Patents

Literature

77 results about "Backhoe loader" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

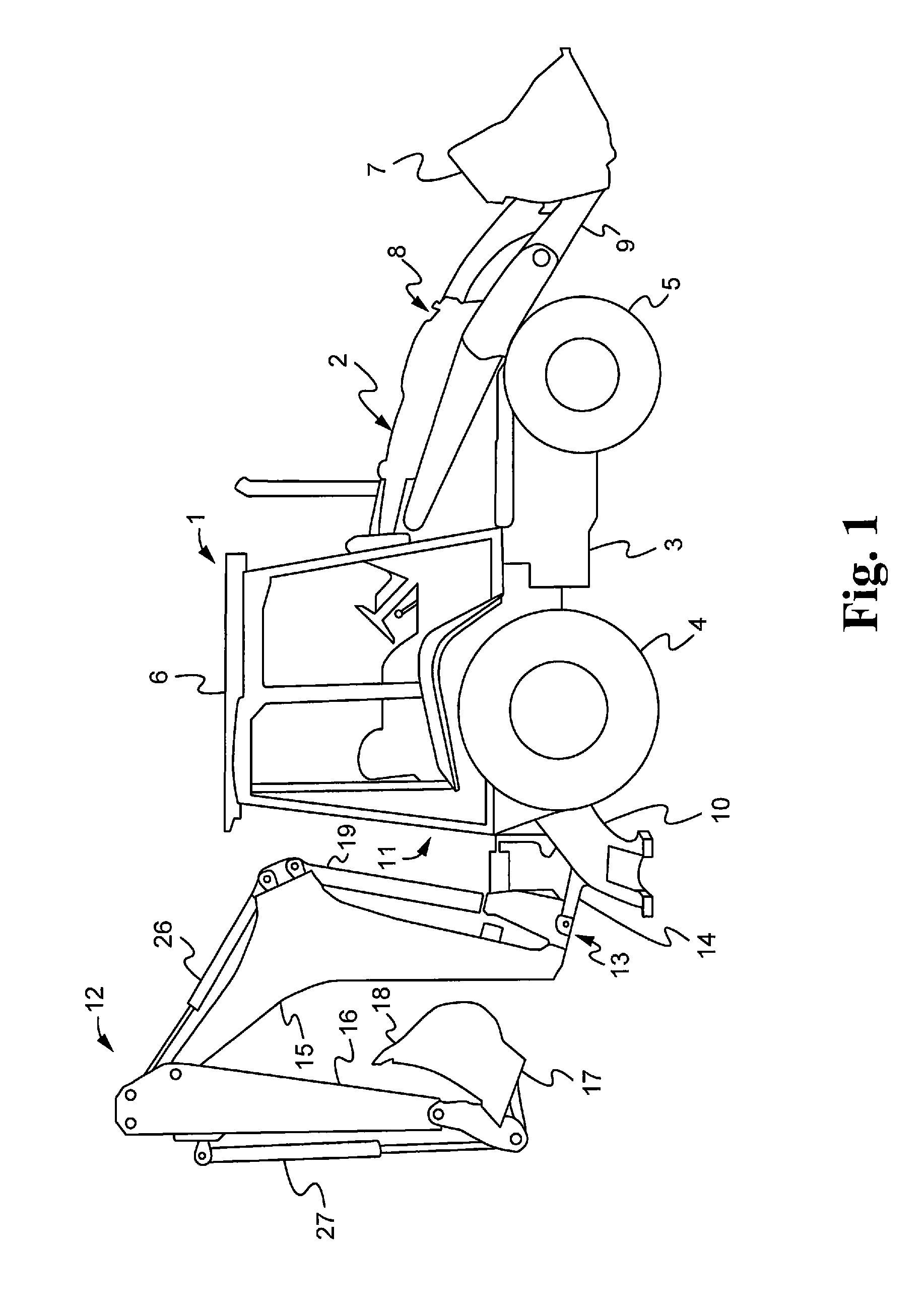

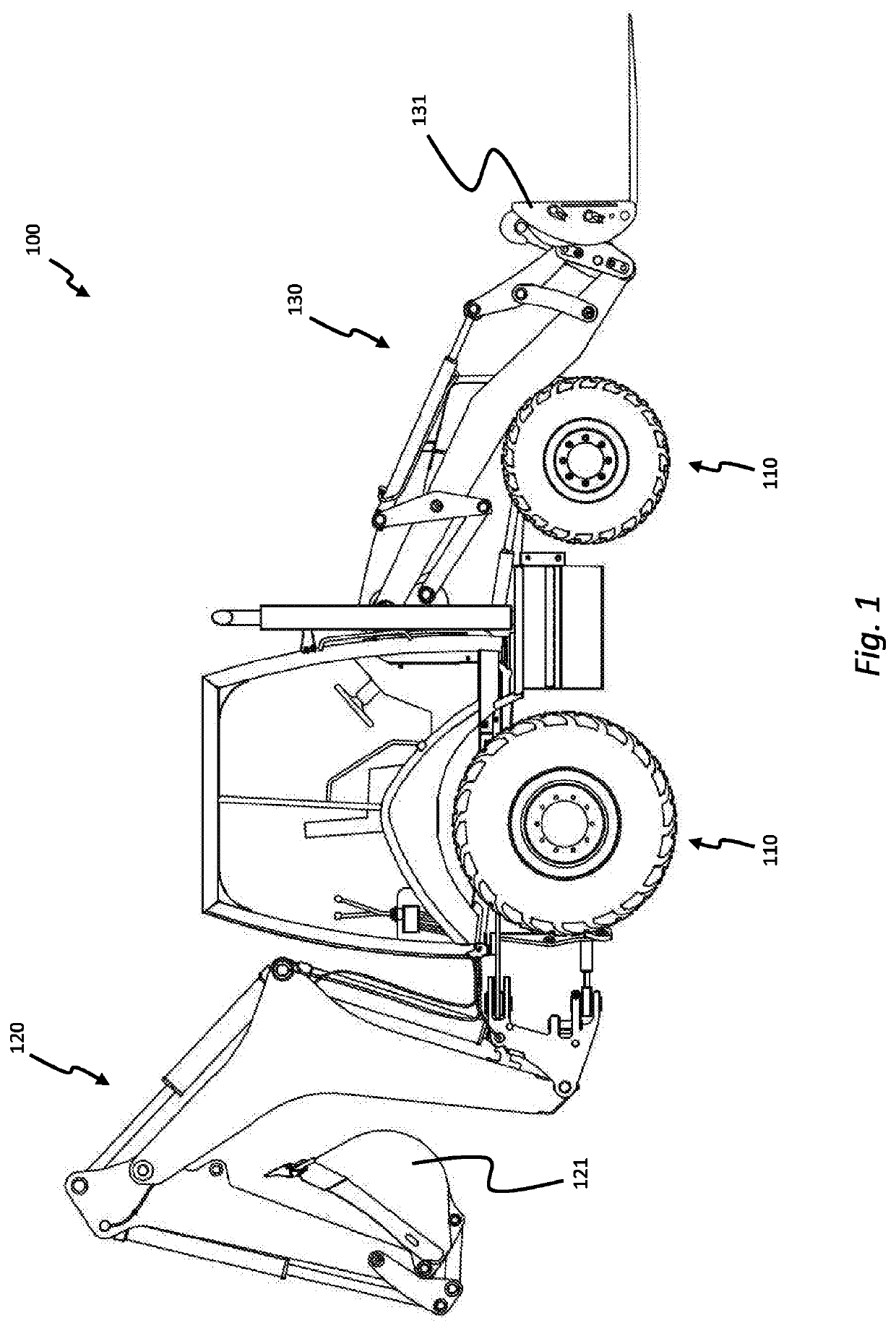

A backhoe loader, also called a loader backhoe, digger in layman's terms, or colloquially shortened to backhoe within the industry, is a heavy equipment vehicle that consists of a tractor-like unit fitted with a loader-style shovel/bucket on the front and a backhoe on the back. Due to its (relatively) small size and versatility, backhoe loaders are very common in urban engineering and small construction projects (such as building a small house, fixing urban roads, etc.) as well as developing countries. This type of machine is similar to and derived from what is now known as a TLB (Tractor-Loader-Backhoe), which is to say, an agricultural tractor fitted with a front loader and rear backhoe attachment.

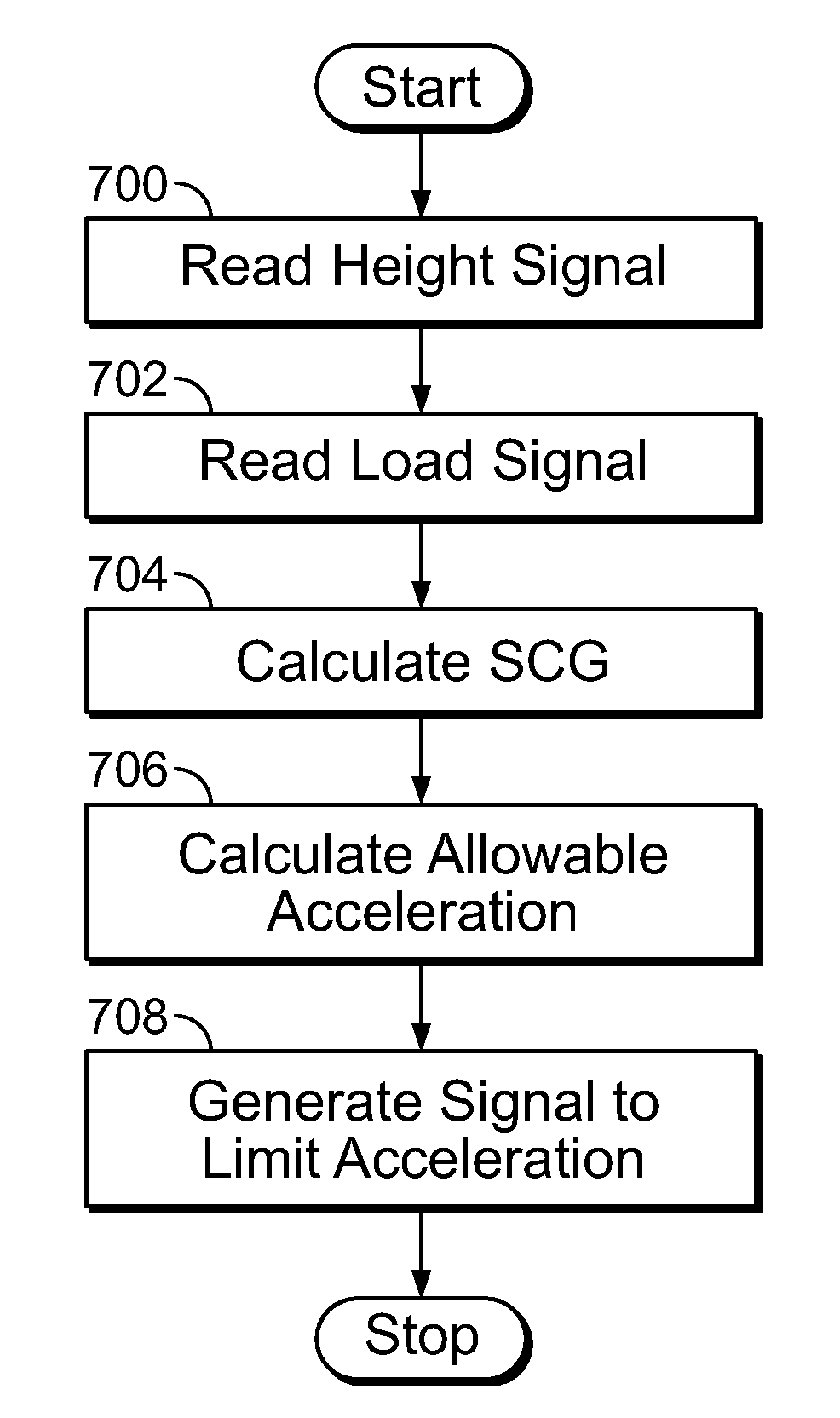

Acceleration control for vehicles having a loader arm

InactiveUS20100204891A1Safety devices for lifting equipmentsAnalogue computers for trafficControl systemLoading arm

A control system for a vehicle having a loader arm, such as a skid steer loader, telescopic handler, wheel loader, backhoe loader or forklift, reads a load height sensor, a load weight sensor; dynamically calculates the static center of gravity of the combined vehicle and load; calculates the acceleration necessary to cause the dynamic center of gravity of the combined vehicle and load to extend exterior of the vehicle's stability polygon; and limits the acceleration of the vehicle to less than the acceleration necessary to cause the dynamic center of gravity of the combined vehicle and load to extend exterior of the vehicle's stability polygon.

Owner:CNH IND AMERICA LLC

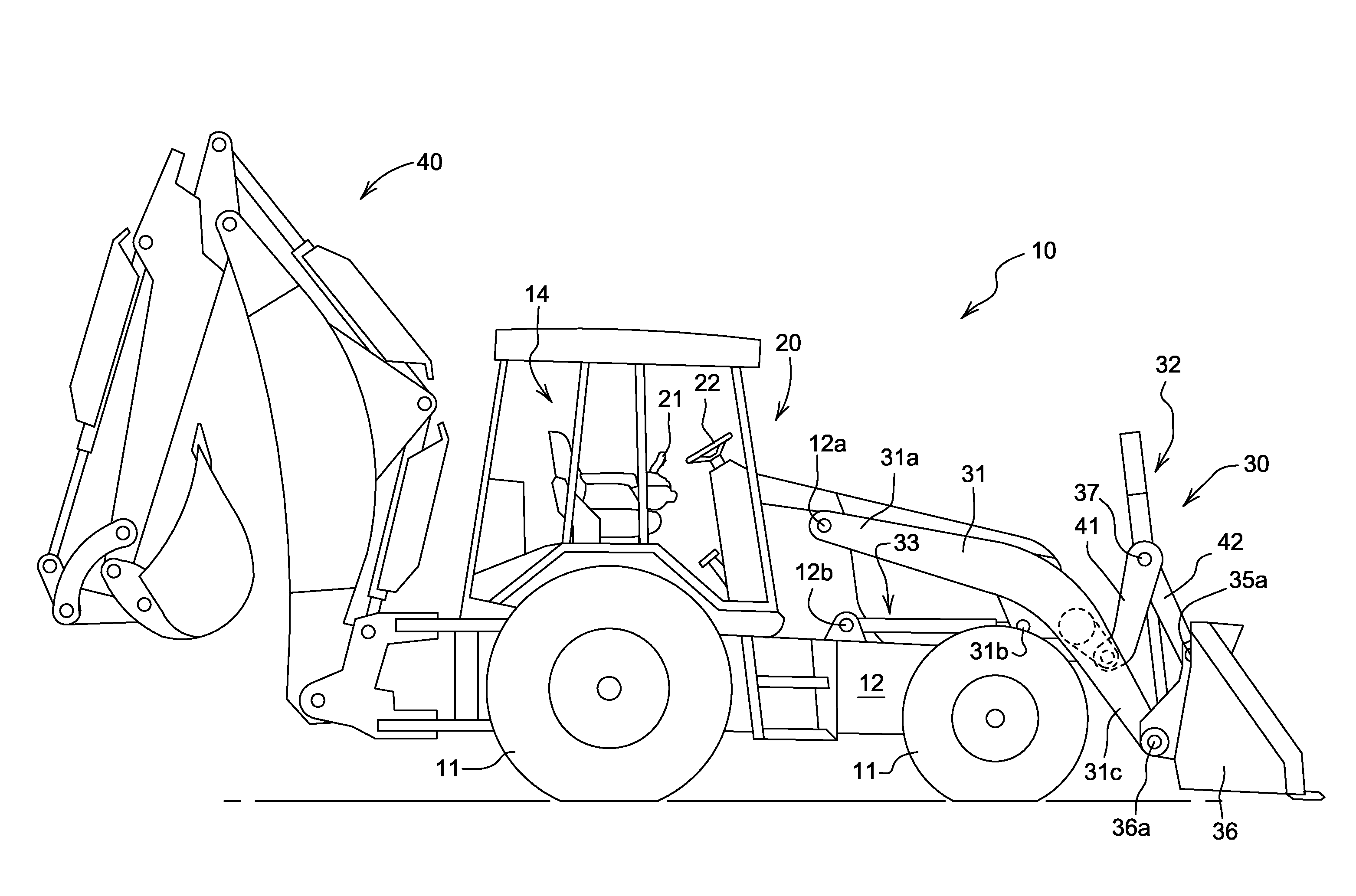

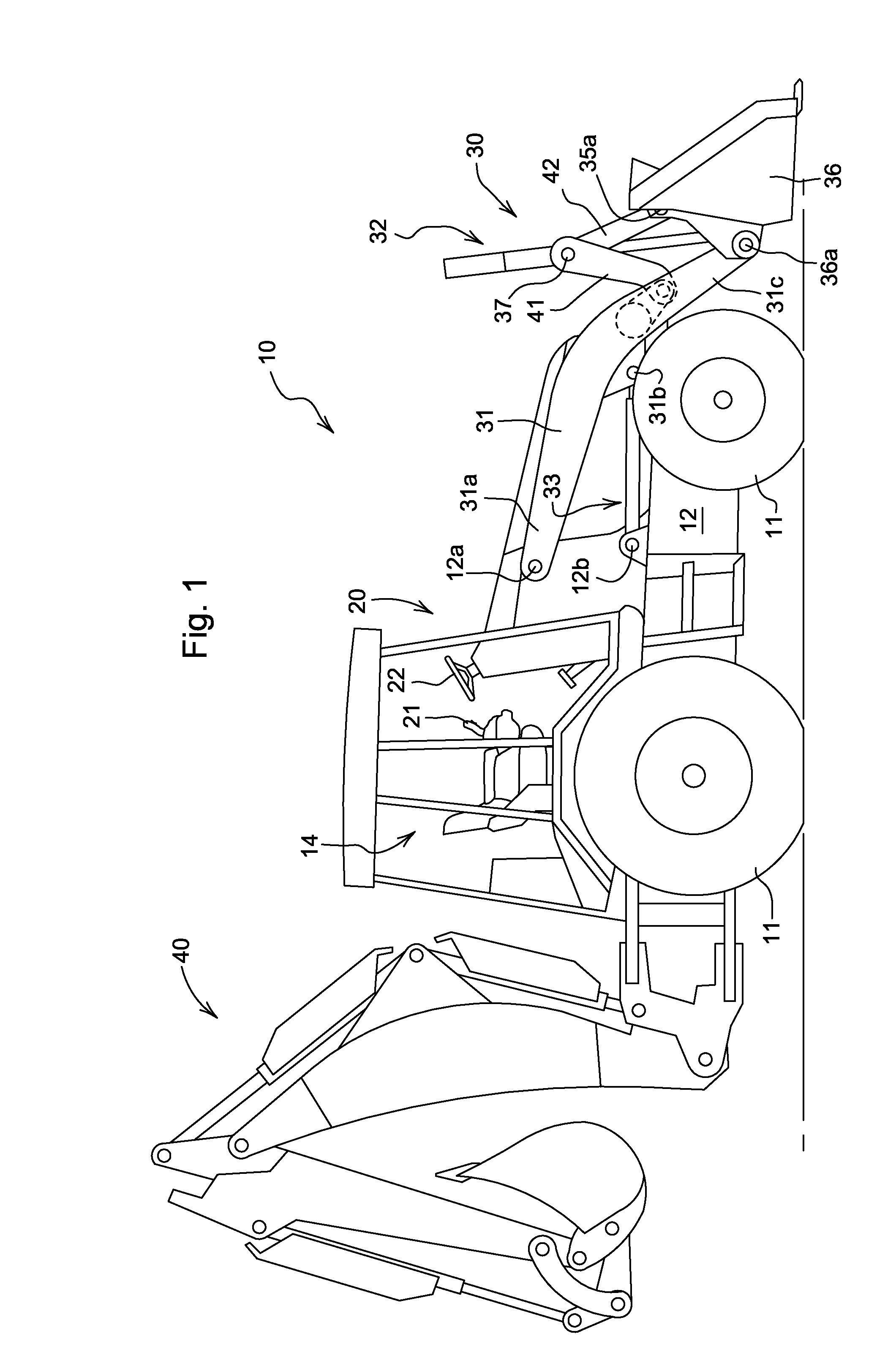

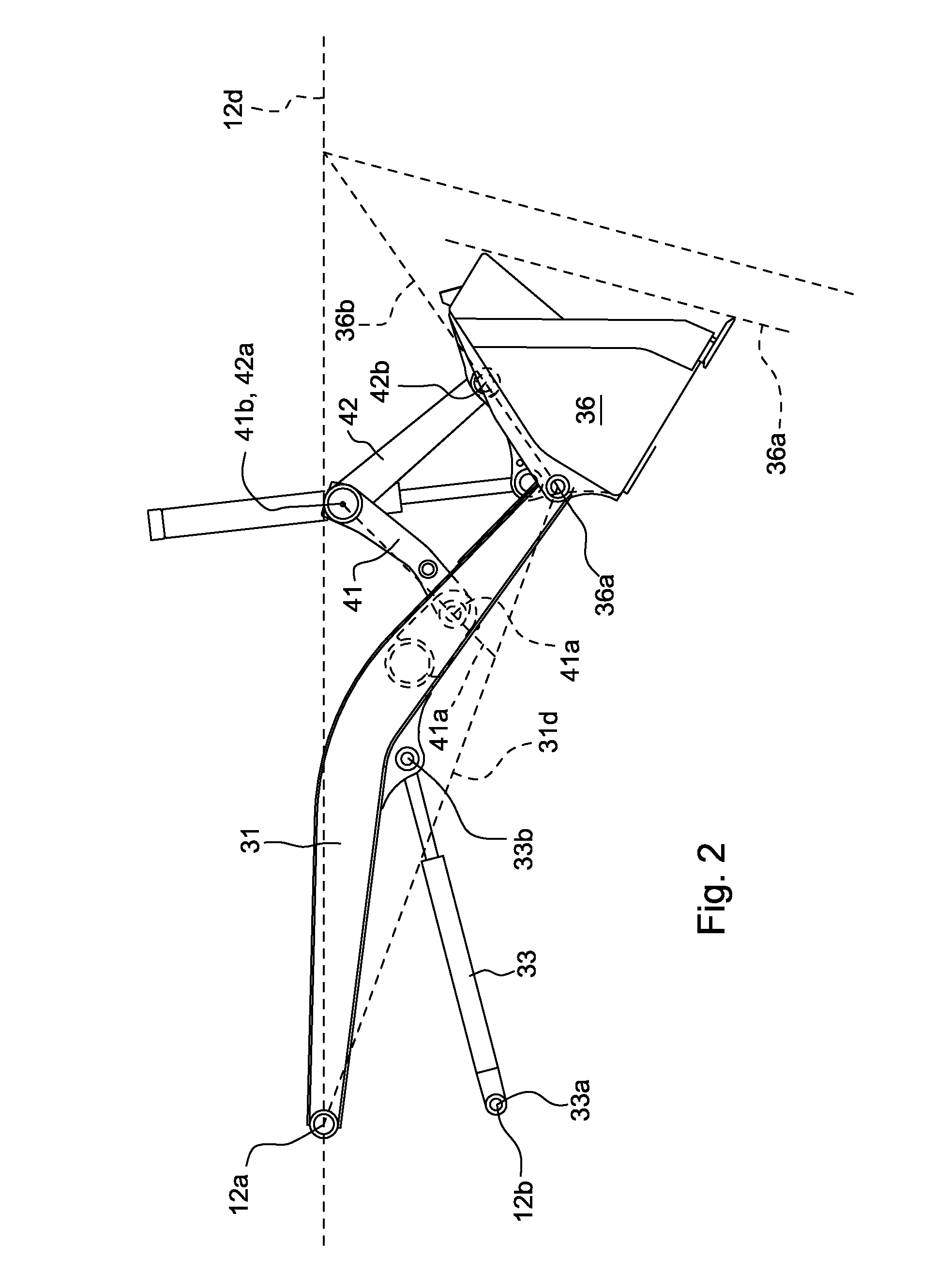

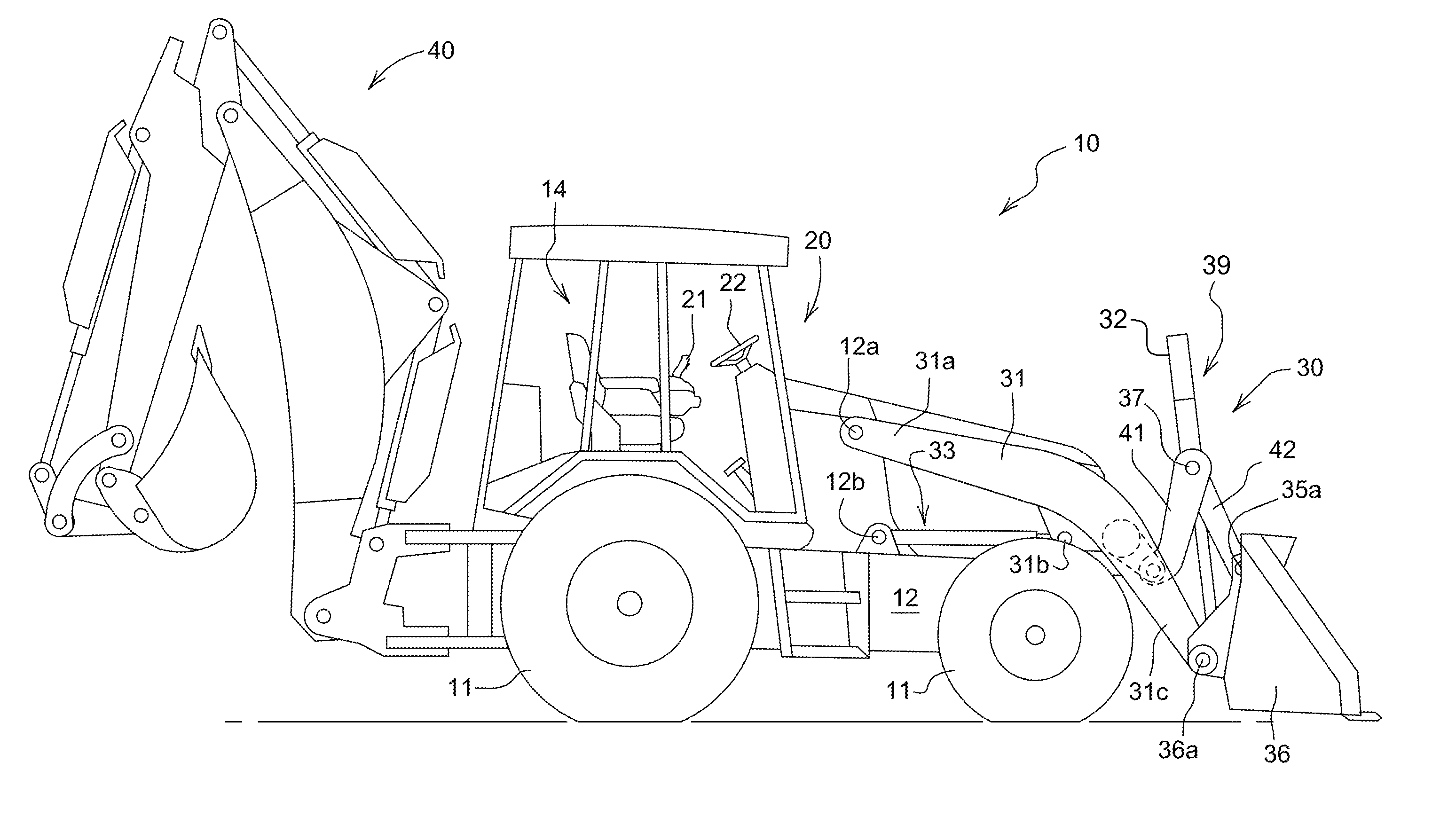

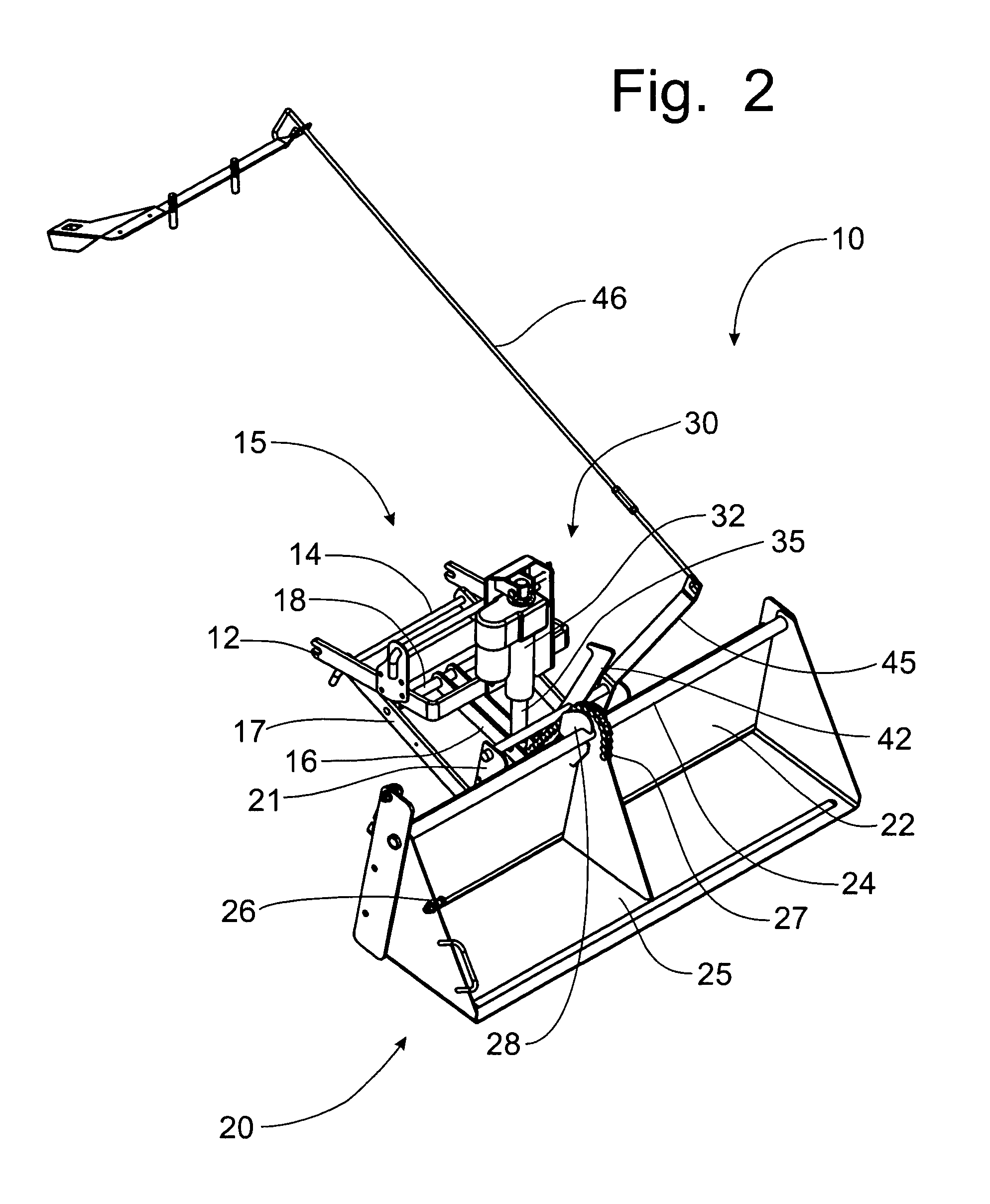

Electronic Anti-Spill

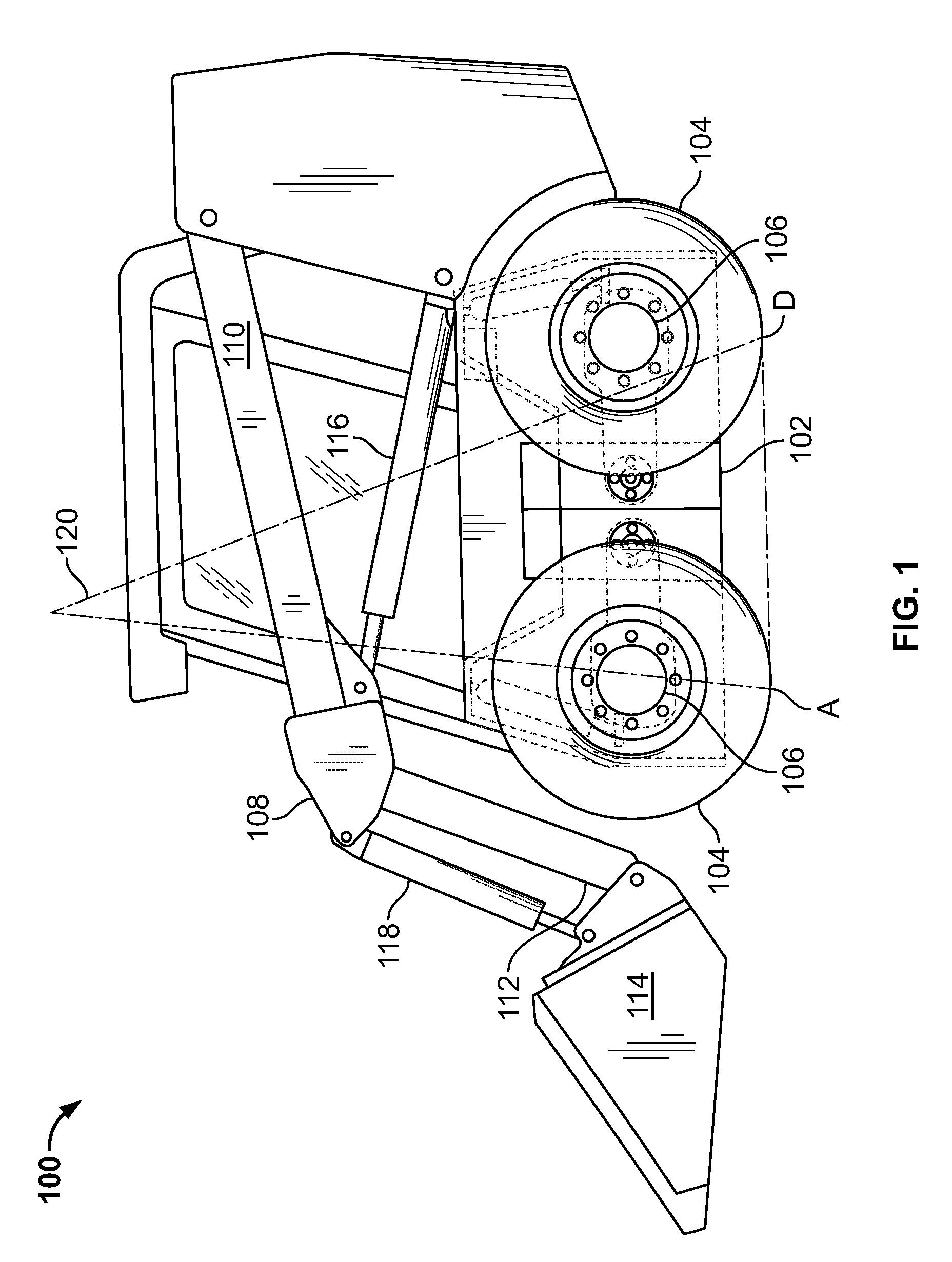

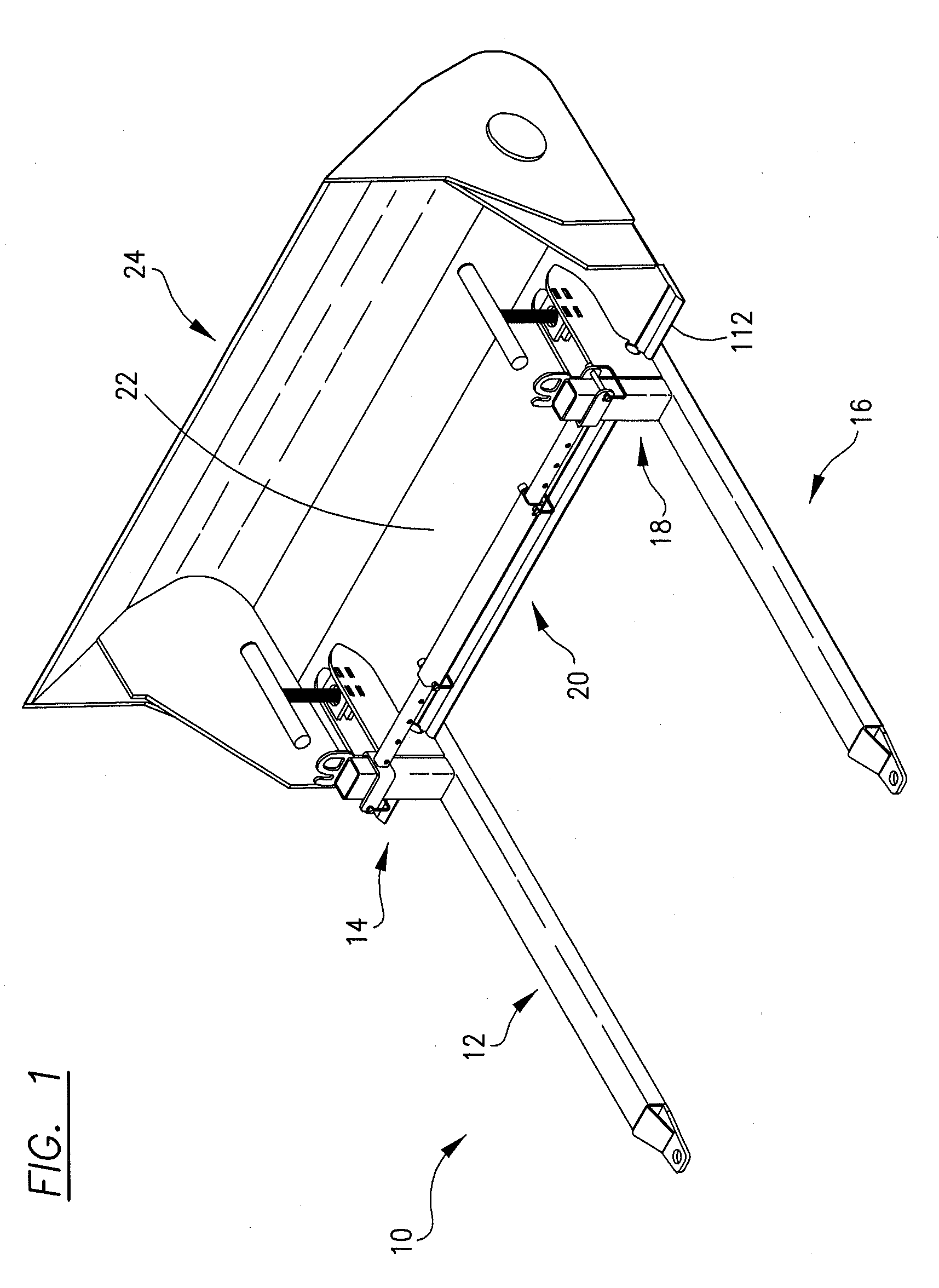

InactiveUS20100254793A1Simple systemAnalogue computers for trafficMechanical machines/dredgersJoystickProportional control

