Patents

Literature

39results about How to "Implement autoboxing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

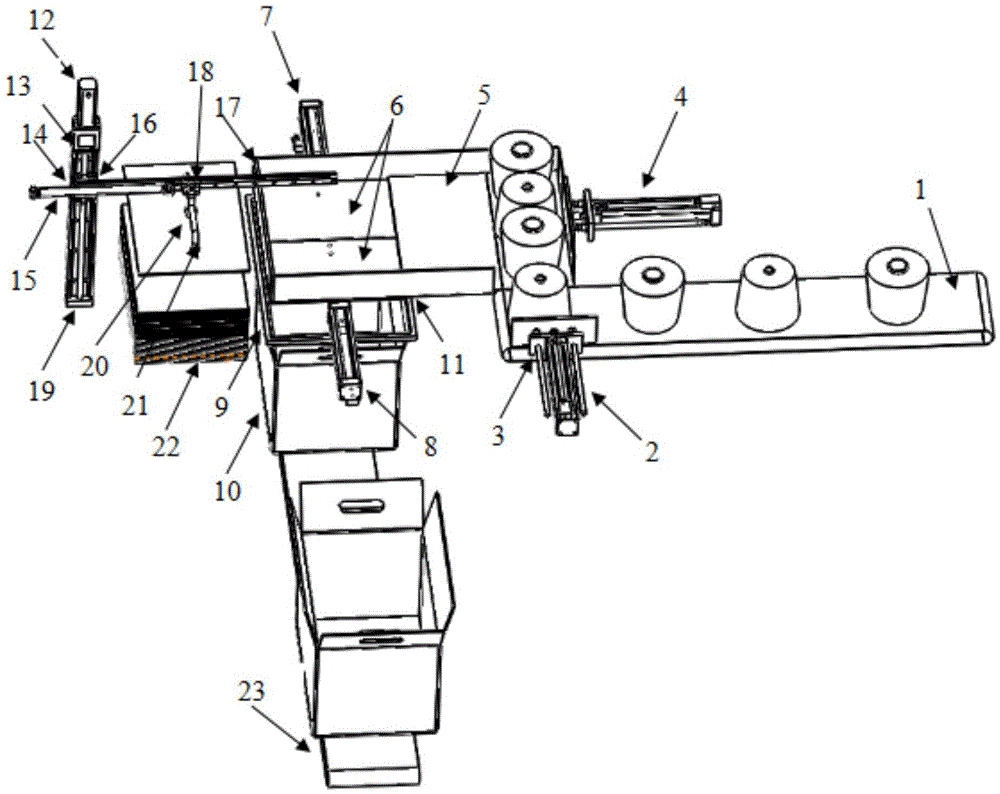

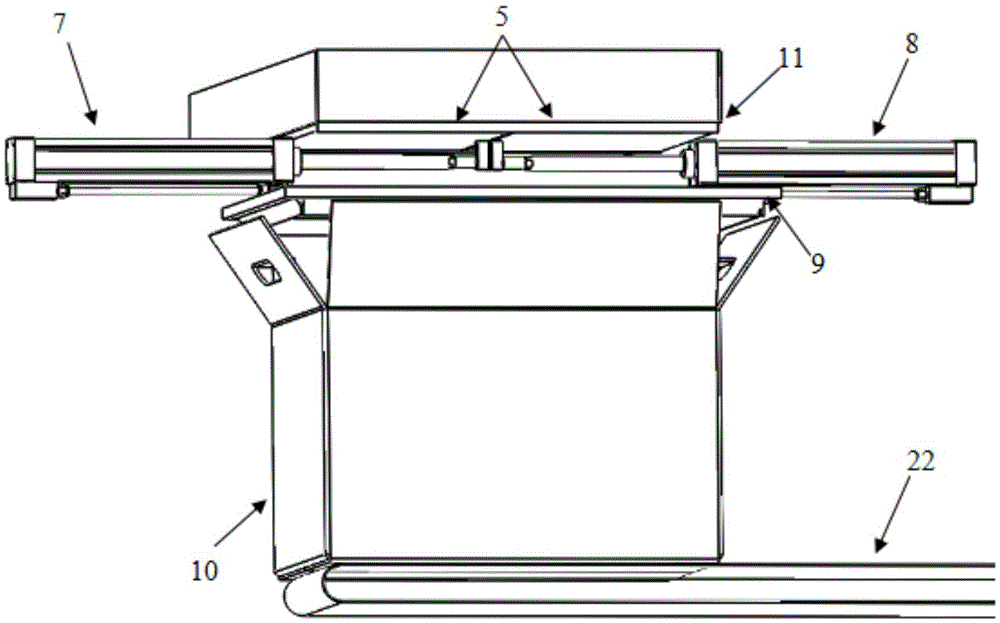

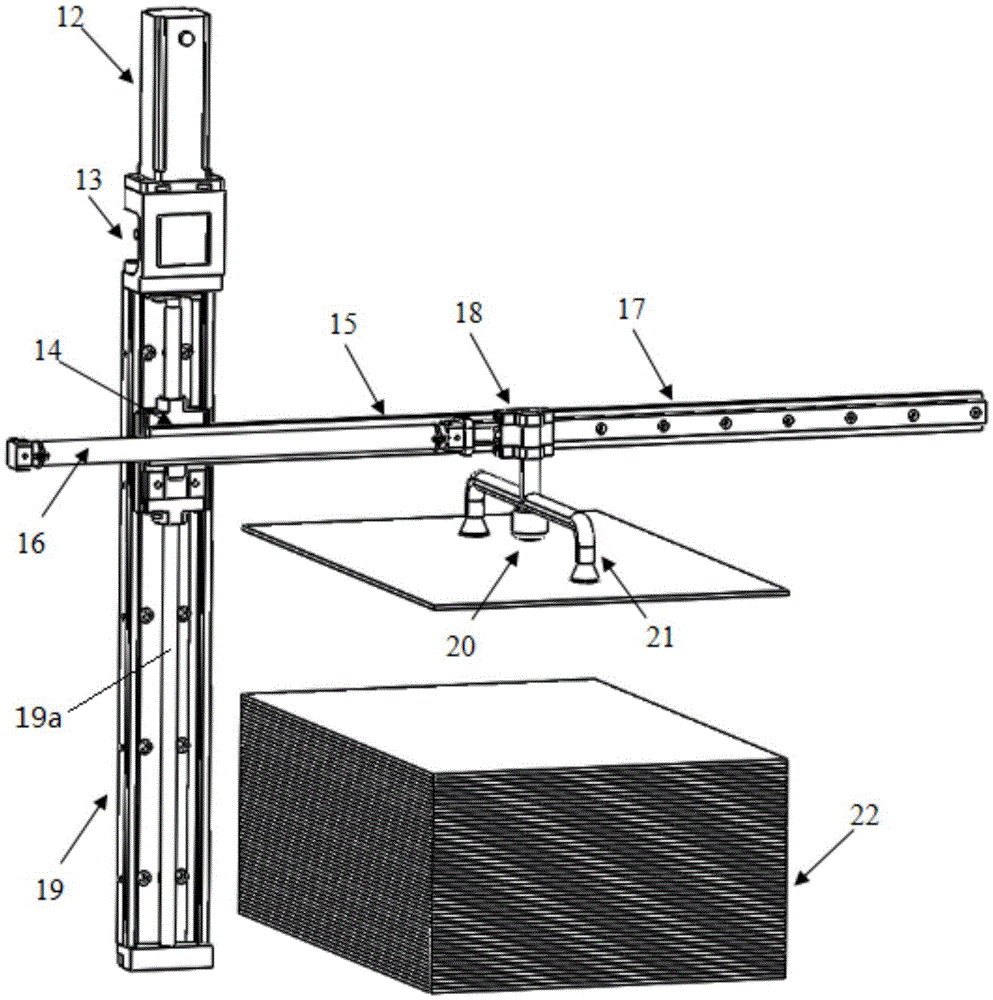

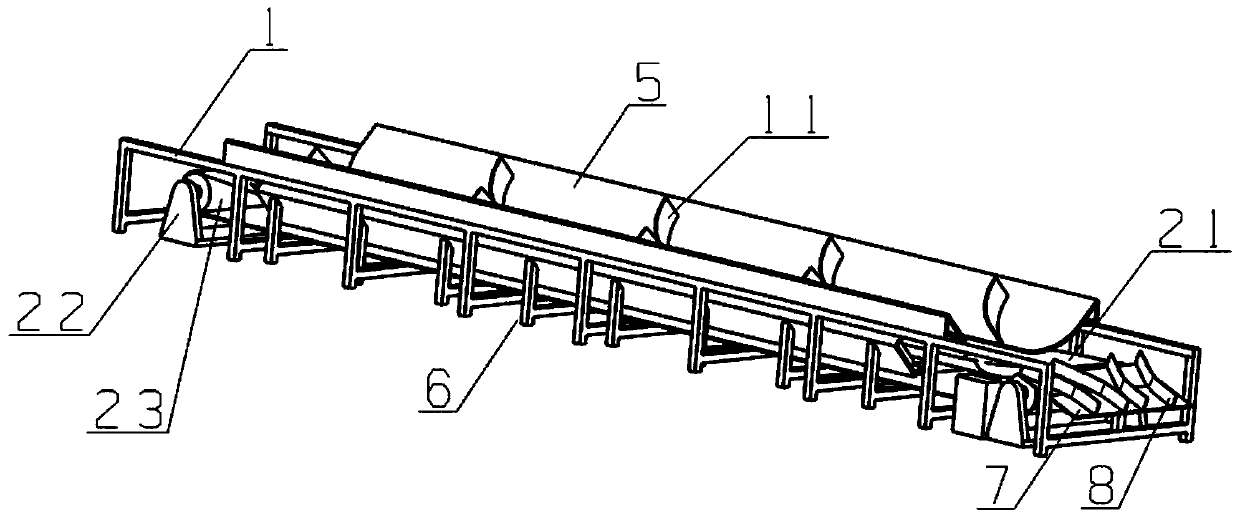

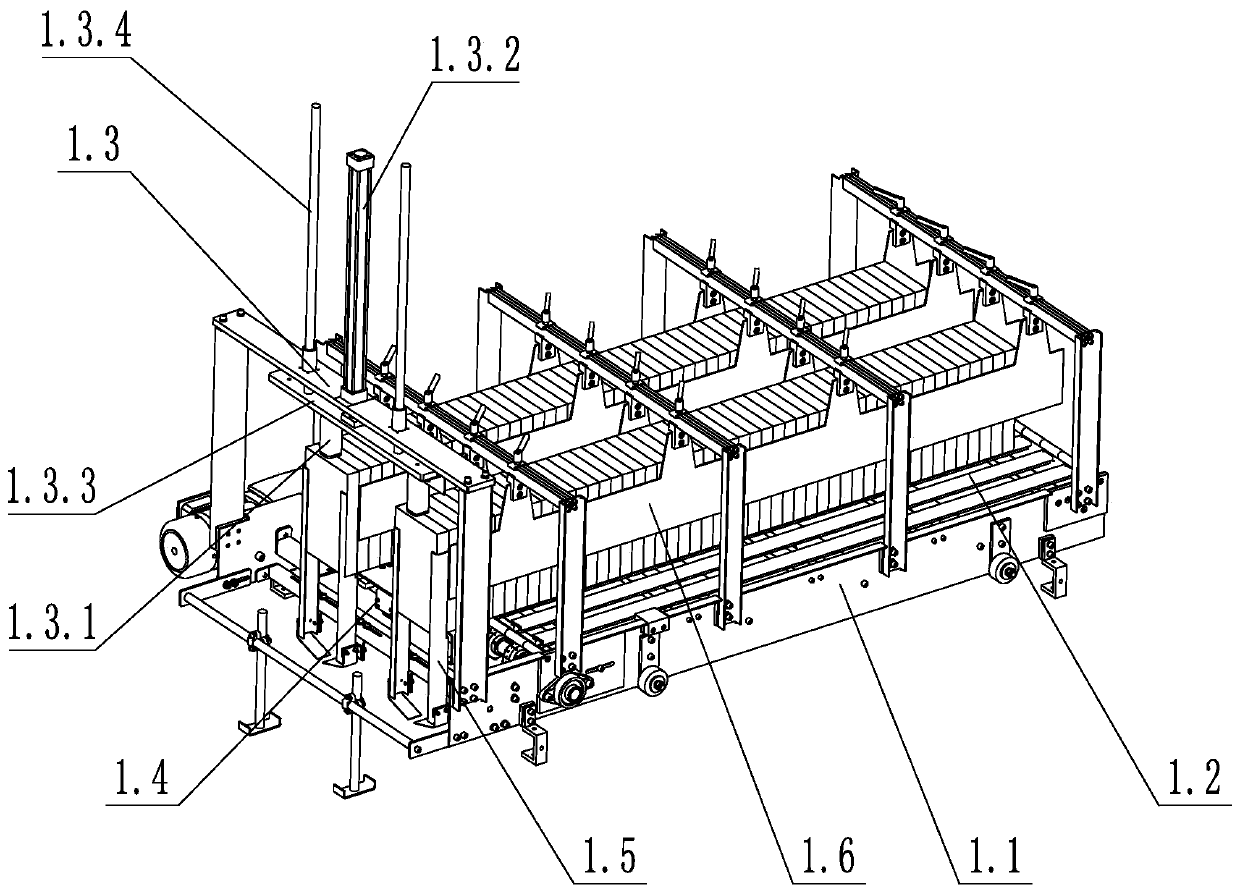

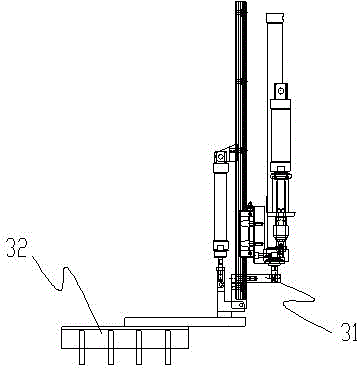

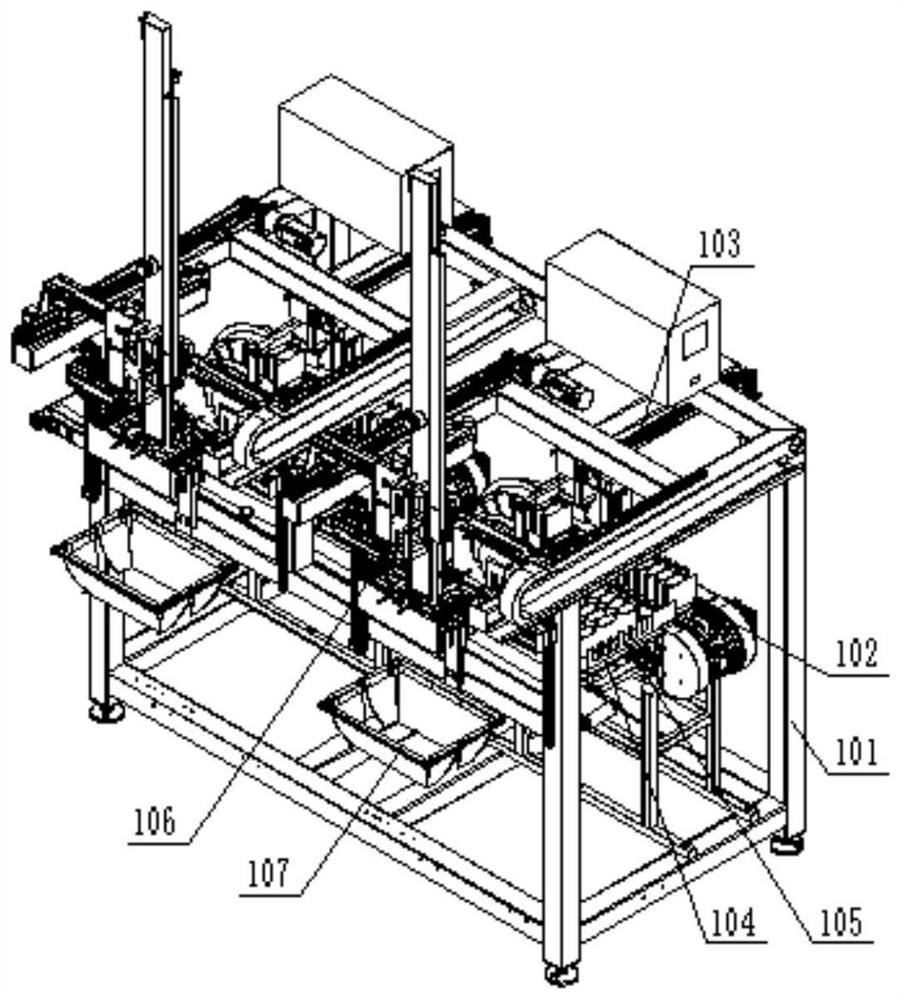

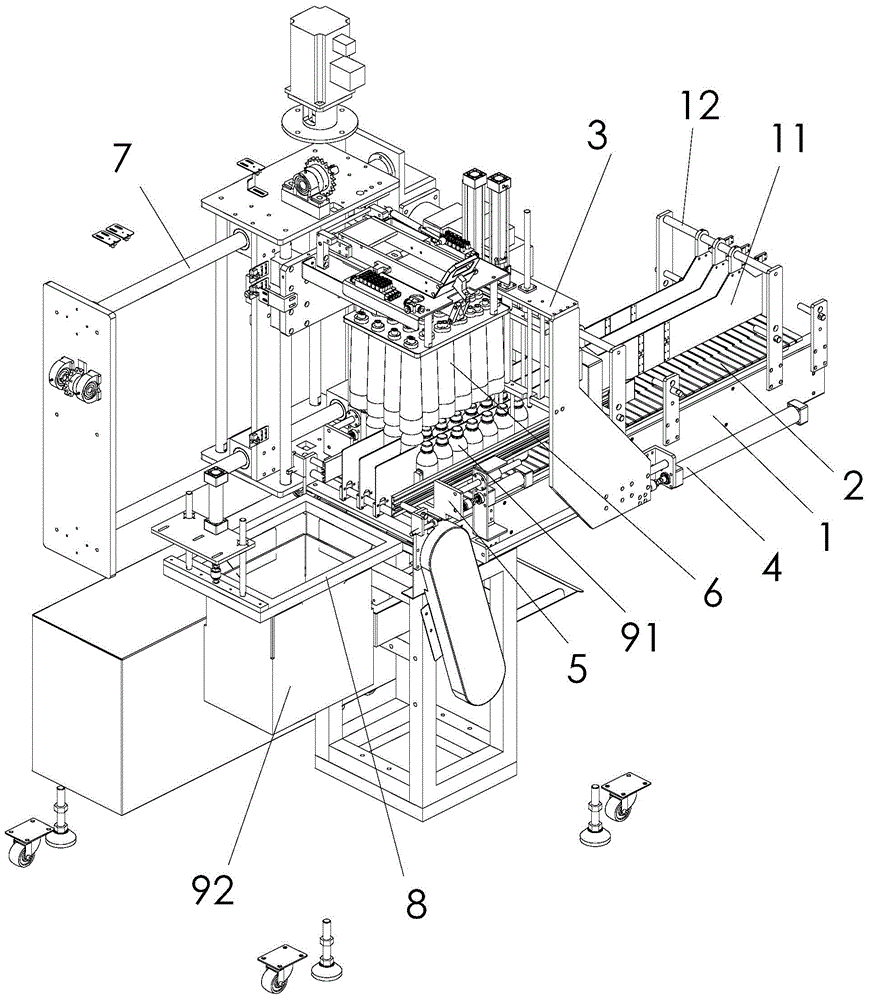

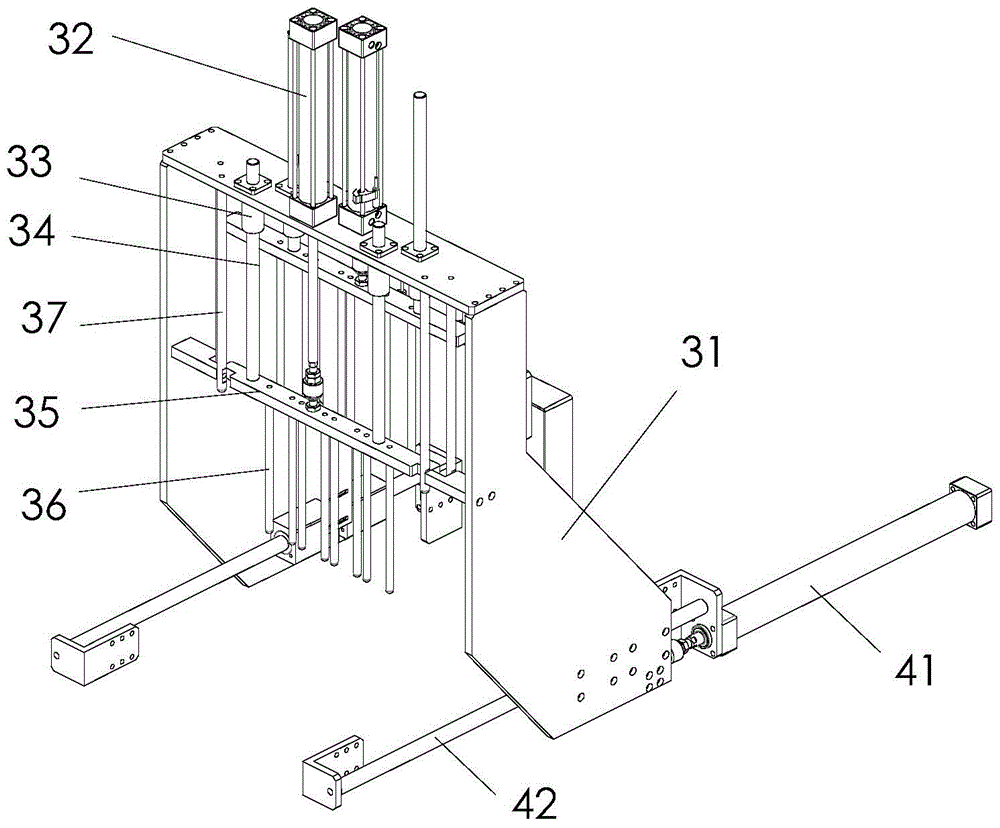

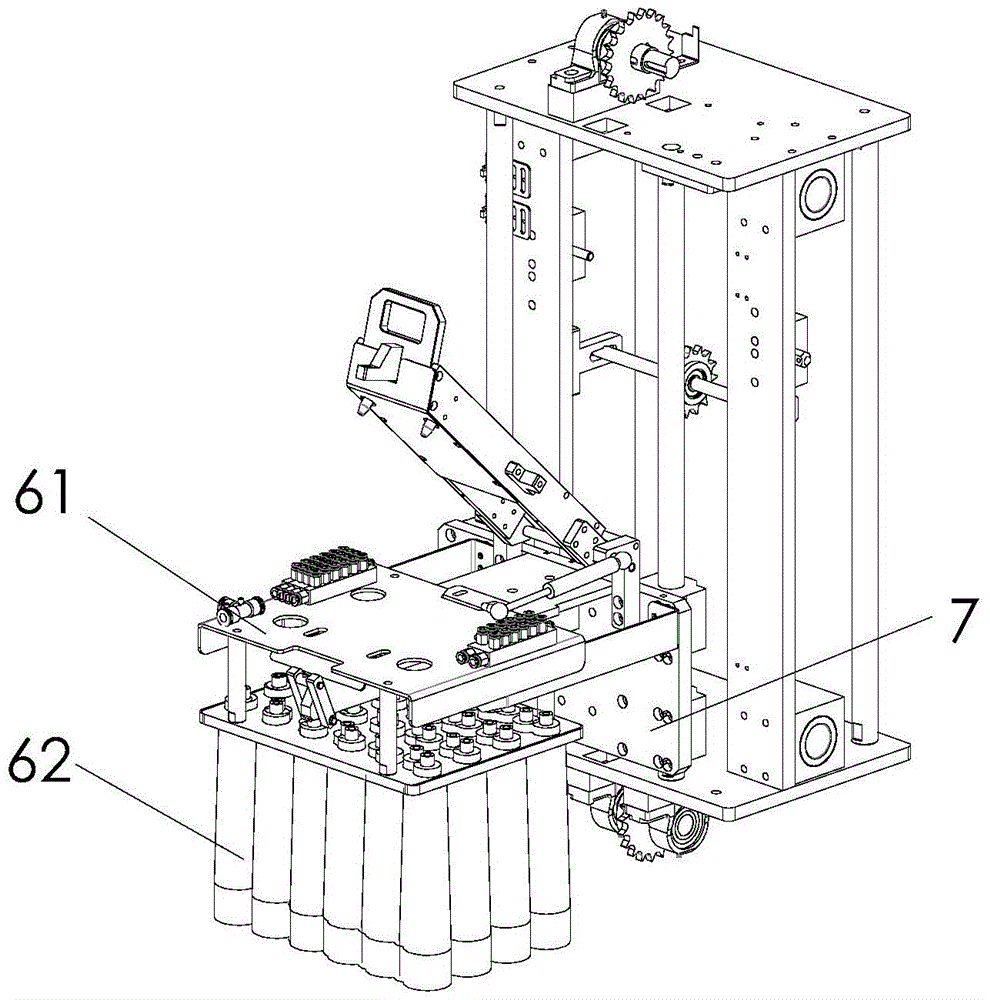

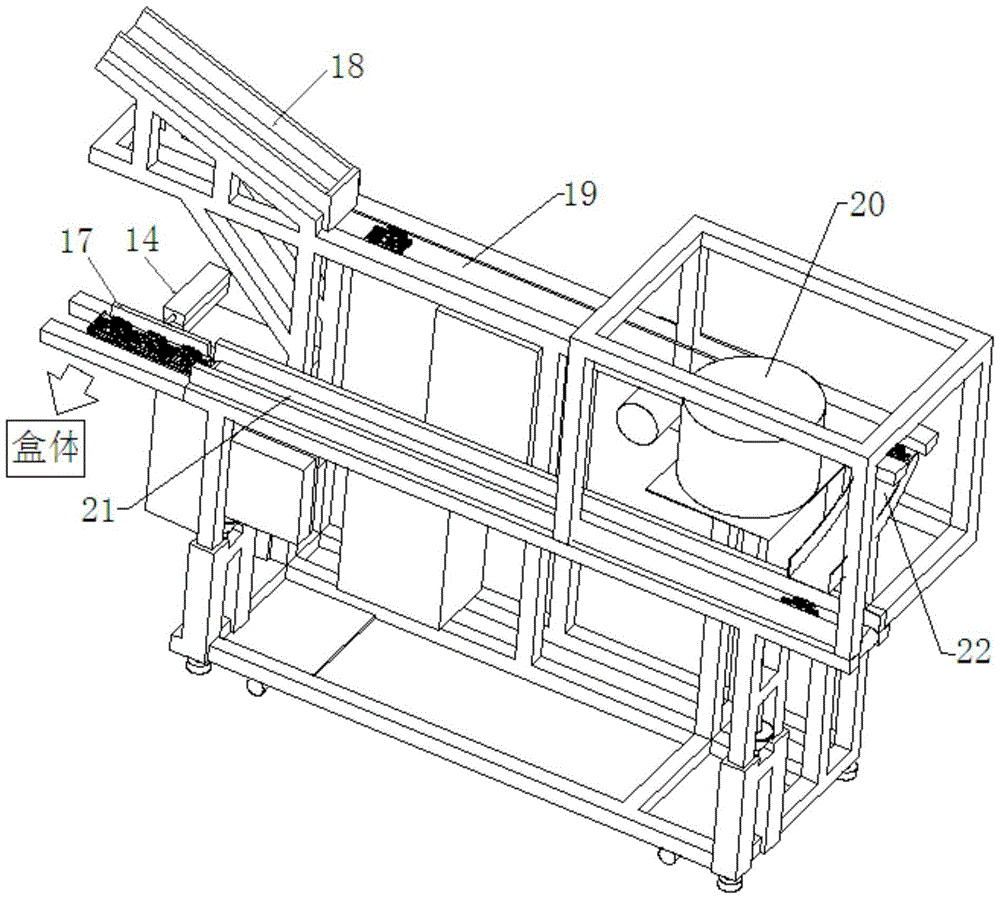

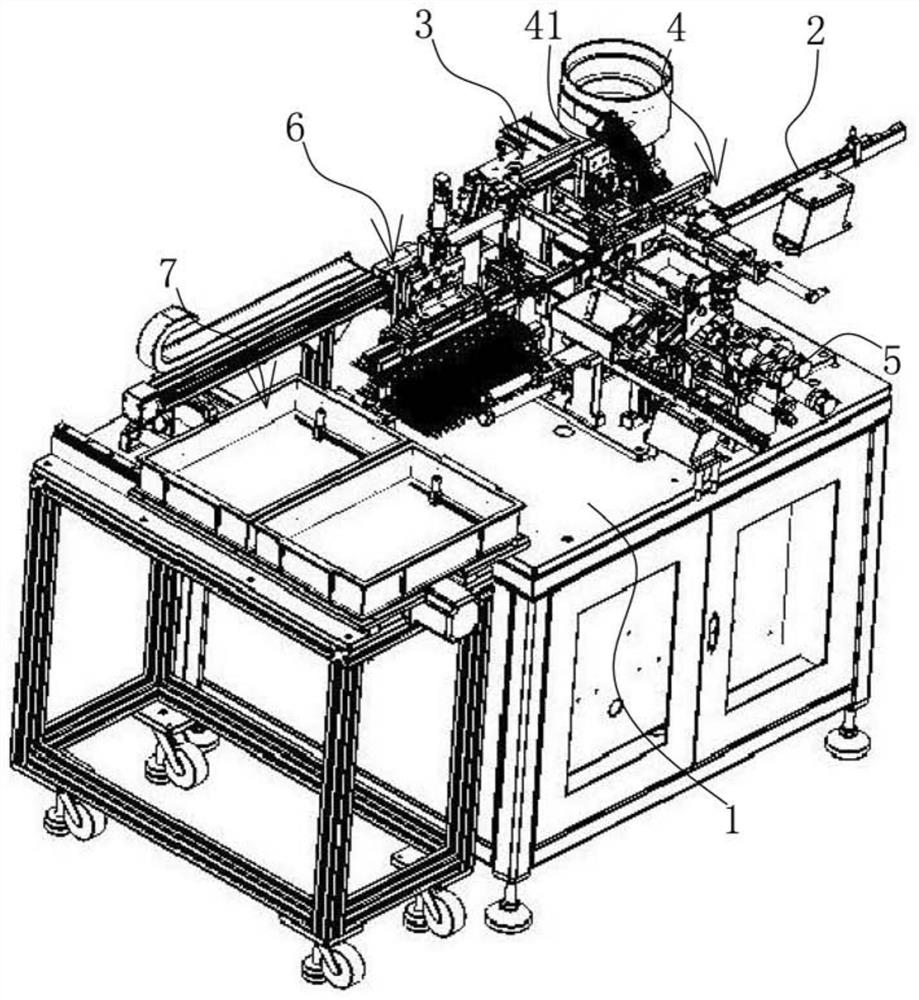

