Perforating machine for support of control cabinet of AGV forklift

A control box and punching machine technology, applied in the direction of manufacturing tools, boring/drilling, drilling/drilling equipment, etc., can solve the problem that the hole size accuracy and position accuracy cannot be guaranteed, the operator's hands are shaking, Problems such as heavy weight, to achieve the effect of strong versatility, ensure accuracy, and improve drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Objects, advantages and features of the present invention will be illustrated and explained by the following non-limiting description of preferred embodiments. These embodiments are only typical examples of applying the technical solutions of the present invention, and all technical solutions formed by adopting equivalent replacements or equivalent transformations fall within the protection scope of the present invention.

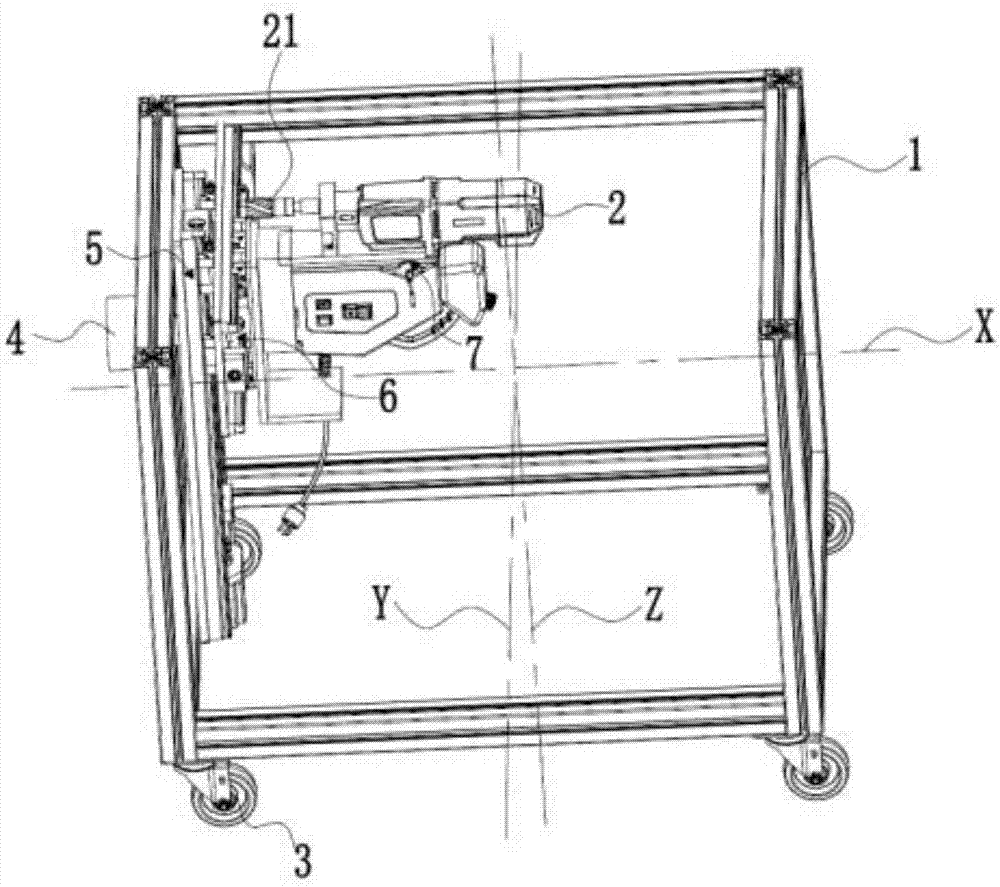

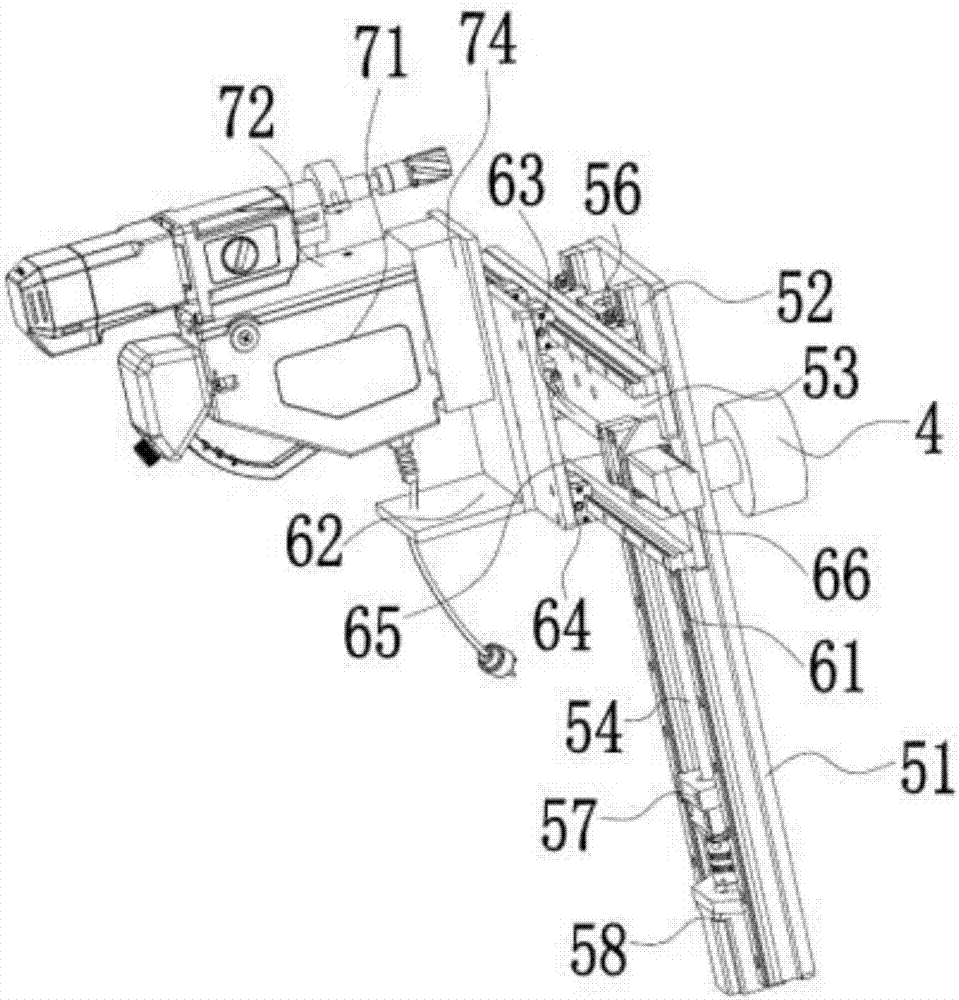

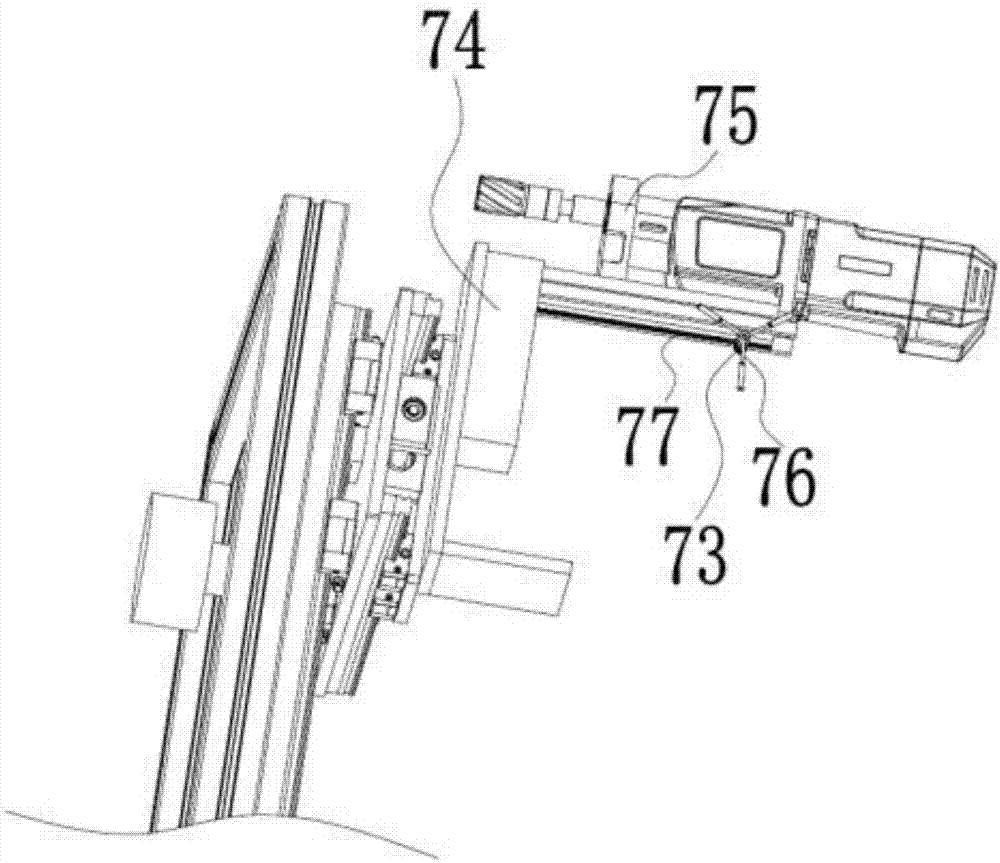

[0027] The invention discloses an AGV forklift control box bracket punching machine, as attached figure 1 As shown, it includes a movable frame 1, the frame 1 is a hollow cuboid, which is formed by connecting 12 profiles, each of the four side walls of the profiles is provided with slide grooves, and the bottom of the frame 1 is four Universal wheels 3 are respectively provided at the top corner positions.

[0028] as attached figure 1 As shown, the frame 1 is also provided with an electric drill 2 that can move relative to the X-axis, Y-axis and Z...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com