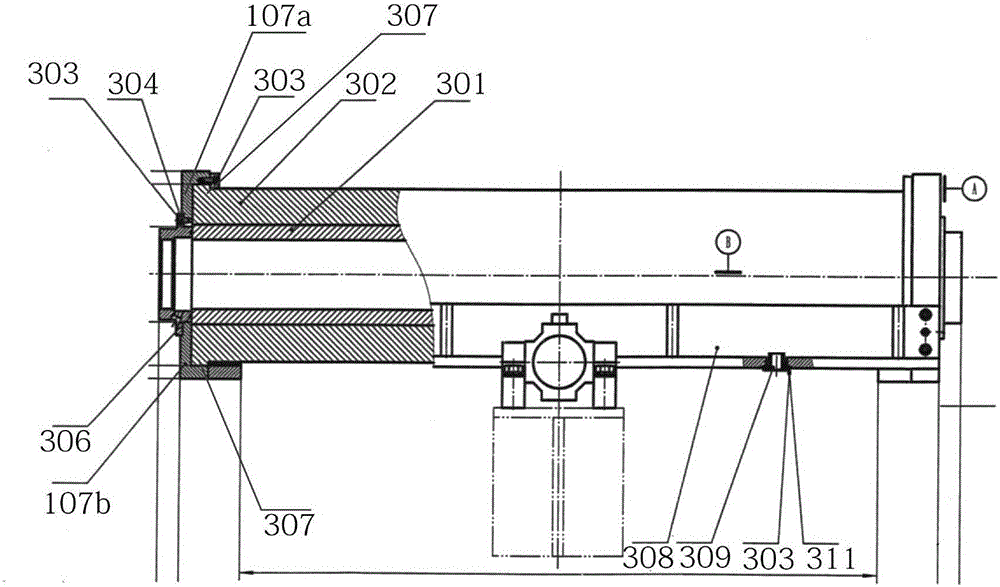

Assembly line type ultrahigh-pressure sterilizing equipment. The invention relates to assembly line type ultrahigh-pressure equipment. The ultrahigh-pressure equipment is characterized by at least comprising a force-bearing framework (101), an ultrahigh-pressure tank body (201), end plates which are used for fixing the ultrahigh-pressure tank body (201) and guide rails which are located at the two sides of a force-bearing seat (203). The ultrahigh-pressure equipment comprises at least two ultrahigh-pressure tank bodies (201), wherein the at least two ultrahigh-pressure tank bodies (201) move along the guide rails arranged on the force-bearing framework through the end plates fixed at the two ends of each ultrahigh-pressure tank body under the action of a driving system, so that the at least two ultrahigh-pressure tank bodies (201) can alternately enter the force-bearing framework (101). According to the assembly line type ultrahigh-pressure equipment provided by the invention, the ultrahigh-pressure tank bodies to be processed are alternately fed to the force-bearing framework by the driving system for ultrahigh-pressure sterilizing, so that a continuous processing process for the ultrahigh-pressure sterilizing of food is achieved, the production efficiency of food processing is increased, and a sterilizing procedure is simplified.

Owner:BEIJING SUYUAN ZHONGTIAN SCI

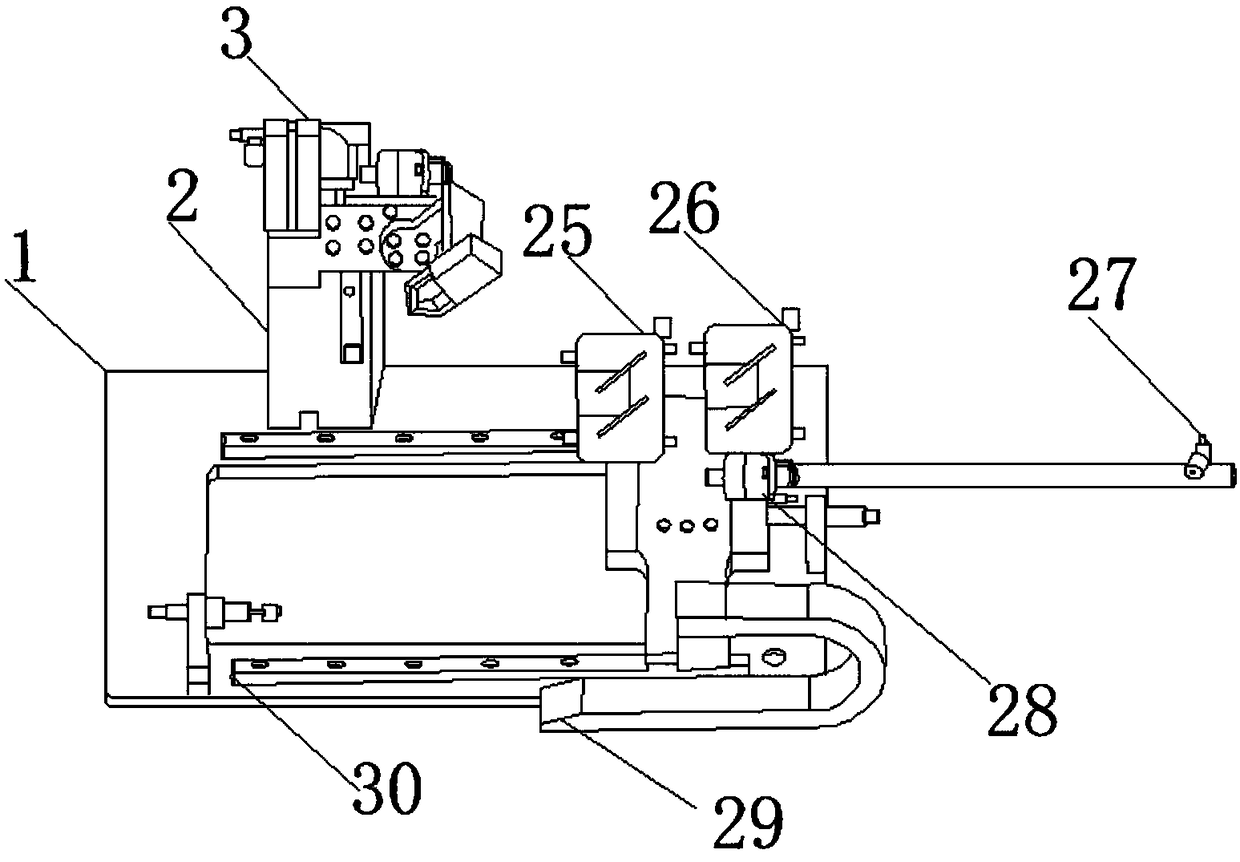

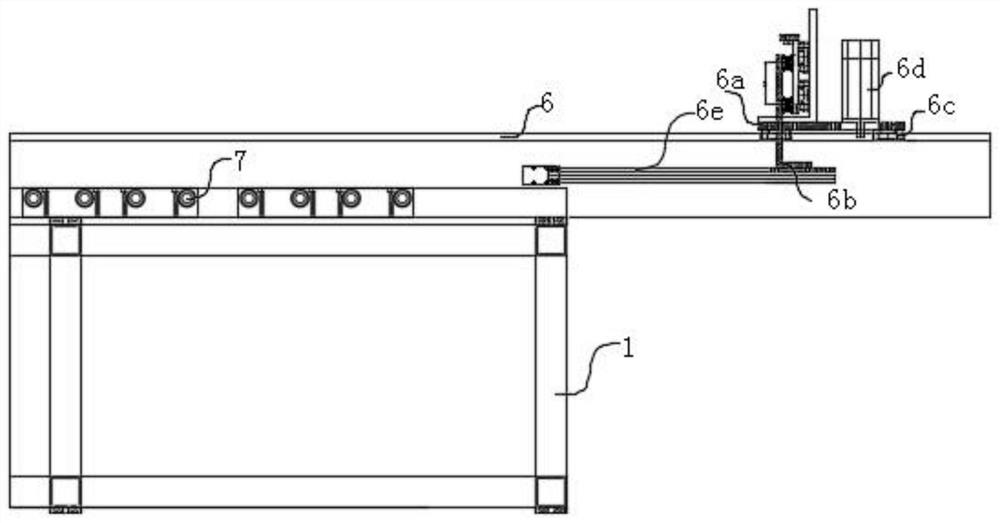

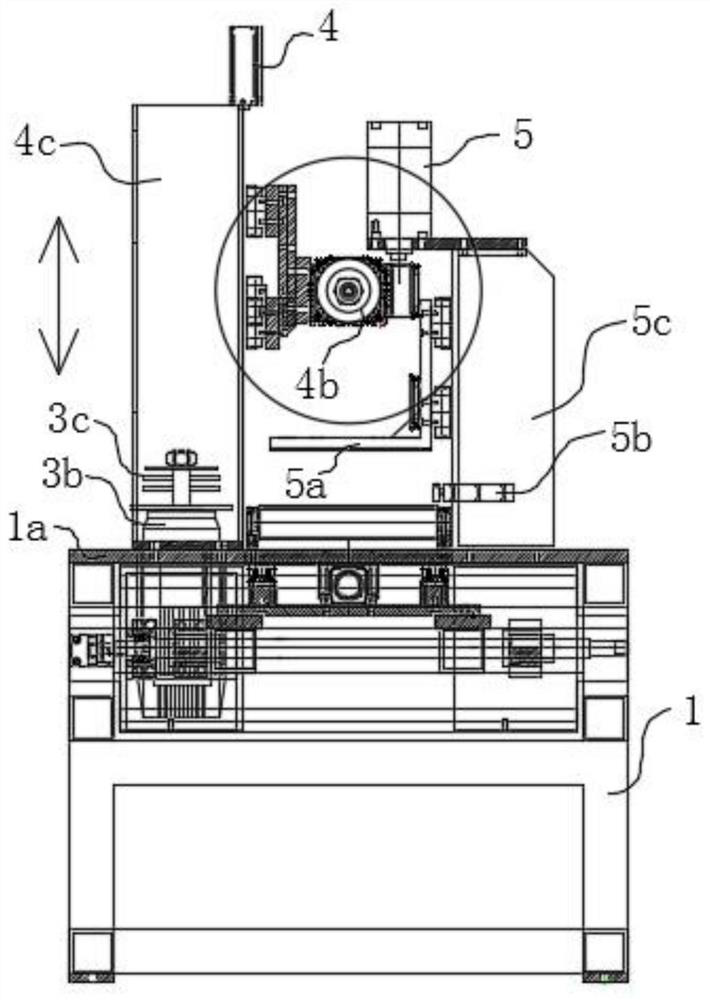

Saw cutting end milling machine

PendingCN111660104AAchieve positioningRealize pipeline operationOther manufacturing equipments/toolsMetal working apparatusMilling cutterReciprocating motion

The invention discloses a saw cutting end milling machine. A first conveying platform, a second conveying platform arranged in the same conveying direction of the first conveying platform in a spacedmanner, a 90-degree saw web motor and a milling tool motor are included, wherein the 90-degree saw web motor is arranged on the first conveying platform and cuts a plurality of side-by-side sectionalmaterials conveyed on the first conveying platform and the second conveying platform, the milling tool motor is arranged on the first conveying platform, reciprocates in the horizontal direction and conducts horizontal end milling on the end portions of the sectional materials cut by the 90-degree saw web motor. The conveying platforms are provided with transverse and longitudinal positioning mechanisms for positioning so that sectional material positioning can be achieved, a cutting motor is utilized for cutting, lifting is controlled, finally, a multi-layer milling tool disc is utilized formachining one-time forming of the sectional materials, a feeding mechanical arm on a feeding moving guide rail is utilized for rapid conveying and material preparing, assembly line type operation is achieved, and the construction efficiency is improved.

