Patents

Literature

507 results about "Chemical Actions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

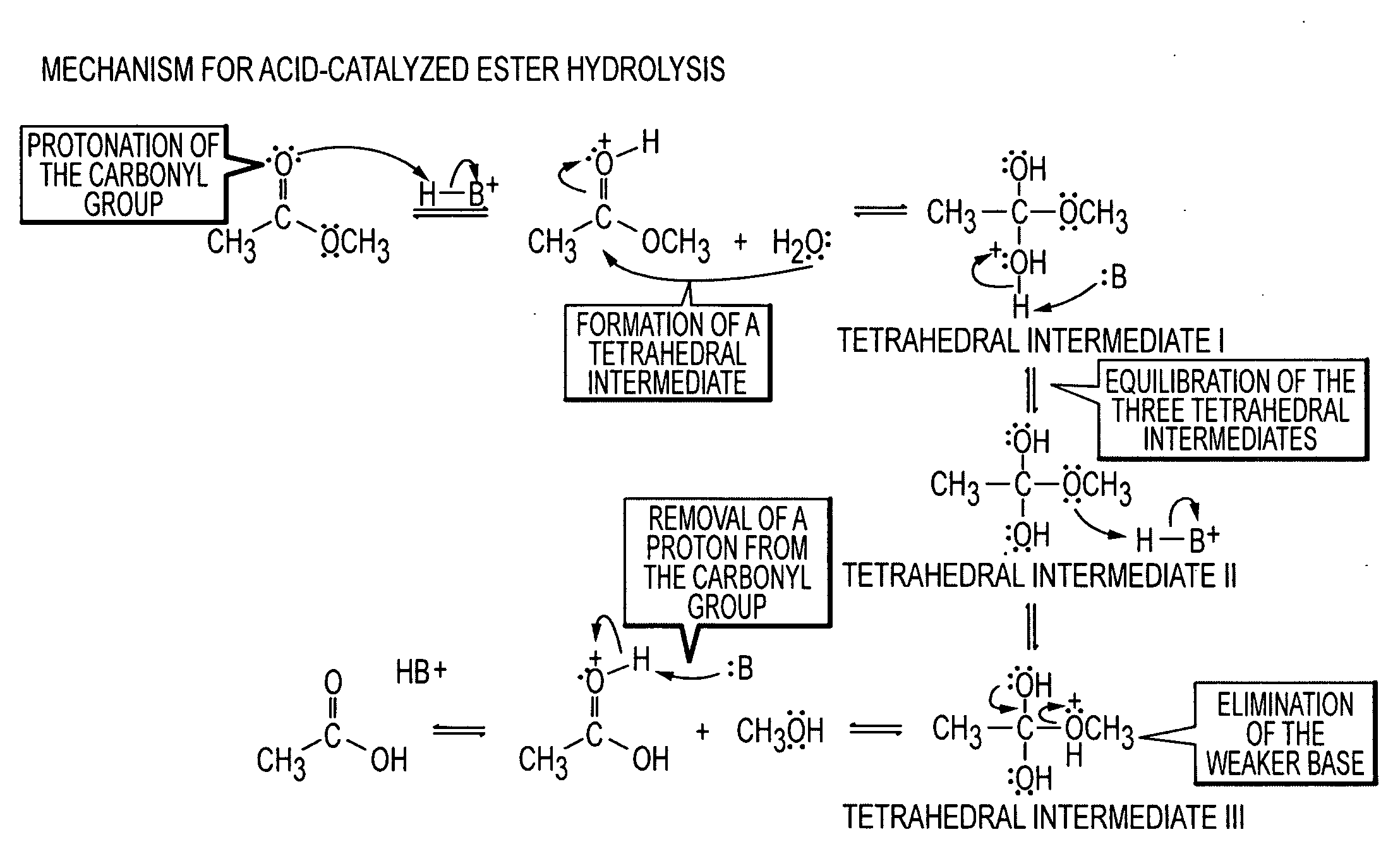

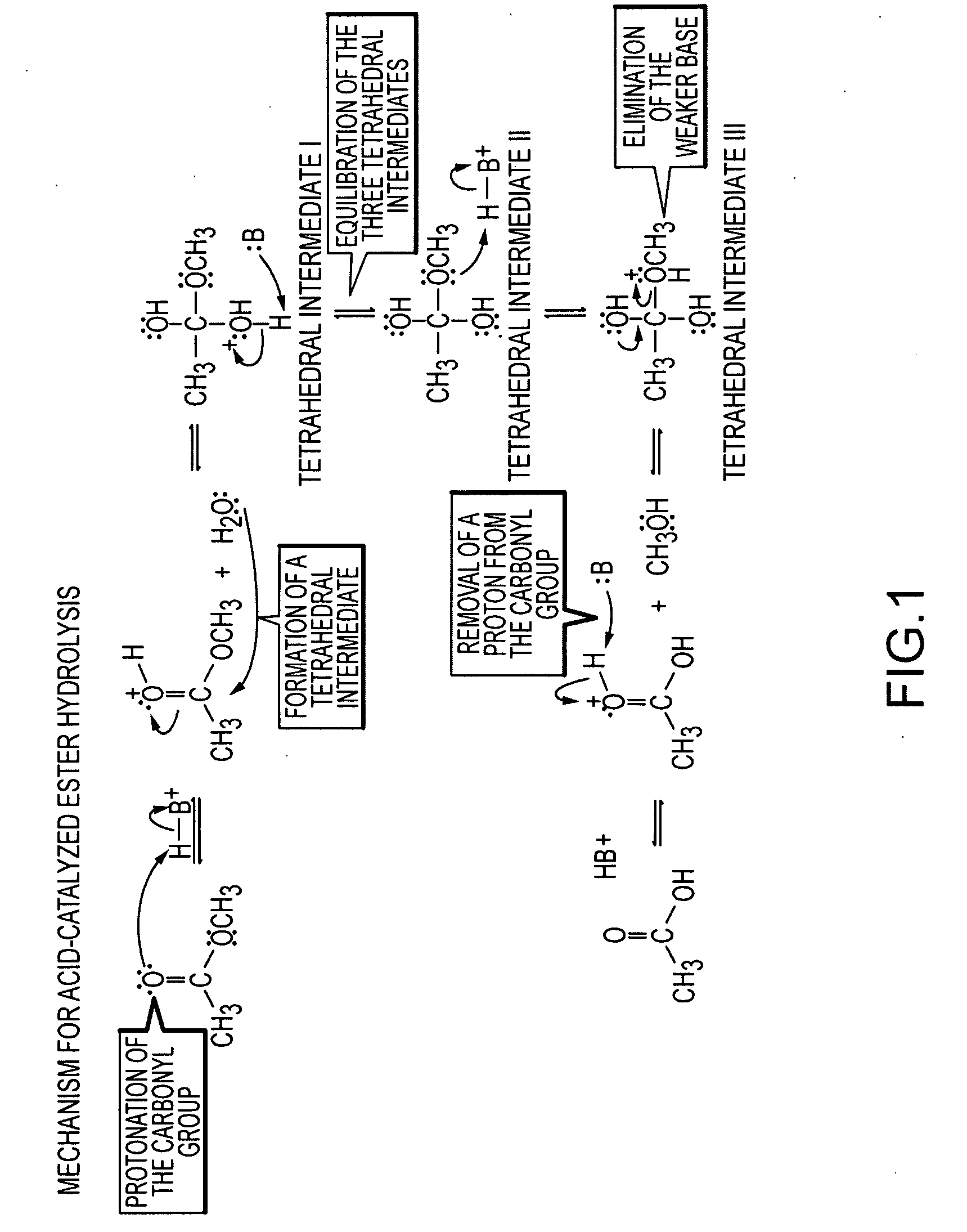

Chemical Reaction Definition. Simply put, a chemical reaction is any transformation from one set of chemicals into another set. If the starting and ending substances are the same, a change may have occurred, but not a chemical reaction. A reaction involves a rearrangement of molecules or ions into a different structure.

