Method for preparing nano-fiber blending composite yarn

A technology of nanofibers and yarns, which is applied in the field of preparation of blended composite yarns, can solve the problems of unusable, low output and high requirements of electrospinning technology, and achieve simple preparation methods, good early market and economic benefits, and increase additional value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Common cotton staple fiber is used, and polyacrylonitrile is used as the polymer.

[0035] (1) Dissolve polyacrylonitrile (molecular weight 75,000) in dimethylacetamide (DMAc) to prepare a uniform electrospinning solution;

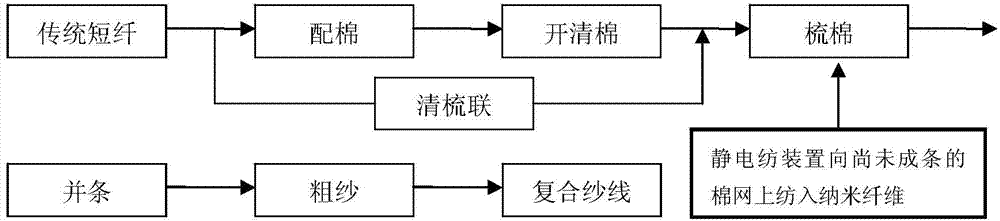

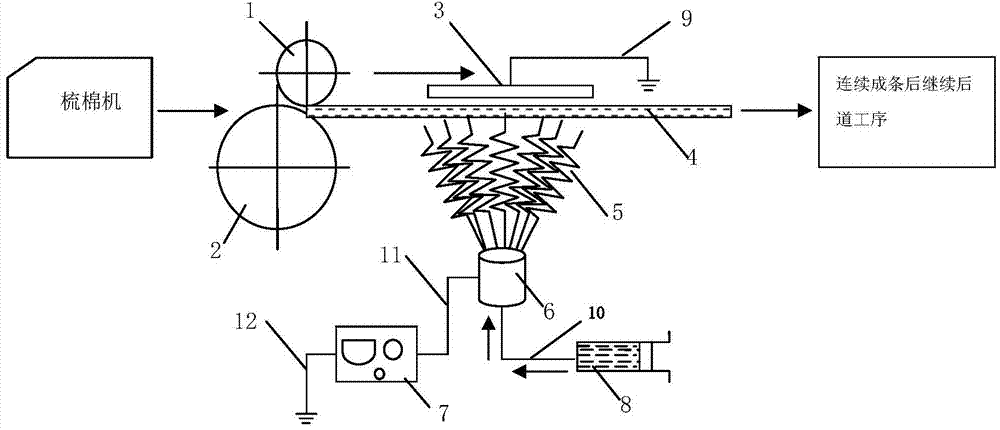

[0036] (2) Carrying out ordinary staple fiber in the traditional spinning process, the traditional spinning process includes the carding process; for example figure 1 As shown, move the electrospinning solution obtained in step (1) to the liquid supply device 8 of the TAYLOR cone multi-nozzle electrospinning machine for electrospinning, and use the 6-direction carding link of the TAYLOR cone multi-nozzle electrospinning machine Spin polyacrylonitrile nanofibers 5 on the cotton web 4 that has not yet been slivered to obtain a cotton web containing nanofibers;

[0037] (3) The above-mentioned cotton web containing nanofibers is slivered and directly enters the subsequent yarn forming process, and finally a continuous blended composite yarn containing...

Embodiment 2

[0040] Adopt the method identical with embodiment 1, wherein staple fiber adopts viscose staple fiber, polymer adopts polyurethane.

[0041] (1) Dissolve polyurethane in dimethylformamide (DMF) to prepare a uniform electrospinning solution;

[0042] (2) Put ordinary viscose staple fiber into the traditional spinning process, and the traditional spinning process includes the carding process; figure 1 As shown, move the electrospinning solution obtained in step (1) to the liquid supply device 8 of the TAYLOR cone multi-nozzle electrospinning machine for electrospinning, and use the 6-direction carding link of the TAYLOR cone multi-nozzle electrospinning machine Polyurethane nanofibers 5 are spun into the viscose staple fiber web 4 that has not yet been slivered to obtain a viscose staple fiber web containing nanofibers;

[0043] (3) The above-mentioned viscose staple fiber web containing nanofibers is slivered and directly enters the subsequent yarn forming process, and finally...

Embodiment 3

[0045] Adopt the method identical with embodiment 1, wherein short fiber adopts polyester short fiber, polymer adopts polyacrylonitrile.

[0046] (1) Dissolve polyacrylonitrile in dimethylacetamide (DMAc) to prepare a uniform electrospinning solution;

[0047] (2) Put ordinary polyester staple fiber into the traditional spinning process, and the traditional spinning process includes the carding process; figure 1 As shown, move the electrospinning solution obtained in step (1) to the liquid supply device 8 of the TAYLOR cone multi-nozzle electrospinning machine for electrospinning, and use the 6-direction carding link of the TAYLOR cone multi-nozzle electrospinning machine Polyacrylonitrile nanofibers 5 are spun into polyester staple fiber webs 4 that have not yet been slivered to obtain polyester staple fiber webs containing nanofibers;

[0048] (3) The above-mentioned polyester staple fiber web containing nanofibers is slivered and directly enters the subsequent yarn forming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com