Patents

Literature

473results about How to "Reduce manual work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

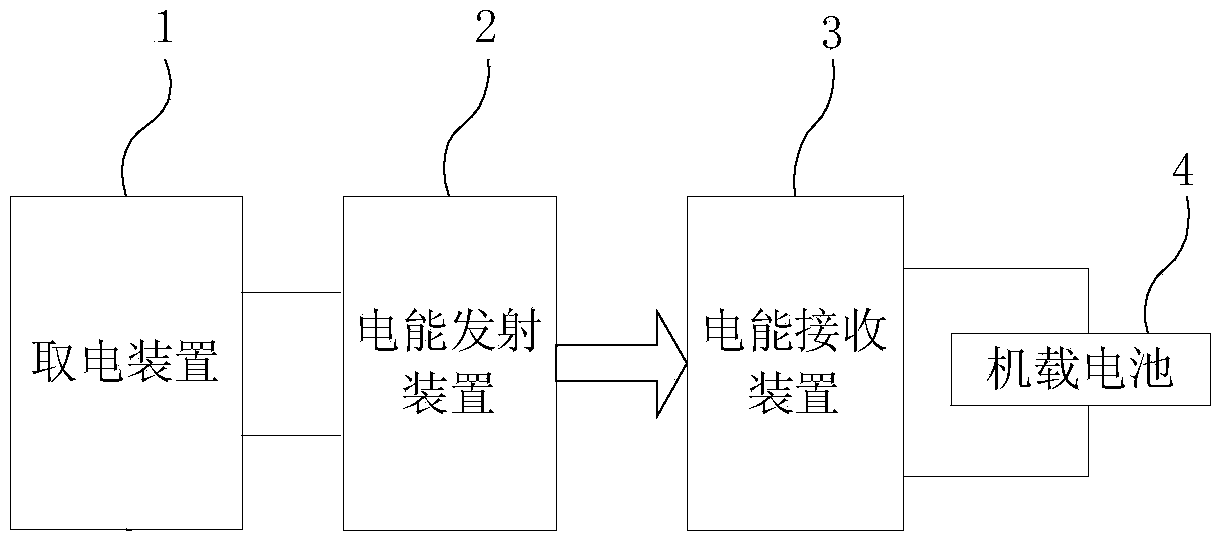

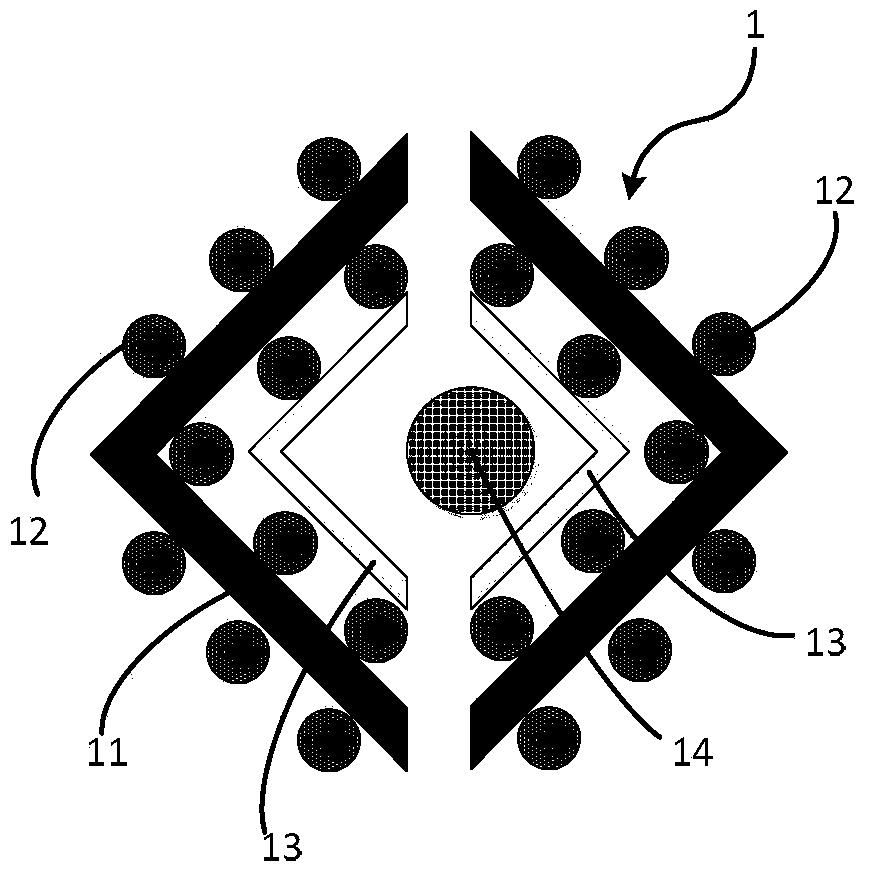

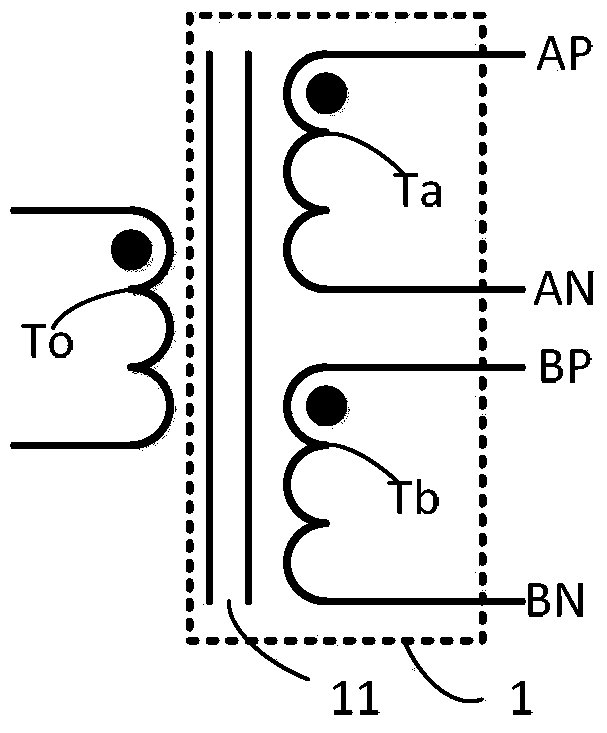

Charging system for unmanned aircraft

ActiveCN103872795AGuaranteed one-way flowEliminate low harmonic injectionElectromagnetic wave systemCircuit arrangementsElectric power transmissionEngineering

The invention discloses a charging system for an unmanned aircraft. The charging system is characterized by comprising a power-taking device, an electric energy transmitting device, an electric energy receiving device and an aircraft-mounted battery, wherein an overhead transmission line is arranged on the power-taking device; the electric energy transmitting device is for converting power frequency alternating current into high-frequency alternating current; the electric energy receiving device is arranged on the unmanned aircraft; electric energy transmission is realized in a wireless manner between the electric energy receiving device and the electric energy transmitting device; the aircraft-mounted battery is arranged on the unmanned aircraft, is used for supplying power to the unmanned aircraft, and is connected in series to a current loop of the electric energy receiving device. Compared with the prior art, an electric unmanned aircraft charging system based on an alternating-current power transmission overhead line provided by the invention has the advantages that a full-autonomous and safe charging way is realized for the unmanned aircraft, and the distance per charge of the unmanned aircraft is prolonged. Meanwhile, a high-frequency inductive constant-current charging circuit based on an unstable alternating-current power supply is provided, so that unmanned charging operation is fully realized, the dependence of the unmanned aircraft on a ground base or a mobile base station is reduced, labor operation is reduced, and labor cost is reduced.

Owner:王洋 +3

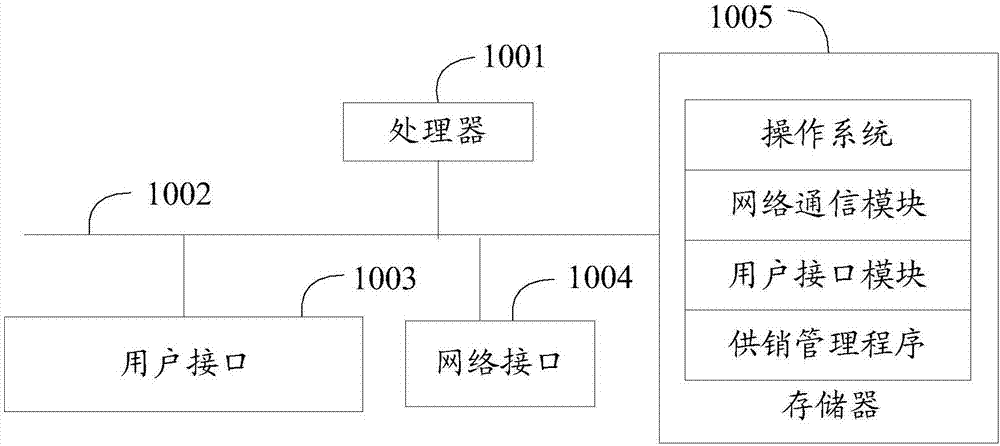

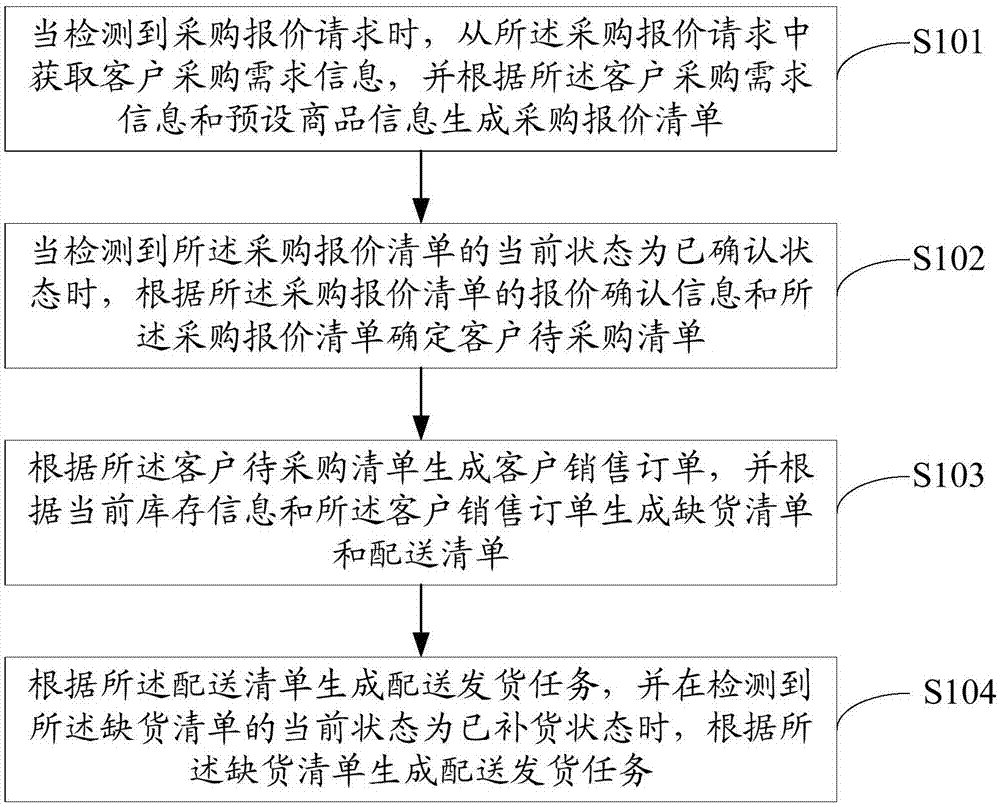

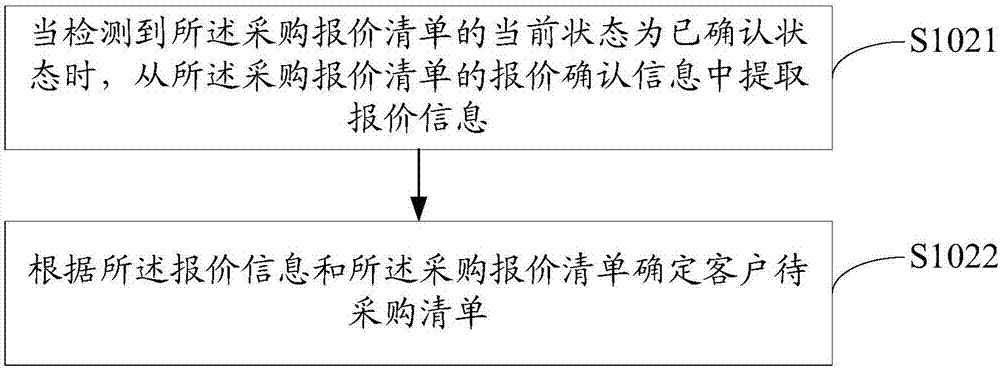

Supply and market management method, device and computer readable storage medium

InactiveCN107886285AReduce manual workReduce omissionsBuying/selling/leasing transactionsLogisticsData miningMarket management

The invention discloses a supply and market management method, device and a computer readable storage medium. The supply and marketing management method includes the following steps: if a purchase quotation request is detected, acquiring client purchase requirement information from the purchase quotation request, and based on the client purchase requirement information and preset commodity information, generating a purchase quotation list; if it is detected that the current state of the purchase quotation list is in a confirmed state, based on the quotation determination information of the purchase quotation list and the purchase quotation list, determining a client to-be-purchased list; based on the client to-be-purchased list, generating a client marketing list, and based on the currentwarehouse information and the client marketing list, generating a shortage list and a delivery list; and based on the delivery list, generating a delivery dispatching task, and if it is detected thatthe current state of the shortage list is in a replenished state, based on the shortage list, generating a delivery dispatching task. According to the invention, the method can effectively lower manpower cost and reduces careless omission.

