Patents

Literature

1675results about "Model making" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

3-D model providing device

InactiveUS7006952B1Efficient and effectiveEffectively and efficiently providingImage analysisDecorative surface effectsThree dimensional shapeMachine learning

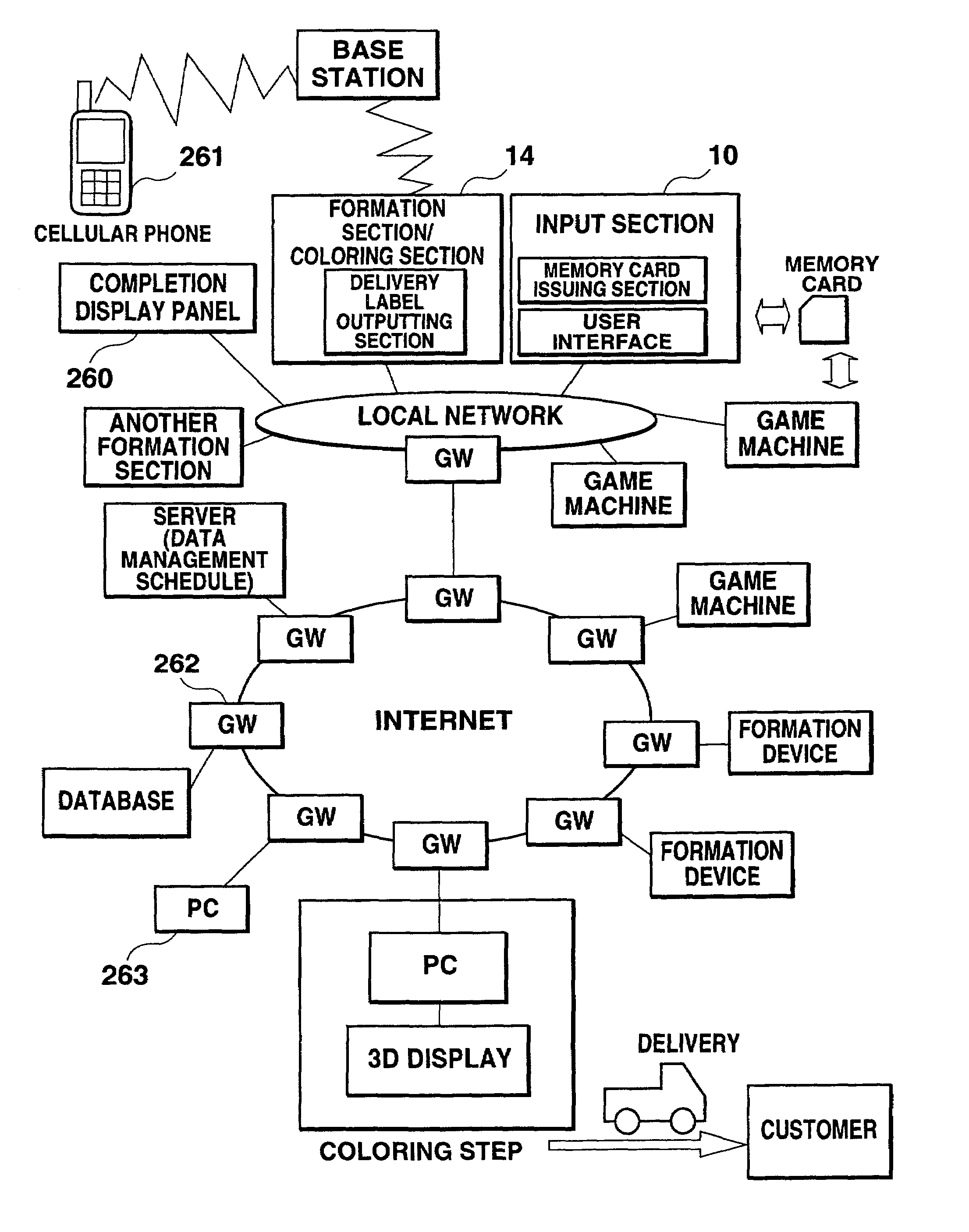

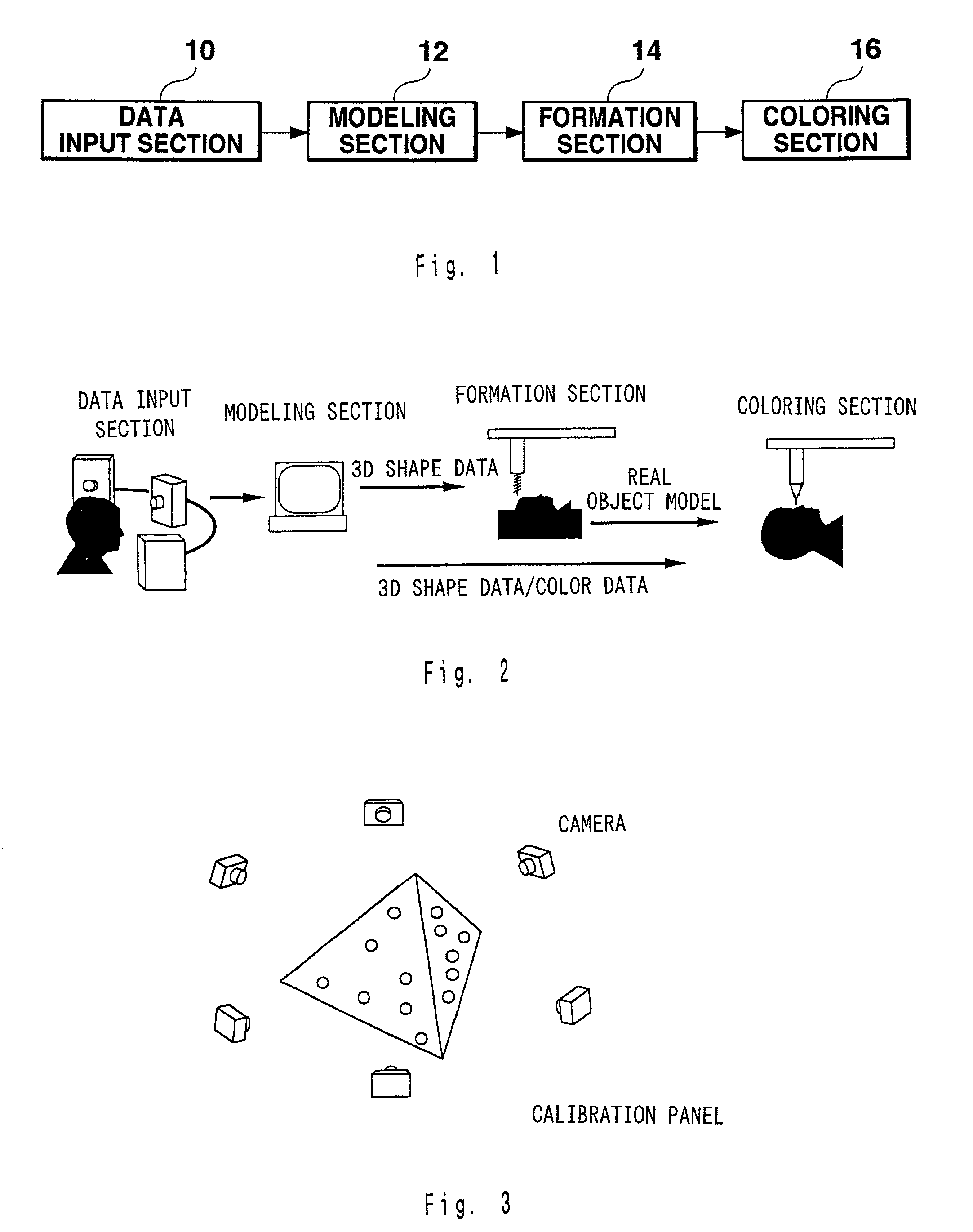

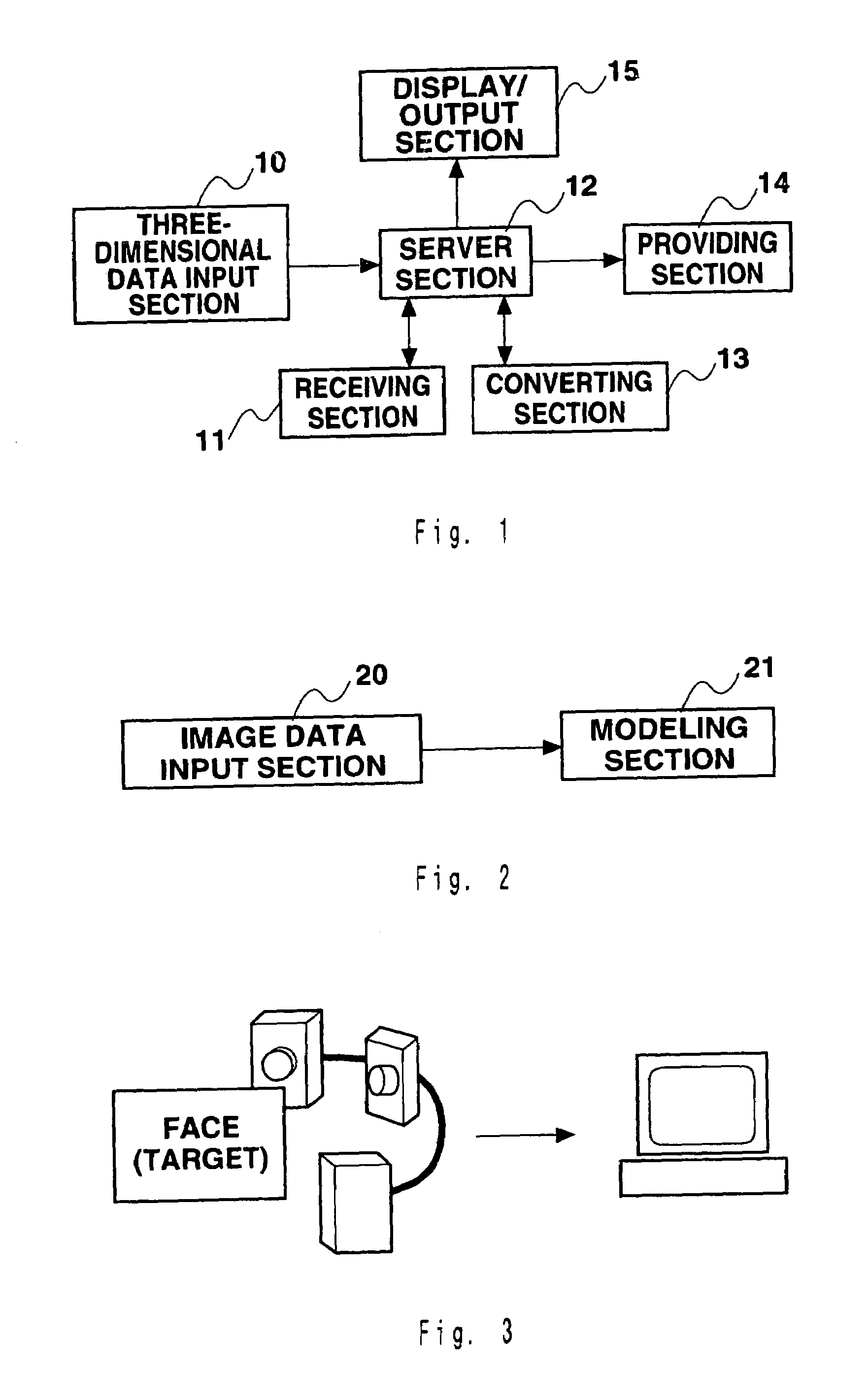

For an apparatus effectively providing a real three-dimensional model to a customer, three-dimensional shape data of a target is obtained at a data input section (10). The data is managed by a server which is connected to a network. A suitable formation section (14) is selected to form a real three-dimensional model based on the data. In addition, the formation completion is automatically notified to the customer via a completion display panel (260), a cellular phone (61), or the like.

Owner:DIGIMEDIA TECH LLC

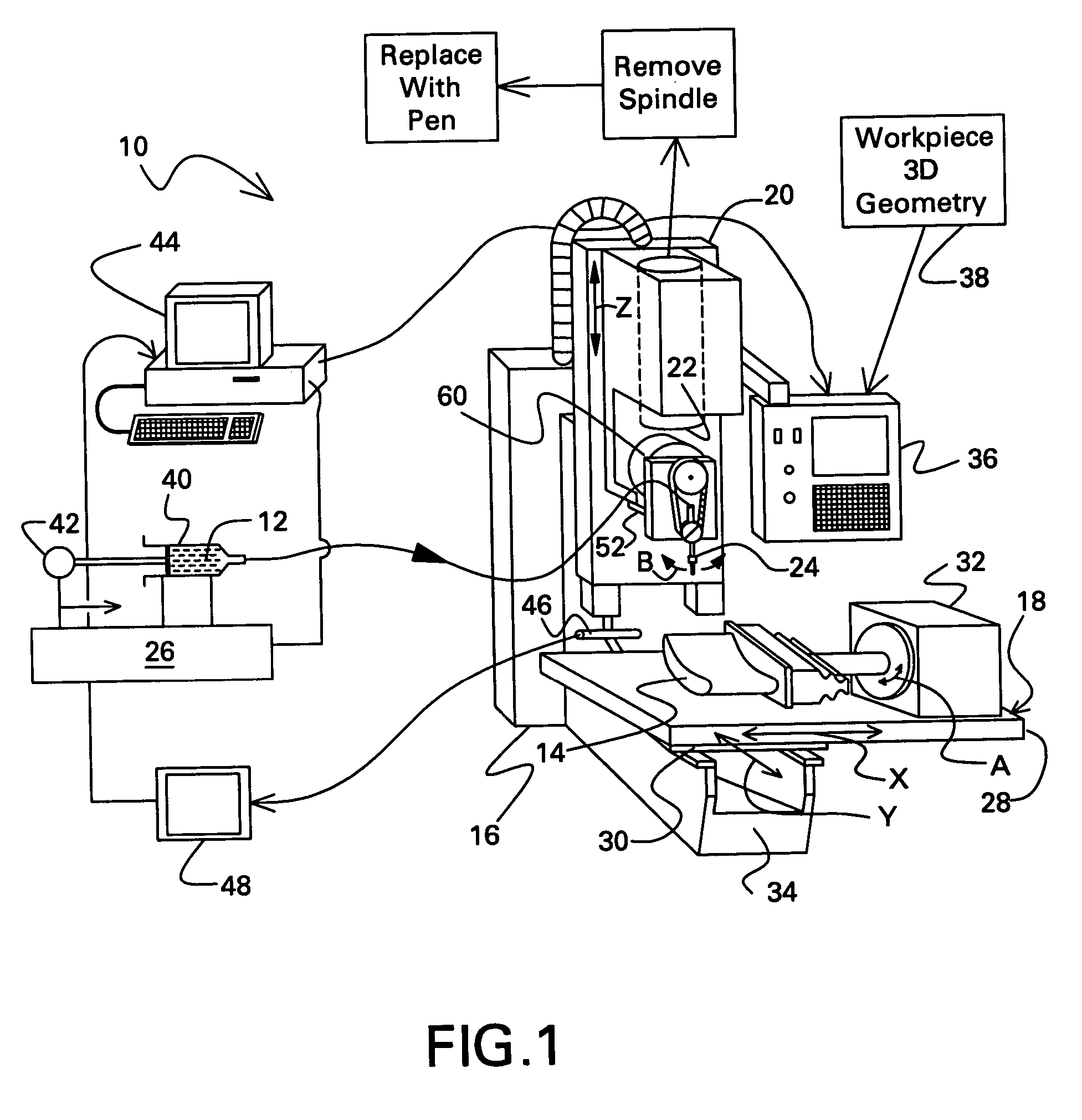

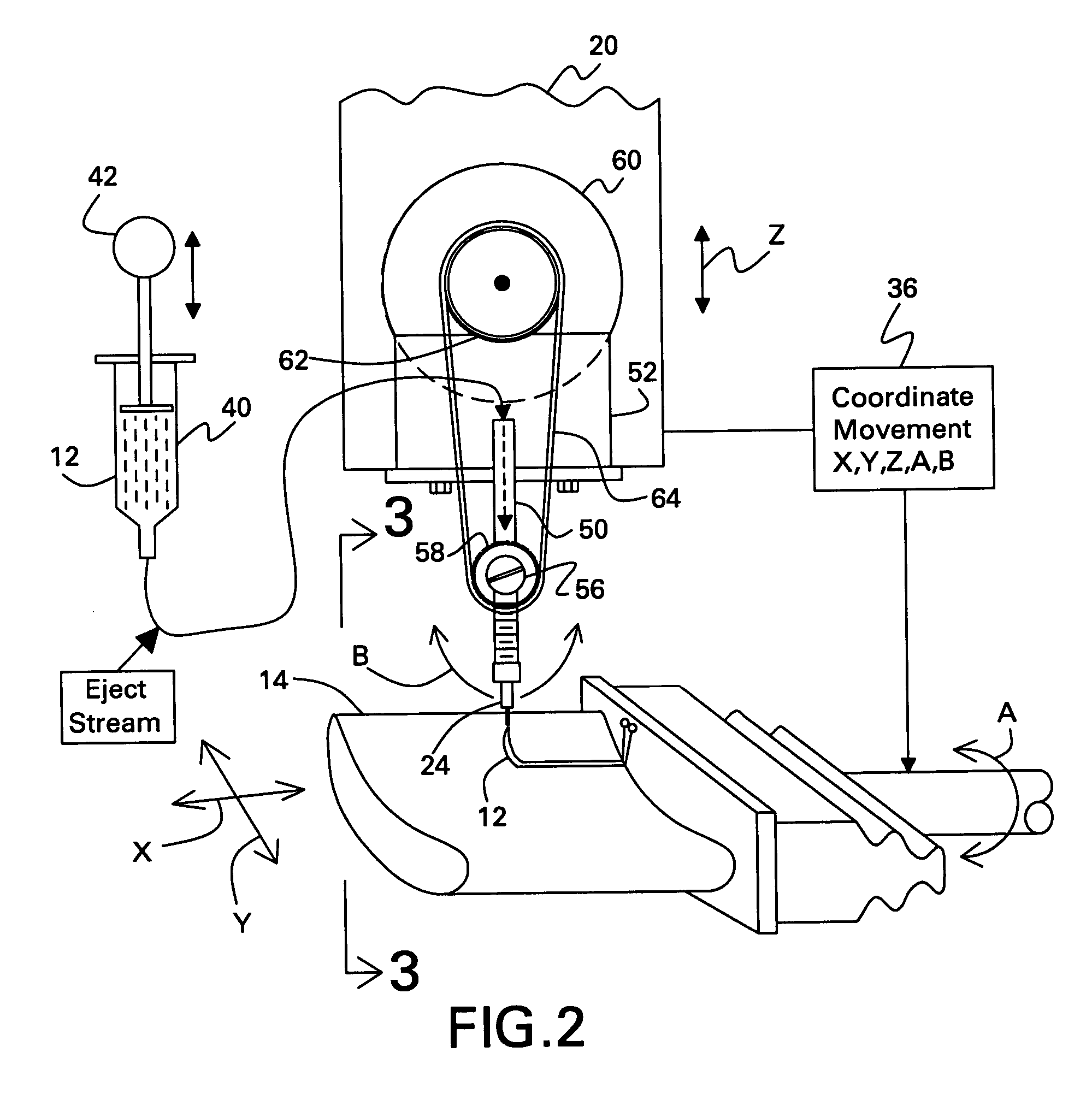

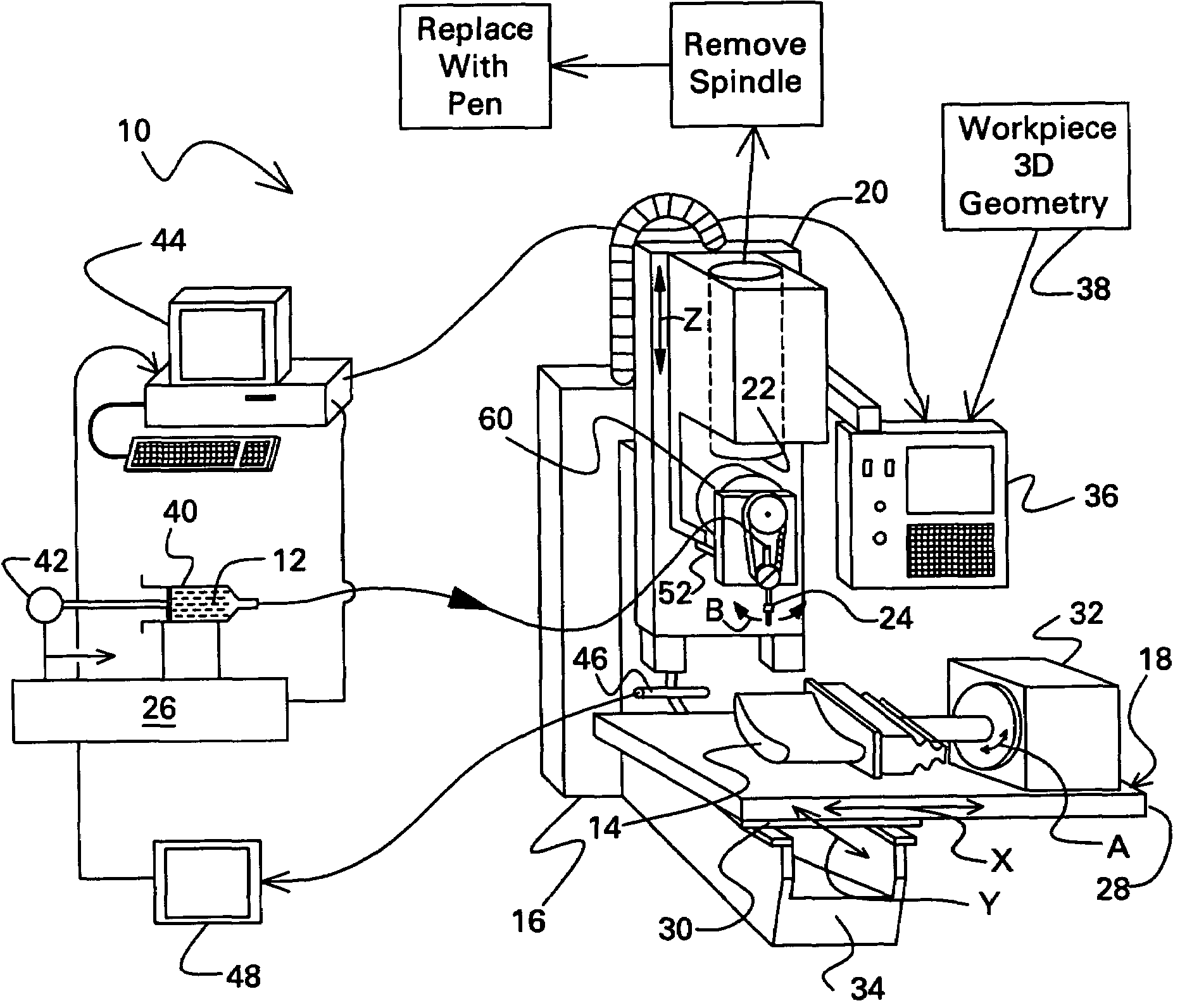

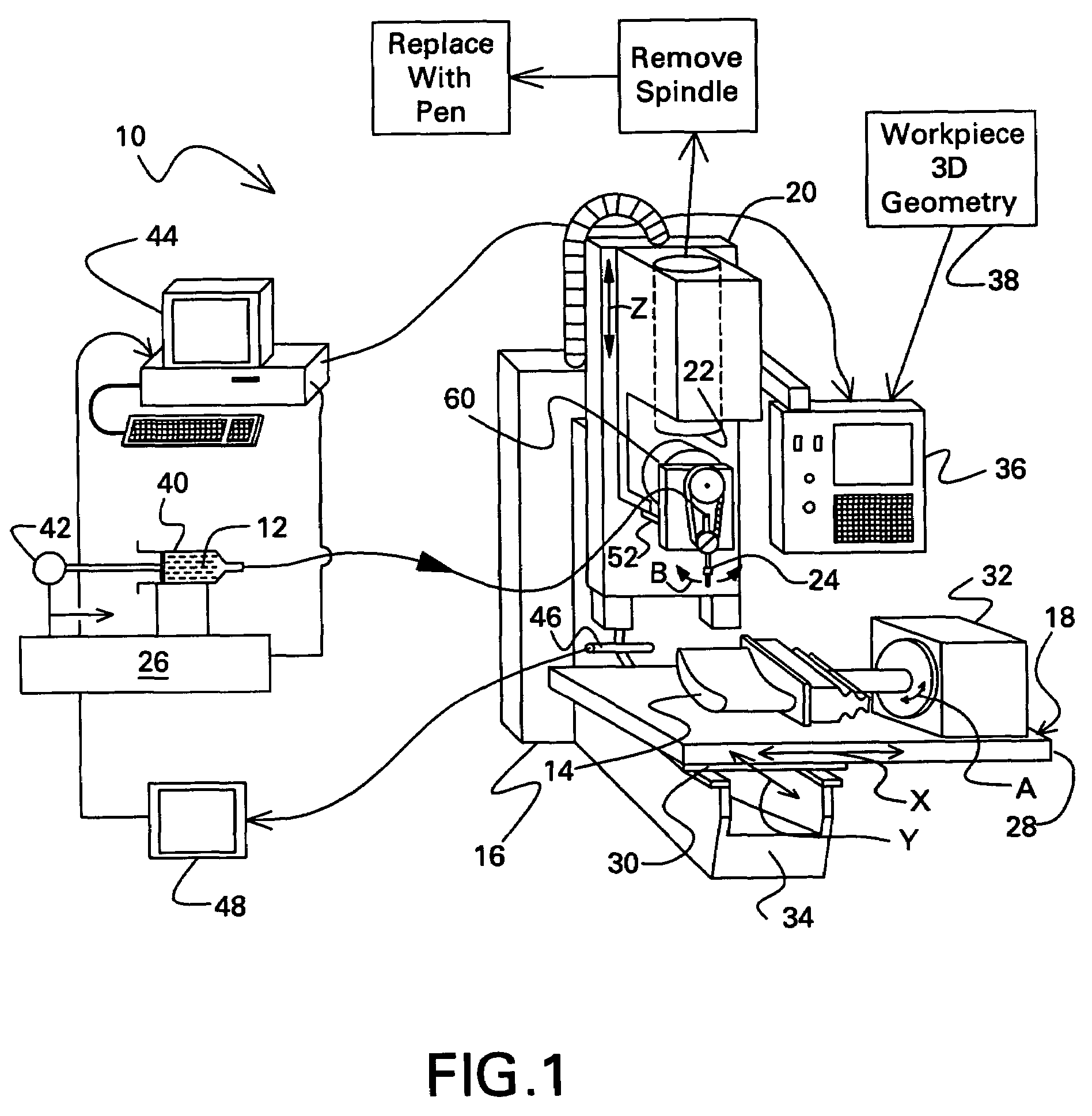

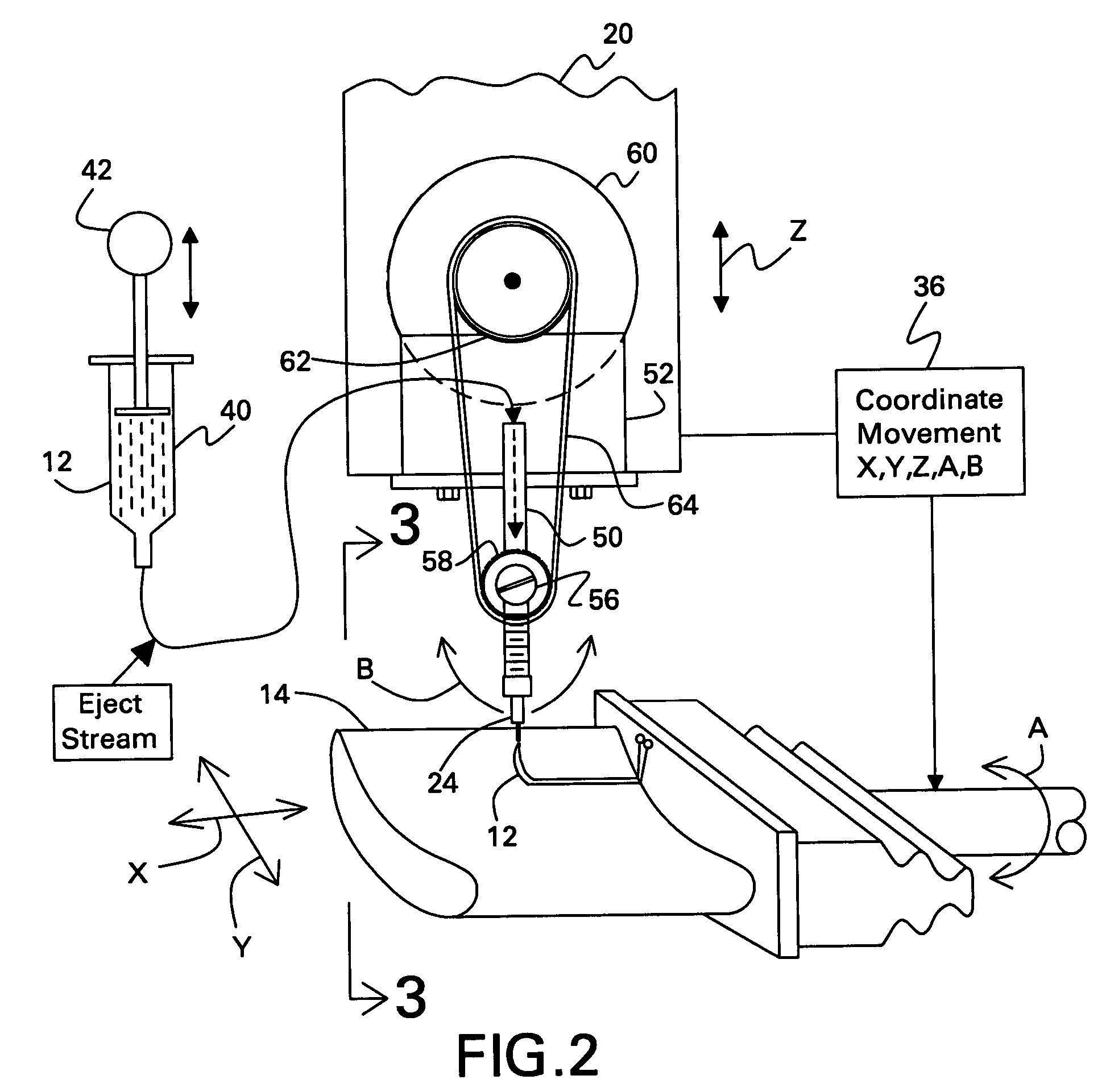

Robotic pen

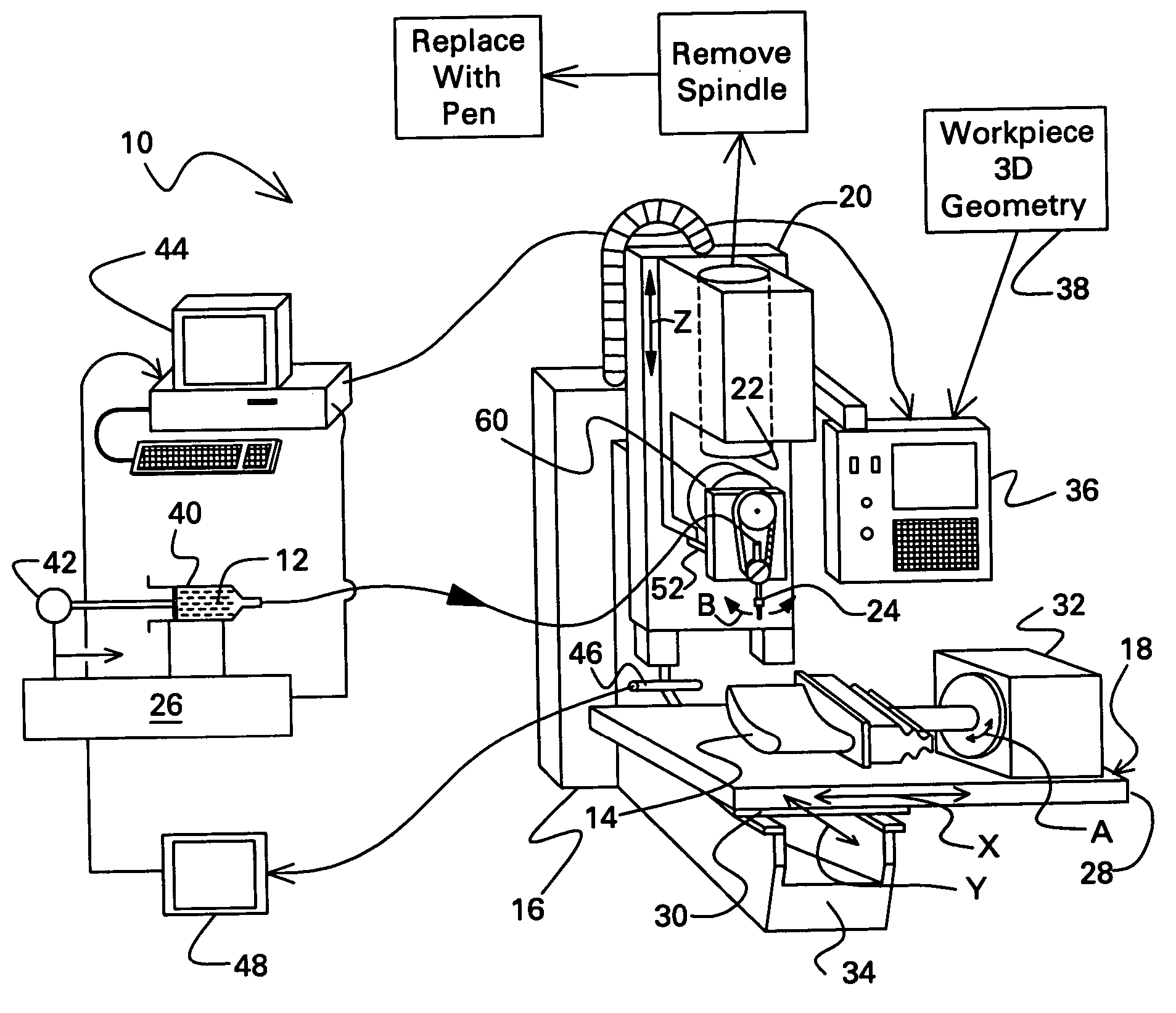

A robotic pen includes a computer numerically controlled machine having a multiaxis stage for mounting a workpiece, and a cooperating elevator which translates relative thereto. A pen tip is rotatably mounted to the elevator. And, a dispenser is joined in flow communication with the pen tip for ejecting a stream of material atop the workpiece as the workpiece moves relative thereto for maintaining a substantially constant gap between said pen tip and the workpiece during relative movement therebetween.

