Patents

Literature

1784results about "Fireworks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

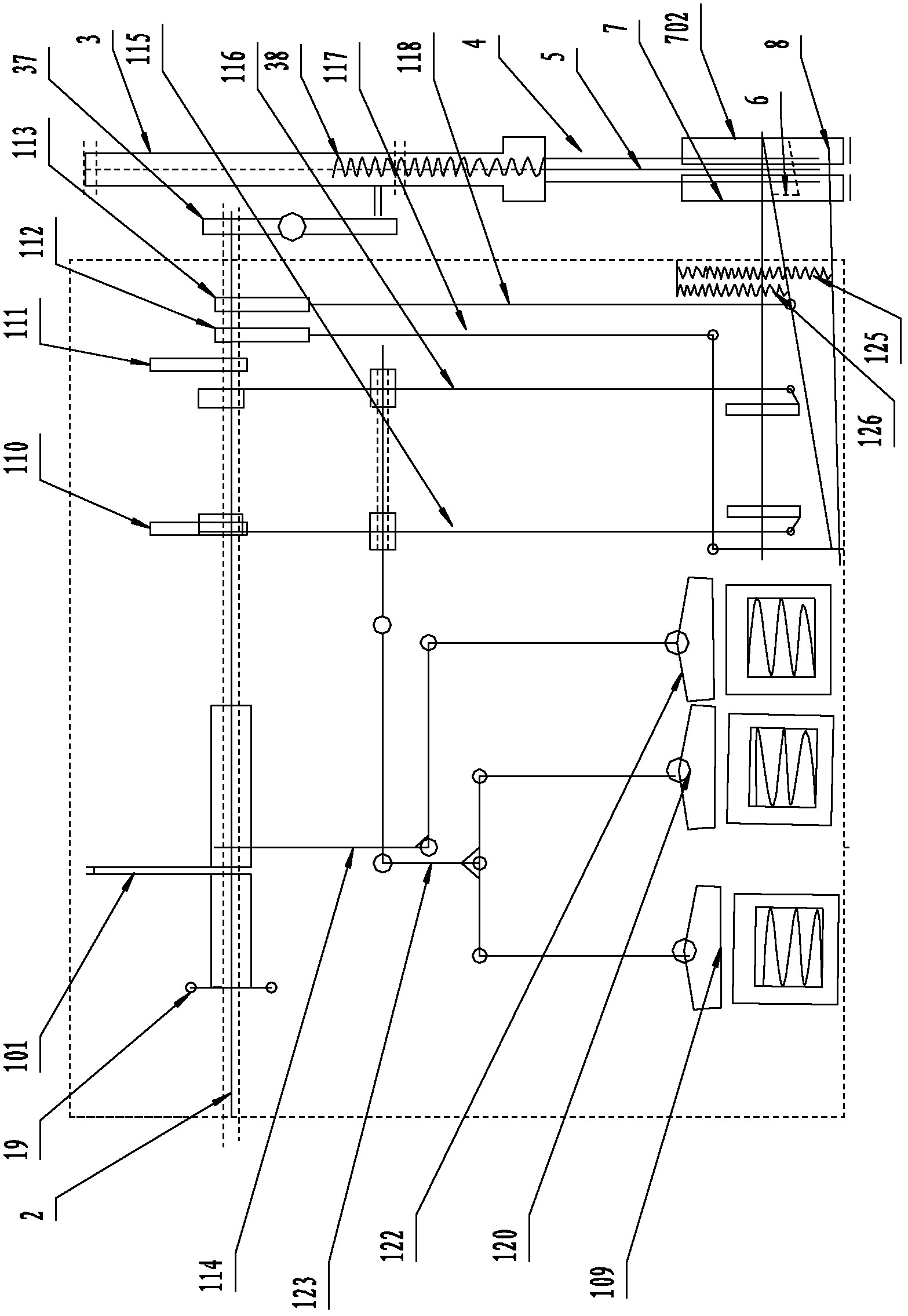

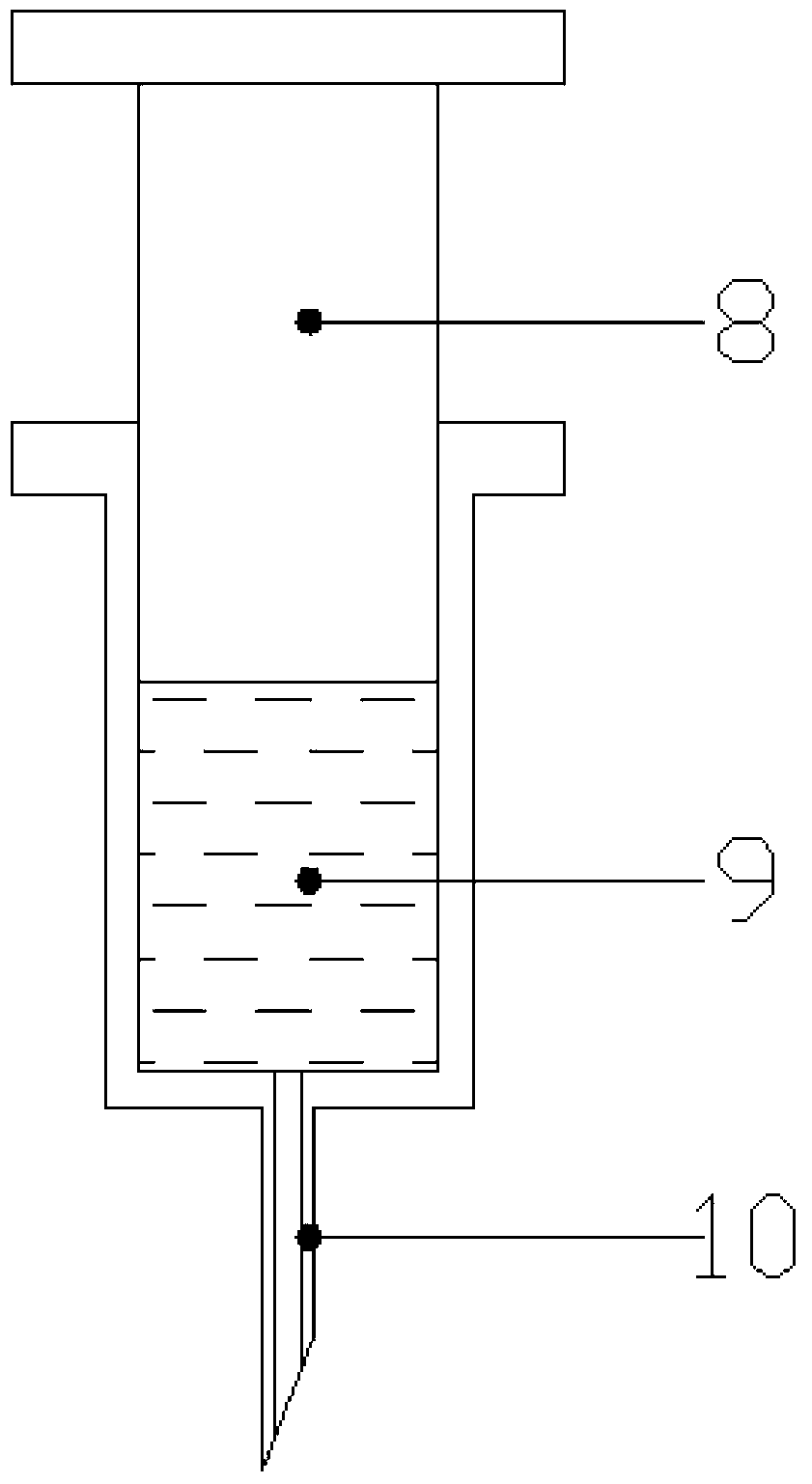

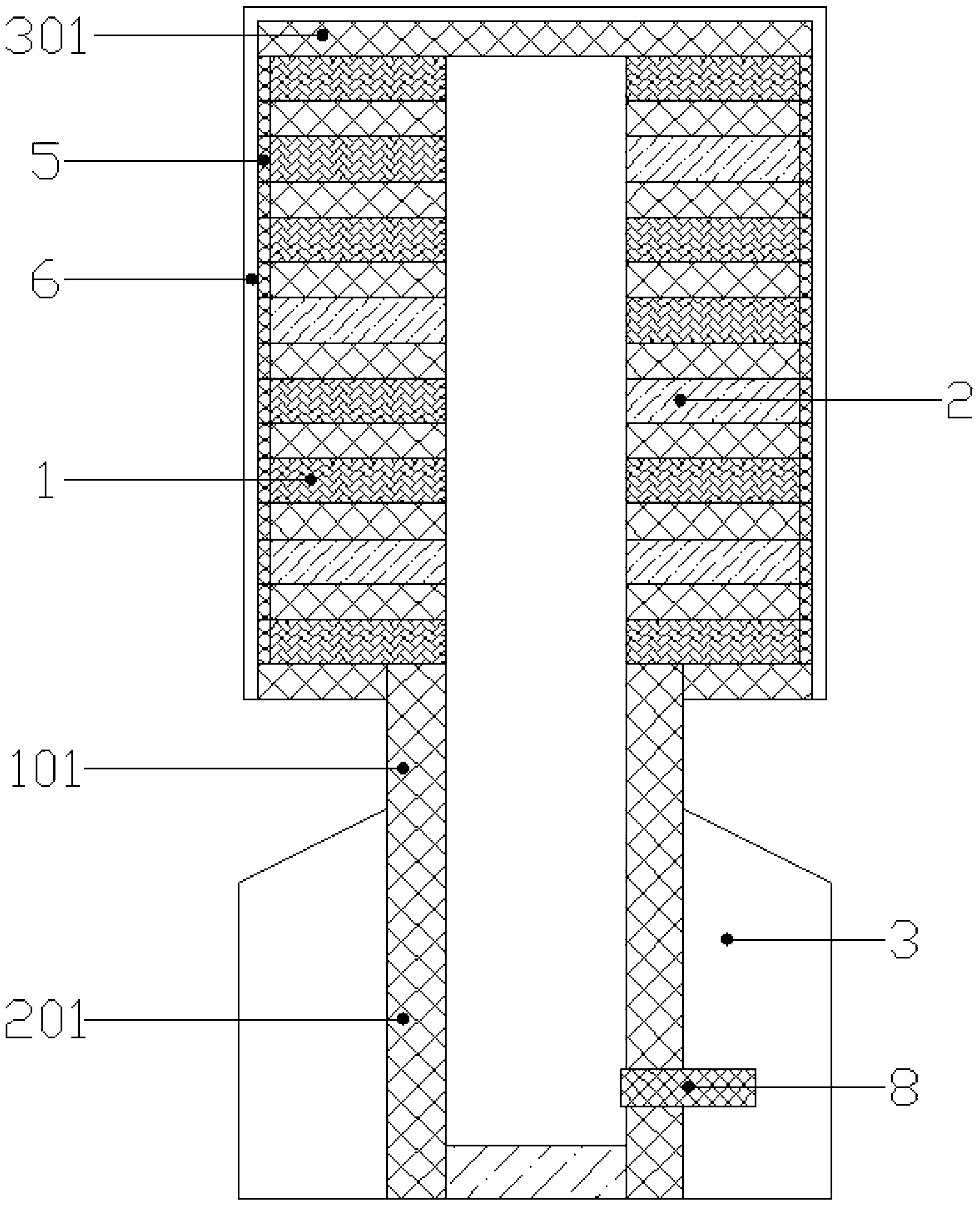

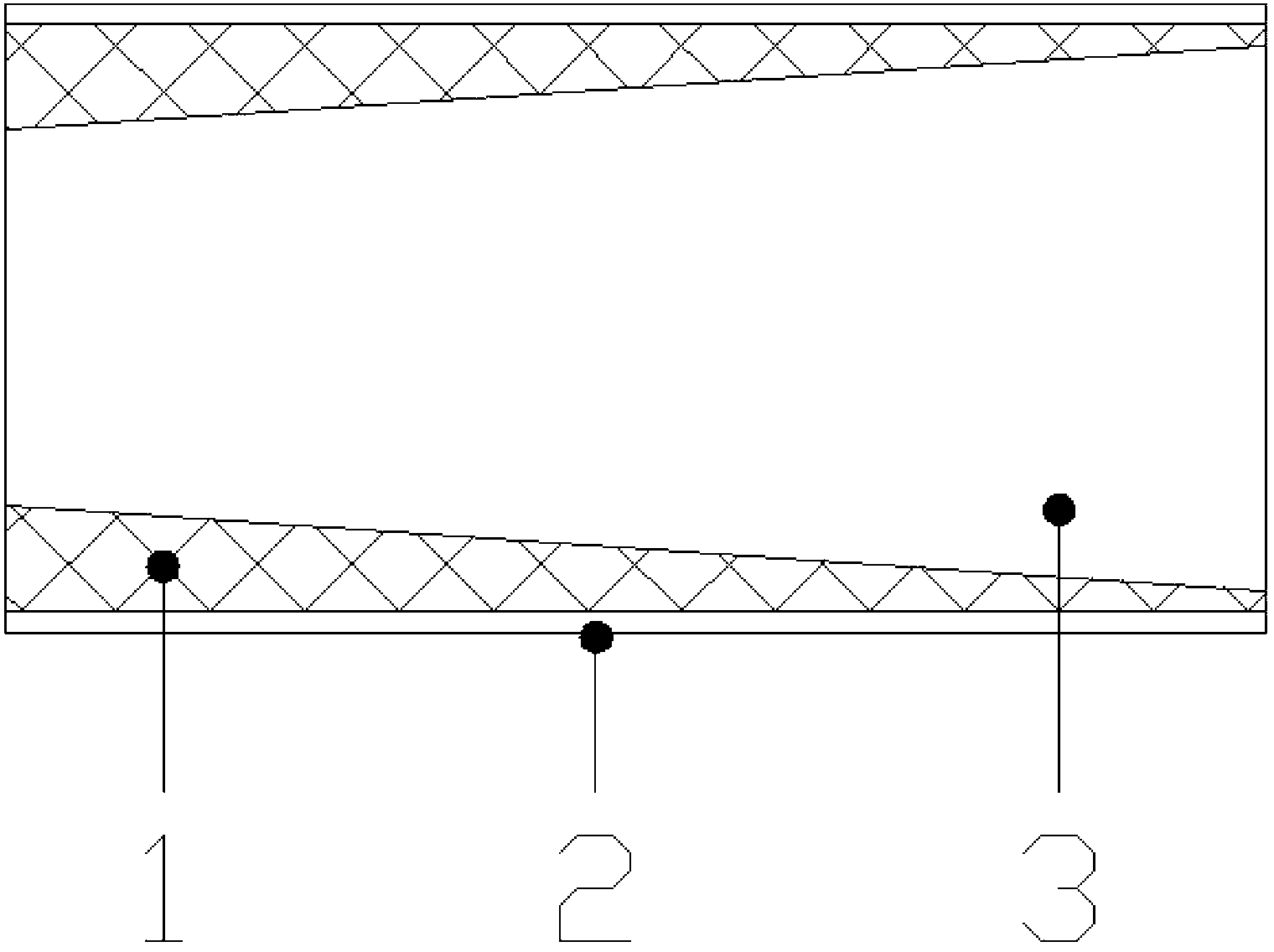

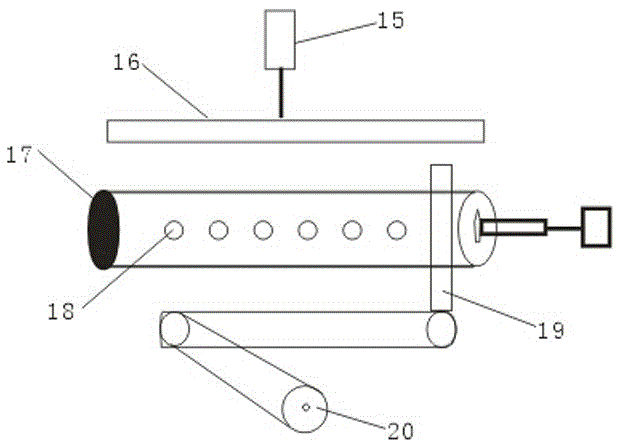

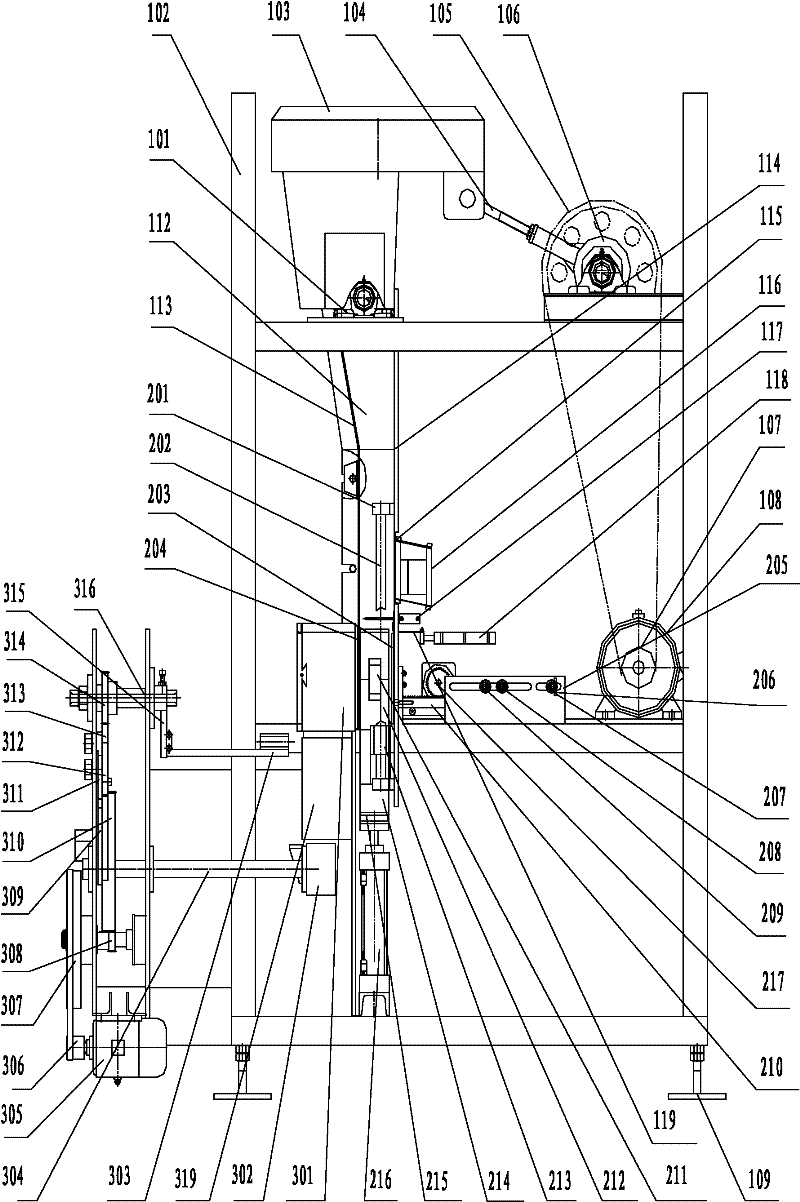

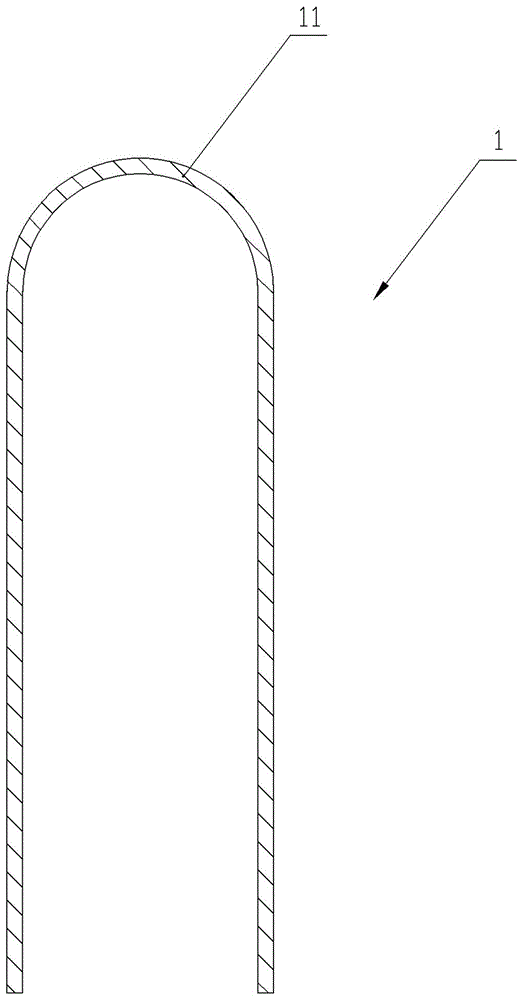

Drilling and lead inserting system for assembling firework

The invention discloses a drilling and lead inserting system for assembling a firework. The system comprises a needle bar, a lead feeding device, a numerical control system and a driving and transmission system, wherein the needle bar can move upwards and downwards in a reciprocating way; the lower end of the needle bar is provided with an n-shaped drilling and lead inserting device which consists of two parallel drilling needles; a large movable tongue and a small movable tongue are arranged between the two drilling needles; the lead feeding device consists of at least one lead supply wheel and a lead guide groove; and the driving and transmission system comprises at least one driving motor and a plurality of transmission devices, is connected with an electromagnet of the numerical control system and is used for driving and controlling every component of the drilling and lead inserting system to run synchronously. The drilling and lead inserting system is arranged above a firecrackerbarrel conveying passageway, can be used for accurately finishing a series of works such as lead supply, lead cutting, lead inserting and the like, has high degree of automation, high working efficiency and working reliability; and drilling and lead inserting are finished synchronously, and the lead inserting quality of is effectively ensured.

Owner:宋俊钦

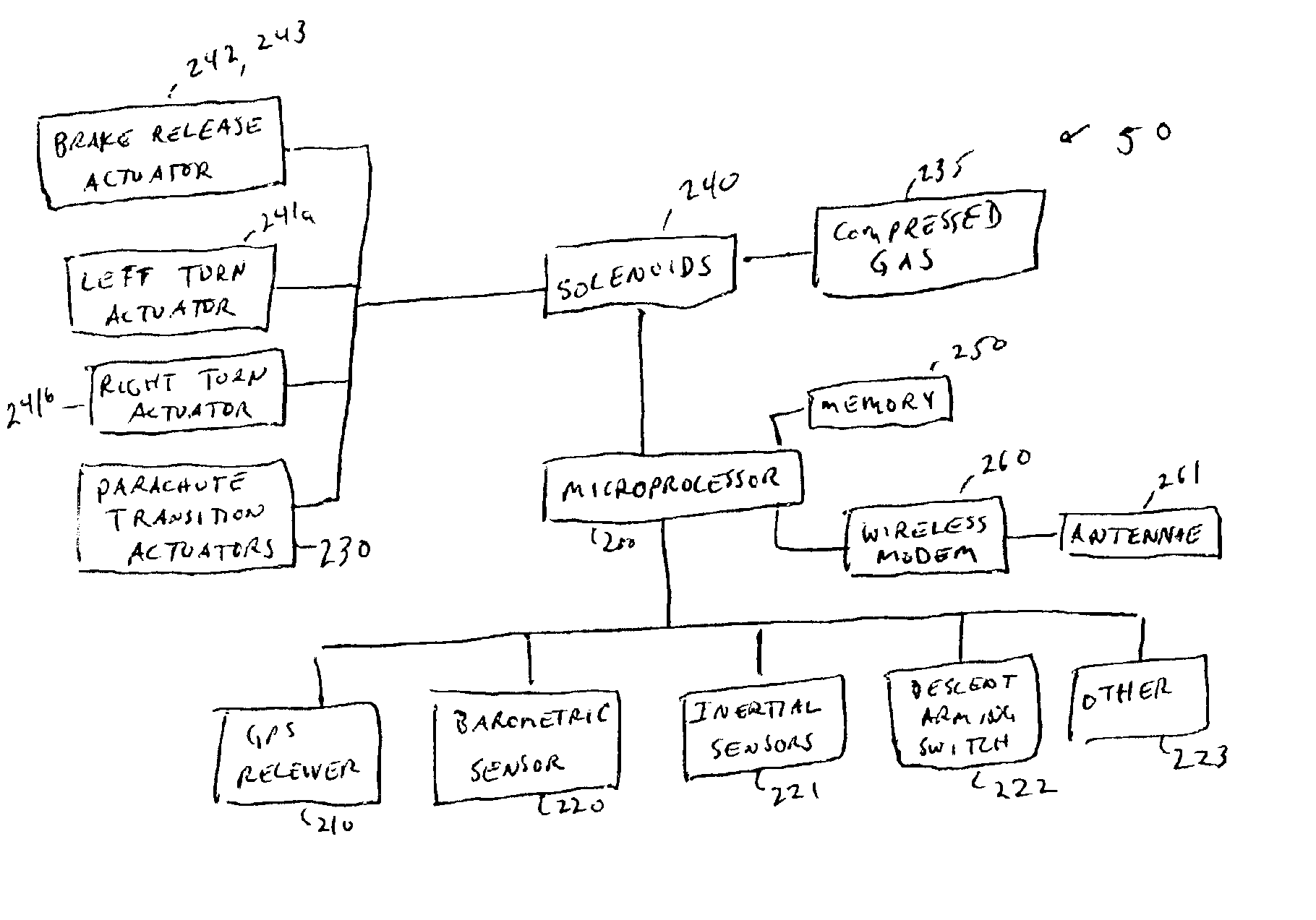

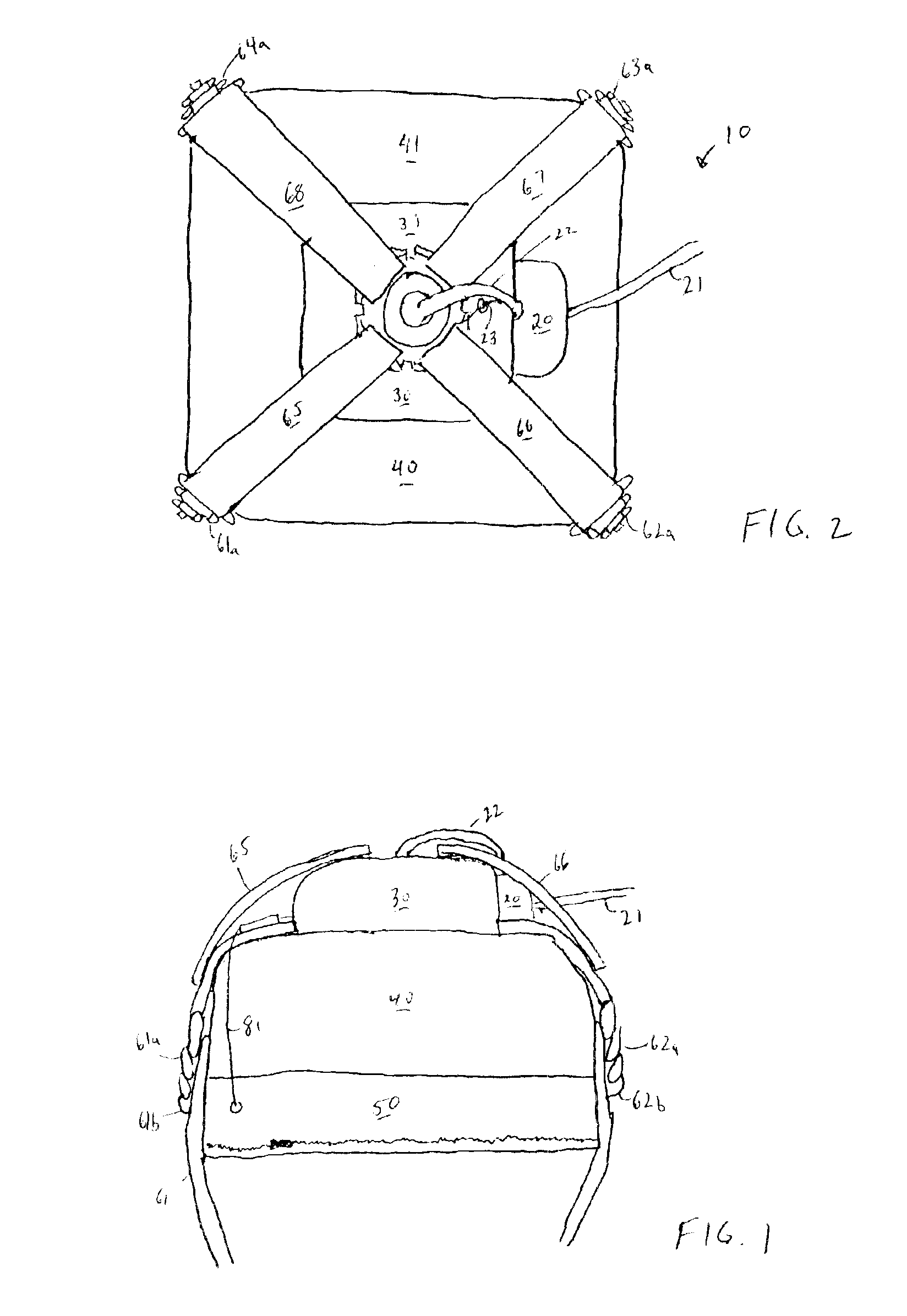

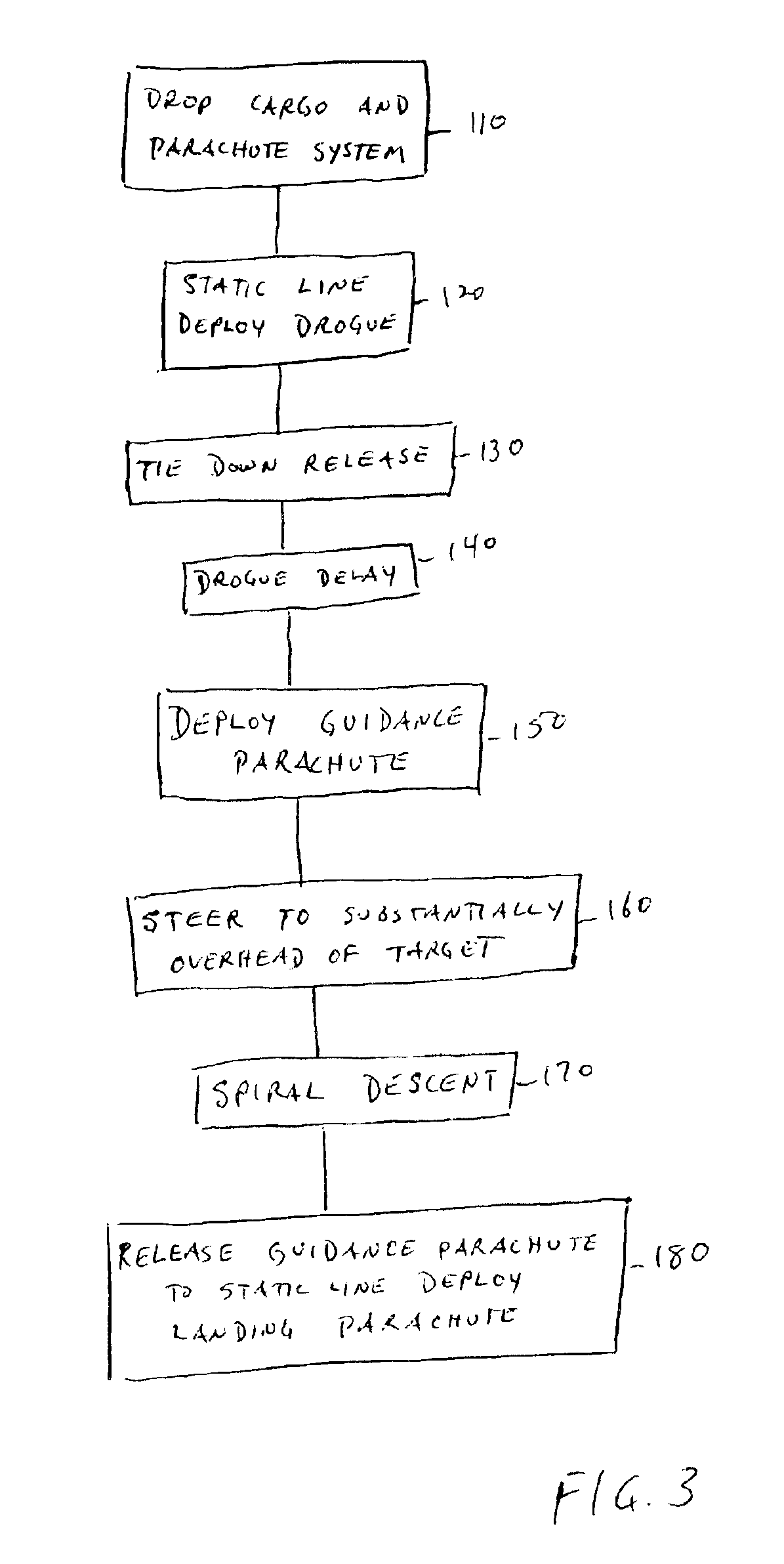

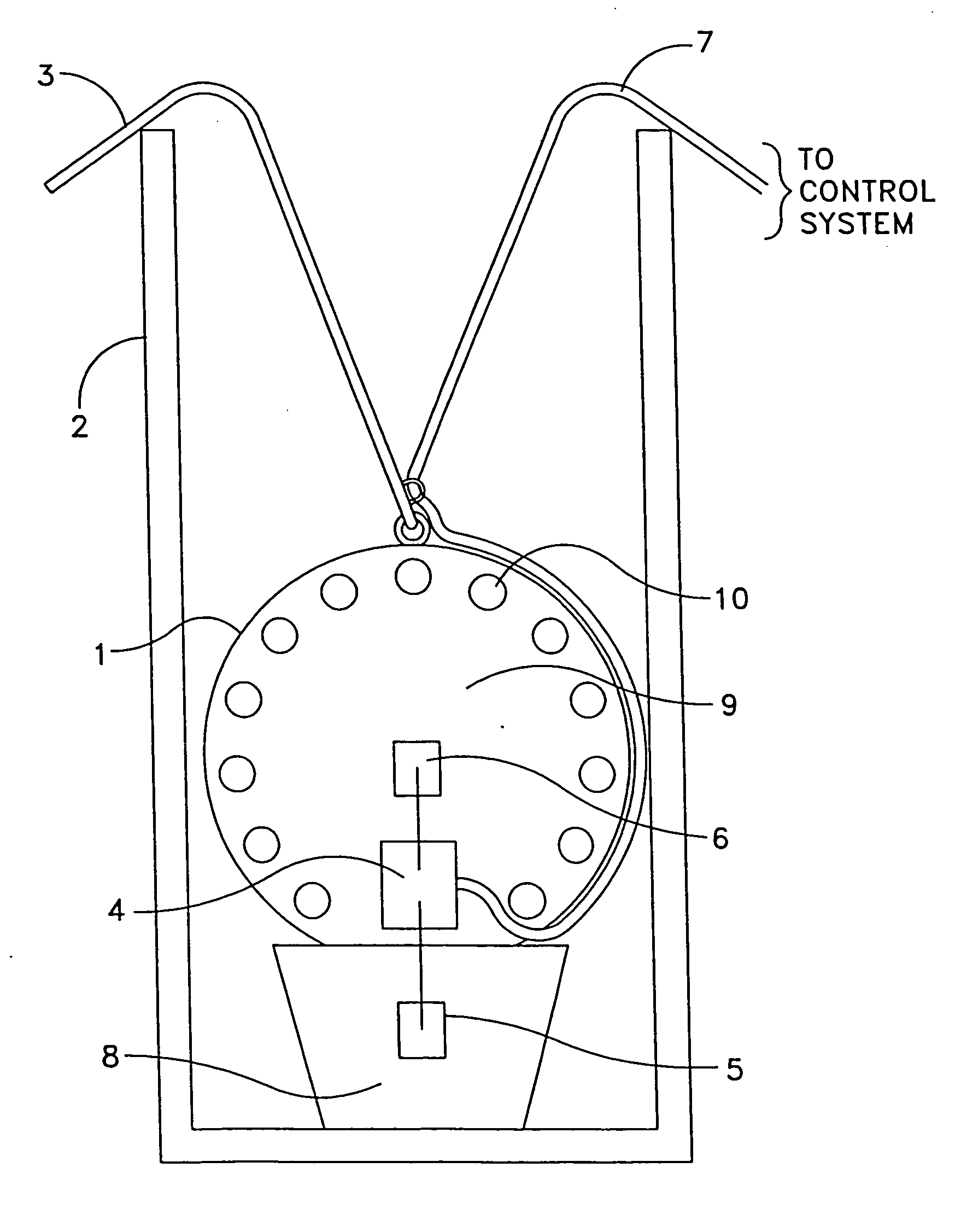

Steerable parachute control system and method

InactiveUS6889942B2Easy to controlImprove performanceParachutesVehicle position/course/altitude controlFlight computerControl system

An autonomous guided parachute system for cargo drops that divides the requirements of guidance and soft landing into separate parachutes. Said invention includes a high wing-loaded ram air parachute for guidance, a larger round parachute for soft landing, a harness / container system, flight computer, position sensors and actuation system. The system is dropped from an airplane. A predetermined period of drogue fall ensures a stable position prior to deploying the guidance parachute. The flight controller determines a heading to intersect with an area substantially above the desired target and controls the guidance parachute via pneumatic actuators connected to the parachutes steering lines to fly on that heading. At a minimum altitude prior to the system's impact with the ground the flight computer transitions the system from the fast high performance guidance parachute to a larger landing parachute by releasing the guidance parachute to static line extract and deploy the landing parachute. If the system reaches a position substantially above target area prior to the parachute transition altitude the flight computer controls the system into a spiral dive or other rapid altitude dropping maneuver until the transition altitude is reached. Once transitioned to the landing parachute the system descends for a brief period unguided under the landing parachute until touchdown.

