Patents

Literature

4865 results about "Forklift truck" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A forklift (also called lift truck, jitney, fork truck, fork hoist, and forklift truck) is a powered industrial truck used to lift and move materials over short distances. The forklift was developed in the early 20th century by various companies, including Clark, which made transmissions, and Yale & Towne Manufacturing, which made hoists.

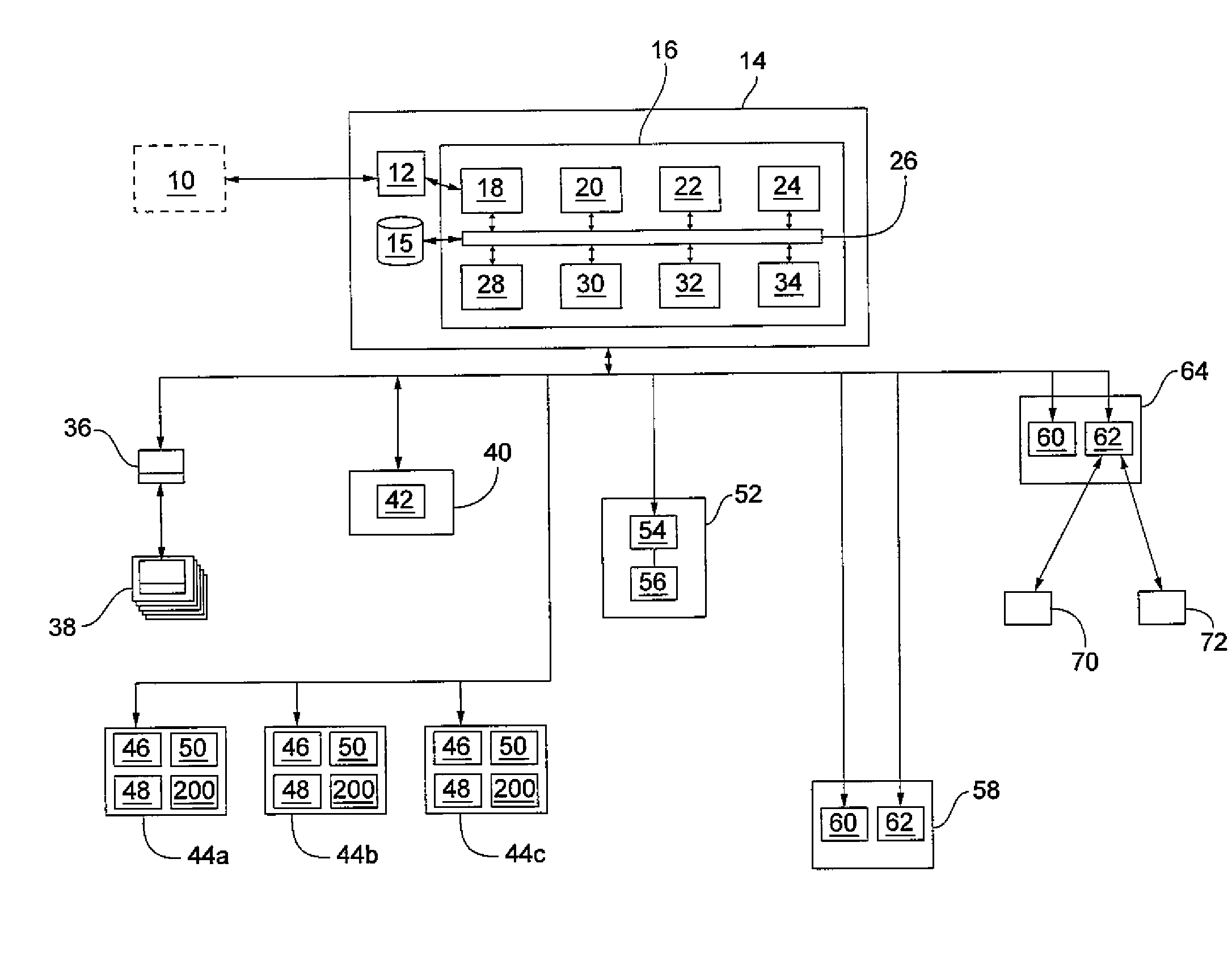

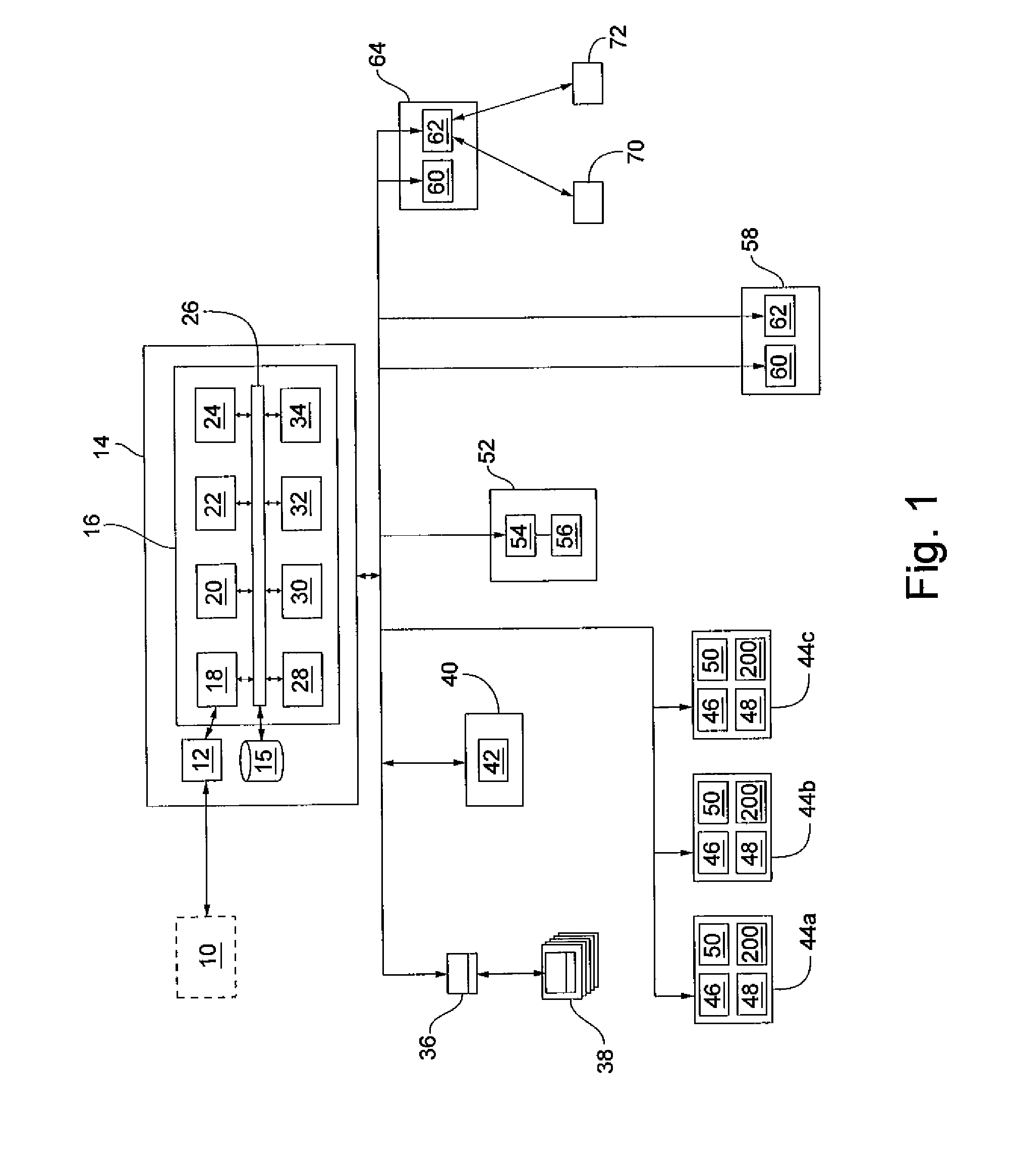

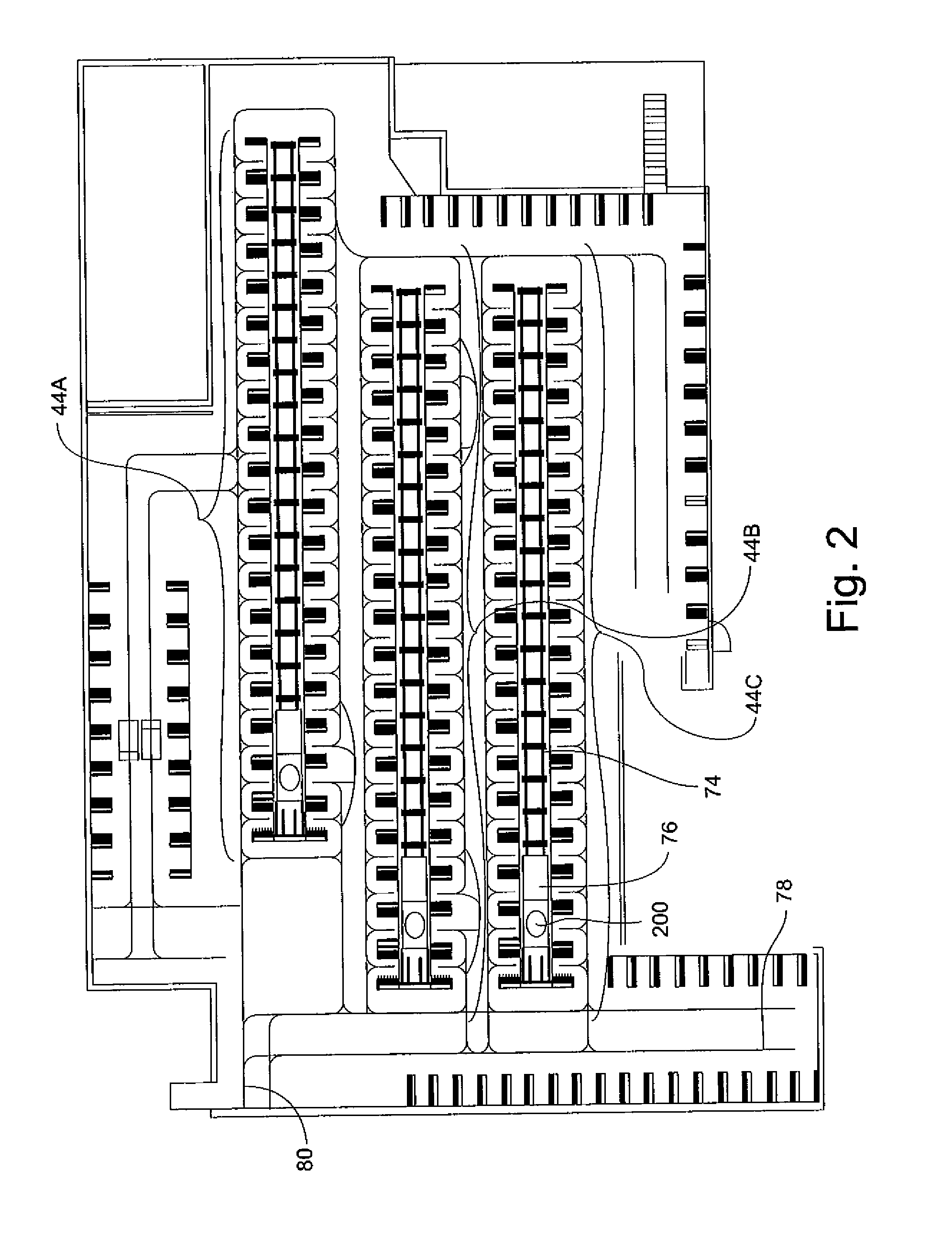

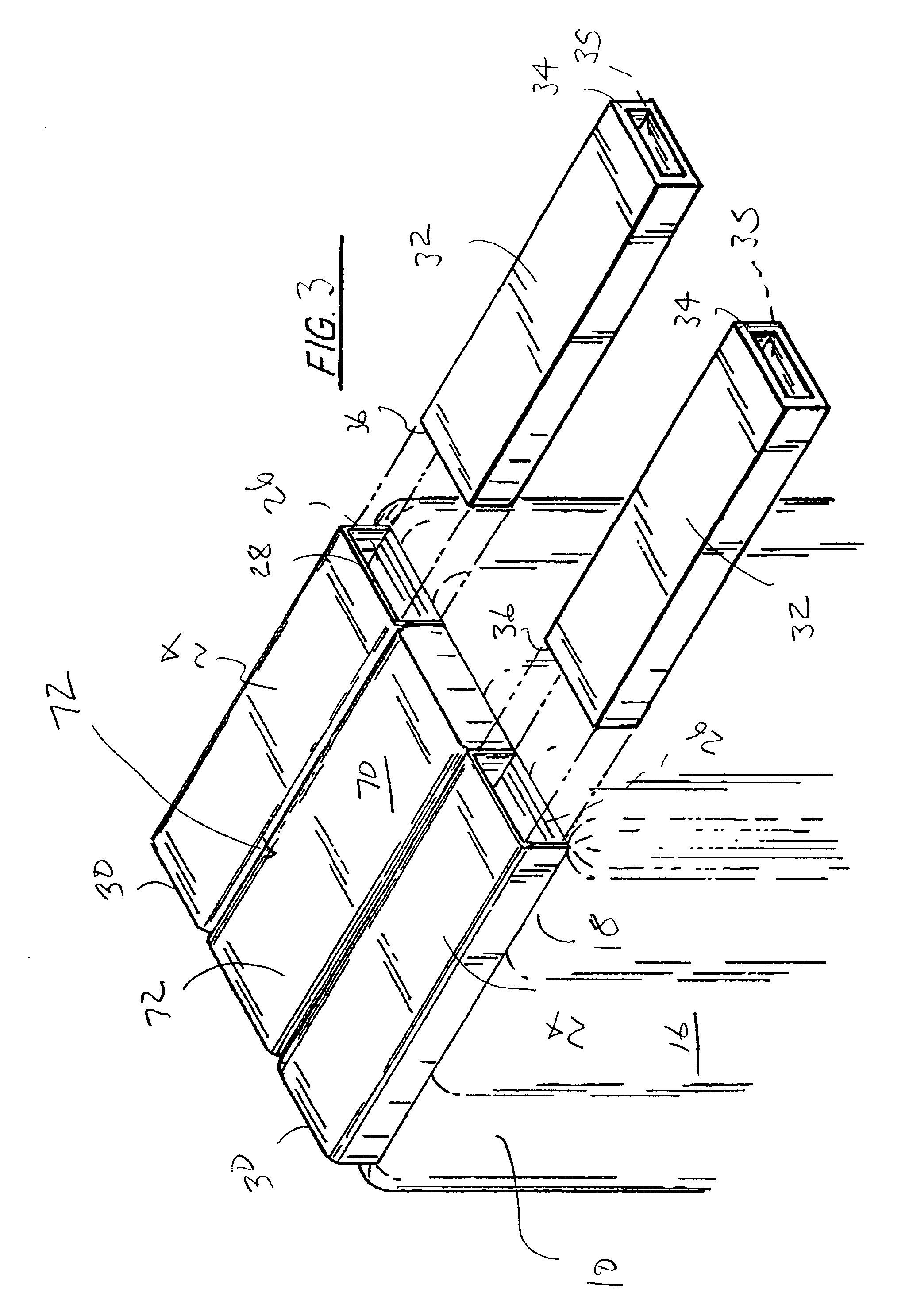

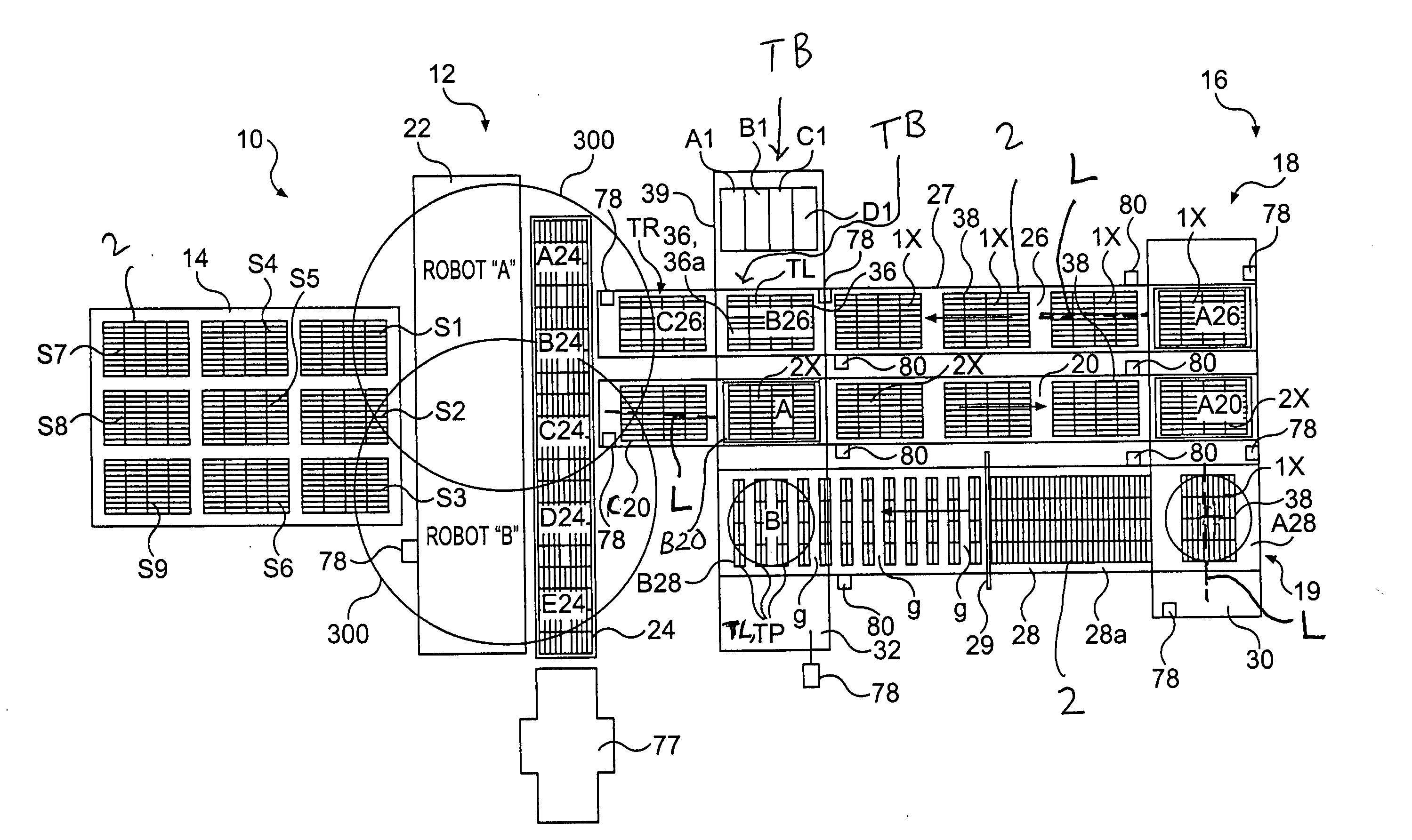

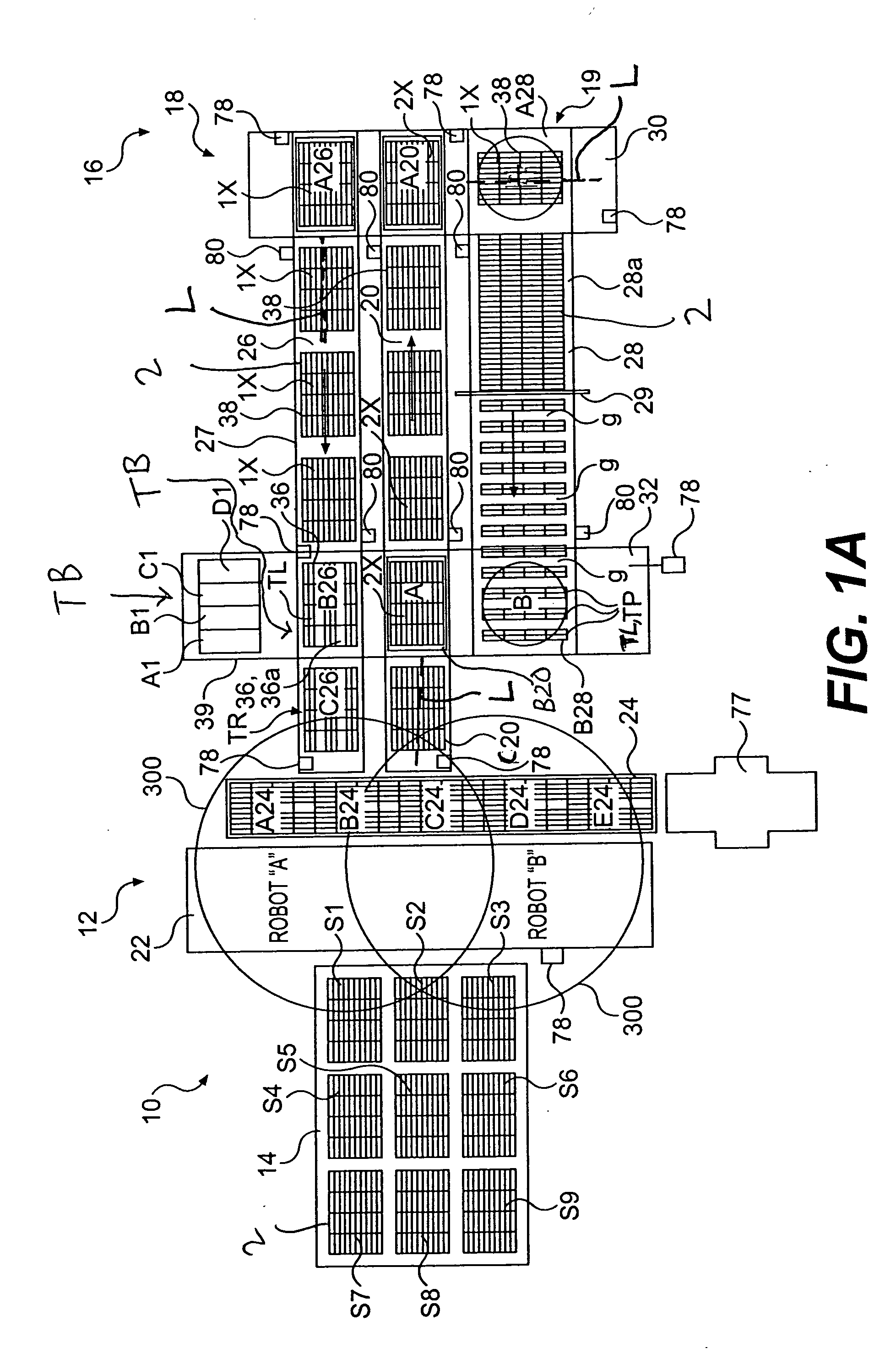

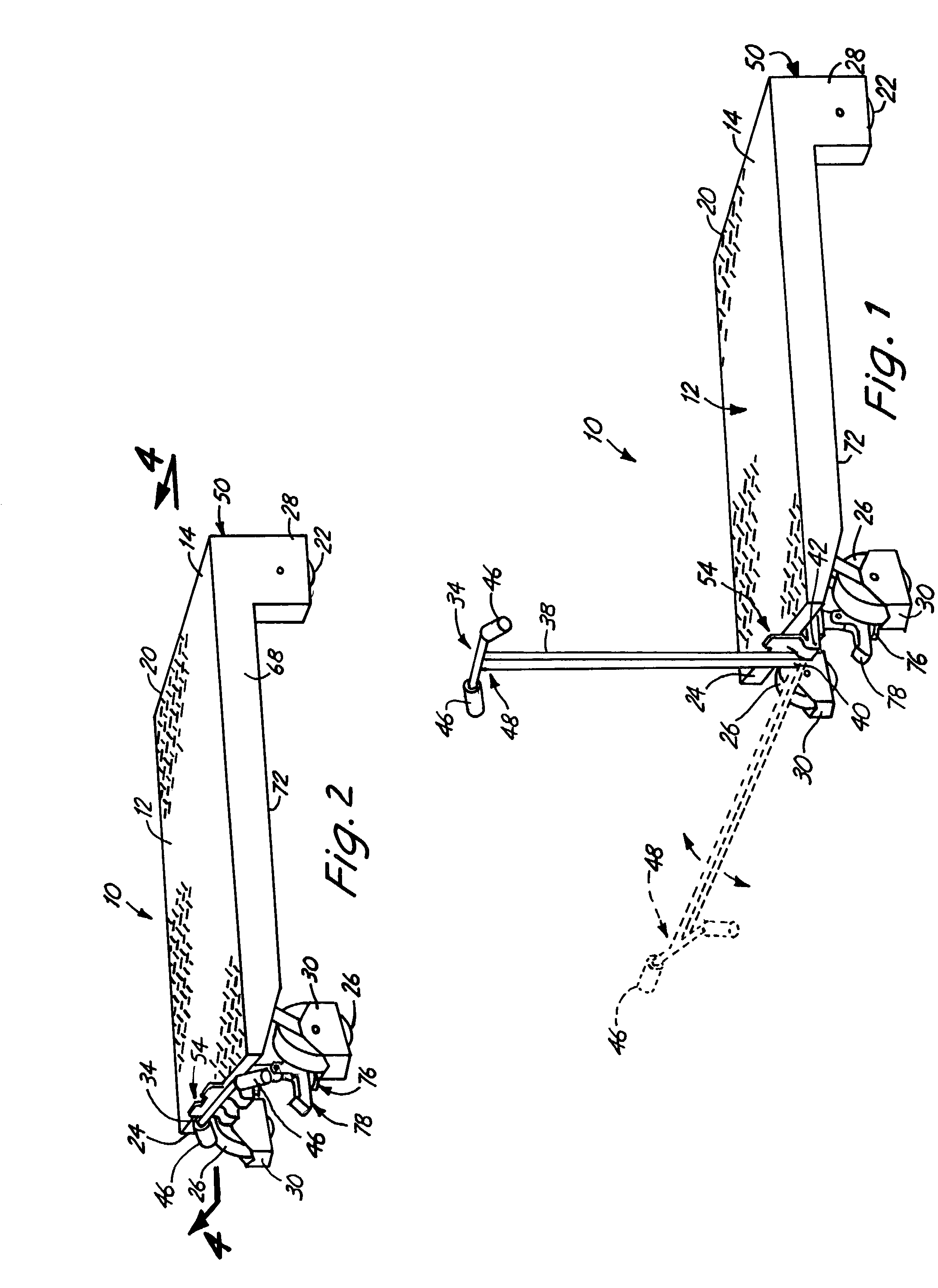

Palletizing systems and methods

InactiveUS20080131255A1Increase order filling efficiencyImprove filling efficiencyLoadersPackagingCustomer orderAutomatic guidance

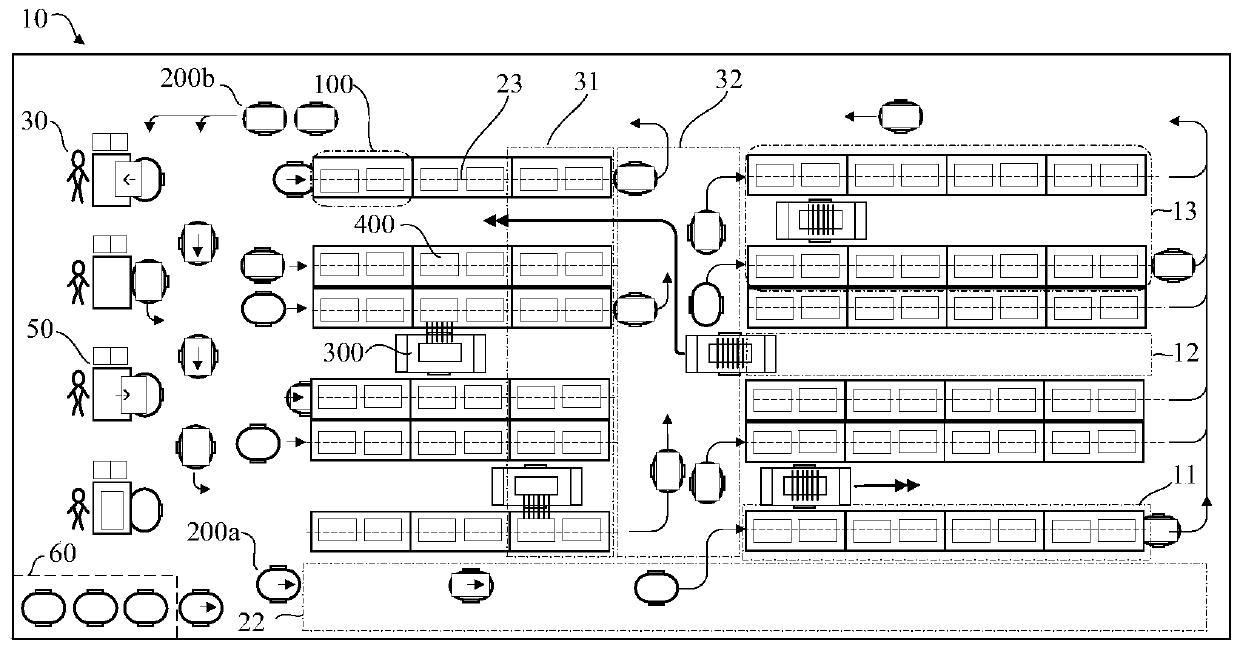

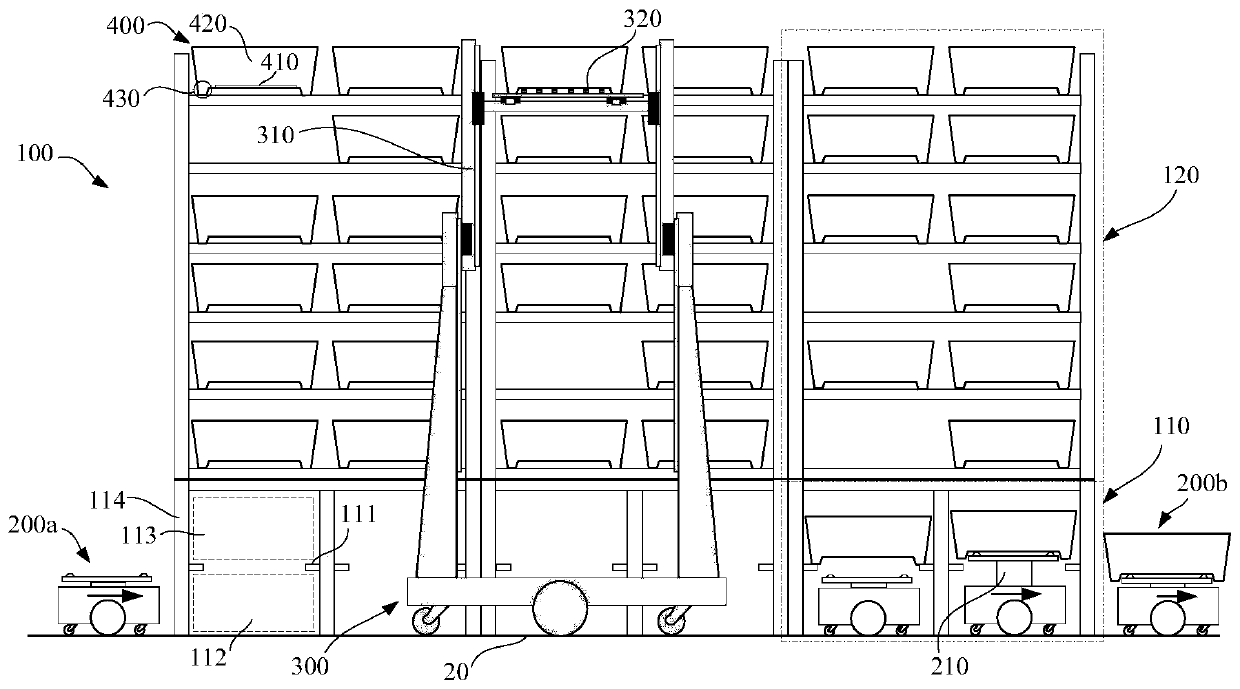

Palletizing systems and methods increasing the efficiency at which pallets of mixed products are built. The systems and methods include a pallet building module for receiving customer orders and generating pallet building instructions for arranging the products on the pallets, among other functions. The pallet building module is in communication with a number of robot cells that include source products and pallet building robots for building pallets based upon instructions generated by the pallet building module. The system includes other modules for system control including conveyor controllers, forklift controllers, and automatic guided vehicle controllers, among other controllers. Methods for building pallets of mixed product from source products within more than one robot cell.