Owner:仝红彬

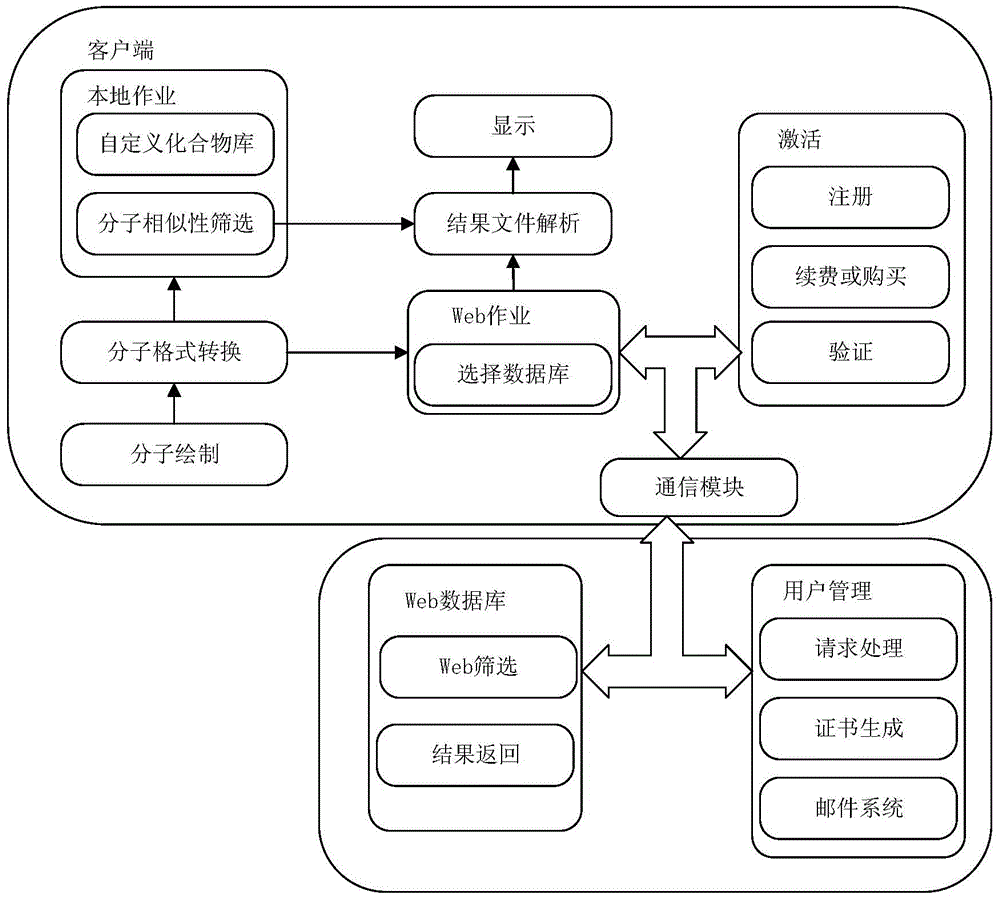

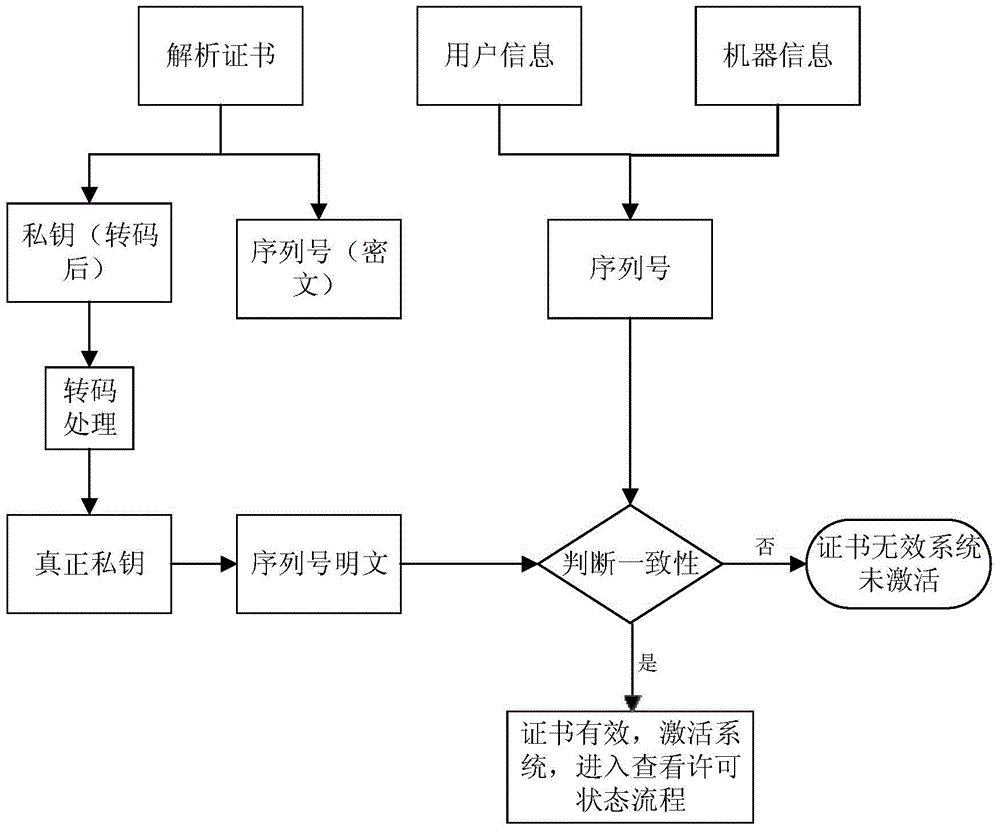

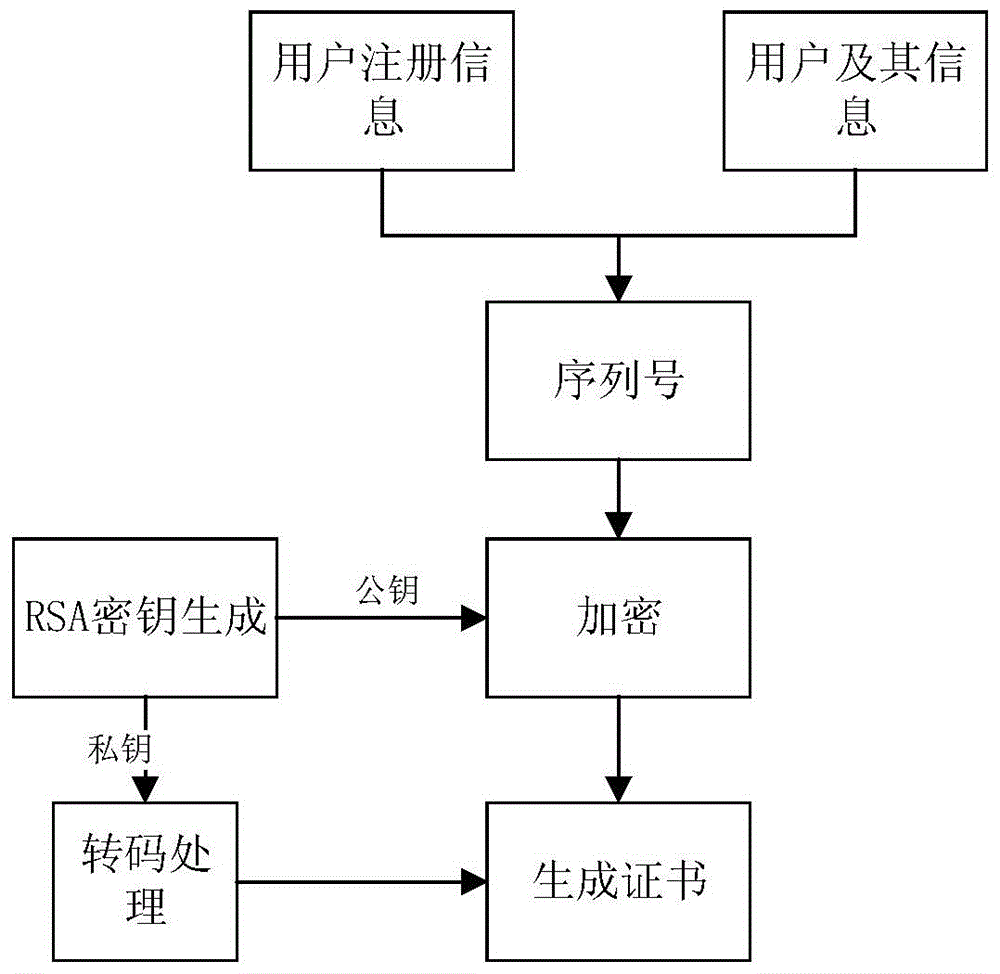

Interactive visual aided drug design system and implementing method

ActiveCN104573268ARealize molecular drawingRealize pipeline operationSpecial data processing applicationsClient-sideBiological activation

The invention discloses an interactive visual aided drug design system and an implementing method. The design system comprises a molecule drawing module, a molecule format conversion module, a molecule display module, an operation module, a file parsing module, a communication module, a molecule similarity screening module, a client activation module, a server user management module and a setting module. The operation module mainly comprises a user defined compound library and a web database which is provided by the system. The server user management module comprises a user request processing module, a certificate generation module, a mailing module and a verification module. According to the arrangement, molecules drawn by the user or existed molecules or ligands acquired from a PDB (protein data bank) are served as the screening input molecules, the screening mode is selected by the user to perform corresponding screenings, and finally, according to ranks, the screening result is displayed through the analysis file.

Owner:EAST CHINA UNIV OF SCI & TECH

Ultrasonic atomization pyrolysis spray coating device and utilization method thereof

ActiveCN105772290AIncreased preparation rateGuaranteed purityLiquid surface applicatorsLiquid spraying apparatusSpray coatingUltrasonic atomization

The invention relates to an ultrasonic atomization pyrolysis spray coating device which comprises a substrate and a rotating mechanism, wherein the substrate is used for placing a plurality of groups of samples to be subjected to spray coating; the rotating mechanism comprises a first rotating mechanism and a second rotating mechanism; the first rotating mechanism is provided with liquid mixing devices; the liquid mixing devices accommodate a solution to be sprayed; the second rotating mechanism is provided with atomization nozzles; and the first rotating mechanism and the second rotating mechanism periodically rotate and can synchronously reach a spray coating zone above the substrate to cooperate with each other to perform spray coating on the samples to be subjected to spray coating on the substrate. The invention further provides a utilization method of the ultrasonic atomization pyrolysis spray coating device. The utilization method comprises the steps that the ultrasonic atomization pyrolysis spray coating device is provided, and the plurality of groups of samples to be subjected to spray coating are placed on the substrate; the first rotating mechanism and the second rotating mechanism are periodically rotated; and when the first rotating mechanism and the second rotating mechanism synchronously reach the spray coating zone above the substrate, the liquid mixing devices of the first rotating mechanism and the atomization nozzles of the second rotating mechanism cooperate to perform spray coating on the samples on the substrate.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Sorting and conveying track for batteries

The invention discloses a sorting and conveying track for batteries. The sorting and conveying track for batteries comprises a conveyor belt connected to sorting equipment, a battery receiving box isarranged on one side of the conveyor belt, a first bracket and a second bracket are separately arranged on the conveyor belt, one end of a screw is hinged to the first bracket, and the other end of the screw is connected to a rotary shaft of a driving motor, a movable plate is in threaded connection with the screw, a lifting air cylinder is fixed to the movable plate, a baffle is fixed to a pistonrod of the lifting air cylinder, a moving plate is inserted onto the back end surface of the baffle, a rack is formed on the front end surface of the moving plate, the rack is meshed with a gear, thegear is connected with the rotary shaft of the motor, a plurality of suction discs which are spaced at an equal interval are arranged on the back end surface of the moving plate, the suction discs are separately connected with a vacuum gas source through pipelines, electromagnetic valves are separately arranged on the pipelines of the suction discs, and the driving motor, the lifting air cylinder, the motor and the electromagnetic valves are electrically connected with a controller connected to the sorting equipment. The sorting and conveying track is precise in sorting and high in work efficiency, and can achieve an assembly line.

Owner:东莞市广荣电子制品有限公司

Bullet-proof glass processing device

InactiveCN106045287AIncrease the level of automationRealize pipeline operationGlass tempering apparatusGlass productionMotor driveAssembly line

The invention discloses a bullet-proof glass processing device. The bullet-proof glass processing device comprises a sheet feeding part, a convection heating part, an air grid cooling part and a sheet taking part. A loaded glass sheet is conveyed to the convection heating part to be heated through the sheet feeding part, then conveyed to the air grid cooling part to the cooled with air and discharged through the sheet taking part. The sheet feeding part and the sheet taking part comprise roller beds, chains, chain wheels and transmission motors, the transmission motors drive the chain wheels to rotate through the chains, and the chain wheels drive the roller beds to rotate. The bullet-proof glass processing device is high in automation degree and capable of achieving assembly line operation, effectively improving processing efficiency, lowering labor intensity and production cost and improving the processing precision of the products through automatic precision control.

Owner:安瑞装甲材料(芜湖)科技有限公司

Cryoprecipitate blood coagulation factor preparation instrument and using method thereof

ActiveCN105399814BRealize pipeline operationShorten the timeFactor VIIPeptide preparation methodsMedicineWater circulation

Owner:佛山沃塘医疗科技有限公司

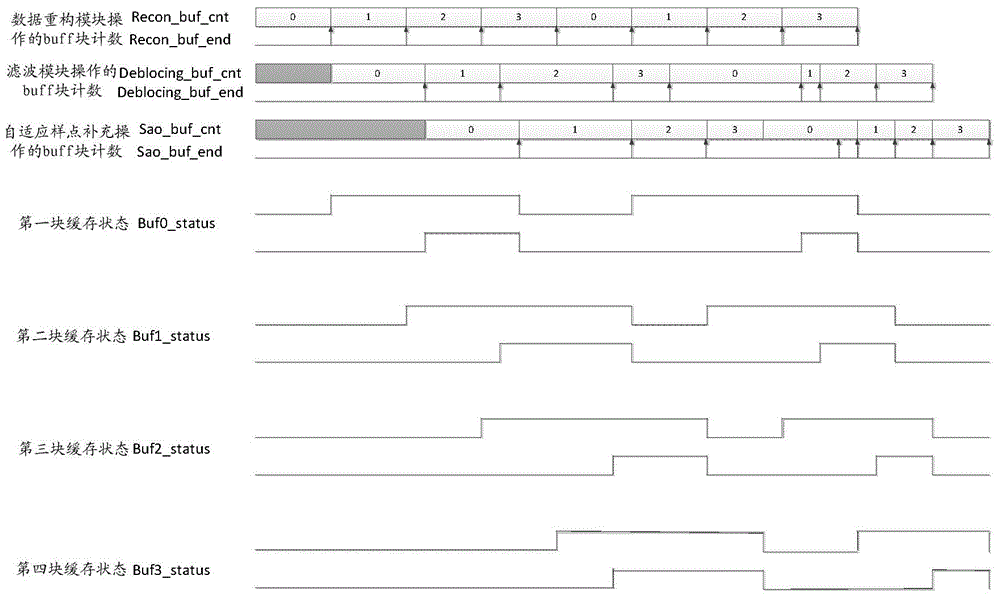

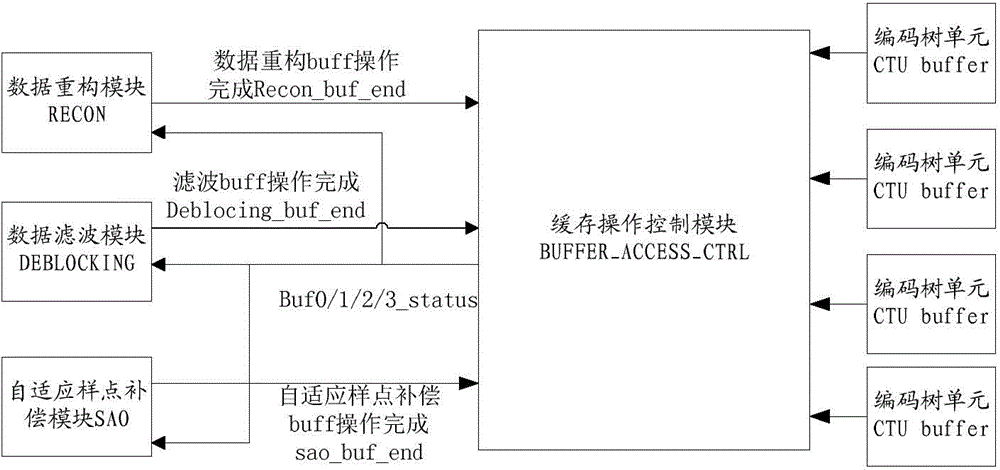

Method and system for realizing cycle operation based on CTU (Coding Tree Unit) buffers

ActiveCN104954808AFacilitate data interactionSimple designDigital video signal modificationOperational systemControl signal

The invention provides a method for realizing cycle operation based on CTU (Coding Tree Unit) buffers. A system comprises a data reconstruction module, a data filter module and a self-adaptive sampling point compensation module; the method also needs to provide a buffer operation control module and four CTU buffers; the buffer operation control module is used for representing that each CTU buffer is operated in which module through a buffer block counting state and a buffer block state control signal, and thus the data reconstruction module, the data filter module and the self-adaptive sampling point compensation module are executed to distribute the use of the four CTU buffers through the buffer operation control module. The invention also provides the system for realizing the cycle operation based on the CTU buffers. According to the method and the system, provided by the invention, the cycle operation is realized by utilizing the four CTU buffers, CTU-stage pipeline operation is realized, thus data writing is accelerated, and the video decoding efficiency is increased.