Owner:KANGMEI PHARMA +1

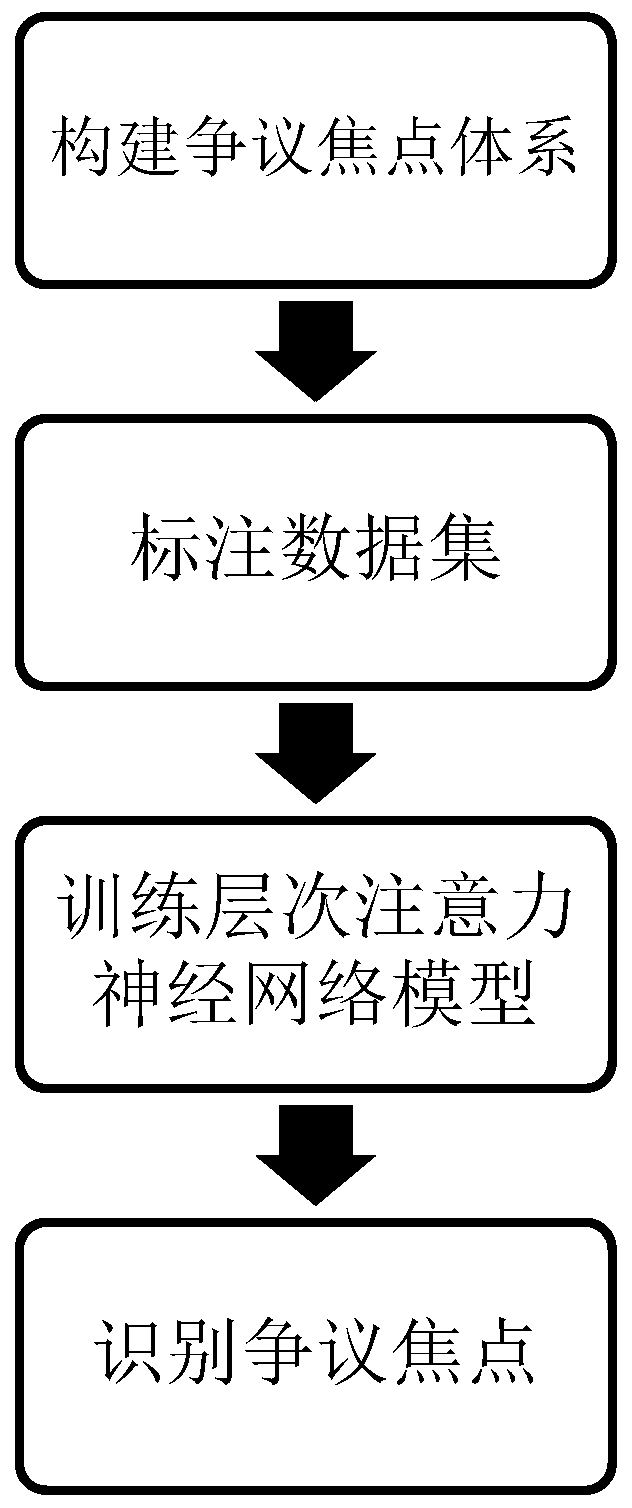

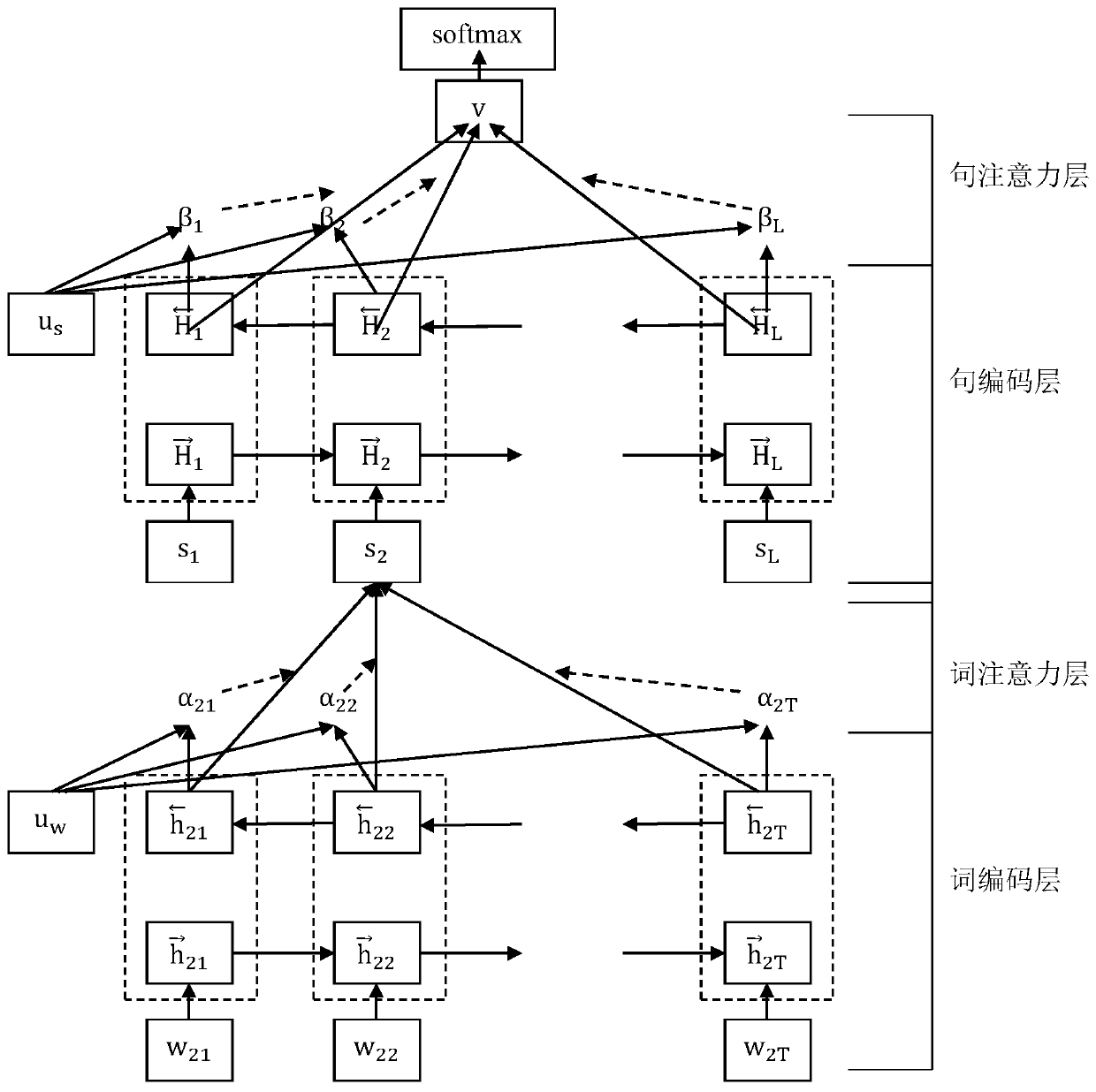

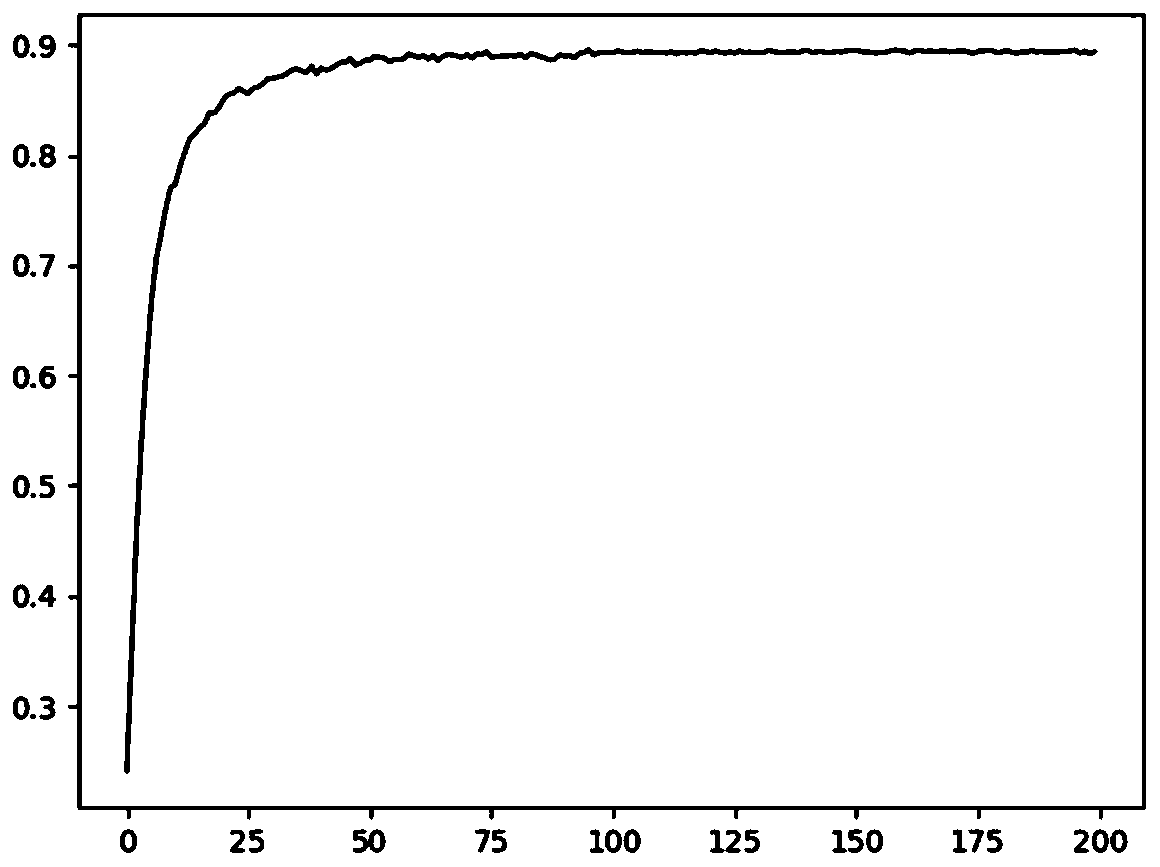

Dispute focus automatic identification method based on hierarchical attention neural network model

ActiveCN111143550AReduce manual workReduce the burden onSemantic analysisSpecial data processing applicationsData setText entry

The invention discloses a dispute focus automatic identification method based on a hierarchical attention neural network model. The method comprises the steps of firstly, extracting a dispute focus statement of a court for case induction from a document containing a dispute focus induced by the court, and constructing a dispute focus system by utilizing a hierarchical clustering method; and marking a plurality of different category labels for each document by utilizing the dispute focus system, constructing a data set, and converting a dispute focus identification problem into a multi-label multi-classification problem; then, training a hierarchical attention neural network model, paying more attention to important words, sentences and paragraphs containing more information, and forming adispute focus recognizer; and finally, inputting the text of which the dispute focus needs to be identified into a dispute focus identifier to obtain the dispute focus of the input text. The method ishigh in prediction accuracy, can accurately identify and judge the dispute focus of the document, and has good expandability.

Owner:ZHEJIANG UNIV

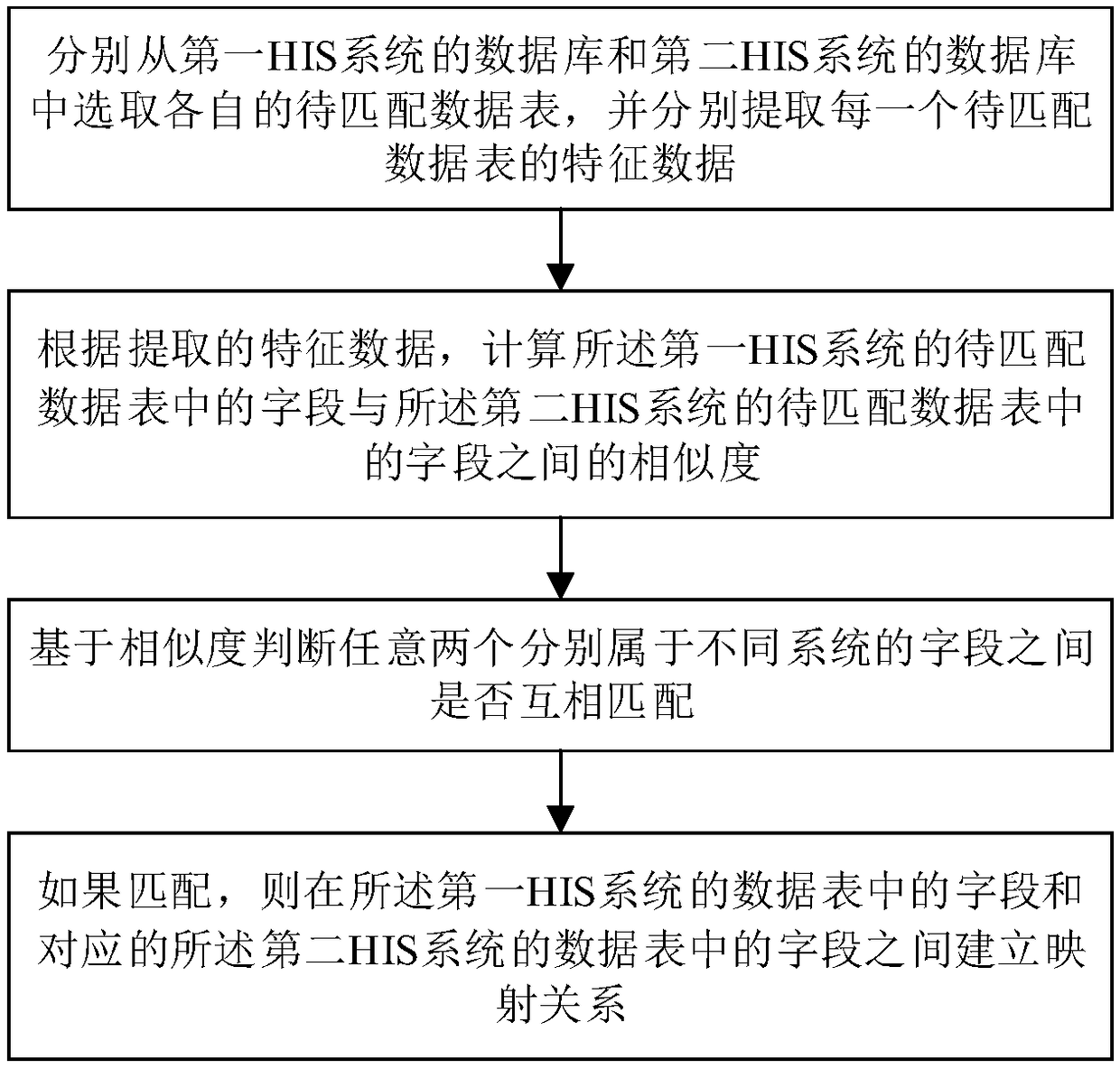

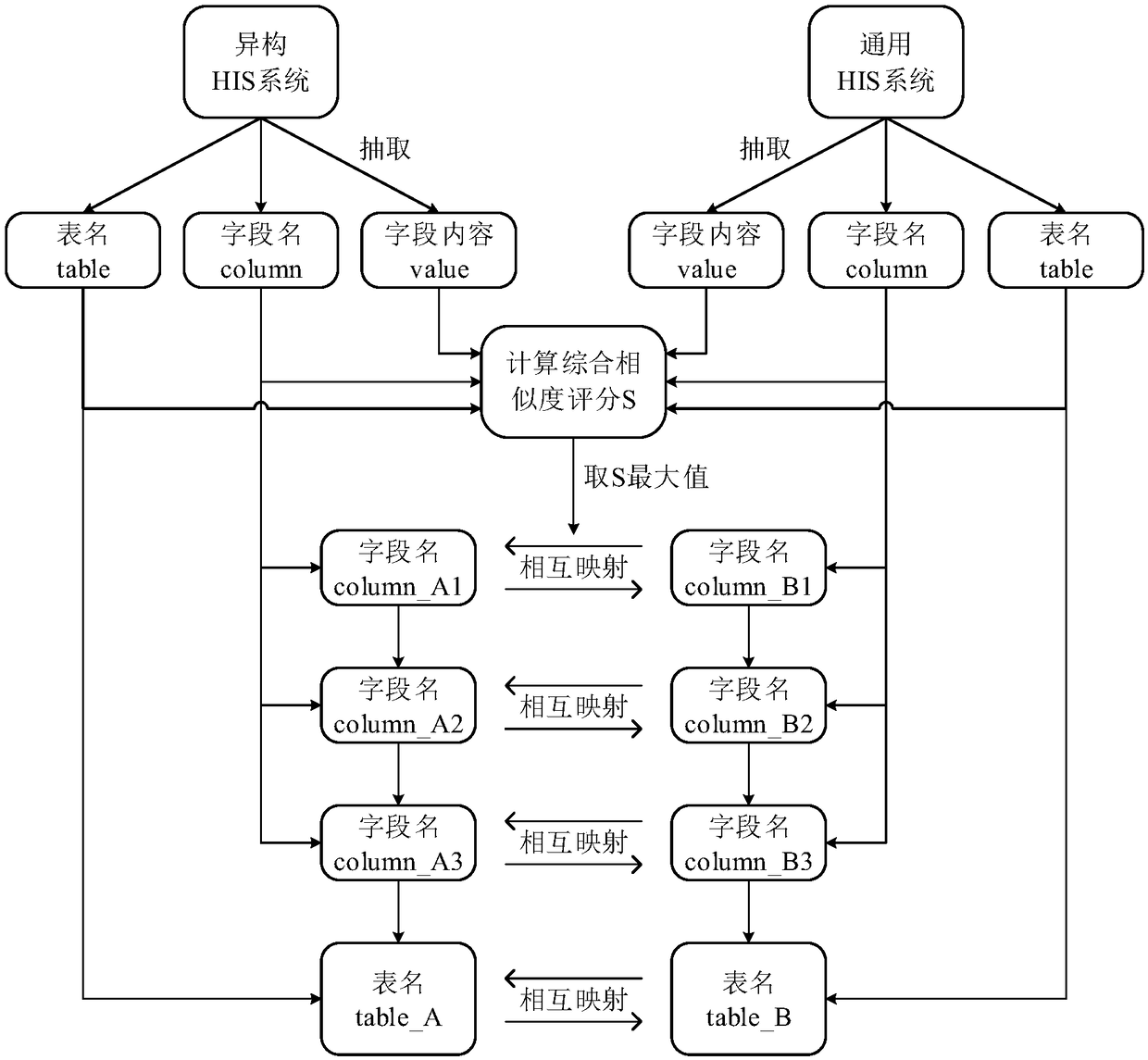

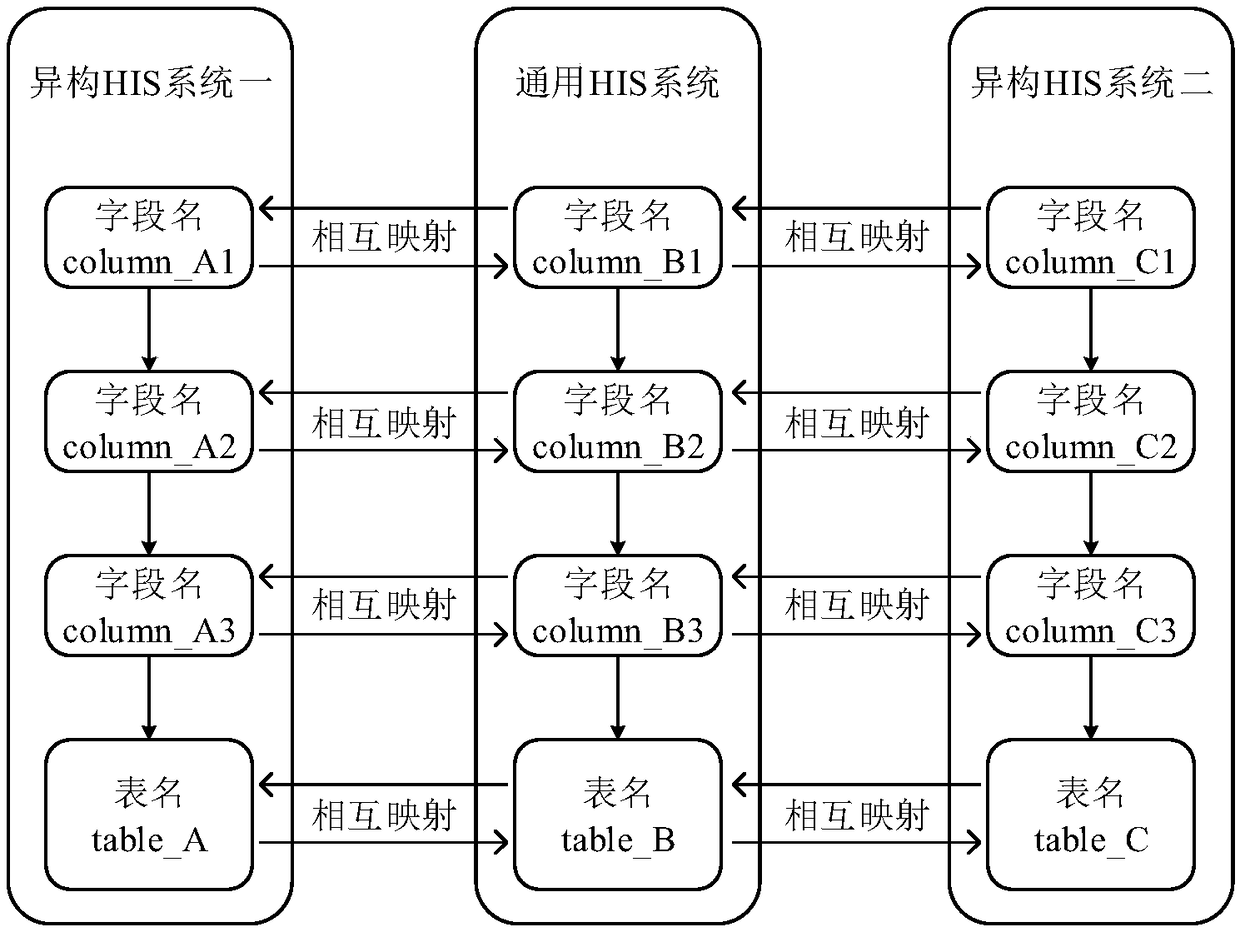

Data table mapping method applied to HIS systems

PendingCN108595614AImplement indirect mappingReduce manual workCharacter and pattern recognitionHealthcare resources and facilitiesFeature dataRepeatability

The invention relates to a data table mapping method applied to HIS systems. The method comprises the following steps of: respectively selecting to-be-matched data tables from a database of a first HIS system and a database of a second HIS system, and respectively extracting feature data of the to-be-matched data tables; calculating similarities between fields in the to-be-matched data table of the first HIS system and fields in the to-be-matched data table of the second HIS system according to the extracted feature data; judging whether any two fields which respectively belong to different systems are matched or not on the basis of the similarities; and if the judging result is positive, establishing a mapping relationship between the fields in the data table of the first HIS system and the fields in the data table of the second HIS system. According to the method, automatic matching between different HIS system data tables is carried out by utilizing a computer, so that manual work low in efficiency and high in repeatability is decreased and the human cost is reduced.

