Patents

Literature

150 results about "Electrospun nanofibers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

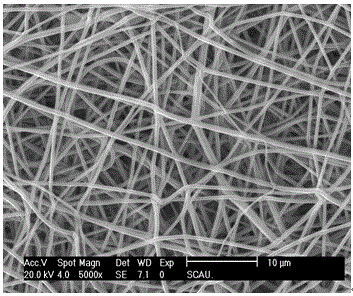

Carbon and electrospun nanostructures

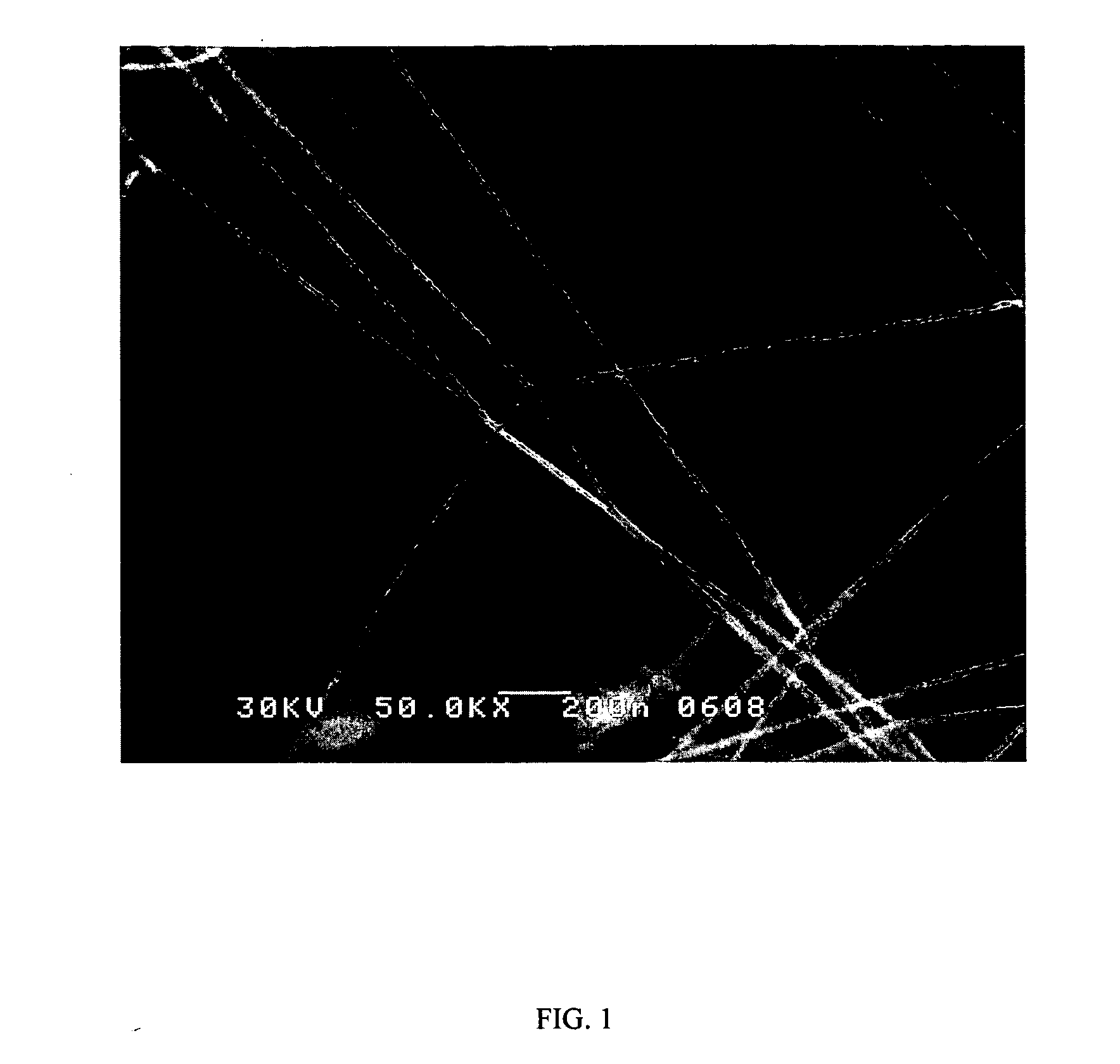

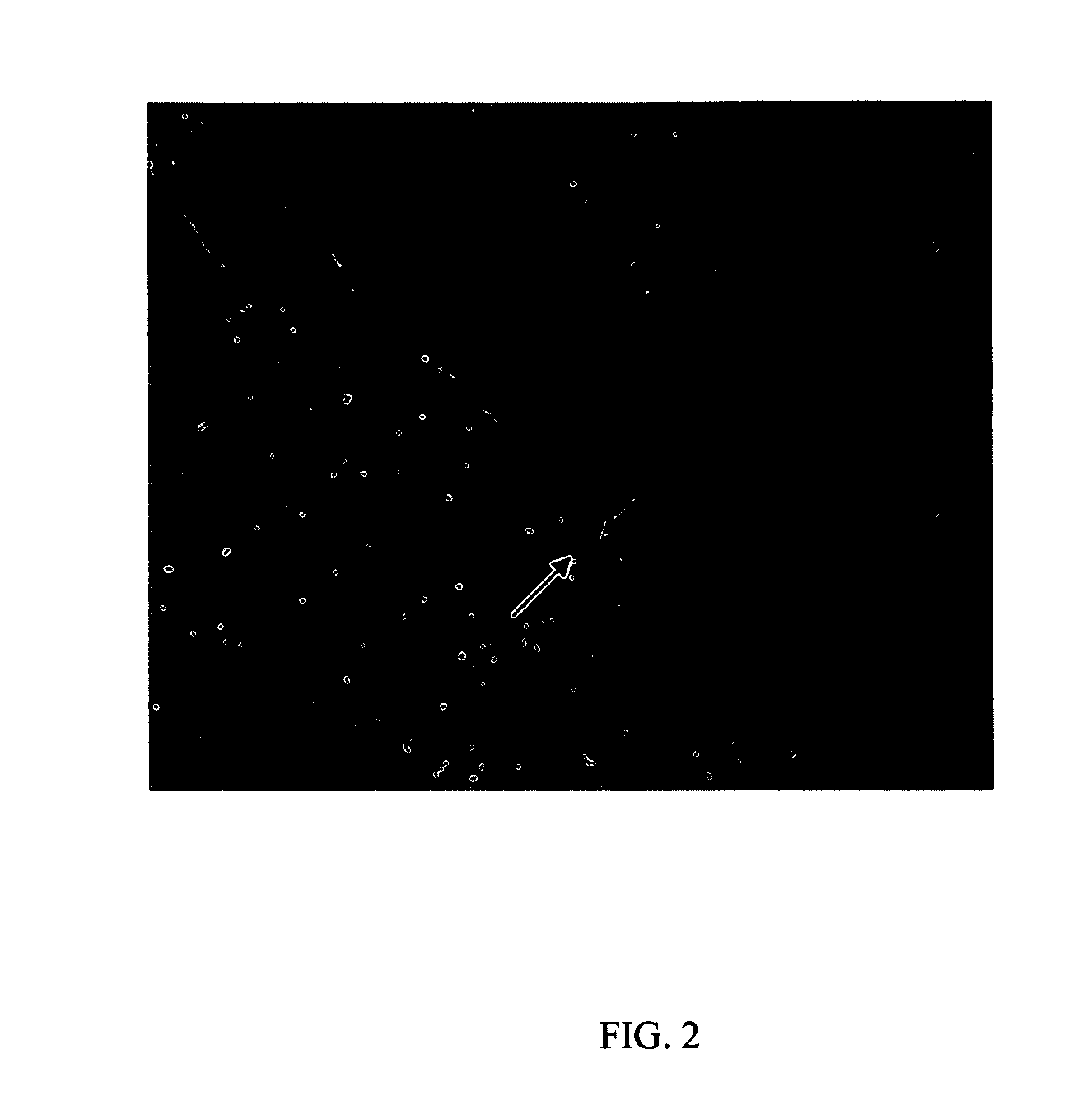

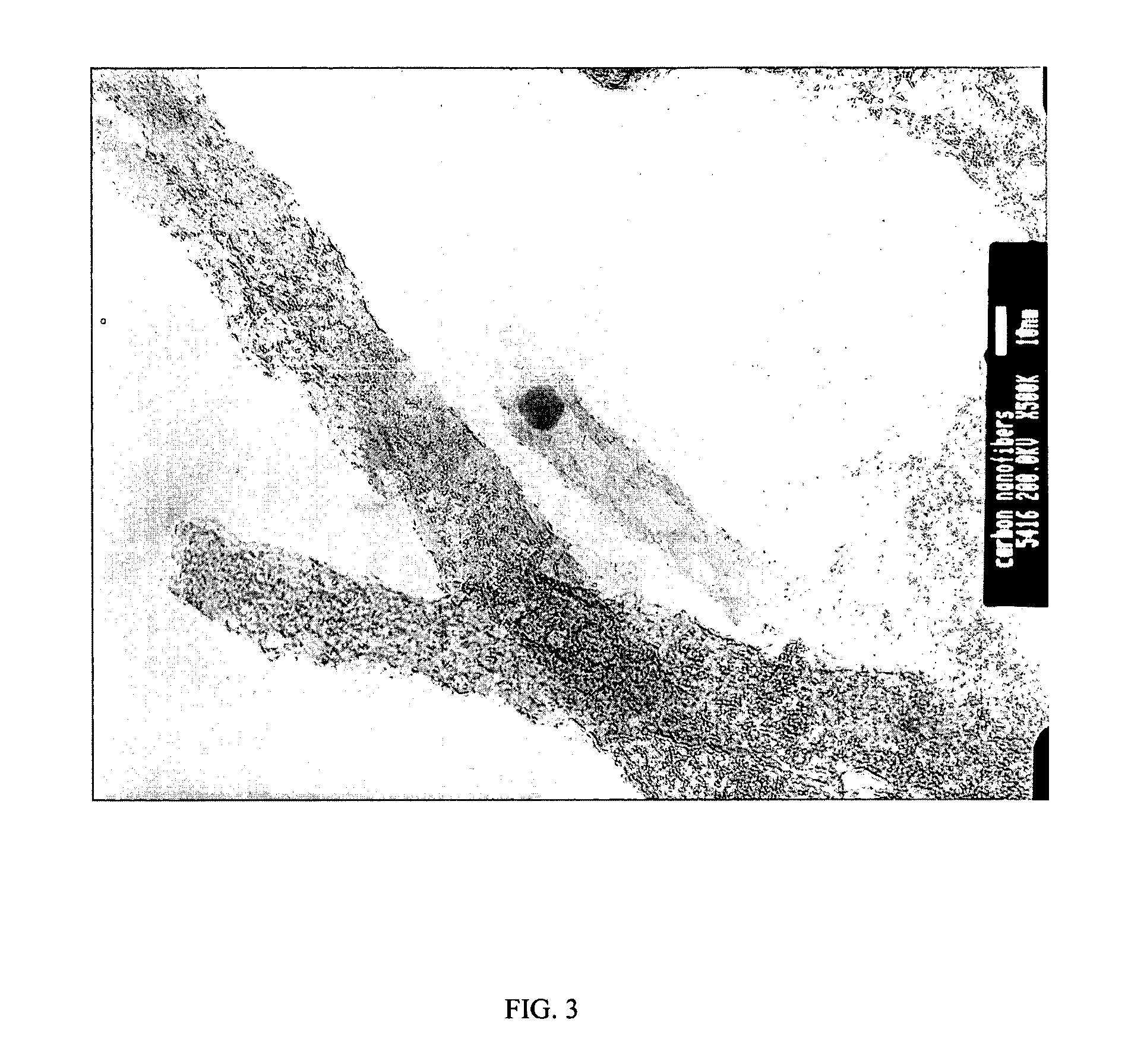

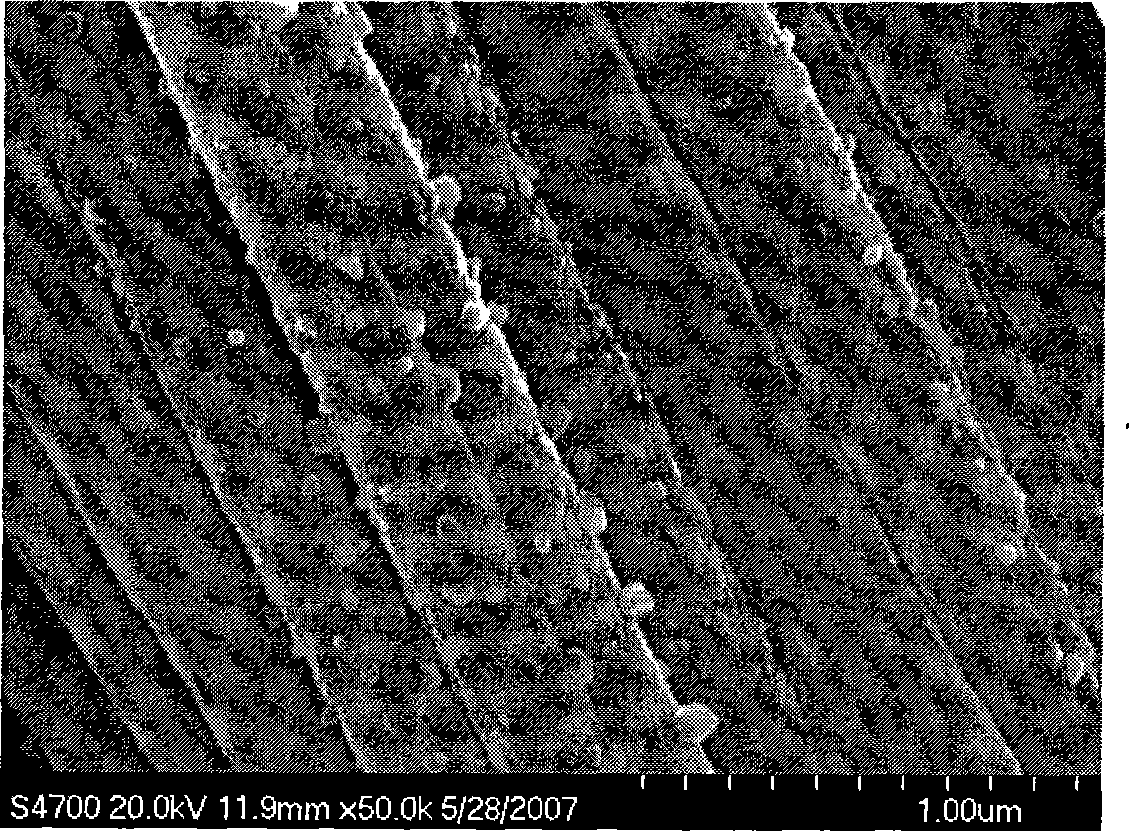

InactiveUS20050025974A1Material nanotechnologyElectric discharge heatingIron saltsElectrospun nanofibers

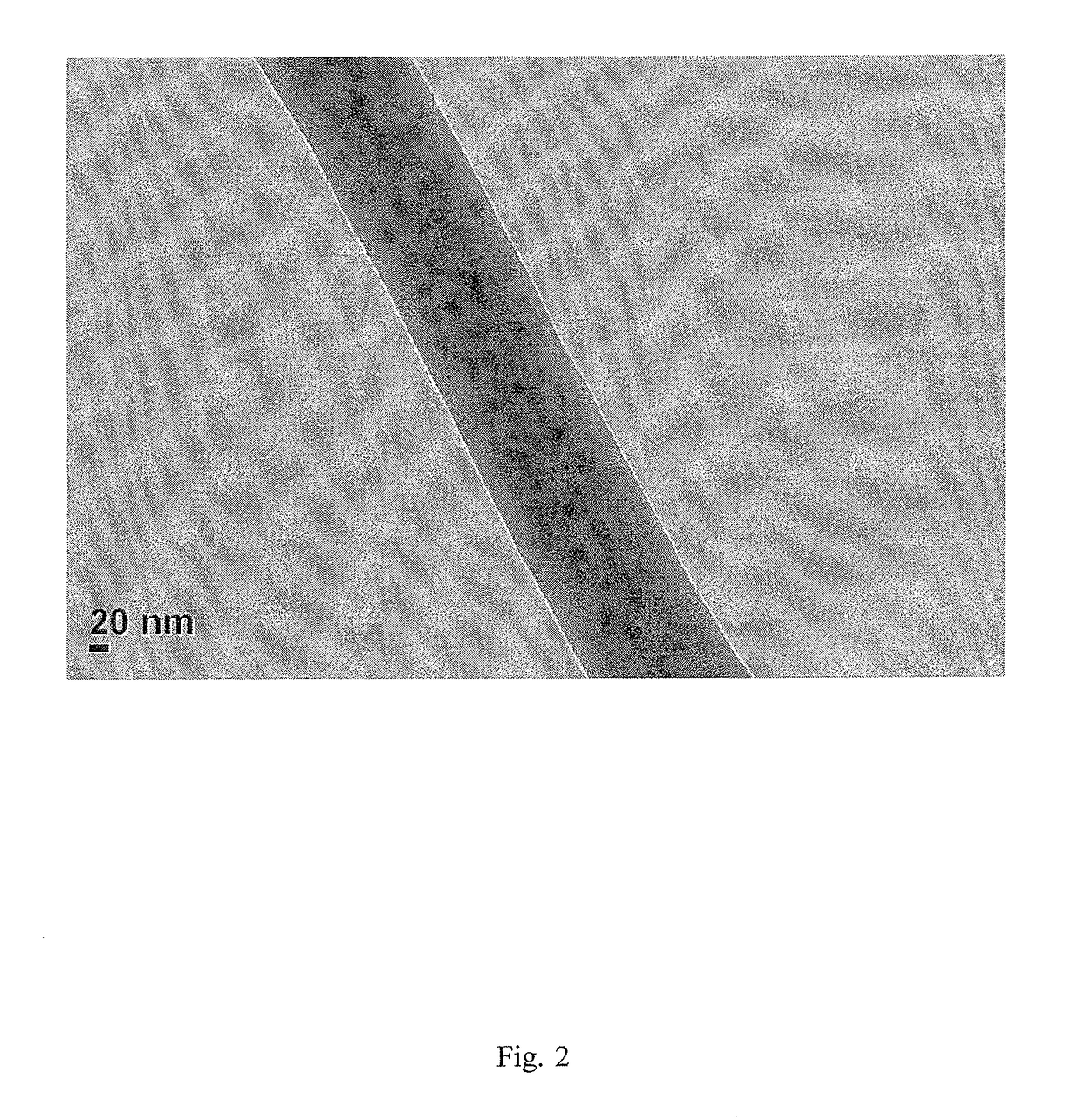

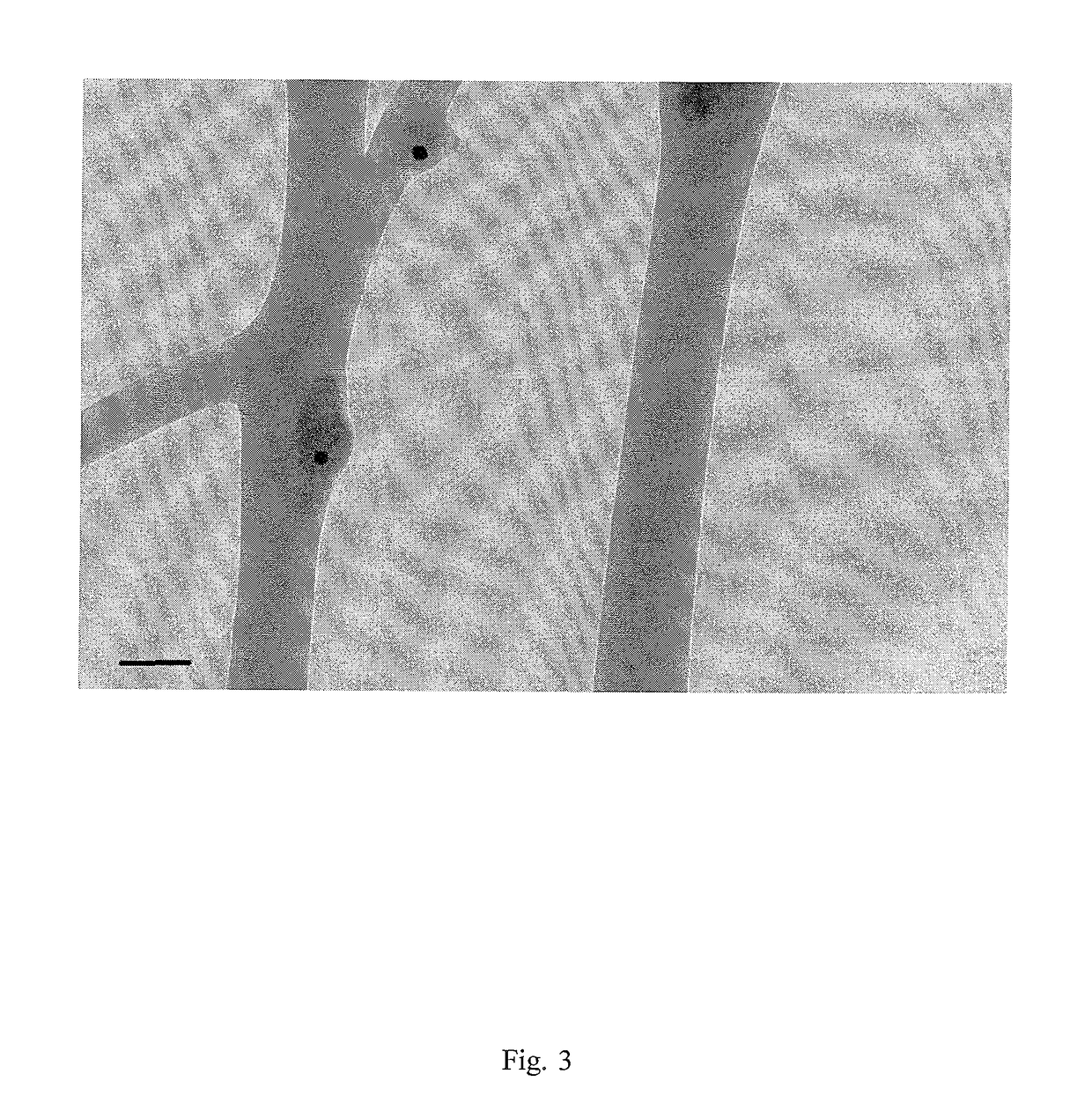

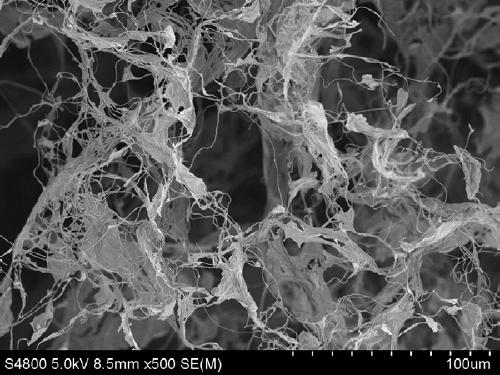

The present invention is directed to the production of nanostructures, e.g., single wall carbon nanotubes (“SWNT”) and / or multi-wall carbon nanotubes (“MWNT”), from solutions containing a polymer, such as polyacrylonitrile (PAN). In particular, the invention is directed to the production of nanostructures, for example, SWNT and / or MWNT, from mixtures, e.g., solutions, containing polyacrylonitrile, polyaniline emeraldine base (PANi) or a salt thereof, an iron salt, e.g., iron chloride, and a solvent. In one embodiment, a mixture containing polyacrylonitrile, polyaniline emeraldine base or a salt thereof, an iron salt, e.g., iron chloride, and a solvent is formed and the mixture is electrospun to form nanofibers. In another embodiment, the electrospun nanofibers are then oxidized, e.g., heated in air, and subsequently pyrolyzed to form carbon nanostructures.

