Patents

Literature

92results about How to "Realize automatic punching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

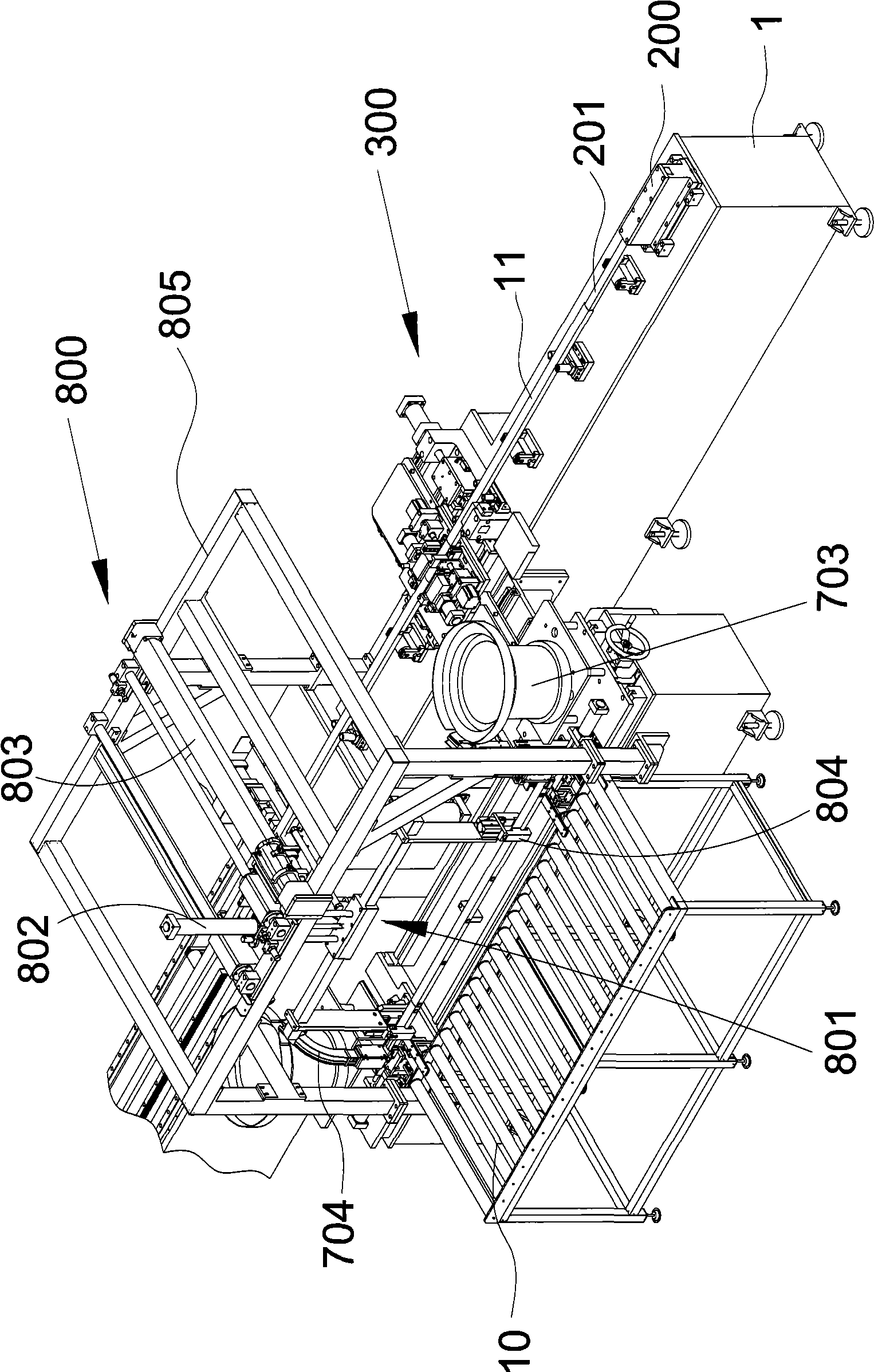

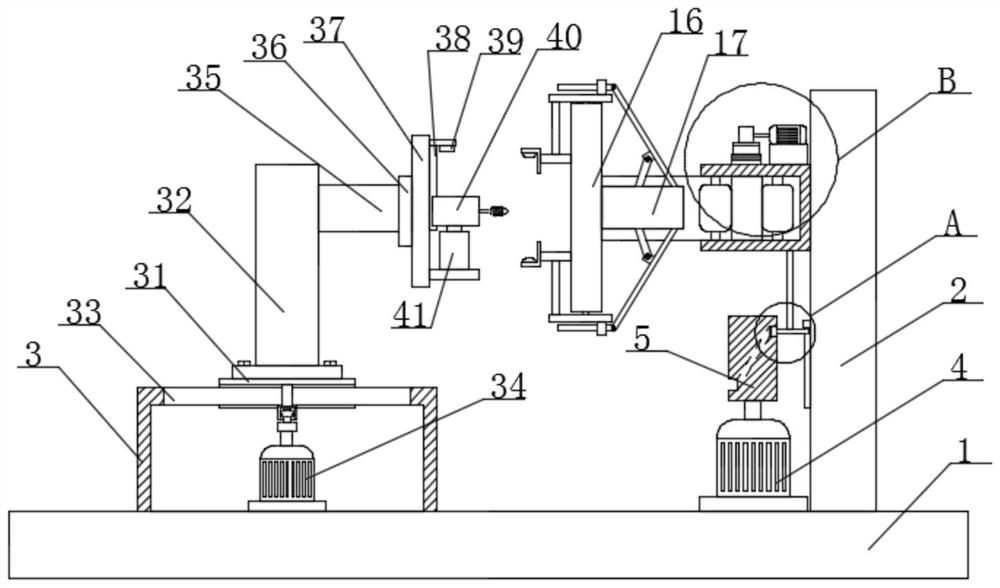

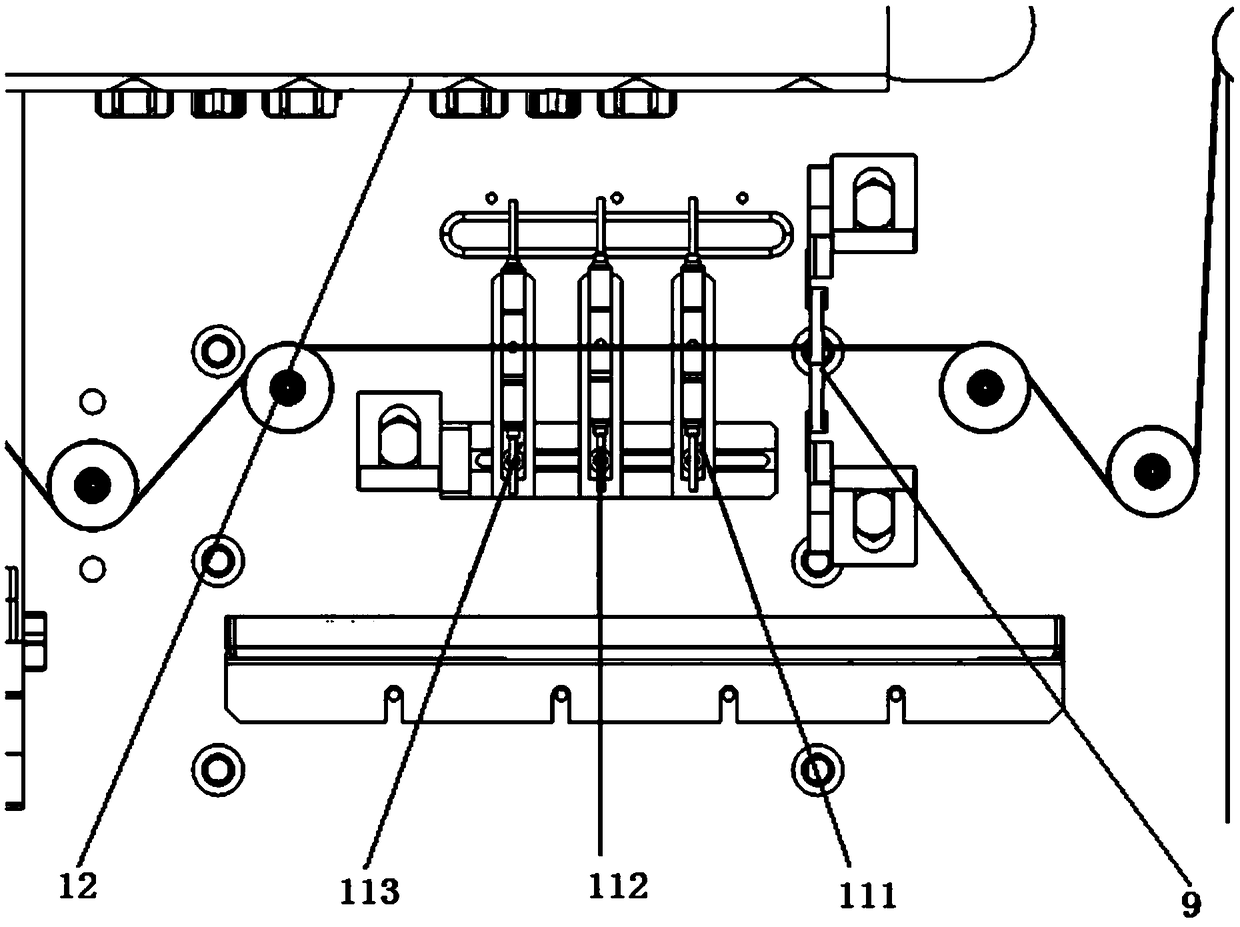

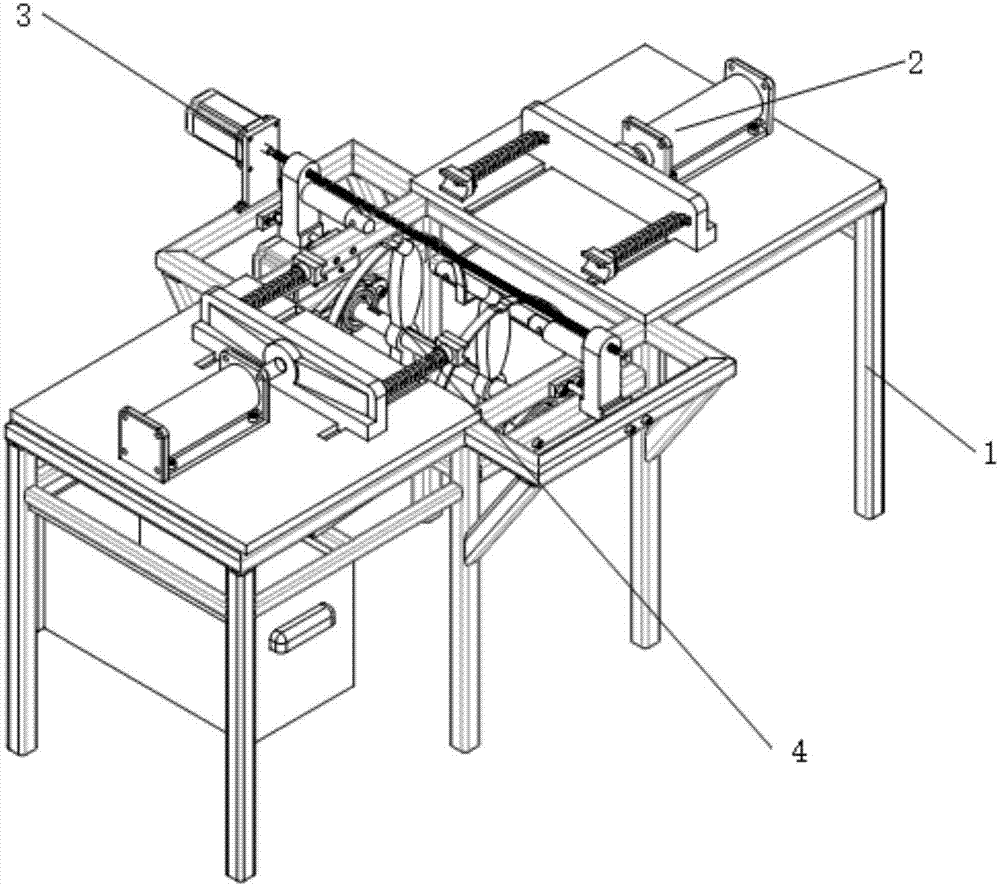

Method for automatically processing pipe fitting and equipment thereof

The invention relates to an automatic pipe fitting processing method and a device designed for implementing the method. The device is mainly used for punching a long raw material pipe, pressing an abrasion resistant sleeve into each punched hole, cutting out short pipes with specific lengths from the long raw material pipe and pressing end covers to both end parts of each short pipe. The method comprises the following steps: the raw material pipe penetrates the outer side of a piercing rod from the back to the front, a position to be punched within an area to be cut is ensured to be positioned in the front of the punching position, a first hole is punched on the area to be cut on the raw material pipe, then the long raw material pipe is retreated to move the first punched hole to the pressing position of the abrasion resistant sleeve, then the abrasion resistant sleeve is pressed into the first punched hole, the next hole is punched on the raw material pipe, and the operation is repeated till all holes within the area to be cut are completely punched and the abrasion resistant sleeves are all completely pressed; the raw material pipe is cut to obtain short pipes till the raw material pipe is entirely and completely processed. Besides, a connecting bar of an electric telescope gate processed by utilizing the invention has high automation degree and low manufacturing cost .

Owner:庄添财

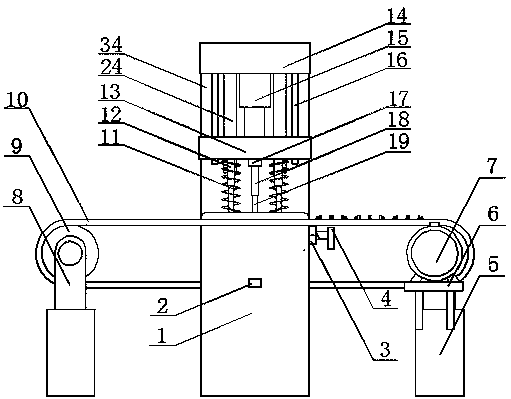

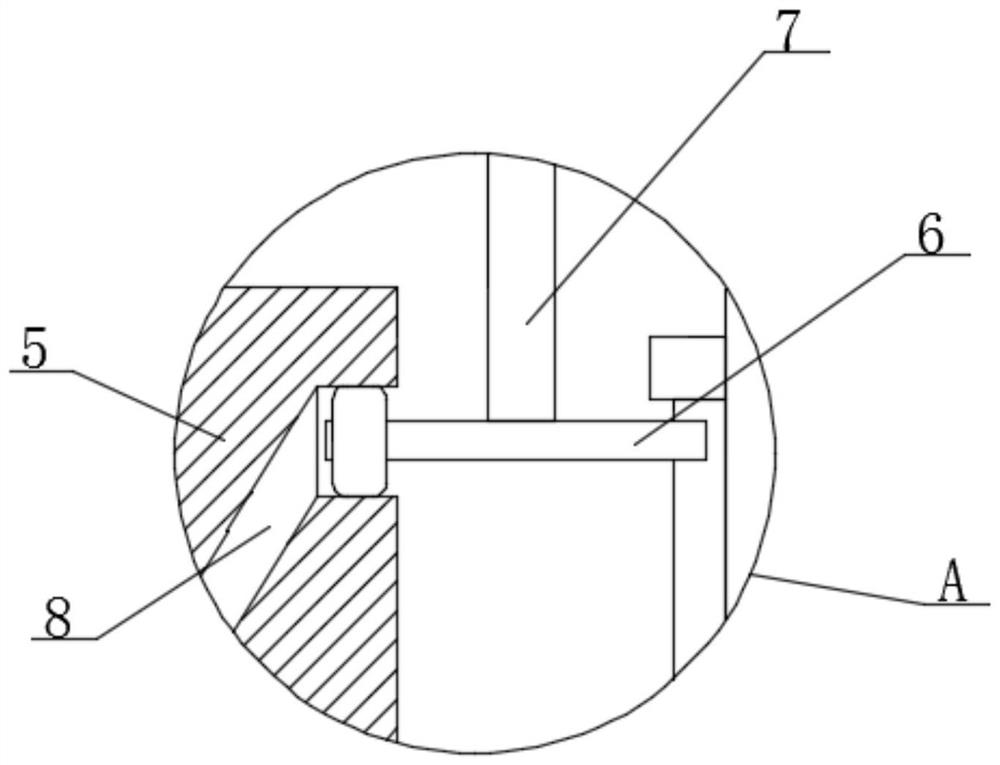

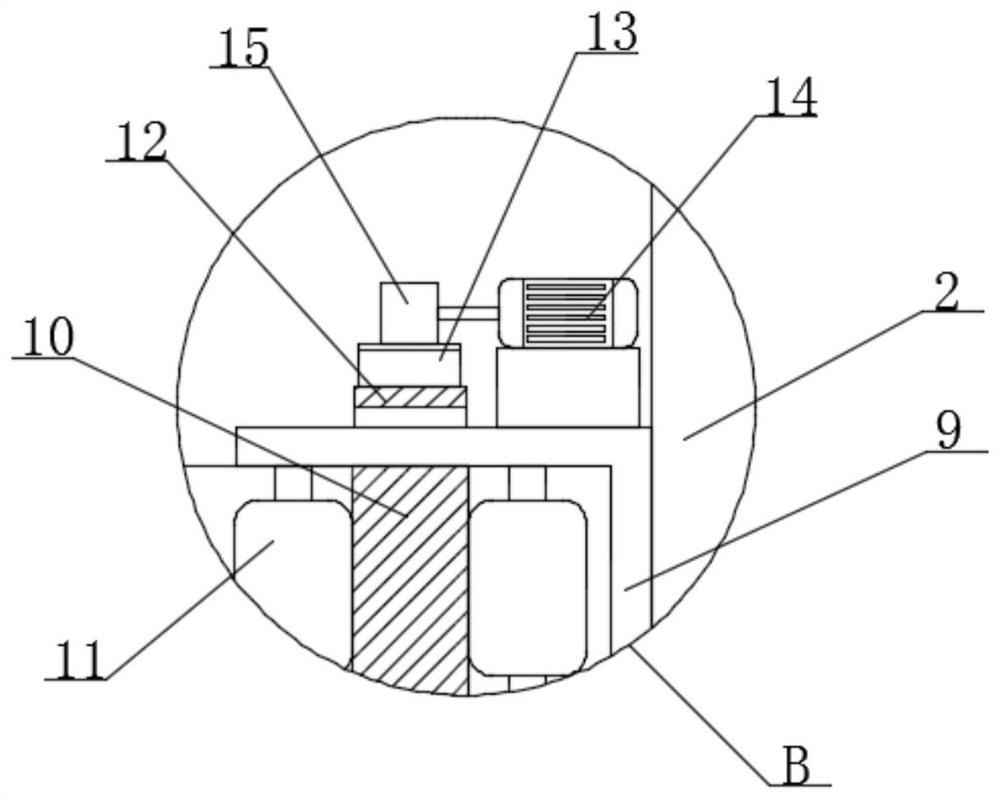

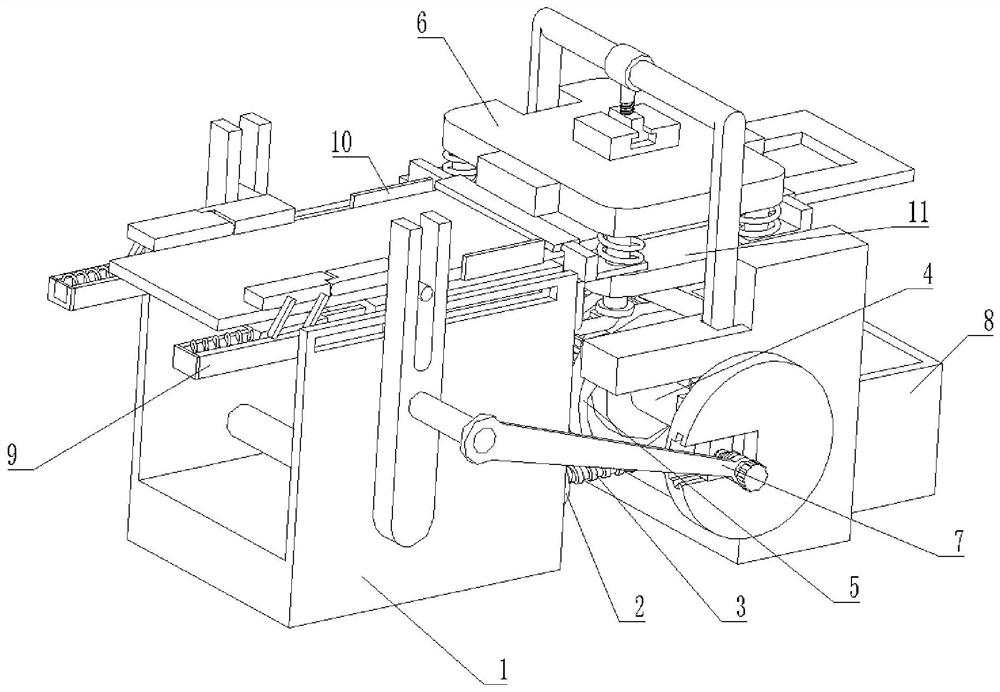

Automatic punching mechanism for automobile die machining

InactiveCN108435896ARealize intermittent deliveryEliminate manual delivery processPerforating toolsMetal-working feeding devicesHydraulic cylinderPunching

The invention discloses an automatic punching mechanism for automobile die machining. The automatic punching mechanism comprises an operation table, a discharging box is arranged on the side wall of one end of the operation table in a penetrating mode, first openings are formed in the opposite side walls of the operation table, two bases are fixed to two sides of the operation table, vertical plates are fixed to the upper ends of the two bases, rollers are connected between the two vertical plates on the same side in a rotating mode, a transmission belt is wound around the portion between thetwo rollers and penetrates through the first openings, and a supporting frame is fixed to the side wall of one end of one base. The automatic punching mechanism has the advantages that by means of thecooperation between a driving motor and a ratchet wheel, intermittent conveying of dies can be realized, the manual conveying process can be omitted, the problems of the high-intensity work of manualreinforcing and auxiliary punching can be solved by utilizing first limiting blocks, second limiting blocks, a hydraulic cylinder and a punch, automatic punching can be realized, the labor intensitycan be lowered, the labor can be saved, the probability of human injuries can be lowered, the working efficiency can be improved, and the operation is simple.