Owner:FUZHOU ROCKCHIP SEMICON

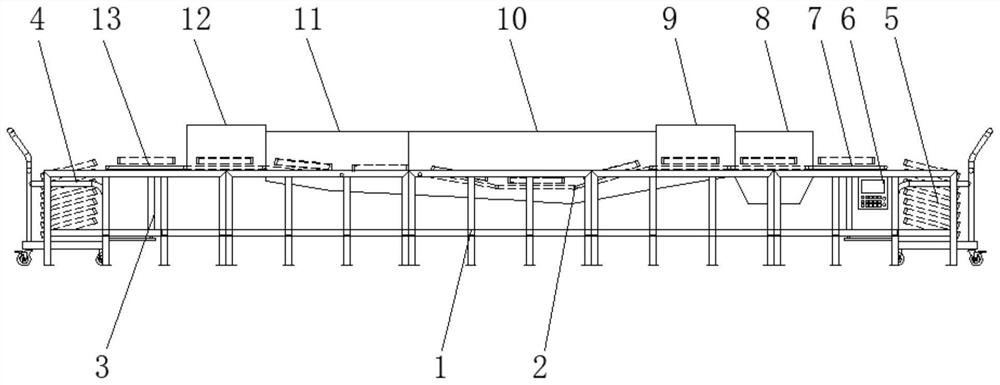

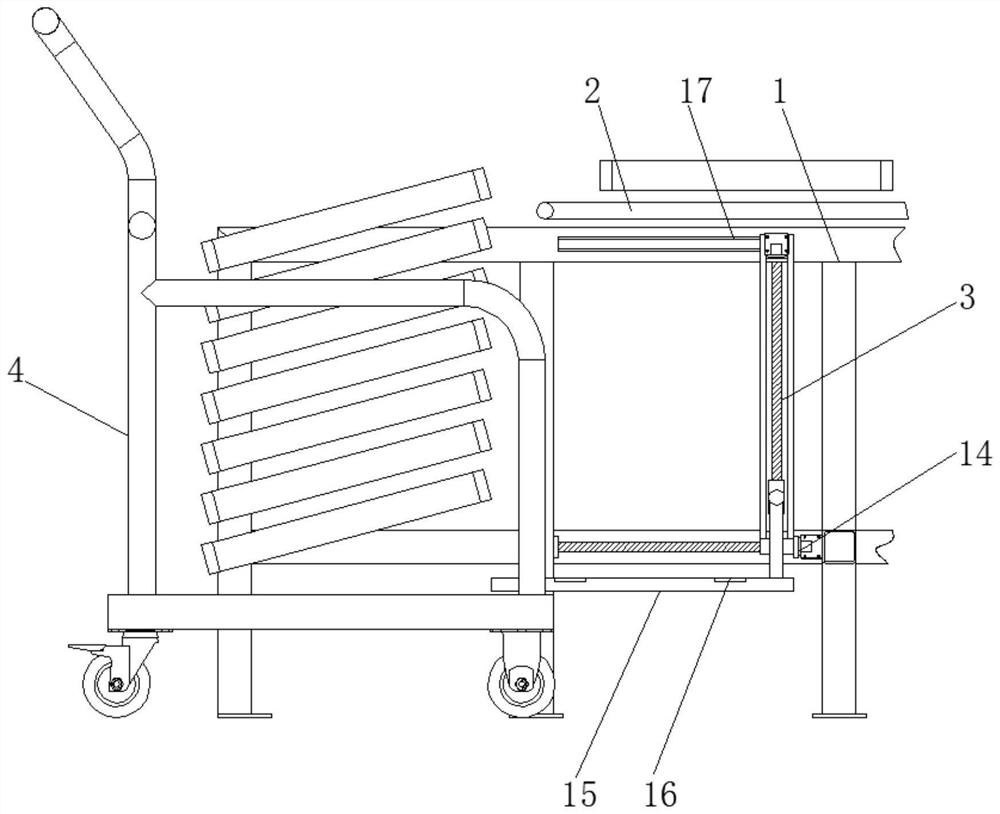

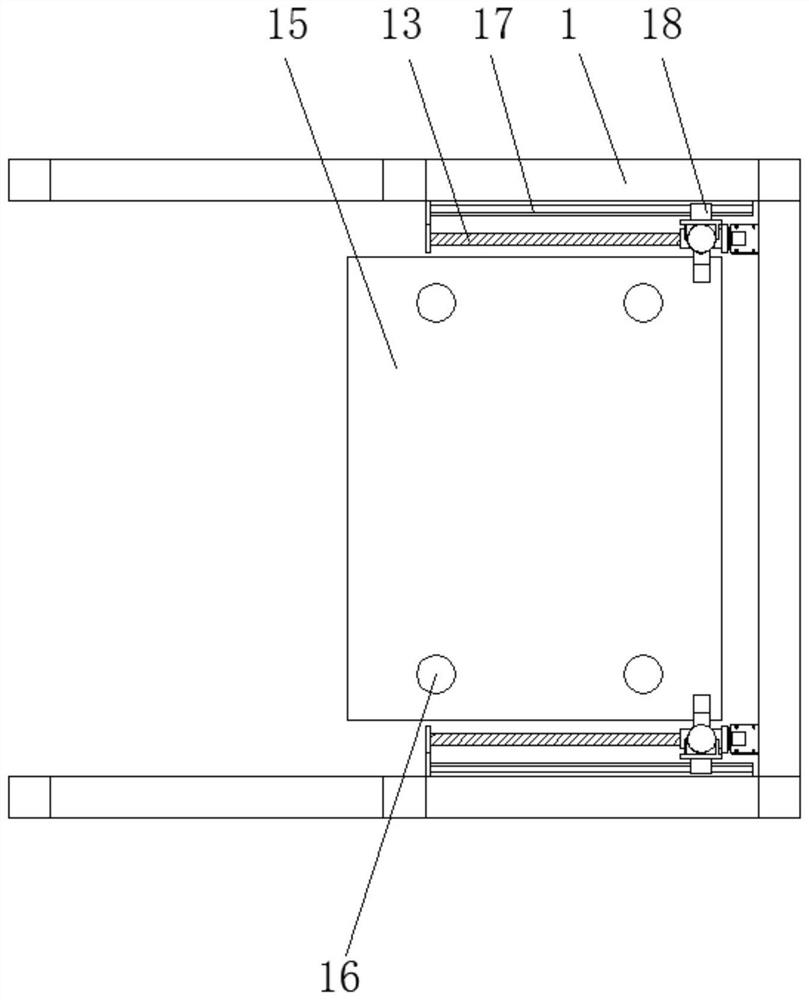

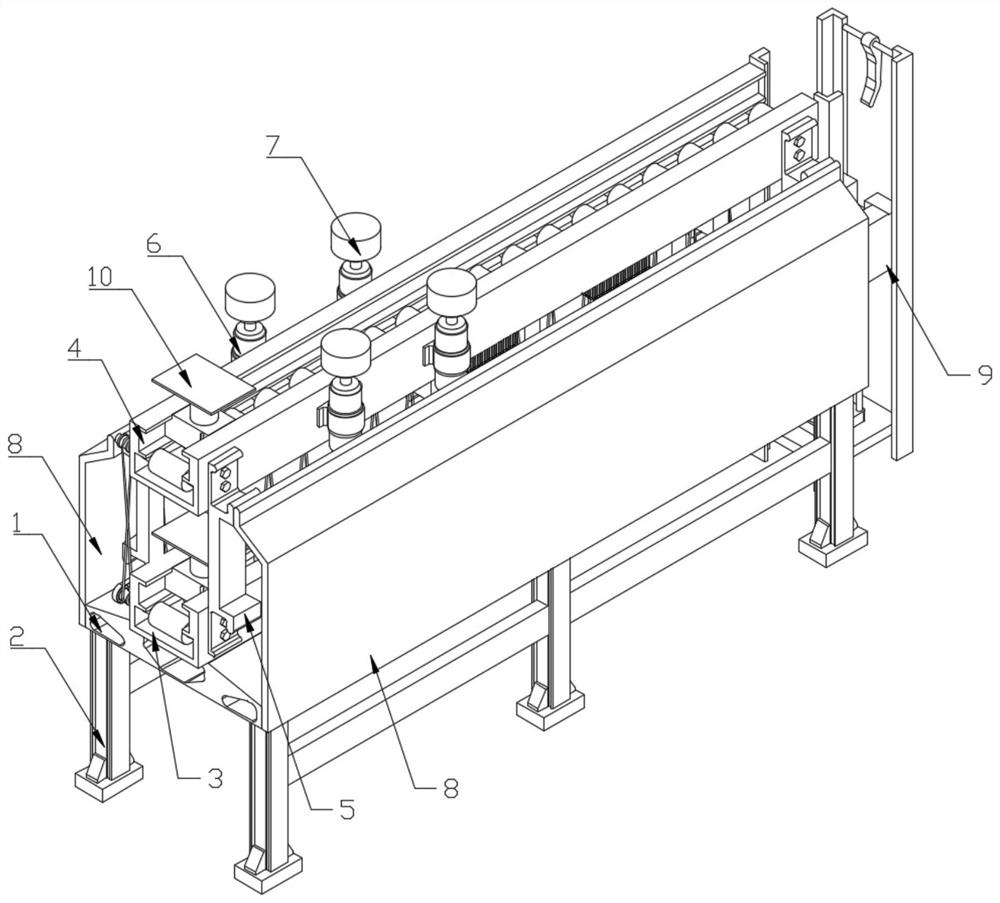

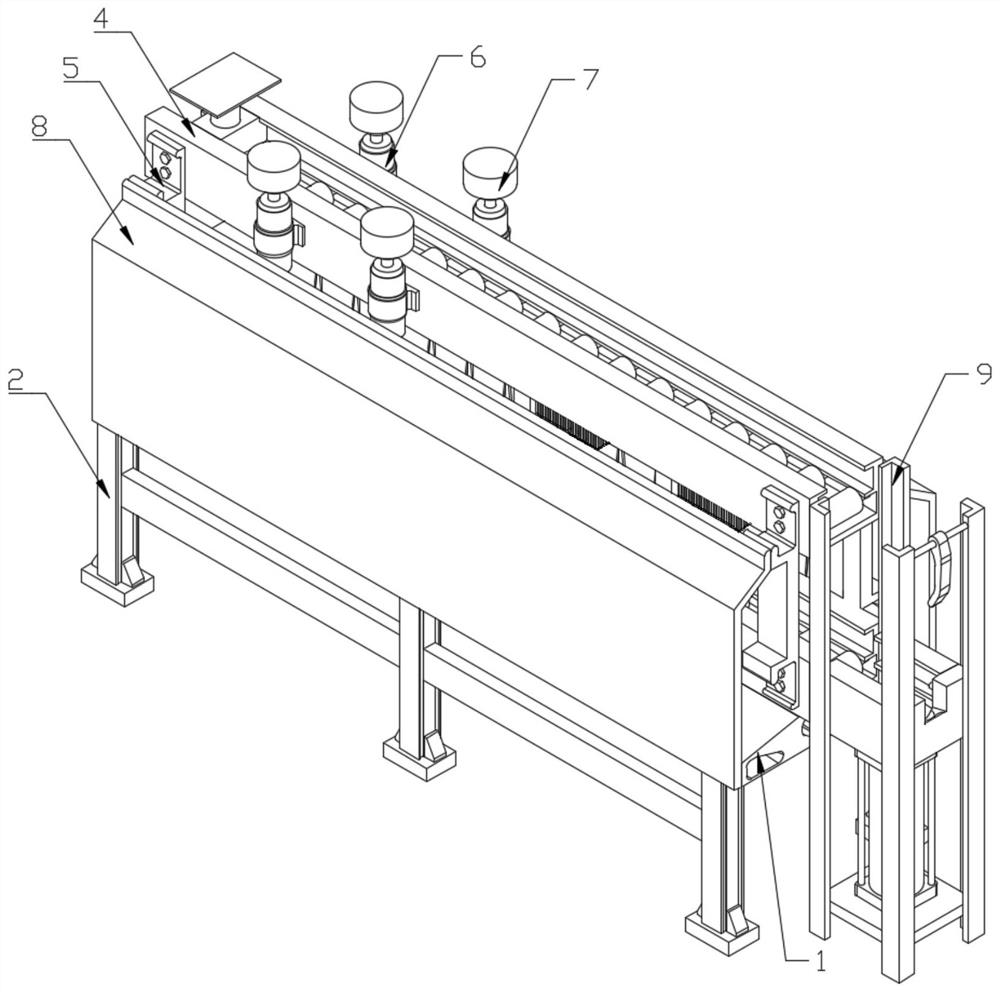

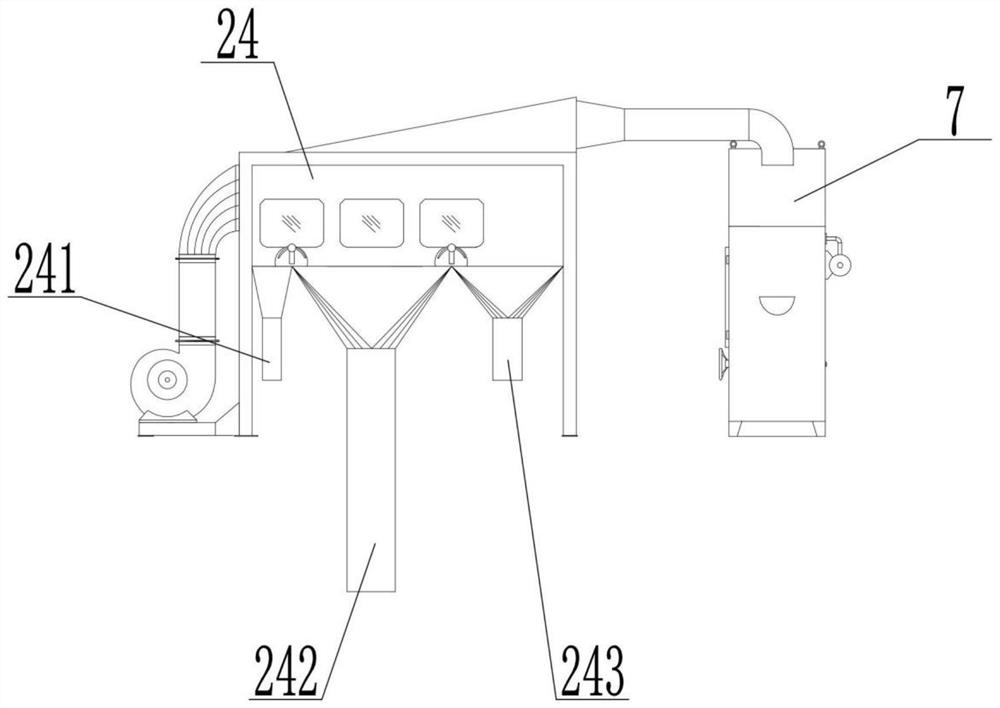

Automatic cleaning device and method for G4-level plate filter

InactiveCN112439260AQuick loading and unloadingAvoid the hassle of bending over to reach the filterAlarmsElectric transmission signalling systemsStructural engineeringSoot

The invention discloses an automatic cleaning device and method for a G4-level plate filter. The automatic cleaning device comprises a machine frame, a vibration soot blowing assembly and a lead screwtranslation assembly, a chain transmission assembly is installed above the machine frame, and lead screw lifting assemblies are arranged on the inner sides of the left end and the right end of the machine frame respectively; a first loading trolley assembly is installed on the left side of the lead screw lifting assembly on the left side of the machine frame, a second loading trolley assembly isinstalled on the right side of the lead screw lifting assembly on the right side of the machine frame, a control assembly is fixed to the front side of the right end of the machine frame, and a plateloading assembly is arranged above the right end of the machine frame; and the vibration soot blowing assembly is installed on the left side of the plate loading assembly, the left side of the vibration soot blowing assembly is connected with a flushing assembly, the lead screw translation assembly is arranged below the lead screw lifting assemblies, and a lifting plate is installed between the front lead screw lifting assembly and the rear lead screw lifting assembly. According to the invention, the filter is cleaned more thoroughly, the automation degree of the whole machine is high, and theburden of workers is reduced.

Owner:岳阳佰胜智慧环保科技有限公司

Conveying robot for wire drawing of waste tires

ActiveCN108974777AReduce labor intensityImprove work efficiencyConveyorsPlastic recyclingTransfer procedureAssembly line

The invention relates to a conveying robot for wire drawing of waste tires. The conveying robot comprises a first bottom plate, a second bottom plate, a conveying device, auxiliary devices, a limitingdevice, an executing fixing device and a pushing device, the conveying device is installed on the middle of the upper end surface of the first bottom plate, the auxiliary devices are symmetrically located on the two sides of the conveying device, the auxiliary devices are installed on the top of the first bottom plate, the limiting device is located right above the conveying device, the limitingdevice is installed on the top of the first bottom plate, the pushing device is installed on the rear side of the right end of the first bottom plate, the executing fixing device is located on the upper end surface of the middle of the second bottom plate, and the executing fixing device is connected with the second bottom plate. According to the conveying robot, the problems that fixing of the waste tires before wire drawing is performed is not firm, the assembly line type operation of wire drawing of the waste tires cannot be realized, steel wires on the other sides of the waste tires cannotbe continuously drawn after steel wires on one sides of the waste tires are drawn, and the waste tires cannot be fixed in the conveying process can be solved.

Owner:安徽新博普曼智能科技股份有限公司

Circuit board edge grinding device with self-overturning function and using method thereof

ActiveCN113714883AEdging achievedRealize automatic flipEdge grinding machinesGrinding carriagesControl engineeringElectric machinery

The invention relates to the technical field of board grinding, in particular to a circuit board edge grinding device with a self-overturning function and a using method thereof, in the using process, a circuit board turning assembly drives a circuit board to move in a lower conveying rail, a double-output-shaft motor drives edge grinding wheels to conduct edge grinding on the two sides of the circuit board, and a clearing brush clears ground chippings; When the circuit board turning assembly drives the circuit board to enter a circuit board turning and reversing mechanism, the circuit board turning and reversing mechanism turns over the circuit board on the circuit board turning assembly by 90 degrees; and after the ground edge of the circuit board is changed, the circuit board is conveyed into the conveying rail above to be ground again; by means of the structure, automatic overturning of the circuit board can be achieved, edge grinding of the circuit board can be achieved in batches, assembly line type operation of equipment can be achieved, and the machining efficiency is greatly improved.