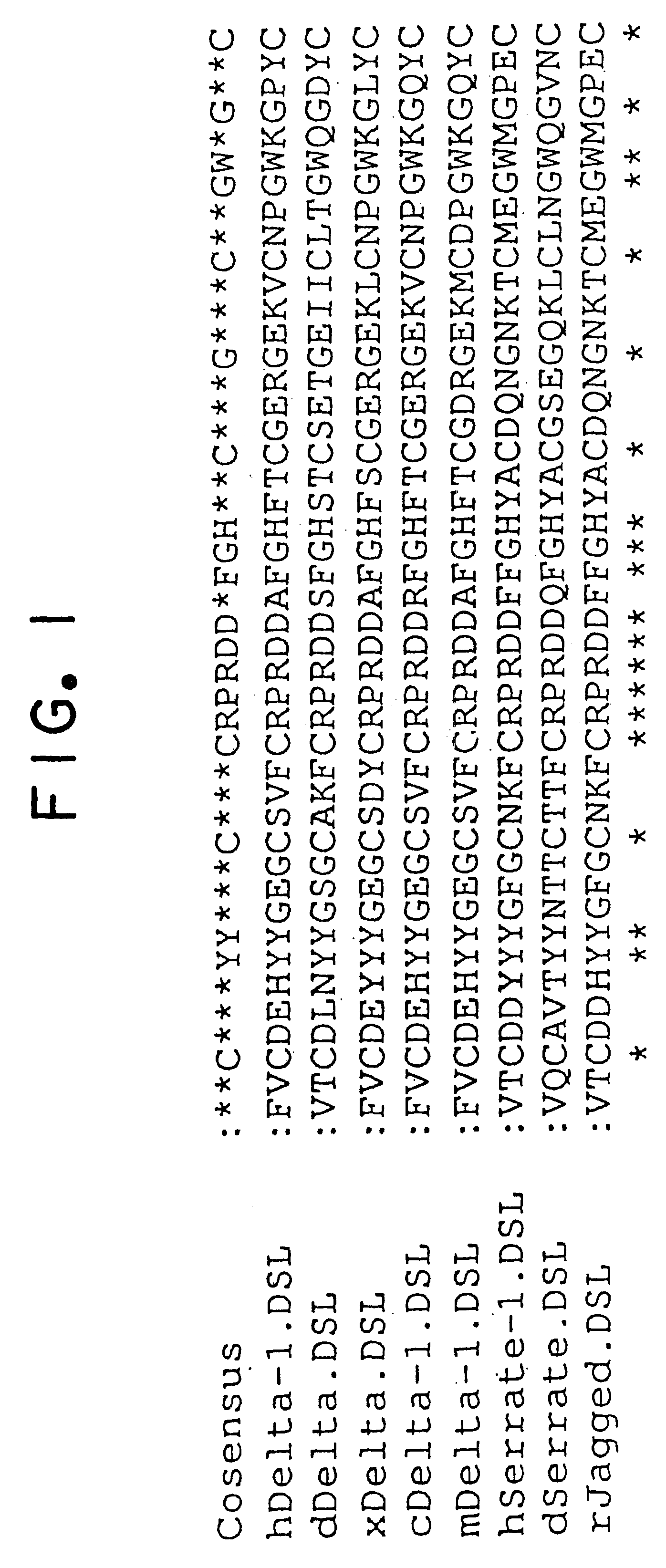

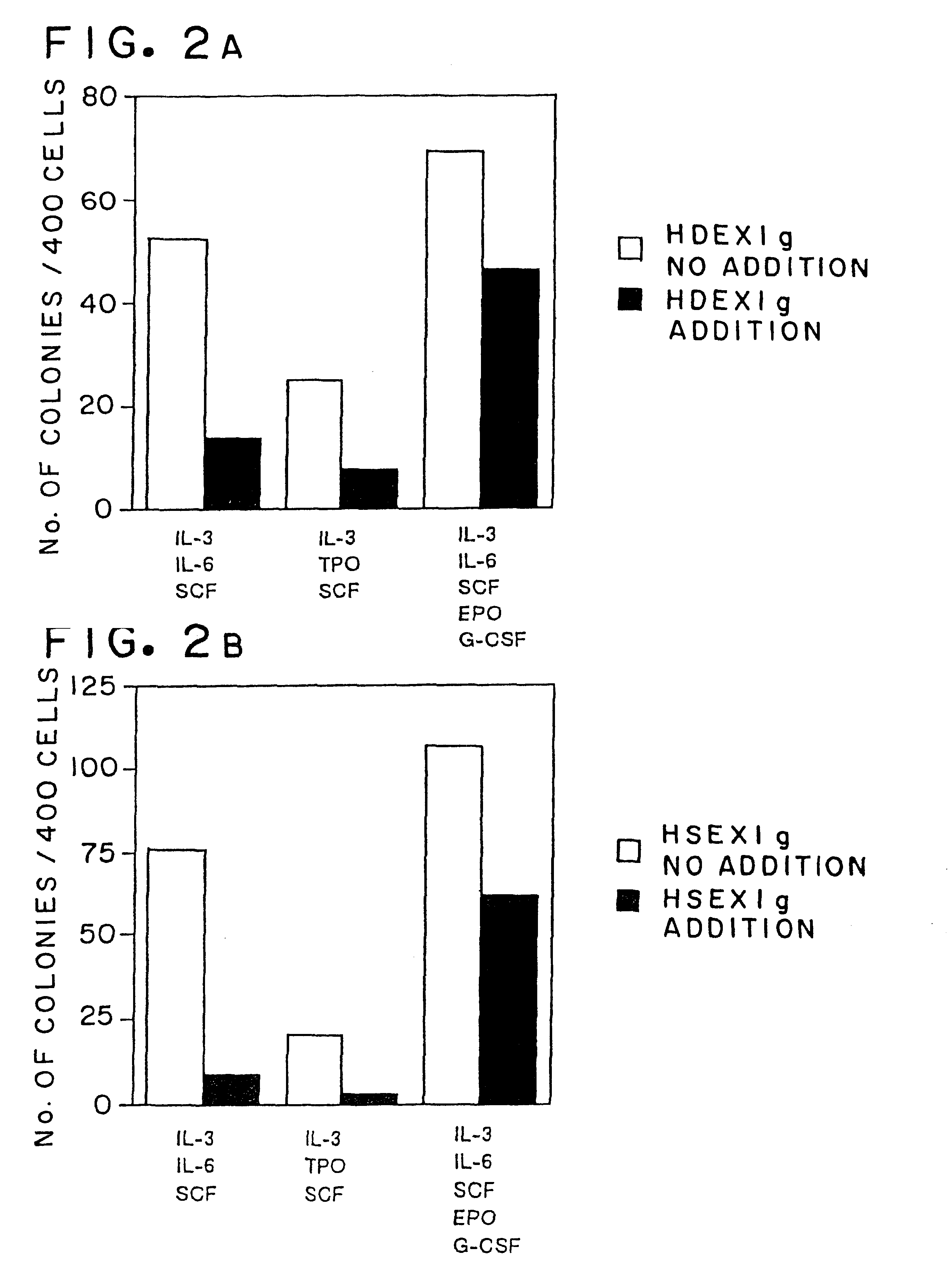

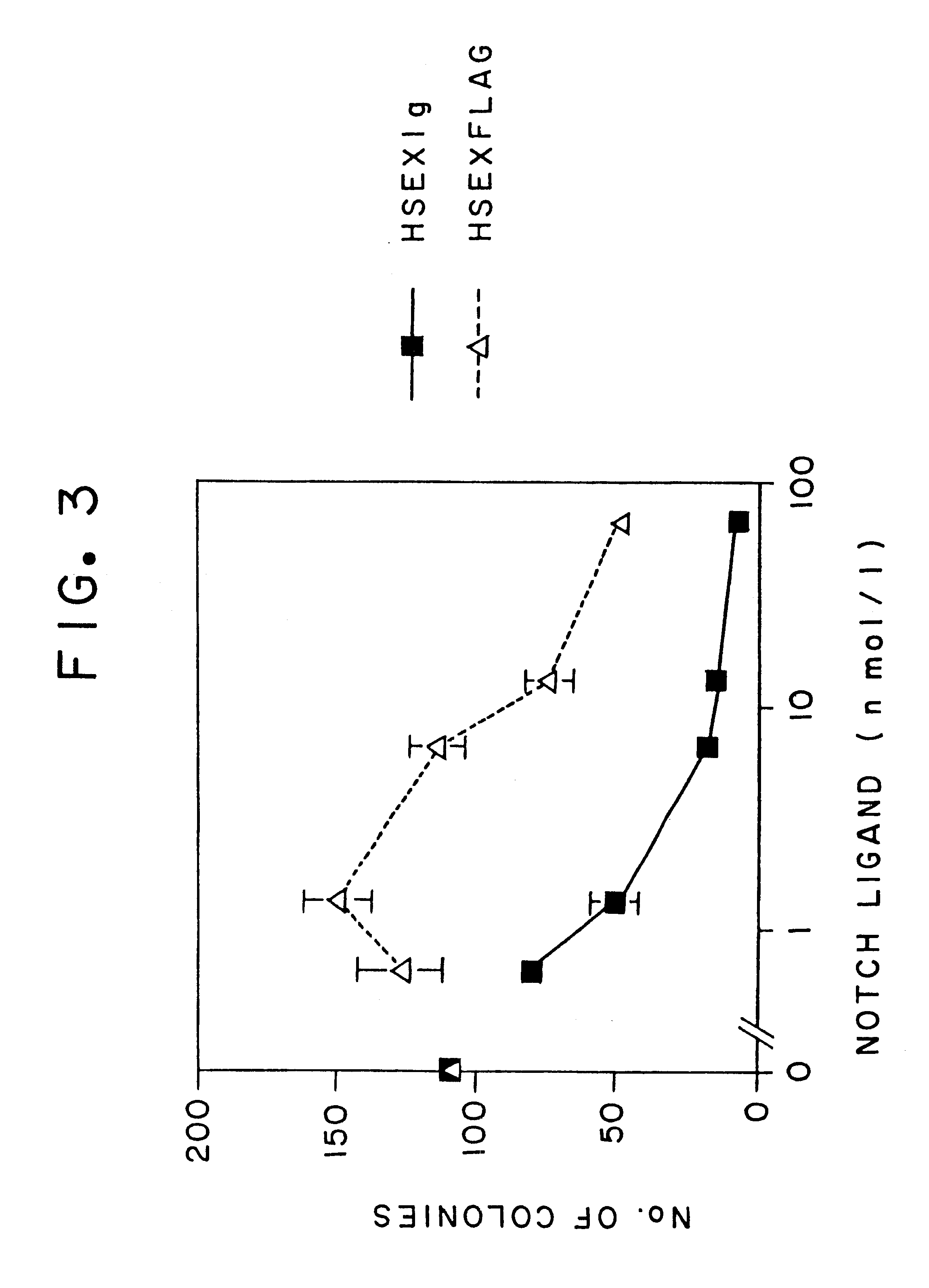

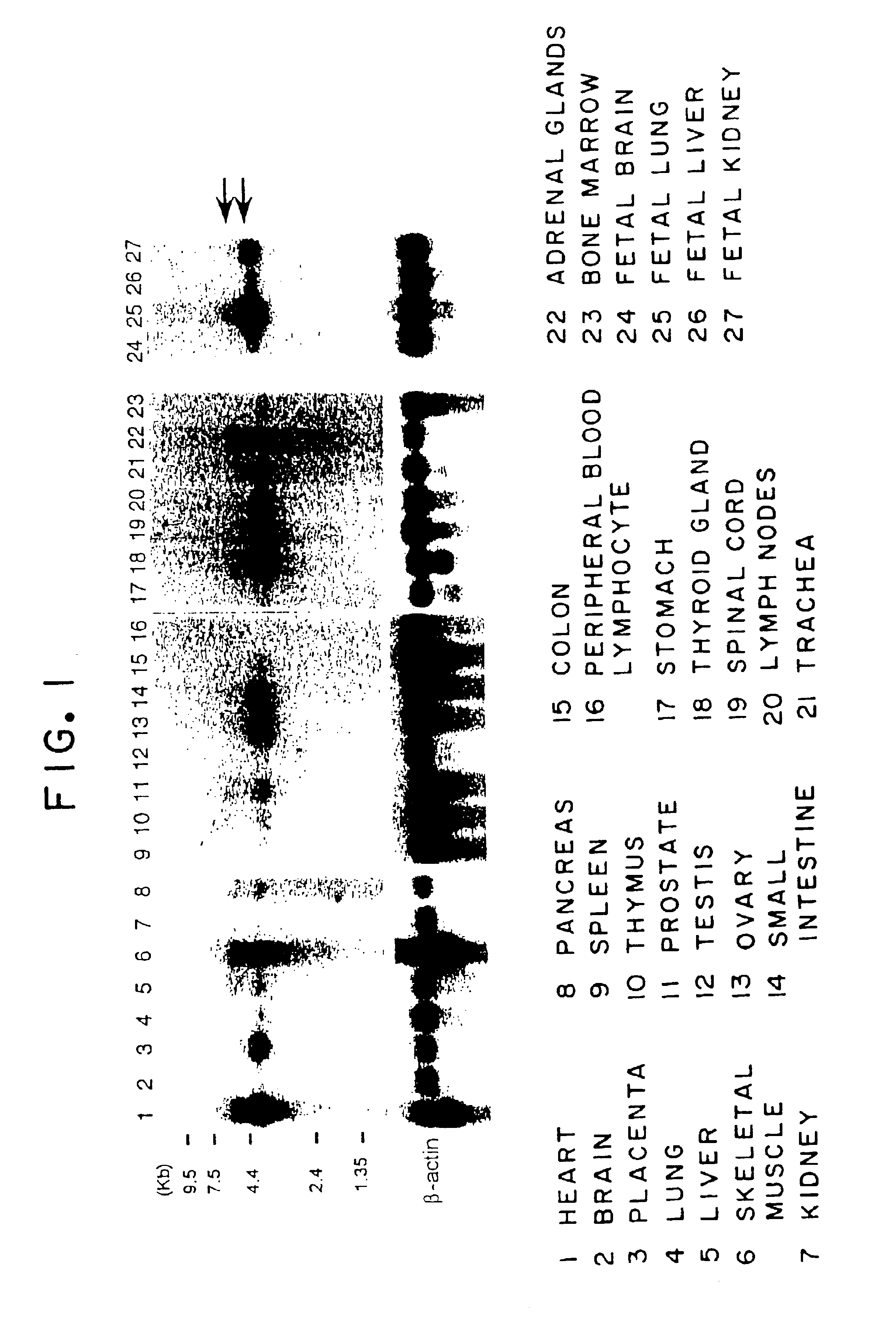

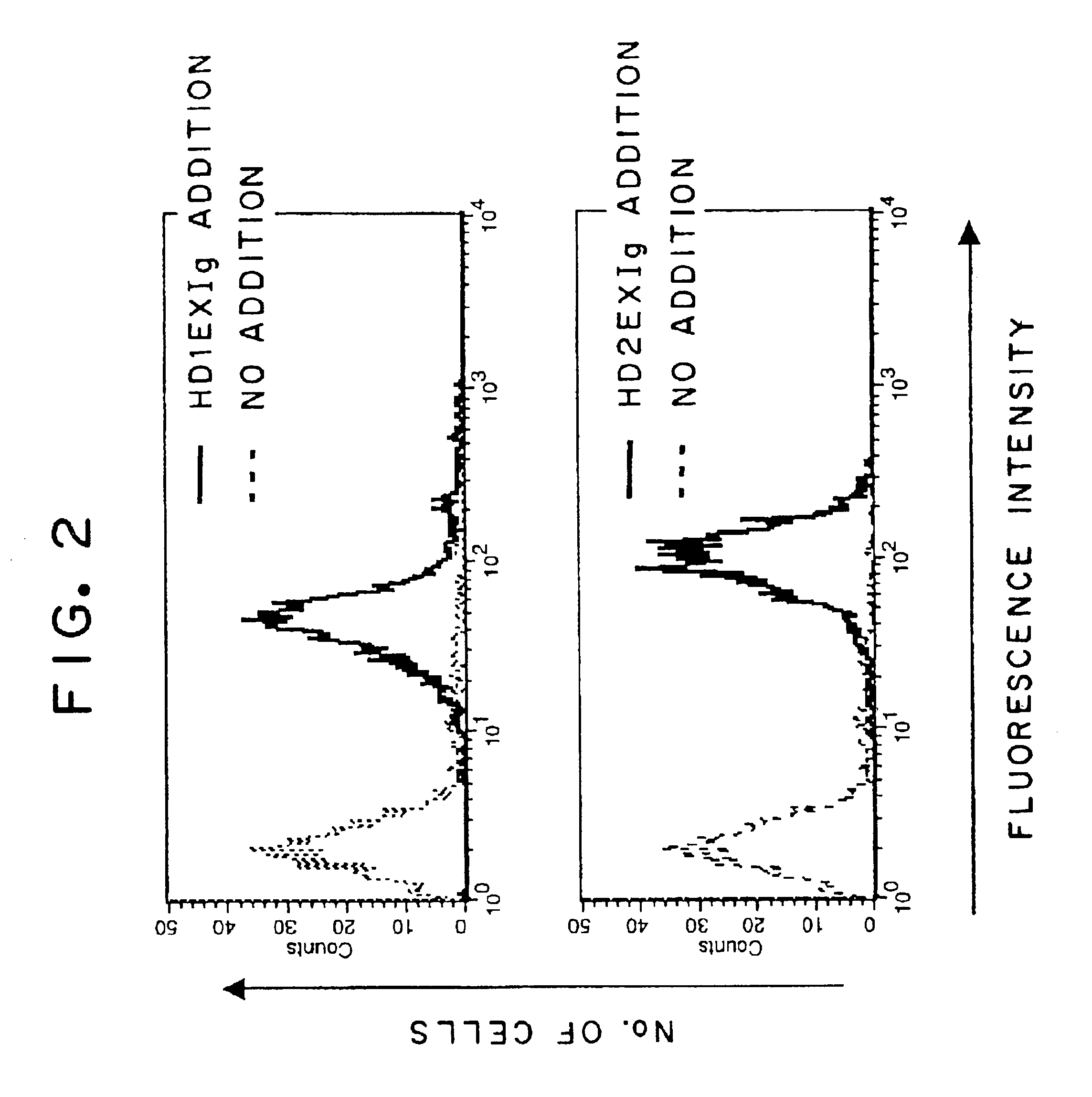

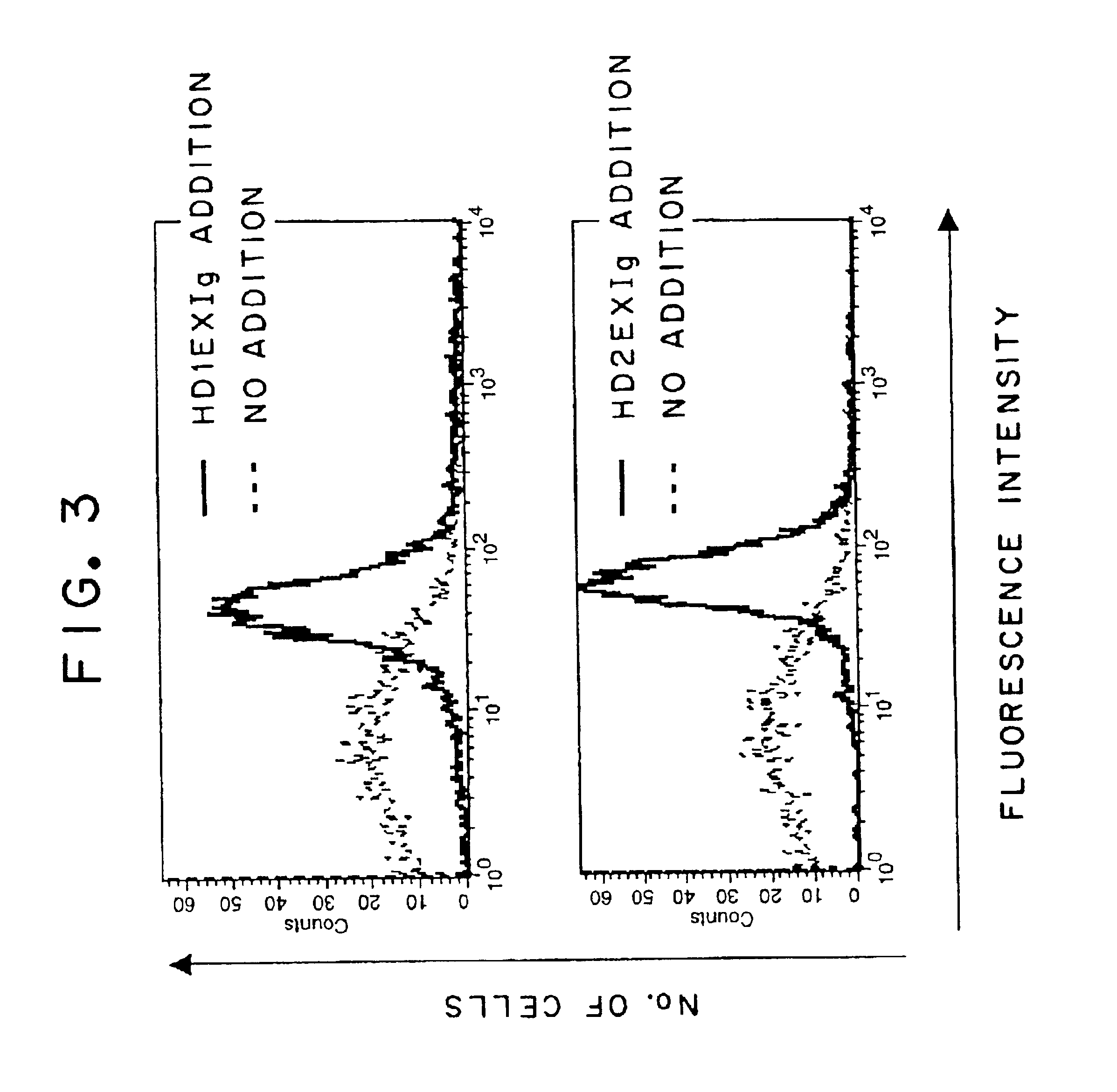

Differentiation-suppressive polypeptide

InactiveUS6337387B1Improve physiological activityEasily mutatePeptide/protein ingredientsDepsipeptidesGeneMedical treatment

A polypeptide which contains the amino acid sequence described in SEQ ID NO: 1 in the Sequence Listing encoded by a gene originating in human being. Because of serving as a chemical efficacious in the supression of the proliferation and defferentiation of undifferentiated blood cells. this polypeptide is expected to be usable in medicines and medical supplies.

Owner:ASAHI KASEI KK

Continuous algal biodiesel production facility

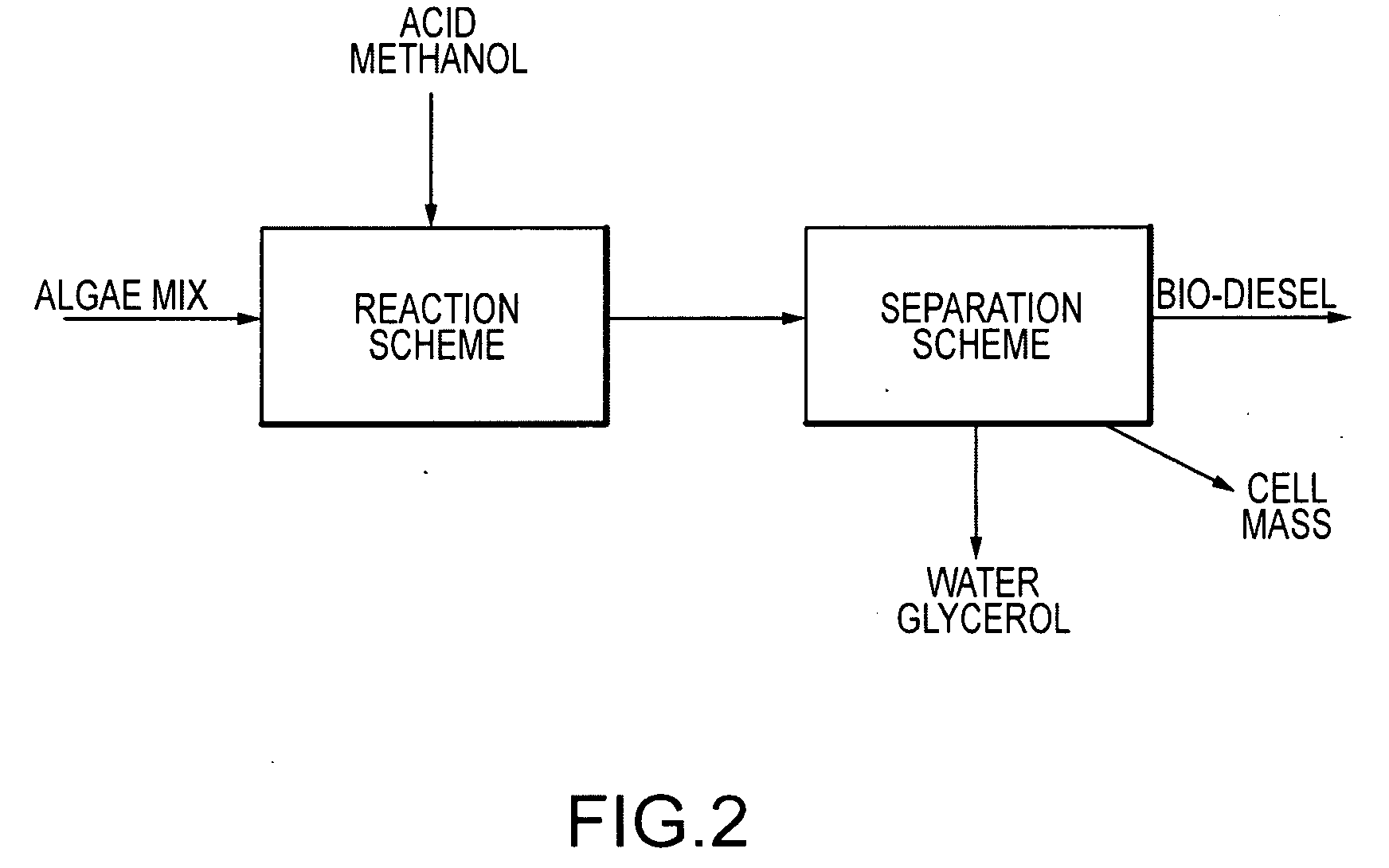

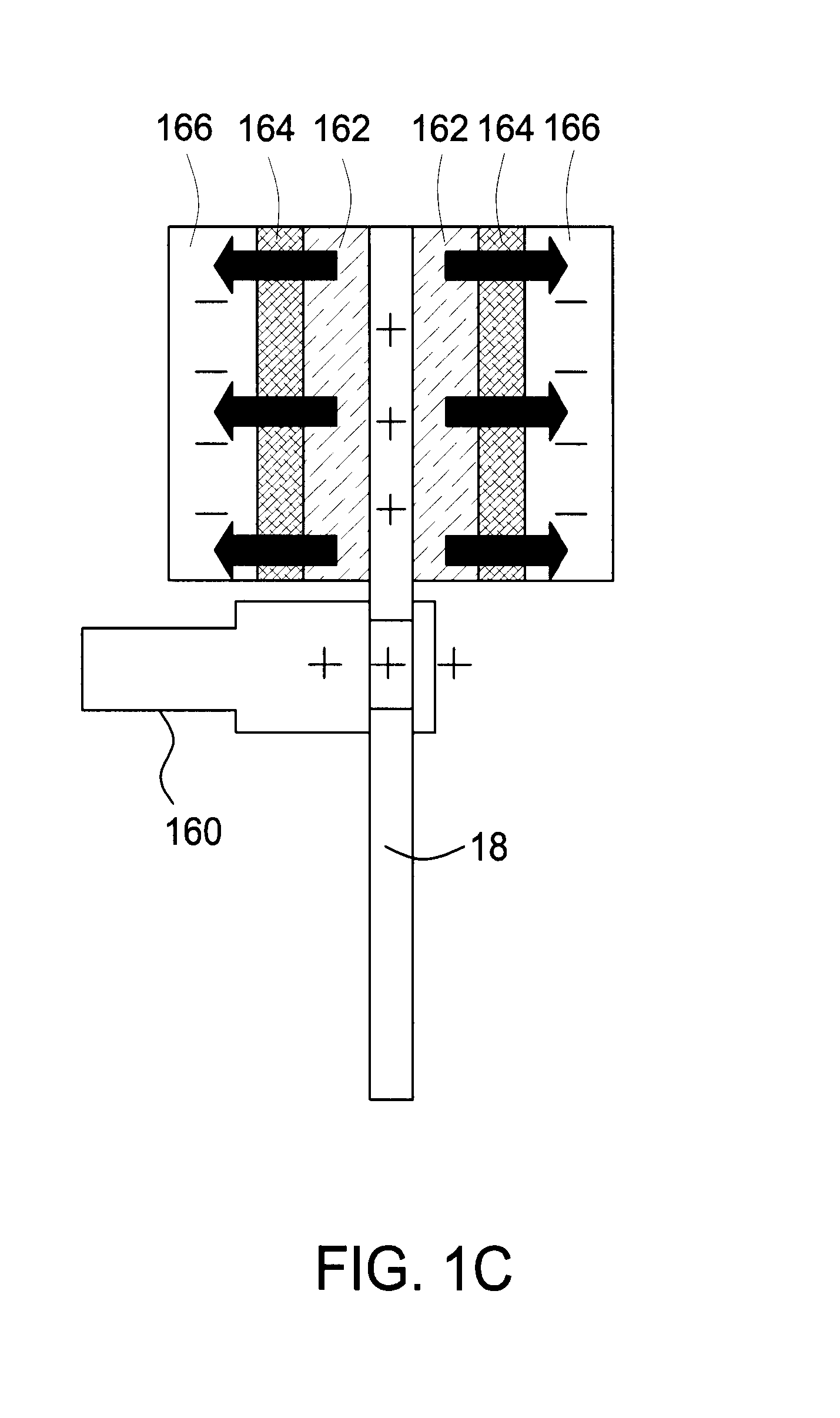

Embodiments of the present invention concern methods, compositions, and apparatus for the continuous conversion of algal lipids into biodiesel. In some embodiments, the biodiesel is formed in a multi-step sequence, the first steps occurring in the presence of water and a strong acid wherein the lipids are released from the algae by means of mechanical and chemical action and are then hydrolyzed to free fatty acids. In a subsequent step, this free fatty acid mixture is reacted with methanol to generate fatty acid methyl esters (also known as biodiesel). Such methods produce biodiesel from algal lipids without the requirement for separate algal cell lysis or lipid extraction or purification prior to the acid catalysis sequence. In other embodiments, the multi-step acid catalysis sequence occurs at 100° C. at two atmospheres of pressure.

Owner:COLORADO STATE UNIVERSITY +1

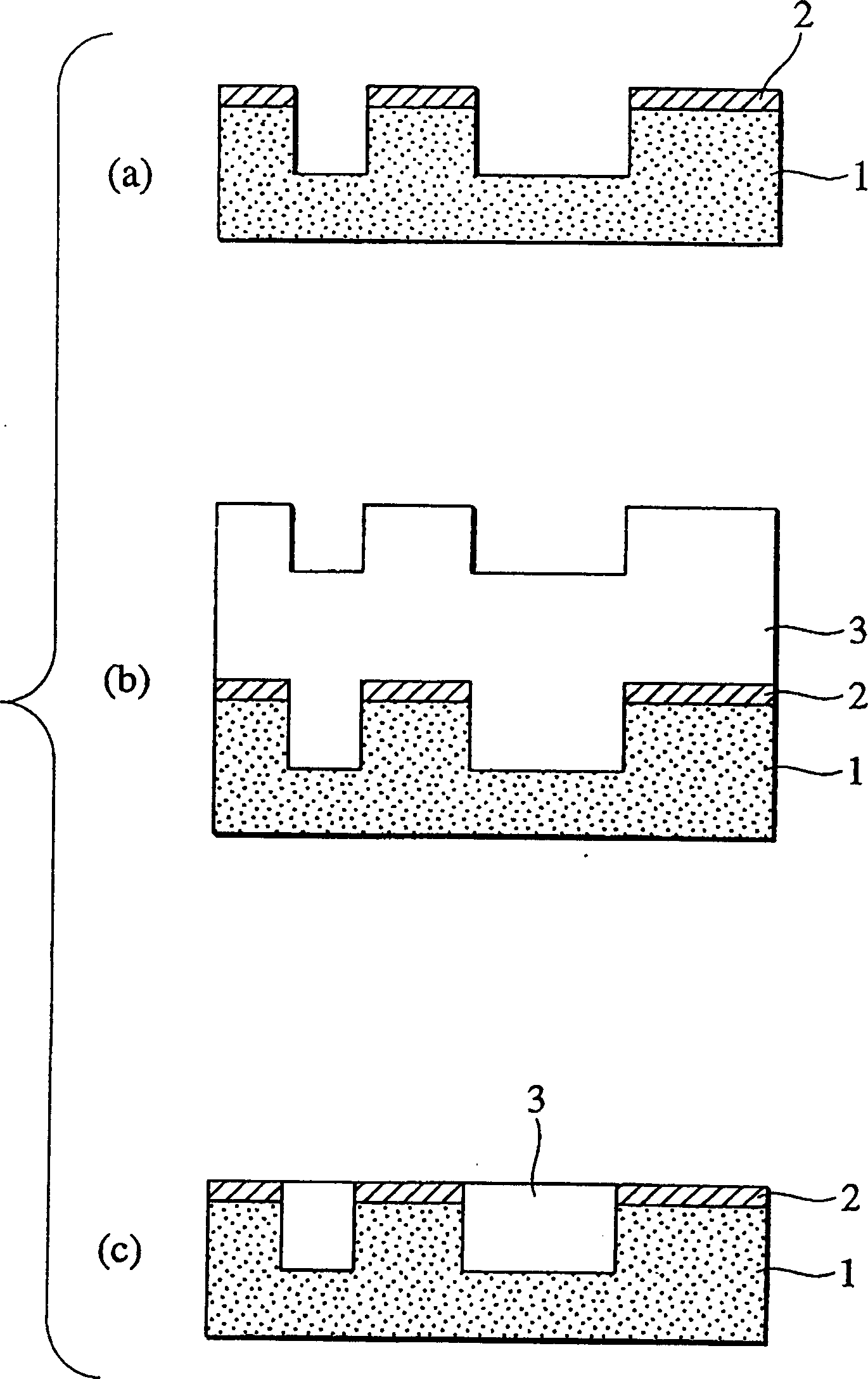

Polishing compound and method for polishing substrate

InactiveCN1457506AGood dispersionEasy to manageOther chemical processesZirconium compoundsCeriumVolumetric Mass Density

A polishing slurry and a polishing method which are suitably used in a CMP technique for flattening a surface of a substrate in a production process of a semiconductor device. The polishing slurry comprises particles and a medium in which at least a part of the particles are dispersed, wherein the particles are made of at least one of (1) a cerium compound selected from cerium oxide, cerium halide and cerium sulfide and having a density of 3 to 6 g / cm<3> and an average particle diameter of secondary particles of 1 to 300 nm and (2) a tetravalent metal hydroxide. A polishing method using the polishing slurry takes advantage of a chemical action of particles in the polishing slurry and minimizes a mechanical action of the particles, thereby achieving a decrease in scratches caused by the particles and an increase in polishing rate at the same time.

Owner:HITACHI CHEM CO LTD

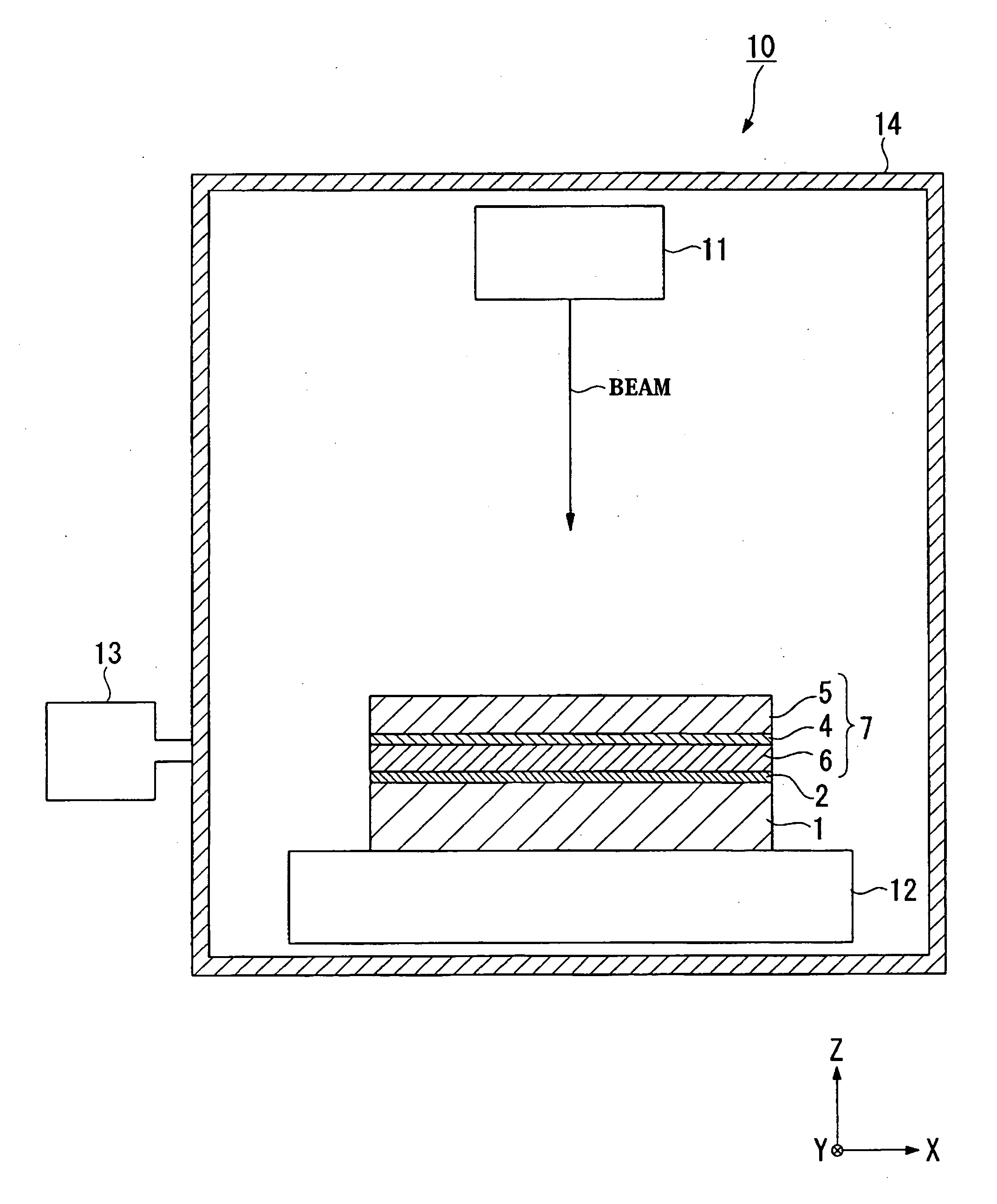

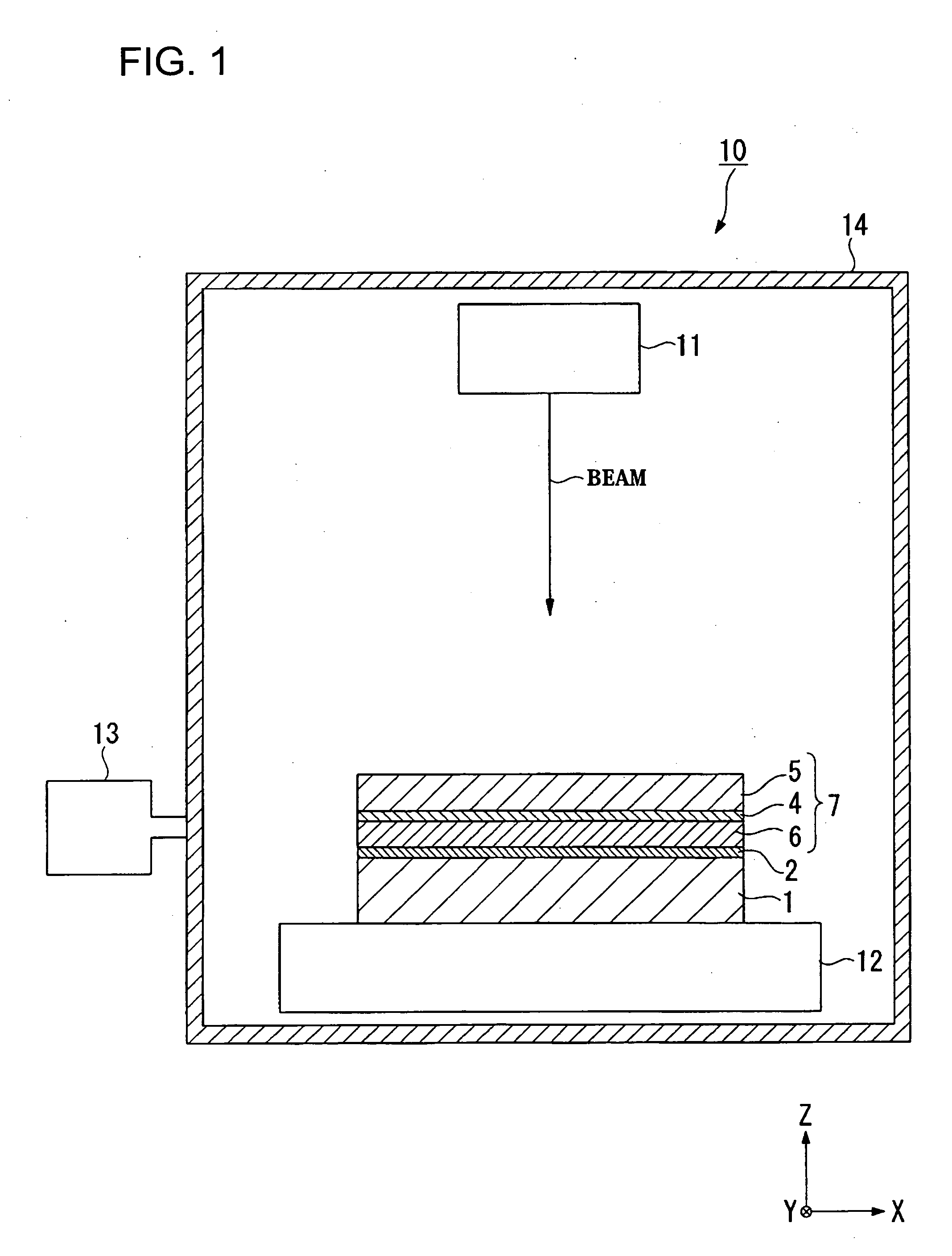

Method for forming film, method for forming wiring pattern, method for manufacturing semiconductor device, electro-optical device, and electronic device

