Patents

Literature

1100results about "Earth drilling and mining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

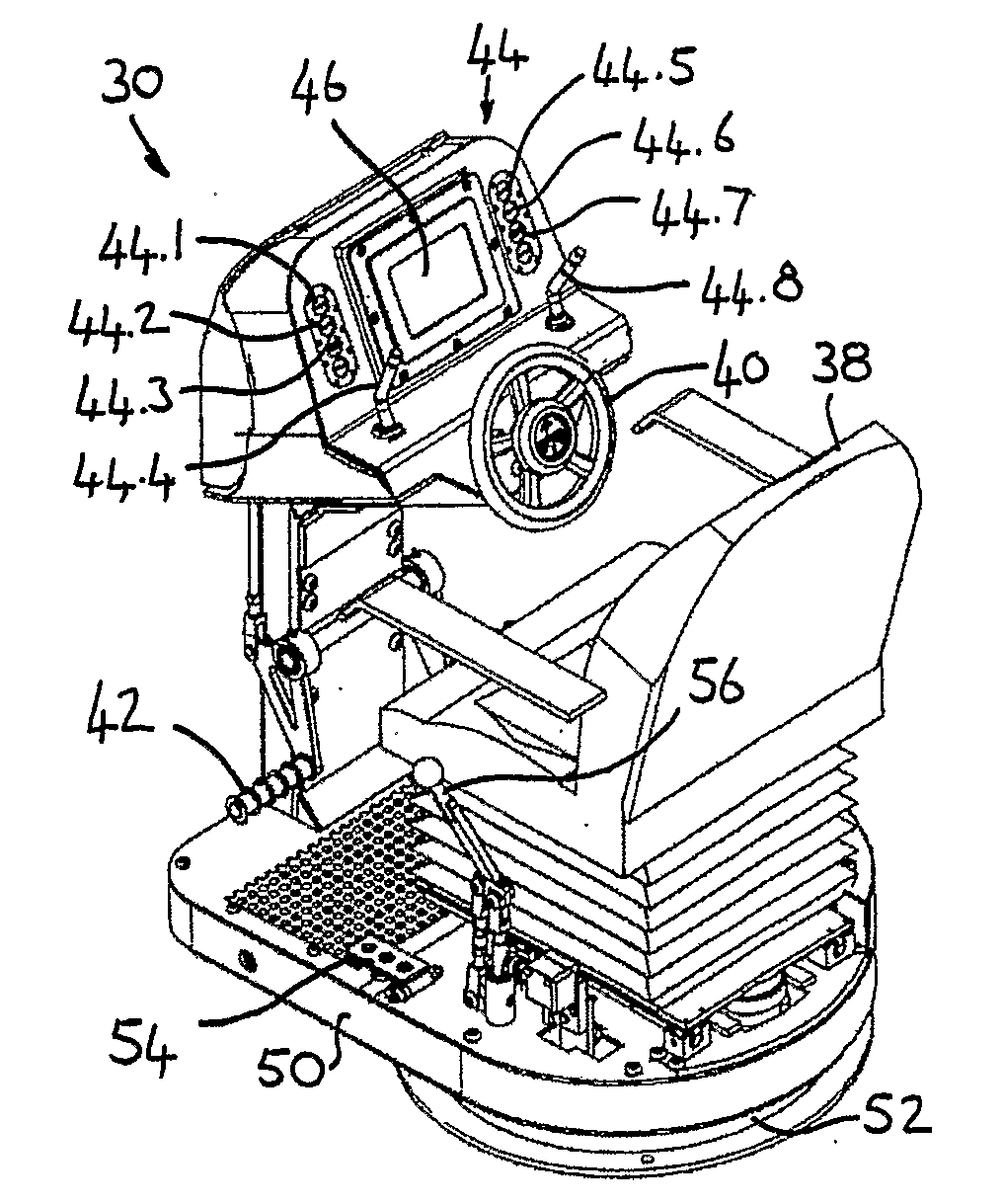

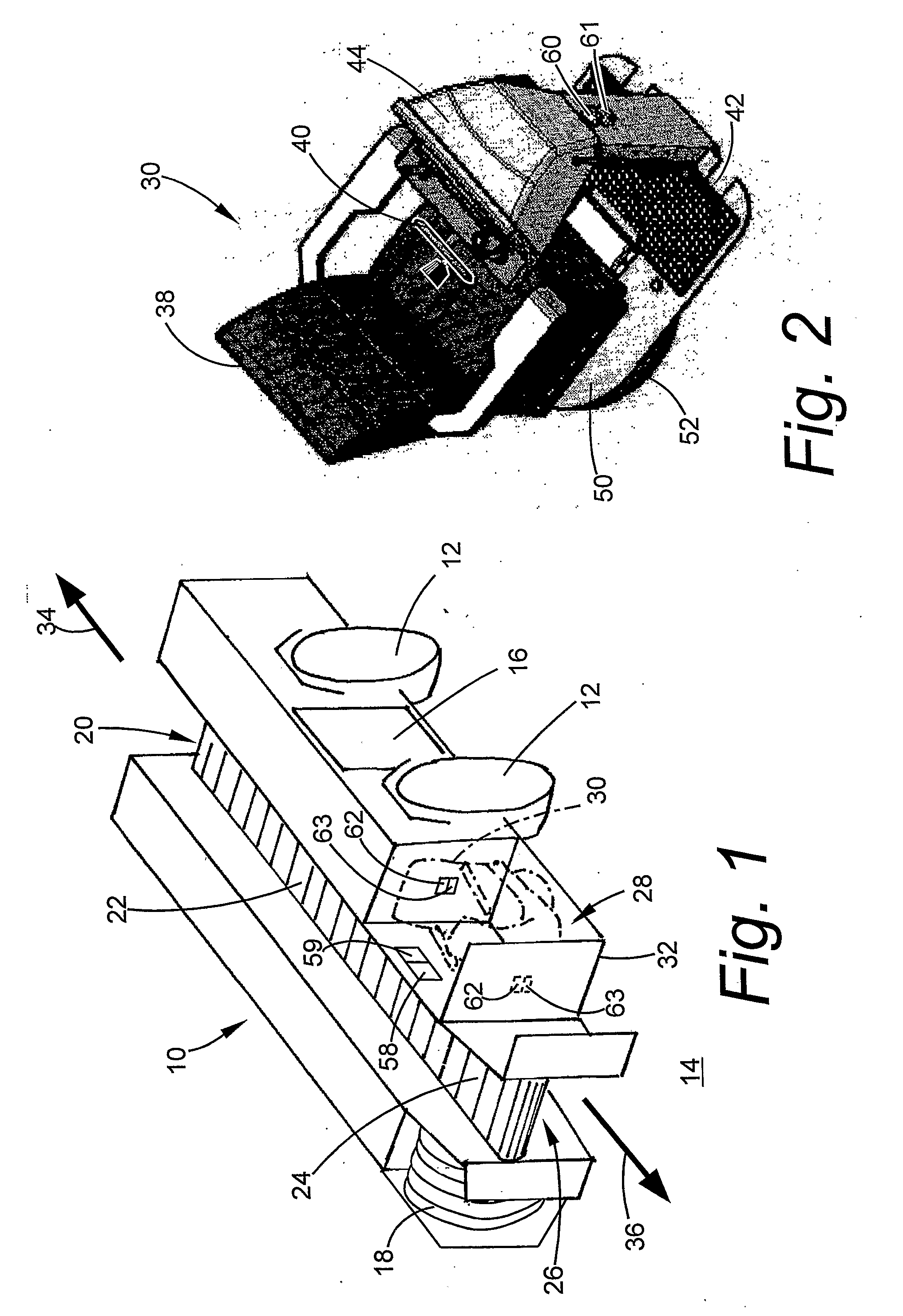

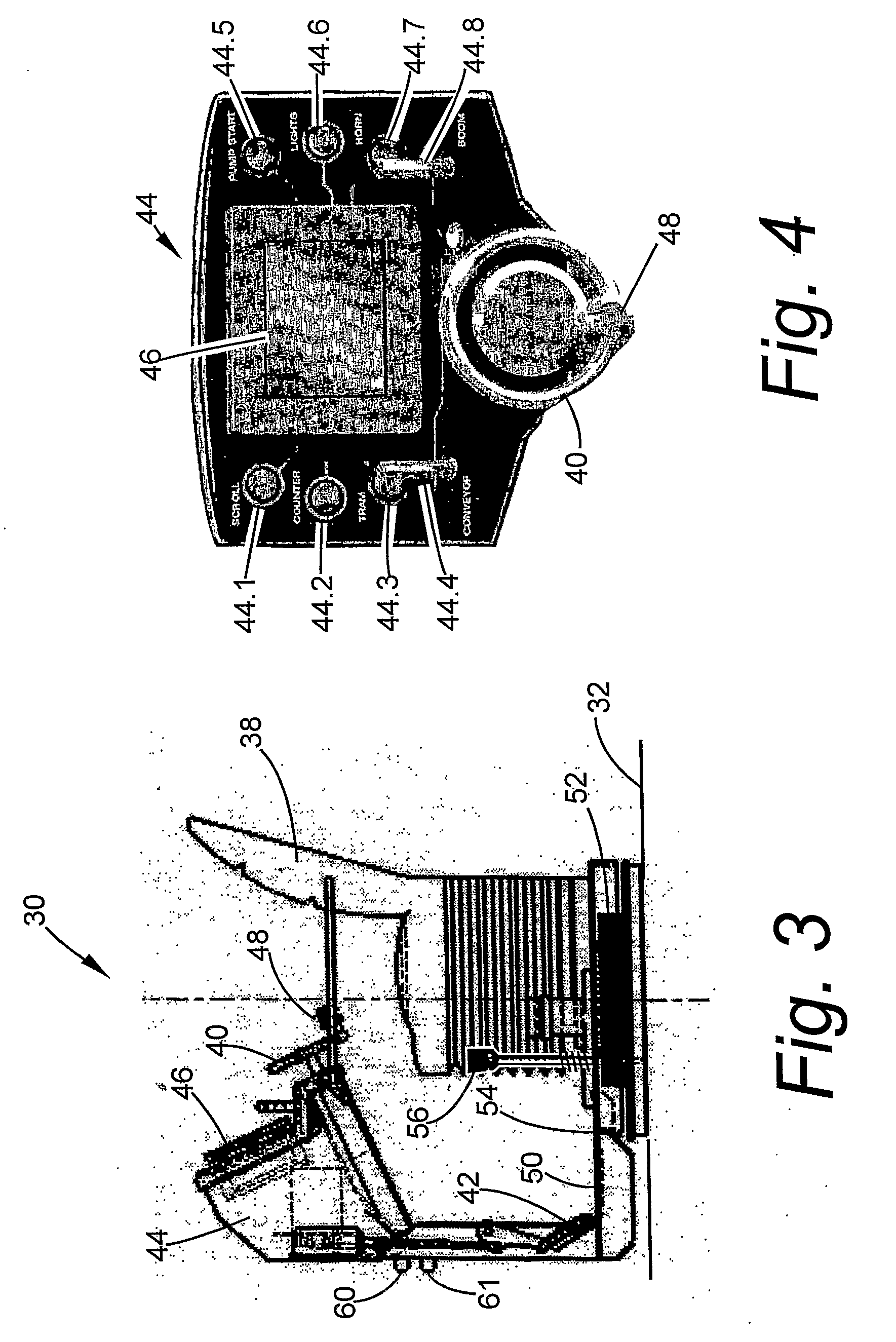

Vehicle with a variable driver position

InactiveUS20100300796A1Prevent rotationPrevent movementVehicle seatsFoot actuated initiationsDriver/operatorSteering wheel

There is disclosed a wheeled vehicle (10) adapted to be driven in a primary direction or an opposite secondary direction. The vehicle has a vehicle platform (32), and a group of vehicle components rotatably mounted on the platform which are rotatable as a group through 180 degrees relative to the platform. The group of components includes a driver's seat (38), steering wheel (40), foot pedals (42) and instrument console (44). Rotation of the group of components enables the driver's seat (and hence the driver) to face in the primary direction or secondary direction.

Owner:PWGK HLDG

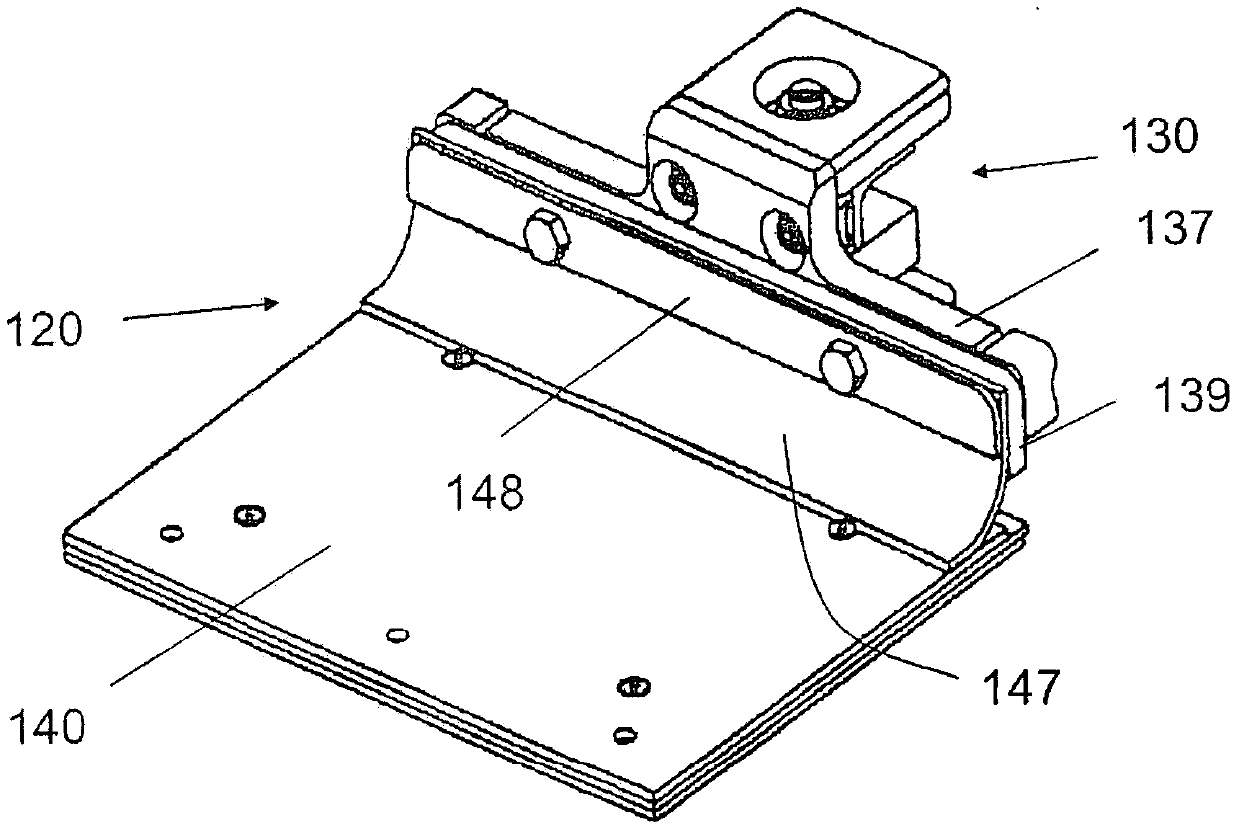

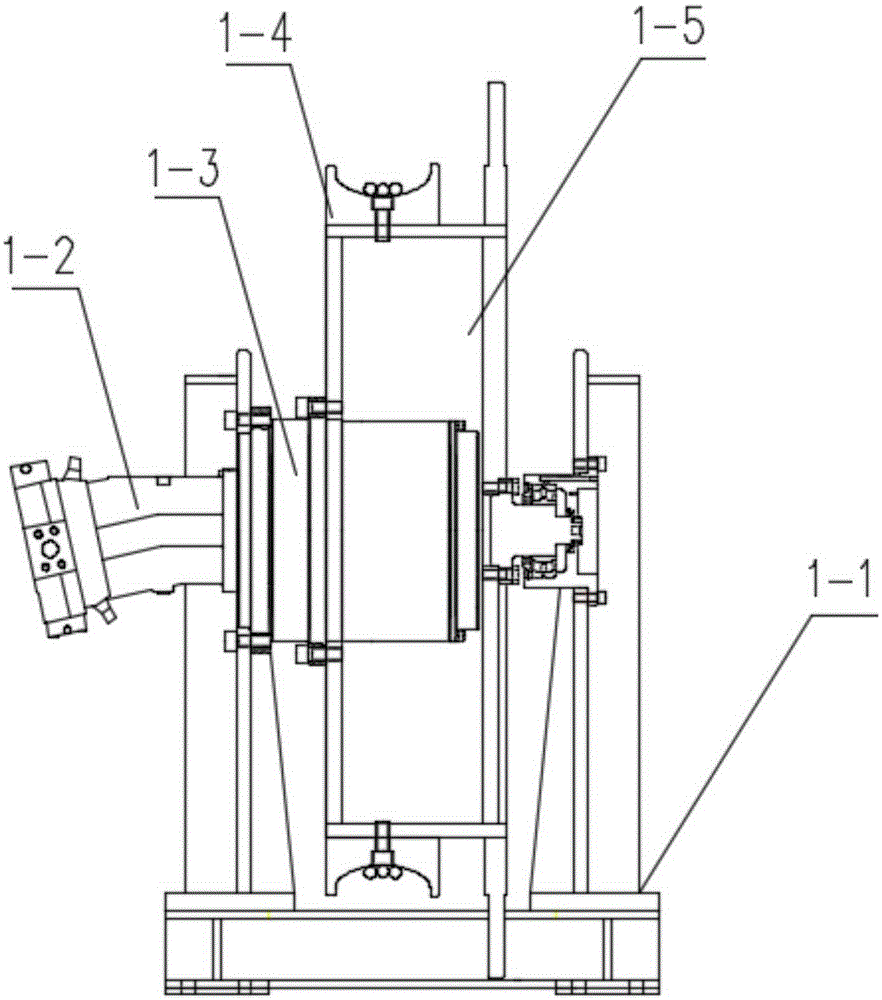

Battery changing system and method

ActiveUS20150071747A1Electric/hybrid propulsionPropulsion by batteries/cellsEngineeringMechanical engineering

A battery changing system includes a grasping assembly and an actuation assembly. The grasping assembly is configured to be disposed onboard a vehicle and to engage a battery box having one or more batteries disposed therein. The actuation assembly is configured to move the grasping assembly away from the vehicle toward the battery box. The actuation assembly also is configured to move the grasping assembly into engagement with a securing assembly of the battery box. The actuation assembly is configured to move the grasping assembly back toward the vehicle while the grasping assembly engages the securing assembly of the battery box to lift the battery box onto the vehicle.

