Explosion-proof flexible connecting pipe

A technology for flexible connection and connection of hoses, applied in the field of connecting pipes, can solve the problems of casualties and economic losses, threatening the safe use of equipment, affecting the normal use of equipment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

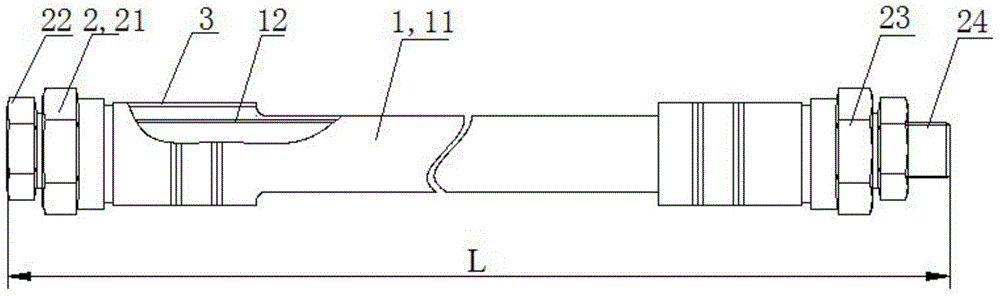

[0020] See figure 1 , the explosion-proof flexible connecting pipe of the present invention has a connecting hose 1 and a connecting head 2 located at both ends of the connecting hose 1; a compression sleeve 3 is also provided outside the connection between the connecting hose 1 and the connecting head 2, which further ensures that the connecting hose The reliability of the connection between 1 and connector 2 fully guarantees the safety of the equipment.

[0021] As a preferred solution of the present invention, the connecting hose 1 includes an outer protective sheath 11 and a metal hose 12 inside the protective sheath 11 . Preferably, the protective sheath 11 on the outside of the metal hose 12 is braided with stainless steel wire, which can satisfy the large flexibility of the connecting pipe, and also has anti-aging and corrosion resistance, which can greatly increase the service life of the connecting pipe.

[0022] The connection head 2 of the connecting hose 1 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com