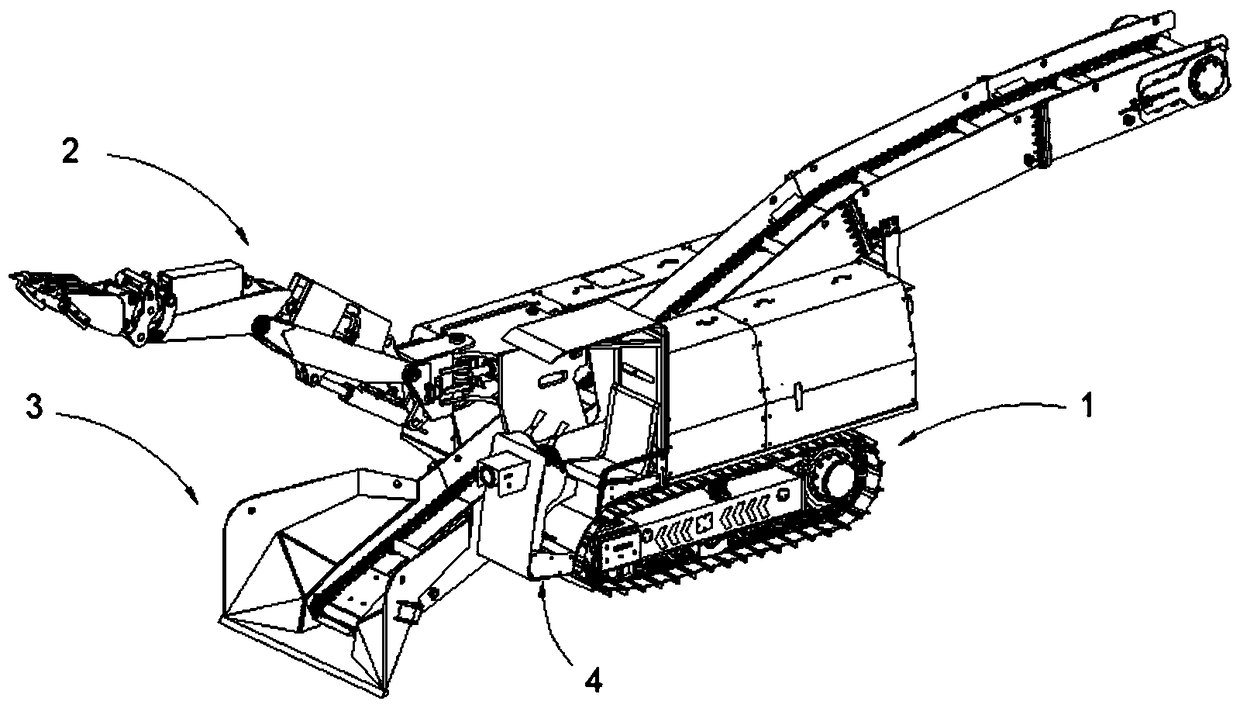

Advanced support device of mining backhoe loader

A technology of backhoe loader and advanced support, which is applied in the directions of earth mover/shovel, transportation and packaging, earth drilling and mining, etc. The effect of small space, large support range and enhanced adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