Owner:GE GLOBAL SOURCING LLC

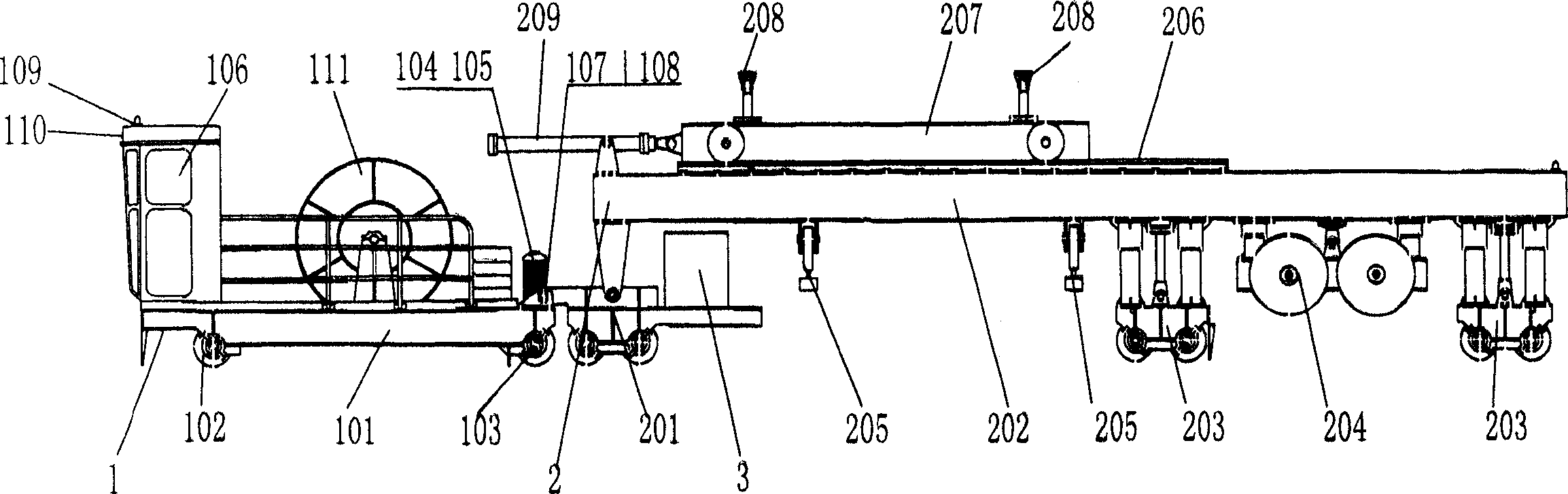

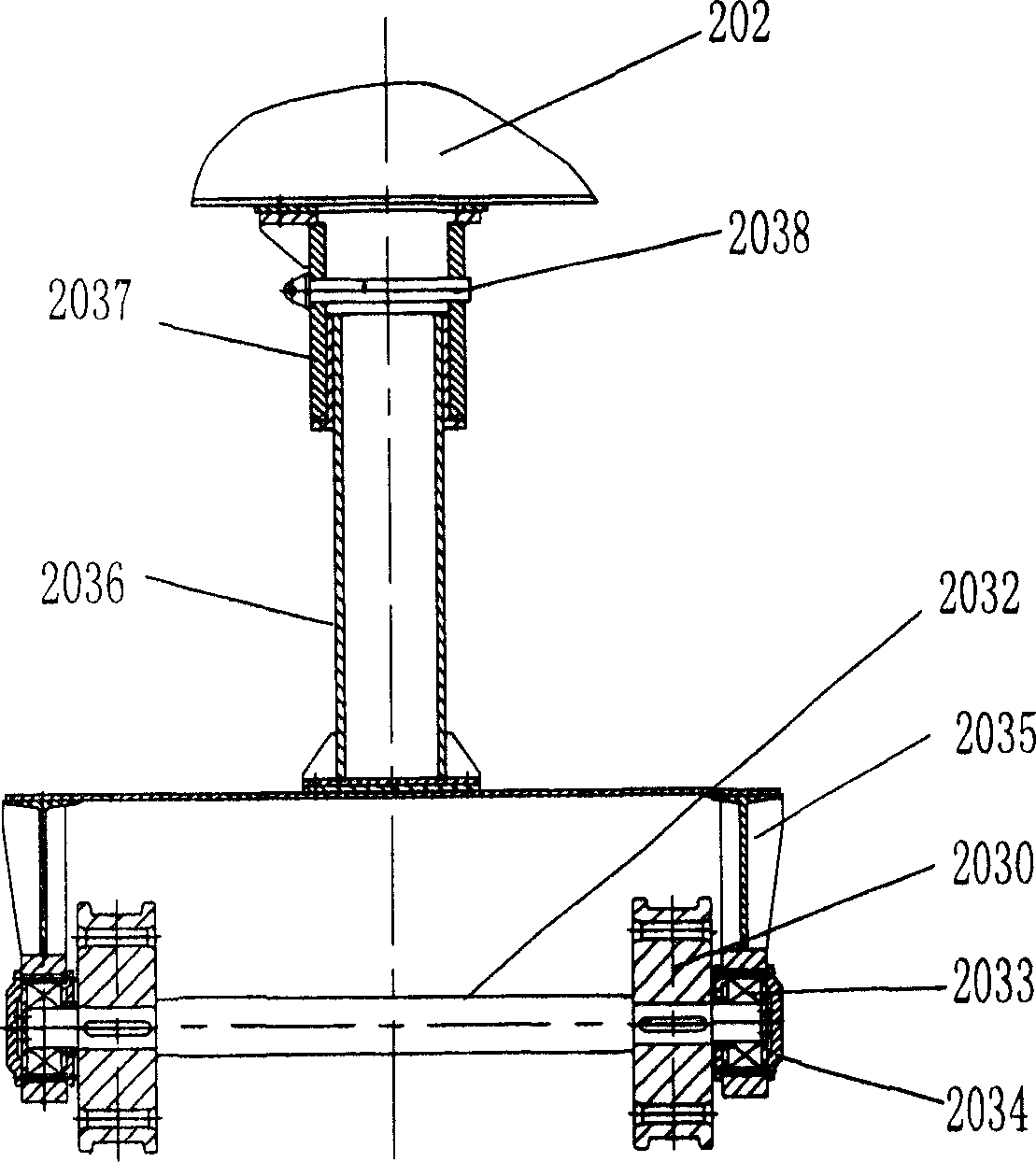

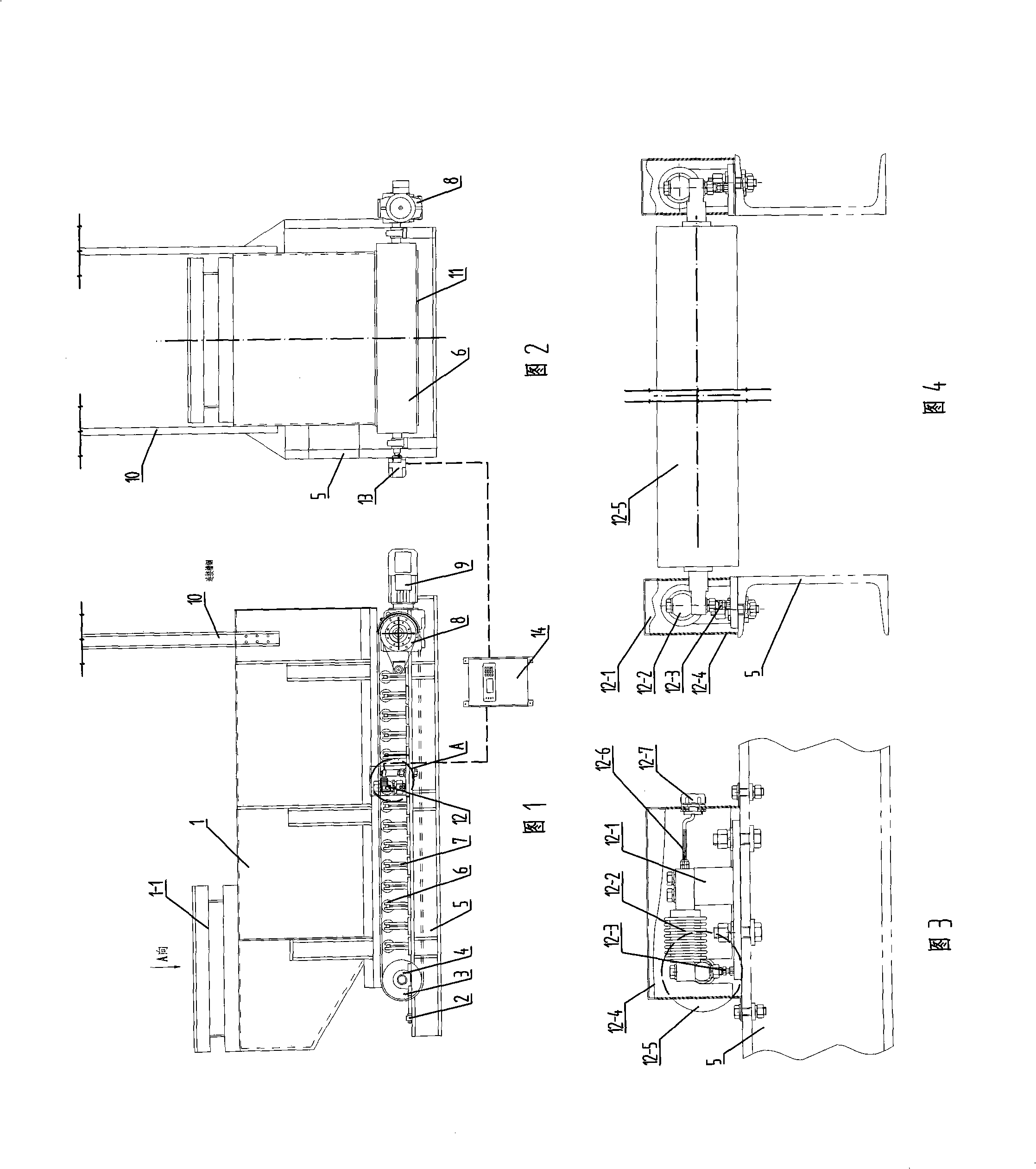

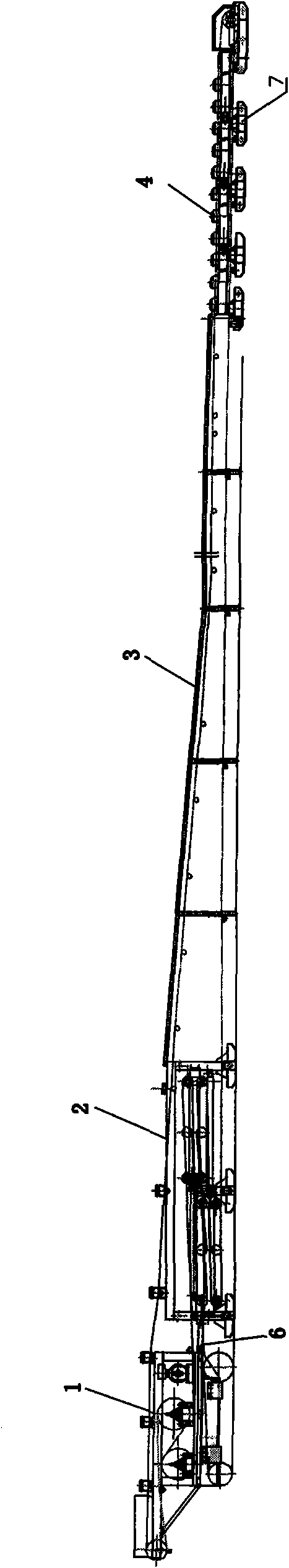

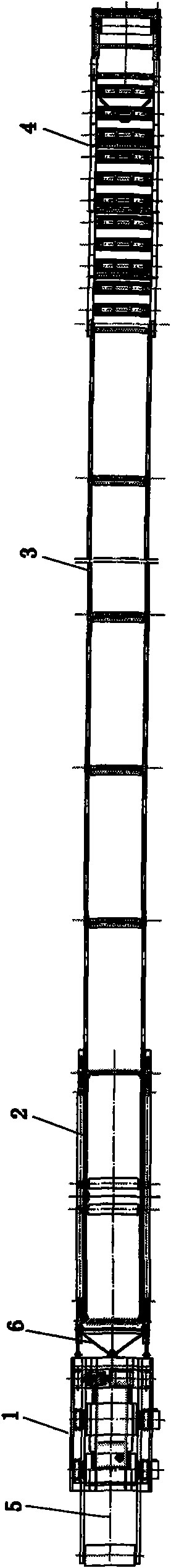

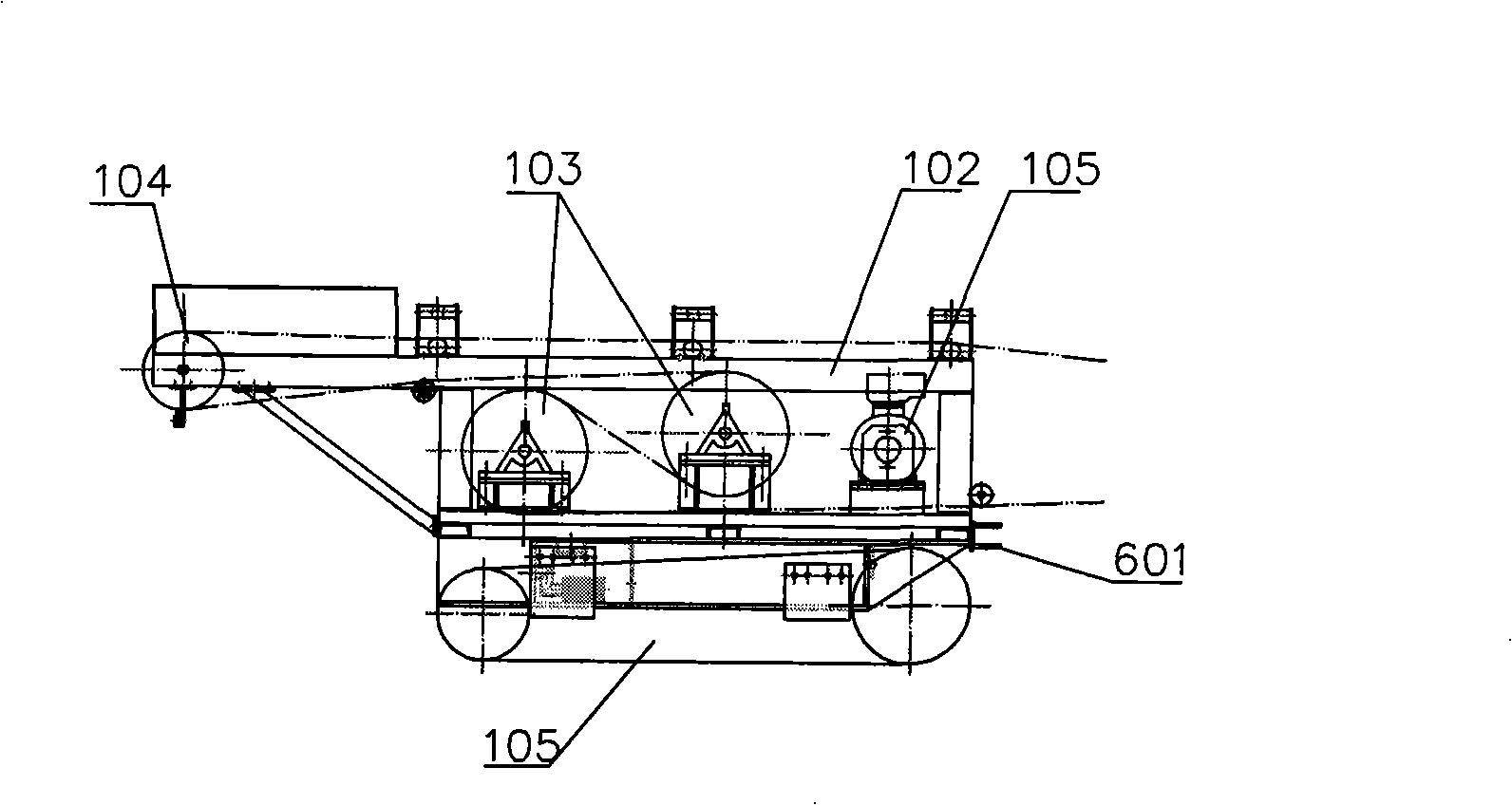

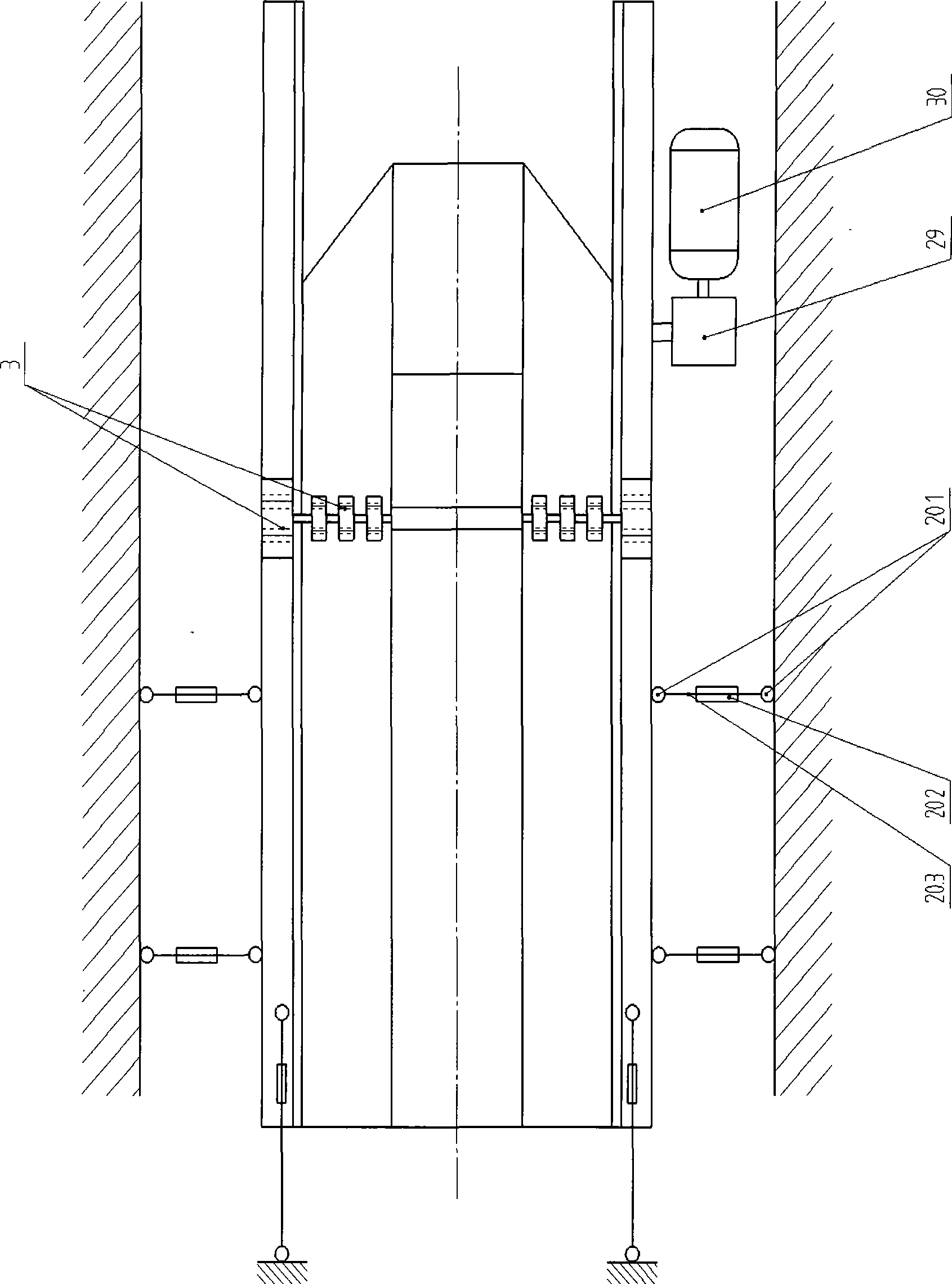

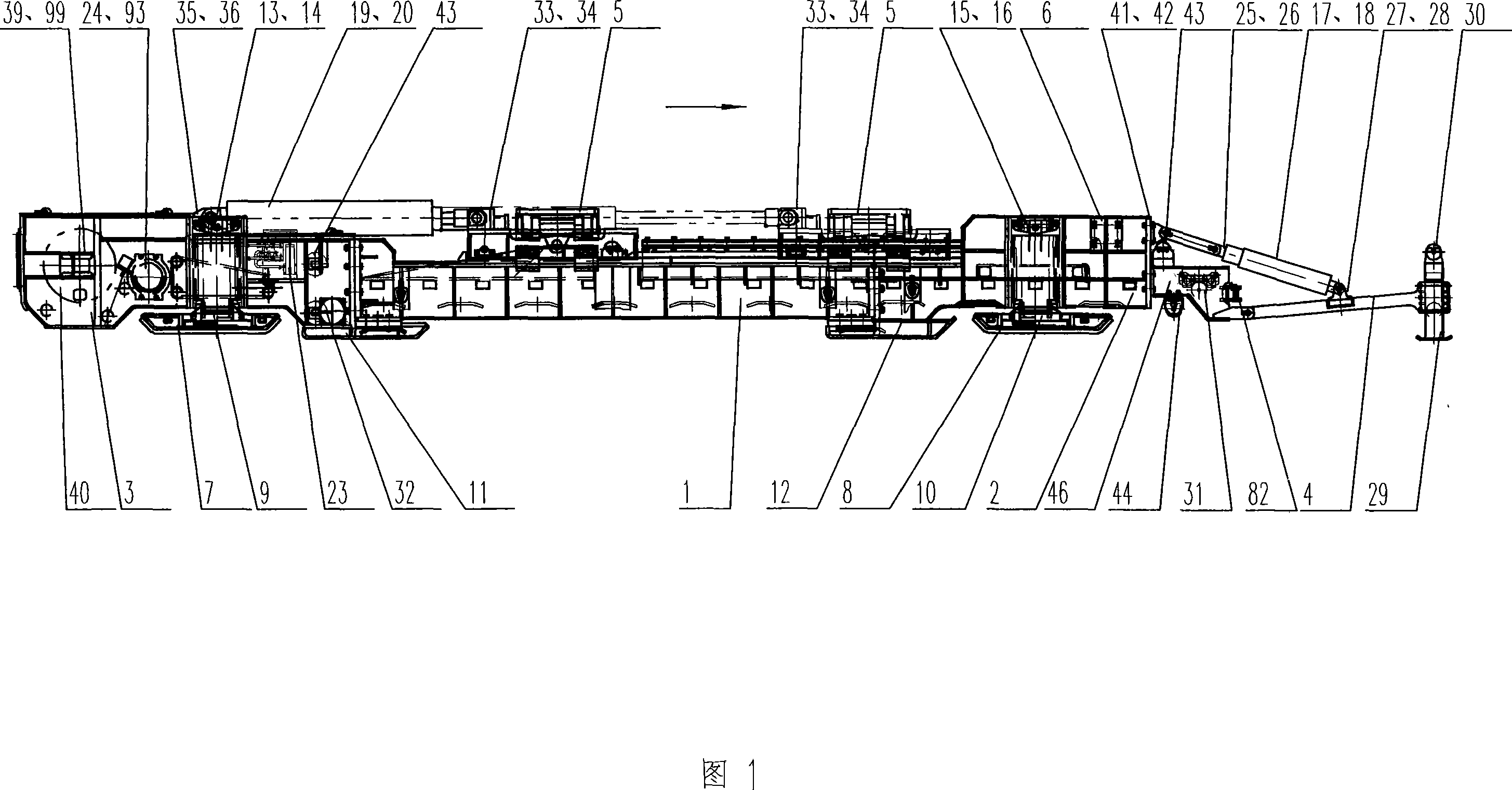

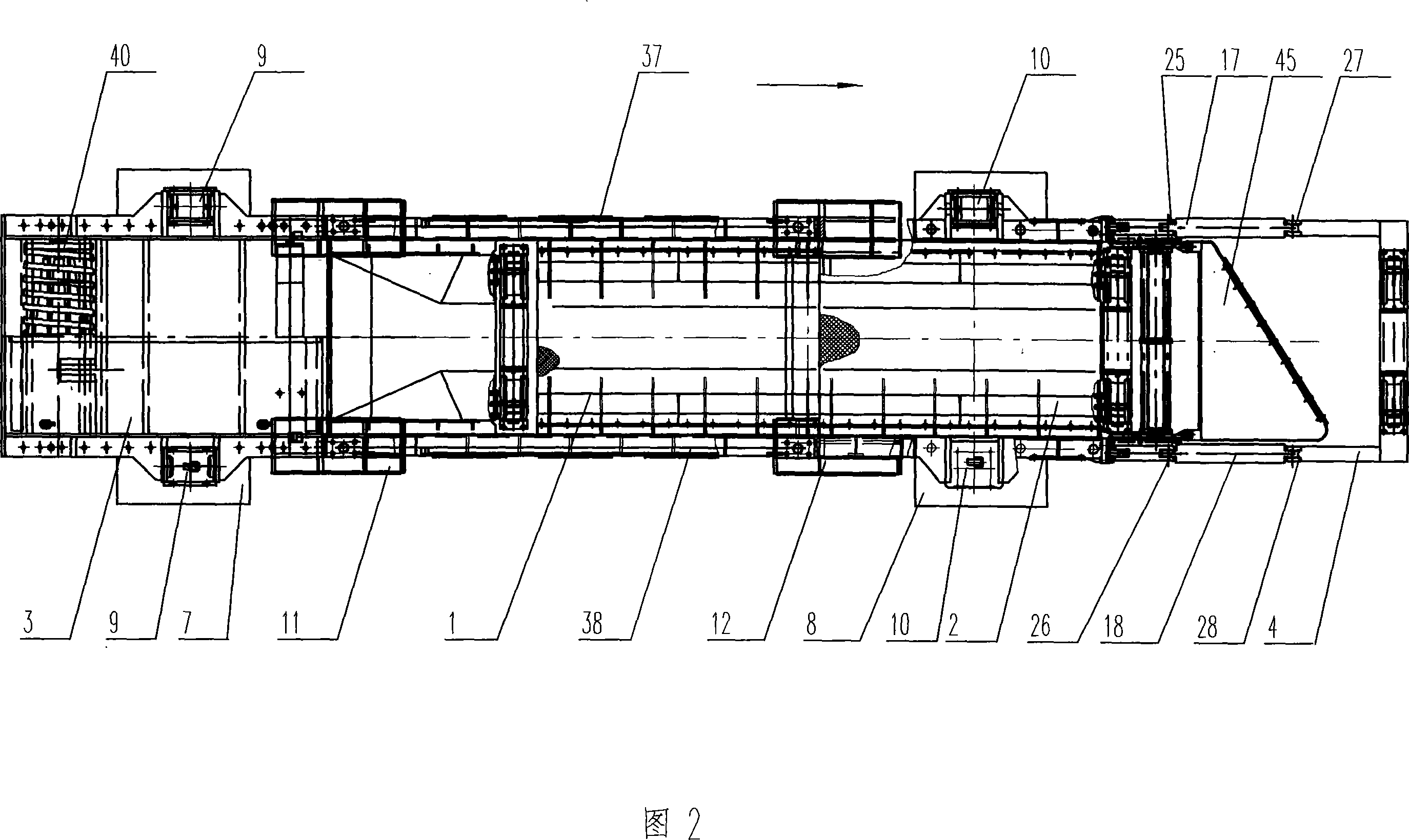

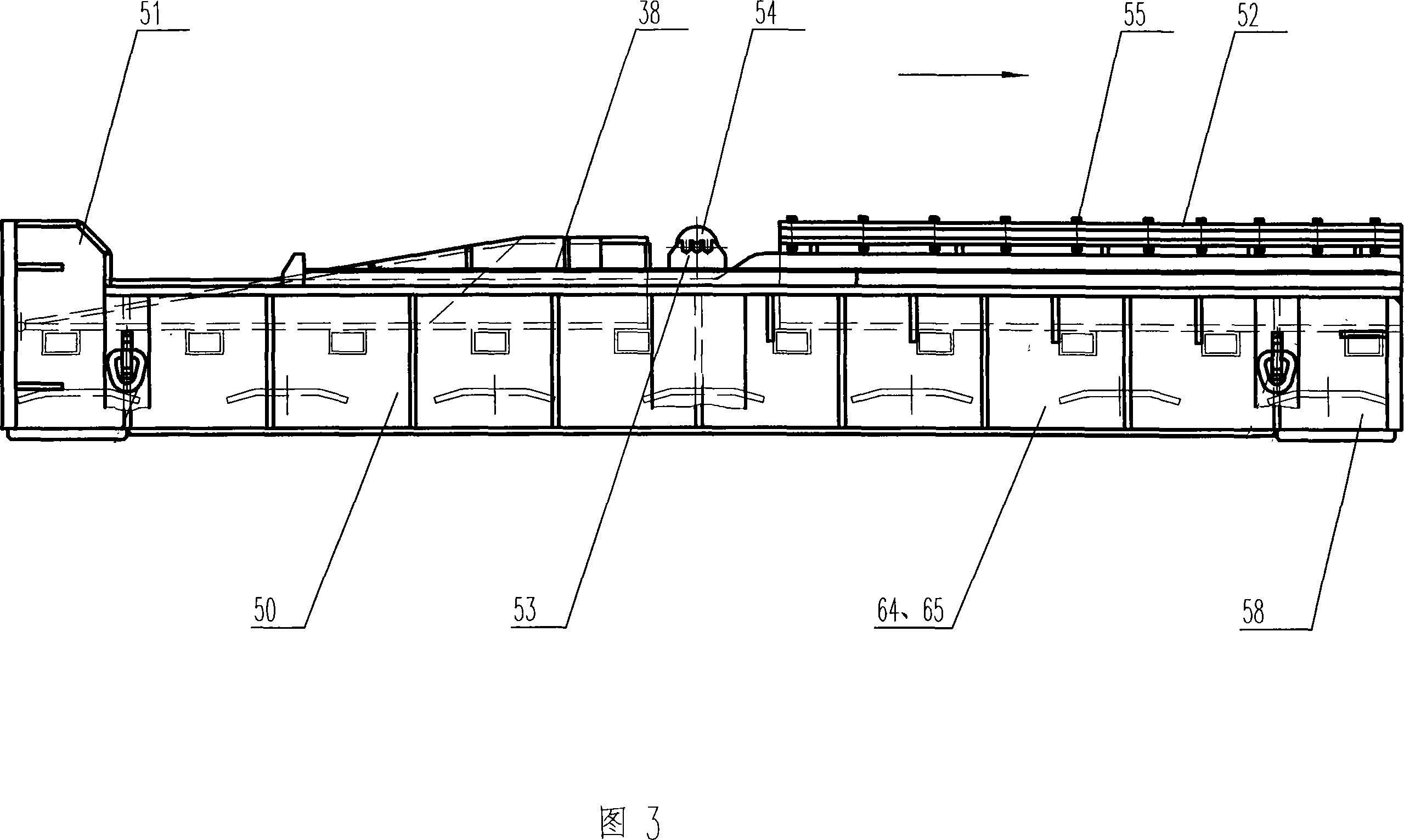

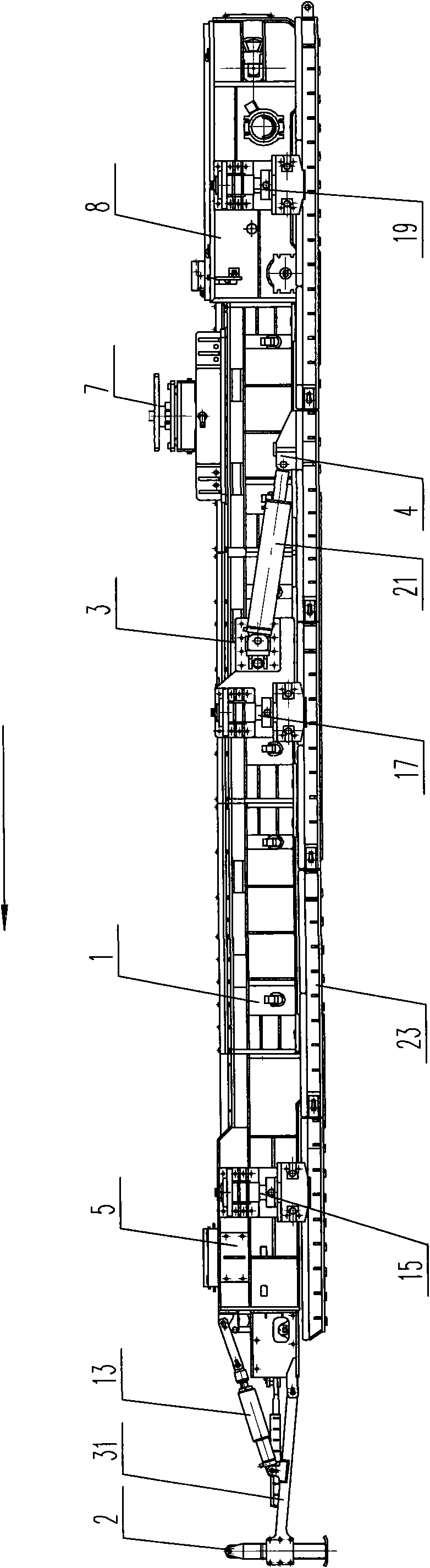

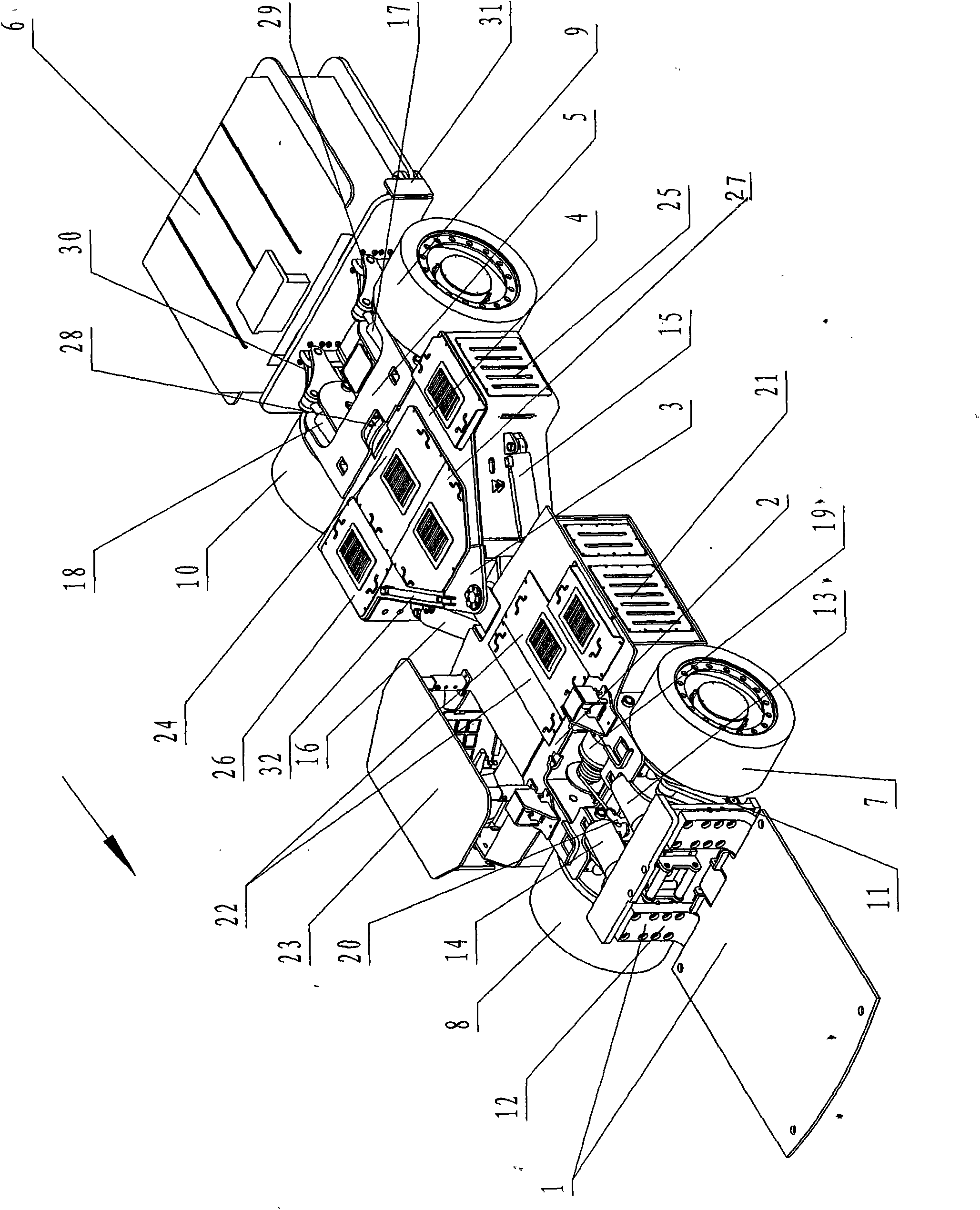

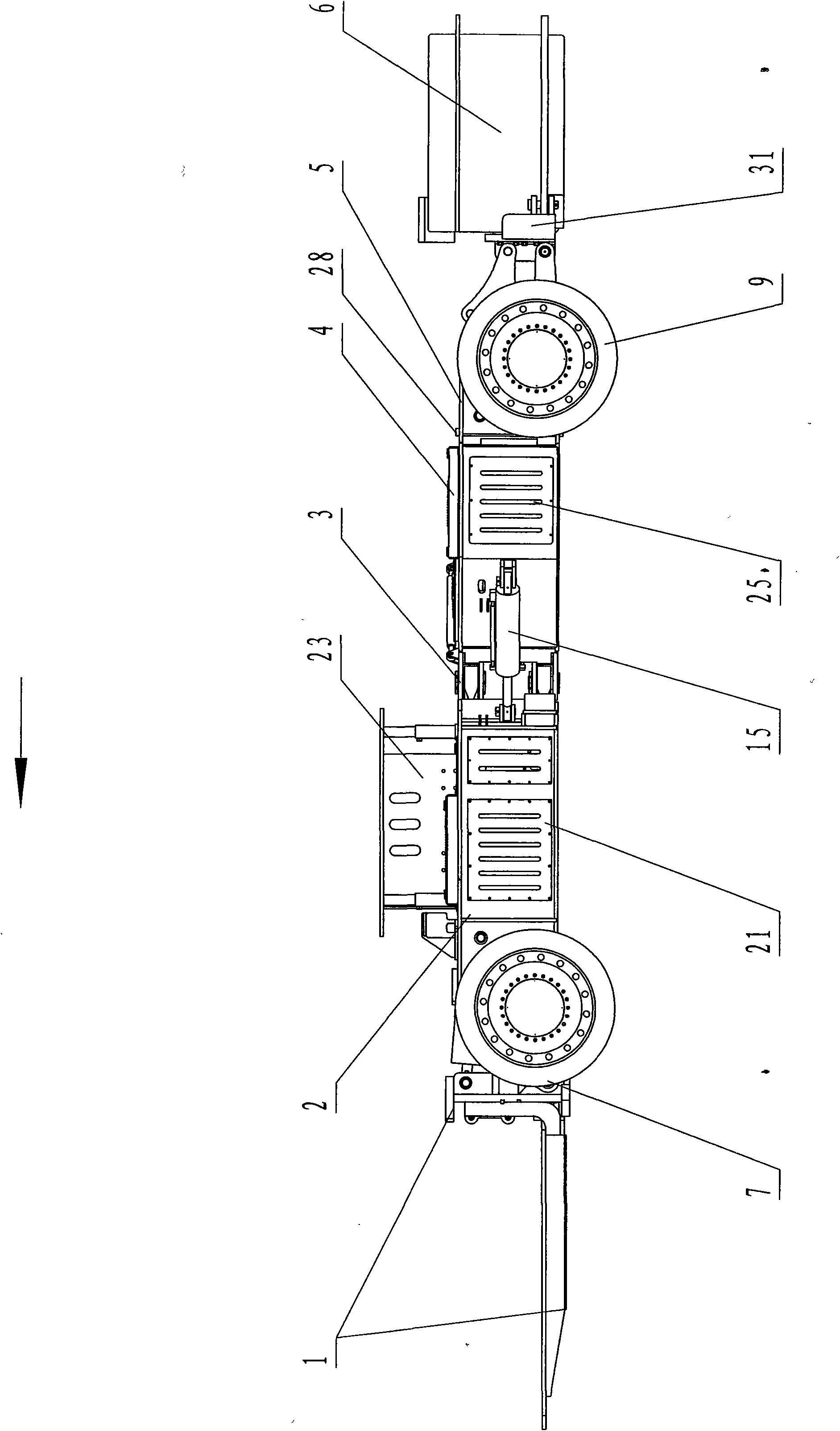

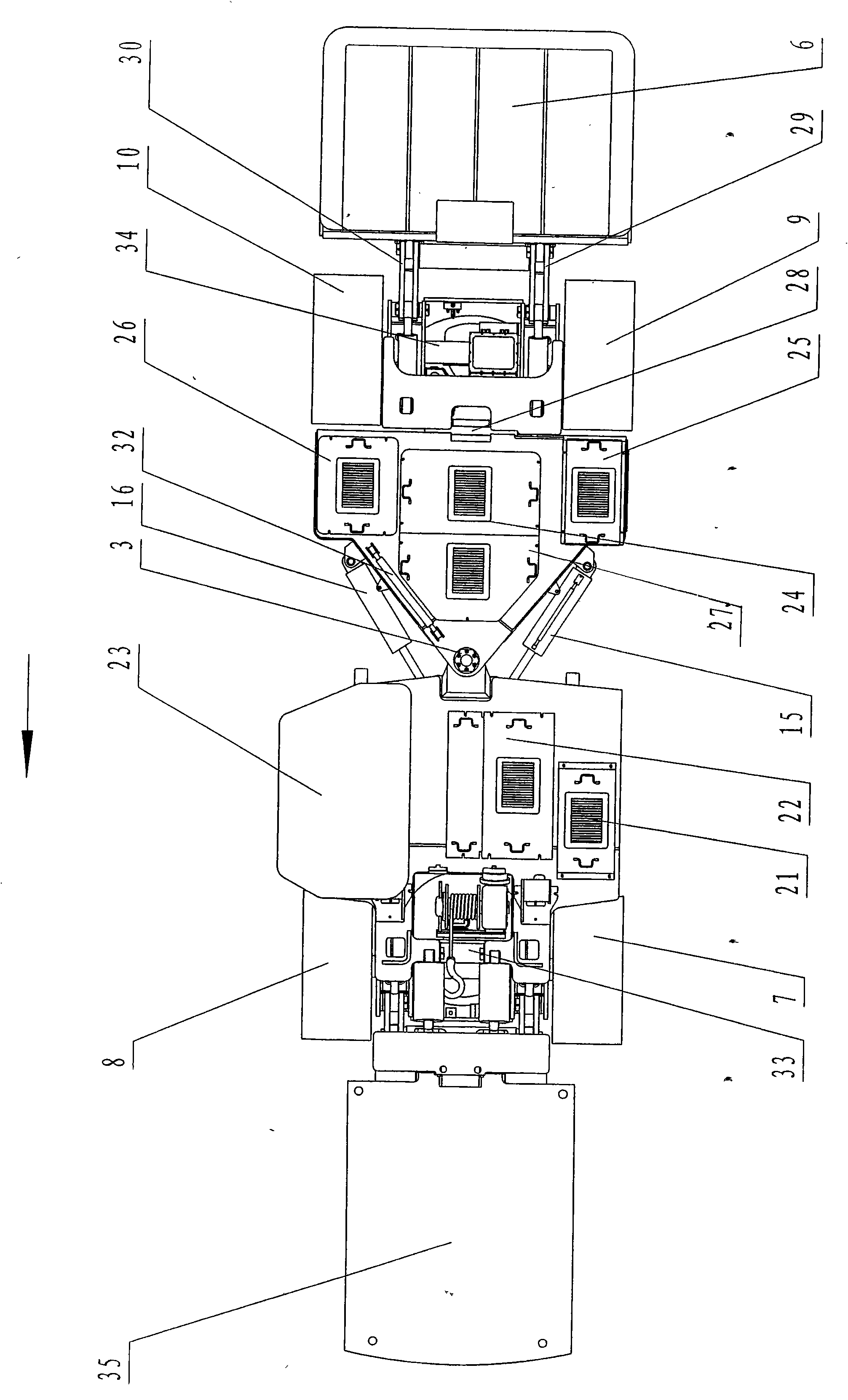

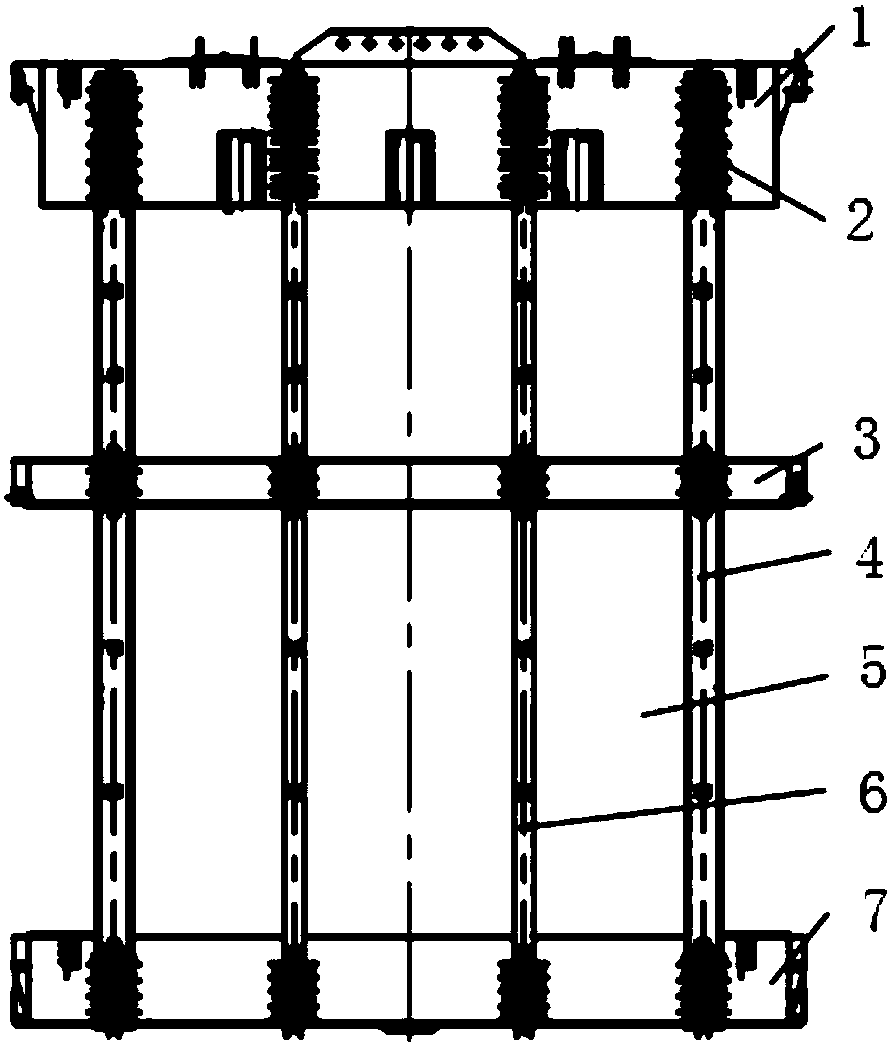

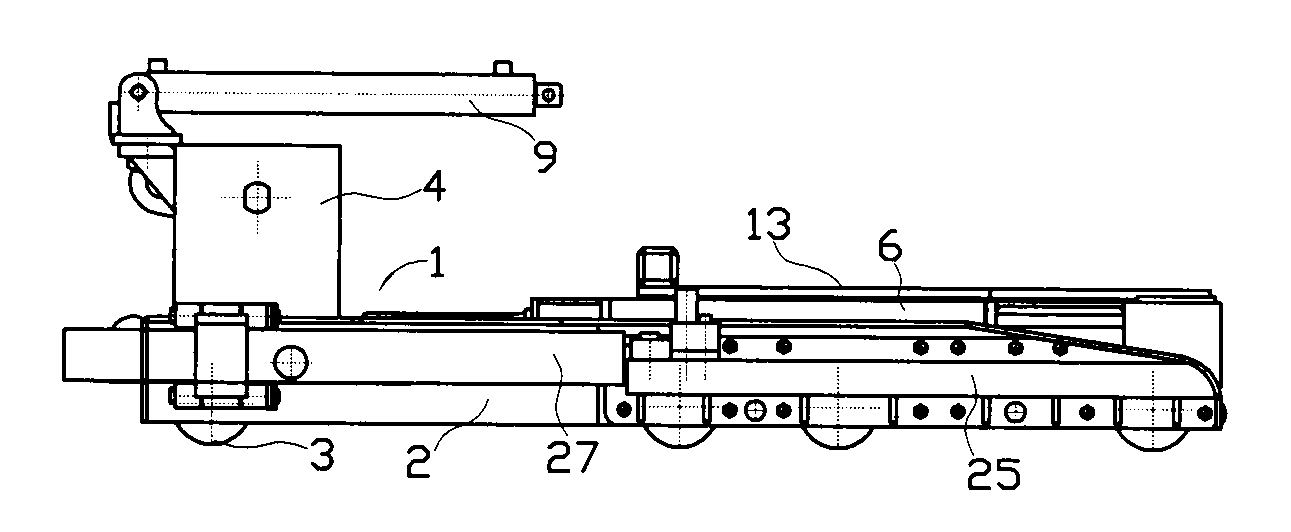

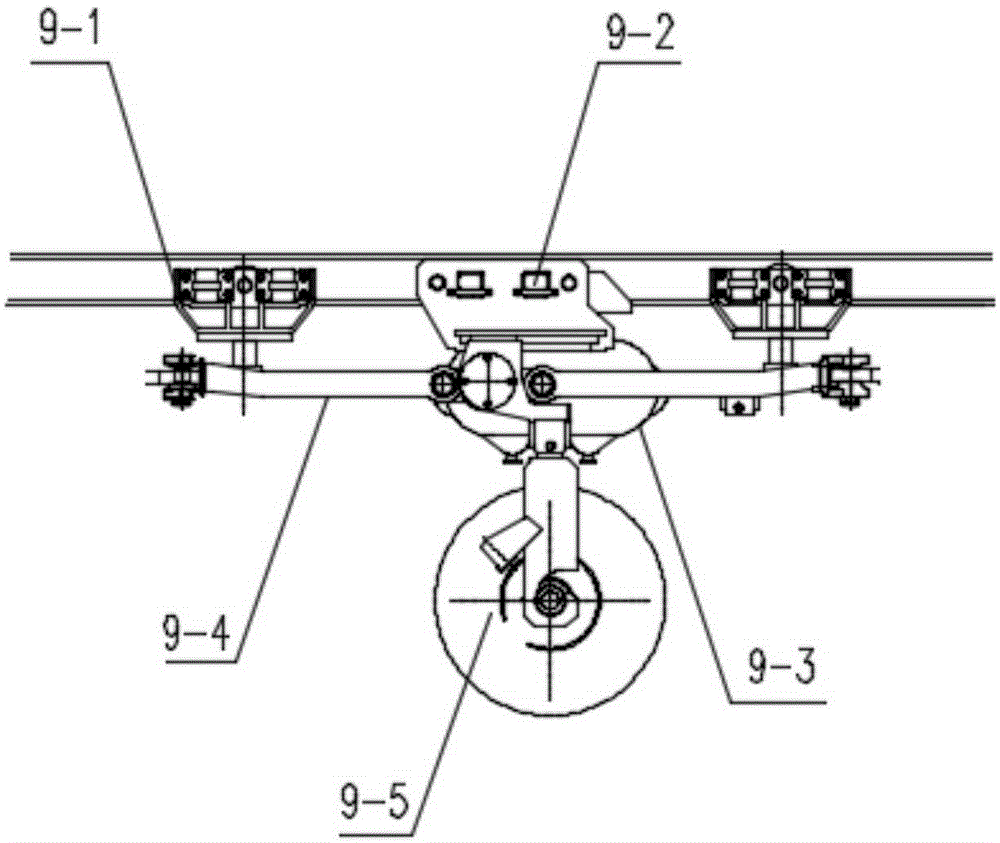

Tunnel pipe transporting mounting vehicle

InactiveCN1380212ACompact structureGuaranteed uptimeEarth drilling and miningWagons/vansDrive wheelPressure transmission

The tunnel pipe trasporting installation vehicle is formed from tractor truck, pipe-carrying vehicle and electric and hydraulic control system. The tractor truck in cludes chassis, driven wheel groupand driving wheel group, power device and speed reducer, cabin, track-cleaning device, warning signal light and headlight; the pipe-carrying vehicle includes front wheel group, front platform, pipe-carrying vehicle beam, lifting wheel group, lifting tyre group, supporting device, pipe-carrying carriage on the pipe-carrying vehicle beam and pipe-carrying lifting device; the described hydraulic control system includes tractor truck static pressure transmission system and hydraulic control system of pipe-carrying vehicle. Said vehicle is compact in structure, stable in operation, can transport, lift and install large-diameter PCCP pipe.

Owner:TAIYUAN HEAVY IND

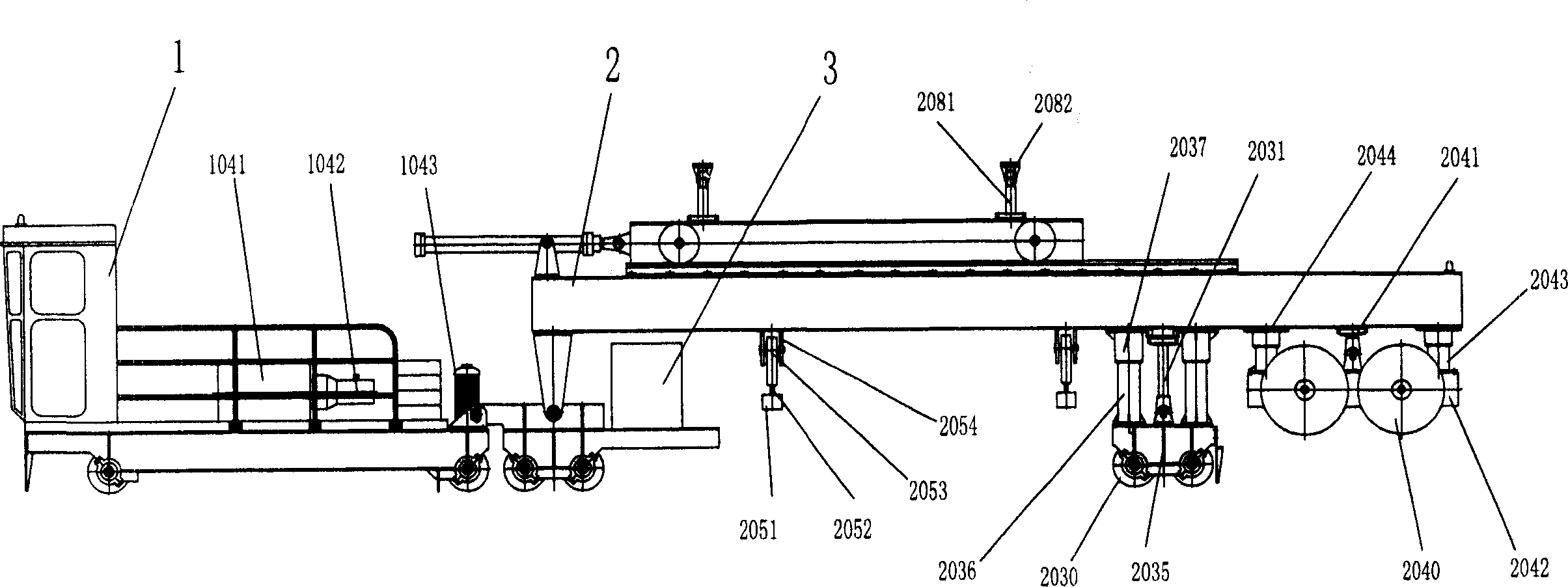

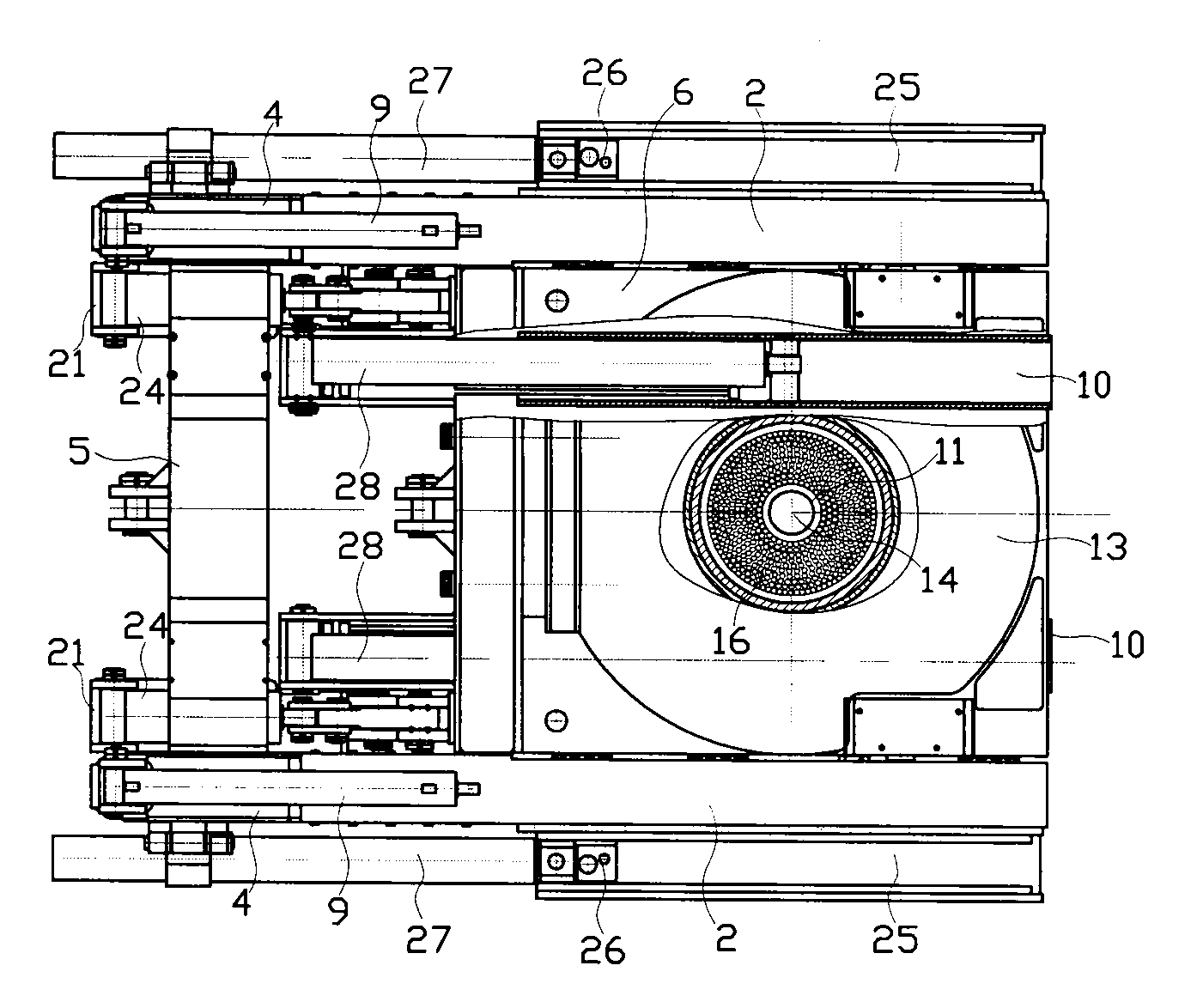

Steel pipe pallet car and uses thereof

ActiveCN1803567AAchieve precise positioningEvenly adjust the installation gapWelding/cutting auxillary devicesTrolley cranesSteel tubeMaterials science

The invention discloses a large-scale steel pipe car, which comprises the following parts: main beam, longitude walking rack, rotary rack, supporting leg, supporting arm and adjusting support. The car can form a multifunctional mechanic construction platform in the steel making, transportation, assembling, surface antiseptic, detecting and concrete casting course, which realizes the mechanic automatic operation in the finite tunnel.