Owner:TRANSBOTICS CORPORATION

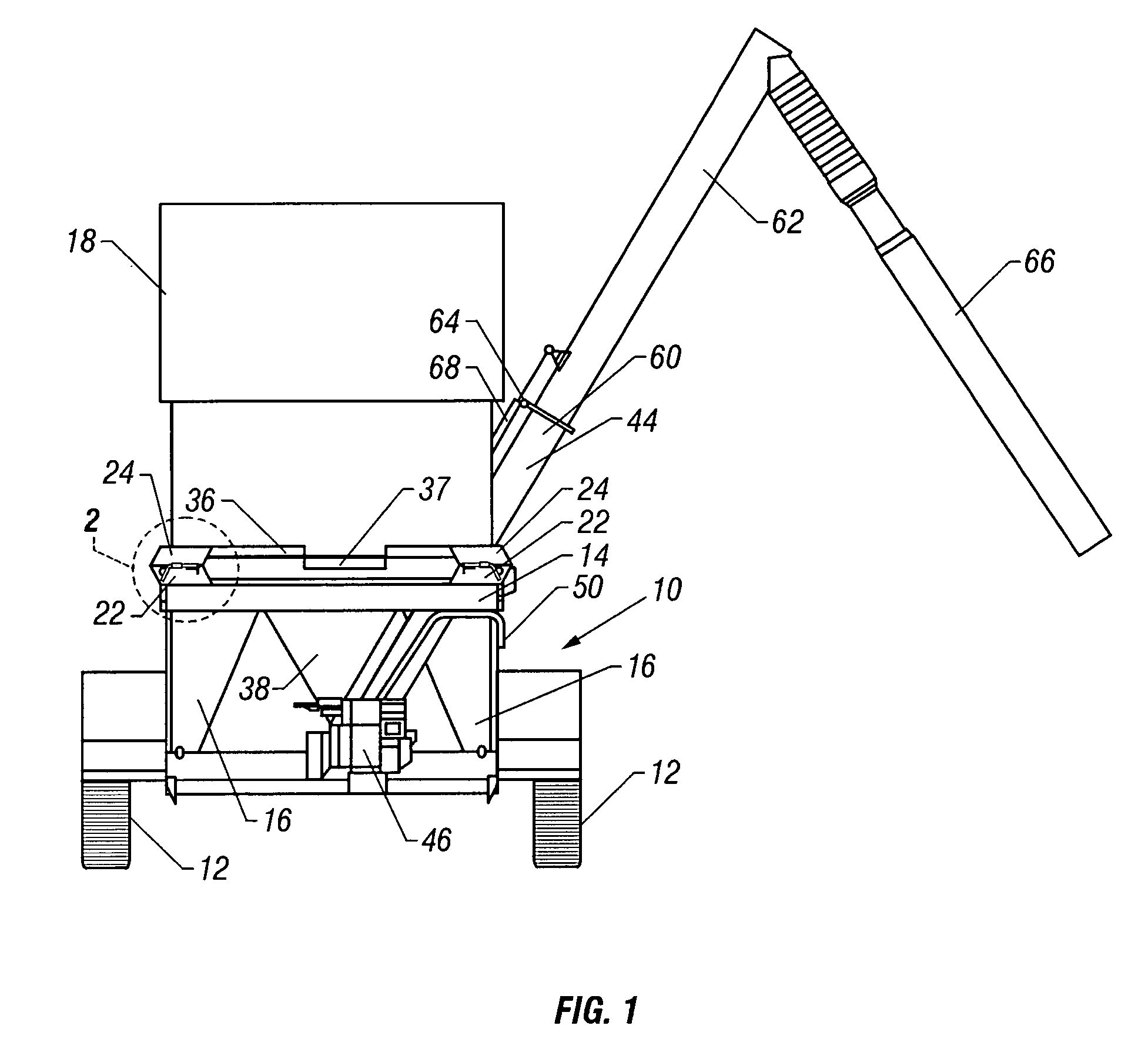

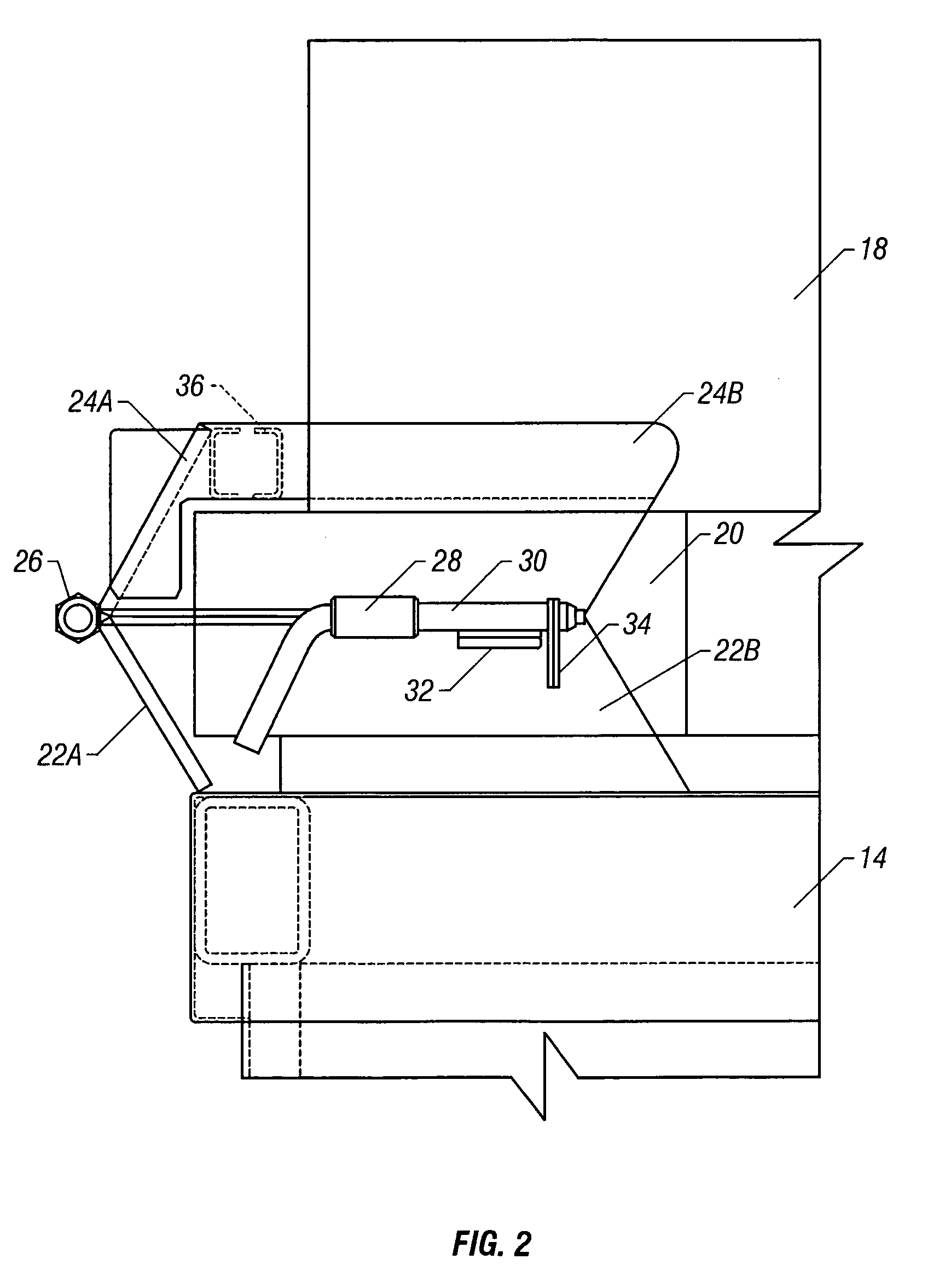

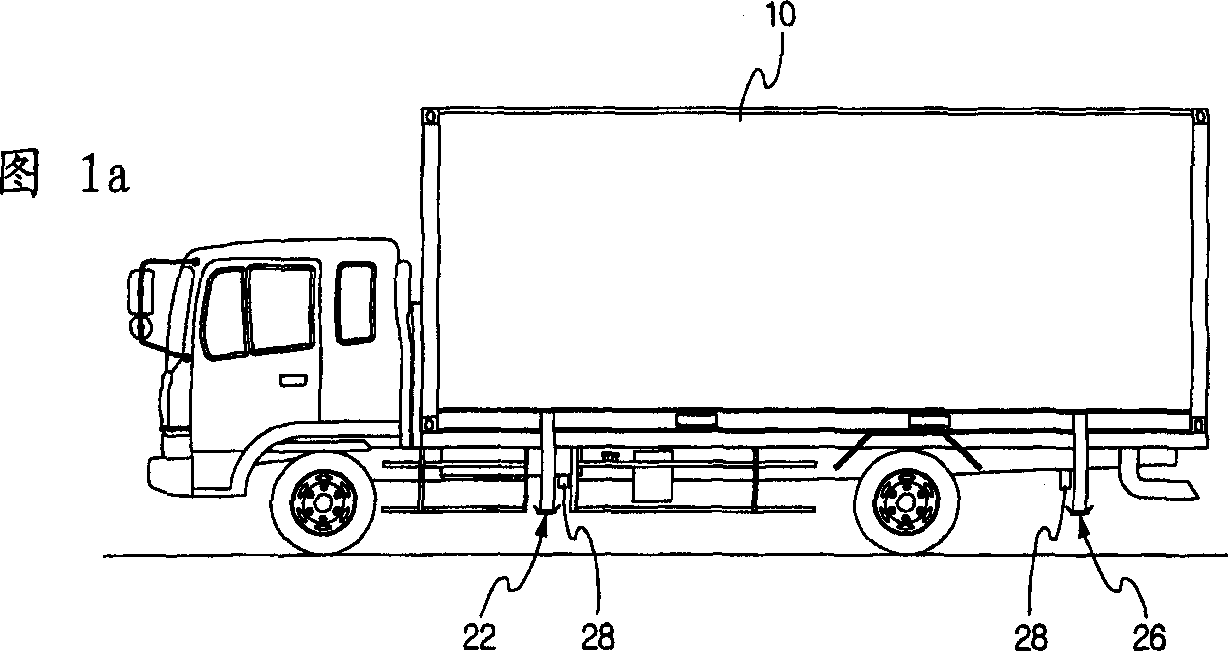

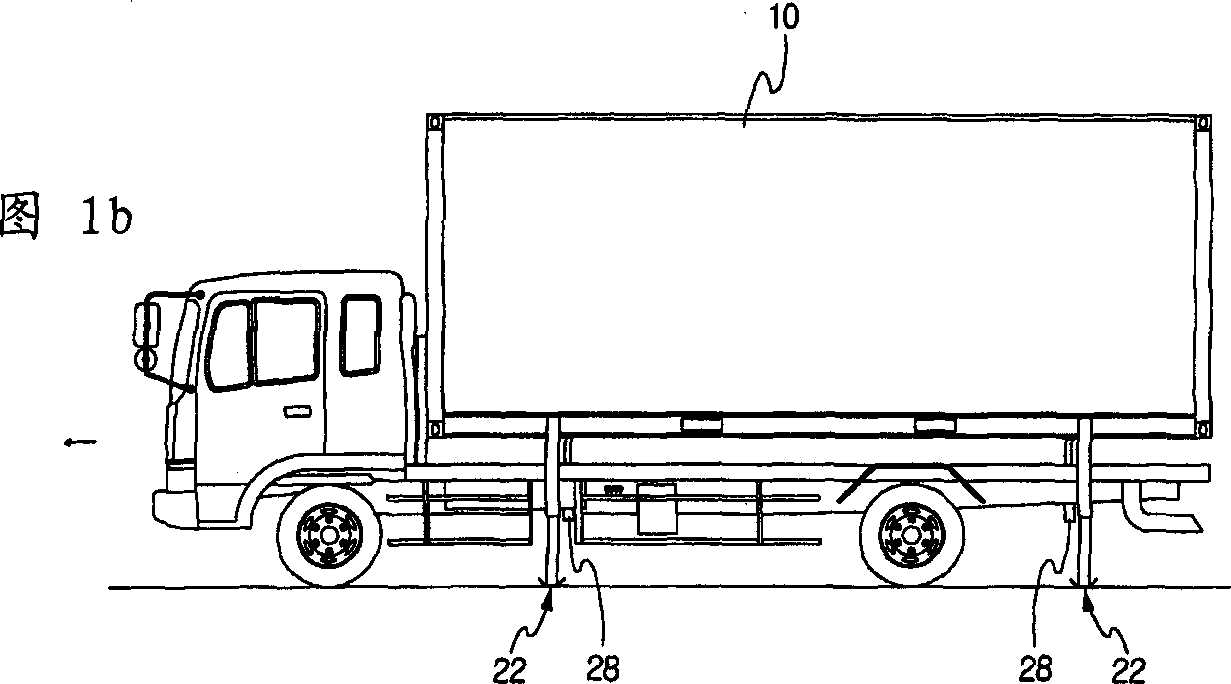

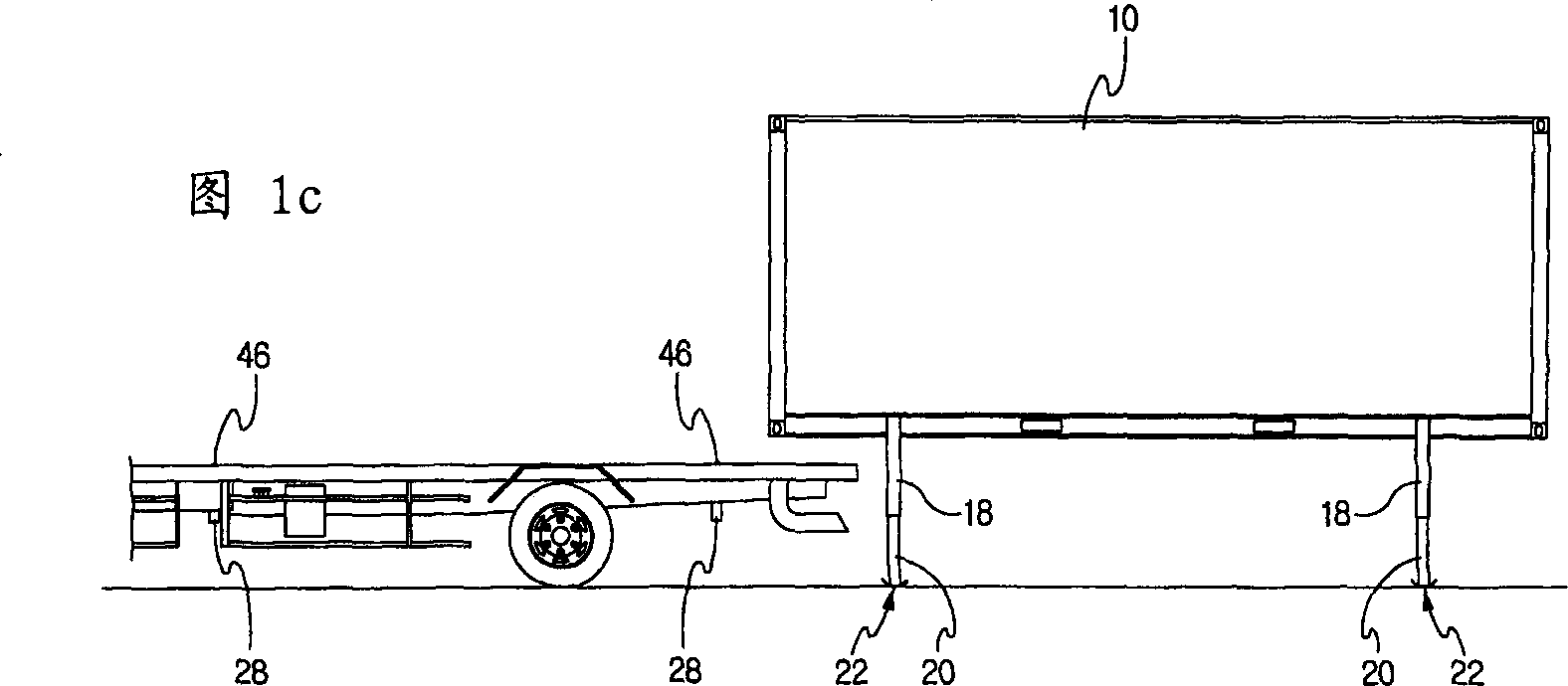

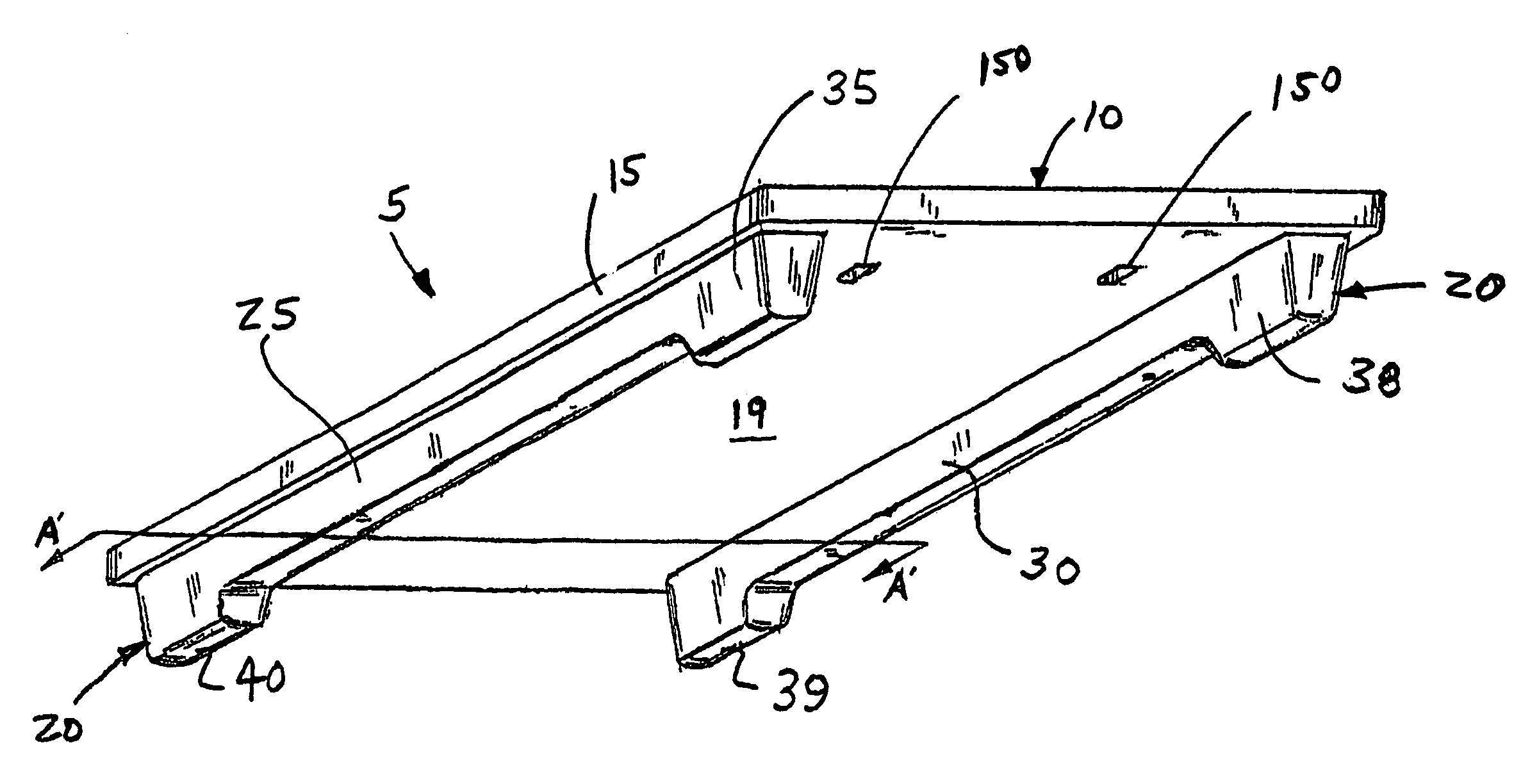

Trailer for transporting bulk seed boxes

InactiveUS6964551B1Promote sportsSecured in quickly and easilyVehicle with removable loadingRefuse receptaclesGas cylinderControl arm

An improved trailer for transporting bulk seed boxes is provided. The trailer includes a bed, a hopper extending below the bed for receiving seed from the bulk seed box, and an auger for unloading seed from the hopper. The bed includes upwardly and outwardly extending guide plates to provide self-centering of the seed box when the box is loaded onto the bed with a forklift truck. The bed includes lock bars moveable between locked and unlocked positions to secure the seed box to the bed. The hopper includes a slide gate with a control arm connected to the gate and extending to the auger side of the trailer for moving the slide gate between open and closed position. The auger includes a foldable upper section which is pivotal between a folded transport position and an extended raised operative position. The folding of the upper auger section is facilitated by a gas cylinder and a lever arm.

Owner:MERIDIAN MFG

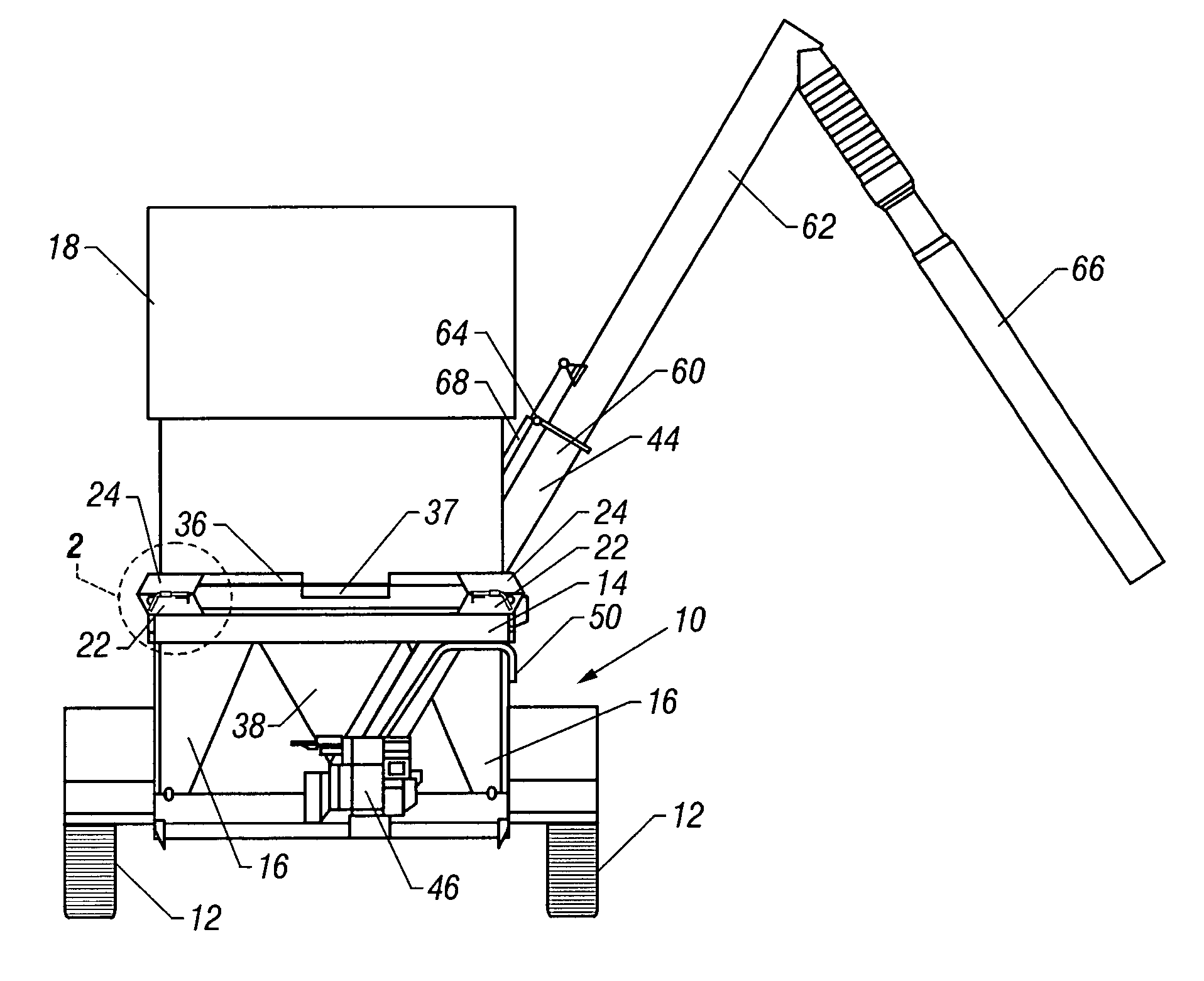

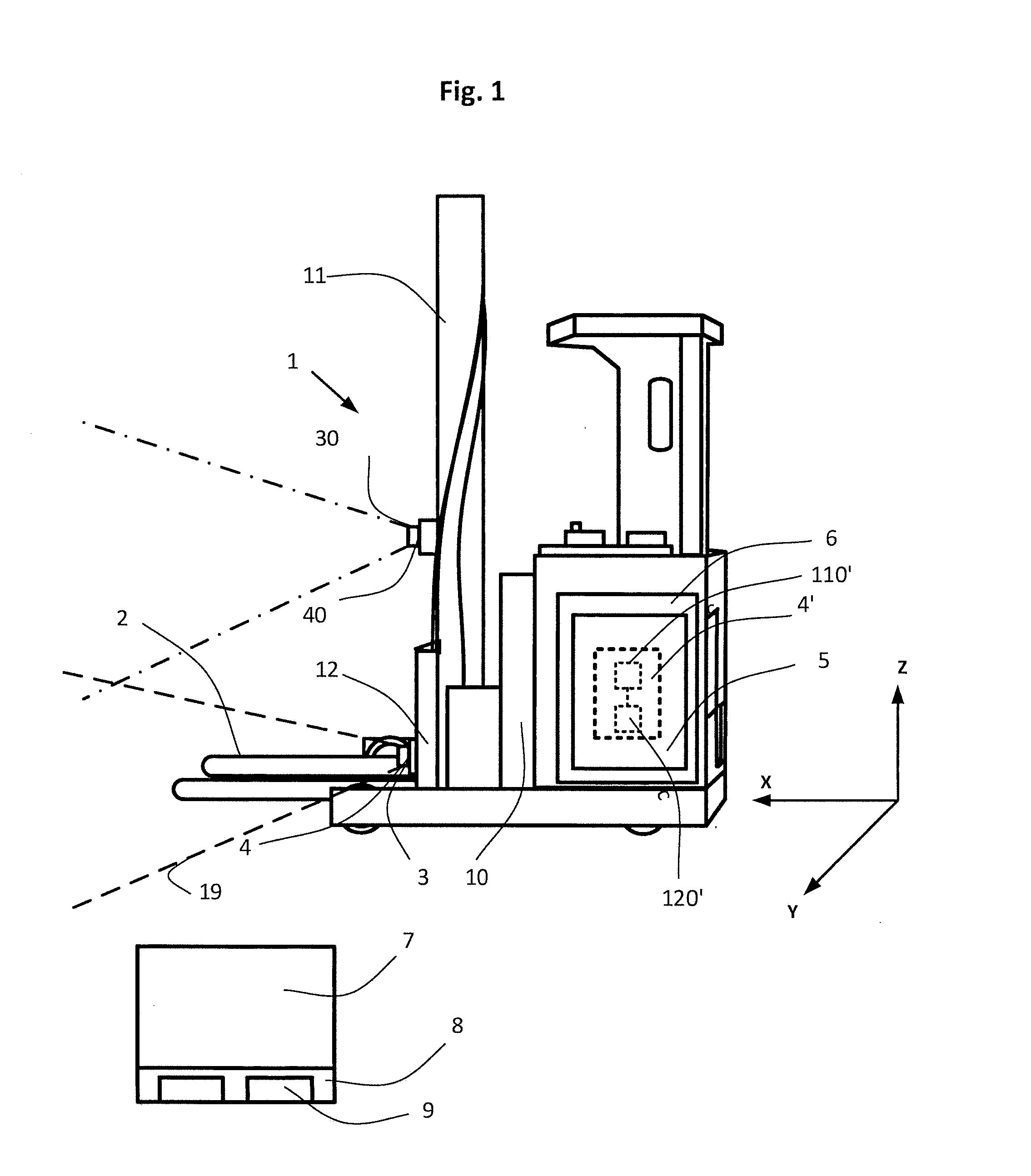

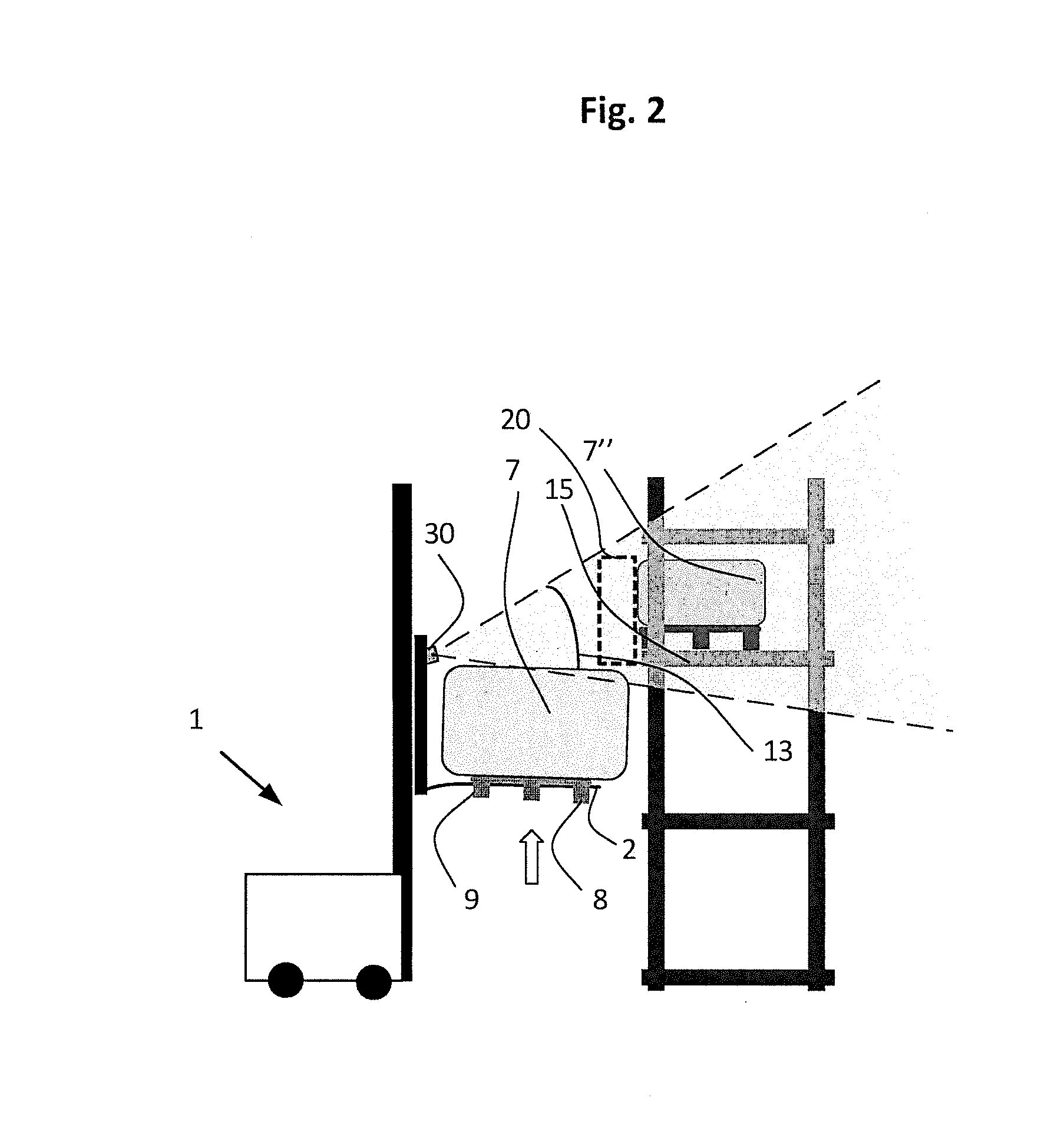

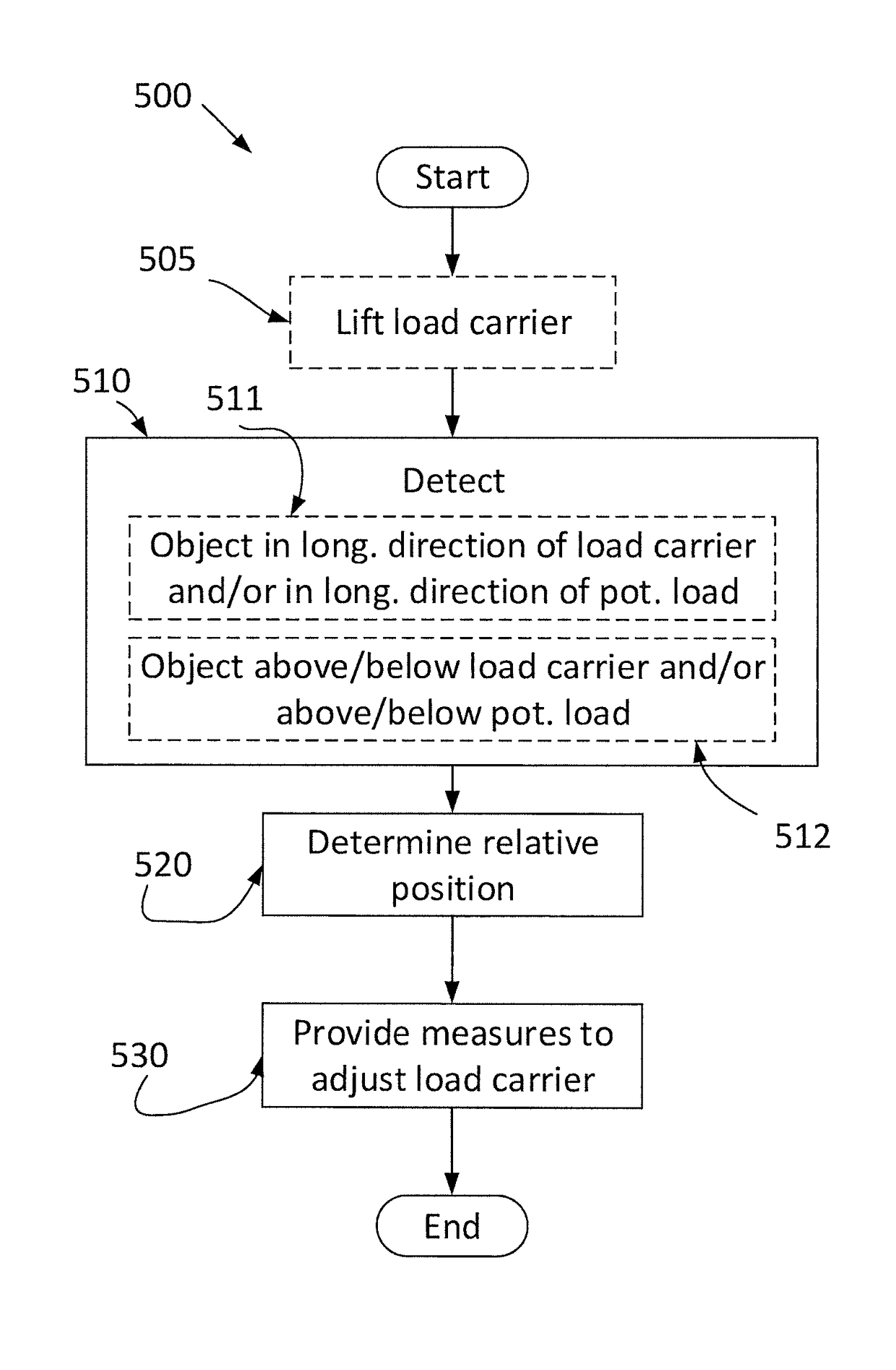

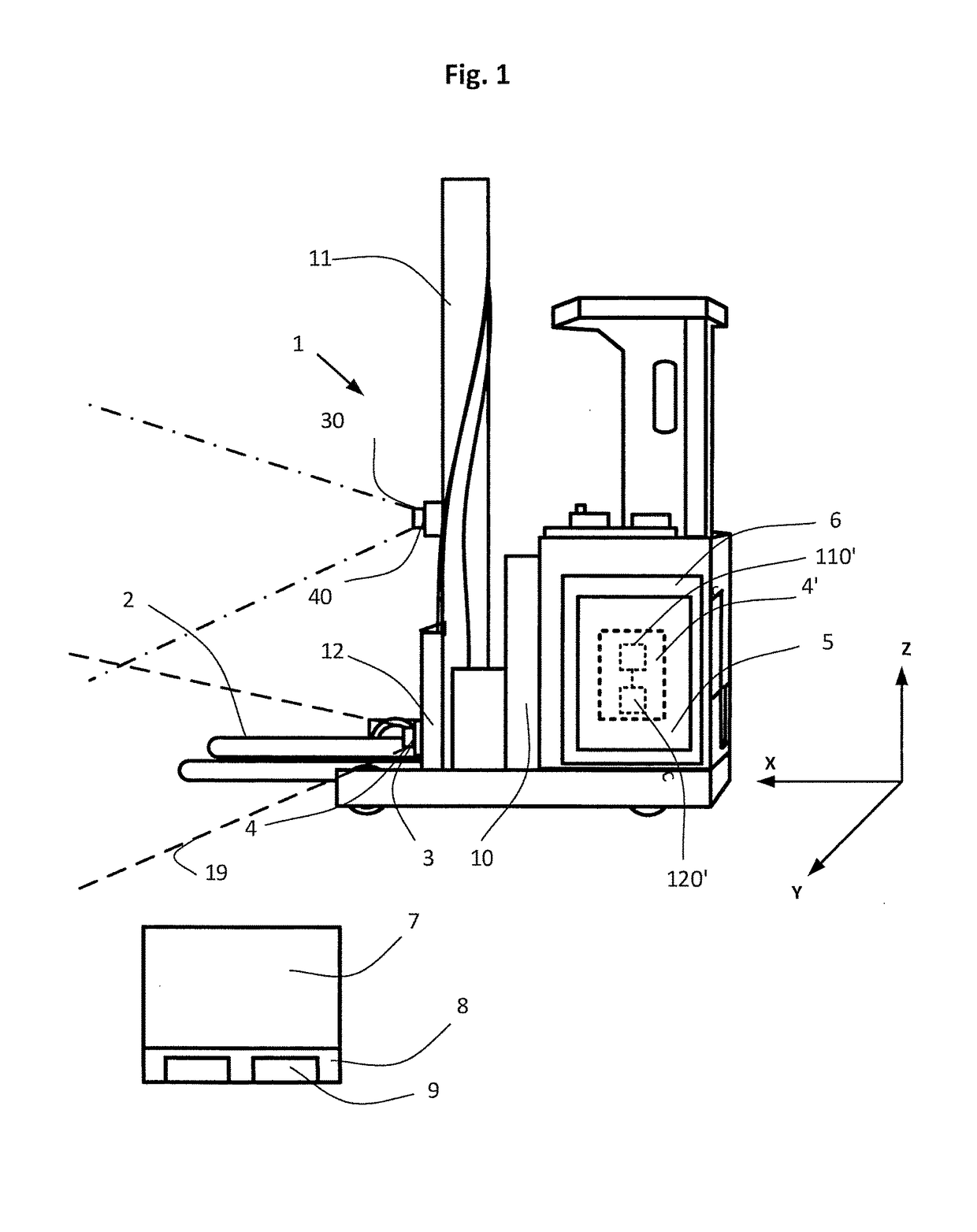

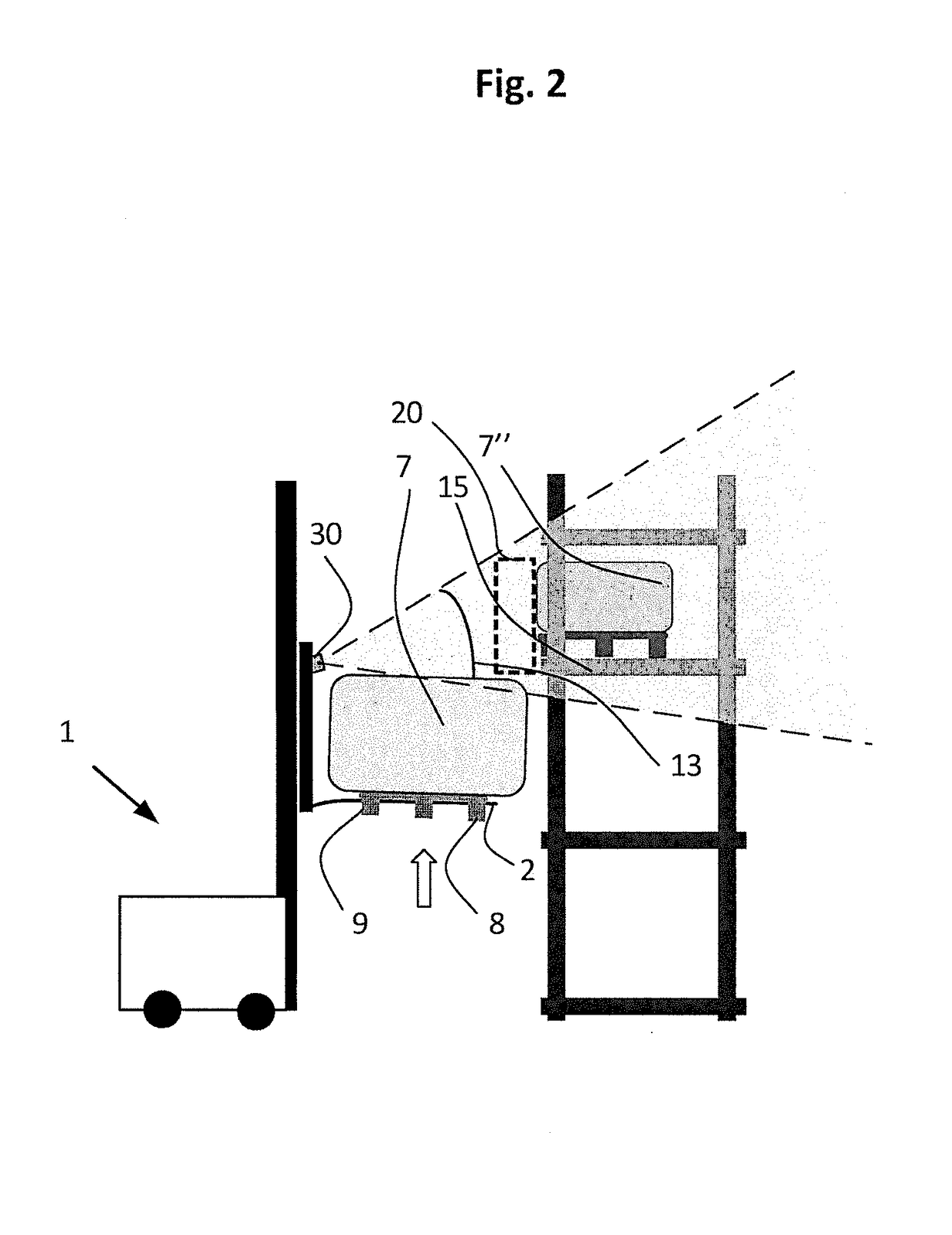

Fork-Lift Truck And Method For Operating a Fork-Lift Truck

ActiveUS20160090284A1Easy to implementImprove securityImage enhancementImage analysisEngineeringField of view

A fork-lift truck includes a load carrier, a first optical detector, an optical analysing unit, and a second optical detector. The analysing unit receives and analyses information from the second optical detector, wherein the first and second optical detector are movable together with the load carrier, and the first optical detector is positioned in relation to the load carrier, such that a first field of view includes at least a part of the load carrier and an extension of the load carrier. The second optical detector is positioned, such that a second field of view includes a predetermined volume above the load carrier The position and orientation of the second detector is calibrated in relation to a predetermined position on the fork-lift truck, in case one or more objects are positioned in the predetermined volume, at least one three-dimensional relative position can be determined.

