Patents

Literature

127 results about "Grinding - action" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

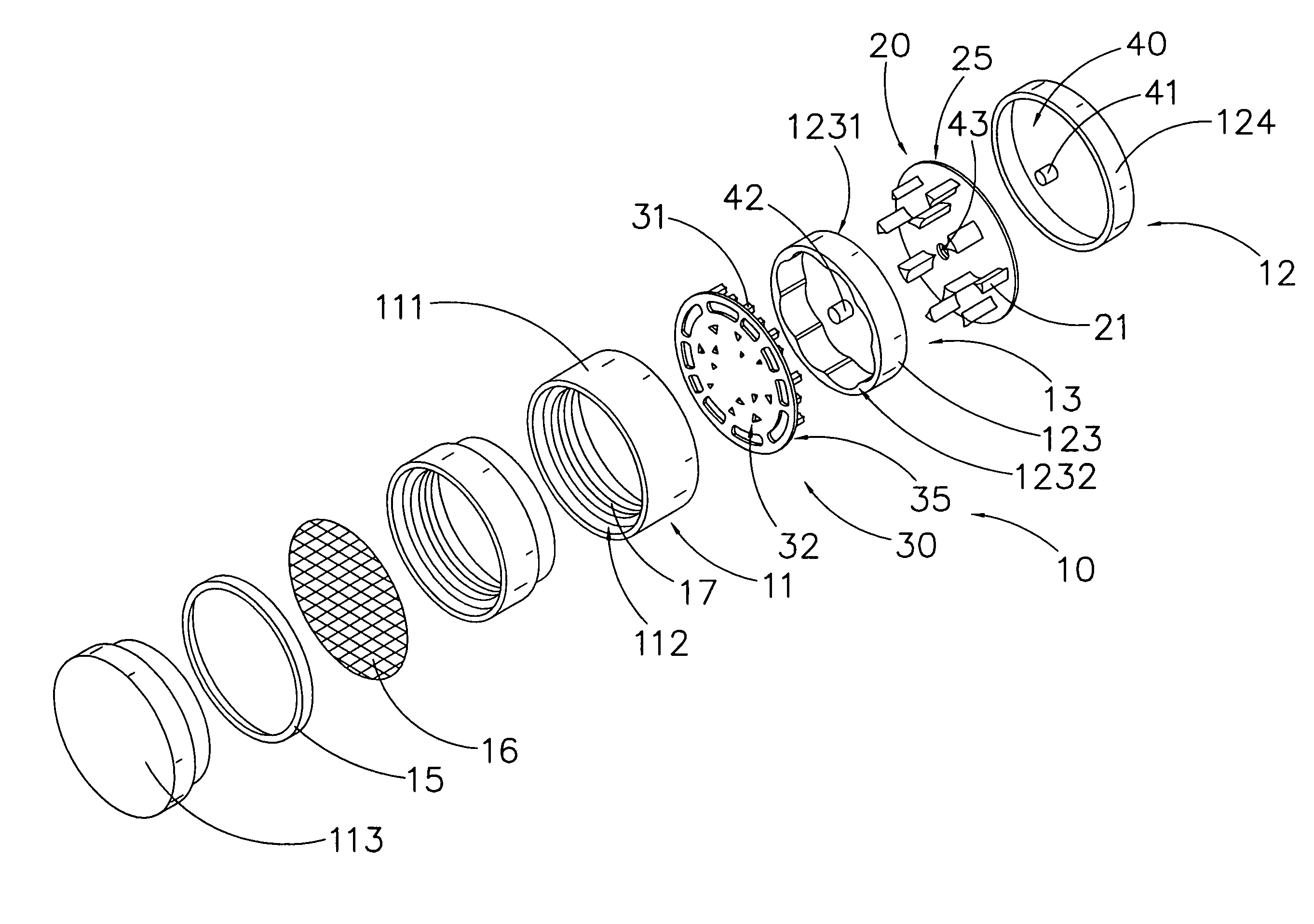

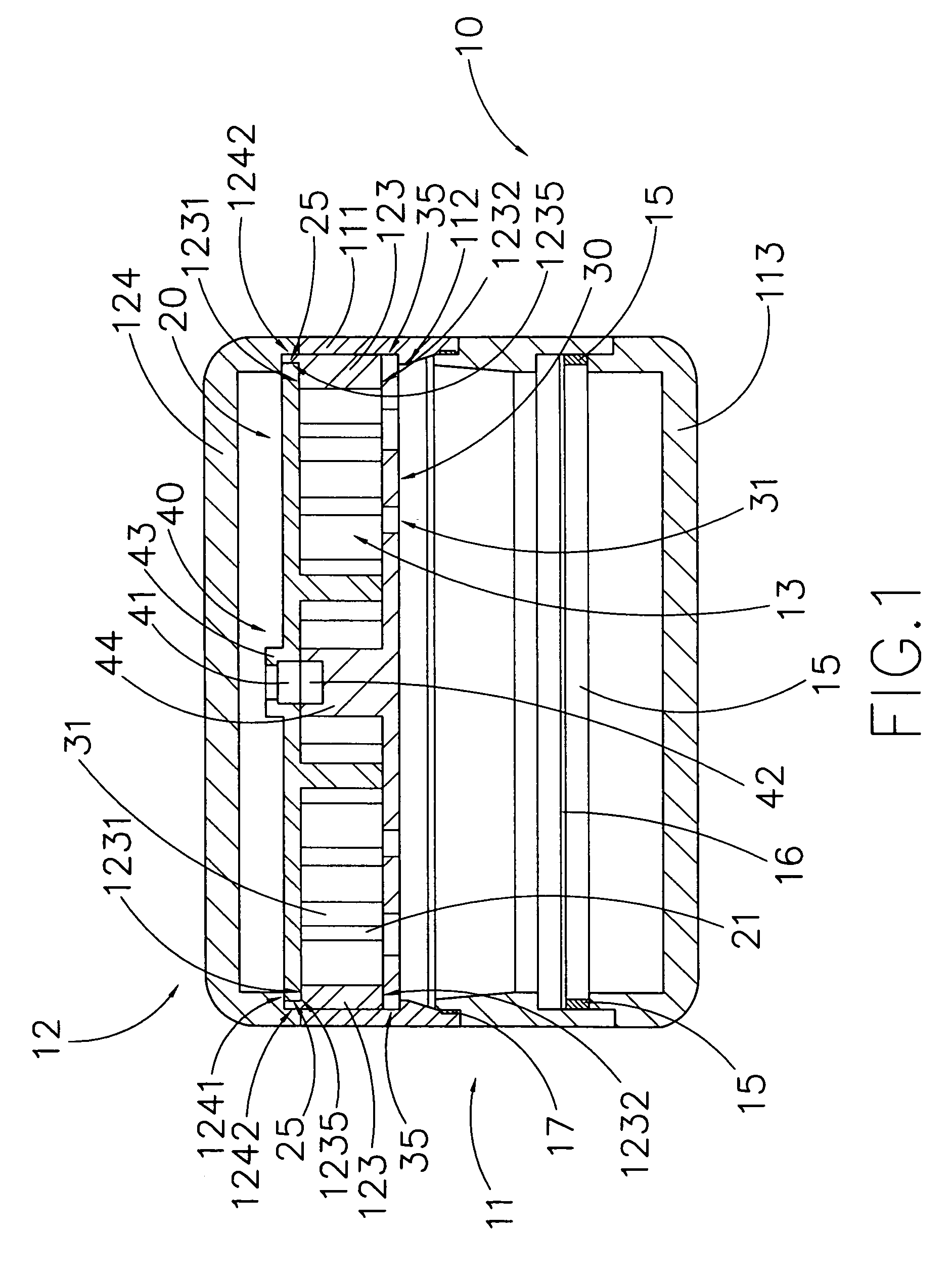

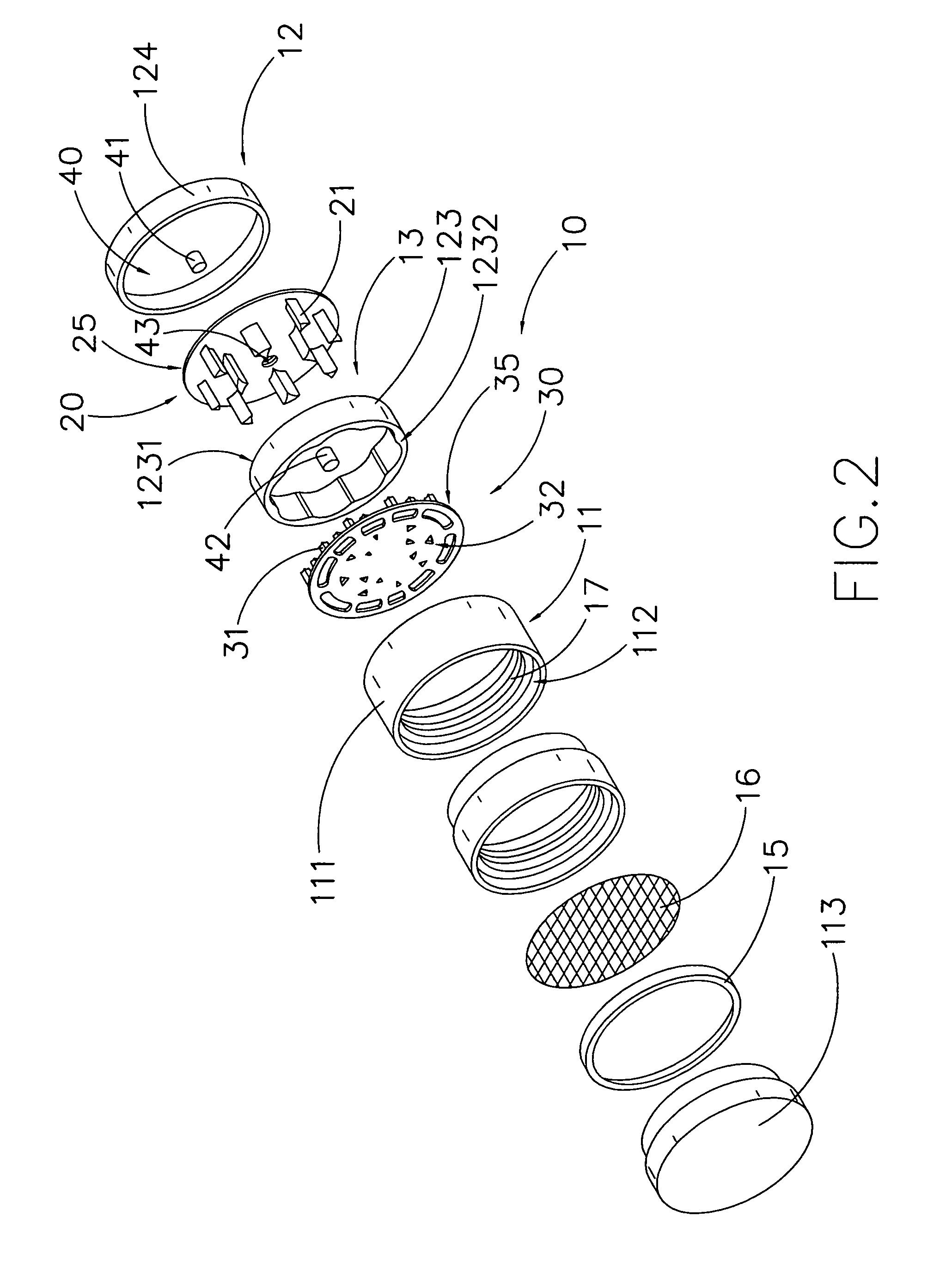

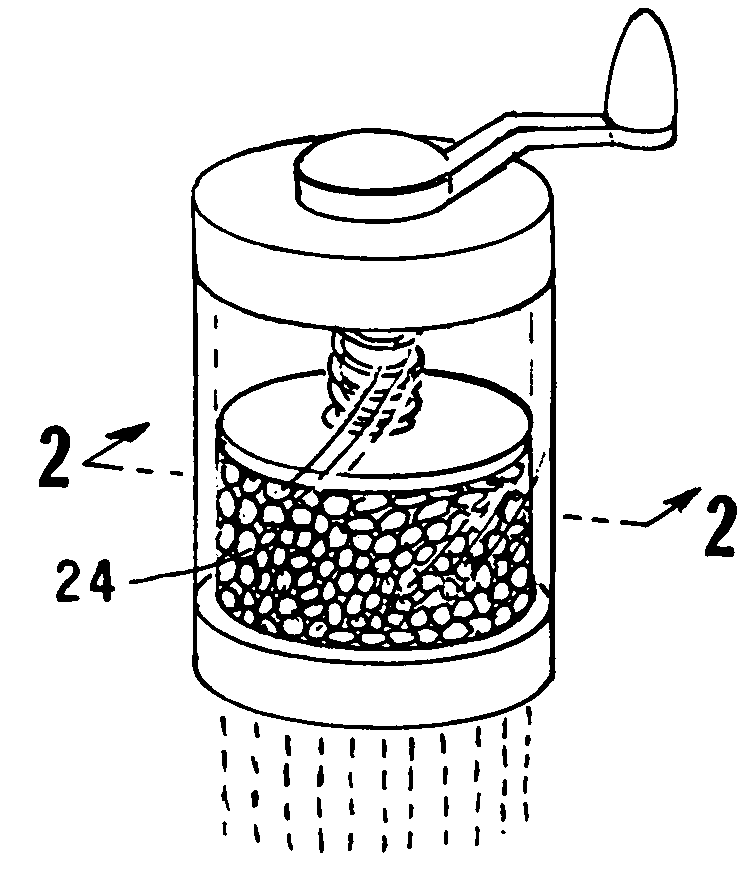

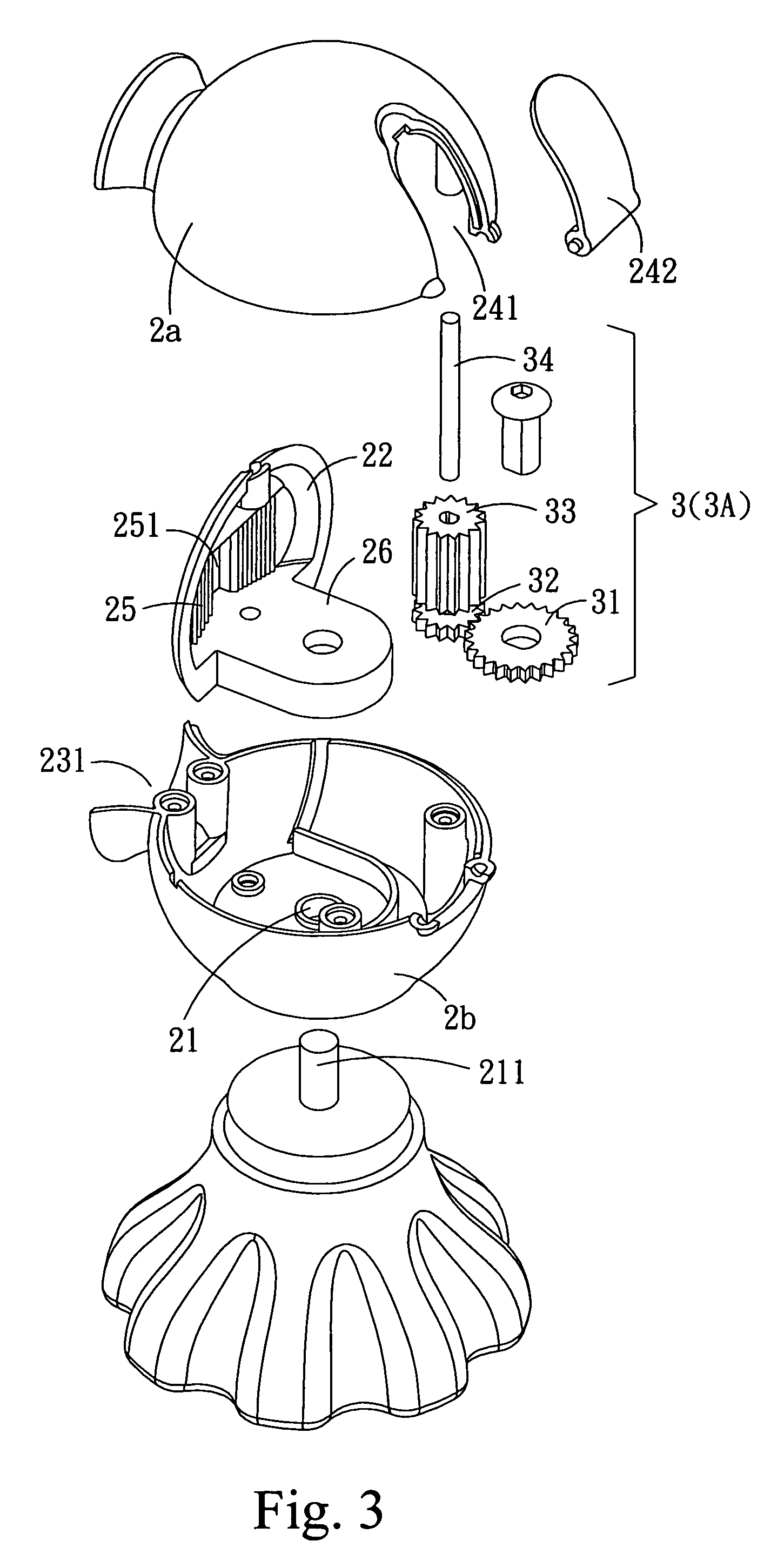

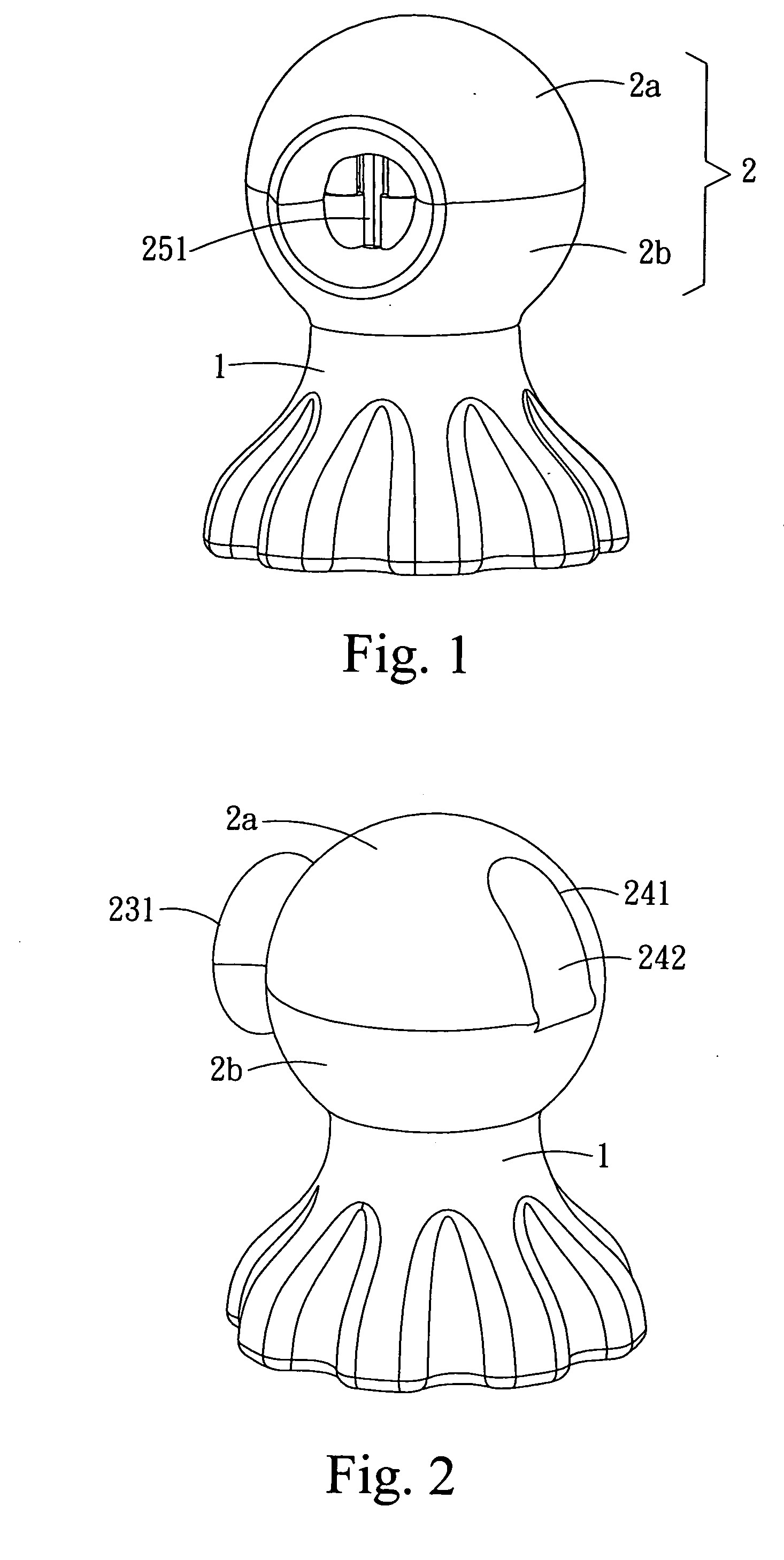

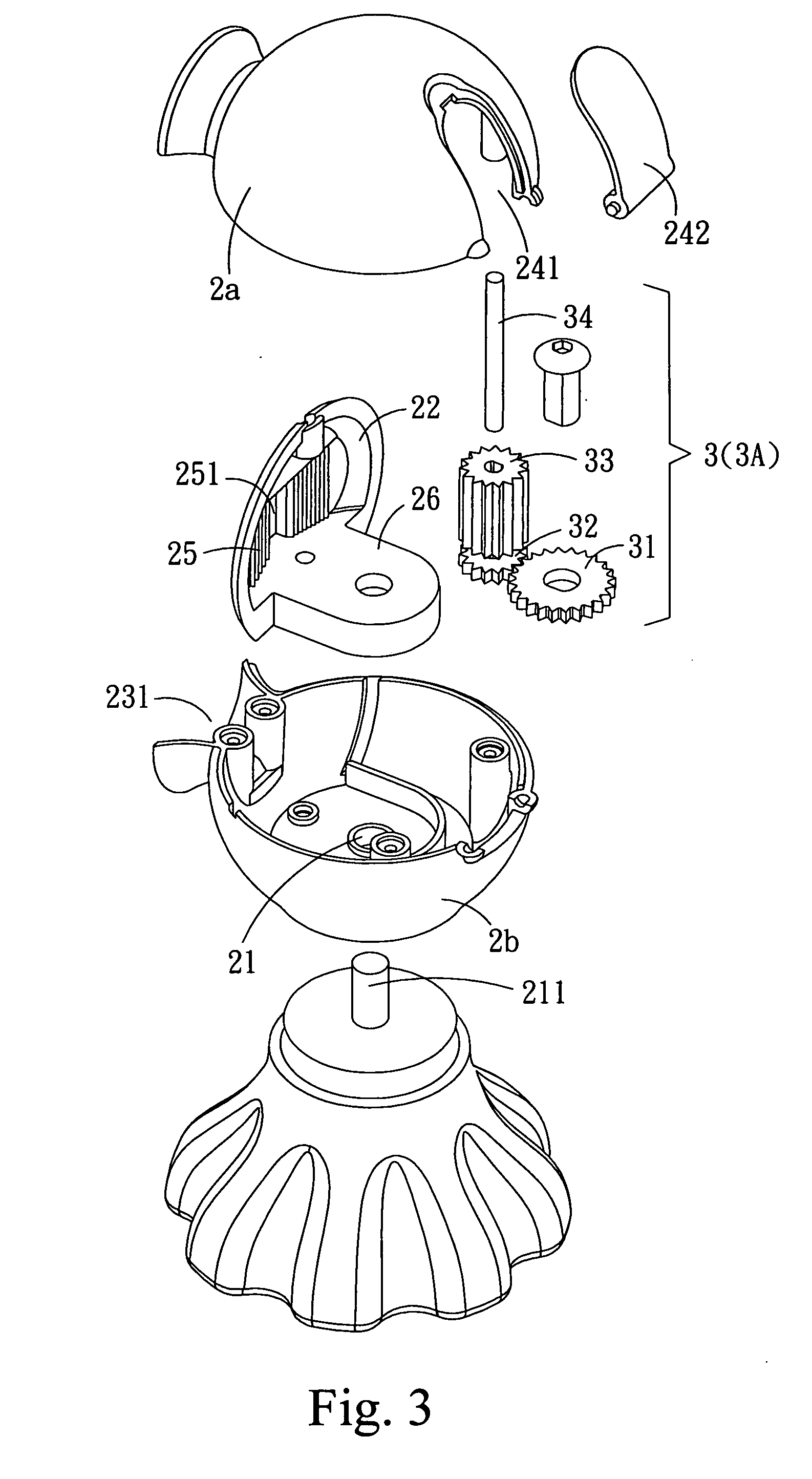

Leaves and seeds hand grinder

A grinder includes a grinder housing having a grinder actuator, a first grinding plate, a second grinding plate and a detachable coupling arrangement. The first grinding plate is detachably coupling with the grinder actuator, wherein the first grinding plate has a plurality of first grinding knifes downwardly and spacedly extended from a bottom side of the first grinding plate. The second grinding plate has a plurality of second grinding knifes upwardly and spacedly extended from the top side of the second grinding plate at a position that the first and second grinding knifes are spacedly disposed within a grinding compartment, such that when the grinder actuator is turned with respect to the grinder base to drive the first grinding plate to rotate, the first and second grinding knifes are correspondingly moved within the grinding compartment to provide a grinding action.

Owner:BAO FAN

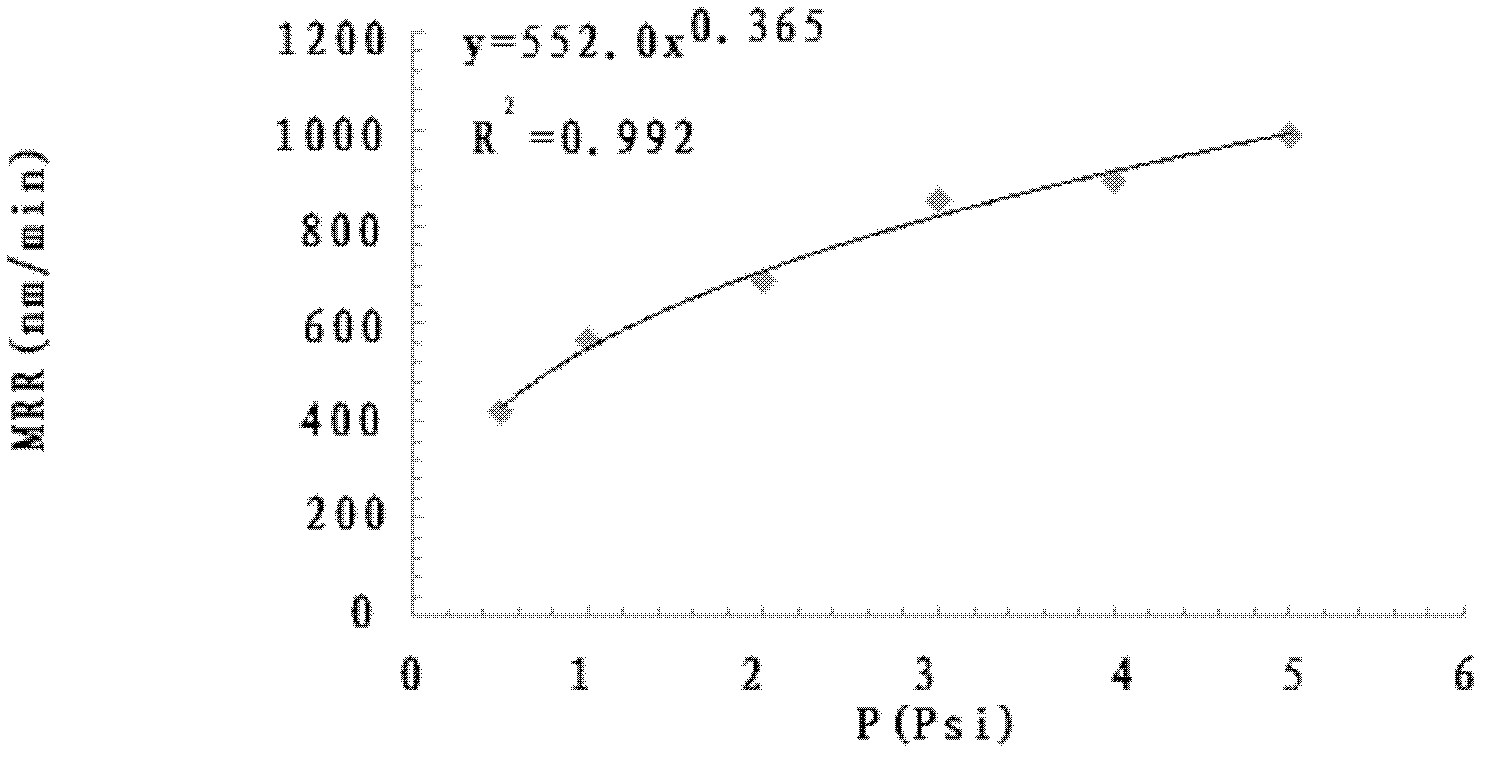

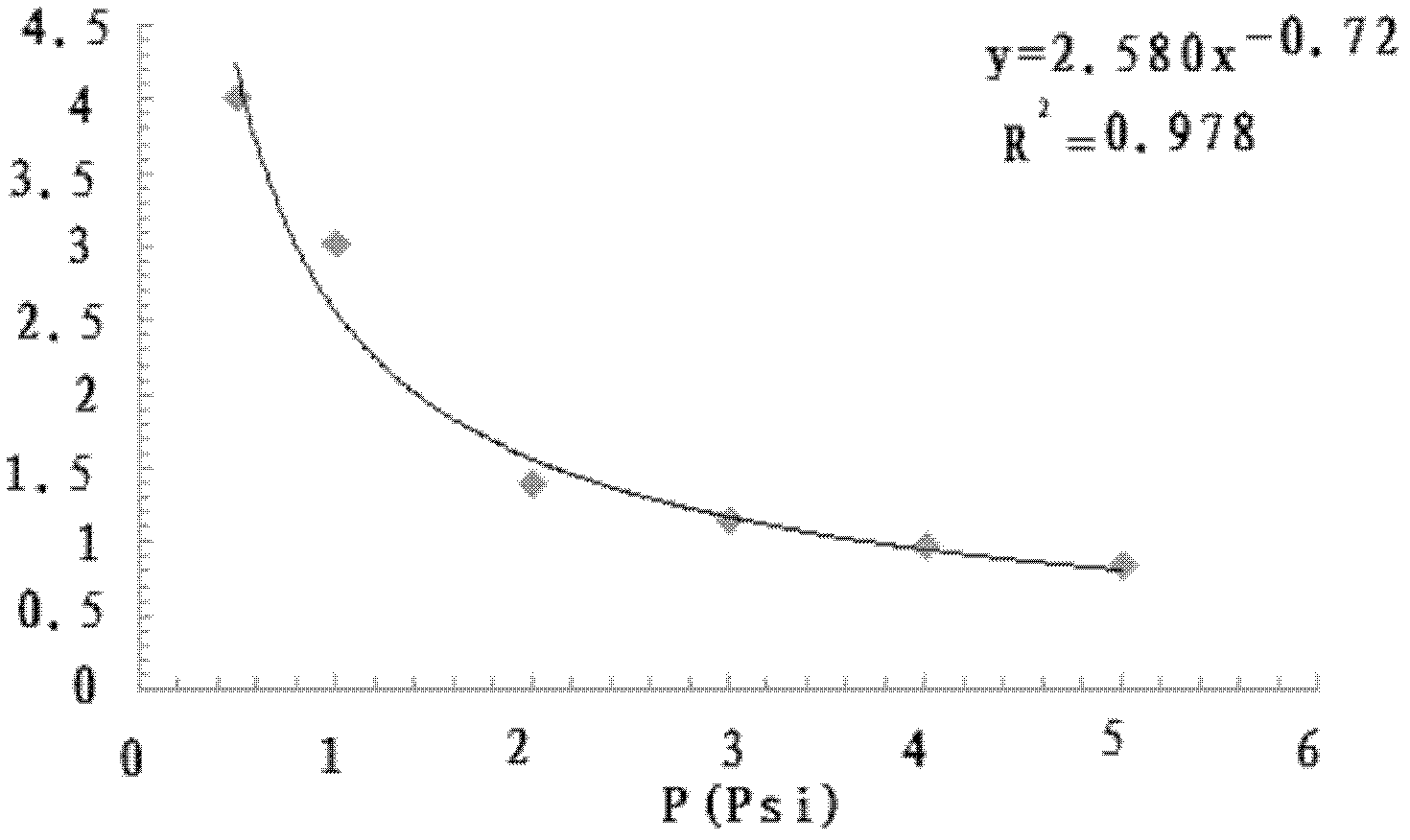

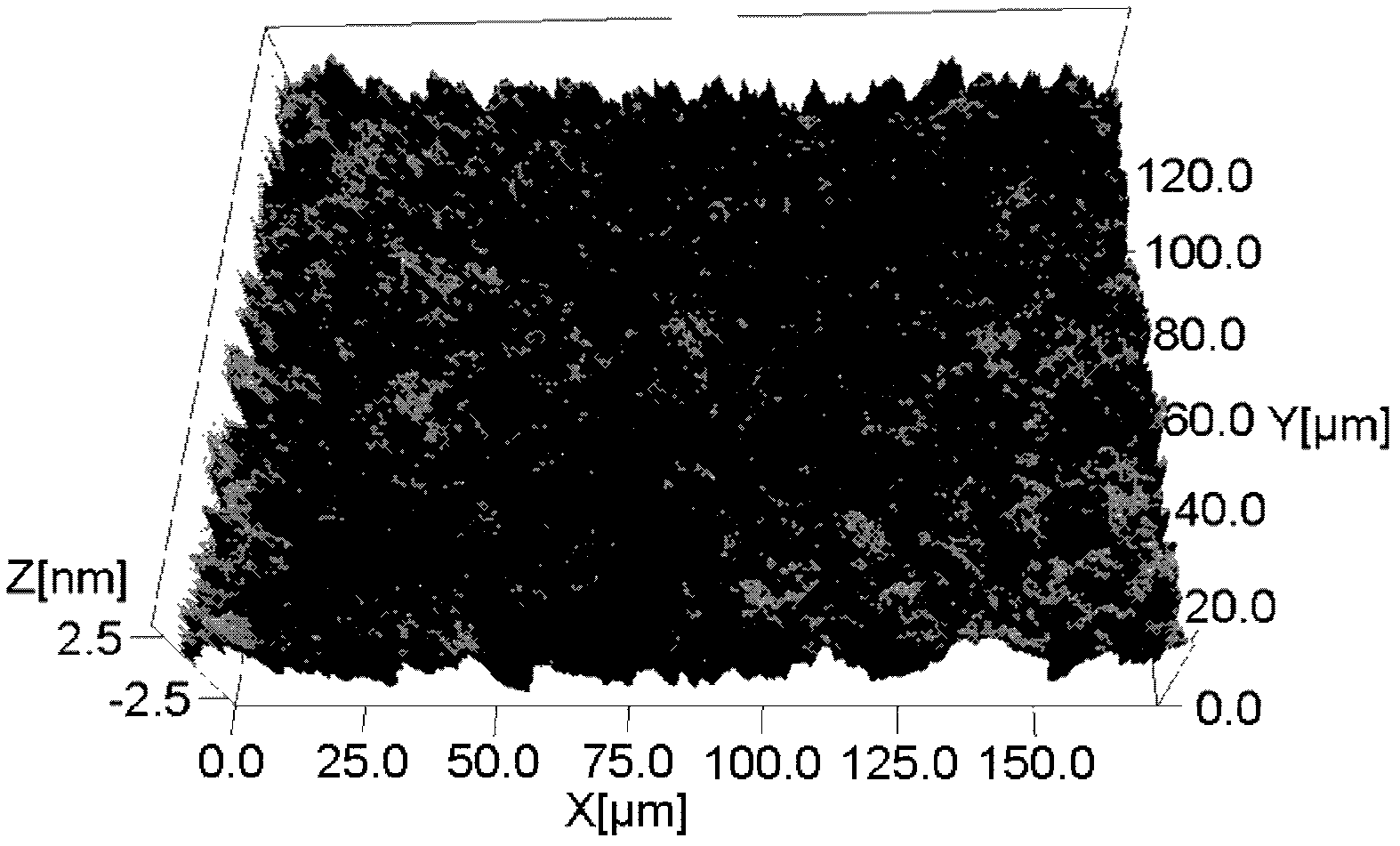

Acidic chemical and mechanical polishing composition

ActiveCN102585706AEasy to polishBoost rateOther chemical processesPolishing compositions with abrasivesColloidal silicaOrganic film

The invention provides an acidic chemical and mechanical polishing composition. The pH value of the acidic chemical and mechanical polishing composition is 2-7, and the acidic chemical and mechanical polishing composition comprises 1-20% by weight of abrasive material, 0.5-10% by weight of oxidant, 0.1-10% by weight of complexing agent, 0.001-1% by weight of corrosion inhibitor, 0.001-5% by weight of organic film-forming auxiliaries and the balance of pH regulator and deionized or distilled water, wherein the abrasive material is of colloidal silica sol after modification in the special step, and the average particle size is of 10-200nm. According to the chemical and mechanical polishing composition provided by the invention, the abrasive material is refined and modified; by using the method, the stability of the abrasive material in polishing slurry can be effectively upgraded, and polishing removal rate and surface roughness degree are respectively optimized to a certain extent; and the unique adding effect of the organic film-forming auxiliaries can well balance the strength of chemical corrosion action and the strength of mechanical grinding action, and achieve the effects of improving polishing removal efficiency and performing global planarization.