Owner:江苏省德懿翔宇光电科技有限公司

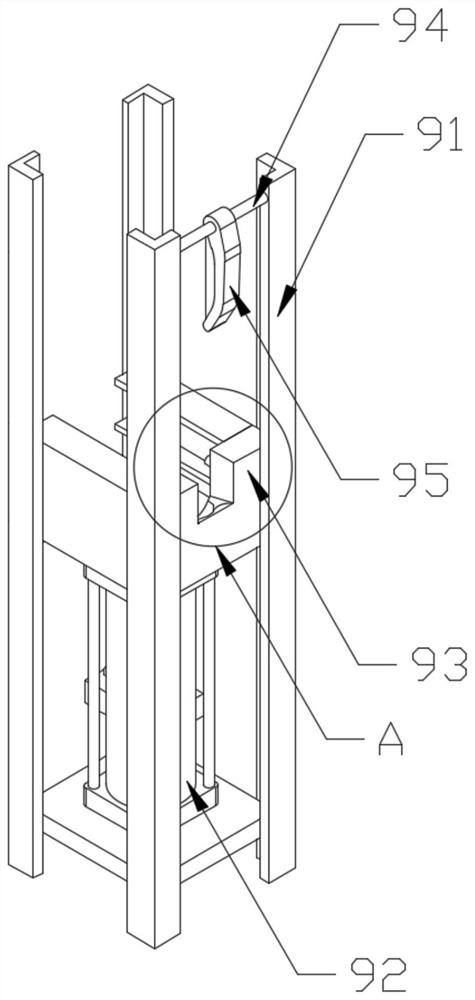

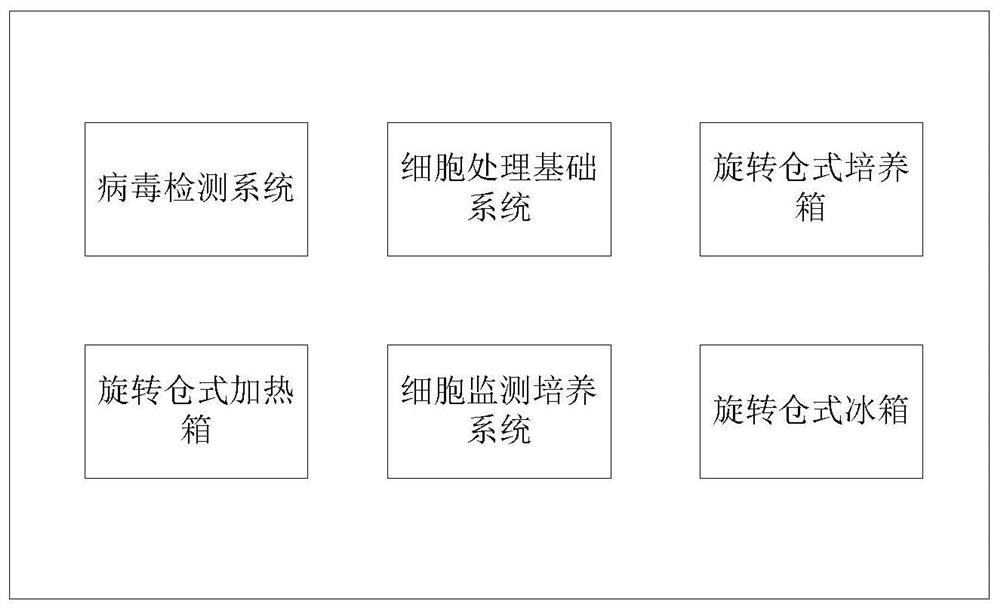

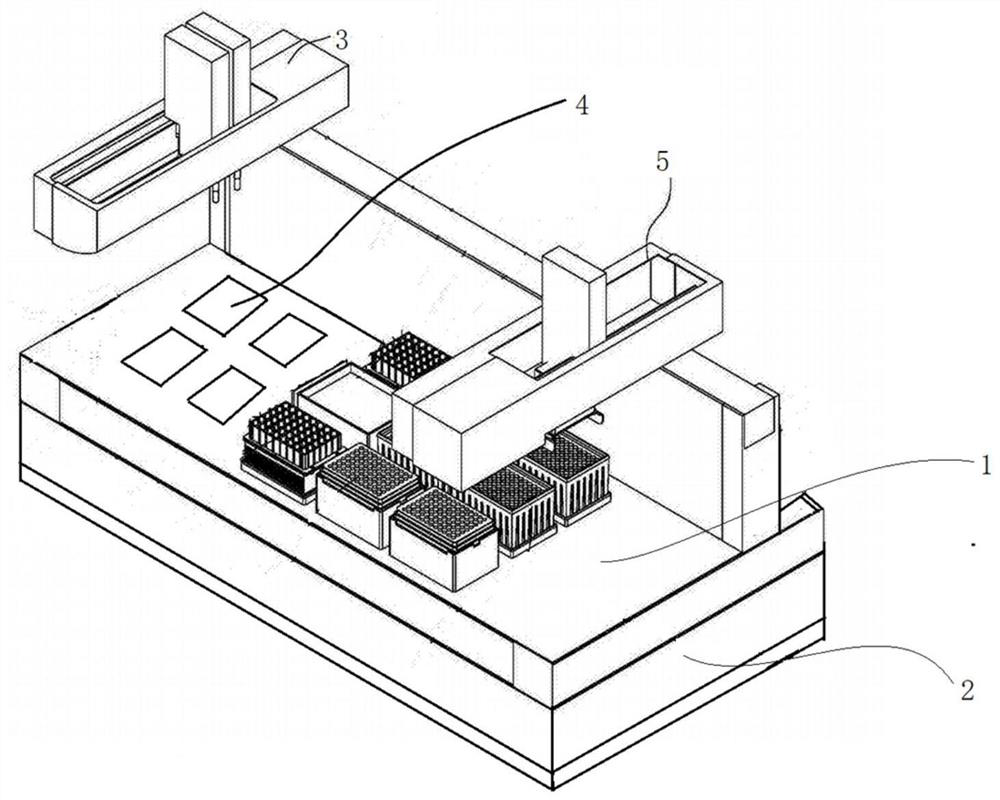

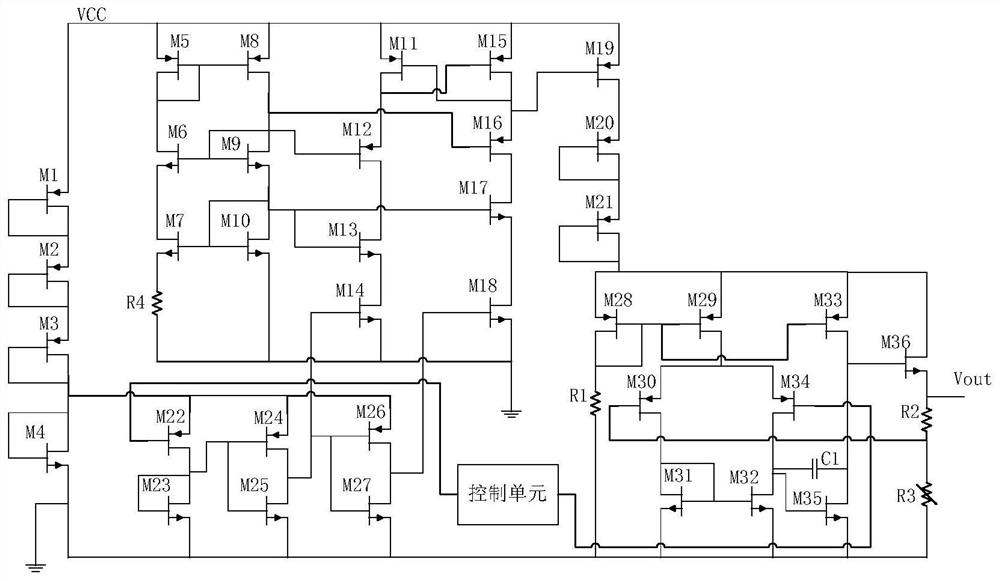

Full-automatic cell treatment pulse type workstation

PendingCN113088433AExquisite structureImprove securityBioreactor/fermenter combinationsBiological substance pretreatmentsStem like cellVirus detection

The invention relates to a full-automatic cell treatment pulsating type workstation and a control method. The full-automatic cell treatment pulsating type workstation comprises a plurality of virus detection systems, a cell treatment basic system, a plurality of rotary bin type incubators, a plurality of rotary bin type refrigerators, a plurality of rotary bin type heating boxes and a stem cell monitoring culture system, the cell treatment basic system comprises a biological safety cabinet and a worktable, and the worktable comprises an on-table part and an under-table part; a connection unit, a quality control unit, a film pasting unit, a device with recognition and clamping functions, a controller and a monitoring system are arranged on the on-table part of the worktable, and the under-table part comprises a butt joint interface.

Owner:TIANJIN CITY THIRD CENT HOSPITAL

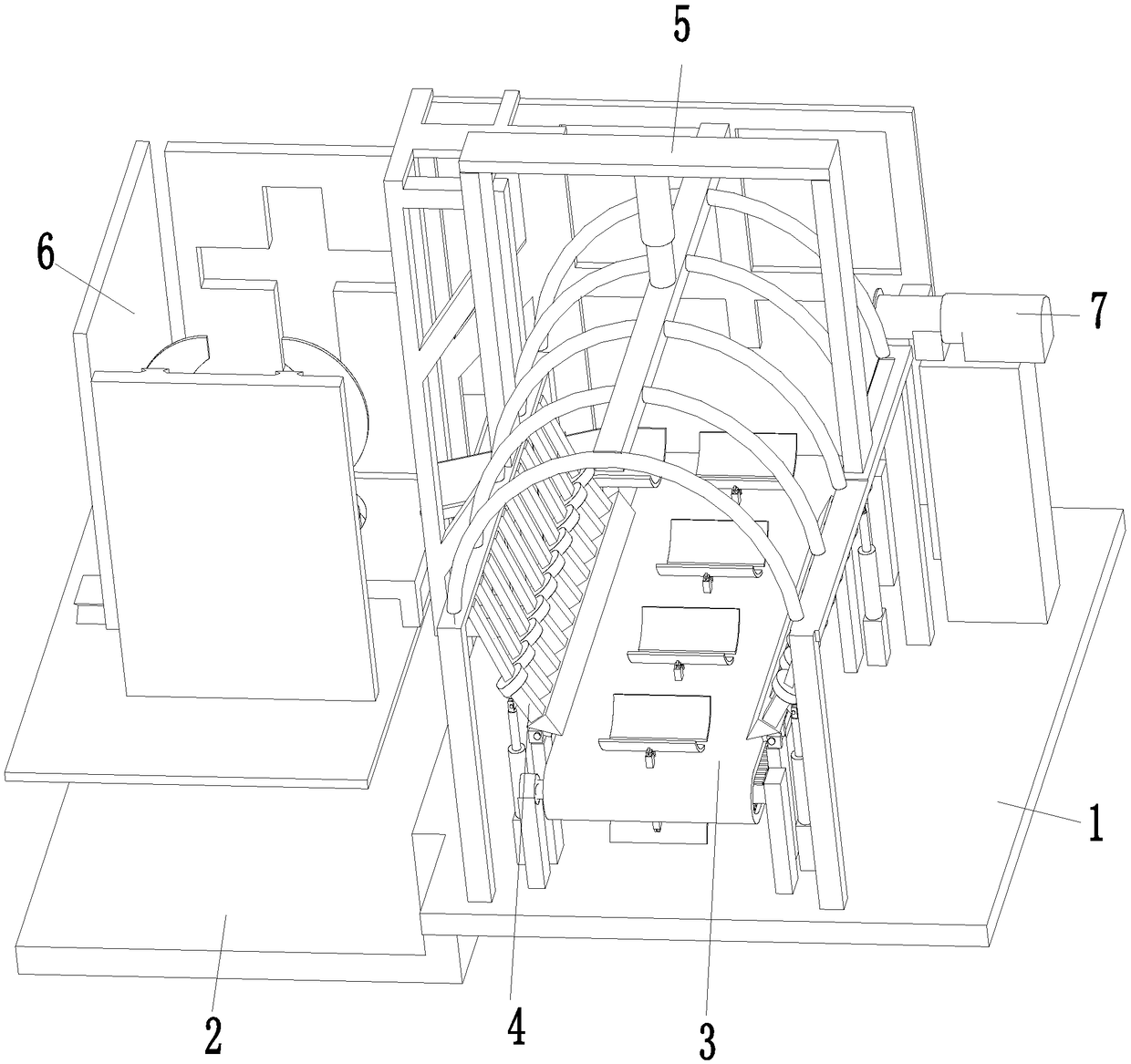

Cattlehide fiber production line and production method

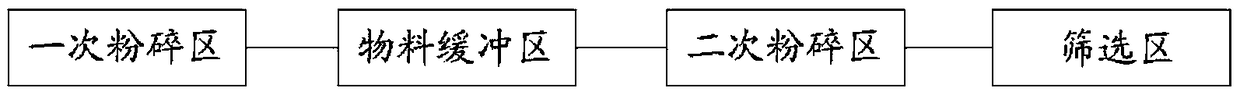

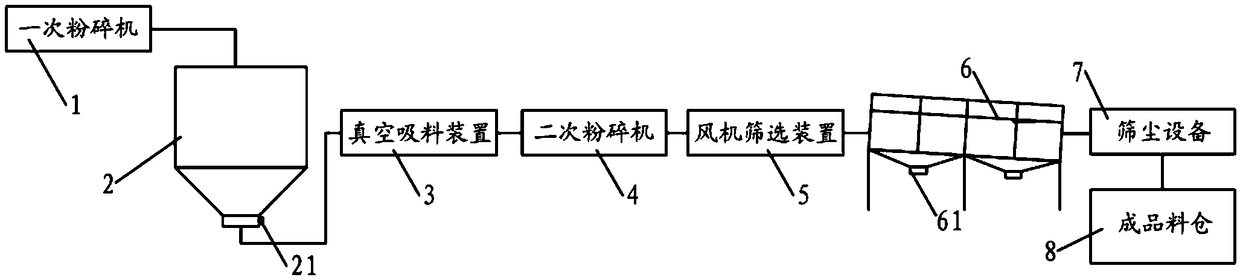

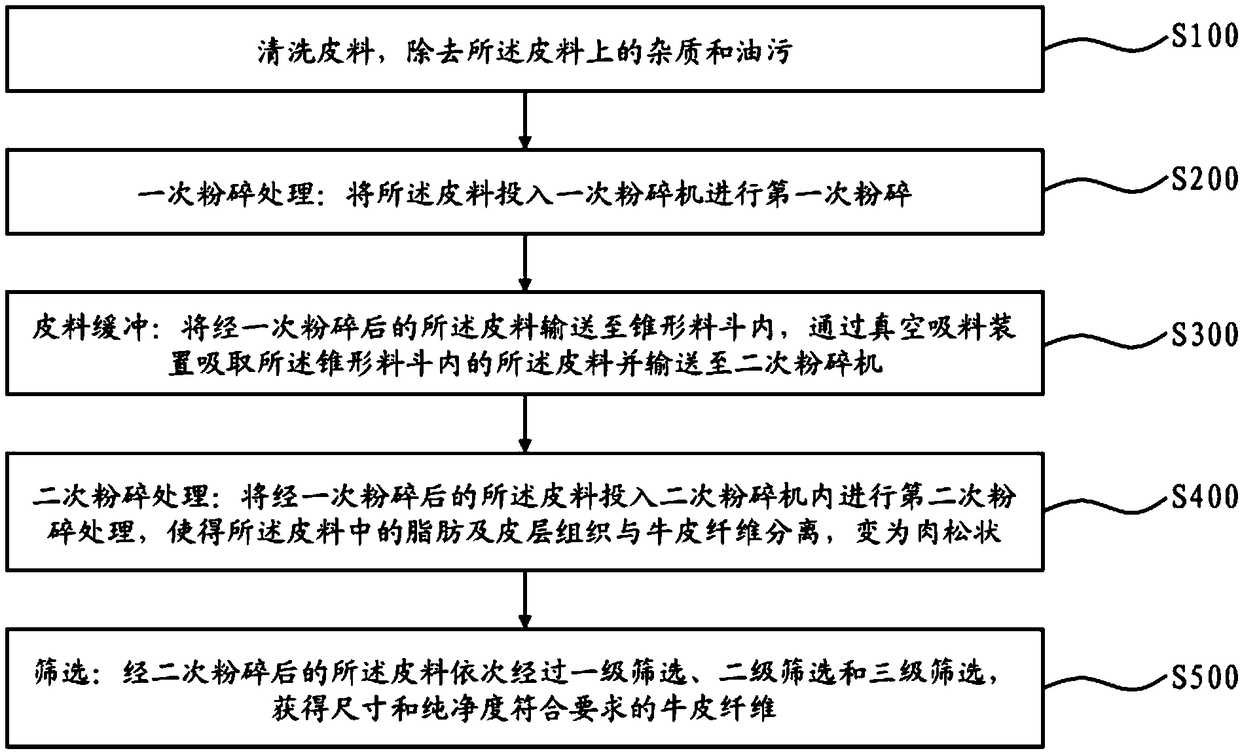

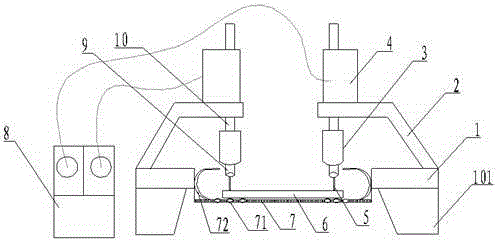

InactiveCN108722629ARealize pipeline operationReasonable settingTextile disintegration and recoveryFibre disintegrationFiberThree level

The invention discloses a cattlehide fiber production line and a production method. The cattlehide fiber production line comprises a primary smashing area, a material buffering area, a secondary smashing area and a screening area which are arranged sequentially. The primary smashing area comprises a primary smashing machine used for carrying out primary smashing on leather. The material bufferingarea comprises a conical hopper used for storing the leather obtained after primary smashing, and a vacuum material sucking device used for sucking the leather in the conical hopper into the secondarysmashing area. The secondary smashing area comprises a secondary smashing machine used for carrying out secondary smashing on the leather obtained after primary smashing. The screening area comprisesa one-level screening device, a two-level screening device and a three-level screening device which are connected sequentially. The one-level screening device is connected with a discharging openingof the secondary smashing machine through a conveying device. The three-level screening device is connected with a finished product material bin. According to the cattlehide fiber production line, assembly line type operation of cattlehide fiber production can be achieved, the production efficiency is effectively improved, the cattlehide fiber production line is safe and environmentally friendly,and the manufactured cattlehide fiber is better in quality and purity.