Owner:SUZHOU ZHONGSHUNRUITAI AUTOMOBILE INSPECTION TOOLS CO LTD

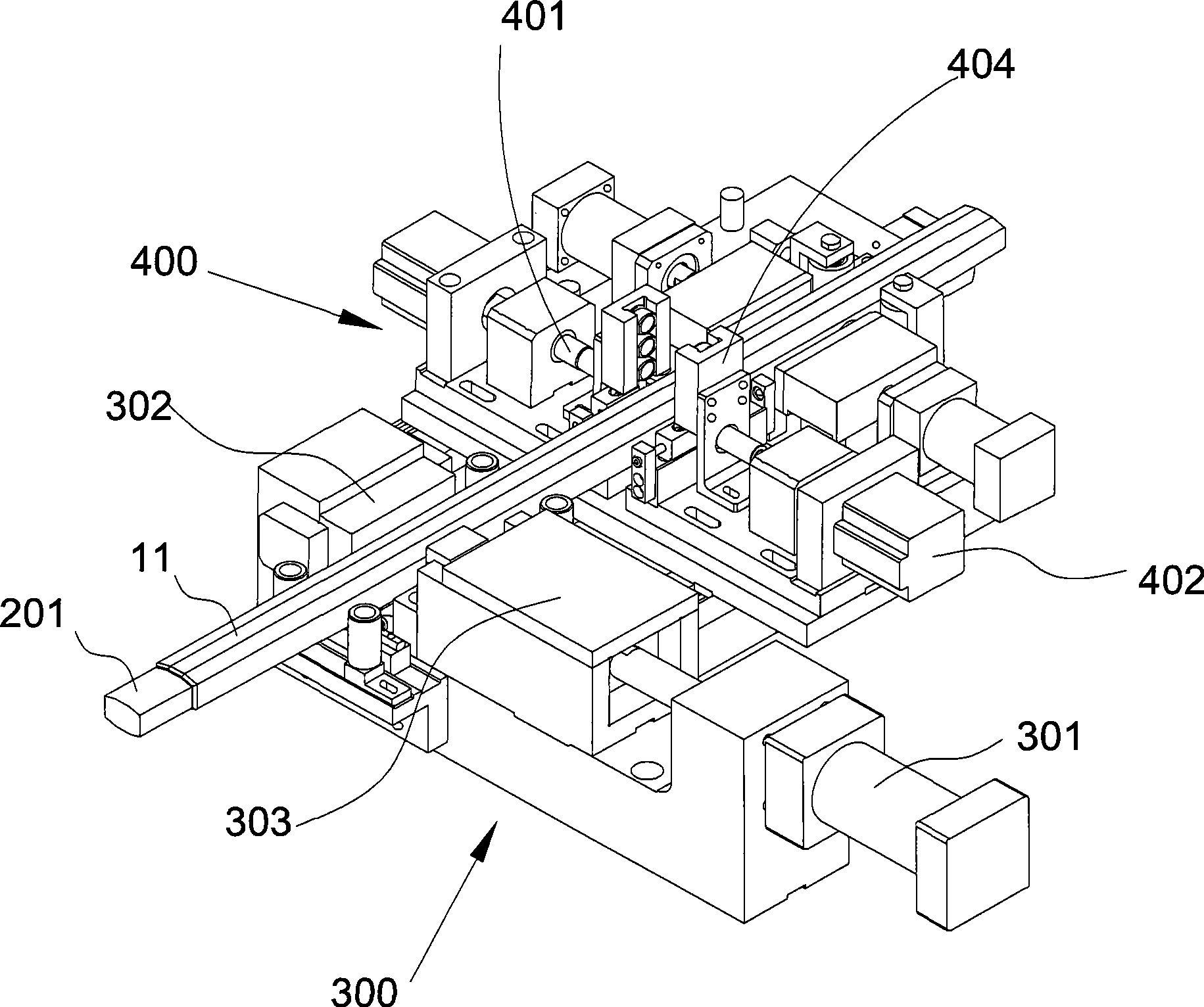

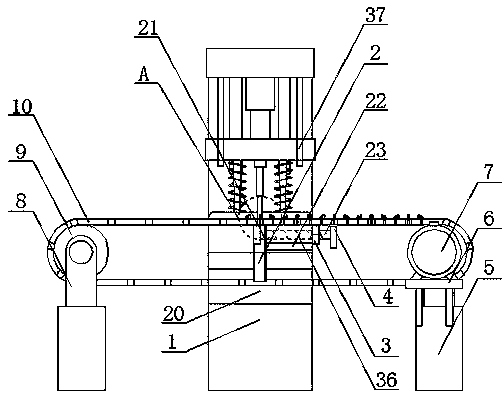

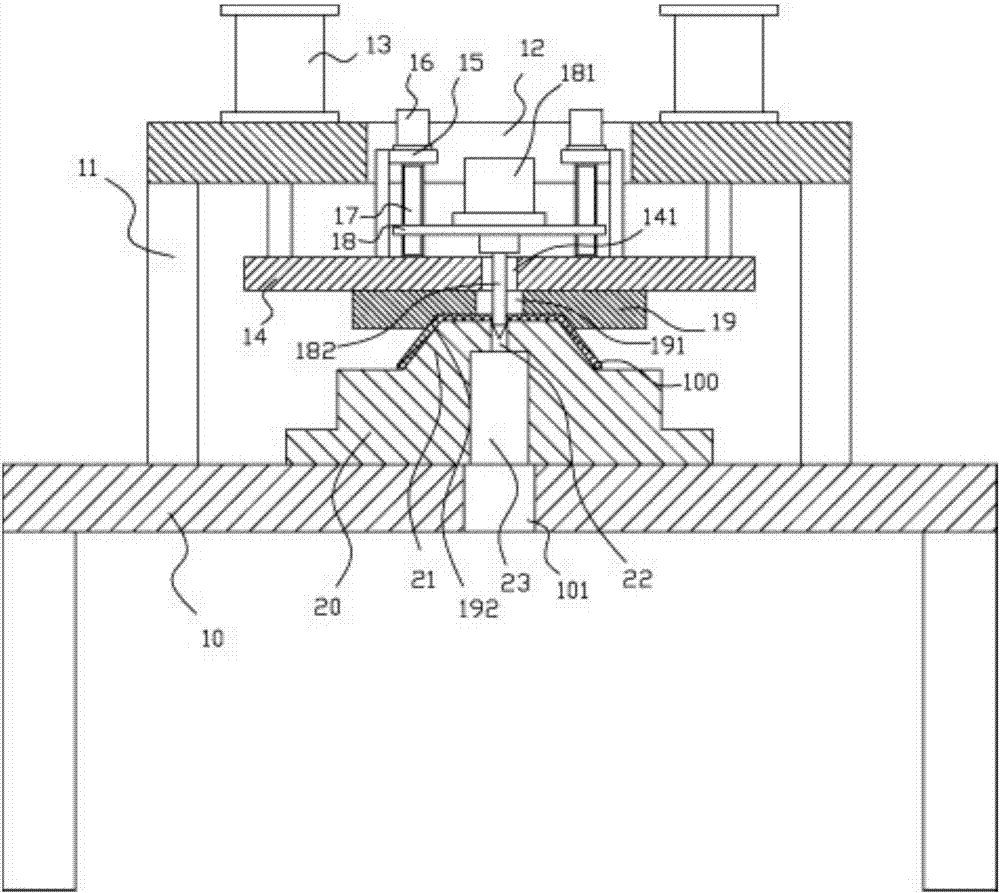

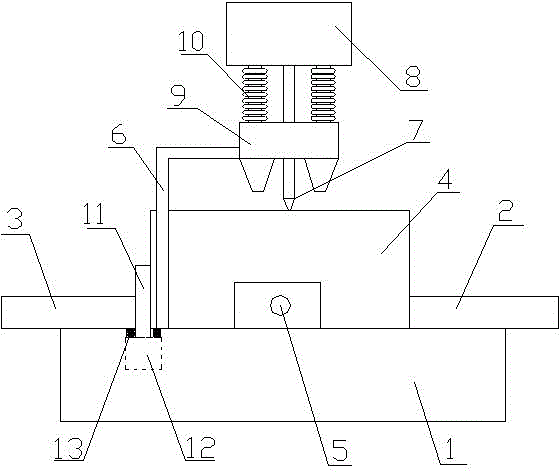

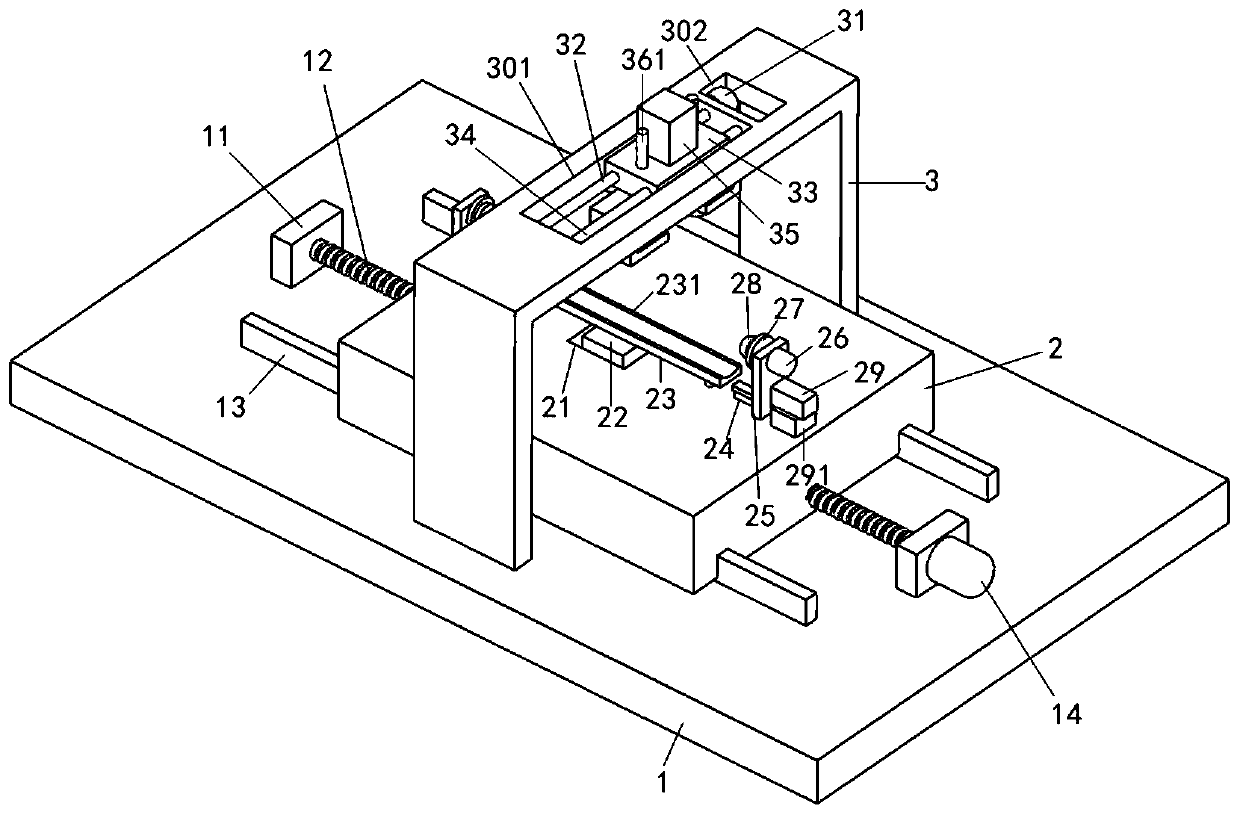

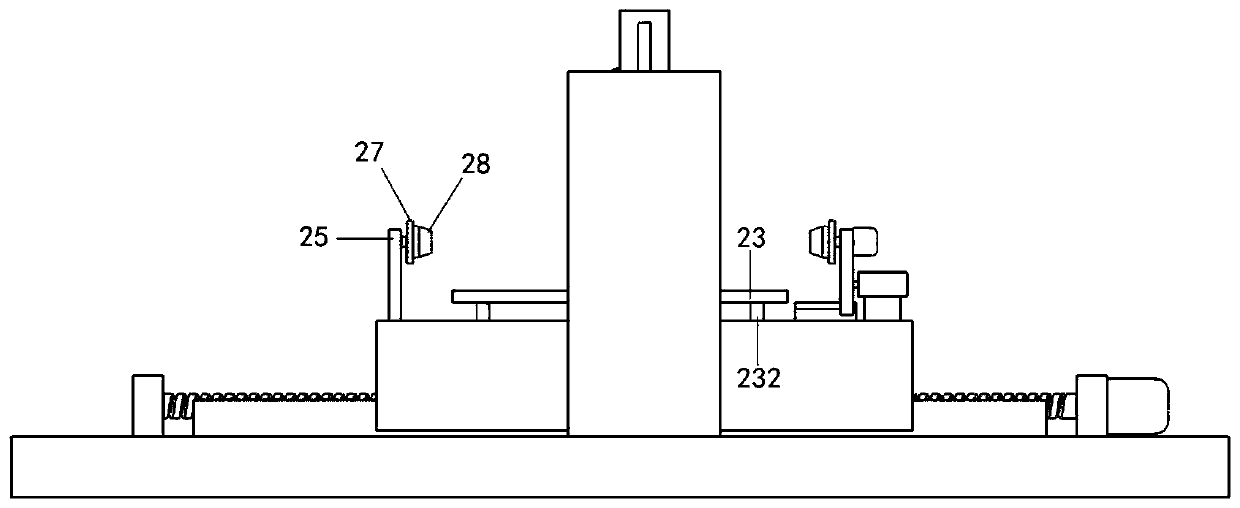

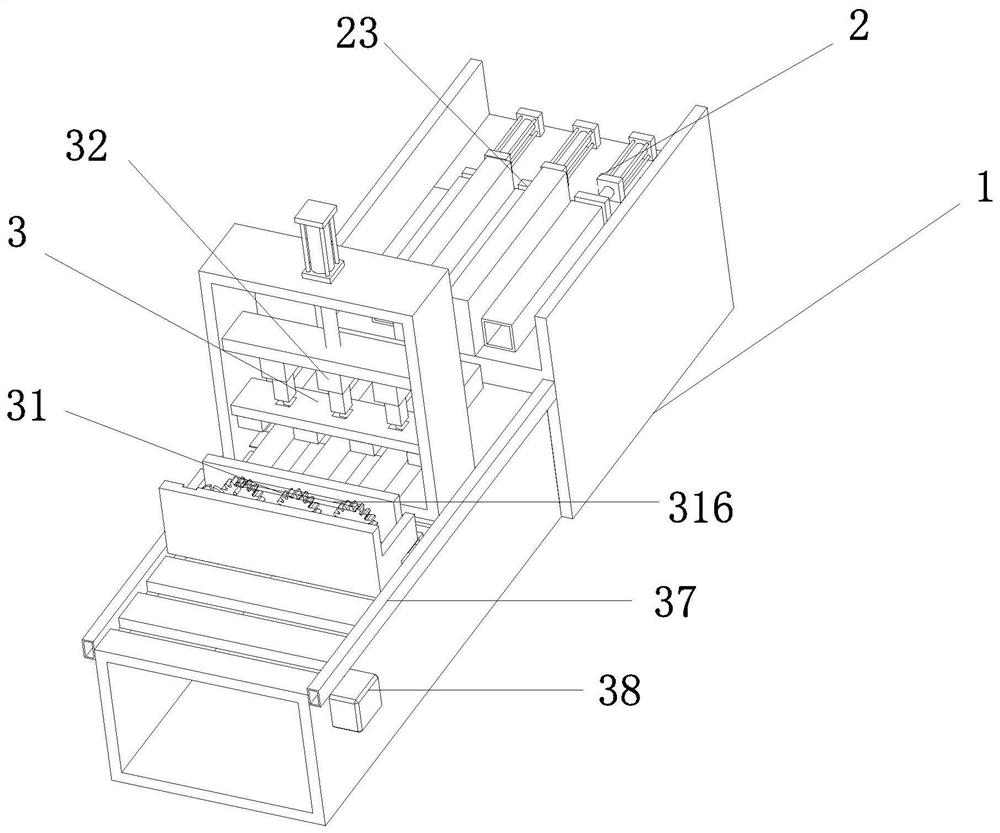

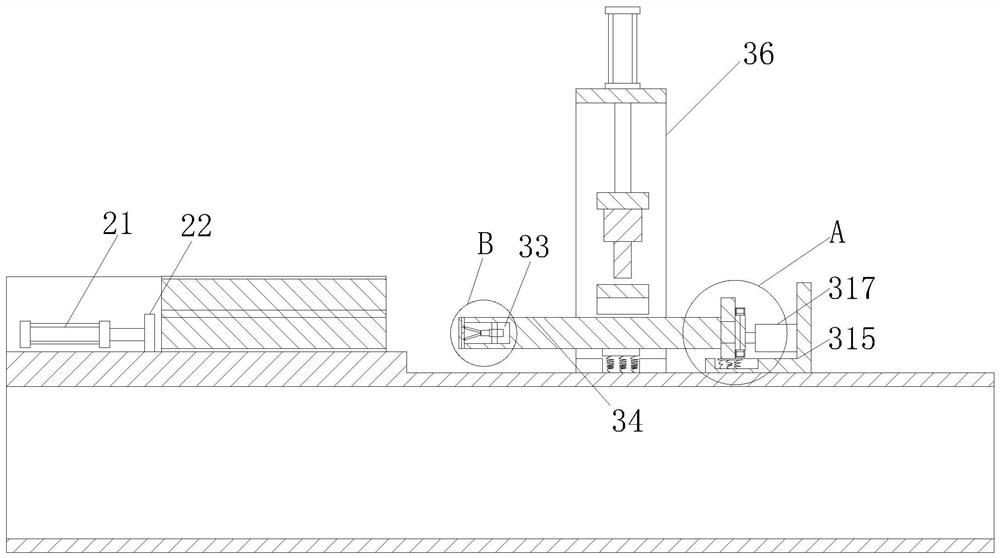

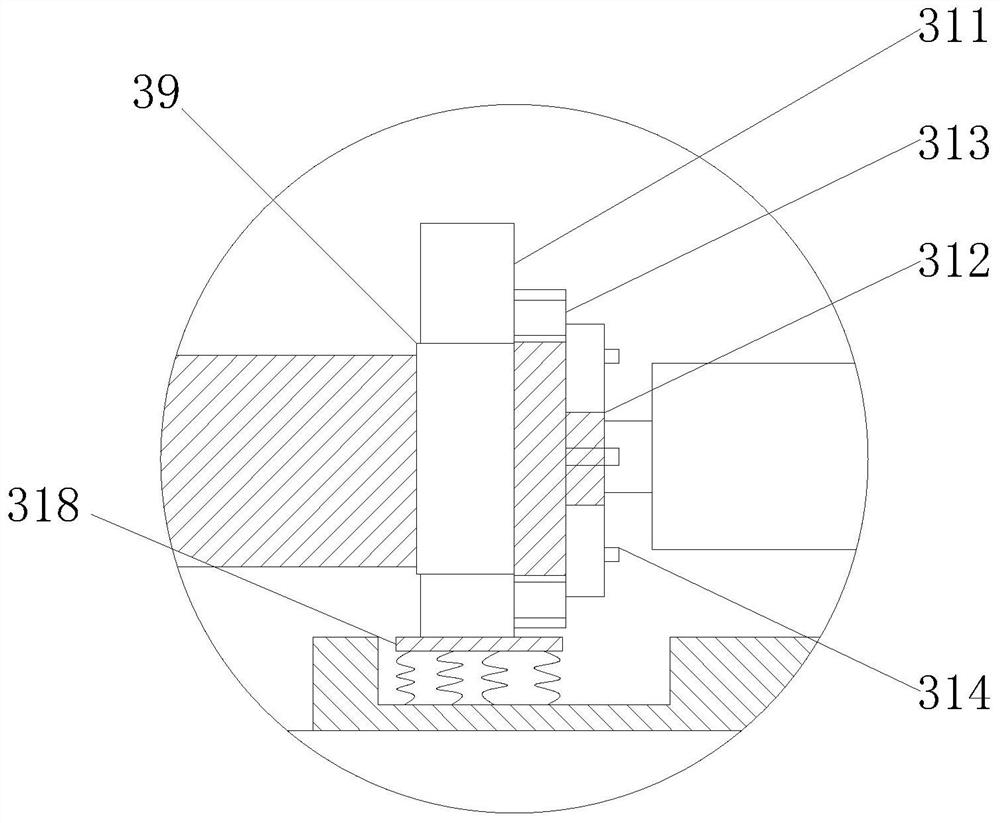

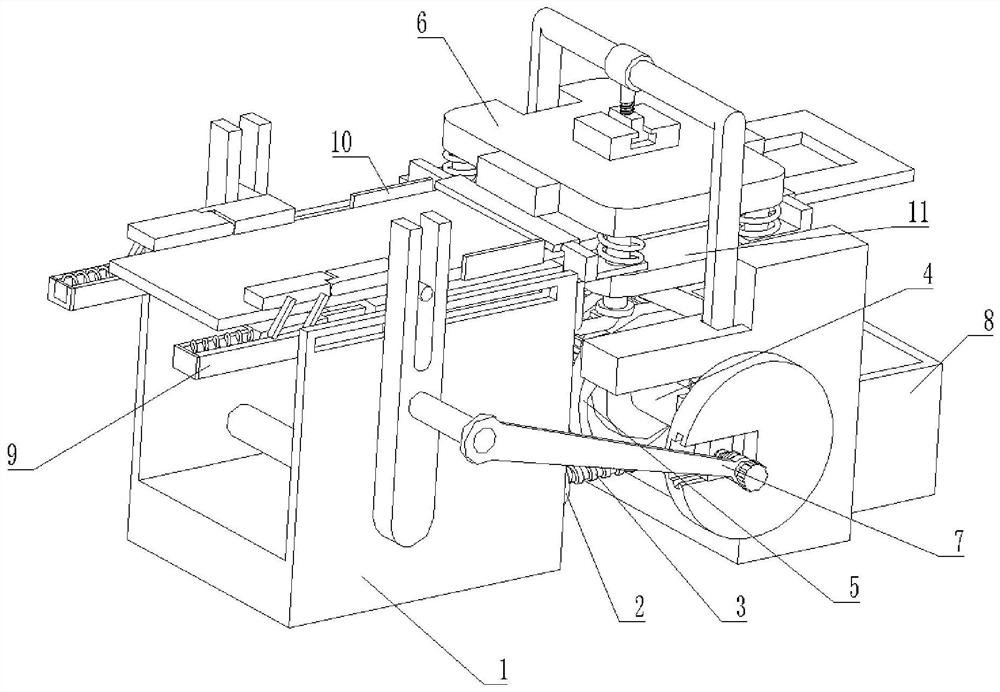

Pipe punching machine

ActiveCN104624779ADischarge in timeImprove punching efficiencyMetal-working feeding devicesStripping-off devicesPunchingUltimate tensile strength

The invention relates to a pipe punching machine. The pipe punching machine comprises a base and an installing base installed on the base, the installing base is provided with a punching device, and the base is provided with a workpiece clamping device and a workpiece lifting device which act in cooperation with the punching device. According to the pipe punching machine, automatic punching without manual intervening can be achieved, the problem that waste is difficult to discharge during punching is solved, the pipe punching precision is improved, the labor intensity of workers is relieved, the production efficiency is high, and the yield is high.

Owner:FOSHAN GOOGOL AUTOMATION TECH

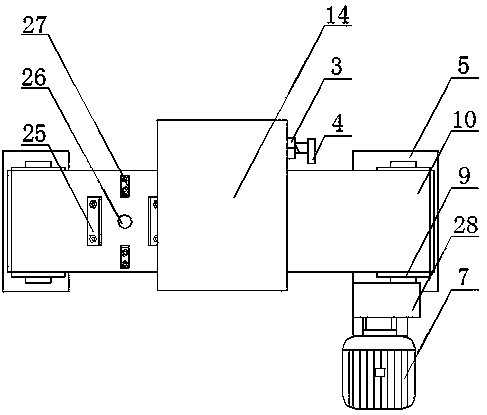

Automatic thread binding equipment for paper

The invention relates to automatic thread binding equipment for paper. The automatic thread binding equipment comprises a rack, a workbench face arranged on the rack, a left support, a right support, a paper containing plate and threading and knotting assemblies, wherein the left support and the right support are fixedly arranged above the workbench face and opposite to each other, the paper containing plate is horizontally mounted between the left support and the right support, and the threading and knotting assemblies are correspondingly mounted on the upper side and the lower side of the paper containing plate and used for performing threading and knotting actions in a cooperative manner. According to the automatic thread binding equipment, the threading work of binding threads is completed under the cooperation of an upper clamp mechanism and a lower clamp mechanism, the upper clamp mechanism is in cooperation with a front clamp mechanism and the lower clamp mechanism for completing the knotting work of the binding threads. The automatic thread binding equipment is high in degree of automation, high in knotting speed and capable of improving thread binding efficiency of the paper greatly.

Owner:庸博(厦门)电气技术有限公司 +3

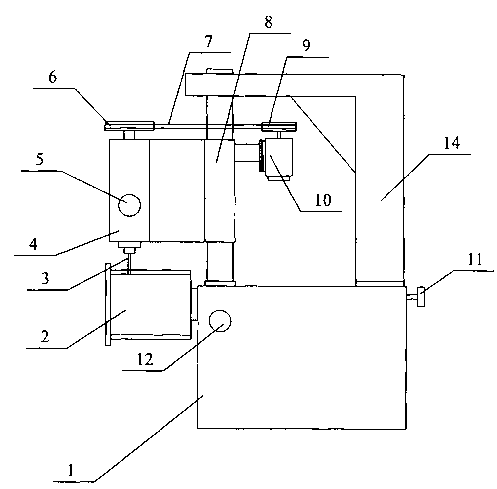

Drilling mechanism for upper shell of wire connecting box

InactiveCN107498093AGuaranteed punching qualityRealize automatic punchingBoring/drilling componentsBoring/drilling machinesEngineeringComputer engineering

The invention discloses a drilling mechanism for an upper shell of a junction box, which includes a frame, a main support frame is fixed on the top surface of the middle part of the top plate of the frame, the middle part of the top plate of the main support frame has a main through groove, and the main support frame Lifting cylinders are fixed on both sides of the top plate, the push rod of the lifting cylinder passes through the top plate of the main support frame and the upper connecting plate is fixed, the two sides of the middle top surface of the upper connecting plate are fixed with lifting support frames, and the lifting support frame The lifting motor is fixed on the top plate, the bottom end of the vertical screw is hinged on the upper connecting plate, the top end of the vertical screw is hinged on the top plate of the lifting support frame, the output shaft of the lifting motor is a spline shaft, and the spline shaft is inserted into the sleeve In the spline hole that the top of the vertical screw rod has, the lifting plate is screwed in the two vertical screw rods, and the middle top surface of the lifting plate is fixed with a drilling motor. It can fix the workpiece and ensure that its bottom and top surfaces are supported, and realize automatic drilling to ensure the quality of drilling.