Owner:TOYOTA MATERIAL HANDLING MFG SWEDEN

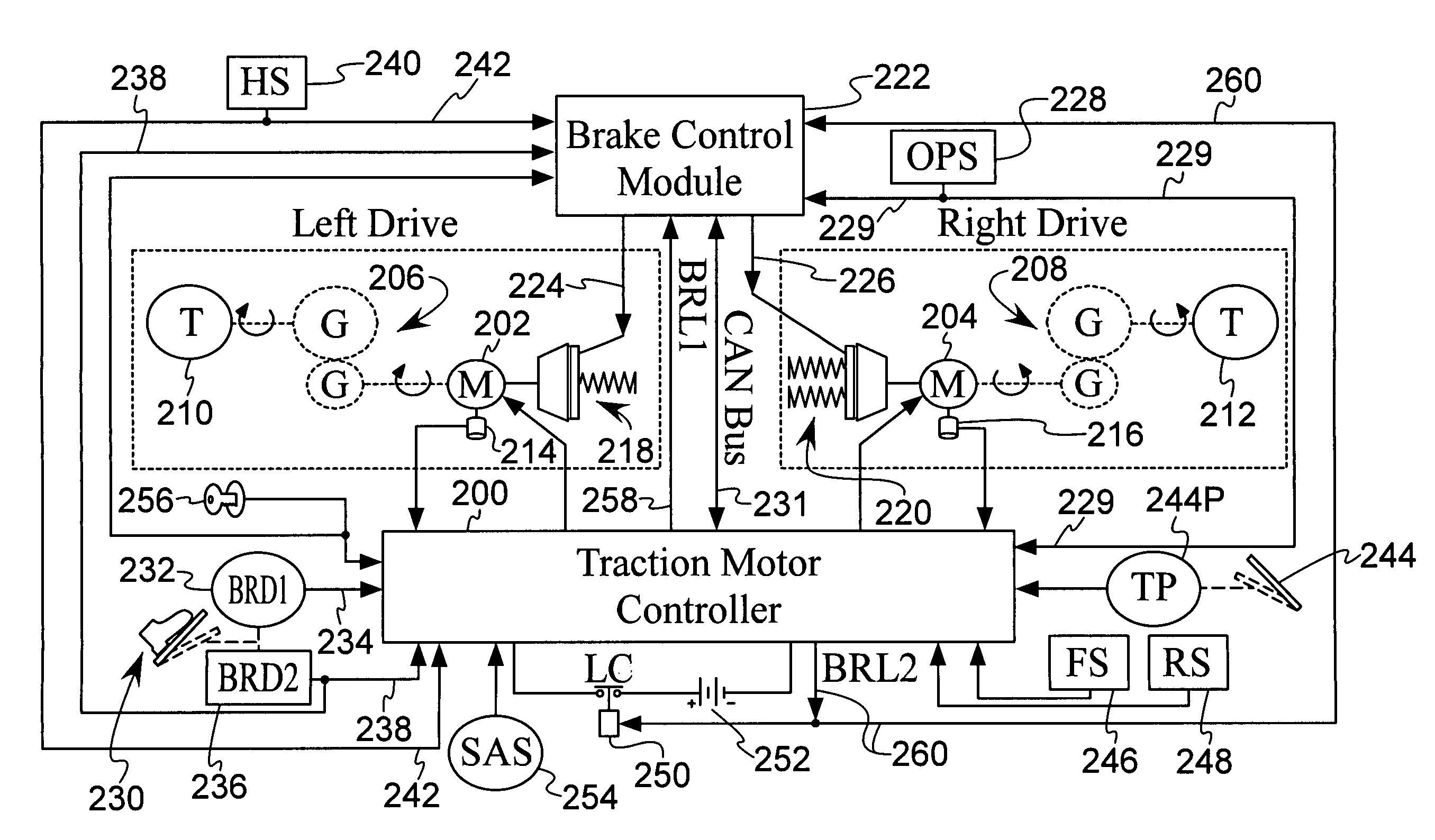

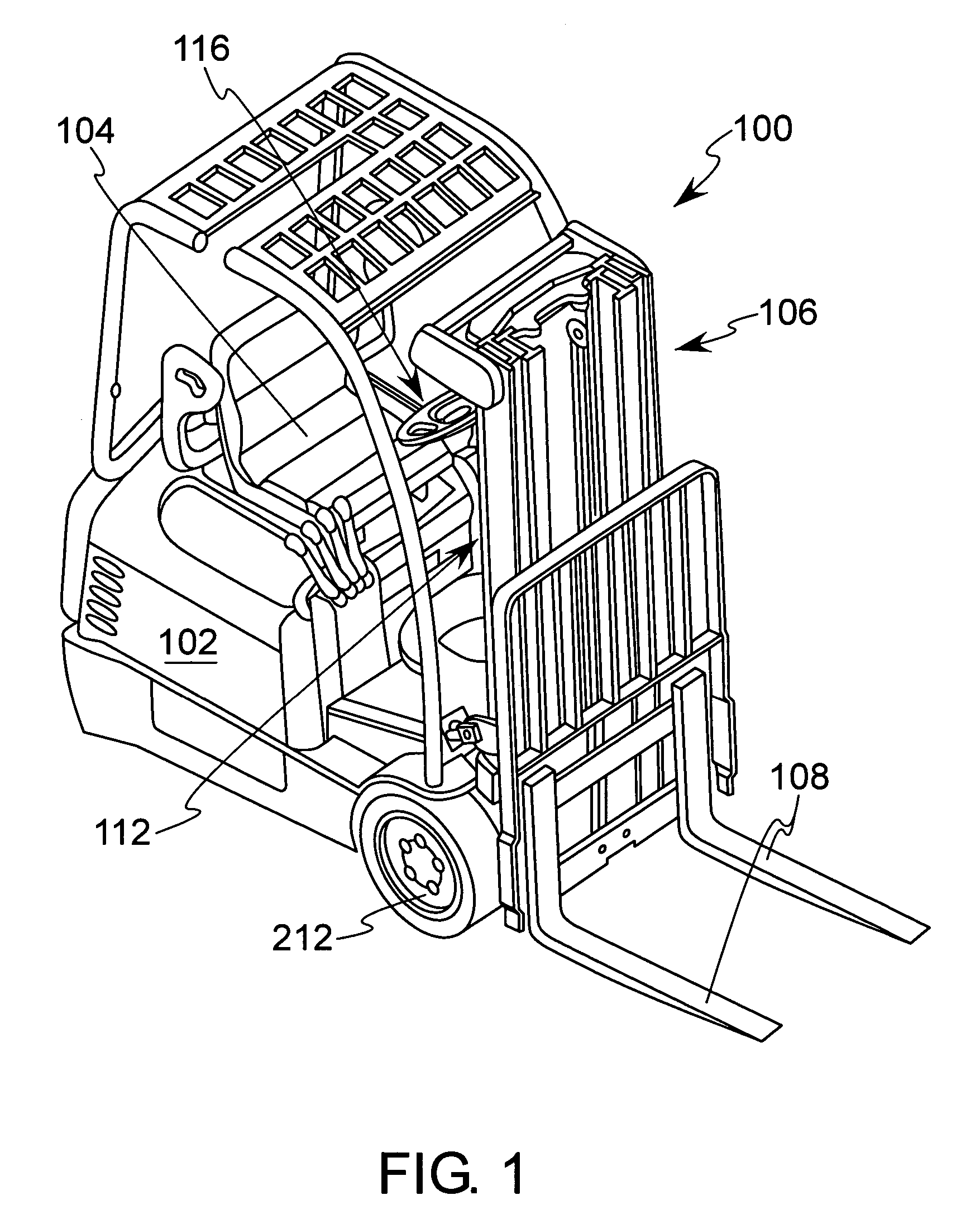

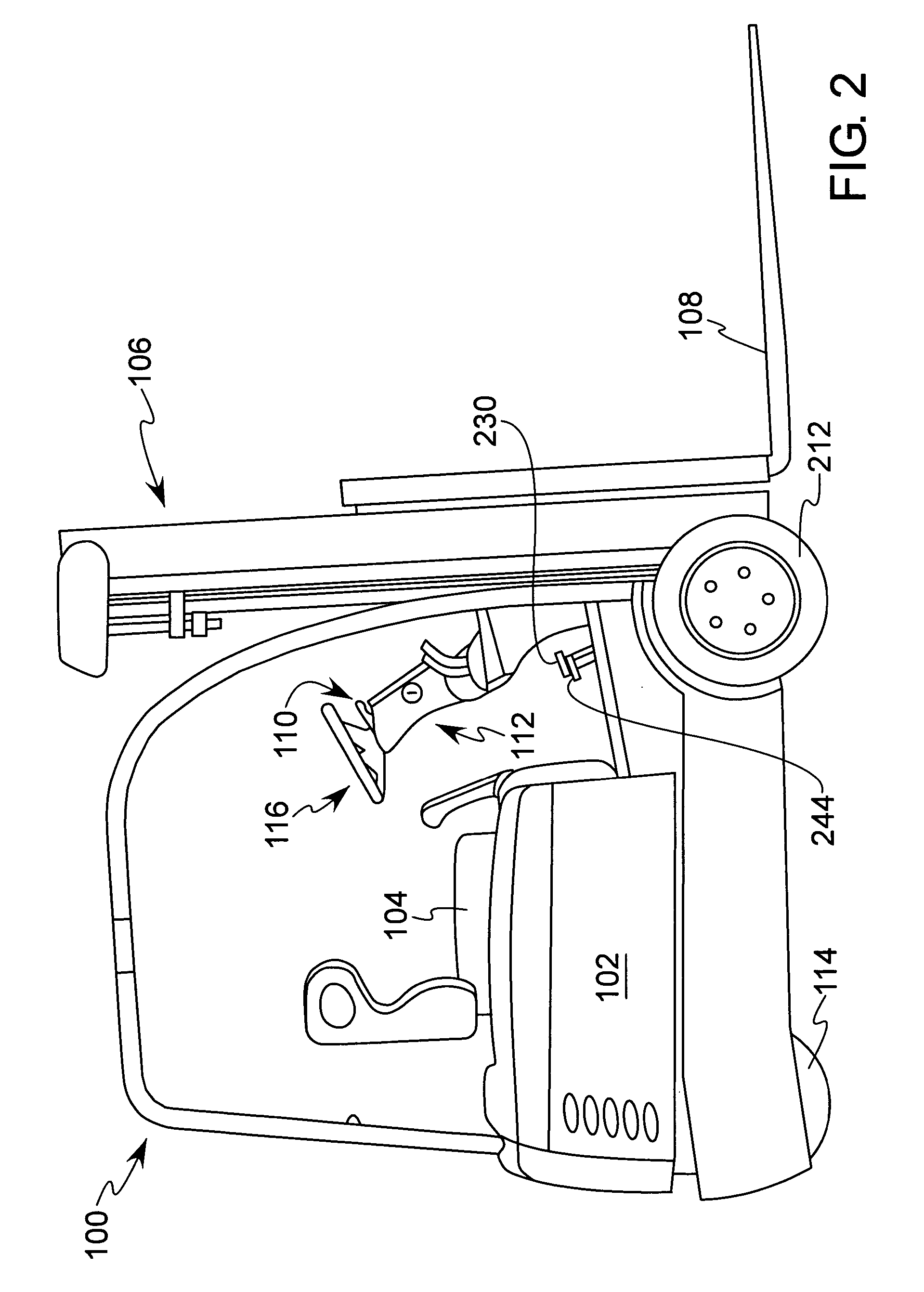

Braking system for a lift truck

Owner:CROWN EQUIP CORP

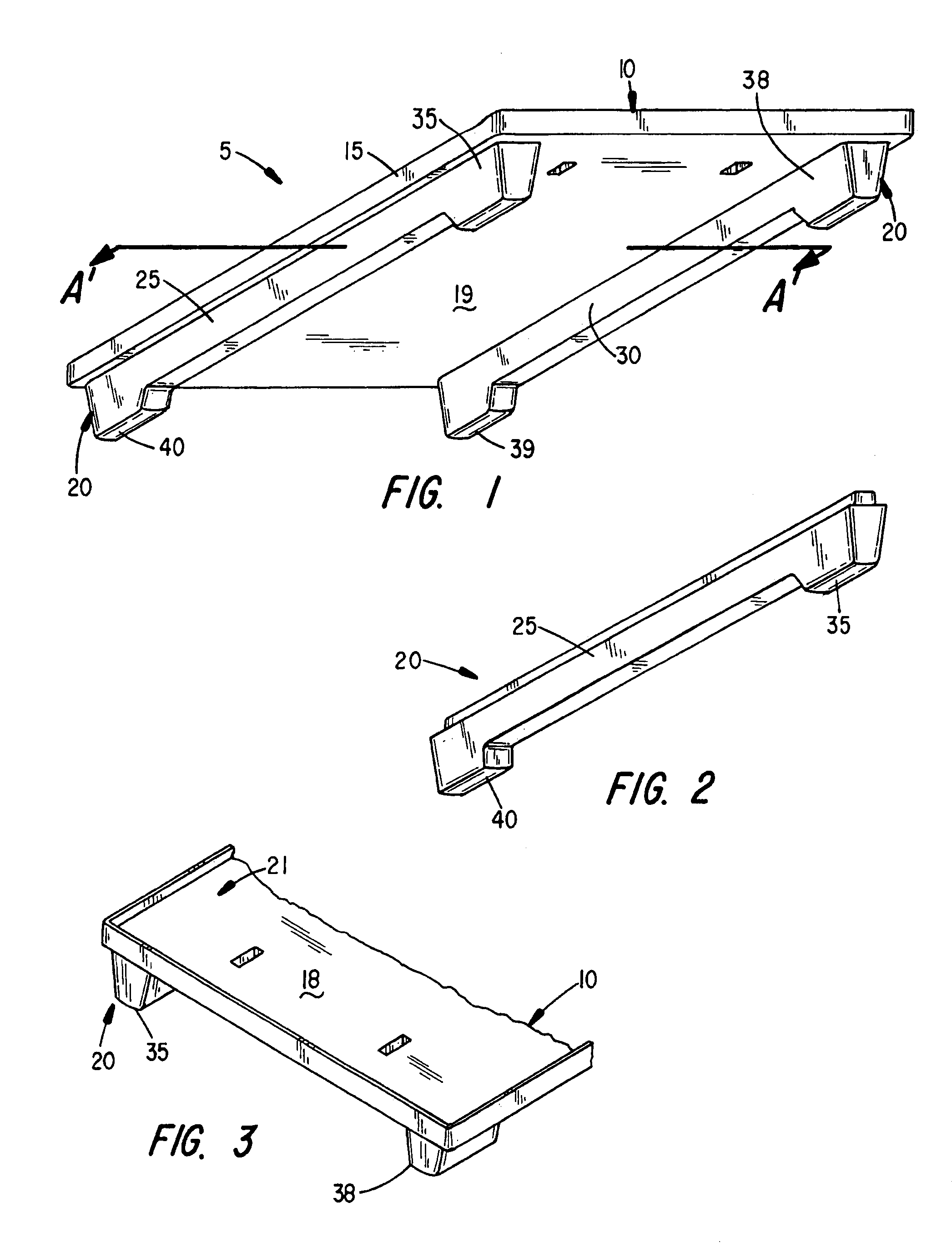

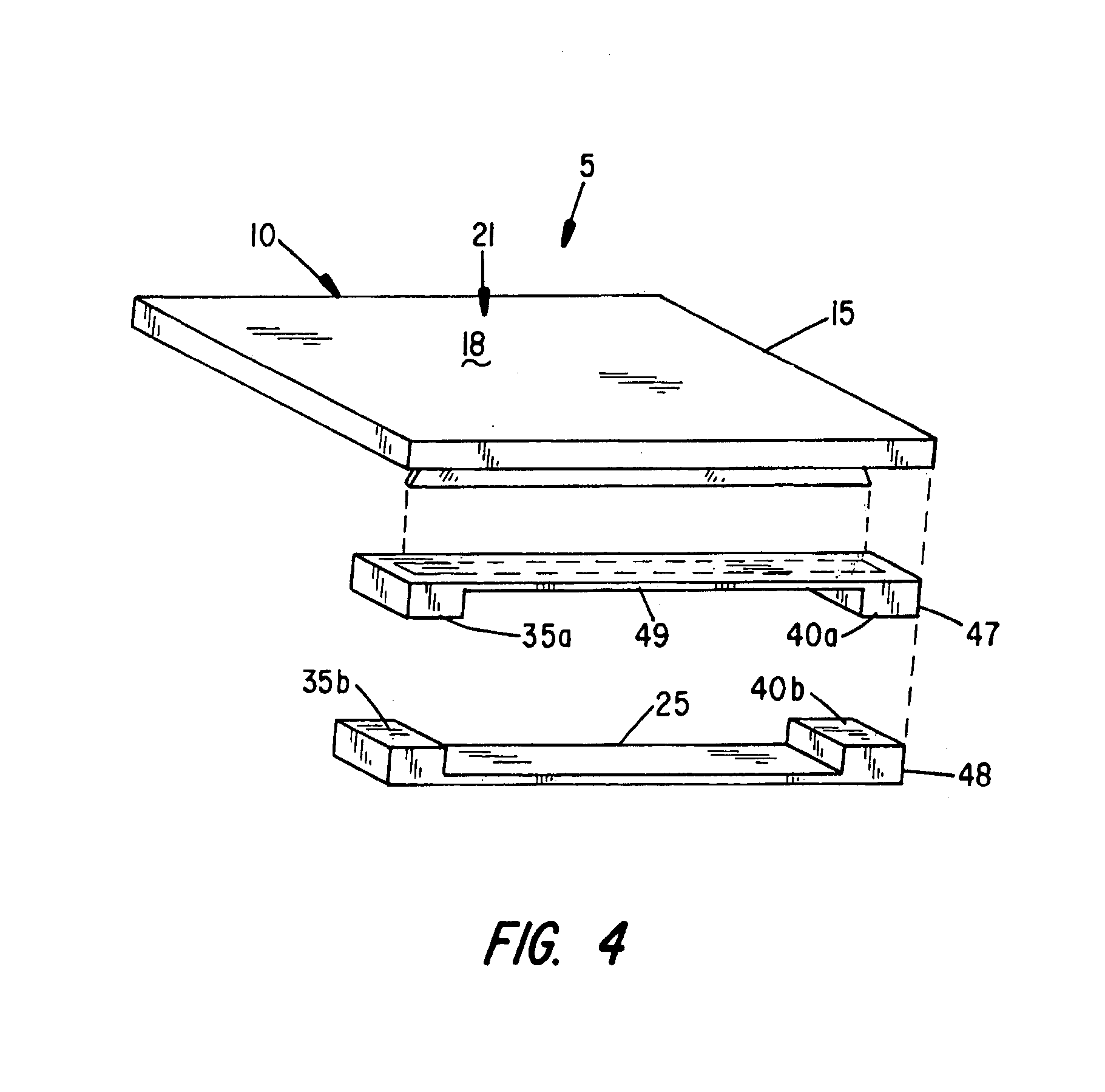

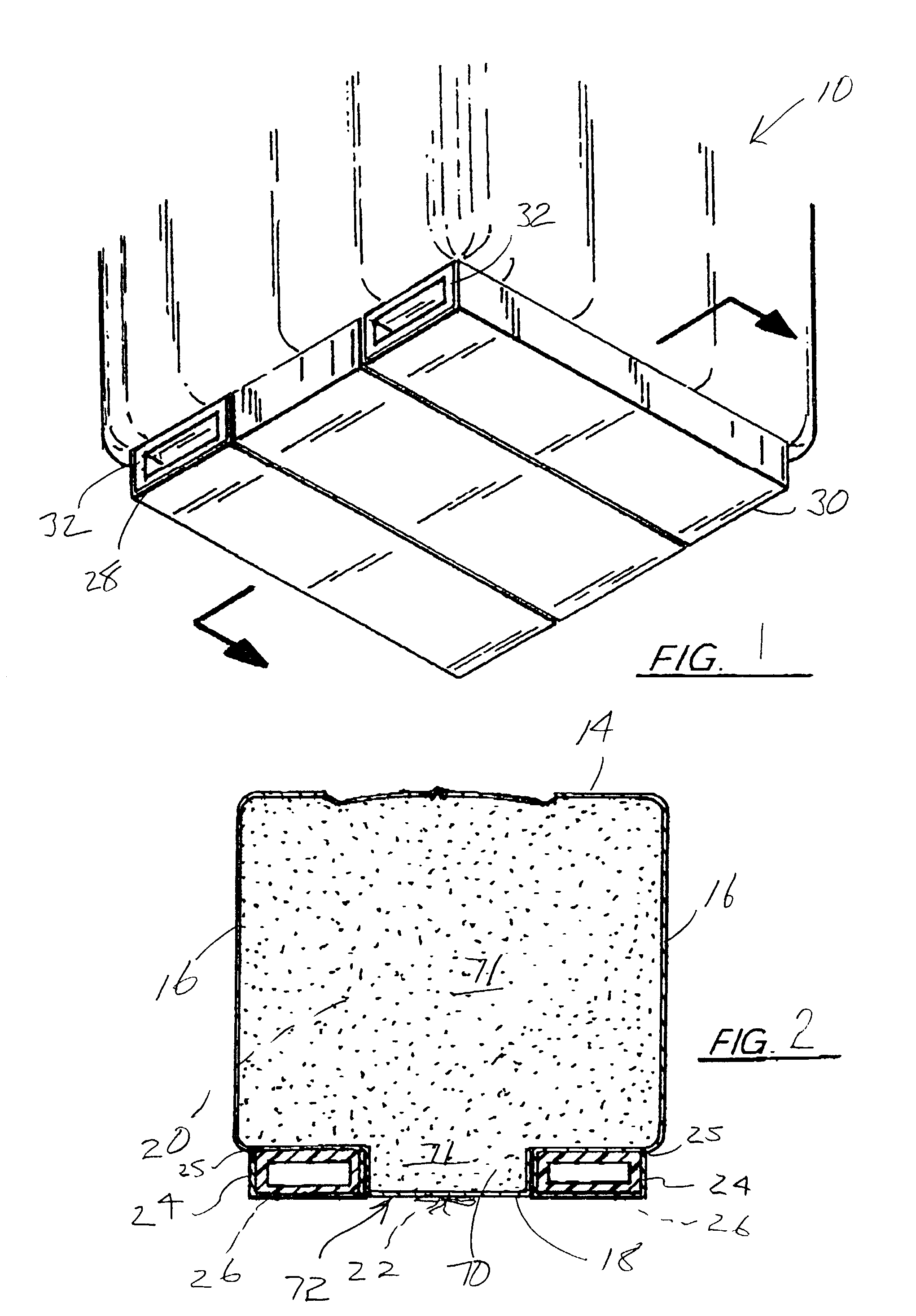

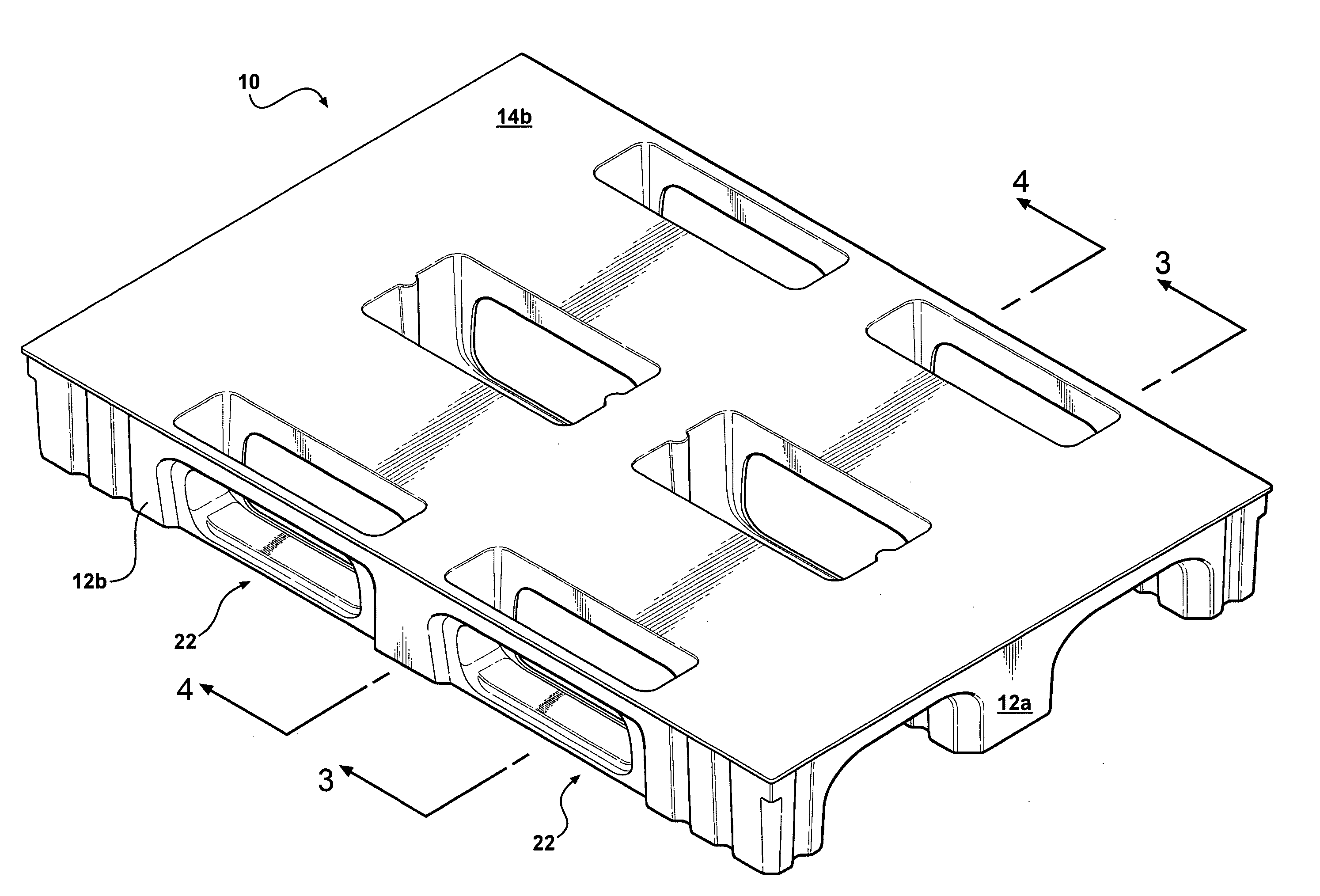

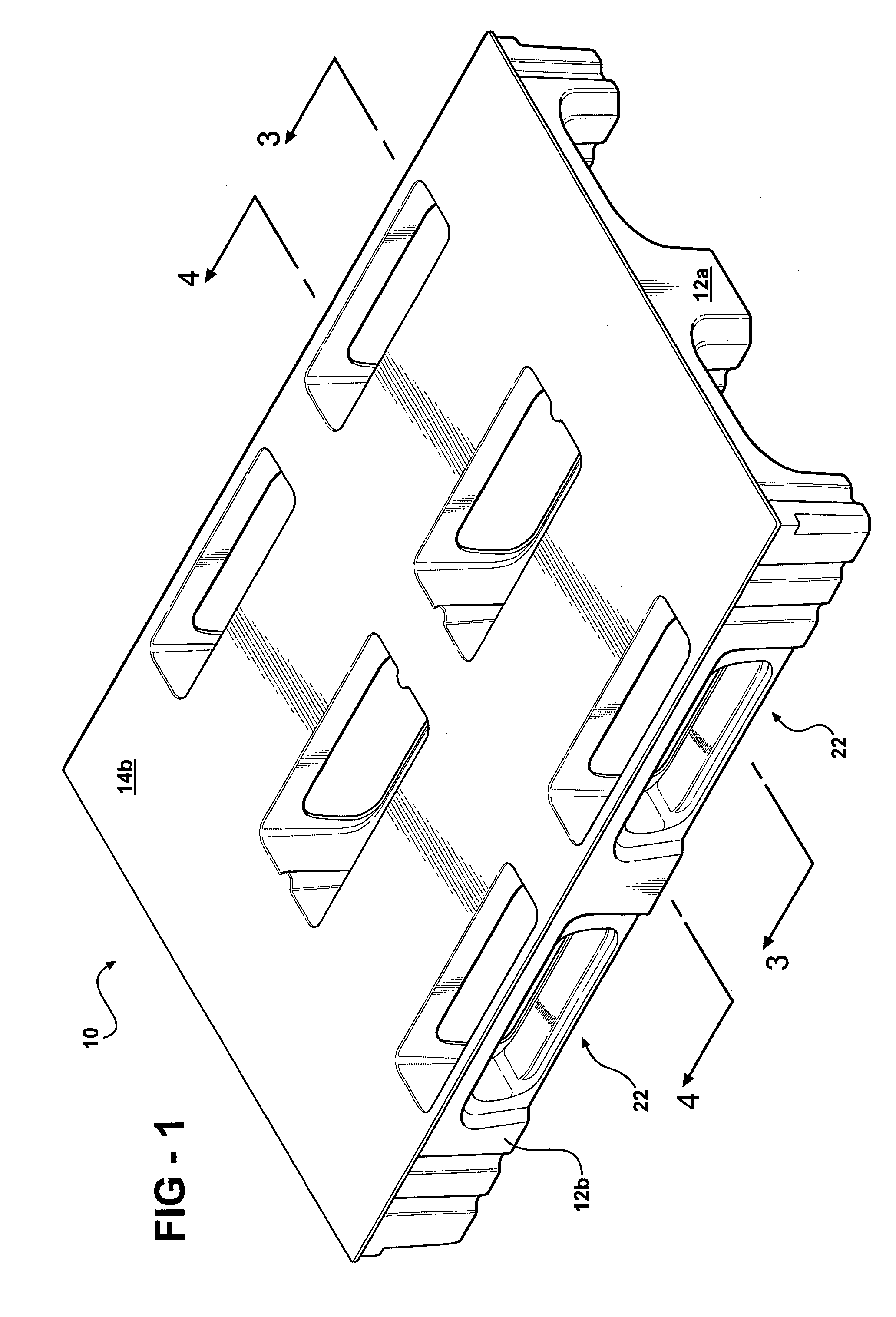

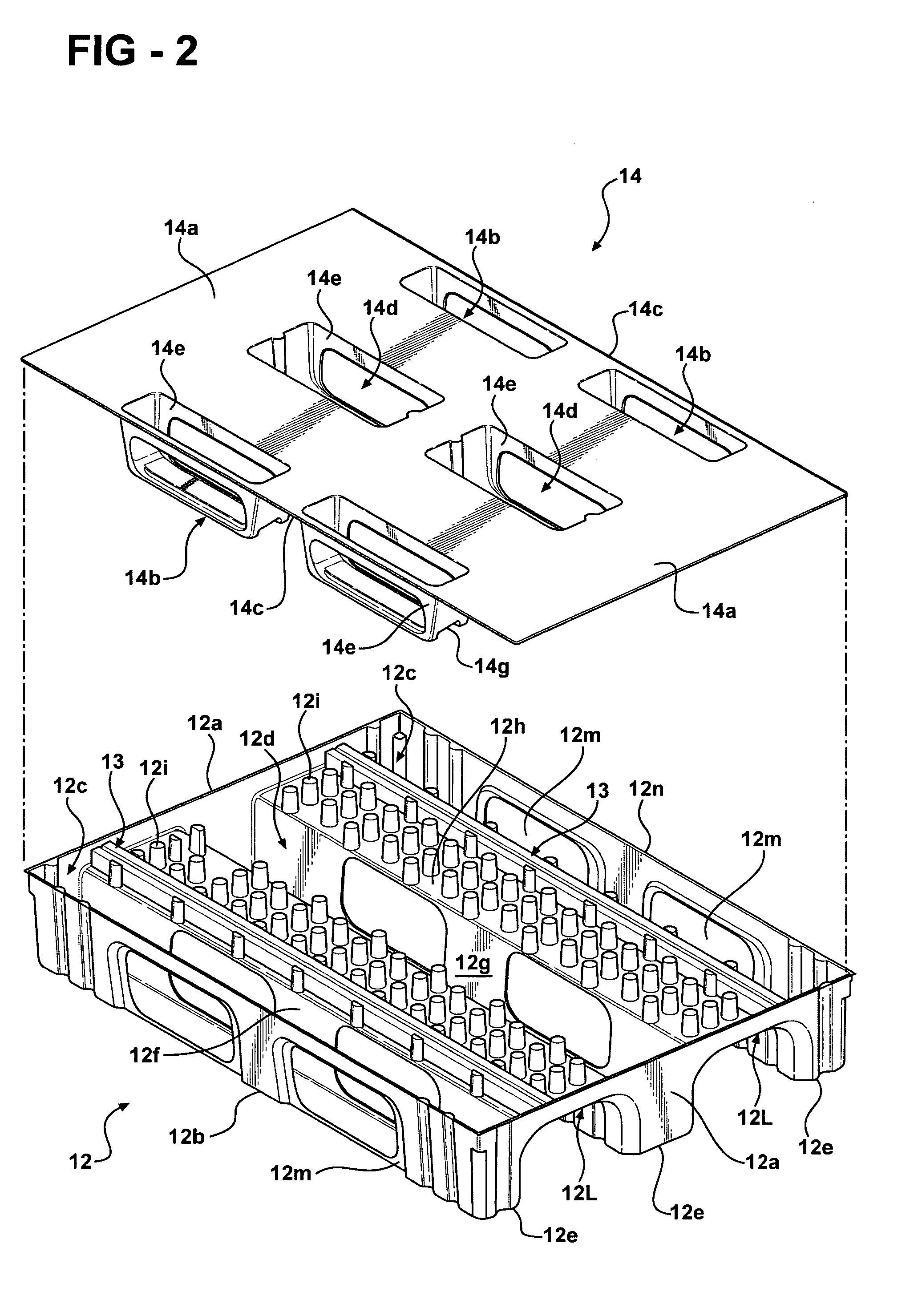

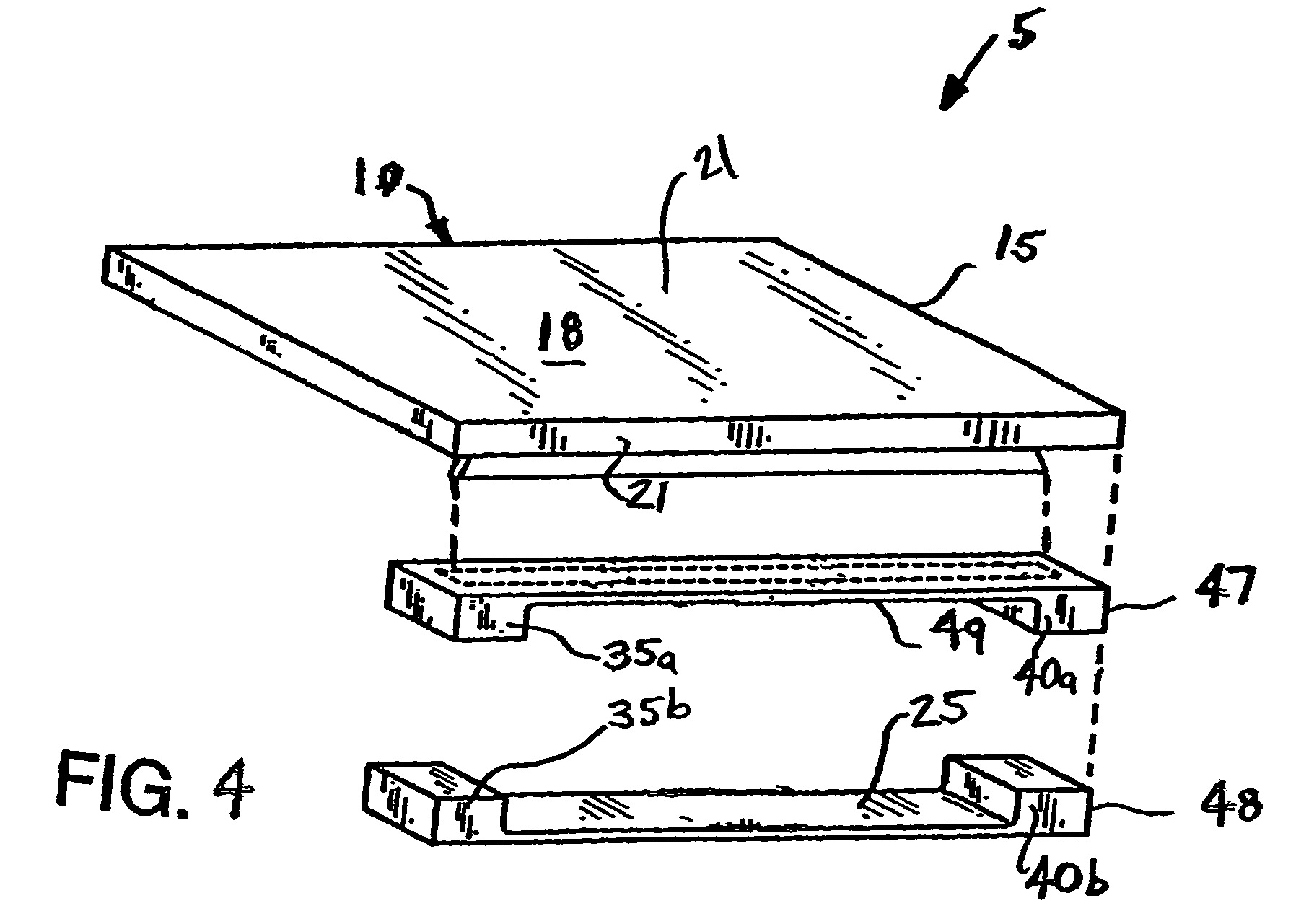

Blow molded pallet with inserts

InactiveUS6976437B2Weight increaseLow production costDomestic articlesRigid containersEngineeringPallet

A pallet system includes a pallet body. The pallet body is formed from a first, independently formed first portion and a second blow molded second upper portion insert molded to the first portion. The pallet body may have two to eight recesses for forklift truck fork access. The second upper portion has a generally rectangular surface for carrying loads. The portions may have anti-skid properties, for example, a knurled topside surface or rubber coated bottom. At least one foot is attached to the second upper portion by insert molding. At least one runner may be attached to each foot to form part of the first portion. At least one stringer is attached to each runner to add further stability to the pallet. The runners and feet have channels or protruding members to effectively mate with the second upper portion. The system may also have top cap and tie members to affix the cap to one or more pallet bodies.

Owner:POLY FLEX INC

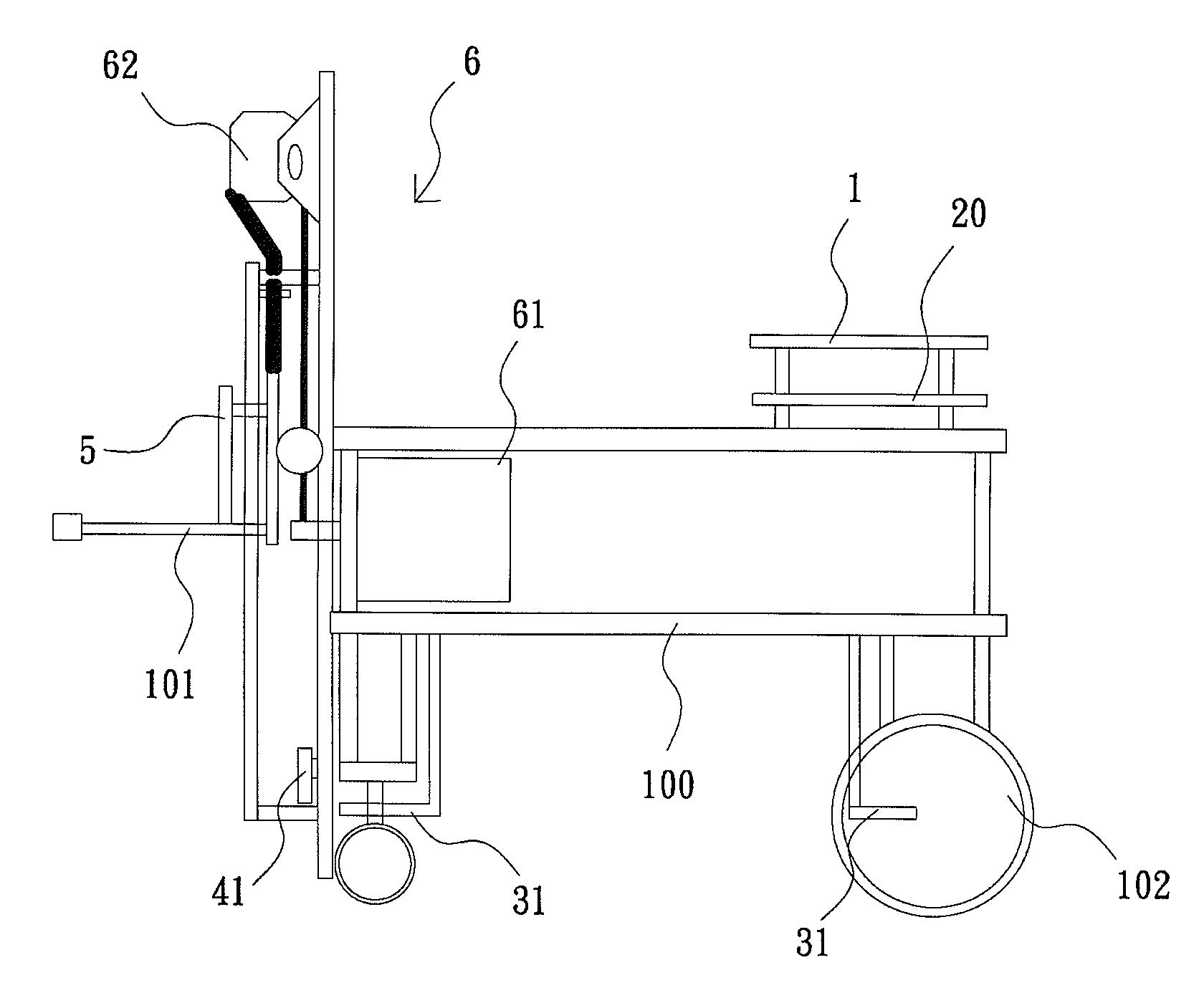

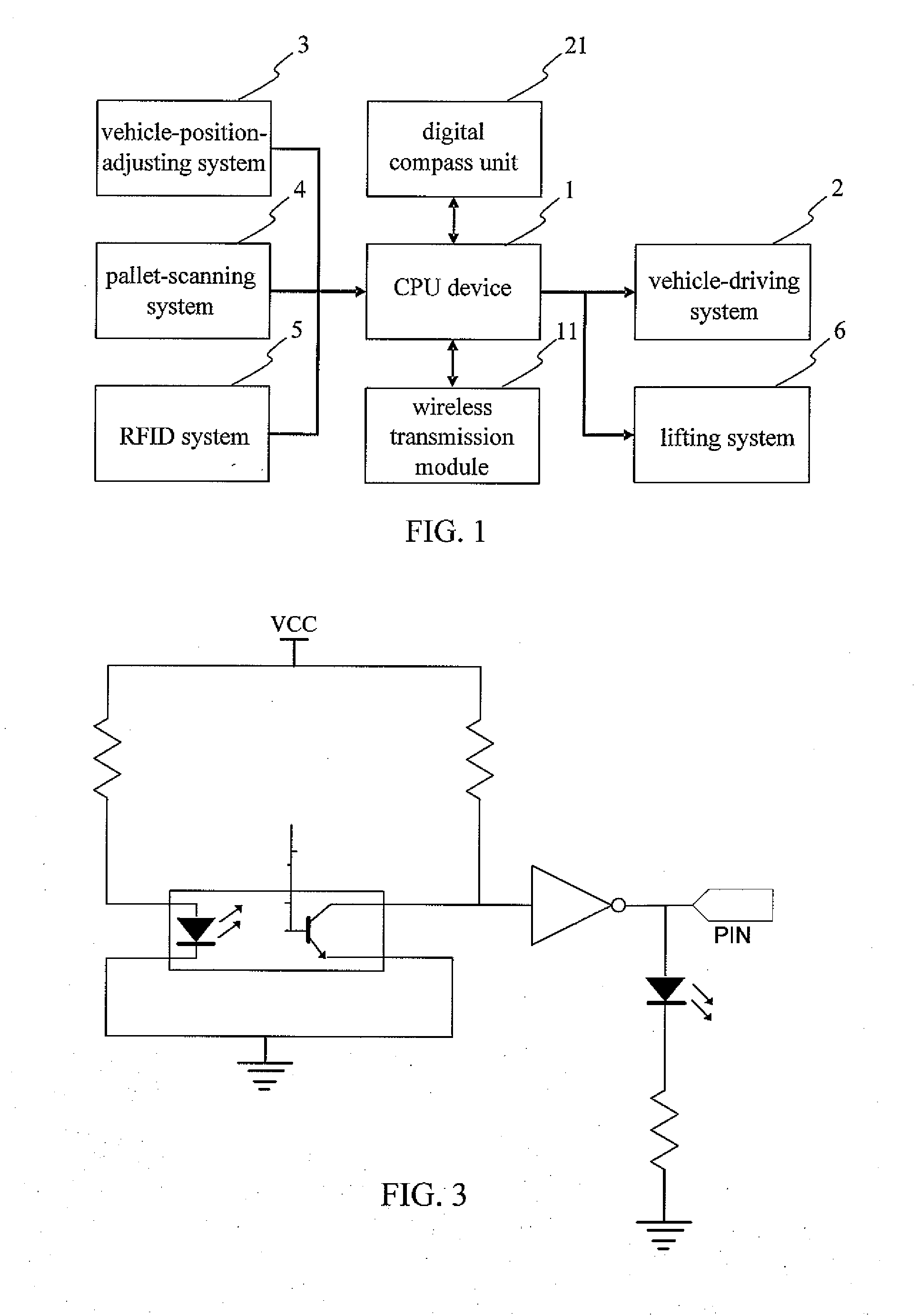

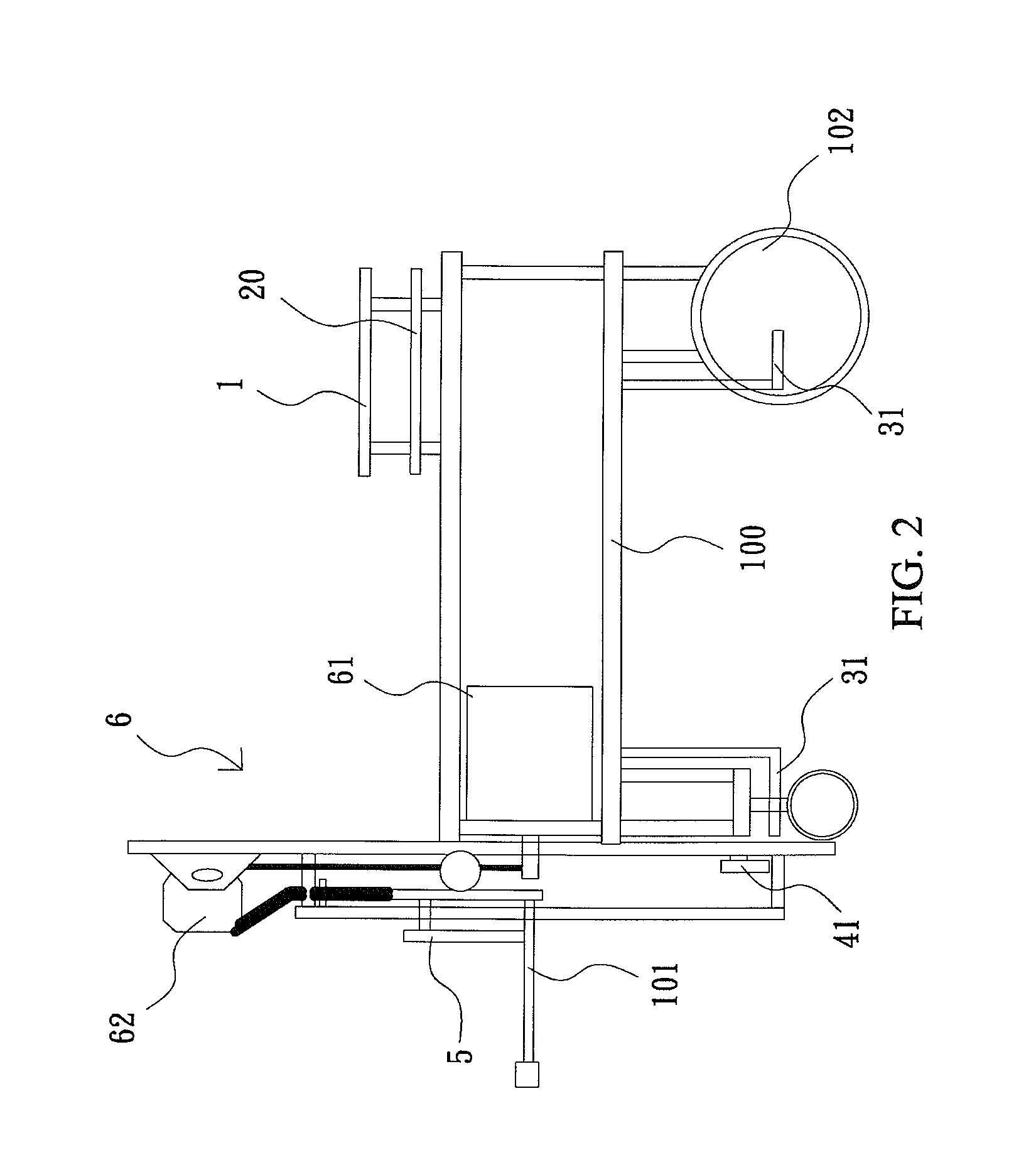

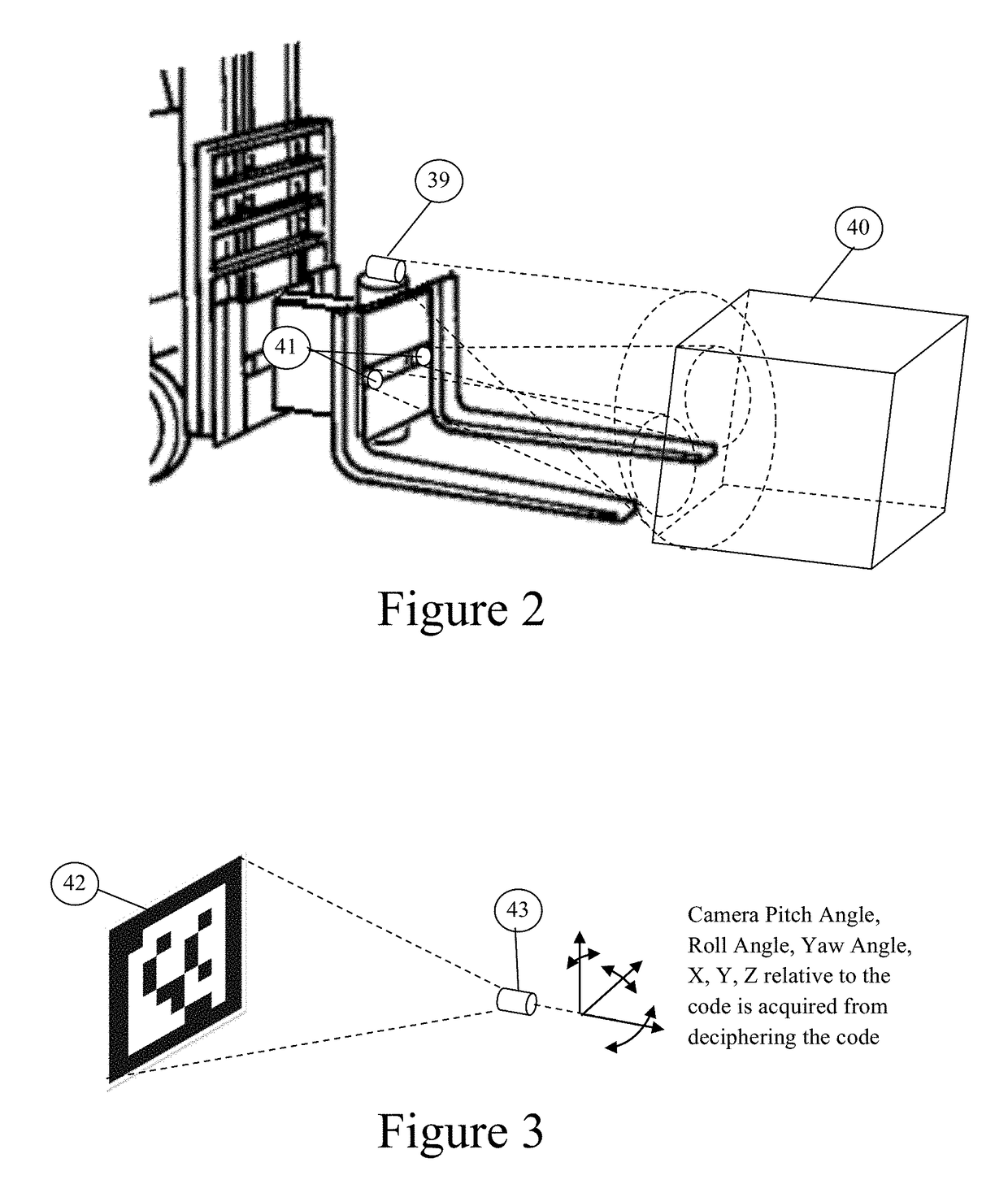

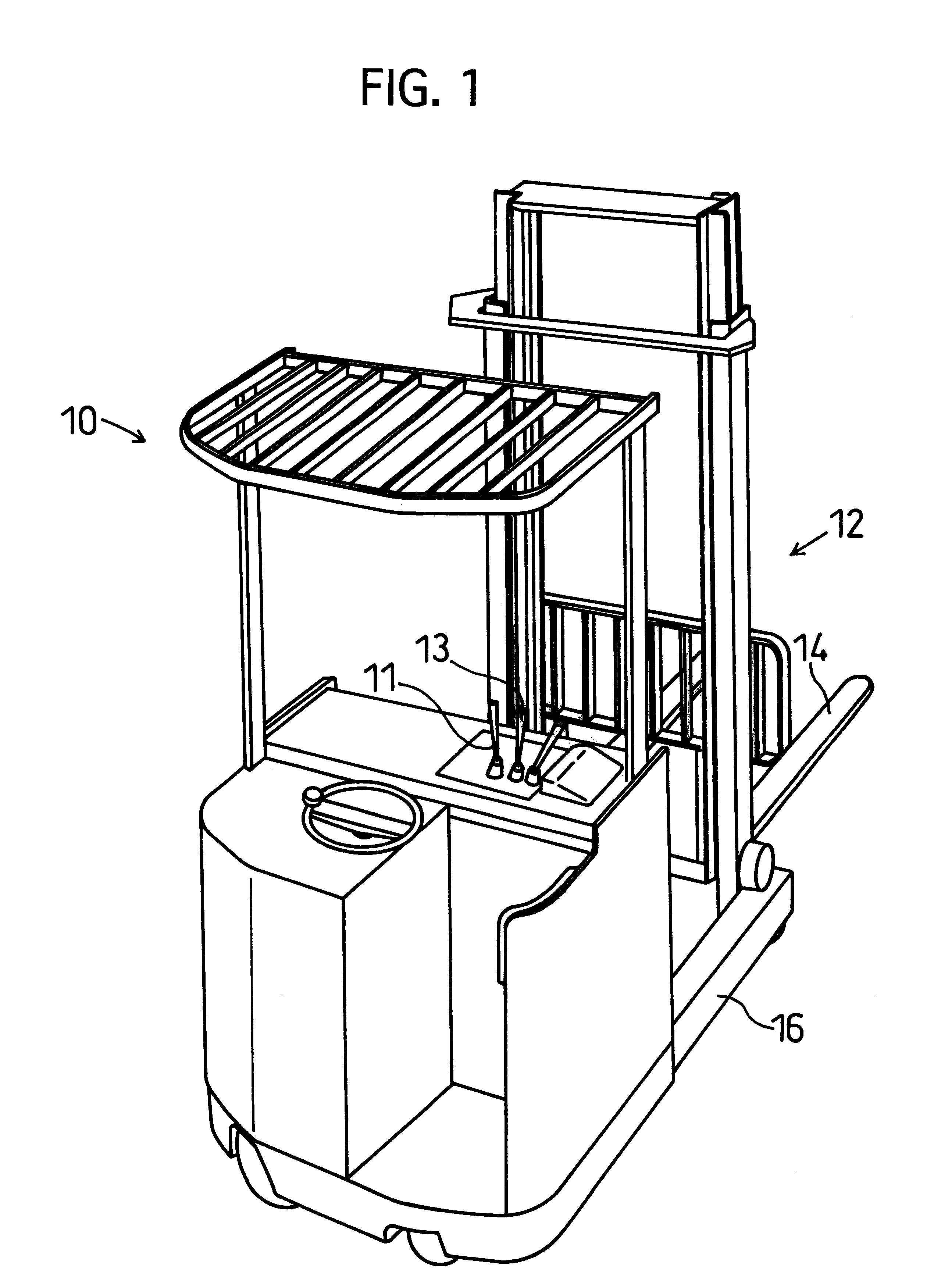

Unmanned trackless order picking forklift system

An unmanned trackless order picking forklift system includes a vehicle-driving system, a vehicle-position-adjusting system and a pallet-scanning system each of which provided in a forklift truck and electrically connected with a CPU device. The vehicle-position-adjusting system is operated to detect a predetermined route so that the CPU device controls the vehicle-driving system to drive the forklift truck along the predetermined route from a first position to a second position. The pallet-scanning system is operated to scan a designated pallet along the predetermined route.

