Patents

Literature

65results about How to "Realize punching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

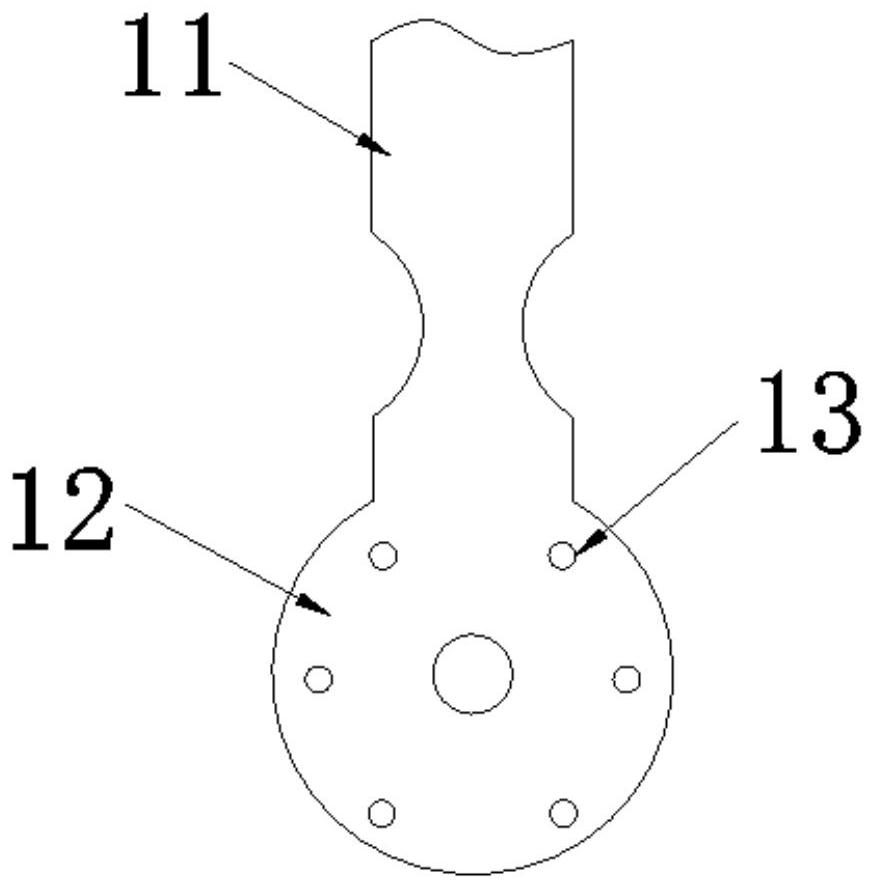

Drum-style drill for sowing-disk base material

InactiveCN1817079ARealize punchingEasy to use and flexiblePlantingFurrow making/coveringEngineeringMaterial Perforation

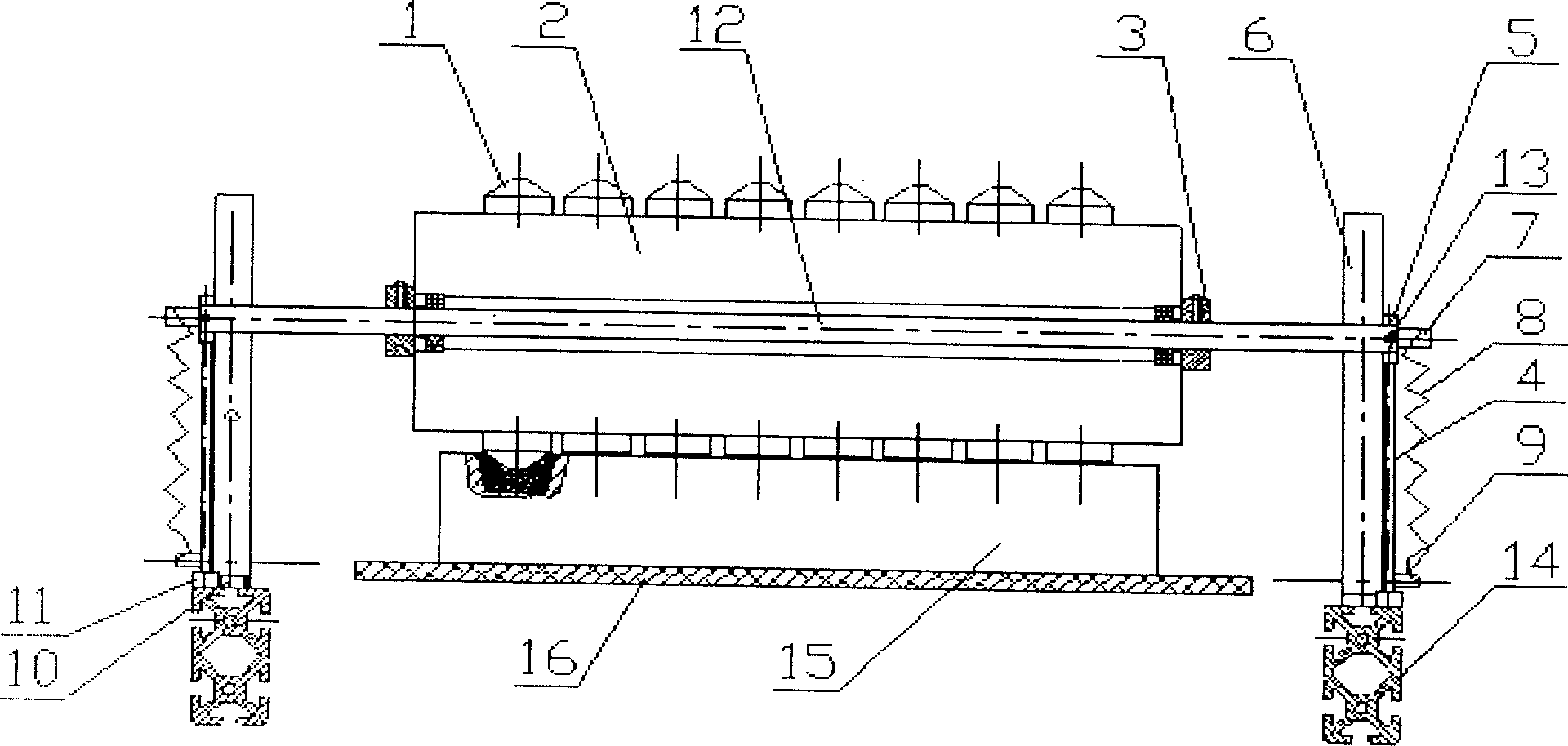

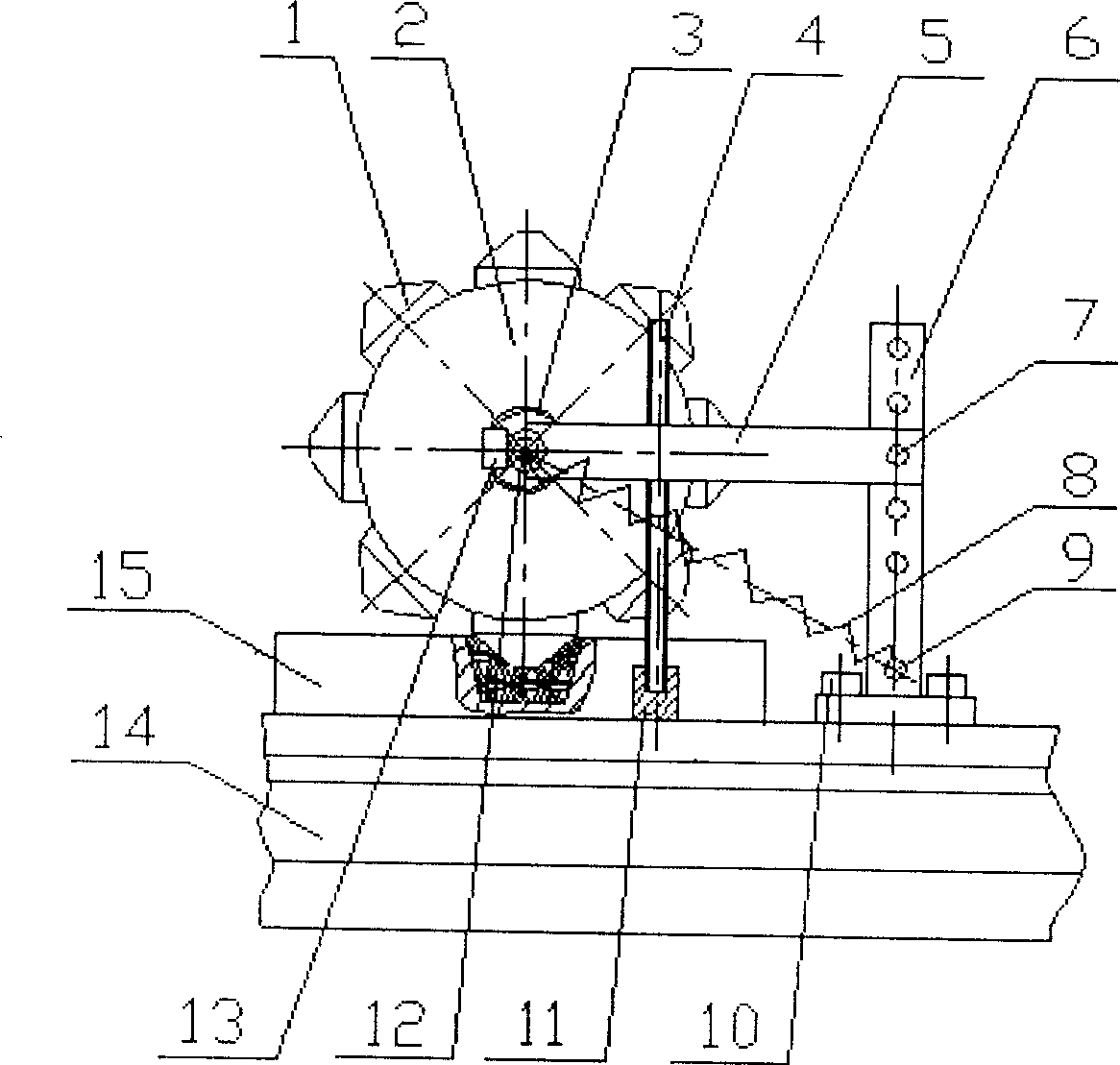

A drum-type punch mechanism for perforating on the matrix bowls in order to plant vegetable or flower is composed of two regulation holders fixed to the supporting frame for sowing, two transverse bars on said regulation holders, a rotary axle on said two transverse bars, a drum on said rotary axle and with conic punch heads uniformly arranged on its surface, and two stop blocks on said rotary axle for fixing said drum. Said bowls is moving on conveying belt to directly drive said drum for perforation.

Owner:ZHEJIANG UNIV

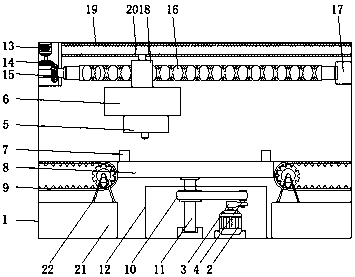

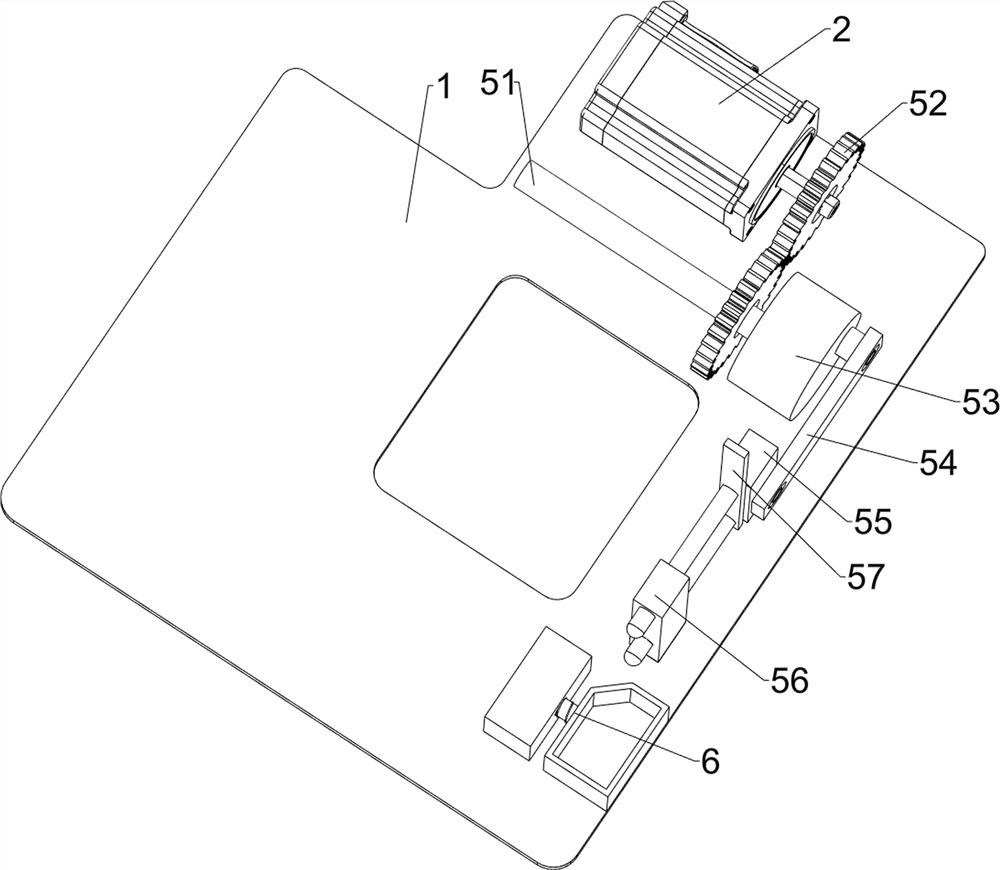

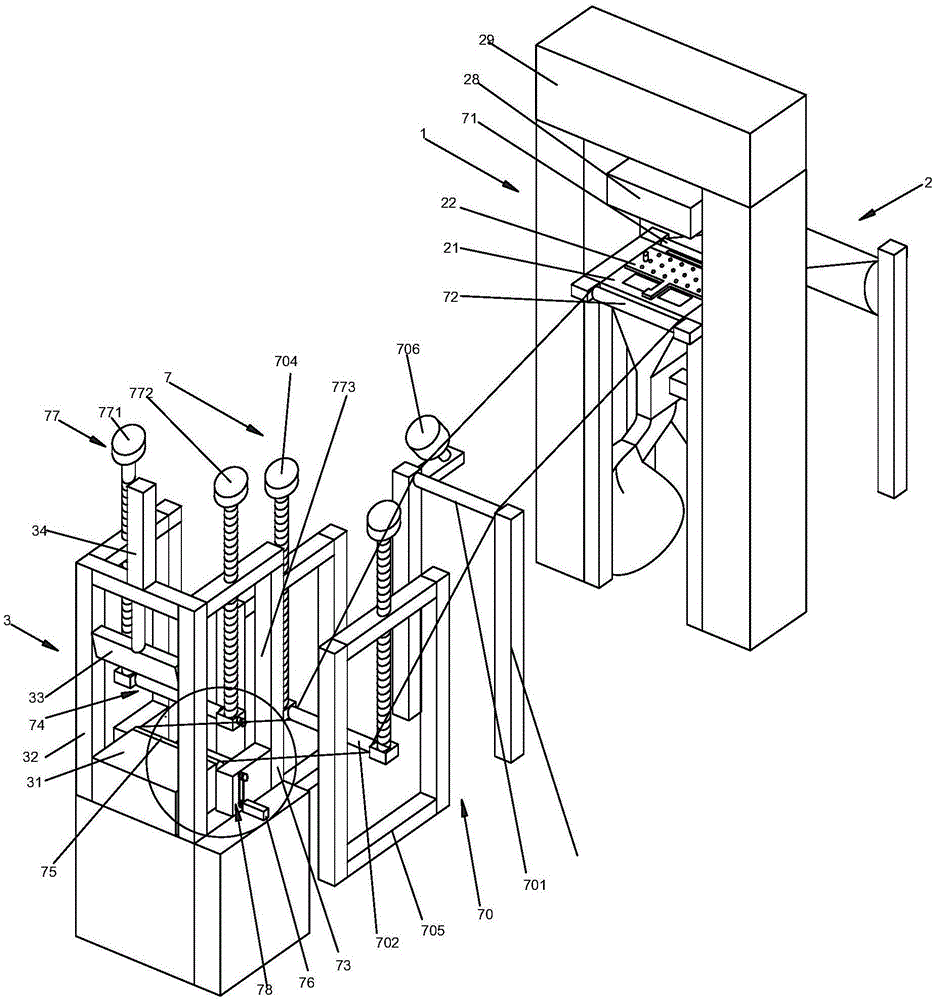

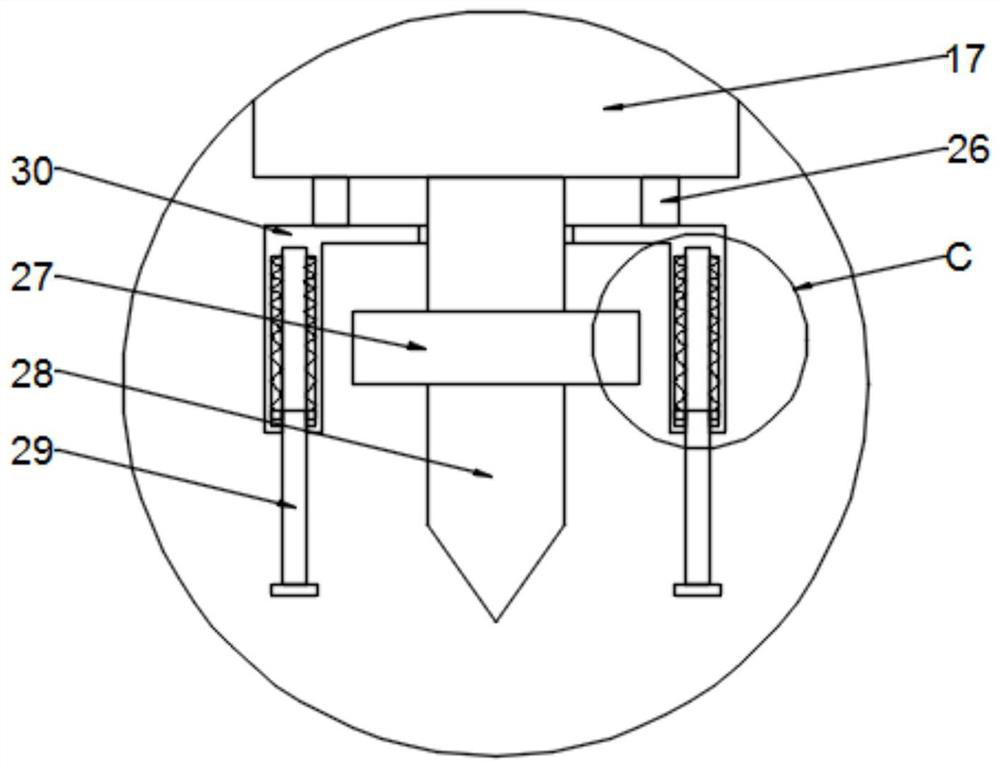

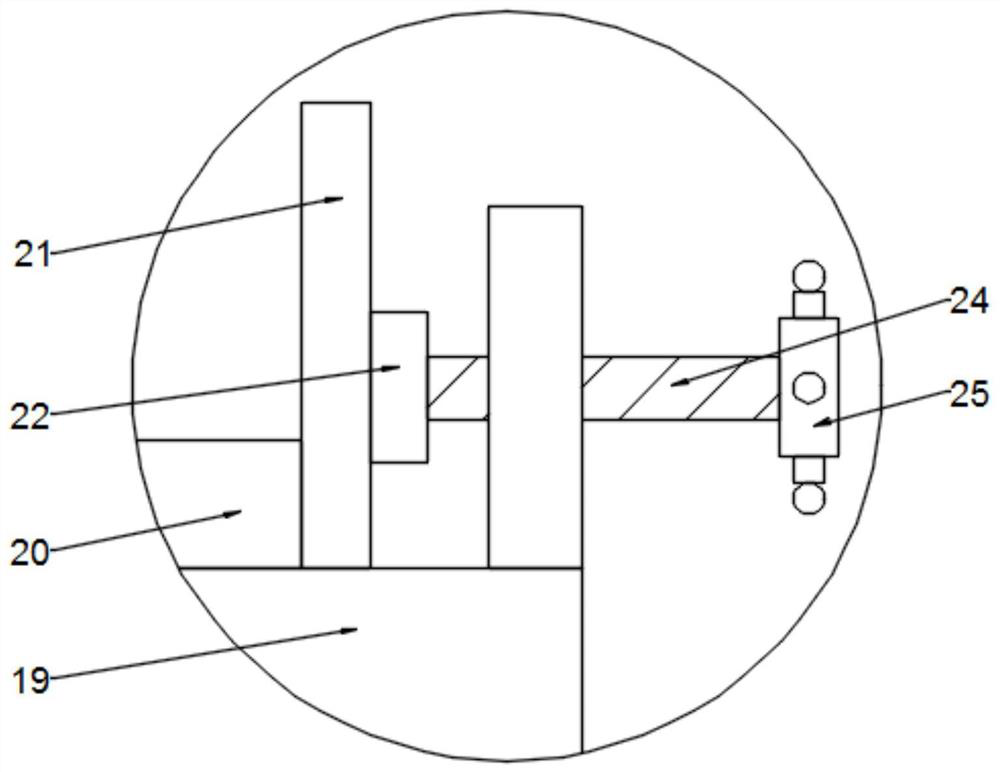

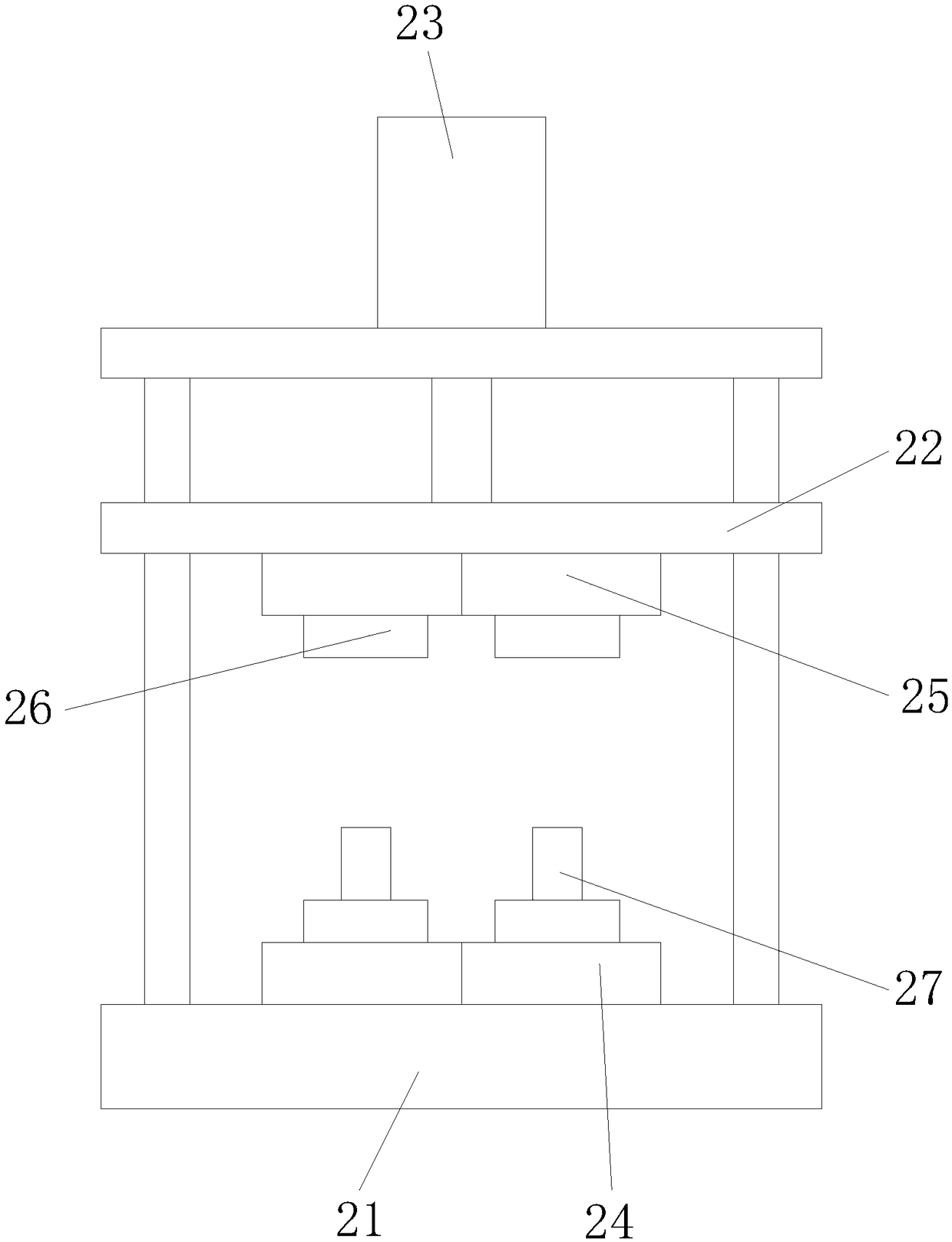

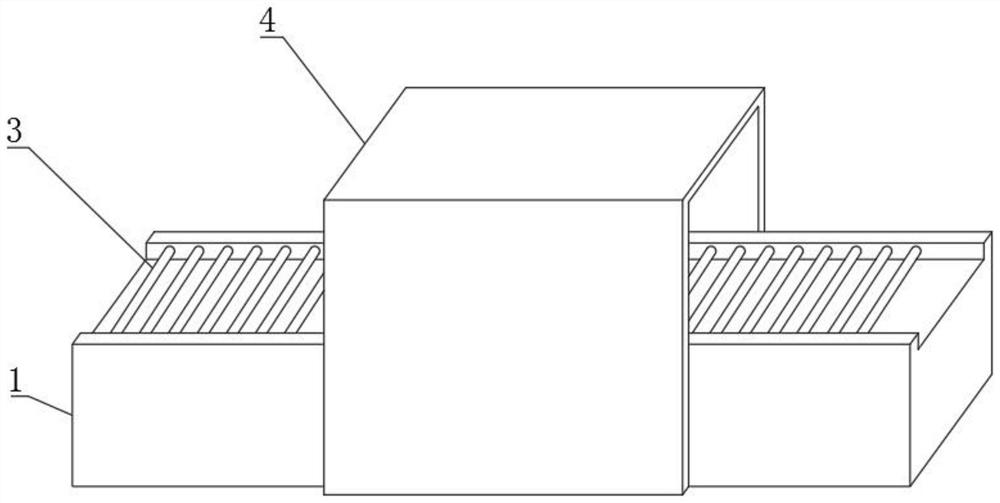

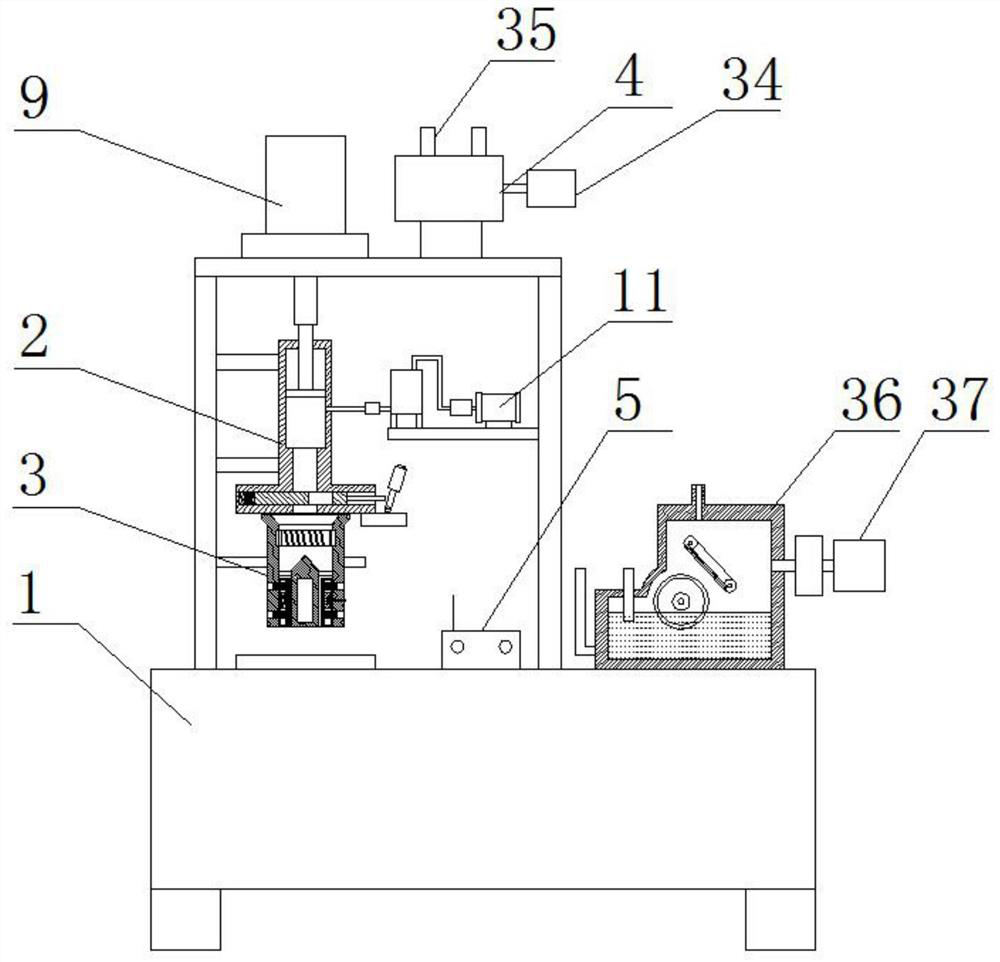

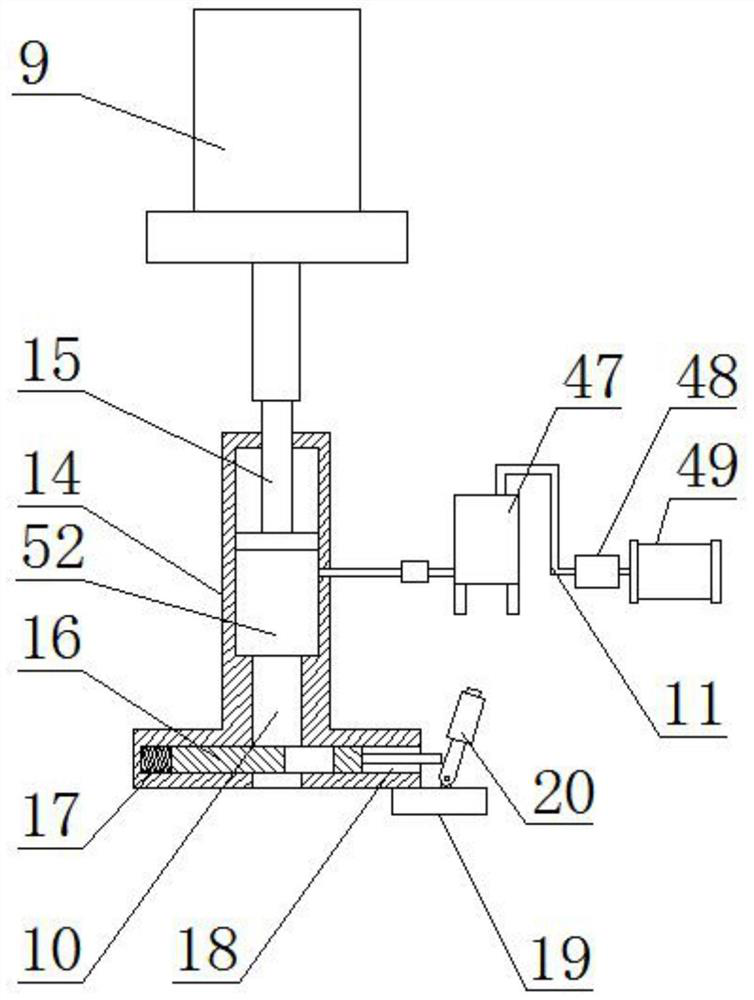

Full-automatic drill bit replacing type perforating machine

ActiveCN106624059ARealize vertical reciprocating movementRealize punchingFeeding apparatusDriving apparatusBall screwPaperboard