Owner:PHYSICAL SCI

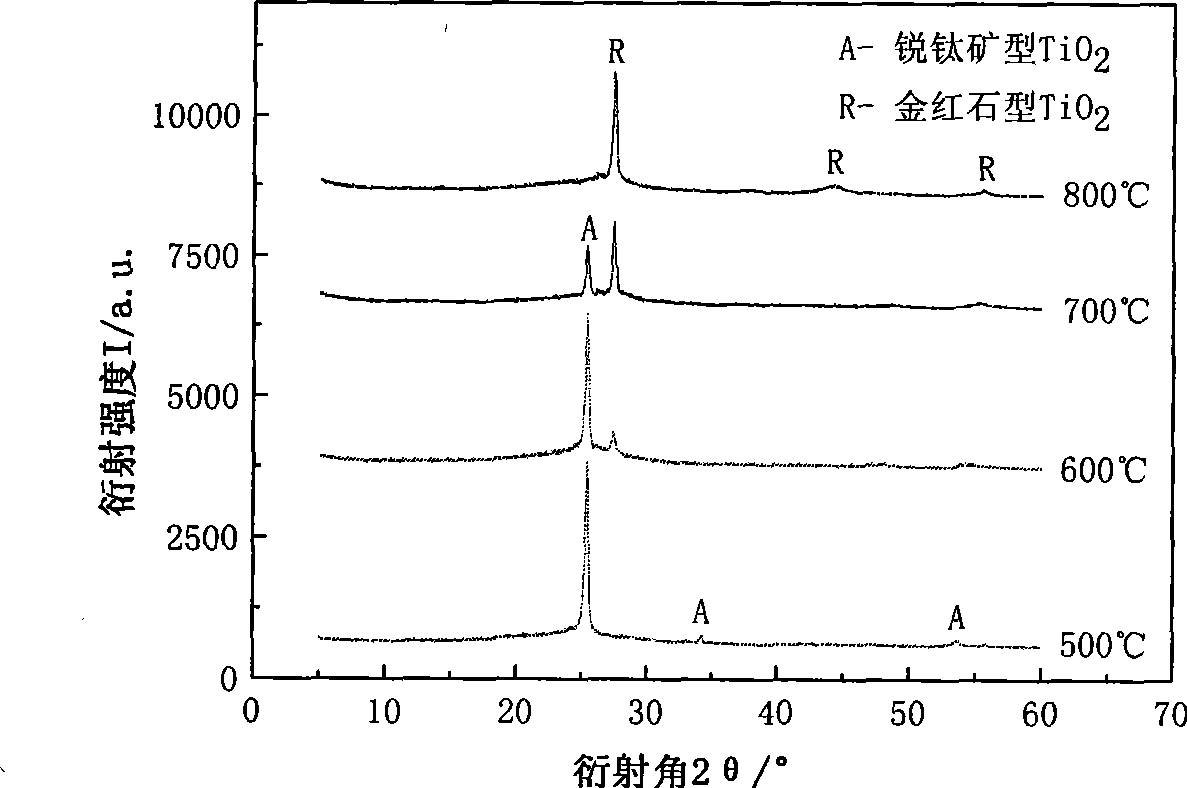

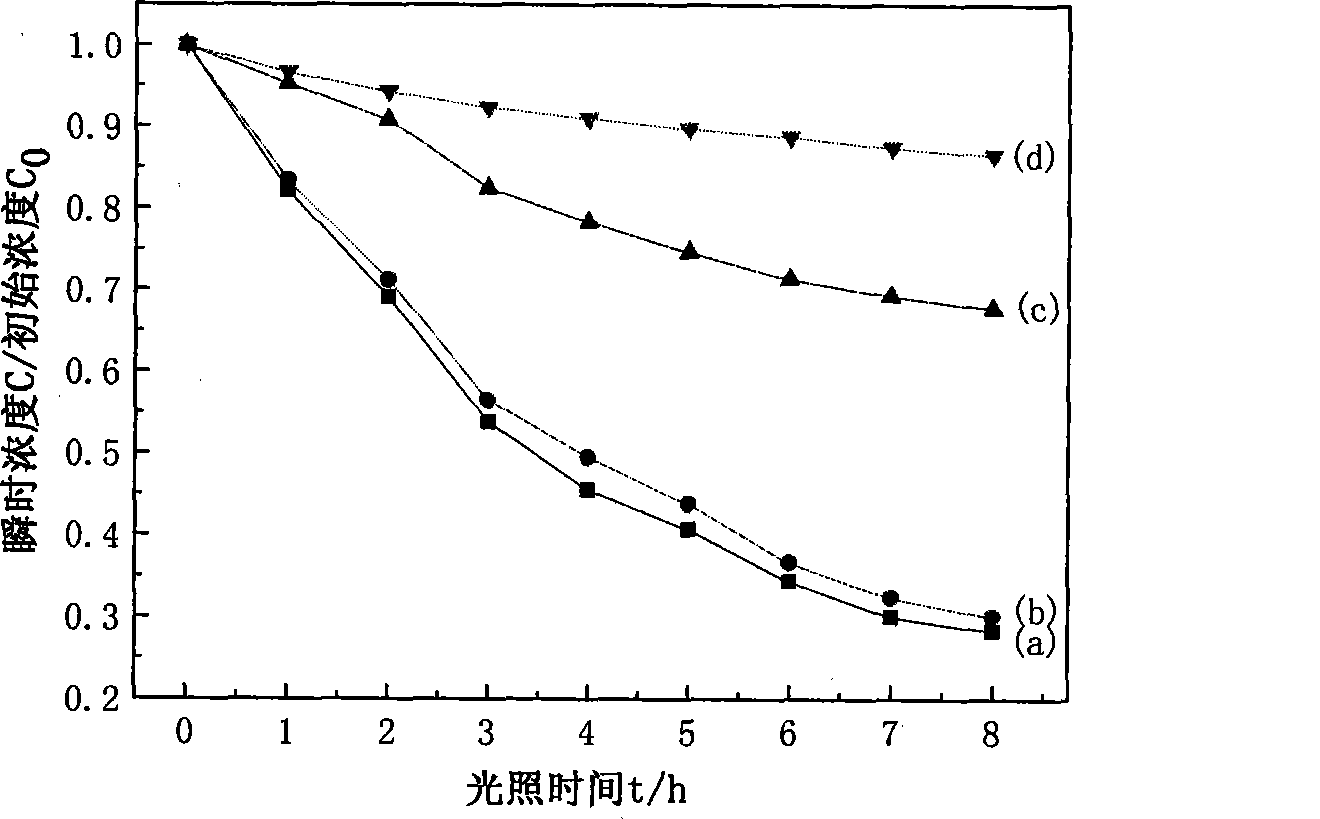

Nano-fibre supported titanium dioxide photocatalyst and preparation method thereof

InactiveCN101428209AImprove bindingImprove photocatalytic activityPhysical/chemical process catalystsFibre treatmentFiberElectrospun nanofibers

The invention provides a nanofiber load titanium dioxide photocatalyst and a preparation method thereof, which belong to the technical field of preparation of novel nanometer photocatalyst functional materials. The method comprises the following steps: preparing a homogeneous spinning solution with titanium precursor, a hydrolysis inhibitor, a polymer and an organic solvent; carrying out spinning according to a proper electrostatic spinning process to obtain a nanofiber felt / film; introducing hydroxyl groups into electrospun nanofiber, and immersing the electrospun nanofiber in an aqueous solution containing an ammoniation agent, so that hydrolysis and ammoniation reaction of titanium precursor occurs and produces titanium-ammino complex; and carrying out post treatment processes such as baking and the like to obtain the nanofiber load titanium dioxide photocatalyst. The catalyst has excellent photo-catalytic activity in response to ultraviolet light or visible light, and can effectively improve the bonding reliability of titanium dioxide with nanofiber with the help of the action of nitrogen bond.

Owner:BEIJING UNIV OF CHEM TECH

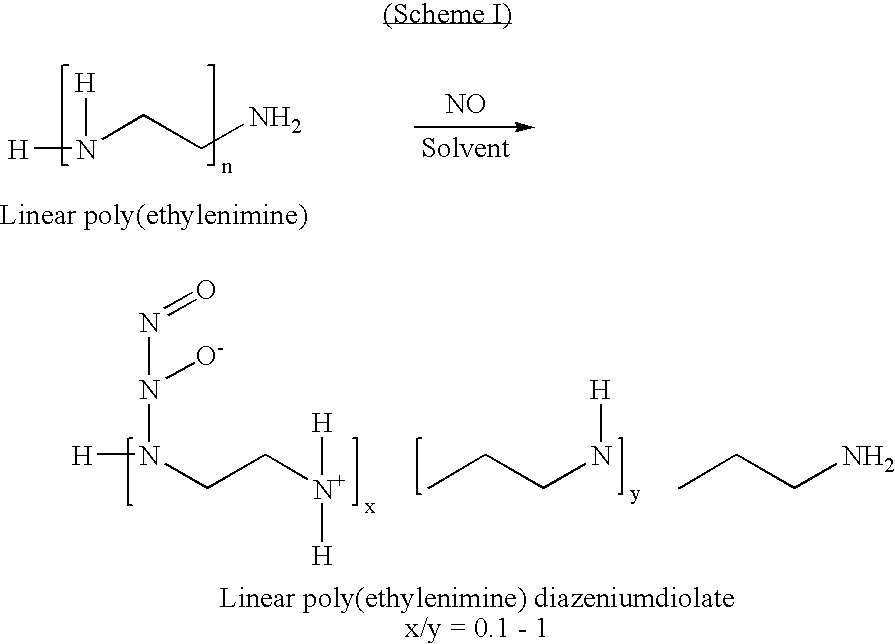

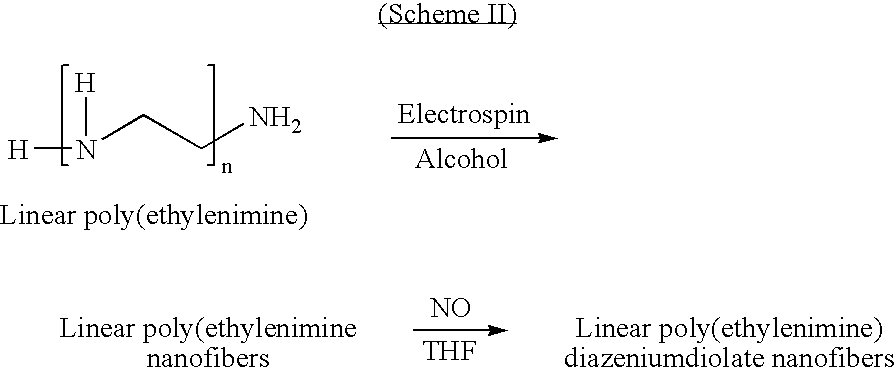

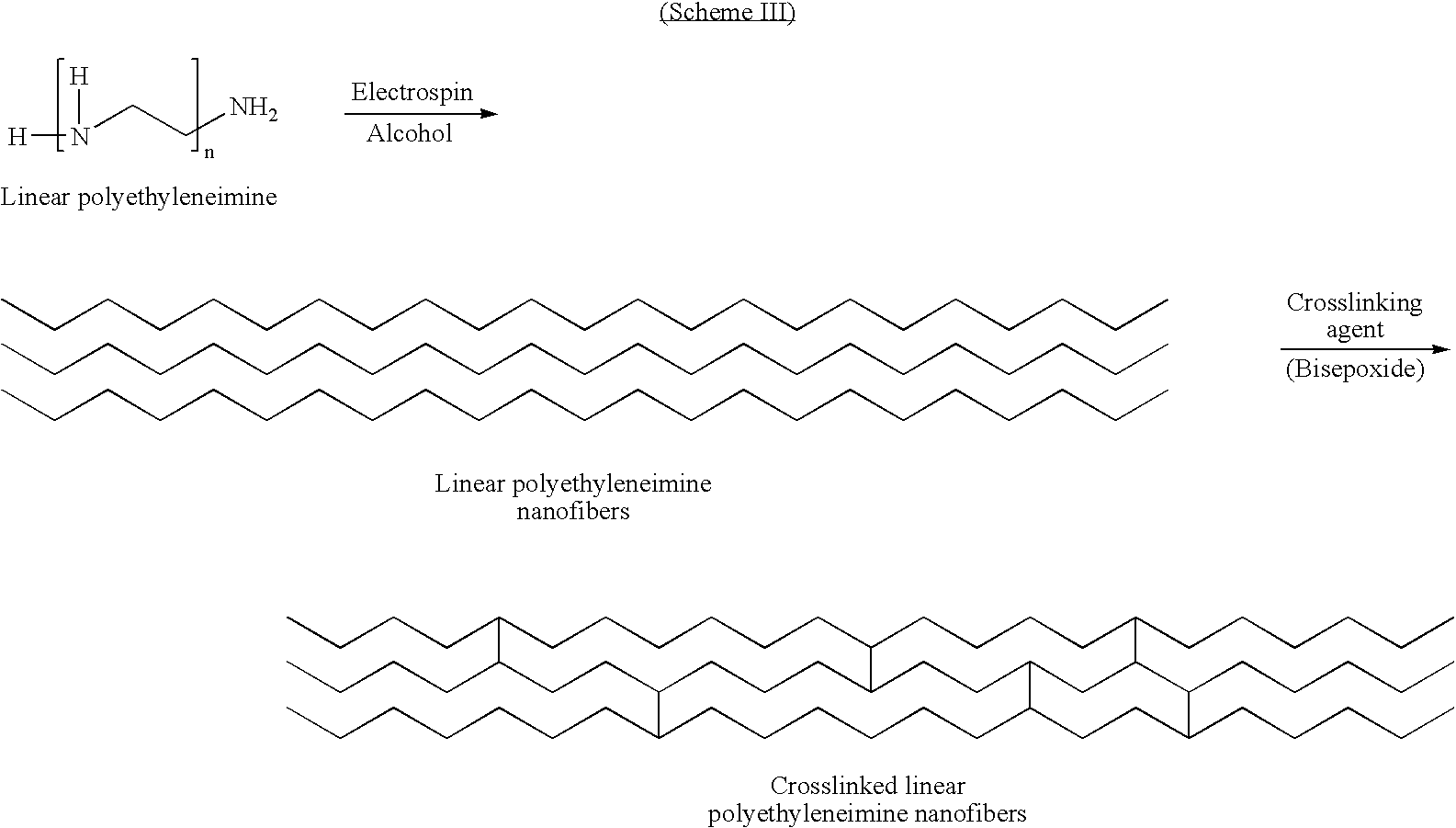

Nitric oxide-modified linear poly(ethylenimine) fibers and uses therefor

A novel coating for medical devices provides nitric oxide delivery using nanofibers of linear poly(ethylenimine)diazeniumdiolate. Linear poly(ethylenimine)diazeniumdiolate releases nitric oxide (NO) in a controlled manner to tissues and organs to aid the healing process and to prevent injury to tissues at risk of injury. Electrospun nano-fibers of linear poly(ethylenimine) diazeniumdiolate deliver therapeutic levels of NO to the tissues surrounding a medical device while minimizing the alteration of the properties of the device. A nanofiber coating, because of the small size and large surface area per unit mass of the nanofibers, provides a much larger surface area per unit mass while minimizing changes in other properties of the device.

Owner:THE UNIVERSITY OF AKRON

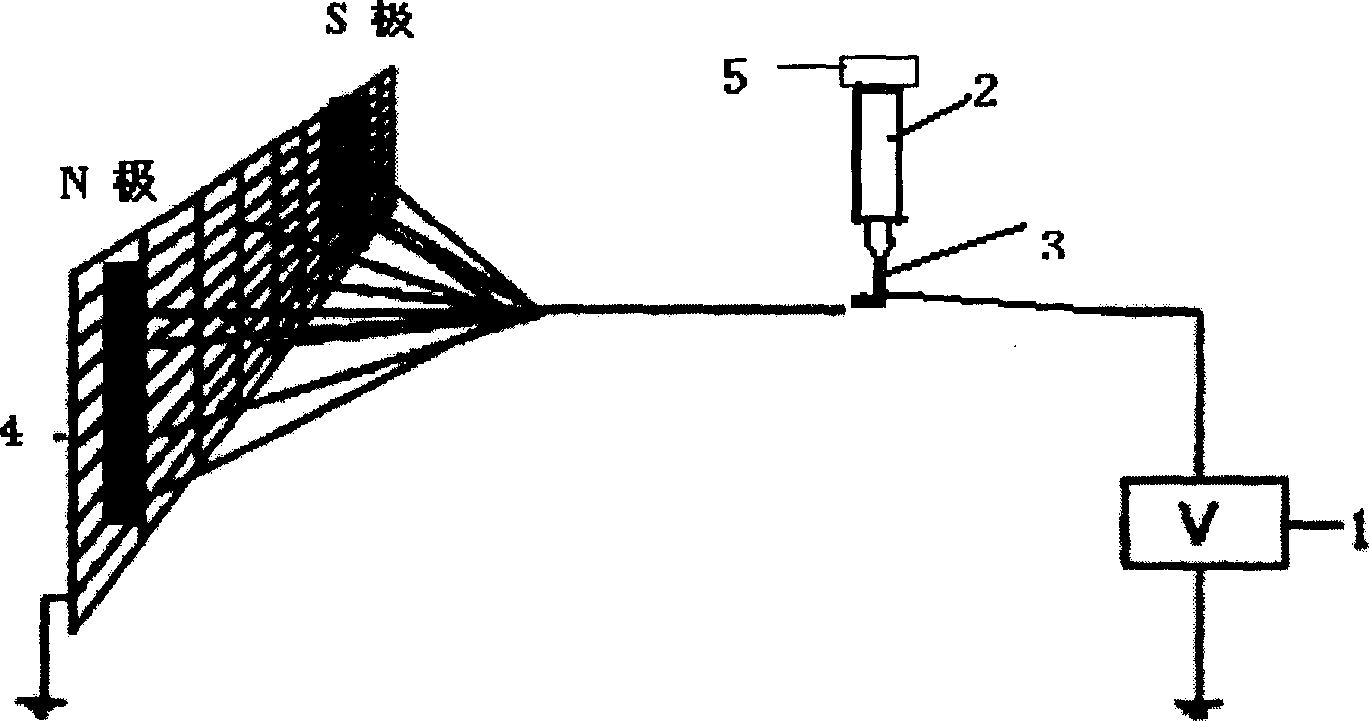

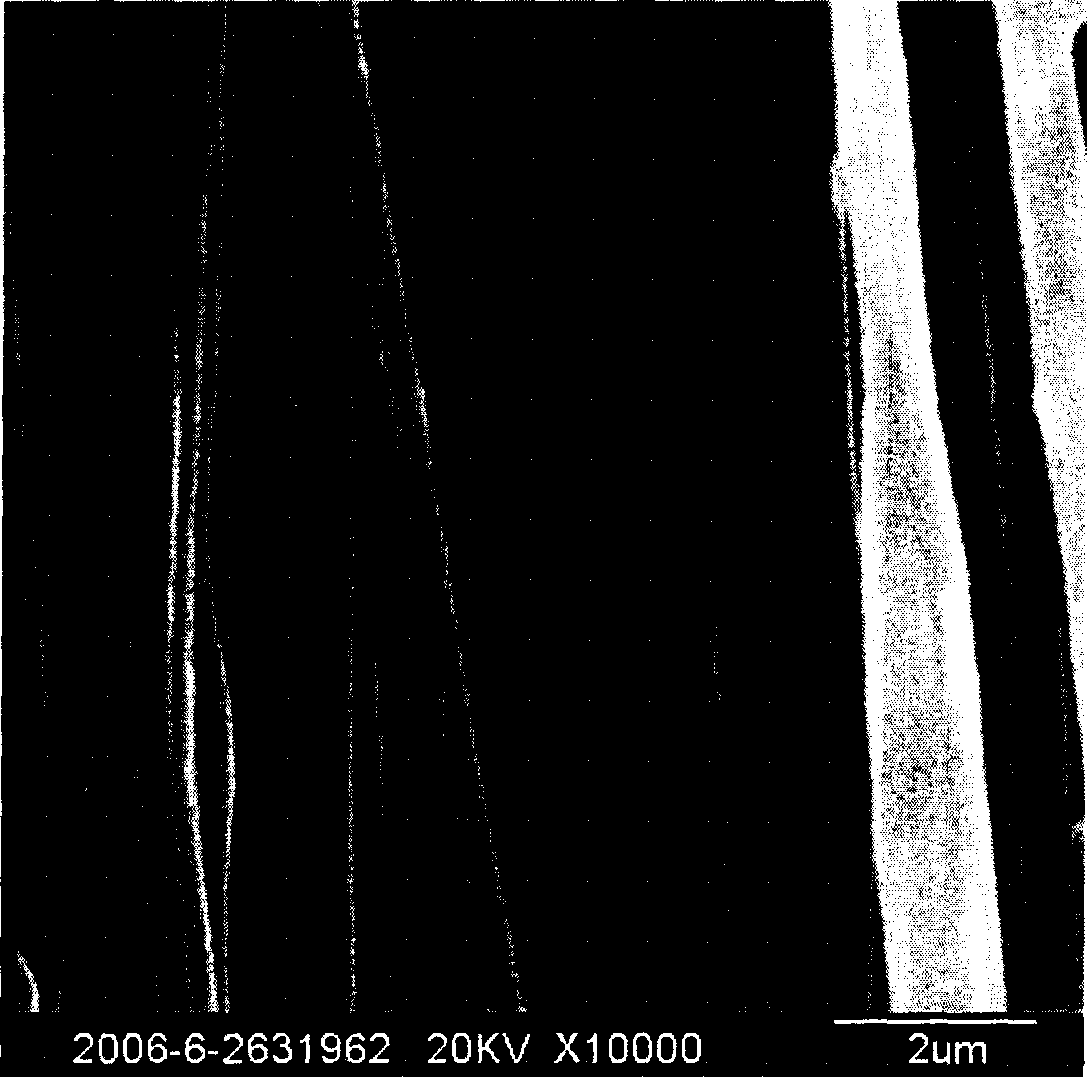

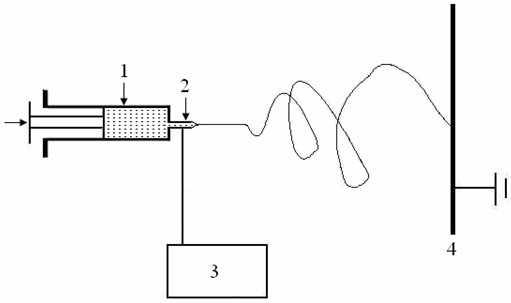

Directional magnetic electrical spinning Nano fibers, preparation method and equipment needed

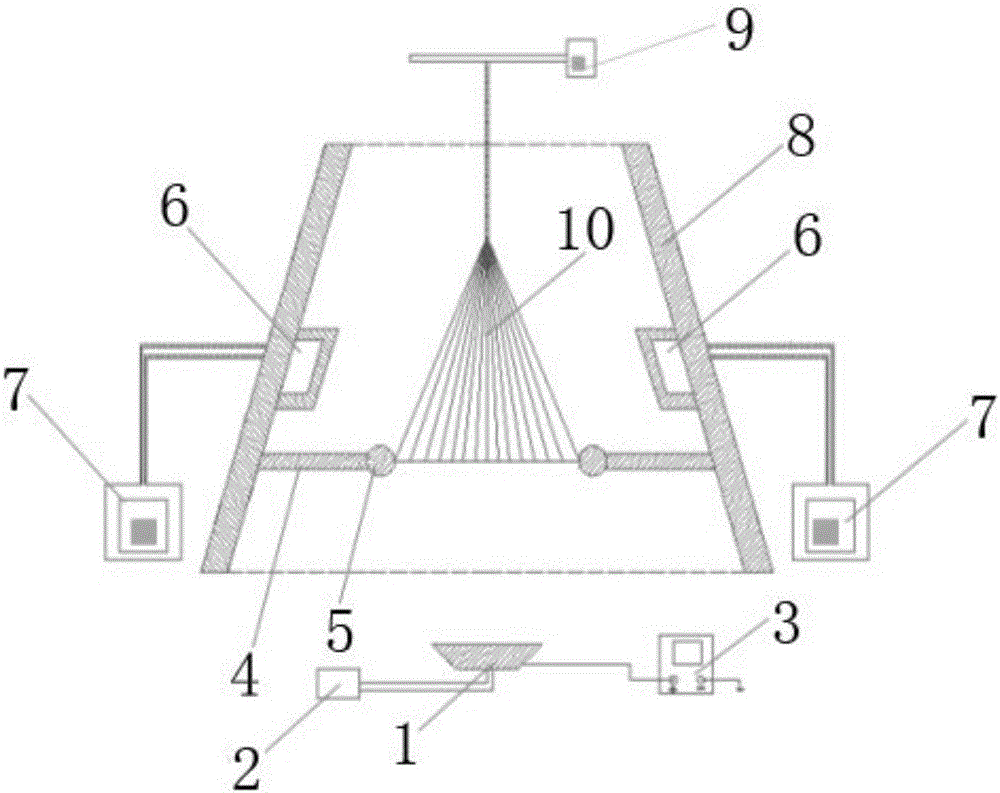

InactiveCN1873064ASimple preparation processEasy to operate and repeatFilament/thread formingMonocomponent polyesters artificial filamentNormal positionEngineering

A method for preparing directional magnetic nanofiber of electric-spinning type includes utilizing Fe3O4 magnetic fluid and high polymer solution as raw material and applying normal position composite means to carry out electric-spinning under certain conditions, setting magnetic field at receiving unit to use magnetic field to induce high polymer nanofiber containing Fe3O4 to be directionally arranged along magnetic field direction for obtaining nanofiber being set with diameter of 100-600nm and being directionally arranged along magnetic direction. The device for realizing said method is also disclosed.

Owner:BEIJING UNIV OF CHEM TECH

Indicator device having an active agent encapsulated in an electrospun nanofiber

ActiveUS20060083657A1Avoid separationBioreactor/fermenter combinationsBiological substance pretreatmentsFiberElectrospun nanofibers

An indicator device for determining the efficacy of an antimicrobial treatment process. The indicator device includes an active agent encapsulated in an encapsulation component. The encapsulation components preferably takes the form of an electrospun nanofiber including a polymer.