Owner:CHENGDU ALANGTECH

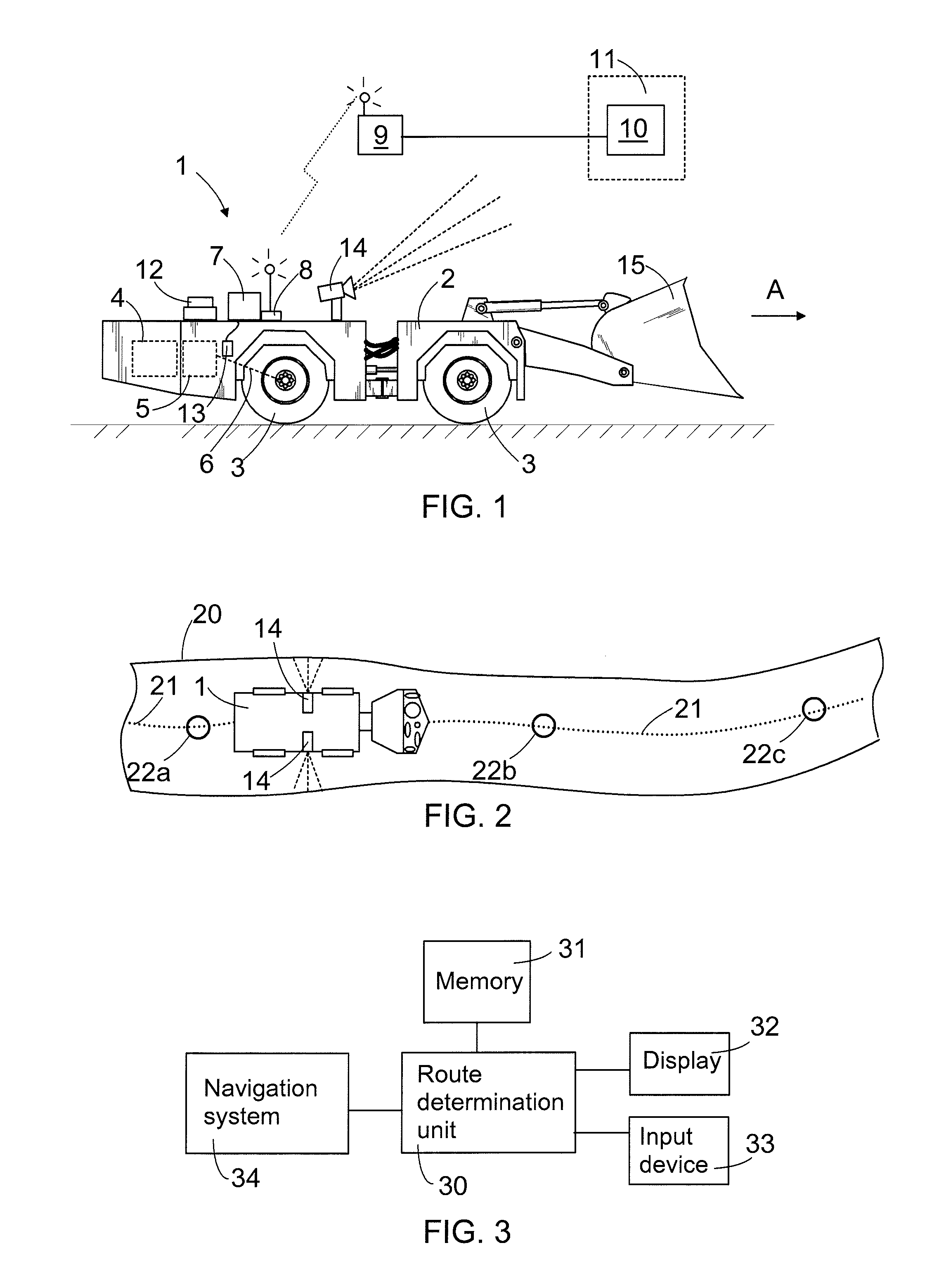

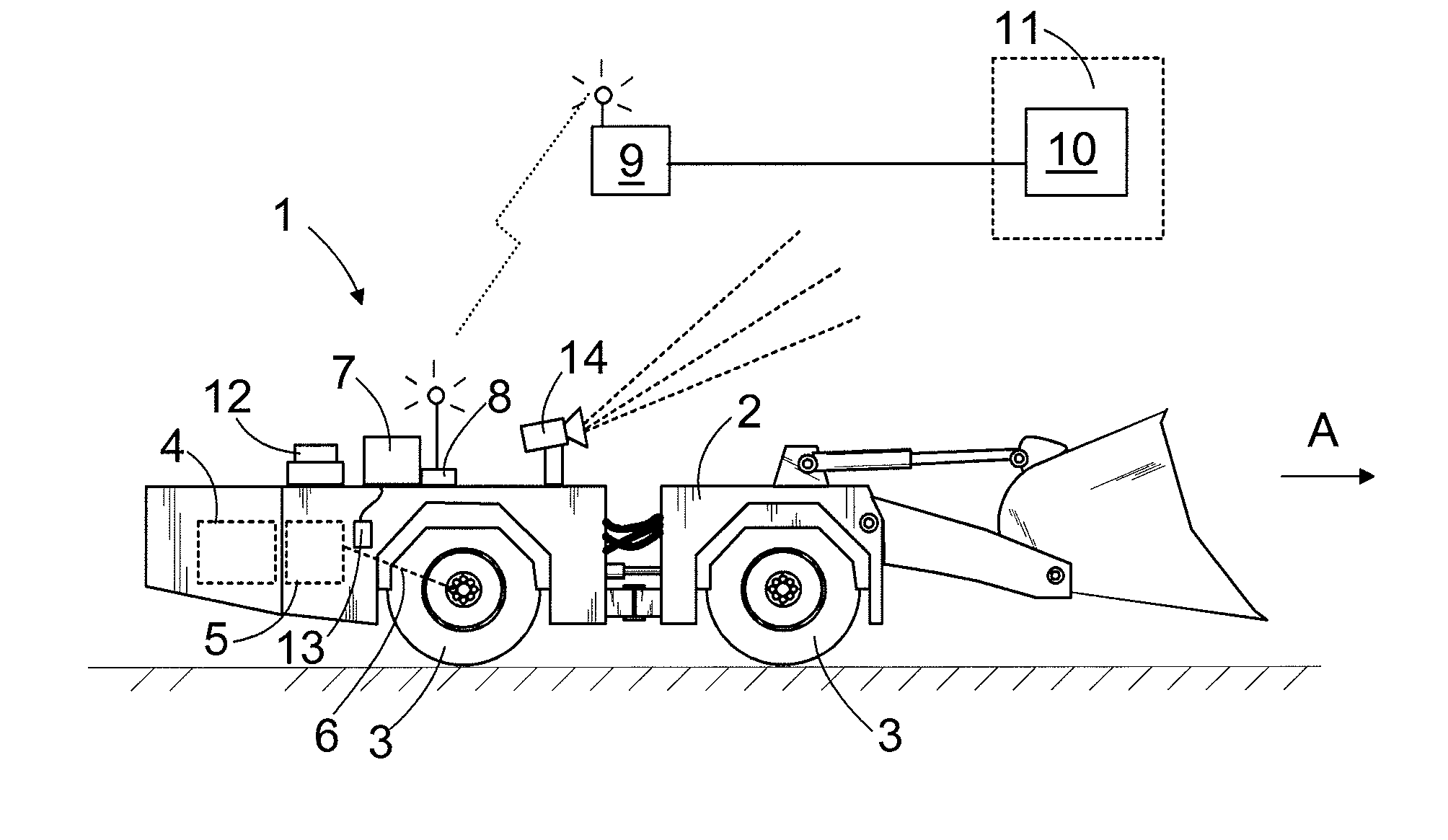

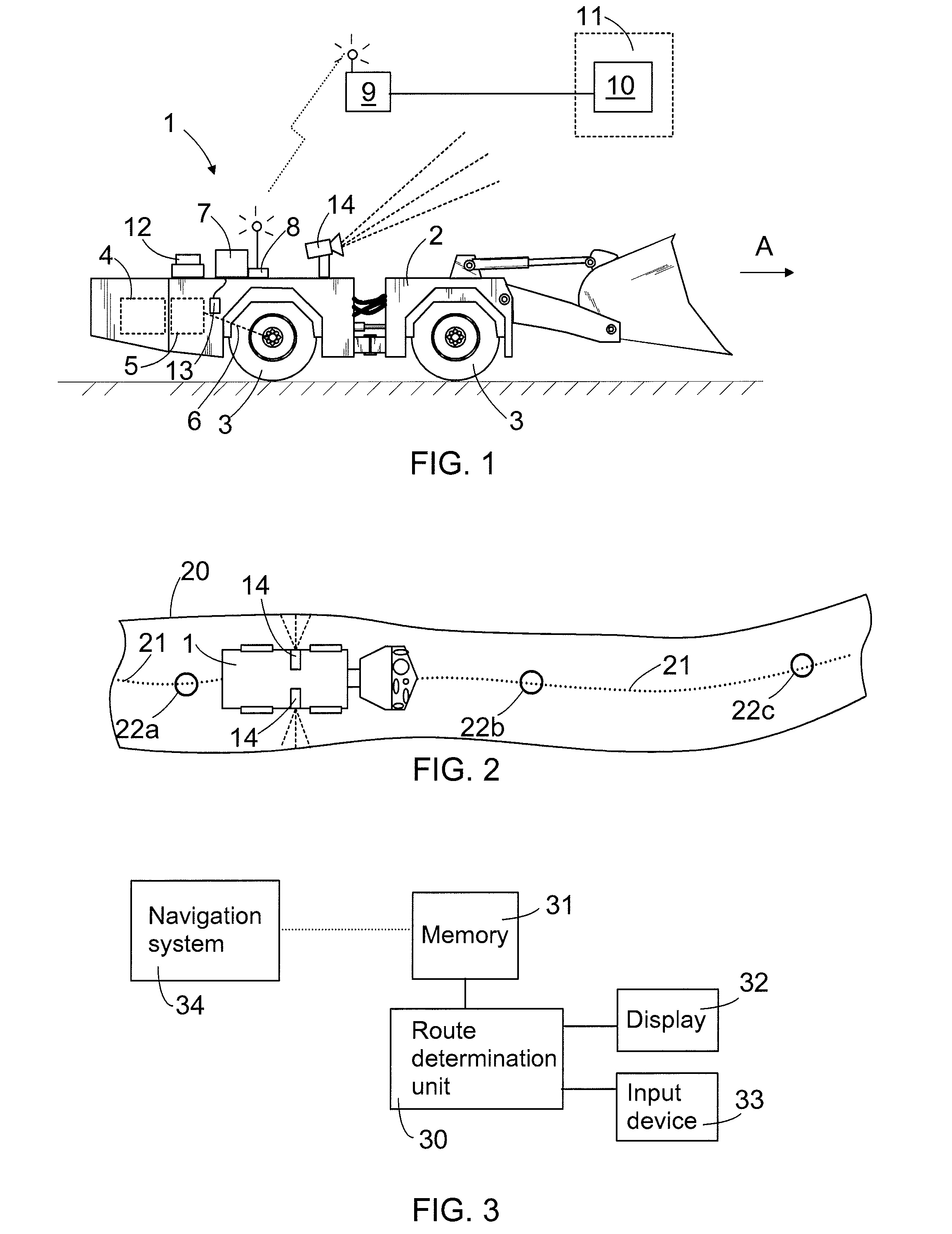

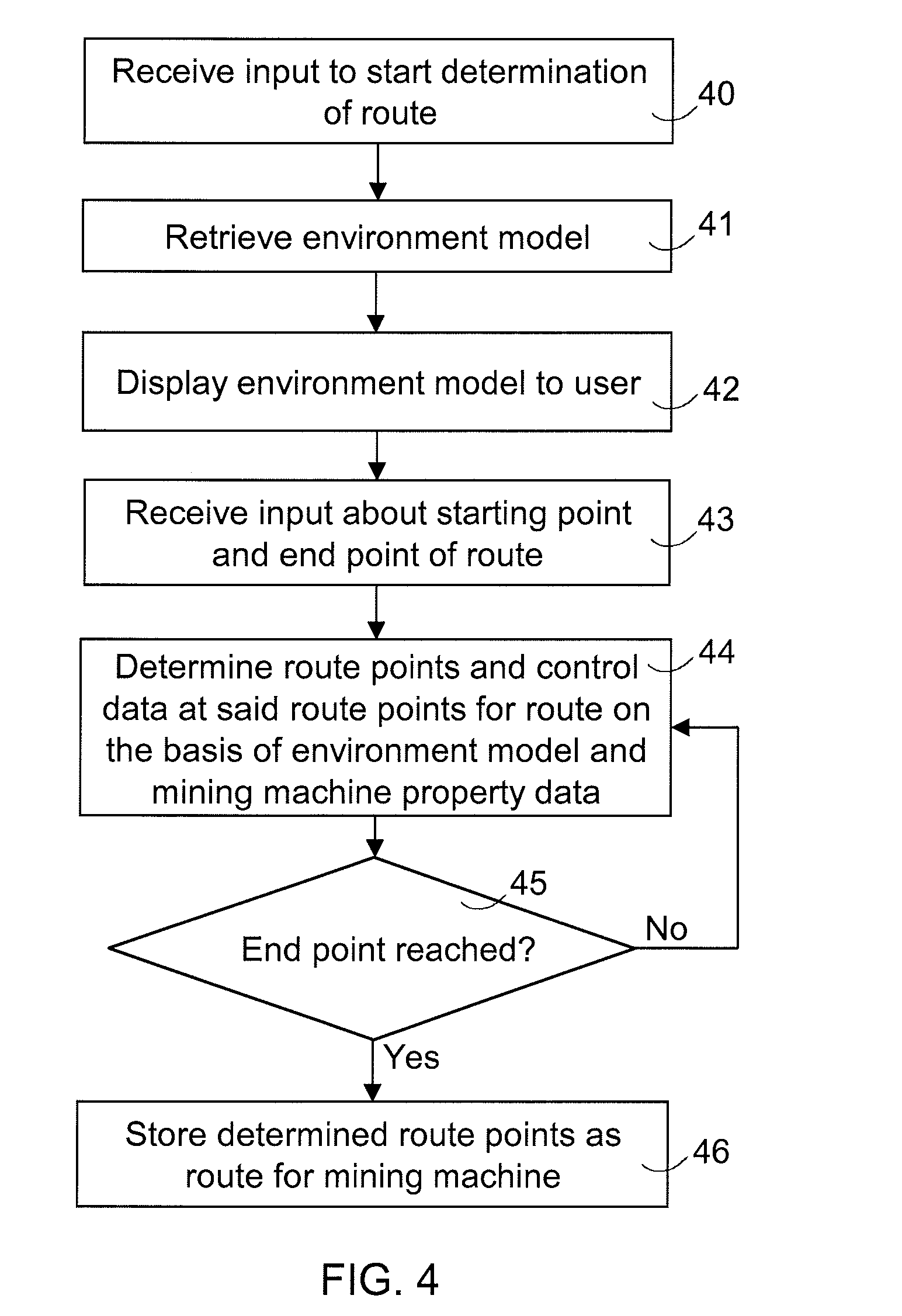

Determination of Route for Arranging Automatic Control of Mobile Mining Machine

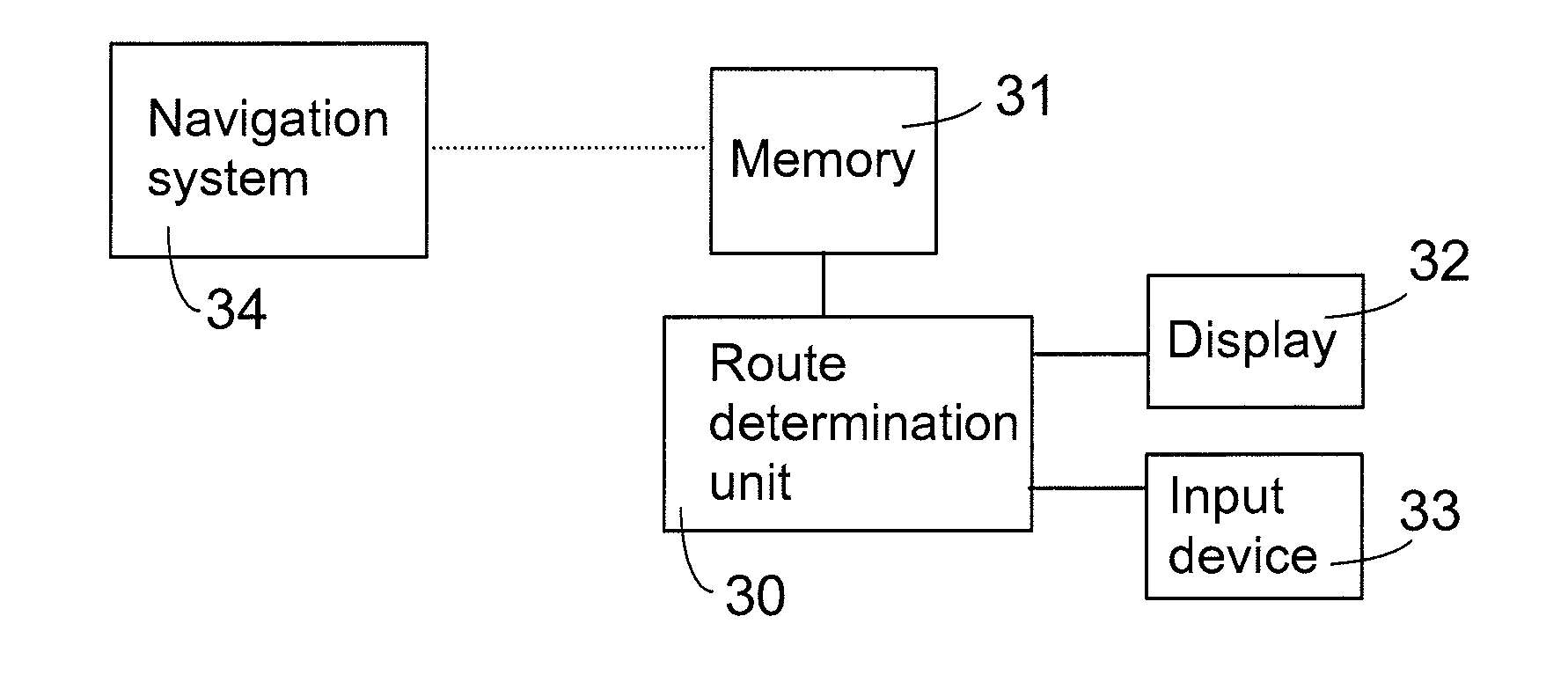

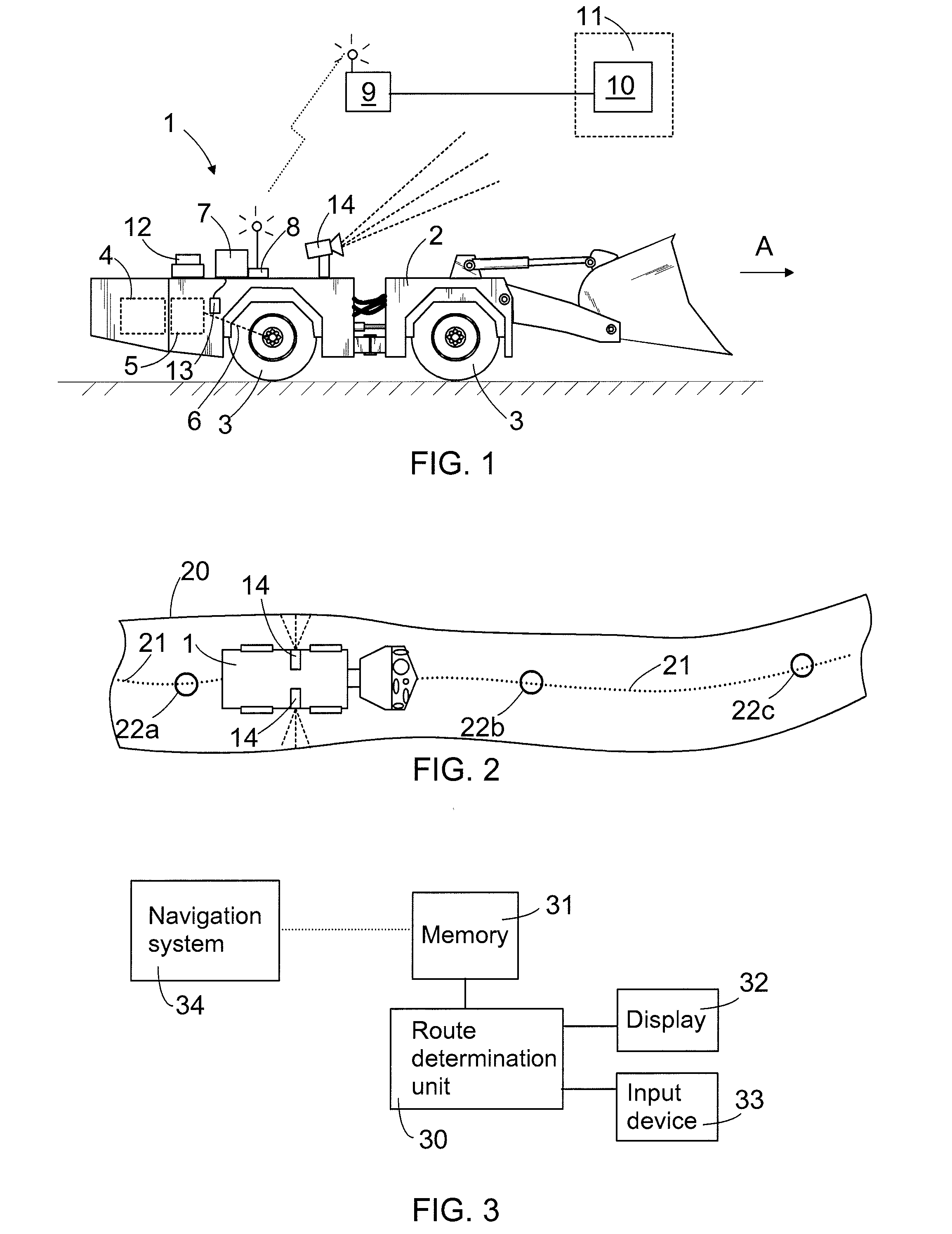

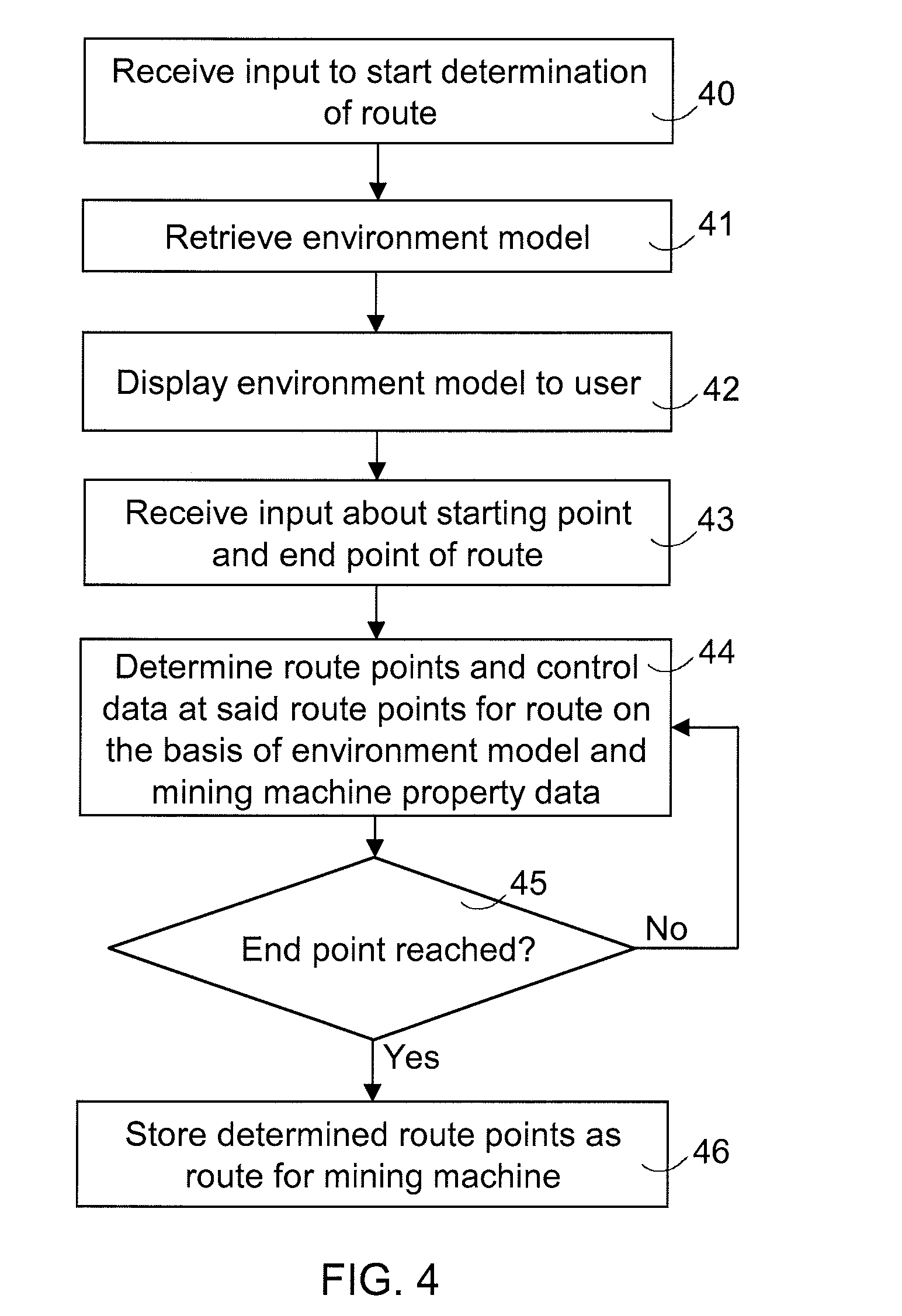

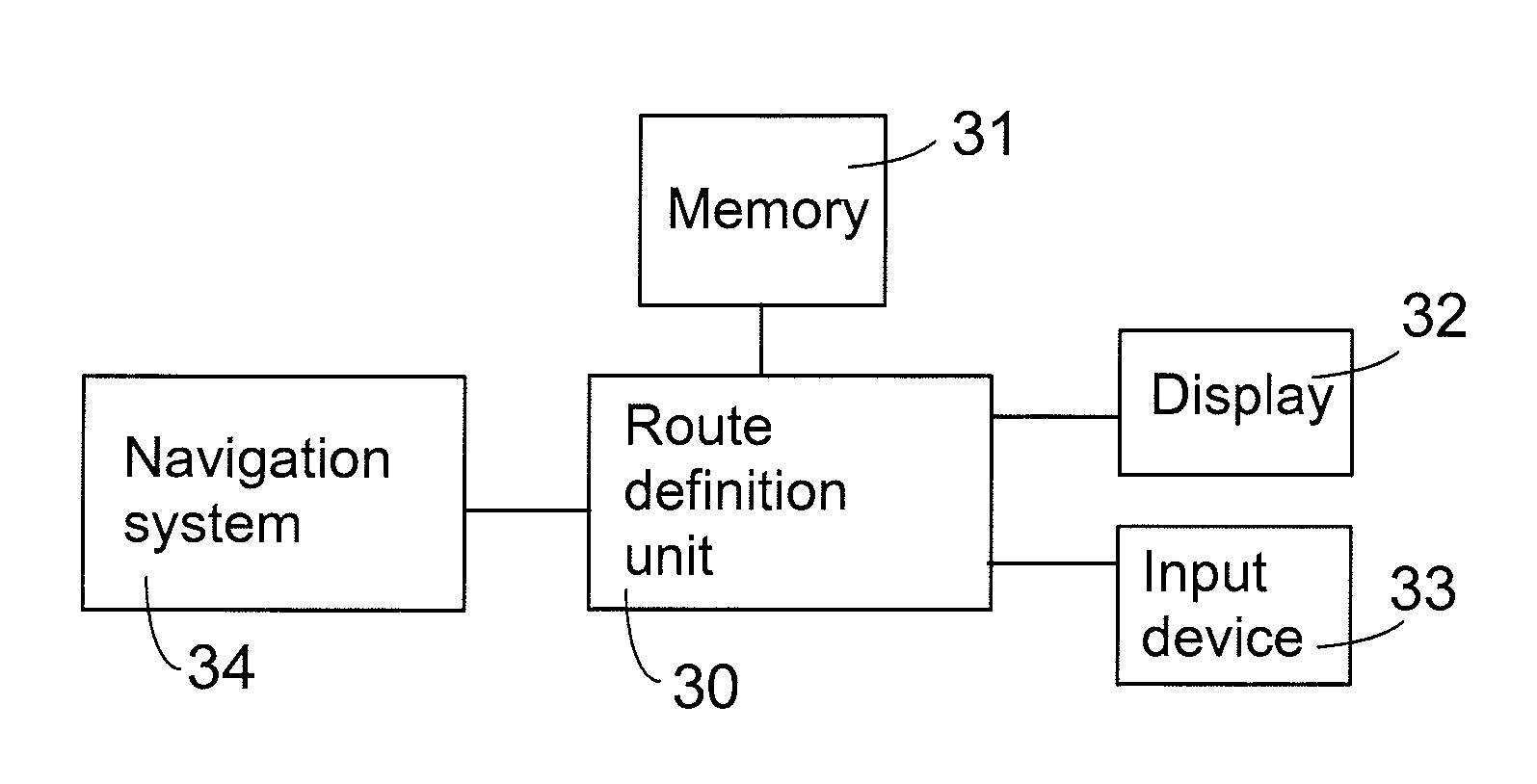

ActiveUS20120116666A1Easy to solveShorten the time necessarily taken by a routeNavigation instrumentsEarth drilling and miningPresent methodAutomatic control

The present method relates to a method of determining a route for automatically controlling a mobile mining machine. The route is determined computer-aidedly by executing, by a data processing machine configured for generating routes, the following steps of: retrieving an environment model comprising wall location data, receiving from a user at least an input for determining a starting point of the route and an input for determining an end point of the route, determining the route between the starting point and the end point on the basis of the environment model and data concerning properties of the mining machine, wherein the route is determined as route points at least for which position data are calculated, and storing the data determining the route to be used for automatically guiding the mining machine.