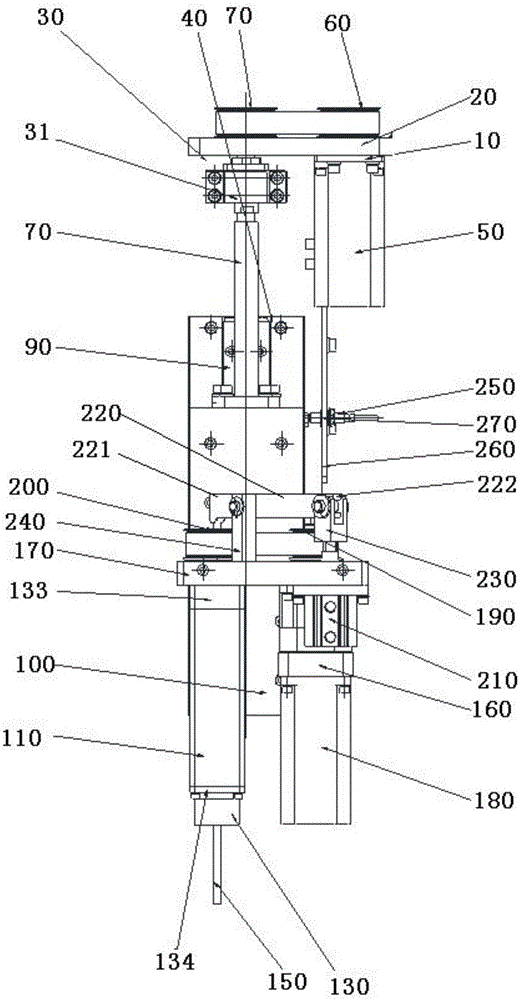

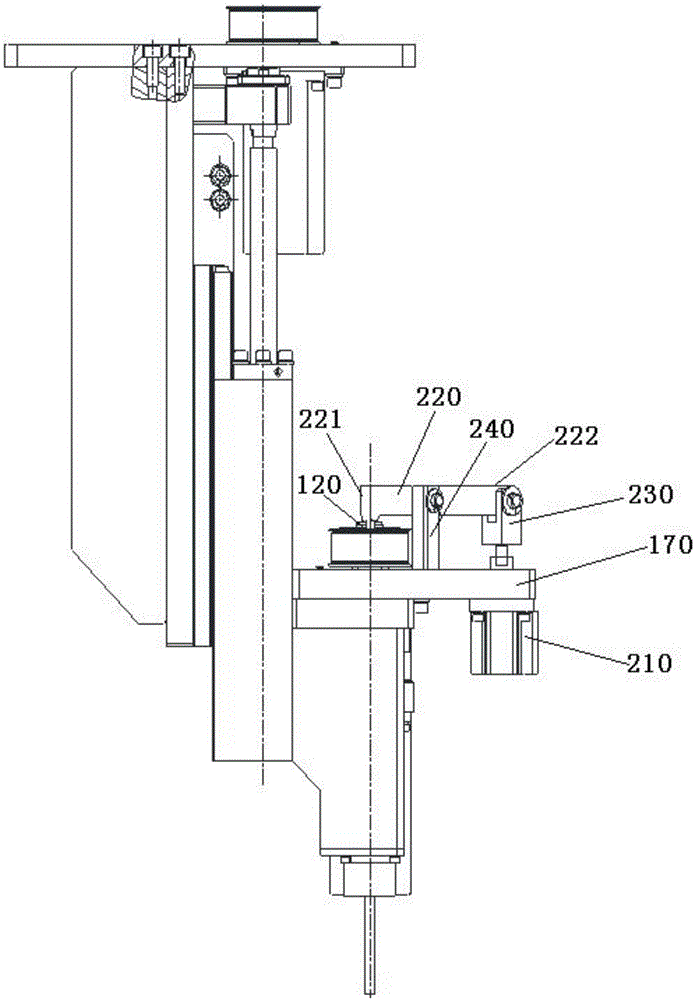

The invention discloses a full-automatic drill bit replacing type perforating machine. The machine comprises a perforating head, a rotating mechanism for driving the perforating head to rotate to perforate, a dismounting mechanism for automatically dismounting a drill bit on the perforating head, and a mounting mechanism for automatically mounting the drill bit on the perforating head, wherein a first servo motor can drive a first synchronous belt wheel and a second synchronous belt wheel during working, and a ball screw can rotate through the transmission of the synchronous belt wheels, and thus the drill bit is driven to lengthways reciprocate; a second servo motor can drive a third synchronous belt wheel and a fourth synchronous belt wheel, and the drill bit is driven to rotate through the transmission of the synchronous belt, thus realizing perforating; a cylinder runs to enable simple, quick and accurate automatic replacing of the drill bit after perforating. The machine is proper in size, simple to assemble, high in assembling performance, and high in transmission torque; the machine is applicable to processing of commonly-used paperboards, plastic, steel plates, workpieces, etc., and the applicable scope is wide; the service life of a cutter can be prolonged; and the production quality and efficiency can be improved.

Owner:西安绿港科技发展有限公司

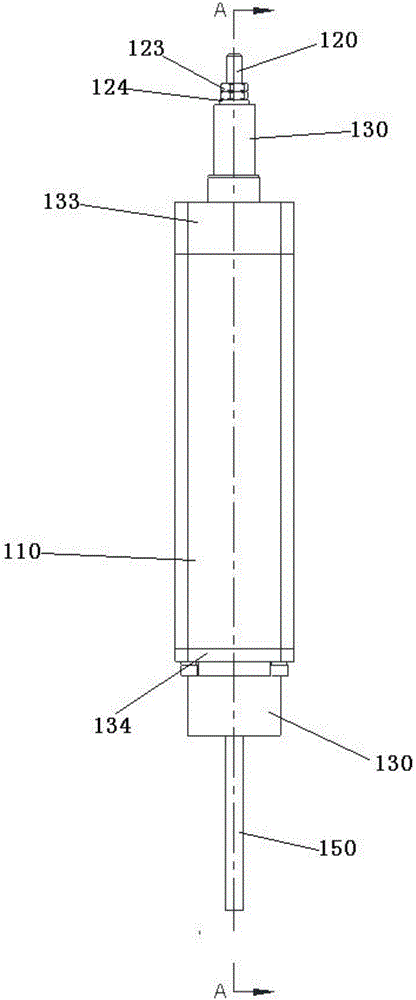

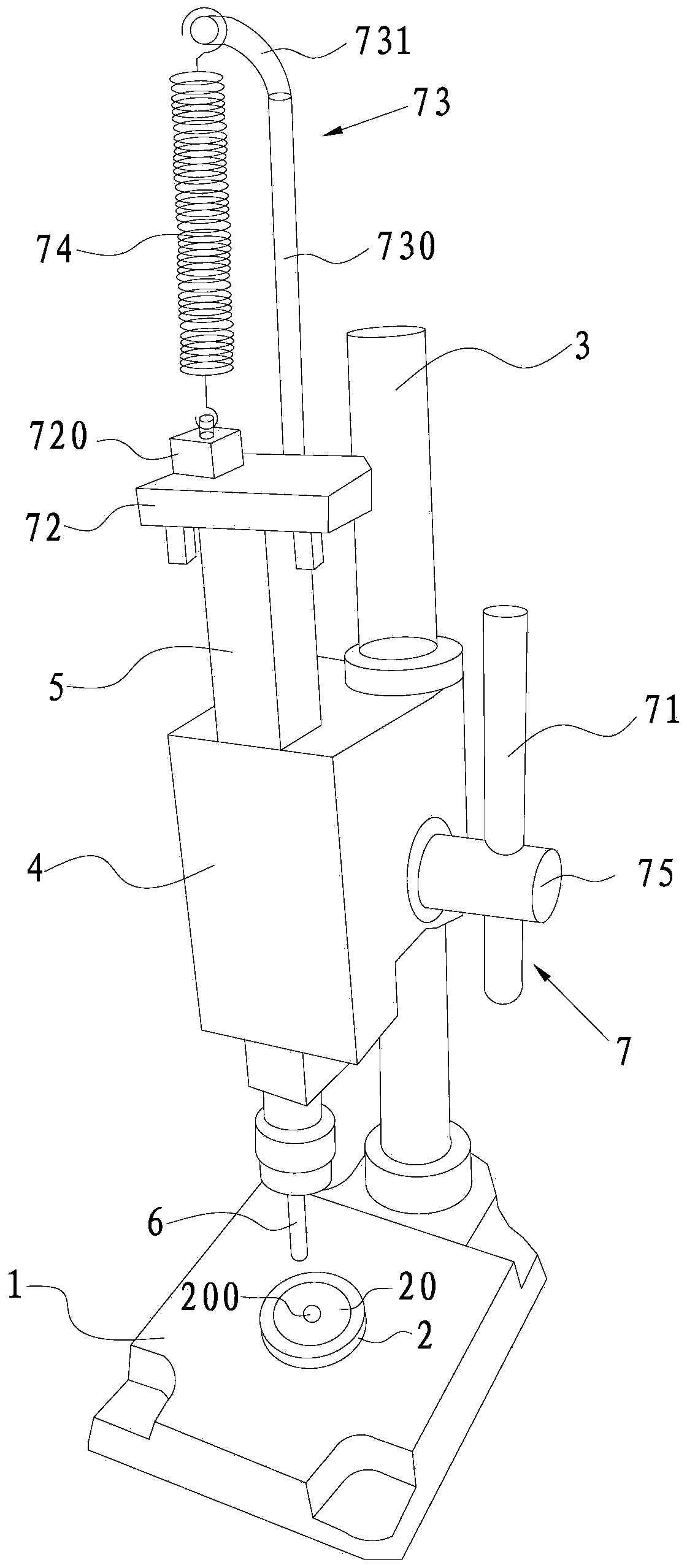

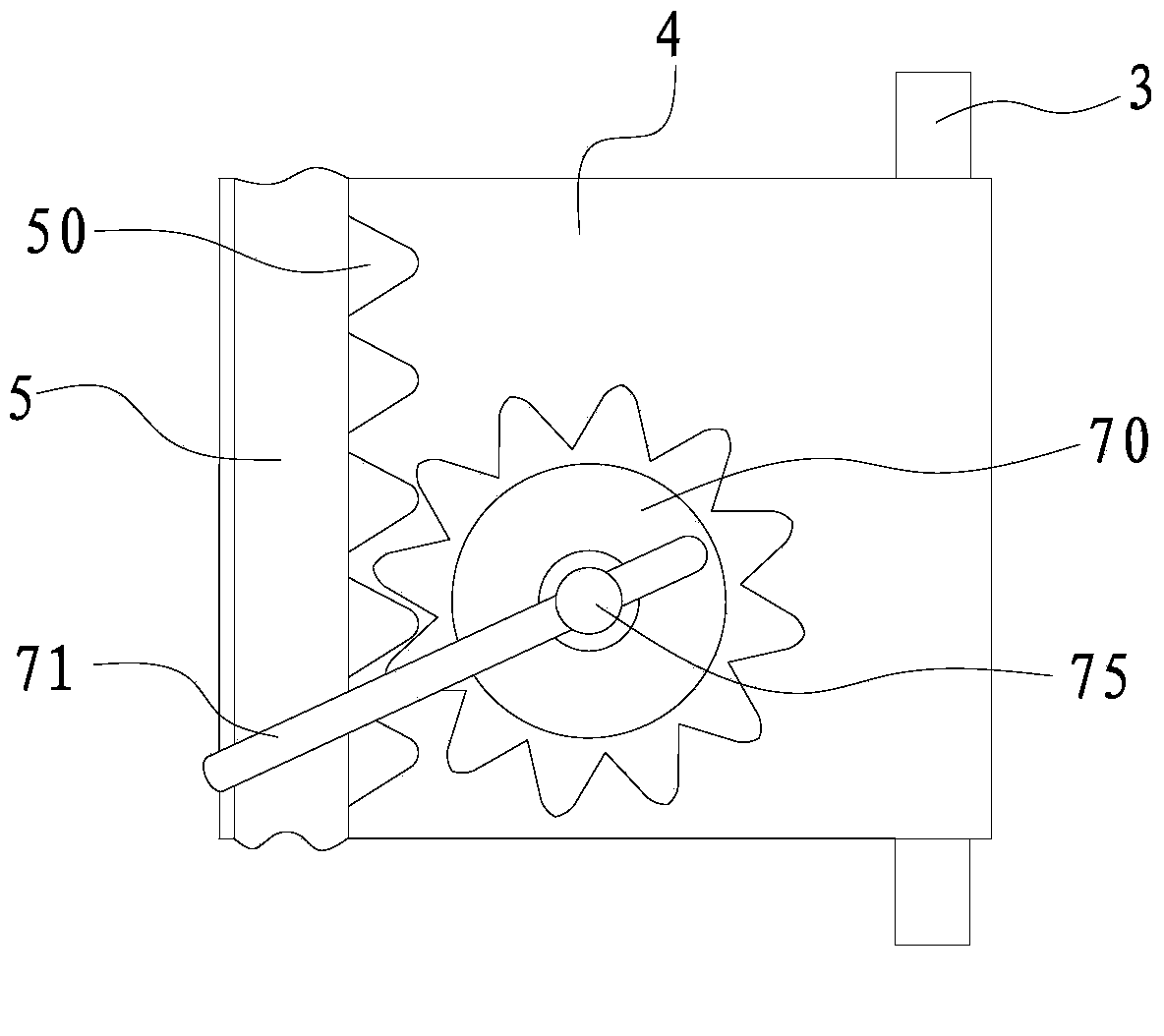

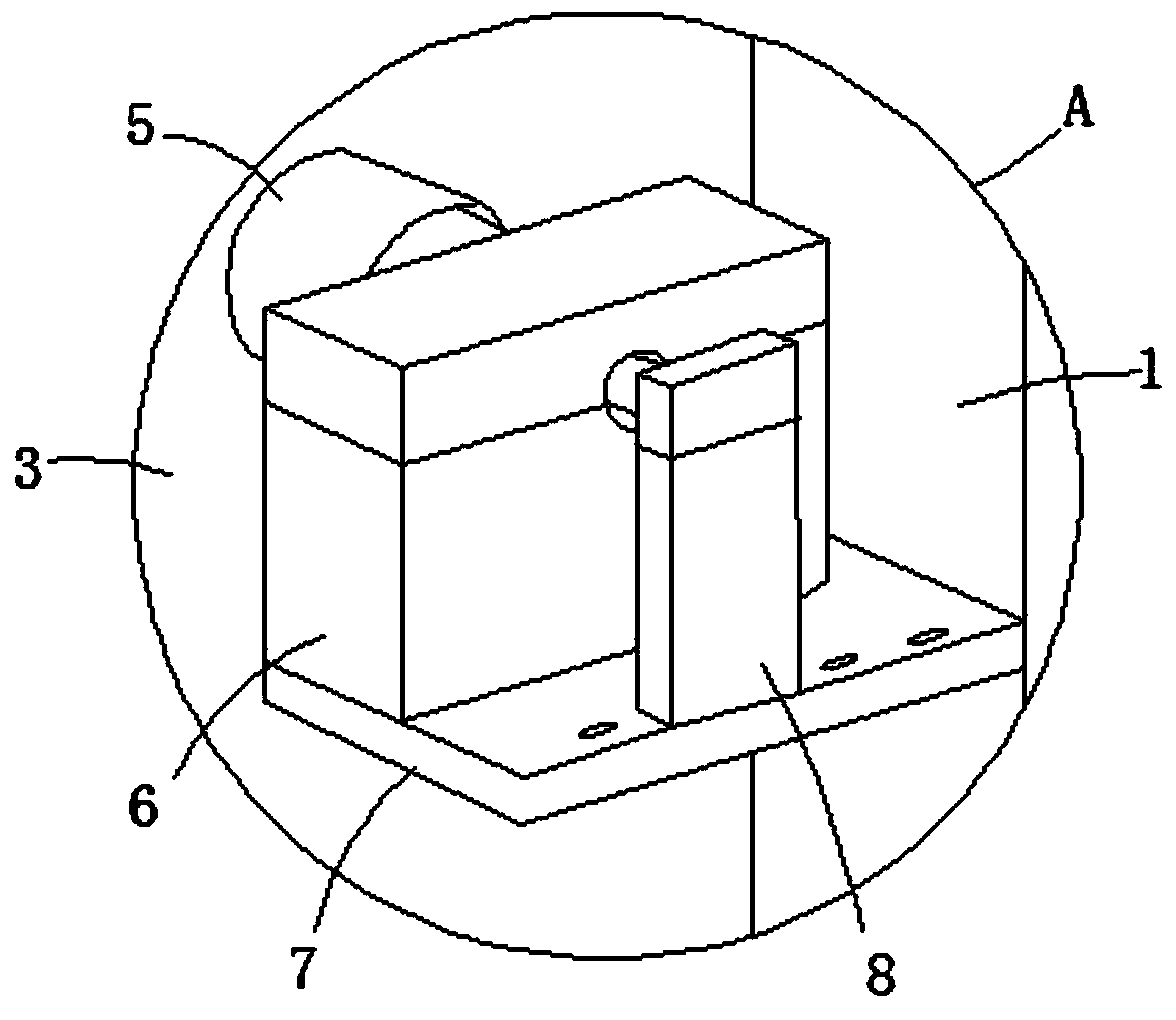

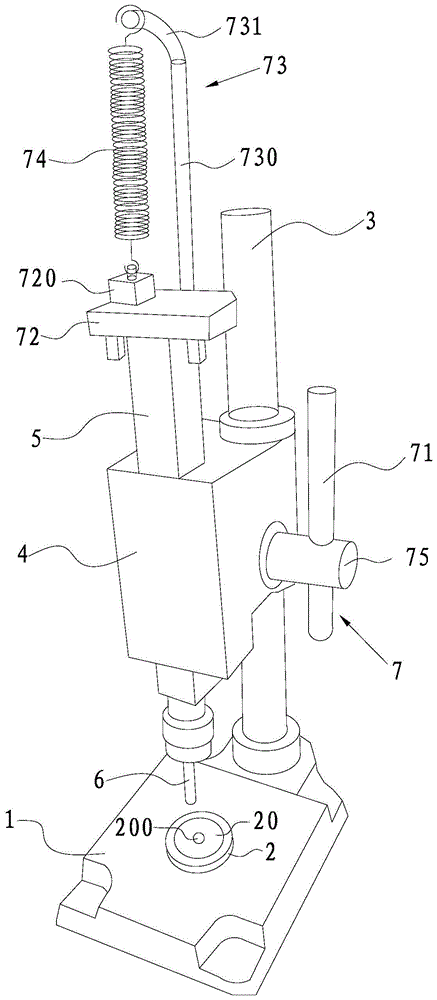

Manual puncher

The invention discloses a manual puncher. The manual puncher comprises a bottom mold arranged on a working table surface, a positioning column vertically arranged on the working table surface, a positioning module which is sleeved on the positioning column above the bottom mold, a core shaft which is parallel to the positioning column and arranged on the positioning module, a punching needle arranged at the lower end of the core shaft and an adjusting mechanism which is used for adjusting the core shaft to move vertically in the self length direction. The bottom mold is provided with a positioning slot for placing a part to be processed, the punching needle is disposed right above the positioning slot, the bottom of the positioning slot is provided with a hole matched with the punching needle. According to the manual puncher, the adjusting mechanism controls the core shaft to move vertically in the self length direction, so that the punching needle can penetrate the hole of the positioning slot of the bottom mold to achieve workpiece punching. The manual puncher is simple in structure, easy to operate and low in cost.

Owner:ZHANGJIAGANG XIAFEI PLASTIC

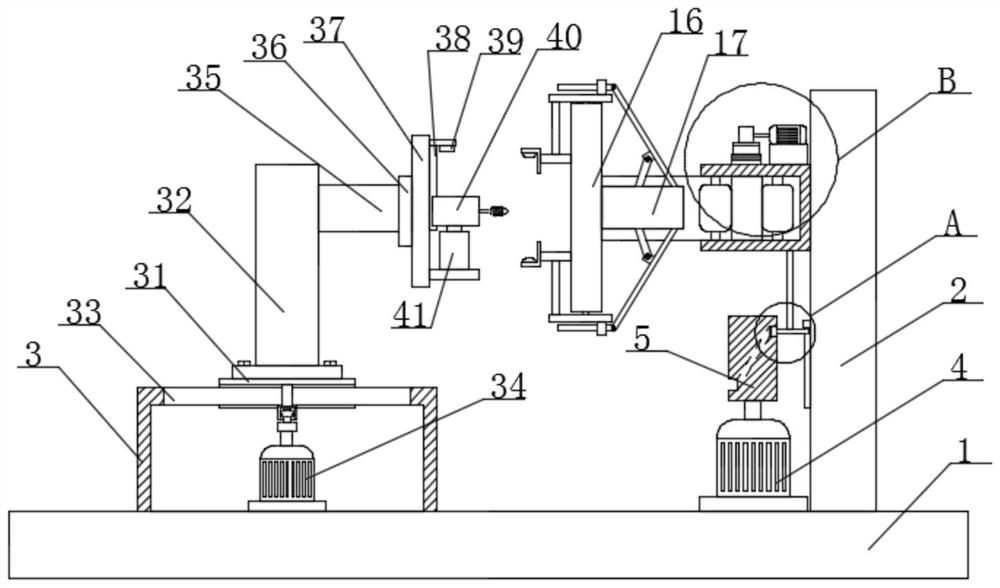

Drilling device for use in machining of air conditioner hanging plate and using method thereof