ActiveUS20050087289A1Efficiently converted into thermal energySmall diameterElectric lighting sourcesSolid-state devicesDevice materialEngineering

Exemplary embodiments of the invention to provide an efficient and productive method to form a reliable film. A method to form a film according to exemplary embodiments of the present invention, in which a transferring layer formed on a substrate is transferred to a workpiece to form a predetermined film on the workpiece, includes treating a surface of the workpiece to enhance or improve the adhesion between the transferring layer and the workpiece by chemical interaction.

Owner:INTELLECTUAL KEYSTONE TECH LLC

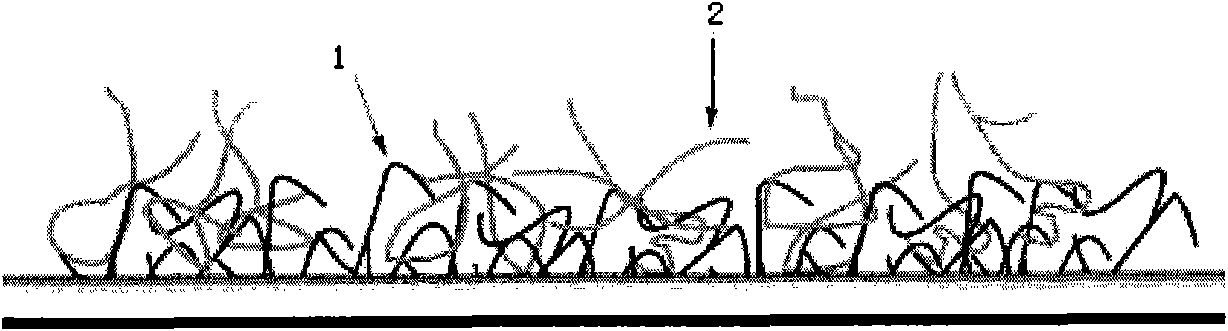

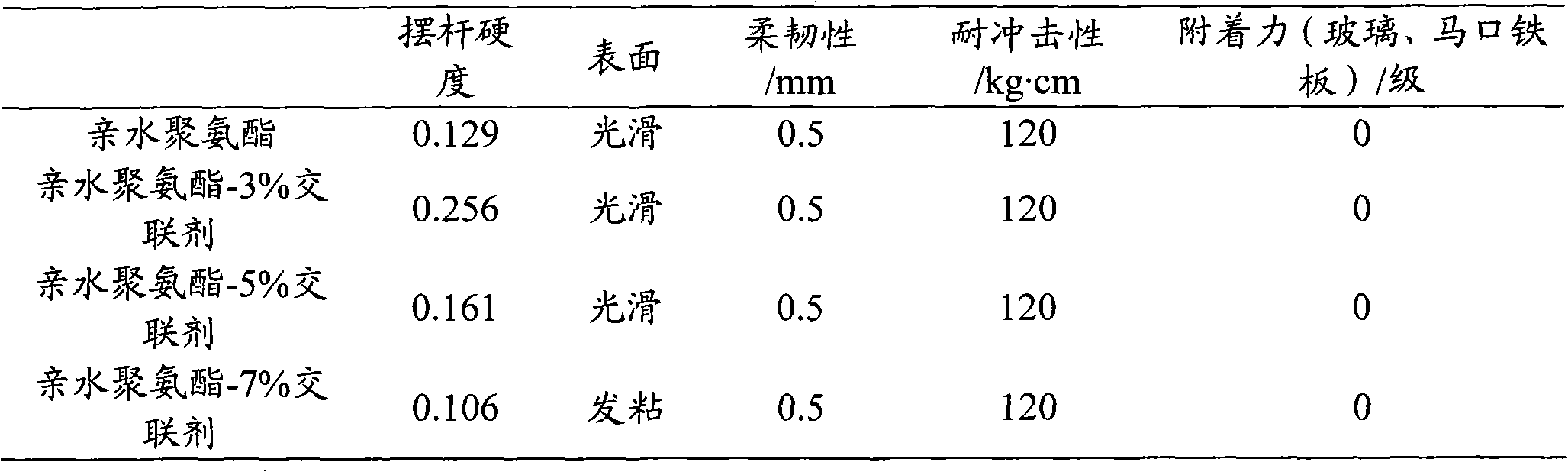

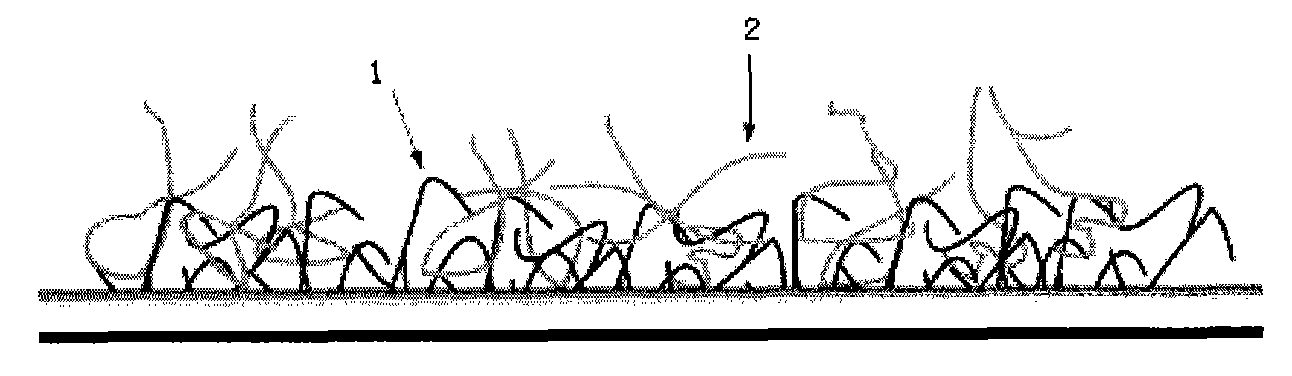

Hydrophilic coating for surface of medical apparatus and preparation method thereof

InactiveCN101934101AHigh mechanical strengthExcellent coating mechanical propertiesSurgeryPolyurea/polyurethane coatingsHydrophilic coatingNetwork structure

Owner:BEIJING DEMAX MEDICAL TECH

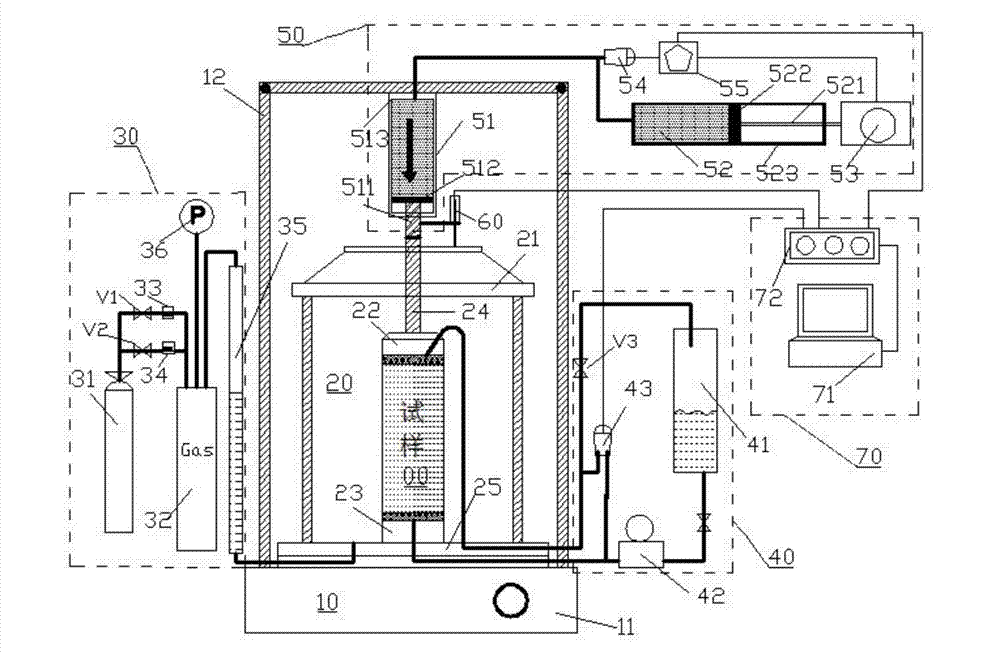

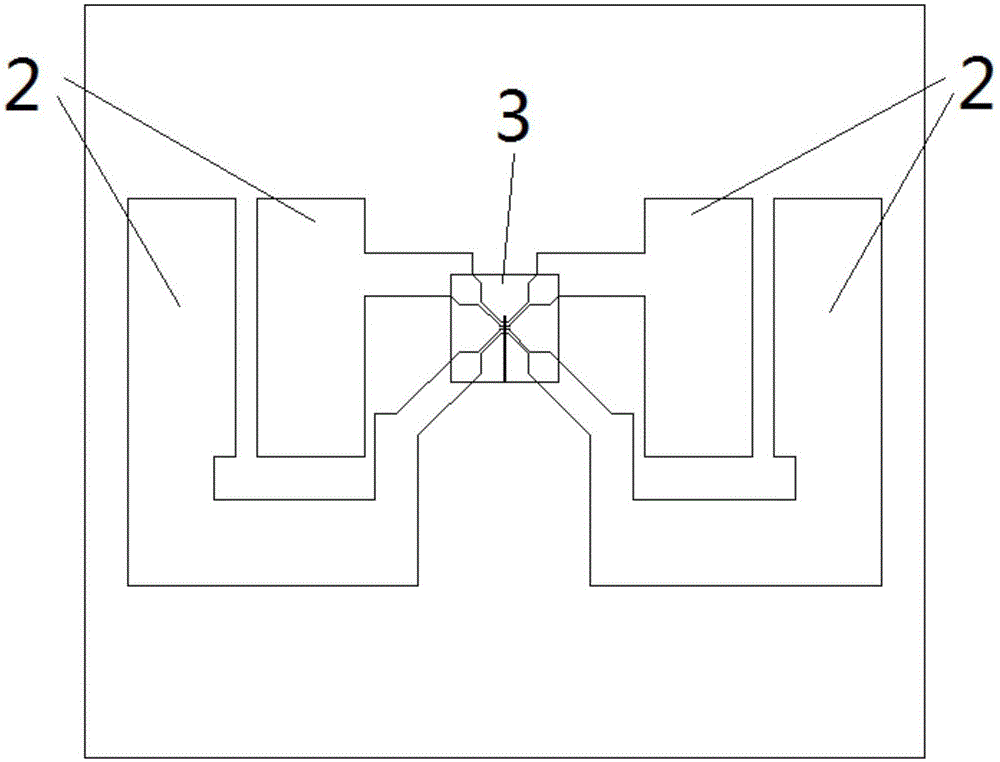

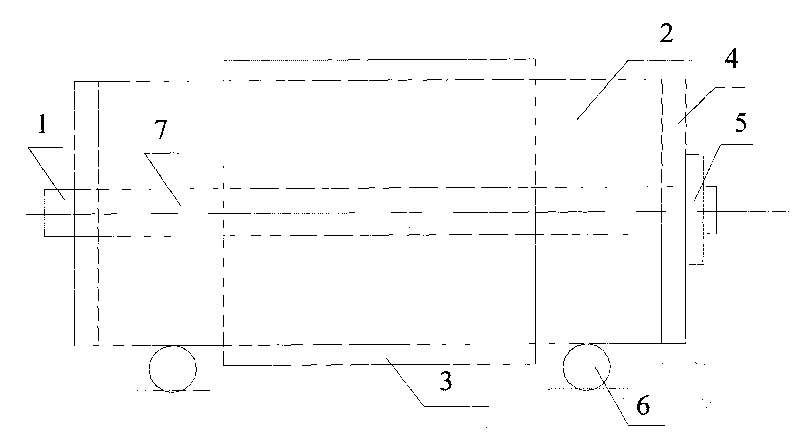

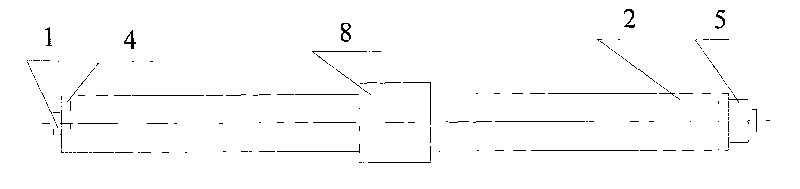

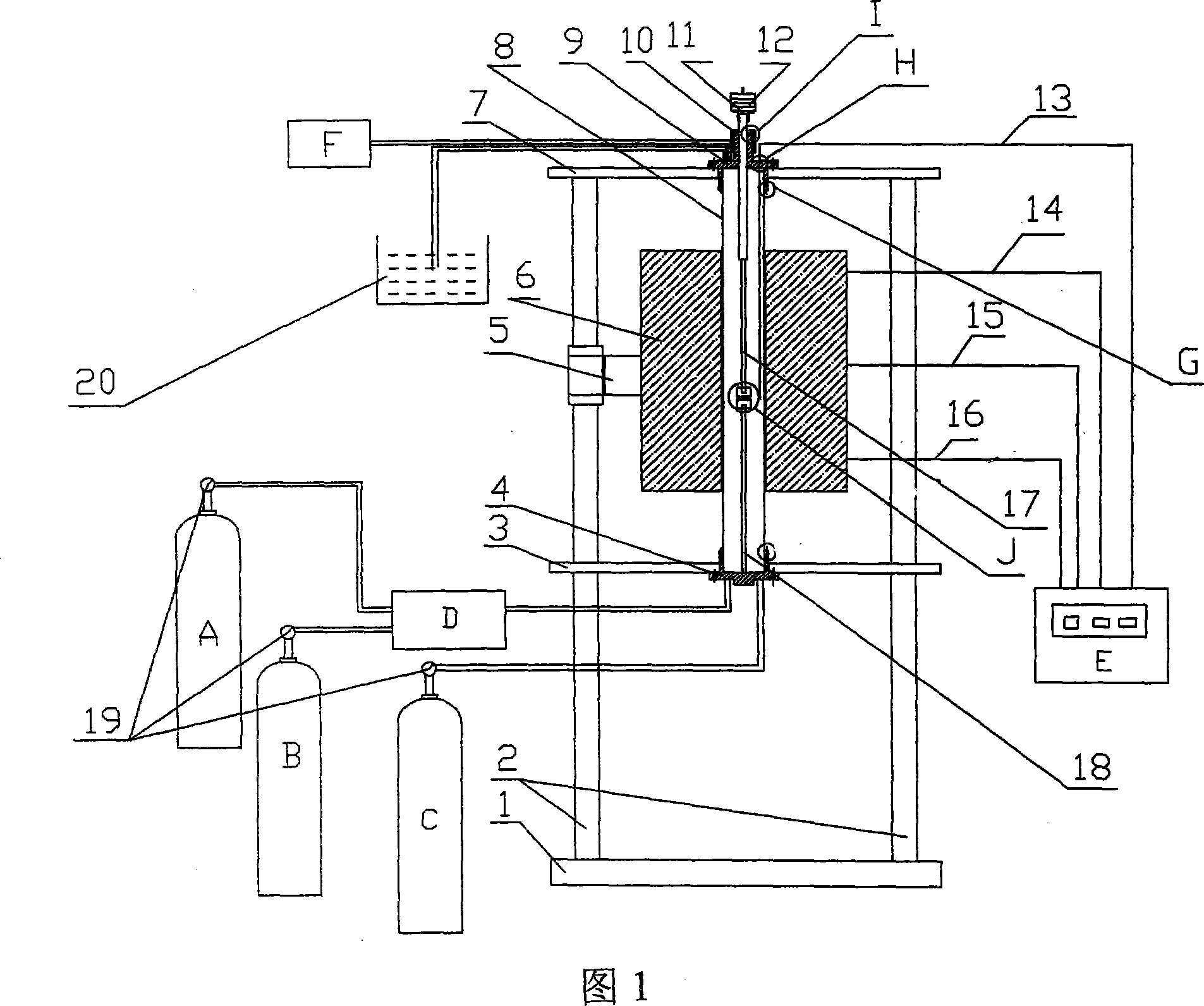

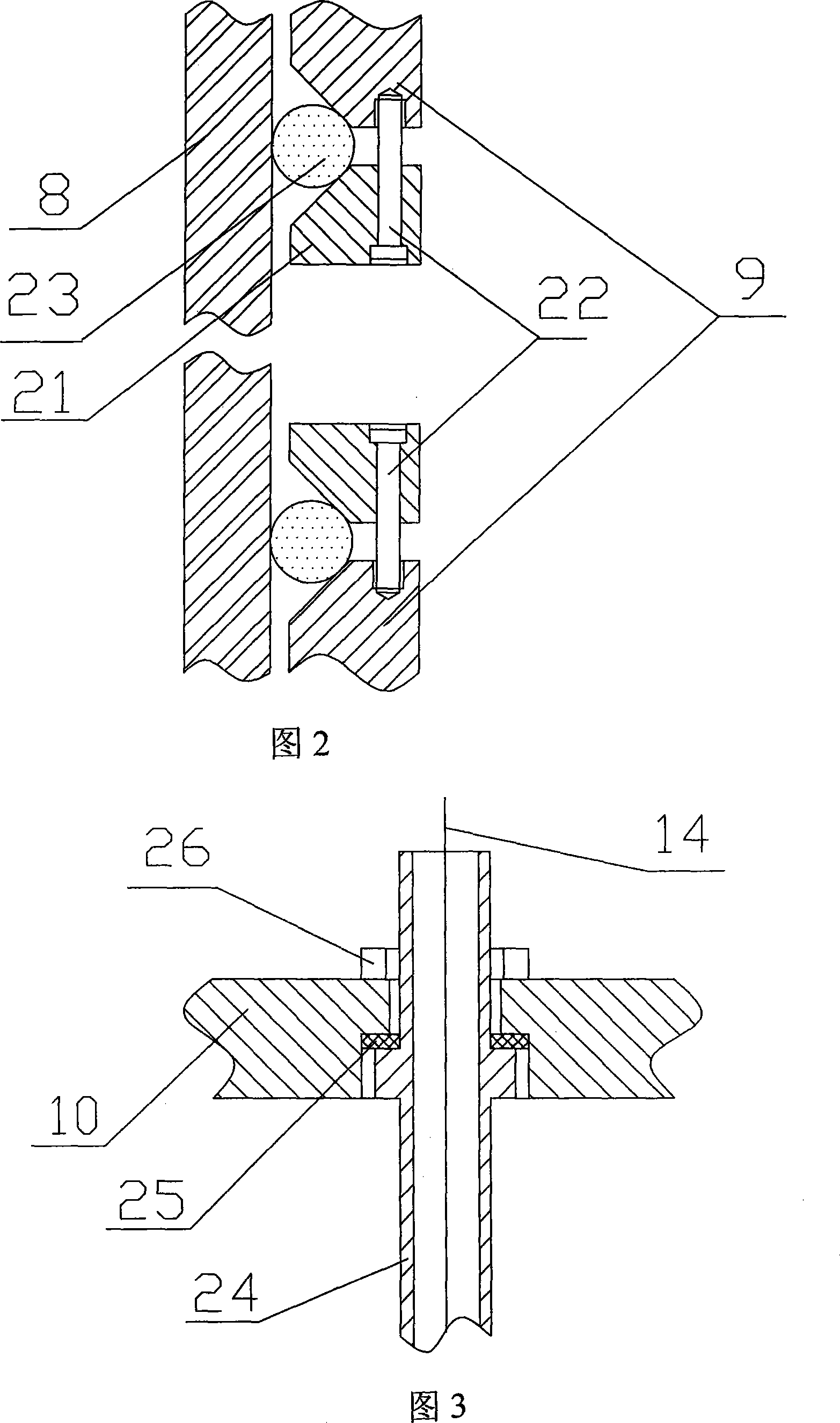

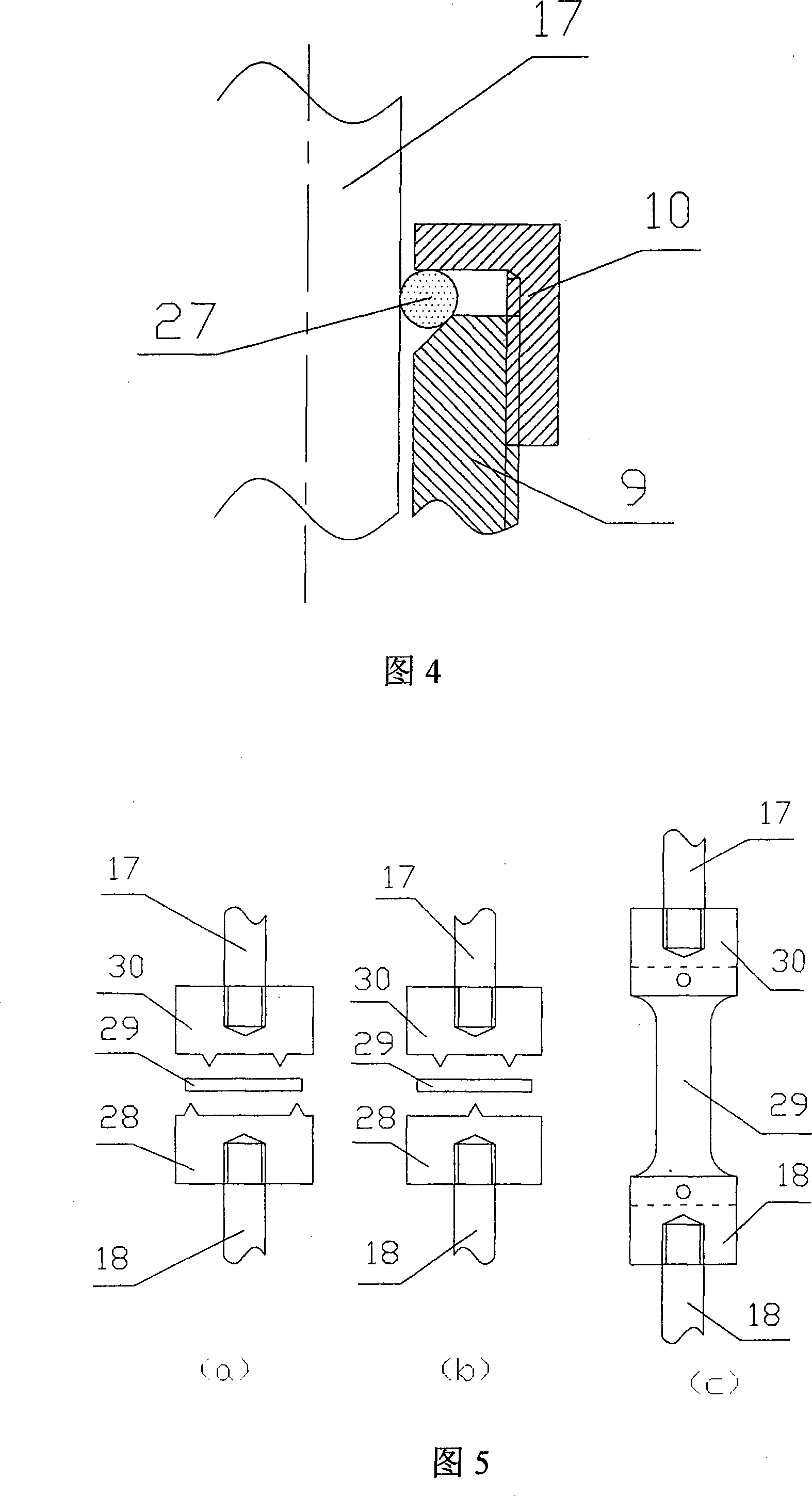

Triaxial test apparatus of soil under water-soil chemical action and method thereof