Owner:江苏万山汽车配件有限公司

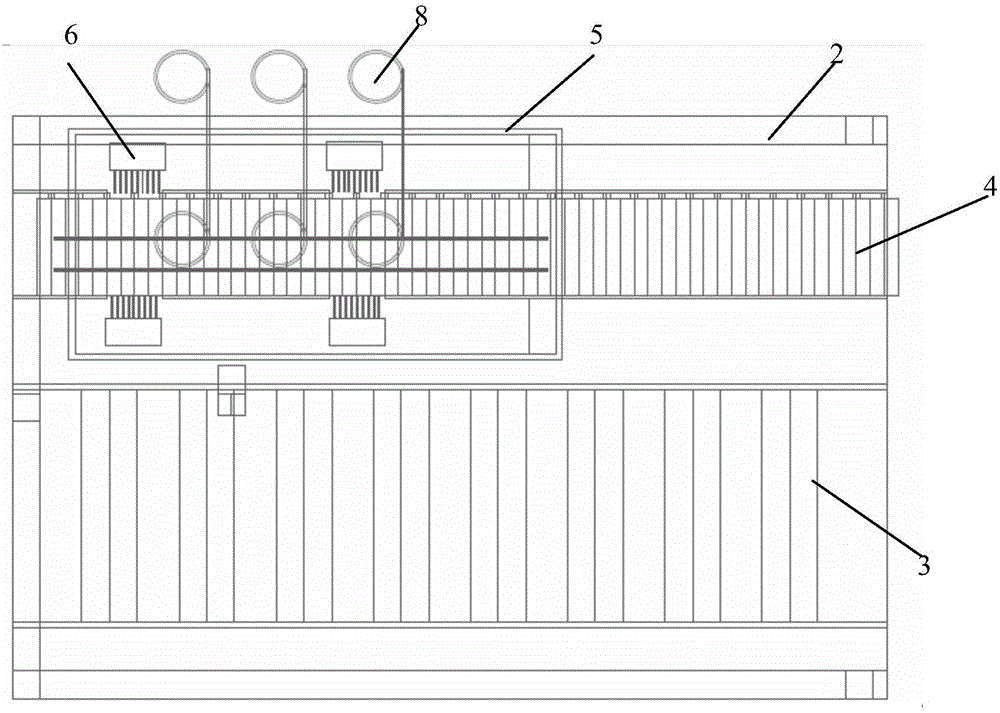

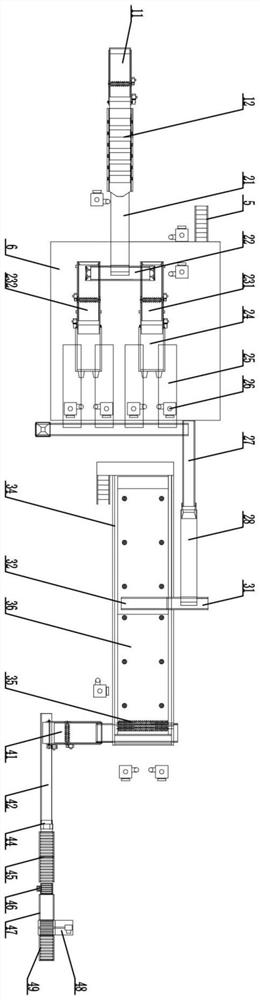

Furniture plate double-row control hole puncher

The invention discloses a furniture plate double-row control hole puncher which comprises a base. The lower end of the base is provided with a bottom foot, a left oblique arm bracket and a right oblique arm bracket are arranged at the upper end of the base, motors are fixedly arranged on the oblique arm brackets, connecting positioning rods are arranged at the lower ends of the motors, hole puncher machine heads are connected through the connecting positioning rods, rotators are positioned at the lower ends of the hole puncher machine heads, the rotary punching position can be adjusted through the rotators, and punching heads are arranged at the lower ends of the rotators. The furniture plate double-row control hole puncher has accuracy in punching, cracks are not generated on the surface of a furniture product, the drilling inside and outside structures of treated plates are uniform, and the dimension is stable.