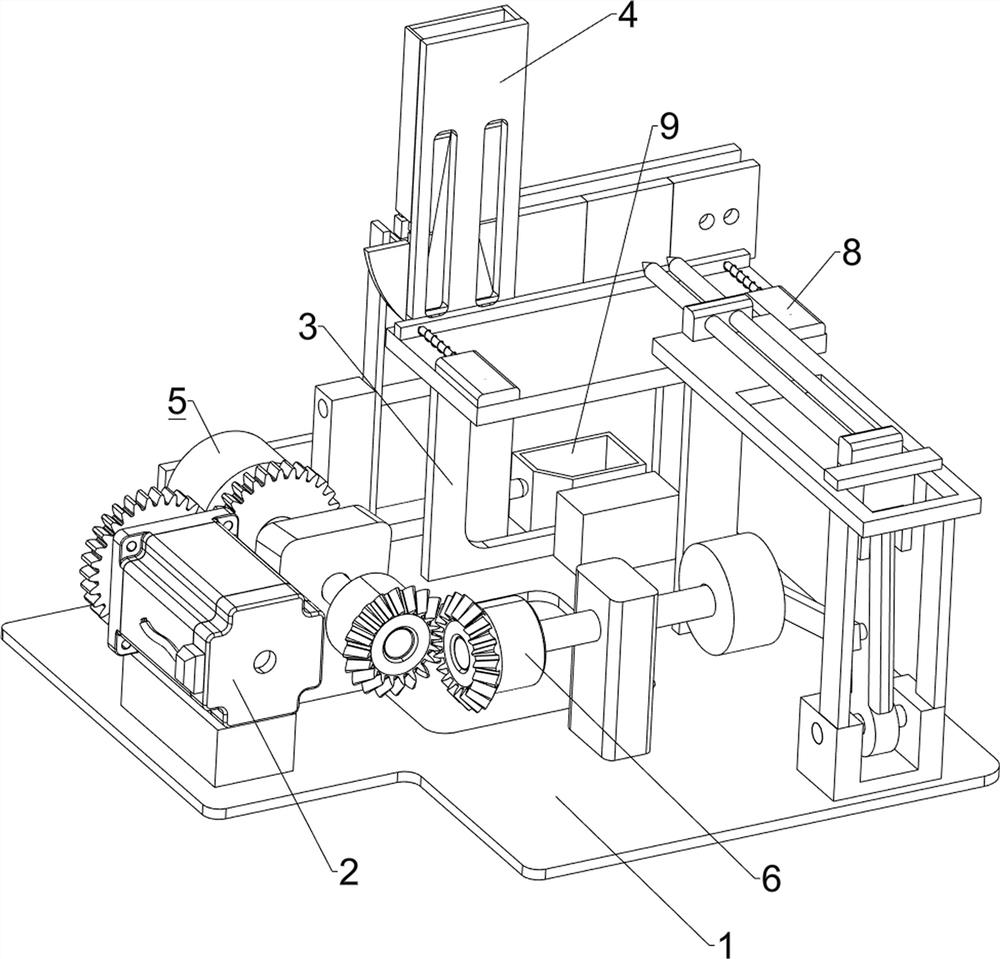

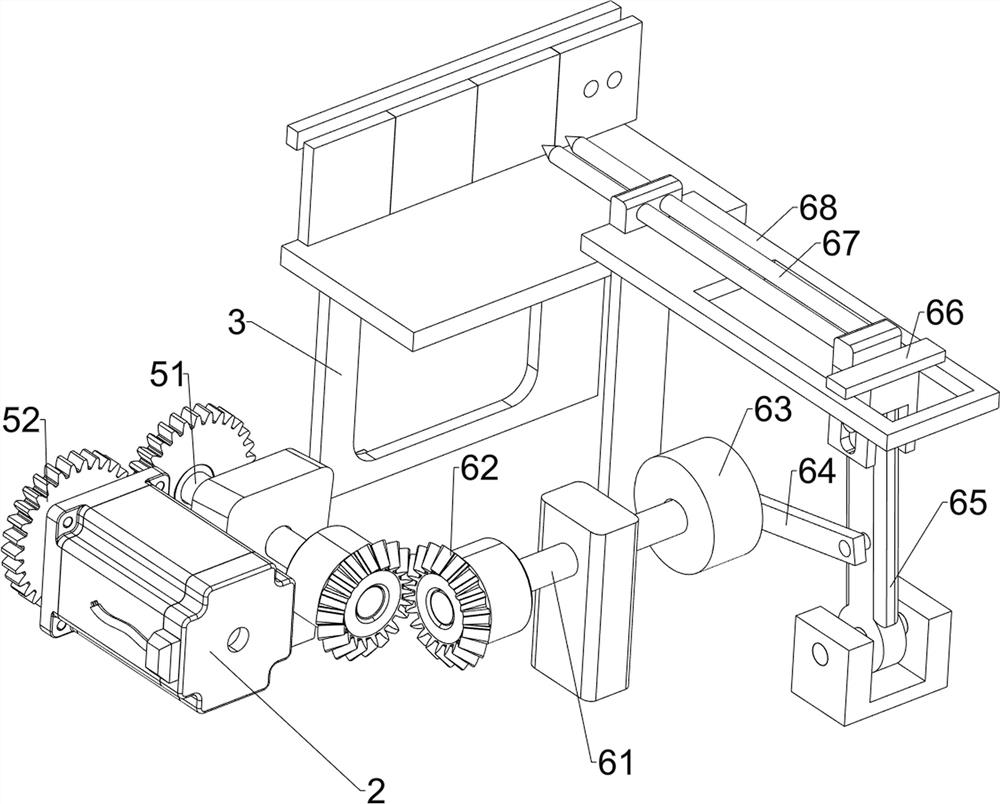

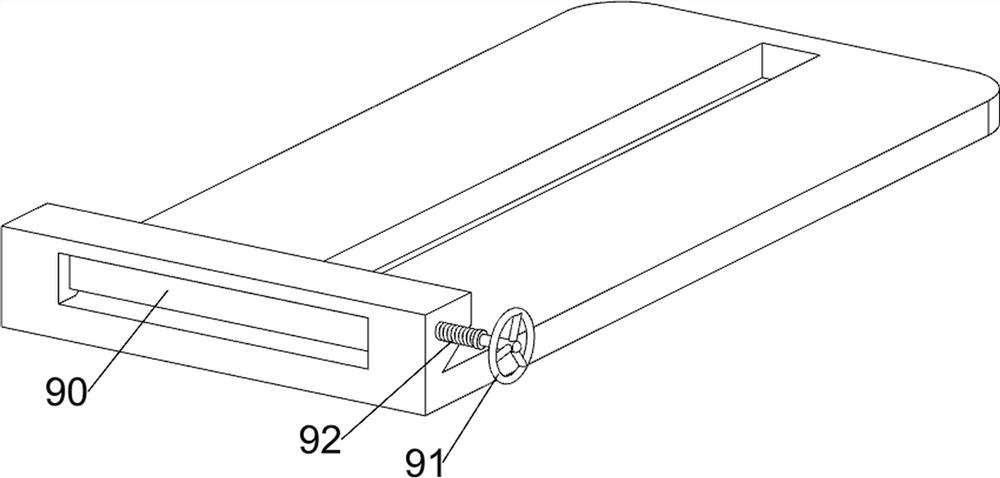

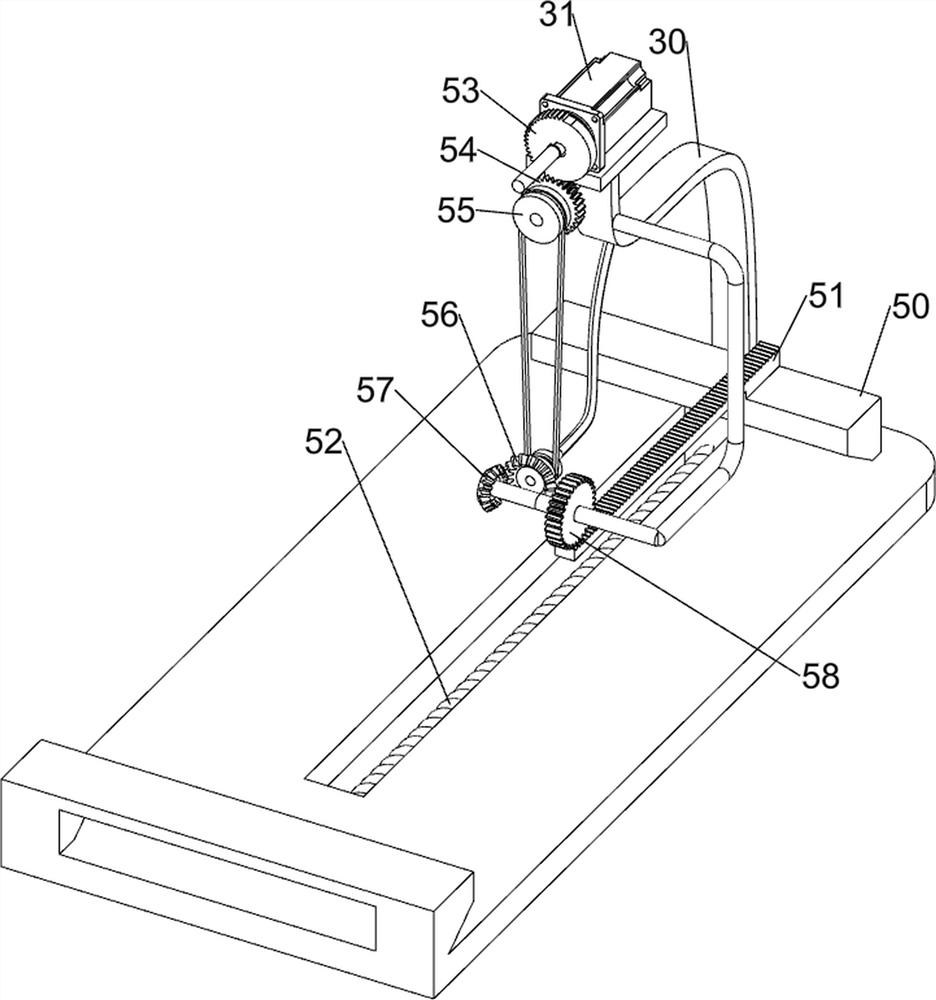

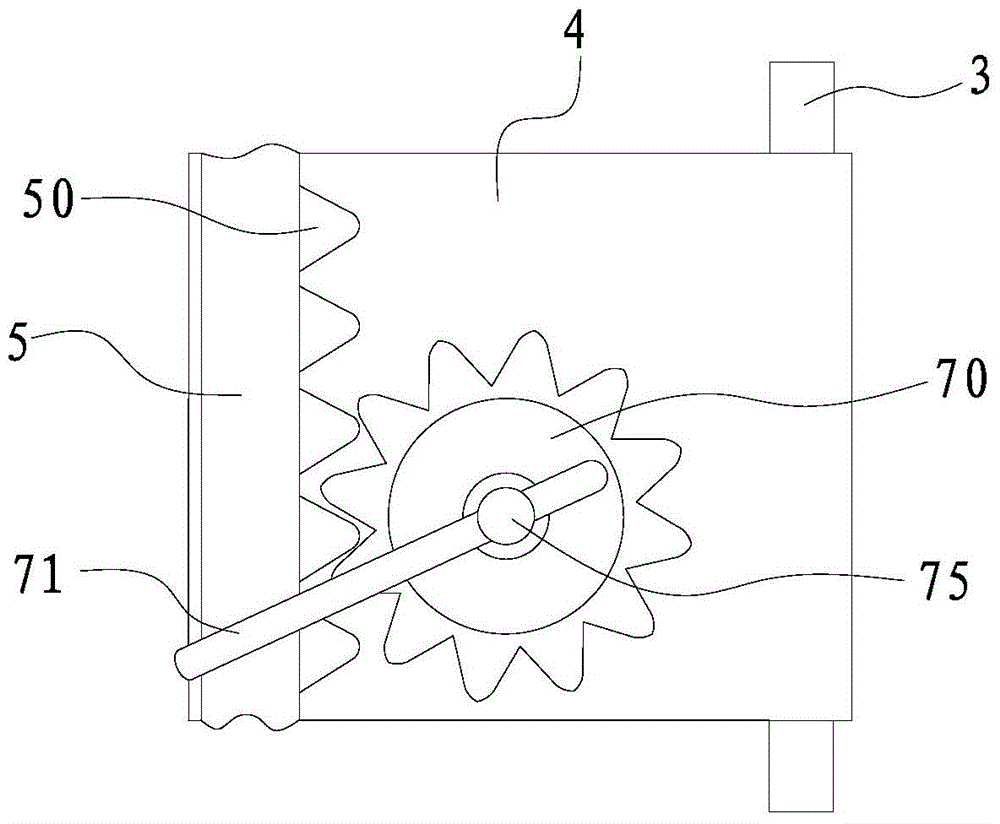

ActiveCN111761369AVertical position adjustmentLateral position adjustmentWork clamping meansMeasurement/indication equipmentsGear wheelElectric machinery

The invention discloses a drilling device for use in machining of an air conditioner hanging plate. The drilling device comprises a base, wherein a mounting column and a U-shaped frame are fixedly arranged on the top of the base respectively; the U-shaped frame is positioned on one side of the mounting column; a mounting frame is connected to the top of one side of the mounting column in a slidingway; a movable frame is connected to the mounting frame in a sliding way; a rack is fixedly arranged on the top of the movable frame; the rack is positioned above the mounting frame; a displacement motor is fixedly arranged on one side of the top of the mounting frame; a gear is fixedly arranged on an output shaft of the displacement motor; and the gear is meshed with the rack. The invention further discloses a using method. Through adoption of the drilling device, automatic clamping and positioning as well as position adjustment of a hanging plate to be drilled can be realized, and automaticdrilling of the hanging plate can be realized. Meanwhile, holes of any size can be formed in the hanging plate, so that great convenience is brought to use. At the same time, the working strength ofoperators can be lowered, so that the drilling device has good market popularization prospect.

Owner:江苏长达交通材料有限公司

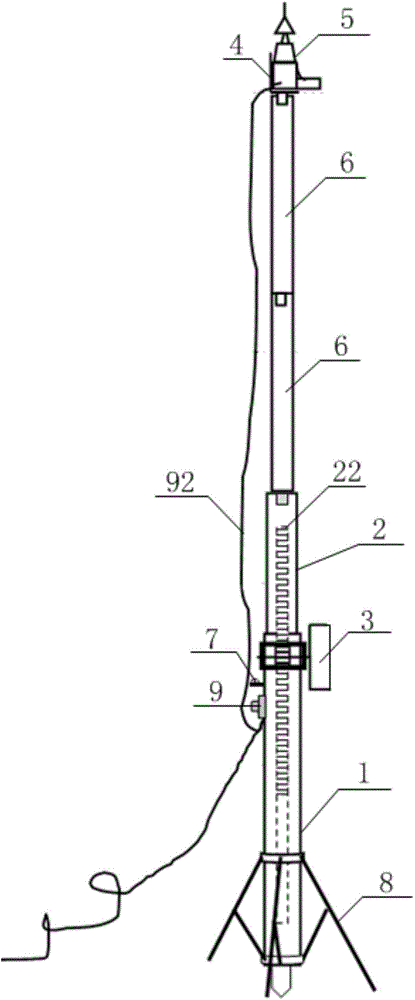

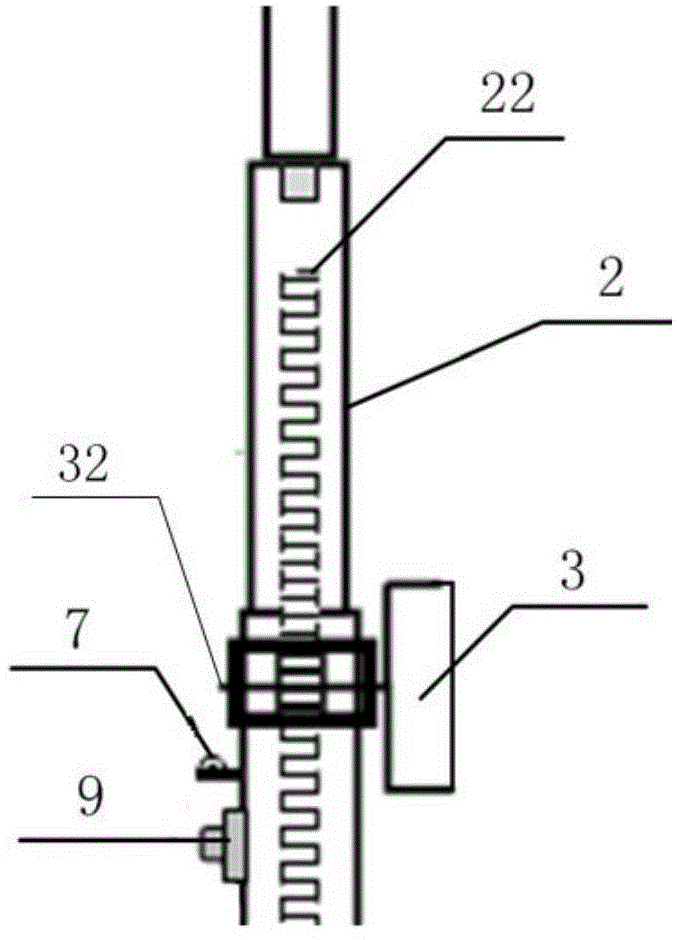

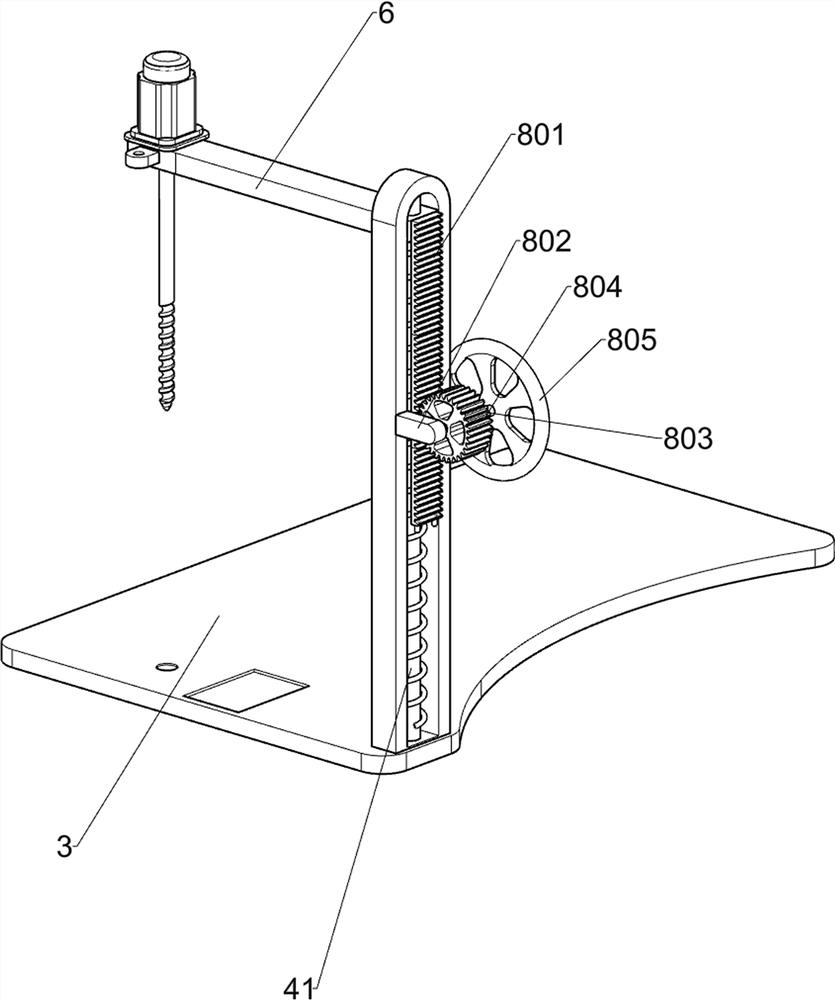

Portable drilling equipment

InactiveCN104439403ARealize punchingReduce leasePortable percussive toolsWork benchesGear driveGear wheel

The invention discloses portable drilling equipment and belongs to the technical field of building construction and architectural decoration. The portable drilling equipment solves the problems that cross operation cannot be conducted during existing drilling construction, time consumed for drilling is long and the risk that staff get injured is high in the construction process. According to the technical scheme, the portable drilling equipment comprises an outer tube, an inner tube, an adjusting gear, an electric hammer mounting frame and an electric hammer, wherein a track cavity is formed in the outer tube, and a mounting hole is formed in the outer tube; a linear rack is arranged on the outer wall of the inner tube, and the inner tube is mounted in the track cavity of the outer tube; the adjusting gear is mounted on the outer tube through a rotating shaft, the rotating shaft penetrates through the mounting hole, the adjusting gear is meshed with the linear rack, and the adjusting gear drives the inner tube to move along the track cavity when the adjusting gear is rotated; the electric hammer mounting frame is detachably connected with the upper end of the inner tube; the electric hammer is fixed to the electric hammer mounting frame, and a drill is vertically upward.

Owner:STATE GRID CORP OF CHINA +1

Grooving and perforating equipment for metal doors and windows

InactiveCN107552842AImplement slottingRealize punchingFeeding apparatusBoring/drilling componentsStable fixationWorking environment

The invention discloses a slotting and punching device for metal doors and windows, which comprises a working box, a workbench power box is fixedly connected to the middle of the bottom of the inner wall of the workbox, and a power motor is fixedly connected to the bottom of the inner wall of the workbench power box. The power motor is rotatably connected to a deceleration connector through an output shaft, and the output shaft of the deceleration connector is fixedly connected to a first pulley through a flat key, and the first pulley is rotatably connected to a second pulley through a belt. The present invention relates to metal door and window processing technology field. The metal door and window slotting and punching equipment solves the transmission and positioning of the workpiece, the change of the position of the workbench and the positioning of the punching device, ensures the stable fixing of the workpiece and the working environment in different directions, and ensures the stable positioning of the punching device , to ensure the accuracy of the workpiece and the stability of the drilling device moving up and down and the power output of the drill bit, and to ensure the quality and accuracy of its punching or slotting.

Owner:ZHEJIANG DEQING DETAI DOOR IND

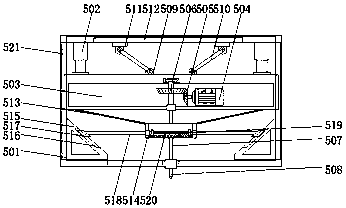

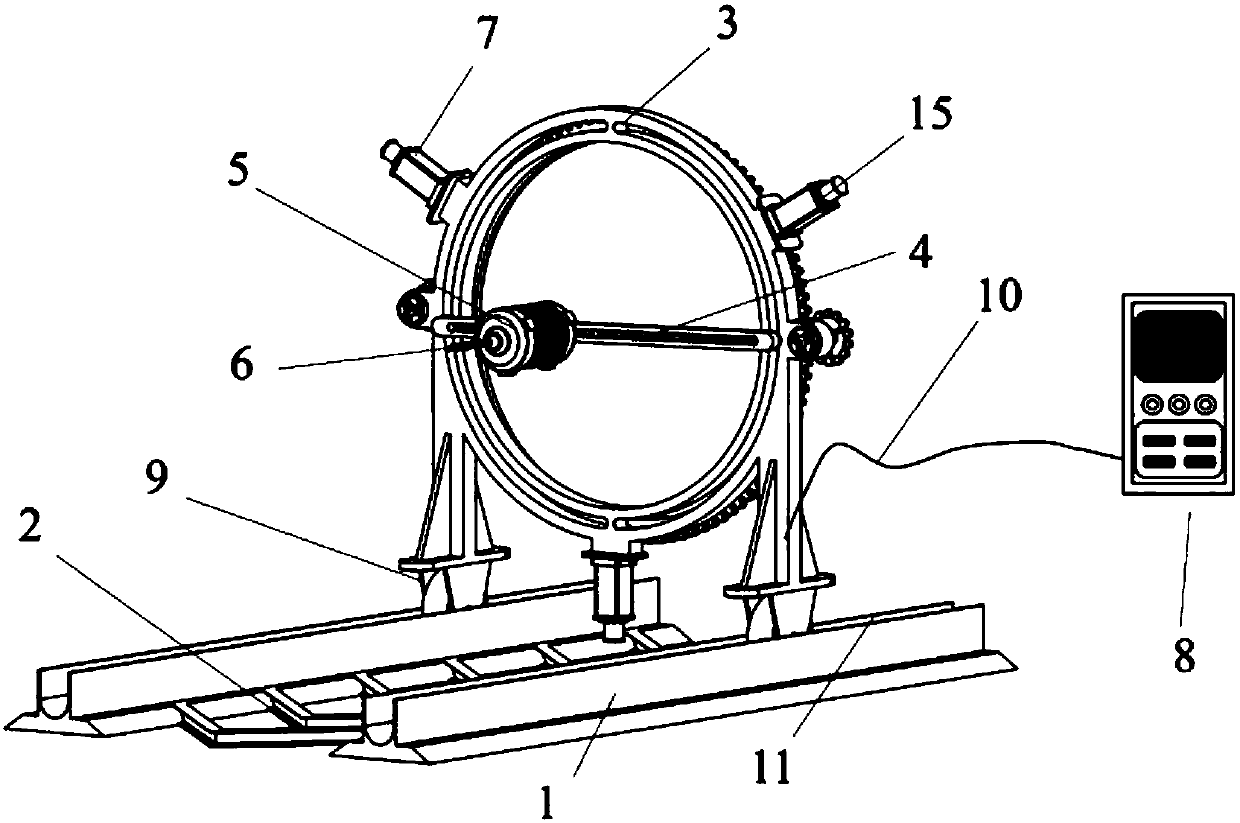

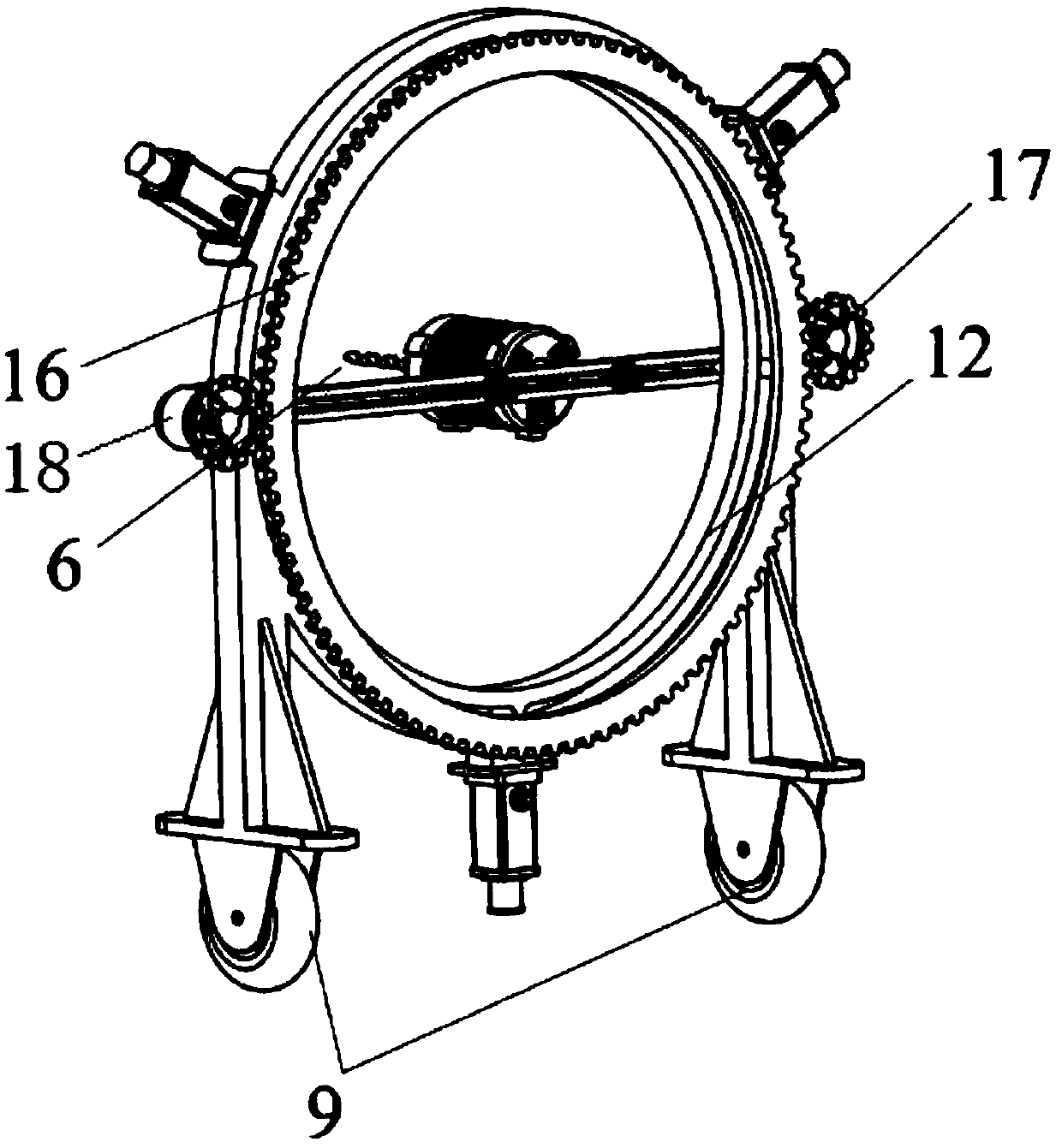

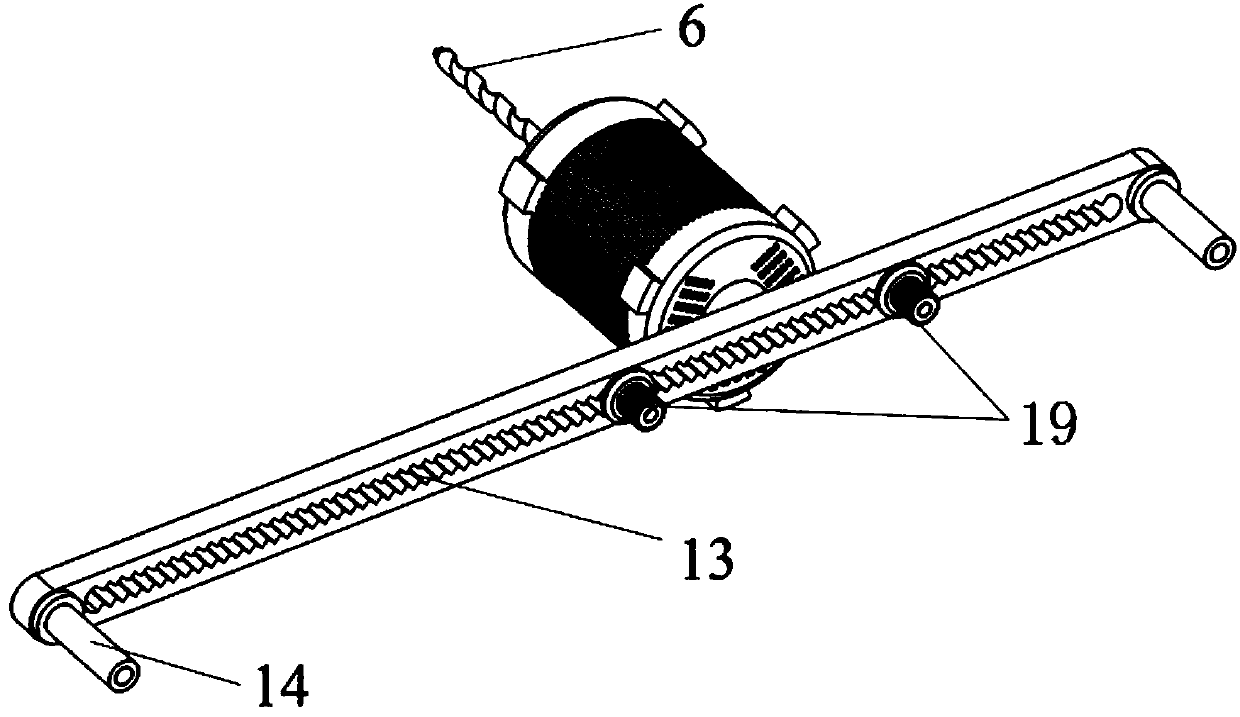

Miniature full cross section drill hole arrangement device for model test and application thereof

ActiveCN108020650AScientific and reasonable structure designHigh degree of automationEarth material testingEngineeringModel test

The invention relates to a miniature full cross section drill hole arrangement device for model test and application thereof. The device comprises a track mechanism, a drill hole mechanism and a controller, the drill hole mechanism is arranged on the track mechanism and moves along the track mechanism, the drill hole mechanism comprises a annular track part, a radial track part, a drill part and asupporting part, the two ends of the radial track part are located on the annular track part and rotates along the annular track part in a circumferential direction, the drill part is arranged on theradial track part and moves along the radial track part in a straight line, the supporting part is located on the outer side of the annular track part and used for fixing the whole drill hole mechanism, and the controller is respectively connected with the annular track part, the radial track part, the drill part and the supporting part. According to the drill hole arrangement device, the structure design is scientific and reasonable, the degree of automation is high, the problem that by a traditional mode, drilling in the full cross section of a model experimental tunnel is difficult is solved, the precision and the efficiency of drilling are high, the coverage of the full cross section of the model experiment and drilling at any position by the drill hole mechanism can be achieved, thedevice is suitable for experimental models with various specifications.

