Multi-station digital-controlled carving machine

A CNC engraving machine and multi-station technology, applied in the field of engraving, can solve the problems of being unsuitable for automatic CNC engraving, inability to guarantee accuracy, and low efficiency, and achieve good economic benefits and application value, wide application, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

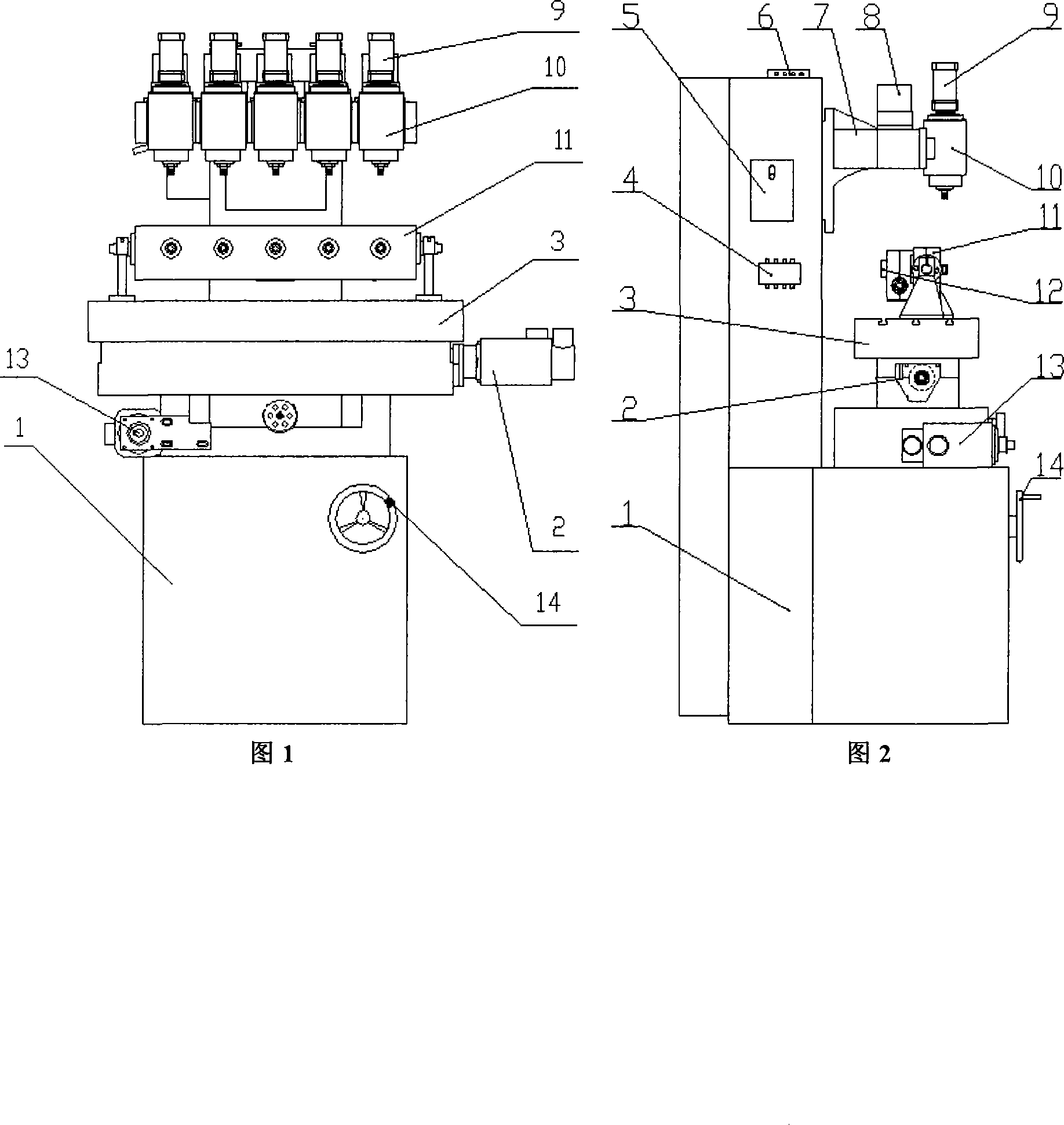

[0019] The structure of the multi-station CNC engraving machine provided by the present invention is shown in Figures 1 to 4: it includes a bed 1, an engraving mechanical part and an electrical part. details as follows:

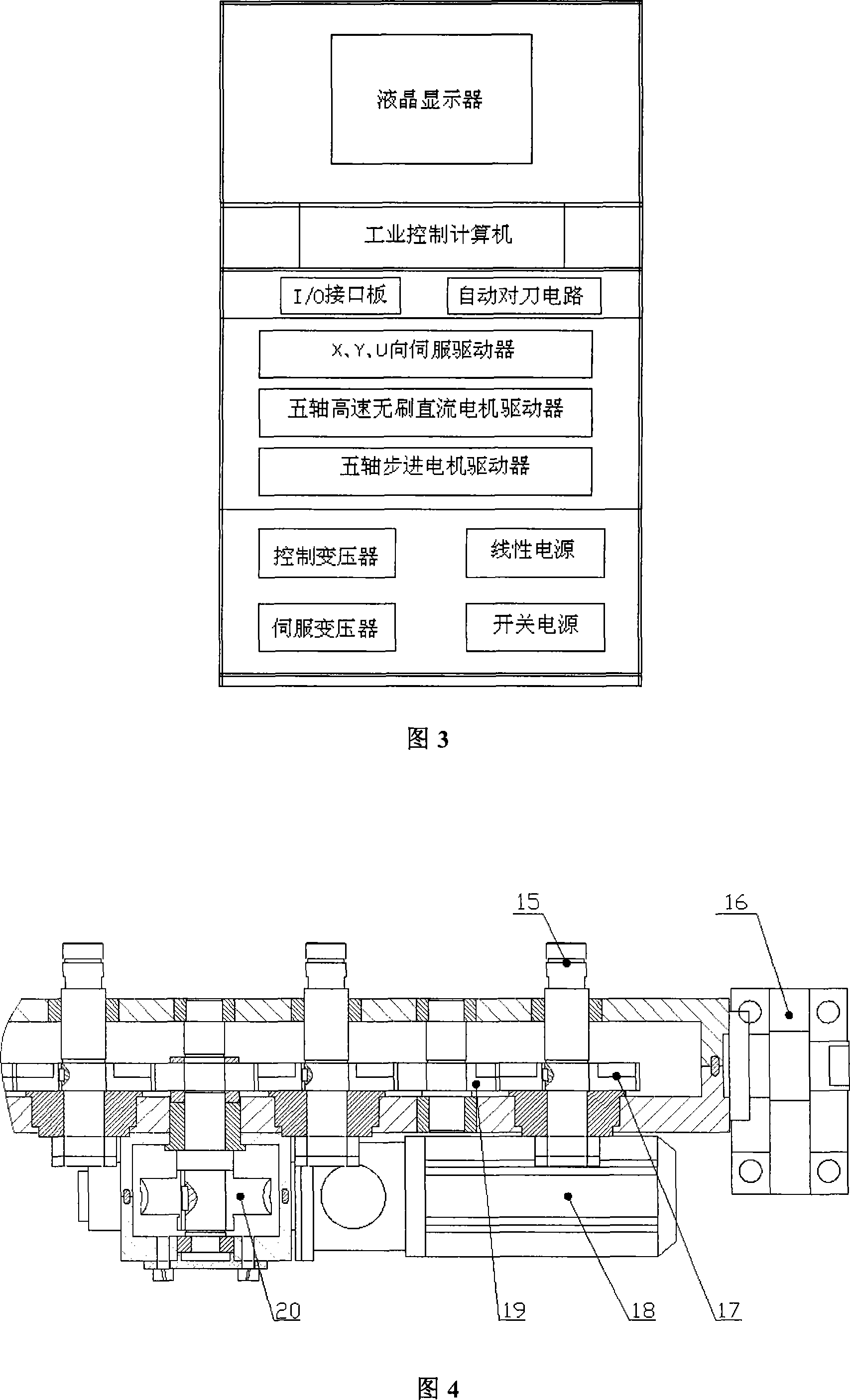

[0020] Electrical part: including hardware and software. The hardware adopts the control core composed of industrial control computer and motion control card. The motion control card is connected to the multi-axis stepping motor or digital servo motor controlled by it through data lines; the software is Visual C++ compiles the application program running under Windows2000 / XP and the application program of 51 single-chip microcomputer.

[0021] The engraving machine part is mainly composed of an engraving head 10, a tool setting device, and a feeding device including an automatic feeding mechanism for the engraving head. Among them: the engraving head 10 uses a brushless DC motor 9 to drive the central axis mechanism; the tool setting device adopts multiple i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com