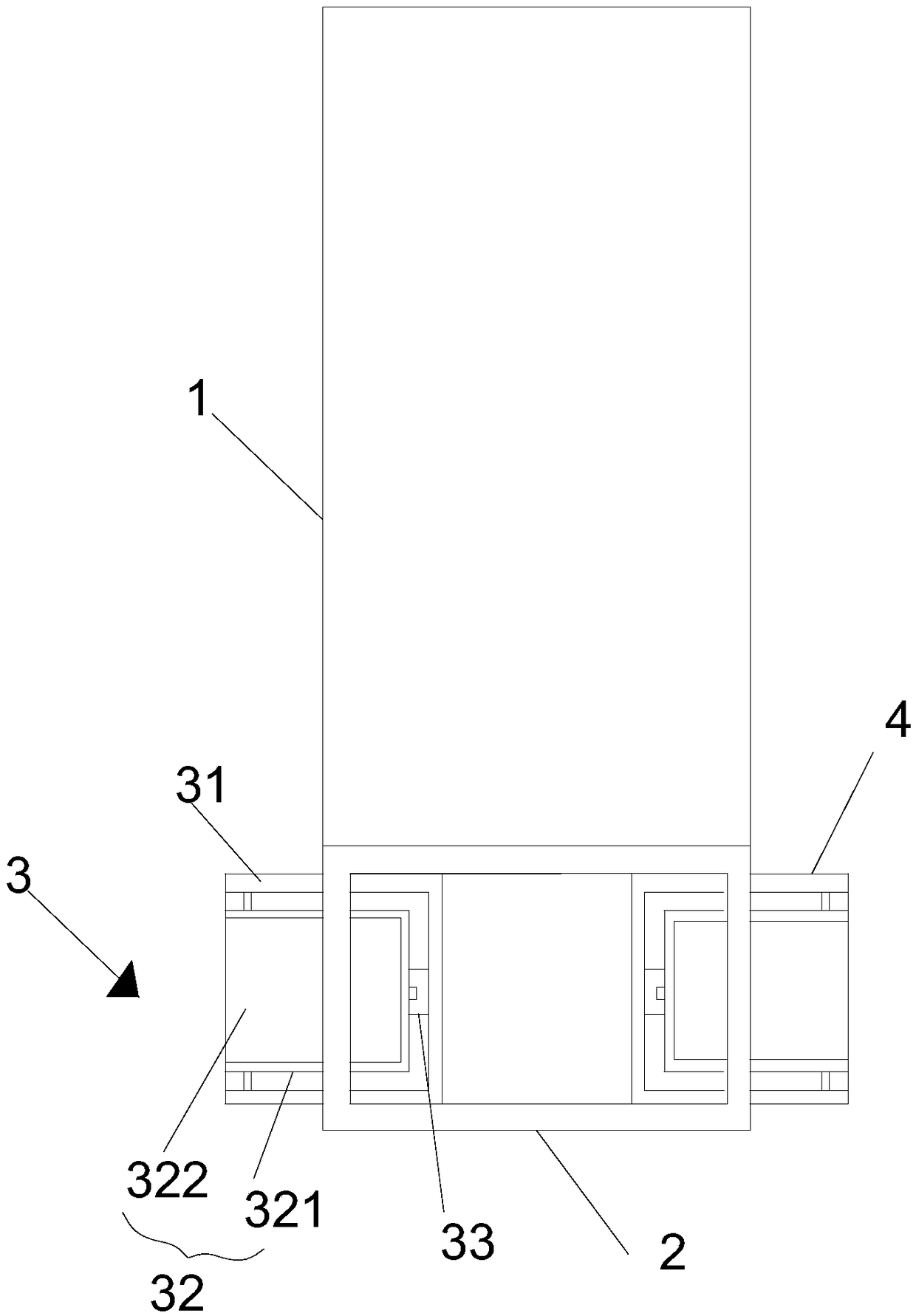

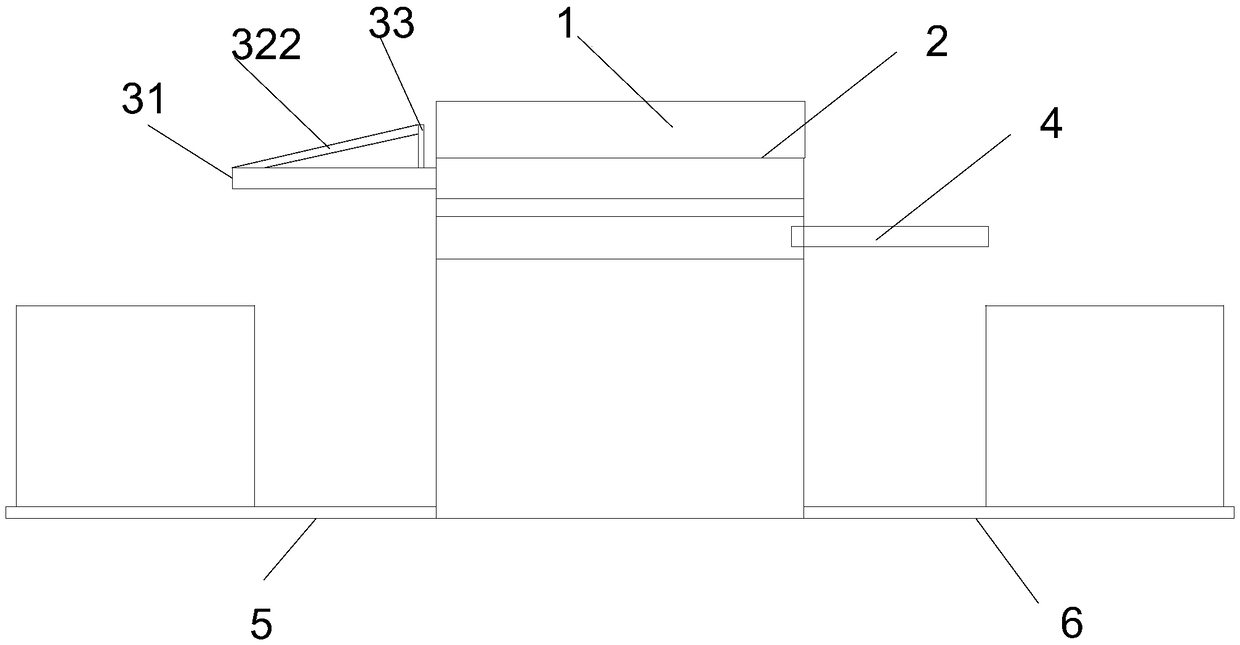

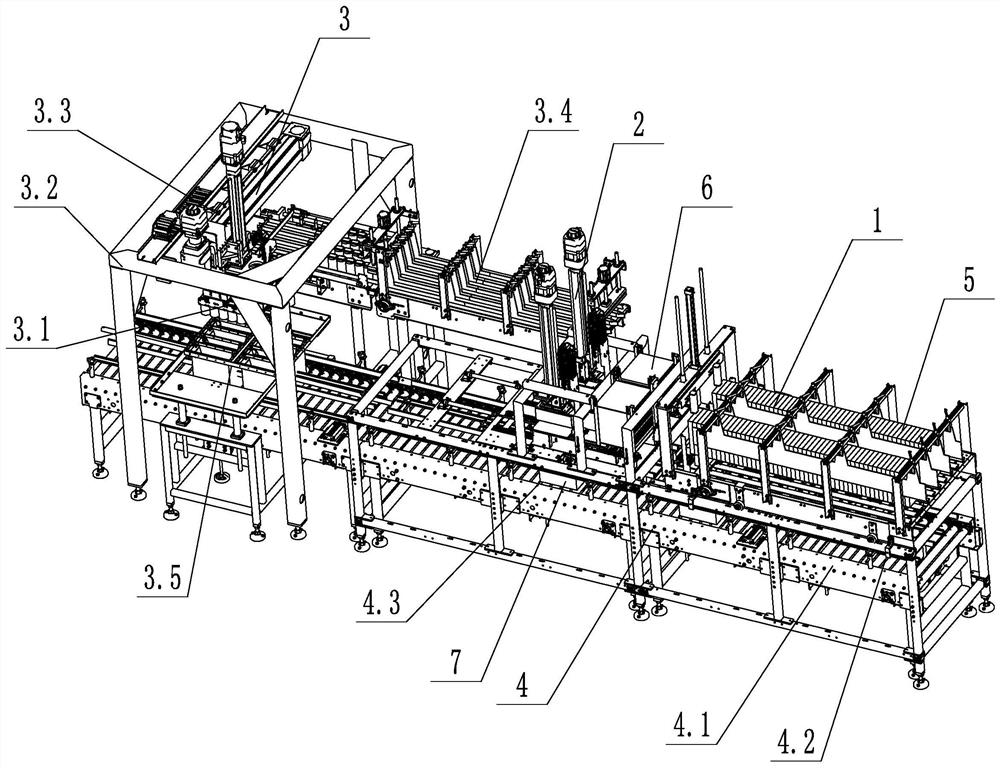

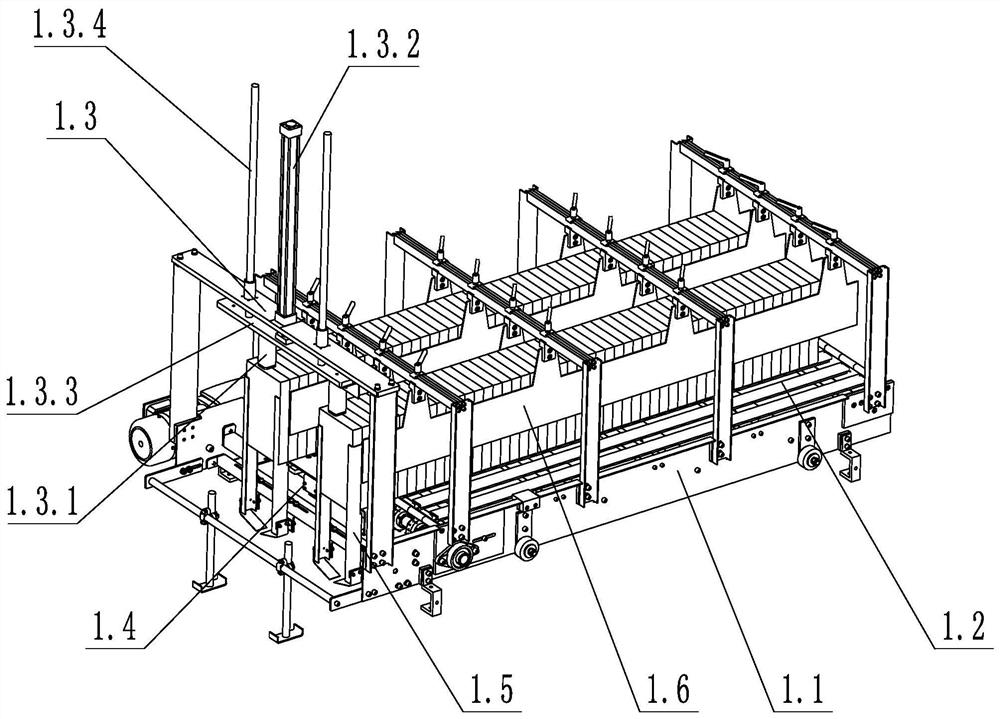

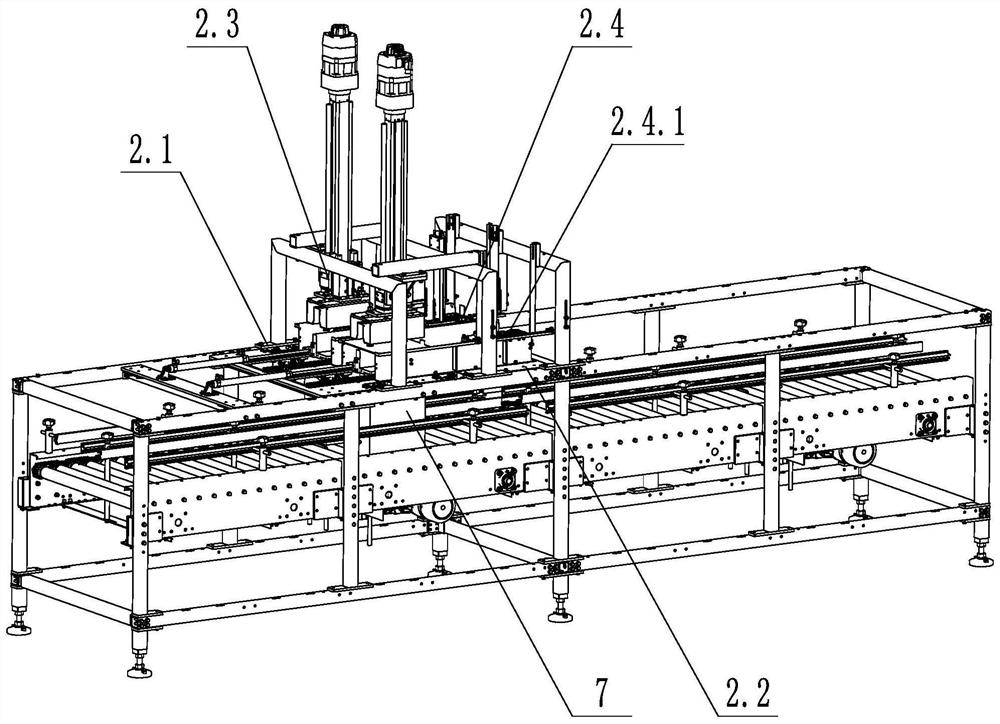

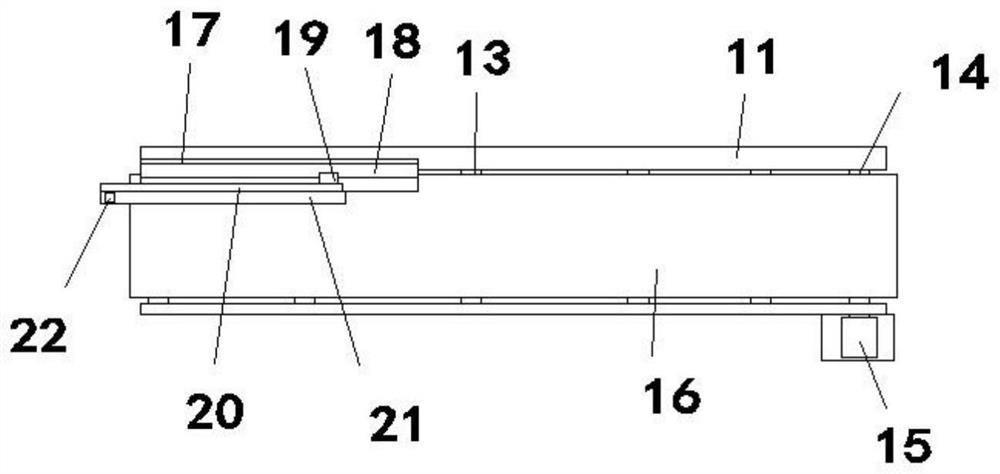

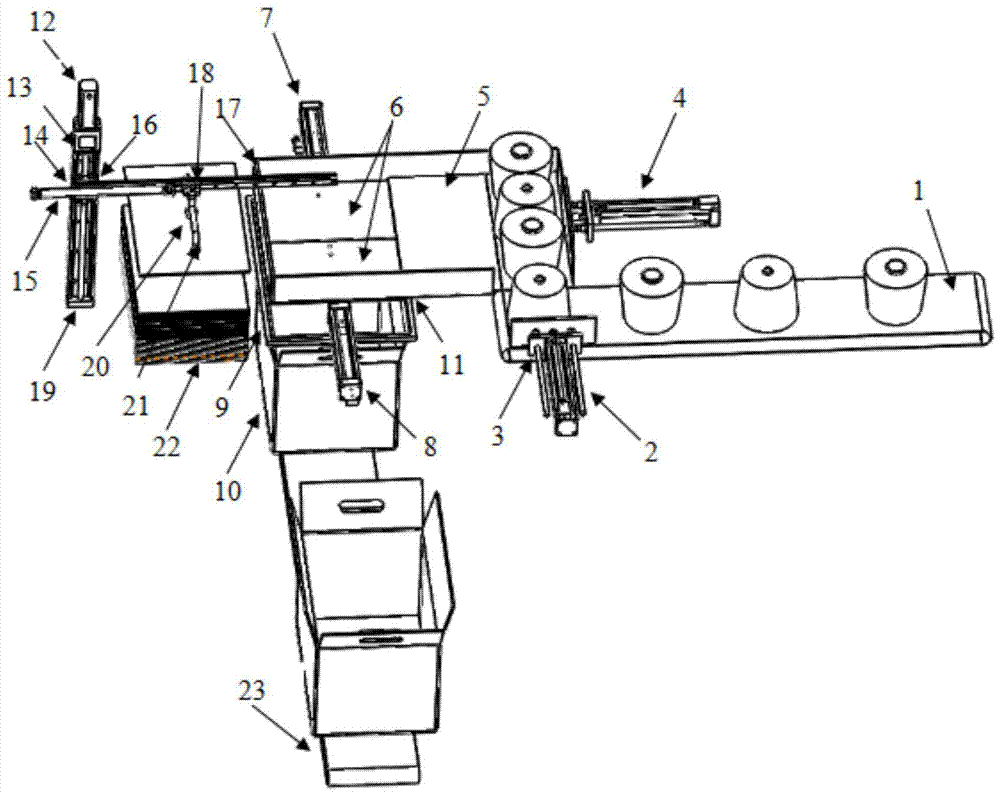

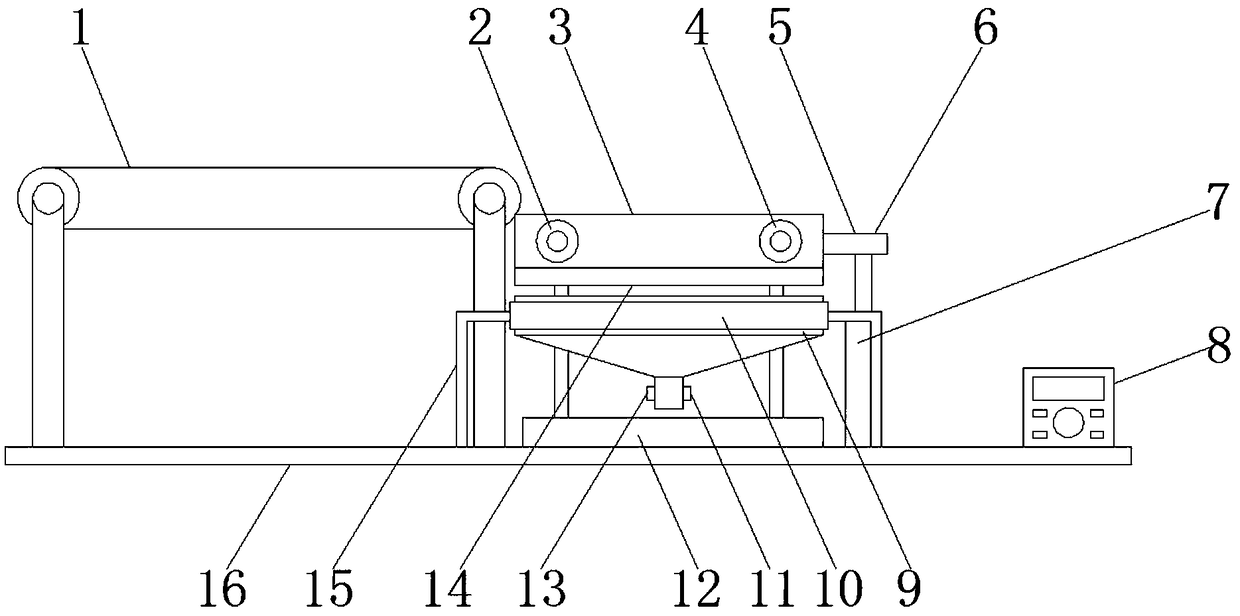

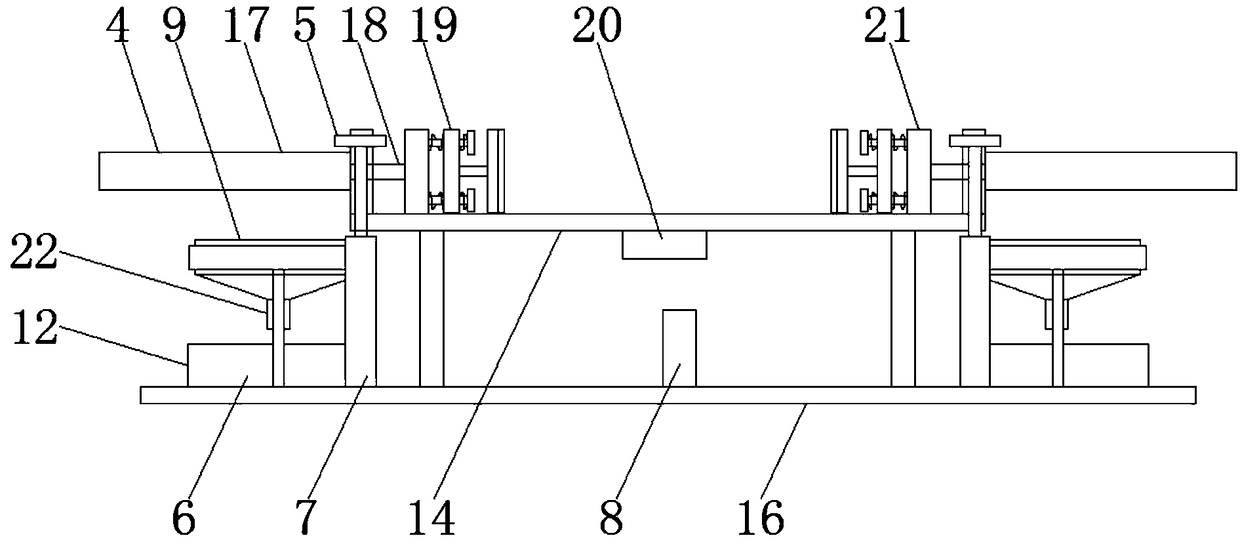

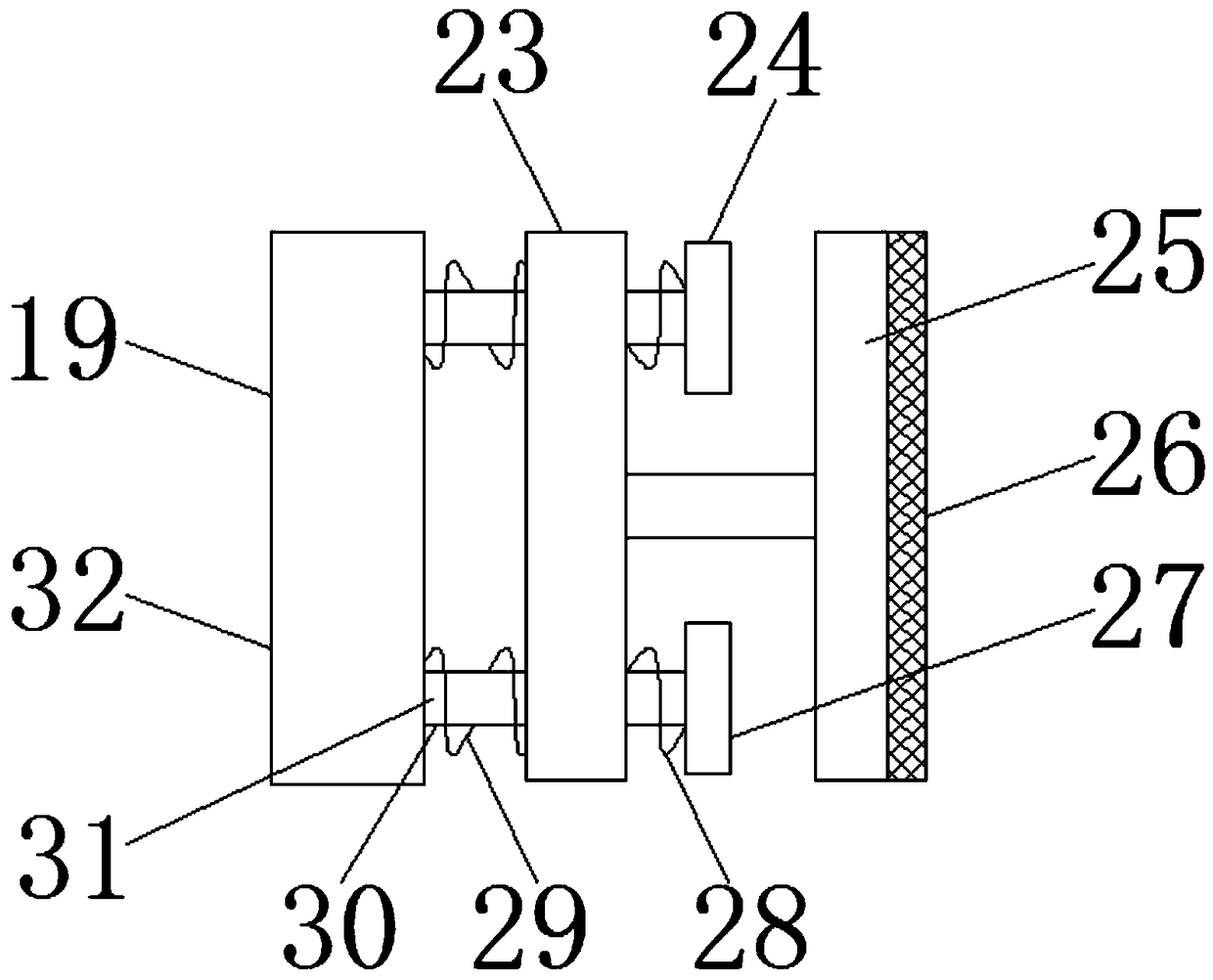

Automatic boxing device for cheese packaging line

ActiveCN105599998AHigh degree of automationEasy to operatePackaging automatic controlBiomedical engineeringAutomation