Owner:SHANDONG UNIV

Wood board stamping and punching equipment for building materials

PendingCN112092109AAutomatic movementHole position specificationStationary drilling machinesBark-zones/chip/dust/waste removalPunchingArchitectural engineering

The invention relates to punching equipment, in particular to wood board stamping and punching equipment for building materials. According to the wood board stamping and punching equipment for the building materials, the wood strip punching precision can be improved, and the risk of workers is reduced. The wood board stamping and punching equipment for the building materials comprises a bottom plate, a servo motor, a mounting plate, a discharging box, a pushing and blocking mechanism and a punching mechanism; the servo motor is installed at one side of the bottom plate; the mounting plate is arranged on the bottom plate; the discharging box is arranged at the side, close to the servo motor, of the mounting plate; the pushing and blocking mechanism is arranged at the side, close to the mounting plate, of the bottom plate; and the punching mechanism is arranged on the mounting plate. According to the wood board stamping and punching equipment, by means of the design of the pushing and blocking mechanism, wood boards are pushed leftwards, the wood boards are automatically moved so as to be matched with operation of the punching mechanism, the wood boards do not need to be moved manually, and the punching position of each wood board is more standard.

Owner:邹自强

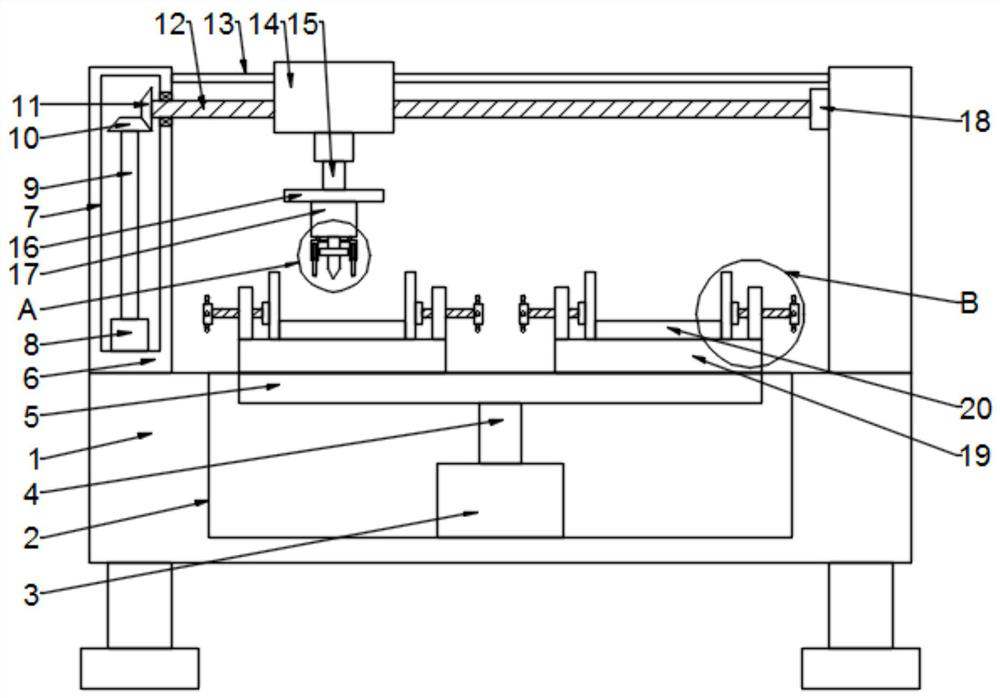

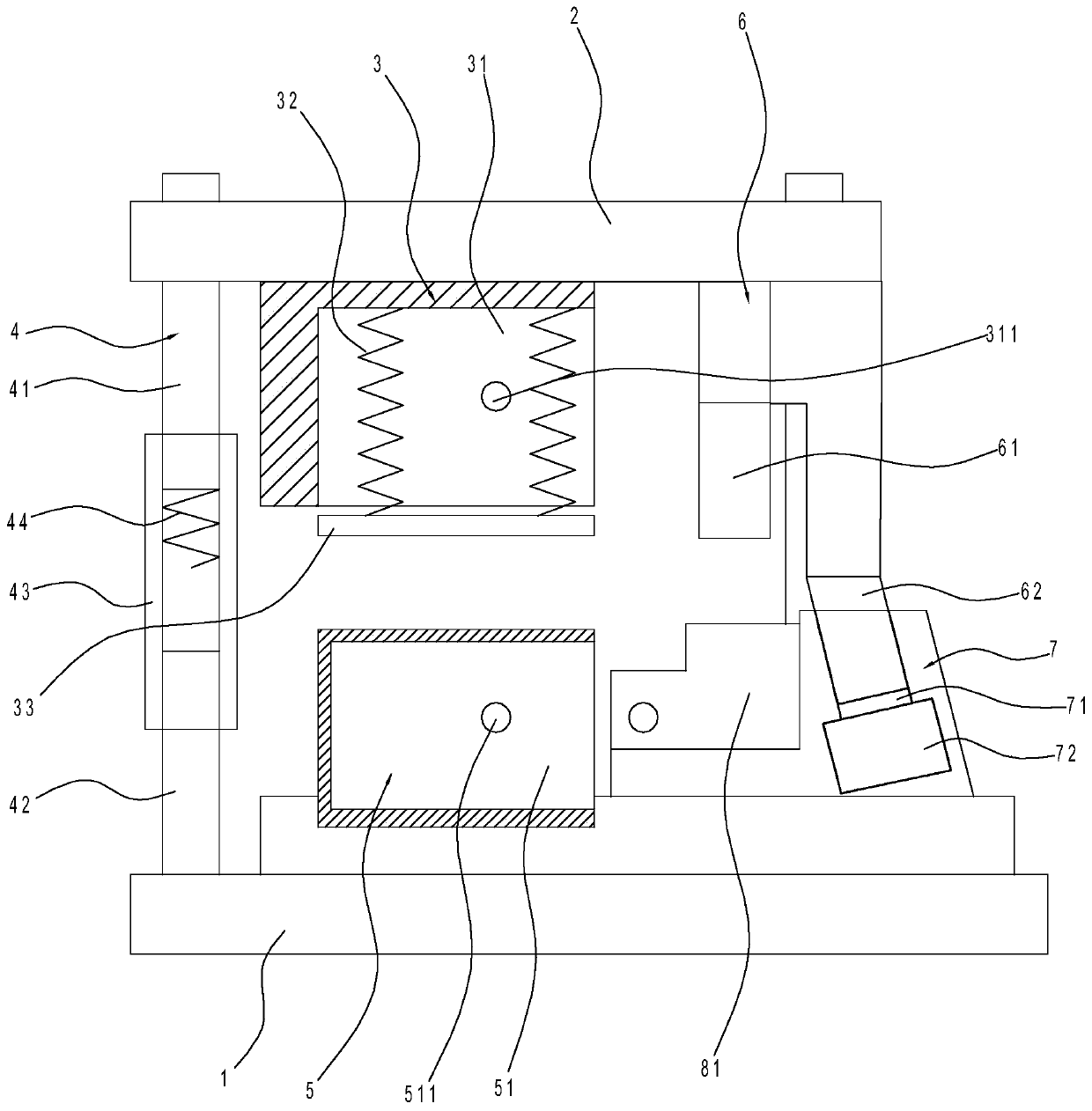

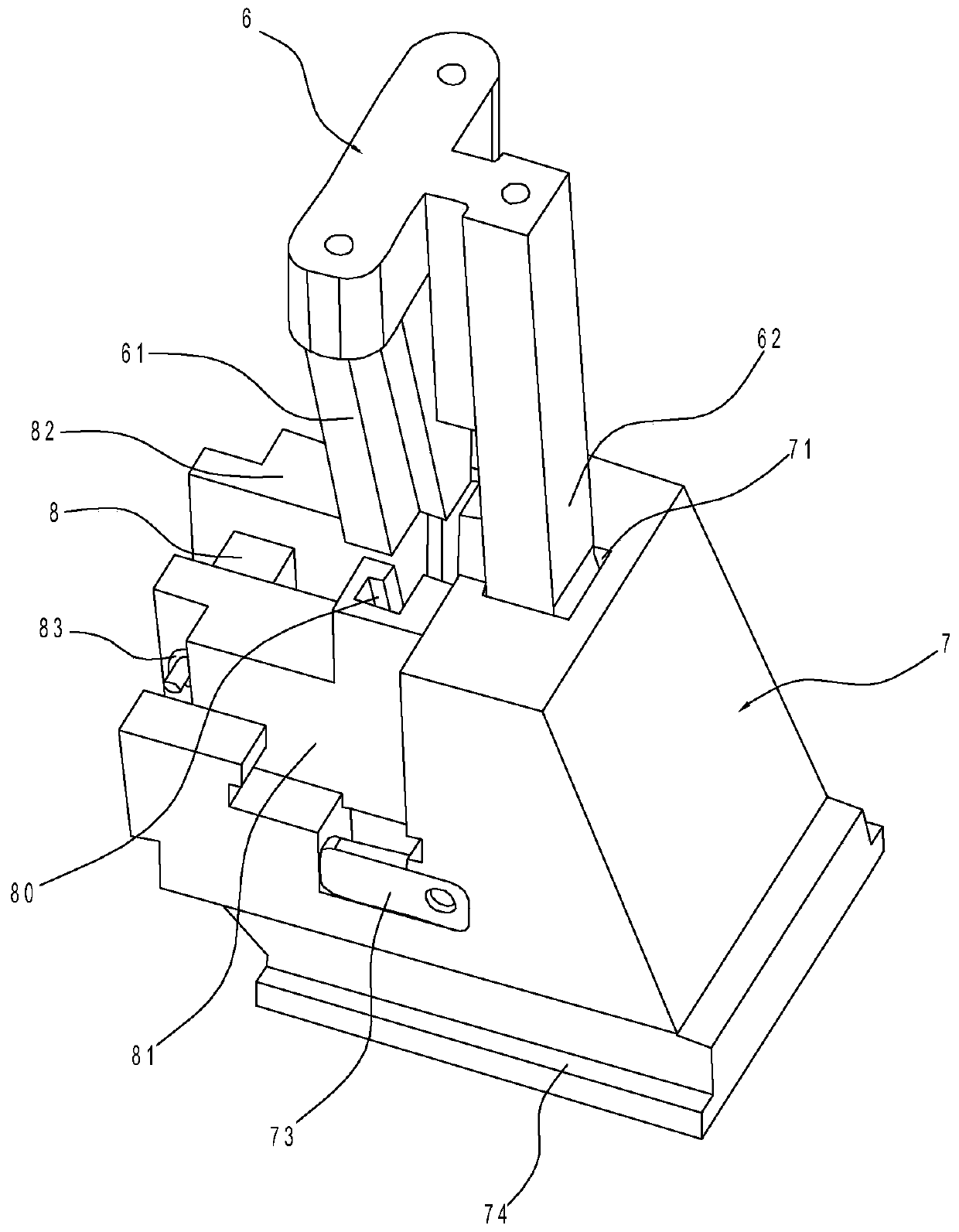

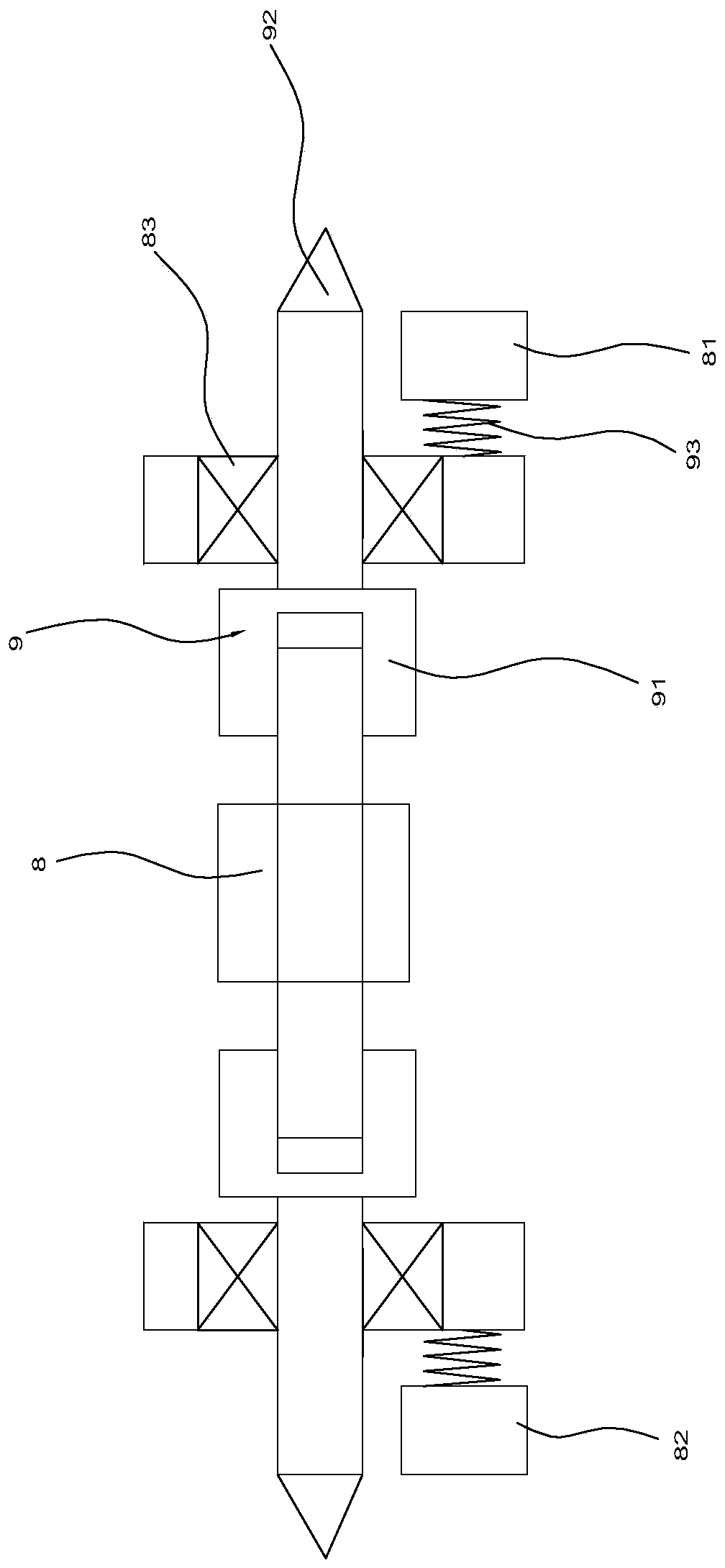

Precise perforating equipment used for notebook computer bottom plate

PendingCN112828343AAchieve clampingRealize punchingFeeding apparatusPositioning apparatusEngineeringMechanical engineering

The invention relates to perforating equipment, in particular to precise perforating equipment used for a notebook computer bottom plate. The precise perforating equipment used for the notebook computer bottom plate is high in automation degree, high in safety and capable of cleaning the bottom plate. The precise perforating equipment used for the notebook computer bottom plate comprises a base, a perforating mechanism and a clamping mechanism. An operation table is arranged on the base. The perforating mechanism is arranged on the operation table. The clamping mechanism is arranged on the perforating mechanism. The bottom plate is clamped through the clamping mechanism, and then the bottom plate is perforated under cooperation with the perforating mechanism; and a pushing mechanism is arranged, and then the bottom plate is automatically pushed leftwards.

Owner:何家焕

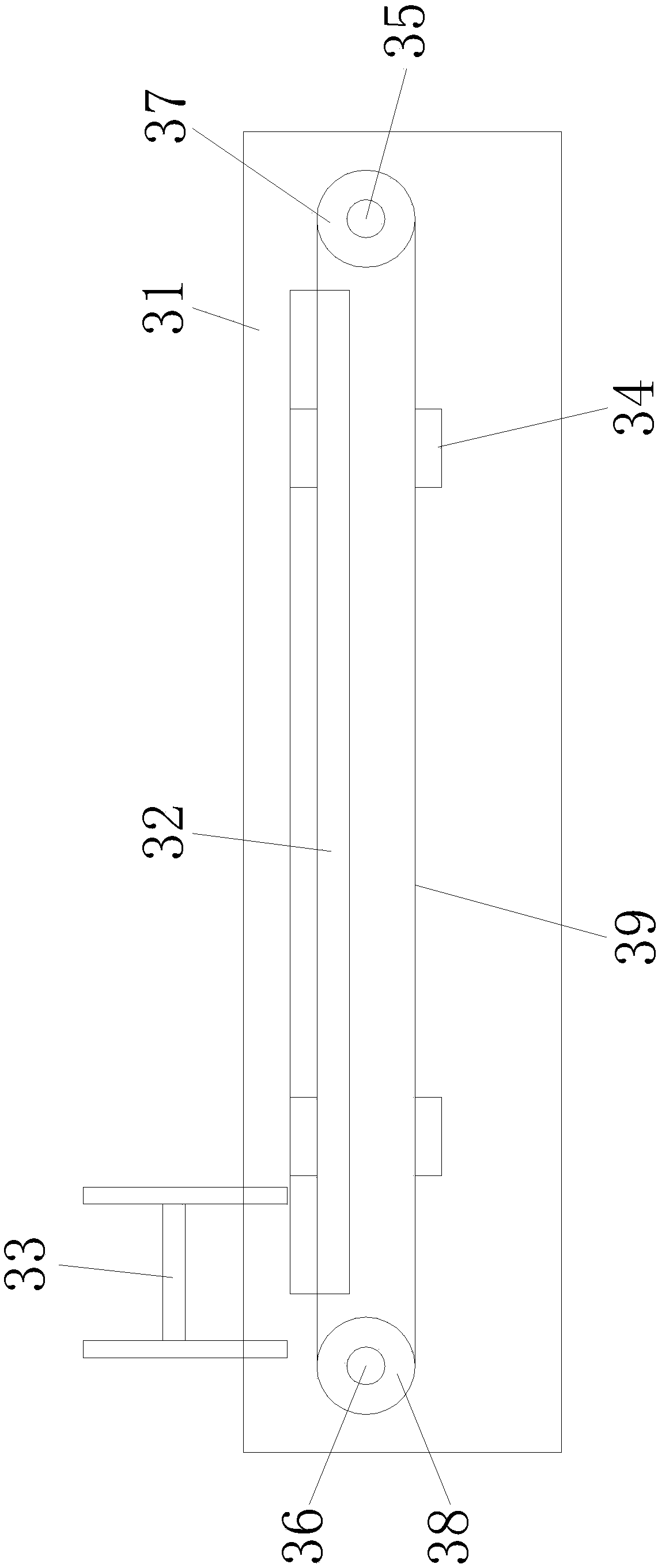

Fabric punching device

InactiveCN109159207ARealize intermittent accurate feedingReduce tensionMetal working apparatusPunchingDrive shaft

The invention provides a fabric punching device, and belongs to the technical field of fabric processing. The fabric punching device comprises a punching mechanism and a fabric supply mechanism; the fabric supply mechanism comprises an unreeling guide assembly, a reeling guide assembly, a supply drive assembly, and an unreeling pressing roller assembly; a fabric unreeling roller is rotatably arranged on the rear side of a supply rack, a fabric reeling roller is rotatably arranged on the front side of the supply rack, a rotating disc of the punching mechanism is rotatably arranged on an upper bearing ring of an upper disc base and a lower bearing ring of a lower disc base, a lever is clamped in a lever mounting groove of the rotating disc, a left pin shaft at the left end of the lever is inserted into a lower U groove in the lower end of a bearing frame of a punching lower supporting plate, punching nails are evenly distributed at the upper end of the punching lower supporting plate, adrive rod is arranged on a drive rod guide base in an up and down sliding manner, the lower pin shaft is inserted into a right U groove in the right end of the lever, and a drive cam is arranged at one end of a drive shaft. Punching machining of fabric can be efficiently achieved, punching efficiency is high, and reliability is good.

Owner:桐乡市宏力纺织股份有限公司

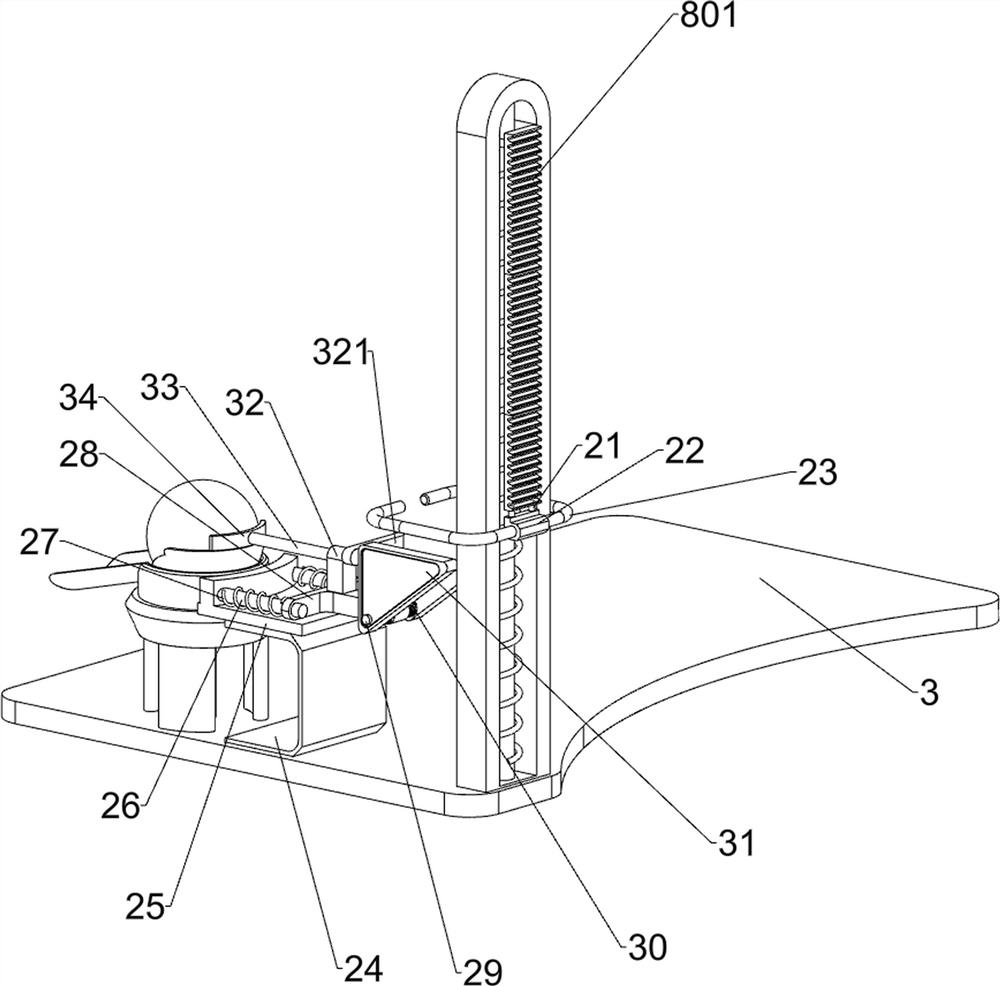

Energy-saving and environment-friendly auxiliary punching device for table tennis balls

InactiveCN113829430ARealize punchingNot easy to shakeMetal working apparatusStructural engineeringWorkbench

The invention relates to a punching device, in particular to an energy-saving and environment-friendly auxiliary punching device for table tennis balls. The energy-saving and environment-friendly auxiliary punching device for the table tennis balls is high in safety and capable of achieving intermittent discharging. The energy-saving and environment-friendly auxiliary punching device for the table tennis balls comprises a bottom plate, a workbench, a first sliding groove plate and a first guide rod, wherein supporting seats are symmetrically arranged on the bottom plate, the workbench is arranged between the tops of the two supporting seats, the first sliding groove plate is arranged on one side of the workbench, and the first guide rod is arranged in the first sliding groove plate. According to the energy-saving and environment-friendly auxiliary punching device, table tennis balls can be placed through a placing mechanism, then a mounting plate is driven to slide downwards on the first guide rod by rotating a downward pressing mechanism, the mounting plate slides downwards to drive a drill bit to make contact with the table tennis balls, and then the table tennis balls are punched.

Owner:黄春爱

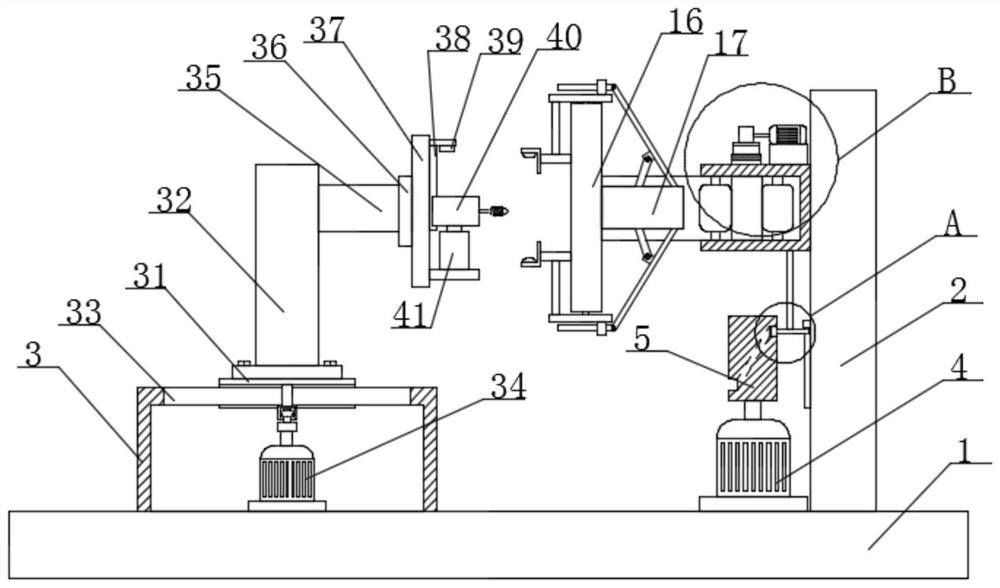

Steel pipe cutting and punching machine

ActiveCN112157436ARealize punchingAchieve reductionMetal sawing devicesOther manufacturing equipments/toolsSteel tubeElectric machinery

The invention discloses a steel pipe cutting and punching machine. The steel pipe cutting and punching machine comprises a shell system, a propelling system, a moving system, a punching system, a mainbody system and a driving system, the shell system is a base device, the shell system is a mounting platform of the moving system and the main body system, the moving system is a mounting platform ofthe propelling system, the shell system is a mounting platform of the driving system, the punching system is an mounting platform of the driving system, a steel pipe is placed on the shell system andthen fixed to the propelling system, the punching system punches the steel pipe, the head of the steel pipe is placed in the main body system, the main body system cuts the steel pipe, a steering motor on the main body system can control the steel pipe to rotate, a propelling motor of the propelling system can control translation of the steel pipe to achieve positioning of the steel pipe, and themoving system can be separated from the shell system to independently move so as to facilitate maintenance.