Owner:CHENGDU ZHIXIN ELECTRONICS TECH CO LTD

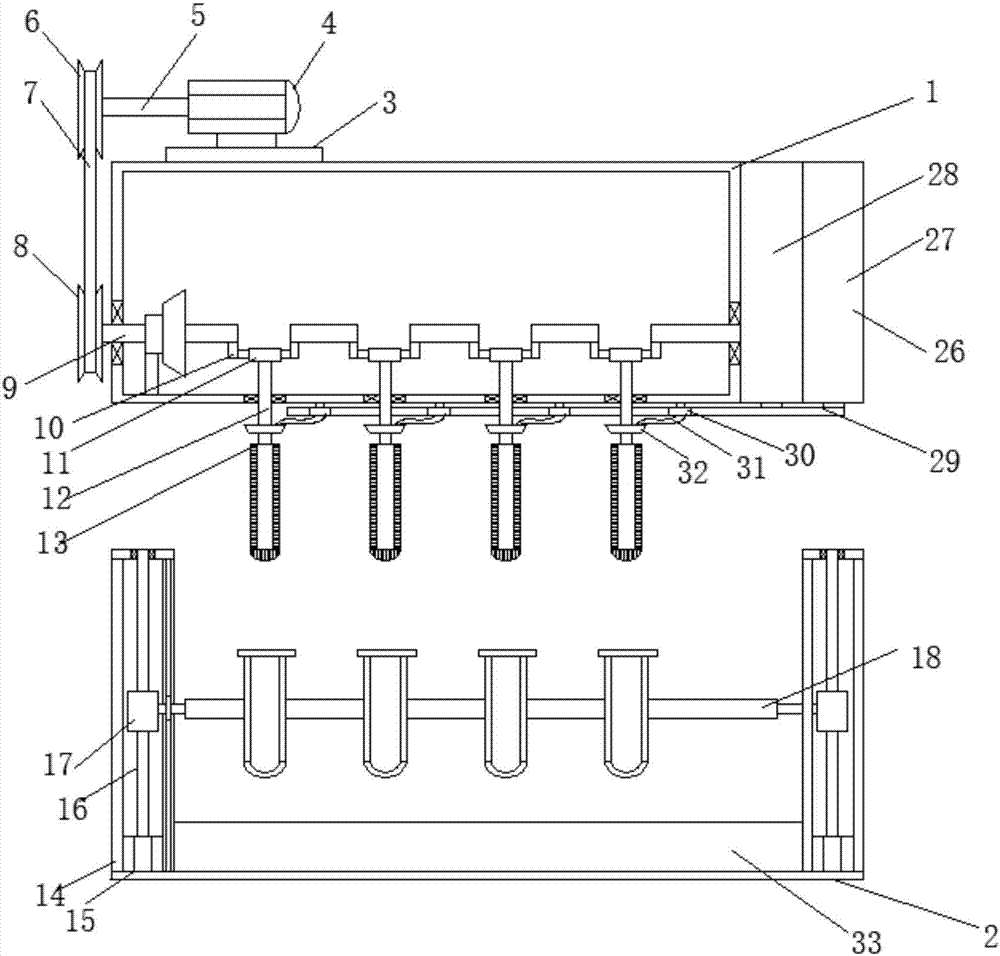

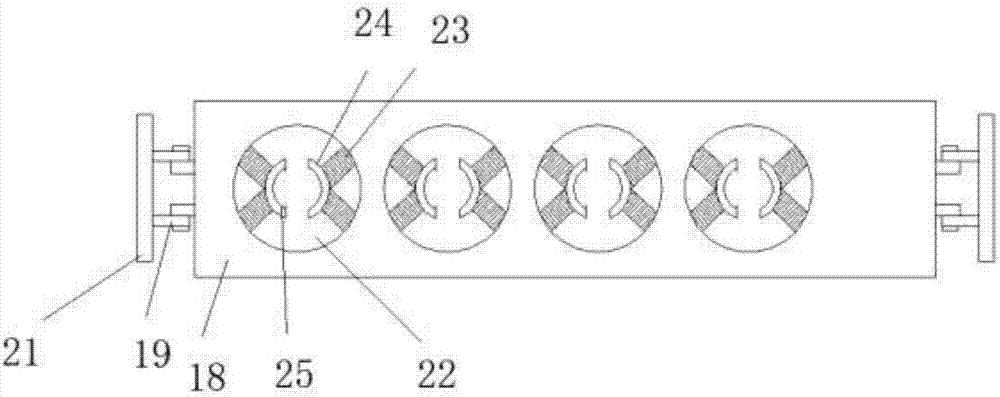

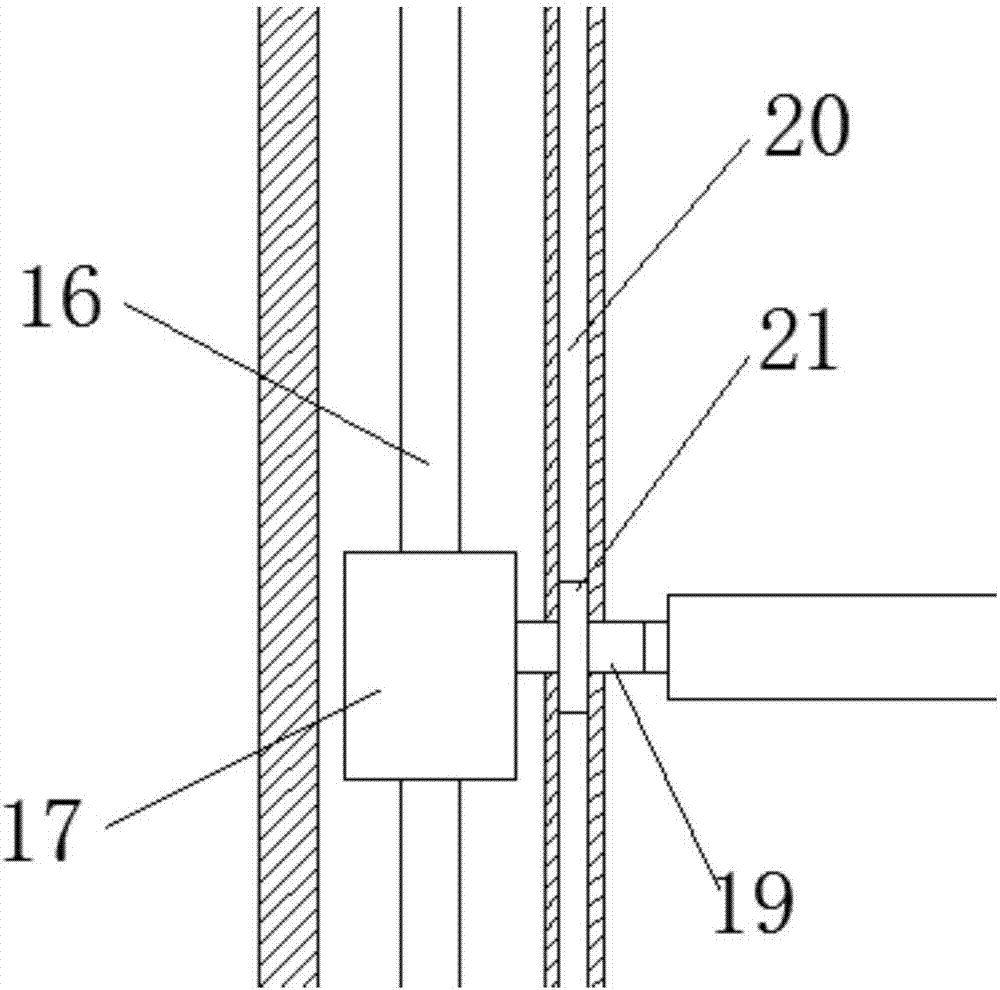

Automatic cleaning device used for medical test tube

InactiveCN107225131ARealize the function of automatic cleaningEasy to cleanHollow article cleaningChemicalsDrive wheelMotor drive

The invention discloses an automatic cleaning device for medical test tubes, which includes a cleaning frame and a fixing frame. A mounting frame is provided on the left side of the top of the cleaning frame, and a cleaning motor is installed on the mounting frame. The left end of the cleaning motor is equipped with a transmission shaft, the left end of the transmission shaft is equipped with a driving wheel, the inner cavity of the cleaning rack is equipped with a transmission shaft, and the right end of the transmission shaft is equipped with a driven wheel. A belt is provided between the driving wheel and the driven wheel to connect, and several U-shaped frames are arranged on the transmission shaft, and connecting sleeves are set on the upper ends of the U-shaped frames, and the bottom ends of the connecting sleeves are A transmission rod is connected, and the bottom ends of the transmission rods are equipped with cleaning brushes. The beneficial effects of the present invention are: the transmission mechanism is used to realize automatic cleaning, the cleaning effect is good, the efficiency is high, manpower is reduced, and cleaning and disinfection solvents are avoided. cause harm.

Owner:WENCHENG JIANCHUANG TECH

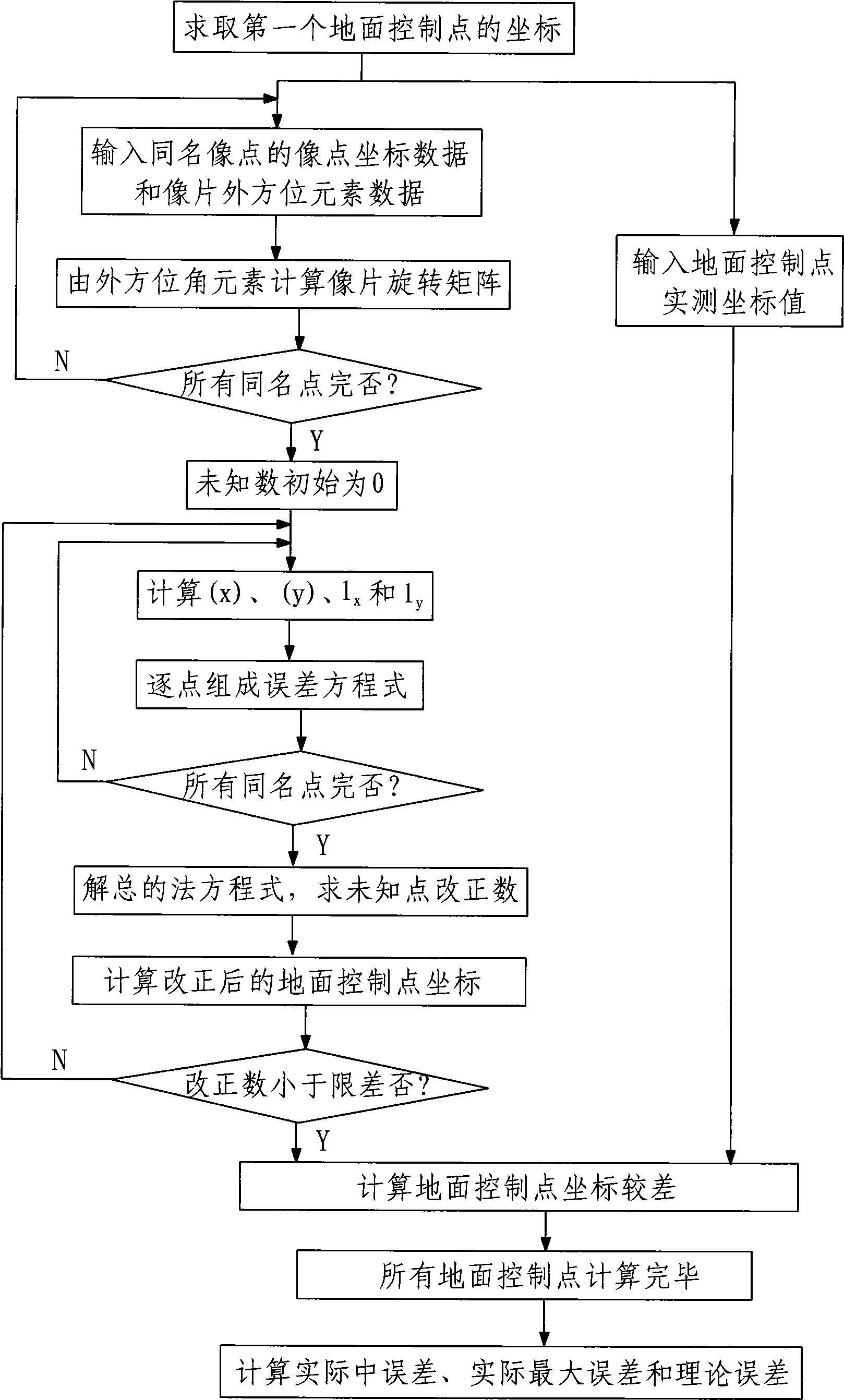

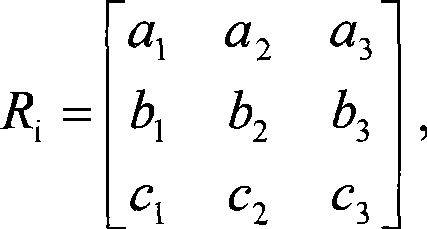

GPS//INS data direct directing precision assessment method

InactiveCN101509784AInnovative designHigh degree of automationInstruments for road network navigationPicture interpretationBundle methodBundle methods

The invention discloses a GPS / INS data direct orientation precision evaluation method, which takes photogrammetric emphasis equation collinearity equation as base and a multi-piece forward intersection of a bundle method as theory basis; the evaluation method is combined with the least square principle for obtaning the coordinate of a ground control point object by compensating calculation; and then a comparison with the actually measured coordinate of the ground control point is carried out for obtaining the error value of the coordinate by the statistics so as to evaluate the direct orientation precision of the outer orientation elements obtained by the GPS / INS system. The method has high evaluation precision and small measurement error, and the evaluation result can be used for manufacture practice directly, thus being capable of effectively avoiding the measurement error of the picpointed coordinate added in manual stereomeasurement; and the algorithm is not limited by image number.