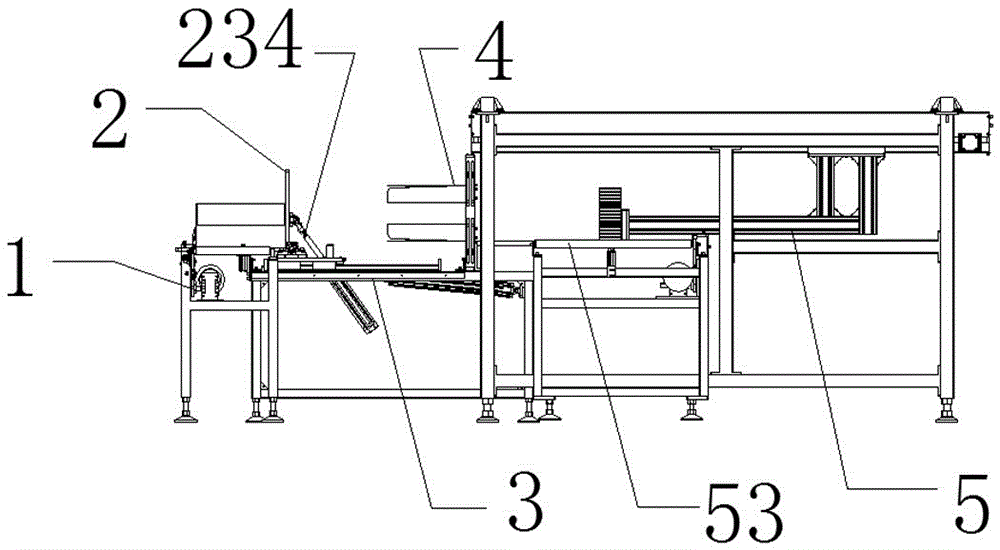

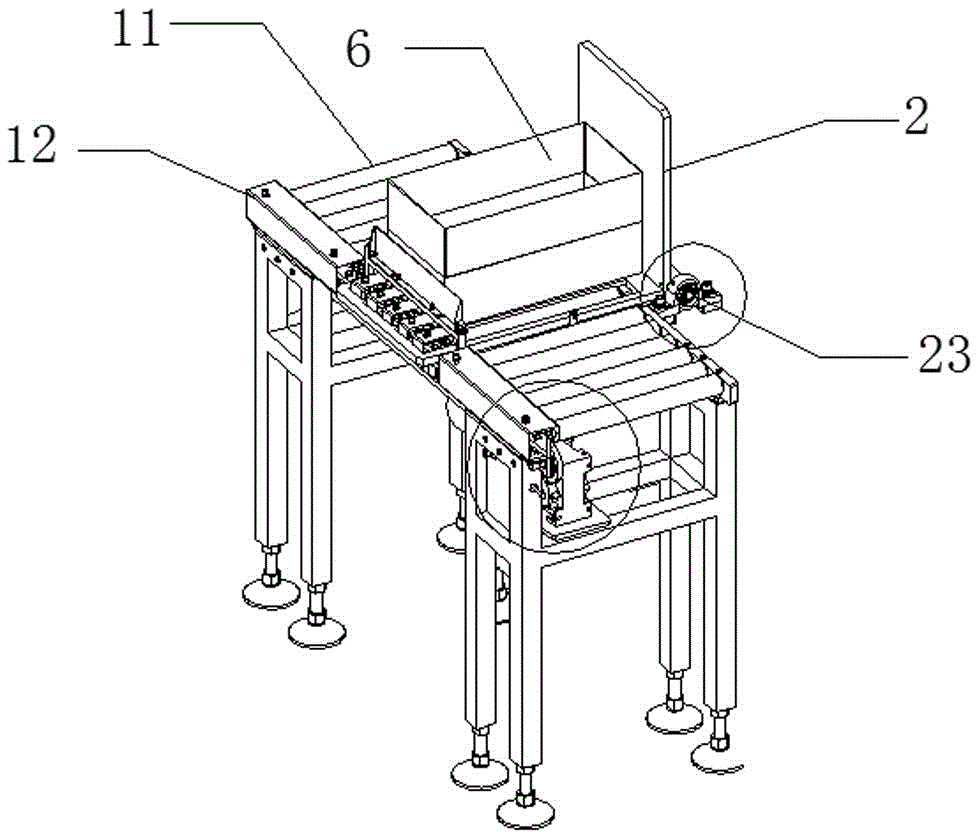

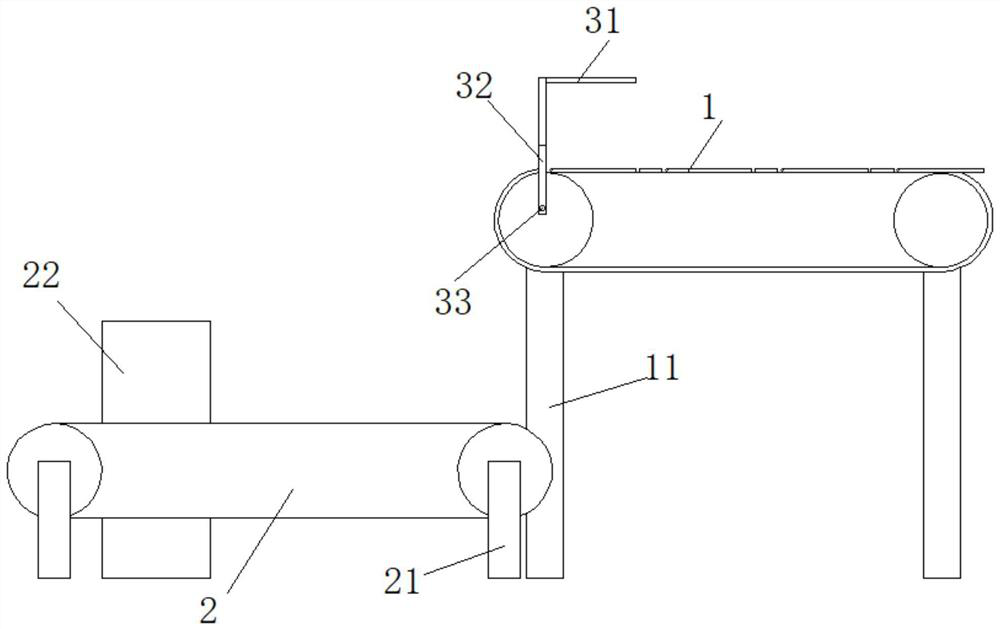

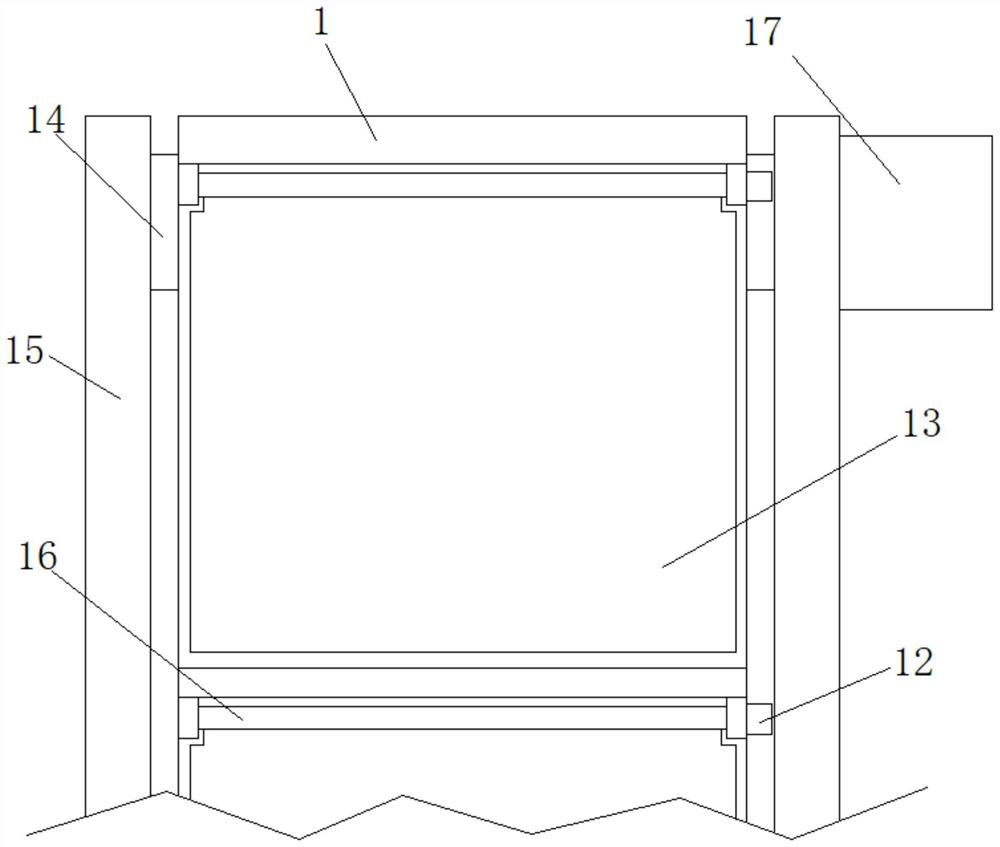

The invention relates to an automatic boxing device for a cheese packaging line. The automatic boxing device comprises a cheese arranging device, an automatic paperboard padding device, an automatic discharging device and a boxing guiding device. The cheese arranging device is located at the input end of an automatic balance weight device, the automatic discharging device and the cheese arranging device are connected, the automatic paperboard padding device is located on the side face of the automatic discharging device, and the boxing guiding device is located below the automatic discharging device. The automatic boxing device has the advantages of being high in automation degree, easy and convenient to operate and the like, automatic boxing of cheese is achieved, and the purposes of saving cost, reducing personnel input, improving the packaging efficiency and increasing the automation level are achieved.

Owner:WUHU ANPU ROBOT IND TECH RES INST

Tile cartonning device and application process

The invention discloses a tile cartonning device, which comprises a rack body, and is characterized in that a carton conveying rack, a carton placing rack, a carton driving mechanism, a carton erecting device and a tile pushing mechanism are sequentially arranged on the rack body from left to right. The tile cartonning device provided by the invention has the characteristics of reasonable and scientific structure design, reliability in operation, high cartonning efficiency, high cartonning quality and the like.

Owner:JINJIANG CITY CHAOJUN MACHINE CO LTD

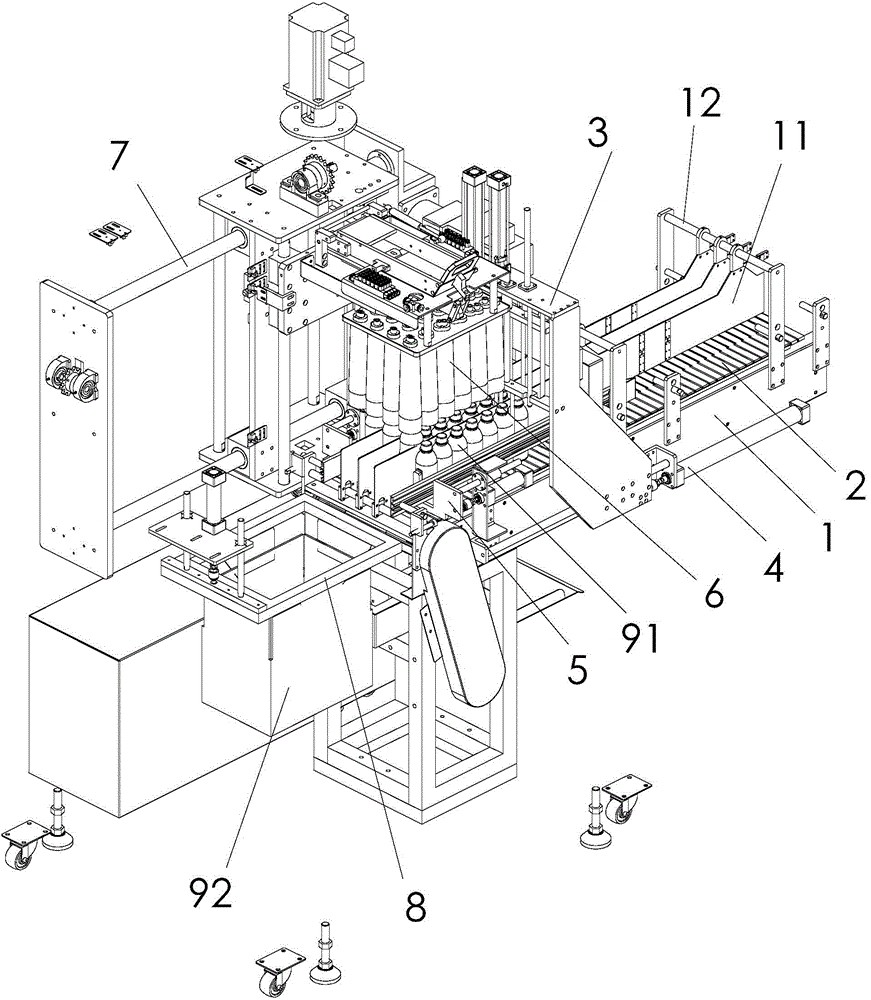

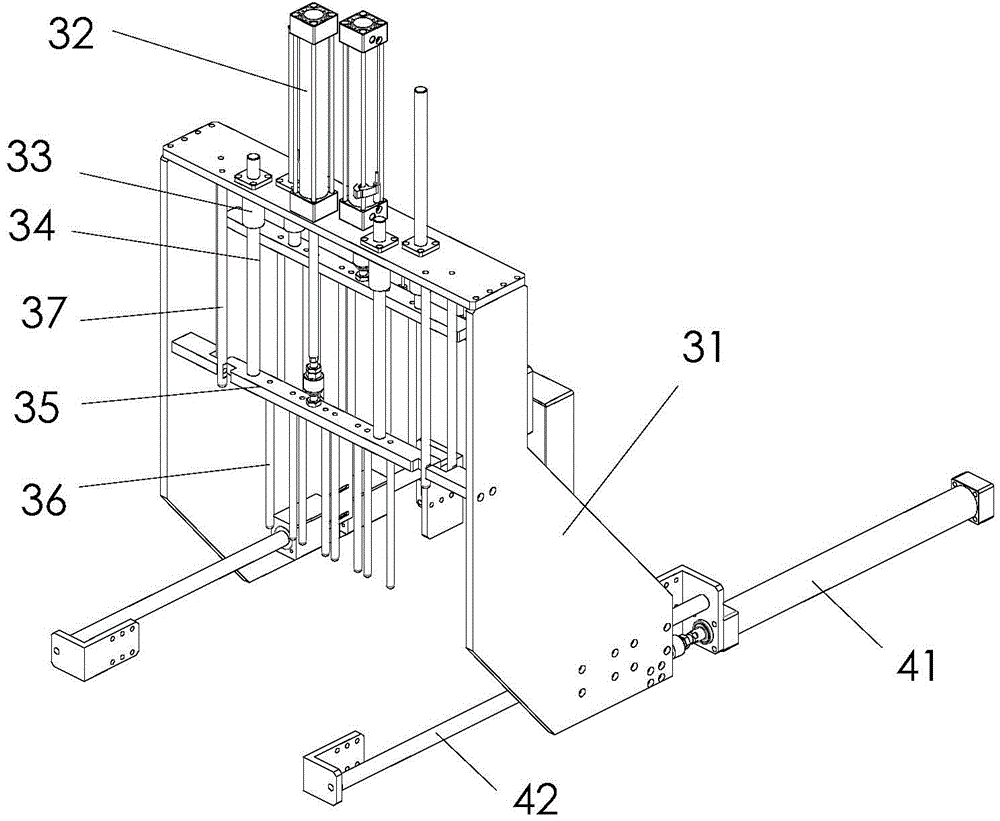

Automatic boxing method and device for bottles

The invention provides an automatic boxing method for bottles. The method includes the following steps that the bottles are attached to a blocking device and move forward, the blocking device returns to an original position, the bottles are separated by the blocking device, the bottles are attached to a baffle and move to a boxing area, the bottles enter boxes, and the baffle returns to an original position. The problem of toppling of the bottles in the moving process can be solved through the method; the bottles located in the boxing area and the bottles located in a feeding area can be separated to form a gap, so that the problem that a moving space is insufficient for a gripping device is solved. The invention further provides an automatic boxing device for the bottles. The device can be used for achieving automatic boxing of the bottles and avoiding topping of the bottles, can provide a sufficient moving space for the gripping device and is high in production efficiency and stability.