Owner:ATAIR AEROSPACE +1

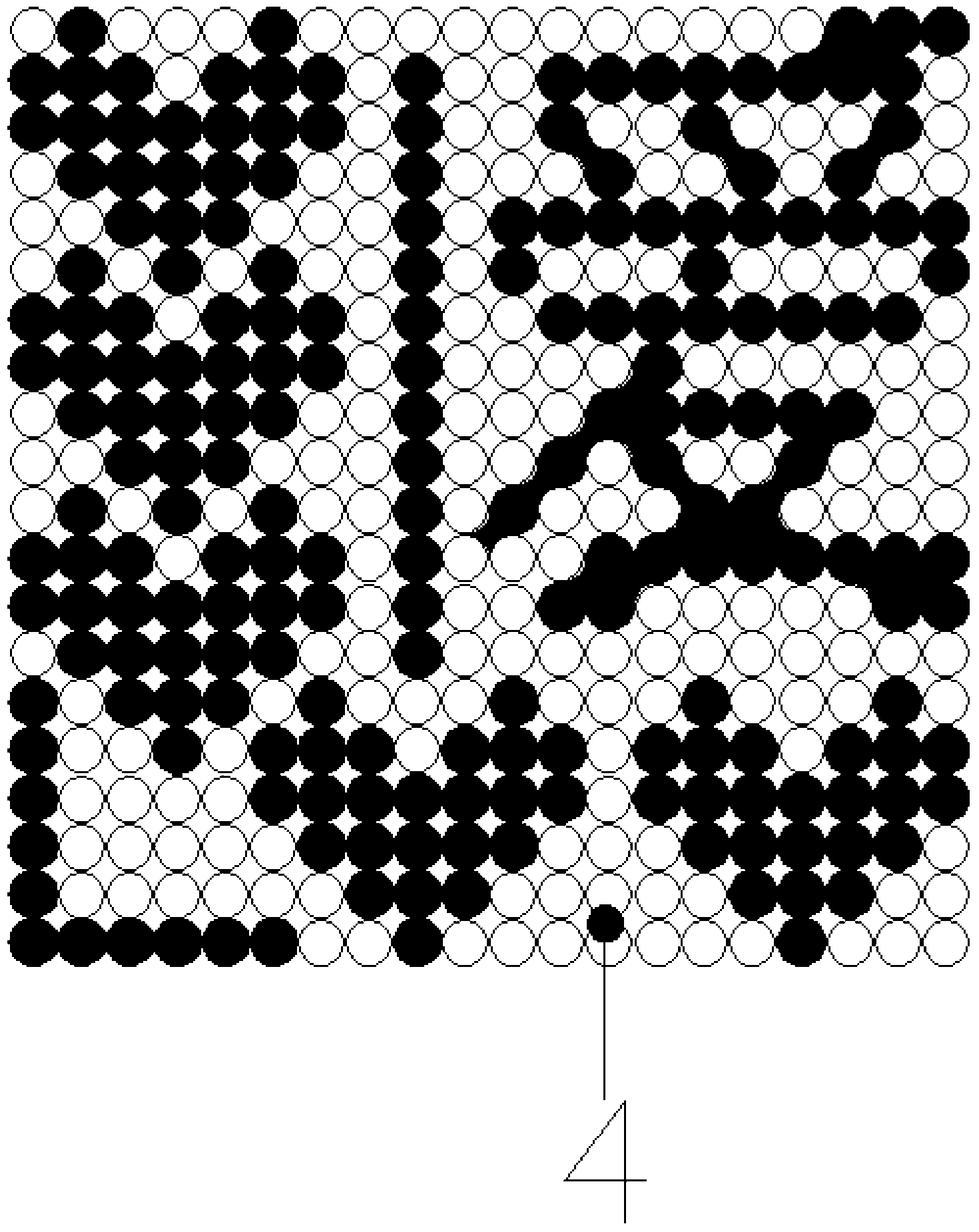

Image-text firework production method with users dyeing partial preset part

ActiveCN103234396AGuaranteed eleganceGuaranteed consistent specificationsFireworksGraphicsText display

The invention discloses an image-text firework production method with users dyeing a partial preset part. The image-text firework production method is characterized in that an image-text firework carrier, dyeing articles and a dyeing image-text production method are adopted. The image-text firework carrier is provided with a lift-off rocket, a lattice structural body, preset image-text display flames, flame primary color powder, simultaneous propellant powder and a simultaneous ignition device, wherein the lift-off rocket is connected with the lattice structural body, and the simultaneous propellant powder, the preset image-text display flames and the flame primary color powder are filled in the lattice structural body. The dyeing articles include a dyeing saline solution and a dyeing device. The dyeing image-text production method includes image-text sample manuscript design, dyeing saline solution application, flame primary color powder penetrating staining, liquid component removing for sufficient drying and the like. According to the image-text firework production method, the displayed picture part of set off fireworks is preset and can be randomly combined according to free expressing of users, and accordingly the users can experience pleasure brought by personal participation and can directly express affection. In addition, the image-text firework production method is simple to implement, low in cost and suitable for volume production.