InactiveCN103091173ASolve the problem of accurate measurementPromote in-depth developmentMaterial strength using tensile/compressive forcesChemical solutionTriaxial shear test

The invention discloses a triaxial test apparatus of soil under water-soil chemical action and a method thereof, and relates to a testing technique of soil under a special environment. The device comprises a device frame (10), a triaxial pressure chamber (20), a confining pressure exerting and deformation test device (30), a solution cyclic displacement device (40), a stress / strain control loading device (50), a displacement sensor (60) and a data collecting and processing device (70). The uniformity of ingredients and concentration of internal pore water solution of a specimen is ensured by solution circulation; the change rules of soil deformation and strength caused by chemical solution transfusion under constant stress can be simulated and researched; the confining pressure exerting principle is improved; accurate measurement of body deformation is achieved; and the conversion of strain control and stress control can be achieved.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Polishing compound and method for polishing substrate

InactiveCN1746255AGood dispersionEasy to manageOther chemical processesZirconium compoundsCeriumVolumetric Mass Density

A polishing slurry and a polishing method which are suitably used in a CMP technique for flattening a surface of a substrate in a production process of a semiconductor device. The polishing slurry comprises particles and a medium in which at least a part of the particles are dispersed, wherein the particles are made of at least one of (1) a cerium compound selected from cerium oxide, cerium halide and cerium sulfide and having a density of 3 to 6 g / cm<3> and an average particle diameter of secondary particles of 1 to 300 nm and (2) a tetravalent metal hydroxide. A polishing method using the polishing slurry takes advantage of a chemical action of particles in the polishing slurry and minimizes a mechanical action of the particles, thereby achieving a decrease in scratches caused by the particles and an increase in polishing rate at the same time.

Owner:RESONAC CORPORATION

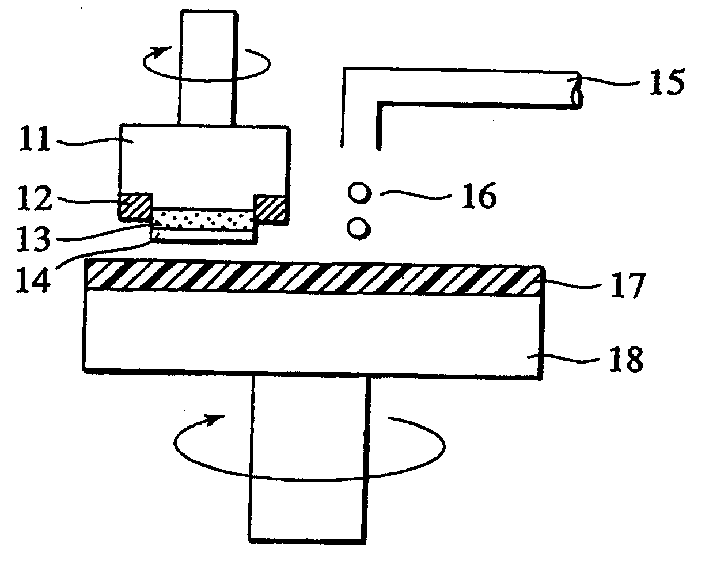

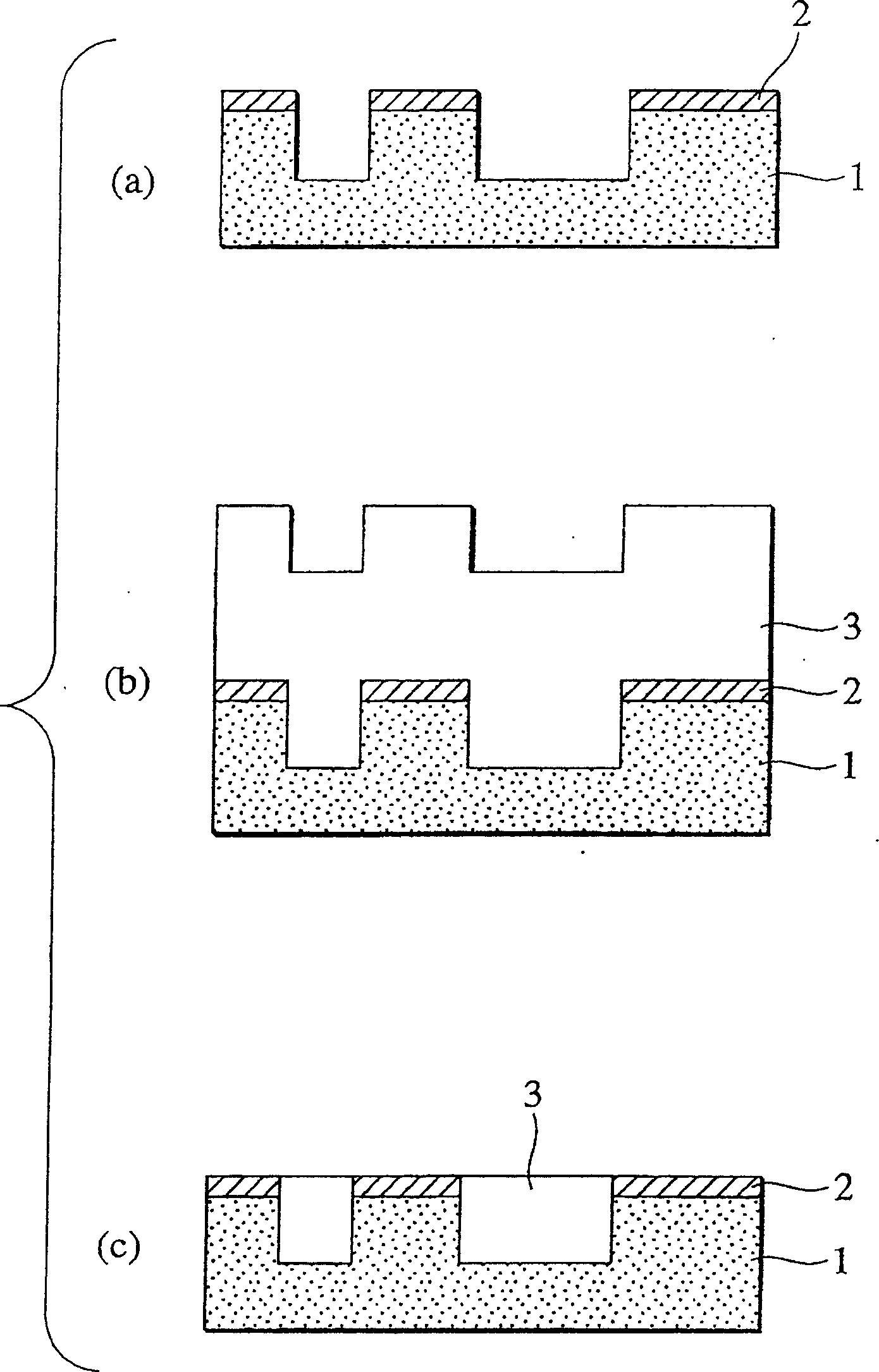

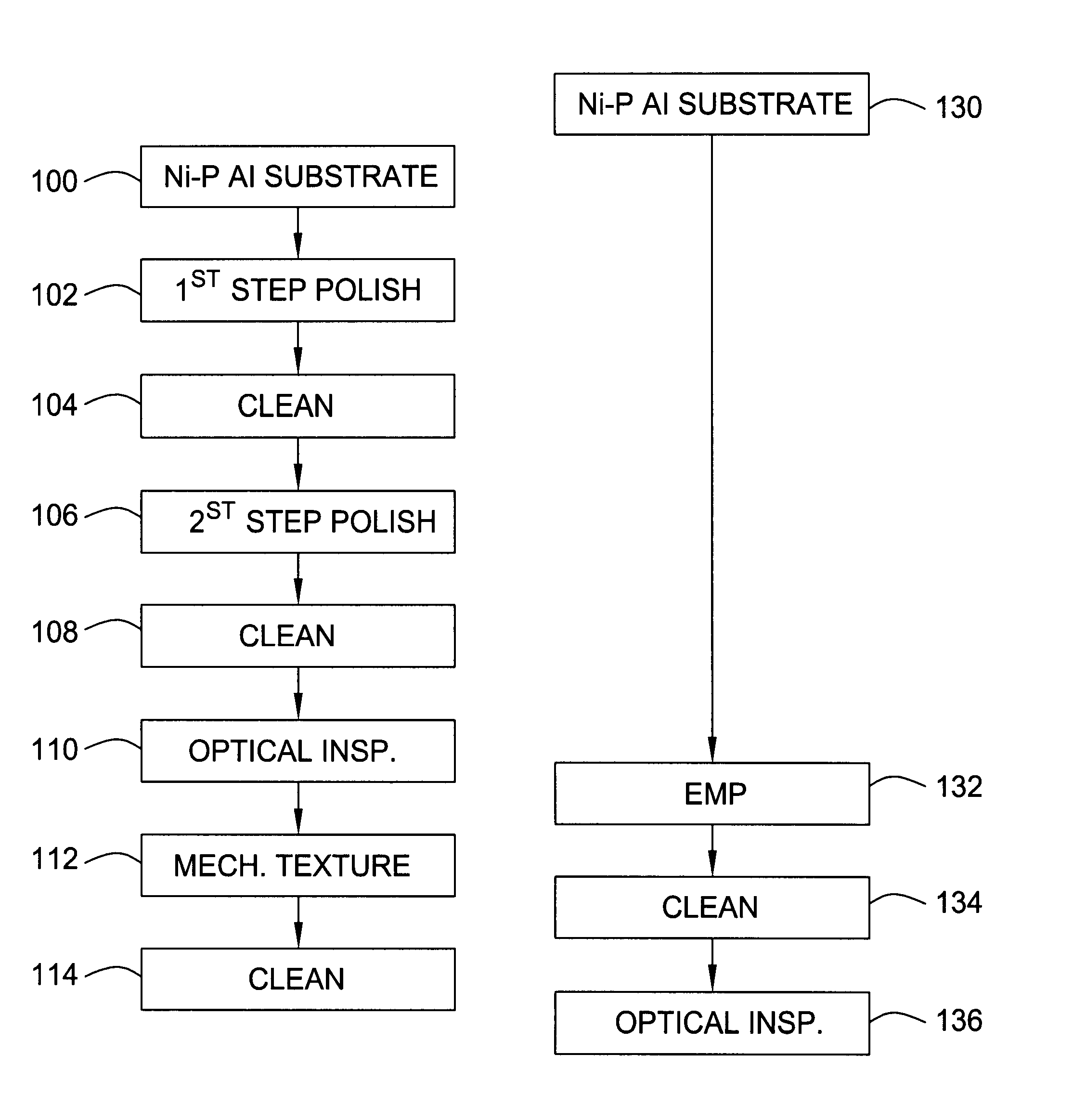

Single-step electromechanical mechanical polishing on Ni-P plated discs

InactiveUS6957511B1Reduce in quantityReduce processing timeBelt grinding machinesLapping machinesElectrical conductorSlurry

Beginning with a smooth ground aluminum blank with a relatively thin layer of leveled Ni—P, circumferential electropolishing / texturing is carried out to achieve a smooth oriented surface. A conductive slurry is provided between the disc and a porous texturing tape which is in contact with a conducting plate or equivalent conductor. The disc serves as the anode, and the conducting plate as the cathode, while the slurry, being conductive, functions as an electrolyte. In the presence of current, a reverse electroplating occurs so that the Ni—P dissolves to form Ni2+, or nickel ions which are carried away by the conductive slurry. The conductive slurry further supports or carries therein abrasive material so that by moving the porous texturing tape past the disc surface, the texturing tape picks up the abrasive material in the slurry and simultaneously with the reverse electroplating, provides the desired mechanical abrasion to achieve texturing of the disc surface. The abrasive material comprises diamond particles. The circumferential electropolishing / texturing polish is achieved by spinning the disc while applying the mechanical-chemical action through the slurry system to the disc surface with electric current passing through the electrically conducting interface during processing.

Owner:SEAGATE TECH LLC

Rare earth polishing powder and production method thereof

The invention discloses rare earth polishing powder and a production method thereof. As an abrasive substance, the polishing powder comprises CeO2, La2O3 and Pr6O11. The total rare earth oxides (TREO) are above 90wt%. Meanwhile, in the TREO of the 877-3 rare earth polishing powder, CeO2 accounts for 70-80%, La2O3 19-29%, Pr6O11 0.05-2% and Nd2O3 less than 0.2%. To ensure necessary polishing speed, fluorine element which has chemical action is added to the wet synthesis process and initial shaping of product granularity is controlled, so that the obtained 877-3 rare earth polishing powder can be used for fast producing polished surface with good polishing effect.

Owner:甘肃稀土新材料股份有限公司

Nucleic acids encoding differentiation inhibitor delta 2

InactiveUS7022499B2Easily mutateEasy to detectPeptide/protein ingredientsImmunological disordersGeneAmino acid

Amino acids constituting a physiologically active molecule human delta 2; a gene arrangement thereof; and an antibody thereto. The human delta 2 molecule, at least the amino acid sequence described in SEQ ID NO: 1 of the sequence listing, functions as a chemical useful for proliferation of undifferentiated blood cells and inhibition of differentiation, and hence can be utilized as pharmaceuticals and medical supplies.

Owner:ASAHI KASEI KK

Method for simultaneously removing phosphorous and nitrogen through synergistic effect of nanoscale-iron and microbes

ActiveCN103803703AEnriched nanovoidsTreatment with anaerobic digestion processesParticulatesFerric hydroxide

The invention provides a method for simultaneously removing phosphorous and nitrogen through the synergistic effect of nanoscale-iron and microbes. The method is characterized in that firstly limonite ore is broken and sieved so as to obtain particulate materials with the required particle size, the particulate materials mainly comprising nanoscale iron and having millimeter particle size and the porous structure characteristic are prepared through high temperature reduction under a hydrogen or carbon monoxide atmosphere, the nanoscale iron in the particulate materials slowly release nascent hydrogen atoms and hydrogen gas, and nitrate is chemically reduced; meanwhile, the particulate materials have relatively high void ratio, and abundant function anaerobic microbe denitrifying bacteria adhere to the inner parts and the outer surfaces of the particulate materials and reduce the nitrate by using hydrogen released through reaction between the nanoscale-iron and water as electron donors; adherent dependent nitrate iron-oxidizing bacteria also have the effect of reducing the nitrate; the nitrate in wastewater is removed under the chemical action of the nanoscale-iron and the synergistic effects of the anaerobic microbes; ferrous and ferric hydroxides are continuously formed on the inner surfaces and the outer surfaces of the porous particulate materials through the chemical reaction of the nanoscale-iron and water and the synergistic effect of the anaerobic microbes, so that the chemical adsorption of phosphorous in water is promoted, thus the effect of simultaneously removing phosphorous and nitrogen is achieved.

Owner:HEFEI UNIV OF TECH

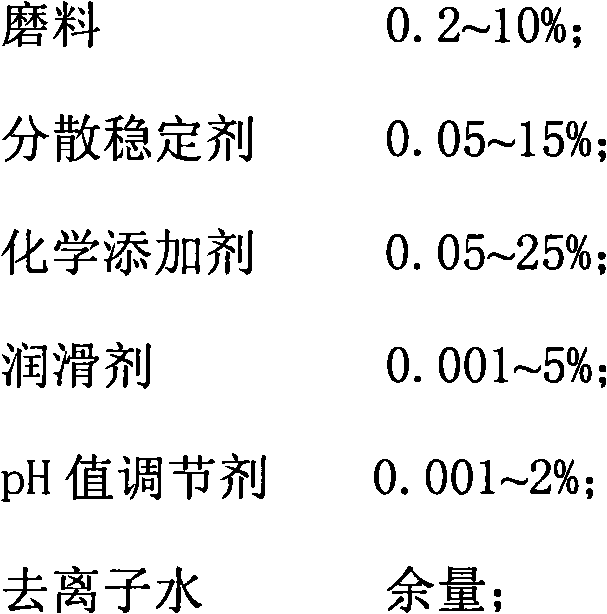

Water-based 6H-SiC monocrystalline substrate chemical mechanical polishing (CMP) solution and preparation method thereof

InactiveCN102337082AHigh removal rateNo damagePolishing compositions with abrasivesMicro nanoWater based

The invention discloses a 6H-SiC single chip global planar chemical mechanical polishing (CMP) solution. In the solution, spherical micro-nano particles are taken as grinding materials. The solution comprises the following components in percentage by weight: 0.2-10 percent of 1-3 types of spherical particles of 10-250 nanometers serving as grinding materials, 0.05-15 percent of dispersion stabilizer, 0.05-25 percent of additive having a chemical function, 0.001-5 percent of lubricating, a pH regulator for regulating the pH value to 9.5-13.5 and the balance of high-purity deionized water. The polishing solution has the advantages of controllable removing rate, no damage to a chip after polishing, high flatness, low price and low cost, and can be applied to the CMP process of hard and brittle crystal materials and precision CMP of other optical materials.