Owner:NAT KAOHSIUNG UNIV OF SCI & TECH

Loading/unloading equipment for container

InactiveCN1333174AEasy loading and unloadingLarge containersVehicle with removable loadingEngineeringRigid body

Disclosed is a container loading and unloading apparatus, which overcomes a problem of a conventional container in that a special equipment such as a forklift truck, a crane or the like is necessarily mobilized whenever the loading or unloading work is performed because the container is simply a cuboidal rigid body. The present invention makes it possible to perform the loading and unloading works of the container main body at the time of its storage and transportation without a separate loading and unloading equipment by providing a container supporter to secure a space for loading the container main body on a chassis of a freight car, thereby reducing equipments and labor as well as facilitating the loading and unloading works.

Owner:KOSMAN

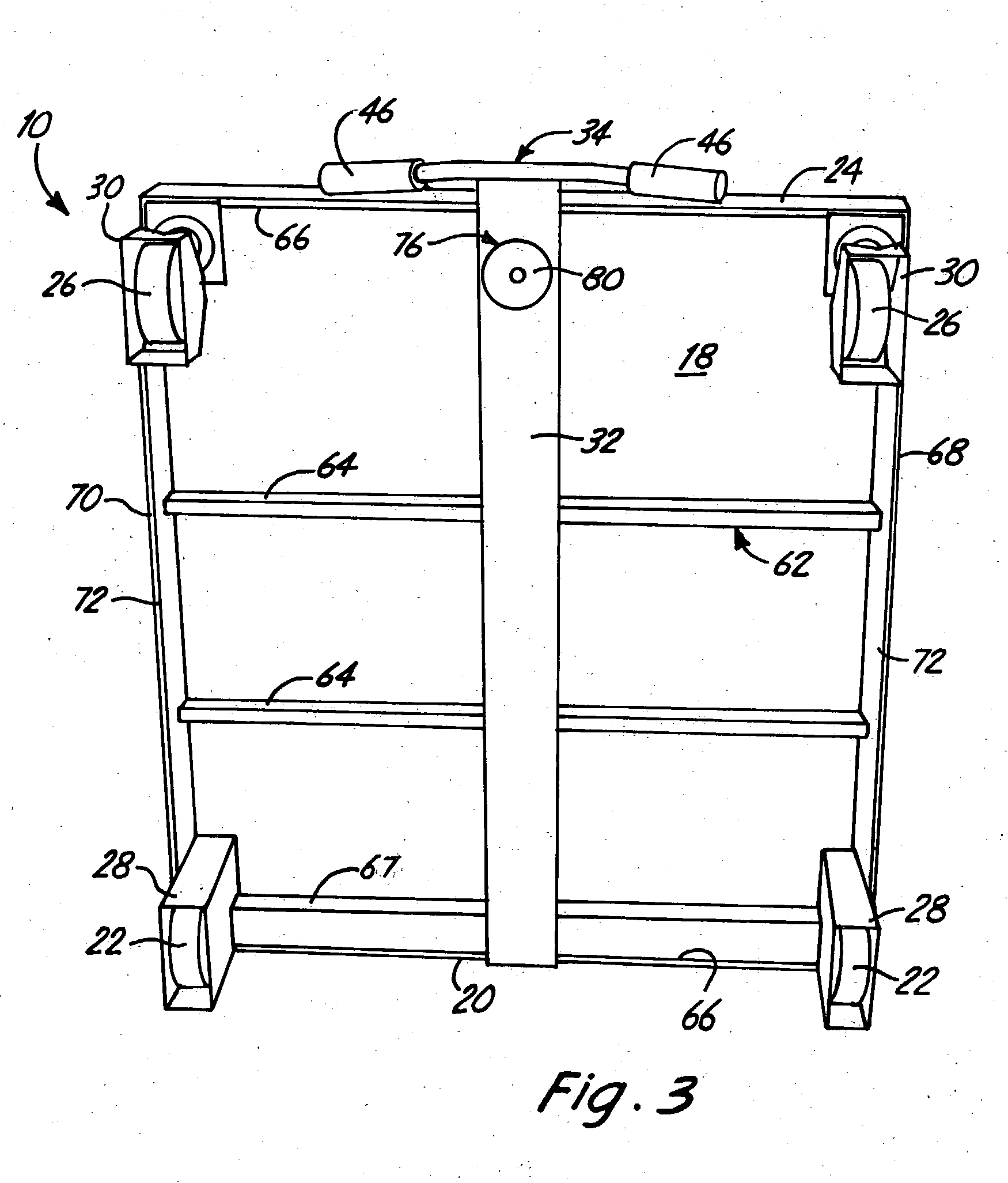

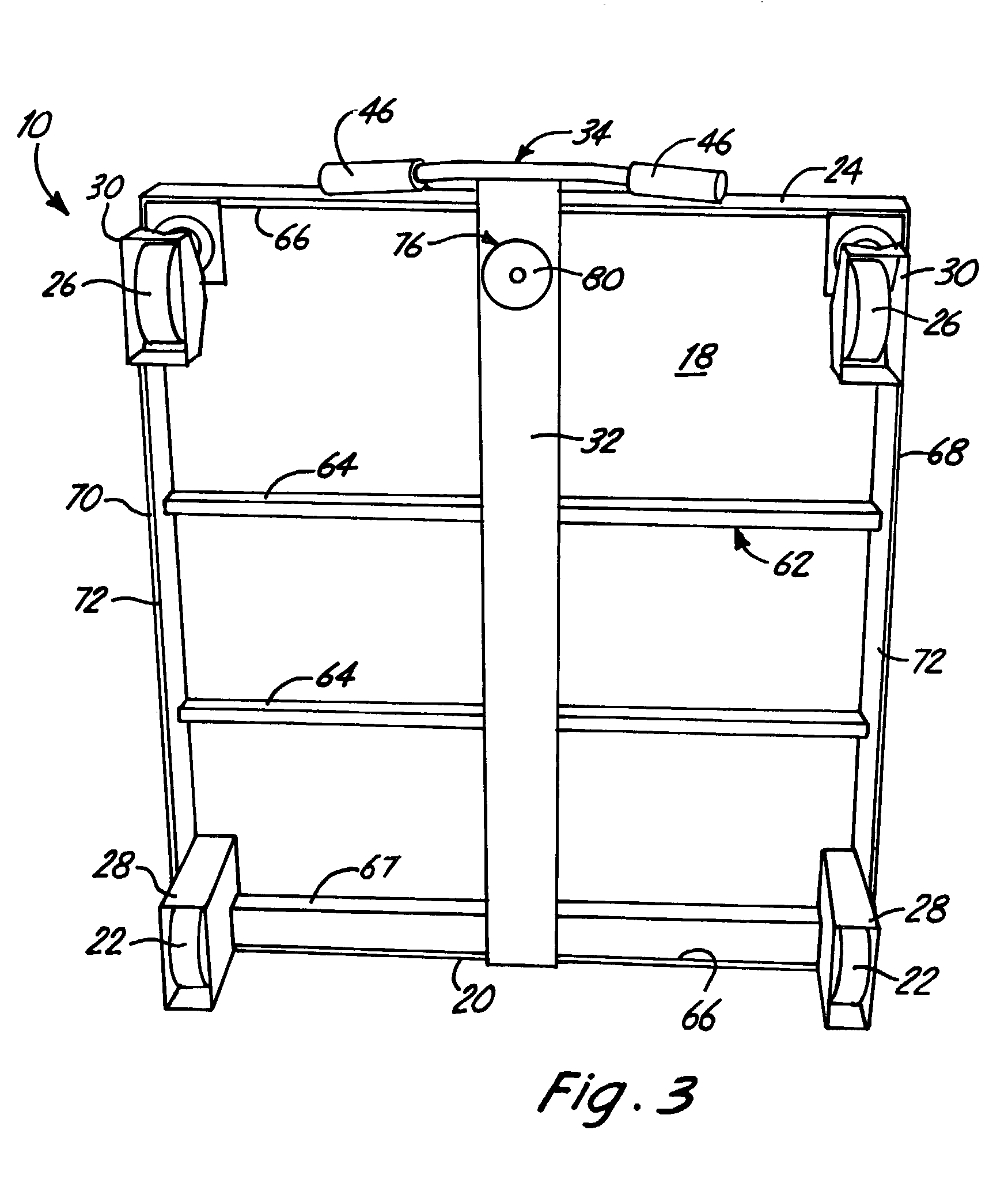

Offshore cargo rack for use in transferring palletized loads between a marine vessel and an offshore platform

A cargo rack for transferring loads between a marine vessel and an offshore marine platform (for example, oil and gas well drilling or production platform) provides a frame having a front, a rear, and upper and lower end portions. The lower end of the frame has a perimeter beam base, a raised floor and a pair of open-ended parallel fork tine tubes or sockets that communicate with the perimeter beam at the front and rear of the frame, preferably being structurally connected (e.g., welded) thereto. Openings in the perimeter beam base align with the forklift tine tubes or sockets. The frame includes a plurality of fixed side walls extending upwardly from the perimeter beam that include at least left and right side walls. A plurality of gates are movably mounted on the frame including a gate at least at the front and at least at the rear of the frame, each gate being movable between open and closed positions, the gates enabling a forklift to place loads on the floor by accessing either the front of the frame or the rear of the frame. Each gate can be pivotally attached to a fixed side wall. The frame has vertically extending positioning beams or lugs that segment the raised floor into a plurality of load-holding positions. Each load holding position has a plurality of positioning beams or lugs that laterally hold a load module (e.g., palletized load) in position once a load is placed on the raised floor.

Owner:NESS DANNY

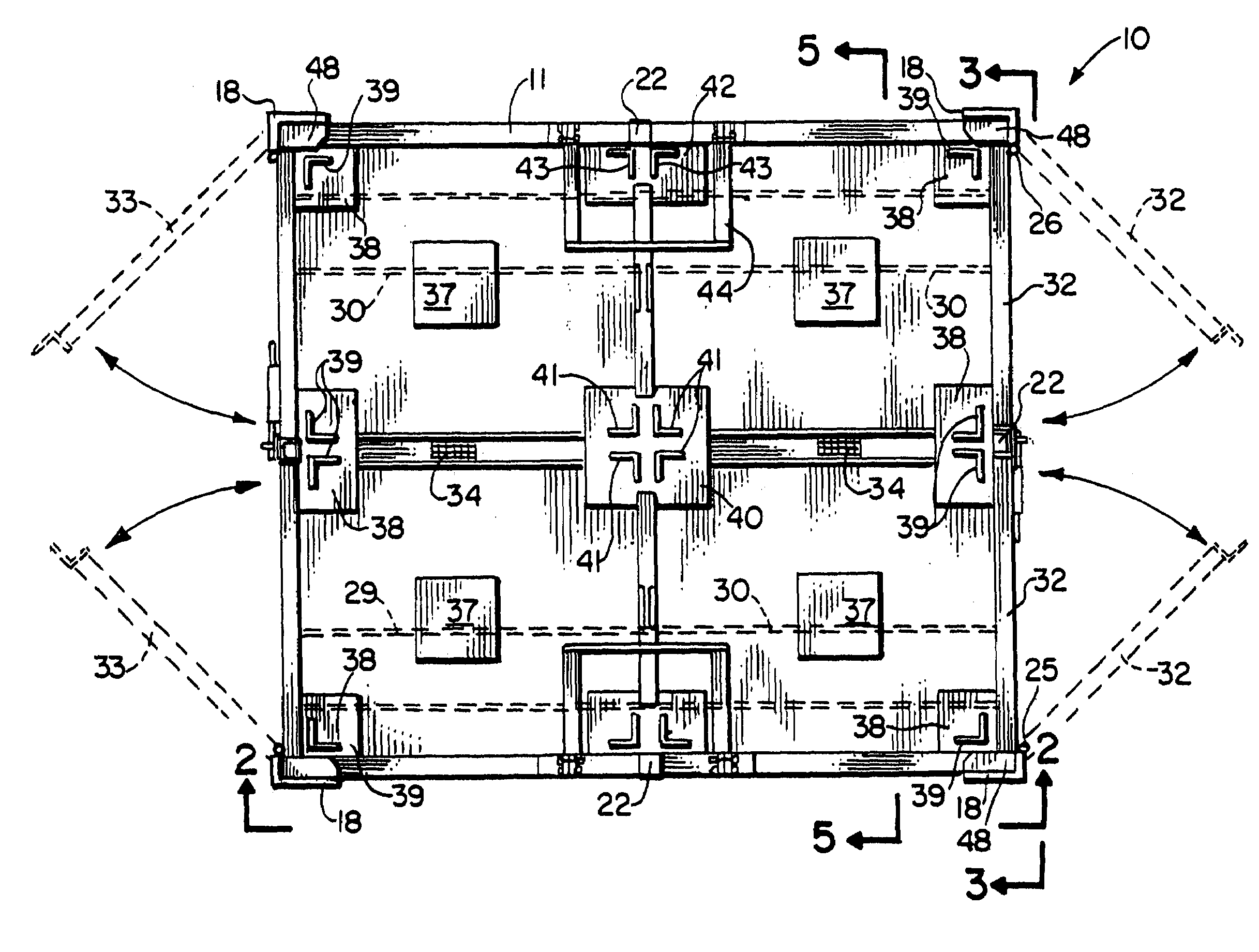

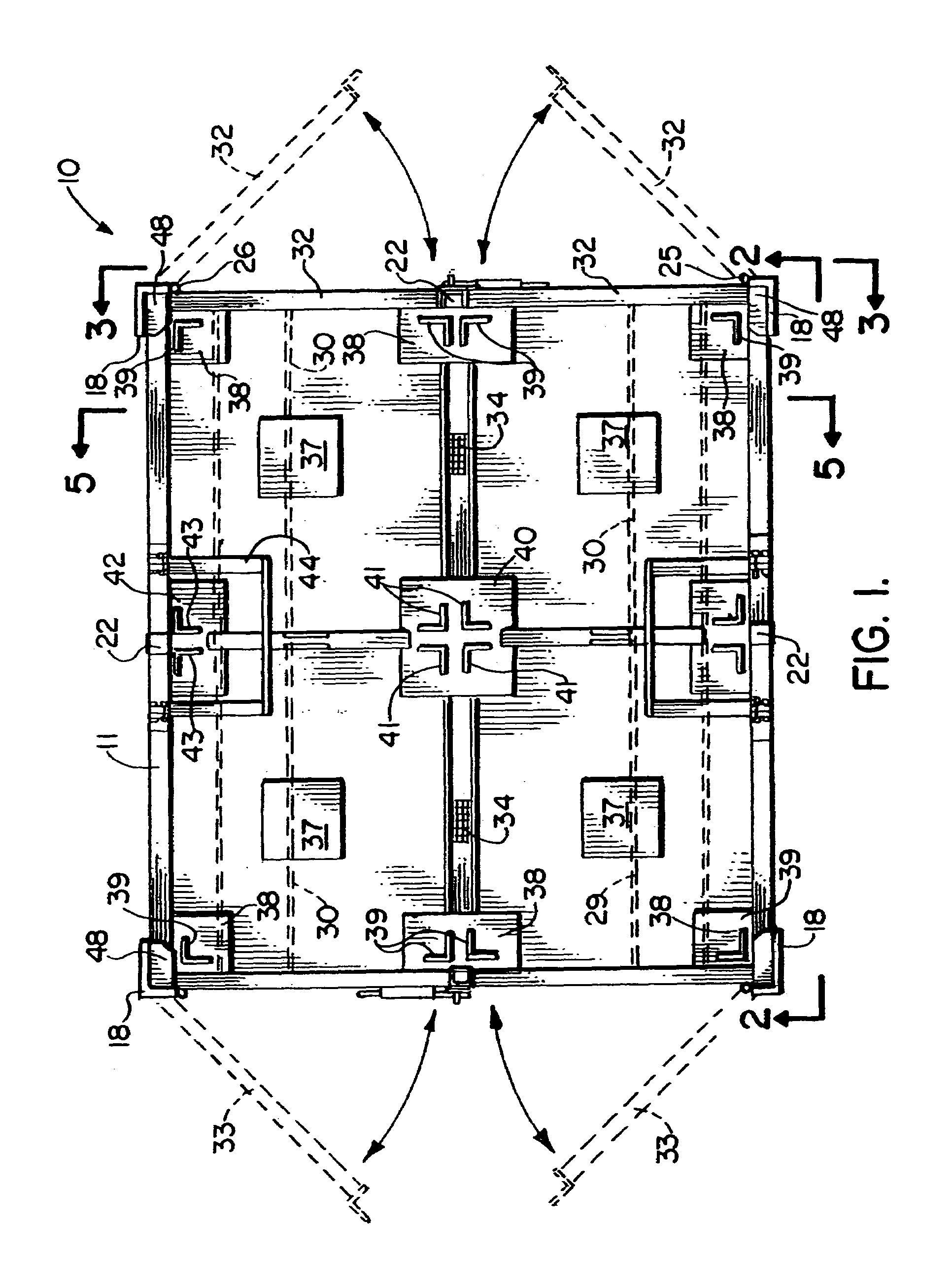

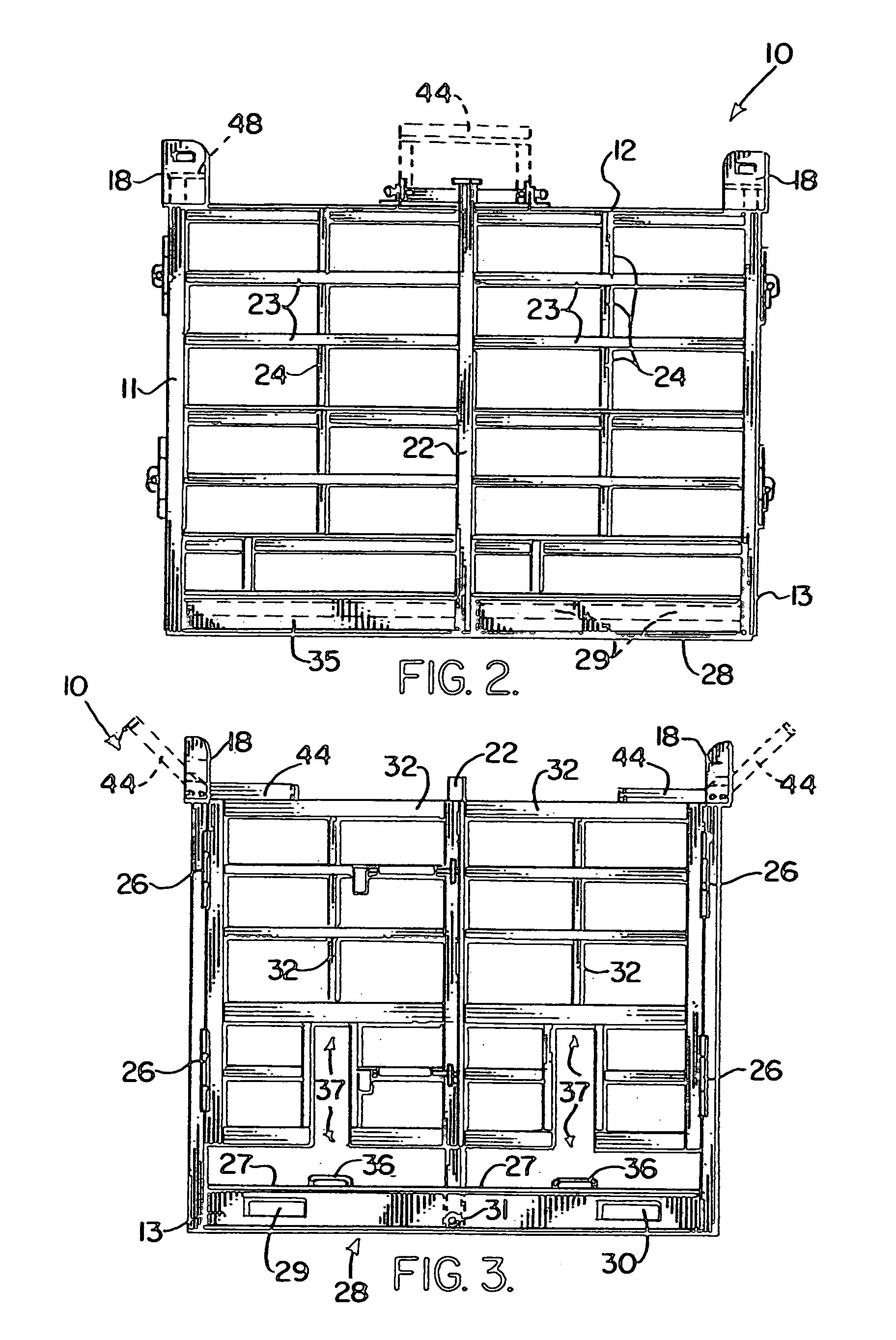

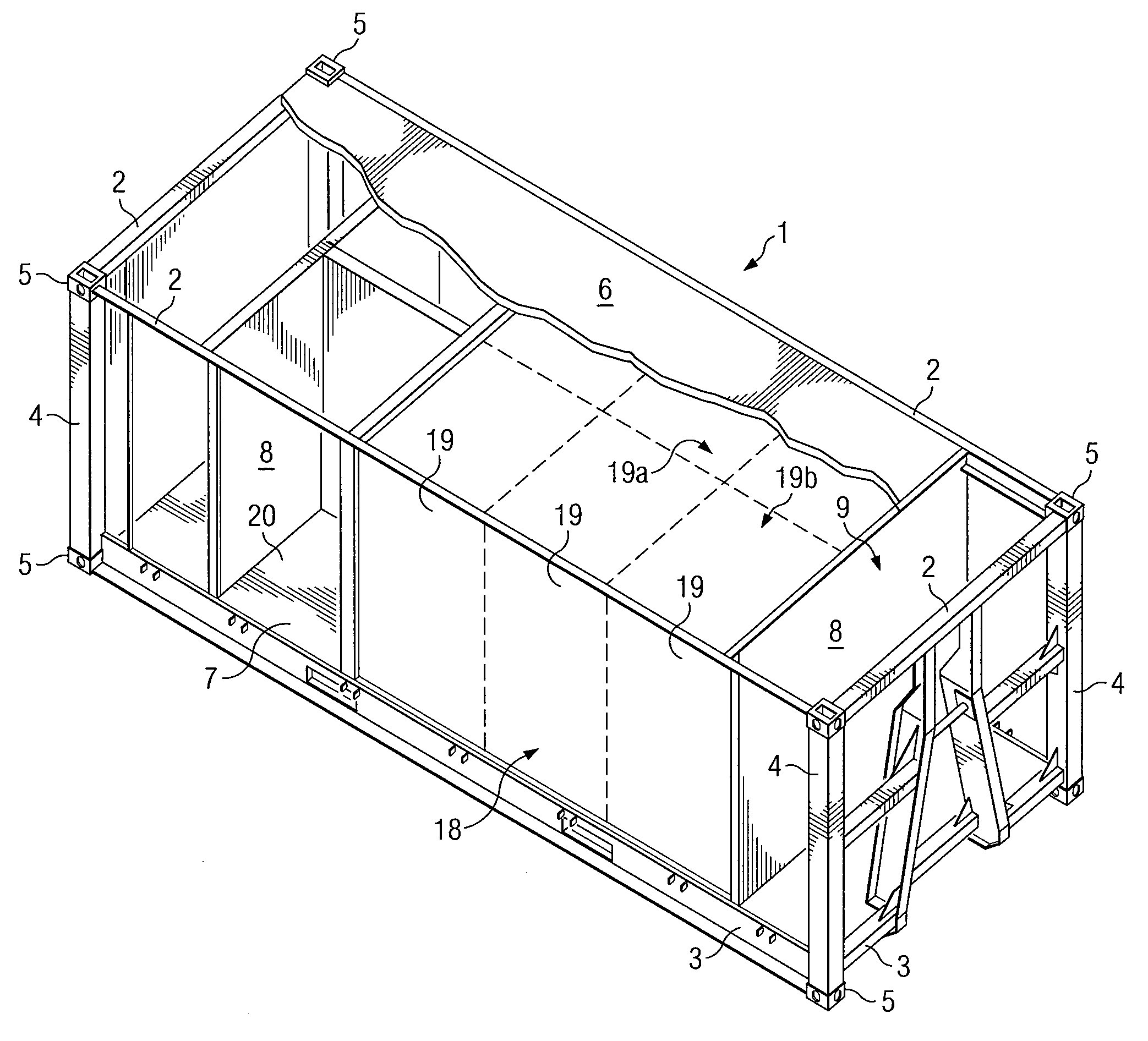

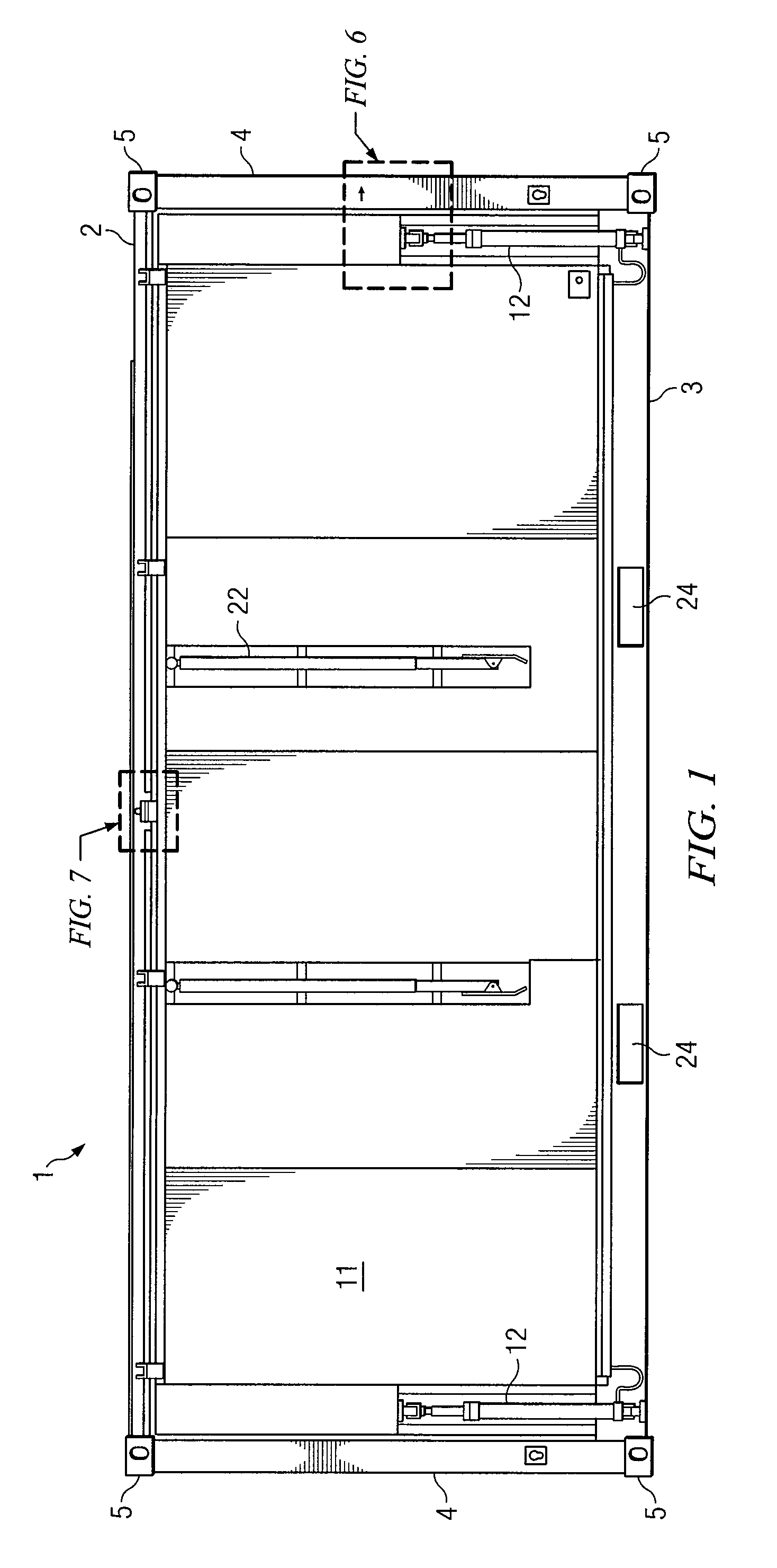

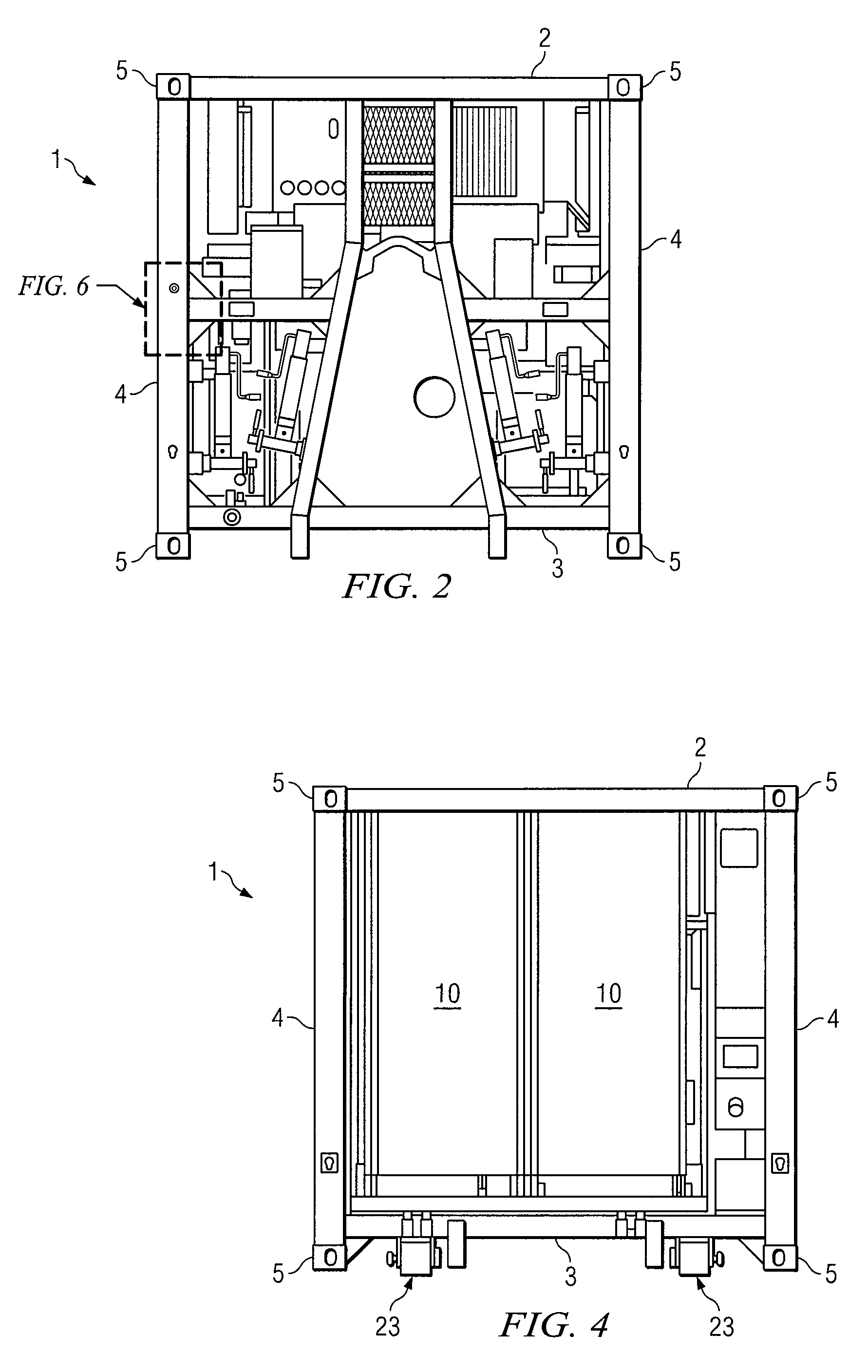

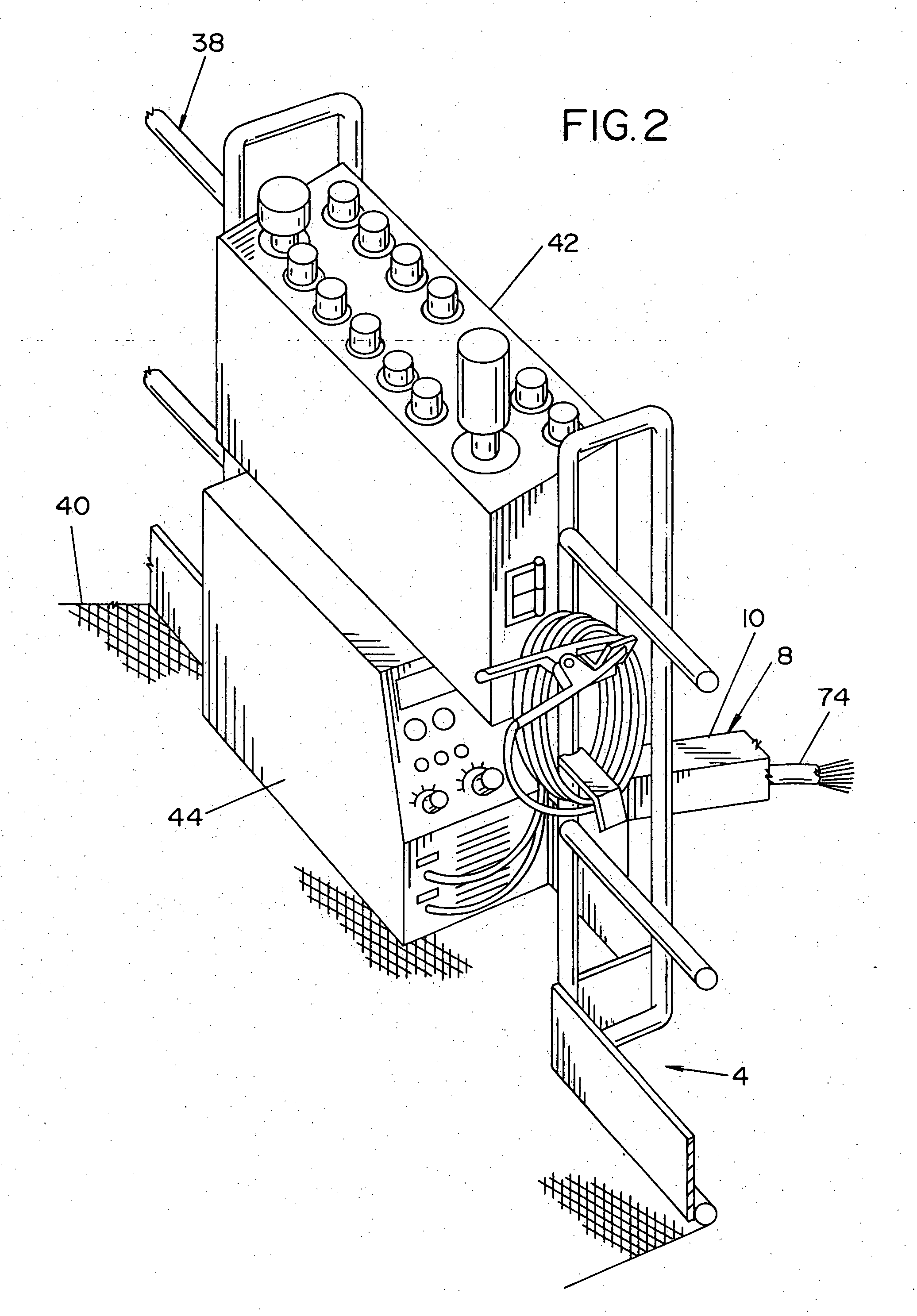

Portable Shippable Facilities

InactiveUS20080256878A1Easy to shipQuickly set into operationPublic buildingsSpecial buildingTransportation FacilityMechanical engineering

The present invention provides a portable shippable morgue system. The system may comprise (1) bottom, top and corner rails, and (2) corner fittings. Corner rails extend between bottom and top rails and connect them together to form a square and / or rectangular shaped frame. Bottom rails may include forklift engagement areas. Corner fittings are located at the connection point of the vertical corner rails and top rails. A top is positioned between the top rails and a bottom is positioned between the bottom rails. Vertically opposed end walls may be positioned between the top and bottom rails. The invention provides first and second spaced apart opposed vertical platforms, each in abutting engagement or engageable with a top rail and a bottom rail. The invention further provides a remains storage unit.