Owner:SUZHOU ZZH INTPROP SERVICES

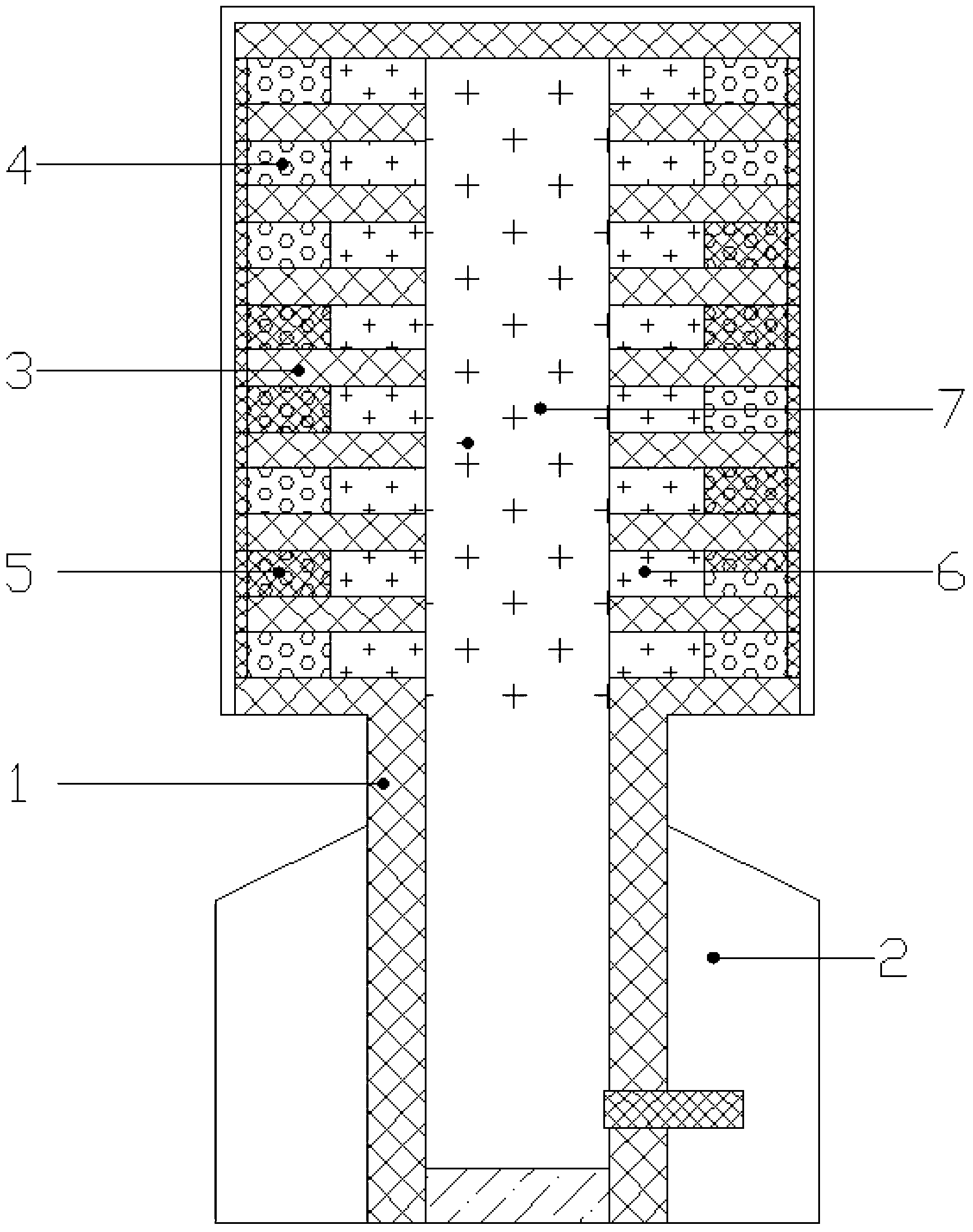

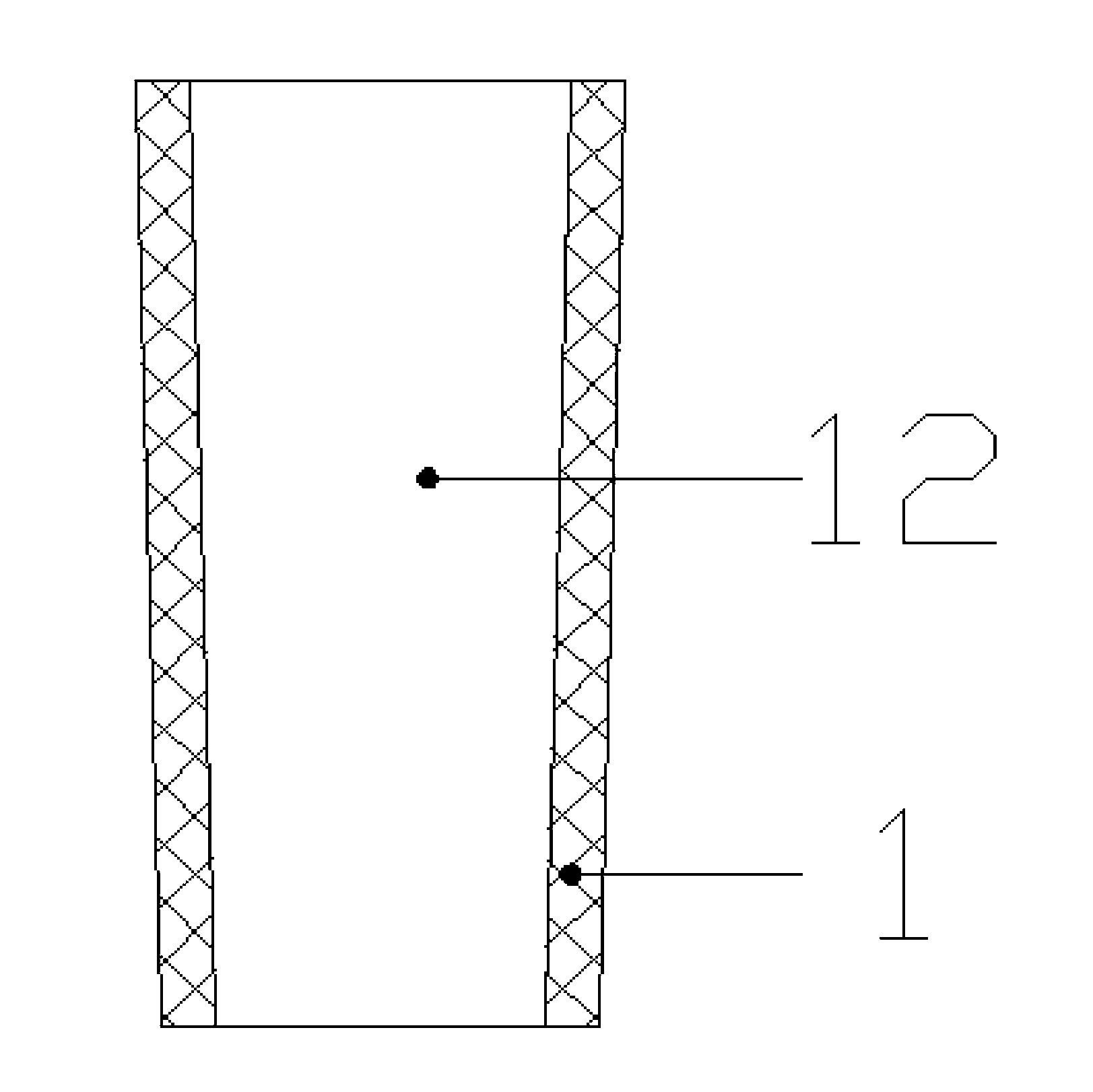

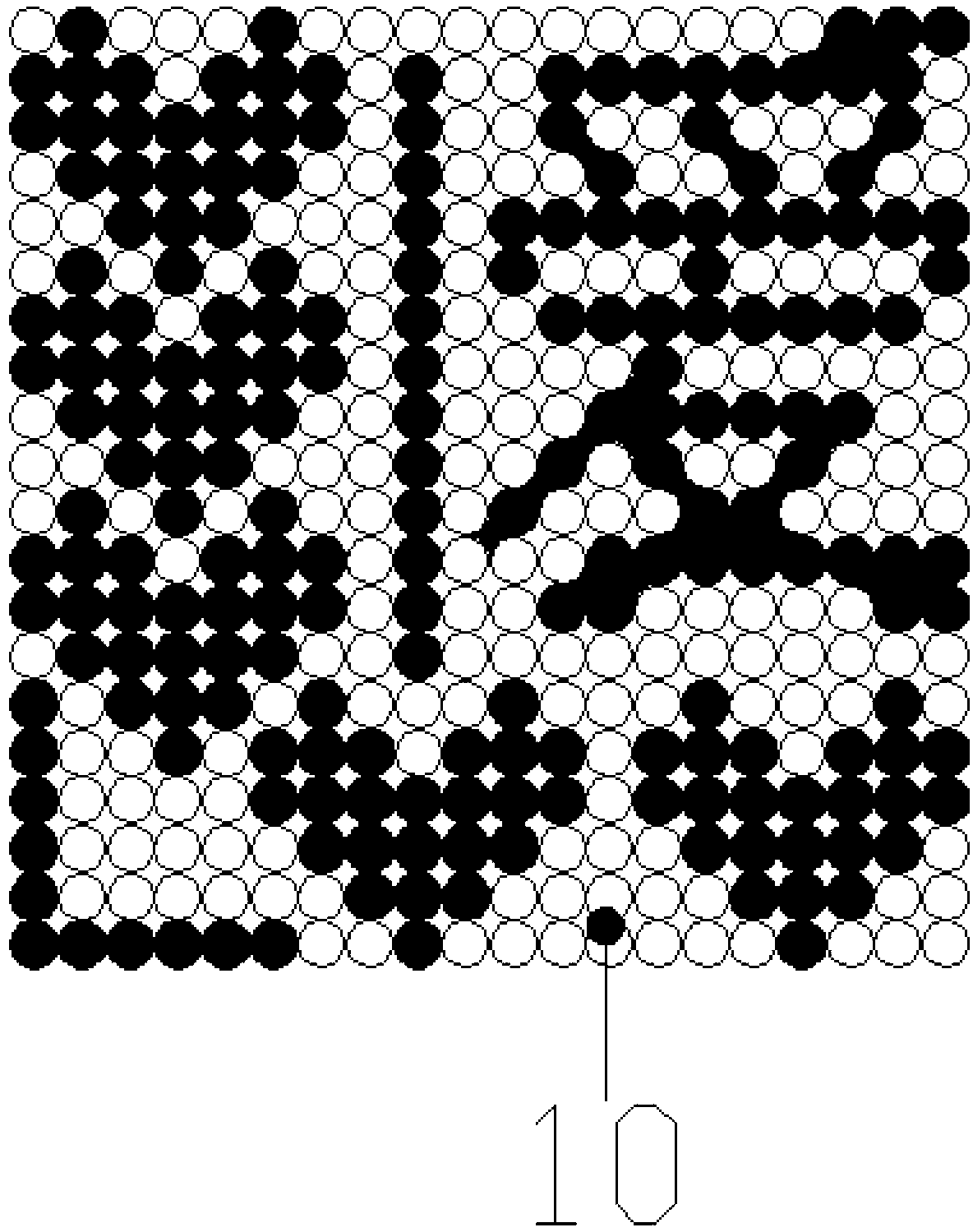

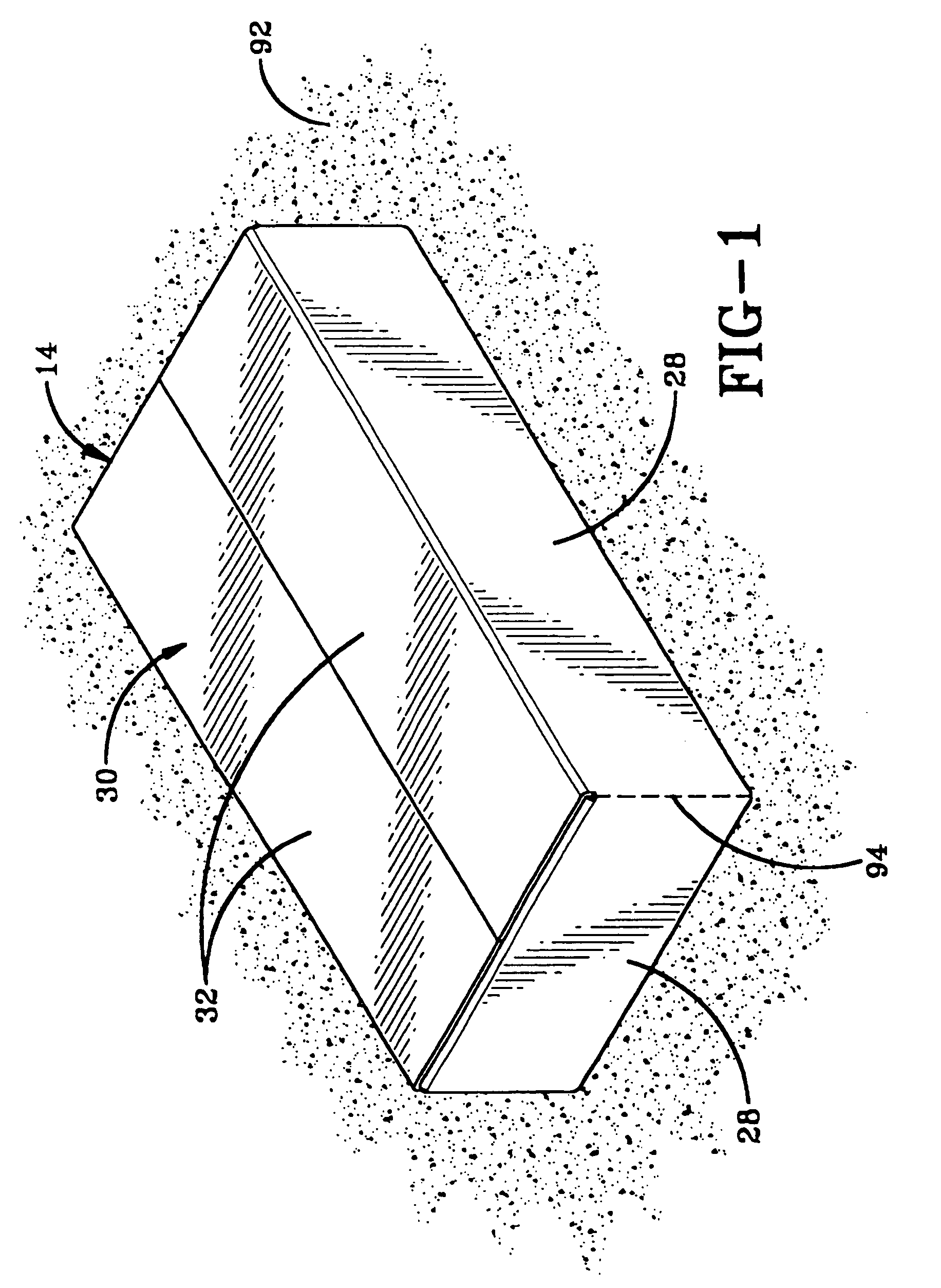

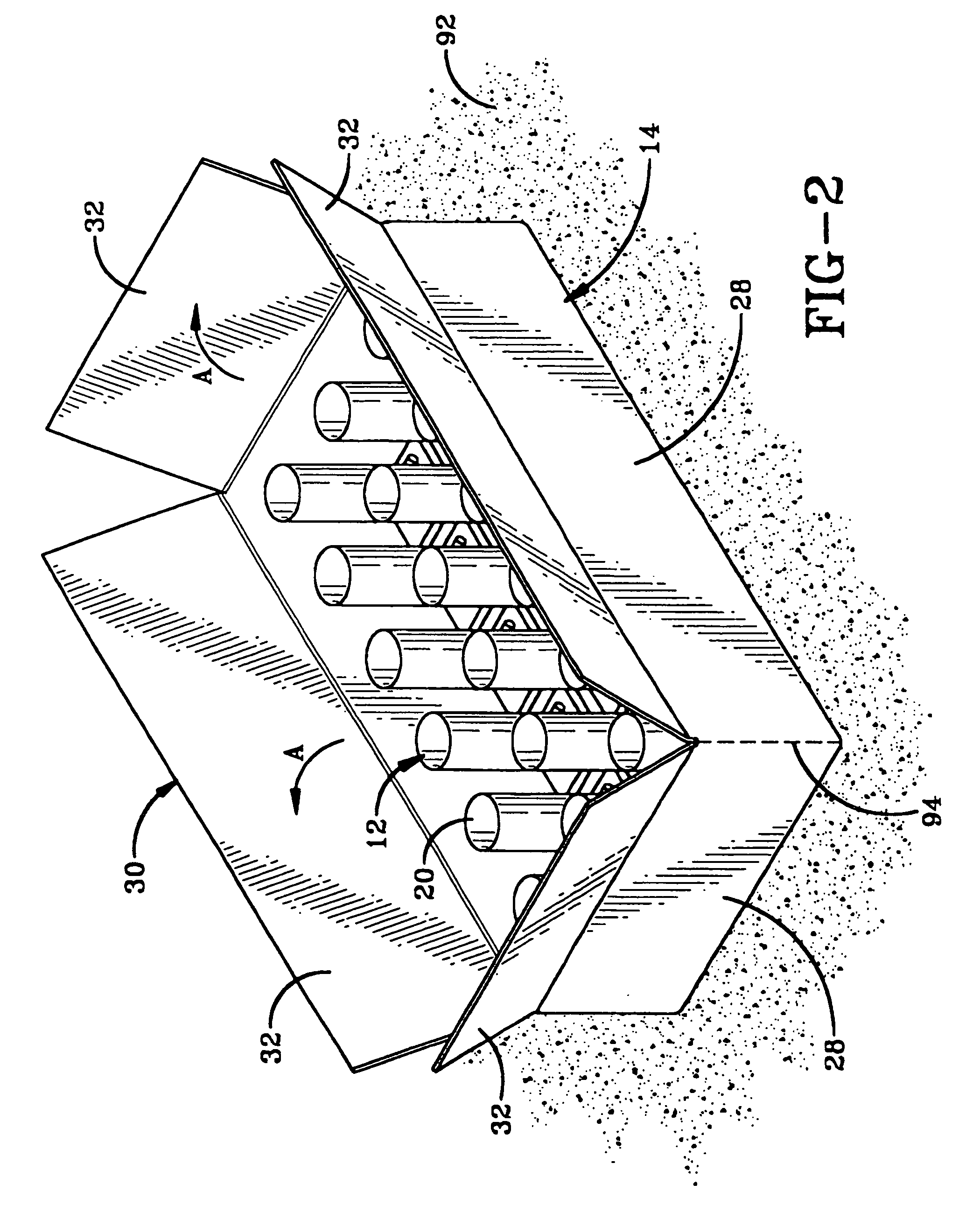

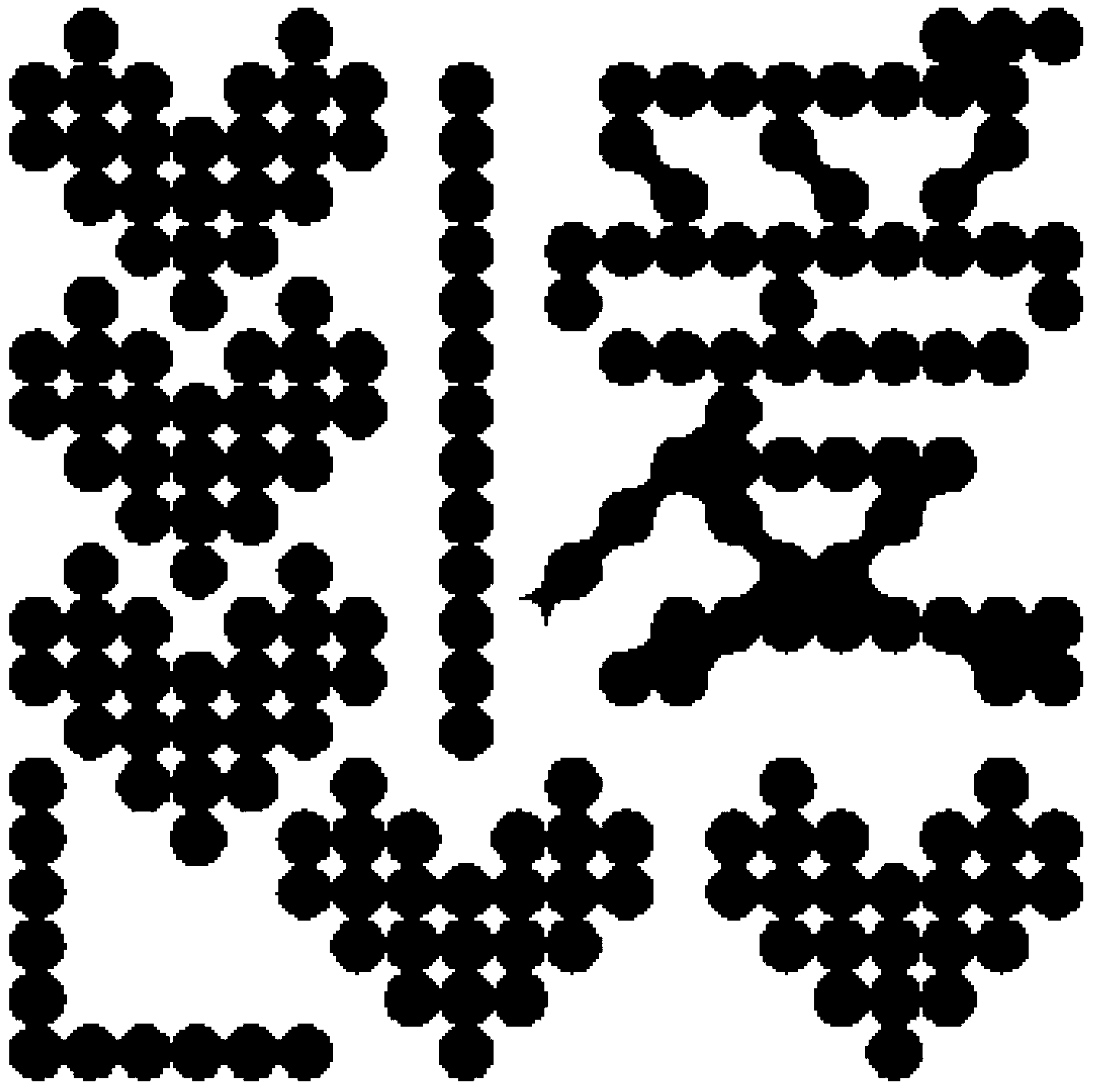

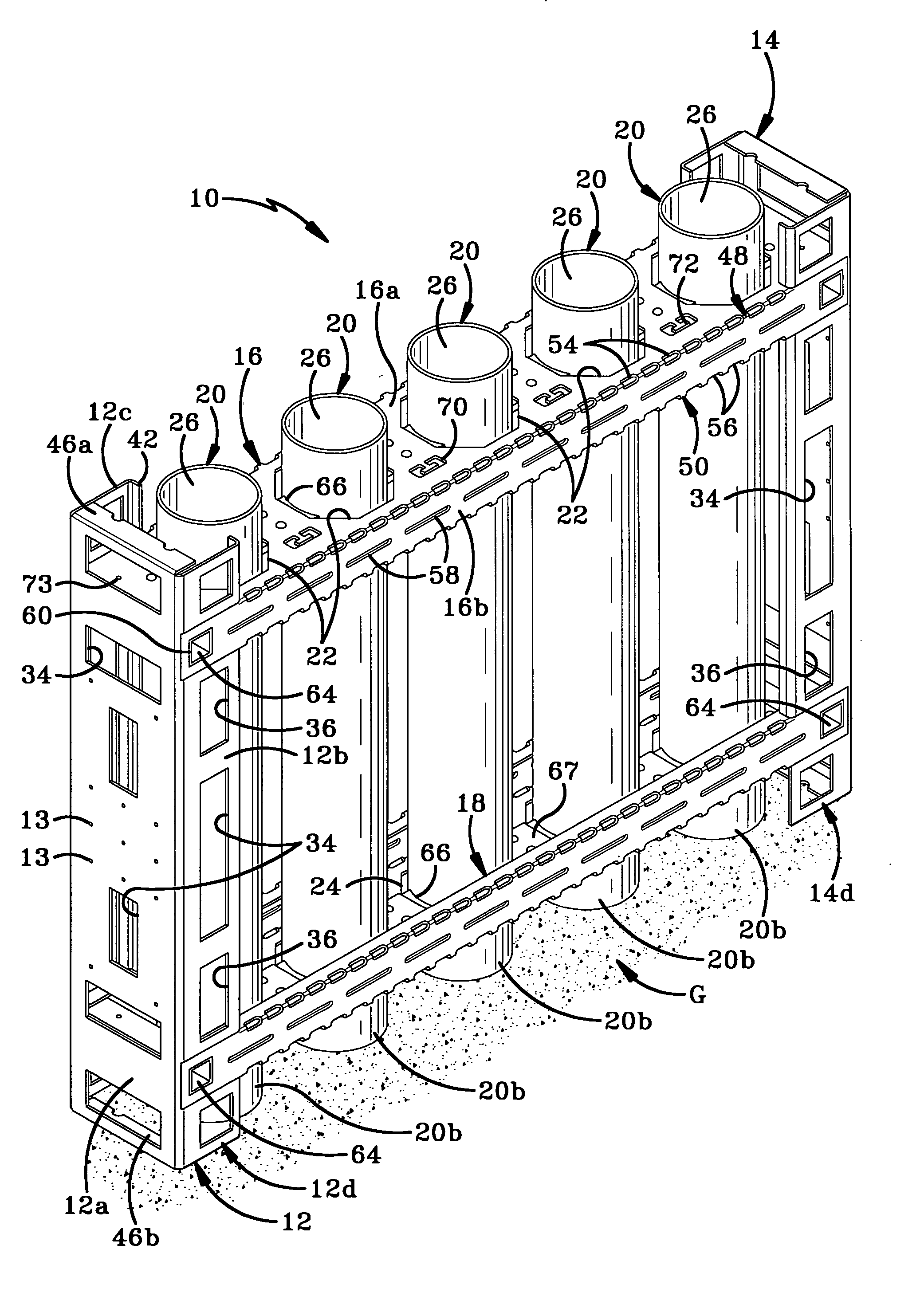

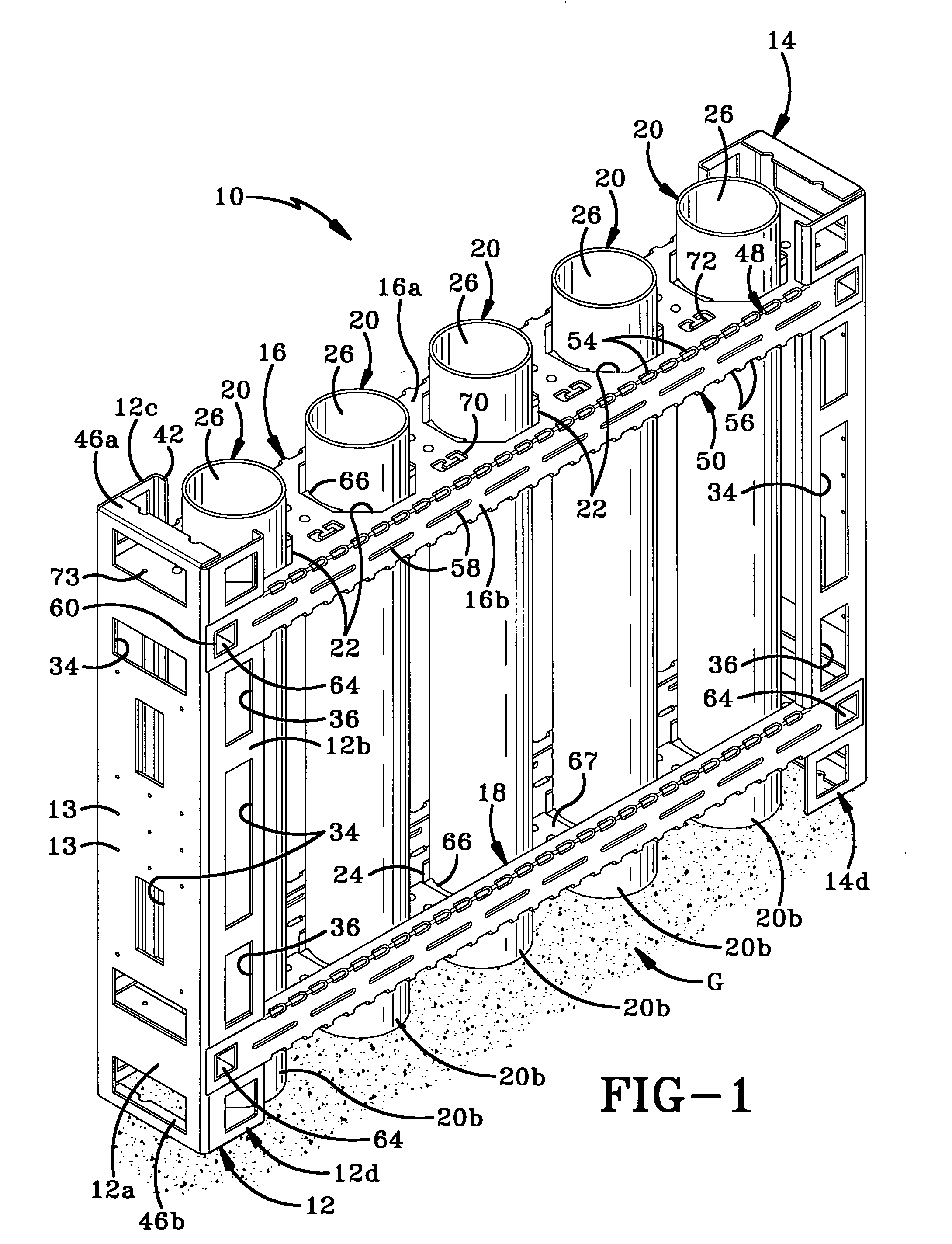

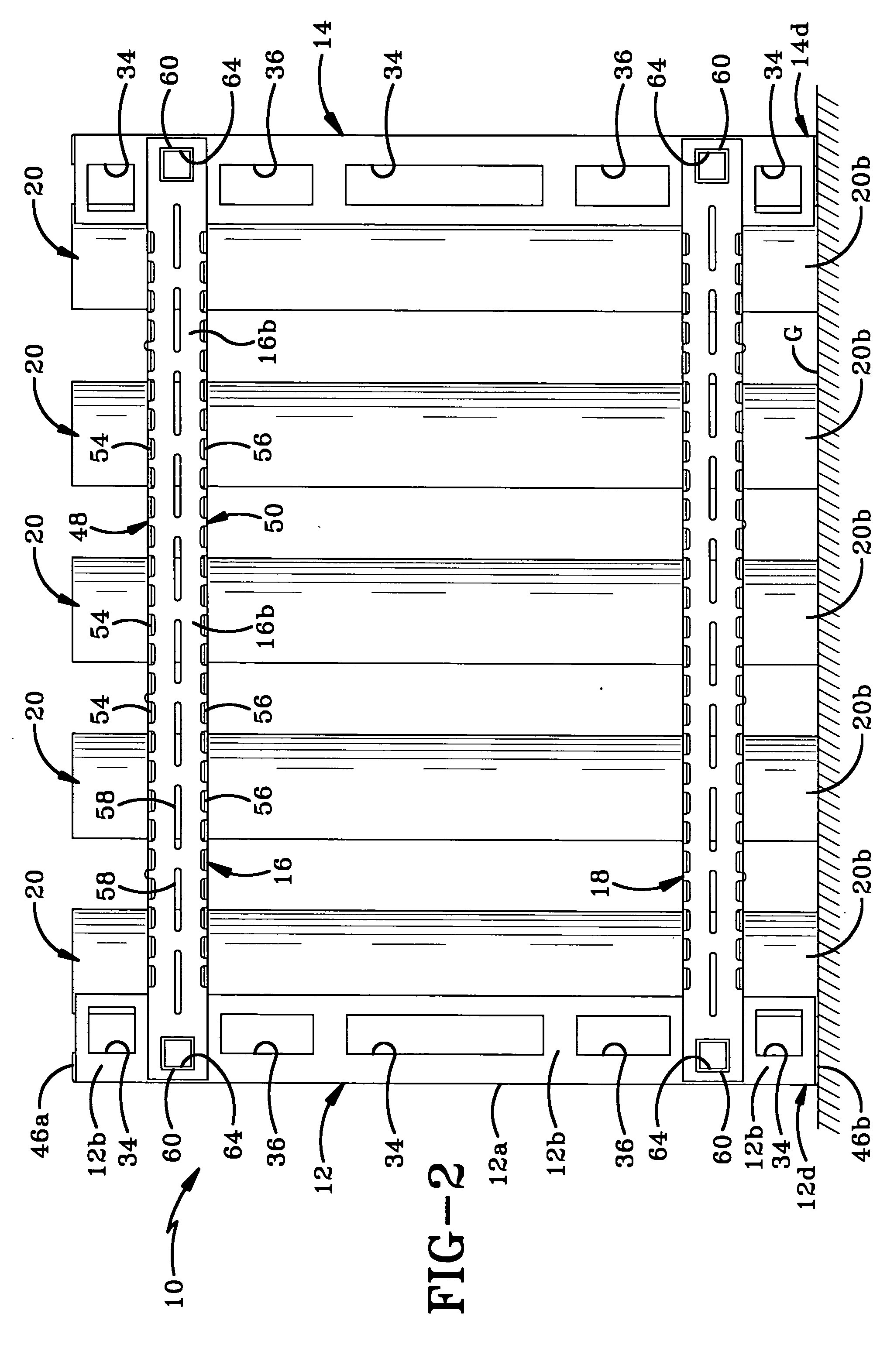

Production method for partitioned unit glued lattice structural bodies of graphic fireworks

The invention discloses a production method for partitioned unit glued lattice structural bodies of graphic fireworks. Partitioned units, a lattice body forming jig and a production method of finished lattice structural bodies are included. The lattice body forming jig is provided with jig inserting holes, and the jig inserting holes are distributed in a lattice shape and used for insertion of the partitioned units. The production method of finished lattice structural bodies comprises step one, presetting contour shapes after graphic fireworks are set off; step two, producing a height-limit lantern ring according to contour shapes; step three, placing the lattice body forming jig; step four, inserting the partitioned units and process plugs into the lattice body forming jig; step five, sleeving the height-limit lantern ring, and using a lattice pressing jig for compaction; and step six, applying glue, performing curing and the like. The production method is simple in implementation and convenient to produce, the complex lattice structural bodies are simplified, the production method is suitable for batch production, costs of graphic fireworks can be reduced substantially, and the production method is the key for graphic fireworks to enter thousands of families at low prices.

Owner:SUZHOU ZZH INTPROP SERVICES

Production method of partitioned independent powder-charged post-dyed graphic fireworks

ActiveCN103234394AEasy to produceFlexible dyeing and moldingSpecial ornamental structuresFireworksFireworksEngineering

The invention discloses a production method of partitioned independent powder-charged post-dyed graphic fireworks. A graphic firework structure and a post-dyed graphic firework production method are included. The graphic firework structure comprises lattice structural bodies, the lattice structural bodies are filled with firework base color powder and connected with simultaneous launchers, the simultaneous launchers are connected with a simultaneous ignition bin, and the simultaneous ignition bin is filled with simultaneous ignition powder and connected with a lift-off rocket. The post-dyed graphic firework production method comprises a dyeing salt solution, a dyeing device and a dyeing method, wherein the dyeing method comprises designing graphic sample manuscripts, contacting the dyeing salt solution with the firework base color powder through the dyeing device, enabling the dyeing salt solution to permeate into the firework base color powder according to rule limitation, mixing, removing liquid components, performing full drying, and displaying desired colors after the original firework base color powder is lighted. The production method is simple in implementation and convenient to produce, inventory is not needed, and the graphic fireworks can be dyed before leaving factories and be dyed by users through free combination after being purchased.

Owner:SUZHOU ZZH INTPROP SERVICES

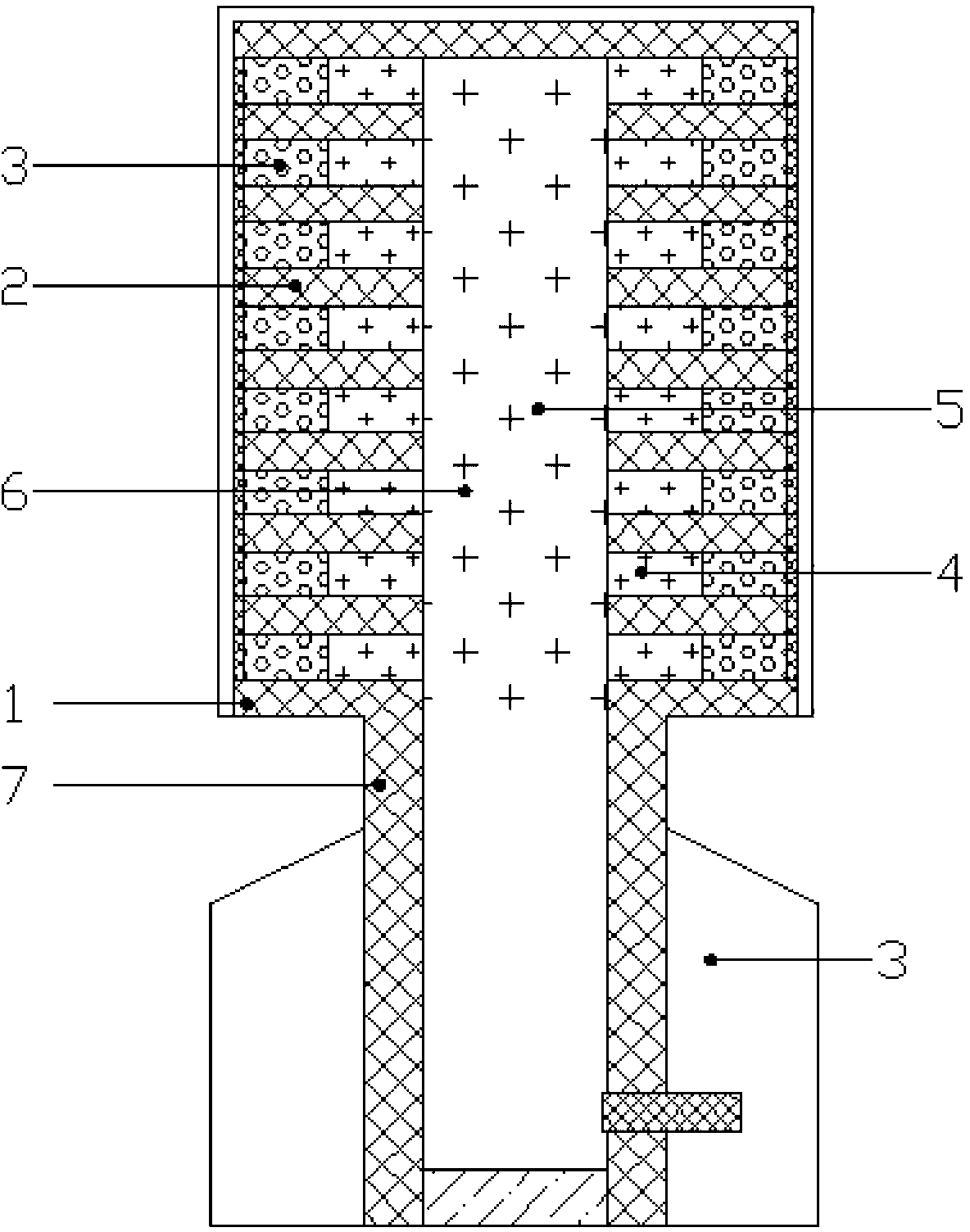

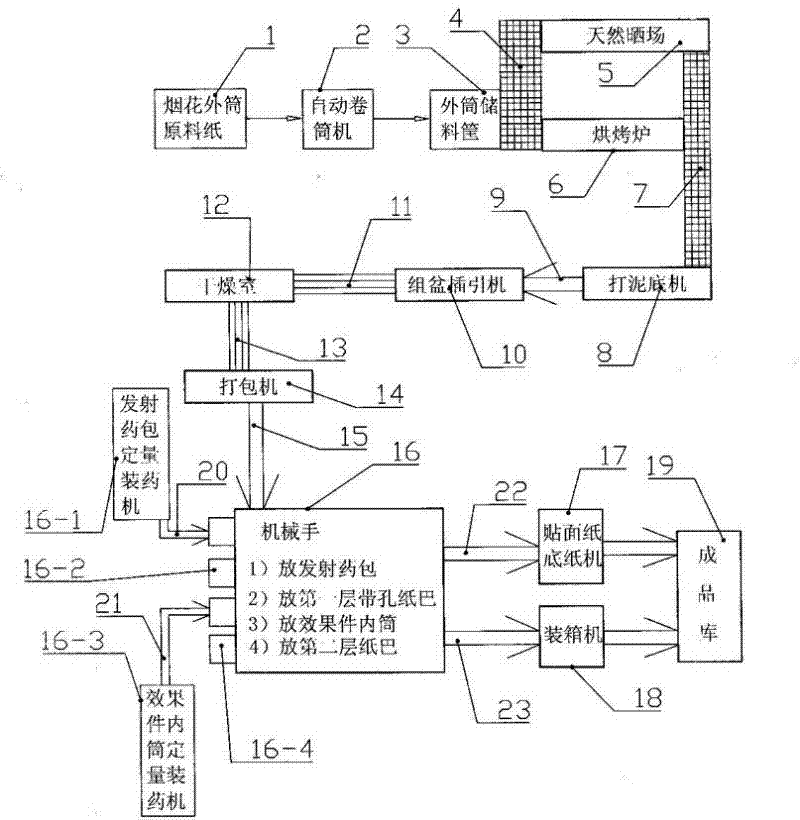

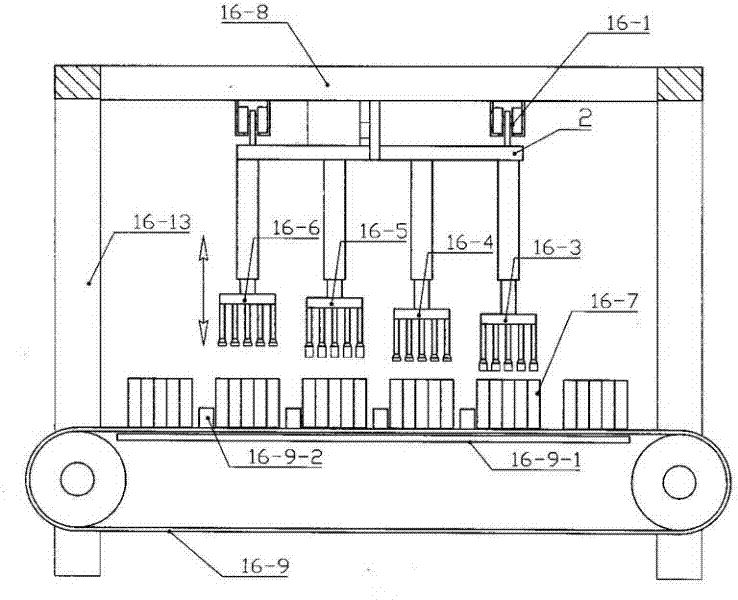

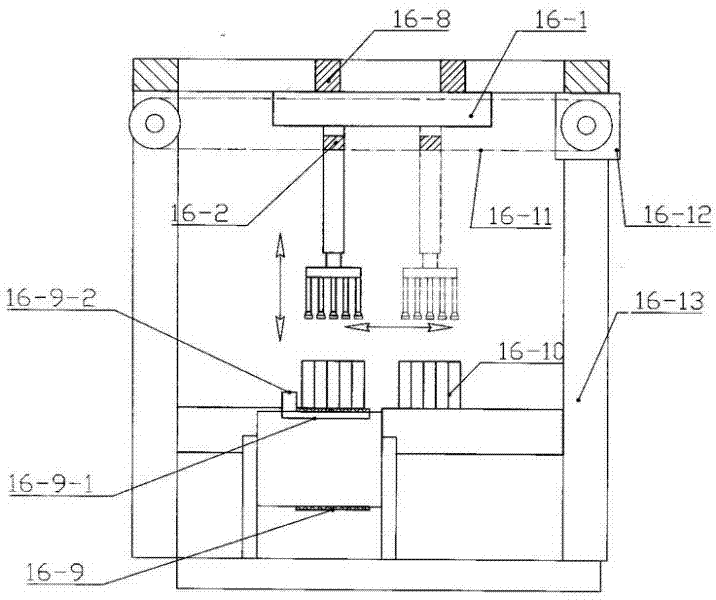

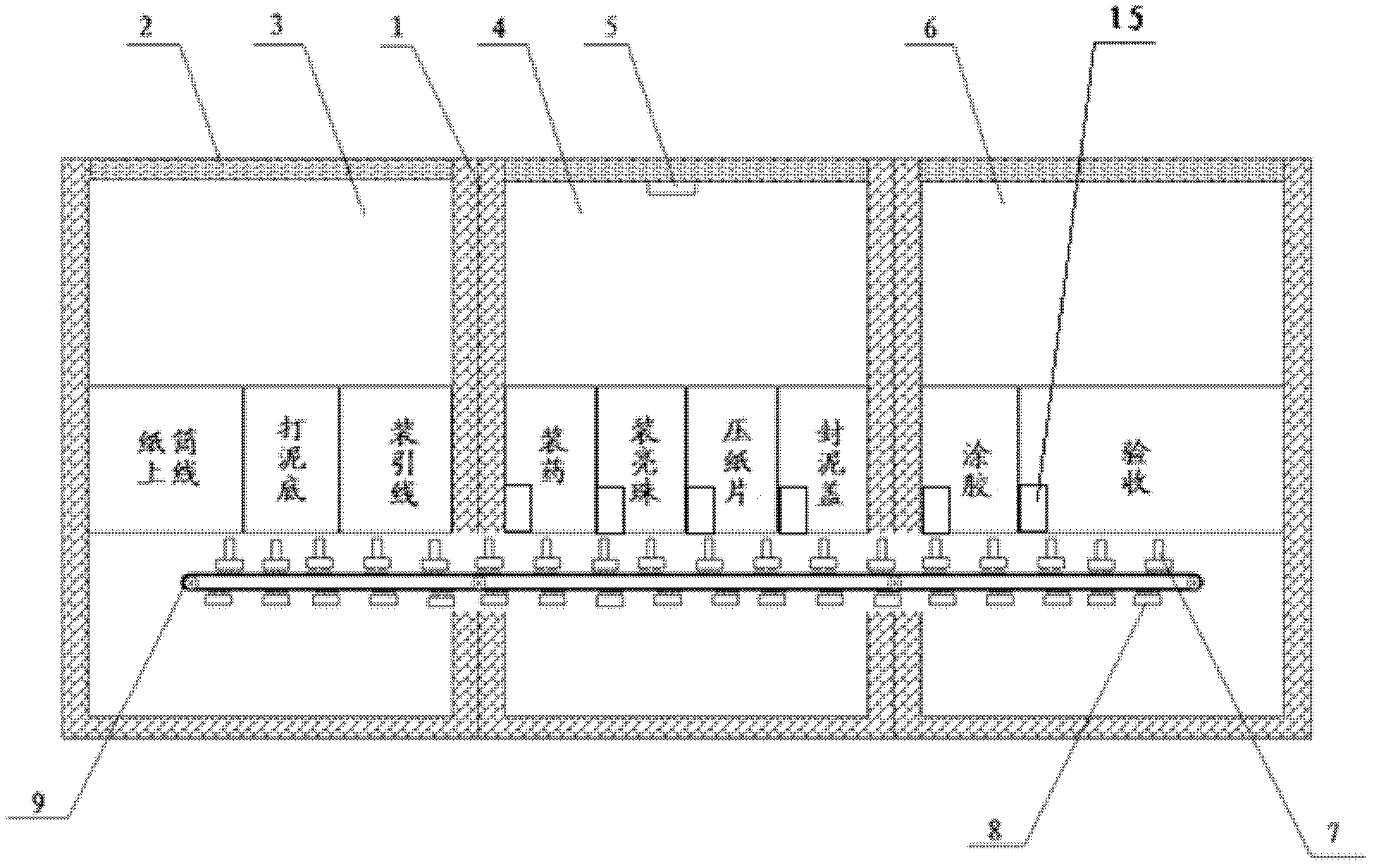

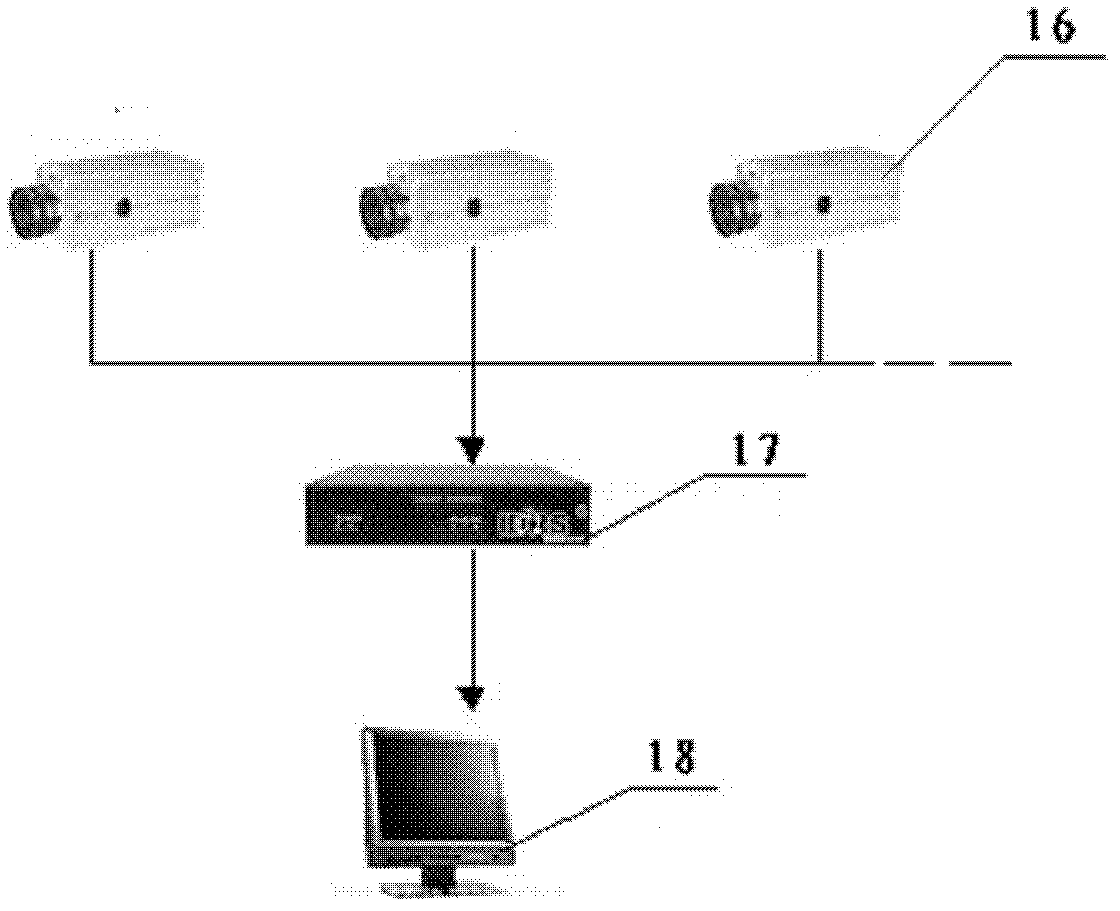

Flexible automatic production system for combined firework

InactiveCN102645135AAccurate and timely deliveryGuarantee quality and efficiencyFireworksFireworksPhotoelectric conversion

The invention relates to a flexible automatic production system for combined fireworks, which comprises an automatic tube rolling machine, a conveyer, a mud filling machine, a cake assembling and fuse inserting machine, a wrapping machine and a manipulator. The system is characterized in that firstly tubes are rolled through the automatic tube rolling machine and are stored in a tube storage basket, the tubes are fed to the mud filing machine for mud filling, cake assembling and fuse inserting after the tubes are dried, then the tubes are wrapped and reinforced by the wrapping machine, the tubes are righted and fed to the inlet port of the manipulator, propelling charges, effect part tubes, a first paper layer and a second paper layer are sequentially filled into the tubes after cake assembling, face paper and labels are stuck, products are boxed and sealed by a boxing and sealing machine and then the finished products are conveyed by the conveyer to a finished product warehouse; and materials among equipment of the entire system are conveyed by adopting the conveyer, and the loading position and the unloading position of each equipment are provided with photoelectrical conversion switches which are used for controlling the startup and the shutdown of the conveyer. Since the materials in the system are conveyed by the conveyer and the startup and shutdown of the conveyer are controlled by the photoelectric conversion switches, the materials are accurately conveyed in time, the product quality and the production efficiency are guaranteed, and the defects that manual handling in the past is time-consuming and labor-consuming and safety accidents are apt to occur are avoided.

Owner:柳真

Kinetic munition or projectile with controlled, non-lethal effects

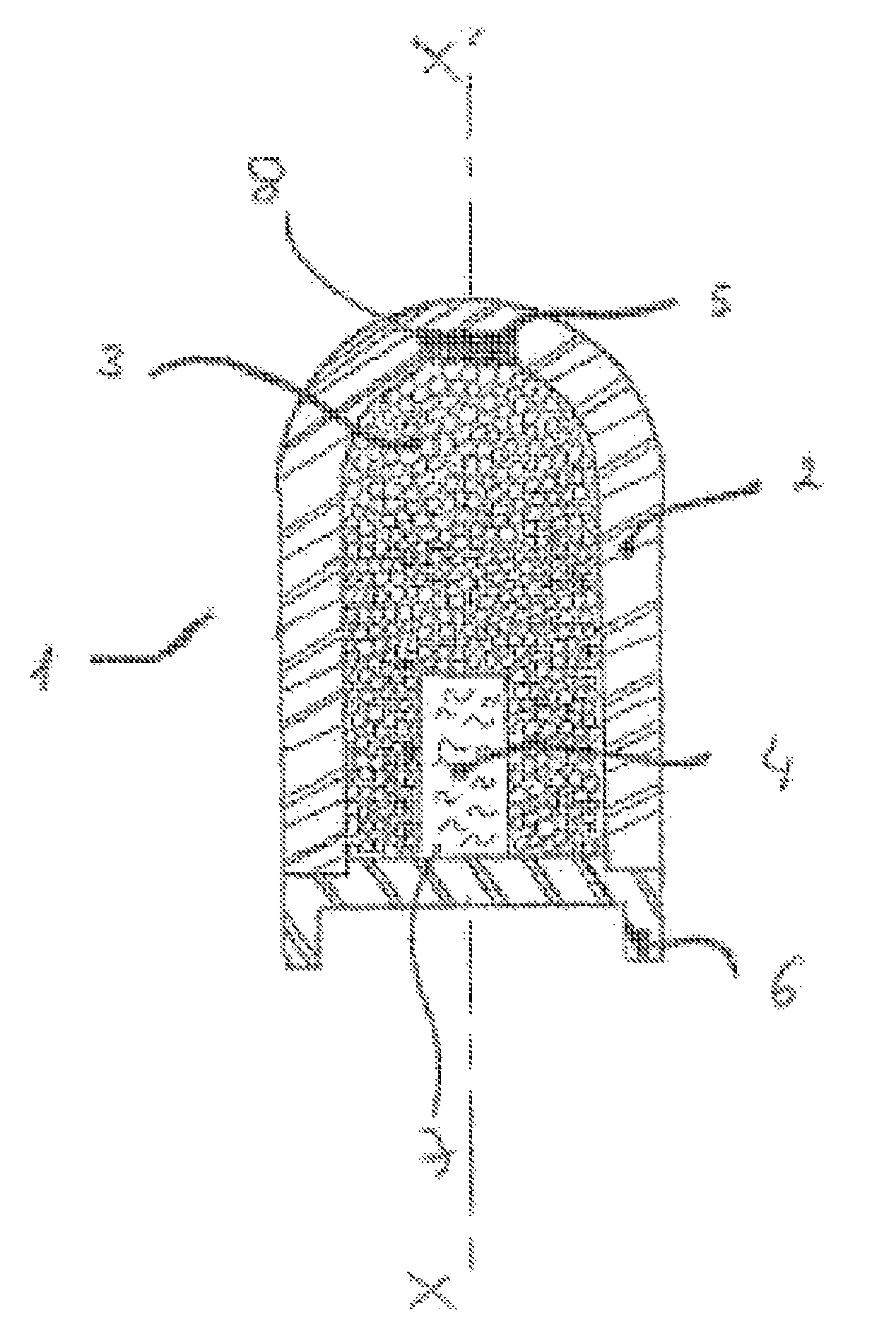

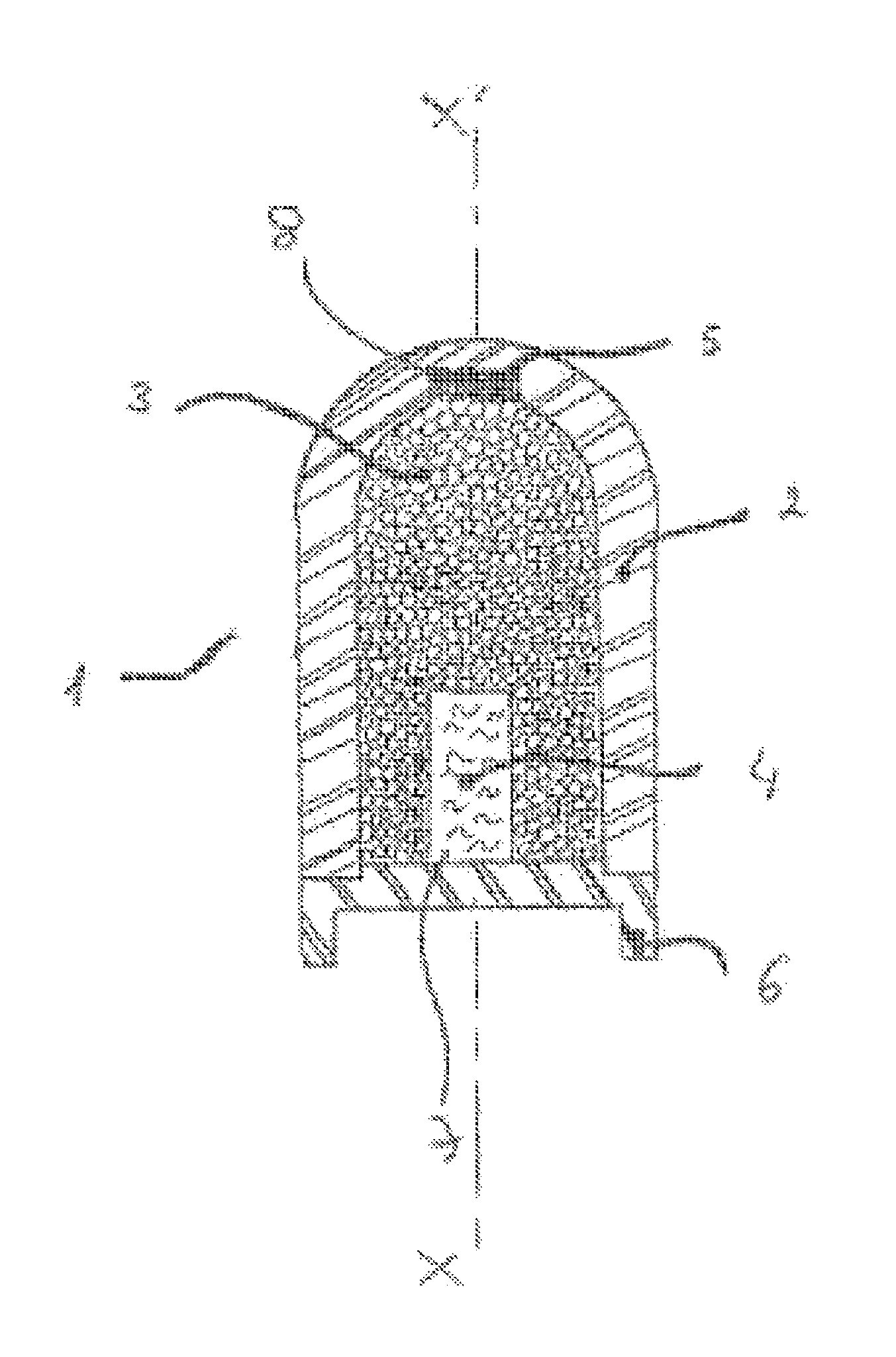

ActiveUS8671841B2Great impact durationWide areaAmmunition projectilesTraining ammunitionHardnessEngineering

The invention relates to a ballistic ammunition or projectile that is non-lethal or has controlled effects, of small or medium caliber. An internal structure is provided, made of a low-density cellular material with an elongation at break of less than 10%. An external casing encases the structure. The casing is made of a low hardness material with an elongation at break in excess of 100%. The casing is attached to the structure. The projectile may contain at least one cavity containing a different material from that of the structure and may also contain a payload.

