Carbon-coated MoSe2/graphene electrospun nanofibers and preparation method thereof

A technology of electrospinning nanofibers and nanofibers, applied in circuits, electrical components, battery electrodes, etc., can solve the problems of graphene agglomeration, affecting electrochemical performance, etc., and achieve the effect of inhibiting volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

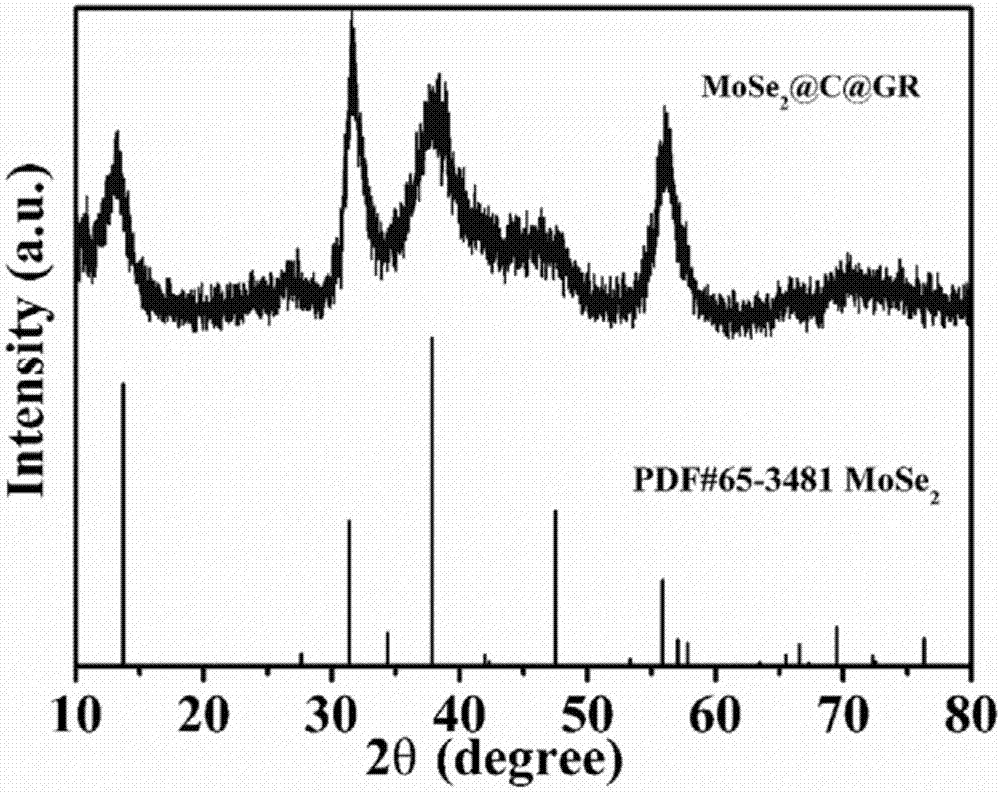

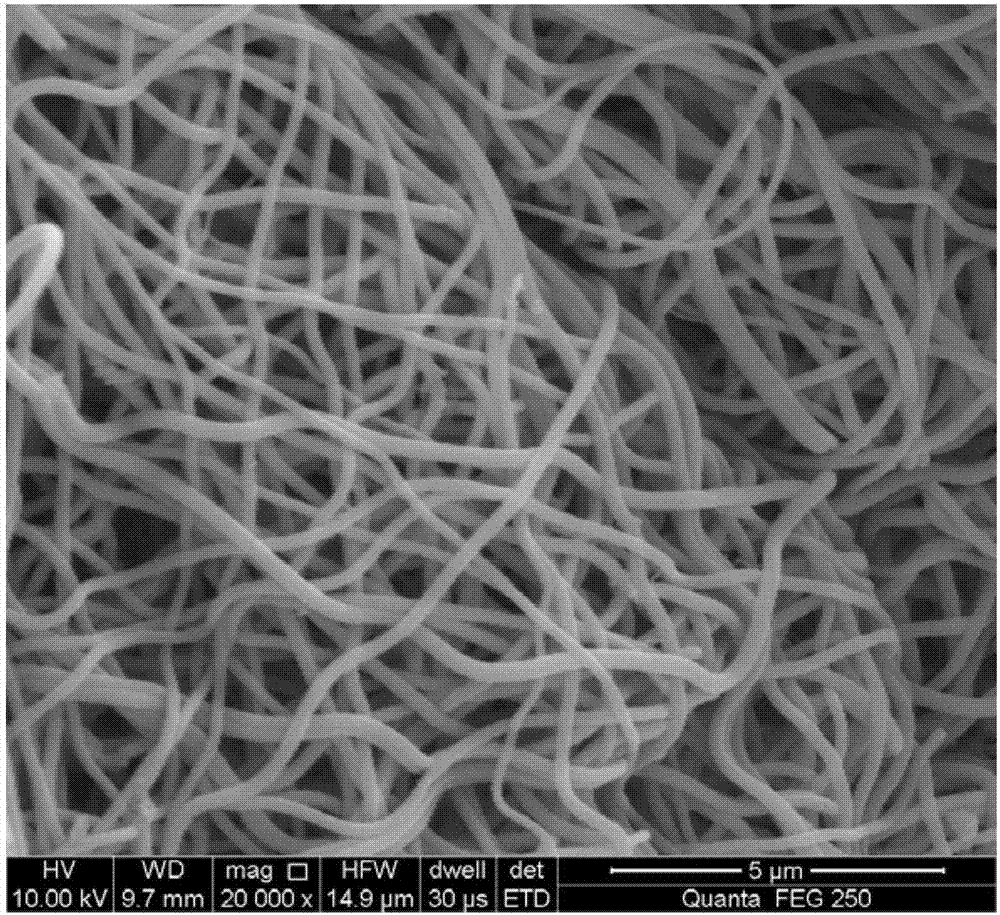

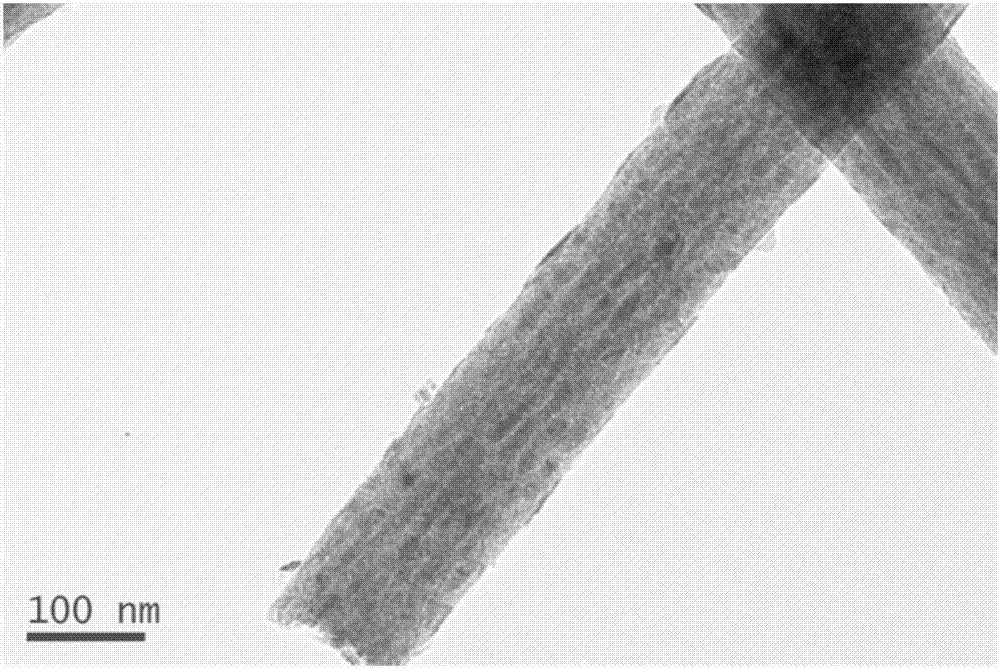

Embodiment 1

[0052] Weigh 0.5297gH 24 Mo 7 N 6 o 24 4H 2 O was dissolved in 1mL of deionized water solution and 1mL of ethylene glycol mixed solution, stirred for use, weighed 0.6114g PVP powder was dissolved in 2mL of deionized water solution and stirred in a 60°C water bath for half an hour to form a transparent sol, Add the molybdenum salt solution, weigh 5 mg of graphene and place it in 2 mL of deionized water, stir at high speed for 5 minutes, add it to the sol solution, stir at room temperature for 6 hours to make an electrospinning solution, put it into a 10 mL syringe, and prepare it by electrospinning Nanofiber, electrospinning parameters: the voltage is 30KV, the distance between the needle and the collecting plate is 20cm, and the advancing speed is 0.3mL / h. The obtained spun fibers were dried in a vacuum oven at 60°C for 12h, and then vacuum sintered with 2g of selenium powder at a temperature of 650°C for 2h and a heating rate of 10°C / min to obtain a carbon coating with a ...

Embodiment 2