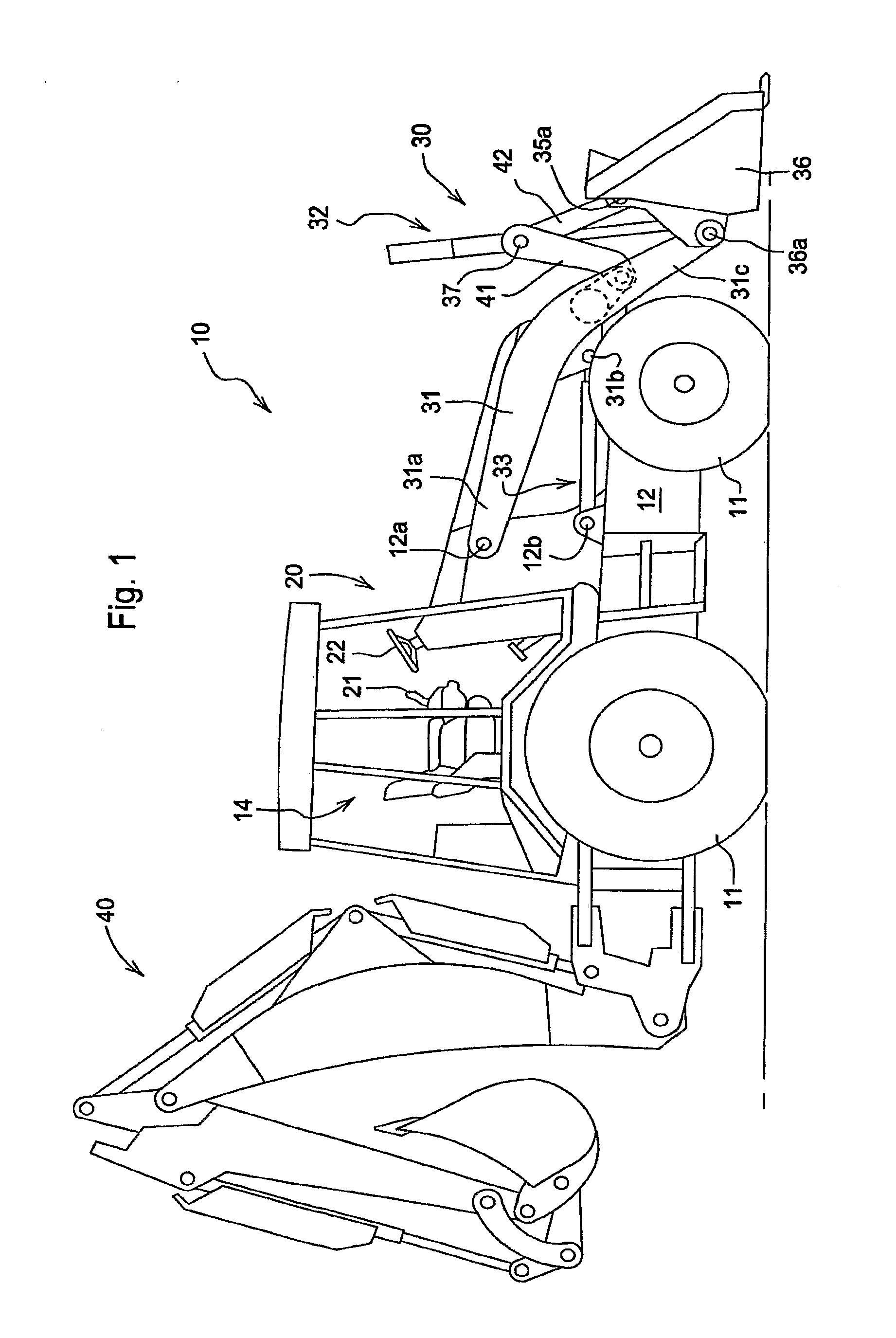

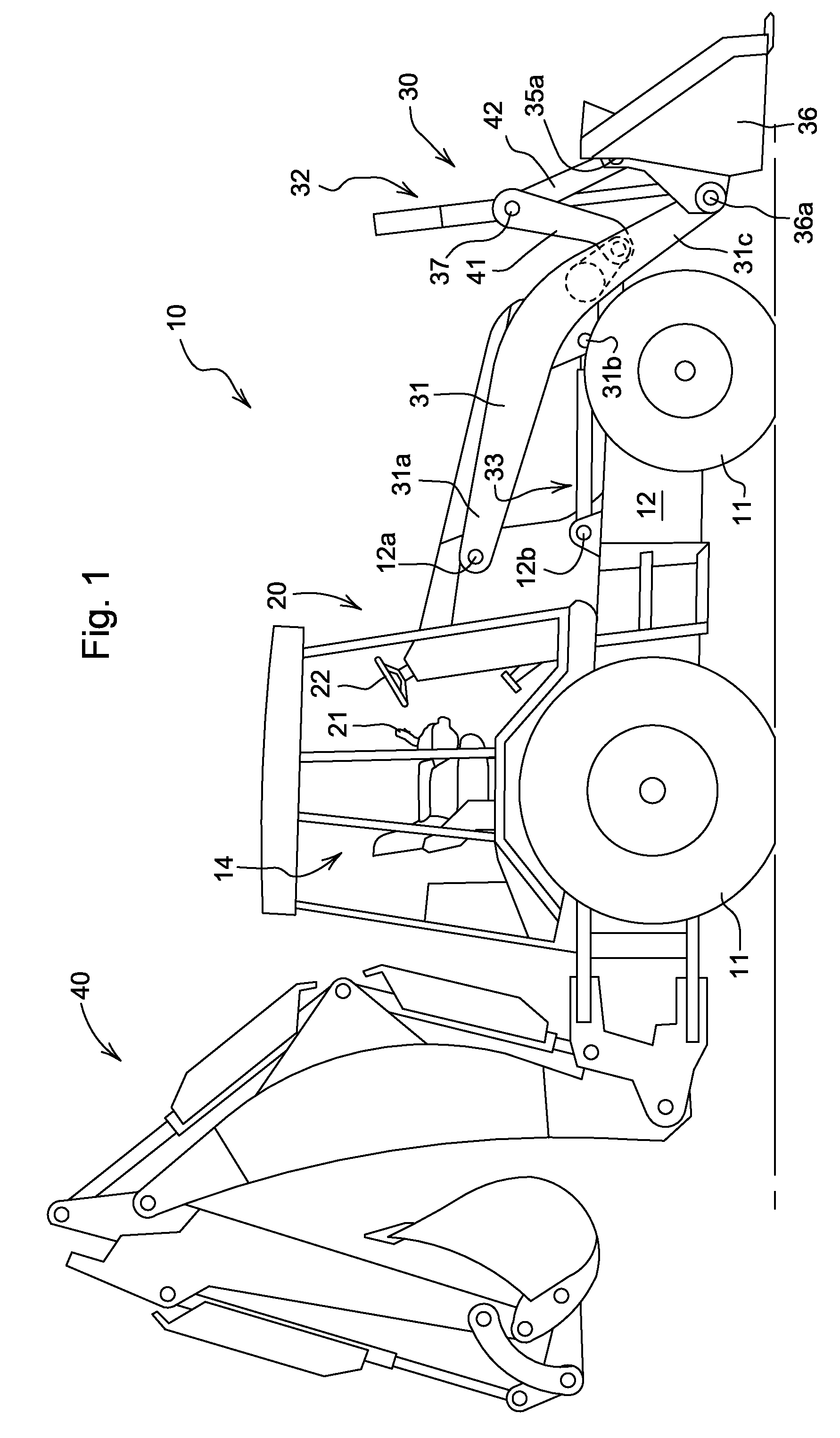

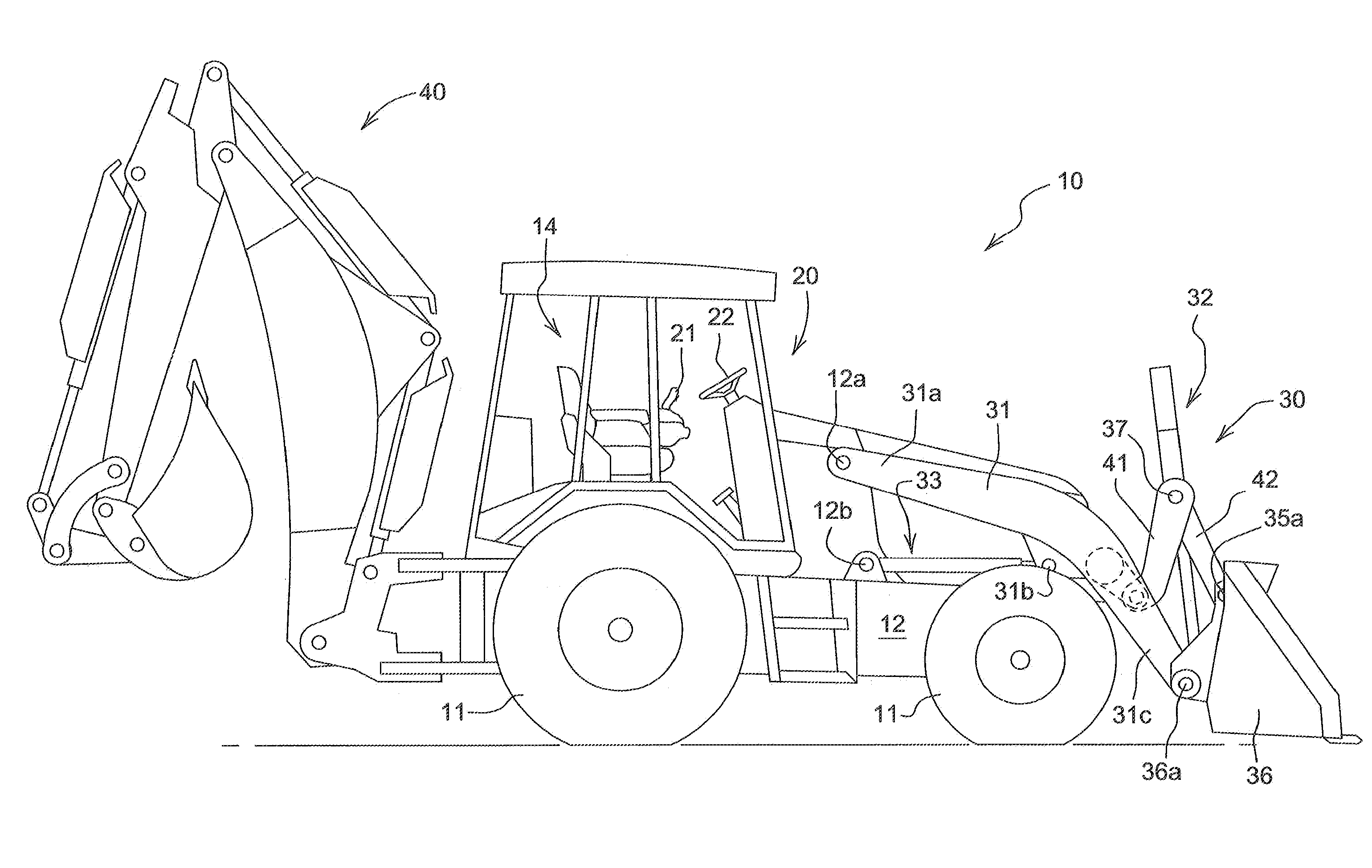

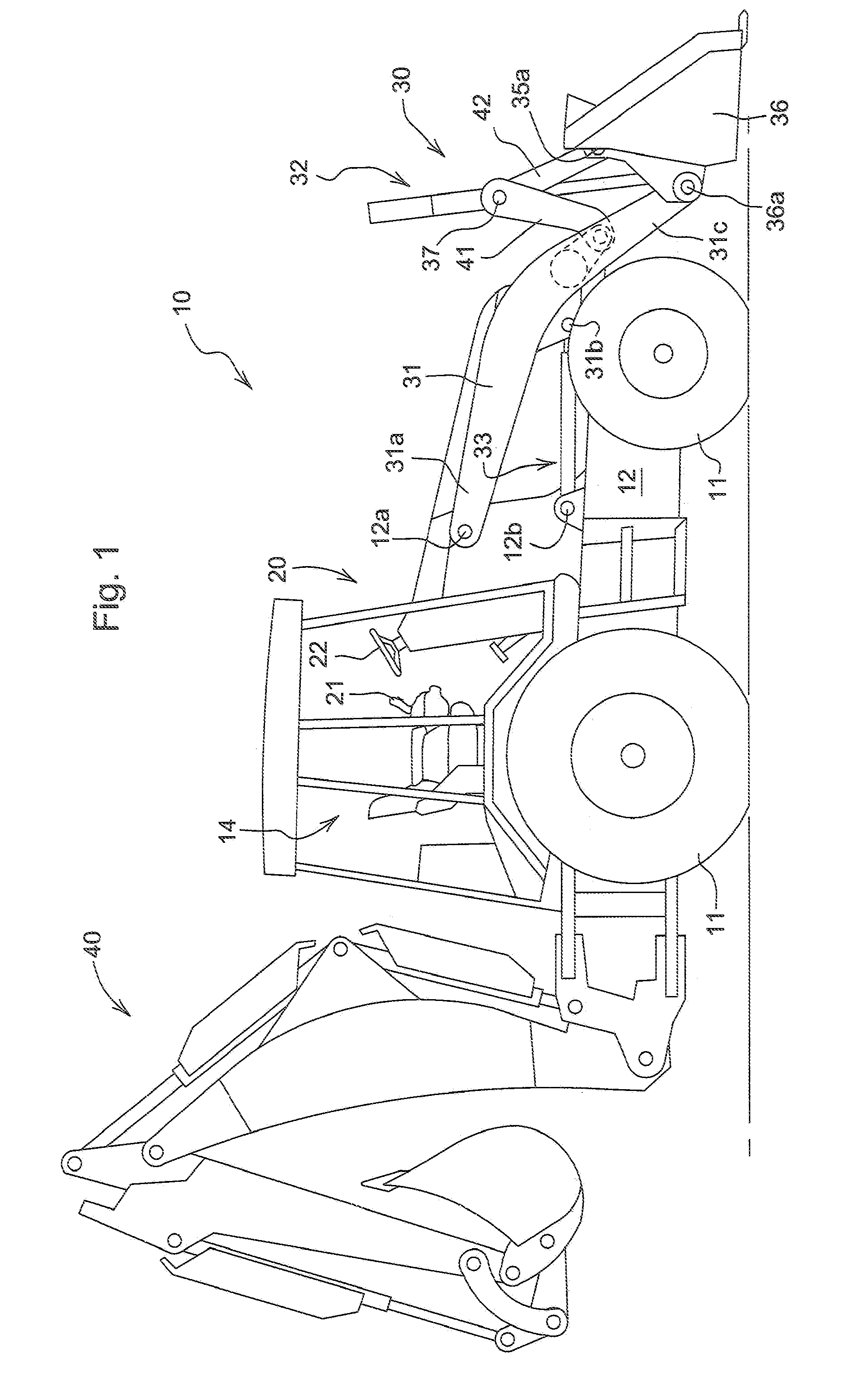

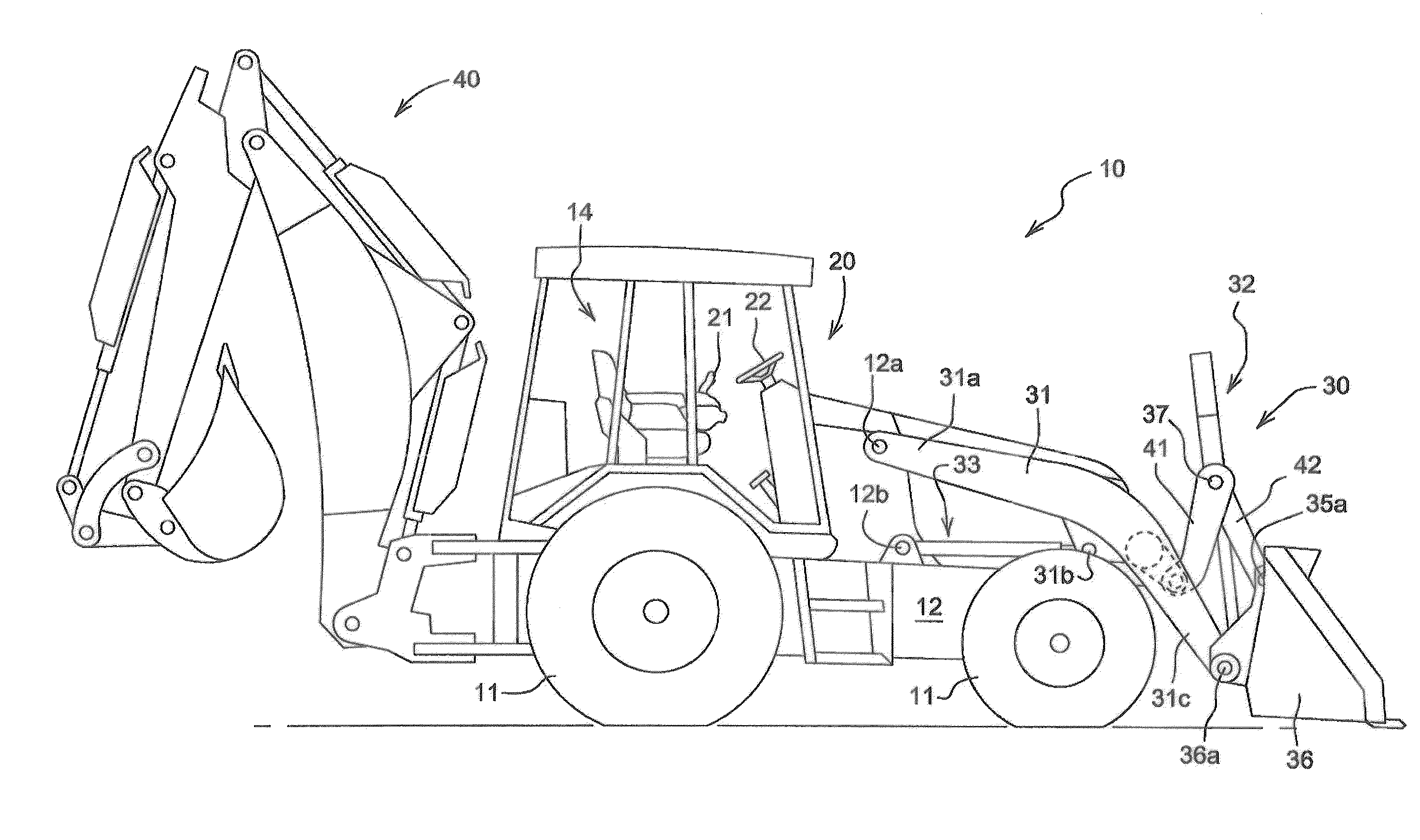

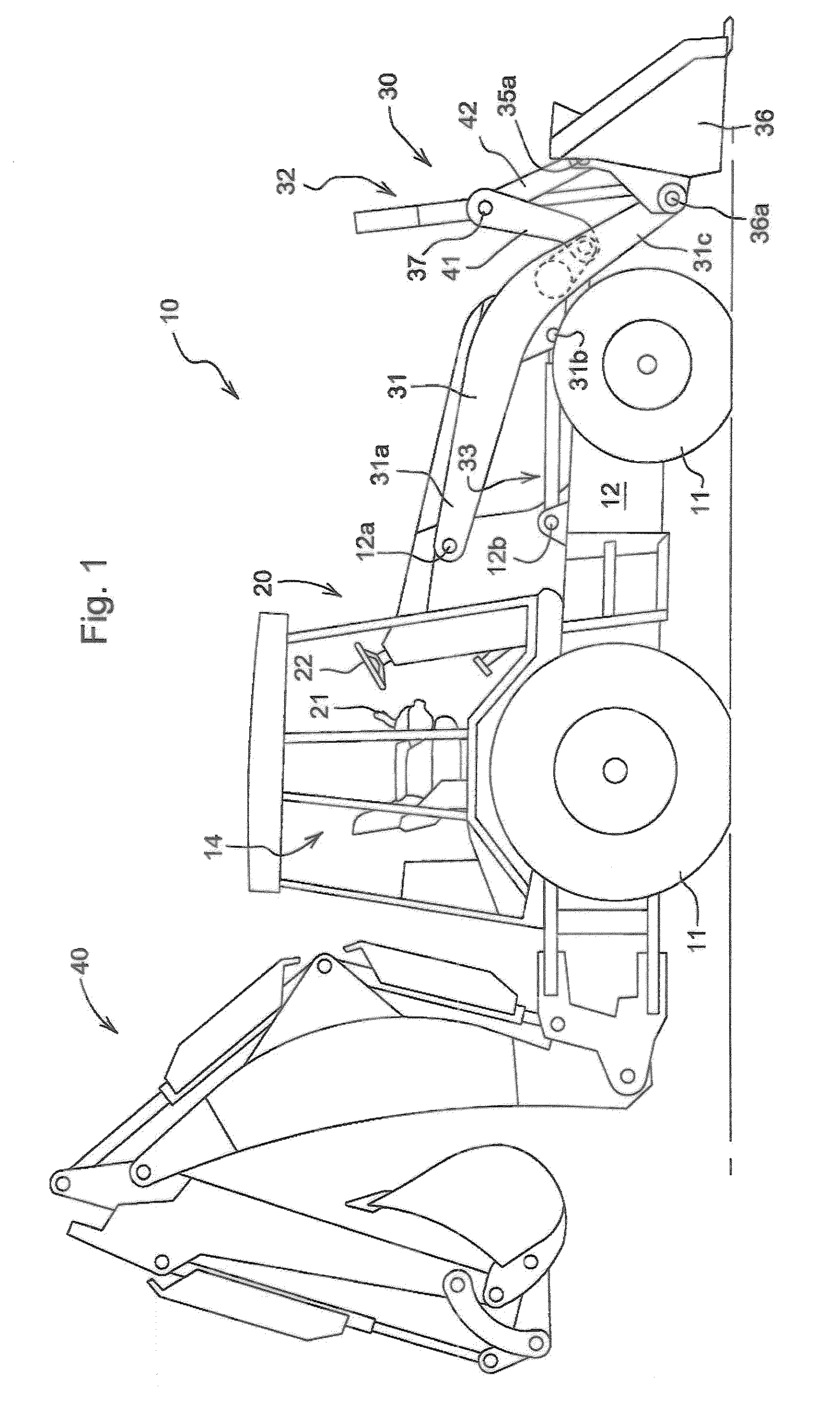

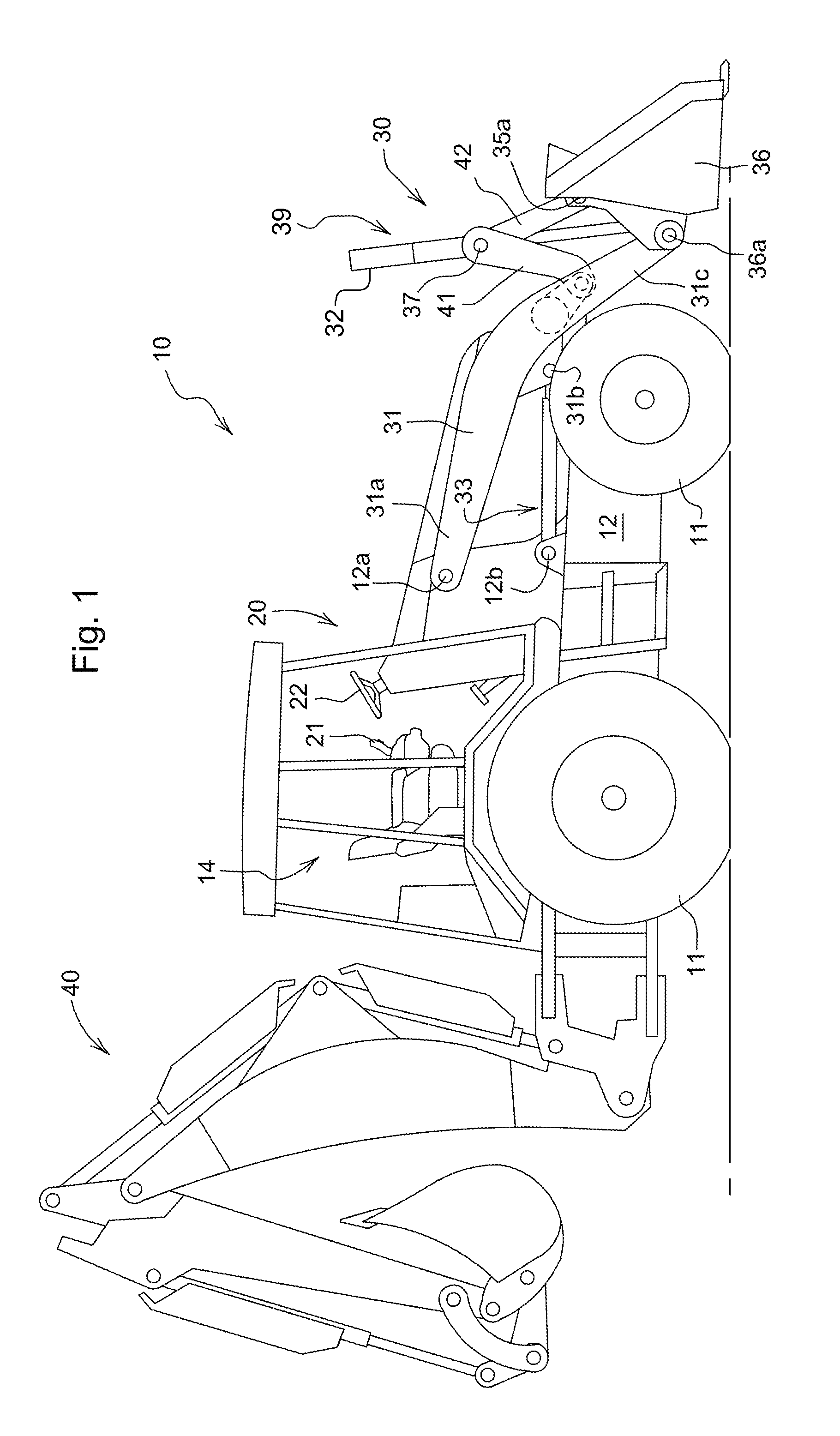

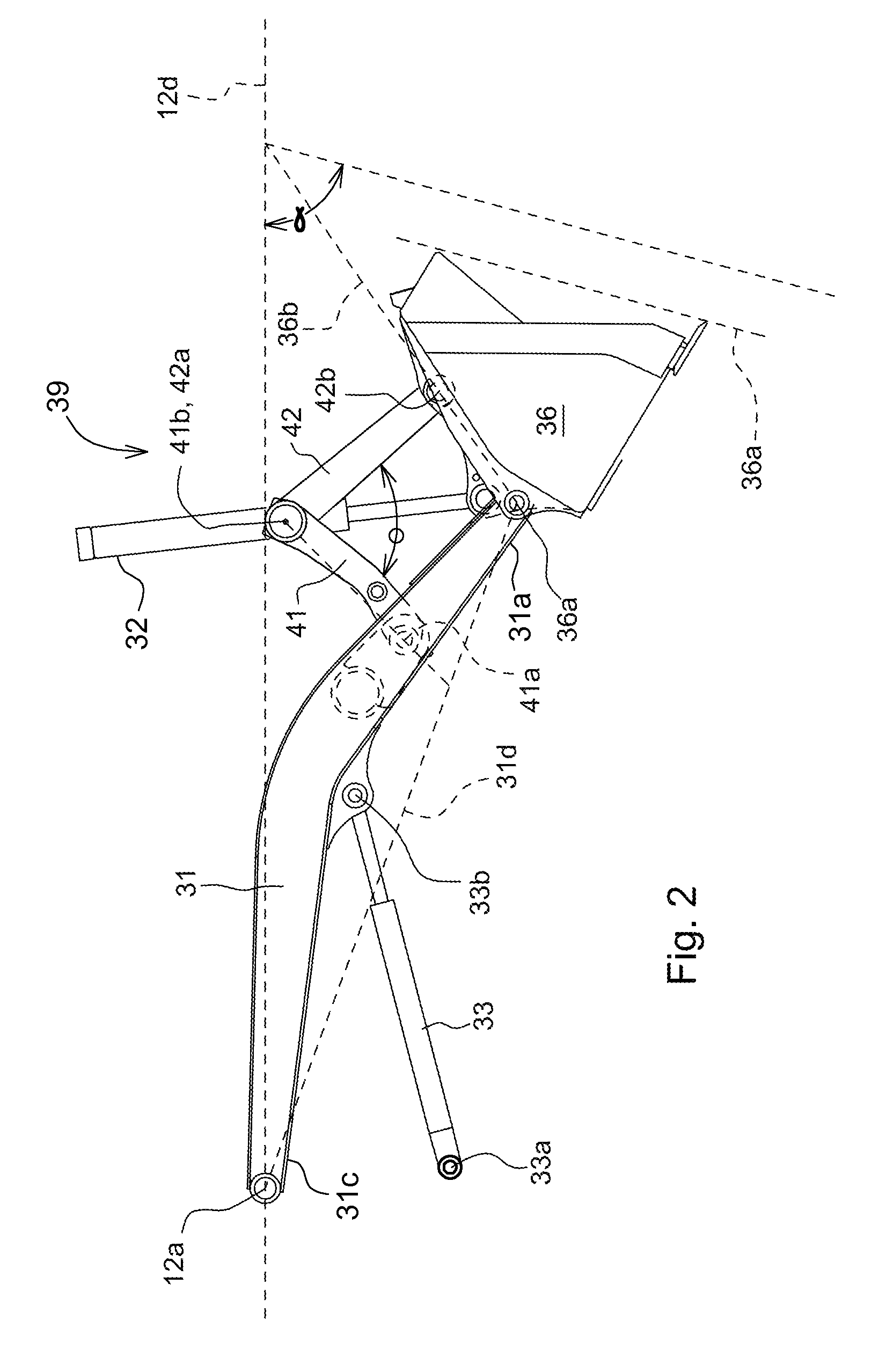

A backhoe loader 10 with a controller 100 that uses angular signals from at least one sensor to calculate a loader tool angle with respect to the vehicle frame 12 or with respect to the earth and to maintain the loader bucket angle via controller generated commands to a bucket actuator 60 as a function of the angular signals and commands to a boom actuator 60. The controller 100 enables proportional control of the tool angle via a command input device such as an electronic joystick 21. The controller 100 is capable of maintaining an inclination of the tool 36 with respect to the frame 12. If the boom 31 rises to an angle that is equal to or above a predetermined anti-spill boom angle the controller 100 drives the tool via commands to the tool actuator 60 to a tool angle that is equal to or less than a predetermined anti-spill bucket angle.

Owner:DEERE & CO

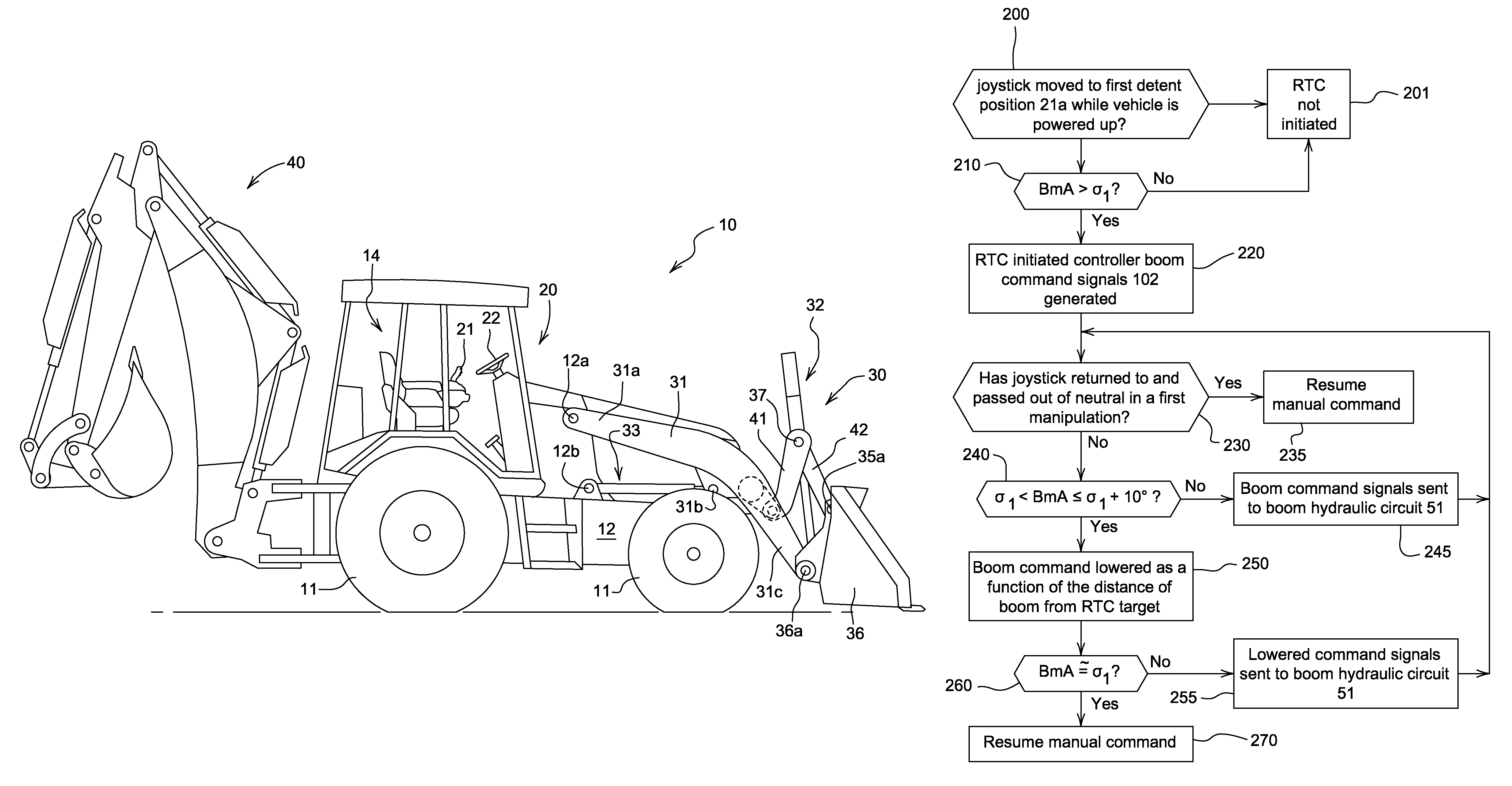

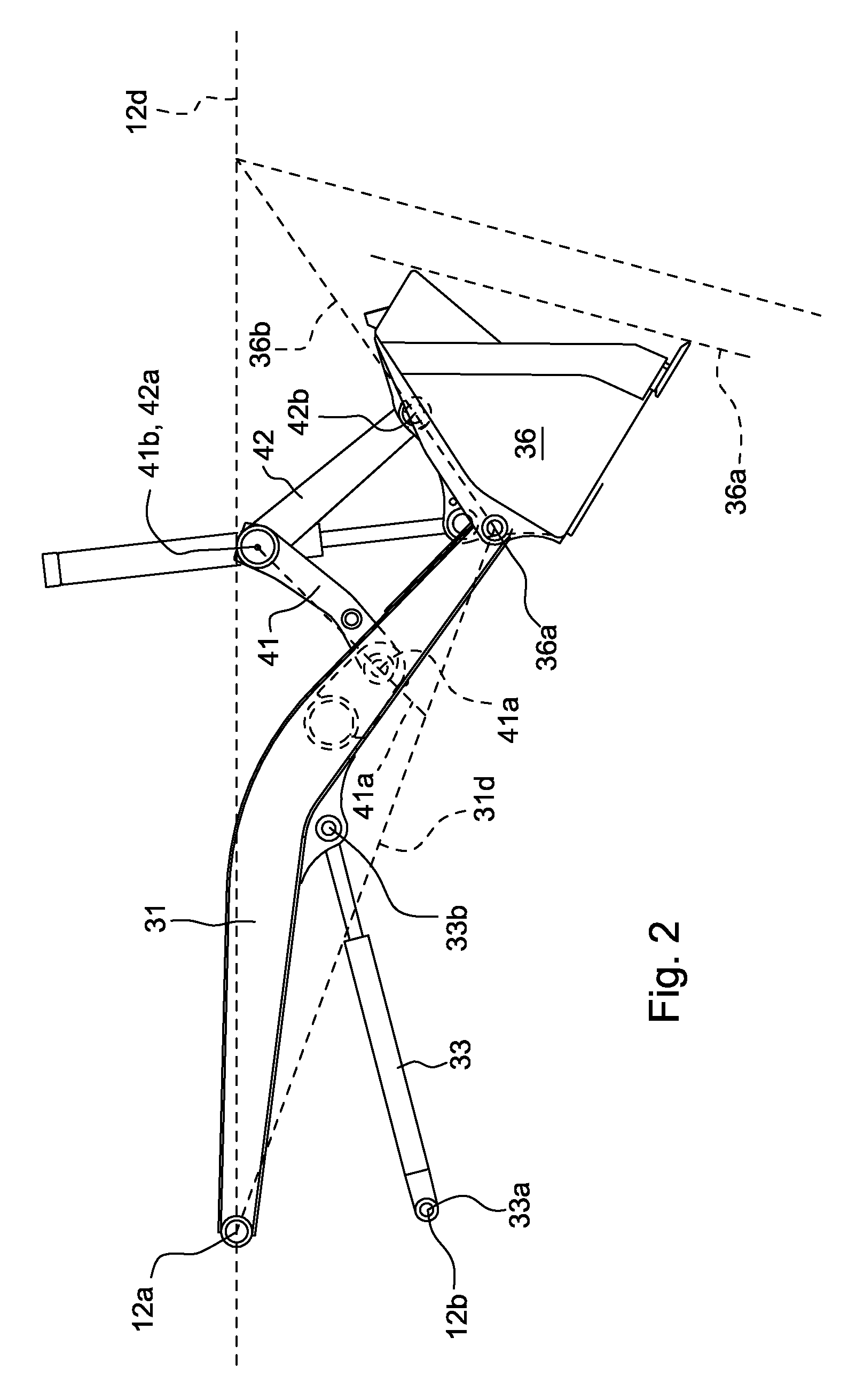

Electronic parallel lift and return to carry on a backhoe loader

A backhoe loader with a controller that uses angular signals from at least one sensor to calculate a loader tool angle with respect to the vehicle frame or with respect to the earth and to maintain the loader tool angle via controller generated commands to a tool actuator as a function of the angular signals and commands to a boom actuator. The controller enables proportional control of the tool angle via a command input device such as an electronic joystick. If the electronic joystick is moved to an appropriate detent position, the controller executes a return to carry function.

