Patents

Literature

52results about How to "High compression force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

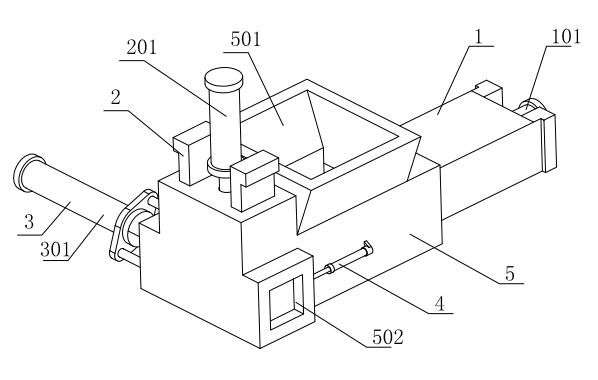

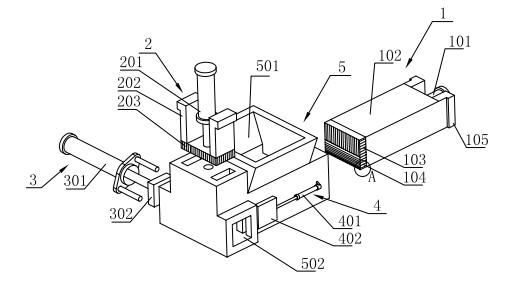

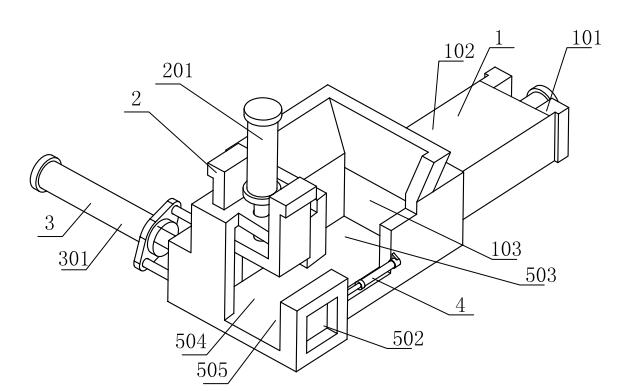

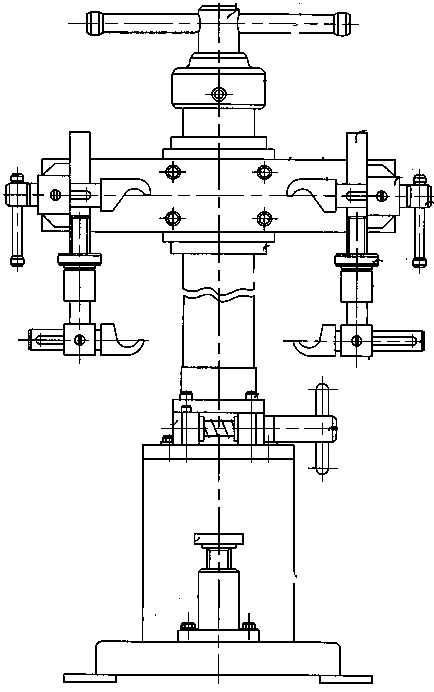

Scrap metal briquetting machine

The invention relates to a scrap metal briquetting machine which comprises a machine body and a three-way hydraulic device, wherein an inlet hopper bin is arranged on the top of the machine body, an outlet is arranged in front of the lower part, a door opening device is arranged at the outlet, and the inside part of the machine body is divided into a pre-extrusion cavity, a secondary extrusion cavity and a third extrusion cavity; the three-way hydraulic device comprises a lateral hydraulic device, a vertical hydraulic device and a longitudinal hydraulic device. Scrap metal is extruded in three ways through the three-way hydraulic device, the compression mode is reasonable, the compression force is great, great compression ratio can be achieved, and the compression efficiency is high. The continuous feeding of the hopper bin can be realized, a lateral pusher head can directly enter the next working cycle after resetting, so that the cycle time is greatly saved, and the working efficiency of the machine is high. A groove is adopted between the pusher head and the inner wall of the machine body for cooperation, therefore, better cooperation can be realized, the service life is long, and the security is good.

Owner:JIANGYIN RUIFENG HYDRAULIC MACHINE CO LTD

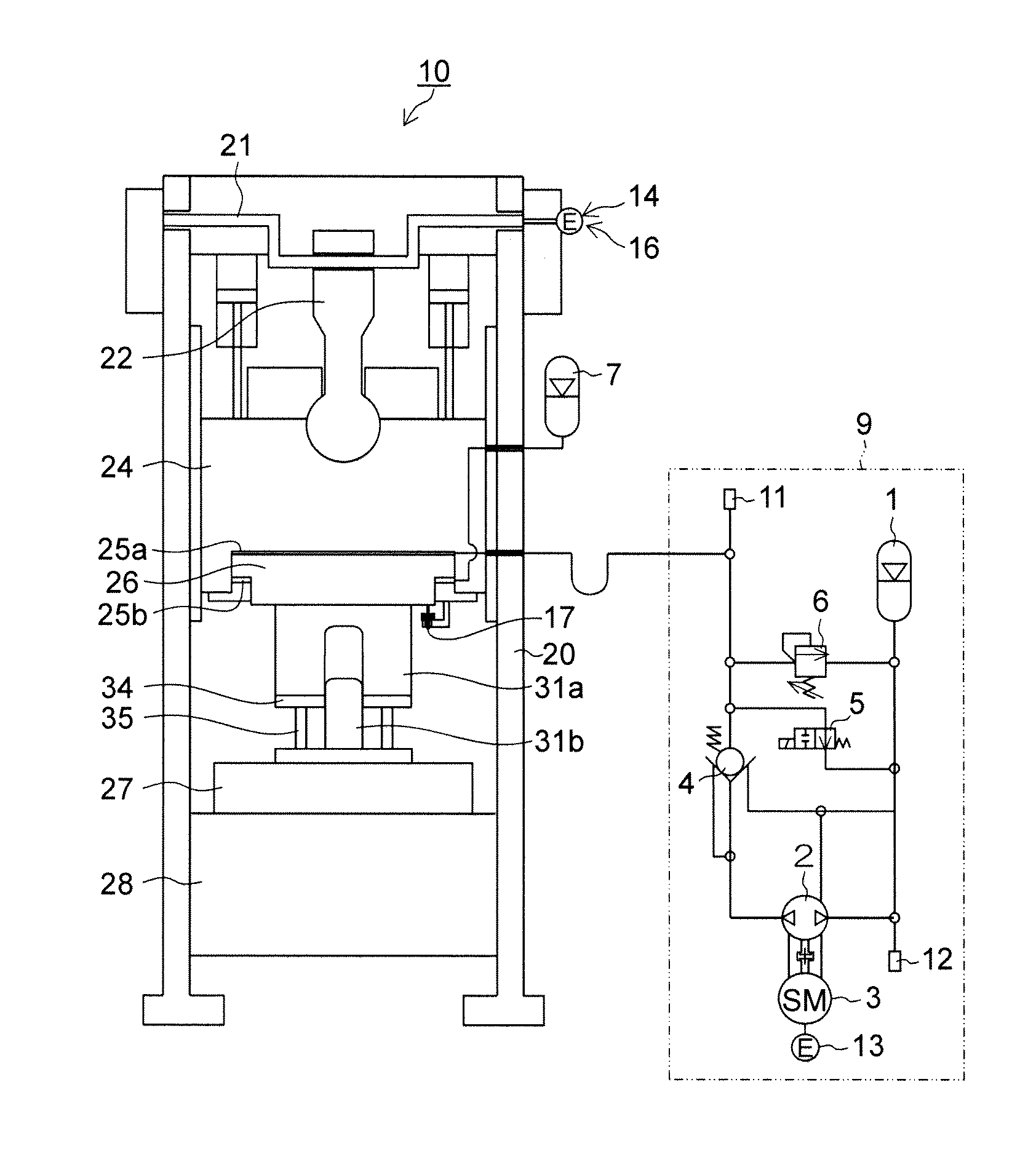

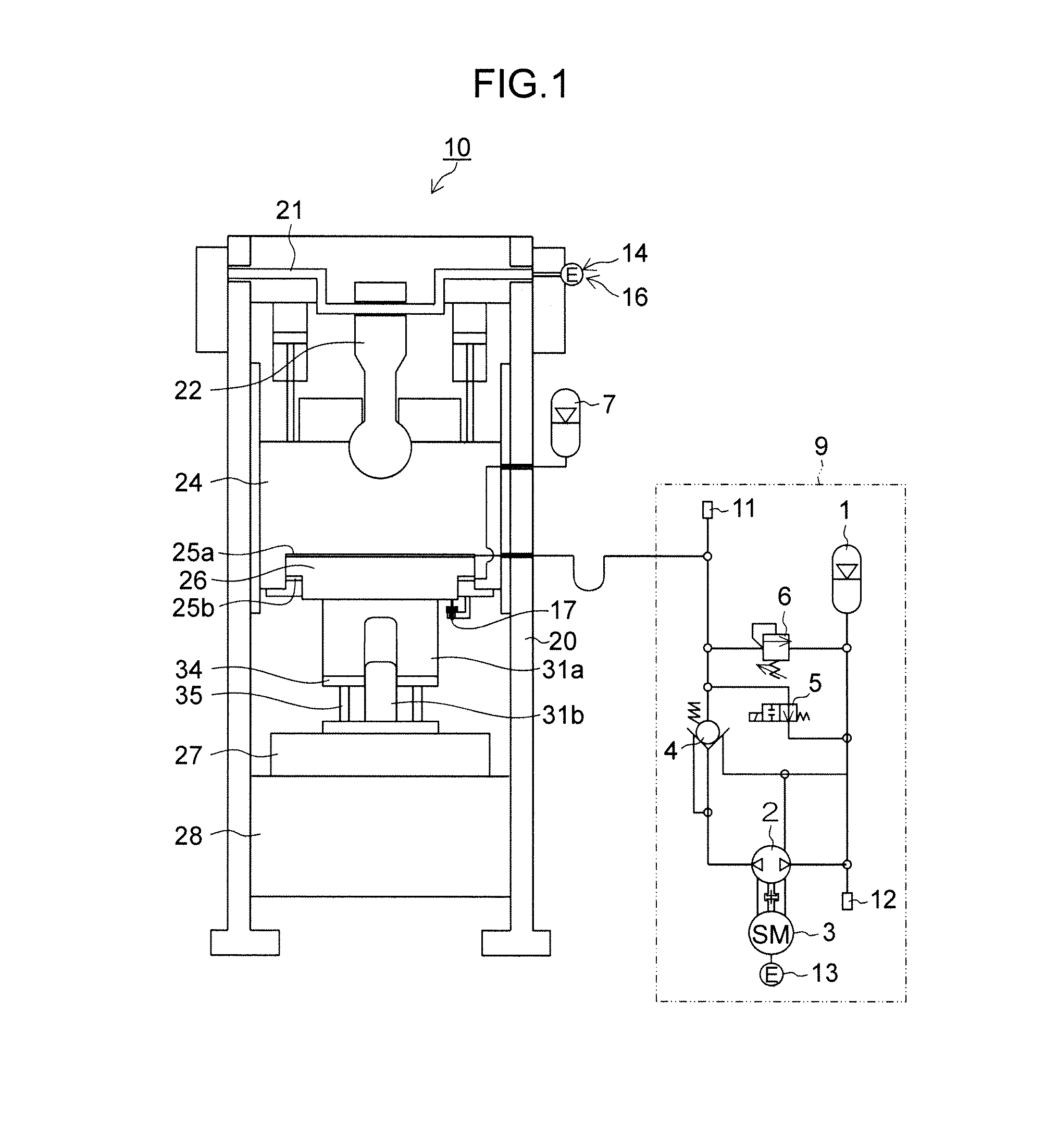

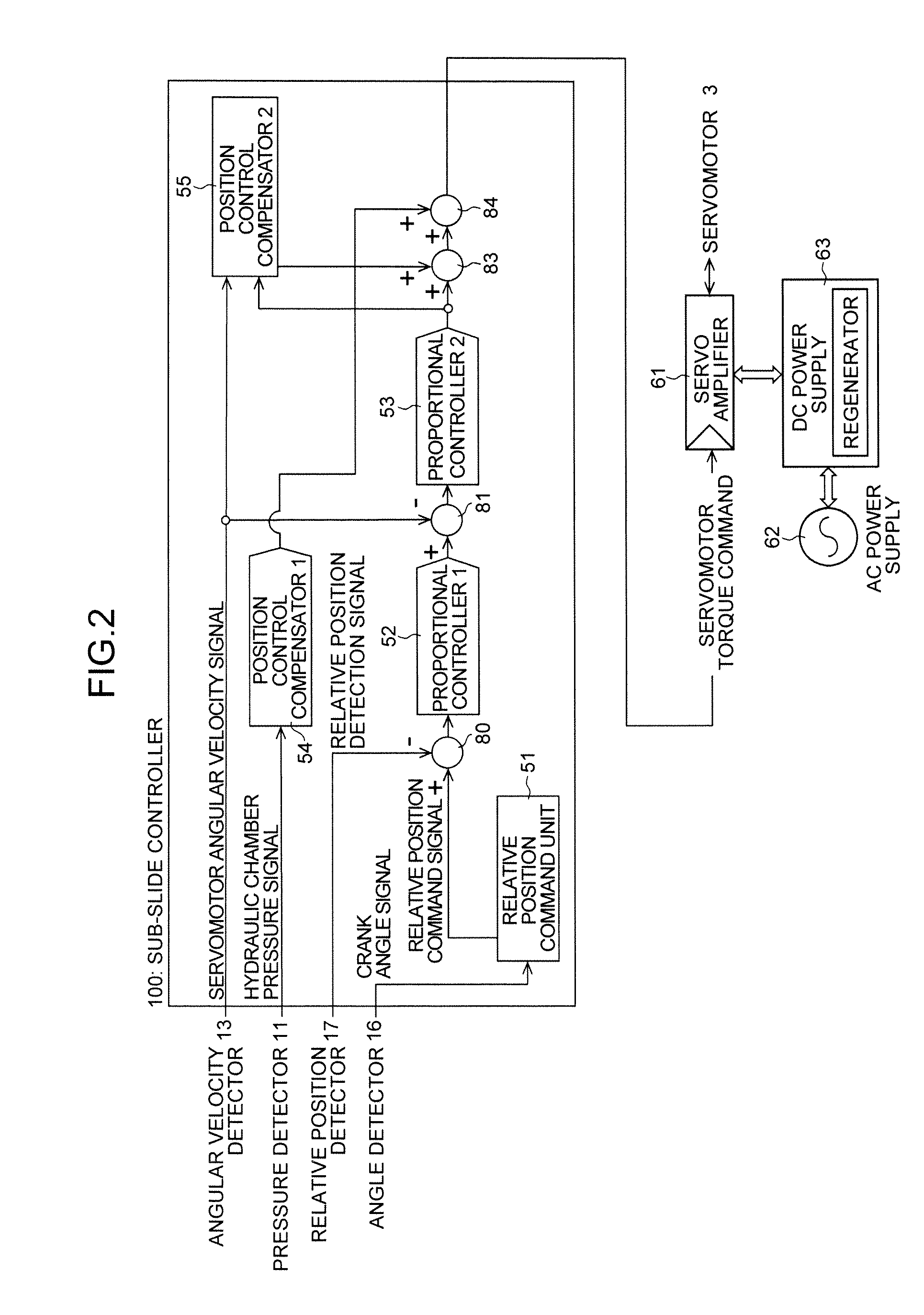

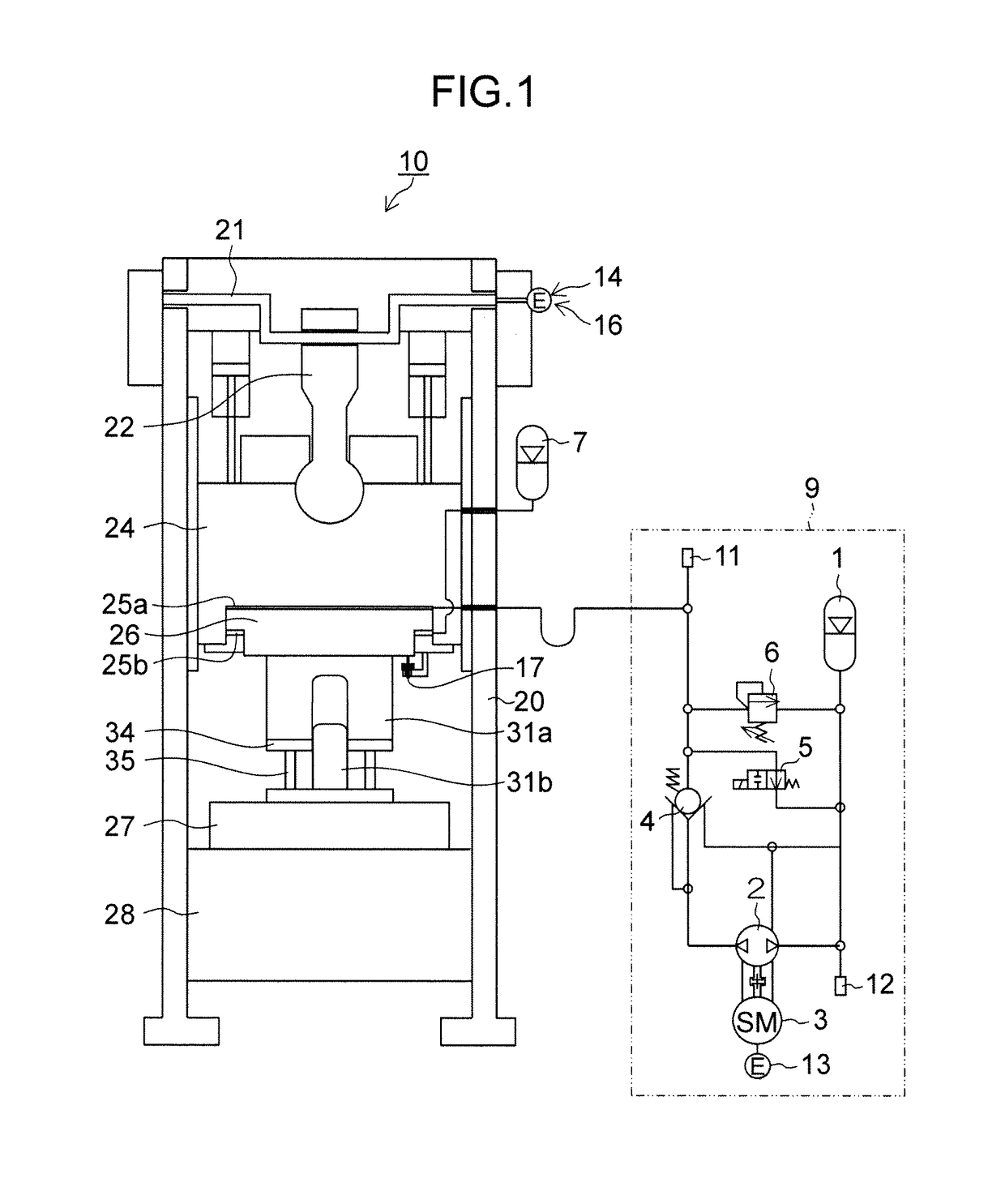

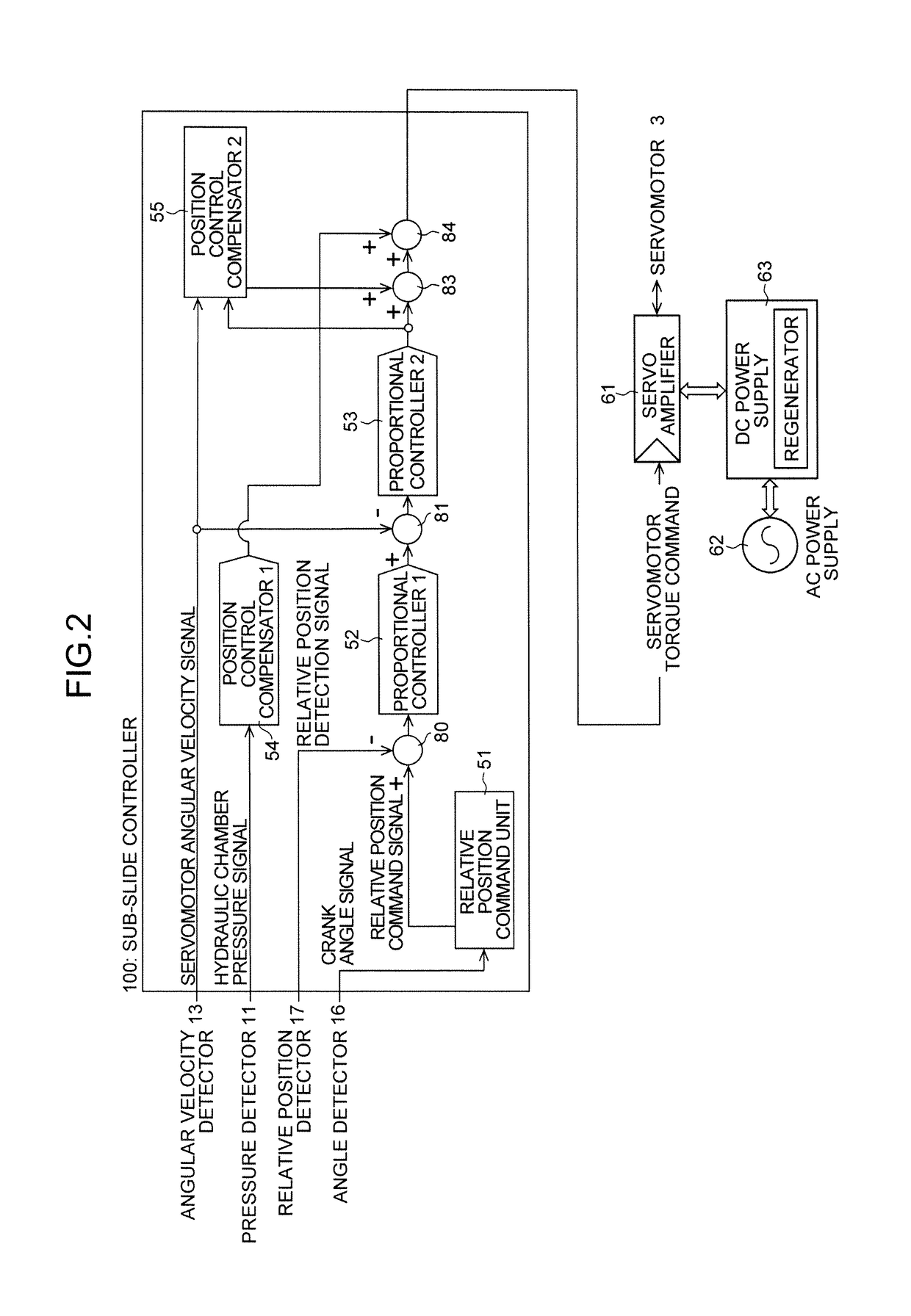

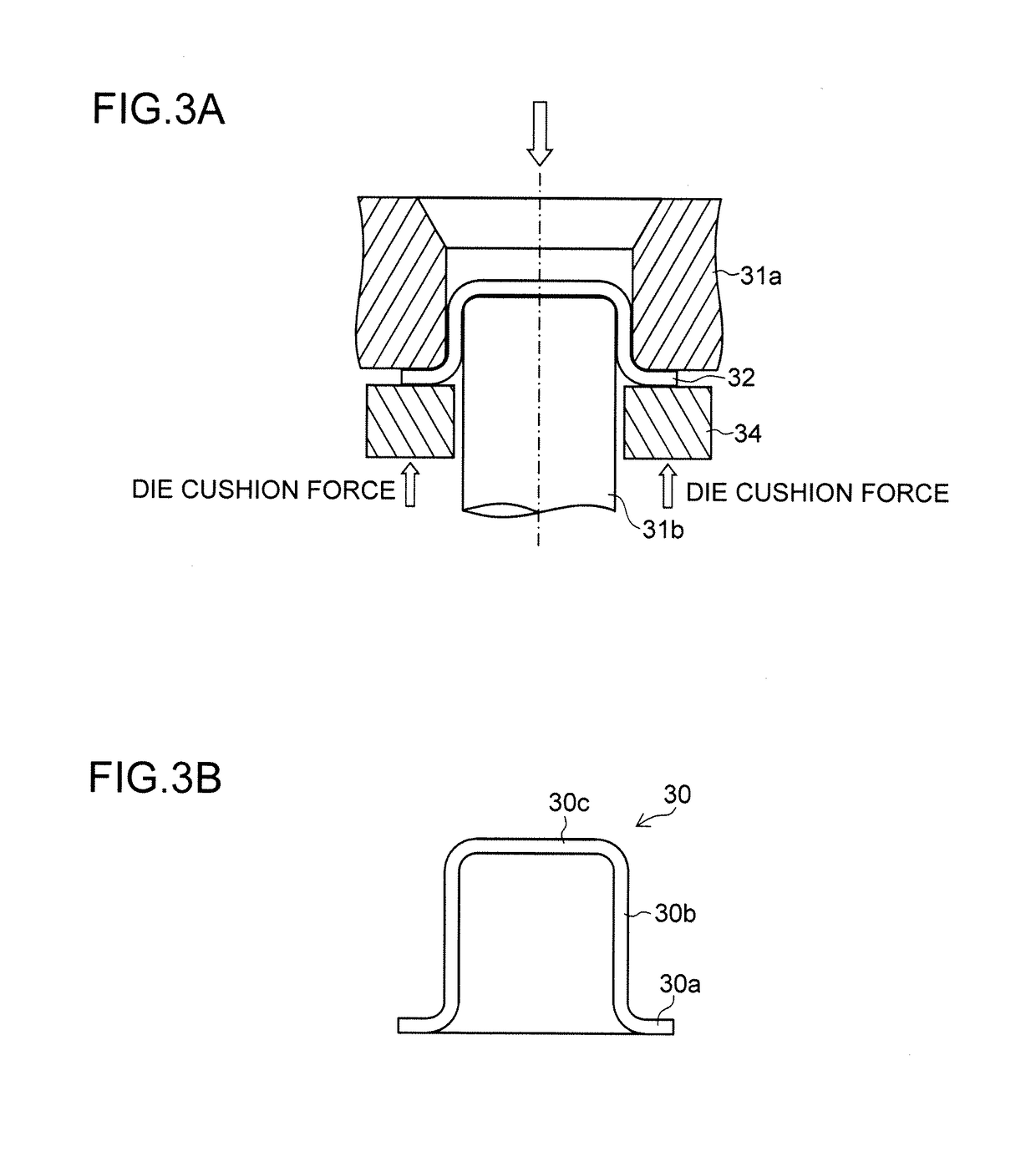

Press machine and method for controlling slide of press machine

ActiveUS20140208964A1High compression forceReduce the total massForging press detailsForging press drivesVibration amplitudePiston

There is provided a press machine which can apply a large compression force to a mold as well as impart smooth vibration only in a rectilinear advancing direction to the mold, and thereby can improve the press-formability. A main slide and a sub-slide constitute a slide and at the same time a cylinder-piston mechanism. During press-forming, a compression force is transmitted to the sub-slide (an upper mold) through hydraulic pressure applied interlockingly with driving of the main slide, and the sub-slide is vibrated with the hydraulic pressure being periodically changed. Favorable press-forming can be performed even under relatively difficult press-forming conditions, by controlling the vibration such that a vibration frequency of the sub-slide (the upper mold) becomes 9 Hz or higher but 33.3 Hz or lower and a vibration amplitude of the sub-slide becomes 0.05 mm or larger but 0.5 mm or smaller.