Owner:HENAN INST OF SCI & TECH

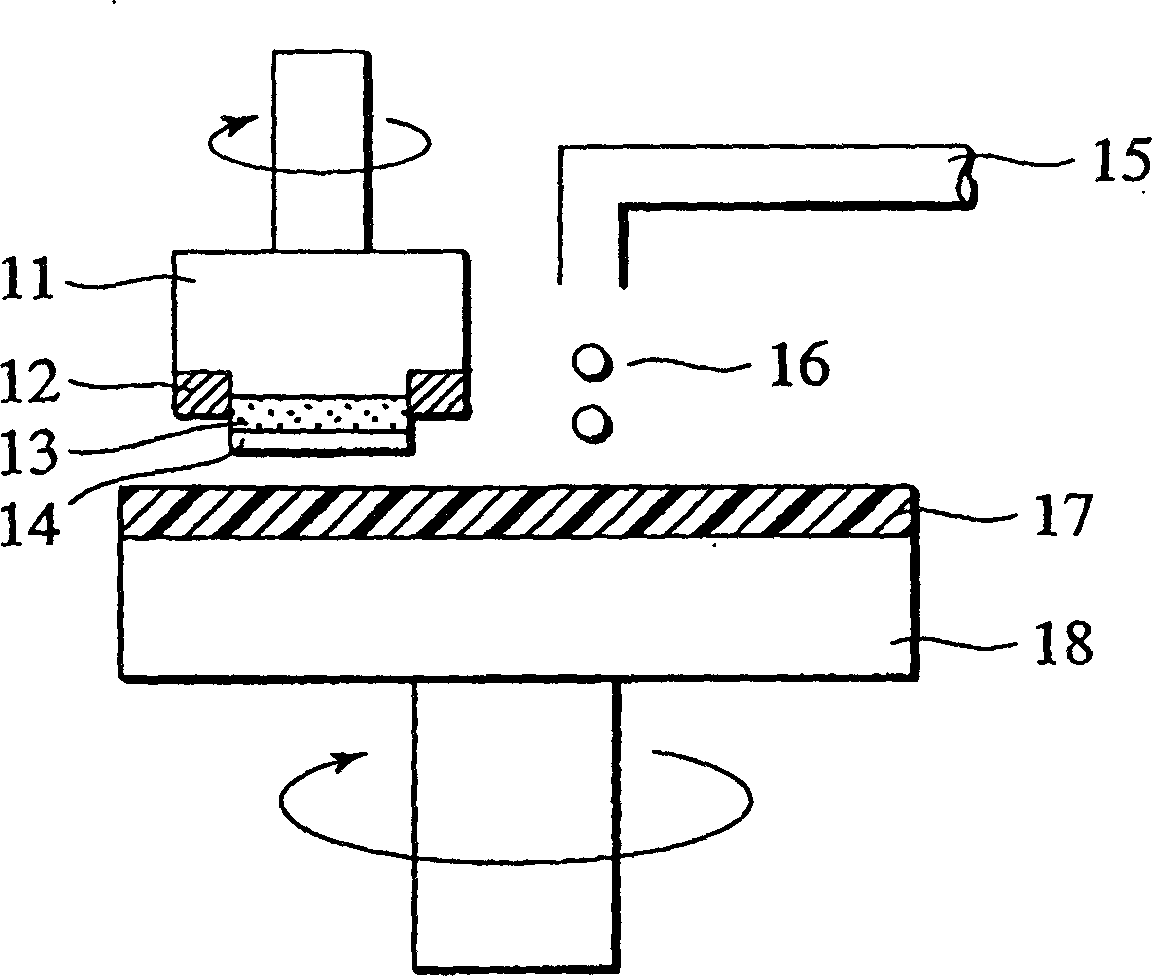

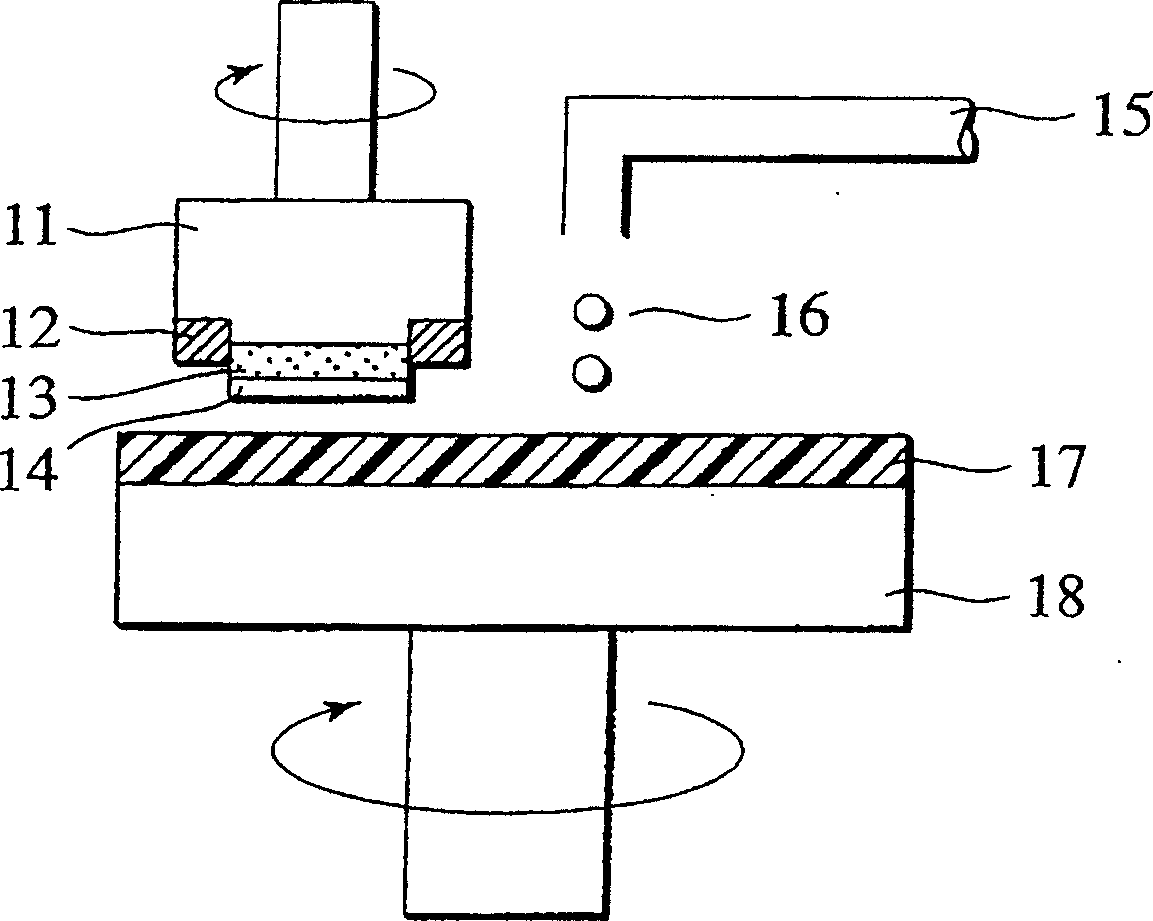

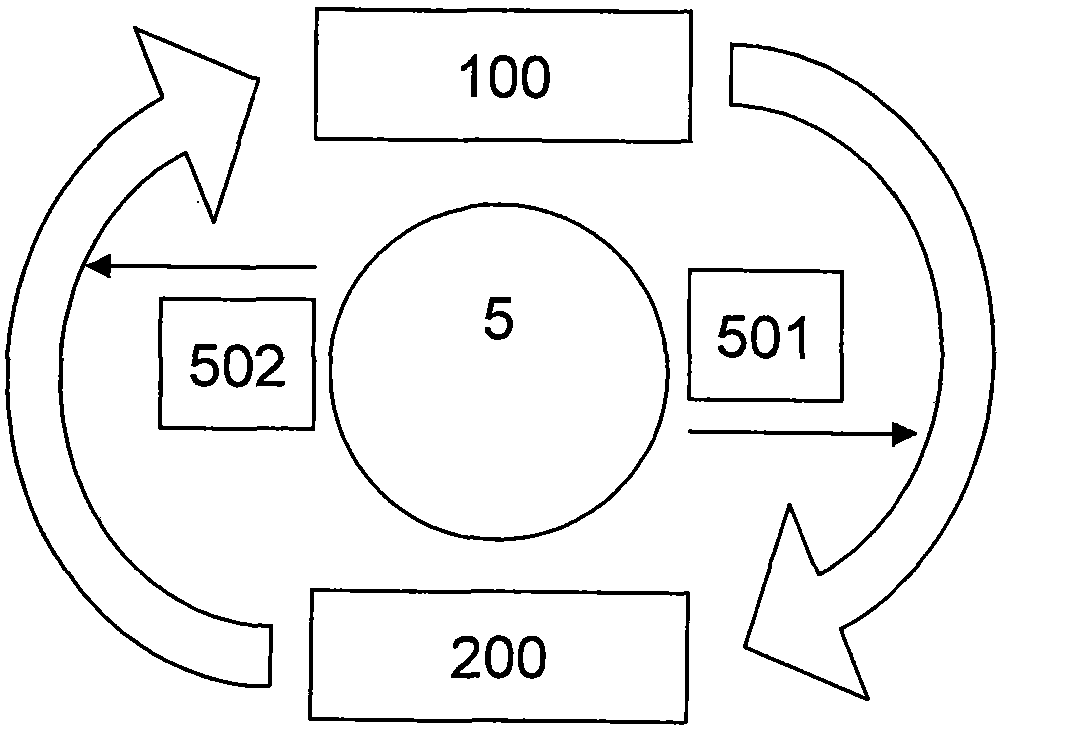

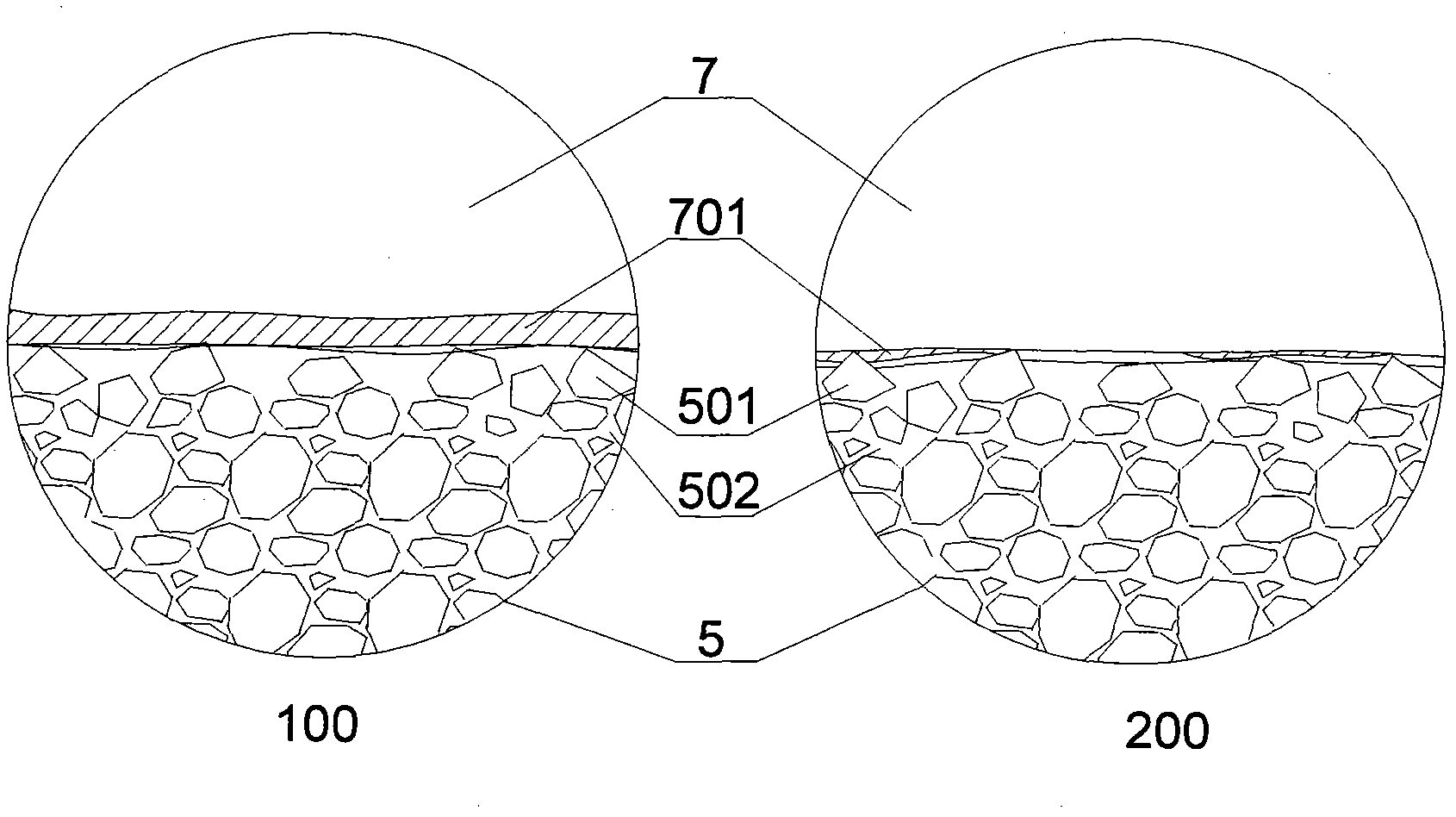

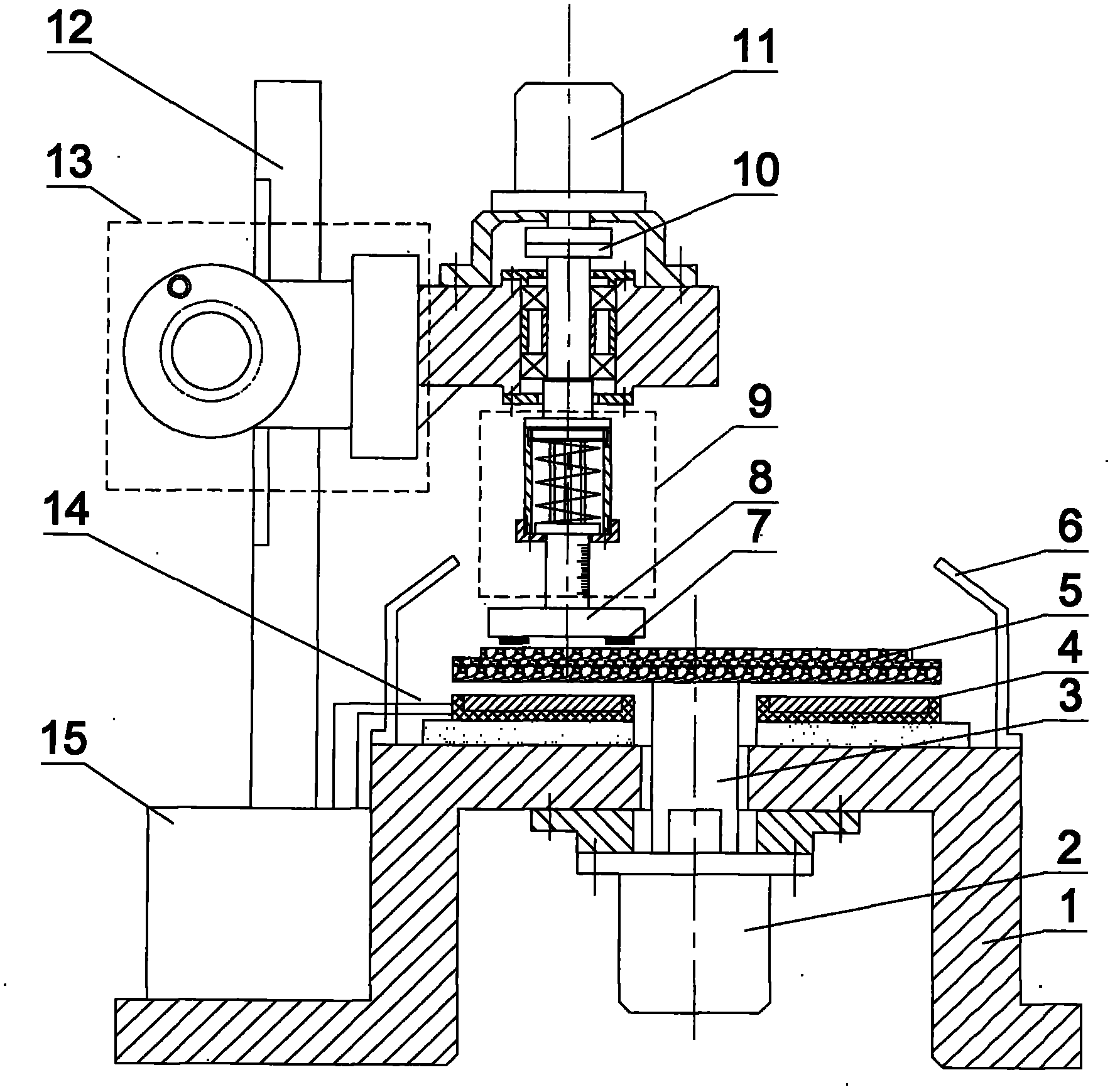

Diamond surface chemical mechanical combined machining method and device thereof

InactiveCN101972979AImprove the efficiency of graphitizationGuaranteed grinding qualityLapping machinesGraphiteAdamite

The invention relates to a diamond surface chemical mechanical combined grinding and polishing method. Composite material is adopted as a tool millstone used for grinding and polishing, the tool millstone is heated to appropriate temperature, and then high speed rotational motion is carried out; certain pressure is utilized to press a diamond film / block to be processed onto the surface of the millstone, so that high speed friction is produced between the diamond film / block and the surface of the millstone, and high efficiency grinding and polishing on the surface of the diamond is realized under the chemical-mechanical combined circulation action of friction region. The method adopts a chemical-mechanical combined way, and the grinding process includes a catalytic surface graphitizing process and a mechanical graphite scraping process. In the combined circulation process of chemical action and mechanical action, diamond surface material is efficiently removed. The related device integrates heating and loading functions, a combined millstone is used as a tool millstone, and the beneficial effects include that processing efficiency is high, mechanical acting force is small and processing quality is good. The invention also relates to a diamond surface chemical mechanical combined grinding and polishing device.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

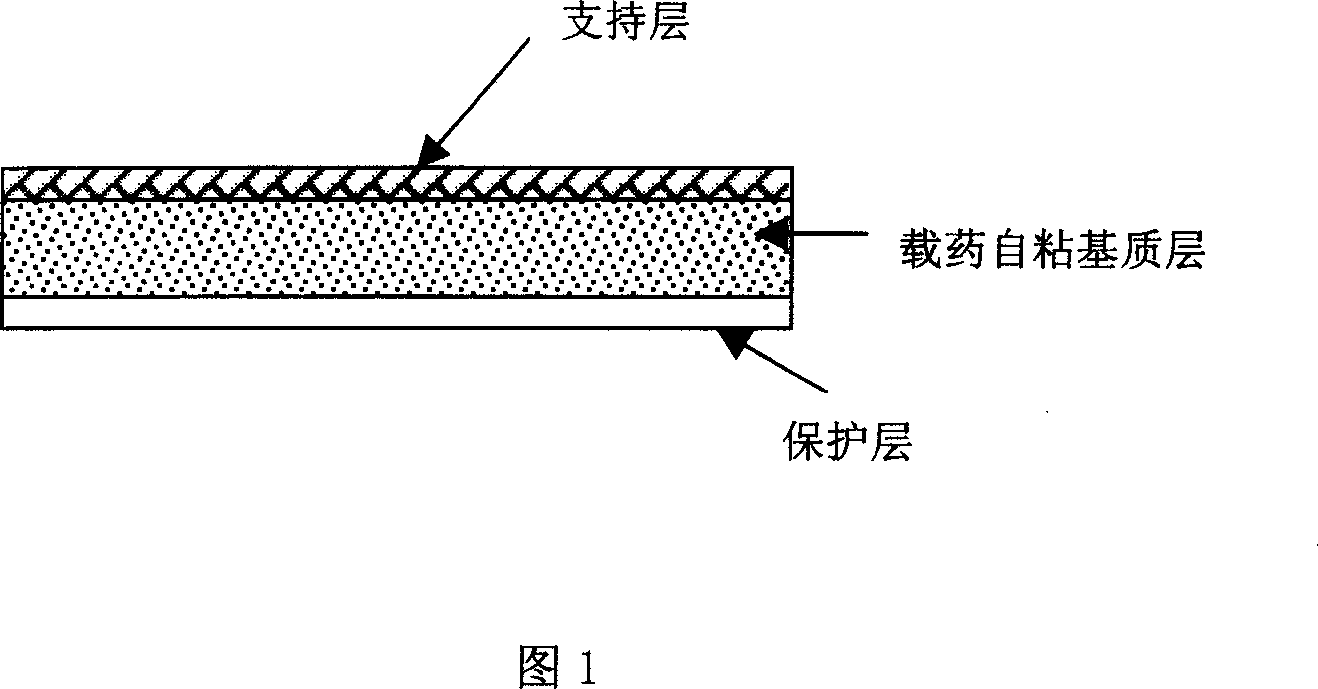

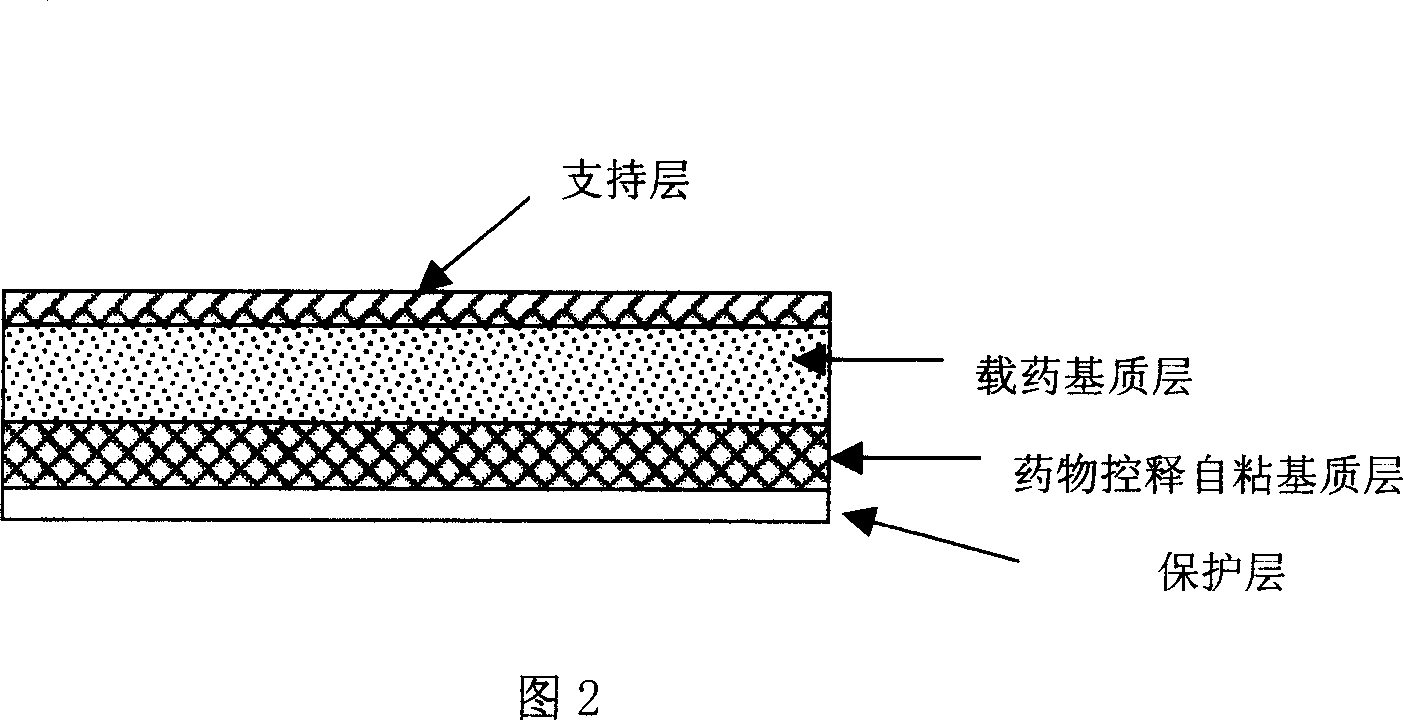

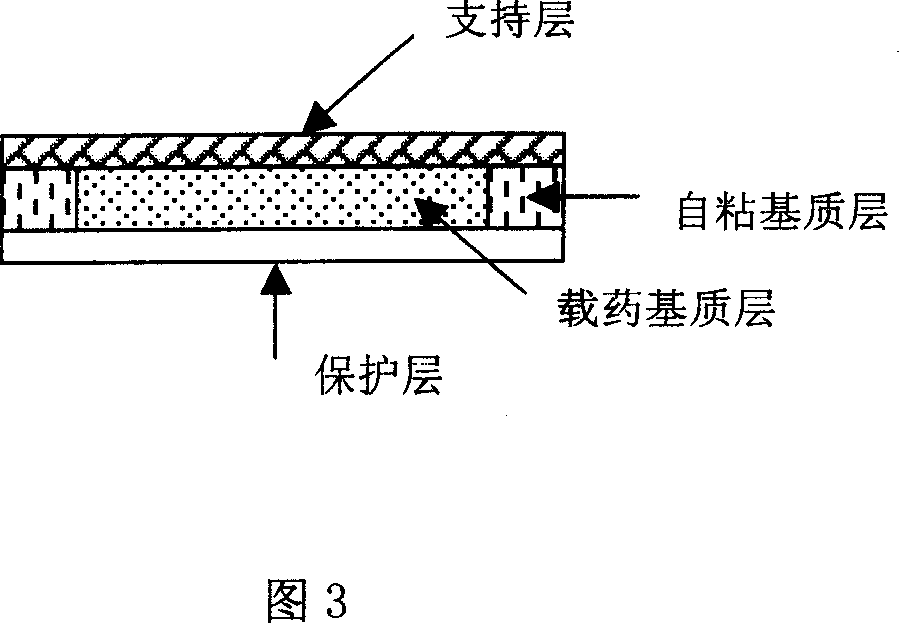

Rasagiline transparent patch for curing and preventing neurological diseases and the preparing method thereof

The present invention relates to one kind of transdermal rasagiline medicine plaster for preventing and treating neurological diseases and its preparation process. The transdermal rasagiline medicine plaster includes one support layer without chemical reaction with the matrix components, one matrix layer containing rasagiline or its pharmaceutically acceptable salt, and operate protecting layer being torn off before the plaster is used. It features the matrix layer with polymer as the basic material, adhering system with inorganic or organic filler, stored rasagiline and matter(s) to promote the transdermal absorption of rasagiline.

Owner:CHONGQING PHARMA RES INST +1

Method for breaking walls of cells of bran by wet grinding

The invention relates to a method for breaking walls of cells of bran by wet grinding, and belongs to the technical field of industrial biochemistry. The invention adopts the technical key point that: bran, water, and enzyme for degrading walls of cells of the bran are mixed, and subjected to wet ball-milling grinding to form superfine wall-breaking powder. By combining an ultramicro-pulverization method, the water and the enzyme for degrading the walls of cells of the bran, the cells of the bran are subjected to wet ball milling for wall-breaking treatment; compared with single ultramicro pulverization, the method can greatly reduce the energy consumption, is simple and has low requirement on operating equipment; and compared with single enzymatic degradation, the method combines wet ball milling, combines chemical action with mechanical force action, and has the advantages of greatly saving energy required by high temperature treatment, avoiding the defect of enzyme inactivation under high temperature treatment, eliminating crystal structures of cellulose and improving enzymolysis efficiency.