Owner:DEERE & CO

Electronic Parallel Lift And Return To Carry On A Backhoe Loader

Owner:DEERE & CO

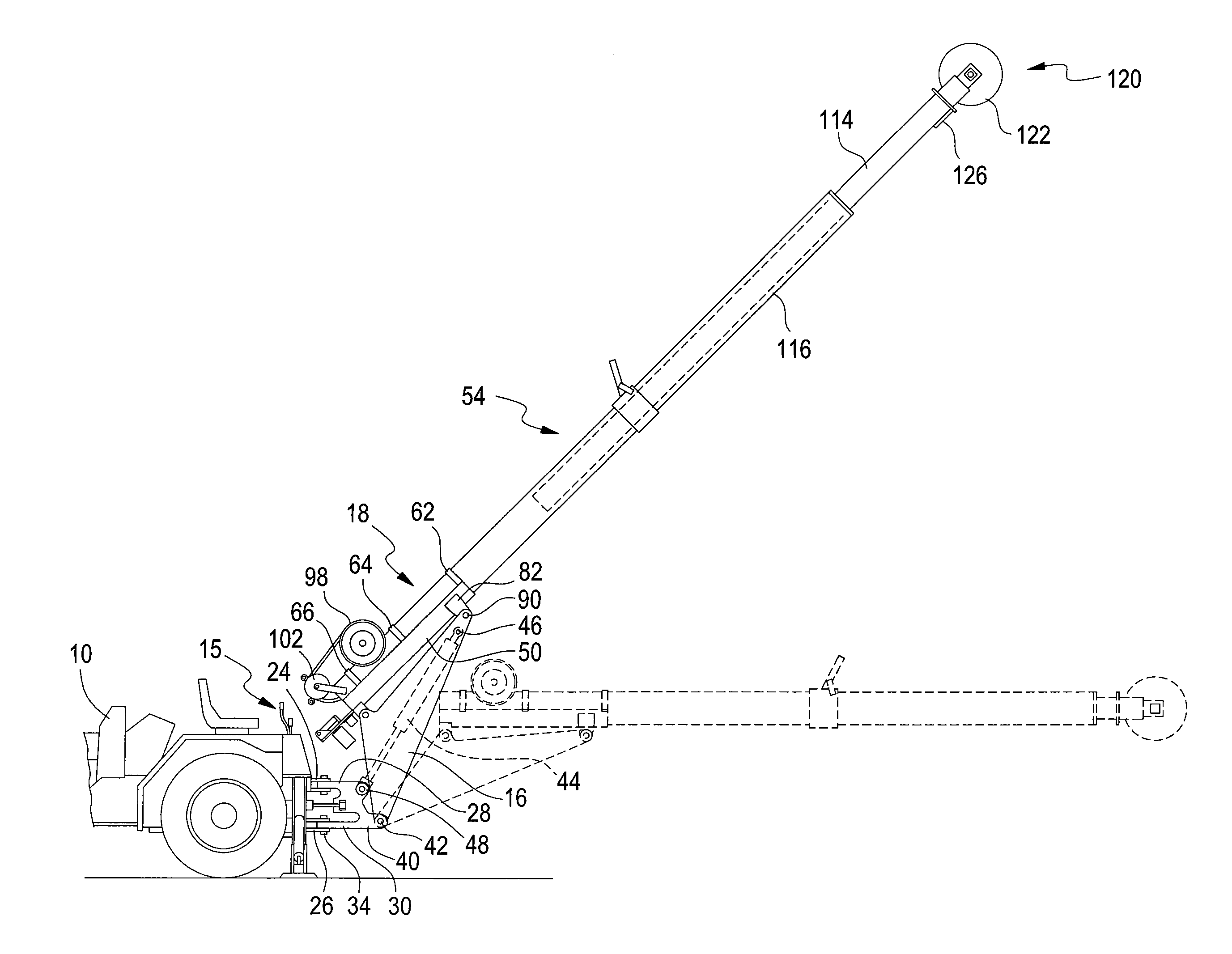

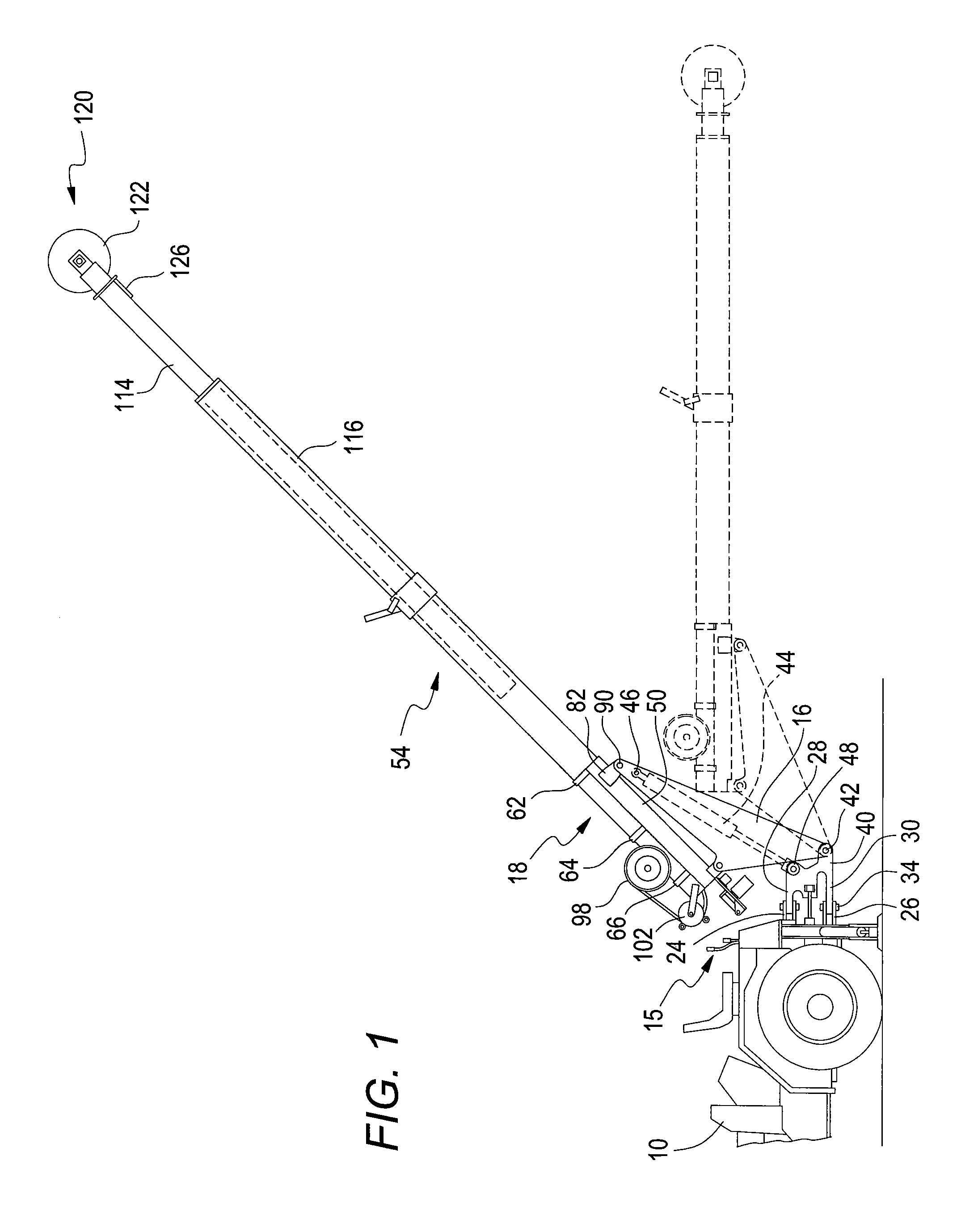

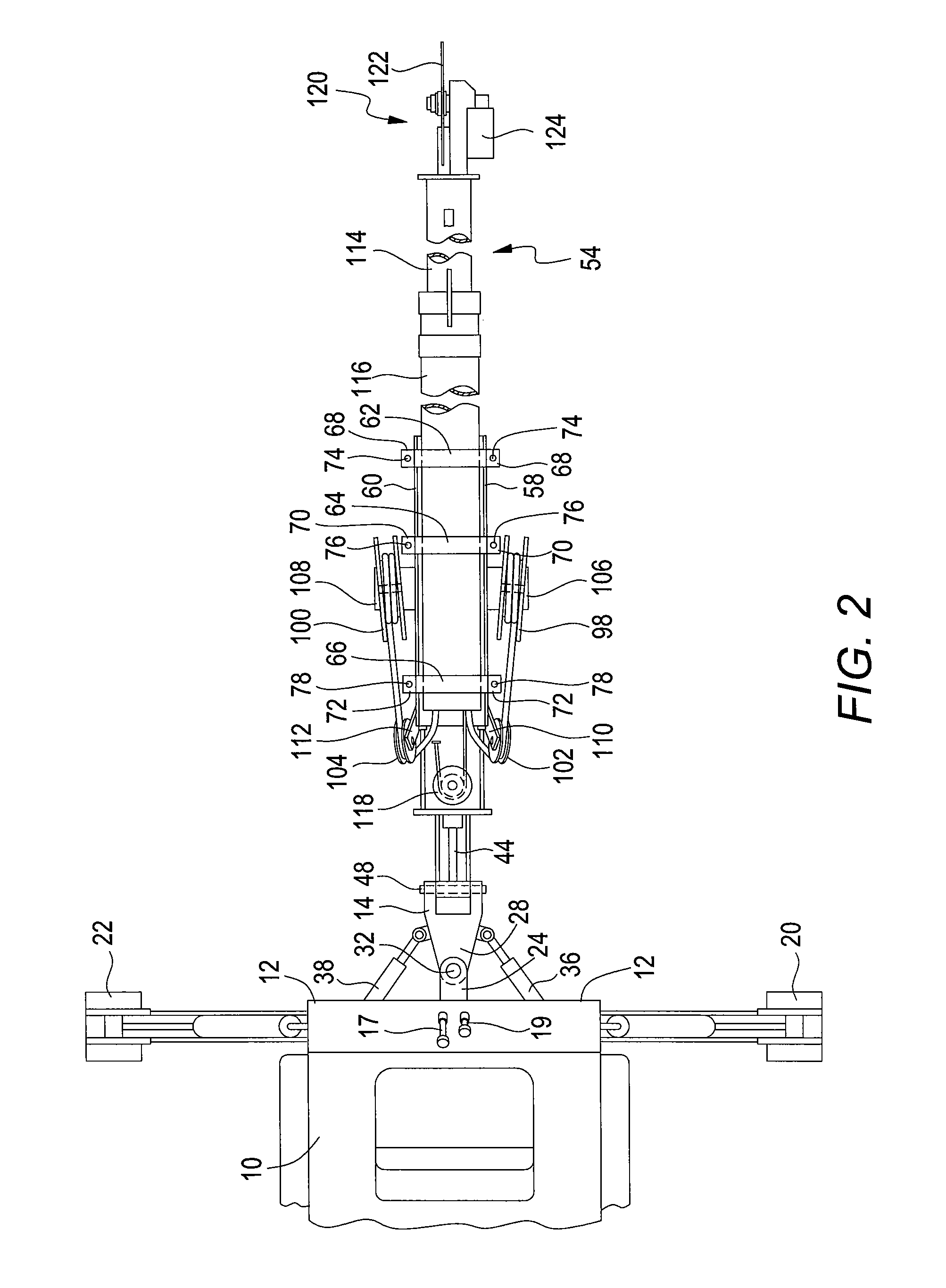

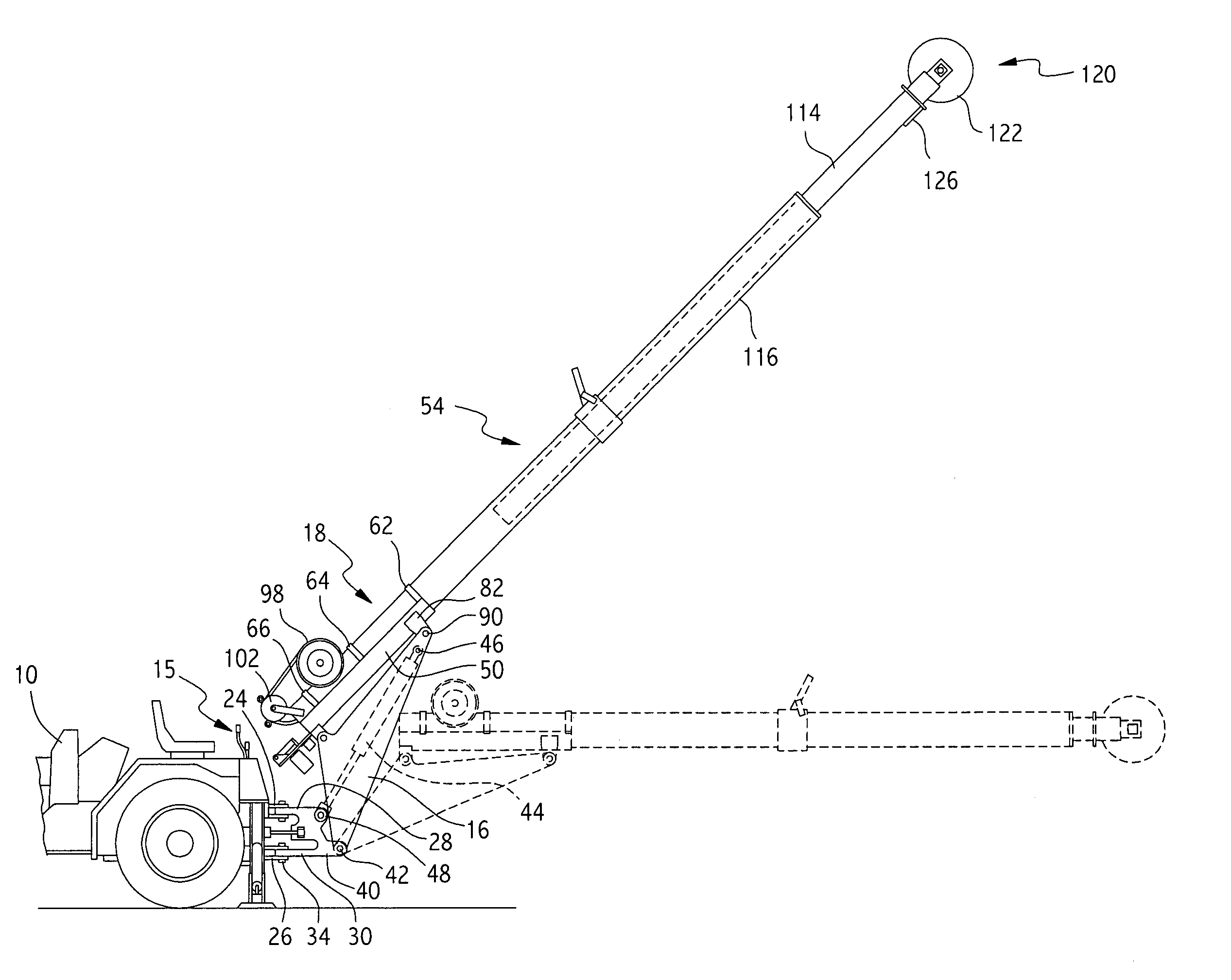

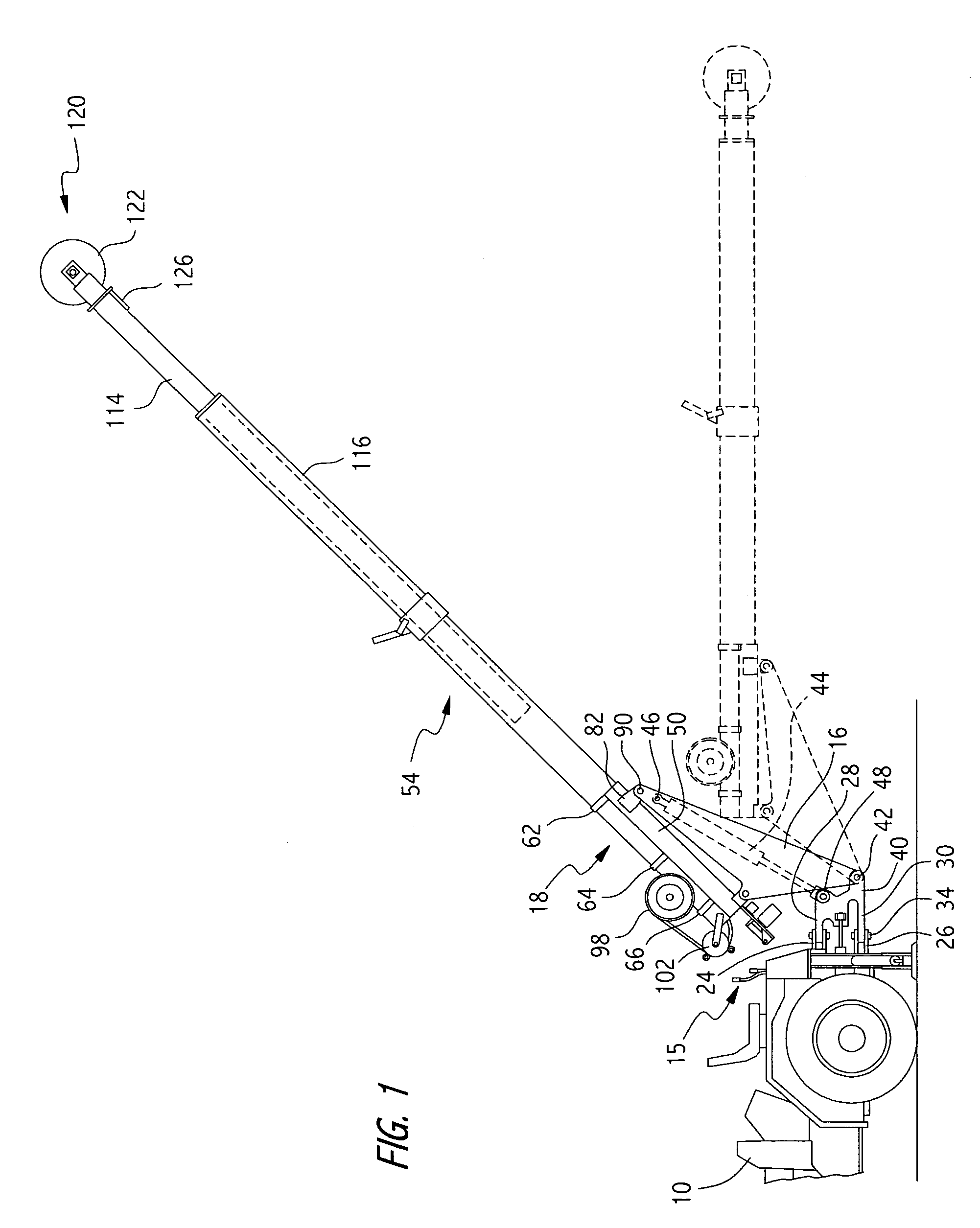

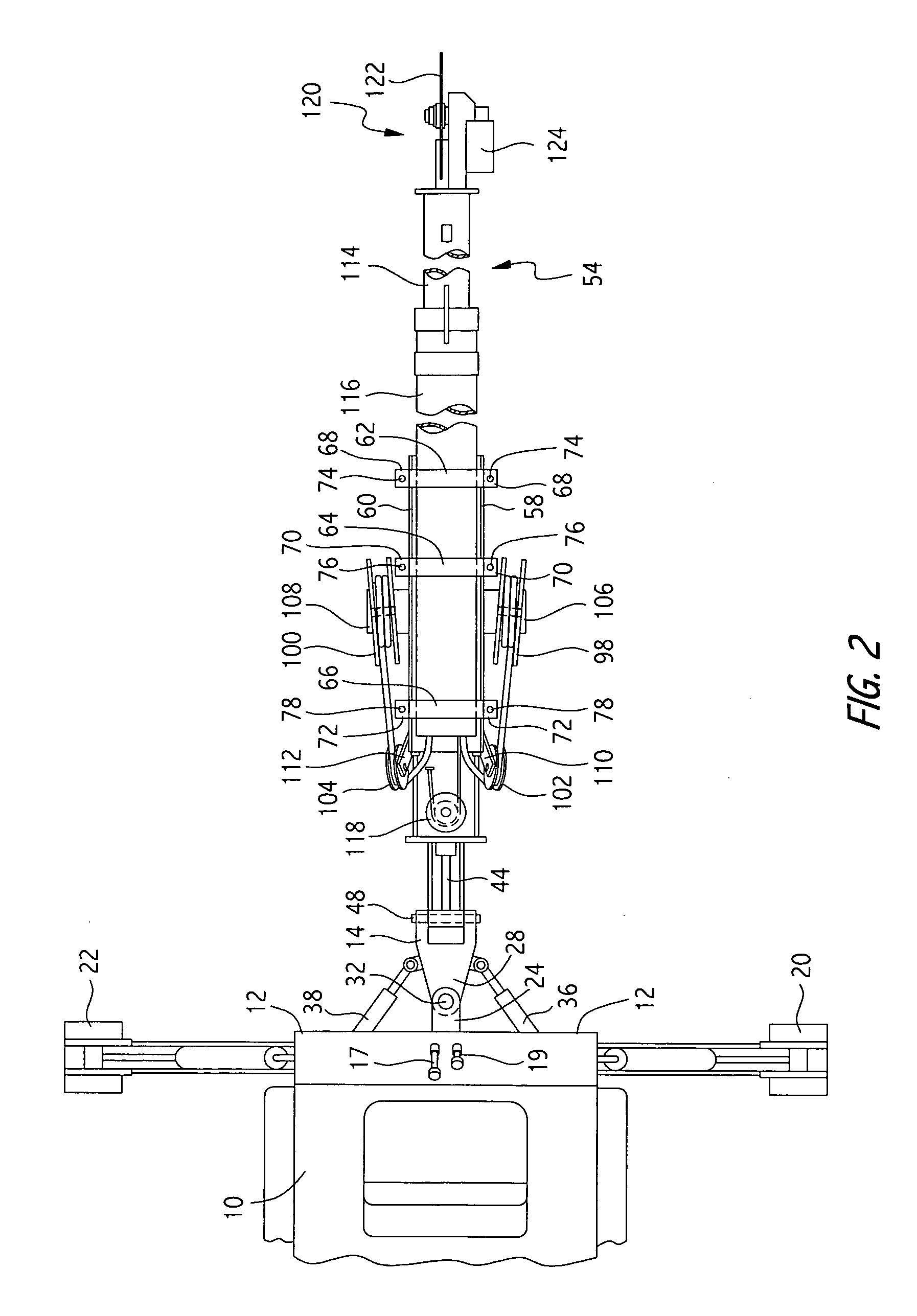

Tree trimmer

InactiveUS7367368B2Linear movement is impededMetal sawing devicesTree debarkingVegetationHorizontal axis

Owner:TRIM ALL EQUIP

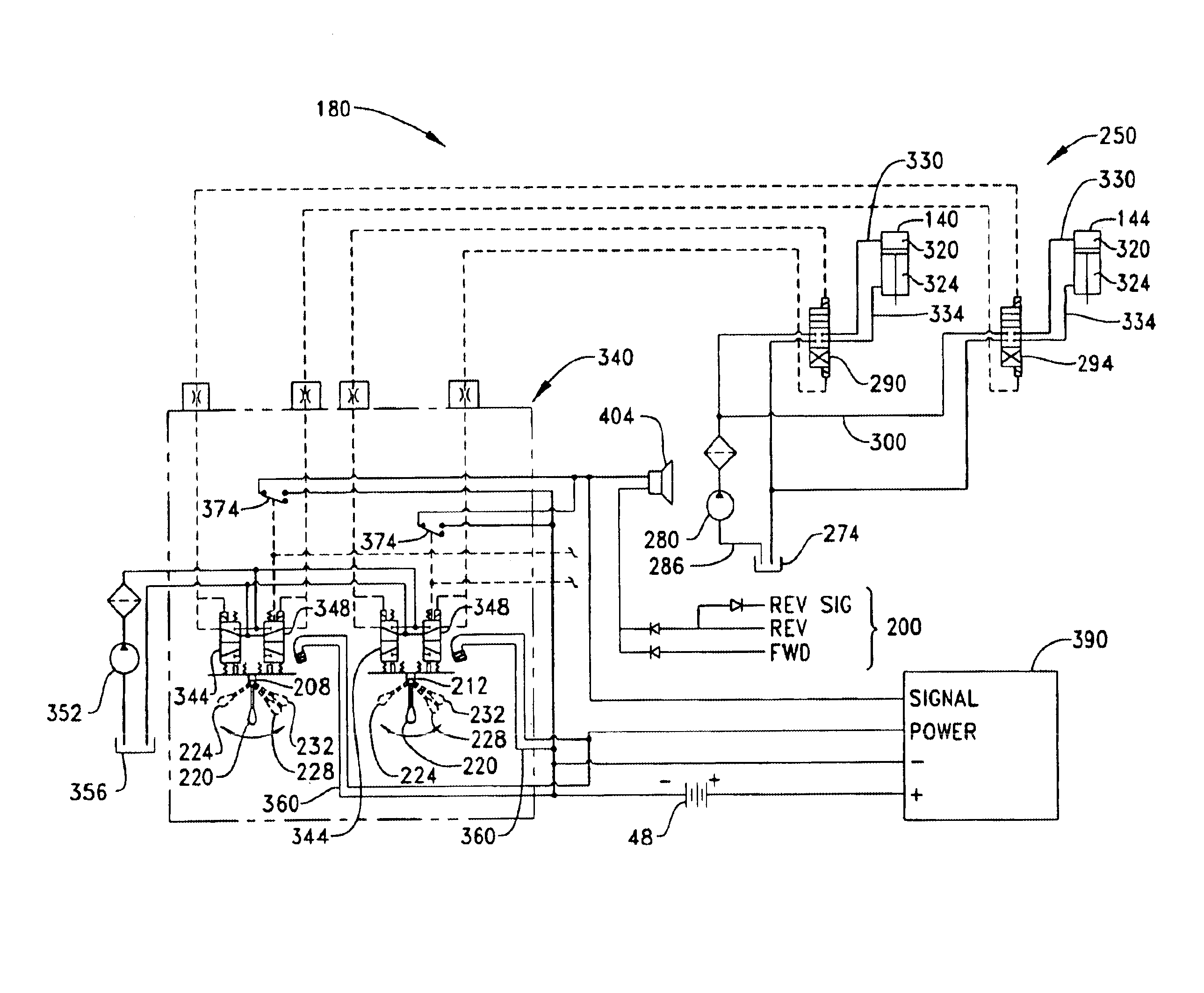

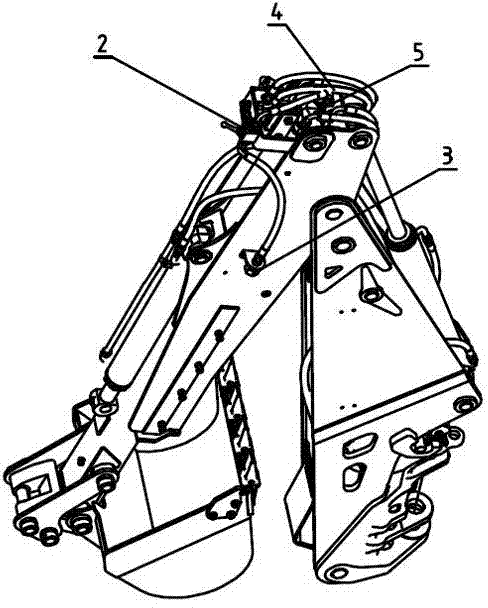

Pilot hydraulic control for a pair of stabilizer legs on a backhoe loader machine

Automatic and simultaneous retraction of a pair of stabilizer legs for a backhoe loader machine is beneficial for the operator (not shown). Instead of retracting the stabilizer legs by manually holding a pair of control levers continuously in a retract position, the operator (not shown) may simply move the control levers to an auto-retract position. The movement of the control levers in such a manner activates a control switch in connection with each of the control levers. The control switches, in turn, activate a timer relay that activates a solenoid detent operative with each control lever. Once the solenoid detents are in an activated state, the operator (not shown) may relinquish contact with the control levers. The solenoid detents will retain the control levers in the auto-retract position via electro-magnetic forces. The timer relay controls the solenoid detents so that the control levers are retained in the auto-retract position for a preselected time to fully retract the stabilizer legs from any one of a plurality of extended positions.

Owner:CATERPILLAR INC

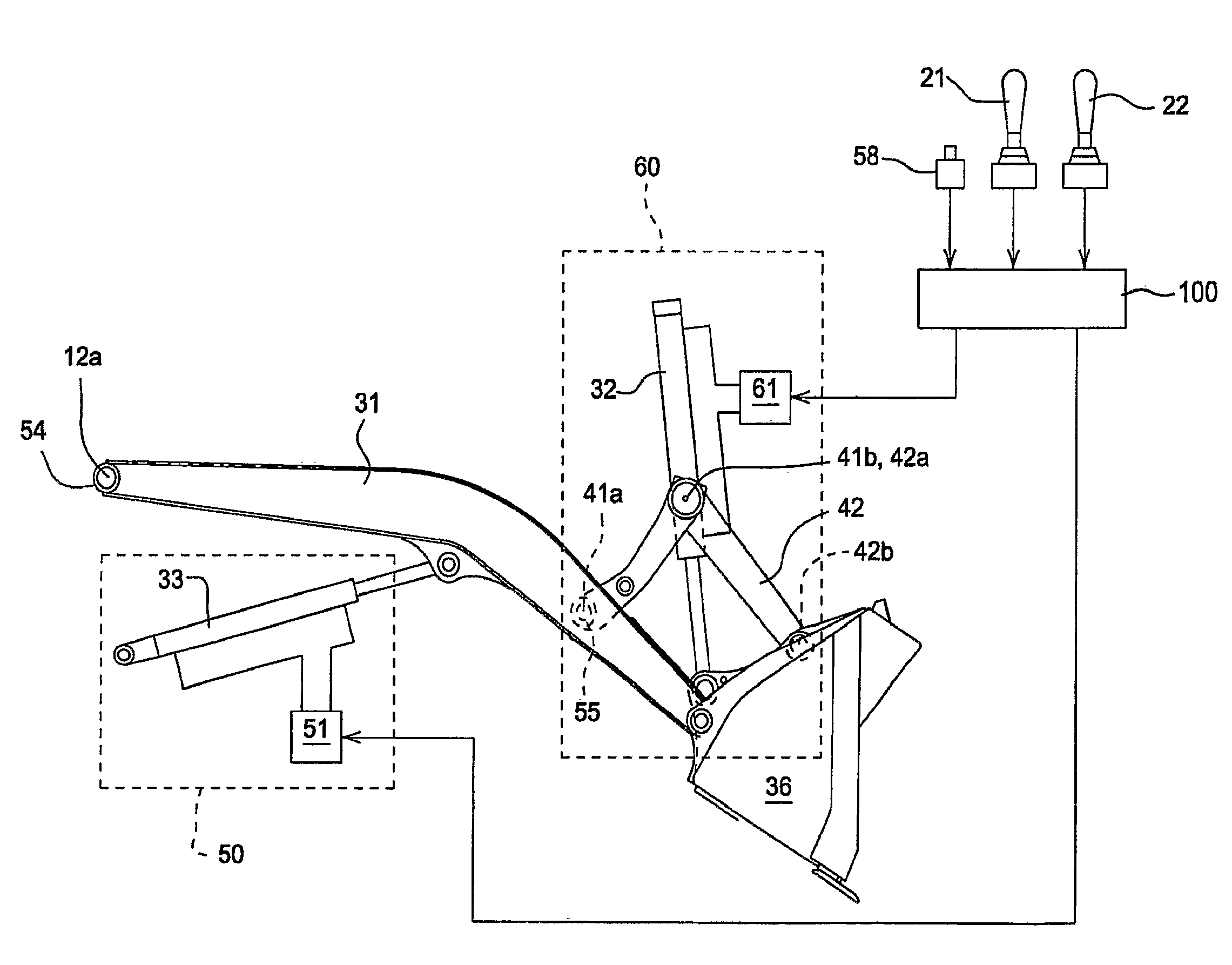

Electronic Parallel Lift And Return To Dig On A Backhoe Loader

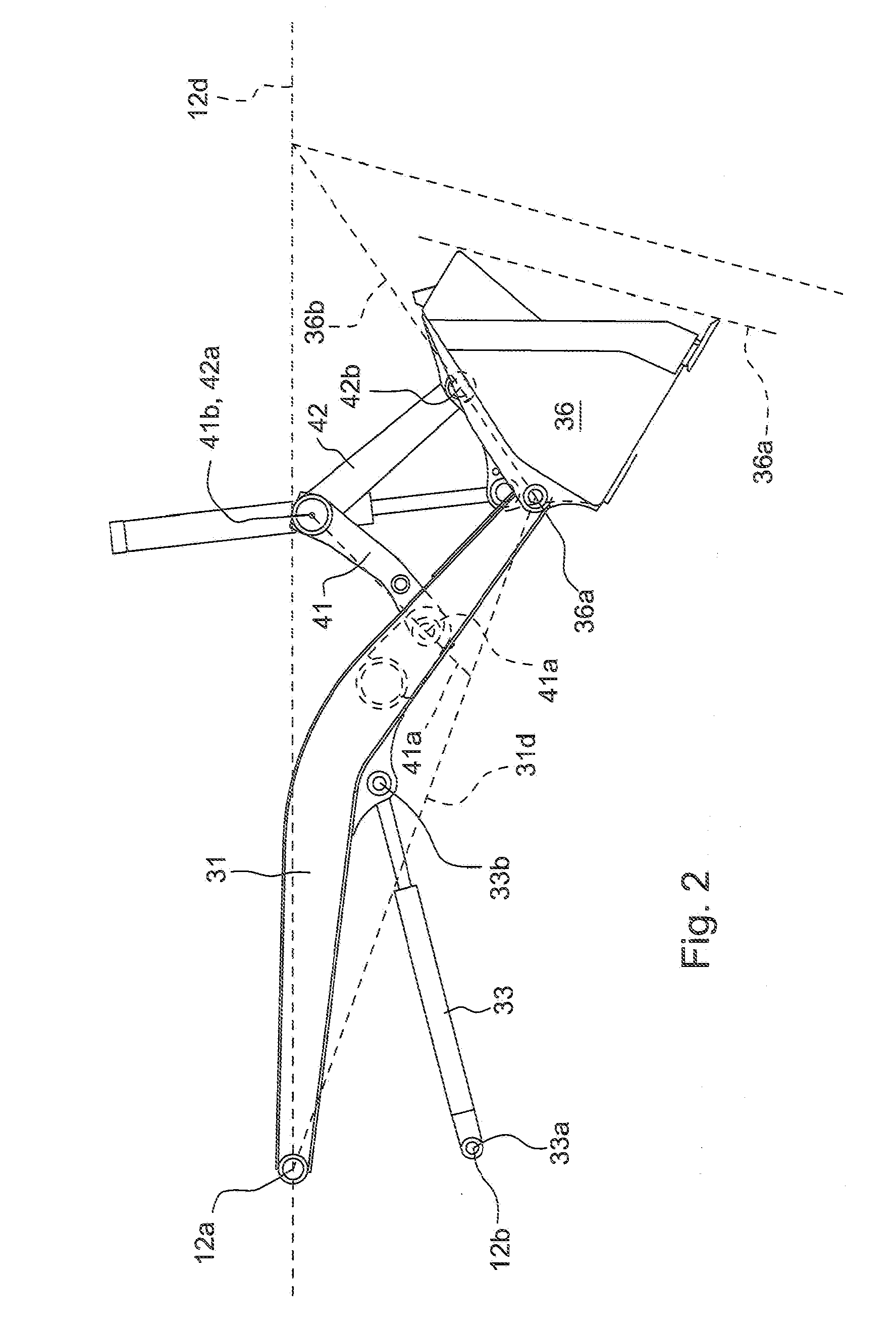

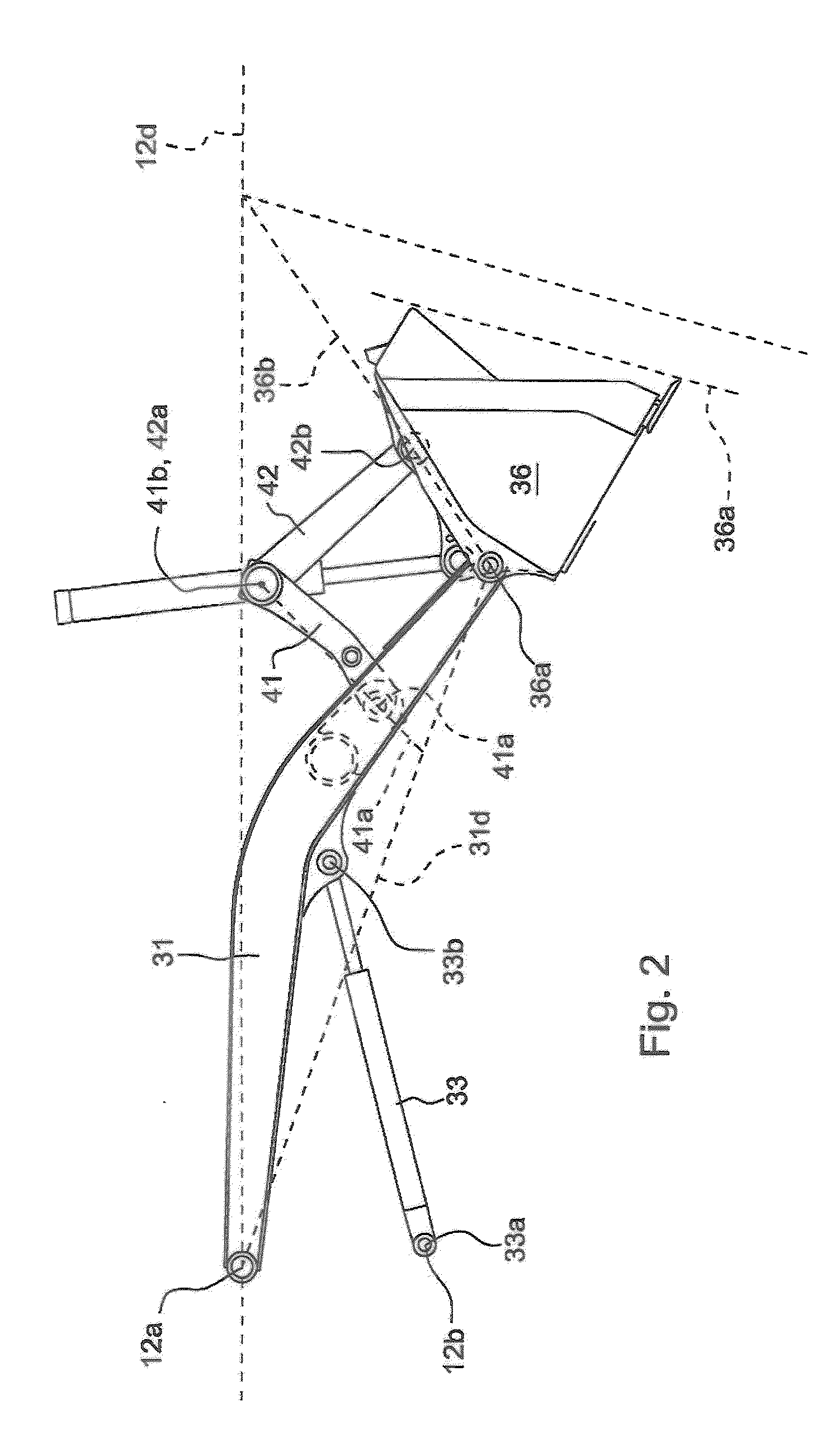

InactiveUS20100215469A1Simple systemMechanical machines/dredgersLifting devicesProportional controlVehicle frame

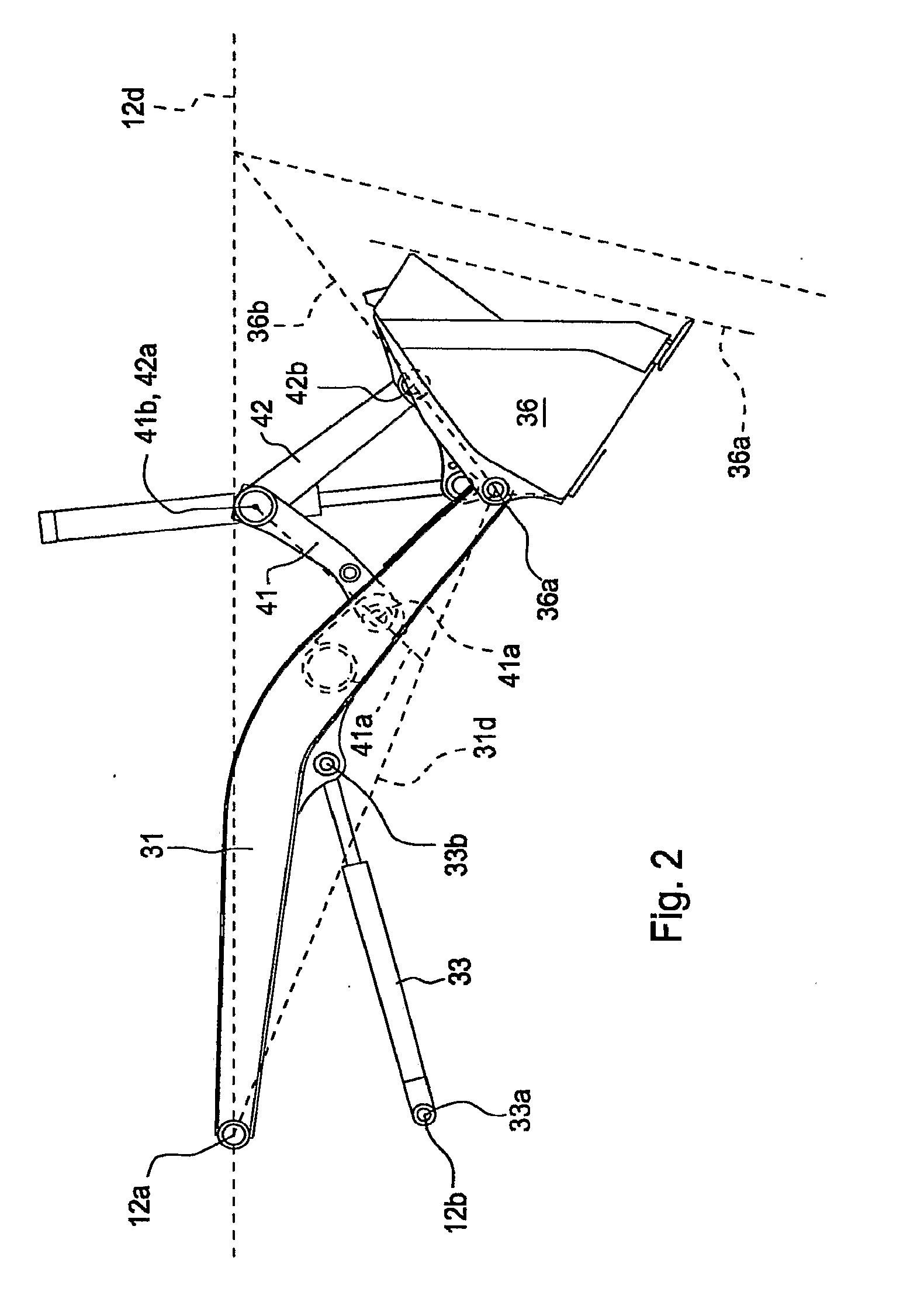

A backhoe loader 10 with a controller 100 that uses angular signals from at least one sensor to calculate a loader tool angle with respect to the vehicle frame 12 or with respect to the earth and to maintain the loader tool angle via controller generated commands to a tool actuator 60 as a function of the angular signals and commands to a boom actuator 50. The controller 100 enables proportional control of the tool angle via a command input device such as an electronic joystick 21. If the electronic joystick 21 is moved to an appropriate detent position, the controller 100 executes a return to dig function. If the bucket 31 is below the return to dig angle at the time the joystick 21 is moved to the detent position, the controller 100 generates commands to move the bucket 36 to the return to dig angle via a curling motion. If the bucket 31 is above the return to dig angle at the time the joystick 21 is moved to the detent position, the controller 100 generates commands to move the bucket 36 to the return to dig angle via a dumping motion. If either return to dig or a return to carry function while the other is being executed then the two are combined such that return to dig is completed prior to return to carry.