Owner:AMERICAN STERILIZER CO

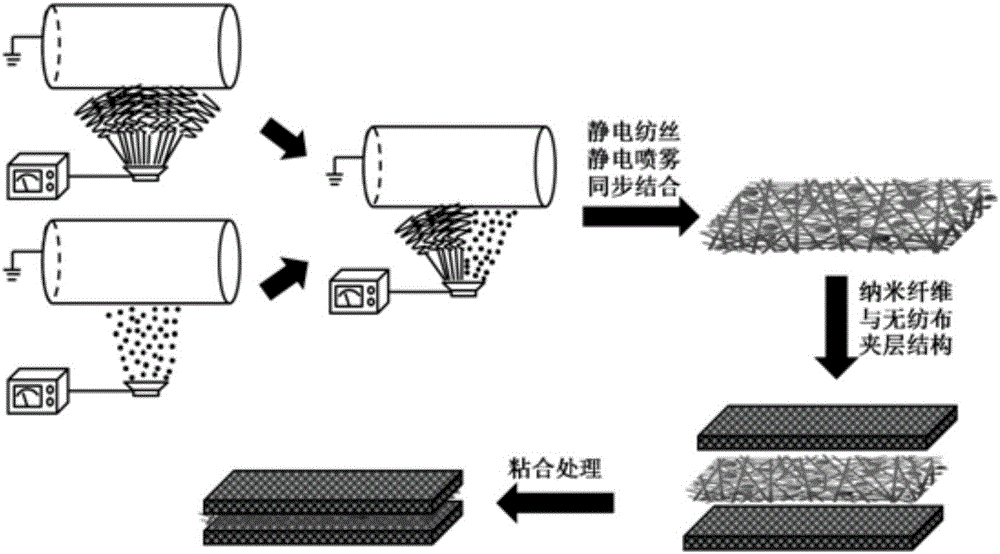

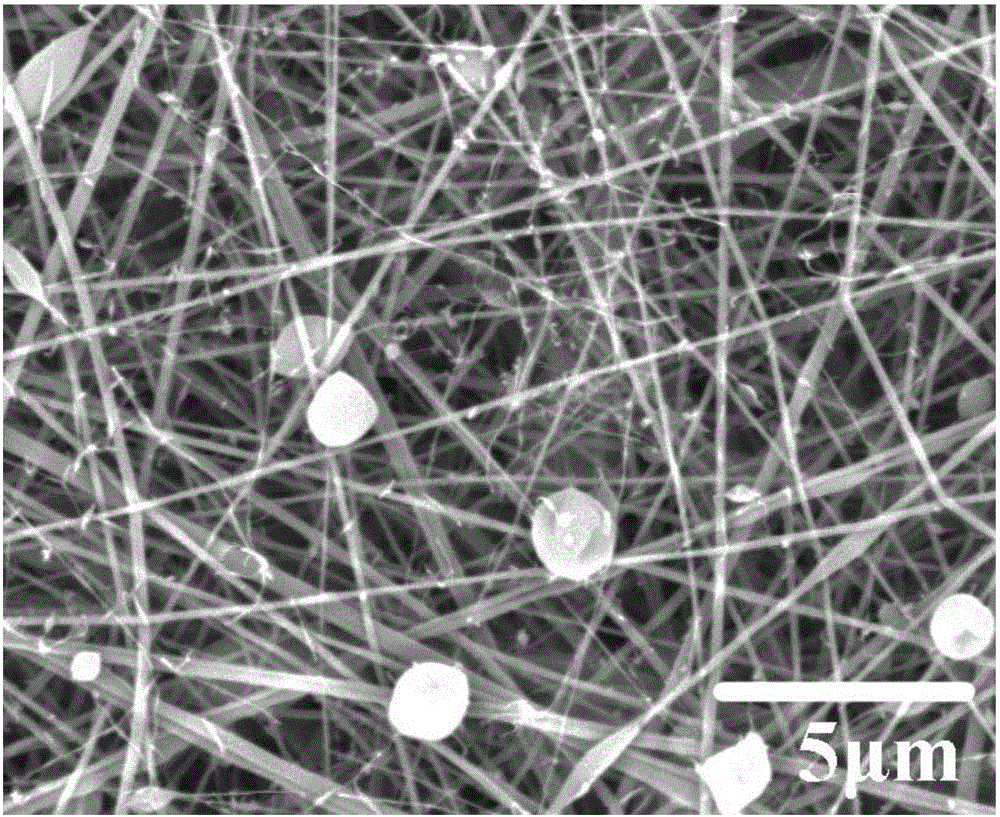

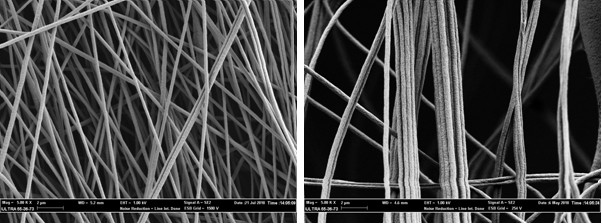

Efficient and low-resistance electrospun nanofiber air filter material and batch preparation method

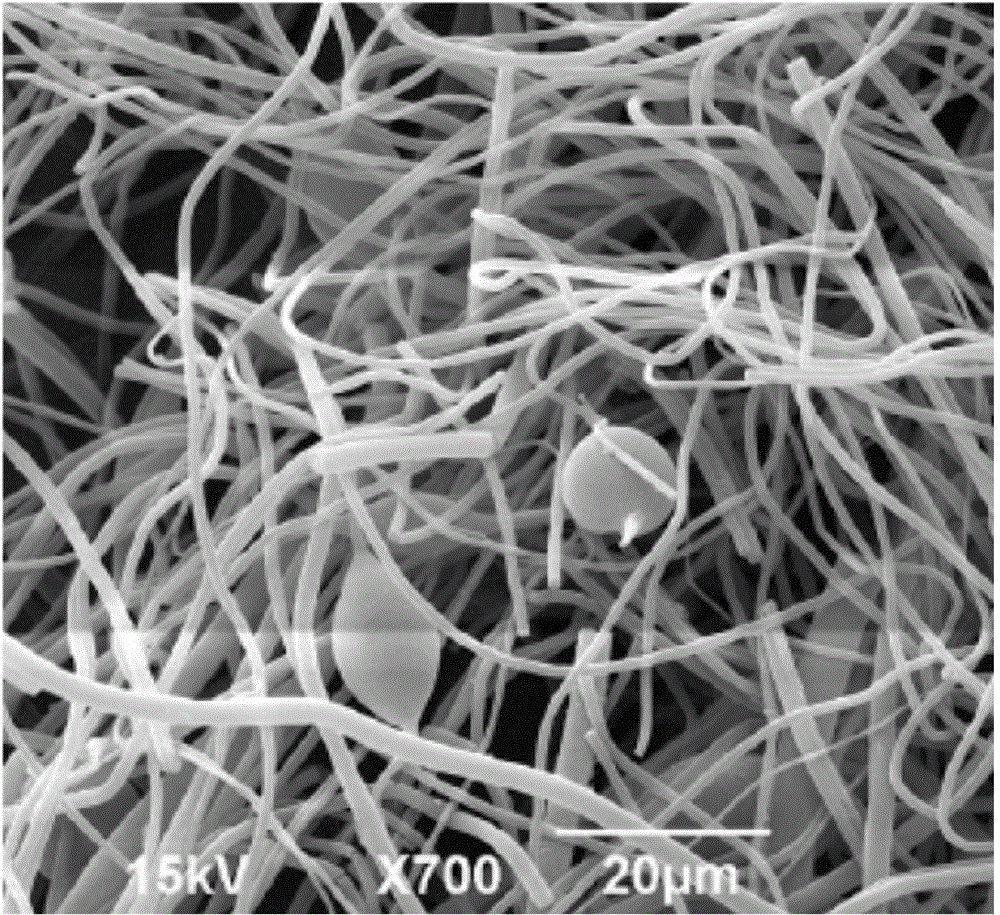

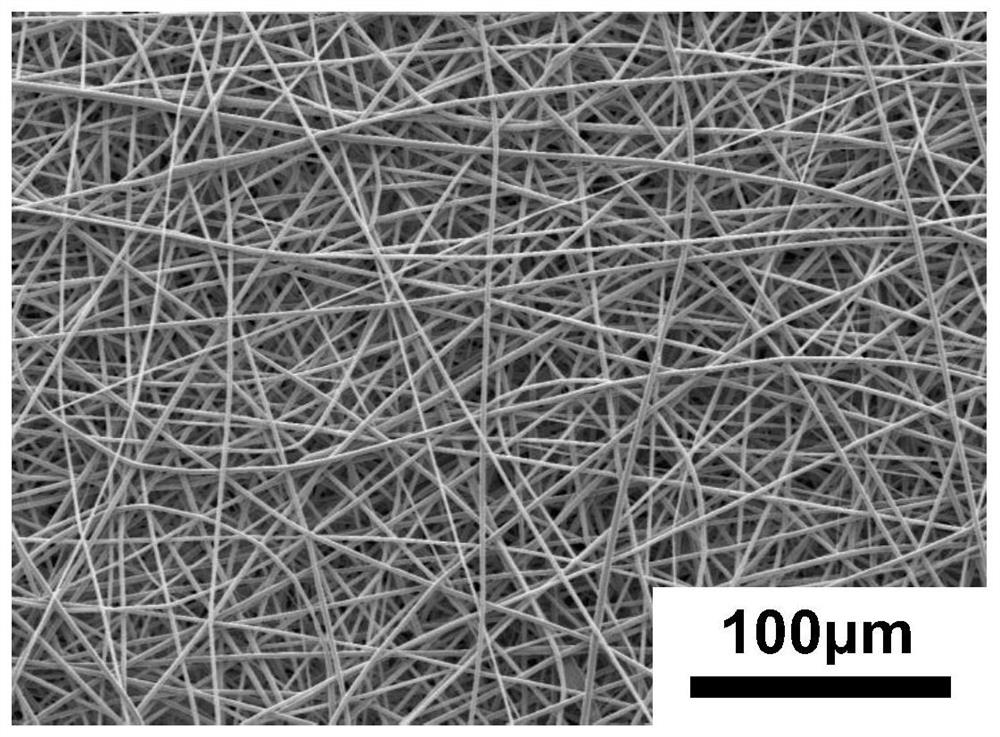

InactiveCN106237717AAvoid damageHigh strengthElectro-spinningFiltration separationFiberComposite film

The invention relates to an efficient and low-resistance electrospun nanofiber air filter material and a batch preparation method. The filter material is of a sandwich structure formed by alternately arraying spun-bonded nonwovens and nanofibers; by the adoption of a pinfree type electrostatic spinning nozzle and by an electrostatic spinning and electrostatic spraying synchronous combination technology, a nanofiber / microsphere composite film is prepared; a revolving rotary drum is used as a receiving device, and the spun-bonded nonwoven is used as a receiving matrix, so that a nanofiber / nonwoven composite material is obtained; a layer of spun-bonded nonwoven covers the surface of the nanofiber / nonwoven composite material to form the sandwich structure with the spun-bonded nonwovens and the nanofibers which are alternately arrayed; the sandwich structure is bonded to obtain the efficient and low-resistance electrospun nanofiber air filter material. The preparation process is simple, and high in controllability and repetitiveness, and the prepared air filter material has the characteristics of high efficiency and low resistance, and is uniform in thickness and stable in filter performance; batch production of the nanofiber filter material can be realized; the efficient and low-resistance electrospun nanofiber air filter material has very good application prospect in the field of air filtering.

Owner:DONGHUA UNIV

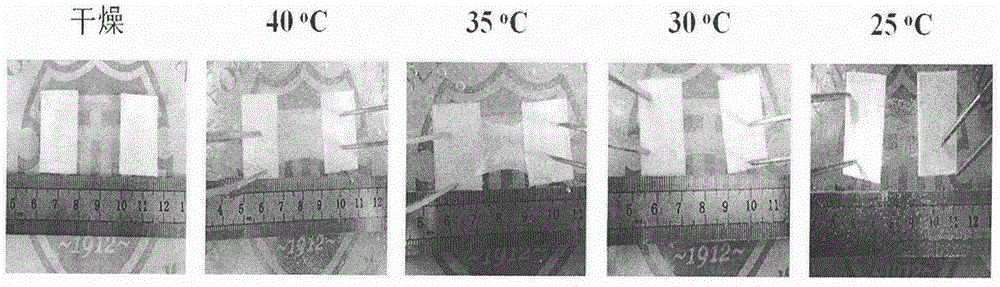

Multiple response type filtration-controllable electrospun nanofiber membrane and preparation method thereof

ActiveCN106319759AAchieving Smart SeparabilityFlux controlNon-woven fabricsElectrospun nanofiberFiber

The invention relates to a multiple response type filtration-controllable electrospun nanofiber membrane and a preparation method thereof. Nanofibers are composed of electrostatic spinning thermosensitive and pH responsive polymers and solvents, and the multiple response type filtration-controllable electrospun nanofiber membrane is formed by putting a prepared mixed solution in an injector and then spinning of an electrostatic spinning apparatus. The multiple response type filtration-controllable electrospun nanofiber membrane and the preparation method thereof have the advantages that since smart response of the thermosensitive and pH responsive polymers in the spinning solution is combined with the advantages of large specific area, high porosity and loose and porous performance of the nanofibers, controllable filtration of air is achieved; the preparation method is simple and easy to implement, low in production cost, high in interception efficiency, low in resistance, rapid in filtration reaction, high in treatment efficiency, reusable and capable of achieving smart separability of the nanofiber membrane and can be applied to the fields such as filtration and adsorption, drug delivery, chemical separation, sensing drive and tissue engineering.

Owner:TIANJIN POLYTECHNIC UNIV

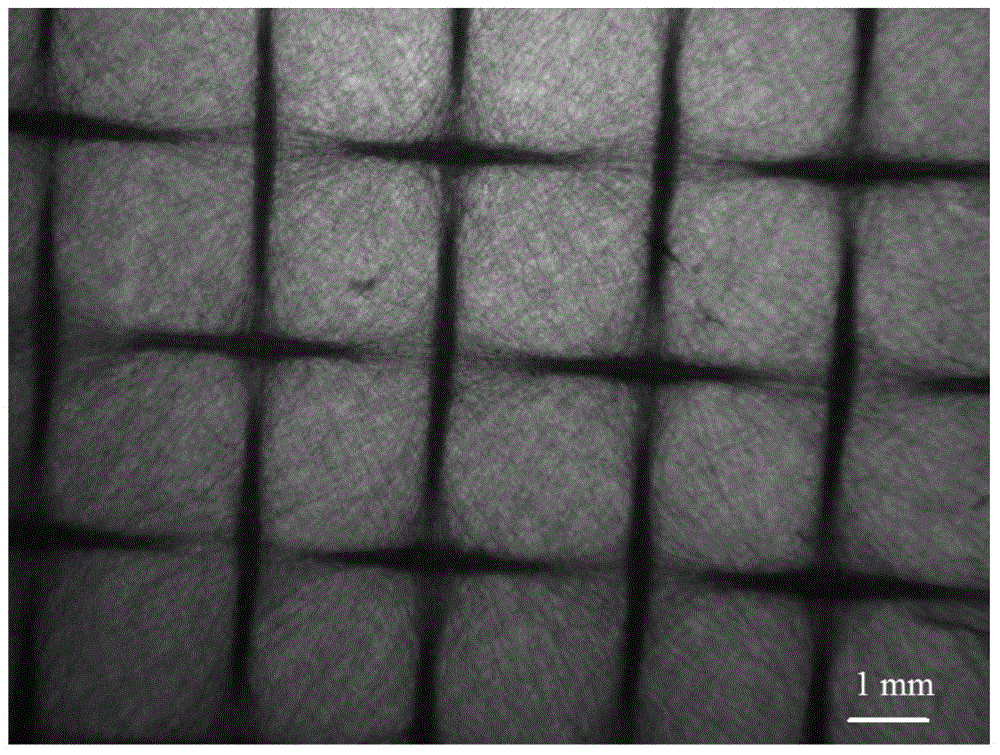

Force-sensitive stretchable electro-spinning patterning conductive nanofiber membrane and preparation method thereof

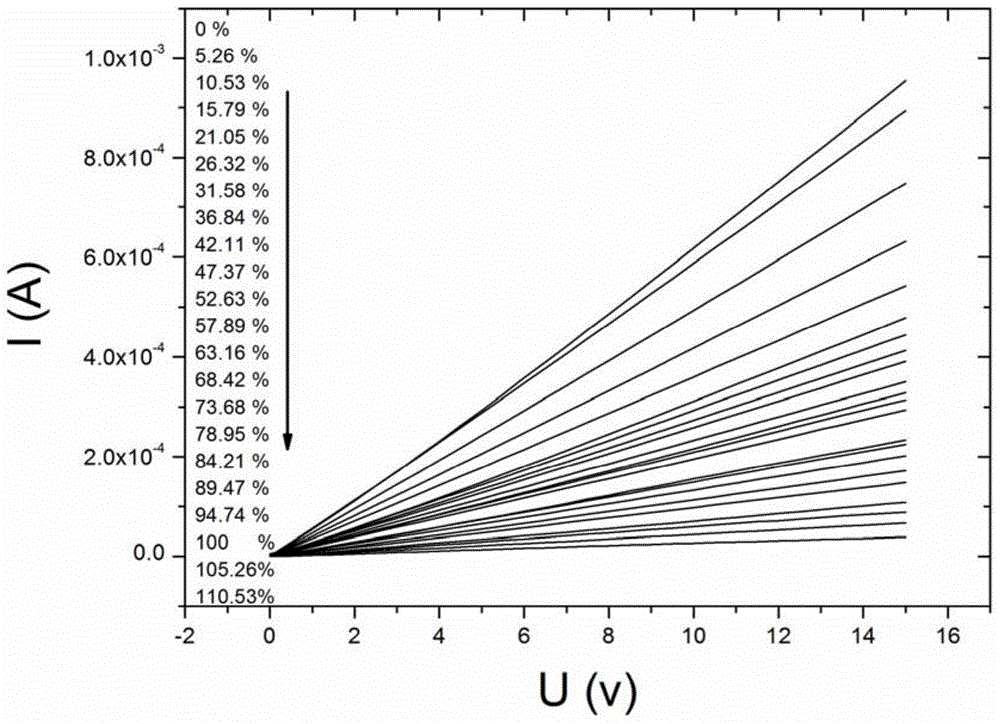

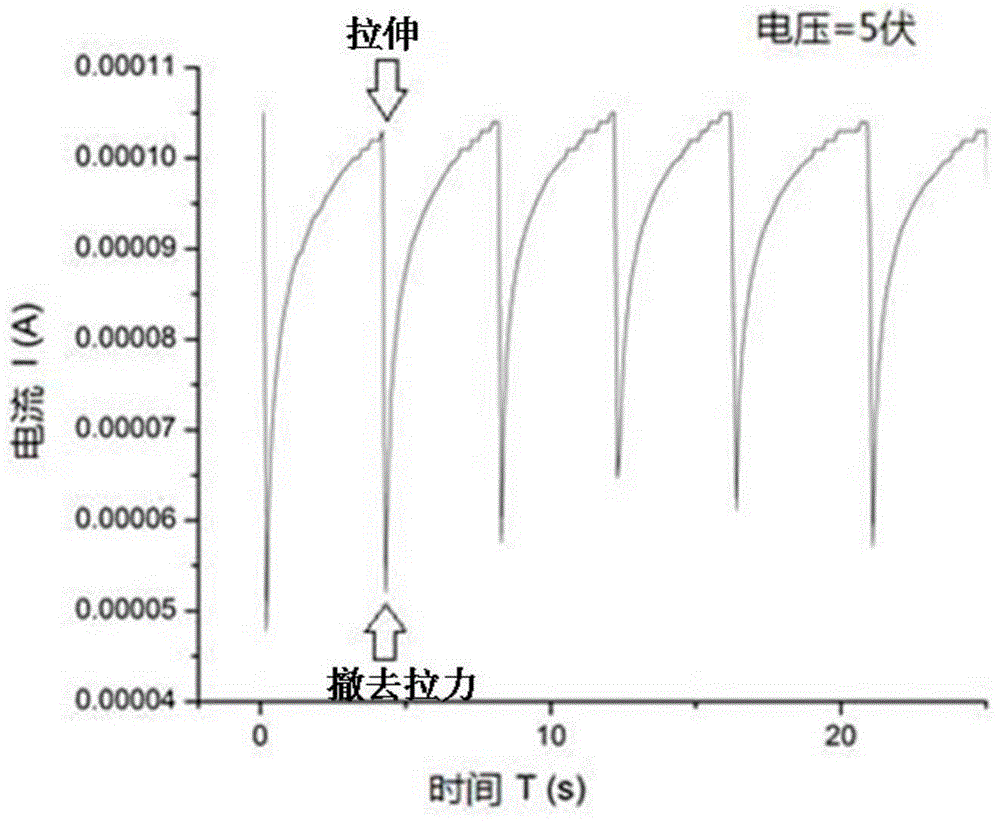

ActiveCN104894750AImprove conductivityHigh Force Sensitive PerformanceFilament/thread formingNon-woven fabricsOrganic solventConductive polymer

The invention discloses a preparation method of a force-sensitive stretchable electro-spinning patterning conductive nanofiber membrane. The preparation method comprises the following steps that (1) a high-molecular polymer and a conductive polymer are fully mixed and dissolved in an organic solvent, and therefore a spinning precursor solution is formed; (2) a patterning collection template is used for electrostatic spinning to collect electrospunpolymer nanofibers, a patterning conductive nanofiber membrane in a non-woven mode is formed on the collection template, and is taken from the collection template, and therefore the force-sensitive stretchable electro-spinning patterning conductive nanofiber membrane can be obtained, wherein the collection template is a metal template, a semiconductor template or an insulating plastic template, and a hollow or protruding pattern structure is arranged on the collection template. The nanofiber membrane prepared through the preparation method can achieve the purposes of high conductivity, good force-sensitive performance and good stability, and can bear large-scale two-dimensional stretching strain. The preparation method is simple and low in cost, and has the good application prospect.

Owner:QINGDAO UNIV

Capacitive ultrathin flexible stress sensor and producing method thereof

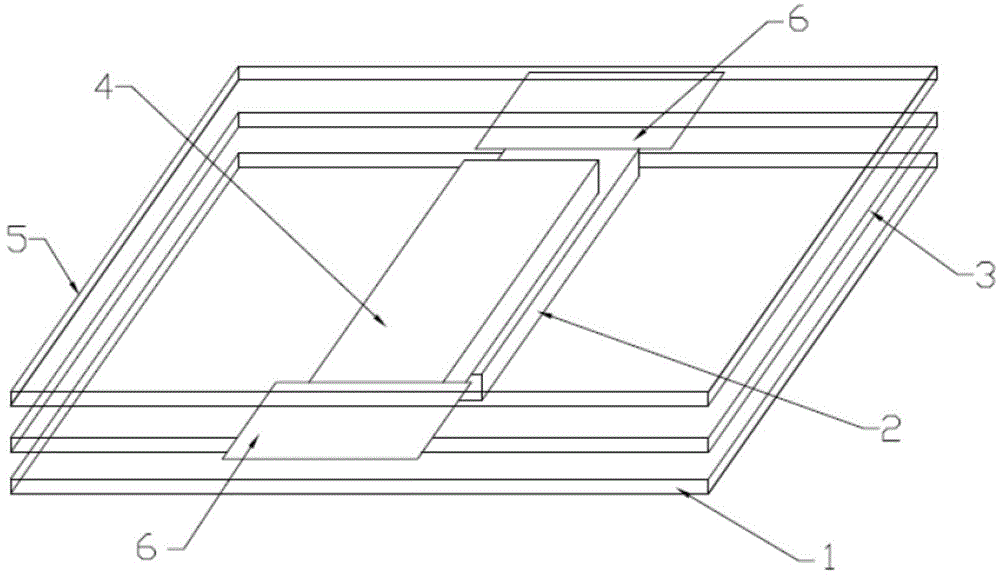

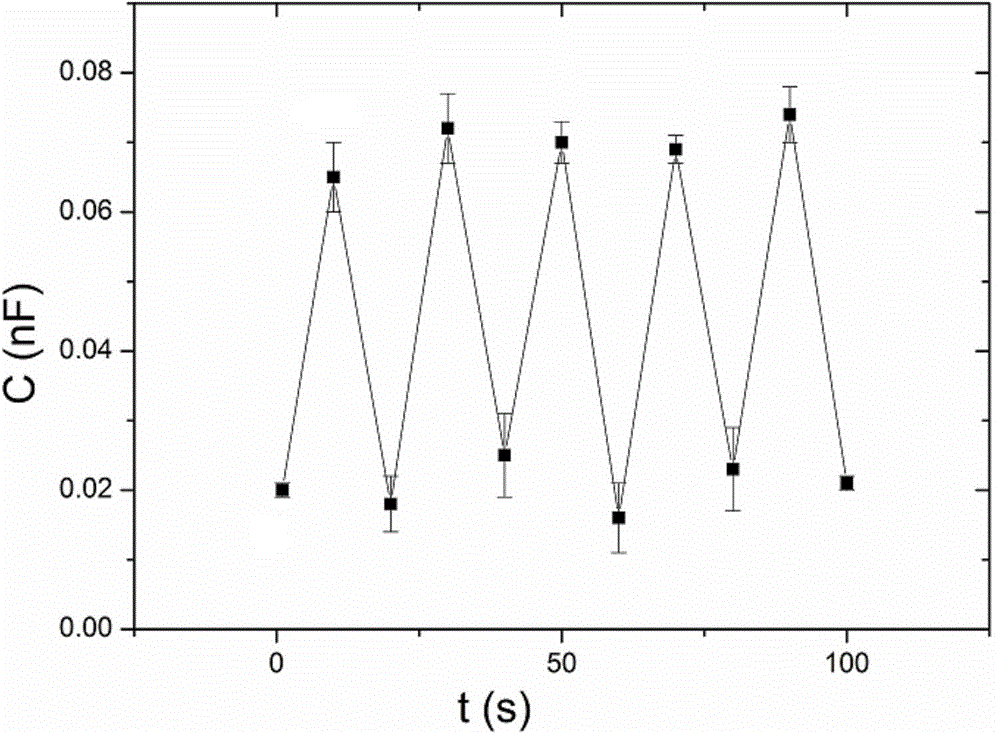

ActiveCN104897316AWith directional deposition functionSimple preparation processForce measurementFiberCapacitance

The invention discloses a capacitive ultrathin flexible stress sensor and a producing method thereof. The capacitive ultrathin flexible stress sensor comprises a bottom elastic protective film, a bottom electrospun nanofiber conductive film electrode, a middle elastic insulated isolating film, a top electrospun nanofiber conductive film electrode, a top elastic protective film, and two metallic electrodes, wherein the two metallic electrodes are connected with the top electrospun nanofiber conductive film electrode and the bottom electrospun nanofiber conductive film electrode respectively. The top electrospun nanofiber conductive film electrode is a conductive nanofiber film produced through an electrostatic spinning method and deposited directionally on the top surface of the middle elastic insulated isolating film and the bottom electrospun nanofiber conductive film electrode is a conductive nanofiber membrane produced through an electrostatic spinning method and deposited directionally on the top surface of bottom elastic protective film. The stress sensor is stretchable in a large range and can be used for measuring a large stretching range. The capacitance of the stress sensor is determined by the induction area of the stretched stress sensor. The stress sensor is simple in preparation technology and has good application prospect.

Owner:QINGDAO UNIV

Jet yarn spinning machine for electrostatic-spun nanofibers and use method thereof

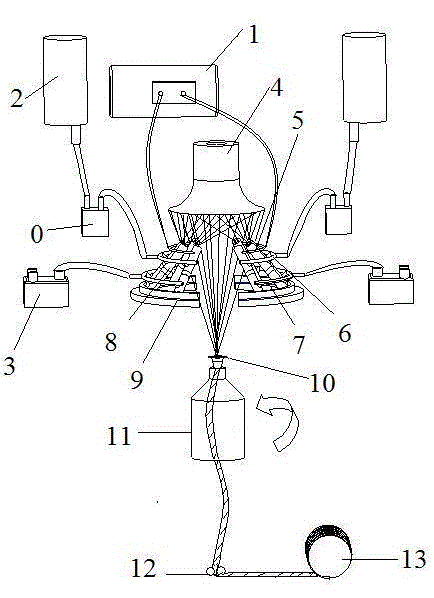

ActiveCN103147179AEnables continuous batch preparationReduce volatilityFilament/thread formingContinuous wound-up machinesYarnFiber

The invention relates to a jet yarn spinning machine for electrostatic-spun nanofibers. The machine comprises a high-voltage static electricity generator, a liquid storage tank with a pressurizing device, a cross-flow air pump, a gathering unit, a spinning unit, a semicircular base, a buncher, a jet nozzle twister, a yarn guide roller and a winding mechanism. The jet yarn spinning machine integrates the functions of spinning, gathering, drafting, twisting and winding and can be used for continuously producing electrostatic-spun nanofiber yarn. The yield of electrostatic-spun nanofibers is greatly increased; and the twister is simple in structure and high in production efficiency. A nanofiber yarn forming method is simple in process and high in yarn yield, is applicable to multiple polymer spinning solutions and can realize the continuous batch preparation of nanofiber yarn.

Owner:河南中纤新材料科技有限公司

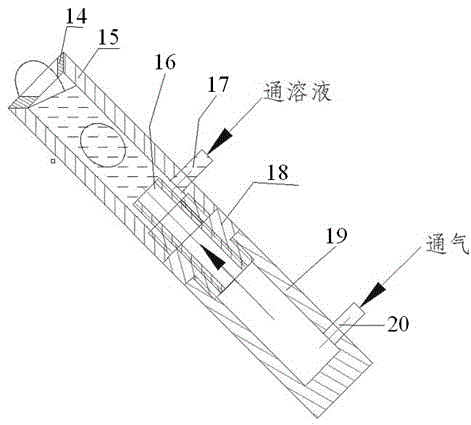

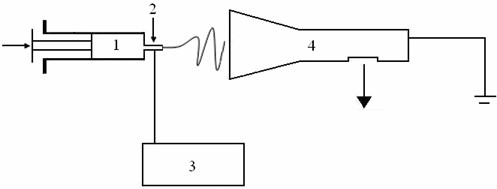

Preparation method and device for electrospinning nanofiber yarn

The invention discloses a preparation method and device for electrostatic spinning nanofiber yarn. It includes a spinneret, a high-voltage generator and a receiving device; the receiving device is a funnel-type receiving device, which is formed by connecting a conical shrinking tube and a cylindrical tube, and the large end of the conical shrinking tube is facing the electrospinning solution The spinneret has an opening at the bottom of the cylindrical tube, and the opening is connected to a vacuum pump, forming an airflow moving from the funnel inlet to the opening of the cylindrical tube in the funnel-type receiving device. In the present invention, electrolyte is added to the high polymer solution used in electrospinning to increase the aggregation effect of fibers; at the same time, a funnel-shaped pipe is used as a receiving device for electrospinning nanofibers, and the cylindrical pipe at the back end of the funnel is tangentially vacuumed to form A certain airflow field gathers the fibers to form a yarn composed of nanofibers. The device of the invention is simple to prepare and convenient to operate, and the prepared nanofiber yarn can be used in fields such as electronics and bioengineering.