Owner:SANDVIK MINING & CONSTR OY

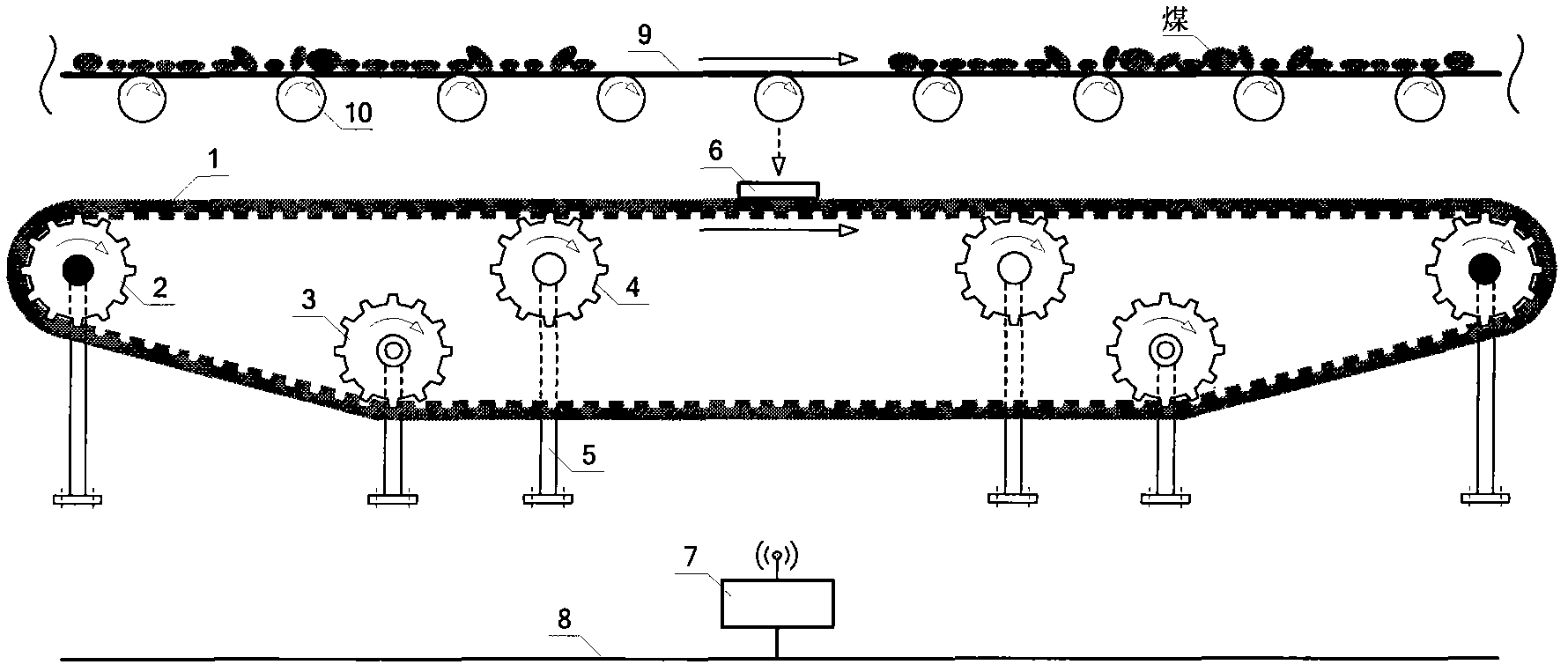

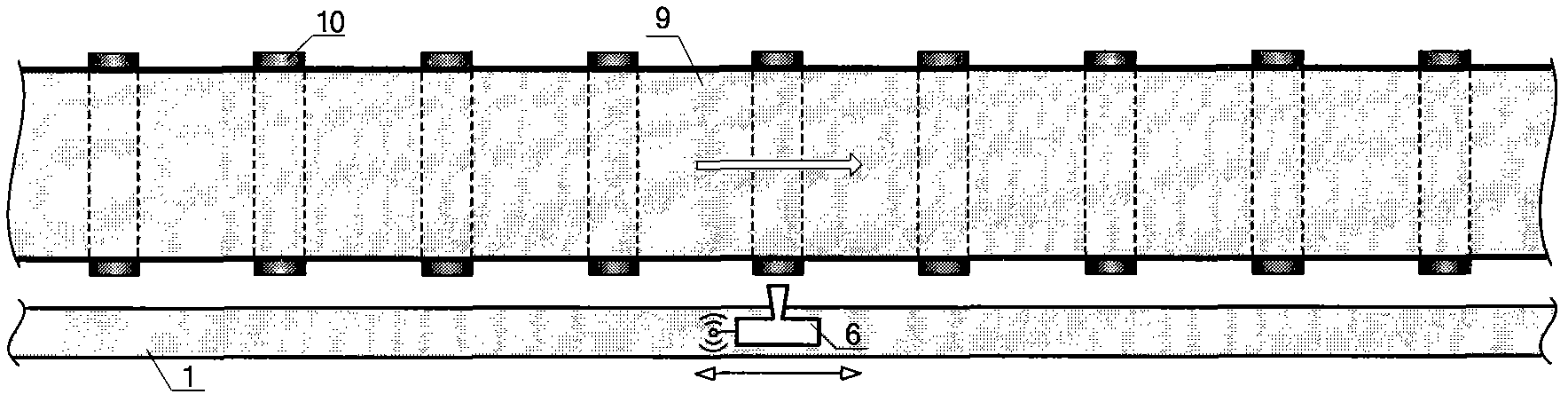

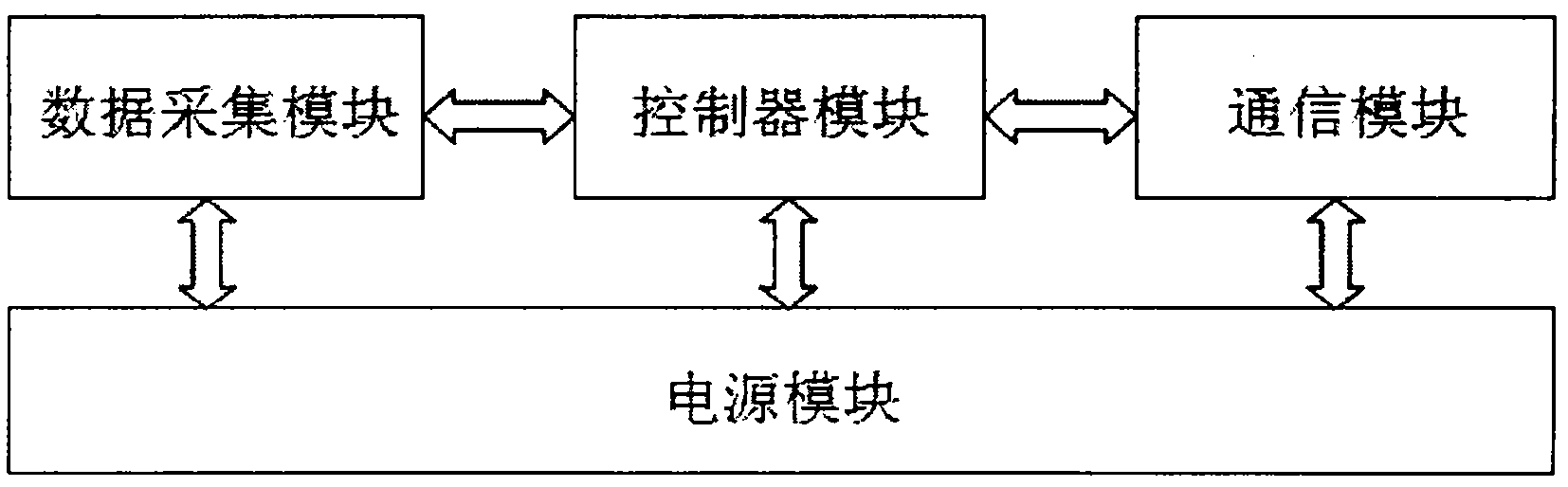

Roller failure monitoring system of belt conveyer

InactiveCN101975083ARealize automatic monitoring functionControl devices for conveyorsEarth drilling and miningAutomatic routingData acquisition

The invention relates to a failure monitoring system of a roller of a belt conveyer, which mainly comprises a sensor, a mechanical device for moving the sensor, a communication substation and the like, wherein the sensor comprises a power module, a data acquisition module, a controller module and a communication module; a sensitive element of the data acquisition module is a unidirectional type electret microphone; the mechanical device comprises a synchronous belt, synchronous belt wheels on both ends of the synchronous belt, a supporting wheel in the middle of the synchronous belt and a stretching wheel; the sensor fixed on the synchronous belt is moved to the position near to any roller position by utilizing the operation of the mechanical device; the sensor collects sound signals and the like generated by the rotation of rollers and carries out the data processing and the extraction of failure signals; and the failure diagnosis result is sent to the communication substation and transmitted to a monitoring room through an optical network. The system is especially suitable for automatic routing inspection of the belt conveyer under a coal mine, discovers the abnormal working condition of the roller in time and guarantees the normal production of the coal mine.

Owner:ZHEJIANG UNIV

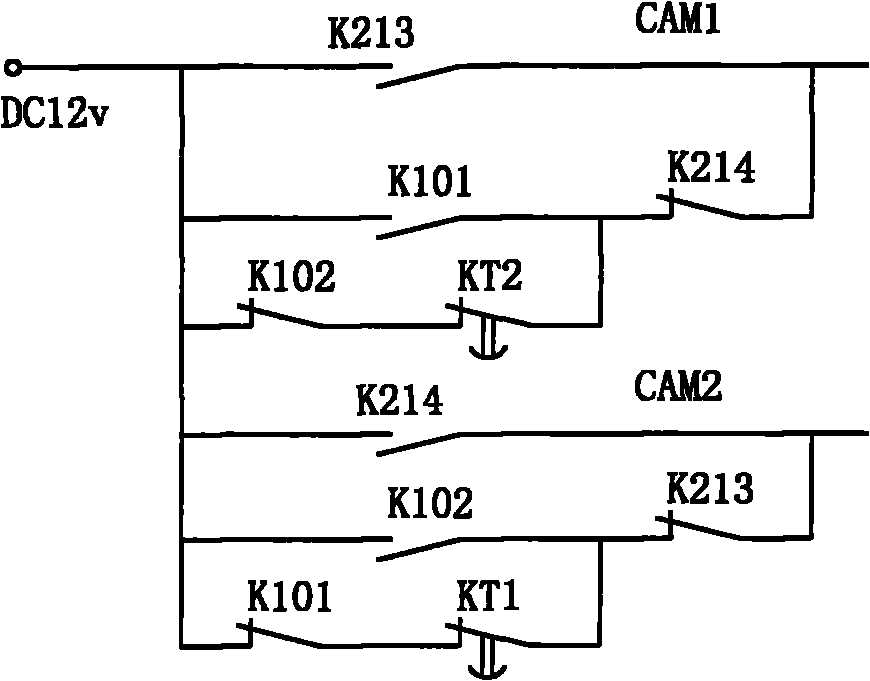

Manual control and remote control integrated electric fork lift truck

InactiveCN101982618AOperational securityImprove securityMechanical machines/dredgersClosed circuit television systemsWireless controlRemote control

The invention discloses a manual control and remote control integrated electric fork lift truck, which belongs to the field of electric fork lift truck and comprises an electrically-driven fork lift truck on a working face. The fork lift truck is provided with an operating room; the operating room is provided with a manipulation button which is connected with a control system; and a power supply end of the control system is connected with a power supply cable arranged on the rear part of the fork lift truck. The fork lift truck is characterized in that: the fork lift truck on the working face is provided with a wireless monitoring system and a wireless control system; a terminal operating floor of the wireless monitoring system and the wireless control system are arranged in a work station; and the wireless control system is connected in parallel and mutually locked with the manipulation button in the operating room and then connected with the control system. An operator can monitor the conditions of the working face and control the work of the electric fork lift truck on the terminal operating floor of the work station. When the wireless control system controls the fork lift truck, the manual operation system stops so that the fork lift truck receives only one command; and the fork lift truck operates in a large range and is convenient to control.

Owner:SHANDONG UNIV OF TECH

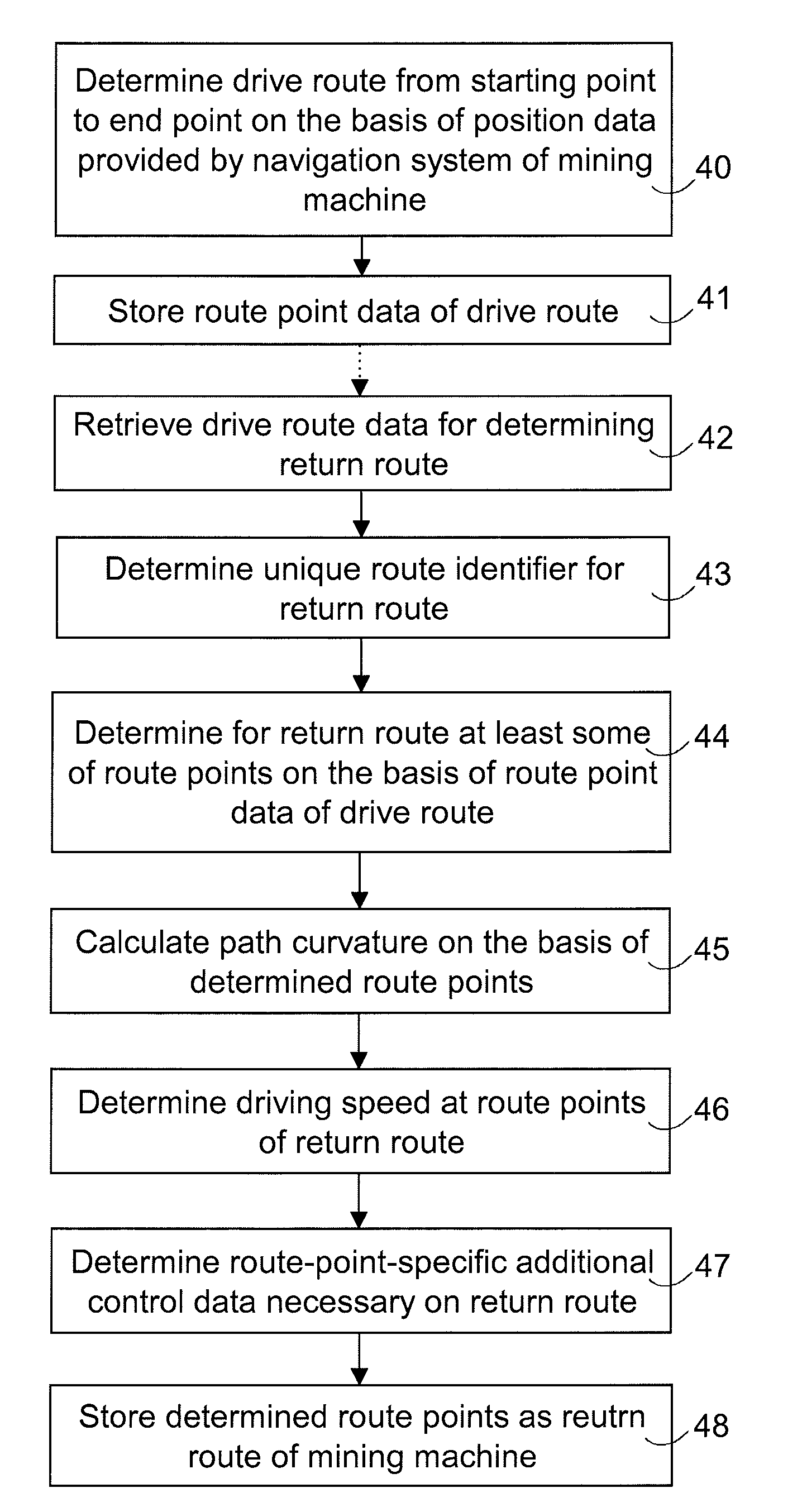

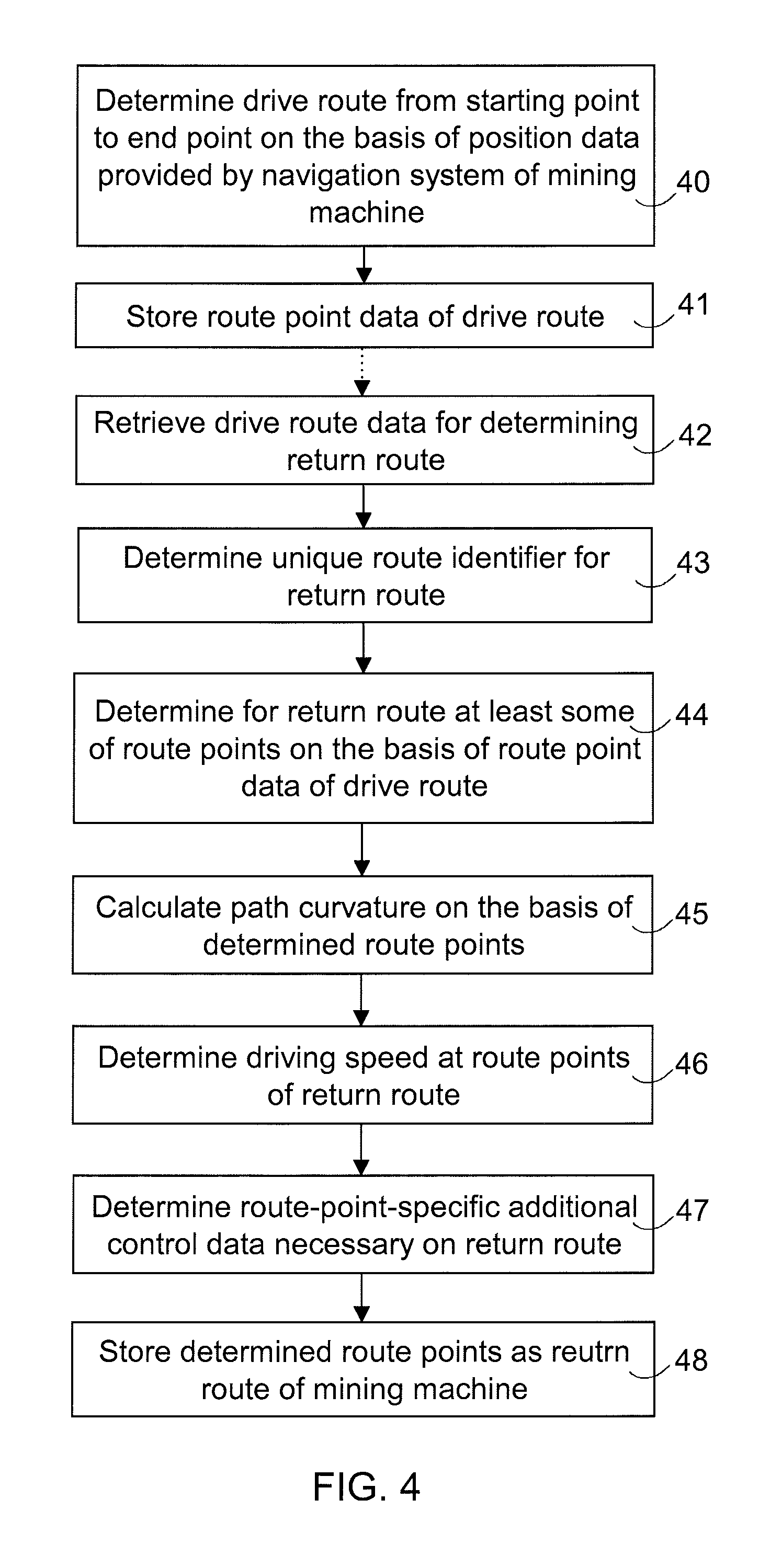

Determination of Routes for Arranging Automatic Control of Mobile Mining Machine

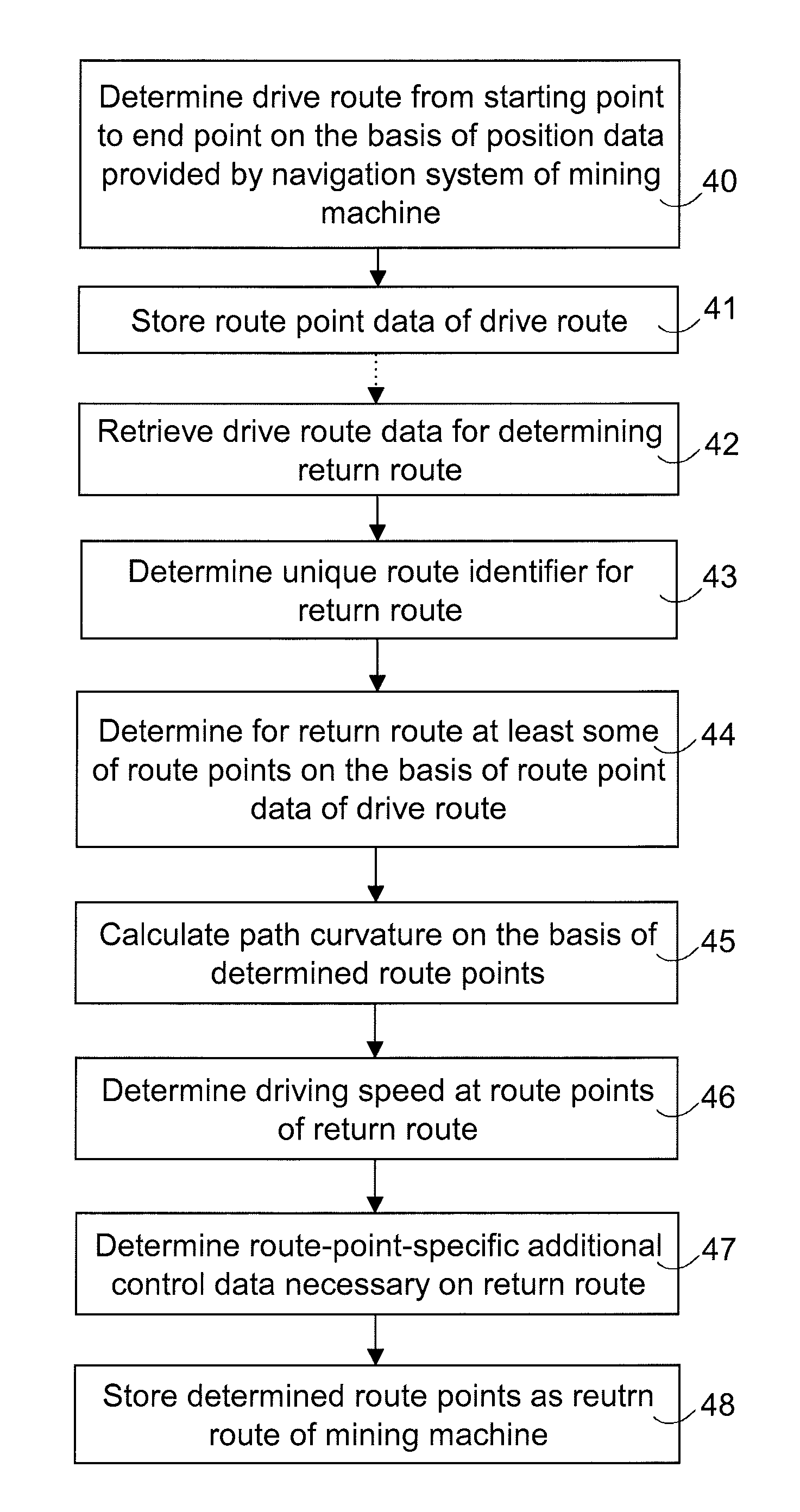

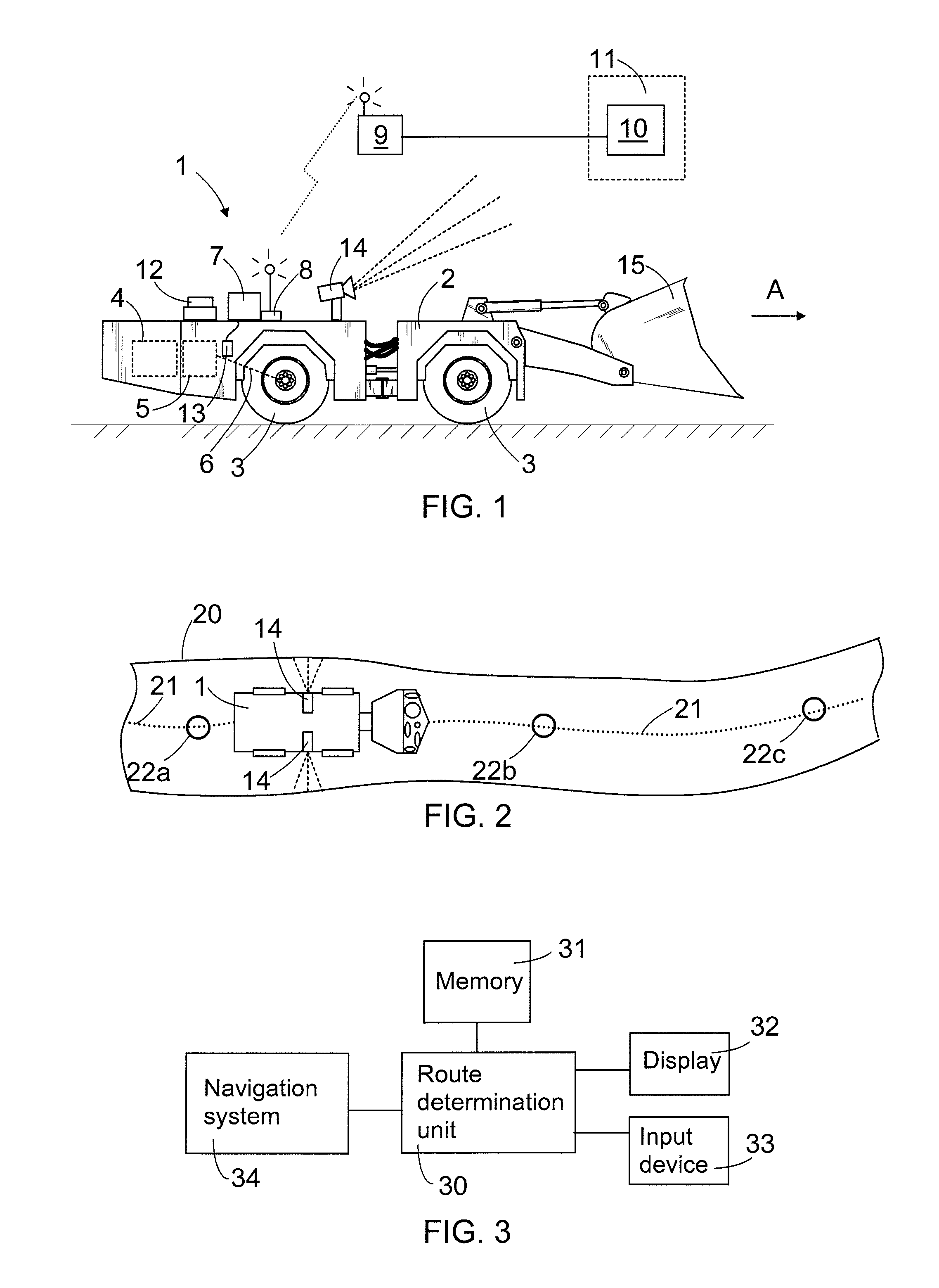

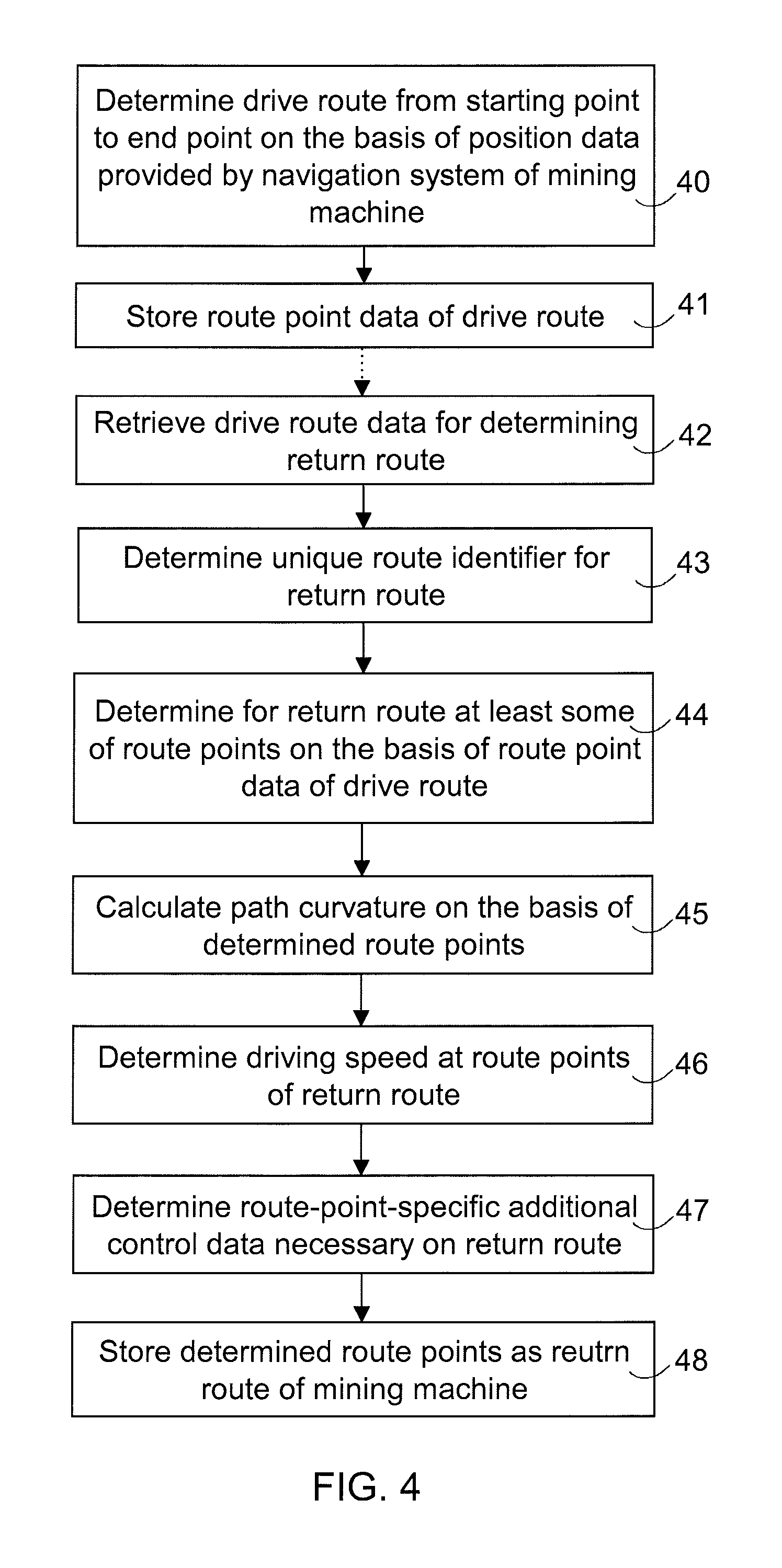

ActiveUS20120095639A1Shorten the timeConsiderable amount of timeInstruments for road network navigationEarth drilling and miningAutomatic controlReverse order

The present invention relates to a method of determining routes for arranging automatic control of a mobile mining machine. A return route is determined computer-aidedly for the mining machine on the basis of data concerning a route taught by driving by executing, by a data processing device configured for generating return routes, at least the following steps: determining a route identifier for the return route, determining as route points of the return route at least some of the route points of the drive route in a reverse order, wherein when determining route point data of the return route on the basis of the route point data of the drive route, deleting additional control data associated with one or more route points of the drive route, and storing the data determining the return route to be used for automatically controlling the mining machine.

Owner:SANDVIK MINING & CONSTR OY

Main shaft skip weight-measuring device for coal supply machine

InactiveCN101332944AAdapt to a wide rangeEasy to installConveyorsControl devices for conveyorsWeight changeInlet valve

The invention discloses a coal feeder type main shaft bucket standard weight device provided with a weighing device on the existing belt conveyor type coal feeder in mines, without occupying other space. The weighing device comprises: an instantaneous weighing device connected with a conveyer belt, a speed sensor connected with a driven roller and a calculator installed outside a machine; the calculator is connected with an inlet valve of a feed inlet by a signal wire. The instantaneous weighing device comprises: a weighing bridge, a weighing sensor, a weighing roller, and the like; the weighing bridge is in floating mode, which floats up and down along with the material weight change at the upper part of the conveyor belt; the weighing sensor connected with the weighing roller and the speed sensor connected with the driven roller input signals into the calculator for calculation so as to calculate the weight of transported material on the conveyor belt in a period of time. When the bucket standard weight load is reached, the calculator sends out signals to close a feed valve so as to realize continuous and uninterrupted bucket standard weight loading.