Owner:QINGDAO HUIJINTONG ELECTRIC POWER EQUIP

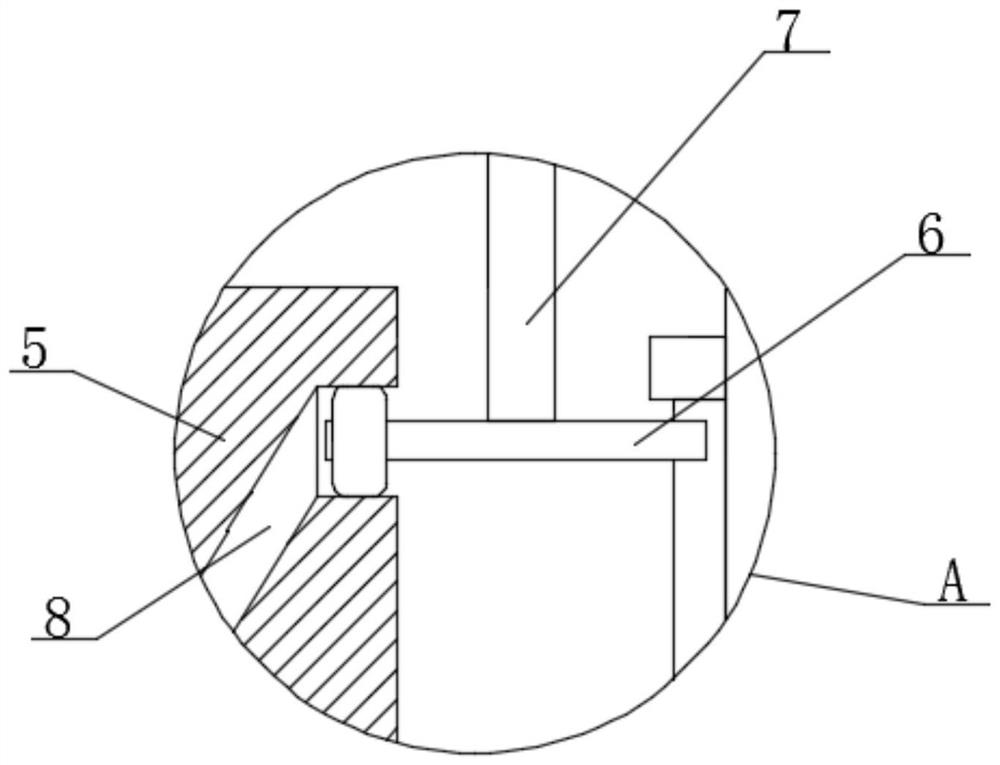

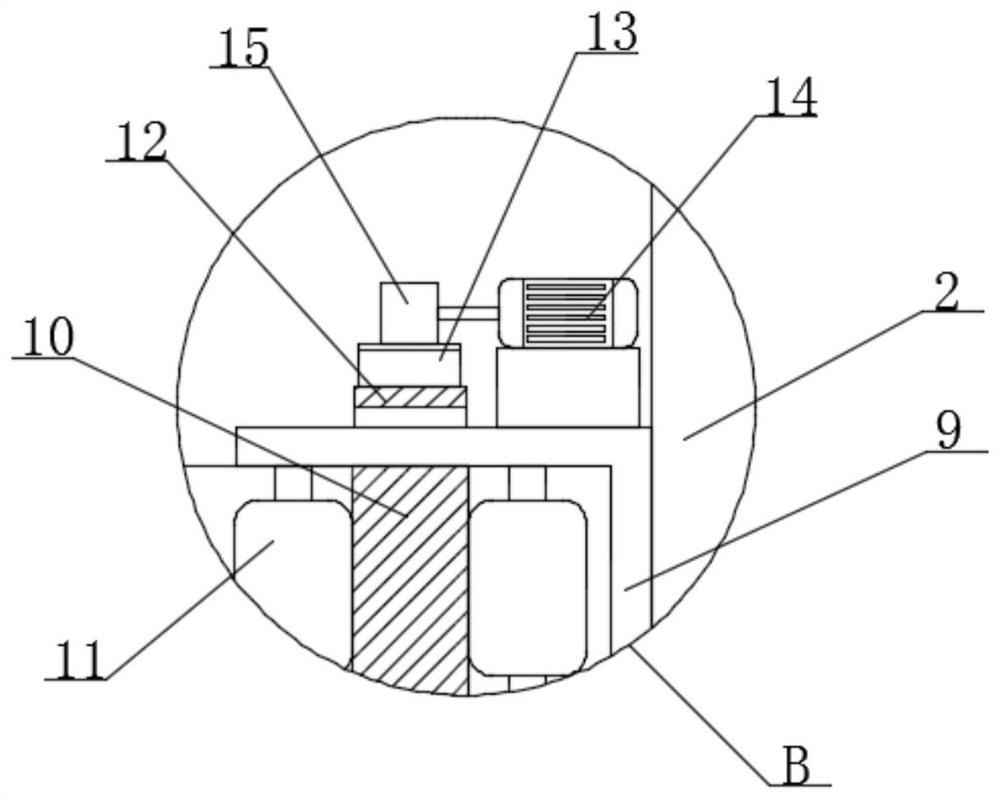

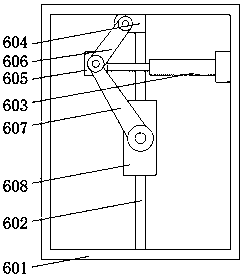

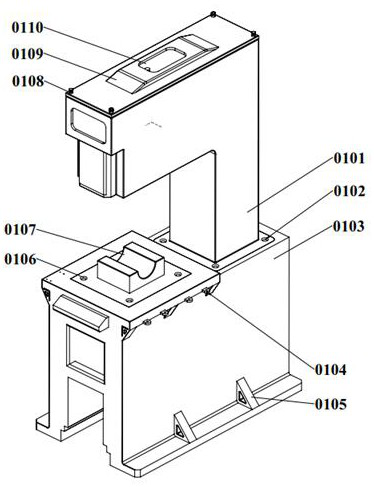

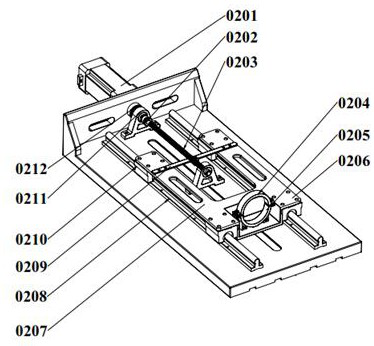

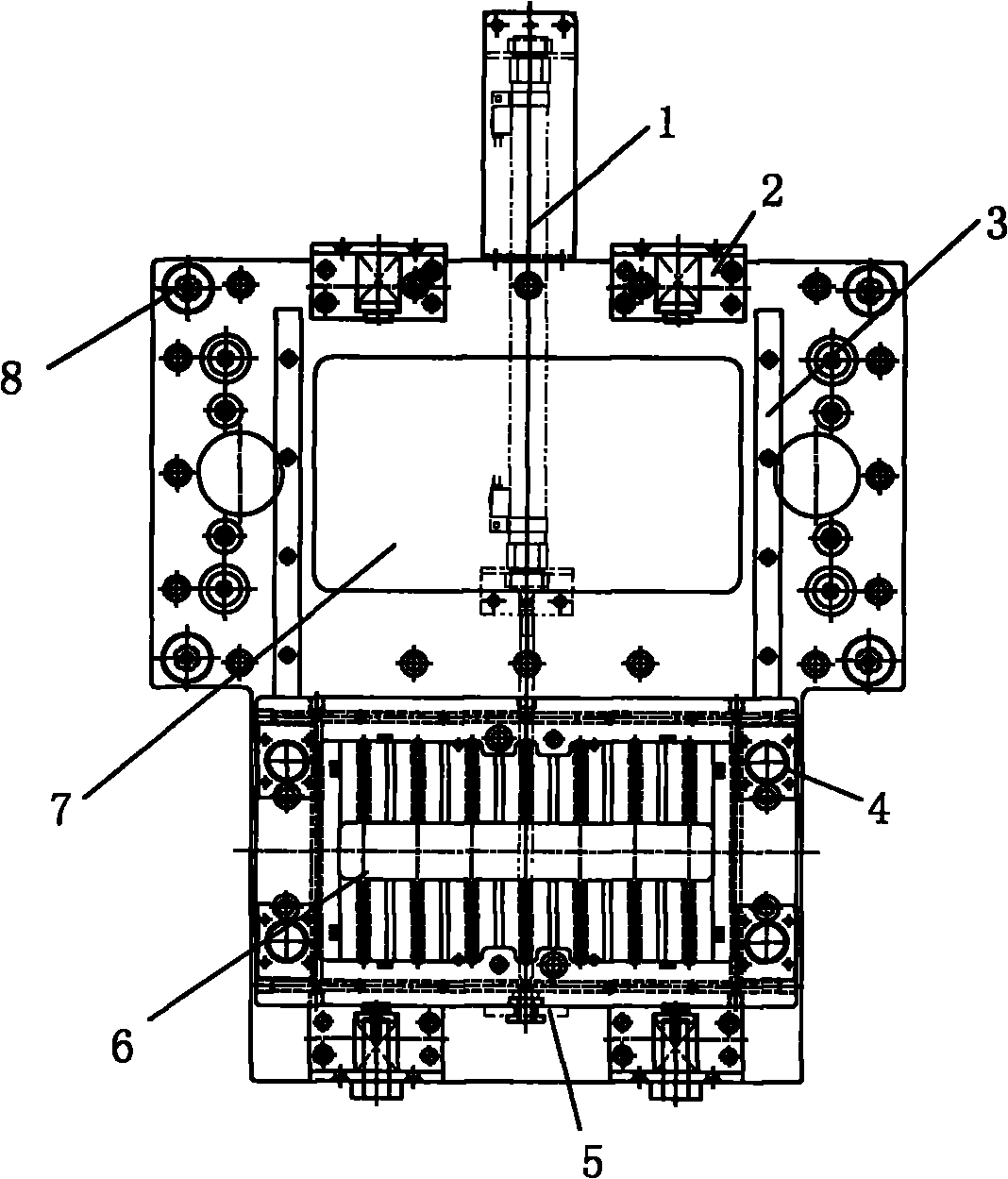

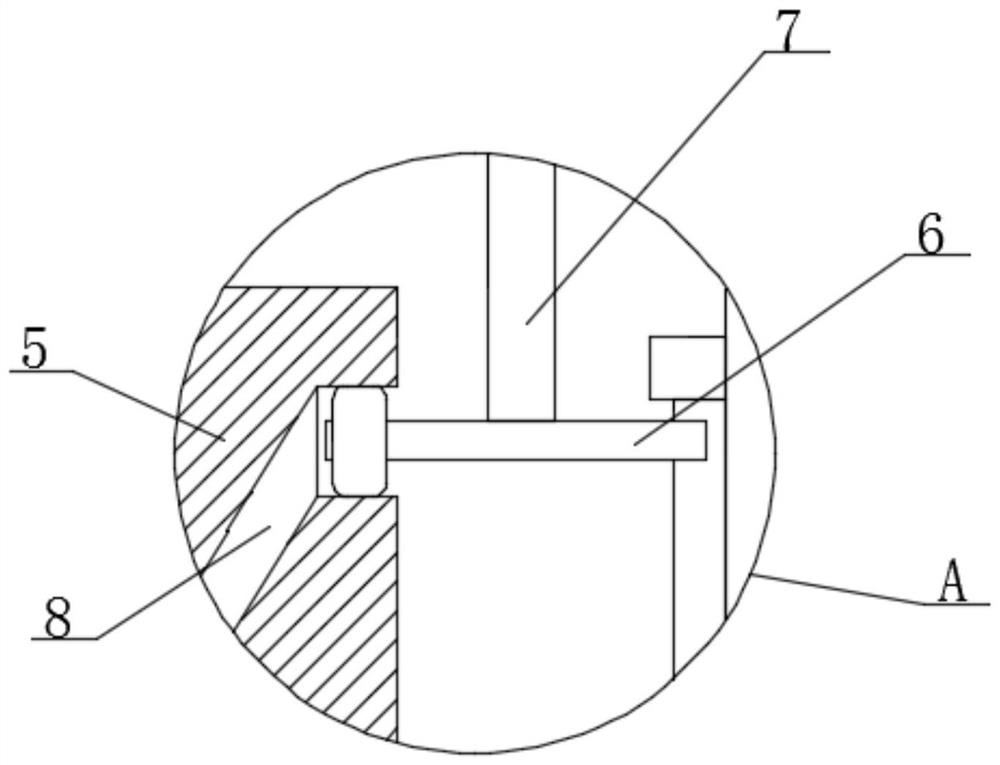

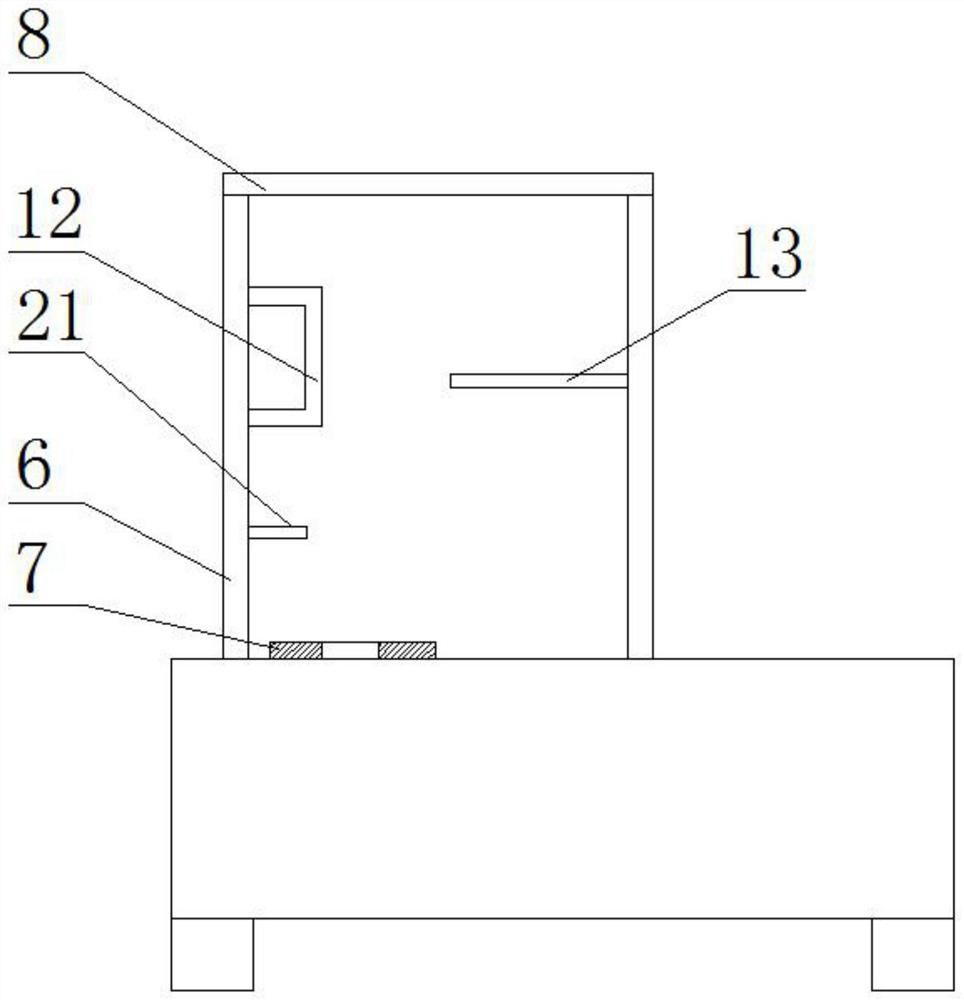

Large scale integrated (LSI) circuit swash runner die with drawer type structure

The invention discloses a large scale integrated (LSI) circuit swash runner die with a drawer type structure, comprising a stand (8), a convex die (7), a concave die (6) and an air cylinder (1), wherein two sides below the stand (8) are respectively provided with a linear guide rail (3) extending out of the stand (8), and the two linear guide rails (3) form a slide way; two sides of the concave die (6) are respectively provided with a slide block (4); the air cylinder (1) is fixed on the stand (8); and the piston rod of the air cylinder (1) is connected with the end part of the concave die (6) to push the concave die (6) to slide in the slide way. In the invention, operating personnel operates outside the stand and cannot be injured on hands while closing the die, thereby the safety is greatly increased.

Owner:TONGLING TRINITY TECH

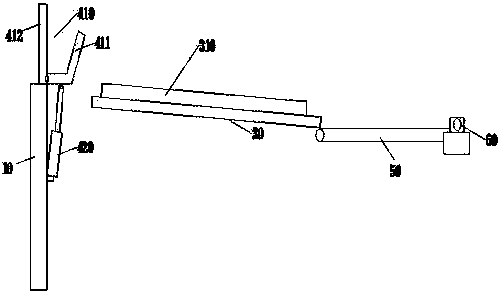

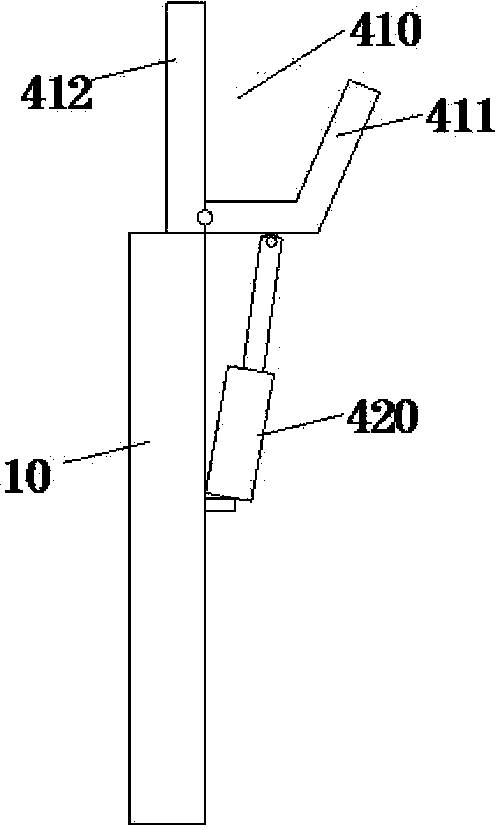

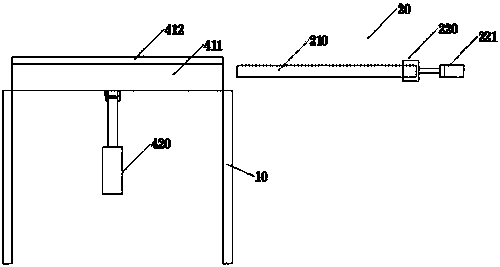

Paper pipe discharging device

InactiveCN109849088ASimple structureImprove efficiencyMetal working apparatusConveyor partsPulp and paper industry

The invention discloses a paper pipe discharging device. The device comprises a rack, a paper pipe delivery device and a discharging platform which is obliquely arranged at the front end of the paperpipe delivery device, a delivery groove which is used for collecting paper tubes pushed by a transporting device is formed in the upper portion of the discharging platform, the delivery groove comprises a cornered moving plate and a vertically arranged fixing baffle, the rear side end of the moving plate is hinged to the fixing baffle, the lower end of the moving plate is provided with a driving air cylinder which is used for driving the moving plate to rotate around a hinge part, the driving air cylinder is fixed to the rack, and a telescopic rod of the driving air cylinder is hinged to the bottom of the moving plate. The device has the advantages that the structure is simple, the feeding of the paper tubes can be conveniently achieved to make subsequent hole punching of the paper tubes convenient, and the efficiency is high.

Owner:常州钟楼高新技术创业服务有限公司

Industrial iron bowl punching equipment

PendingCN112496131ARealize punchingEasy to removeMetal-working feeding devicesStripping-off devicesPunchingStructural engineering

The invention relates to punching equipment, in particular to industrial iron bowl punching equipment. By means of the industrial iron bowl punching equipment, the labor intensity of workers can be relieved, and iron bowls do not need to be manually taken down. The industrial iron bowl punching equipment comprises a base, a workbench, a punching mechanism and a taking mechanism, wherein a servo motor is arranged at the top of the base, the workbench is arranged at the top of the base, the punching mechanism is arranged on the base, and the taking mechanism is arranged on the punching mechanism. According to the industrial iron bowl punching equipment, the servo motor is started to enable the punching mechanism to operate, and then punching of the iron bowls is performed through the cooperation of the punching mechanism and the taking mechanism. The taking mechanism can attract the iron bowls obtained after punching, then the iron bowls are separated from the punching mechanism, and then the workers can conveniently take down the iron bowls.