Owner:ZHEJIANG SCI-TECH UNIV

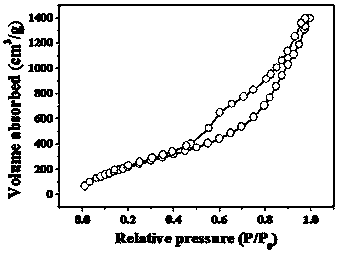

Method for preparing electrospun nanofiber reinforced silica aerogel

InactiveCN108467276ASmall fiber diameterLarge specific surface areaCeramicwareSupercritical dryingFiber

The invention relates to a method for rapidly preparing electrospun nanofiber reinforced silica aerogel blocks with excellent mechanical properties by atmospheric pressure drying. Used nanofibers areprepared by electrospinning; the prepared nanofiber reinforced silica aerogel not only maintains the advantages of low density and high porosity, but also overcomes the disadvantages of poor integrityand large brittleness. Silica sol formed by hydrolysis of alkoxysilane is used as a receiving body of electrospinning, and the nanofibers are evenly dispersed in the silica sol; the silica sol is allowed to form gel with ammonia water as a catalyst, then the gel is aged and modified, and the electrospun nanofiber reinforced silica aerogel is obtained. The method has the prominent characteristicsthat the method does not need dangerous or expensive supercritical drying, the operation is simple, the process is controllable, the cycle is short, the cost is low, and the product can be produced continuously; the obtained product has excellent physical properties and excellent mechanical properties.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

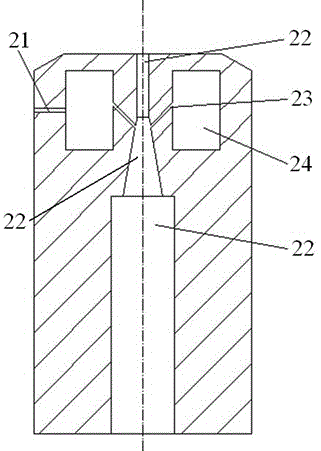

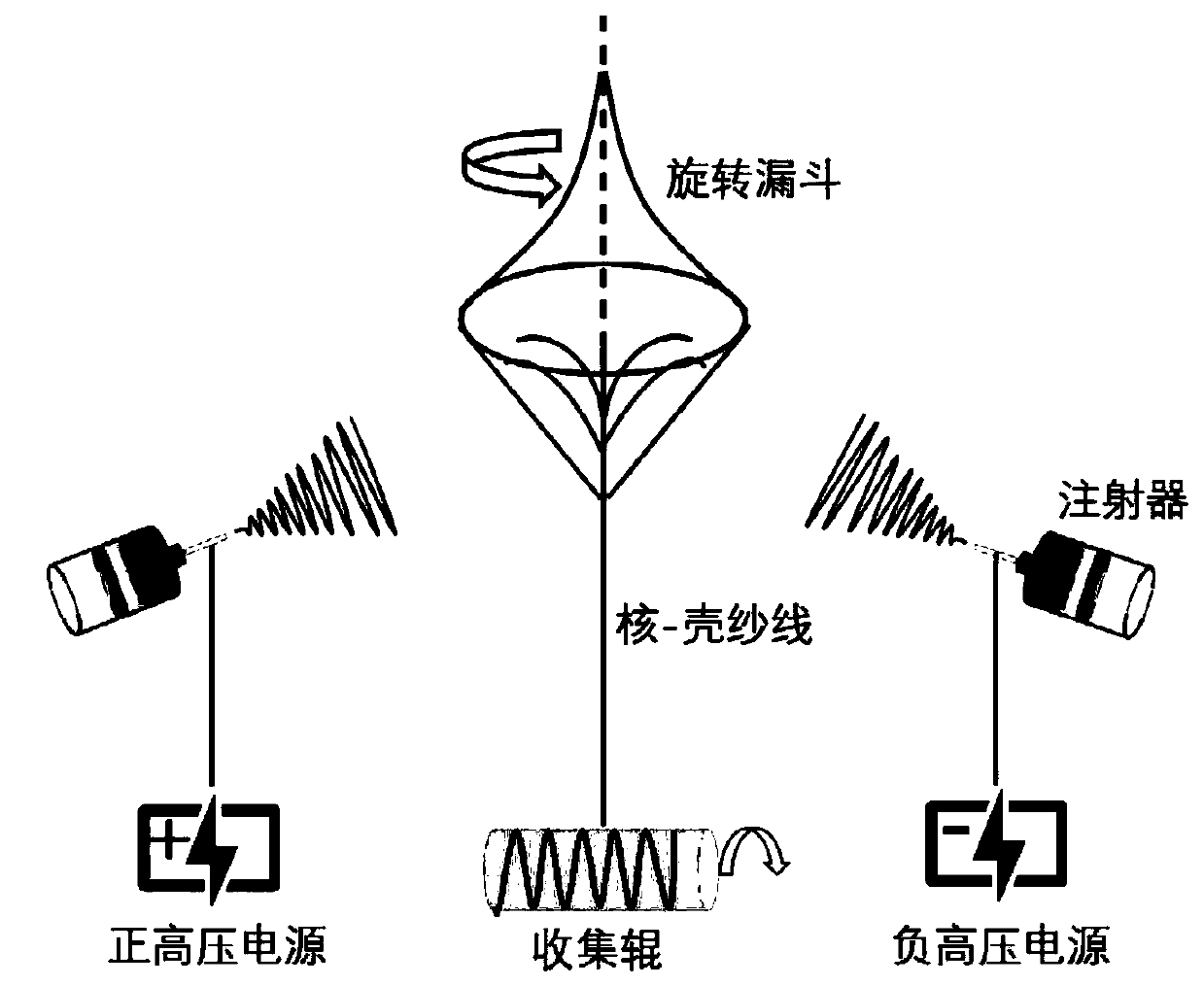

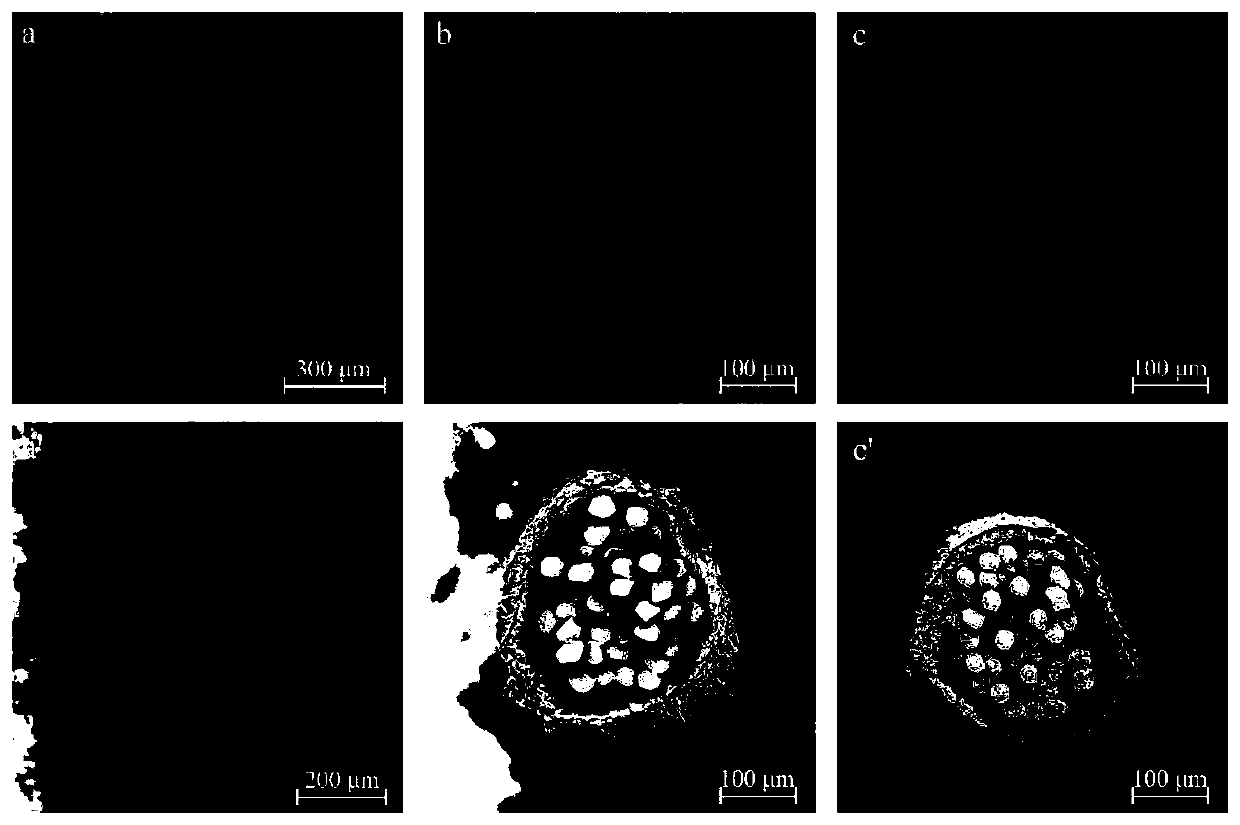

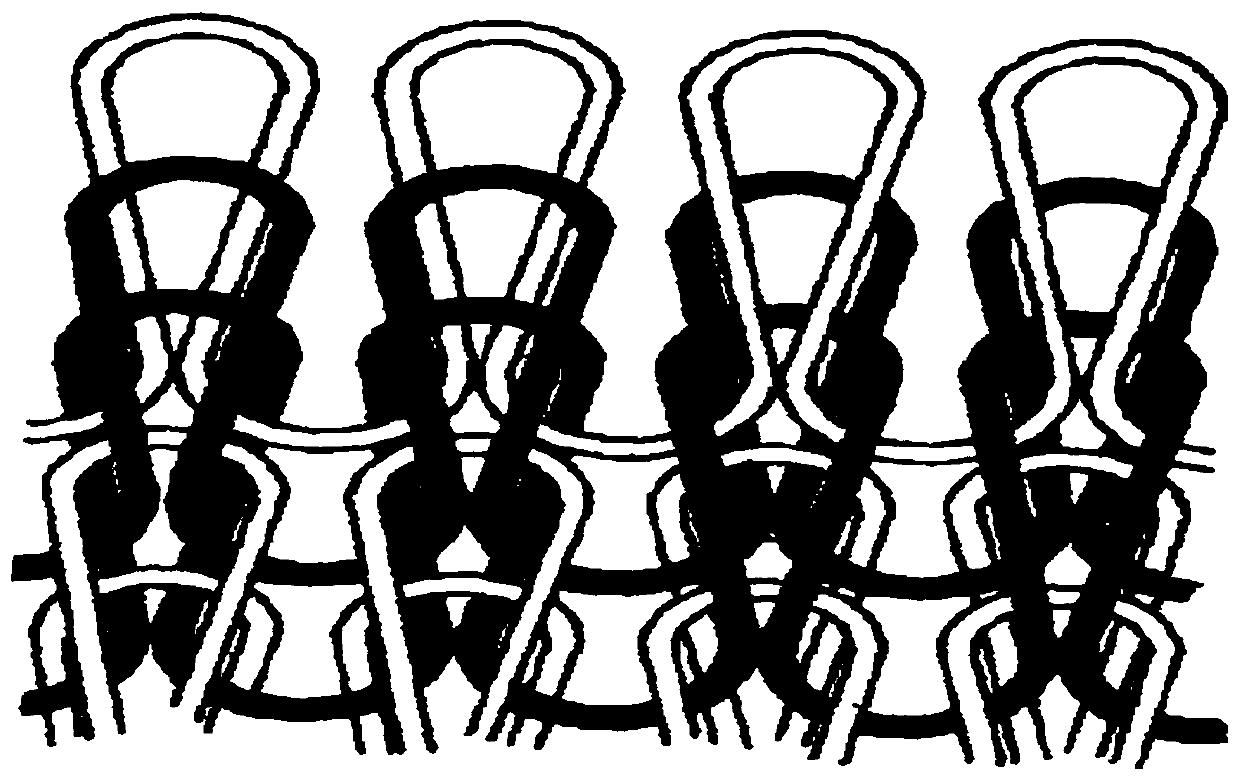

Knitted multilayered-structure nanofiber yarn tendon scaffold as well as preparation and application thereof

InactiveCN110331486AAppropriate pore sizeImprove growth abilityWeft knittingLigamentsBiocompatibility TestingBiomedical engineering

The invention relates to a knitted multilayered-structure nanofiber yarn tendon scaffold as well as preparation and application thereof. Yarn is of a multilayered core spun structure. The preparationcomprises steps as follows: core layer yarn penetrates through a hollow rotating funnel to serve as a receiving device, positive and negative high-voltage power sources are applied to double needles on the two sides respectively, electrospun nanofibers are twisted to the core layer yarn, and double-layer continuous nanofiber yarn is prepared; the double-layer nanofiber yarn is taken as a core layer, electrospun natural polymer nanofibers are arranged on the outer layer, and three layers of nanofiber yarn are prepared; finally, the 3D knitted scaffold is prepared from the different layers of nanofiber yarn with a knitting technology and is used for tendon repair. The knitted multilayered-structure nanofiber yarn scaffold has the characteristics that a function of enhancing mechanical properties of regenerated tissue for a long time is realized, biocompatibility is good and repair and normal function recovery of tendon injury are facilitated.

Owner:DONGHUA UNIV

Nanofiltration membrane, preparation method and dye separation method

ActiveCN110449048AEasy to separateImprove throughputSemi-permeable membranesWater contaminantsFiberElectrospun nanofibers

According to the invention, an electrospun nanofiber membrane is selected as a base membrane; meanwhile, through a simple doped cross-linking method, polyethyleneimine is introduced into a transitionlayer; and amine functional groups exposed in fiber exert great effects in the process of interfacial polymerization. Thus, the overall separation performance of a membrane is improved; meanwhile, a prepared membrane has good stability and good rejection effect on a dye; when a test pressure is 2 bar, the rejection rate of the membrane is 90% or above; and the prepared membrane has good pure waterflux which is in a range of 34.5 to 42.5 L m<-2>h<-1>bar<-1>. When the range of a pressure is in a range of 1 and 5 bar, the rejection performance of a composite membrane is basically unchanged, andthe flux and pressure are basically in a linear relationship, so a low-pressure nanofiltration membrane is prepared. In a stability test of 48 h, the composite membrane has good stability.

Owner:NANJING UNIV OF TECH

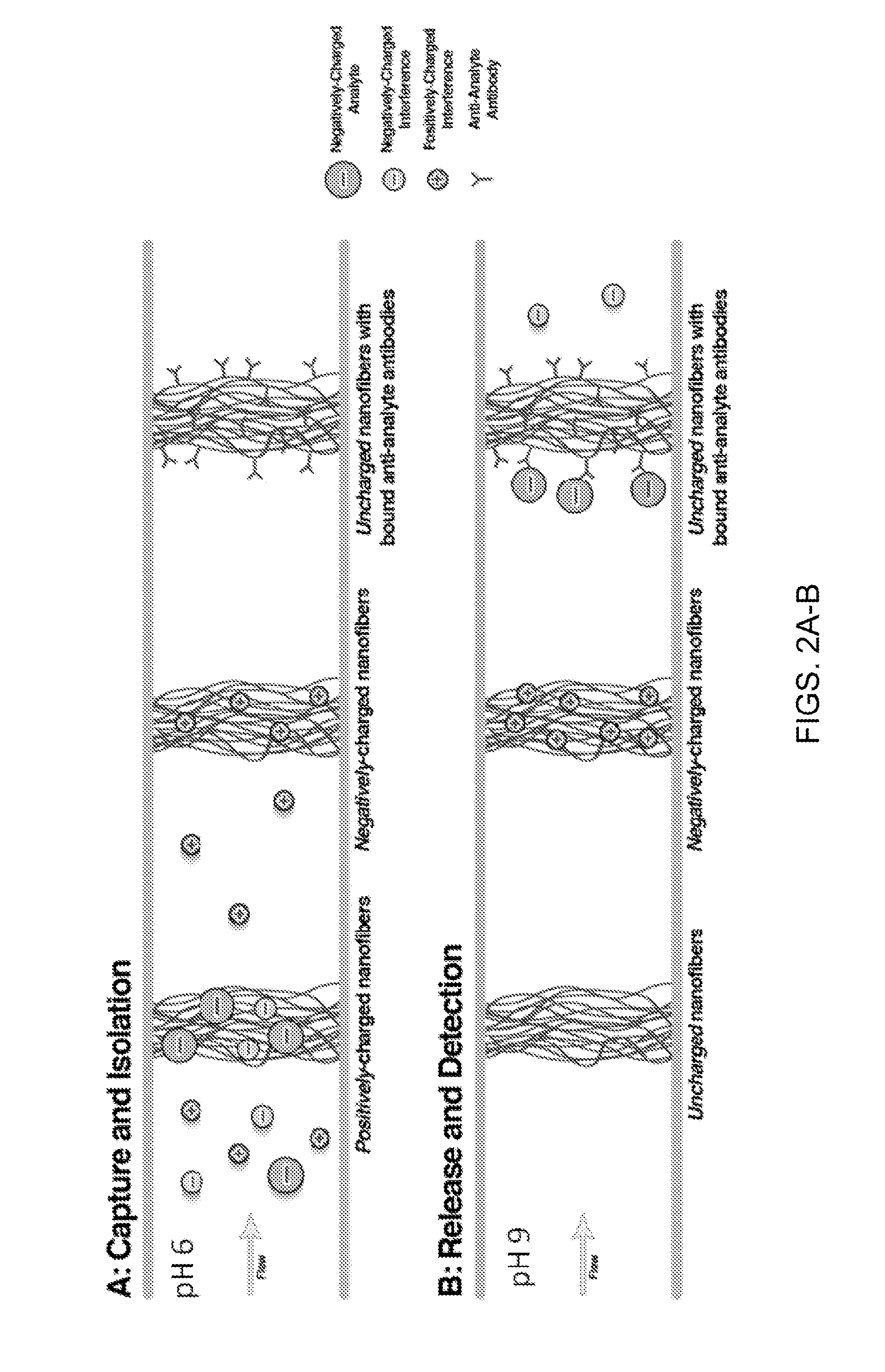

Electrospun nanofibrous membrane assembly for use in capturing chemical and/or biological analytes

InactiveUS20060148066A1Bioreactor/fermenter combinationsBiological substance pretreatmentsFiberAnalyte

A membrane assembly adapted for use in capturing an analyte of interest, the membrane assembly comprising in one embodiment (a) an electrospun nanofibrous membrane, the electrospun nanofibrous membrane comprising a random mat of electrospun nanofibers, at least some of the electrospun nanofibers including one or more types of functional groups; and (b) at least one molecular recognition element immobilized on the random mat via a functional group, the molecular recognition element being adapted to selectively bind the analyte of interest. The membrane assembly may be incorporated into a sensor.

Owner:SENECAL KRIS J +5

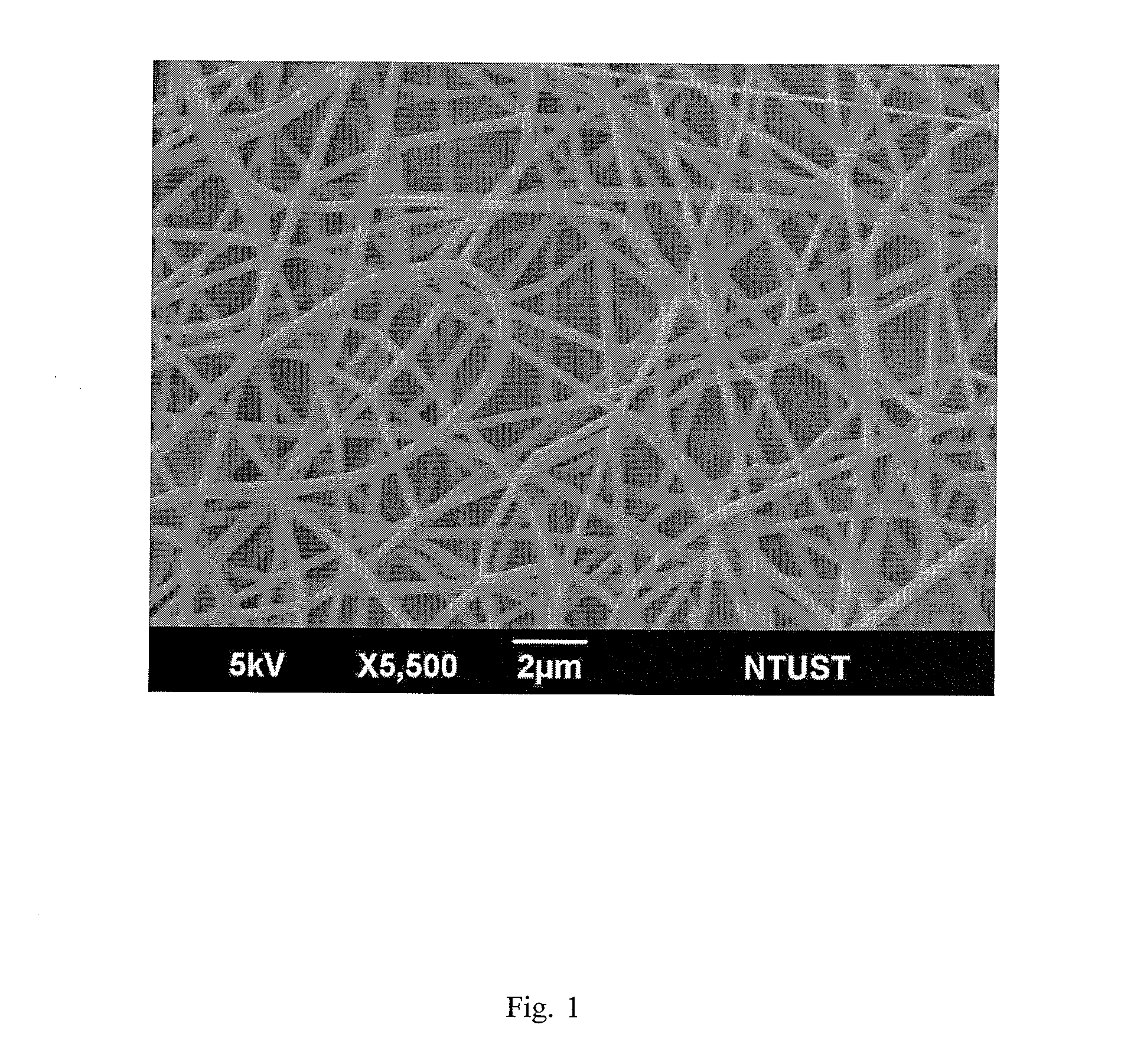

Electrospun nanofibrous membranes and disposable glucose biosensor

ActiveUS9708640B2Low costHigh sensitivityMicrobiological testing/measurementMaterial analysis by electric/magnetic meansFiberCross-link

An electrospun nanofibrous membrane is sheet like and is formed by multiple glucose oxidase / potassium hexacyanoferrate(III) modified electrospun nanofibers. The glucose oxidase / potassium hexacyanoferrate(III) modified electrospun nanofibers are PVA electrospun nanofibers containing glucose oxidase and potassium hexacyanoferrate(III) homogeneously dispersed therein. The glucose oxidase / potassium hexacyanoferrate(III) modified electrospun nanofibers are PVA electrospun nanofibers and are cross-linked by glutaraldehyde vapor with ultrasonic energy assistance. Graphene modified PVA / GOx electrospun membranes were prepared to examine the immobilization mechanism between graphene and GOx. The electrochemical measurement results show that the sensitivities increased with increasing graphene concentrations up to 20 ppm. The highest sensitivity recorded 38.7 μA / mM was for a PVA / GOx membrane with 20 ppm graphene representing a 109% increase over a membrane made without graphene.