Owner:AIDA ENG LTD

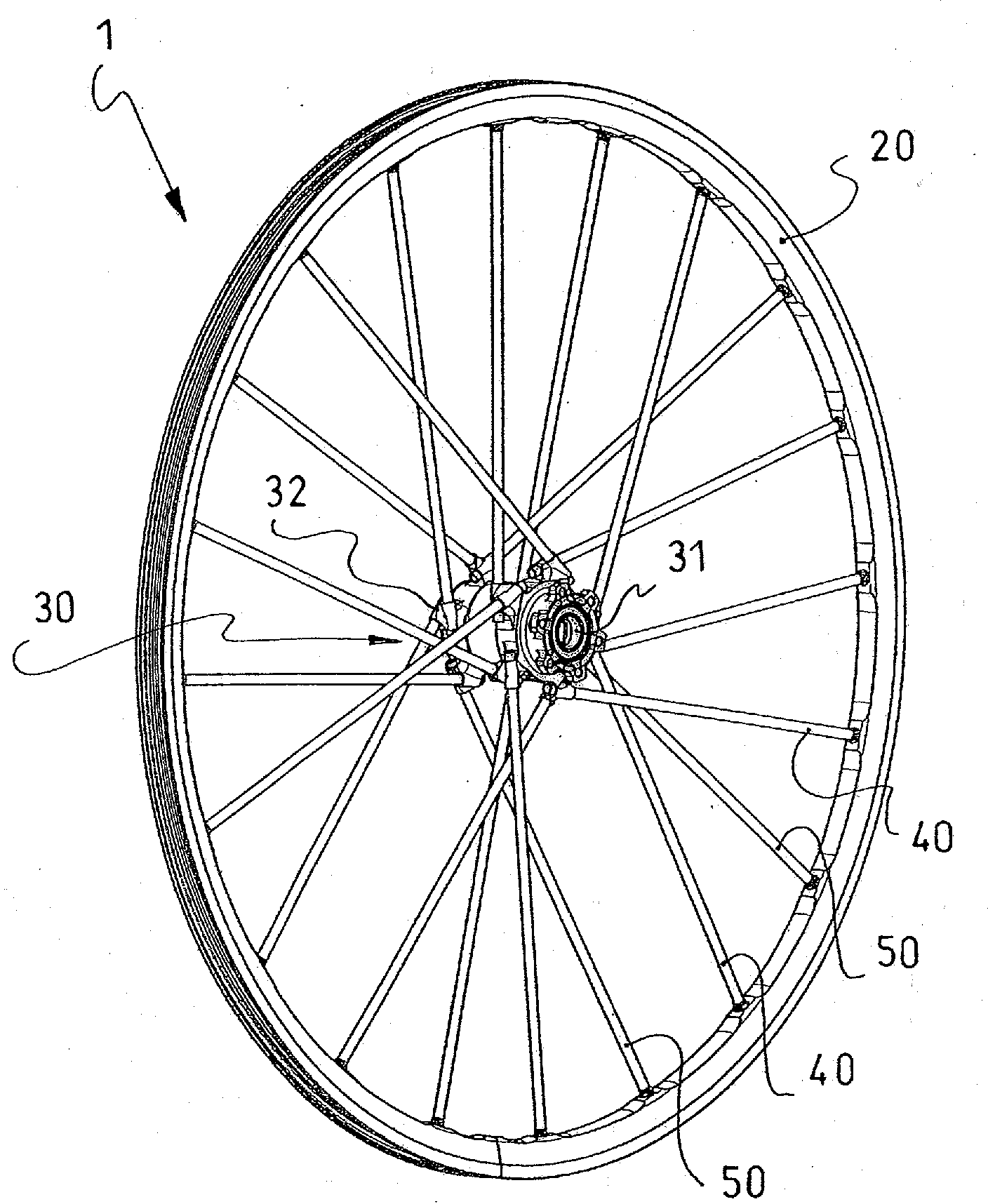

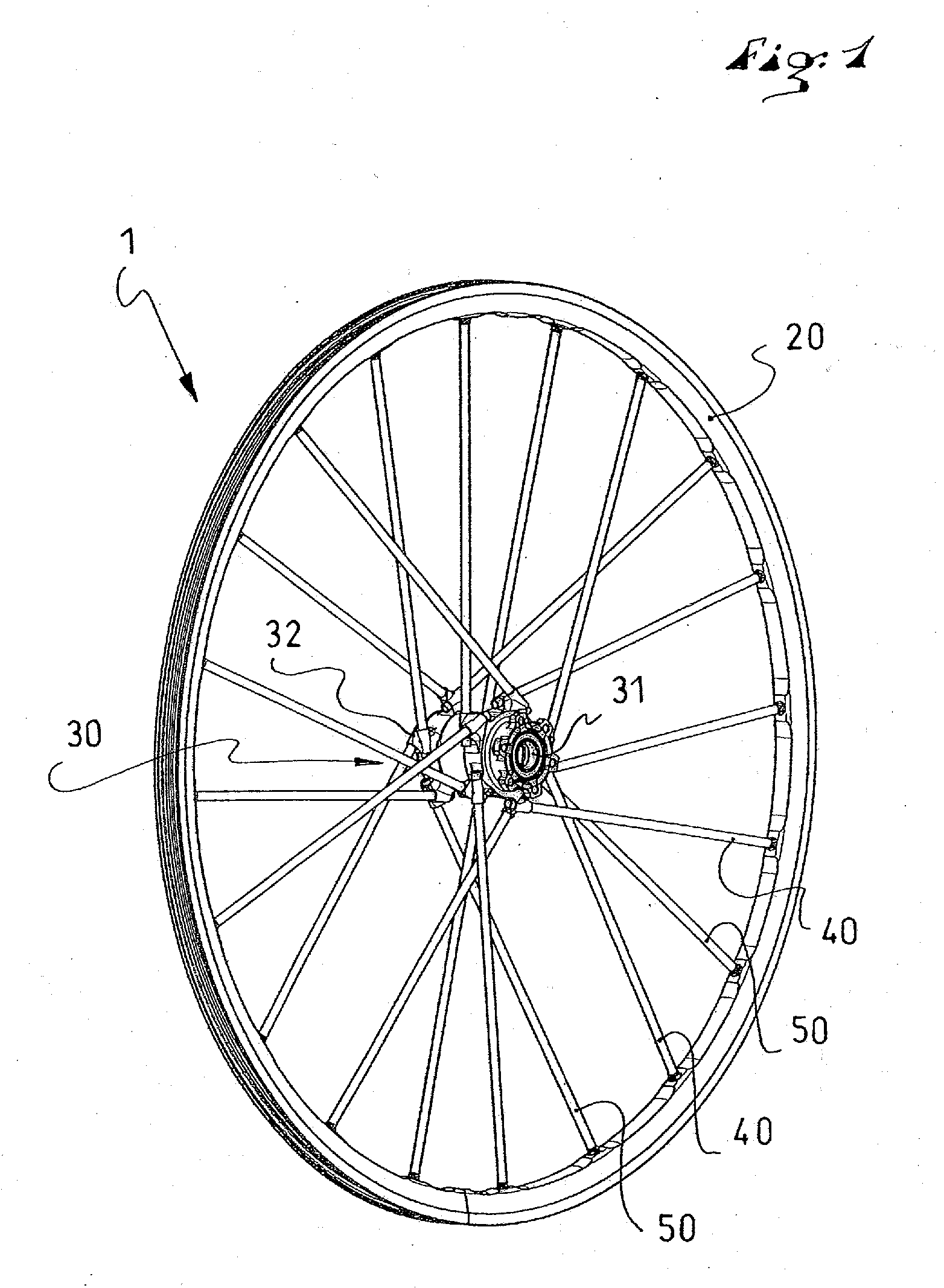

Spoke wheel

InactiveUS20090160243A1Relieve pressureHigh compression forceHubsRimsFree stateMechanical engineering

The invention relates to a spoke wheel that includes a peripheral rim, a central hub, and individual connecting spokes between the rim and the hub. In their free state, the spokes of the wheel are mounted without tension or compression between the rim and the hub, and each spoke can bear a compression load of at least 60 daN without bowing. Furthermore, the wheel includes a play-free connection or bilateral connection device for connecting at least one end of each spoke to the rim or the hub.

Owner:MAVIC SA

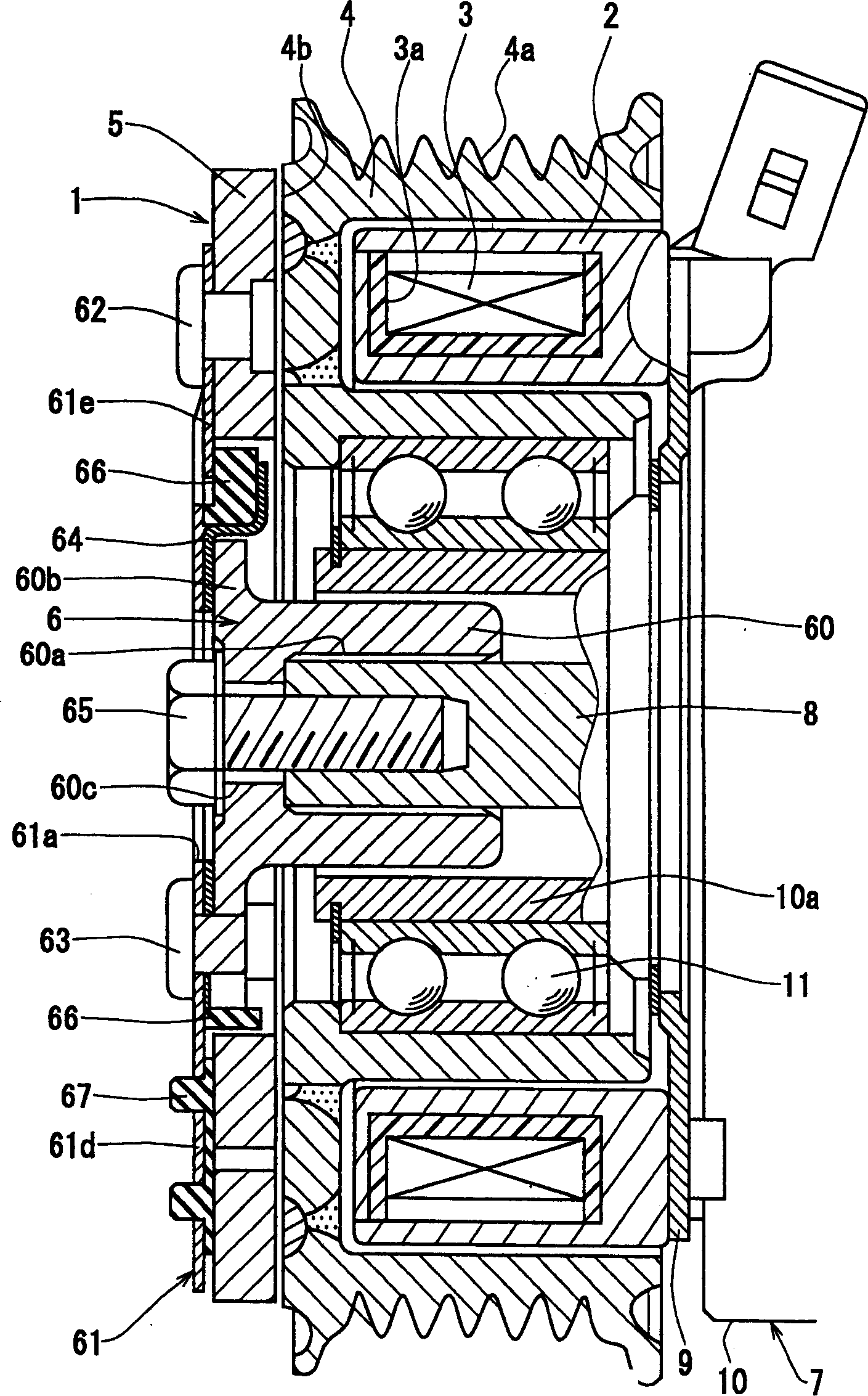

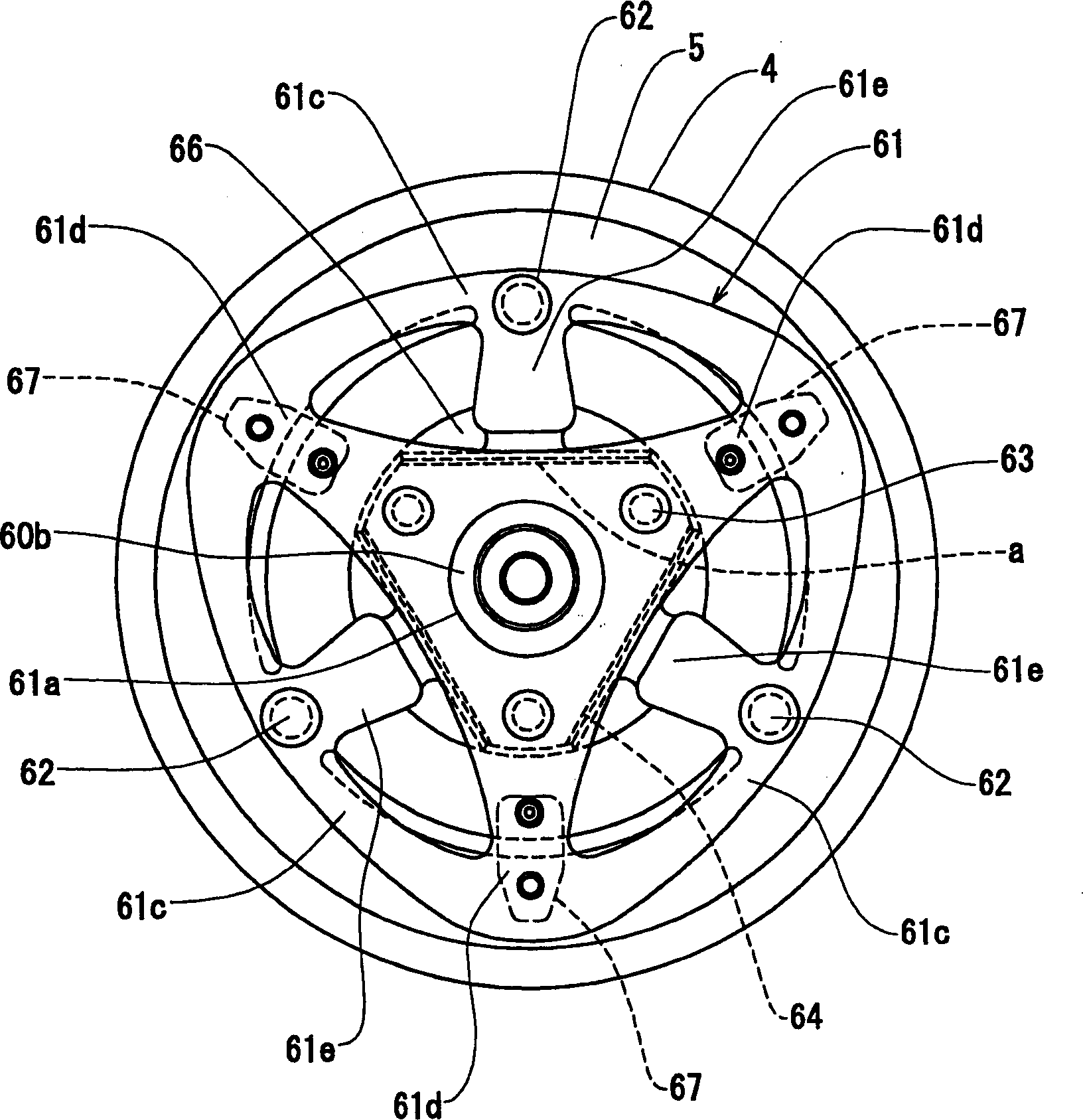

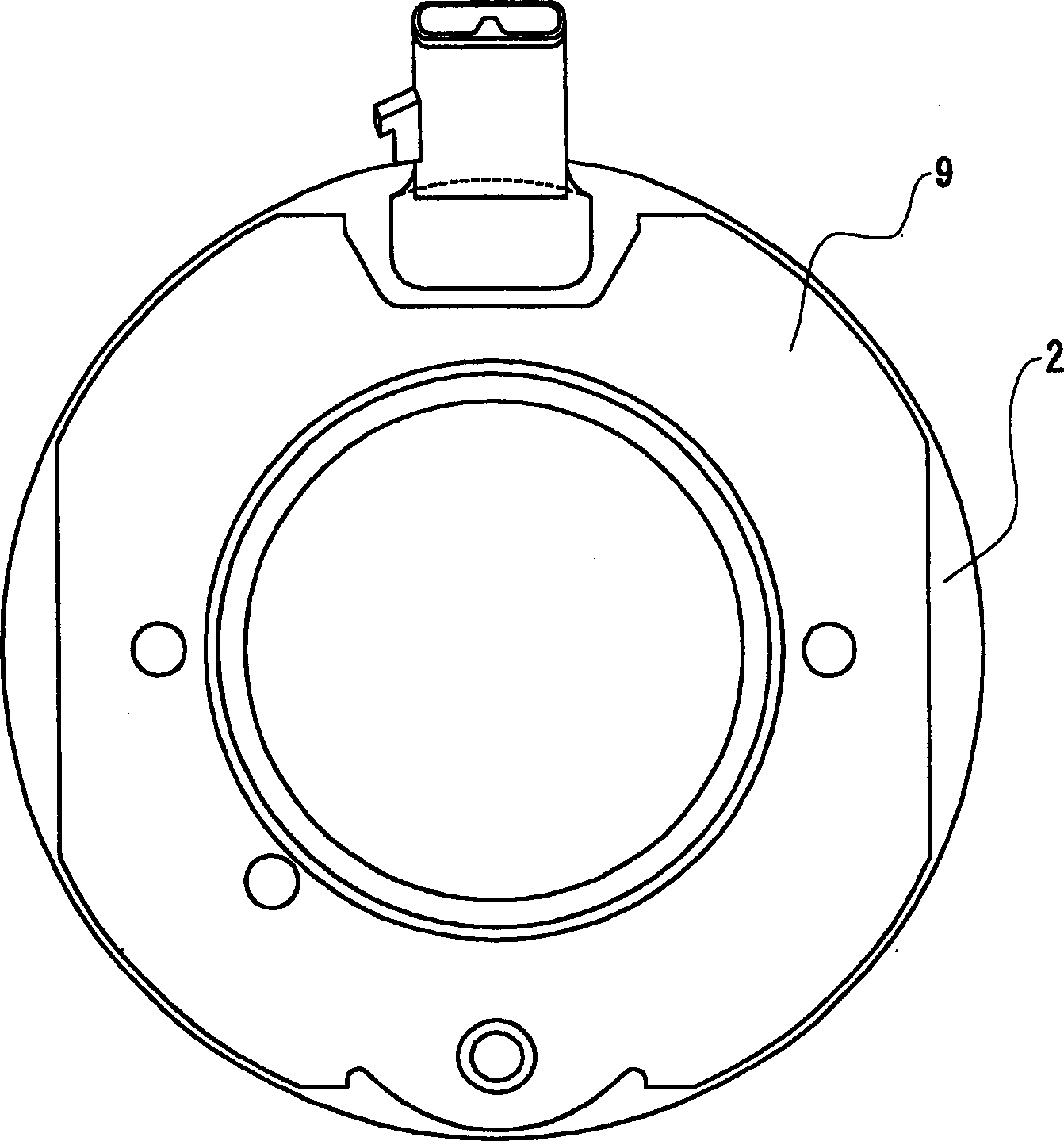

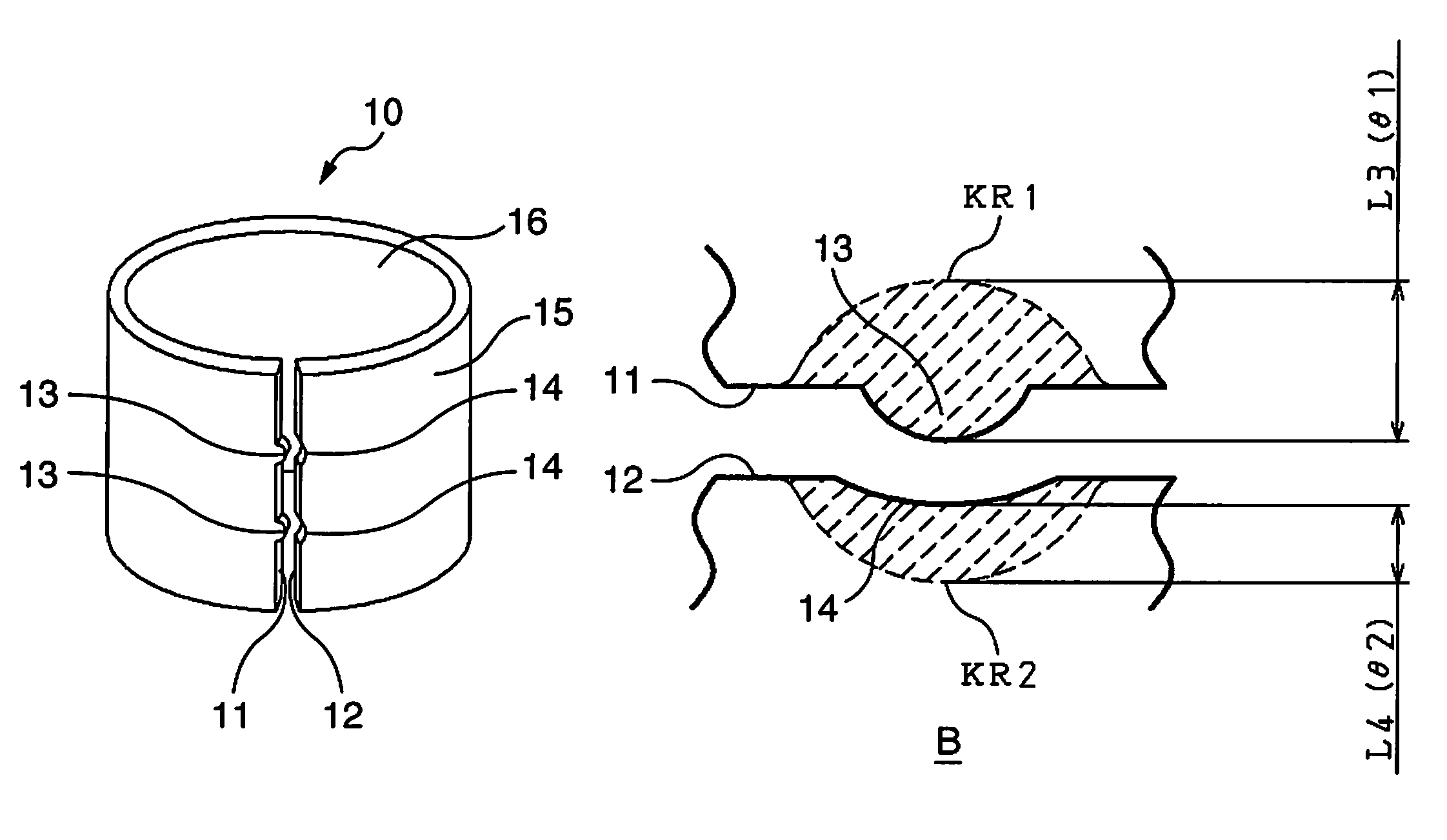

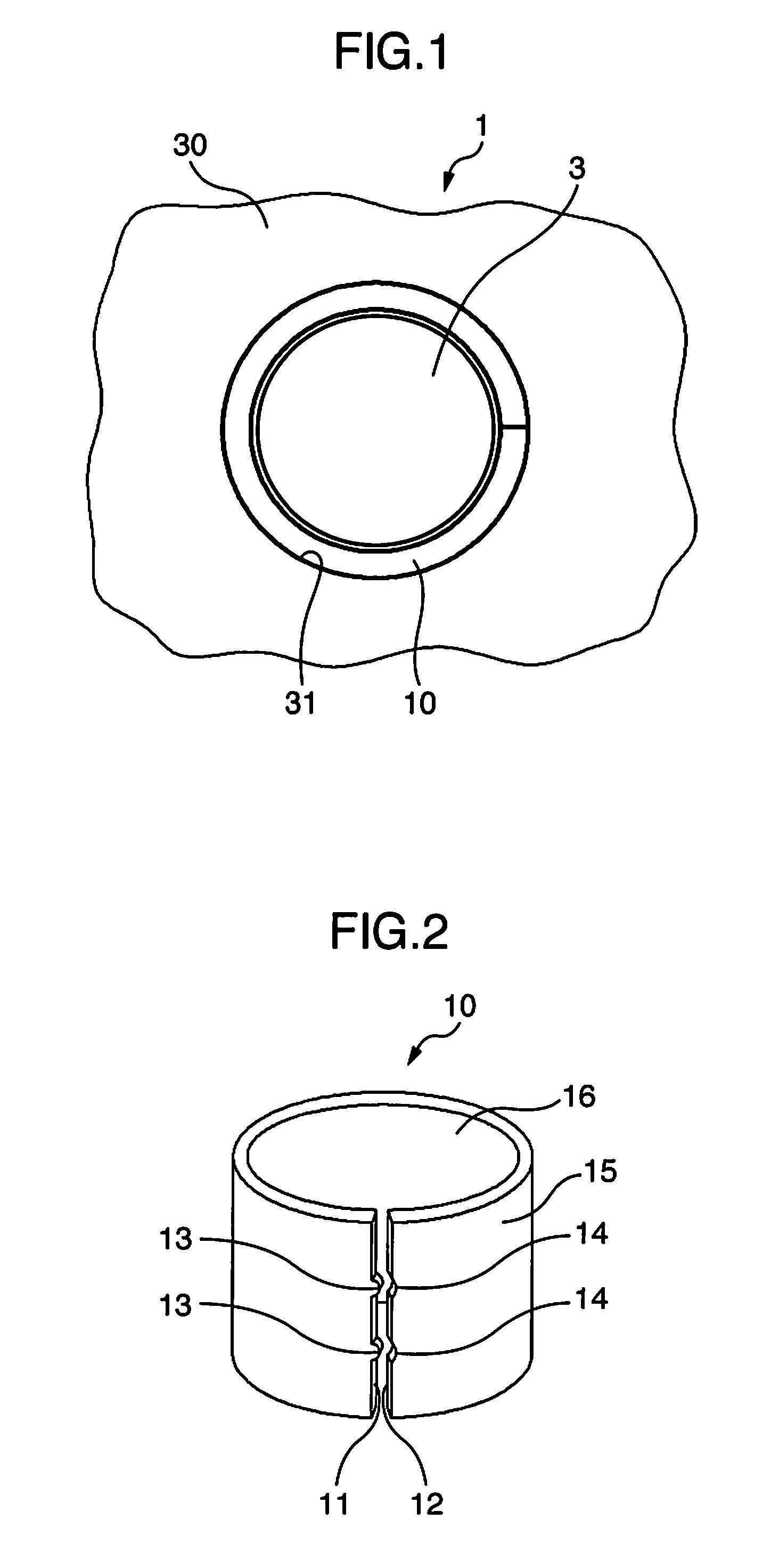

Electronmagnetic clutch

InactiveCN1441177AReduce running noiseIncrease elastic reaction forceMagnetically actuated clutchesElectromagnetic clutchSpring force

An electromagnetic clutch reduces clutch operating noise at a low cost by utilizing elastic members which are suited to a spring force of a leaf spring. An approximate nonagonal leaf spring has an outer ring portion, attachment portions connected to a hub, and connecting portions. Under the outer ring portion, securing portions of an armature are disposed. First elastic members are disposed at intermediate points of the securing portions, and a second elastic member is disposed in a gap between the leaf spring and the hub along an axial direction. When actuating the electromagnetic clutch, the leaf spring compresses the second elastic member, and when stopping the electromagnetic clutch, the armature collides with the first elastic member so that an axial position of the armature is secured.

Owner:DENSO CORP

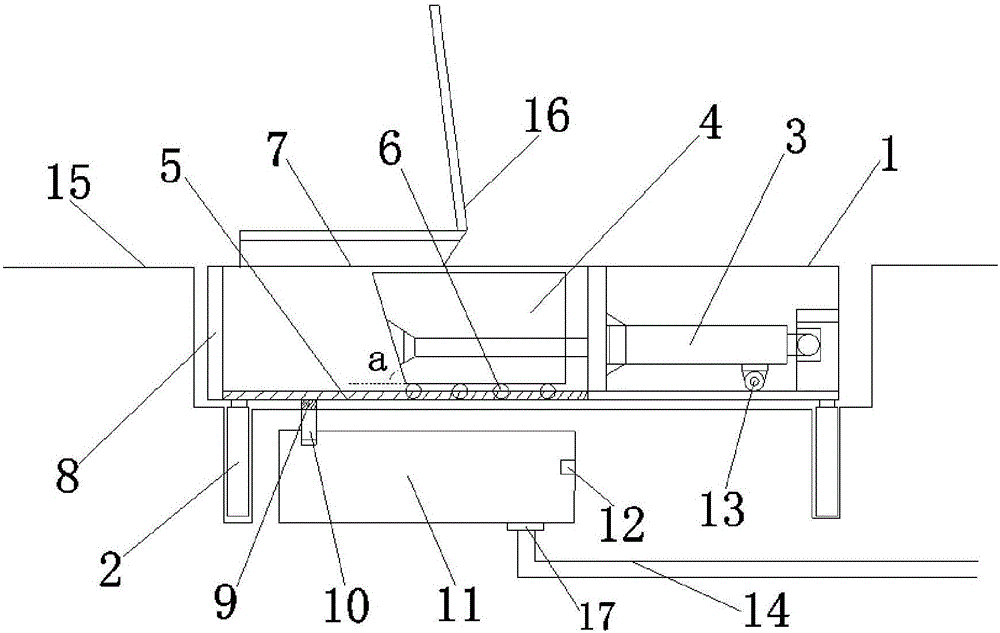

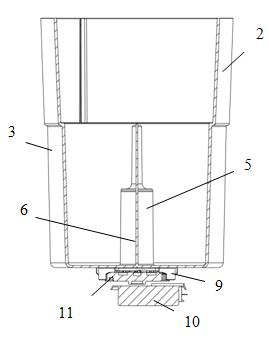

Underground horizontal rubbish compressor

InactiveCN106115138AUniform compressionVersatileRefuse receptaclesRefuse transferringAcute angleEngineering

The invention discloses an underground horizontal garbage compressor, comprising a machine case, four lifting oil cylinders are arranged at the bottom of the machine case, the machine case and the lifting oil cylinders are fixed in a pit, and the upper end of the machine case is level with the ground; There is a main oil cylinder inside, and the cylinder body of the main oil cylinder is fixed on the right end of the chassis. The load-bearing wheels for supporting the cylinder body are connected under the cylinder body through a bracket. The piston rod end of the main oil cylinder is fixed with a pressure head. The angle between the compression surface of the head and the bottom surface of the chassis is an acute angle; at least two rollers are symmetrically installed on both sides of the lower end of the pressure head, and two slide rails are correspondingly provided on both sides of the chassis, and the rollers and the slide rails are movable Connection; the garbage compressor of the present invention has comprehensive functions and simple structure, adopts an underground installation structure, has strong adaptability to the surrounding environment, and has higher work efficiency.