Owner:DEERE & CO

Electronic Parallel Lift And Return To Carry Or Float On A Backhoe Loader

ActiveUS20100226744A1Simple systemAnalogue computers for trafficMechanical machines/dredgersProportional controlJoystick

A backhoe loader 10 with a controller 100 that uses angular signals from at least one sensor to calculate a loader tool angle with respect to the vehicle frame 12 or with respect to the earth and to maintain the loader tool angle via controller generated commands to a tool actuator 61 as a function of the angular signals and commands to a boom actuator 50. The controller 100 enables proportional control of the tool angle via a command input device such as an electronic joystick 21. If the electronic joystick 21 is moved to an appropriate detent position, the controller executes a return to carry function. If the boom 31 is at or below the return to carry angle at the time the joystick 21 is moved to the detent position, the controller 100 executes a float function allowing the bucket 36 and the boom 31 to rest on the ground and follow the contours of the earth as the vehicle moves over the earth.

Owner:DEERE & CO

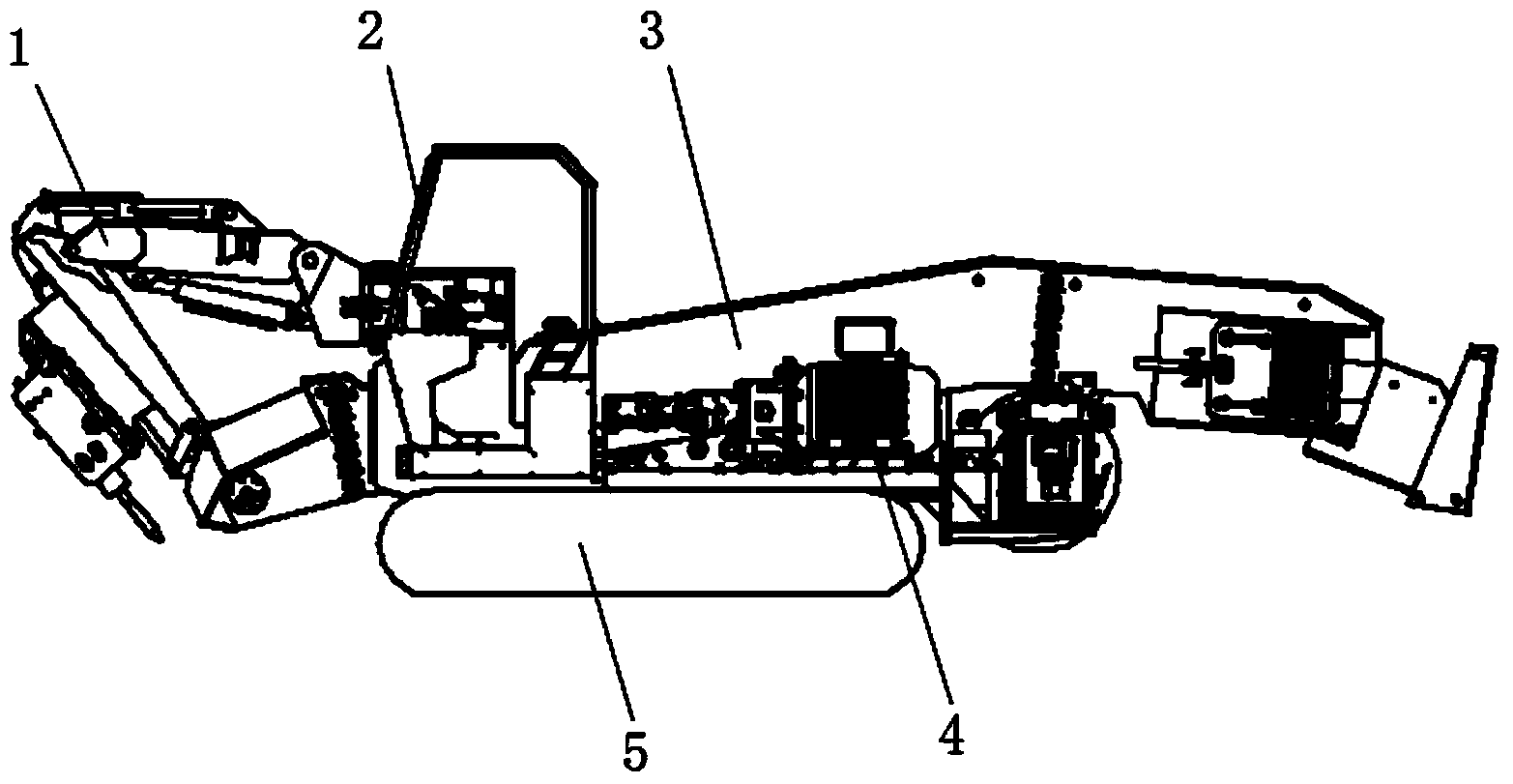

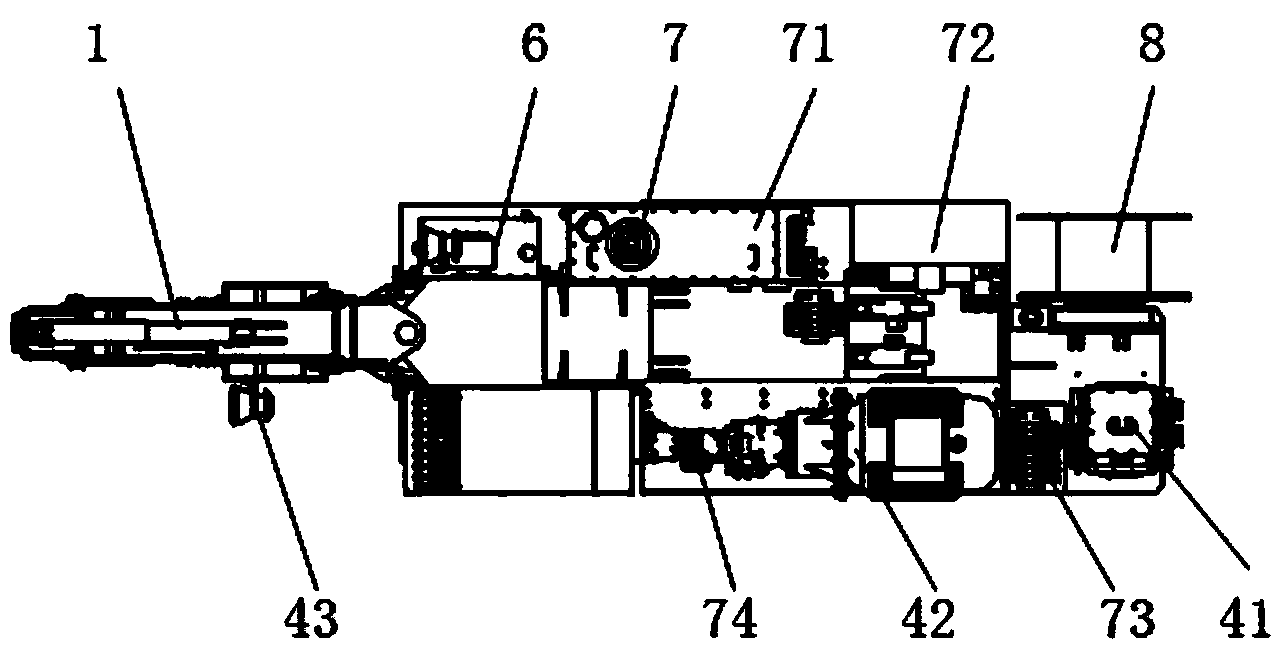

Roadway repair machine integrating drilling, digging, transporting and loading

ActiveCN103643707ASolve the manual replacement of bucketsSolving the breaker woesMechanical machines/dredgersEngineeringUltimate tensile strength

The invention discloses a roadway repair machine integrating drilling, digging, transporting and loading, and applies to management and construction of floor heave and rib spalling of a coal mine roadway. The roadway repair machine mainly comprises an operating mechanism 1, a cab 2, a scraper blade transporter 3, an electrical system 4, a vehicle body assembly 5, a dust collection device 6, a hydraulic system 7 and a cable coiling device 8, wherein a digging bucket 19 and a breaking hammer 18 are mounted on the operating mechanism 1, so that the repair machine can perform breaking work while digging and loading, and the auxiliary time for previous manual replacement is saved; and an unloading chute is mounted at the tail of the scraper blade transporter 3, so that the repair machine can turn and transfer a material to a belt or a mine car, and the work efficiency is improved. The whole machine is high in construction efficiency, high in applicability and diverse in function, not only can be used for repairing floor heave and rib spalling of the coal mine roadway, but also can replace a backhoe loader to perform most engineer operation, and the labor intensity of a worker is small.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Electronic parallel lift and return to carry or float on a backhoe loader

ActiveUS8500387B2Simple systemAnalogue computers for vehiclesAnalogue computers for trafficVehicle frameJoystick

A backhoe loader 10 with a controller 100 that uses angular signals from at least one sensor to calculate a loader tool angle with respect to the vehicle frame 12 or with respect to the earth and to maintain the loader tool angle via controller generated commands to a tool actuator 61 as a function of the angular signals and commands to a boom actuator 50. The controller 100 enables proportional control of the tool angle via a command input device such as an electronic joystick 21. If the electronic joystick 21 is moved to an appropriate detent position, the controller executes a return to carry function. If the boom 31 is at or below the return to carry angle at the time the joystick 21 is moved to the detent position, the controller 100 executes a float function allowing the bucket 36 and the boom 31 to rest on the ground and follow the contours of the earth as the vehicle moves over the earth.

Owner:DEERE & CO

Sleeper replacing implement

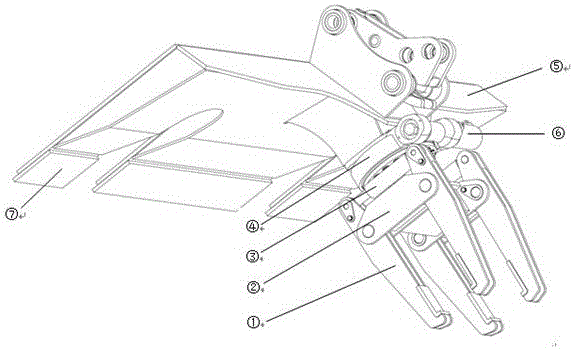

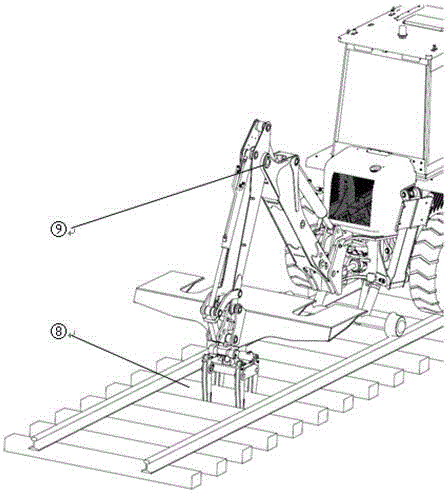

InactiveCN106065550AInhibit sheddingHigh precisionRailway track constructionCrushed stoneEngineering

The invention relates to a sleeper replacing implement which comprises two pairs of clamps used for holding a sleeper, a swing mechanism, and a scraper blade for pushing crushed stone aside, wherein a connection part to be connected with an operating mechanism of an engineering vehicle is arranged on the scraper blade; the swing mechanism is connected with the lower side of the scraper blade; a support rack is connected to the lower side of the swing mechanism; a motor is mounted on the swing mechanism, and used for driving the swing mechanism to rotate; the clamps are mounted on the support rack, and connected to two ends of an oil cylinder; the oil cylinder is used for controlling the opening / closing angles of the clamps. The sleeper replacing implement can be connected to engineering vehicles, such as excavators, backhoe loaders and loaders, is high in universality, and can be operated by one person; a sleeper can be replaced fast; not only is the work efficiency improved, but also labor cost is reduced; the whole process is simple to operate, safe, reliable, and easy to implement.

Owner:XUZHOU XUGONG SPECIAL CONSTR MASCH CO LTD

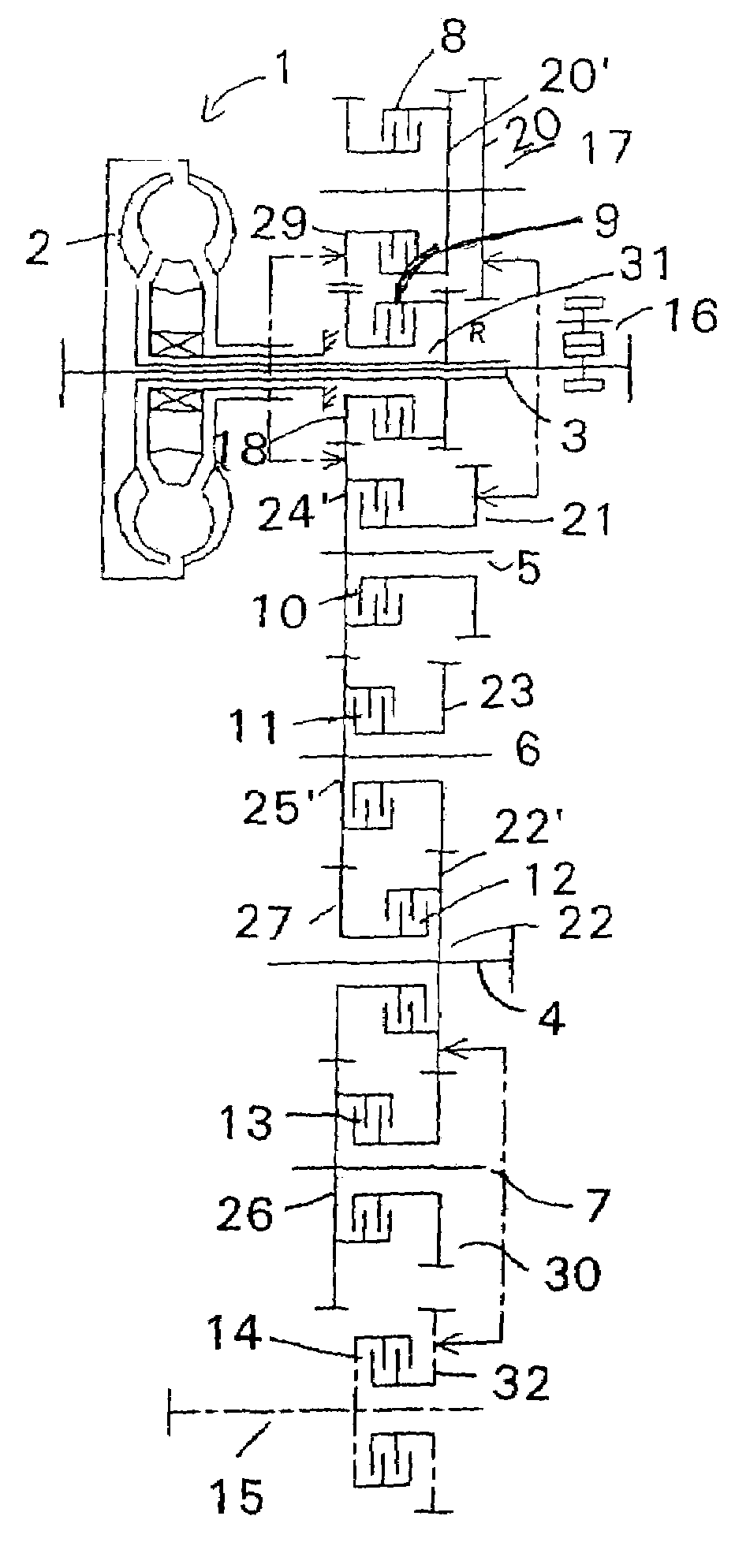

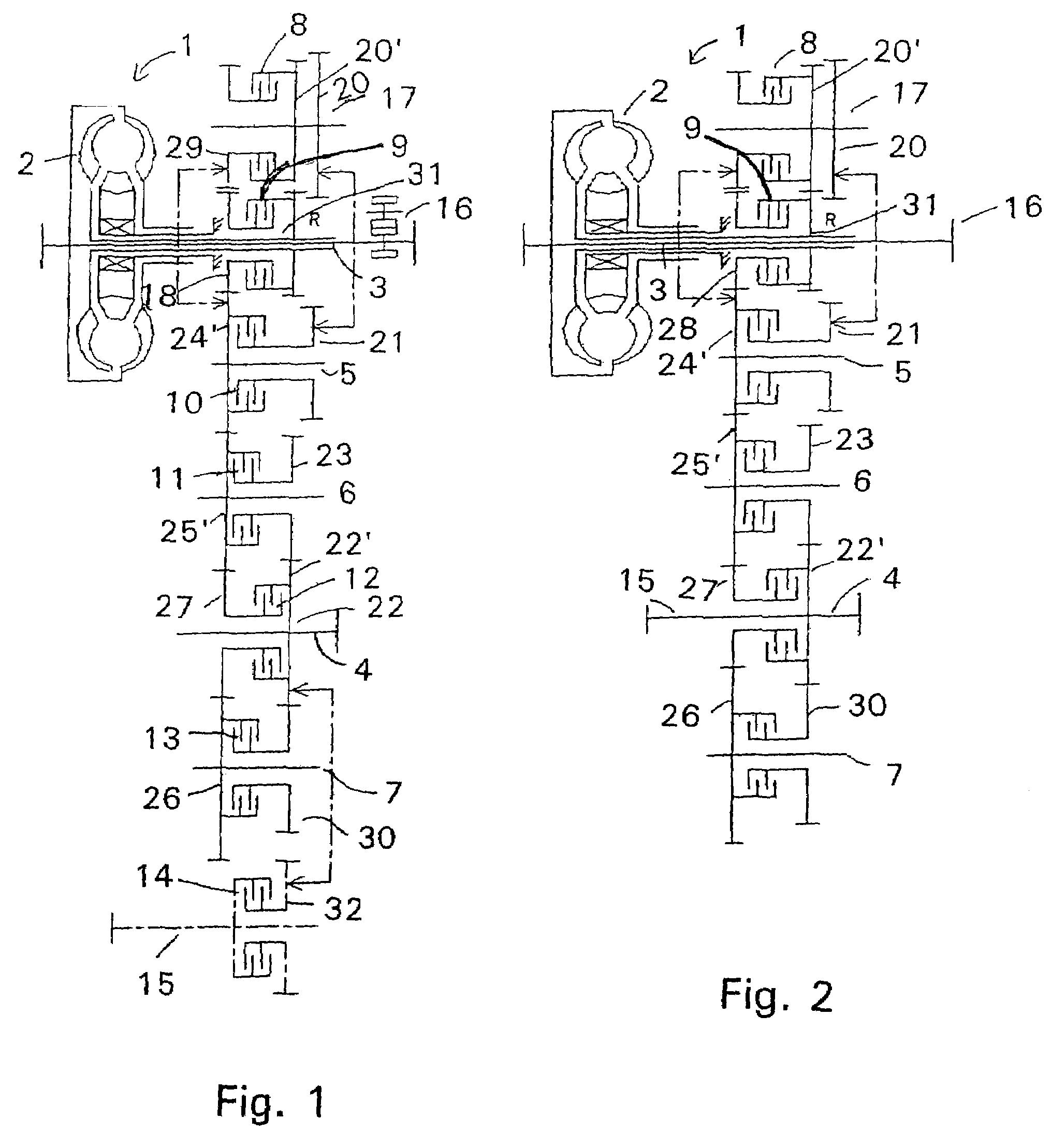

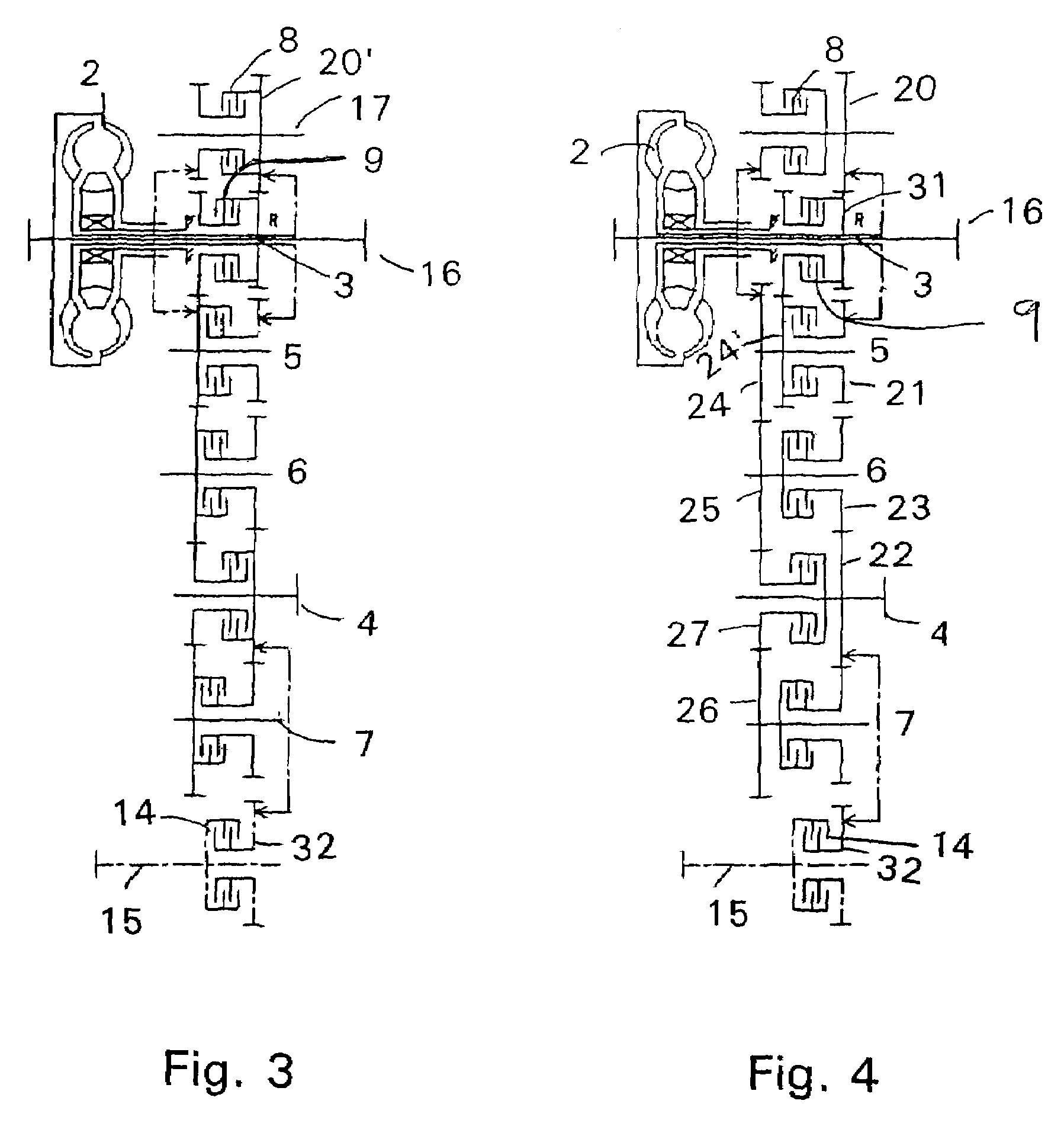

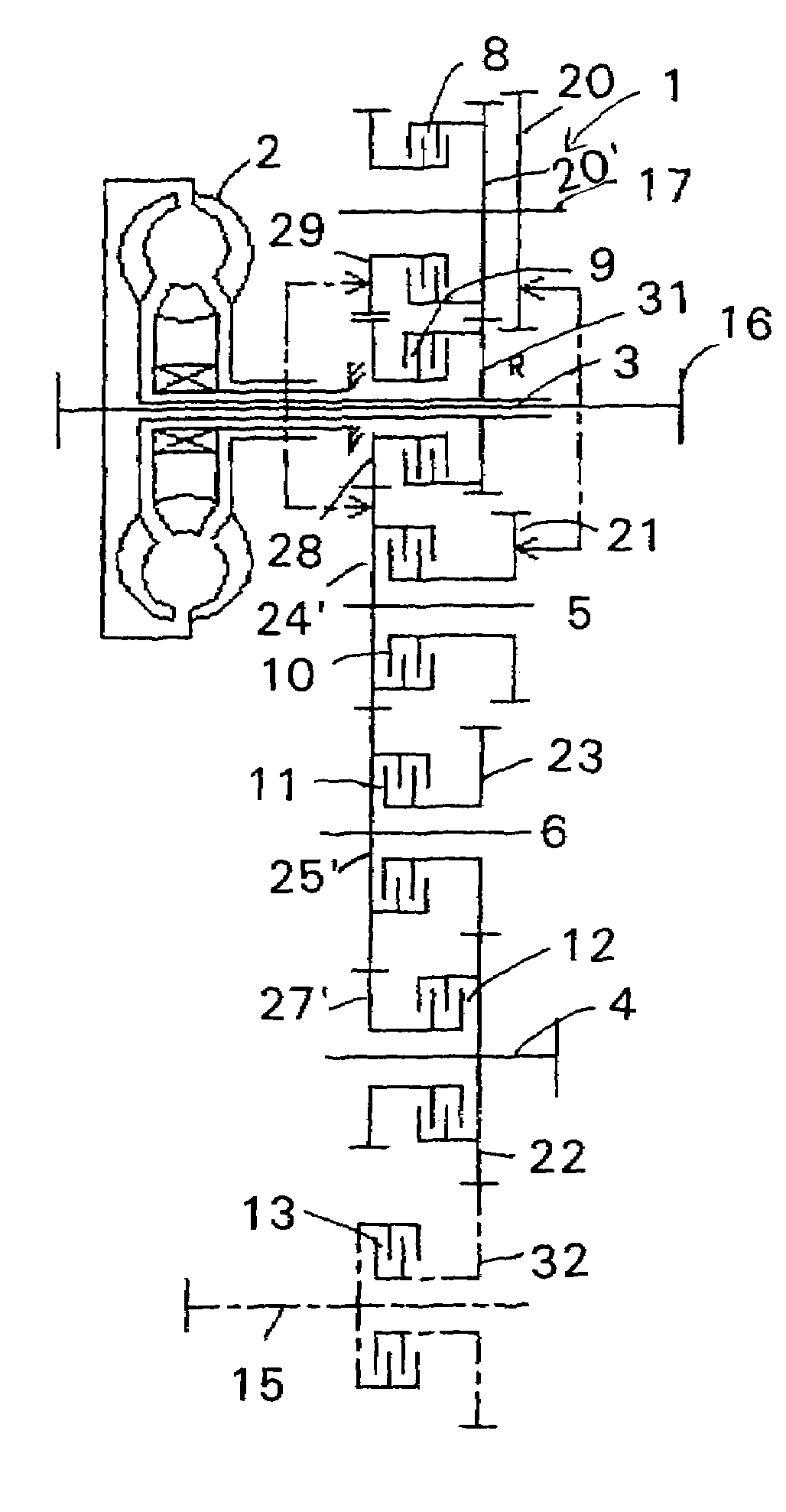

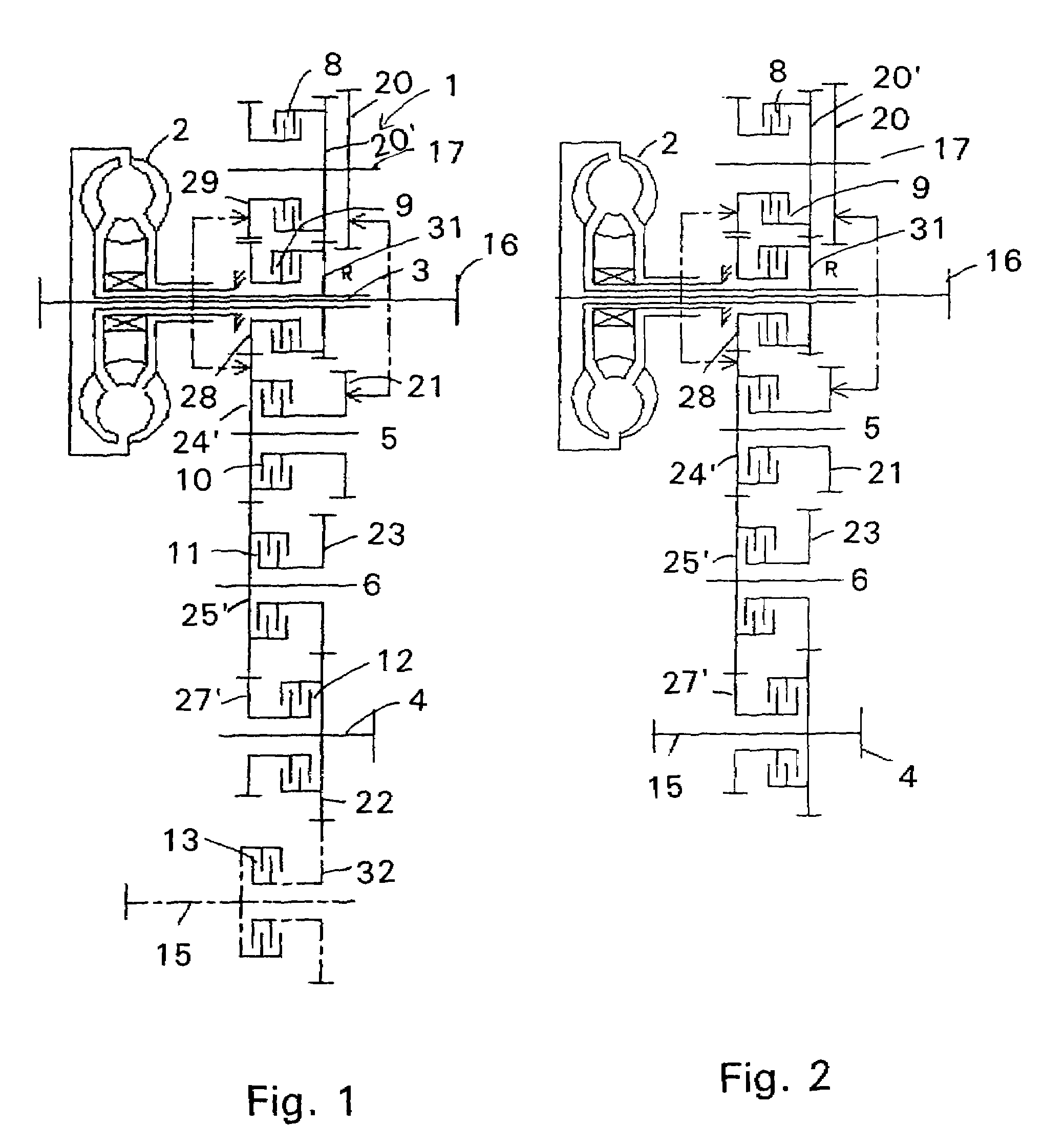

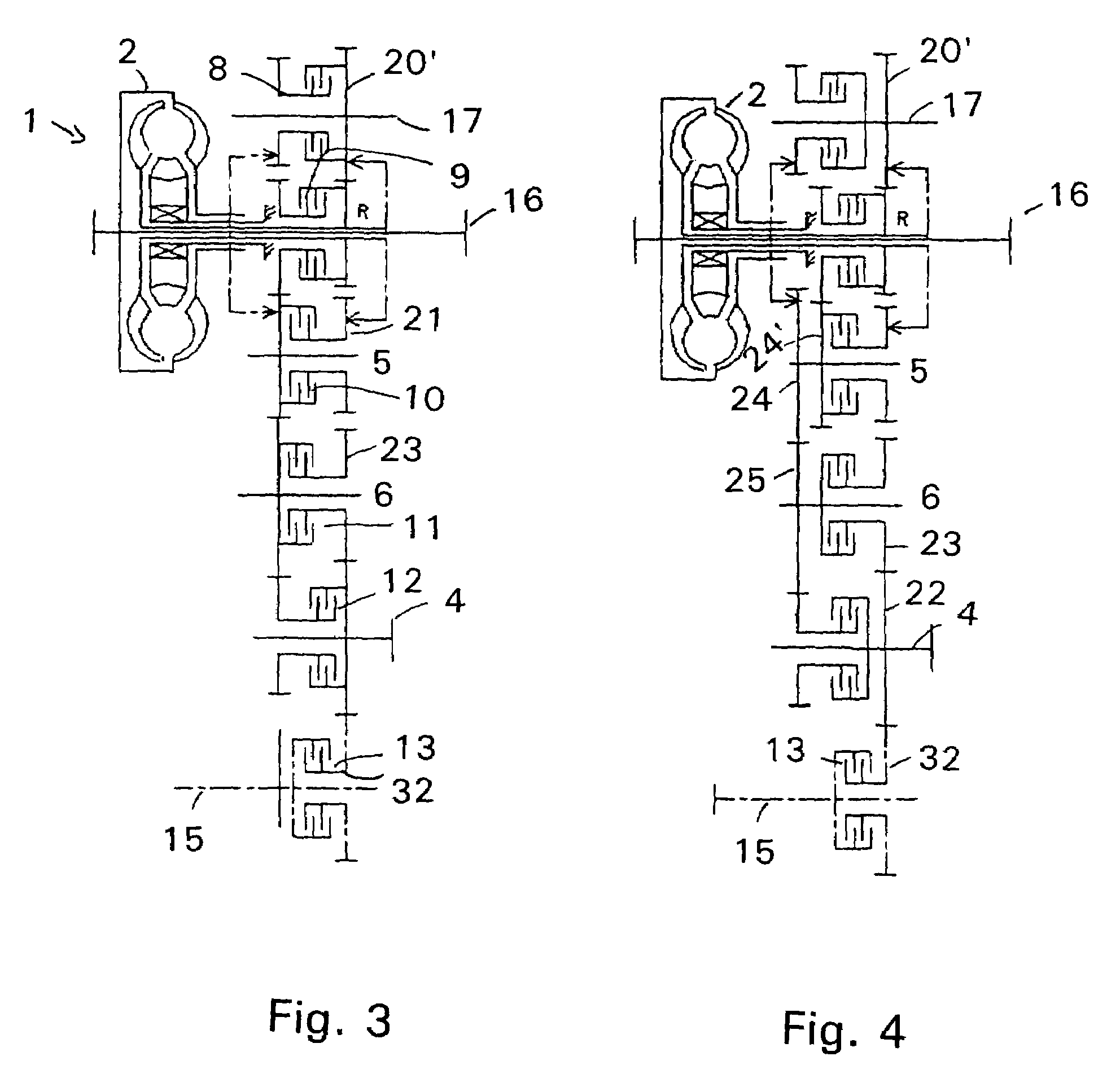

Powershift gearbox for construction machines, especially for a tractor backhoe loader and a telescopic handler

A multi-geared high-low clutch for construction machines and telescopic handlers, with a torque converter, a drive shaft, an output shaft and several jack shafts, with distributed idlers on the shafts, fixed wheels and shift clutches, which form several reduction gear units for the gearshift and direction circuit, containing six forward gears and three reverse gears, whereby output shaft is also used as a jack shaft for a gear, with which the corresponding jack shaft of forward gear unit and the corresponding jack shaft of a further forward gear unit engages with drive shaft. Both jack shafts can be rotated around drive shaft, where corresponding jack shafts of the gears, applied to drive shaft, are arranged one behind the other on a side of the drive shaft and where the corresponding jack shafts of the further gears, can currently be rotated around the next jack shaft.