Owner:NAT TAIWAN UNIV OF SCI & TECH

Biofunctional nanofibers for analyte separation in microchannels

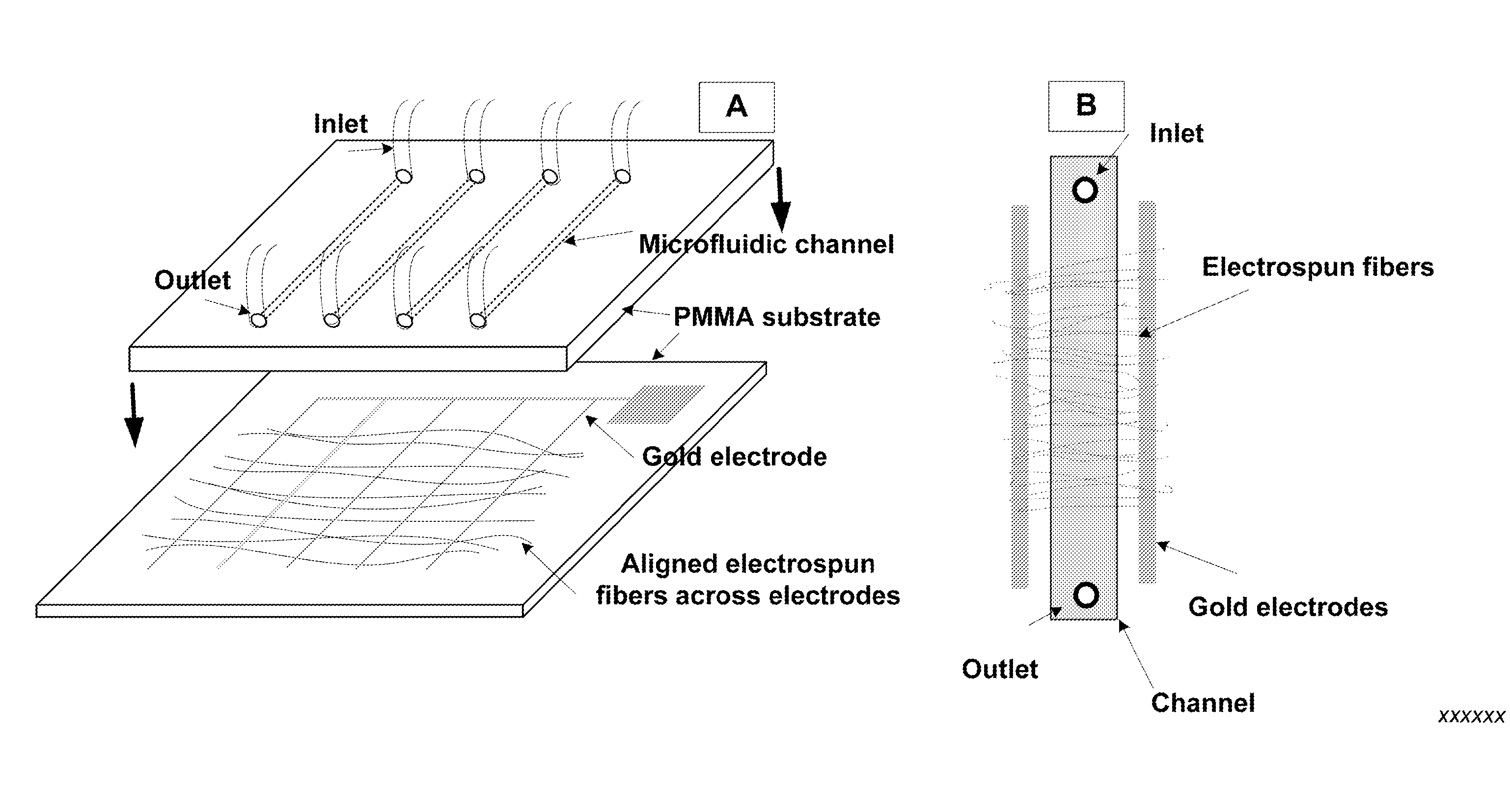

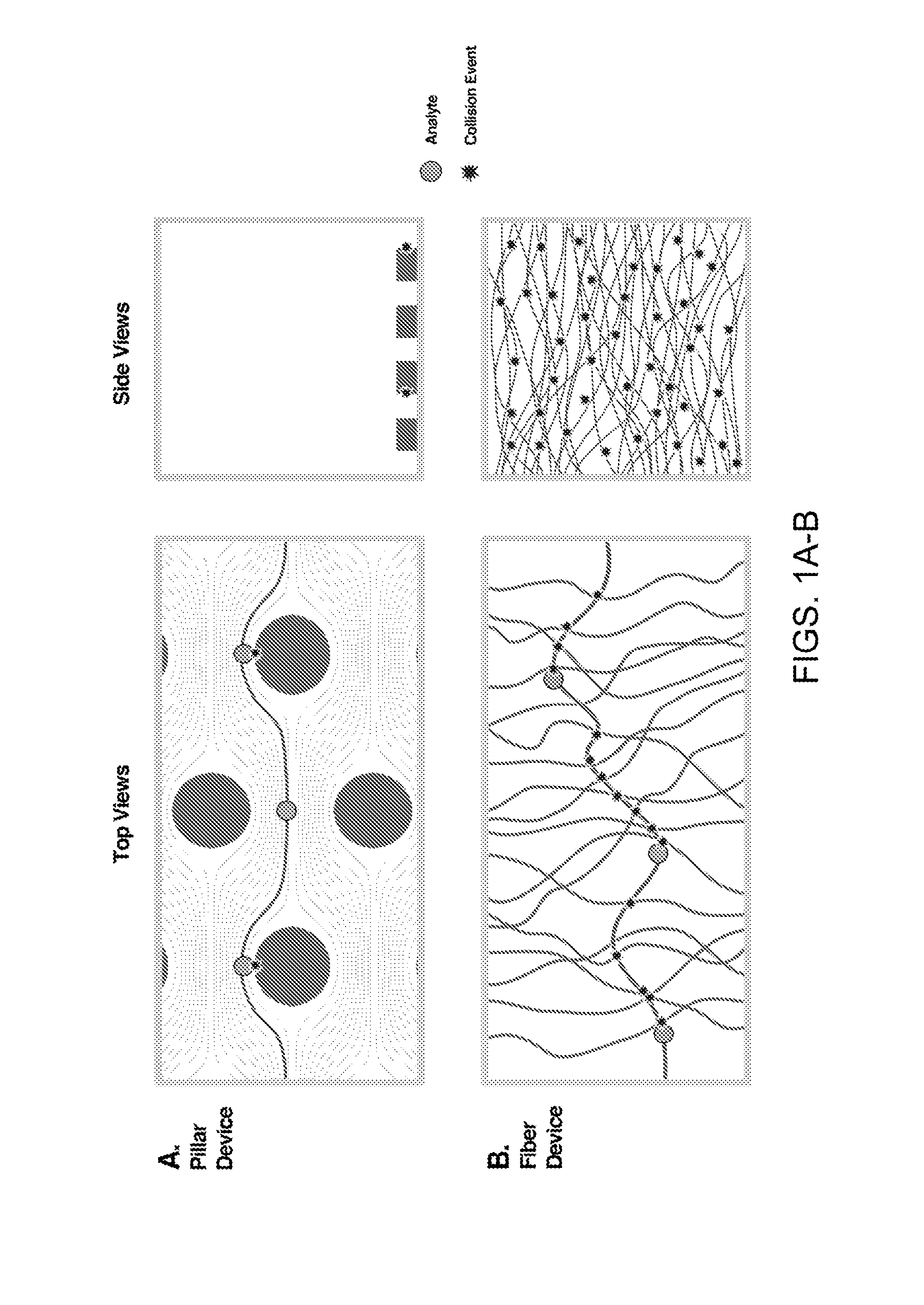

A method is provided for producing, in a substrate, an enclosed channel or enclosed cavity comprising at least one functional nanofiber, the method comprising the steps of providing a first substrate and a second substrate; forming a channel or cavity on the first substrate or the second substrate; electrospinning at least one functional nanofiber on the first substrate; assembling the first and second substrates, wherein the first substrate is placed over the second substrate, or the second substrate is placed over the first substrate; and bonding the first substrate and the second substrate to form the substrate, thereby forming an enclosed channel or enclosed cavity comprising the at least one functional nanofiber in the substrate. An enclosed channel or cavity comprising at least one functional electrospun nanofiber is also provided. A microfluidic device is also provided comprising an enclosed channel or cavity comprising at least one functional electrospun nanofiber.

Owner:CORNELL UNIVERSITY

Electrospun Nanofibrous Membranes and Disposable Glucose Biosensor

ActiveUS20160153025A1Low costHigh sensitivityImmobilised enzymesBioreactor/fermenter combinationsCross-linkFiber

An electrospun nanofibrous membrane being sheet like and being formed by comprising multiple glucose oxidase / potassium hexacyanoferrate (III) modified electrospun nanofibers, wherein the glucose oxidase / potassium hexacyanoferrate (III) modified electrospun nanofibers are PVA electrospun nanofibers containing glucose oxidase and potassium hexacyanoferrate (III) homogeneously dispersed therein; and the glucose oxidase / potassium hexacyanoferrate (III) modified electrospun nanofibers are PVA electrospun nanofibers and are cross-linked by glutaraldehyde vapor with ultrasonic energy assistance. In the present invention, graphene modified PVA / GOx electrospun membranes were prepared to examine the immobilization mechanism between graphene and GOx. The electrochemical measurement results show that the sensitivities increased with increasing graphene concentrations up to 20 ppm. The highest sensitivity recorded 38.7 μA / mM was for a PVA / GOx membrane with 20 ppm graphene representing a 109% increase over a membrane made without graphene.

Owner:NAT TAIWAN UNIV OF SCI & TECH

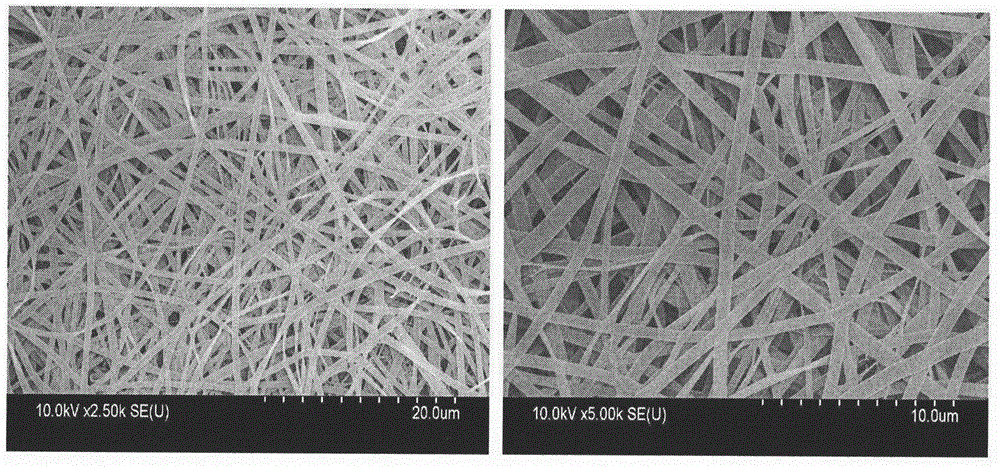

Electrostatic-spinning nano fiber air filter material and preparation method thereof

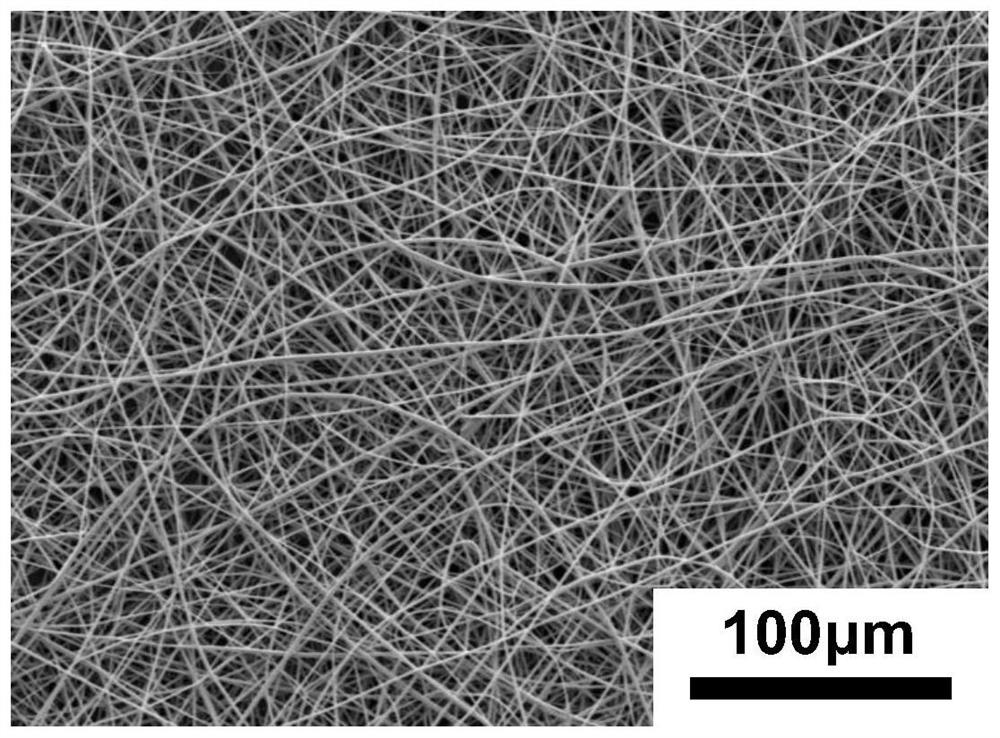

InactiveCN105749767ASimple processEasy to manufactureSemi-permeable membranesNon-woven fabricsFiberAir filtration

The invention discloses an electrostatic-spinning nano fiber air filter material and a preparation method thereof, aiming at solving the problems of an electrostatic-spinning nano fiber membrane product that the filtering resistance is high, the air permeability and the moisture penetrability are poor, and the industrial application is difficult. By adjusting solution properties and a spinning process, the diameter, pore diameter and orientation distribution of nano fibers can be effectively controlled; the prepared nano fibers have narrow diameter and pore diameter distribution, and the orientation degree is about 0.26-0.33; the filtering efficiency of a prepared nano fiber membrane and a prepared air filtering product is up to 99.55%, the filtering resistance is 150Pa-200Pa, the air permeability can reach 355L.m<-2>.<-1> and the moisture penetrability can reach 9.6m<2>.Pa / w, namely, the air permeability and the moisture penetrability are good; and the preparation method is convenient and rapid, small-batch production can be reduced, and the product has a very good application prospect in the field of air filtering.

Owner:DONGHUA UNIV +1

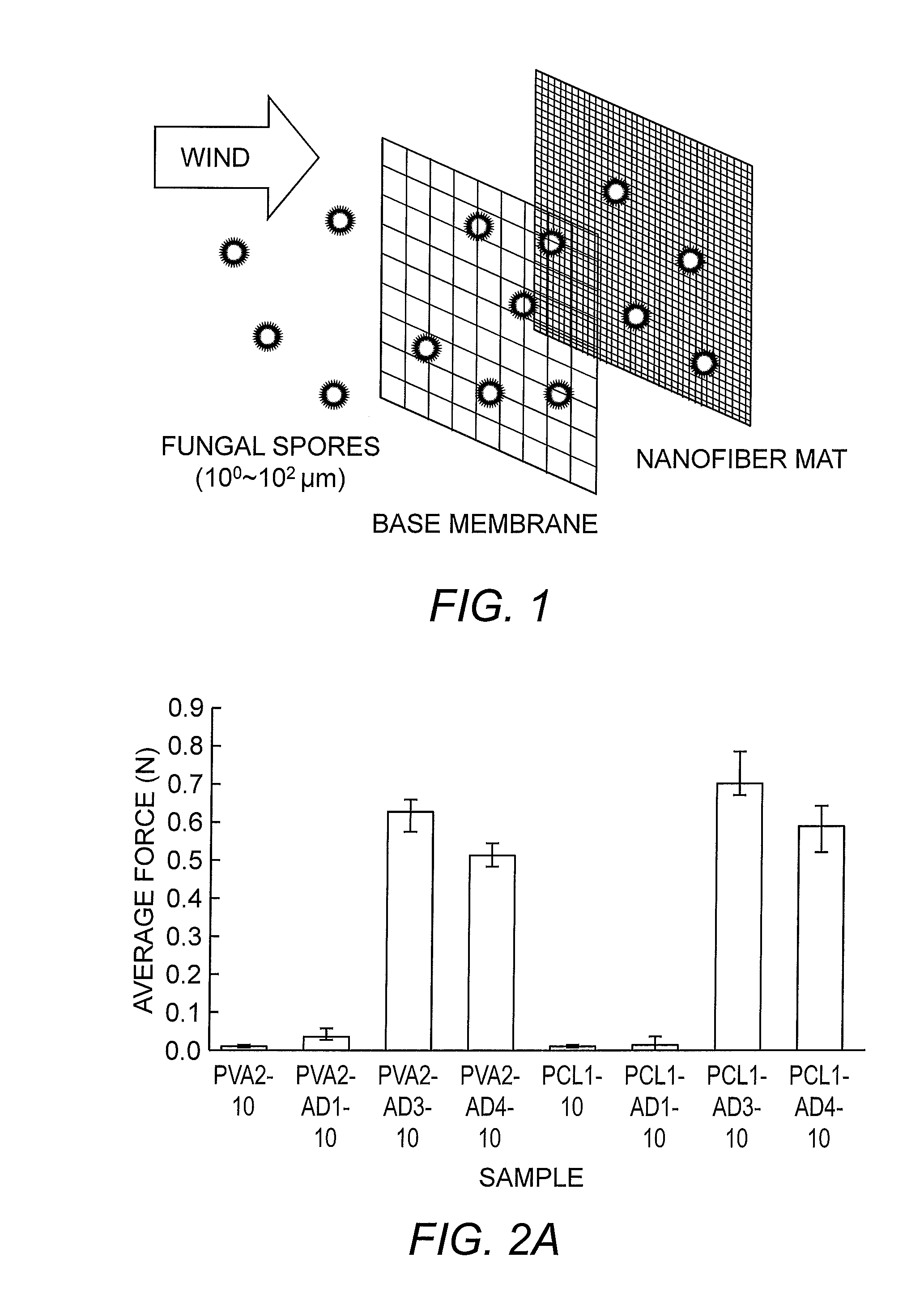

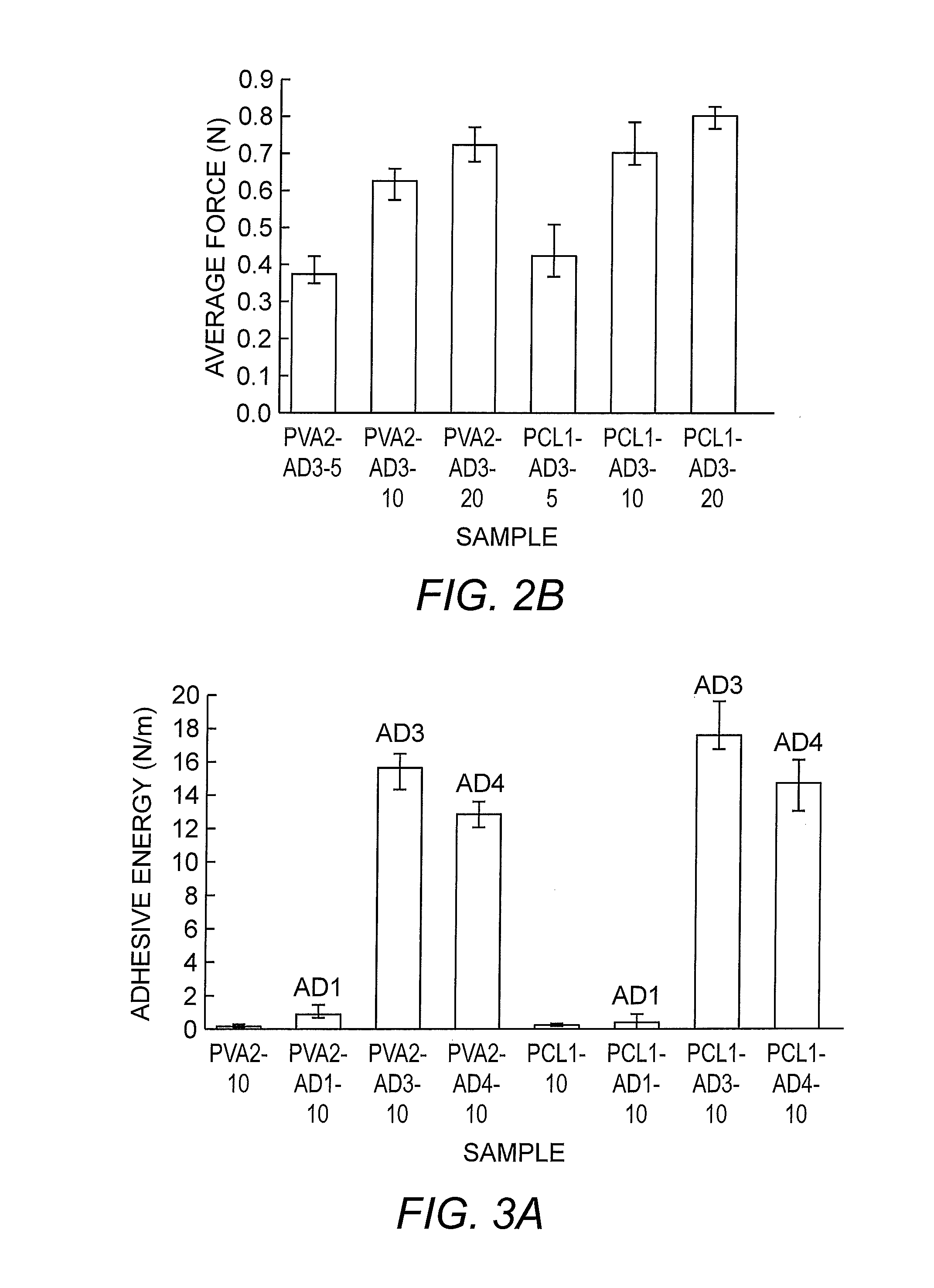

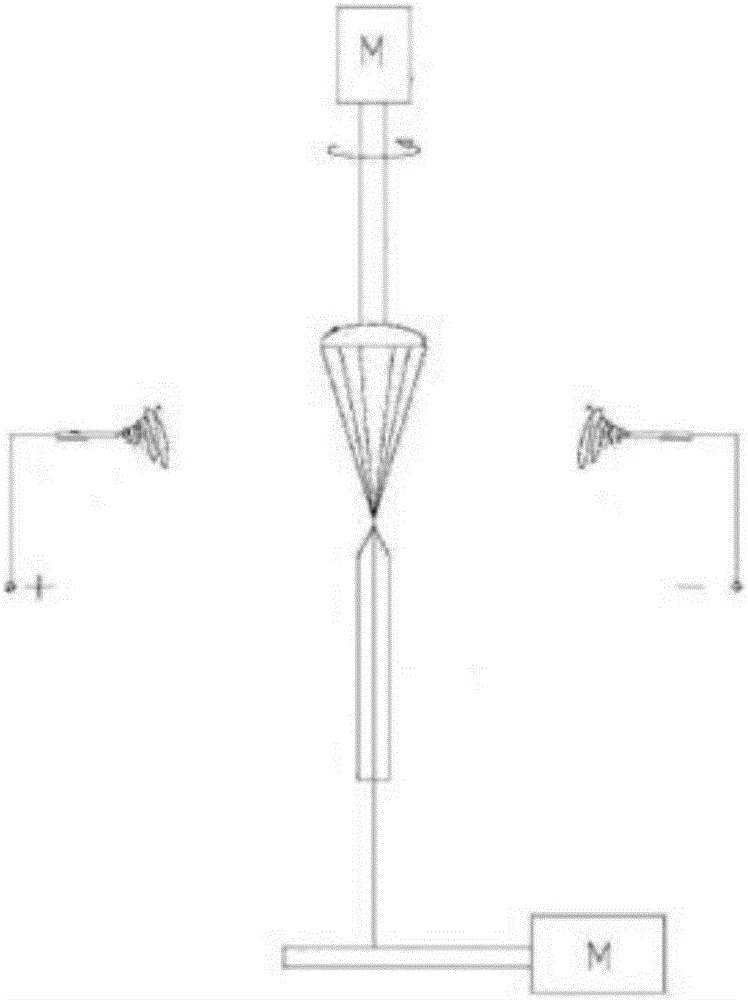

Biodegradable plant wound dressing composed of electrospun nanofibers

InactiveUS20160219874A1Prevent microbial infectionBiocideMonocomponent protein artificial filamentPolymer scienceWound dressing

A plant wound dressing composed of a blend of polymers and methods for their manufacture and use are described.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

Method and device for preparing oriented electrospun nanofiber yarns based on self-magnetic field

ActiveCN106835387AHighly oriented orderContinuous and stable productionNew-spun product collectionFilament/thread formingFiberYarn

The invention relates to a method and a device for preparing oriented electrospun nanofiber yarns based on a self-magnetic field. The method includes stably producing nanofibers; driving the nanofibers to move directionally by spiral air flow; forming conical nanofiber bundles in spiral movement; bundling and performing fine drawing to obtain the oriented electrospun nanofiber yarns. The device comprises a spinning nozzle, a liquid supply device, an insulating cover, a round metal ring and a winding device, wherein the spinning nozzle is communicated with the liquid supply device through a guide tube and is disposed below the insulating cover and under the round metal ring, the insulating cover is in the shape of a cone with two ends open, the round metal ring is fixed to the lower half portion of an inner cavity of the insulating cover through metal rods, a plurality of air nozzles are evenly circumferentially distributed on the inner sidewall of the insulating cover and above the round metal ring, and the winding device is arranged above the insulating cover. The method and the device have the advantages that the nanofiber yarns can be produced continuously and stably, the nanofibers are orderly in height orientation arrangement in the yarns, and the oriented electrospun nanofiber yarns are obtained finally.