Owner:SECURINOV

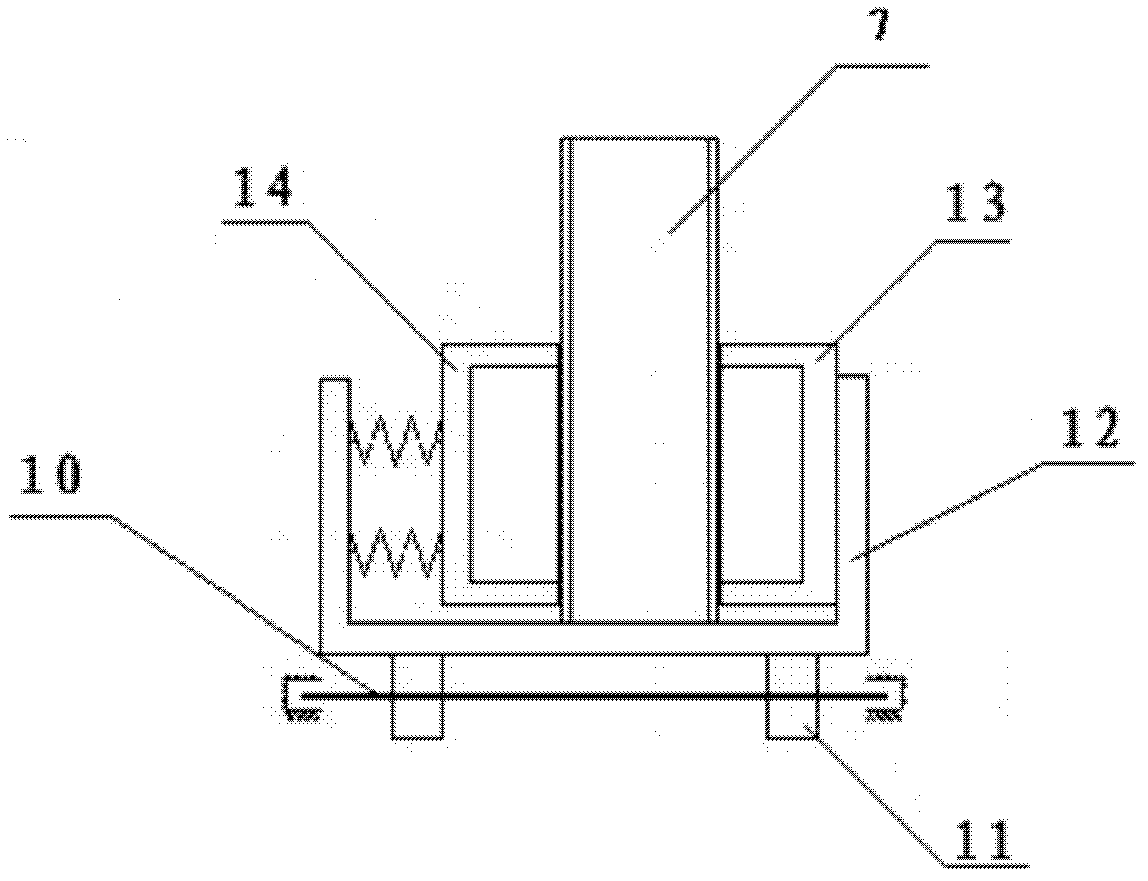

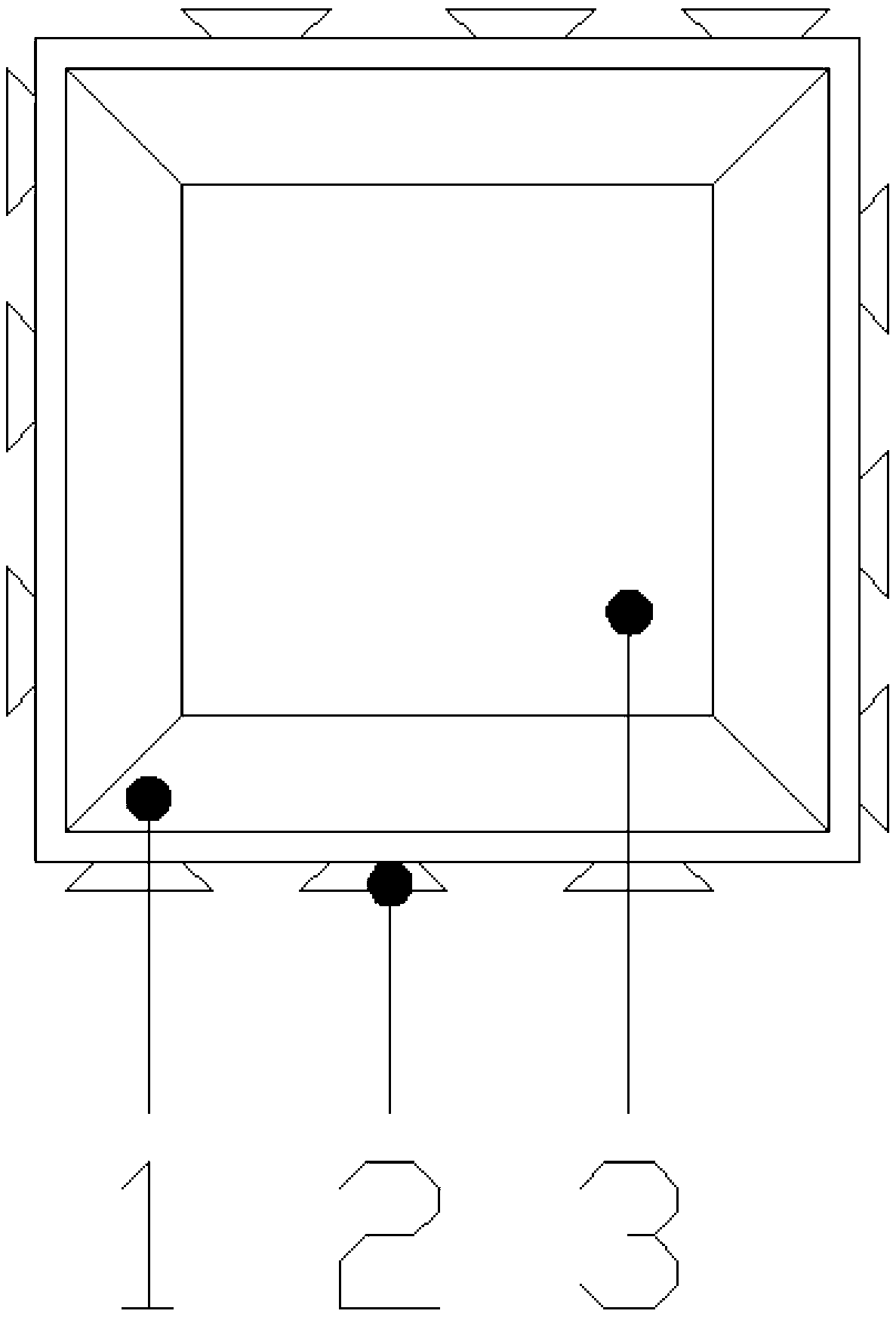

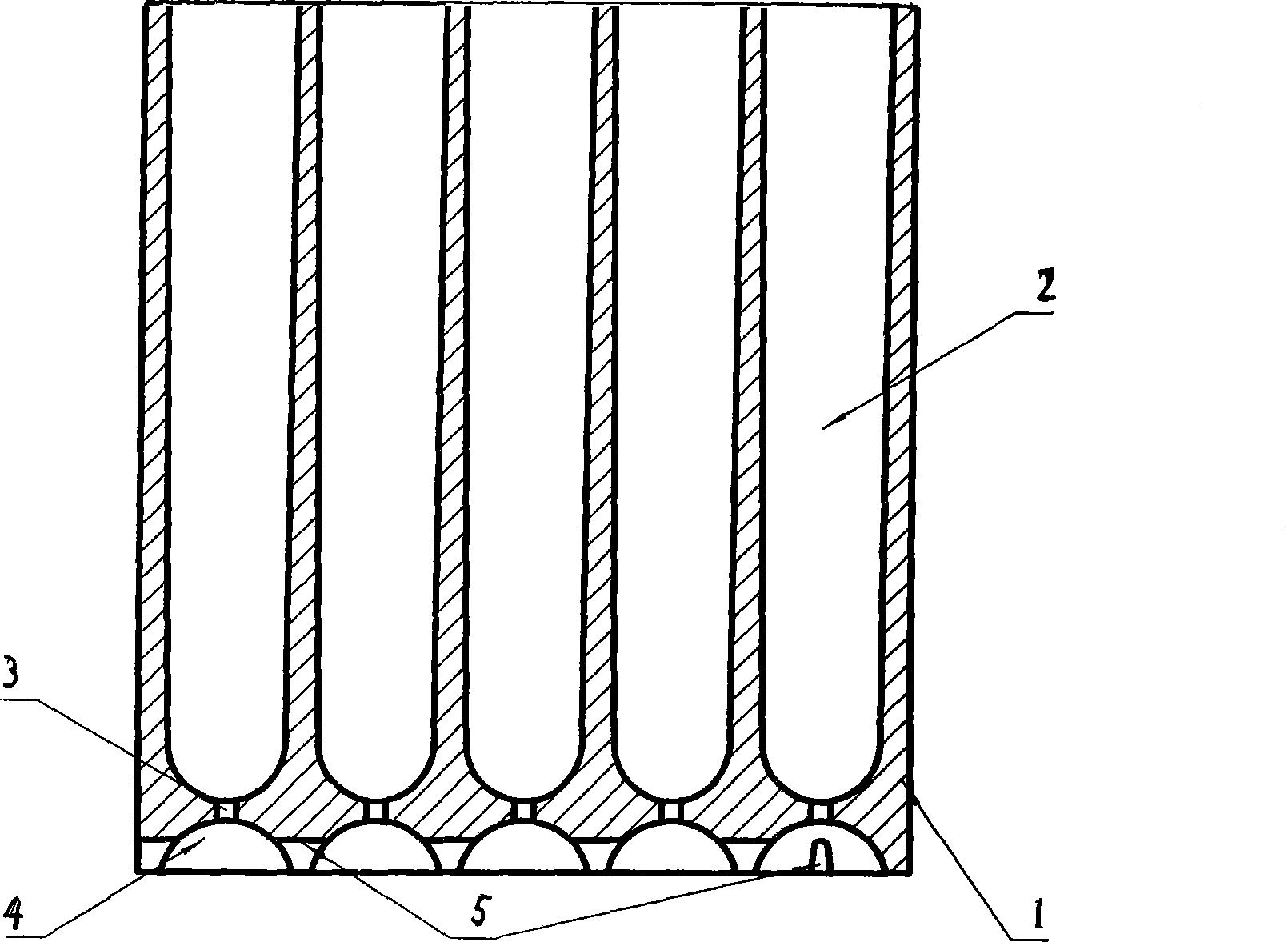

Automatic paper scrap-pressing device for combined fireworks

The invention discloses an automatic paper scrap-pressing device for combined fireworks, which comprises a fireworks external cylinder positioning mechanism and a circular paper scrap-pressing mechanism arranged on a rack. The automatic paper scrap-pressing device can automatically, quickly, conveniently and synchronously finish the processing and filling for the circular paper scrap of one product and can finish the processing for at least eight products per minute, so that the production efficiency is greatly increased. Since human factors are removed, the phenomenon of missing packaging or uneven circular paper scrap is avoided, and the product quality is ensured.

Owner:LIUYANG YIHELONG FIREWORKS GRP

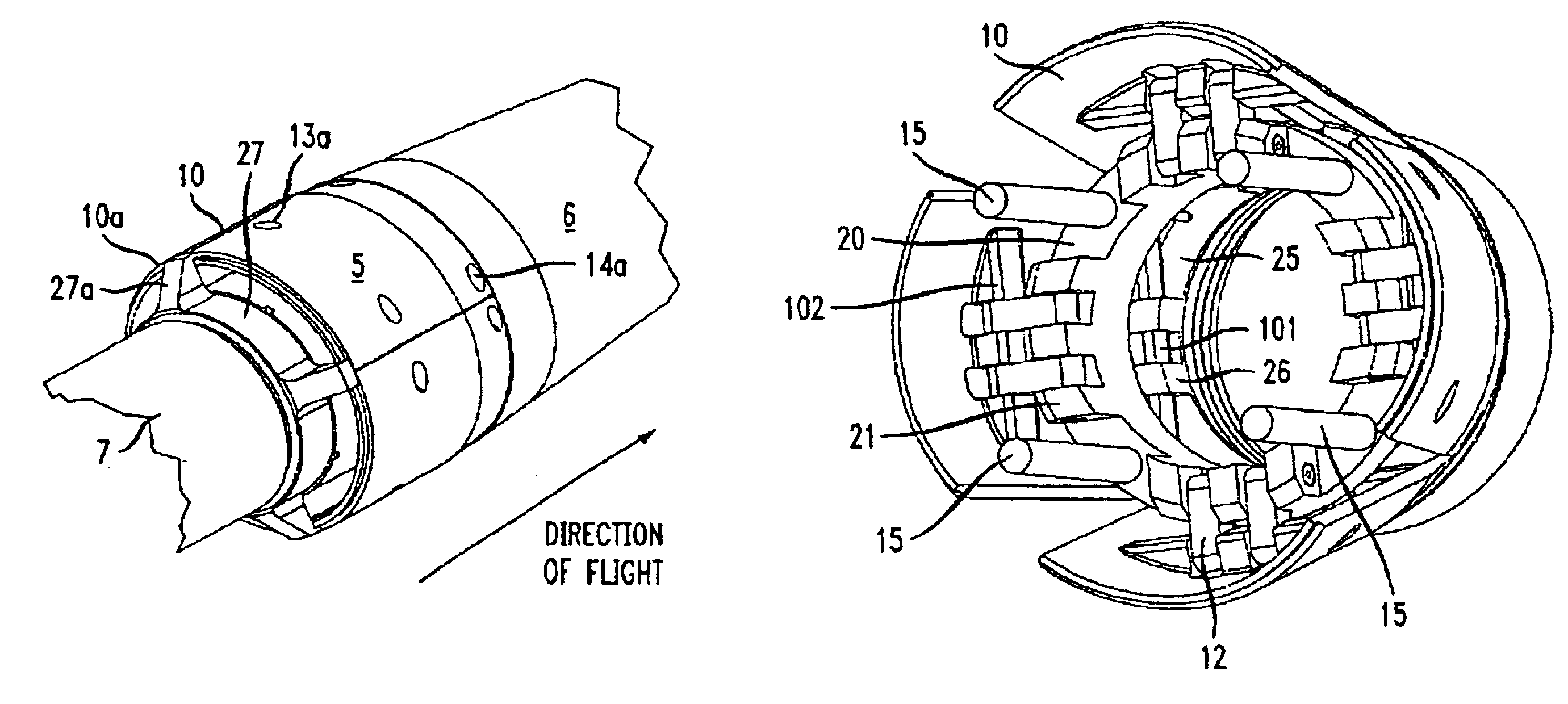

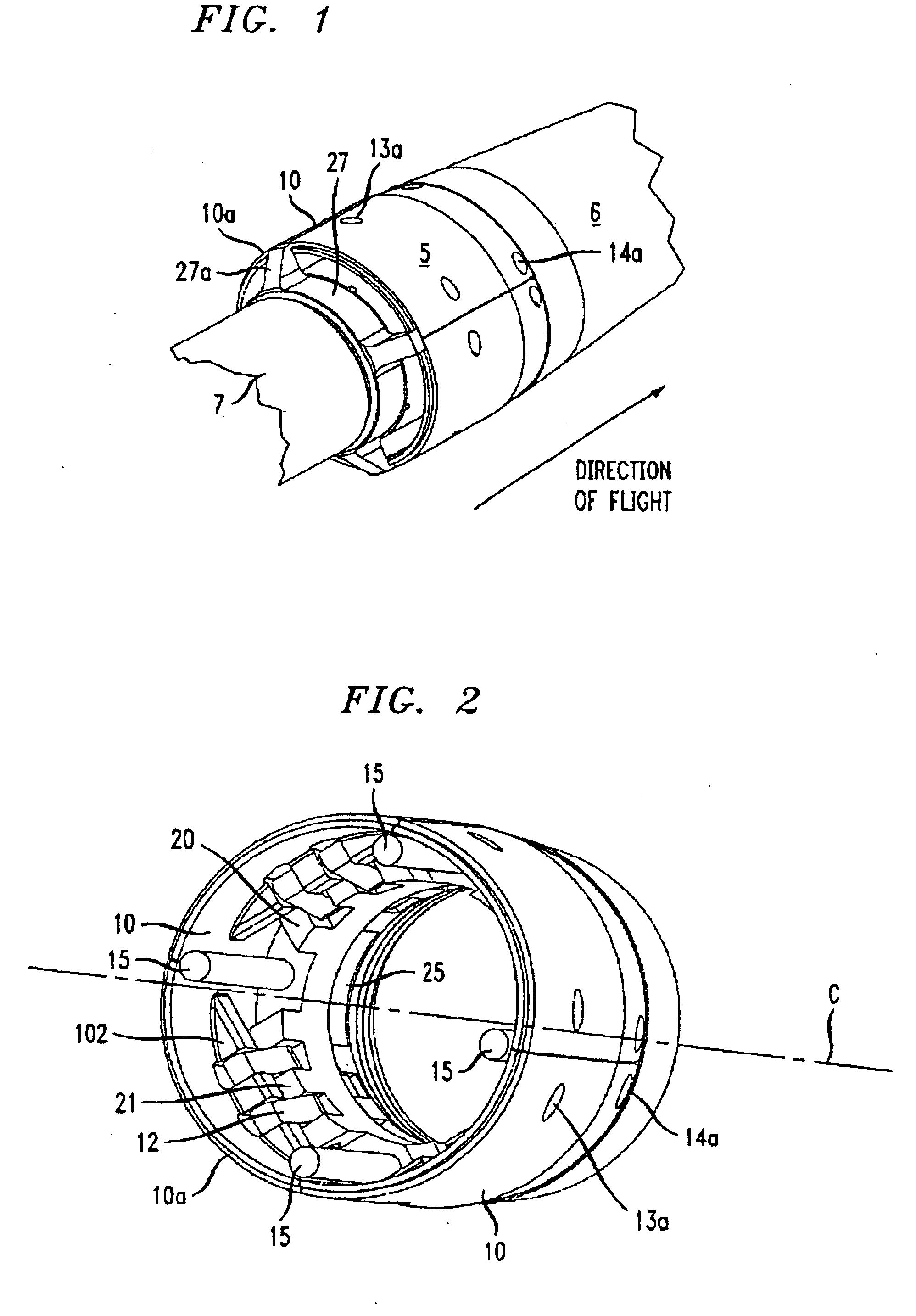

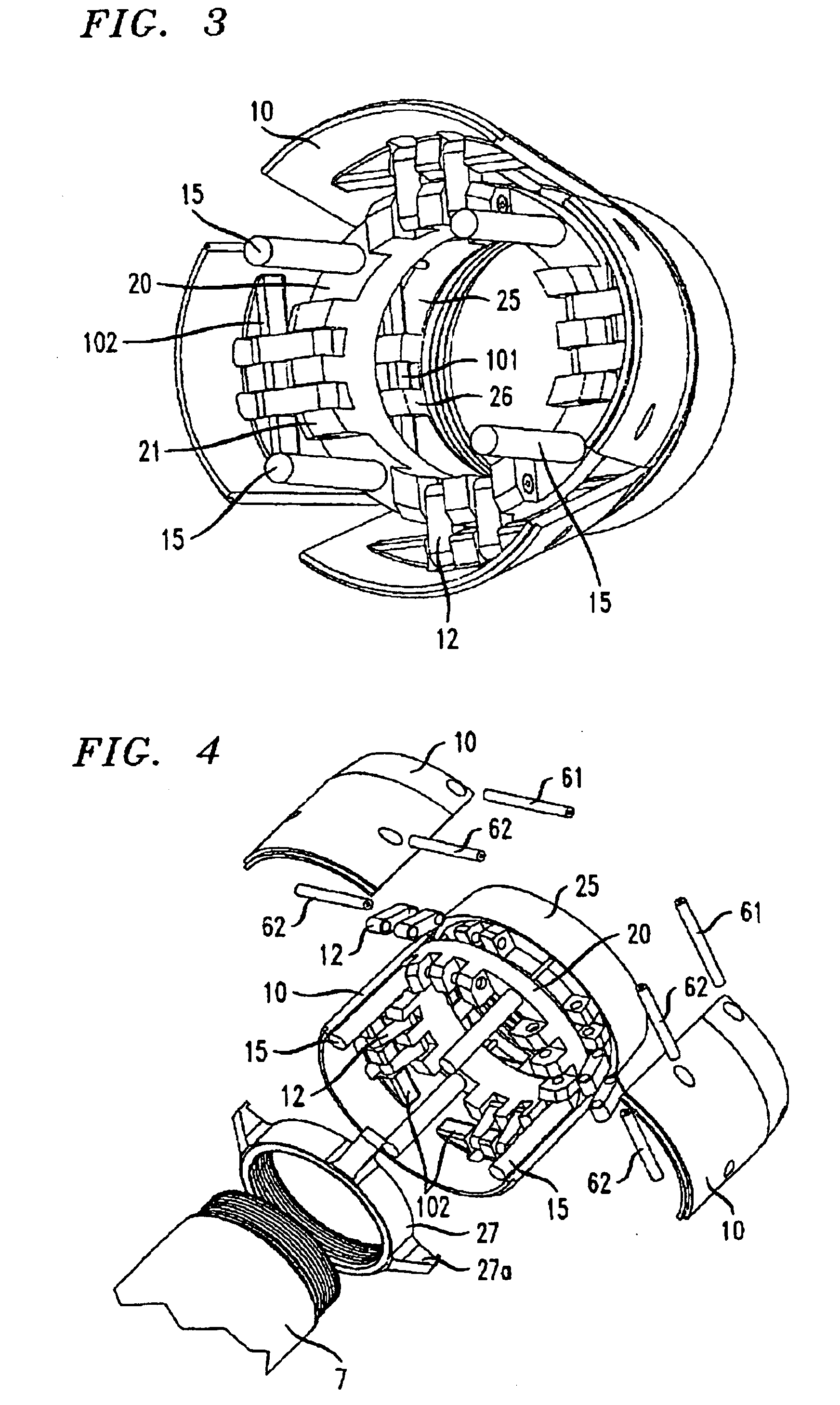

Deployable flare with simplified design

InactiveUS6869043B1Reduce the number of partsReduce manufacturing costAmmunition projectilesDirection controllersDetentStatic margin

The center of pressure of a projectile is caused to move upon the occurrence of an event that changes the static margin, such as the jettisoning of a body previously attached to the projectile, as noted above. In particular embodiments, this is achieved by a flare disposed toward the rear of the projectile. The flare has petals that deploy from a first, stowed position to a second, deployed position upon the occurrence of the event. In the stowed position, the petals are aligned with the air stream, in order to minimize drag. In the deployed position, the petals project into the air stream in such a way as to move the lift center rearward. A slide ring within the flare has sufficient inertia that it shifts aft in response to an acceleration that occurs when the attached body and the projectile are separated from one another. The slide ring is linked to the petals in such a way that the petals are deployed by the displacement of the slide ring. Detents lock the slide ring in its displaced position.

Owner:AMERICAN TELEPHONE & TELEGRAPH CO

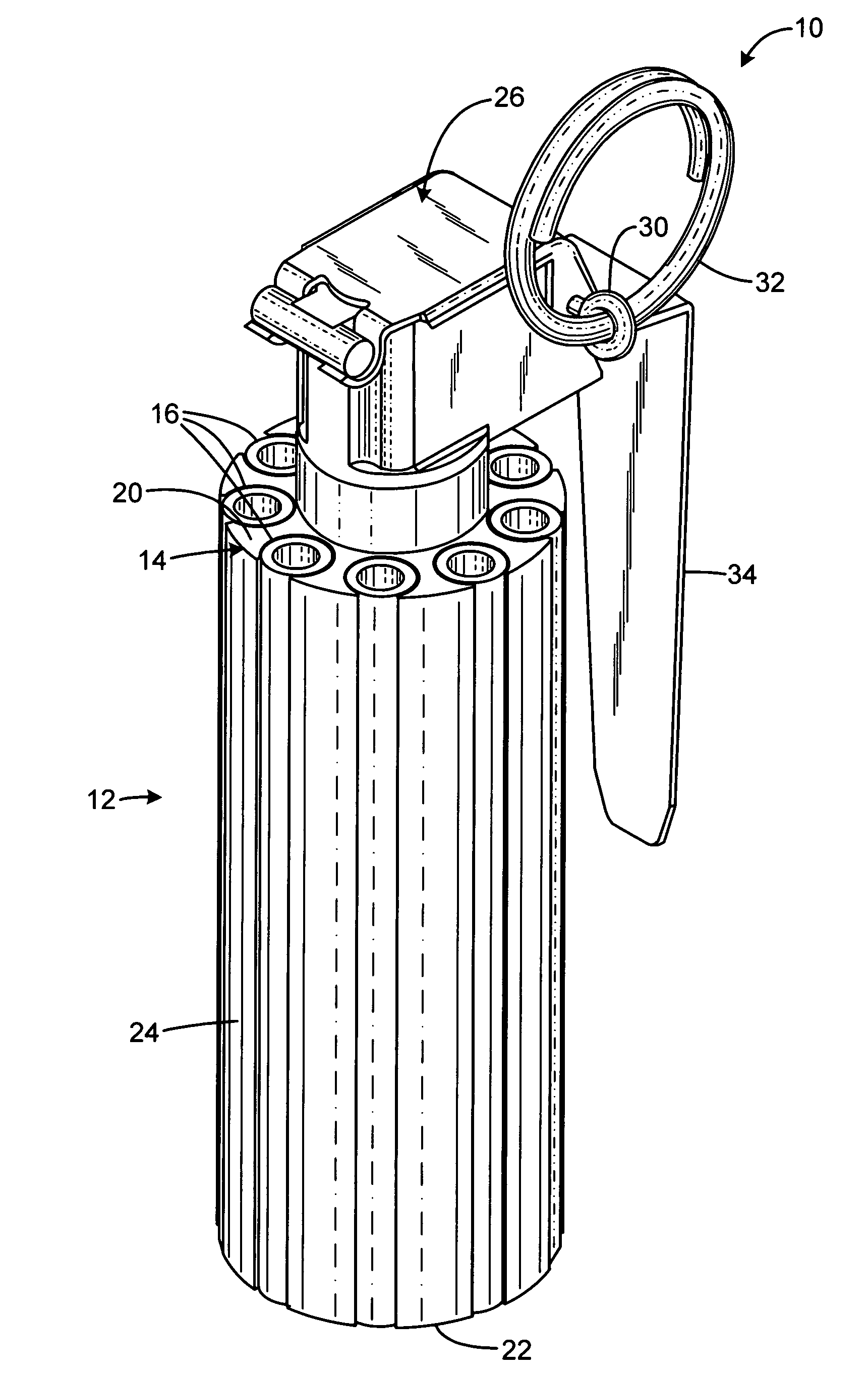

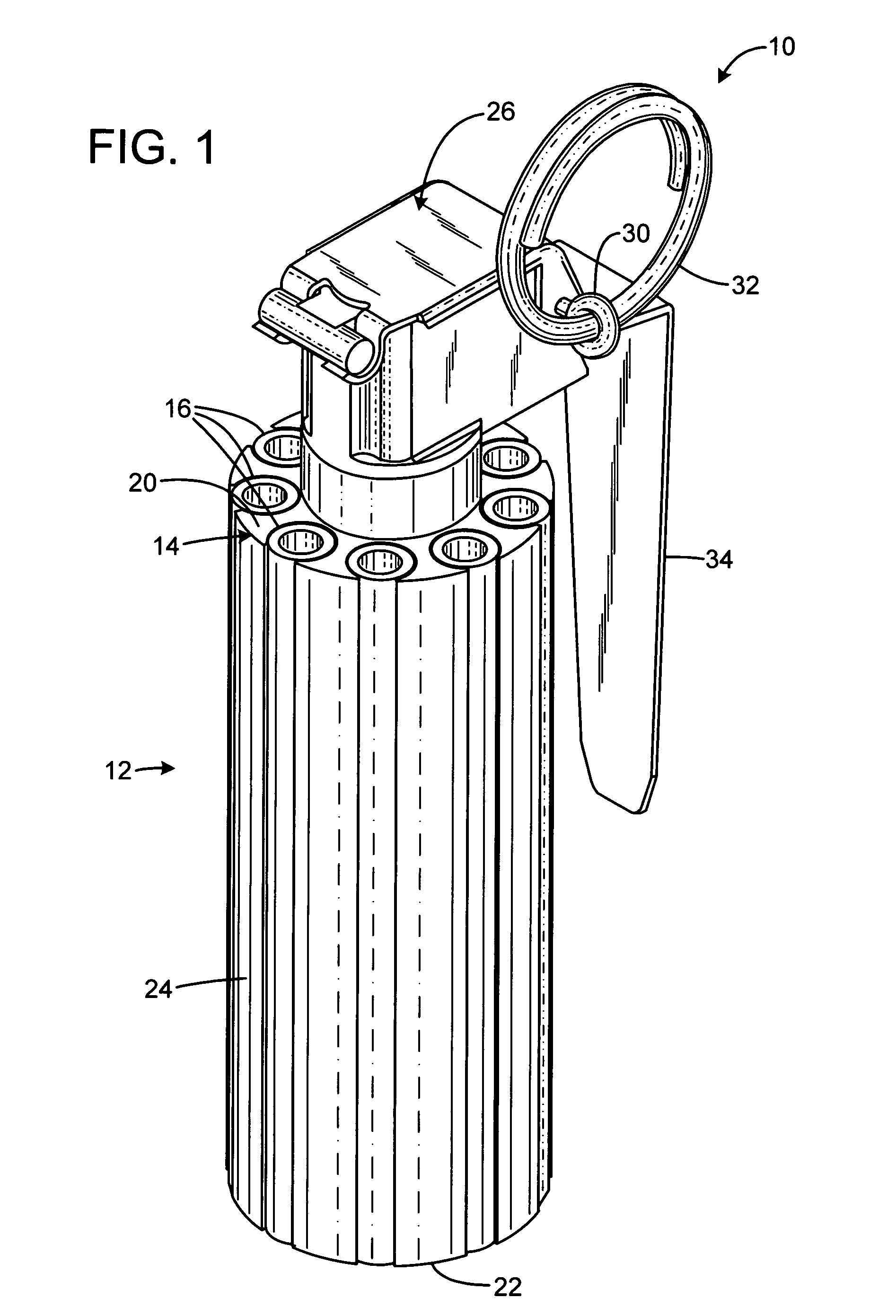

Multiple report stun grenade

The present invention overcomes the limitations of the prior art by providing a stun grenade device with an elongated cylindrical body having a cylindrical sidewall and opposed top and bottom end faces. The body includes a delay chamber containing a delay material, and has a number of flash charge chambers each containing a quantity of flash charge material. The body defines a number of ignition passages, each communicating from a respective flash charge chamber to the delay chamber. Each flash charge chamber has at least one exhaust aperture penetrating the top or bottom end face. Each flash charge chamber may be formed in an elongated tubular sleeve inset in a frame of a different material.

Owner:COMBINED SYST

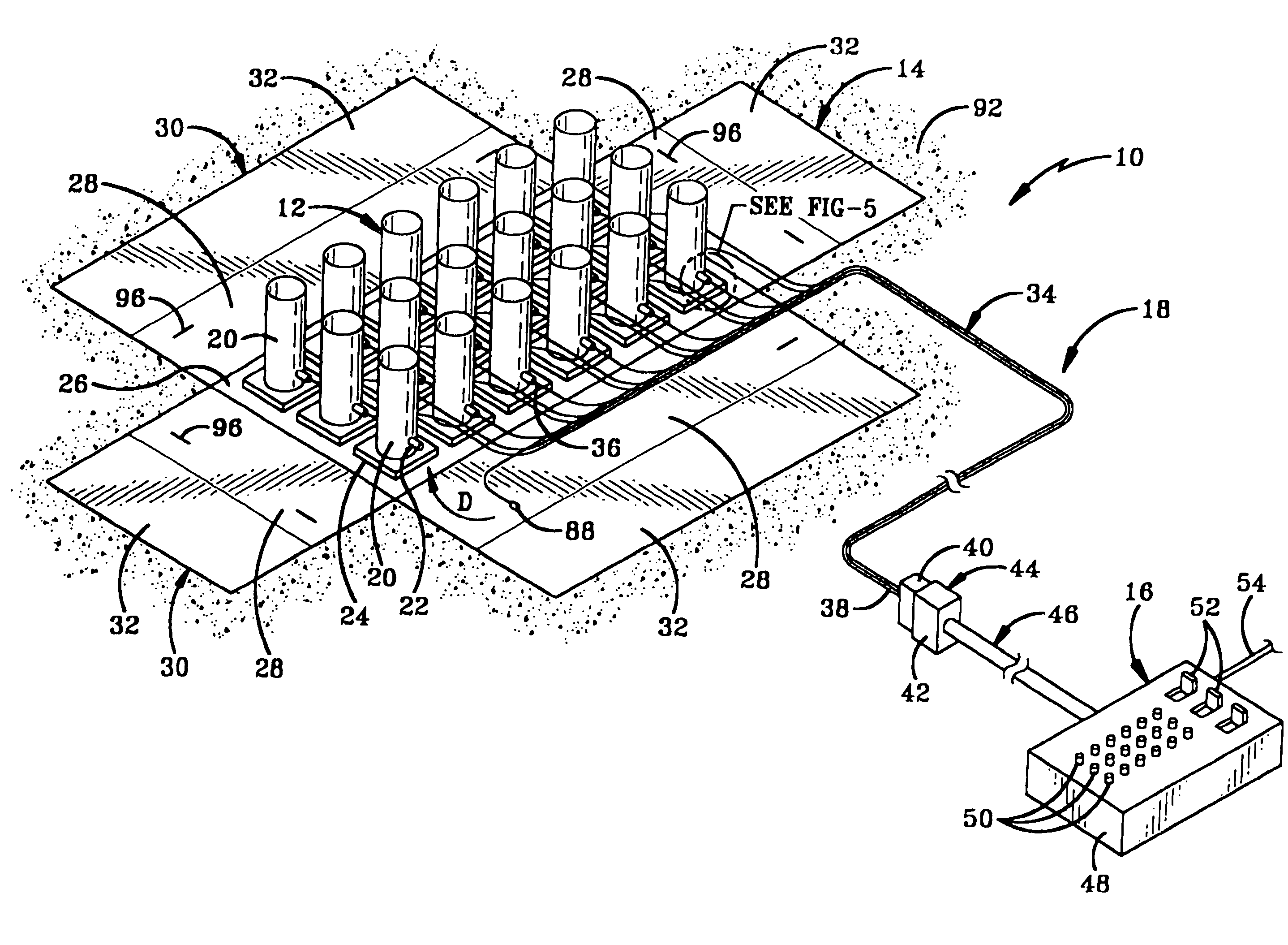

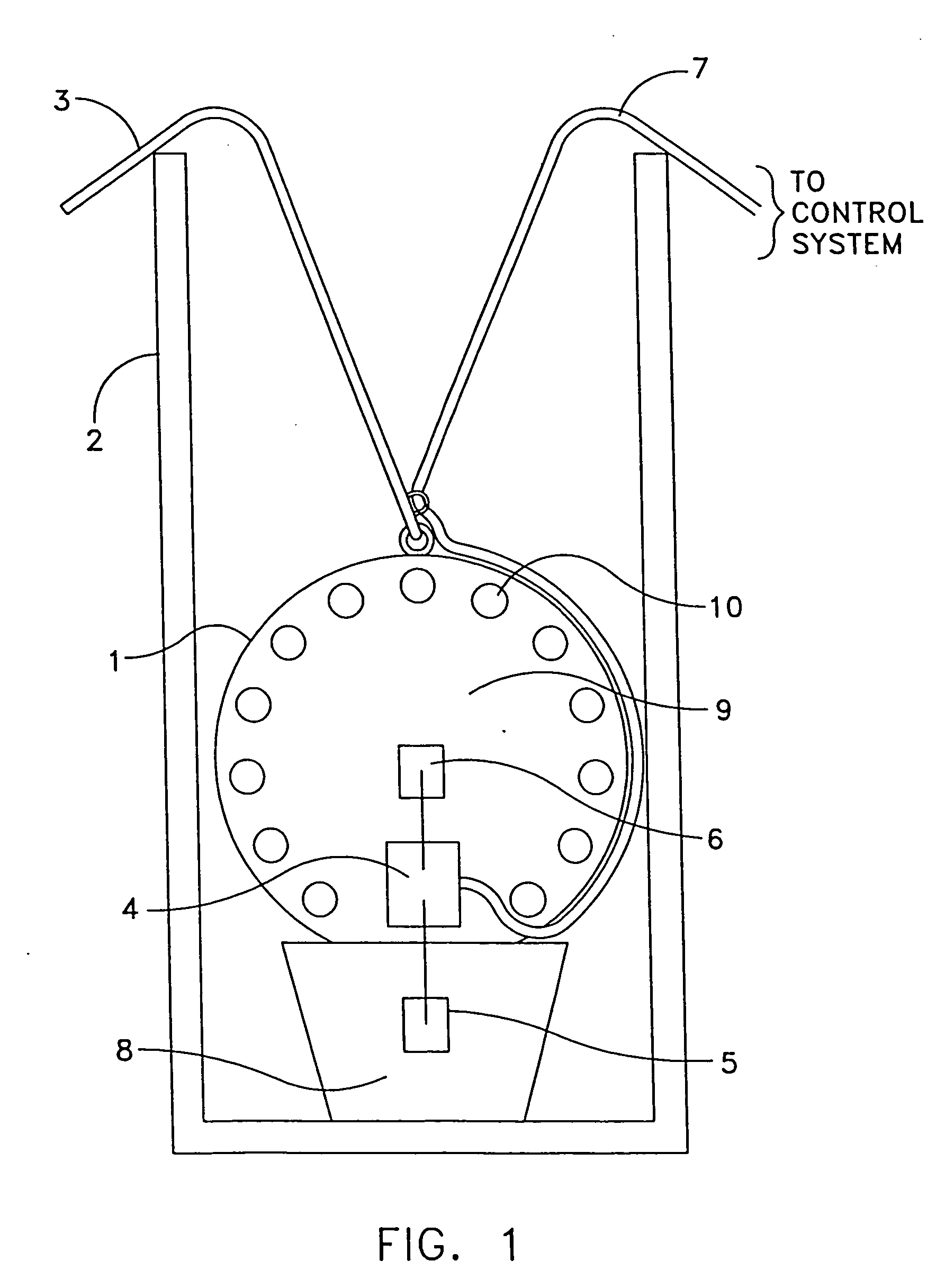

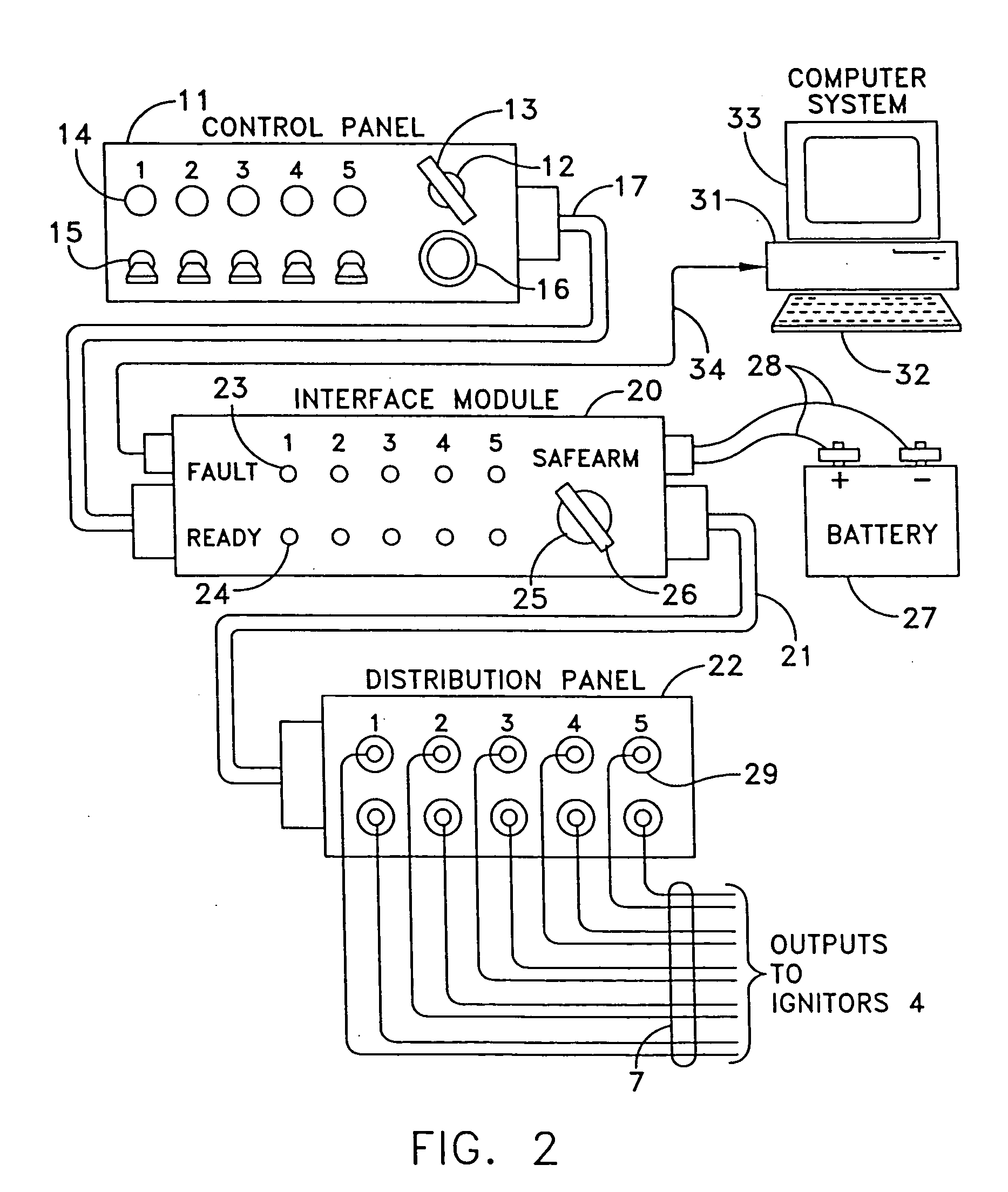

Fireworks ignition system for 1.4 fireworks

An ignition system for 1.4 g or consumer fireworks includes a base to which the fireworks are secured to prevent tipping thereof during shooting. The base is secured to the ground or other surface for stability. Preferably, the base is part of a container which encloses the fireworks in a pre-mounted fashion to protect the fireworks from the elements. Electrical matches or E-matches are used to ignite the fireworks and are controlled by an electrical control at a safe distance from the fireworks during the firing thereof.