Owner:GENERAL ELECTRIC CO

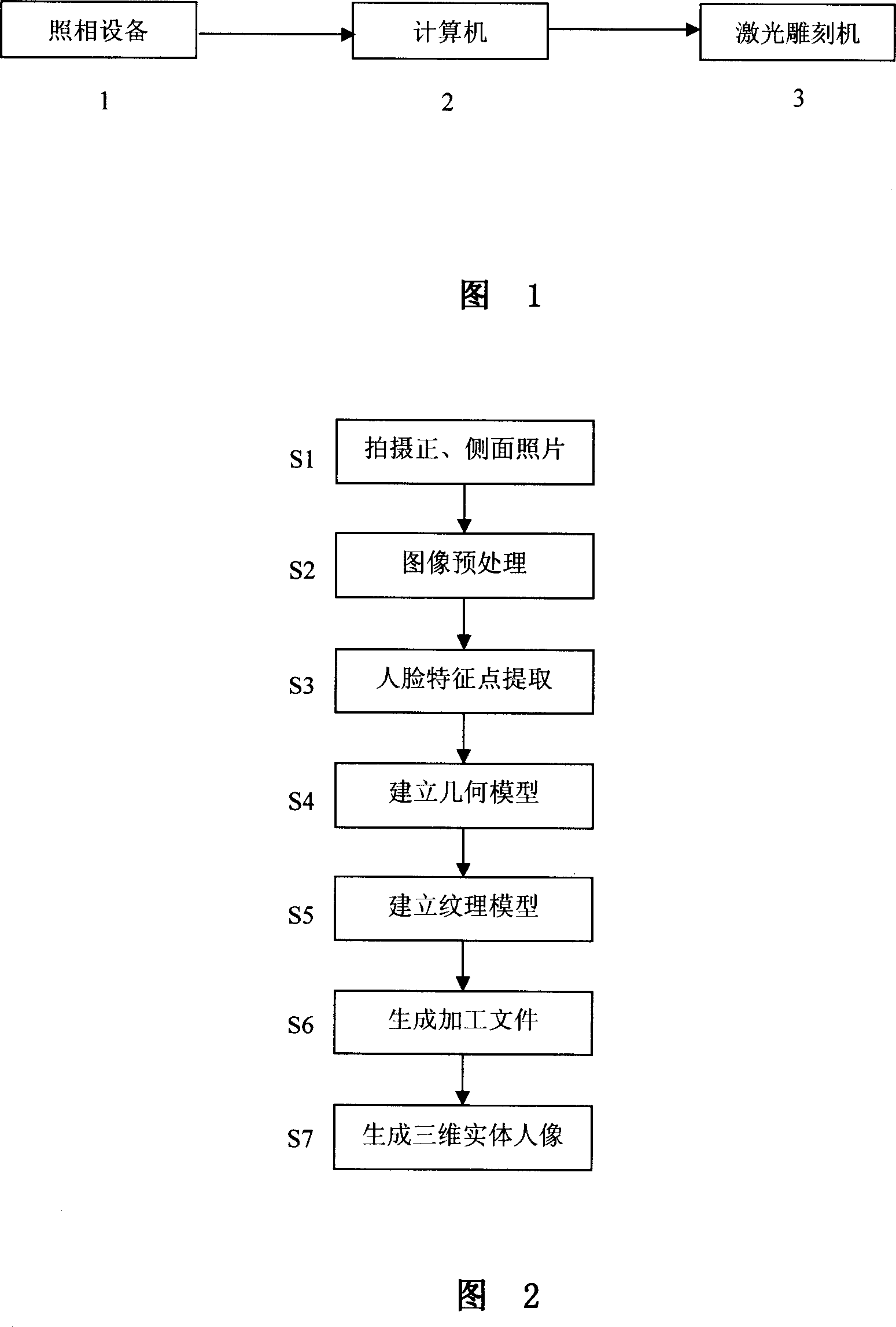

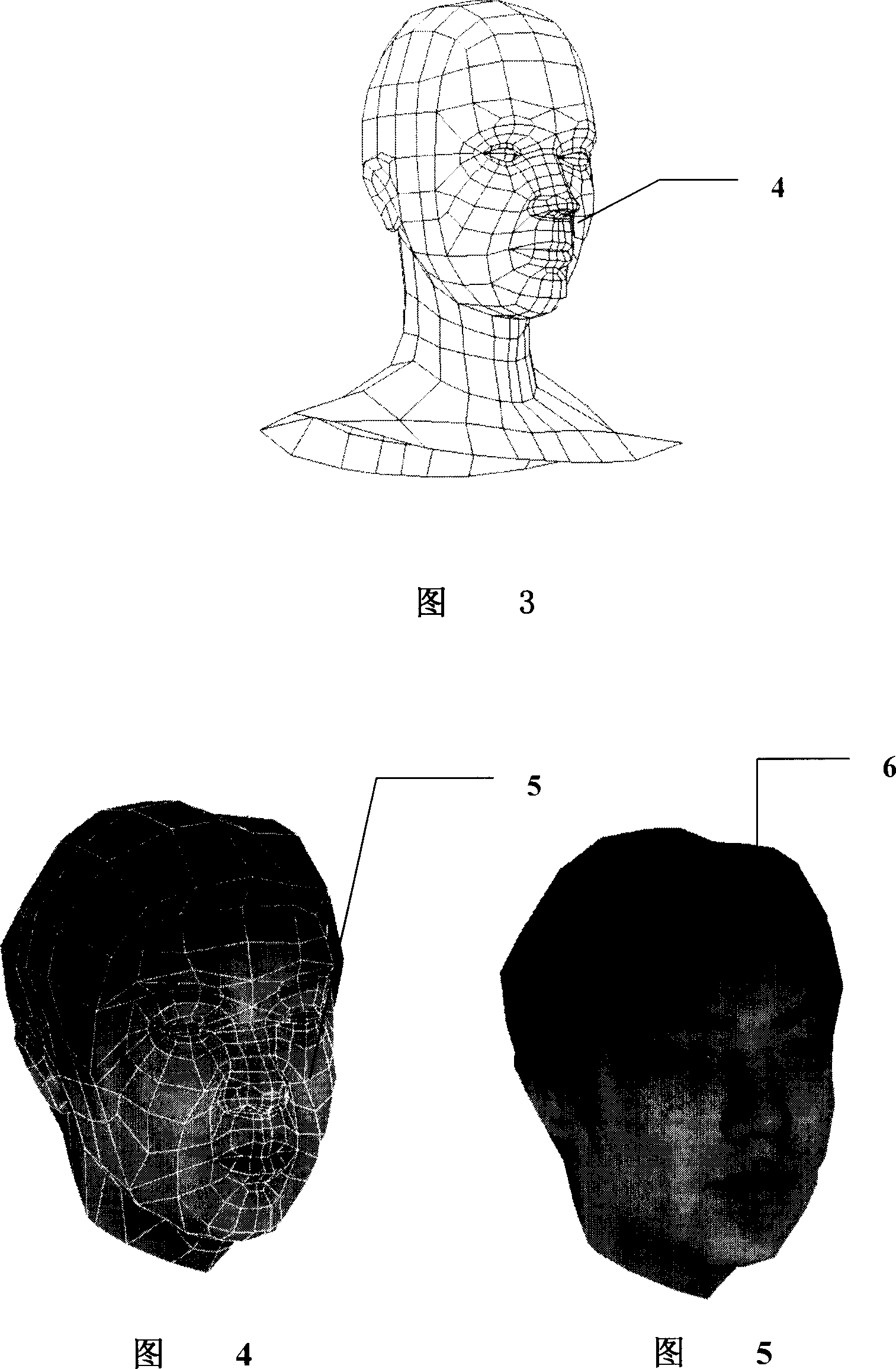

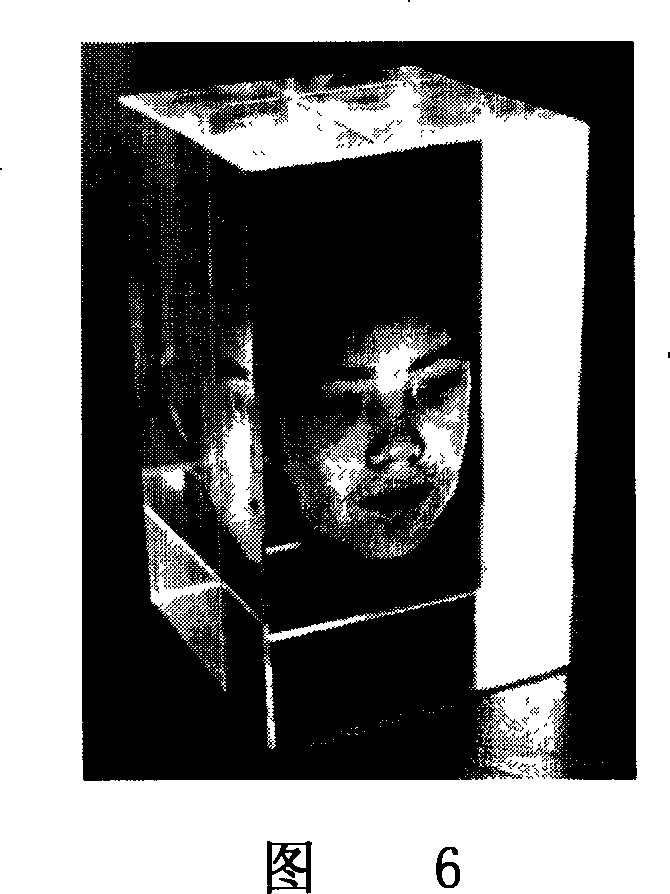

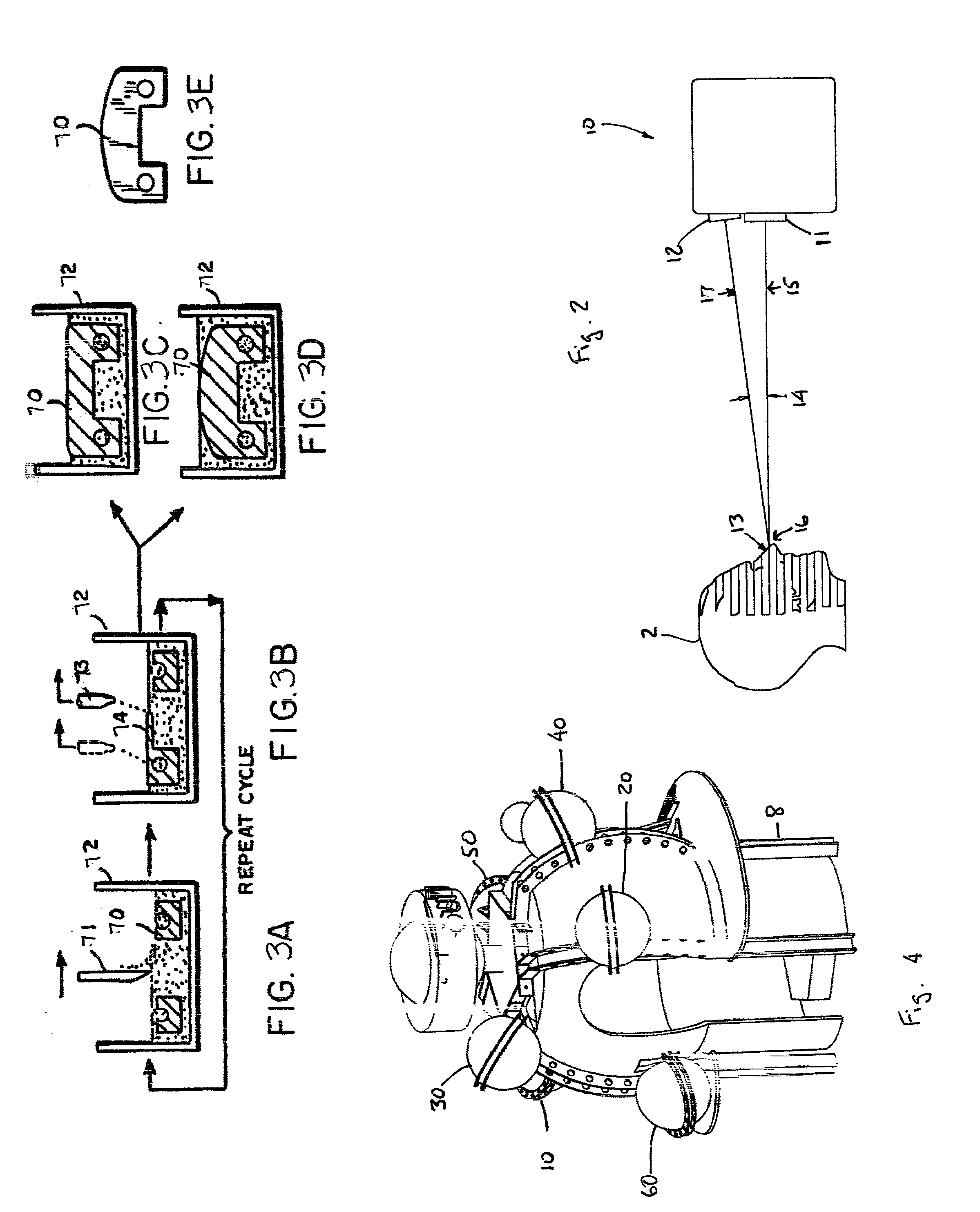

Three-dimensional portrait photograph system and realizing method thereof

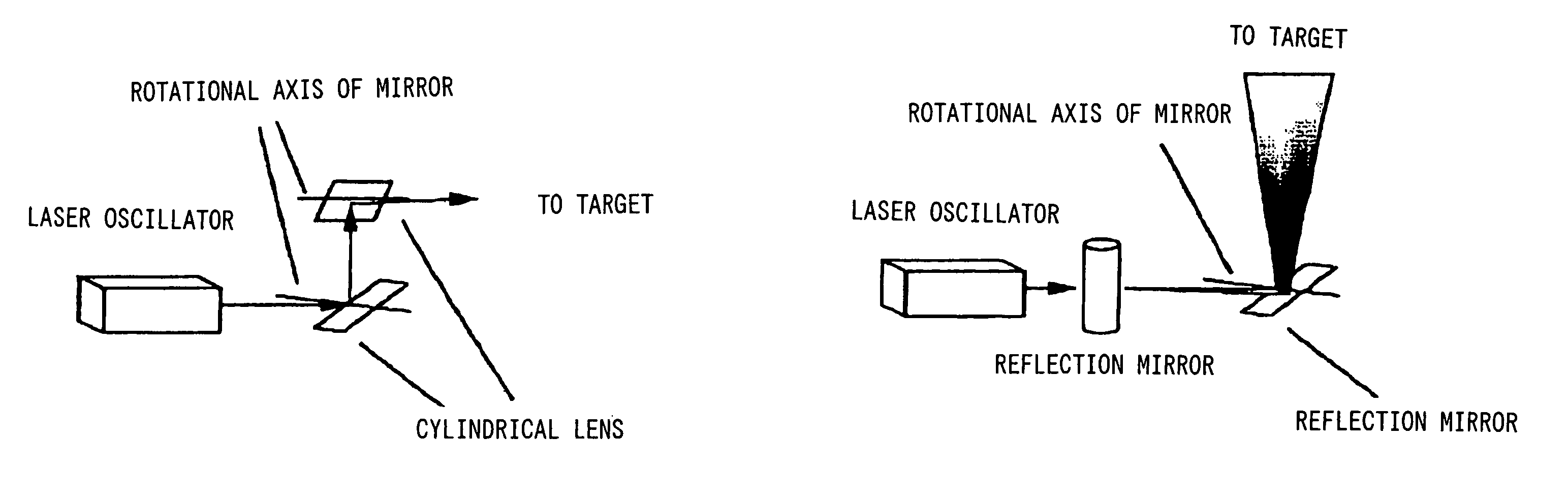

InactiveCN101082765AHard textureNew Visual EnjoymentPrintersProjectorsContinuous toneLaser engraving

The invention discloses a three-dimensional portrait shooting system and realizing method, which comprises the following steps: using common camera to shoot positive and lateral photos of portrait; adopting computer visual algorism to acquire three-dimensional geometrical model of head; projecting the photo as texture on the three-dimensional mould according to the projecting relationship of photo and geometrical model; obtaining the three-dimensional portrait model with photo-grade true sense; using spatial semi-tone method to modulate the space of texture grey image continuously; printing binary image approaching three-dimensional image on the visual observing effect in the artificial crystal through laser carving machine; forming the three-dimensional entity head portrait with true sense.

Owner:高宏 +1

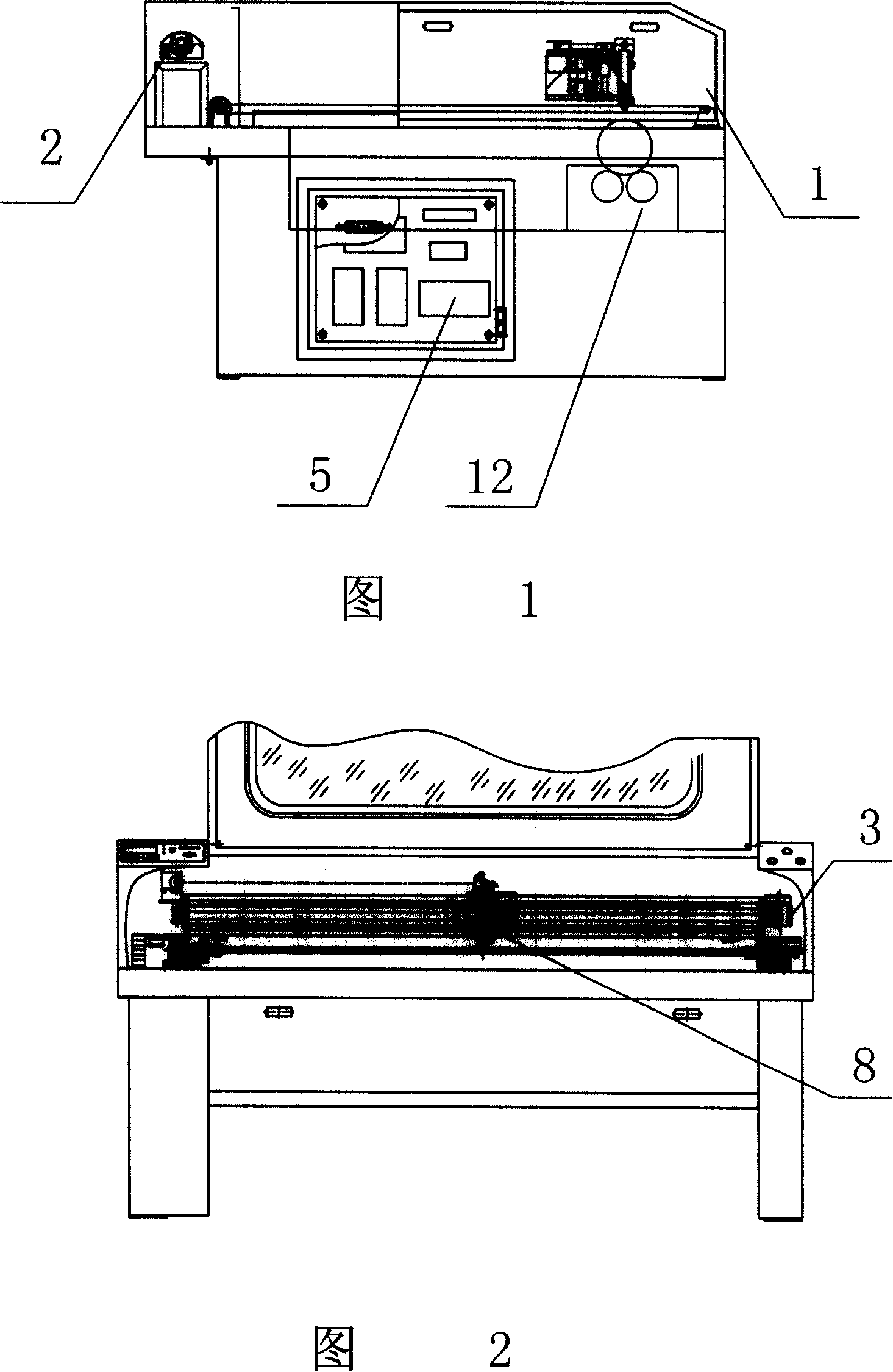

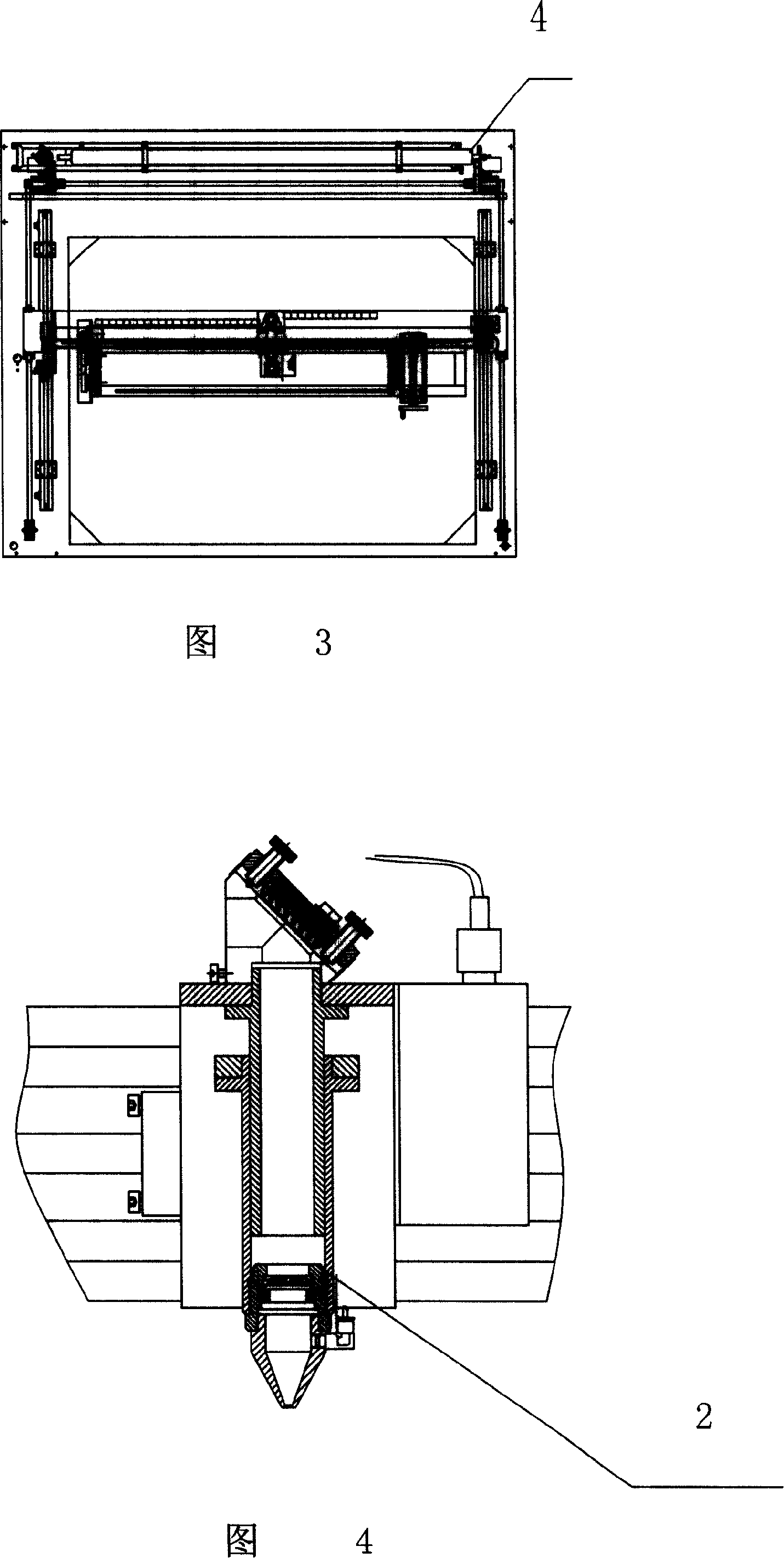

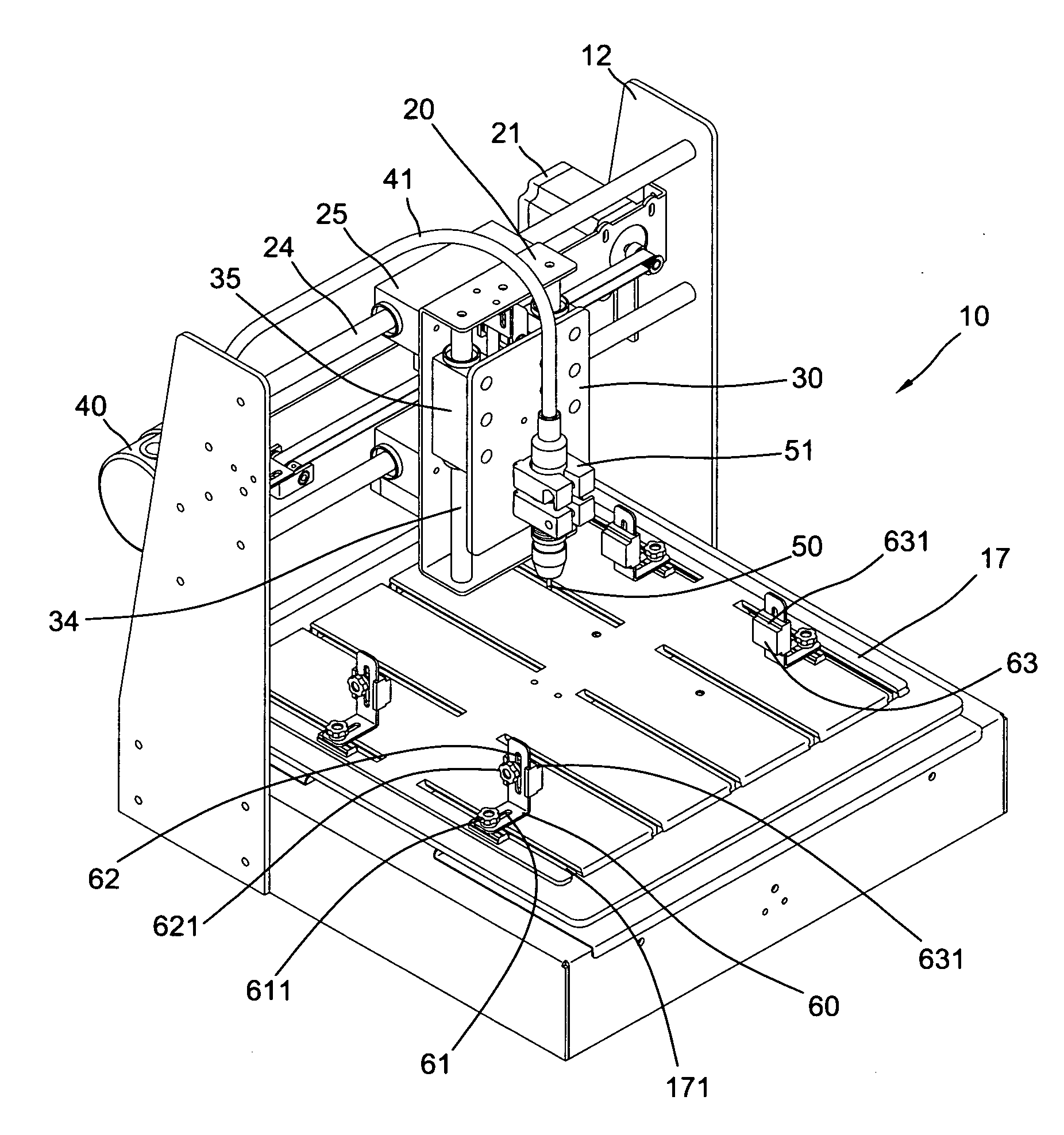

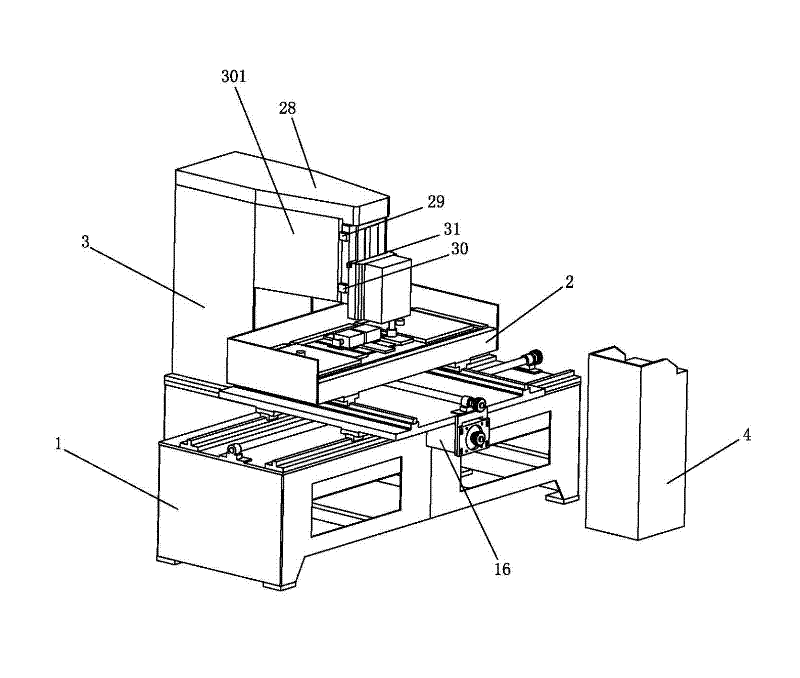

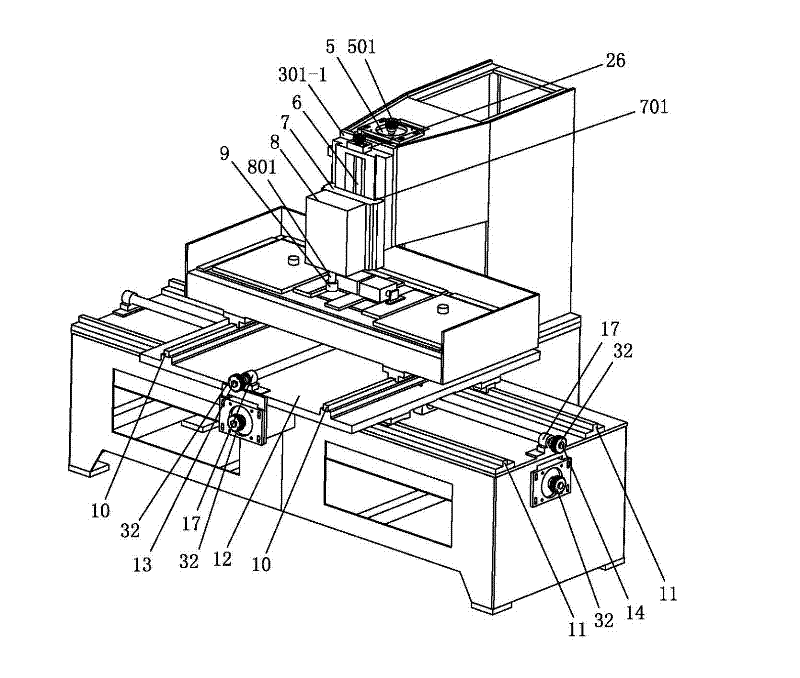

Profile modeling laser engraving process method and laser carving machine thereof

InactiveCN101138926ARealize dynamic focusRealize special-shaped plane engravingComputer controlProgramme control in sequence/logic controllersPid control algorithmLaser engraving

A method of form copying laser carving processing belongs to the laser carving processing field. The method uses a CCD laser displacement sensor to detect the distance between a laser head and a workpiece for processing to generate a three-dimensional relief map of the material for carving; a PID control arithmetic is used to control the position of the laser head to ensure that a focus of the laser falls at the surface of the workpiece for processing, so as to realize laser cutting and carving towards irregular materials. A laser carving machine is also provided, including a machine frame, a leaser head, an X-axial and Y-axial flying mechanism which is connected with the laser head, a Z-axial driving mechanism which is vertical with the surface of the workpiece, a CCD laser displacement sensor and an upper controller which is used for controlling form copying carving. The present invention provides a method of form copying laser carving processing which can realize dynamic focusing and real-time focusing during the course of carving and can realize plane carving of the irregular materials, and also provides the laser carving machine of the method.

