Fireworks packaging equipment

A technology for packaging equipment and fireworks, which is applied in offensive equipment, fireworks, weapon types, etc., can solve the problems of unstable production quality, high labor cost, low packaging efficiency of fireworks, and achieve high production efficiency, fast packaging speed, and low cost. The effect of labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

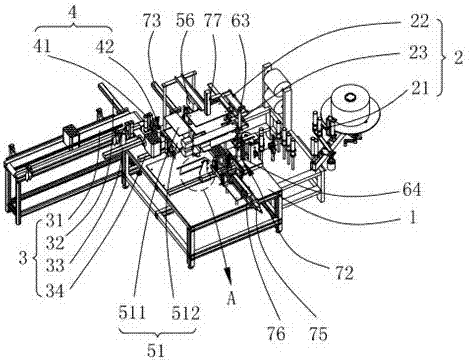

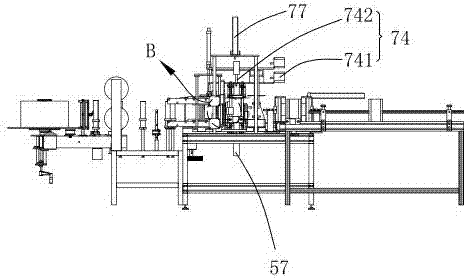

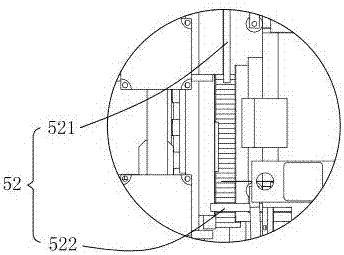

[0034] Please refer to figure 1 , is a structural schematic view of the fireworks packaging equipment of the present invention at a first viewing angle. The fireworks packaging equipment includes a frame 1, a paper feeding device 2, a mold feeding device 3, a gluing device 4, a top and bottom paper sticker device (unlabeled), an adhesive tape device (unlabeled) and a siege paper sticker device ( not numbered).

[0035] The paper feeding device 2 is fixed on the frame 1, and the paper feeding device 2 includes a paper feeding mechanism 21 for surrounding paper, a paper feeding mechanism 22 for top paper and a paper feeding mechanism 23 for bottom paper. The encircling paper feeding mechanism 21 , the top calling paper feeding mechanism 22 and the bottom calling paper feeding mechanism 23 are respectively composed of several rollers. The siege paper fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com