Sectional type wind wheel vanes of wind power generator set and assembly method thereof

A technology for wind turbines and wind rotor blades, which is applied to wind engines, wind power generation, and wind engines in the same direction as the wind. It can solve the problems of large aerodynamic losses, high risks, and complicated assembly operations, and achieves convenient assembly and operation. The effect of small aerodynamic loss and high connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to facilitate the understanding of the structure and the achieved effects of the present invention, the preferred embodiments are listed in detail as follows with reference to the accompanying drawings.

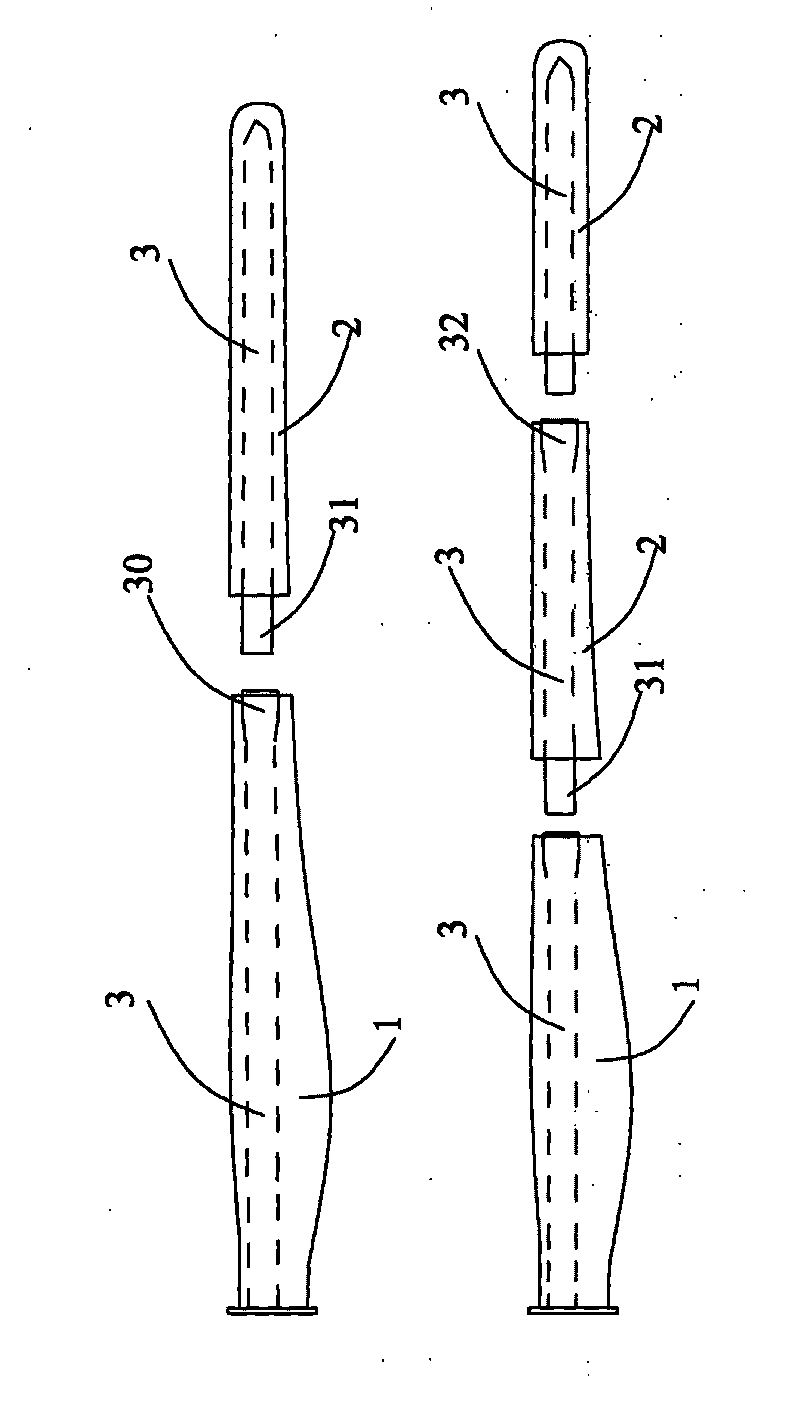

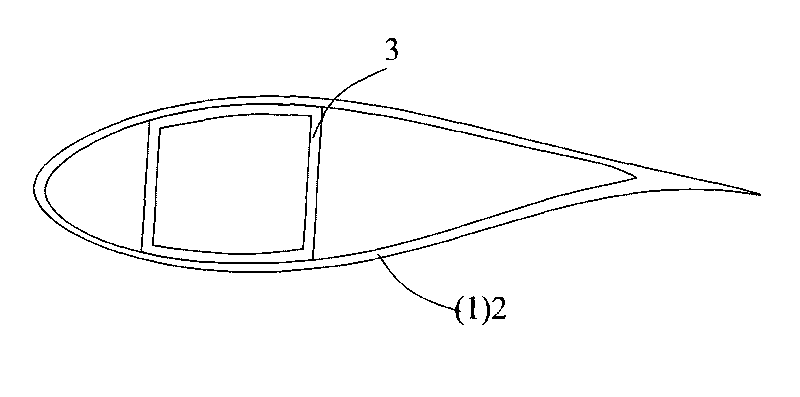