Owner:GUILD ASSOCS

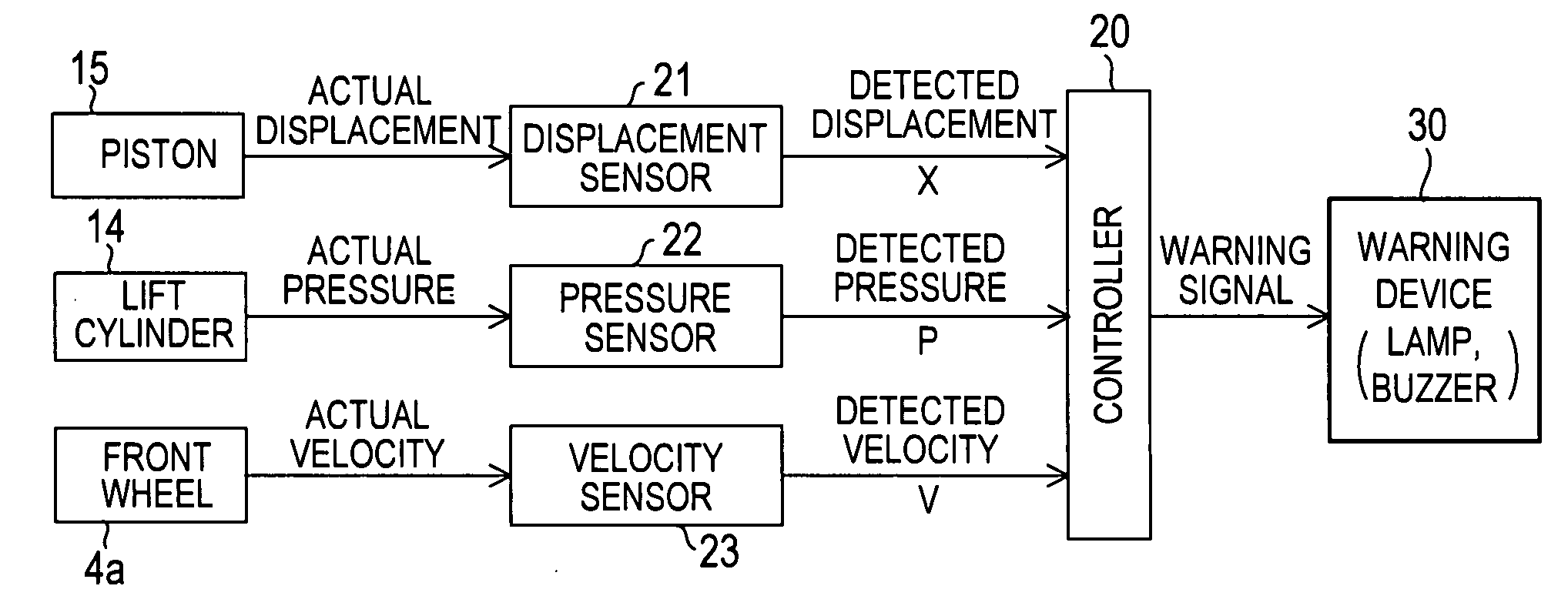

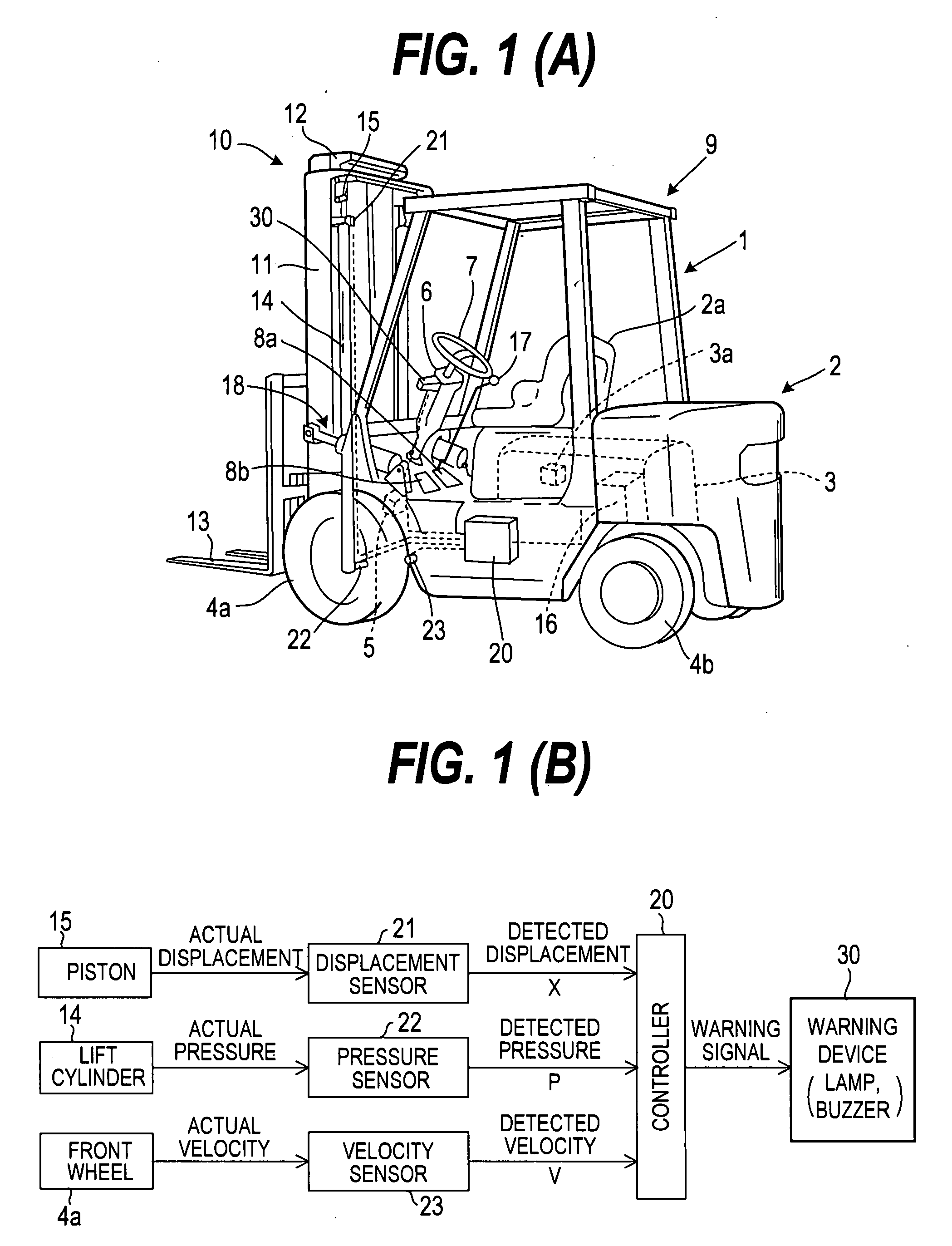

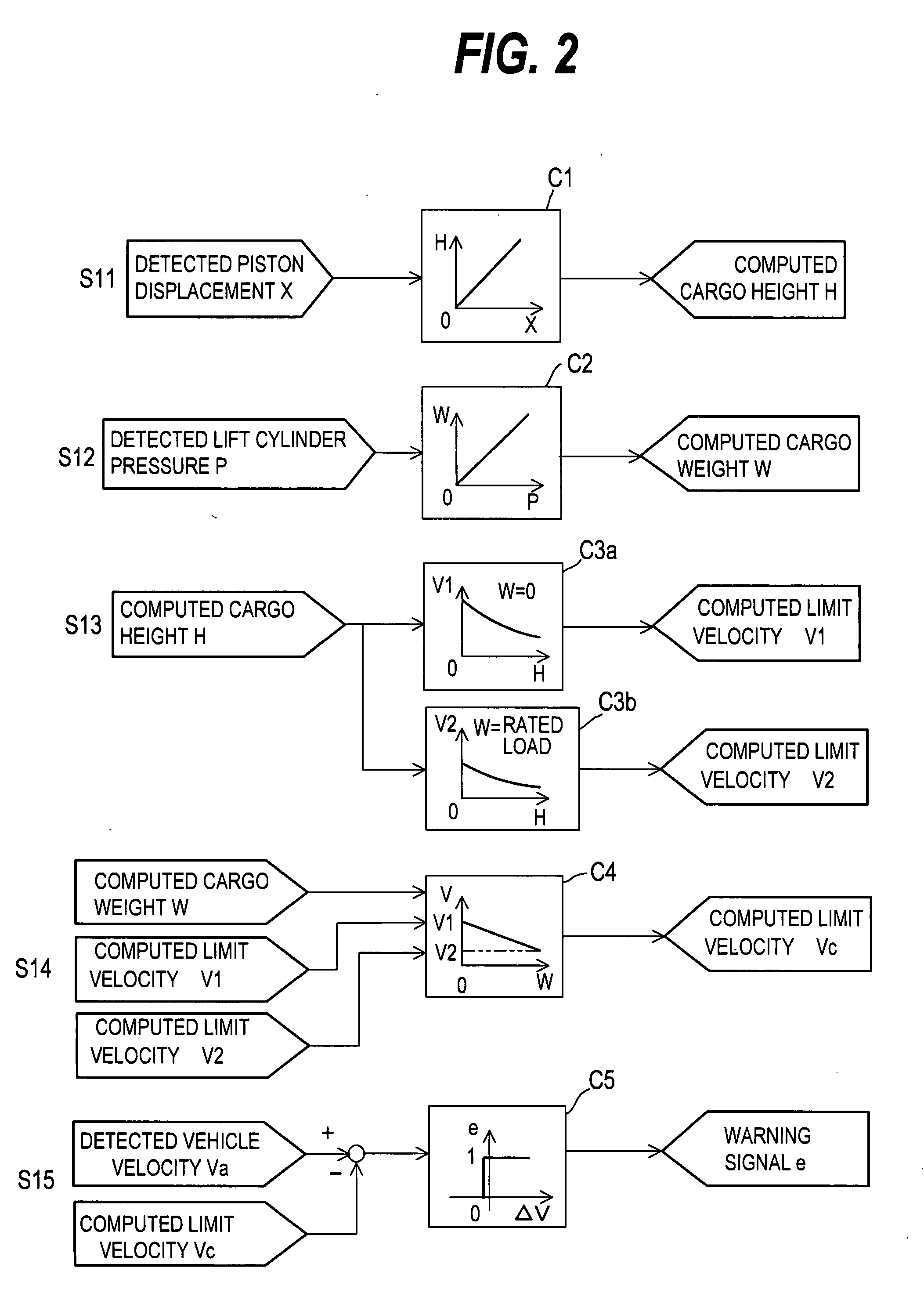

Overturning prevention device for forklift vehicle

InactiveUS20100063682A1Reduce the overall heightAvoid overall overturningAnalogue computers for trafficSteering initiationsControl theoryPiston

A subject of the present invention is to provide an overturning prevention apparatus for a forklift with various means. A cargo height H is calculated from a piston displacement detected by a displace sensor 21 and a cargo weight W is calculated by pressure P detected by a pressure sensor 22. A controller 20 detects a limit speed V1 in the case of non-cargo weight and a limit speed V2 in the case of the maximum cargo weight. By linearly interpolating the limit speeds V1 and V2, limit velocity Vc in the case that the cargo weight is W by utilizing a minimum turning radius memorized in the controller as a turning radius. If an actual velocity Va measured by a velocity sensor 23 is reached to the limit velocity Vc, the warning device 30 is actuated for warning an operator.

Owner:MITSUBISHI HEAVY IND LTD

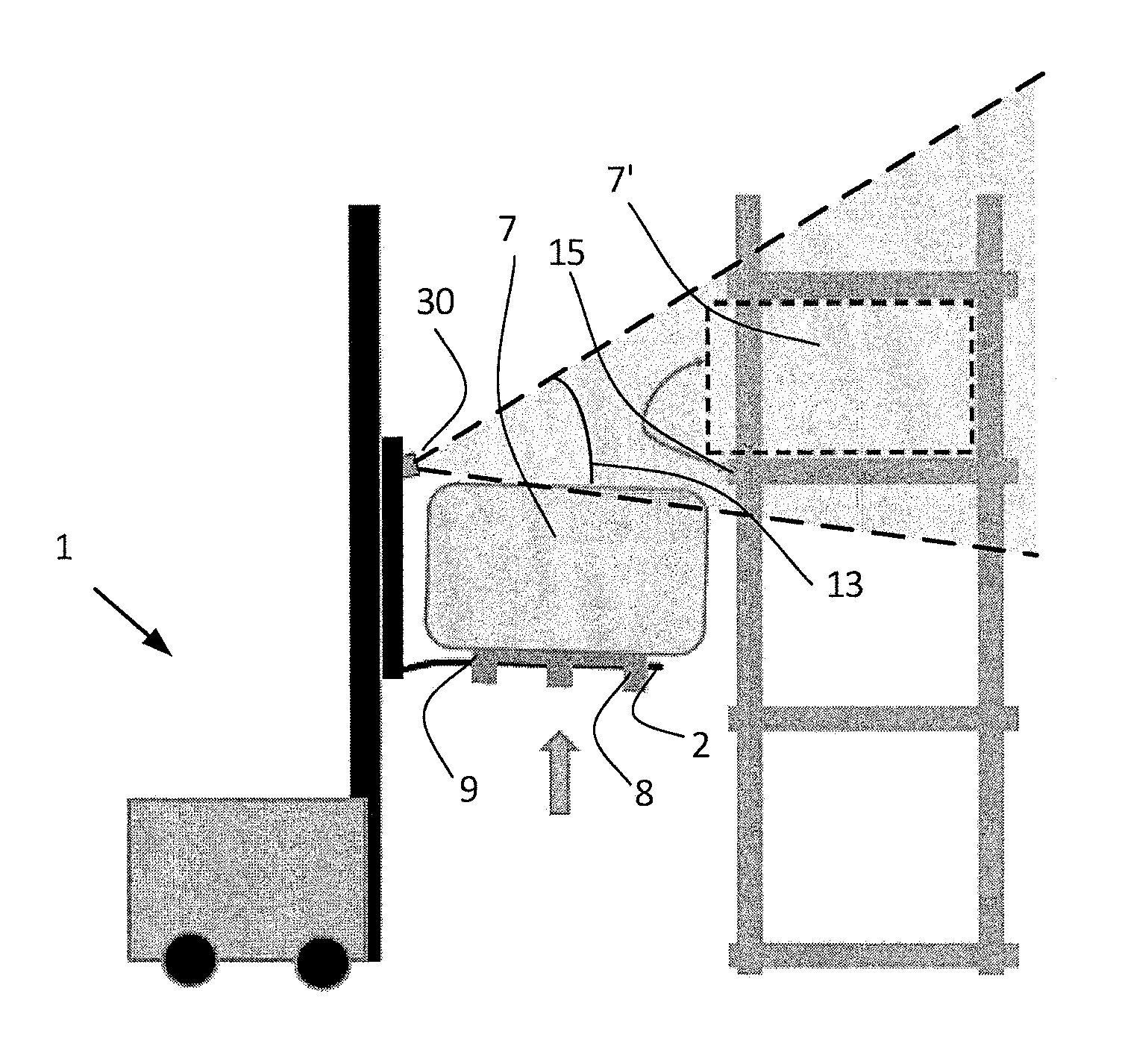

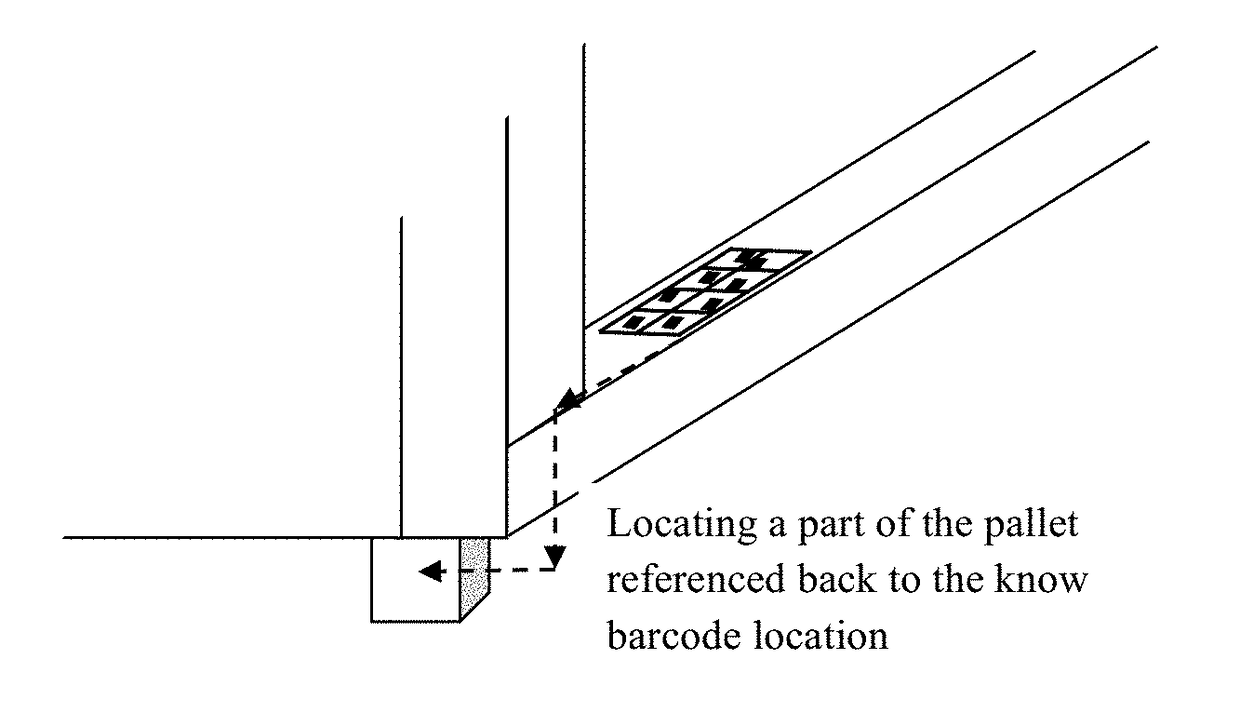

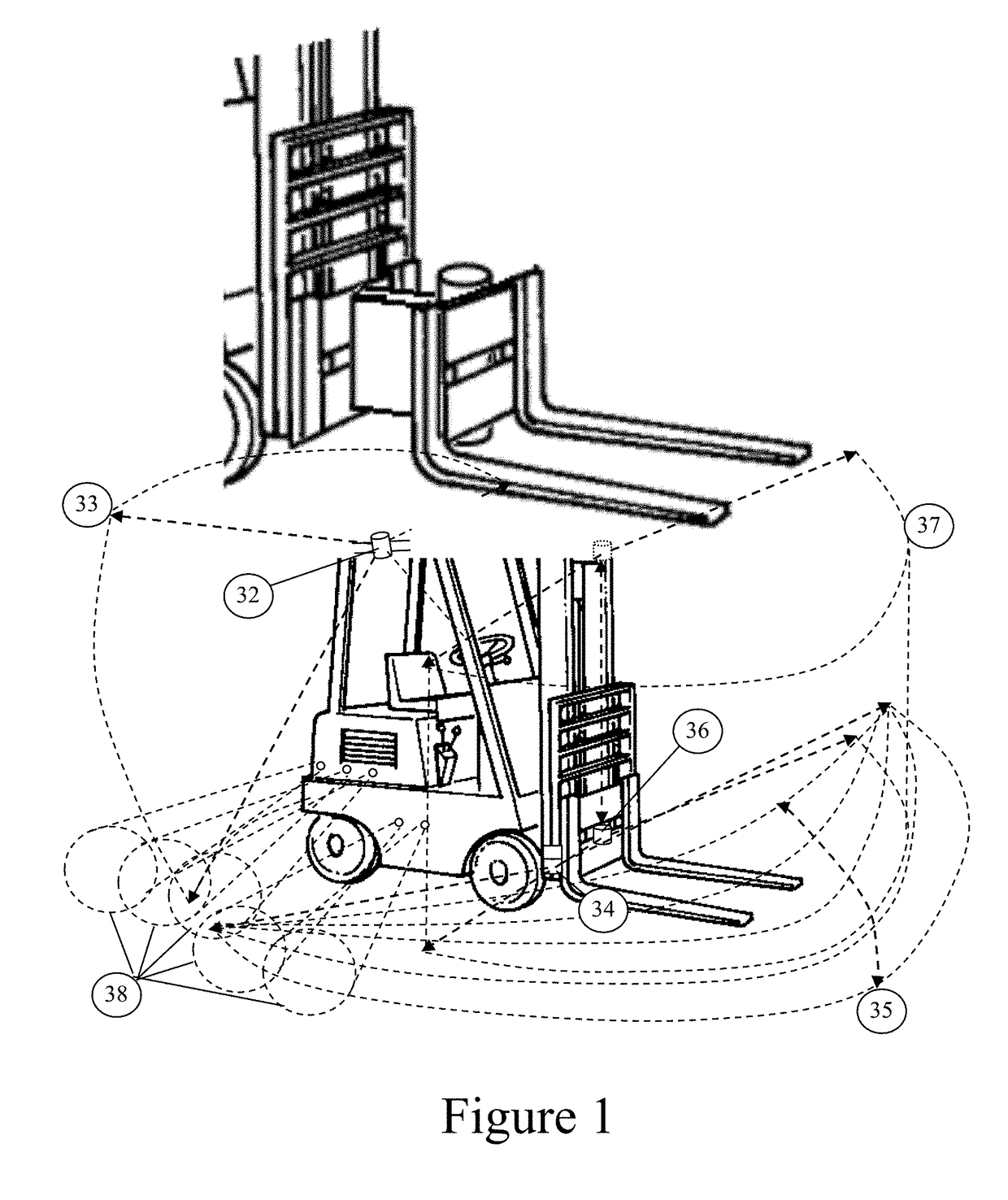

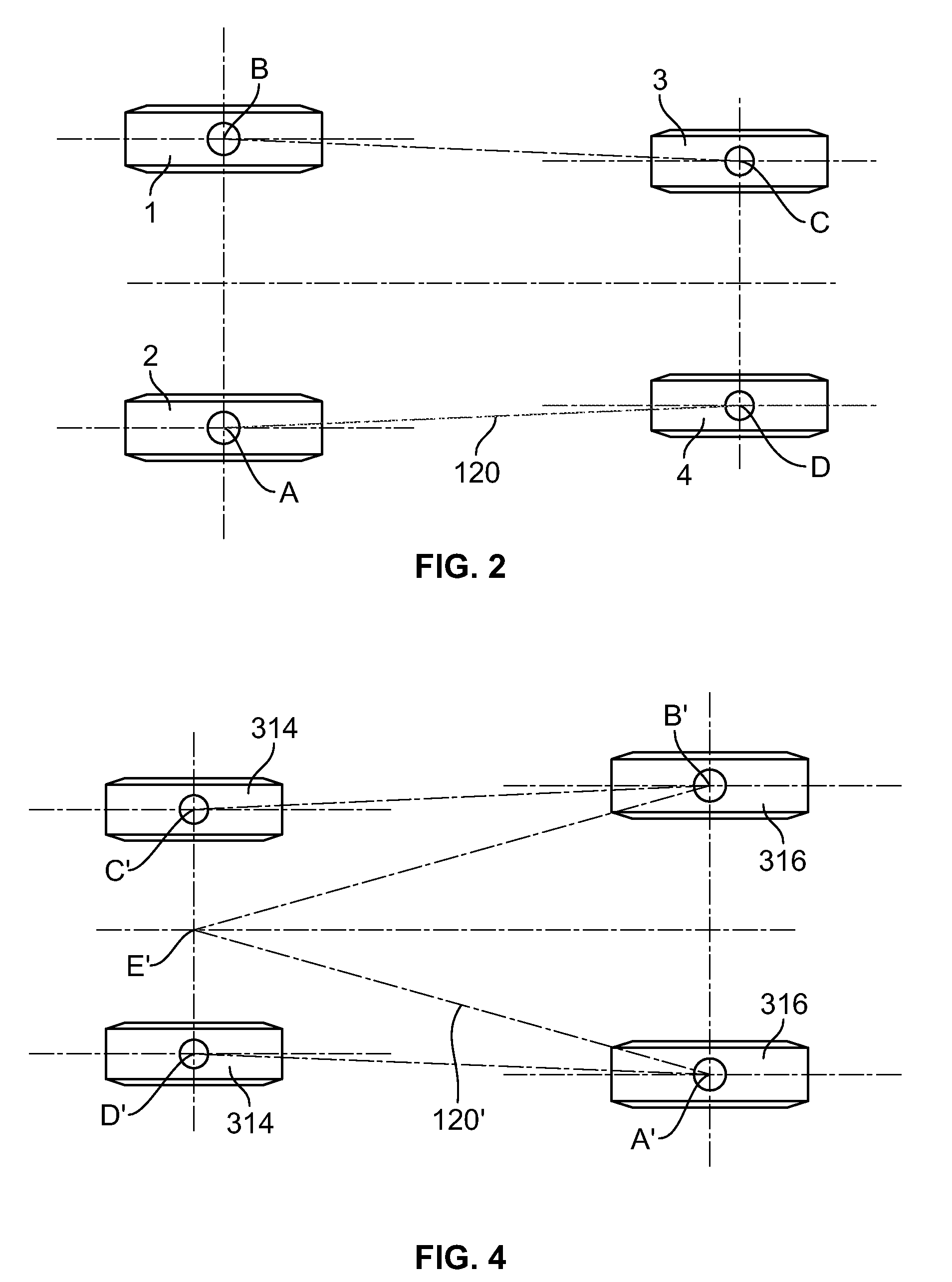

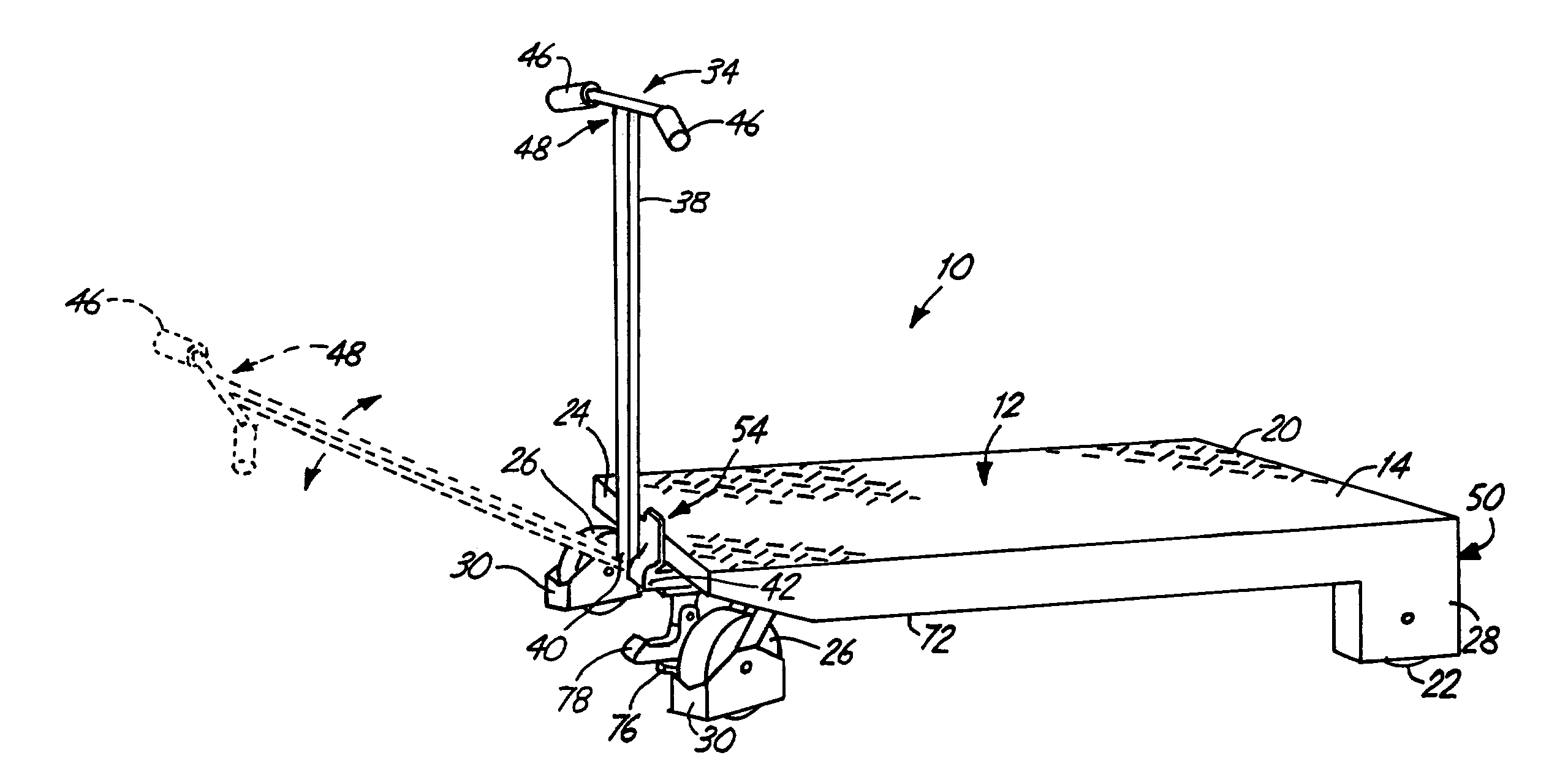

Path and load localization and operations supporting automated warehousing using robotic forklifts or other material handling vehicles

ActiveUS20180089616A1Reduce maintenanceLess clean upLifting devicesLogisticsOn boardInventory management

Automated inventory management and material (or container) handling removes the requirement to operate fully automatically or all-manual using conventional task dedicated vertical storage and retrieval (S&R) machines. Inventory requests Automated vehicles plan their own movements to execute missions over a container yard, warehouse aisles or roadways, sharing this space with manually driven trucks. Automated units drive to planned speed limits, manage their loads (stability control), stop, go, and merge at intersections according human driving rules, use on-board sensors to identify static and dynamic obstacles, and human traffic, and either avoid them or stop until potential collision risk is removed. They identify, localize, and either pick-up loads (pallets, container, etc.) or drop them at the correctly demined locations. Systems without full automation can also implement partially automated operations (for instance load pick-up and drop), and can assure inherently safe manually operated vehicles (i.e., trucks that do not allow collisions).

Owner:CYBERNET SYST

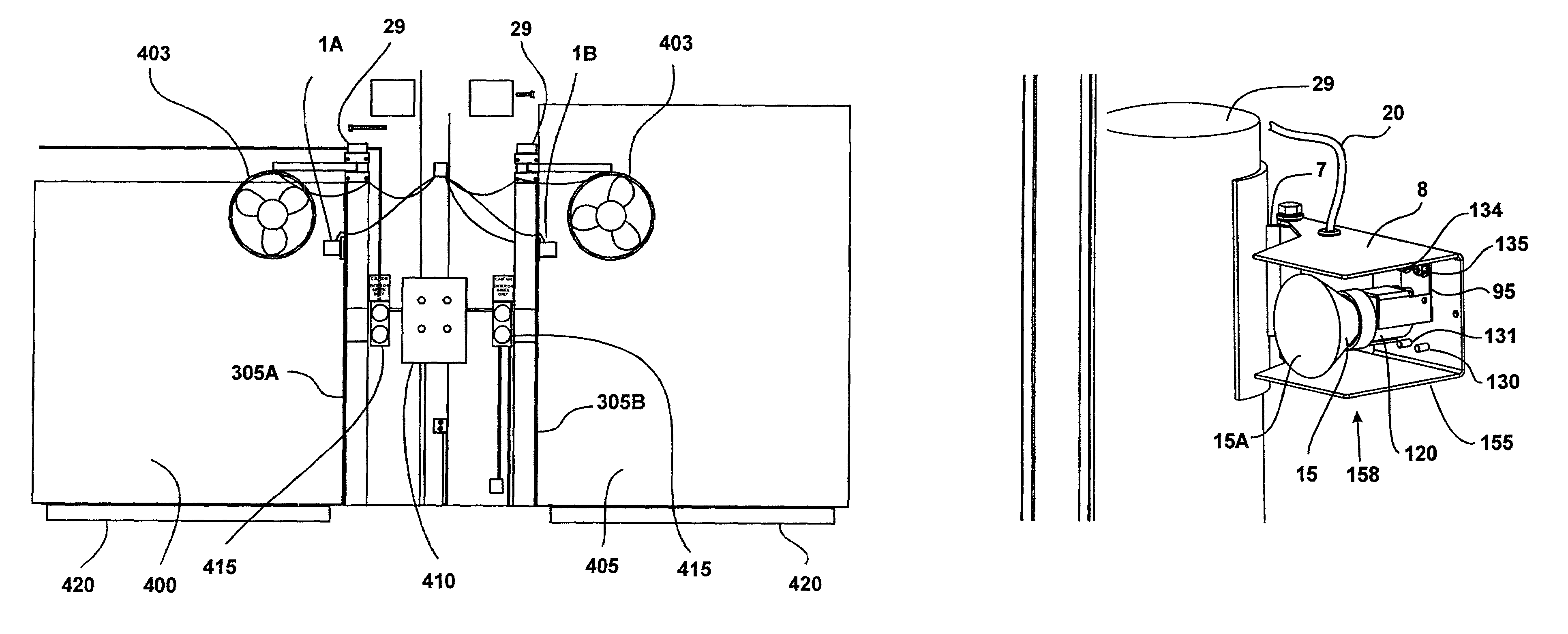

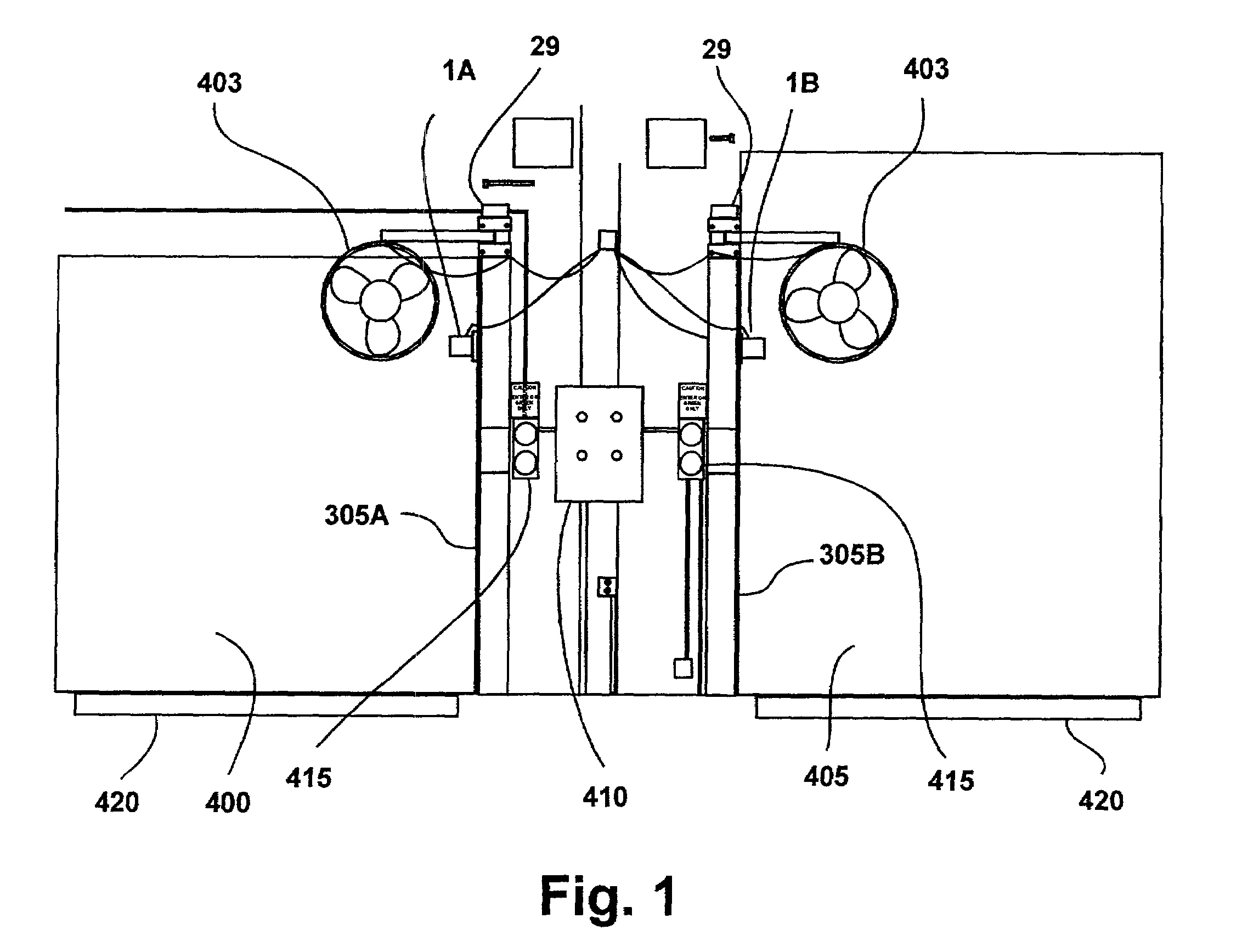

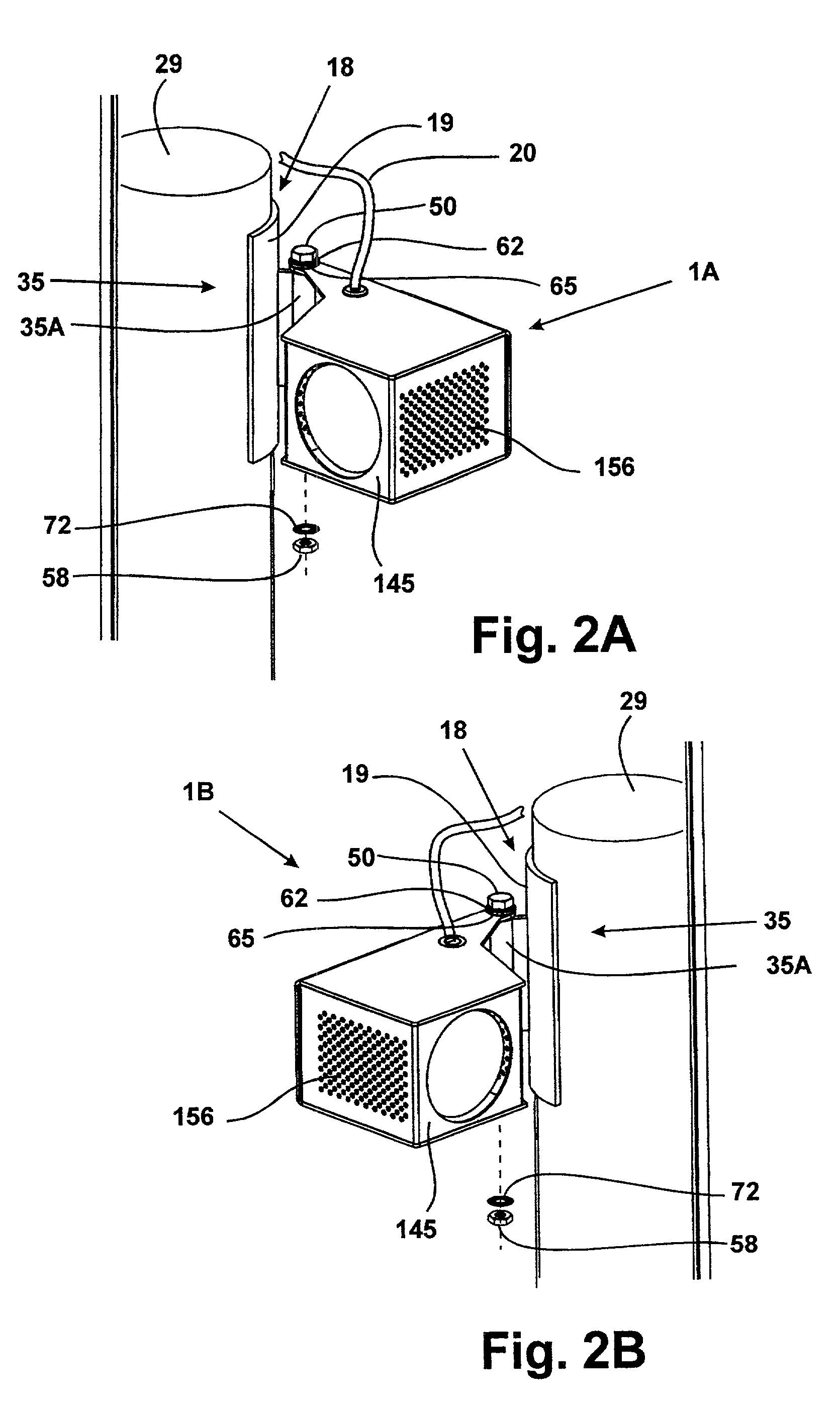

Loading dock light system

InactiveUS7101064B2Cool to the touchReduce confusionLighting support devicesLight fasteningsTruck-trailerEngineering

Owner:ANCEL THOMAS A

Fork-lift truck and method for operating a fork-lift truck

ActiveUS9828223B2Easy to automateImprove securityImage enhancementImage analysisEngineeringField of view

A fork-lift truck includes a load carrier, a first optical detector, an optical analyzing unit, and a second optical detector. The analyzing unit receives and analyses information from the second optical detector, wherein the first and second optical detector are movable together with the load carrier, and the first optical detector is positioned in relation to the load carrier, such that a first field of view includes at least a part of the load carrier and an extension of the load carrier. The second optical detector is positioned, such that a second field of view includes a predetermined volume above the load carrier The position and orientation of the second detector is calibrated in relation to a predetermined position on the fork-lift truck, in case one or more objects are positioned in the predetermined volume, at least one three-dimensional relative position can be determined.