Owner:SUZHOU DONGBANG FURNITURE

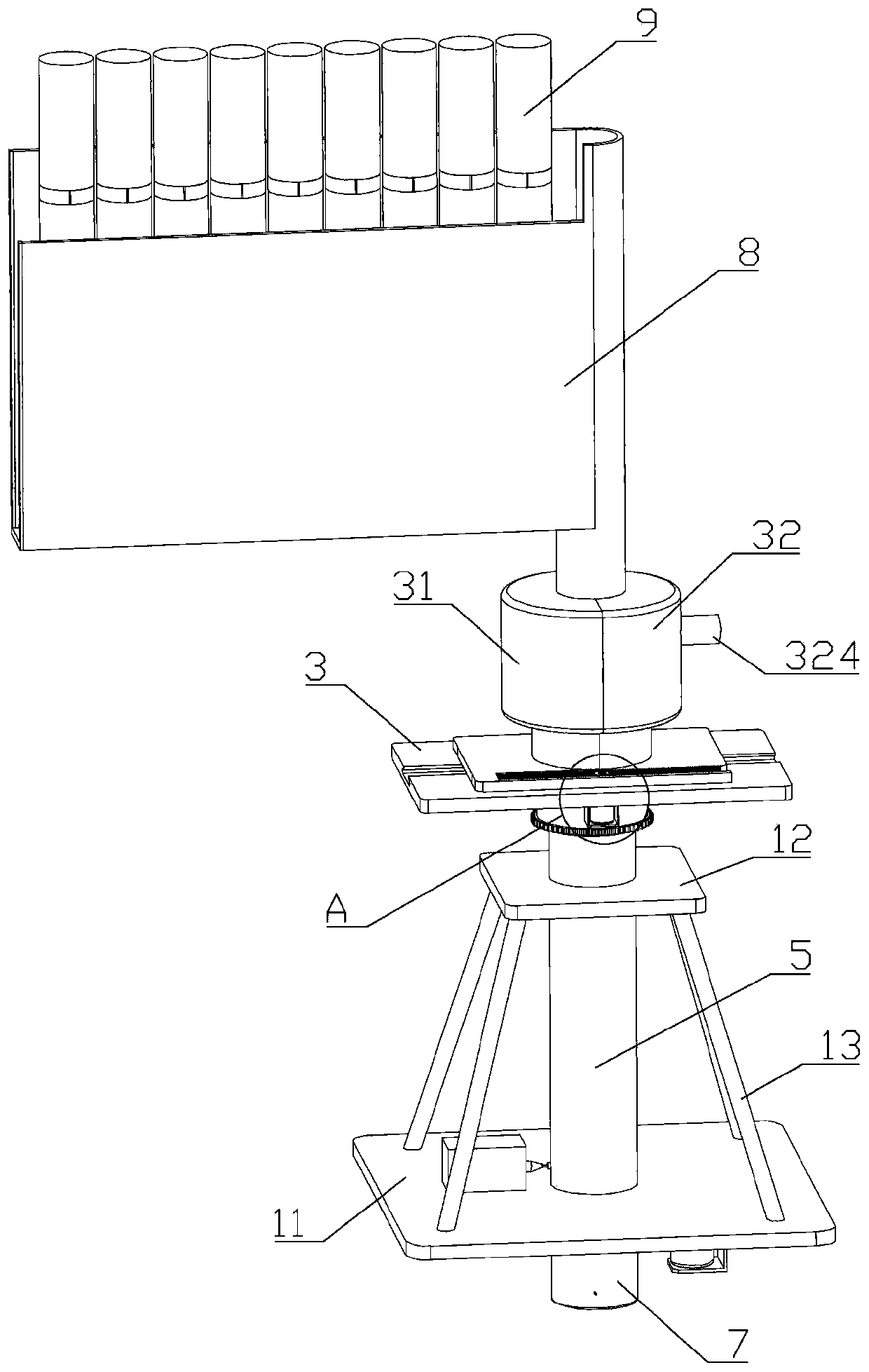

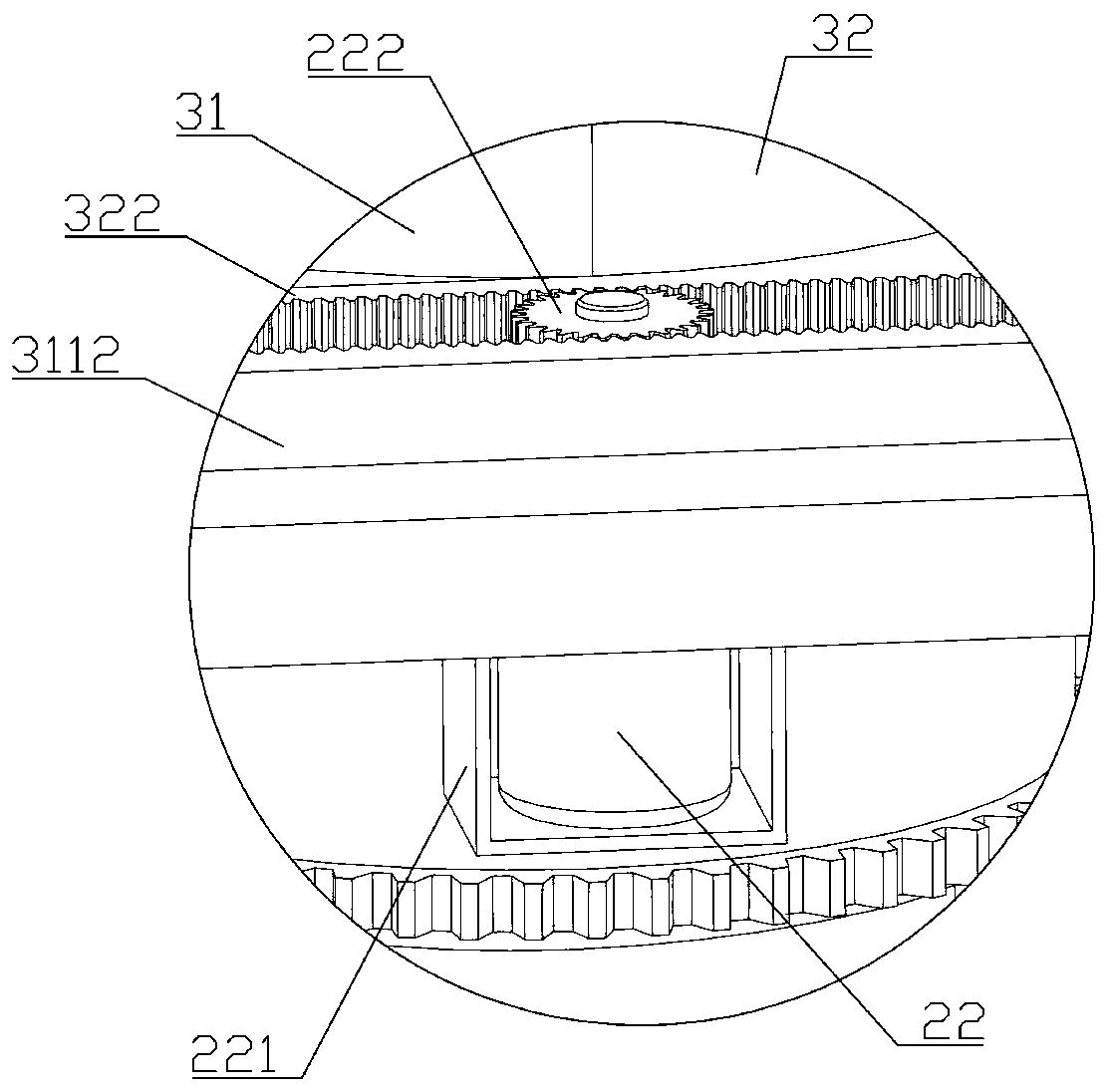

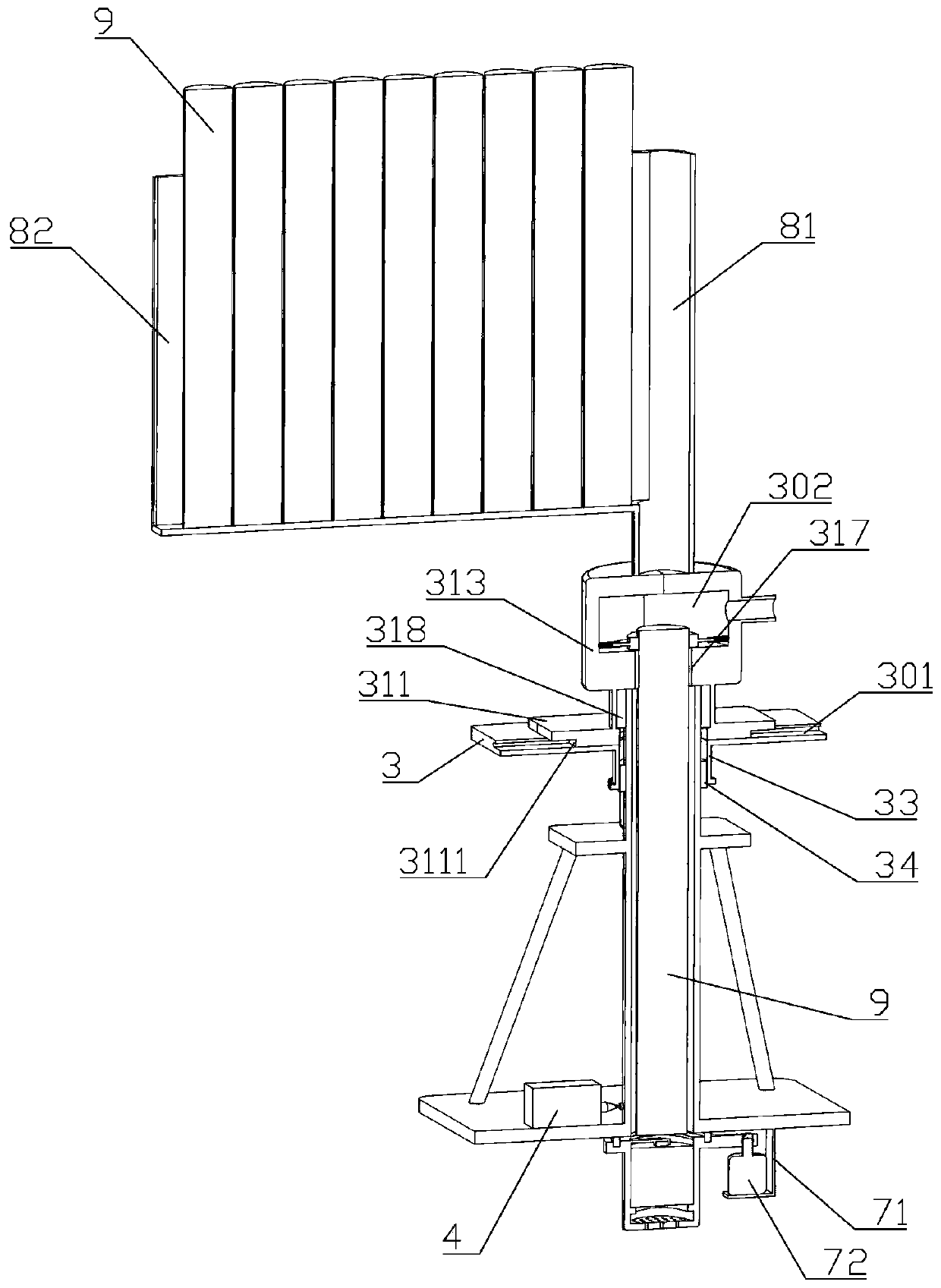

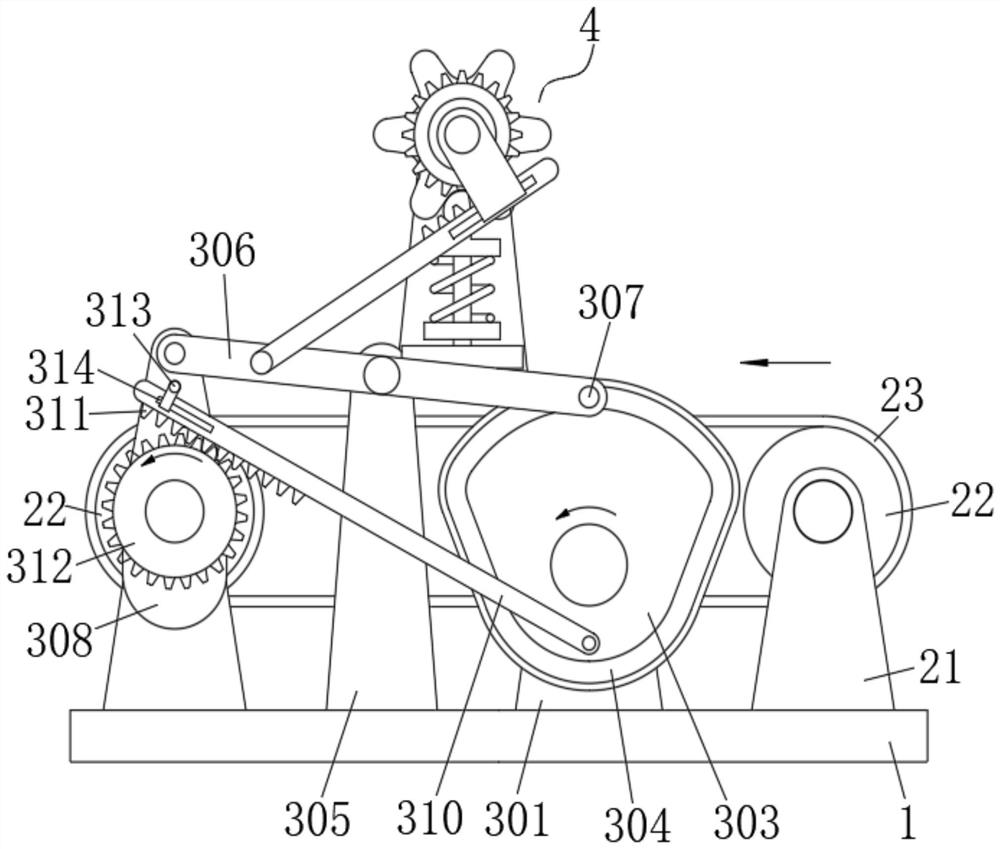

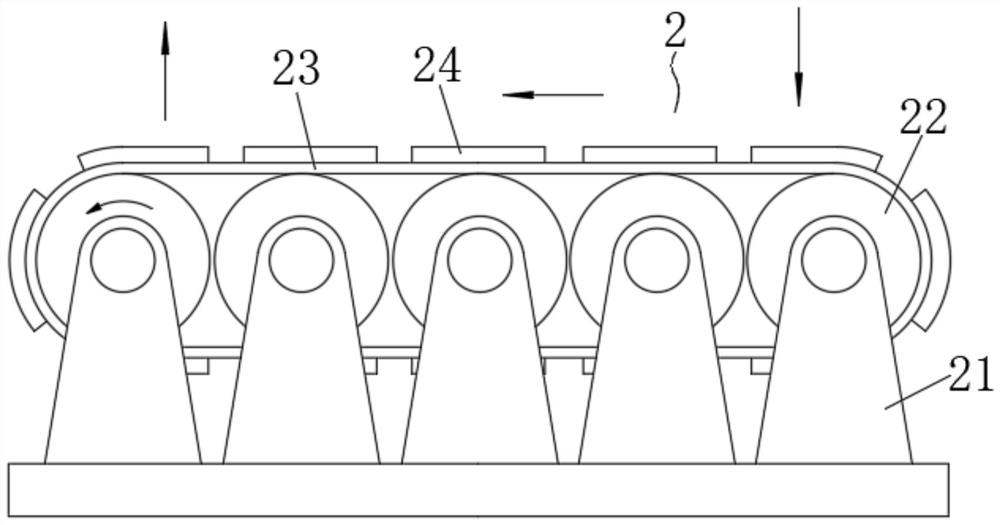

Assembly-line-type annular perforating device for cigarettes

PendingCN110025038AAffect the tasteRealize pipeline operationCigarette manufacturePermeability/surface area analysisAssembly lineEngineering

The invention belongs to the technical field of tobacco leaf production and mainly relates to an assembly-line-type annular perforating device for cigarettes. The assembly-line-type annular perforating device for cigarettes comprises a mounting frame, an industrial computer, a first detection cylinder and a laser perforator. A laser head of the laser perforator penetrates through the wall of the first detection cylinder, the tip of the laser output end of the laser head is positioned in the first detection cylinder, both the laser perforator and the first detection cylinder are mounted on themounting frame, the input end of the laser perforator is connected to the output end of the industrial computer, cigarettes are placed in the first detection cylinder, a cigarette clamping mechanism is rotatably mounted on the first detection barrel, an air cavity is formed in the cigarette clamping mechanism and is communicated with the first detection cylinder, and a rotatable pressure detectoris mounted at the bottom end of the first detection cylinder. The assembly-line-type annular perforating device for cigarettes can effectively perforate the cigarettes according to their air permeability and is suitable for assembly-line production.

