A kind of ultrafine pulverizer

A technology of ultrafine pulverizer and crushing rod, which is applied in the fields of cocoa, grain processing, food science, etc. It can solve the problems of unsatisfactory dispersion effect, high energy consumption, and low efficiency, and achieve uniform particle size and fine grinding particle size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

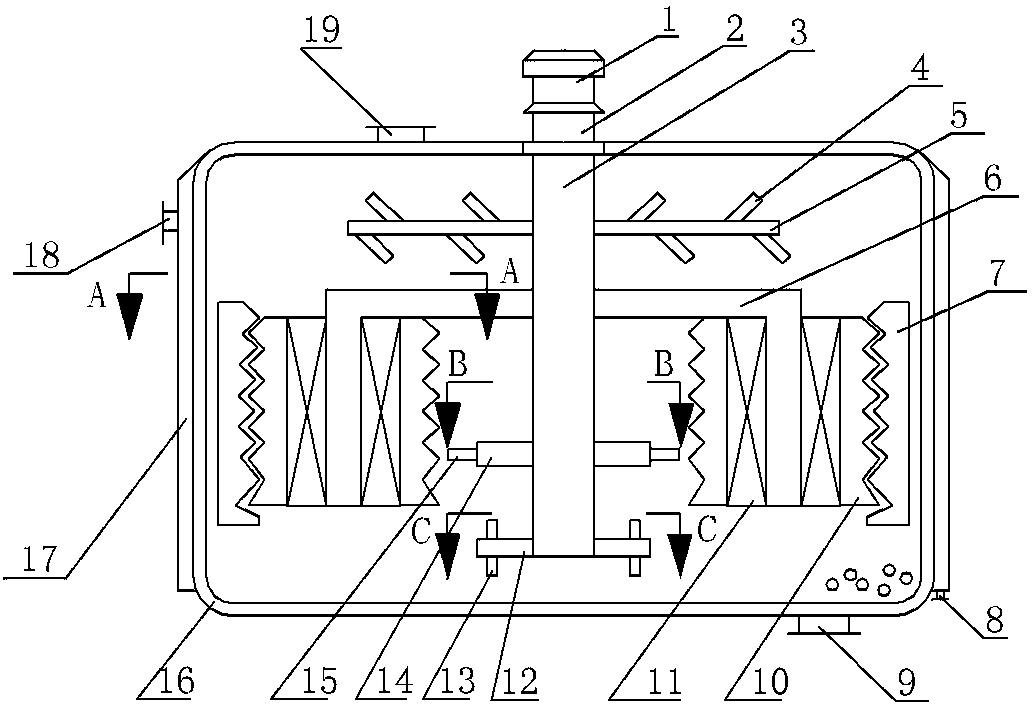

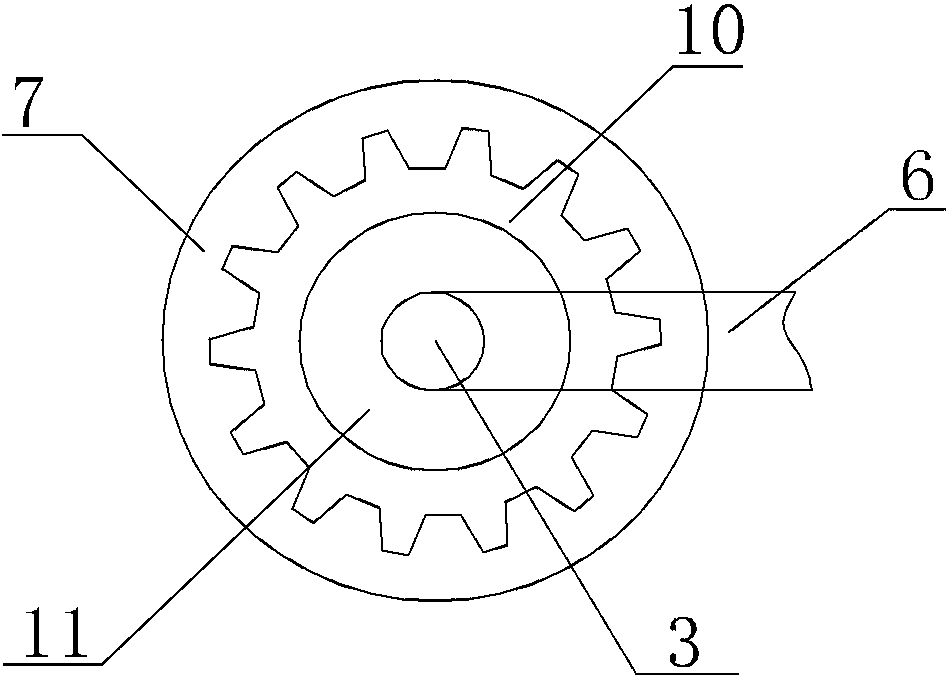

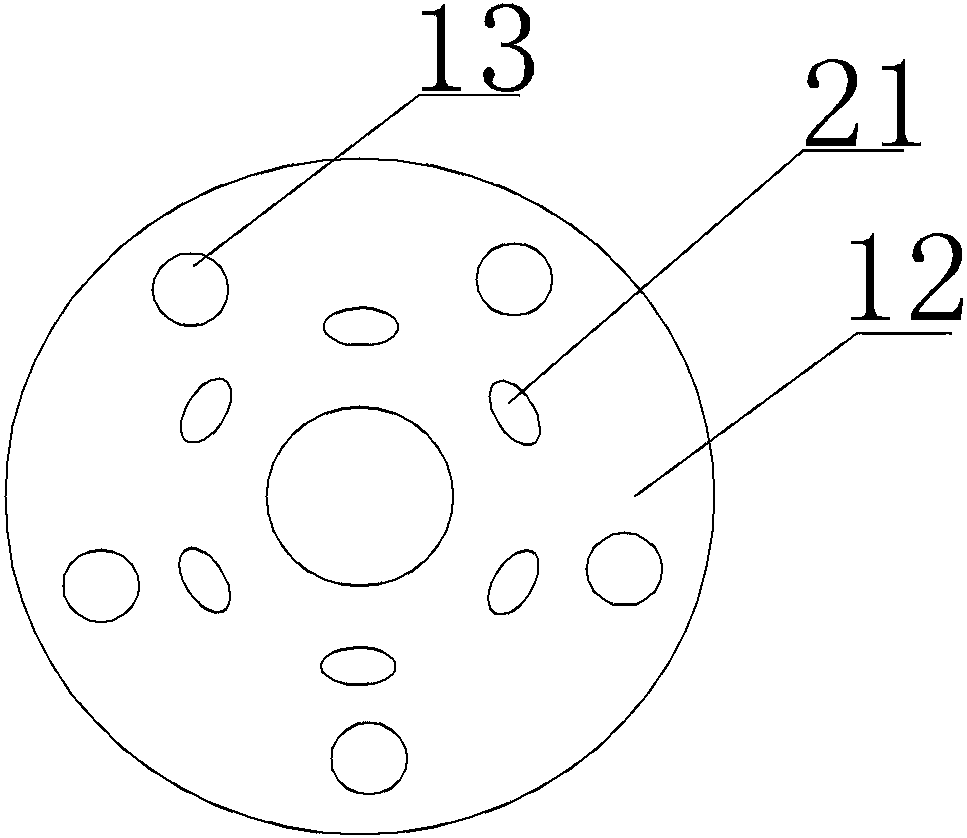

[0016] Such as Figure 1~Figure 5 As shown, the present invention comprises motor 1, and after motor 1 is connected with speed reducer 2, connects with one end of main shaft 3 extending in the cylinder 16 through a coupling, on the main shaft 3 in cylinder 16, stirring bar 5, rotating Arm 6, crushing disc I14, crushing disc II12, eight rotating arms 6 are evenly installed on the axial ring surface of the main shaft 3, and the rotating arms 6 are inverted L-shaped; Medium 10, crushing medium 10 is ring-shaped gear type, cylinder 16 inner wall is equipped with ring gear 7 corresponding to the upper gear of crushing medium 10, then ring-shaped gear type crushing medium 10 can roll on ring gear 7; Six stirring rods 5 are evenly installed on the axial ring surface of the main shaft 3, and each stirring rod 5 is equipped with round rods 4 arranged in a staggered manner; eight crushing rods I15 are evenly installed on the outer ring surface of the crushing disc I14, and the crushing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com