Owner:谢艳珍

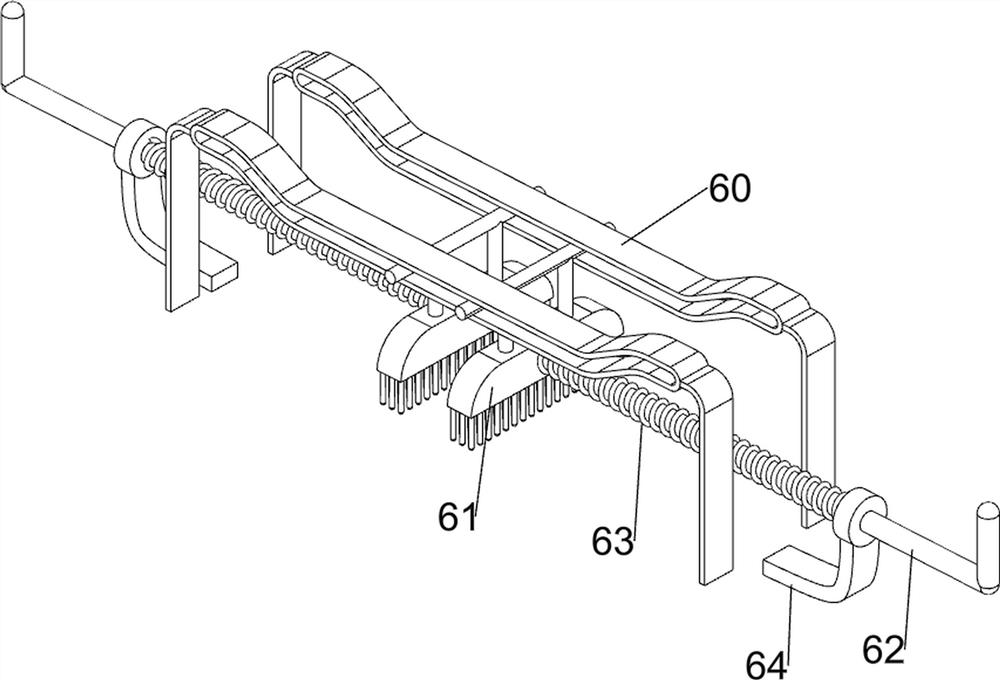

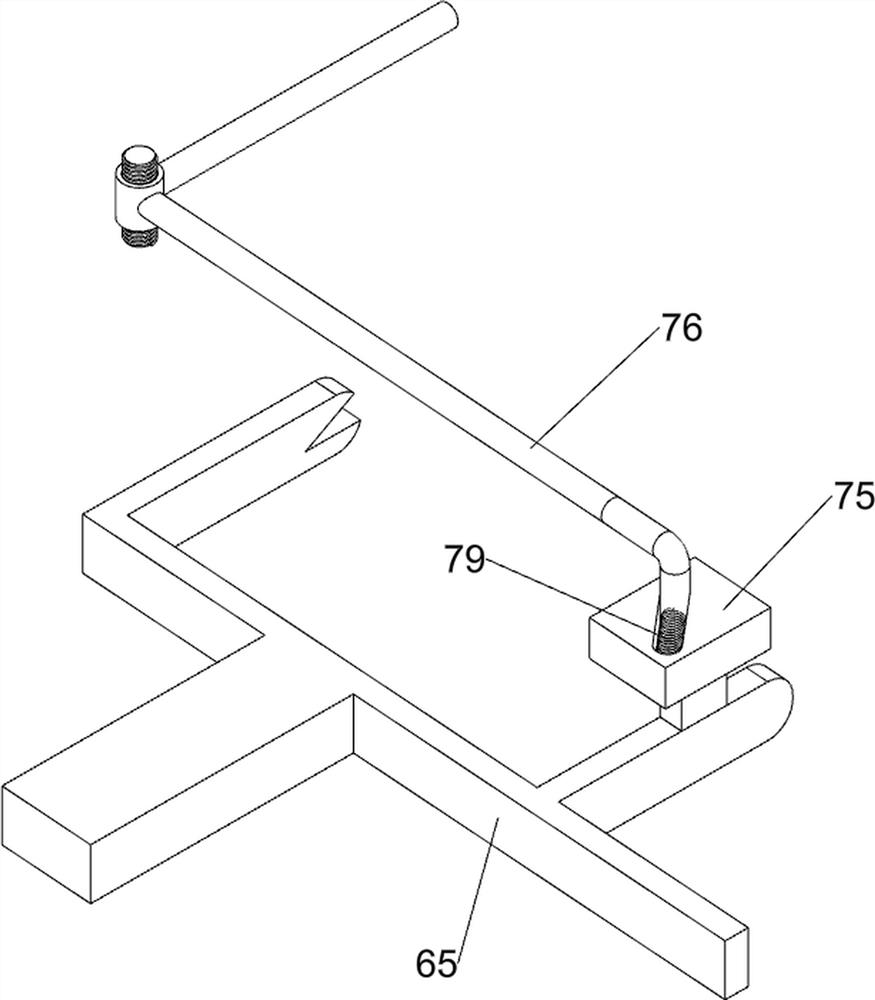

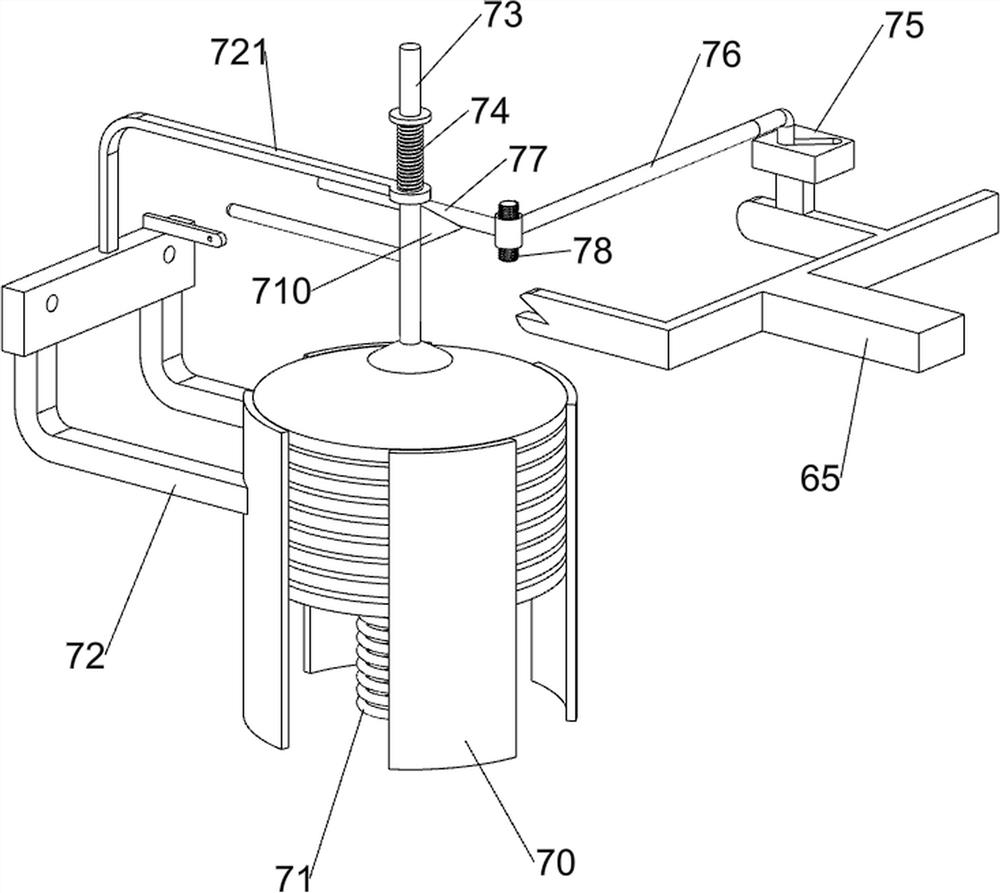

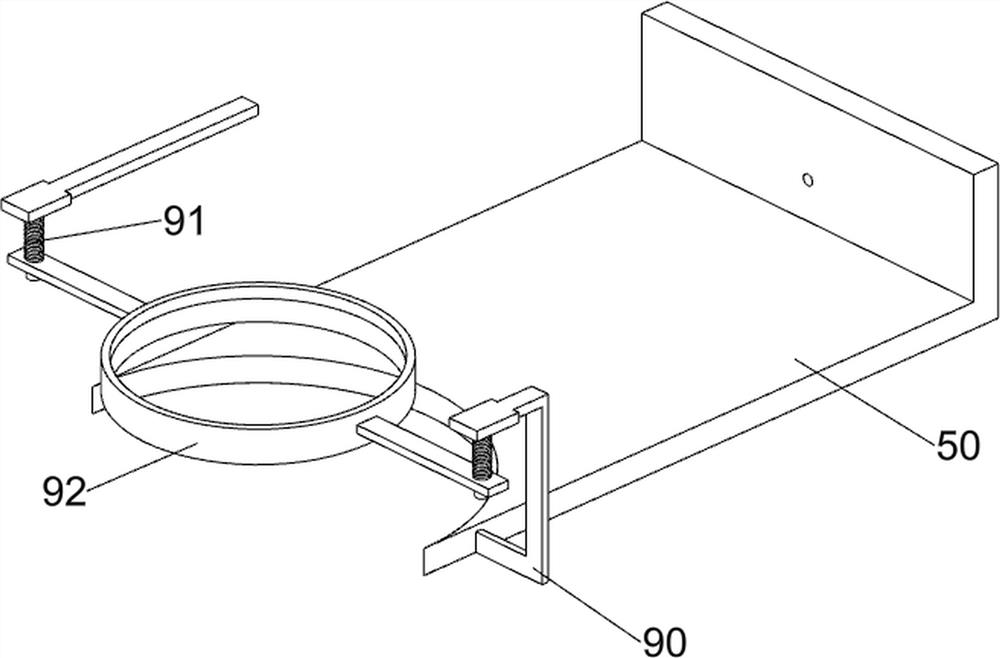

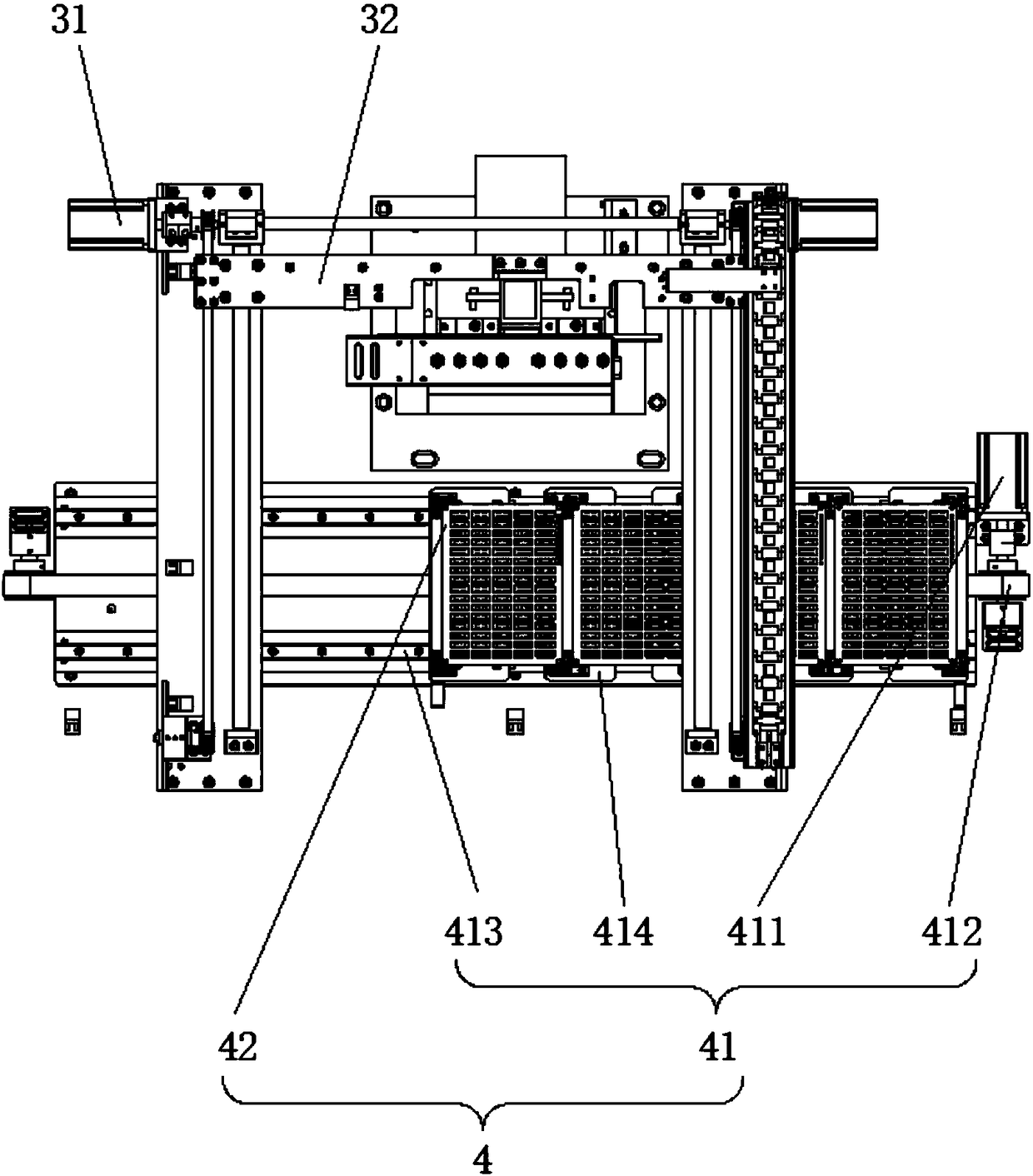

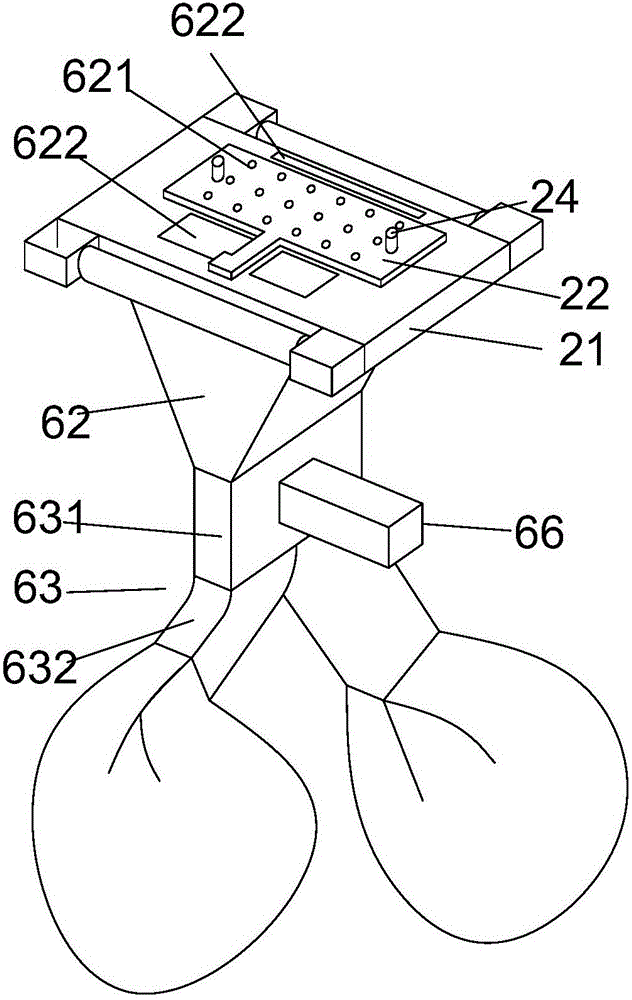

Automatic punching and placing machine

PendingCN108127723AReduce turnaround processIncrease productivityMetal working apparatusPunchingEngineering

The invention relates to an automatic punching and placing machine. The automatic punching and placing machine comprises a machine frame; a punching mechanism, a transferring mechanism and a placing mechanism are arranged on the machine frame; the punching mechanism comprises a base plate, a clamping assembly capable of clamping workpieces and a punching assembly capable of punching the workpiecesare arranged on the base plate, a plurality of clamping positions are arranged on the clamping assembly, and punching heads corresponding to the clamping positions in a one-by-one mode are arranged on the punching assembly; the transferring mechanism comprises a supporting frame fixedly connected on a sliding device, and a plurality of holding assemblies corresponding to the clamping positions ina one-by-one mode are arranged on the supporting frame; the placing mechanism comprises a plurality of placing discs arranged on a transmission device, and the quantity of the placing discs is equalto the quantity of the clamping positions; a plurality of containing grooves for containing the workpieces are formed in the placing discs in a rectangular-array mode; the holding assemblies are driven by the sliding device to reciprocate between the clamping assembly and the placing discs. According to the automatic punching and placing machine, the punching working procedure and the placing working procedure are integrated, and product tracking can be achieved.

Owner:CHANGZHOU GIAN TECH

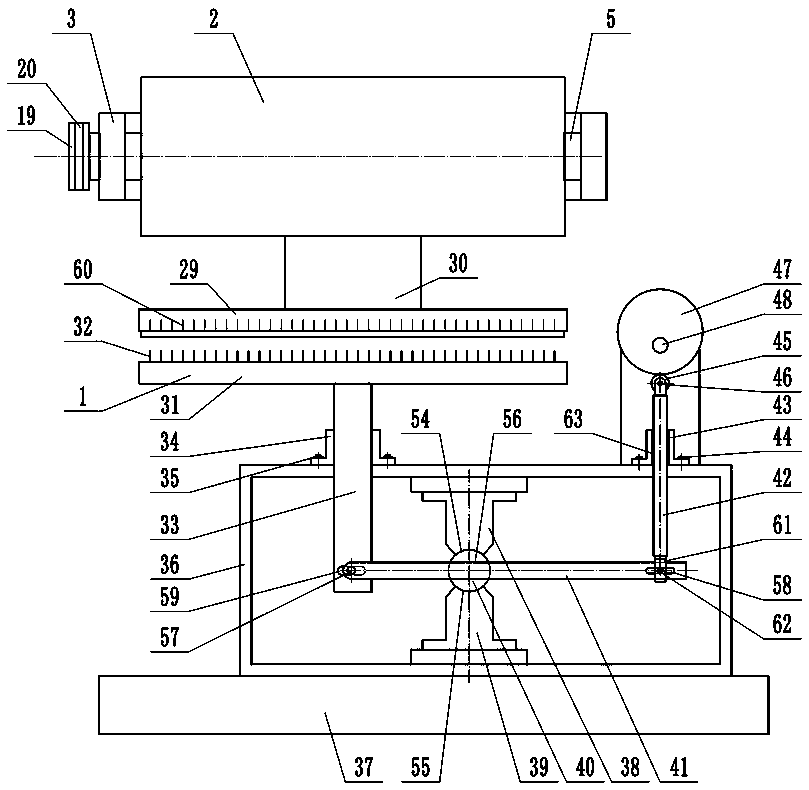

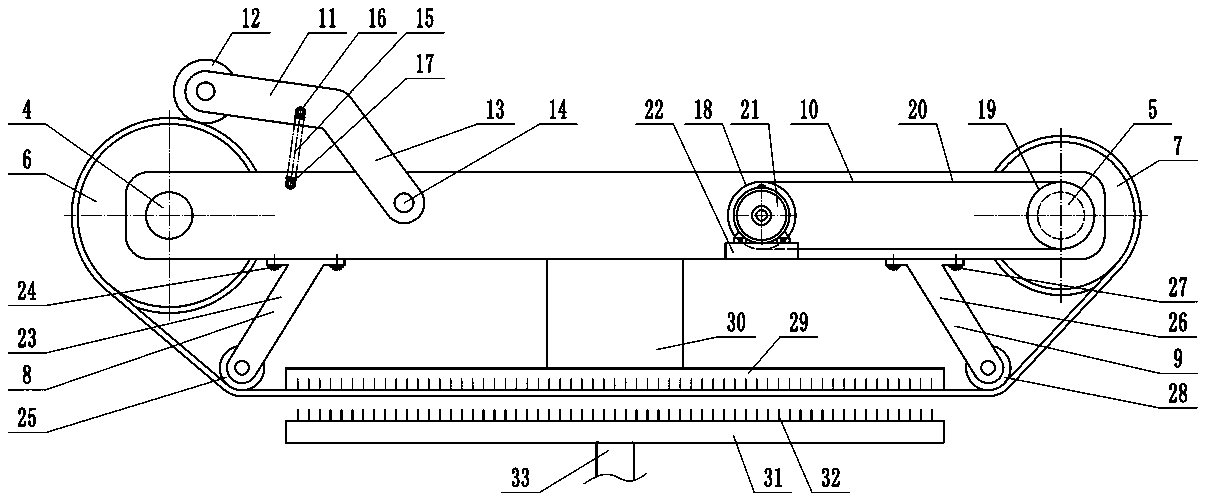

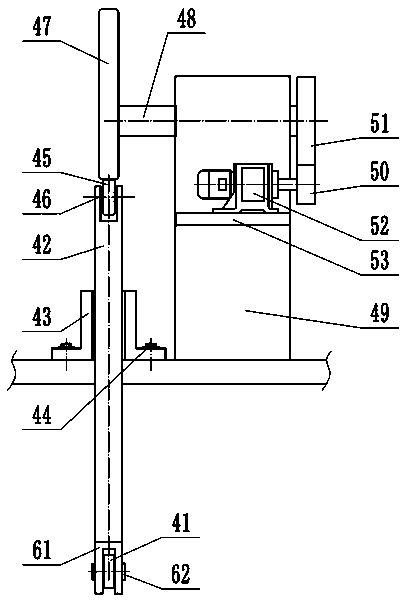

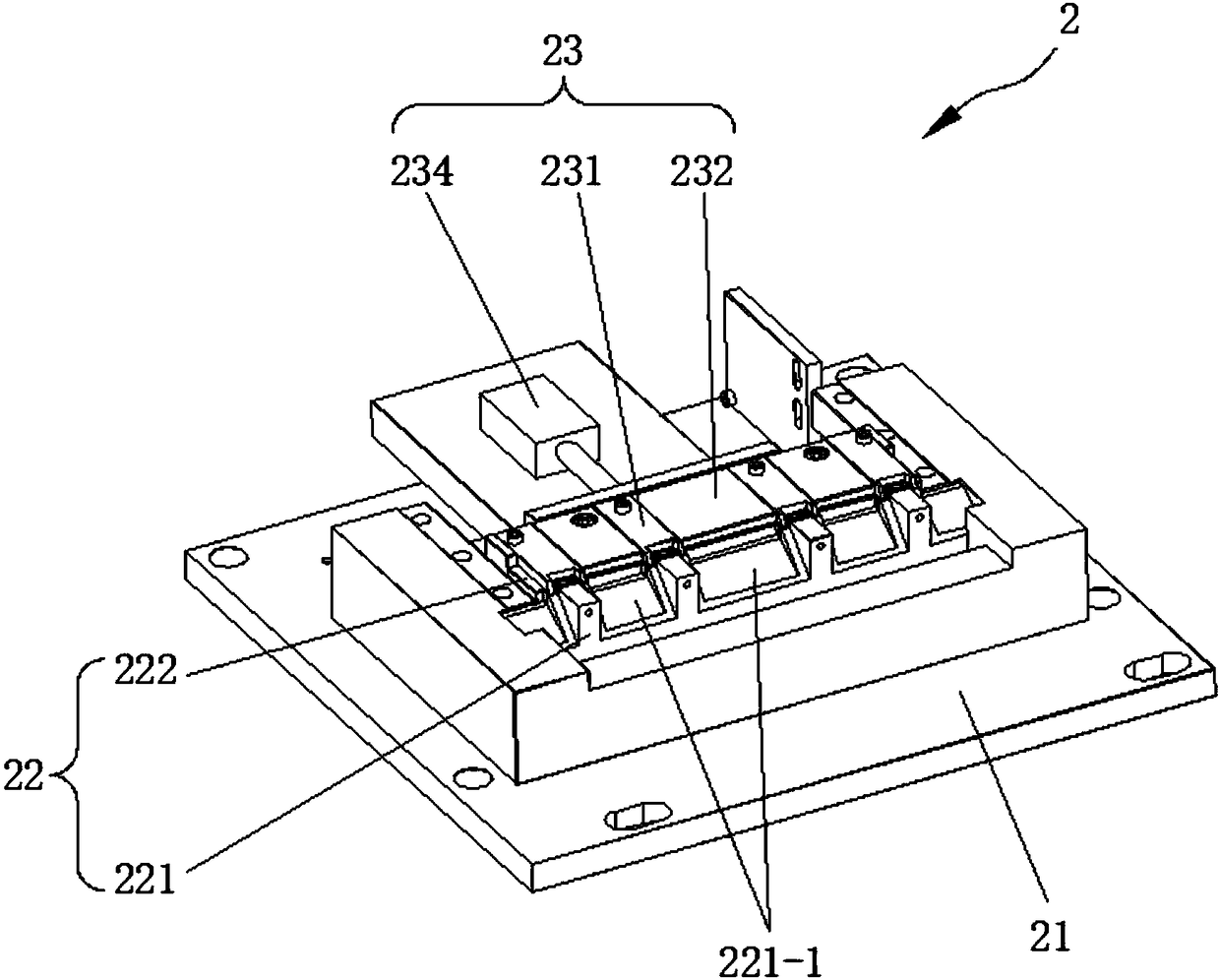

Full-automatic separation sheet production equipment

InactiveCN106426380APull outRealize punchingMetal working apparatusWebs handlingPunch pressWork in process

The invention provides full-automatic separation sheet production equipment. The full-automatic separation sheet production equipment comprises a reeling device, a punching machine, a glue film slicing mechanism, a cutter driving mechanism and a glue film conveying mechanism, wherein the reeling device comprises a reeling barrel for reeling a glue film; the reeling barrel is supported by a barrel frame body; the punching machine comprises a portal frame and a supporting frame; a punching part is mounted on the portal frame; a punching station is arranged just below the punching part; a bearing plate and a placement mold are arranged just below the punching part; the placement mold is mounted on the bearing plate; the placement mold is used for storing a semi-finished product; the supporting frame is used for supporting the bearing plate; the glue film slicing mechanism comprises a slicing platform, a tool rest, a cutter and a cutter driving mechanism, wherein the reeling barrel and the slicing platform are arranged at two ends of the portal frame respectively; the tool rest is mounted on the surface of the slicing platform; the cutter is arranged just below the tool rest; the cutter driving mechanism is mounted on the tool rest; and an output part of the cutter driving mechanism is connected with the cutter and is used for driving the cutter to move in a direction of getting close to the slicing platform or in a direction of getting far away from the slicing platform. The full-automatic separation sheet production equipment has the beneficial effects that full-automatic production of separation sheets is realized.

Owner:重庆淳祥电子科技有限公司

Automatic punching device for hardware instrument machining

PendingCN112846783APrevent splashEasy to cleanFeeding apparatusOther manufacturing equipments/toolsComputer hardwareElectric machinery

The invention discloses an automatic punching device for hardware instrument machining. The automatic punching device comprises a workbench, a fixing base and a telescopic cylinder, a groove is formed in the upper end of the workbench, a first motor is arranged in the groove, a first rotating shaft is arranged at the upper end of the first motor, and a supporting plate is arranged at the upper end of the first rotating shaft. When the automatic punching device is used, a hardware instrument is placed in the fixing base, a rotating handle drives a second threaded rod to rotate, the second threaded rod drives two clamping plates to move close to each other, and therefore the hardware instrument is clamped and fixed, then a second motor is started to drive a rotating rod, a first bevel gear, a second bevel gear and a first threaded rod to rotate, a first threaded rod drives a first sliding block, an electric telescopic rod, a transverse plate, a second support and a drill bit to move left and right, so that the drill bit is adjusted to the position where punching is needed, then the electric telescopic rod is started to drive the transverse plate, the second support and the drill bit to move downwards, meanwhile, a third motor is started to drive the drill bit to rotate, the drill bit punches the hardware instrument, and the surfaces of the punched holes are ground through an arranged grinding disc.

Owner:安徽鑫森仪表电缆集团有限公司

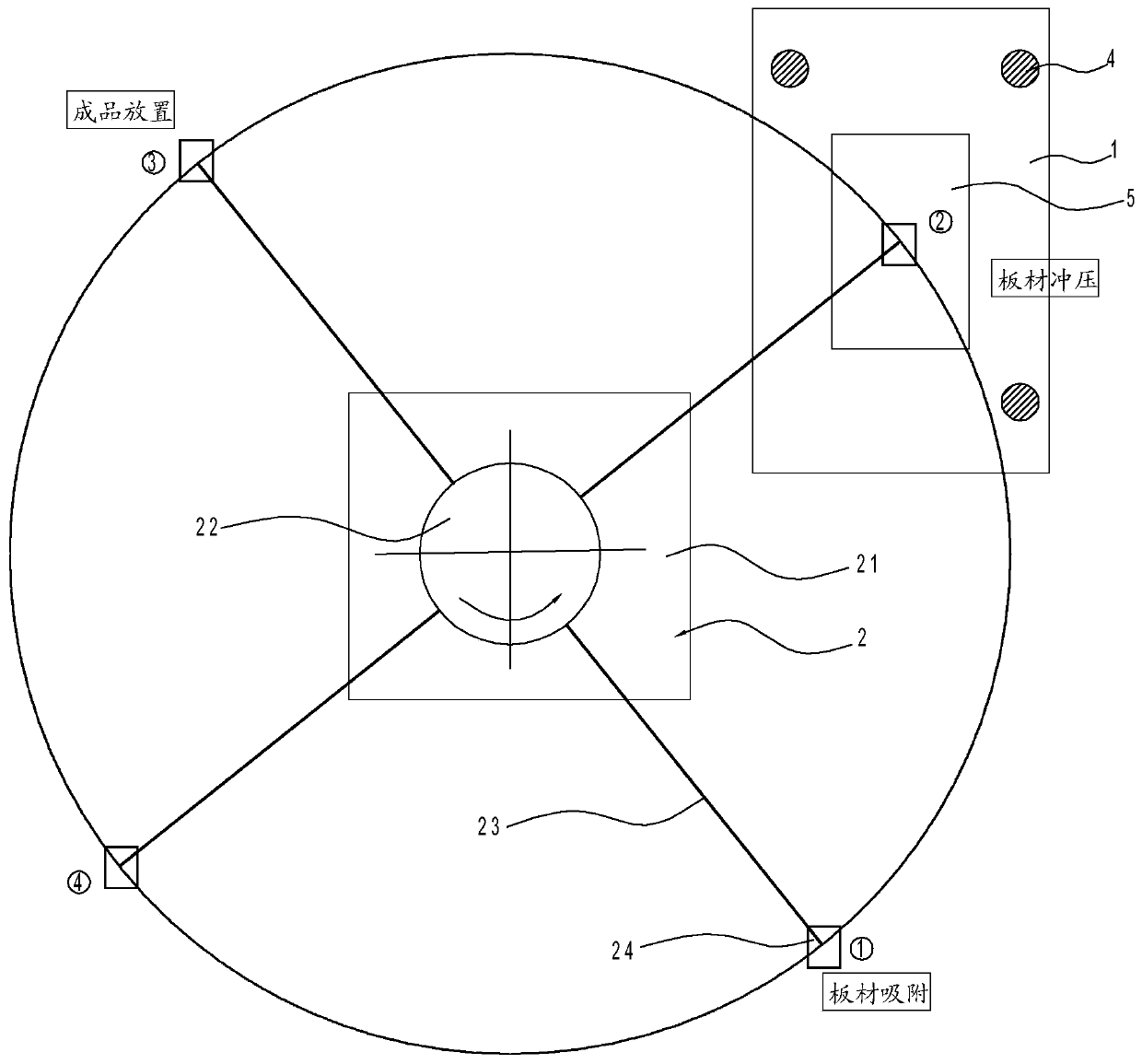

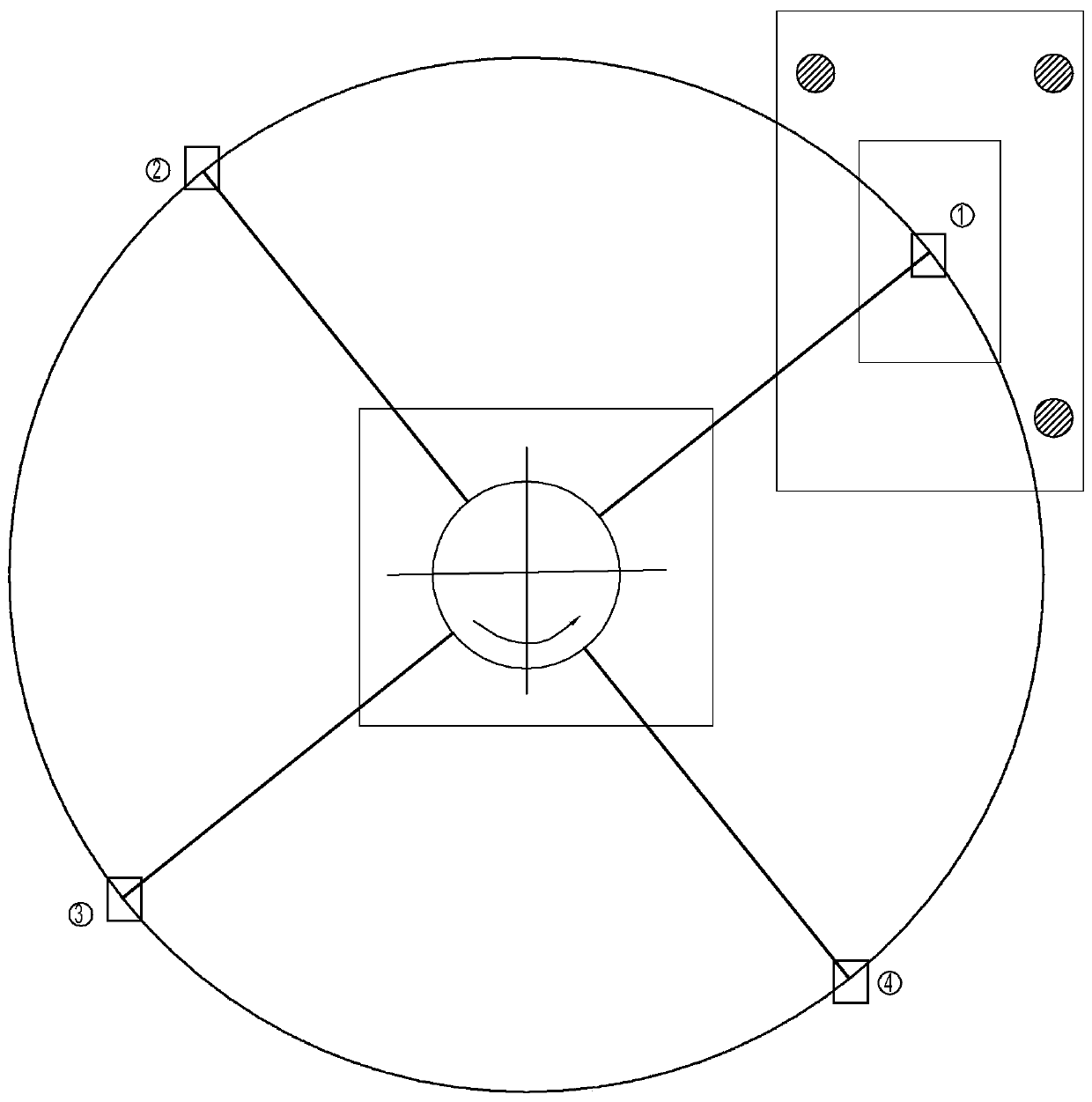

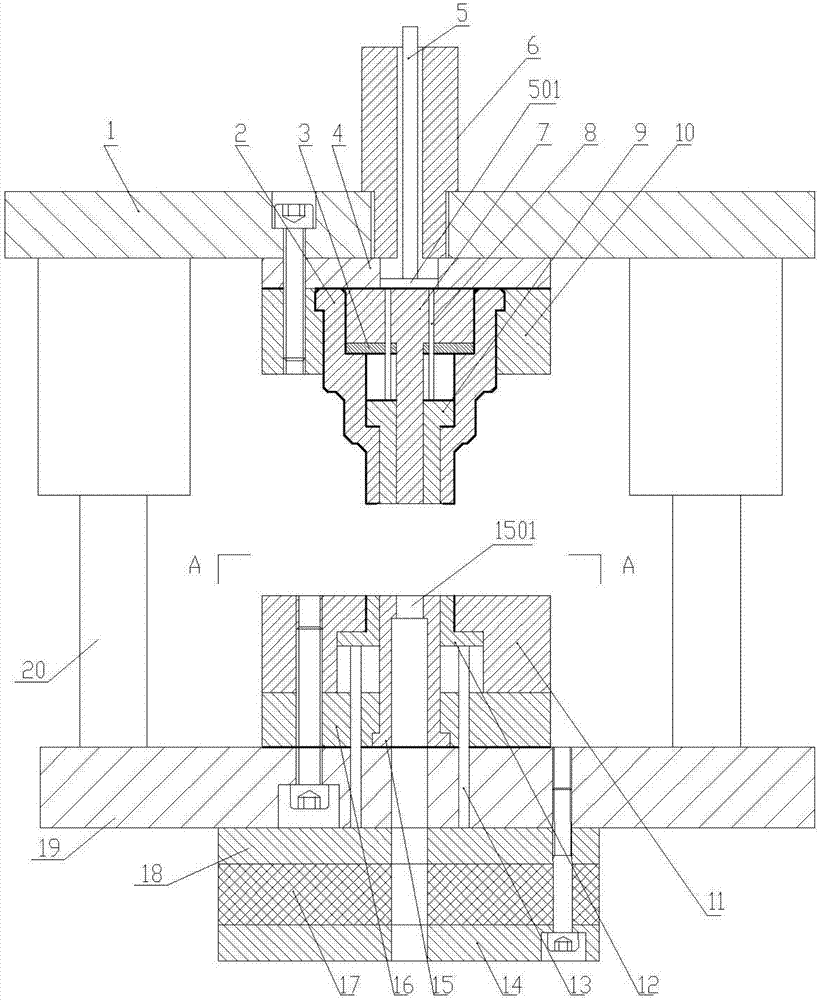

Double-station continuous stamping die for sheet metal parts

InactiveCN111438531ARealize punchingImprove processing efficiencyOther manufacturing equipments/toolsStampingElectric machinery

The invention discloses a double-station continuous stamping die for sheet metal parts. The double-station continuous stamping die comprises a bottom plate, an upper die and a lower die, and is characterized in that a cavity is formed in the upper die, the shape of the lower die is matched with the cavity, a side groove is formed in the right side wall of the lower die, a linkage piece is arrangedon the lower part of an upper template, the linkage piece comprises a conical plate part and an inclined rod part, a sliding seat is slidably arranged on the right side of the bottom plate, a front sliding block and a rear sliding block are slidably arranged on the left side of the sliding seat, support bearings are correspondingly arranged at the left ends of the front sliding block and the rearsliding block, rotating pieces are arranged on the support bearings, a hollow motor is fixedly arranged at the left end of a sliding cavity, and the front end and the rear end of the hollow motor arecorrespondingly connected with the rotating pieces. According to the double-station continuous stamping die for the sheet metal parts, two stations of the sheet metal are continuously processed by apair of die, the efficiency of the sheet metal processing is improved, and meanwhile the cost of step-by-step processing caused by use of two pairs of dies is lowered.