Owner:CHONGQING CHINA TOBACCO IND CO LTD

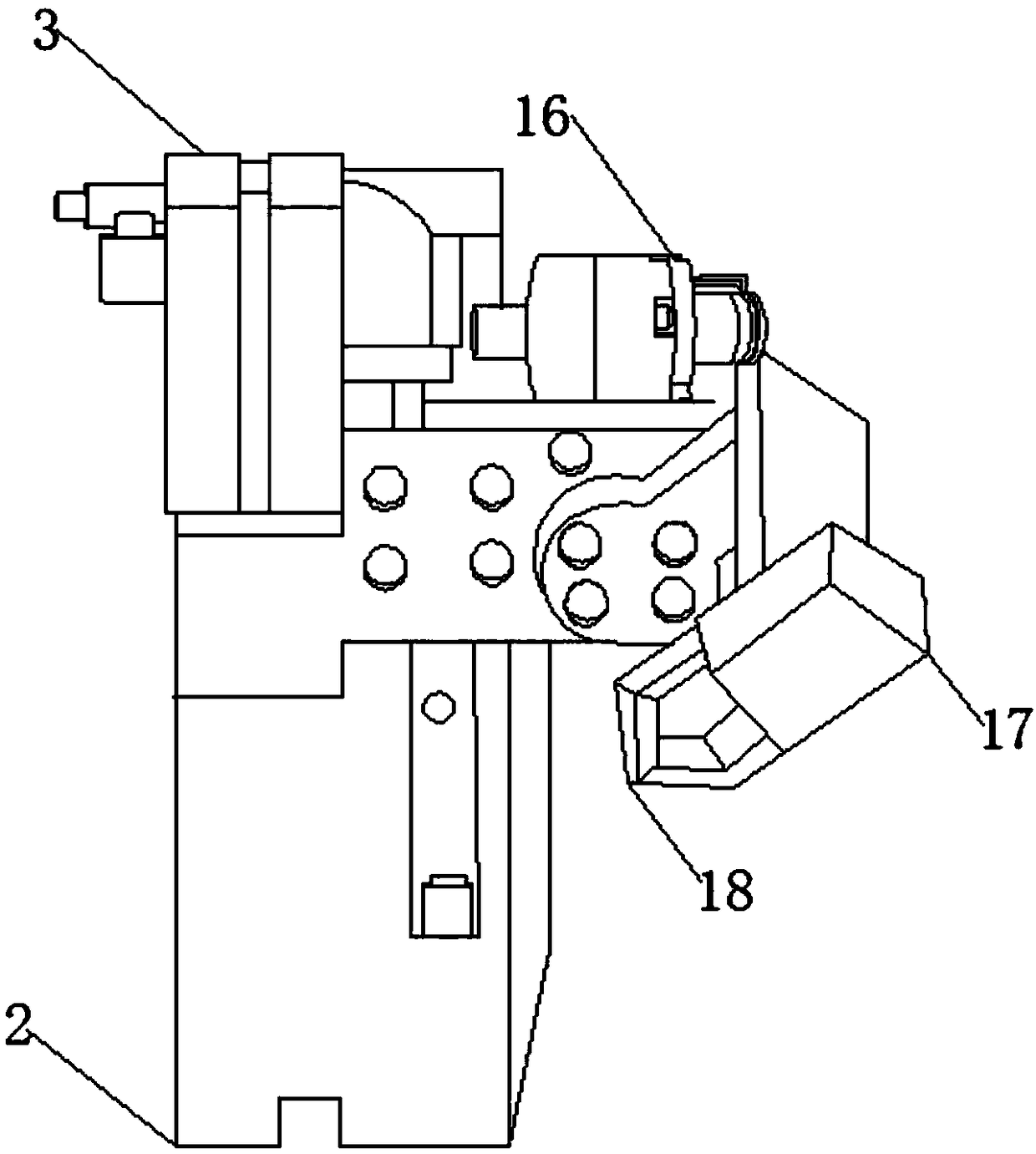

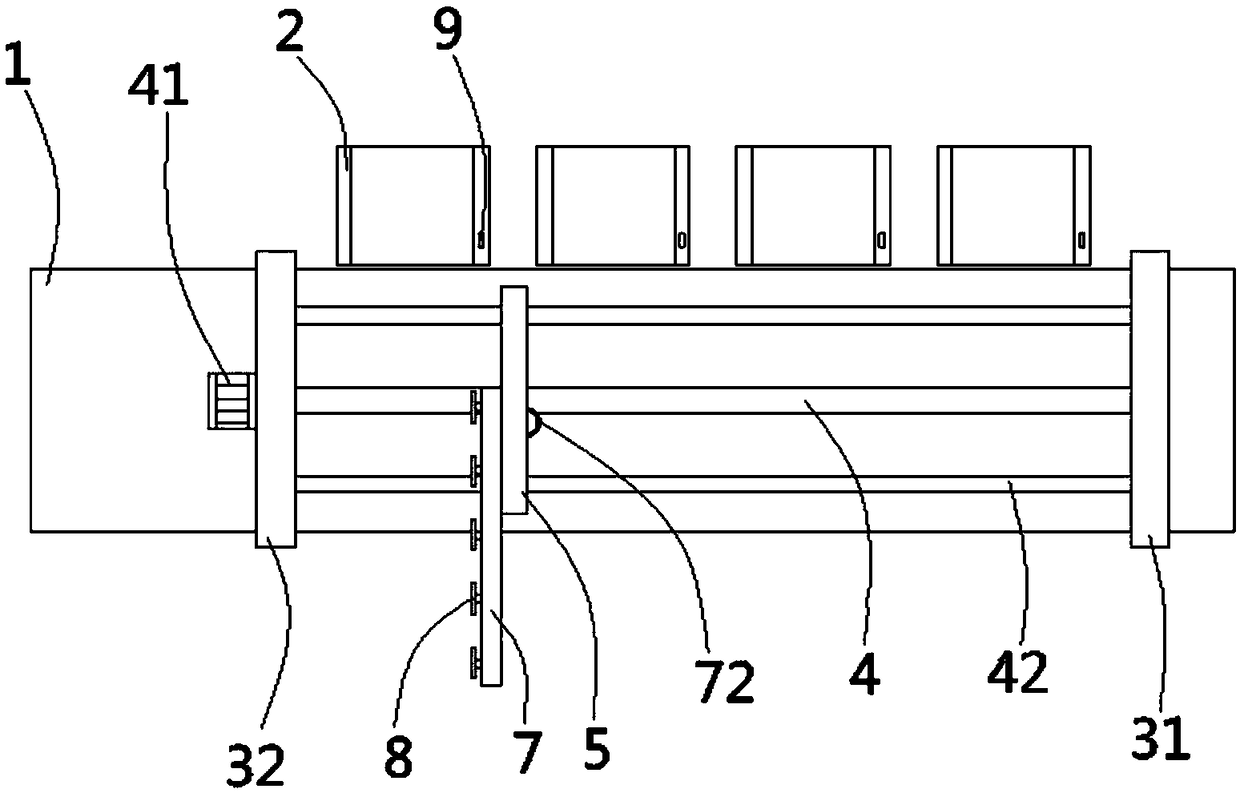

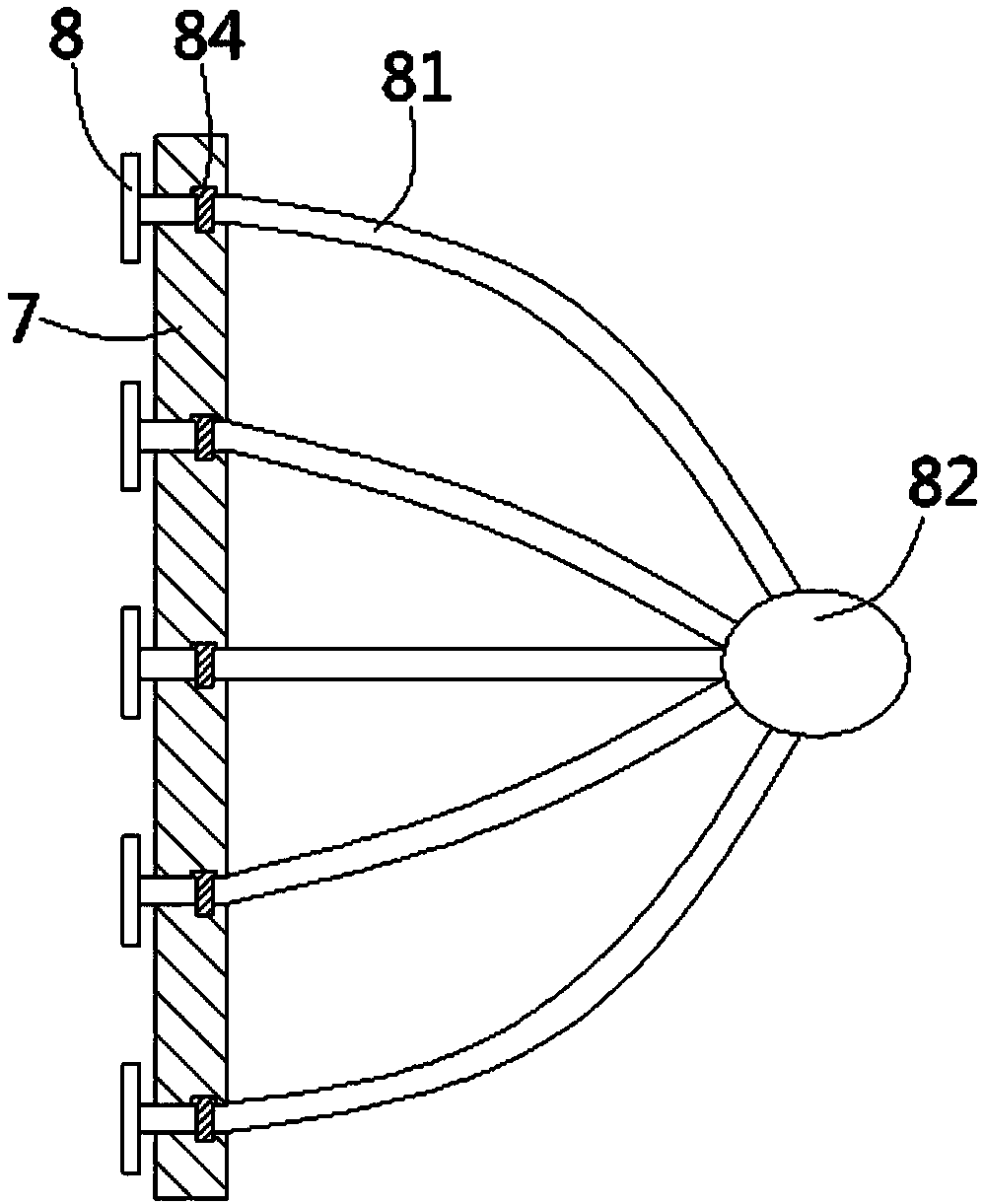

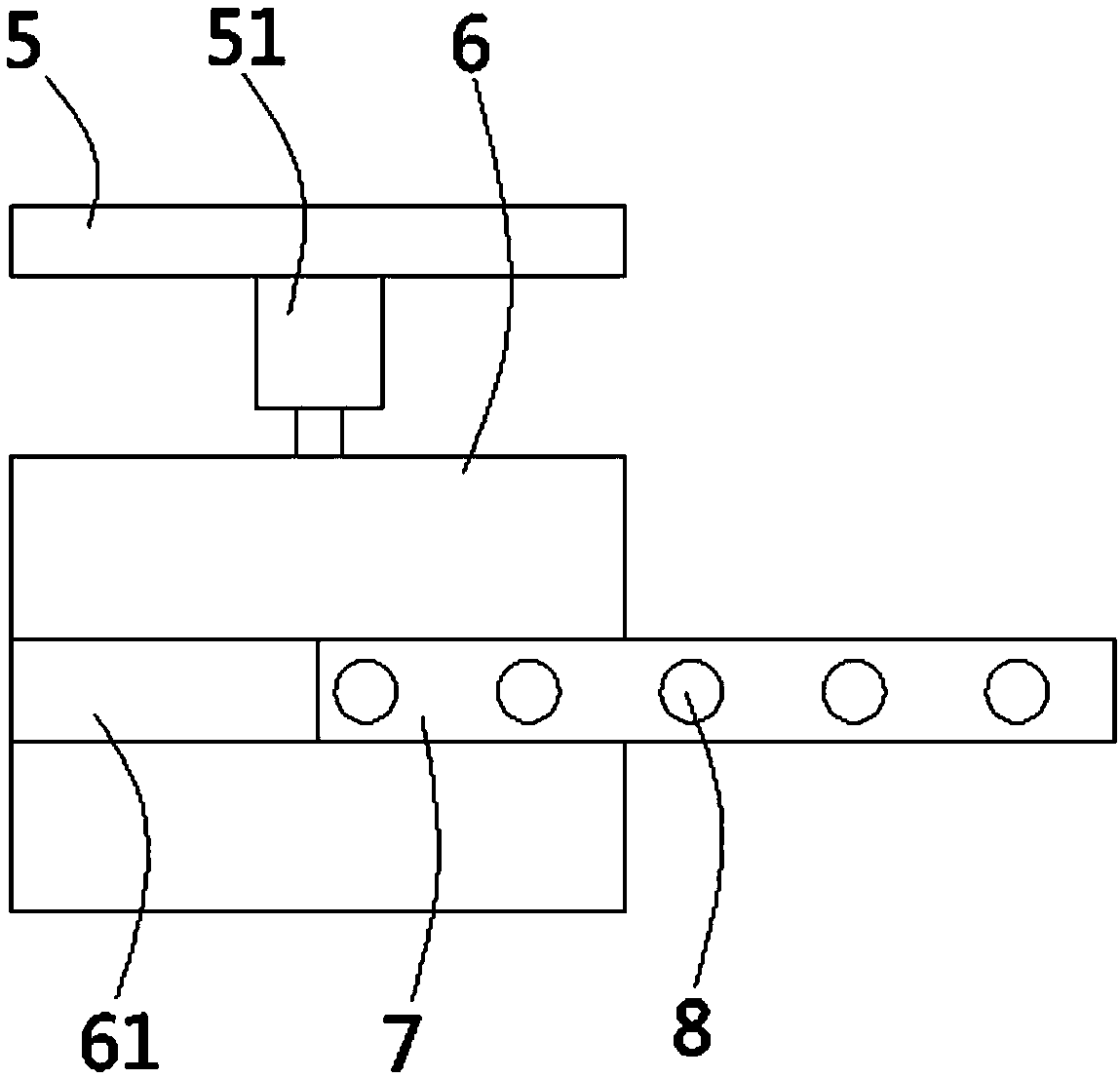

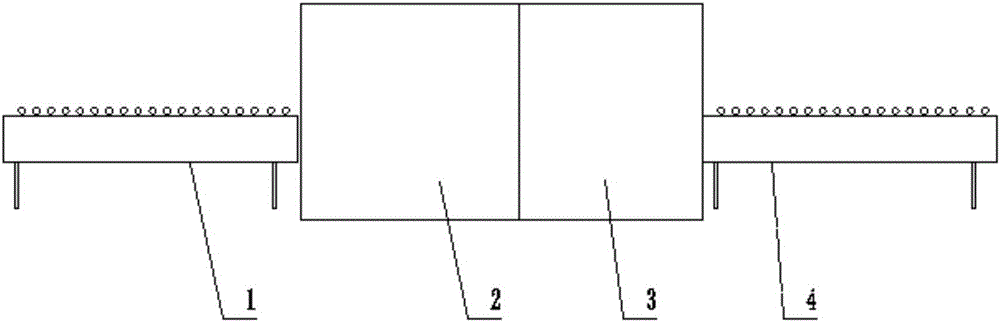

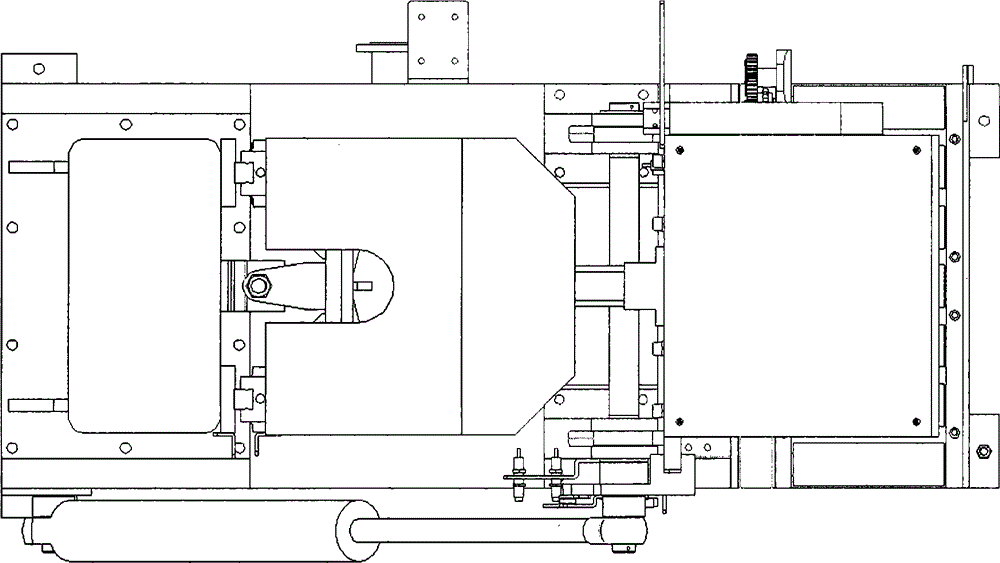

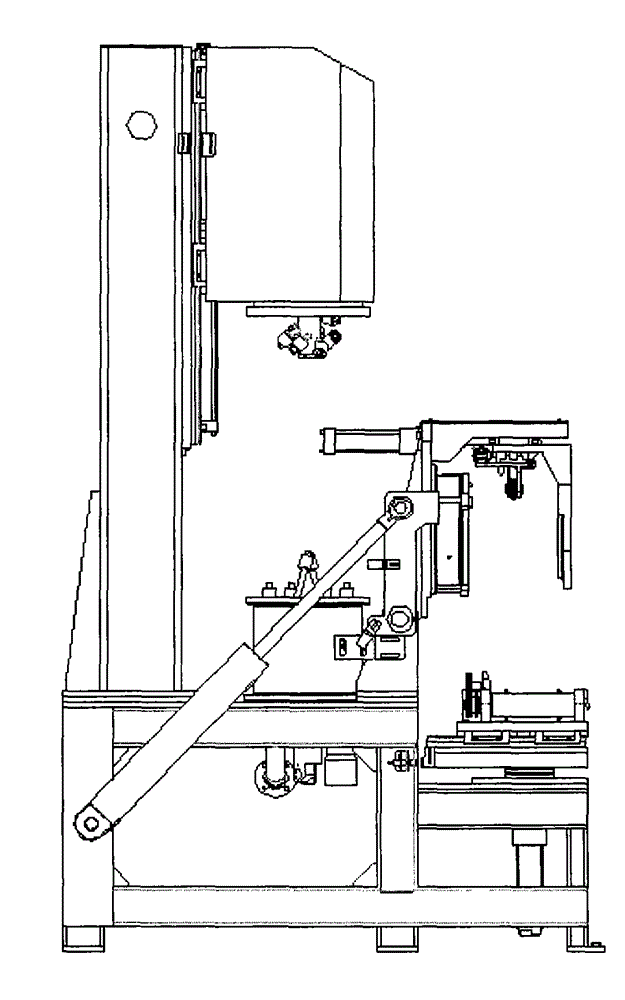

Passenger train axle box bore cleaning machine

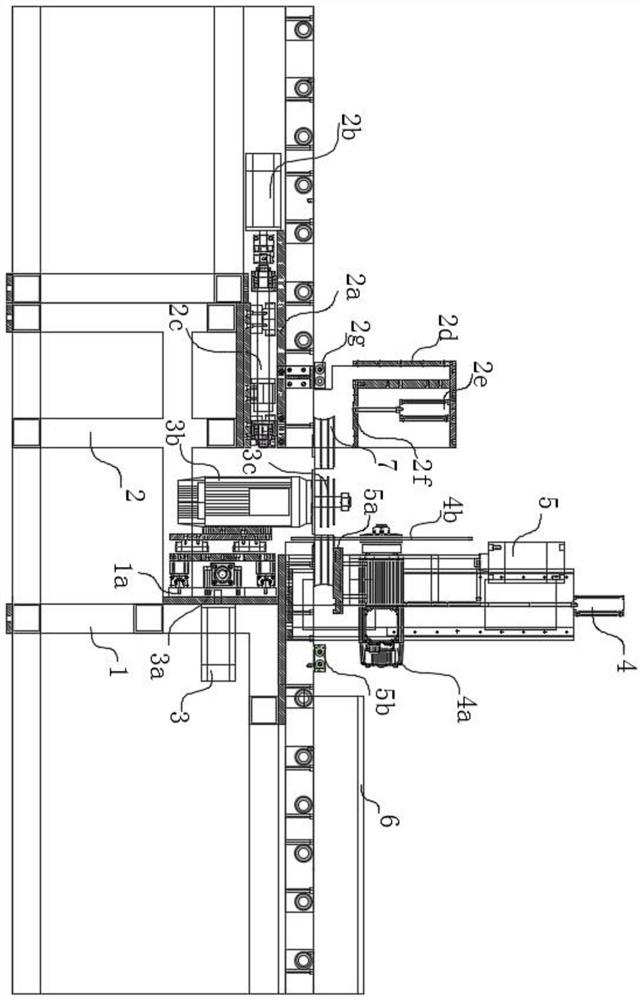

ActiveCN105032806AFulfil requirementsRealize pipeline operationAxle-boxesCleaning using liquidsRailway passenger carPassenger train

The invention discloses a passenger train axle box bore cleaning machine. The passenger train axle box bore cleaning machine is composed of a machine pedestal, an axle box transmitting and locating raceway, an axle box clamping and locating tool, an axle box bore cleaning nozzle, an axle box bore cleaning nozzle frame, a cleaning nozzle frame lifting oil cylinder, a cleaning nozzle support, an axle box locating seat, and an axle box clamping and locating tool driving oil cylinder. The passenger train axle box bore cleaning machine can clamp and locating an axle box after detecting an axle box to be cleaned by a detecting switch, the axle box clamping and locating tool driving oil cylinder starts to work to put the axle box flat on the axle box locating seat, the cleaning nozzle frame lifting oil cylinder starts to work to make the axle box bore cleaning nozzle decline along the axle box bore cleaning nozzle frame, so that the axle box bore cleaning nozzle can clean the axle box bore to remove spots in the axle box bore.

Owner:QIQIHAER SIDA RAILWAY EQUIP

Optical disc mold pressing device for optical disc production

ActiveCN112365903ATo achieve the purpose of intermittent operationRealize pipeline operationConveyorsRecord information storageElectric machineryEngineering

The invention discloses an optical disc mold pressing device for optical disc production, which comprises a bottom plate, a conveying mechanism is mounted at the top of the bottom plate, a driving mechanism is arranged in front of the conveying mechanism, a mold pressing mechanism is arranged above the conveying mechanism, the conveying mechanism comprises a first mounting frame, the first mounting frame is mounted at the top of the bottom plate, a conveying roller is rotatably connected to the first mounting frame, a conveying belt sleeves the conveying roller, a positioning seat used for placing an optical disc is fixedly connected to the conveying belt, the driving mechanism comprises a second mounting frame, and the second mounting frame is mounted at the top of the bottom plate. A motor is installed behind the second installation frame, an incomplete cam is installed at the shaft end, penetrating out of the front face of the second installation frame, of the motor, and a guide groove is formed in the surface of the incomplete cam. The device is combined with an assembly line, assembly line type operation is achieved, and the production efficiency can be greatly improved.

Owner:BEIJING ZHONGKE KAIDI SOFTWARE CO LTD

Automatic industrial cleaning method

InactiveCN108144881ATo achieve the purpose of cleaningRealize pipeline operationInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsEngineering

The invention belongs to the technical field of cleaning, and particularly relates to an automatic industrial cleaning method. The automatic industrial cleaning method includes the steps that firstly,cleaning liquid is prepared; secondly, the cleaning liquid is made; thirdly, a feeding box is prepared, to-be-cleaned nuts are placed in the feeding box, and a rotating disk for automatically suckingthe nuts in the feeding box is installed above the feeding box; and a cleaning mechanism for cleaning the outer walls and the inner walls of the nuts at the same time in the rotating process and an intermittent mechanism for making the cleaning mechanism intermittently leave the nuts on the rotating disk are installed on one side of the rotating disk; fourthly, the cleaning liquid made in the second step is added in the cleaning mechanism in the third step; fifthly, secondary cleaning is performed; and sixthly, drying is performed. By means of the scheme, the cleaning effect of the nuts can be improved.

Owner:重庆创赢清洗有限公司

Full-automatic numerical control punching machine

The invention discloses a full-automatic numerical control punching machine which comprises a base. A punching die holder is arranged on the base. Workpiece fixing die holes are formed in the arc surface of the outer circle of the punching die holder. Vertical supporting frames are arranged on the base. A punching machine crossbeam is connected between the upper ends of the vertical supporting frames. A moving guide rail is arranged on the punching machine crossbeam. Two parallel punching machine heads are arranged on the moving guide rail. A motor and a speed reducer are arranged in each punching machine head. The full-automatic numerical control punching machine can be used for punching precise hardware workpieces, has high machining efficiency and achieves an assembly line work mode.