Owner:FOSHAN XUNAOJIE AUTOMATION TECH CO LTD

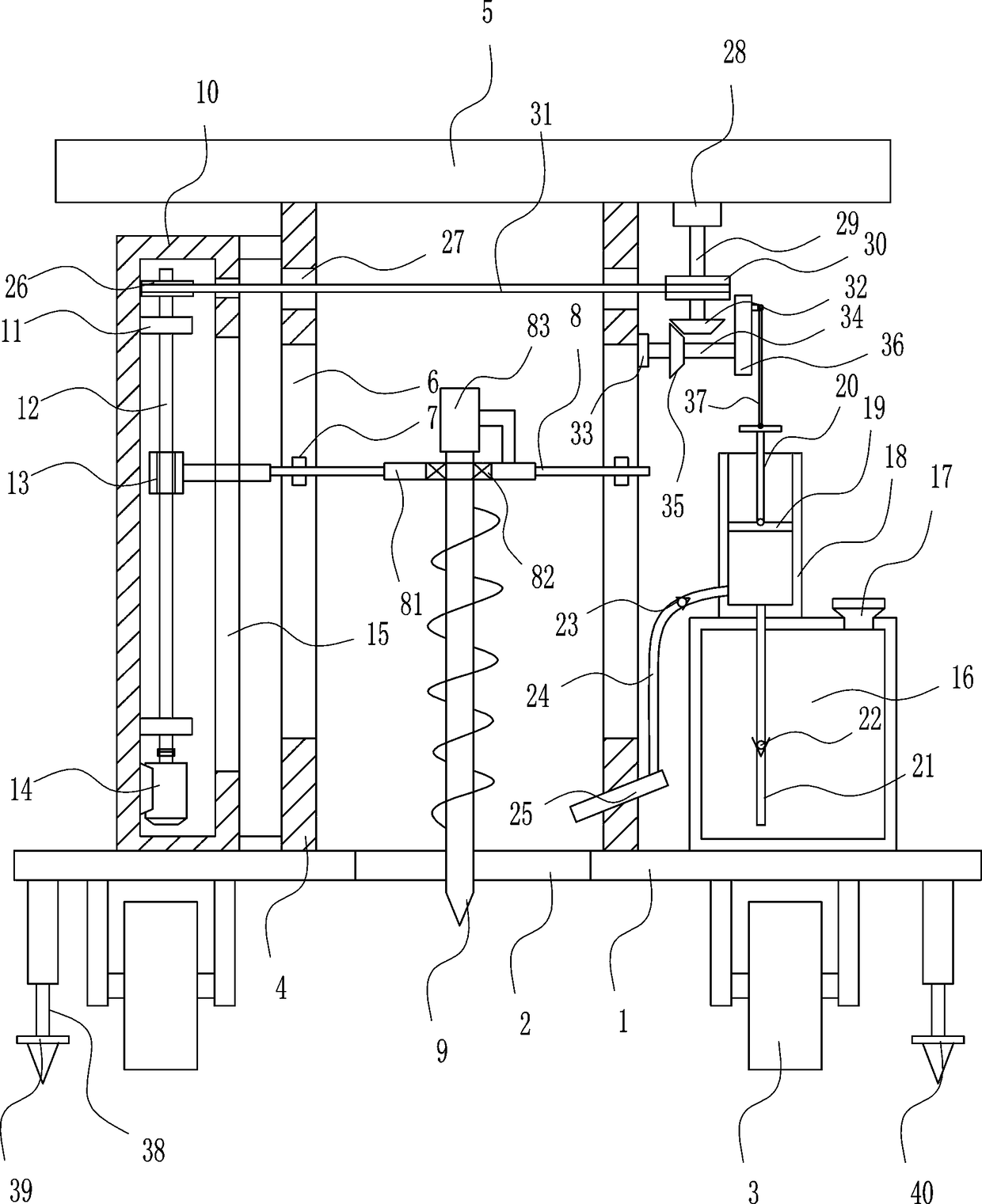

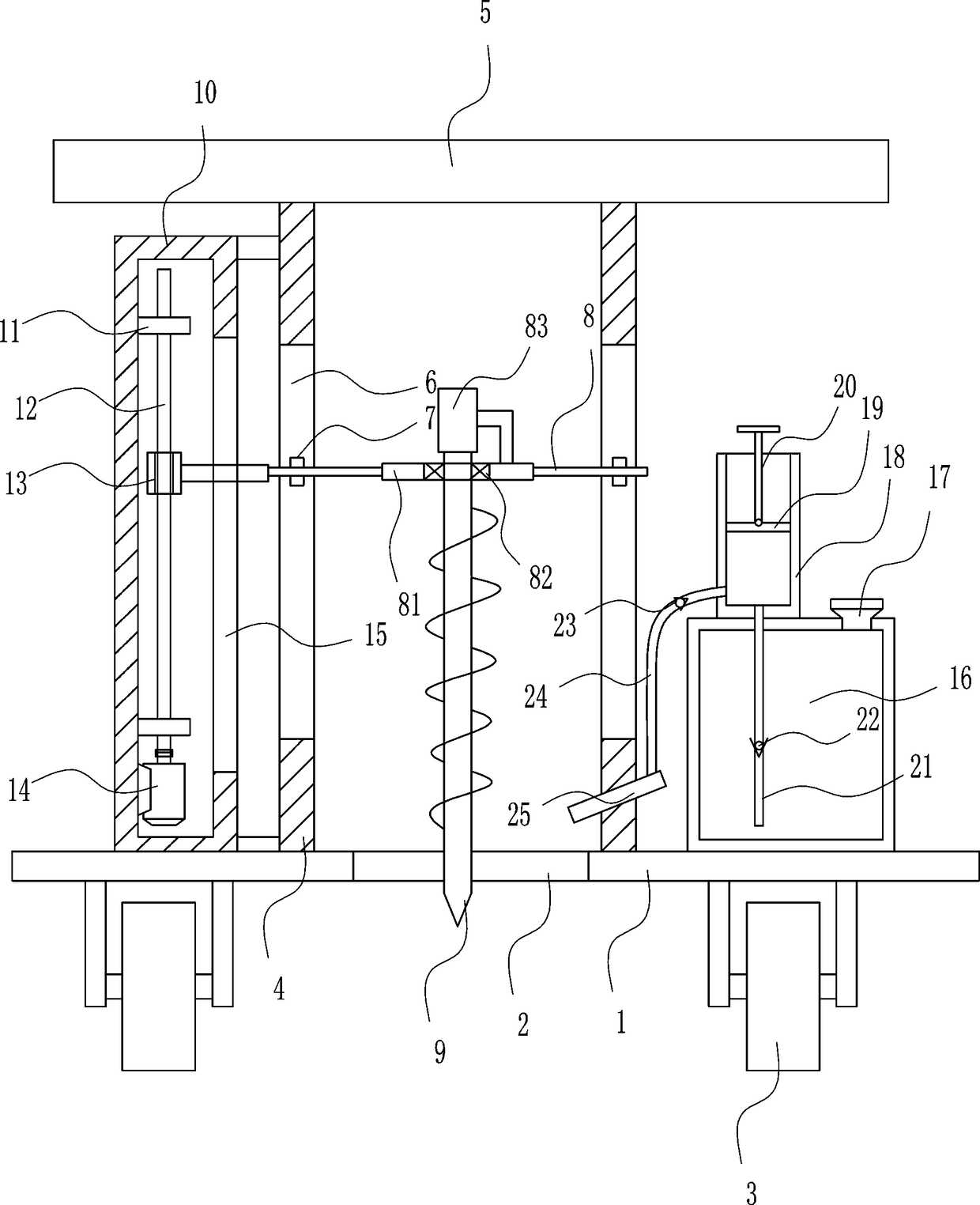

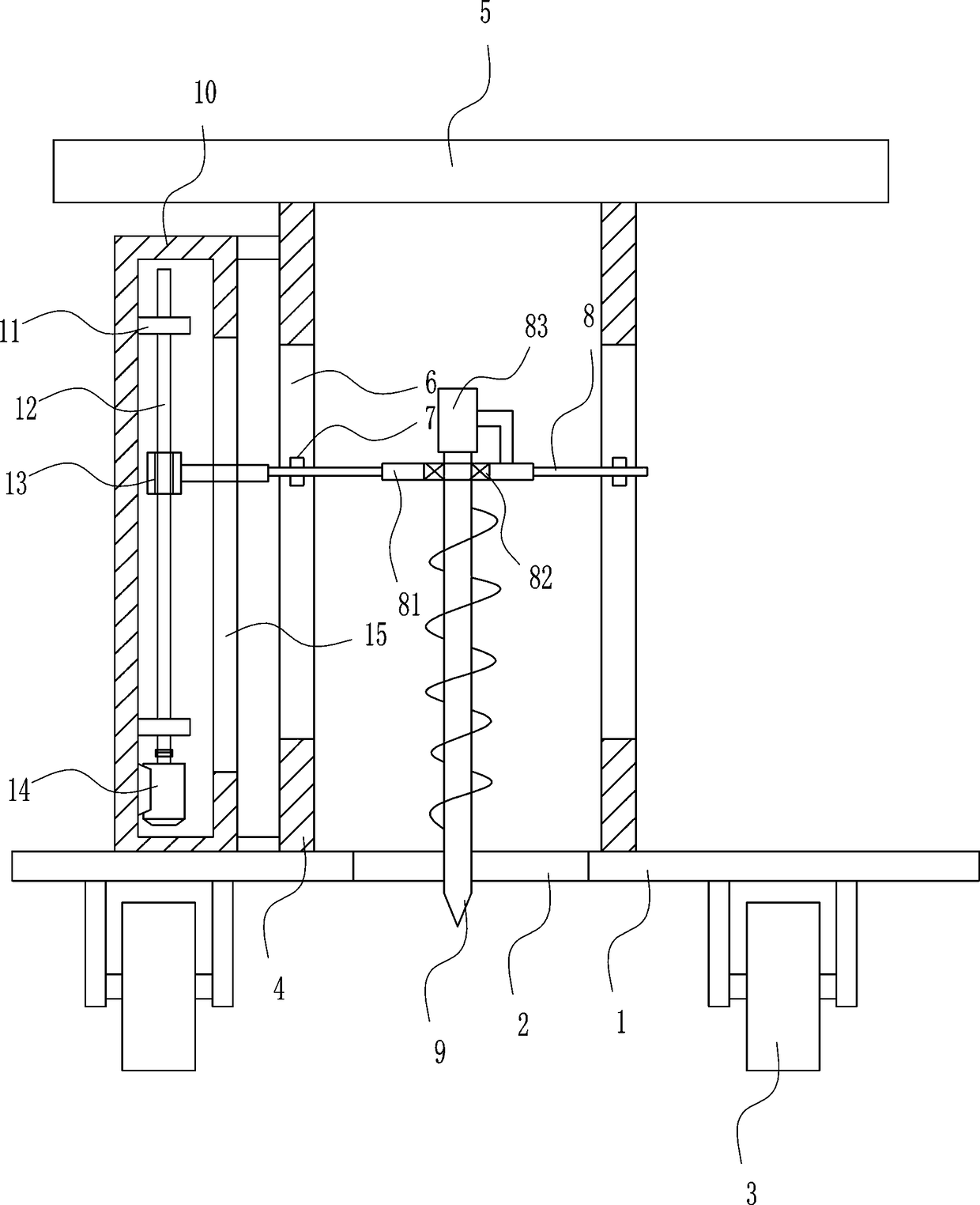

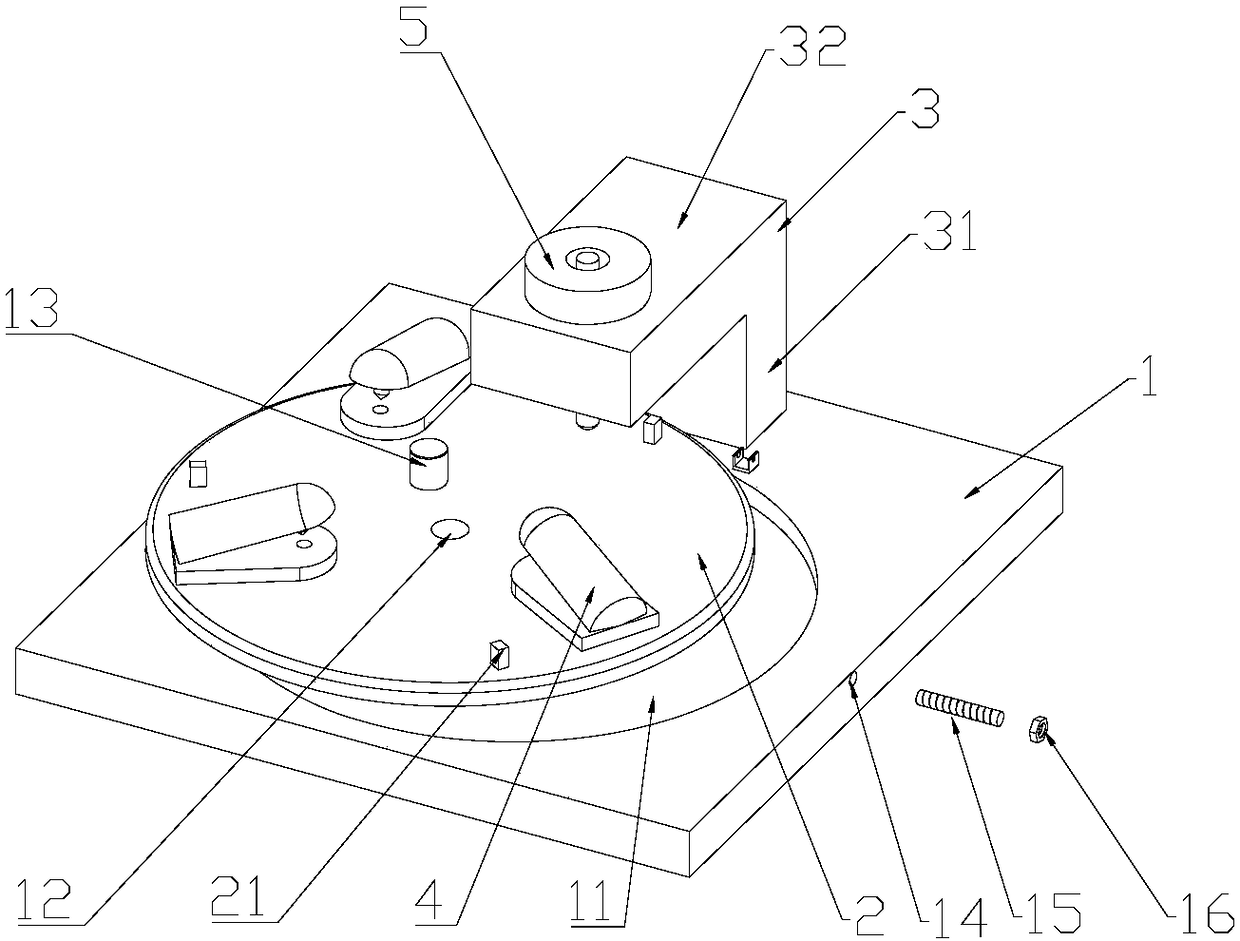

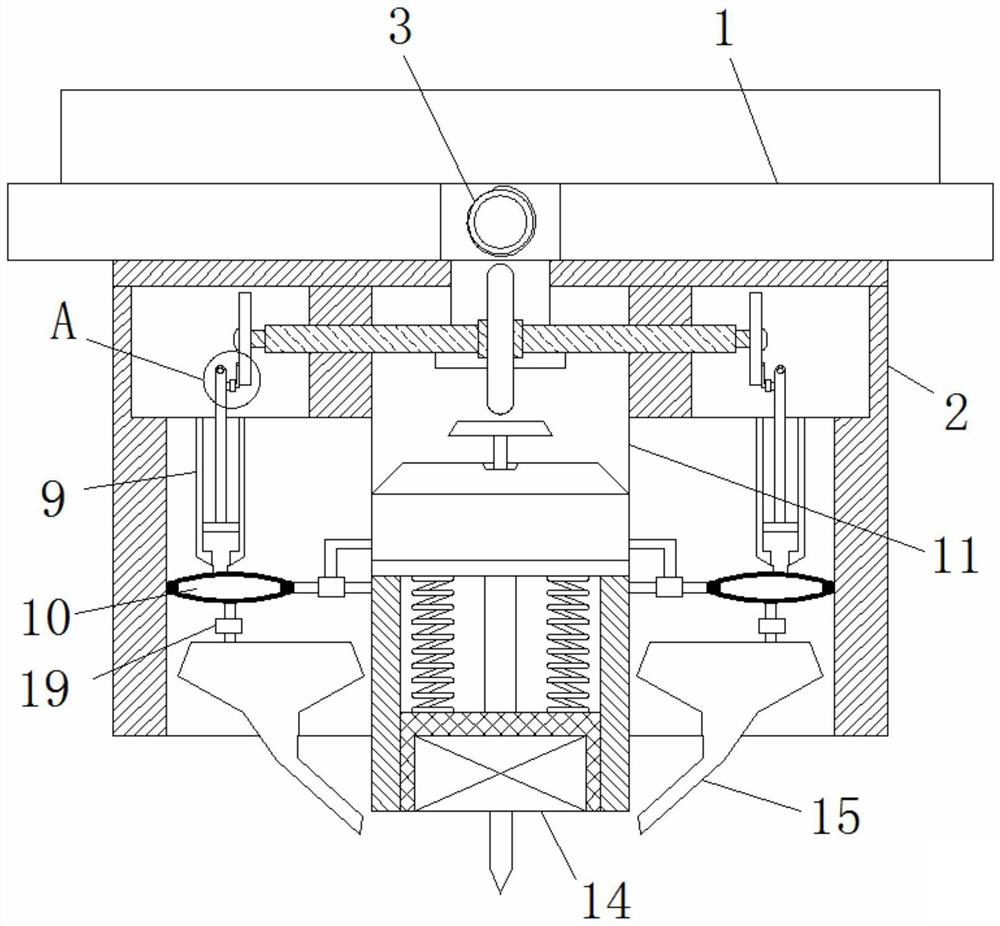

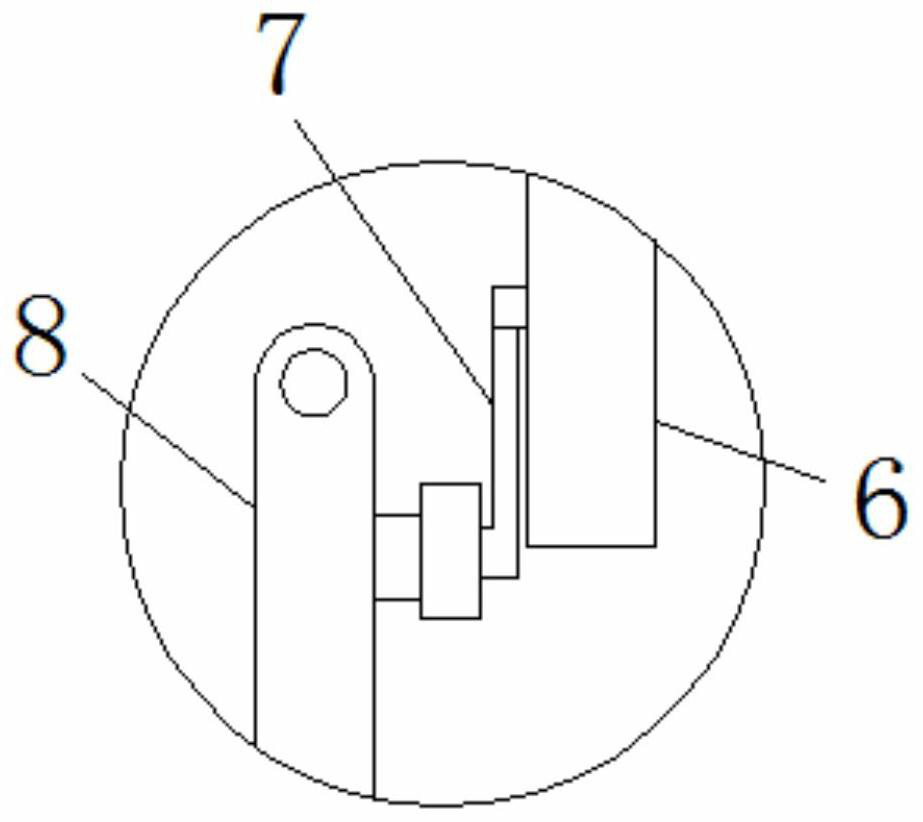

Rotary type punching equipment for gardens

ActiveCN108450088AReduce workloadRealize automatic water sprayPlantingFurrow making/coveringPunchingElectric machine

The invention relates to punching equipment, in particular to rotary type punching equipment for gardens. The invention aims to provide the rotary type punching equipment for the gardens, which is simple to operate and has high punching efficiency and high punching quality. In order to achieve the above aim, the invention provides the rotary type punching equipment for the gardens. The rotary typepunching equipment for the gardens comprises a bottom plate, wheels, mounting frames, a top plate, sliding rails, a sliding block, a first connecting rod, a mounting plate, a first bearing pedestal,a first motor, a spiral rotary drill bit and the like; a small hole is formed in the center of the bottom of the bottom plate; the wheels are arranged at the bottom of the bottom plate in a bilaterally symmetrical mode; the mounting frames are arranged at the top of the bottom plate in a bilaterally symmetrical mode; the top plate is arranged at the tops of the mounting frames; and the sliding rails are arranged on the front sides of the mounting frames. The rotary type punching equipment for the gardens achieves the effects of simplicity in operation, high punching efficiency and high punching quality, realizes automatic punching, is simple to operate, has high punching efficiency of mechanical punching, can punch holes with uniform size, and is novel in structure and high in practicability.

Owner:姚啸啸

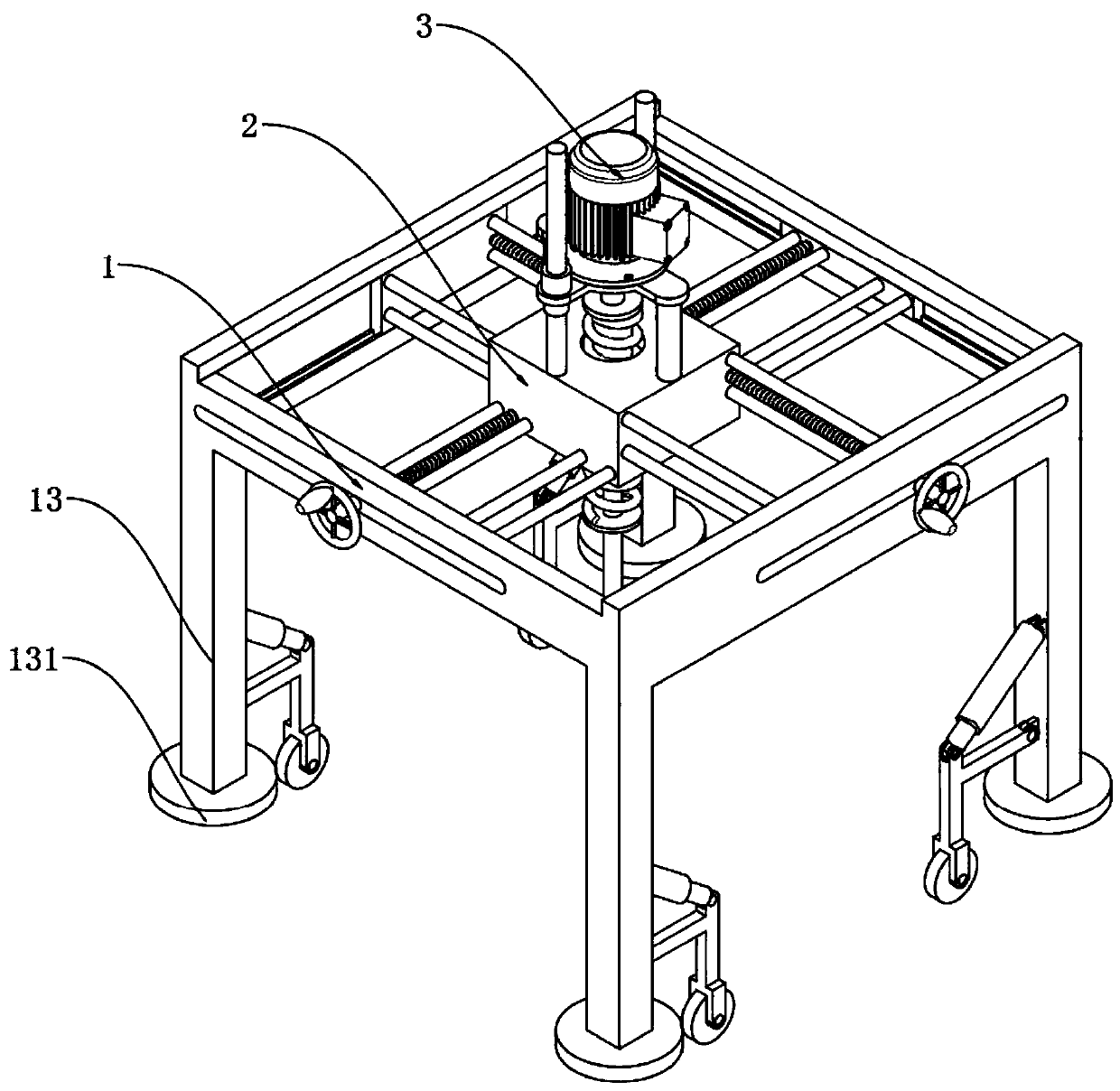

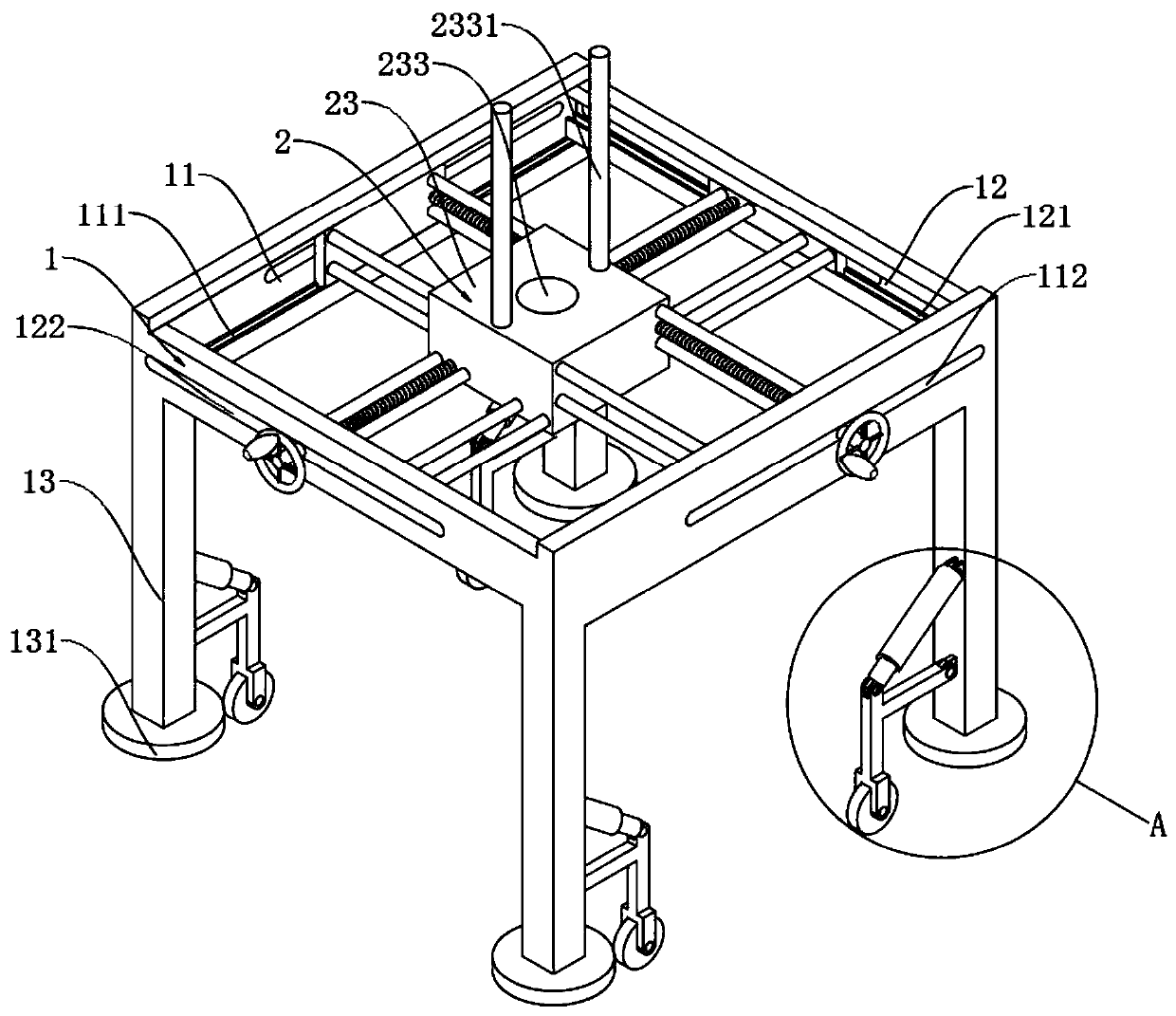

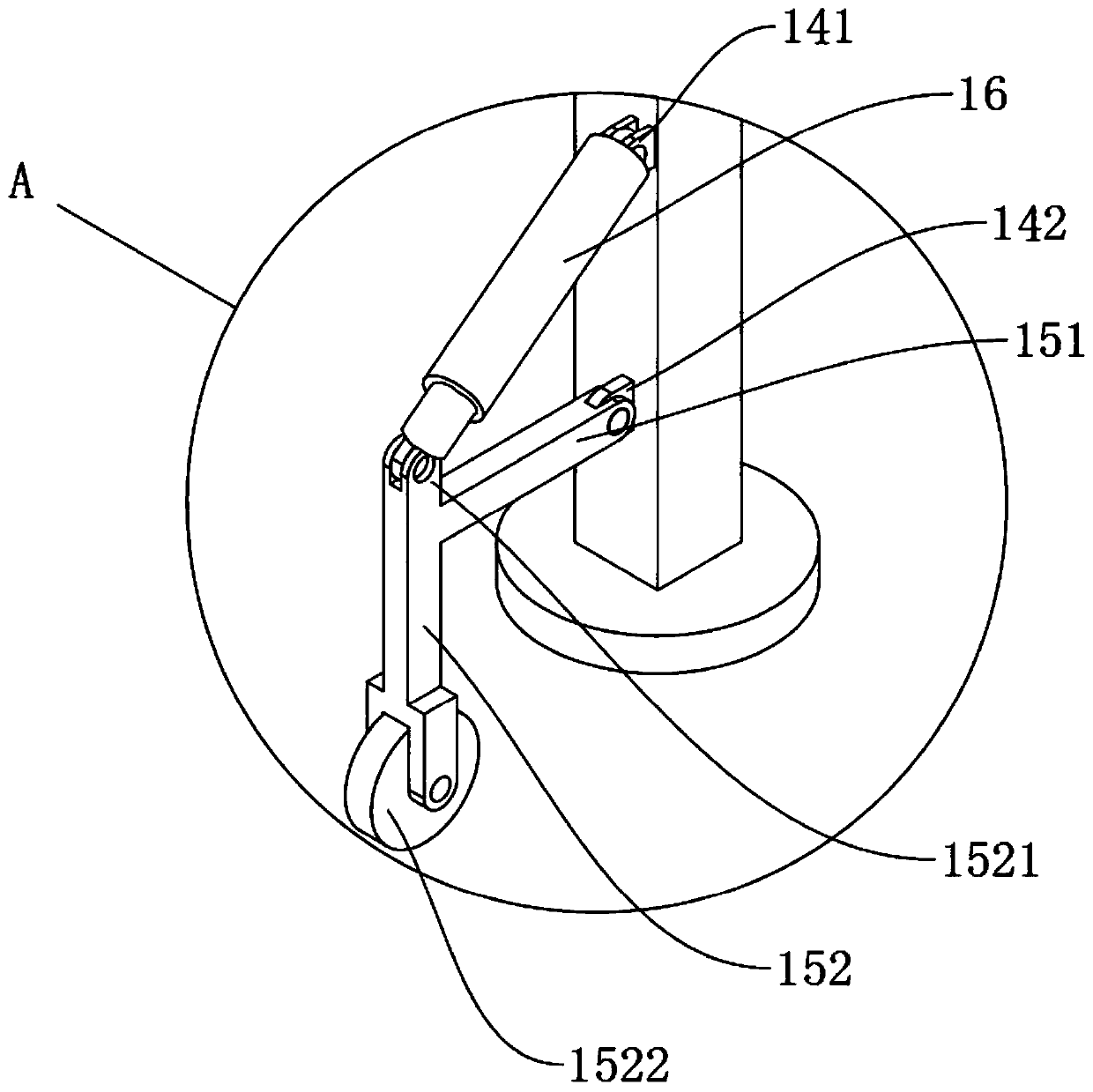

Drilling device with positioning function for building construction

InactiveCN111571719AAccurate mobile positioningRealize convenient mobileMetal working apparatusHydraulic cylinderArchitectural engineering

The invention discloses a drilling device with a positioning function for building construction. The drilling device with the positioning function for the building construction comprises a support, apositioning structure on the support and a drilling structure on the positioning structure, wherein first sliding grooves are formed inside the two ends of the support correspondingly, first limitingsliding grooves are formed in the upper ends and the lower ends of the first sliding grooves correspondingly, first rotating plate sliding grooves are formed in the first sliding grooves, and second sliding grooves are formed in the interiors on the two sides of the support. According to the drilling device, a rolling supporting leg structure is pushed through extension of a arranged roller hydraulic cylinder to rotate downwards by taking a lower hinge lug as the axis, so that the device is supported through rolling wheels, the convenient movement of the device is realized, the number of revolutions of a arranged second lead screw and a arranged first lead screw is in direct proportion to the moving distance of a moving block, so that the drilling structure is accurately moved and positioned along with the moving block, the drilling structure is pulled to move downwards through contraction of a arranged drilling hydraulic cylinder, automatic drilling of the device is achieved, and theproblems in the background art are solved.

Owner:吴阳

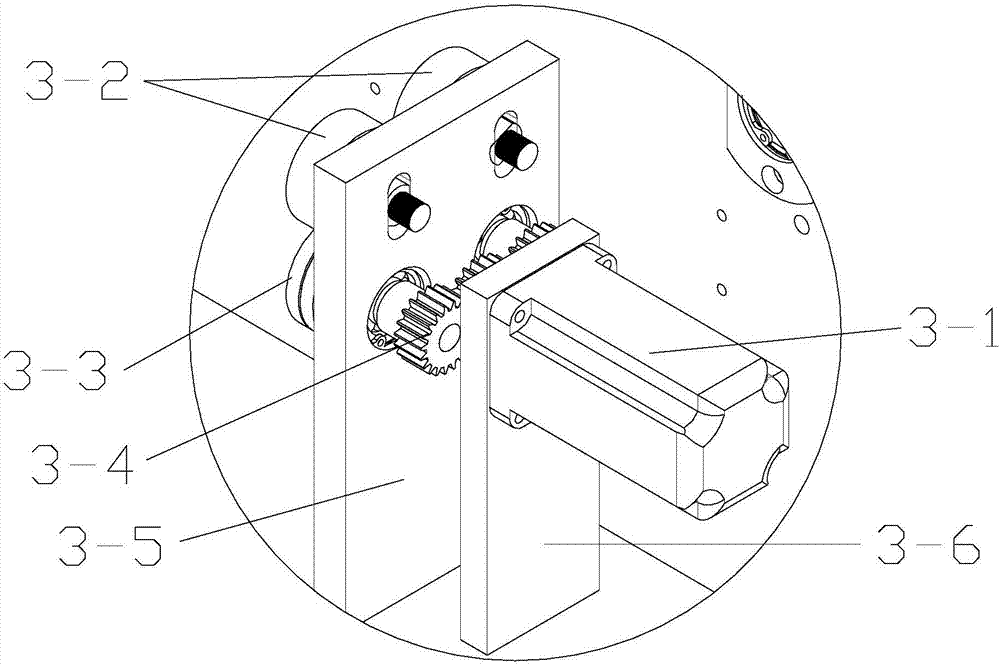

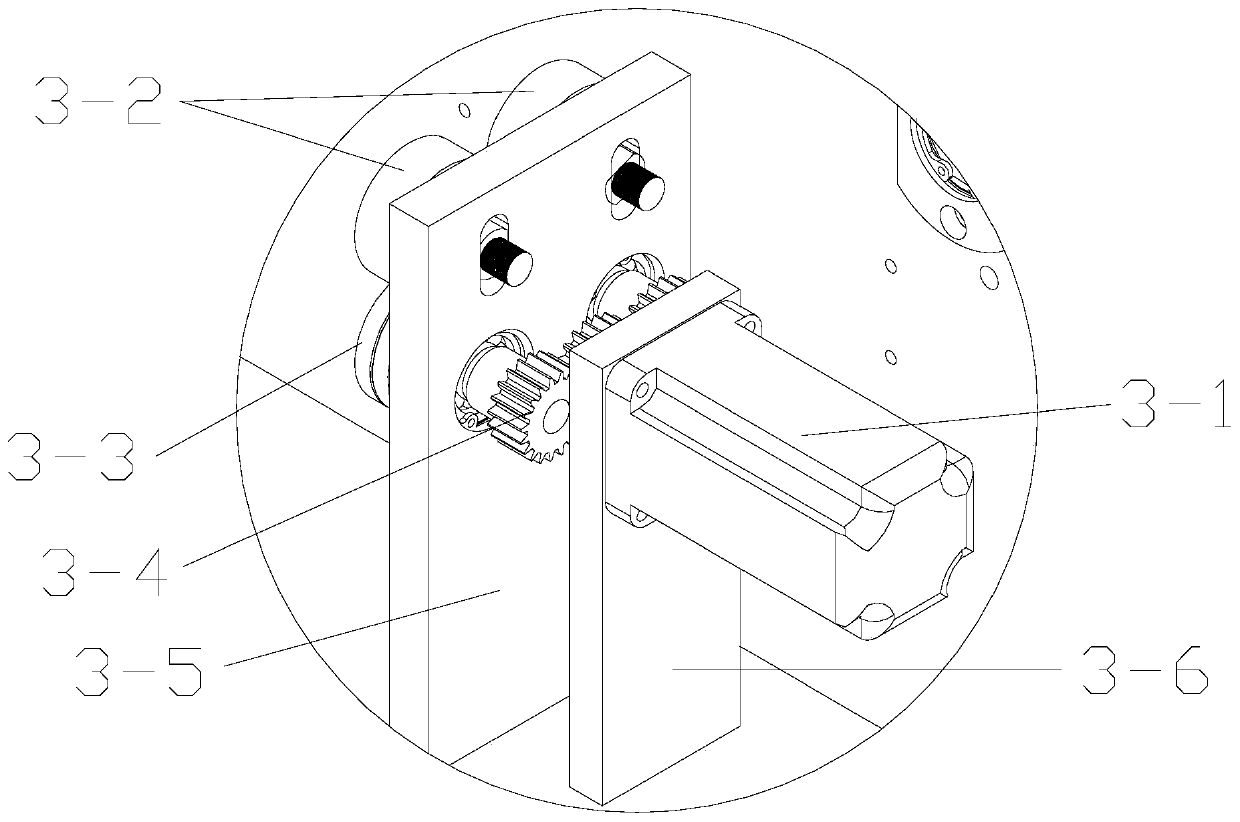

Drilling device for use in machining of air conditioner hanging plate and using method thereof

ActiveCN111761369AVertical position adjustmentLateral position adjustmentWork clamping meansMeasurement/indication equipmentsGear wheelElectric machinery

The invention discloses a drilling device for use in machining of an air conditioner hanging plate. The drilling device comprises a base, wherein a mounting column and a U-shaped frame are fixedly arranged on the top of the base respectively; the U-shaped frame is positioned on one side of the mounting column; a mounting frame is connected to the top of one side of the mounting column in a slidingway; a movable frame is connected to the mounting frame in a sliding way; a rack is fixedly arranged on the top of the movable frame; the rack is positioned above the mounting frame; a displacement motor is fixedly arranged on one side of the top of the mounting frame; a gear is fixedly arranged on an output shaft of the displacement motor; and the gear is meshed with the rack. The invention further discloses a using method. Through adoption of the drilling device, automatic clamping and positioning as well as position adjustment of a hanging plate to be drilled can be realized, and automaticdrilling of the hanging plate can be realized. Meanwhile, holes of any size can be formed in the hanging plate, so that great convenience is brought to use. At the same time, the working strength ofoperators can be lowered, so that the drilling device has good market popularization prospect.

