Manufacturing technique of dyeing bamboo filament plate

A production process, bamboo silk technology, applied in the direction of manufacturing tools, wood processing equipment, wood treatment, etc., can solve the problems of monotonous products, single design and color quality, etc., to increase competitiveness, expand application fields, and improve the utilization rate of bamboo processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

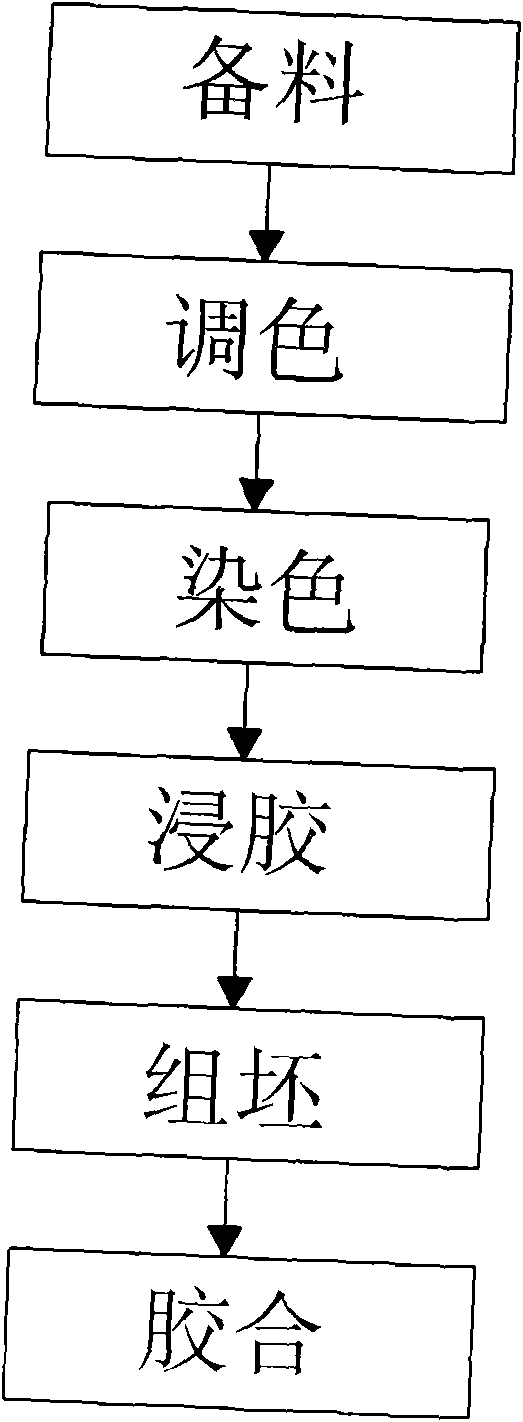

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

[0020] First prepare the bamboo material needed for the dyed bamboo silk board, scrape off the green bamboo on the outer layer of the bamboo, and cut the bamboo into 450-550mm long bamboo sections, preferably 500mm in length. Roll the cut bamboo segments until the bamboo segments are completely decomposed into bamboo filaments, then dry the bamboo filaments to a moisture content of 5-15%, preferably 10%, and use natural drying for drying .

[0021] Then, analyze the color sample according to market needs or simulated objects, determine the product tone, color matching ratio and dyeing scheme, and dye the bamboo silk after confirmation.

[0022] Add 0.3-0.7% water-soluble bamboo dyeing agent in soft water according to the weight ratio of soft water, the preferred range is 0.4-0.6%, the most preferred is to add 0.5% water-soluble bamboo dyeing agent, the color of the dy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com