Owner:XIAN MEIHANG INFORMATION IND

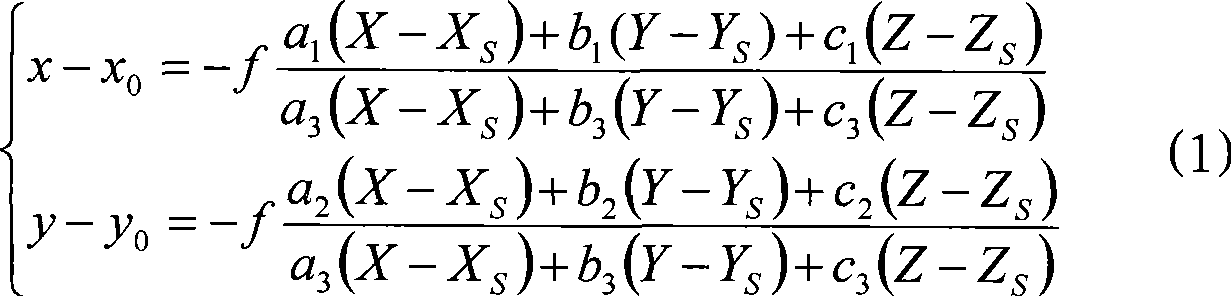

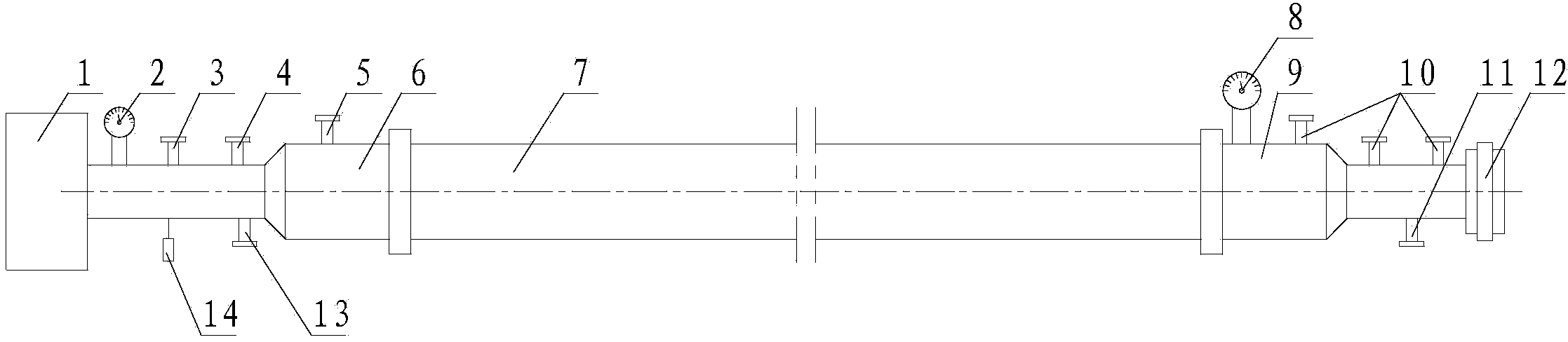

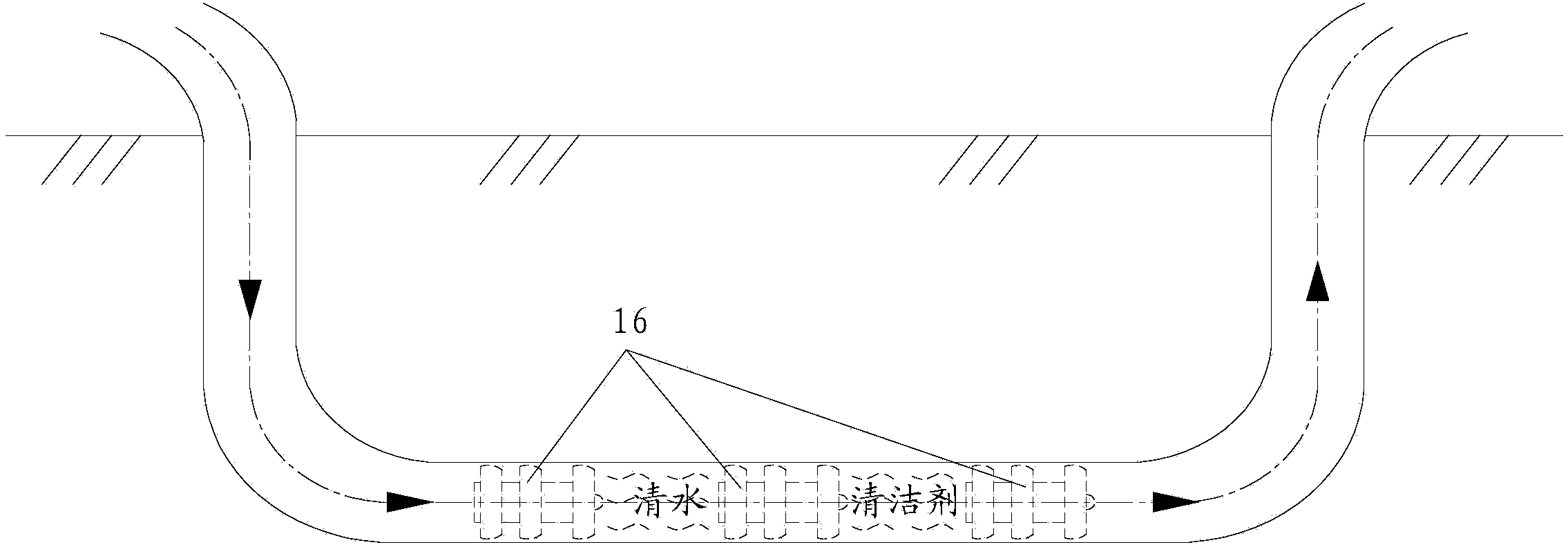

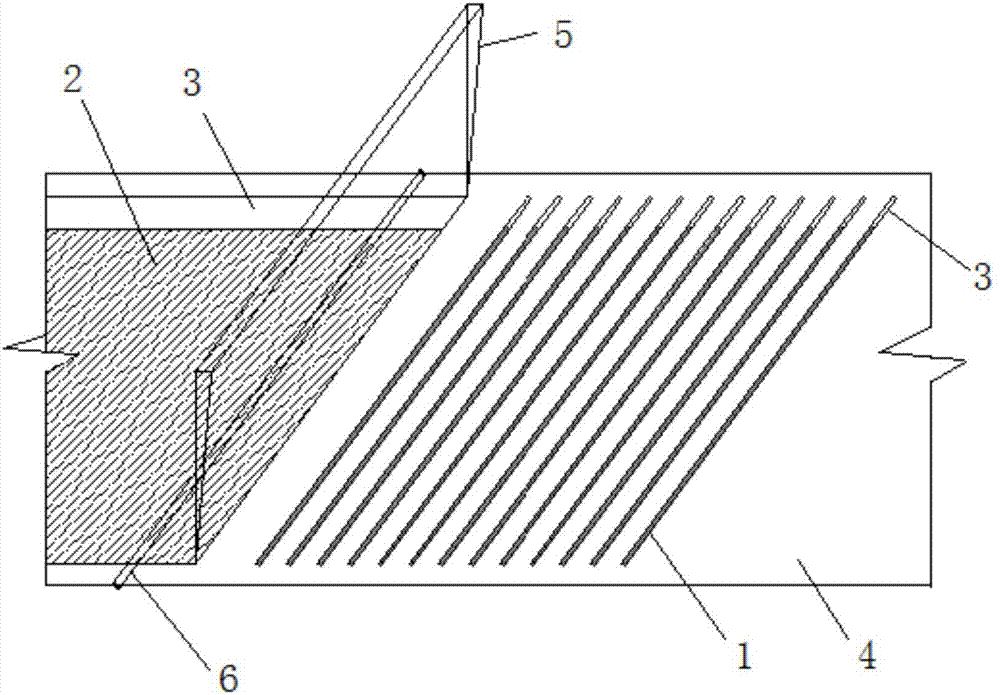

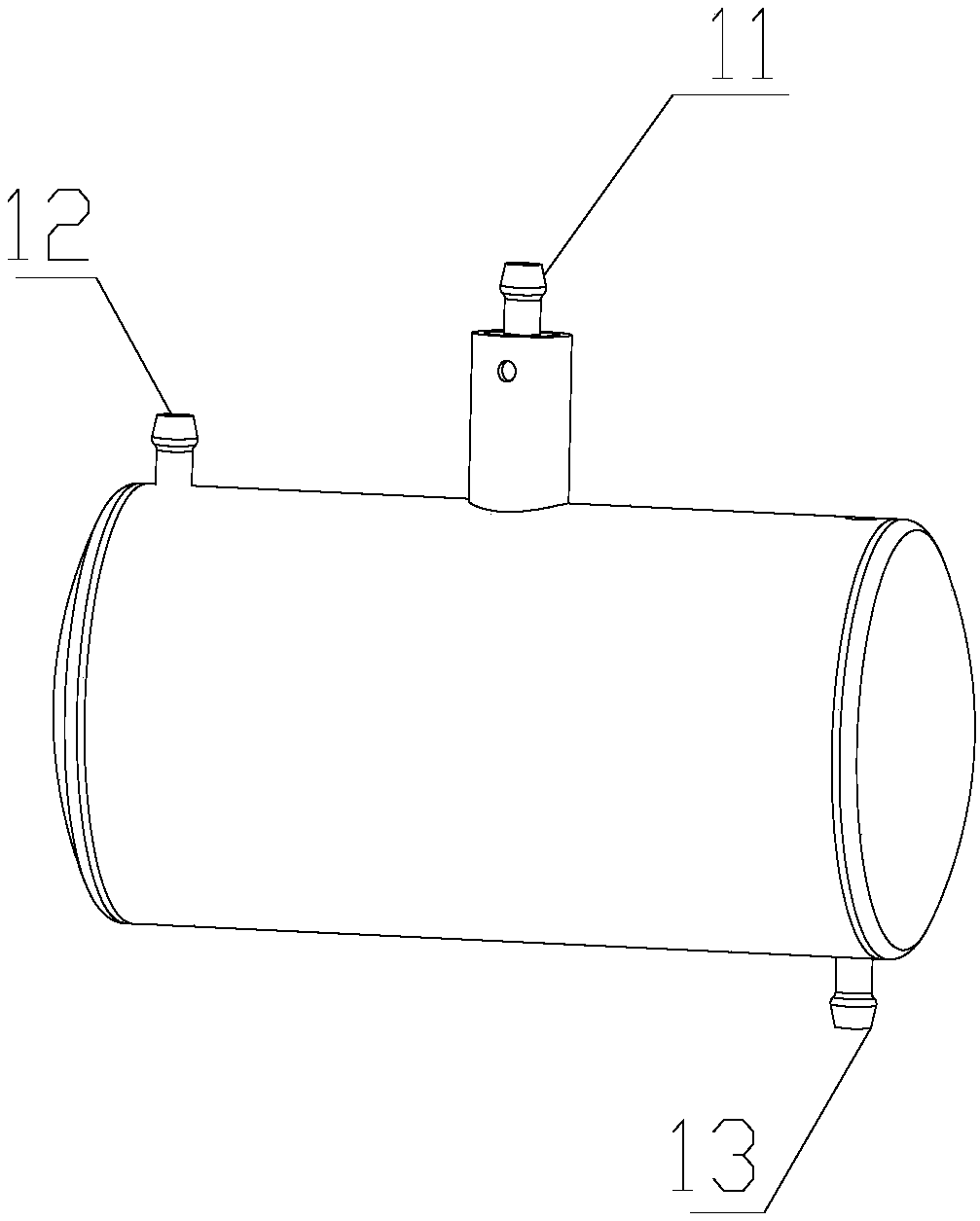

Process for cleaning whole inner wall of long pipeline for high-purity gas

ActiveCN104014562ASpeed upImprove cleanlinessDrying solid materials without heatHollow article cleaningImpurityRust

The invention relates to a process for cleaning the whole inner wall of a long pipeline for high-purity gas. The process includes the following steps that (1), present situation investigation and processing are carried out on the pipeline; (2), rust removal and dedusting cleaning processing is carried out on the inner wall of the pipeline, wherein a leather cup steel brush pipe cleaner and a foam pipe cleaner are pushed through oil-free compressed air to rapidly move in a laid long-distance pipeline in one direction so as to push quantities of residues and other impurities in the long-distance pipeline out of the pipeline; (3), drying processing is conducted on the inner wall of the pipeline, wherein a large-scale compressor and a gas storage tank accumulator are utilized to purge a pipeline system; (4) protection is conducted on a finished pipeline. The process for cleaning the whole inner wall of the long pipeline for high-purity gas is reasonable in design, easy and convenient to operate and especially applied to processing the inner wall of the pipeline for high-purity gas. By the adoption of the process, the construction progress can be quickened, construction quality can be improved, manual operation can be reduced, construction cost can be saved, and efficiency of construction operation is effectively improved.

Owner:TIANJIN PIPELINE ENG GROUP

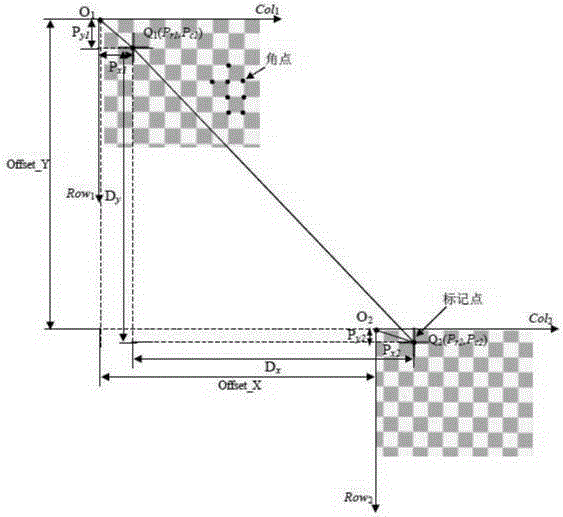

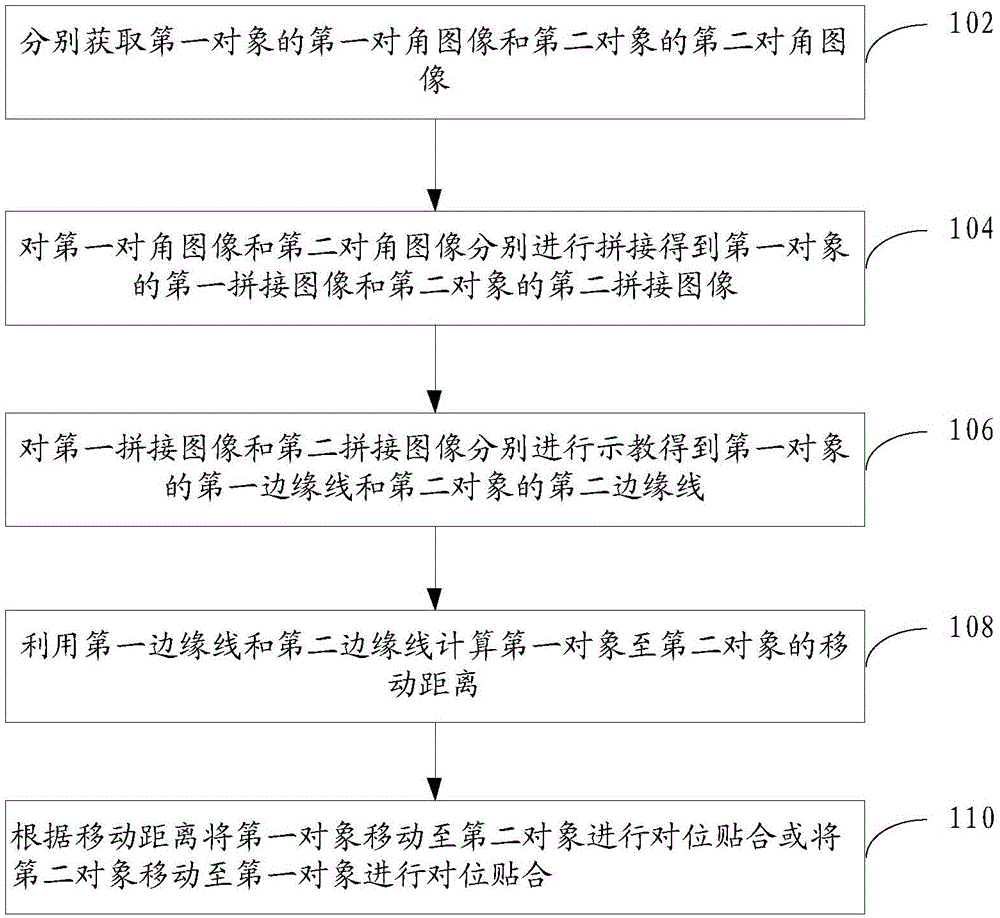

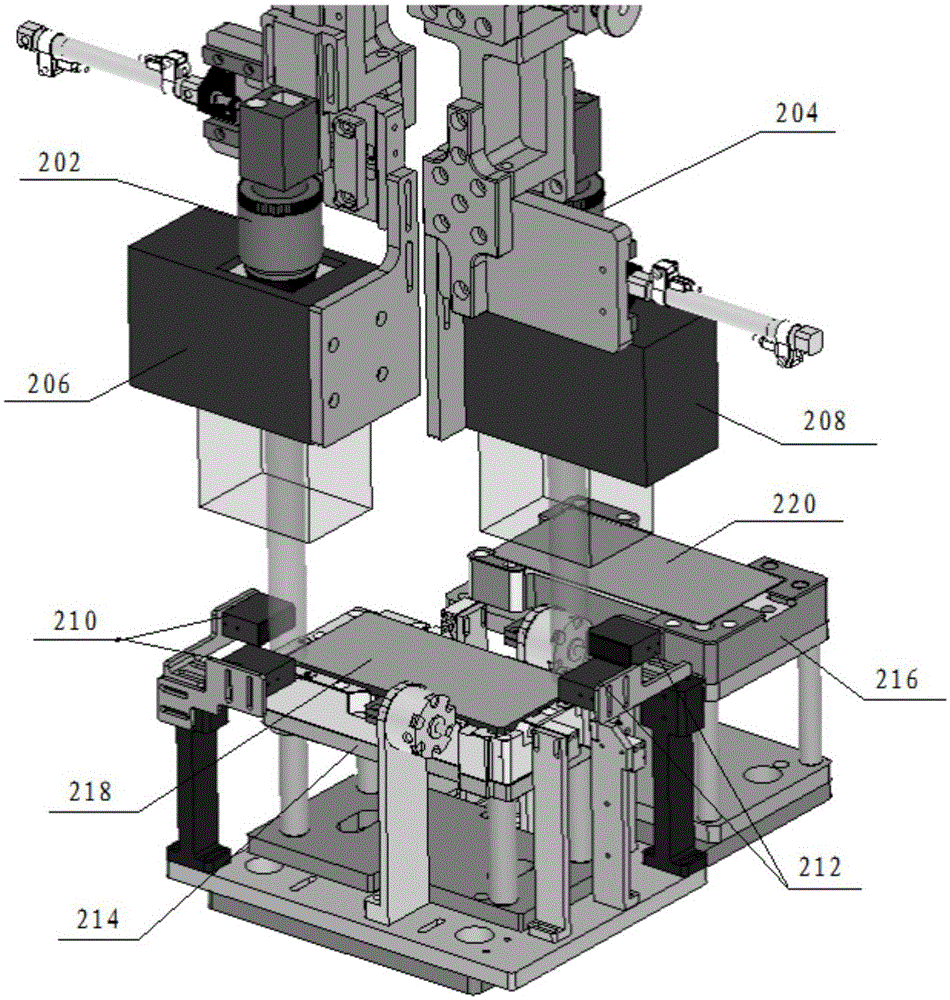

Aligned adhering method and device

ActiveCN105118042AReduce manual workIncrease productivityImage enhancementGeometric image transformationComputer vision

The invention relates to an aligned adhering method applied to a first object and a second object. The method comprises steps of: acquiring a first diagonal image of the first object and a second diagonal image of the second object; splicing the first diagonal image to obtain a first spliced image of the first diagonal image and splicing the second diagonal image to obtain a second spliced image of the second diagonal image; performing teaching on the first spliced image to obtain a first edge line of the first object and performing teaching on the second spliced image to obtain a second edge line of the second object; computing the displacement distance between the first object and the second object by using the first edge line and the second edge line; according to the displacement distance, moving the first object to the second object or moving the second object to the first object in order to perform aligned adherence. The method may effectively aligned adhering precision and production efficiency. Further, an aligned adhering device is provided.