Owner:江苏长达交通材料有限公司

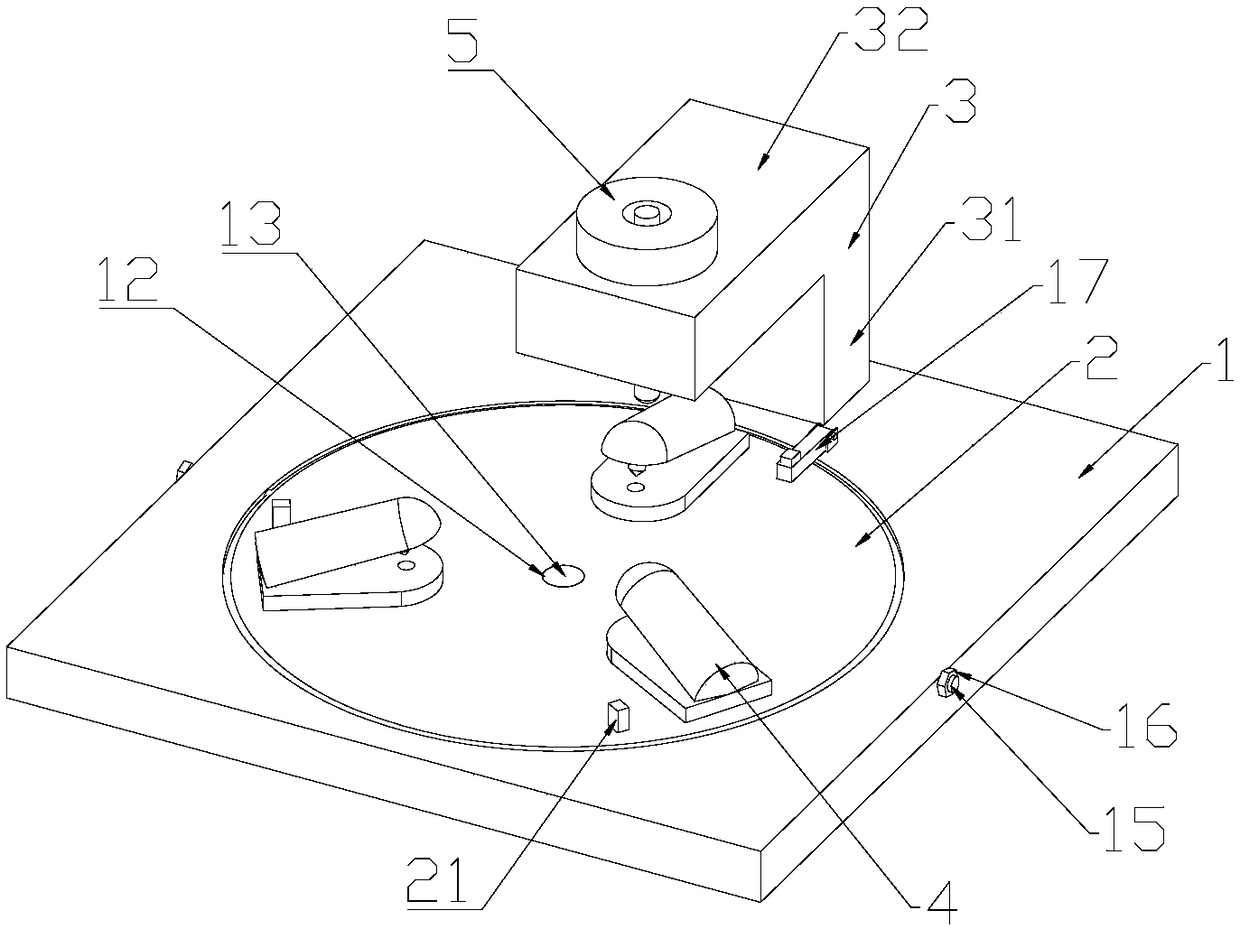

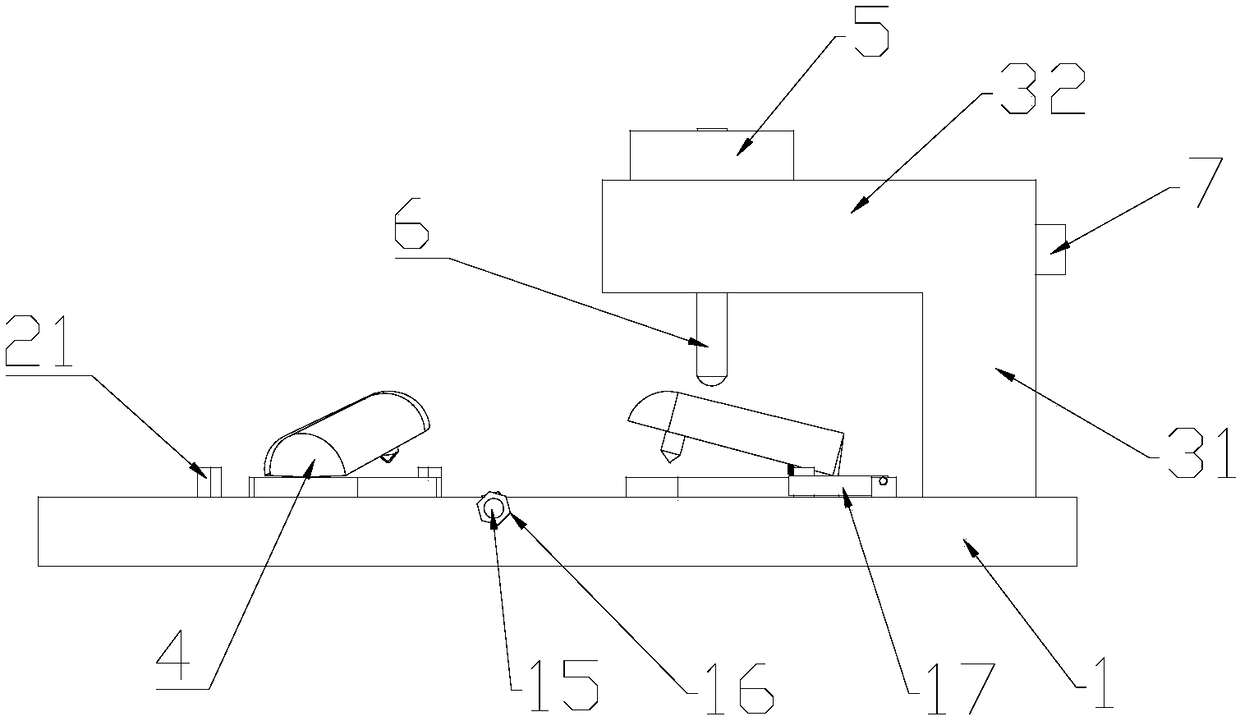

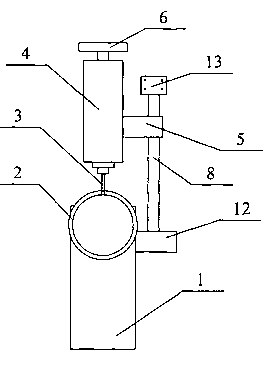

Automatic drill of ring part

InactiveCN104475801ARealize automatic punchingImprove drilling efficiencyPositioning apparatusMetal-working holdersBiochemical engineeringDrilling machines

The invention provides an automatic drill of a ring part. The automatic drill of the ring part comprises a machine body, a feeding channel is arranged at the right side of the machine body, a discharging channel is arranged at the left side of the machine body, a clamping groove is formed on the machine body, the clamping groove is formed between the feeding channel and the discharging channel, two sides of the clamping groove are respectively provided with a clamping air cylinder, a right angle rack is arranged on the machine body and is provided with a drill, and the drill is driven by the drilling machine arranged at rear side. The ring part is clamped by the clamping groove and located by a locating device, the drilling machine is used for drilling, the ring part is automatically drilled with the hole, and the drilling work efficiency of the ring part is raised for avoiding rejects and saving the production cost.

Owner:WUHU POWER TECH

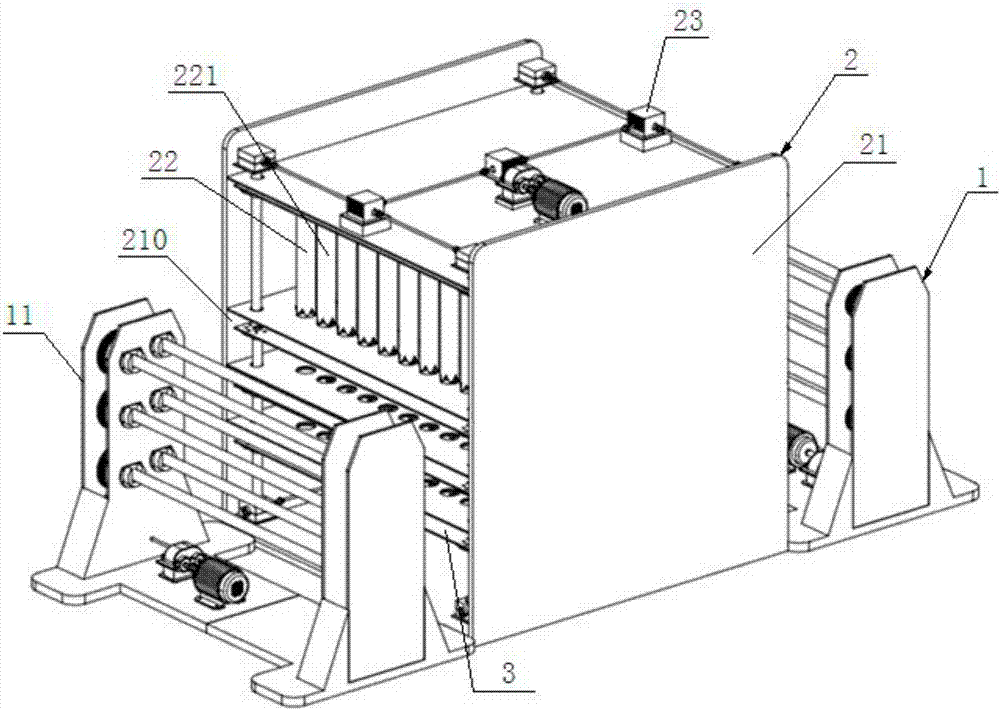

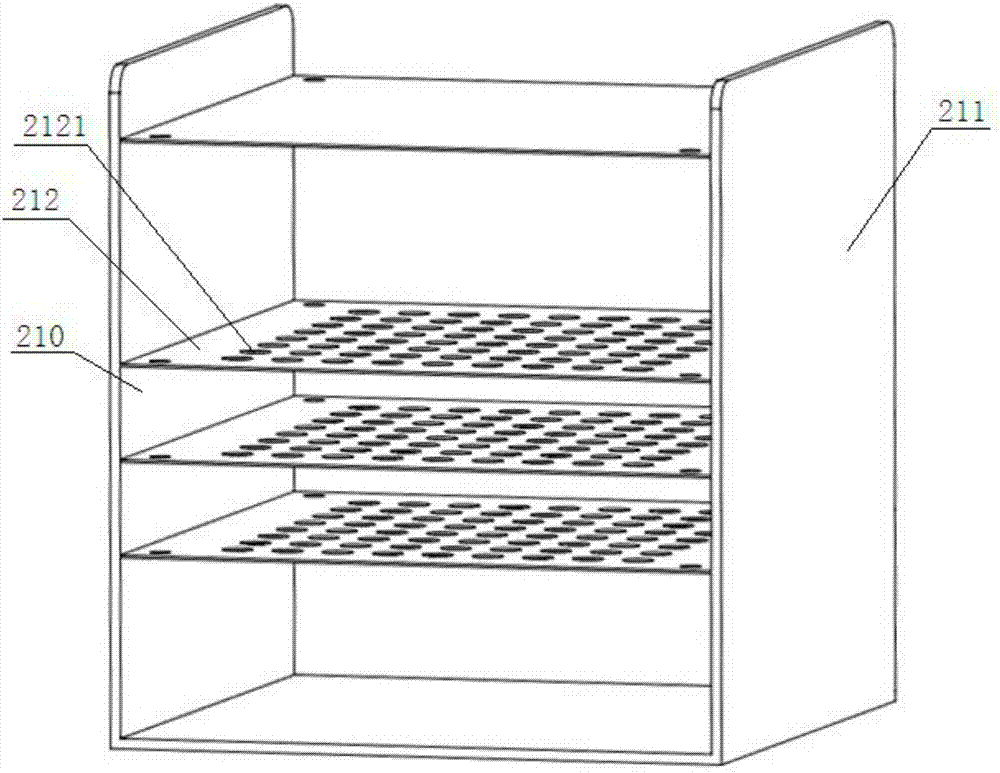

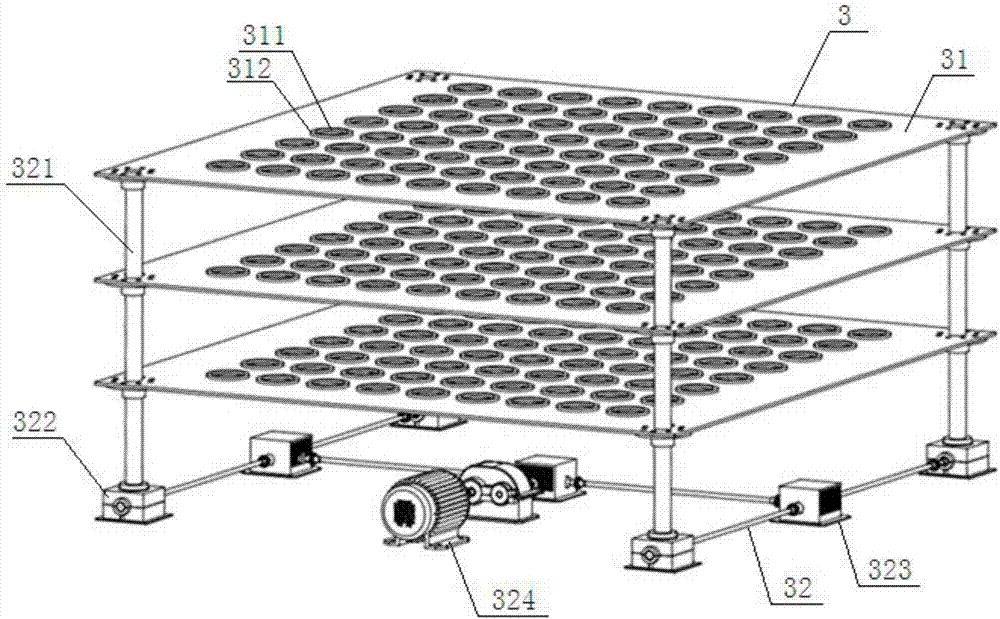

Multilayer film punching device

ActiveCN107199594AAvoid displacementPrevent excessive deformationMetal working apparatusWebs handlingPunchingEngineering

The invention provides a multilayer film punching device. The multilayer film punching device comprises a conveying assembly, a punching assembly and a controller. The punching assembly comprises a rack, a tool rest mechanism and a tool rest transmission mechanism. A plurality of film channels are formed in the rack in the horizontal direction. The film channels are distributed at intervals in a stacked mode in the vertical direction. A plurality of tool hole channels communicating with the film channels are formed in the rack in the vertical direction. The tool rest mechanism is fixed to the rack through the tool rest transmission mechanism in the mode that the tool rest mechanism can reciprocate in the vertical direction. The tool rest mechanism comprises a plurality of tools. The tools are matched with the tool hole channels. The tool rest transmission mechanism and a conveying assembly are in communication connection with a controller. Through the multilayer film punching device, multilayer films can be subjected to multipoint punching simultaneously, and the multilayer film punching device has the advantages of being high in machining efficiency, easy to operate, high in automation degree and good in safety.

Owner:SHANGHAI DIANJI UNIV

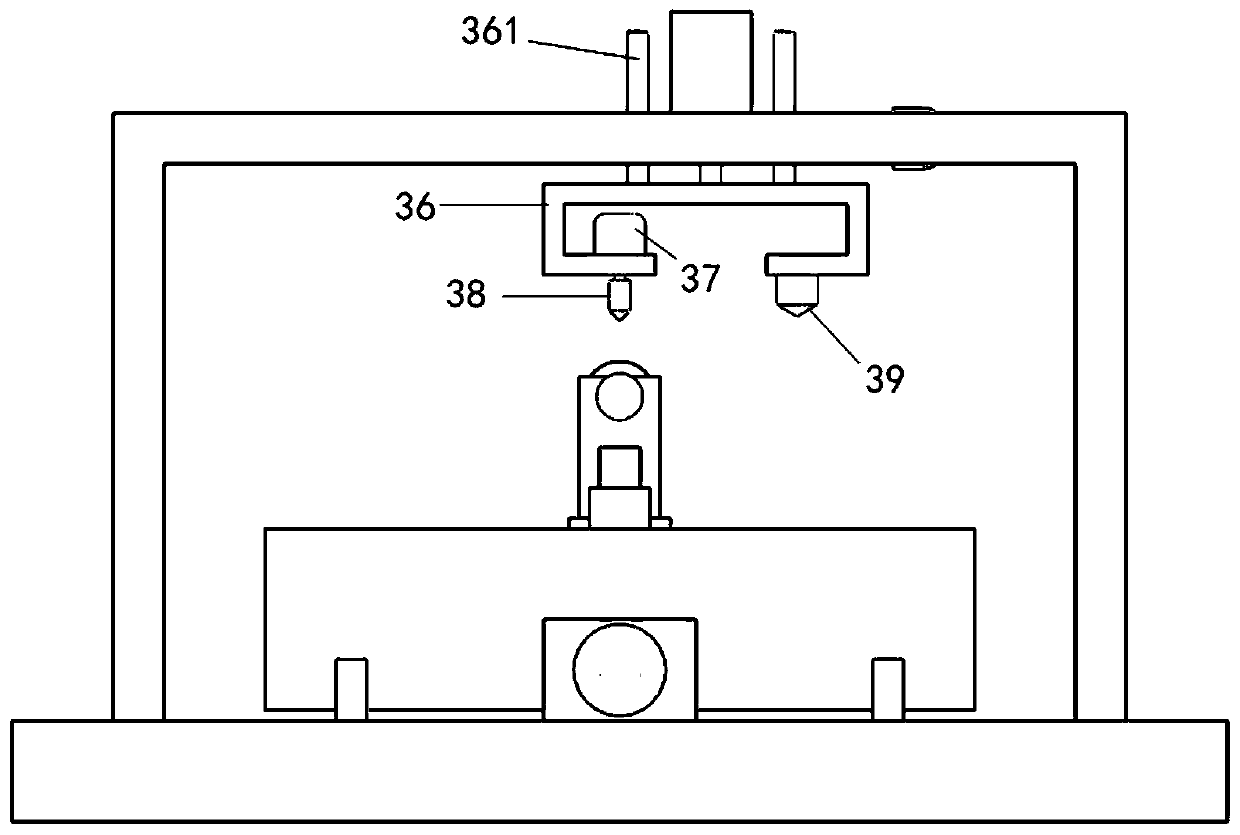

Rotary-moving-type automatic punching device for construction steel pipe

InactiveCN111299648ARealize automatic punchingHigh degree of automationWork clamping meansCentre punchesPunchingElectric machinery

The invention discloses a rotary-moving-type automatic punching device for a construction steel pipe. The rotary-moving-type automatic punching device comprises a bottom plate, a pair of guide rail strips is arranged on the top face of the bottom plate, a moving base is slidably arranged on the guide rail strips, a pair of vertical fixing plates is arranged at the front end and the rear end of thetop face of the moving base, a pair of rotatable pipe clamping blocks is rotationally arranged between the two vertical fixing plates, one of the pipe clamping blocks is fixed to the movable verticalfixing plate, a supporting frame is arranged above the moving base, a lifting air cylinder is arranged on a top plate of the supporting frame, a piston rod of the lifting air cylinder vertically faces downwards and is connected with a mounting frame, and a drilling motor and a drill bit are arranged on the mounting frame. The rotary-moving-type automatic punching device has the advantages that the rotary-moving-type automatic punching device is provided with the movable base, a rotatable pipe clamping plug is arranged on the base, a movable and lifting punching device body is arranged above the base, thus any position of the steel pipe can be automatically punched, the automation degree is high, and the effect is good.

Owner:章晋华

Punching die for plastic film or polyester carbonate film product

InactiveCN102126230AEasy to brewRealize automatic punchingMetal working apparatusPolyesterPolymer science

The invention discloses a punching die for a plastic film or polyester carbonate film product. The punching die is characterized by comprising an upper die and a lower die, wherein the upper die and the lower die are arranged corresponding; the surface of the upper die is provided with a steel plate, a plurality of punching blocks are arranged on the steel plate, and the shapes of the punching blocks are consistent with the hole shapes of the plastic film or polyester carbonate film product; and the lower die is fixed on a stand, and the surface of the lower die is provided with waste discharge holes which are consistent with the punching blocks in shapes and formed corresponding. Automatic punching is realized, the operation time is shortened, the production efficiency is improved, the capacity is improved by 4 to 5 times compared with the traditional manual operation, wastes can be directly discharged through the waste discharge holes, and meanwhile, the product quality is ensured; in addition, by arranging a steel knife on the steel plate, a split line between the adjacent plastic film or polyester carbonate film products can be conveniently punched, so the products can be conveniently separated.

Owner:琨诘电子(昆山)有限公司

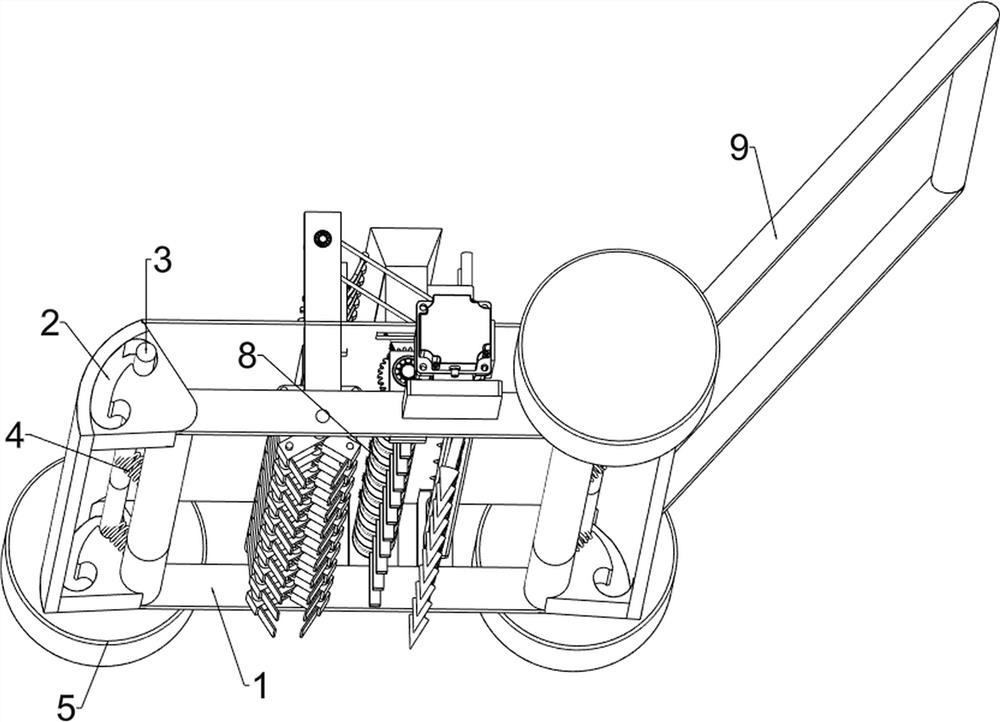

Automatic uniform drilling device for birdcage top frame

InactiveCN111761656ARealize intermittent rotationRealize intermittent movementStationary drilling machinesGear wheelElectric machinery

Owner:温丹丹

Efficient rotary puncher

InactiveCN108068166AMeet the needs of punching holes of different sizesQuick switchMetal working apparatusPunchingParallel plate

The invention provides an efficient rotary puncher. The efficient puncher comprises a worktable. The worktable includes a rotary table and a bracket. A puncher is arranged on the rotary table. Different sizes of punching needle are correspondingly arranged in the puncher. The bracket comprises a vertical plate and a horizontal plate. The vertical plate is fixedly connected with the worktable. Thehorizontal plate is arranged on the upper portion of the worktable, and is parallel to the worktable. The horizontal plate is fixedly connected with a cylinder unit. A cylinder piston rod is connectedwith a push rod. The push rod extends out of the lower portion of a parallel plate. The need of punching with different sizes is met. The operating rotary table can conveniently and quickly switch different punchers, and accurately locate the puncher through a limit part, so that the mismatch between the push rod and the puncher position is avoided. The cylinder unit can realize automatic punching, so that manpower is effectively saved.

Owner:TIANJIN MODERN VOCATIONAL TECH COLLEGE

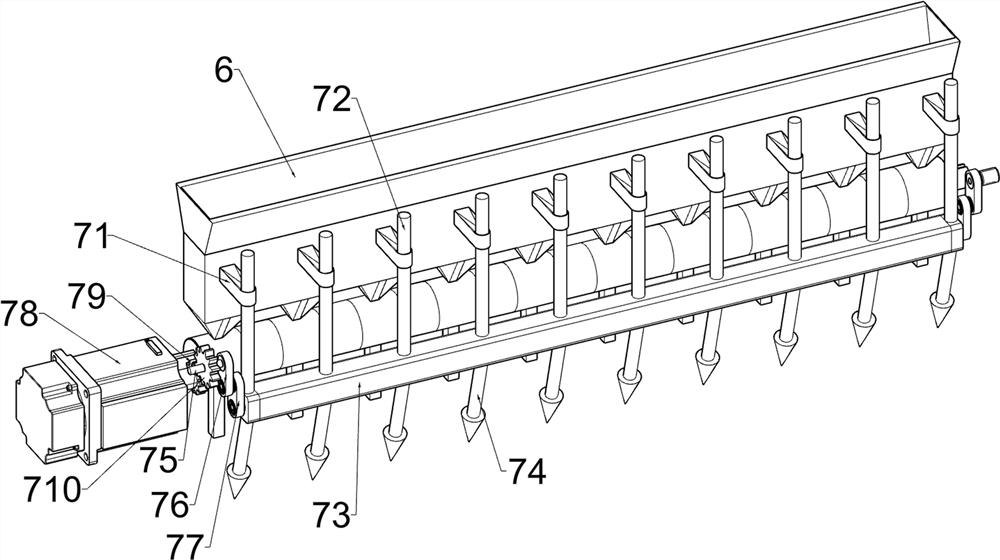

Agricultural automatic corn seeding device

ActiveCN111837521ARealize automatic punchingIncrease heightPlantingDibble seedersSeederAgricultural engineering