Owner:TSINGHUA UNIV

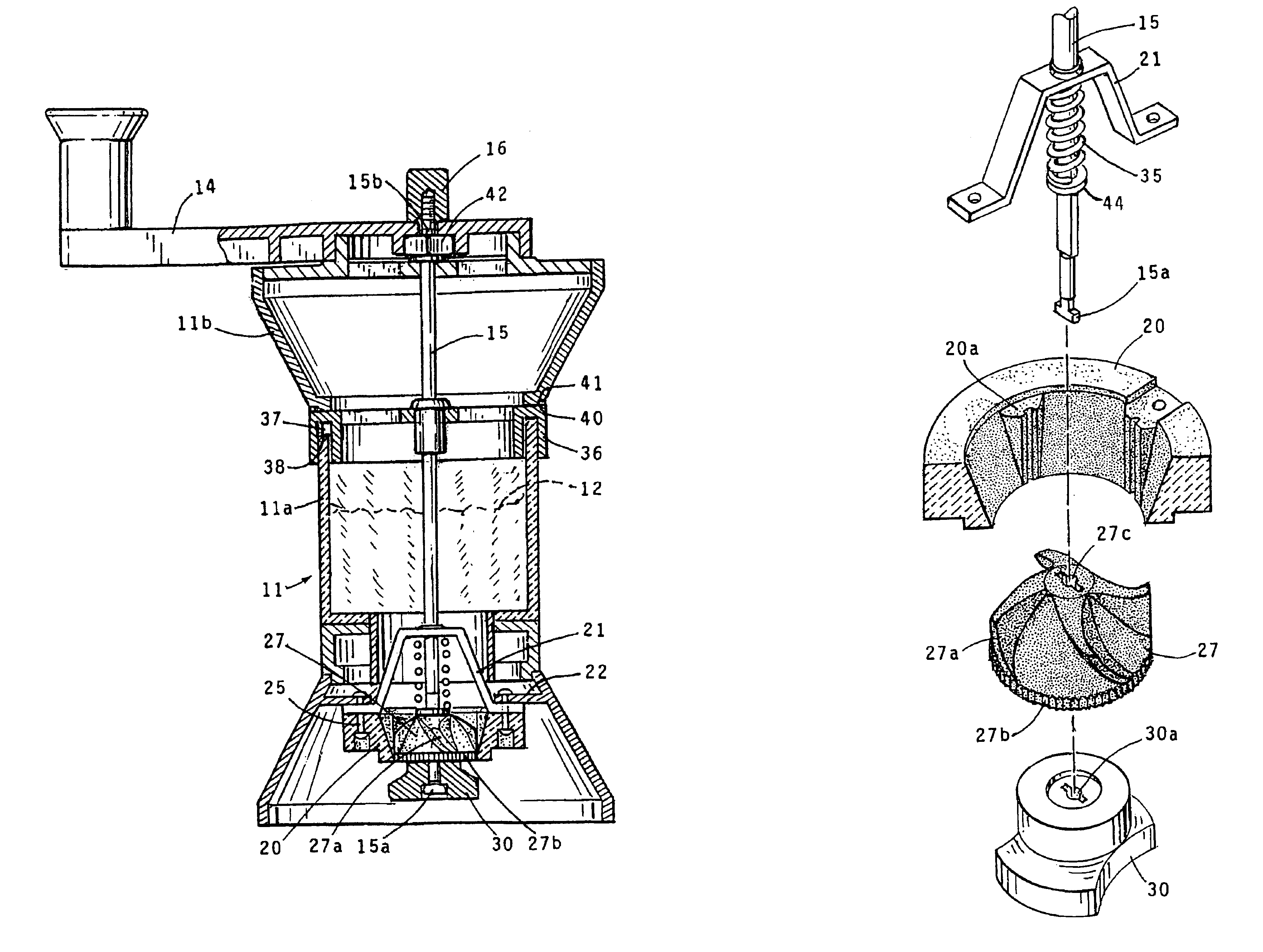

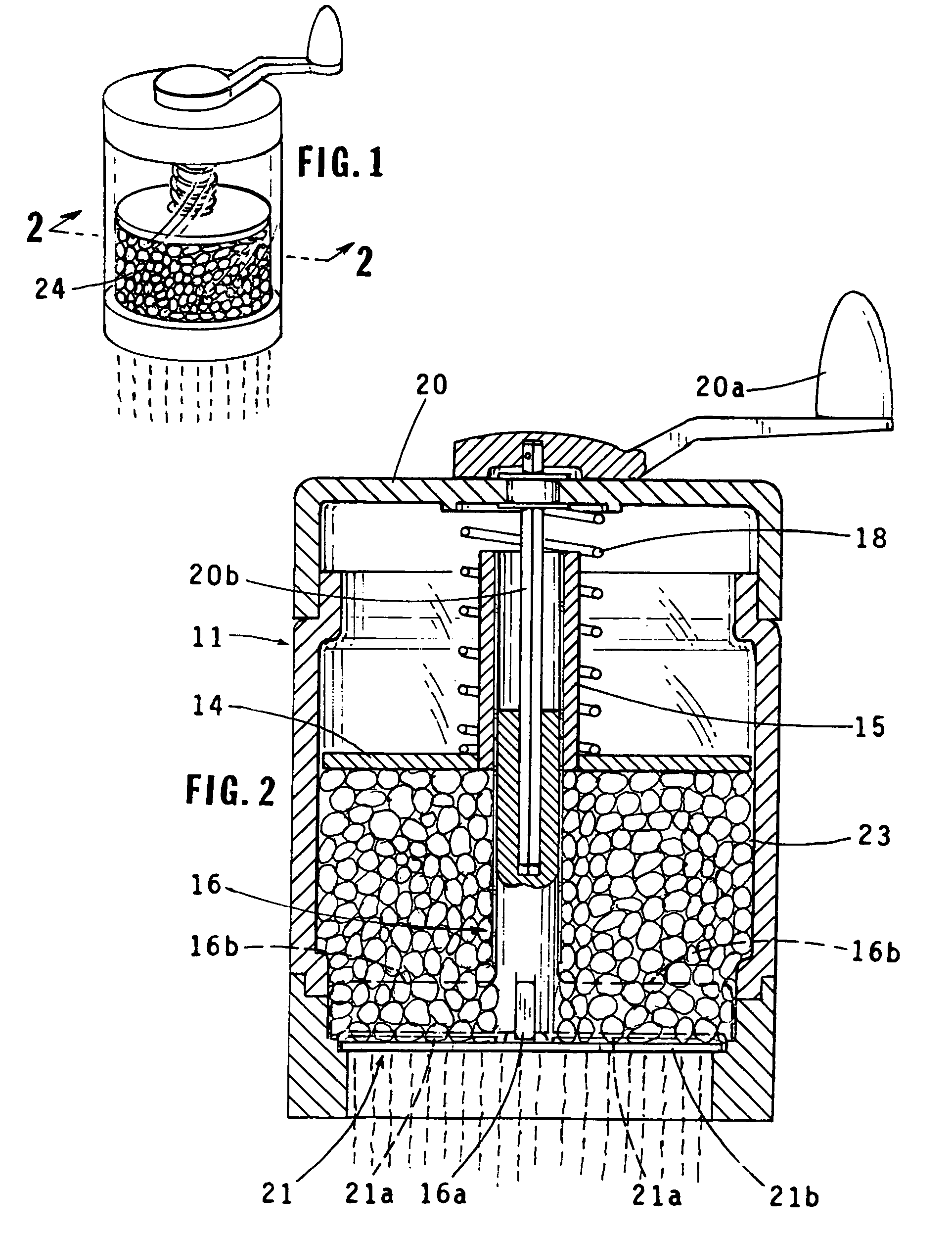

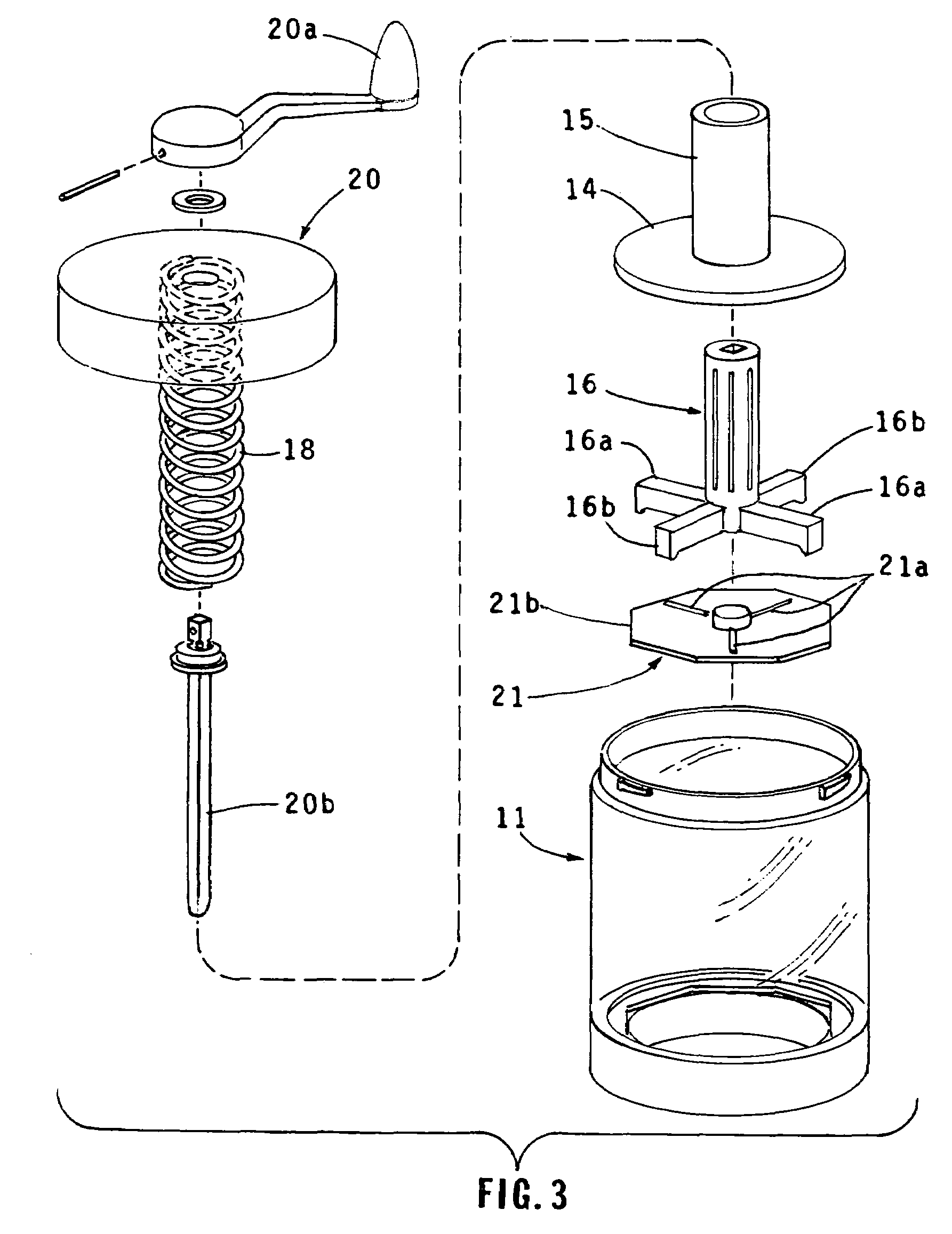

Condiment mill

InactiveUS6851635B2Easy to disassembleCoarseness of the grind can be achievedCoffee millsSpice millsFlavorMaterials science

A device for grinding spices such as salt, pepper, cinnamon, etc. has a grinder rotor which has a removable keeper member which facilitates the ready removal of the rotor for cleaning or replacement. The grinder elements are made of ceramic material such as alumina silicate which eliminates the possibility of corrosion or rusting as with metal parts. The mill provides dual grinding action by utilizing separate grinding elements to provide either coarse grinding or fine grinding, as may be desired. For coarse grinding, the condiment only passes through the coarse grinding element while for fine grinding, the condiment first passes through the coarse grinding element and then passes through the fine grinding element.

Owner:WILLIAM BOUNDS

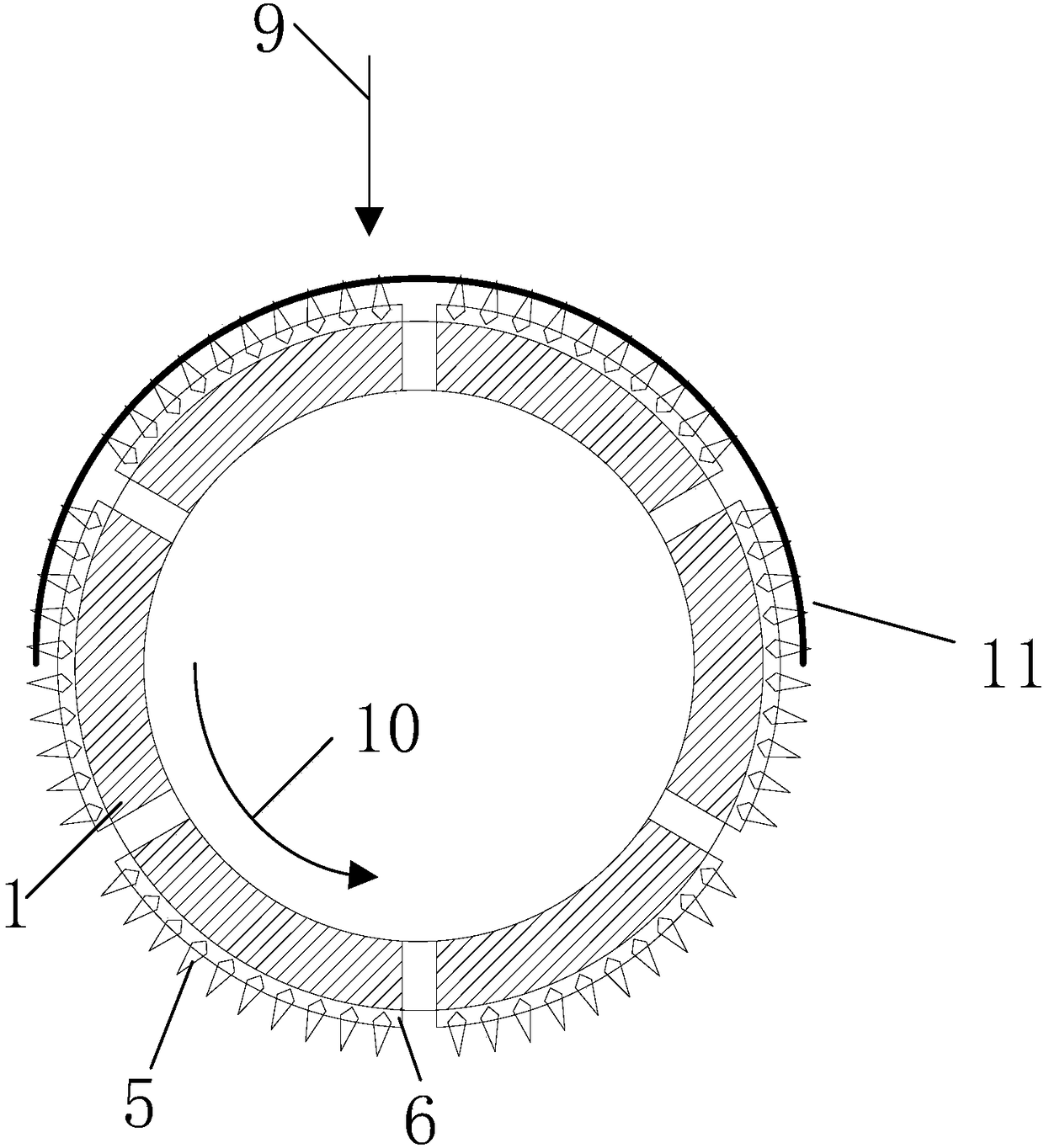

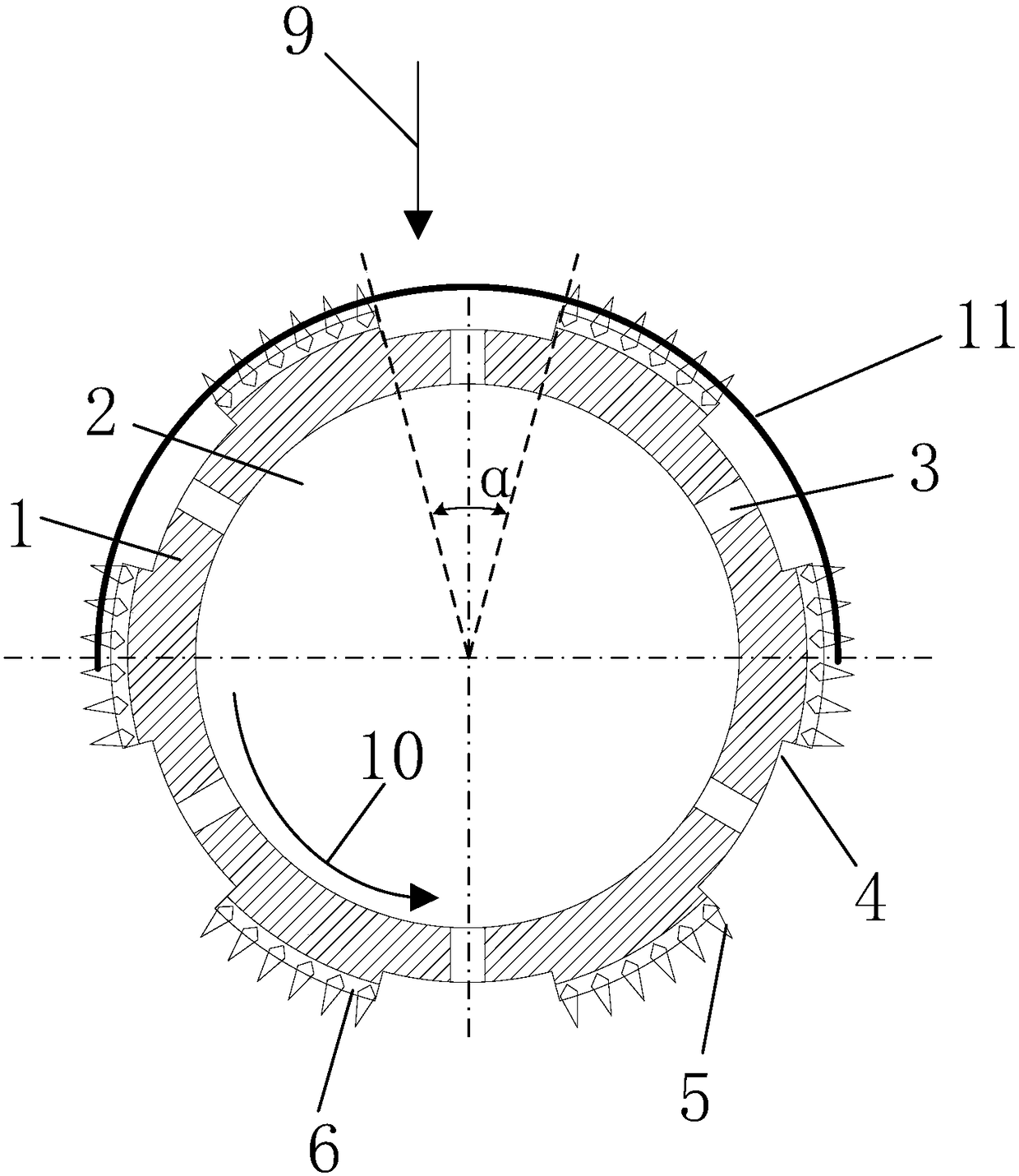

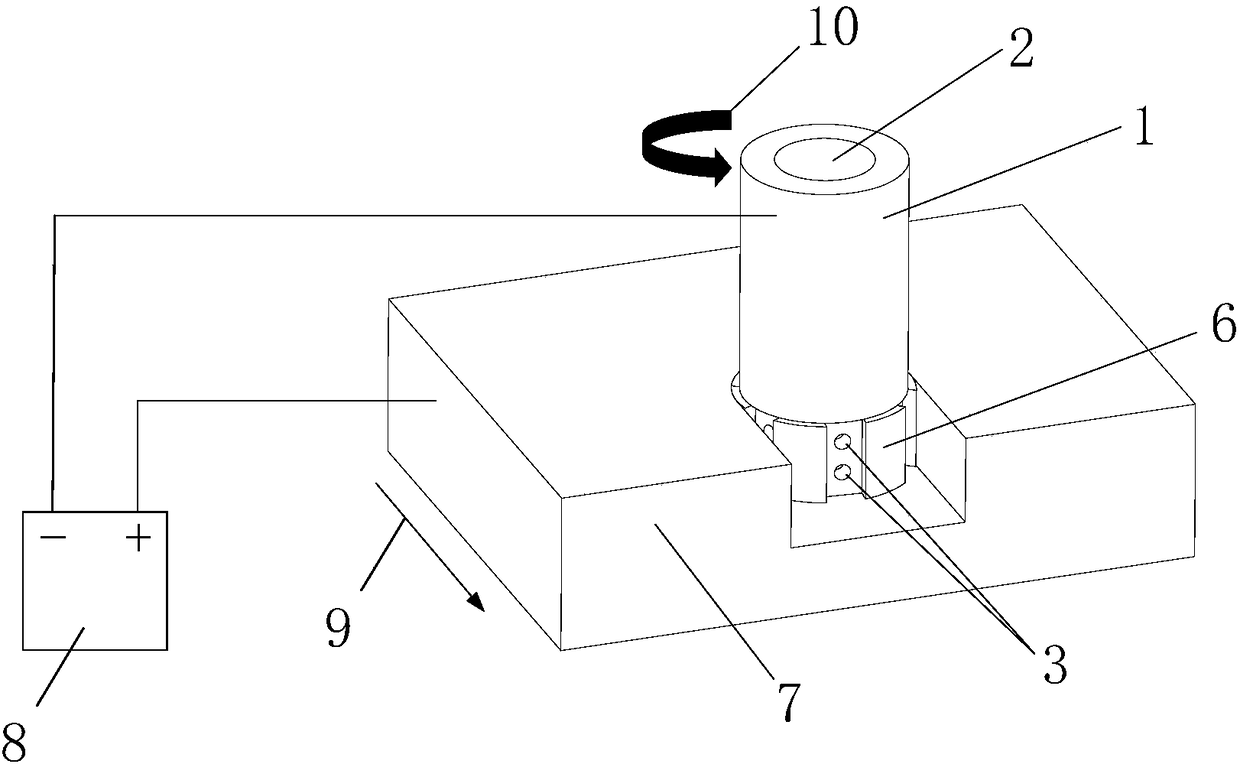

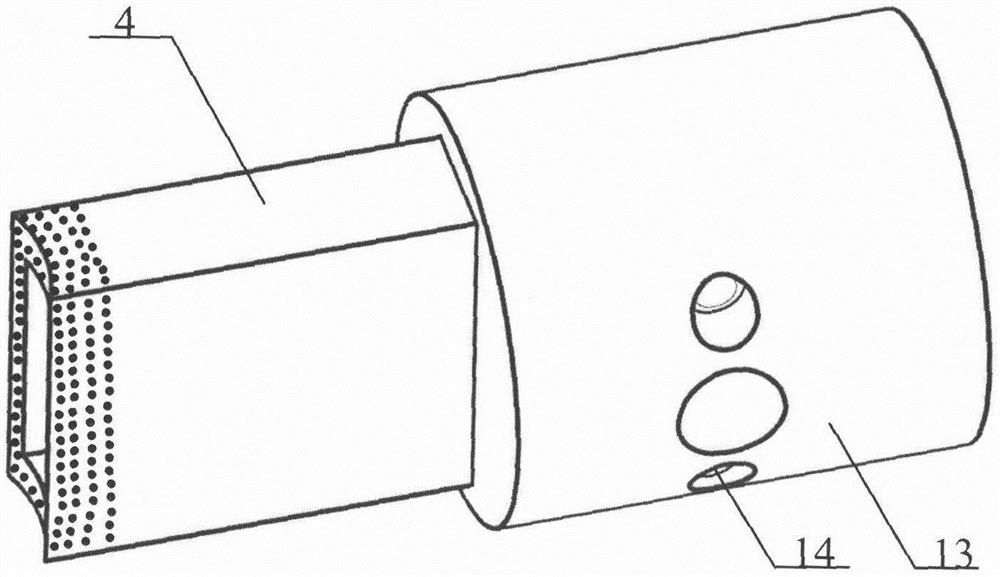

Electrolytic milling-grinding machining tool cathode with efficiency and precision and electrolytic milling-grinding method

The invention relates to an electrolytic milling-grinding machining tool cathode with efficiency and precision and an electrolytic milling-grinding method, and belongs to the field of electrolytic milling-grinding composite machining. According to the electrolytic milling-grinding machining tool cathode and the electrolytic milling-grinding method, a plurality of arc-shaped grooves at equal intervals are formed in the lower end of the side wall of the tool cathode, the side walls of the grooves are insulated, and diamond abrasive particles are inlaid in the wall surfaces of the portions, except for the grooves, of the side wall of a cathode base body through a resin binder, so that electrochemical anodic dissolution only exists in the surfaces of the portions, opposite to the grooves, of aworkpiece, at the moment, the depths of the grooves become a part of a machining gap, accordingly the contact depth between the diamond abrasive particles in the portions, except for the grooves, ofthe side wall of the cathode base body and the machining surface of the workpiece is increased, then the grinding effect of the diamond abrasive particles on the workpiece in the electrolytic milling-grinding process is enhanced, and the precision and the surface quality of the electrolytic milling-grinding machining can be improved; and moreover, compared with the electrolytic milling-grinding finish machining under the low current density in the past, the tool cathode can adopt higher current density, and the machining efficiency can be improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