Owner:TOYOTA MATERIAL HANDLING MFG SWEDEN

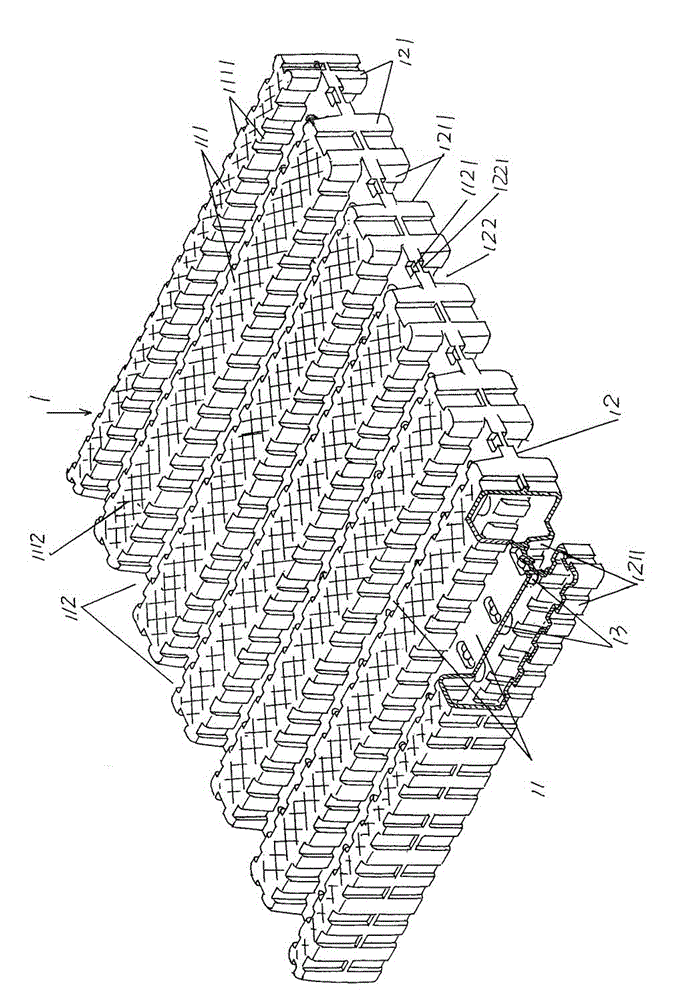

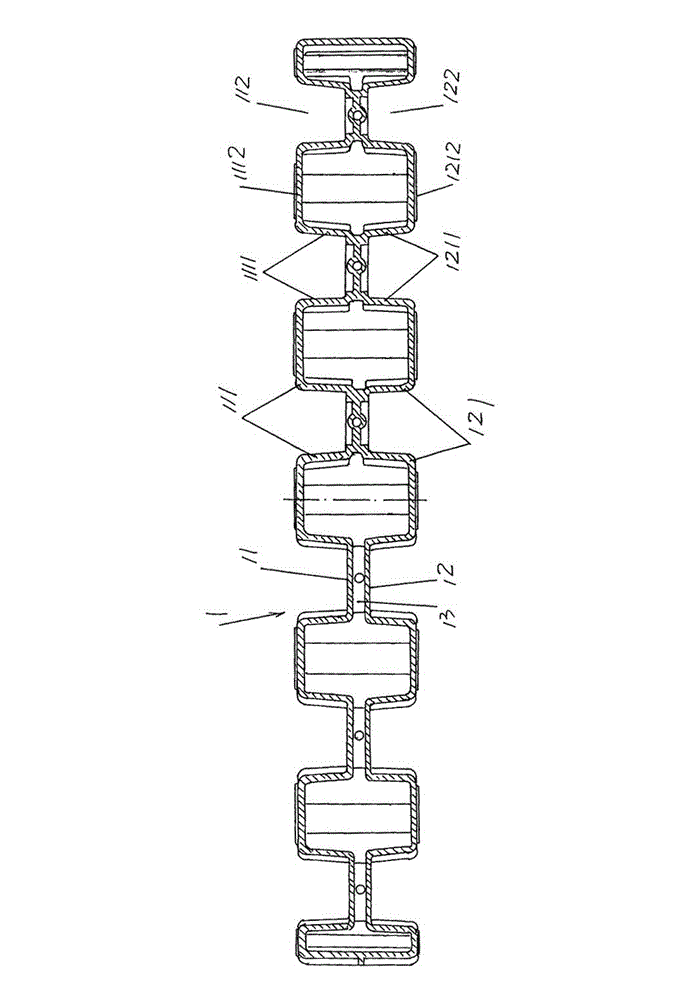

Tray

The invention relates to a tray, which belongs to the technical field of stacking and packaging materials. The tray comprises a rectangular or square tray body which is obtained by blowing and is formed in a manner that first and second tray sections with the same structures are connected with each other. The tray is characterized in that: first carrying bosses which are extended to the other side from one side of the first tray section and are protruded on the surface of the first tray section are formed at intervals on the first tray section; and a first shovel arm slot is formed between the adjacent first carrying bosses; second carrying bosses which are extended to the other side from one side of the second tray section and are protruded on the surface of the second tray section are formed at intervals on the second tray section; and a second shovel arm slot is formed between the adjacent second carrying bosses; the first and second carrying bosses are corresponding to each other; and the first and second shovel arm slots are corresponding to each other. The advantages are that: flexible selection requirement on insertion of the shovel arm of the forklift truck into the first shovel arm slot or the second shovel arm slot can be satisfied, the labor intensity of workers in loading and unloading can be reduced and the transfer efficiency of goods can be improved.

Owner:SUZHOU TONGDA MACHINERY

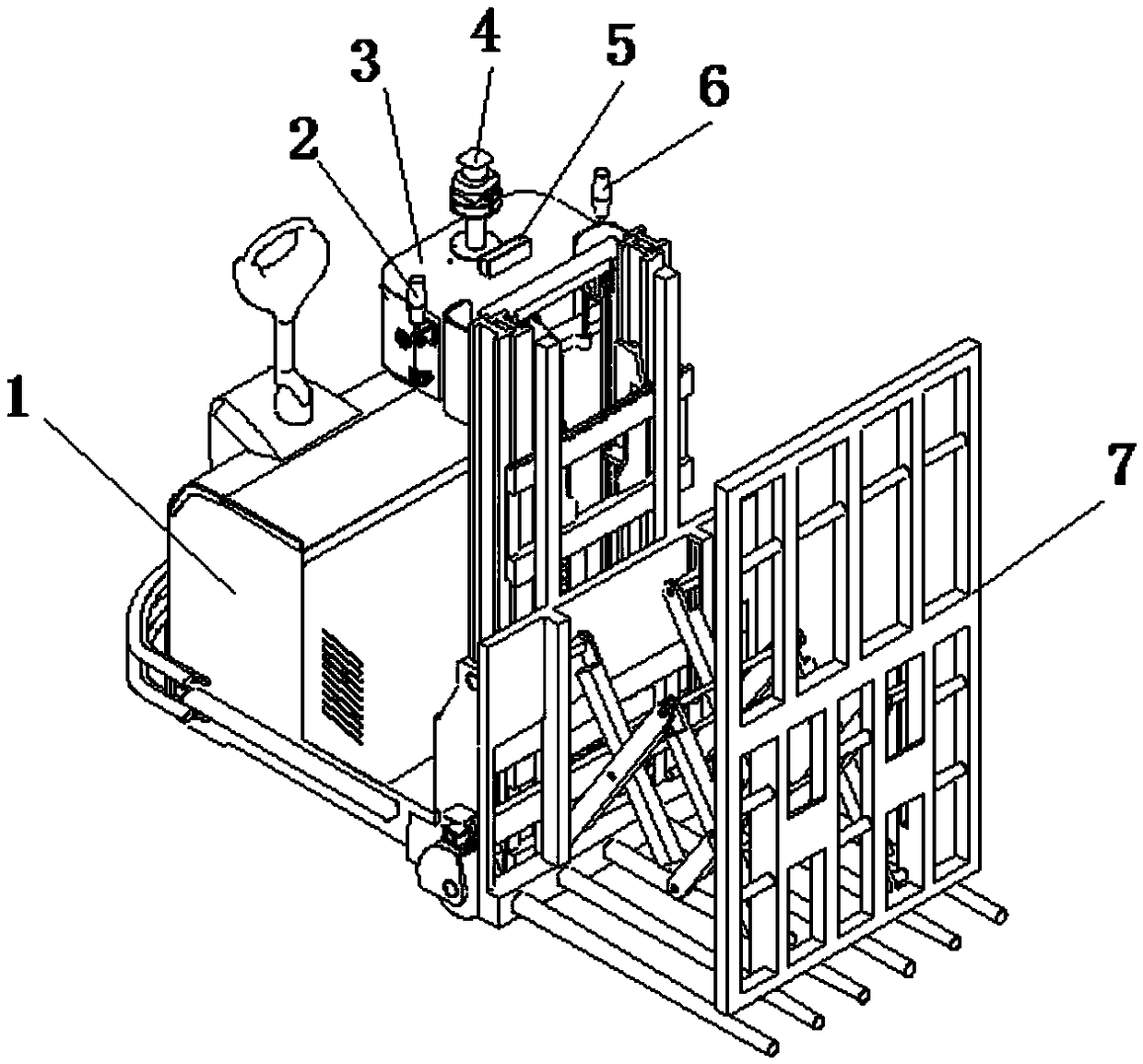

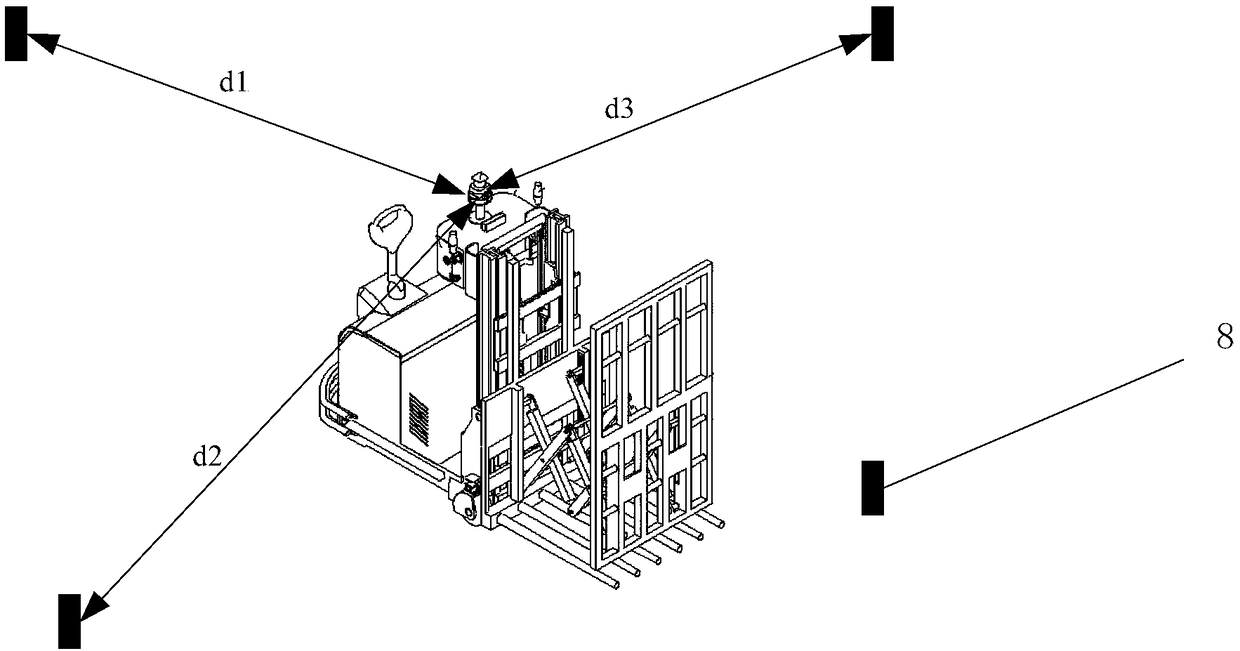

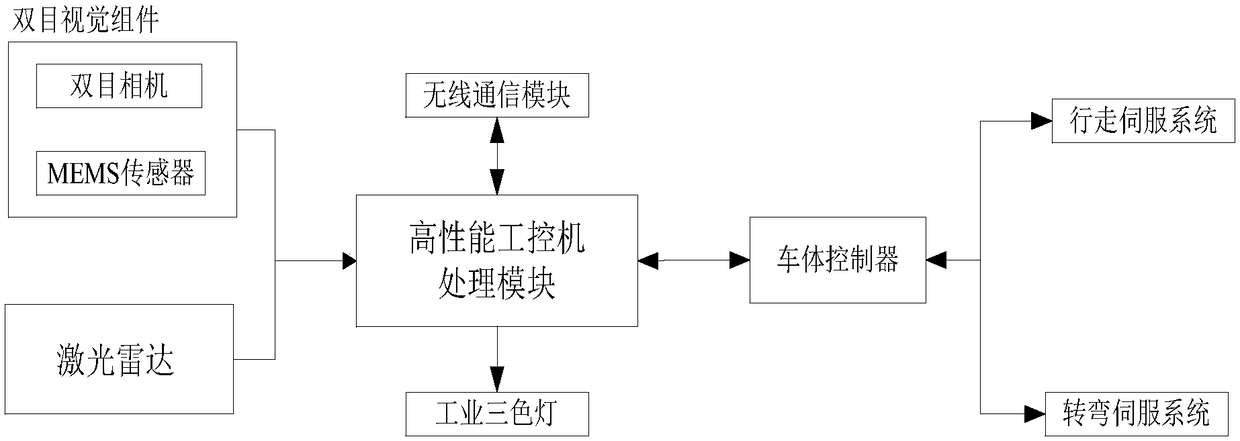

Unmanned transfer forklift based on laser positioning and stereoscopic vision and navigation method

ActiveCN109160452AWide detection rangeImprove stabilityLifting devicesPosition/course control in two dimensionsRadarComputer module

The invention discloses an unmanned transfer forklift based on laser positioning and stereoscopic vision and a navigation method. The unmanned transfer forklift comprises multiple reflection targets and tray targets arranged in a working scene of a forklift body; the forklift body comprises a control mechanism arranged at the front part, and a multi-gear pusher arranged at the back part; a laser radar and a binocular vision module scan the reflection targets to obtain distance signals of the forklift body and the reflection targets, and the distance signals are output to an industrial personalcomputer processing module; the industrial personal computer processing module controls the forklift body to advance and avoid from obstacles; the laser radar and the binocular vision module scan thetray targets to obtain distance and position information of the forklift body and goods on trays, and the distance and position information is output to the industrial personal computer processing module; and the industrial personal computer processing module controls the multi-gear pusher of the forklift body to operate. Through laser positioning and stereoscopic vision navigation, the navigation dead angle can be precisely detected, and the navigation accuracy is improved; and the obstacles can be accurately avoided, and the goods can be accurately forked, so that the transfer, taking and placement of the goods through unmanned driving are realized.

Owner:XIAN ZHONGKE PHOTOELECTRIC PRECISION ENG CO LTD

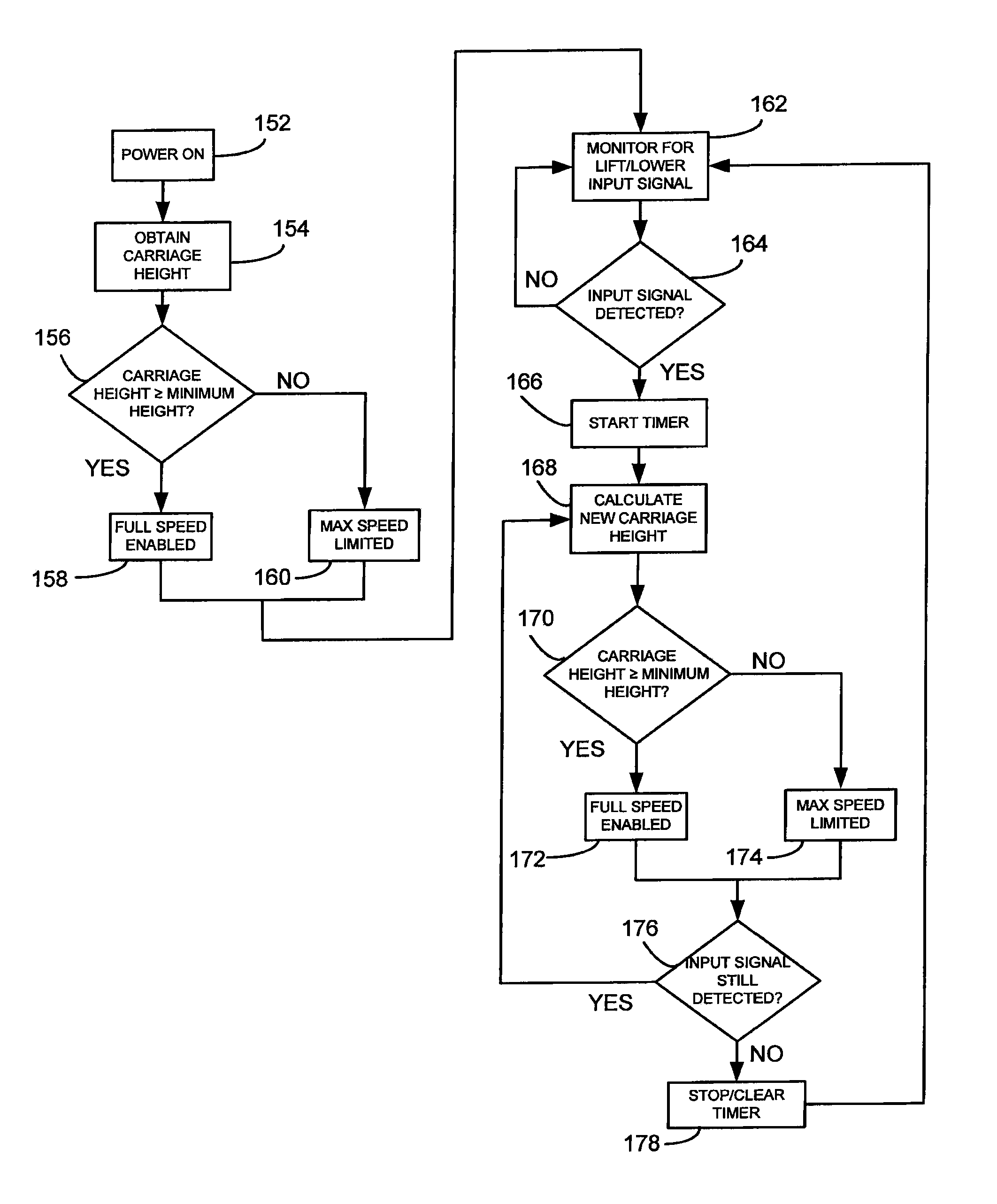

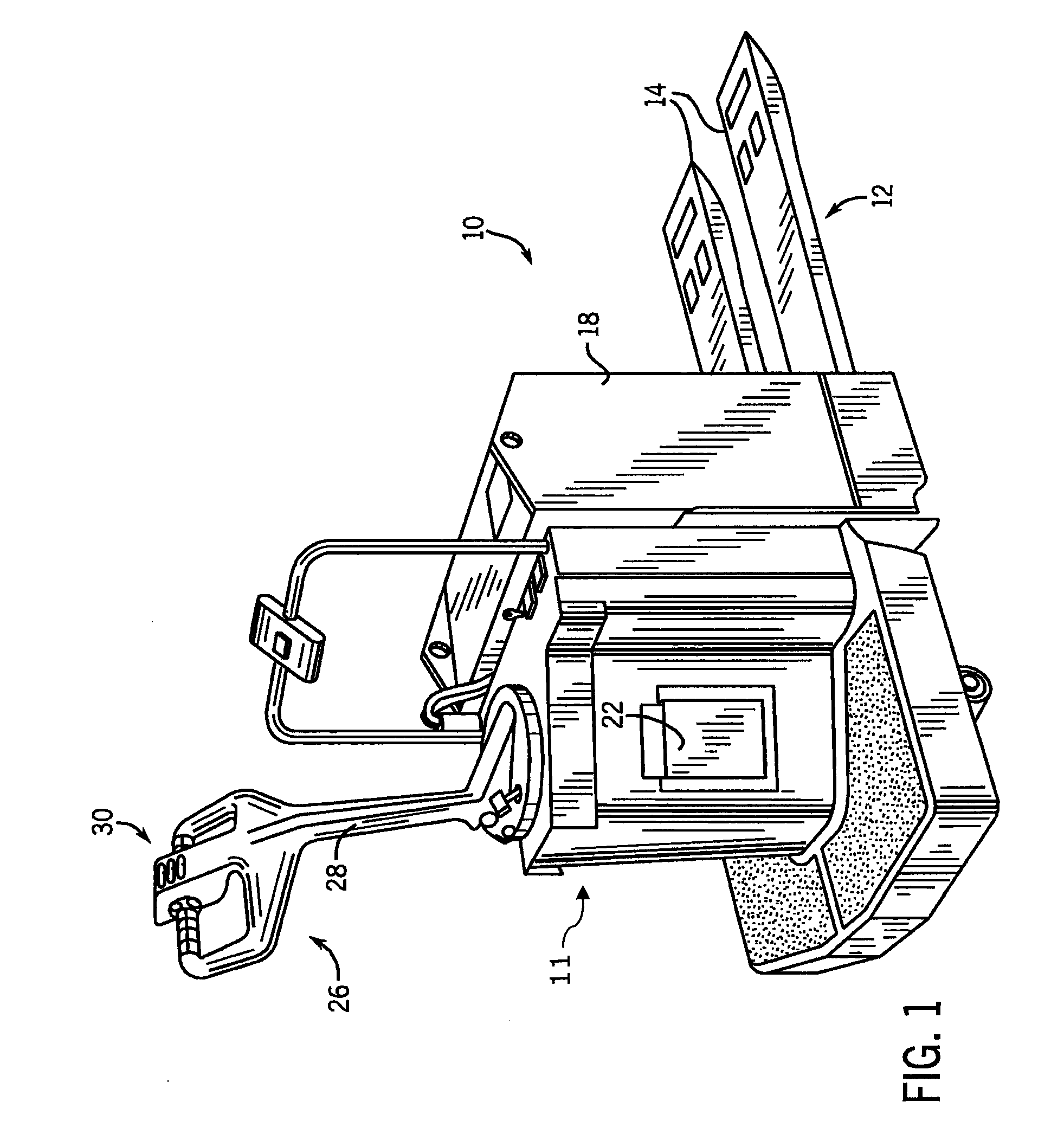

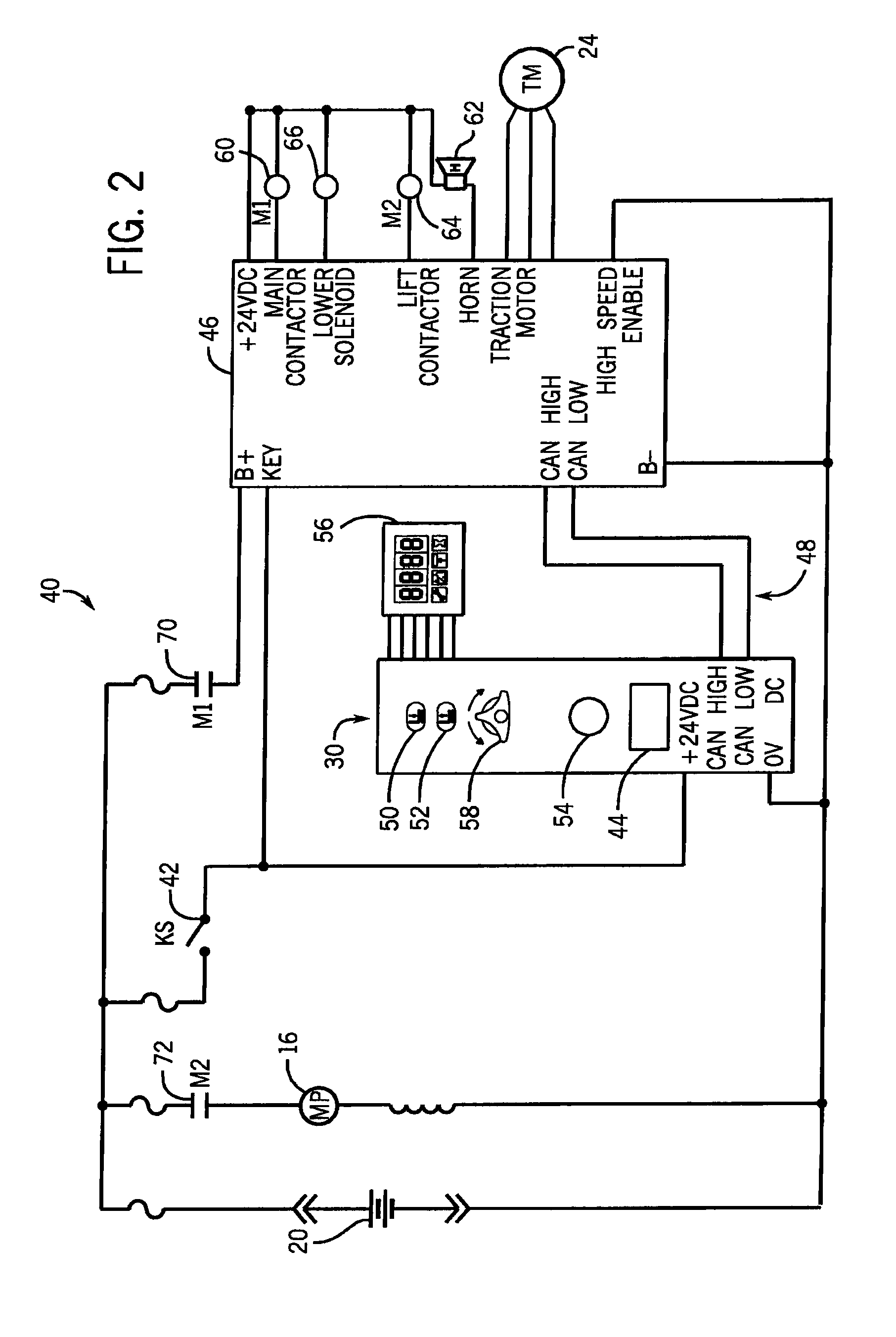

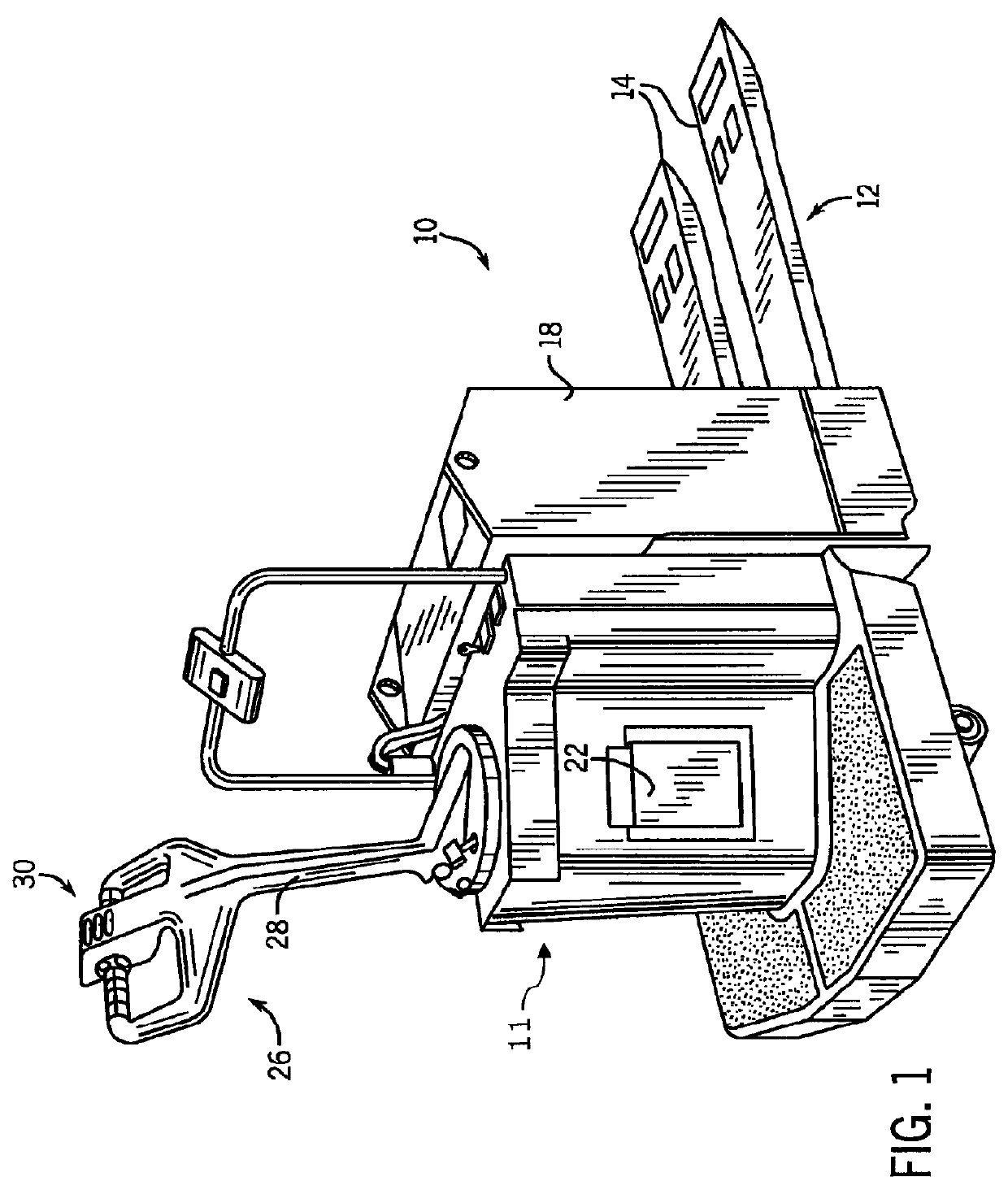

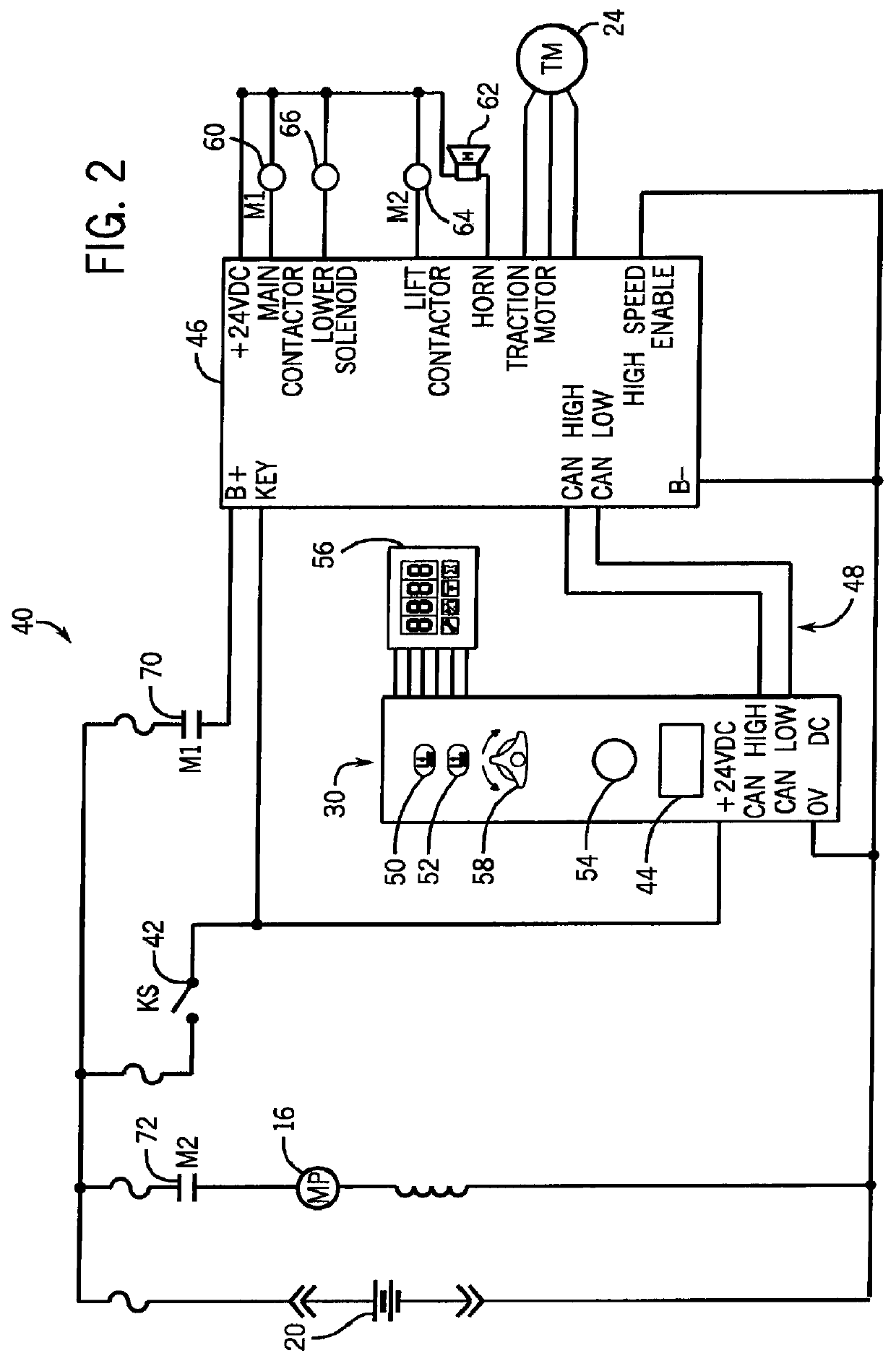

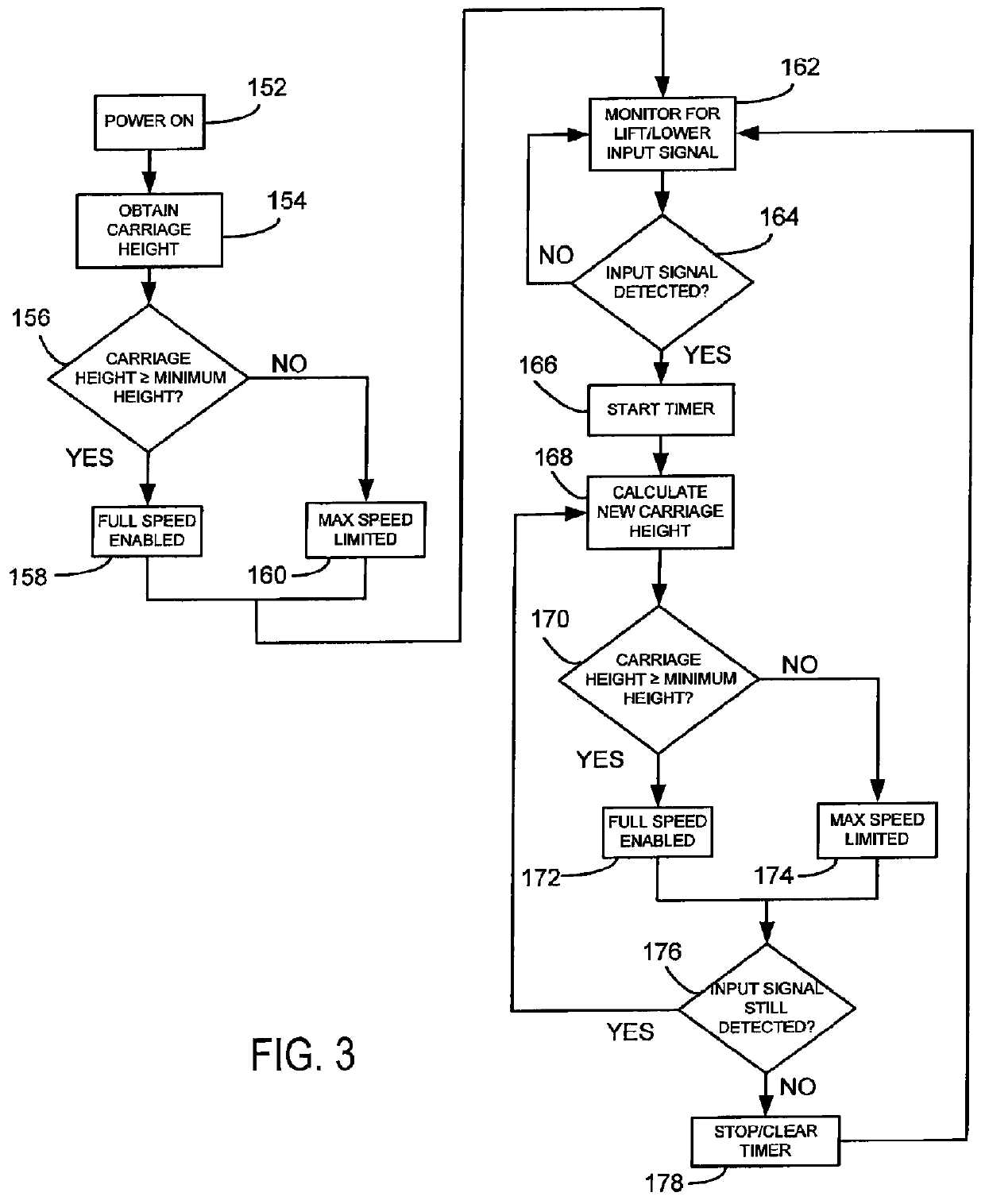

Pallet truck with calculated fork carriage height

A pallet truck including a controller that calculates the height of the fork carriage without the use of mechanical devices such as switches or sensors. A calculated carriage height is derived by adding the amount of time that a carriage is commanded to be raised and offsetting that by the amount of time that the carriage lower button is depressed. The calculated carriage height is essentially an accumulated lift time where the time that the carriage is lifting is a positive value and the time that the carriage is lowering is a negative value. When these values are combined, the result is the present calculated carriage height. The controller further monitors the calculated carriage height such that if the carriage is too close to the ground, the maximum speed of the pallet truck is limited to prevent damage to the forks or ground due to striking or scraping between them.

Owner:RAYMOND LTD

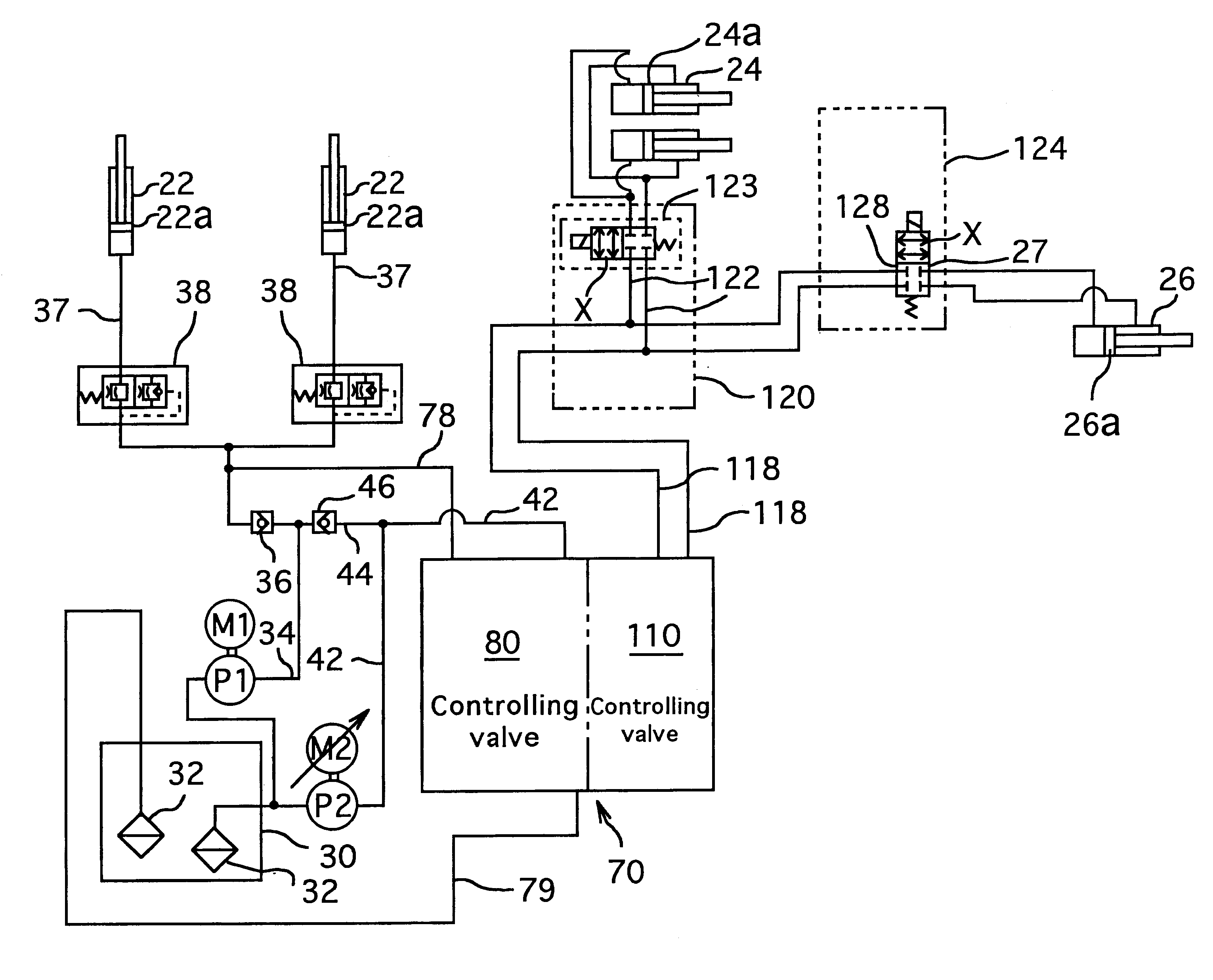

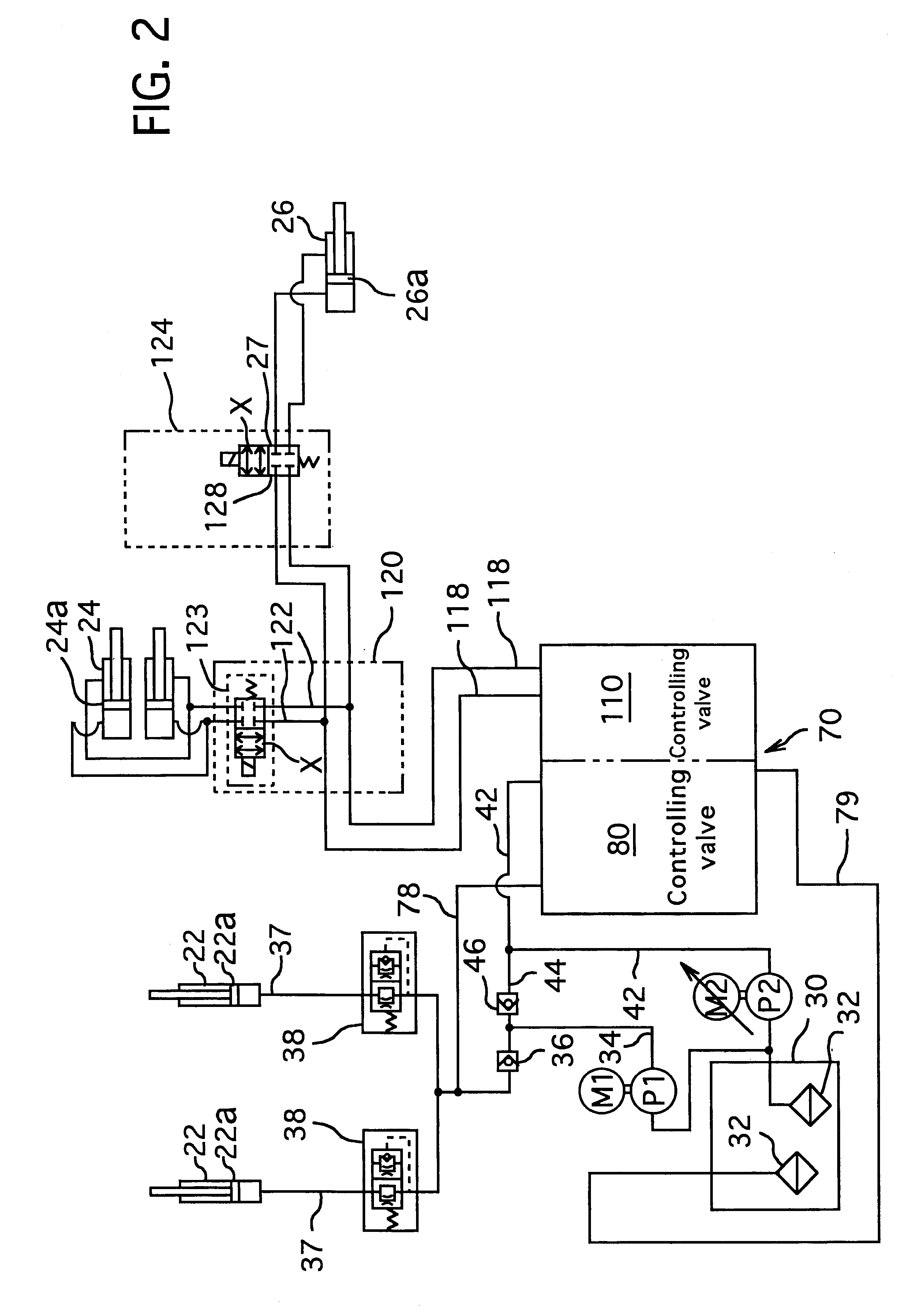

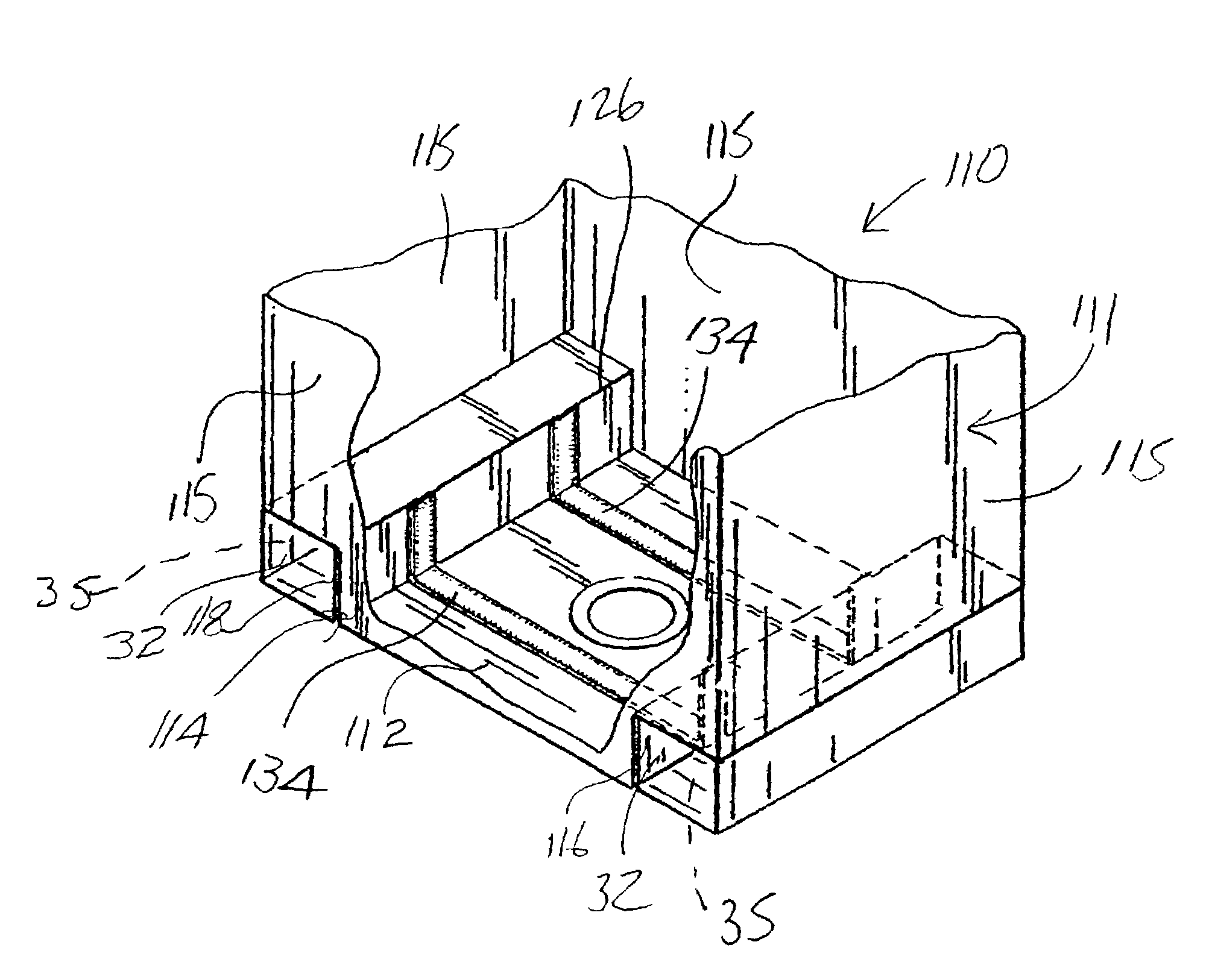

Hydraulic circuit for forklift

This invention relates to a hydraulic circuit for a forklift, and intends to lift a fork for lifting in high speed, or to inch the fork little by little, as occasion demands. In this hydraulic circuit, a first electric motor for driving a first electric motor disposed on a first route extending from a tank to a lift cylinder is on-off controlled. A check valve disposed on the first route downstream of the first hydraulic pump allows only an oil-flow from the oil tank to the lift cylinder. A second motor for driving a second electric motor disposed on a second route extending from a tank to a lift cylinder is PMW-controlled. A flow controlling valve is disposed on the second route downstream of the second hydraulic pump and including an electro-magnetic valve operated associating with the PMW-controlling of said second electric motor. A separating element hydraulically separates the check valve and the electro-magnetic valve of the flow controlling valve.