Owner:ZHENJIANG AGRI SCI INST JIANGSU HILLY AREAS

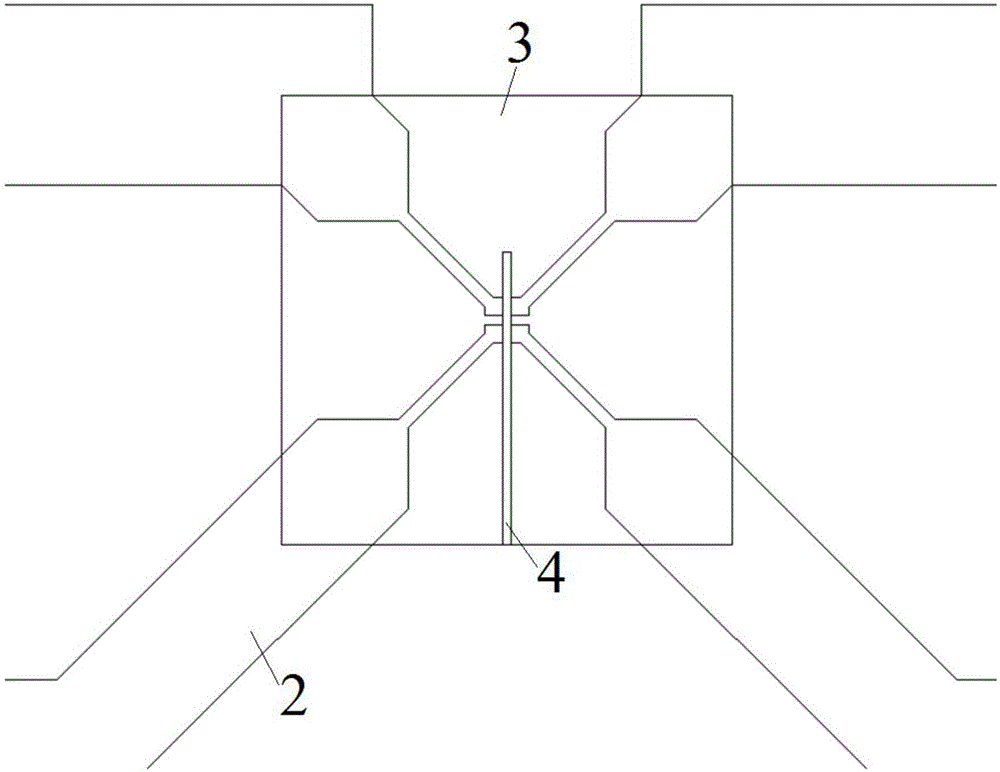

Nanometer material transmission electron microscope in-situ testing chip, preparation method and applications thereof

ActiveCN105136822AReduce the conditions of useReduce use costTelevision system detailsMaterial analysis using wave/particle radiationHeterojunctionElectron

The present invention discloses a nanometer material transmission electron microscope in-situ testing chip, a preparation method and applications thereof, and belongs to the technical field of nanometer material performance in-situ testing. The chip comprises a silicon substrate, insulating layers and a film window, wherein the insulating layer respectively grows on both surfaces of the silicon substrate, a metal film or device or a semiconductor function film or device grows on the chip front surface insulating layer so as to apply various physical and chemical effects on a sample, the center of the chip is provided with the film window, and the film window region is provided with a electron beam penetrating long hole or electron beam penetrating long groove having a large aspect ratio. According to the present invention, the transmission electron microscope sample can be subjected to in-situ measurement under the atomic scale resolution, the nano-wire samples and the nano-tube samples can be subjected to in-situ characterization, the bulk samples and the heterojunction interface samples can be subjected to in-situ characterization, the placement of the sample through the micro manipulator in the focused ion beam system and the laboratory can be achieved, and the sample transferred and fixed on the chip can be continuously processed by using the ion reduction equipment.

Owner:NANJING UNIV

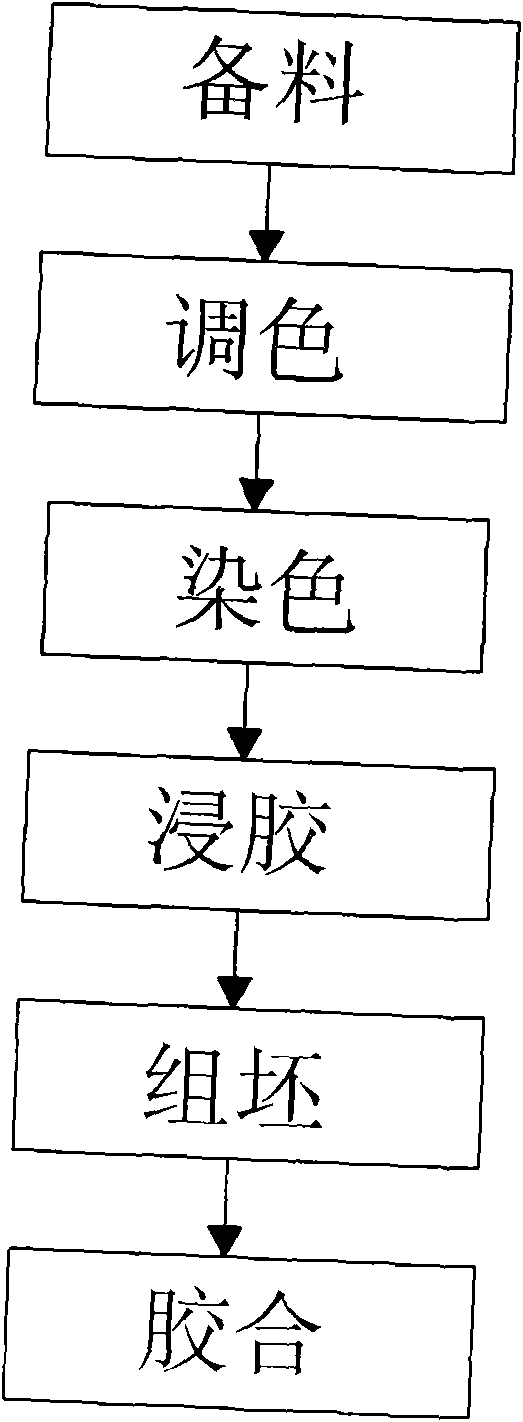

Manufacturing technique of dyeing bamboo filament plate

InactiveCN101579880AIncrease added valueImprove visual propertiesWood treatment detailsFlat articlesMaterials preparationEngineering

The invention relates to a manufacturing technique of a dyeing bamboo filament plate, belonging to the technical field of bamboo board. The technique comprises: material preparation, bamboo wood is made into bamboo filament, the color is adjusted, and the bamboo filament is dyed and then processed by gum dipping to form a plastic film; assembly, the bamboo filament is paved and assembled to be a plate blank and made into the dyeing bamboo filament plate by high temperature and high pressure agglutination. The invention integrally combines the latest research results of multiple subjects such as wood science, dyestuff chemistry, surface physical chemistry, organic chemistry, mechanical processing and the like into a new material, and the bamboo filament is processed by dyeing and recombination to simulate woody texture and color of precious woods such as red wood, teak and hickory, so that the bamboo filament is combined with the dye by chemical action and physical chemistry action, and the bamboo filament has a certain fast color, so that the visual characteristic and the added value of the bamboo wood can be improved. The manufacturing technique can be widely used for manufacturing high quality floor, slicing veneer bamboo, making furniture, decorating materials and the like, thus improving the processing utilization rate of the bamboo wood of China, enhancing the competitive strength of the bamboo wood product and expanding the application field of bamboo articles.

Owner:国家林业局竹子研究开发中心 +1

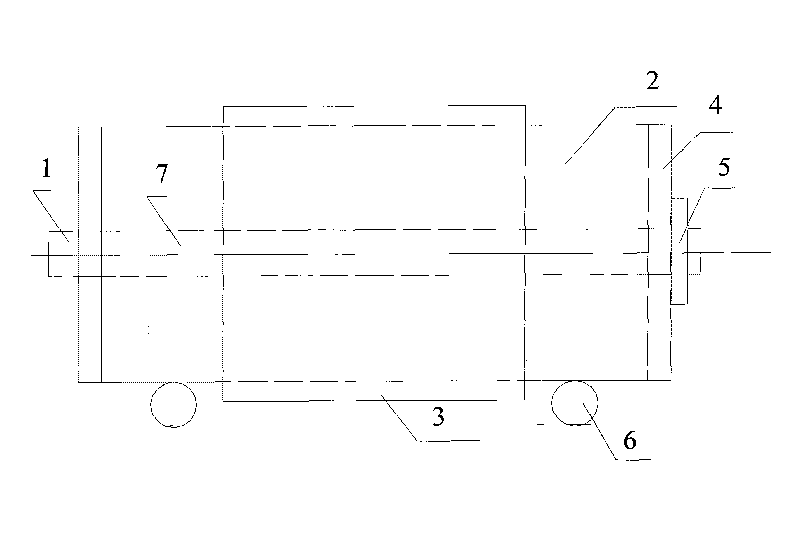

Method for testing concrete performance under pressure stress-chemical coupling effect and device thereof

InactiveCN101726439AConvenient performance testSmall footprintWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesCarbonizationEngineering

The invention discloses a method for testing concrete performance under pressure stress-chemical coupling effect and a device thereof. The method applies a pressure stress to a test piece through a prestressing mode, and provides specific chemical corrosion action through a matched sealing device so as to apply a pull force to concrete and apply common chemical action at the same time. The internal stress of the concrete is monitored through a pressure sensor, the pressure stress is kept constant through secondary tension prestressing force, and the sealing device is arranged on the middle part of the concrete test piece to provide the chemical action, so the corrosion action of the chemical medium on a loading device is avoided; and a sealed box can provide one or more chemical erosion environments of carbonization, sulfate erosion, alkali-aggregate reaction, chloride ion erosion and corrosion. The device has a string structure, and can conveniently apply the pressure stress-chemical coupling effects of different conditions to a plurality of concrete test pieces.

Owner:SOUTHEAST UNIV

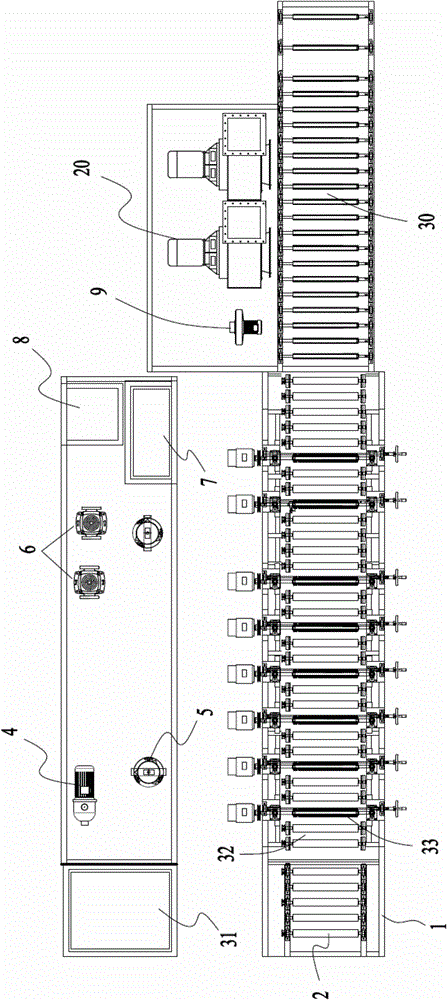

Through type cleaner and cleaning method thereof

ActiveCN103909079AImprove cleaning efficiencyConsistent cleaning qualityCleaning processes and apparatusLiquid storage tankEngineering

The invention discloses a through type cleaner. The through type cleaner is used for cleaning workpieces and comprises a frame, a roller transmission system, a hairbrush alkali-washing device, a spray cleaning device, a cleaning rinsing device, a water air cutting device and a drying device, wherein the roller transmission system is mounted on the frame and used for conveying the workpieces, the hairbrush alkali-washing device comprises a liquid storage tank, a cleaning tank and hairbrush rollers, the liquid storage tank and the cleaning tank are communicated through a liquid injecting pump and a filter, the workpieces are immersed inside alkali cleaning liquid of the cleaning tank, and the hairbrush rollers are driven by a motor to clean the surfaces of the workpieces. The invention also discloses a cleaning method of the through type cleaner. According to the through type cleaner and the cleaning method thereof, the surfaces of the workpieces can be cleaned through abrasion of the hairbrush rollers and the chemical action of cleaning agent. The through type cleaner achieves automatic cleaning and is high in cleaning efficiency, uniform in cleaning quality and applicable to mass production.

Owner:ZHANGJIAGANG ULTRASONIC & ELECTRIC

Biological compound fertilizer and production process thereof

InactiveCN101555173ASolve watering and irrigation problemsLow input costBio-organic fraction processingWaste based fuelContinuous croppingChemical reaction

The invention relates to a biological compound fertilizer and a production process thereof, which relates to the field of agricultural fertilizers and the production thereof. The prior biological bacterial fertilizer has the problems of not comprehensive enough nutrition, poorer water retention and drought-resistant degree and lower survival rate of biological bacteria. The invention provides a prescription that the biological compound fertilizer contains liquid-fertilizer sustained release agent with micropores, compound biological fertilizer, high-efficient organic matters, inorganic N P, K and micro elements in the lack of soil; and the production process adopts a method of roller- extrusion cold prilling and has no drying and air-cooling procedures and no any chemical actions. The invention has the advantages of more comprehensive nutrition, water retention, drought and continuous cropping resistance, the improvement of the survival rate and the reproduction rate of biological bacteria and balanced crop growth.

Owner:NANYANG BOLIDA FERTILIZER

Porous nano composite abrasive particle containing polishing active elements, polishing solution composition and preparation method thereof

ActiveCN102408871AImprove chemical performanceFast polishingOther chemical processesPolishing compositions with abrasivesCeriumSilicon oxide

The invention relates to a porous nano composite abrasive particle containing polishing active elements, a polishing solution composition and a preparation method thereof. The composite abrasive particle is: a. composite silicon oxide abrasive particle formed by silicon oxide and oxide containing polishing active elements; or b. composite aluminum oxide abrasive particle formed by aluminum oxide and oxide containing polishing active elements. The composite abrasive particle is in a nano pore structure, and can lower the abrasive hardness and reduce the excess collision of the inorganic compact abrasive particle onto the substrate, thereby reducing the polishing damage; the abrasive particle contains iron or copper, cerium, nickel, titanium, silver or any other polishing active element in the aspect of chemical composition, and can enhance the chemical action of the abrasive particle; and the porous structure of the abrasive particle can adsorb and store the polishing solution component to enhance the chemical activity of the abrasive particle. The enhancement of the chemical action can increase the polishing speed of the abrasive particle, and the abrasive particle designed in such a way can simultaneously achieve the goals of high speed and high precision in polishing. When being used for polishing an electronic device, such as a hard disk substrate, the polishing solution provided by the invention can effectively lower the surface roughness of the memory hard disk substrate, and has high polishing speed.

Owner:昆山捷纳电子材料有限公司

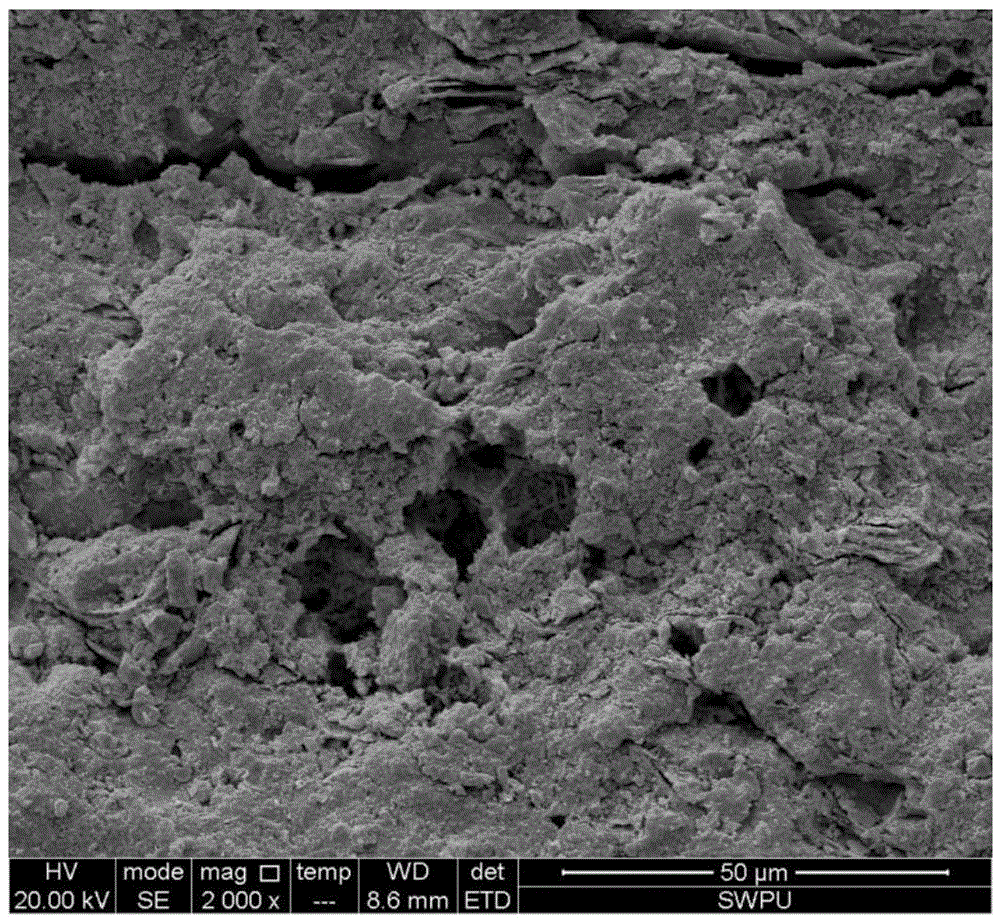

Method for preparing functionalized graphene by synchronous ultrasonic chemical and mechanical chemical method

InactiveCN107792848AIncrease concentrationUnique craftGrapheneBulk chemical productionDispersion stabilityChemical reaction

The invention discloses a method for preparing functionalized graphene by a synchronous ultrasonic chemical and mechanical chemical method. The method comprises the steps of adding a graphite raw material and a functionalized reagent into ultrasonic ball milling equipment, and carrying out ultrasonic ball milling for 1-72h at a rotating speed of 100-500rpm under an ultrasonic environment to obtainfunctionalized graphene containing functional groups. According to the method, graphite is stripped by synchronous ultrasonic ball milling to obtain graphene, and by virtue of ultrasonic chemical andmechano-chemical actions, the functionalized reagent and the graphene rapidly react chemically, and functionalized modification of the graphene is realized at the same time, so that the stripping efficiency and dispersion stability of the graphene are effectively improved, the structure and the performance of the graphene material are regulated and controlled, and the application field of the graphene material is expanded.

Owner:广东烯谷碳源新材料有限公司 +1

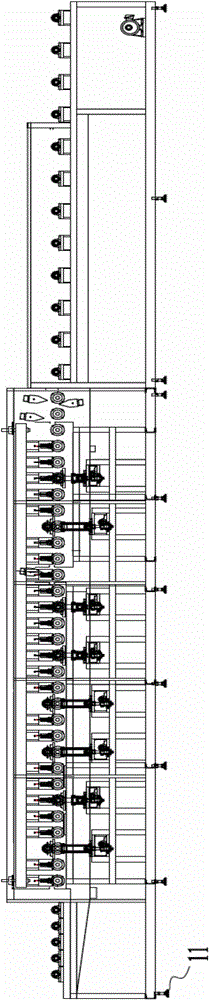

Multi-stress high-temperature corrosion testing system apparatus

InactiveCN101025395AEasy to installImprove sealingWeather/light/corrosion resistanceHybrid systemEngineering

The invention relates to a test equipment, specially relates to a high temperature corrosion test system of material under the much stress state. The test system is composed of loading system, sealing system, heating and temperature controlling system, corrosion aura hybrid system and support platform frame; the invention partly solves the problem of mechanics and chemical action unable to combined in the existing test technology, it provides a high temperature corrosion test system of materials under the much stress state with simple operate, uniform test temperature, high test precision, low cost.