Owner:ZF FRIEDRICHSHAFEN AG

Powershift gearbox for construction machines, especially for a tractor backhoe loader and a telescopic handler

A multi-geared high-low clutch for construction machines with a torque converter, a drive shaft, an output shaft and several jack shafts, with distributed idlers on the shafts, fixed wheels and shift clutches, which form several reduction gear units for the gearshift and direction circuit, containing four forward gears and two reverse gears, whereby output shaft is also used as a jack shaft for a gear, with which the corresponding jack shaft of forward gear unit and the corresponding jack shaft of another forward gear unit engage with drive shaft, where both jack shafts can be rotated in every desired angle position around drive shaft, whereby corresponding jack shafts of the gears, applied to drive shaft, are arranged one behind the other on a side of the drive shaft and whereby, that corresponding jack shafts of the gears, can currently be rotated around the next visibly arranged jack shaft.

Owner:ZF FRIEDRICHSHAFEN AG

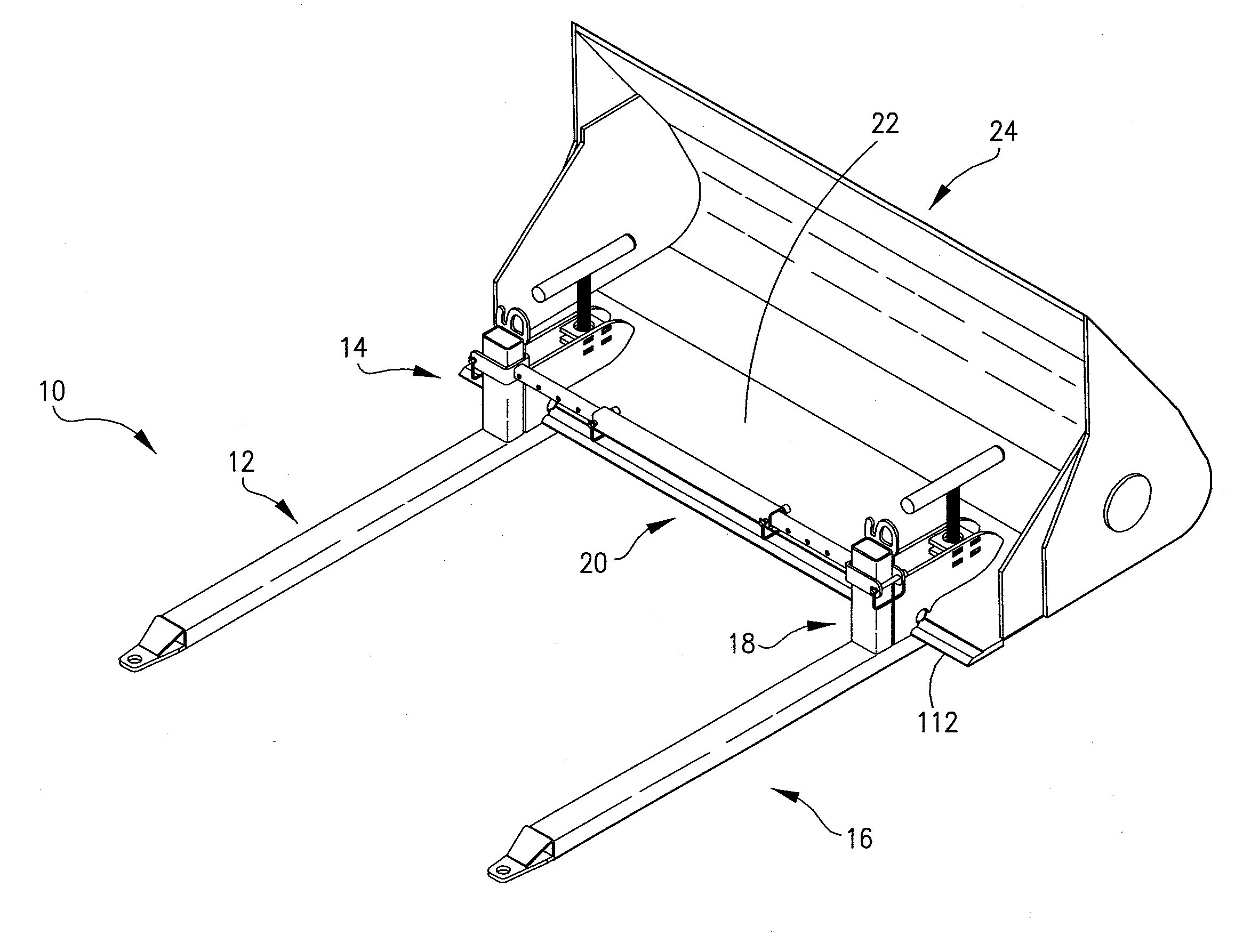

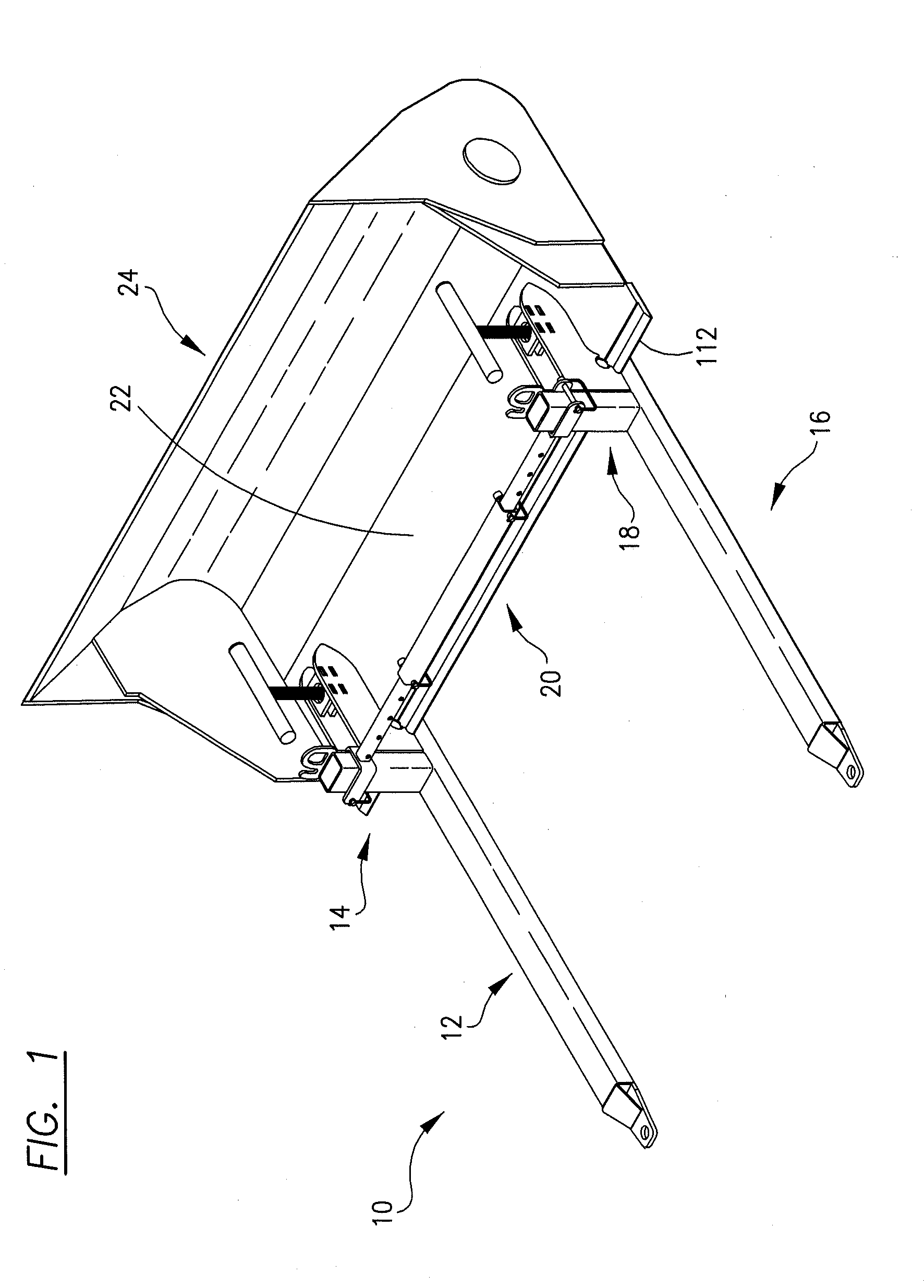

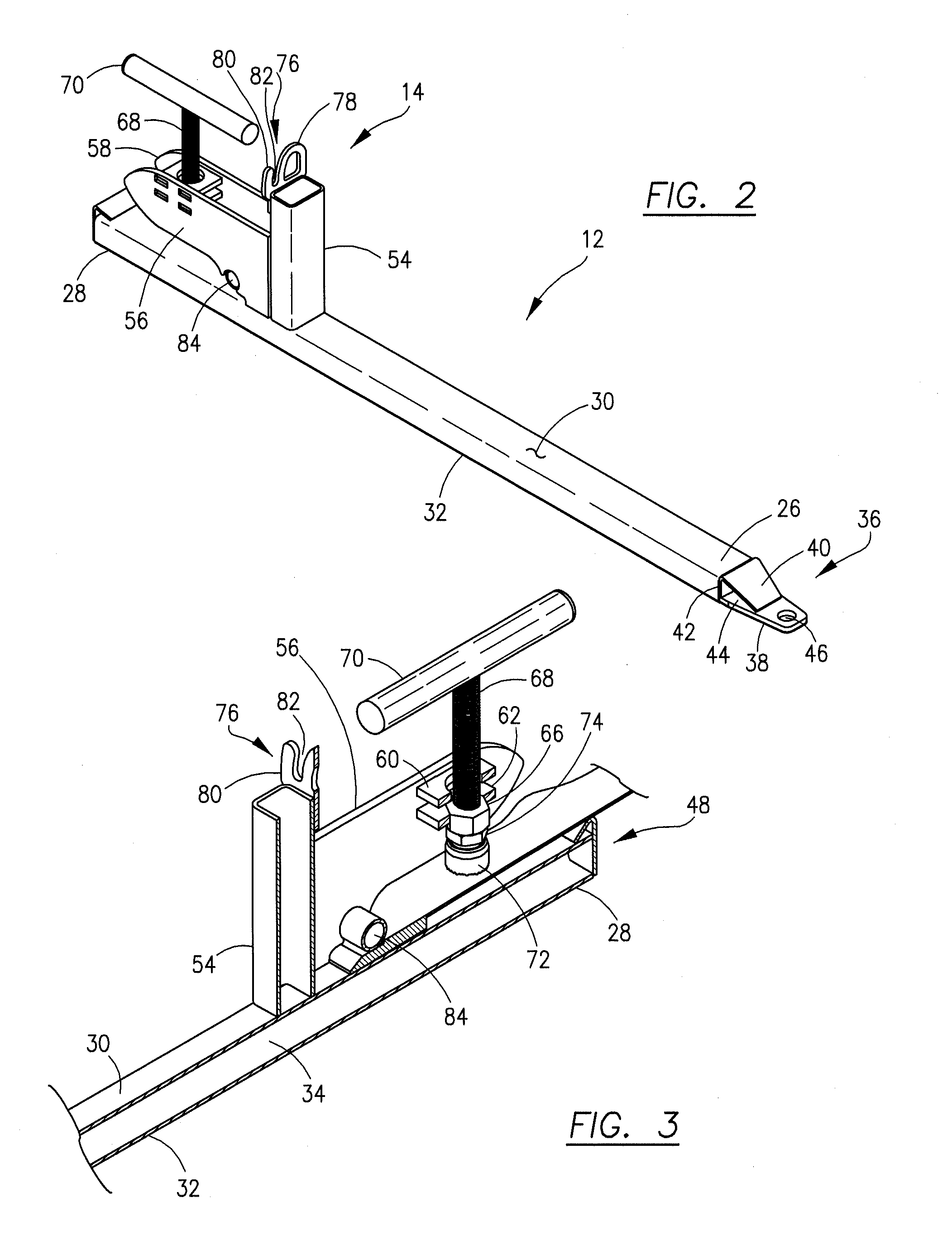

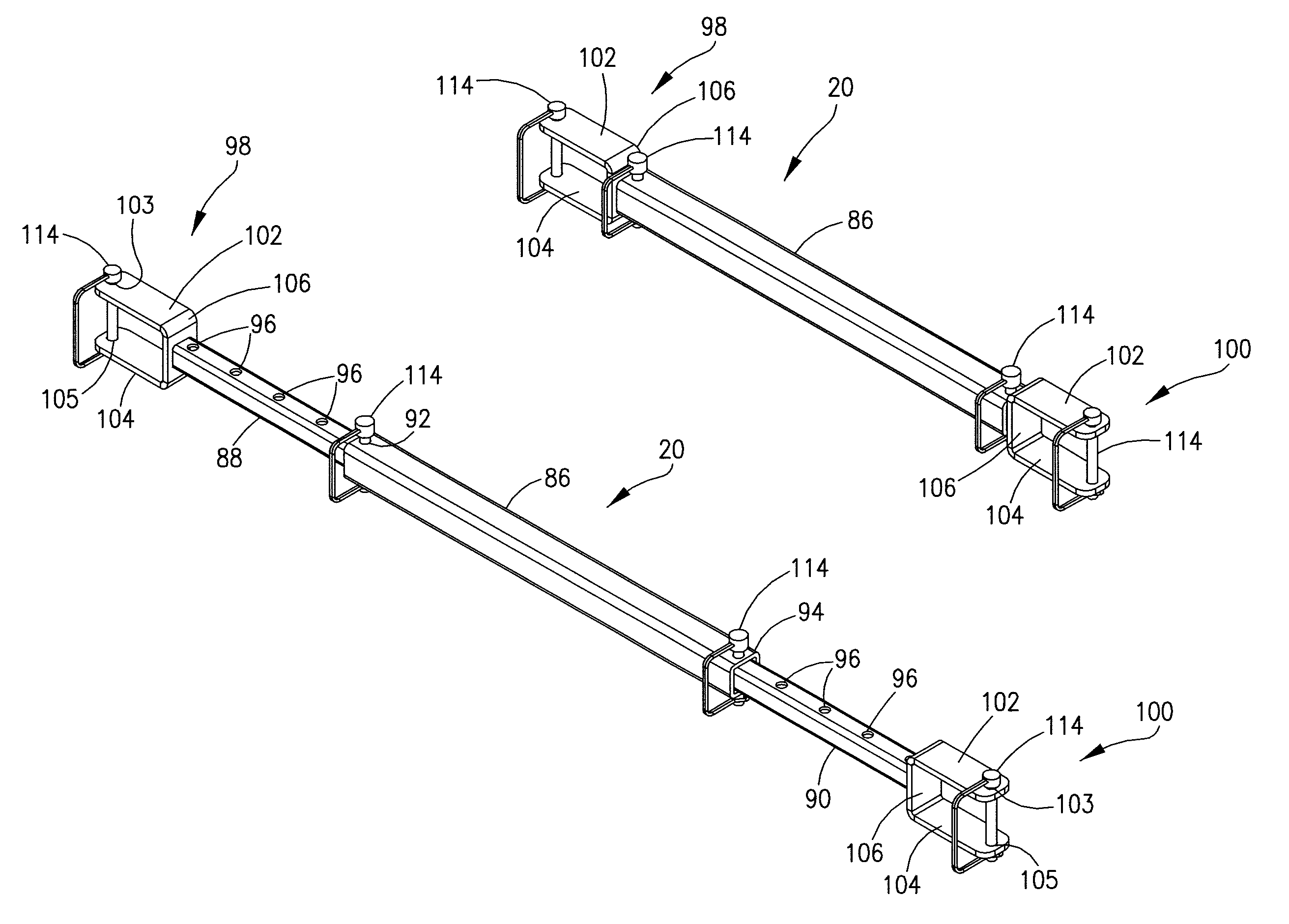

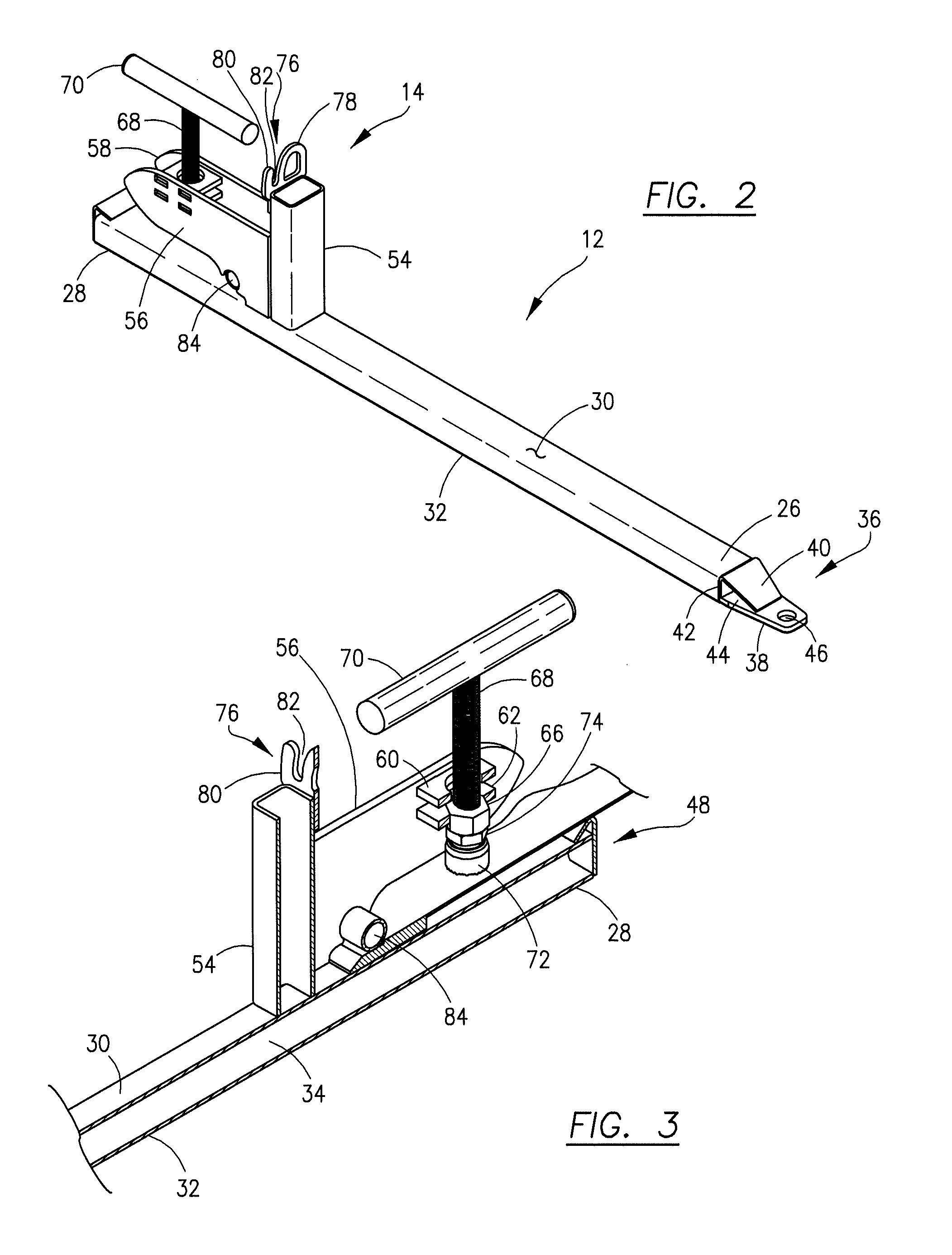

Clamp-on fork lift attachment

ActiveUS20140248111A1Improve rigidityMechanical machines/dredgersLifting devicesEngineeringBackhoe loader

A clamp-on fork lift attachment having spaced tines which may be temporarily secured to the blade portion of a loader bucket used on equipment such as backhoe loaders and front end loaders includes a lifting plate, a leveling indicator, tie-down elements and a stabilizer bar connected between the spaced tines.

Owner:WERNER CO

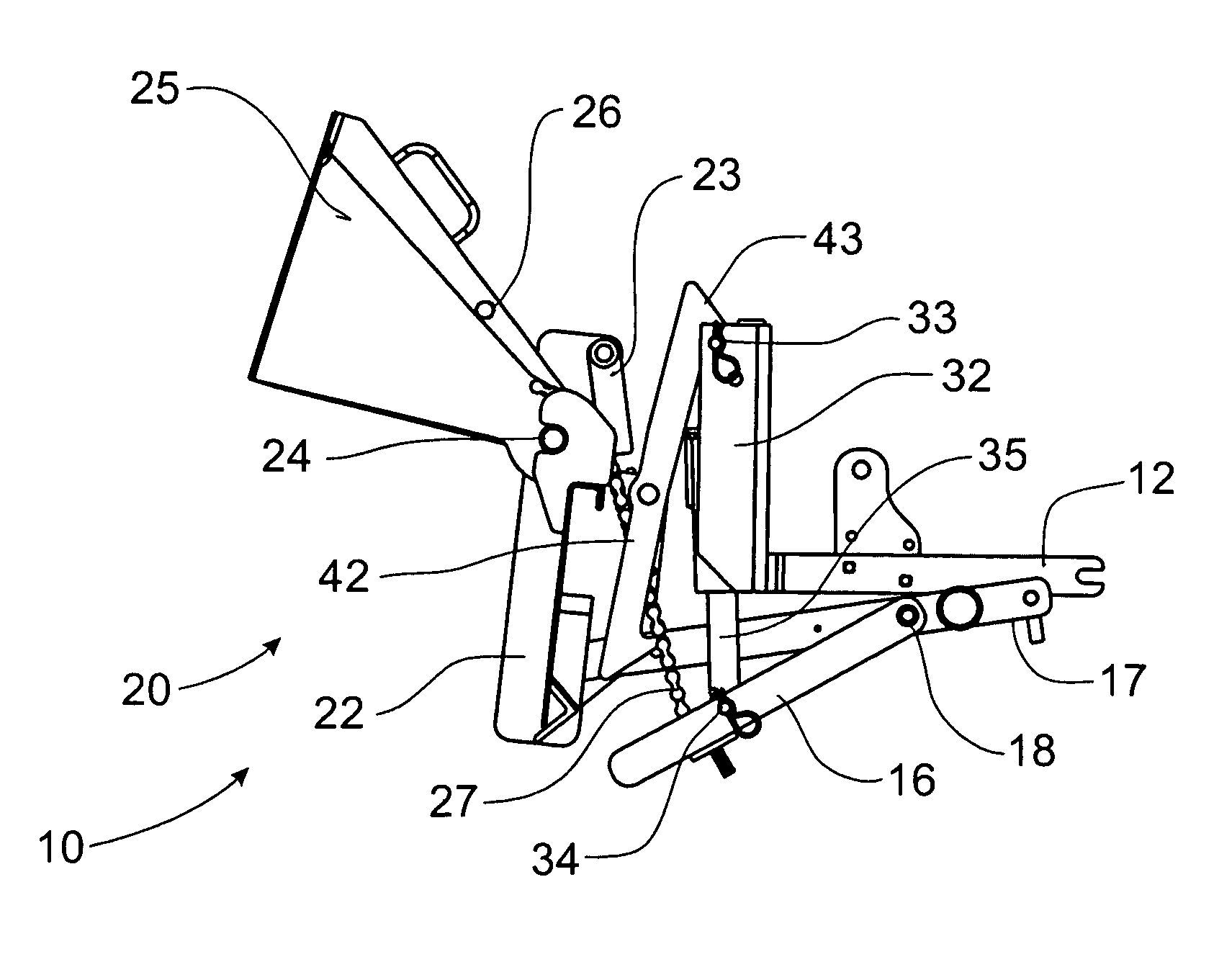

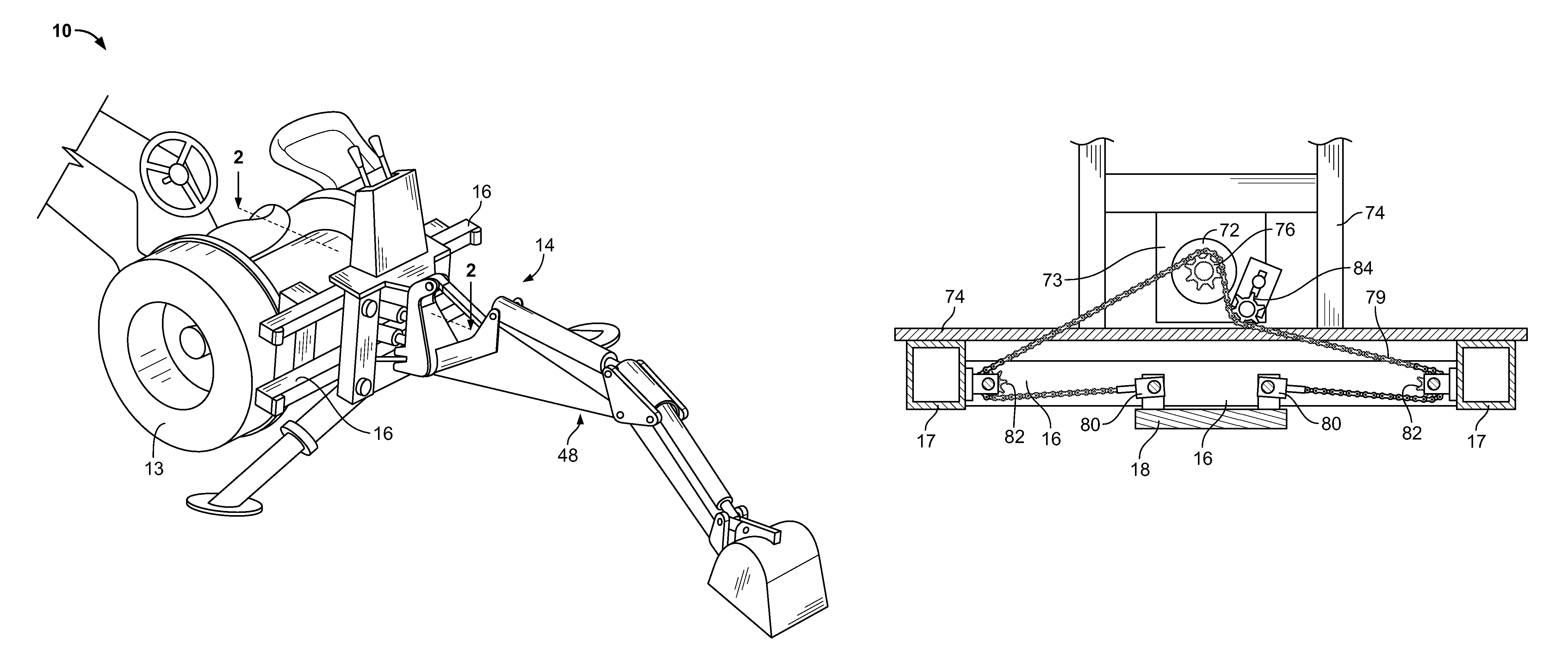

Bucket loader for small tractors and all terrain vehicles

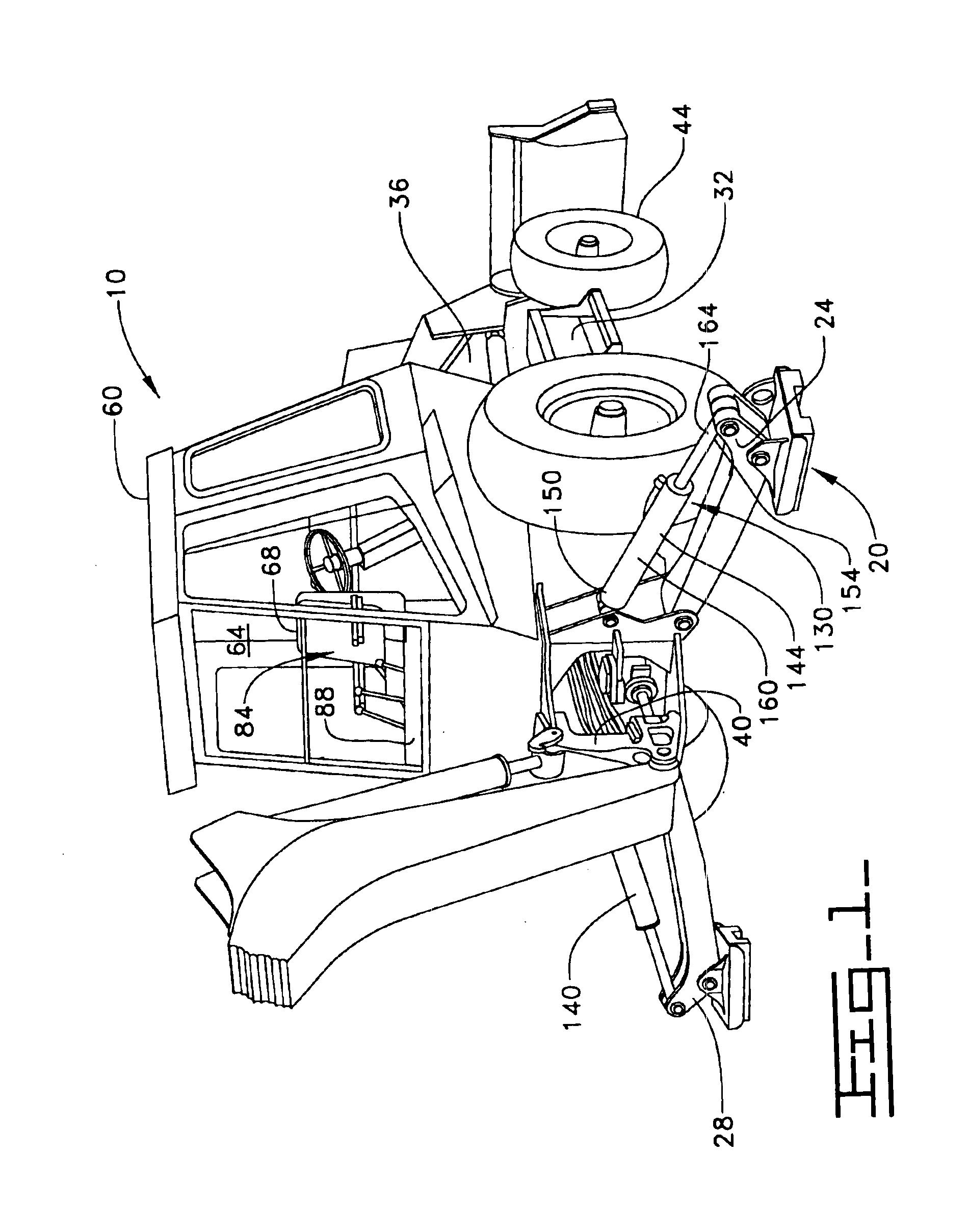

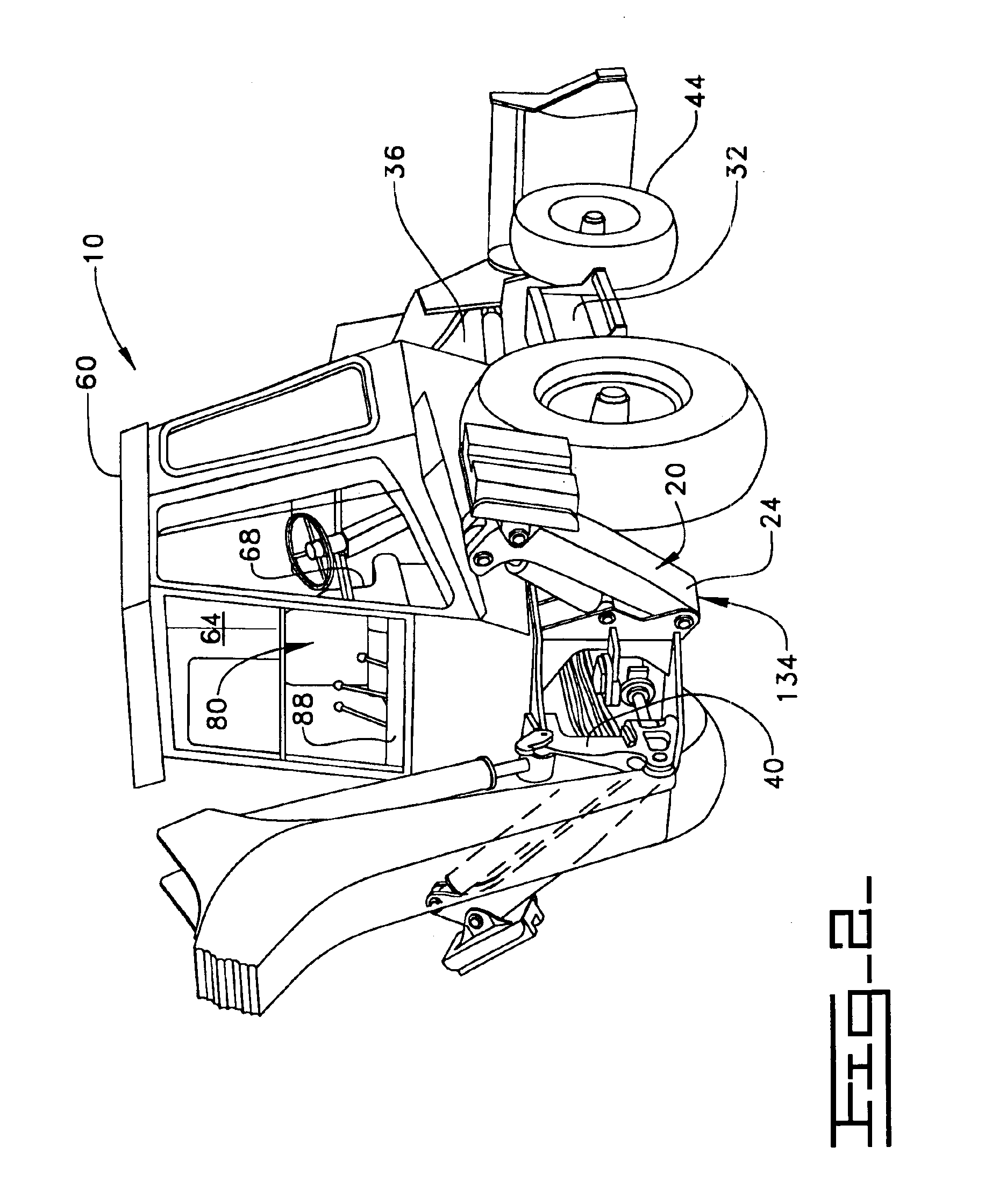

InactiveUS7789613B1Reliable constructionReduce manufacturing costMining devicesMechanical machines/dredgersEngineeringControl theory

A control apparatus for a bucket loader allows a single linear actuator to provide multiple operative functions for the bucket loader. A selector link is pivotally mounted on the back plate of loader bucket to selectively connect the back plate to the base portion of the linear actuator so that the extendable portion powers a pivoting of the bucket shell to dump material from the bucket, or connect the back plate to the extendable portion of the linear actuator to power the vertical movement of the back plate. A chain interconnects the extendable portion of the linear actuator and the pivotable bucket shell to power the pivoting of the bucket shell when the selector link is connected to the base portion. The bucket shell can be mechanically locked into an open position to allow the back plate to be utilized as a push blade.