[0055] Weigh 0.5297gH 24 Mo 7 N 6 o 24 4H 2 O was dissolved in 1mL of deionized water solution and 1mL of ethylene glycol mixed solution, stirred for use, weighed 0.6114g PVP powder was dissolved in 2mL of deionized water solution and stirred in a 60°C water bath for half an hour to form a transparent sol, Add the molybdenum salt solution, weigh 5 mg of graphene and place it in 2 mL of deionized water, stir at high speed for 5 minutes, add it to the sol solution, stir at room temperature for 6 hours to make an electrospinning solution, put it into a 10 mL syringe, and prepare it by electrospinning Nanofiber, electrospinning parameters: the voltage is 25KV, the distance between the needle and the collecting plate is 20cm, and the advancing speed is 0.3mL / h. The obtained spun fibers were dried in a vacuum oven at 60°C for 12h, and then vacuum sintered with 2g of selenium powder at a temperature of 650°C for 2h at a heating rate of 10°C / min to obtain a carbon coating with a d...

Embodiment 3

[0057] Weigh 0.5297gH 24 Mo 7 N 6 o 24 4H 2O was dissolved in 1mL of deionized water solution and 1mL of ethylene glycol mixed solution, stirred for use, weighed 0.6114g PVP powder was dissolved in 2mL of deionized water solution and stirred in a 60°C water bath for half an hour to form a transparent sol, Add the molybdenum salt solution, weigh 1 mg of graphene and place it in 2 mL of deionized water, stir at high speed for 5 minutes, add it to the sol solution, stir at room temperature for 6 hours to make an electrospinning solution, put it into a 10 mL syringe, and prepare it by electrospinning Nanofiber, electrospinning parameters: the voltage is 30KV, the distance between the needle and the collecting plate is 20cm, and the advancing speed is 0.3mL / h. The obtained spun fibers were dried in a vacuum oven at 60°C for 12h, and then vacuum sintered with 2g of selenium powder at a temperature of 650°C for 2h and a heating rate of 10°C / min to obtain a carbon coating with a d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com