[0030] The wind rotor blades in the present invention are multi-section wind rotor blades, such as figure 1 As shown, the wind rotor blade includes a blade root section 1 and at least one radial blade 2, and main beams 3 are embedded in the blade root section 1 and each radial blade 2, and through the sequential connection between the main beams 3, The blade root section 1 is connected end to end with each radial blade 2 to form a complete wind rotor blade.

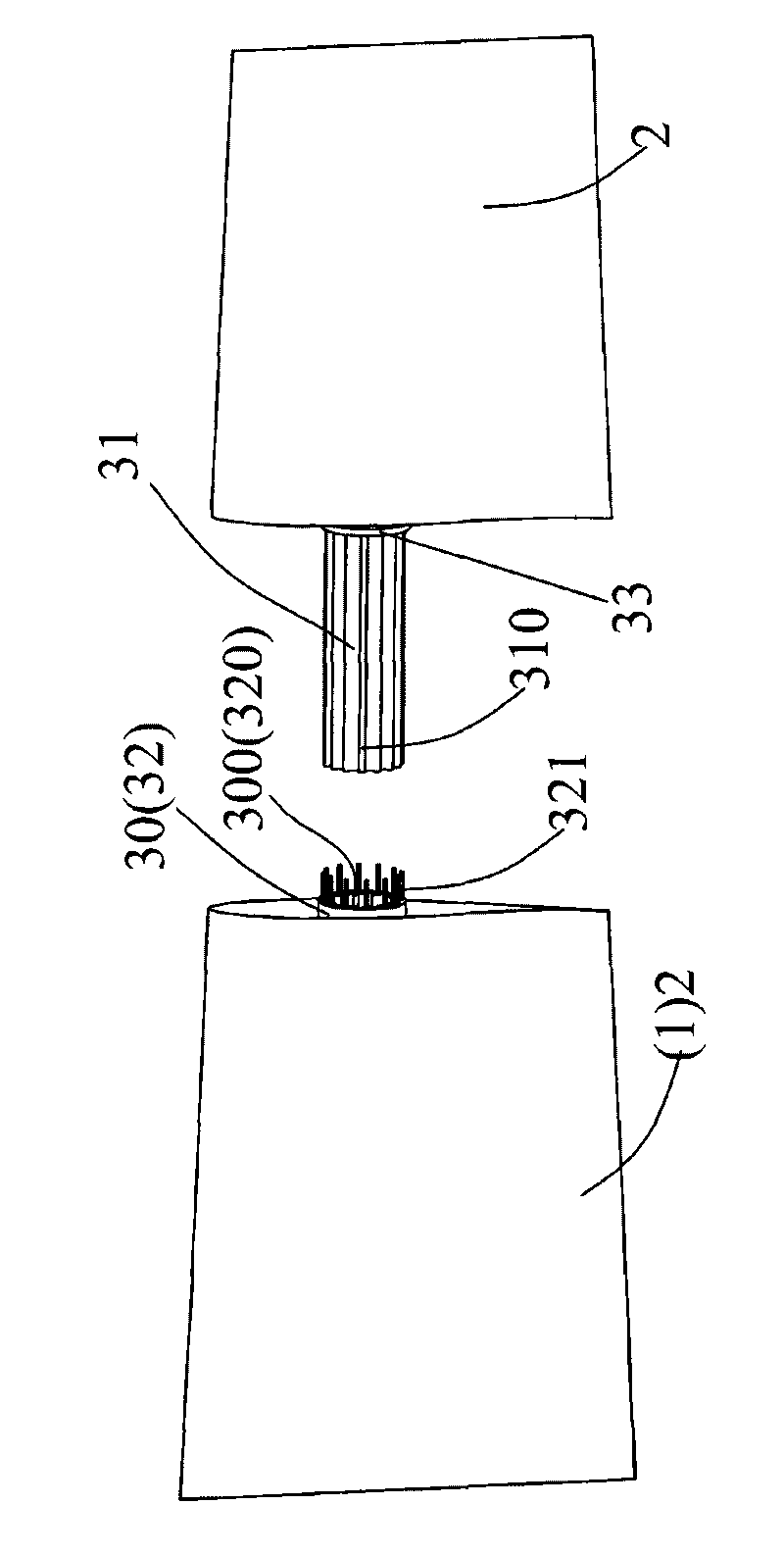

[0031] Such as image 3 As shown, the blade root section 1 in the wind turbine blade of the present invention is close to the hub side, and the blade root section 1 and the internal main beam 3 are consolidated together during manufacture, and the end surface of the blade root section 1 on the side away ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com