Weather-resisting injection molding and over-molding thermoplastic elastomer composition

A thermoplastic elastomer and composition technology, applied in the field of thermoplastic elastomer composition, can solve the problems of poor weather resistance, not fine enough appearance, poor thermal stability, etc., achieve excellent appearance, avoid weather resistance defects, and fast molding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] In each of the following examples or comparative examples, the raw material components were weighed according to the proportions shown in Table 1 or Table 2, and the styrenic thermoplastic elastomer and mineral oil were fully mixed first, and the styrenic thermoplastic elastomer After fully absorbing the oil, add an appropriate amount of polystyrene resin, mineral filler, stabilizer and other processing aids according to the formula and mix them evenly in the mixer. After mixing, the materials are fed into a twin-screw extruder (CTE35 Coperion Keya (Nanjing) Machinery Co., Ltd.), and processed under the conditions of processing temperature (190°C~240°C) and screw speed (180rpm~300rpm). The raw material mixture is sheared at high speed by twin-screw, kneaded, extruded, drawn, cooled and granulated. The injection-bonded thermoplastic elastomer compositions of each example or comparative example were obtained.

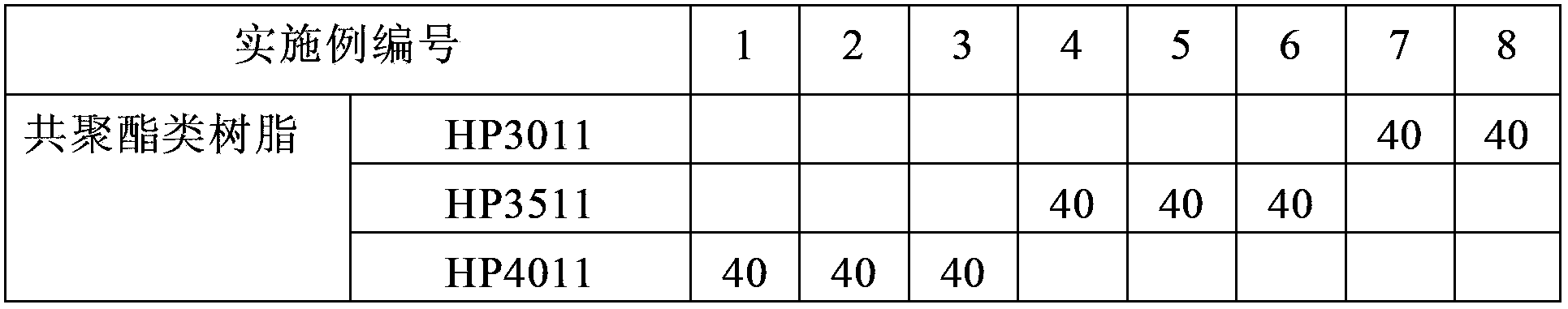

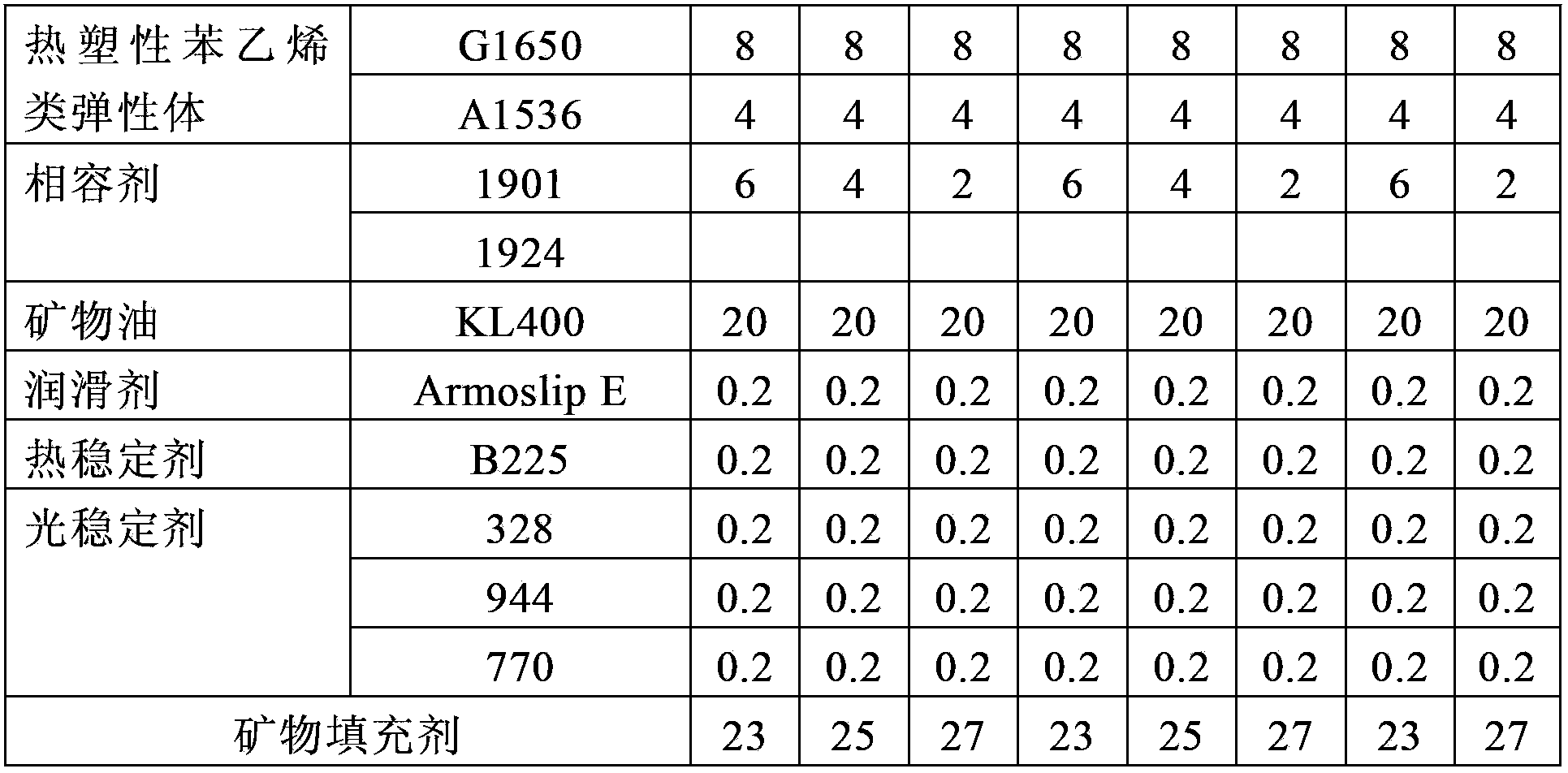

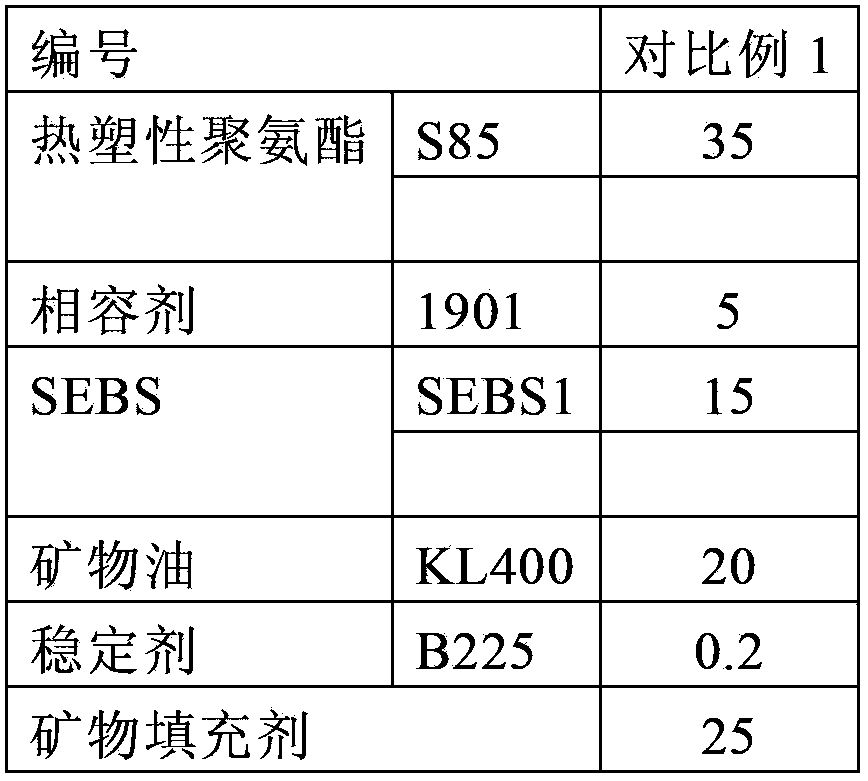

[0034] 1. Raw material ratio

[0035] Copolyester resins: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com