Owner:ZHEJIANG FORESTRY ACAD +1

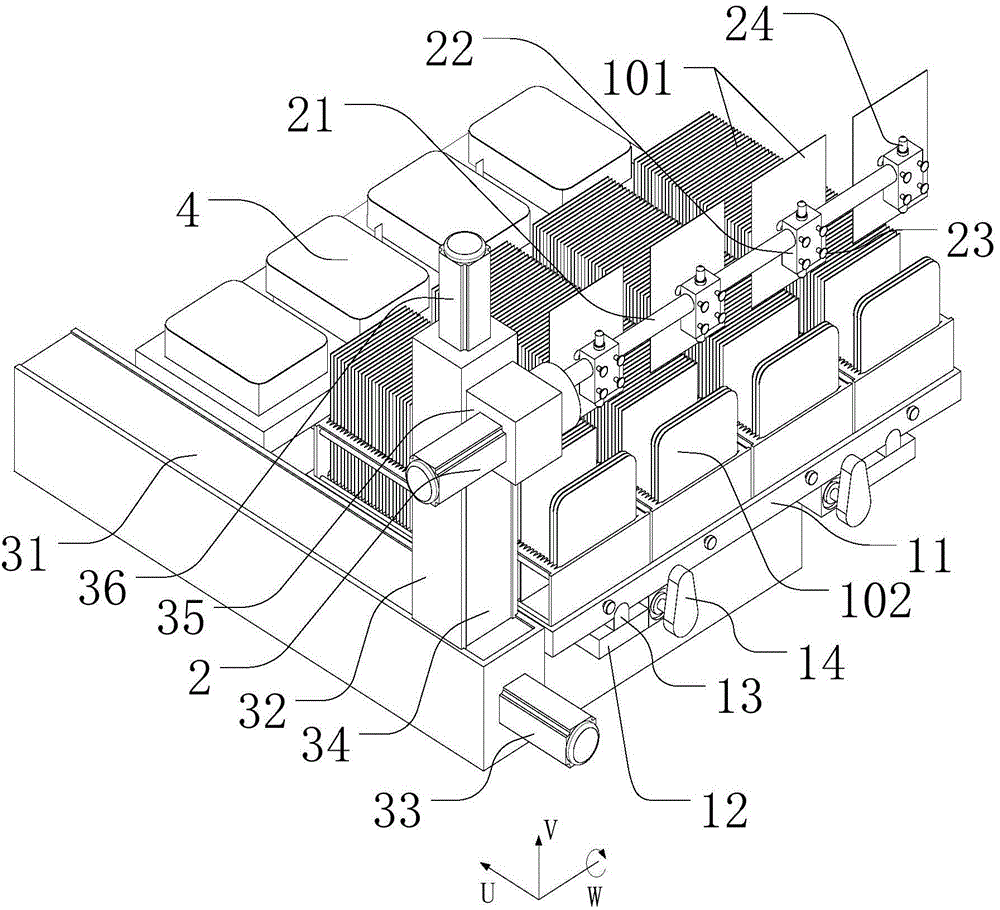

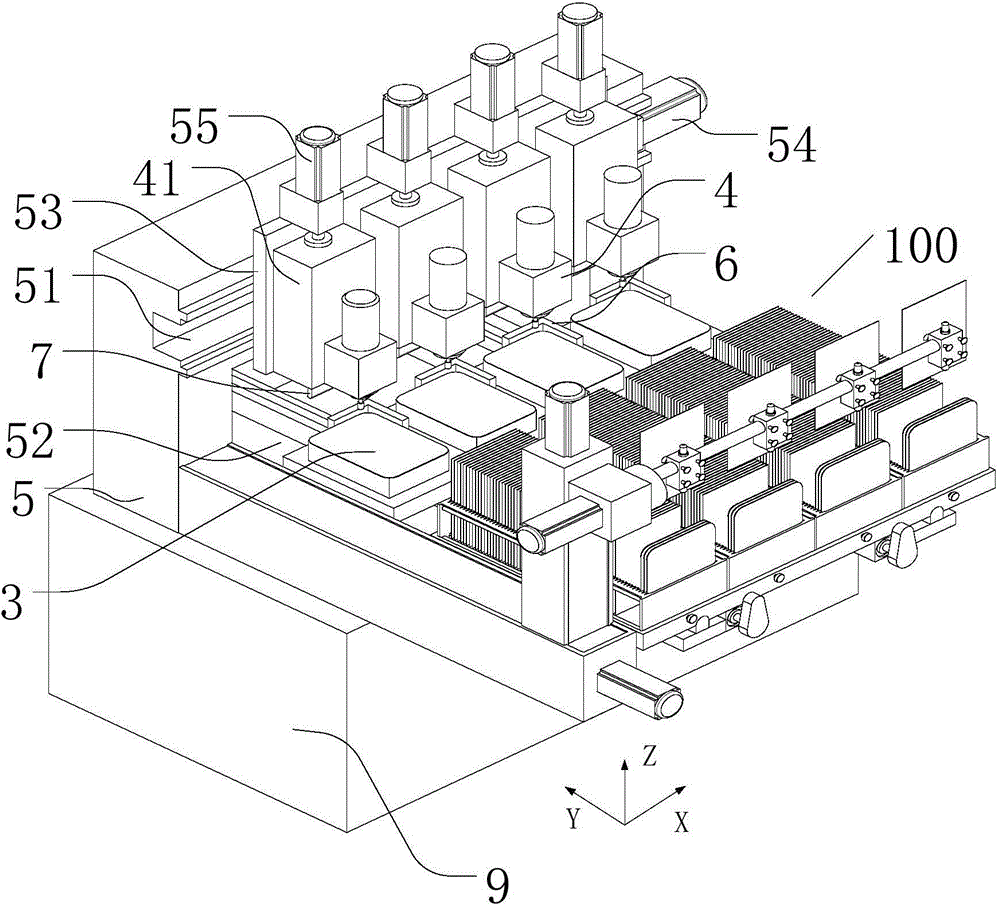

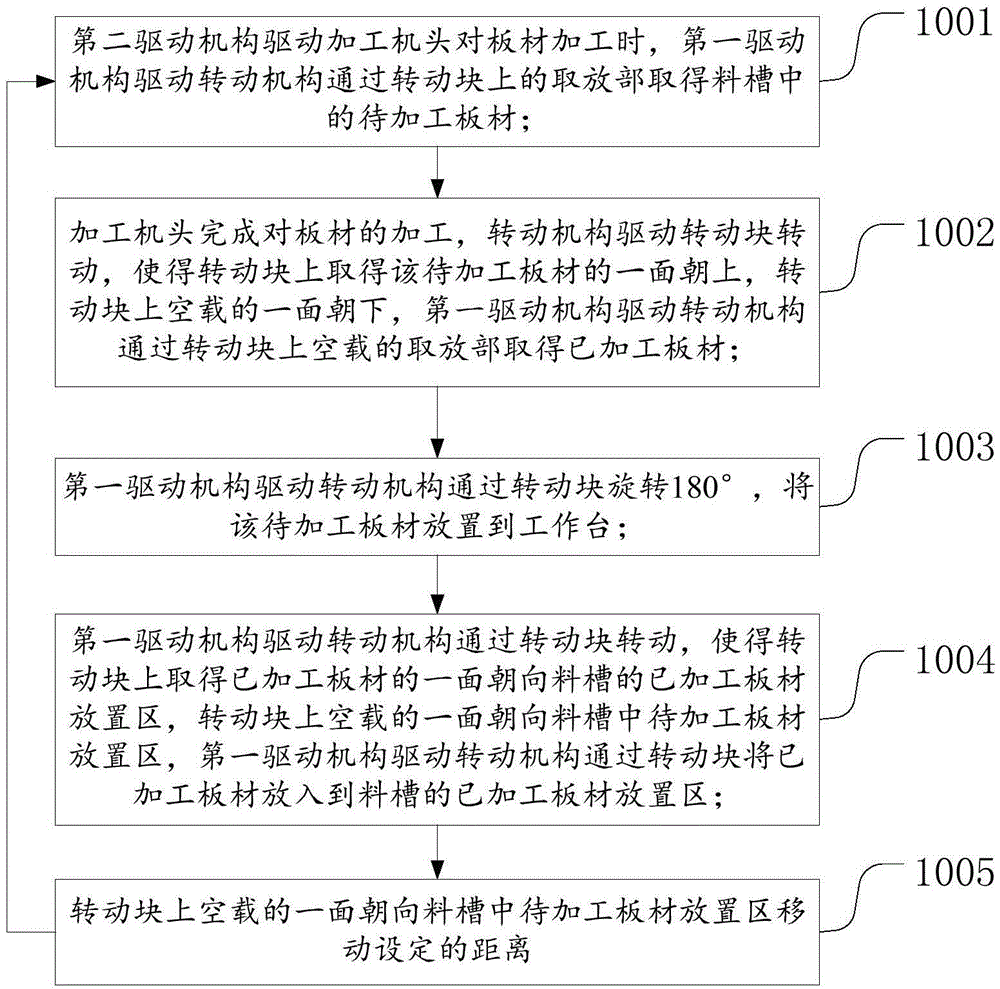

Sheet material feeding and discharging device, mobile phone glass machining center and machining method

ActiveCN104890422AFlexible loading and unloading methodsImprove the efficiency of picking and unloadingGrinding feedersOther artistic work equipmentsEngineeringMachine tool

The invention discloses a sheet material feeding and discharging device, a mobile phone glass machining center and a machining method. The device comprises a material groove, a rotating mechanism provided with a rotating rod, a first drive mechanism and rotating blocks installed on the rotating rod; and taking and placing parts are respectively installed on the front and rear sides of each rotating block, the rotating mechanism is installed on the first drive mechanism, and the rotating blocks are located over the material groove. Two faces of the rotating blocks are provided with the taking and placing parts, the rotating mechanism can drive the rotating blocks to perform 360-degree rotation, a feeding and discharging mode is more flexible, and taking and placing efficiency is greatly improved. After the sheet material feeding and discharging device is applied to the mobile phone glass machining center, a mode that the rotating blocks are fixed to the rotating rod is adopted, and the rotating rod extends to the other side to form a gantry crane type structure, so the rotating blocks can be unlimitedly expanded on the rotating rod, a machining table and the material groove can be correspondingly increased, a plurality of working positions can be increased on one machine tool to the maximum extent, and machining efficiency is greatly improved.

Owner:苏州恒远精密数控设备有限公司

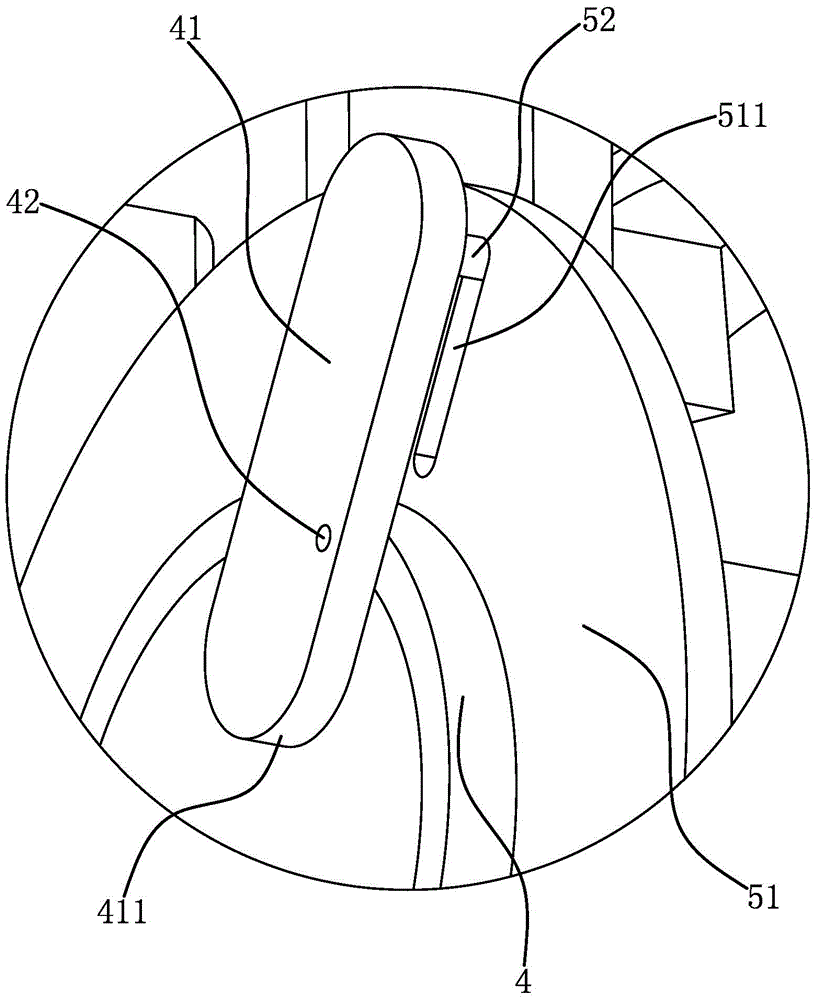

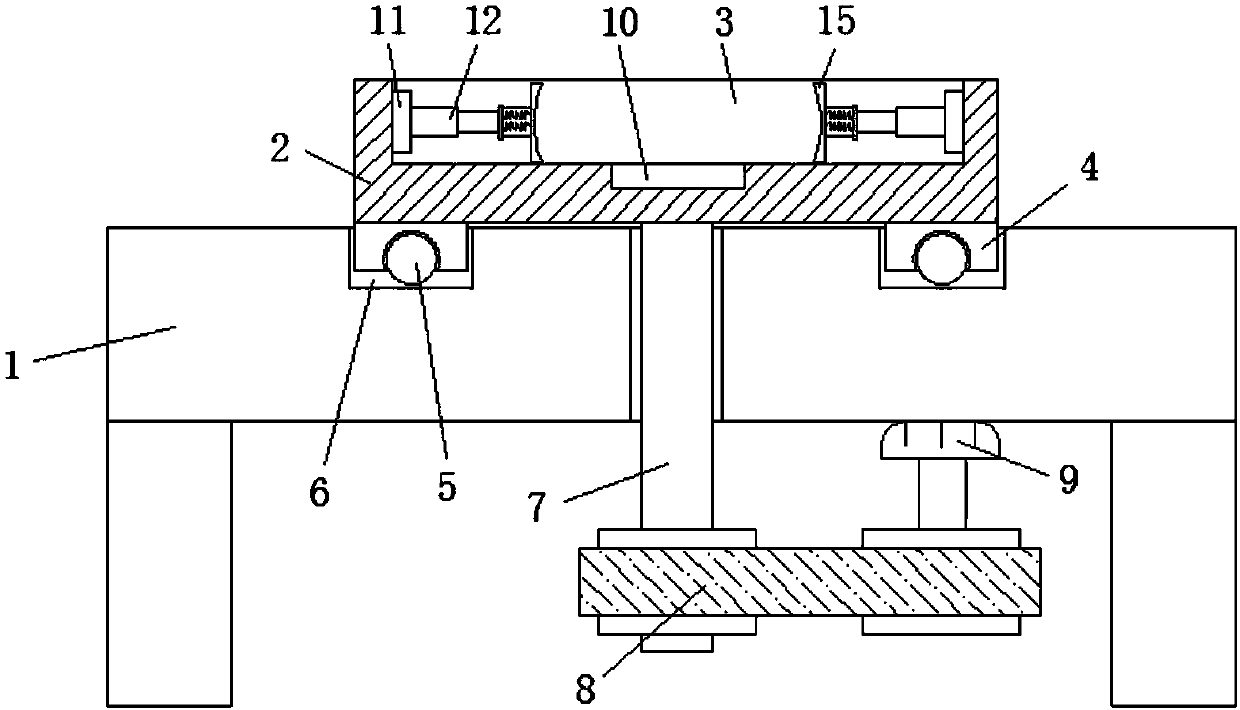

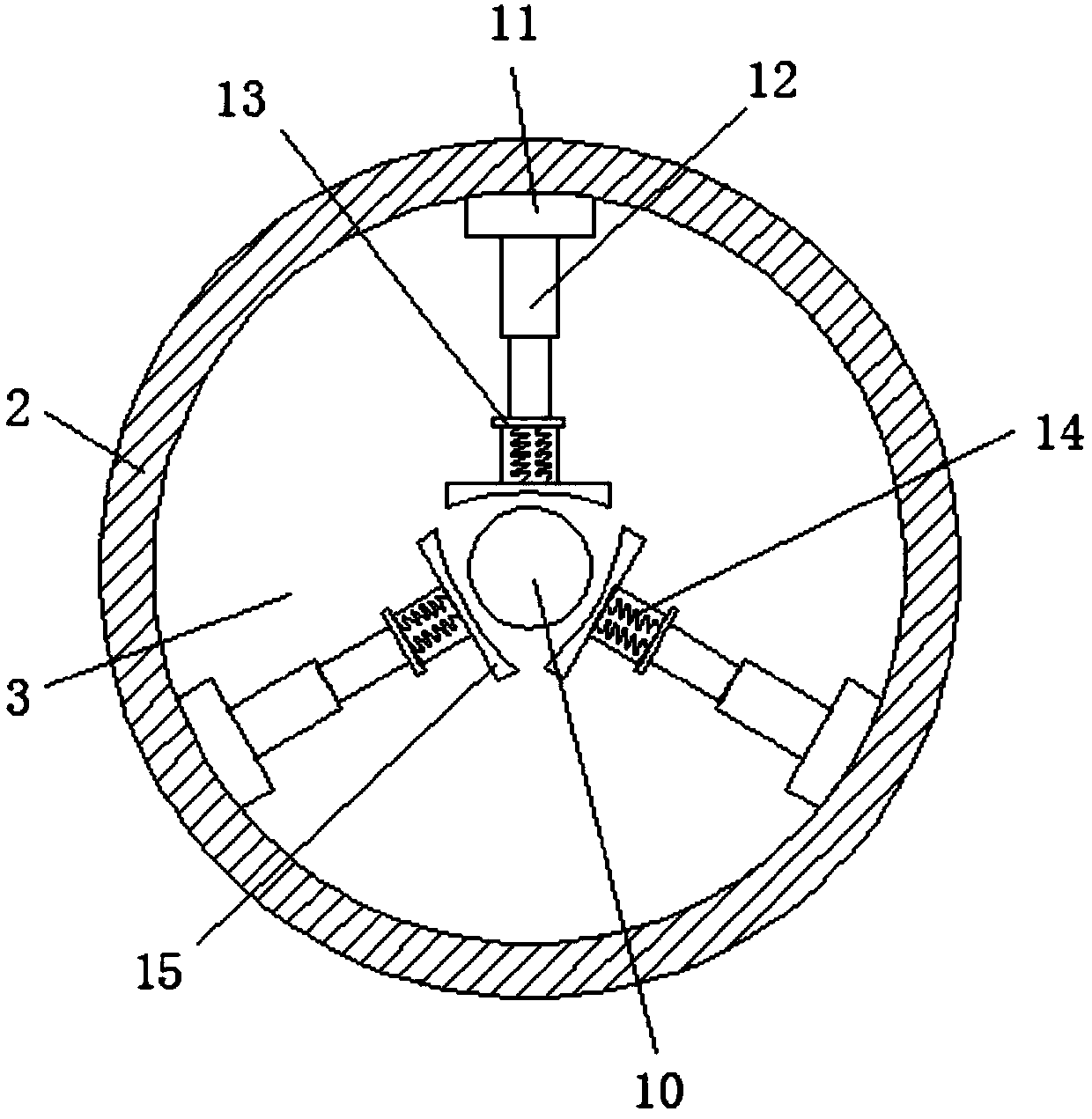

Cylindrical workpiece engraving machine automatic clamp device

ActiveCN104985969ACircumferential positioning force is stableCircumferential force is stablePositioning apparatusMetal working apparatusMachiningPositioning system

The invention provides a cylindrical workpiece engraving machine automatic clamp device, belongs to the machining equipment technical field, and solves the problems that an existing cylindrical workpiece cannot be stably clamped in engraving; the engraving machine comprises a frame having a work table; the work table is provided with a lifting plate, and fixedly connected with a positioning sleeve; two end edges of the positioning sleeve are respectively hinged to a plurality of positioning sheets; a pin shaft is arranged on one positioning face of the positioning sheet; the frame is provided with a drive piece; the positioning sleeve is connected with a plurality of supercharging columns in a radial direction in a slide manner; the supercharging columns are driven by the drive piece so as to abut against an outer circumferential wall of the cylindrical workpiece. The cylindrical workpiece engraving machine automatic clamp device can automatically clamp and position the cylindrical workpiece with high clamp precision and stability.

Owner:葆冈金属制品(珠海)有限公司

Three dimension color printing quick forming device and method

InactiveCN1857930ASimple processFast molding speedCeramic shaping apparatusPrintingColor printingLayer thickness

The present invention discloses a kind of 3D color printing and quick forming device and method. The 3D color printing and quick forming device includes an X-Y scanning platform and a Z motion mechanism. The X-Y scanning platform is provided with powder providing tank, forming tank, powder roller and printing head; and the Z motion mechanism includes pistons inside the powder providing tank and the forming tank. The quick forming process is one combination of quick forming technology and color printing technology and includes the following steps: jetting pigment of different colors with the precise printing head to the compact powder material inside the forming tank to form color cross section pattern, curing the powder material, lowering the powder material inside the forming tank by the height of one layer thickness while raising the powder material inside the powder providing tank by one layer thickness, forming one new powder material layer, and so on until forming the cured body.

Owner:XI AN JIAOTONG UNIV

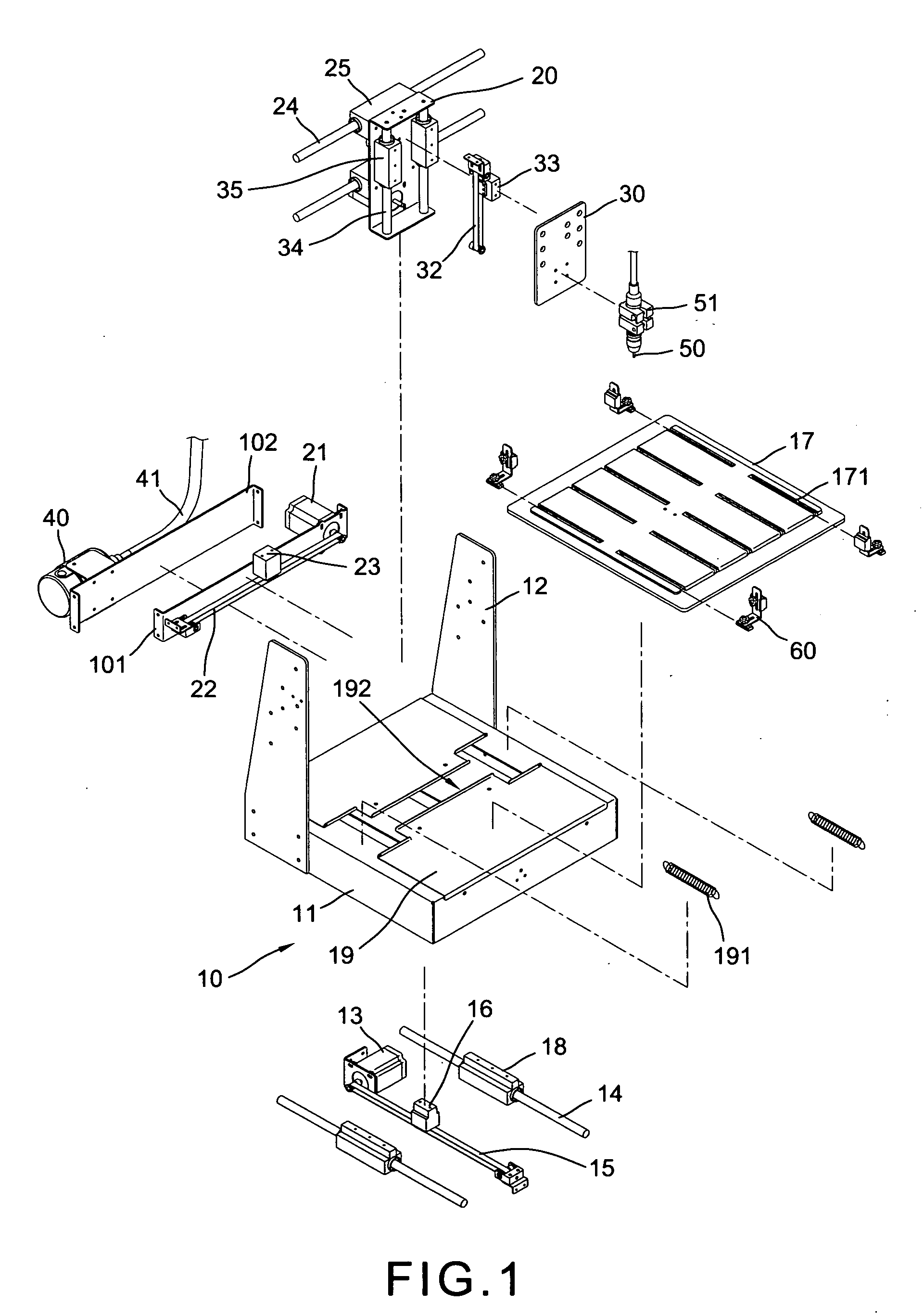

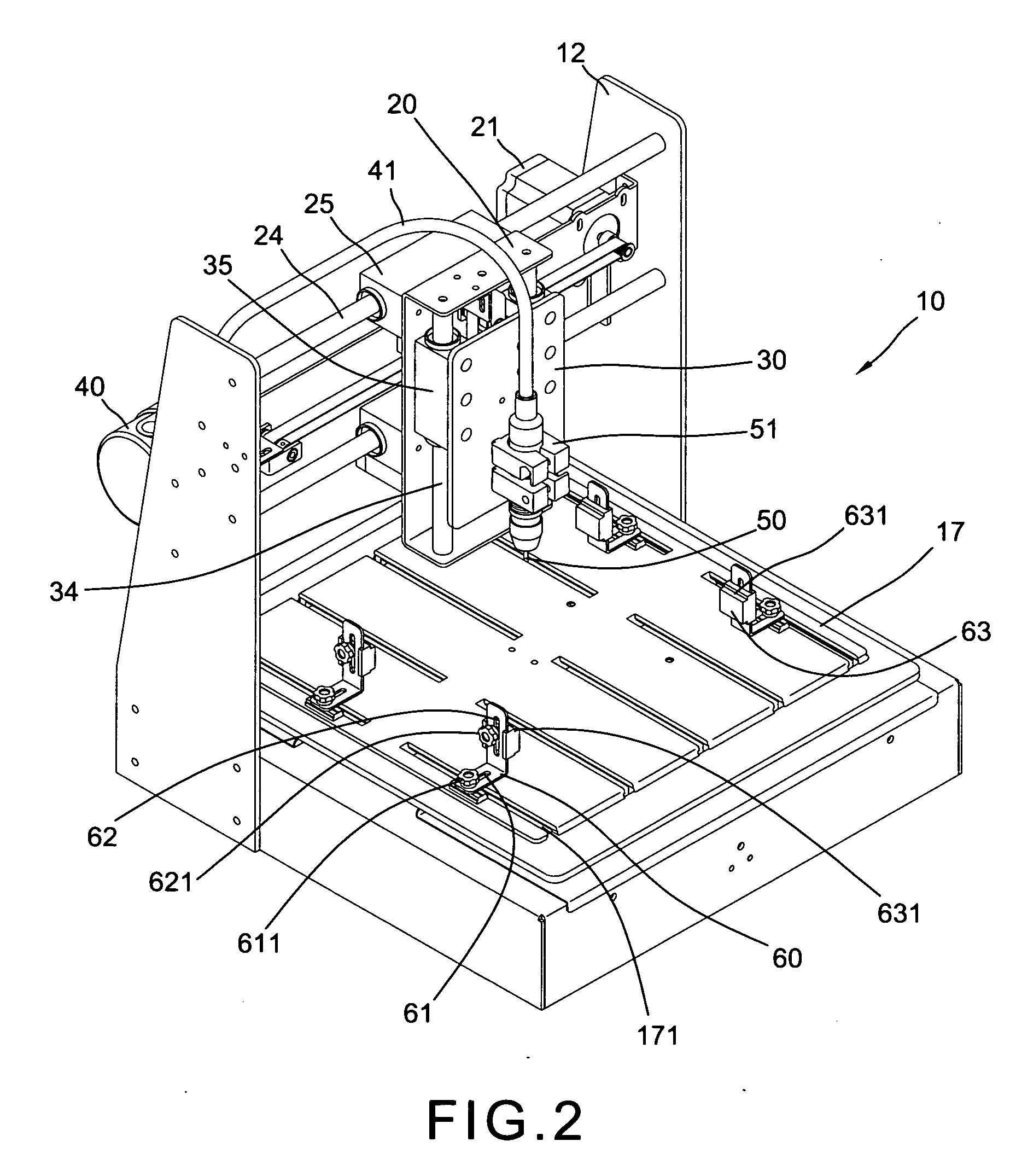

Compact engraving machine

An engraving machine includes a base with two side panels extending upward from two sides of the base, and a top board is driven horizontally by a motor in the base. A horizontal frame is movably mounted on two rods connected between the two side panels by a motor. A vertical frame is located on a front side of the horizontal frame and is movable along two rods in vertical direction by another motor. The horizontal frame, the vertical frame and the top board are movable along X, Y and Z directions by three independent motors. A chuck is connected to the vertical frame and secures an engraving tool which is driven by a main motor connected between the two side panels. The object to be engraved is secured on the top board and engraved by the engraving tool in X, Y and Z directions.

Owner:CHEN YUEHTING

Robotic pen

A robotic pen includes a computer numerically controlled machine having a multiaxis stage for mounting a workpiece, and a cooperating elevator which translates relative thereto. A pen tip is rotatably mounted to the elevator. And, a dispenser is joined in flow communication with the pen tip for ejecting a stream of material atop the workpiece as the workpiece moves relative thereto for maintaining a substantially constant gap between said pen tip and the workpiece during relative movement therebetween.

Owner:GENERAL ELECTRIC CO

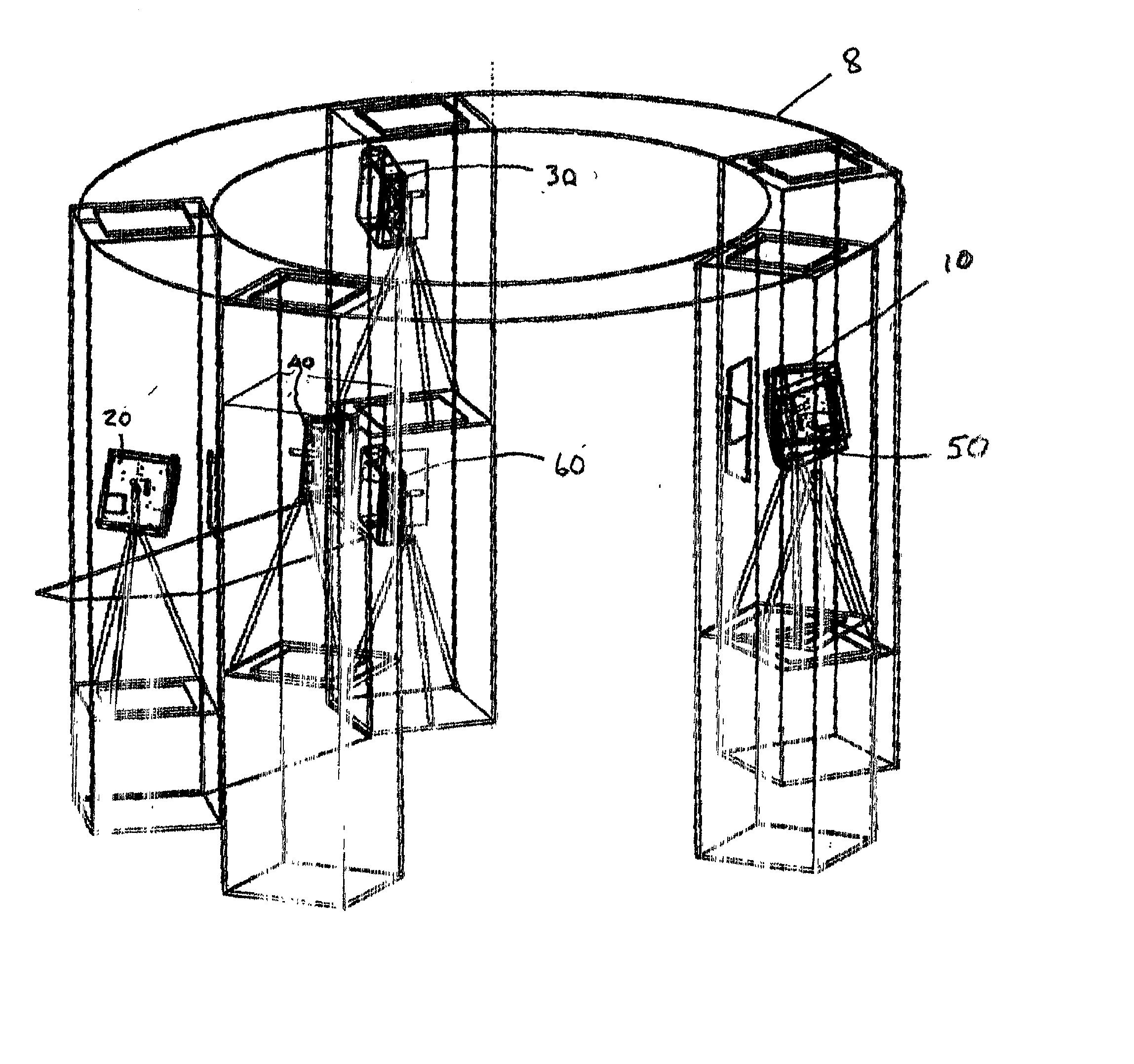

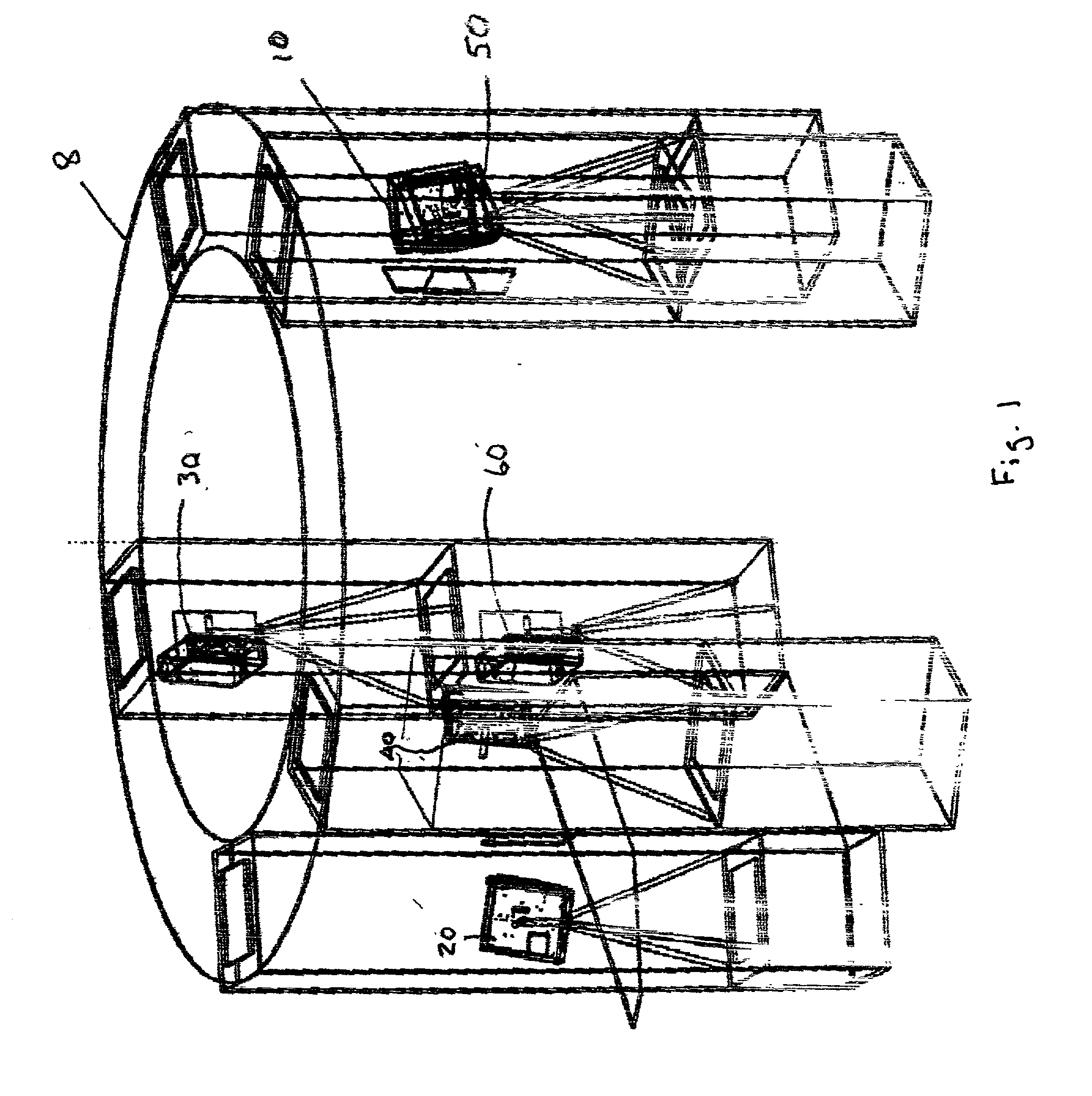

Apparatus and method for three-dimensional scanning of a subject, fabrication of a natural color model therefrom, and the model produced thereby