Owner:SICHUAN SHENGSHAN BAIYULAN IND CO LTD

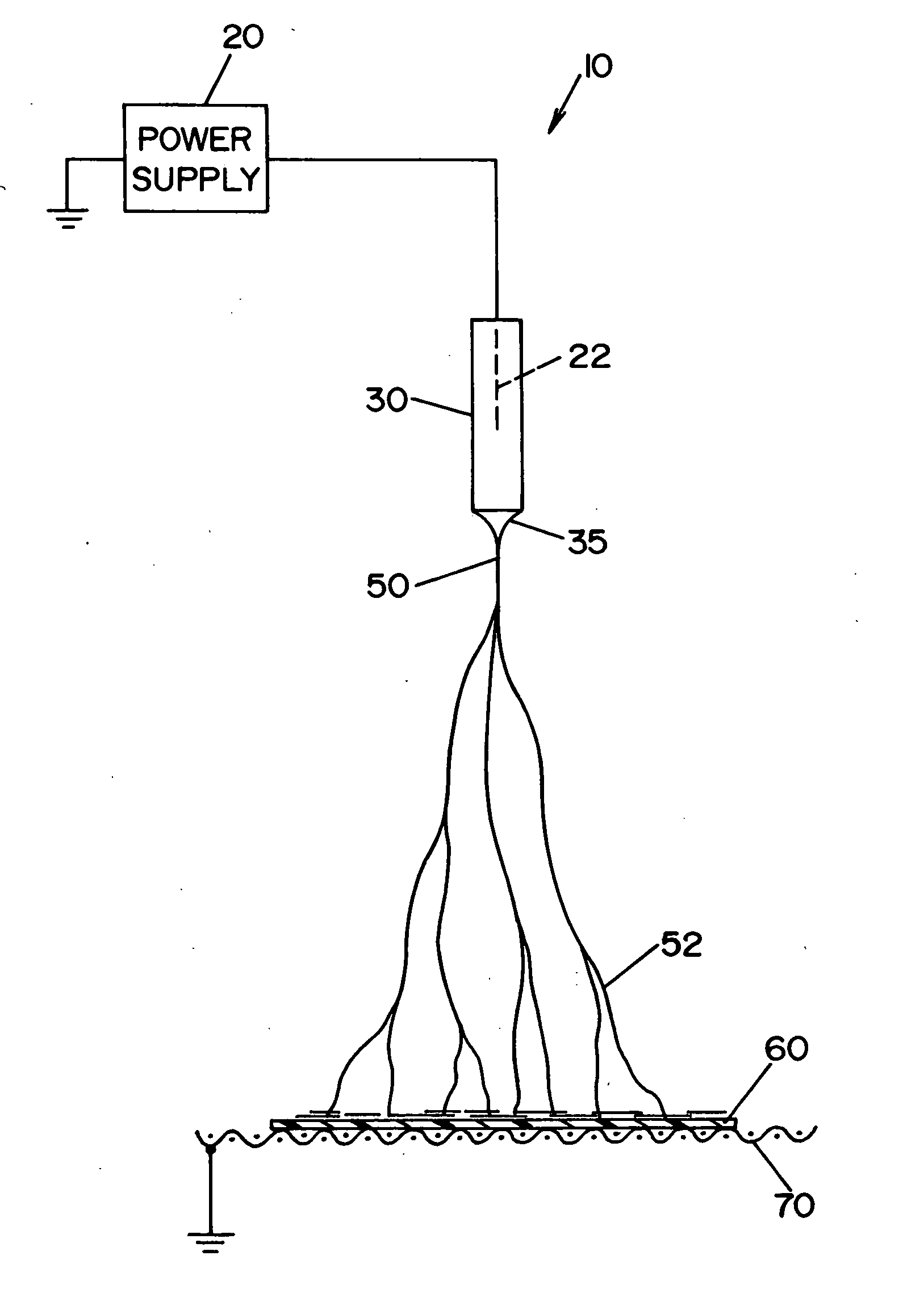

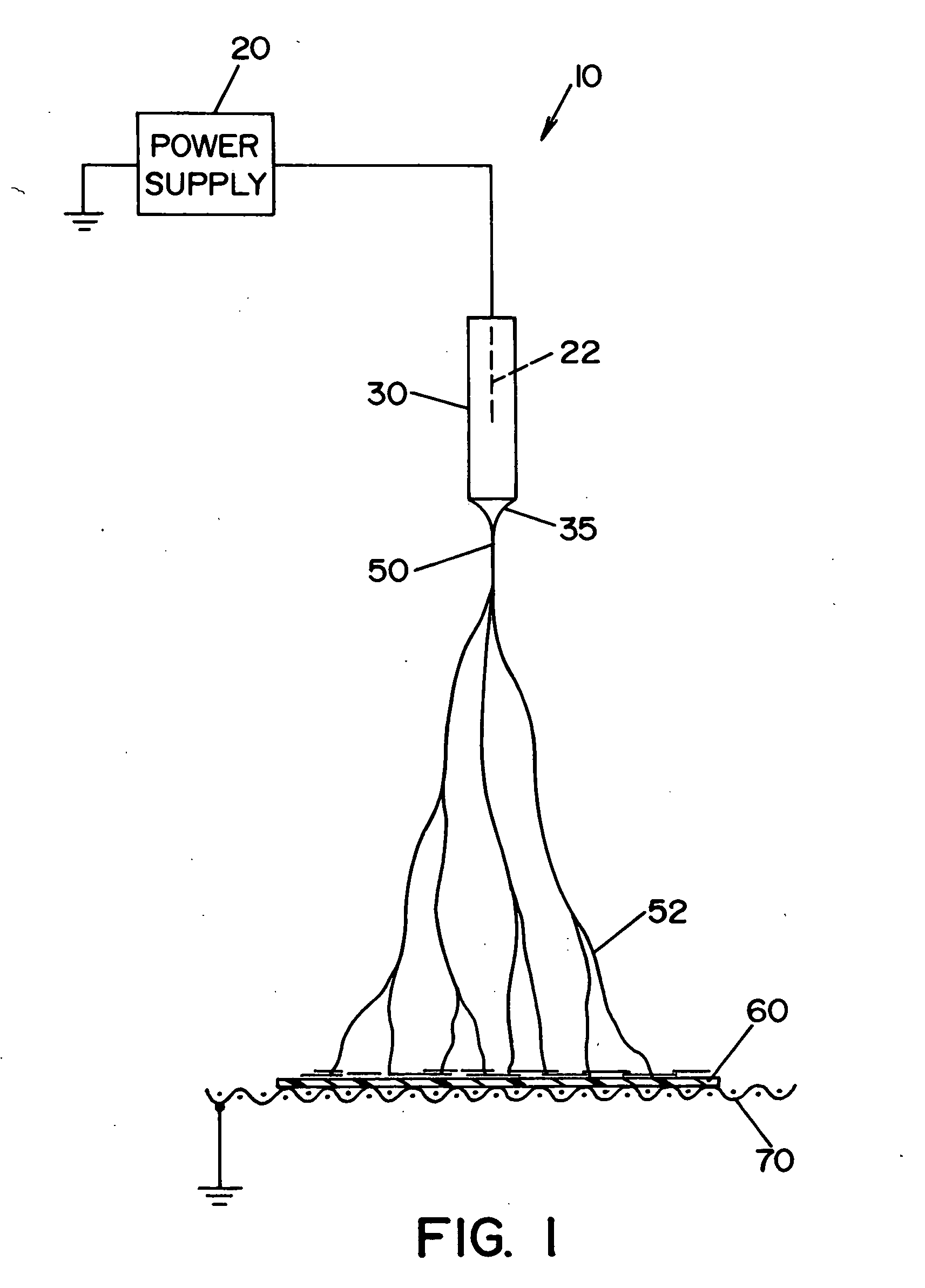

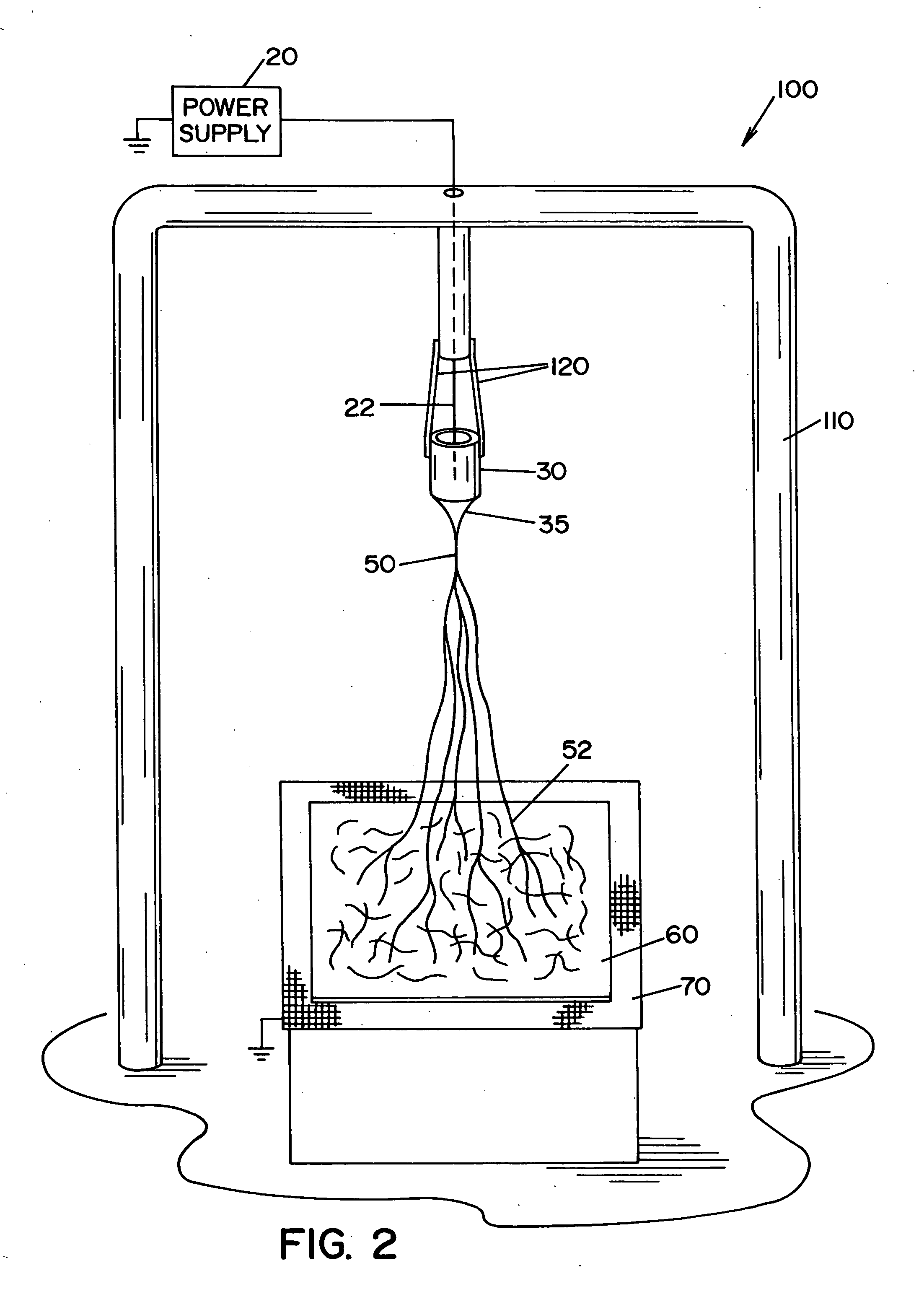

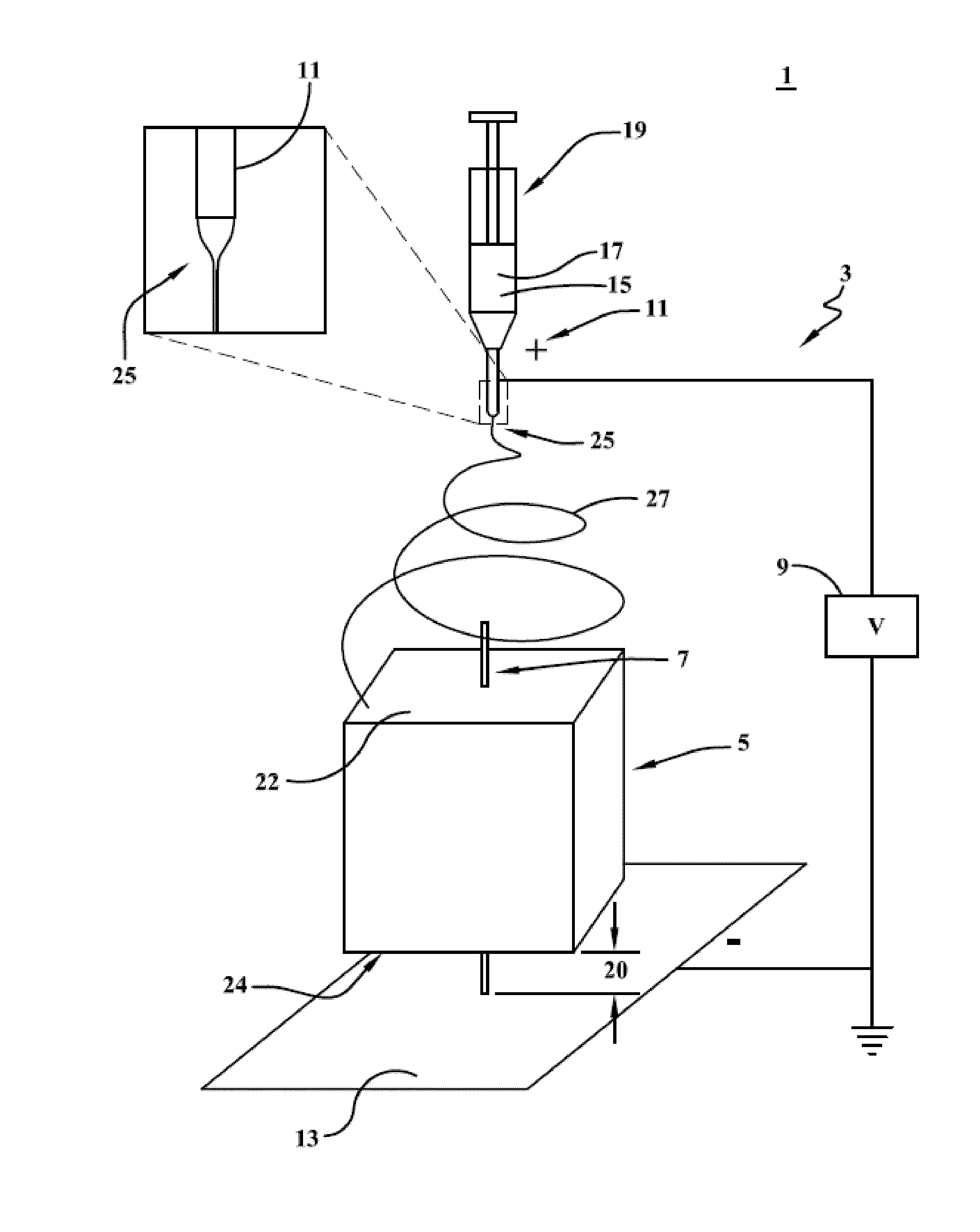

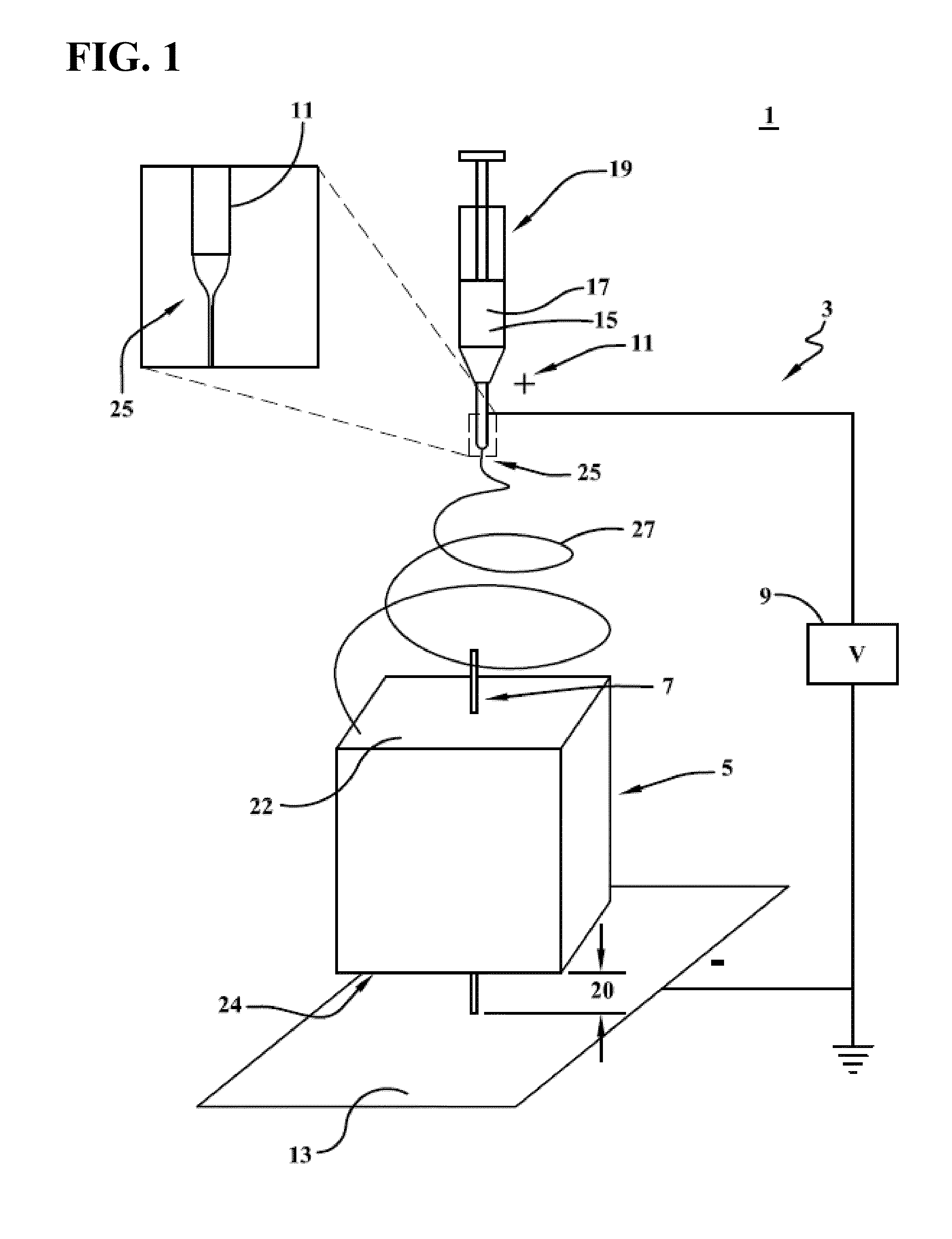

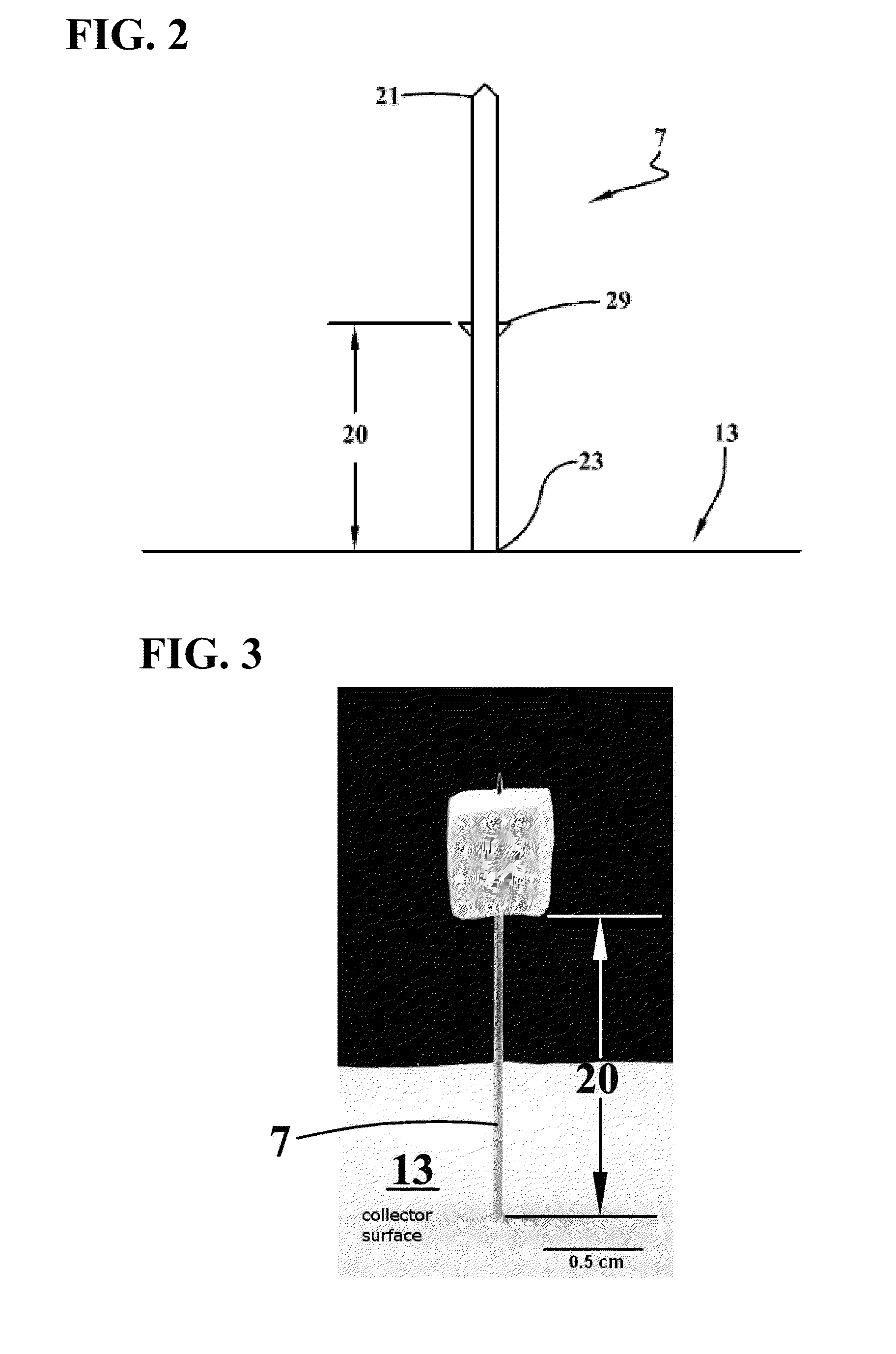

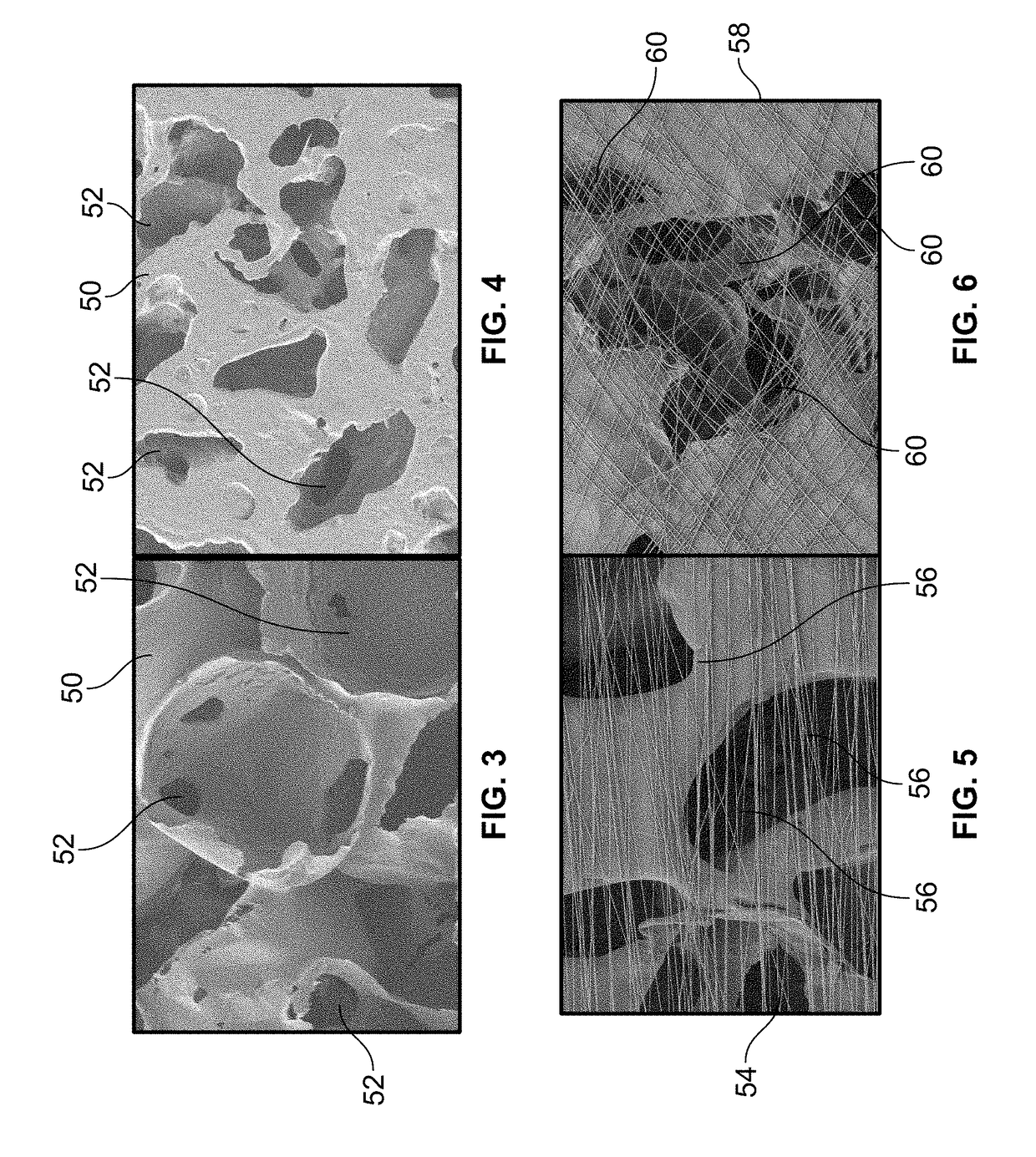

Apparatus and method for electrospinning a nanofiber coating on surfaces of poorly conductive three-dimensional objects

ActiveUS20150273110A1Effective applicationFacilitate depositionFilament/thread formingCoatingsElectrospun nanofibersNanofiber

The present invention is directed to a novel method and apparatus for facilitating and improving efficient application of nanofibers to the surface of poorly conductive three-dimensional objects using electrospinning. The apparatus and associated methods of the present invention provide a much more direct connection between the object and the grounded plate collector while allowing the object to be supported above the collector in a manner which promotes nanofiber deposition over the top, bottom and side surfaces of the object, closely covering all of its surfaces with nanofibers. Moreover, the deposition of electrospun nanofibers according to various embodiments of the present invention expands electrospinning technology to greater numbers of applications in which three-dimensional coatings of a wide nature are advantageous.