Owner:内蒙古种星种业有限公司

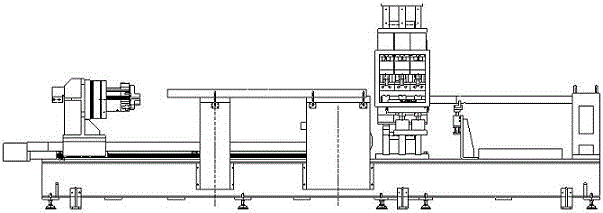

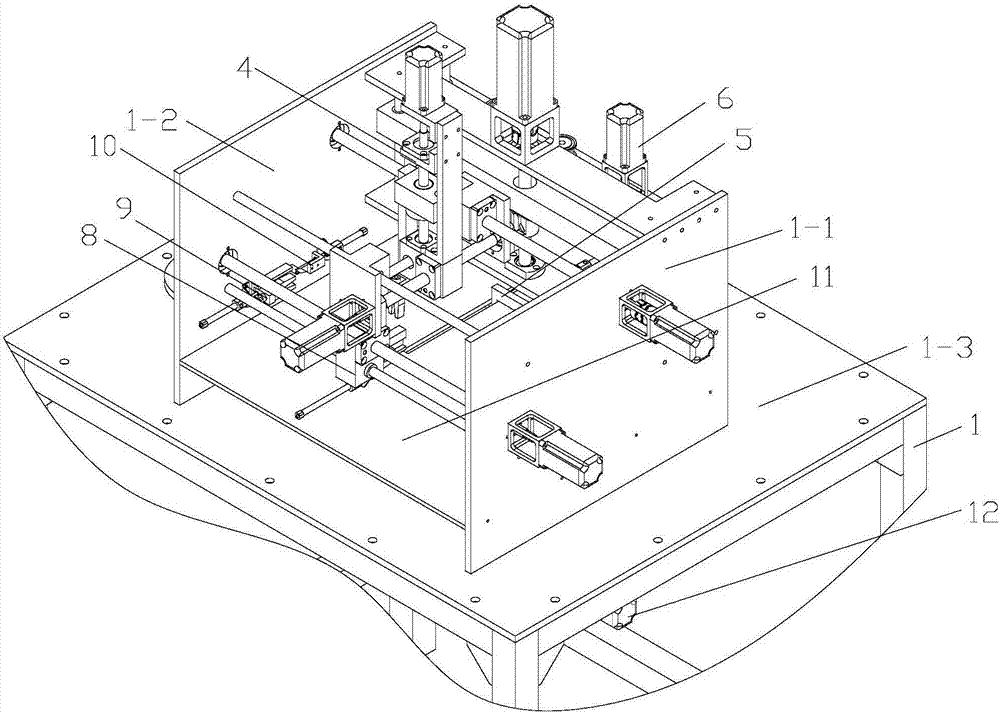

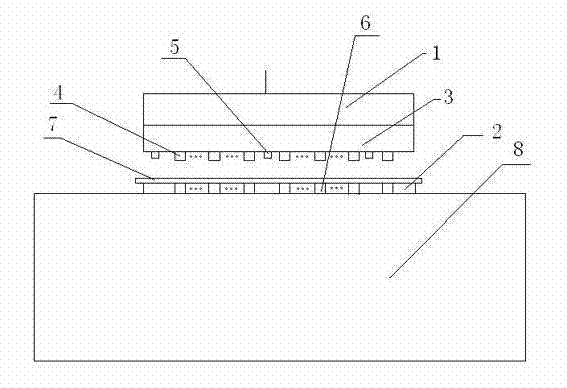

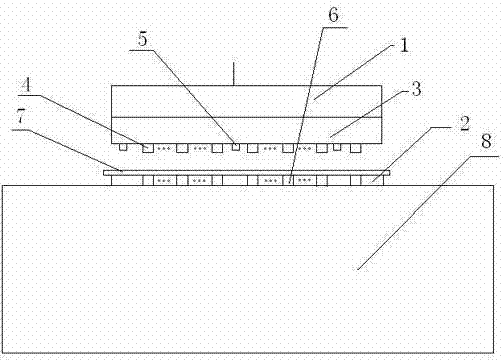

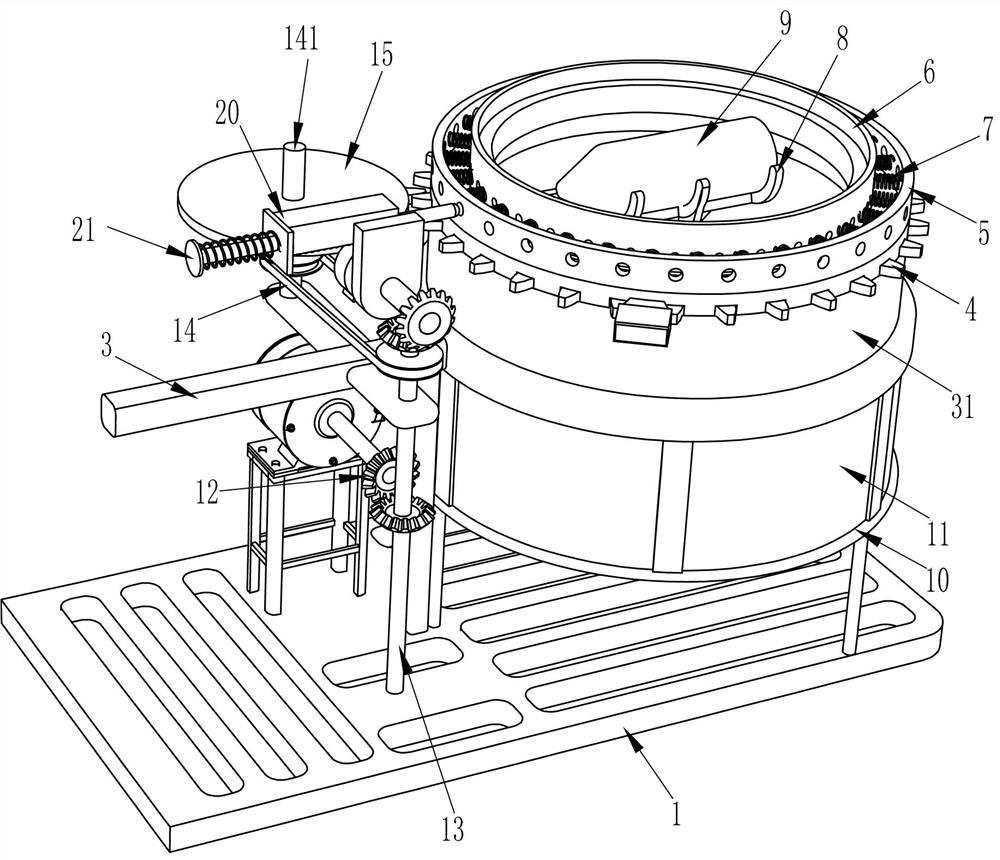

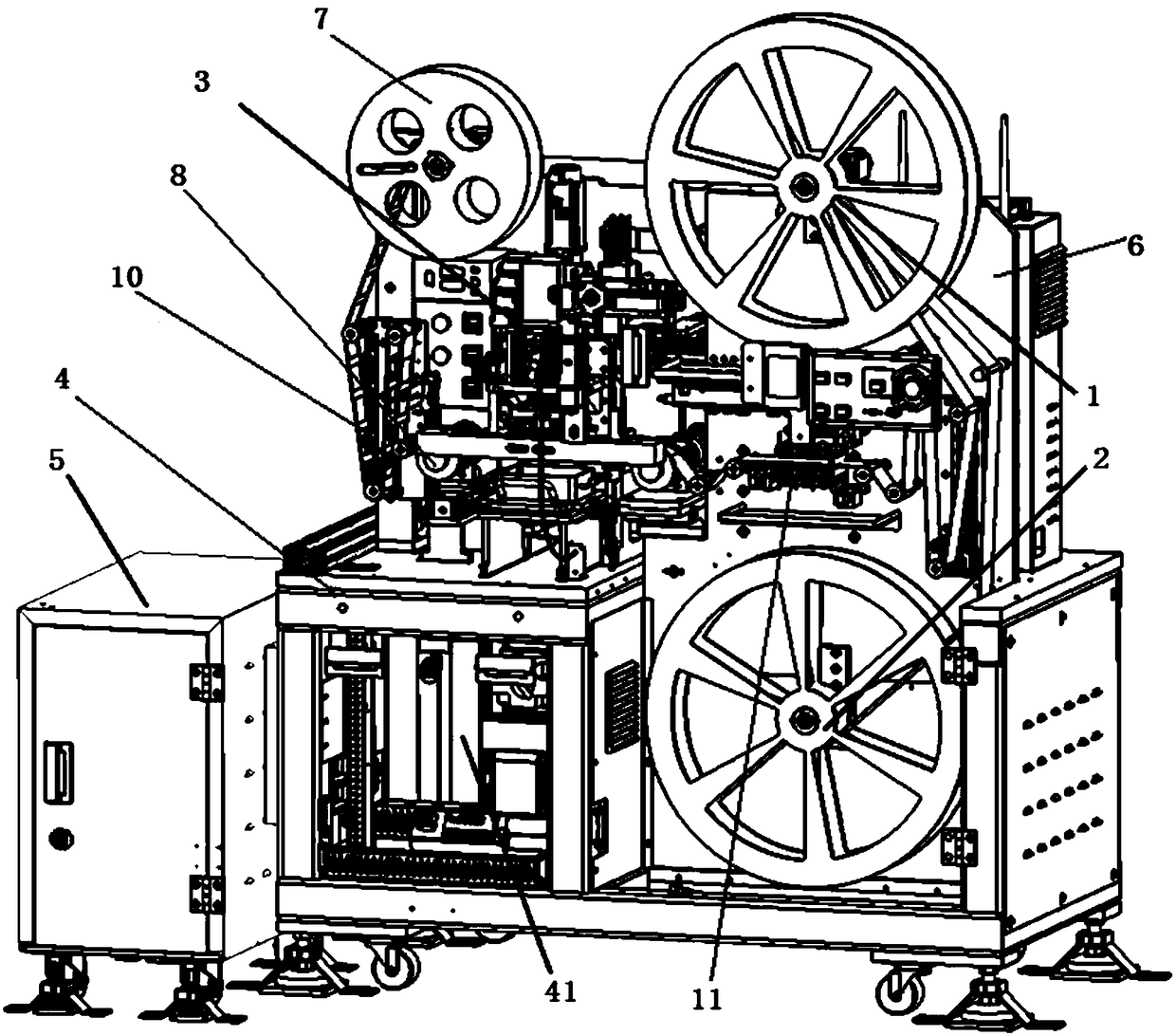

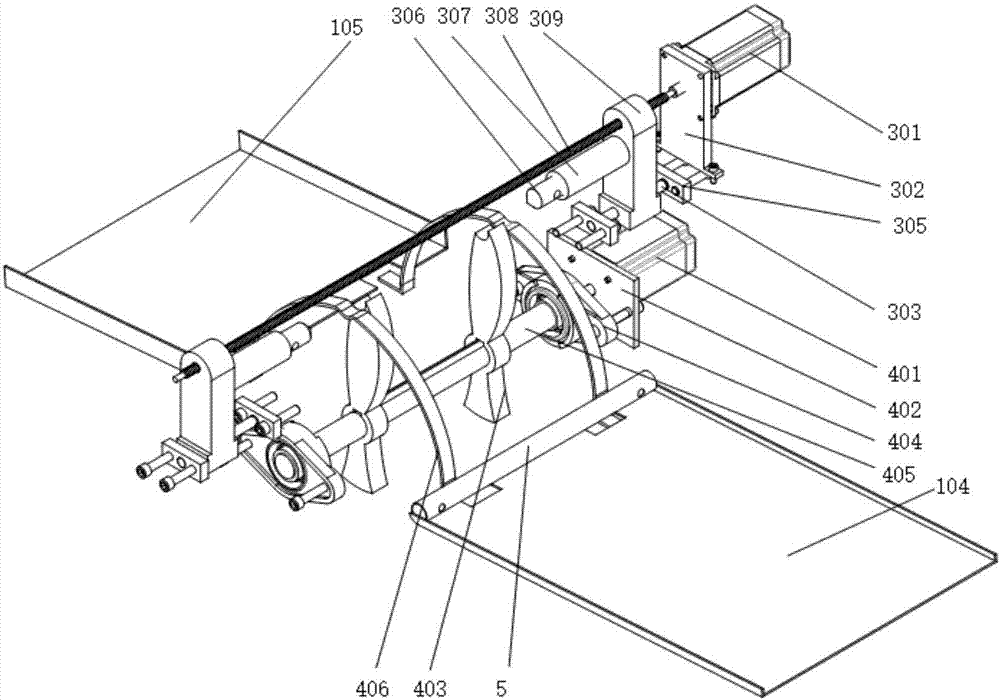

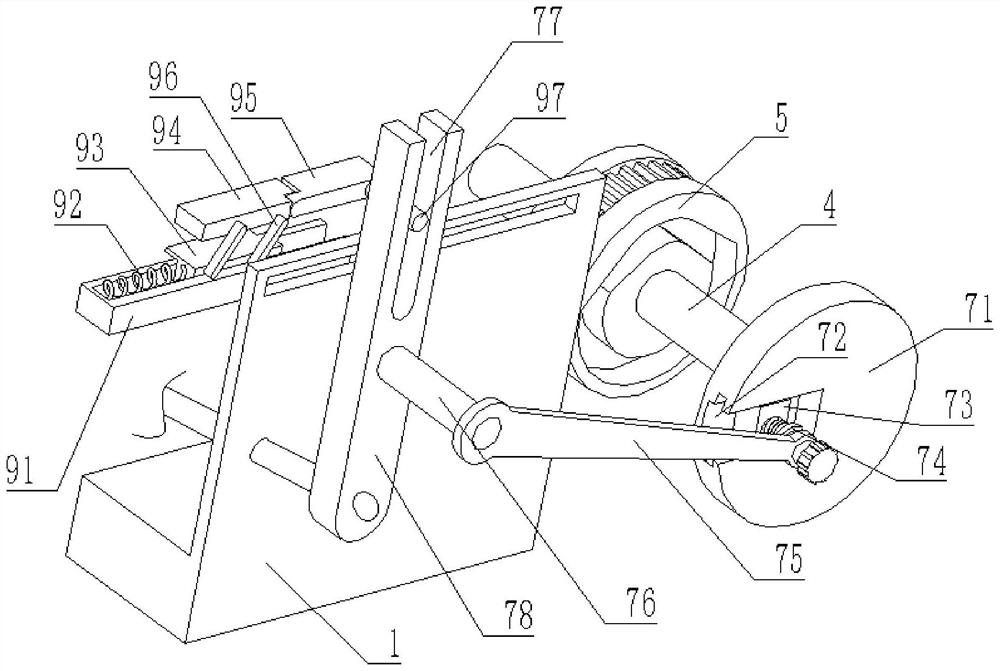

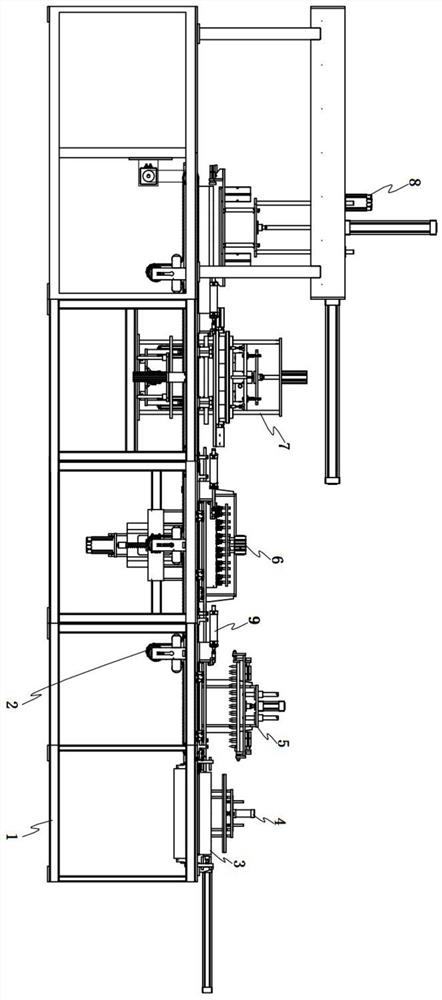

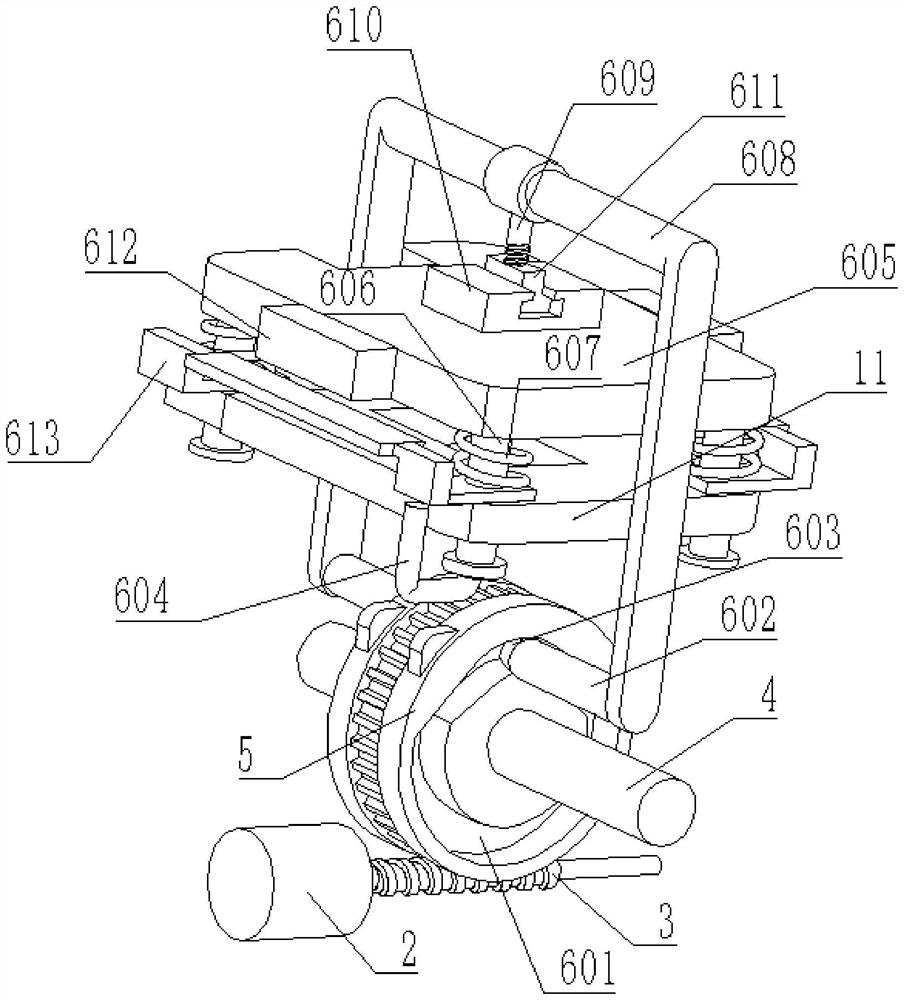

Automatic circular mould perforating machine

InactiveCN103008720AEasy to punchGood punch qualityDrilling/boring measurement devicesPrecision positioning equipmentDrill bitAutomation

The invention relates to a perforating machine, in particular to an automatic circular mould perforating machine which comprises a bed (1), a drill bit (3), a drill bit power head (4), a first servo motor (5), a sliding rail (8), a main motor (10), a control cabinet (13) and a sliding rail bracket (14). The drill bit (3) is arranged at the power output end of the drill bit power head (4); the power output end of the main motor (10) is connected with the power input end of the drill bit power head (4); one end of the first servo motor (5) is connected with the drill bit power head (4) and the other end is slidingly connected with the sliding rail (8) which is fixedly connected with the bed (1) through the sliding rail bracket (14); and the control cabinet (13) is arranged at the top of the sliding rail (8) and is electrically connected with the main motor (10) and the first servo motor (5). The automatic circular mould perforating machine is high in perforation efficiency, good in perforation quality and high in automation degree and can realize automatic perforation.

Owner:溧阳市华生机械制造有限公司

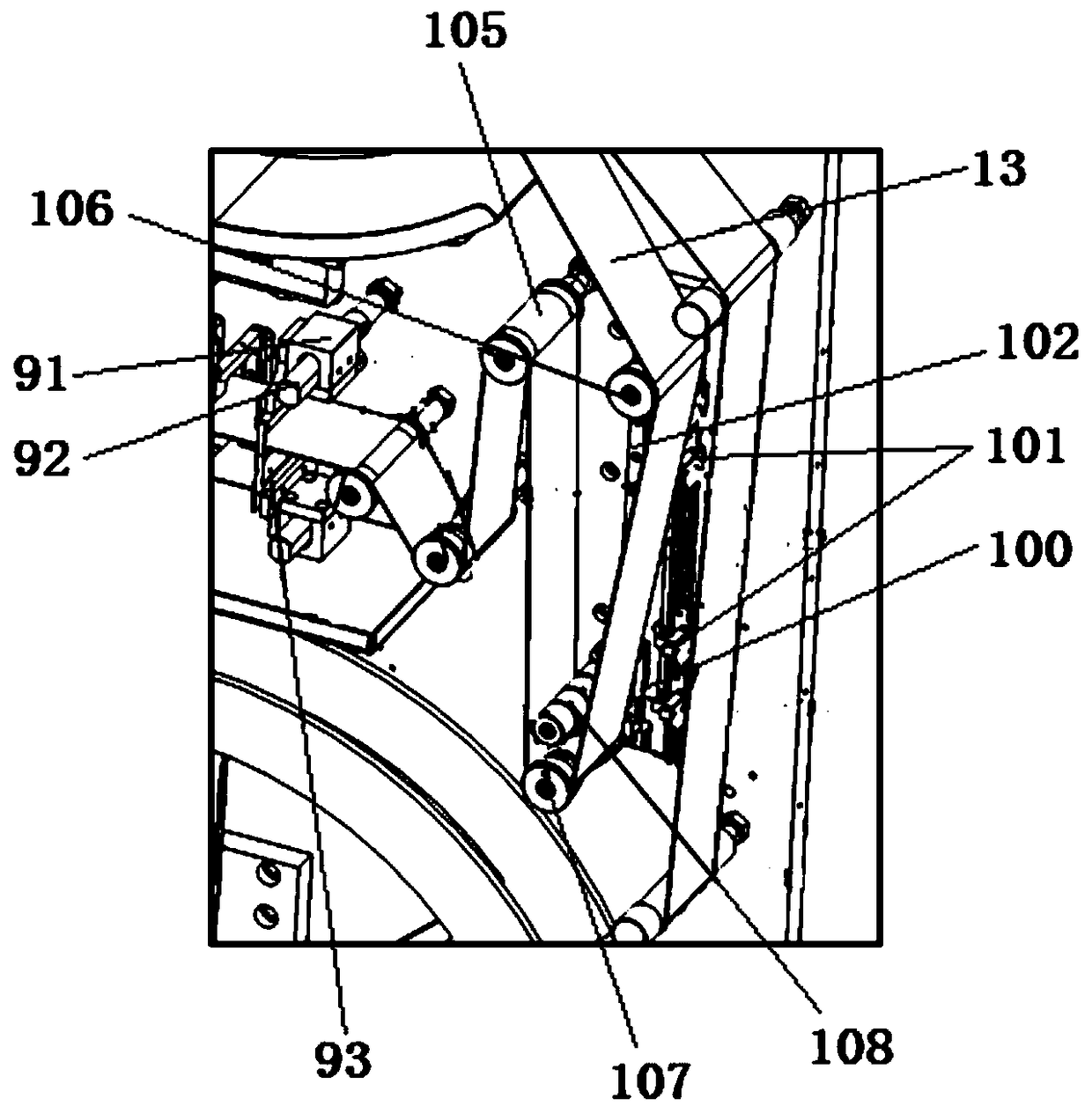

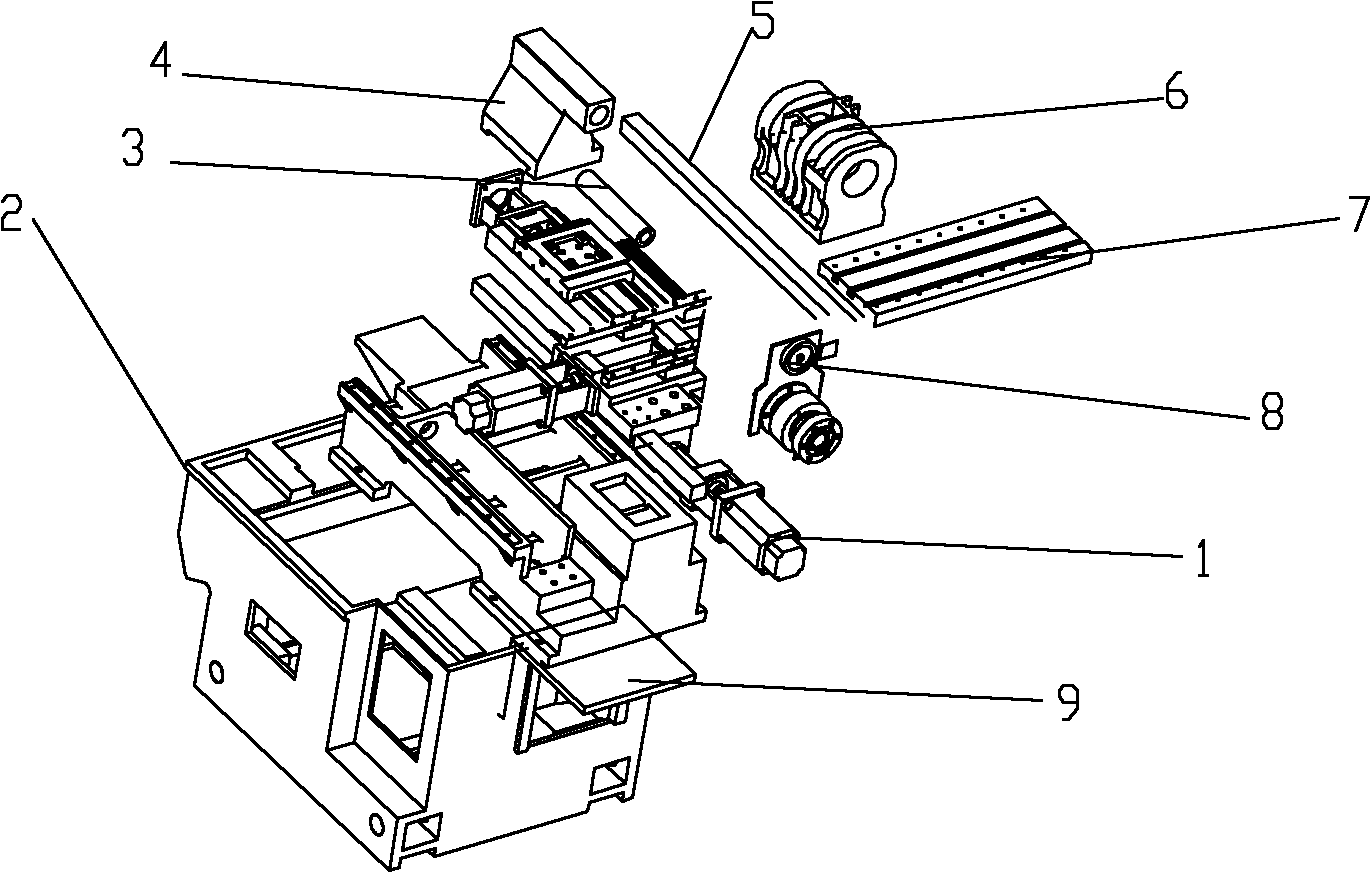

Automatic COF coil punching device

InactiveCN109109089AImprove yieldImprove automation and work efficiencyCleaning using toolsCleaning using gasesEngineeringWaste recycling

The invention provides an automatic COF coil punching device. The automatic COF coil punching device comprises a COF material strip, a rack, a cabinet and a UPS, and is characterized by further comprising a new material wheel, a protective film recycling wheel, a waste recycling wheel, ratchet wheels, a punching mechanism and a plurality of guide wheels, wherein the two ratchet wheels are vertically arranged on the portion, between the new feeding wheel and the protective film recycling wheel, of the rack; the punching mechanism is arranged between the two ratchet wheels; the punching mechanism comprises a mounting block, a Z-direction servo motor, a screw rod, a horizontal correction block, a finished product box and a punching die; the mounting block is vertically arranged on the rack; the Z-direction servo motor is vertically arranged on the mounting block; one end of the screw rod is connected with the output end of the Z-direction servo motor; the other end of the screw rod penetrates through a supporting block of the punching die; the other end of the screw rod and the supporting block of the punching die form a screw rod transmission structure; the horizontal correction block is horizontally connected to the rack and is rectangular; the punching die penetrates through the horizontal correction block and can move in the vertical direction through the screw rod transmission structure; and the finished product box is arranged below the punching die.

