Reliability robust design method for multi-failure mode of superdeep well lifting container

A robust design and failure mode technology, applied in design optimization/simulation, instruments, calculations, etc., can solve design and later maintenance deviations, reduce accuracy and other issues, to ensure robustness, improve robustness, improve modeling efficiency and The effect of computational precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

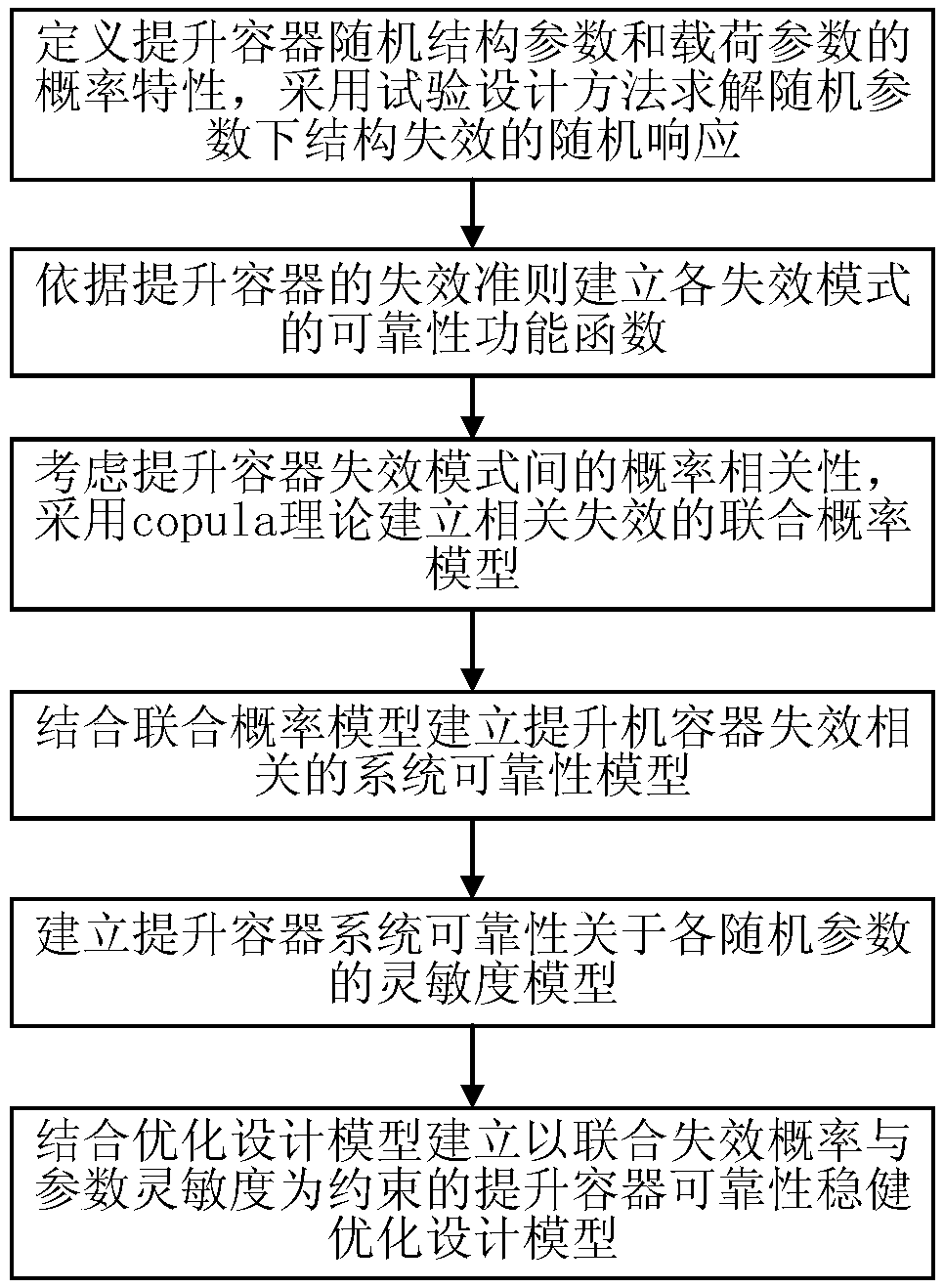

[0047] Such as figure 1 As shown, the reliability and robust design method of the multi-failure mode of the ultra-deep well hoisting vessel proposed by the present invention comprises the following steps:

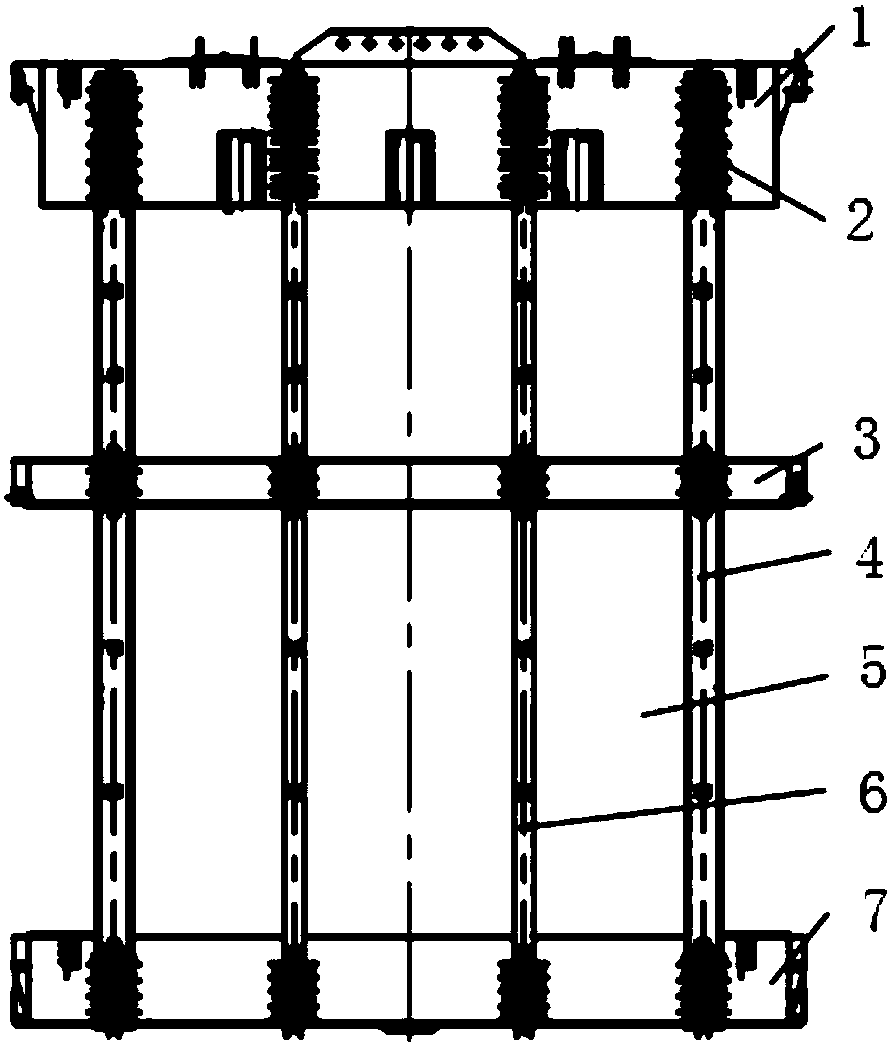

[0048] Step 1. According to the original design drawings of the lifting container or through on-site surveying and mapping, obtain the mean value and variance of parameters such as the structural size, material properties and dynamic load of the lifting container;

[0049] Step 2. According to the structural parameters of the lifting container, a three-dimensional parametric model of the lifting container is established, and a finite element static analysis is performed on the established virtual prototype model;

[0050] Step 3, by experimental design method, according to the mean value and the variance of each basic parameter of lifting container ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com