Precision pyrotechnic display system and method having increased safety and timing accuracy

a pyrotechnic display and timing accuracy technology, applied in the direction of launching weapons, ammunition fuzes, electric fuzes, etc., can solve the problems of time delay, preventing the industry from achieving the timing accuracy and repeatability necessary for precisely choreographed pyrotechnic displays, and difficulty in controlling the delay time of a black powder fuse to better than +/ 1%, so as to increase the safety of the pyrotechnic display and reduce the potential of mis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

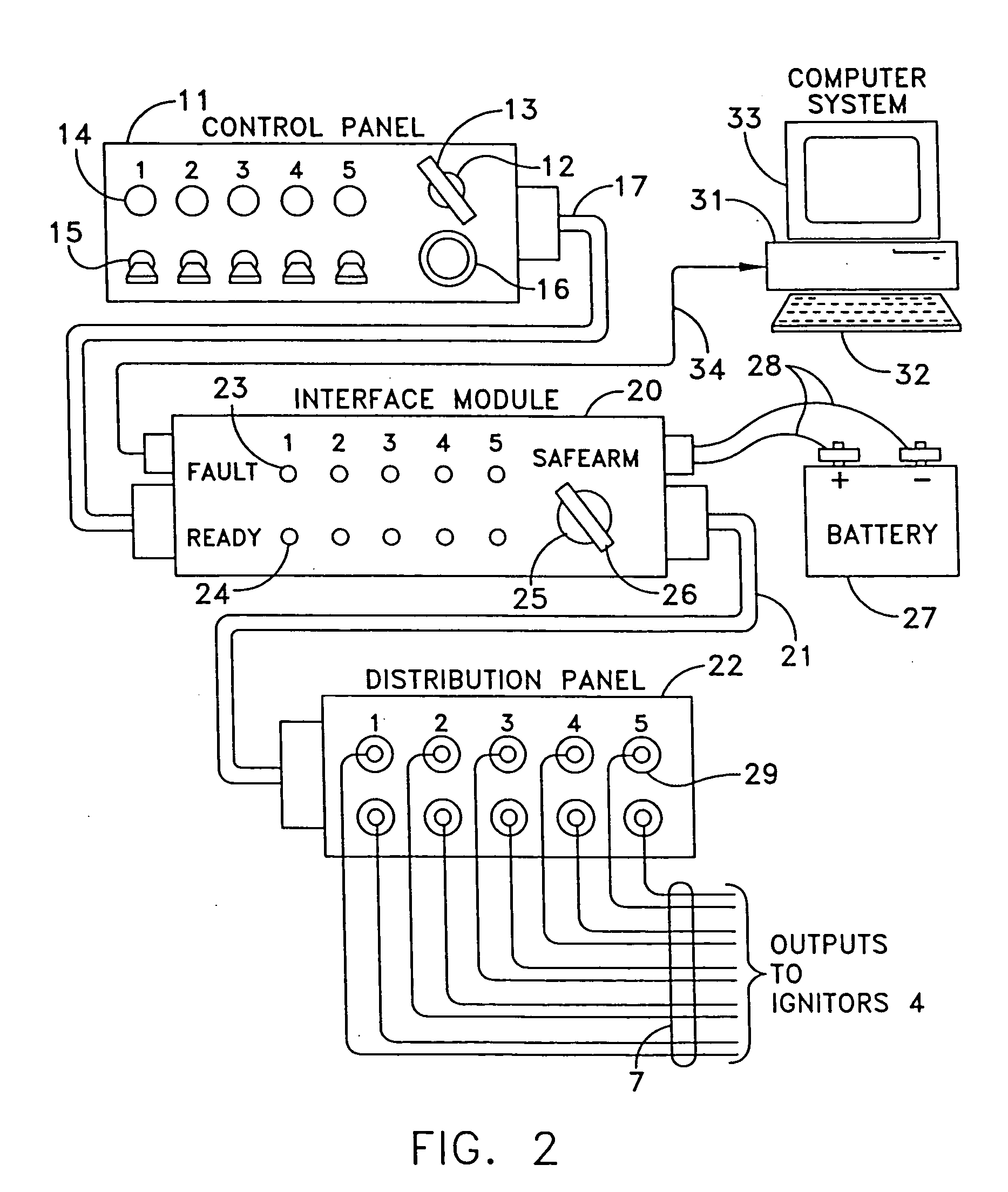

[0029] The present invention involves a system and method for controlling the launch and burst of pyrotechnic projectiles in a pyrotechnic, or “fireworks,” display.