Owner:NANJING UNIV OF TECH

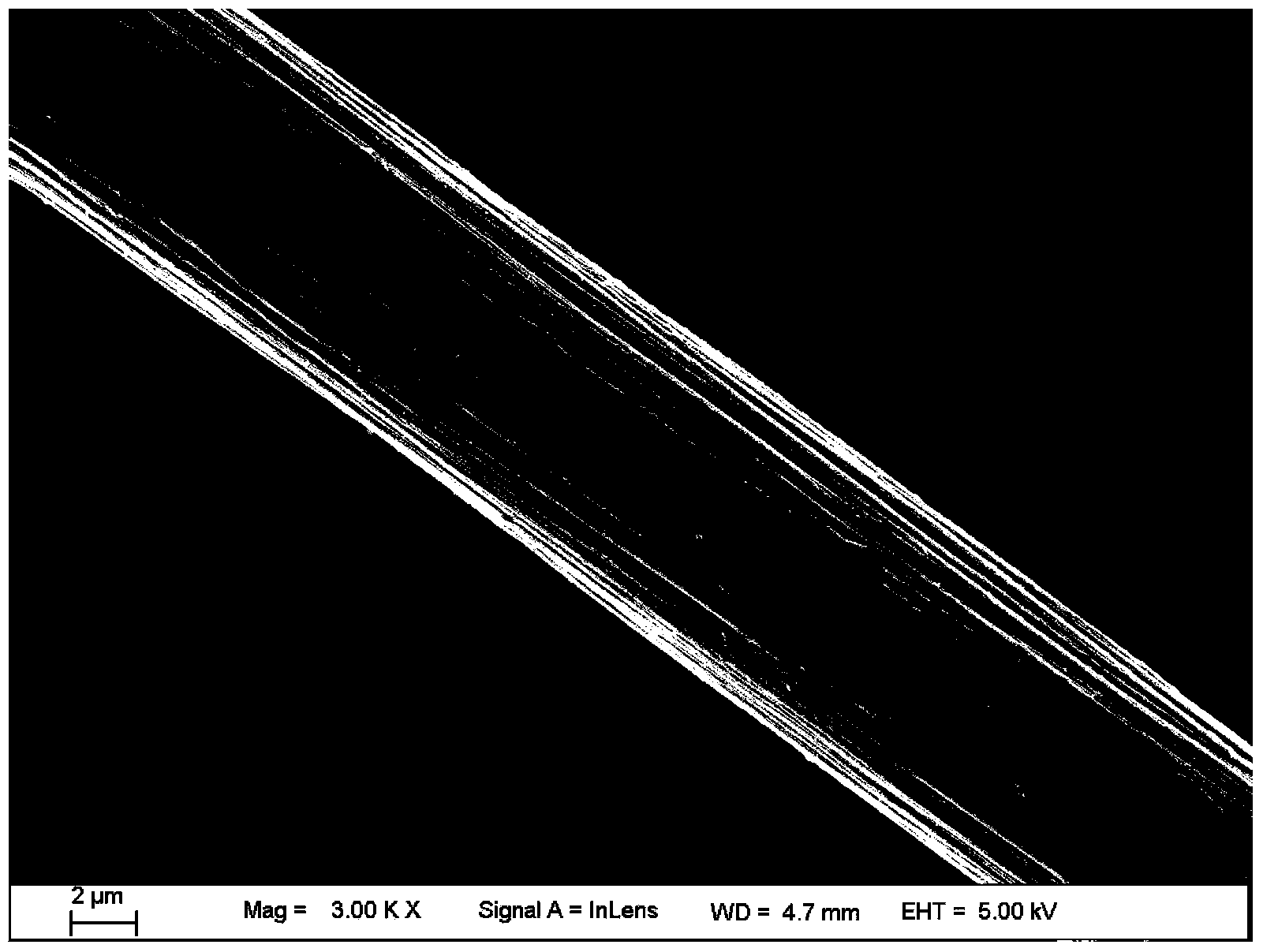

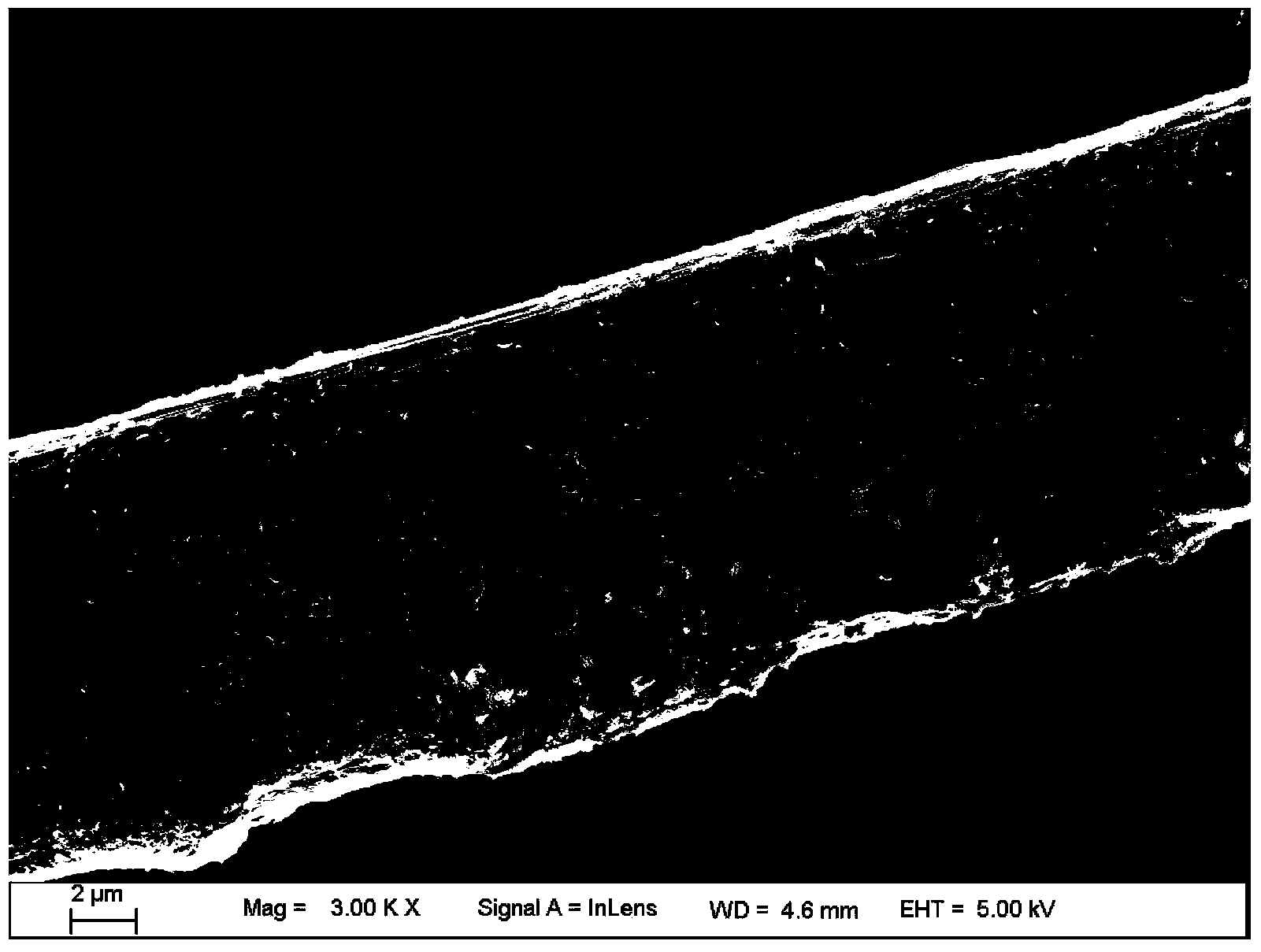

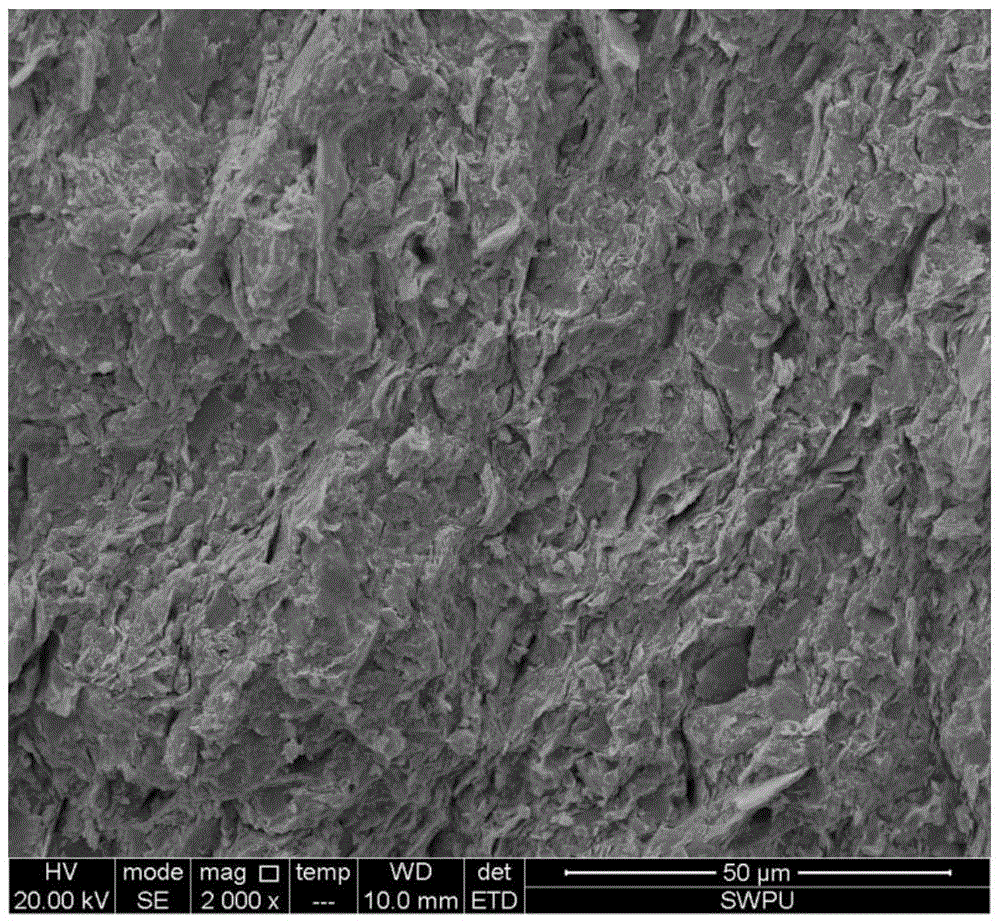

Preparation method of carbon nano tube loaded carbon fiber

The invention discloses a preparation method of carbon nano tube loaded carbon fiber, which belongs to the technical field of surface treatment of inorganic powder material. According to the invention, the carbon nano tube of which the surface is rich in active groups, is loaded to the surface of the carbon fiber after liquid phase oxidation treatment so as to increase the number of active groups on the surface of the carbon fiber and improve the chemical acting force of a base body and the surface of the carbon fiber on the one aspect, and to increase the surface roughness of the carbon fiber and improve the riveting action of the carbon fiber and the base body on the other aspect. Through the combined action on the two aspects, the mechanical property of a composite material is improved. After the carbon nano tube loading treatment, the tensile strength and the tensile modulus of the carbon nano tube loaded carbon fiber / epoxy resin composite material are increased by 17.4% and 44.8% respectively in comparison with those of the carbon fiber composite material without loading the carbon nano tube.

Owner:江苏三强复合材料有限公司

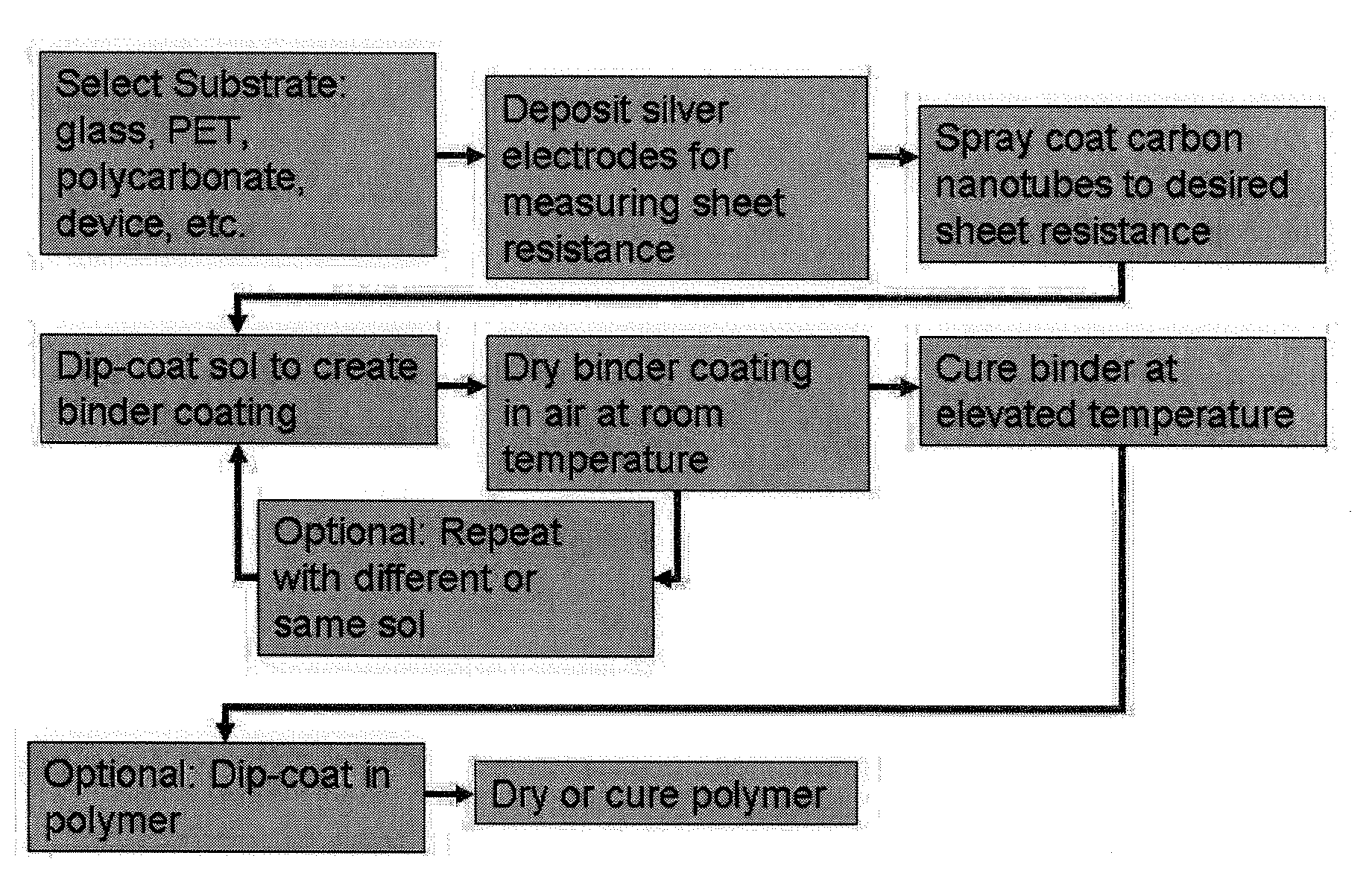

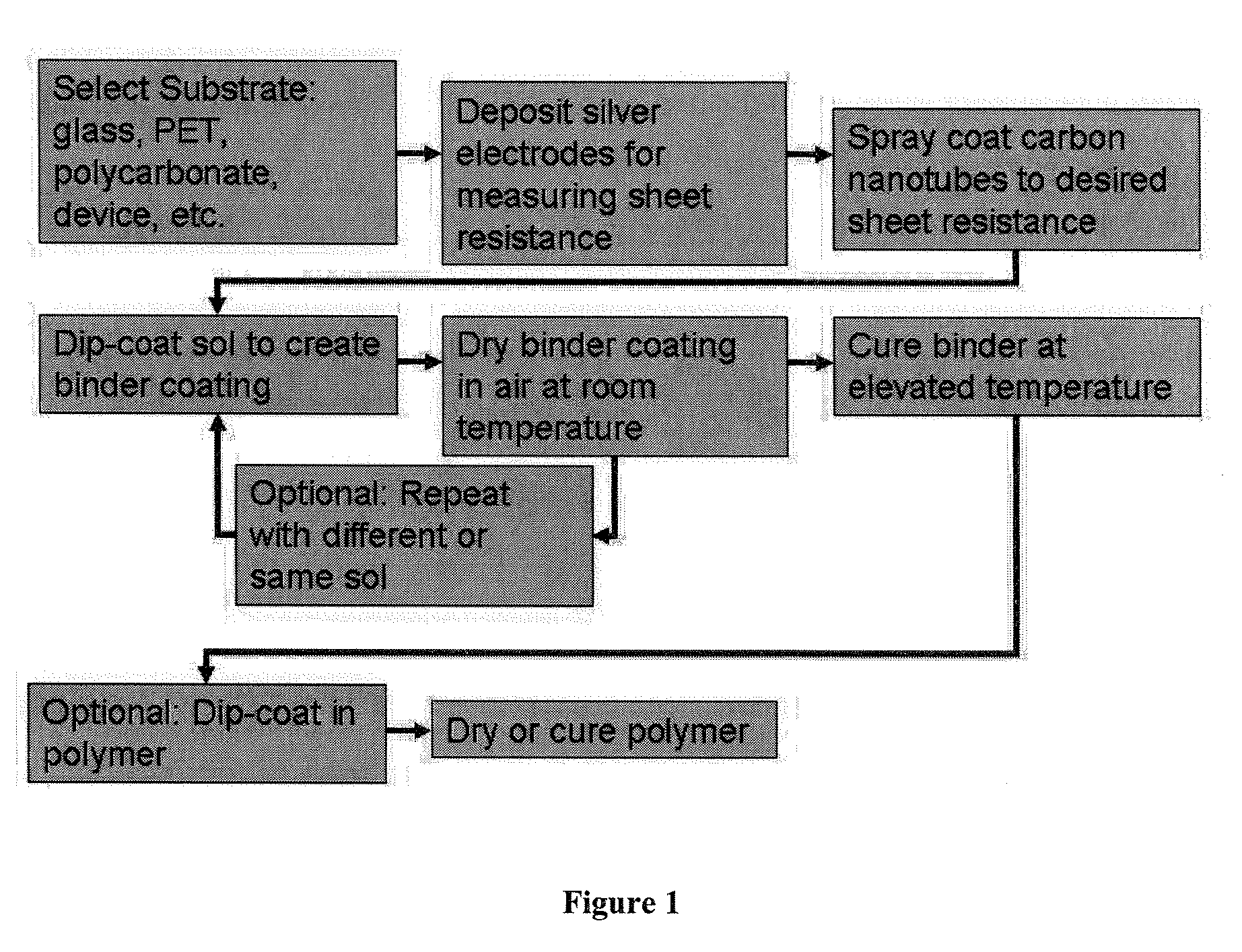

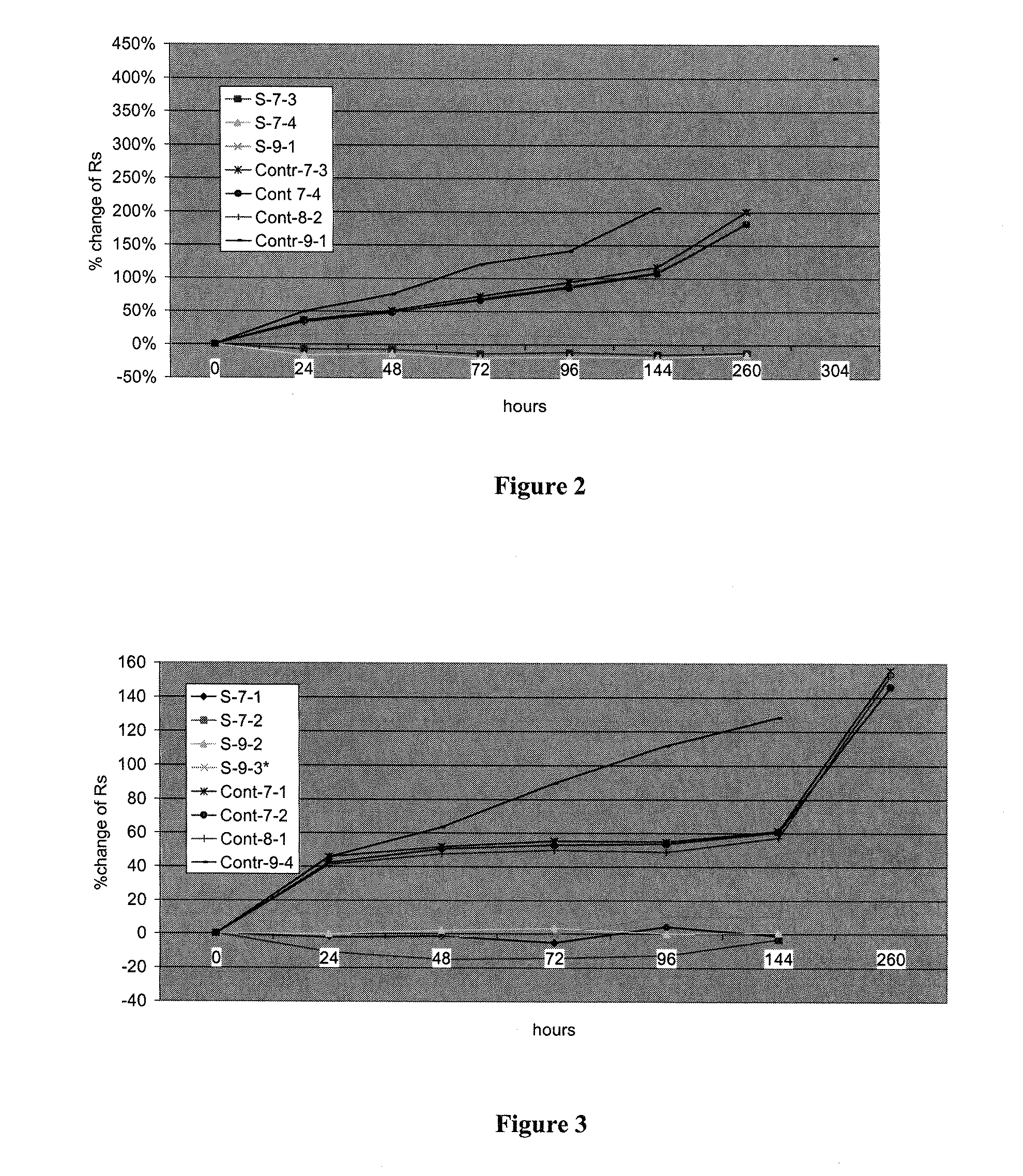

Metal oxide coatings for electrically conductive carbon nanotube films

InactiveUS20100028634A1Improve stabilityPrevent degradationSynthetic resin layered productsNon-conductive material with dispersed conductive materialElectrical resistance and conductanceChemical effects

This invention are directed to methods and compositions preferably comprising non-silicate metal oxides as a treatment for transparent electrically conductive carbon nanotube coatings that prevents resistance changes during exposure to environmental conditions; both chemical effects (for example, water, heat, light, or other compounds) and physical effects (for example, abrasion, scratch, adhesion). The protective properties instilled by these coatings occur preferably through the careful selection of the appropriate metal oxide depending on the application.