Owner:佛山市嘉荣智能机械有限公司

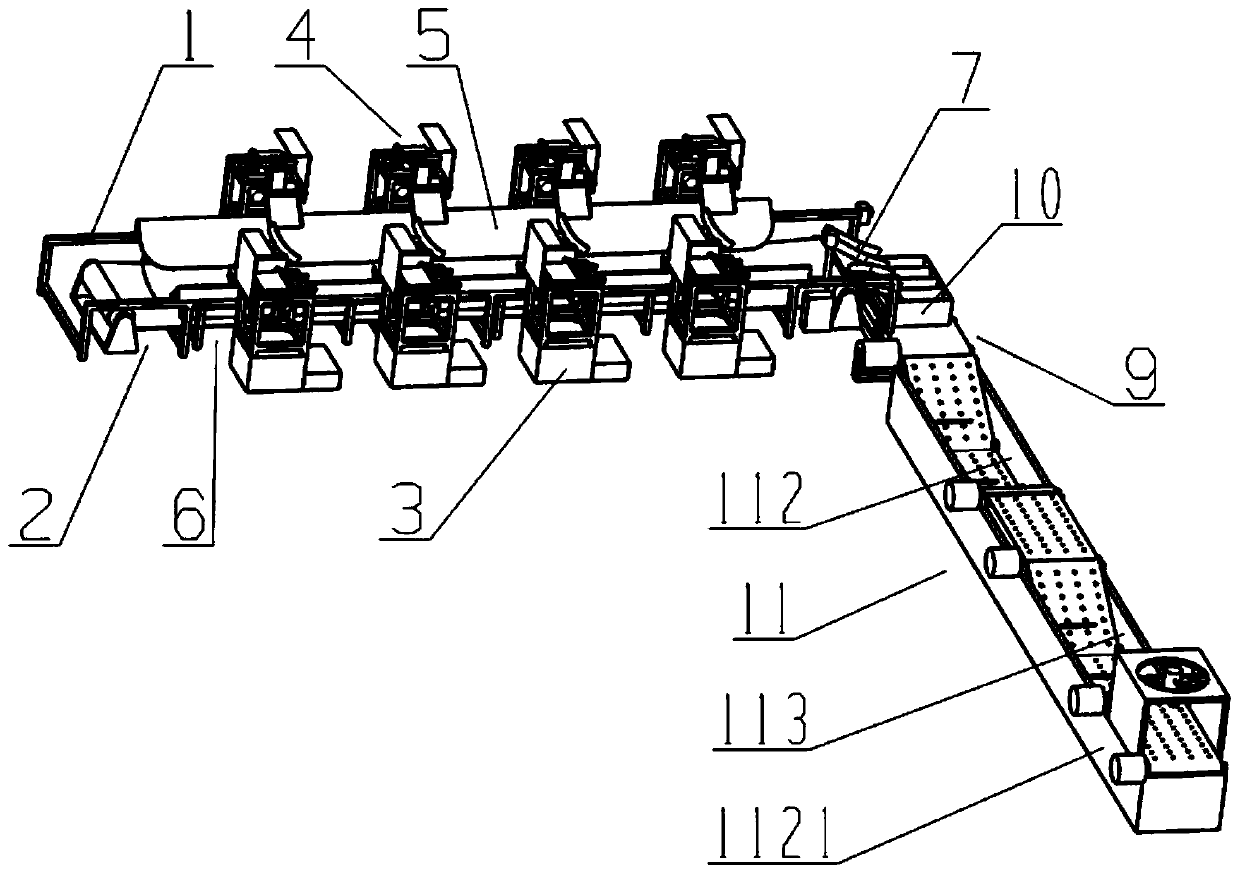

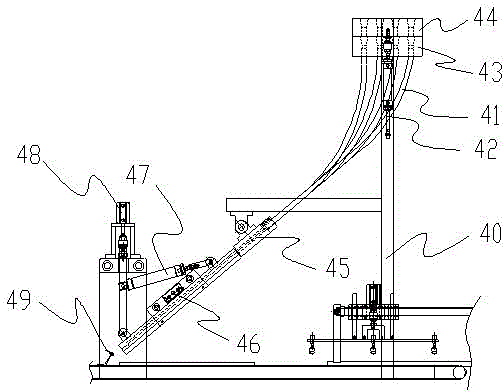

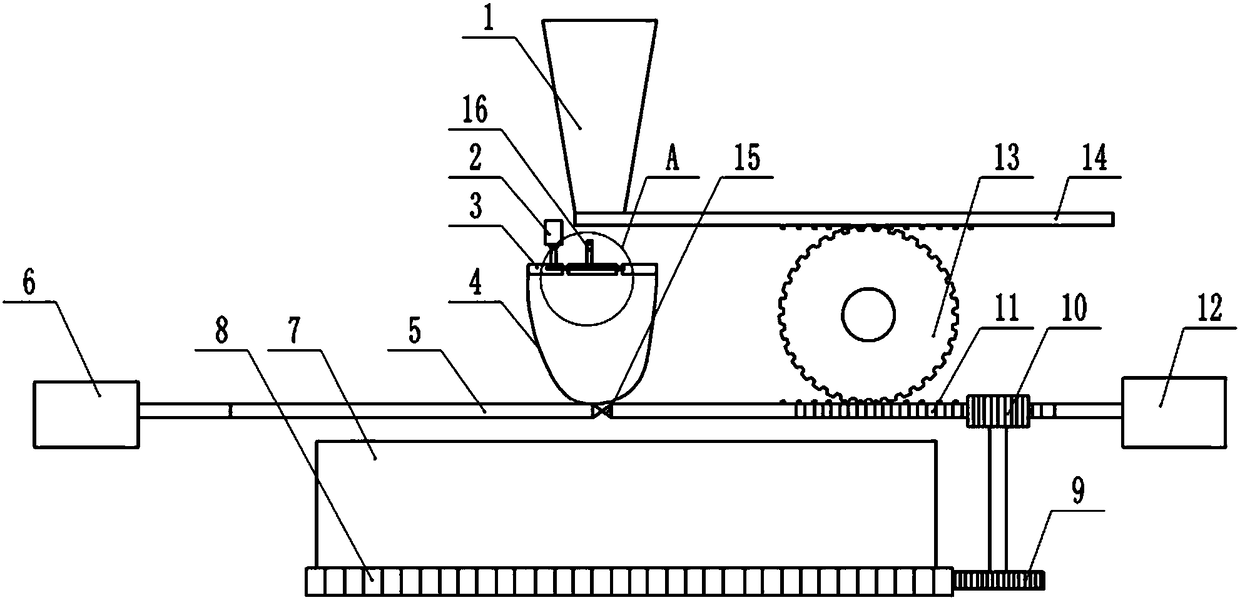

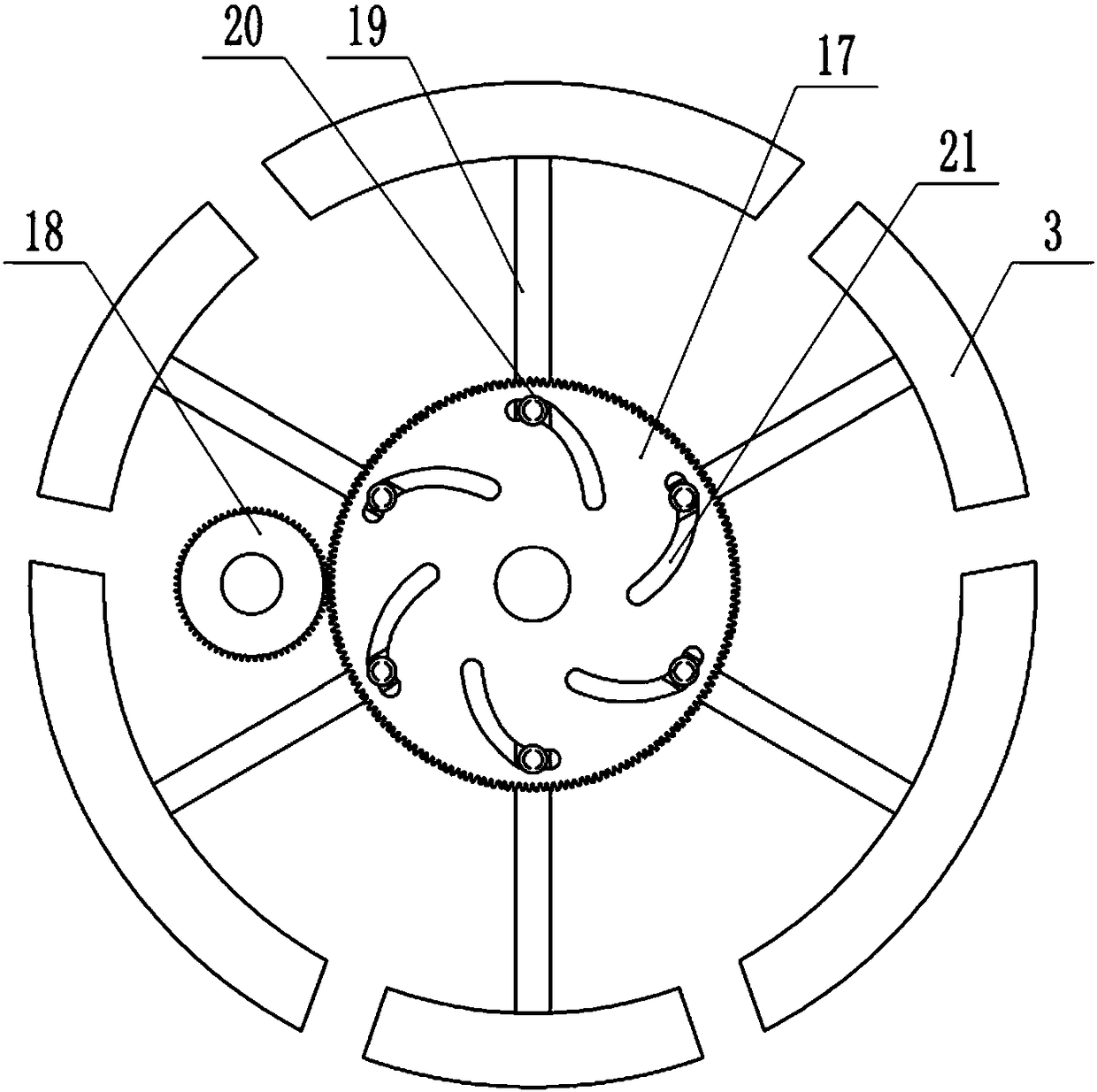

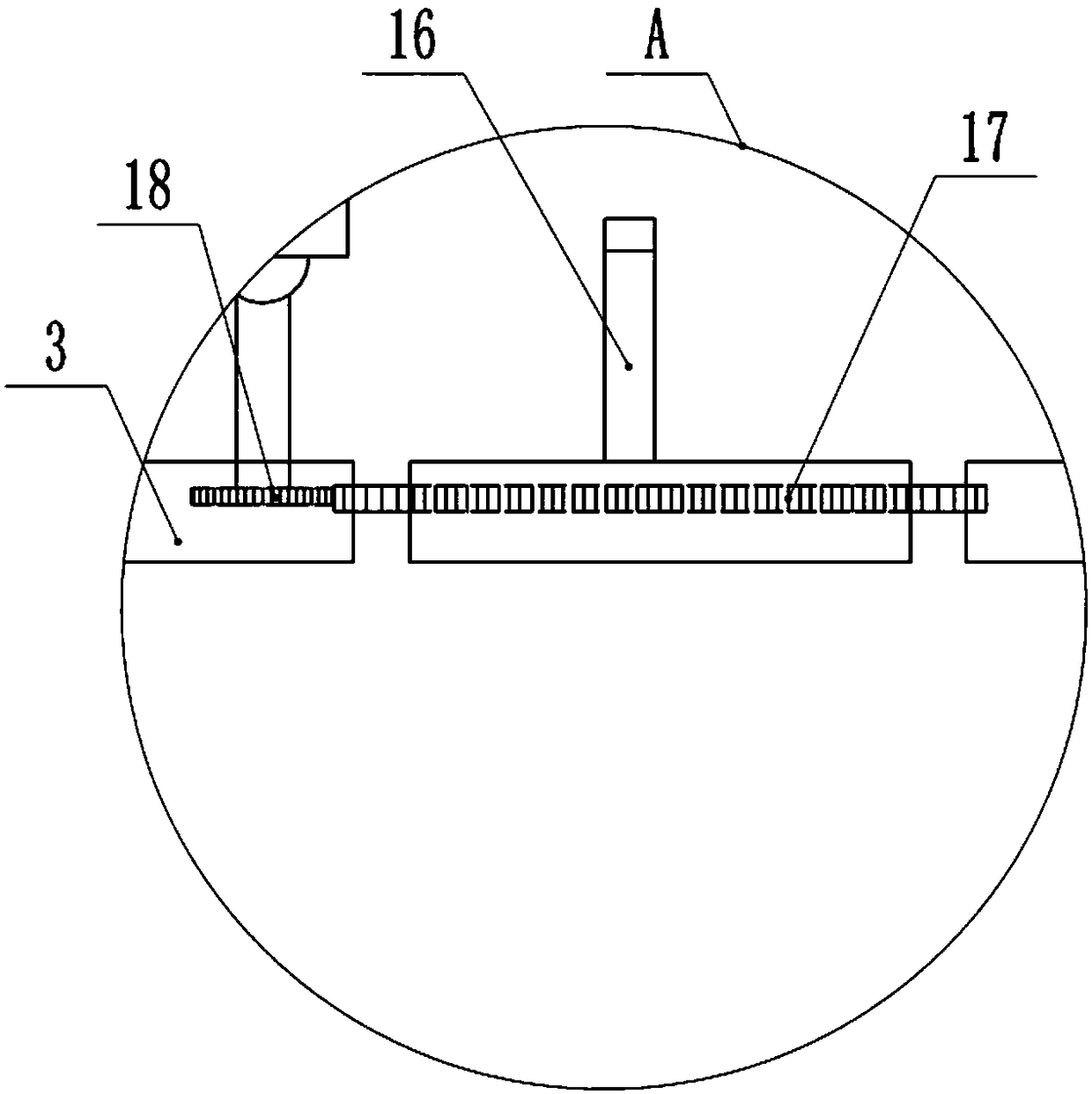

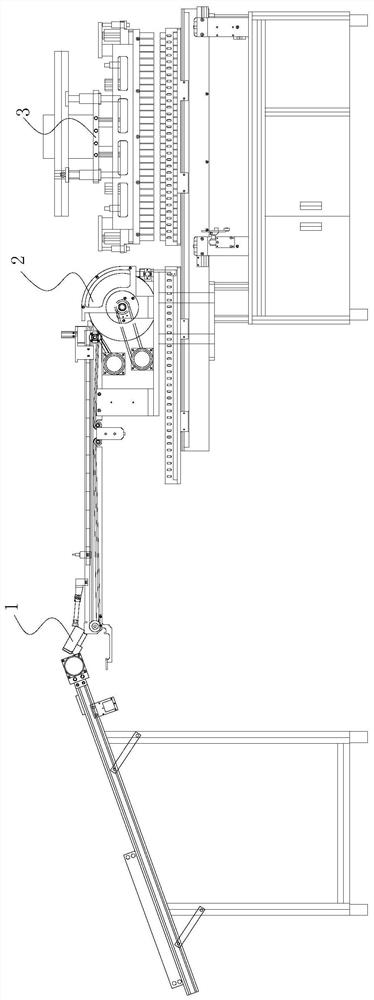

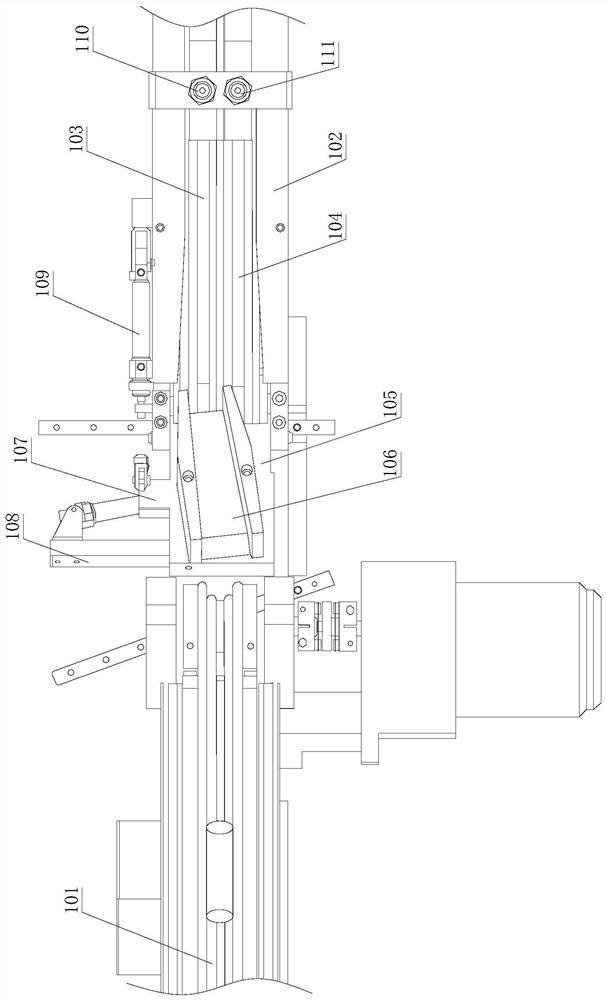

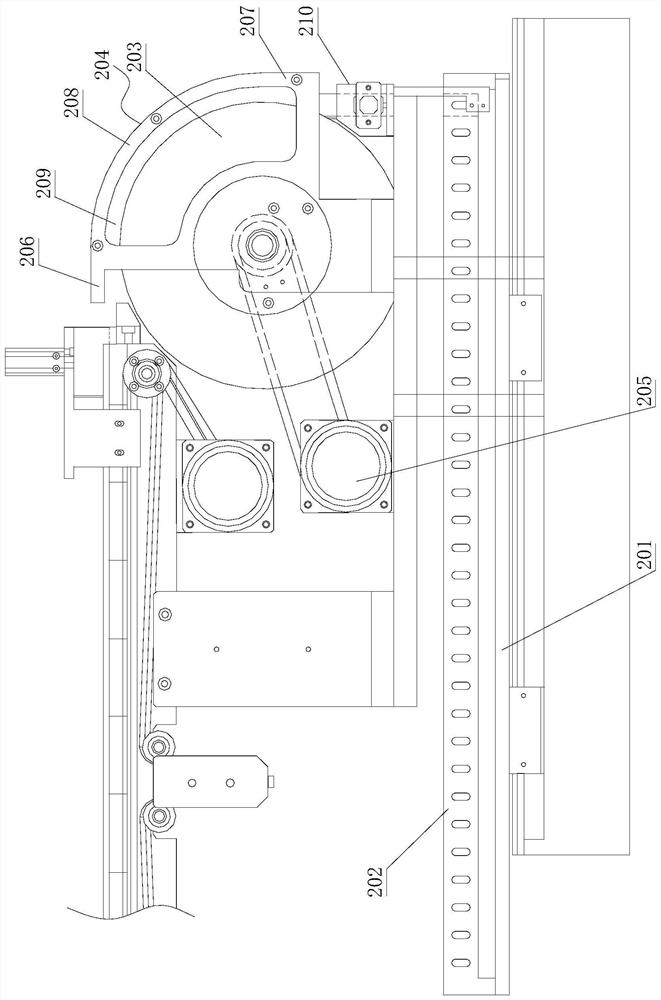

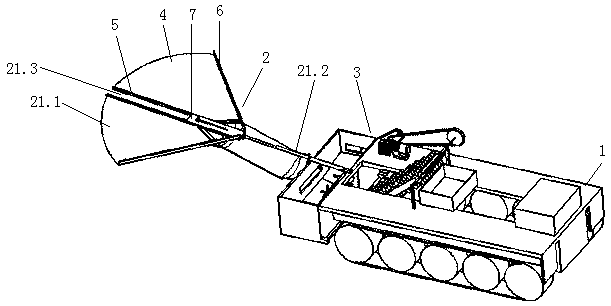

Healthy sugarcane seed stem production line

ActiveCN110583140ANeat cutImplement autoboxingDrying gas arrangementsMetal working apparatusProduction lineEngineering

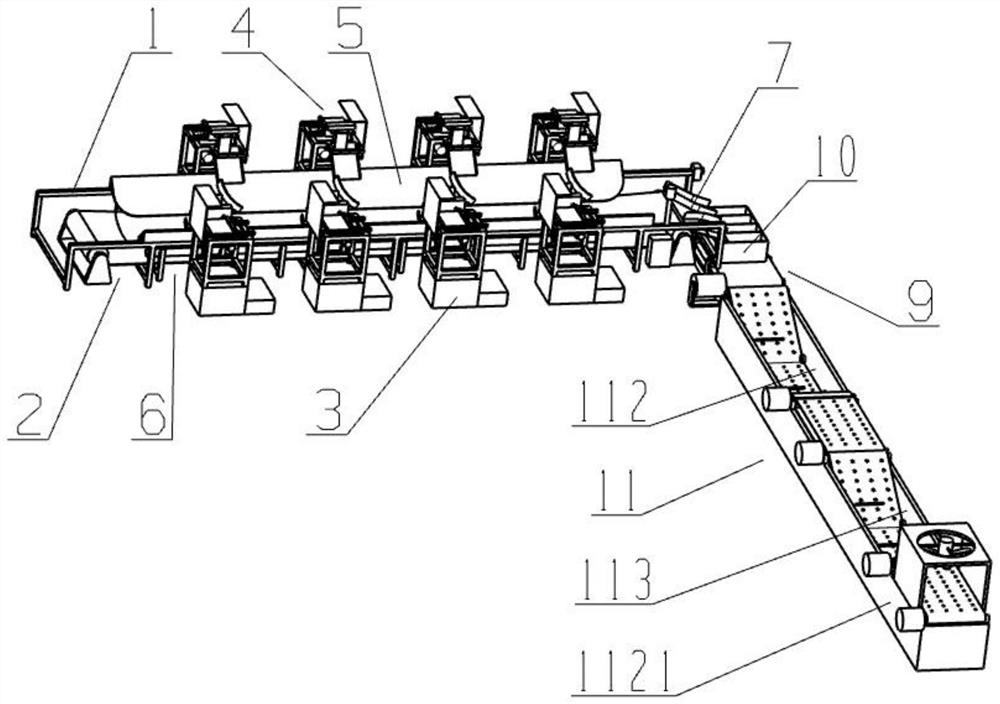

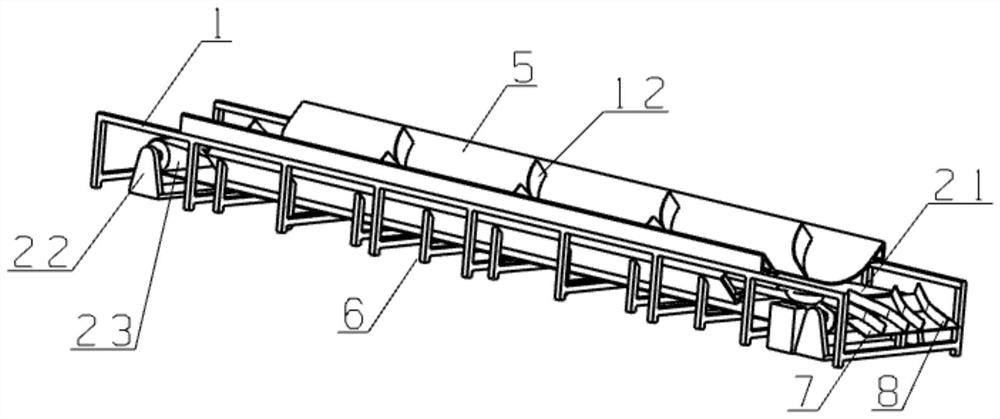

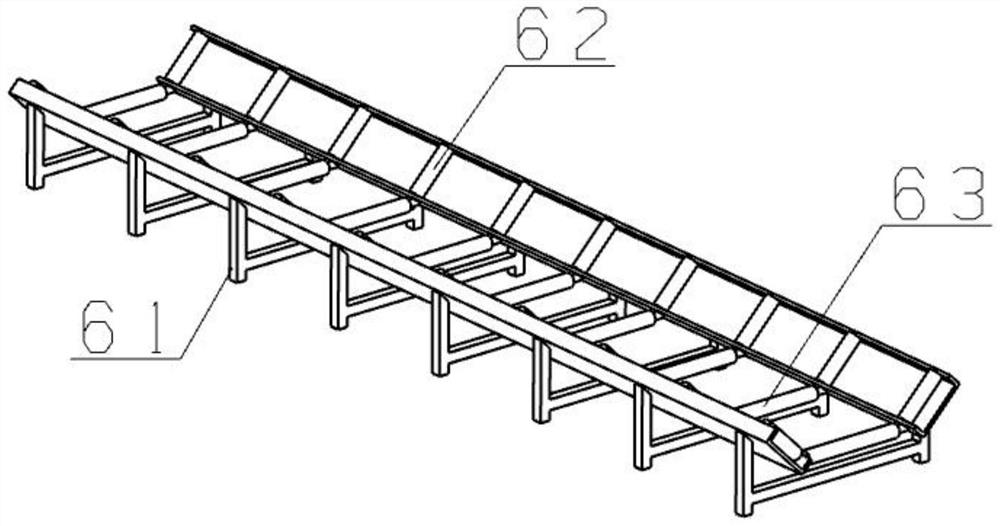

The invention relates to the technical field of sugarcane planting, and particularly discloses a healthy sugarcane seed stem production line. The healthy sugarcane seed stem production line comprisesa first rack, a conveying device, seed cutting devices, side slip plates, a belt bending mechanism, a feeding plate, a vibrating device, a material box and a disinfecting and coating device. Accordingto the production line, through the seed cutting devices, sugarcane stalks can be orderly and quickly cut into sugarcane seed stems; when the sugarcane seed stems are conveyed by the conveying device, the side slip plates and the belt bending mechanism can place the sugarcane seed stems to be parallel to the conveying direction in orientation, and then boxing is facilitated; the feeding plate andthe vibrating device can achieve automatic boxing of the sugarcane seed stems, and the sugarcane seed stems can be orderly stacked in the material box; the disinfecting and coating device can automatically disinfect, coat and blow-dry the sugarcane seed stems, it is avoided that an operator is in direct contact with disinfecting liquid and coating liquid, the safety of the production operation environment is guaranteed, and the operation efficiency is also improved.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

Automatic boxing device and method for canned products in gift box

Owner:HANGZHOU WAHAHA PRECISION MACHINERY

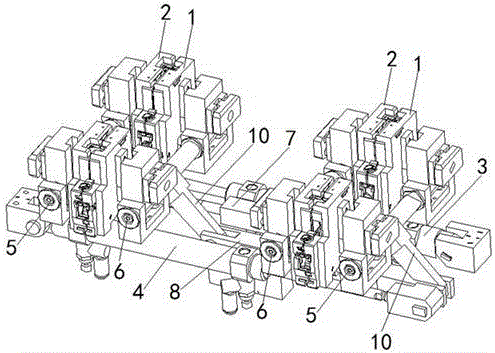

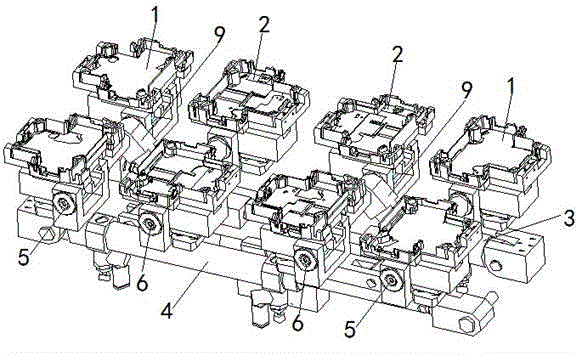

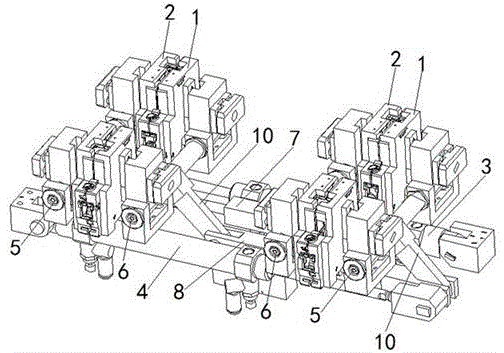

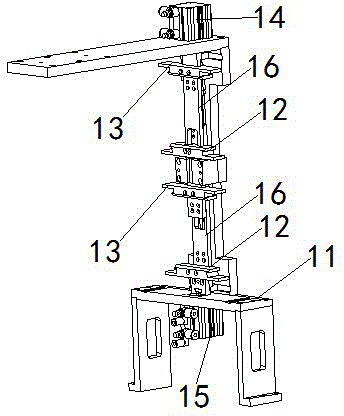

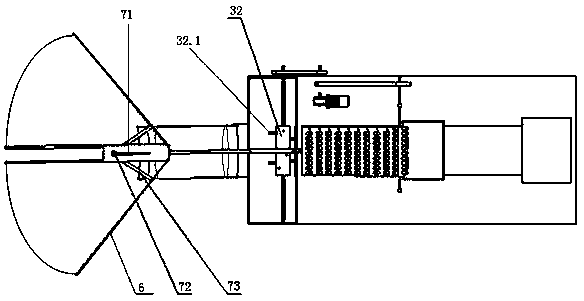

Automatic arrangement box filler for injection-molded rod-like parts

ActiveCN104058118AReduce labor intensityImplement autoboxingIndividual articlesInjection mouldingWorkload

The invention relates to an automatic arrangement box filler for injection-molded rod-like parts and aims to solve the problems that manually arranging, placing and boxing injection-molded rod-like part products are high in workload and low in efficiency. The automatic arrangement box filler comprises a worktable and an injection molding manipulator, and is characterized in that a conveyor belt is arranged on the worktable, an arrangement jig device is arranged above the conveyor belt, and the injection molding manipulator is mounted above the arrangement jig device; a material receiving device matched with a take-out clamp at the lower end of the injection molding manipulator is arranged at the top of the arrangement jig device, and the material receiving device guides products to an arrangement jig collecting and distributing part through a downgoing transition pipe; a waved plate supply device is arranged at one end of the conveyor belt, and a dishful extraction device is arranged at the other end of the conveyor belt. Unified boxing size setting and ordering are carried out at the arrangement jig collecting and distributing part, automatic boxing is realized, continuous action is ensured, the labor intensity of manual boxing is relieved and high safety and efficiency are achieved.

Owner:NINGBO JIELI COSMETIC PACKAGING

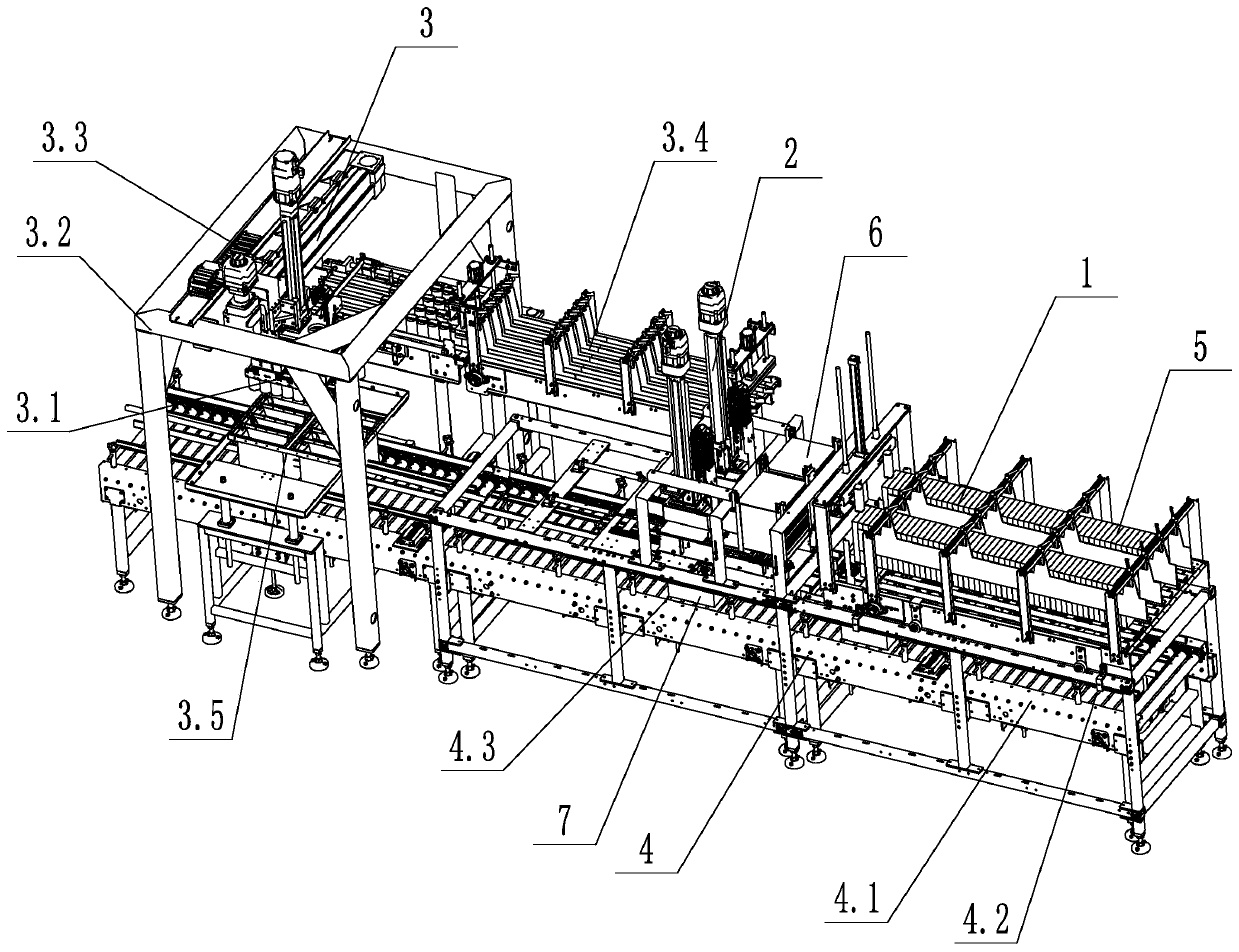

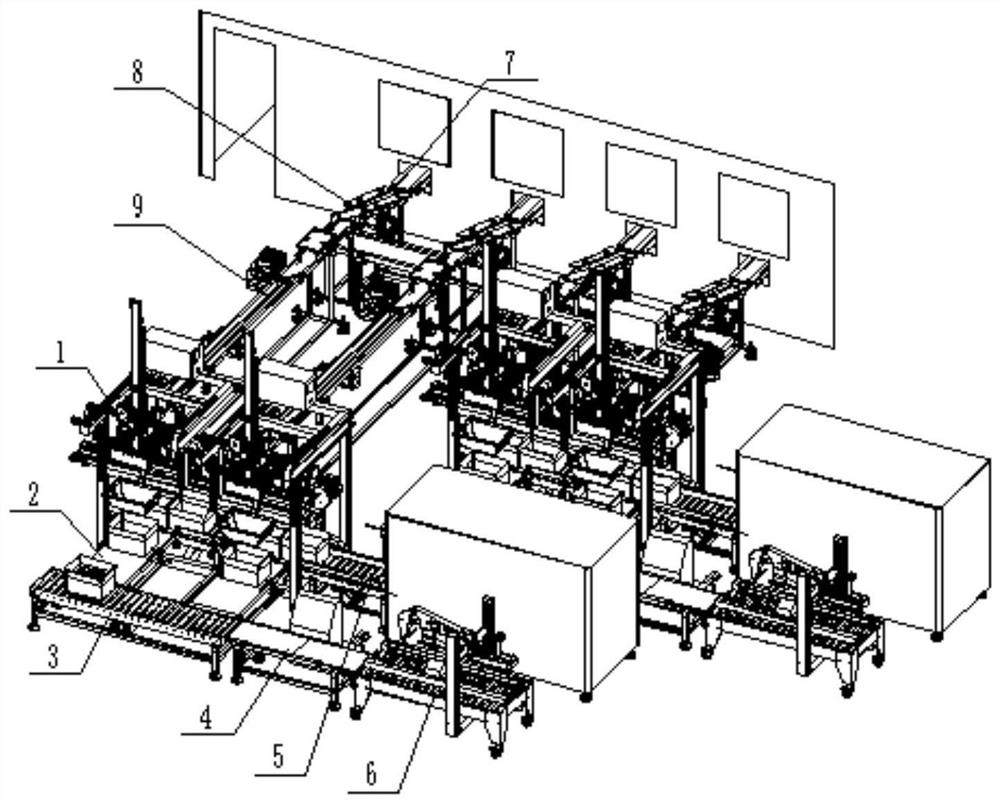

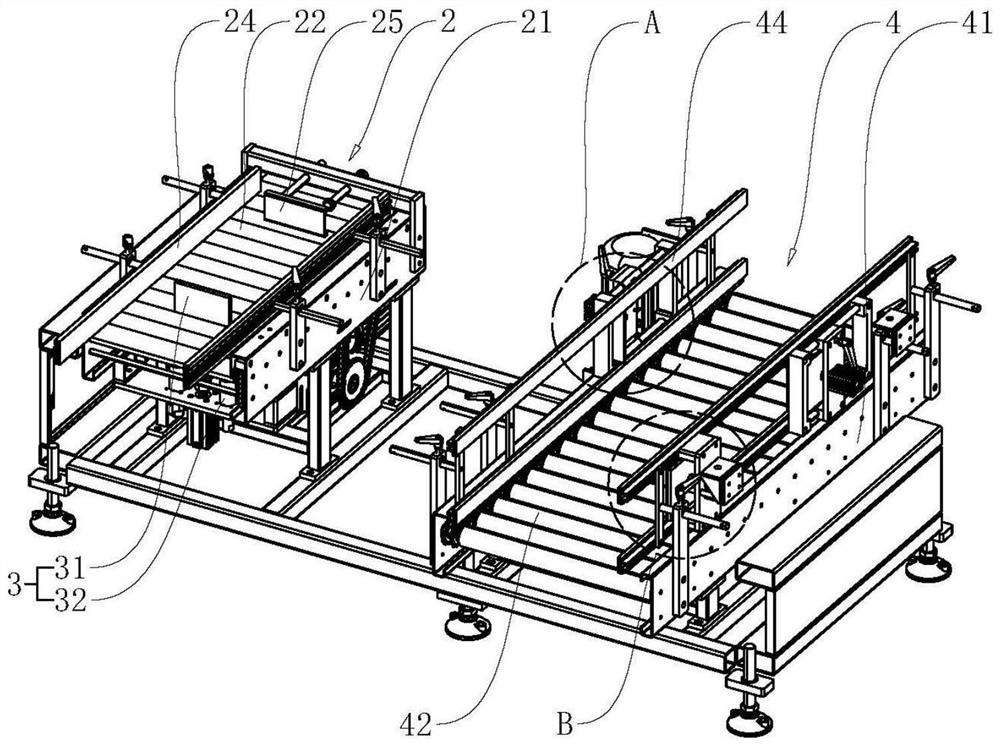

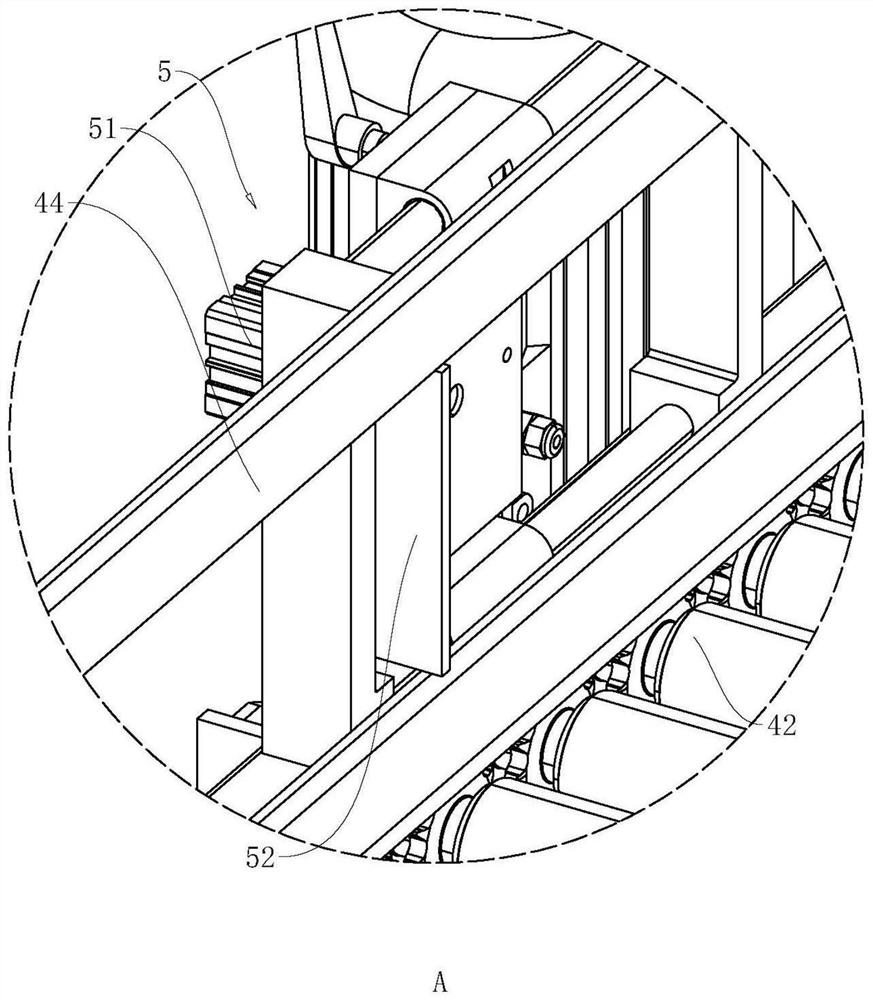

Automatic boxing production system

PendingCN111924238AImplement autoboxingImprove packaging effectConveyorsGas current separationIndustrial engineeringEMPTY CONTAINER

The invention discloses an automatic boxing production system. The automatic boxing production system comprises a boxing component, an empty box positioning rack and a box sealing machine, wherein anempty box conveying mechanism is arranged at an input end of the empty box positioning rack; a weighing and conveying mechanism is arranged at an input end of the box sealing machine; a full box conveying rack is arranged between the weighing and conveying mechanism and the empty box positioning rack; a box pushing mechanism is arranged on the outer side of the empty box positioning rack; the boxing component comprises a boxing rack; an arraying and conveying mechanism, a material sorting table and a grabbing mechanism are sequentially arranged on the boxing rack in a direction from a part away from the empty box positioning rack to the empty box positioning rack; a pushing mechanism is arranged between the arraying and conveying mechanism and the material sorting table; a material sortingcomponent is arranged on the surface of the material sorting table; and the grabbing mechanism is closely adjacent to the empty box positioning rack. The automatic boxing production system has the beneficial effects that automatic boxing can be realized; a boxing effect is good, and efficiency is high; unqualified products can be removed; missing boxing and error boxing are avoided; and a using effect is good.