InactiveUS20020048396A1Improve accuracyGood precisionDetails involving processing stepsAdditive manufacturing apparatusManufacturing technologyData file

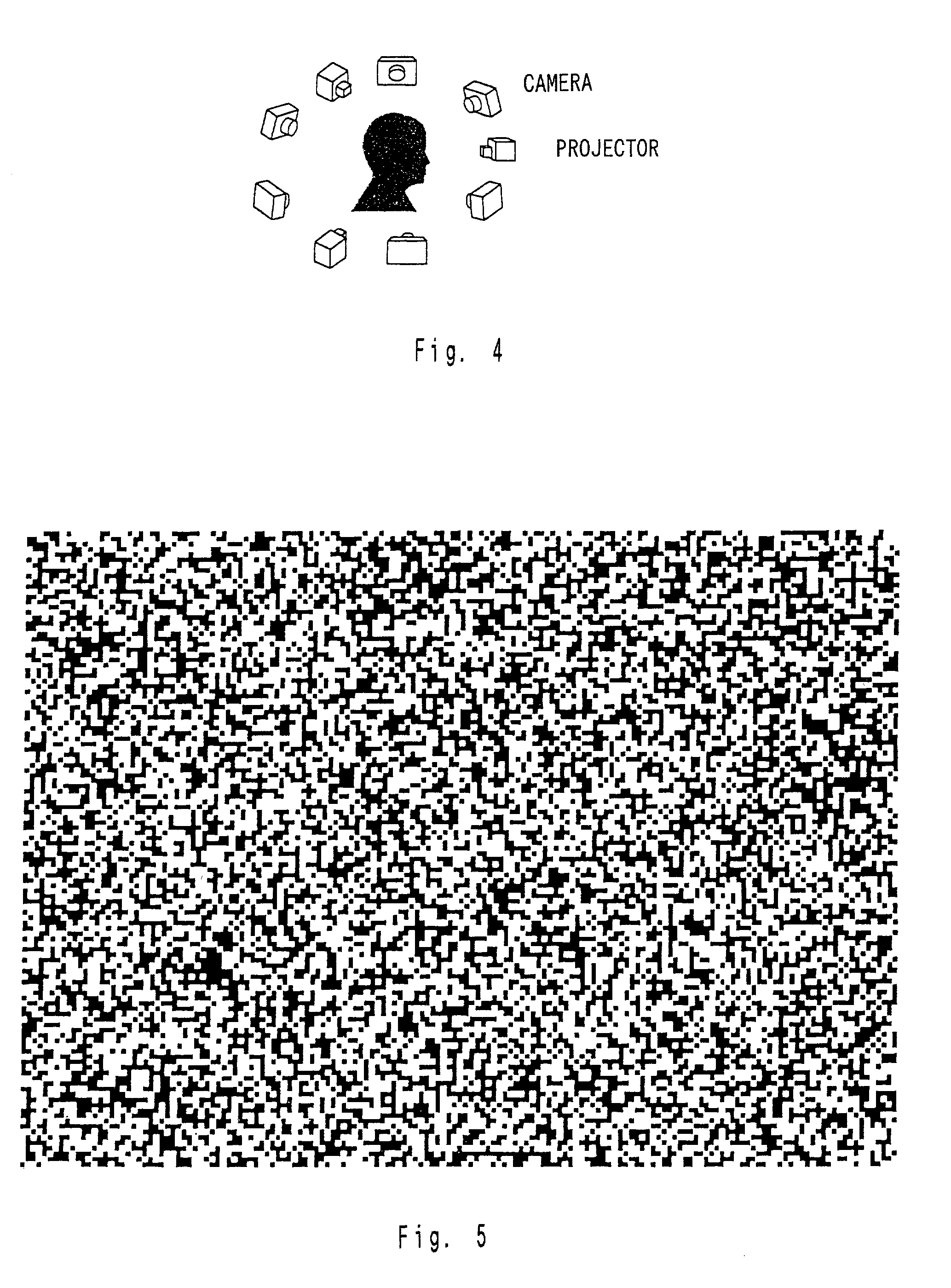

An apparatus and method for obtaining a data file representing a natural color three-dimensional image of the surface of a subject are disclosed. The apparatus incorporates a plurality of scanners, each comprising illuminating means and digital camera means, disposed about the subject, and computer means to correlate the images and store the data file. An apparatus and method for producing a natural color three-dimensional model from that data file are also disclosed. The use of rapid prototyping and manufacturing technology for manufacturing a model is disclosed. The present invention is particularly applicable to human subjects.

