Automatic feeding and blanking mechanism for lens grinder

An automatic loading and unloading and grinding machine technology, applied in the field of loading and unloading, can solve the problems that the position of the sheet material cannot be single and accurate, it is difficult to guarantee product quality, and there is no automatic loading and unloading function, so as to improve production efficiency and product qualification rate, and easily Controlling and avoiding duplication of effort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

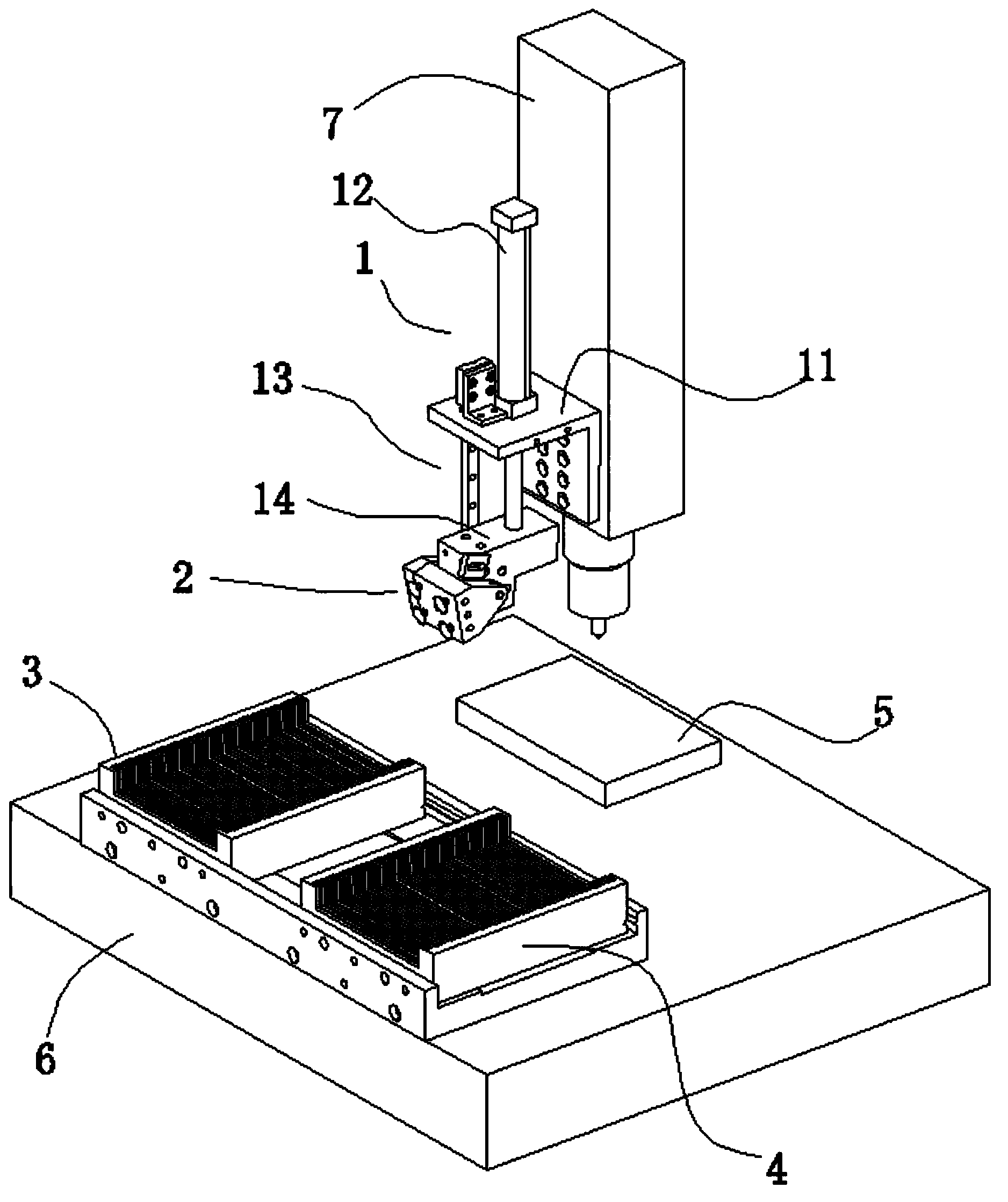

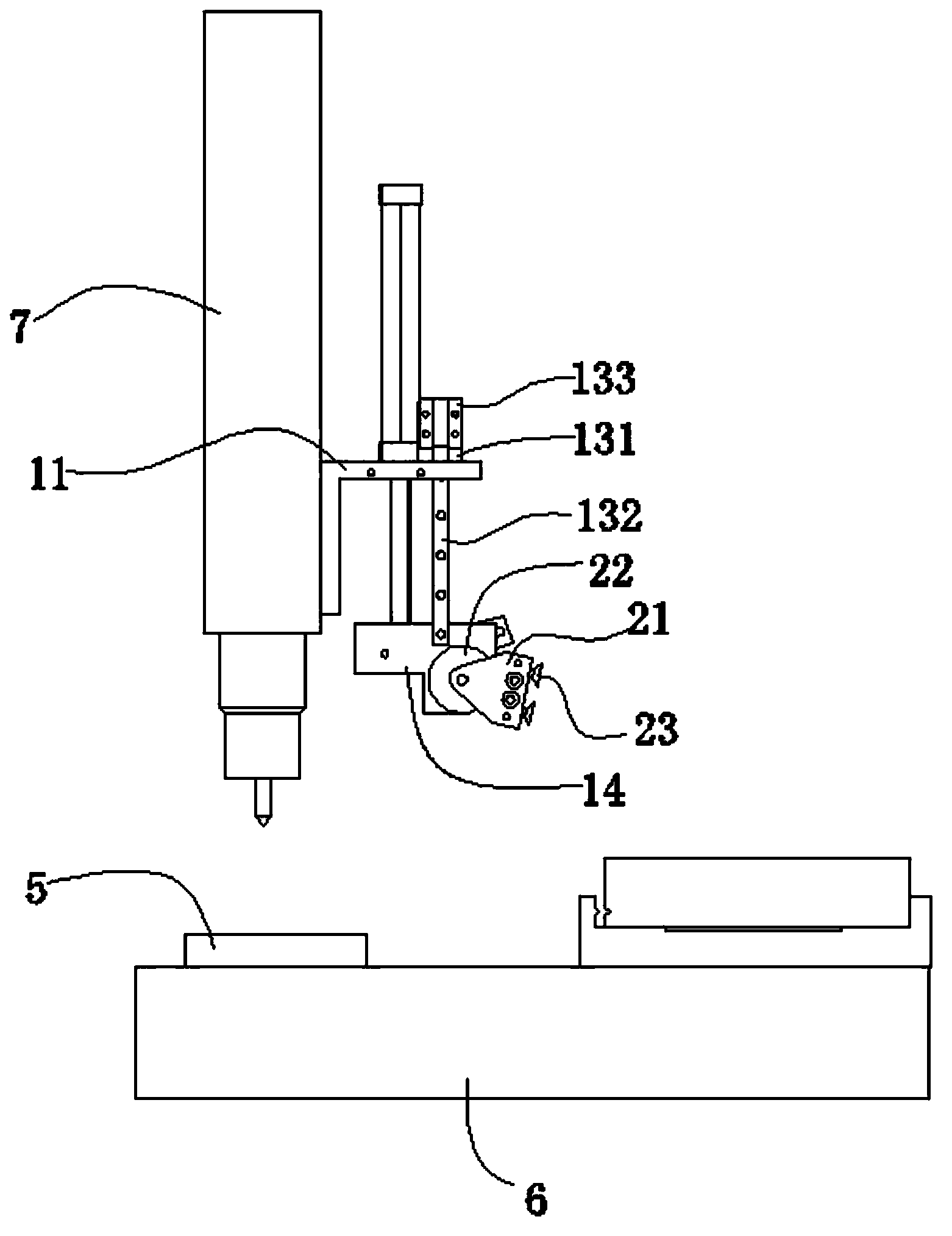

[0015] Examples, see figure 1 and figure 2 , an automatic loading and unloading mechanism for a lens grinder provided in this embodiment, which includes a lifting assembly 1, an overturning assembly 2, a loading frame 3, a blanking frame 4, a processing platform 5, and a mobile workbench 6. The loading The frame 3 and the blanking frame 4 are arranged side by side at the front end of the mobile workbench 6, the processing platform 5 is set on the mobile workbench 6 corresponding to the rear position between the loading frame 3 and the blanking frame 4, and the lifting assembly 1 is set On the headstock 7, the turning assembly 2 is arranged on the lifting assembly 1, and is driven by the lifting assembly 1 to move upwards or downwards accordingly.

[0016] The lifting assembly 1 includes a fixed base 11, an upper and lower cylinder 12, a guide bracket 13 and a fixed block 14, the guide bracket 13 is vertically arranged on the fixed base 11, and the fixed block 14 is fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com