Owner:HANS LASER TECH IND GRP CO LTD +1

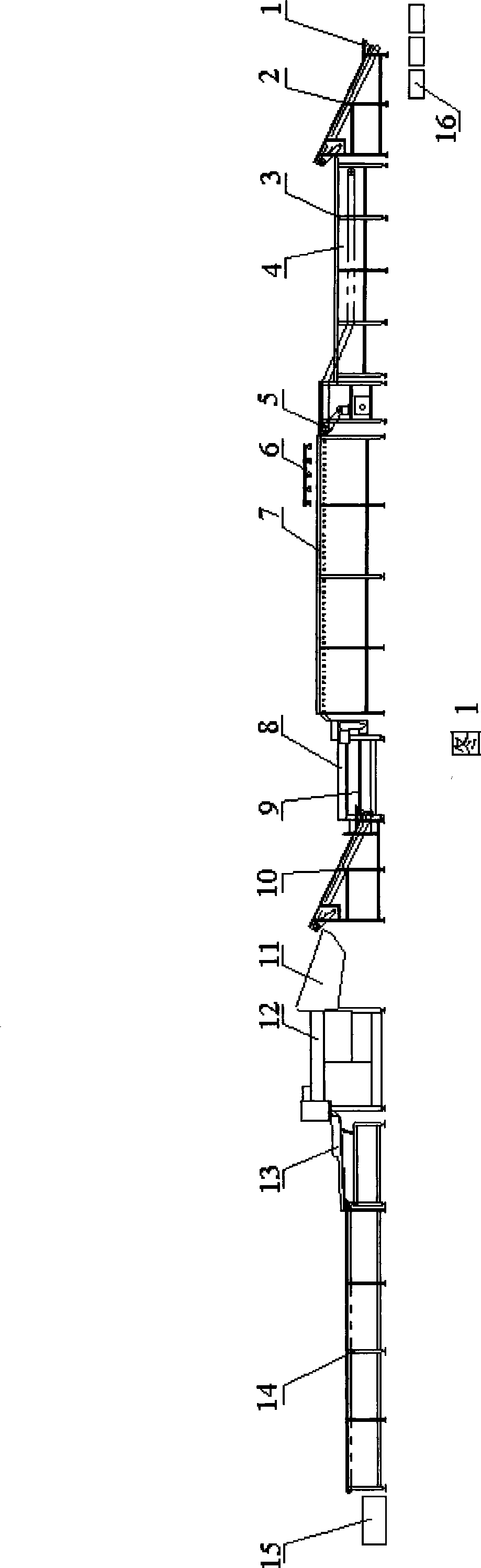

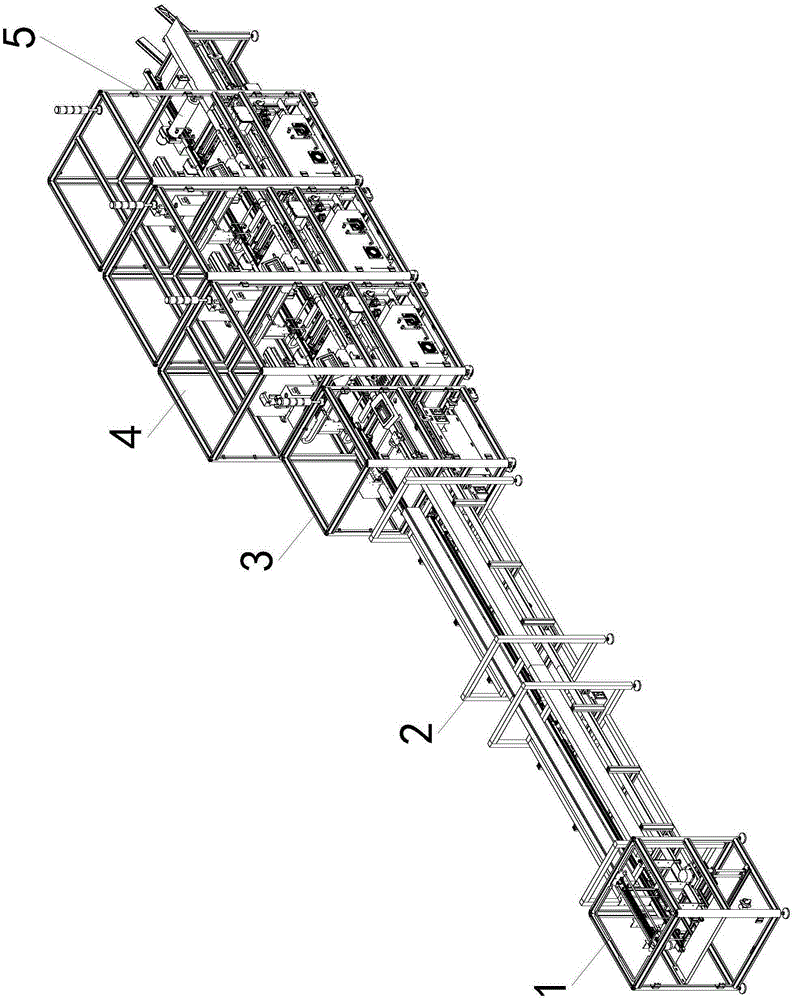

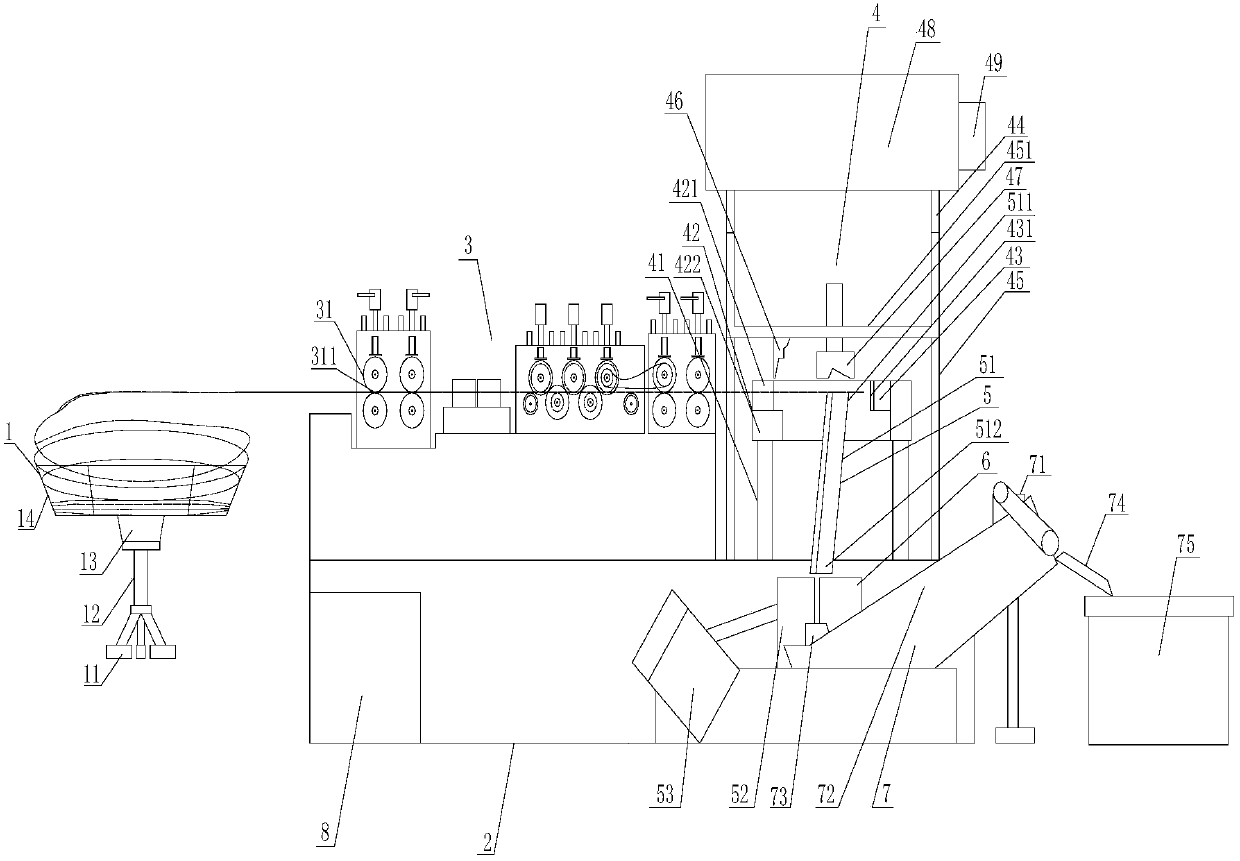

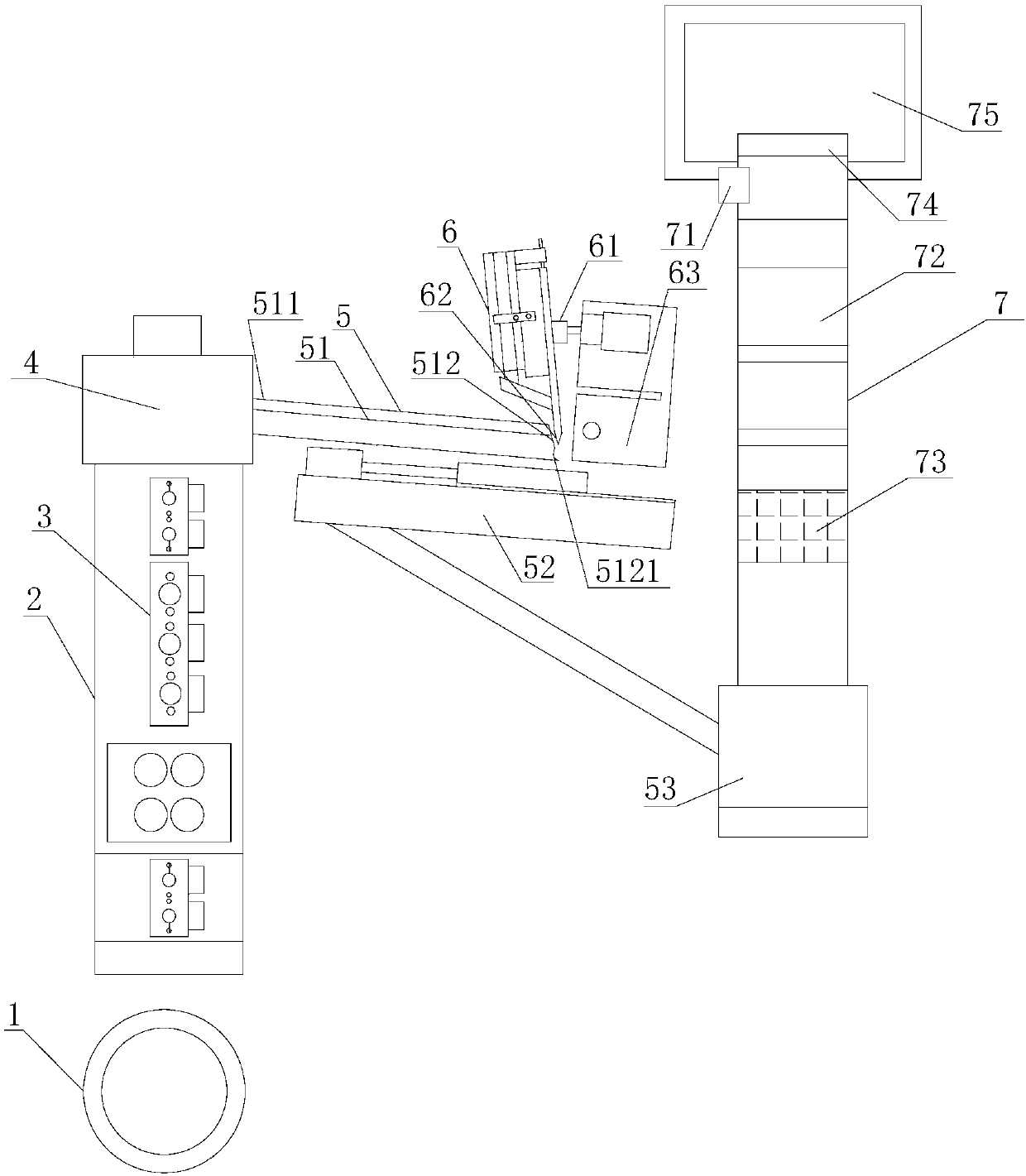

Production technique of removing kernel from the apricot and mechanical production chain

InactiveCN101396165AReduce manual workIncrease productivityFruit stoningContinuous operationDried fruits

The invention relates to a method for processing fruits, in particular to an apricot (stone fruit) cutting and coring production process and a mechanical production line. The apricot cutting and coring production process comprises the processing procedures of washing, selecting apricots, classifying, lining, automatically directing, cutting and coring, separating the pulp from the stone, turning the pulp, selecting the pulp and the like. The mechanical production line comprises an elevated conveyer, a vapor bubble cleaning machine, a high pressure spray device, a rolling lever fruit selector, a classifier, a cutting and coring machine, a pulp turner, a picking conveyer and the like. The apricot cutting and coring mechanical production line can realize continuous operation of apricot cutting and coring, and cuts apricots into halves along the fruit suture according to the process requirements of food production to obtain unbroken carpel which can be widely used for the production of candied fruit, dried fruit and canned fruit. The apricot cutting and coring production process meets the food safety and sanitation requirements, and the mechanical production line has reasonable link among the procedures and has high production efficiency.

Owner:INST OF AGRI MECHANIZATION XINJIANG AGRI INST

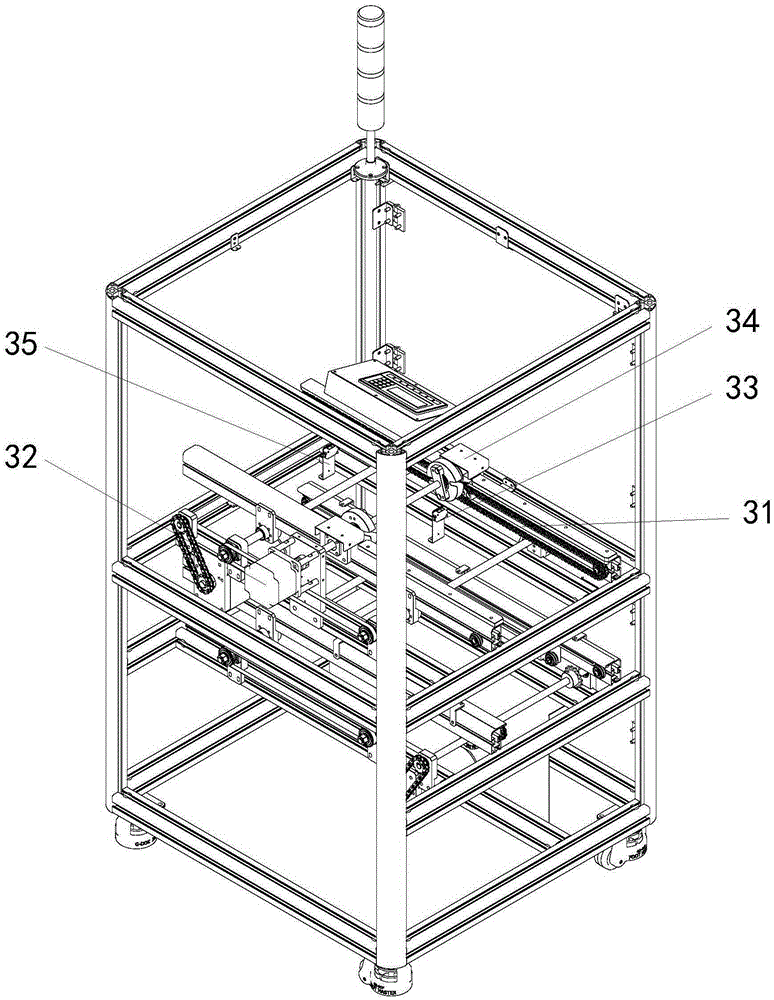

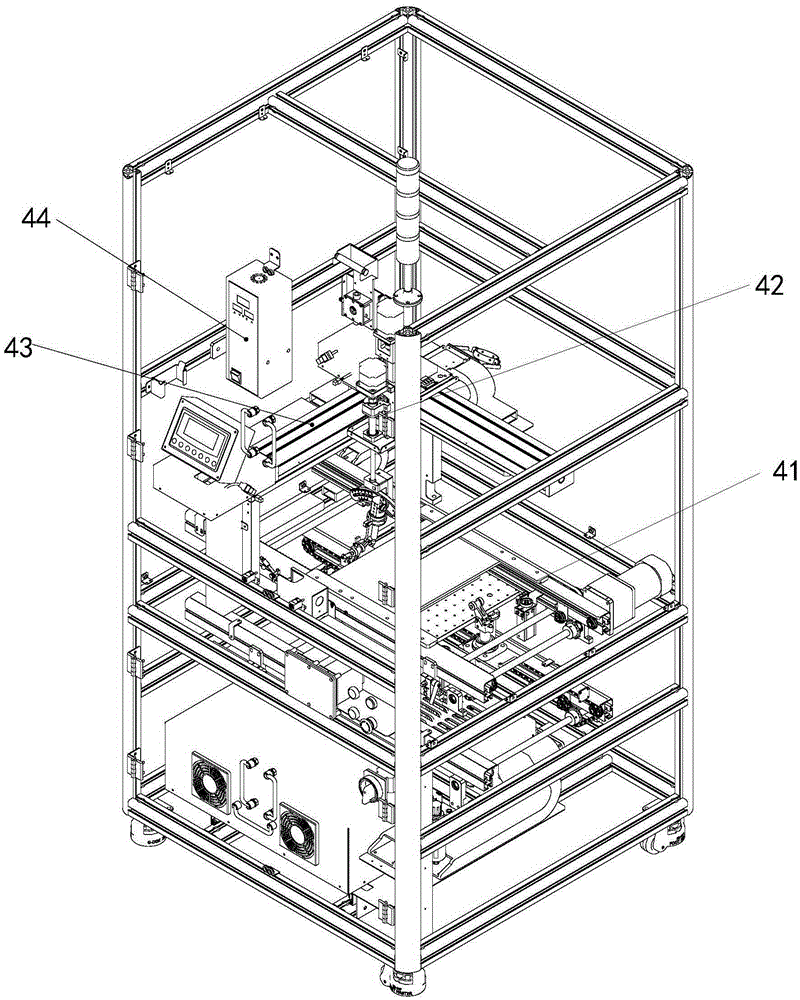

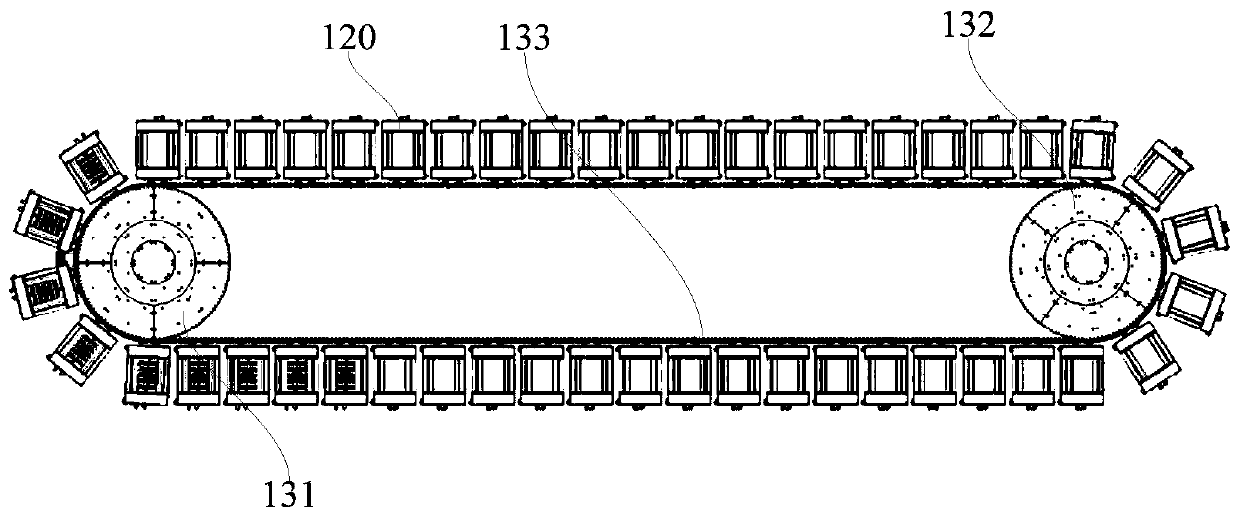

Automatic tin welding line

ActiveCN105345193ARealize cycle processing operationsReduce manual workSoldering apparatusPrinted circuitsEngineeringWeld line

The invention discloses an automatic tin welding line. The automatic tin welding line comprises a lifter, a plugging machine, a board turning machine, a tin welding machine and a sweeper which are sequentially connected, wherein a conveying track is arranged between the lifter and the plugging machine and is used for conveying a carrier loaded with products to the plugging machine for plugging; the board turning machine is used for overturning the plugged products and then conveying the products to the tin welding machine; the tin welding machine is used for carrying out tin welding on the products and then conveying the products to the sweeper for sweeping. The automatic tin welding line further comprises a returning track arranged on the lower portions of the mechanisms and used for recycling the carrier. When the automatic tin welding line is used, the lifter lifts the carrier to the height of the conveying track, a worker puts the products to be machined on the carrier, the conveying track conveys the products to the plugging machine for plugging, the products are conveyed to the tin welding machine for tin welding after plugging is finished, the products are swept through the sweeper after tin welding is finished, the swept products are taken down by a worker at the output end of the sweeper, and the carrier is put on the returning track on the lower portion of the sweeper.