Owner:BEWLEY WILBUR C JR +1

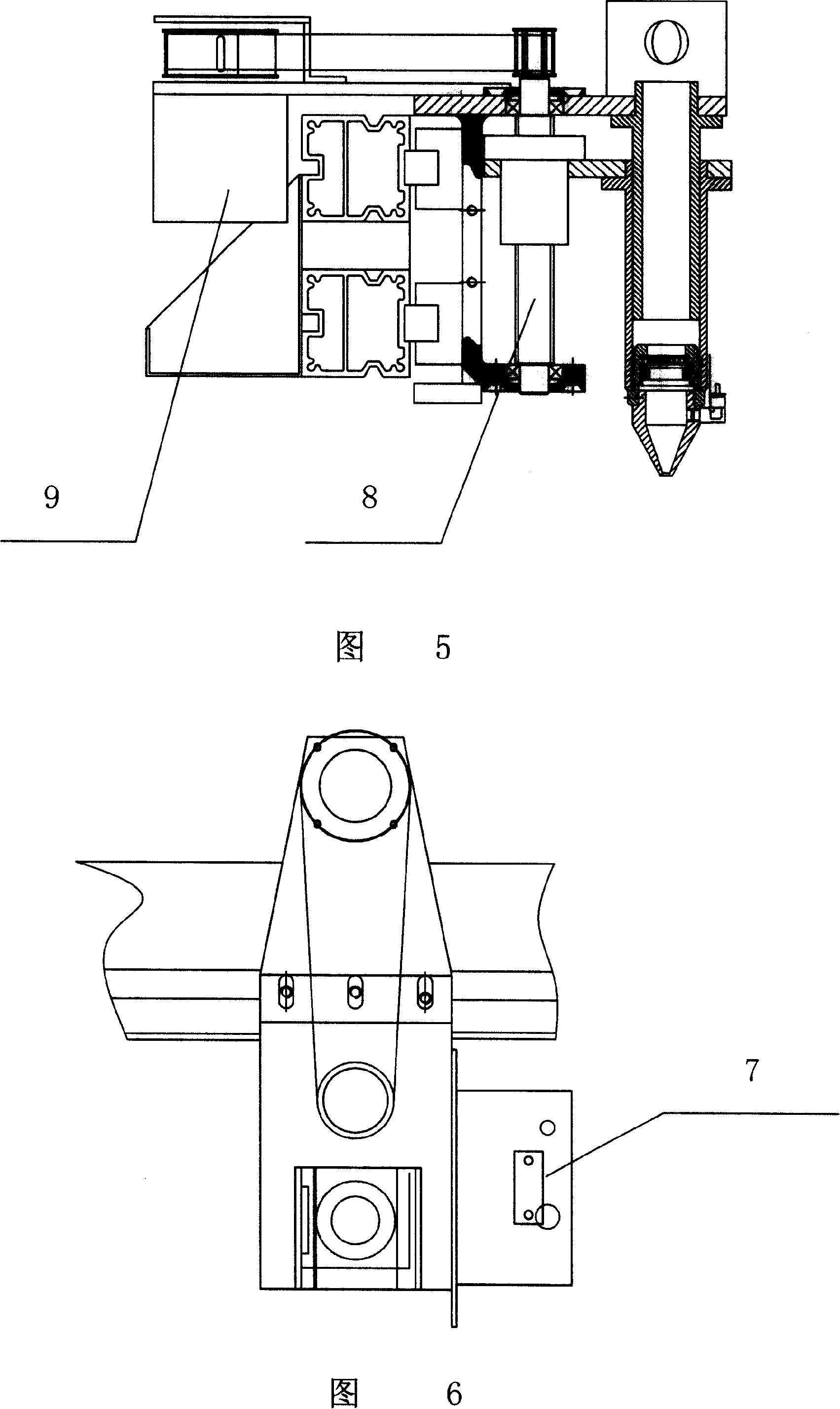

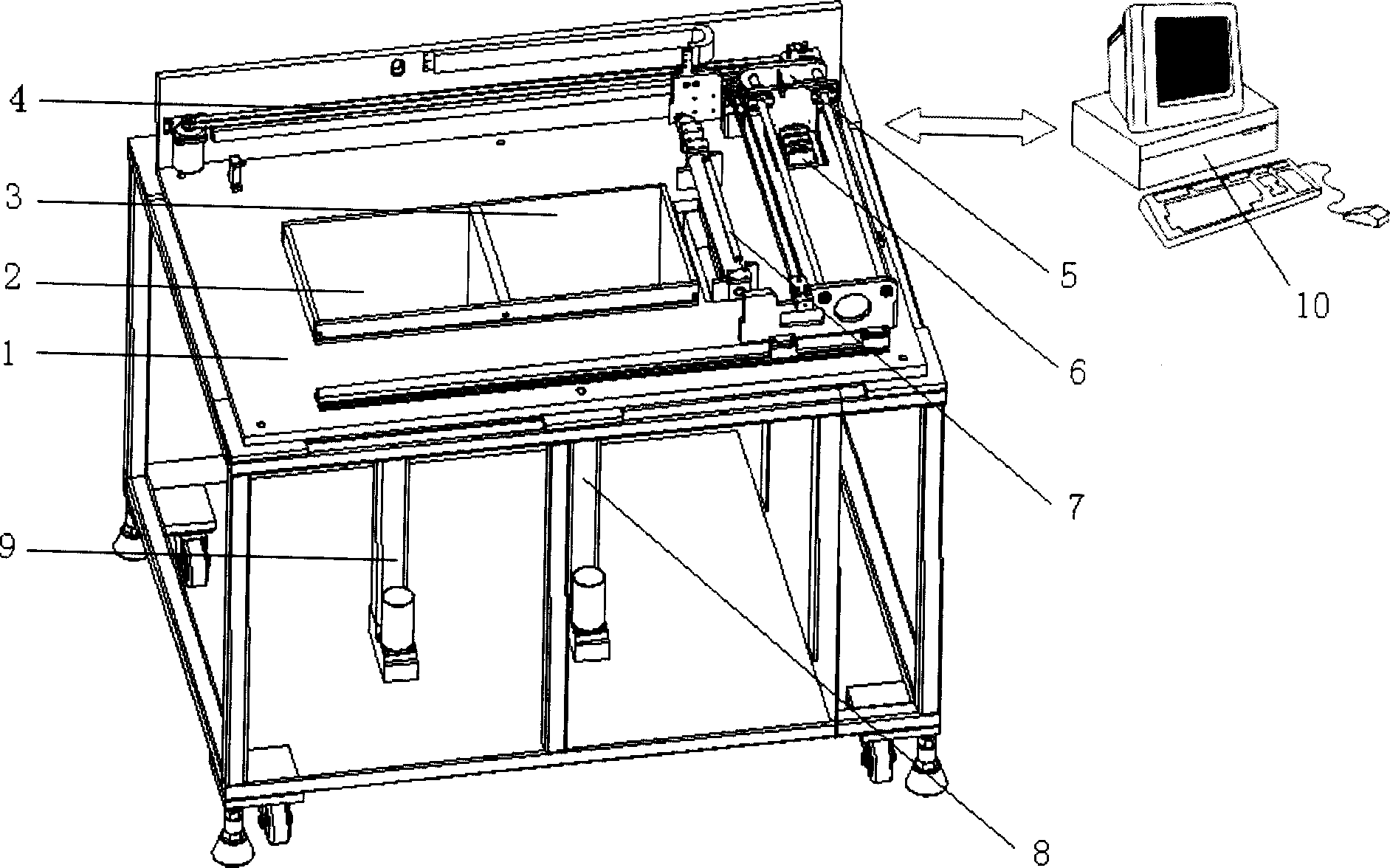

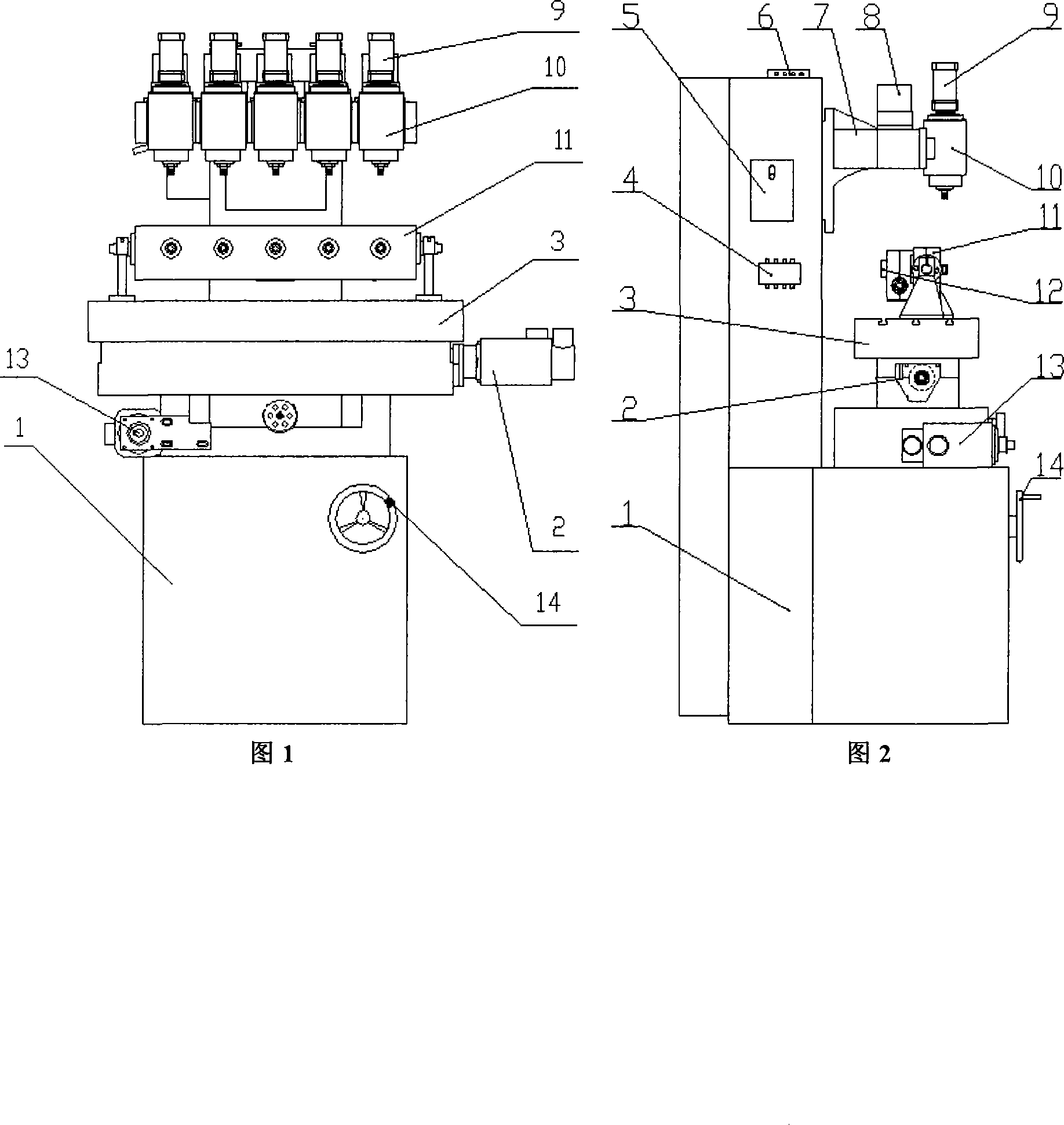

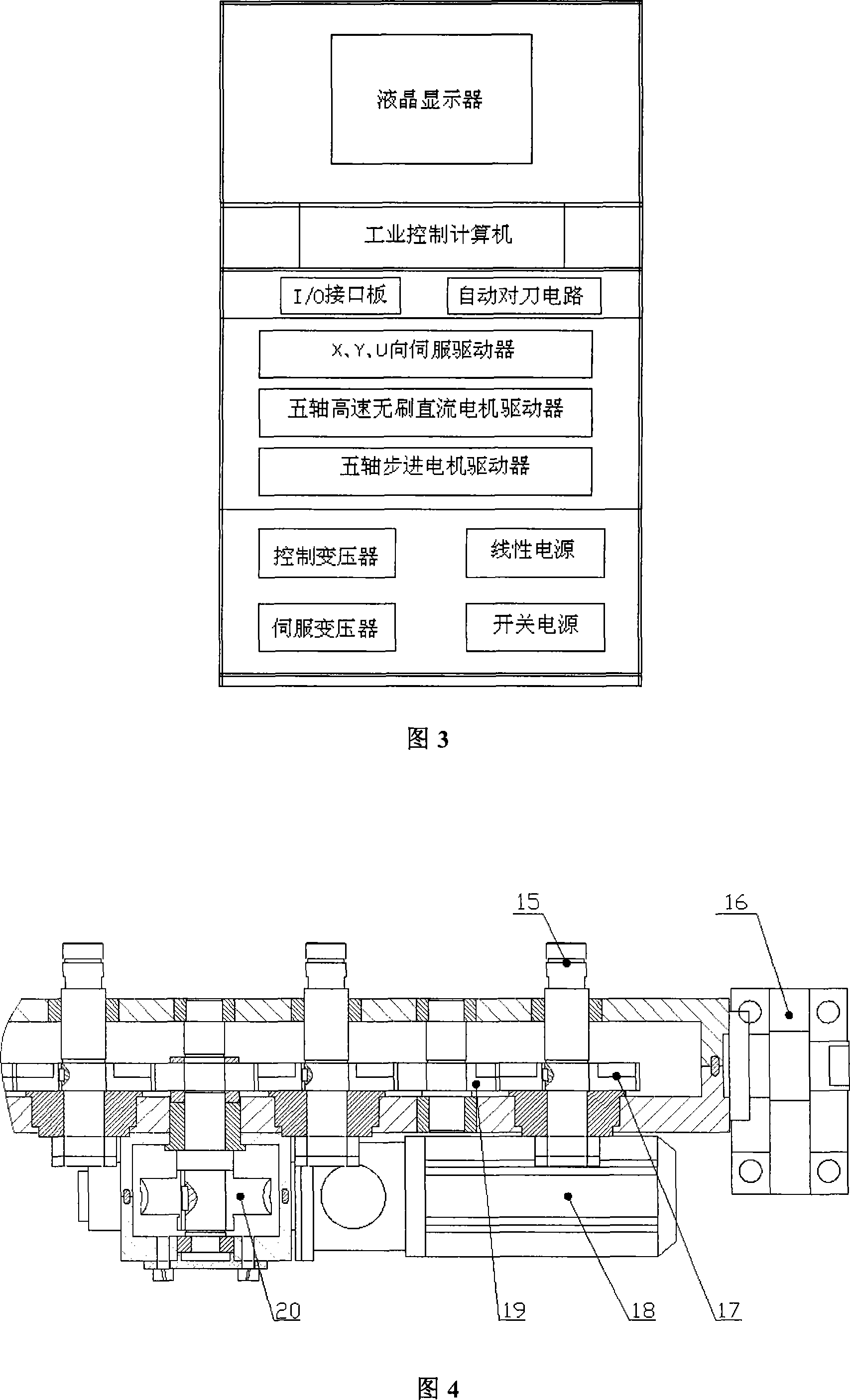

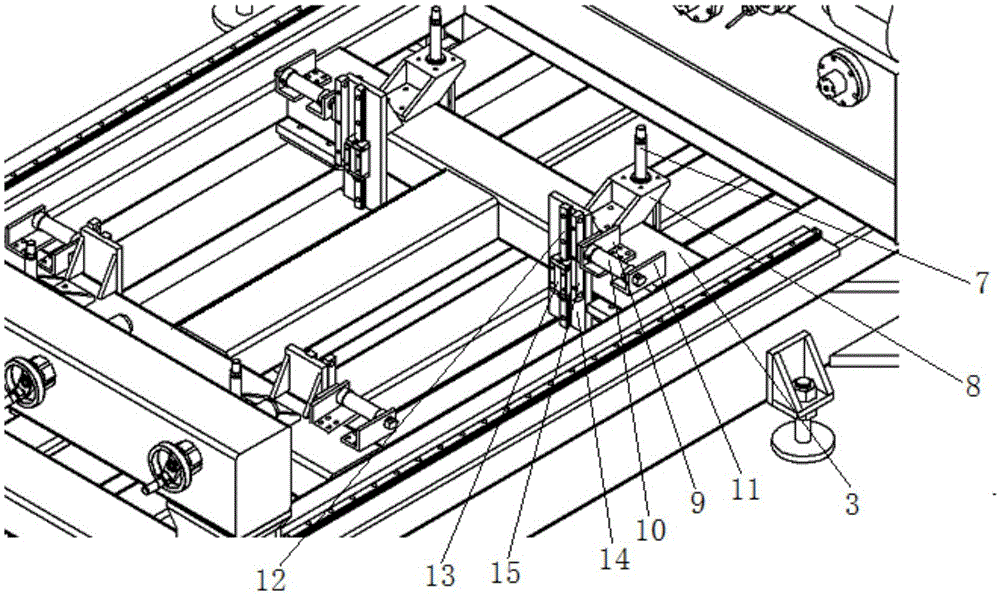

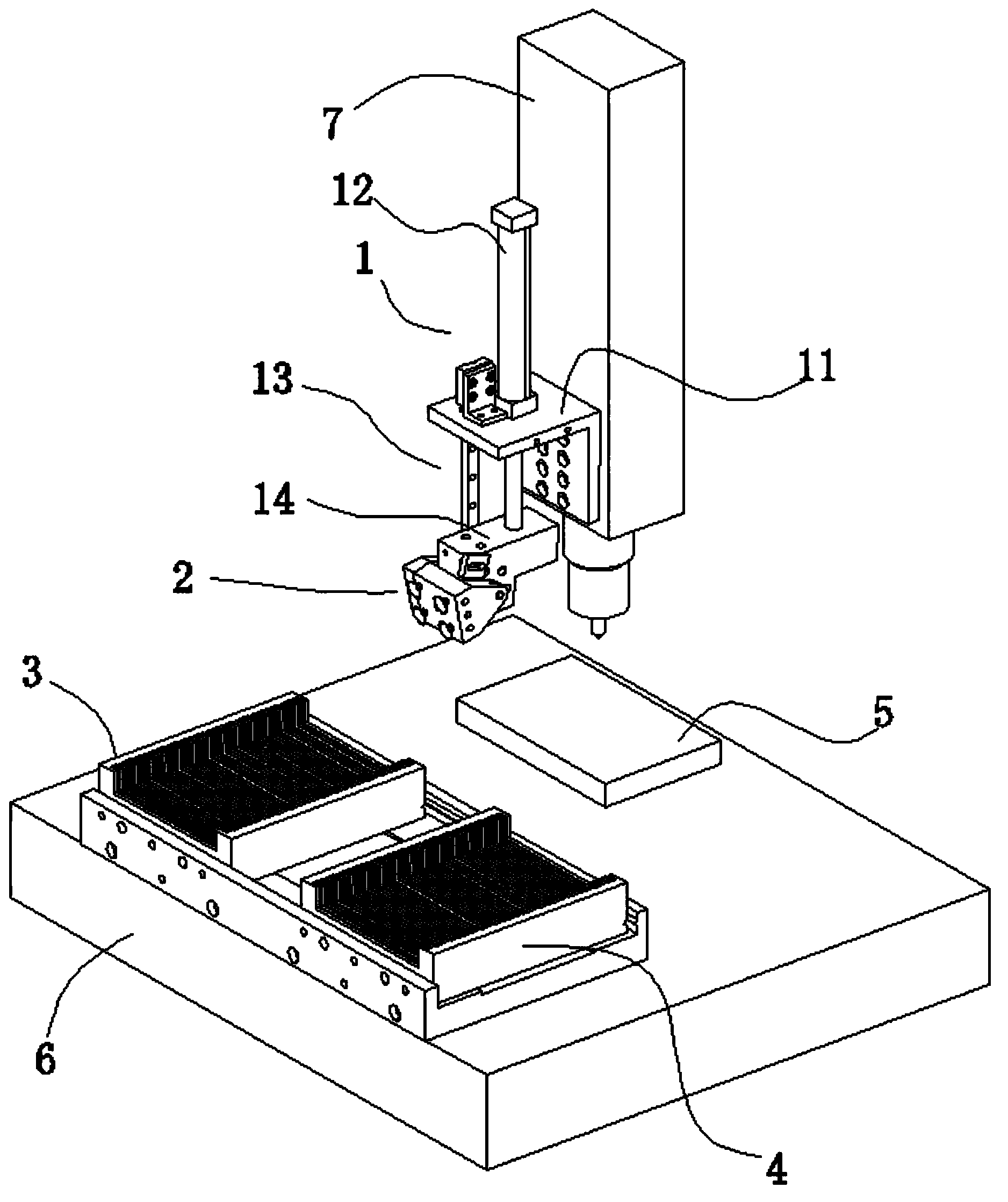

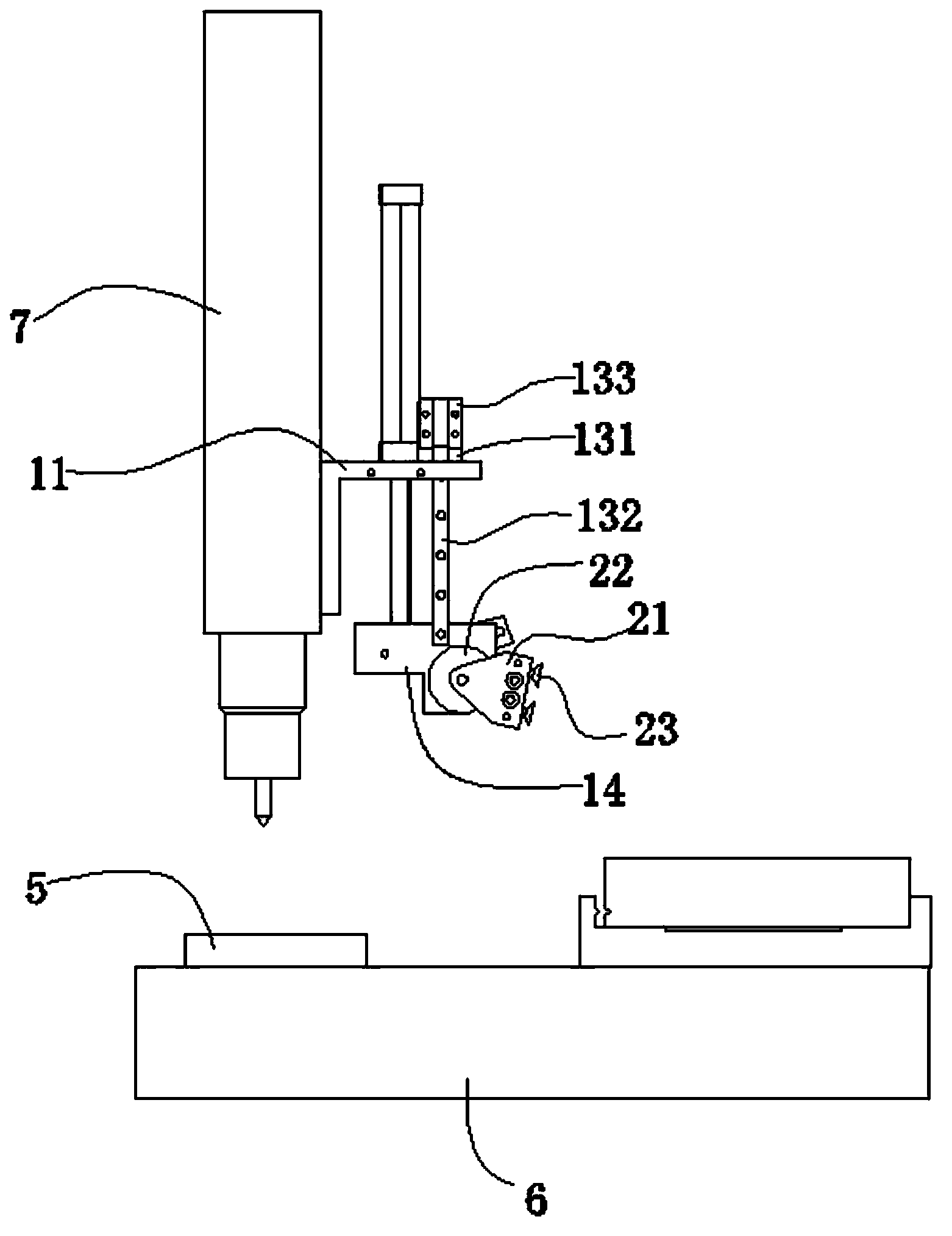

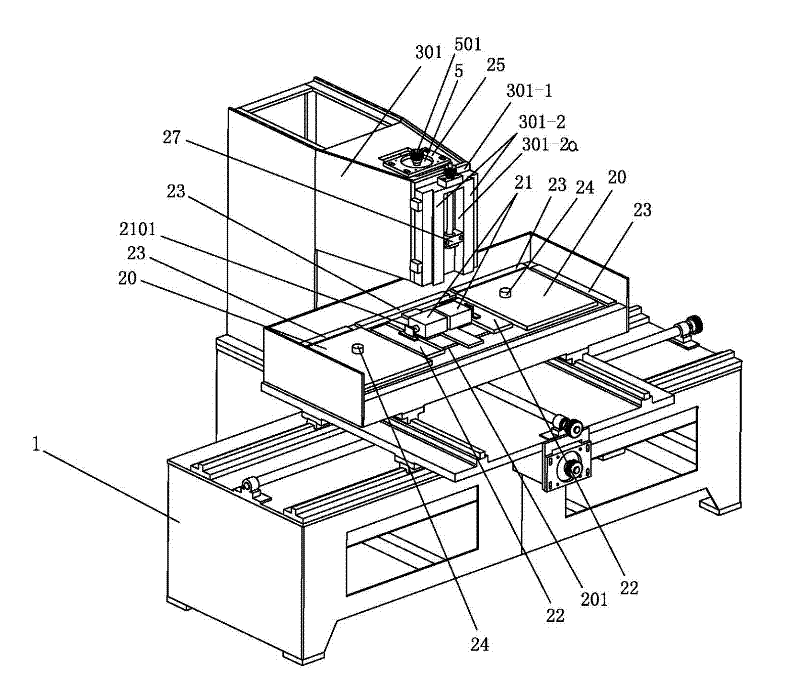

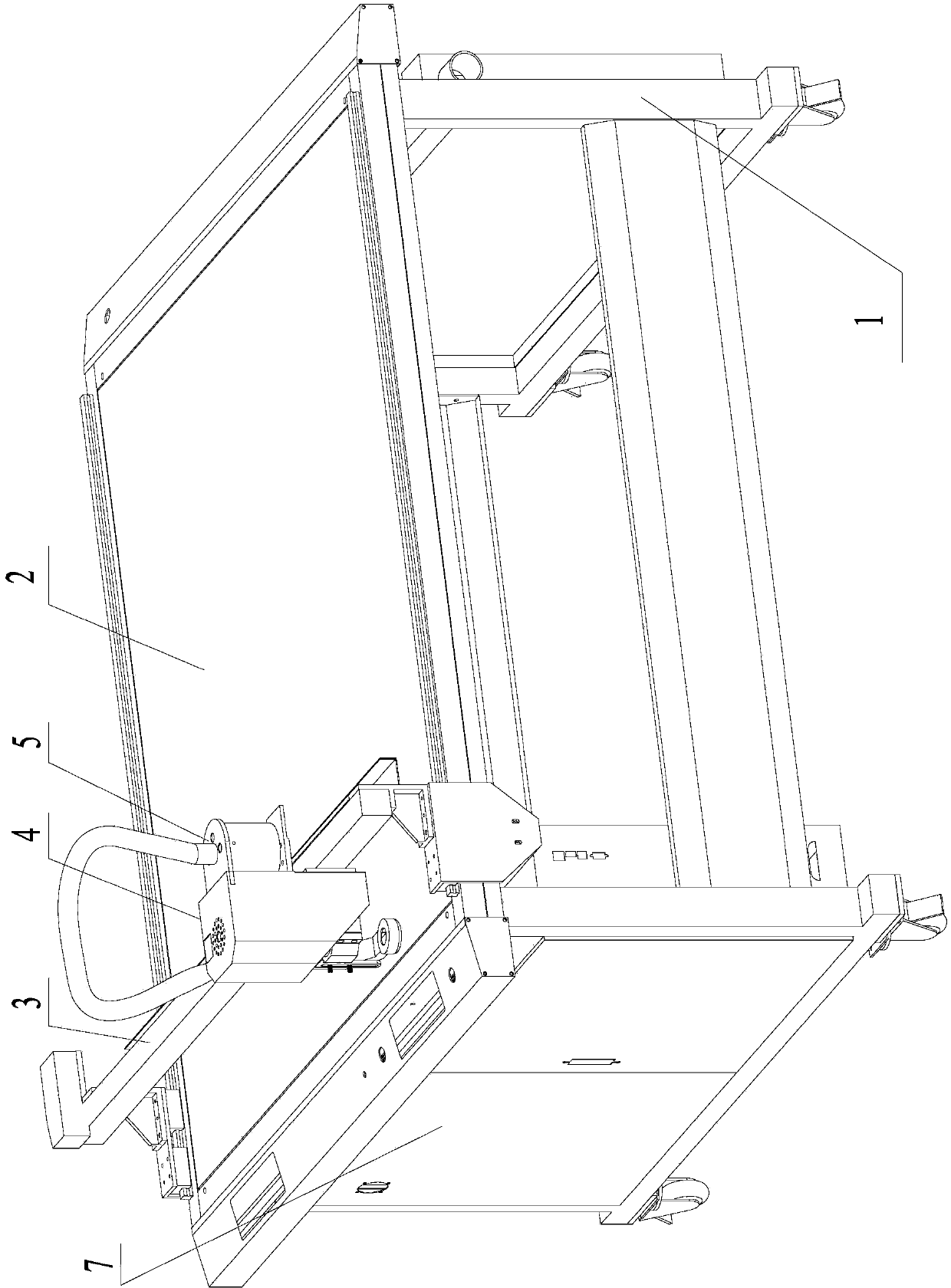

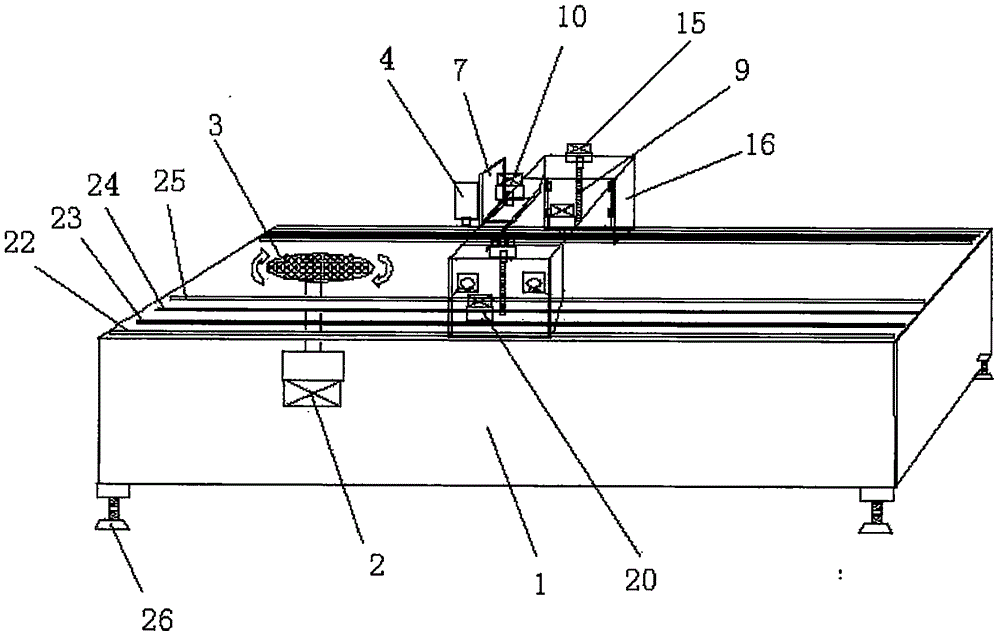

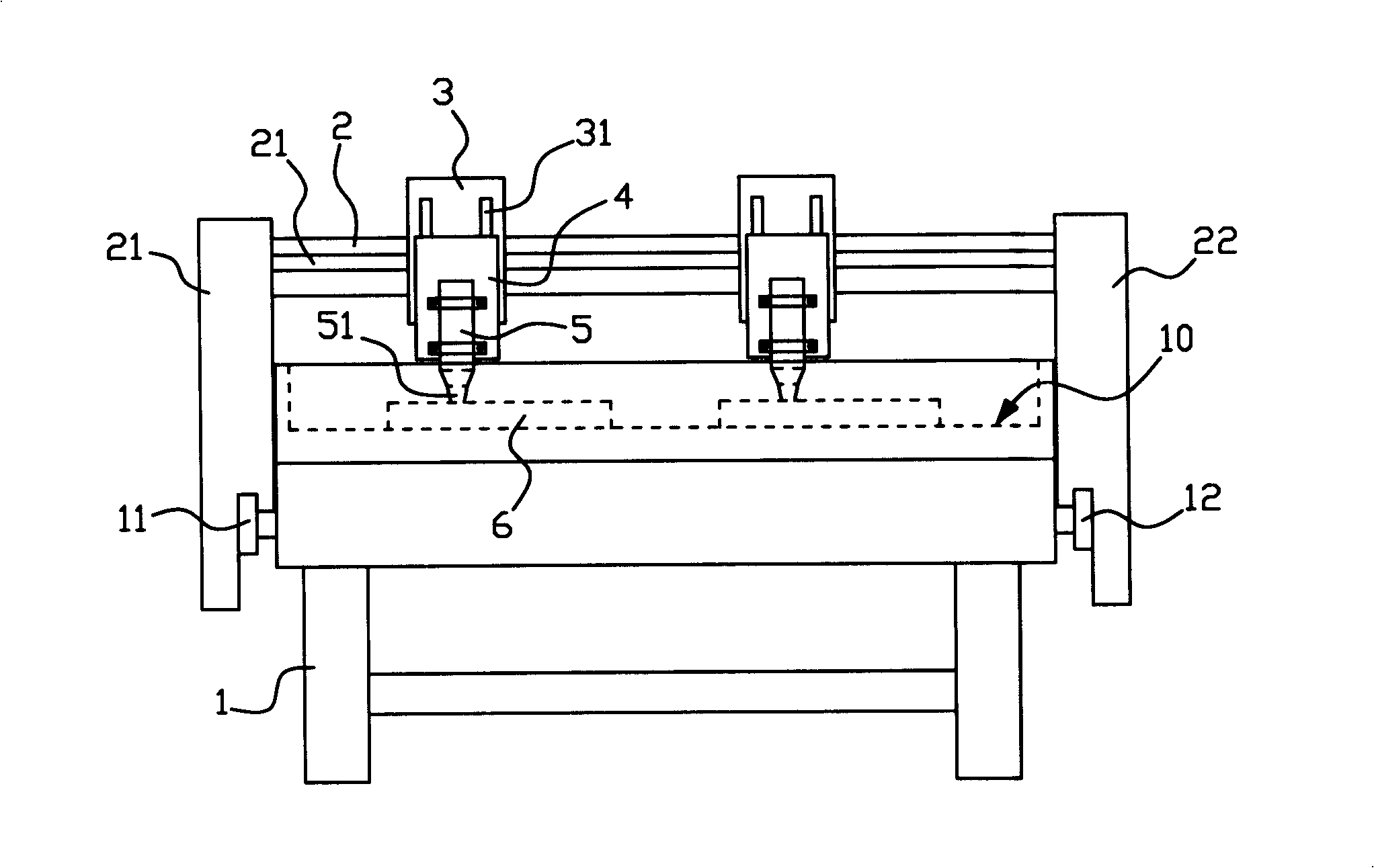

Multi-station digital-controlled carving machine

InactiveCN101195318AGood interface functionGuaranteed radial errorAutomatic control devicesFeeding apparatusNumerical controlDigital control

The invention relates to a multi-station numerical control engraving machine comprising a machine body (1), an engraving machine portion and an electric portion, wherein the electric portion comprises a software portion and a hardware portion, the hardware portion employs a control core combined by an industrial control computer and a movement control card, the movement control card is connected with a digital servo-actuator or multi-shaft stepping motor which are controlled by the movement control card by data wire, the software employs an application running under Visual C++ program Windows 2000 XP and an application of 51 single chip computer, the engraving machine portion is mainly composed of an engraving head (10), a multi-station tool device (11) and a tool setting and feeding device, the engraving head uses a brushless direct current motor (9) to drive the central axis. The multi-station numerical control engraving machine can simultaneously engrave various Chinese characters, curves and patterns with single line or double line on cylindrical surfaces, conical surfaces and geometric plane surfaces at multiple stations, and additionally engraving patterns and characters can be edited and designed by users.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

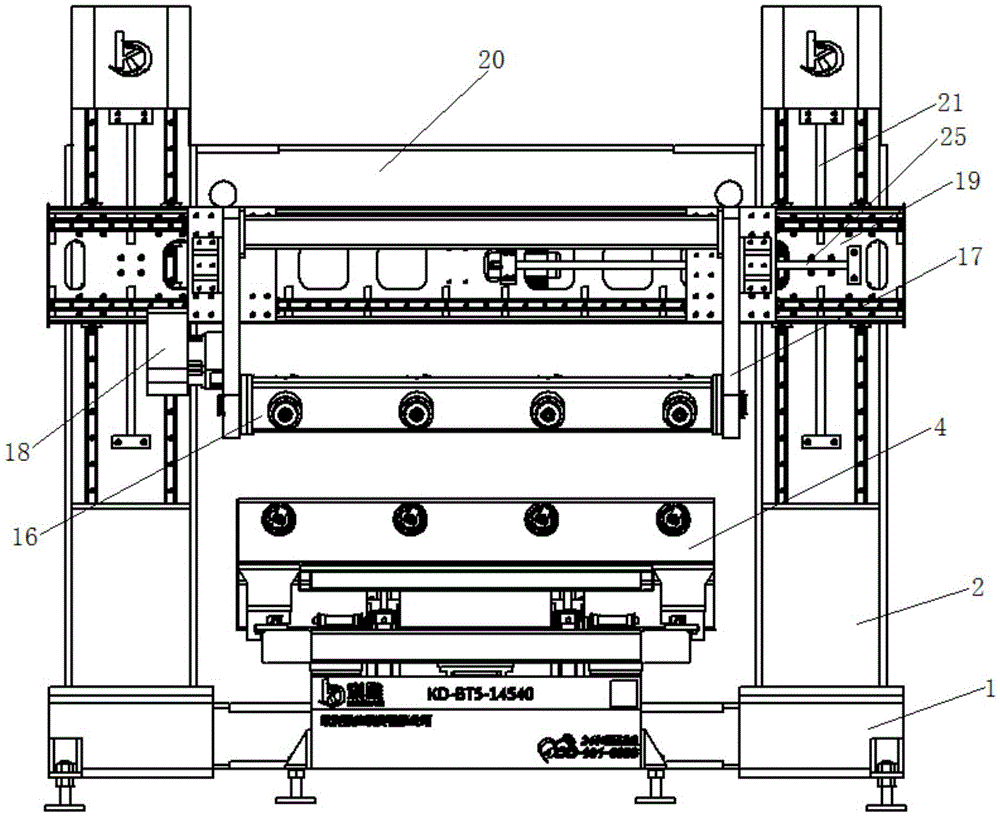

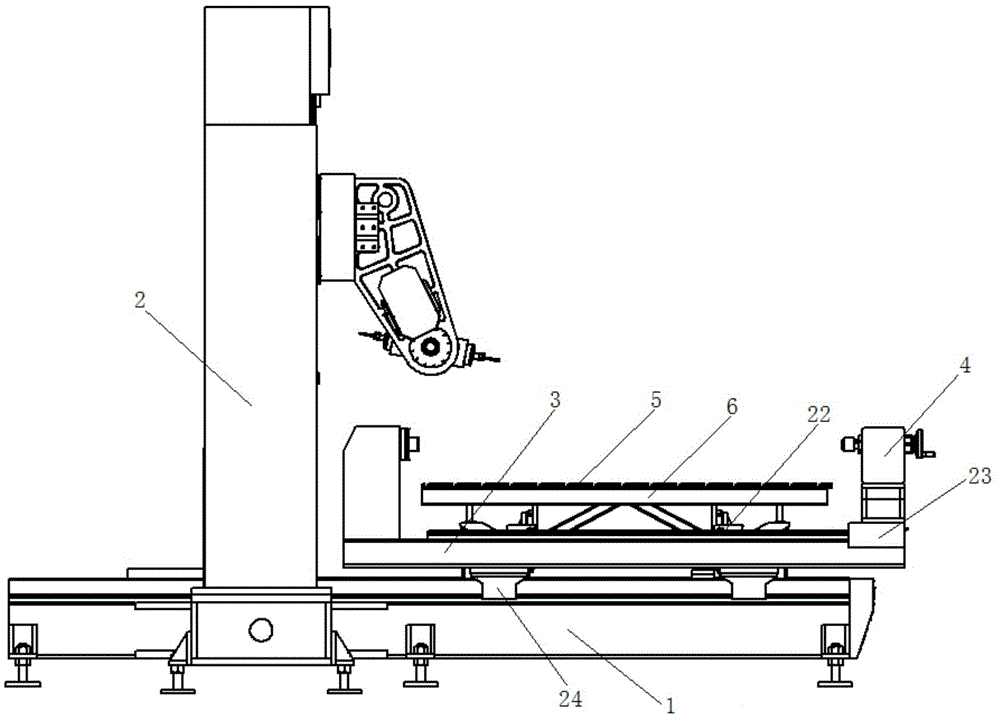

Multifunctional carving machine

ActiveCN105620148AHigh degree of automationWide range of usesModel makingEngravingMarine engineeringMachining

The invention relates to the field of machining, in particular to a multifunctional carving machine which comprises a base, stand columns, a carving platform and a cutter mechanism. The carving platform comprises a movable platform and a workpiece clamping device; an automatic lifting platform is arranged on the movable platform, and comprises a platform board, a platform board lifting rack and automatic platform board lifting mechanisms; the automatic platform board lifting mechanisms are fastened on a cross beam in the middle of the movable platform; the platform board lifting rack is fixed to the automatic platform board lifting mechanisms; and the platform board is fixed to the platform board lifting rack. The multifunctional carving machine is additionally provided with the platform board capable of being lifted automatically on the basis of an existing high-precision three-dimensional carving machine; the lifting platform can be automatically lifted through program codes, and the platform board is lifted up when a plane is carved and is automatically lifted down when a three-dimensional structure is carved. The multifunctional carving machine is high in automation degree, wide in application and convenient and safe to operate.

Owner:NANTONG OUKE CNC EQUIP CO LTD

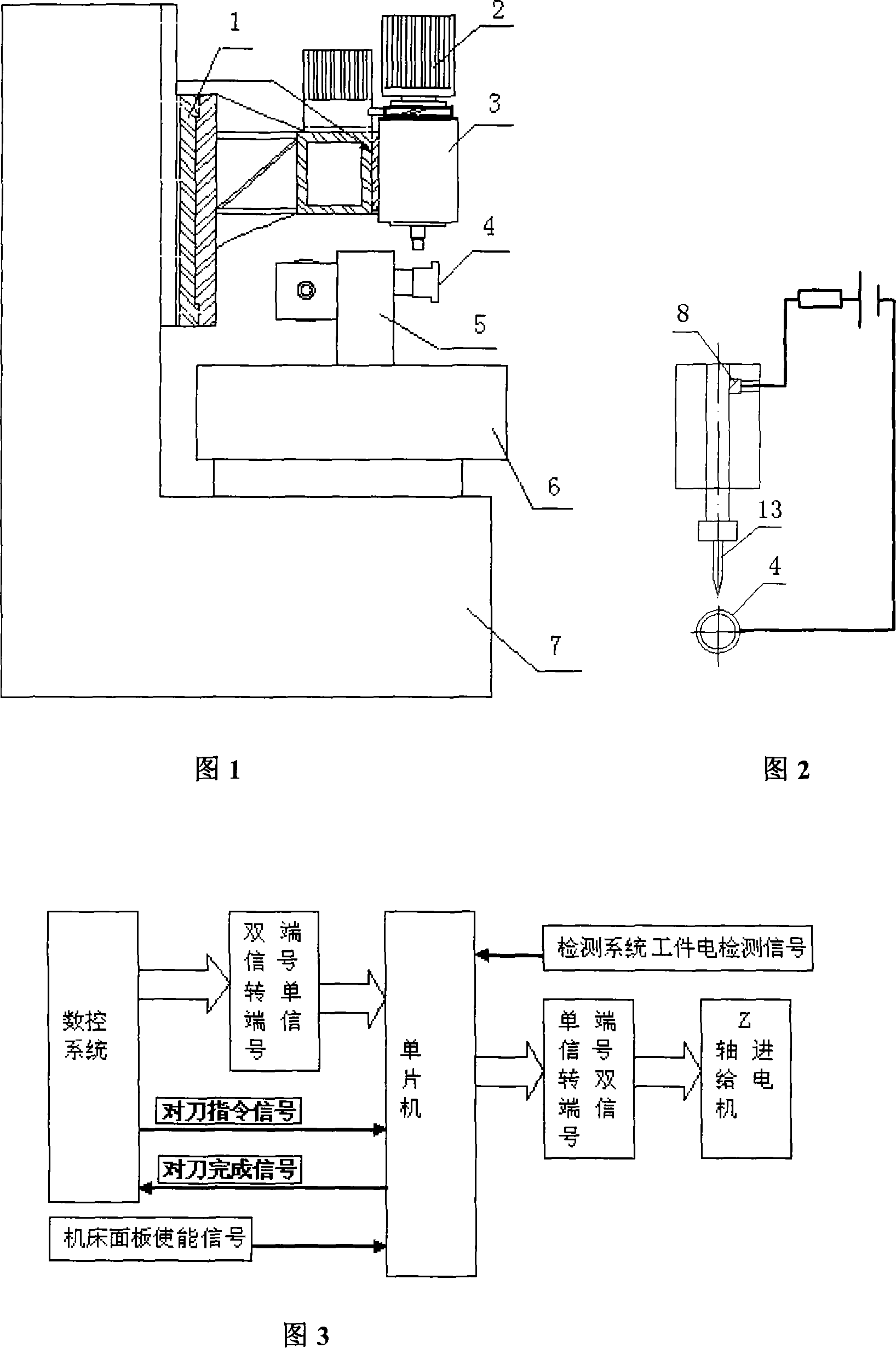

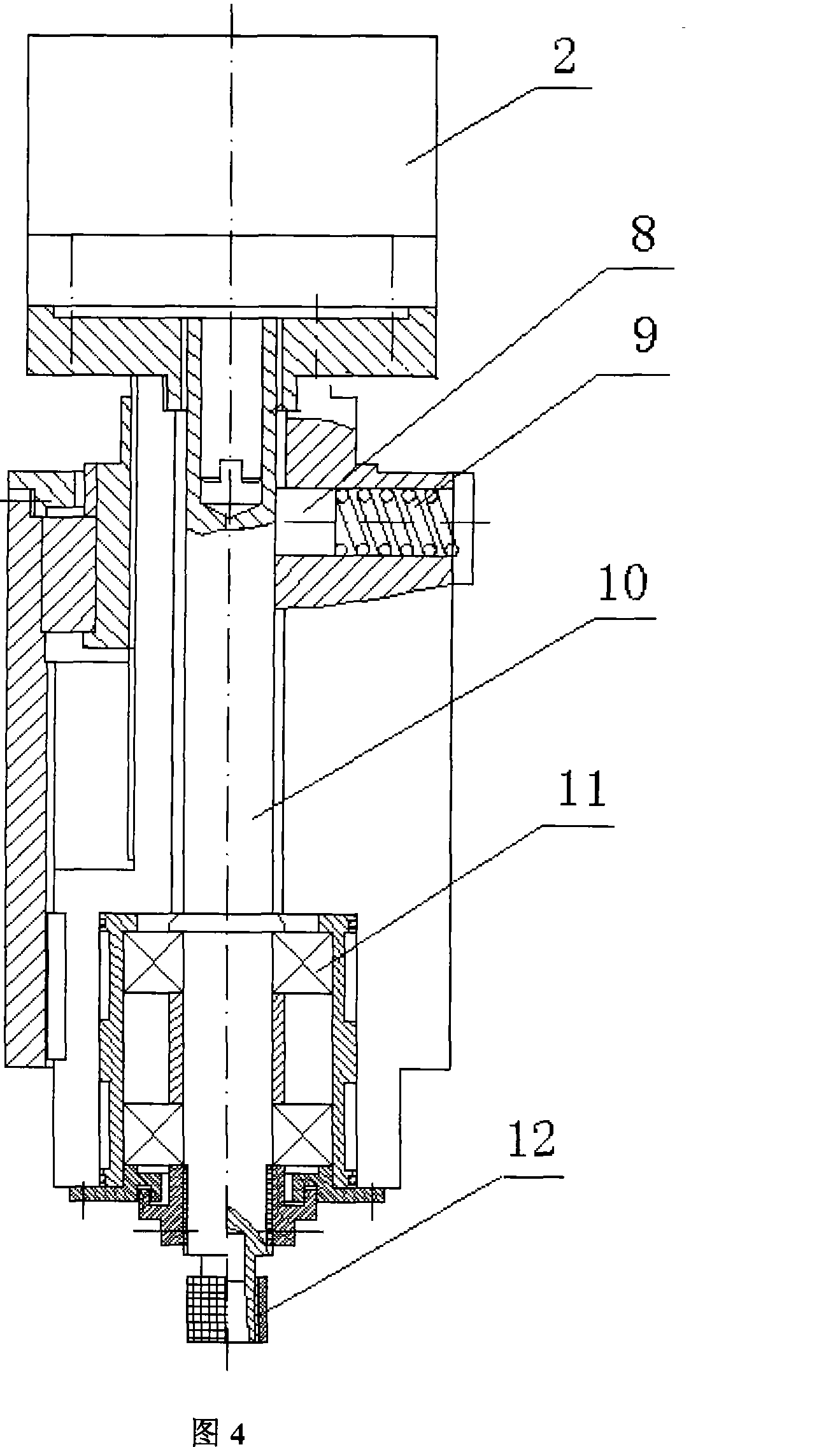

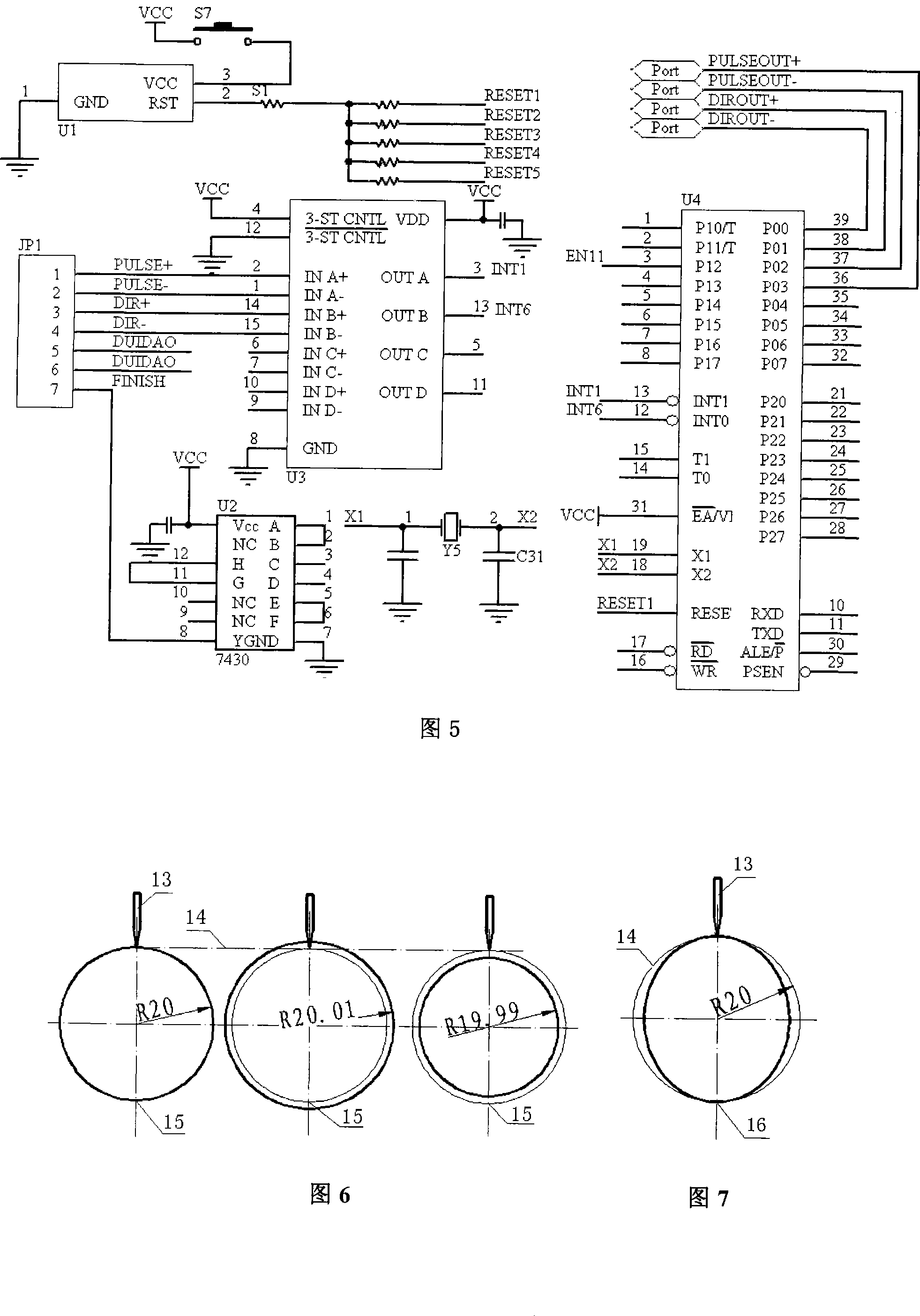

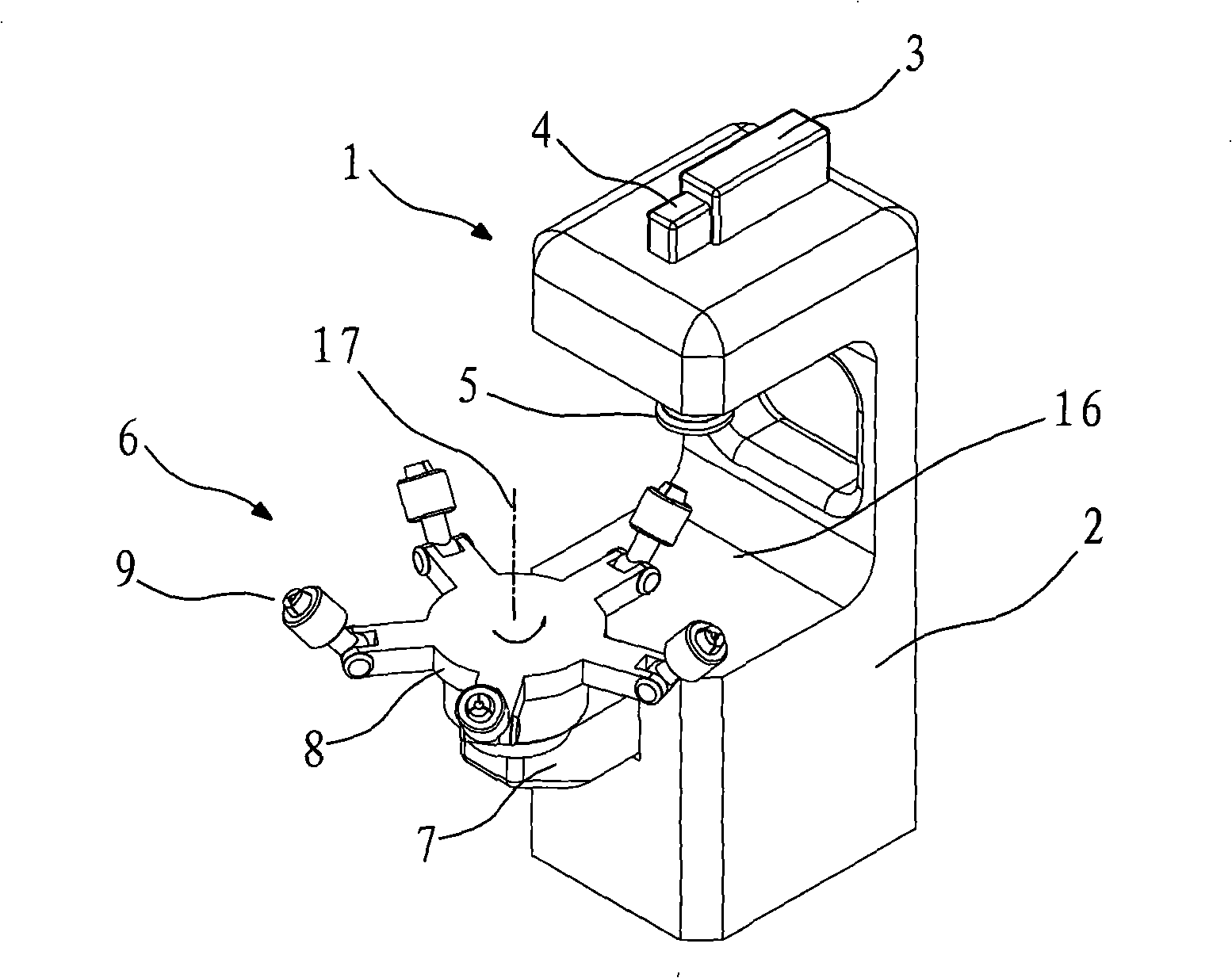

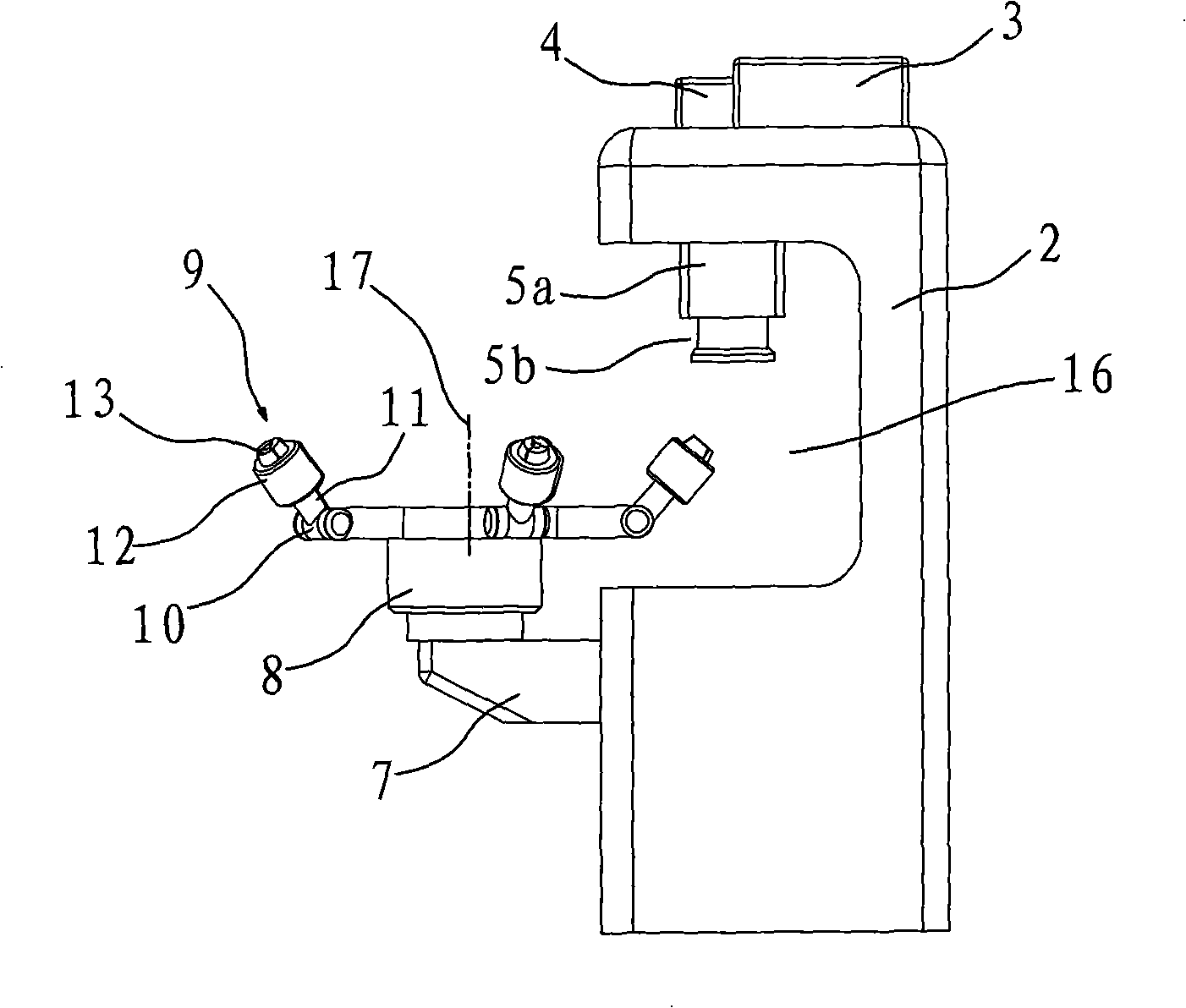

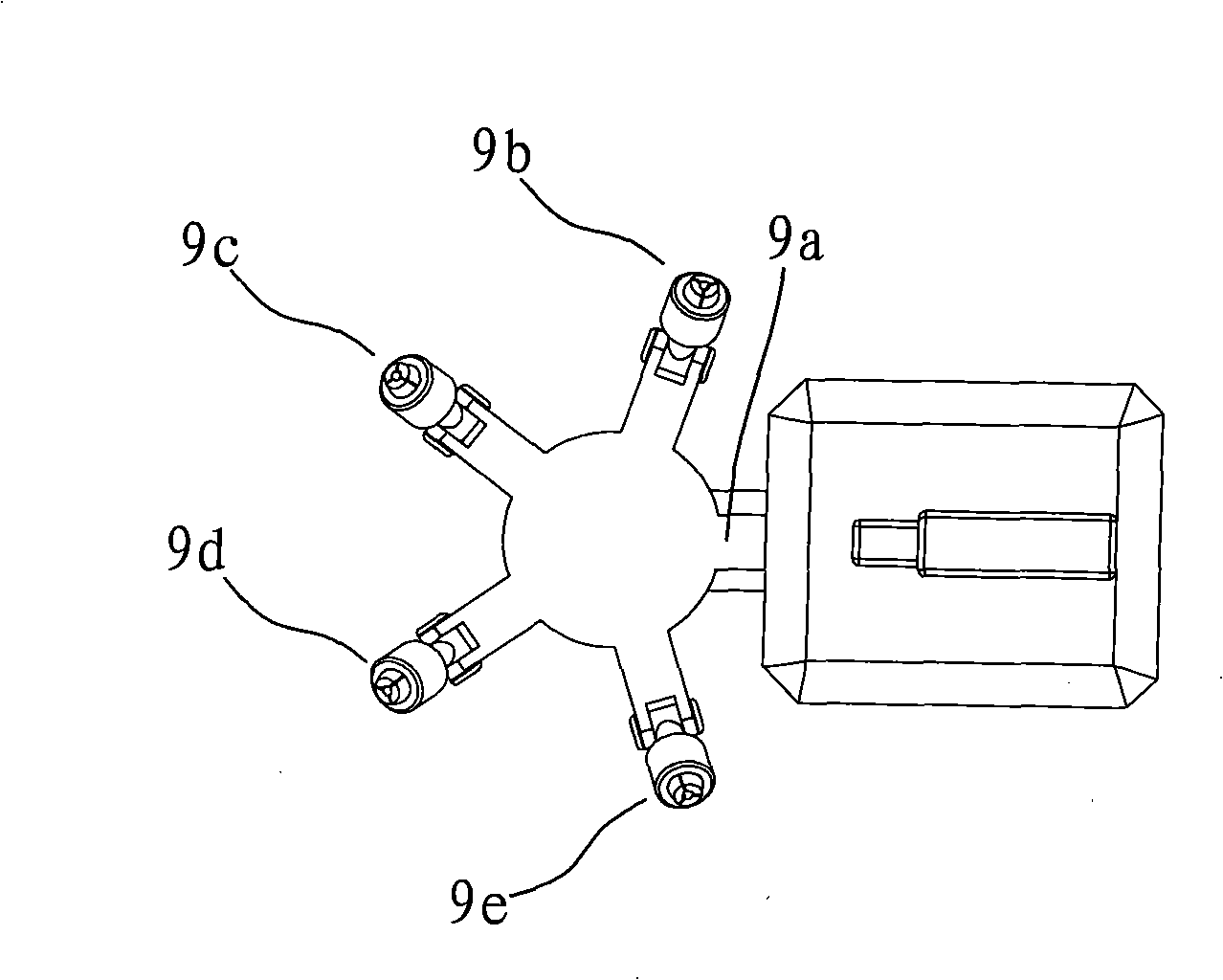

Multi-station numerical controlled carving tool setting device

InactiveCN101195319AGuaranteed engraving depth consistencyHigh precisionAutomatic control devicesFeeding apparatusElectricityNumerical control