Owner:HEFEI BAIYUN ENVIRONMENTAL SANITARY EQUIP

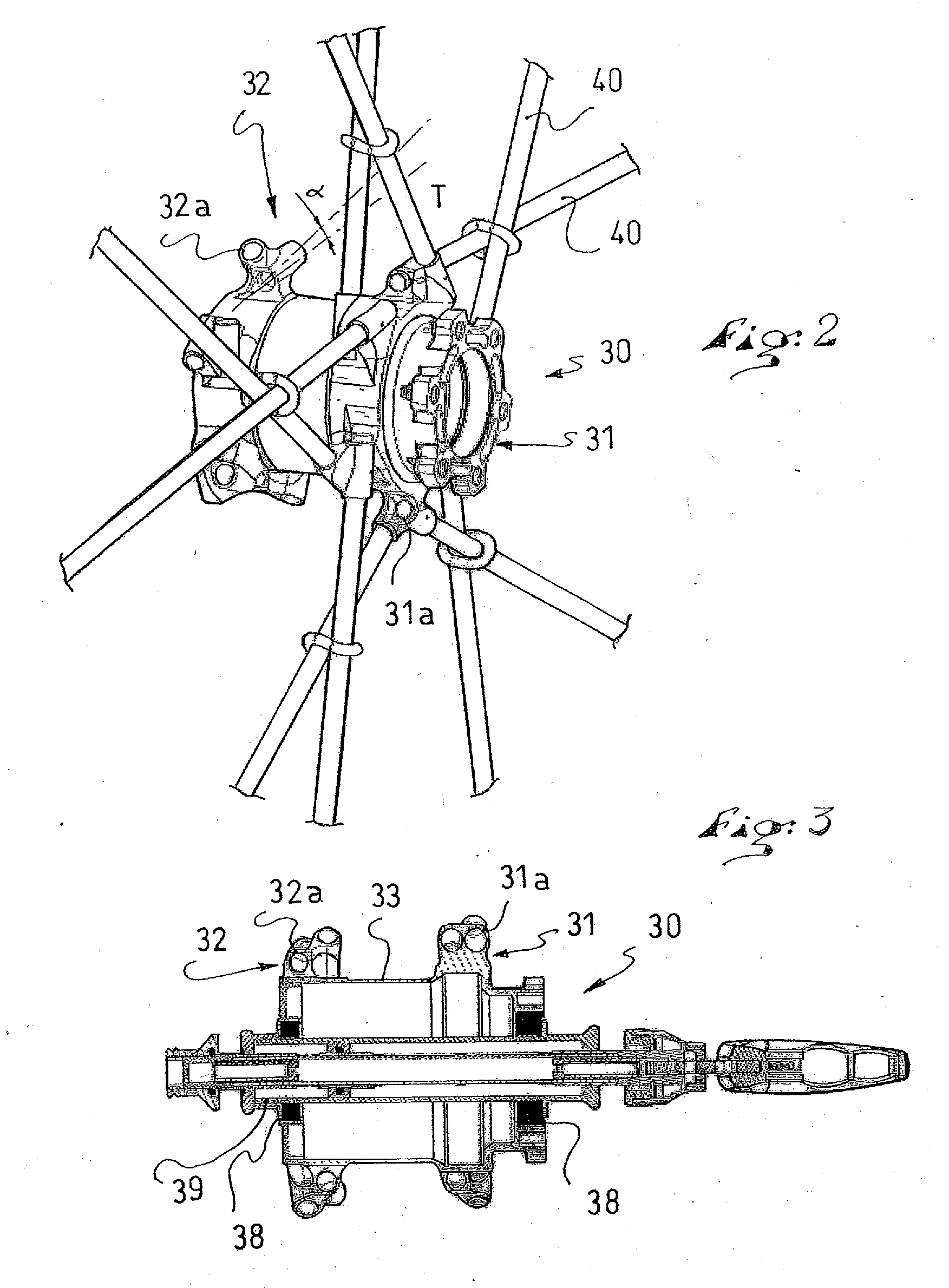

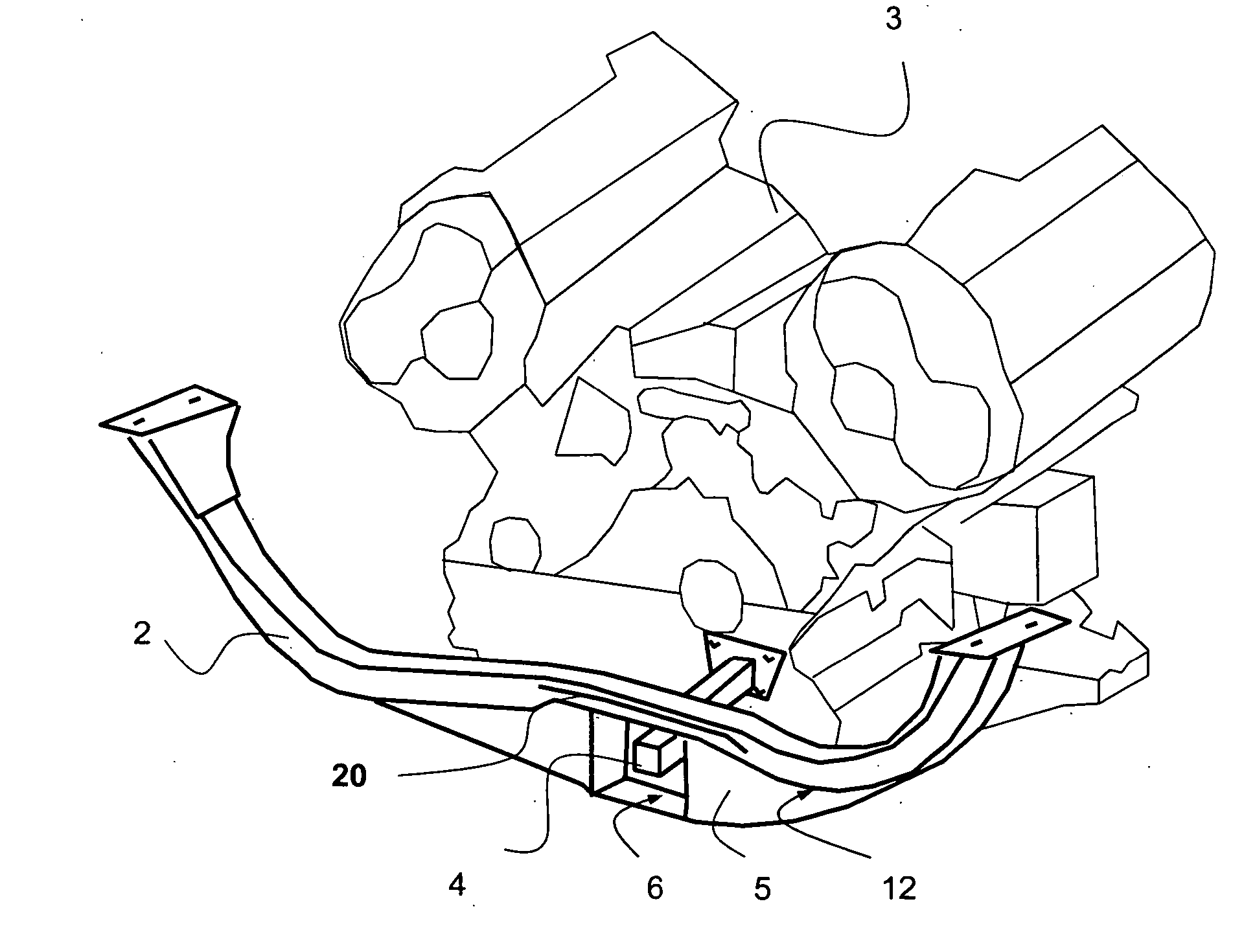

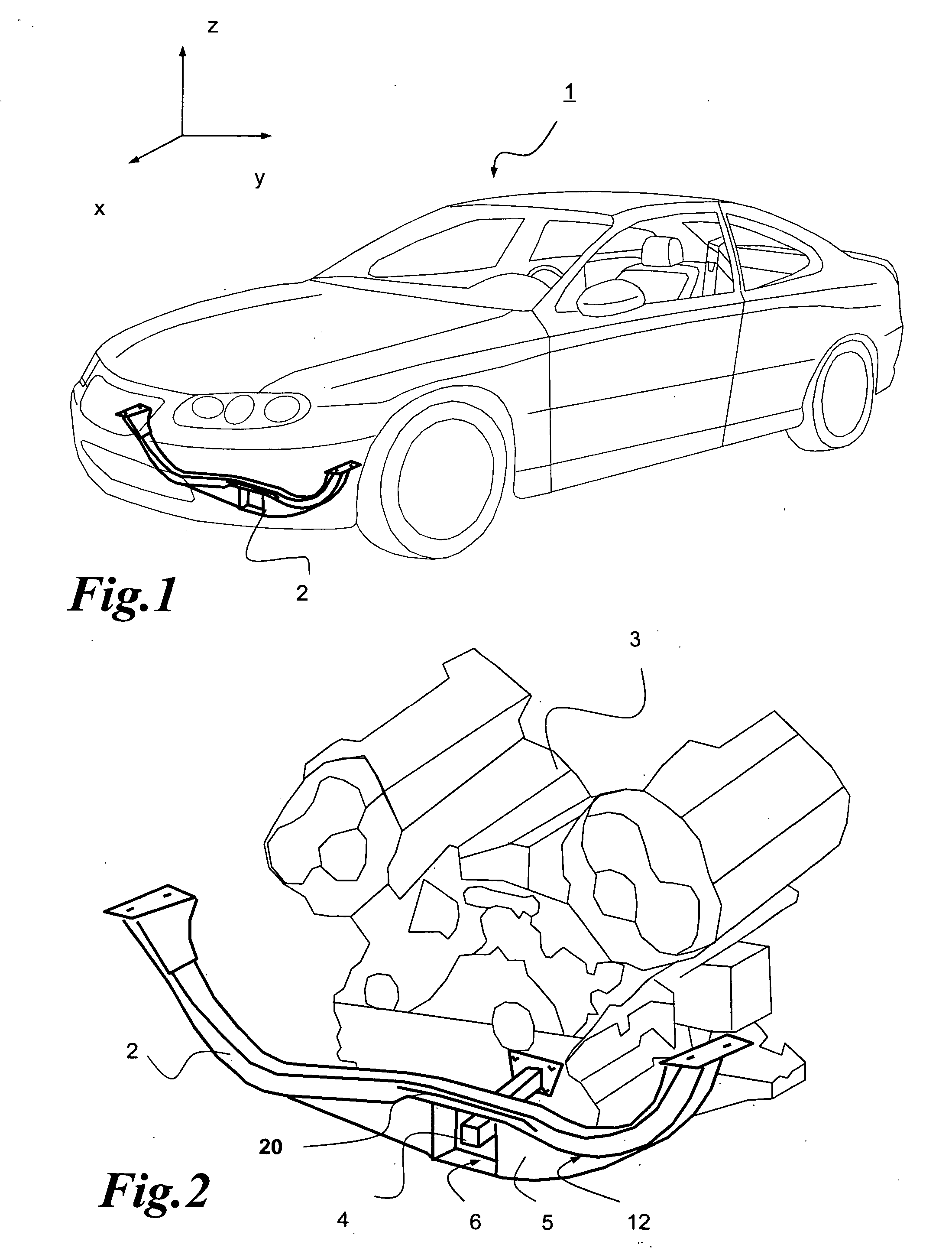

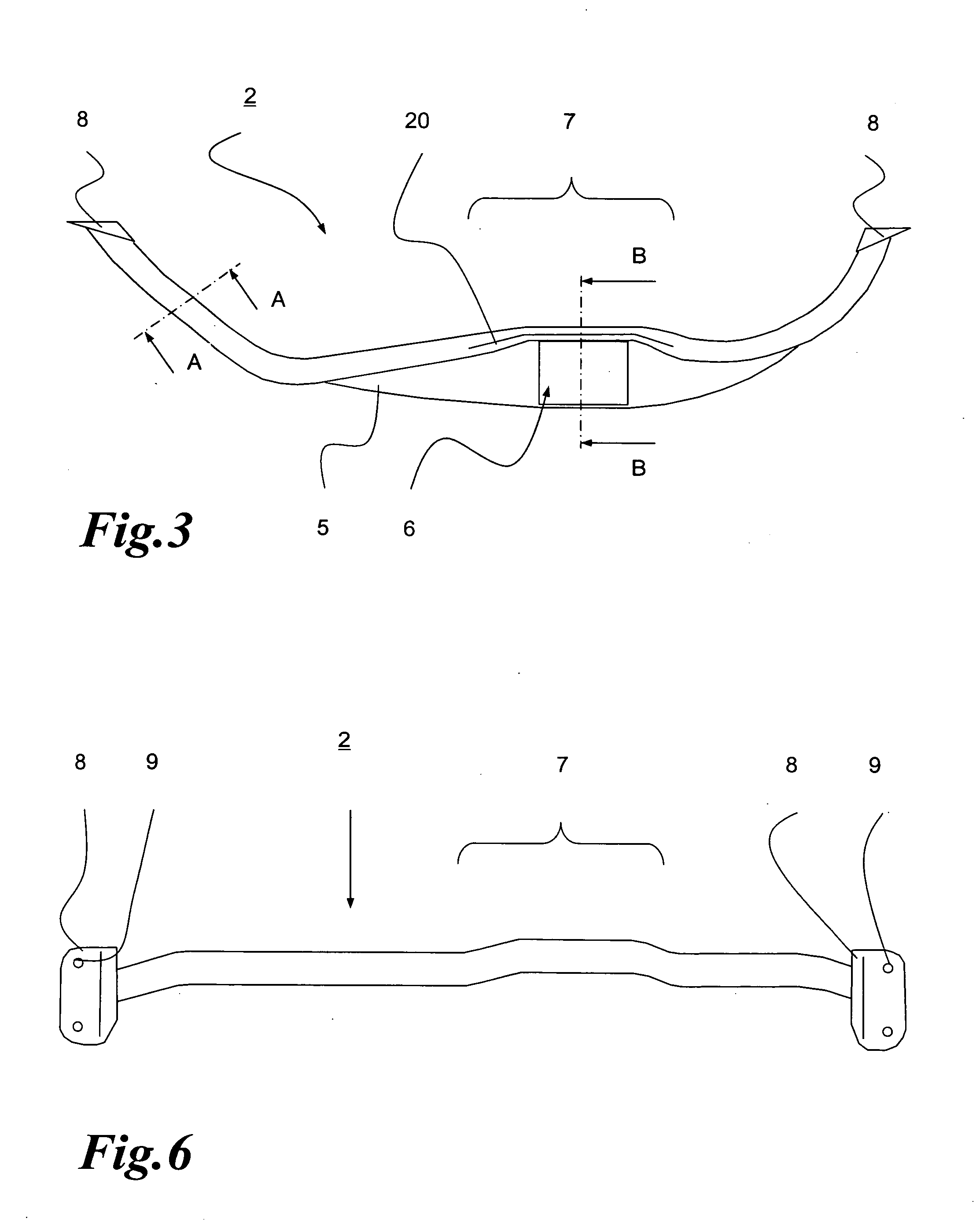

Torque crossmember

InactiveUS20070108802A1Improve rigidityHigh compression forceVehicle seatsUnderstructuresEngineeringTorsional Forces

A crossmember for supporting and limiting torsional forces of an engine unit relative to a mounting frame, particularly a vehicle body, wherein the crossmember is provided with at least one area or one device for introducing torsional forces into the crossmember.

Owner:ISE INNOMOTIVE SYST EURO

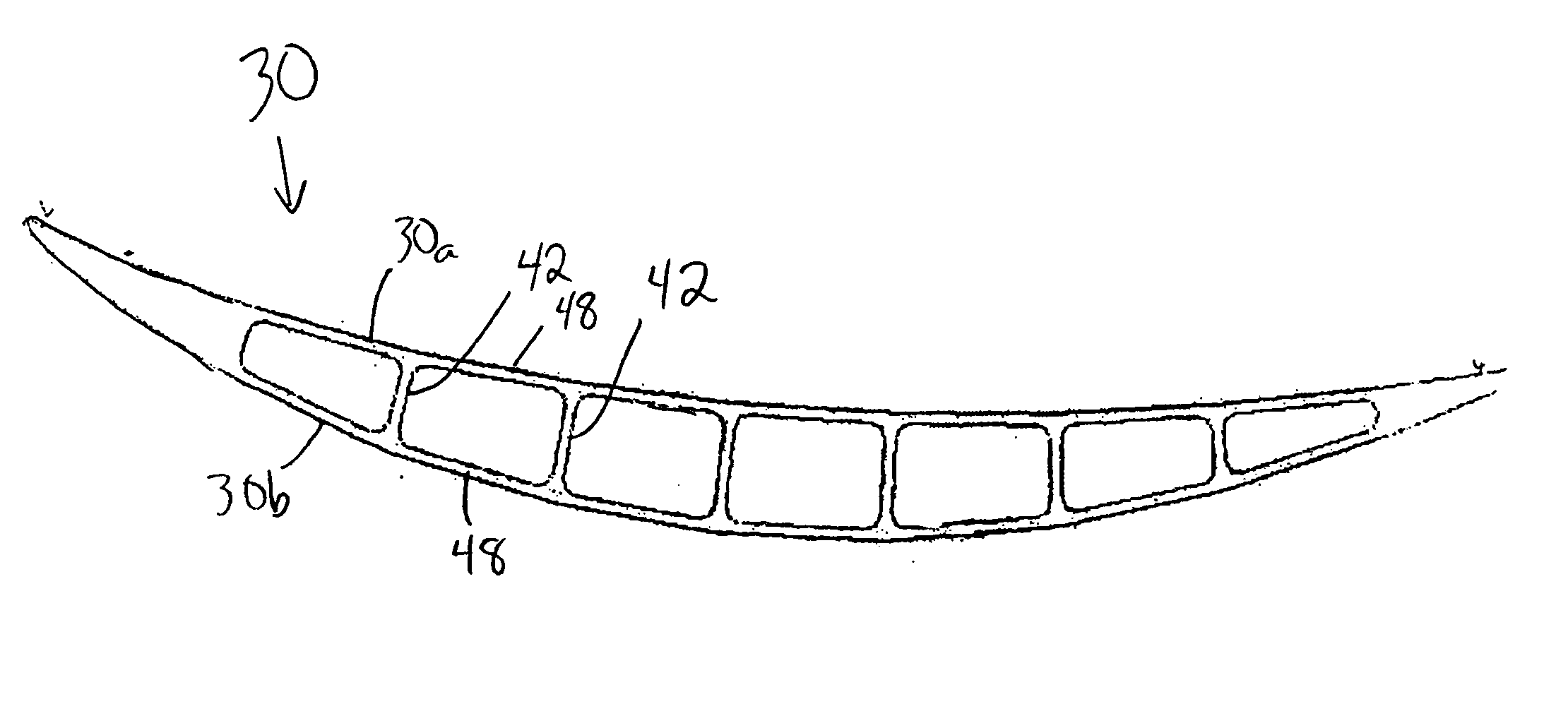

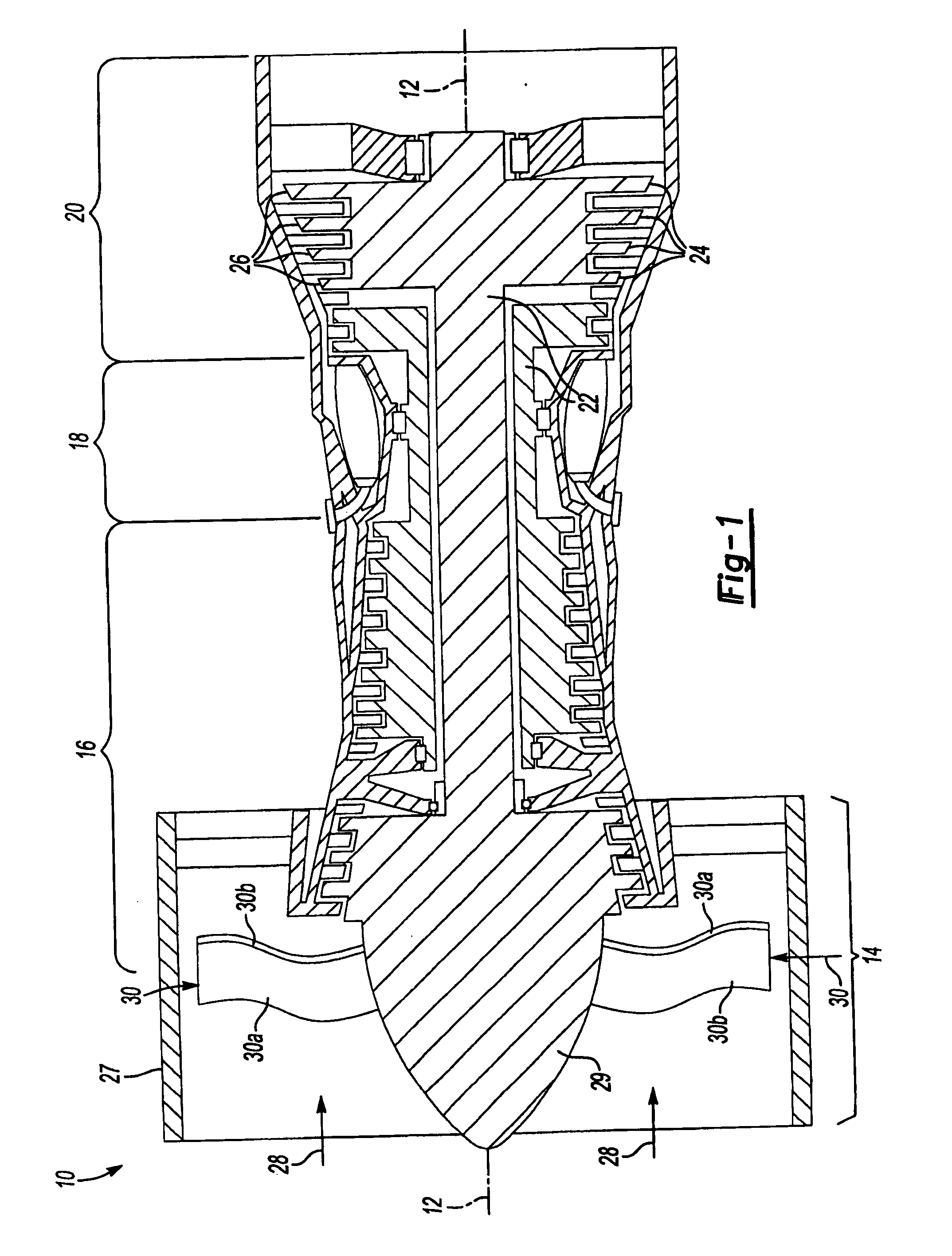

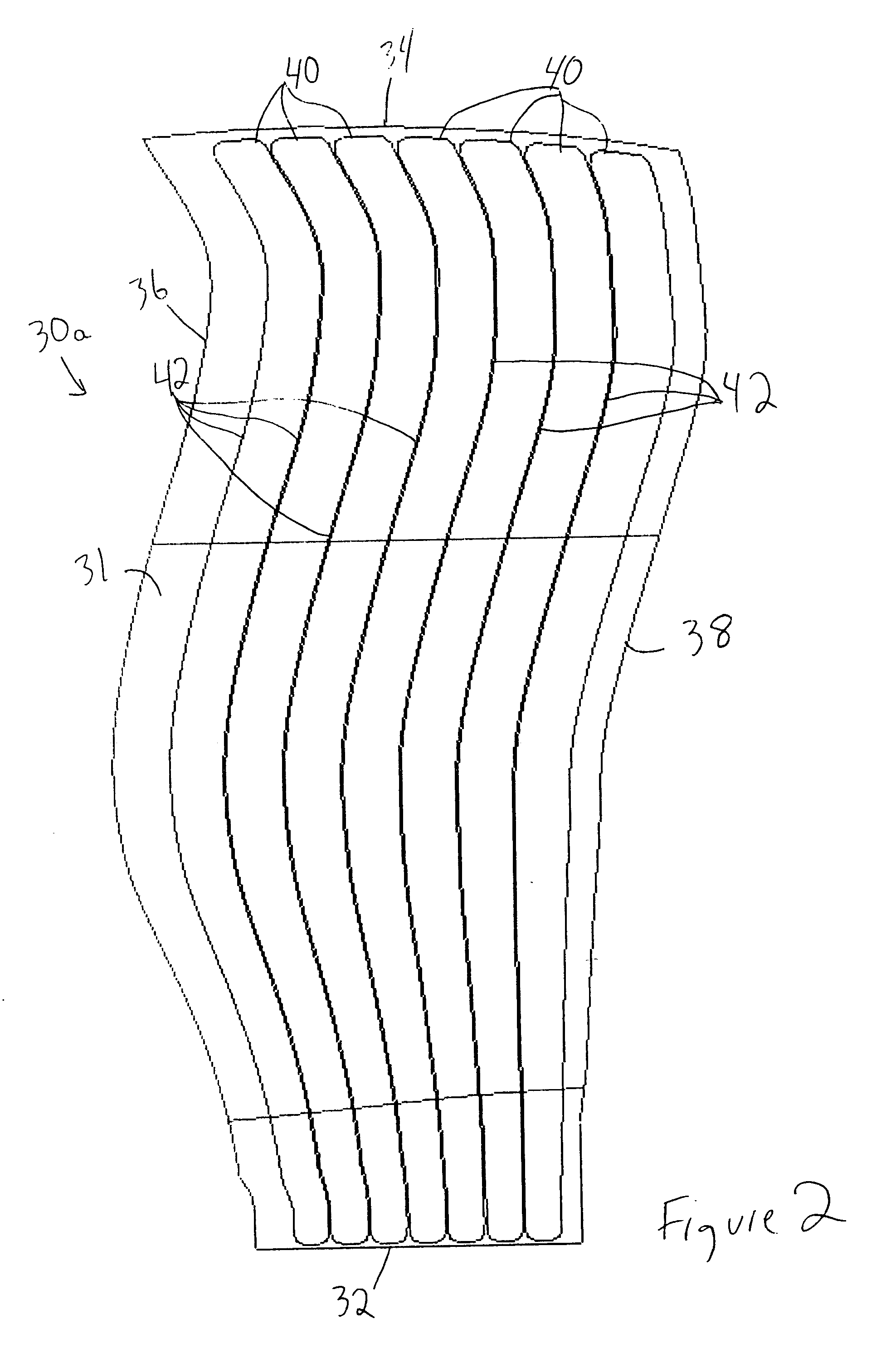

Hollow fan blade for gas turbine engine

ActiveUS20070128042A1High compression forceReduce wall thicknessPropellersPump componentsSuction stressFan blade

A hollow fan blade for a gas turbine engine provides improved resistance to buckling without adding wall thickness. The hollow fan blade includes a pressure side wall and a suction side wall separated and supported by ribs. In the present invention, each wall segment between each adjacent pair of ribs is straight, not curved. At least some of the adjacent walls segments extend at non-parallel angles relative to one another to form the airfoil shape to the hollow fan blade. The resulting fan blade side walls have faceted surfaces, rather than a continuous smooth, curved surface. The straight wall segments between adjacent ribs can withstand higher compressive forces without buckling. As a result, the wall thickness can be reduced.