Owner:WEINLADER J KEITH

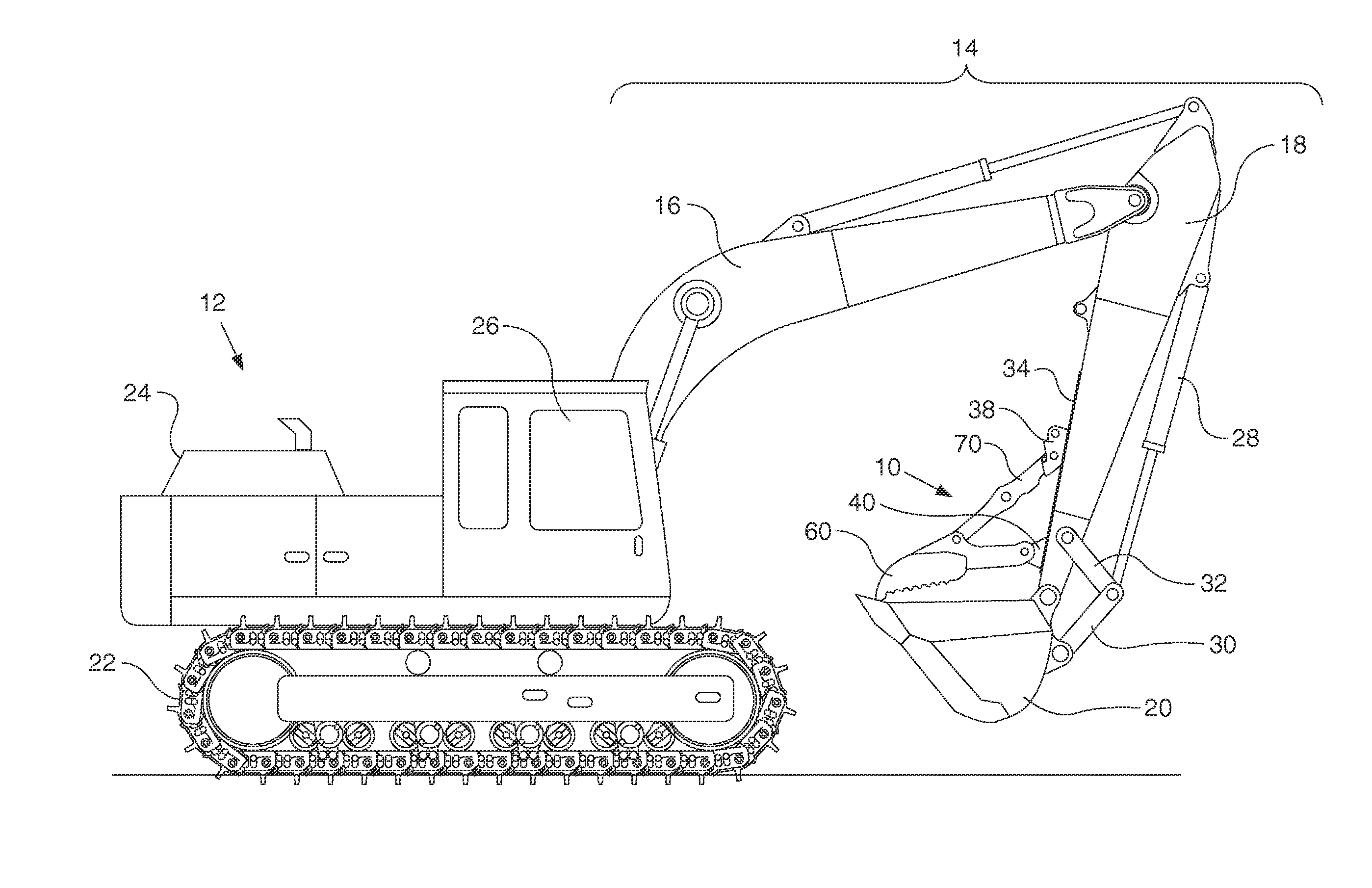

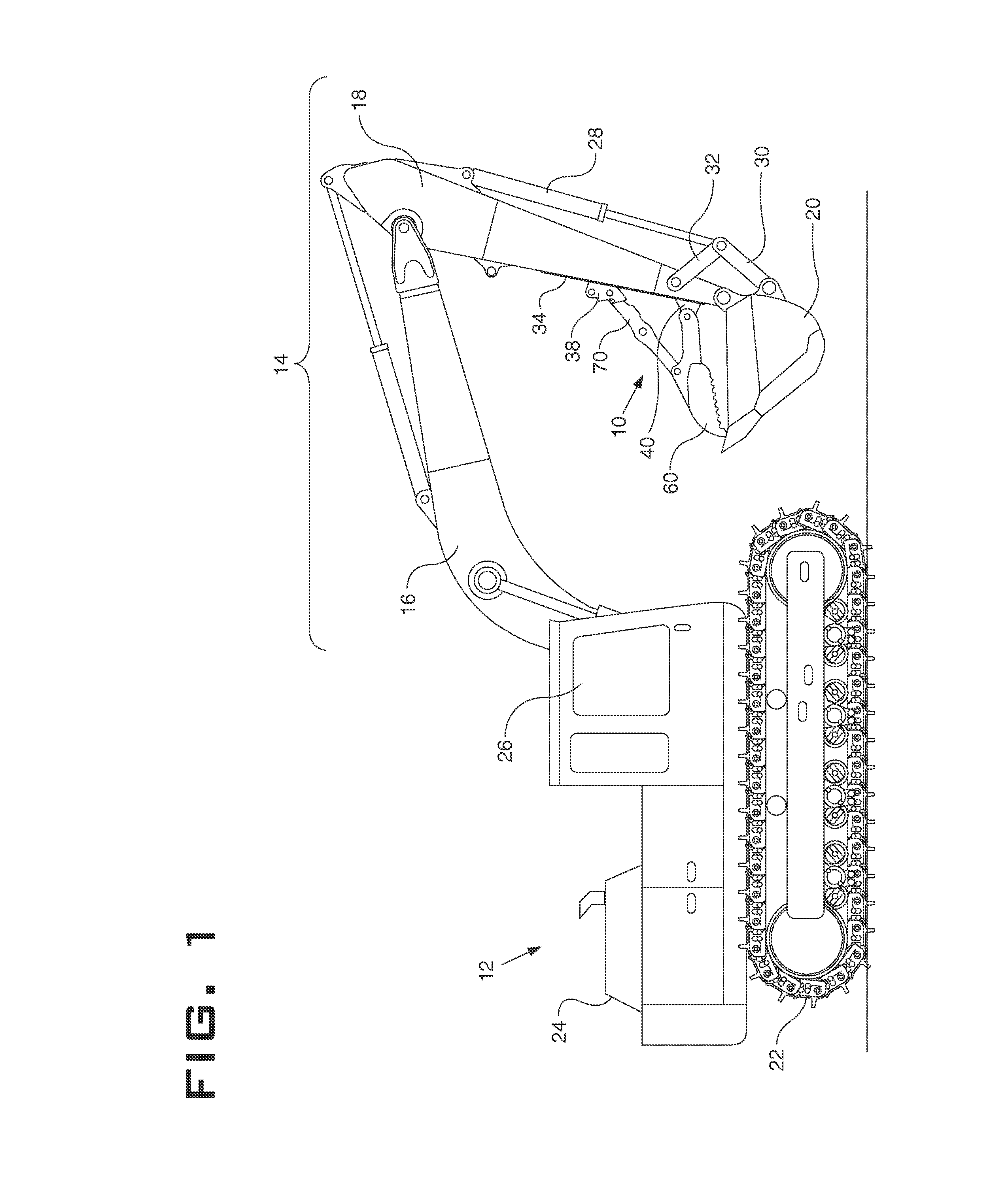

Bucket thumb assembly

A bucket thumb assembly mountable to a lifting arm of a machine (e.g., an excavator or a backhoe loader) includes a mounting lug and a thumb member pivotably coupled to the mounting lug. The bucket thumb assembly also includes a link member extending from the thumb member. The link member has a first aperture at a first end of the link member. The link member has an indicator block extending from the link member. The bucket thumb assembly further includes a mounting plate having a second aperture and a catch. The mounting plate is configured to selectively couple with the link member using a pin inserted through the first and second apertures when the indicator block is resting on the catch such that a face surface on the indicator block and a face surface of the catch are substantially co-planar.

Owner:CATERPILLAR INC

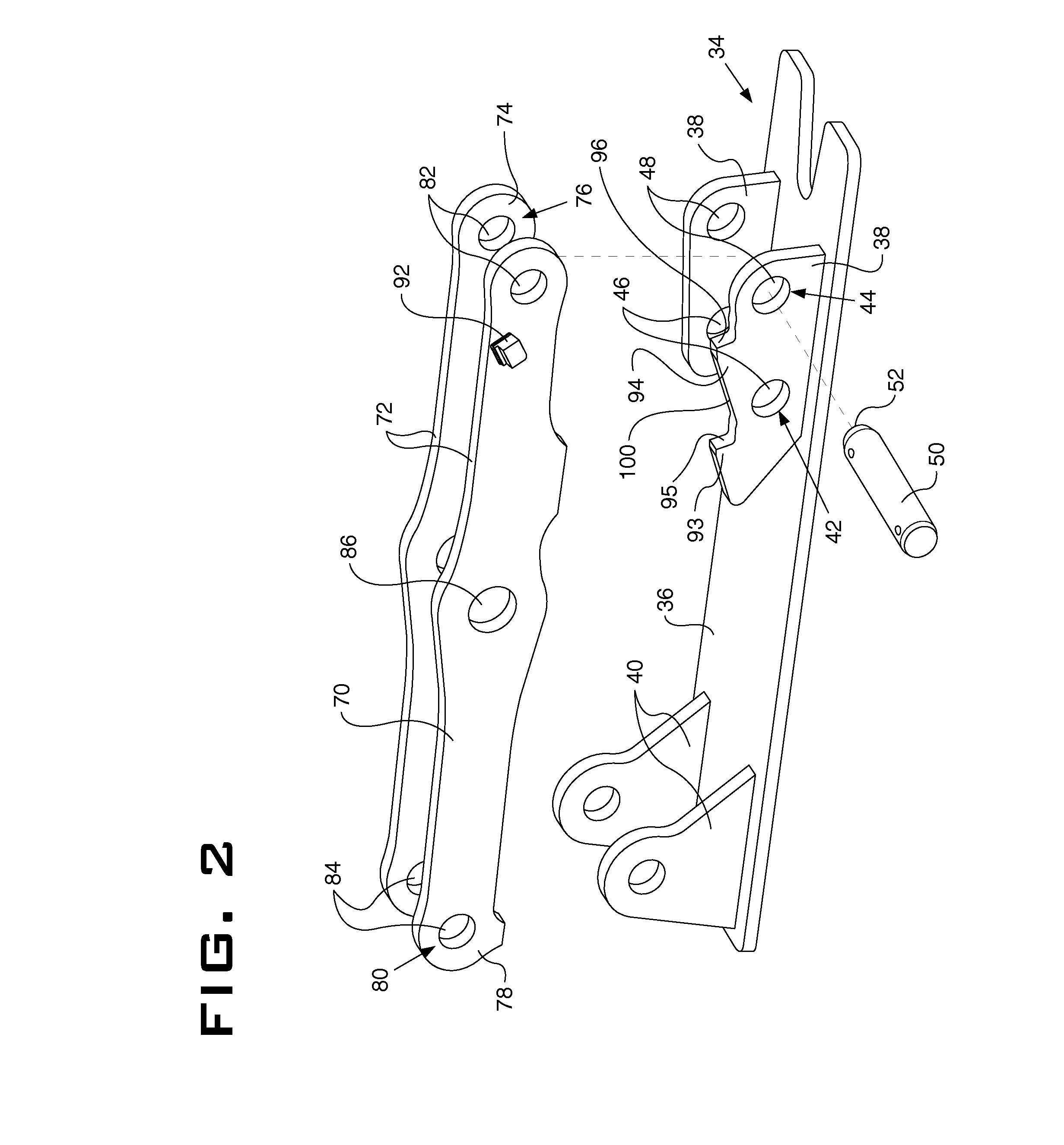

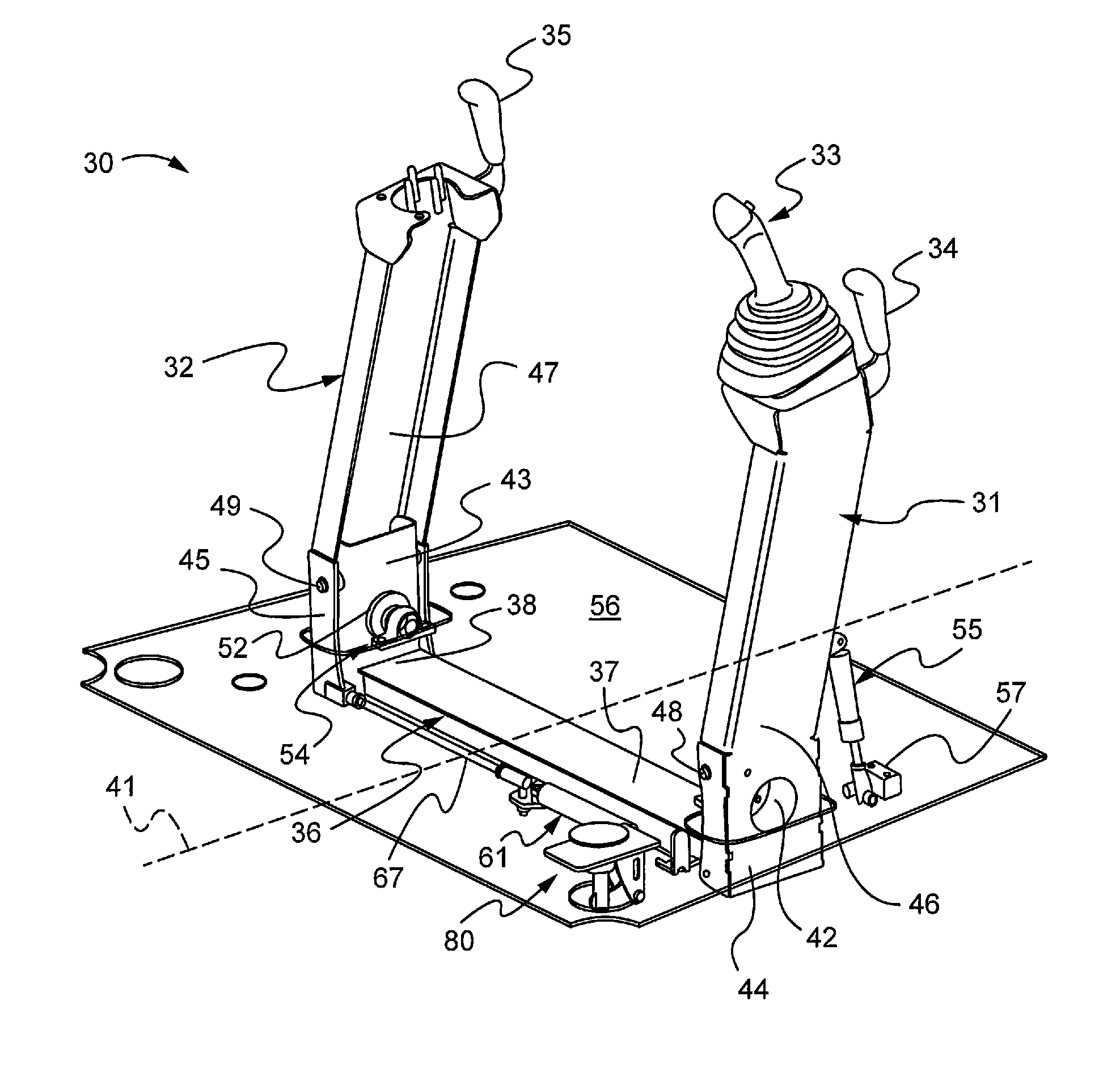

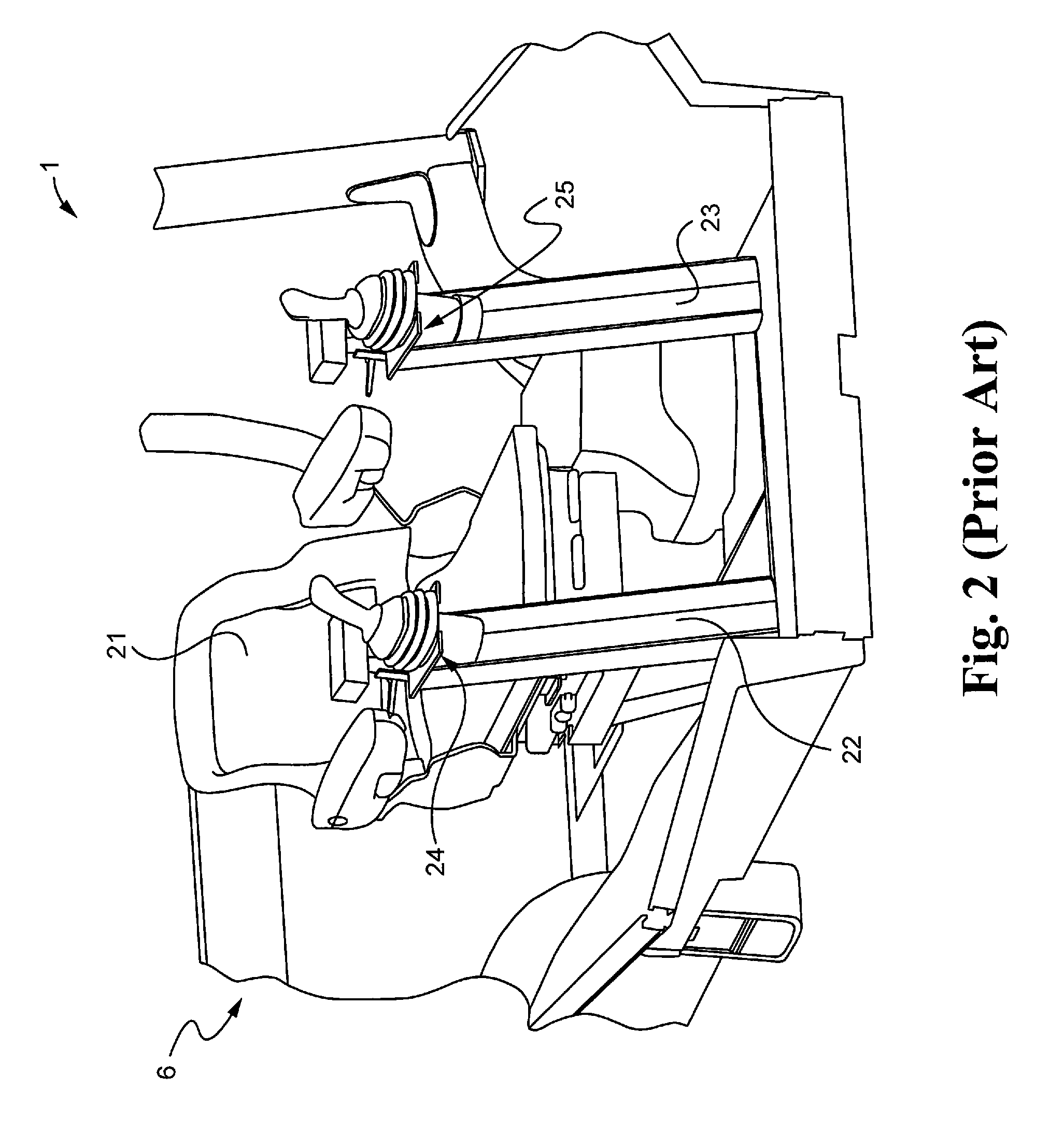

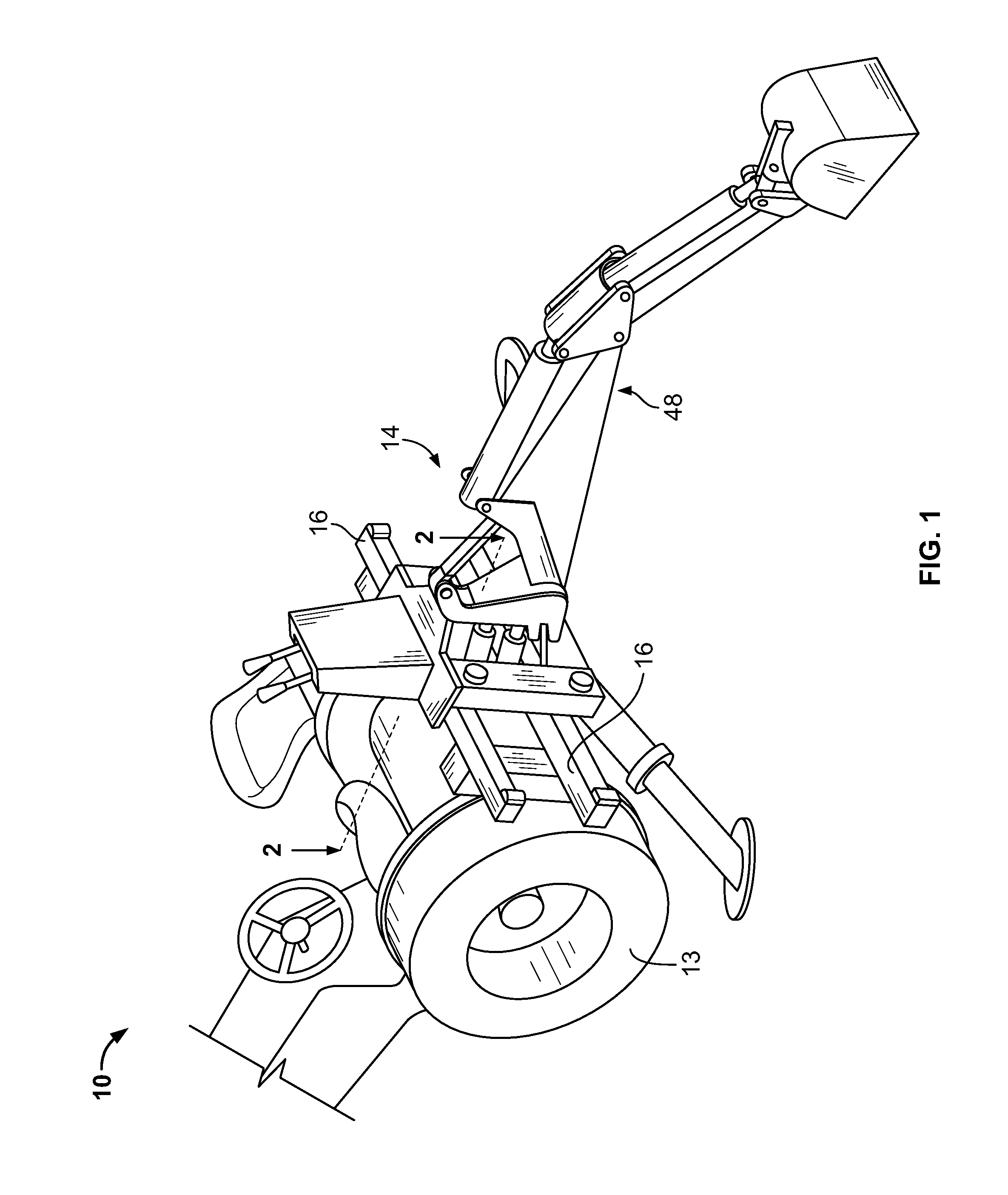

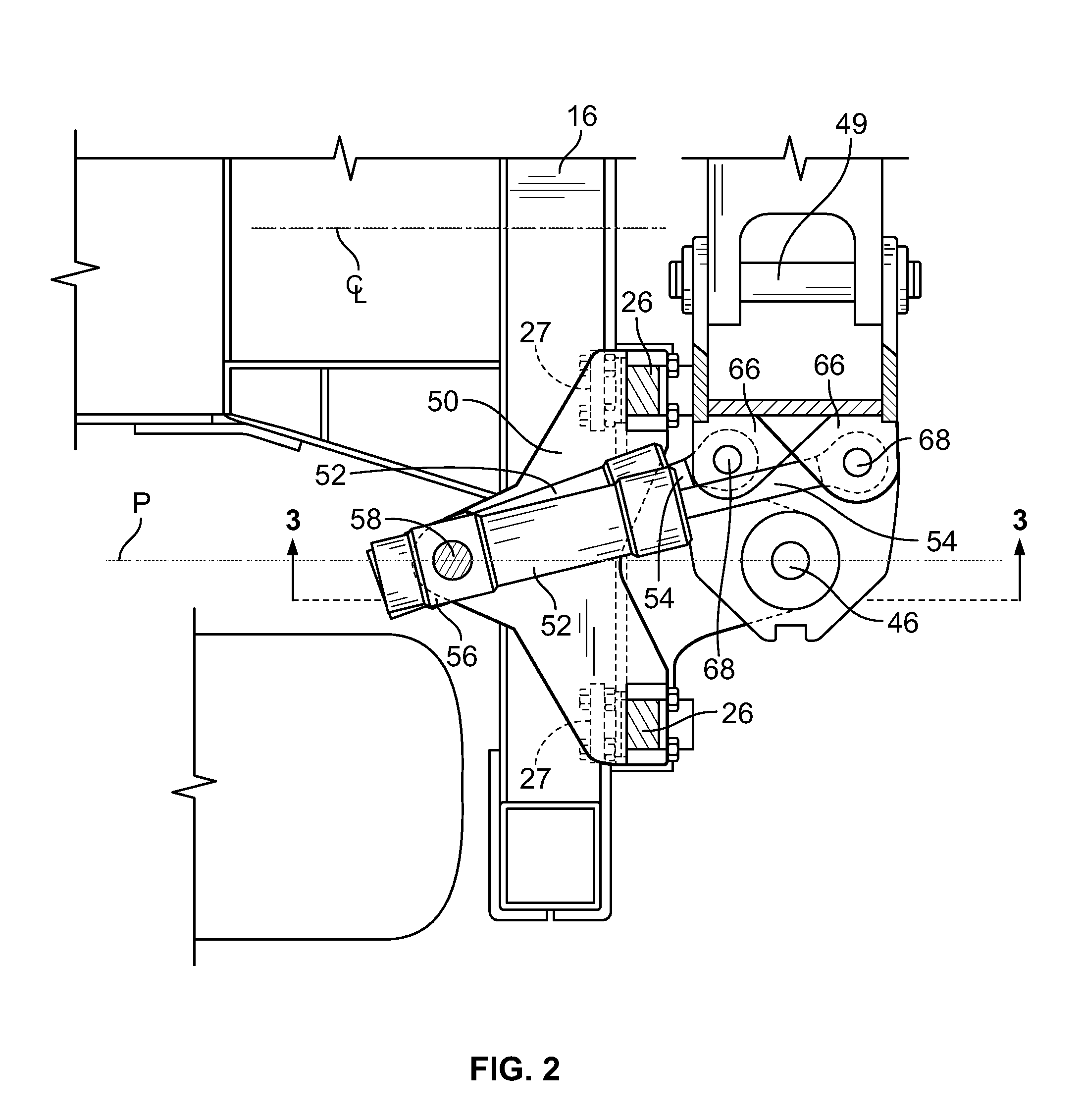

Multi-directionally adjustable control pods

ActiveUS8651220B2Manual control with multiple controlled membersMechanical apparatusControl systemControl theory

A position-adjustable, dual-pod control system for a machine, such as a backhoe loader is disclosed. The system includes a horizontal cross beam connected to a pair of brackets. The pair of brackets are mounted to the machine by way of a pair of bearings that enables pivotal movement of the cross beam in the fore and aft directions while the cross beam is positioned perpendicularly to the fore and aft direction or the fore-aft centerline of the machine. The bottom end of each pod arm is pivotally coupled to the brackets thereby enabling the pod arms to be pivoted towards or away from the centerline. Each bracket includes a through hole that accommodates a bearing that is mounted to the machine, such as to the floor of the machine.

Owner:CATERPILLAR INC

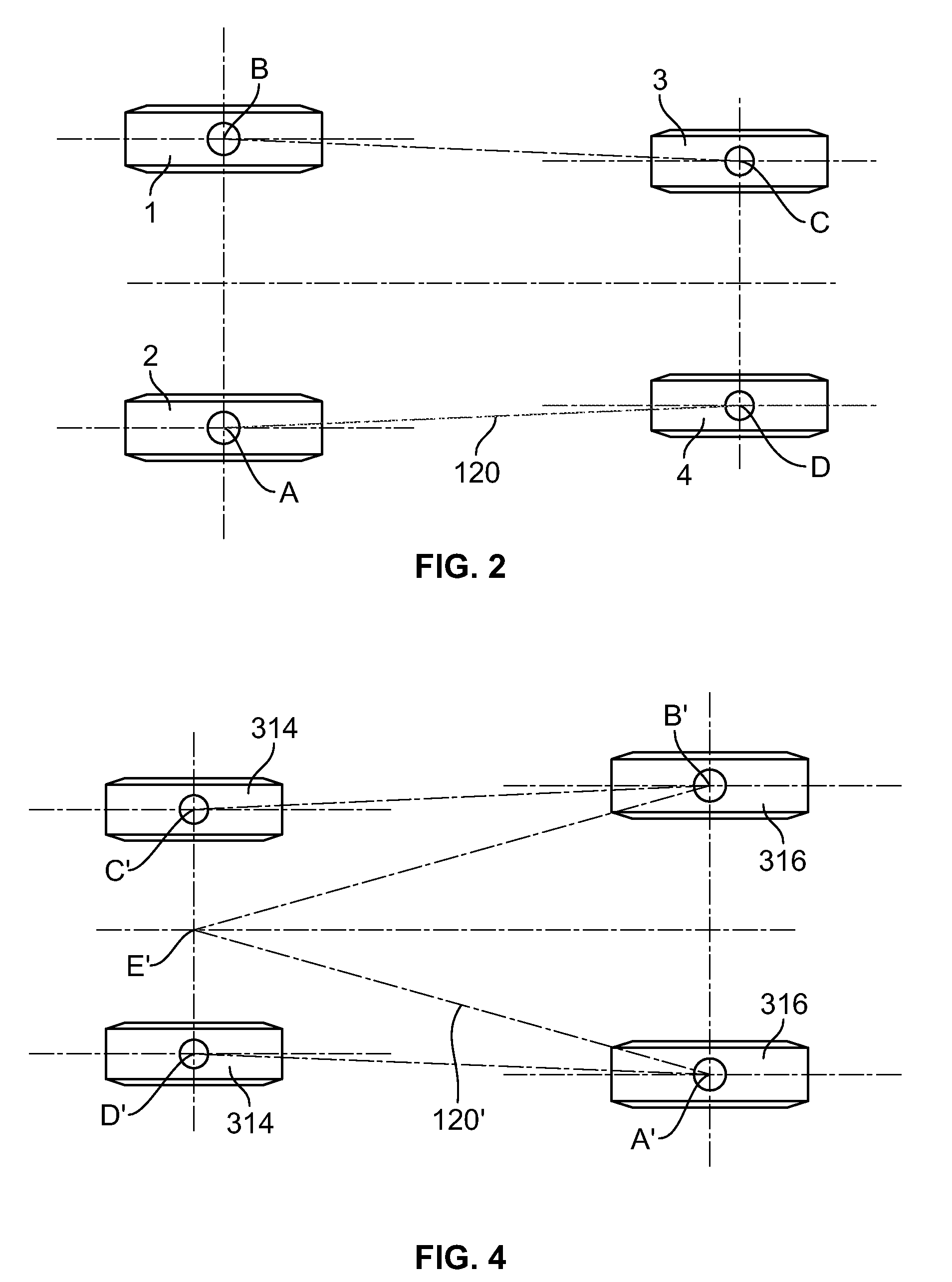

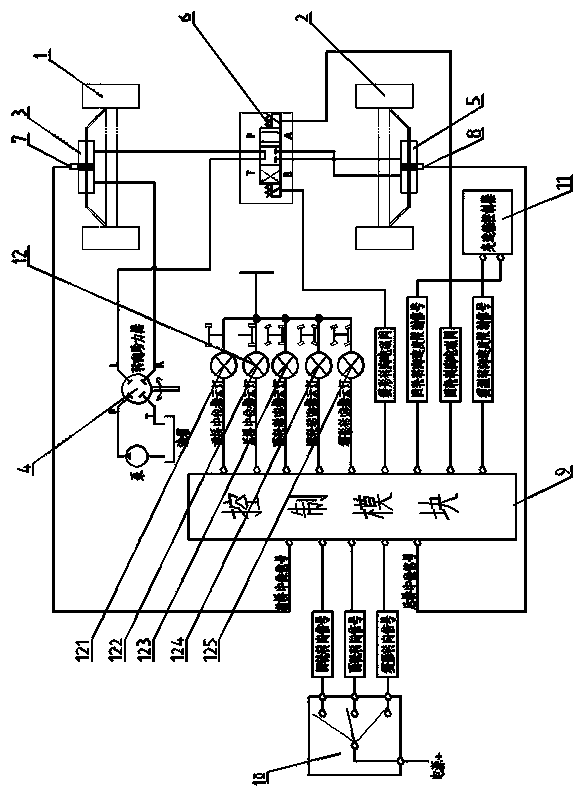

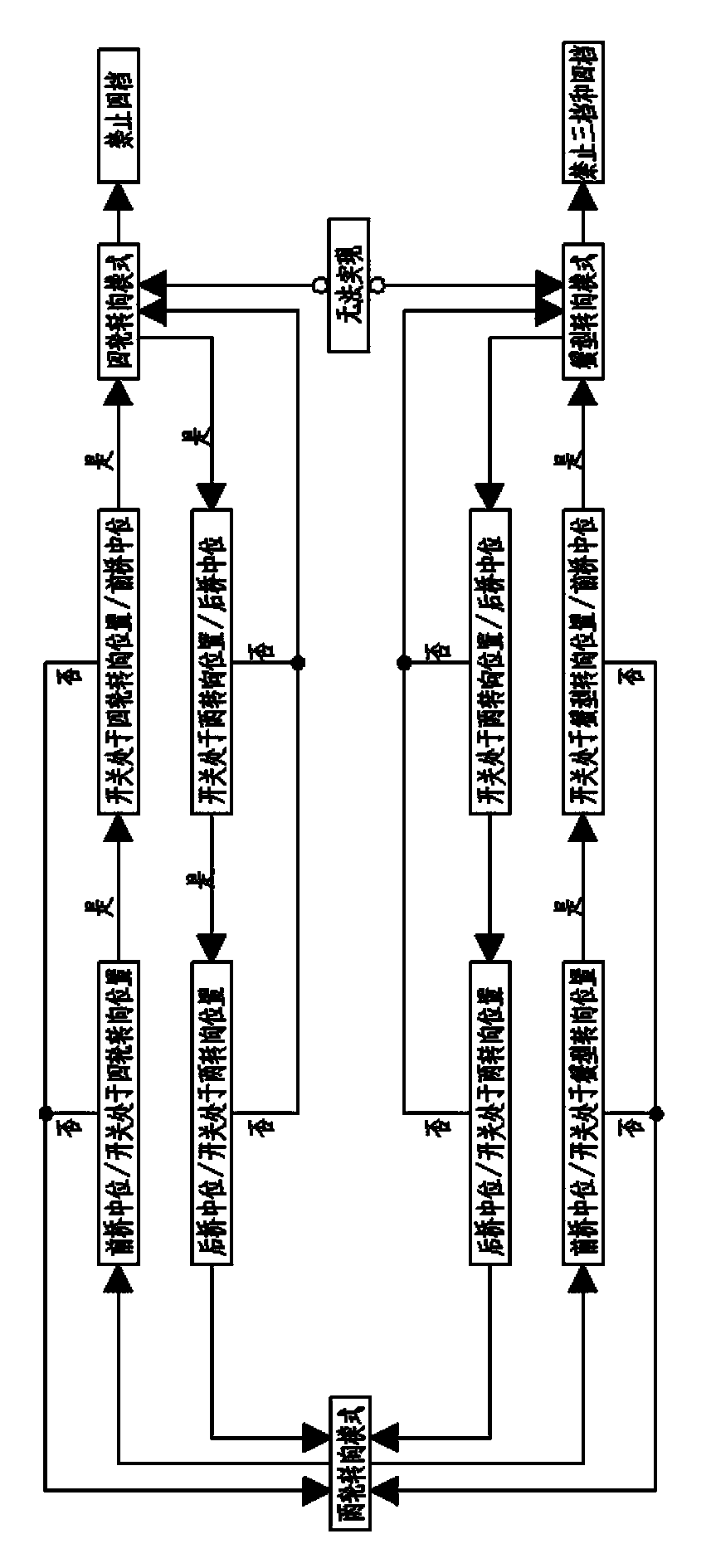

Four-wheel steering control system of backhoe loader

InactiveCN104354762AOperation guideAvoid security issuesSteering linkagesFluid steeringGear driveControl system

The invention relates to a four-wheel steering control system of a backhoe loader. The four-wheel steering control system comprises a front axle, a rear axle, a front axle steering gear and a steering booster, wherein the front axle steering gear drives wheels on the two sides of the front axle to swing so as to realize steering, and the steering booster is connected with the front axle steering gear to provide a driving force; a rear axle steering gear is arranged on the rear axle, and the front axle steering gear and the rear axle steering gear are connected with the steering booster through a mode conversion solenoid valve; a front axle neutral-position sensor is arranged on the front axle steering gear, and a rear axle neutral-position sensor is arranged on the rear axle steering gear; the front axle neutral-position sensor and the rear axle neutral-position sensor are connected with a control module, and the control module is connected with a steering mode selection switch; the steering mode selection switch controls the switching of the mode conversion solenoid valve through the control module. The four-wheel steering control system can avoid the safety problem caused by improper operation of an operator, while an indicator light can intuitively display the current steering mode of a vehicle, and the operation of the operator is guided well.