Owner:浙江鼎晶科技有限公司

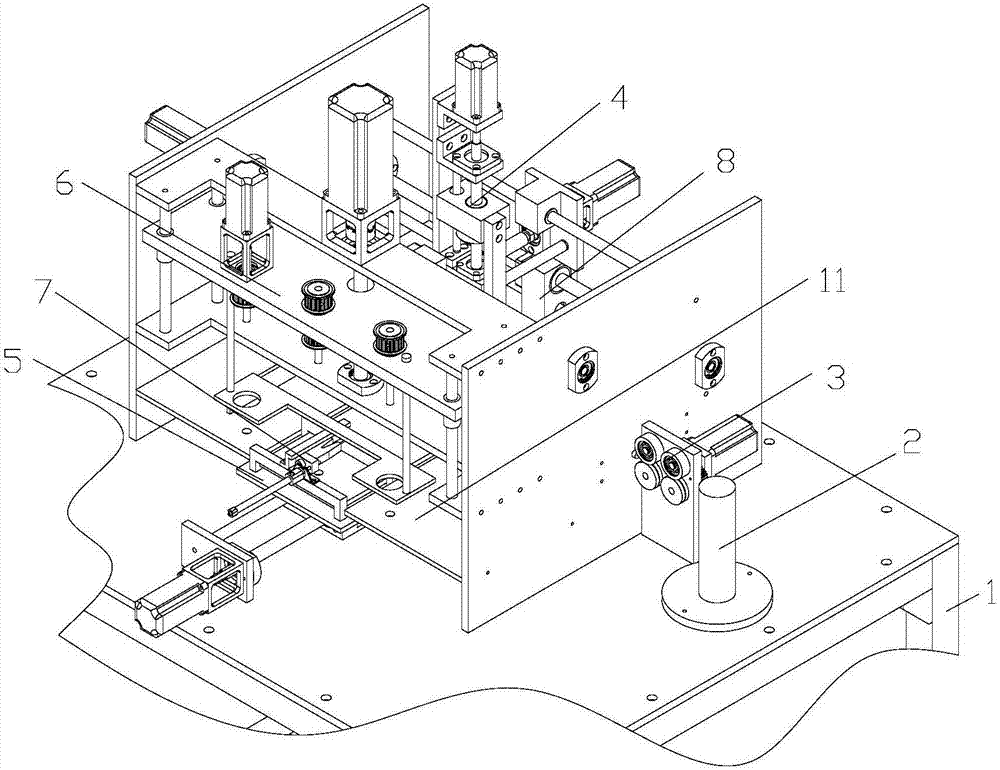

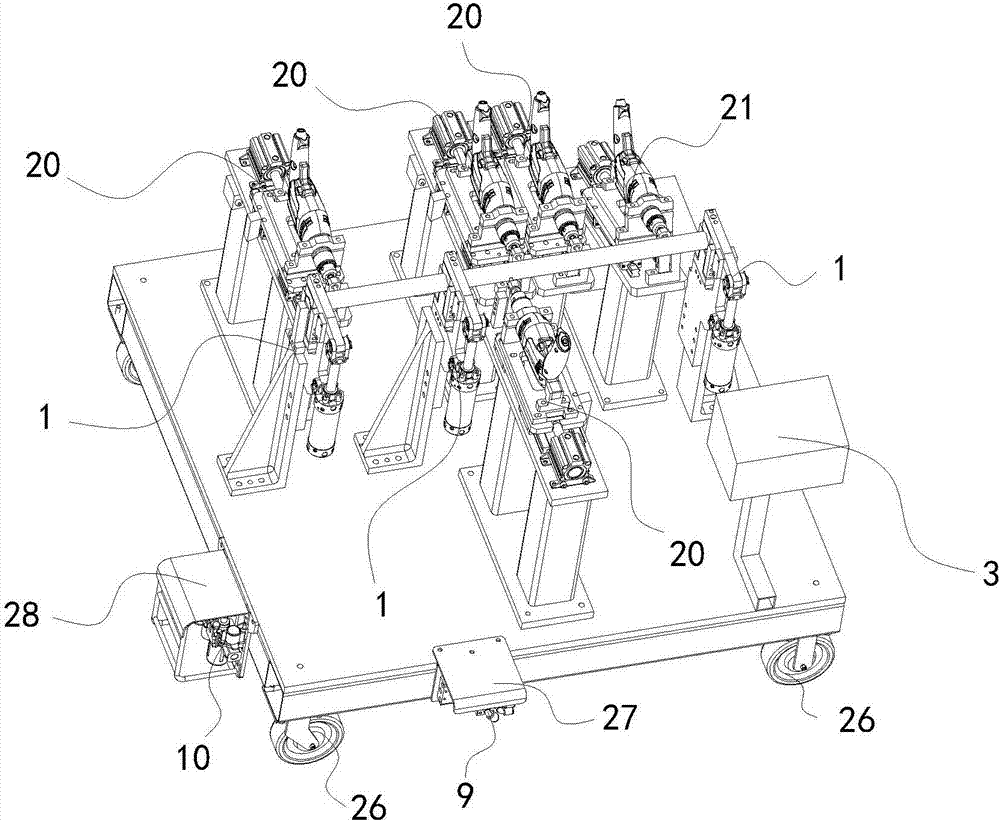

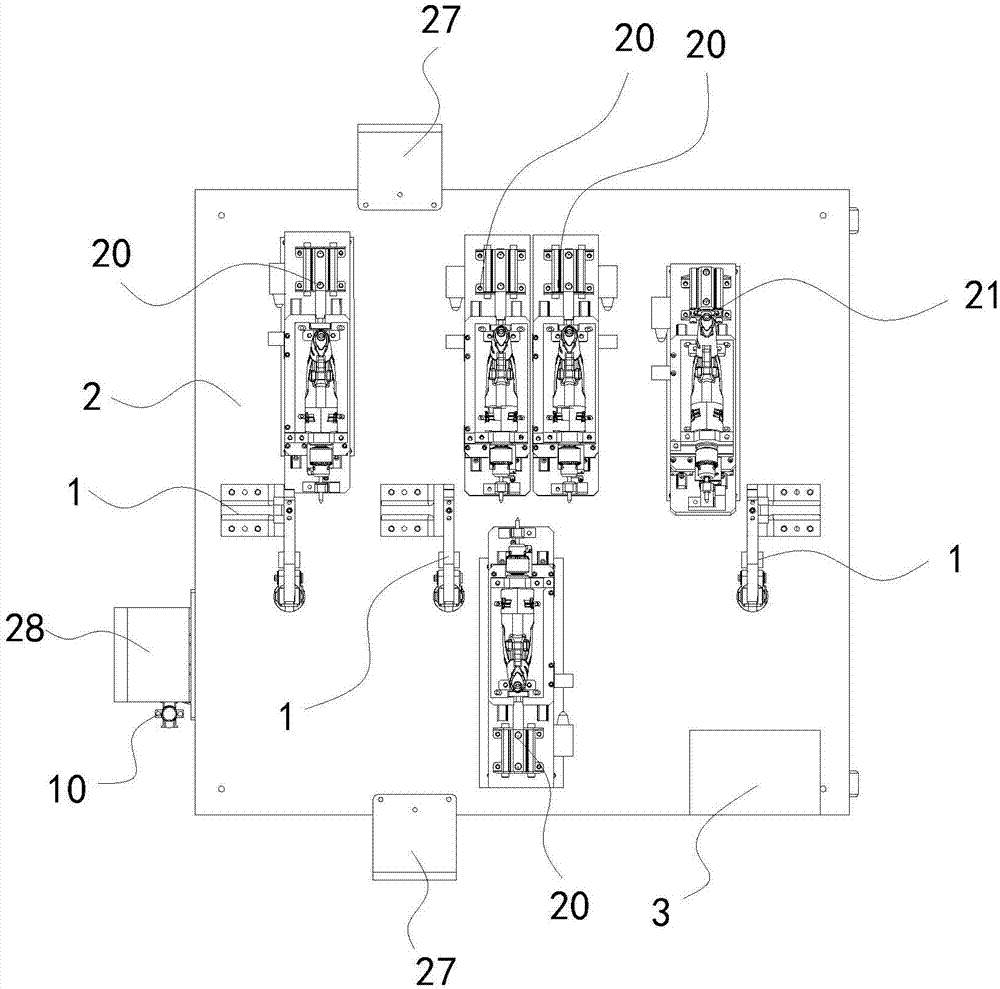

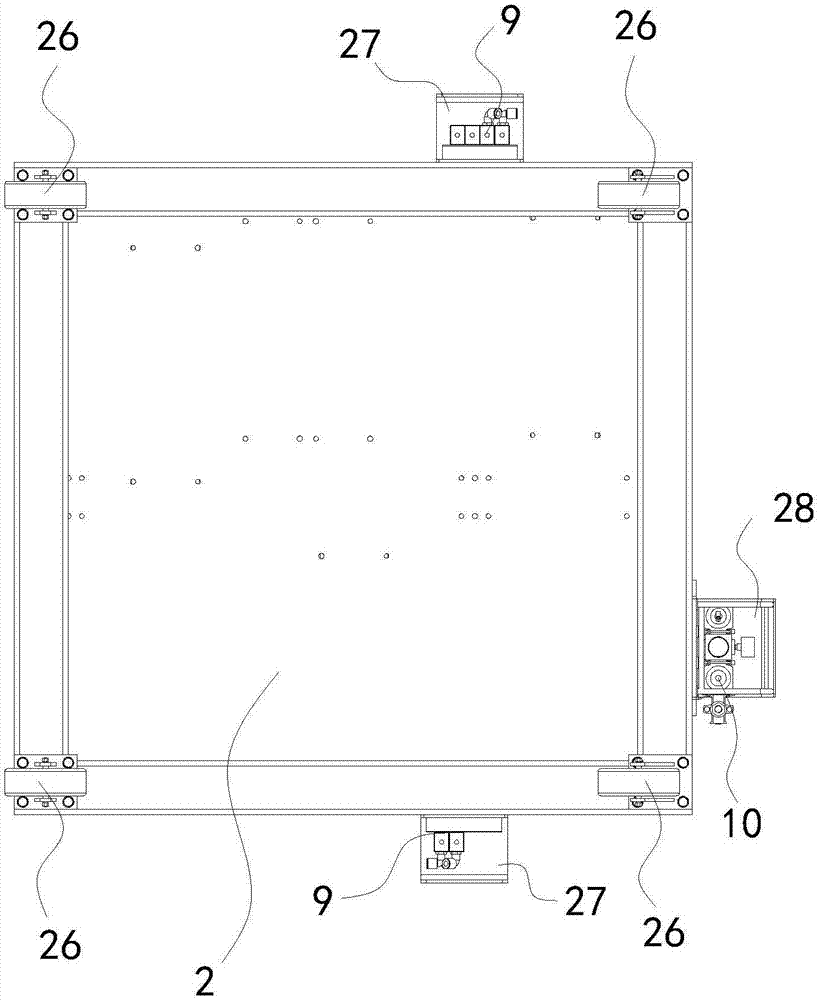

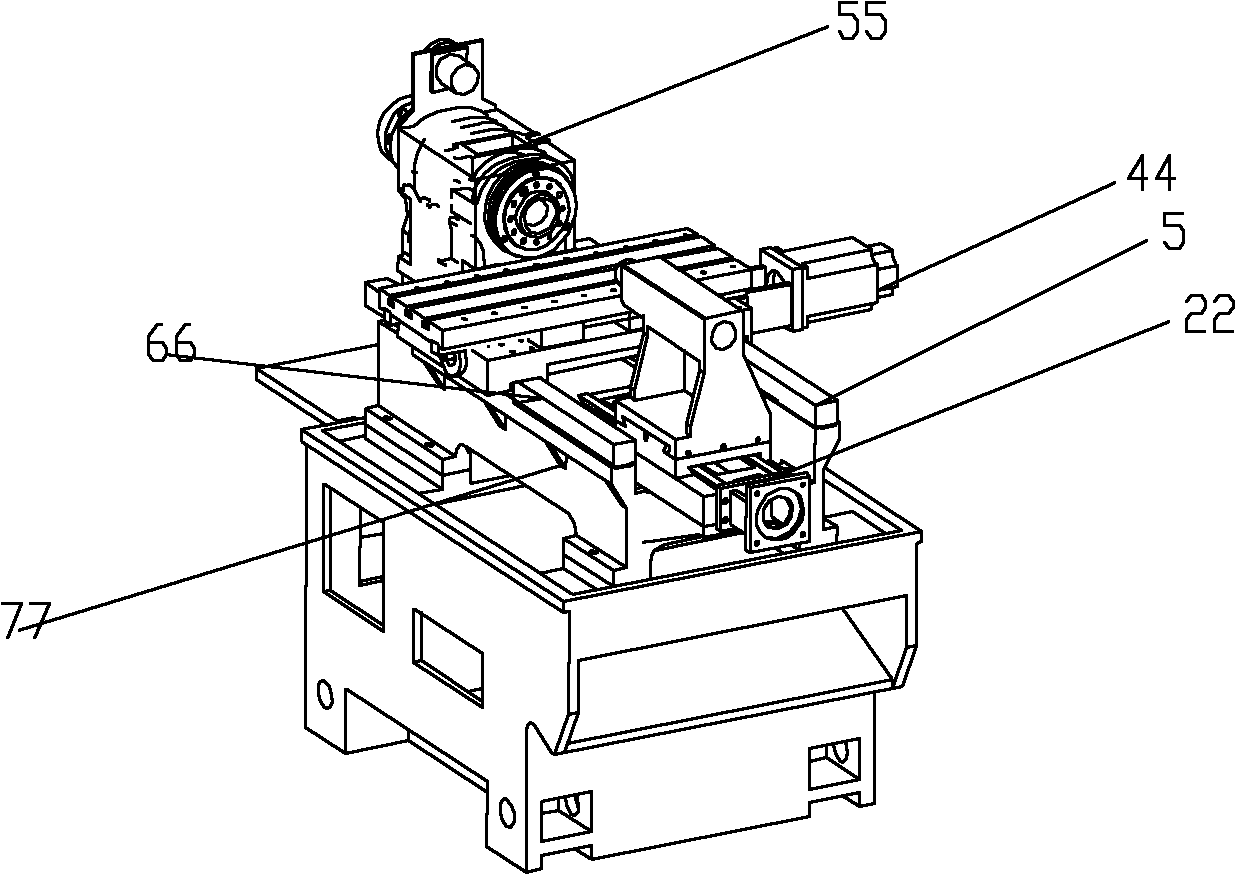

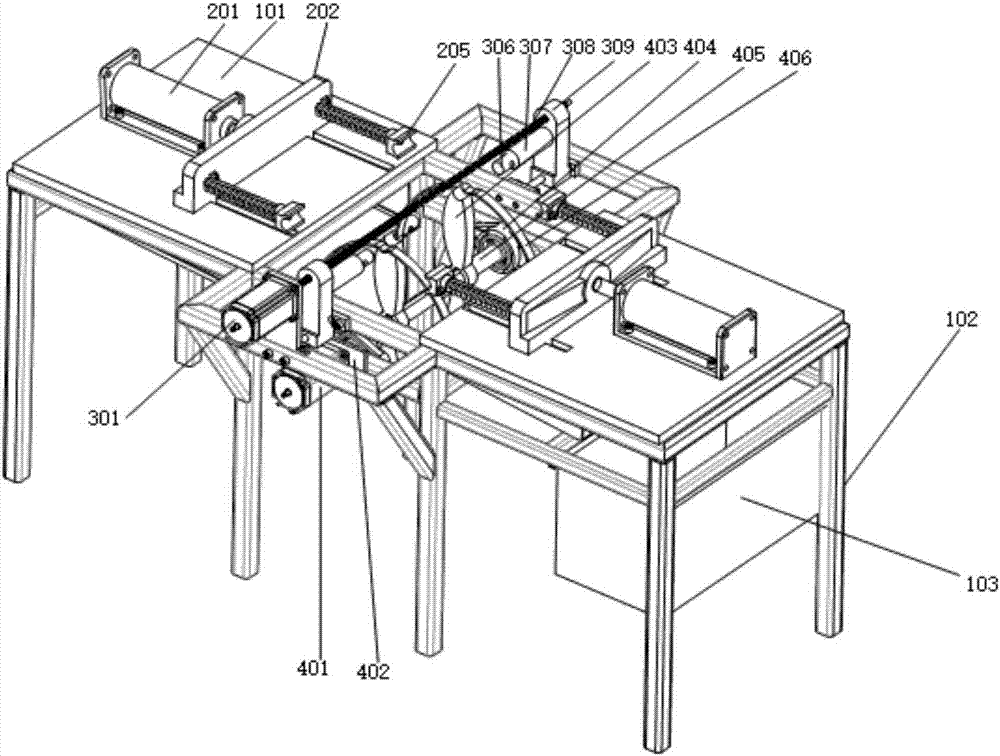

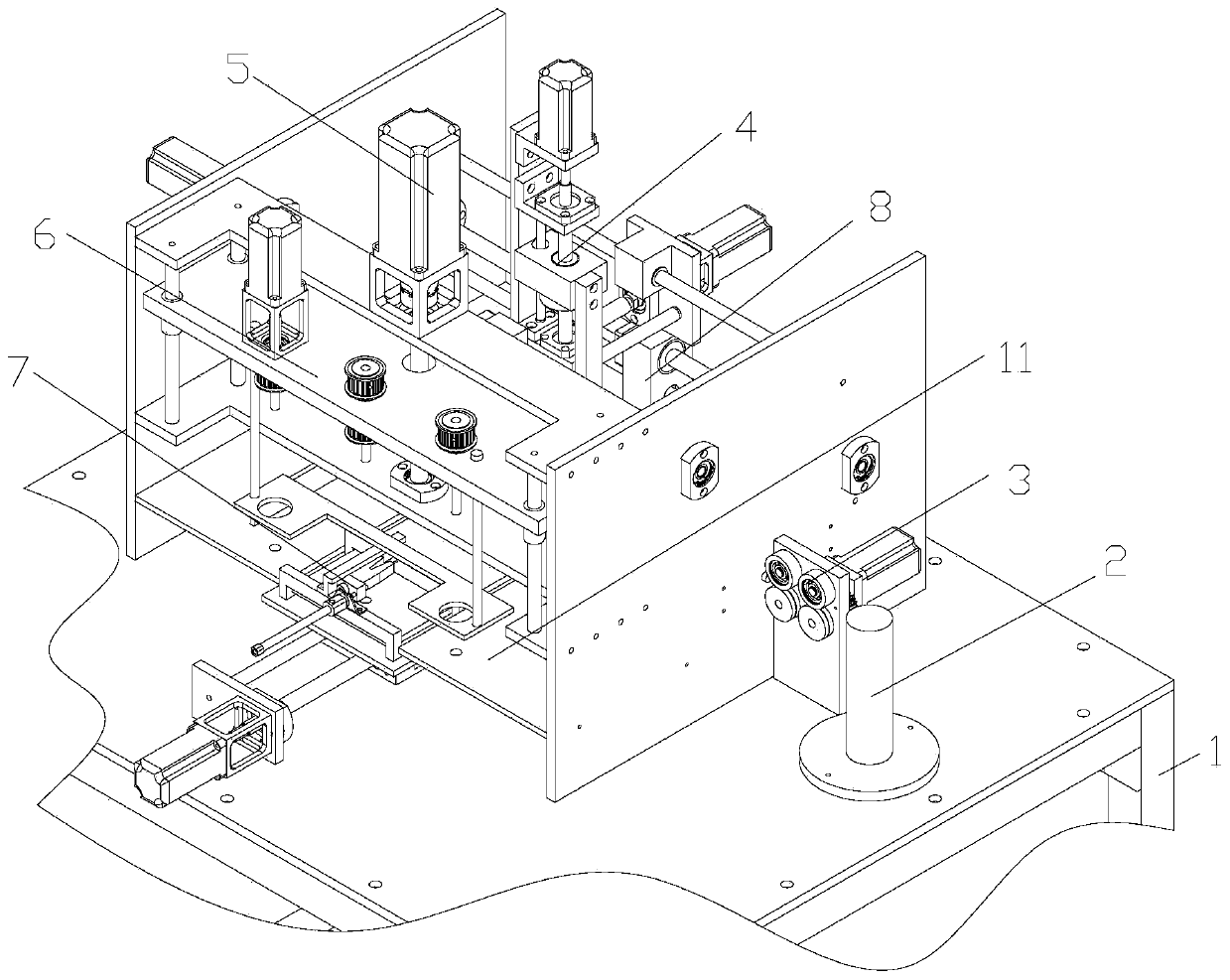

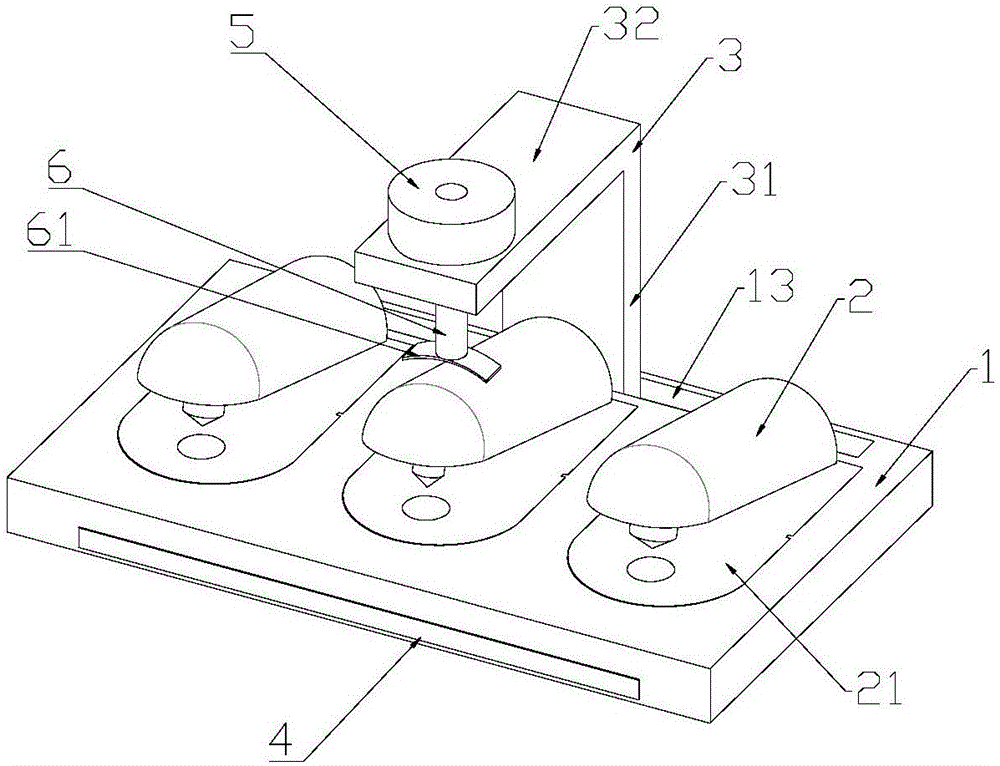

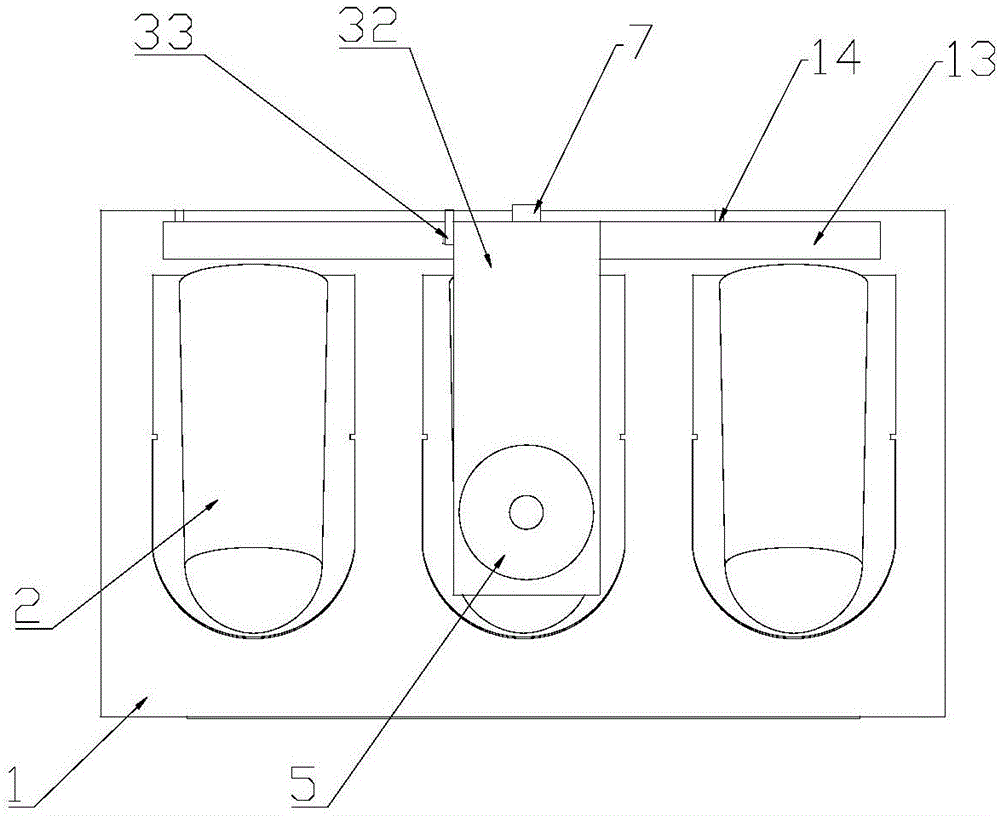

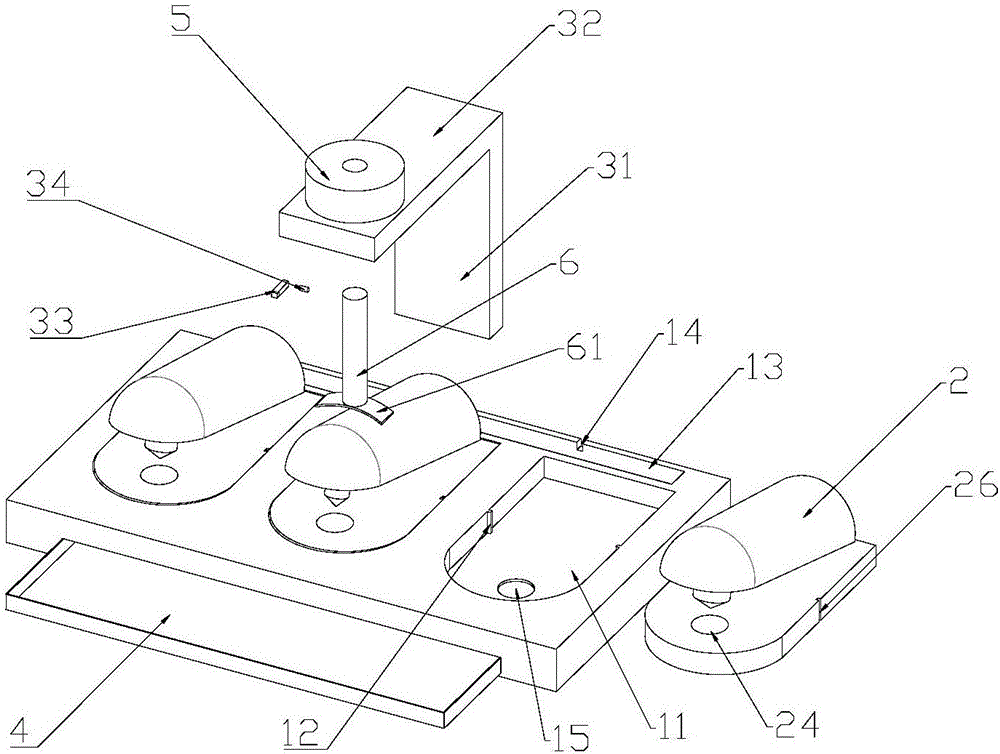

Device for drilling tubular beam

PendingCN107984438AIncrease productivitySimple structureWork benchesBoring/drilling machinesBiomedical engineeringDrill hole

The invention relates to the technical field of main tubular beam drilling tools of an automobile instrument panel, in particular to a device for drilling a tubular beam. The device comprises a plurality of drilling mechanisms, a plurality of tubular beam clamping mechanisms and a base, and each drilling mechanism comprises a support base and a drilling tool used for drilling the tubular beam andconnected to the upper end of the support base; each tubular beam clamping mechanism comprises footstand used for supporting the tubular beam, and a pressing component used for clamping the tubular beam; the pressing component is connected to the upper end of the footstand; the drilling mechanisms are arranged on the both sides or one side of the tubular beam clamping mechanisms; the support baseand the footstand are both connected to the upper surface of the base separately; and the base is provided with a switch control box used for controlling the operation of the drilling mechanisms and the tubular beam clamping mechanisms. According to the device provided by the invention, the production efficiency of main tubular beams of the automobile instrument panel is improved greatly, and thedevice has the advantages of simple structure, low cost, good processing effect and manpower saving.

Owner:重庆能正机械有限公司

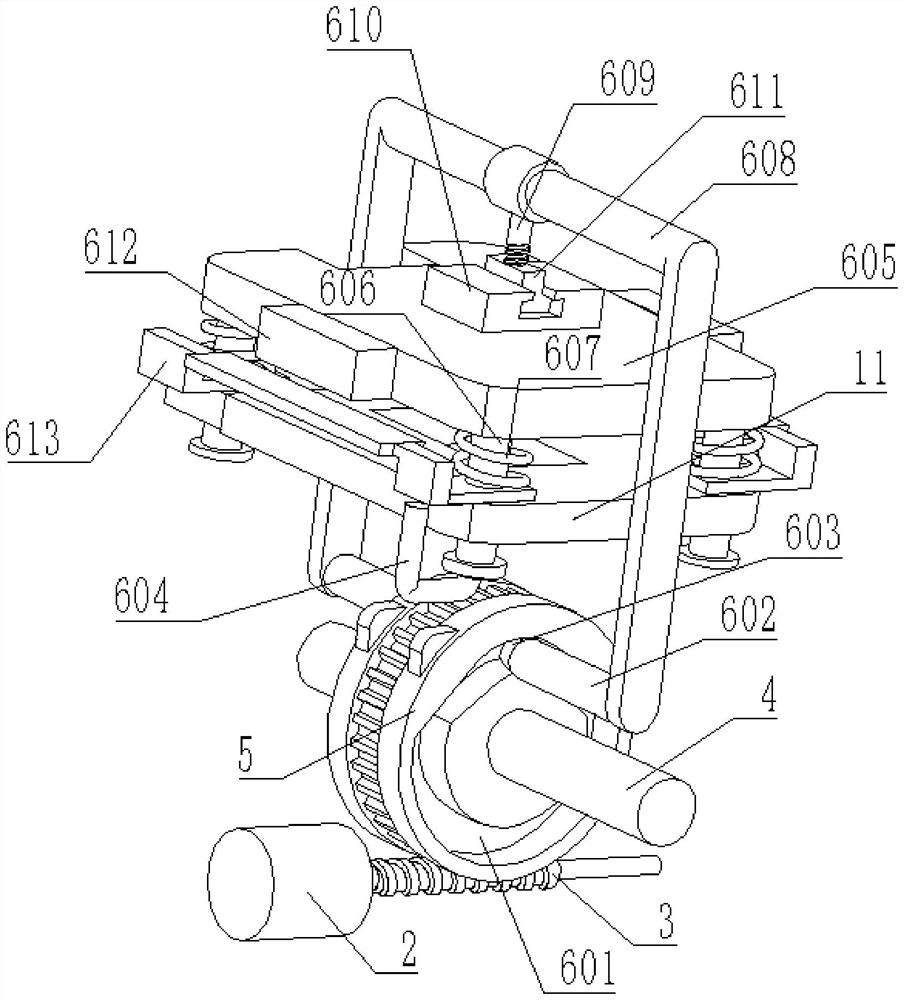

Metallurgical pipe fitting punching equipment and pipe fitting punching process

InactiveCN112024703AIncrease productivityRealize automatic punchingPerforating toolsPunchingPipe fitting

The invention relates to metallurgical pipe fitting punching equipment and a pipe fitting punching process. The metallurgical pipe fitting punching equipment comprises a base, a feeding device, a turnover mechanism, a clamping mechanism and a punching mechanism, the feeding device is used for conveying a metallurgical pipe fitting, the clamping mechanism is opened to clamp the metallurgical pipe fitting after the metallurgical pipe fitting reaches a designated place, and then the punching mechanism and the turnover mechanism are matched to carry out turnover and punching operation. According to the metallurgical pipe fitting punching equipment, automatic pipe fitting punching is achieved, the problem that punching is completed at a time is solved, the workload of workers is reduced, meanwhile, the percent of pass of pipe fitting machining can be well increased, and the working efficiency of the equipment is effectively improved.

Owner:王浩宇

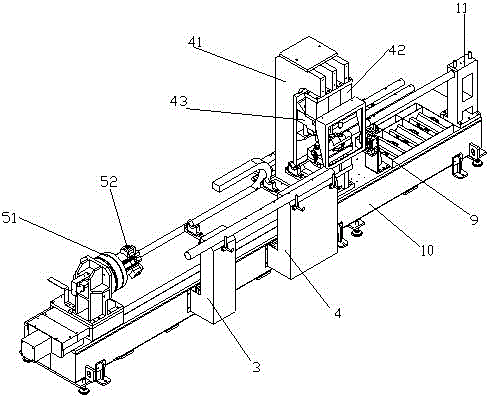

Numerical control lathe with automatic punching device

InactiveCN103170657AEasy to operateReduce labor intensityFeeding apparatusAttachable boring/drilling devicesEngineeringTailstock

A numerical control lathe with an automatic punching device in particular relates to structural improvement of a tail seat punching device of a numerical control lathe. The numerical control lathe with the automatic punching device is convenient to operate, low in labor intensity, high in production efficiency and high in drilling accuracy. The numerical control lathe with the automatic punching device comprises a machine seat, a lathe body and a tail seat, wherein the tail seat is positioned at one end of the lathe body, a lathe head is arranged at the other end of the lathe body, the tail seat is mainly composed of a tail seat guide rail, a tail seat carriage plate, a tail seat body, a tail seat sleeve and a hydraulic oil cylinder, the tail seat is installed on the lathe body through the tail seat guide rail, the tail seat sleeve is positioned in a round hole of the tail seat, a left linear guide rail or change rail and a right linear guide rail or change rail are arranged on the lathe body on two sides of the tail seat and the lathe head, the carriage plate is positioned above the linear guide rails, a motor seat is arranged on the lathe body under the carriage plate, the lathe head is arranged above the lathe body, the motor seat is positioned on the lathe body, a servo motor is arranged at the front end of the motor seat, the slidable tail seat carriage plate is arranged in the middle of the lathe body, the tail seat guide rail is connected with the tail seat carriage plate, and the tail seat body is connected with the tail seat carriage plate. The numerical control lathe is simple to operate and high in production efficiency.