Owner:龙海市安得马富机械有限公司

Automatic packaging device

ActiveCN108502267APrevent shrinkageAvoid stackingWrapper twisting/gatheringIndividual articlesSlide plateEngineering

The invention relates to an automatic packaging device. The automatic packaging device comprises a machine frame, wherein a first sliding plate and a second sliding plate are slidably connected to themachine frame, the side parts, right opposite to each other, of the first sliding plate and the second sliding plate are correspondingly provided with heat sealing knives, a first air cylinder is arranged on the first sliding plate, and a second air cylinder is arranged on the second sliding plate; a rotating disc is arranged below the first sliding plate and the second sliding plate, and meshingteeth are arranged on the outer wall of the rotating disc; a first gear meshes with the meshing teeth, a vertical shaft is connected to the first gear, and a one-way bearing is connected between thevertical shaft and the first gear; the first sliding plate is connected with a first mechanism used for enabling the vertical shaft to rotate, a supporting ring with adjustable diameter is arranged above the first sliding plate and the second sliding plate, and the supporting ring is connected with an adjusting mechanism used for adjusting the diameter of the supporting ring; and a hopper is arranged above the supporting ring, a discharging plate is connected to the bottom of the hopper in a sliding mode, and a second mechanism is connected between the discharging plate and the first sliding plate. According to the scheme, food can be conveniently put into plastic bags with different sizes, and packaging is not limited by the size of the plastic bags.

Owner:重庆市长寿区你我他商贸连锁有限公司

A bottle automatic packing method and packing equipment thereof

The invention provides an automatic boxing method for bottles. The method includes the following steps that the bottles are attached to a blocking device and move forward, the blocking device returns to an original position, the bottles are separated by the blocking device, the bottles are attached to a baffle and move to a boxing area, the bottles enter boxes, and the baffle returns to an original position. The problem of toppling of the bottles in the moving process can be solved through the method; the bottles located in the boxing area and the bottles located in a feeding area can be separated to form a gap, so that the problem that a moving space is insufficient for a gripping device is solved. The invention further provides an automatic boxing device for the bottles. The device can be used for achieving automatic boxing of the bottles and avoiding topping of the bottles, can provide a sufficient moving space for the gripping device and is high in production efficiency and stability.

Owner:佛山市嘉荣智能机械有限公司

A product fastening device and a fully automatic reclaiming device with the product fastening device

ActiveCN104309116BRealize automatic buckleReduce labor costsStructural engineeringMechanical engineering

Owner:CWB AUTOMOTIVE ELECTRONICS

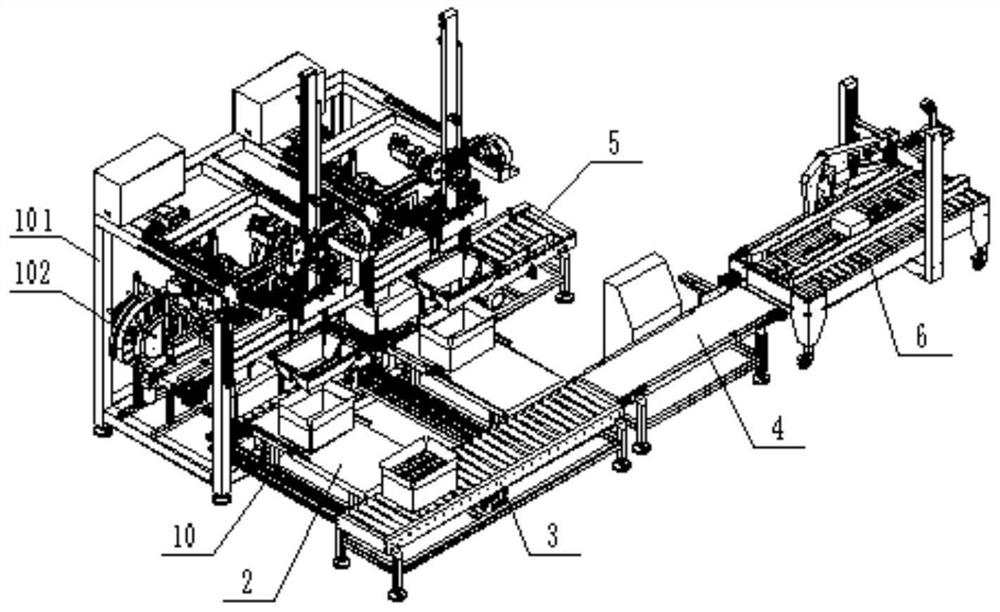

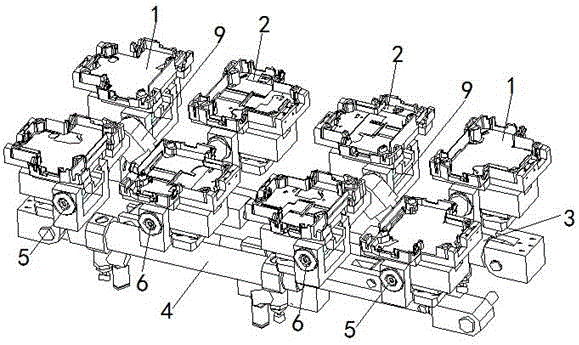

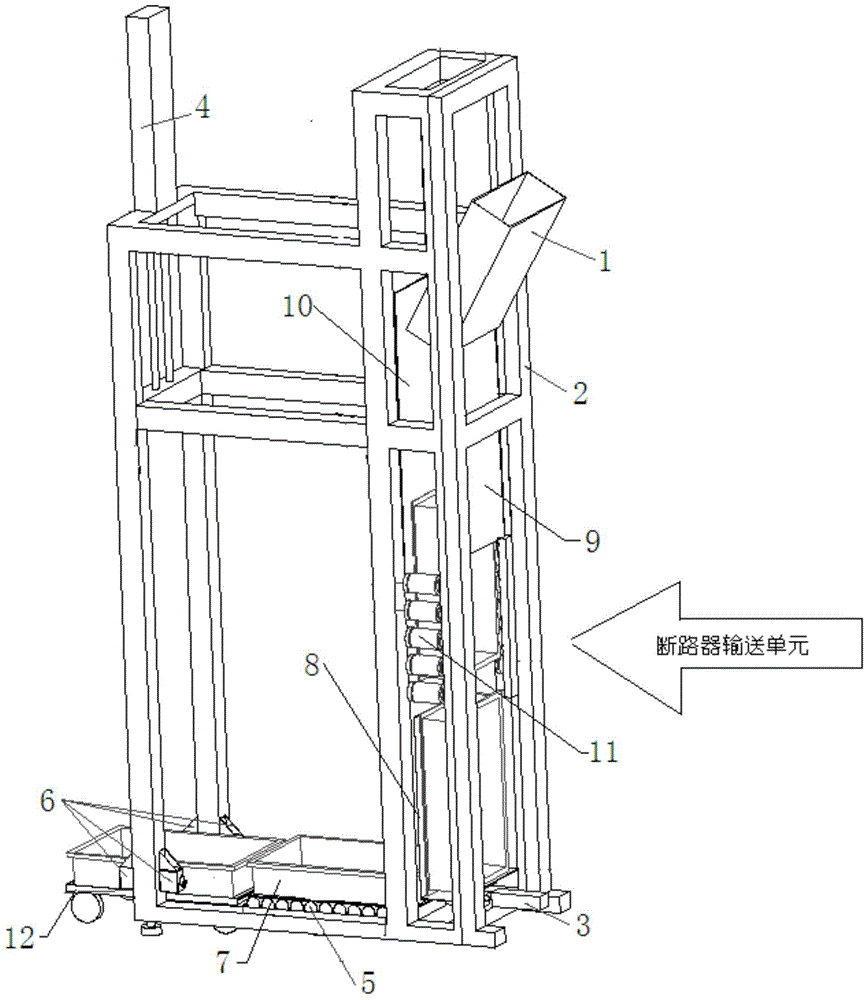

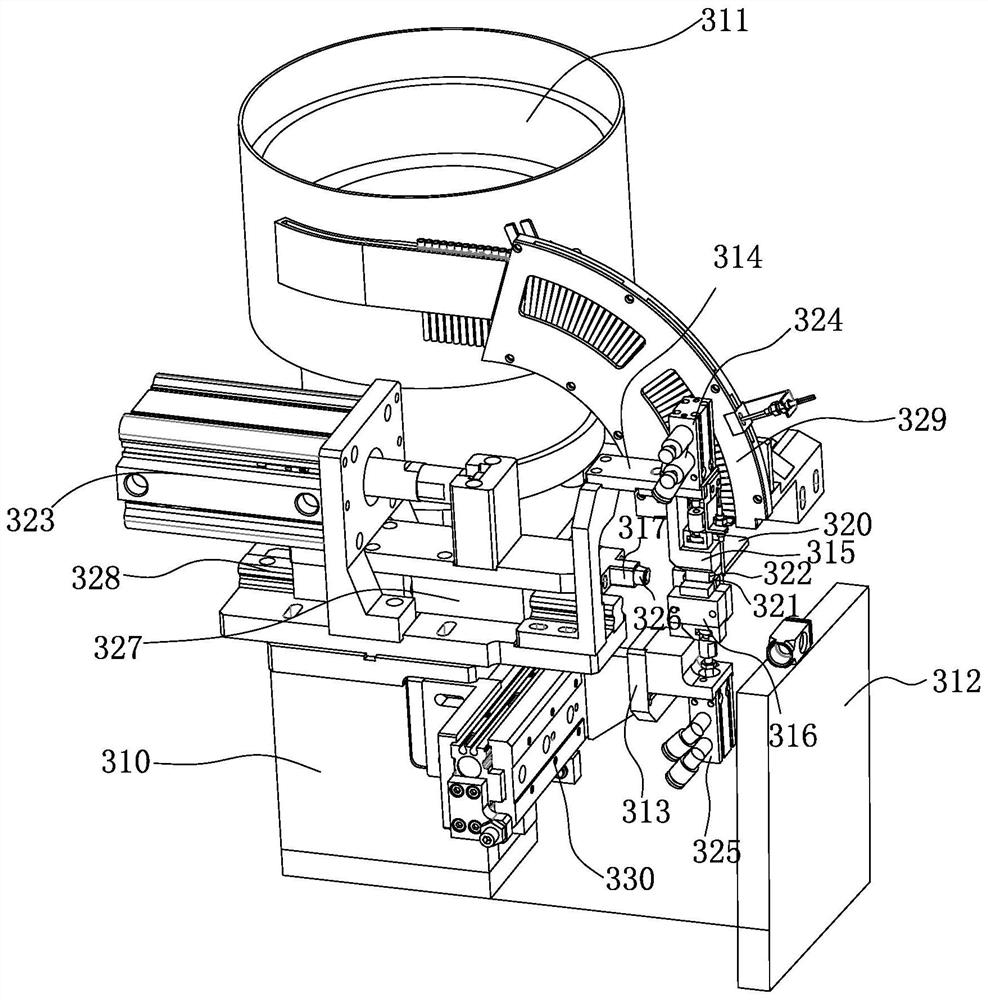

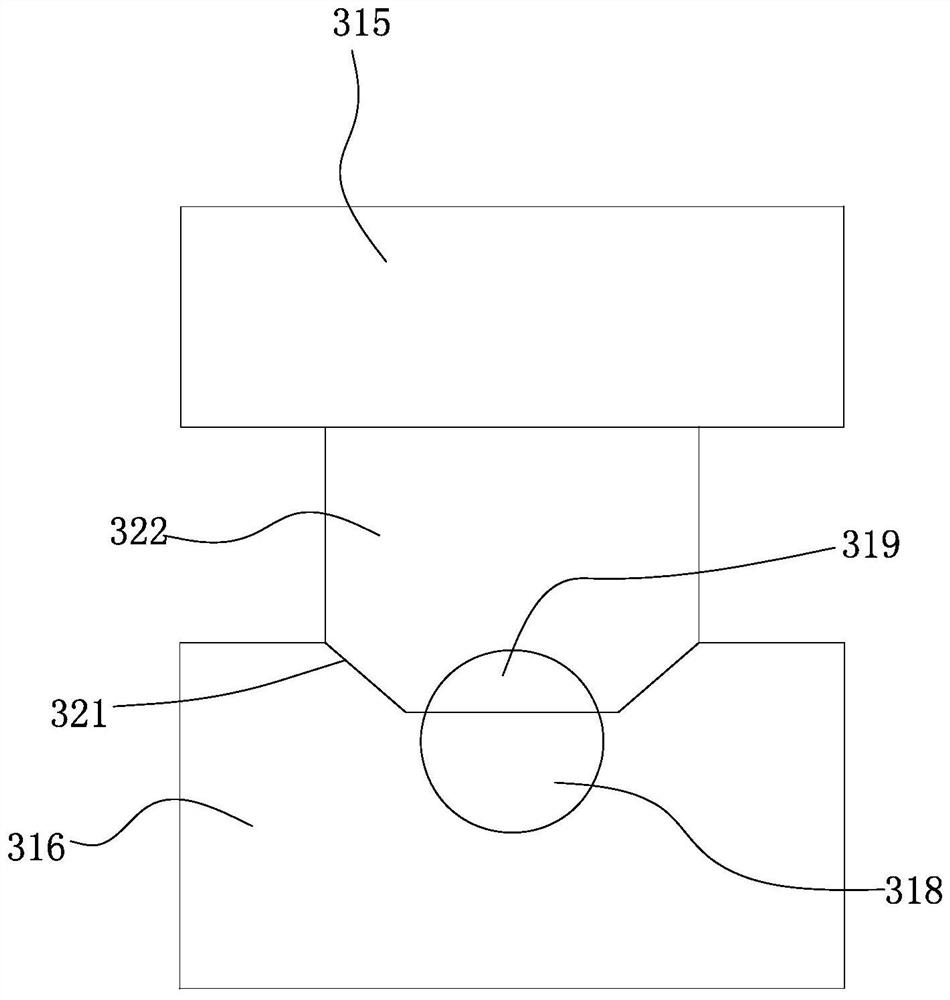

Screw installation automatic production line

ActiveCN105035675BReduce labor intensityImprove securityMechanical conveyorsProduction lineEngineering

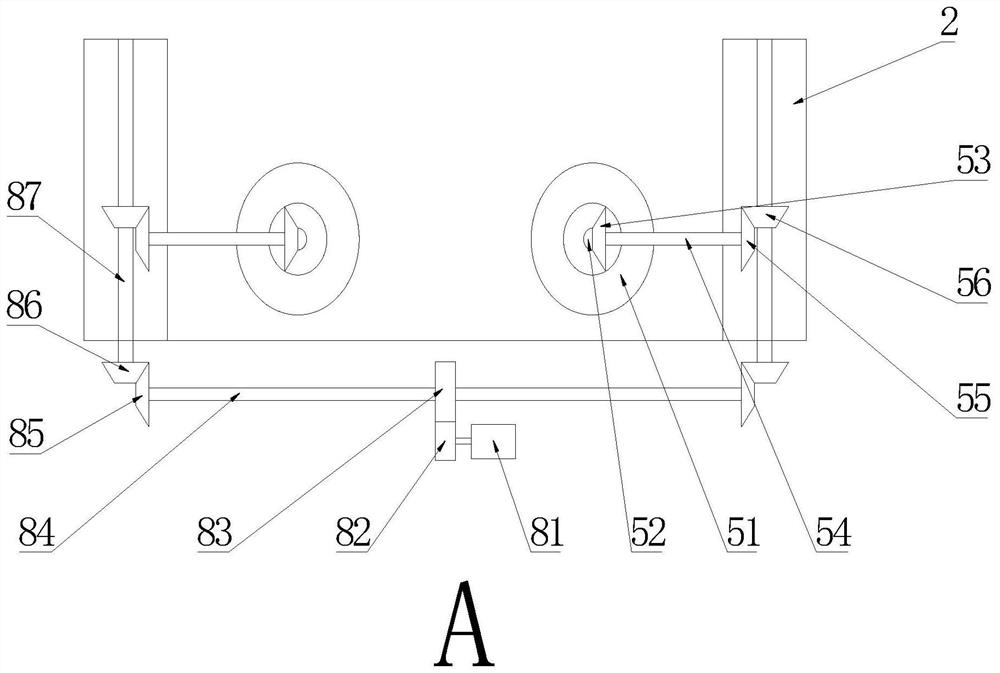

The invention provides an automatic screw installing production line. The automatic screw installing production line comprises a product conveying device, a screw conveying device and a screw installing die. The product conveying device, the screw conveying device and the screw installing die are all intermittent. The screw conveying device is arranged at one side of the product conveying device. The output end of the screw conveying device is connected with the input end of the screw installing die. The portion below the screw installing die is right opposite to the screw installing portion on a product. The product conveying device is a similar U-shaped conveying rail with one side arranged in a downwards-inclined manner. Conveying belts are arranged in the two parallel sides of the rail. The portion connecting the two parallel sides is a sliding way arranged in a downwards-inclined manner. The circuit breaker shell conveying device, the heat adjusting screw conveying device and a screw installing jig are arranged, so that automatic screw installation of heat adjusting screws in circuit breaker shells is achieved; the labor intensity of workers is relieved, and meanwhile the working safety of the workers is improved.

Owner:TIANJIN DONGMING ELECTRONICS IND

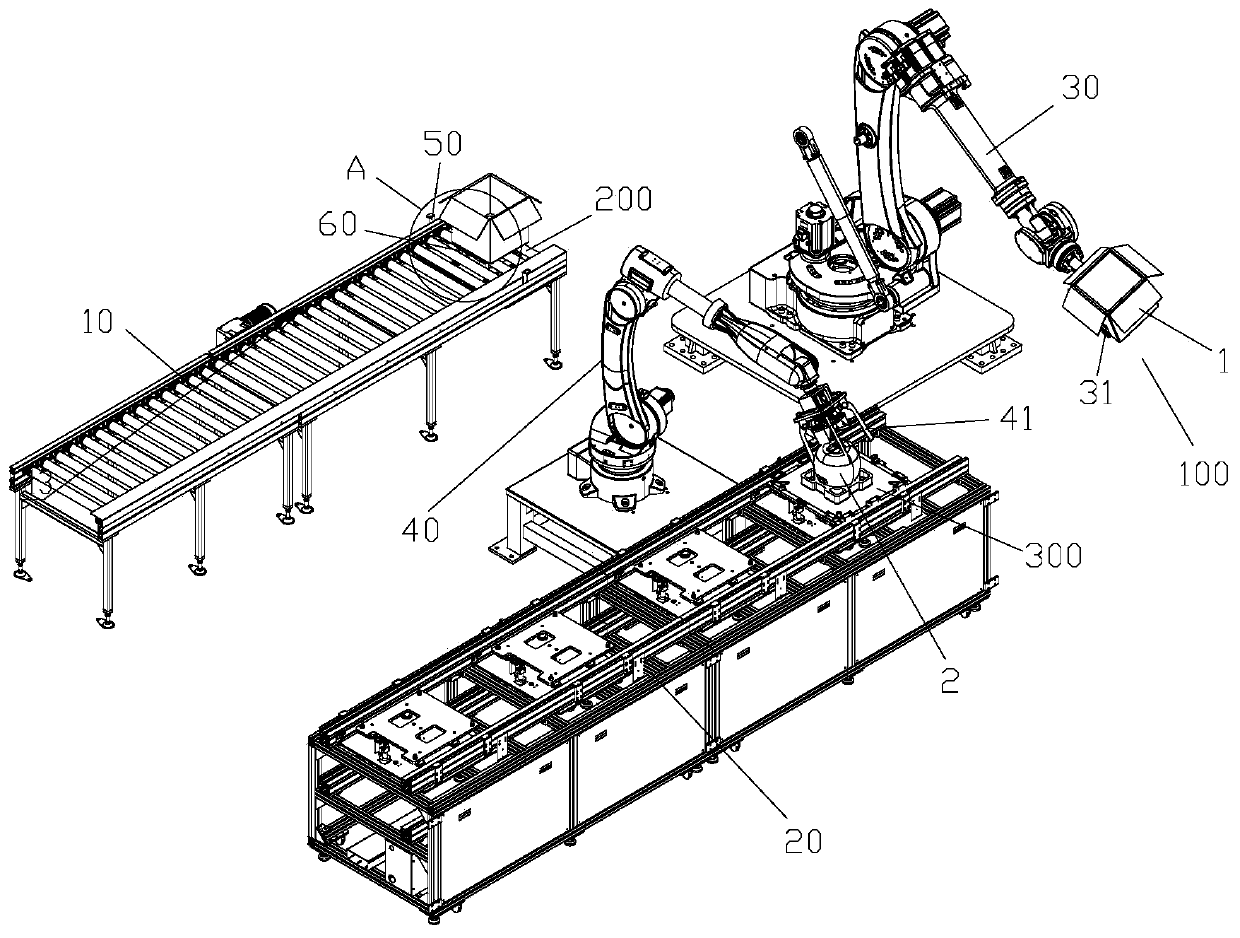

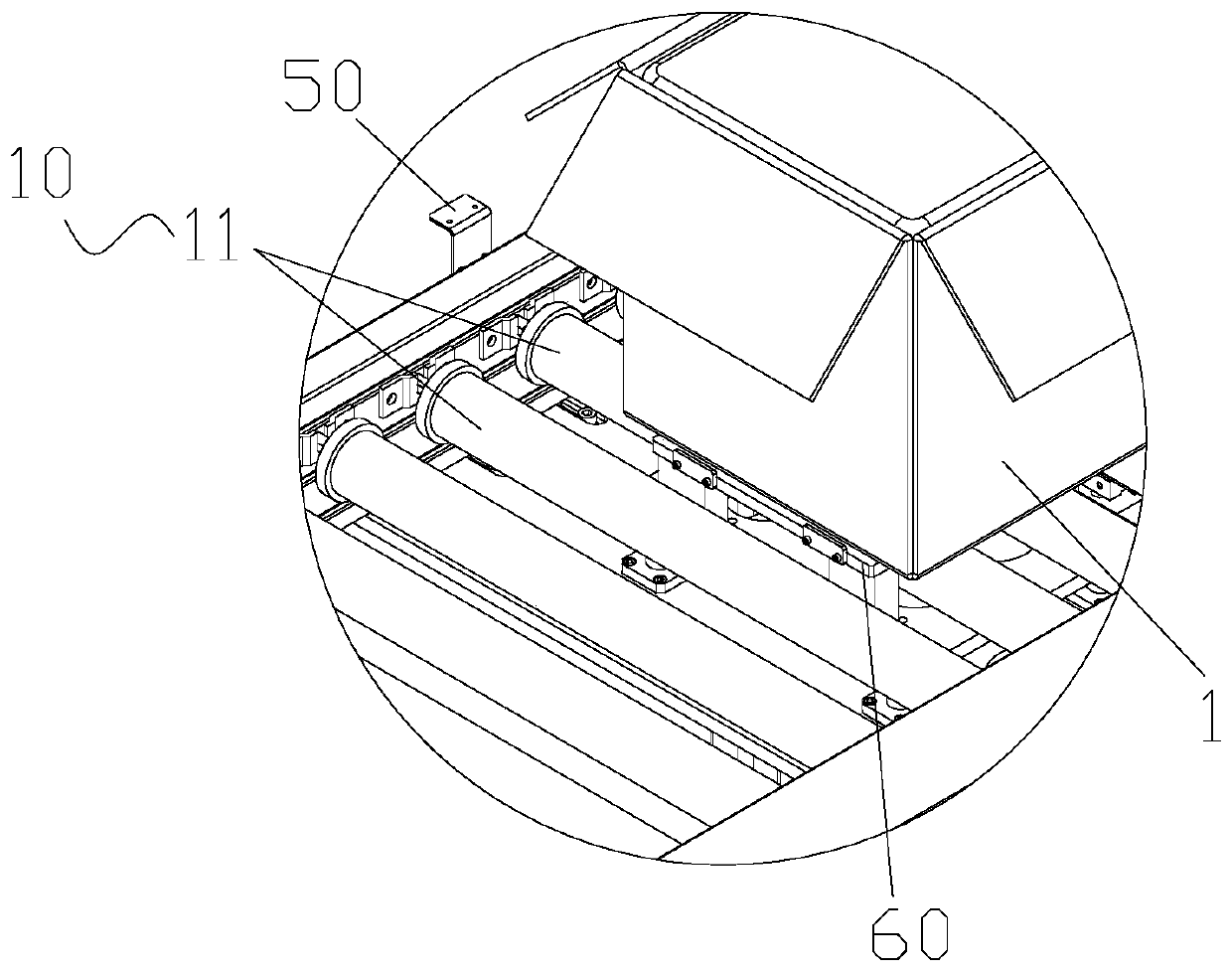

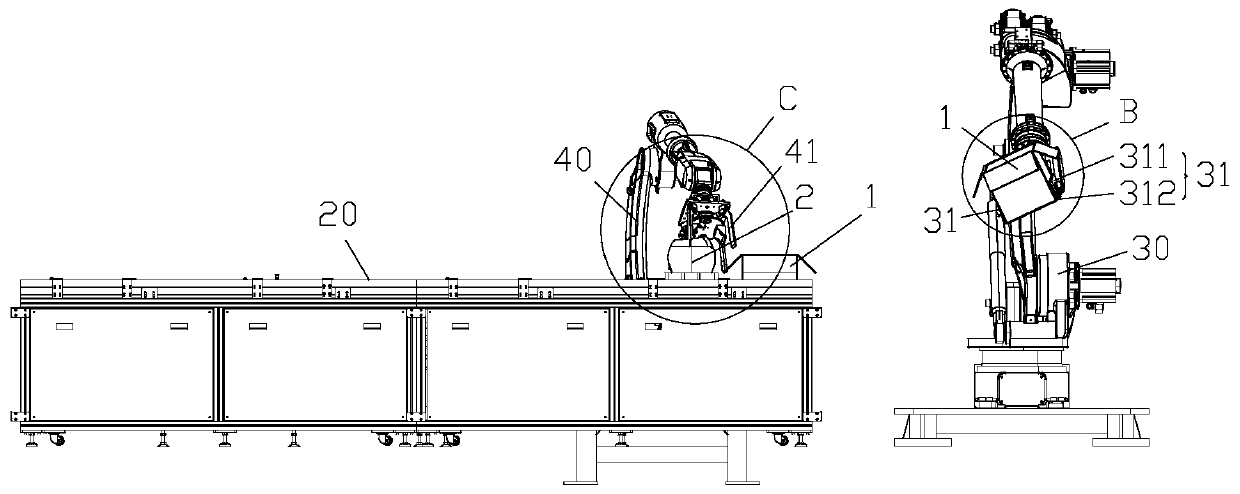

Packaging production line of electric cookers

InactiveCN110654626AHigh degree of automationImprove packaging efficiencyPackagingManufacturing lineCooker