Owner:李文昌 +1

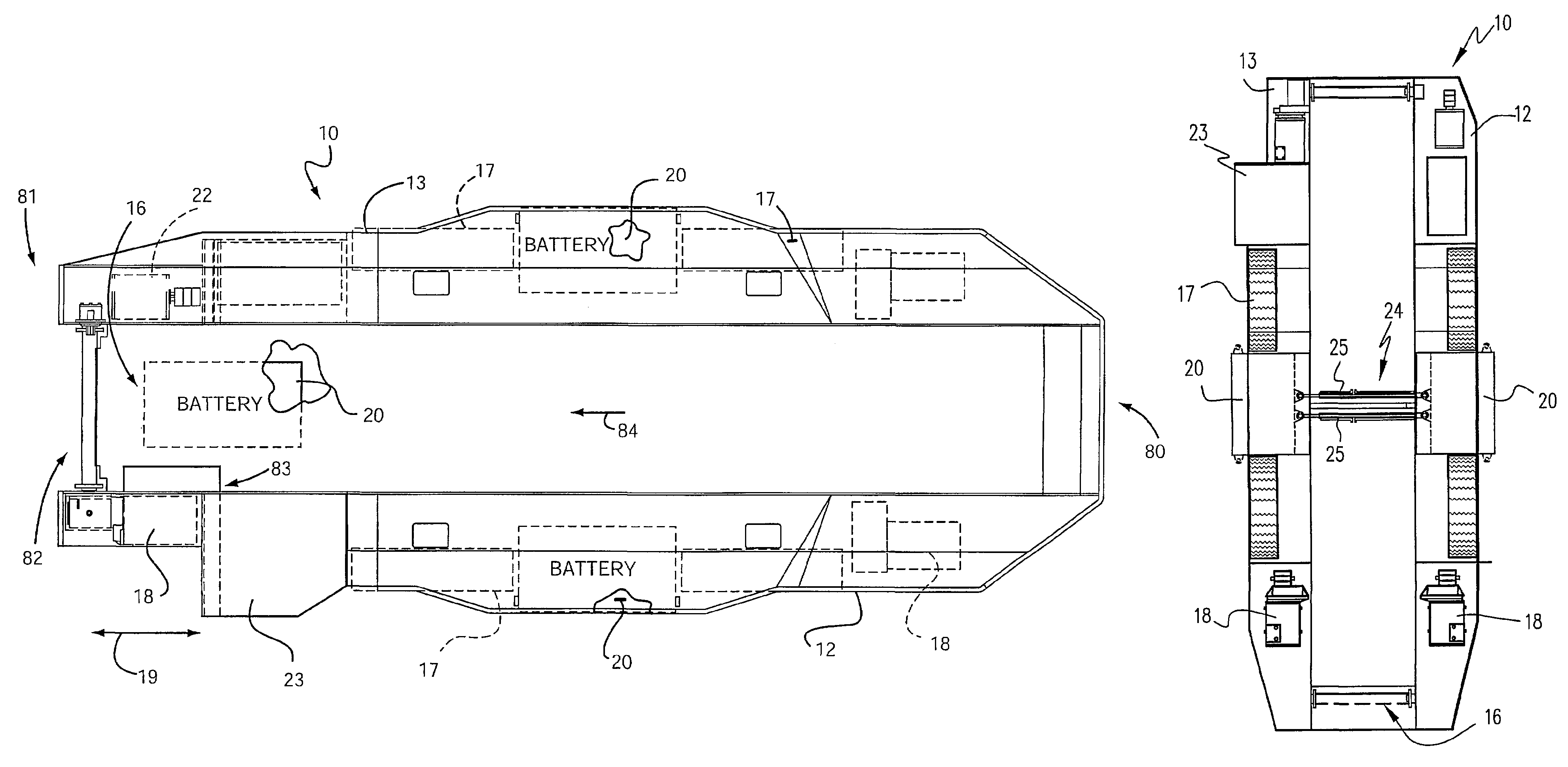

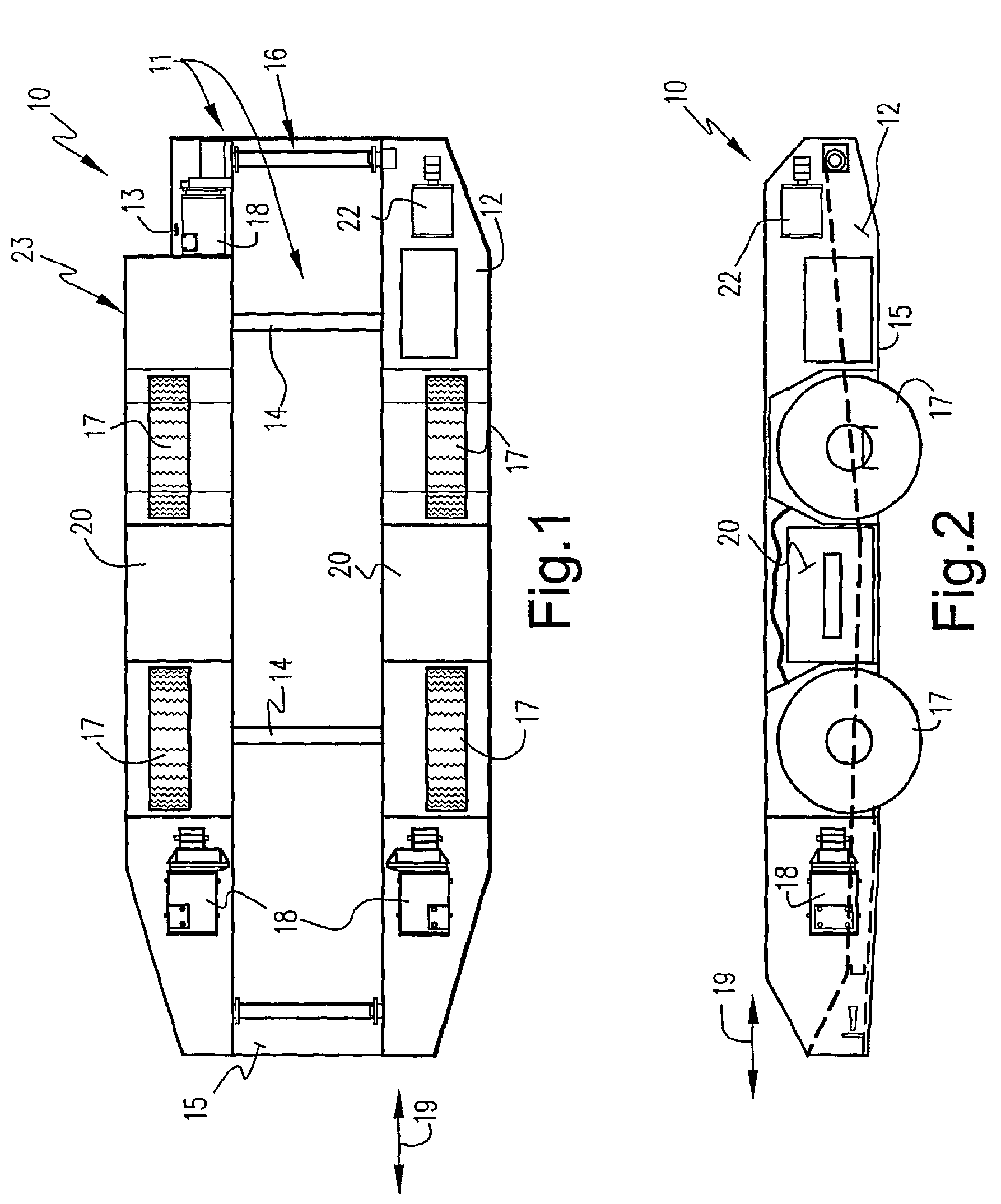

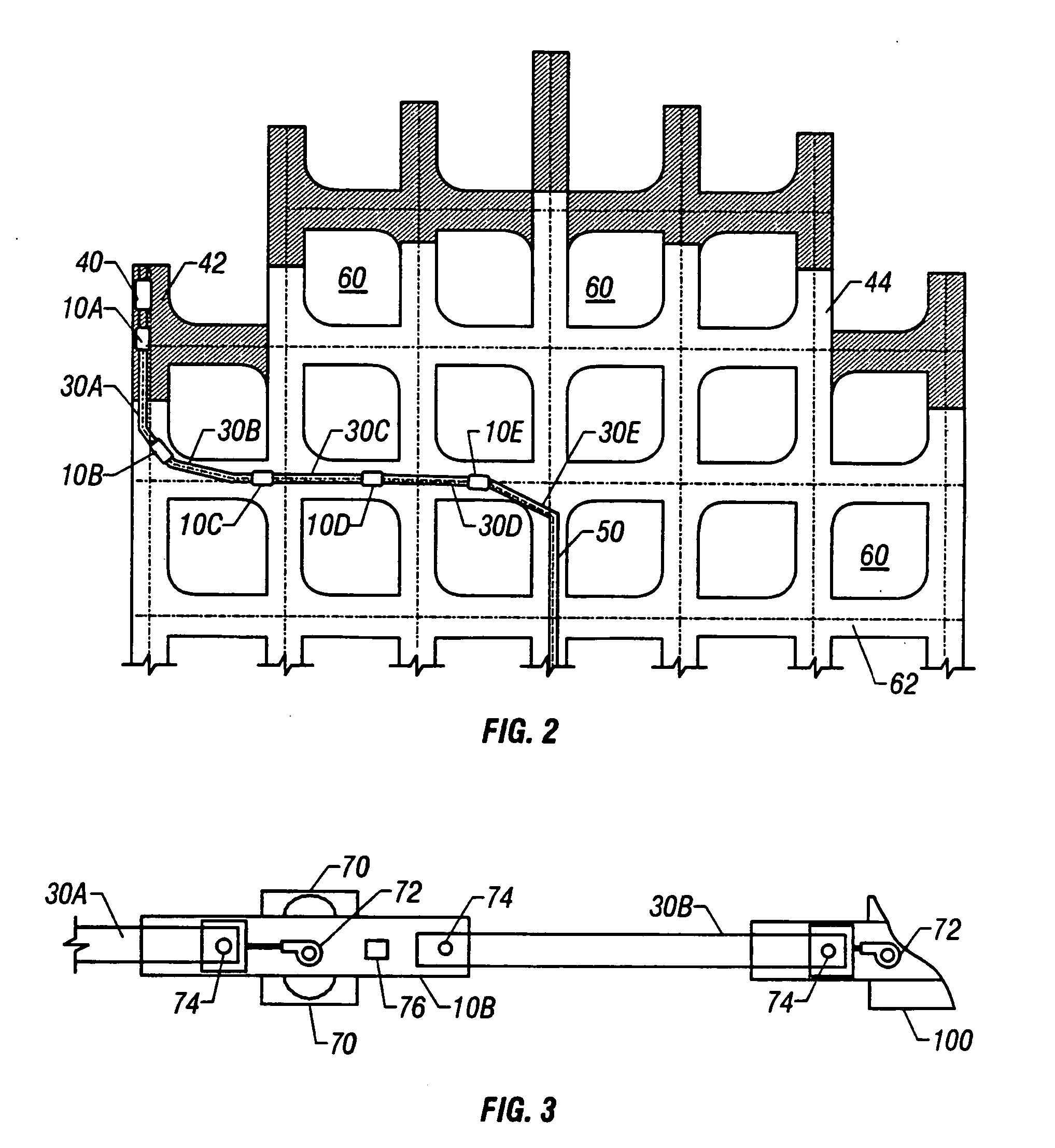

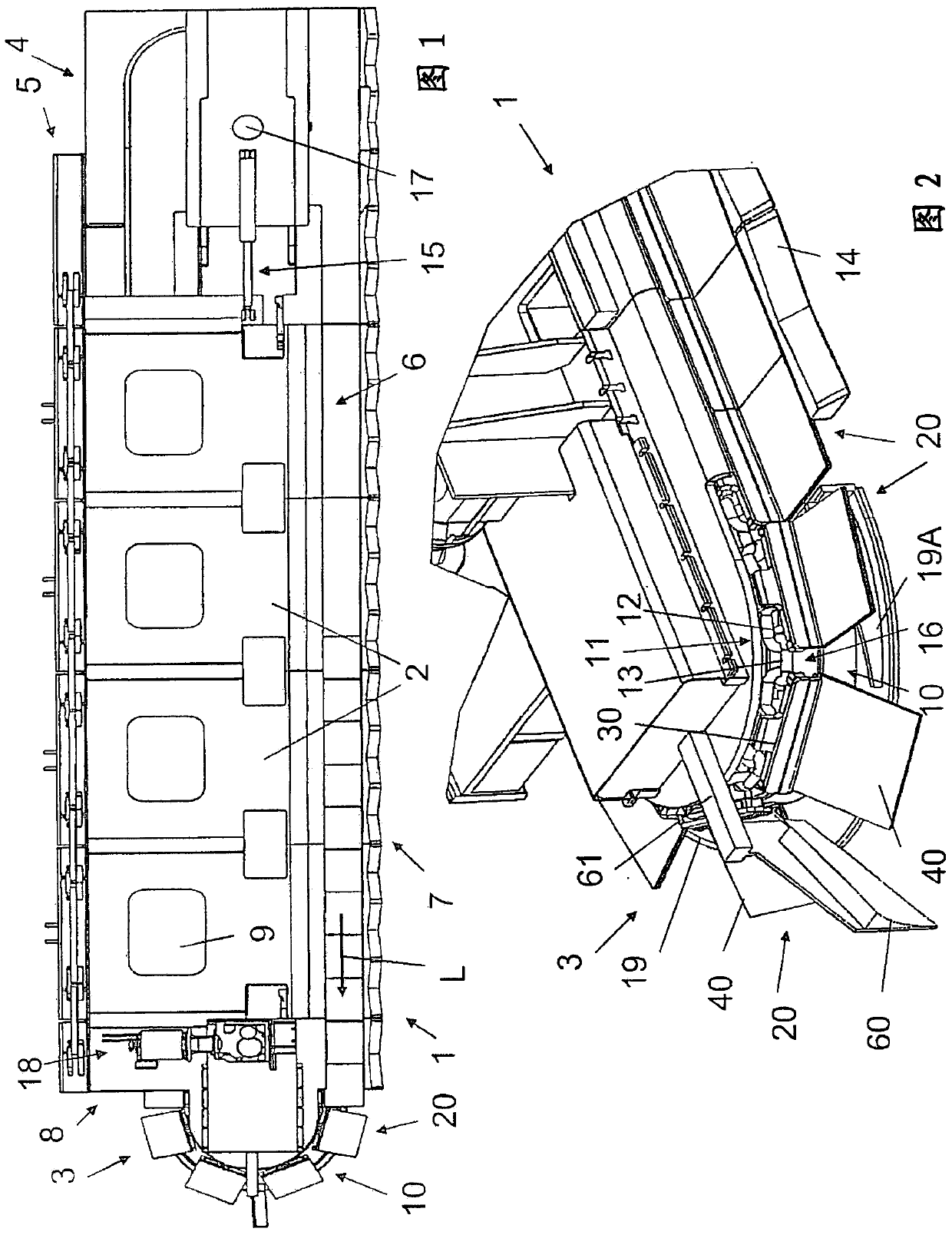

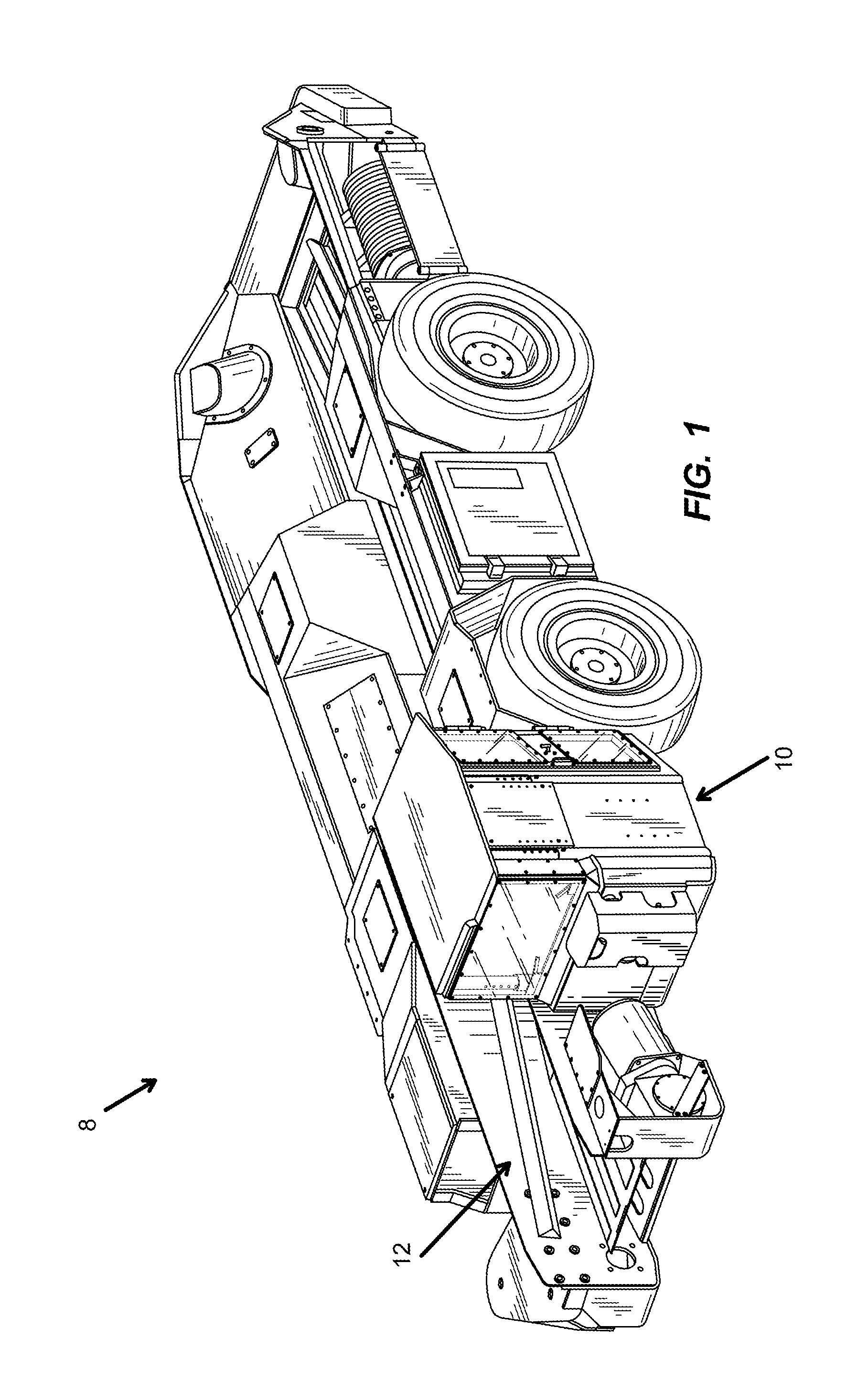

Battery powered shuttle car

InactiveUS7770673B2The process is simple and effectiveUniform tire loadingRailway vehiclesRefuse receptaclesVehicle frameElectrical battery

A battery powered shuttle car (10) incorporates features and components that facilitate use and operation and effect efficient application in a mining environment. The shuttle car (10) incorporates at least one battery (20) that is secured to the vehicle frame (11) between one of a left front wheel (17) and a left rear wheel (17) or the right front wheel (17) and the right rear wheel (17). A battery change-over mechanism (51) facilitates battery replacement. Additionally, the shuttle car (10) may be provided with an integral discharge end (81) having a substantially fixed height (82). A full load indicator mechanism (83) provides an indication when the conveyor (16) is substantially full to maximize use and operation of the shuttle car (10).

Owner:PHILLIPS MACHINE SERVICE

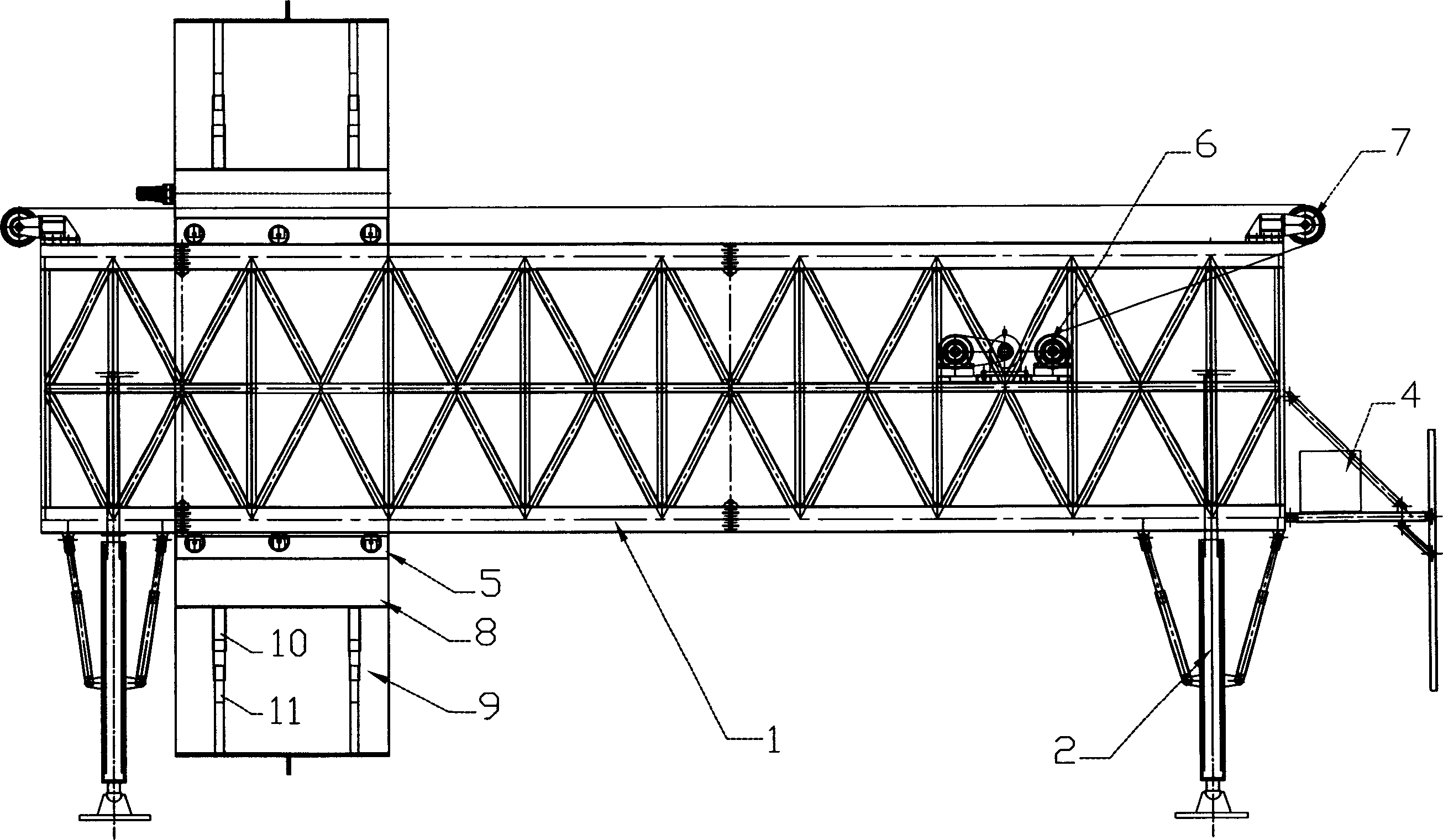

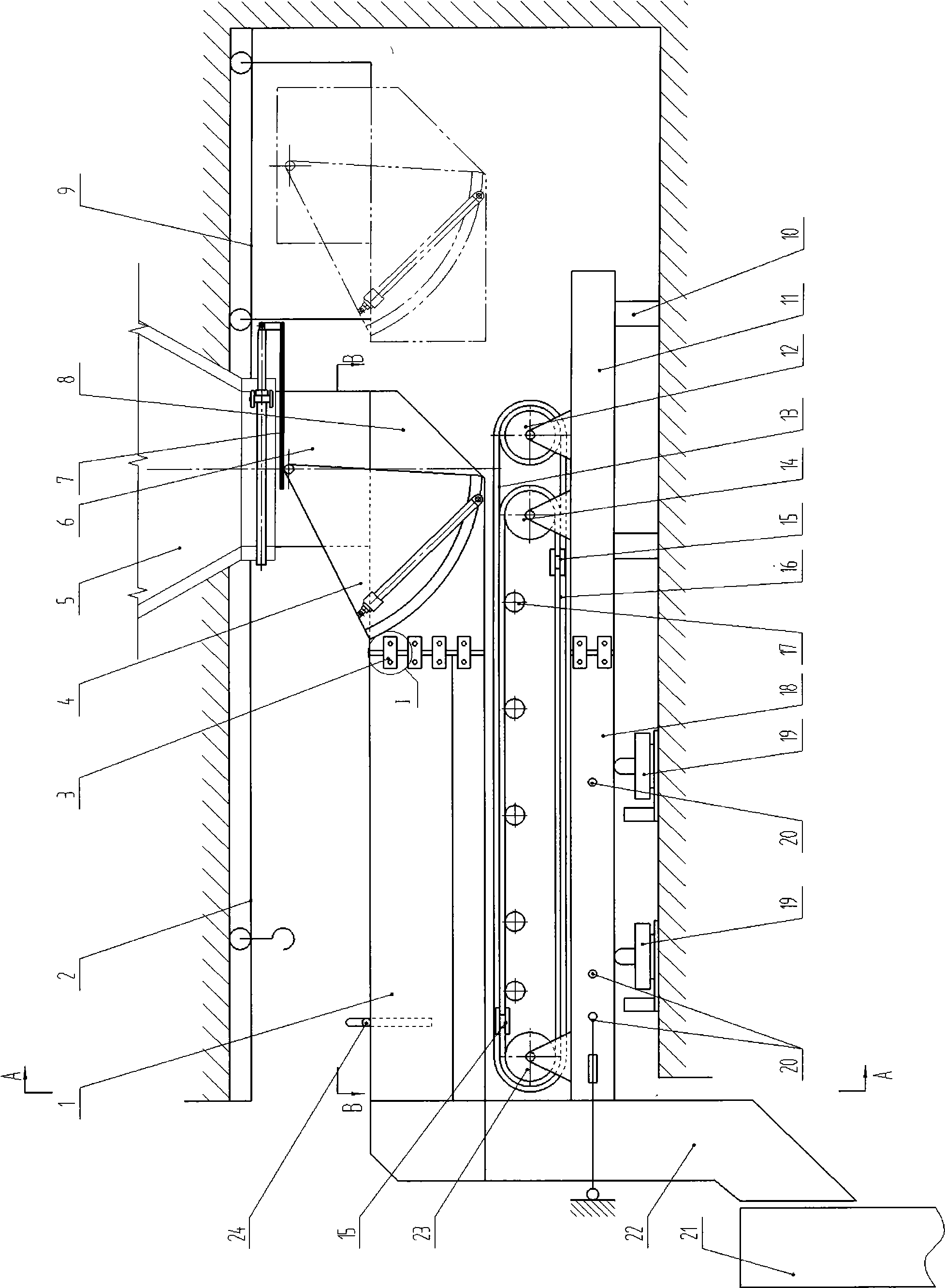

Self-portable belt conveyer

InactiveCN101537925AHighlight substantiveGuaranteed uptimeConveyorsControl devices for conveyorsTransportation technologyCoal

The invention provides a self-portable belt conveyer, which comprises a belt conveying machine head, a hydraulic belt tightener, a belt conveyer middle part, a belt conveyer tail and a belt and is characterized in that the belt conveyer also comprises the belt conveying machine head and a dragging device connected with the hydraulic belt tightener; the machine head of the belt conveyer is the self-portable belt machine head, has the functions of free-installation and dismantling, easy maintenance, constructor reduction, labor intensity of constructor reduction, increasing working performance, creating safe operating environment, self moving a hydraulic dram tightening belt, free drag of tightening system and the like, and has the advantages of good explosion prevention and safe performance, high flexibility and the like. The self-portable belt conveyer increases the transportation technology of coal mine underground coal and rock, provides unitized technical equipment for coal mine coal and rock transportation system, and creates the fundamental conditions for realizing the safe production of big, medium and small-size coal mines.

Owner:闫振东

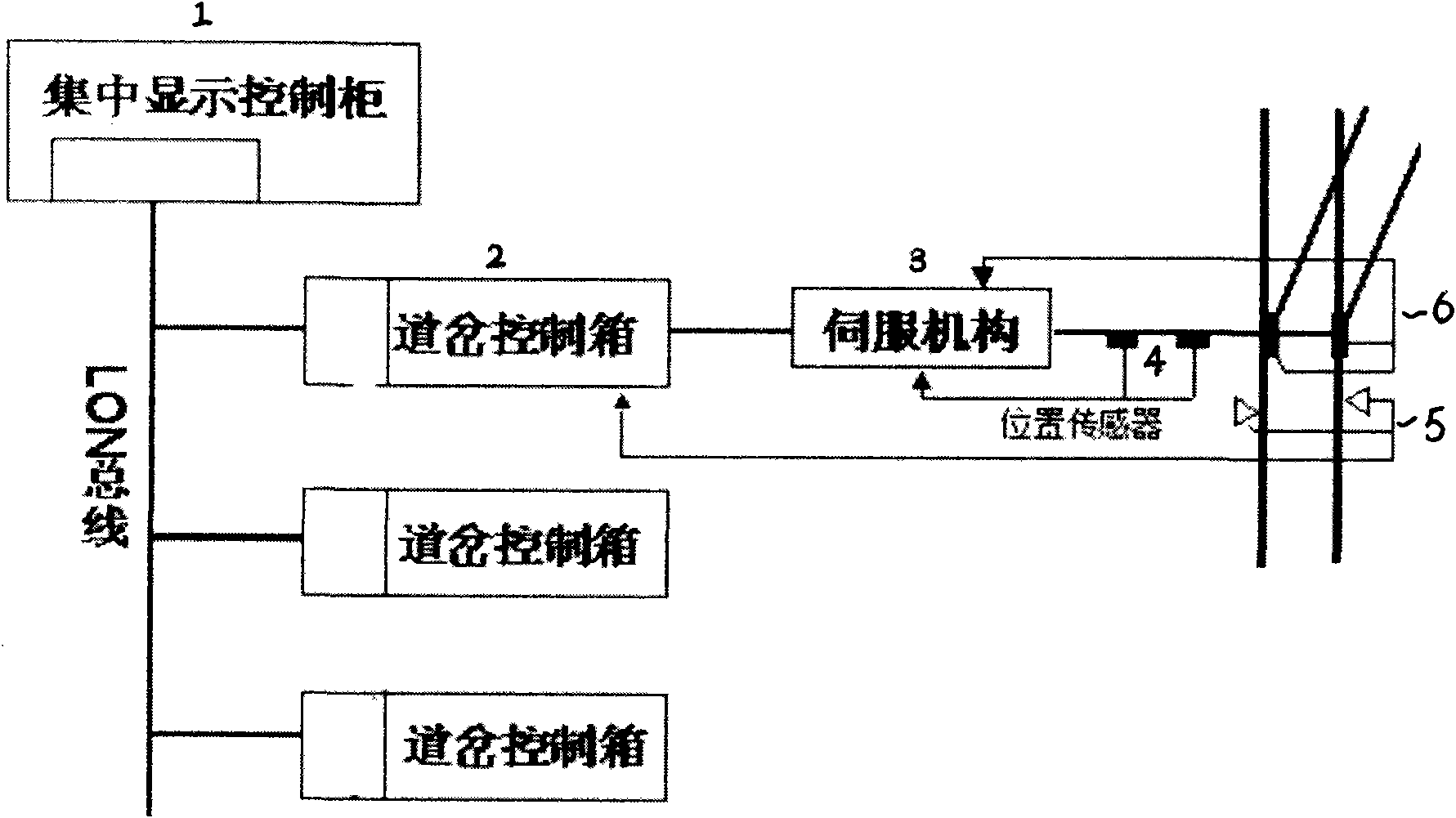

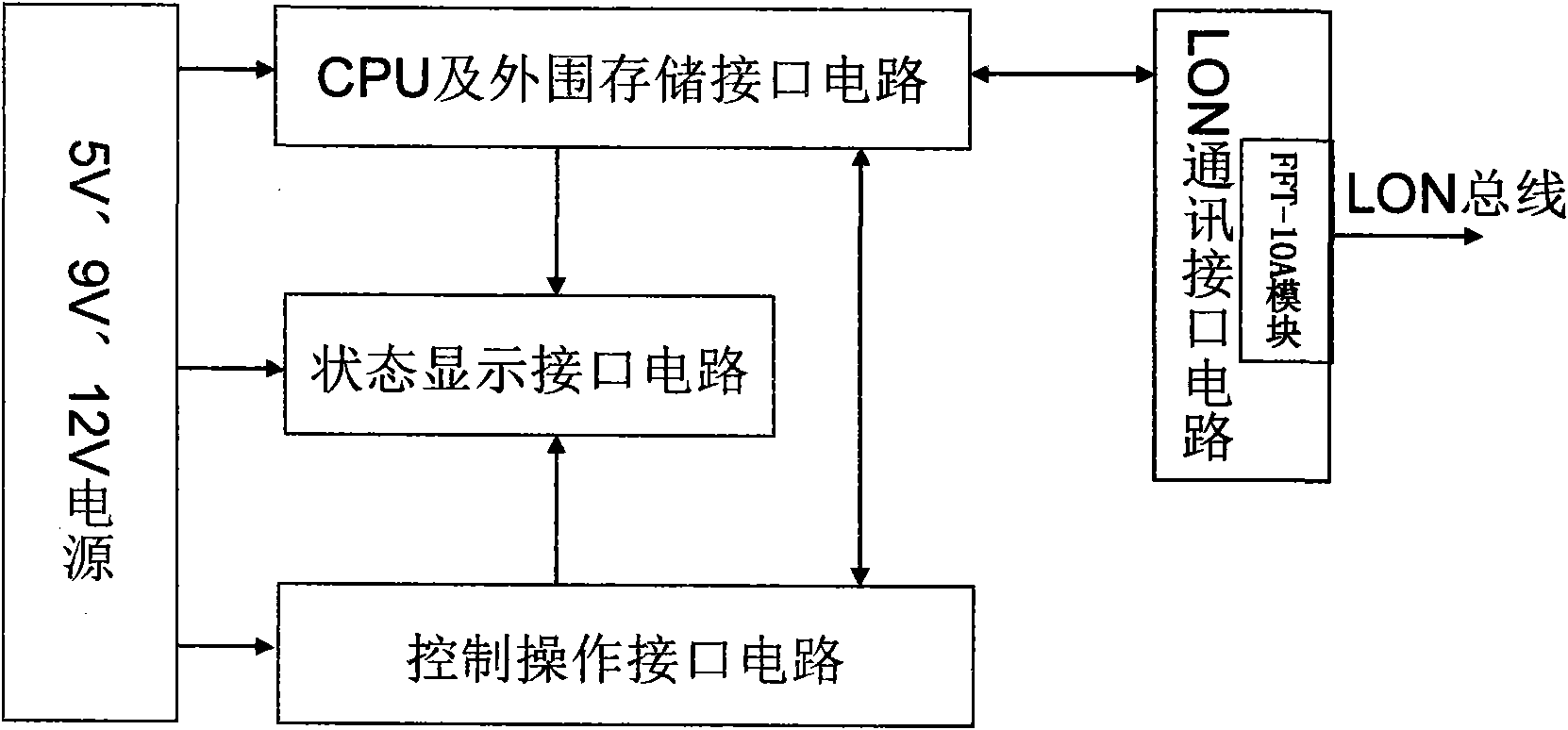

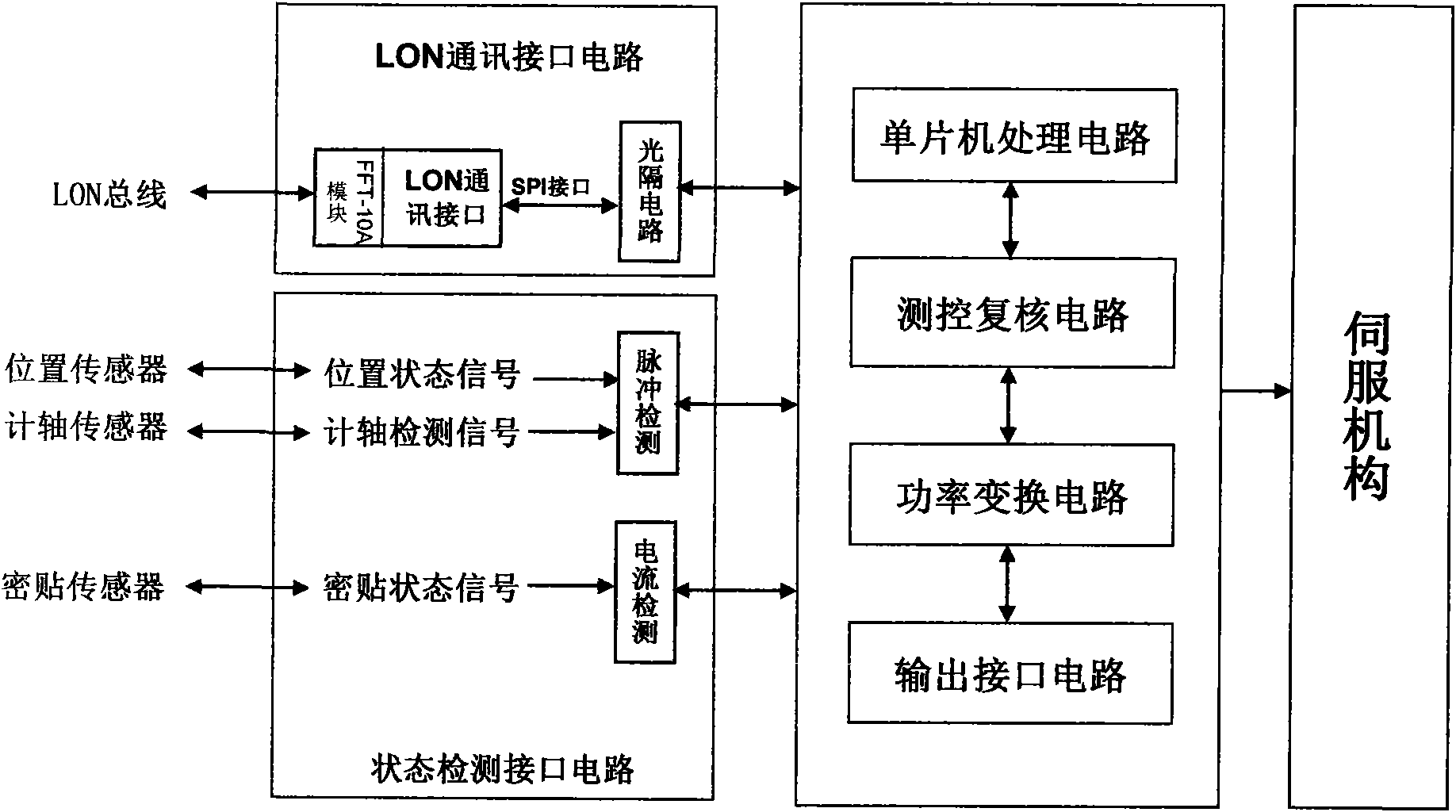

Turnout remote central control device for mine inclined drift track transportation and detection control method thereof

InactiveCN101630159ARealize automatic controlAchieve protectionComputer controlSimulator controlCommand and controlClosed loop

The invention relates to a turnout remote central control device for mine inclined drift track transportation and a detection control method thereof. A central display control cabinet communicates with a turnout control cabinet by using an LON bus; a closed-loop control circuit is formed among the turnout control cabinet, a servo mechanism and a position sensor; a two-wire system current-type detection interface is formed among the turnout control cabinet, a track axle counter and a closed sensor; the central display control cabinet transmits a state command and a control executing command to the turnout control cabinet according to an operational command and the sampling state of the position sensor and the closed sensor, and combining the vehicle detection result of the orbit axle counter; the turnout control cabinet can set the self state to be a central control state or on-site control state according to the received central display control cabinet command for positioning / anti-position driving output to the servo mechanism; during driving output, turnout driving rejection is realized according to the configuration condition of the turnout associated axle coupler on the LON bus.

Owner:HEFEI GOCOM INFORMATION &TECH CO LTD

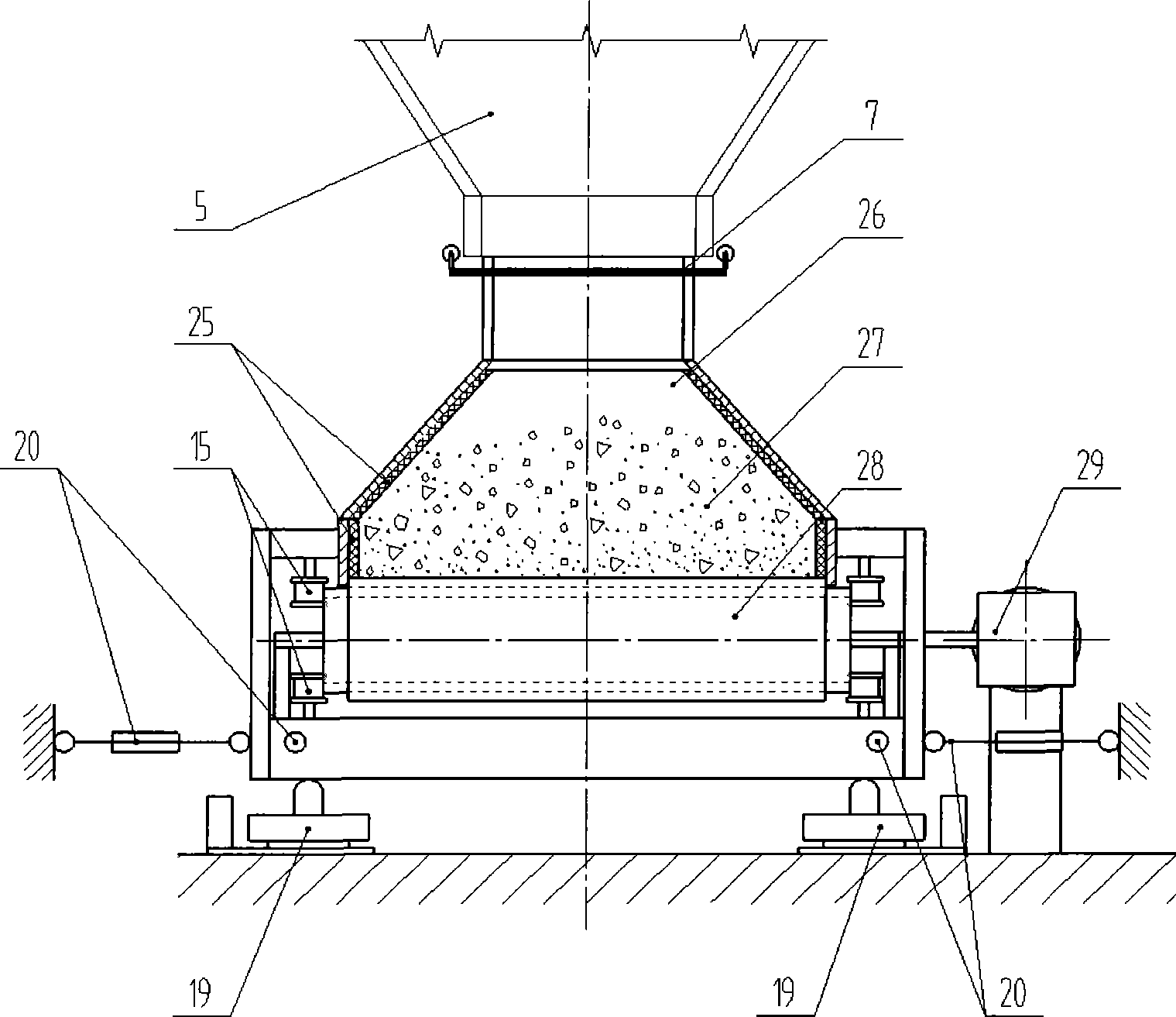

Fixed-weight loading equipment

InactiveCN101497402AGuaranteed uptimeReduce frictionConveyorsControl devices for conveyorsLoad cellMechanical engineering

The invention relates to a fixed weight loading device for bulk materials, and belongs to the field of mine transportation equipment. The fixed weight loading device for the bulk materials comprises a drive unit, a material guide groove, a conveying device and a support, wherein the material guide groove is arranged on the conveying device which is connected with the support. The fixed weight loading device for the bulk materials is characterized in that the support and the material guide groove are divided into a material receiving part and a weighing part; a weighing sensor is arranged under the weighing part, namely the support; a conveyer belt of the conveying device can be an adhesive tape, a shell belt or a composite adhesive tape and shell belt; the material receiving part and the weighing part, namely the support and the material guide groove are in flexible connection of which the displacement in the vertical direction is not limited; the weighing part, namely the support, is provided with a tensioning device for limiting the displacement in the horizontal direction; and side-slipping resistant wheels are arranged on both sides of the adhesive tape or the shell belt close to a directive point of a roller. The fixed weight loading device for the bulk materials combines a shell belt feeder and force sensor technology, and has the advantages of high weight measuring precision, small mounting space, strong universality, small operating power, reliable use, convenient maintenance, low operating cost and strong environmental adaptation ability.

Owner:孟凡英

Self-movable foot end of belt conveyer

ActiveCN101092208ACompact structureReasonable layoutConveyorsEarth drilling and miningPulp and paper industrySewage

The invention relates to belt conveyer self moving discharge end. It includes middle frame, head end frame, tail end frame, float frame, walk dolly, hydraulic mechanism, maneuvering valve set, column oil cylinder, passage oil cylinder, level oil cylinder, float cylinder, carrying roller assembly, screw drum, slide shoe, slide seat, and base seat. The middle frame, head end frame, tail end frame, float frame, and the walk dolly are connected wholly. The float frame can make the self moving discharge end be transition join with the belt conveyer. The tail end frame adopts left-right screw drums to squeeze out the sewage. While self moving, the joint between the walk dolly and the lower of the loading mechanism end is used as fulcrum; the slide seat, base seat, column oil cylinder are used as support to process oil cylinder stretching to make whole machine move forward that once self moving travel can reach 2.7m. The column oil cylinder can adjust the height for the complete machine. Thus the invention has the advantages of compact structure, large force, safe flameproof, stable and reliable etc.

