Manganese dioxide nanosheet coated carbon/sulphur compound, preparation method and application thereof

A manganese dioxide and composite technology, which is applied in electrical components, battery electrodes, non-aqueous electrolyte batteries, etc., can solve the problems of sulfur extraction, poor electrical performance, battery performance degradation, etc., achieve good in-situ composite, improve electronic The effect of transfer speed, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

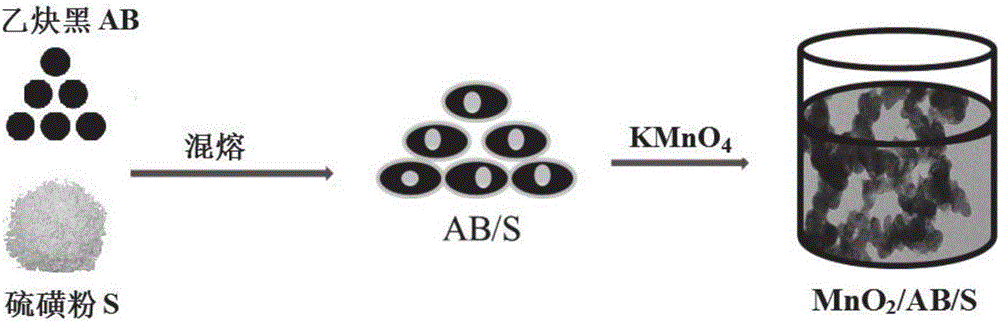

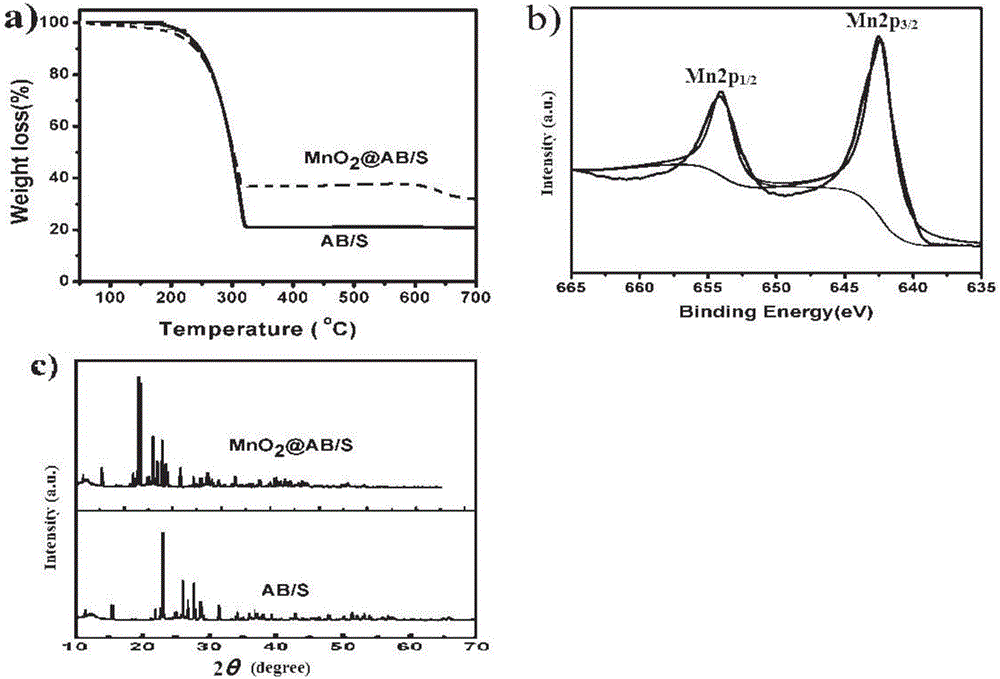

[0079] Step (1): Preparation of carbon / sulfur complex (C / S complex)

[0080] Mix 0.7 g of acetylene black and 3.1 g of sublimed sulfur and mill for 15 minutes. Then the mixed powder was sealed in a vacuum quartz tube and heated at 150°C for 6 hours under nitrogen protection. During the melting process, the S powder will melt into a liquid state and be embedded in a specific cavity of acetylene black. After cooling to normal temperature, an acetylene black / sulfur composite is obtained.