Owner:TOYOTA IND CORP

Bulk bag with support system

InactiveUS6935500B1Eliminate overlapping costLower performance requirementsBagsLarge containersSupporting systemEngineering

An improved fabric bulk bag with pallet combination, of the type having wall portions, a top portion, and a floor portion, all defining a space for storing bulk therein, and in a first embodiment providing a pair of channels, substantially parallel in relation, secured along the outer surface of the floor portion, each channel having two open ends; a substantially elongated rigid support member insertable into each channel, for receiving the tines of a forklift, while providing a stable pallet foundation for the bag when the bag is positioned atop another filled bag. A bulk containing portion of the floor of the bag extending between the two support members when the bag has sufficient bulk, so that the portion filled with bulk defines a continuous support surface between the two support members and together define a continuous support across the floor of the bag.

Owner:AMERIGLOBE

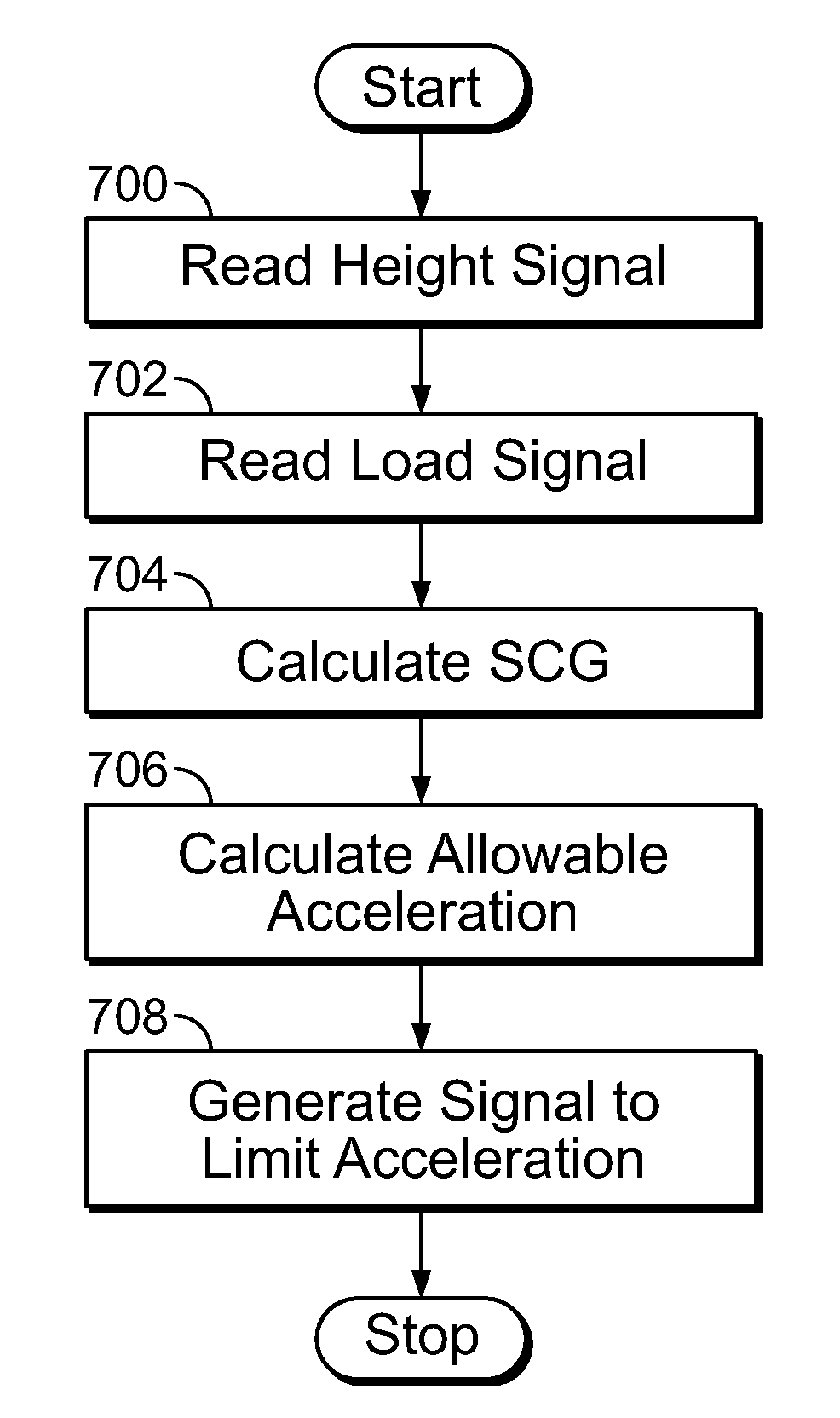

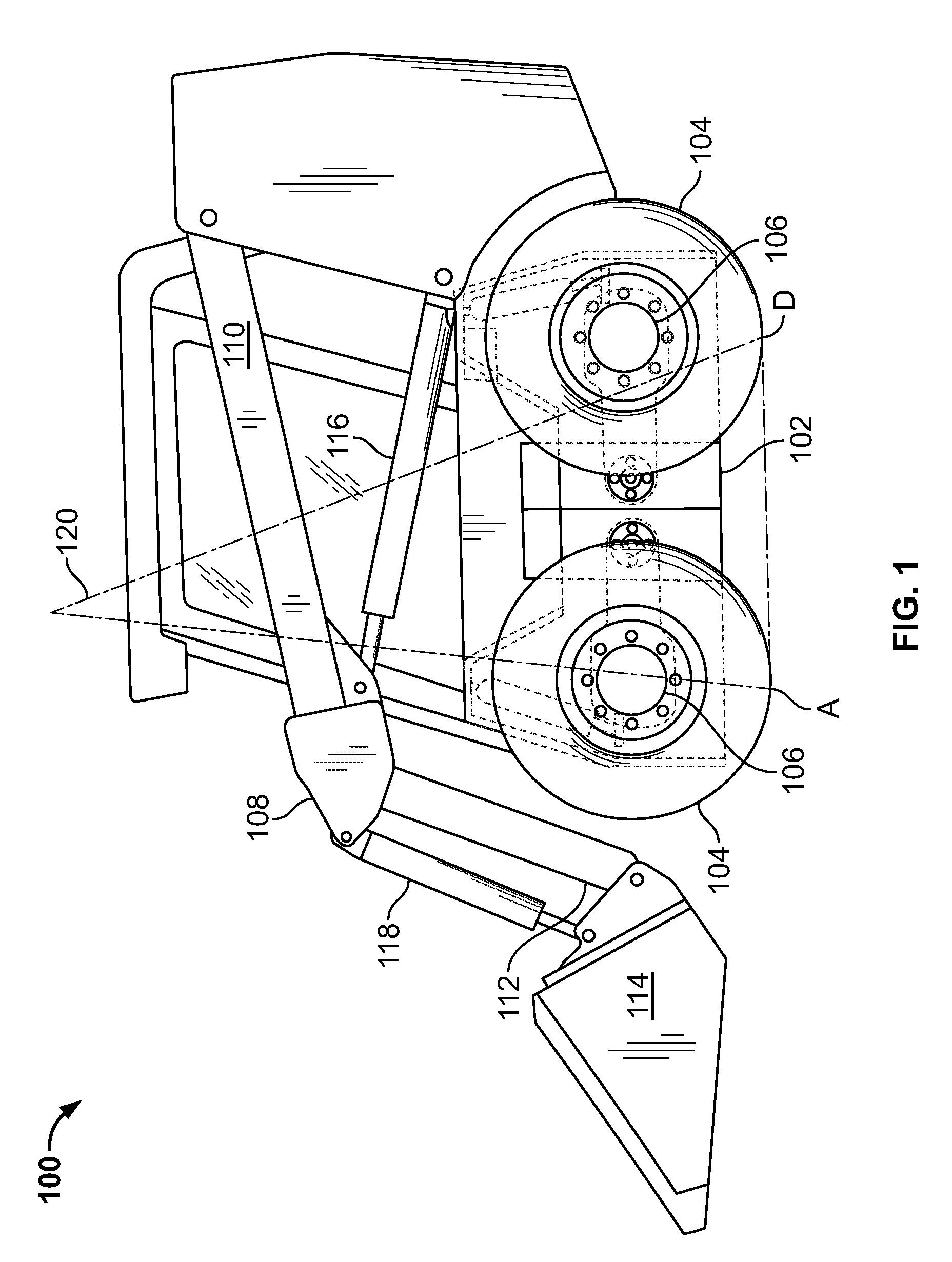

Acceleration control for vehicles having a loader arm

InactiveUS20100204891A1Safety devices for lifting equipmentsAnalogue computers for trafficControl systemLoading arm

A control system for a vehicle having a loader arm, such as a skid steer loader, telescopic handler, wheel loader, backhoe loader or forklift, reads a load height sensor, a load weight sensor; dynamically calculates the static center of gravity of the combined vehicle and load; calculates the acceleration necessary to cause the dynamic center of gravity of the combined vehicle and load to extend exterior of the vehicle's stability polygon; and limits the acceleration of the vehicle to less than the acceleration necessary to cause the dynamic center of gravity of the combined vehicle and load to extend exterior of the vehicle's stability polygon.

Owner:CNH IND AMERICA LLC

Pallet truck with calculated fork carriage height

A pallet truck including a controller that calculates the height of the fork carriage without the use of mechanical devices such as switches or sensors. A calculated carriage height is derived by adding the amount of time that a carriage is commanded to be raised and offsetting that by the amount of time that the carriage lower button is depressed. The calculated carriage height is essentially an accumulated lift time where the time that the carriage is lifting is a positive value and the time that the carriage is lowering is a negative value. When these values are combined, the result is the present calculated carriage height. The controller further monitors the calculated carriage height such that if the carriage is too close to the ground, the maximum speed of the pallet truck is limited to prevent damage to the forks or ground due to striking or scraping between them.

Owner:RAYMOND LTD

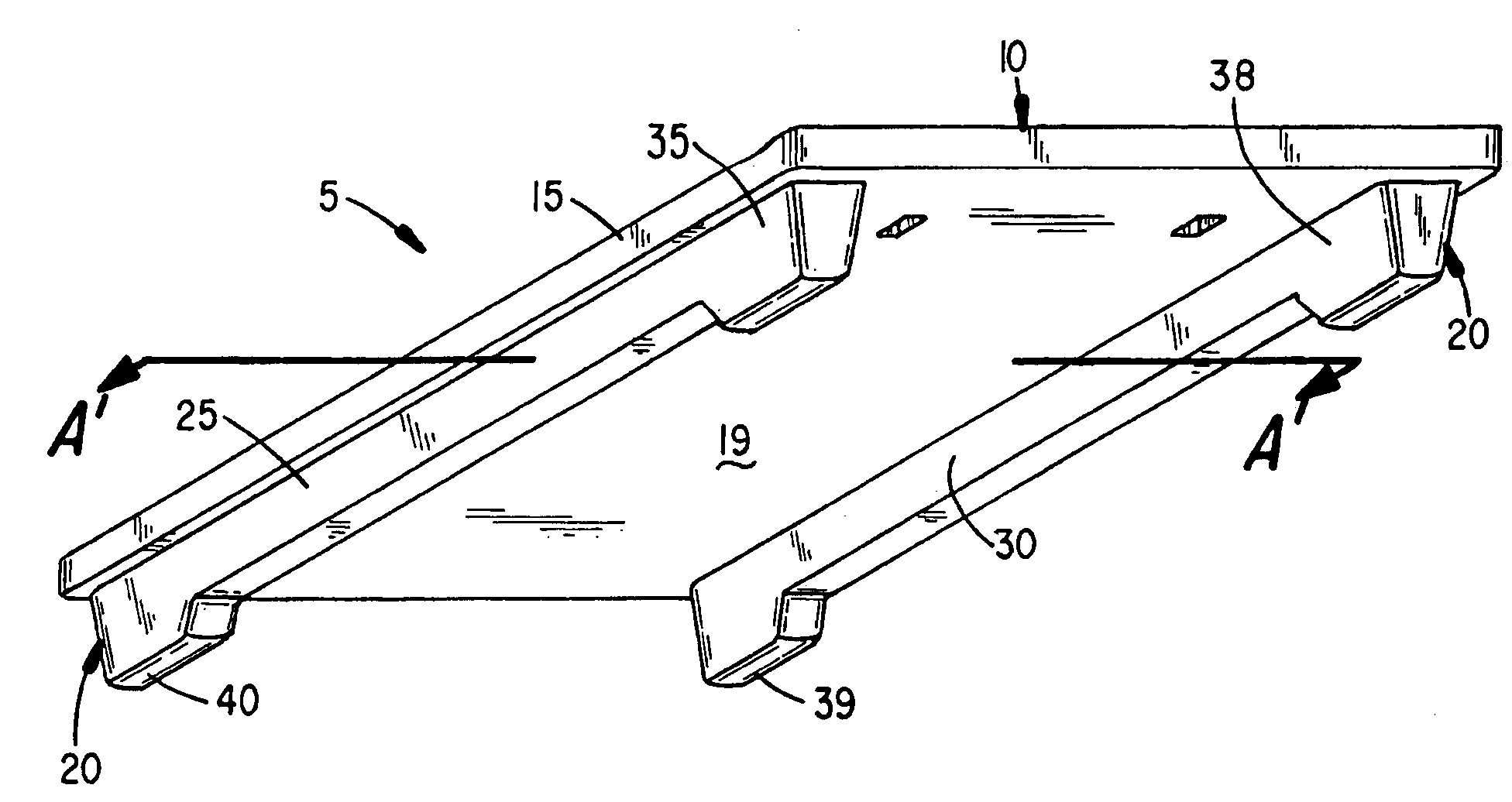

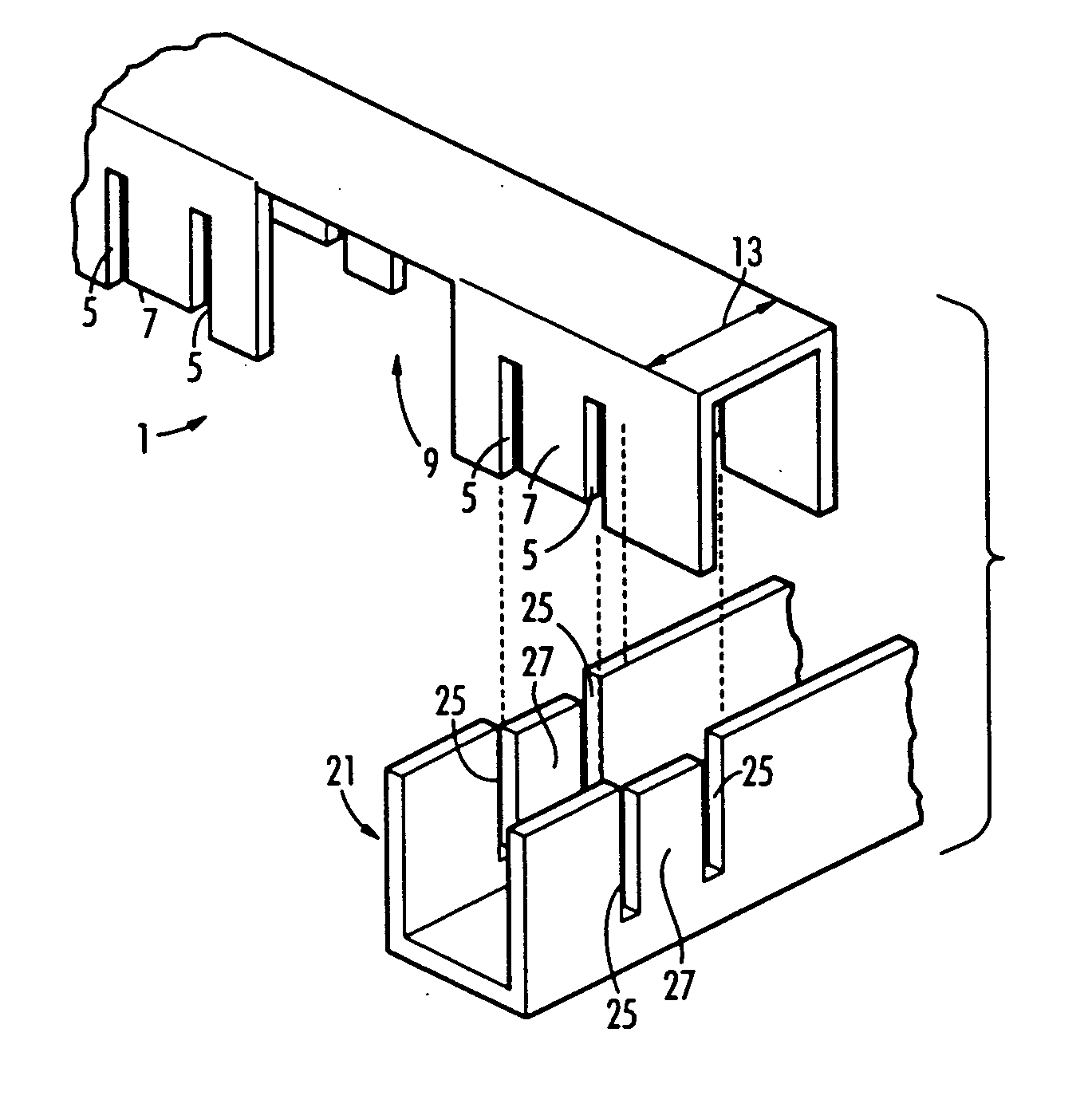

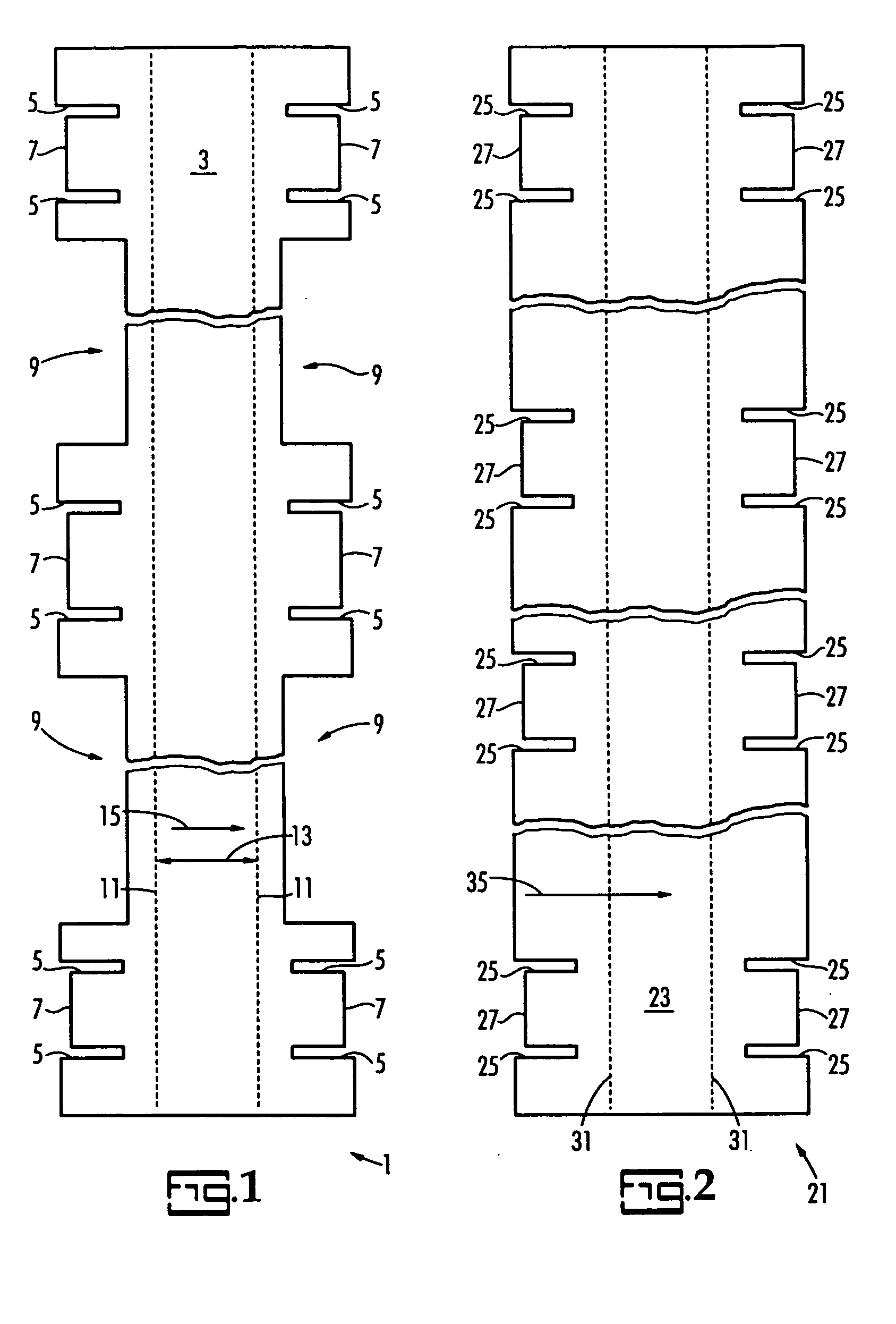

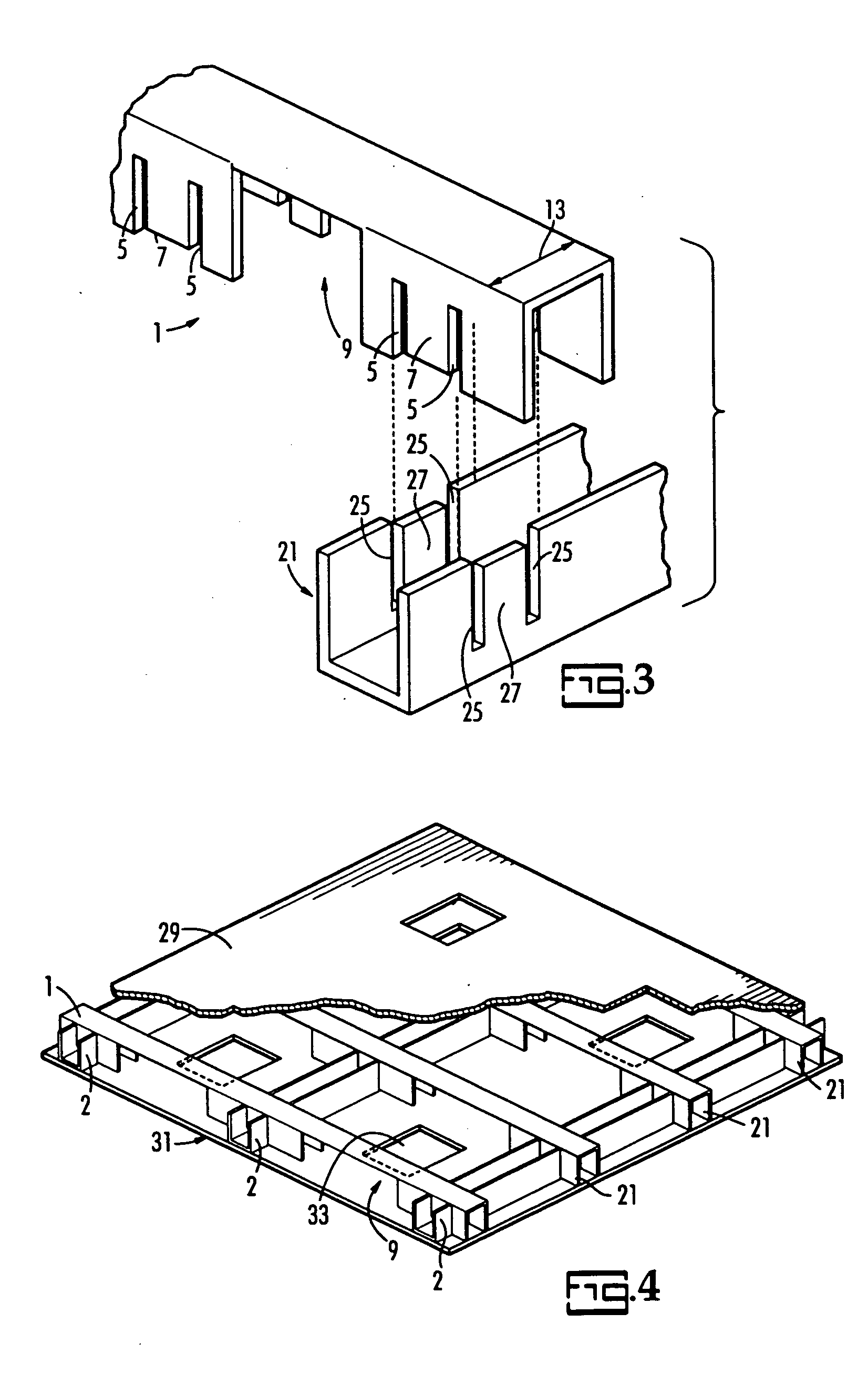

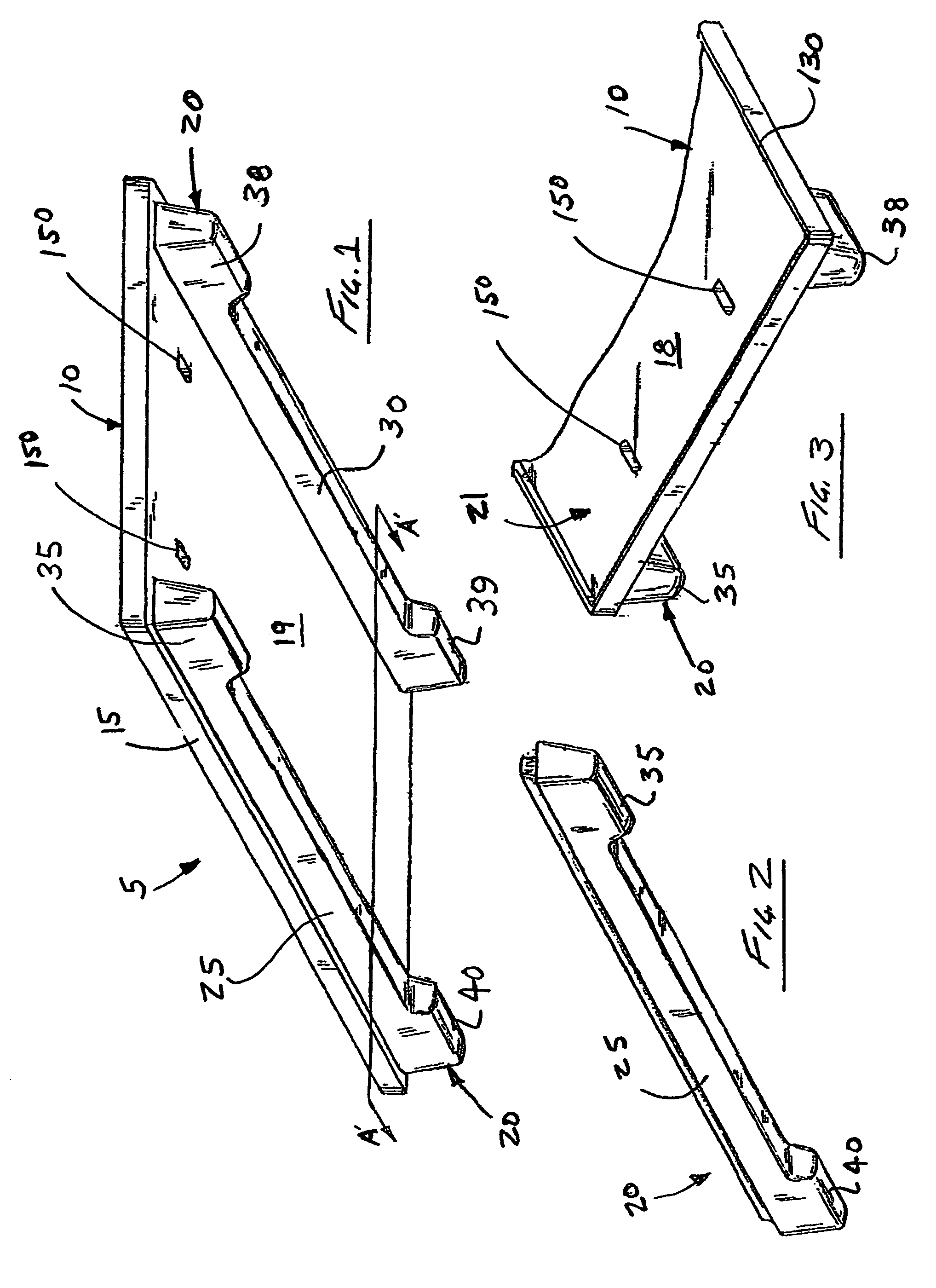

Twin sheet pallet

ActiveUS20060075939A1Prevent tippingFacilitates firm positive receiptRigid containersEngineeringPallet

A twin sheet plastic pallet comprising an upper plastic sheet and a lower plastic sheet selectively fused to the upper sheet. The lower sheet has a generally rectangular configuration, including sidewalls and end walls, and includes a plurality of separate parallel upwardly opening longitudinally extending U-shaped grooves extending from end to end of the sheet and a plurality of downwardly opening U-shaped grooves interspersed between the upwardly opening grooves and opening in the end walls of the sheet. The upper sheet defines a top wall, defining the platform surface of the pallet, and a plurality of upwardly opening U-shaped protrusions extending downwardly from the top wall and sized to nest within the upwardly opening grooves of the lower sheet, whereby with the upper sheet positioned over the lower sheet and the protrusions positioned in the upwardly opening grooves, the sheets may be fused together to form double thickness U-shaped wall structures at the interfaces of the protrusions and the upwardly opening grooves. The pallet further includes a pair of longitudinally extending metallic beams positioned between the upper and lower sheets, and laterally aligned slots are formed in the U-shaped wall structures to allow passage of the forks of a forklift truck.

Owner:SHUERT TECH

Unmanned storage system and warehouse output and input method

ActiveCN109987366AIncrease flexibilityEfficient transportStorage devicesComputer scienceOverall efficiency

The invention discloses an unmanned storage system and a warehouse output and input method. The problems that an existing system is complex in deployment, inconvenient to maintain, high in cost and the like are solved. In the embodiment of the invention of the system, two-layered channel supporting frames are arranged below storage racks, lower layers are used for allowing automatic guided vehicles to pass, upper layers are used for allowing normalized containers to be temporally cached or pass through, and interlayer supporting plates are through in the length direction or width directions ofthe whole storage racks. During implementation of goods warehouse output, forklift trucks move to the specified storage racks automatically and align the corresponding storage racks, the normalized containers on the storage racks are taken out with a goods collecting mechanism, then the forklift trucks descend to the upper layers of the supporting frames, and the containers are cached on the supporting plates; afterwards, the automatic guided vehicles move to the lower sides of the containers via the lower layers of the supporting frames to jack up the containers and further be disengaged from supporting pieces; and then the vehicles move to sorting sites via channels and roadways, and the warehouse input process is just on the contrary. The system can be deployed easily and is easy to maintain and low in cost, a large quantity of robots can execute concurrent operations through a scheduling system and the overall efficiency is high.

Owner:杭州大氚智能科技有限公司

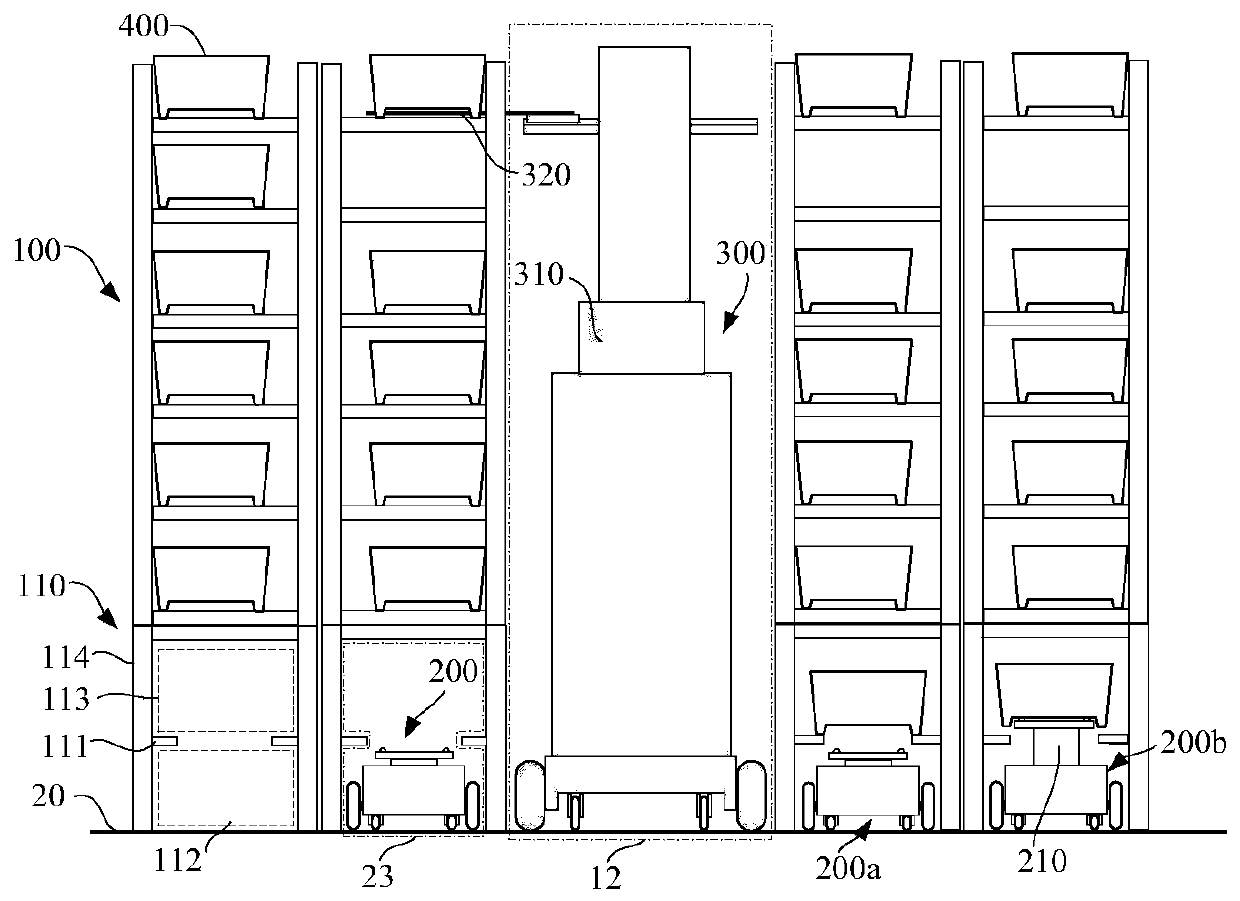

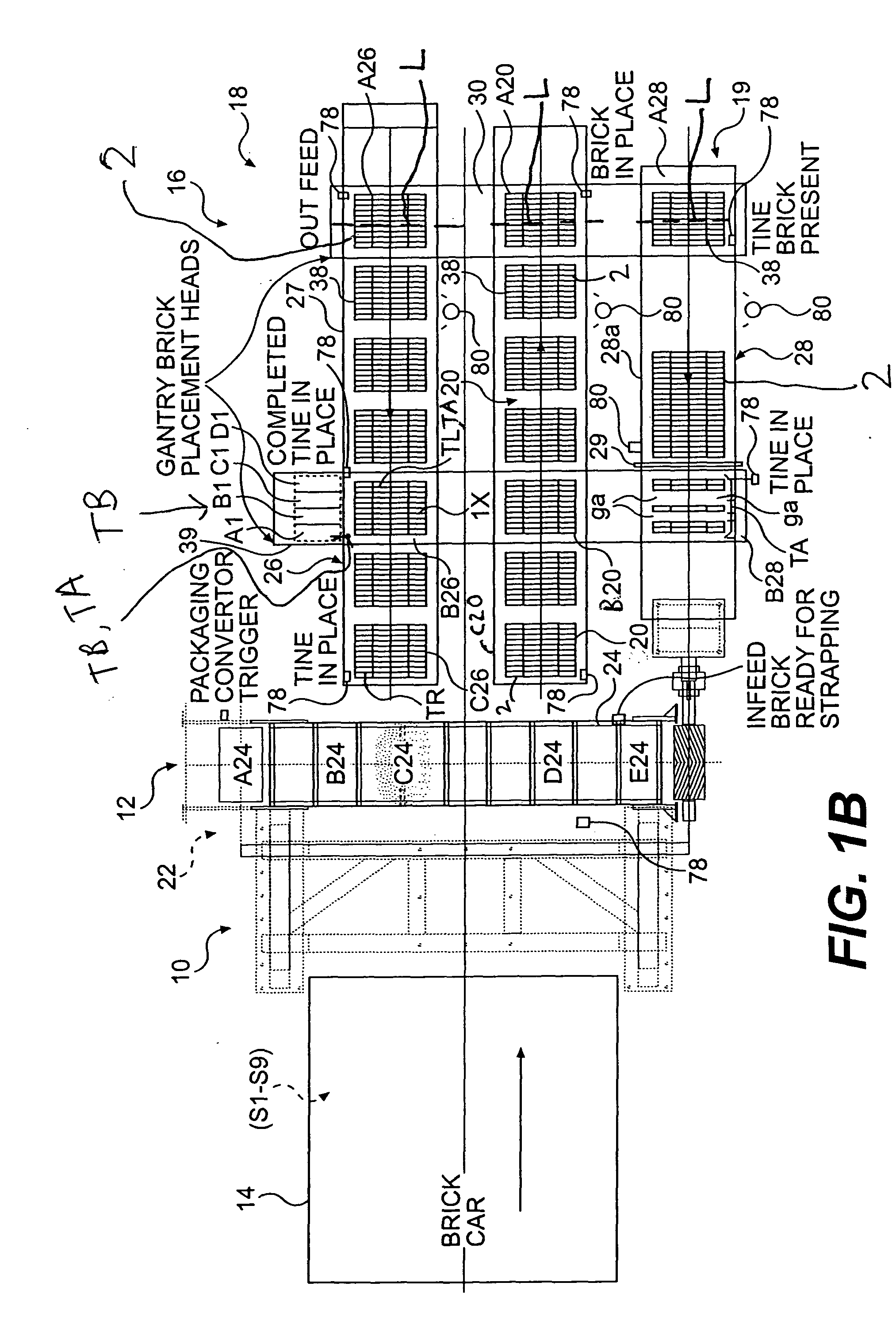

Apparatus and method for automatically unloading brick from kiln cars and preparation for shipment

InactiveUS20050056521A1Enabling repositioning of the bundlesConveyorsPackagingEngineeringMechanical engineering

Apparatus and methods for unloading and binding brick or other components include an infeed conveyor that delivers layers of brick to a transfer distribution carriage. The distribution carriage repositions the brick layers on either an outfeed conveyor or a tine conveyor. The layers of bricks carried by the outfeed conveyor are moved to where a tine layer is positioned on their upper surface. The tine conveyor divides the bricks into an arrangement of rows spaced apart to define openings for receiving a lifting or moving member, so that when the tine layer is positioned in a completed stack , enables movement of the stack by a forklift or other suitable moving means. Additional layer or layers are then positioned on the tine row on a packaging conveyor so that completed stacks are delivered to a package station that binds the stack of bricks or other components into an integrated structure.