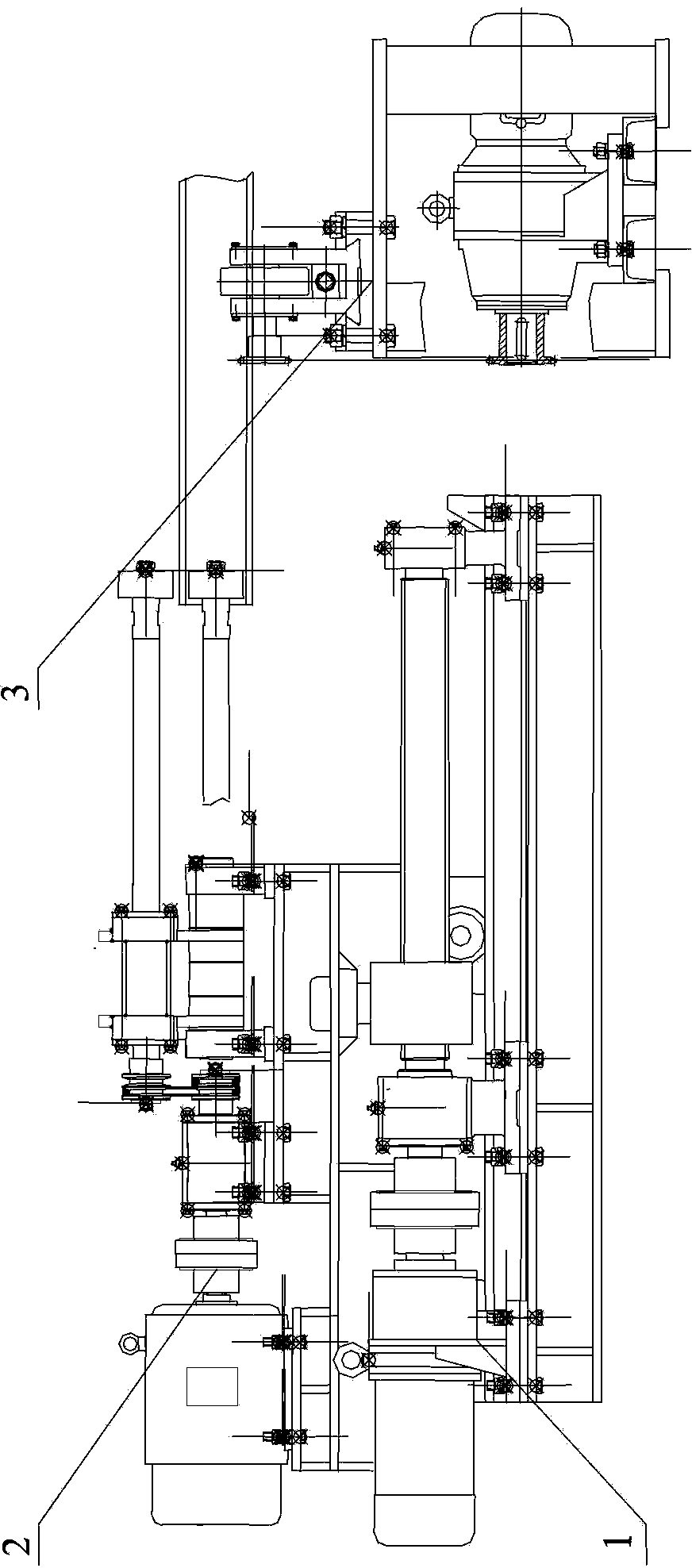

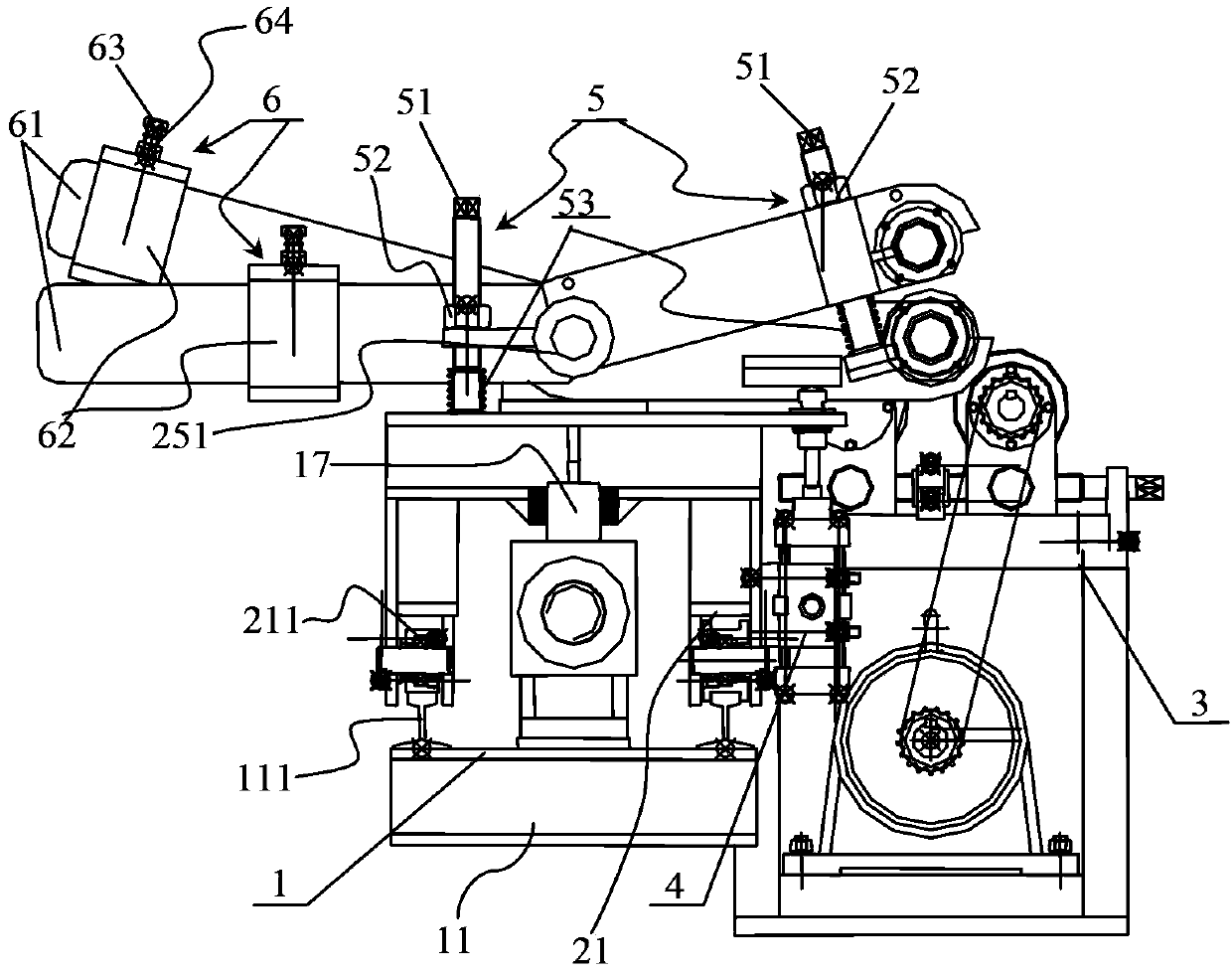

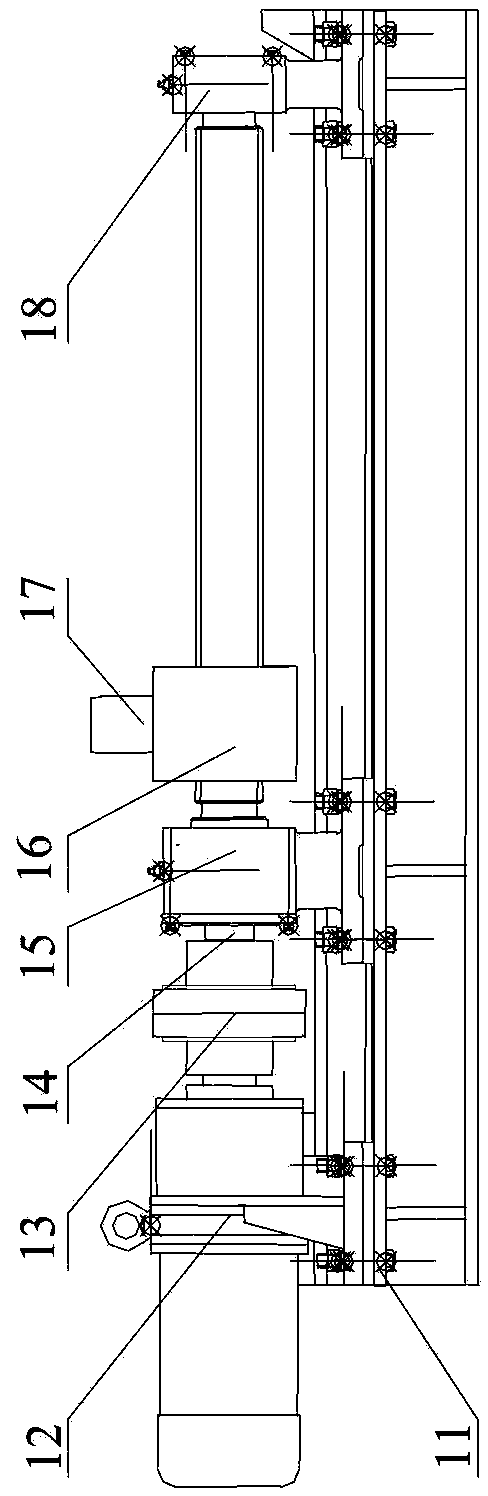

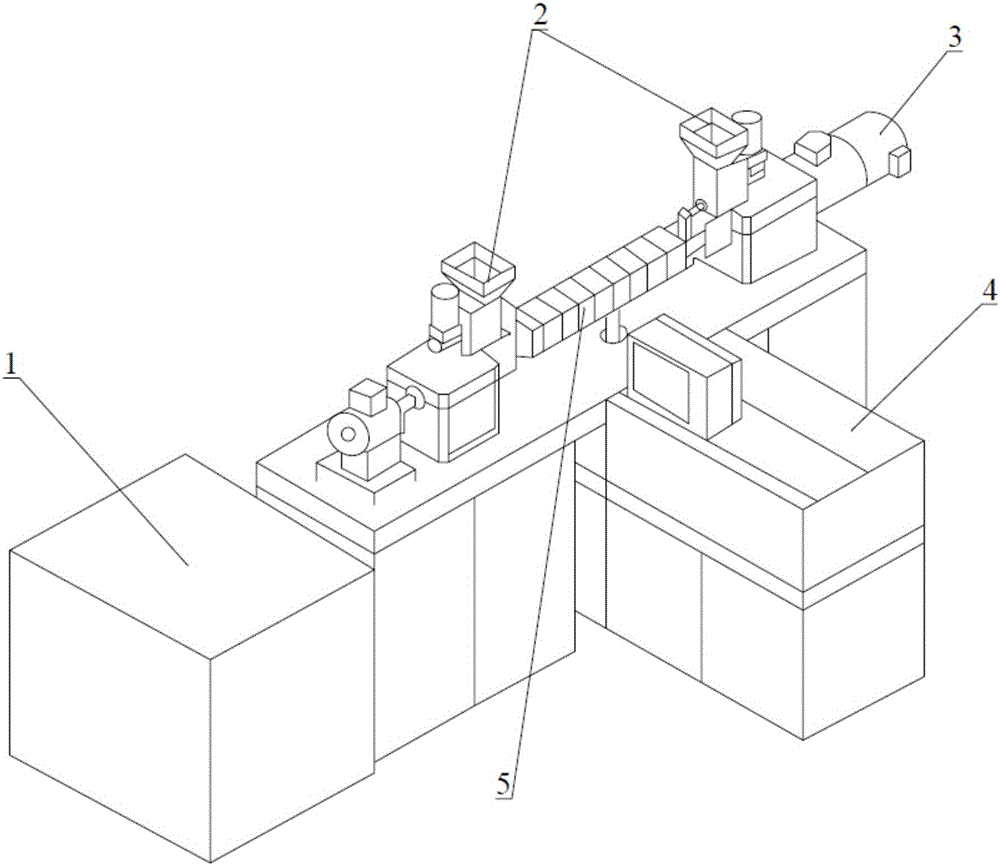

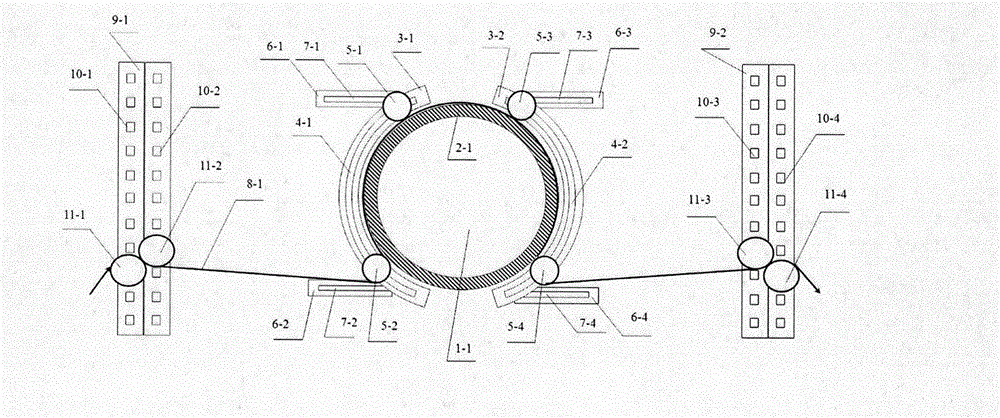

Synchronous grinding device for inner surface and outer surface of steel pipe end

ActiveCN103991013AImprove grinding qualityImprove labor efficiencyRevolution surface grinding machinesGrinding drivesElectric machineryEngineering

The invention relates to a synchronous grinding device for the inner surface and the outer surface of a steel pipe end. The synchronous grinding device comprises an axial feed mechanism and a grinding mechanism driven by the axial feed mechanism to move in the axial direction. The synchronous grinding device is characterized in that the grinding mechanism is a synchronous grinding mechanism and comprises a grinding motor, an inner grinding component, an outer grinding component and a steel pipe rotating roller mechanism; the inner grinding component and the outer grinding component are driven by the grinding motor to rotate synchronously, and the grinding motor drives a grinding head of the inner grinding component and a grinding head of the outer grinding component to rotate; the steel pipe rotating roller mechanism drives chain transmission through a geared motor and drives a roller mechanism to make a steel pipe to rotate in the circumferential direction. According to the synchronous grinding device for the inner surface and the outer surface of the steel pipe end, as the scheme that grinding shafts arranged in two independent swing shaft seats are driven in a single-motor dual-drive mode to achieve synchronous grinding actions, the feed motion of the grinding heads is achieved by driving a nut and a lead screw through the geared motor, and circumferential rotation of the steel pipe is achieved by driving rollers is adopted, the inner surfaces and the outer surfaces of the steel pipe ends with different outer diameters and wall thicknesses can be ground synchronously, grinding quality is improved, labor efficiency is enhanced, auxiliary time is shortened, and production cost is lowered.

Owner:BAOSHAN IRON & STEEL CO LTD

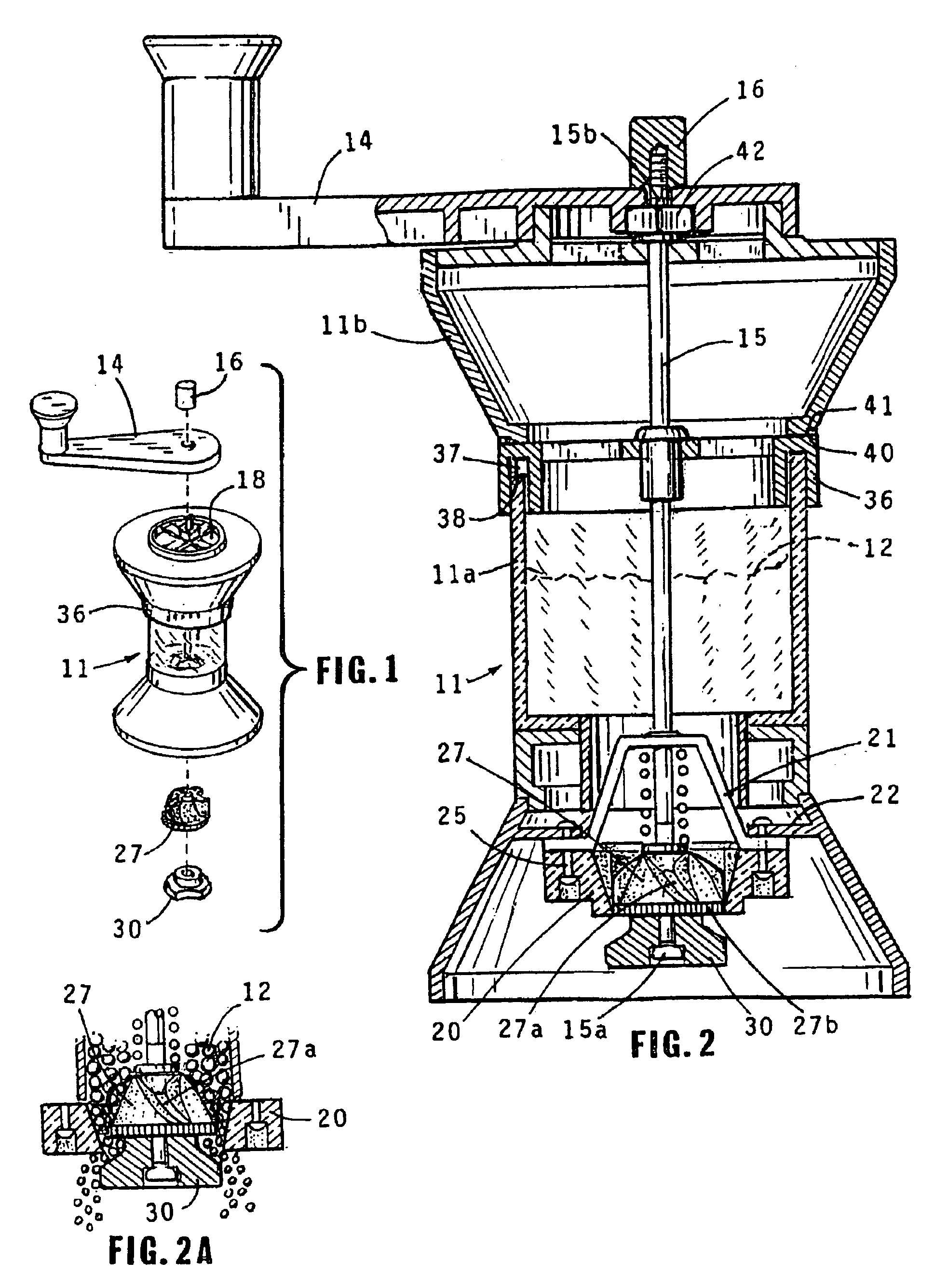

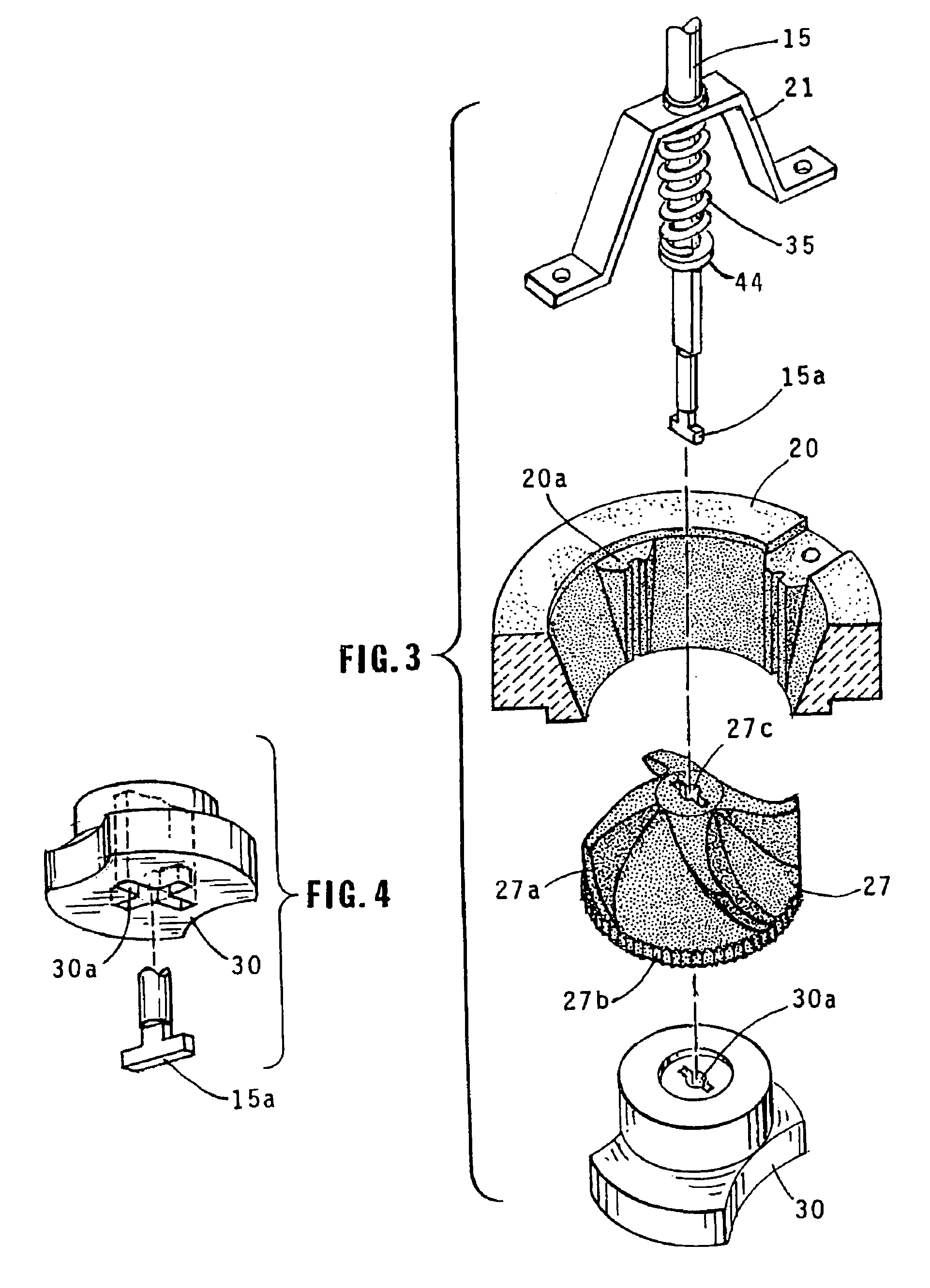

Slicing condiment grinder

A condiment grinder has a main container with a top rotatable drive portion having Drive arms are rotatably mounted in the bottom portion of the container in a compartment formed between a flat top plate and a flat bottom plate having cutting blades formed therein. The top plate is resiliently urged towards the flat bottom plate by a spring mounted in the container between the drive portion and the top plate. Condiment to be ground is placed in the compartment. The top drive portion is connected to the drive arms such that when the top drive portion is rotated, the drive arms drive the condiment against the cutting blades to effect the grinding action, the ground condiment being passed out from the container.

Owner:WILLIAM BOUNDS

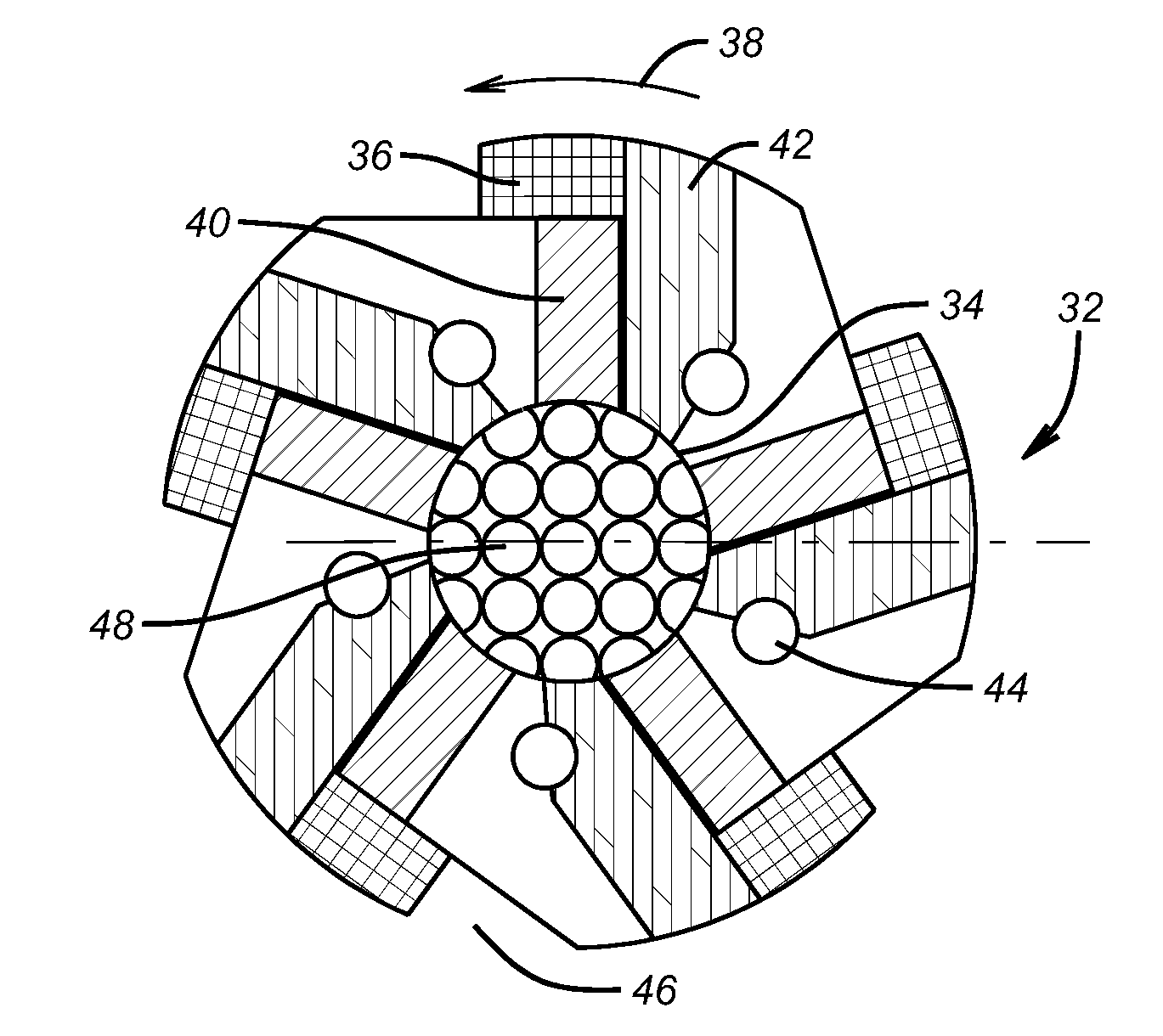

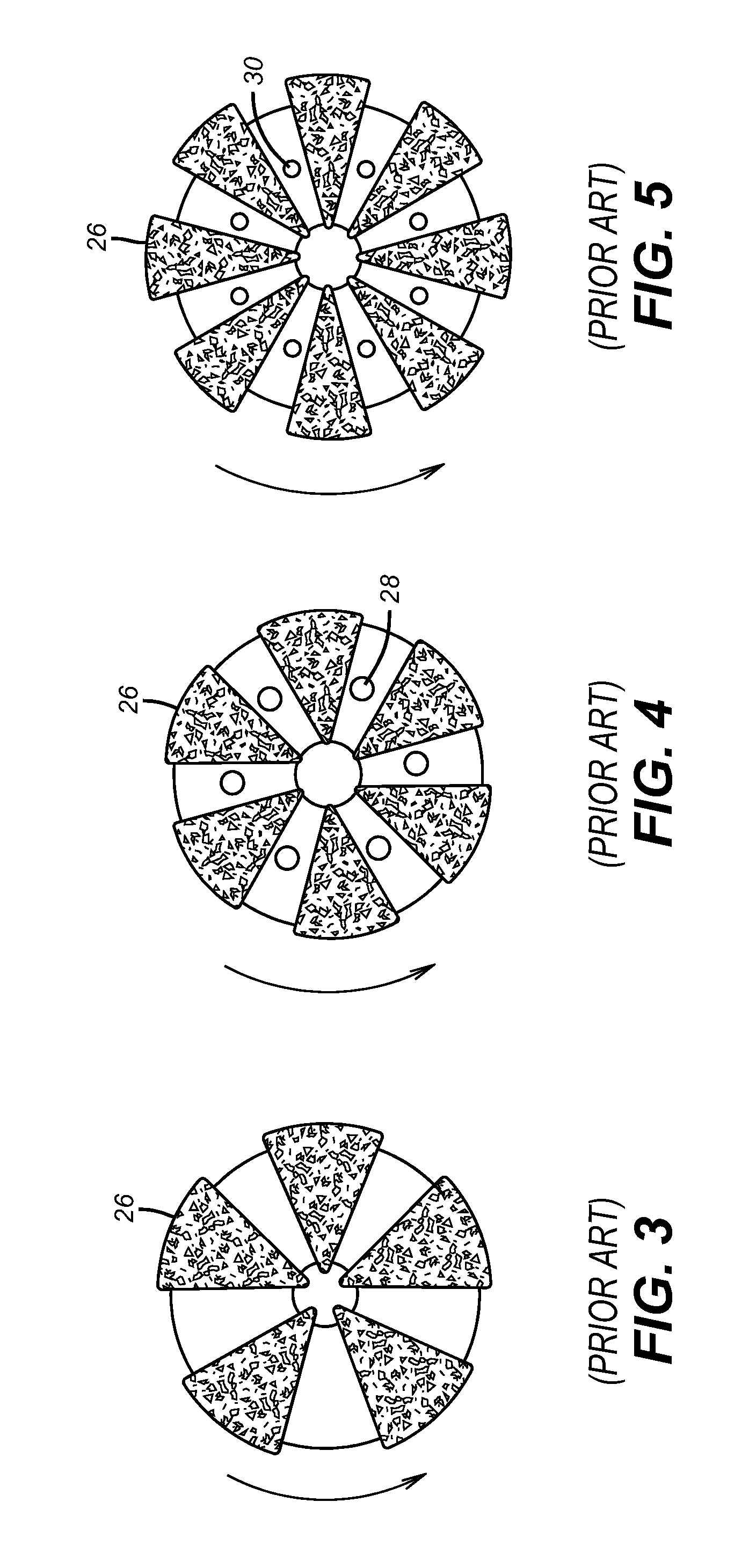

Subterranean Cutting Tool Structure Tailored to Intended Use

ActiveUS20120073880A1Improve wear resistanceGood temperature bond strengthDrill bitsConstructionsWear patternWear resistant

A mill cutting structure is differently configured in three zones. Those zones are the center, the outer edge and in between. At the center has highly wear resistant material that has good temperature bond strength and high impact resistance. The outer periphery can have a material that is highly resistant to wear and impact. In between can be inserts such as used in the Metal Muncher® mills using sintered carbide shapes that resist tracking and create a chipping rather than a grinding action. The shapes should have high edge retention capability and shapes such as a double sided pyramid can be used. The wear patterns of prior designs are addressed to allow longer and faster milling of the fish.

Owner:BAKER HUGHES INC

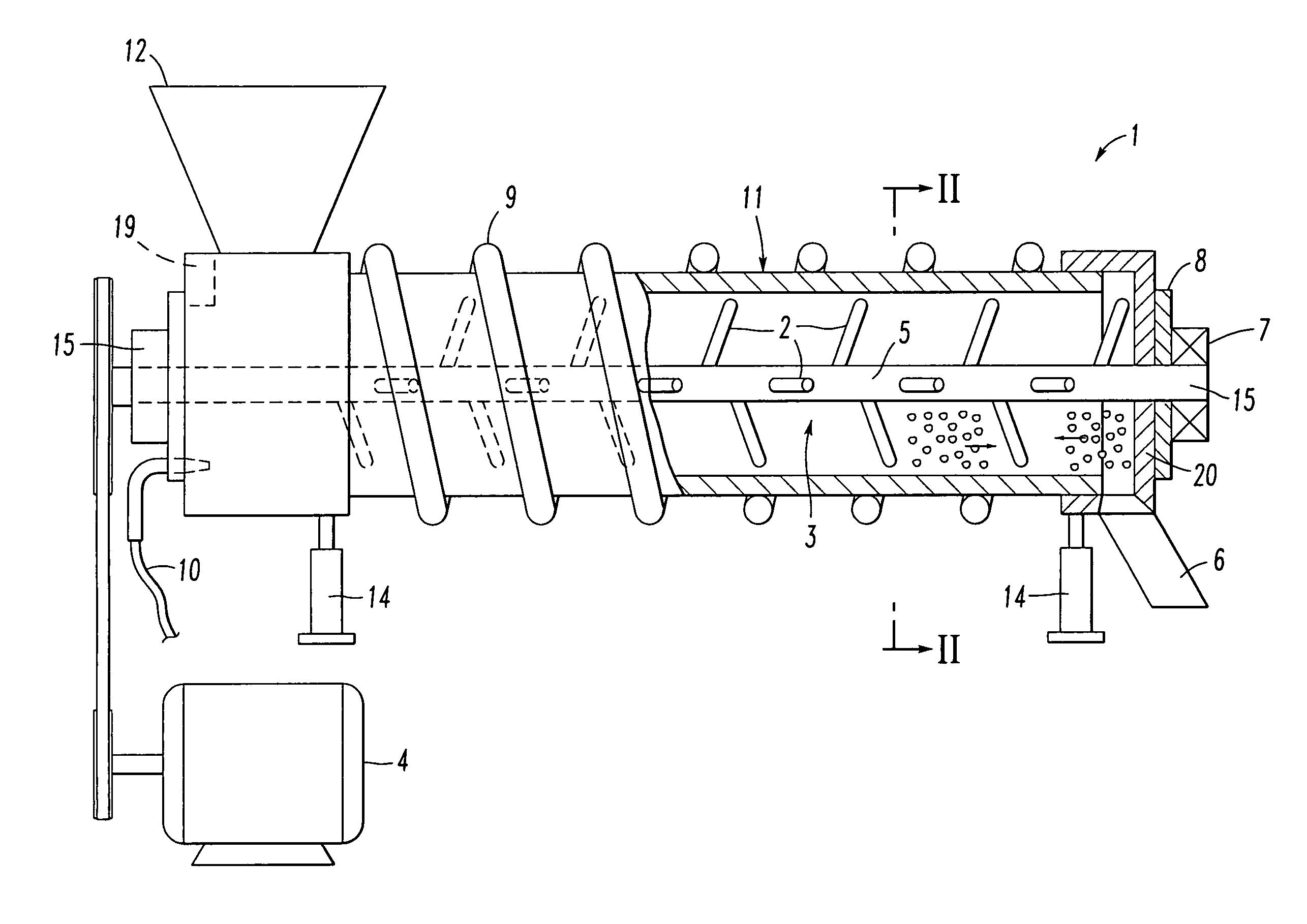

Method and apparatus for pulverizing solid materials

InactiveUS20070040055A1Material size reductionUniform shapeGrain millingEngineeringVolumetric Mass Density

A method and apparatus to pulverize materials directs solid materials through a generally horizontal chamber. A rotating center element that directs the material along the chamber by basic thrust using projections such as tines, paddles, knives or blades to develop motion and resulting kinetic energy of the material. The material is directed along the axis from the material inlet toward the material outlet and reverses flow at the end of the chamber to recycle back toward the material inlet causing particles of material to collide and fracture. The rotating speed of the center element can be adjusted to affect the grinding rates and particle size distribution. The rotating center element can also be fixtured to optimize material size reduction, differences in material density and the horizontal chamber can be tilted in a declined or inclined plane to affect the grinding rates and size reduction. This method of grinding and pulverizing can accommodate material feed stocks that have as much as 10% moisture since the grinding action creates heat and can drive off the moisture from the material.