Owner:PYROMASTER

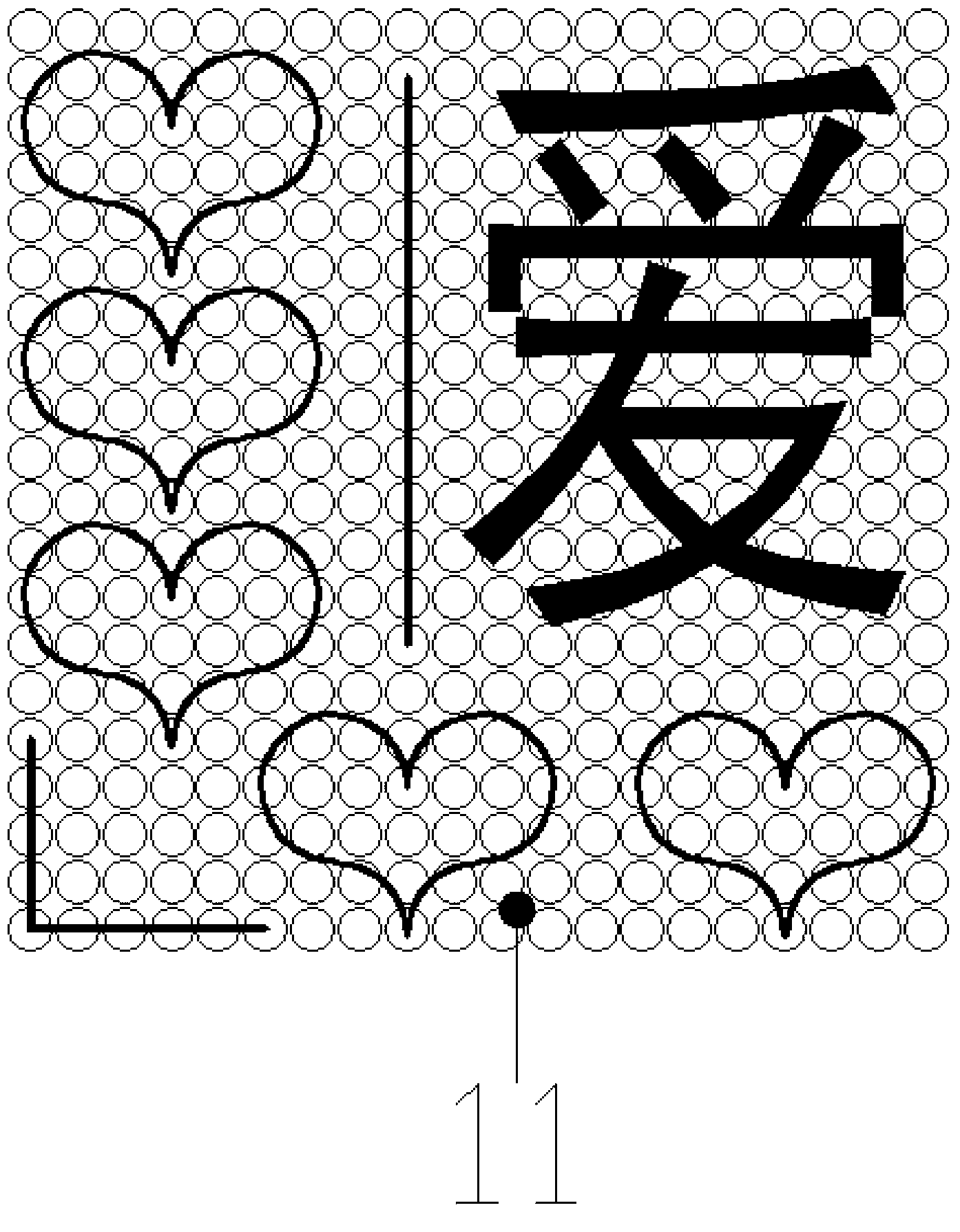

Method for manufacturing preset type display image and text fireworks

ActiveCN103234399AReduce manufacturing costEasy to implementFireworksDot matrixHigh volume manufacturing

The invention discloses a method for manufacturing preset type display image and text fireworks. The method adopts an image and text firework carrier and a preset image and text displaying method. The image and text firework carrier is provided with a lift-off rocket, a dot matrix structure body and image and text displaying fireworks, wherein the lift-off rocket is connected with the dot matrix structure body, and the image and text displaying fireworks are filled in the dot matrix structure body. The preset image and text displaying method adopts a preset image color dot matrix diagram and a method for filling the image and text displaying fireworks, wherein the method for filling the image and text displaying fireworks includes a double-color and inverse-color filling method, a method for filling vacancies of non image regions and other heavy gunpowder isolating blocks and a color programme filling method. The method is simple in implementation, images and texts mostly required by people in daily life are pre-manufactured into corresponding image and text fireworks, users can freely select and optionally combine the fireworks to dress up the sky to be bright and colorful and directly express affection, and the preset type image and text fireworks are suitable for large-scale production, are low in manufacture cost and are suitable for wide application and popularization.

Owner:SUZHOU ZZH INTPROP SERVICES

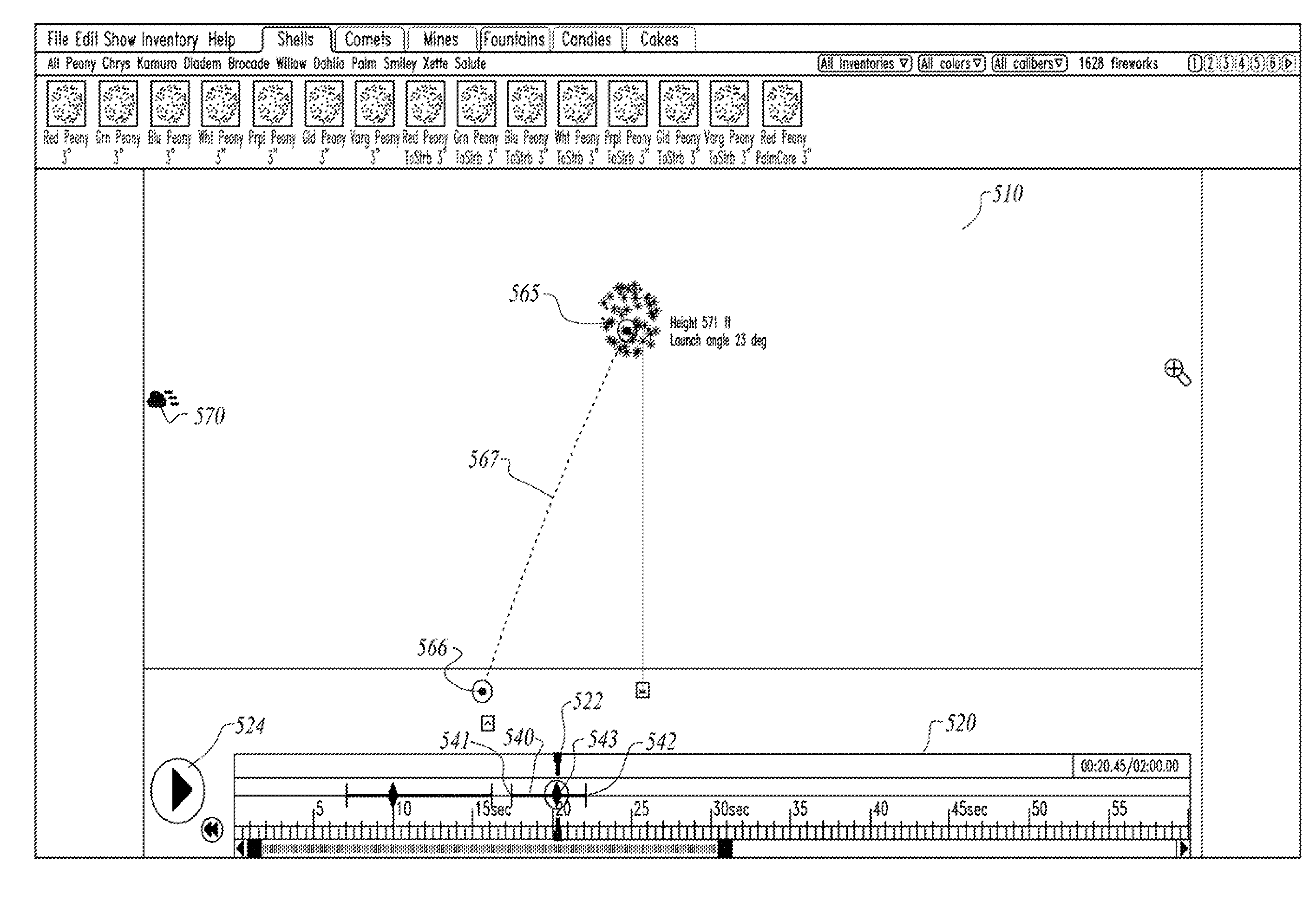

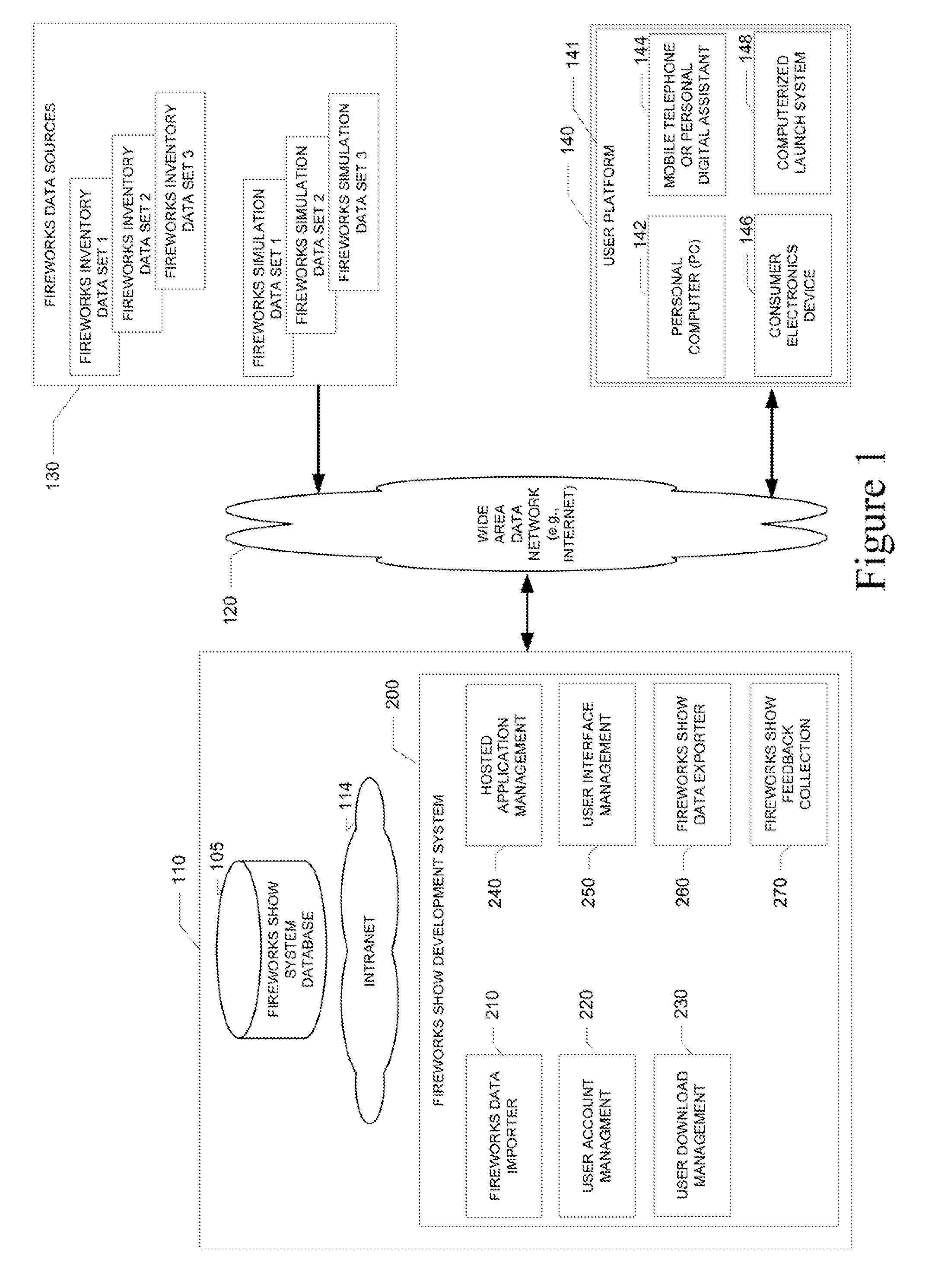

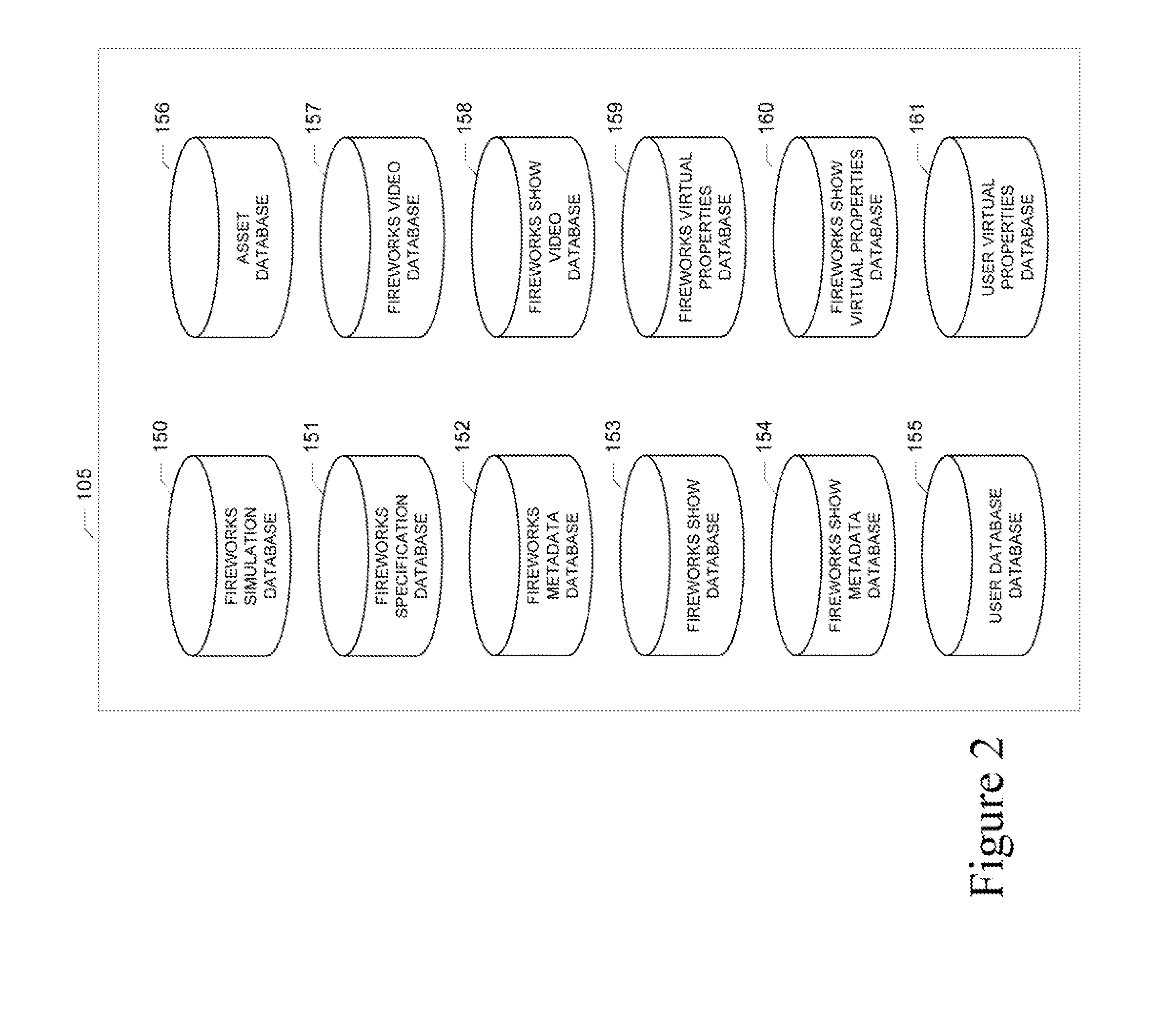

System and method for designing and simulating a fireworks show

A system and method for enabling computer users to design and simulate a fireworks show is disclosed. A particular embodiment includes storing firework data in a database, the firework data including firework specification data including parameters corresponding to attributes of a particular firework; using a processor to automatically construct in a user interface a visual firework simulation from the firework data, the visual firework simulation including visual elements that are also part of the user interface, the visual firework simulation depicting a sky field representing a location of a fireworks show and the spatial location of visual elements therein, the visual elements including fireworks, launch positions, and trajectories being simulated by the visual firework using the user interface to directly manipulate the visual elements of the visual firework simulation, including dragging the visual elements in the sky field of the visual firework simulation: using the processor to automatically adjust the firework data according to the user's direct manipulation of the visual elements; and using the processor to automatically update the visual firework simulation and the visual elements in real time in response to the user's direct manipulation of the visual elements and the adjustment of the firework data.

Owner:HARVEY WILLIAM

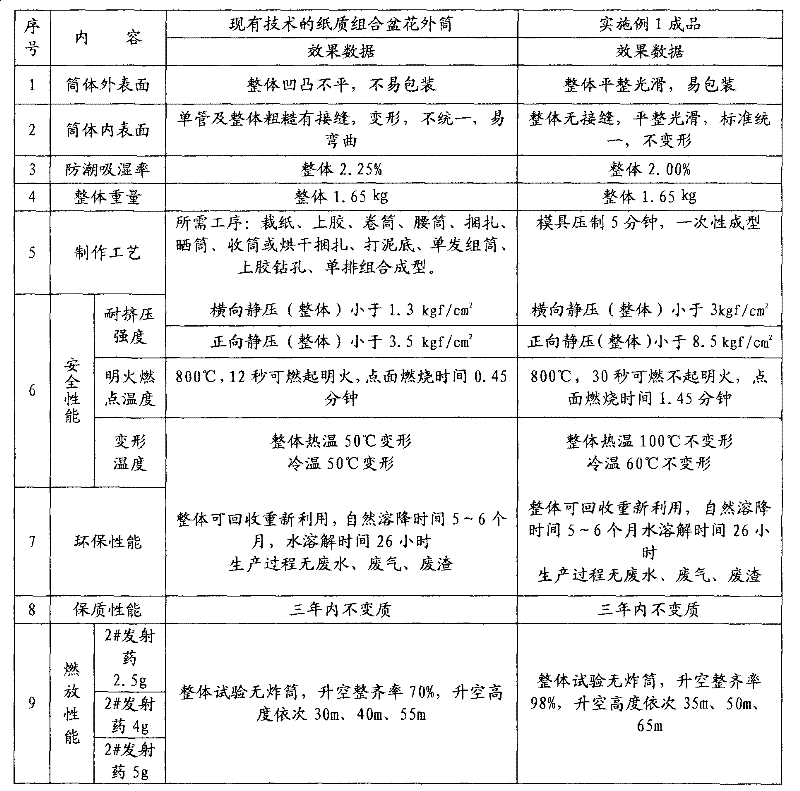

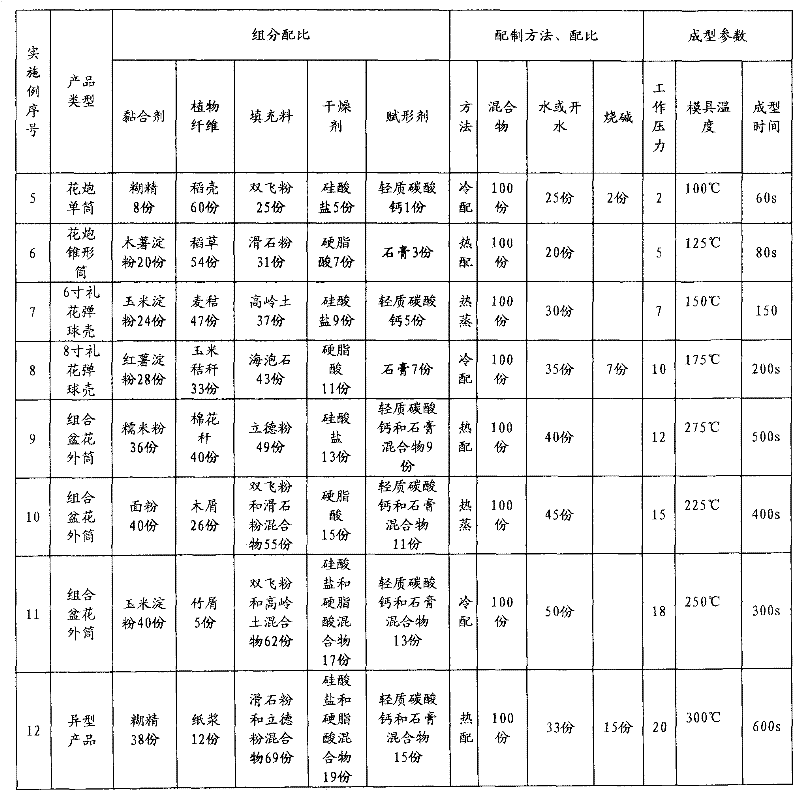

Pressure forming firework external cylinder and fireworks display marble casing and manufacturing method thereof

ActiveCN101377395BImprove discharge qualityChange shape and sizeWood working apparatusDomestic articlesCompression moldingFiber

The invention discloses a compression molding fireworks outer cylinder, a marble shell and a preparation method thereof, comprising the components of plant fiber, binder, filler, excipient and dryer. The fireworks outer cylinder and marble shell is made after the components are prepared and processed compression molding. The lead-through is just needed to be installed by the fireworks manufacturers, and the fireworks cylinder can be made by using the technical proposal. The process is simple, the procedures are few and the production efficiency is high. The utilization rate of the raw materials can be reached to 100 percent. The plastics can be totally banished and the effect of environmental protection is good. The products have standard specification and good pressure resistance. The distortion and bending phenomena can not be generated, and the display quality of the fireworks is greatly improved which ensures the safety. The shape, size and intensity of the fireworks cylinder and marble shell can be flexibly and conveniently changed as required. The preparation method also can be used for the production and development of the special shaped shell or package in the fireworks industry.

Owner:LIUYANG YIHELONG FIREWORKS GRP +1

Automatic pyrotechnic composition charging system

InactiveCN102620610AImprove securityIncrease productivityFireworksProduction linePyrotechnic composition

The invention discloses an automatic pyrotechnic composition charging system. Through reasonable layout of the procedures of the pyrotechnic composition charging process according to the characteristics of automation and mechanization, and in combination with the manufacturing practice of initiators and pyrotechnics, the design method of the automatic pyrotechnic composition charging system is explored out, the utility system composition with sound functions is planned, a series of single procedure equipment and test method and equipment suitable for automatic pyrotechnic composition charging process are developed, and the single procedure mechanical equipment is assembled to form an automatic flow production line. The burdensome manual work is replaced by automatic production, so as to greatly improve the safety and efficiency of fireworks production, and highly promote the updating and upgrading of the traditional fireworks industry.

Owner:LIUYANG HAILONG FIREWORKS MFG

Precision pyrotechnic display system and method having increased safety and timing accuracy

InactiveUS20060086277A1Improve accuracyImprove securityAmmunition projectilesFiring/trigger mechanismsDisplay deviceFireworks

