Processing and production technology for impurity removal and blending of white tea

A production process and technology for white tea, applied in the directions of transportation and packaging, pre-extraction tea treatment, solid separation, etc., can solve the problems of excessive debris content and low efficiency, improve clean production, reduce error rates, and ensure stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

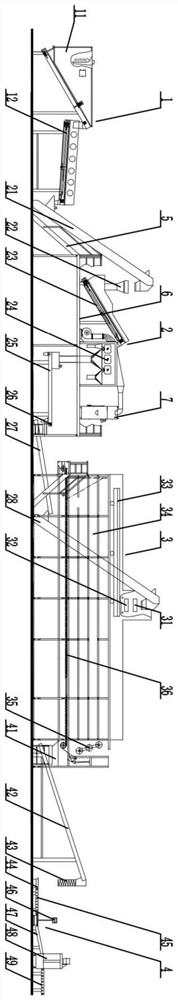

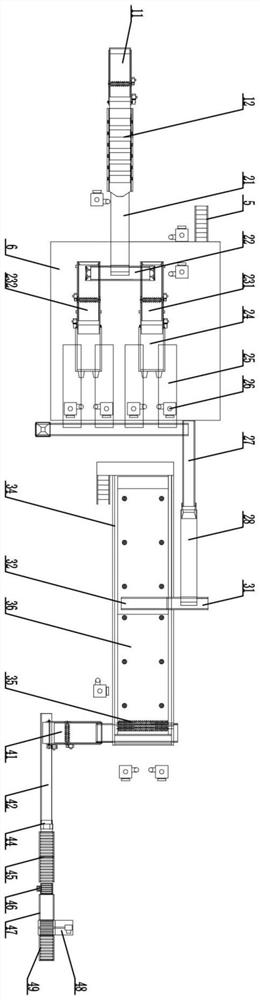

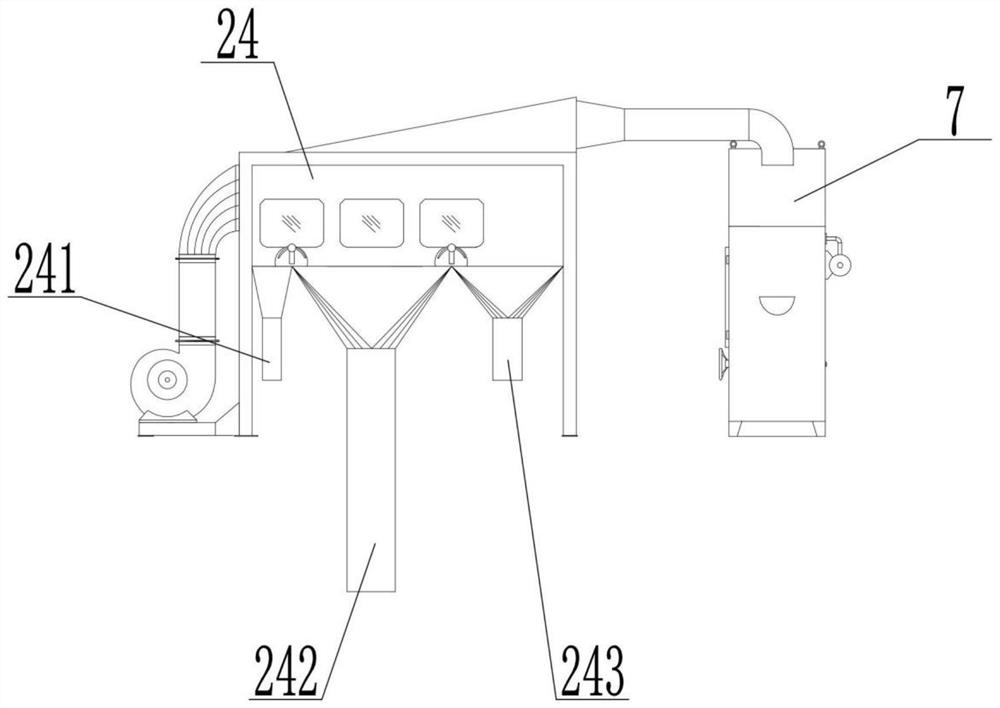

[0062]A processing and production process for removing impurities and blending of white tea, using a production line device including a sorting component 1, an air selection and removing impurities component 2, an even stacking and blending component 3, and a weighing and packaging component 4 for removing impurities and blending. The sorting assembly 1 includes a feeder 11, an electrostatic sorting machine 12, and the wind separation impurity removal assembly 2 includes an inclined bucket elevator 21, a plane conveyor 22, an air separation feeding inclined conveying unit 23, a double-row wind turbine Sorting machine 24, visual picking machine 25, magnetic roller 26, inclined bucket elevator 27 and bucket elevator 28, described inclined bucket elevator 21, plane conveyor 22, winnowing feeding oblique conveying unit 23 , the width of the oblique conveyor 27 is 500cm, and the oblique conveying unit 23 of the wind selection feed material comprises the first wind selection feed mat...

Embodiment 2

[0083] A processing and production process for removing impurities and blending of white tea, using a production line device including a sorting component 1, an air selection and removing impurities component 2, an even stacking and blending component 3, and a weighing and packaging component 4 for removing impurities and blending. The sorting assembly 1 includes a feeder 11, an electrostatic sorting machine 12, and the wind separation impurity removal assembly 2 includes an inclined bucket elevator 21, a plane conveyor 22, an air separation feeding inclined conveying unit 23, a double-row wind turbine Sorting machine 24, visual picking machine 25, magnetic roller 26, inclined bucket elevator 27 and bucket elevator 28, described inclined bucket elevator 21, plane conveyor 22, winnowing feeding oblique conveying unit 23 , the width of the oblique conveyor 27 is 600cm, and the oblique conveying unit 23 of the wind selection feed material comprises the first wind selection feed ma...

Embodiment 3

[0104] A processing and production process for removing impurities and blending of white tea, using a production line device including a sorting component 1, an air selection and removing impurities component 2, an even stacking and blending component 3, and a weighing and packaging component 4 for removing impurities and blending. The sorting assembly 1 includes a feeder 11, an electrostatic sorting machine 12, and the wind separation impurity removal assembly 2 includes an inclined bucket elevator 21, a plane conveyor 22, an air separation feeding inclined conveying unit 23, a double-row wind turbine Sorting machine 24, visual picking machine 25, magnetic roller 26, inclined bucket elevator 27 and bucket elevator 28, described inclined bucket elevator 21, plane conveyor 22, winnowing feeding oblique conveying unit 23 , the width of oblique conveying machine 27 is 550cm, and the oblique conveying unit 23 of described winnowing feeding material comprises the first winnowing fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com