Owner:NEW AGE FASTENING SYST

Electrolysis milling-grinding efficient rough and fine machining integrated machining method

The invention relates to an electrolysis milling-grinding efficient rough and fine machining integrated technology and a tool cathode, and belongs to the field of electrolysis milling-grinding composite machining. According to the provided technology, when the tool cathode with diamond abrasive particles is used for rough machining, the machining voltage of 20 V or above is adopted, and materialsare efficiently removed in a large-allowance manner under leading of the electrolysis action; during fine machining, the machining voltage of 5V or below is adopted firstly, the electrolysis action isonly used for generating a passivating film on the surface of a workpiece, the material surface is softened, then, the material is removed under the grinding action of the diamond abrasive particles,and the uneven machined surface during rough machining is preliminarily flattened; and then, the machining voltage is adjusted to be zero, electrolysis action marks left on the workpiece surface areremoved only through the grinding action of the diamond abrasive particles, the machining precision is further improved, and the surface quality is improved. According to the provided method, tool replacement is not needed, the same tool can be adopted for achieving efficient rough and fine machining of materials hard to machine, the positioning error caused by technology replacement do not exist,the workpiece machining efficiency and precision can be effectively improved, and the service life of a cutter is prolonged.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

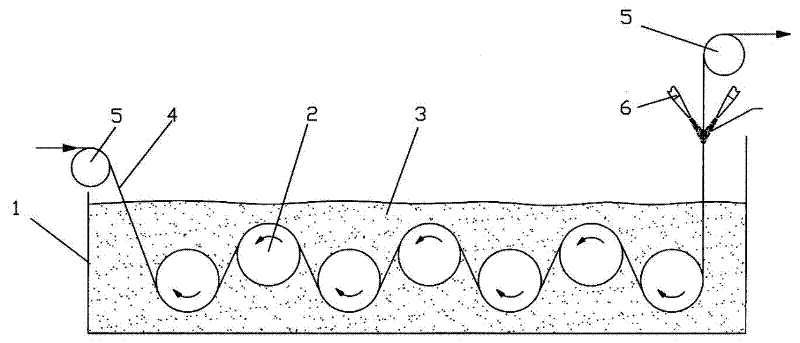

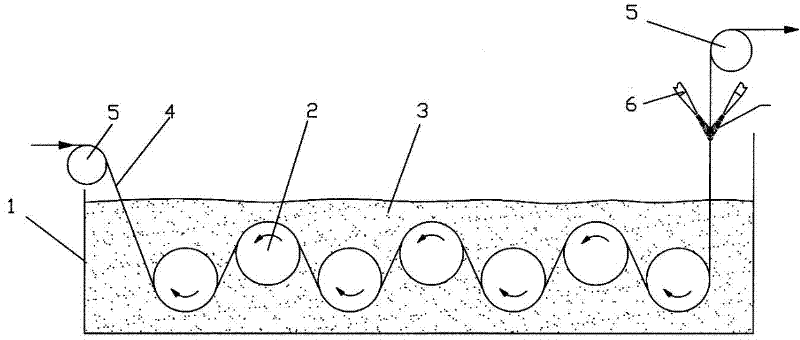

Mechanical descaling method

InactiveCN102452032AReduce roughnessQuality improvementGrinding machinesMetal stripsContact pressure

The invention discloses a mechanical descaling method, which is characterized in that in a mud pool filled with grinding mud, a plurality of brush rolls are arranged in an up-and-down staggered mode, the brush rolls are completely soaked in the grinding mud, and the surface of each brush roll is provided with bristles; a metal strip passes through the brush rolls which are arranged in an up-and-down staggered mode, by using the tensioning actions of front and rear tension roll sets, a certain tensioning action is generated between the metal strip and each brush roll, namely, a certain contact pressure is generated; the metal strip moves under the pulling actions of the front and rear tension roll sets, and the brush rolls rotate in the opposite direction so that relative motion is generated between the surface of each brush roll and the surface of the metal strip, the bristles carry a lot of grinding mud, and during relative sliding between the bristles and the surface of the metal strip, mud slides relative to the surface of the metal strip for realizing grinding effect, thereby achieving an effect of surface brushing. In the invention, through fully using the rotary brushing action of the brush rolls and the grinding action of the grinding mud, the grinding mud is driven by the bristles closely arranged on the brush rolls so as to remove and grind matters attached to the surface of the metal strip.

Owner:BAOSHAN IRON & STEEL CO LTD

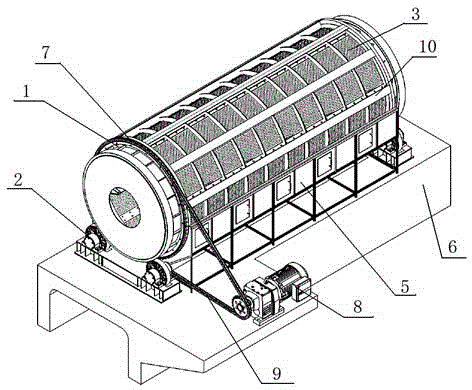

Roller type screening crusher and design method thereof

PendingCN106140400ASmall environment adaptabilityAvoid secondary crushingGrain treatmentsGear wheelProcess engineering

The invention discloses a roller type screening crusher and a design method thereof. The crusher elevates crushed materials to a certain height, and crushing is achieved through mutual impacting and grinding actions of material falling; and after crushing, the materials smaller than screen plate holes fall into a material collecting hopper at the lower portion of the roller type screening crusher through the screen plate holes and are continuously discharged through a conveying device, and therefore the functions of synchronous crushing and screening of the crushed material are achieved. The roller type screening crusher is large in crushing ratio, high in productivity, low in energy consumption and simple in structure, and the product granularity guaranteeing degree is high. The riding wheel supporting design is adopted and is high in environment adaptability, capable of saving investment and low in maintaining difficulty in comparison with a hybrid bearing supporting manner. A chain drive manner is adopted in a roller body and similarly has the beneficial effects of being high in environment adaptability, capable of saving investment and low in maintaining difficulty in comparison with a gear engagement transmission manner. Metal and sundries contained in the materials can be discharged from the tail end of the crusher in a regular material emptying manner, and downstream production and equipment cannot be influenced, wherein the sundries are not prone to breakage.

Owner:贵州莱利斯机械设计制造有限责任公司

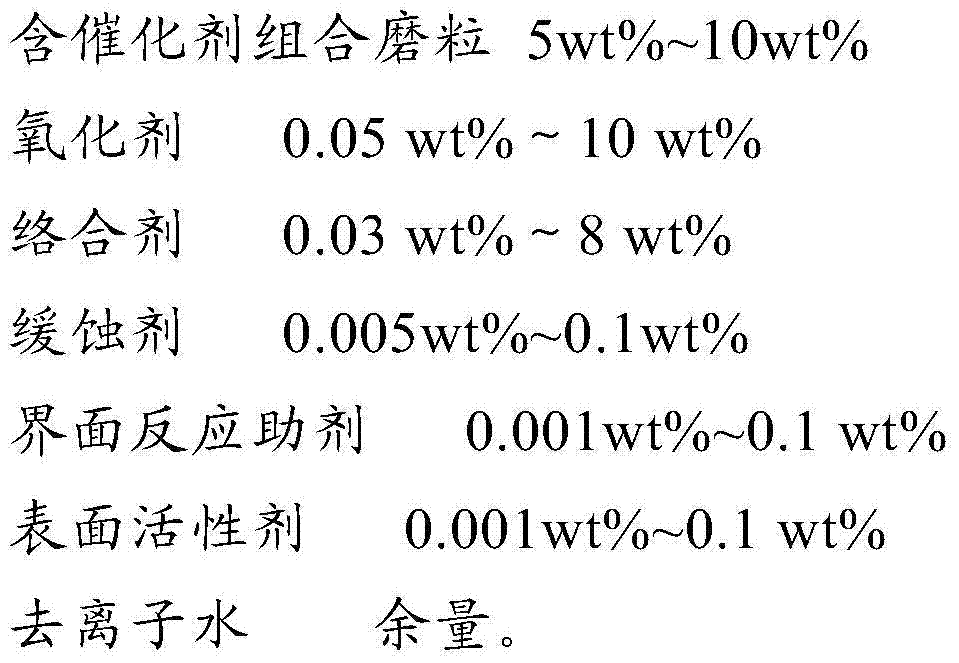

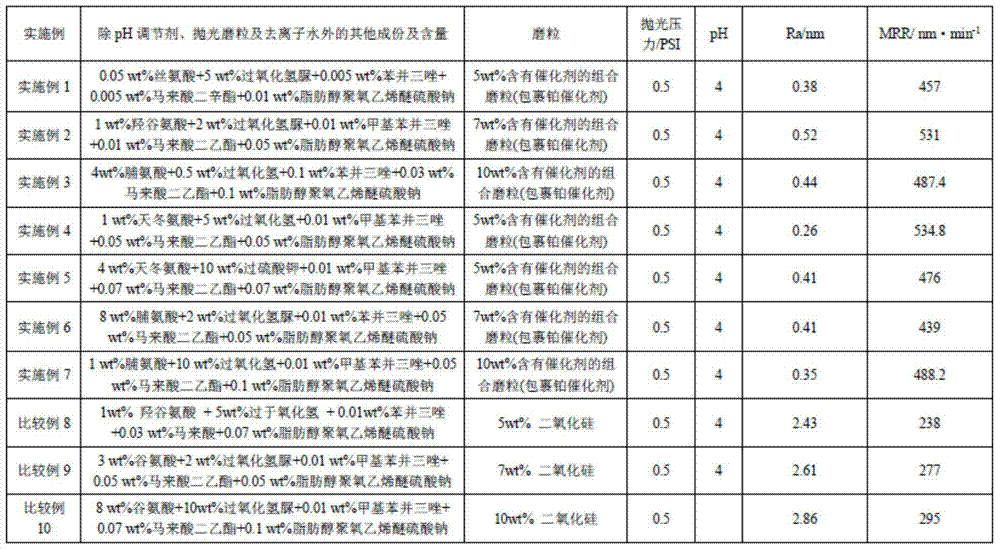

Integrated circuit copper CMP composition and preparation method thereof

InactiveCN104513627AProduce moreSolve the problem of low removalPolishing compositions with abrasivesCatalytic oxidationSurface-active agents

The invention relates to an integrated circuit copper CMP composition and a preparation method thereof, belongs to the technical fields of micro-electronics auxiliary materials and ultra-precision machining technology, and particularly relates to a polishing composition with a catalytic action. The composition comprises deionized water, combined abrasive particles containing catalysts, an oxidizing agent, a complexing agent, a corrosion inhibitor, an interface reaction assistant, a pH conditioning agent and a surface active agent, and the pH value of a polishing liquid composition is 2.0-5.5. The polishing abrasive particles are combined with the catalysts, so that the polishing abrasive particles have catalytic activity while reaching a mechanical grinding action, have the capacity of catalytic oxidation, and also double as a mechanical action and a chemical action; the polishing surface quality can be kept, and a copper chemical mechanical polishing composition realizing quick removal can be realized.

Owner:SHENZHEN LEAGUER MATERIAL +2

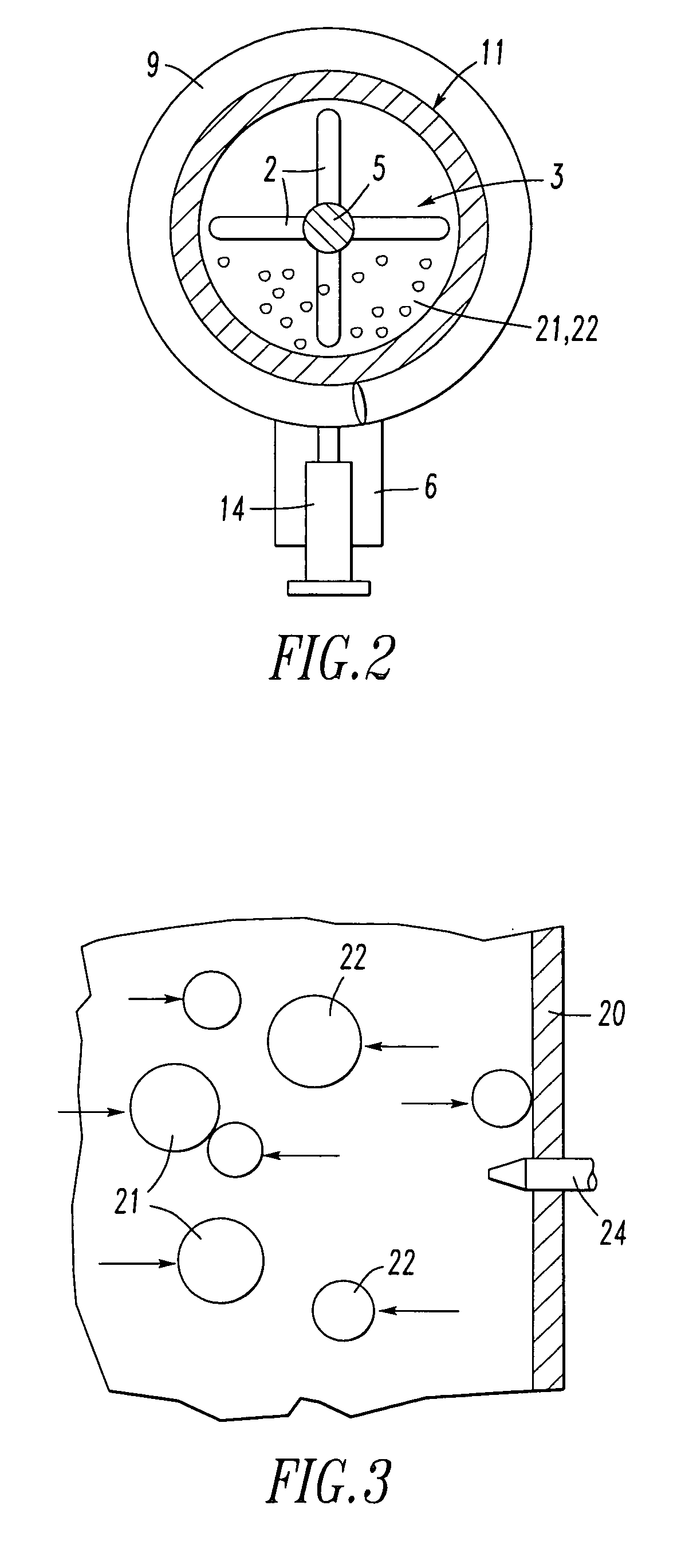

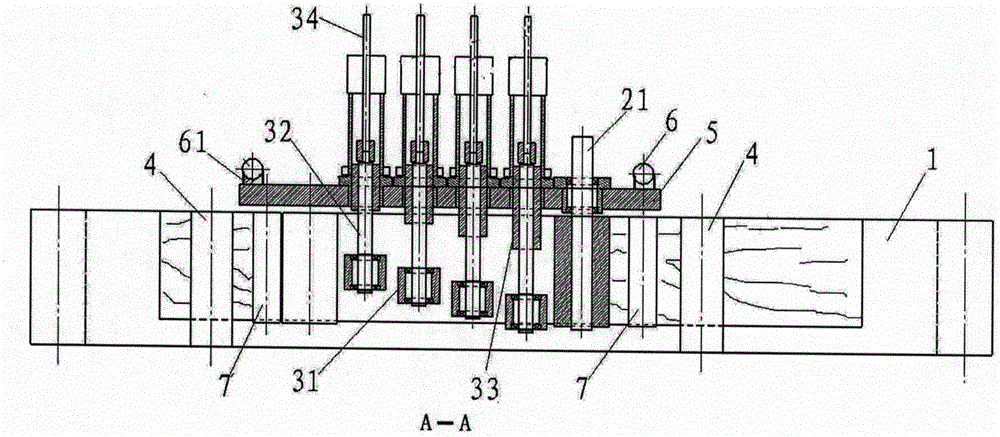

Balanced type triple-screw vibrating force field reinforced plasticizing mixing extrusion method and equipment

ActiveCN105856530AGood plasticizing and mixing effectReduce energy consumptionScrew systemEngineering

The invention discloses balanced type triple-screw vibrating force field reinforced plasticizing mixing extrusion method and equipment. According to the method, an axial vibrating force field is added on a main screw of a triple-screw system, meanwhile, a bidirectional feeding manner is adopted, so that when the triple-screw system rotates, the main screw axially vibrates, and the material suffers from the shearing action and the axial vibrating extrusion grinding action at the same time in the triple-screw system, and thus increasing the mixing effect of the material. The equipment comprises a hydraulic excitation device, a triple-screw system, a measuring and control device, a driving motor and feeding hoppers, wherein two ends of the triple-screw system are respectively provided with the feeding hoppers, two ends of the main screw of the triple-screw system are respectively connected with the hydraulic excitation device and the driving motor, the measuring and control device is arranged at one side of the triple-screw system, and the driving motor and the hydraulic excitation device are respectively in electric connection with the measuring and control device. According to the invention, a conventional plasticizing mixing method is broken through, the vibrating force field is increased, and the plasticizing mixing effect of the material during conveying can be enhanced; and since bidirectional feeding is adopted, the axial resistance of the vibrating force field is eliminated.

Owner:SOUTH CHINA UNIV OF TECH +1

Burr removal method and apparatus for oil ejector body pressure regulating cavity

InactiveCN101244544AStrong grinding forceImprove processing efficiencyAbrasive blasting machinesSlurryHigh pressure

The invention relates to a deburring method for the pressure regulating cavity of an oil injector body and the device, which is characterized in adopting grinding medium slurry jet for deburring. The method is as follow: a high pressure generator is used for generating high-speed jet of grinding medium slurry, wherein, the grinding medium particles with greater kinetic energy in the grinding medium slurry jet has strong grinding force; the burr and oxide on the channel inner wall of the pressure regulating cavity of the oil injector body are removed with the eroding and grinding function of the grinding medium particles. The device comprises a generator of high pressure slurry jet, a nozzle reciprocating movement mechanism, a workpiece rotary mechanism and a feed mechanism. The deburring method has the advantages of high processing efficiency and high processing quality together with the device.

Owner:SHANGHAI UNIV +1

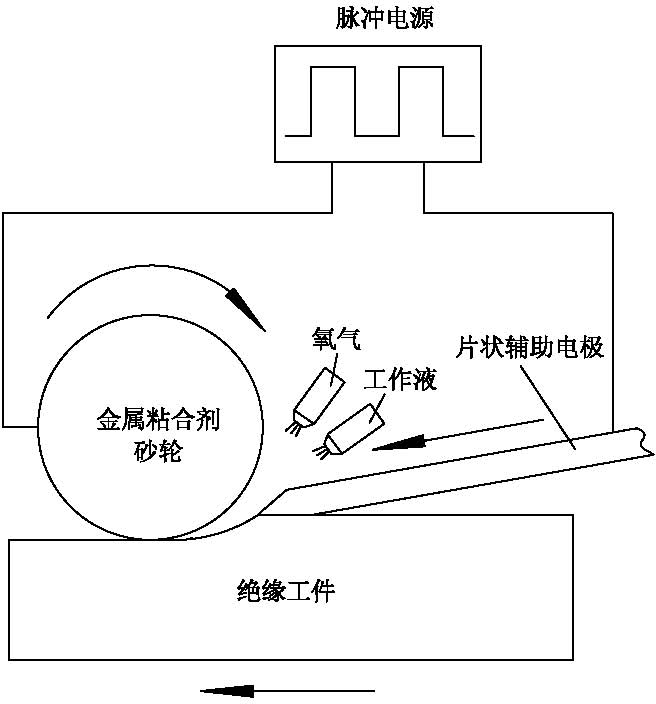

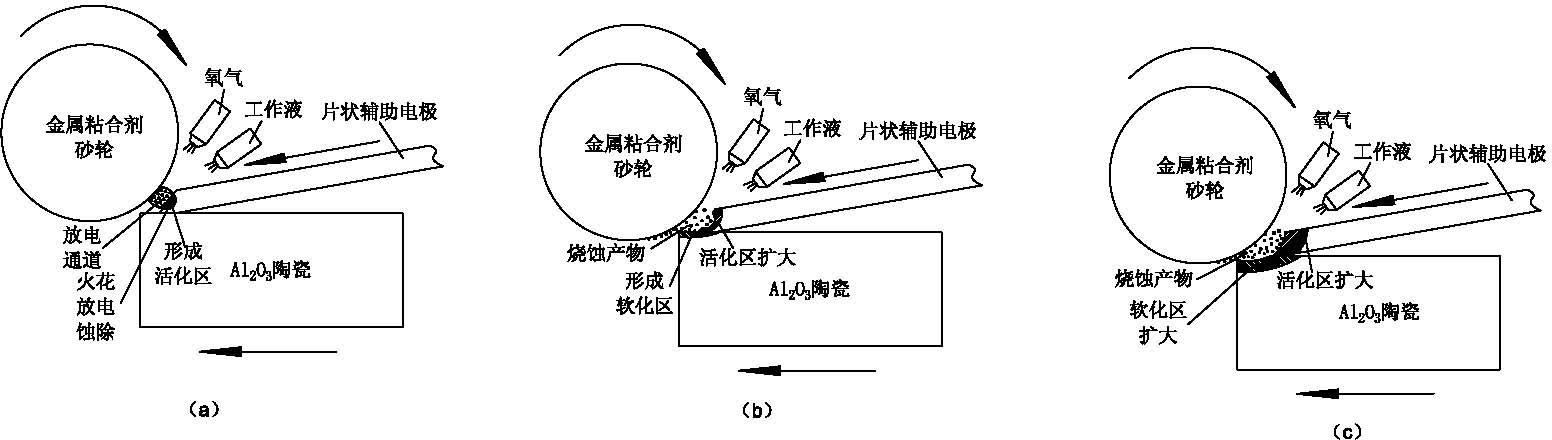

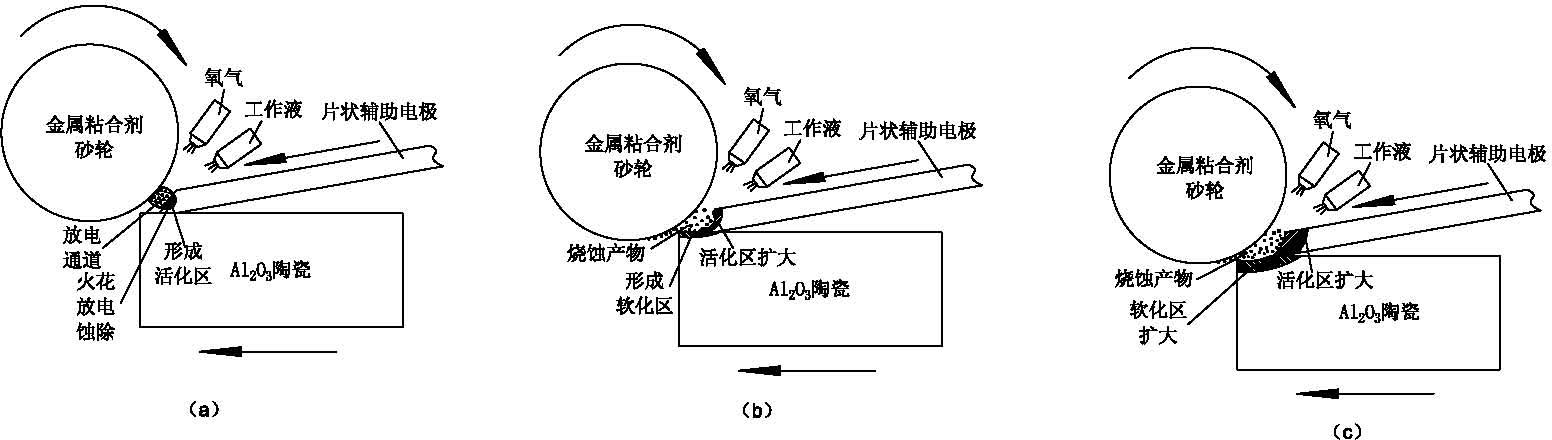

Controllable and ablated non-conductive engineering ceramic grinding method based on discharge induction

InactiveCN102172833AKeep sharpSmall grinding forceOther manufacturing equipments/toolsAdhesiveAuxiliary electrode

The invention discloses a controllable and ablated non-conductive engineering ceramic grinding method based on discharge induction, and is characterized in that a conductive metal adhesive grinding wheel is adopted as a grinding wheel, conductive auxiliary electrodes are continuously fed between the grinding wheel and the non-conductive engineering ceramic, electric sparkle discharge is generated between the grinding wheel and the conductive auxiliary electrodes under the action of pulse voltage, and a combustion-supporting gas capable of generating ablation exothermic reaction with the platy conductive auxiliary electrodes is led into a machining area continuously or intermittently during the process, thus leading machining to be in a state of discharge induced by electric sparkle-ablating of auxiliary electrodes-grinding of the grinding wheel on the non-conductive engineering ceramic; the grinding wheel and the conductive auxiliary electrodes generate discharge under the action of the electric sparkle discharge, the conductive auxiliary electrode materials reach over ignition temperature and are in a melting or even gasification state to generate ablating reaction with the combustion-supporting gas capable of generating ablation exothermic reaction, thus producing ablation product, releasing a large amount of heat acted on the surface of the non-conductive engineering ceramic material, and further leading the surface of the non-conductive engineering ceramic to be heated in a softening or even melting state, and removing the grinding under the grinding action of the grinding wheel. The method has the advantages of high machining efficiency, greening and environment friendliness.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

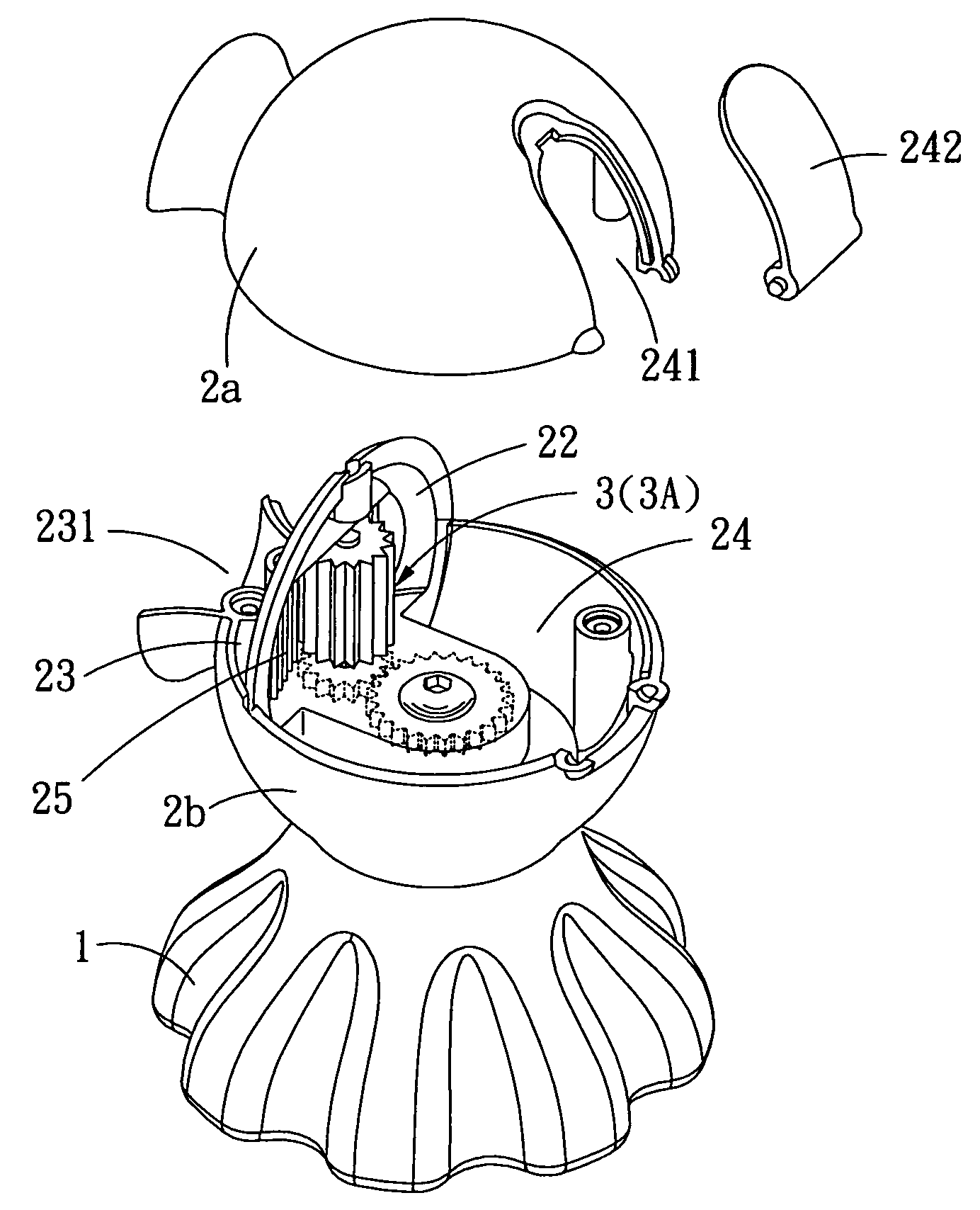

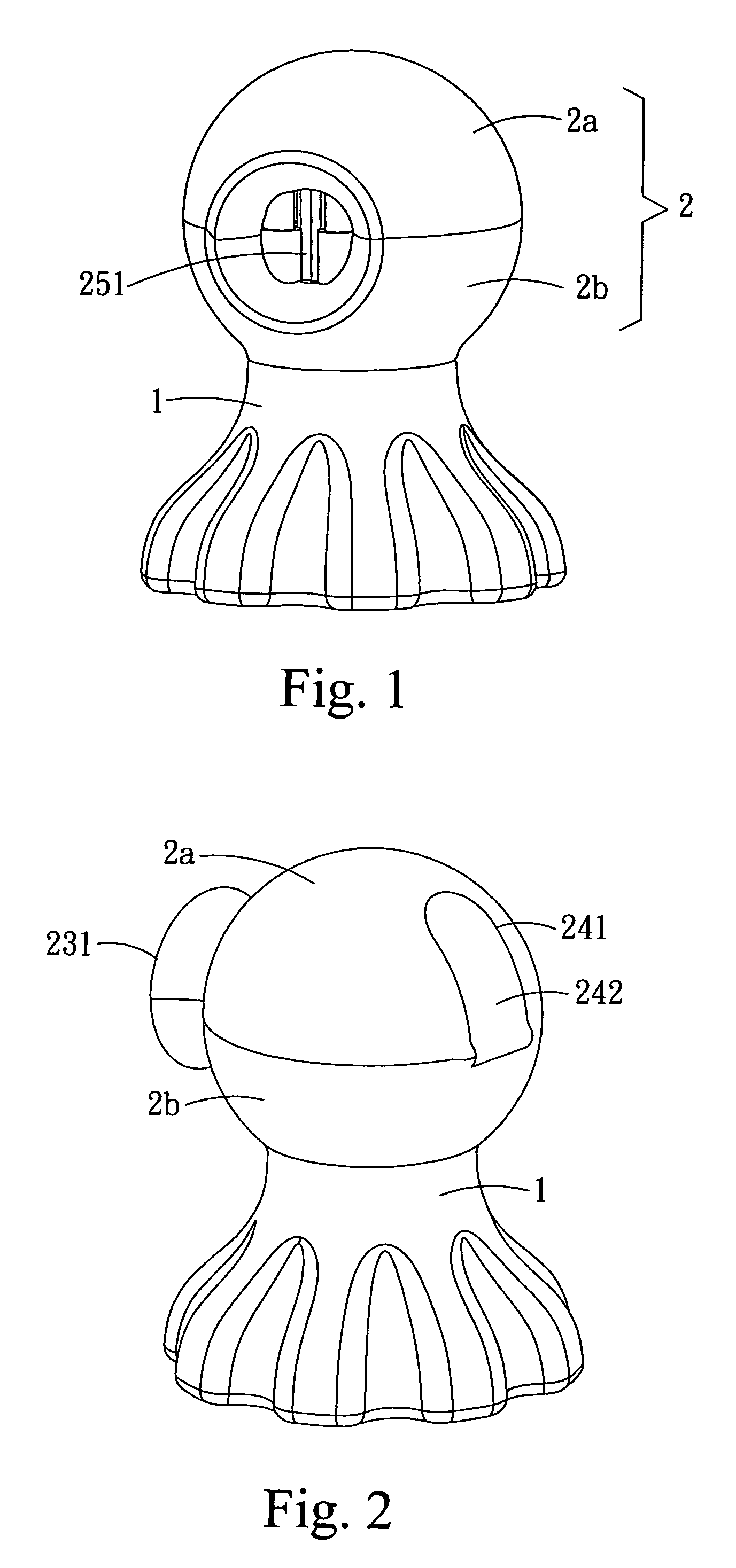

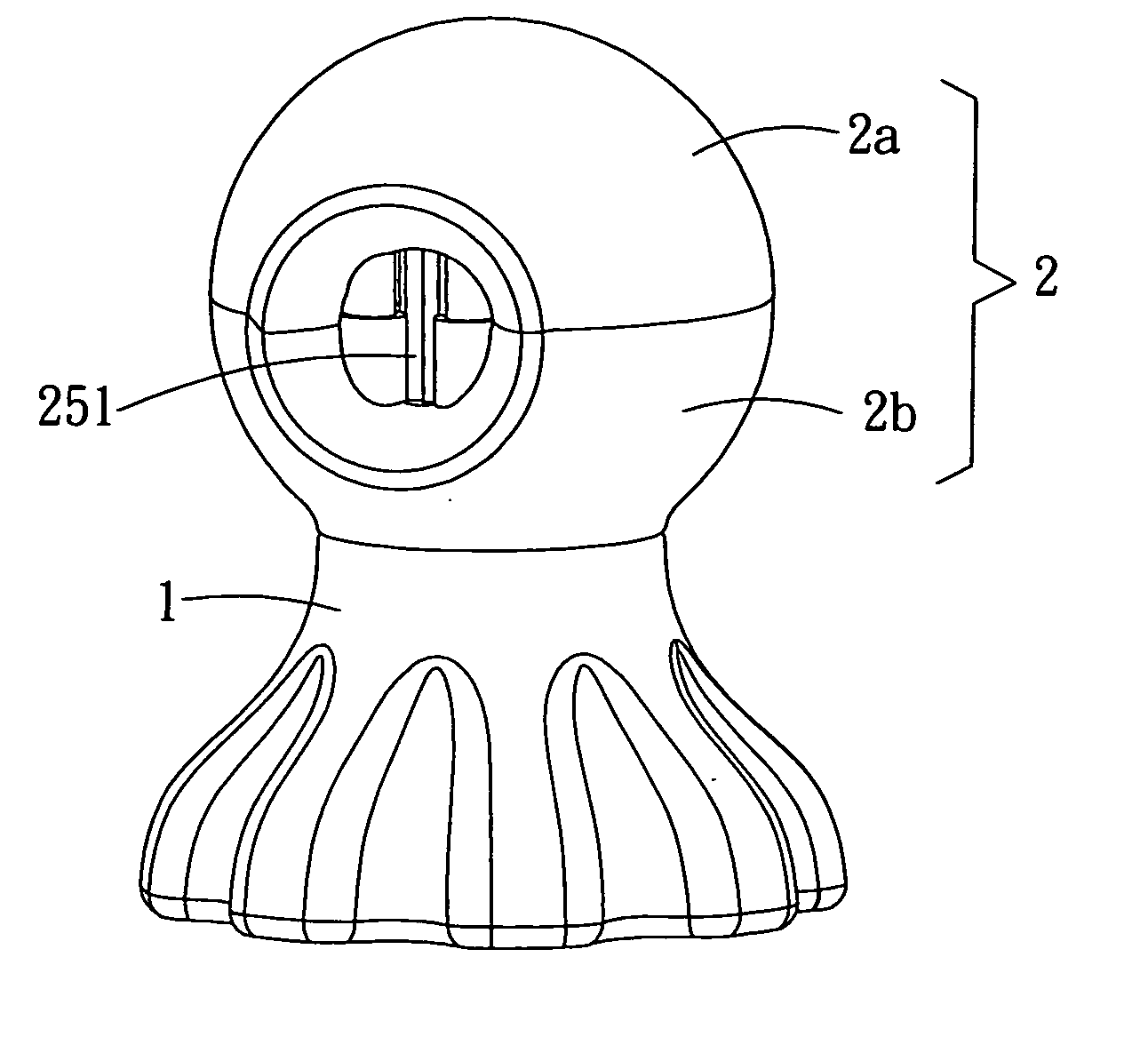

Pepper mill

A pepper mill including a hollow body having a through hole formed thereon, a clockwisely and counterclockwisely rotatable transmission unit mounted therein, and a grinding device mounted therein corresponding to the transmission unit. There is a base including a pivot having a free end inserted into the hollow body via the through hole and fixedly coupled to the transmission unit to enable the base and the hollow body to be pivotally rotatable, whereby the transmission unit is driven to perform a grinding action on the grinding device clockwisely and counterclockwisely.