The invention provides a tool setting device for multi-station numerical control engraving, which is composed of a control system and an electrical contact signal detecting system, wherein the control system comprises four circuits of a single chip computer control group circuit, a signal input and transformation circuit and a signal output and transformation circuit, the single chip computer control group circuit is composed of a plurality of independent single chip computers U4 and peripheral circuits thereof, the electrical contact signal detecting system is a good conductor composed of a body (7), a worktable, a clamp and a workpiece (4), and connected with the power supply via 'earth' connection, the positive electrode of the power supply is connected with an engraving head (3) which is connected with a main shaft motor (2). The invention can realize automatic tool setting, and enable all the tools to be positioned on the surface of the workpiece before engraving feed, particularly consistency of engraving depth is guaranteed in high precision engraving, further the performance is reliable and the breaking edge rate is smaller than 0.0001%. The device of the invention can be widely applied to precise engraving of numerical control engraving machines and multi-station processing systems of numerical control milling machines, machining centers and the like.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

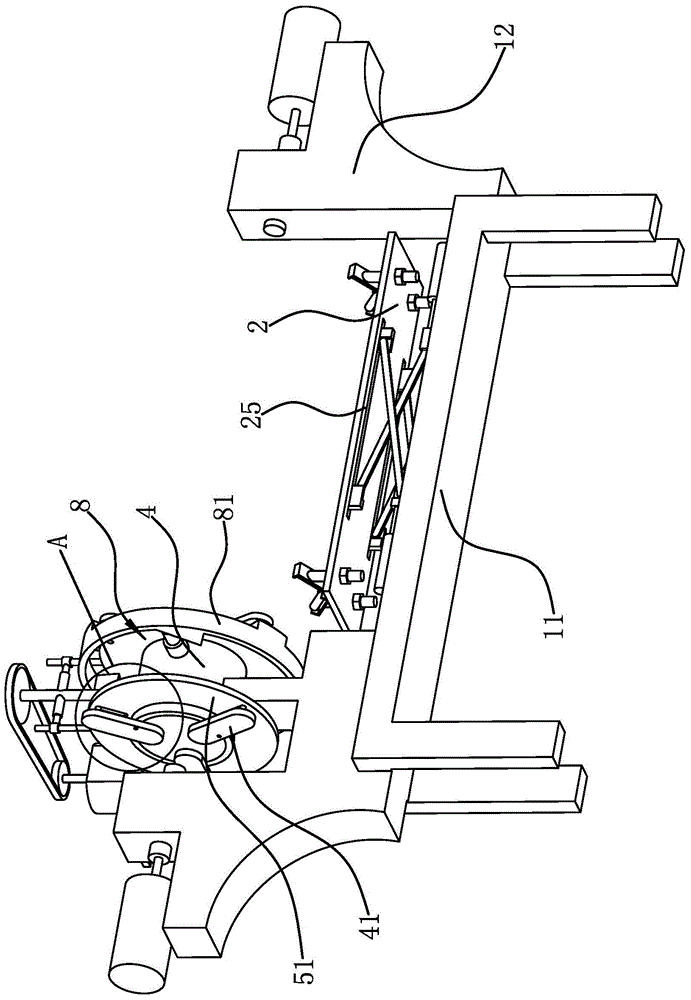

Automatic feeding and blanking mechanism for lens grinder

InactiveCN103846762AEnsure safetyReasonable structural designOptical surface grinding machinesGrinding feedersPass rateLens plate

The invention discloses an automatic feeding and blanking mechanism for a lens grinder. The automatic feeding and blanking mechanism comprises a lifting module, an overturning module, a feeding frame, a blanking frame, a processing platform and a moving working table. The lifting module comprises a fixed seat, an up-down cylinder, a guide support and a fixed block. The guide support is vertically arranged on the fixed block, the fixed block is fixed at the lower end of the guide support, a cylinder body of the up-down cylinder is fixed on the fixed seat, and a piston rod of the up-down cylinder is connected to the fixed block. The automatic feeding and blanking mechanism is reasonable in structural design, automatic feeding and blanking motions can be achieved rapidly through the matching between the lifting module, the overturning module and the moving working table, an automatic mode is adopted to replace a manual mode, and the automatic feeding and blanking mechanism has motion flexibility, is convenient to operate, easy to control, high in efficiency and quick in speed and greatly improves production efficiency and product pass rate.

Owner:陈哲雄

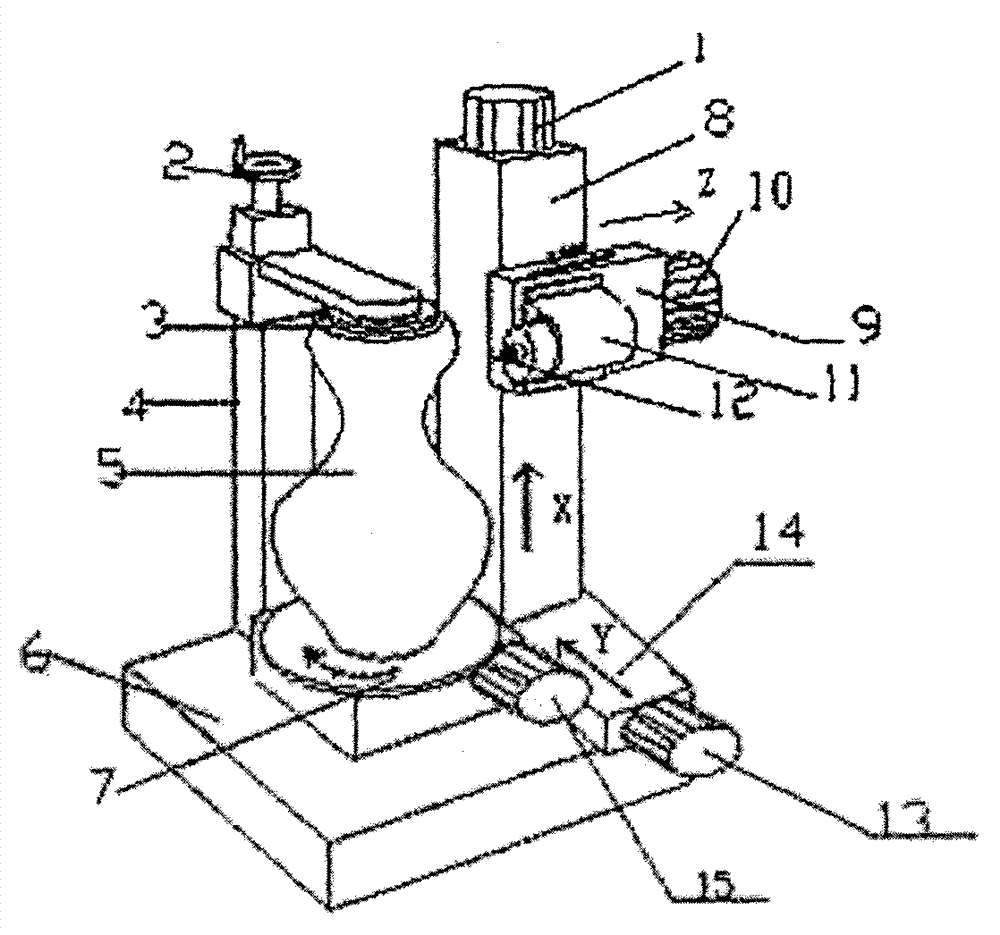

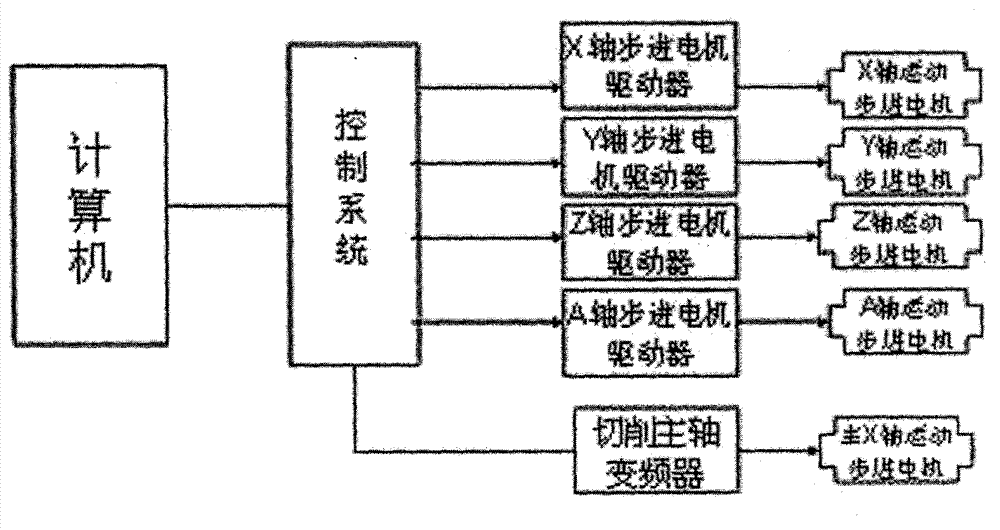

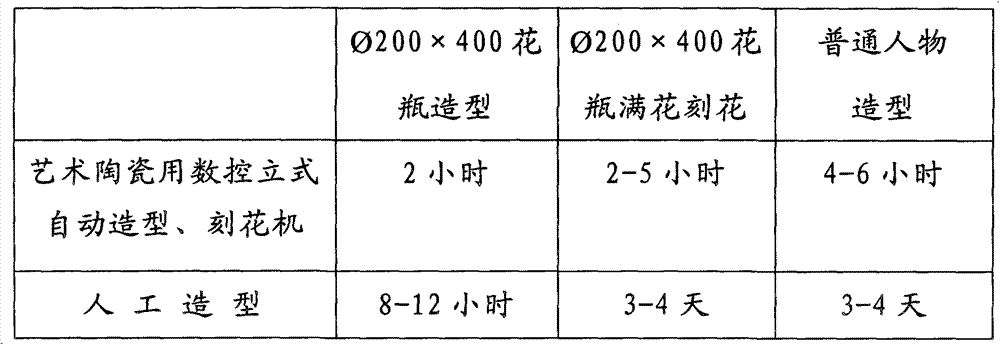

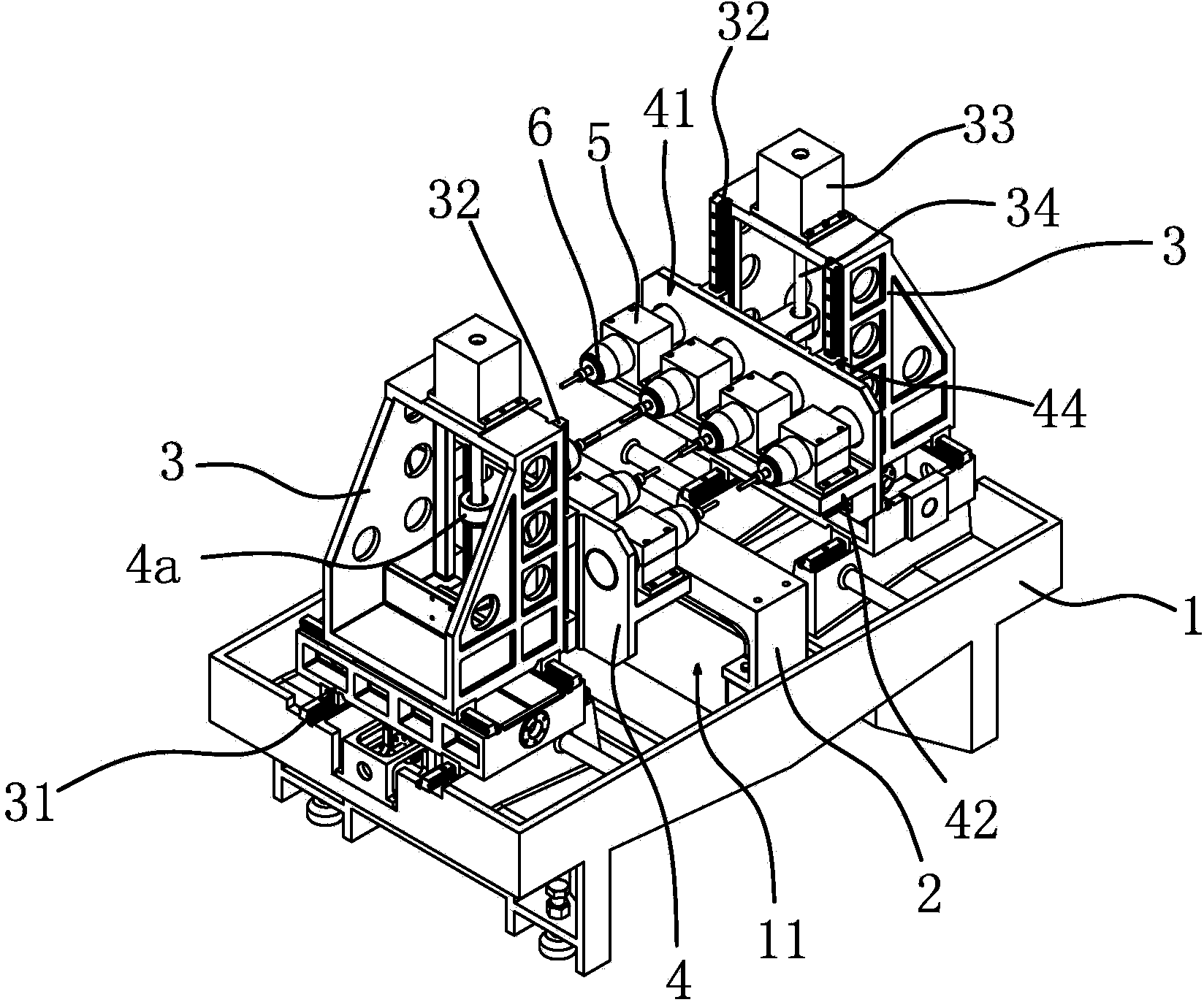

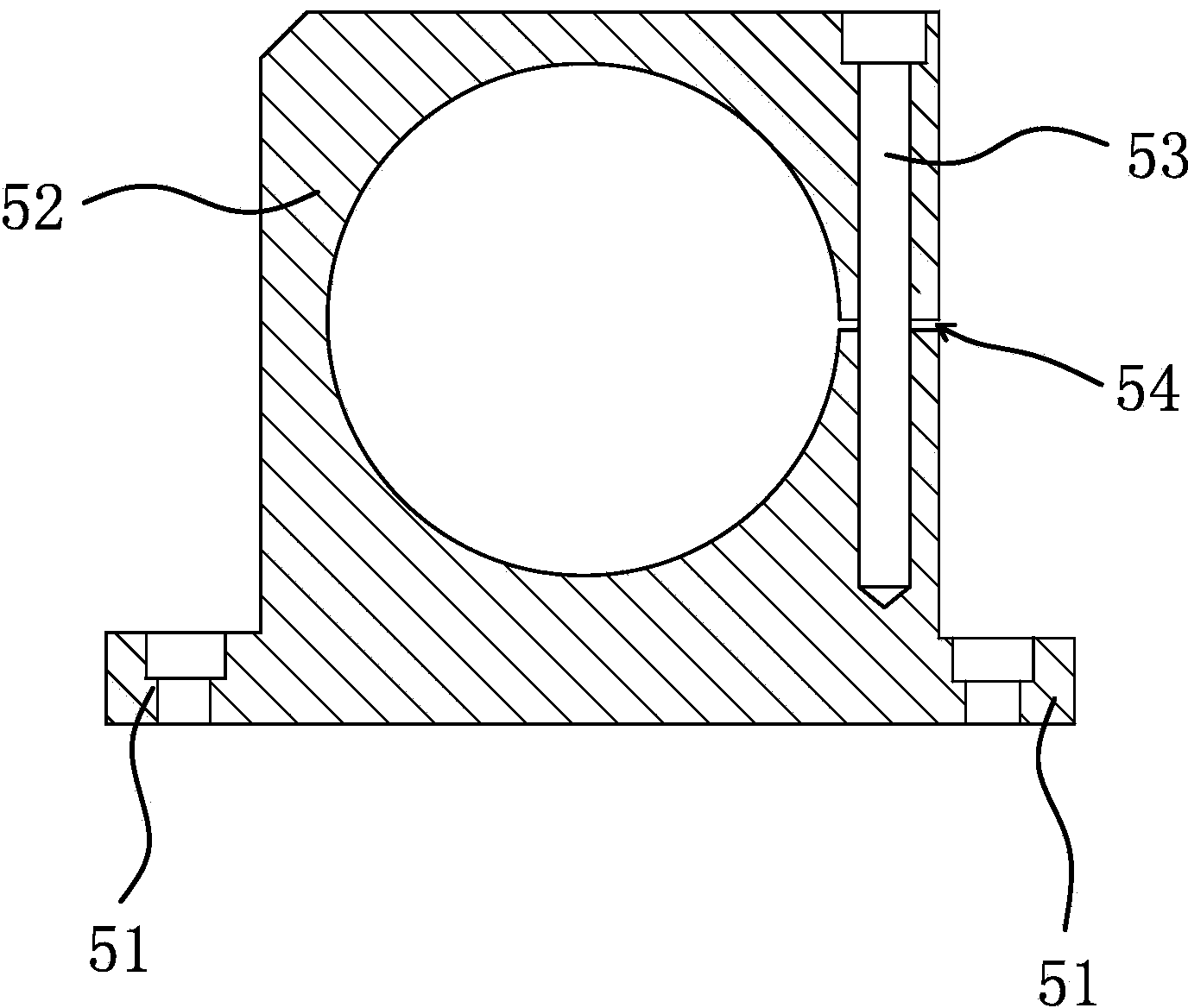

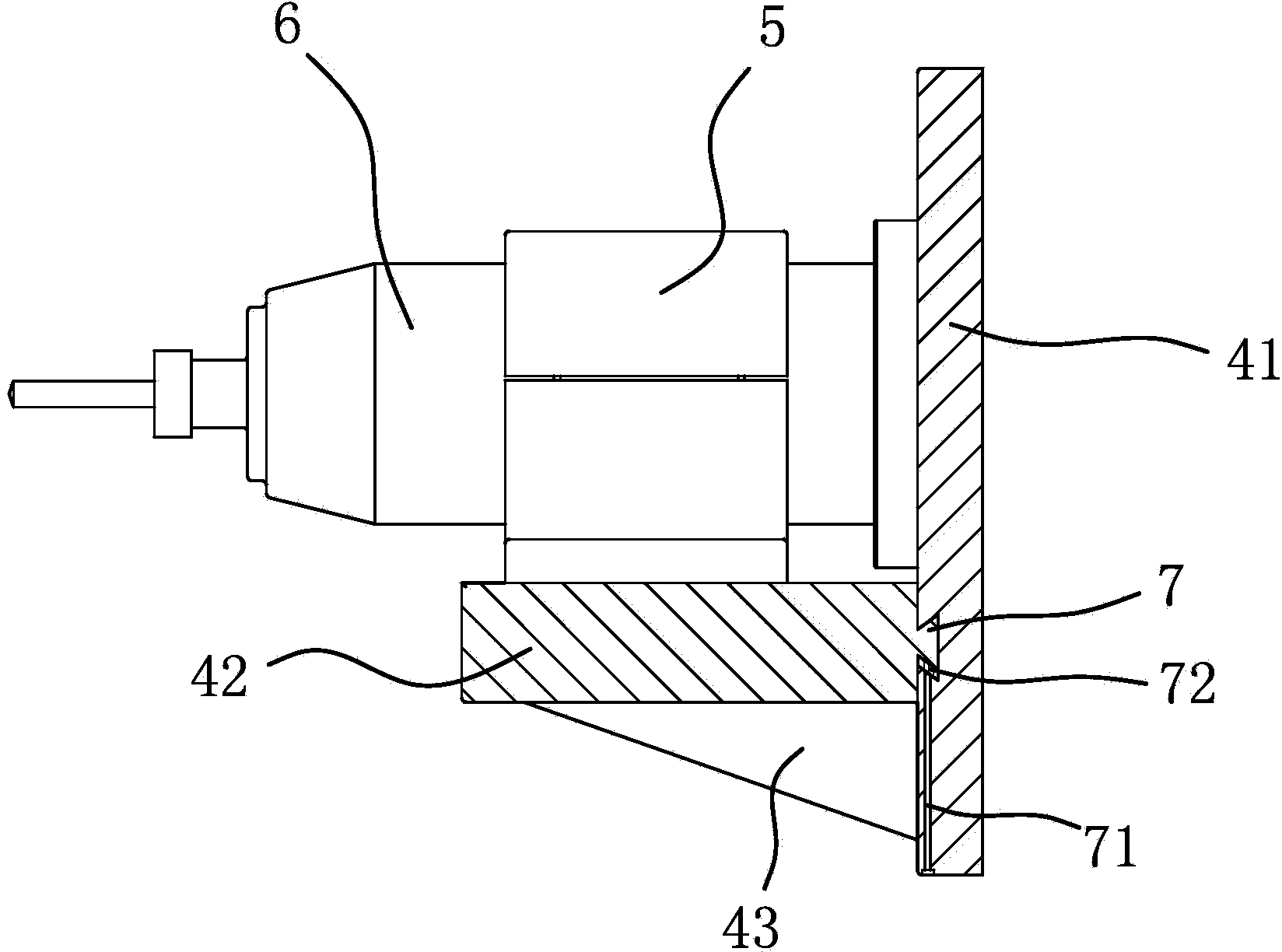

Numerical control modeling flower-carving machine for vertical type art pottery

InactiveCN103317925AImprove modeling efficiencyImprove production efficiencyNumerical controlModel makingNumerical controlEngineering

The invention relates to a numerical control modeling flower-carving machine for vertical type art pottery. The numerical control modeling flower-carving machine is characterized by comprising a computer, a controller and a main machine, wherein the controller is arranged between the computer and the main machine; the main machine comprises a machine base, a workpiece mounting device, an X-axis working system, a Y-axis working system and a Z-axis working system, the workpiece mounting device and the Y-axis working system are arranged on the machine base, the X-axis working system is arranged on the Y-axis working system, and the Z-axis working system is arranged on the X-axis working system; and a spindle motor is further arranged on the Z-axis working system, and a carving knife is arranged at one end of the spindle motor and linked with the spindle motor. The numerical control modeling flower-carving machine for the vertical type art pottery can improve the modeling efficiency of the art pottery and the labor production efficiency, and simultaneously, pottery shape varieties of the art pottery are further enriched.

Owner:徐维茂

Efficient engraving and milling machine

The invention provides an efficient engraving and milling machine and belongs to the field of mechanical technology. The efficient engraving and milling machine solves the problem that scraps generated during the engraving process of existing engraving and milling machines can stay on workpieces to result in influence on the engraving efficiency and the like. The efficient engraving and milling machine comprises a working table, a support and a plurality of engraving and milling motors, wherein the working table is provided with a fixing table for fixing workpiece clamps, the support is arranged on the working table and on one side of the fixing table and provided with a mounting plate, and the engraving and milling motors are mounted on the mounting plate; the output shafts of the engraving and milling motors are parallel to the surface of the working table and face towards the fixing table; the engraving and milling motor can move in the horizontal direction and the vertical direction relative to the working table. The efficient engraving and milling machine has the advantages of guaranteeing the engraving precision and the operating smoothness.

Owner:陈美青

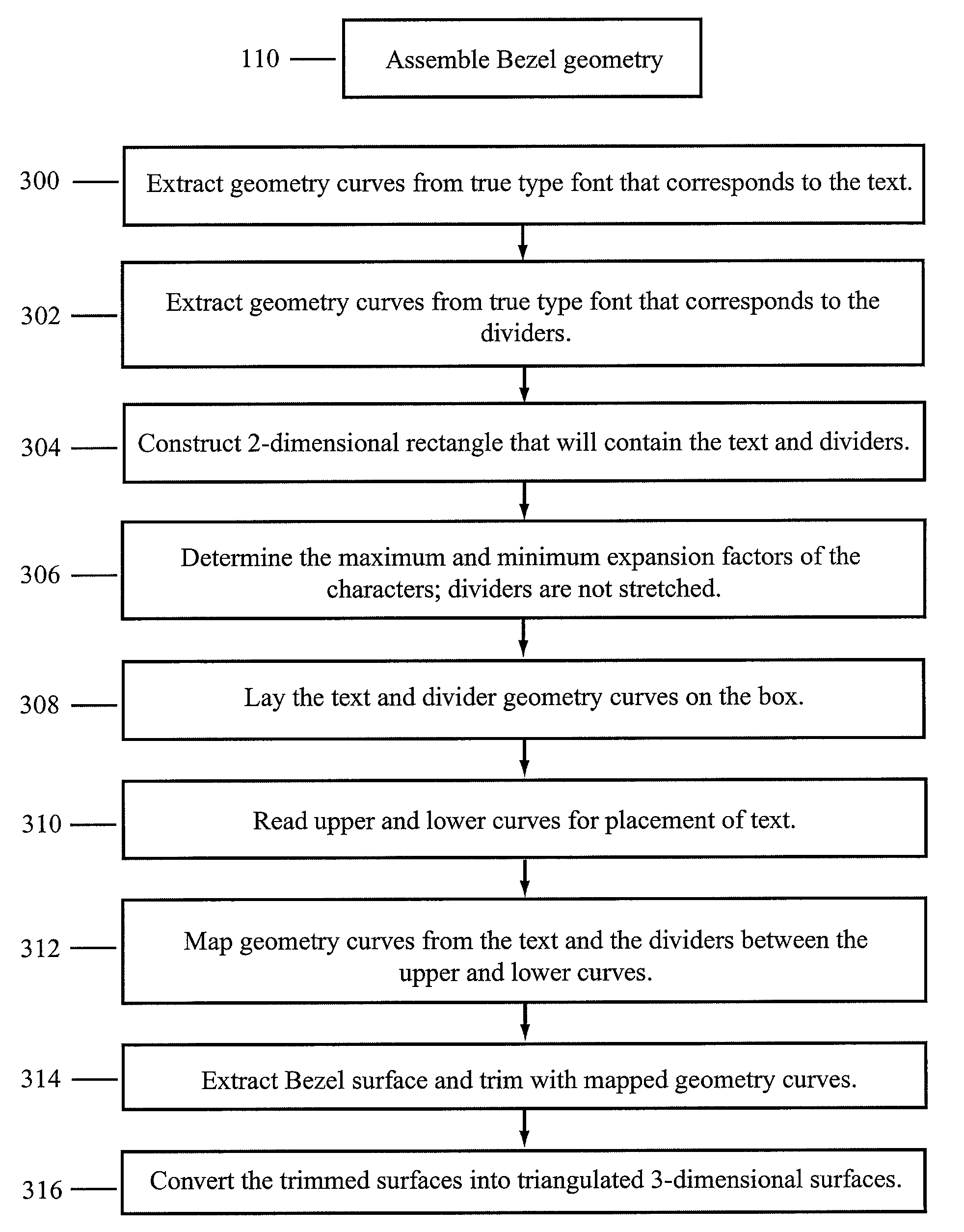

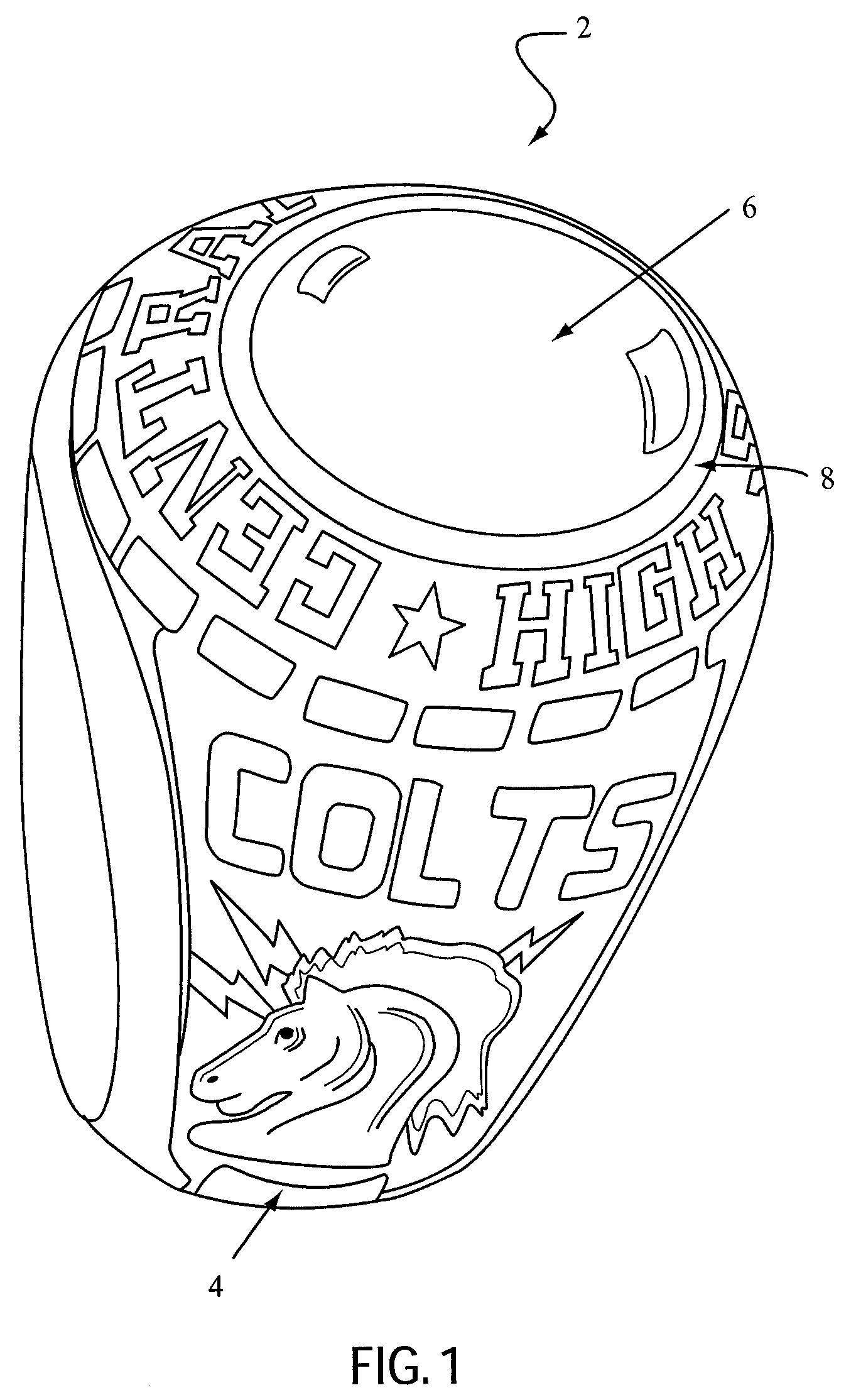

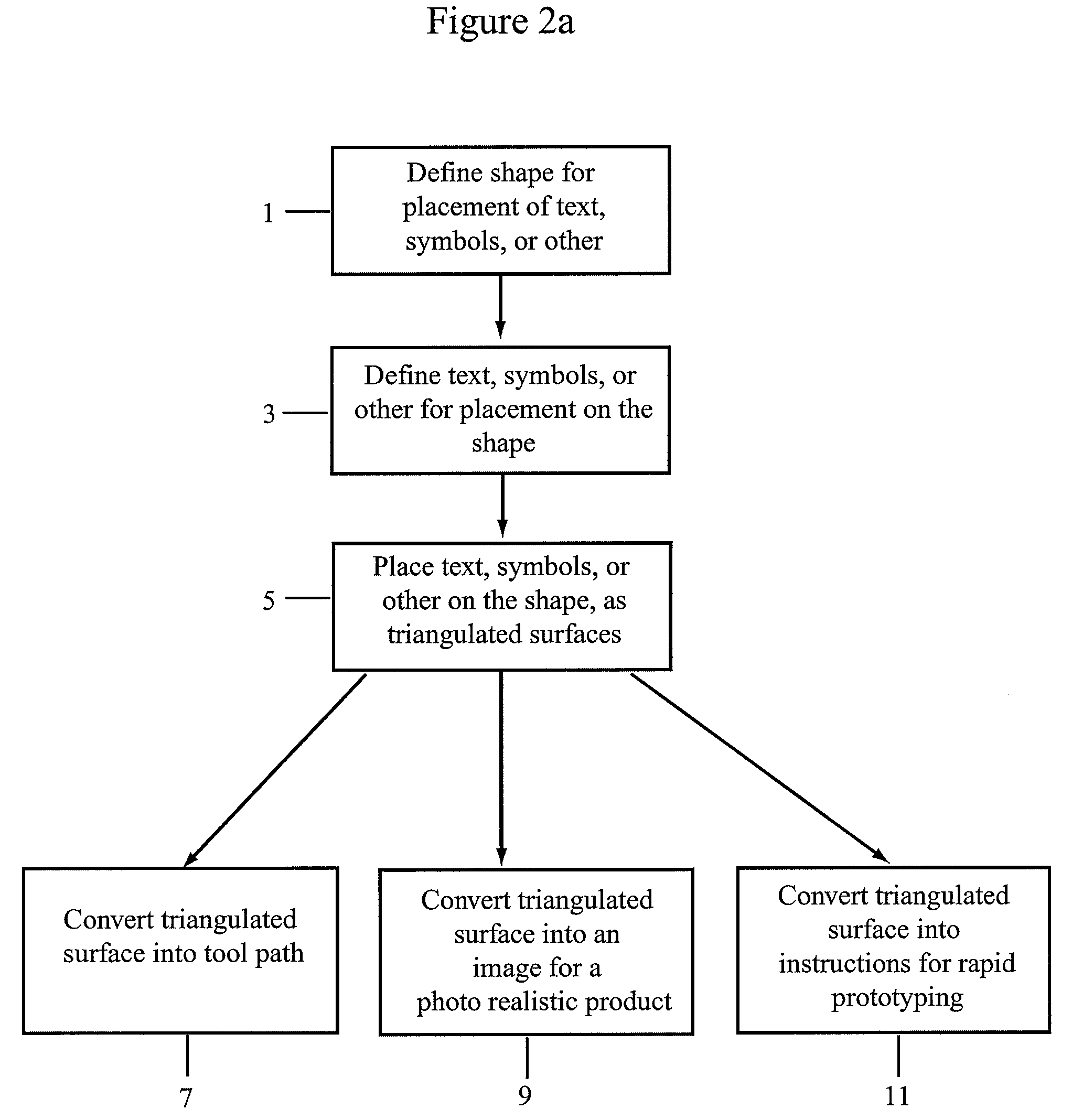

System and method for generating instructions for customization

ActiveUS20080177410A1Planing/slotting machinesComputer aided designNatural language processingComputer graphics (images)