The invention provides a packaging production line of electric cookers. The packaging production line of the electric cookers comprises a first conveying device, a second conveying device, a first robot and a second robot. The first conveying device is used for conveying packaging boxes. The second conveying device is used for conveying the electric cookers. The first robot comprises a first clamp, and the first clamp is used for clamping the packaging boxes located on the first conveying box and driving the packaging boxes to move to the boxing station. The second robot comprises a second clamp, and the second clamp is used for clamping the electric cookers on the second conveying device and driving the electric cookers to move to the boxing station, so that the second clamp is driven tomove to load the electric cookers into the packaging boxes clamped by the first clamp. By means of the technical scheme, the problem that in the prior art, the automation degree of a packaging production line of electric cookers is low is solved.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

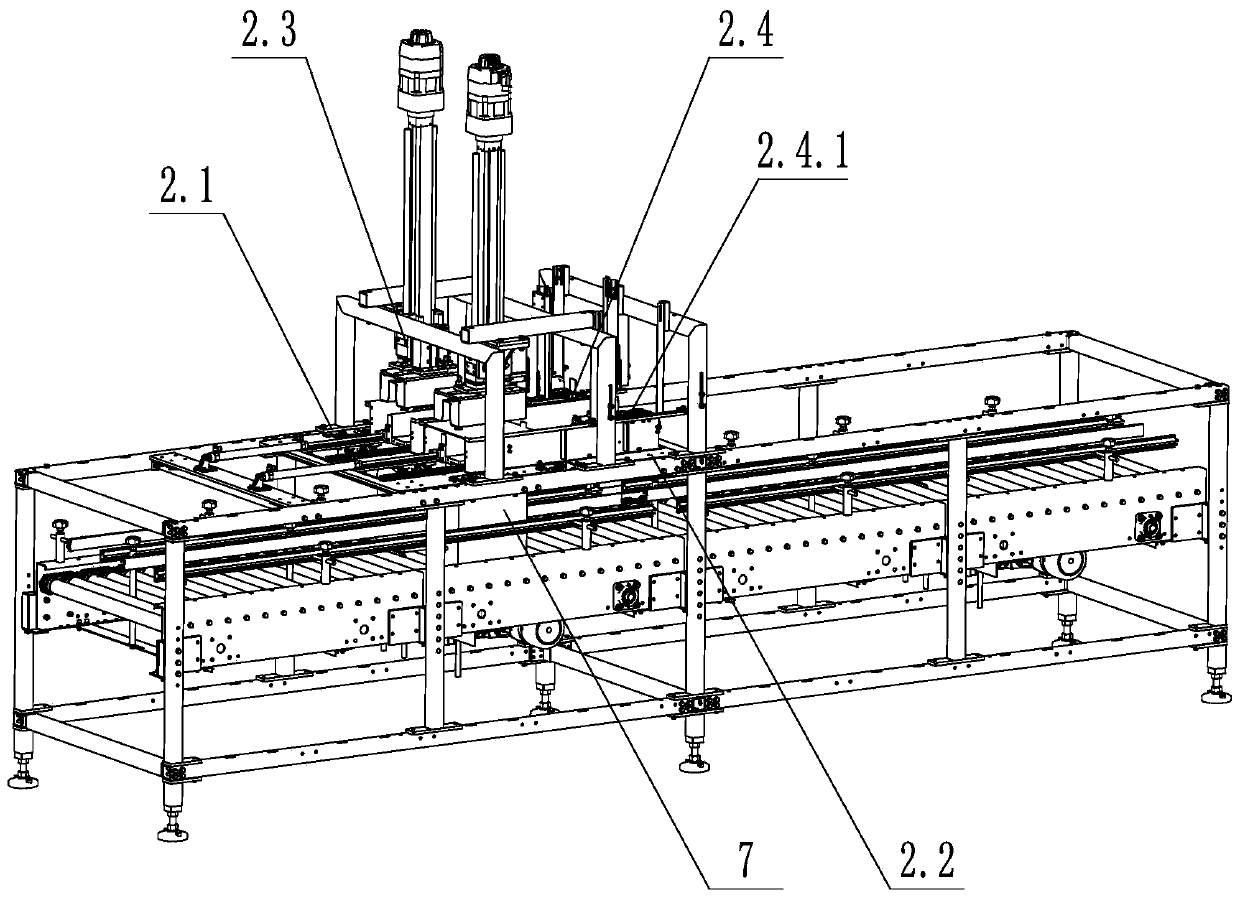

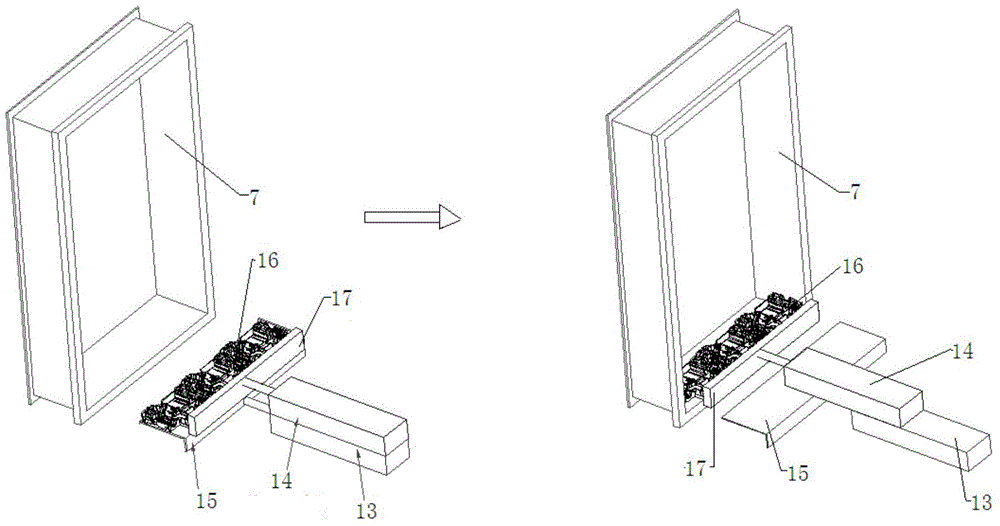

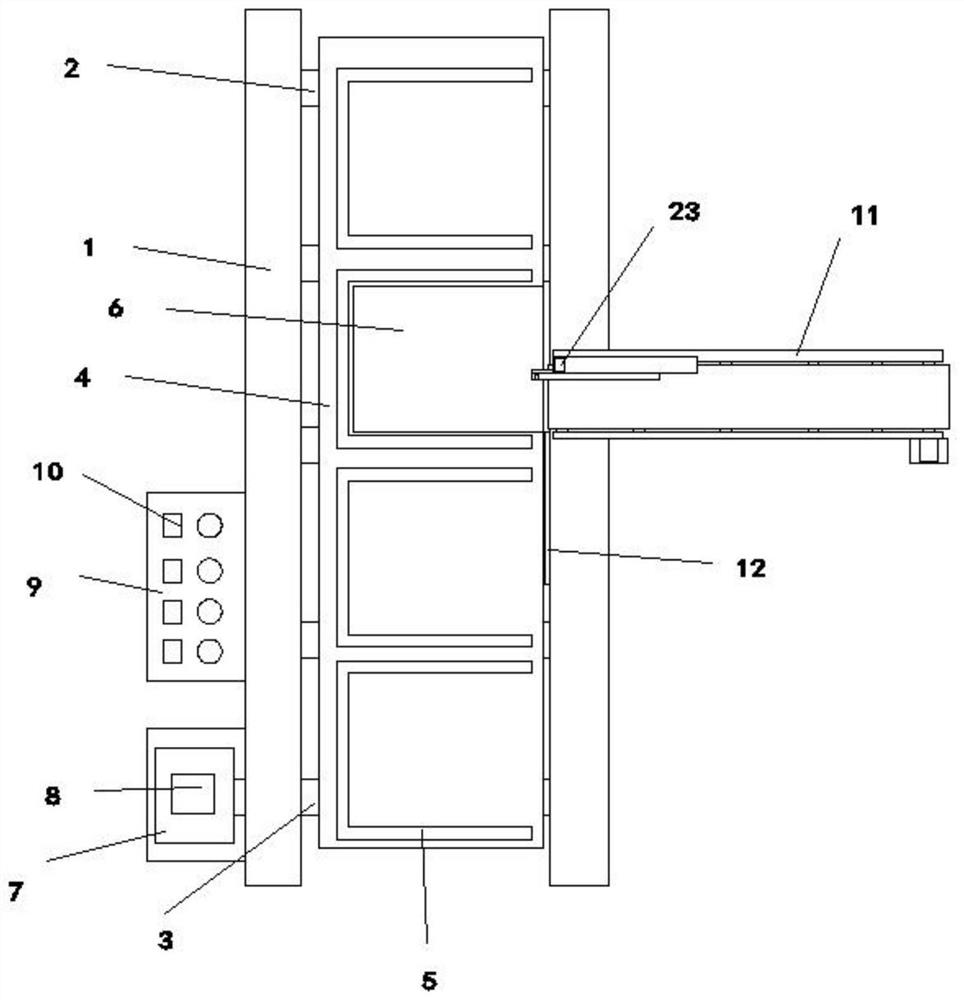

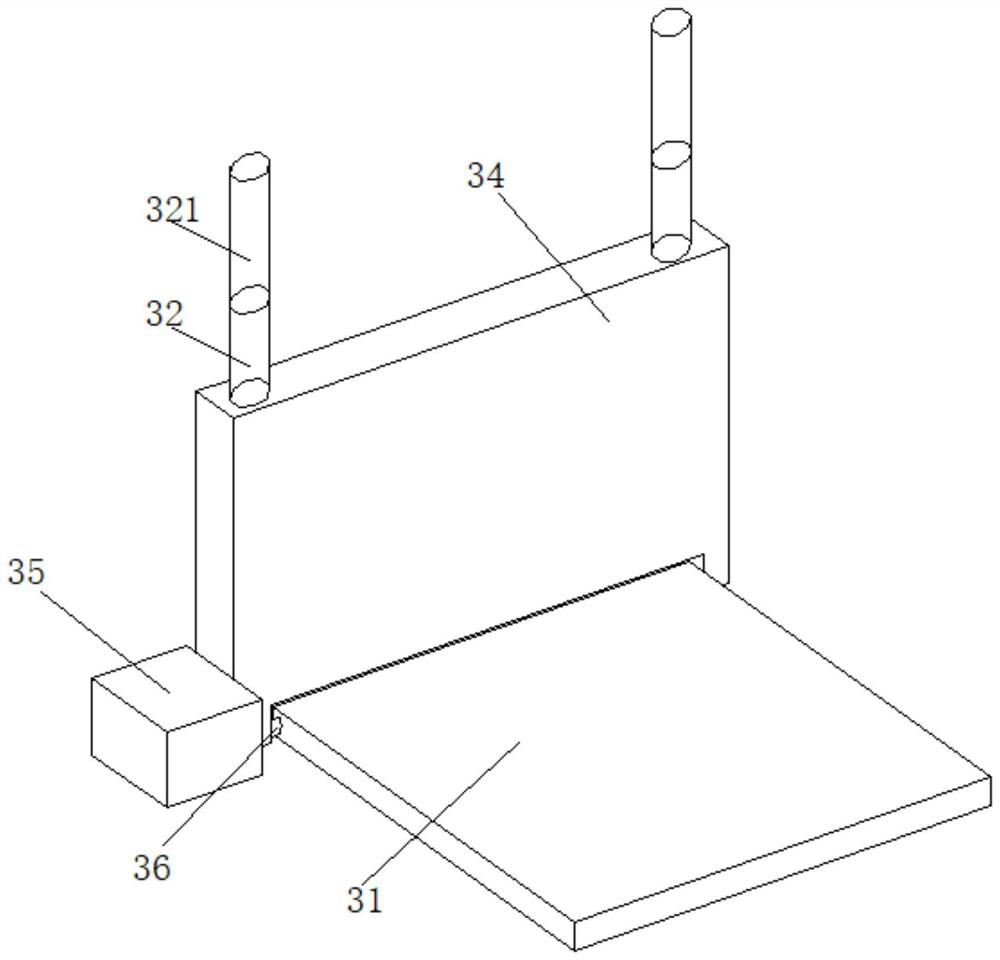

Automatic gift box lining plate boxing machine and method

PendingCN111251659AImplement autoboxingRealize flanging fixationBox making operationsPaper-makingPunchingCarton

The invention discloses an automatic gift box lining plate boxing machine and a method. The machine is used for mounting lining plates and boxes and comprises a rack, a lining plate discharging moduleand a lining plate forming module which are sequentially arranged from top to bottom are arranged on the rack, and a box conveying module capable of conveying the boxes to directly face the lining plate discharging module is arranged at the bottom of the rack; the lining plate discharging module comprises stock bin grooves for placing the lining plates and a paper punching mechanism, stock bin groove outlets are formed in the lower portions of the stock bin grooves, and the stock bin grooves are provided with lining plate detection sensors; the rack is further provided with a positioning frame capable of pressing the boxes, and the positioning frame is provided with an ascending sensor and a descending sensor; the lining plate forming module comprises a limiting frame used for limiting the lining plates, the limiting frame is located below the paper punching mechanism, a pushing-out mechanism used for pushing the lining plates to be matched with the limiting frame to complete flangesis arranged on the outer side of the limiting frame, and the lining plate forming module comprises a lining plate forming sensor; and the box conveying module comprises a box in-place sensor. The machine and the method have the advantages that limiting of lining plate flanges can be completed, and automatic lining plate boxing is achieved.

Owner:HANGZHOU WAHAHA BEVERAGE

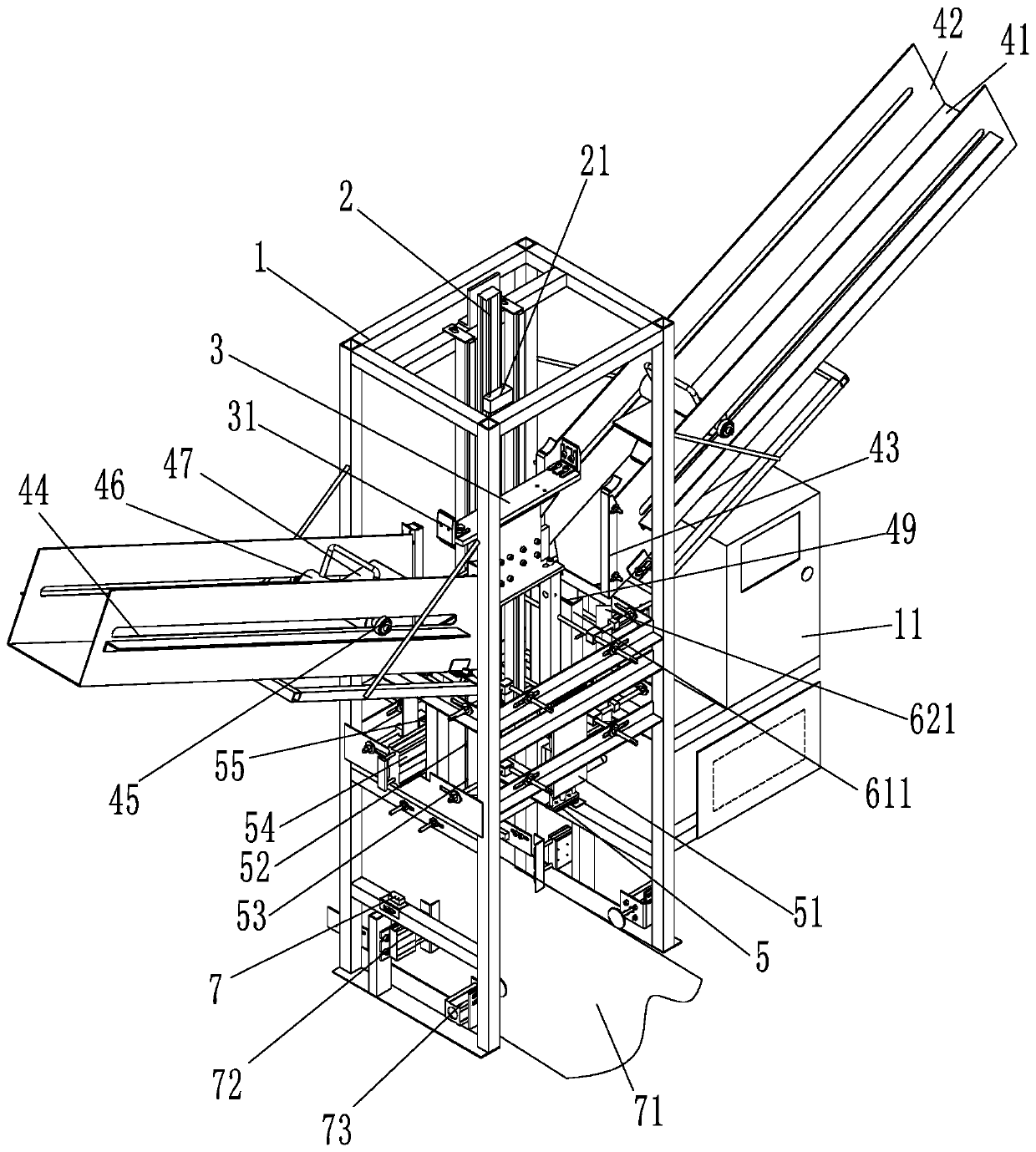

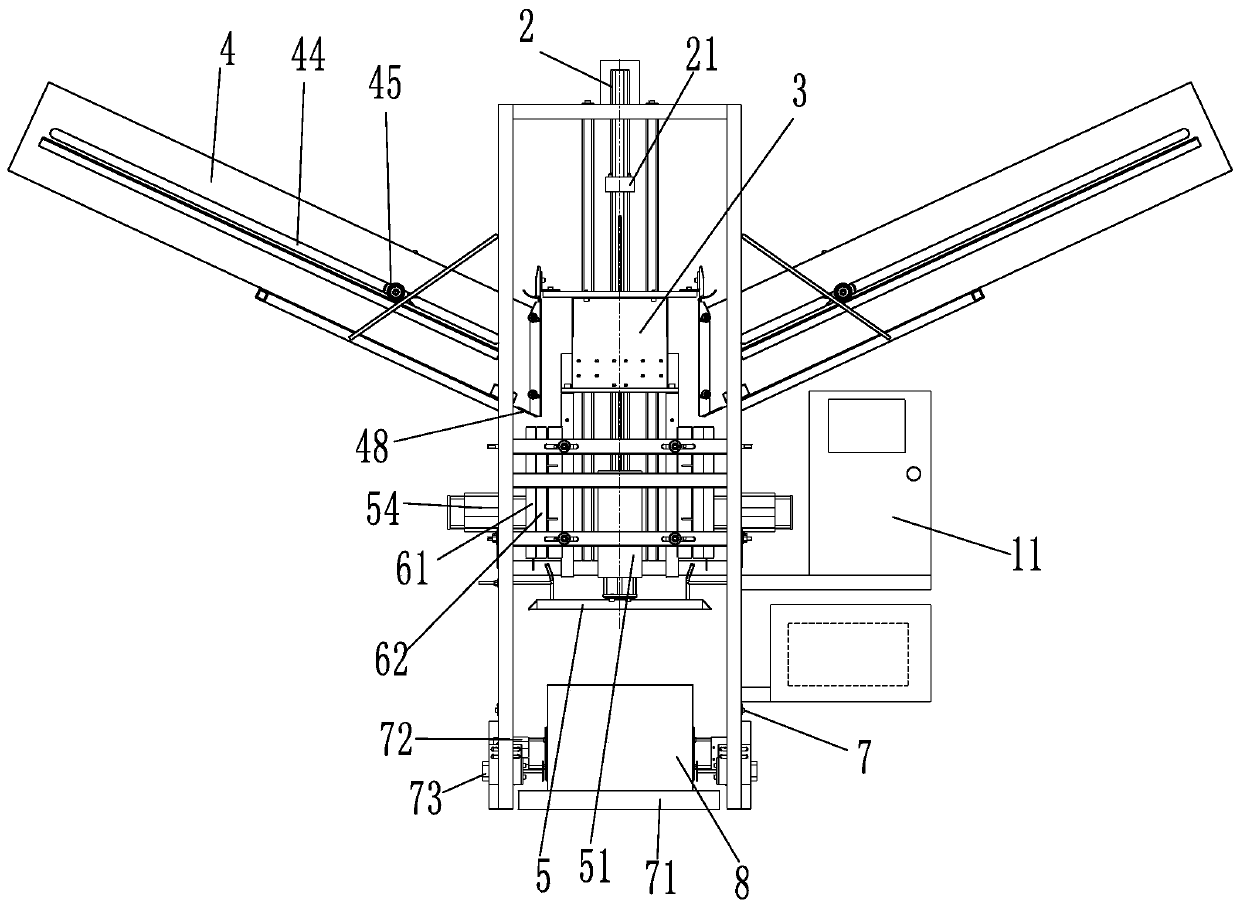

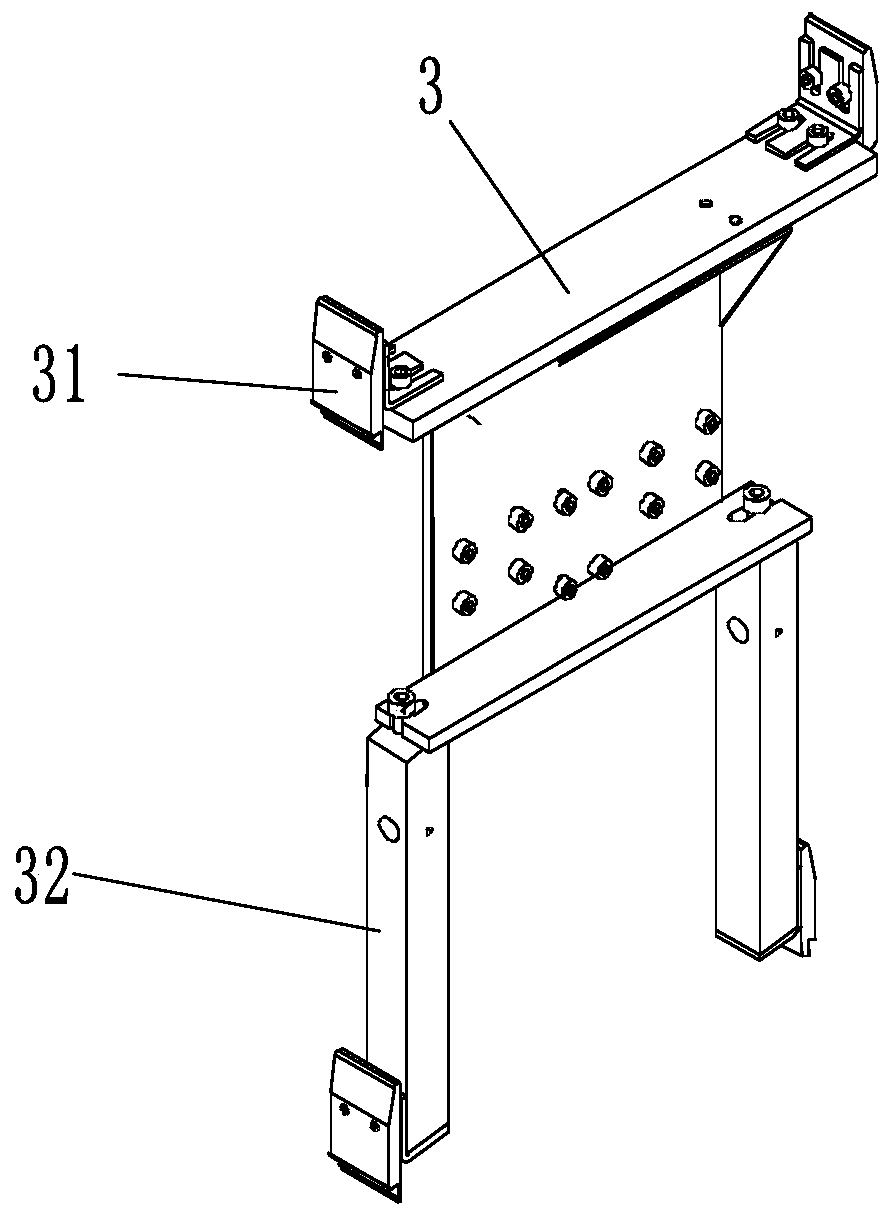

Grabbing type bucket boxing machine

PendingCN112623347AImplement autoboxingSmall footprintPackaging automatic controlCartonIndustrial engineering

The invention relates to the field of packaging equipment, in particular to a grabbing type bucket boxing machine which comprises an integrated rack, a bucket conveying device, a paper box conveying device and a bucket transferring device; the bucket conveying device, the paper box conveying device and the bucket transferring device are all arranged in an integrated frame; the bucket conveying device is used for conveying buckets to be boxed; the paper box conveying device is used for conveying paper boxes; and the bucket transferring device is used for transferring buckets to be boxed at the bucket conveying device into the paper boxes at the paper box conveying device. The grabbing type bucket boxing machine has the effects that the buckets can be automatically boxed, and the overall occupied area of equipment is reduced.