Owner:BOSSARTE GEORGE +1

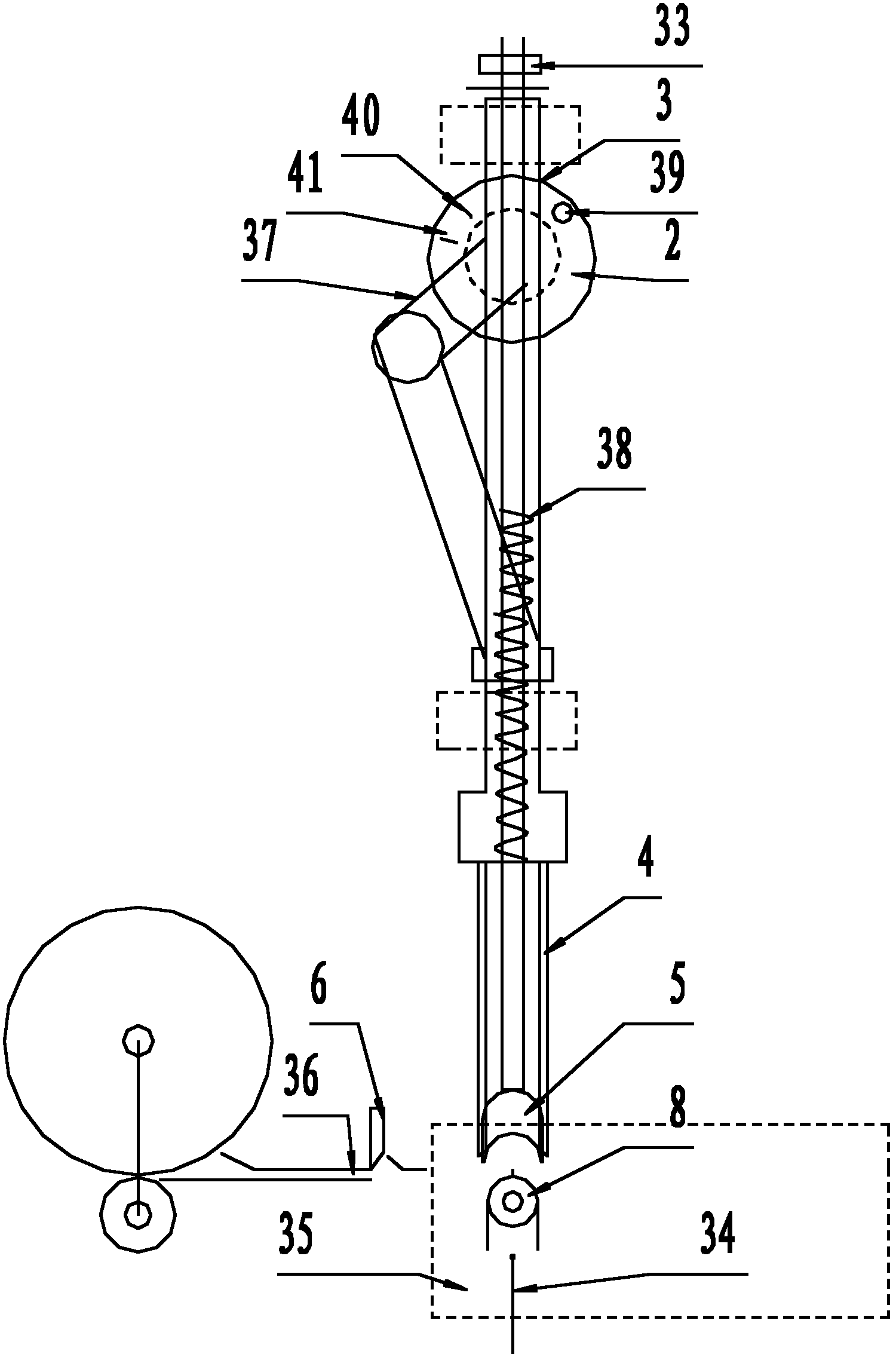

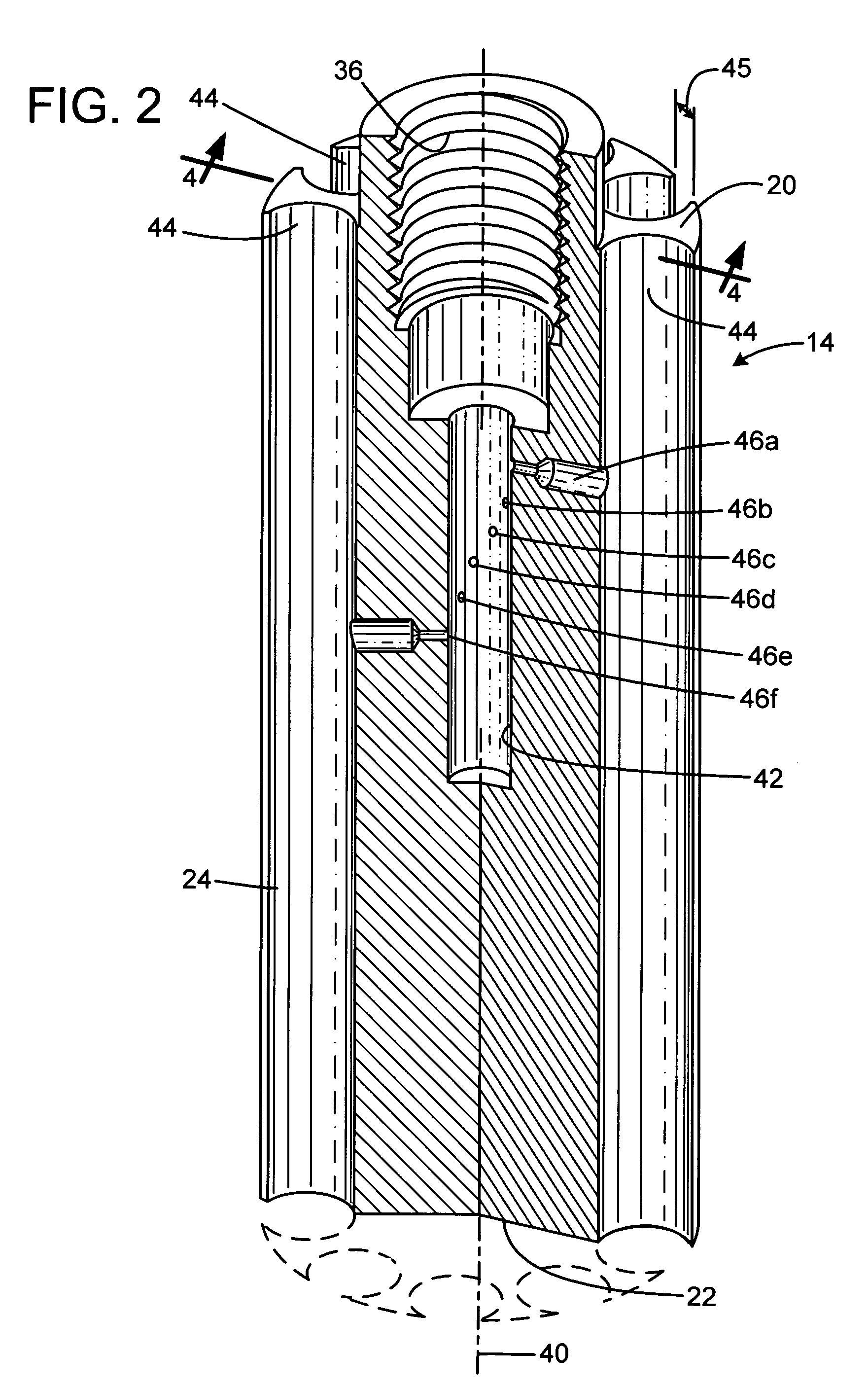

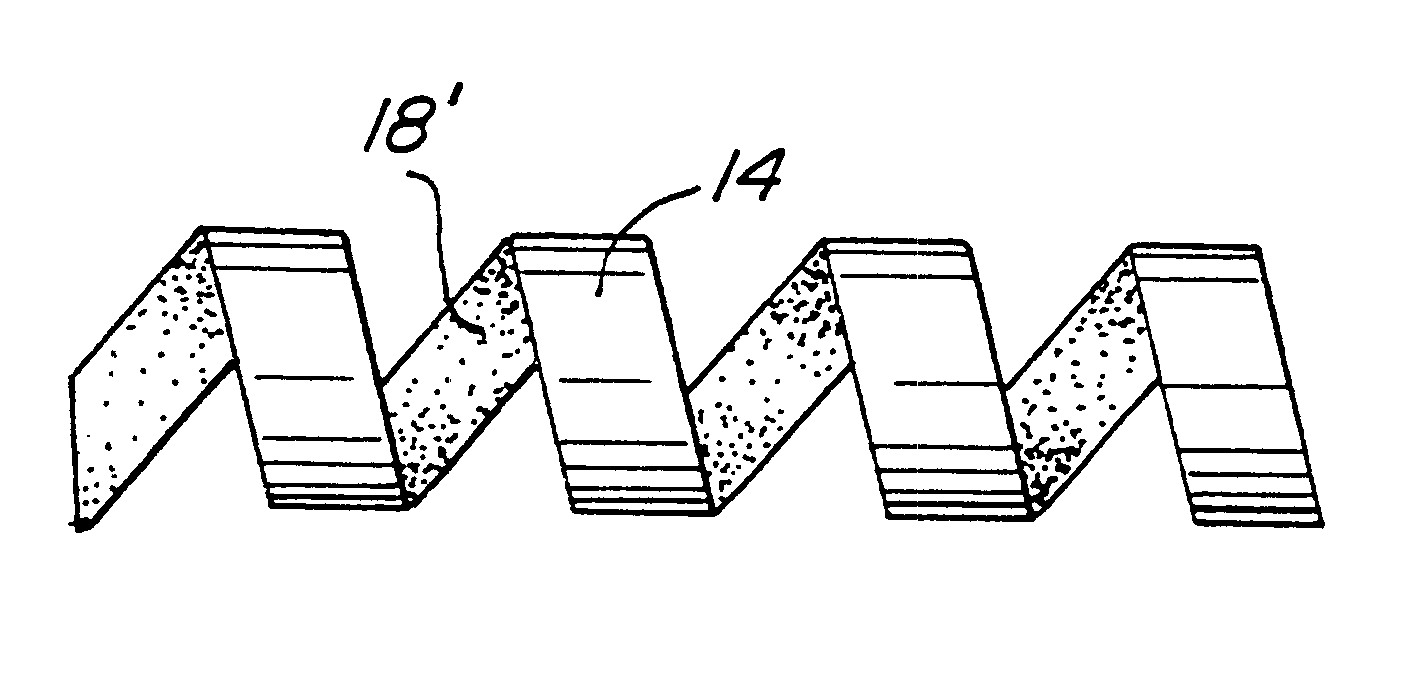

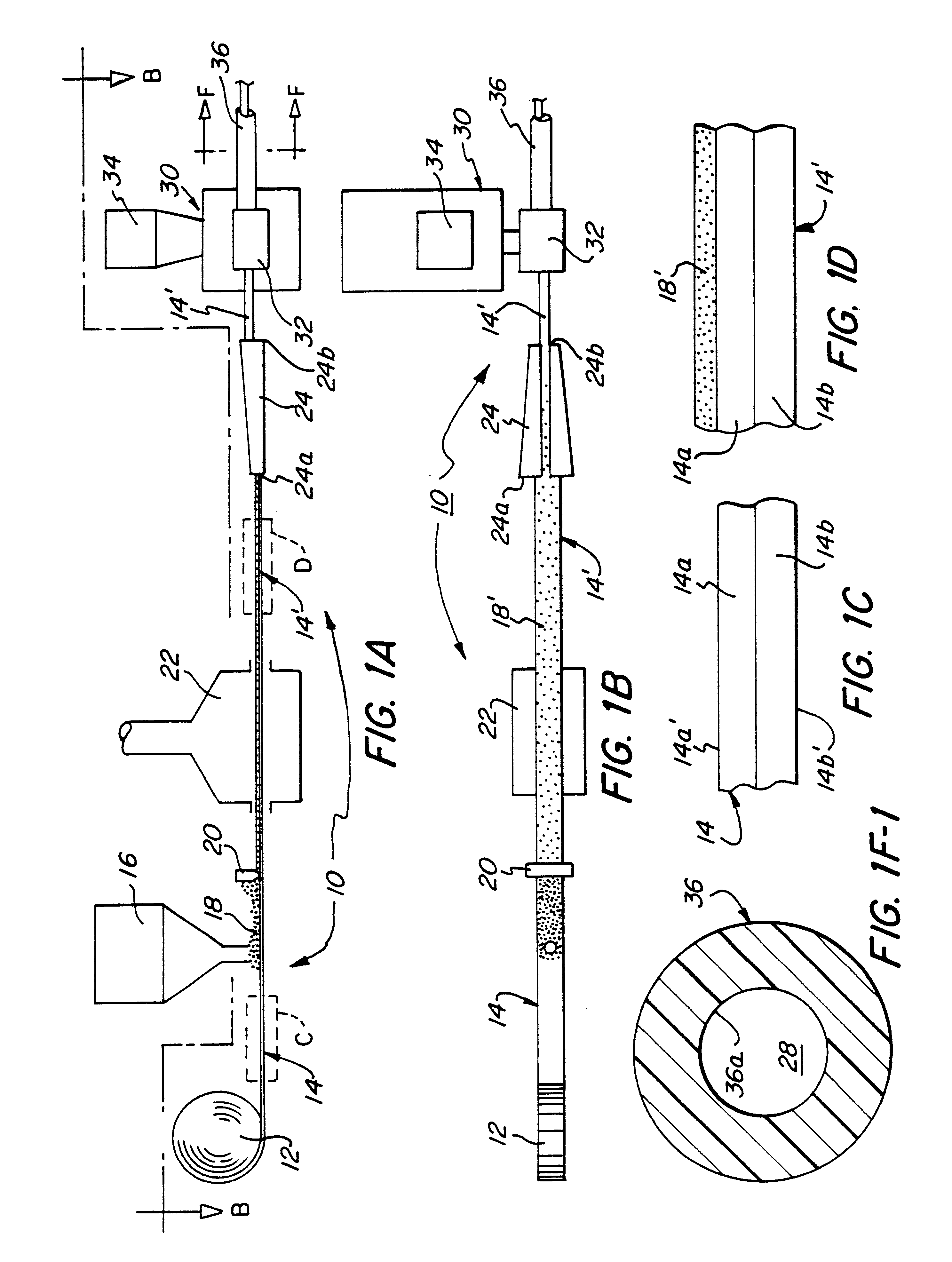

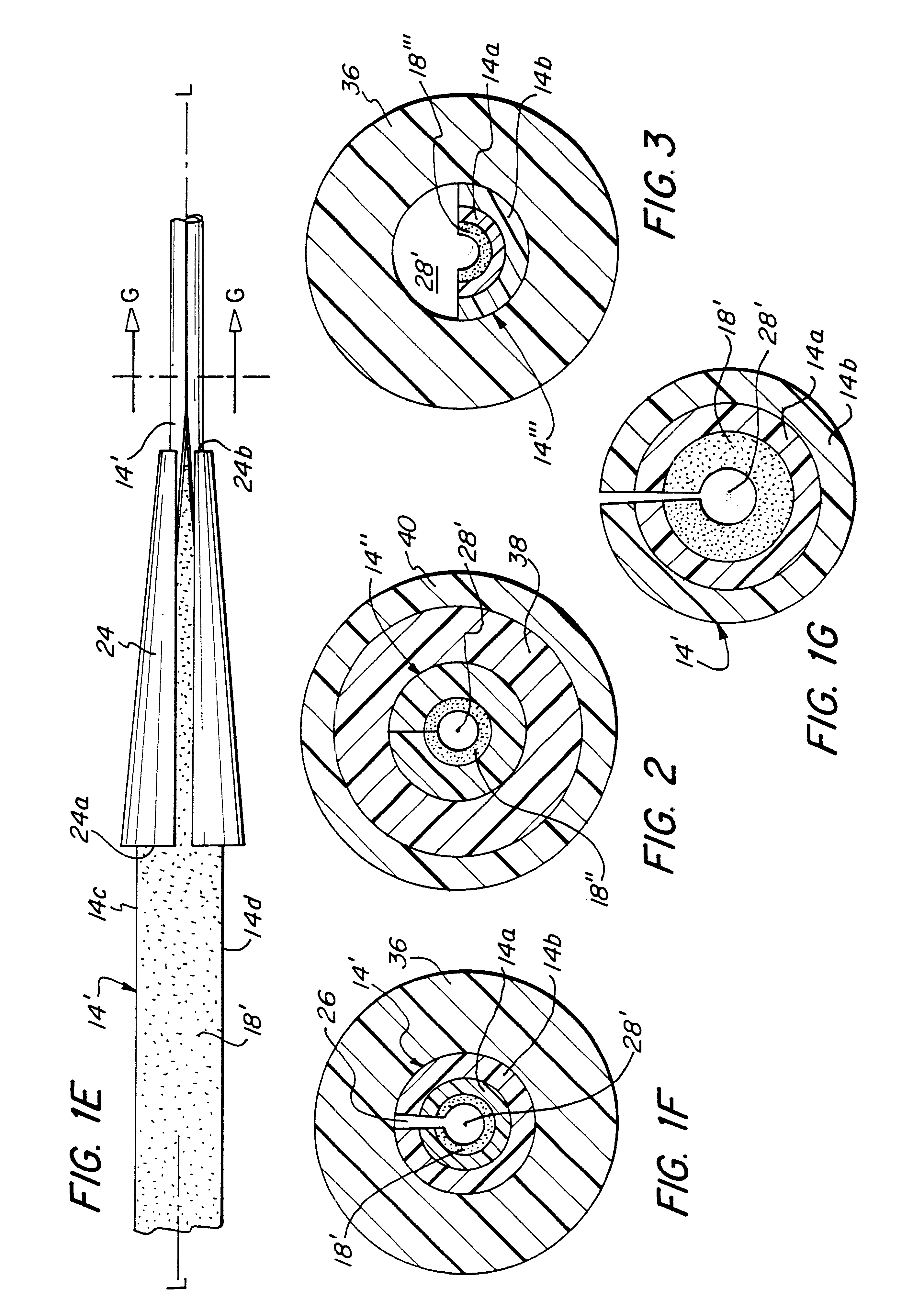

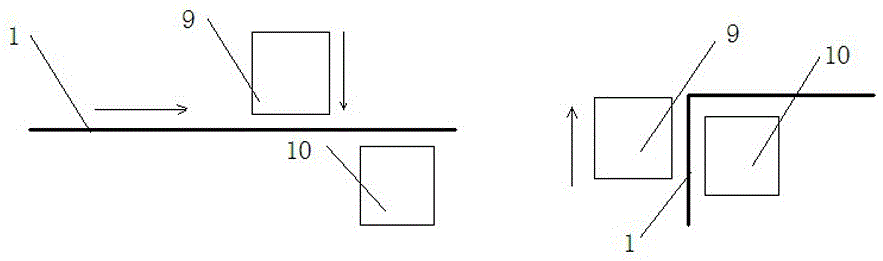

Method of making a signal transmission fuse

InactiveUS6347566B1Avoid less flexibilityEasy loadingBlasting cartridgesExplosive working-up apparatusEngineeringMechanical engineering

A signal transmission fuse is made of a tube (36) which encases a support tape (14) having a reactive coating (18') which is adhered to one side of the tape by a binder. A method of making the signal transmission fuse includes depositing on the support tape (14) a reactive paint (18) including a binder, which paint dries to form a reactive coating (18'). The coated support tape (14') is then folded, i.e., formed into a channel configuration, to provide an inner concave side of the tape on which the reactive coating (18') has been disposed. The coated support tape is then enclosed, e.g., within an extruded plastic tube (36). One side of the support tape may be made of a first material (14a) to which the reactive coating adheres, and a second side may be made of a second material (14b) which bonds or adheres to the inner surface (36a) of the plastic tube (36) enclosing the coated support tape (14'). The binder causes even high loadings of the reactive coating (18') to adhere to the coated support tape (14') to prevent reactive material migration. The support tape also shields the reactive material from the hot, freshly extruded surrounding plastic tube (36) during manufacture.

Owner:DYNO NOBEL INC

Firework structure

The invention discloses a firework structure comprising an outer box in which ten rows of firework setoff barrels are arranged. A firework main ignition lead is arranged outside the outer box. Each firework setoff barrel consists of an outer barrel and an inner barrel arranged inside the outer barrel. The bottom of the outer barrels is provided with bottom mud, a black powder layer is arranged on the bottom mud, one end of the black powder layer is connected to and arranged at a setoff barrel ignition lead, and the other end is provided with a fire transfer lead. A perforated paper board is arranged on the black powder layer. The inner barrels are arranged on the perforated paper board. A tail powder layer is arranged at the bottom of the inner barrels and above the perforated paper board. A mud isolation layer is arranged on the tail powder layer. Exploding powder is arranged inside the inner barrels and above the mud isolation layer. Multiple bright beads are uniformly arranged in the exploding powder. A fire passing lead is vertically arranged inside each inner barrel, and the fire passing lead is connected with the exploding powder and the black powder layer. The firework structure has the advantages of safe setoff and reasonable arrangement.

Owner:HUNAN FUXING FIREWORKS CO LTD

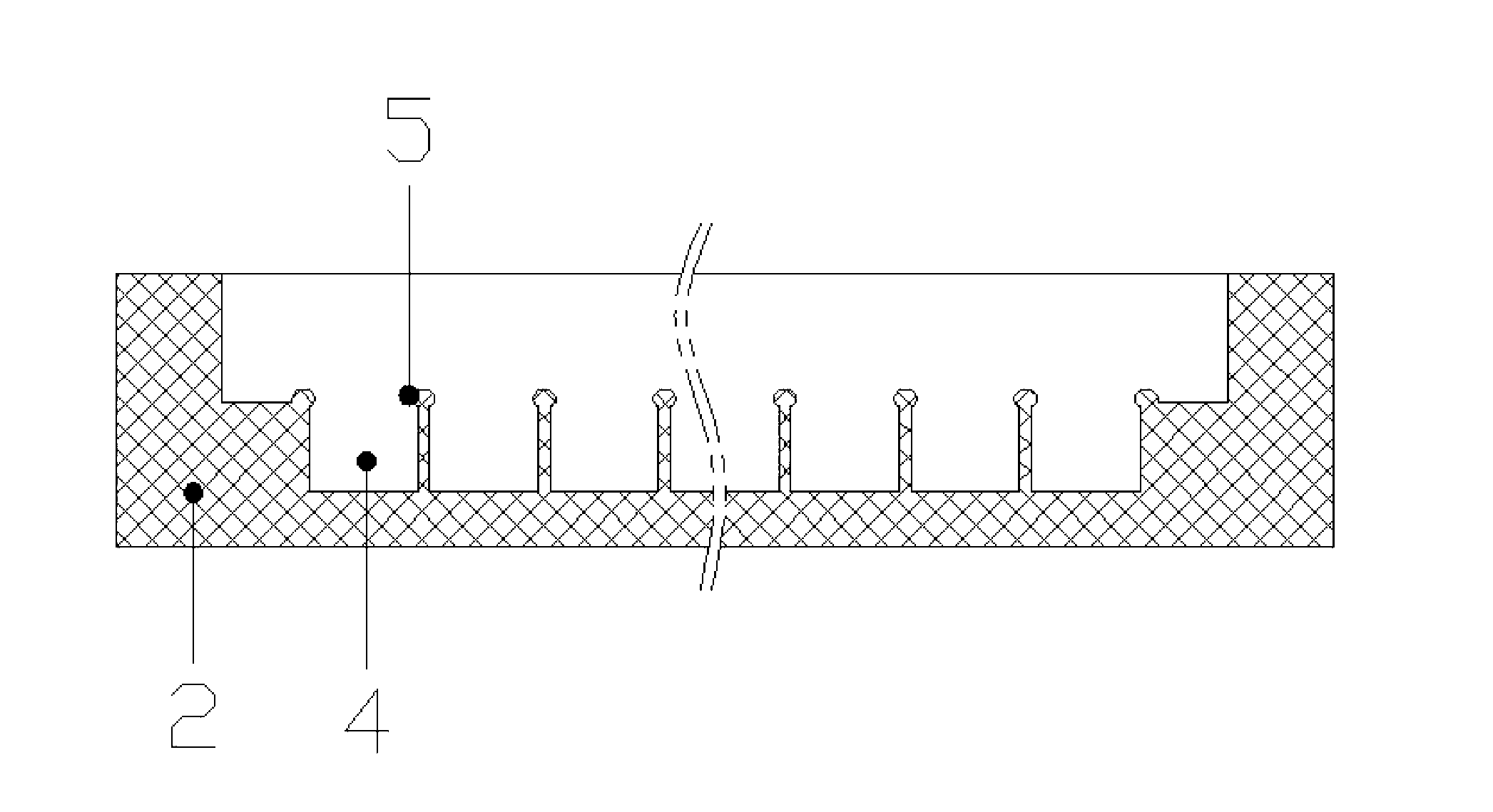

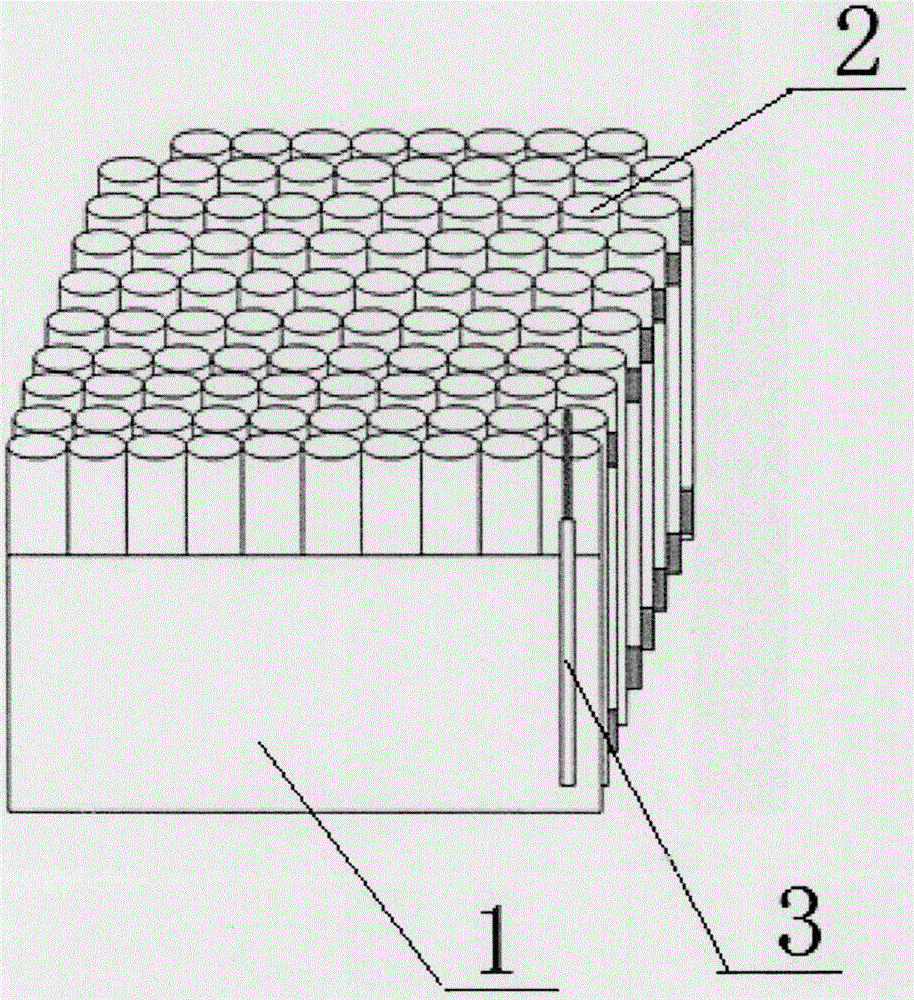

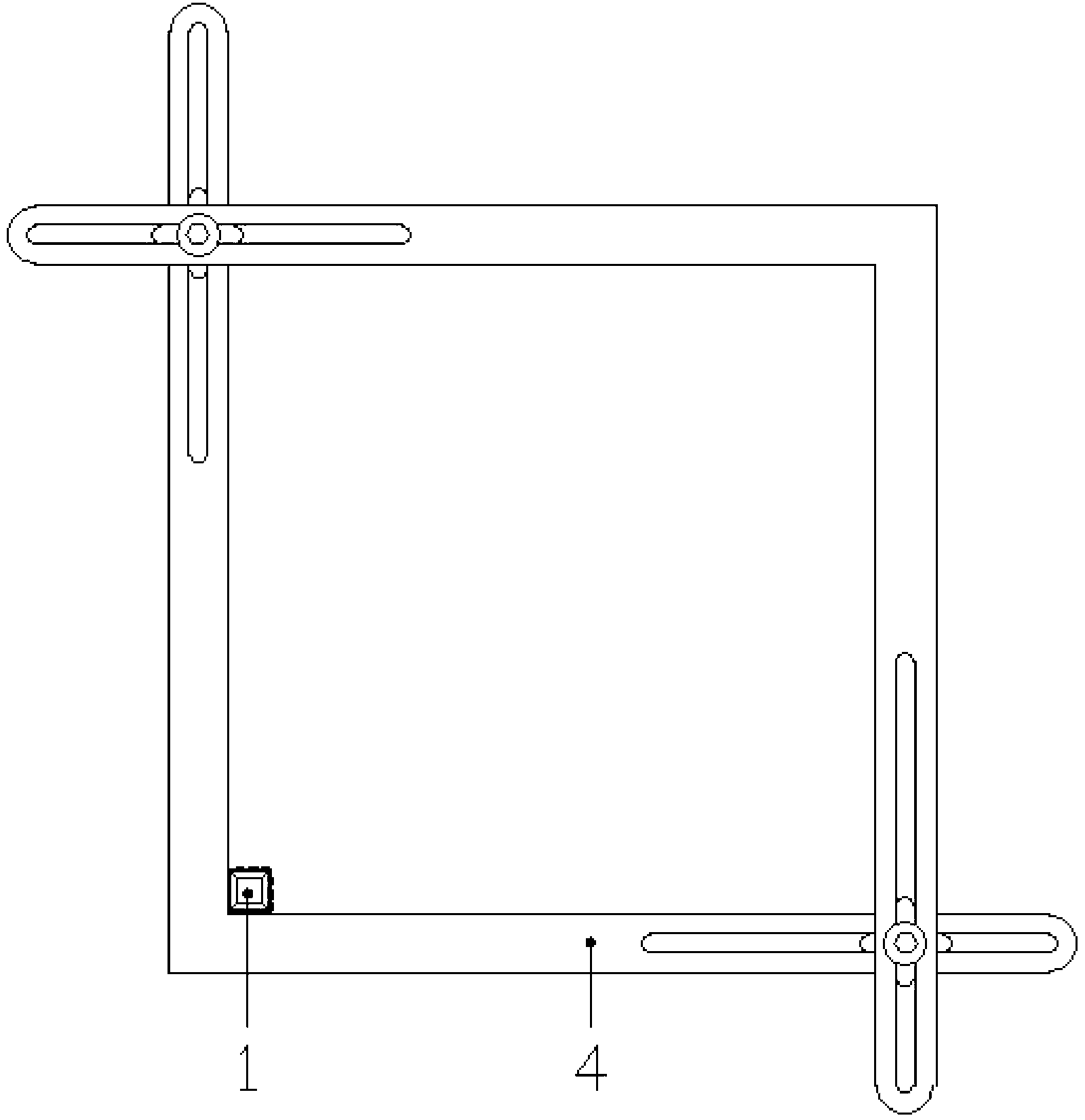

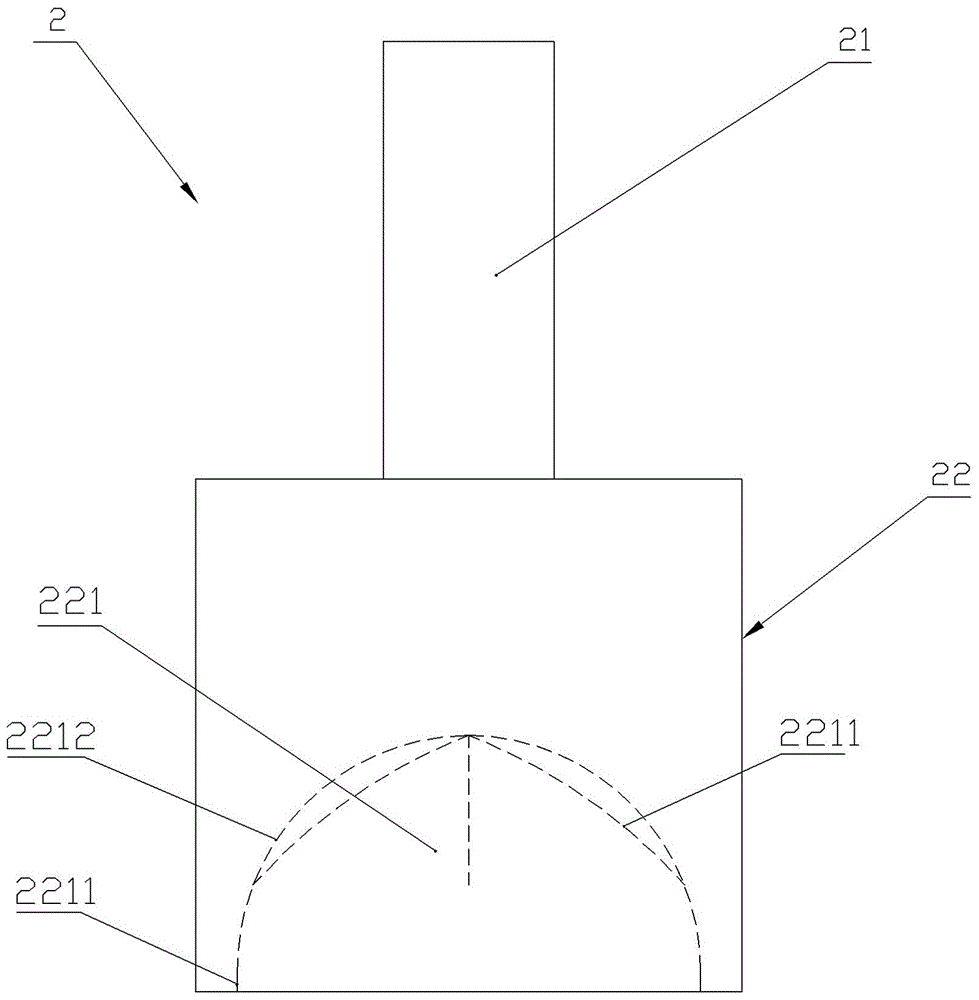

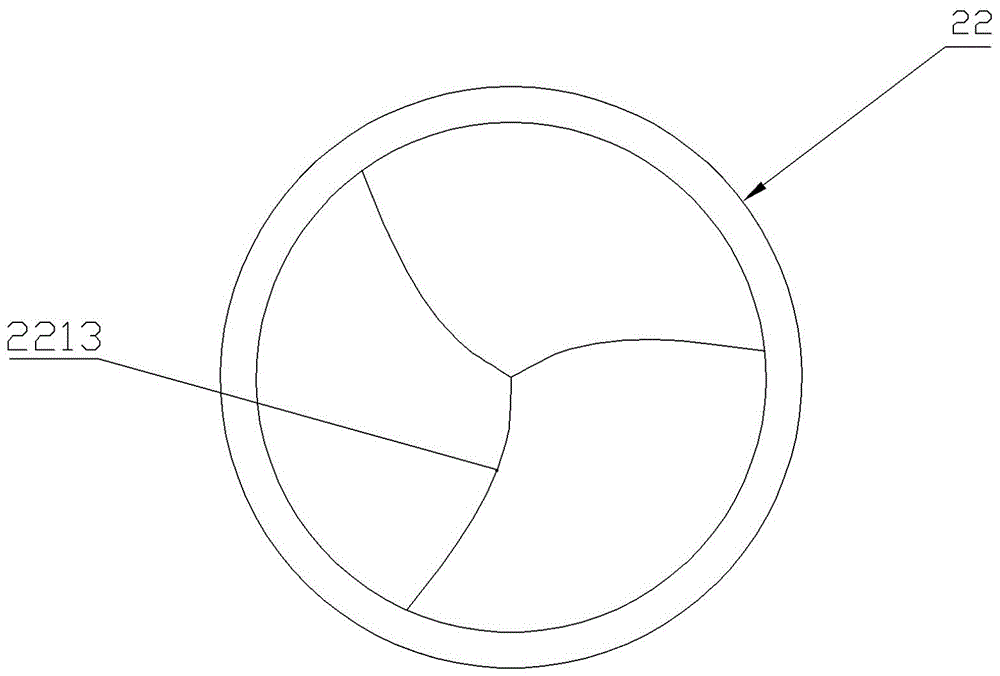

Automatic rowing device of combined fireworks

The invention discloses an automatic rowing device of combined fireworks. The device comprises a discharging hopper which stores a plurality of firework cylinders, a first discharging control mechanism which enables the firework cylinders to drop in a one-by-one mode is arranged in an outlet in the discharging hopper, a material receiving disc which bears the dropped firework cylinders is arranged below the discharging hopper, a firework cylinder positioning mechanism is arranged on the material receiving disc, bears the dropped firework cylinders, and enables the dropped firework cylinders to be positioned according to the dropping position, the material receiving disc is provided with a displacement driving mechanism which drives the material receiving disc to conduct linear reciprocating translation, and all the working mechanisms conduct coordination work according to the working procedure under the action of a control system. The device has the advantages that cylinder rowing is convenient, accurate and flexible, and is not limited by the specifications of the firework cylinders, the cylinder rowing requirement of up-right paper cylinders with all the different gaps and specifications can be met, the device is stable in working, manual intervention is not required, and the production efficiency is high.

Owner:浏阳市海立达机械科技有限公司

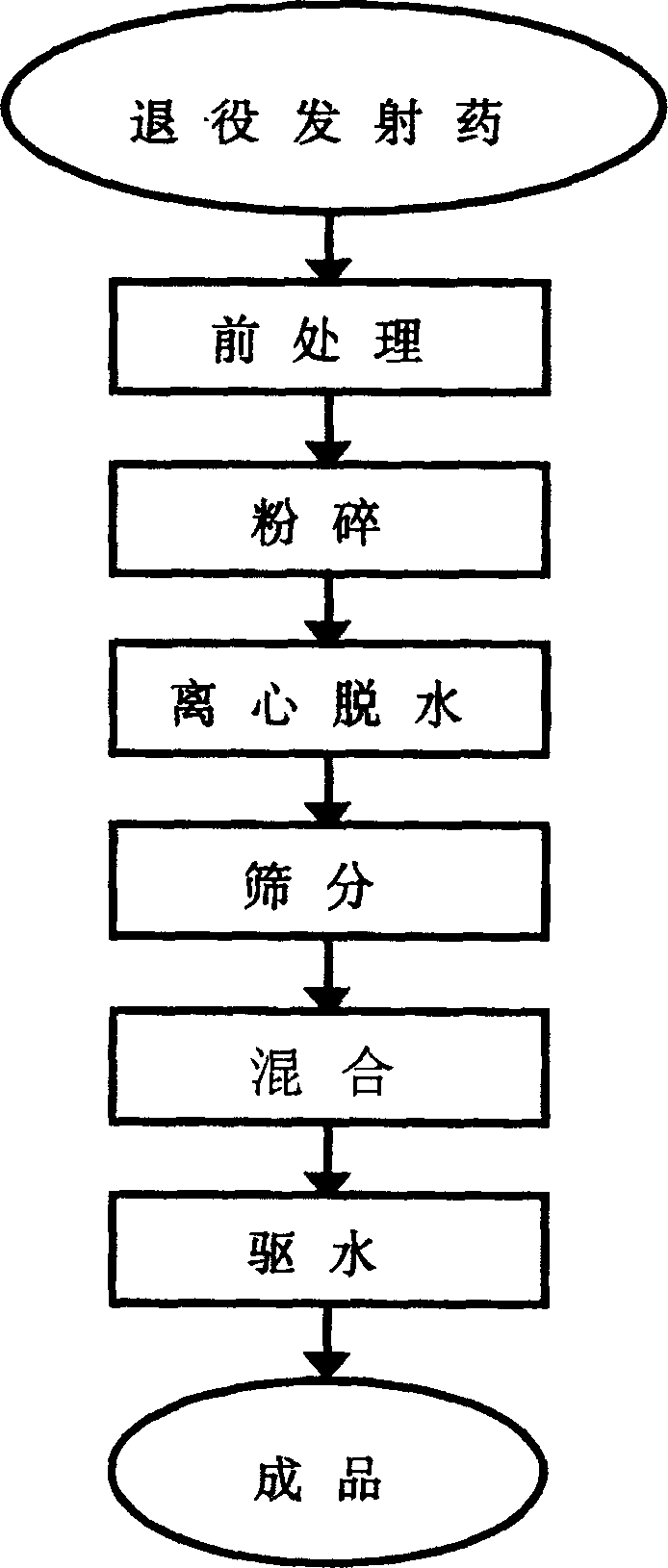

Smokeless gun propellant for fireworks and its prepn

InactiveCN1526687AReduce generationReduce pollutionExplosive working-up apparatusInorganic oxygen-halogen salt explosive compositionsFireworksOxidizing agent

The smokeless gun propellant for fireworks consists of retired gunpowder 70-90 wt%, oxidant 5-10 wt% and inflammable 1-5 wt%. The oxidant is nitrate, chlorate or perchlorate; and the inflammable is carbon powder, aluminum powder, magnesium powder or aluminum-magnesium alloy powder. The preparation process includes crushing, dewatering, mixing, dispelling water and drying. The smokeless gun propellant is used in ground fireworks product to replace black powder as propellant agent, and this can reduce smoke produced during firing fireworks greatly, reduce dust pollution to environment and lower production cost. The present invention paves one way of utilizing retired gun powder resource in large scale.