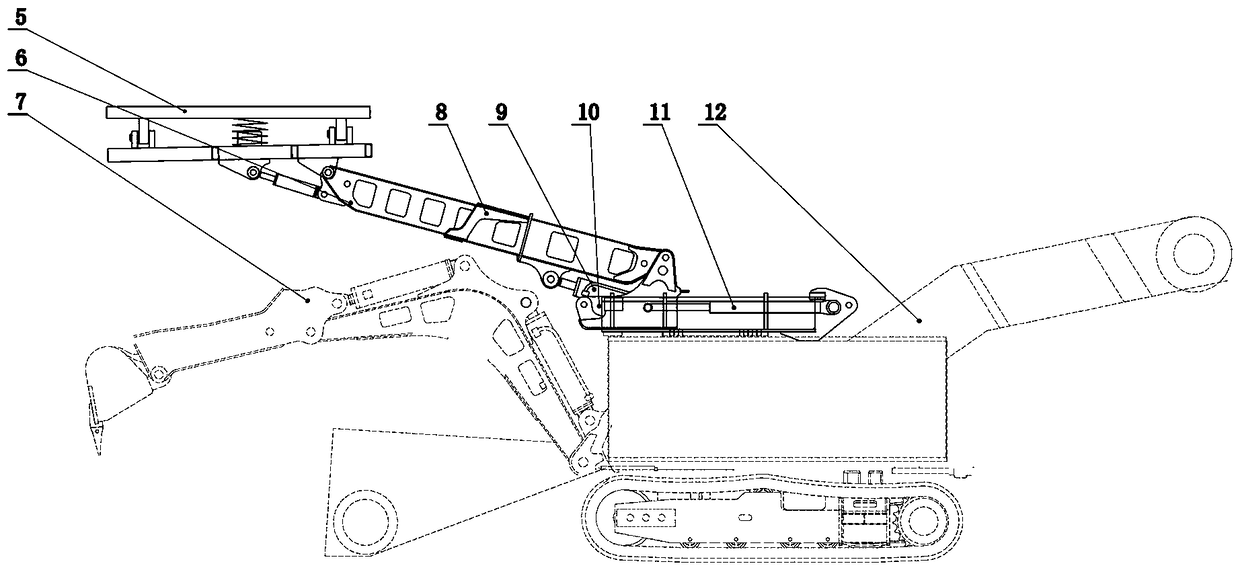

Method used

Image

Examples

Embodiment approach 1

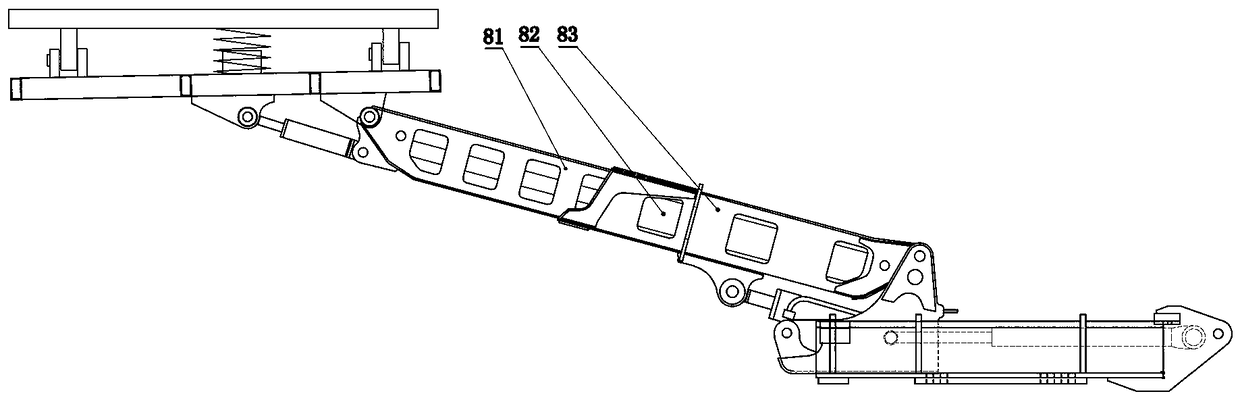

[0033] The supporting frame 131 is a rectangle with four sides lying on the same plane, two of which are parallel to the plane where the supporting working arm 6 is located. Preferably, the support frame is in the shape of a "field" with beams in the middle. The middle beam of the support frame is welded with a support installation plate 132 with installation holes. The support frame is welded by square tubes, and all tailor-welded parts are welded with reinforcement plates 134 .

Embodiment approach 2

[0035] Such as Figure 5 As shown, one pair of opposite sides of the support frame 13 is two arc-shaped sides, the other pair of opposite sides is straight sides, and a support installation plate 132 is installed in the middle of the arc-shaped sides. The support frame 131 formed by the above four sides is located on an arched surface. The arched supporting frame is suitable for supporting the top surface of the arched roadway. The support frame is welded by square tubes, and all tailor-welded parts are welded with reinforcement plates 134 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com