Owner:LEE TUNG HSIEN

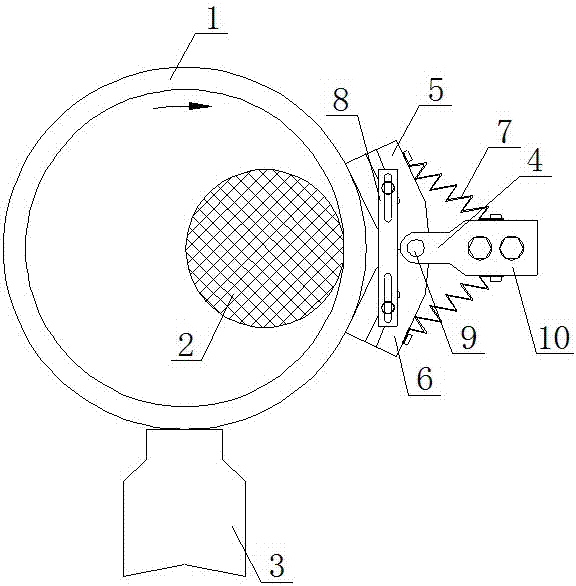

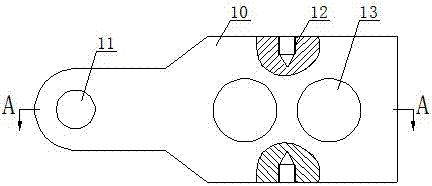

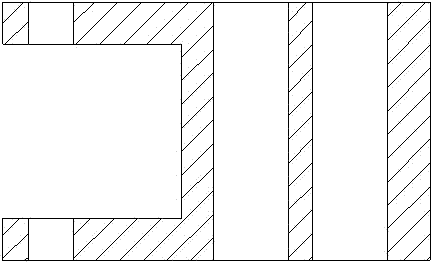

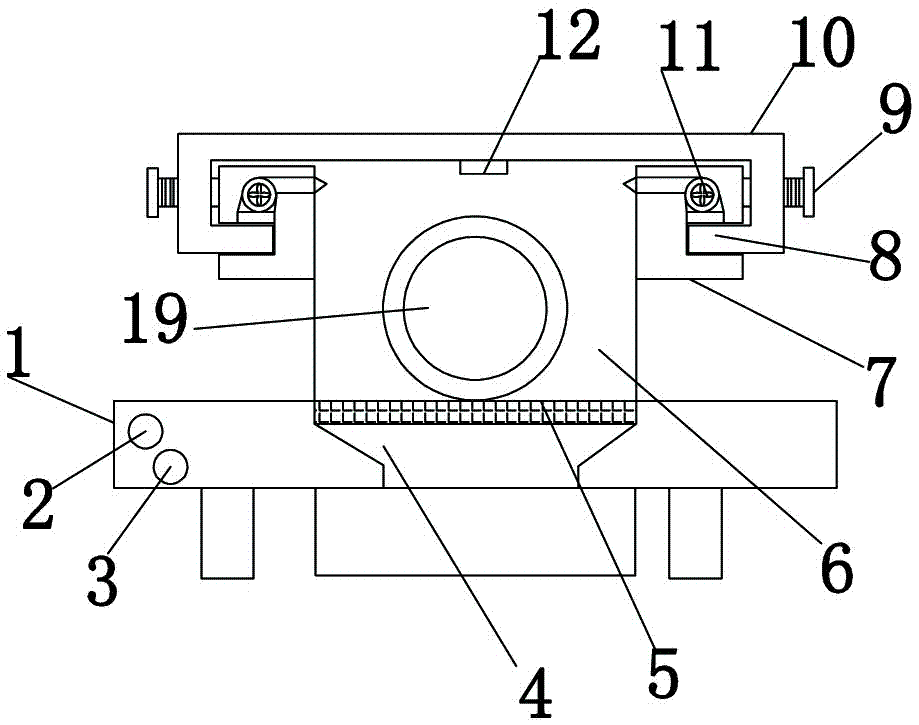

Adjustable floating supporting device and adjusting method

ActiveCN107243788AReduce machining errorsReduce angleRevolution surface grinding machinesEngineeringGrinding wheel

The invention provides an adjustable floating supporting device and an adjusting method, and aims to solve the problem that in the prior art, the precision is not high because a fixture remains stationary during a bearing machining process. The adjustable floating supporting device comprises a workpiece and a grinding wheel, wherein a fixed support is arranged at the bottom of the outer side of the workpiece; a floating support is arranged at the right part of the outer side of the workpiece, and comprises an upper floating head, a lower floating head and a floating supporting seat; a mounting hole I is formed in the left side of the floating supporting seat; fixing holes are formed in the right side of the floating supporting seat; spring fixing holes I are formed in both the top surface and the bottom surface of the right side of the floating supporting seat; and a spring fixing hole II is formed in the top surface of the upper floating heat. The adjustable floating supporting device provided by the invention has the advantages that the floating supporting design is adopted; when being machined, the workpiece rotates along with the clockwise direction shown in figure 1; the workpiece is machined under the grinding action of the grinding wheel, thereby greatly improving the machining precision; and the circumstance that the machining precision is lowered and the normal use is influenced because the error of a bulge is reflected on an inner hole of the workpiece when the bulge is formed on the outer cylindrical surface of the machined workpiece is avoided.

Owner:ZHONGYUAN ENGINEERING COLLEGE

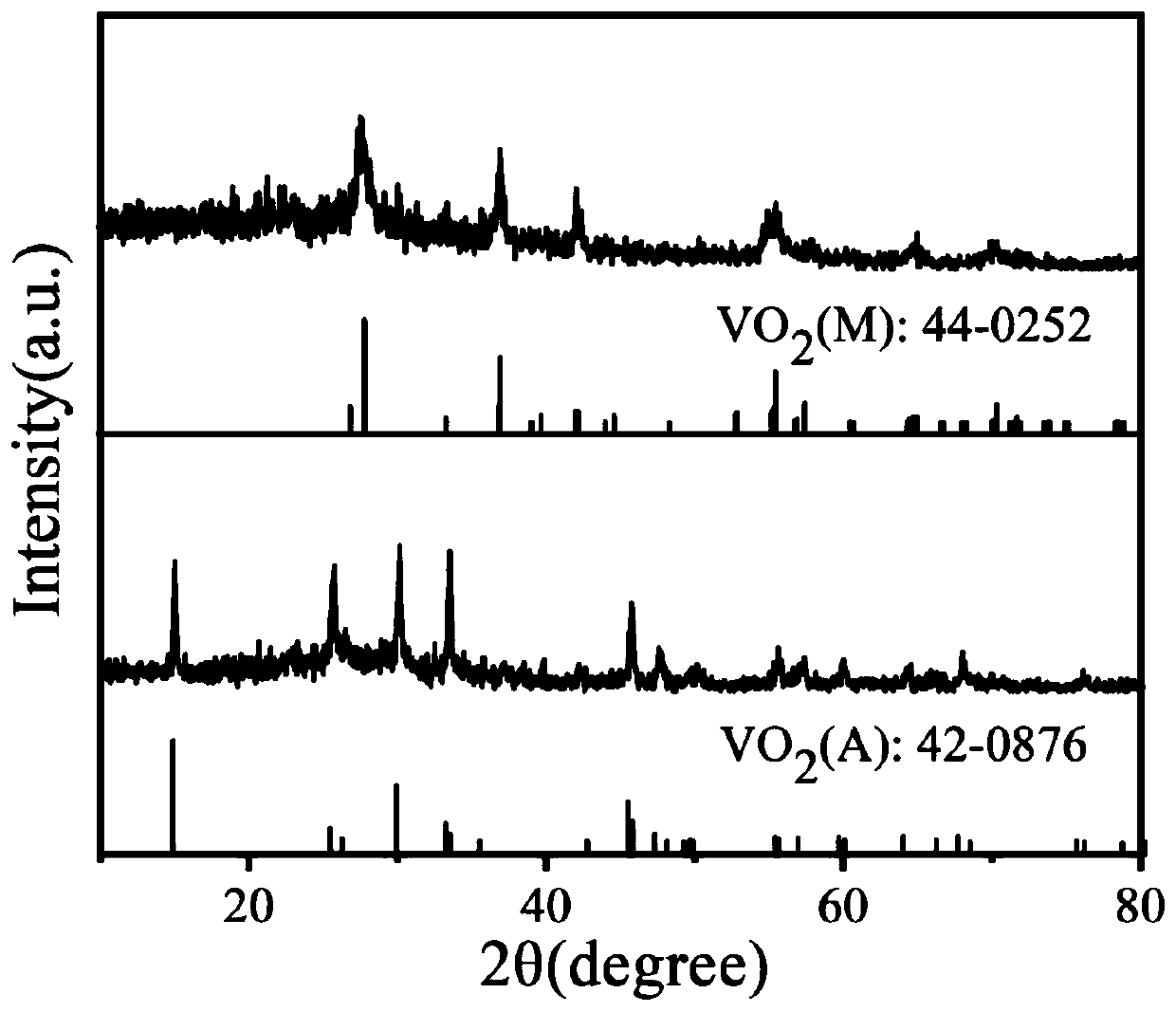

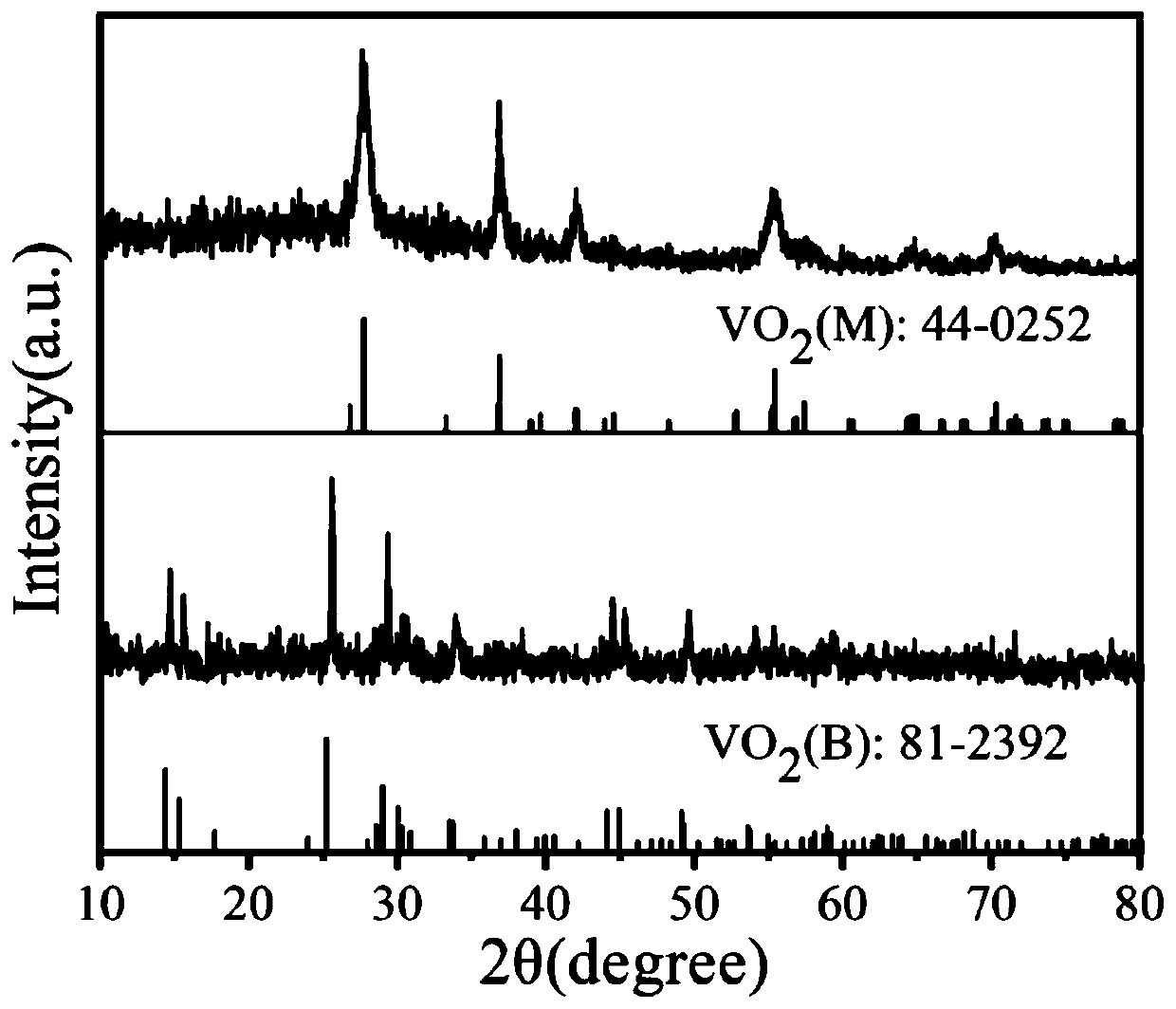

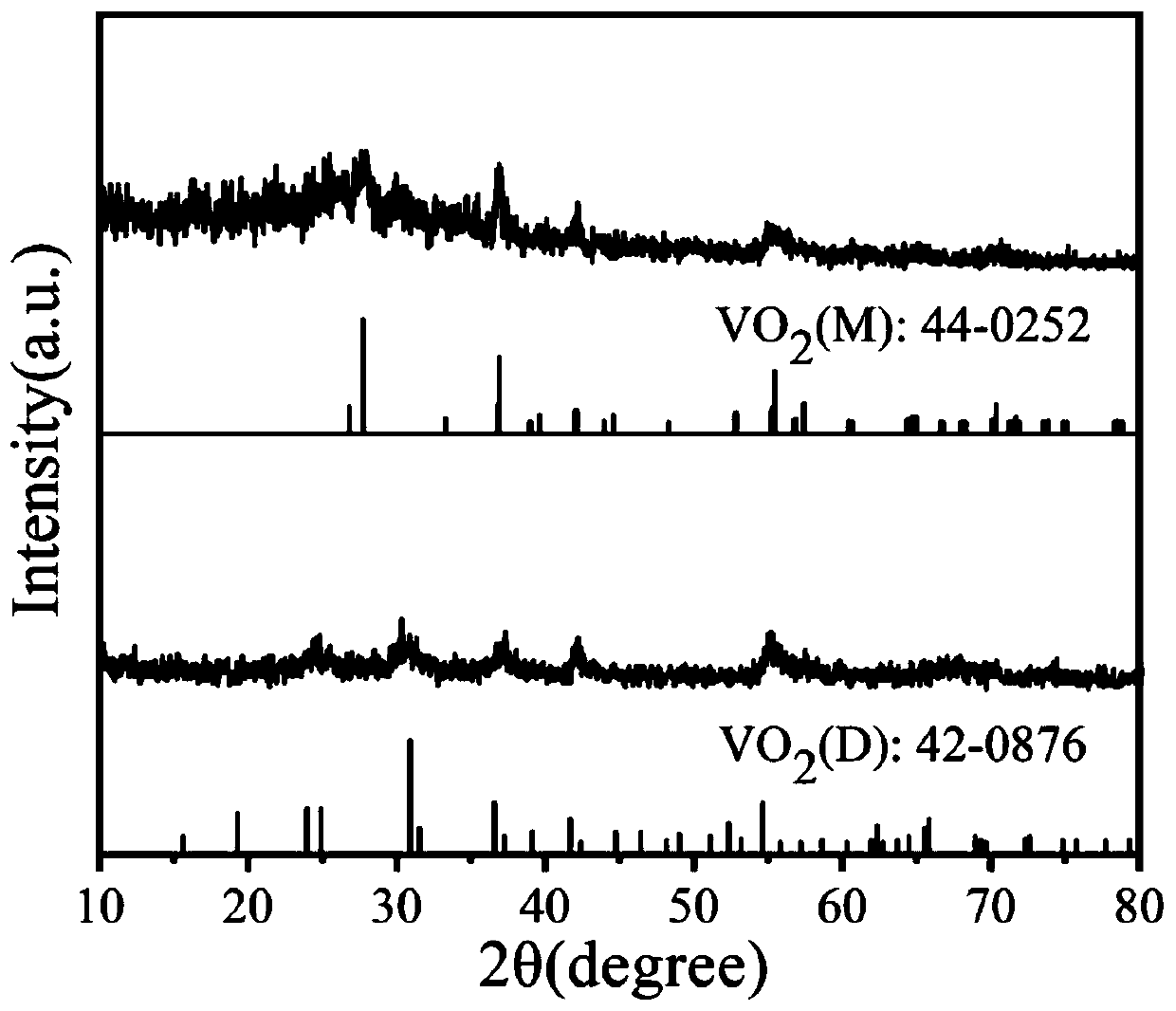

Preparation method of monoclinic phase vanadium dioxide nanometer powder

ActiveCN110342574ASmall particle sizeReduce energy consumptionMaterial nanotechnologyVanadium oxidesVanadium dioxideAdditive ingredient

The invention provides a preparation method of monoclinic phase vanadium dioxide nanometer powder, and belongs to the field of preparation of VO2 powder by a ball-milling method. The preparation method comprises the following steps that (1) vanadium dioxide powder is prepared by a hydrothermal method; (2) the vanadium dioxide powder prepared in the step (1) is mixed and stirred with a grinding aid; (3) the ingredients obtained by mixing in the step (2) are added to a grinding device, and grinding balls are added to perform grinding; and (4) abrasive obtained in the step (3) is washed and driedto obtain the monoclinic phase vanadium dioxide. According to the preparation method of the monoclinic phase vanadium dioxide nanometer powder, the monoclinic phase VO2 is prepared by the ball-milling method, phase transition of an impurity phase of the VO2 is promoted by mechanical force, and the particle size of materials is continuously reduced due to the grinding action in the continuous ball-milling process. The preparation method does not require heating, and energy consumption is reduced; and the phase transition can occur in a short time, the time is short, and the production efficiency is high.

Owner:蒋绪川

Pepper mill

A pepper mill comprises a hollow body comprising a through hole formed thereon, a clockwisely and counterclockwisely rotatable transmission unit mounted therein, and a grinding device mounted therein corresponding to the transmission unit; and a base comprising a pivot having a free end inserted into the hollow body via the through hole and fixedly coupled to the transmission unit to enable the base and the hollow body to be pivotally rotatable, whereby the transmission unit is driven to perform a grinding action on the grinding device clockwisely and counterclockwisely.

Owner:LEE TUNG HSIEN

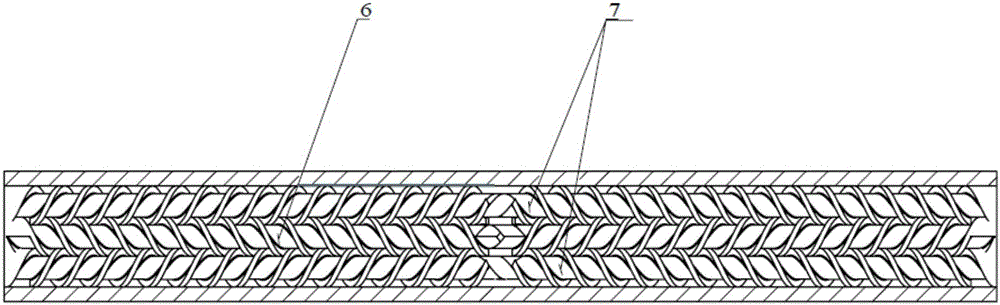

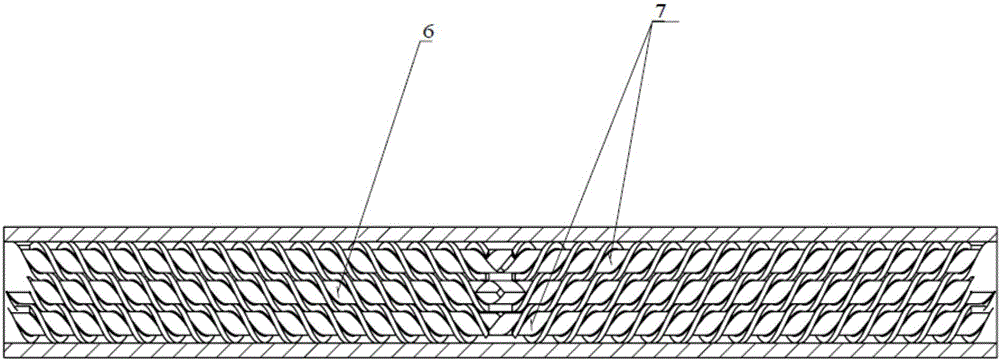

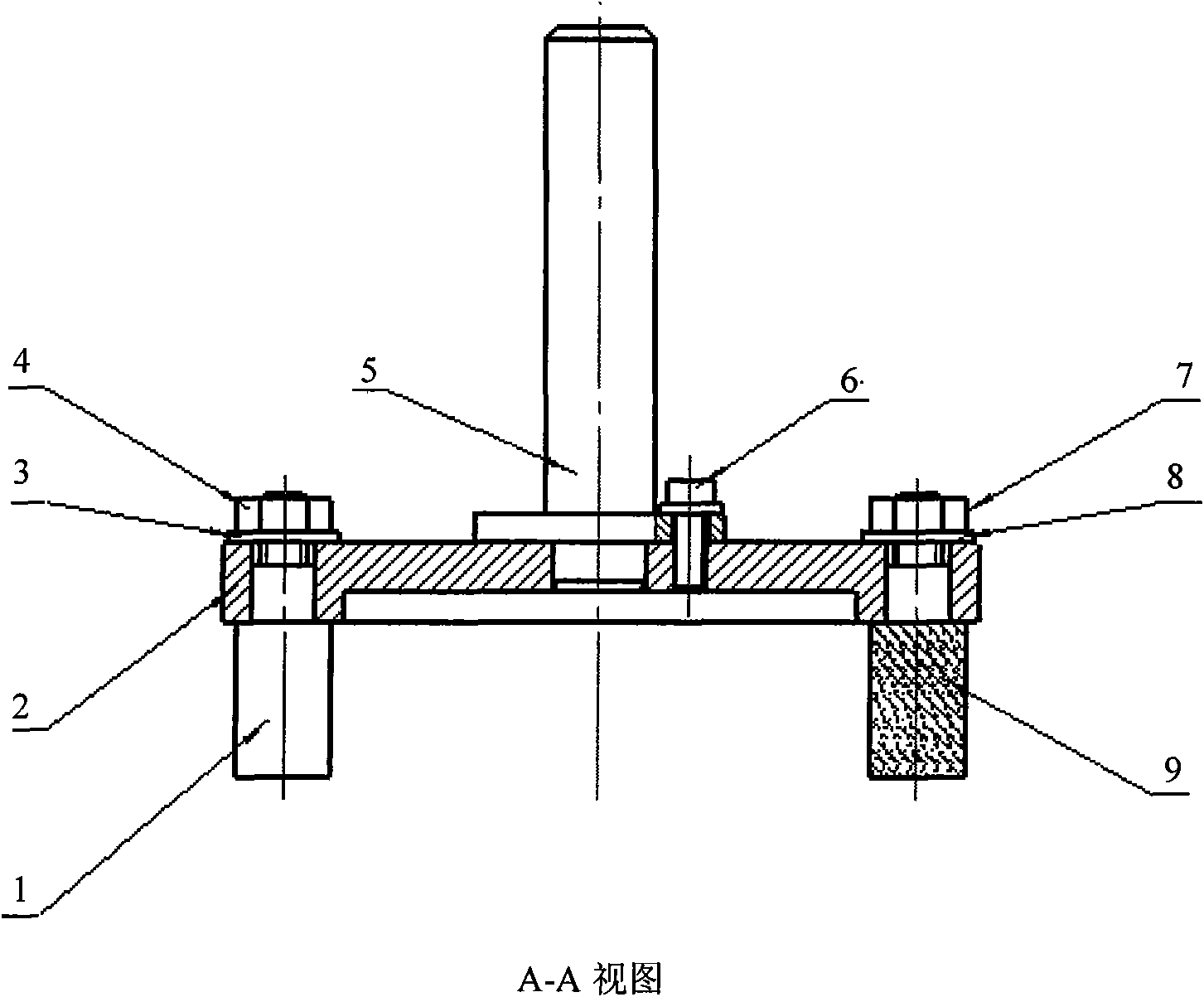

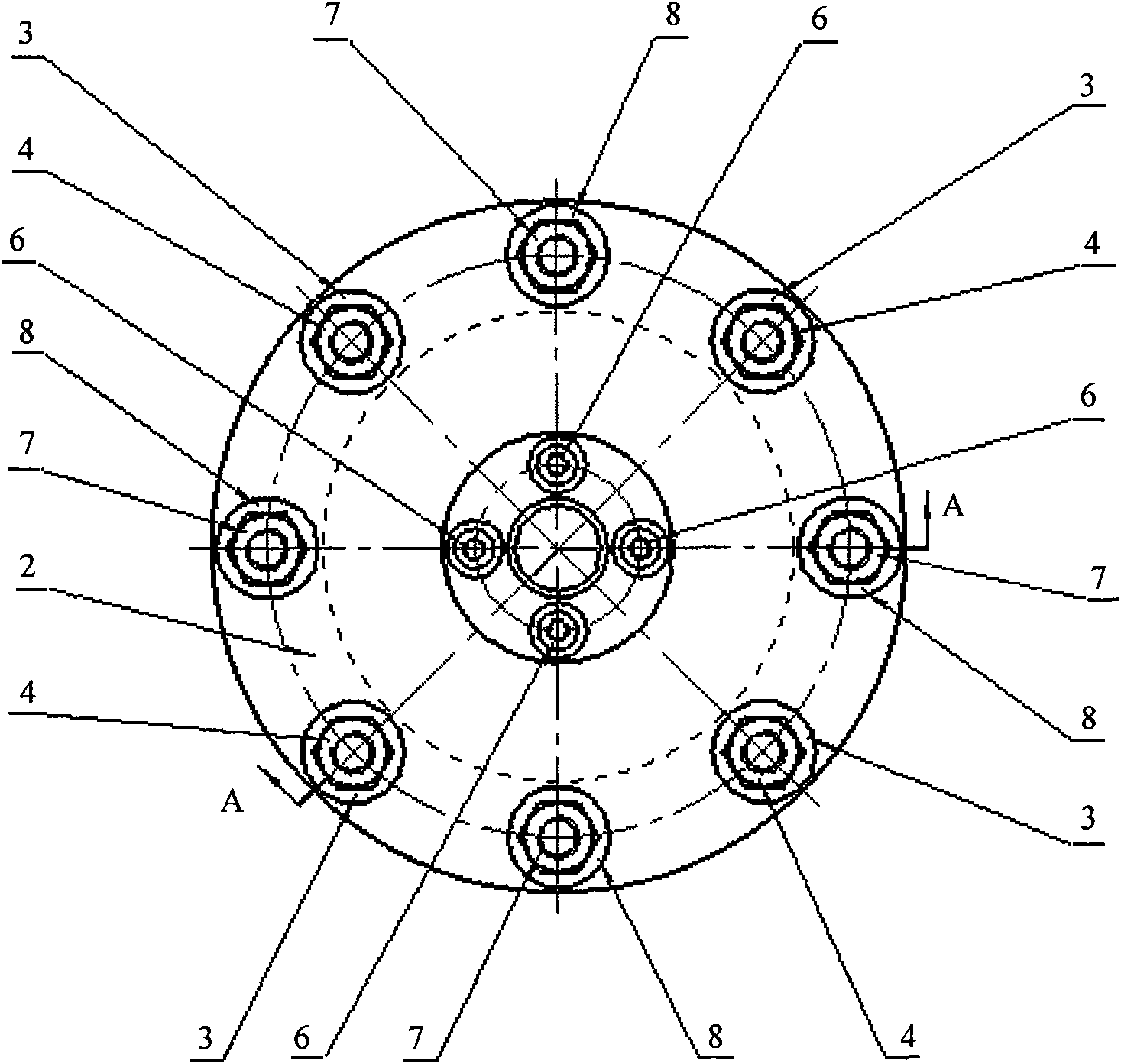

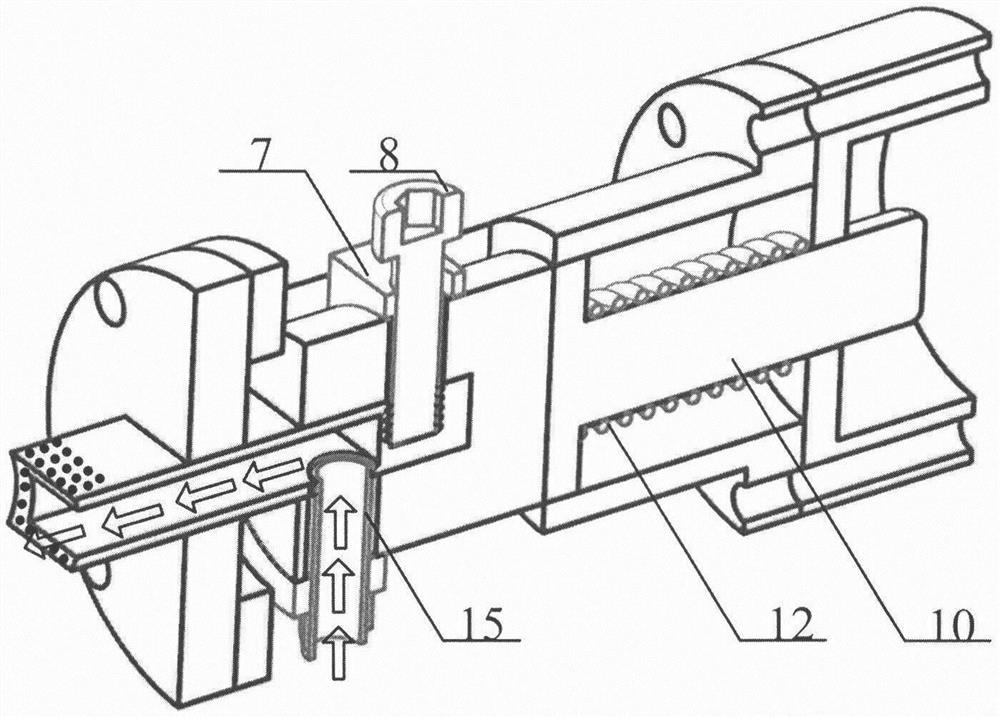

Tool electrode compositely processed by electric spark end face milling and mechanical grinding