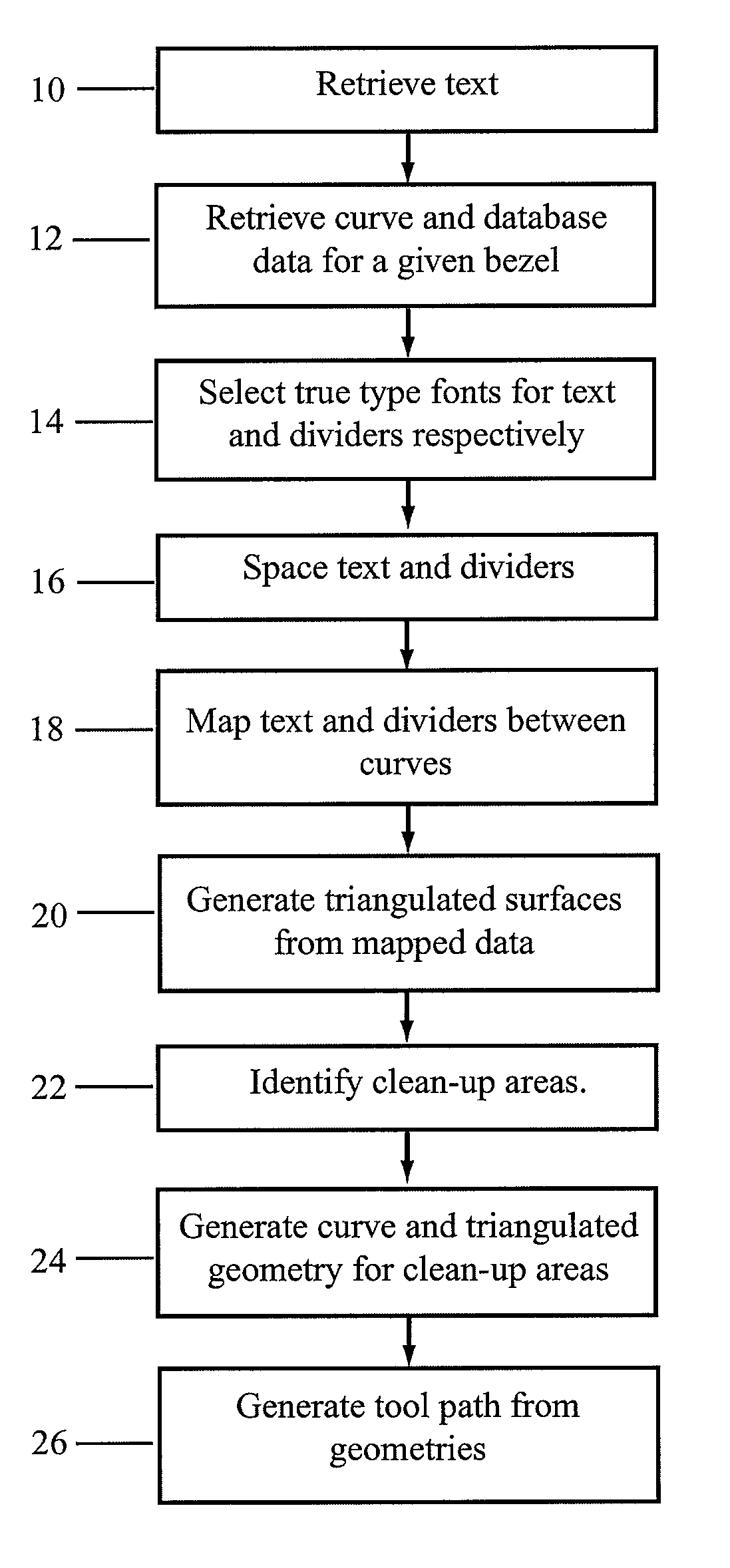

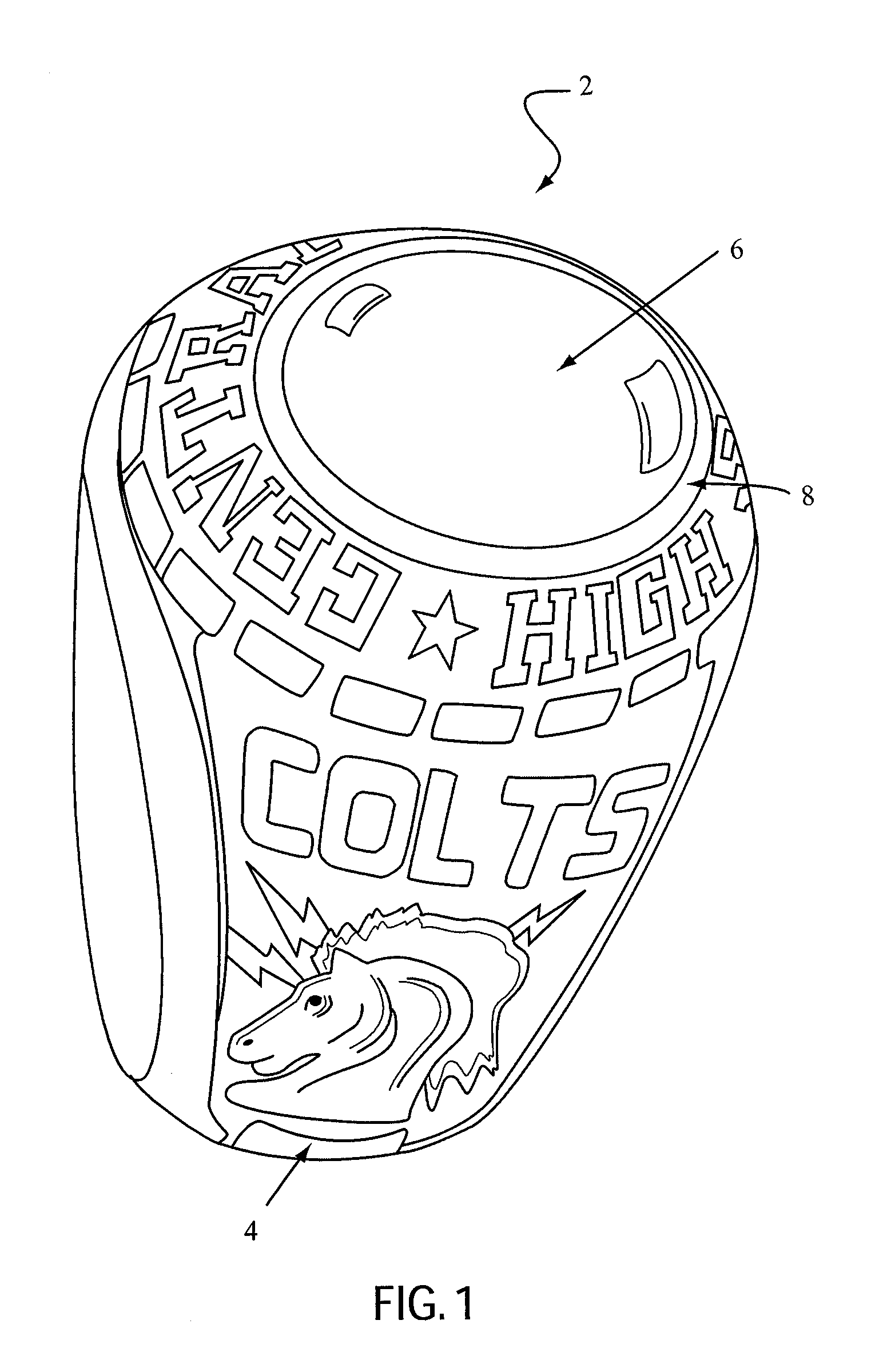

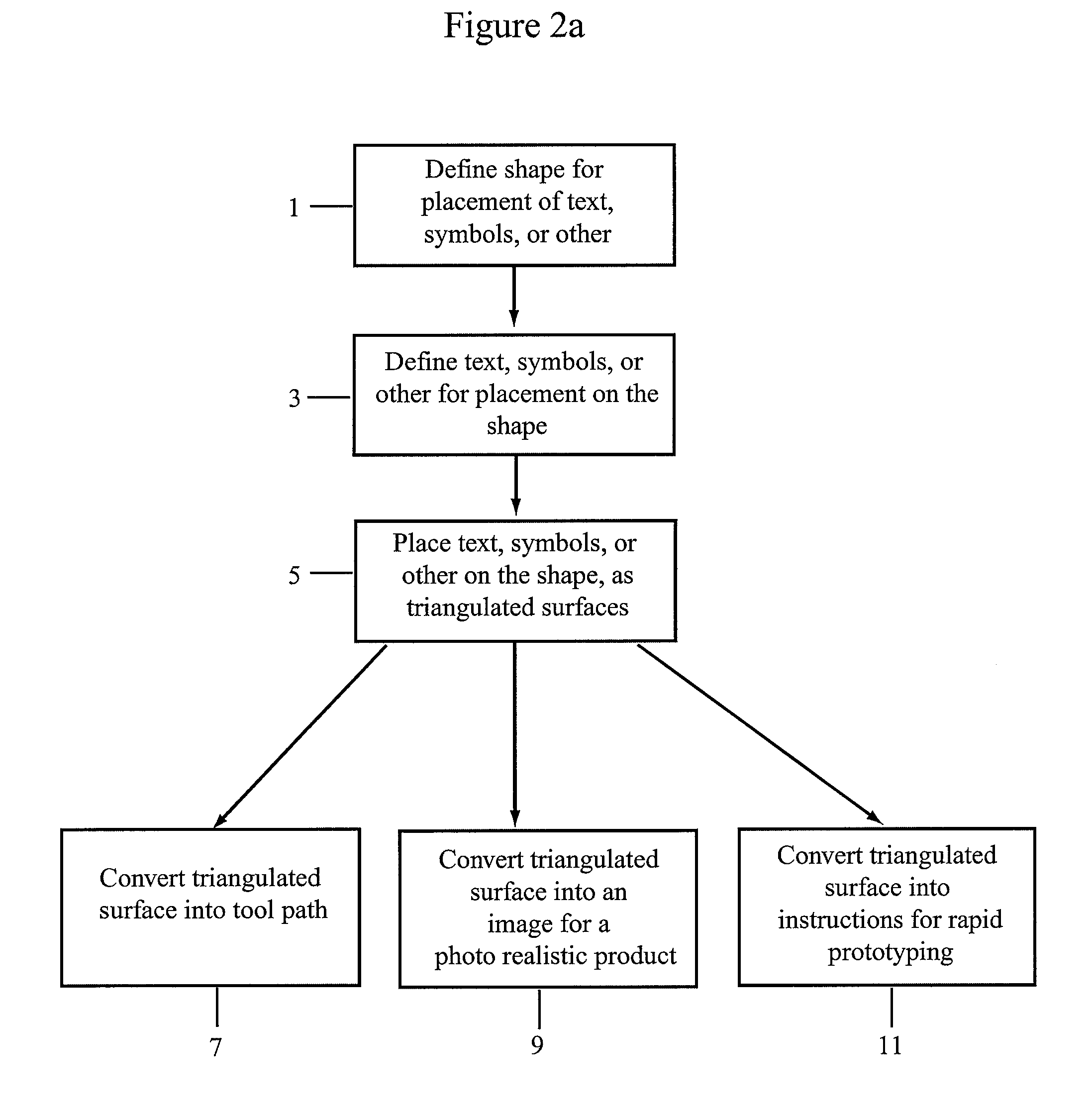

A method of creating a triangulated surfaces for generating machine readable instructions for customization is provided. The method comprises selecting text or symbols. The text or symbols are spaced. The text or symbols are mapped between first and second curves. Triangulated surfaces are generated from the mapped text or symbols. The triangulated surfaces are converted to machine readable instructions.

Owner:JOSTENS INC

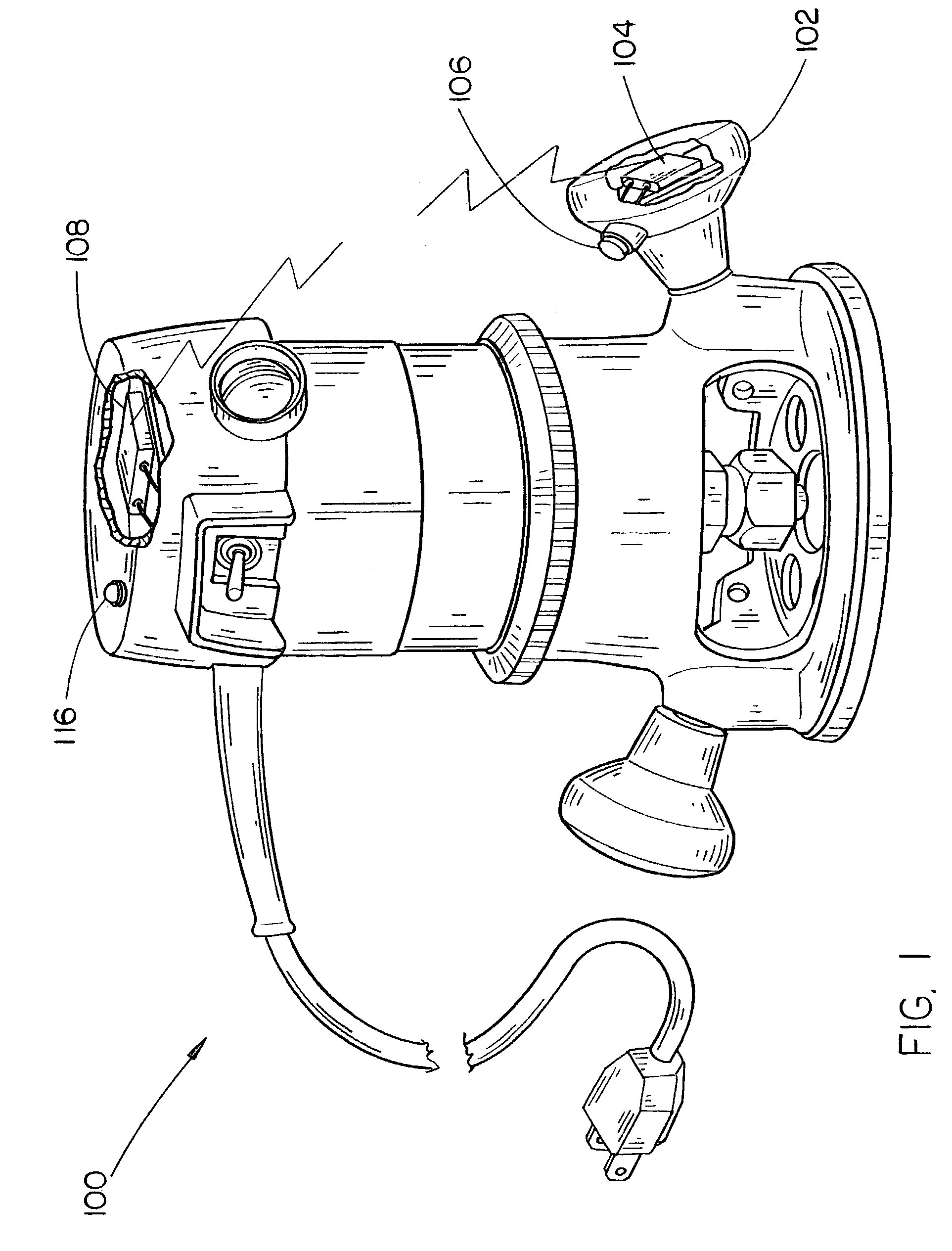

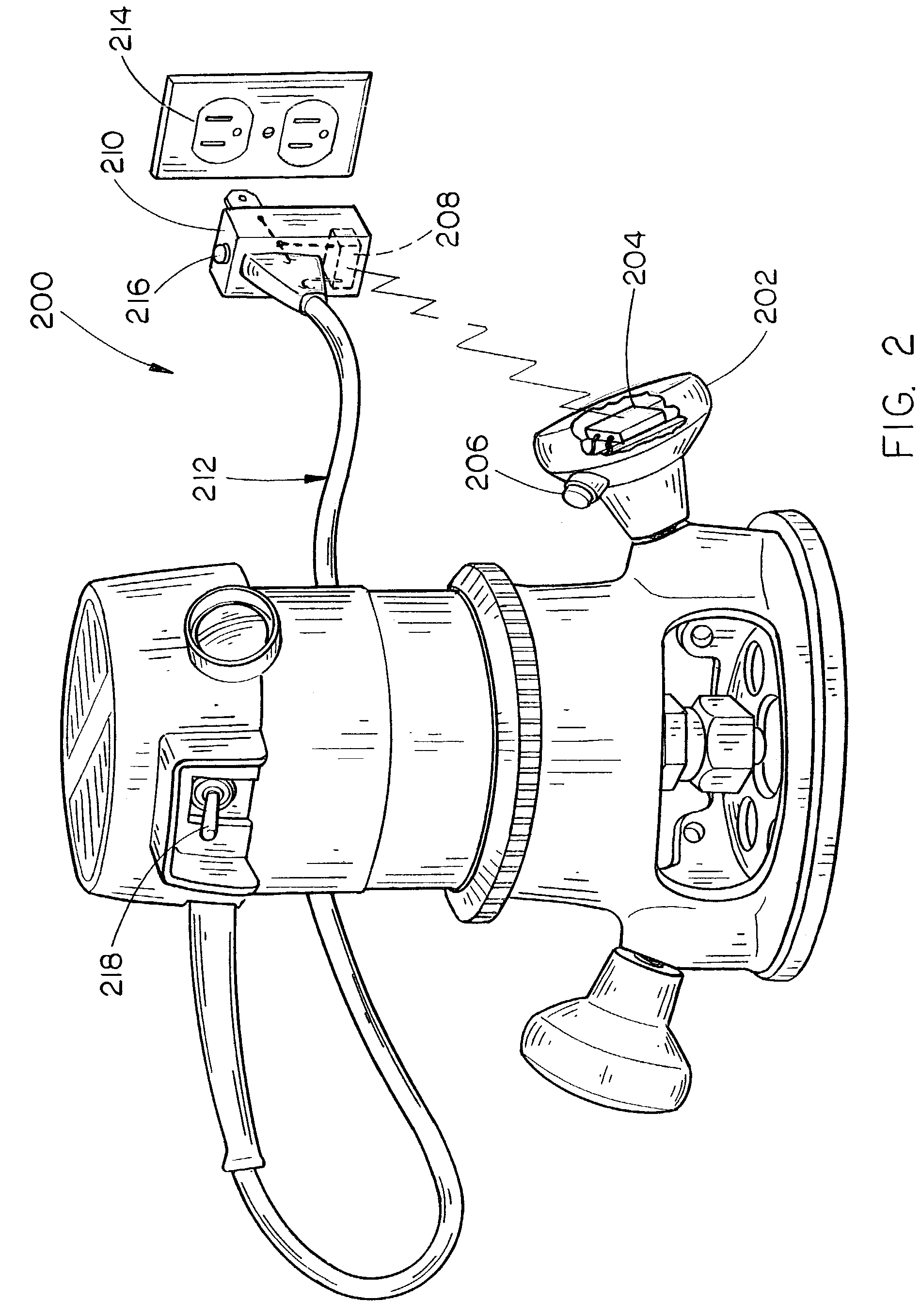

Wireless electrical control system

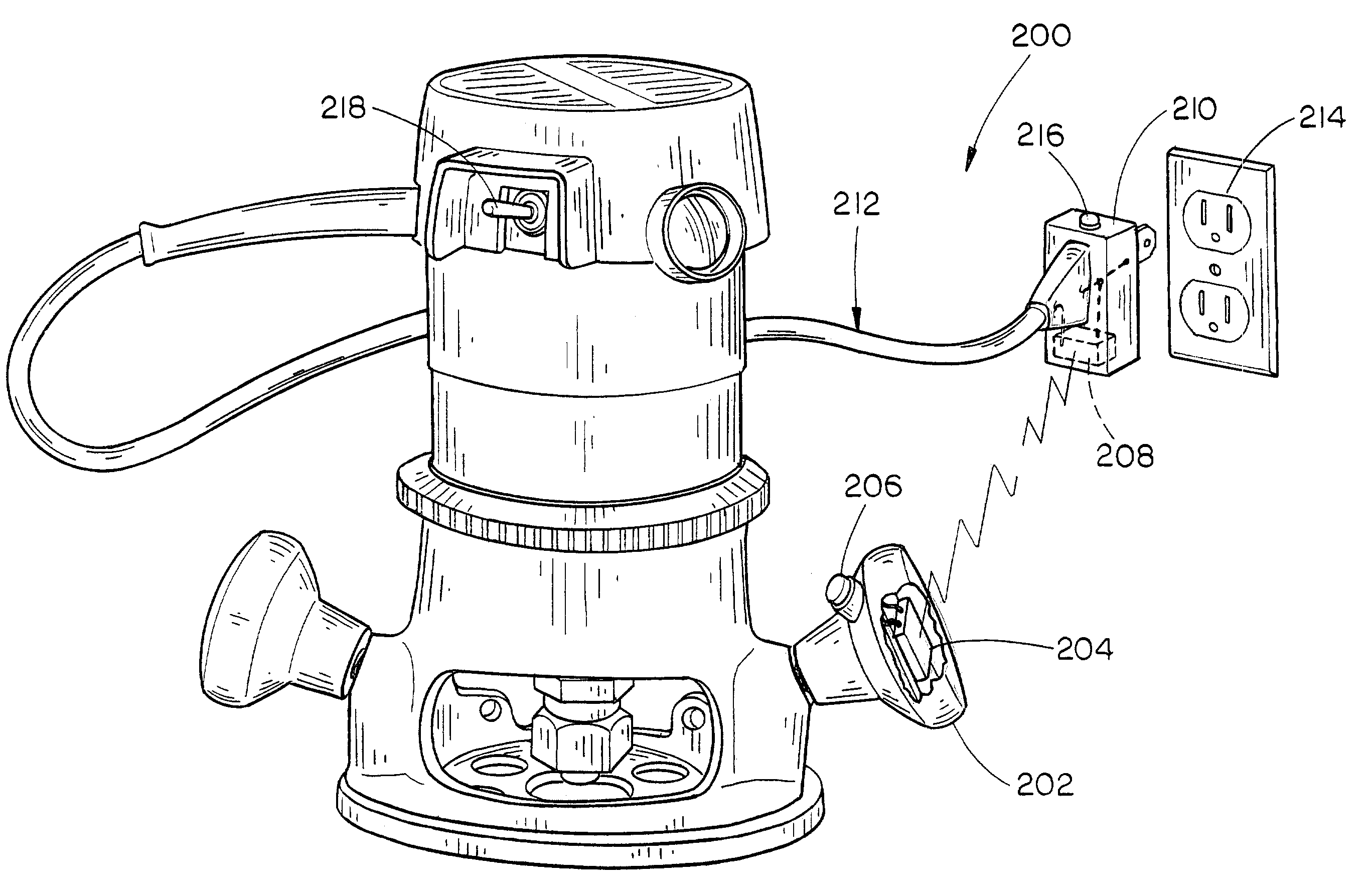

The present invention is directed to a wireless electrical control system for power tool and specifically to a wireless control device for a router. The electrical control system may include a handle suitable for manipulating a router. A switch and a wireless transmitter are disposed in the handle. Communicatively coupled to the transmitter is a wireless receiver capable of receiving the transmissions from the transmitter in the handle. In alternative embodiments the wireless receiver is disposed in the router itself or the receiver is disposed in an outlet unit, which is capable of electrically coupling to the router's electrical cord and an electrical outlet. The wireless receiver of the present invention is capable of controlling the flow of electricity to the electrical system of the router so that the router is capable of being altered from the switch mounted on the handle, thus allowing users to change the power setting while retaining secure control of the router.

Owner:BLACK & DECKER INC

Full-automatic numerical control woodworking, enchasing and forming machine

InactiveCN102173258ARealize full machine automatic processing controlStable structureModel makingEngravingNumerical controlMilling cutter

The invention relates to a full-automatic numerical control woodworking, enchasing and forming machine. A workbench, a main shaft fixed seat and a numerical control device are arranged on a machine body, wherein a cross arm box body which is suspended above the workbench of the machine body is fixed on and extends out from the main shaft fixed seat, a main shaft lifting servomotor is fixed in the cross beam box body, an output shaft of the main shaft lifting servomotor extends out of the top end of the cross beam box body and is connected with a lifting screw rod fixed on the front end surface of the cross beam box body through a belt, a lifting planker which can slide up and down along the lifting screw rod is further sheathed on the lifting screw rod on the front end surface of the cross beam box body, a main shaft high-speed motor is fixed on the lifting planker, a milling cutter is sheathed on the output shaft of the main shaft high-speed motor, an X-axis / Y-axis servomotor, the main shaft lifting servomotor and the main shaft high-speed motor are electrically connected with the numerical control device so that the numerical control device can control the corresponding motors to start and close according to a program, and a lifting structure and the cutting of the milling cutter are controlled by different motors, thereby achieving a more stable structure, and effectively improving the enchasing precision of the milling cutter.

Owner:黄丽汶

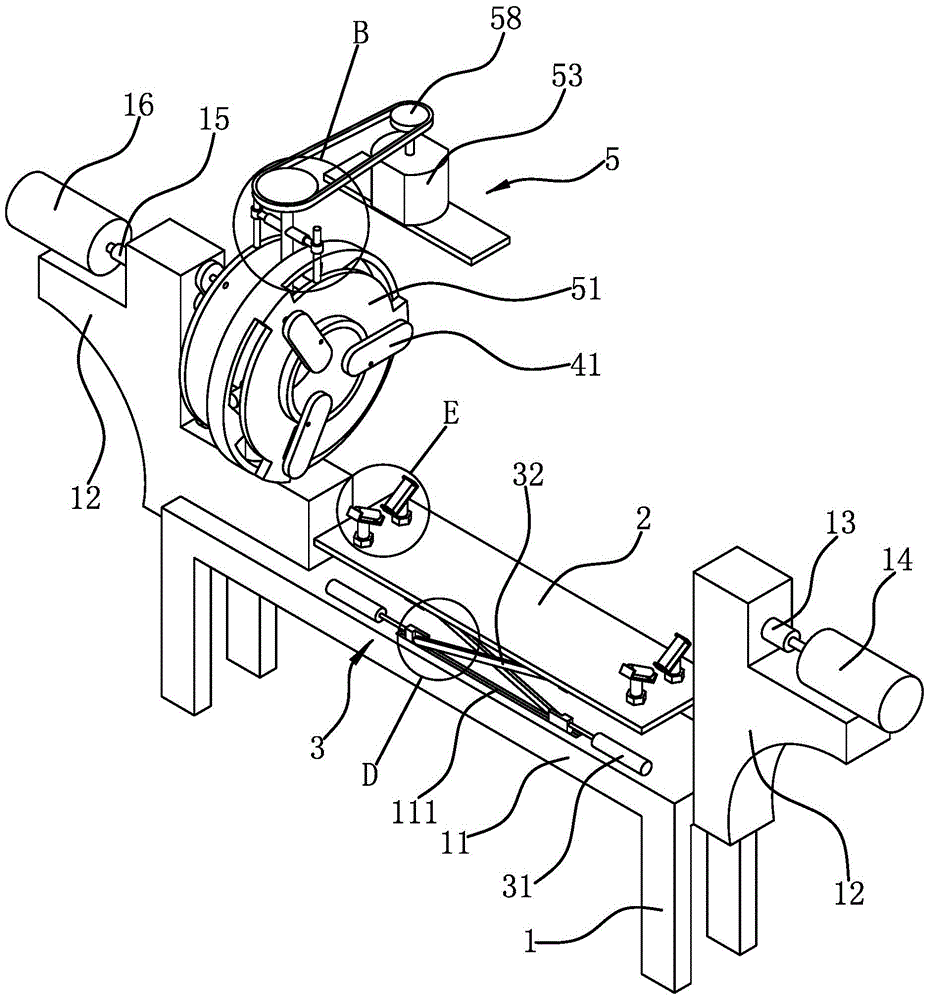

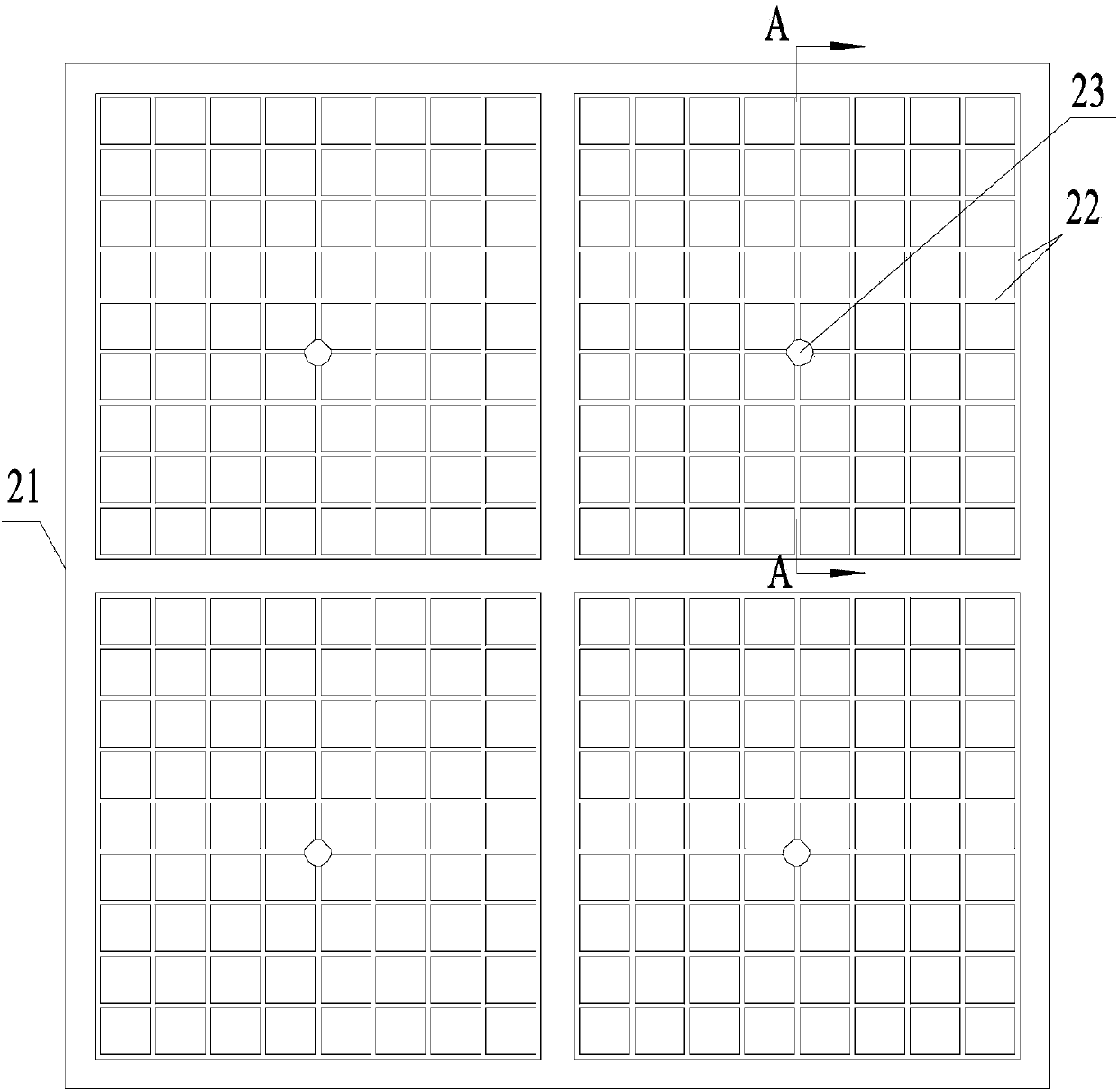

Multi-loading-unit rotary exchange type laser engraving device

InactiveCN101332738AReduce preparation timeImprove efficiencyLaser beam welding apparatusModel makingLaser engravingOperation mode

The invention relates to a multi-carrying unit rotary exchange typed laser carving machine, comprising a laser operation device and a rotary exchange carrying device; the laser operation device consists of a main frame, a laser, an optical path and a laser operation head; the laser operation head is arranged on the main frame; the carving machine also comprises a rotary exchange carrying device which consists of an auxiliary frame, a rotary mechanism and a carrying mechanism which is rotated under the control of the rotary mechanism; the rotary mechanism and the carrying mechanism are arranged on the auxiliary frame; the carrying mechanism is provided with two or more carrying units; each carrying unit is corresponding to the working position; furthermore, each carrying unit sequentially enters in and out of laser working position below the laser operation head of the laser operation device in a rotary exchange type; the existing single working position operation structure is replaced by the rotary exchange carrying device which is provided with the multi-carrying unit, namely, the intermittent and fitful operation mode is replaced by the continuous exchange operation mode, so as to improve the integrated efficiency of the laser operation.