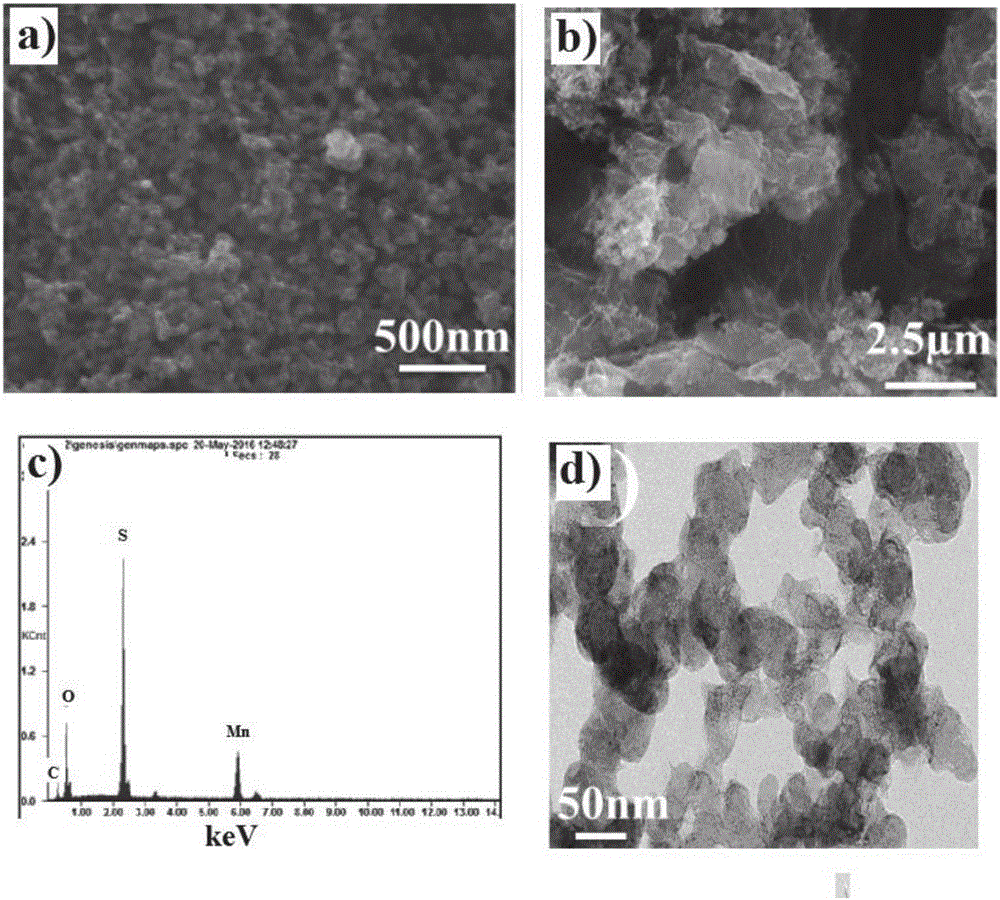

[0081] Step (2): Preparation of acetylene black / sulfur composite coated with manganese dioxide nanosheets

[0082] Disperse 0.805g of acetylene black / sulfur complex in 170ml of distilled water and stir slowly for 1h to make it fully dispersed. Dissolve 0.3 g of potassium permanganate in 60 ml of water and stir well. Pour the potassium permanganate solution into the above mixed solution, and heat to 60°C, and continue to stir at a rotation speed of 300 r / min until the color of the solution changes ...

Embodiment 2

[0090] Step (1): Preparation of Acetylene Black / Sulfur Complex

[0091] Mix 2.0 g of acetylene black and 10.5 g of sulfur and mill for 20 minutes. Then the mixed powder was sealed in a vacuum quartz tube and heated at 200°C for 6 hours under nitrogen protection. During the melting process, sulfur will melt into a liquid state and become embedded in the acetylene black. After cooling to normal temperature, an acetylene black / sulfur composite is obtained.

[0092] Step (2): Preparation of acetylene black / sulfur composite coated with manganese dioxide nanosheets

[0093] Disperse 2.5g of acetylene black / sulfur complex in 500ml of distilled water and stir slowly for 0.5h to make it fully dispersed. Dissolve 1.0 g of lithium permanganate in 200 ml of water and stir evenly. Drop the lithium permanganate solution into the above mixed solution, and heat to 80° C., and continue stirring at a rotation speed of 200 r / min until the color of the solution changes from purple to black brown. T...

Embodiment 3

[0097] Step (1): Preparation of conductive carbon black / sulfur composite

[0098] 3.0 g of acetylene black and 17.2 g of sulfur were mixed and milled for 20 minutes. Then the mixed powder was sealed in a vacuum quartz tube and heated at 180°C for 10 hours under nitrogen protection. During the melting process, sulfur will melt into a liquid state and be embedded in the conductive carbon black. After cooling to room temperature, a conductive carbon black / sulfur composite is obtained.

[0099] Step (2): Preparation of conductive carbon black / sulfur composite coated with manganese dioxide nanosheets

[0100] Disperse 2.5g of conductive carbon black / sulfur composite and 0.6g of manganese sulfate monohydrate in 500ml of distilled water, and stir slowly for 1.0h to make them fully dispersed. Dissolve 0.5 g of potassium permanganate in 100 ml of water and stir well. Drop the potassium permanganate solution into the above mixed solution, and heat to 60°C, and continue to stir at a rotatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com