Owner:JIANGSU TOM PACKAGING MACHINERY

Product buckling device and full-automatic take-out device with product buckling device

Owner:CWB AUTOMOTIVE ELECTRONICS

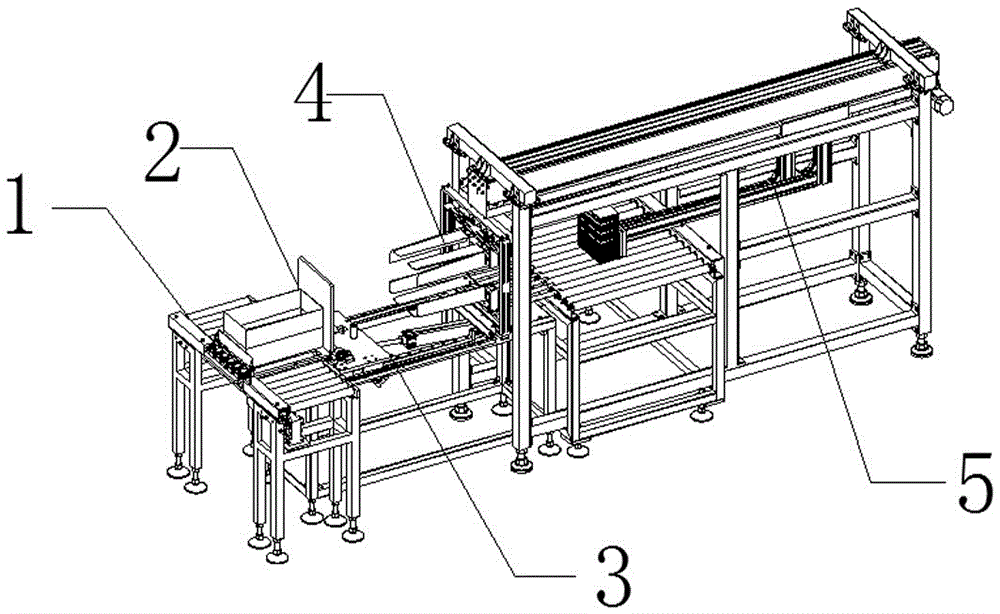

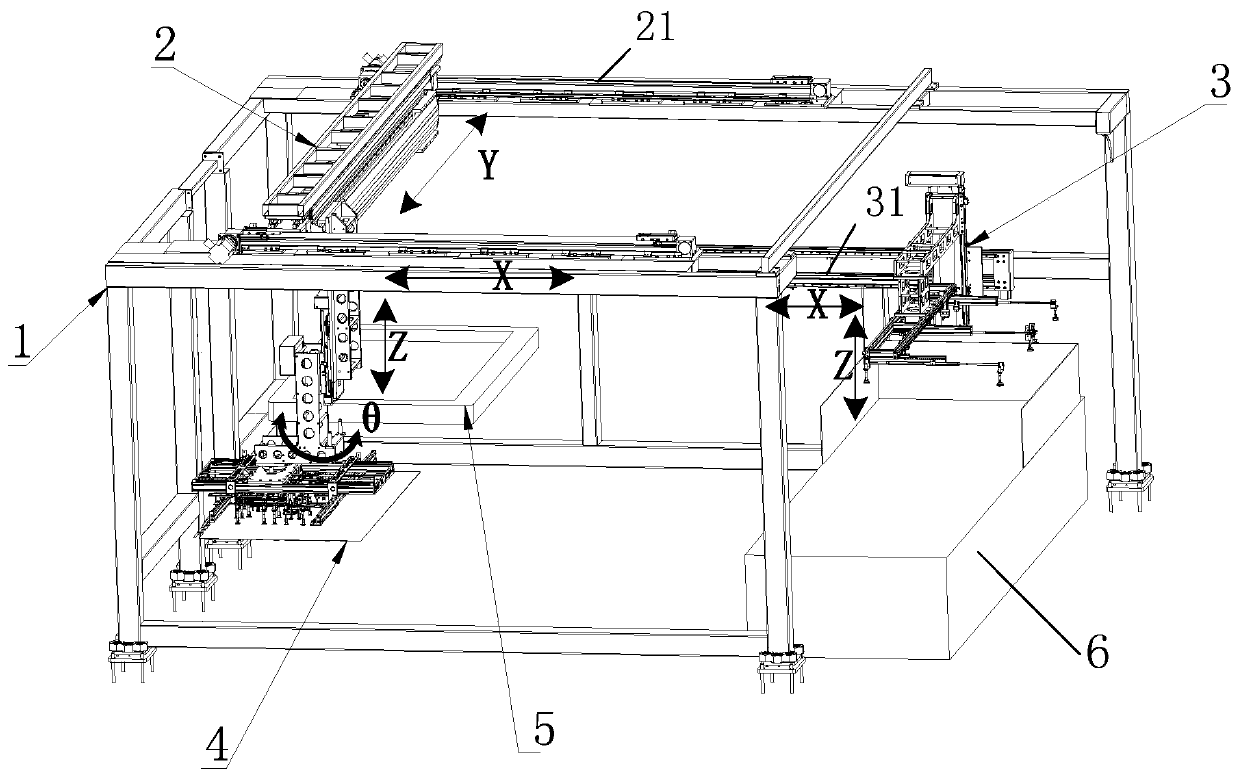

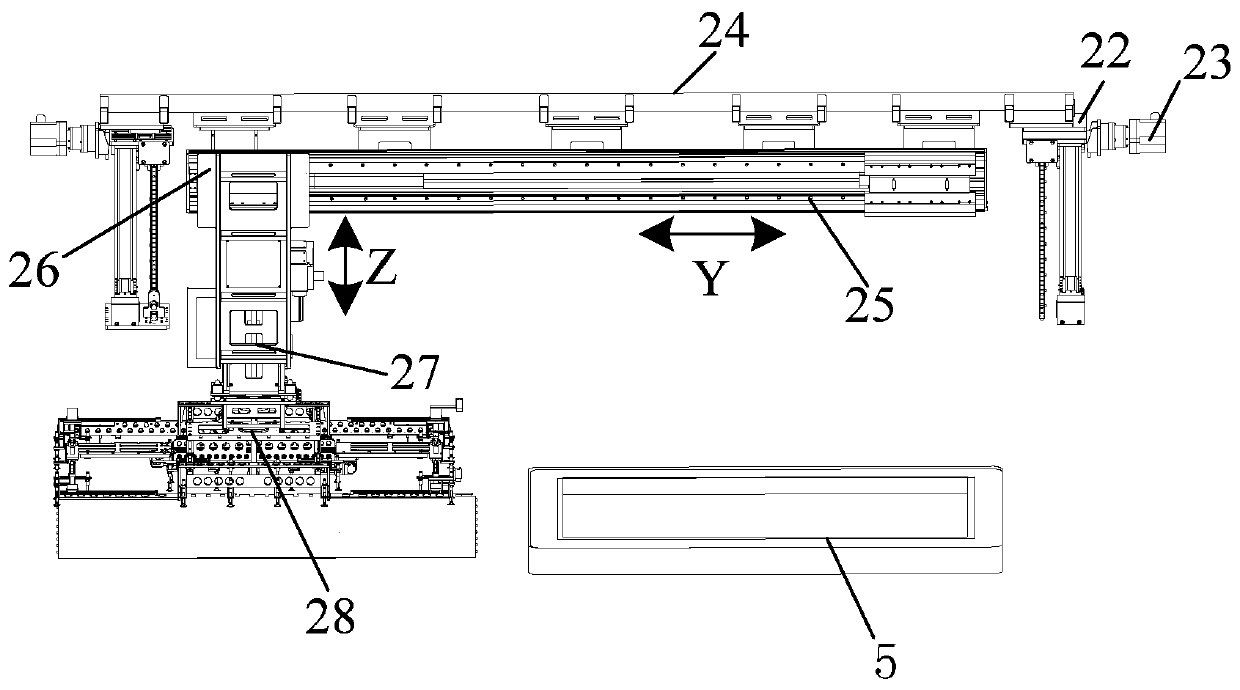

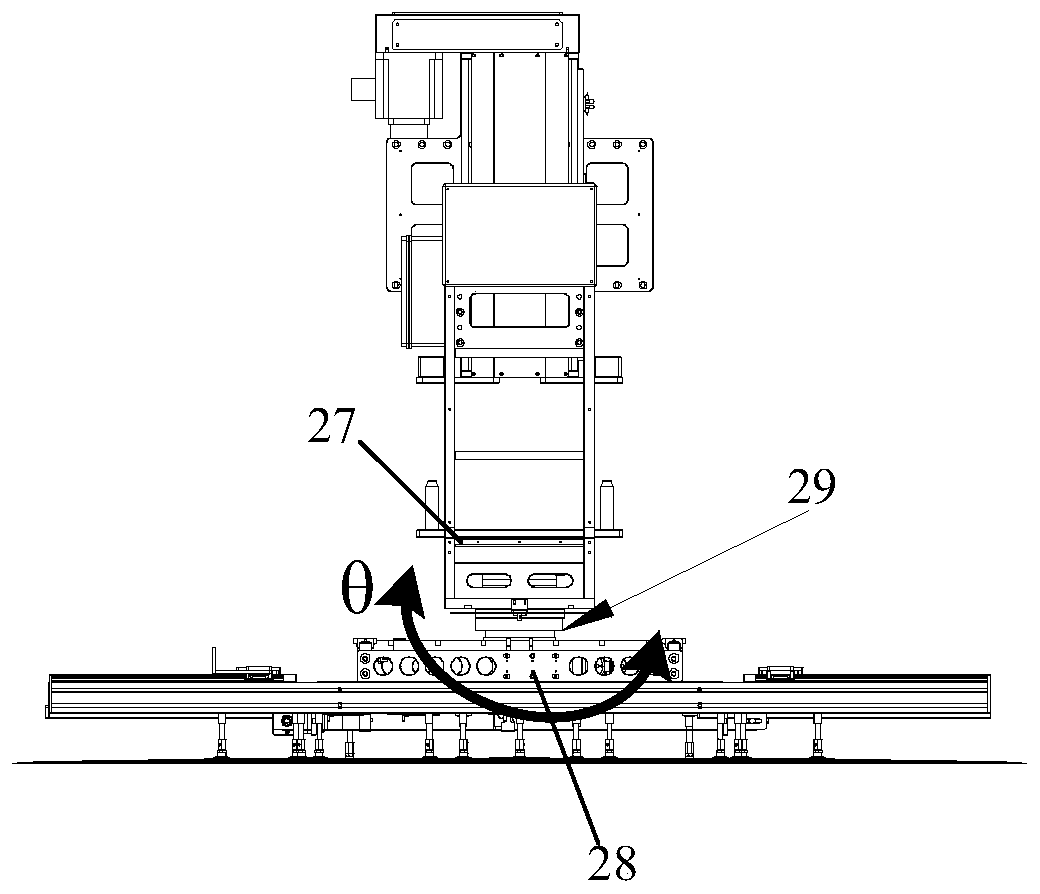

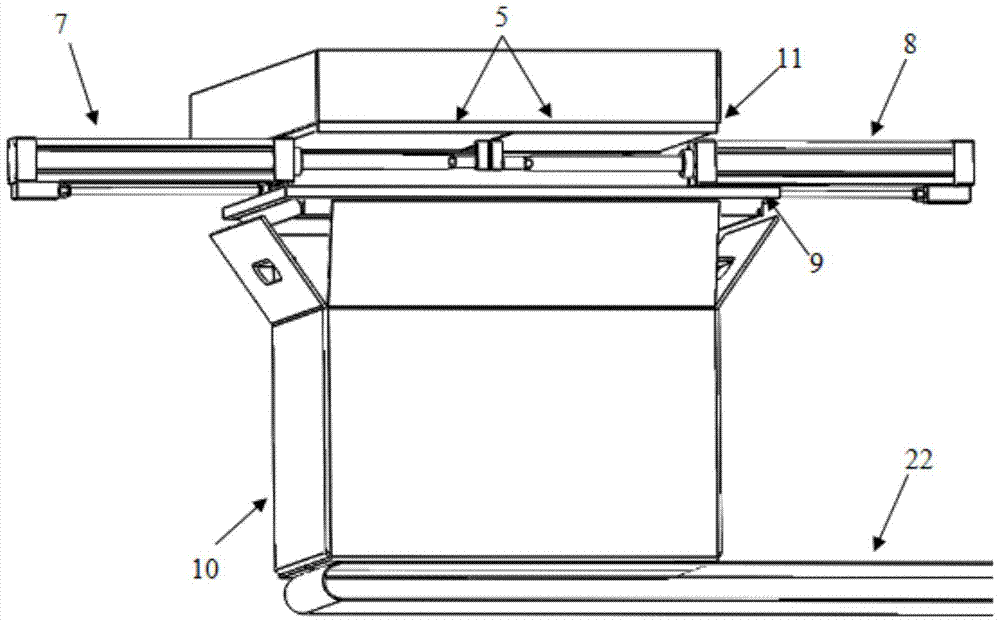

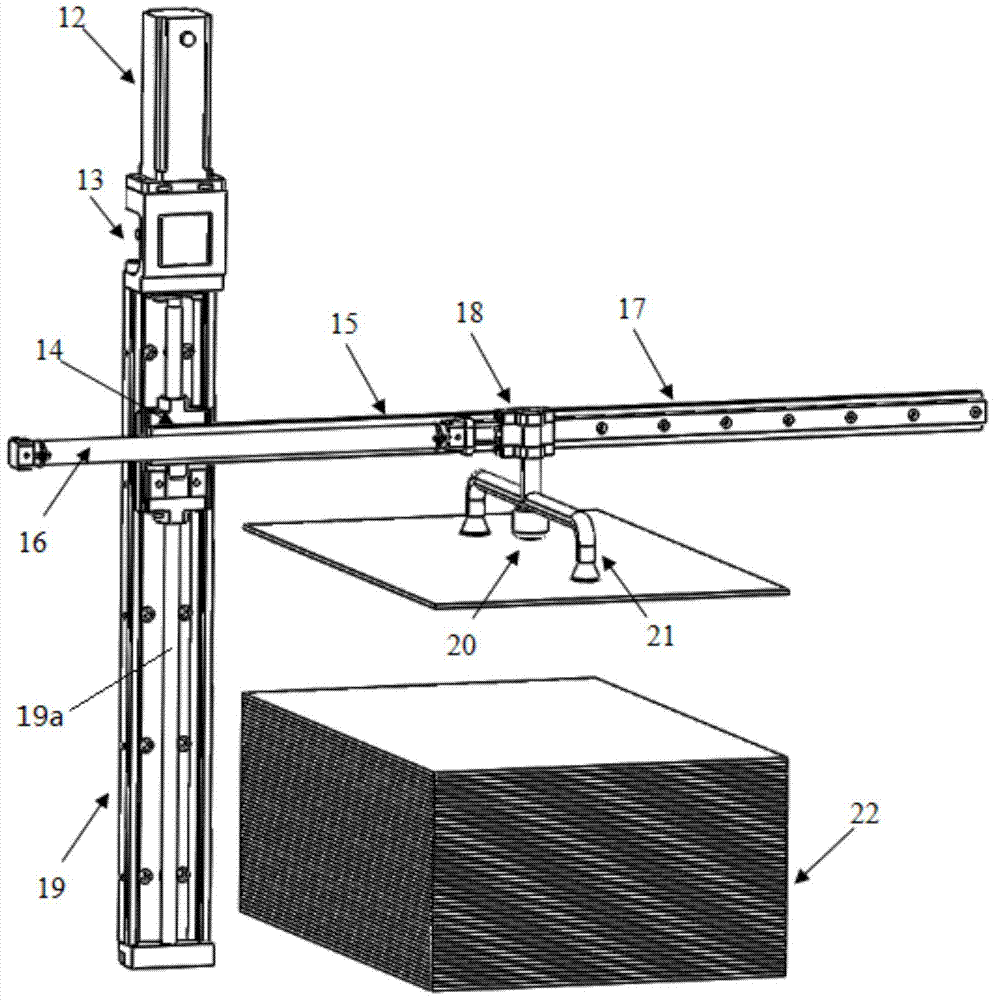

Multi-station boxing equipment

PendingCN109969503AReduce manual workHigh positioning accuracyIndividual articlesEngineeringMechanical engineering

The invention relates to multi-station boxing equipment. An X-axis connecting plate I is arranged on an X-axis sliding rail I of a product adsorption moving mechanism, and X-axis driving units I drivethe X-axis connecting plates I; a Y-axis slide rail is arranged on a moving cross beam, a Y-axis connecting plate is arranged on the Y-axis slide rail, and a Y-axis driving unit drives the Y-axis connecting plate; and a Z-axis slide rail I is arranged on the Y-axis connecting plate, a Z-axis connecting plate I is arranged on the Z-axis slide rail I, a Z-axis driving unit I drives the Z-axis connecting plate I, the Z-axis connecting plate I is provided with a theta-axis rotary motion unit, and a suction cup I is arranged on the theta-axis rotary motion unit. An X-axis connecting plate II of aspacing paper adsorption moving mechanism is arranged on an X-axis sliding rail II, and an X-axis driving unit II drives the X-axis connecting plate II; and a Z-axis slide rail II is arranged on the X-axis connecting plate II, a Z-axis connecting plate II is arranged on the Z-axis slide rail II, a Z-axis driving unit II drives the Z-axis connecting plate II, and a suction cup II is arranged on theZ-axis connecting plate II.

Owner:SUZHOU YOUBEI PRECISION INTELLIGENT EQUIP CO LTD

Capillary assembly machine

ActiveCN111822978BHigh precisionImprove assembly efficiencyMetal working apparatusCapillary TubingProcess engineering

The invention provides a capillary assembly machine. It solves the problems of inconvenient assembly of the existing capillary tubes, including the assembly rack, the pilot valve conveying mechanism for conveying the pilot valve body is installed on one side of the assembly frame, the pilot valve conveying mechanism is connected with the conveying material channel, and the conveying material channel is equipped with a There is a positioning and pressing device for tube D, and a three-tube positioning and pressing device is provided on the other side. Equipment packing device. Its advantage is that it can realize automatic feeding and press-fitting of D tubes and three capillaries, with high precision, without manual placement, positioning and press-fitting, which reduces production costs and has high assembly efficiency. The assembled finished products can be adjusted to a suitable angle for storage and basically unloaded. There is no need for manual post-placement, saving time and effort. It can realize automatic packing and arrange in order, with a high degree of automation.

Owner:ZHUJI RUN TUO MECHANICAL AUTOMATION TECH

Sunshade net packing device

InactiveCN109250170AImplement autoboxingNo human intervention requiredPackaging automatic controlIndividual articlesMechanical engineeringEngineering

Owner:巢湖市聚汇遮阳设备科技有限公司

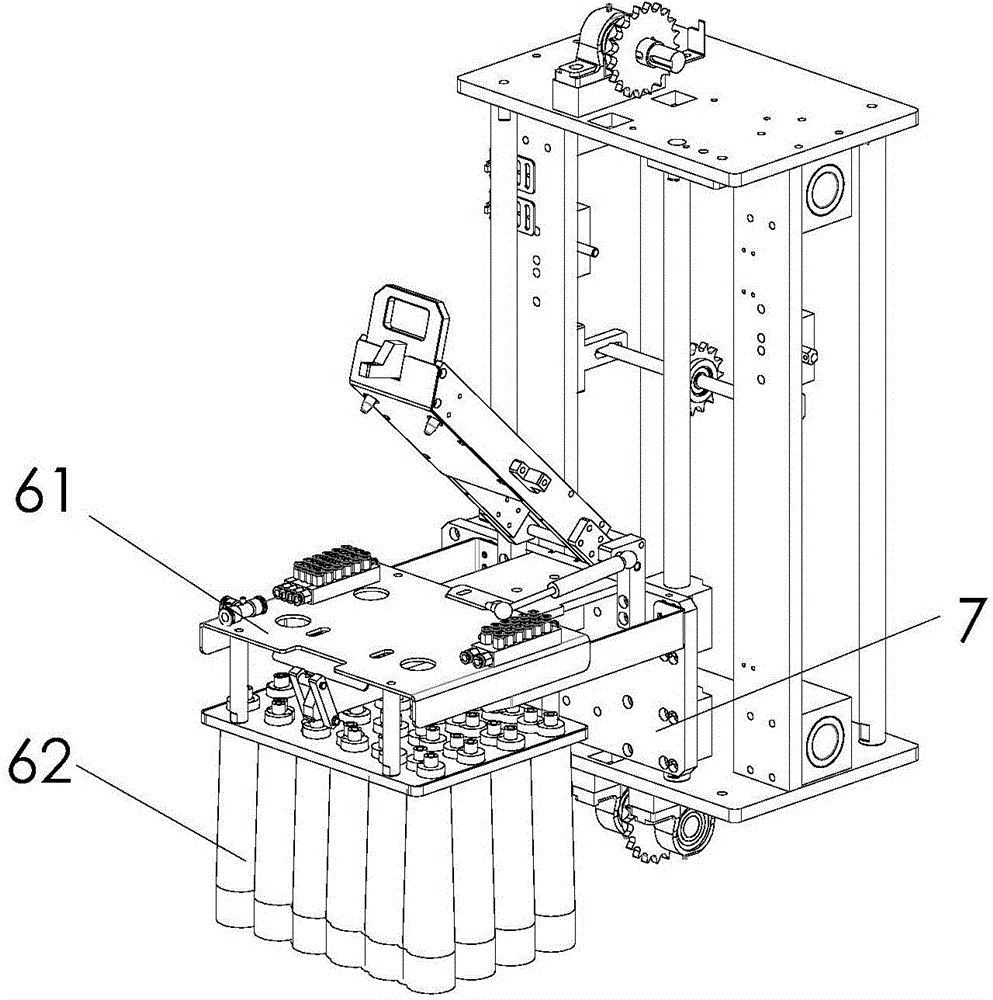

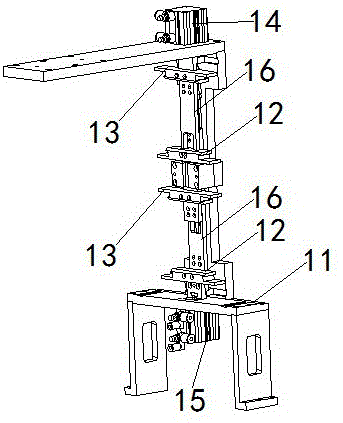

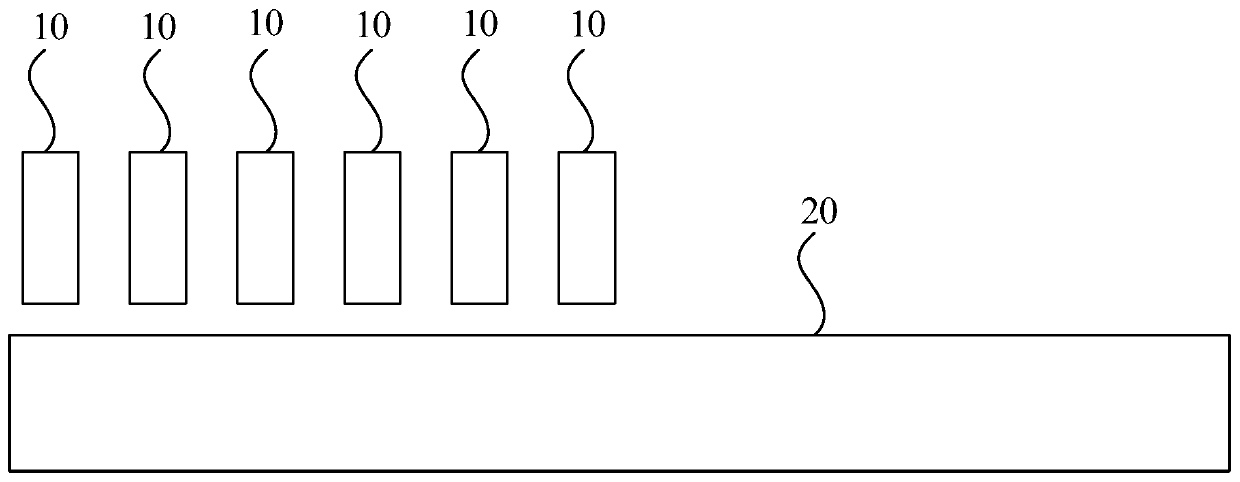

Automatic box filling machine for battery cases

PendingCN112660518AImplement autoboxingReduce labor intensityPackaging automatic controlIndividual articlesElectrical batteryProcess engineering

The invention discloses an automatic box filling machine for battery cases. The automatic box filling machine comprises a one-to-two conveying device, a material placing device and a transferring device, wherein the one-to-two conveying device is used for conveying the battery cases in multiple rows; the material placing device is used for receiving the battery cases conveyed by the one-to-two conveying device and placing the battery cases into a material placing tray, and the material placing device is located at the rear end of the one-to-two conveying device; and the transferring device is used for transferring the battery cases in the material placing tray into a material receiving box, and the transferring device is located at the rear end of the material placing device. Compared with the prior art, the automatic box filling machine can achieve automatic box filling of the battery cases, the automation degree of the automatic box filling machine is high, the labor intensity of workers is greatly reduced, and the working efficiency is improved.

Owner:无锡金杨丸伊电子有限公司

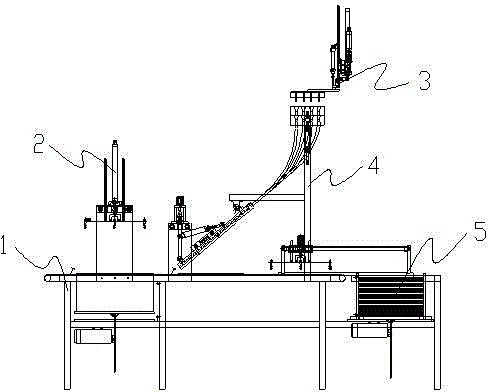

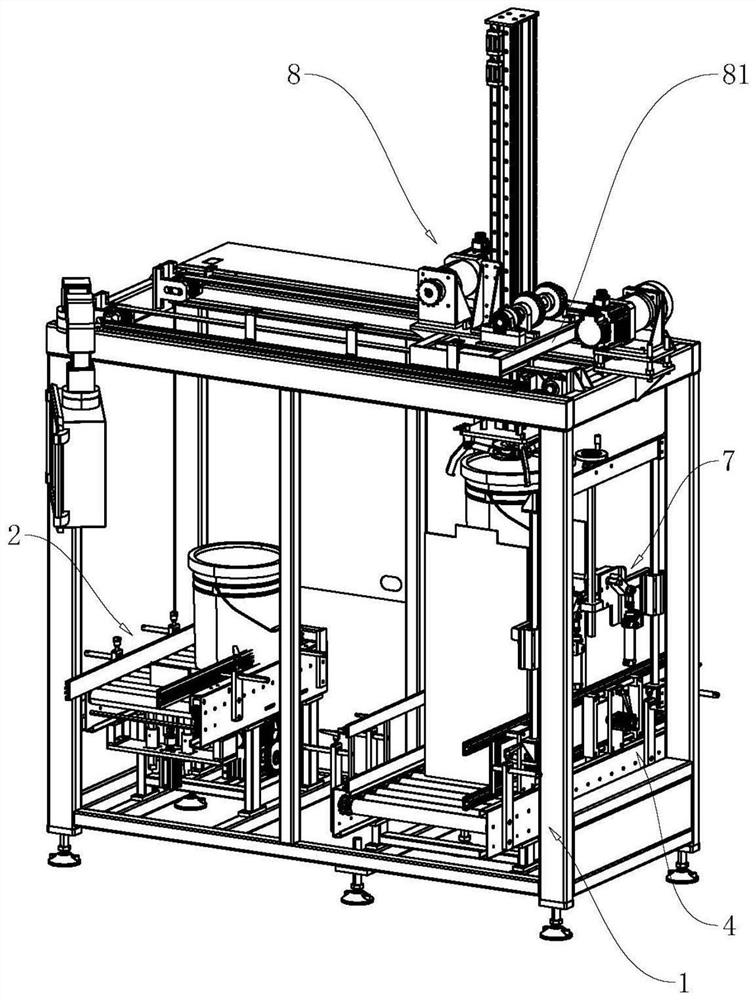

An automatic packing device and method for gift box canned products

The invention discloses an automatic boxing device and method for canned products in a gift box, comprising: a foam adding mechanism for adding foam boards into the carton; an inner lining forming and adding mechanism for pressing and forming the inner lining board , and add the inner liner to the carton; the product packing mechanism, which is used to pack the canned product into the carton; the conveying mechanism, which is used to convey the carton and position the carton under each station, the foam adding mechanism, the inner The lining forming and adding mechanism and the product boxing mechanism are fixed above the conveying mechanism, and are arranged sequentially from upstream to downstream along the conveying direction. The invention provides an automatic boxing device and method for canned products in gift boxes, which can realize automatic boxing of canned products in gift boxes, and has a coherent boxing process with high efficiency and can reduce labor costs.

Owner:HANGZHOU WAHAHA PRECISION MACHINERY

Bottle collecting machine

InactiveCN113184257AImplement autoboxingReduce laborPackaging automatic controlPackaging bottlesLaser rangingElectric machinery

The invention discloses a bottle collecting machine. The bottle collecting machine comprises a supporting frame, and is characterized in that a conveying belt support is connected onto the supporting frame through bolts and nuts; a baffle is welded to the supporting frame; the conveying belt support is provided with conveying belt driven rotating rollers; the conveying belt support is provided with conveying belt driving rotating rollers; a driving motor is arranged on the conveying belt support; a first conveying belt is arranged on the conveying belt driven rotating rollers and the conveying belt driving rotating rollers; a sliding groove is connected onto the conveying belt support through bolts and nuts; a rodless hydraulic device is connected in the sliding groove through bolts and nuts; the rodless hydraulic device is connected with an external piston through magnetic adsorption; a sliding rod is welded to the external piston; the outer side of the sliding rod is connected with a limiting plate through bolts and nuts; a laser distance measurement sensor is arranged on the limiting plate; and a counter is arranged on the outer wall of the sliding groove. The bottle collecting machine of the invention implements automatic boxing, so that labor amount is reduced, efficiency is improved, and errors are reduced.

Owner:青岛四时新型建材有限公司

Automatic packing device for package yarn packing line

ActiveCN105599998BReduce investmentHigh degree of automationPackaging automatic controlPaperboardBiomedical engineering

The invention relates to an automatic boxing device for a cheese packaging line. The automatic boxing device comprises a cheese arranging device, an automatic paperboard padding device, an automatic discharging device and a boxing guiding device. The cheese arranging device is located at the input end of an automatic balance weight device, the automatic discharging device and the cheese arranging device are connected, the automatic paperboard padding device is located on the side face of the automatic discharging device, and the boxing guiding device is located below the automatic discharging device. The automatic boxing device has the advantages of being high in automation degree, easy and convenient to operate and the like, automatic boxing of cheese is achieved, and the purposes of saving cost, reducing personnel input, improving the packaging efficiency and increasing the automation level are achieved.

Owner:WUHU ANPU ROBOT IND TECH RES INST

An automatic packing mechanism for wine production line

Owner:刘伶醉酿酒股份有限公司

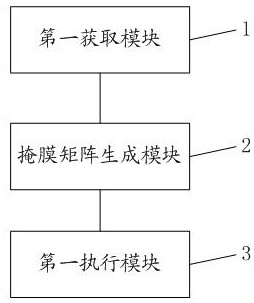

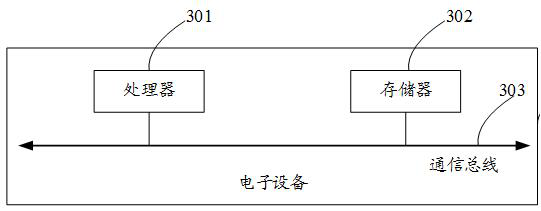

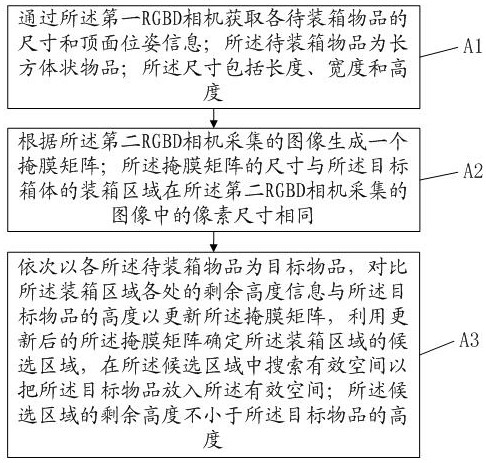

Box-packing method, device, electronic equipment and storage medium for cuboid objects

ActiveCN114013751BImplement autoboxingAccurate placementPackaging automatic controlIndividual articlesComputer graphics (images)Algorithm

This application belongs to the field of robot control, and discloses a boxing method, device, electronic equipment, and storage medium for cuboid items. The size and top surface pose information of each item to be boxed is obtained through a first RGBD camera; the item to be boxed It is a cuboid-shaped article; the size includes length, width and height; a mask matrix is generated; the size of the mask matrix is the same as the pixel size of the boxing area of the target box in the image collected by the second RGBD camera; The boxed item is the target item, and the mask matrix is updated by comparing the remaining height information of each place in the boxed area with the height of the target item, and the candidate area of the boxed area is determined by using the updated mask matrix, and the effective space is searched in the candidate area The target item can be put into the effective space; thus the target item can be accurately placed in a position that can accommodate the target item, and the automatic boxing of each item to be boxed is realized, which has better practicability and versatility.