ActiveCN101670519AReduce processing stepsAvoid feesOther manufacturing equipments/toolsEngineeringPulse power supply

The invention relates to a tool electrode compositely processed by electric spark end face milling and mechanical grinding, belonging to the special processing field. The tool electrode comprises a discharge electrode (1), a supporting disk (2), a discharge electrode compression gasket (3), a disk charge electrode compression nut (4), a tool electrode shaft (5), a screw (6), a grinding bar compression nut (7), a grinding bar compression gasket (8) and a grinding bar (9). when in processing, the tool electrode compositely processed by the electric spark end face milling and the mechanical grinding is arranged on a main shaft head of a machine tool, and performs the rotation motion and the movement in Z direction under the drive of the main shaft head; the tool electrode and a workpiece arerespectively connected with the cathode and the anode of a pulse power source, operating fluid is poured between the tool electrode and the workpiece; and the tool electrode is subject to the electricspark milling by the discharge action generated between the end face of the discharge electrode (1) and the workpiece and the mechanical grinding by the grinding action between the end face of the grinding bar (9) and the workpiece.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

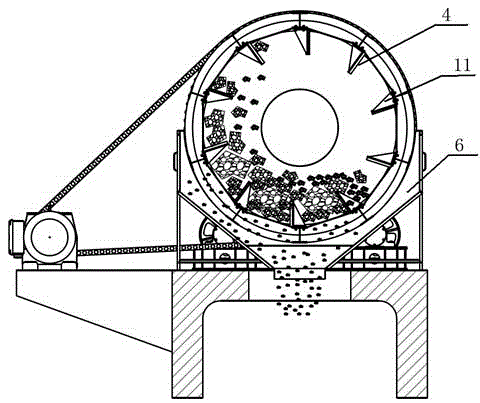

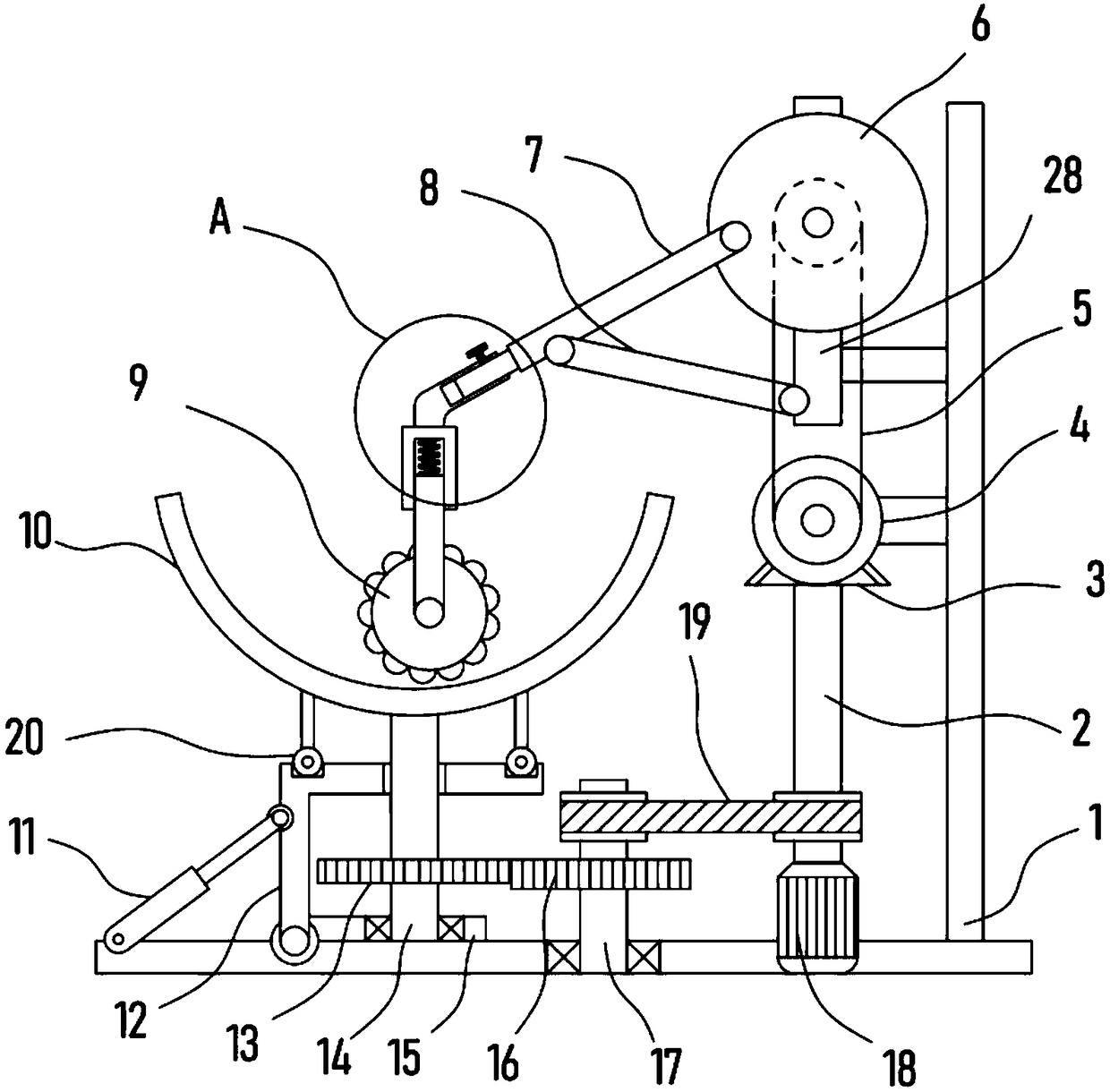

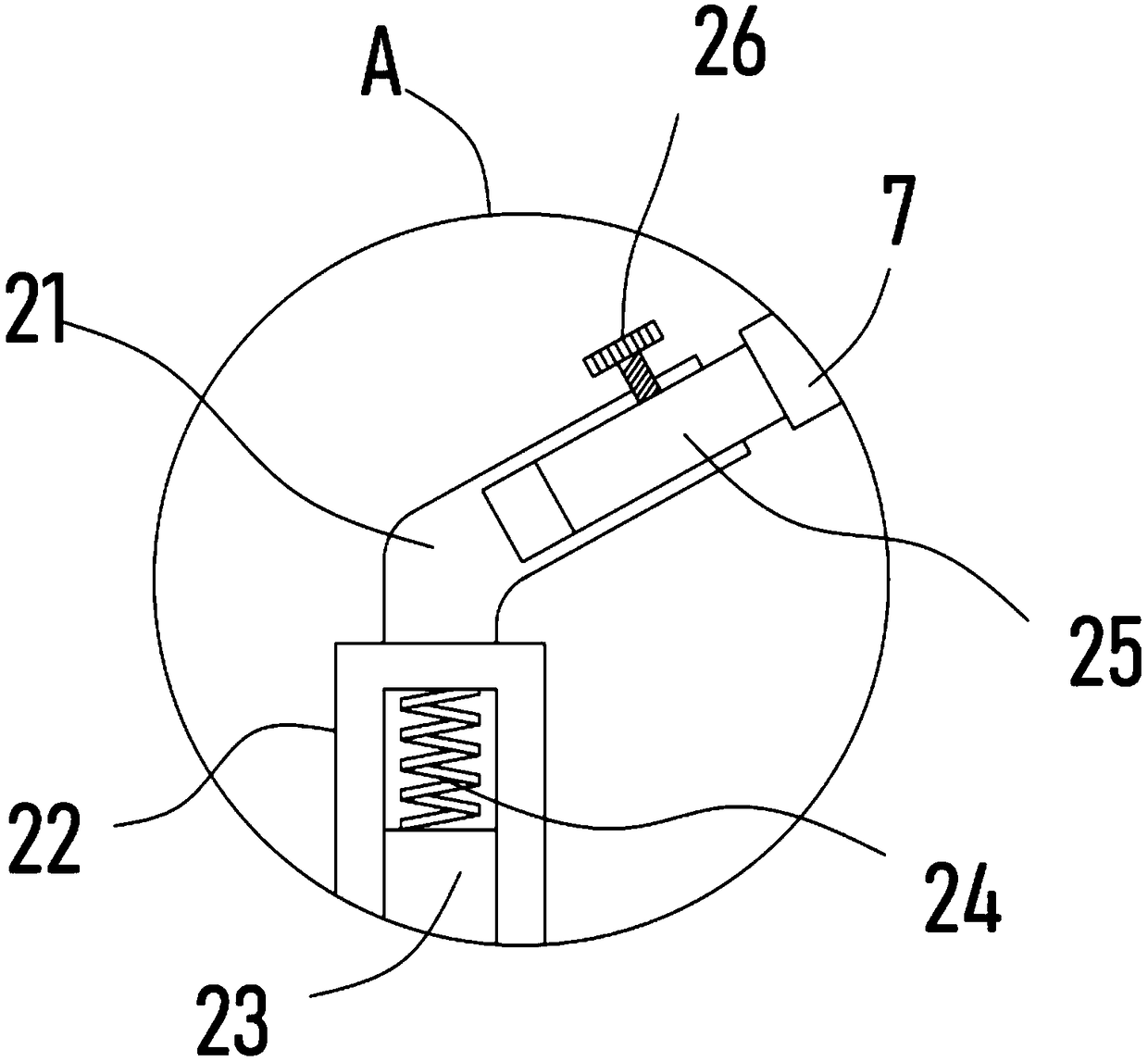

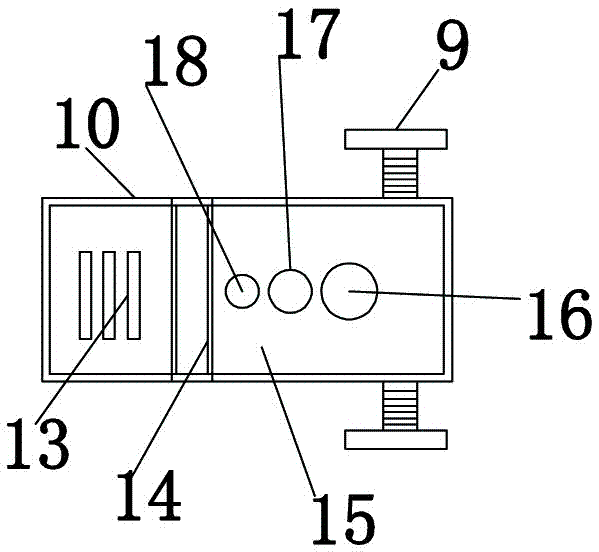

Pediatric granular drug grinding equipment

ActiveCN109351422AEasy to clean and maintainGrinding effect is sufficientGrain treatmentsDrive shaftEngineering

The invention discloses pediatric granular drug grinding equipment, and relates to the technical field of grinding devices. The pediatric granular drug grinding equipment includes a supporting frame,a supporting plate is hinged to the supporting frame, a vertical plate is fixed to the supporting frame, the vertical plate is rotatably provided with a rotating wheel, and a pulling rod is eccentrically hinged to the rotating wheel; and a folding rod is fixed to the pulling rod, a sleeve is fixedly installed at the lower end of the folding rod, the sleeve is internally and slidably provided witha sliding frame pivotally connected with a grinding roller, a supporting rod is hinged between the vertical plate and a pulling rod, and a grinding groove is of a hemispheric shell structure. According to the pediatric granular drug grinding equipment, swing of the grinding roller is realized by the sliding frame swings with the sleeve, and then repeated grinding action of drug particles in the grinding groove is realized; at the same time, the grinding groove is driven by a driven shaft to rotate to disperse the drug particles in the grinding groove; and meanwhile the full grinding effect ofthe grinding roller on the drug particles in grinding groove is realized, the folding rod and the pulling rod can be disassembled and separated, and clearing and maintaining of the grinding roller areconvenient.

Owner:THE FIRST AFFILIATED HOSPITAL OF HENAN UNIV OF SCI & TECH

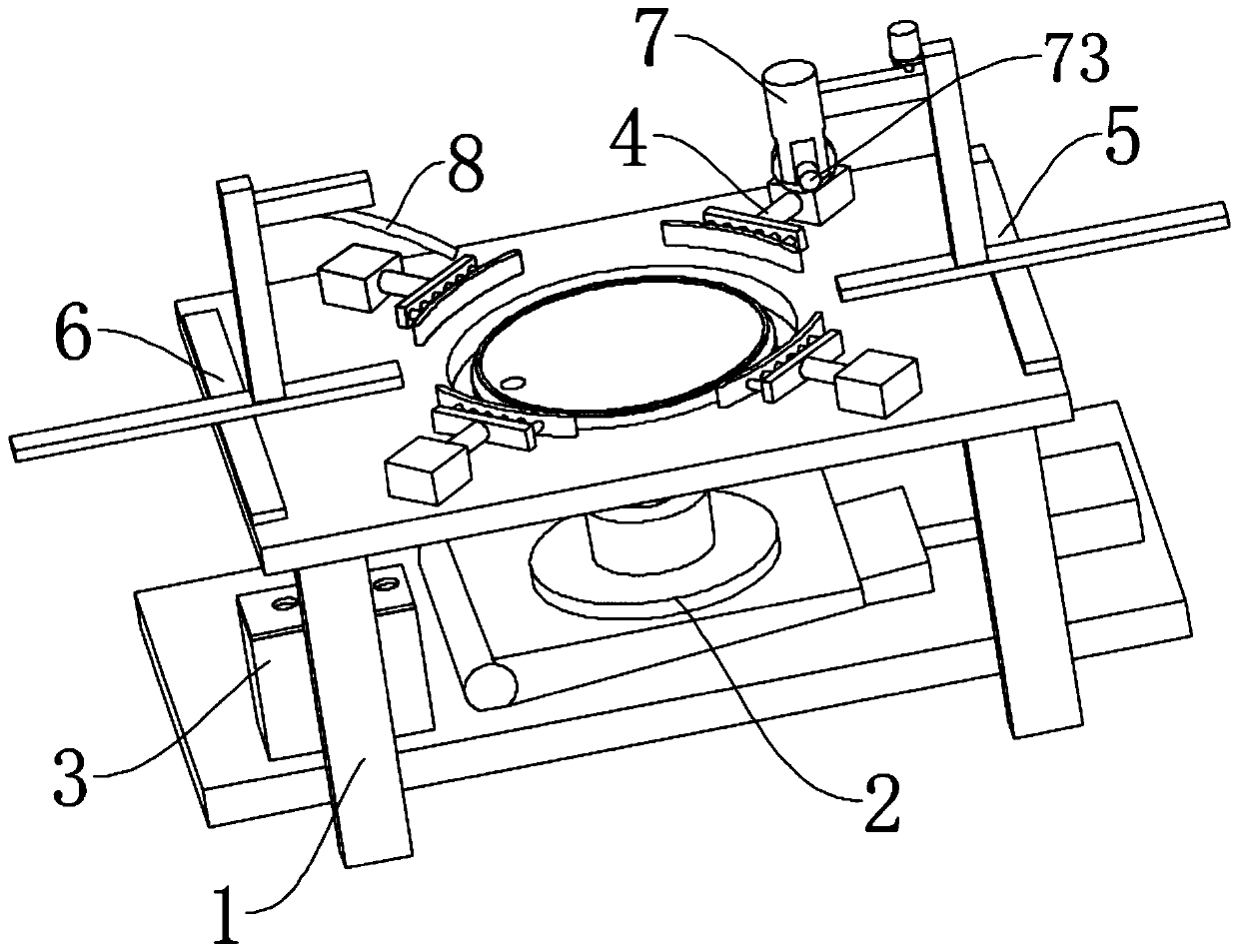

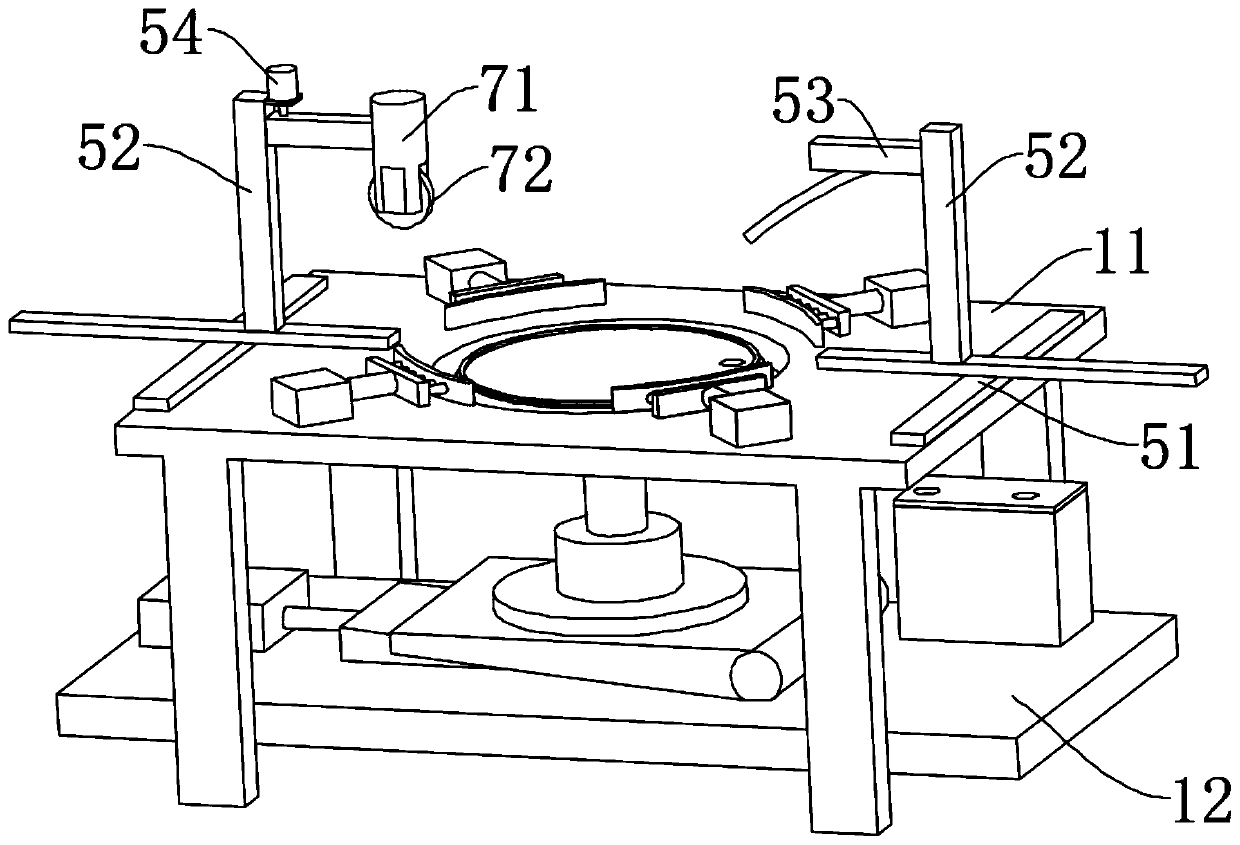

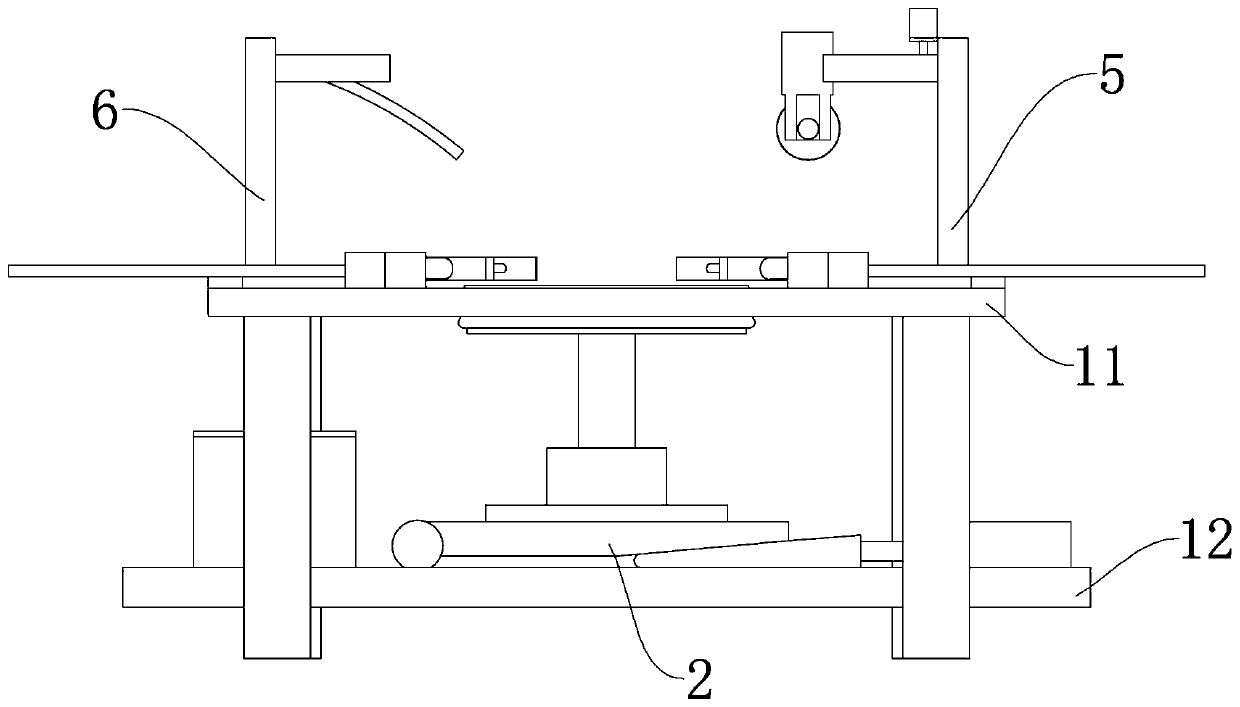

Surface grinding machine

InactiveCN110757272AConvenient and reliable grinding actionReduce workloadGrinding drivesGrinding feed controlHydraulic cylinderEngineering

The invention discloses a surface grinding machine. The surface grinding machine comprises a rack, a workpiece bearing device, multiple workpiece clamping devices, a first three-dimensional moving device and a controller. The rack is provided with a work platform with a work through hole and a bearing platform, the workpiece bearing device comprises a base, a rotating disc, a first hydraulic cylinder and a workpiece bearing table, a turnover assembly is arranged on the bearing platform, a rotating driving assembly is arranged on the base, the workpiece bearing table can penetrate through the work through hole upwards, the workpiece clamping devices are arranged on the work platform in an annularly arrayed manner, each workpiece clamping device comprises an air cylinder, a mounting plate, aflexible clamping block and multiple elastic parts, and the function output end of the first three-dimensional moving device is provided with a grinding wheel assembly. According to the technical scheme, grinding action of a workpiece can be conveniently and reliably executed, the automation degree is higher, and workloads of an operator can be greatly reduced.

Owner:镇江达奥精密工具有限公司

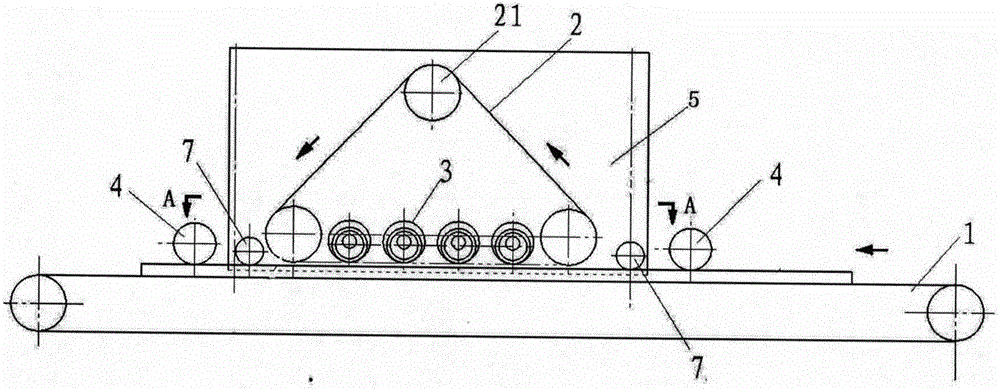

Device for machining irregular uneven surface of wood plate

InactiveCN105881160ARealize automatic processingReduce labor intensityBelt grinding machinesMechanical constructionEngineering

The invention discloses a device for machining an irregular uneven surface of a wood plate. The device comprises a conveyor belt, an abrasive belt and press rolls, wherein the conveyor belt is used for conveying and laying the wood plate; the abrasive belt is arranged above the wood plate and used for grinding the wood plate; and the press rolls are arranged above the abrasive belt, can move up and down in the direction perpendicular to the wood plate, can drive part of the abrasive belt to protrude from the wood plate subjected to grinding, and can also move horizontally in the own axial direction so as to form a nonlinear grinding route. The device provided by the invention has the advantages that the grinding function of the abrasive belt is ingeniously utilized; by adoption of such a unique mechanical structure, the irregular uneven surface of the wood plate can be automatically machined; and compared with a process for manually machining the irregular uneven surface, the device is lower tin labor intensity.