Owner:山西煤矿机械制造股份有限公司

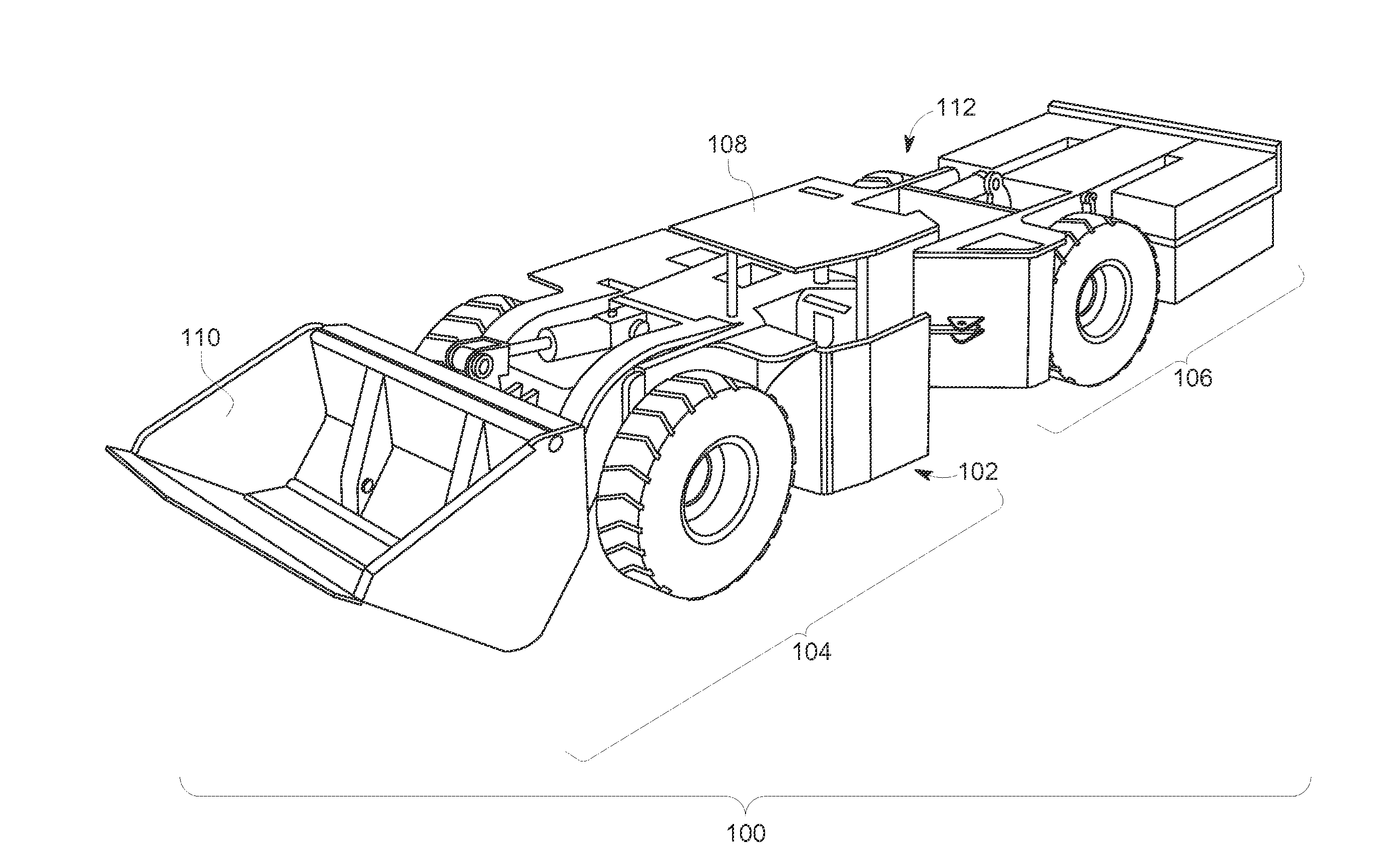

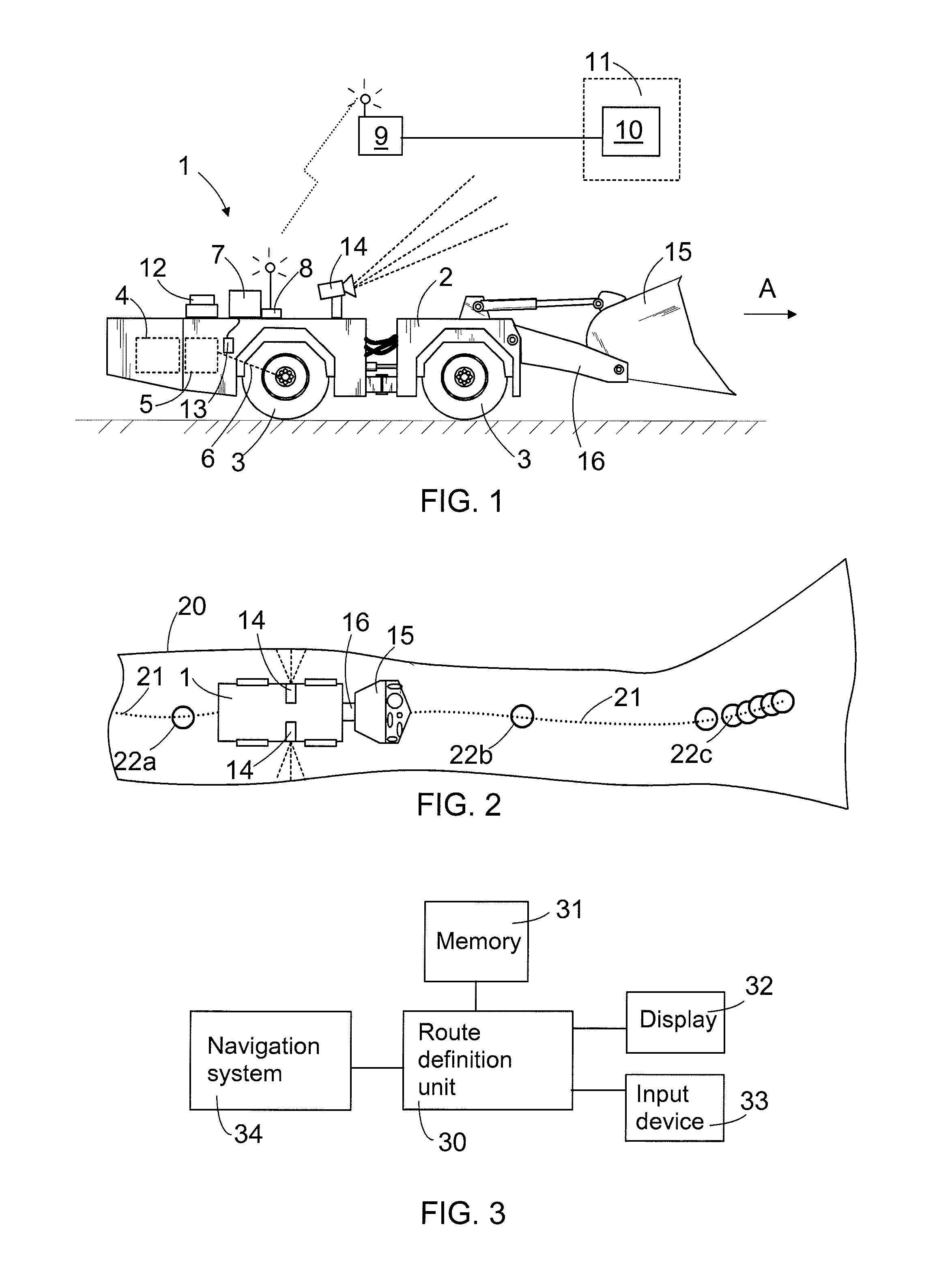

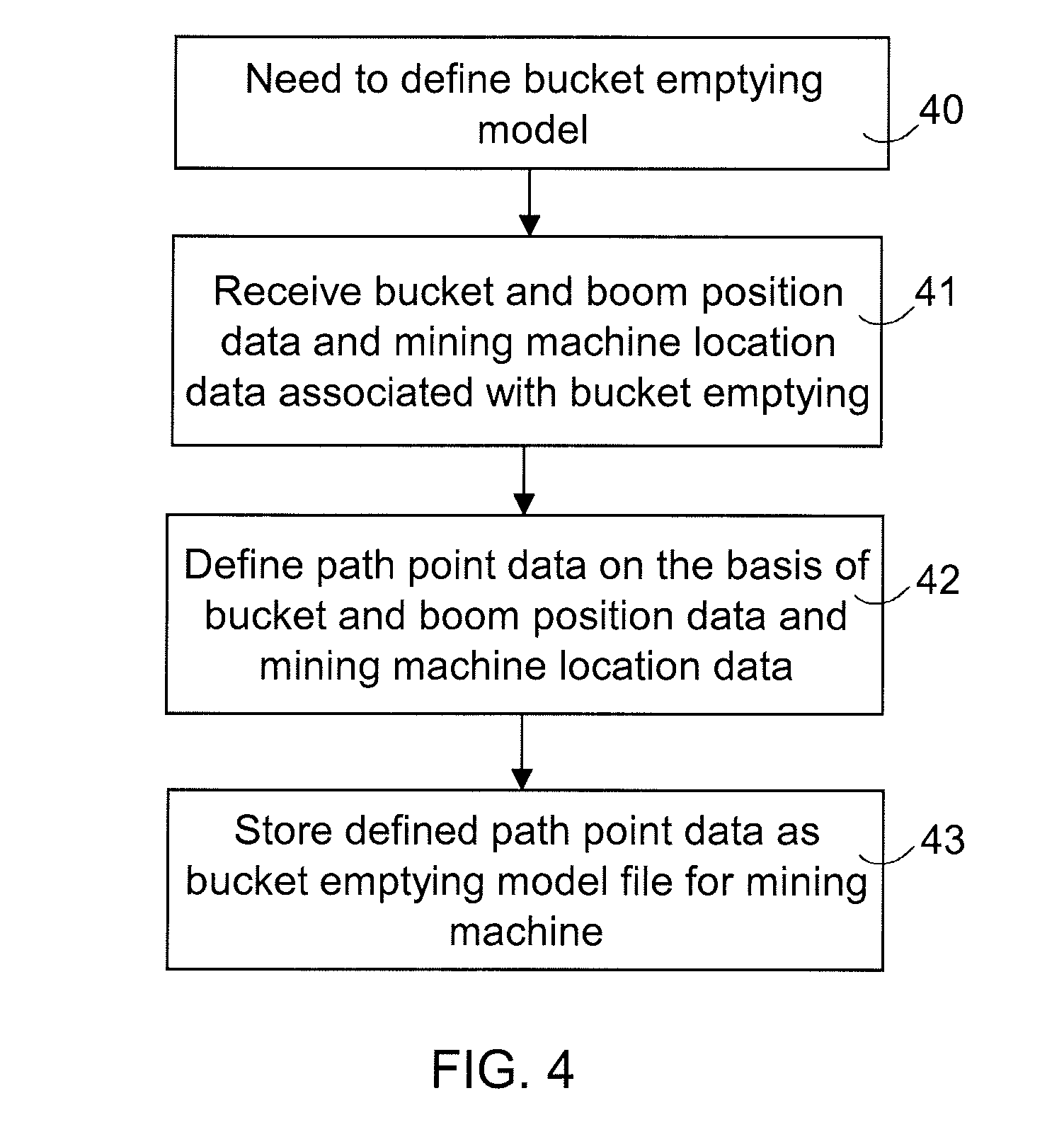

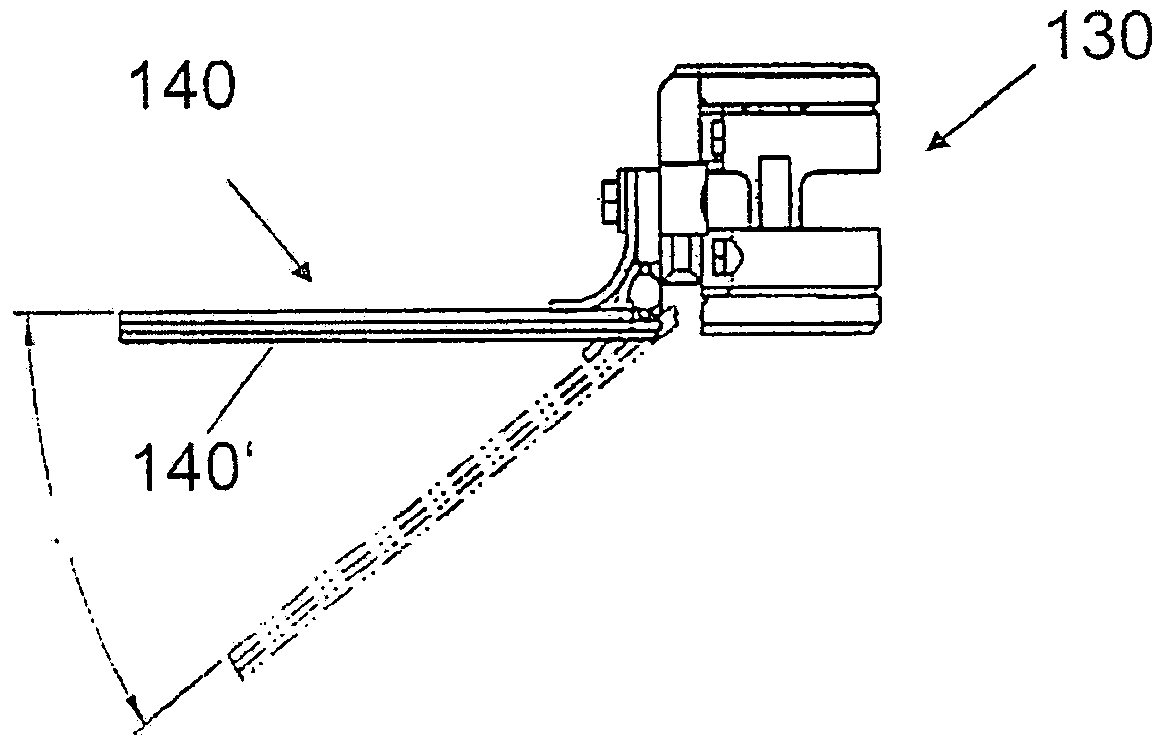

Definition of control data for automatic control of mobile mining machine

ActiveUS20120095640A1Speed up introductionAnalogue computers for trafficSoil-shifting machines/dredgersGeneral purposeAutomatic train control

The present invention relates to a method for arranging automatic control of a mobile mining machine equipped with a bucket. The method comprises generating a general purpose bucket emptying model that defines at least the path of the bucket of the mining machine for emptying it. The bucket emptying model is stored on a memory means. The bucket emptying model is fetched from the memory means in response to a need to define emptying the bucket for the route. At least data defining the path of the bucket in the fetched bucket emptying model are appended to the path data for use in the automatic control of the mining machine.

Owner:SANDVIK MINING & CONSTR OY

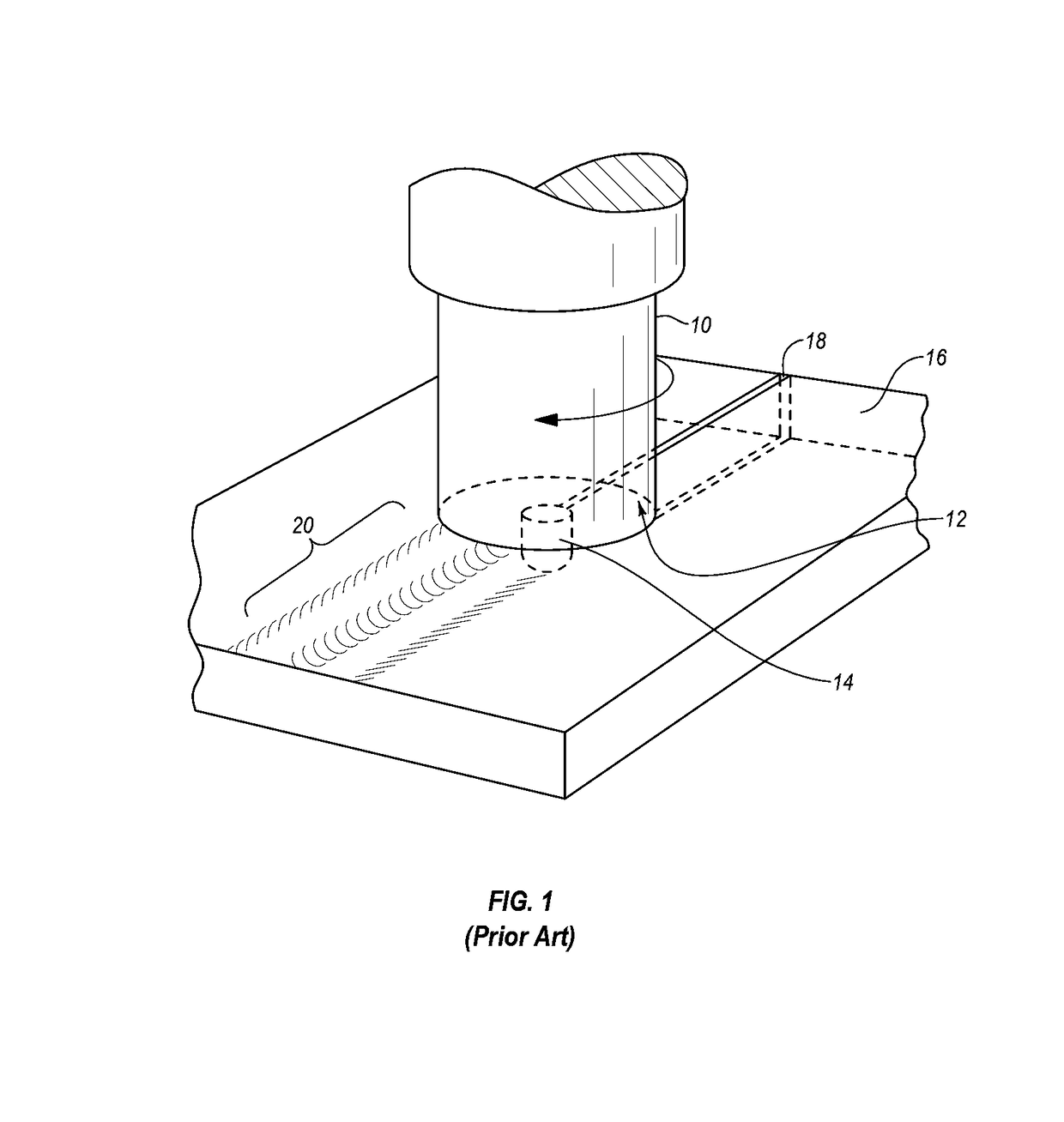

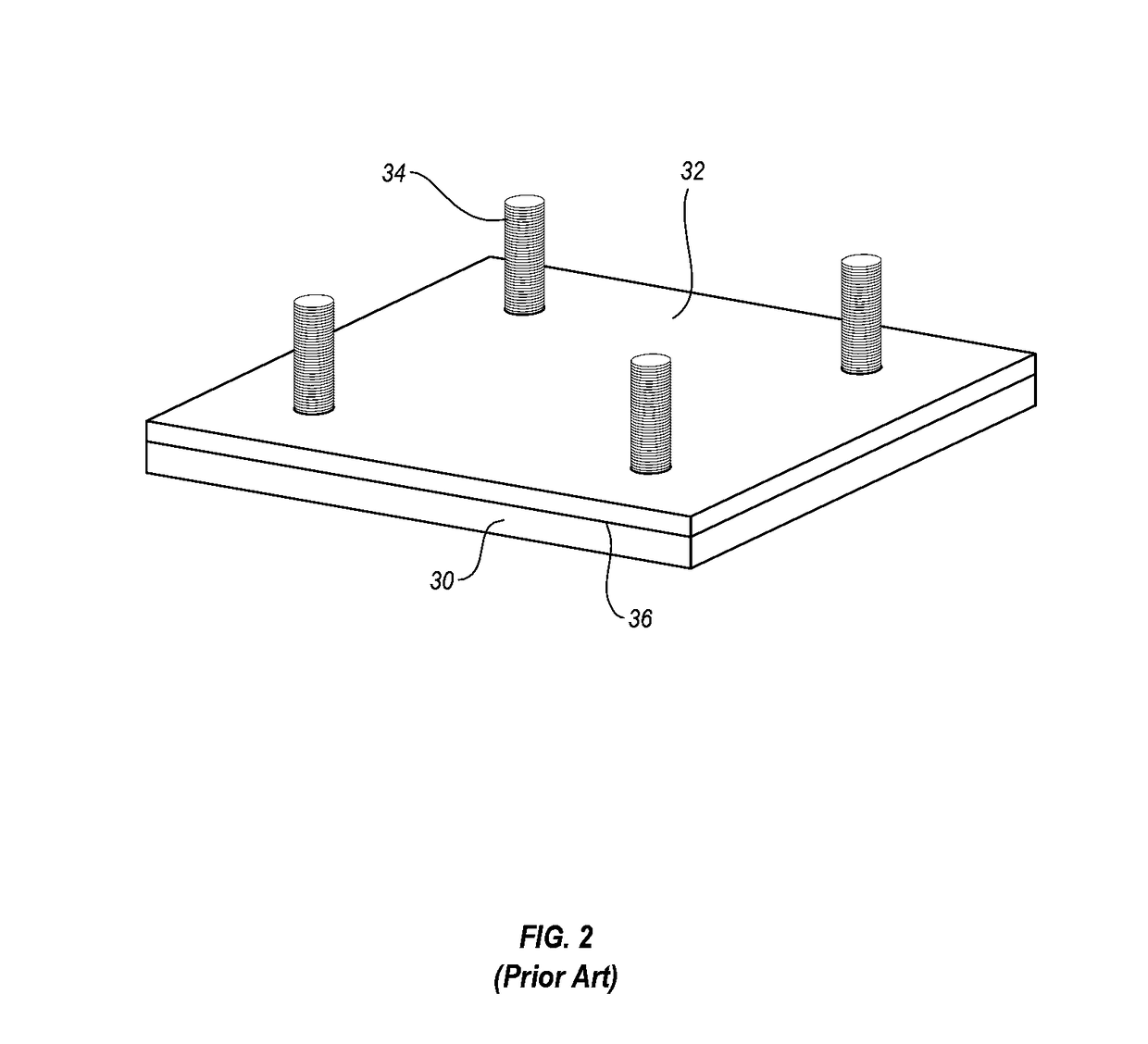

Mechanical flow joining of high melting temperature materials

InactiveUS20170197274A1Earth drilling and miningWelding/soldering/cutting articlesMelting temperatureMicrostructure

A system and method for securely joining a high melting temperature material and a backing substrate using a mechanical connection includes a backing substrate integrally formed with a material positioned inside a dovetail recess in the high melting temperature material, mechanically fixing the backing substrate to the high melting temperature material without fusion or bonding of the microstructure.

Owner:MAZAK CORP

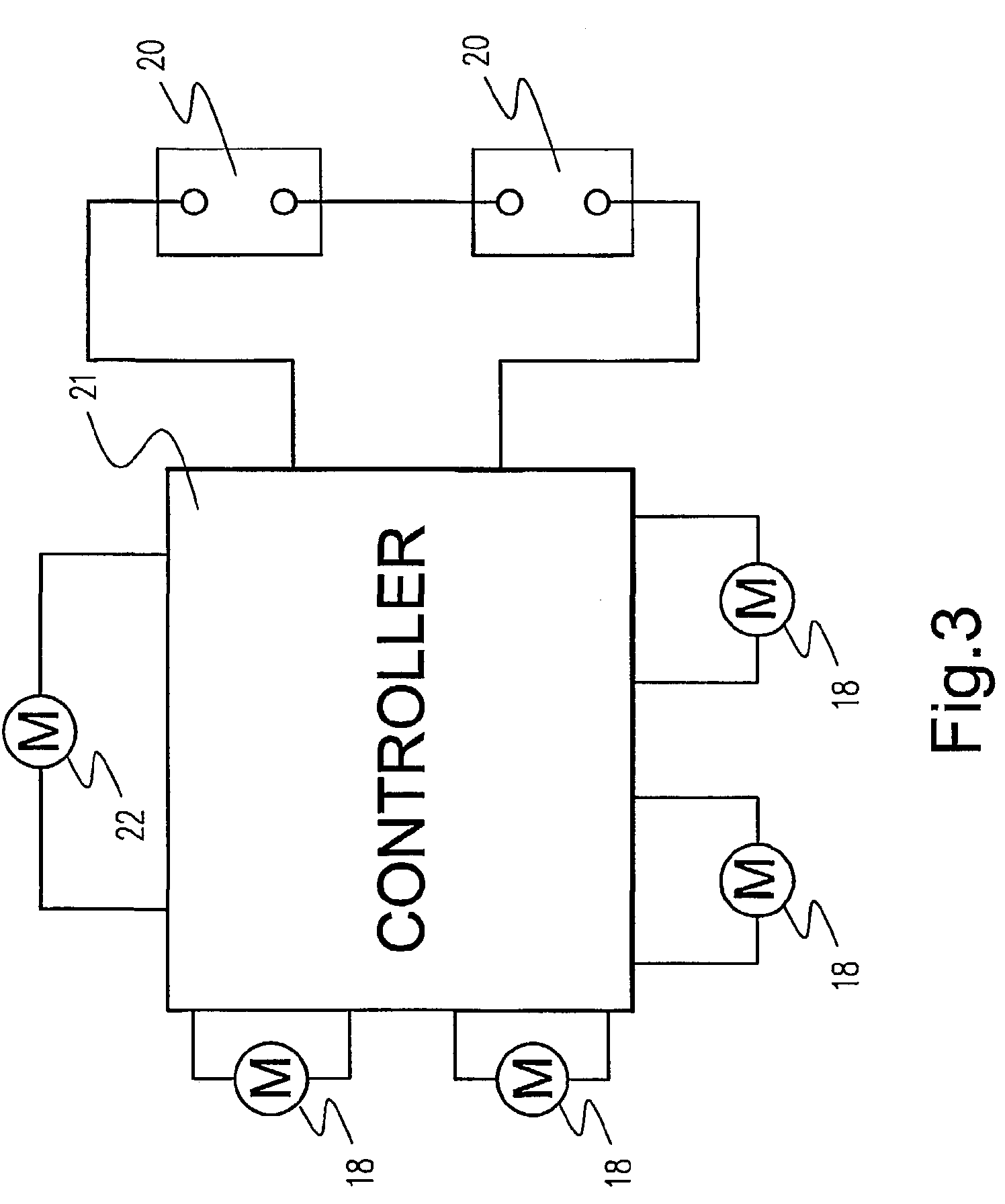

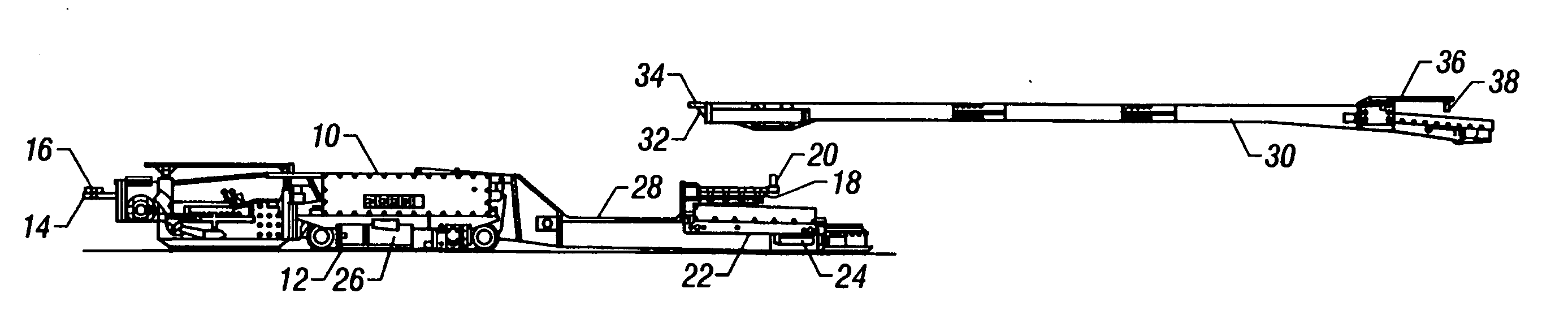

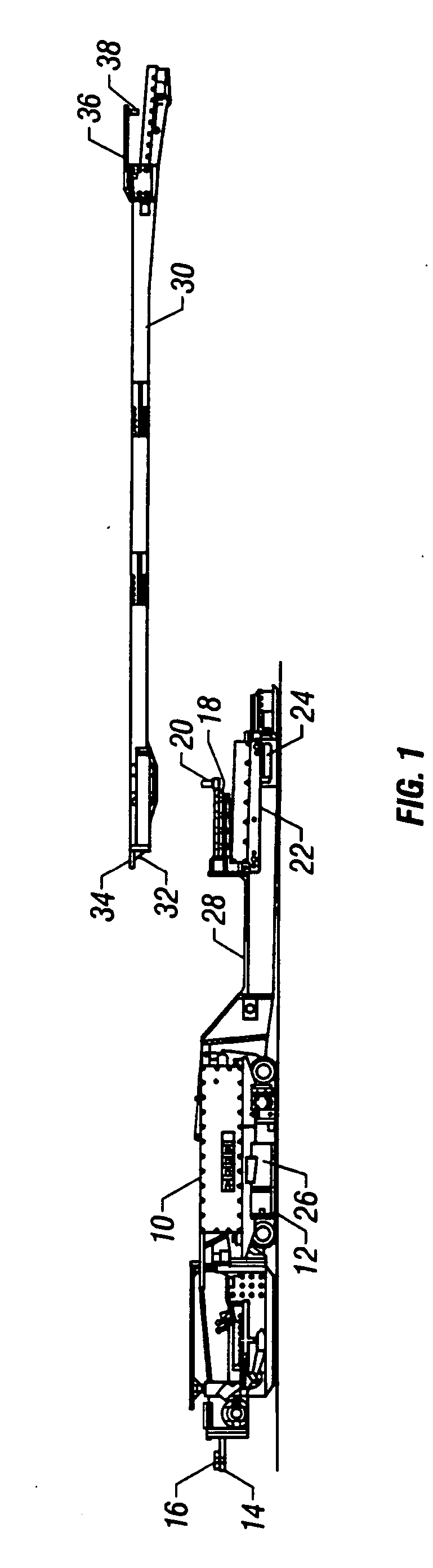

Automated continuous haulage system

InactiveUS20040054434A1Digital data processing detailsEarth drilling and miningElectronic controllerDistance measurement

The present invention relates to an automated continuous haulage apparatus and method designed for use in underground environment. Each mobile bridge carrier (10) contains distance measurement (70) and angular position (74) means for determining the mobile bridge carrier's (10) position and the angular position of attached piggyback conveyors (30). Means for determining the ceiling height (76) are utilized to adjust the height of the piggyback conveyors (30). On each mobile bridge carrier (10), input from the various sensors is received by an electronic controller (80) that calculates the position and orientation of the bridge carrier (10) and attached piggyback conveyors (30). The controller then plans an optimal path of movement for the bridge carrier (10) and computes the rate of movement for each independently operated track assembly on the bridge carrier such that the bridge carrier (10) and piggyback conveyors (30) arrive as close as possible to the planned path.

Owner:CATERPILLAR GLOBAL MINING AMERICA LLC +1

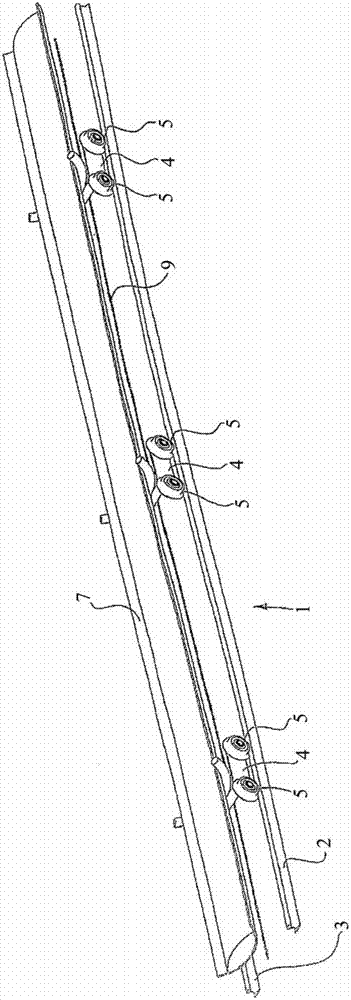

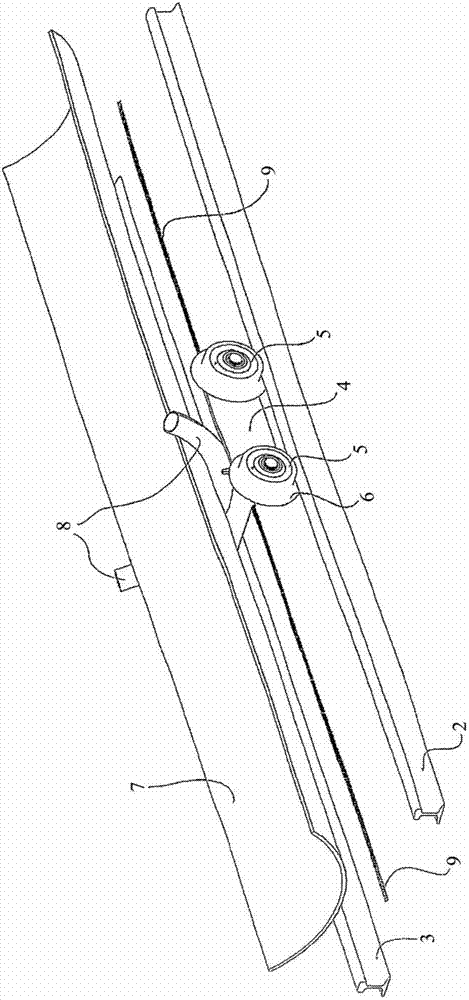

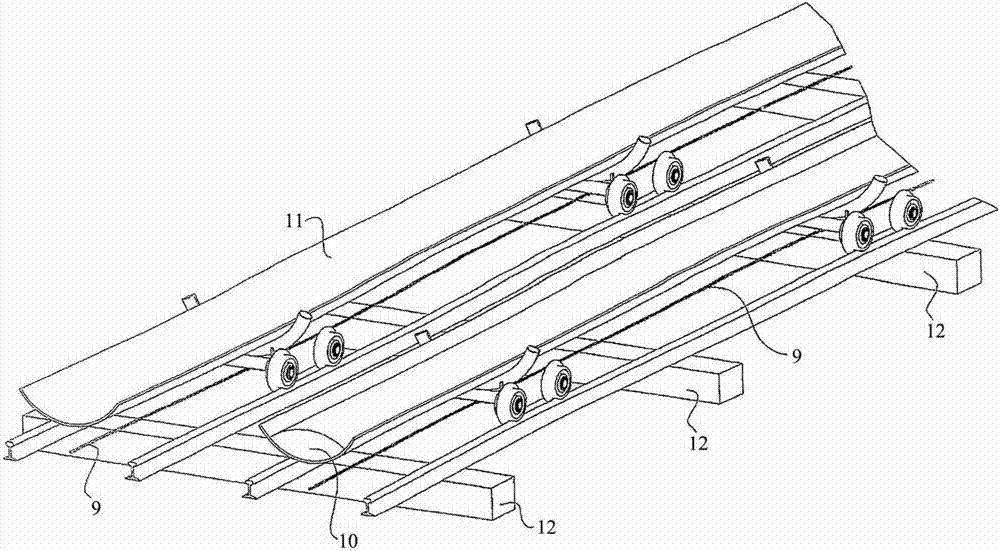

Rail conveyor system

A rail conveyor system combining the low friction attributes of railway transportation with the continuous bulk handling advantages of belt conveyors, uses a multiplicity of spaced carriages (4) running on steel wheels (5) on rail tracks (2, 3) to support a continuous carry belt (7). The system is driven by various means including a rope (9) extending between the carriages. Various other drive means including drive belt technology are also described along with loading and unloading stations and distributed drive stations.

Owner:NEWCASTE INNOVATION LTD

Determination of routes for arranging automatic control of mobile mining machine

ActiveUS8694193B2Shorten the timeConsiderable amount of timeInstruments for road network navigationEarth drilling and miningReverse orderAutomatic control

The present invention relates to a method of determining routes for arranging automatic control of a mobile mining machine. A return route is determined computer-aidedly for the mining machine on the basis of data concerning a route taught by driving by executing, by a data processing device configured for generating return routes, at least the following steps: determining a route identifier for the return route, determining as route points of the return route at least some of the route points of the drive route in a reverse order, wherein when determining route point data of the return route on the basis of the route point data of the drive route, deleting additional control data associated with one or more route points of the drive route, and storing the data determining the return route to be used for automatically controlling the mining machine.