Owner:东莞市粤铭激光技术有限公司

3-d model providing device

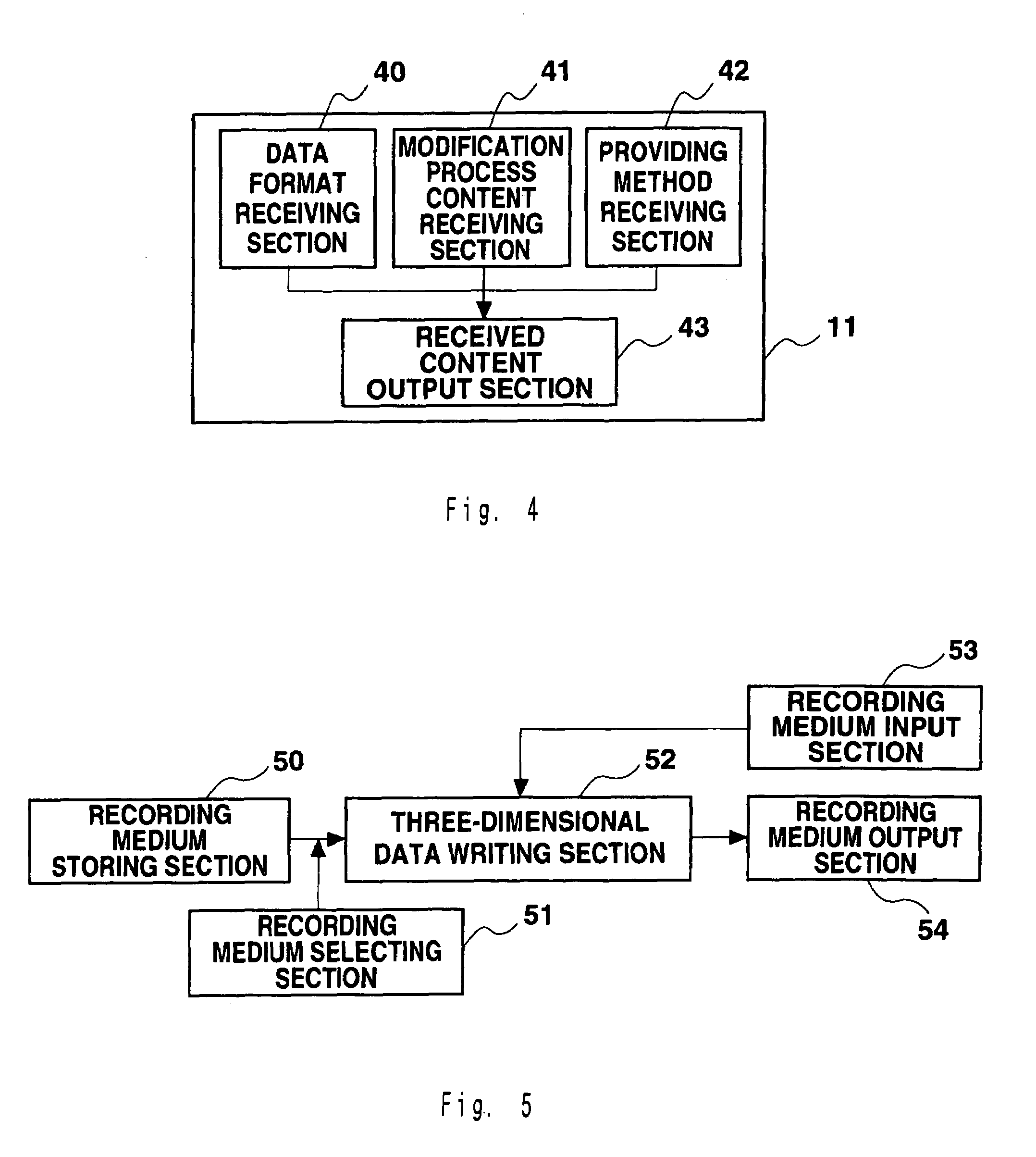

A three-dimensional model providing apparatus in which a customer can easily modify the input three-dimensional data. The apparatus comprises an input section (10) for inputting three-dimensional data, a server section (12) for managing the processes on the three-dimensional data from input to output, a providing section (14) for providing three-dimensional data, a communicating section for communicating the three-dimensional data between the input section, server section, and providing section, a receiving section (11) for receiving instruction contents from the customer, and a converting section (13) for modifying, processing, or converting the three-dimensional data according to the instruction contents.

Owner:DIGIMEDIA TECH LLC

Template engraving machine

InactiveCN103434317AIncrease productivityEasy to operateModel makingEngravingPulp and paper industryAdsorption effect

The invention discloses a template engraving machine. The template engraving machine comprises a rack, wherein the rack is provided with a working table; the working table is provided with a transverse guide rail capable of sliding forward or backward along the working table; a head which can slide left and right along the transverse guide rail is arranged on the transverse guide rail; the working table consists of a PU (Polyurethane) bottom plate and a density board which is arranged on the PU bottom plate; the working table is provided with a regional vacuum adsorption device; the working table is divided into a plurality of independent control regions by the regional vacuum adsorption device; each region can be used for separately performing vacuum adsorption on a processing board in the region; the PU bottom plate in each region is provided with air suction grooves which are transversely and vertically intercommunicated; the PU bottom plate in each region is also provided with an air suction opening which is communicated with the air suction groove; the air suction opening in each region is correspondingly connected with one end of an air suction pipe; the other end of the air suction pipe is connected with a vacuum pump; each air suction pipe is provided with a valve capable of controlling the on / off of the air suction pipe. The template engraving machine is simple and convenient to operate and has good adsorption effect and good dust collection effect.

Owner:HEFEI AORUI DIGITAL CONTROL SCI & TECH

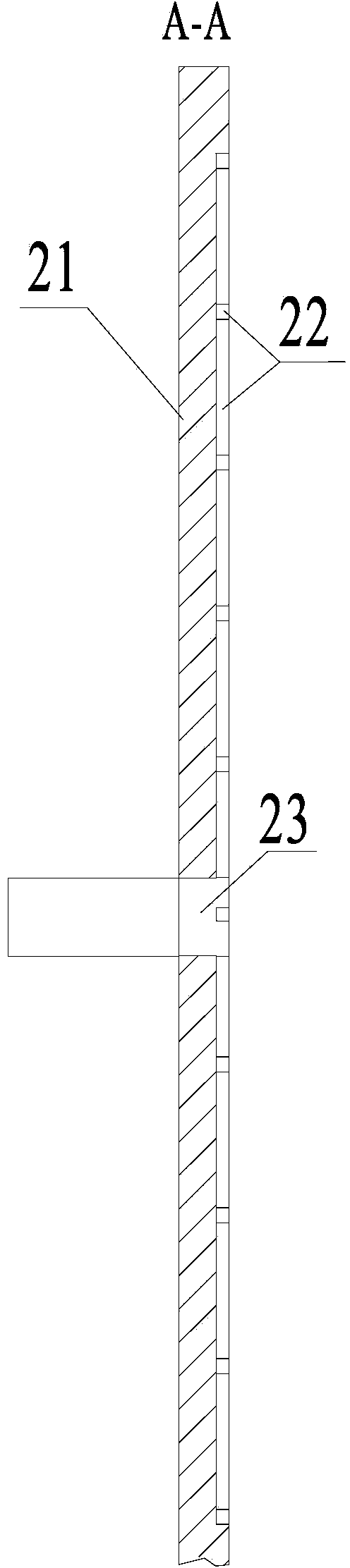

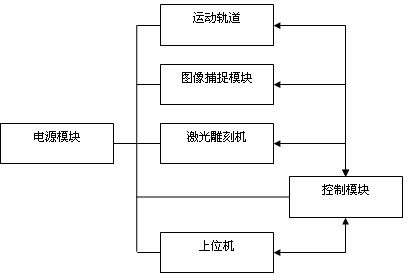

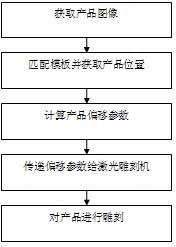

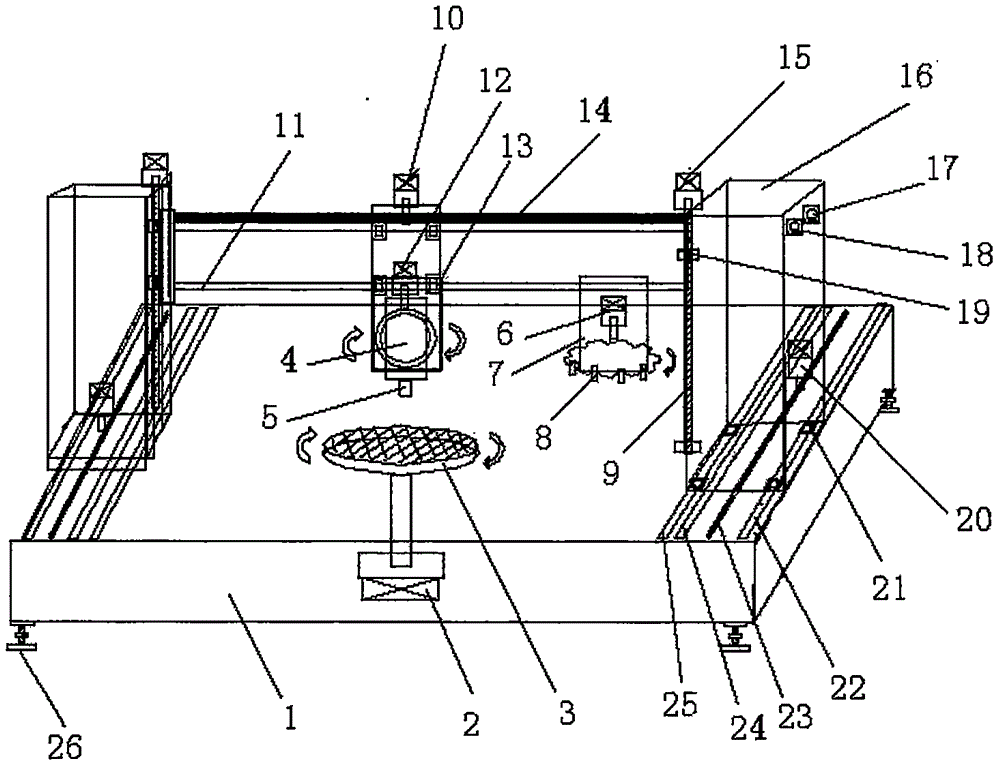

Automatic laser engraving system based on computer vision and service method of automatic laser engraving system

The invention relates to an automatic laser engraving system based on computer vision and a service method of the automatic laser engraving system. The system comprises a movement track, an image capture module, a laser engraving machine, a control module, an upper computer and a power module. The service method of the automatic laser engraving system includes realizing distortion rectification and adjustment of a coordinate system for the image capture module, adjusting a coordinate system of the movement track, setting production parameters, and recording matching information related to positioning of a product during production; conveying the product to a shooting area via the movement track, shooting the product by the image capture module, matching and comparing shot image information with the matching information, obtaining position information of engraved patterns, finally conveying the product to the laser engraving machine via the movement track to realize laser engraving for the product, and completing a production cycle after the laser engraving is completed. The automatic laser engraving system and the service method thereof have the advantages that precision is greatly improved, labor cost is reduced by means of enhancing production efficiency, rejection rate of products is reduced, production success rate of the products is improved, and accordingly production cost is lowered.

Owner:WUHAN UNIV

Numerical control stereoscopic ceramic body relief engraving system

ActiveCN105835581AAchieve multi-functionalitySmall footprintGrinding machinesModel makingNumerical controlControl system

The invention discloses a numerical control stereoscopic ceramic body relief engraving system. The numerical control stereoscopic ceramic body relief engraving system is characterized in that a control system is used for controlling the numerical control stereoscopic ceramic body relief engraving system to work, a gantry walking mechanism is mounted on Y-axis fore-and-aft movement outer slide rails, Y-axis fore-and-aft movement inner slide rails and Y-axis fore-and-aft movement middle slide rails by gantry side plates on two sides, a machining tool is mounted on the gantry walking mechanism by a tool support which is equipped with a tool replacement rotary motor, a spindle motor is further mounted on the gantry walking mechanism and connected with a machine head rotary motor arranged above, a clamp is arranged at the front end of the spindle motor, and a workpiece rotary platform is arranged on a support platform and driven to rotate by the workpiece rotary motor. The numerical control stereoscopic ceramic body relief engraving system integrates engraving, cutting, drilling and polishing of ceramic bodies to achieve multiple purposes, occupies a small area, realizes multifunctional and automatic machining equipment, is a planar and stereoscopic integrated machine, and is high in production efficiency.

Owner:山东正夏自动化股份有限公司

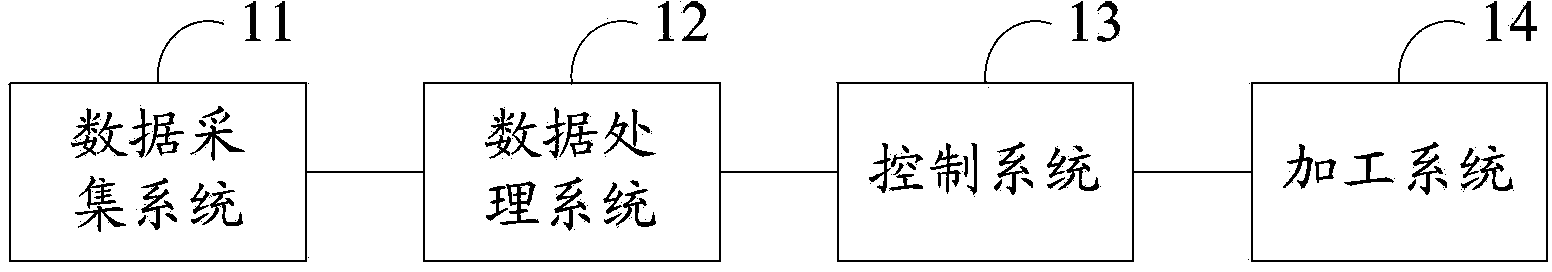

Numerical control precise wood carving processing system

InactiveCN103909776AImprove processing efficiencyImprove machining accuracyProgramme controlComputer controlData processing systemNumerical control

The invention discloses a numerical control precise wood carving processing system. The numerical control precise wood carving processing system comprises a data acquisition system, a data processing system, a control system and a processing system, wherein the data acquisition system is electrically connected with the data processing system and is used for acquiring image information of the wood carving and sending the image information to the data processing system; the data processing system is electrically connected with the control system and is used for processing the received image information into codes capable of being identified by the control system and sending the codes to the control system; the control system is electrically connected with the processing system and is used for reading the codes, simulating a processing path, outputting the codes and controlling the processing system to process. The numerical control precise wood carving processing system is capable of finishing the complex processing technique and overcoming the disadvantages of low processing efficiency, unideal processing precision and unstable control system of a traditional machine tool.

Owner:北京建筑工程学院 +1

Surface-treated three-dimensional laser etching process

InactiveCN102616067AExquisite three-dimensional pattern effectPretreated surfacesCoatingsLaser etchingLacquer

The invention discloses a surface-treated three-dimensional laser etching process. Ink is sprayed or silk-printed on the back side of a transparent plastic casing; due to the adoption of laser etching, three-dimensional uneven patterns are represented in products, UV (Ultraviolet) primer is prayed on the products and UV or PU (Poly Urethane) colored paint is electroplated on the products; and gradient paint, middle paint and finish paint are sequentially sprayed on the front sides of the products. According to the surface-treated three-dimensional laser etching process disclosed by the invention, a delicate three-dimensional pattern effect on the surface of a coating is realized and patterns are obtained by laser etching.

Owner:SHENZHEN LIANMAO PLASTIC

System and method for generating instructions for customization

ActiveUS7856285B2Planing/slotting machinesComputer aided designNatural language processingSymbol mapping

A method of creating a triangulated surfaces for generating machine readable instructions for customization is provided. The method comprises selecting text or symbols. The text or symbols are spaced. The text or symbols are mapped between first and second curves. Triangulated surfaces are generated from the mapped text or symbols. The triangulated surfaces are converted to machine readable instructions.

Owner:JOSTENS INC

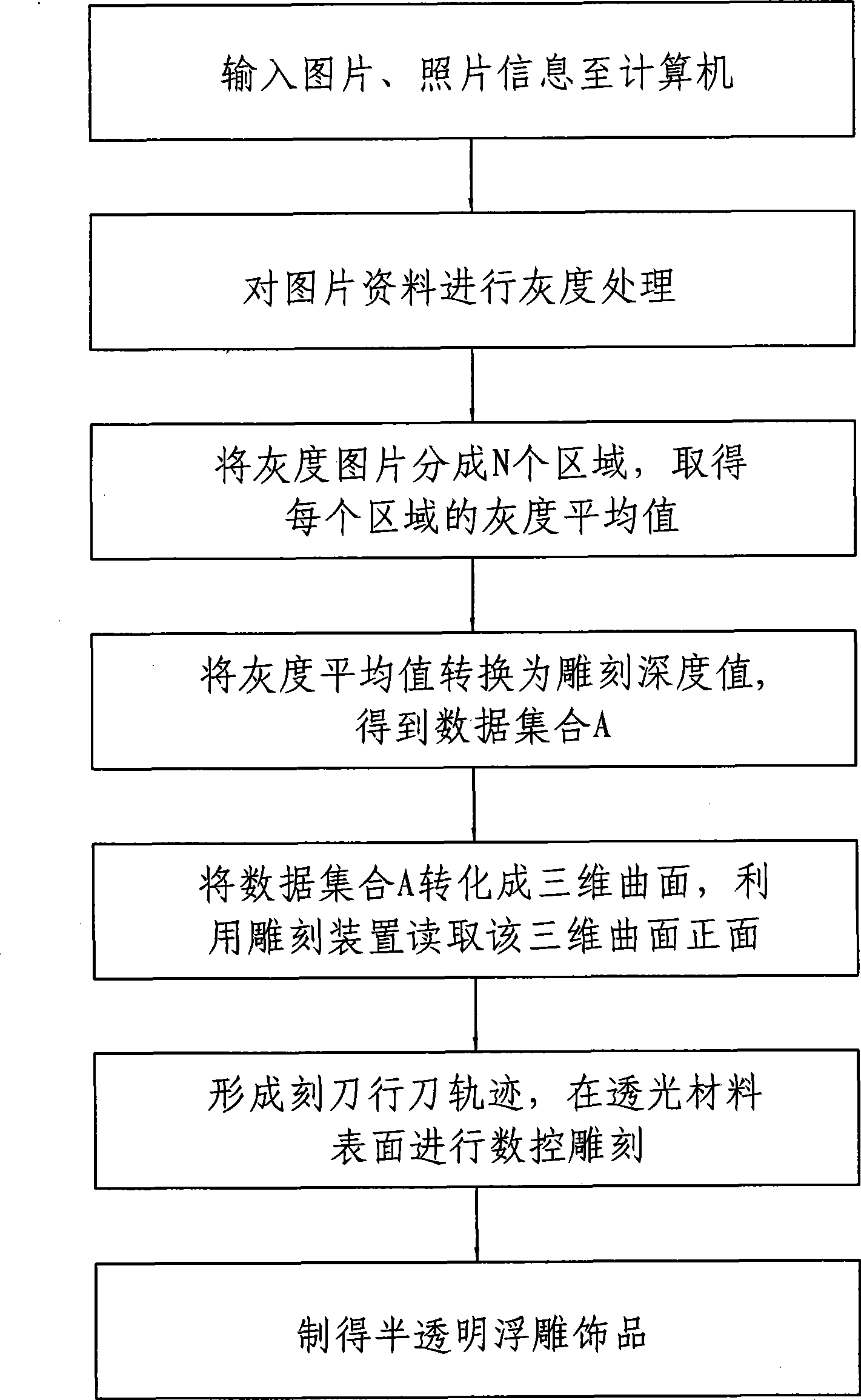

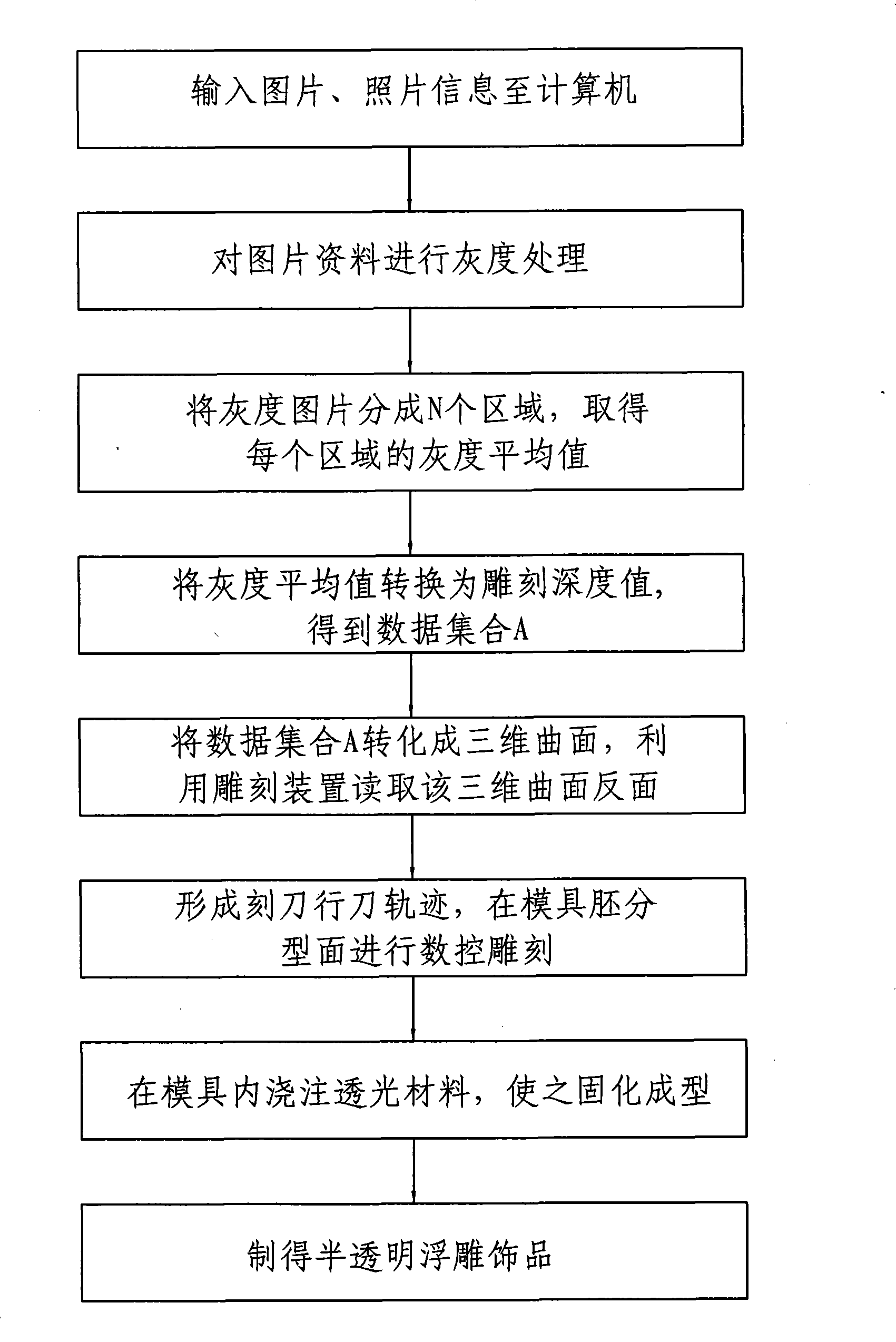

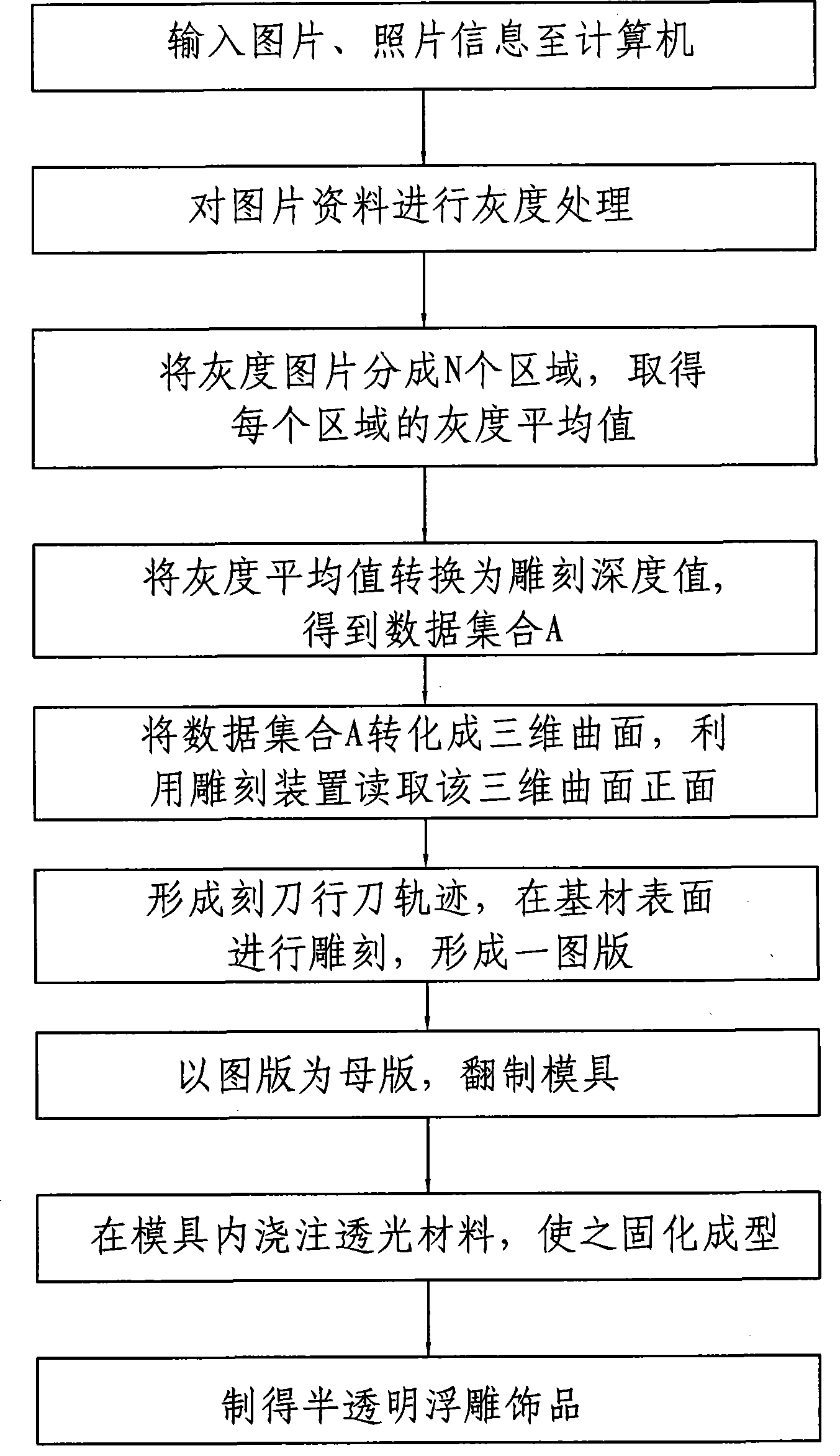

Method for preparing semi-transparent relief ornament

InactiveCN101445017AMeet the requirements of engraving effectLow costOrnamental structuresImage data processing detailsComputer scienceGrayscale

The invention relates to the technical field of ornament carving, in particular to a method for manufacturing a semi-transparent relief ornament, comprising the procedures as follows: image information is input into a computer, greyscale processing is carried out so as to gain greyscale images; the greyscale images are divided into N regions and the greyscale means of all regions are gained; the greyscale means are converted into carving depth values; the carving sequence and carving depth values of all regions are programmed into a control program of a carving device so as to form a cutter-moving program; the carving device carries out the carving on the surface of the material according to the cutter-moving program, thus forming the relief pattern and manufacturing the semi-transparent relief ornament. The method has the effects of fine and realistic carving patterns, the used equipment has low cost and the applicable carving material has wide source.

Owner:陆宏业

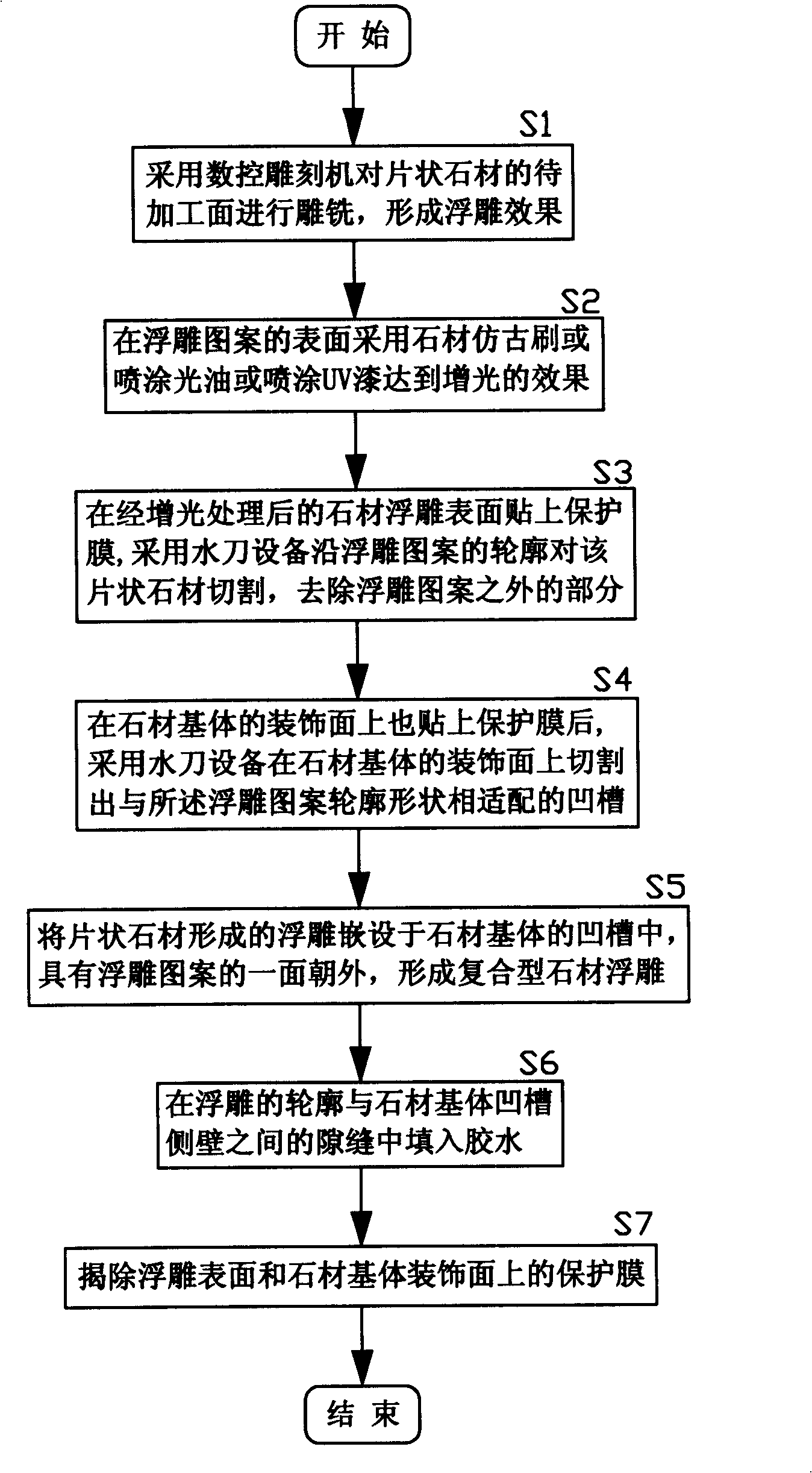

Mixed mode stone embossed preparing technique and adoptive sculpturing machine

InactiveCN101254729ASame qualityReduce laborOrnamental structuresArtistic surface treatmentNumerical controlMixed mode

The manufacture process of composite stone relief comprises the following steps: engraving and milling stone sheet on the surface to be processed by a numerical control engraving machine to form relief effect; cutting the stone sheet along the profile of the relief patter by water-jet equipment to remove sections outsides the relief pattern; cutting a decorative surface of a base body by the water-jet equipment to form a groove matched with the relief pattern in profile shape; and inlaid the relief formed on the stone sheet in the groove of the base body to make the side having the relief pattern facing outwards to obtain the composite stone relief. The equipment adopted includes the numerical control engraving machine and the water-jet equipment. The process can greatly reduce the desired labor force, improve the production efficiency and facilitate large-batch and large-scale production, and can ensure the product quality to make all products same in quality.

Owner:NANAN BESTTIME STONE

Workpiece rotating device for numerical control engraving machine

InactiveCN107891694AImprove processing efficiencyImprove processing qualityModel makingEngravingNumerical controlEngineering

The invention discloses a workpiece rotating device for a numerically controlled engraving machine, which comprises a workbench, a rotating tray is arranged on the upper end of the workbench, and an annular block is fixedly connected to the bottom edge of the rotating tray, and the upper end of the workbench The inner wall is provided with an annular clamping groove corresponding to the annular clamping block, and a weight sensor is installed at the center of the bottom wall of the clamping groove, and several driving devices are uniformly surrounded on one side of the inner wall of the clamping groove, and the driving device is installed There is a controller, one side of the driving device is provided with a telescopic rod, and the end of the telescopic rod away from the driving device is fixedly connected with a fixed plate, and the outer wall side of the fixed plate is fixedly connected with a clamping plate through several springs, so The bottom wall of the rotary tray is fixedly connected with a connecting shaft. The invention is simple in structure and easy to operate, and can carry out rotary engraving after the workpiece is fixed, improves the efficiency and quality of workpiece processing, and satisfies the needs of workpiece processing.

Owner:湖北瑞联智能机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com