Owner:中国北方化学工业总公司

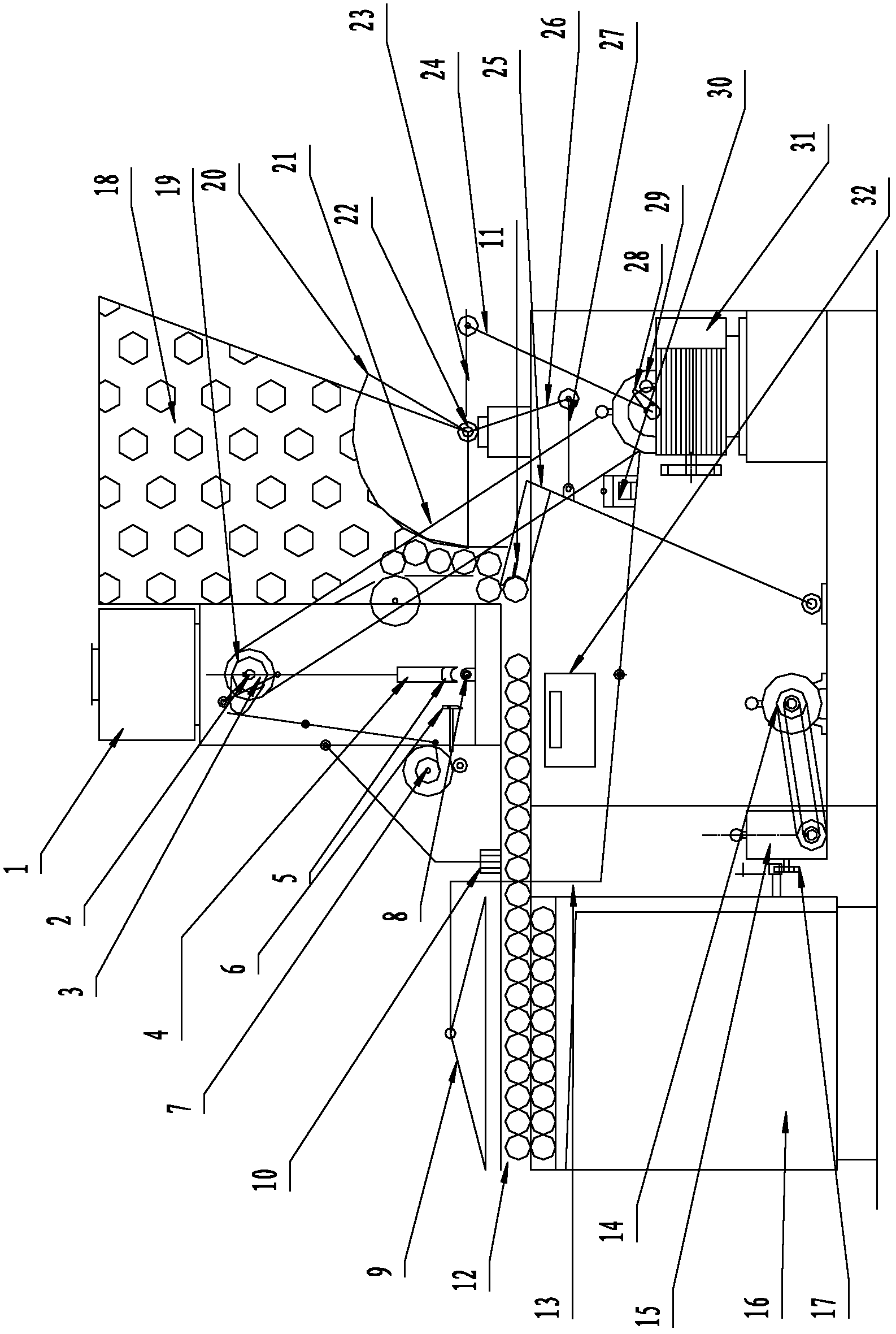

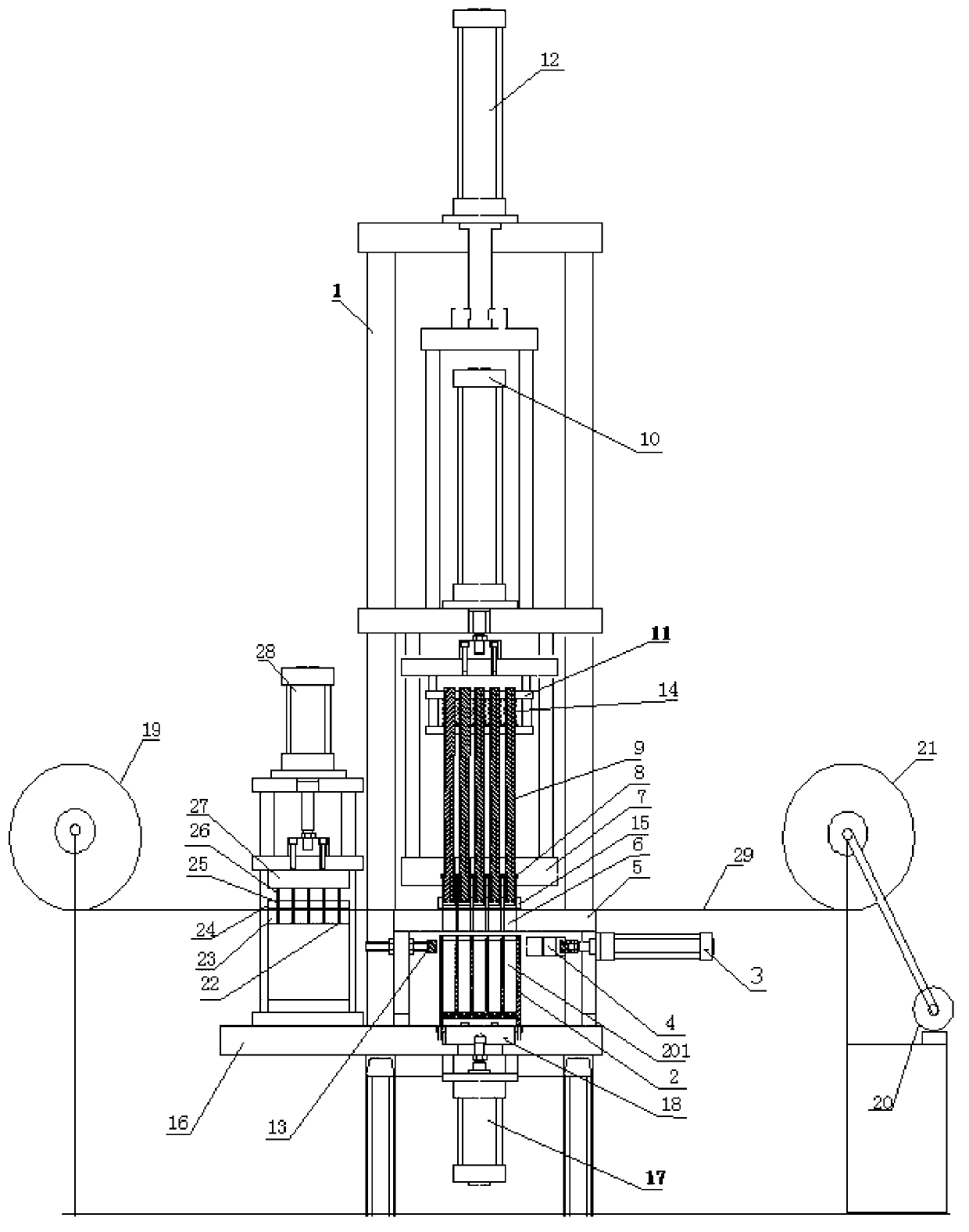

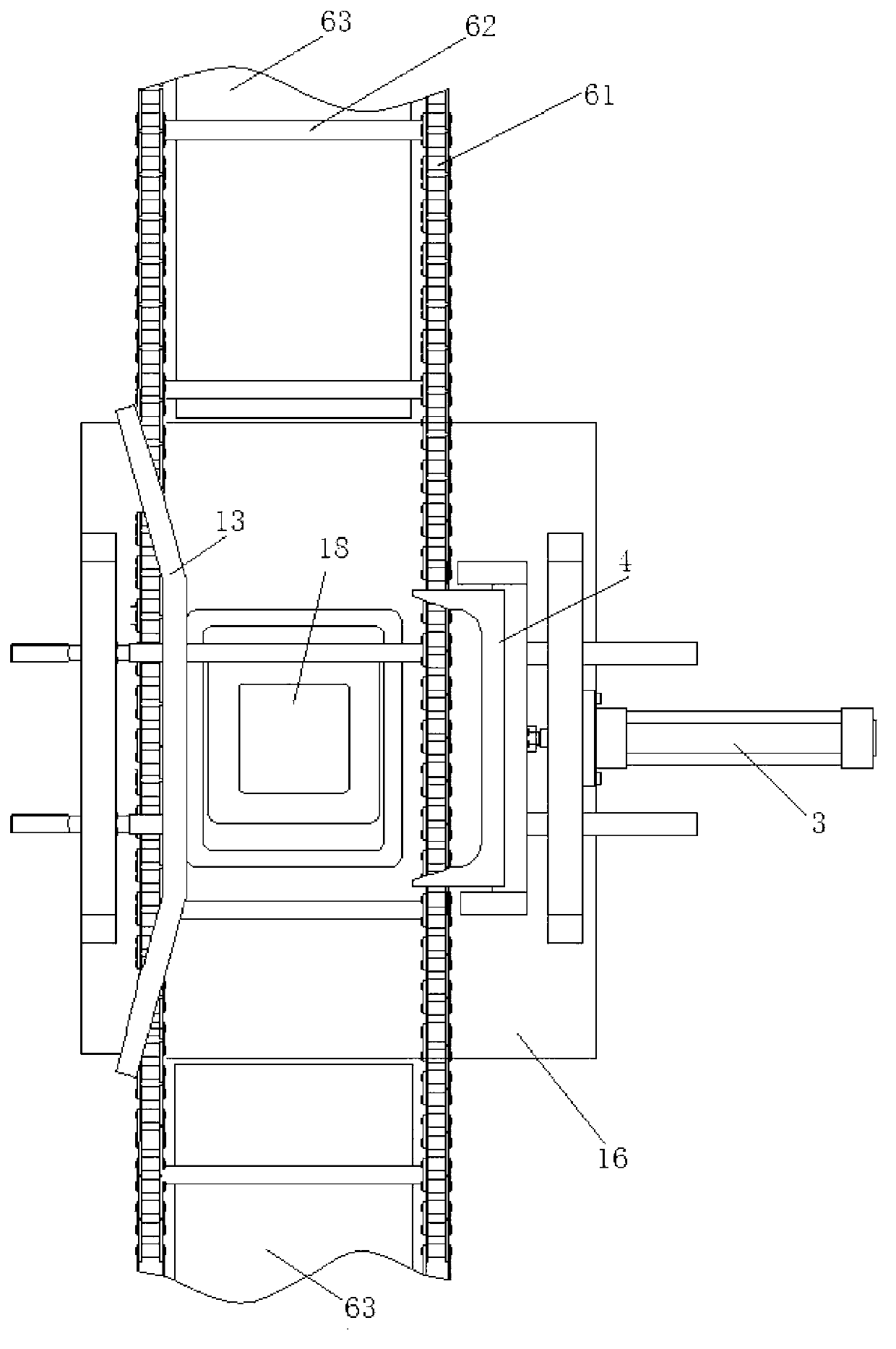

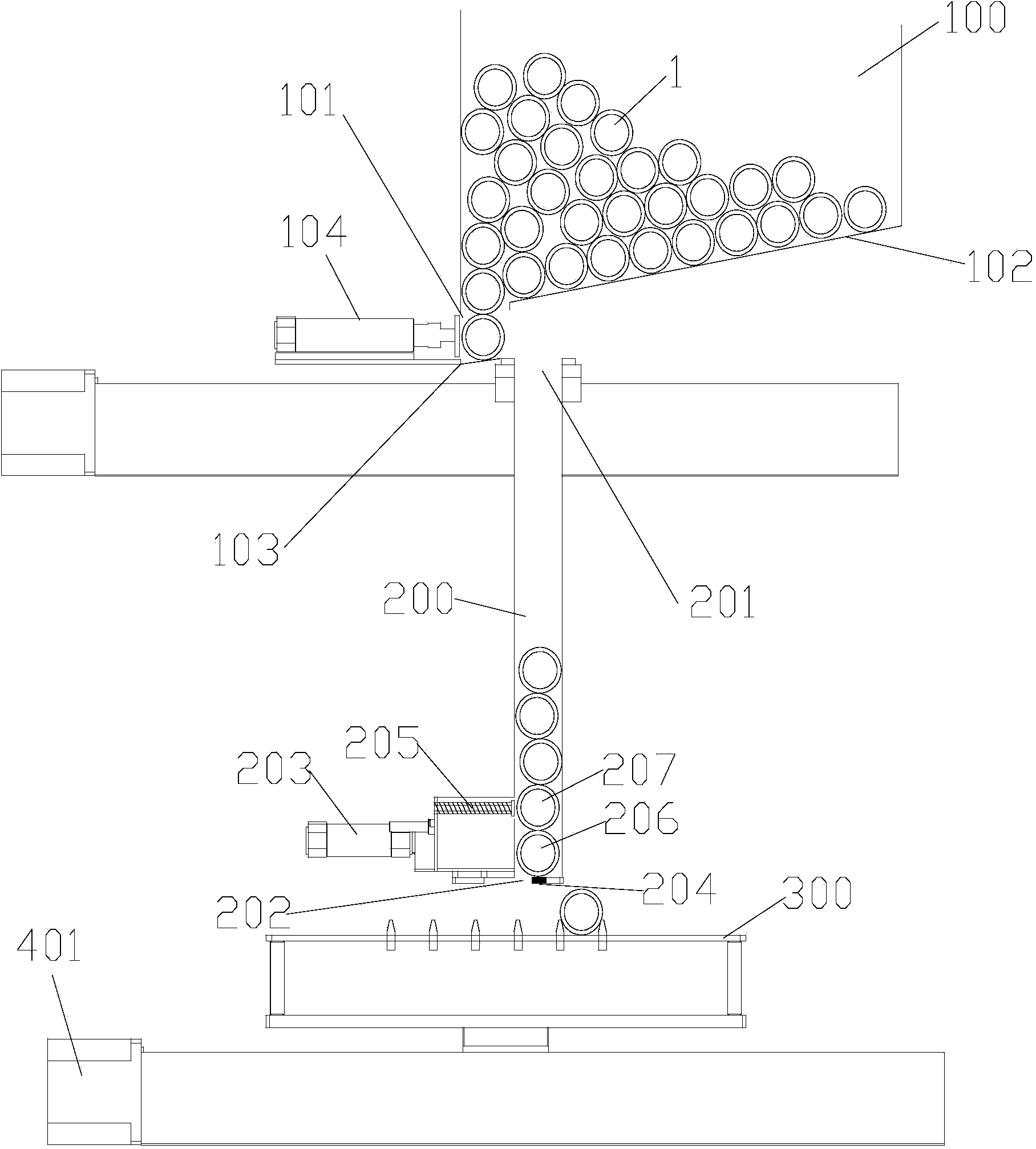

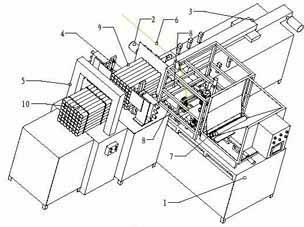

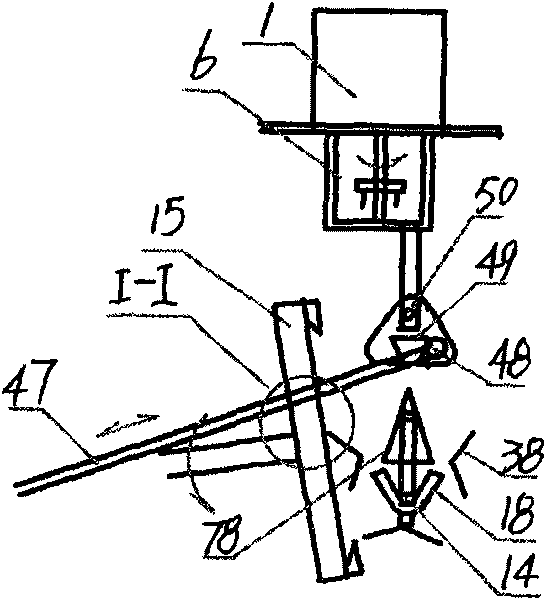

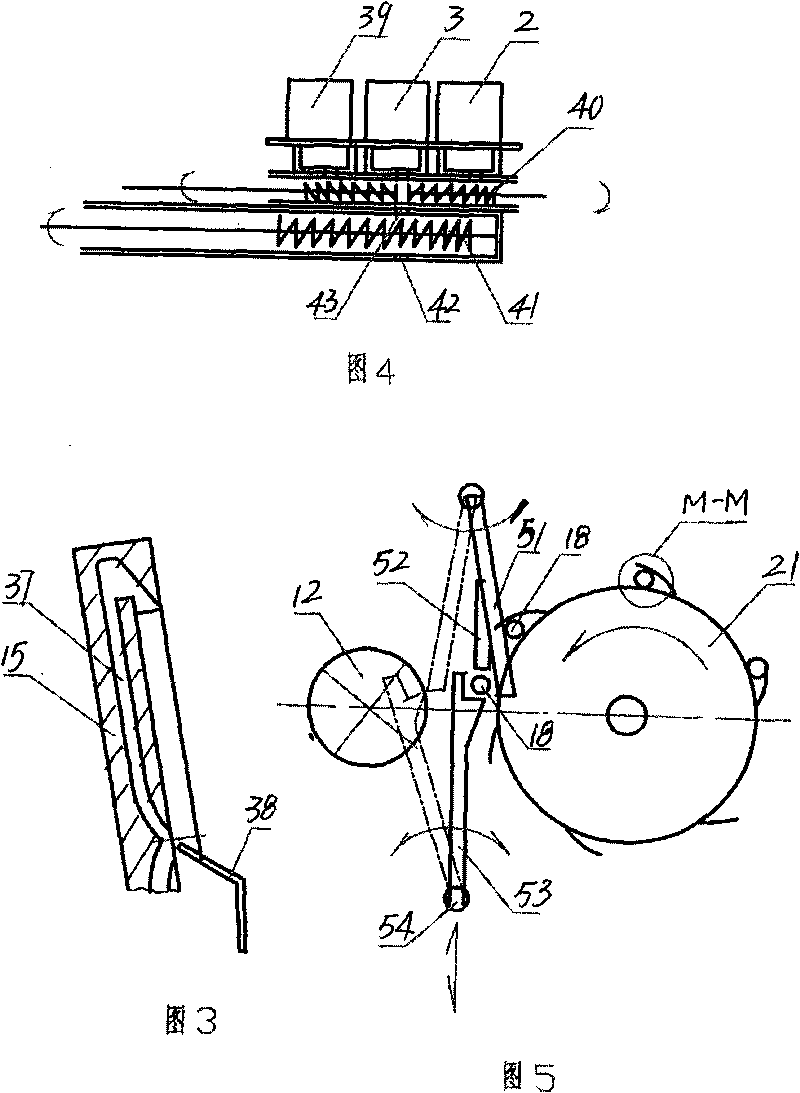

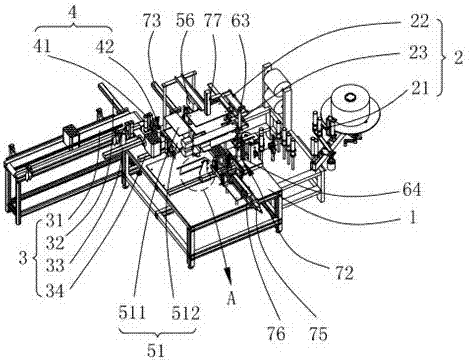

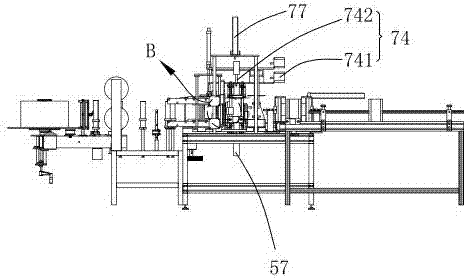

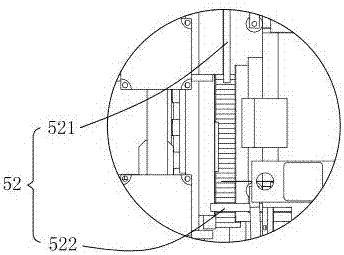

Automatic assembly machine set of fireworks

InactiveCN102353308AHigh degree of automationIncrease productivityFireworksHuman–machine interfaceManufacturing engineering

The invention provides an automatic assembly machine set of fireworks. The automatic assembly machine set is organically assembled by a main machine, a lifting subsidiary machine, a barrel box horizontal position-pushing subsidiary machine, a lateral hole subsidiary machine and a barrel box bundling subsidiary machine according to the sequence of working procedures, the motion direction and the spatial distribution, and is formed by the means of mechanical connection, electric connection, counter-aperture connection during working procedures; and the whole machine set is connected into a whole body by uniform electric connection, the working procedures of the whole machine set are uniformly controlled and harmonized by a control box, and a plurality of parameters are modified by a human-computer interface. All the working procedures such as pushing barrel bodies, punching, inserting and guiding, connecting the barrel bodies into a barrel row, assembling the barrel row into a barrel box by means of glue base rolling, laterally punching and bundling to form a finished product can be automatically realized.

Owner:熊孝柱

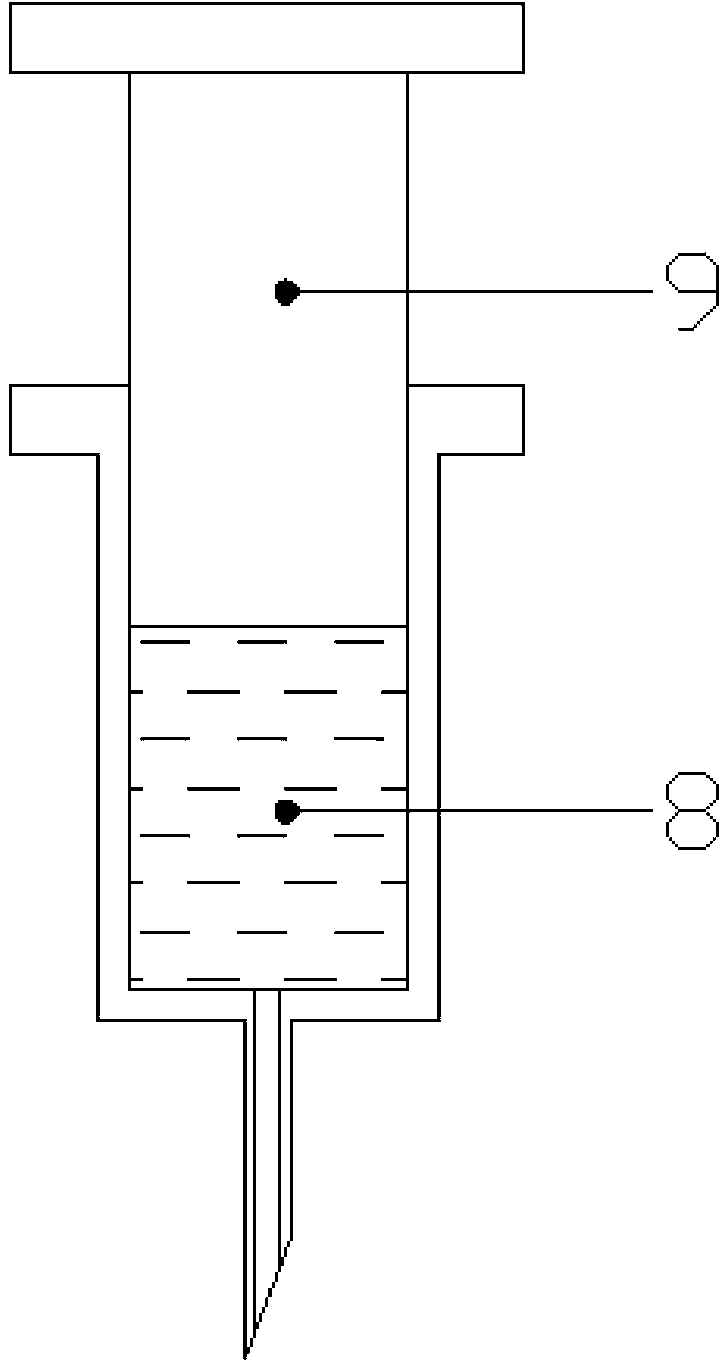

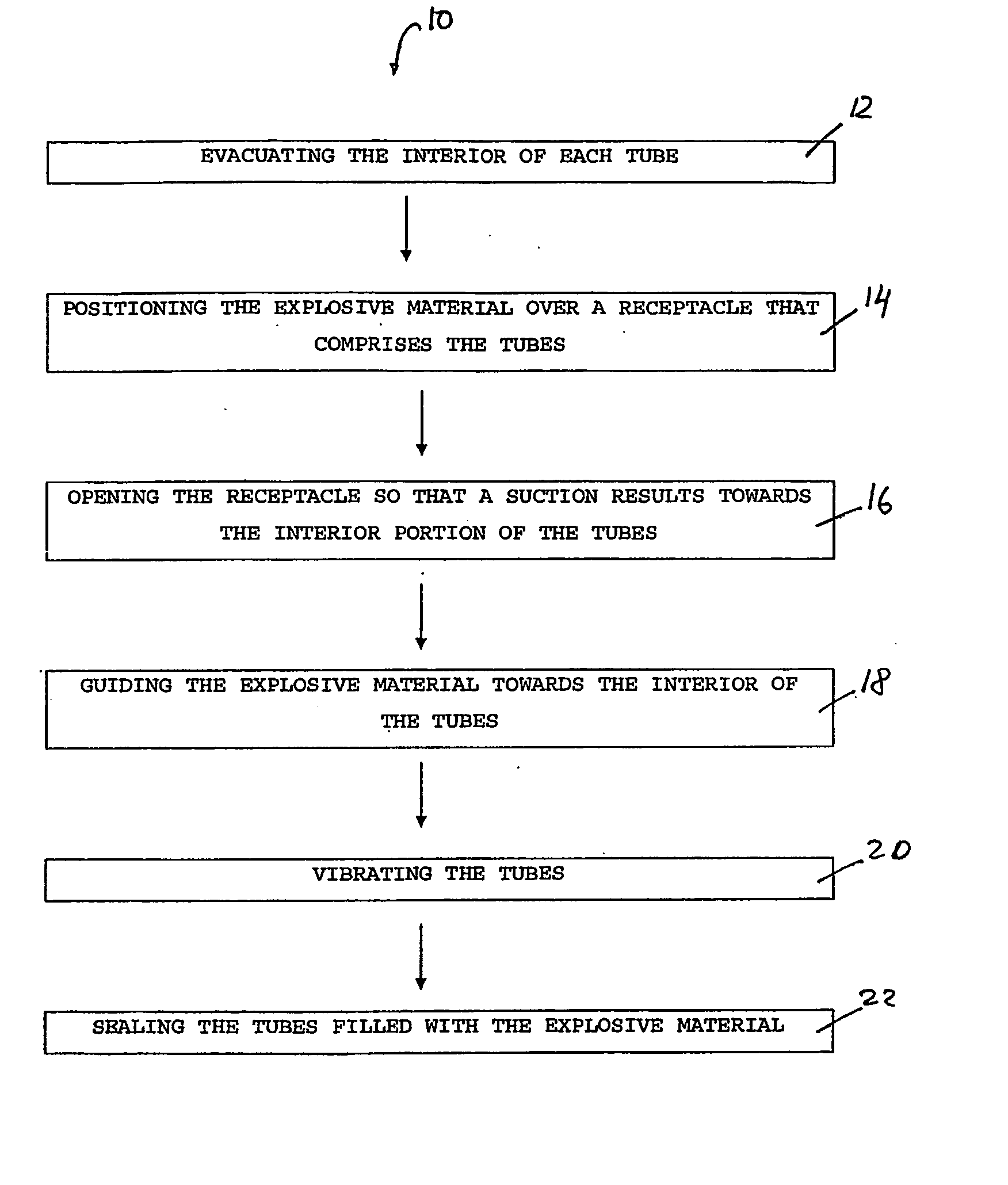

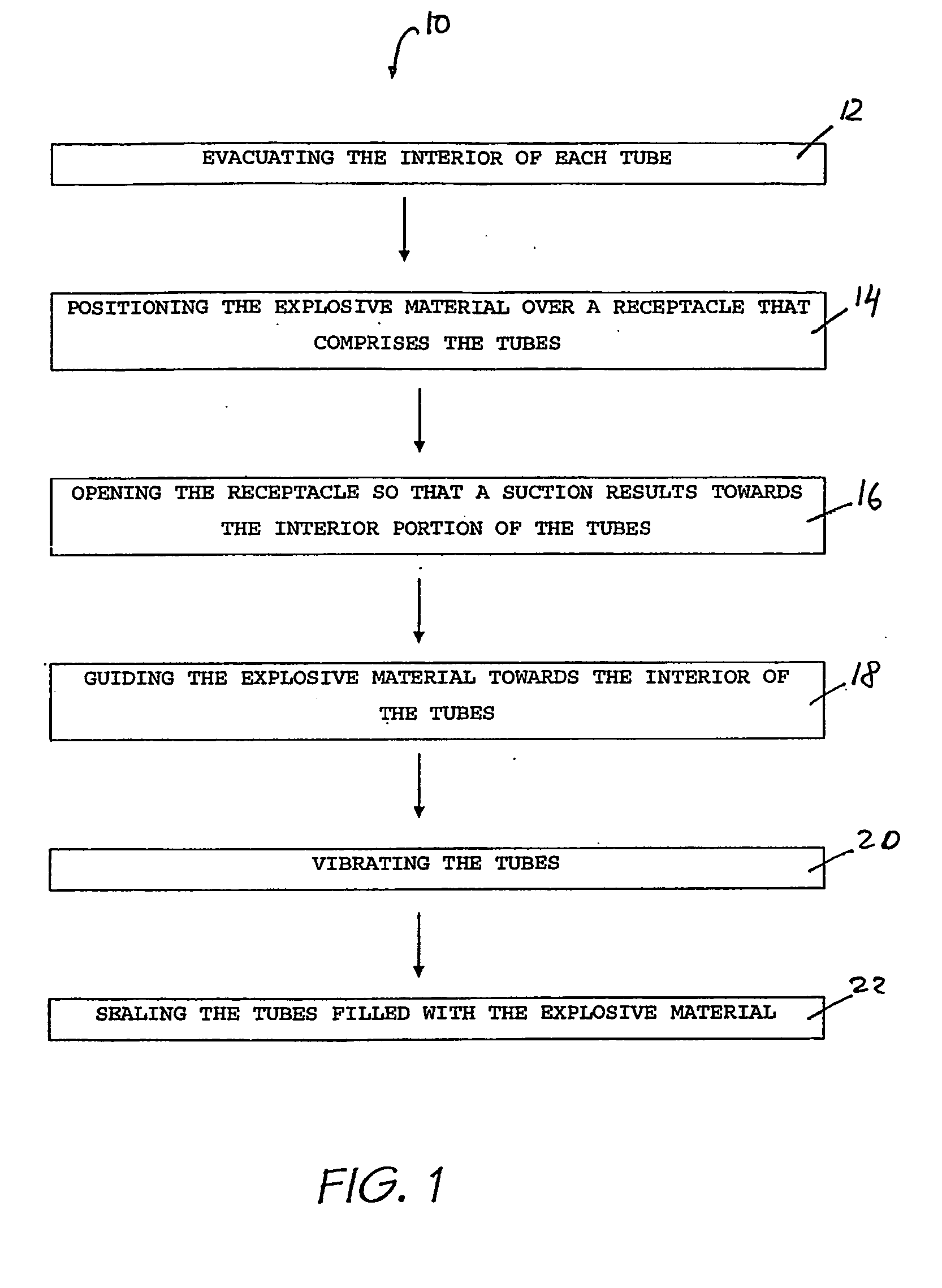

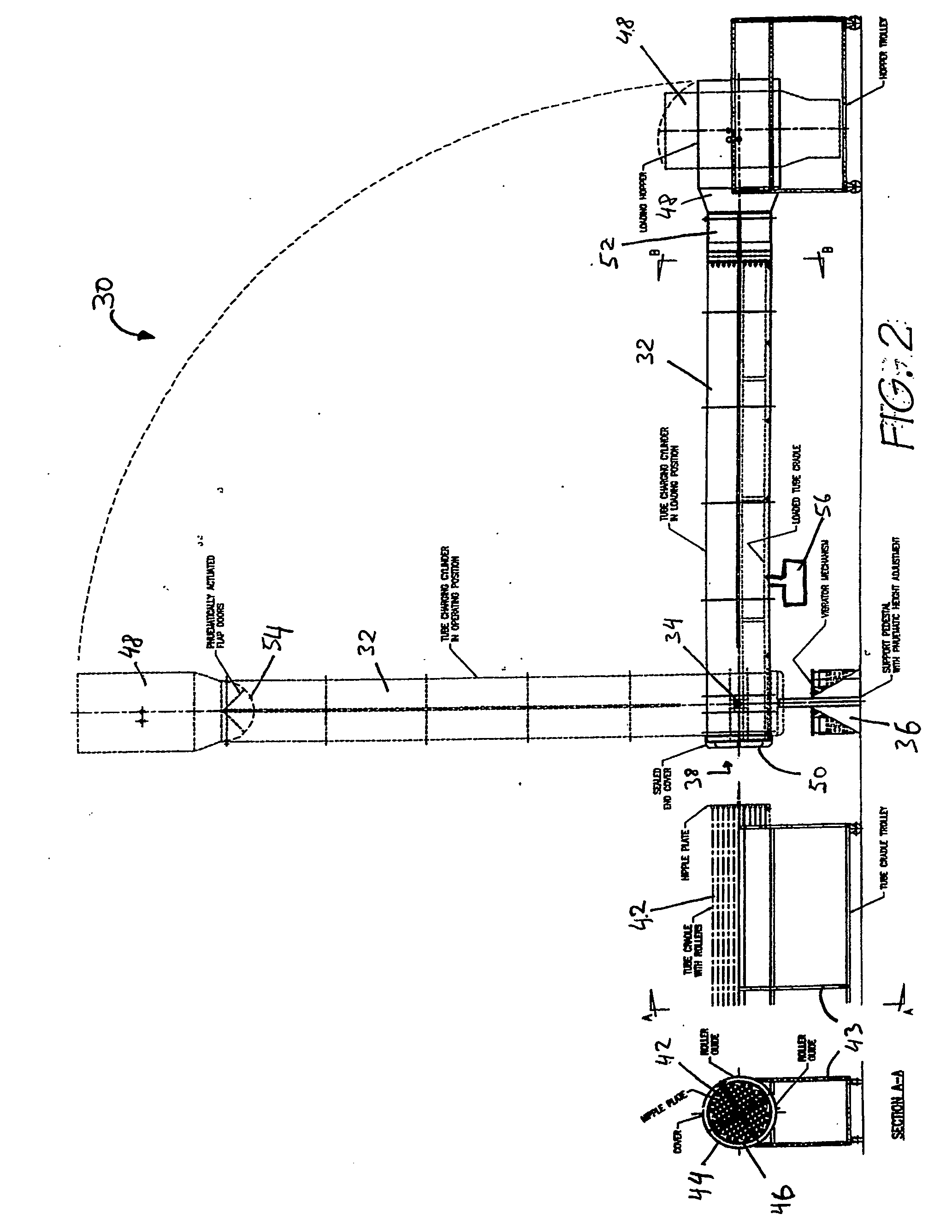

Method of charging a container with an energetic material

InactiveUS20070184219A1Facilitates dense packagingReduce fluid pressureEnvelopes/bags making machineryLayered productsMechanical engineeringEnergetic material

The present invention provides a method of charging at least one container, such as a tube, with an energetic material. The method comprises the step of reducing a pressure of a fluid in an interior portion of the or each container. The method also comprises the step of positioning the energetic material at a position that is exterior to the or each container and at which a pressure is higher than in the interior portion of the or each container in a manner such that a suction results which sucks the energetic material into the interior portion of the or each container and thereby charges the or each container with the energetic material.