Owner:JIANGSU LIUGONG MACHINERY

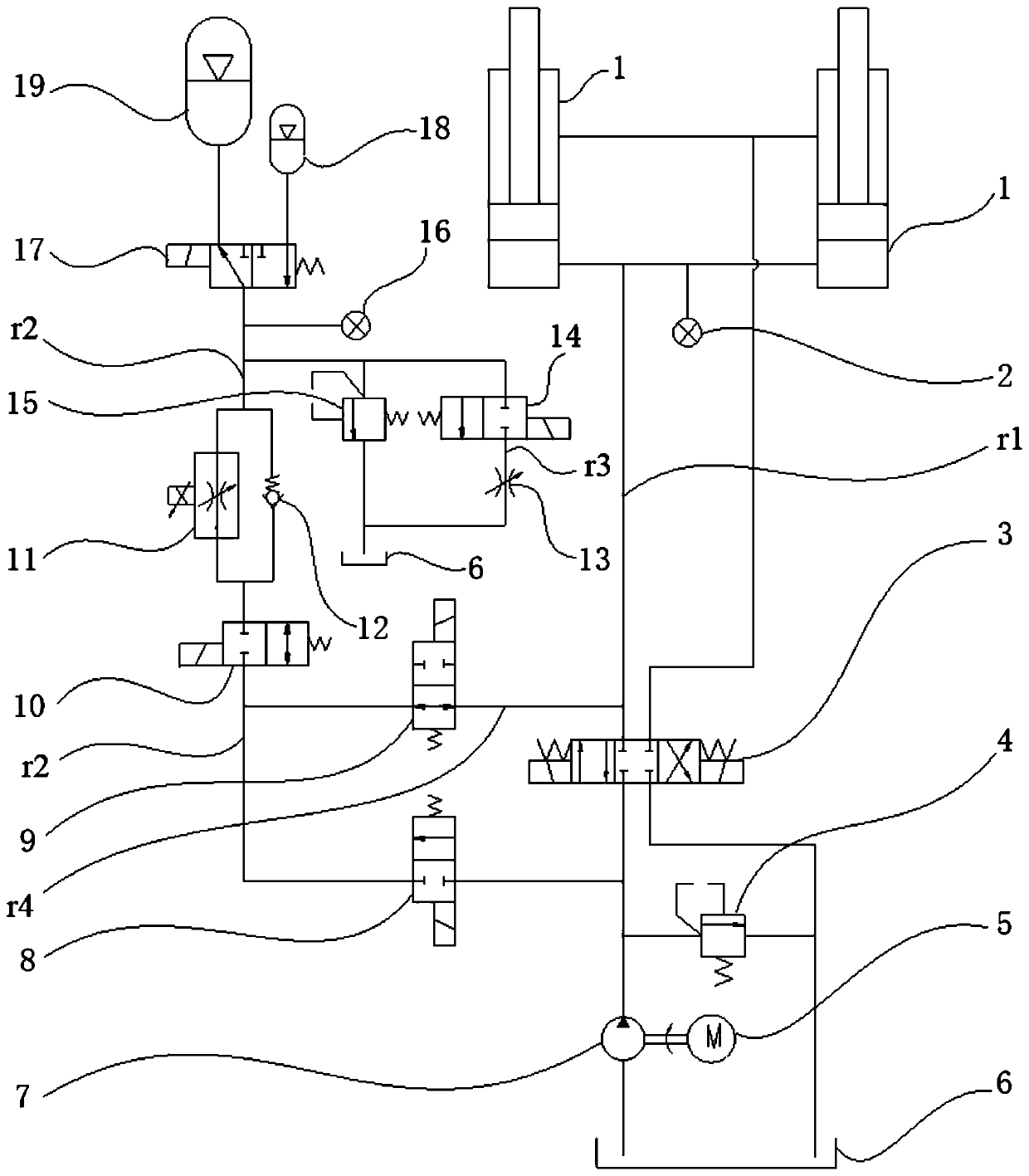

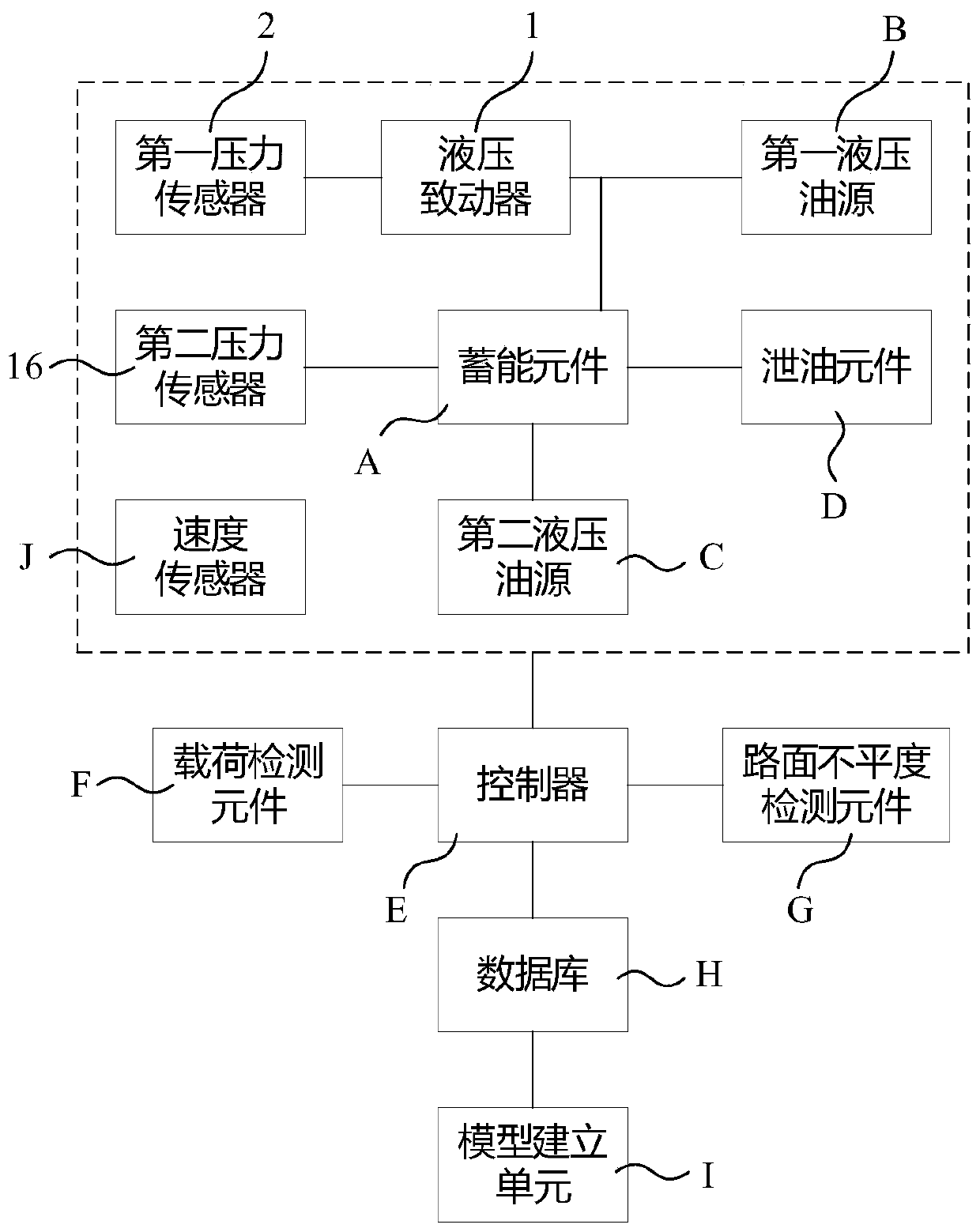

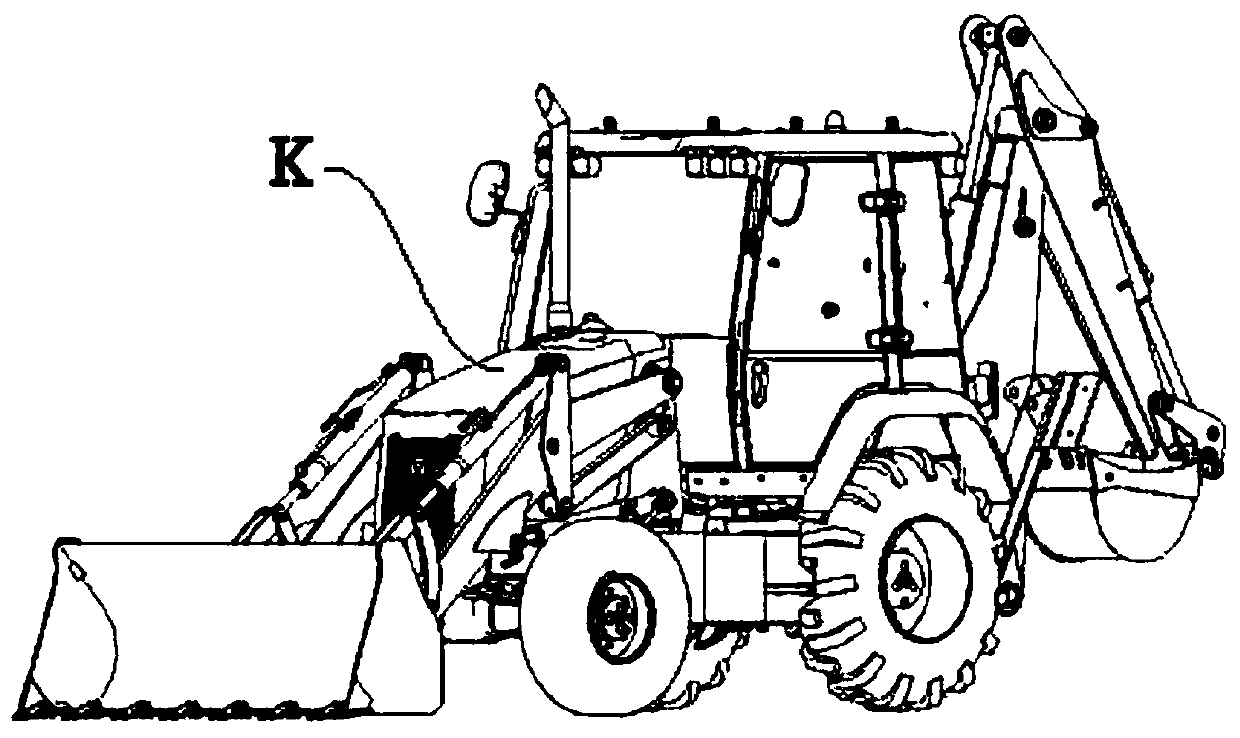

Driving stabilizing system, backhoe loader and control method

The invention relates to a driving stabilizing system, a backhoe loader and a control method. The driving stabilizing system comprises a hydraulic actuator (1), a first hydraulic oil source (B), an energy storage element (A) and a controller (E), wherein the first hydraulic oil source (B) is operably connected with the hydraulic actuator (1) and is configured to provide pressure oil for the hydraulic actuator (1); the energy storage element (A) is operably connected with a first oil supply oil way (r1) between the first hydraulic oil source (B) and the hydraulic actuator (1); and the controller (E) is configured to compare the oil pressure of the hydraulic actuator (1) to the oil pressure of the energy storage element (A) after the driving stabilizing system is started, and enable the oilpressure of the energy storage element (A) and the oil pressure of the hydraulic actuator (1) to be balanced before the energy storage element (A) is connected into the first oil supply oil way (r1).

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

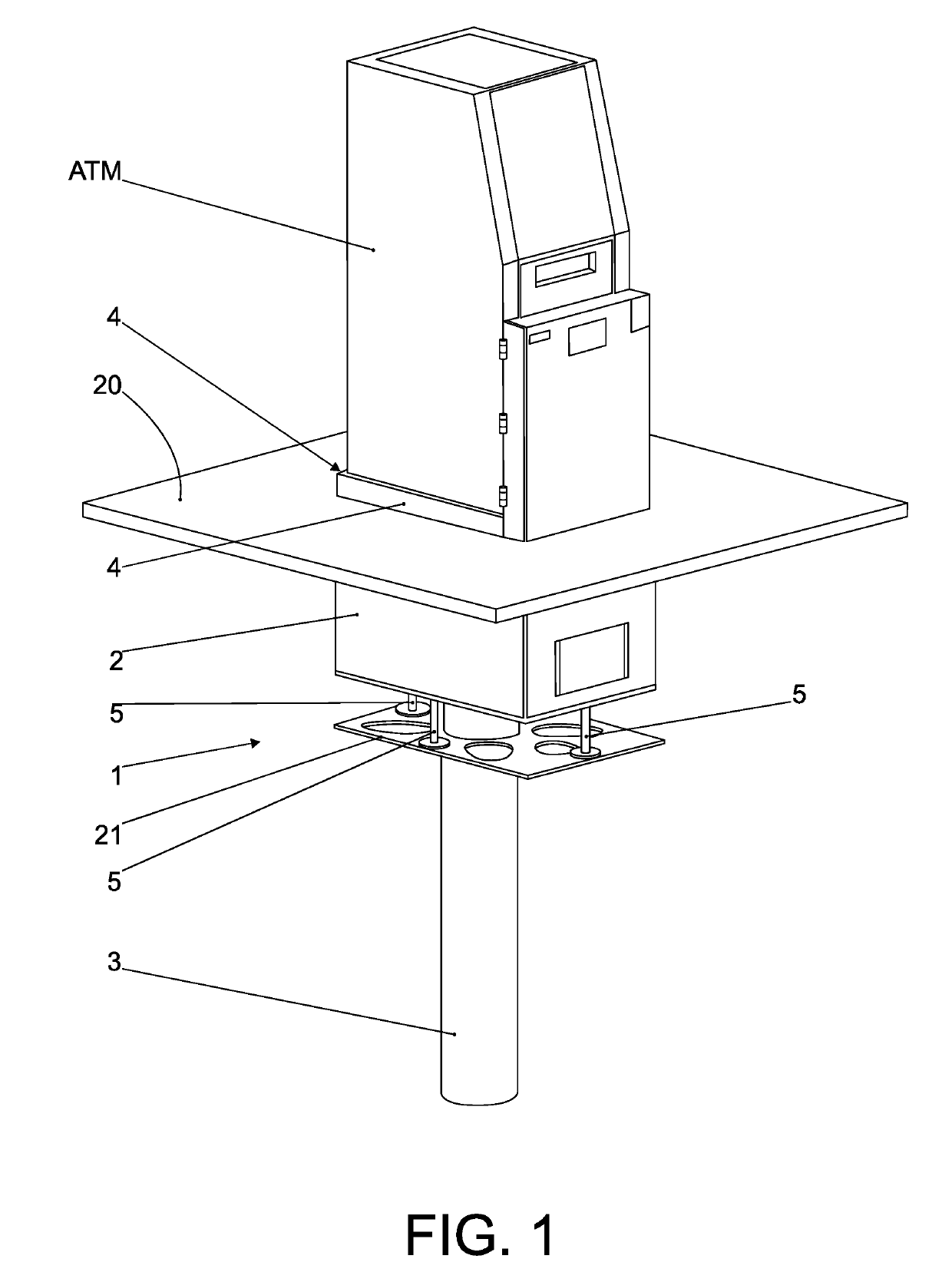

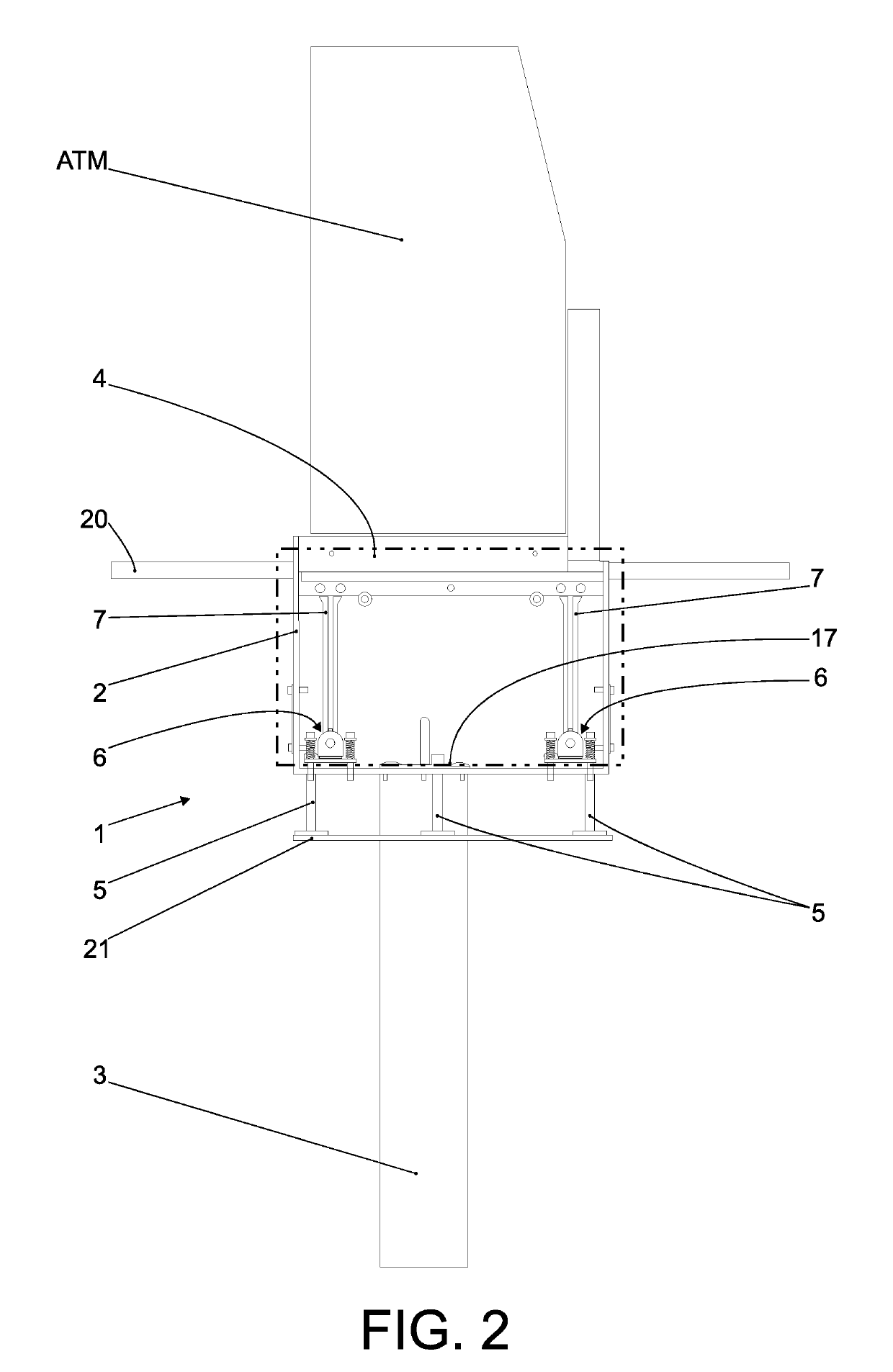

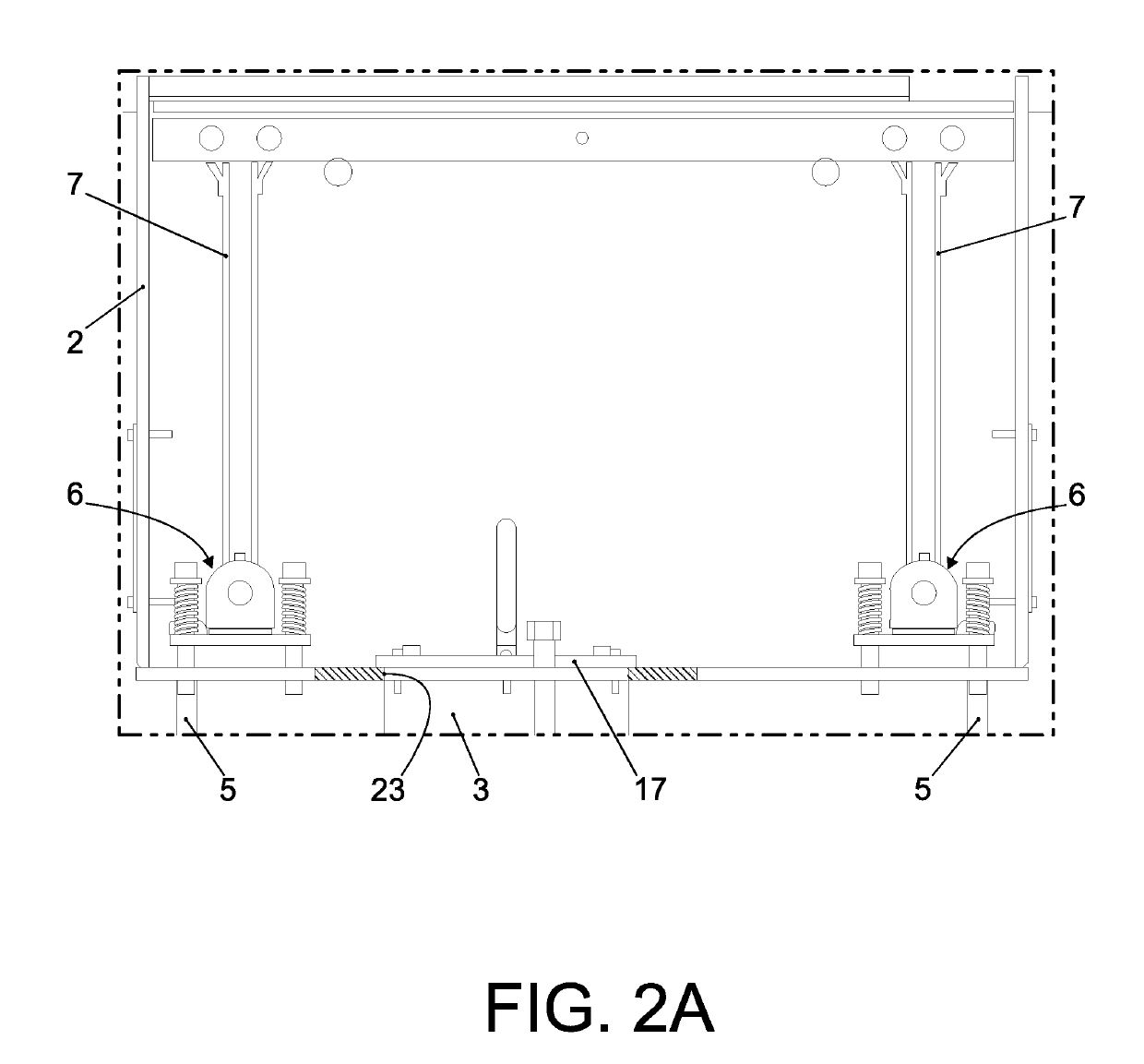

Device for anchoring and protecting self-service terminals and vaults in general

“DEVICE FOR ANCHORING AND PROTECTING SELF-SERVICE TERMINALS AND VAULTS IN GENERAL”, developed for application on self-service bank terminals (ATMs), as well as cash dispensing equipment, ATM recyclers, recycler vaults and general vaults, as defense against frequent theft in which the equipment is fully displaced using backhoe loaders, said device basically comprising a box (2) and a vertical and central lower column (3), four bearings (6), each including a strap (7) and, below said box (2), a laminate support panel (21), partially vented and including vertical setting screws (5) for height adjustment; in addition, pins (14) driven by springs (16) are provided, said pins (14) being released when the self-service terminal (ATM) is lifted at least 3 mm from the ground, releasing said equipment anchoring plate (15) and, consequently, causing said ATM to drop down inside the metallic box (2) and providing, therefore, increased defense against criminal raids using backhoe loaders, even on sandy soils, with said device being capable of moving downwards at an attempt of lifting the equipment (ATM).

Owner:TECH BANCARIA SA

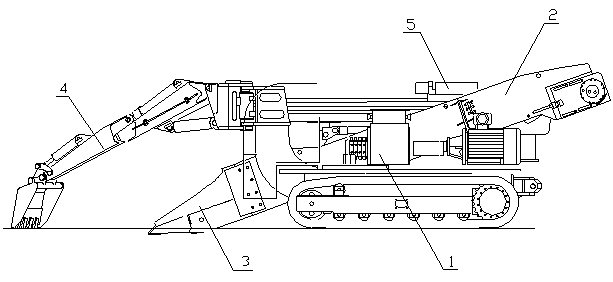

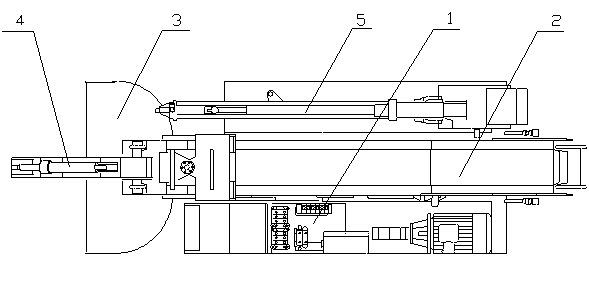

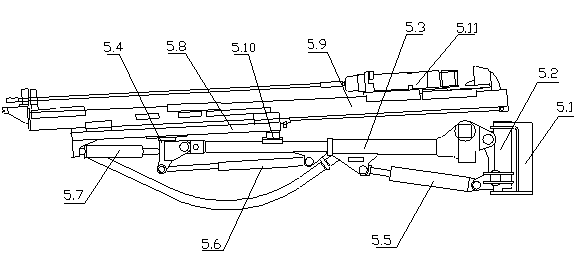

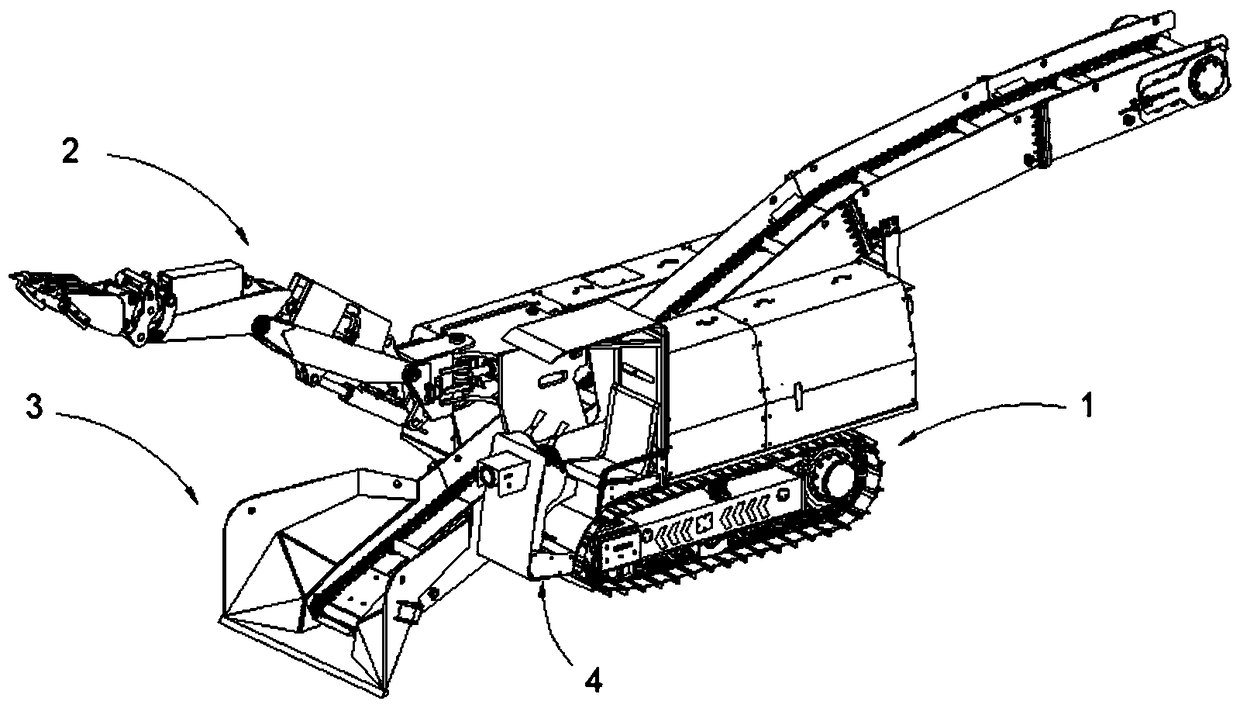

Efficient multi-function backhoe loader with hole and rock drilling function

The invention relates to an efficient multi-function backhoe loader with a hole and rock drilling function. The efficient multi-function backhoe loader comprises a machine body (1), wherein the machine body (1) is provided with a conveying mechanism (2), a shovel plate mechanism (3) matched with the conveying mechanism (2), a bucket mechanism (4) matched with the shovel plate mechanism (3), and a rock drilling mechanism (5), the rock drilling mechanism (5) comprises a connection frame (5.1), a rotation shaft (5.2), a drilling arm frame (5.3), a rocker arm (5.4), a lifting cylinder (5.5), a pitching cylinder (5.6), a swing angle cylinder (5.7), a slide rail support (5.8), a slide rail (5.9), a support pad (5.10) and a propeller (5.11). According to the efficient multi-function backhoe loader, the rock drilling mechanism is integrated on the whole machine so as to achieve integration operation manner.

Owner:JIANGSU ZHONGMEI MINING EQUIP

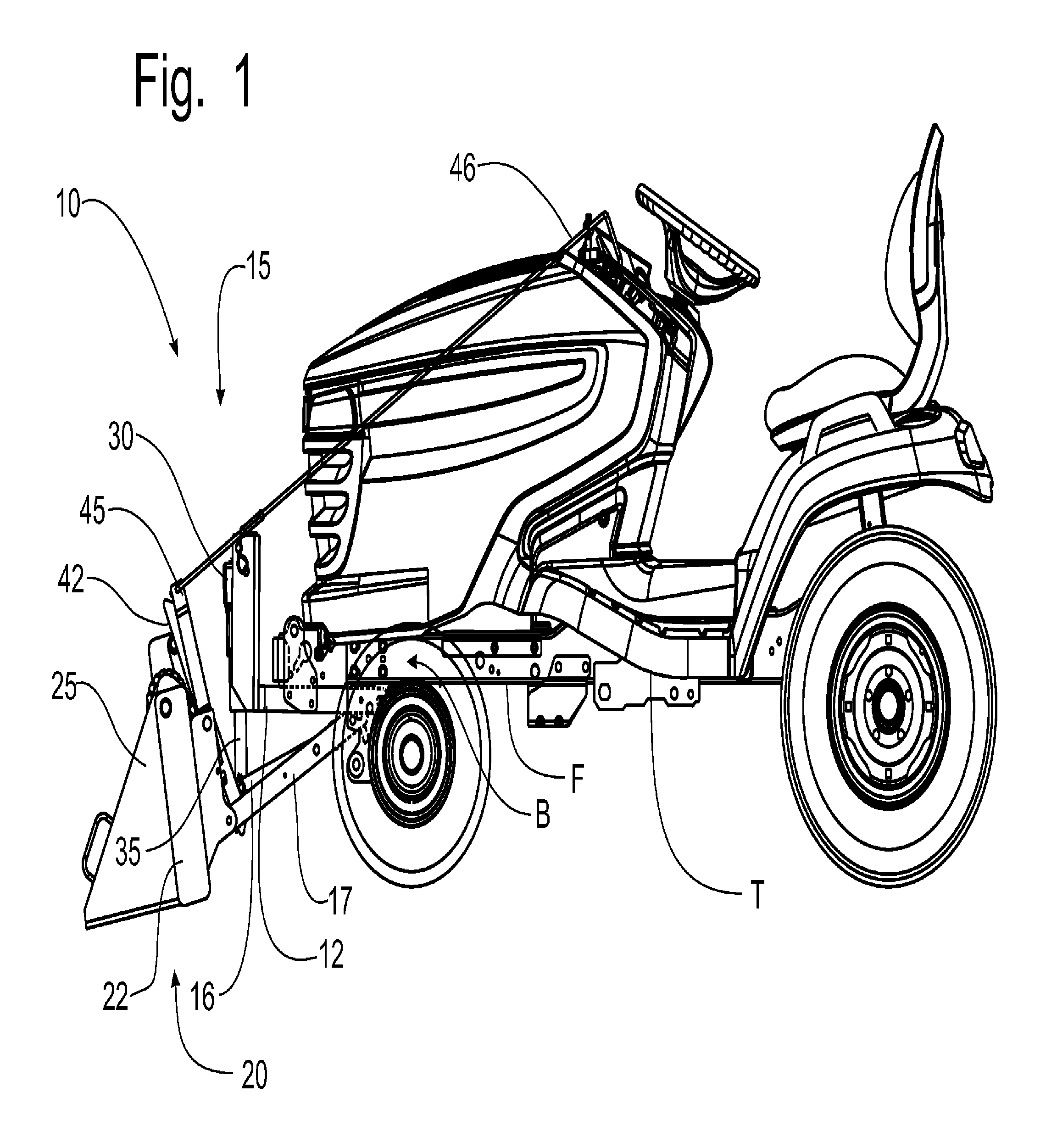

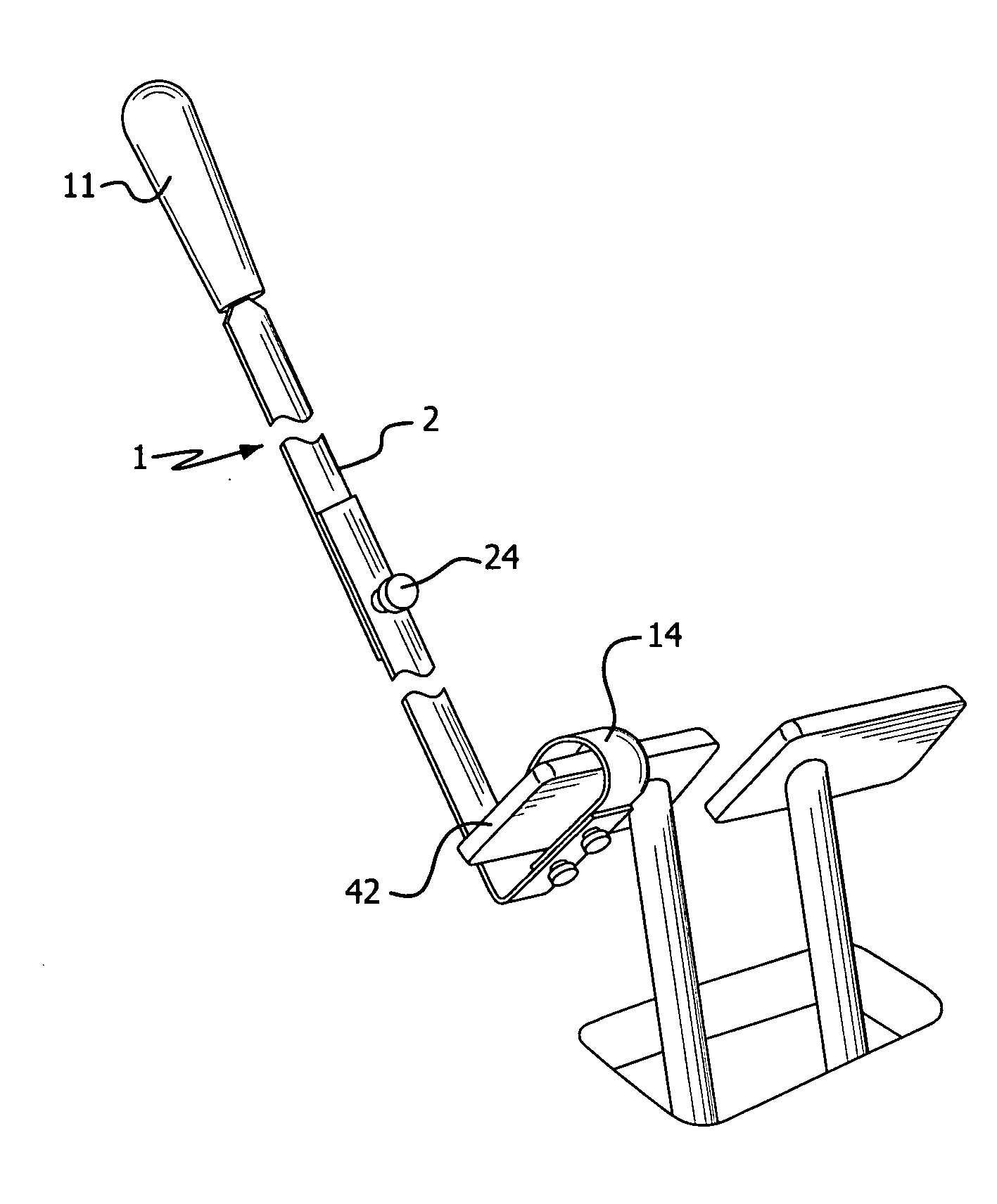

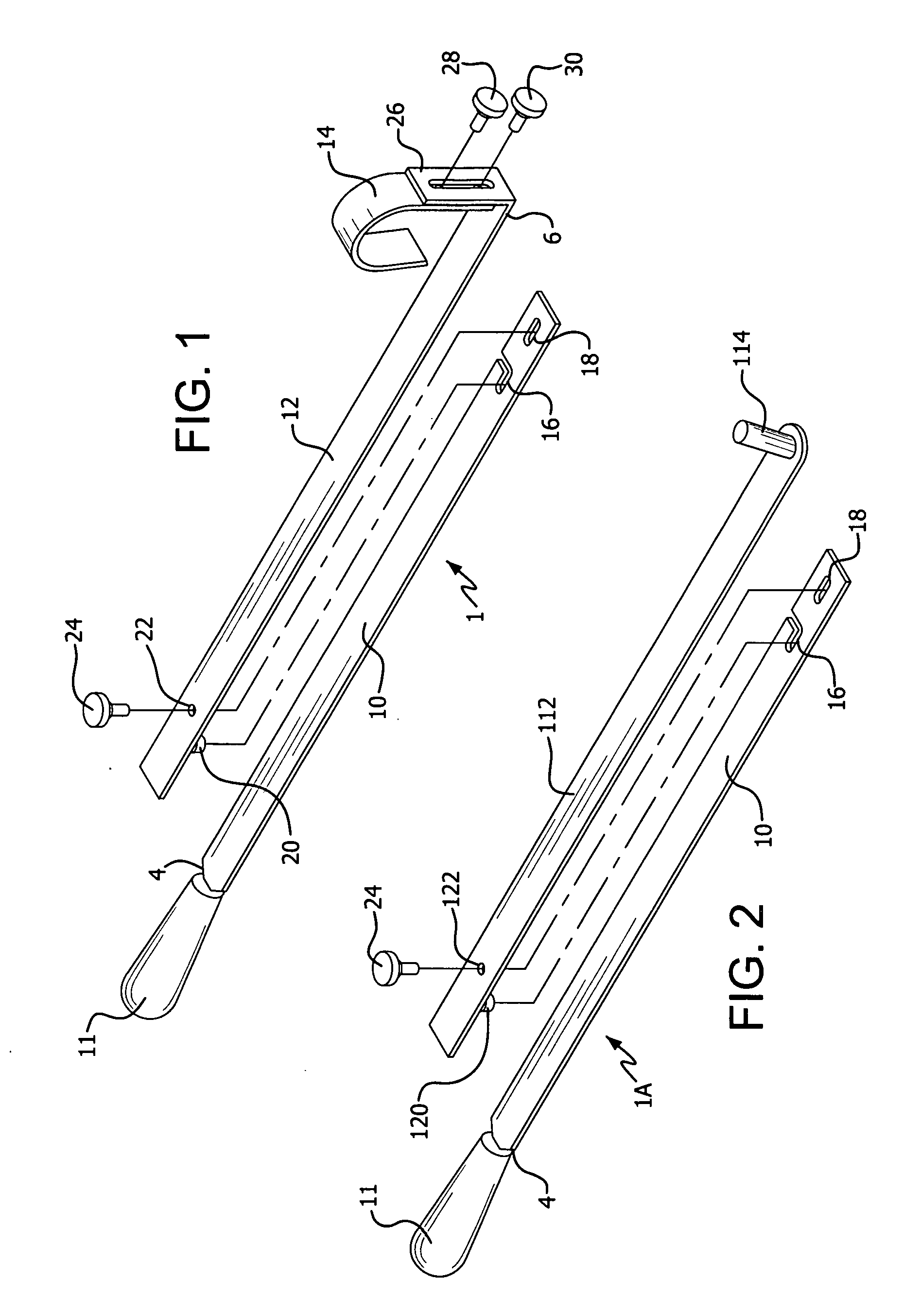

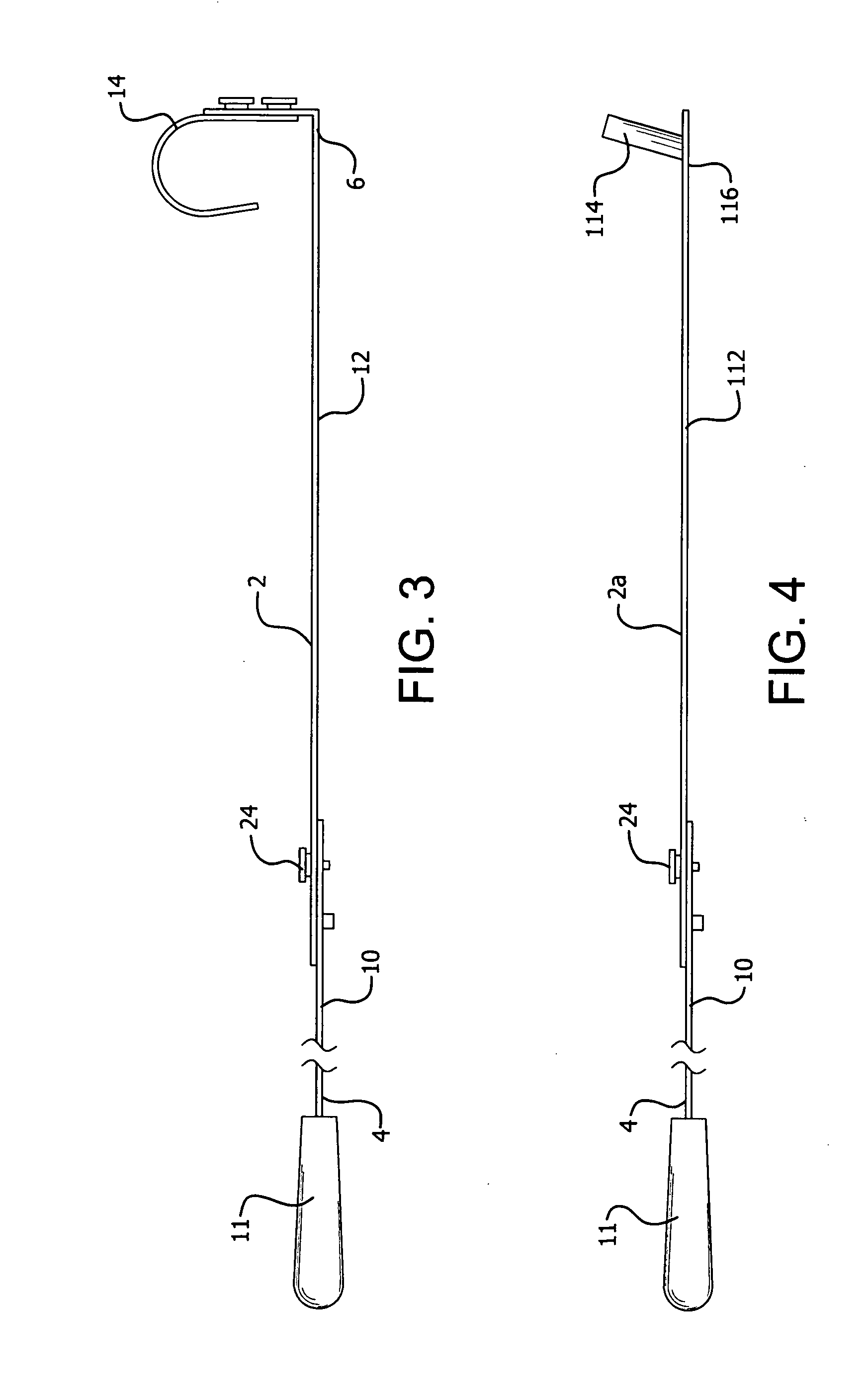

Driver assistance device for a backhoe loader vehicle

InactiveUS20110308881A1Operational securityEasily and safely controlControlling membersVehiclesDriver/operatorSteering wheel

A drive assistance device for a backhoe loader vehicle has an elongated bar member having a hook or post component at its lower end which is configured to be placed around or adjacent to the directional control pedal of a hydrostatically controlled backhoe loader vehicle. The elongated bar member has a handle at its upper end to allow the vehicle operator to grasp the bar member. When the lower end of the bar member is connected to the pedal, the bar member extends up to the operator, who can then easily and safely control the movement of the pedal, allowing it to be placed in neutral to maintain the vehicle in a stationary position while digging is being done, and to be moved ahead, while safely operating the steering wheel, to move the vehicle in the appropriate forward direction.