Owner:SANDVIK MINING & CONSTR OY

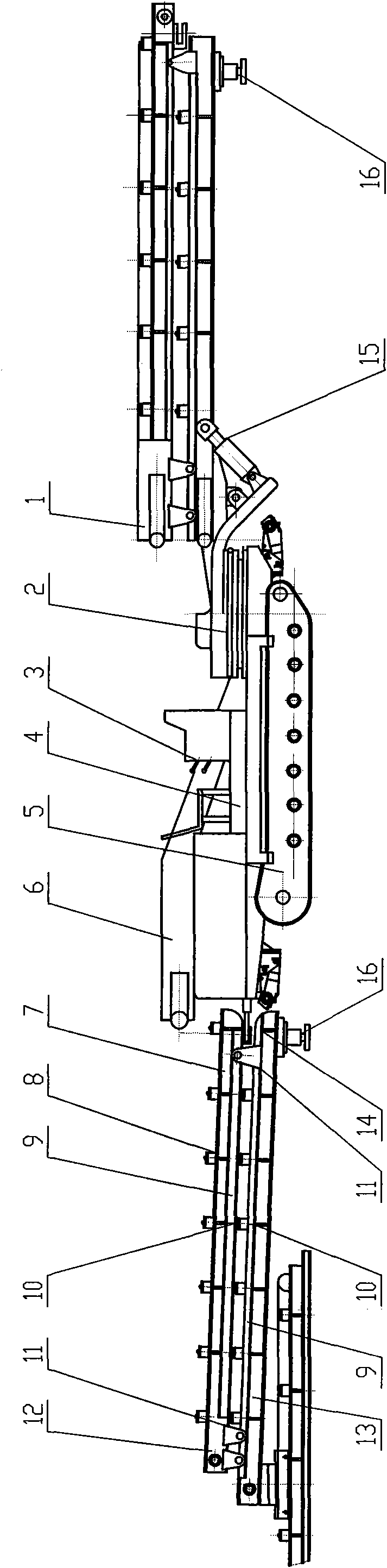

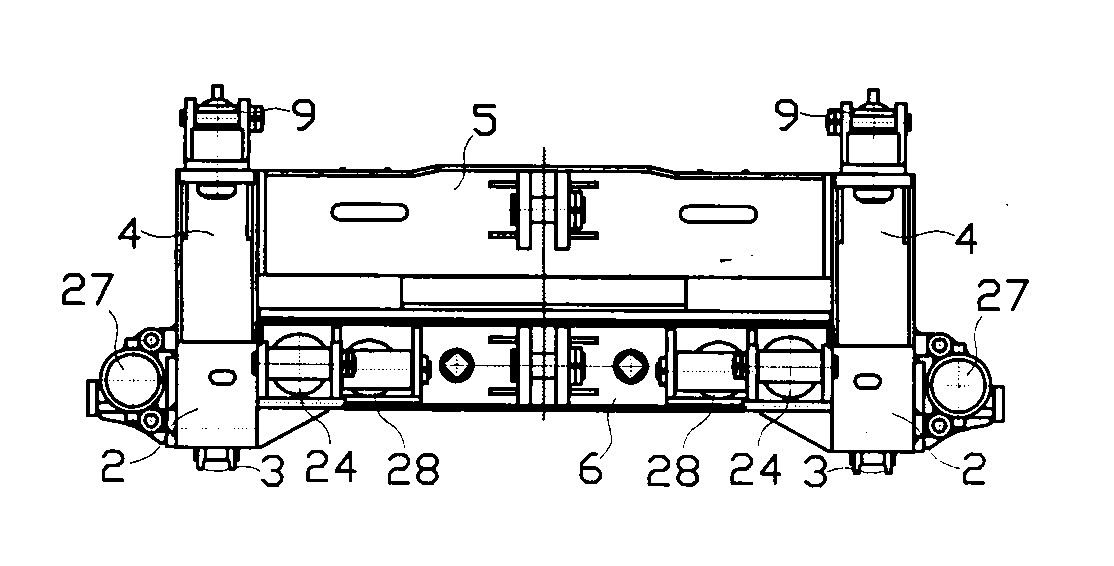

Walking running device for self-advancing tail

InactiveCN102011609AAdvancedSimple designEarth drilling and miningUnderground transportEngineeringFuselage

The invention relates to a walking running device for a self-advancing tail, which mainly comprises a body, running oil cylinders, lifting oil cylinders, oil cylinder holders, a roller frame, guide rails, a floating carrier roller, a movable trolley base and a hydraulic mechanism. Aiming at the actual situation that the self-advancing tail is 20 meters long, 1.5 meters high and 40 tons heavy and is difficult to move, traction movement is changed into walking running movement, a high-power hydraulic power is adopted, the lifting oil cylinders are symmetrically arranged on the left, right, front, middle and rear of the body, the guide rails and the running oil cylinders are arranged on left and right sides of the body; and when the body is lifted, the guide rails are pulled and pushed by the running oil cylinders synchronously to slide forwards, so that the function of walking and running synchronously is realized, wherein the lifting height of the body is 220 millimeters, the displacement at each stroke is 1,200 millimeters, and the power of the lifting oil cylinders and the running oil cylinders is 31.5 MPa. The self-advancing tail can move forwards in a left-to-right or right-to-left manner, and the walking running device is advanced in design, reasonable in arrangement, convenient for operation, safe, stable and reliable.

Owner:山西煤矿机械制造股份有限公司

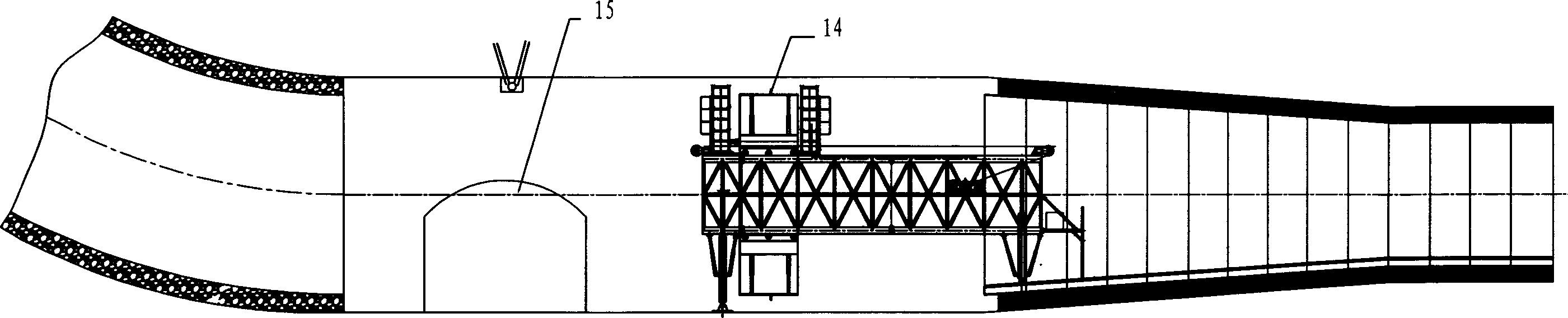

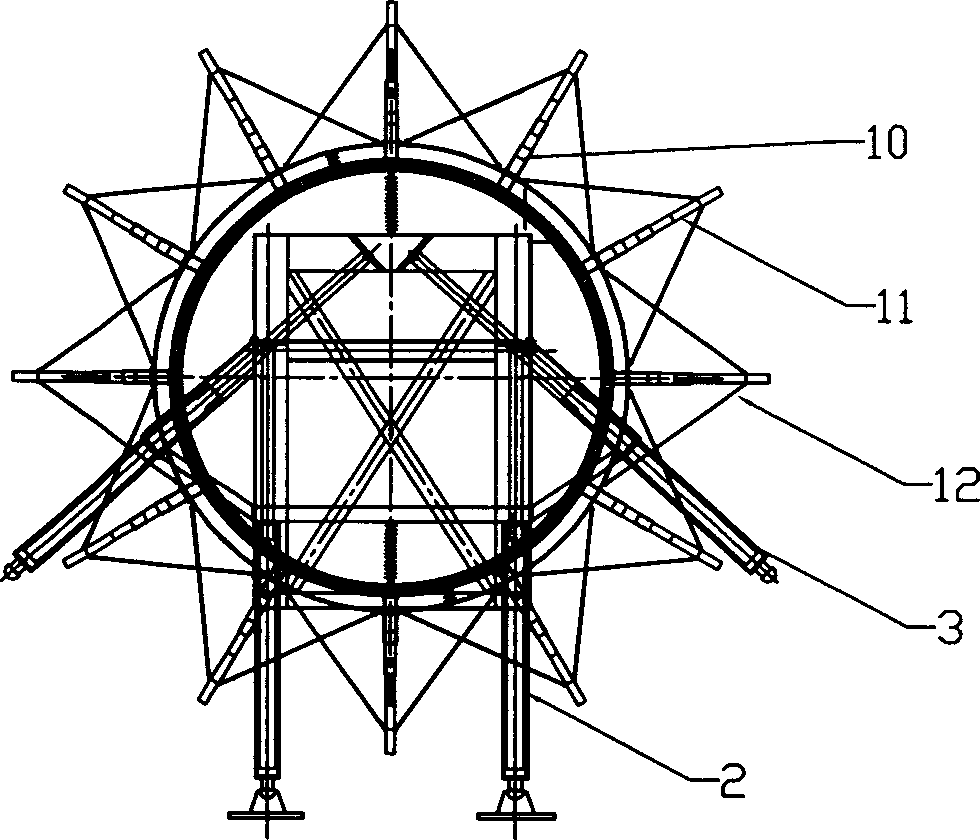

Corner-crossing transfer conveyer

InactiveCN101624138AReduce labor intensityImprove shipping speedControl devices for conveyorsEarth drilling and miningMechanical engineeringEngineering

The invention relates to a conveyer, in particular to a corner-crossing transfer conveyer which comprises a left walking part, a right walking part, a front conveyer, a middle conveyer, a tail conveyer and a hydraulic system, wherein a stand is arranged on the left walking part and the right walking part, a rotary table which can be rotated for 90 degrees left and right is arranged at the front part of the conveyer, the front conveyer is arranged on the rotary table, the middle conveyer is arranged between the left walking part and the right walking part, and the tail conveyer is hung at the tail part of the conveyer. The front conveyer and the tail conveyer are both of telescopic belt conveyers, and conveying distances of the front conveyer and the tail conveyer can be regulated. The invention changes the lagging production mode that coals at the corners need to be shoveled by manpower in the original drifting process, realizes the mechanical production, greatly improves the conveying speed of coals, lightens the labor intensity of workers, saves the manpower, and can be used at both corners and straight tunnels.

Owner:SHANXI DONGHUA MACHINERY

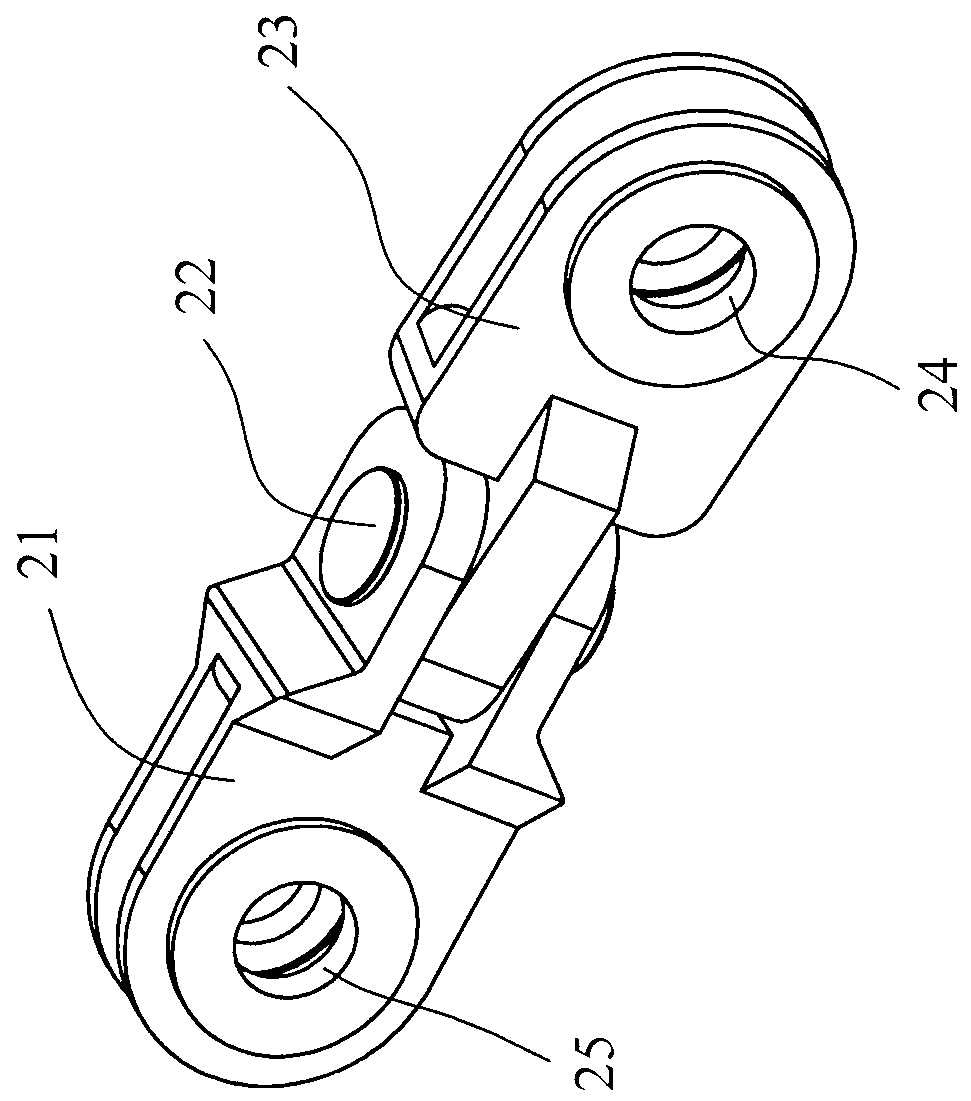

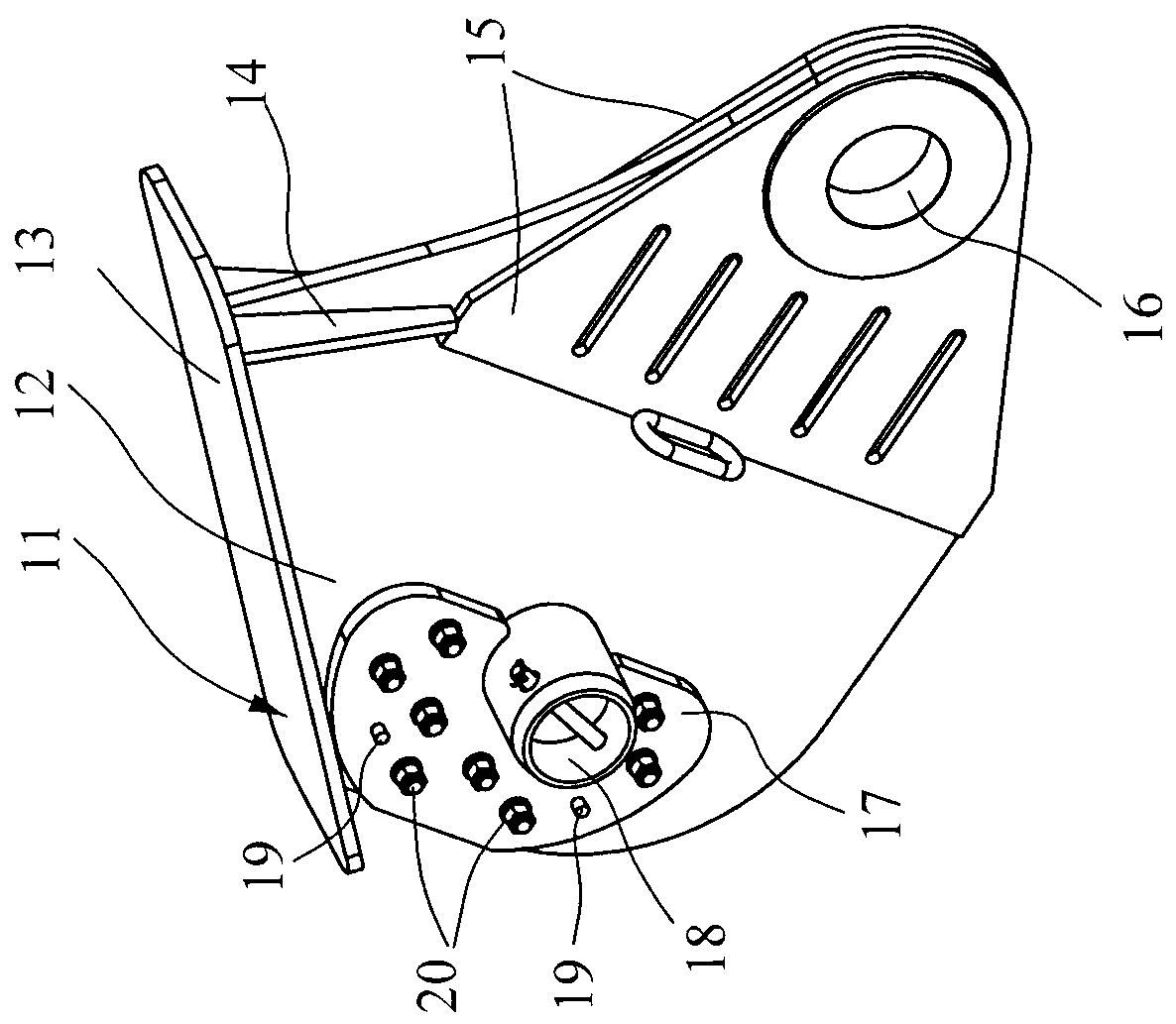

Movable pulley traction connecting device of inclined roadway winch used for transportation of hydraulic support

ActiveCN103334782AHigh strengthEnsure transportation safetyEarth drilling and miningUnderground transportTransportation capacityEngineering

The invention discloses a movable pulley traction connecting device of an inclined roadway winch used for transportation of a hydraulic support. The movable pulley traction connecting device comprises an auxiliary transport cart and a movable pulley unit, and is characterized in that a support connecting plate of a support connecting seat is vertically formed by welding a transverse plate to a vertical plate, a connecting hole is formed in the front end of the support connecting plate, and a limiting pin shaft hole is formed in the back end of the support connecting plate; the transverse plate is inserted into a gap between support connecting rods and a top beam, the vertical plate is inserted into a gap between two support connecting rods at the back part of the hydraulic support, the limiting pin shaft hole is exposed on the inner sides of the support connecting rods, a connecting rod spacer pin is arranged in the limiting pin shaft hole, so that the support connecting seat is connected to the support connecting rods; a middle connector is formed by hinging a front connecting piece to a back connecting piece through a middle pin shaft, the front connecting piece is connected to the connecting hole at the back end of the movable pulley unit, and the back connecting piece is connected with the support connecting seat; when the support is transported, a wire rope surrounds the movable pulley unit, and the end of the rope is fixed nearby the winch, so that the transportation capacity of the winch is doubled to meet overall transportation requirements of some heavy supports.

Owner:CHINA UNIV OF MINING & TECH +2

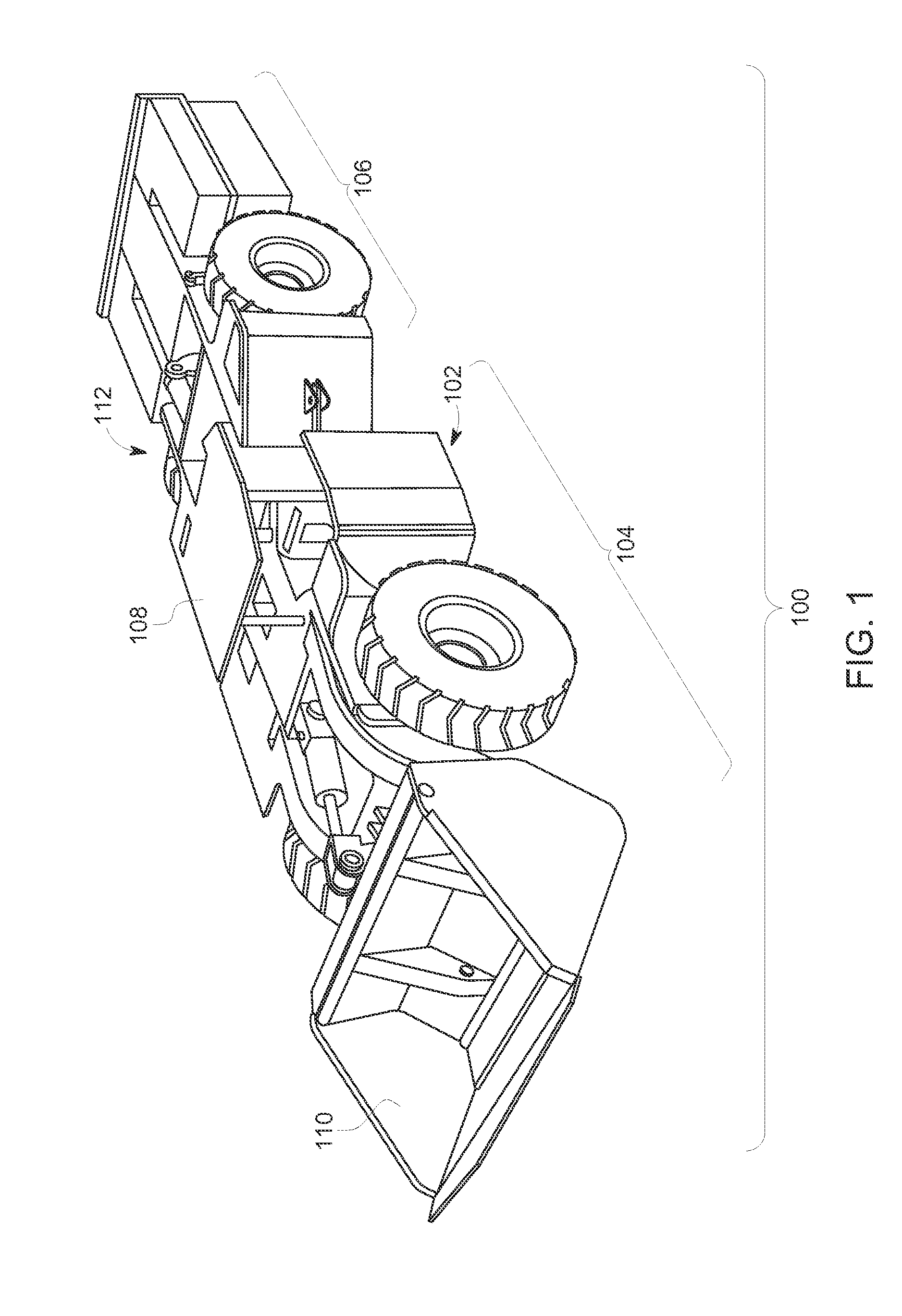

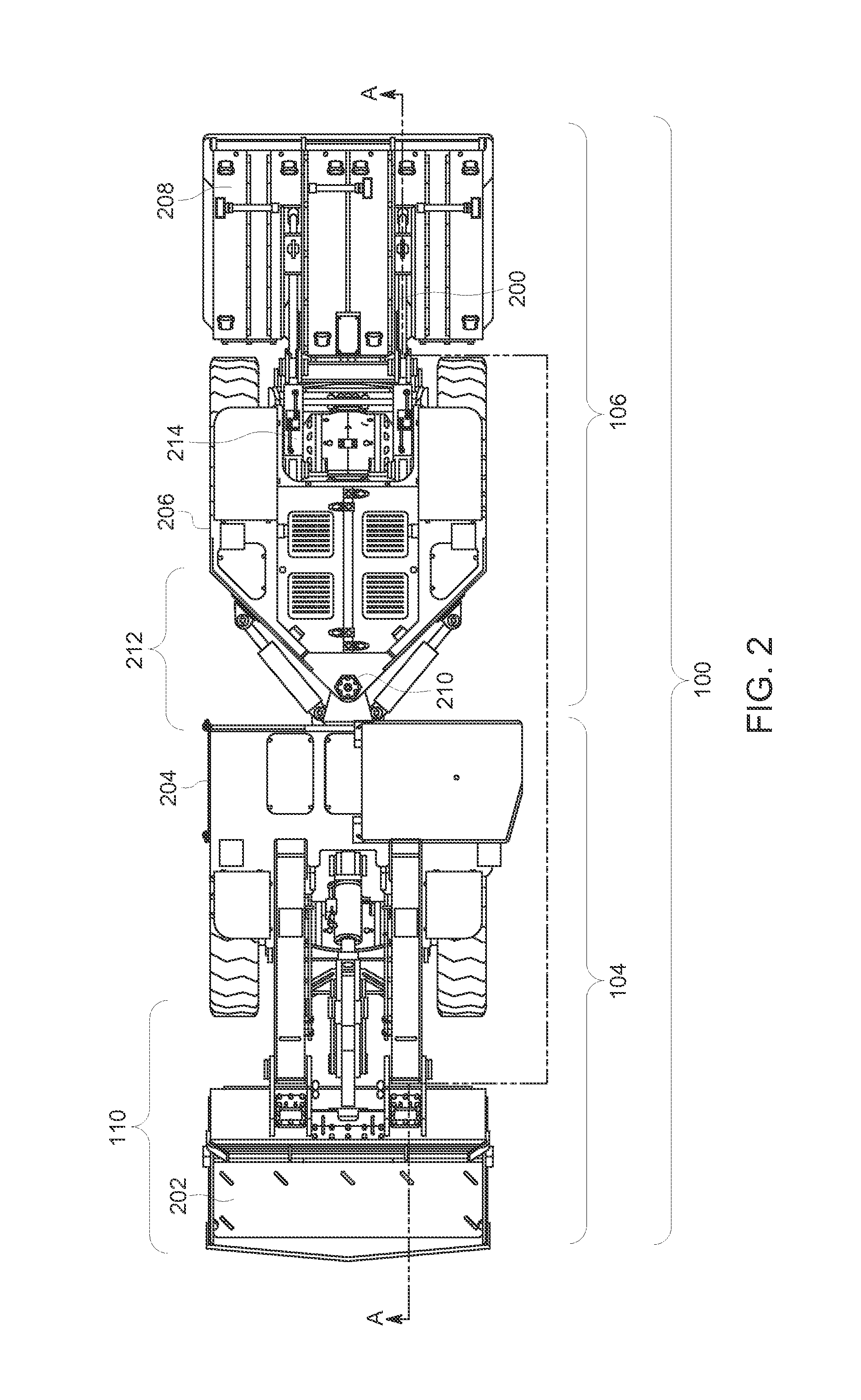

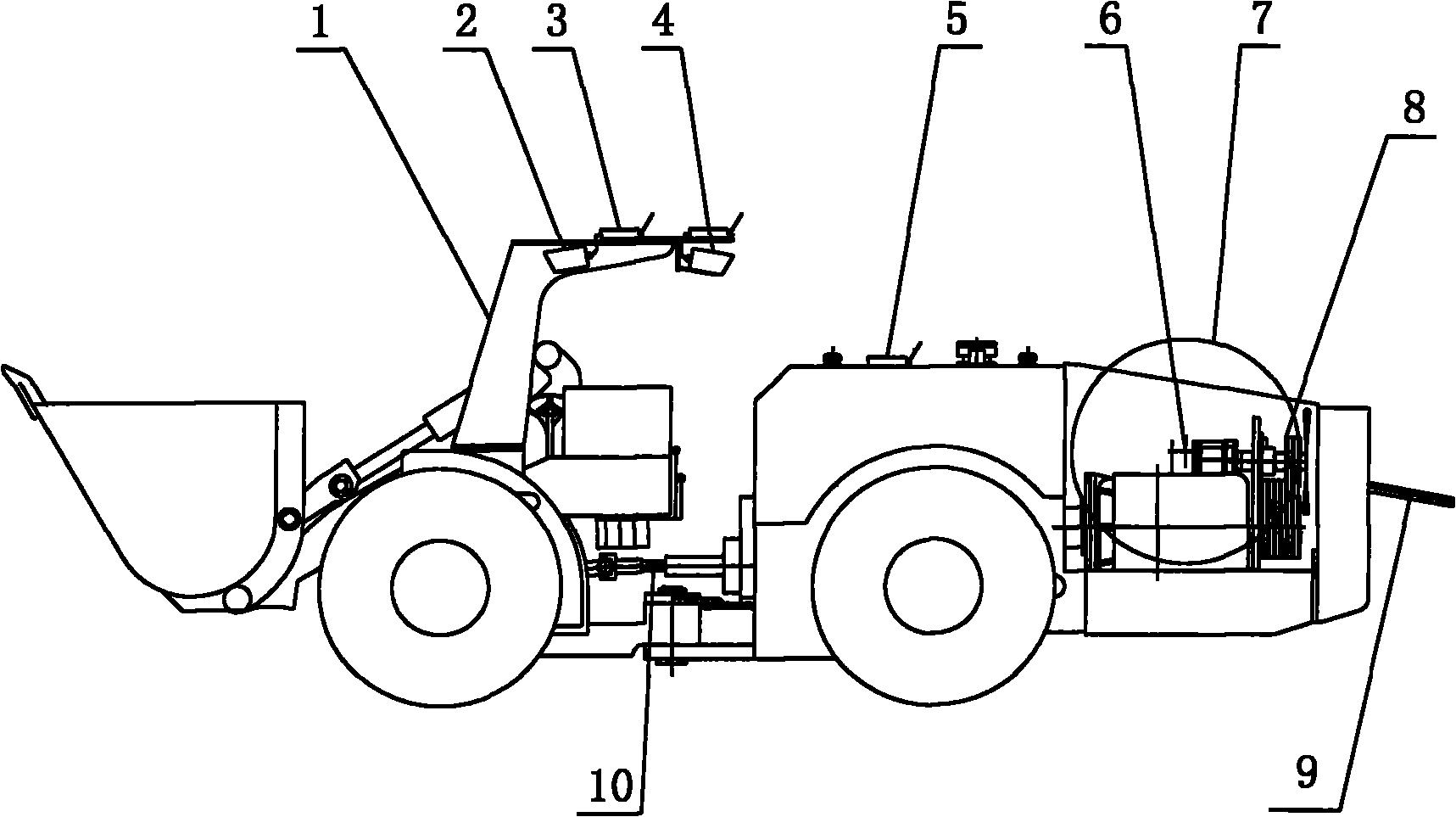

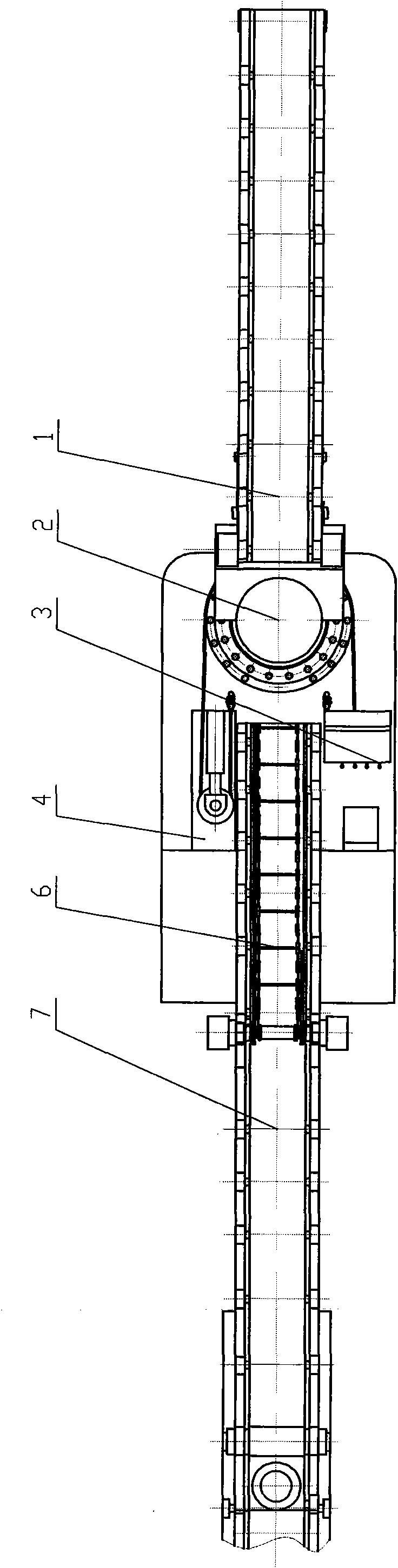

Storage battery shield hauler

ActiveCN102030283AOvercoming the disadvantages of using diesel enginesNo pollutionLifting devicesEarth drilling and miningElectric machineHydraulic pump

The invention relates to a storage battery shield hauler which mainly comprises a shovel plate mechanism, a front stander, an articulated frame, a middle stander, a back stander, a battery rack, direct current storage batteries, front and rear wheels, electric cabinets, a cab, a hydraulic pump station, a fuel tank, an erector, a rotary supporting frame, a locking rod, lifting, pushing and steering oil cylinders, a shovel plate, front and rear drive axles, front and rear running motors and speed reduction mechanisms. The high-power direct current storage batteries are used to supply power, and the cab controls electric appliances, mechanical and hydraulic mechanisms to complete various functions; and the batteries with the weight of 10 tons can not only supply direct current power, but also play a role in counterweight and balance. The ideal storage battery shield hauler is advanced in design and compact in structure, does not pollute environment, is safe, stable, reliable, energy-saving and environmental-friendly, and provides clean energy.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

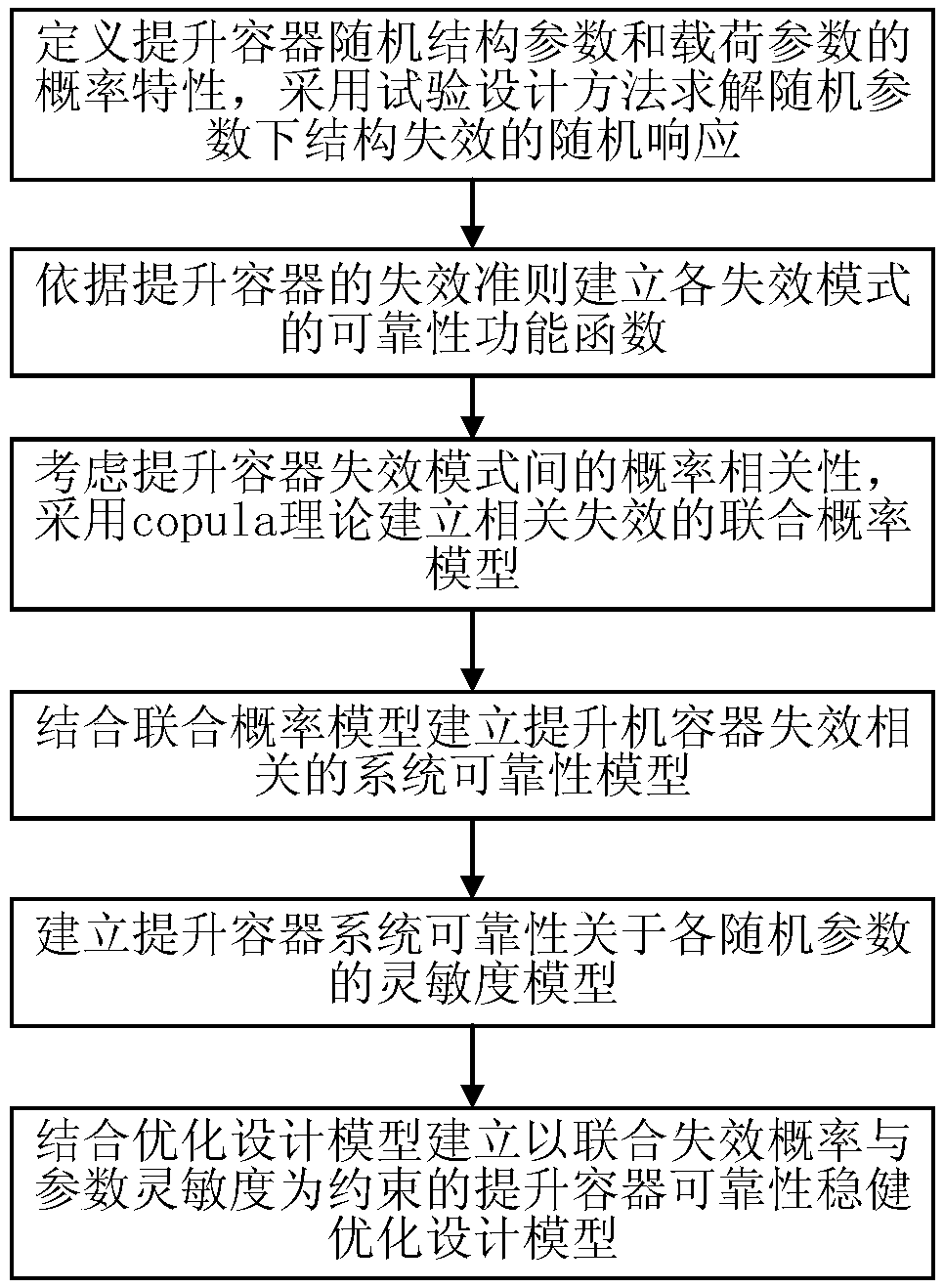

Reliability robust design method for multi-failure mode of superdeep well lifting container

PendingCN107832511AImprove modeling efficiencyImprove calculation accuracyGeometric CADDesign optimisation/simulationPerformance functionDependability

The invention discloses a reliability robust design method for a multi-failure mode of a superdeep well lifting container. The method includes the following steps of (1) determining structural parameters, material properties and dynamic load randomness of the lifting container, and adopting an experiment design method for figuring out a random response to a structure failure under random parameters; (2) according to a failure criterion of the lifting container, creating a reliability performance function under each failure mode; (3) taking the probability correlation among the failure modes into account, and adopting a copula theory for creating a combined probability model of correlative failures; (4) creating a system reliability model correlative with failures of the lifting container under the combination of the combined probability model; (5) creating a sensitivity model of the system reliability of the lifting container for each random parameter; (6) under the combination of an optimization design model, creating a lifting container reliability robust optimization design model with the combined failure probability and parameter sensitivity as constrains.