Owner:SUZHOU WISETECH AUTOMATION TECH CO LTD

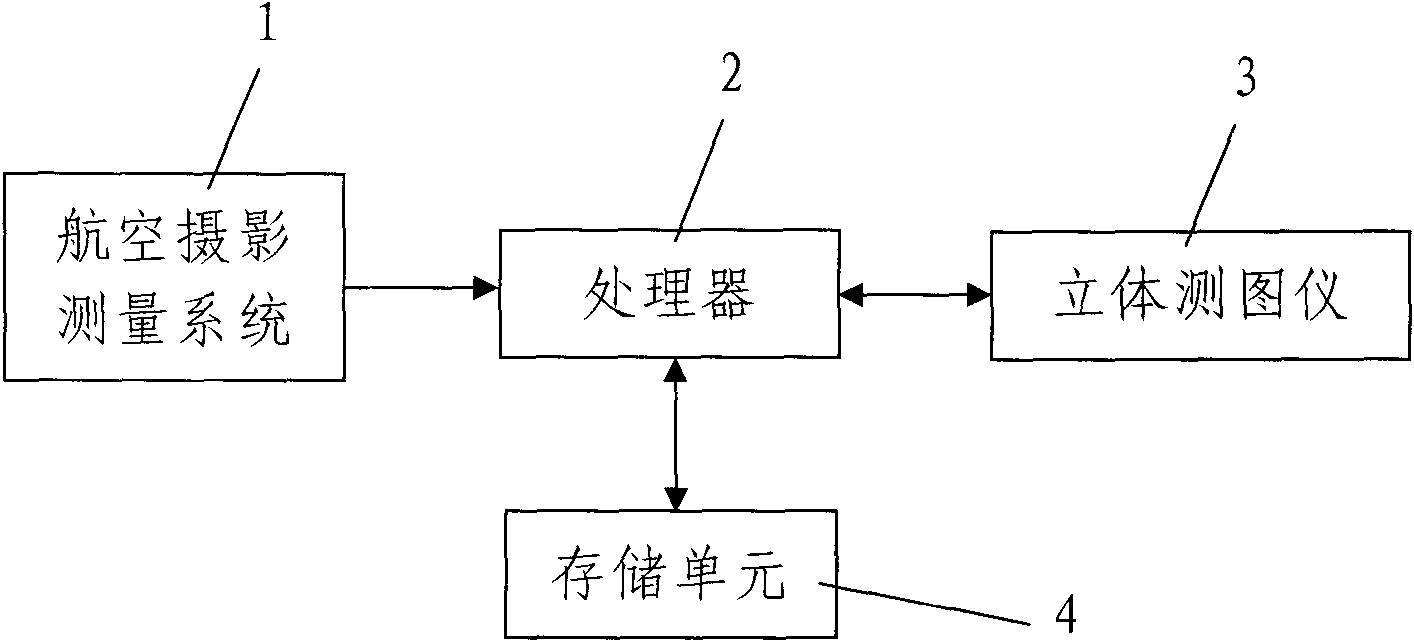

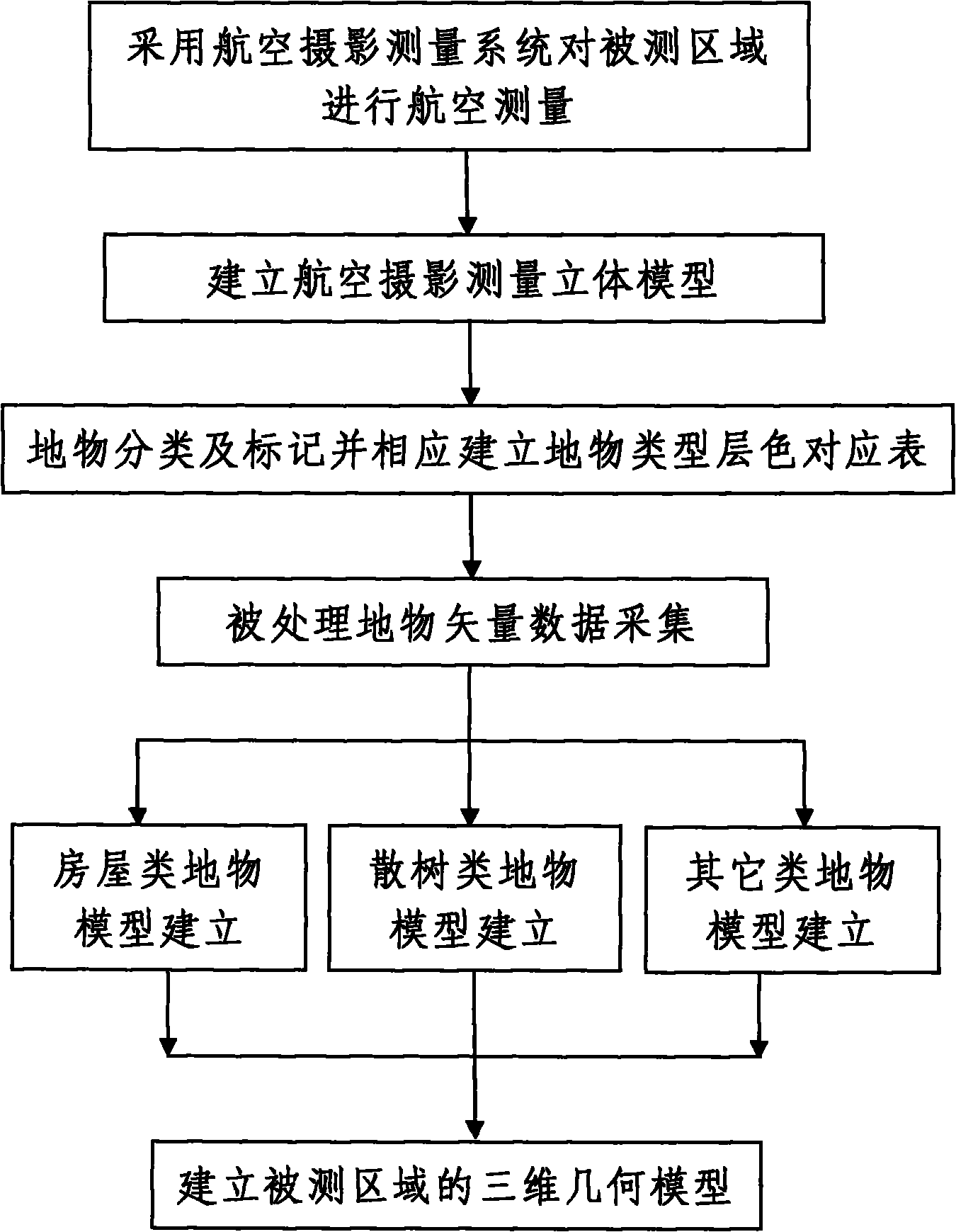

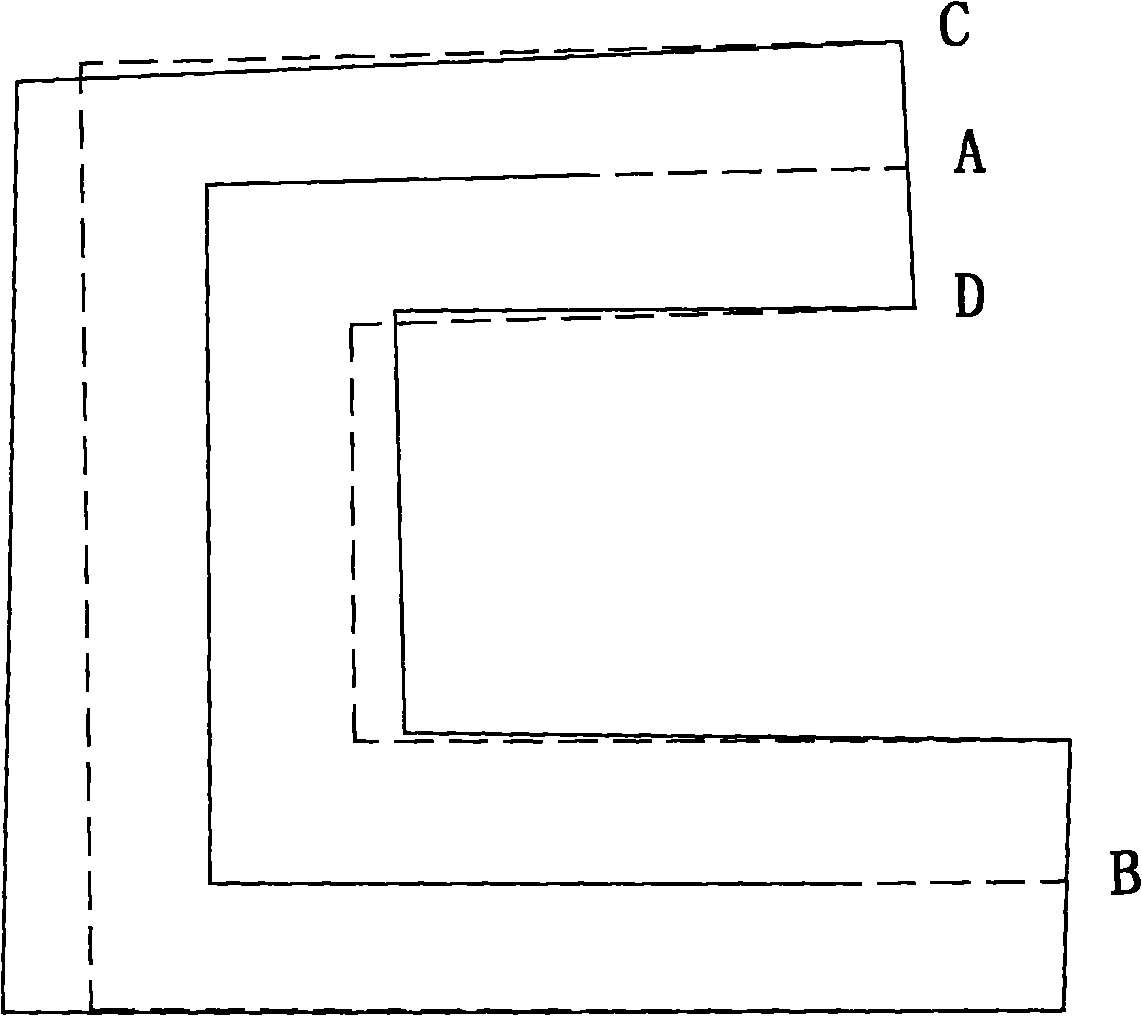

Microstation v8i-based city rapid-modeling method

The invention discloses a Microstation v8i-based city rapid-modeling method, which comprises the following steps of: performing an aerial survey on a tested area according to a conventional aerial photogrammetric survey method by adopting an aerial photogrammetric survey system; and 2, performing analysis processing on aerial survey data in a Microstation v8i software environment by using a processor, namely, establishing a three-dimensional aerial photogrammetric survey model, performing land feature classification and marking, correspondingly establishing a land feature type layer-color mapping table, performing vector data acquisition, establishing models of houses, scattered trees and land features of other types respectively, processing all the land features in the tested area respectively, and obtaining three-dimensional geometric models of all the land features in the tested area.

Owner:XIAN MEIHANG INFORMATION IND

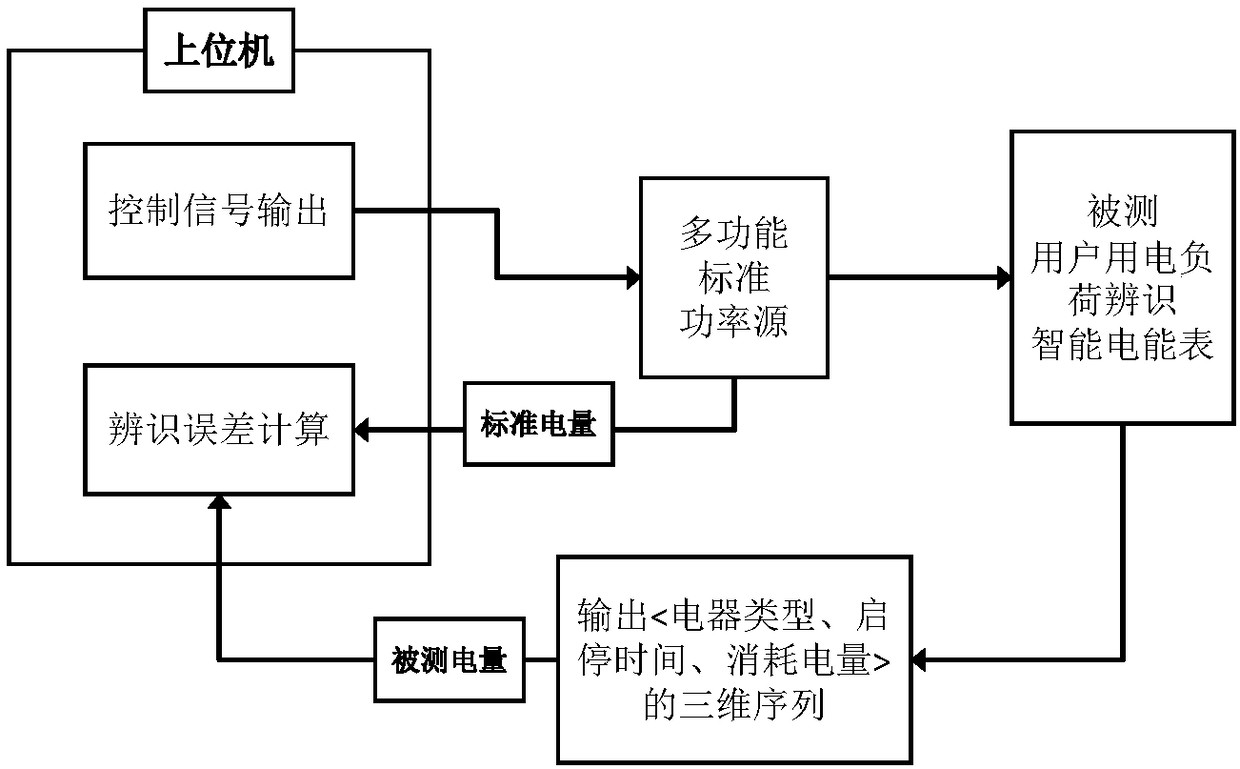

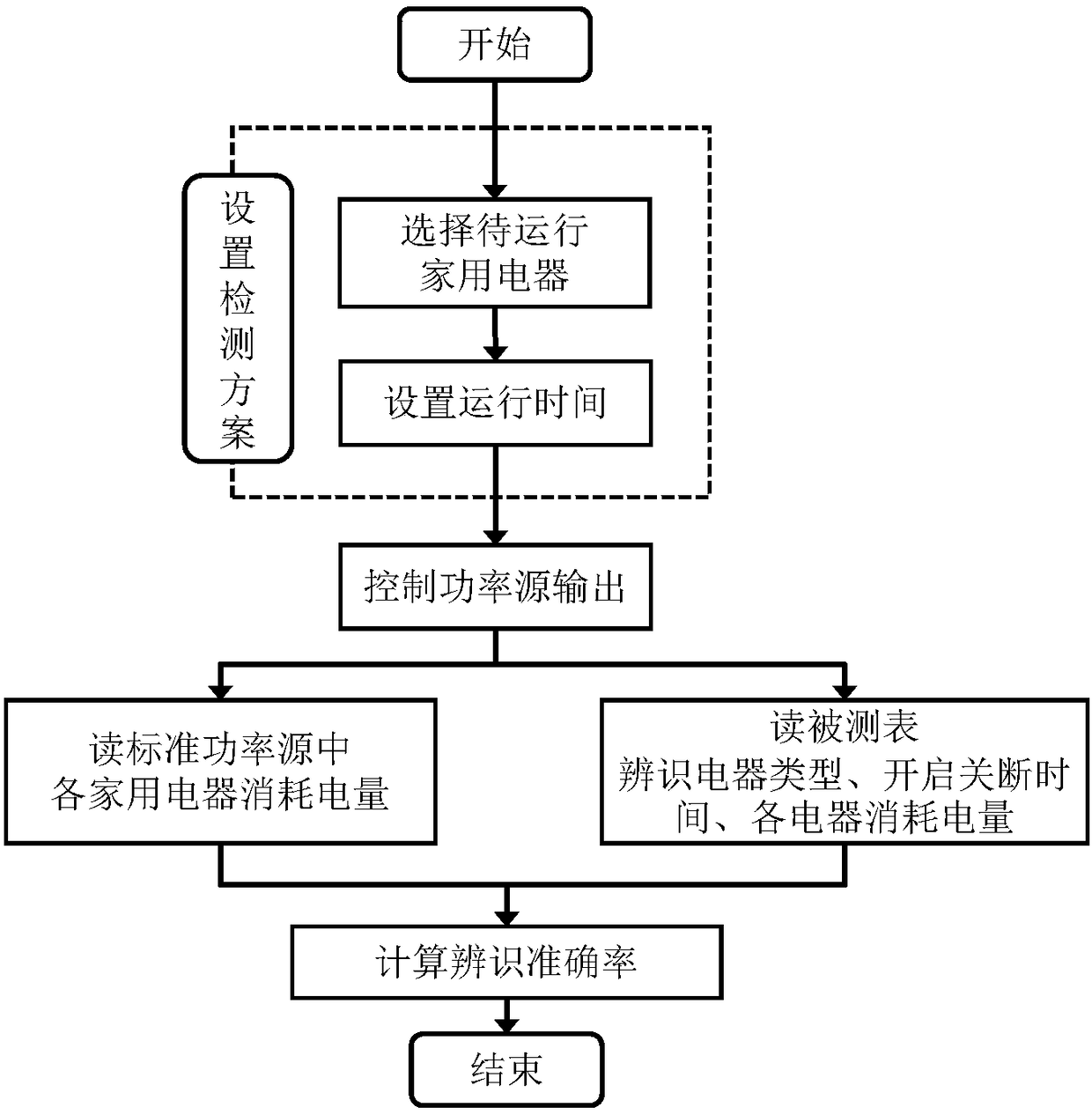

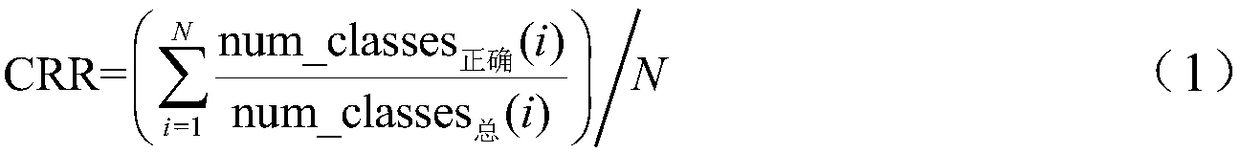

User power consumption load identification intelligent electric energy meter detection system and method

ActiveCN108693499ASave money on purchasing electrical appliancesReduce manual workElectrical measurementsAutomatic controlStop time

The invention discloses a user power consumption load identification intelligent electric energy meter automatic detection method based on a standard power source. In the automatic detection method, an upper computer controls a standard power source to output a household appliance load curve, the upper computer compares the intelligent electric energy meter identification results with an output electric appliance type of the standard power source, electric appliance start and stop time and standard power, and the identification accuracy of a detected user power consumption load identificationintelligent electric energy meter is obtained. The automatic detection method can simulate two working environments of a simple working condition and a complex working condition of the user power consumption load identification intelligent electric energy meter. The automatic detection method sets the output sequence of different electric appliances through the upper computer, and synchronous or asynchronous output of load characteristics of multiple electric appliances can be realized. The upper computer automatically controls output of the electric appliance through an interface, automatic detection on the user power consumption load identification intelligent electric energy meter in a home power consumption environment can be realized and simulated, and the application prospect is wide.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO ELECTRIC POWER RES INST +3