Owner:蔡利英

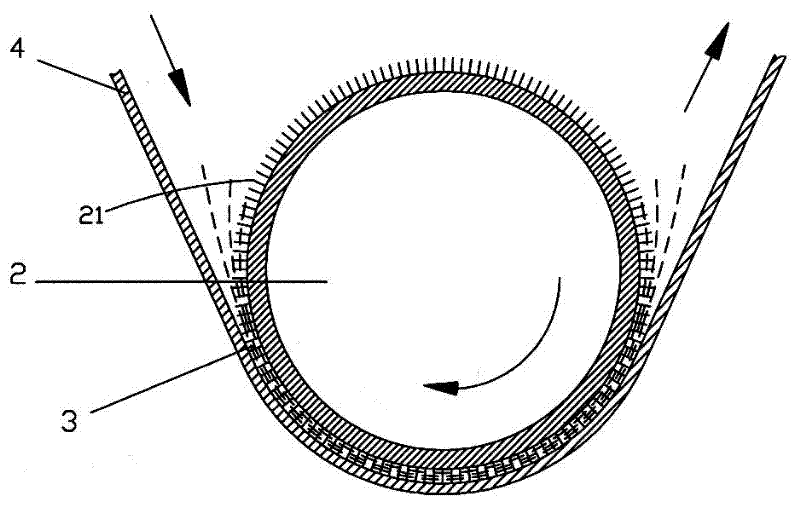

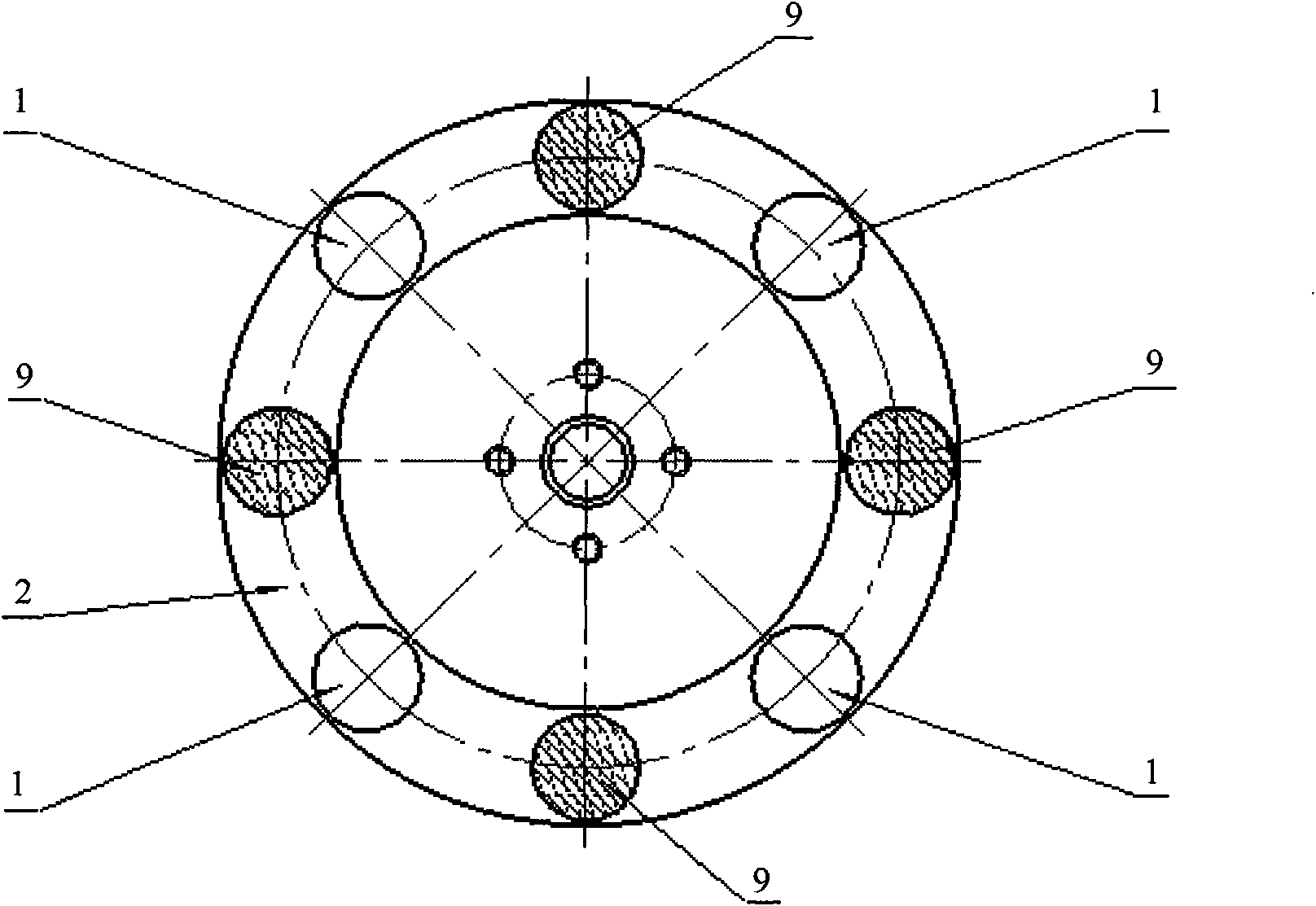

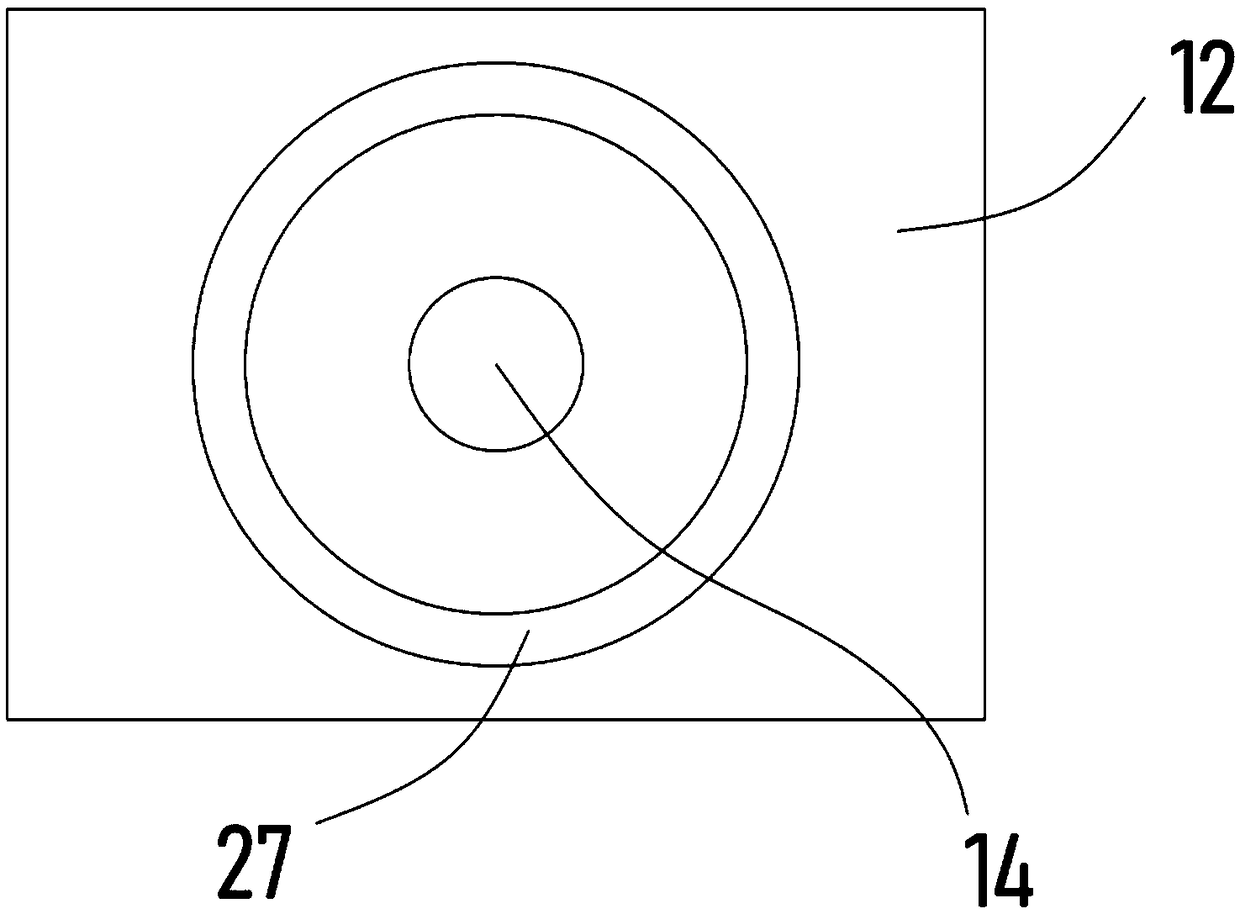

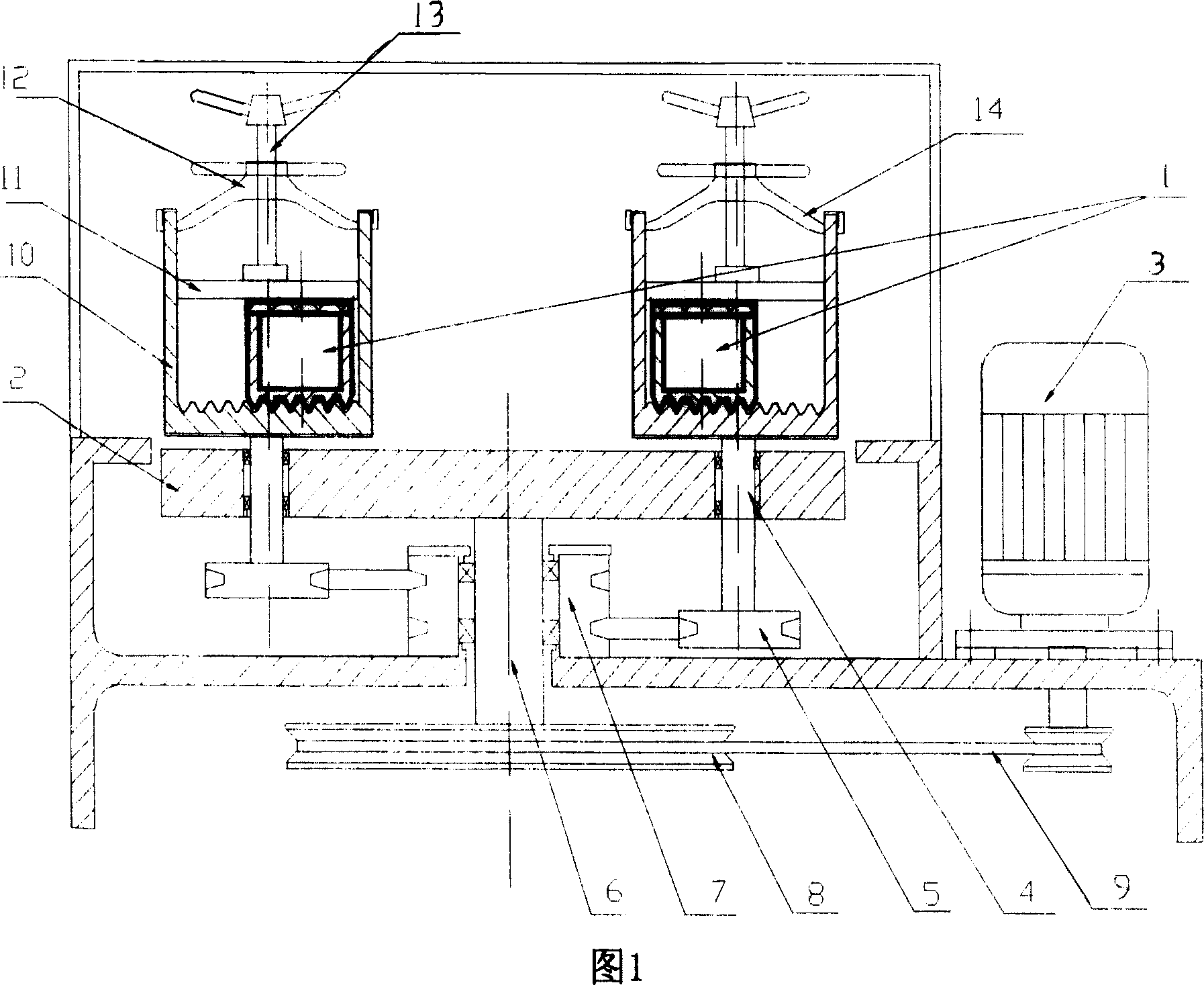

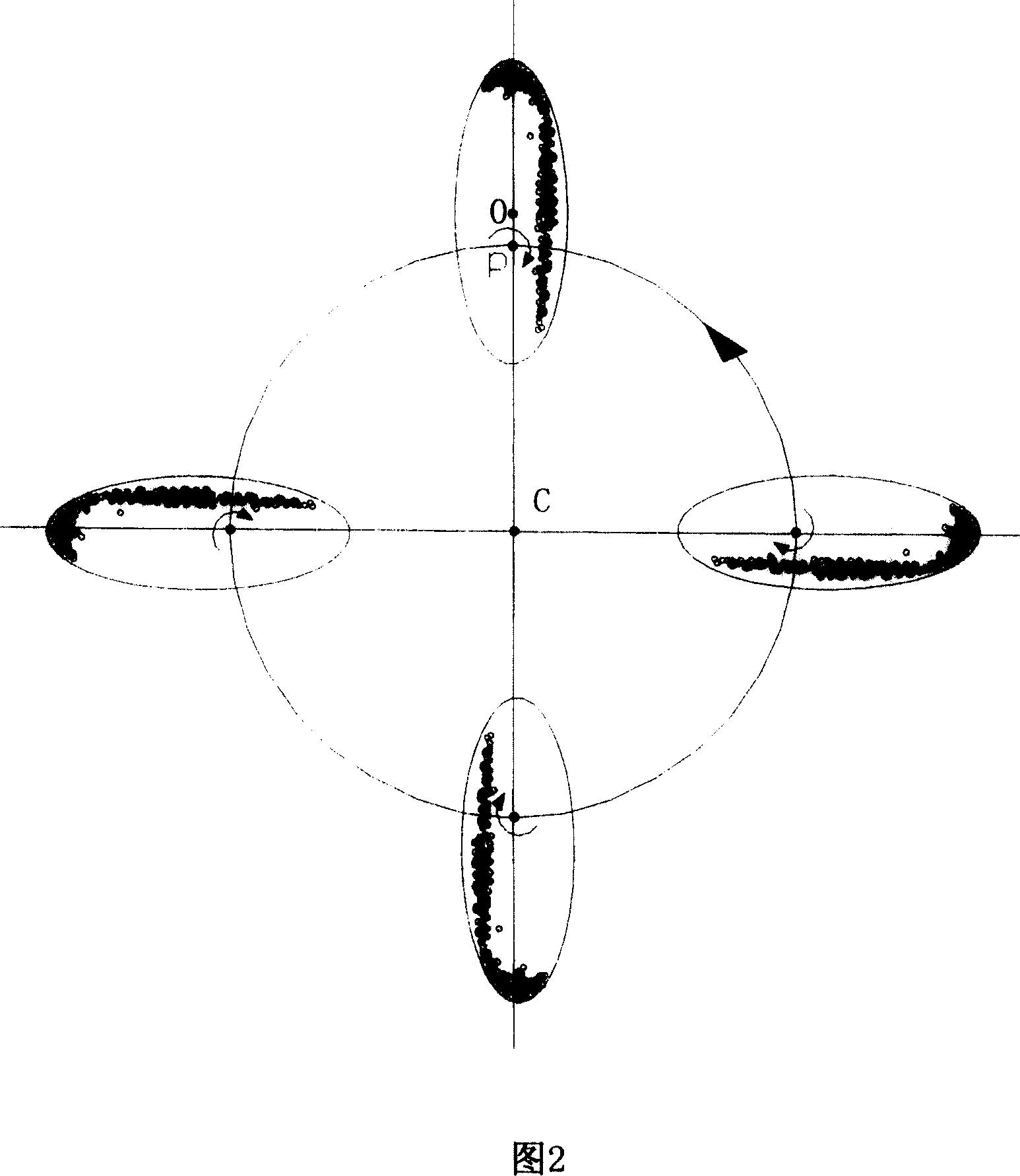

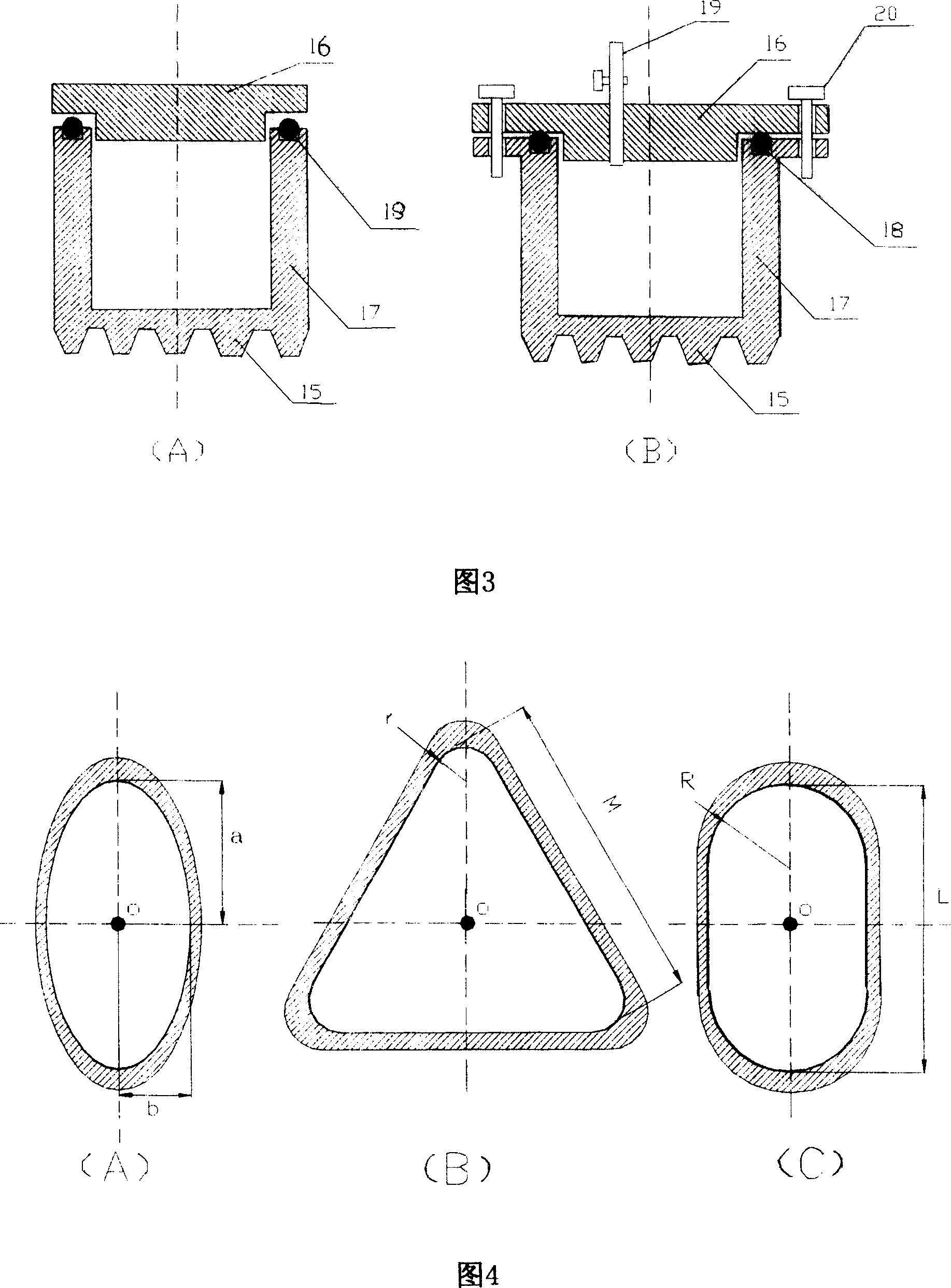

Planetary ball mill

A planetary ball grinder is composed of drive motor, transmission gear train, revolving mainshaft and rotary disc, multiple rotational axles and the ball grinding cylinders rotating around own axle. It features that said ball grinding cylinder is eccentrically installed in such manner that the central line of rotational axle is parallel with the geometric central line of the cross-section of ball grinding cylinder, and its eccentrical degree can be changed for changing the ratio of grinding action to impact action.

Owner:SUN YAT SEN UNIV

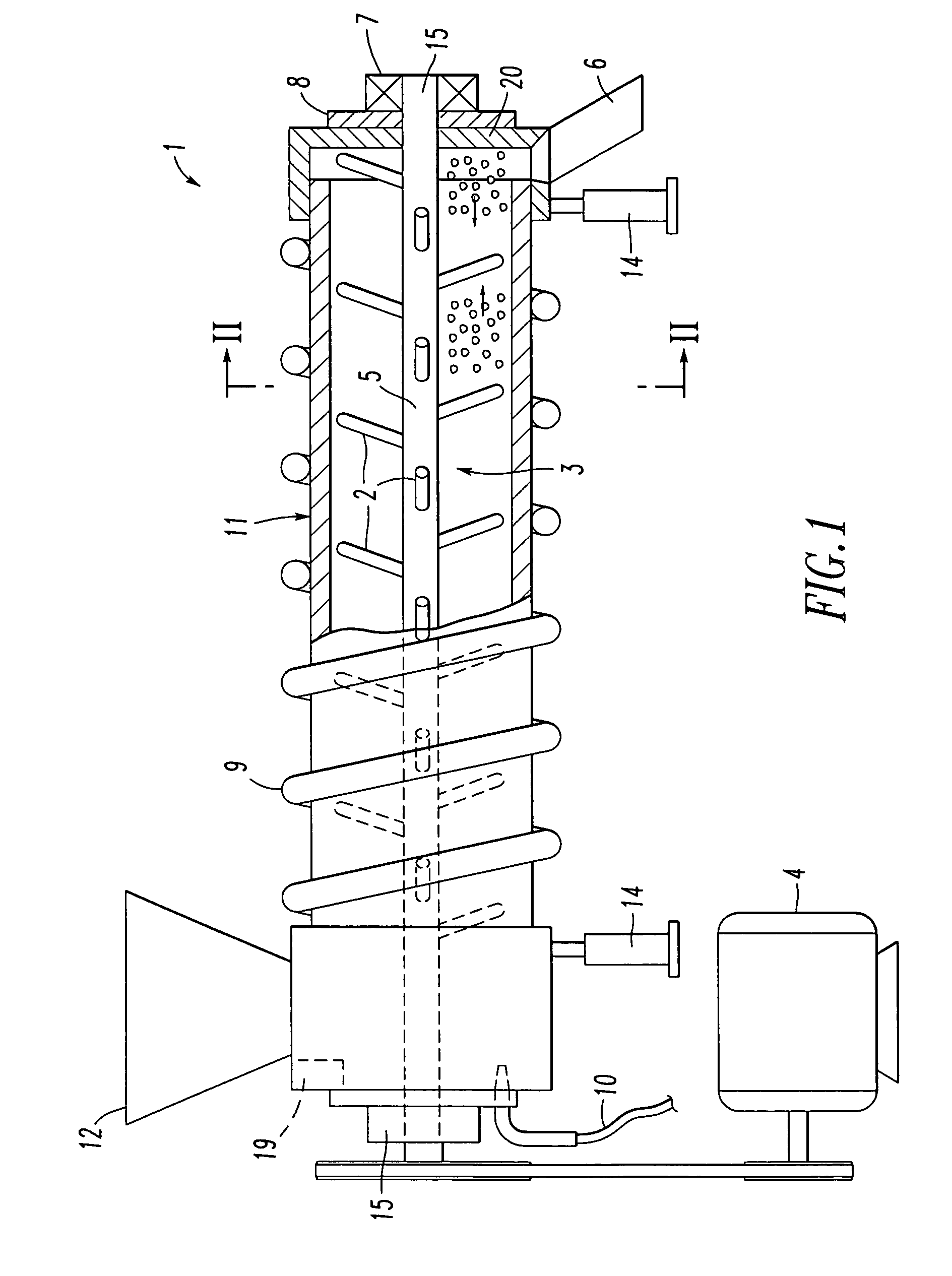

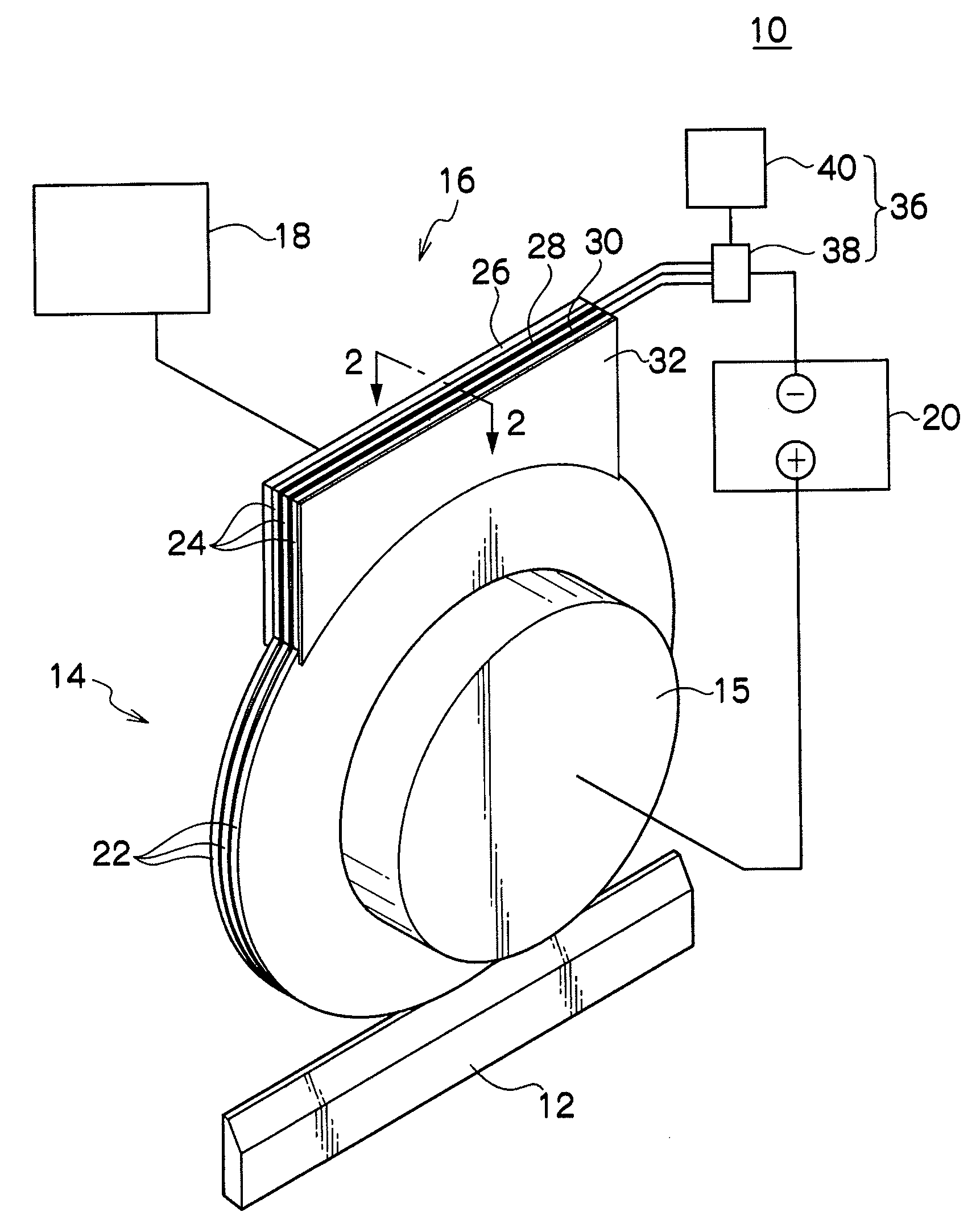

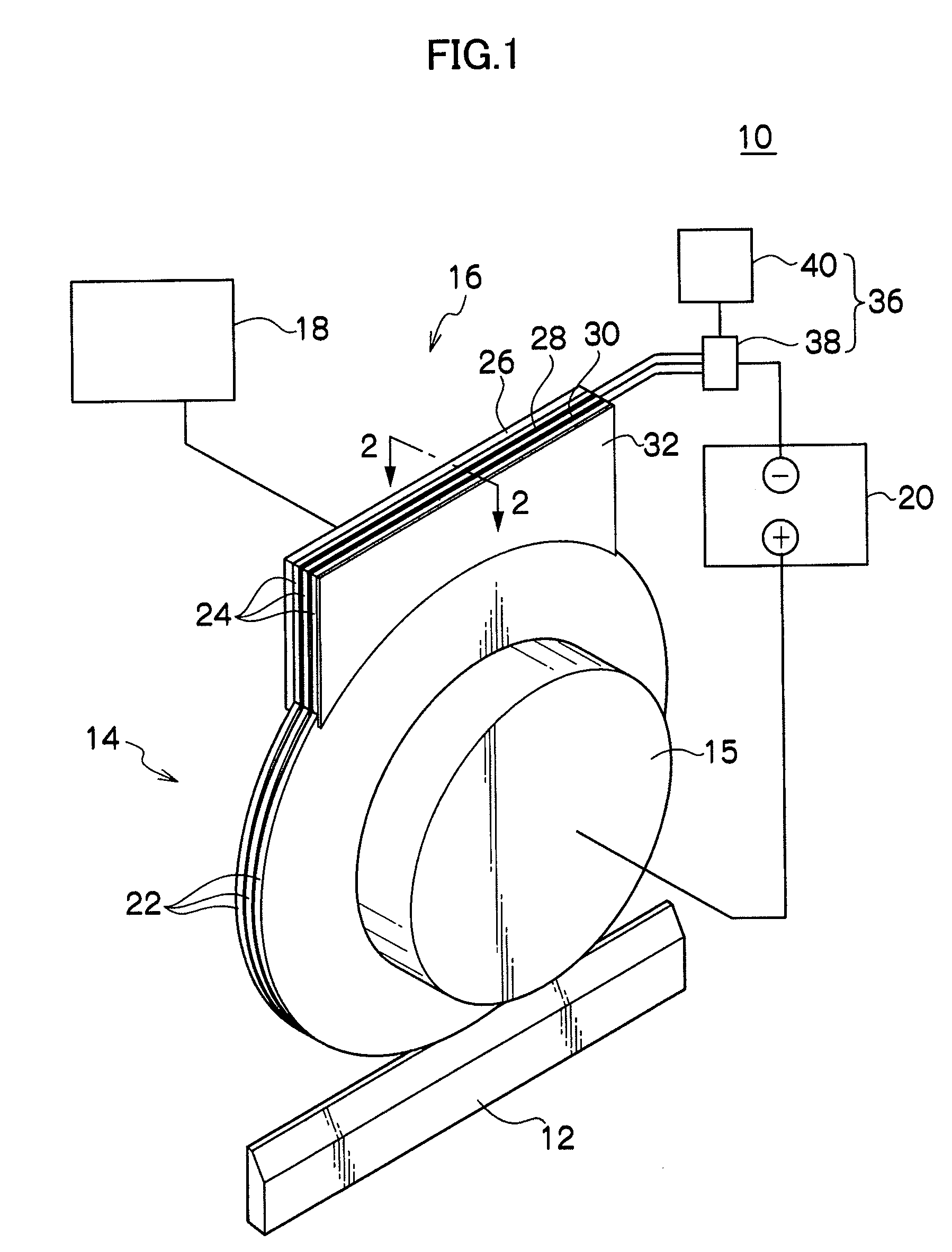

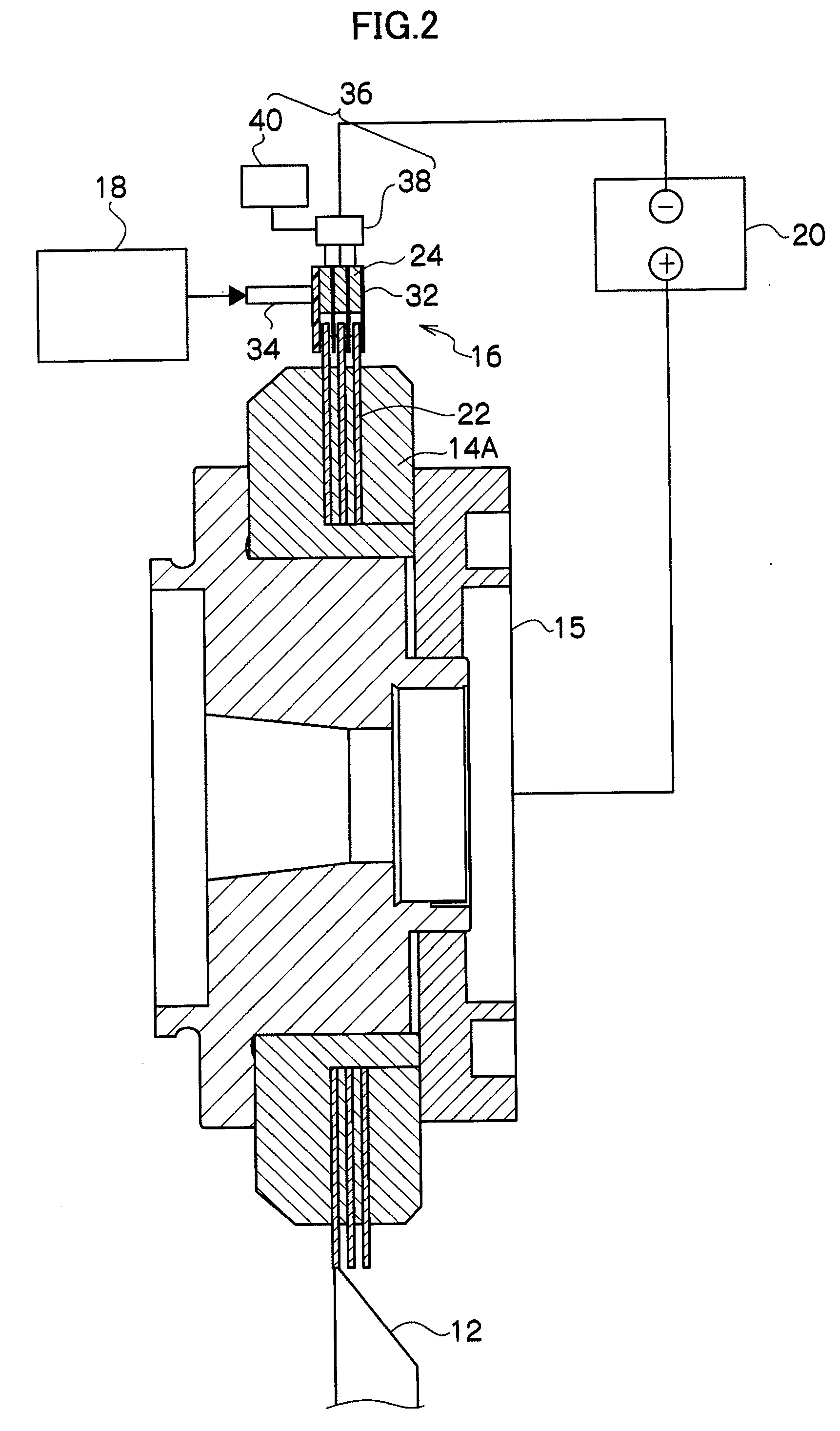

Grinding method, grinding device and electrode therefor

InactiveUS20090186558A1Easy to holdShortage of electrolysis can be suppressedEdge grinding machinesGrinding feed controlEngineeringGrinding wheel

A grinding device including a multi-wheel grindstone and an electrode arranged opposite to a grinding action surface of the multi-wheel grindstone with an interval, in which a work is ground and machined while the grinding action surface of the multi-wheel grindstone is electrolytic-dressed by supplying conductive machining fluid between an electrode action surface of the electrode and the grinding action surface of the multi-wheel grindstone, and applying a voltage between the multi-wheel grindstone and the electrode, wherein the electrode has a laminate body in which electrode plates whose electrode action surfaces are arranged so as to oppose the grinding action surface of each of the grinding wheels are alternately sandwiched by a plurality of insulating plates; and a flow passage for distributing the machining fluid supplied to between the grinding action surface and the electrode action surface is formed at the electrode plate and the insulating plate.

Owner:FUJIFILM CORP

Positioning device for globar machining

InactiveCN107972191ALow efficiencyEasy to operateWorking accessoriesFine working devicesEngineeringControl switch

The invention discloses a positioning device for globar machining. The positioning device comprises a base and a moving shield plate, wherein supporting legs are mounted at both the left and right ends of the bottom of the base; a switch button is arranged at the left end of the base; a control switch is arranged below the switch button, a fixing tank is fixedly connected with the top of the base;a filter screen is arranged at the joint between the fixing tank and the base; a dust hopper is arranged inside the base; a dust collecting tank is arranged at the bottom of the base; and a clampinghole is formed inside the fixing tank. According to the positioning device, a sliding rail is arranged on supporting frames, sliding blocks are arranged at the bottoms of both the left and right endsof the moving shield plate, and the sliding blocks and the sliding rail are slidably connected, so that the specific positon of the moving shield plate can be freely adjusted as required and the use can be facilitated; air outlet pipes of miniature air blowing devices are fixedly connected with the inner wall of the fixing tank, so that dust generated during the cutting or grinding action of a user can be cleared through air blown by the miniature air blowing devices; and the positioning device is simple to operate and convenient to use.

Owner:河南格锐新材料科技有限公司

Carbon fiber unfolding device

ActiveCN103334192AEnhanced fiber spreading effectImprove mechanical propertiesTextiles and paperYarnCarbon fibers

The invention relates to a carbon fiber unfolding device for regulating and controlling heating of a carbon fiber bundle by a method of controlling a contact area of the carbon fiber bundle on a heating roll, and unfolding the carbon fiber bundle under the grinding action of yarn guide rolls. According to the carbon fiber unfolding device, the carbon fiber bundle can be heated more uniformly, and can become lighter and thinner by controlling a heating area; a fiber unfolding effect is better; with the adoption of the technical scheme, the carbon fiber bundle can be broadened and thinned obviously; and a carbon fiber is low in strength loss and reliable in quality.