Owner:GENERAL SHALE PRODS

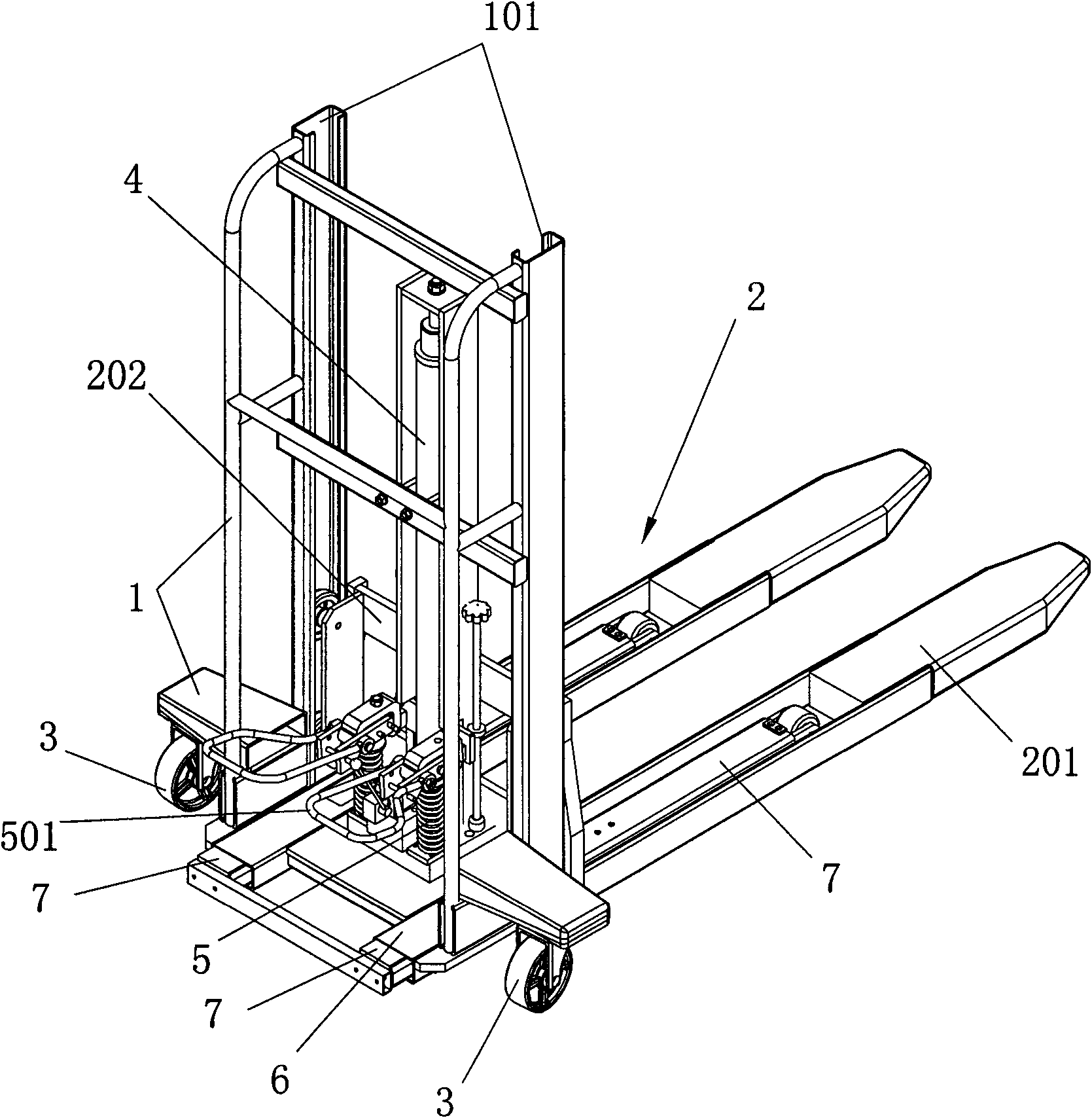

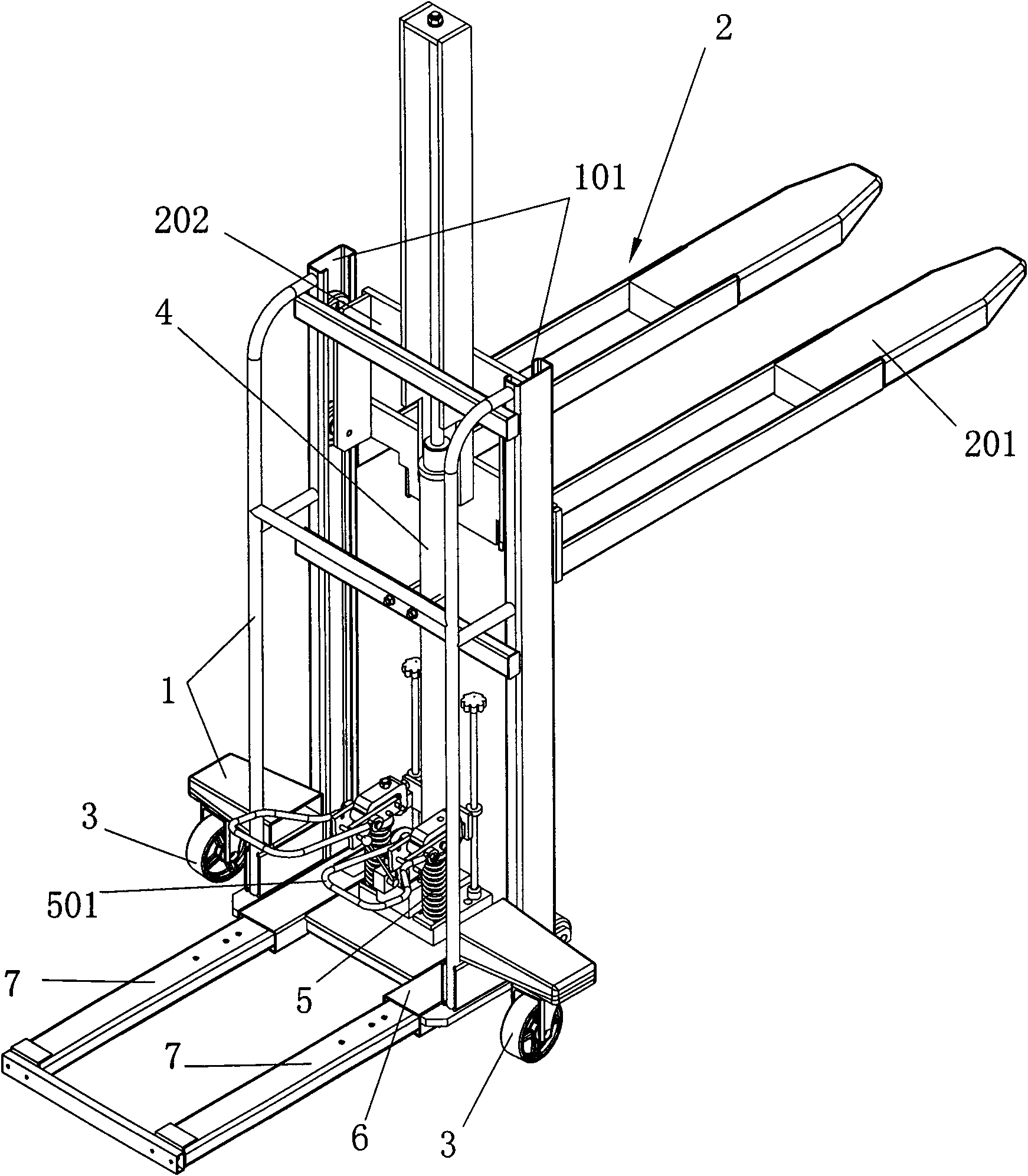

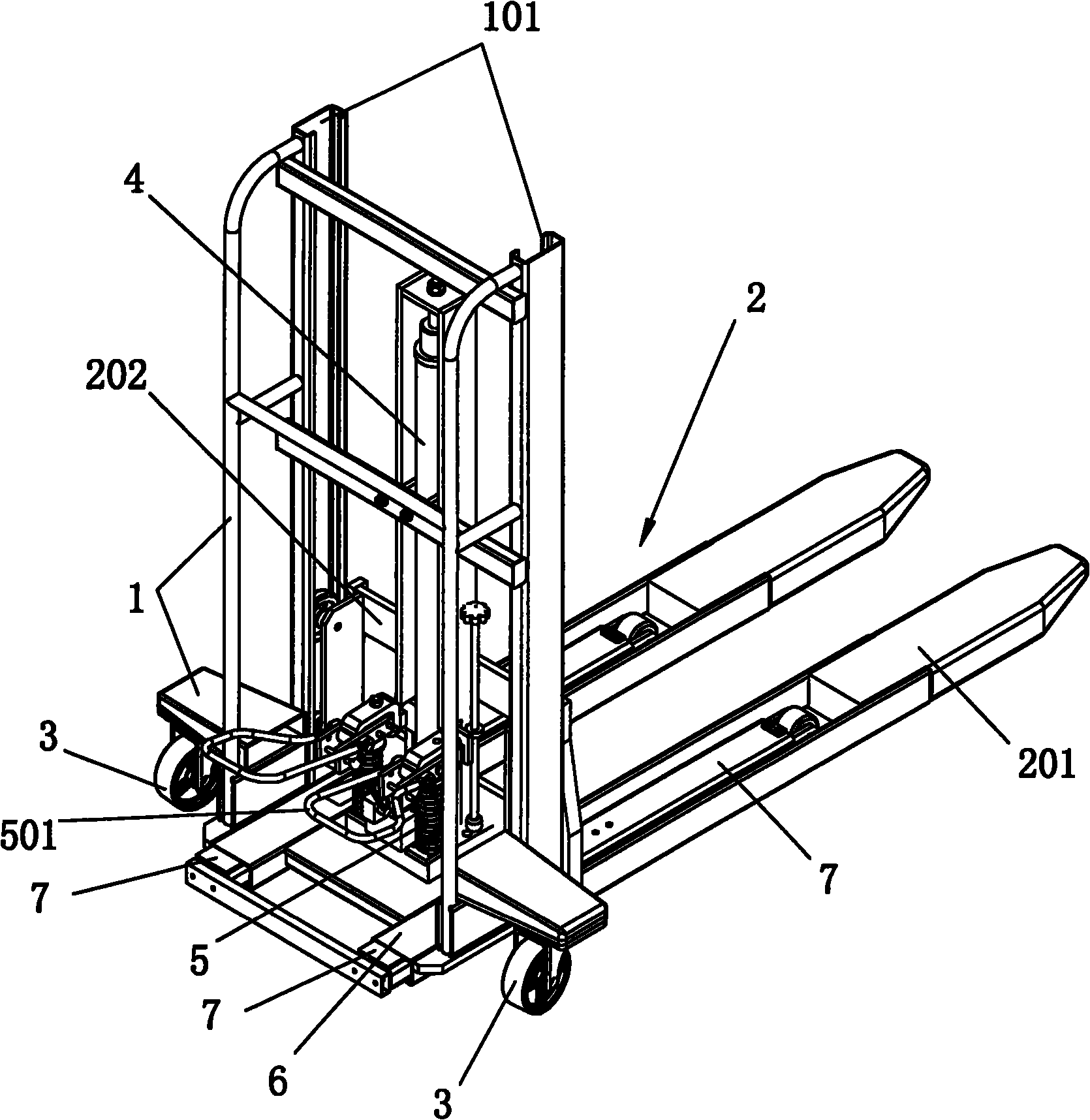

Manual self-elevating pallet truck

The invention discloses a manual self-elevating pallet truck, which comprises an upright post bracket and an elevating pallet fork. A manual hydraulic drive device is arranged on the upright post bracket, and comprises a hydraulic oil cylinder and a hydraulic oil pump, wherein the hydraulic oil pump is a manual oil pump and is provided with a drive handle which can be pressed by hands or pedaled; and one of a hydraulic cylinder body and a piston rod of a difunctional hydraulic cylinder which is the hydraulic oil cylinder is fixedly connected with the upright post bracket, and the other of the hydraulic cylinder body and the piston rod is in drive connection with a pallet fork sliding bracket. Caster stand sliding chutes are formed at the lower end of the upright post bracket, and telescopic caster stands are arranged in a matching way in the caster stand sliding chutes. Front and rear support casters are arranged at the front and rear ends of each telescopic caster stand. The manual self-elevating pallet truck provided by the invention has a simple structure and a small volume, works stably, and is well designed and easy to operate and maintain and difficult to fail when working.

Owner:上海海资国际贸易有限公司

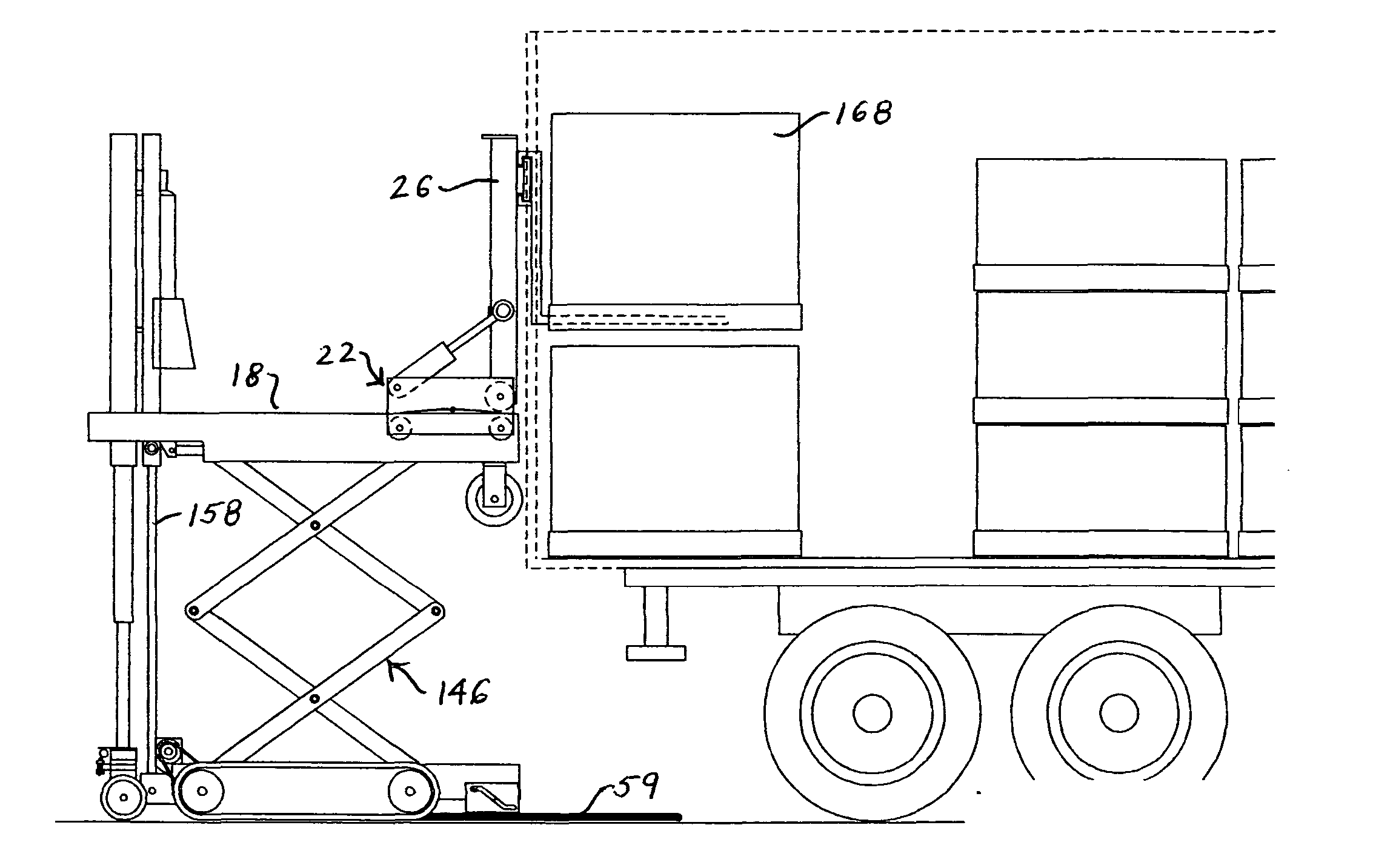

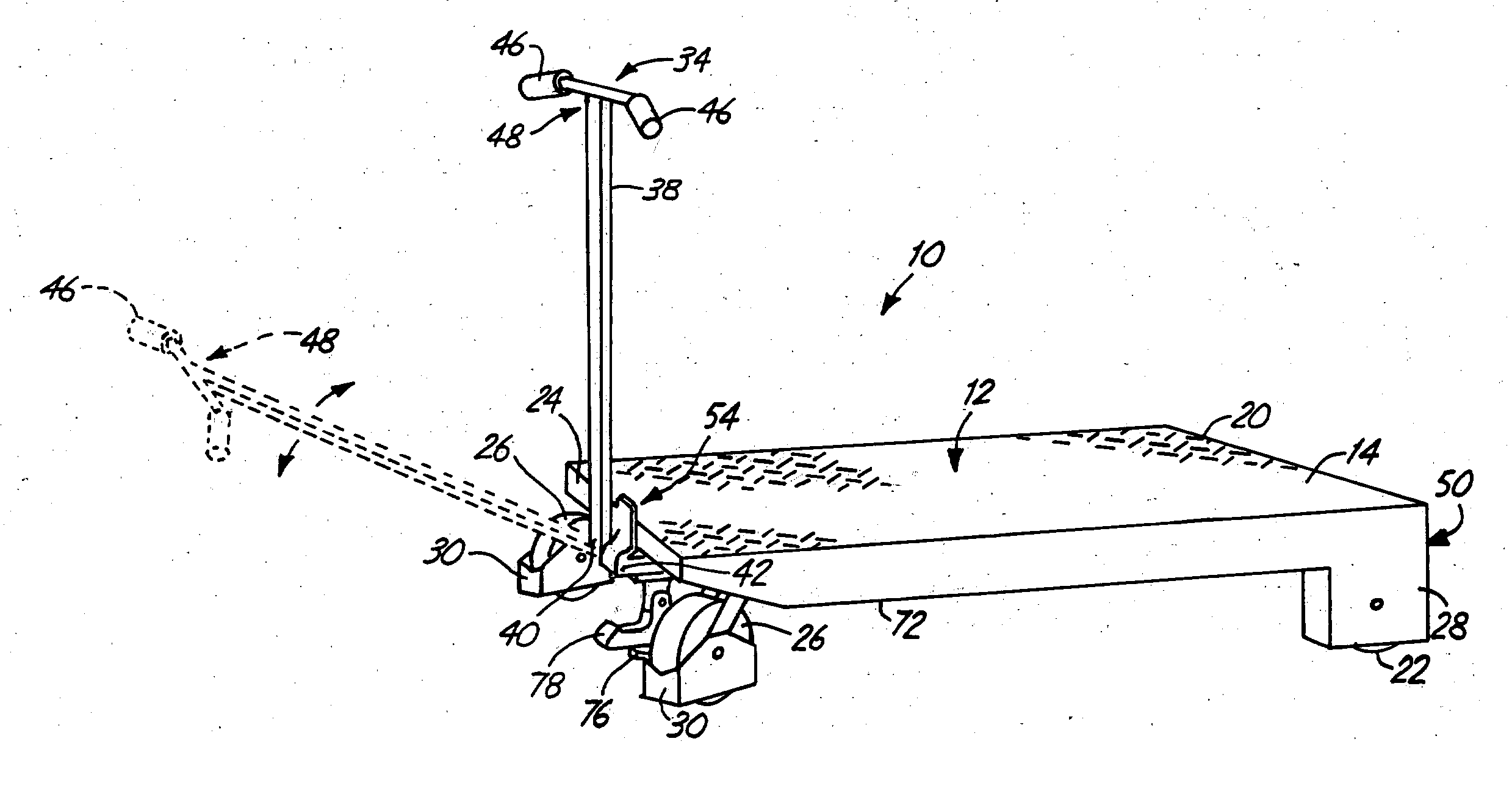

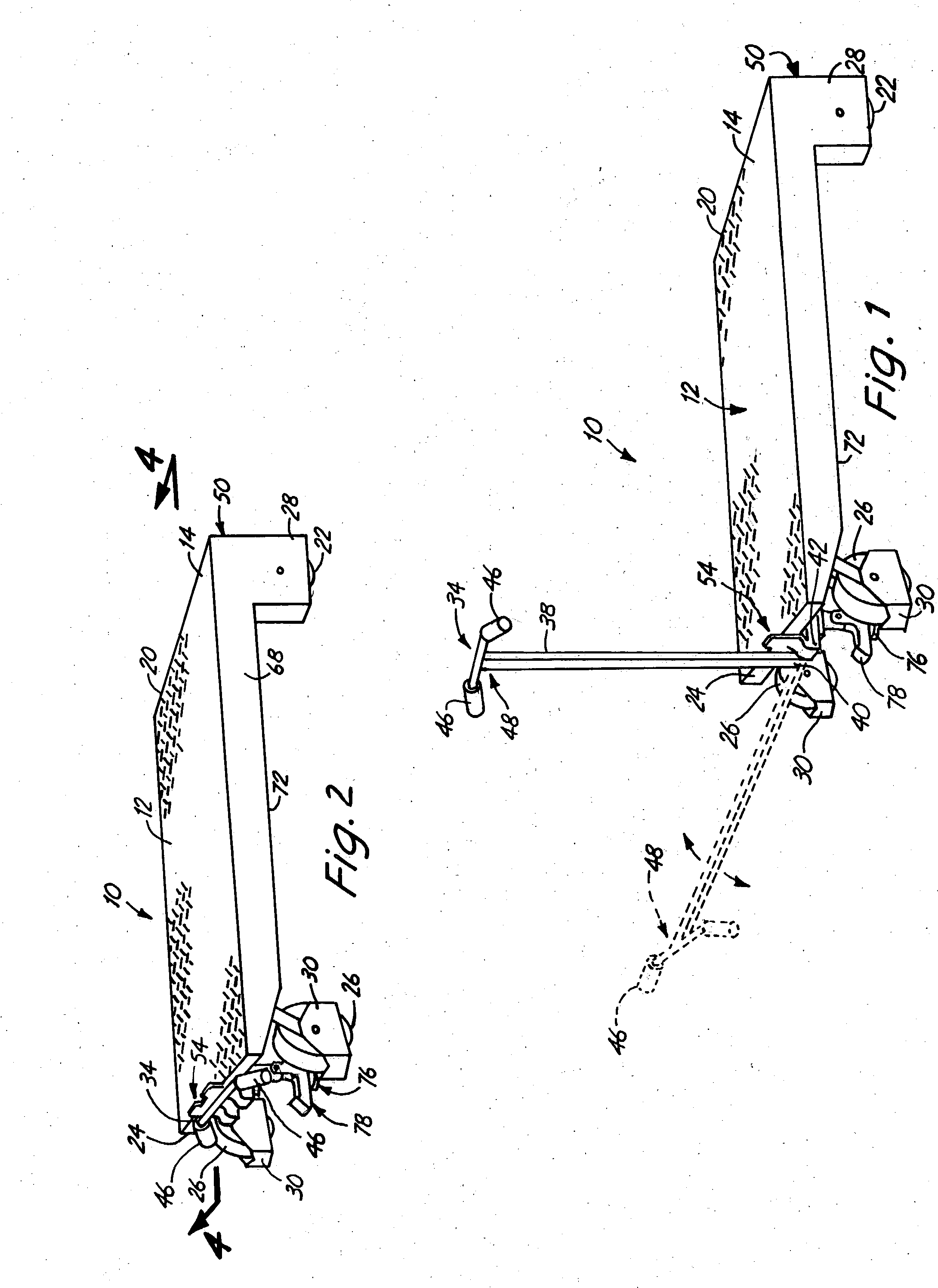

Forklift with stabilizing forks

A forklift that can move itself and loads between two heights uses multiple sets of forks to stabilize the forklift while raising and lowering loads. A conventional set of pallet forks is mounted on a forward and rearward horizontally moveable chassis. Upper stabilizing forks are selectively extended forward from the forklift chassis to rest on a surface located below the load being moved. Lower stabilizing forks extend downward and forward from the bottom of the forklift for additional stability. A set of extendable front wheels extends forward to stabilize the forklift when moving the forklift between two heights. The pallet forks are mounted on a deck that can be raised and lowered. There are two independent drive systems that move the forklift depending on whether the main drive system is on the ground or elevated. The entire forklift can be remote controlled.

Owner:EHMEN RONALD

Hand-truck apparatus

InactiveUS20050002766A1Carriage/perambulator accessoriesHand carts with one axisEngineeringInfinite number

A hand-truck for supporting and transporting the load placed thereon includes a stowable handle. The stowable handle is positionable between a stowed position, a locked position and an infinite number of positions therebetween. The handle is accessible by a user at each position. The hand-truck can transport a load by hand and is accessible to be lifted by a forklift from any side.

Owner:GRAND STEER

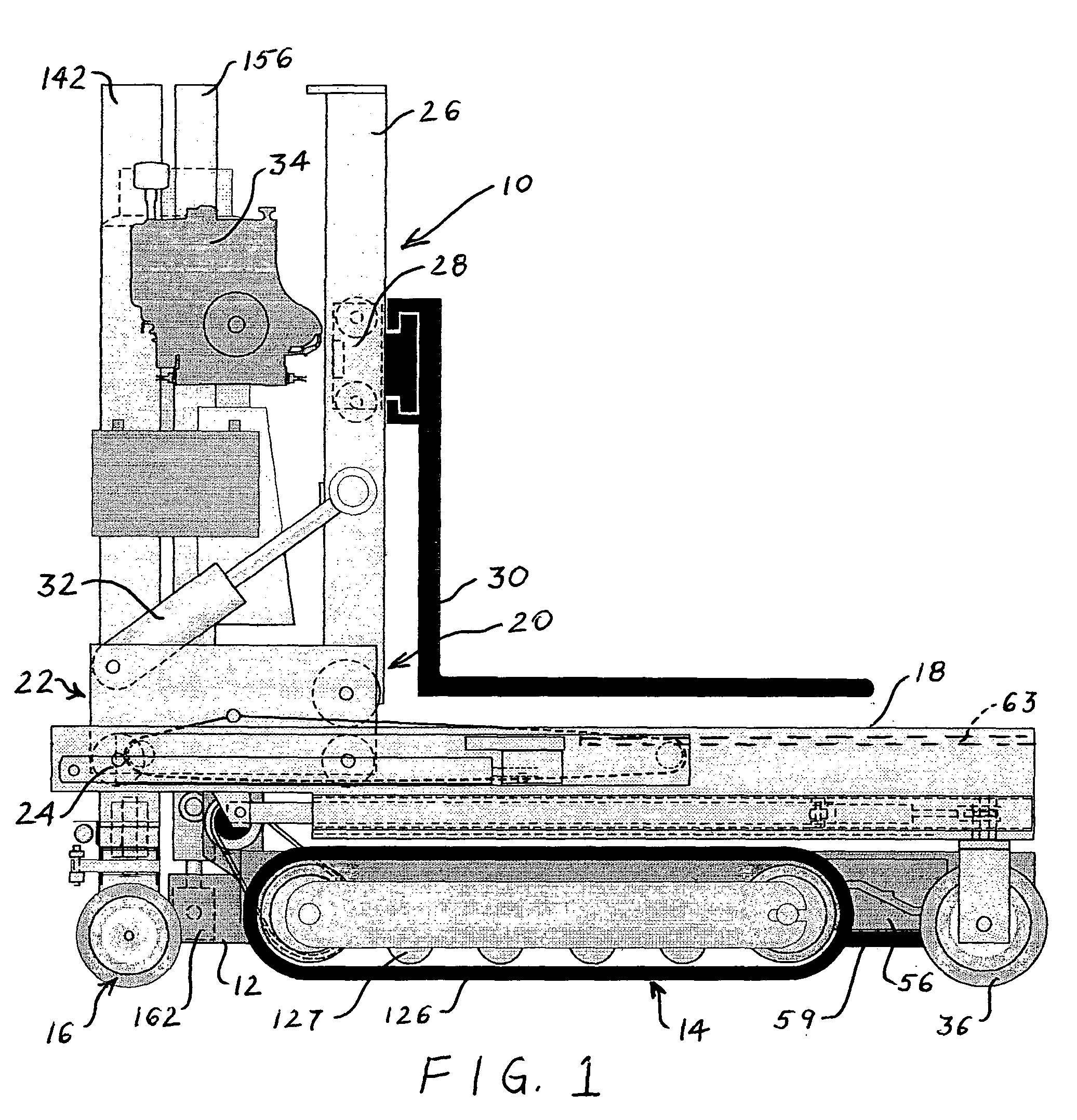

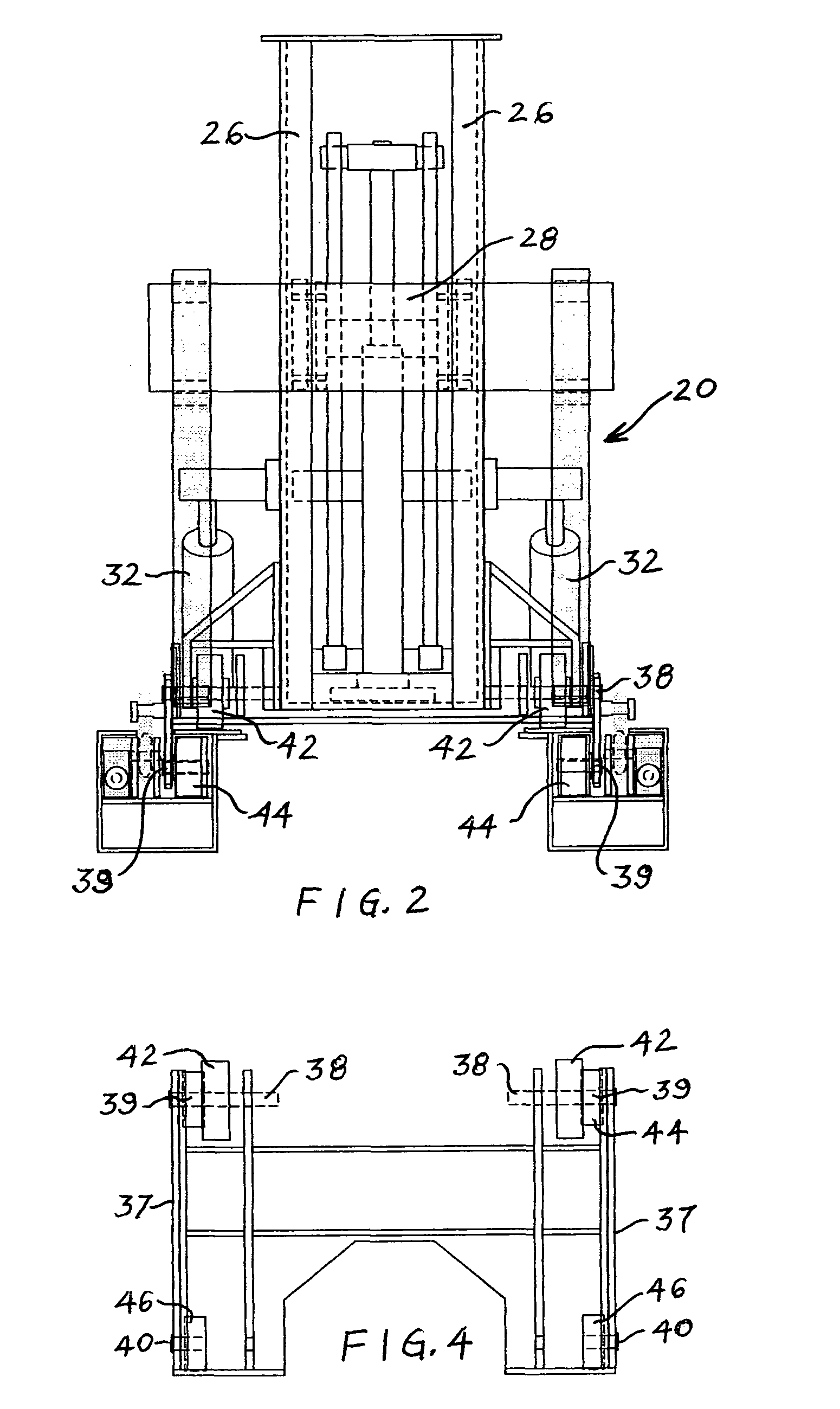

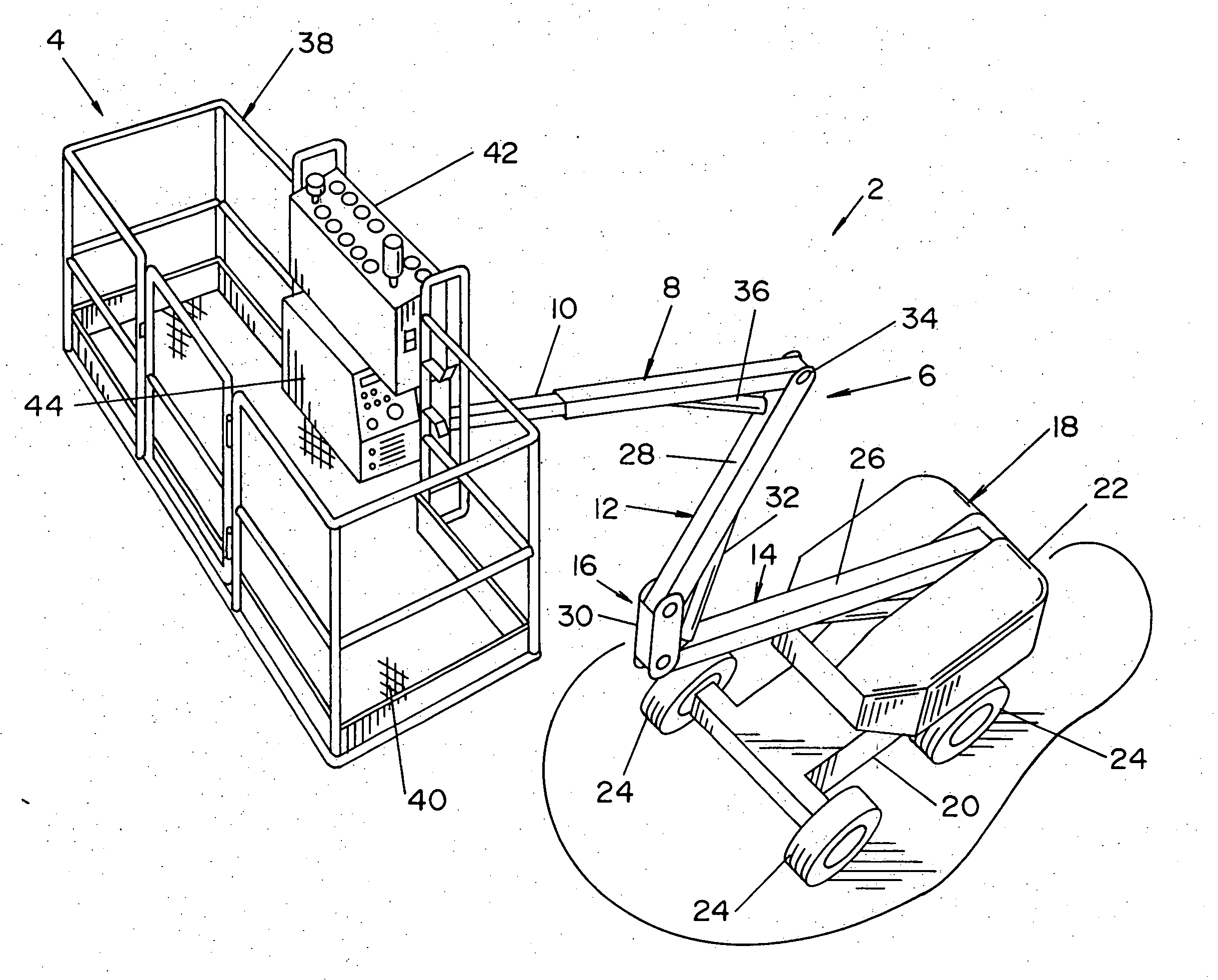

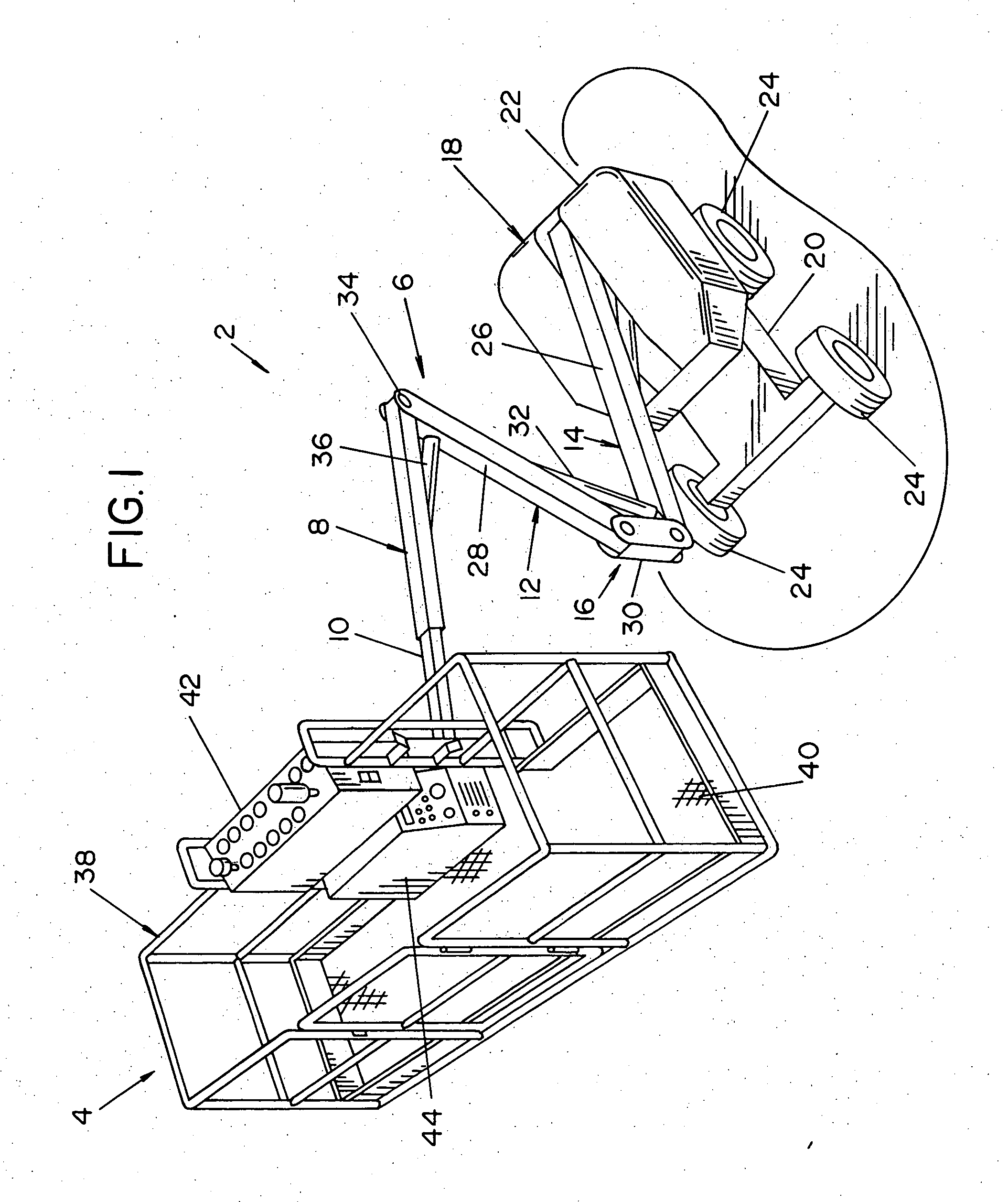

Extension lift truck modification

An apparatus for welding, including a lift mechanism for lifting a personnel platform attached to an end of the lift mechanism, a drive system for moving the apparatus, where the drive system includes a DC power source, a set of controls mounted on the platform for controlling the drive system and the lift mechanism, and an electric arc welding system for creating a DC welding arc between an electrode and a workpiece, where the welding system is mounted on the personnel platform and powered by the DC power source.

Owner:LINCOLN GLOBAL INC

Corrugated pallet

InactiveUS20050247240A1Improve carrying capacityHigh stackingsContainer decorationsLevel indicationsAdhesiveEngineering

A shipping pallet compatible with fork-lifts and pallet-trucks is made from stamped or die cut flat corrugated board. Stringer and cross-braces form an interlocking grid work to which a top and bottom flat sheet are attached by an adhesive. The pallet may be recycled as paper and not returned to the sender. Additional reinforcement structures may be added for heavier loads.

Owner:NELSON DUANE

Hand-truck apparatus having locking handle

InactiveUS7462009B2Carriage/perambulator accessoriesHand carts with one axisEngineeringInfinite number

Owner:GRAND STEER

Blow molded pallet with pre-formed inserts

InactiveUS6962115B2Weight increaseLow production costDomestic articlesRigid containersEngineeringPallet

A pallet system includes a pallet body. The pallet body is formed from a first, independently formed first portion and a second blow molded second upper portion insert molded to the first portion. The pallet body may have two to eight recesses for forklift truck fork access. The second upper portion has a generally rectangular surface for carrying loads. The portions may have anti-skid properties, for example, a knurled topside surface or rubber coated bottom. At least one foot is attached to the second upper portion by insert molding. At least one runner may be attached to each foot to form part of the first portion. At least one stringer is attached to each runner to add further stability to the pallet. The runners and feet have channels or protruding members to effectively mate with the second upper portion. The system may also have top cap and tie members to affix the cap to one or more pallet bodies as well as high-friction inserts to permit the pallet from sliding on a surface or objects from sliding on the pallet.

Owner:POLY FLEX INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com