Owner:JIHUA LAB

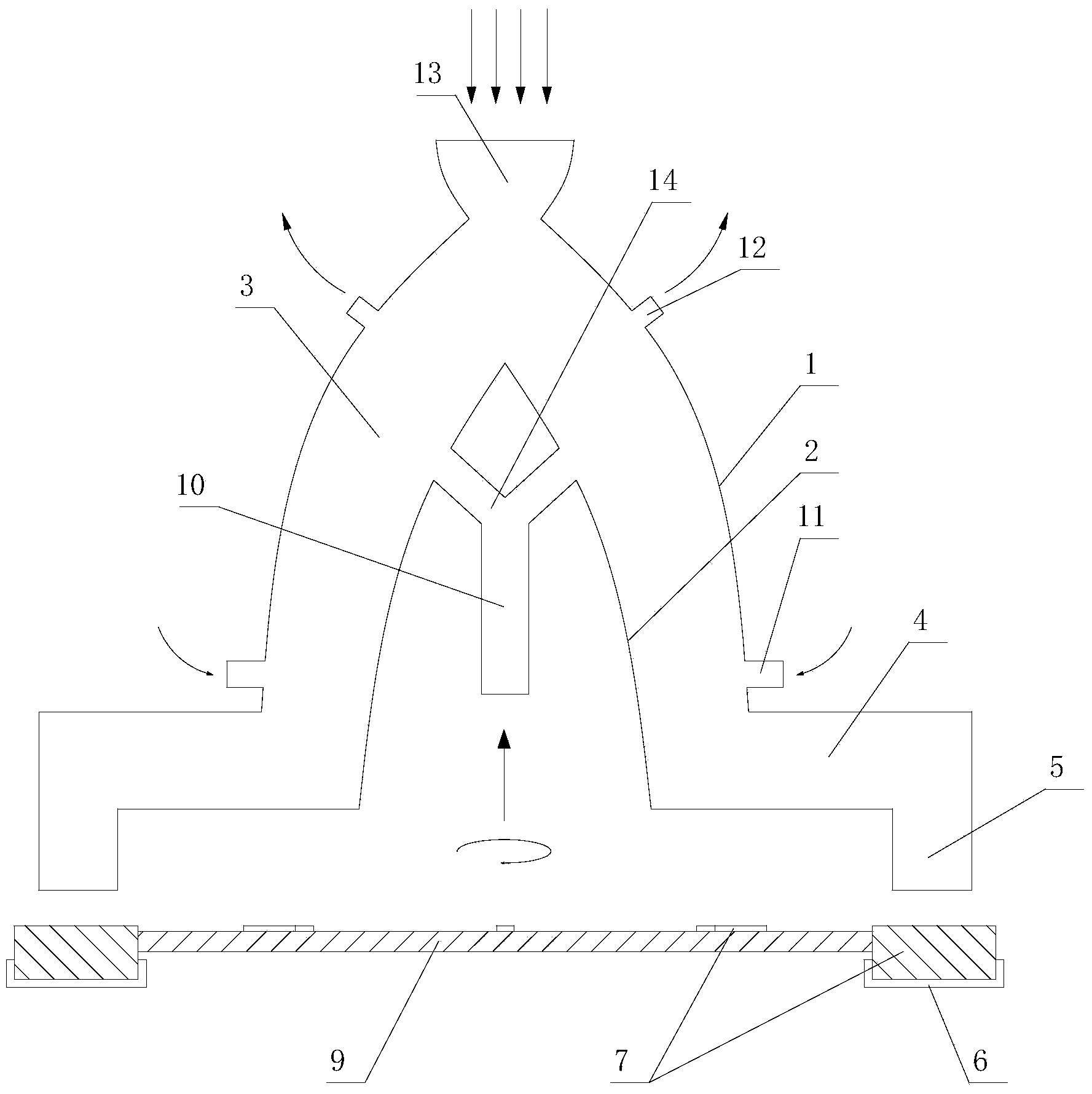

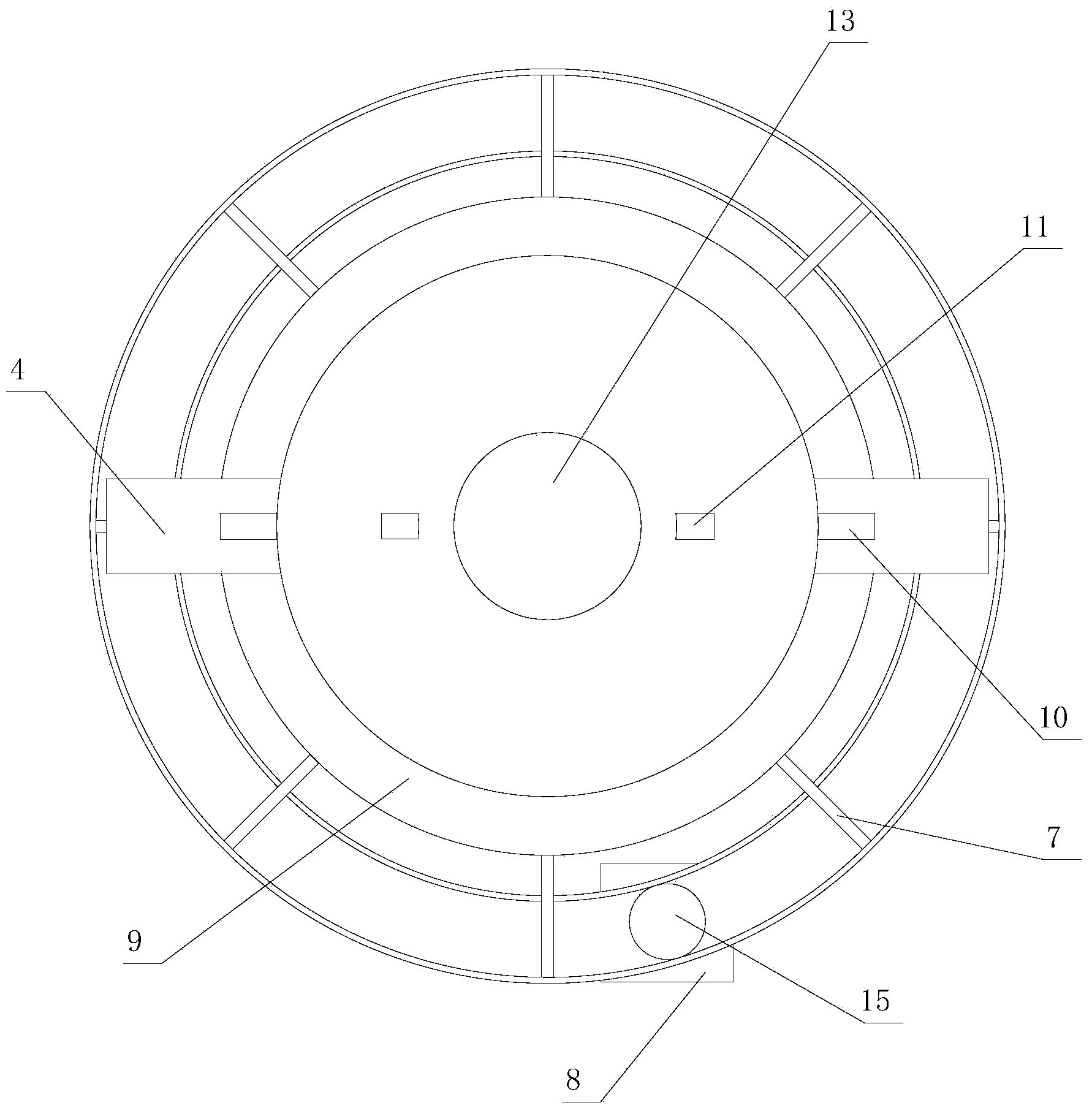

Thin-layer gas-collecting dry distiller

InactiveCN103773401AImplement autoboxingIncrease chance of contactDirect heating destructive distillationSpecial form destructive distillationSlagThin layer

The invention discloses a thin-layer gas-collecting dry distiller belonging to the field of the dry distiller. The thin-layer gas-collecting dry distiller comprises an outer shell body and an inner shell body, wherein the outer shell body and the inner shell body are coaxially arranged; a gap between the outer shell body and the inner shell body is a reaction cavity; a reaction slag channel is arranged at the periphery of the outer shell; a reaction slag outlet is formed in the tail end of the reaction slag channel; a reaction slag storage groove is formed under the reaction slag outlet and is internally provided with a plurality of pushing plates moving along the reaction slag storage groove; a through hole is formed in the bottom part of the reaction slag storage groove; a slag collecting box is arranged under the through hole; the reaction slag moves along the reaction slag storage groove under the action of the pushing plates, and finally flows out of the through hole to fall into the slag collecting box. The thin-layer gas-collecting dry distiller disclosed by the invention has the advantages that automatic box filling of reaction slag can be realized, so that not only is the operation simple and the use is convenient, but also the cost is lower and the maintenance is easy.

Owner:李伟

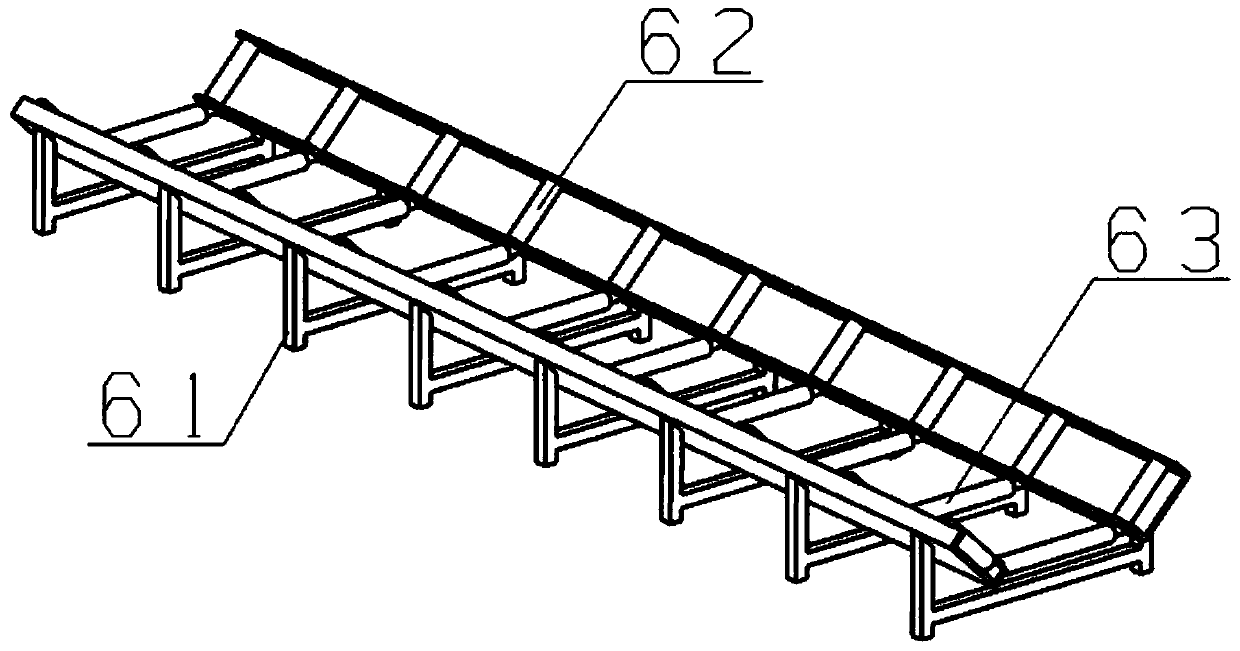

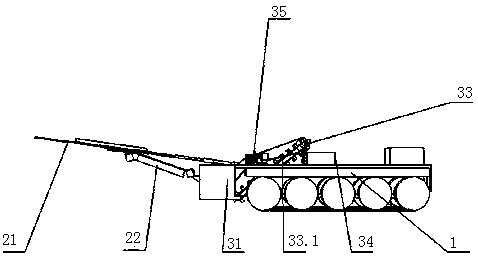

Tea oil fruit collecting and sorting machine

ActiveCN109964639AIncrease the level of mechanizationReduce labor intensityPicking devicesGradingFruit treeTree trunk

A tea oil fruit collecting and sorting machine comprises a vehicle body and is characterized by further comprising a collecting device for collecting fallen fruits from a fruit tree, and a sorting device for sorting and boxing the fruits. The collecting device is arranged at the front end of the vehicle body obliquely, the sorting device is arranged on the vehicle body, the outlet of the collecting device is in butt joint with the inlet of the sorting device, and the fruits pass through the collecting device and then directly fall into the sorting device. The tea oil fruits are synchronously collected after falling from a tree trunk, the cooling procedure and the sorting procedure are completed through one device, the after-picking collecting and sorting effect of the tea oil fruits is improved, the collecting mechanical level of the tea oil fruits is improved, and the collecting labor intensity of the tea oil fruits is lowered.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

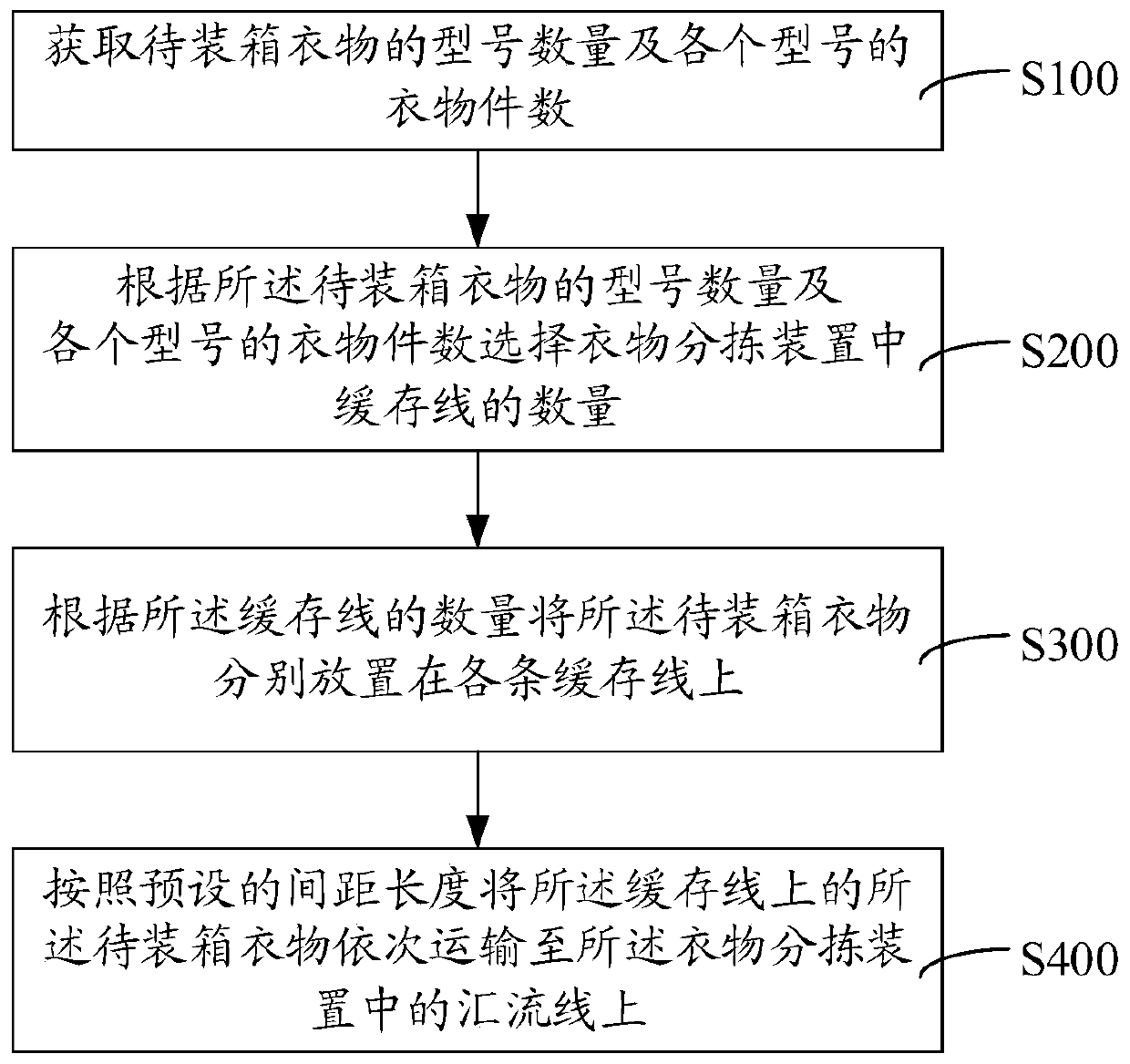

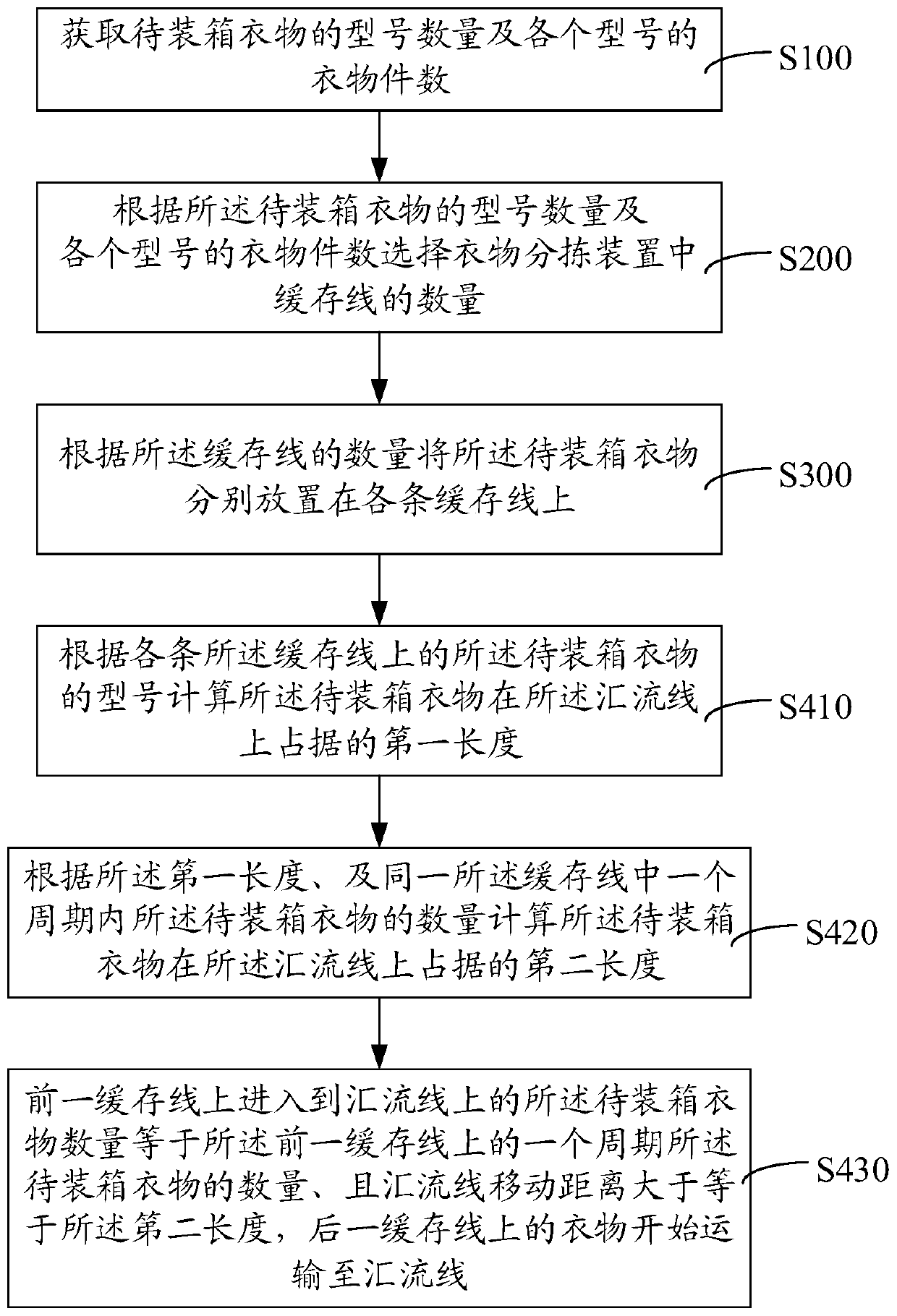

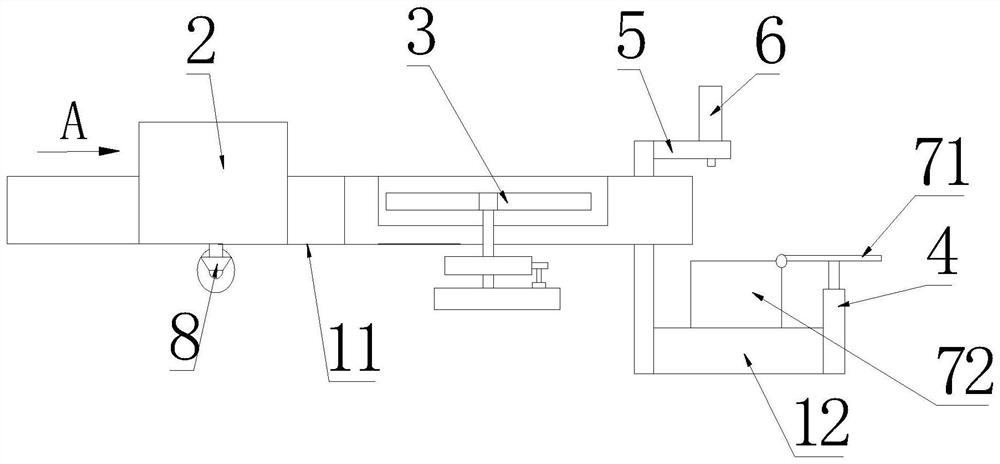

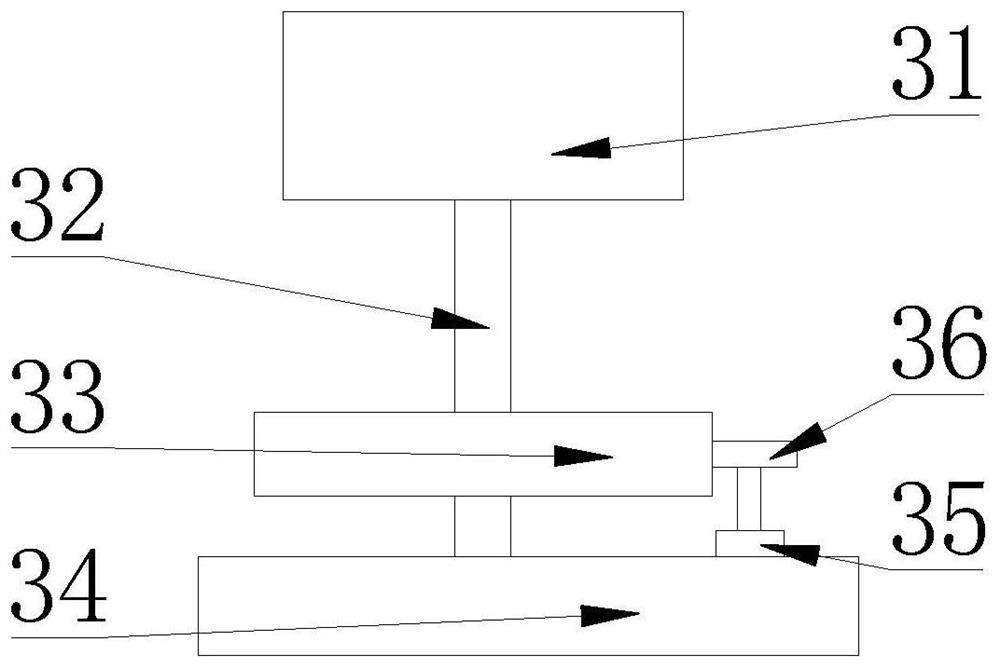

Clothes sorting and packing method and clothing sorting and packing device

The invention relates to a clothes sorting and casing method and device. The clothes sorting and casing method comprises the following steps that the number of types of to-be-cased clothes and the number of clothes of each type are acquired; the number of temporary storage lines of the clothes sorting and casing device is selected according to the number of types of to-be-cased clothes and the number of clothes of each type; the to-be-cased clothes is arranged on all the temporary storage lines according to the number of the temporary storage lines; and the to-be-cased clothes on the temporarystorage lines is sequentially conveyed to a collection line of the clothes sorting and casing device according to preset intervals. The clothes sorting and casing device comprises the collection line, the temporary storage lines, a first acquiring module, a selecting module, a placement module and a conveying module. According to the clothes sorting and casing method and device, the to-be-cased clothes is arranged on all the temporary storage lines, then the clothes on all the temporary storage lines is sequentially conveyed to the collection line, and thus the clothes of the same type and size are put together when the clothes is cased.

Owner:GUANGZHOU SEYOUNTH AUTOMATION TECH CO LTD

Mining packaging device based on unmanned mining

The invention is suitable for the technical field of unmanned mining, and provides an unmanned mining-based mining packaging device which comprises a first conveying belt, a crushing assembly and a material distributing assembly are arranged on the first conveying belt, a second conveying belt is arranged at the tail of the first conveying belt, and coal conveying boxes are regularly arranged on the second conveying belt at intervals. A top cover electric cylinder is fixedly connected to one side of the second conveying belt, a supporting frame is fixedly connected to the other side of the second conveying belt, and a cover pressing electric cylinder is fixedly connected to the supporting frame; the smashing assembly comprises two smashing units which are oppositely arranged, each smashing unit comprises a roller, the rollers are provided with protruding threads, and supporting shafts are arranged at the two ends of each roller. In this way, large coal blocks can be smashed, the coal can be conveyed at intervals according to the capacity of the coal box, the quantity of the coal in the coal box is ensured, automatic coal boxing can be achieved, and manual operation is reduced.

Owner:LINYI MINING GRP CO LTD

A sugarcane healthy seed stem production line

ActiveCN110583140BNeat cutImplement autoboxingDrying gas arrangementsIndividual articlesAgricultural engineeringCane

The invention relates to the technical field of sugarcane planting, and specifically discloses a sugarcane healthy seed stem production line. Sterilize the coating device. The invention can cut the sugarcane stems neatly and quickly into sugarcane stems through the seed cutting device; when the sugarcane stems are conveyed by the conveying device, the side sliding plate and the bending belt mechanism can place the sugarcane stems in a direction parallel to the conveying direction, which is convenient for Packing; the blanking plate and the vibration device can realize the automatic packing of sugarcane stems, and can neatly stack the sugarcane stems in the material box; the disinfection coating device can automatically sterilize, coat and dry the sugarcane stems , which avoids the operator's direct contact with the disinfectant and coating liquid, which not only ensures the safety of the production operation environment but also improves the operation efficiency.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

Food encasing device with automatic screening and counting function

InactiveCN108945595ASave human effortEasy to operatePackaging automatic controlPistonInfrared emitter

The invention discloses a food encasing device with an automatic screening and counting function. The device comprises air cylinders, a second encasing device, discharging pipes, storage cases, a base, a controller, receiving hoppers and hydraulic cylinders. The air cylinders are utilized for driving piston rods to stretch, and accordingly, baffles are pushed to move upwards; by arranging the second encasing device, food at the top of a holding plate is pushed to fall into the receiving hoppers, the food entering the receiving hoppers further falls into the storage cases through the corresponding discharging pipes, accordingly, the food with the qualified weight is automatically encased, manpower encasing is not needed, and the manual labor is greatly saved; the food passing through the discharging pipes blocks infrared rays emitted by infrared emitters, accordingly, the purpose that the food with the qualified weight is counted automatically is achieved, and operation is easy; and byarranging a first encasing device and the second encasing device, the food with the qualified weight and food with the unqualified weights are automatically encased and counted in a classified mode, and the practicability of the equipment is improved.

Owner:芜湖博创新能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com