Owner:THE UNIVERSITY OF AKRON

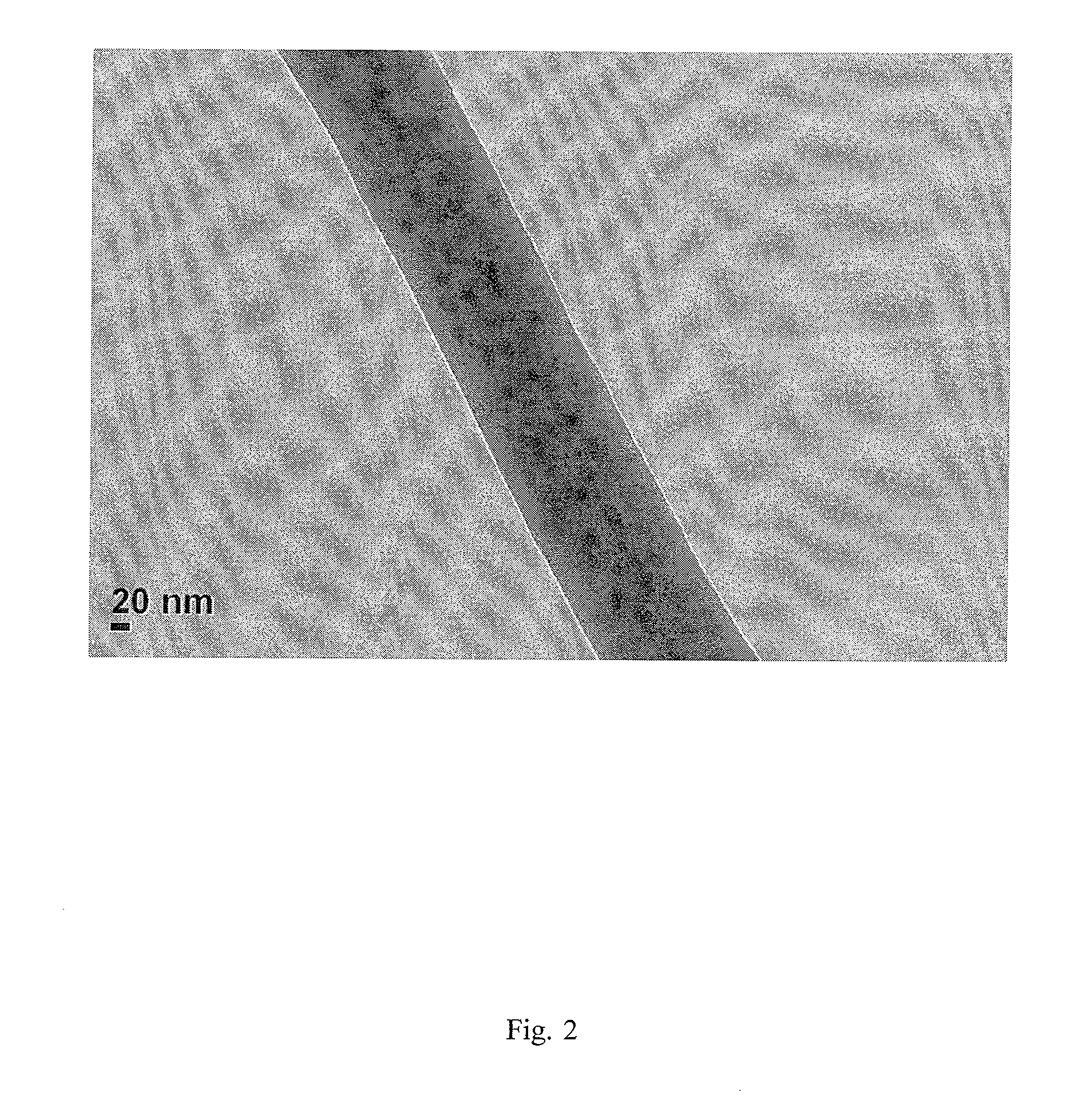

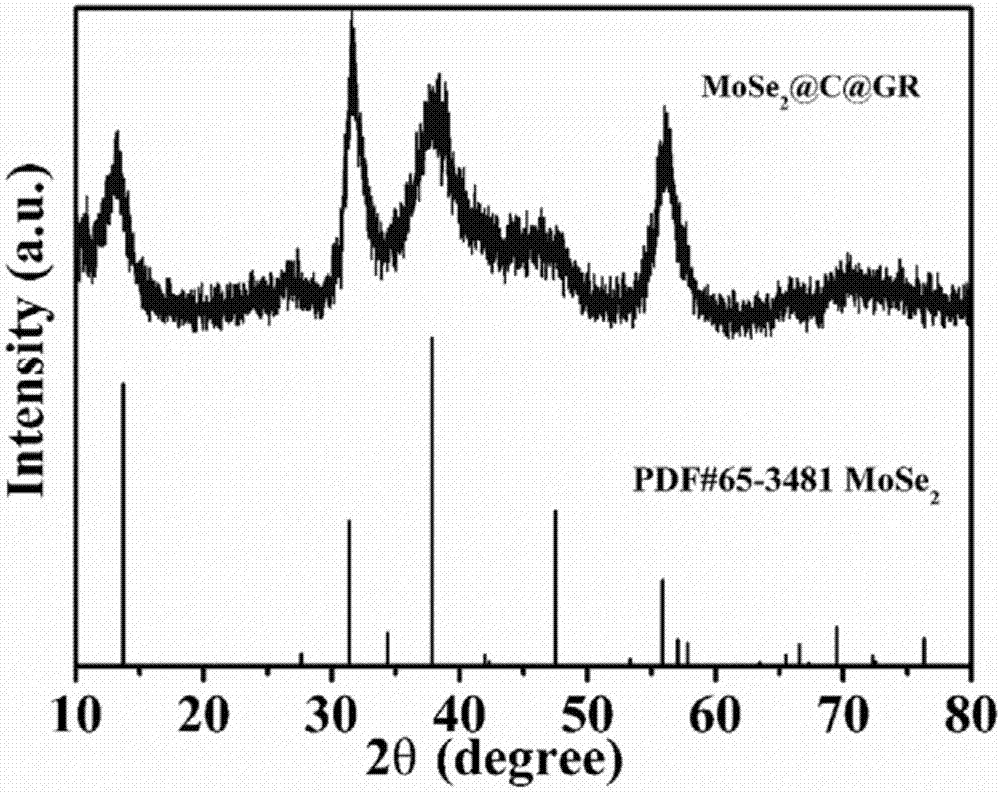

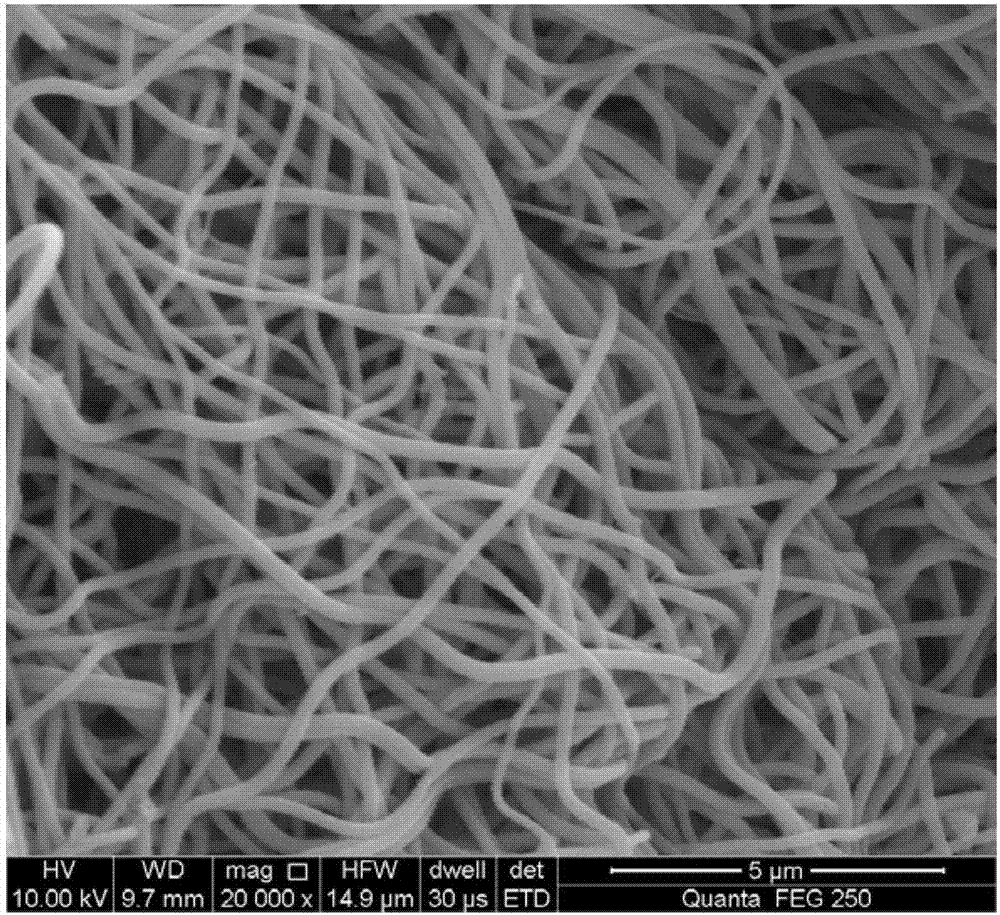

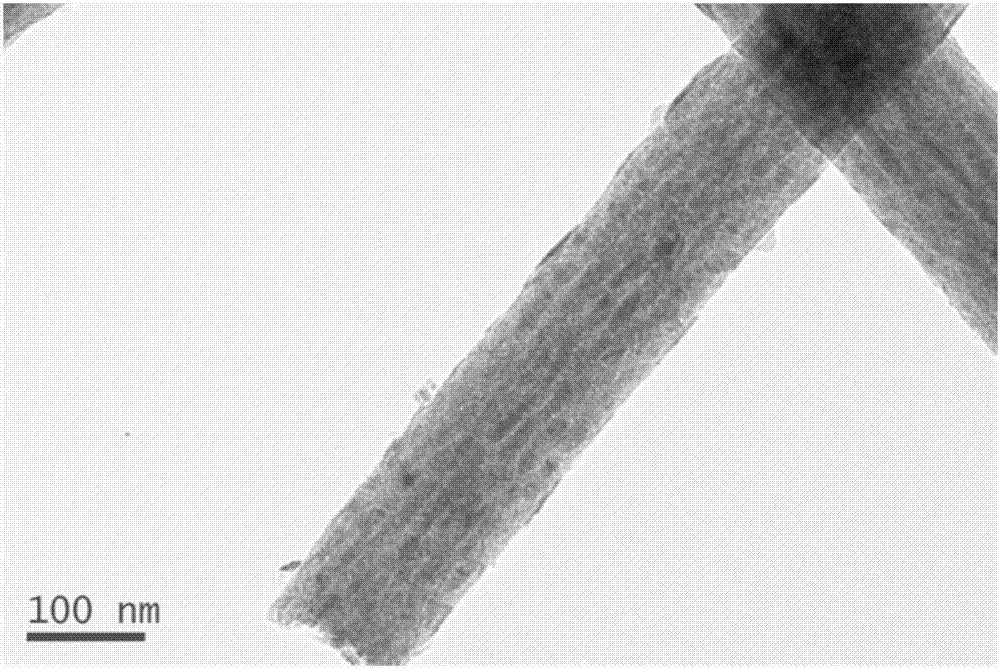

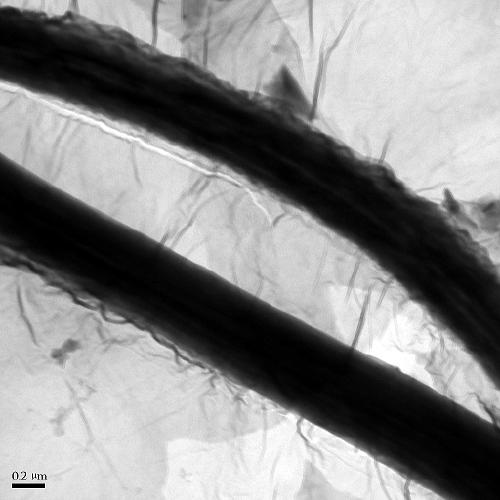

Carbon-coated MoSe2/graphene electrospun nanofibers and preparation method thereof

ActiveCN107170974AInhibition of volume expansionImprove performanceCell electrodesElectrospun nanofiberFiber

The invention relates to carbon-coated MoSe2 / graphene nanofibers prepared by electrospining and a preparation method thereof. The nanofibers are composed of coated carbon, MoSe2 and graphene. The preparation method comprises the following steps: dissolving water soluble molybdenum salt and a high polymer in a mixed solution of deionized water and ethylene glycol, heating the mixed solution till a stable transparent sol is formed, adding the graphene into the molybdenum salt solution to form an electrospining solution; electrospining the electrospining solution to obtain hybridized fibers; and then vacuum sintering the hybridized fibers obtained in the step 2 and zero valent selenium powder in a tubular furnace to obtain a carbon-coated MoSe2 / graphene nanofiber material. The fibers are uniform in shape and length, and MoSe2 crystals are uniformly distributed in the fibers and are coated by amorphous carbon; and the graphene as a conductive network is uniformly distributed in the fibers. According to the carbon-coated MoSe2 / graphene nanofibers provided by the invention, the raw materials are easily available, the preparation process is simple and controllable reaction conditions are mild, and the obtained product has a relatively high specific surface area, excellent conductivity and structural stability and can be used as an ideal lithium / sodium ion battery cathode material and a high performance electrocatalytic material.

Owner:CENT SOUTH UNIV

Electrospun nanofiber composite carbon aerogel and preparation method thereof

ActiveCN109133962AUniform structureOvercome the shortcoming that it is difficult to evenly disperse into the interior of the fiber blockFibre chemical featuresCeramicwareFiberFreeze-drying

The invention provides a preparation method of nanofiber composite carbon aerogel and belongs to the field of nanofiber carbon aerogel. The method comprises the steps of obtaining a composite dispersion liquid of nanofibers and a support body by means of electrospinning and receiving of a support body dispersion liquid; obtaining the fluffy carbon aerogel through freeze-drying, pre-oxidation and carbonization treatment. According to the method for directly receiving the electrospun nanofibers through the support body dispersion liquid, the support body can be simultaneously diffused into fibernetworks in the spinning process, so that the step of mechanically dispersing and re-crosslinking fiber membranes in most preparation methods is omitted, and the problem of nonuniform dispersion of additives is also solved. The interior of the composite carbon aerogel prepared by means of the method is of an open pore structure formed by assembling the nanofibers and the support body, and the material has excellent mechanical performance and compression resilience. The carbon aerogel can be applied to environmental governance and has a good application prospect in the field of supercapacitorelectrode materials.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI +1