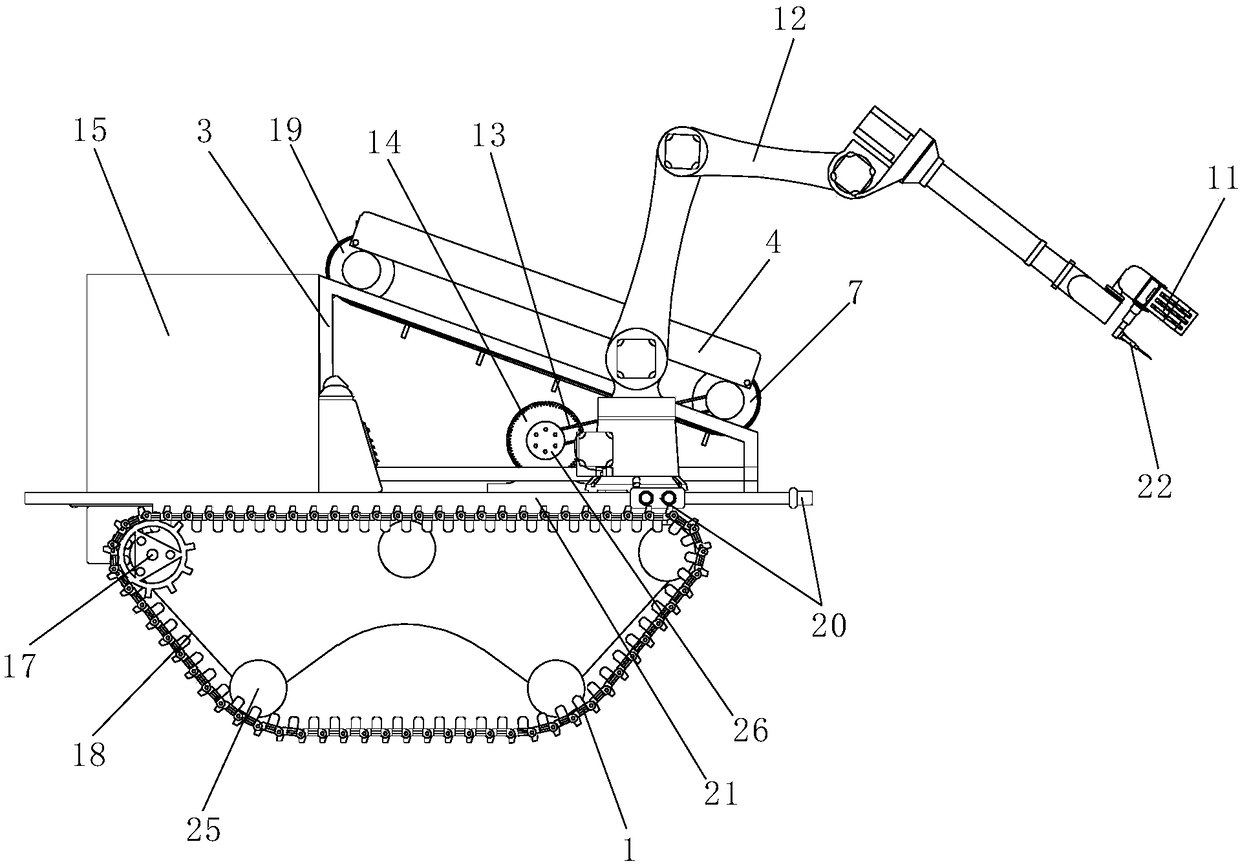

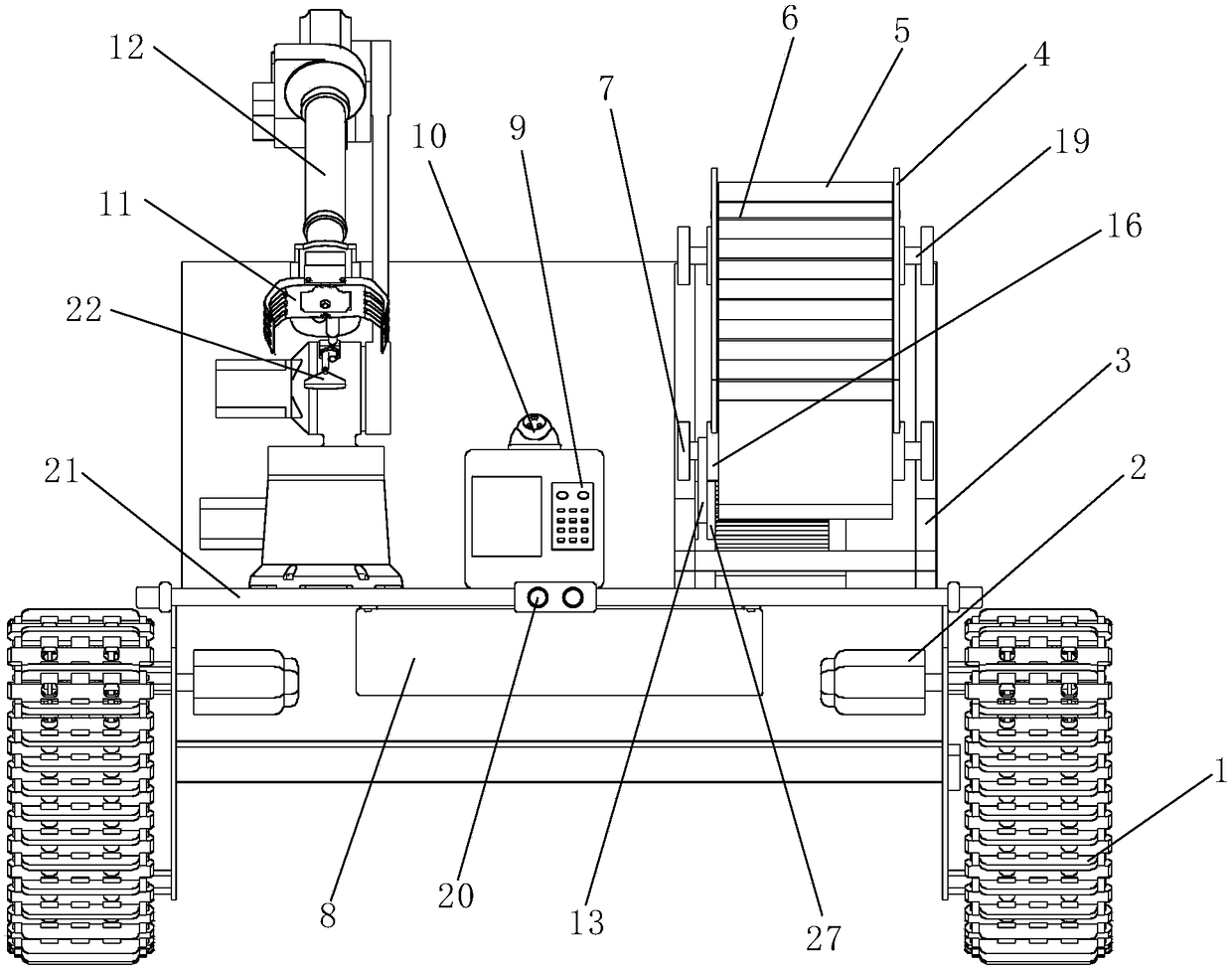

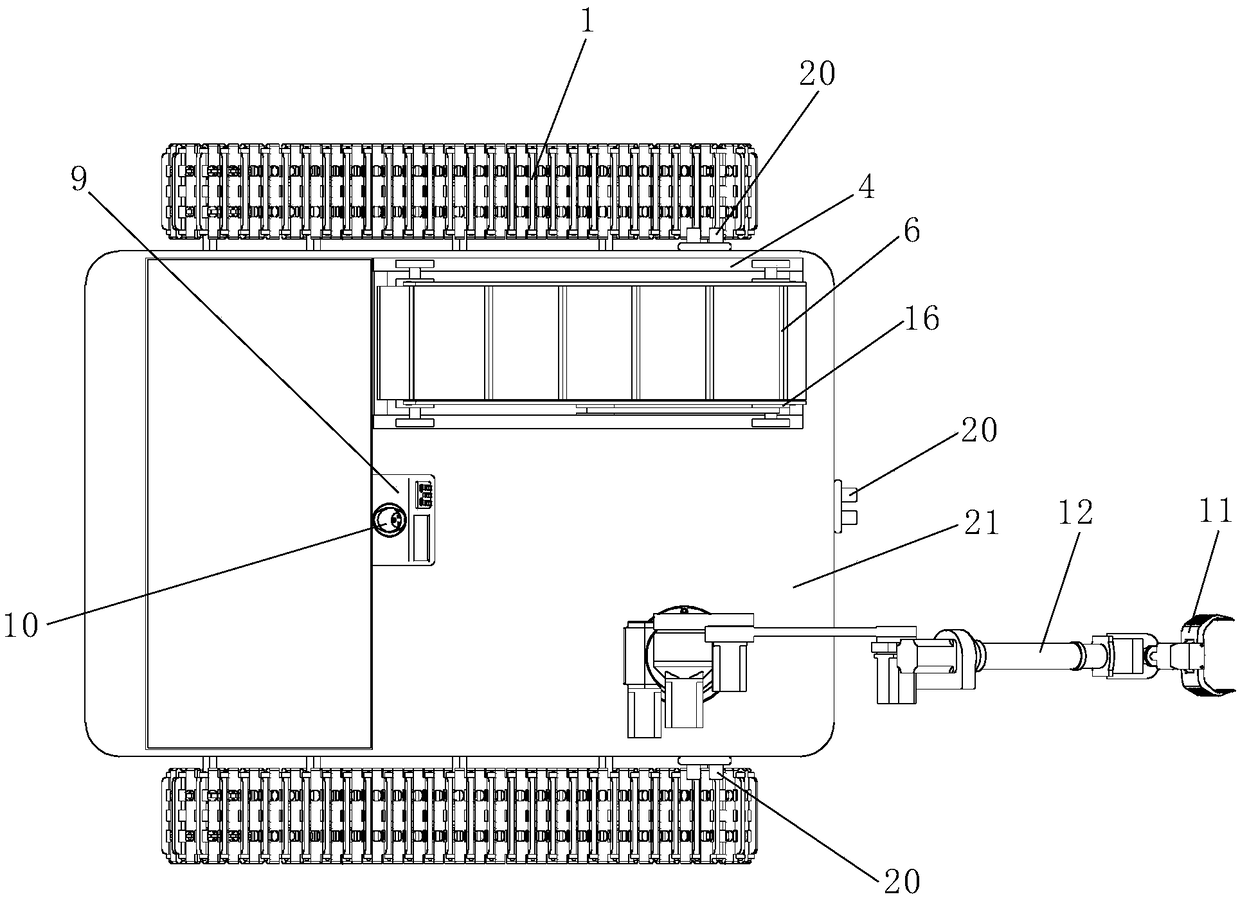

Crawler type pineapple picking machine

PendingCN109328631AStrong adhesion to the groundImprove adaptabilityHarvestersObstacle avoidanceWireless camera

The invention discloses a crawler type pineapple picking machine, which comprises a vehicle body, a crawler traveling mechanism, a mechanical arm picking device, a pineapple conveying mechanism, a pineapple collecting box, a power supply lithium battery and a control box, wherein the crawler traveling mechanism is arranged at the bottom of the vehicle body, the mechanical arm picking device is arranged on the right side of the top of the vehicle body, the pineapple conveying mechanism is arranged on the left side of the top of the vehicle body, and the pineapple collecting box and the controlbox are arranged on the rear side of the top of the vehicle body. The mechanical arm picking device comprises a mechanical arm and a cutting picking mechanism, wherein the cutting picking mechanism comprises a mechanical picking claw and a pineapple stem cutting mechanism, the pineapple stem cutting mechanism is arranged at the bottom of the picking claw, the picking claw is arranged at the outerend of the mechanical arm, and an identification sensor is arranged in the mechanical picking claw. The middle part of the front side and the two sides of the front part of the vehicle body are respectively provided with an obstacle avoidance sensor, and the top of the control box is provided with a wireless camera and an image transmission module. According to the crawler type pineapple picking machine, an intelligent and mechanical picking mode is adopted, so that the picking efficiency is improved, and the picking cost is reduced.

Owner:XIAN AERONAUTICAL UNIV

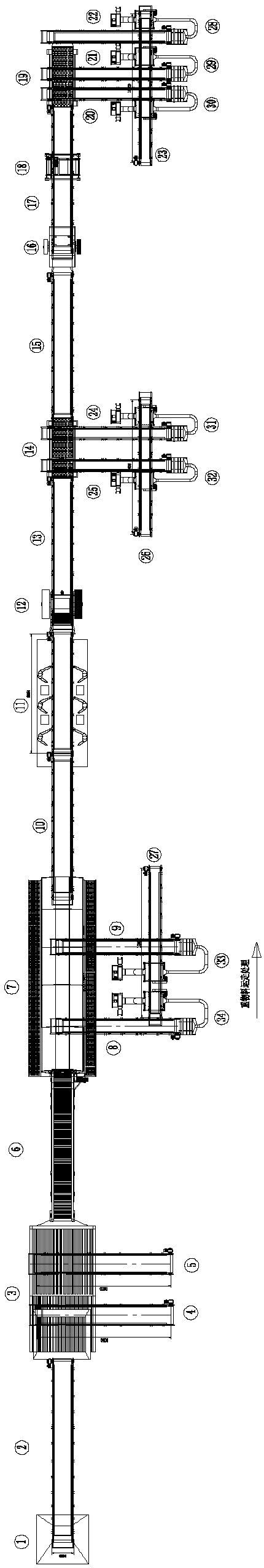

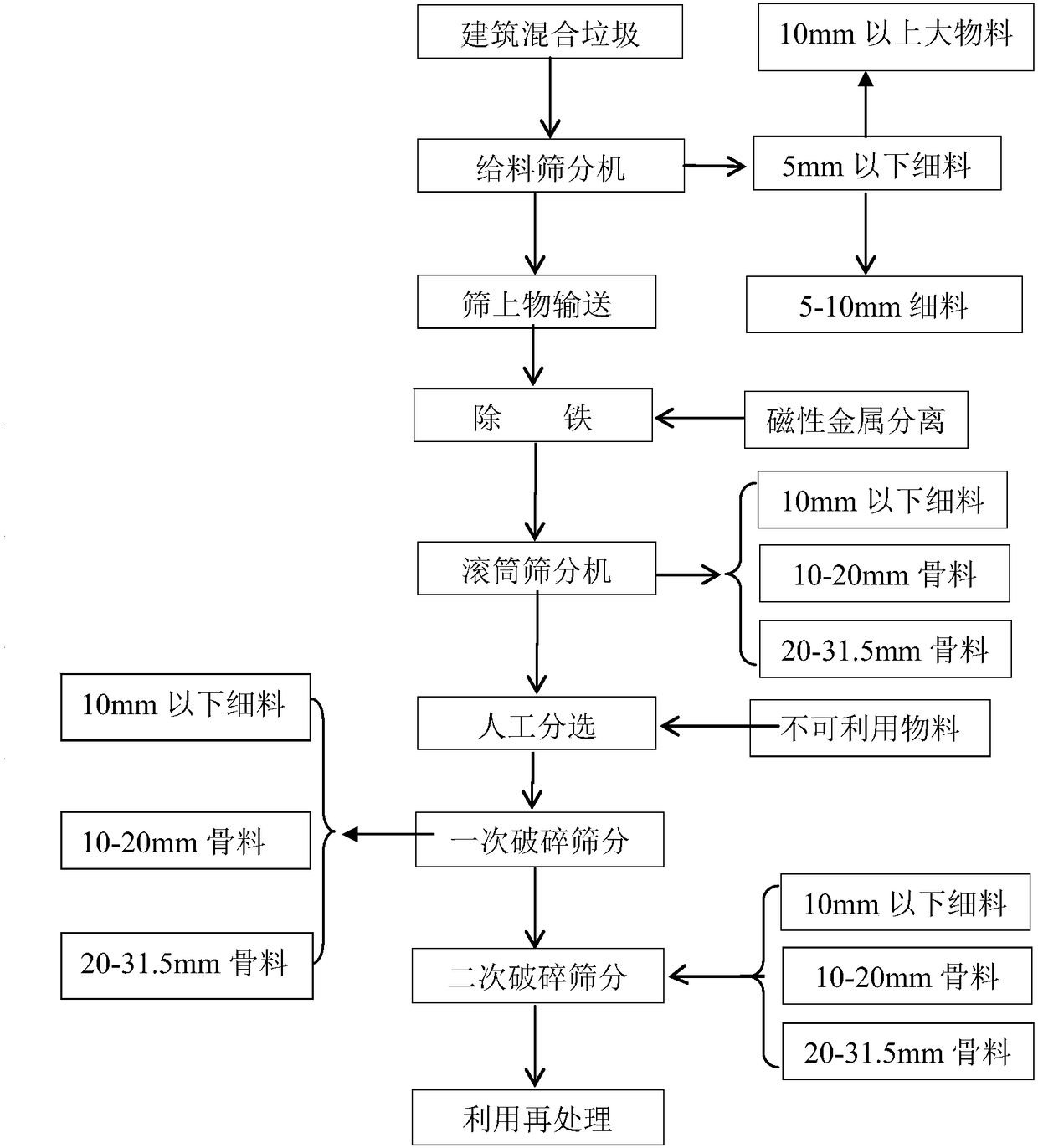

Mixed construction waste sorting comprehensive treatment system and method

InactiveCN108176697AAvoid secondary pollutionReduce processing timeConstruction waste recoverySolid waste disposalLitterArchitectural engineering

The invention relates to a new construction and decoration mixed waste (hereinafter referred to as mixed construction waste) sorting comprehensive treatment system. By adoption of the system, the mixed construction waste with complicated components can be accurately sorted, various sorts of sorted materials can be comprehensively treated, and thus various sorts of recovered materials capable of meeting the national standard and being used for production are obtained. The system comprises a mixed construction waste feeding bin, a feeding screening machine, a first de-ironing separator, a drum screening machine, a first crushing machine, a first vibration screening machine, a second crushing machine and a second vibration screening machine which are sequentially connected. The mixed construction waste sorting comprehensive treatment system is high in degree of automation, the manual intervention degree is low, and various sorts of the mixed construction waste can be efficiently treated.The invention further relates to a mixed construction waste sorting comprehensive treatment method.