Owner:CAPPUCCIO LOUIS W +1

Tree trimmer

An apparatus for removing obstructions caused by both high and low lying vegetation, the apparatus including a conventional industrial type vehicle, such as a tractor or backhoe loader, a swing frame swingably connected about a substantially vertical axis on the vehicle, an arm, such as backhoe boom, pivotally connected about a substantially horizontal axis on the swing frame, a telescoping boom connected with the arm, means of detachably connecting the telescoping boom with the arm and cutting means mounted about a first end of the telescoping boom. The apparatus is supported, powered and controlled using the standard attachments, power systems and controls of a conventional industrial-type vehicle.

Owner:TRIM ALL EQUIP

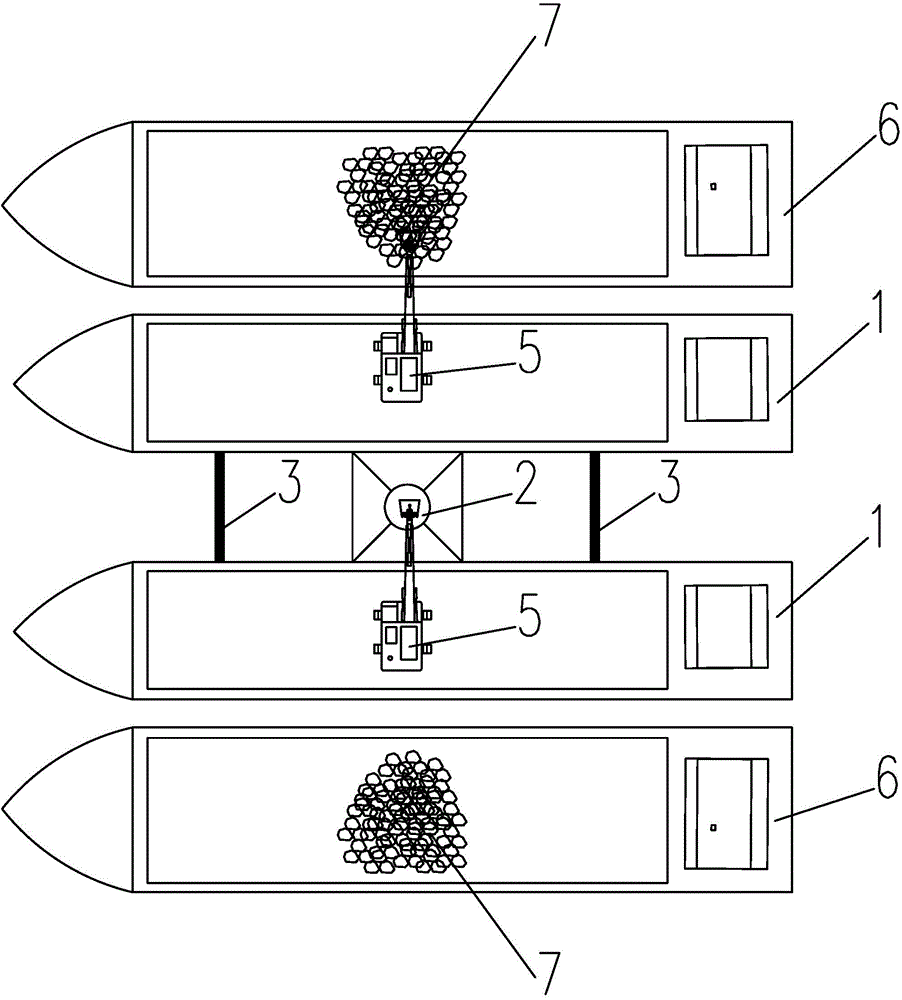

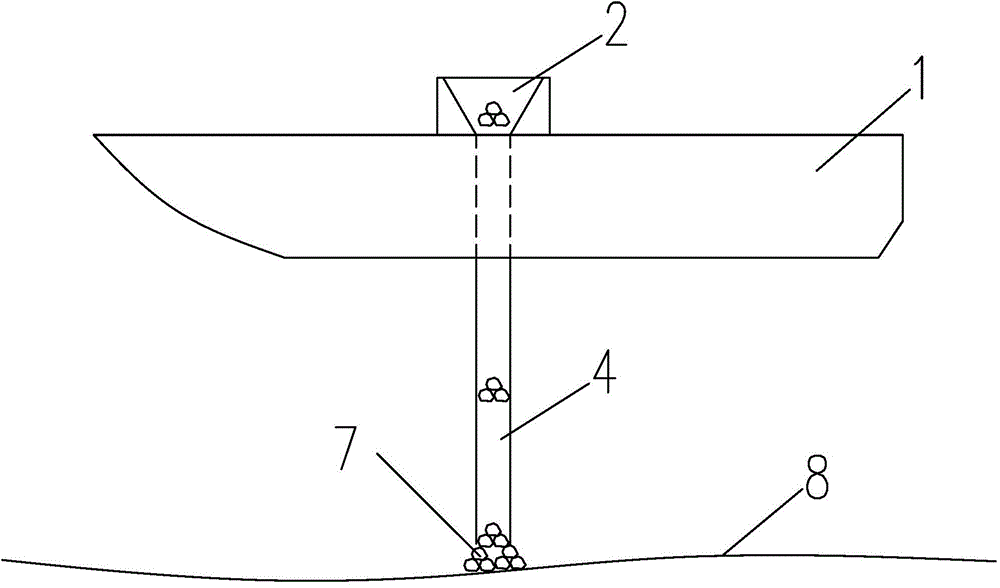

Deepwater riprapping method and equipment

InactiveCN105672186AImprove stabilityStrong wind and wave resistanceWaterborne vesselsHydraulic engineering apparatusUnderwaterWater flow

The invention provides a deep water riprap method and equipment. The equipment includes two fixedly connected barges. A riprap conduit extending into the water is installed between the two barges. The barge is equipped with a riprap conduit for transporting stone materials to stone transfer device. The riprap conduit is positioned above the riprap point with the barge, and the stone transfer device obtains the stone from the barge, and then transports the stone to the riprap conduit, and the stone falls along the riprap conduit to the riprap point. The barges are connected by a rigid structure. The rigid structure is made of steel sections, steel tubes or steel trusses. The stone transfer device is a backhoe excavator or a grab bucket excavator. The length of the riprap conduit can be adjusted according to the water depth of the riprap water area, and the radial dimension can be adjusted according to the particle size of the stone. The deep water riprap method and equipment provided by the present invention have strong wind and wave resistance, overcome the influence of water flow velocity on riprap, reduce the loss of stone materials during the throwing process, and realize accurate positioning and throwing in deep water.

Owner:SHANGHAI INVESTIGATION DESIGN & RES INST

Hydraulic backhoe shift mechanism

An earth-working vehicle, such as a backhoe loader, has an implement, such as a backhoe, mounted in a manner that the implement can be shifted transversely with respect to the vehicle. A hydraulic motor and roller cable or rack are secured to the vehicle main frame and implement supporting plate to position the implement transversely of the vehicle without the jerky movements of prior backhoe loaders.

Owner:BLUE LEAF I P INC

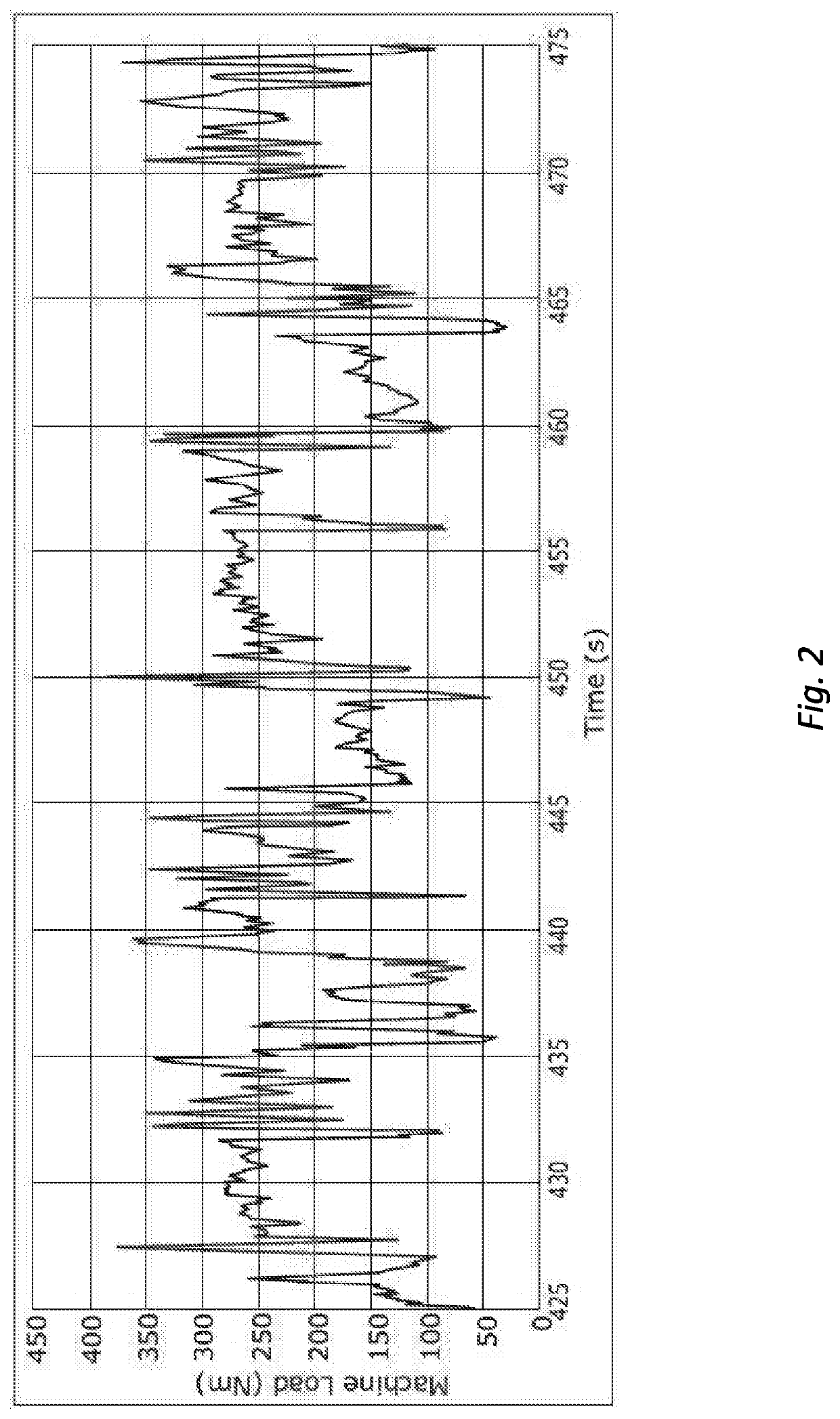

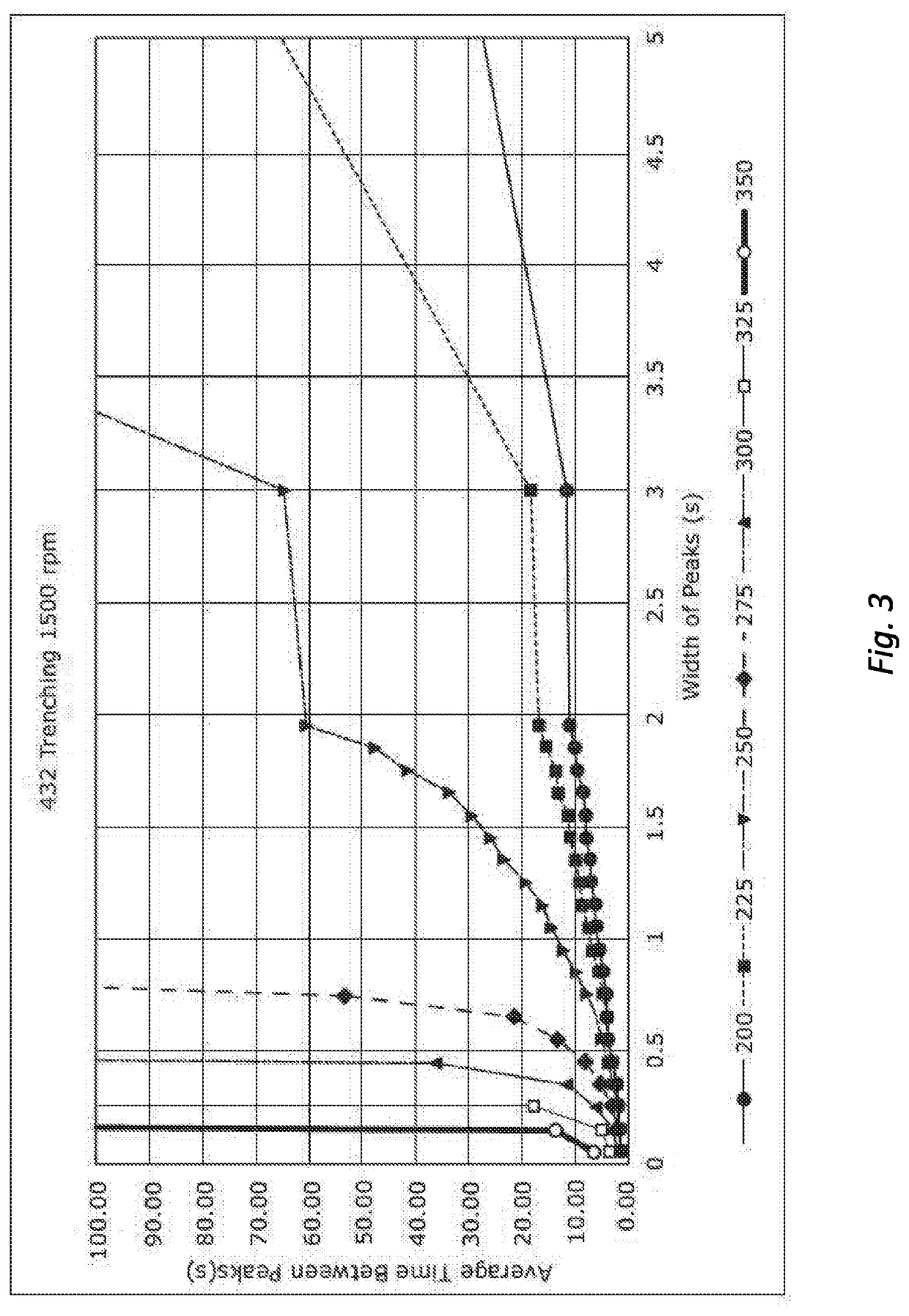

Method of reducing fuel consumption in loaders, excavators, backhoe loaders and the like

InactiveUS20210025136A1Reduce fuel consumptionHybrid vehiclesElectrical controlHydraulic pumpGround propulsion

A method of reducing fuel consumption in a machine with an internal combustion engine. The machine has a hybrid mode in which the engine is used for simultaneous ground propulsion via a torque convertor and hydraulic implement propulsion via a hydraulic pump. The engine controller uses a first engine map that defines primary operating constraints. The method comprises: obtaining an initial torque limit from a torque limit profile providing operating constraints that fall within the primary operating constraints. The method further comprises: implementing a torque limit that corresponds to the initial torque limit value such that in an event that a torque demand exceeds the torque limit then the engine speed will drop below the desired engine speed. The method further comprises, in an event that torque converter speed ratio between engine and ground propulsion drops below a speed ratio threshold, removing the torque limit profile and reverting to primary operating constraints.

Owner:CATERPILLAR INC

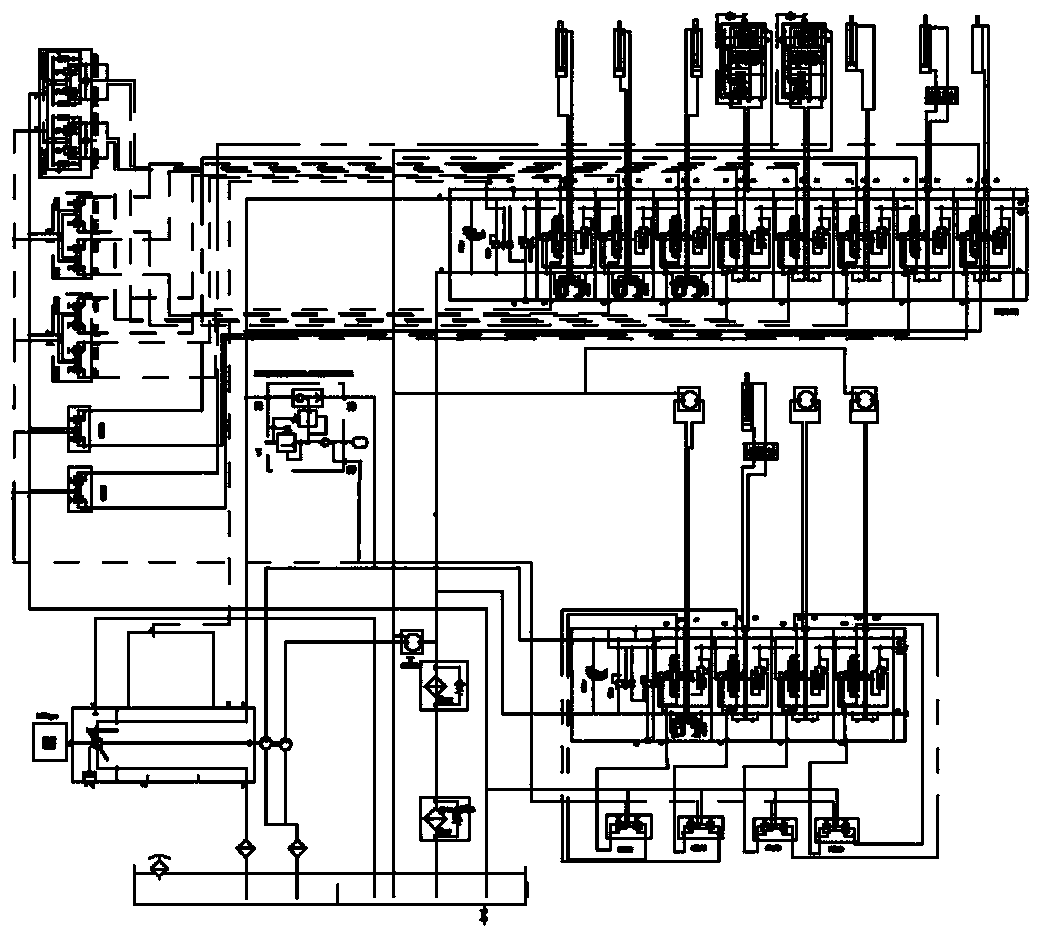

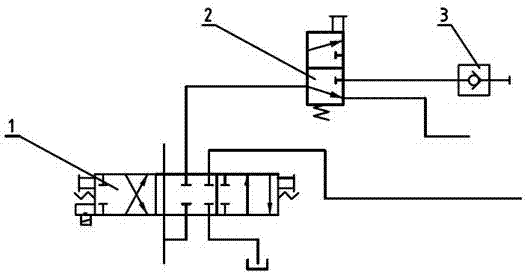

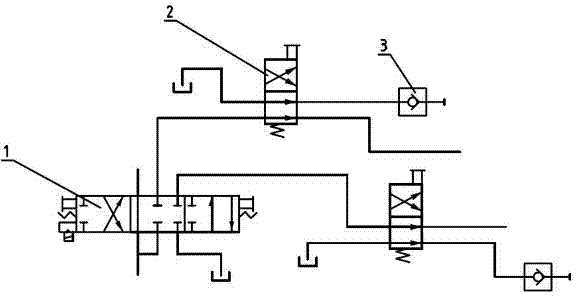

Hydraulic auxiliary coupler loop of backhoe loader

InactiveCN103572789AThe principle is simpleSimplify complexityServomotor componentsMechanical machines/dredgersEngineeringControl valves

The invention discloses a hydraulic auxiliary coupler loop of a backhoe loader. The hydraulic auxiliary coupler loop comprises a main control valve and a switching valve, wherein the main control valve is a three-position six-way reversing valve; the switching valve is arranged on a working oil line of the main control valve; and a quick joint is arranged at the tail end of the working oil line of switching valve. The working oil line of the main control valve can be divided into two oil lines through the switching valve, the principle of the switching valve is simple, the structure can be generally manufactured to be small and exquisite, and the arrangement is convenient, so that the complexity of a hydraulic system can be greatly simplified in an arrangement process of the whole hydraulic pipeline of a complete machine, the reliability of the system is improved, and requirements of connecting accessories can be met at the same time.

Owner:JIANGSU LIUGONG MACHINERY

Clamp-on fork lift attachment with stabilizer bar

Owner:WERNER CO

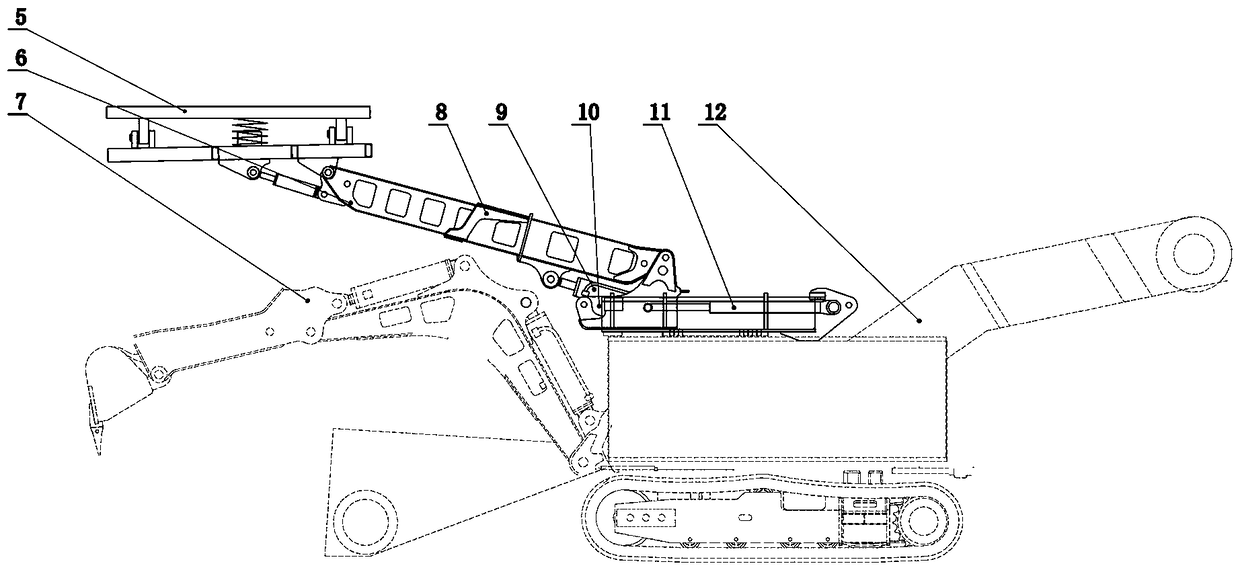

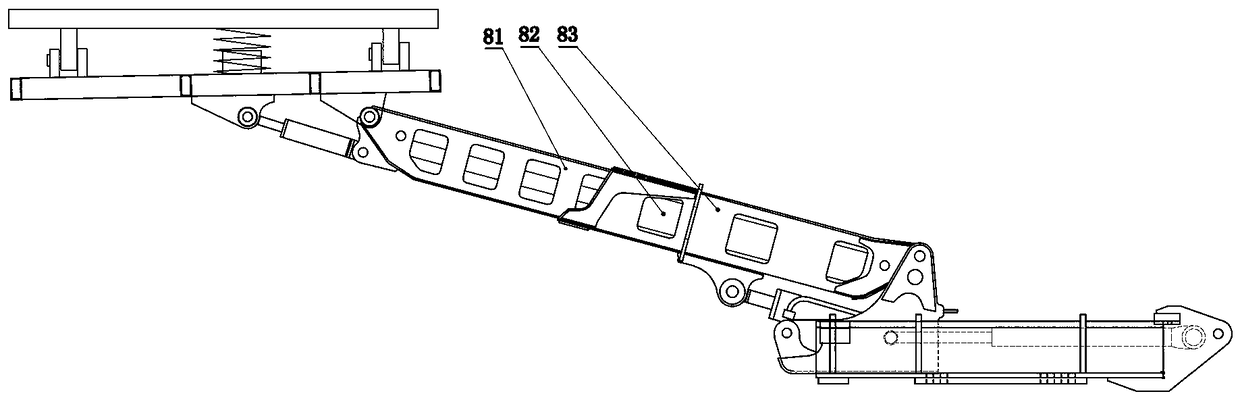

Advanced support device of mining backhoe loader

PendingCN108193733ASmall footprintEasy to installSoil-shifting machines/dredgersEarth drilling and miningEngineeringSafe operation

The invention discloses an advanced support device of a mining backhoe loader, and aims to provides the mining backhoe loader with the advanced support device, so that the safe operation can be ensured, using is convenient, no hydraulic single body is required to be placed for supporting, and time and labor are saved. The advanced support device of the mining backhoe loader comprises a mounting base, a support working arm, a working arm sliding block and a plurality of hydraulic oil cylinders; the mounting base is detachably mounted on a machine frame, the working arm sliding block is locatedin a sliding groove of the mounting base, and a sliding oil cylinder is connected between the working arm sliding block and the mounting base; the support working arm is hinged to the working arm sliding block, a support top plate is hinged to the top end of the support working arm, and the support top plate and the support working arm are further connected in a hinged mode through a support oil cylinder; and the support top plate is detachably connected with a support frame.

Owner:枣庄联鑫实业有限责任公司

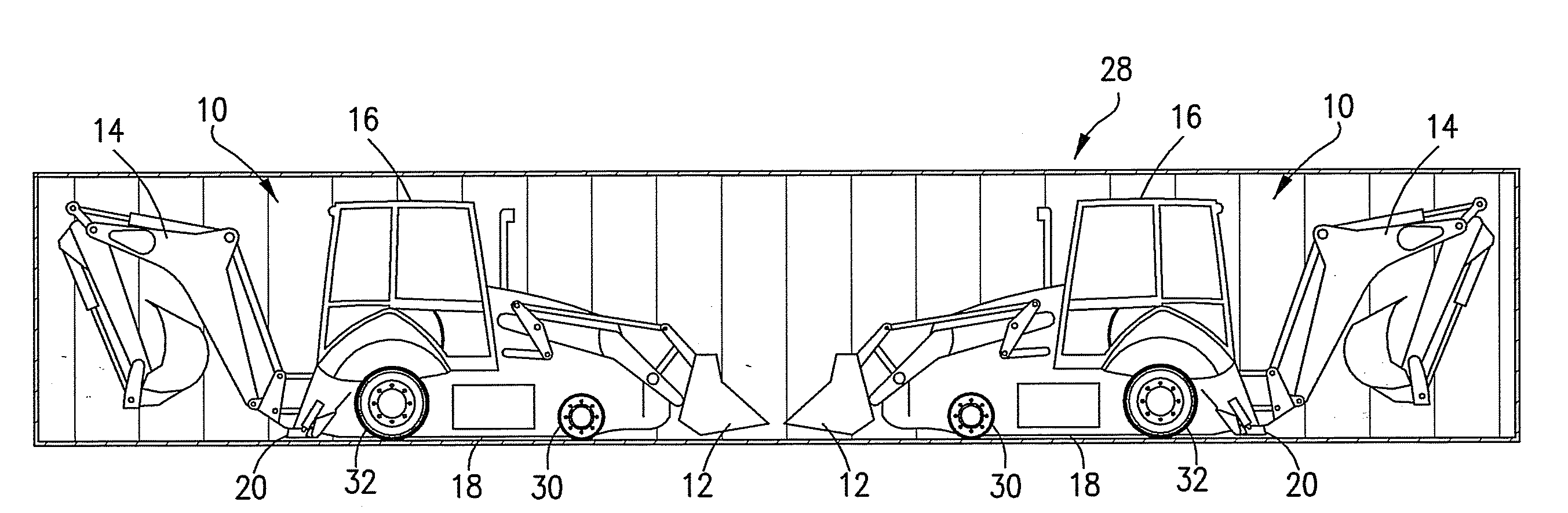

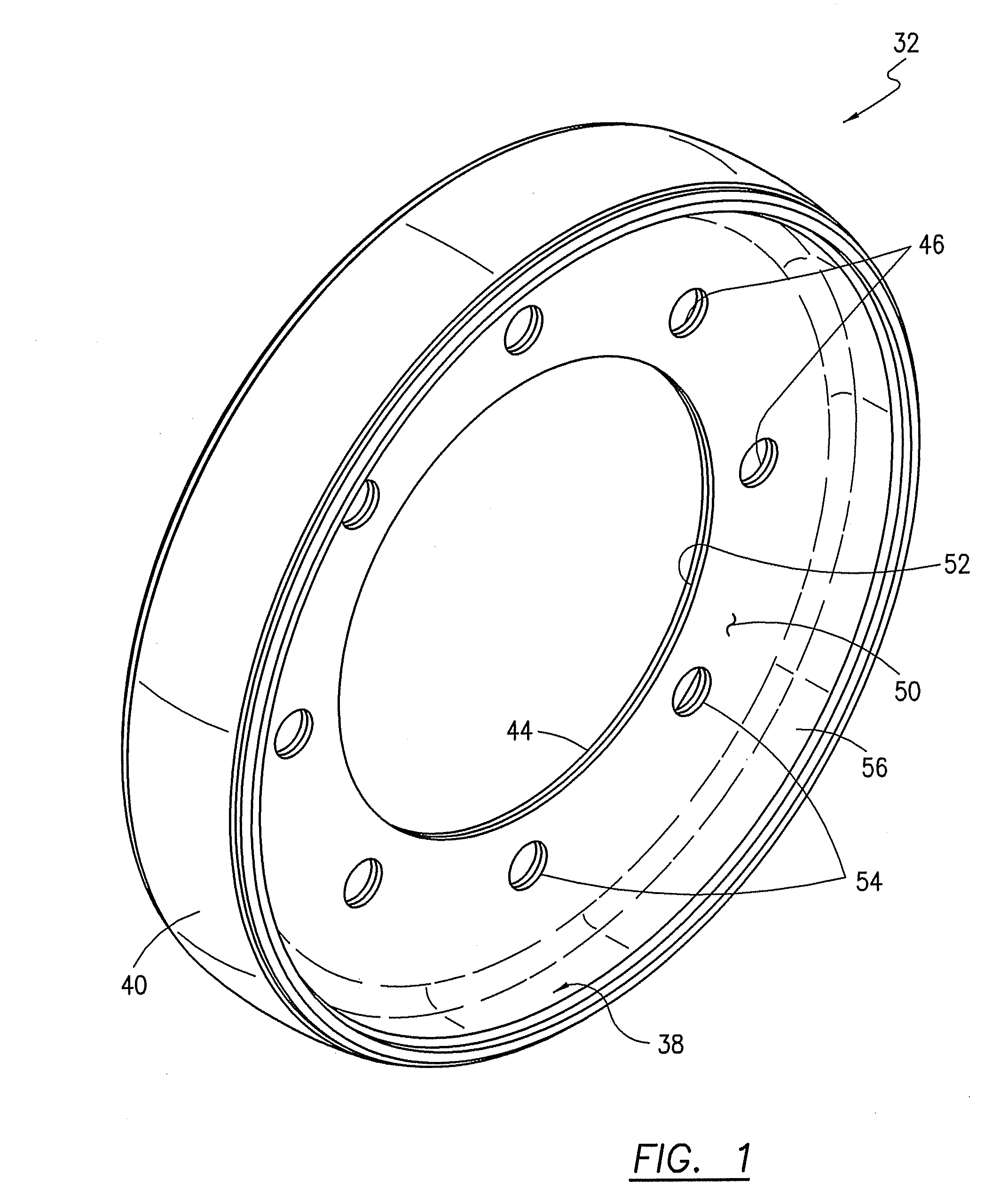

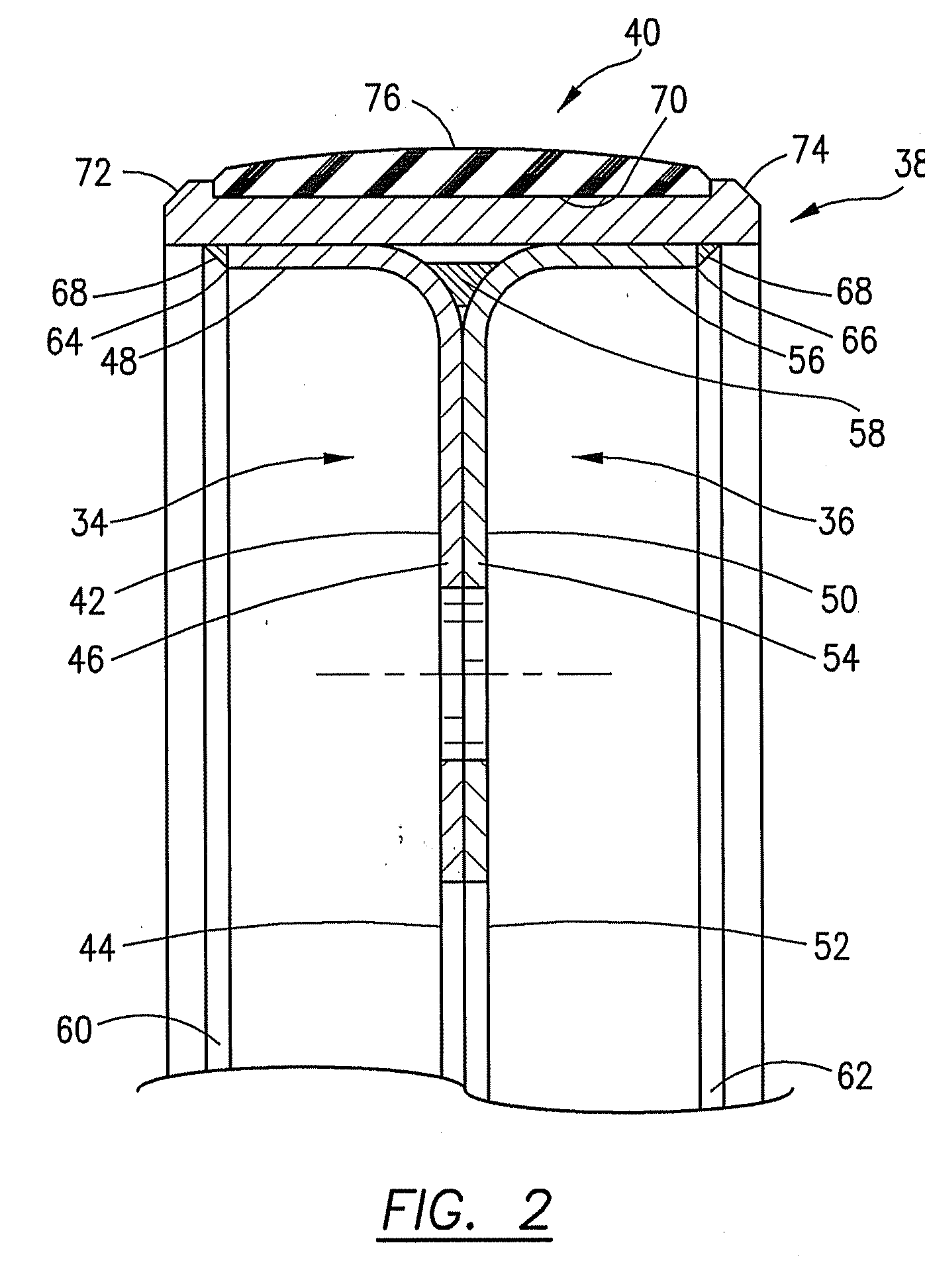

Method and apparatus for transporting construction equipment in an enclosed container within the hold of a vessel

ActiveUS20100119339A1Efficient mannerReduced overall height dimensionRimsConvertible cyclesCargo containerSea transport

A method and apparatus for permitting construction equipment, and particularly backhoe loaders, to be transported in the hold of a seagoing vessel within the interior of an enclosed cargo container includes front and rear rollers that temporarily replace the wheels of the equipment and allow it to be driven into and out of the container without any disassembly of the equipment.

Owner:PRINZ ADALBERTO +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com