Owner:RTX CORP

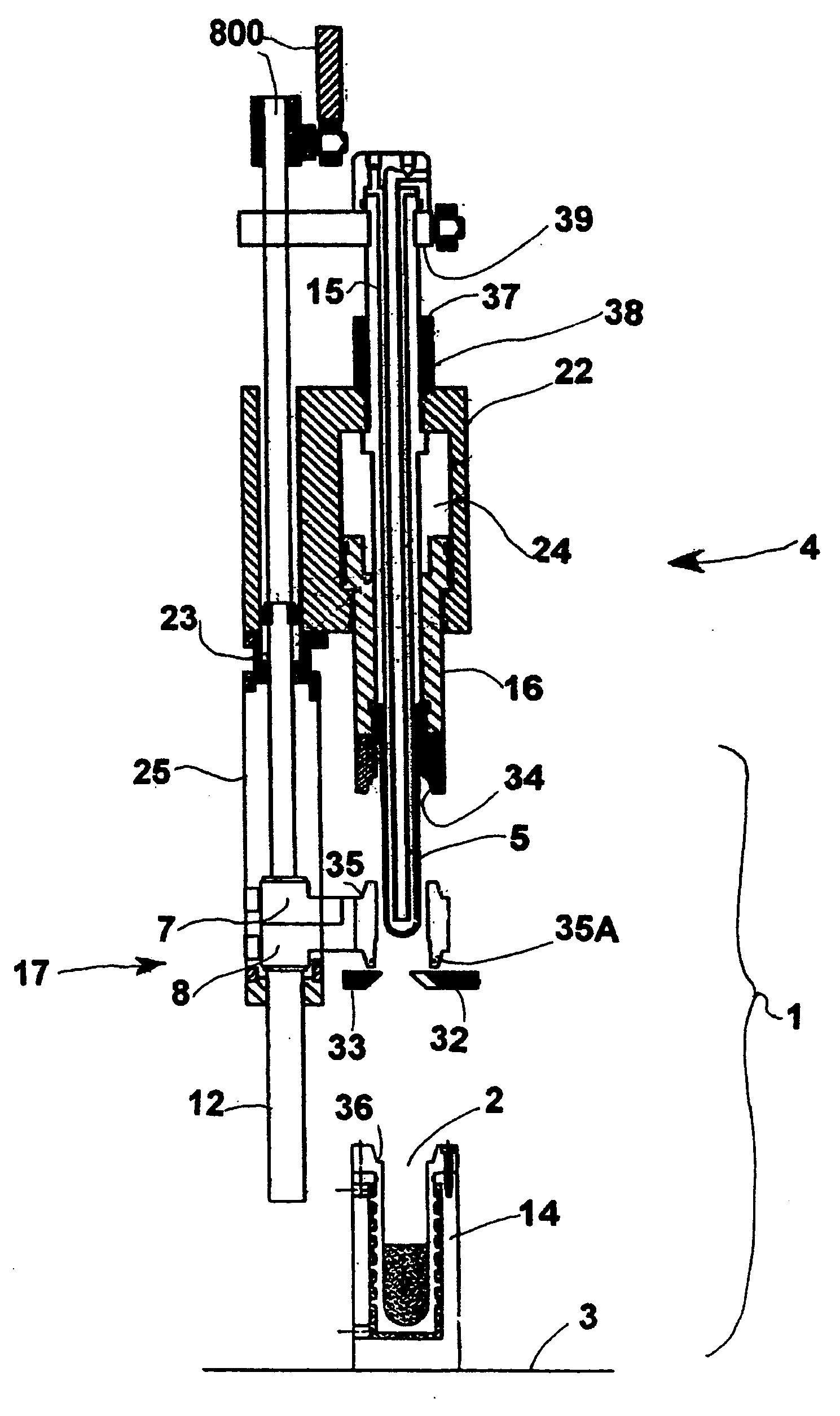

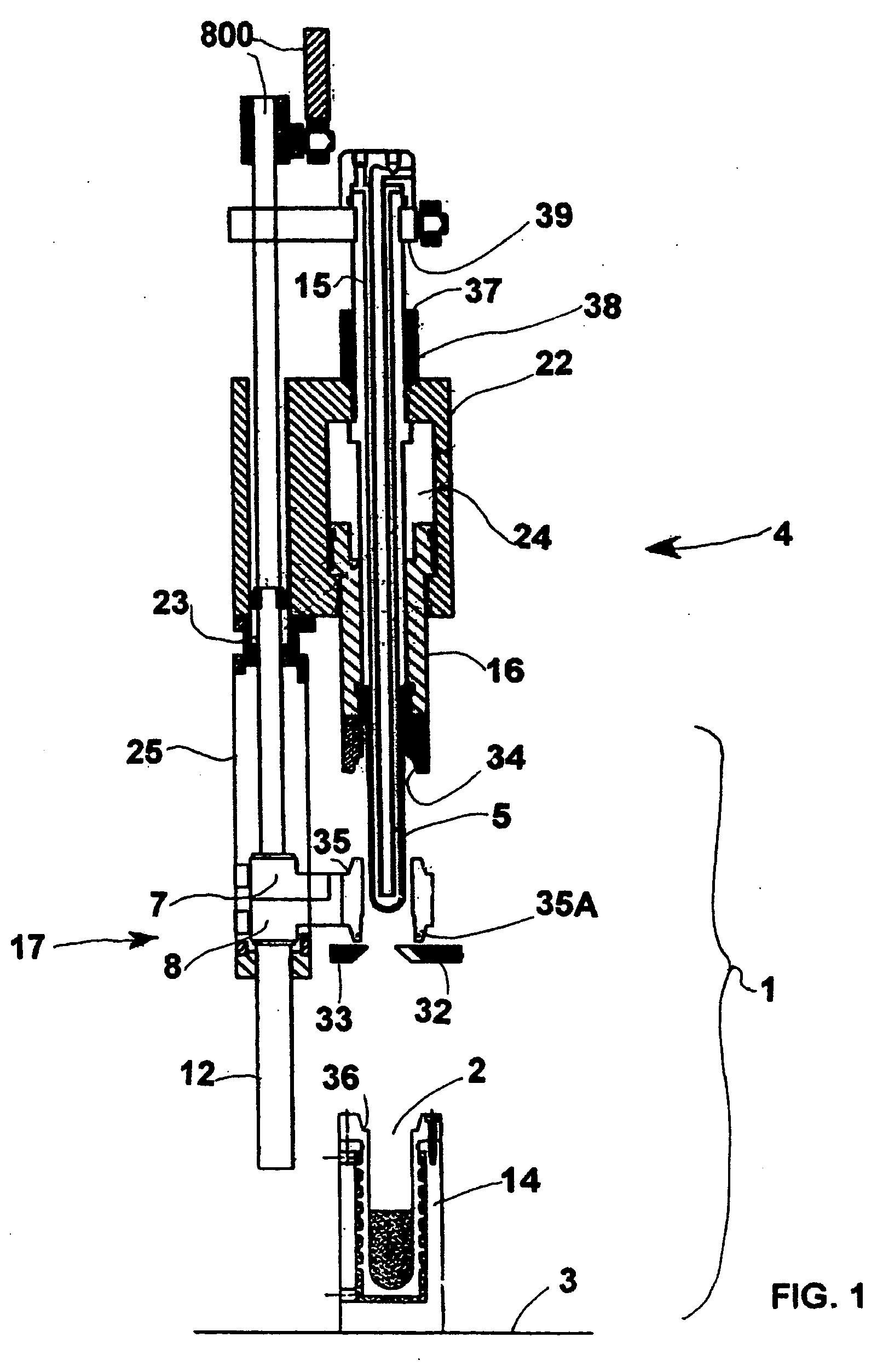

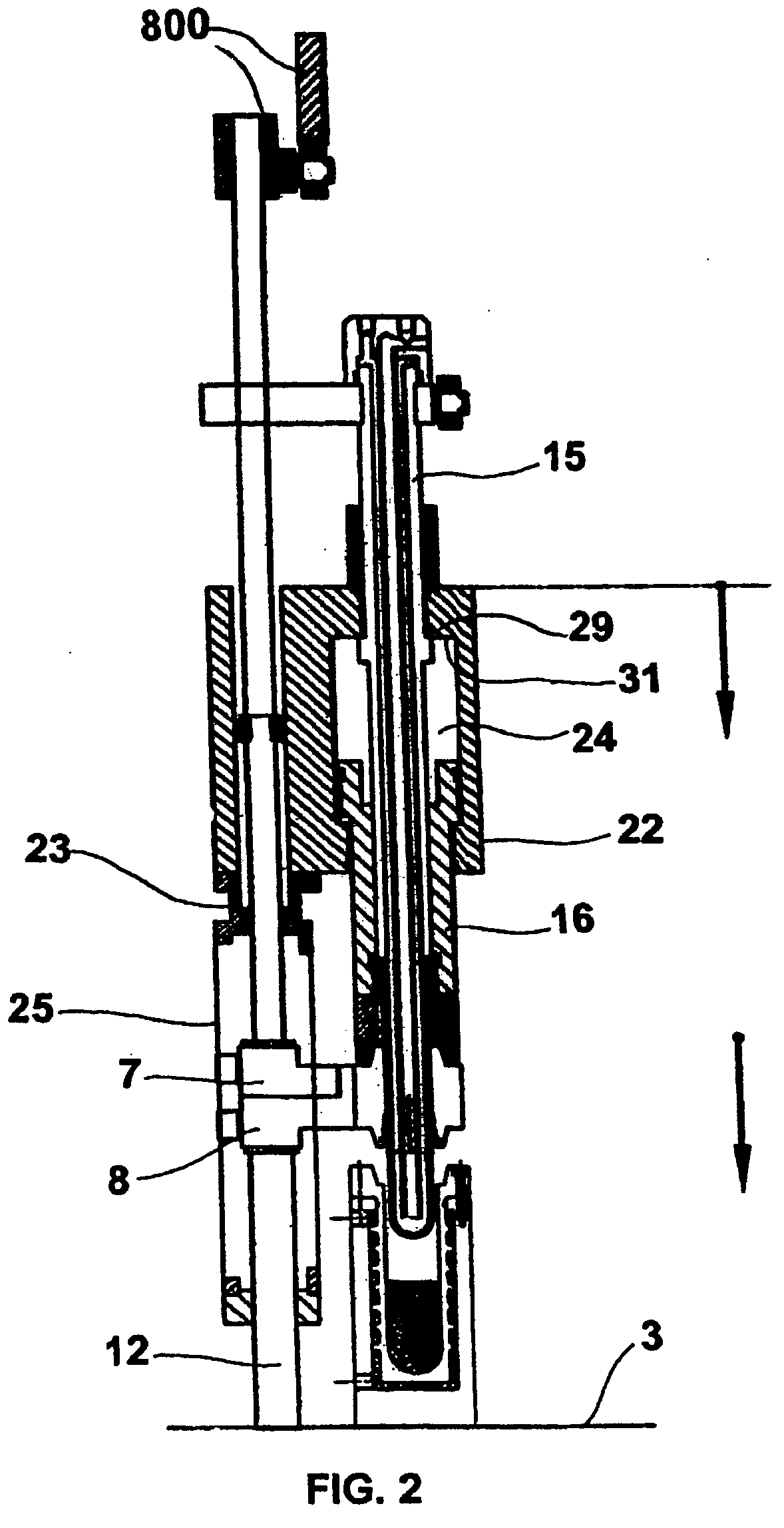

Device and method for compression moulding plastic containers

ActiveUS20050158421A1Fast response timeHigh compression forceConfectionerySweetmeatsCompression moldingPlunger

A compression-moulding press for moulding plastic containers (P) consisting of a moulding cavity formed by a plunger (5), a female mould (14), and two separable lips (7, 8). A cylinder (16) slides inside a sliding slide (22) to keep the lips (7, 8) closed. The plunger (5) slides inside the cylinder (16), with respect to both the cylinder (16) and the slide (22), when moulding the containers (P). Finally, a method for making plastic containers by means of compression moulding using said device is also described.

Owner:SIPA SOCIETA INDUSTRIALIZZAZIONE PROGETTAZIONE E AUTOMAZIONE SPA

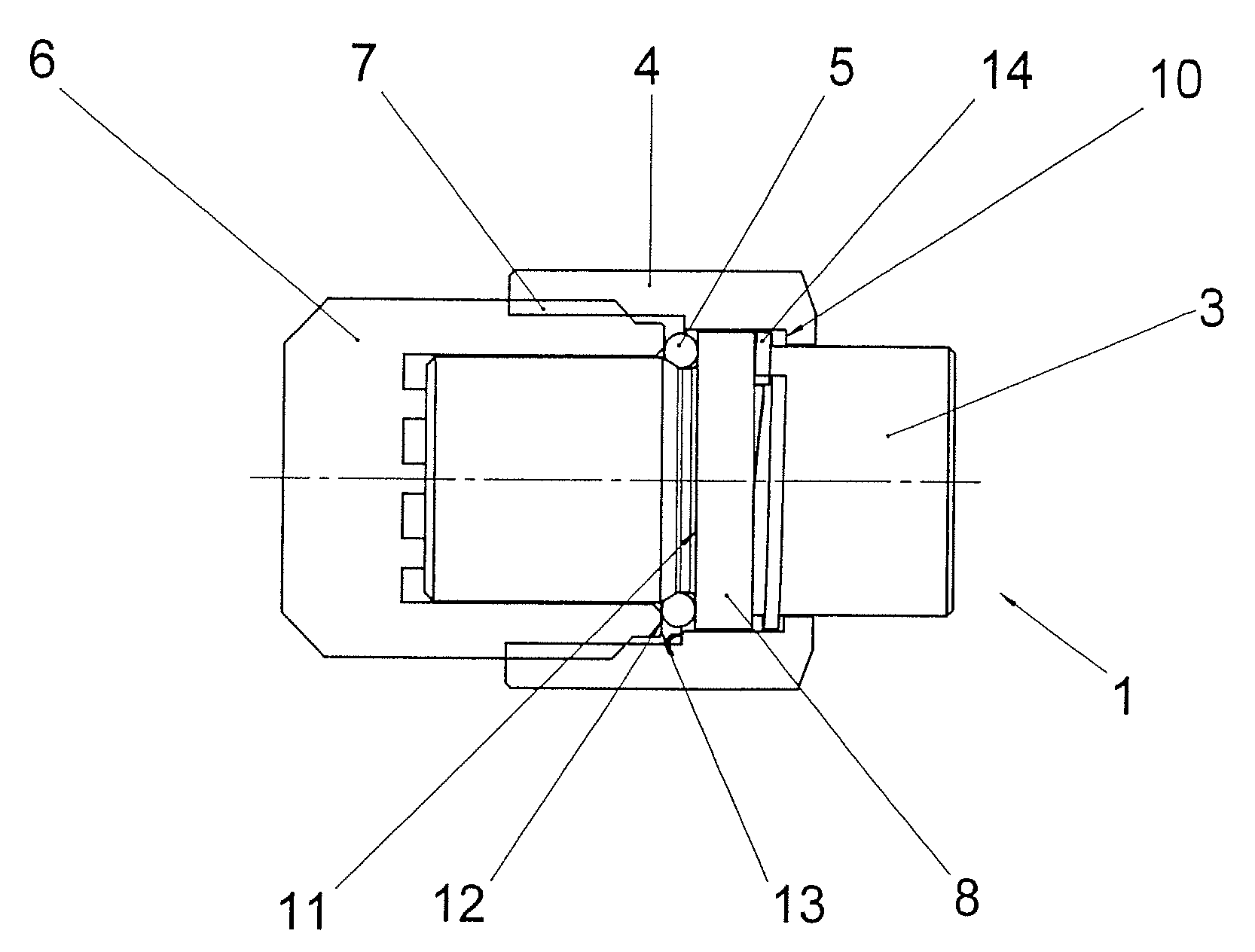

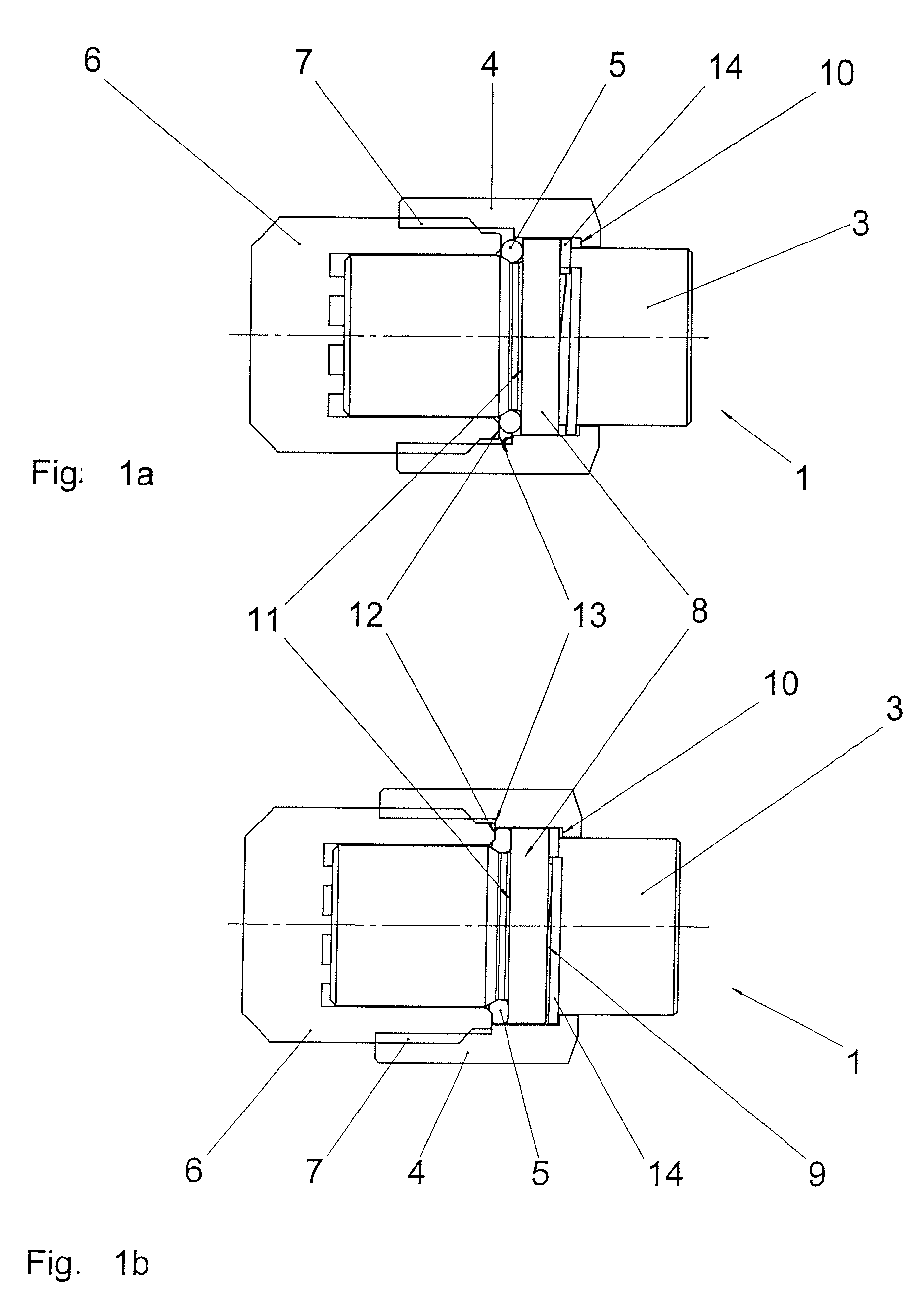

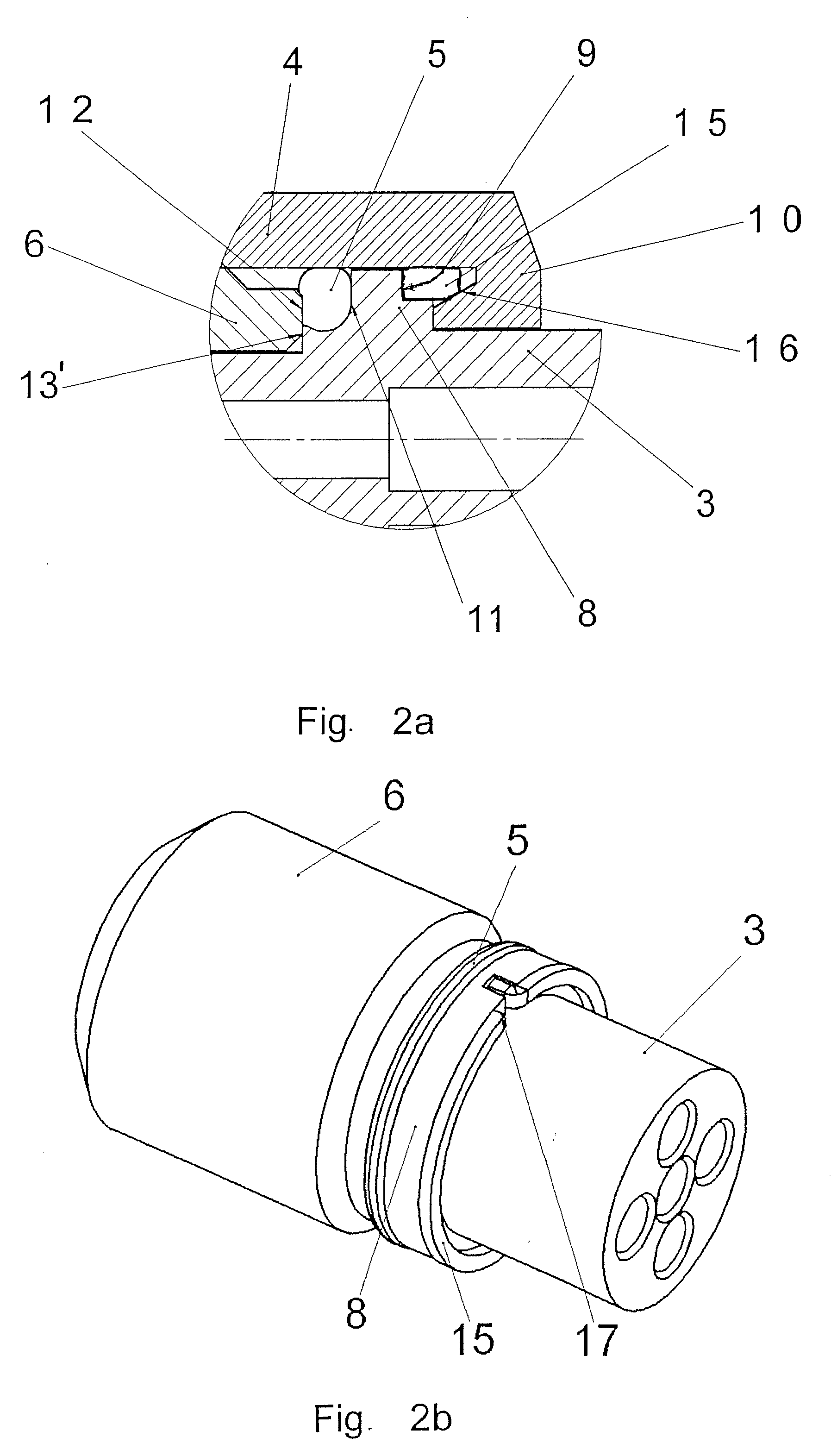

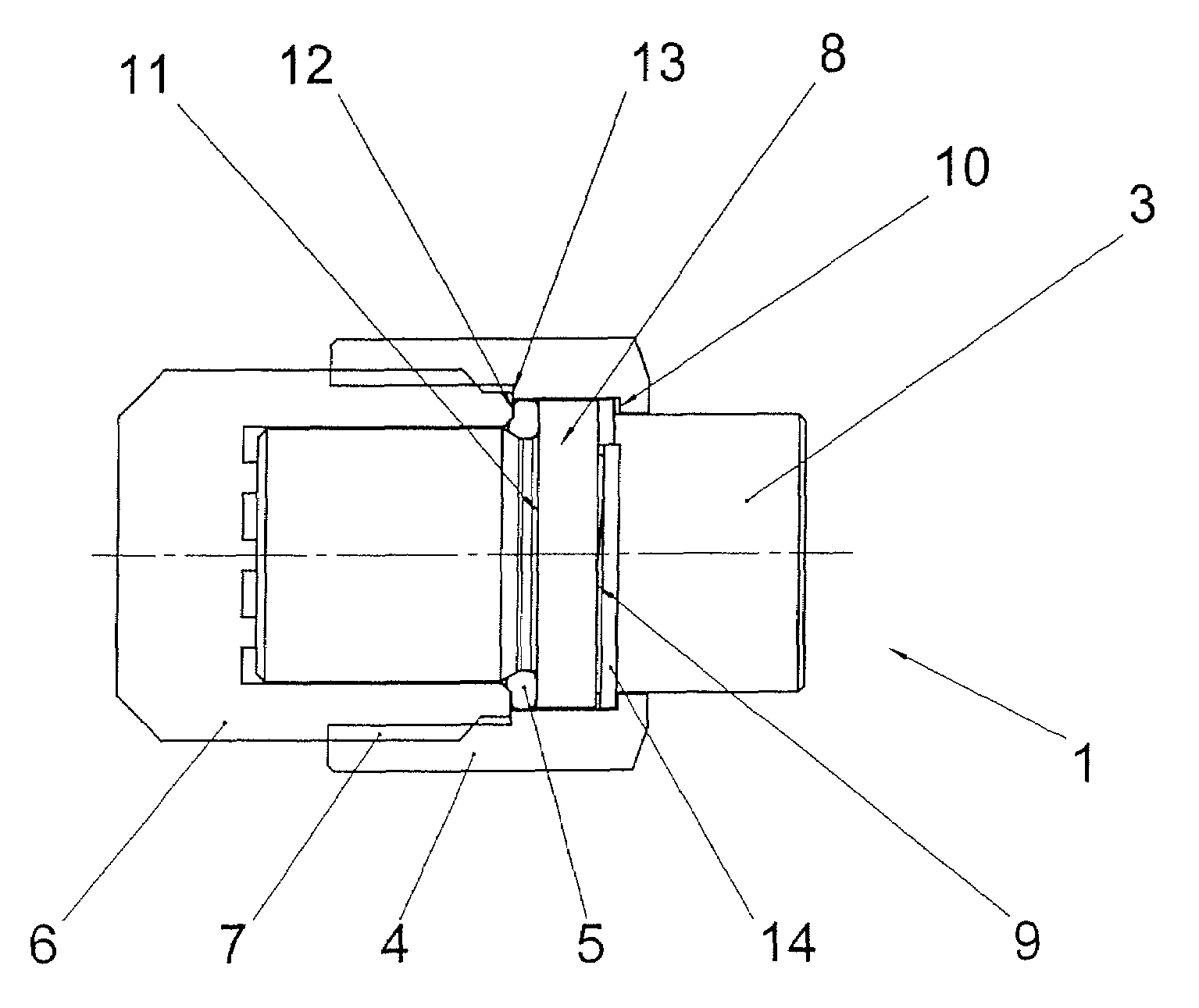

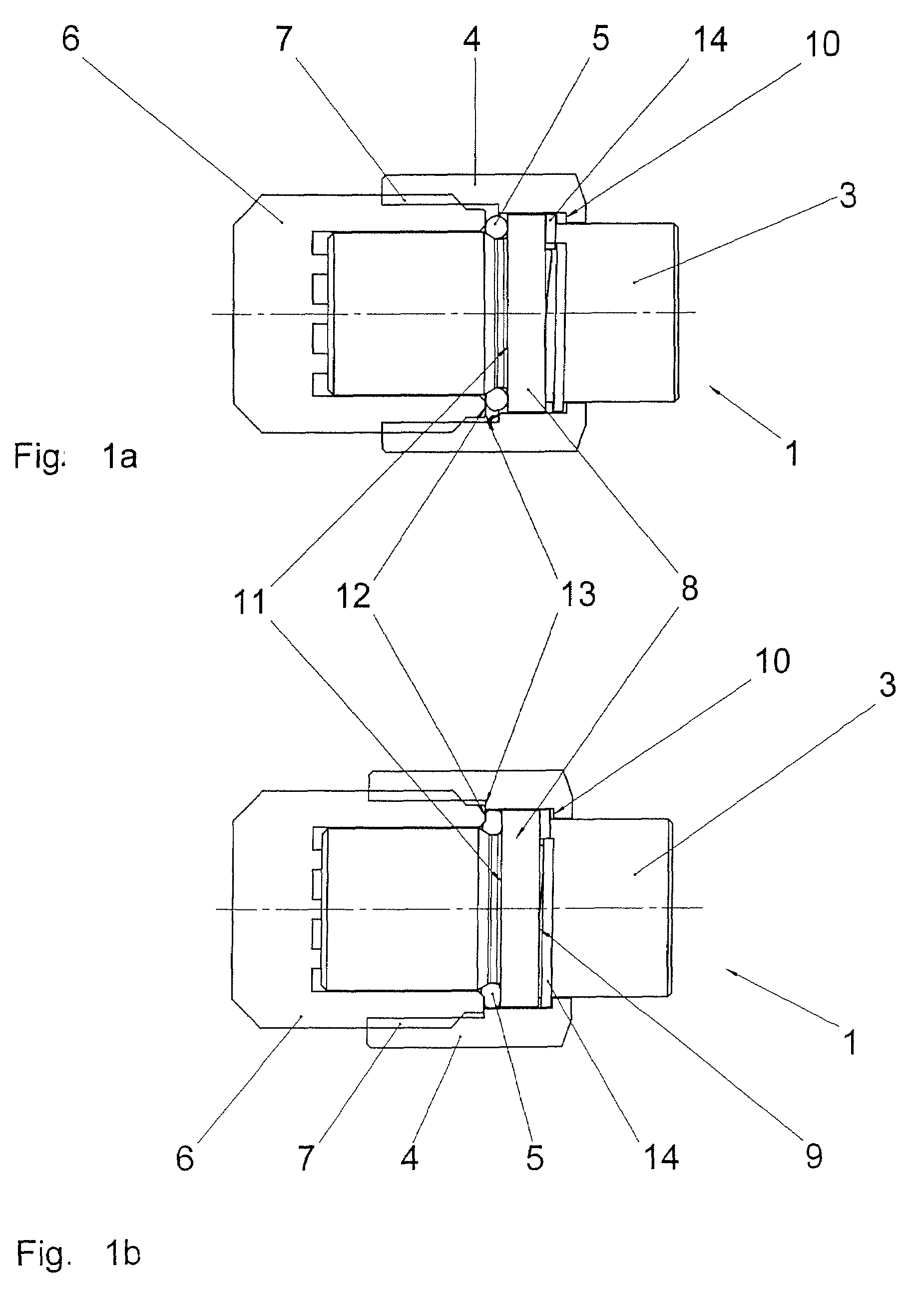

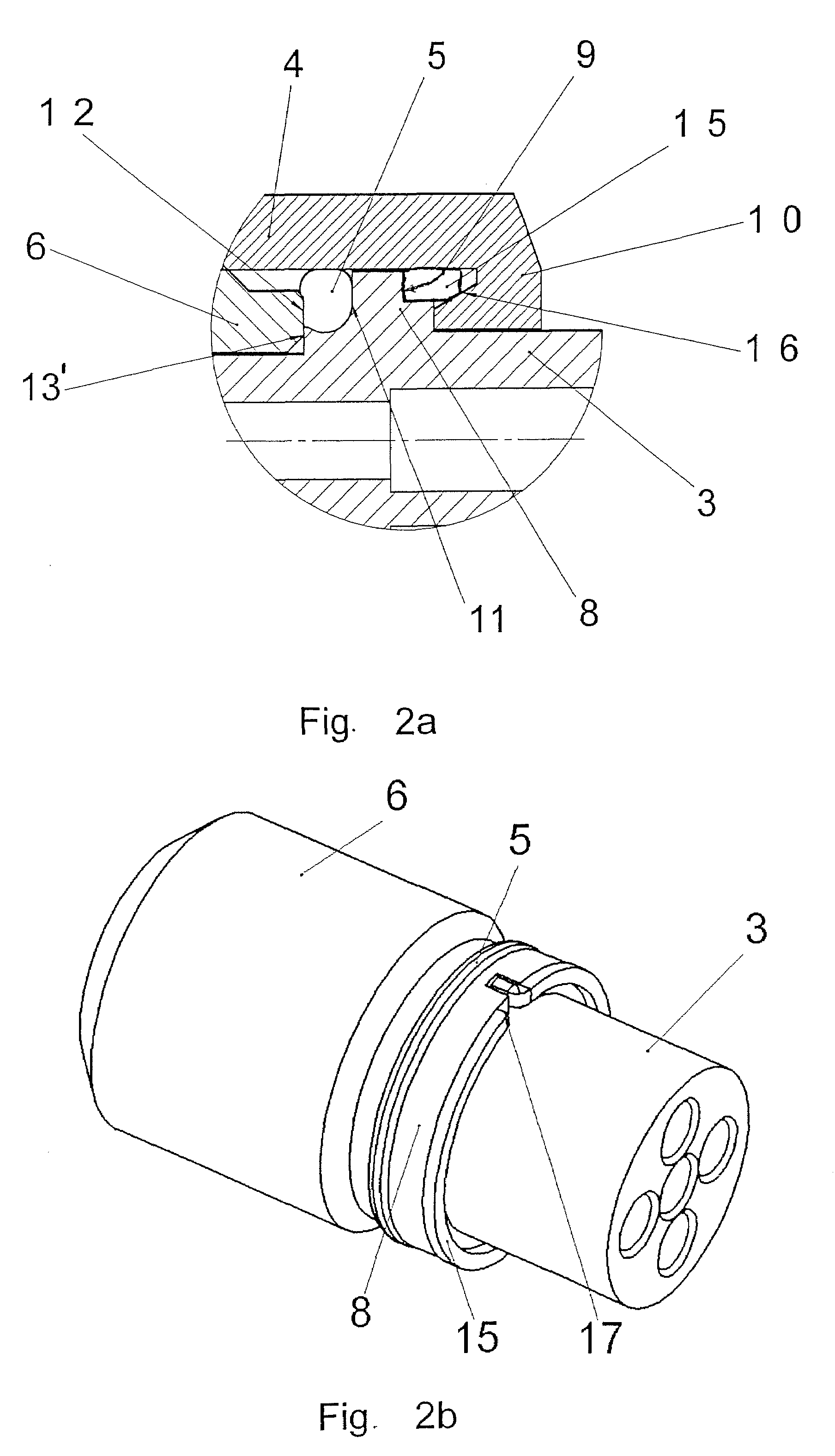

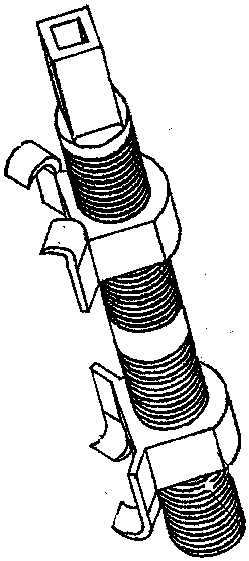

Electrical connector and electrical plug and socket connection

ActiveUS20070145744A1Avoid damageAvoid disadvantagesEngagement/disengagement of coupling partsPipe elementsElectricityMating connection

An electrical connector connects to a mating connector by a rotatable union nut that is axially displaceable on a contact carrier with a sealing element therebetween. Damage to the sealing element is prevented by a stop that limits the maximum path by which the union nut can be screwed onto the mating connector, such that when the union nut is screwed on, the elastic sealing element is intentionally compressed, but is not damaged or destroyed. A vibration guard can also be provided in the connection.