Owner:郑冬青

Device for rapid forming production

ActiveCN108326128ARealize punchingRealize automatic feeding processShaping toolsPerforating toolsPunchingEngineering

The invention discloses a device for rapid forming production. The device comprises a rack, wherein a punching assembly, an automatic feeding assembly and a power conversion assembly are mounted on the rack; the punching assembly is used for punching workpieces; the automatic feeding assembly is used for feeding the workpieces; the power conversion assembly is used for converting power of the punching assembly during work into work power of the automatic feeding assembly. Under cooperation of the punching assembly and the automatic feeding assembly, punching and automatic feeding for pedals are realized, manual work is replaced, manpower and material resources are saved, and the punching assembly can be adjusted as required, so that through holes of different specifications can be formed in the pedals through punching, and the application range of the device is enlarged.

Owner:SHANDONG JINGUANG COMPOSITE MATERIALS

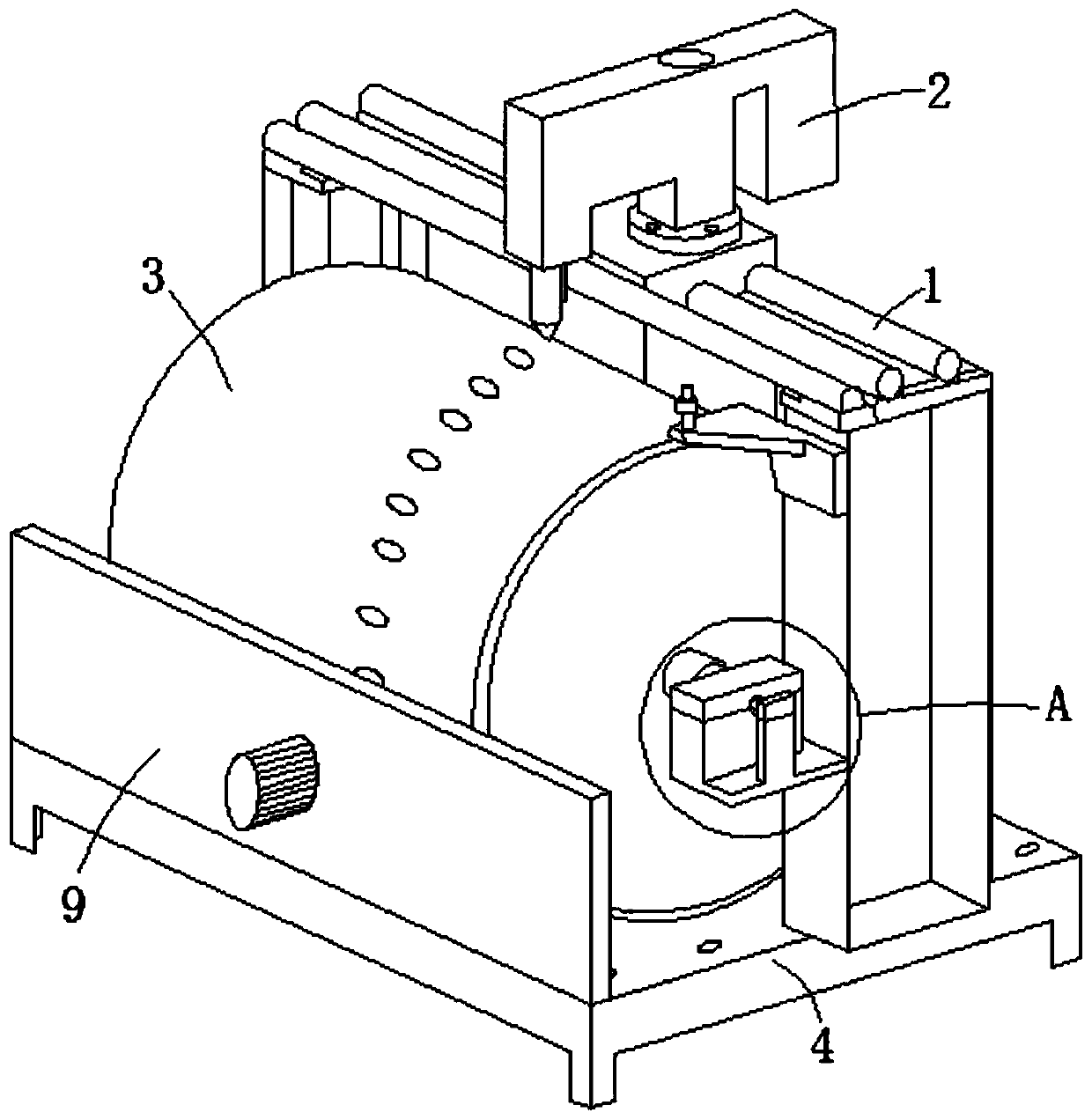

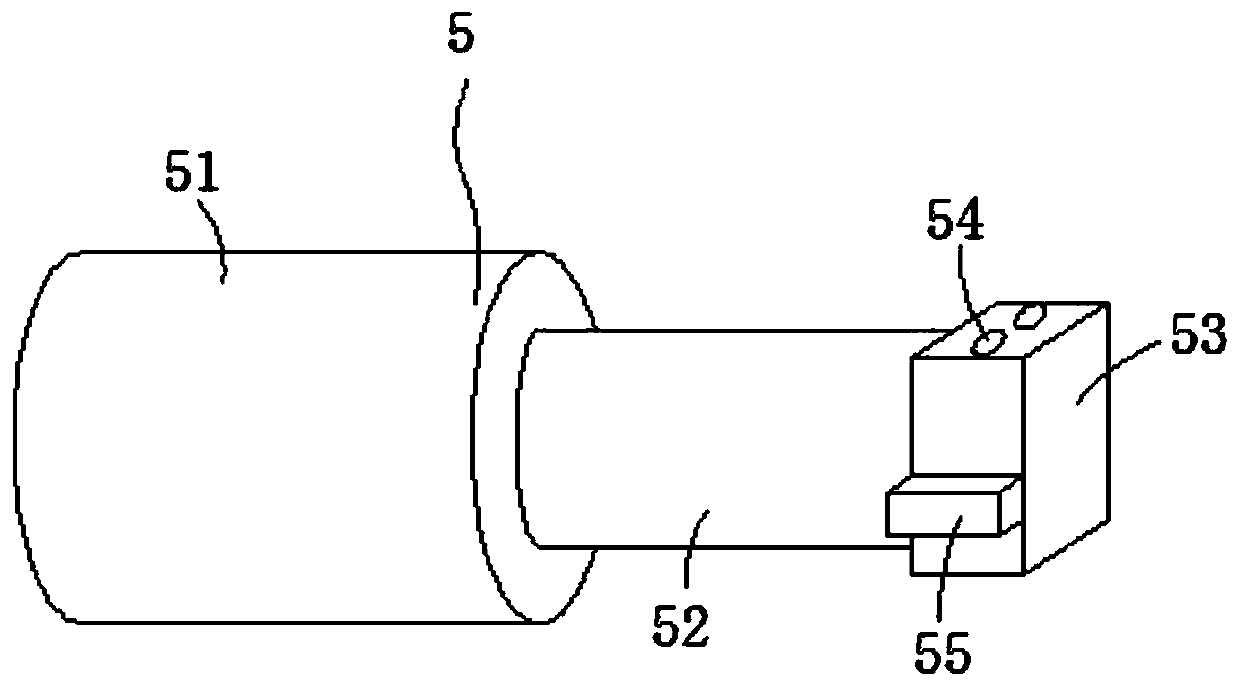

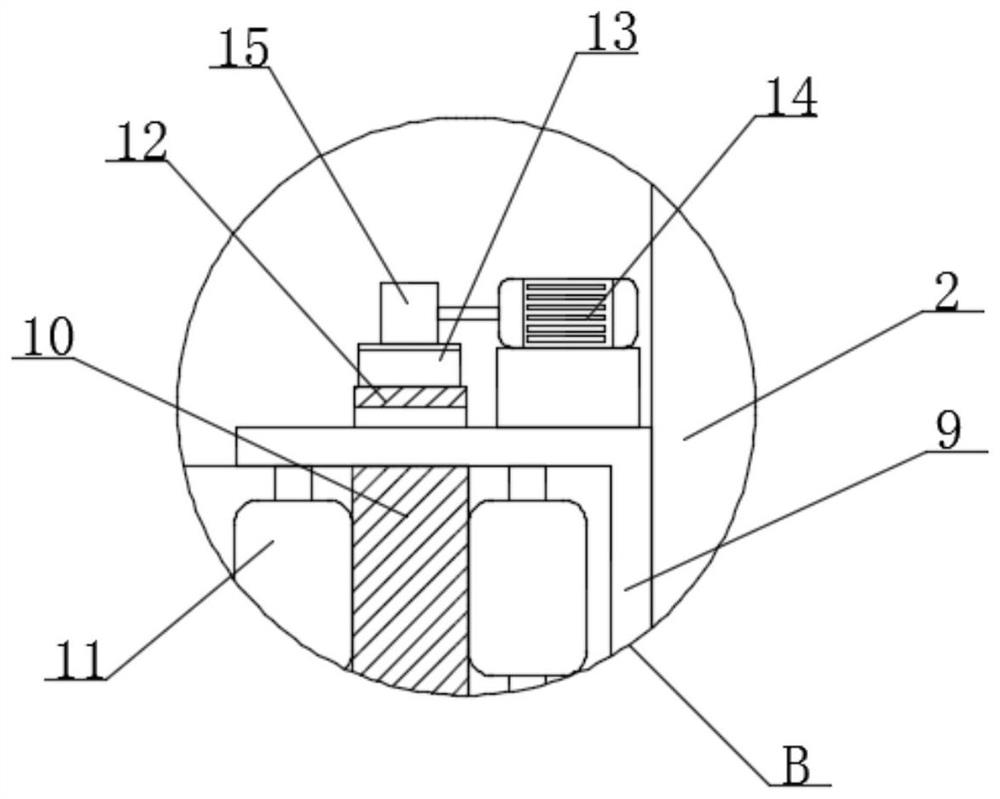

Fixing and mounting structure for power system

ActiveCN110480357AEasy to replaceImprove work efficiencyOther manufacturing equipments/toolsDriving apparatusEngineeringPunching

The invention relates to a fixing and mounting structure for a power system. The structure comprises a connecting column, wherein the connecting column is connected to a roller, the end, far away fromthe roller, of the connecting column is provided with one end of a supporting column, a connecting block is fixedly arranged at the other end of the supporting column, a clamping hole is formed in the top end of the connecting block, and a positioning block is fixedly arranged on the side wall of the connecting block. In the structure, the roller is detachably installed, the damaged roller can beconveniently replaced, punching on cylindrical filter screens with various bore diameters can be realized by replacing rollers with different diameters, meanwhile, the punching and deburring procedures can be carried out at the same time through the structure, so that the effects of saving time and saving labor are achieved.

Owner:ANHUI TELECOMM ENG

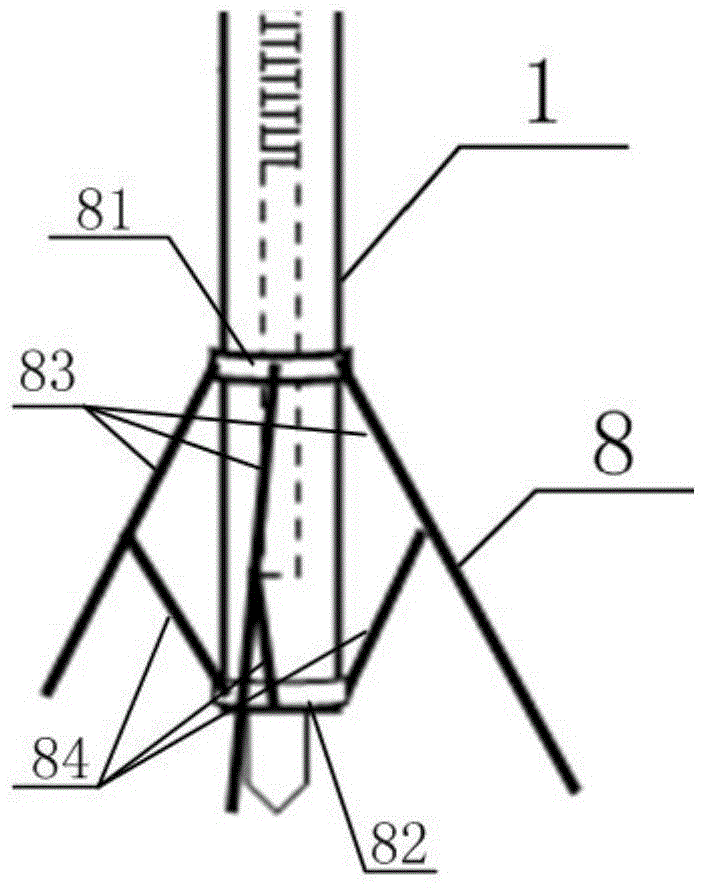

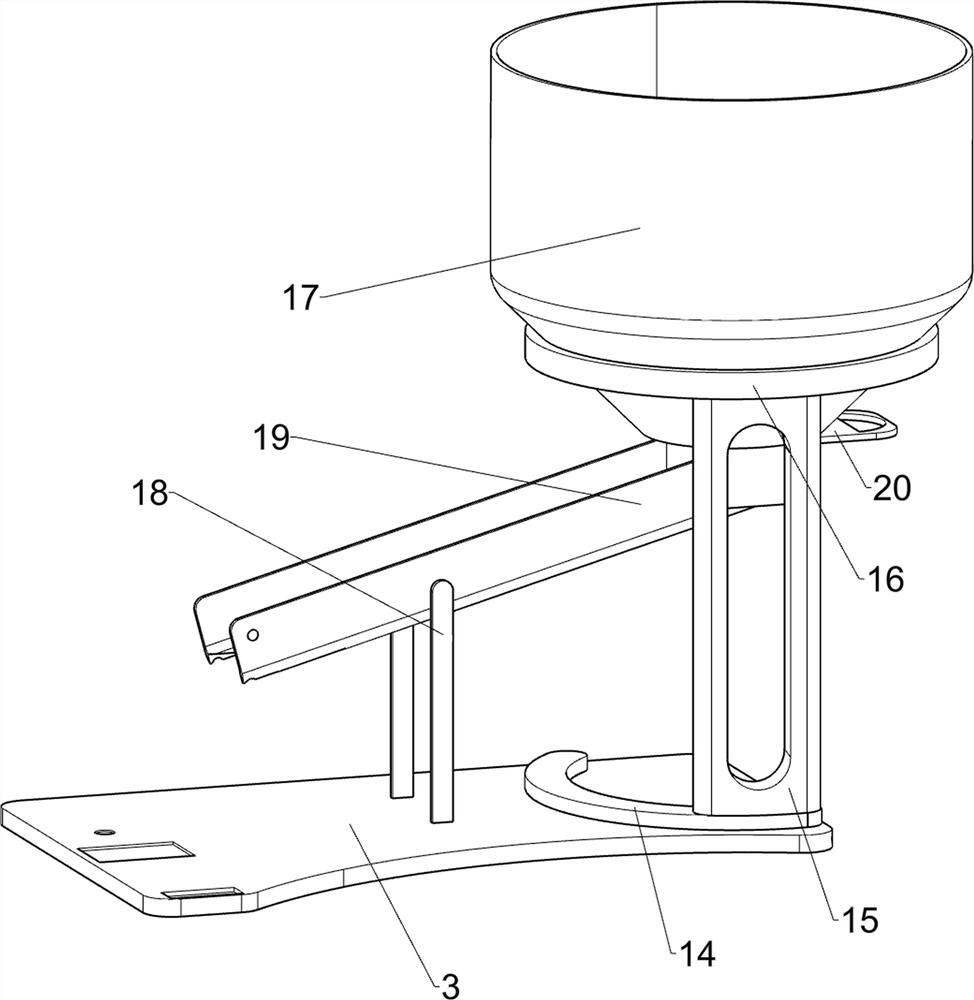

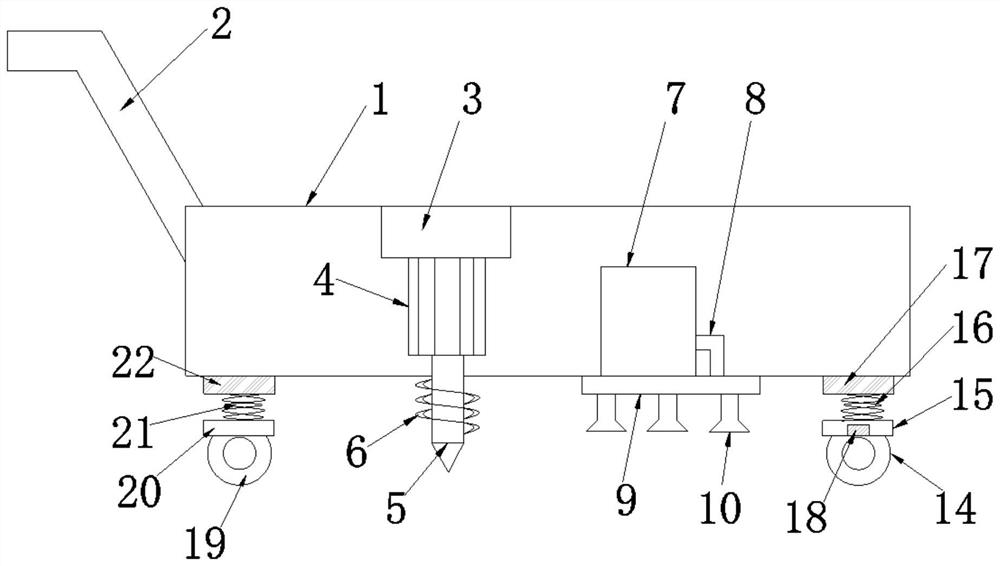

Farm tool facilitating tea planting

InactiveCN111972082ARealize sprayingRealize punchingPlantingWatering devicesAgricultural scienceAgricultural engineering

The invention discloses a farm tool facilitating tea planting, which comprises a bottom frame, a drilling assembly and a spraying assembly, the bottom of the bottom frame is provided with a walking wheel assembly, one side of the bottom frame is provided with a handrail, and the drilling assembly and the spraying assembly are both installed in the bottom frame. The humidity and softness of soil can be adjusted, tea planting is facilitated, and the tea planting efficiency can be improved.

Owner:湖南瑶园生态农业科技发展有限公司

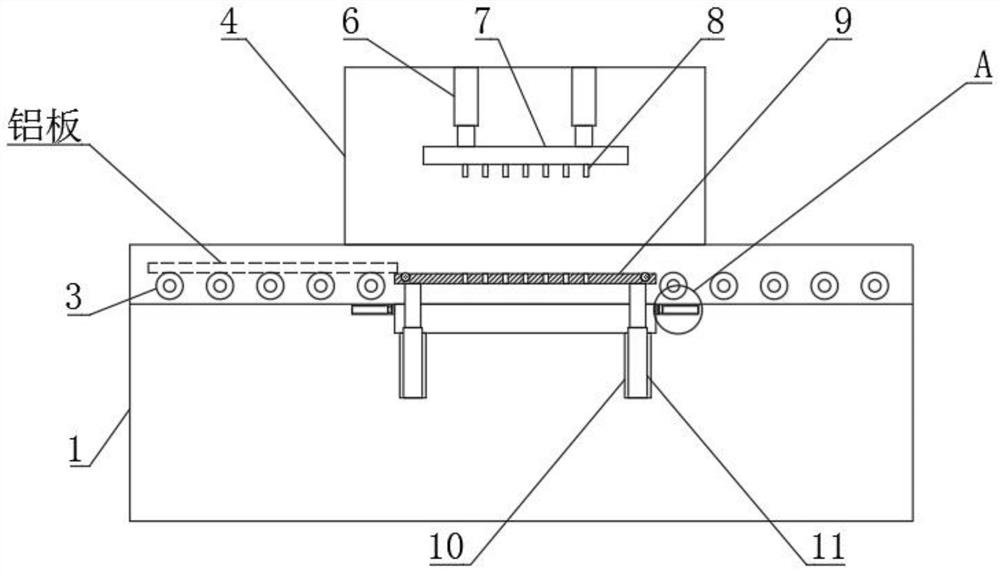

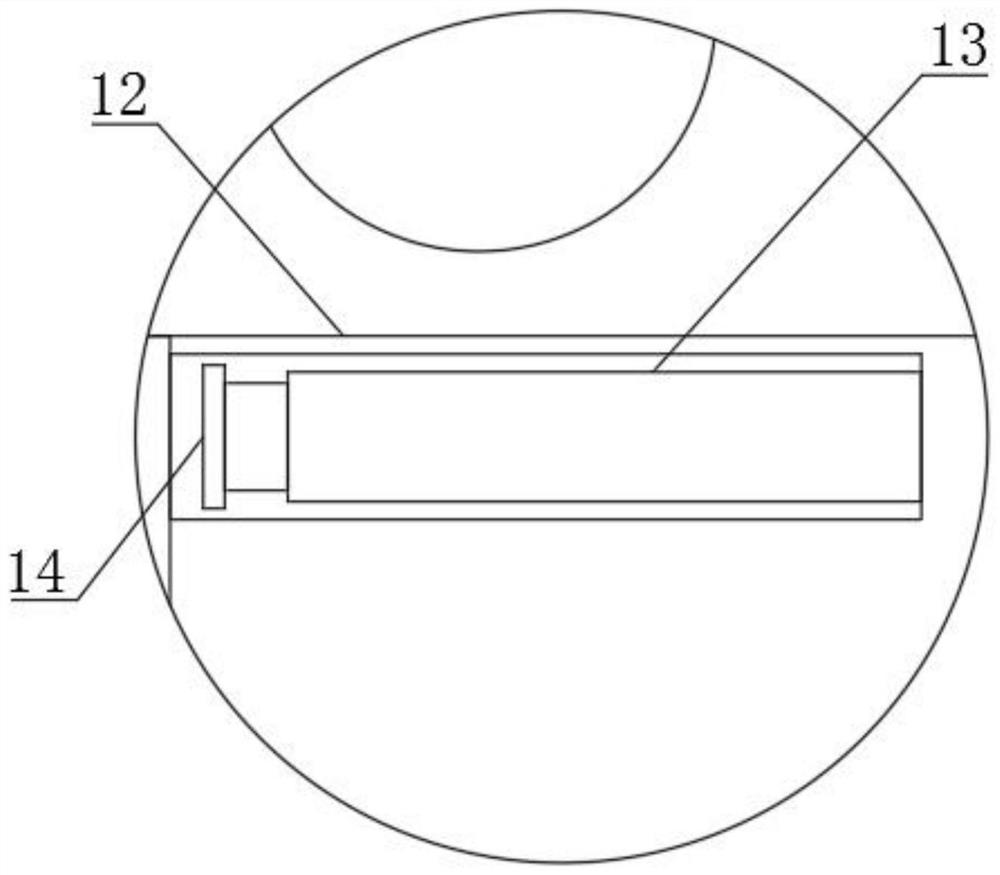

Processing method of communication equipment aluminum plate

InactiveCN114633080AEasy to separateConducive to stable transmissionMetal-working feeding devicesPositioning apparatusStructural engineeringManufacturing engineering

The invention discloses a processing method for an aluminum plate of communication equipment, and belongs to the field of aluminum plate processing, and according to the scheme, when the aluminum plate is processed, the aluminum plate is conveyed to a processing interval through rotation of a transmission shaft, the aluminum plate is moved to the middle position of a supporting plate through a rolling shaft on the upper side of the supporting plate, and a second electric push rod retracts; a top plate at the outer end of a limiting rod clamps an aluminum plate, a punching rod at the lower end of a pressing plate punches the aluminum plate through pushing of a first electric push rod, meanwhile, a third electric push rod ejects a hollow flaring plate outwards, the diameter of a hole in the surface of the aluminum plate is enlarged through the hollow flaring plate, and the outer side of the hollow flaring plate is attached to the inner wall of the hole; when the pressure value of the deformation sensor reaches a top value, the booster pump pressurizes the interior of the hollow flared plate, a release agent in the hollow flared plate is extruded out through the release hole and flows to the position between the hollow flared plate and the inner wall of the hole, and therefore the hollow flared plate and the aluminum plate can be better separated.