Owner:王布兴

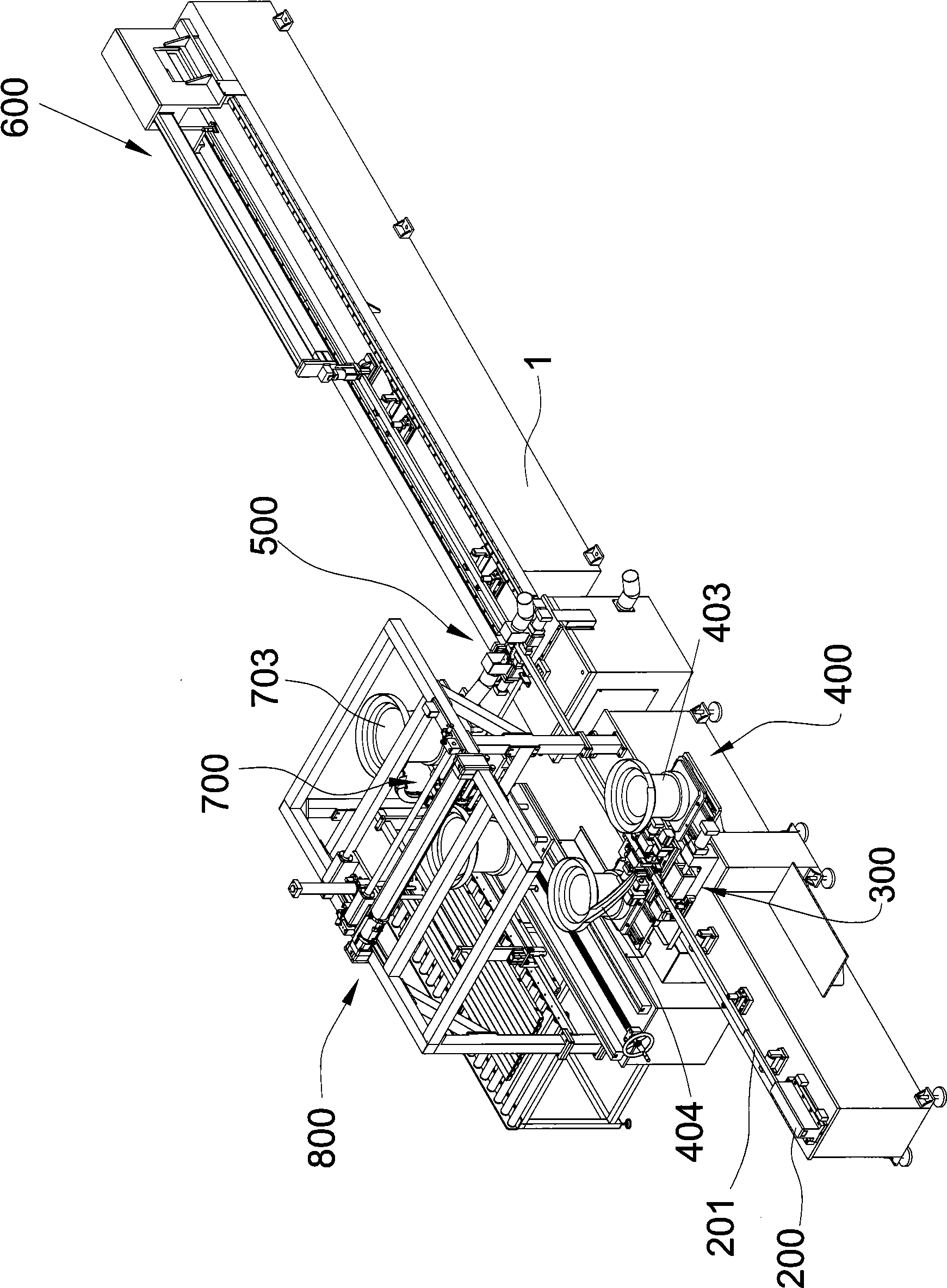

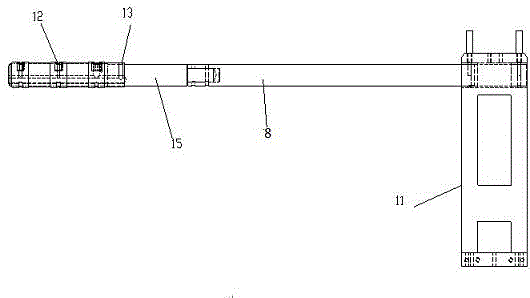

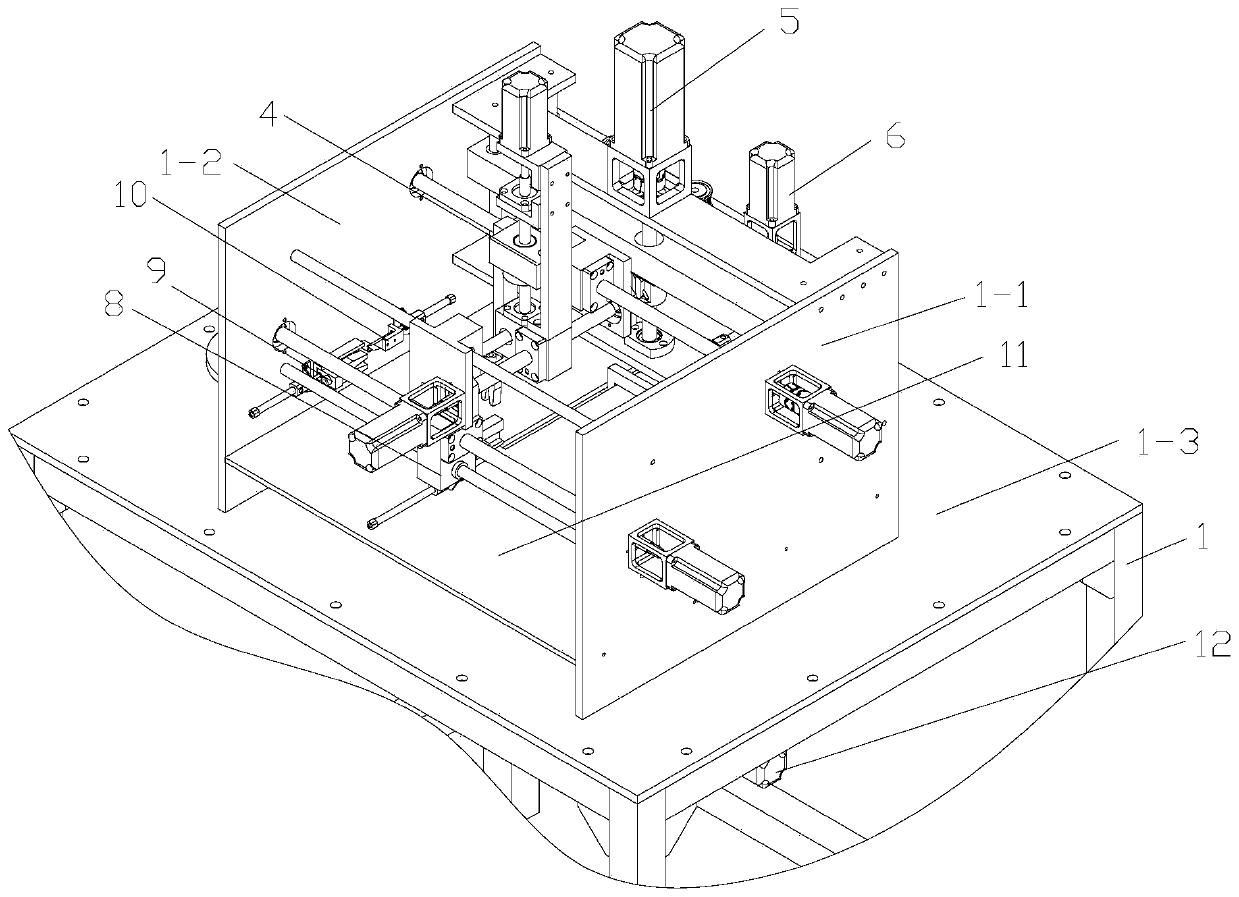

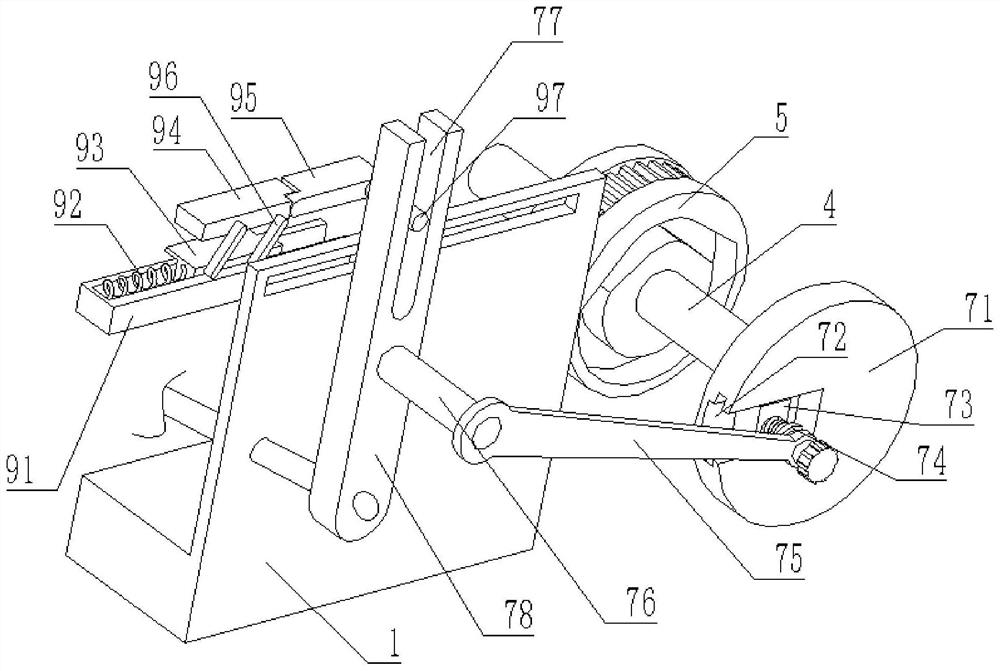

Automatic round pipe punching machine capable of being applied to production line

ActiveCN106984699ASimple picking processWide range of applicationsPerforating toolsMetal-working feeding devicesSteel tubeEngineering

The invention relates to an automatic round pipe punching machine capable of being applied to a production line. The automatic round pipe punching machine capable of being applied to the production line comprises a platform, a punching device, a locating device and a material fetching device. The round pipe punching machine capable of being applied to the production line is characterized in that the platform comprises a support, two supporting plates, a hopper, a feeding steel tube storage support and a discharging steel tube storage support, the support comprises a middle portion, a left portion and a right portion, the left portion and the right portion are symmetrical about the middle portion, the two supporting plates are fixed to the upper surface of the left portion and the right portion correspondingly, the two steel tube storage supports are fixed to the portions, below the two supporting plates, of the support, the left side of each steel tube storage support is lower than the right side of the steel tube storage support, a plurality of gaps are formed in the corresponding positions of the inner sides of each steel tube storage support, the steel tube storage support located on the right side is the feeding steel tube storage support, the steel tube storage support on the left side is the discharging steel tube storage support, the included angle between the feeding steel tube storage support and the horizontal plane is beta, the included angle between the discharging steel tube storage support and the horizontal plane is alpha, and the angle beta and the angle alpha can guarantee that steel tubes can roll off from left to right through the gravity on the feeding steel tube storage support and the discharging steel tube storage support.

Owner:HEBEI UNIV OF TECH

Device for realizing automatic punching and being capable of absorbing dust based on air pressure

InactiveCN111890462AWill not polluteEnvironmentally friendlyMetal working apparatusPunchingGear wheel

The invention relates to the technical field of new materials and discloses a device for realizing automatic punching and being capable of absorbing dust based on air pressure. The device comprises asupporting plate, the lower end of the supporting plate is slidably connected with a rack, the supporting plate is internally and rotatably connected with a screw rod, and the rack is internally and rotatably connected with a rotating gear corresponding to the screw rod and is internally and rotatably connected with rotating shafts. According to the device for realizing the automatic punching andbeing capable of absorbing the dust based on the air pressure, the rack is driven to inflate airbag devices in the moving process by controlling a driving device to run, when the gas quantity is highenough, the screw rod stops rotating, control valves are jacked open, gases enter into an extrusion device to extrude a punching device to perform punching on a plastic new material downwards, and thegases are sucked in from dust absorption bins through one-way valves in the decreasing process of the gases inside the airbag devices, the fact that the dust and odorous gases generated by the punching can be absorbed in the punching is realized.

Owner:季守航

High-precision plate punching device

ActiveCN112170630AGuaranteed stabilityQuality improvementShaping toolsPerforating toolsPunchingElectric machinery

The invention relates to the technical field of stamping machining, and discloses a high-precision plate punching device. The high-precision plate punching device comprises a rack, a motor driving motor is connected to the interior of the rack through bolts, a worm is fixedly connected to the output end of the driving motor, a driving disc is meshed with the surface of the worm, a fixed rotating shaft is fixedly connected to the axis of the driving disc, a transmission mechanism is arranged at the front end of the fixed rotating shaft, a machining mechanism is arranged on the surface of a fixed bottom die, a material receiving mechanism is arranged on the right side of the rack, and a feeding mechanism is arranged inside the rack. According to the high-precision plate punching equipment, the two sides of a punched plate are clamped and fixed in the punching operation process of the plate, so that the stability of the plate in the machining process is guaranteed, the situation that punching size changes due to deformation of the plate during punching is avoided, the high quality of the whole plate in the punching process is improved, the deviation is reduced, and the high-precisionpunching operation is achieved.

Owner:佛山市巨雷建材有限公司

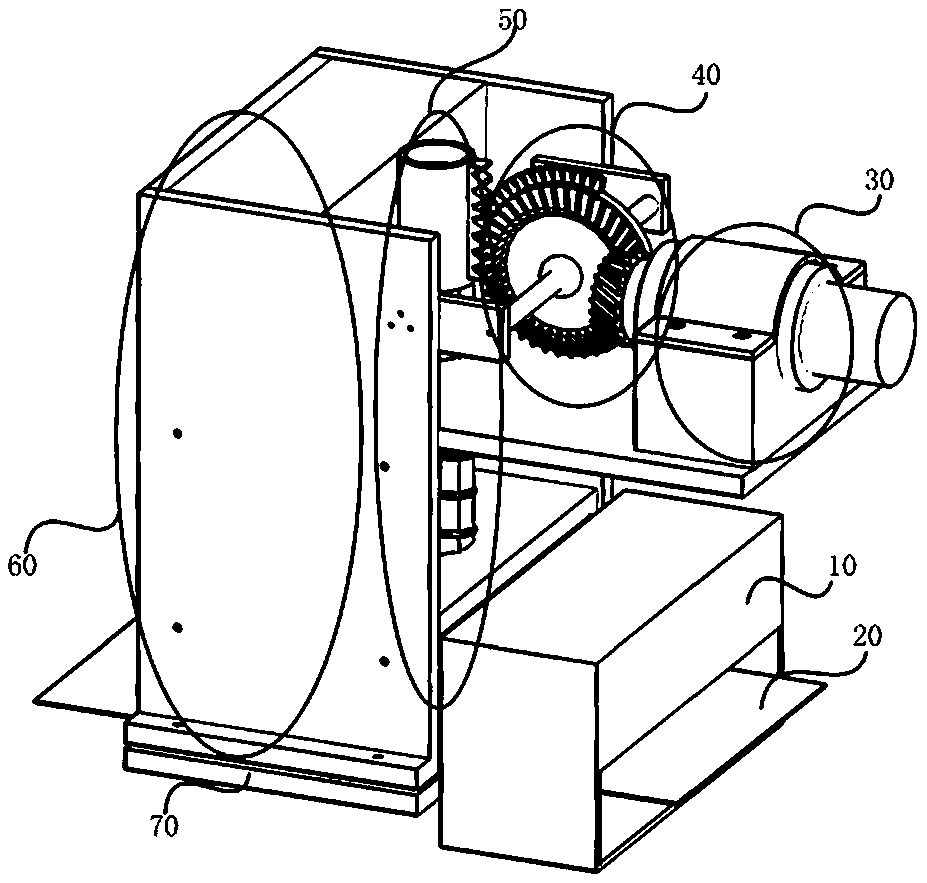

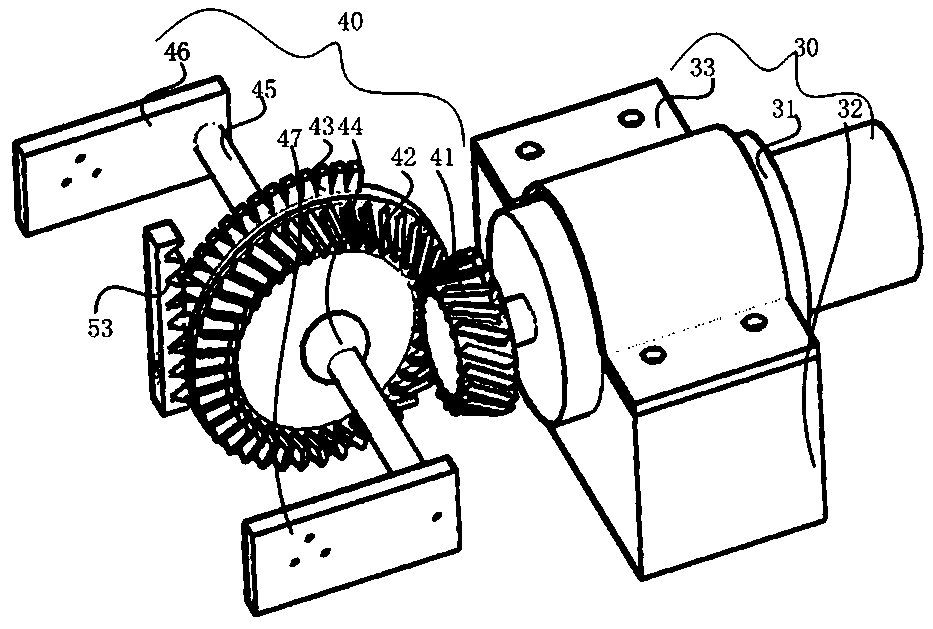

Apparatus for automatically hollowing out label paper

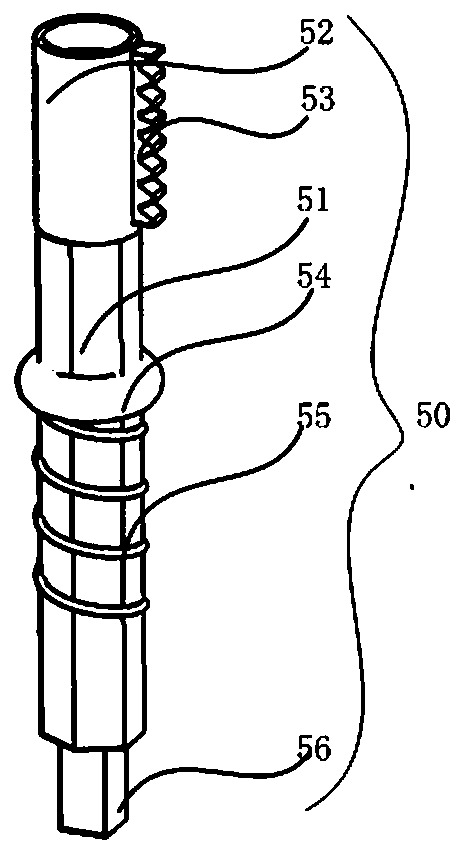

InactiveCN109571632ASimple driving circuitNovel structurePrintingMetal working apparatusPower apparatusPaper sheet

The invention relates to an apparatus for automatically hollowing out label paper. The apparatus for automatically hollowing out the label paper is characterized in that the apparatus comprises a transmission apparatus (40), a power apparatus (30), a mold core (50), and a frame (60). The mold core (50) is vertically arranged inside the frame body (60), the power apparatus (30) is horizontally arranged on the upper part of the frame body (60), the transmission apparatus (40) is arranged between the power apparatus (30) and the mold core (50), and the power apparatus (30) and the transmission apparatus (40) drive the mold core (50) to vertically move downwards to punch the label paper so that the label paper can be hollowed out. According to the apparatus for automatically hollowing out thelabel paper, the structure is novel, using is convenient, performance is stable, the apparatus is suitable for connection of any small-type intelligent devices, printing labels are automatically punched, and thus the apparatus has broad market prospects.