Owner:IMF ELECTRONIC GMBH

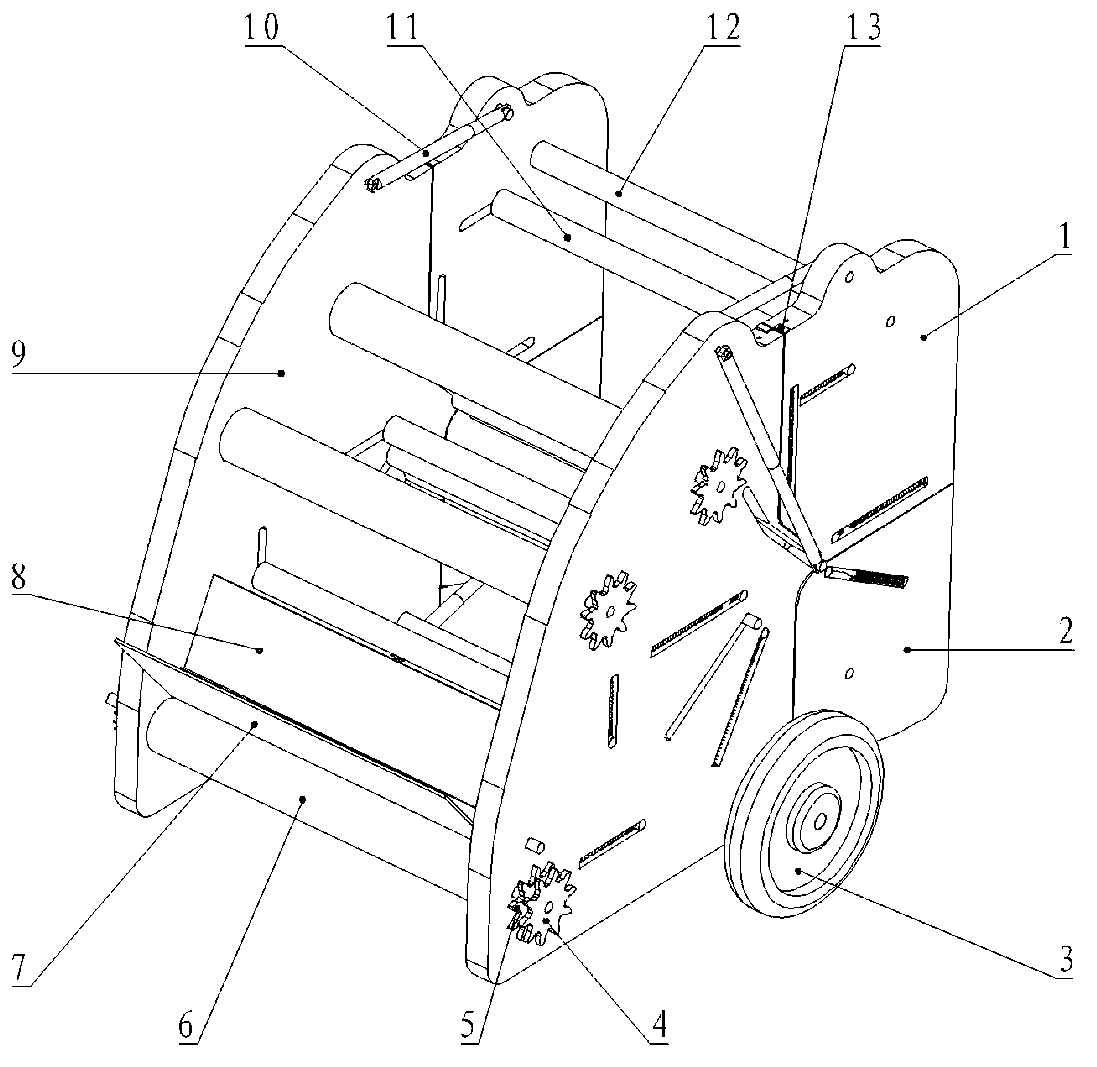

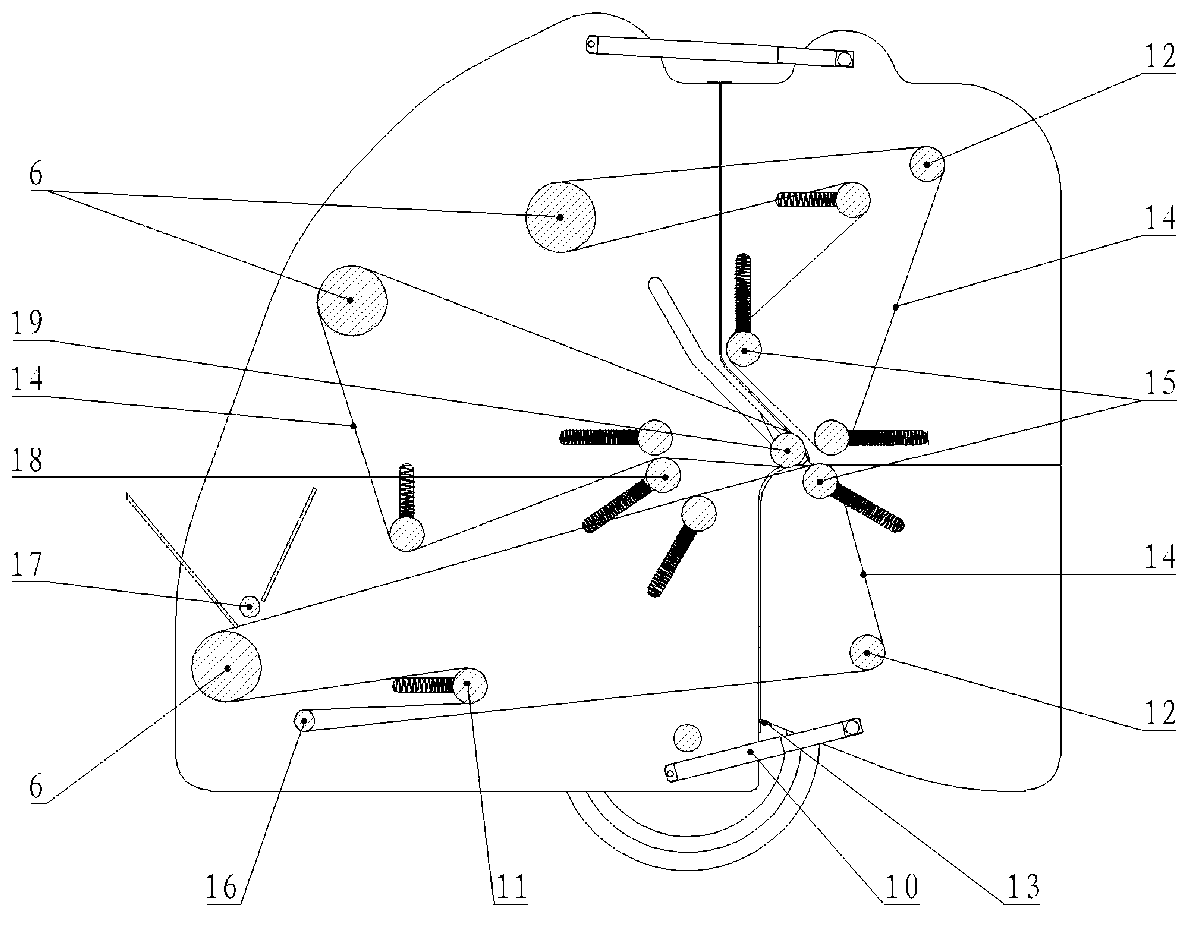

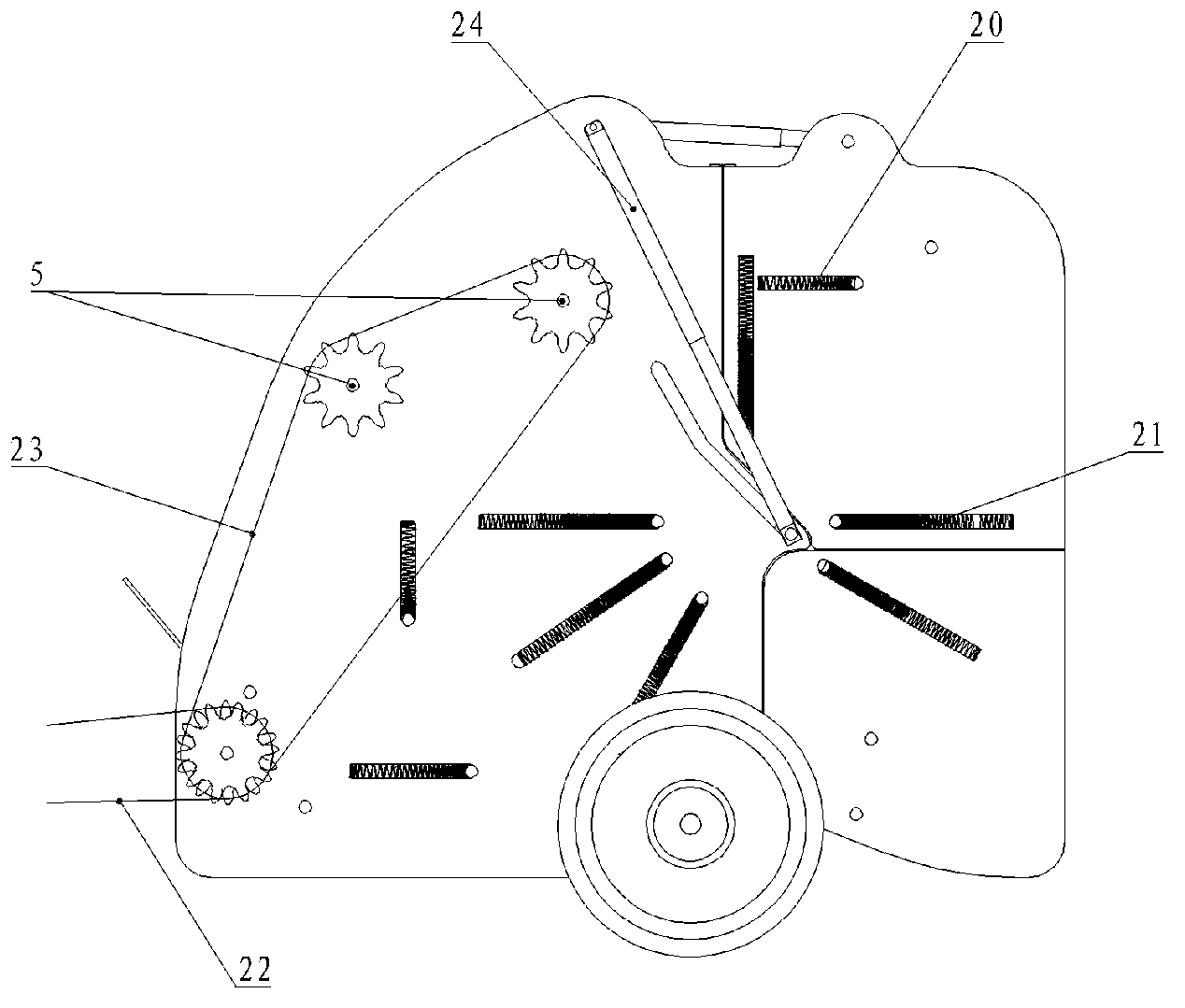

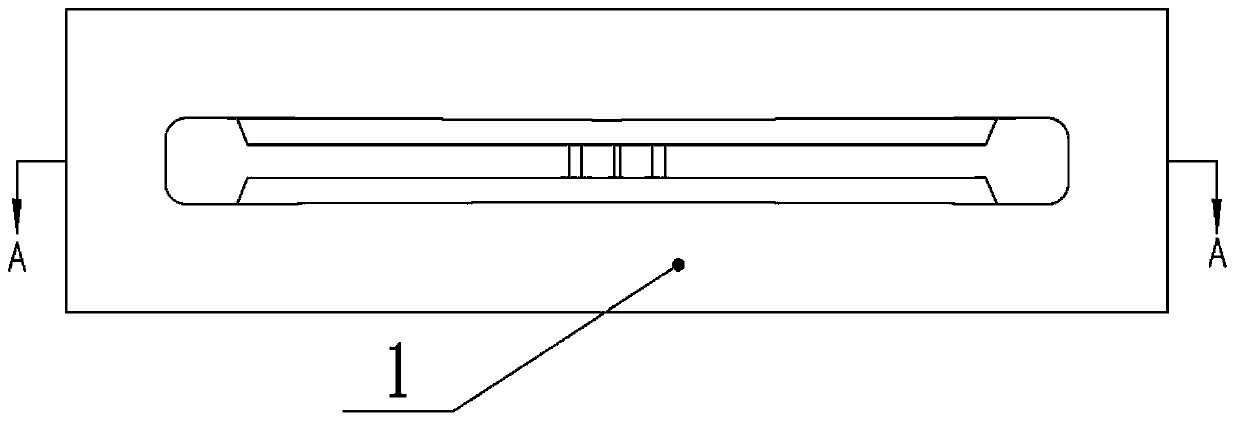

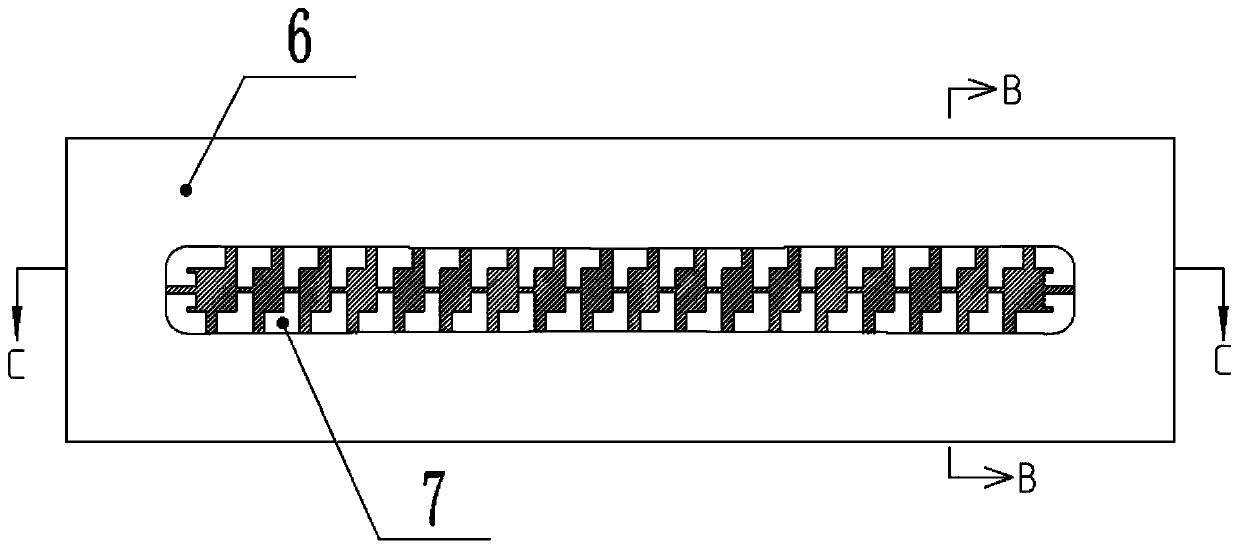

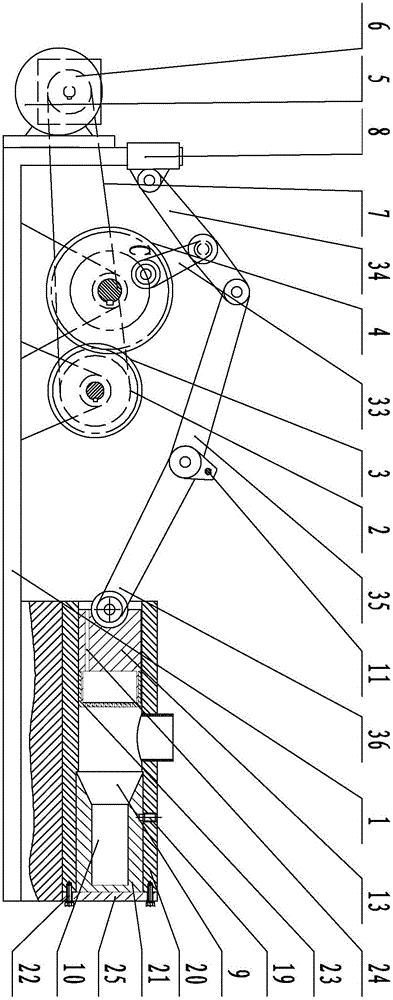

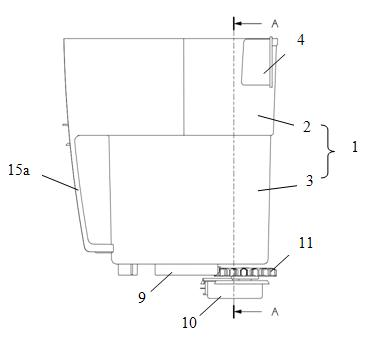

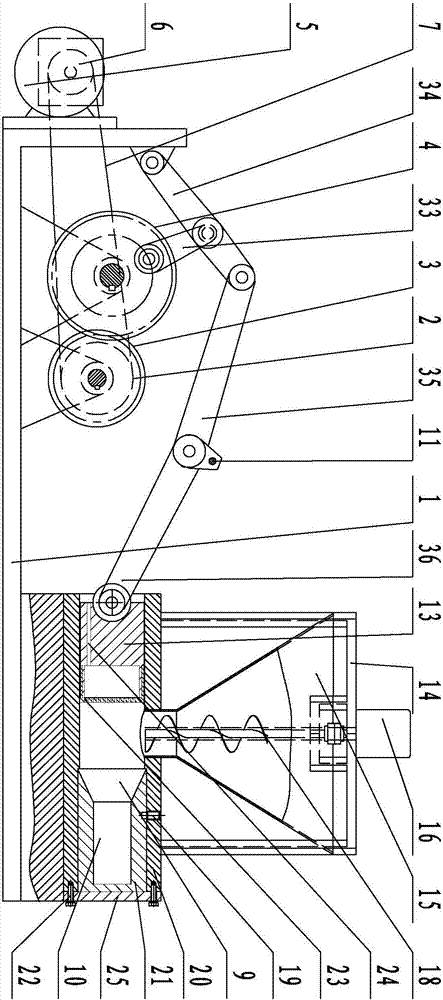

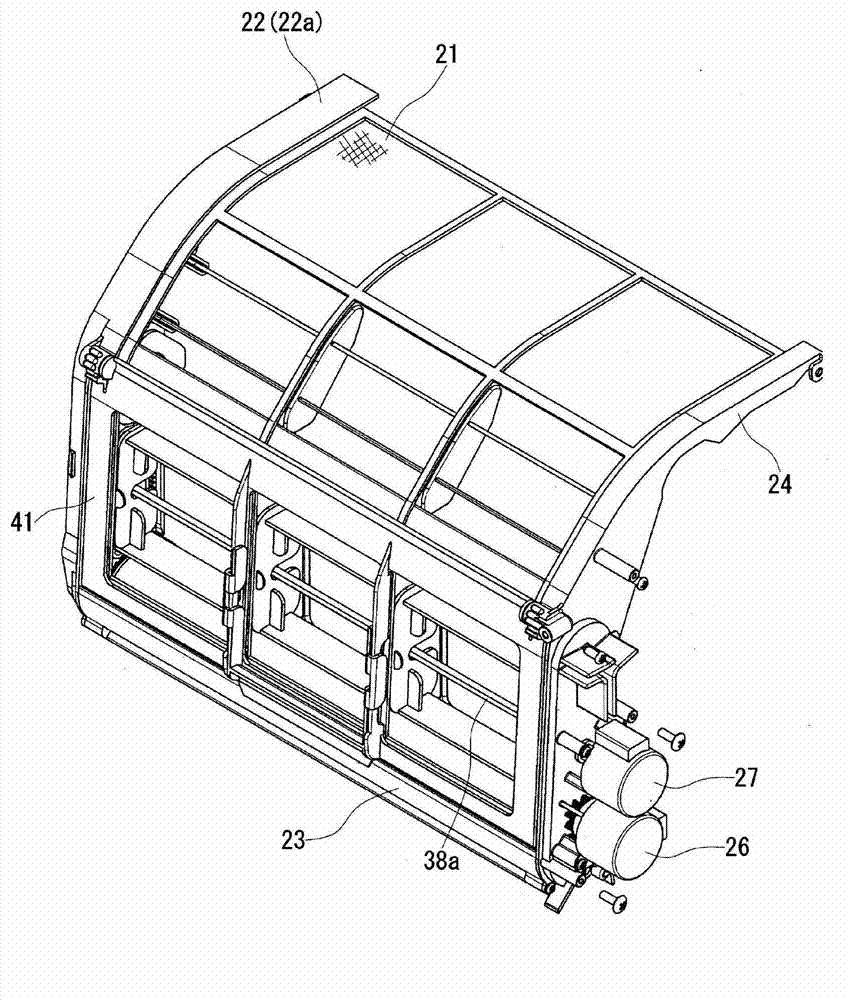

Room-changing belt-type binding machine

The invention discloses a room-changing belt-type binding machine. The binding machine consists of installation plates, a feed channel, a chain mechanism, a compressor and wheels, wherein the feed channel is arranged on the lower part in front of a space between the two installation plates and is connected with a discharge hole of a harvester; the compressor is arranged in middle of the space between the installation plates; and the chain mechanism is arranged on the front parts of the outer side surfaces of the installation plates. When the room-changing belt-type binding machine works, straws are primarily compressed, so that gaps among the stalks are fully reduced, part of gas is exhausted, the surfaces of fibers can be sufficiently contacted with one another, and the compression rate of the stalks can be improved since the fibers are staggered with one another in the compression process; and the stalks are secondarily compressed by a rubbing and pressing forming manner with a high core forming rate, thereby guaranteeing the forming rate of bales. When the compressor is used for forming roll cores, a hydraulic control mechanism implements force application in a rubbing and pressing process, so that compressing force is large, the bales are stressed uniformly in the compression process, and the shapes of hay cores and the formed bales are regular. The room-changing belt-type binding machine is simple in structure and low in cost, can achieve a high binding efficiency, and can be widely applied to agricultural production.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Electrical connector and electrical plug and socket connection

ActiveUS7413457B2Avoid damageHigh compression forceEngagement/disengagement of coupling partsPipe elementsMating connectionElectrical bonding

An electrical connector connects to a mating connector by a rotatable union nut that is axially displaceable on a contact carrier with a sealing element therebetween. Damage to the sealing element is prevented by a stop that limits the maximum path by which the union nut can be screwed onto the mating connector, such that when the union nut is screwed on, the elastic sealing element is intentionally compressed, but is not damaged or destroyed. A vibration guard can also be provided in the connection.