Owner:JOHNSON RICHARD JOHN

Rack for holding fireworks for ignition

A rack for holding fireworks in position for ignition. The rack is a lightweight frame having end supports that are connected together by a brace. The brace includes at least one aperture into which a firework-holding tube is received. A resilient bushing extends into the aperture and the frame includes an ignitor cord retaining system. The frame rests upon a flat surface and the end supports and tube both contact that flat surface. The recoil from the launched fireworks is transmitted into the flat surface and into the bushing that surrounds the tube. The frame includes holes that allow air to escape if a device explodes and also includes ways for the frame to disintegrate to reduce the production of shrapnel if a firework device explodes within the tube. A number of frames may be connected together to form a bank of firework holding devices.

Owner:SHOOTING STAR PRODS

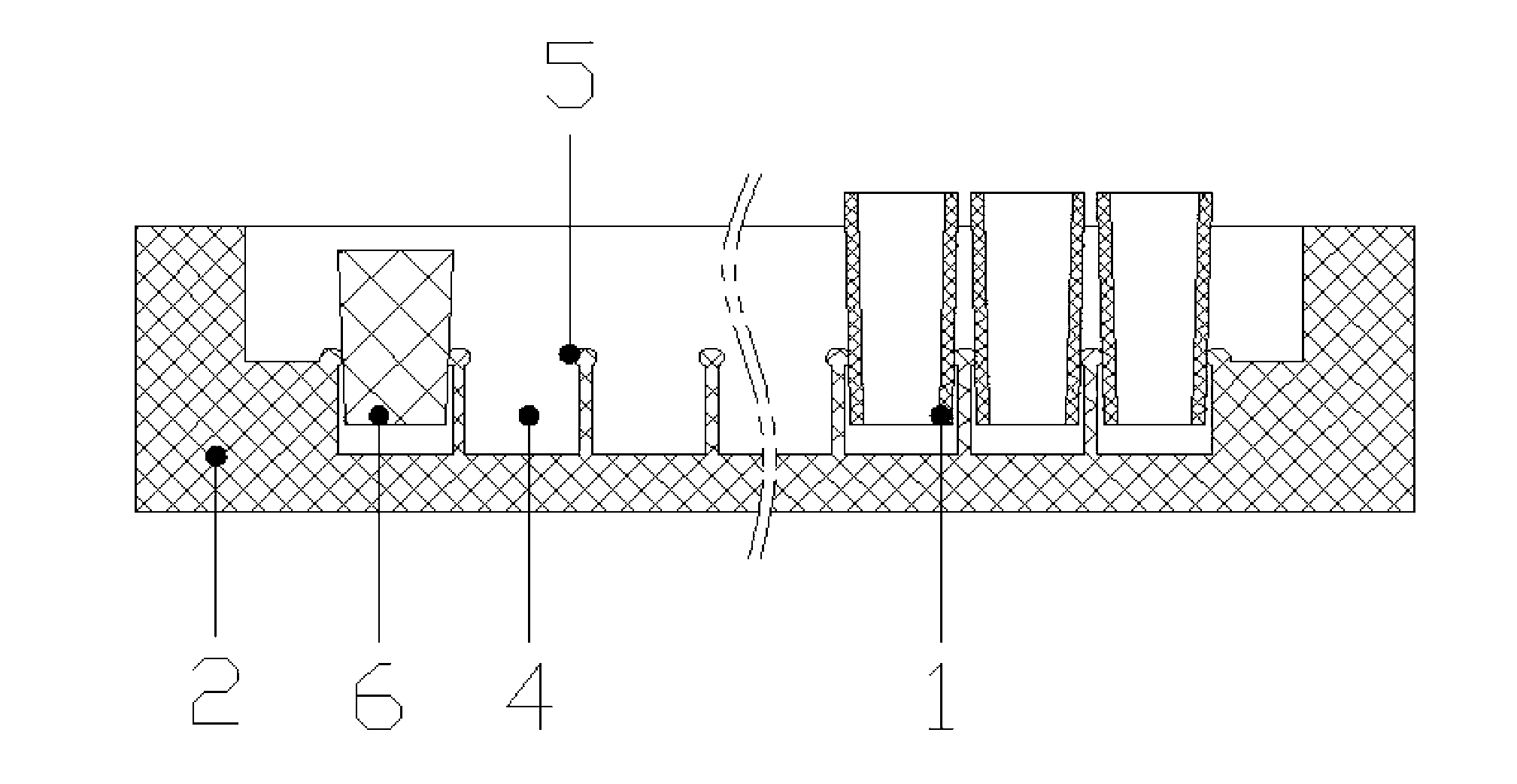

Unit splicing image-text firework lattice structure body manufacturing method

InactiveCN103234395ALow costCheap walk inSpecial ornamental structuresFireworksEngineeringBatch production

The invention discloses a unit splicing image-text firework lattice structure body manufacturing method which comprises a splicing unit and a lattice structure finishing body splicing method. The splicing unit is provided with splicing structures capable of being connected with one another. The lattice structure finishing body splicing method includes the following steps: 1 designing and manufacturing a splicing backup plate jig, 2 enabling a first splicing unit to cling to a corner of the splicing backup plate, 3 splicing a second splicing unit and a third splicing unit on two sides of the first splicing unit, 4 splicing a new splicing unit on the non-splicing side of each splicing unit till the space in the splicing backup plate jig is filled completely, and 5 pressing a lattice structure finishing body flat. The unit splicing image-text firework lattice structure body manufacturing method is simple in implementation, manufacturing is convenient, the complex lattice structure body is combined by simple splicing units through splicing, ultra-large-batch production can be achieved, the cost of image-text firework is greatly reduced, and the method is the key to enable the image-text firework to be popularized in thousands of households cheaply.

Owner:SUZHOU ZZH INTPROP SERVICES

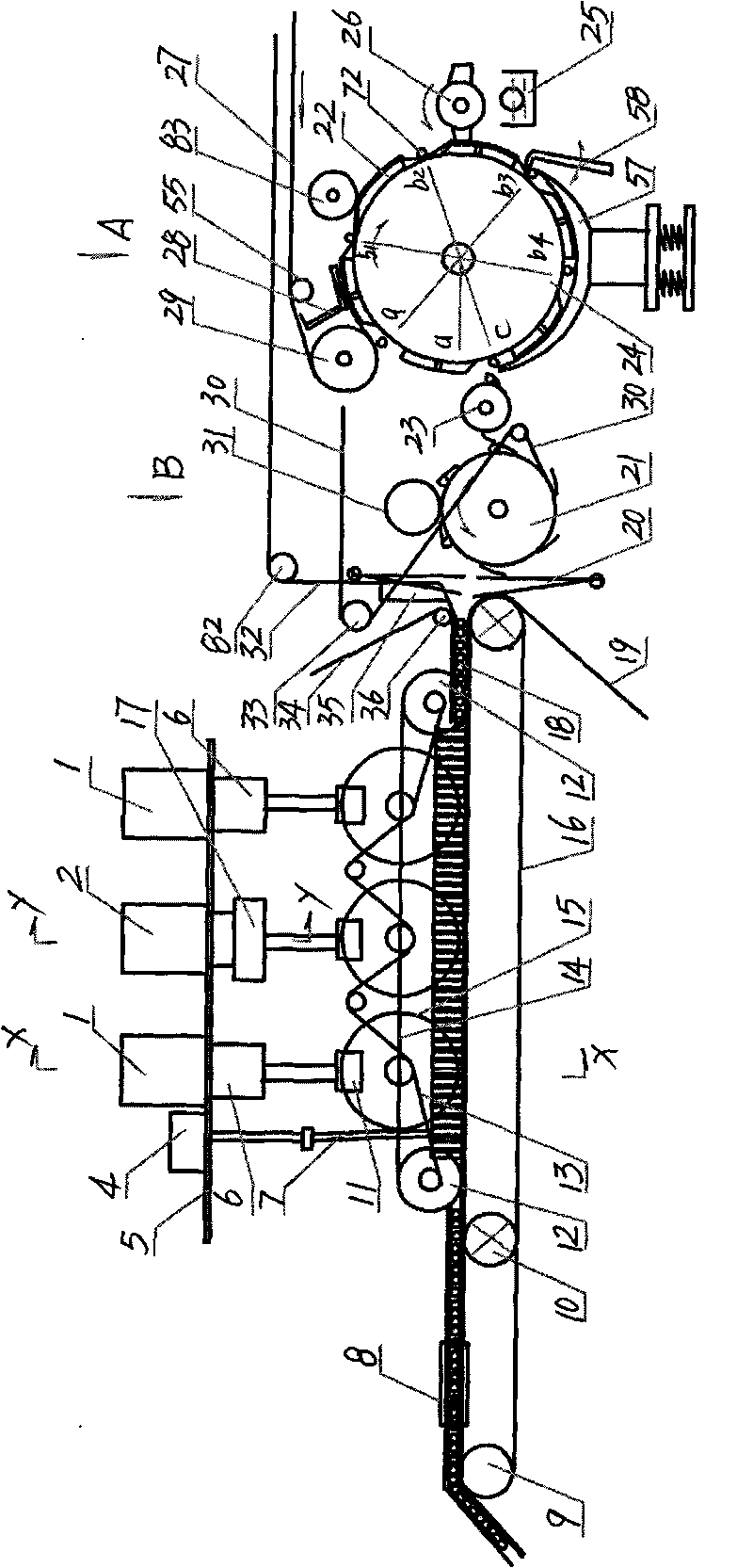

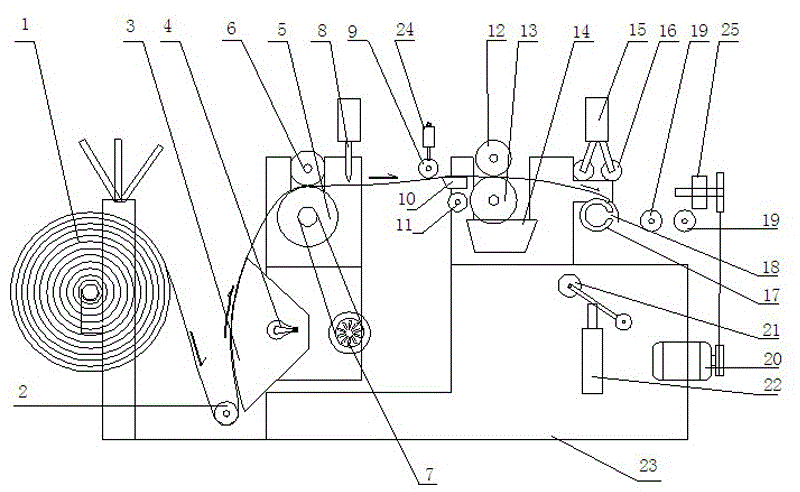

Firecracker manufacturing all-in-one machine

InactiveCN101713622AImprove production and processing efficiencyImprove processing qualityFireworksFirecrackerDistributor

The invention discloses a firecracker manufacturing all-in-one machine comprising a reel mechanism, a fuse inserting mechanism, a firecracker connecting mechanism, a conveying mechanism, a powder charging mechanism and an encapsulating mechanism, wherein the reel mechanism comprises a center wheel (24), and at least four tiles and rollers, wherein the tiles and the rollers are evenly arranged in the middle of the axial direction of the excircle of the center wheel at intervals; the fuse inserting mechanism comprises a fuse inserting wheel (21), and at least four pairs of shuttle needle pipes (65) and shuttle needles (66), wherein the shuttle needle pipes (65) and the shuttle needles (66) are evenly arranged on one end of the fuse inserting wheel at intervals; a transition wheel (23) and a clamping hook (44) are arranged between the fuse inserting wheel and the center wheel; a swing flask conveying device (20) on the conveying mechanism is arranged between the fuse inserting wheel and a delivery wheel (10); the powder charging mechanism comprises a spiral conveyor (17) and distributors (11), wherein the distributors on both ends are respectively connected with an agitating vessel; the distributor in the middle is connected with the spiral conveyor; and the spiral conveyor is connected with the distributors. The invention greatly increases the firecracker producing and processing efficiency, improves the firecracker processing quality, and can ensure the firecracker processing safety, thereby being beneficial to organizing scale production and processing of firecrackers, and lowering the firecracker processing cost.

Owner:黎高明 +4

Firework coiling machine

ActiveCN106313638AReduce moistureReduce hardnessPaper/cardboard wound articlesFireworksFireworksPulp and paper industry

The invention discloses a firework coiling machine. The firework coiling machine comprises a paper feeding mechanism, a paper cutting mechanism, a coating mechanism, a coiling mechanism, a drum cutting mechanism and a drum receding mechanism, all of which are sequentially arranged on a rack. The firework coiling machine is characterized by further comprising a paper heating mechanism and a paper shaping mechanism, the paper heating mechanism is arranged at the front end of the paper feeding mechanism and comprises a driver with a heat source, and coiling paper is heated when conveyed to the paper feeding mechanism through the driver; and the paper shaping mechanism comprises an extrusion component and an extrusion face corresponding to the extraction component, the extrusion component moves towards the extrusion face, and the running coiling paper is shaped into an arc through the joint action of the extrusion component and the extrusion face. The firework coiling machine is simple in structure and convenient to use, the phenomenon of seam slippage of a paper drum is eradicated through the produced firework paper drum, the water content is extremely low, the production efficiency is improved, and the production cost is saved.

Owner:李金亮

Fireworks packaging equipment

The invention provides fireworks packaging equipment. The fireworks packaging equipment comprises a rack, a paper feeding device fixed on the rack, a molded fireworks barrel feeding device fixed on the rack, a gluing device fixed on the rack, a top and bottom poster paper gluing device, an adhesive tape feeding device and a peripheral poster paper gluing device, wherein the top and bottom poster paper gluing device comprises a paper receiving mechanism, a first paper cutting mechanism and a paper pressing mechanism; and the adhesive tape feeding device comprises a guide rail vertically fixed on the rack, an adhesive tape coil arranged on the guide rail, an adhesive tape pulling cylinder for driving the adhesive tape coil to slide downwards, a vacuum suction board arranged below the adhesive tape pulling cylinder and an adhesive tape pressing mechanism and an adhesive tape cutting mechanism which are fixed on one side of the bottom end of the guide rail. Compared with the prior art, the fireworks packaging equipment provided by the invention has the benefits as follows: through the coordination of the paper feeding device, the molded fireworks barrel feeding device, the gluing device, the top and bottom poster paper gluing device, the adhesive tape feeding device and the peripheral poster paper gluing device, the packaging of fireworks barrel by adopting the packaging paper is realized, the packaging speed is high, the production efficiency is high, and the human cost is reduced.

Owner:浏阳大吉润华精密机械制造有限公司

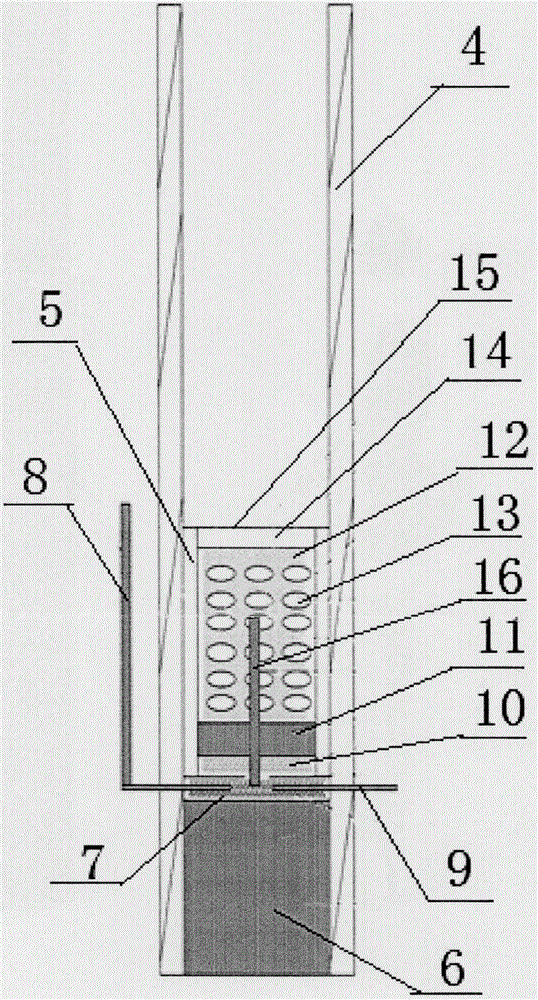

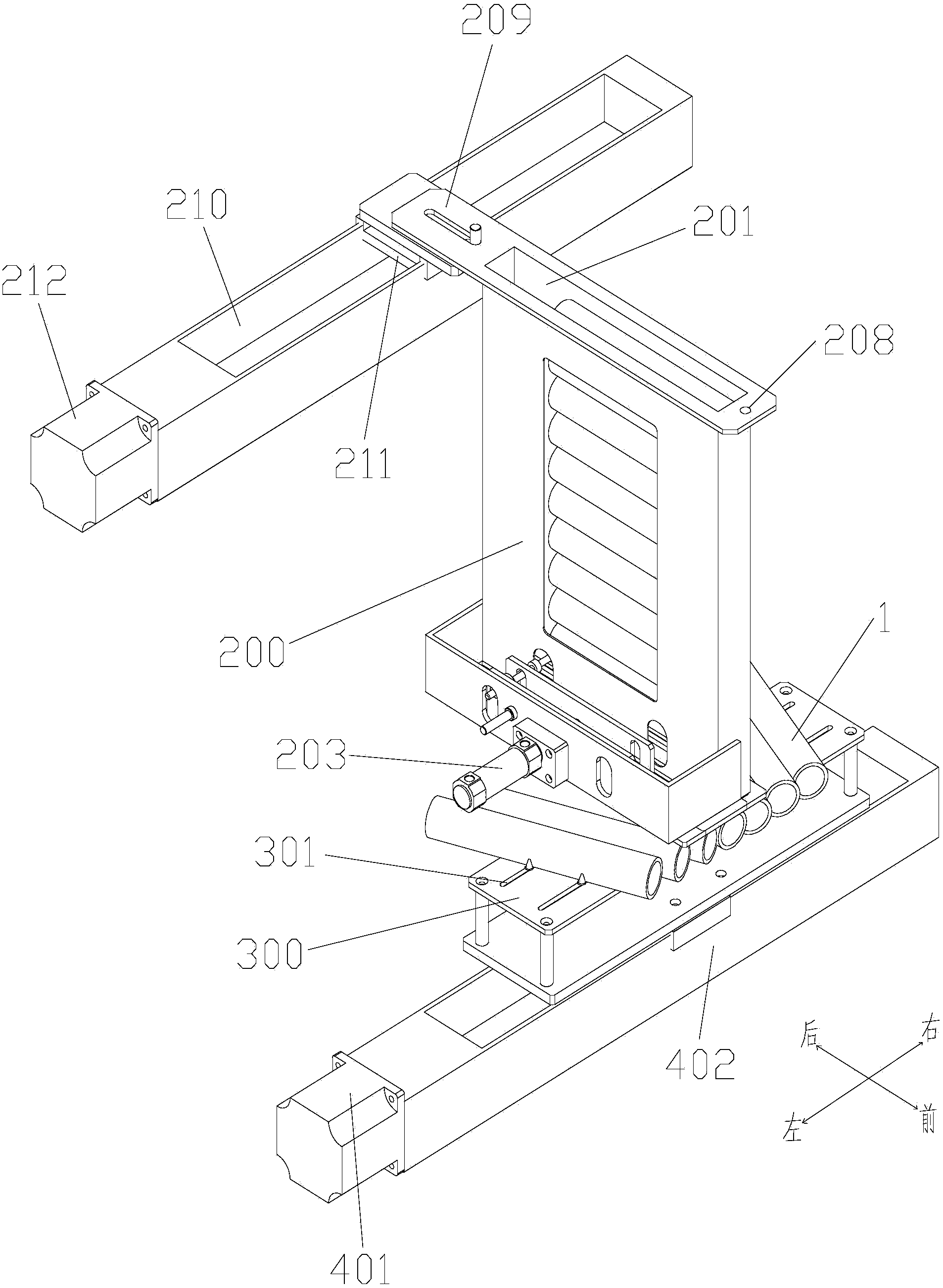

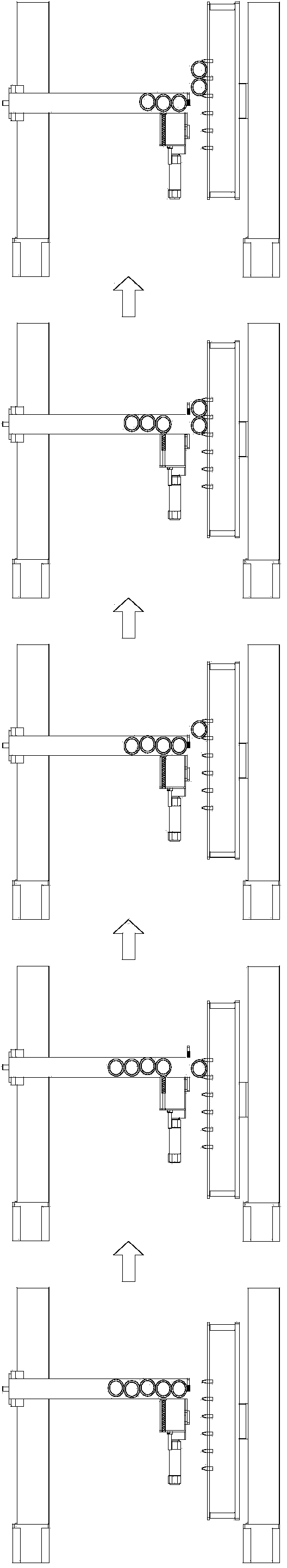

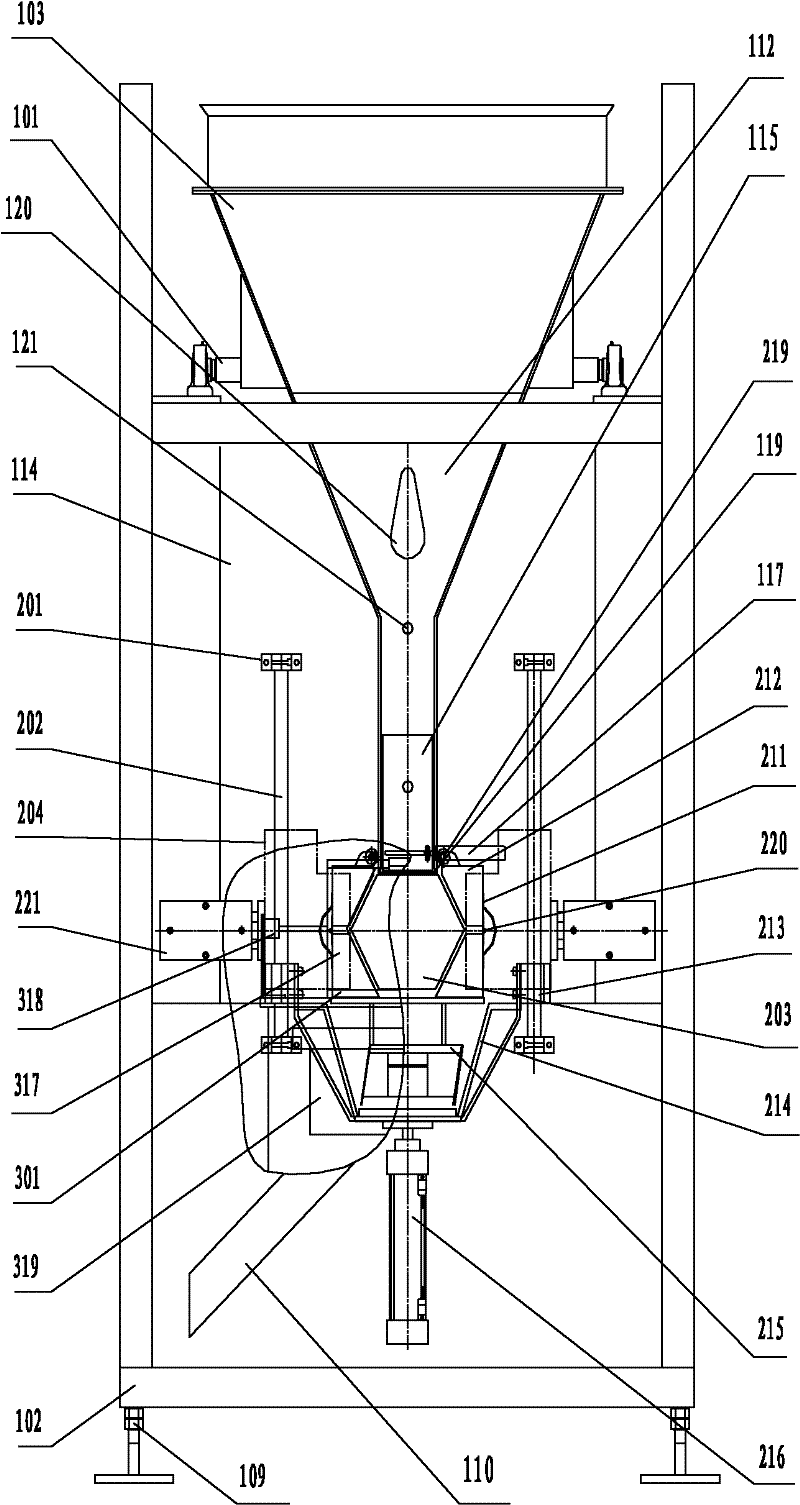

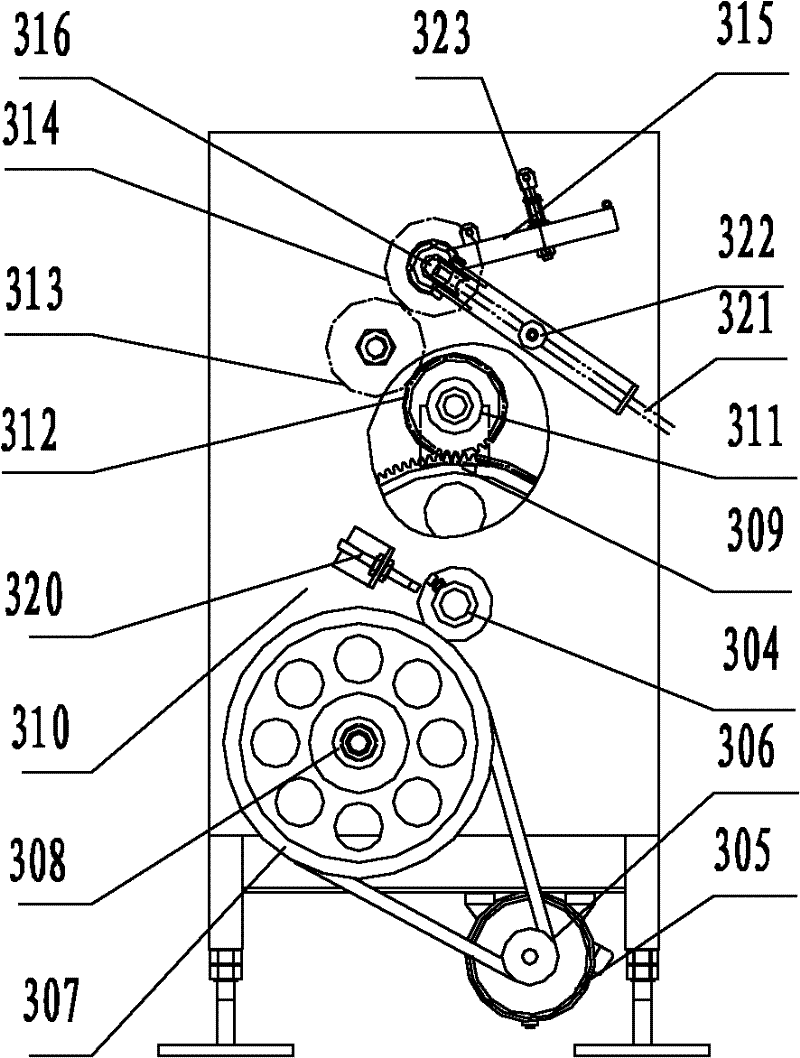

A molding binding device of firecrackers tube cake

The invention discloses a molding binding device of firecrackers tube cake, comprising a vertical feeding system, a loading molding system, a binding system and a control system. The beneficial effects of the molding binding device of firecrackers tube cake are lie in that(1) the arrangement, combination molding and binding of the firecrackers tube cake are completed in full-automation, the molding speed is fast, the binding is tight and the shape of the firecrackers tube cake is regular and beautiful; more than 300 firecrackers tube cakes can be finished per hour, which saves the human resources significantly, improves the work efficiency and solves the problem of labor shortage; (2) each part of the molding binding device is modular designed and installed, the size can be adjusted in accordance with the product, and the operation is convenient and the maintenance is fast; the abrasion of the contact site is low by employing a pneumatic roller structure, so that the device can be used for a long time without worrying about the precision to be effected.

Owner:浏阳市鸿隆综合贸易有限公司

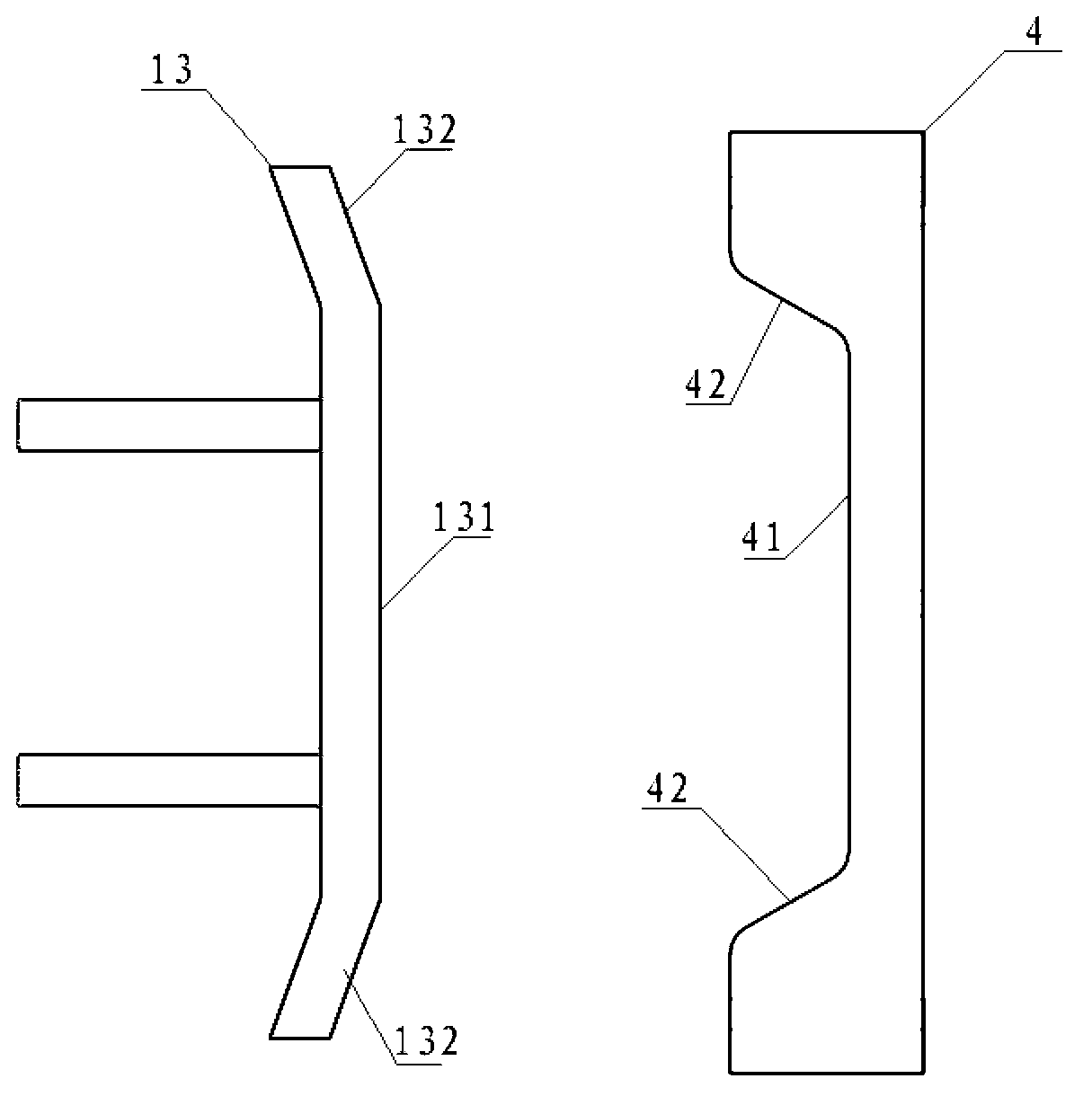

Firework paper tube, sealing mold and sealing method for firework paper tube, and effect tube of firework paper tube

The present invention discloses a firework paper tube, comprising a tube body, one end of the tube body is open, and the other end of the tube body is provided with a bottom seal that is formed by extruding the tube body itself. The invention also discloses a sealing mold, comprising a male part and a female part, the male part includes a cylinder accessible into the tube body, one end of the cylinder is a forming end for the bottom seal, the female part has a forming socket mating with the forming end of the male part, and the female part can sleeve one end of the tube body to rotationally pressurize the tube body so that the end of the tube body forms the bottom seal. The forming socket includes a cylindrical segment and an arc segment, the inner wall of the arc segment is provided with a plurality of sector grooves, an apex of each sector groove is positioned at an apex of the arc segment, and the depth of every sector groove peripherally decreases from one end to the other end so that an arc ridge naturally forms between the adjacent sector grooves. The step of pressing fire clay is omitted, production efficiency is improved, water and soil loss due to yellow clay production is avoided, environment protection is benefited, pollution by firing wastes is reduced, and injury by droppings is avoided.

Owner:浏阳市银都烟花制造有限公司

Firework touch off base material taking amylum as base and method for preparing

InactiveCN101158565AHigh strengthReduce the possibility of bottoming outTextiles and paperFireworksFiberStearic acid

The invention provides a firework display base materials based on starch and the preparation method and relates to a preparation method of firework display base material and the base. The preparation method is that proper amount of water is poured after starch, grain powder or pulp are fragmented, part or all of release agent is added, then after being agitated uniformly, agitating while heating until the starch is totally gelatinized, slightly cooler, residual materials are poured in and mixed thoroughly into gray gunk. The gray gunk is filled into a die with a temperature of 150-280 DEG C, the die is closed to keep the heat until being dried, then a product is get after unloading from the die. The pulp is waste or new pulp or a market pulp board and the release agent is stearic acid, silicone oil or stearate. Based on the starch as the base material and supplemented by paper fiber, the invention has high strength and reduces possibilities of impacting the bottom when transmitting; a contour forging once-through shape craft is adopted which is very simple, the quality of the product is stable, and the individual difference is little without any deforming, moreover manpower is saved. By replacing the die, the invention can produce display shells, firework display tubes and various firework bases.

Owner:吕启晟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com