Owner:JIANGNAN UNIV

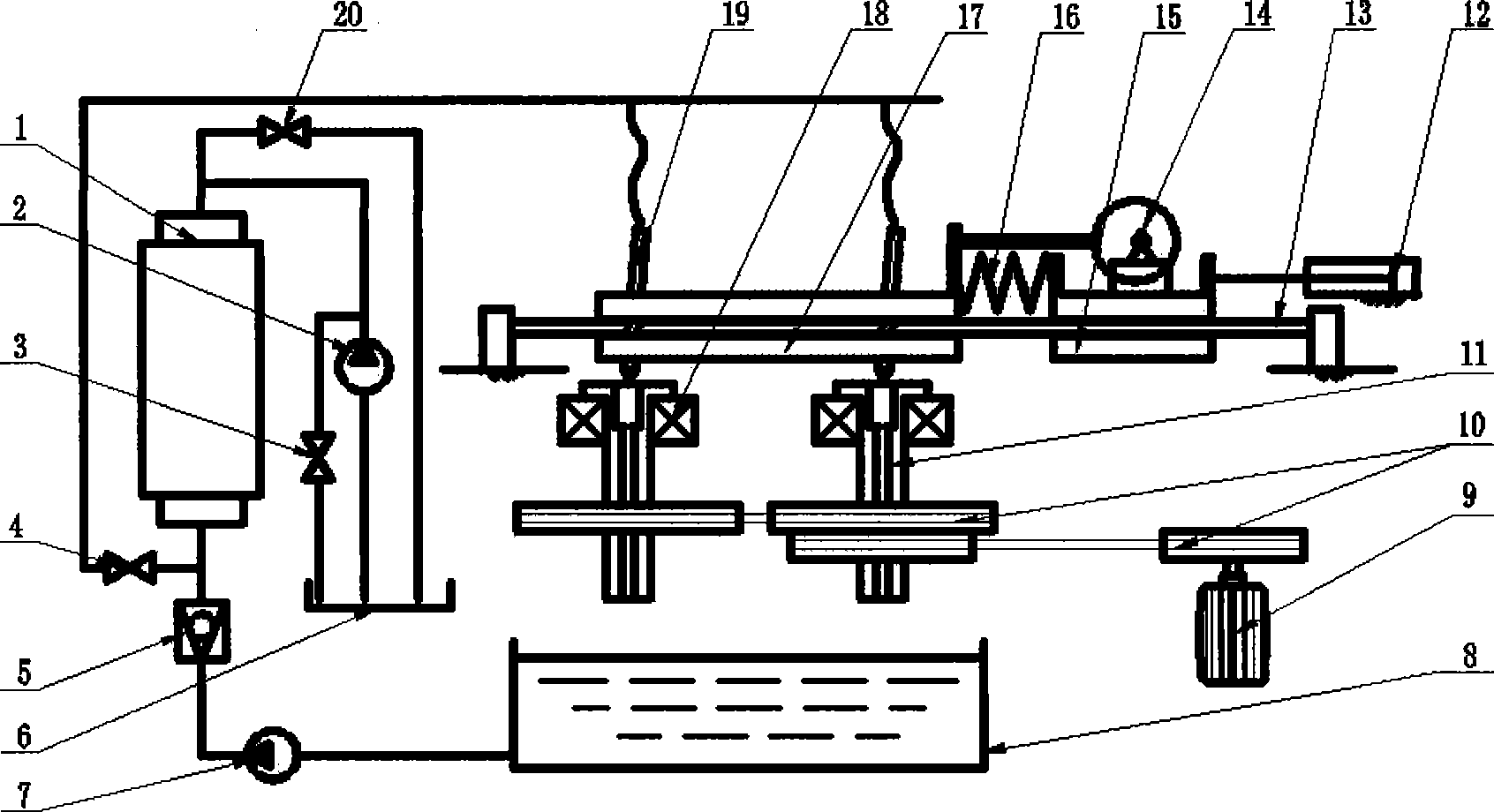

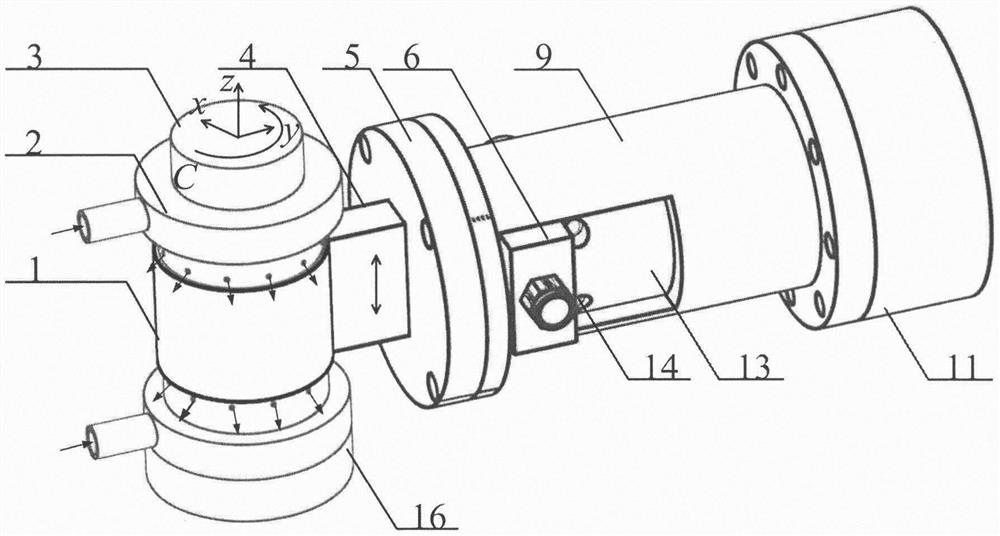

Floating tool electrolytic turning and grinding integrated machining method and implementation device

ActiveCN111805028AImprove localizationStable and adjustable grinding forceElectrical-based auxillary apparatusElectrolytic agentReciprocating motion

The invention discloses a floating tool electrolytic turning and grinding integrated machining method and implementation device, and belongs to the technical field of electrolytic mechanical combinedmachining. The method is characterized in that a tool grinding head is driven by a compression spring to make flexible contact with the surface of a rotary workpiece, controllable adjustment of electrolysis and grinding effects is achieved, the service life of the tool grinding head is prolonged, and the rotary workpiece machining precision is improved; the tool grinding head reciprocates at a high speed relative to the axial direction of the rotary workpiece, so that discharge of electrolysate in a machining area is promoted, and a good microscopic leveling effect on the surface of the rotaryworkpiece is achieved; and high-pressure air flowing in a rotating mode is introduced into a non-machining area of the rotary workpiece, diffusion and flowing of electrolyte to the non-machining areaare blocked, and locality of electrolytic turning and grinding integrated machining is improved. The implementation device comprises a rotary ventilation device, an electricity and flow leading device, the rotary workpiece, the tool grinding head and a tool clamp. The method and the device are of great significance in improving the electrolytic turning and grinding integrated machining precisionand the microscopic leveling effect of the rotary workpiece.

Owner:NANJING AGRICULTURAL UNIVERSITY

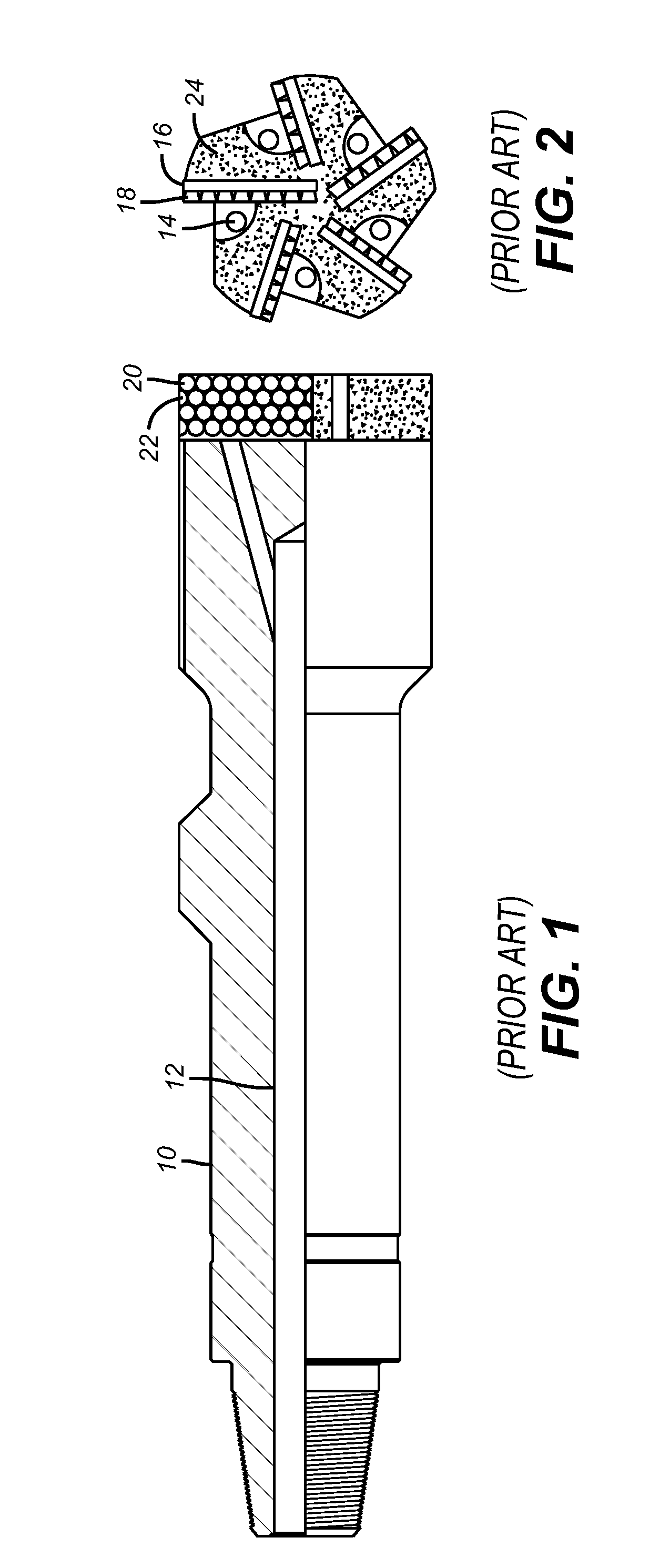

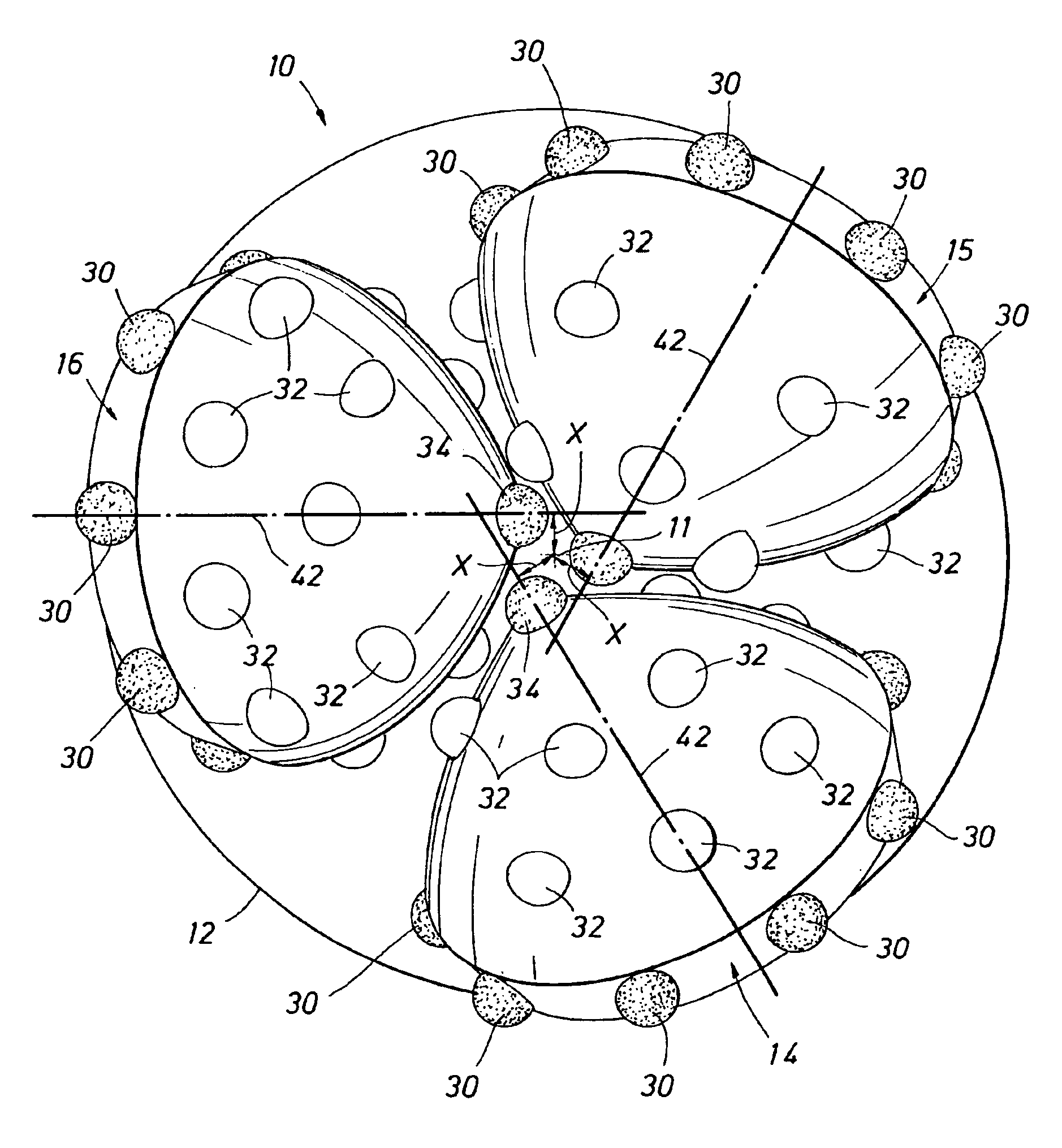

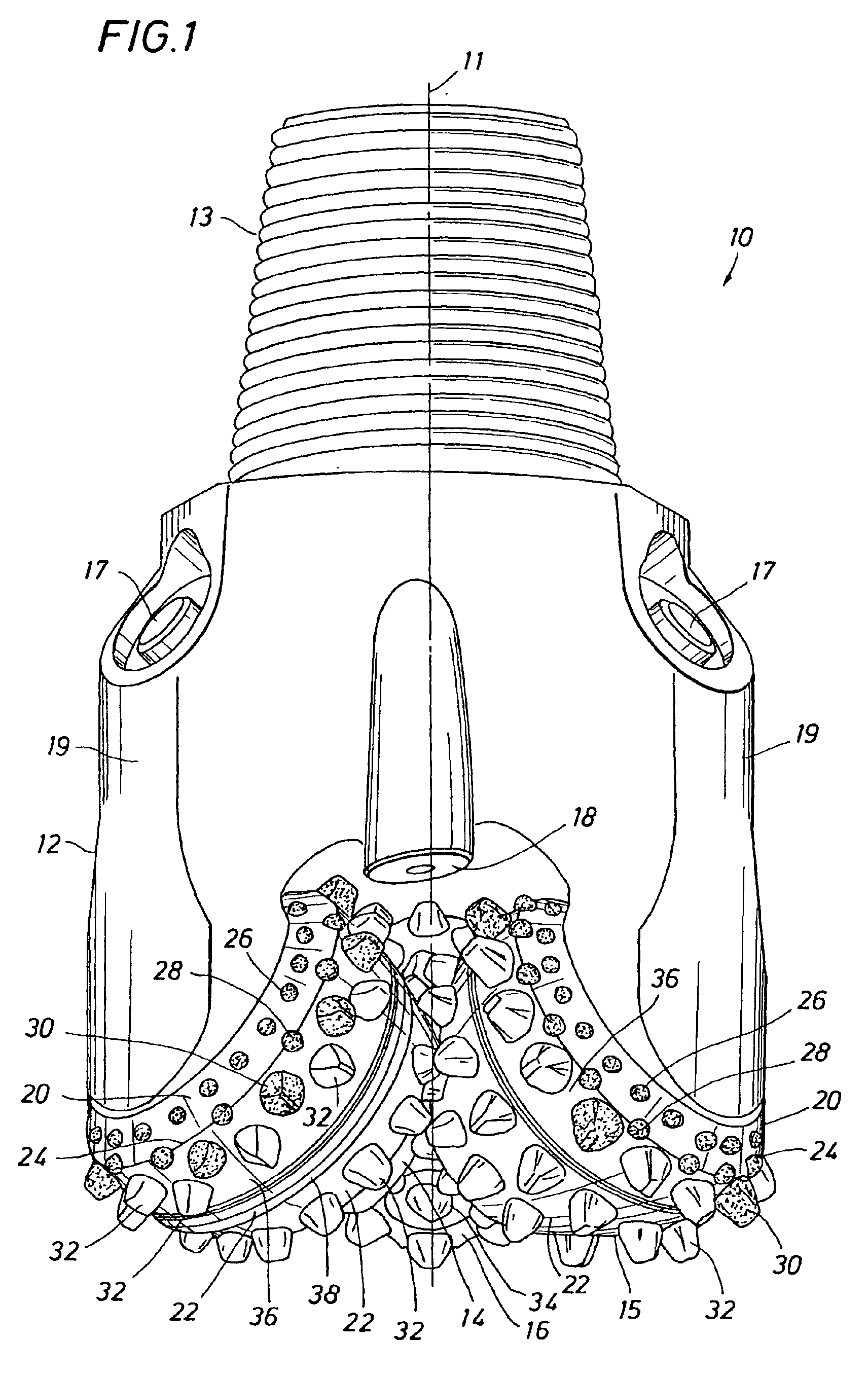

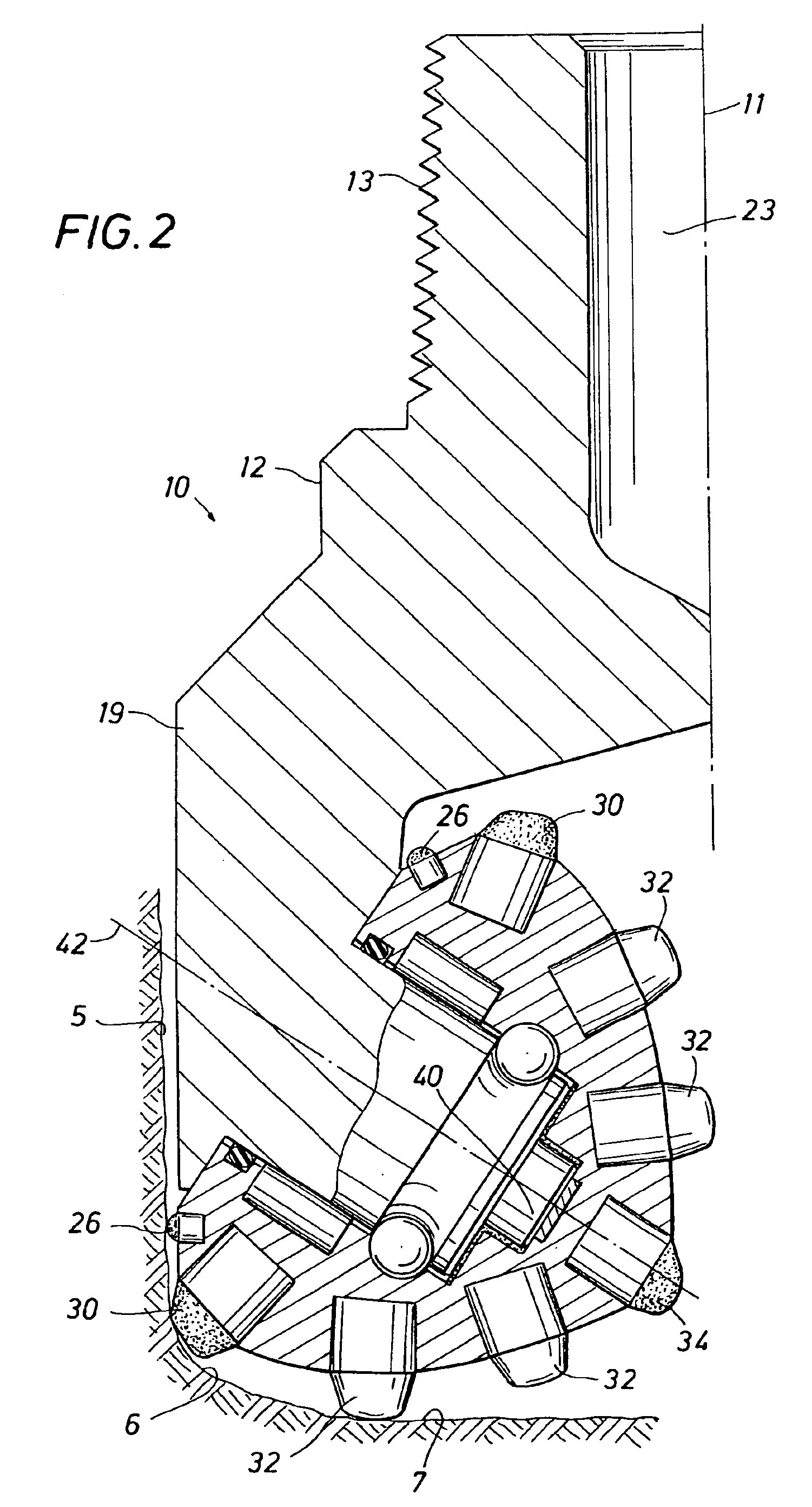

High offset bits with super-abrasive cutters

A roller bit is provided having super-abrasive inserts on cutting portions to assure that the bit will maintain cutting efficiency. In the described exemplary bits, the axes of the roller cones are also offset by a significant or “high offset” amount from the central longitudinal axis of the bit, thereby providing for increased shearing and grinding action by the bit. The use of high offset in combination with super-abrasive inserts provides for optimal bit cutting designs which provide increases in ROP while preserving the bit's ability to hold gage and remain durable to achieve acceptable footage. Minimum high offsets and preferred high offsets are described for various bit sizes, designs and nomenclatures, including milled tooth bits and insert-type bits designed for use in soft-through-medium formation hardnesses as well as formations with greater hardnesses.

Owner:SMITH INT INC

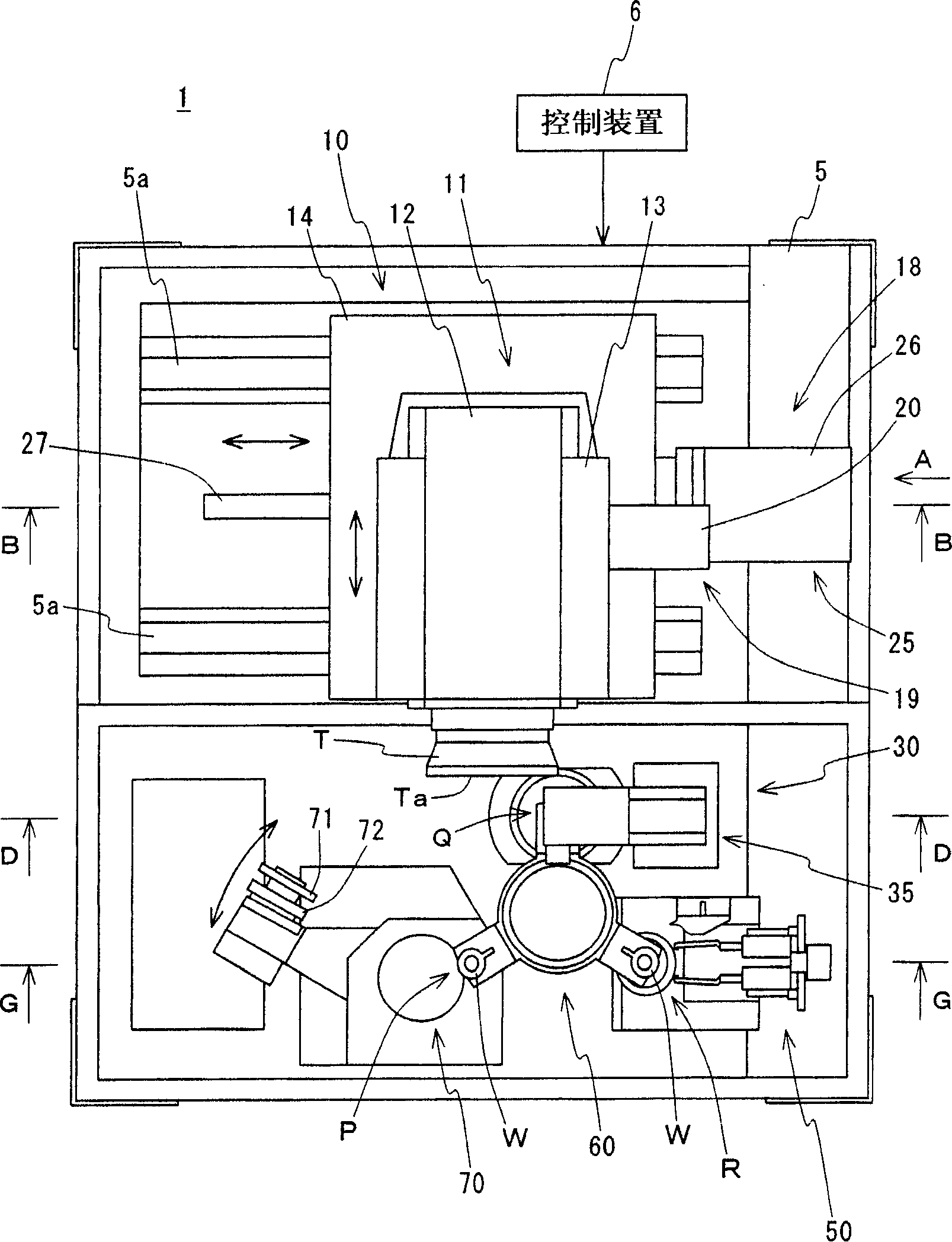

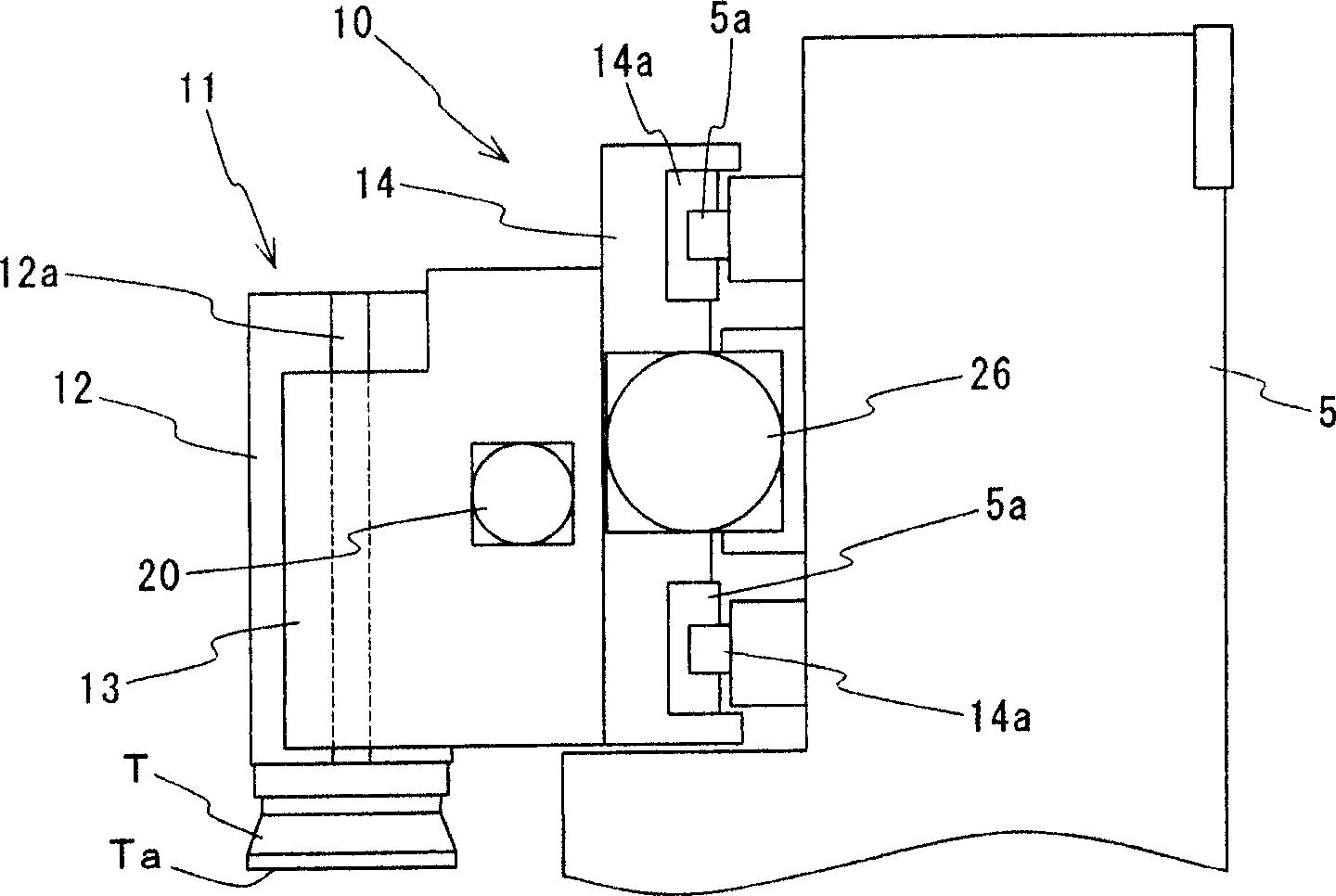

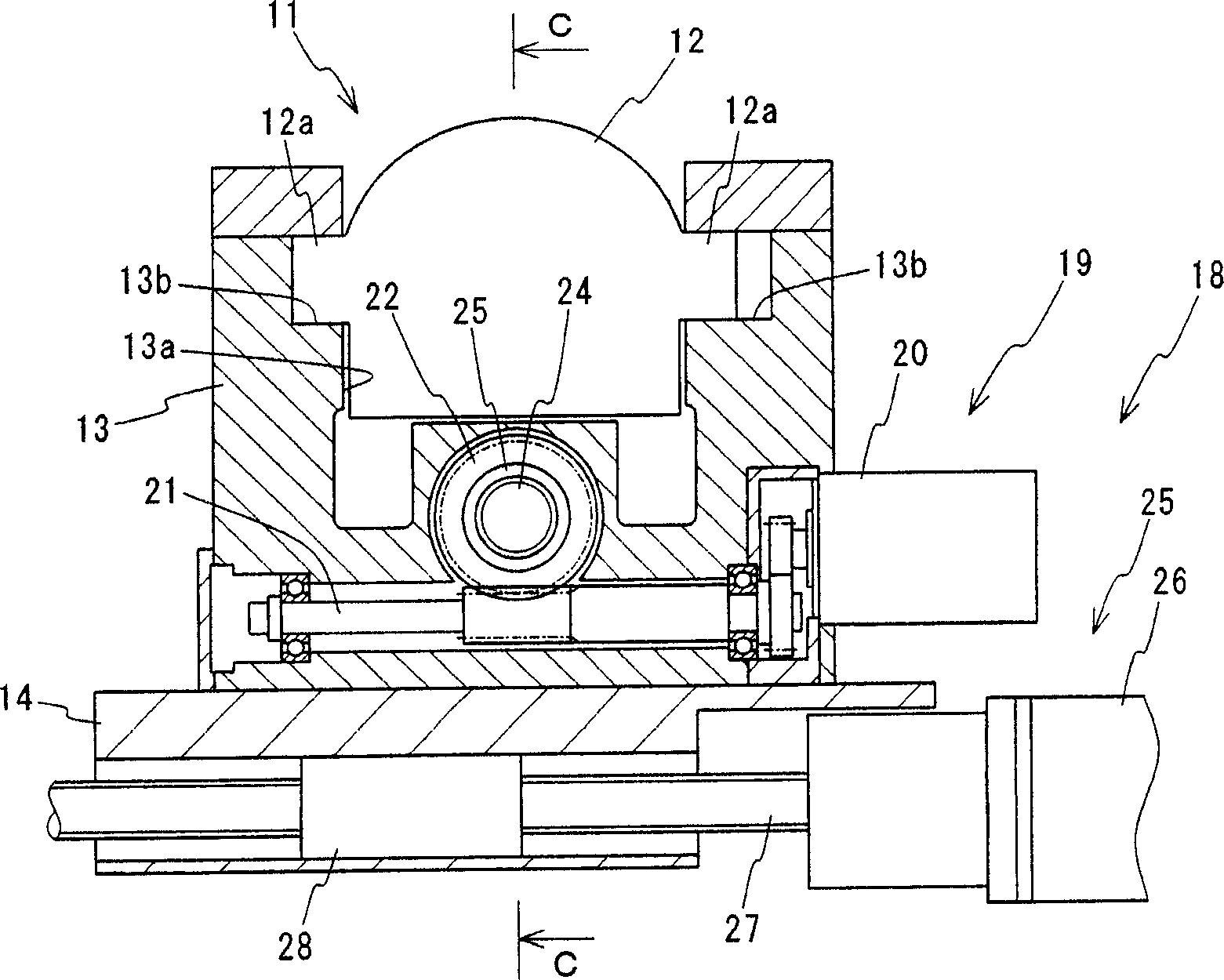

Method and device for grinding

The present invention provides a grinding method capable of preventing abrasion of only a part of a grinding action surface of a cup-shaped grinding wheel, by changing a contact position of the cup-shaped grinding wheel and a work. The cup-shaped grinding wheel T having the annular grinding action surface and the cylindrical work W are respectively arranged so that these axes are mutually orthogonal, and the cup-shaped grinding wheel T and the work W are rotated around the axis. An outer peripheral surface of the work W is ground by contacting the grinding action surface with the outer peripheral surface of the work W. Every time when rotating the work W by a preset frequency in a state of contacting the grinding action surface of the cup-shaped grinding wheel T with the outer peripheral surface of the work W, the cup-shaped grinding wheel T and the work W are relatively moved in the direction orthogonal to both the axis of the cup-shaped grinding wheel T and the axis of the work W, to change a position for contacting the grinding action surface with the outer peripheral surface of the work W.

Owner:KOYO MASCH IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com