Owner:IMF ELECTRONIC GMBH

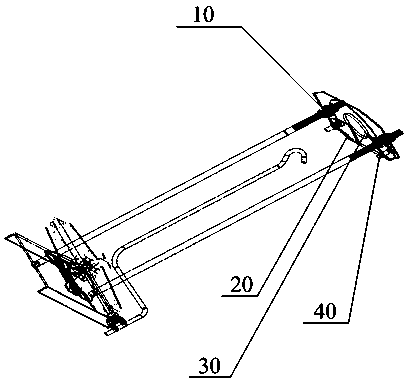

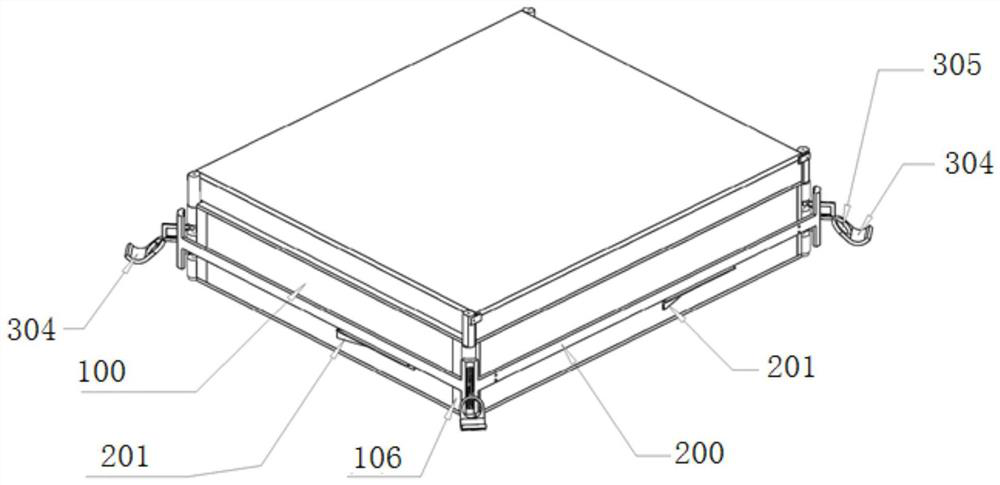

Portable automotive suspension disassembly and assembly device and disassembly and assembly method thereof

InactiveCN103722523ASimplify the disassembly processEasy to operateMetal-working hand toolsAutomotive engineeringJackscrew

The invention provides an automotive suspension disassembly and assembly device and a disassembly and assembly method thereof. The automotive suspension disassembly and assembly device comprises an upper plate and a lower plate, wherein the upper plate and the lower plate are connected through at least one vertical column. The upper plate is provided with a movable plate and a locating pin, one end of the movable plate is connected with the upper plate through a bolt, an installation hole matched with the locating pin is formed in the other end, and a hole is formed in the middle of the upper plate. The lower plate is provided with a jack and a rocking lever used for controlling the height of the jack. The automotive suspension disassembly and assembly device has the advantages that the operation is easy, convenient, safe and reliable. The disassembly and assembly process of a suspension is simple, and the automotive suspension disassembly and assembly device can be used without training. In addition, the automotive suspension disassembly and assembly device can bear large compression force and restoration force, is stressed uniformly, and is safe and reliable.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

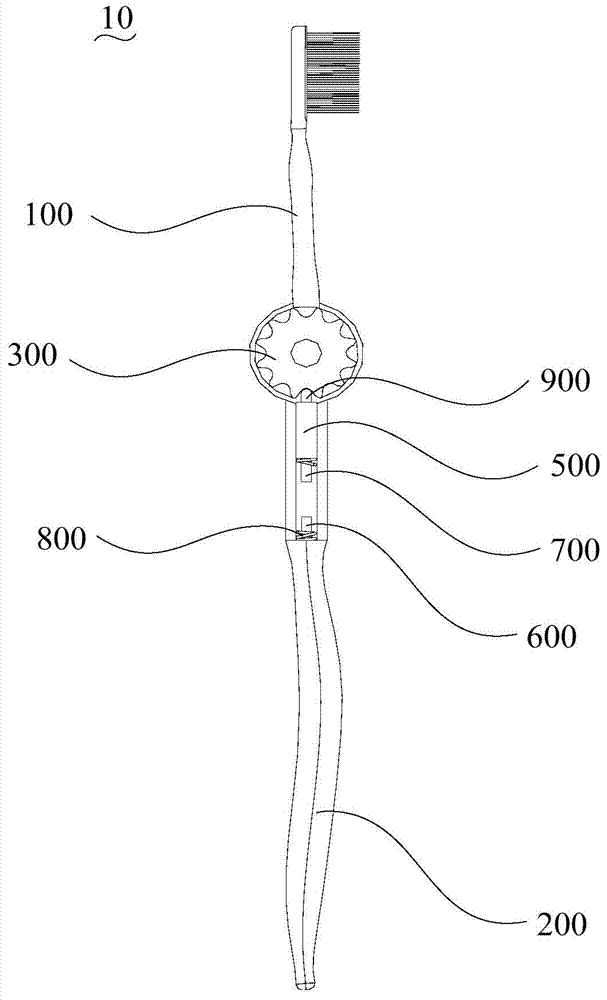

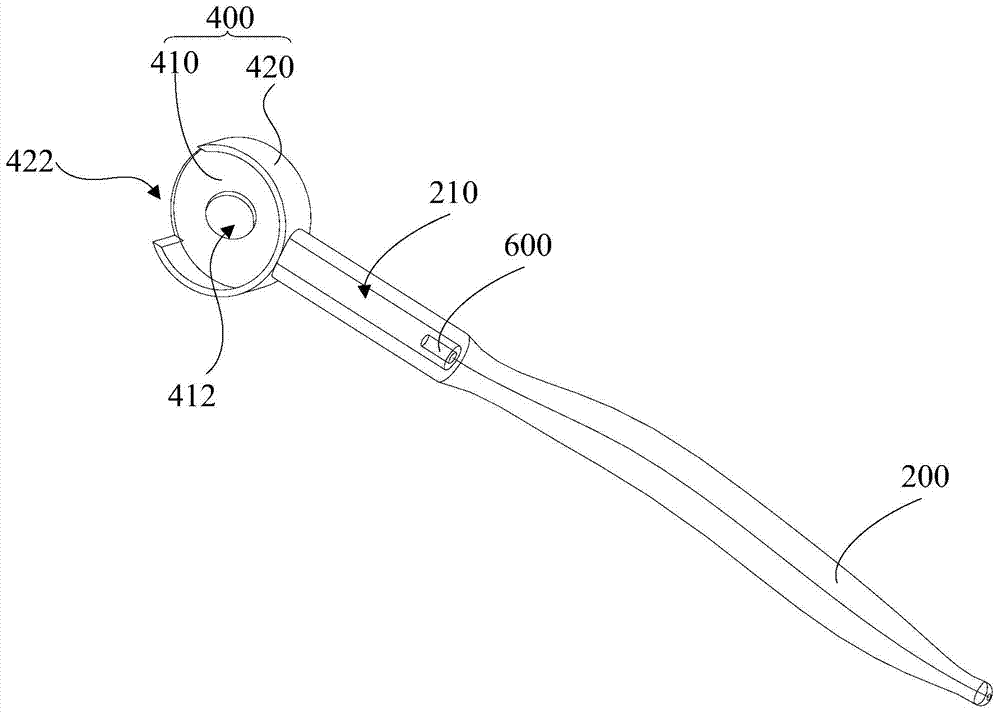

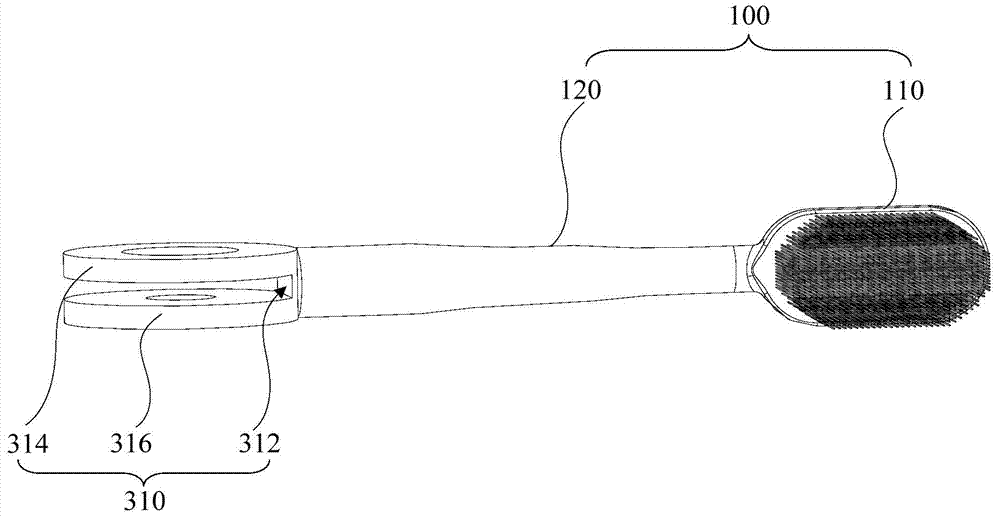

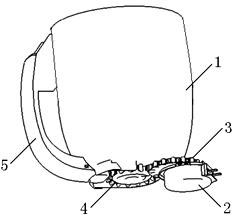

Toothbrush

ActiveCN103494434AHigh compression forceBrush bodiesBristle carriersAgricultural engineeringTooth brushing

The invention relates to a toothbrush which comprises a brush head, a brush handle, a drive mechanism, a shell body, a follower lever and an abutting column. The drive mechanism comprises a body, a rotating wheel and a pawl. The body comprises a connecting plate, a first fixing plate and a second fixing plate, wherein the connecting plate is connected with the brush head, and the first fixing plate and the second fixing plate are arranged on the two opposite sides of the connecting plate respectively. The periphery of the rotating wheel is provided with a circular arc groove. The rotating wheel is located between the first fixing plate and the second fixing plate, is fixed on the first fixing plate and can rotate in the body. The pawl is fixed on the surface of the second fixing plate and used for driving the rotating wheel to rotate. The shell body comprises a bottom plate and a flange part which is connected with the brush handle, wherein the second fixing plate is fixed on the bottom plate, and the body can rotate in the shell body. The follower lever is contained in a brush handle cavity in one end of the brush handle, and the end, away from the brush head, of the follower lever is elastically connected with the bottom of the brush handle cavity. The abutting column is arranged at the end, close to the brush head, of the follower lever and penetrates through the flange part to be connected with the bottom of the circular arc groove in an abutting mode. The toothbrush can limit the maximum tooth brushing strength.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

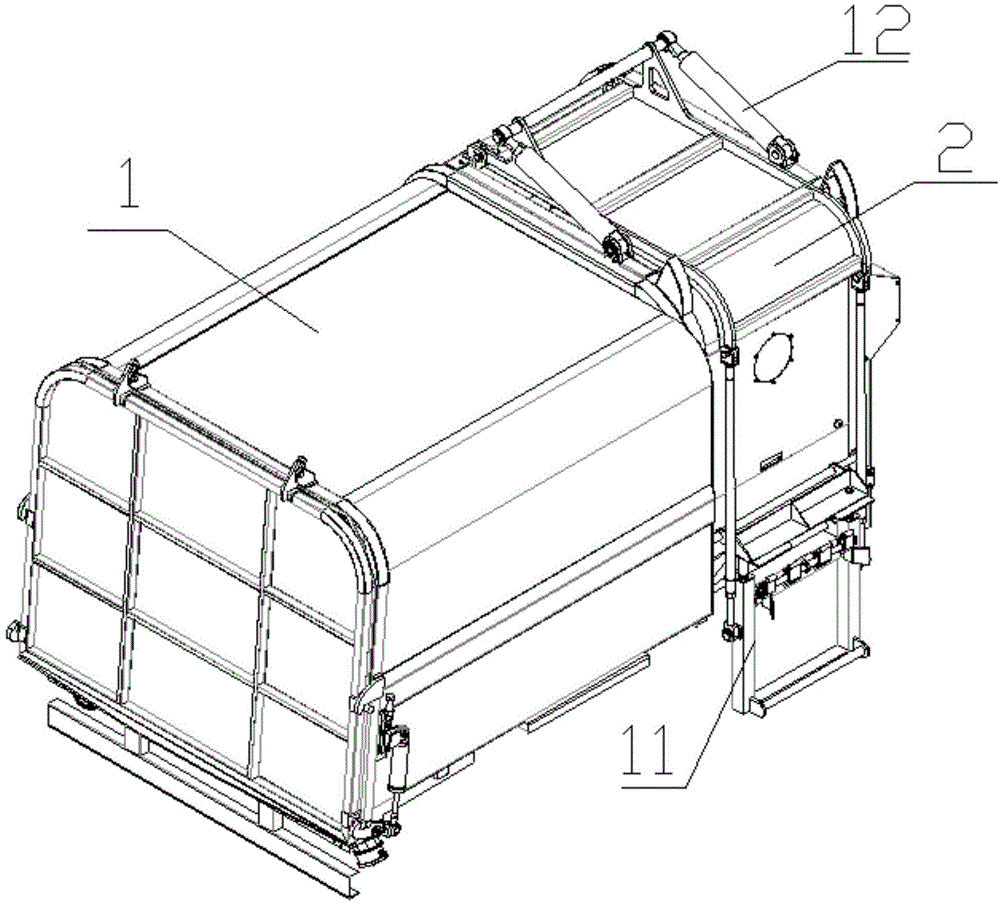

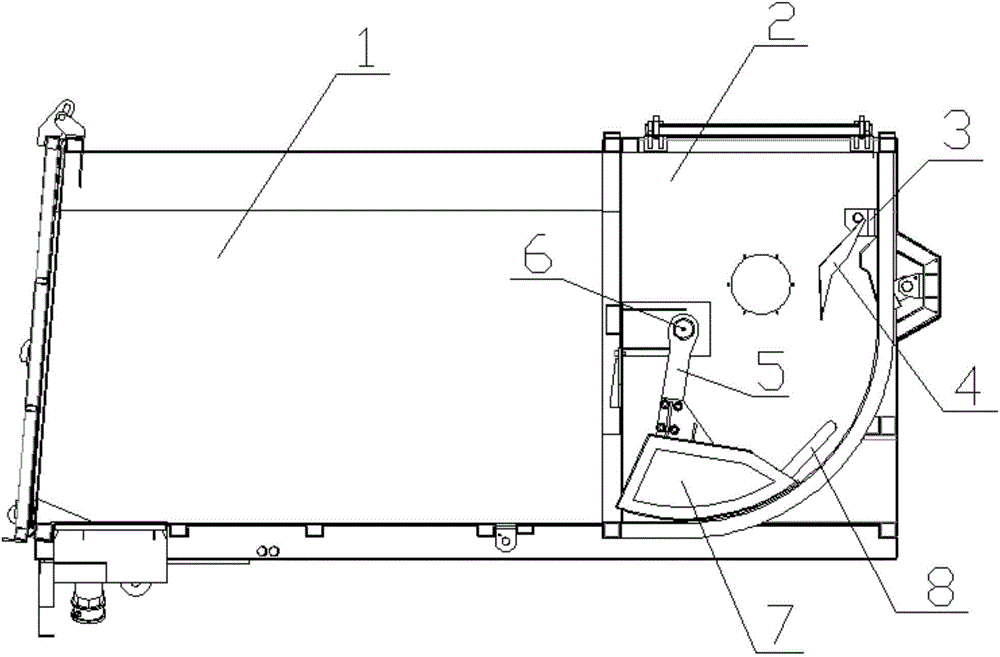

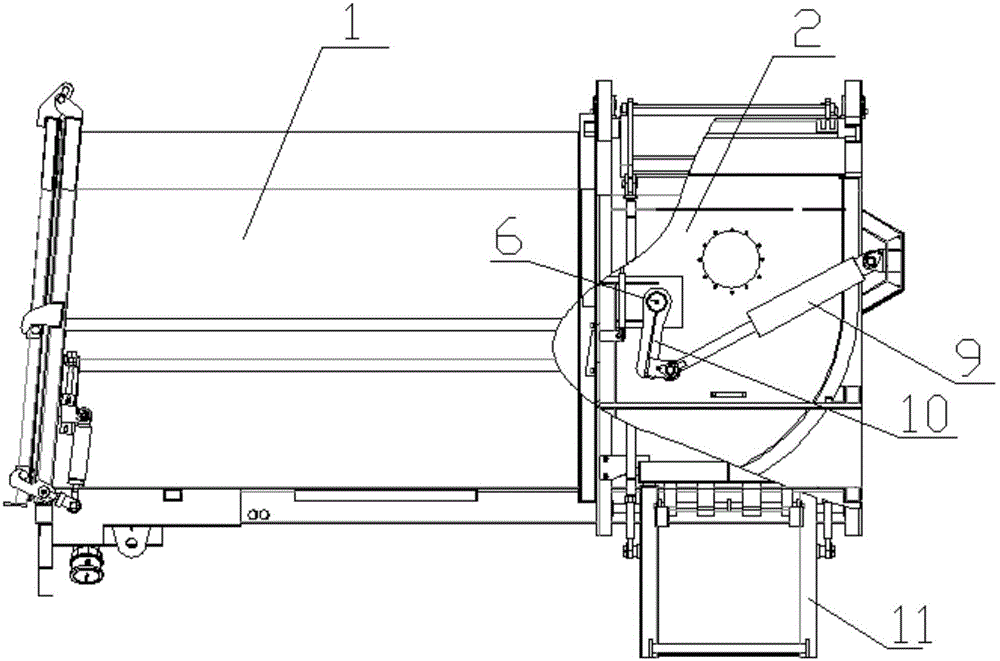

Side-loading compression garbage truck

ActiveCN104875999AIncrease the compression ratioIncrease storage capacityRefuse vehiclesCompression deviceEngineering

The invention discloses a side-loading compression garbage truck. The side-loading compression garbage truck comprises a storage chamber, a compression chamber, a lifting can-overturning mechanism and a rotary compression device, wherein the compression chamber is arranged at one end of the storage chamber and is in communicated connection with a compression opening in the storage chamber, the lifting can-overturning mechanism is mounted on the side portion of the compression chamber, and the rotary compression device is disposed in the compression chamber and comprises a rotary push head and an oscillating rod. One end of the oscillating rod is fixed on the upper portion of the rotary push head, and the other end of the oscillating rod is connected with a rotary shaft arranged on the side wall of the compression chamber, so that the rotary push head closes the compression opening when being closest to the storage chamber. A compression oil cylinder and a power arm are arranged on the outer side of the compression chamber, the power arm is fixedly connected with the rotary shaft, the other end of the power arm is movably connected with the extension end of the compression oil cylinder, and the tail end of the compression oil cylinder is fixed on the outer side wall of the compression chamber. The side-loading compression garbage truck has the advantages that on the premise of not enlarging the compression oil cylinder, compression ratio of the compression chamber can be increased effectively, and garbage storage quantity is increased; wear is little, and jamming of the compression oil cylinder during compression is reduced greatly.

Owner:LIXIN JIANGHUAI YANGTIAN AUTOMOBILE

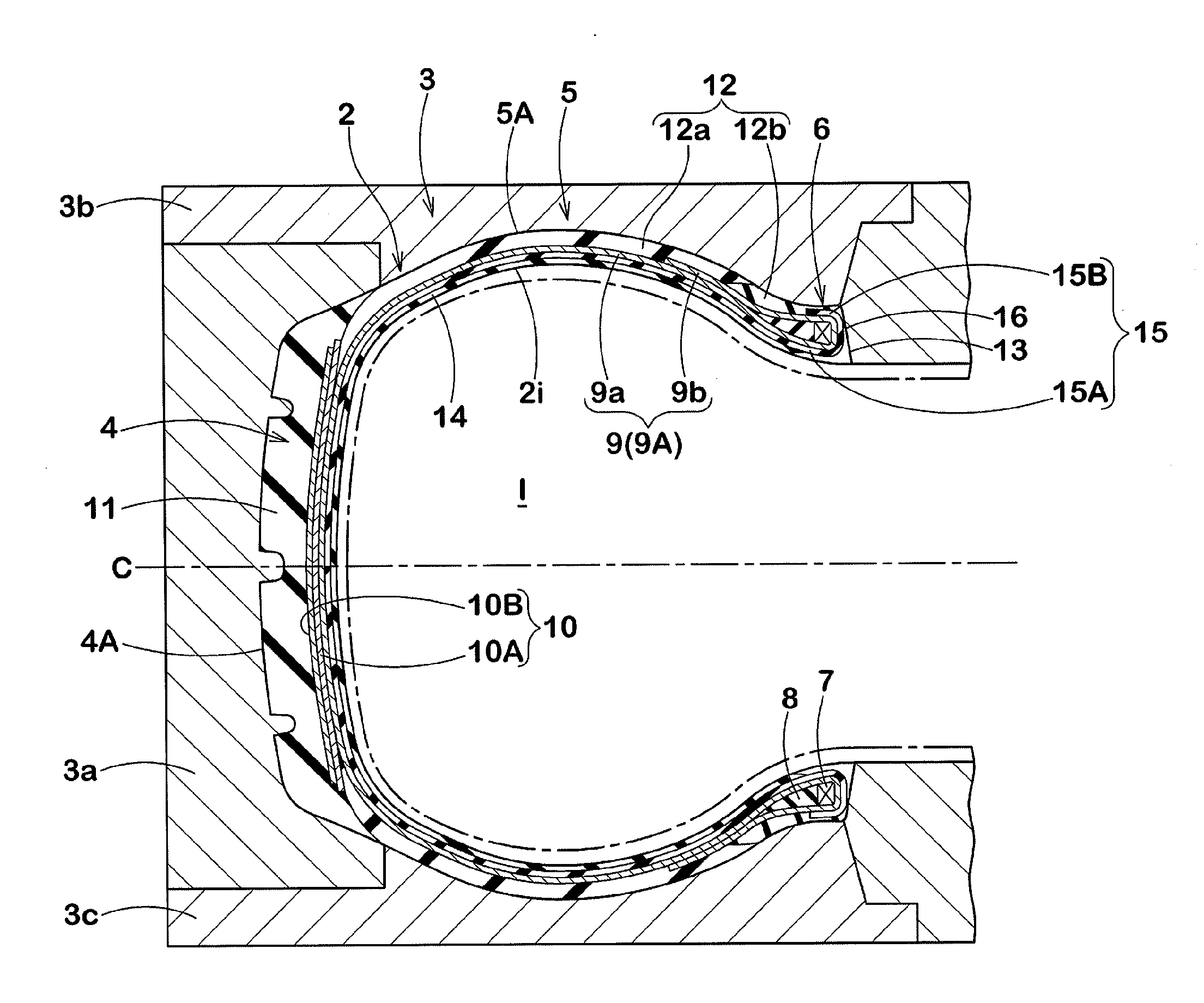

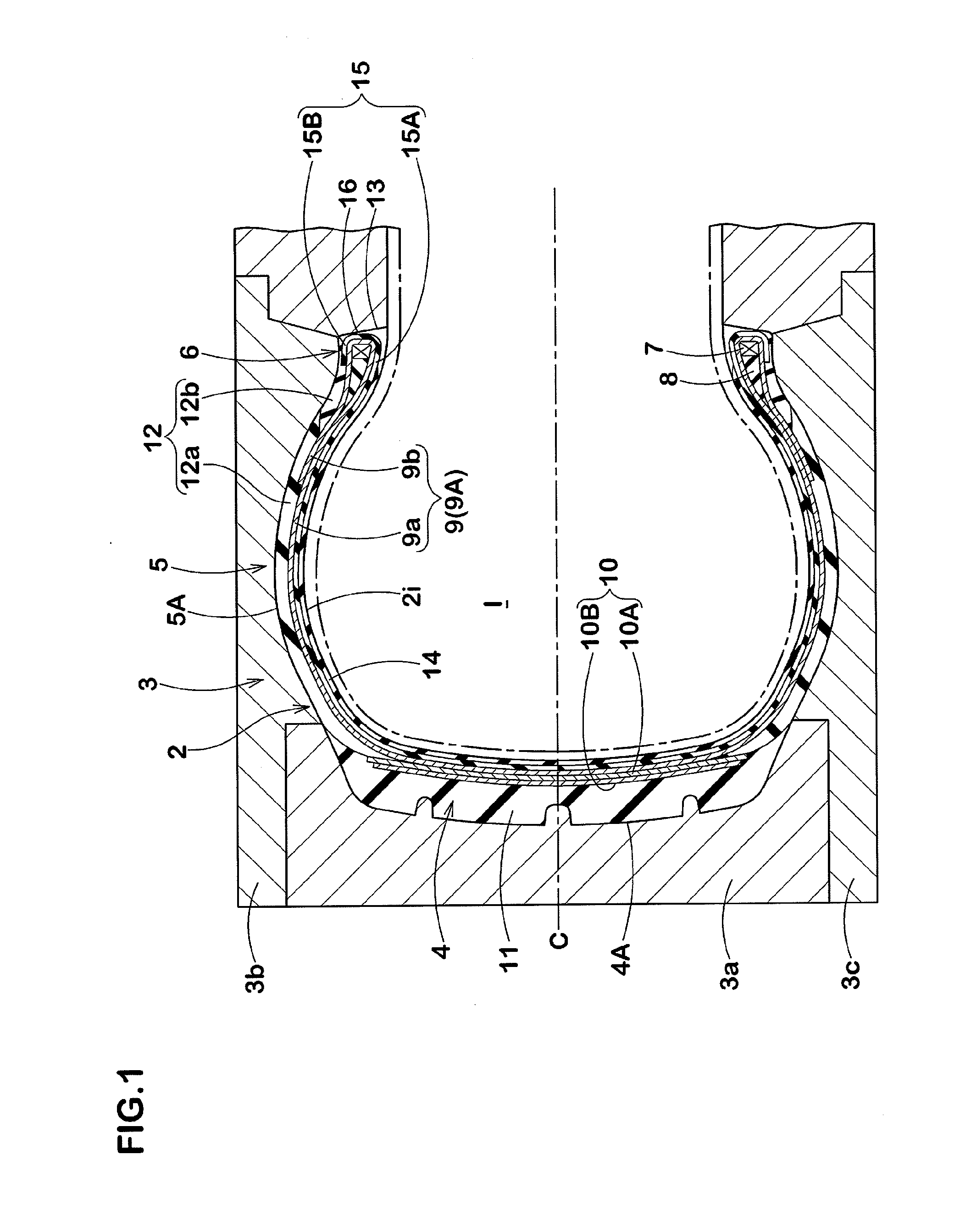

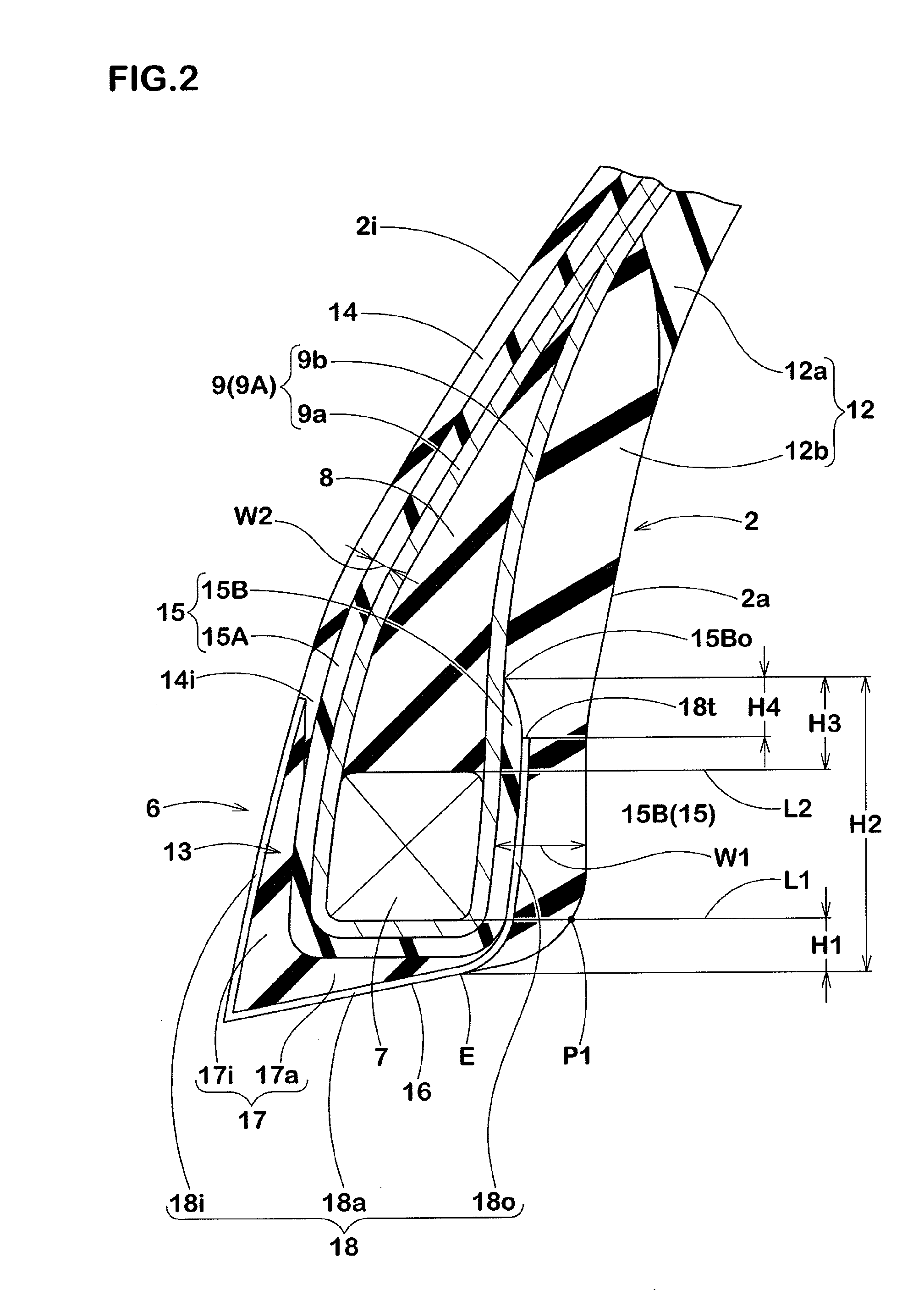

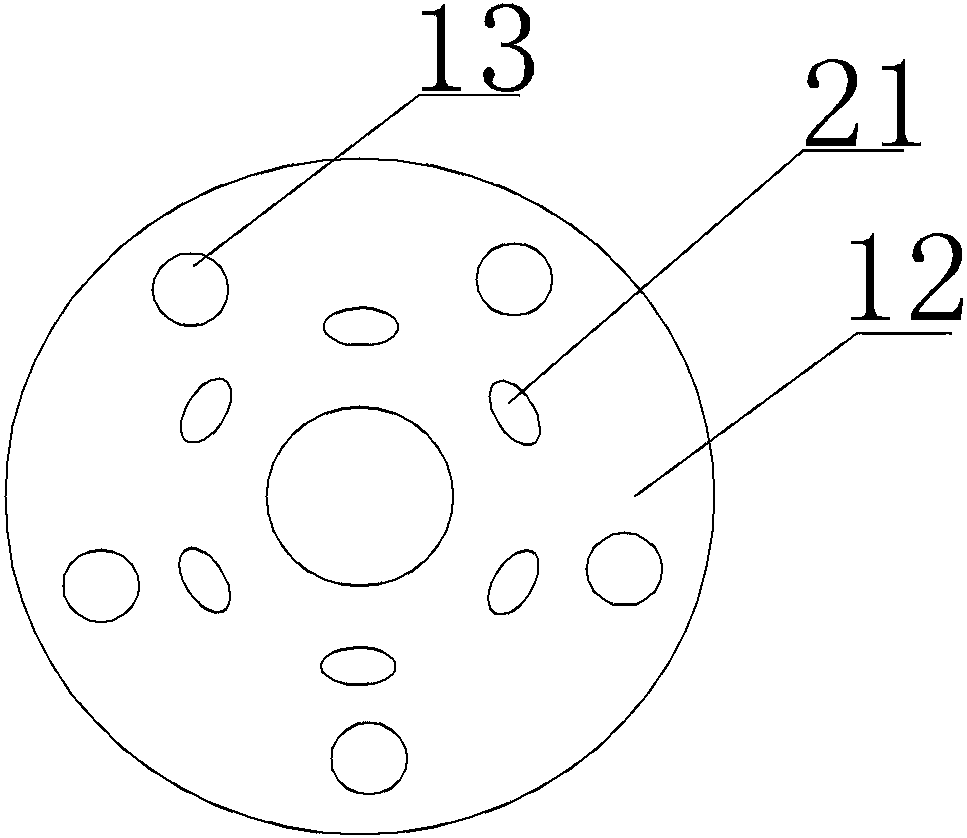

Manufacturing method for pneumatic tire

InactiveUS20120285606A1Suppression of deformationIncrease rubber thicknessTyresTyre beadsVulcanizationEngineering

A manufacturing method for pneumatic tire includes a process in which a raw cover (2) for a tire is formed, and a vulcanization process in which said raw cover (2) is inserted into a mold (3) and subjected to vulcanization molding. With the raw cover (2) inserted into the mold (3), a sidewall rubber edge (E), which is a boundary part between a bead chafer (13) and a sidewall rubber (12) that appears on an outer surface (2a) of the raw cover, is located further to the inside of the tire in the radial direction than an inner core point (P1), which is the intersection point between the outer surface (2a) of the raw cover and an axial line (L1) that passes through a bead core (7) on the inner edge of the tire in the radial direction.