Owner:SUZHOU BAOMA NUMERICAL CONTROL EQUIP

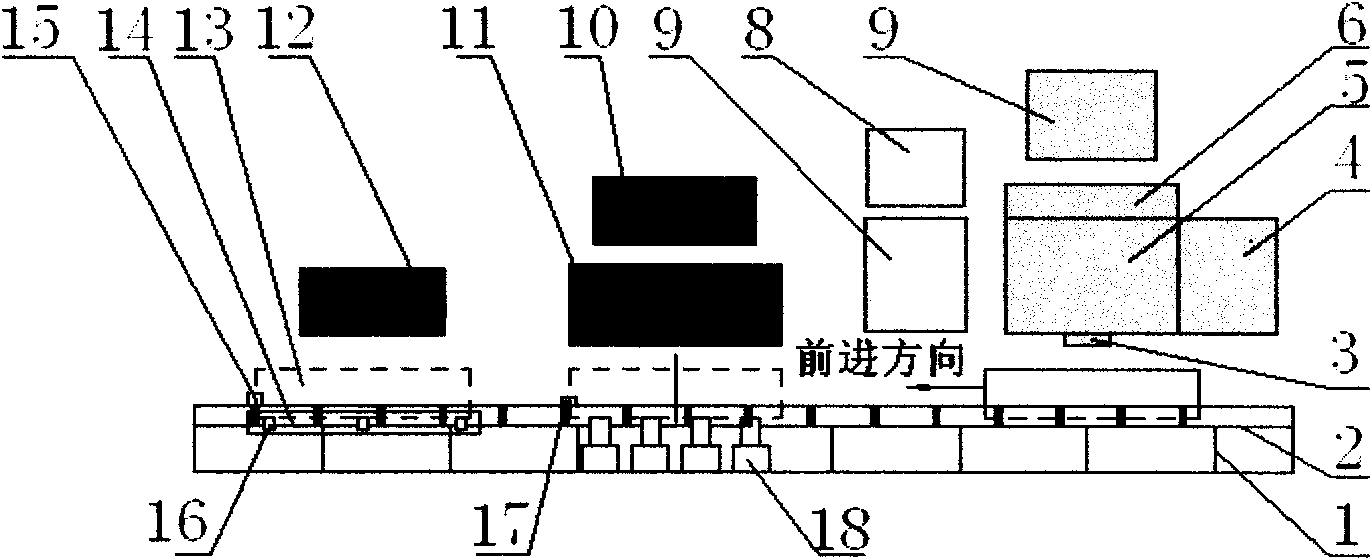

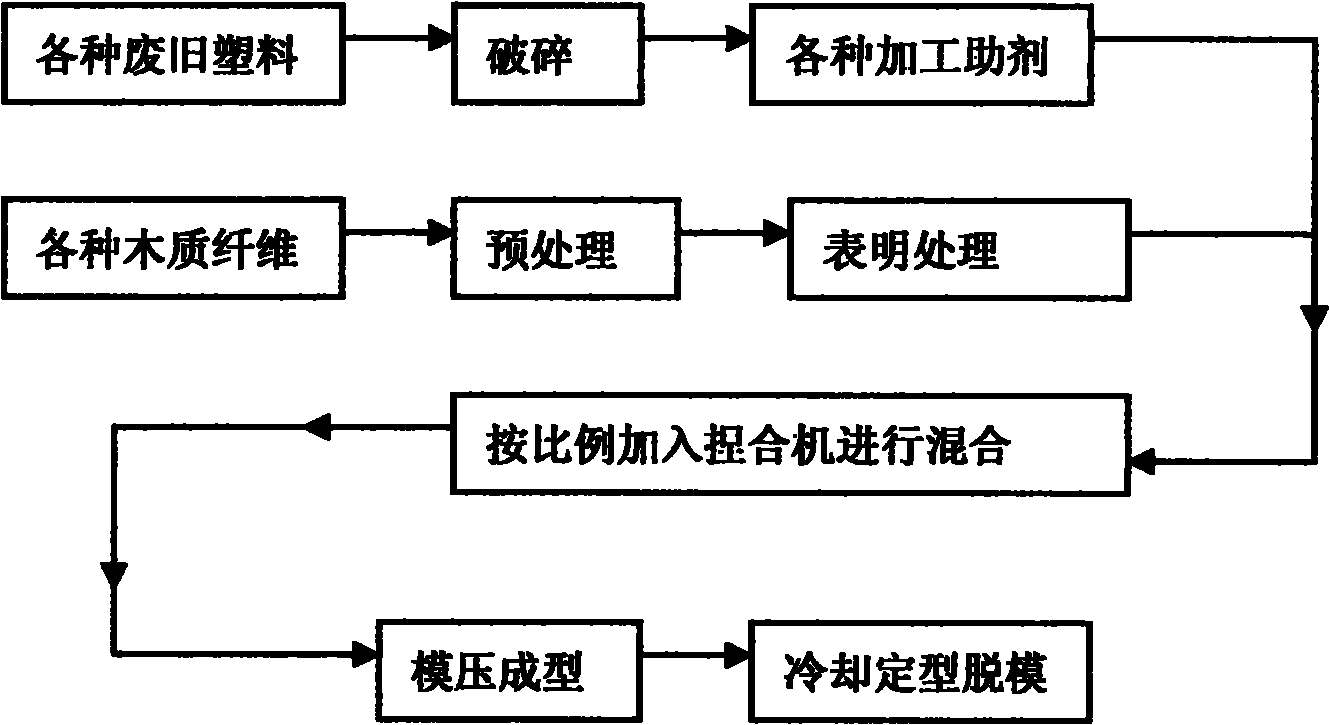

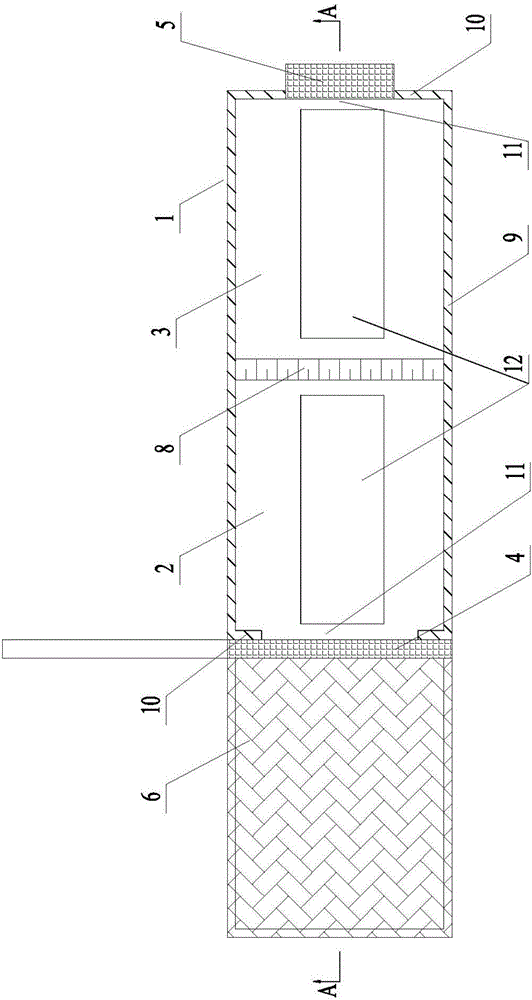

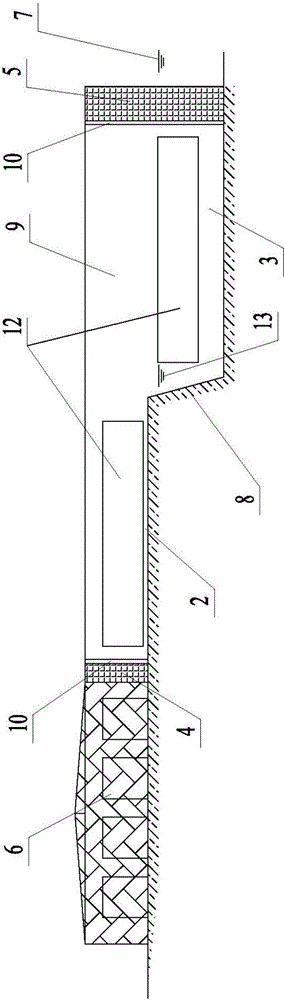

Laminated wood plate forming method

ActiveCN102248571BHigh strengthImprove local strengthWood working apparatusDomestic articlesFiberProduction line

The invention relates to laminated wood plate forming equipment and a laminated wood plate forming method, in particular to laminated wood material forming equipment and a laminated wood material forming method, which form a new composite material with high strength, high hardness and low cost by plasticizing mixed recovered waste plastics, kneading the plasticized mixed recovered waste plastics, a crushed wood fiber material and a processing assistant and die-pressing to form a common continuous phase structure. The production equipment comprises a kneading machine (5), a rail (3), a hydraulic press (11), a demolding mechanism (14) and a corresponding control panel.

Owner:BEIJING HENGTONG INNOVATION LUXWOOD TECH +1

Processing and production technology for impurity removal and blending of white tea

PendingCN113231317AHygieneEnsure safetyPre-extraction tea treatmentSolid separationForeign matterProduction line

The invention discloses a processing and production technology for impurity removal and blending of white tea. A production line device comprising a grading assembly, a winnowing impurity removal assembly, a uniform stacking and blending assembly and a weighing and packaging assembly is adopted for carrying out impurity removal and blending. The production technology comprises the following steps that Q1, white tea is subjected to metal foreign matter adsorption treatment and electrostatic adsorption; Q2, the white tea is conveyed to a winnowing feeding inclined conveying unit through an inclined bucket elevator and a plane conveyor; Q3, a double-row winnowing machine selects out and discharges sand and stone foreign matter and grass and hair foreign matter in the white tea; Q4, a foreign matter picking and removing procedure is carried out; Q5, a magnetic grading procedure is carried out; Q6, a uniform stacking and blending procedure is carried out; Q7, a conveying and lifting procedure is carried out; Q8, a weighing procedure is carried out; Q9, a boxing procedure is carried out; and Q10, a packaging procedure is carried out. The automatic control technique of automatic feeding, automatic impurity removal, automatic blending, automatic weighing, automatic boxing and automatic packaging is applied, the production efficiency is effectively improved, the product quality is improved, and continuous and automatic refining processing of white tea is successfully achieved.

Owner:福建茶叶进出口有限责任公司

Deep and shallow dock assembly and assembly line operation method for producing and shipping large prefabricated components

ActiveCN103669920BRealize pipeline operationShorten construction timeArtificial islandsUnderwater structuresMarine engineeringAssembly line

The invention relates to a working method for manufacturing large prefabricated components on a large scale in an assembly line manner and outfitting, lifting and shipping the large prefabricated components by the aid of a deep and shallow dock combination which comprises a shallow dock zone and a deep dock zone. The deep and shallow dock combination comprises a fence for stopping seawater from flowing into the deep and shallow dock combination. The shallow dock zone for primarily outfitting and lifting the large prefabricated components and the deep dock zone for secondarily outfitting and lifting the large prefabricated components are arranged in the fence; a shallow dock gate for opening and closing the shallow dock zone is arranged at one end of the fence, and a deep dock gate for opening and closing the deep dock zone is arranged at the other end of the fence. The working method has the advantages that large prefabricated component manufacturing, outfitting, lifting and shipping procedures can be carried out in an assembly line manner owing to the design of the shallow dock zone and the deep dock zone, accordingly, the construction time can be saved, and the construction progress can be accelerated.

Owner:CCCC FHDI ENG

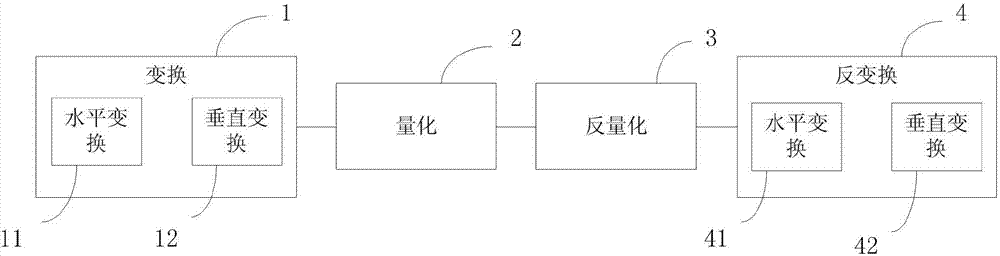

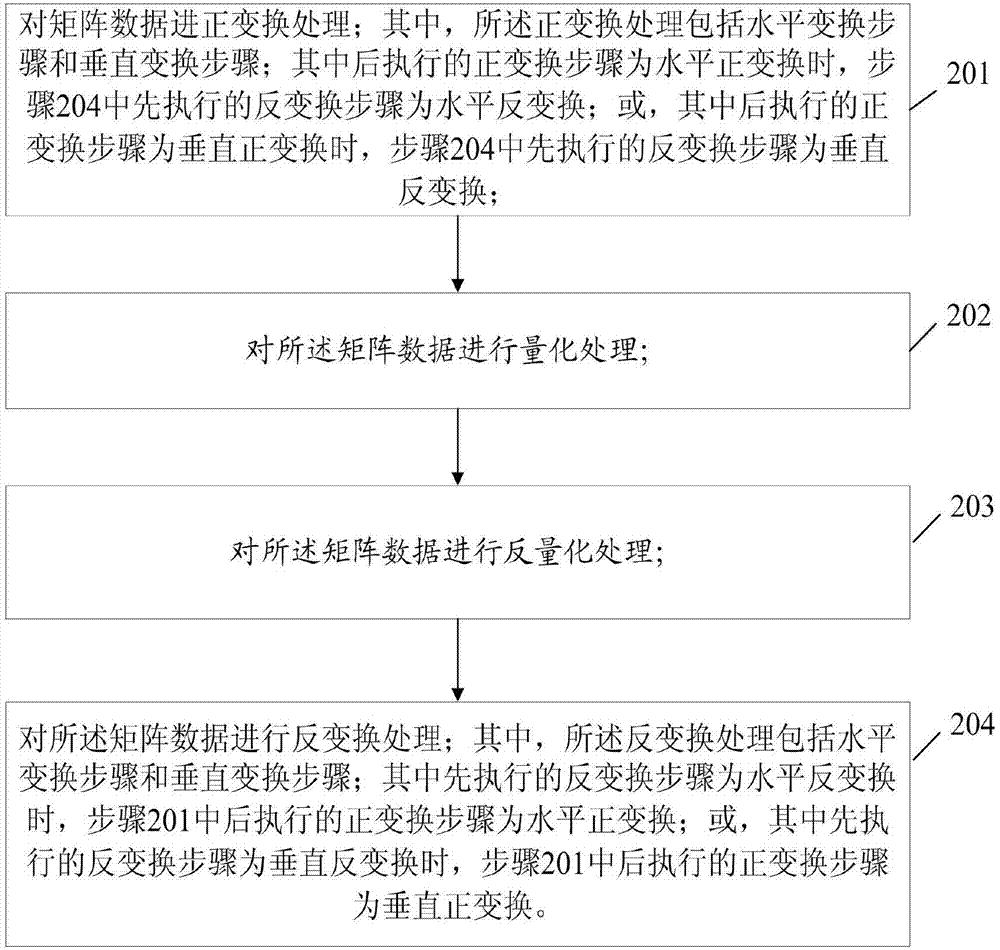

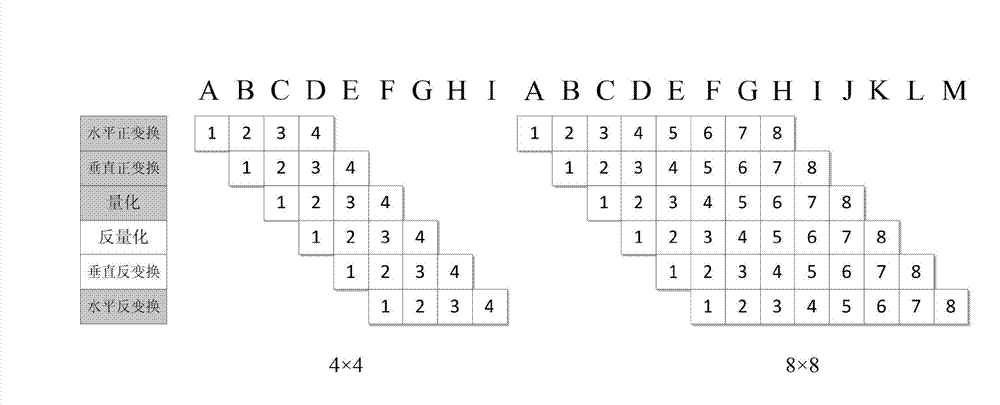

Video coding transforming and quantifying method and device

ActiveCN104519366AImprove computing efficiencyRealize pipeline operationDigital video signal modificationVideo encodingComputer science

Owner:BEIJING VIMICRO ARTIFICIAL INTELLIGENCE CHIP TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com