Template engraving machine

A template engraving and frame technology, applied in engraving, model processing, decorative art, etc., can solve the problems of unsuitable clothing templates, low production efficiency, slow cutting speed, etc., achieve high production efficiency, self-adjustment of height, and guarantee normal The effect of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

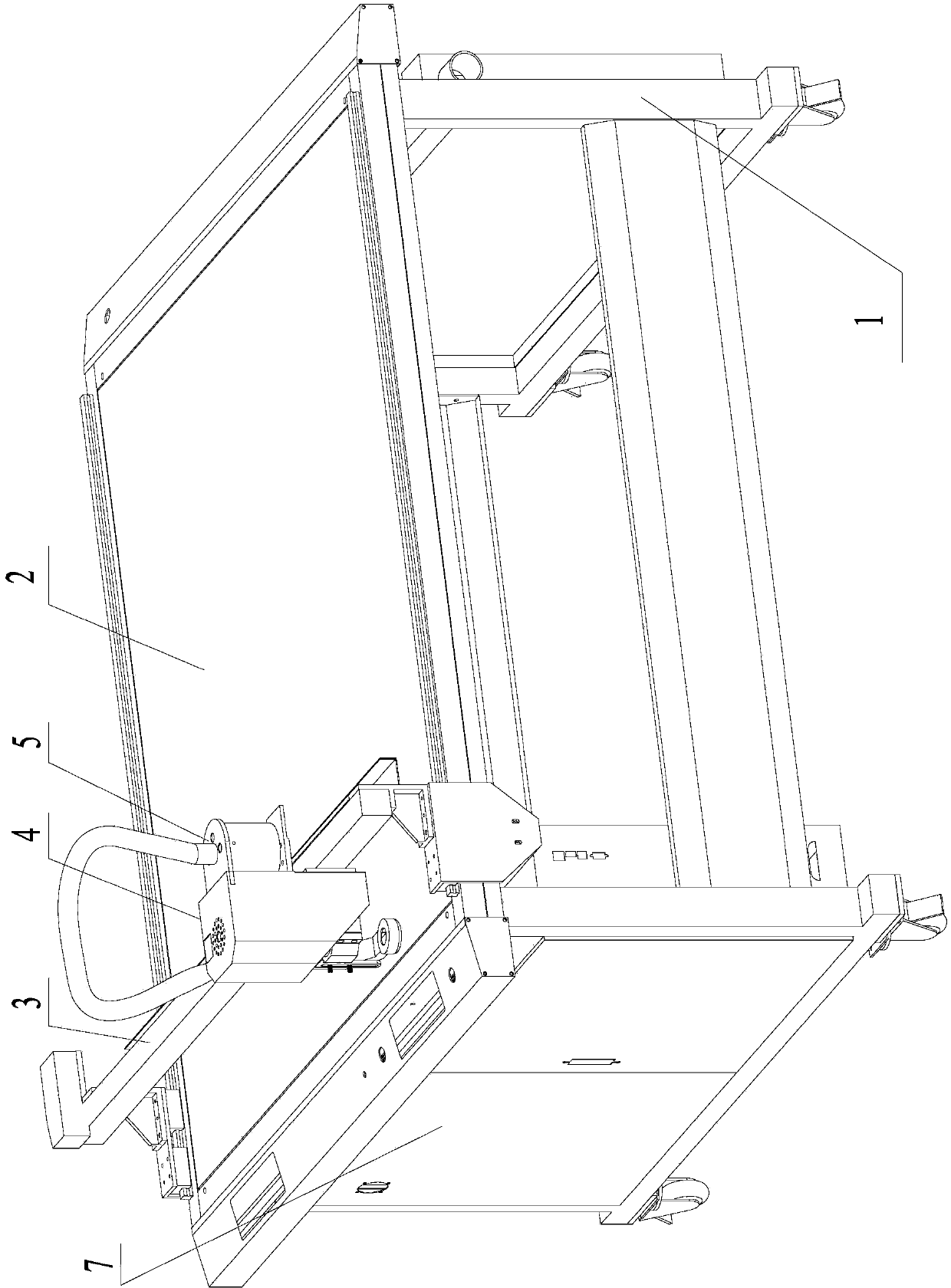

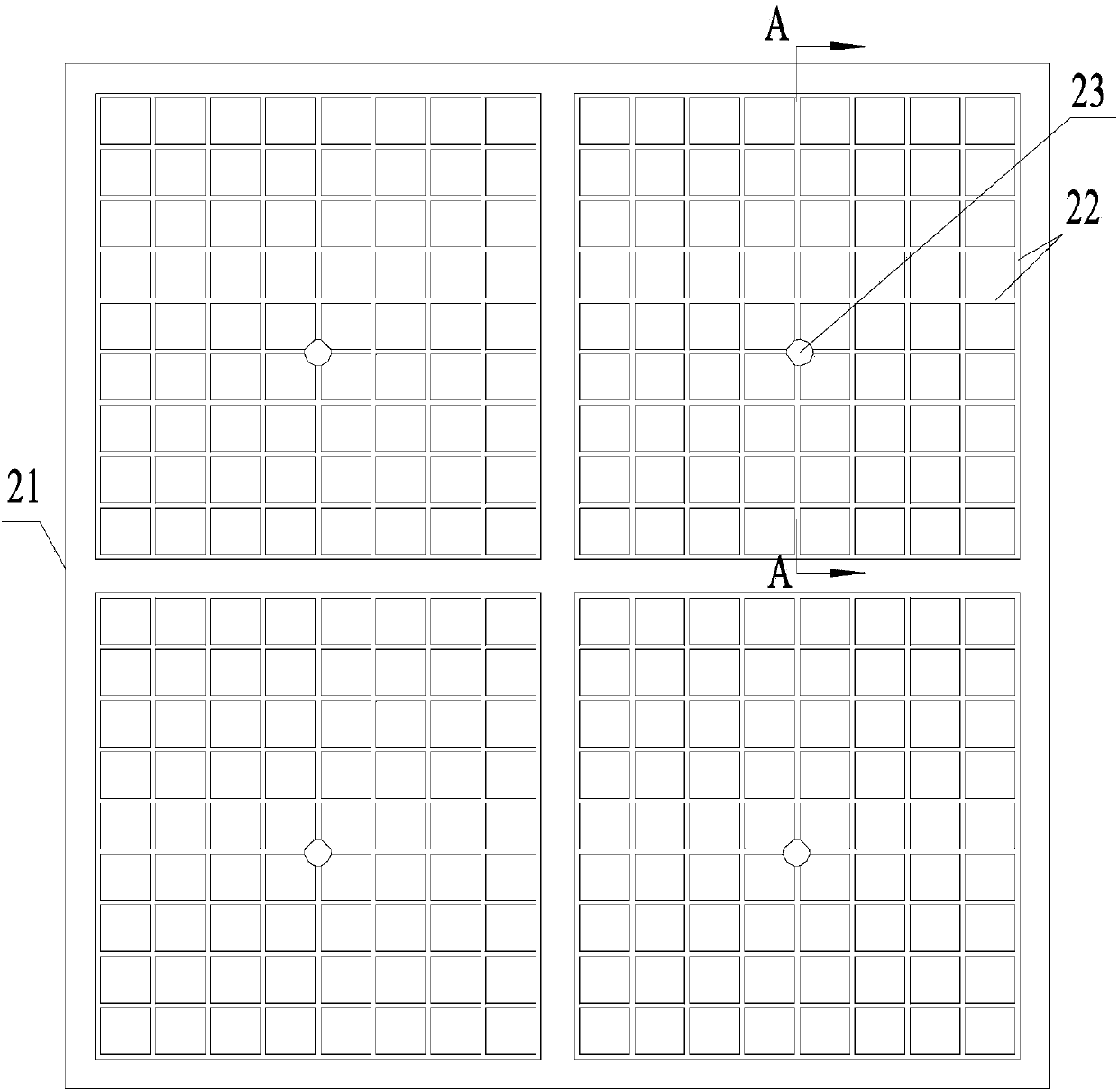

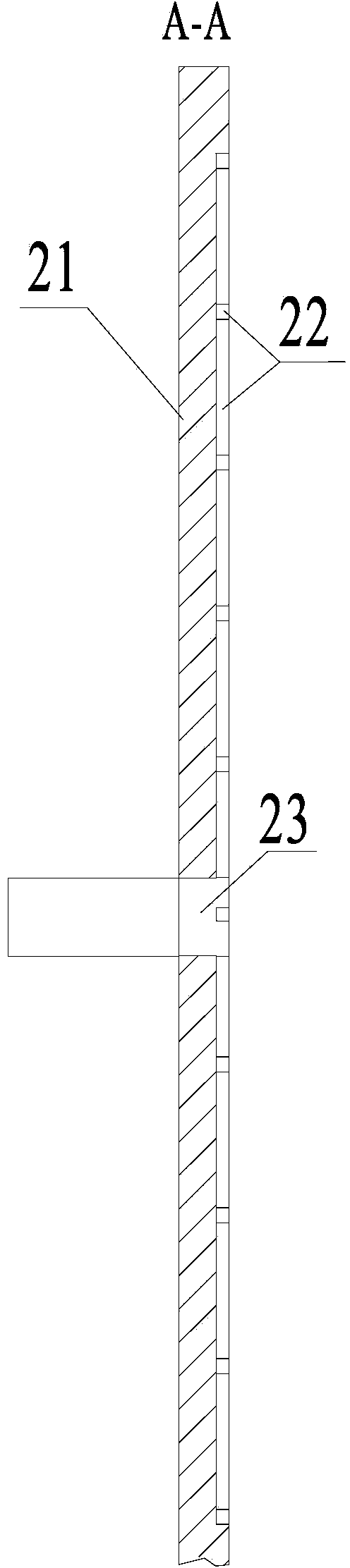

[0019] see figure 1 , figure 2 and image 3 , the template engraving machine that the present invention provides, comprises frame 1, and frame 1 is provided with workbench 2, is provided with control box 7 under workbench 2, and workbench 2 is provided with and can slide along the transverse direction of workbench 2 back and forth. The guide rail 3 and the horizontal guide rail 3 are provided with a machine head 4 that can slide left and right along it. The workbench 2 is composed of a PU base plate 21 and a density board placed on the PU base plate 21. Due to the good air permeability of the density board, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com