Three dimension color printing quick forming device and method

A color printing and fast technology, applied in the advanced manufacturing field of the manufacturing industry, can solve the problems that monochrome 3D printing cannot fully meet the practical application, and achieve the effect of powerful color 3D printing function, fast forming speed and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

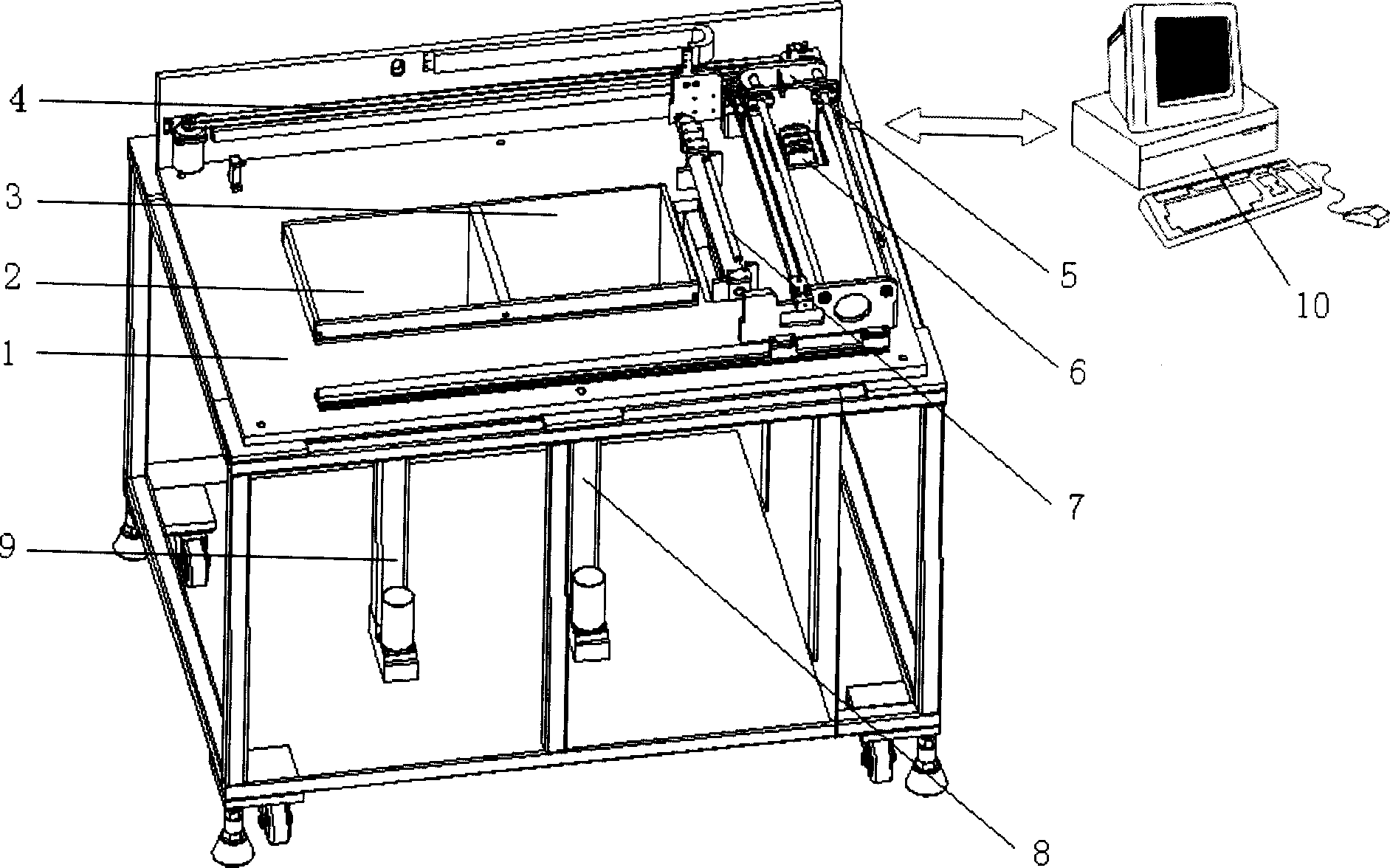

[0023] The technical idea of realizing the above-mentioned invention is that, according to the basic principle of rapid prototyping manufacturing technology, that is, the principle of layered manufacturing, the layered section data of the three-dimensional model processed by the professional layered software of the computer drives the precision printing head, according to the cross-sectional shape of the model Spray liquids of various colors on the pre-laid powder layer, so that part of the powder is bonded together to form a colorful cross-sectional figure. After one layer of powder is formed, another layer of powder is laid to bond the next layer of powder. The unbonded powder plays a supporting role in the molding of the part. This cycle continues until the workpiece is completed, and then the colored shaped parts are obtained through post-processing.

[0024] The three-dimensional color printing rapid prototyping device of the present invention includes:

[0025] An X-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com