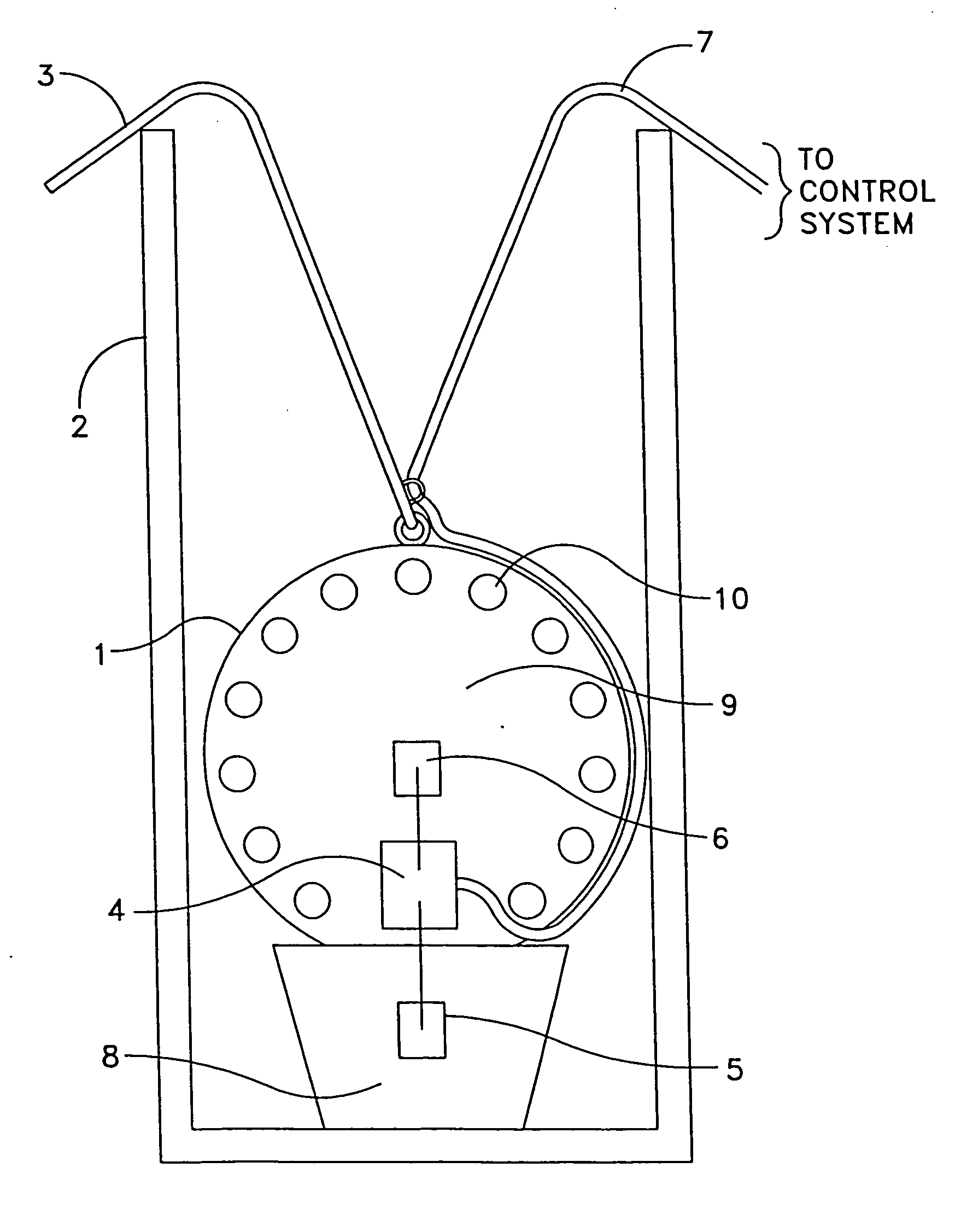

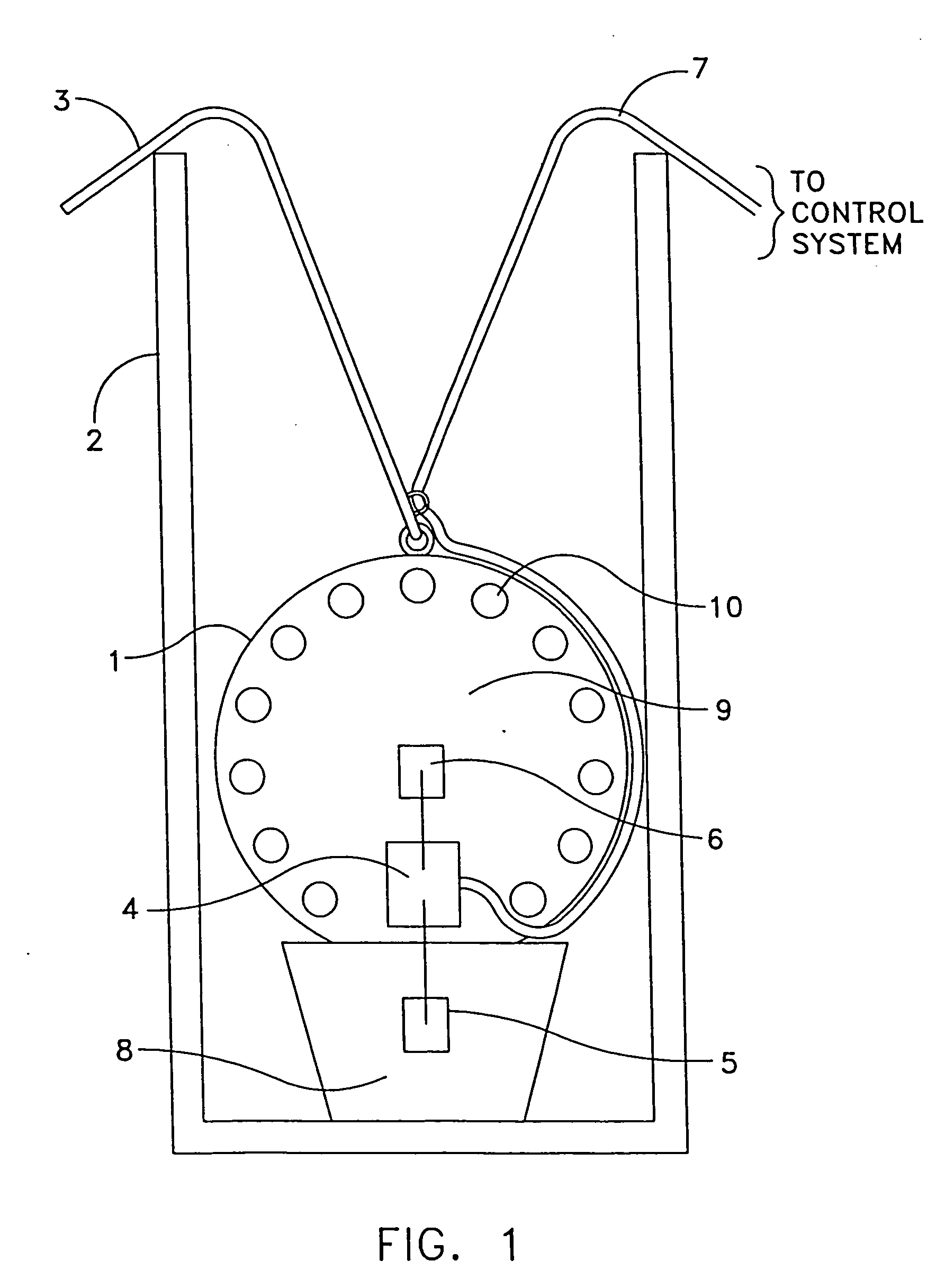

Pyrotechnic Projectile

[0030]FIG. 1 shows a typical pyrotechnic projectile 1 placed in mortar 2. Projectile 1 utilizes load cord 3 to allow the pyrotechnic operator to easily place the projectile into mortar 2. Embedded inside projectile 1 is ignitor 4 which is connected to the lift electric match (e-match) 5 and to the break e-match 6. Wires 7 connect ignitor 4 to the pyrotechnic control system. Lift e-match 5 is embedded in lift charge 8, which is typically made of black powder. Lift charge 8, when ignited, provides the force to propel projectile 1 high into the air. Break e-match 6 is embedded in break charge 9, which is also typically made of black powder. Break charge 9, when ignited by break e-match 6, causes projectile 1 to burst and provide the visual or auditory effect desired. Projectile 1 may contain additiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com