Integrated circuit copper CMP composition and preparation method thereof

A technology of integrated circuits and compositions, applied in the field of polishing compositions with catalytic action, can solve problems such as reducing the polishing rate of CMP, and achieve the effect of high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

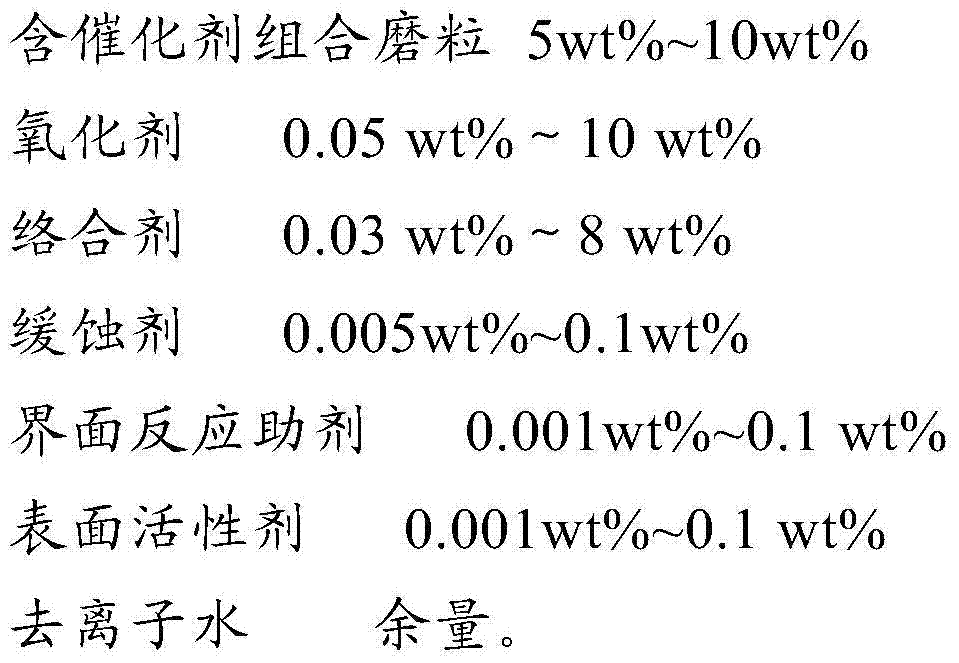

Method used

Image

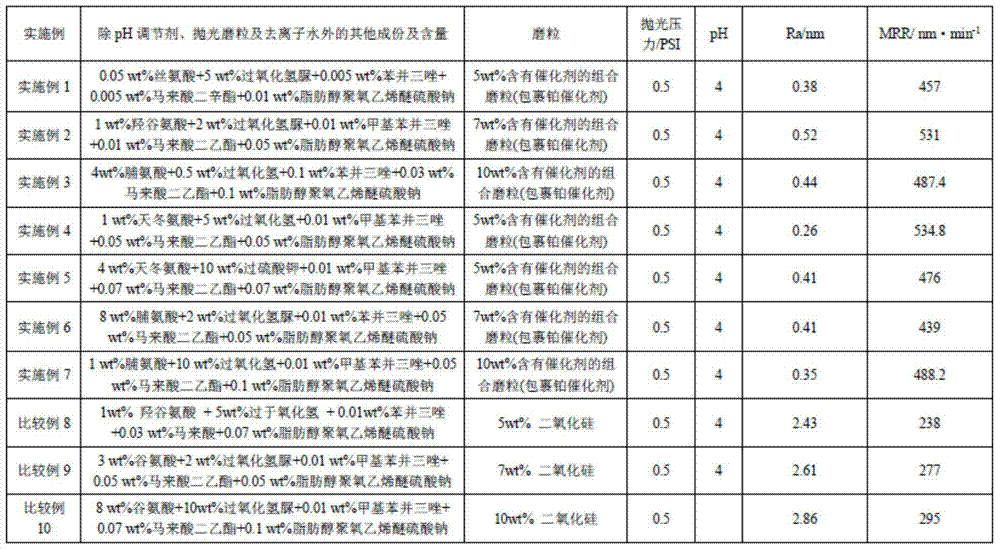

Examples

Embodiment Construction

[0026] The configured polishing liquid is used for polishing experiments, and the parameters of the polishing experiments are as follows:

[0027] Polishing machine: 12-inch chemical mechanical polishing machine (Strasbaugh 6EG type), equipped with a polishing head, which can polish a 12-inch copper-plated sheet (customized from Huali Semiconductor, the thickness of the copper layer is 2 microns);

[0028] Polishing turntable speed: 100 rpm;

[0029] Polishing head speed: 95 rpm;

[0030] Specifications of polished copper-plated sheet: diameter 3 00mm;

[0031] Polishing time: 1min;

[0032] Polishing pad: IC 1000-XY / SUBA IV20 composite polishing pad;

[0033] Polishing fluid flow rate: 80ml / min;

[0034] Polishing pressure: 0.2-0.5psi;

[0035] Polishing temperature: 25°C

[0036] Polishing rate: The polishing removal rate is calculated by the change of the wafer weight before and after polishing. It can be measured by an electronic balance. The polishing rate is the ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com