Owner:SUMITOMO RUBBER IND LTD

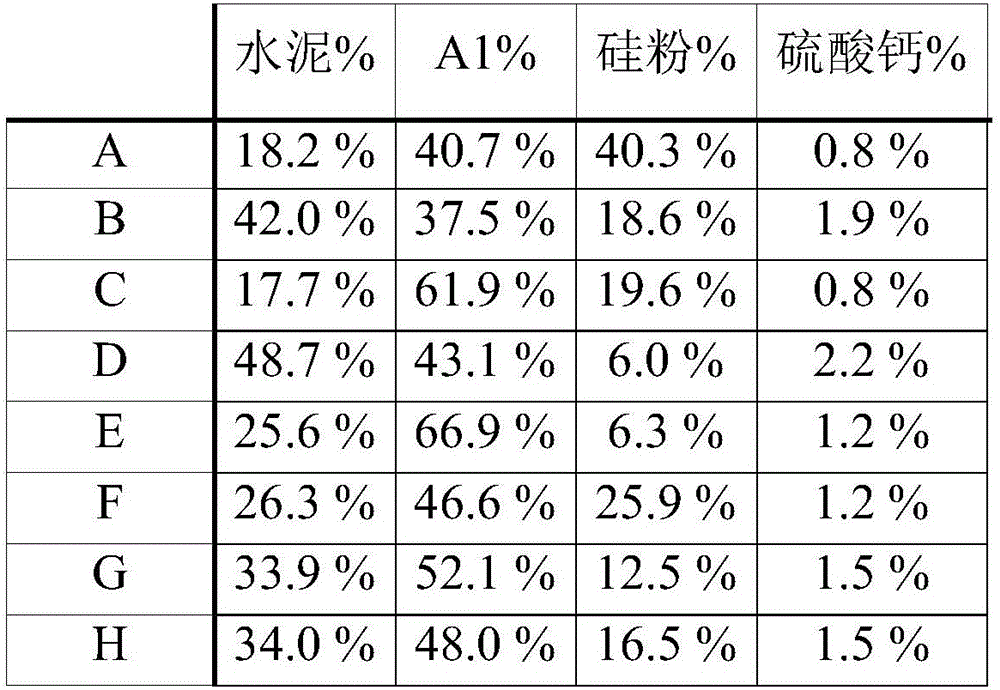

Ultra-high performance concretes having a low cement content

The present invention relates to a hydraulic binder comprising, as percentage by mass: from 17 to 55% of a Portland cement, the particles of which have a D50 of from 2 mum to 11 mum; at least 5% of silica fume; from 36 to 70% of a mineral addition A1, the particles of which have a D50 of from 15 to 150 mum; the sum of these percentages being from 80 to 100%; the sum of the percentages of cement and of silica fume being greater than 28%; the mineral addition A1 being selected from slags, pozzolanic additions or siliceous additions such as quartz, silico-calcareous mineral additions, calcareous additions such as calcium carbonate or mixtures thereof.

Owner:HOLCIM

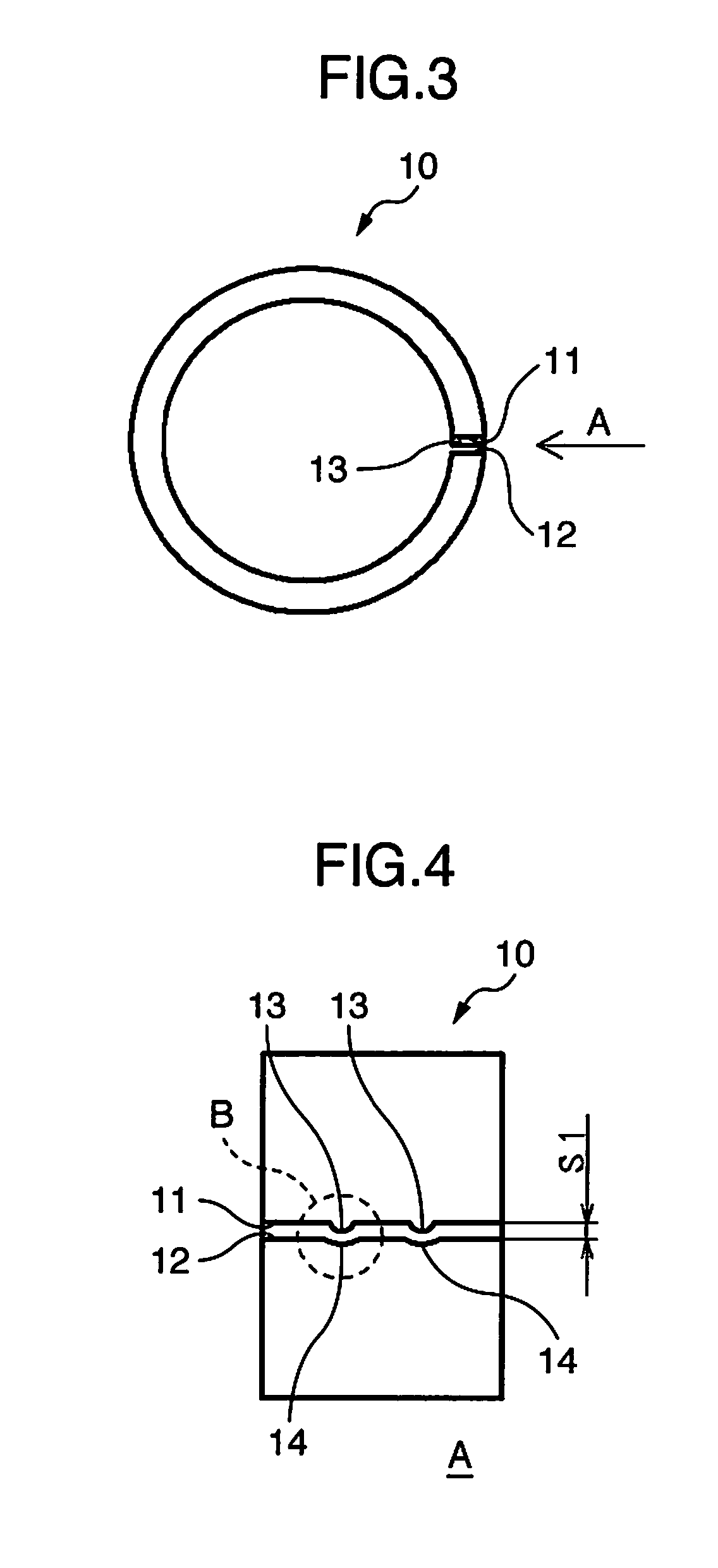

Bearing device

Disclosed is a bearing device including: a bearing housing made of an Al alloy and having a bearing holding hole; a sliding bearing having a cylindrical shape and forced into the bearing holding hole; and a shaft supported with an inner circumferential surface of the sliding bearing, wherein in the sliding bearing to be forced into, a plurality of hardened convex portions projecting toward the second circumferential direction end surface being formed on the first circumferential direction end surface, a plurality of hardened concave portions corresponding to the plurality of hardened convex portions being formed on the second circumferential direction end surface, a first hardened area being formed on each of the hardened convex portions of the first circumferential direction end surface and its vicinity, and a second hardened area being formed on each of the hardened concave portions of the second circumferential direction end surface and its vicinity.

Owner:DAIDO METAL CO LTD

Organosilicon microemulsion antisticking agent and preparation method thereof

InactiveCN101406928BSolution to short lifeHigh particleFoundry mouldsFoundry coresSilanesFatty alcohol

Owner:武汉亿强科技开发股份有限公司

Wood-plastic door plank micro-foaming forming device and using method thereof

The invention relates to the field of wood-plastic production technology, in particular to a wood-plastic door plank micro-foaming forming device and using method thereof. The wood-plastic door plankmicro-foaming forming device comprises an extruder and an extruding mould. The extruding mould comprises a converging module. Core rods are arranged inside the converging module. A separation blade isvertically arranged between the core rods. The upper end face and the lower end face of the separation blade are fixedly connected with the converging module. The device is novel in structure, a wood-plastic material can be cut into a plurality of material units through the separation unit, in this way, the material units do not affect one another, flow crossing among the material units is avoided, balanced material flow and consistent material pressure of the material units are guaranteed, and stable friction force between the material units and the core rods is guaranteed.

Owner:濮阳市东宝科技发展有限公司

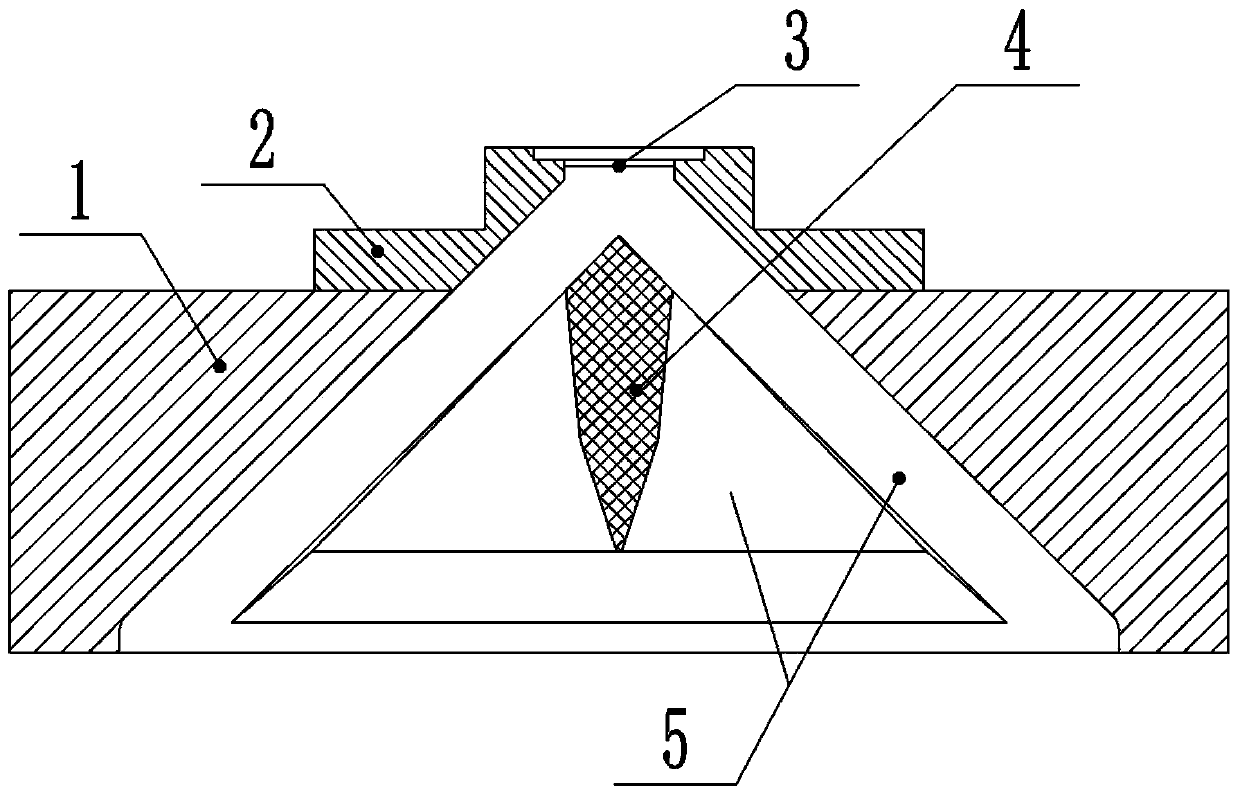

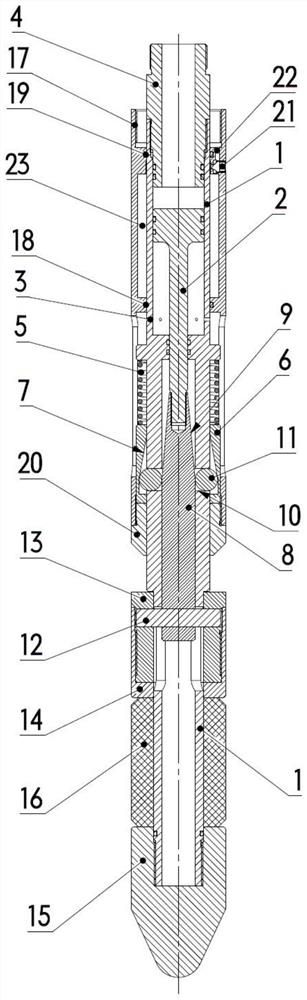

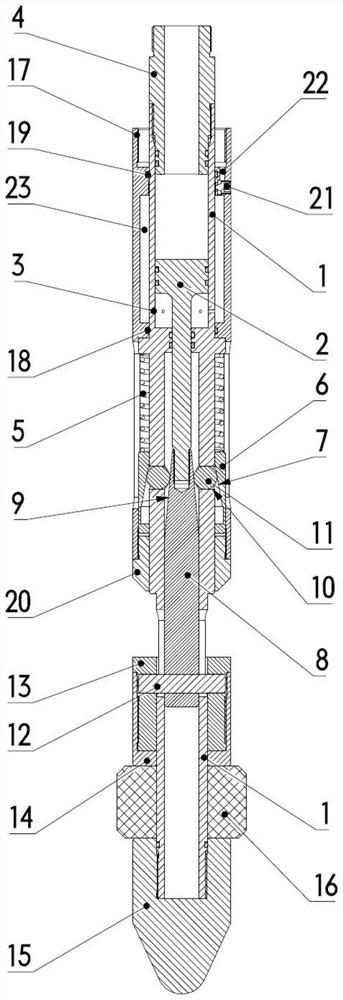

Setting and unsealing mechanism for underground sealing short section

ActiveCN112127826AReduce frictional resistanceReliable lockingSealing/packingStructural engineeringSteel ball

The invention provides a setting and unsealing mechanism for an underground sealing short section. The setting and unsealing mechanism comprises a piston cylinder, wherein a piston rod is arranged inthe piston cylinder; the bottom of the piston rod is connected with the top end of a push rod; a sleeve, a spring, an inner taper sleeve, a screw ring, a thrust ring, a pressing sleeve, a rubber cylinder and a guide cone are sequentially sleeved on the outer side of the piston cylinder from top to bottom; an air cavity is formed between the piston cylinder and the sleeve; a plurality of circular holes are formed in the wall of the piston cylinder; steel balls are arranged in the circular holes; the inner sides of the steel balls are pressed on the push rod; the outer sides of the steel balls are clung to the inner taper sleeve; the upper end of the thrust ring is integrally connected with the lower end of the push rod through a bolt; the pressing sleeve is arranged on the outer side of thethrust ring; the rubber cylinder is arranged between the pressing sleeve and the guide cone at the bottom of the piston cylinder; the rubber cylinder communicates with the outside through a pressureguide hole; and the upper part of the rubber cylinder communicates with the outside through a pressure relief valve and a pressure relief hole; the inner taper sleeve, the push rod and the steel ballsform a double-conical-surface self-locking structure, so that the locking is more reliable, the borne reverse thrust is larger, and the locking cannot be invalid unless a part is damaged. The settingand unsealing mechanism has the advantages of reasonable structure, convenience in operation, safety and reliability in setting, high efficiency and practicability.

Owner:XIJING UNIV

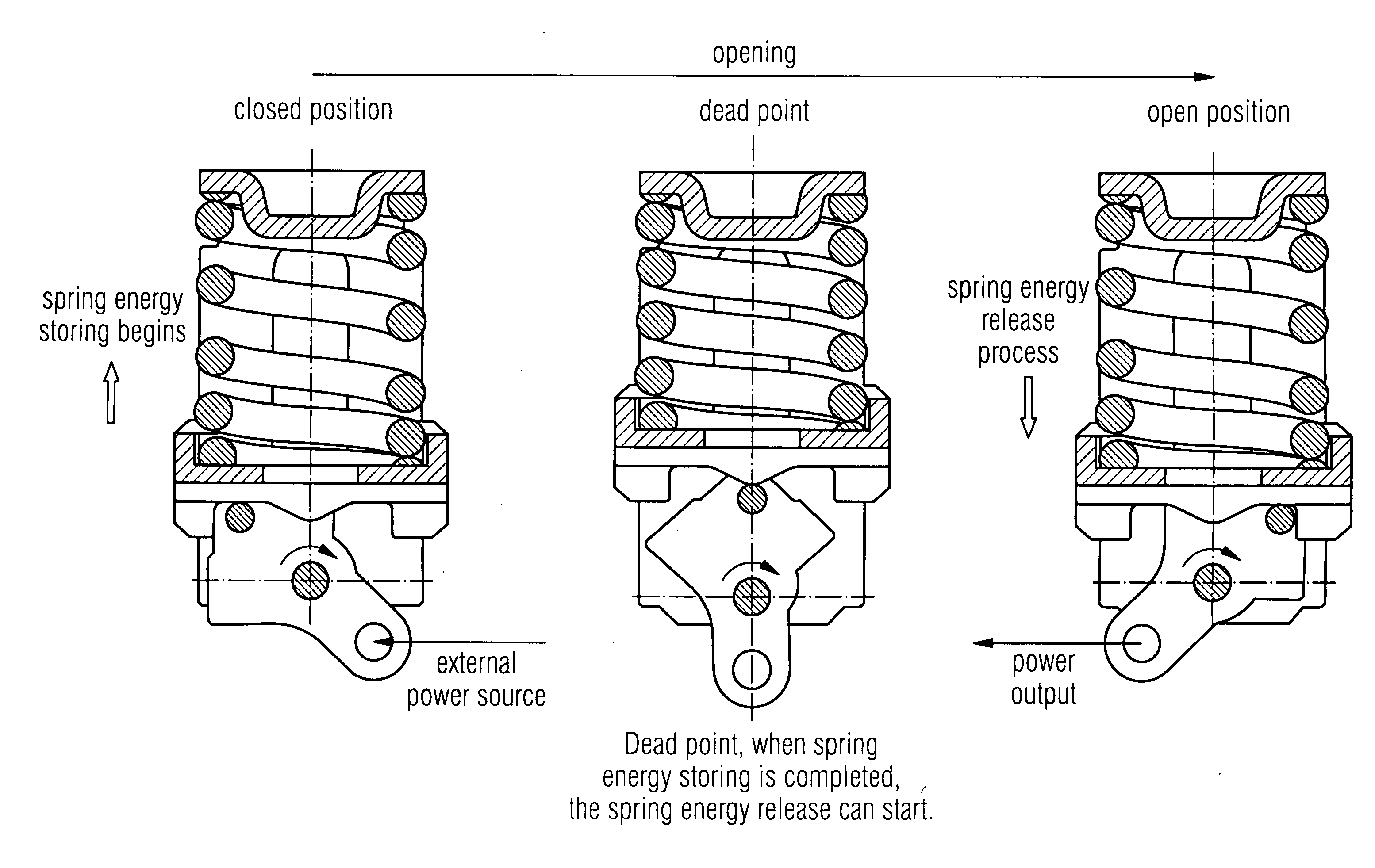

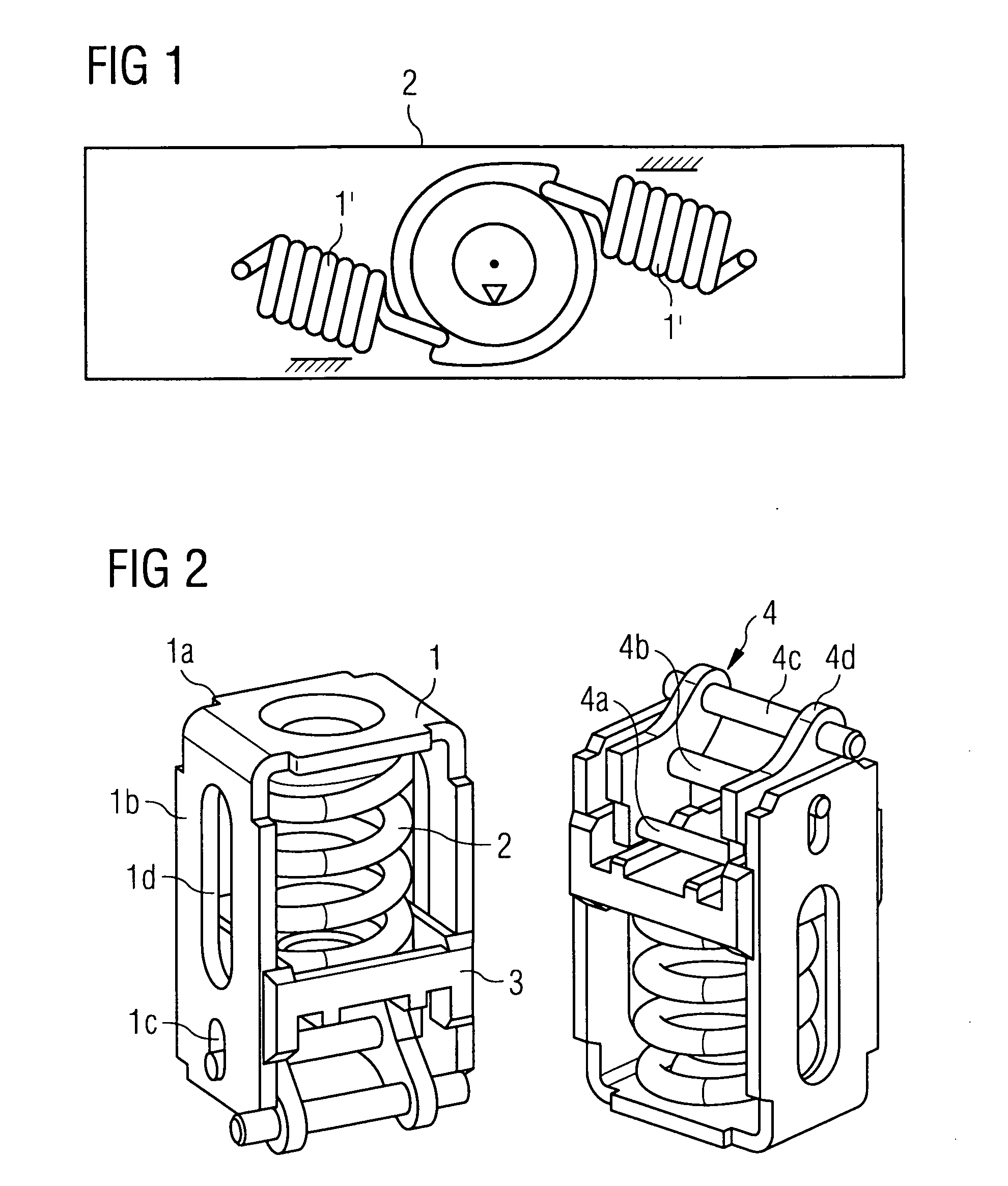

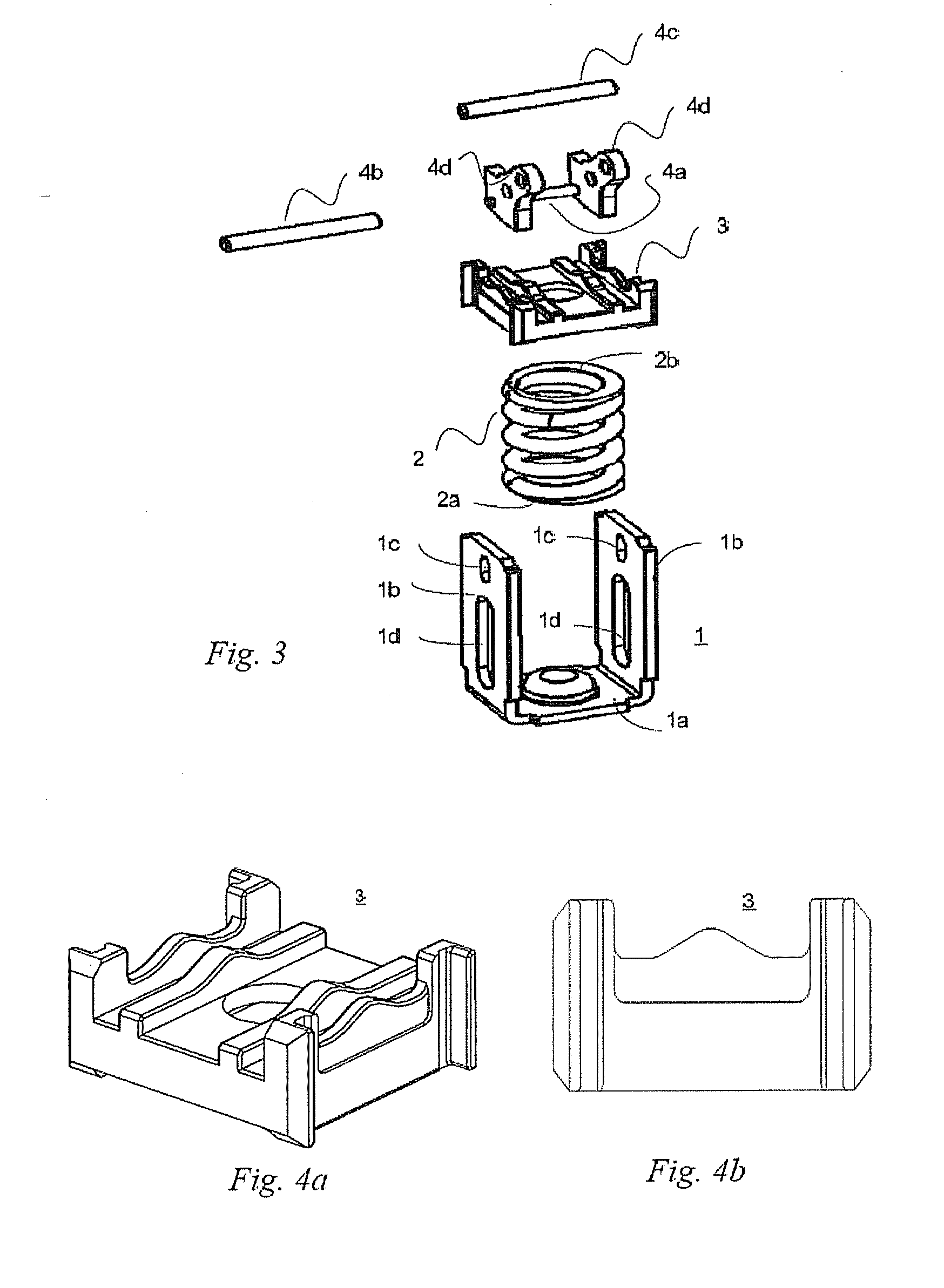

Spring operation device and method for assembling the same and switching device

InactiveUS20110048148A1Rotate accurately and efficientlyEmit energySpringsTumbler/rocker switchesEngineeringElectrical and Electronics engineering