Owner:EIKOS

Long-acting slow release type aluminum foil paper and preparing method thereof

ActiveCN101215803AImprove qualityImprove inner qualityNon-fibrous pulp additionFlexible coversChemical reactionPulp and paper industry

The invention discloses a long-acting slow-release-type aluminum foil liner paper and a process for preparation, and the process comprises choosing inner lining paper whose permeating degree is 10-30000CU, coating cigarette modified addition agent or flavoring agent on the surface of the inner lining paper, or adding in the existing adhesive agent which is used by aluminum foil liner paper according to the proposition which is 0.01%-5%, bonding the aluminum foil liner paper and ventilating inner lining paper according to the conventional process, and getting acceptable products after cutting and removing peculiar smell. The invention makes full use of the characters that aluminum foil liner paper directly contacts with cigarette, material which is added can continuously give off flavor components when cigarettes are stored in a storeroom, and which can effectively have a physical and chemical reactions with cigarettes, inner quality is prompted to be improved, and absorbing taste is more pure and comfortable. The invention can have a good connection with the existing cigarette technique and equipment, and production can be achieved by the invention without adjusting the existing equipment.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

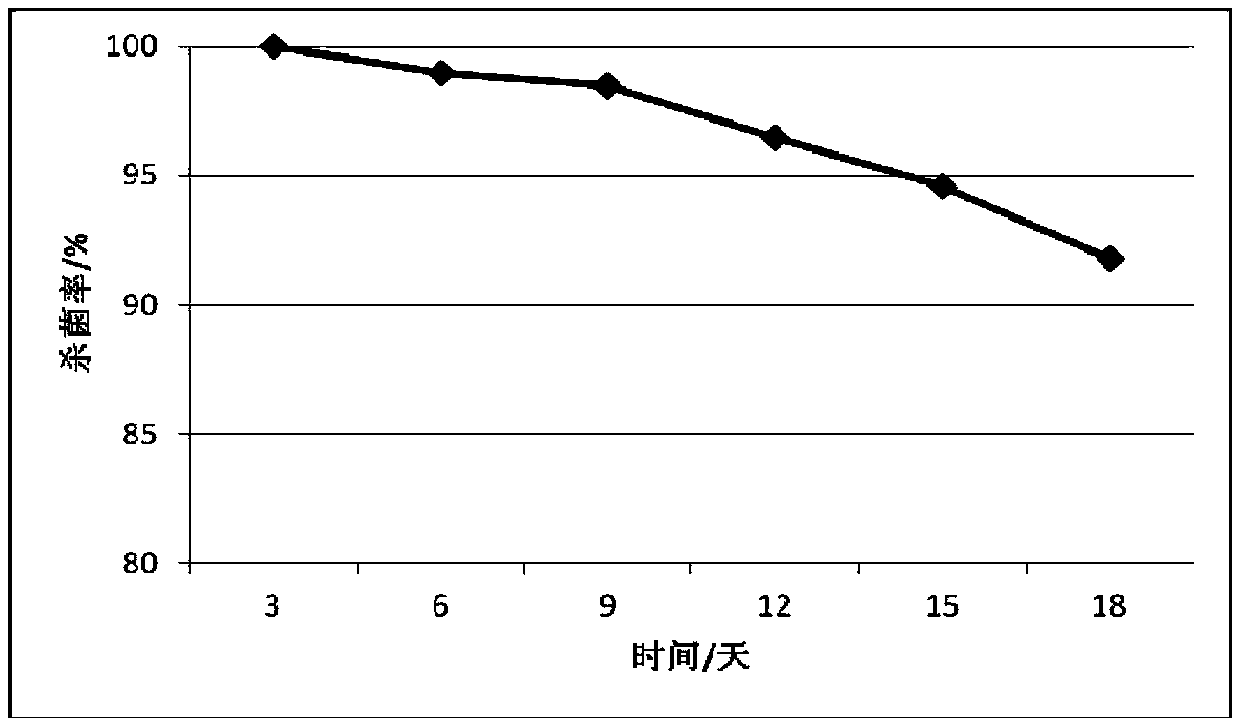

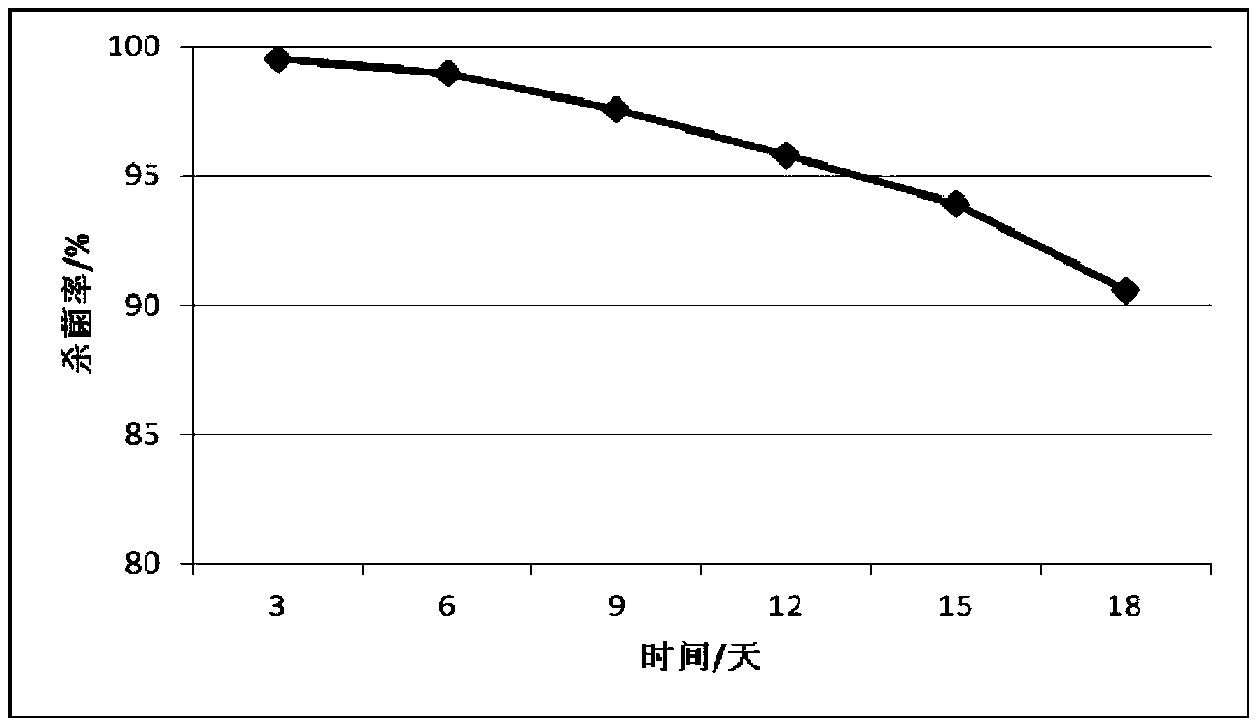

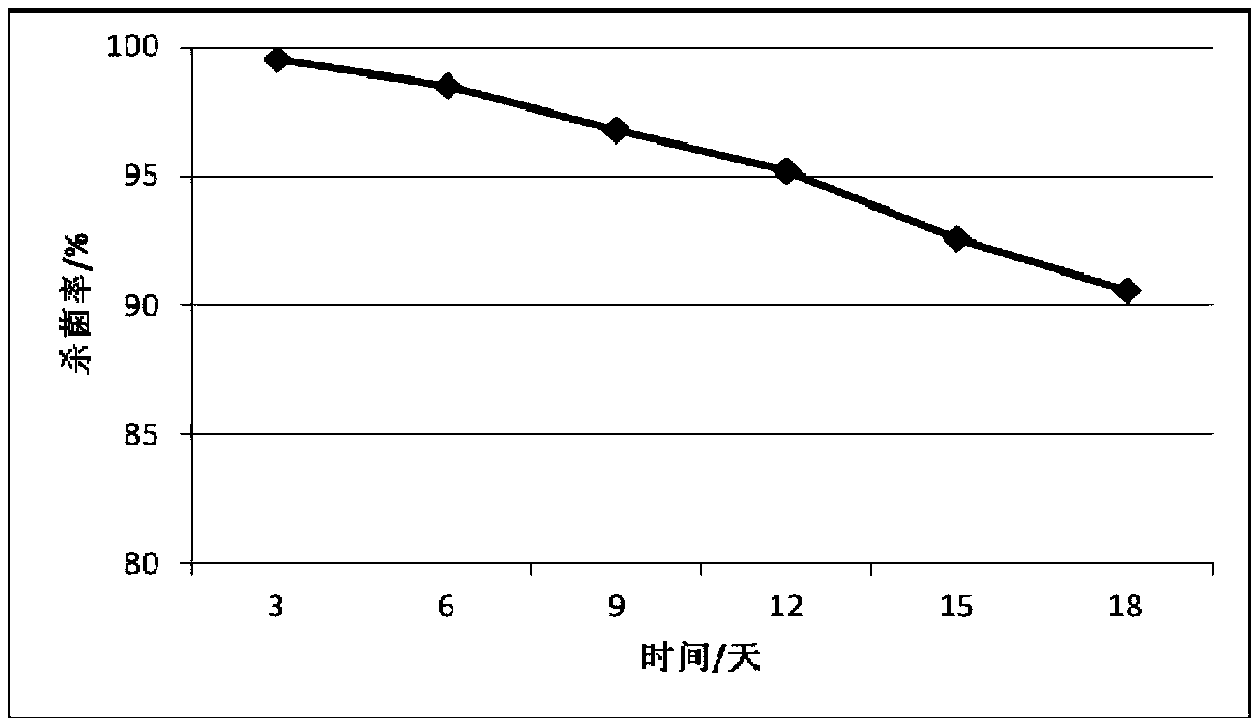

Oil field sewage bactericide and preparation method thereof

ActiveCN103478164ALarger than surfaceImprove adsorption capacityBiocideDisinfectantsSulfate-reducing bacteriaIron bacteria

The invention discloses an oil field sewage bactericide and a preparation method thereof, belonging to the technical field of chemical agents for oil fields and preparation thereof. The oil field sewage bactericide is prepared by mixing the following components in percentage by mass: 10-15% of nano titanium dioxide powder, 0.5-2% of crosslinking agent, 5-10% of surfactant, 5-10% of oxidizer and the balance of water. The bactericide can be deposited on pipe walls, bent angles and other parts along with a liquid flow; a main agent can be slowly diluted out, has persistent chemical action and causes no corrosion to pipelines; the comprehensive sterilizing rate of the bactericide with respect to sulfate reducing bacteria, saprophytic bacteria and iron bacteria can be still up to 90% or above 18 days after filling; and the filling period of the chemical agent is 15-25 days which is 10-15 times longer in comparison with a common chemical agent, thereby greatly relieving the operation intensity and lowering the cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Flyash-hollow-microsphere-based composite titanium white and preparation method thereof

The invention discloses flyash-hollow-microsphere-based composite titanium white and a preparation method thereof. According to the preparation method, flyash hollow microspheres serve as inner cores, crystals TiO2 serve as coating powder, and the TiO2 can be coated on the surfaces of the flyash hollow microspheres through mechano-chemical action, so that composite titanium white can have the nature of pigment TiO2. The composite titanium white disclosed by the invention has the characteristics that the preparation process is simple, the TiO2 is uniformly coated on the surfaces of the flyash hollow microspheres and firmly bonded to the flyash hollow microspheres, the hiding power is high, the cost is low, and the like. The flyash-hollow-microsphere-based composite titanium white, as white pigment, can be applied to the fields of coatings, plastics, inks and the like in a manner that the flyash-hollow-microsphere-based composite titanium white partially substitutes titanium white. Furthermore, when the composite titanium white is applied to the coatings, the hollow heat conductivity coefficient of the flyash hollow microspheres is small, the TiO2 has a high reflection role on sunlight, and then, a complete hollow isolation layer is formed in a manner that the flyash hollow microspheres are closely arranged after a coating is dried, so that the composite titanium white has a good heat insulating effect. The flyash-hollow-microsphere-based composite titanium white has the nature of pigment and heat insulating and heat preservation roles.

Owner:FUJIAN NORMAL UNIV +1

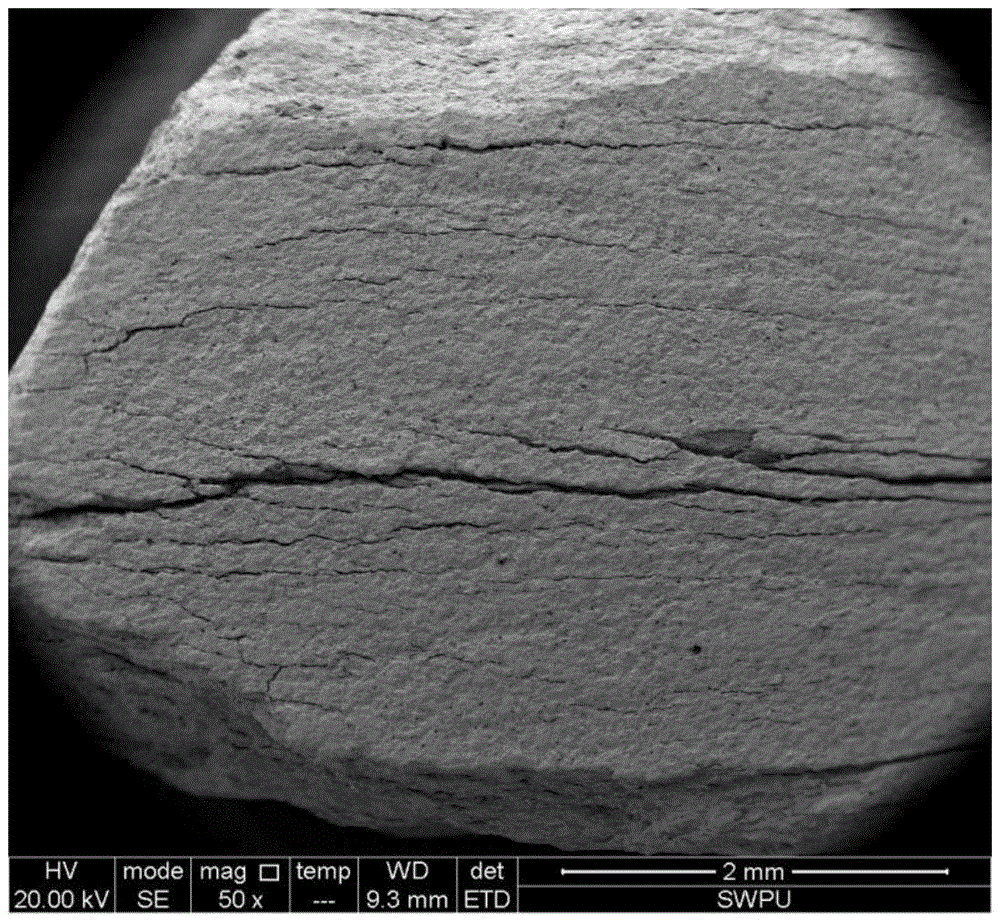

Method of increasing fracture network density for shale gas well fracturing improvement

Owner:SOUTHWEST PETROLEUM UNIV

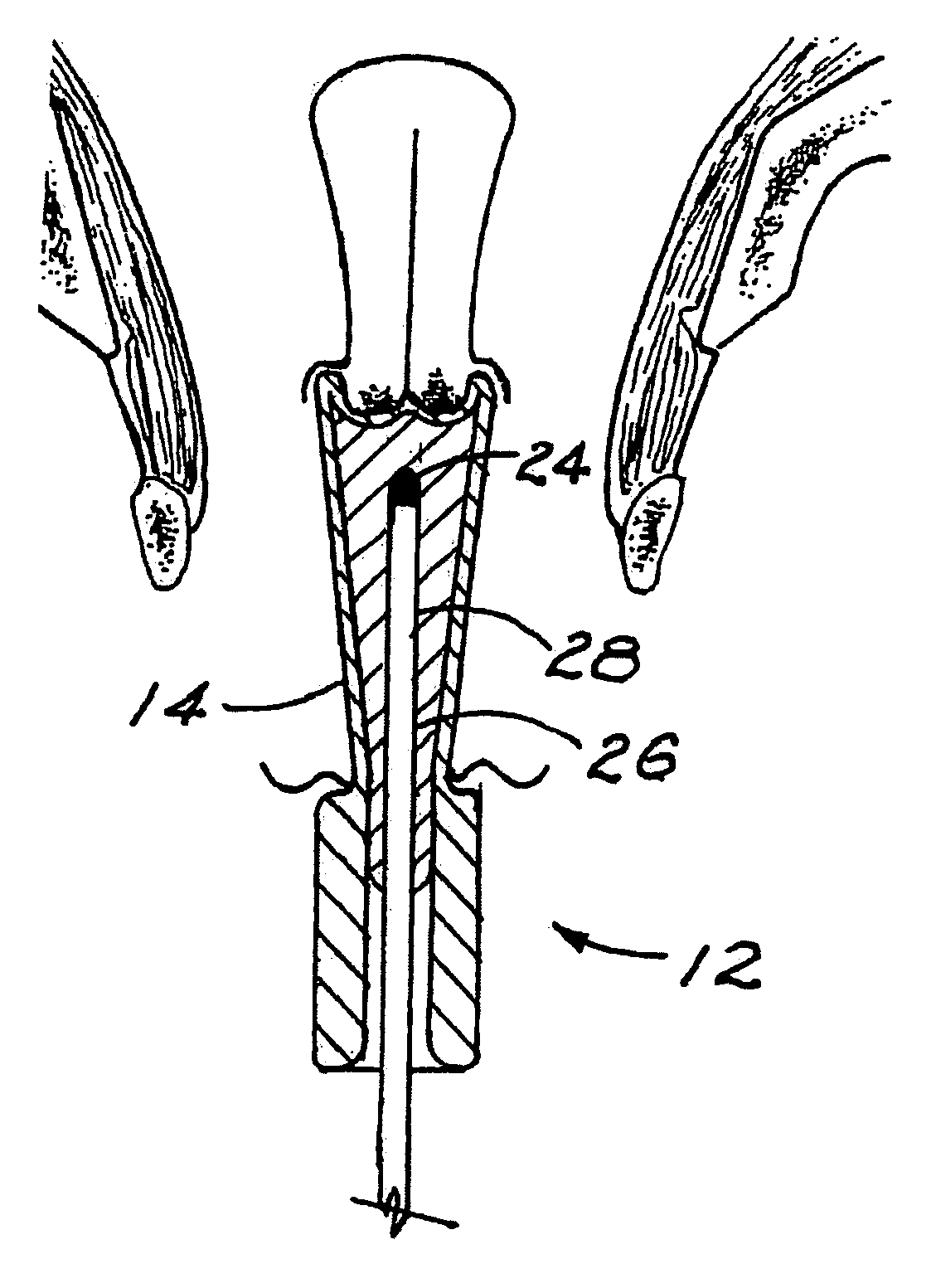

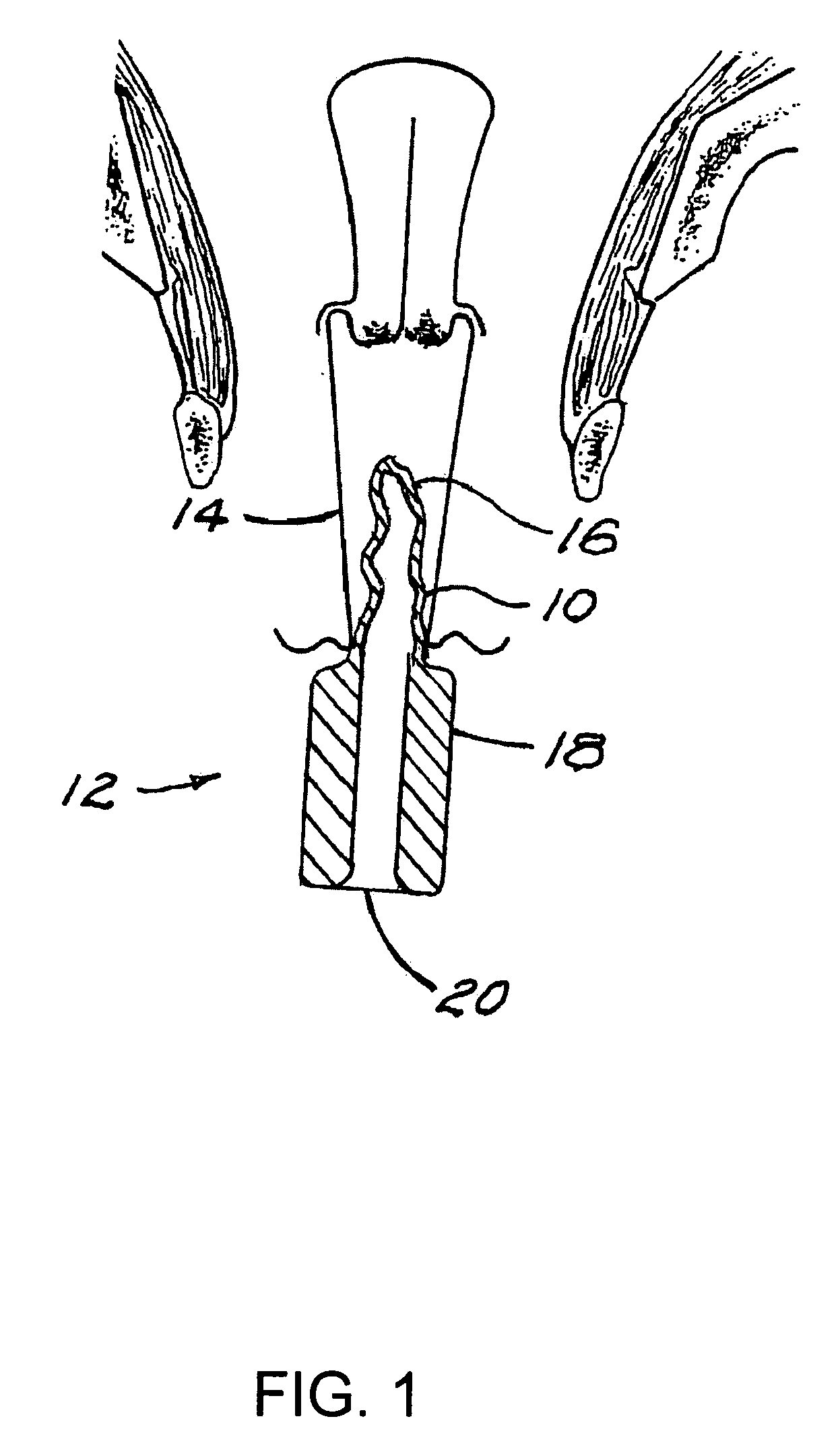

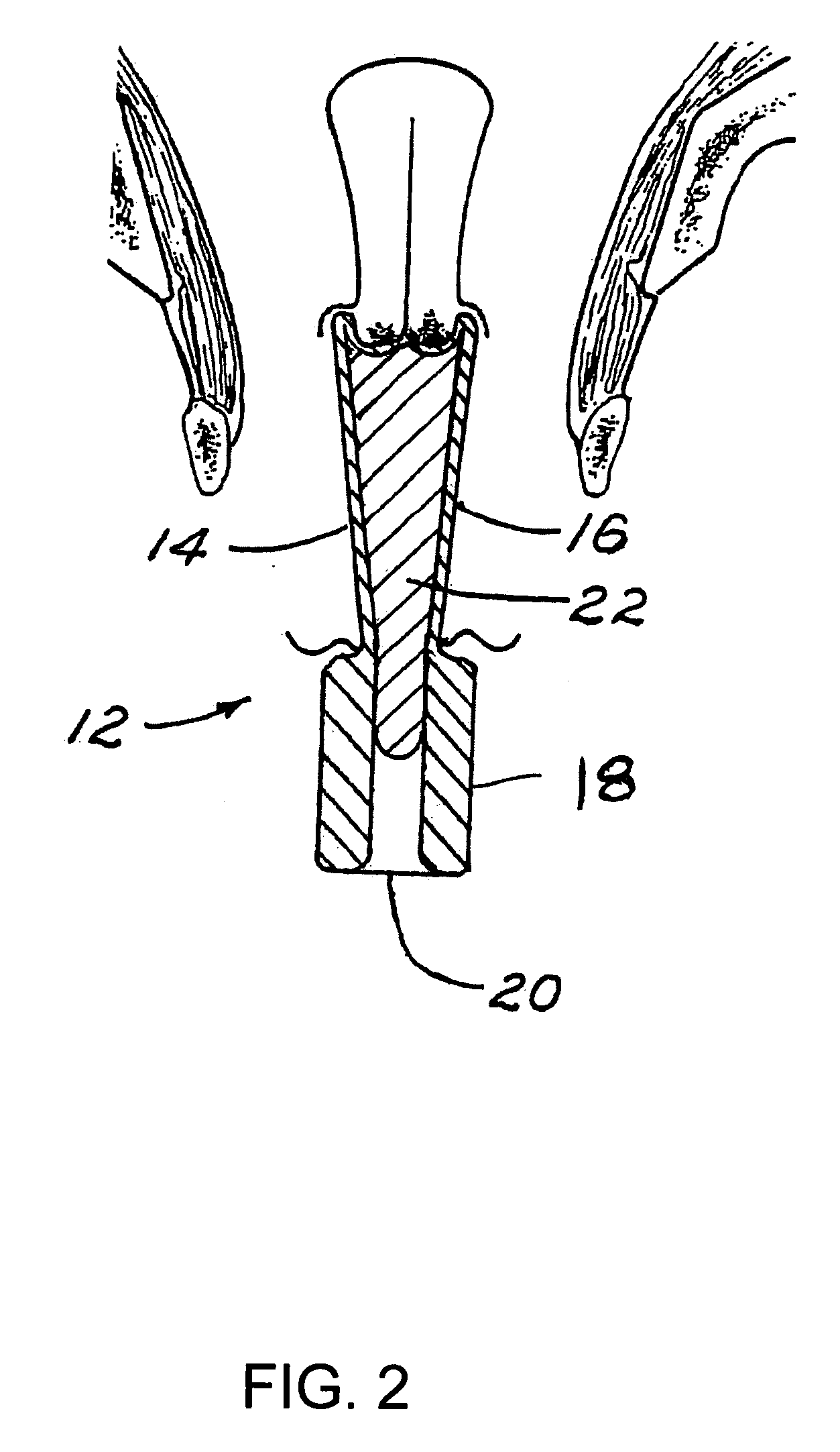

Customized gynecological brachytherapy applicator and method

A customized gynecological brachytherapy applicator is formed by placing a molded balloon, which is secured to a handle, into a vaginal cavity and then filling the mold balloon with a settable liquid material. The material may be an expanding foam or any other form of curable material that becomes solid, rigid or pliable, when set by chemical action, temperature change, oxidation, a curing means such as a light, or other curing regime. The mold balloon can be elastic or inelastic, depending on the degree to which the applicator is to conform its external surfaces to the vaginal contours. One or more lumina are provided in the set filler material to receive a radiation source, with additional lumina optionally provided for purposes such as drainage or administration of therapeutic agents. The applicator may be withdrawn and reinserted into the vagina during treatment, and selected tissues adjacent to the applicator are irradiated in accordance with a radiation prescription.

Owner:XOFT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com