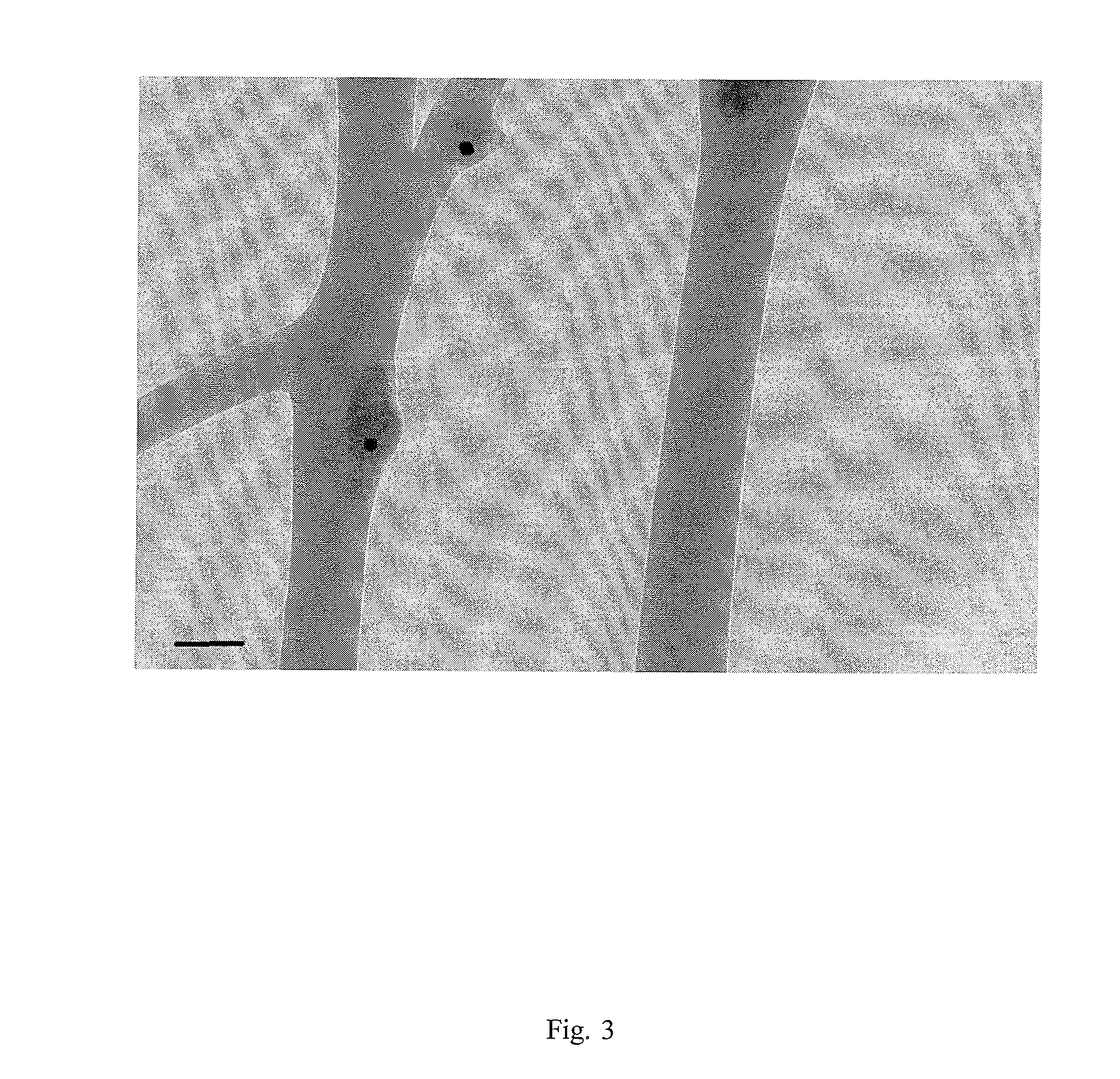

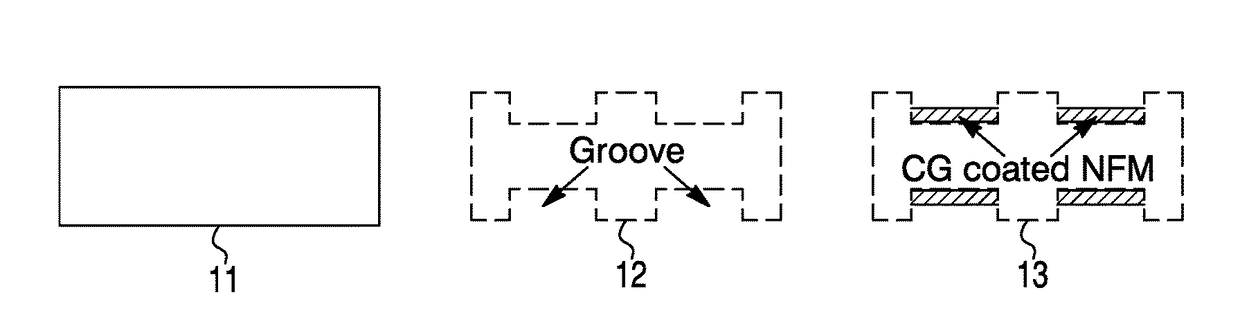

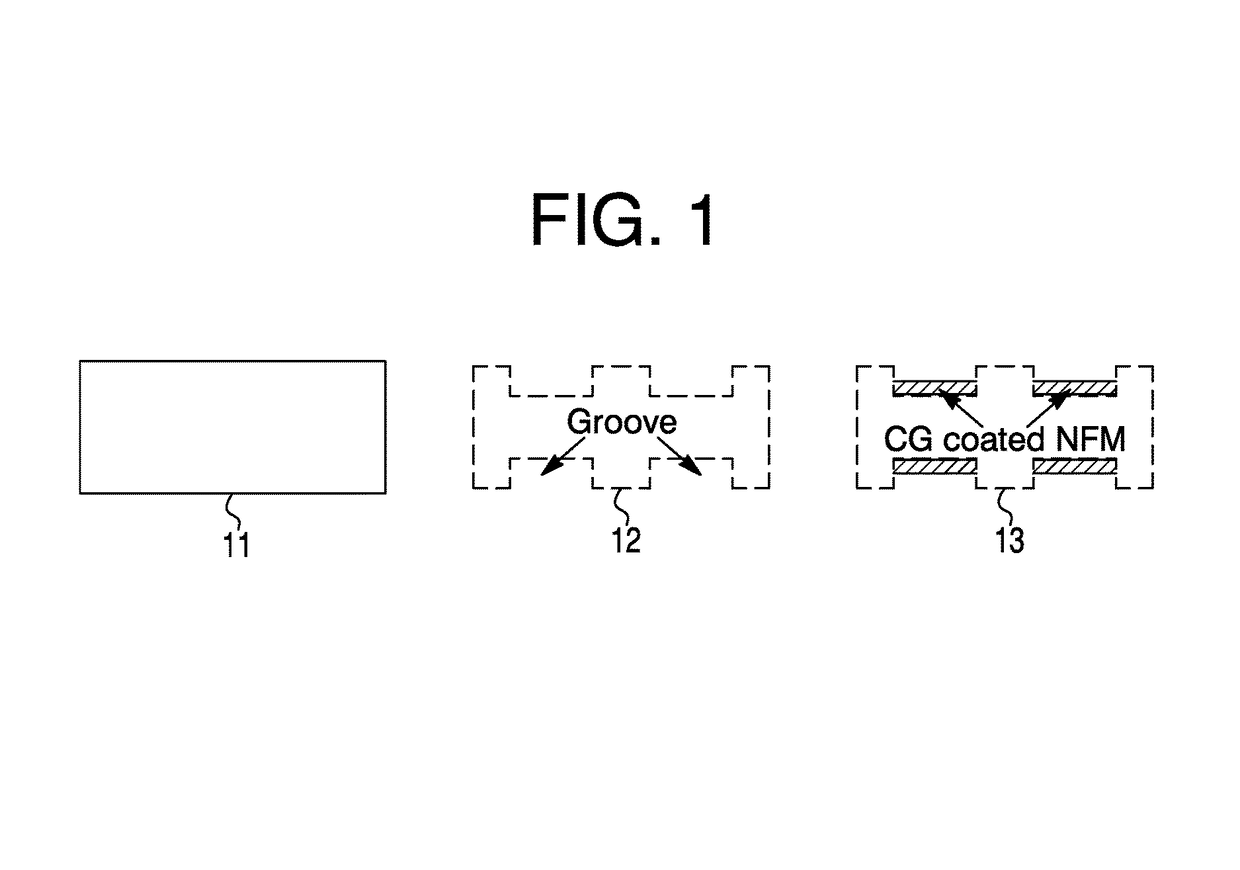

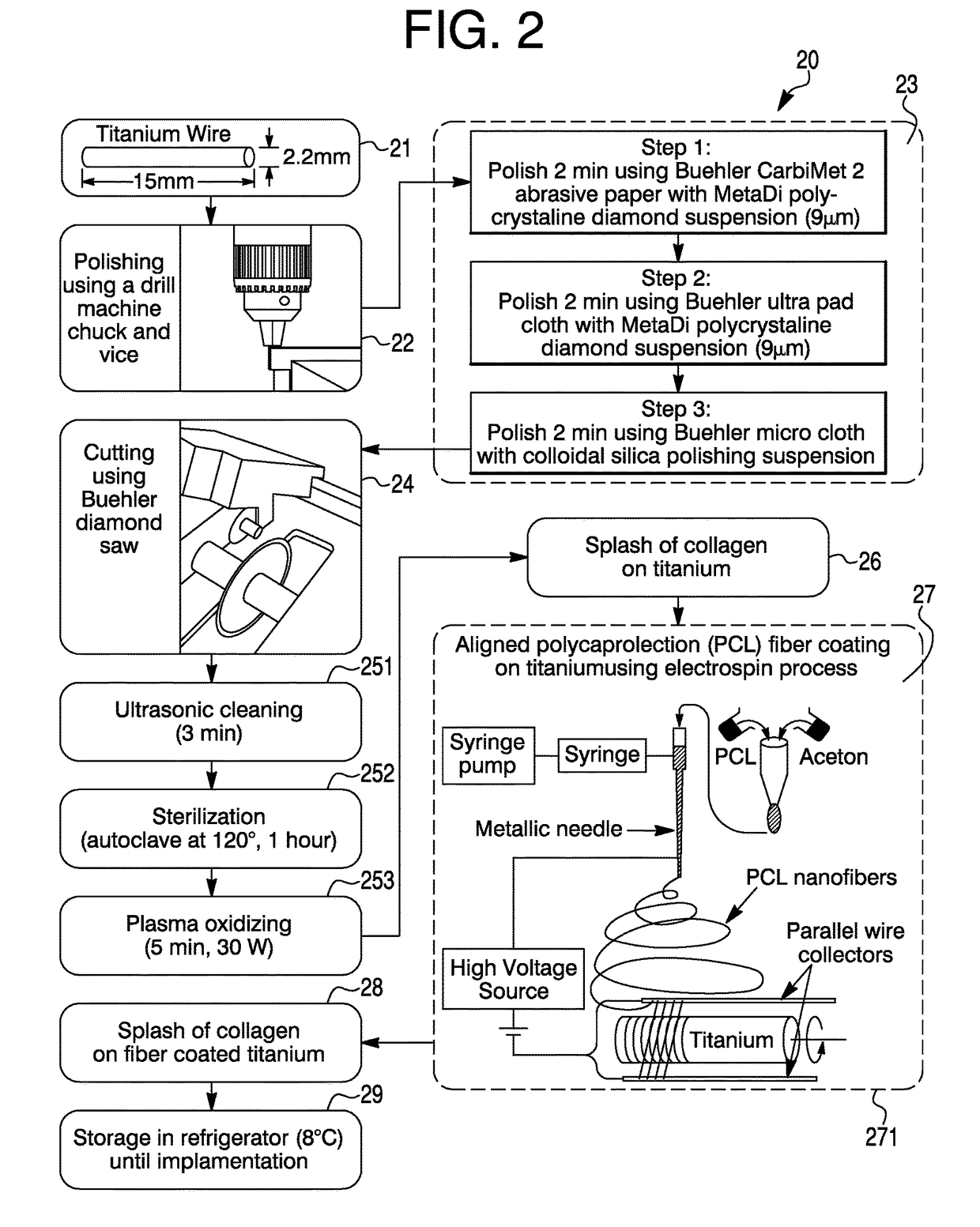

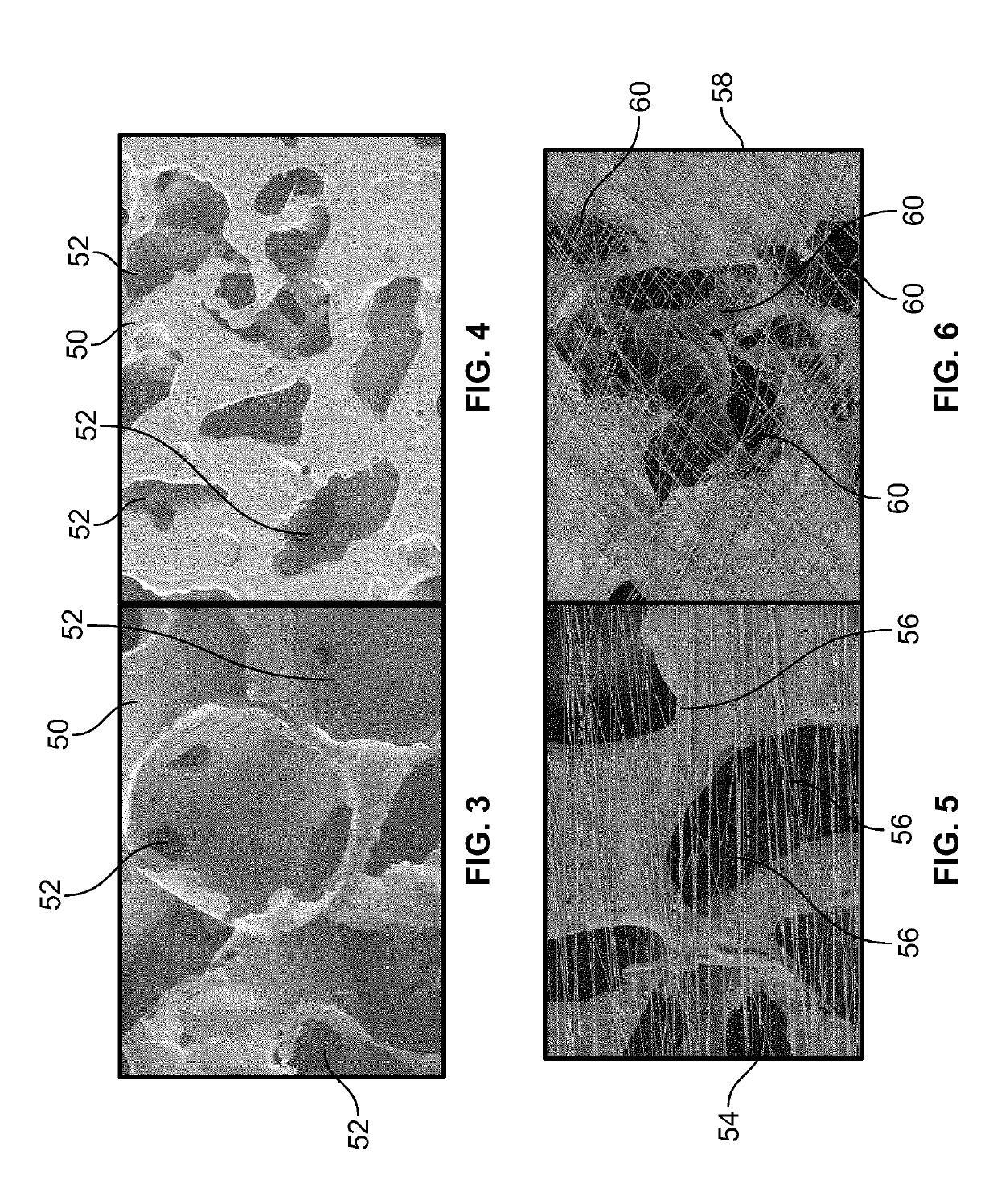

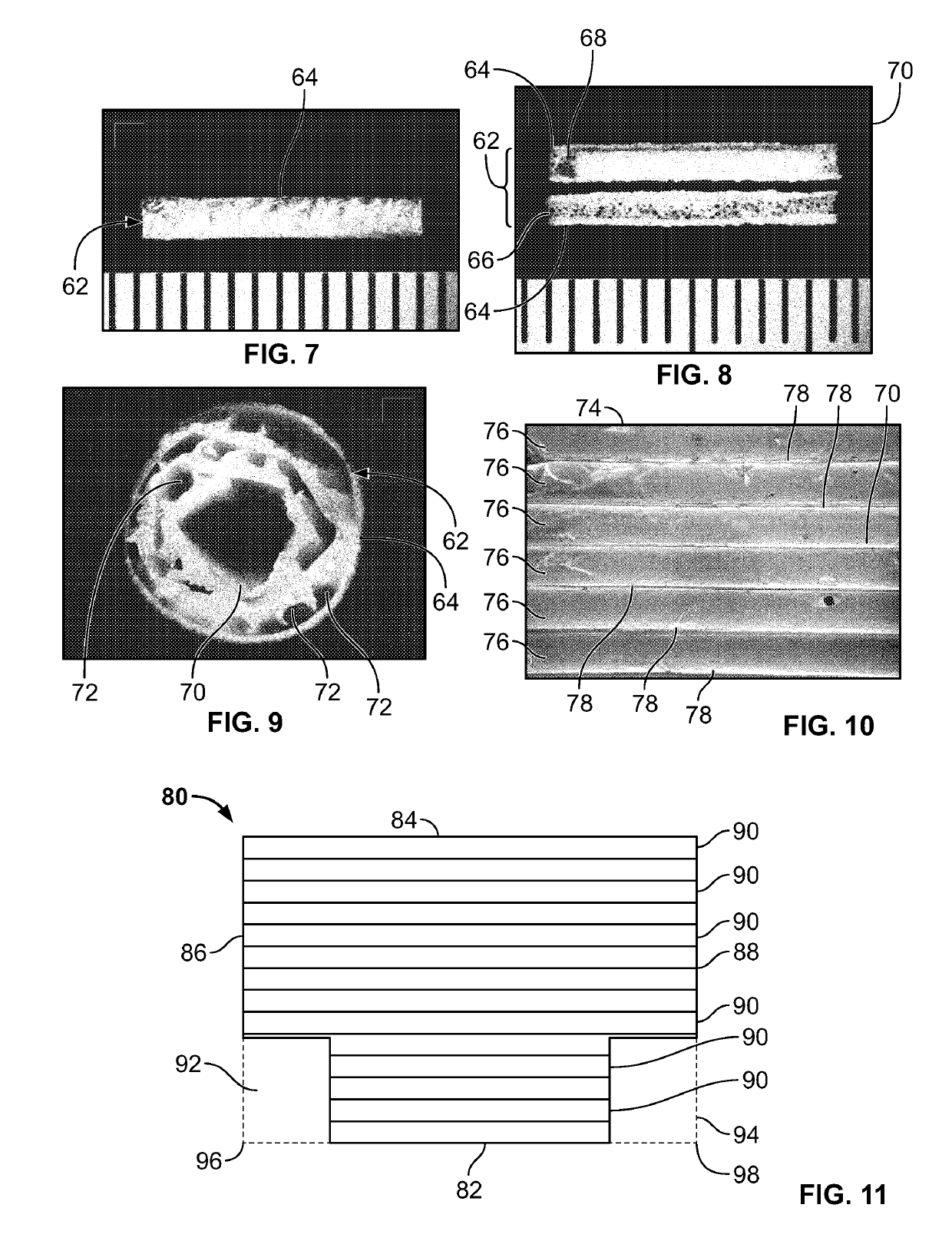

Method and apparatus to coat a metal implant with electrospun nanofiber matrix

ActiveUS9809906B2Increase surface areaPromote osseointegrationBone implantFilament manufactureOsseointegrationElectrospun nanofibers

The present invention implements a set of grooves / ridges created on Ti at the circumferential direction to increase surface area of implant in contact with bone. These grooves / ridges protect nanofiber matrix (NFM) made with Polycaprolactone (PCL) electrospun nanofiber (ENF) and collagen at the groove from physiological loading. Controlled fabrication of a ridge made with titanium nitride (TiN) around the circumference of Ti is provided using a plasma nitride deposition technique. PCL ENF may be deposited along the sub-micrometer grooves using the electrospin setup disclosed. The method provides for fabrication of microgroove on Ti using machining or TiN deposition and filling the microgrooves with the NFM. This method has proven through experimentation to be successful in increasing in vivo mechanical stability and promoting osseointegration on Ti implants. The immobilization of MgO NP and FN with the PCL-CG NFM on microgrooved Ti as provided in the invention optimizes biological performances of Ti.

Owner:UNIVERSITY OF CENTRAL OKLAHOMA

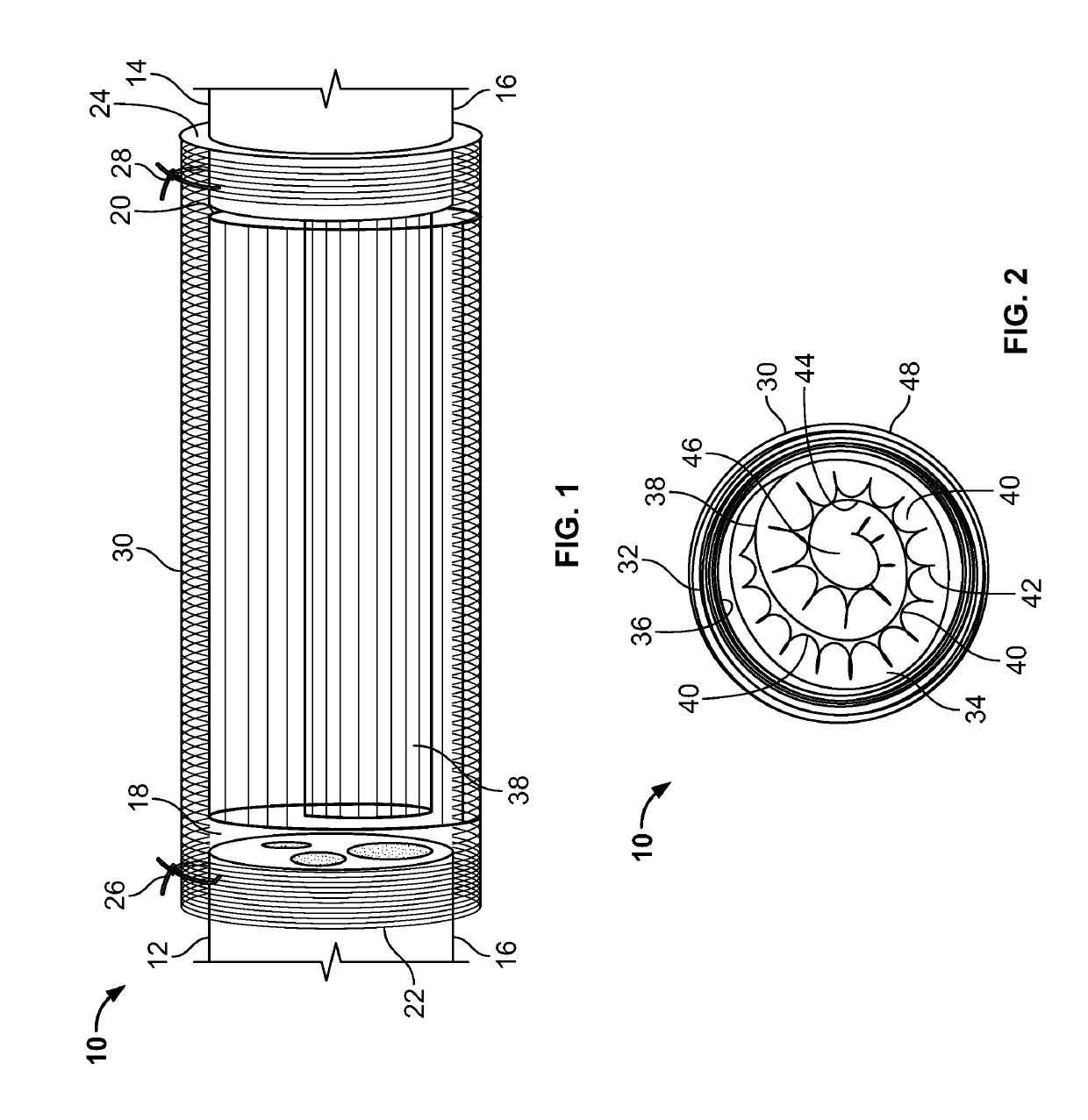

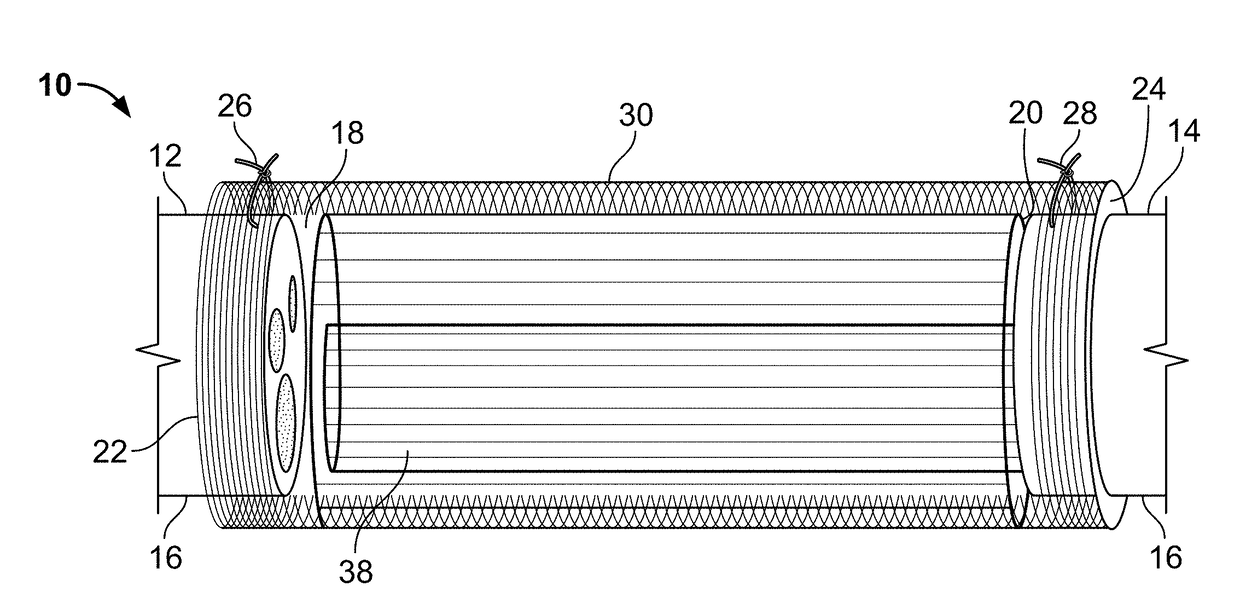

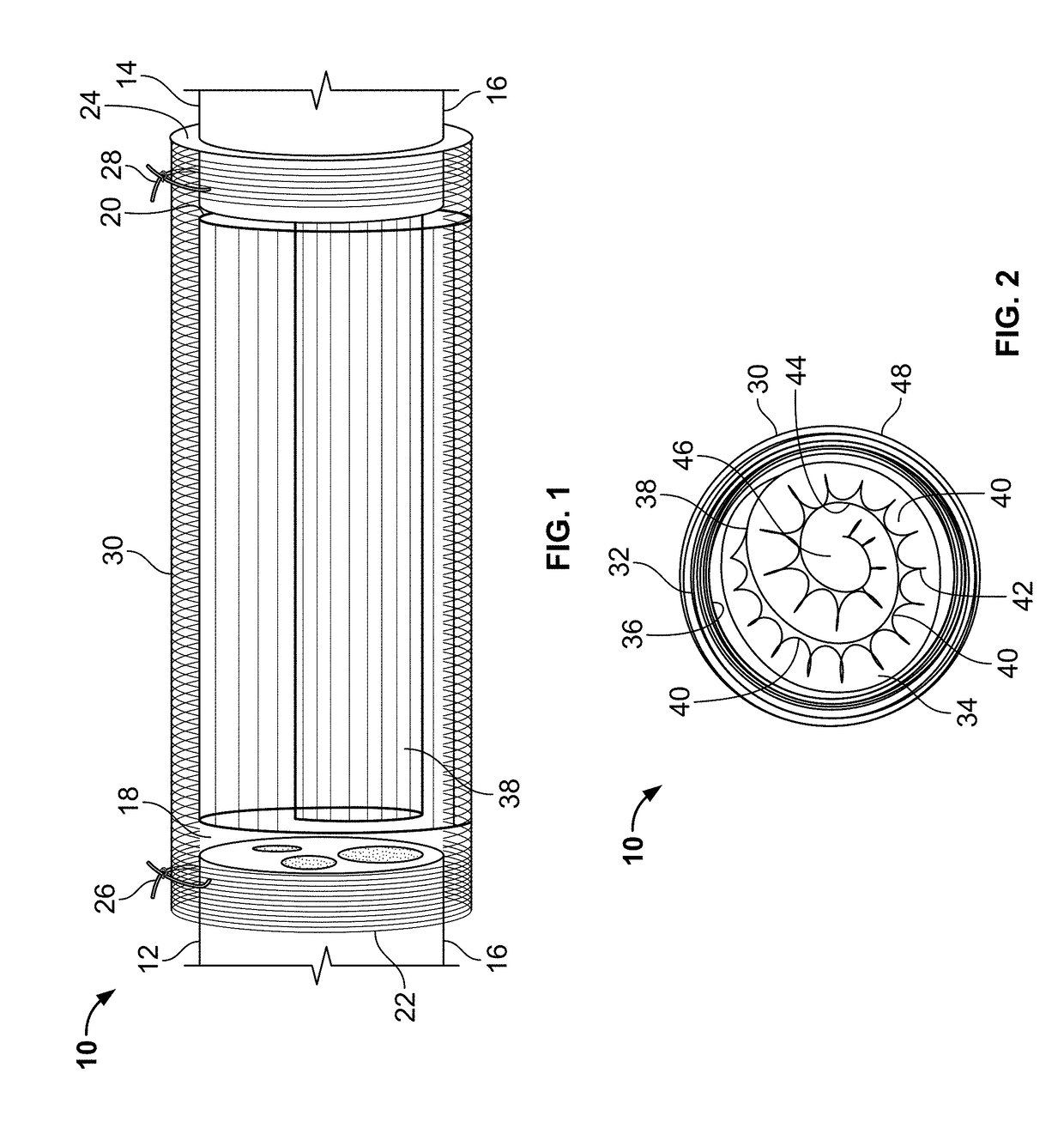

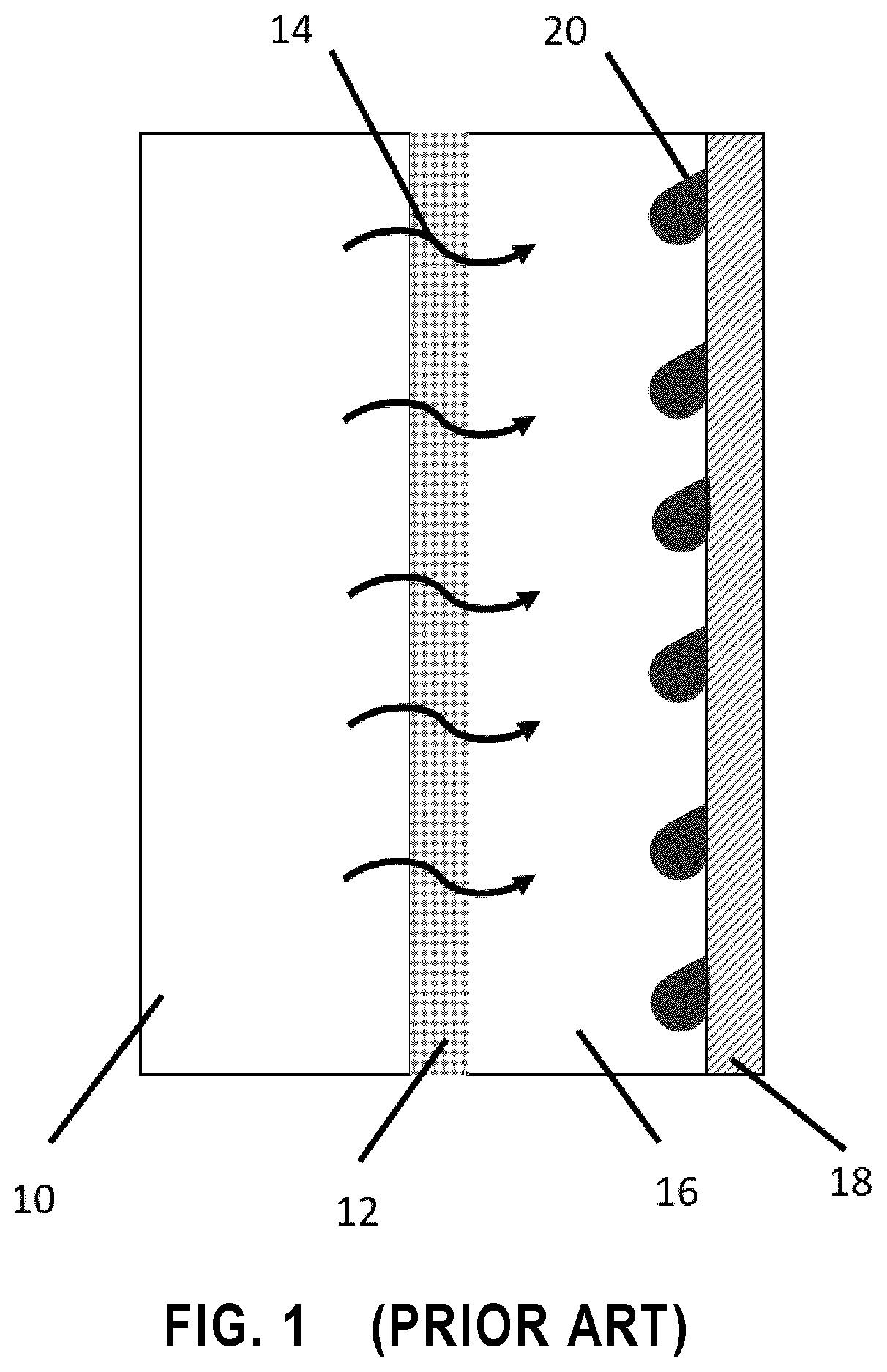

Implantable nerve guidance conduits having polymer fiber guidance channel

ActiveUS20190328393A1Promote regenerationRestore function to of injurySurgeryPharmaceutical delivery mechanismFiberElectrospun nanofibers

A nerve guidance conduit includes one or more guidance channels formed as porous polymeric structures. The guidance channels are within an outer tubular structure that includes randomly-oriented nanofibers. The guidance channels may have electrospun nanofibers on their inner and outer surfaces in a parallel alignment with the guidance channels. Such aligned nanofibers may also be present on the inner surface of the outer tubular structure. The outer surfaces of the guidance channels and the inner surface of the tubular structure define additional guidance channels. Such a nerve guidance conduit provides augmented surface areas for providing directional guidance and enhancing peripheral nerve regeneration. The structure also has the mechanical and nutrient transport requirements required over long regeneration periods.

Owner:STEVENS INSTITUTE OF TECHNOLOGY

Wound dressing and preparation method thereof

InactiveCN105769442AImprove breathabilitySmall sizeNon-adhesive dressingsPlastersFiberWound dressing

Provided are a wound dressing and a preparation method thereof.The wound dressing is composed of a silicone membrane layer and an electrospun nanofiber layer.The preparation method comprises the steps that silicone, liquid paraffin, normal hexane and span-80 are mixed to be uniform, the mixed solution is cast in a polytetrafluoroethylene mold through a membrane casting method, after a membrane is formed through drying, a silicone membrane is soaked in ethyl alcohol, the composition of paraffin is removed, and the silicone membrane with a pore structure is obtained; eletrospinning is conducted on the silicone membrane to form a layer of biodegradable polymer nanofibers through an eletrospinning method, after drying is conducted, radiation sterilization is conducted, and a finished product is obtained.The wound dressing prepared through the method has good moisture retention and air permeability, the wound can be kept moist, hypertrophic scars are prevented, body tissue generation can be promoted by means of the unique support function of the nanofiber layer, and wound healing is accelerated.

Owner:GUANGZHOU DIANFANG BIOTECH CO LTD

Implantable nerve guidance conduits having polymer fiber guidance channel

ActiveUS20170172578A1Promote regenerationRestore function to of injurySurgeryPharmaceutical delivery mechanismFiberElectrospun nanofibers

A nerve guidance conduit includes one or more guidance channels formed as porous polymeric structures. The guidance channels are within an outer tubular structure that includes randomly-oriented nanofibers. The guidance channels may have electrospun nanofibers on their inner and outer surfaces in a parallel alignment with the guidance channels. Such aligned nanofibers may also be present on the inner surface of the outer tubular structure. The outer surfaces of the guidance channels and the inner surface of the tubular structure define additional guidance channels. Such a nerve guidance conduit provides augmented surface areas for providing directional guidance and enhancing peripheral nerve regeneration. The structure also has the mechanical and nutrient transport requirements required over long regeneration periods.

Owner:STEVENS INSTITUTE OF TECHNOLOGY

Membranes for forward osmosis and membrane distillation and process of treating fracking wastewater

PendingUS20220008867A1Waste water treatment from quariesMembranesPolymer scienceHydrophilic polymers

Membranes for membrane distillation (MD) and forward osmosis (FO) are provided with methods of manufacture and use thereof. The MD membrane comprises a microporous mat of electrospun nanofibers made of a nanocomposite comprising reduced graphene oxide dispersed in a hydrophobic polymer with their surface grafted with a silane coupling agent or with hydrophobic nanoparticles. The FO membrane comprises a microporous support layer and a rejection layer formed on one side of the support layer, wherein the support layer is a microporous mat of electrospun nanofibers made of a nanocomposite of hydrophilic nanoparticles dispersed in a hydrophilic polymer, and the rejection layer is made of nanocomposite of hydrophilic nanoparticles dispersed in a crosslinked meta-aramid of formula (I). There is also provided a process for treating a high-salinity and / or high-strength feed, such as fracking wastewater, comprising microfiltration or ultrafiltration, followed by forward osmosis, and then membrane distillation.

Owner:REVEAU TECH & SOLUTIONS INC

High-strength polylactic acid-based electrospun nanofiber membrane and preparation method thereof

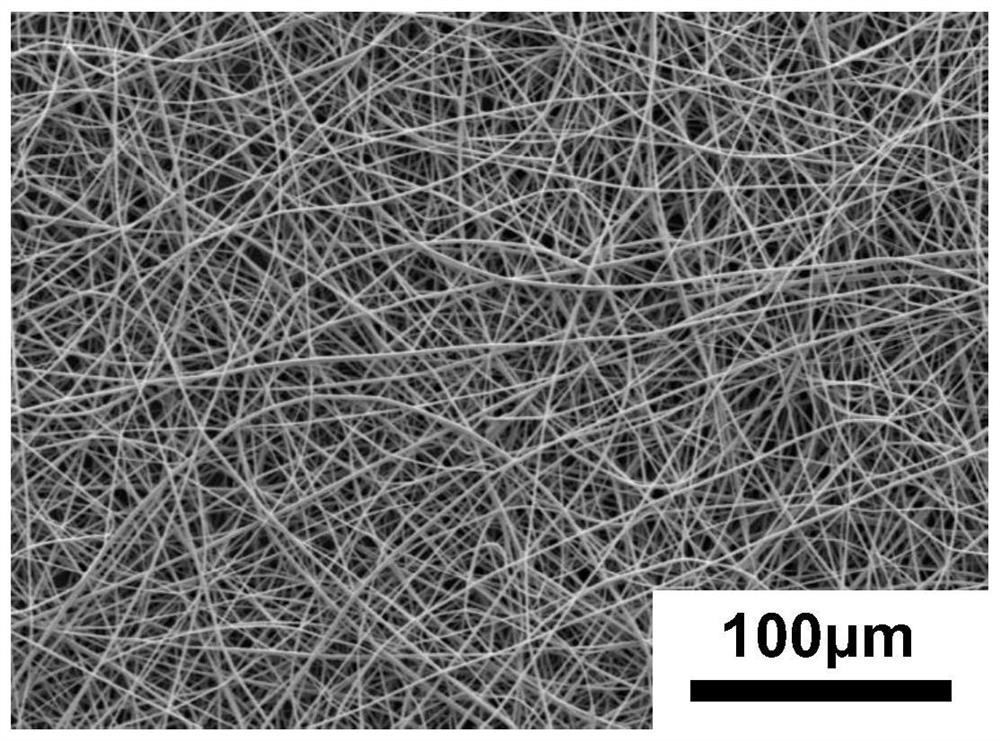

PendingCN112981704ADissolve fastShorten the dissolution timeNon-woven fabricsSpinning solutions preparationFiberPolymer science

The invention discloses a high-strength polylactic acid-based electrospun nanofiber membrane and a preparation method thereof. The high-strength electrostatic spinning nanofiber membrane comprises polylactic acid matrix resin and a reinforced nanofiller; the reinforced nanofiller is modified cellulose nanocrystal, and the preparation method of the modified cellulose nanocrystal comprises the following steps of firstly, oxidizing cellulose nanocrystal TEMPO and then introducing carboxyl; and reacting the processed cellulose nanocrystal with aminated polyethylene glycol under the dehydration condensation action of 1-ethyl-3-[3-dimethylaminopropyl] carbodiimide and N-hydroxysuccinate, so as to obtain the modified cellulose nanocrystal. The preparation method of the electrostatic spinning nanofiber membrane comprises the following steps of preparing a polylactic acid solution and a modified cellulose nanocrystal solution which are dissolved in a mixed solvent of chloroform / acetone (the volume ratio is 1: 1), and mixing the polylactic acid solution and the modified cellulose nanocrystal solution according to a certain proportion to prepare a mixed spinning solution with different modified cellulose nanocrystal contents; and then preparing the corresponding high-strength nanofiber membrane by adopting an electrostatic spinning technology. Compared with a pure polylactic acid fiber membrane, the polylactic acid / modified cellulose nanocrystal fiber membrane has the advantages that the tensile strength is obviously improved, the elongation at break is still kept to be slightly reduced, the product is biodegradable, the preparation method is simple, the cost is low, the control is easy, and the polylactic acid / modified cellulose nanocrystal fiber membrane has a wide application prospect in the fields of biomedicine and the like.

Owner:徐州工牛高新材料有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com