Owner:SIEMENS AG

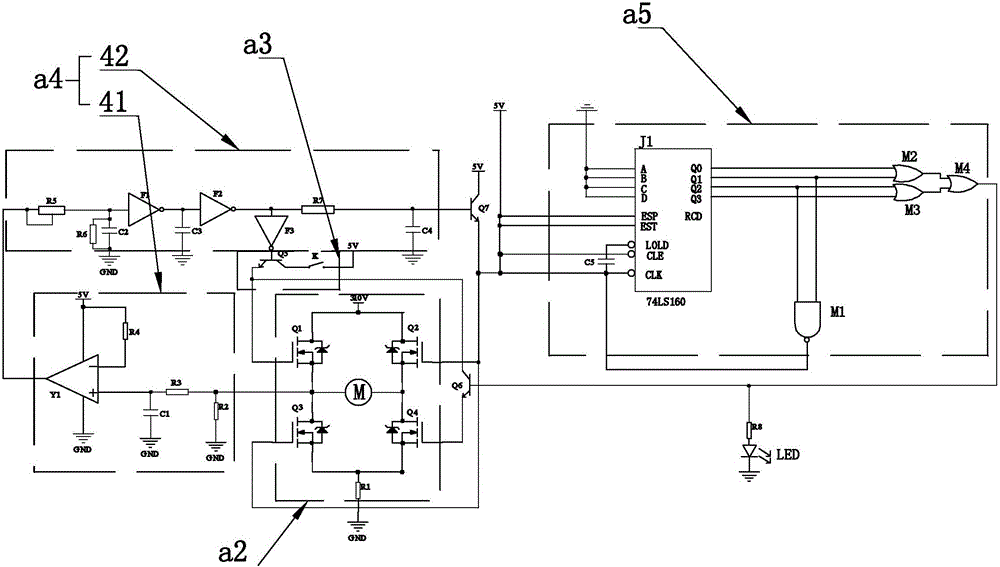

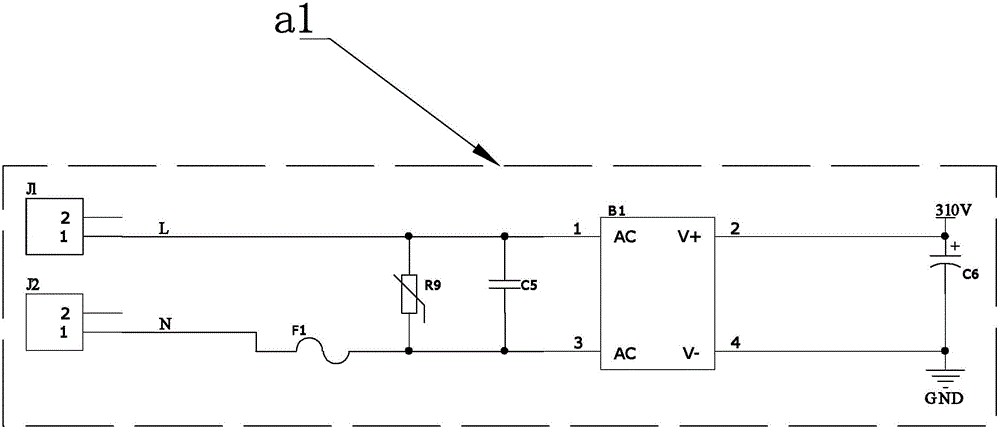

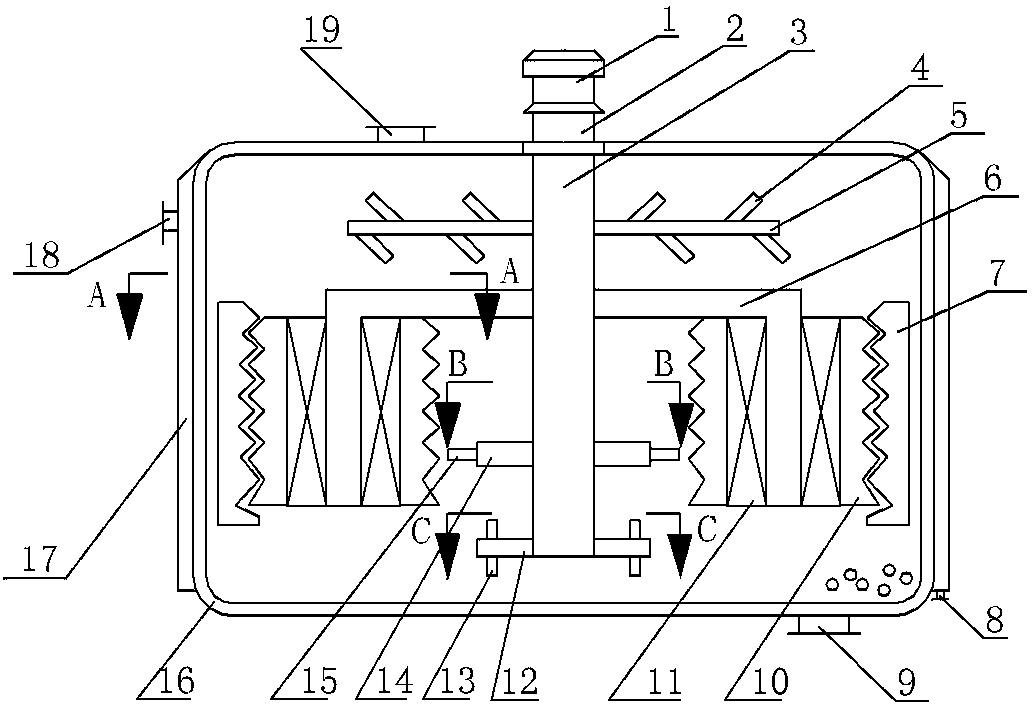

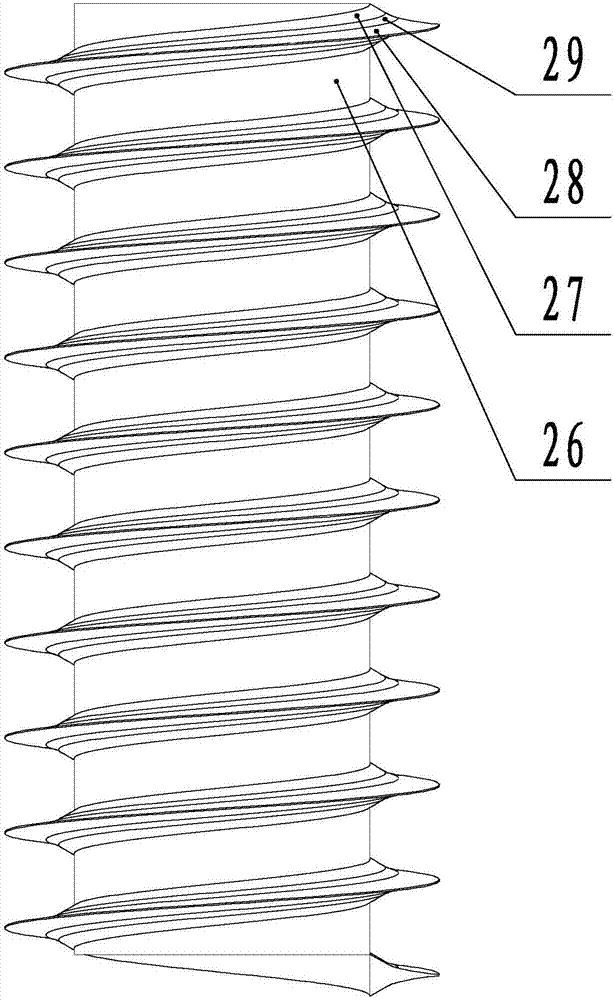

Compression structure for compression forming machine

ActiveCN105965931AIncrease input powerHigh compression forceElectric motor controlEmergency protective circuit arrangementsCompression moldingEngineering

The invention discloses a compression structure for a compression forming machine. The compression structure comprises a rack, a controller, a main motor, a reducing mechanism and a compression mechanism. The main motor is fixedly mounted on one side of the rack. The reducing mechanism is fixedly mounted on the rack and fixedly connected with the main motor. The compression mechanism is fixedly mounted on the side, back to the reducing mechanism, of the rack and fixedly connected with the reducing mechanism. The compression structure is characterized in that the reducing mechanism comprises a driving gear, a driven gear and a connecting rod mechanism; the compression mechanism comprises a compression sleeve, a compression die and a compression sliding block; and the compression die comprises a feeding part and a forming part, and a feeding opening is formed in the top of the compression sleeve. According to the compression structure for the compression forming machine, the connecting rod mechanism drives the compression sliding block to conduct compression forming on garden stuff residues, the period of storage of the garden stuff residues can be prolonged, the storage space is saved, long-distance transportation is facilitated, and good conditions are created for following deep machining such as active constituent extraction and feedstuff utilization.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

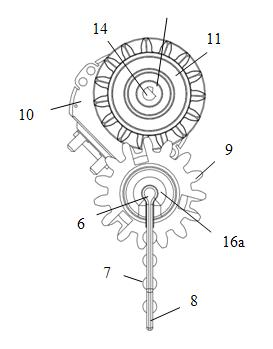

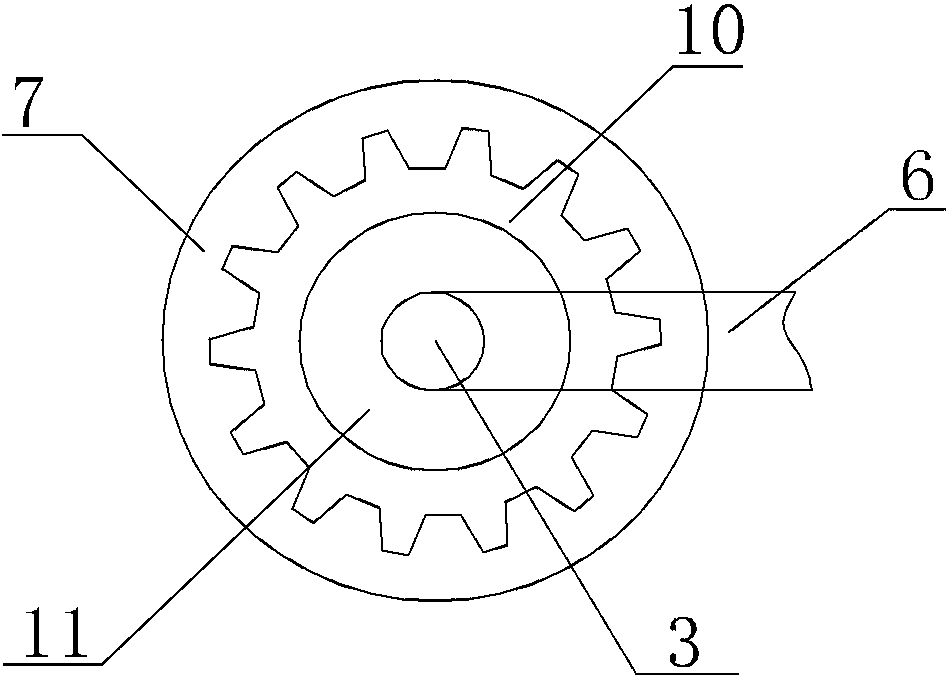

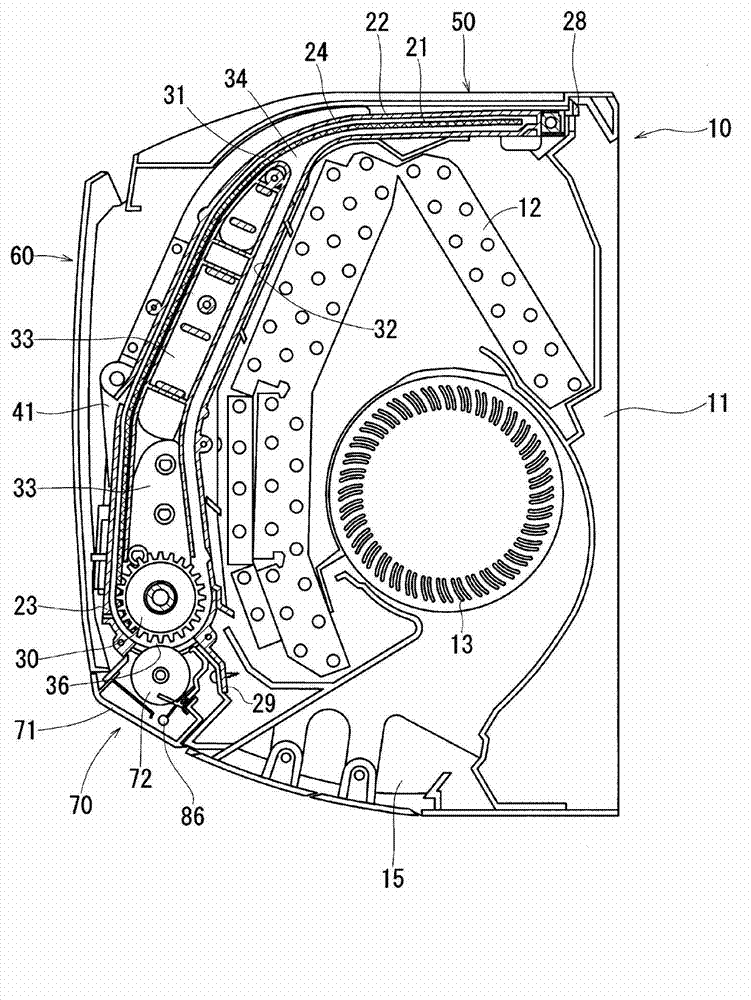

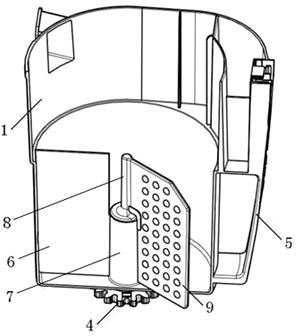

Eccentric gear driving structure of compressing plate in dust collection drum

The invention discloses an eccentric gear driving structure of a compressing plate in a dust collection drum and belongs to components of a dust collector dust storage device. The eccentric gear driving structure comprises a rotary shaft and a driving structure, wherein the rotary shaft is integrally connected with the compressing plate in the dust collection drum and is protruded outside the bottom of the dust collection drum through a shaft sleeve, the driving structure is arranged outside the bottom of the dust collection drum, and an eccentric gear is meshed with an eccentric outer gear fixedly connected with the rotary shaft. According to the eccentric gear driving structure disclosed by the invention, two eccentric gears are meshed so that the arm of force of each gear is changed, and the arm of force of the eccentric outer gear is larger when the compressing plate driven by the eccentric outer gear is closer to a fixed plate. Therefore, a larger force moment is realized through change of two arms of forces when a motor outputs same power; and in a manual compressing structure of the dust collection drum, a large compression force can be realized through a smaller force manually holding a handle so as to better compress dusts. According to the eccentric gear driving structure disclosed by the invention, the maximum of energy utilization is realized, and the dust compression effect can be better.

Owner:NANJING LG PANDA APPLIANCES

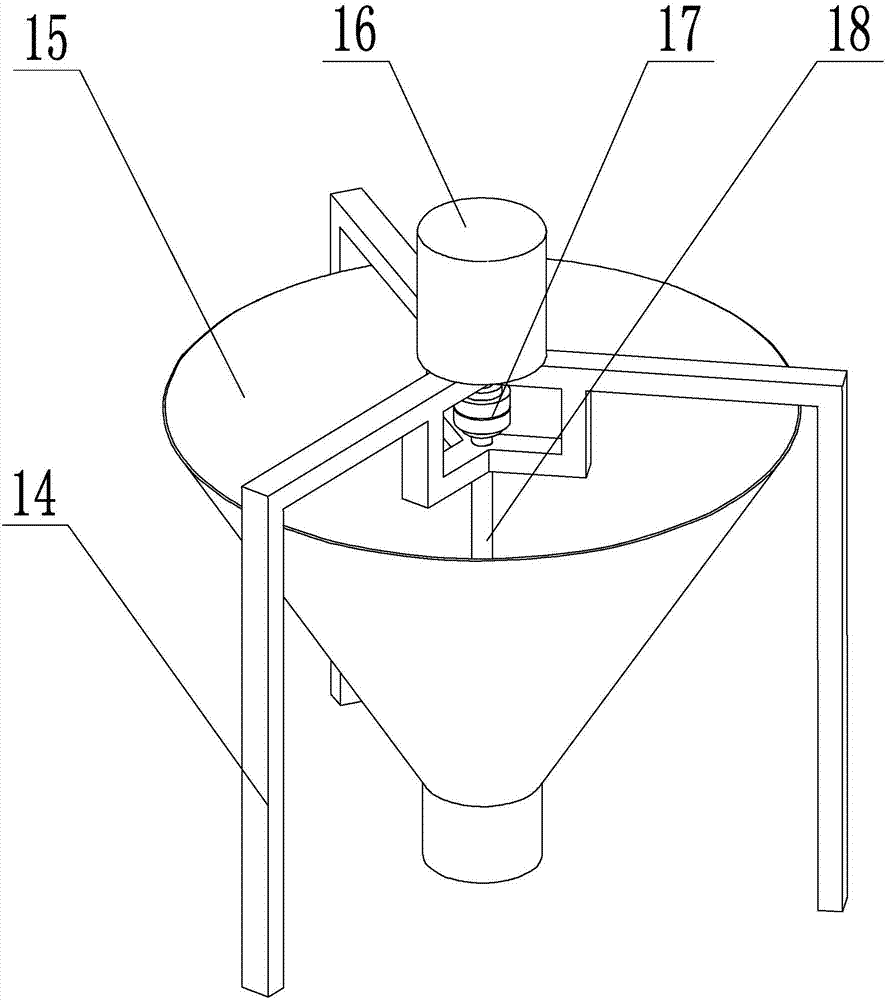

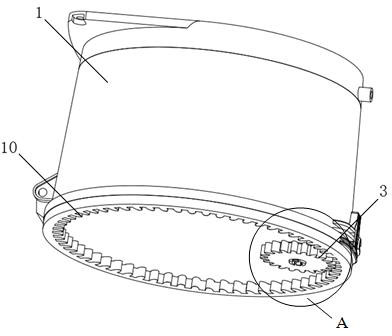

A kind of ultrafine pulverizer

ActiveCN105944814BIncrease productivityHigh compression forceCocoaGrain treatmentsCircular discCoupling

The invention provides an ultrafine grinder capable of conducting strong grinding and scattering on materials, good in grinding granularity and high in production efficiency. The ultrafine grinder comprises a motor. After being connected with a speed reducer, the motor is connected with one end of a main shaft stretching into a cylinder through a coupler. The main shaft in the cylinder is sequentially provided with stirring bars, rotation arms, a first grinding disc and a second grinding disc. At least two rotation arms are evenly arranged on the axial ring face of the main shaft. The lower ends of the rotation arms are sleeved with grinding media. The grinding media are in a ring-shaped gear shape. Gear rings corresponding to gears on the grinding media are arranged on the inner wall of the cylinder.

Owner:广东华辰玫瑰生物科技有限公司

Press machine and method for controlling slide of press machine

ActiveUS10160175B2High compression forceGood molding effectDriving apparatusPress ramVibration amplitudeEngineering

There is provided a press machine which can apply a large compression force to a mold as well as impart smooth vibration only in a rectilinear advancing direction to the mold, and thereby can improve the press-formability. A main slide and a sub-slide constitute a slide and at the same time a cylinder-piston mechanism. During press-forming, a compression force is transmitted to the sub-slide (an upper mold) through hydraulic pressure applied interlockingly with driving of the main slide, and the sub-slide is vibrated with the hydraulic pressure being periodically changed. Favorable press-forming can be performed even under relatively difficult press-forming conditions, by controlling the vibration such that a vibration frequency of the sub-slide (the upper mold) becomes 9 Hz or higher but 33.3 Hz or lower and a vibration amplitude of the sub-slide becomes 0.05 mm or larger but 0.5 mm or smaller.

Owner:AIDA ENG LTD

A kind of fruit and vegetable skin dregs compression molding equipment

ActiveCN105946276BImprove transmission efficiencyEasy to processShaping pressCompression moldingActive component

The invention discloses fruit and vegetable peel residue compression moulding equipment. The equipment comprises a frame, a main motor, a speed reducing mechanism and a compressing mechanism, wherein the main motor is fixedly mounted at one side of the frame, the speed reducing mechanism is fixedly mounted on the frame and is fixedly connected to the main motor, and the compressing mechanism is fixedly mounted on one side, back on to the speed reducing mechanism, of the frame. The equipment is characterized in that the speed reducing mechanism comprises a driving gear, a driven gear and a connecting rod mechanism; the compressing mechanism comprises a compressing sleeve, a compressing mould and a compressing slide block; the compressing mould comprises a feeding part; a feed inlet is formed on the top of the compressing sleeve; and a feeding device is arranged at the feed inlet. The equipment disclosed by the invention drives the compressing slide block to compress and mould fruit and vegetable peel residues through the connecting rod mechanism, so that the storage time of the fruit and vegetable peel residues is favorably prolonged, the storage space is favorably saved, and long-distance transportation is facilitated; and good conditions for follow-up deep processing such as extraction of active components and feed-base utilization are created.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

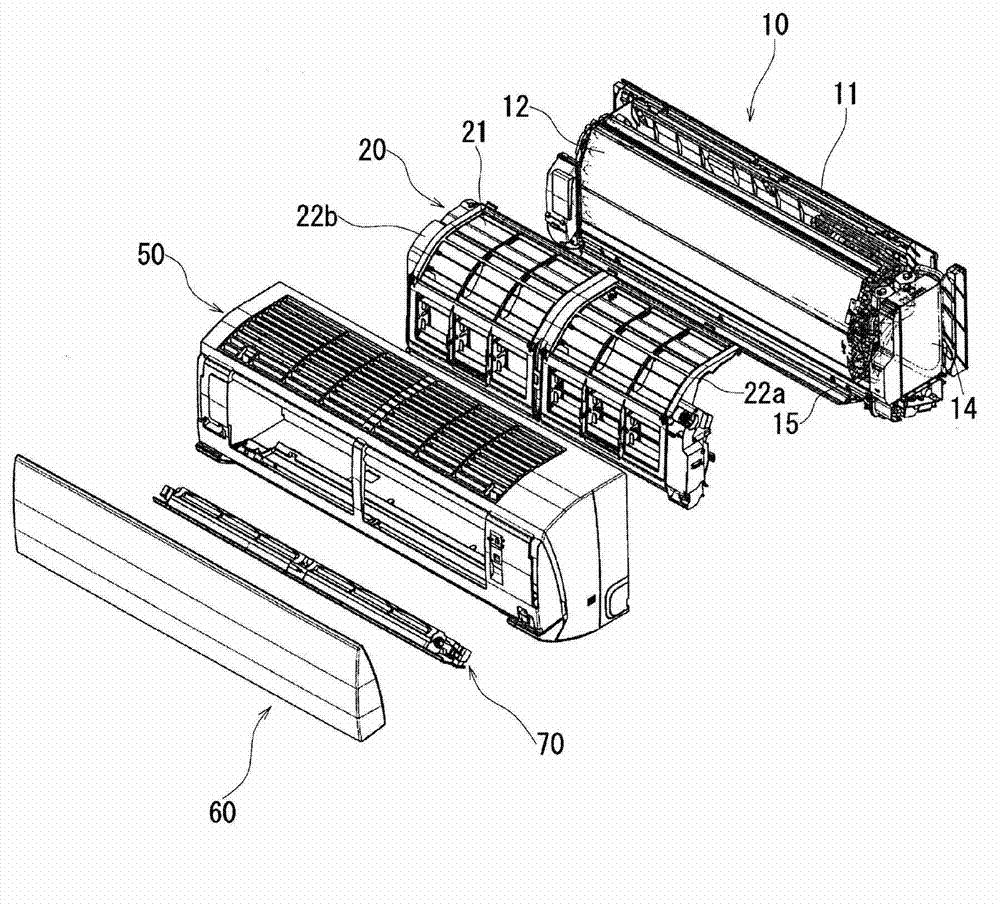

Air conditioning apparatus

ActiveCN103032946ASuppression of scatteringHigh compression forceMechanical apparatusLighting and heating apparatusAir filterEngineering

Owner:DAIKIN IND LTD

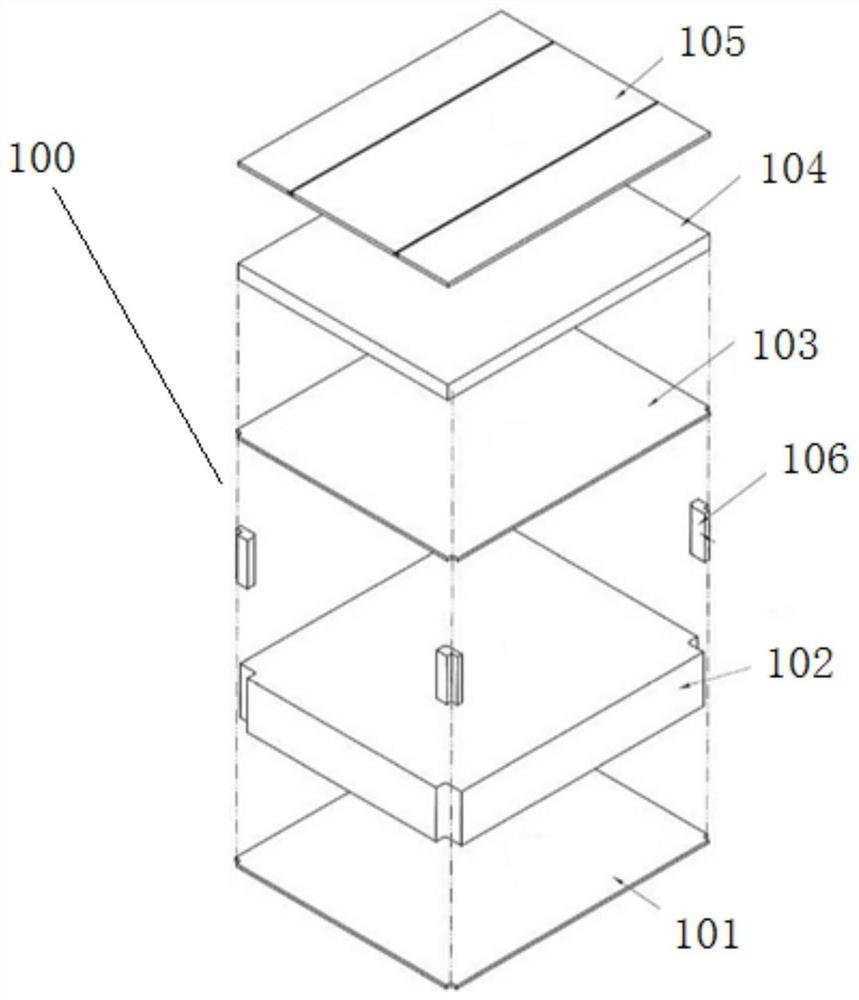

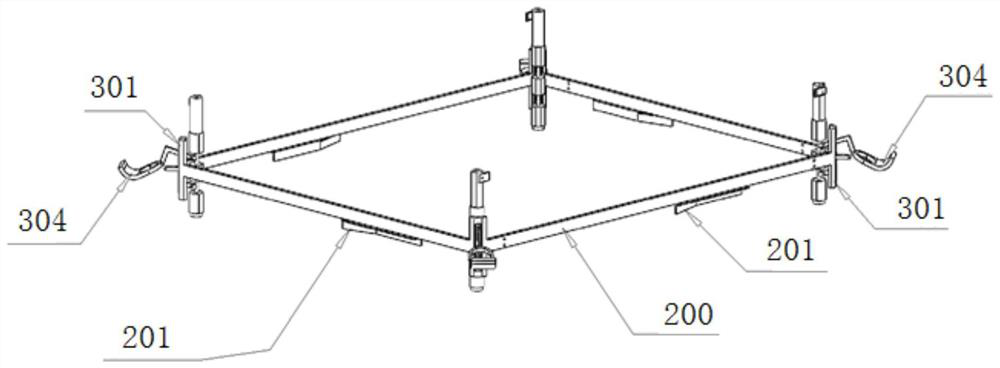

A corner splint positioning and tensioning device

ActiveCN109954634BPrecise positioningEven by forcePretreated surfacesCoatingsHigh densityStructural engineering

The invention relates to a corner clamping plate locating tensioning device. The corner clamping plate locating tensioning device includes an outer frame with inner side size not less than the side surface contour size of an insulation box and corner frames distributed on the four corners of the outer frame, wherein the corner frames include corner plates fixed to the outer frame, compression rollers located on the inner sides of the corner plates and connecting rod mechanisms connected with the compression rollers and used for driving the compression rollers to compress second concave right-angle grooves. Compared with the prior art, the quality and the efficiency of corner clamping plate assembling can be effectively improved through the corner clamping plate locating tensioning device,installation and disassembling works are more easy and can be operated by one person, furthermore, the corner clamping plate locating tensioning device can be neatly stacked with high density, and fully automated operation and the logistic circulation efficiency are convenient to achieve.

Owner:SHANGHAI JIAO TONG UNIV +1

Dust collection bucket with novel power transmission structure

The invention relates to a dust collection bucket with a novel power transmission structure, including a bucket body consisting of a bucket bottom and a bucket wall, a baffle arranged inside the bucket body and a compression plate. An inner gear that is meshed with a driving gear and drives the bucket body to rotate is formed on the lower side of the bucket bottom, the compression plate is fixedly connected with the bucket body, and the baffle is fixedly connected onto the wall of a cyclone separator above the bucket body. In the dust collection bucket in the invention, the compression plate is fixedly connected with the bucket body, an inner gear that is meshed with a driving gear and drives the bucket body to rotate is formed on the lower side of the bucket bottom, and the baffle is fixedly connected onto the wall of a cyclone separator above the bucket body. The driving gear drives the inner gear to rotate, and the inner gear drives the bucket body and the compression plate to rotate in order to compress dust, while the baffle does not rotate. In this way, the power of the compression plate comes from the bucket body around, power transferred in this way acts to the outer edge of a circle formed by the rotation of the compression plate, the compression plate is driven to rotate in the tangent direction of the circle, the compression power of the whole compression plate is great, the compression effect is better, and it is more convenient for users to use.

Owner:NANJING LG PANDA APPLIANCES

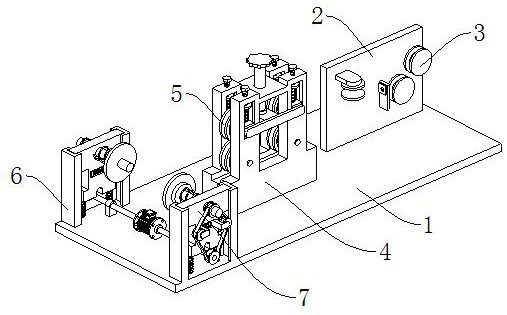

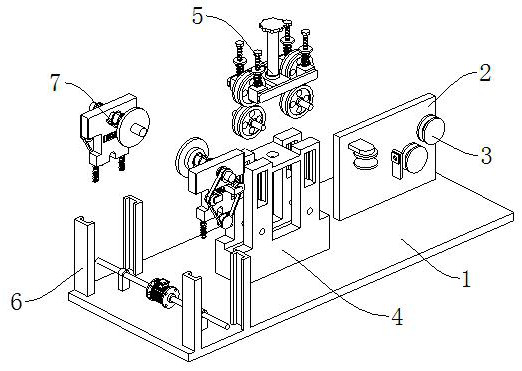

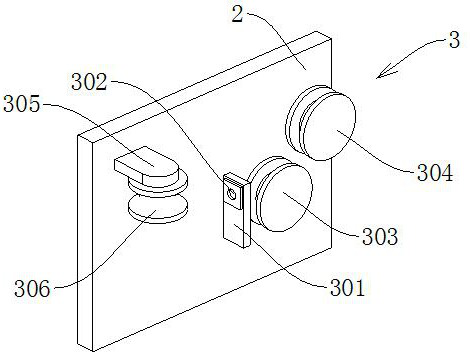

Straightening and winding device applied to tire bead wire production

PendingCN112897228AImprove torsion resistanceGuaranteed tightnessGrinding machine componentsFilament handlingTire beadStructural engineering

The invention discloses a straightening and winding device applied to tire bead wire production, and belongs to the technical field of tire bead wire production equipment. The straightening and winding device applied to tire bead wire production comprises a mounting base, a mounting plate, a fixing frame and a mounting frame, the mounting plate is fixedly connected to the mounting base, a steel wire dephosphorization mechanism is connected to the mounting plate, the fixing frame is fixedly connected to the middle of the mounting base, and a steel wire straightening mechanism is connected to the fixing frame; and the mounting frame is fixedly connected to the end, away from the mounting plate, of the mounting base, the mounting frame is connected with a driving winding device, and the driving winding device comprises a driving mechanism and a winding mechanism. The straightening and winding device effectively solves the problems that an existing design structure is simple, the function is single, a good straightening effect cannot be achieved, a damping structure is not arranged, and the tire bead wire winding effect can be affected by vibration in the using process.

Owner:JIANGSU SHENGDA TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com