Owner:江苏古戈尔精密五金科技有限公司

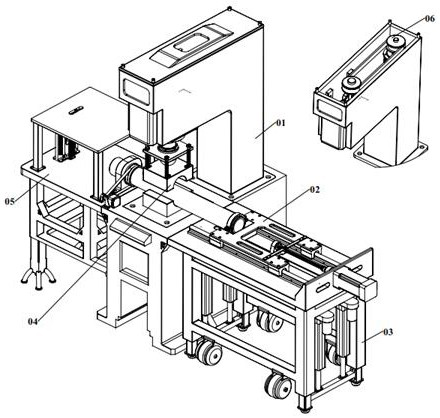

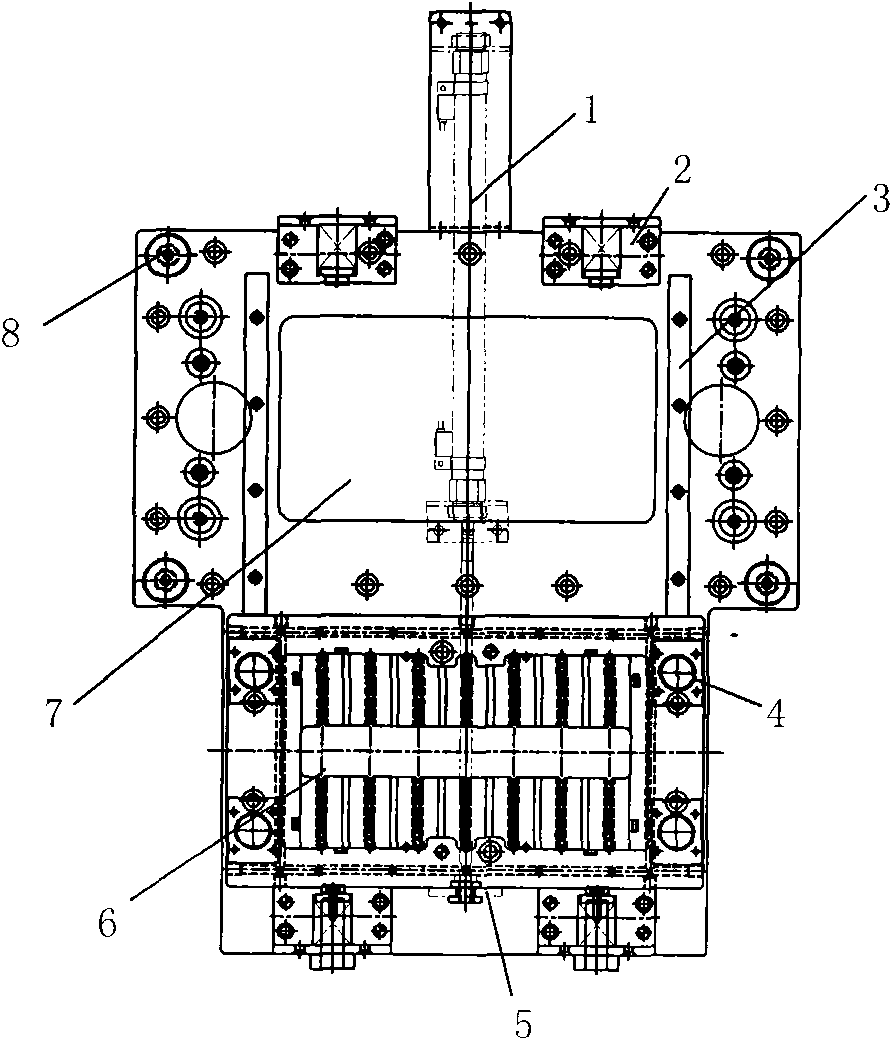

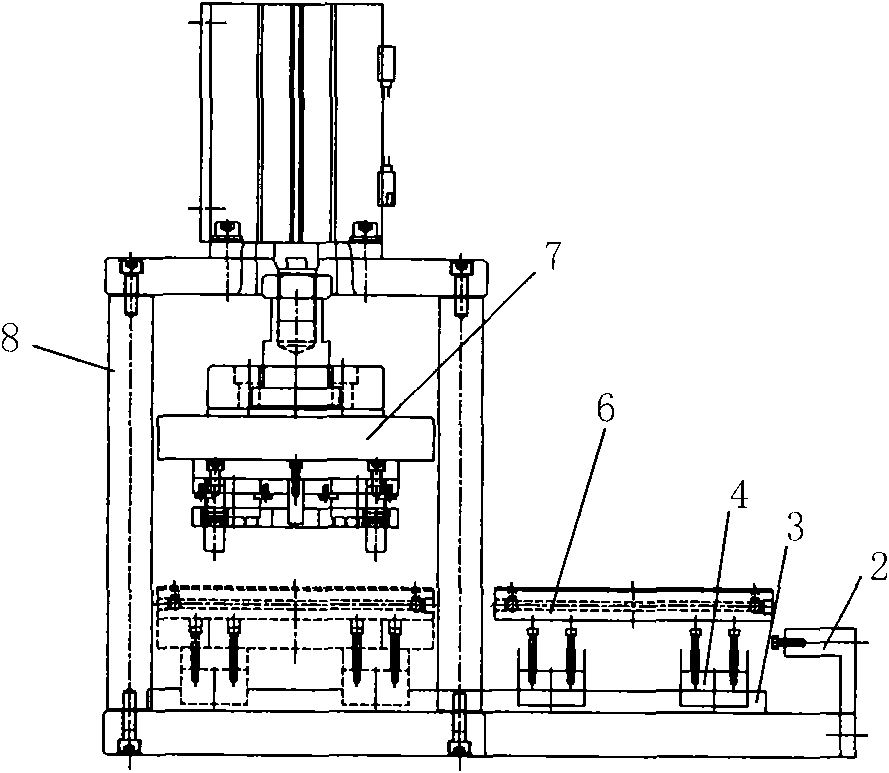

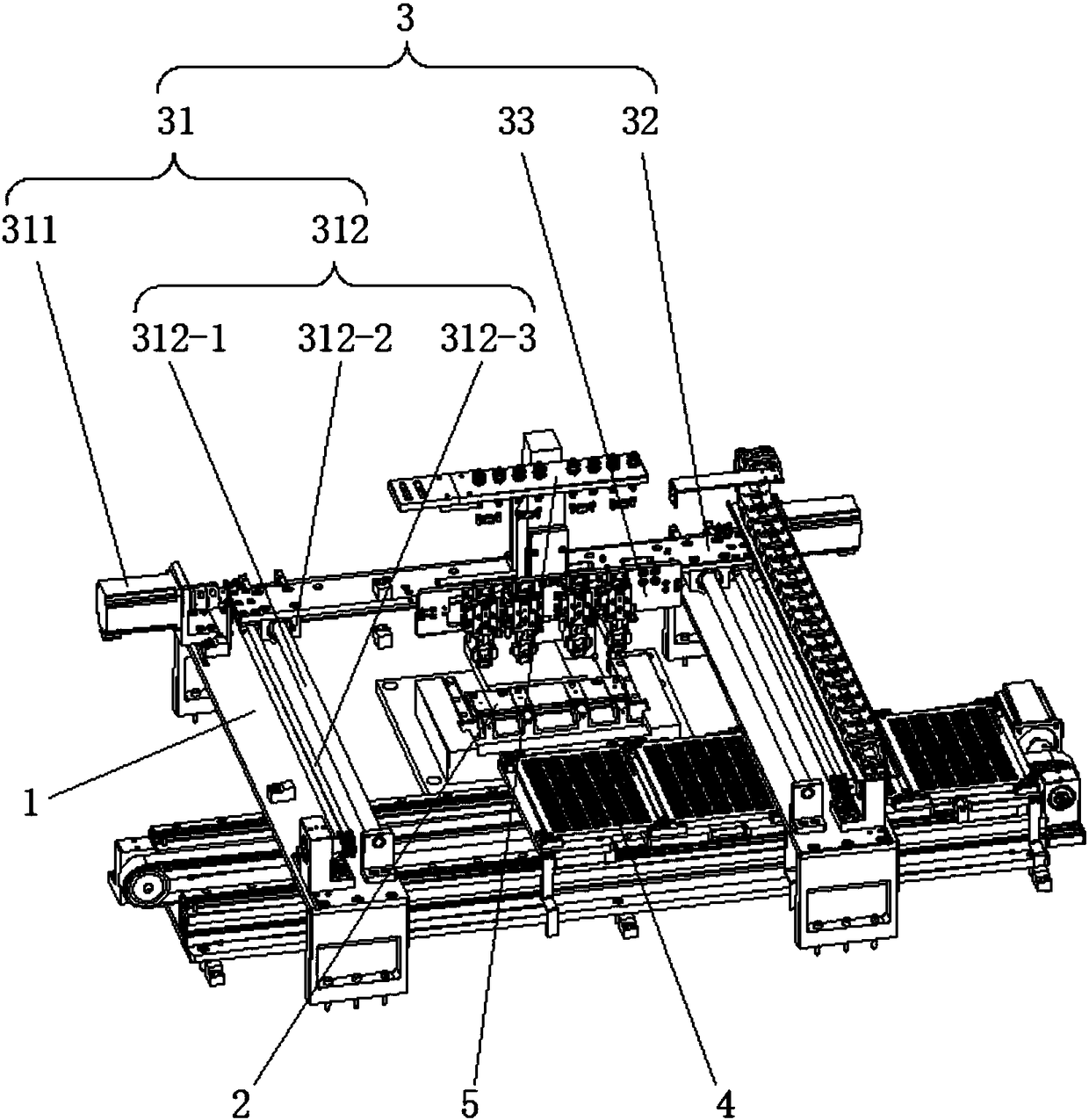

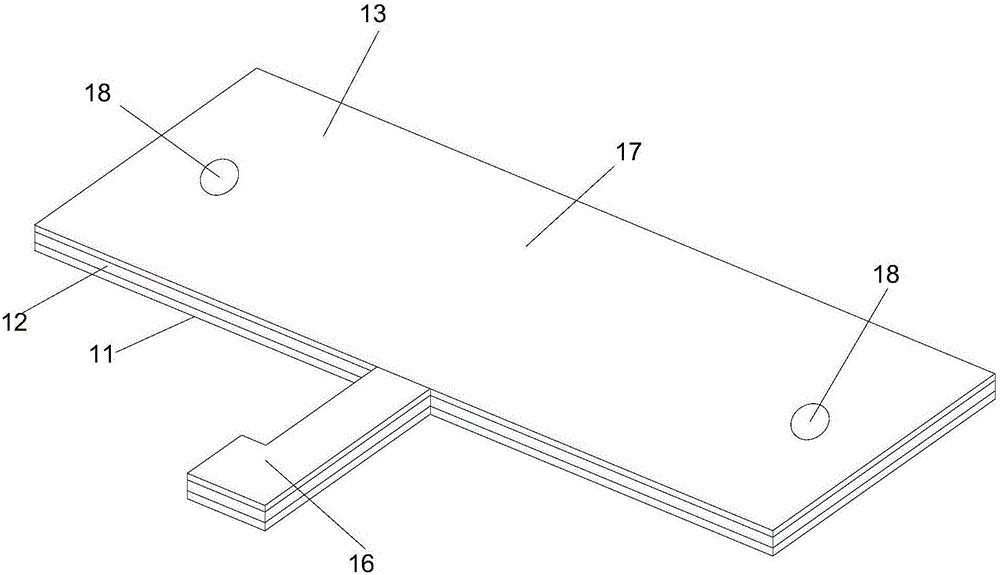

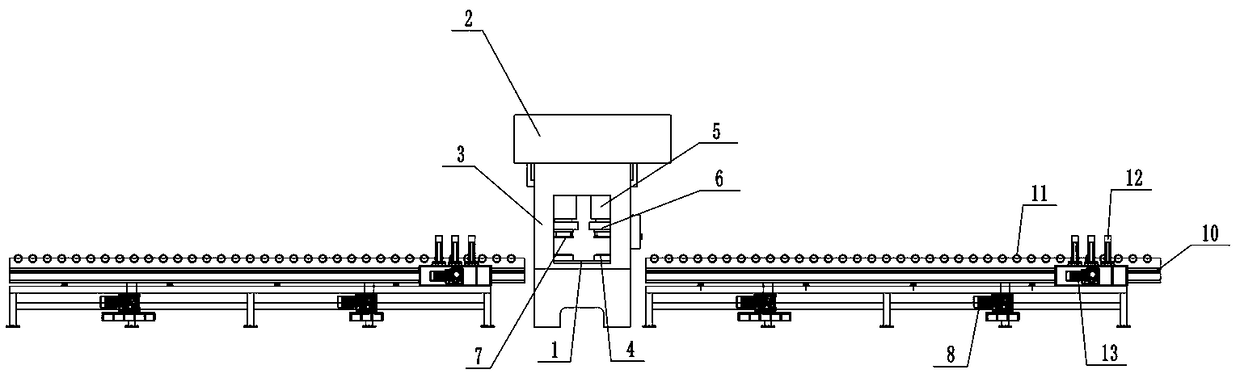

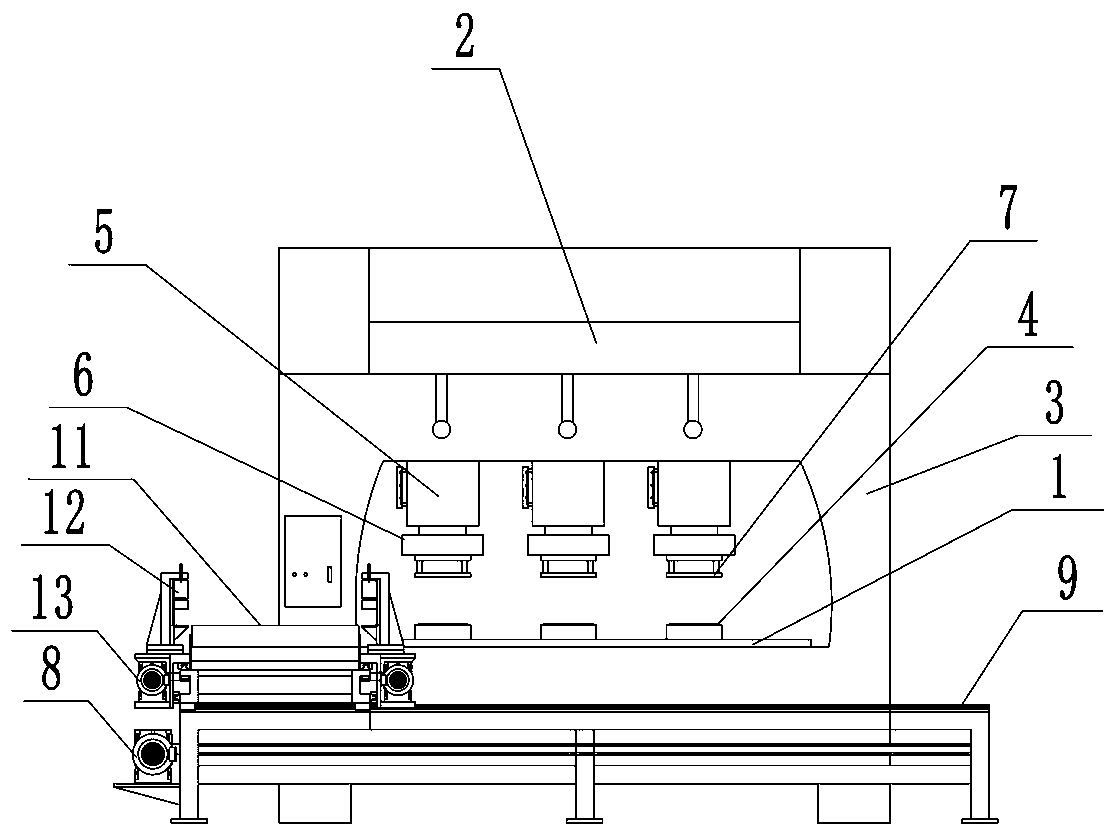

Special manufacturing production line for automotive web plate

PendingCN108213179ARealize punchingAdjustable positionMetal-working feeding devicesVehicle componentsProduction linePunch press

The invention discloses a special manufacturing production line for an automotive web plate. The manufacturing production line comprises a punch press main machine, a feeding mechanism, a material receiving mechanism and a control mechanism; the punch press main machine comprises a punch press body, hydraulic punching equipment and a punching working platform; the punch press body is a closed typerack structure defined and formed by a cross beam, two side frames and a base; the punching working platform is arranged on the base; a plurality of punching lower dies are arranged on the punching working platform; the hydraulic punching equipment is arranged on the cross beam; the feeding mechanism and the material receiving mechanism are arranged on the two sides of the punching working platform; and the feeding mechanism and the material receiving mechanism each comprise a strip-shaped conveying platform, two X-direction guide rails, at least a pair of transverse moving motors and at least a pair of hydraulic clamps. The special manufacturing production line for the automotive web plate has the advantages that the special manufacturing production line is scientific in design, a long plate can be punched, the positions of the material receiving mechanism and the feeding mechanism can be adjusted, the stability is high, and the automation degree of punching is high.

Owner:ZHUMADIAN DALI TIANJUN SPECIAL VEHICLE MFG

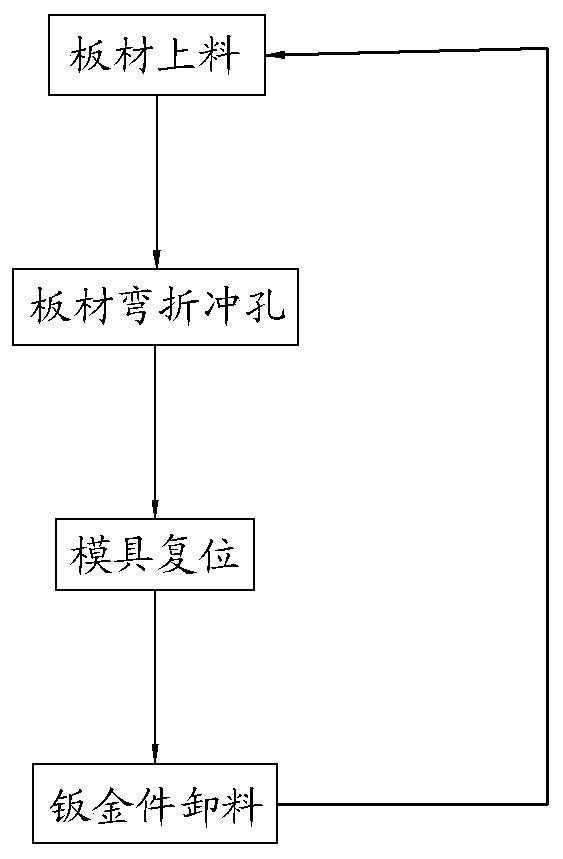

Double-station continuous stamping method for sheet metal part

The invention discloses a double-station continuous stamping method for a sheet metal part. The double-station continuous stamping method comprises the steps of 1, feeding a plate; 2, bending and punching the plate, specifically, an upper die firstly descends, the lower end of an inclined rod part of a linkage part is inserted into an inclined rod groove of a sliding seat, the plate is bent into an upper die cavity, then a conical plate part on the linkage part is inserted into a chute formed by a front sliding block and a rear sliding block, and a drill bit is driven by a hollow motor througha rotating part to rotate so as to achieve the punching and machining of the plate; 3, resetting the dies, specifically, the upper die ascends, and the sliding seat is pushed away from a lower die bythe inclined rod part of the linkage part; 4, discharging the sheet metal part; and 5, repeatedly carrying out the steps 1-4 to achieve automatic continuous stamping of the plate. According to the double-station continuous stamping method for the sheet metal part, continuous machining of two stations of the sheet by using one pair of dies, the efficiency of sheet metal machining is improved, andmeanwhile, the cost due to step-by-step machining by using the two pairs of dies is reduced.

Owner:郑冬青

Gasket protection ring composite forming mold

PendingCN107497963ARealize punchingTake advantage ofMetal-working apparatusManufacturing cost reductionPunching

The invention discloses a gasket protection ring composite forming mold. The mold comprises an upper mold plate and a lower mold plate; a lower fixing plate and a female mold are sequentially arranged on the lower mold plate, a lower punch mold is fixed to the lower fixing plate, a lower discharging sleeve is arranged between the lower punch mold and the female mold, an upper clamping plate, an elastic base plate and a lower clamping plate are sequentially connected to the lower face of the lower mold plate, and multiple lower ejection rods are arranged between the upper clamping plate and the lower discharging sleeve; and an upper base plate and an upper fixing plate are sequentially arranged on the lower face of the upper mold plate, an upper punch mold and a male mold are fixed to the lower face of the upper base plate, an upper discharging sleeve is arranged between the upper punch mold and the male mold, a punch sleeve is arranged on the upper face of the upper mold plate, a punching rod is arranged in a center hole of the punch sleeve, and multiple upper ejection rods are arranged between the lower end of the punching rod and the upper discharging sleeve. The mold has the beneficial effects that through one-time punching, complete forming of a protection ring can be finished, manufacturing cost can be reduced, production efficiency is improved, the mold number is small, occupied punching devices are few, time for mold replacing can be saved, and the punching devices can be sufficiently used.

Owner:JINZHOU FUSHAN SEALING TECH CO LTD

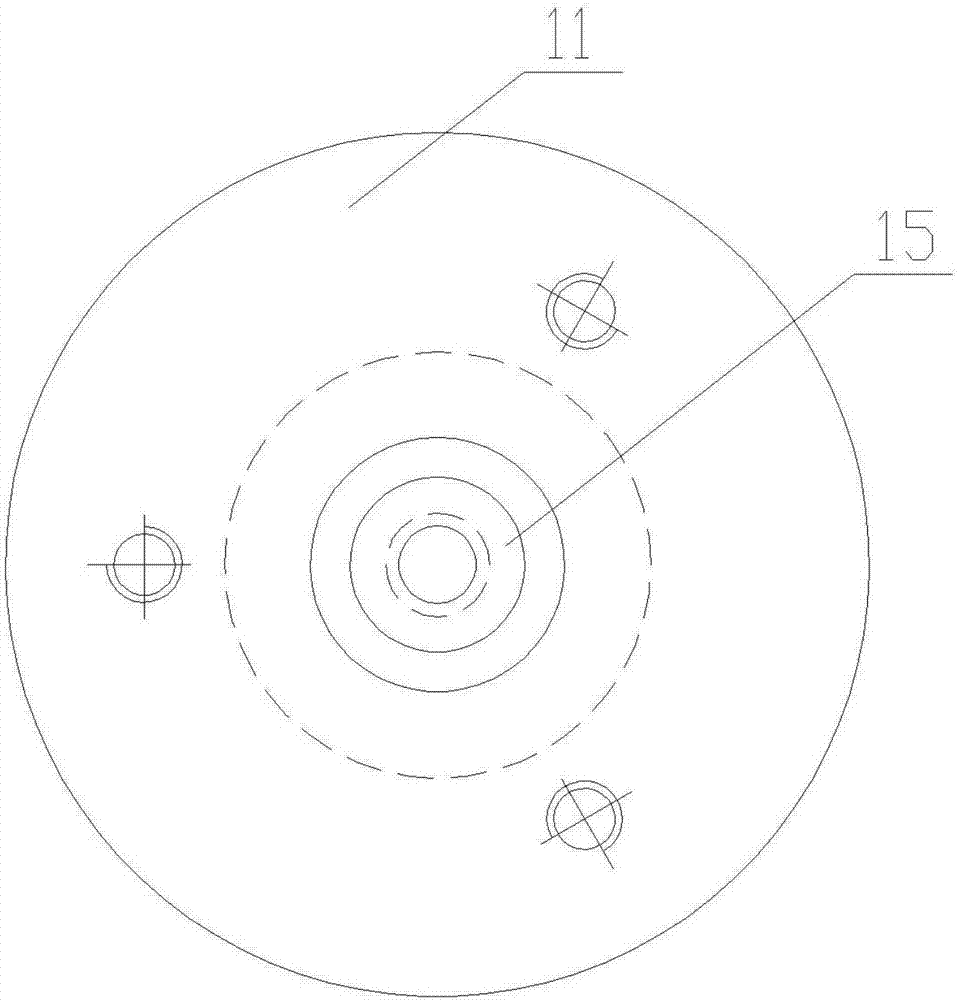

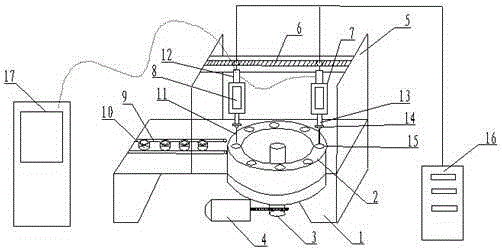

Full-automatic numerical control punching machine

The invention discloses a full-automatic numerical control punching machine which comprises a base. A punching die holder is arranged on the base. Workpiece fixing die holes are formed in the arc surface of the outer circle of the punching die holder. Vertical supporting frames are arranged on the base. A punching machine crossbeam is connected between the upper ends of the vertical supporting frames. A moving guide rail is arranged on the punching machine crossbeam. Two parallel punching machine heads are arranged on the moving guide rail. A motor and a speed reducer are arranged in each punching machine head. The full-automatic numerical control punching machine can be used for punching precise hardware workpieces, has high machining efficiency and achieves an assembly line work mode.

Owner:SUZHOU BAOMA NUMERICAL CONTROL EQUIP

A manual punching machine

The invention discloses a manual puncher. The manual puncher comprises a bottom mold arranged on a working table surface, a positioning column vertically arranged on the working table surface, a positioning module which is sleeved on the positioning column above the bottom mold, a core shaft which is parallel to the positioning column and arranged on the positioning module, a punching needle arranged at the lower end of the core shaft and an adjusting mechanism which is used for adjusting the core shaft to move vertically in the self length direction. The bottom mold is provided with a positioning slot for placing a part to be processed, the punching needle is disposed right above the positioning slot, the bottom of the positioning slot is provided with a hole matched with the punching needle. According to the manual puncher, the adjusting mechanism controls the core shaft to move vertically in the self length direction, so that the punching needle can penetrate the hole of the positioning slot of the bottom mold to achieve workpiece punching. The manual puncher is simple in structure, easy to operate and low in cost.

Owner:ZHANGJIAGANG XIAFEI PLASTIC

Drilling device for processing air-conditioning hanging panels and using method thereof

ActiveCN111761369BVertical position adjustmentLateral position adjustmentWork clamping meansMeasurement/indication equipmentsElectric machineGear wheel

The invention discloses a drilling device for air conditioner hanging board processing, which comprises a base, and the top of the base is respectively fixed with a mounting column and a U-shaped frame, and the U-shaped frame is located on one side of the mounting column, and the mounting column A mounting frame is slidably connected to the top of one side, and a mobile frame is slidably connected to the mounting frame. A rack is fixedly installed on the top of the mobile frame, and the rack is located above the mounting frame. One side of the top of the mounting frame is fixedly installed. There is a displacement motor, and a gear is fixedly installed on the output shaft of the displacement motor, and the gear is engaged with the rack; it also discloses a use method. The invention can realize automatic clamping, positioning and position adjustment of the hanging board to be punched, and can realize automatic punching of the hanging board, and at the same time can open holes of any size on the hanging board, so it has good convenience in use Sex, and can reduce the work intensity of the operator at the same time, so it has a good market promotion prospect.

Owner:江苏长达交通材料有限公司

A hydraulic high-speed water hammer punching machine

ActiveCN110977780BReduce punching noiseLow melting pointAbrasive feedersAbrasive machine appurtenancesHydraulic cylinderPunch press

The invention discloses a hydraulic high-speed water-hammering punch press. The hydraulic high-speed water-hammering punch press comprises a punch rack, a hydraulic water washing unit, a pore diametercontrol unit, a cooling device and a control electrical box, wherein a supporting frame and a punch table are arranged on the punch rack; the top of the supporting frame is equipped with a seat tableboard; the hydraulic water washing unit comprises a pressurizing hydraulic cylinder, a water washing pressurizing cylinder and a water supply system; a positioning sleeve is arranged on the seat table board; the pressurizing hydraulic cylinder is mounted on the seat table board through the positioning sleeve; and one side of the supporting frame is equipped with a washing fixing frame. The hydraulic high-speed water-hammering punch press adopts the pressurizing hydraulic cylinder to indirectly apply pressure to the water washing pressurizing cylinder, so that large oil cylinder pressure is converted into air pressure of the water washing pressurizing cylinder, and therefore, large air pressure instantaneously pushes water flow in the water washing pressurizing cylinder, water flow is sprayed to a to-be-processed object with high-speed impact force, water flow punching replaces conventional mould punching, and punching noises can be reduced; and meanwhile, a mould is not needed for assisting processing.

Owner:盐城青松机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com