Owner:CHINA UNIV OF MINING & TECH

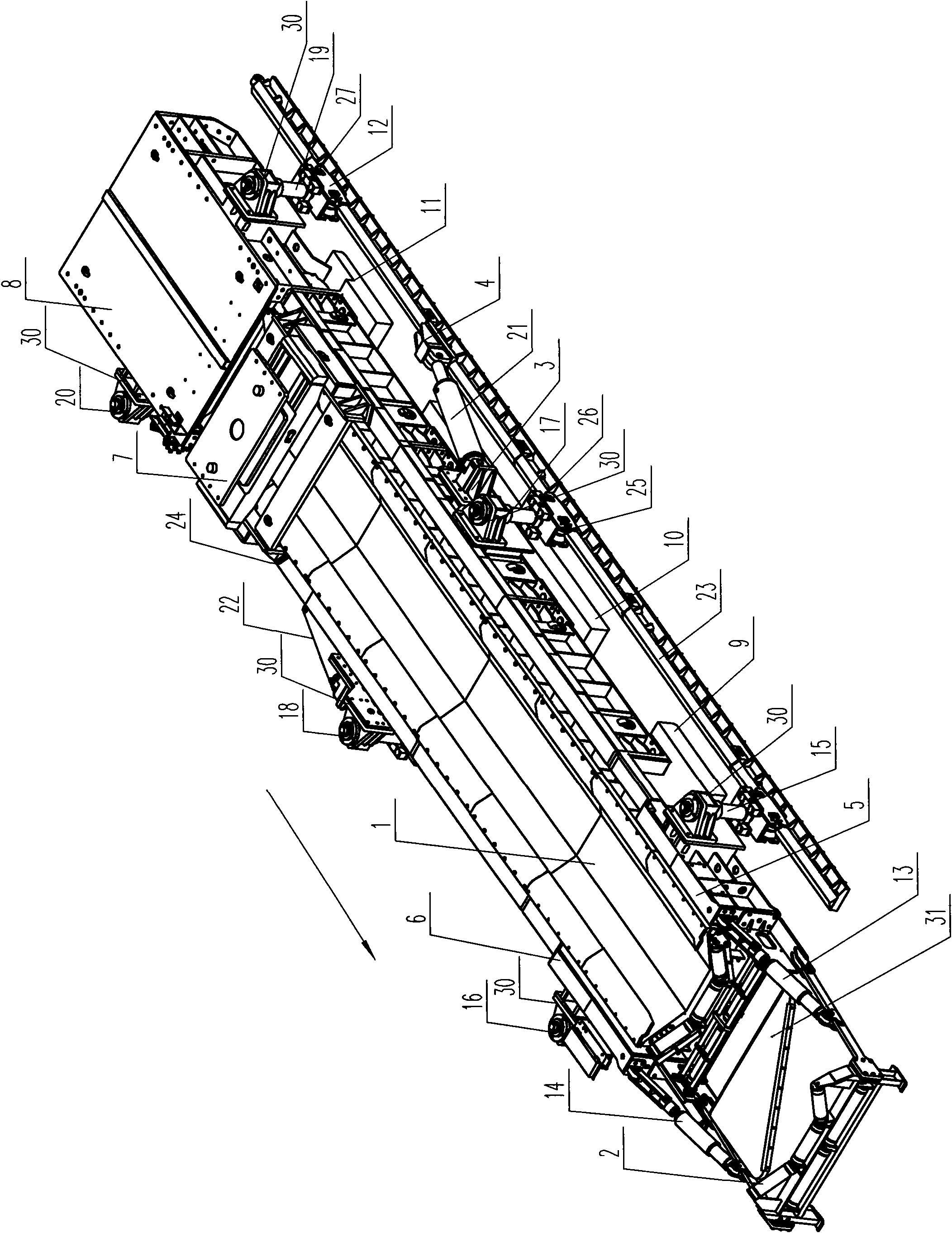

Slat conveyor for extraction systems and transport plates therefor

Owner:CATERPILLER GLOBAL MINING EURO GMBH

Determination of route for arranging automatic control of mobile mining machine

ActiveUS8744746B2Shorten the time necessarily taken by a routeNavigation instrumentsEarth drilling and miningAutomatic controlAutomatic train control

Owner:SANDVIK MINING & CONSTR OY

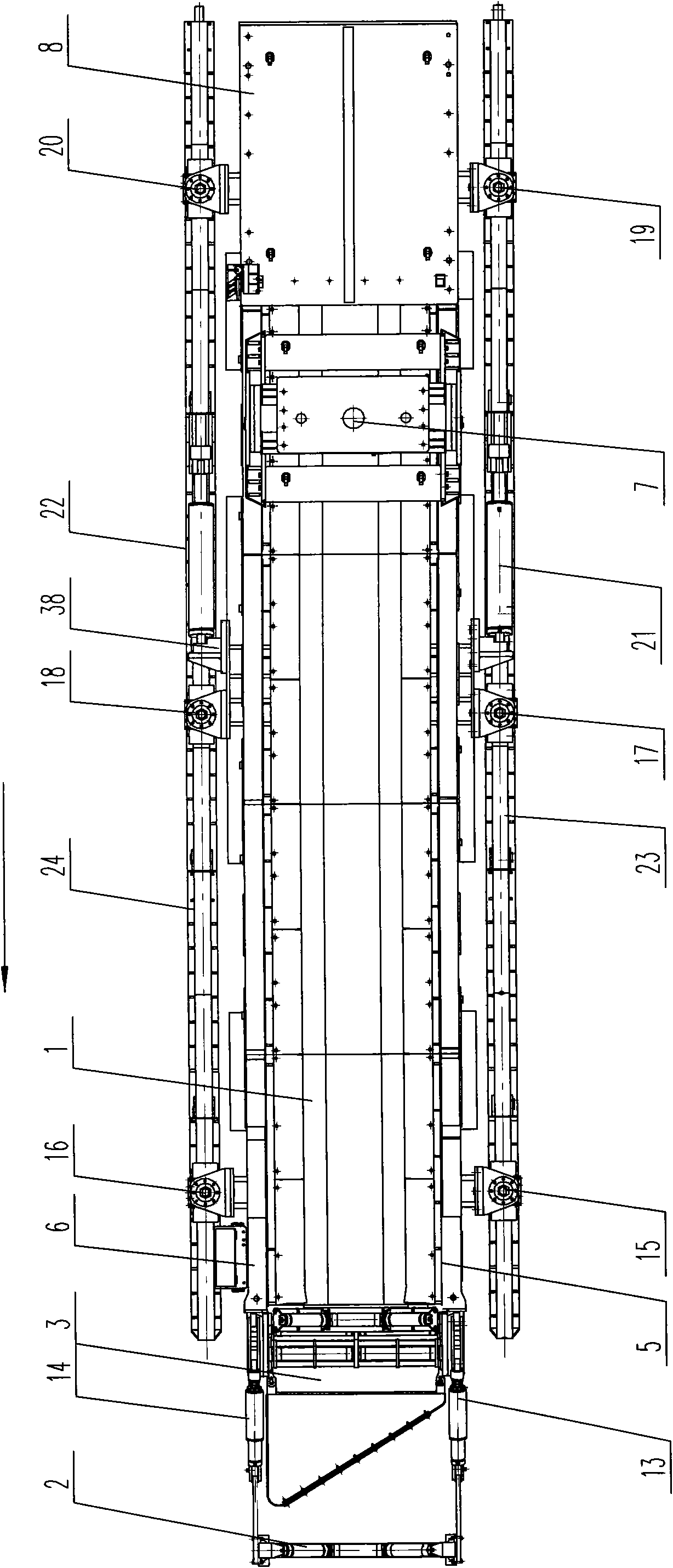

Fully mechanized mining hydraulic support installation and transport truck

ActiveCN103075186AEasy loadingEasy to unloadEarth drilling and miningUnderground transportHydraulic cylinderVehicle frame

The invention discloses a fully mechanized mining hydraulic support installation and transport truck. A cross beam and a loading plate are arranged between the left and right longitudinal beams of a frame; the front and rear parts of the loading plate are provided with two lifting driving devices respectively; a hydraulic stretching wedge is arranged on each of the left and right sides inside the loading plate respectively; an axial hole is formed in the middle of the loading plate; a rotating plate shaft in the axial hole is provided with a rotating plate; balls are uniformly distributed in the groove between the rotating plate and the loading plate; the external sides of the left and right longitudinal beams are connected with two trough push-pull frames respectively; a sliding block is arranged in the groove of each push-pull frame; and pull frame hydraulic cylinders are connected between the sliding blocks and the rear ends of the push-pull frames. Both the front and rear sides of the loading board can lift, the left and right sides of the loading board are provided with the hydraulic stretching wedge respectively, and the left and right pull frame hydraulic cylinders are outside the left and right horizontal longitudinal beams, so that the loading, unloading and transportation of the fully mechanized mining hydraulic support are facilitated; a rotating plate is arranged above the loading plate to facilitate the fully mechanized mining hydraulic support on the truck to turn easily; and the fully mechanized mining hydraulic support is provided with a fastening device to facilitate the fully mechanized mining hydraulic support to be fastened on the truck.

Owner:LIAONING XINFENG MINE IND GRP CO LTD

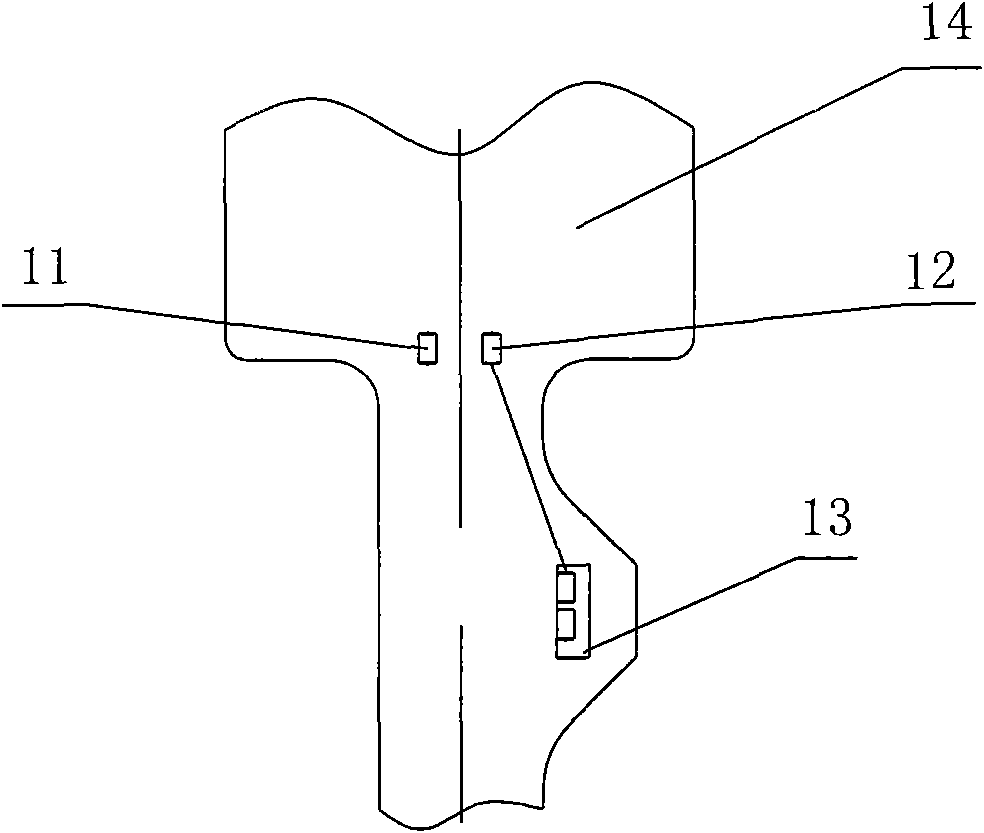

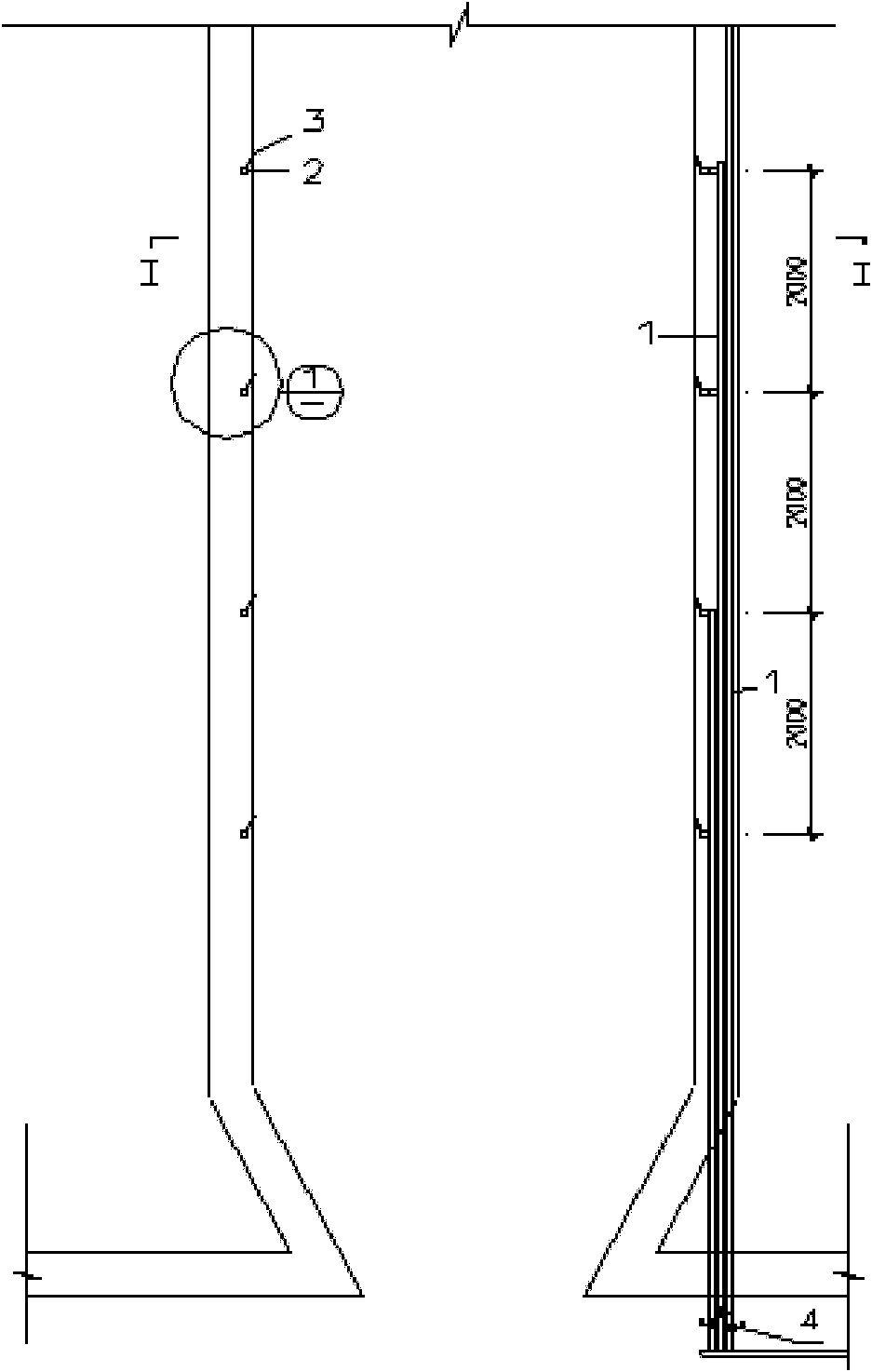

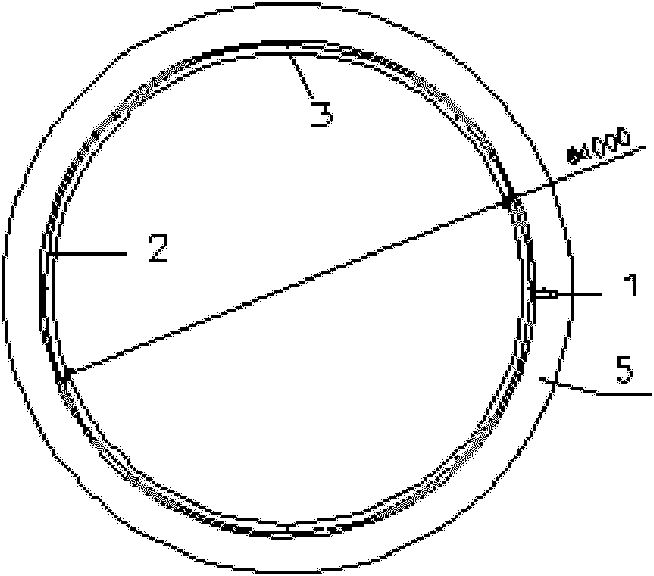

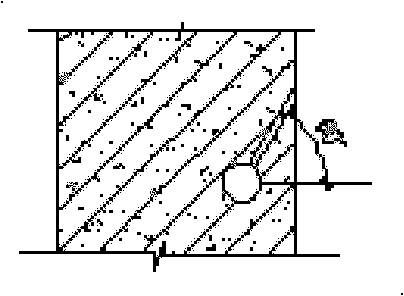

Method and system for clearing blockage of ore chute

InactiveCN102162372AExtended service lifeAvoid destructionEarth drilling and miningUnderground transportReinforced concreteMining engineering

The invention relates to a method and a system for clearing the blockage of an ore chute, and can be widely applied to handle the problem of arc-shaped caking or blockage of materials in open-pit-to-underground mines, underground mines and surface ore material storage bins. The system comprises first steel tubes (1), second steel tubes (2), third steel tubes (3) and a valve (4), wherein the first steel tubes (1) are embedded in the reinforcing concrete of the ore chute, two ring-shaped steel tubes (2) are connected on each first steel tube (1), the vertical distance between every two ring-shaped steel tubes (2) is 2 meters, eight third steel tubes (3) are welded on the ring-shaped steel tubes (2), the third steel tubes (3) are uniformly distributed on the ring-shaped steel tubes (2), the third steel tubes (3) in the upper layer and the lower layer are staggered, the blockage of the third steel tubes (3) is prevented during the concrete pouring of the wall of the ore chute, and the first steel tubes (1) are connected with a mine air supply pipe and provided with the valve (4).

Owner:UNIV OF SCI & TECH BEIJING

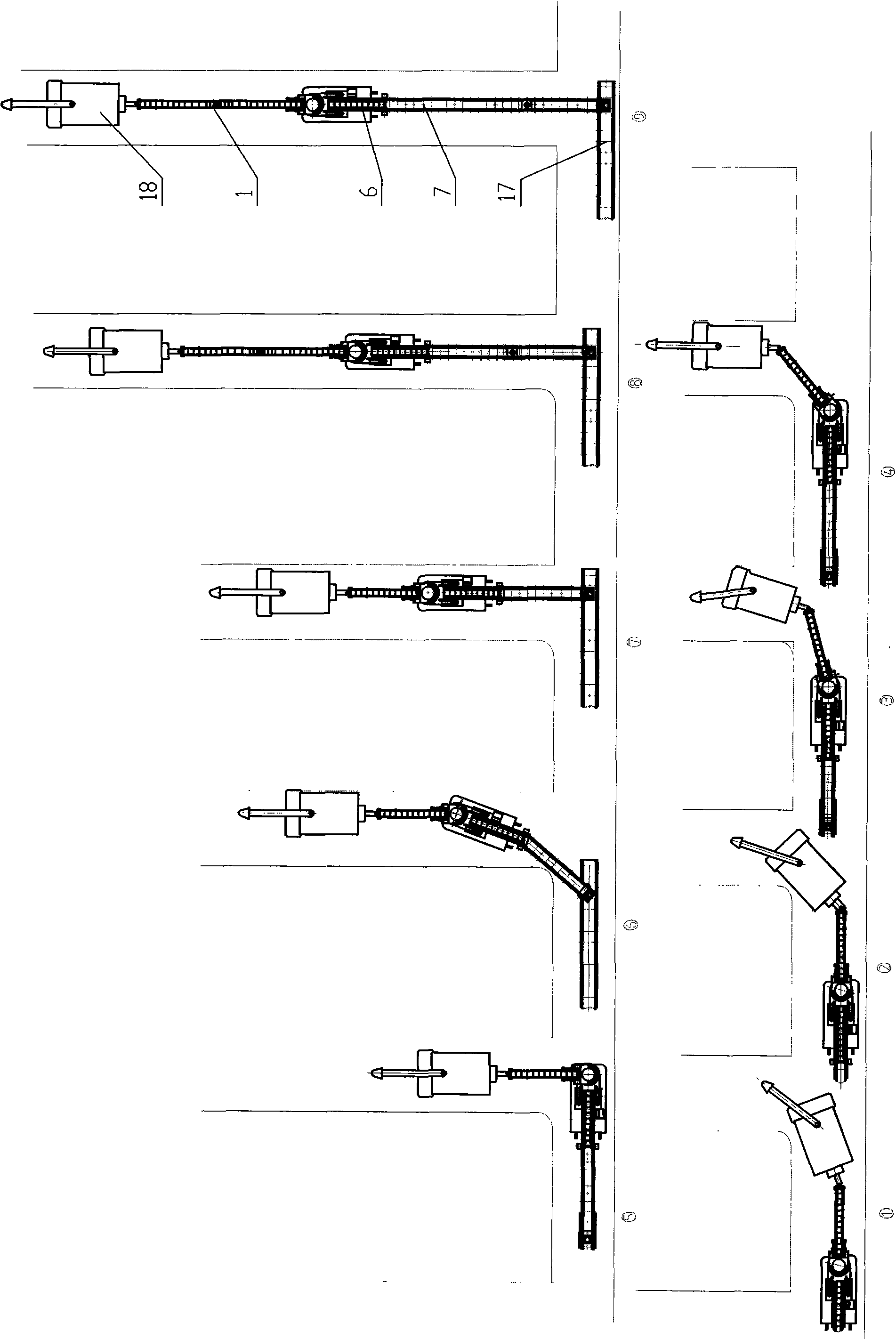

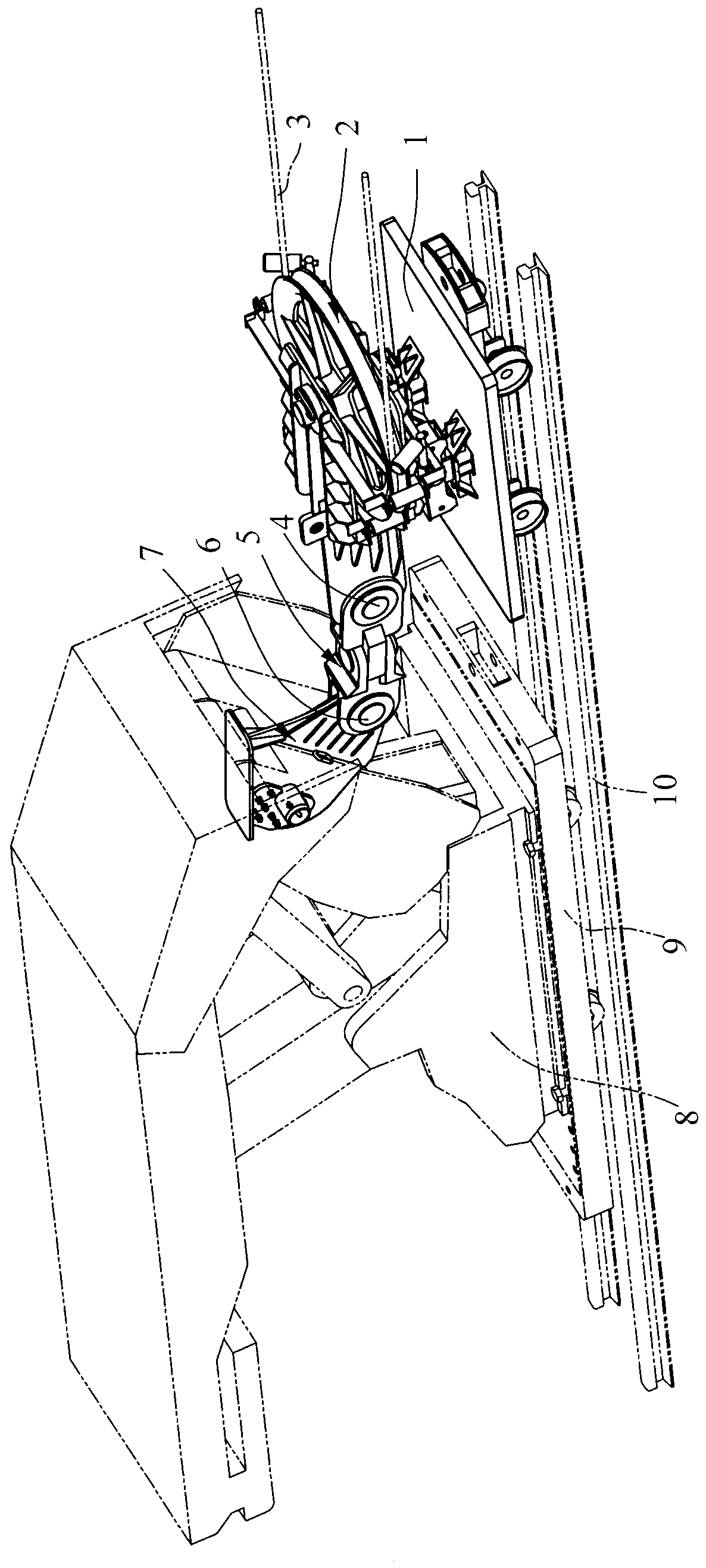

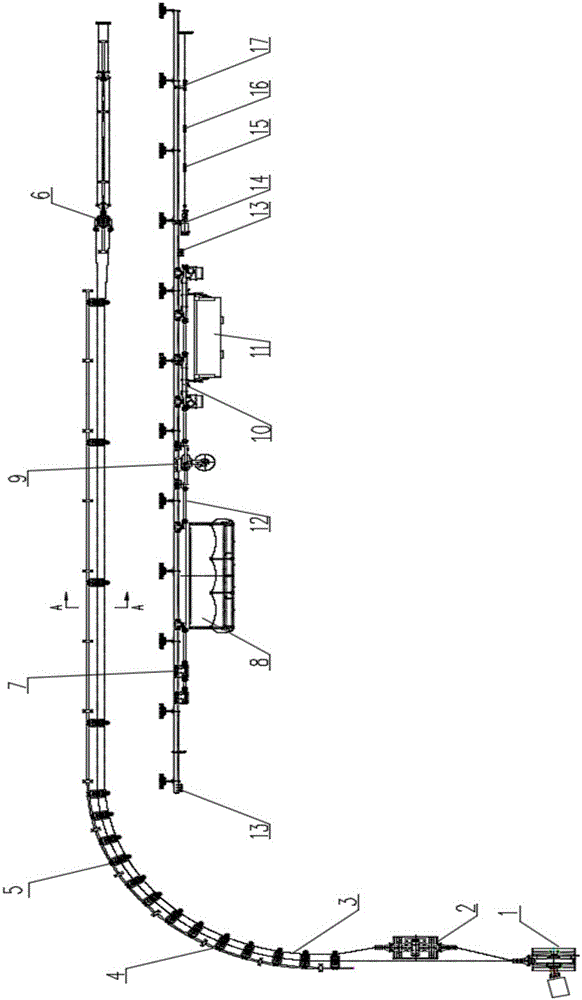

Monorail crane transportation system pulled by steel wire rope of hydraulic winch

InactiveCN105174053ARealize continuous transportationEasy constructionEarth drilling and miningUnderground transportTowerWinch

The invention discloses a monorail crane transportation system pulled by a steel wire rope of a hydraulic winch. The monorail crane transportation system comprises a suspended rail, a steel wire rope, the hydraulic winch, a tensioning tower, a rotary station, a tractor, a braking vehicle, a manual vehicle and a hoisting beam, wherein the steel wire rope penetrates through the hydraulic winch and the tensioning tower and penetrates through wheel guide frames and the rotary station to form a closed endless rope; the head and tail parts of the steel wire rope are fixedly connected with the tractor; in a transportation process, a monorail crane is pulled and controlled by the steel wire rope to operate; the braking vehicle, the manual vehicle, the tractor and the hoisting beam are suspended on the suspended rail and are in sliding connection with the suspended rail; the tractor is connected with the manual vehicle and the hoisting beam respectively through pull rods; and the manual vehicle is connected with the braking vehicle through a pull rod. The monorail crane transportation system is driven by the hydraulic winch, has a compact structure and a reasonable layout and is simple to operate, and the speed is convenient to regulate; endless speed regulation is realized, and transportation links and post workers are reduced; and security coefficients in the transportation process are improved.

Owner:徐州华东机械有限公司

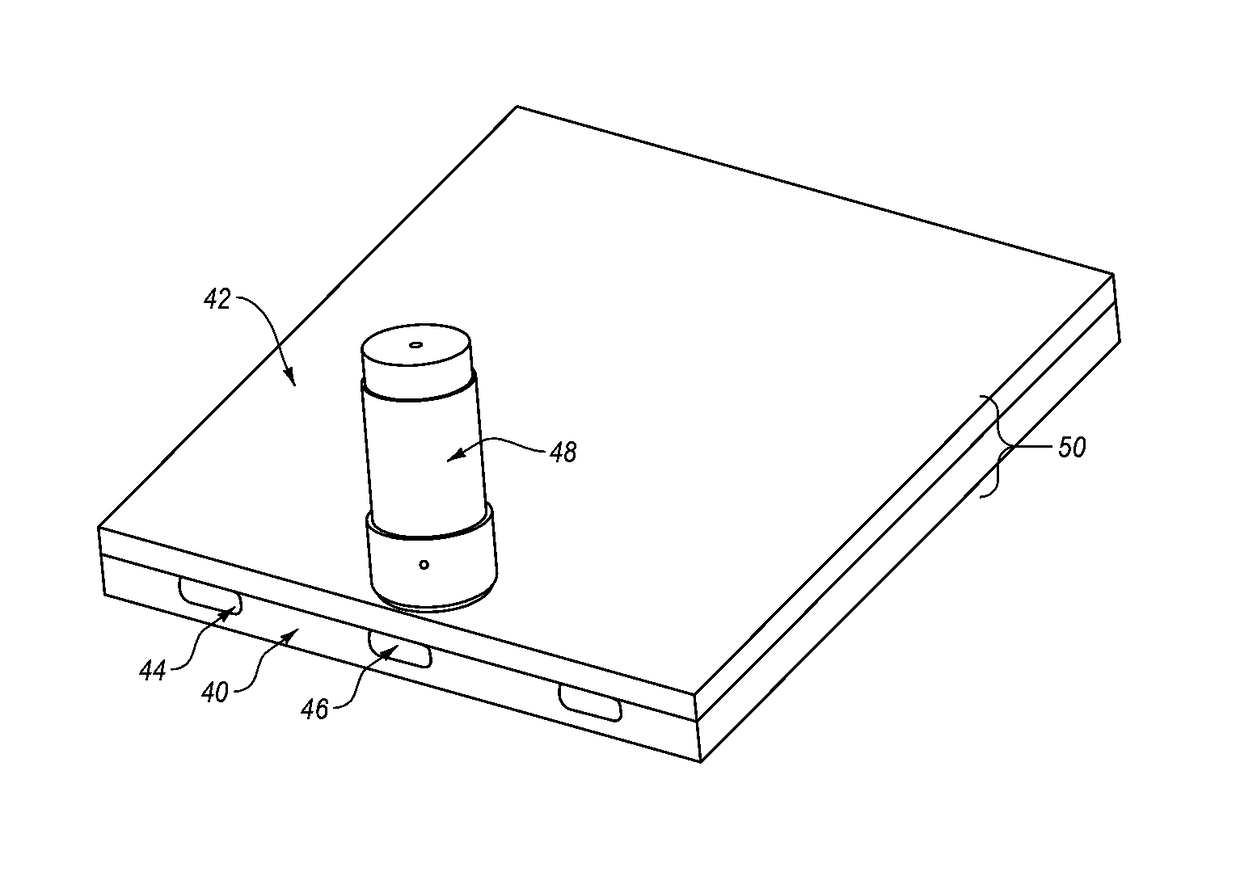

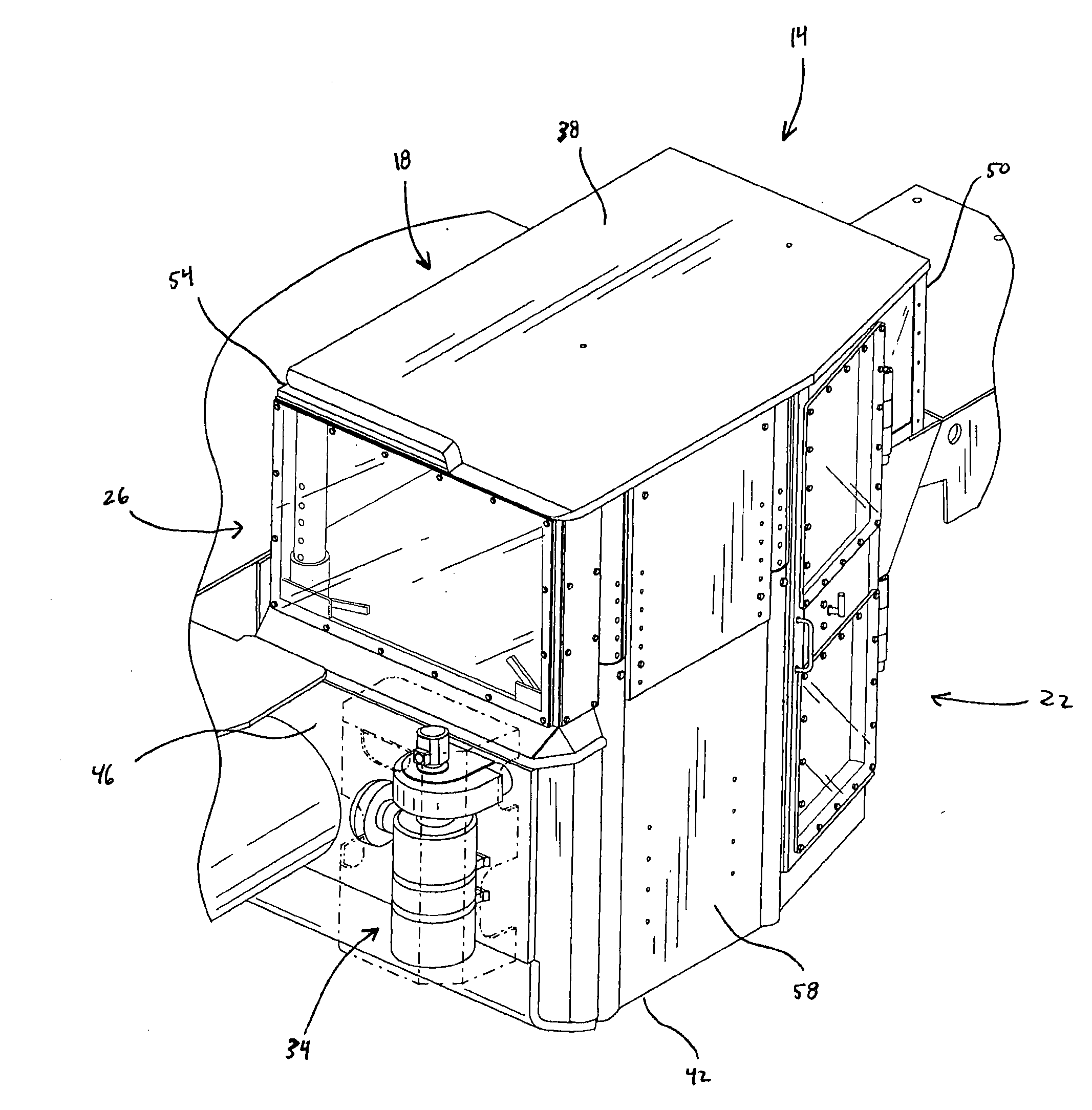

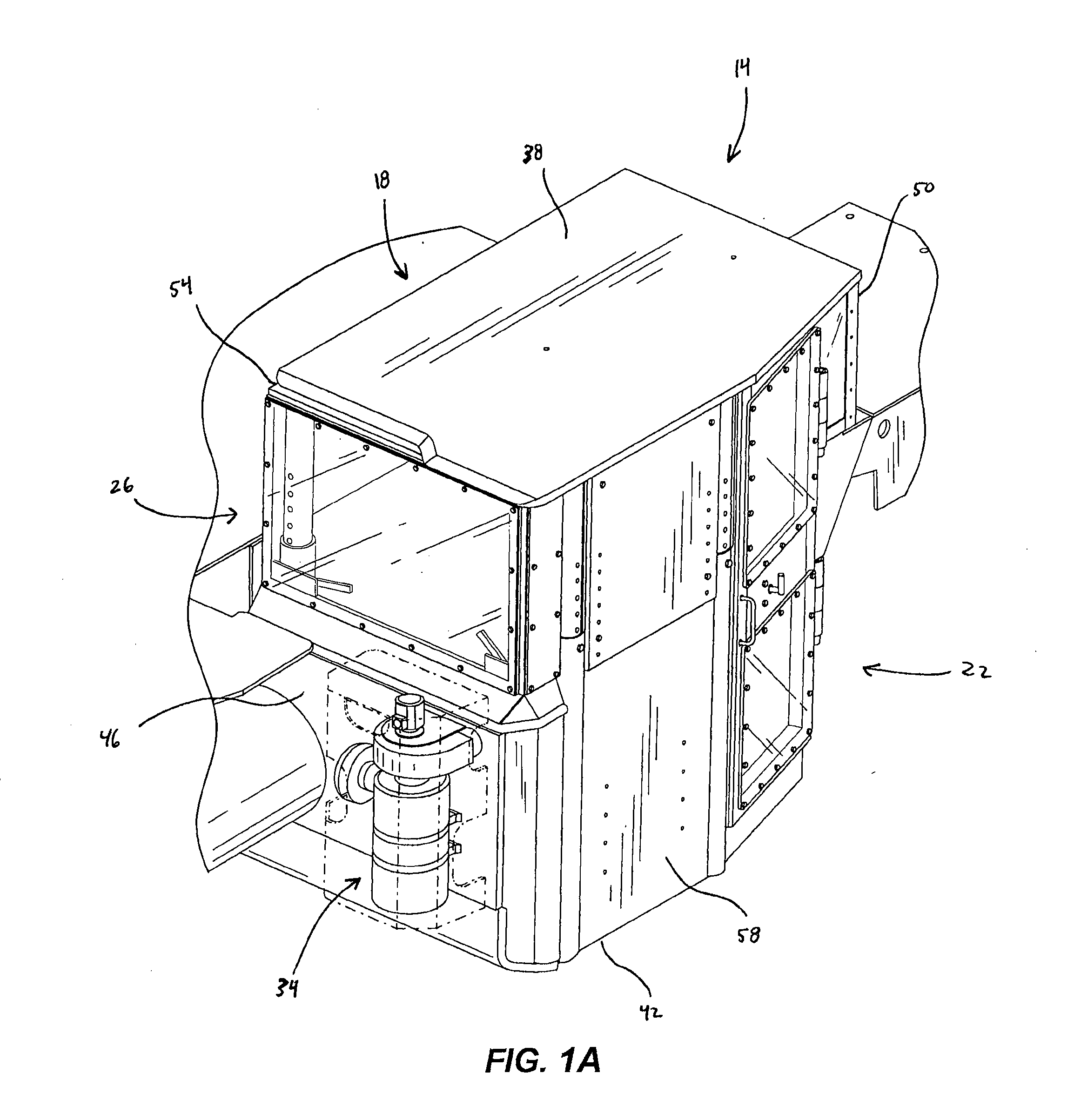

Enclosed cab system for mining equipment

An operator's cab for a shuttle car including a cab frame, a window assembly, and a pressurization system. The cab frame defines an interior chamber and an opening. The window assembly includes a pane and a pane seal. The pane is coupled to the cab frame such that the pane covers the opening and encloses the interior chamber. The pane seal is positioned between the pane and the cab frame. The pressurization system provides a positive pressure in the interior chamber relative to the surrounding environment. The pressurization system includes a blower and a motor for driving the blower. The blower is in fluid communication with the interior chamber.

Owner:JOY GLOBAL UNDERGROUND MINING LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com