Owner:JINGDEZHEN CERAMIC INSTITUTE

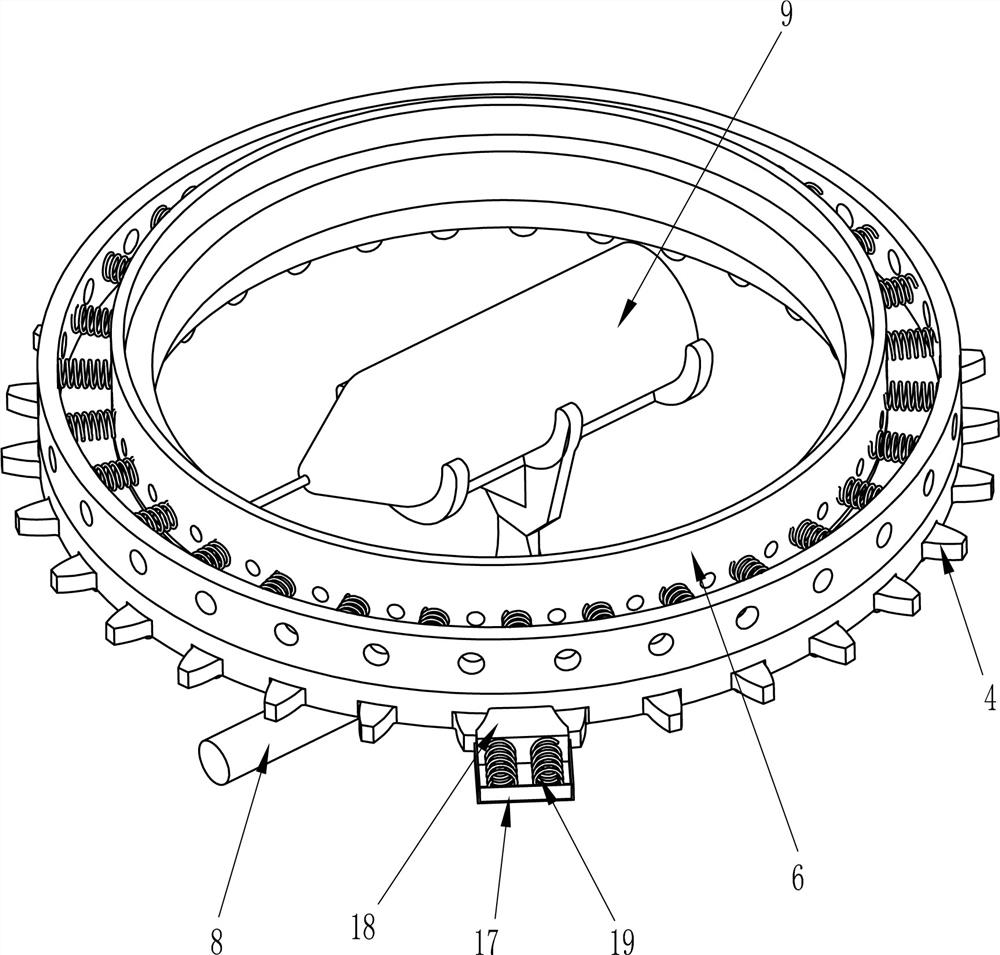

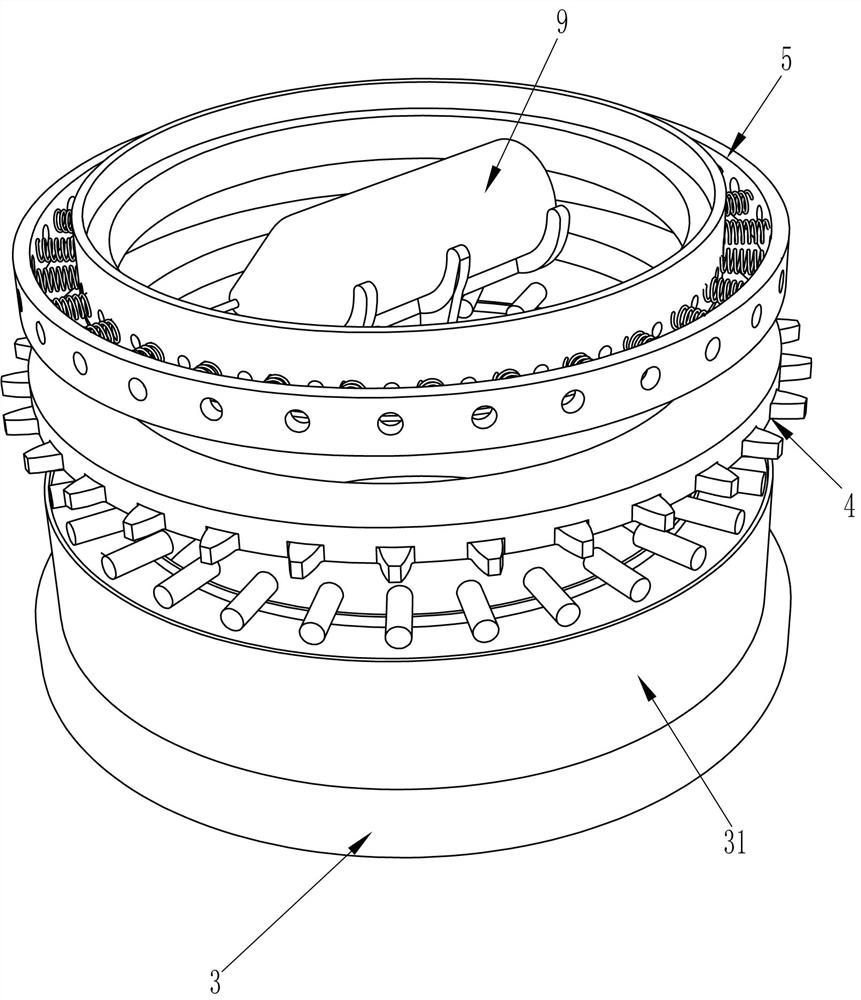

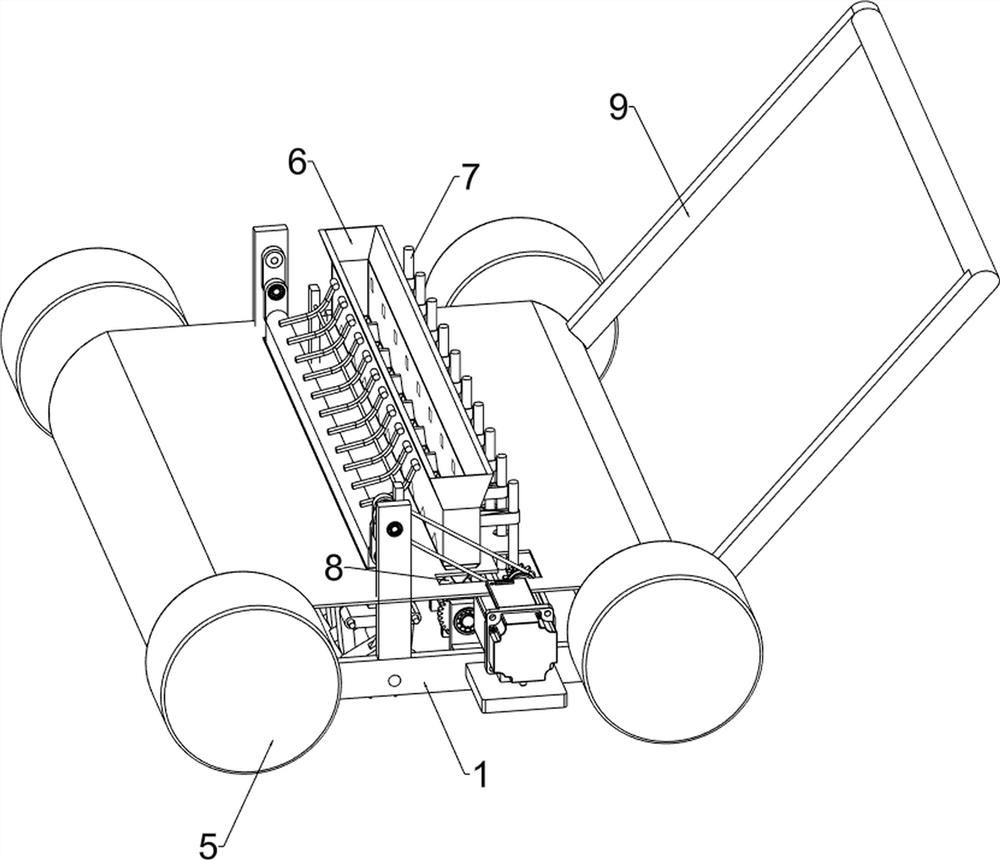

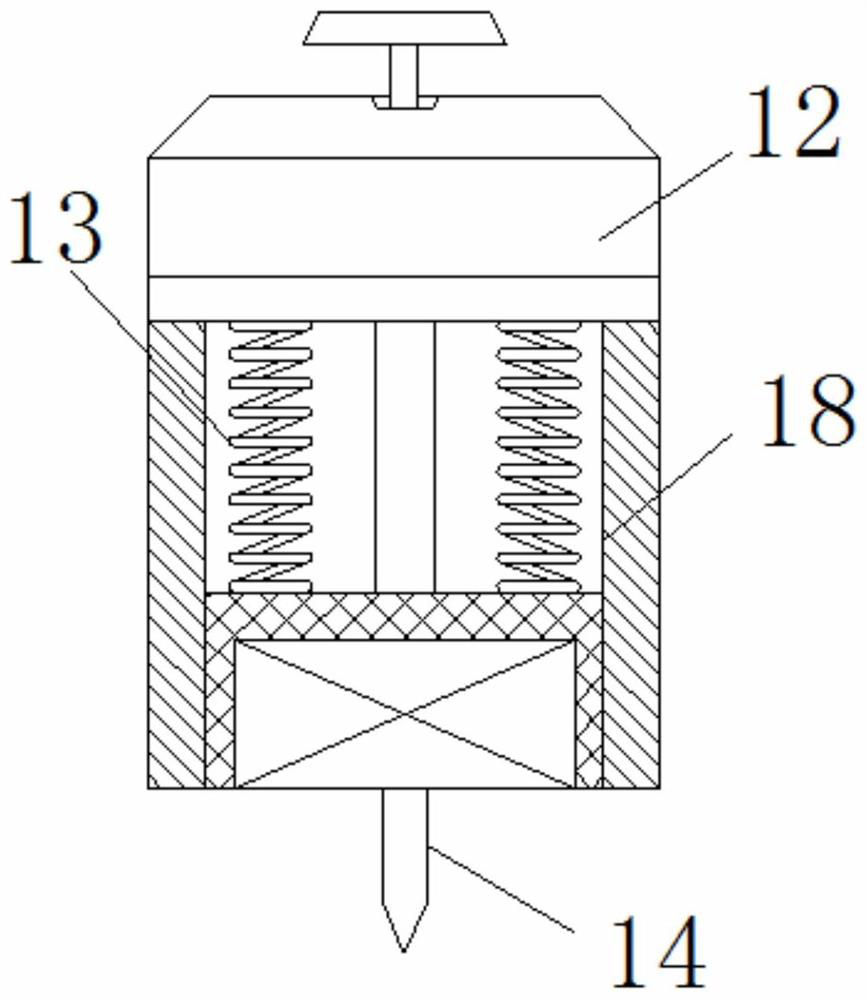

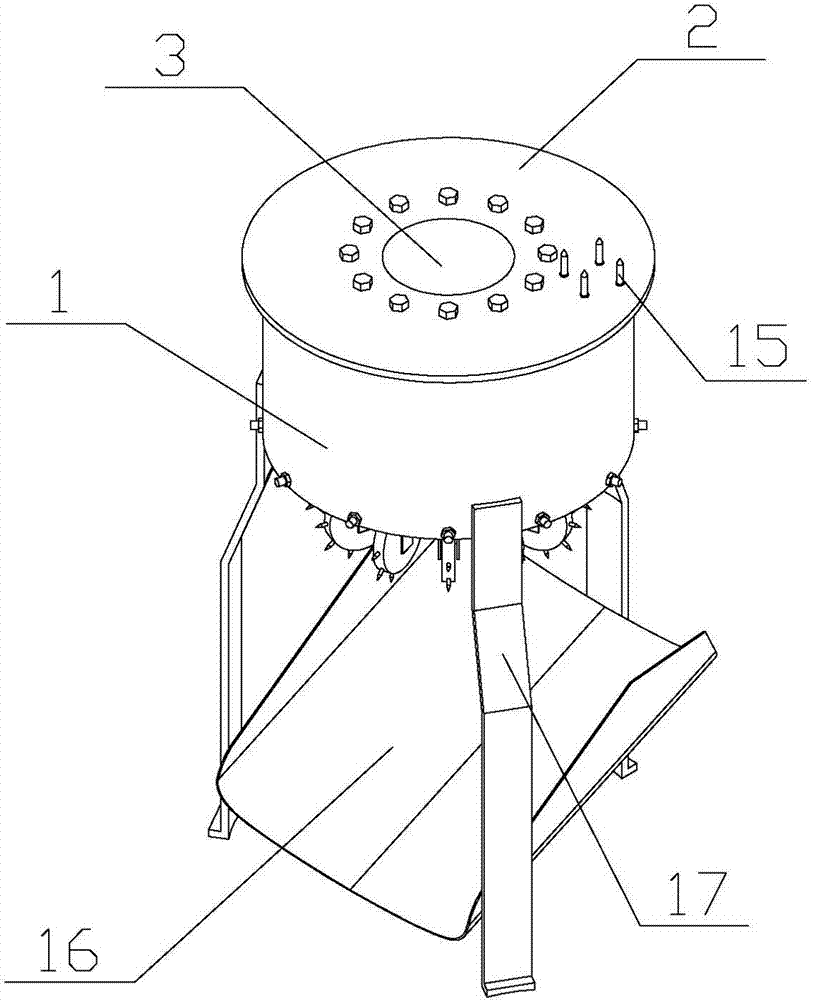

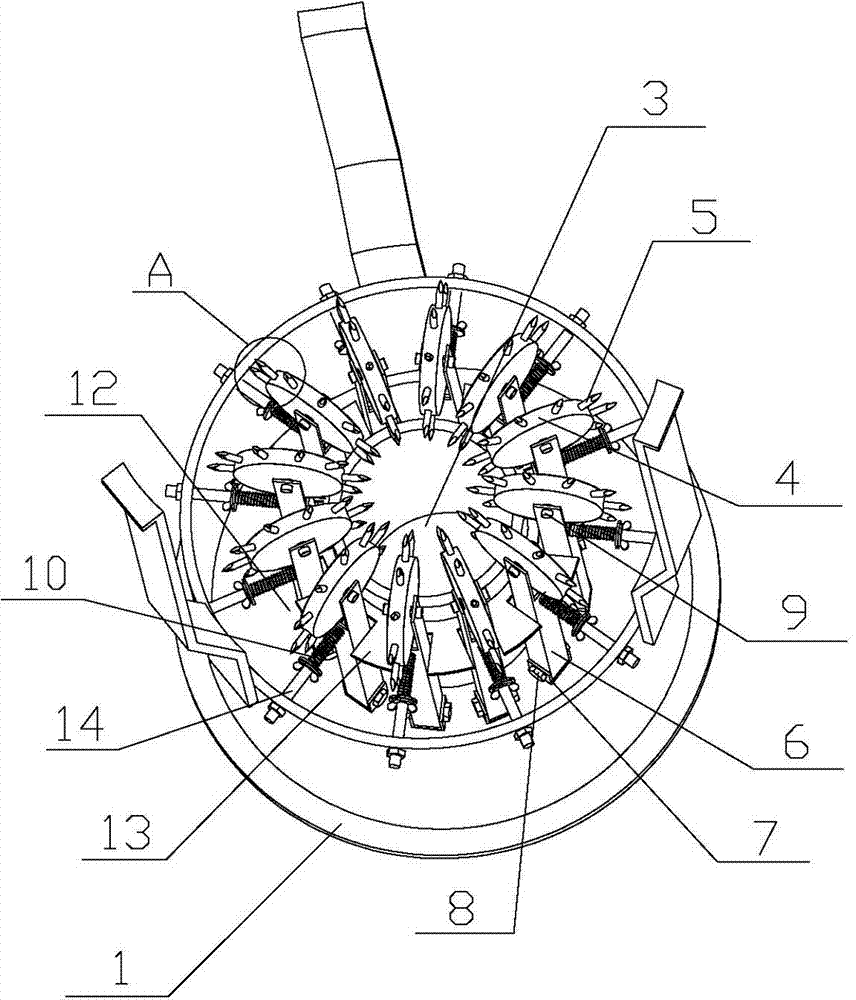

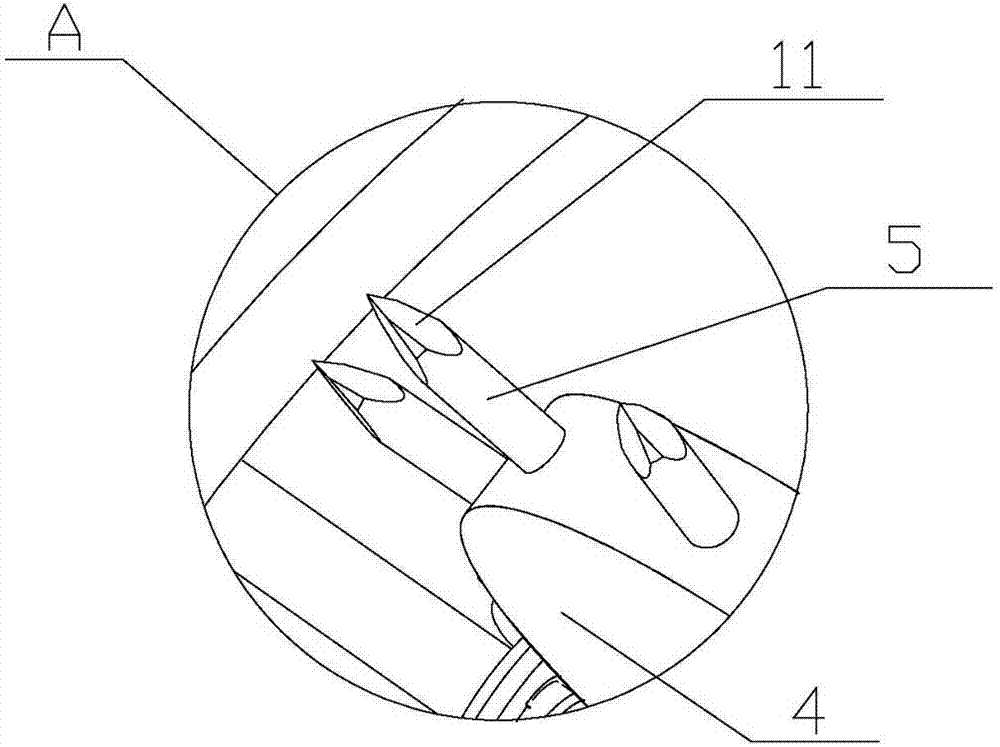

Bacteria stick quick perforating machine

A bacteria stick quick perforating machine comprises a machine frame, wherein a circular table is arranged on the machine frame, a bacteria stick channel is formed in the circular table, piercing blocks are arranged at an outlet of the bacteria stick channel, stings are arranged on the piercing blocks, a support is arranged on the bottom face of the circular table, and the support is connected with the circular table through springs. The bacteria stick quick perforating machine has the advantages that the structure is reasonable, using is convenient, installing and maintaining are convenient, automation of bacteria stick perforating is achieved, work efficiency is improved, labor intensity of workers for perforating operation is lowered, production cost is lowered, perforated bacteria stick holes can be evenly distributed, mycelia in bacteria sticks can normally grow, yield of mushrooms can be improved, income of bacteria growers can be improved, accidental injuries of workers can not occur in the automatic bacteria stick perforating process, personal safety of the workers is protected, the using effect is good, and popularization is facilitated.

Owner:李明

Automatic paper punching, threading and knotting machine

The invention relates to an automatic paper punching, threading and knotting machine comprising a rack, a work table surface arranged on the rack, left and right brackets fixedly arranged on the worktable surface and oppositely arranged, a paper containing plate horizontally mounted between the left bracket and the right bracket and threading and knotting assemblies mounted on the upper and lowersides of the paper containing plate and used for cooperating to achieve threading and knotting actions. According to the automatic paper punching, threading and knotting machine, an upper clamp mechanism and a lower clamp mechanism cooperate to complete threading work of a binding line, and the upper clamp mechanism cooperates with a front clamp mechanism and the lower clamp mechanism to completeknotting work of the binding line, so that the automation degree is high, the knotting speed is high, and the paper thread stitching efficiency is greatly improved.

Owner:WENZHOU ELECTRIC POWER BUREAU +2

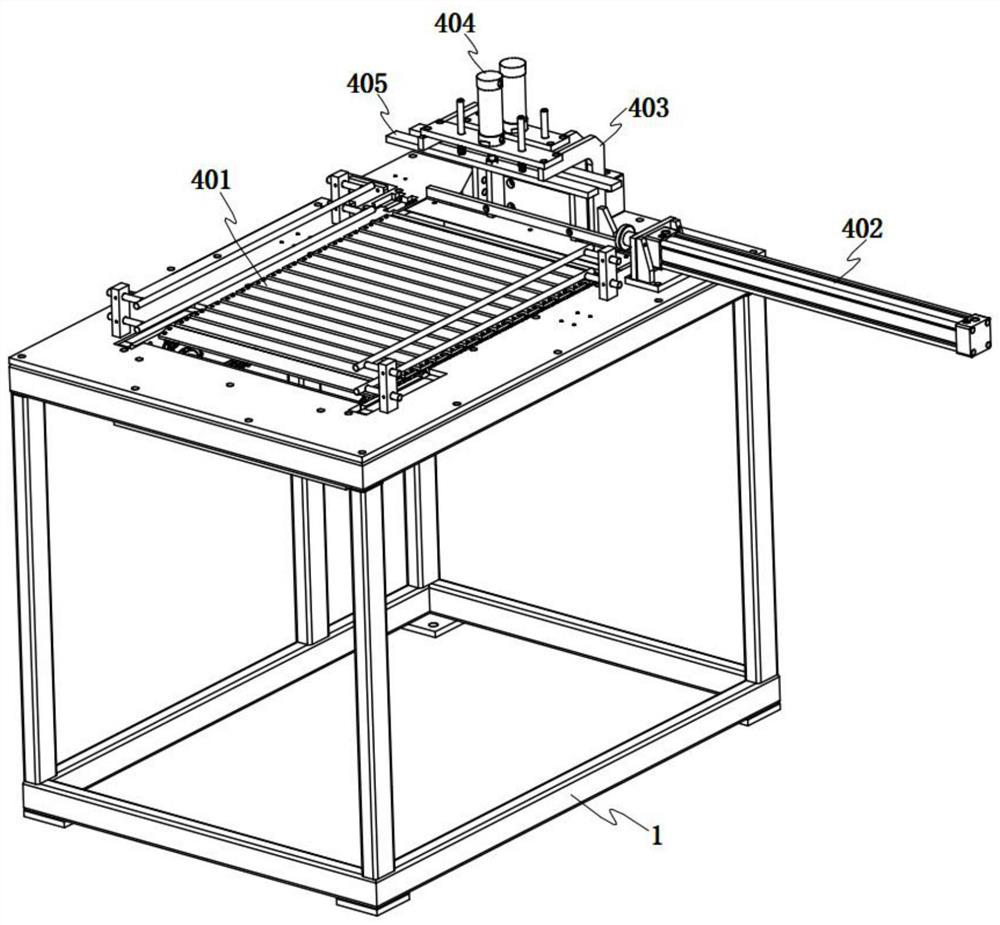

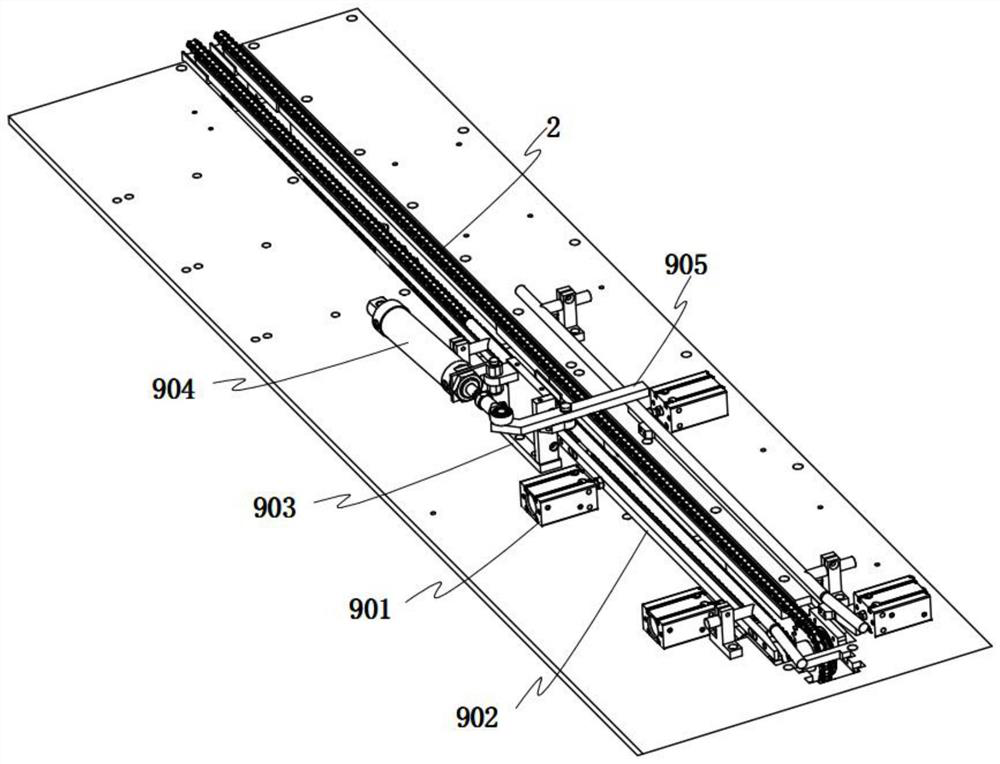

A press-fitting device for composite exterior wall panels in construction engineering

ActiveCN110842581BRealize automatic punchingImprove processing efficiencyOther manufacturing equipments/toolsPunchingEngineering

The invention relates to a combined external wallboard press fitting device for constructional engineering. The device comprises a device table body and a conveying chain belt arranged on the device table body, wherein a flat input mechanism, a punching mechanism, an outer decoration plate adding mechanism and a pressing mechanism are sequentially arranged on one side of the conveying chain belt on the device table body along a belt body. Clamping limiting mechanisms are arranged on the two sides of the conveying chain belt, and the device table body is provided with a taking-out mechanism atthe upper part of the output end of the conveying chain belt. Automatic punching, plate pressing assembling and output stacking of combined external wallboards are achieved, the processing efficiencyof the combined external wallboards is improved, assembling is convenient, meanwhile, outer decorative plates of the combined wallboards can be replaced according to different decoration styles, production and processing requirements of the combined wallboards of different decorative styles can be met, and the application range is wide.

Owner:广东衡太建设有限公司

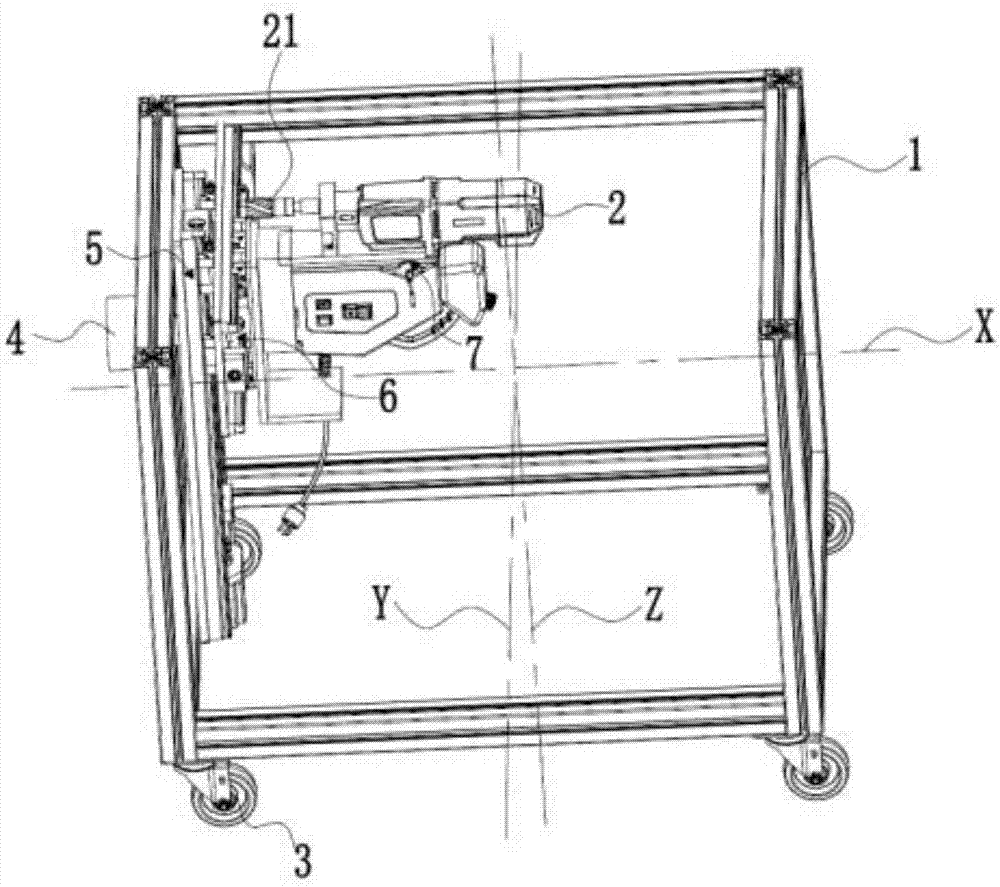

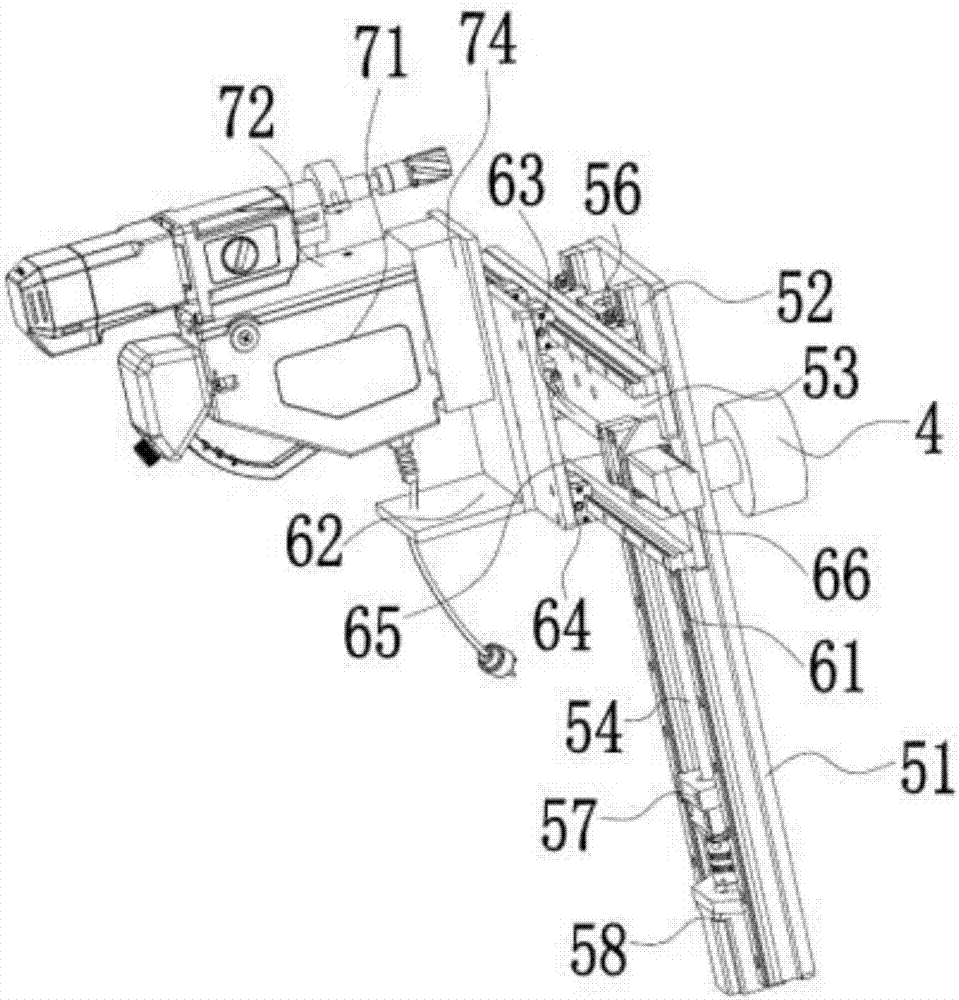

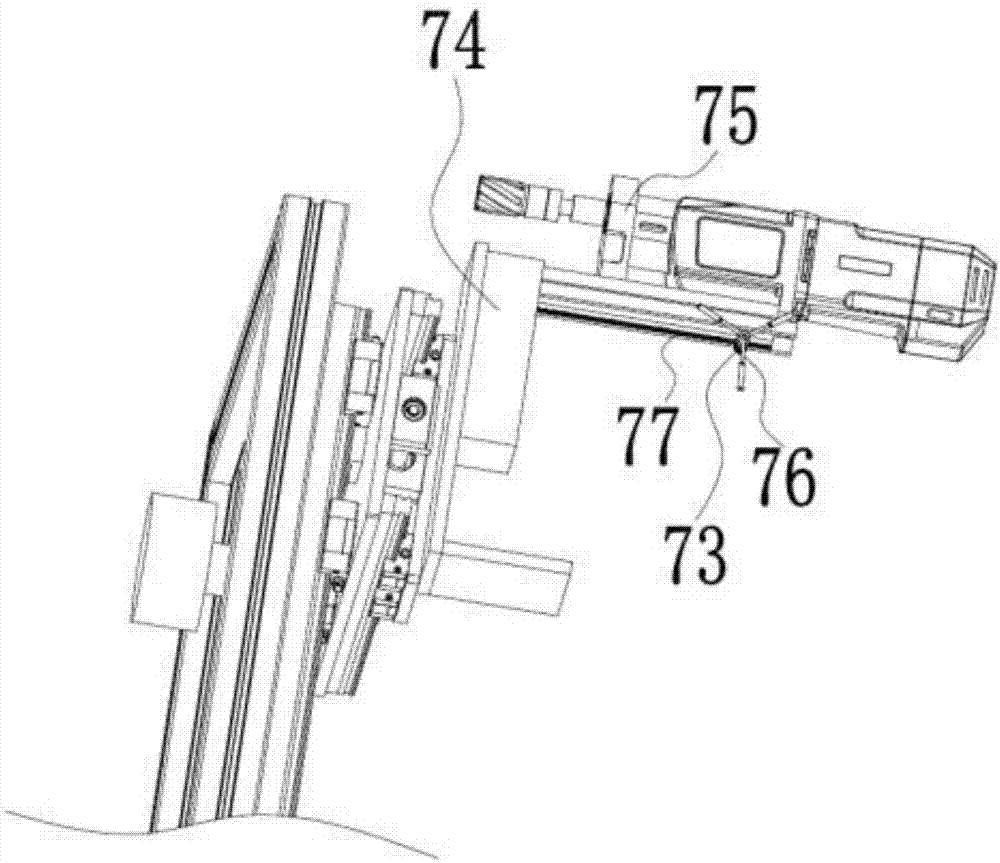

Perforating machine for support of control cabinet of AGV forklift

PendingCN107486573AAvoid changeExquisite designFeeding apparatusLarge fixed membersControl engineeringProcess engineering

The invention discloses a perforating machine for a support of a control cabinet of an AGV forklift. The perforating machine comprises a movable framework; the framework can be fixedly connected to the AGV forklift to be perforated through the magnetic force; an electric drill capable of performing X-axis, Y-axis and Z-axis movement relative to the framework is arranged on the framework; and a drill bit of the electric drill can move to the outer side of the framework. The perforating machine has the advantages that the design is ingenious, the structure is simple, the electric drill capable of performing X-axis, Y-axis and Z-axis movement is arranged on the movable framework so that the position of the electric drill can be adjusted according to the positions to be perforated, hand-held operation is not needed so that the labor intensity can be greatly reduced, the perforating efficiency can be improved, in addition, the framework and a forklift body are fixed in an attracted mode through an electromagnet so that the electric drill and the forklift body can be effectively prevented from changing, and the perforating precision and the position accuracy can be guaranteed.

Owner:苏州罗伯特木牛流马物流技术有限公司

Full-automatic plate punching equipment

InactiveCN112191735AGuaranteed stabilityQuality improvementShaping toolsPerforating toolsPunchingElectric machinery

The invention relates to the technical field of stamping machining, and discloses full-automatic plate punching equipment which comprises a machine frame. A driving motor is connected to the inner part of the machine frame through bolts, a worm is fixedly connected to the output end of the driving motor, and a driving disc meshes with the surface of the worm. A fixed rotating shaft is fixedly connected to the axis of the driving disc, a transmission mechanism is arranged at the front end of the fixed rotating shaft, a machining mechanism is arranged on the surface of a fixed bottom die, a material receiving mechanism is arranged on the right side of the machine frame, and a feeding mechanism is arranged in the machine frame. According to the high-precision plate punching equipment, the punched two sides of a plate are clamped and fixed in a punching operation process of the plate, so that the stability of the plate in a machining process is guaranteed, the condition that the punching size is changed due to deforming of the plate in the punching process is avoided, the high quality of the whole plate in the punching process is improved, the deviation is reduced, and high-precision punching operation is achieved.

Owner:东莞三励科技有限公司

Three-in-one automatic punch device

InactiveCN106738039AMeet the needs of punching holes of different sizesQuick changeMetal working apparatusPunchingEngineering

The invention provides a three-in-one automatic punch device. The three-in-one automatic punch device comprises a workbench, wherein punches and a bracket are arranged on the workbench, the punches are distributed on the workbench in parallel, and punch pins in different specifications are arranged in the punches respectively; each punch comprises a press cover and a base, the side edge of the tail end of the press cover is hinged with the side edge of the tail end of the base, a through hole a is correspondingly formed in the base below the corresponding punch pin, and a spring assembly is compressed between the press cover and the base; a drawer is arranged in one side of the workbench to facilitate collection of punch chips; the bracket comprises a vertical plate and a horizontal plate, the horizontal plate is arranged above the workbench and parallel to the workbench, a cylinder unit is fixedly connected onto the horizontal plate, and a piston rod of the cylinder is connected with a push rod which extends below the horizontal plate. The three-in-one automatic punch device is provided to meet requirements for punching in different sizes, an automatic binding way is provided simultaneously to replace the traditional manually pressing binding way, and the binding efficiency is increased.

Owner:TIANJIN SHENGLIDA MECHANICAL EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com