Owner:广东昕旺环保科技发展有限公司

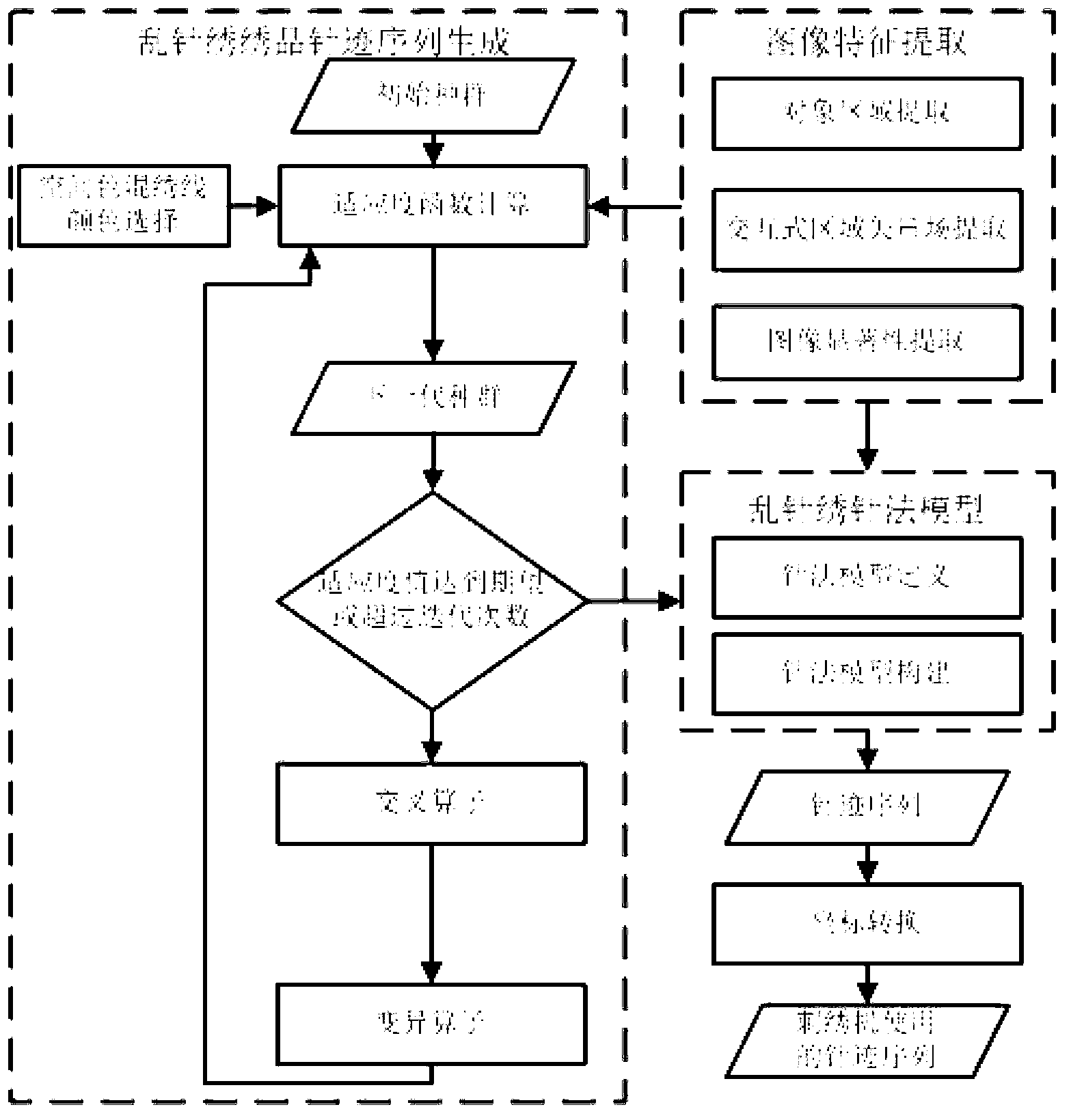

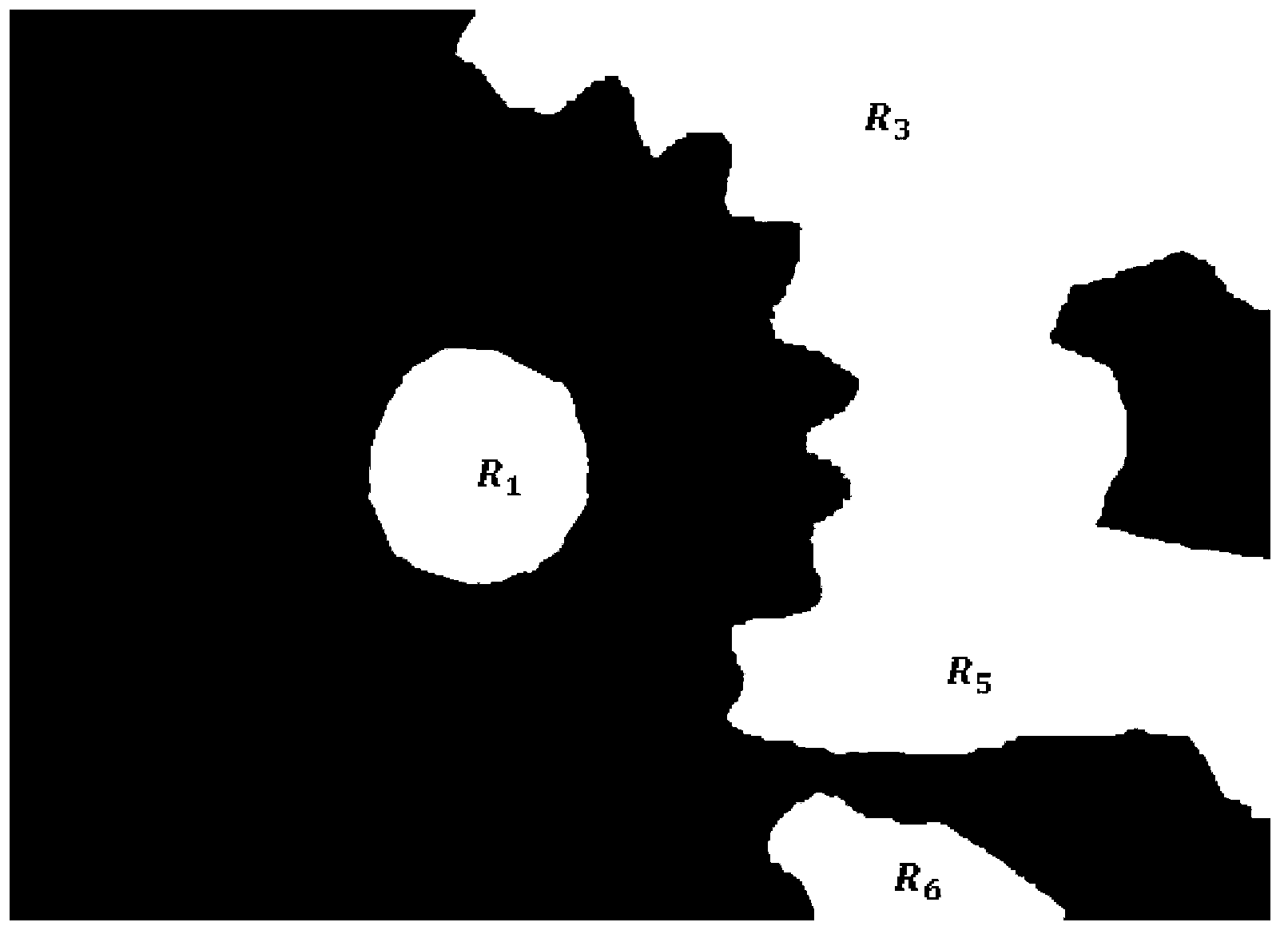

Computer-aided disordered needlework manufacture method using genetic algorithms

InactiveCN103294864AImprove production efficiencyReduce manual workCharacter and pattern recognitionSpecial data processing applicationsColor imageGenetic algorithm

The invention discloses a computer-aided disordered needlework manufacture method using genetic algorithms. The method includes the steps of firstly, using an input color image as a reference image, and using imaging segmentation, area vector field extraction and image consistency line extraction to extract image features such as different object areas, area vector fields and image saliency; secondly, defining three-layer parameterized knitting models including each embroidery thread, each cross needle and cross needle arrangement according to features of disordered needlework, and describing a method for obtaining embroidery thread collection according to the parameterized knitting models; thirdly, using the genetic algorithms to obtain disordered needlework needle tracking sequence according to knitting model parameters determined according to image features; fourthly, converting needle tracking coordinates into coordinates required by a computerized embroidery machine, and inputting the coordinates into the computerized embroidery machine to obtain the corresponding disordered needlework. The method is significant to mechanical standardized production of the disordered needlework.

Owner:NANJING UNIV

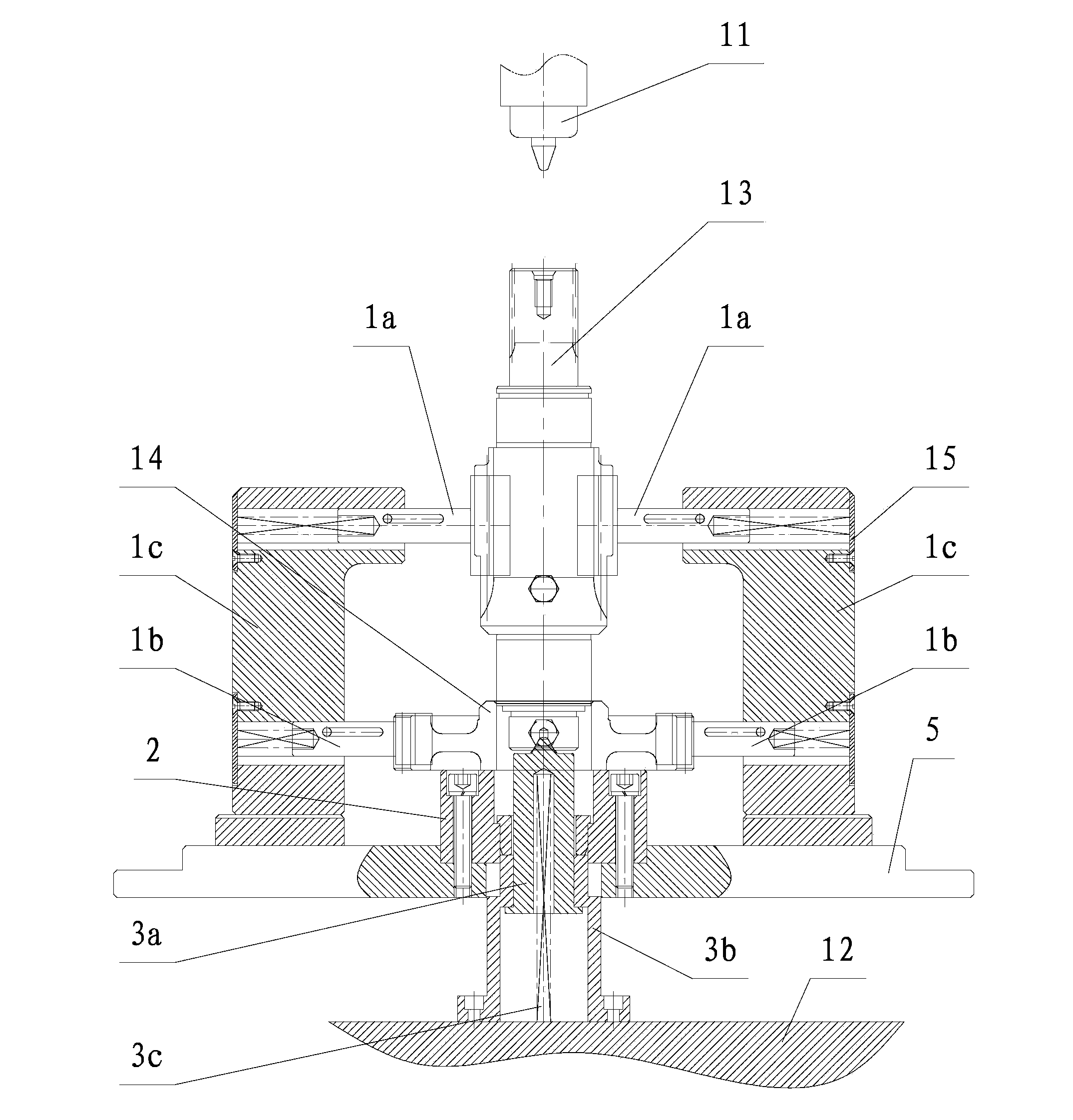

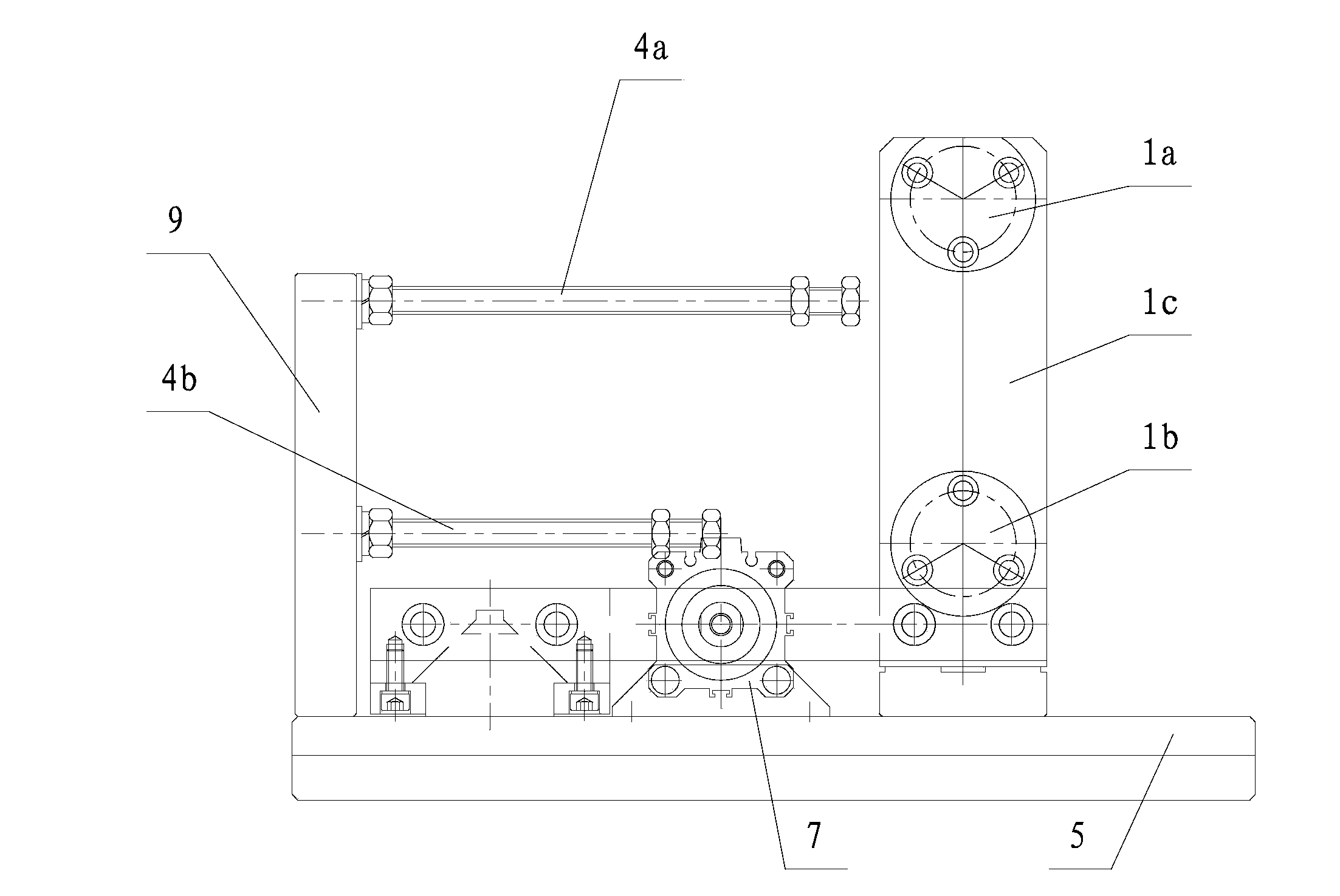

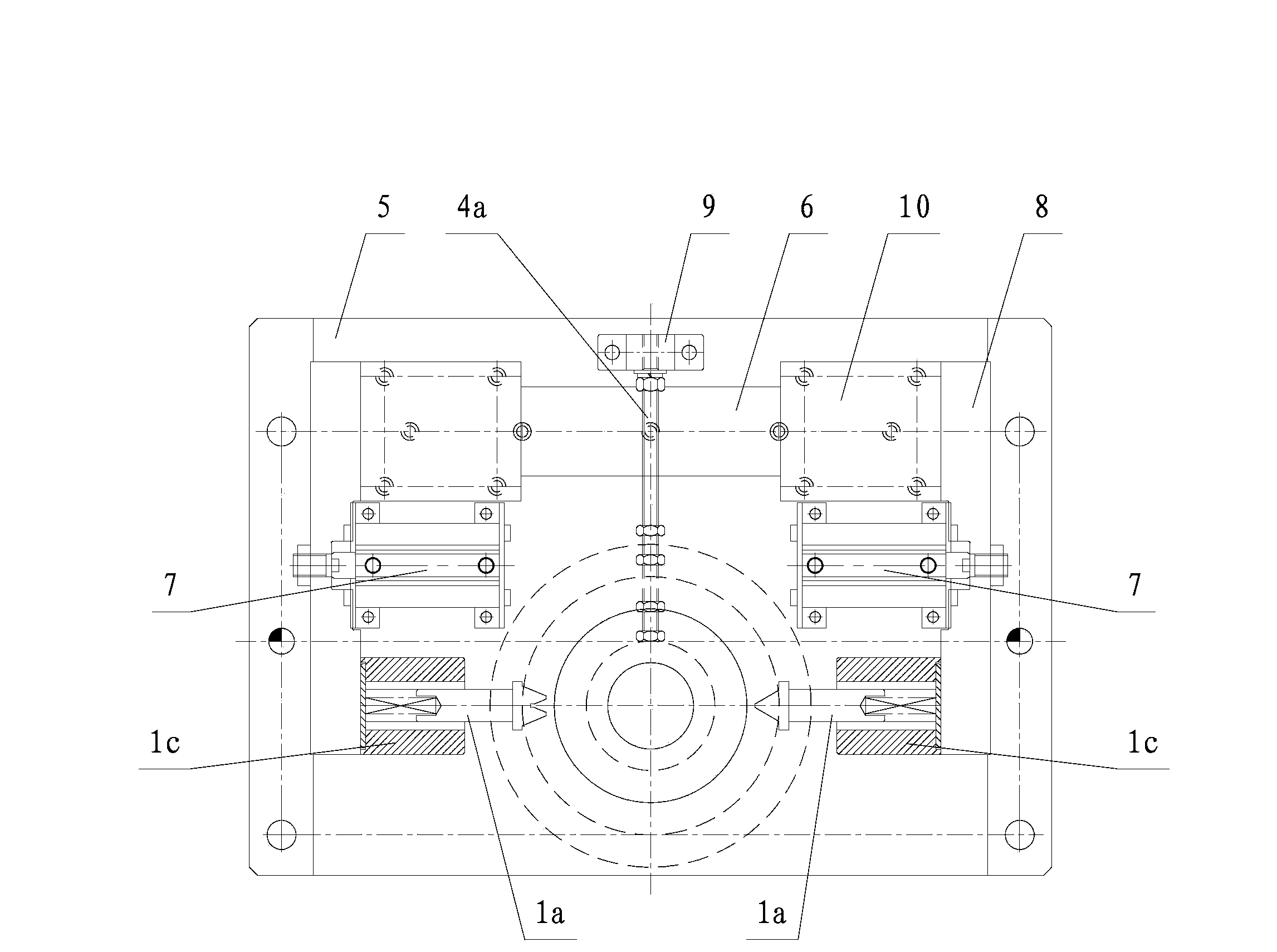

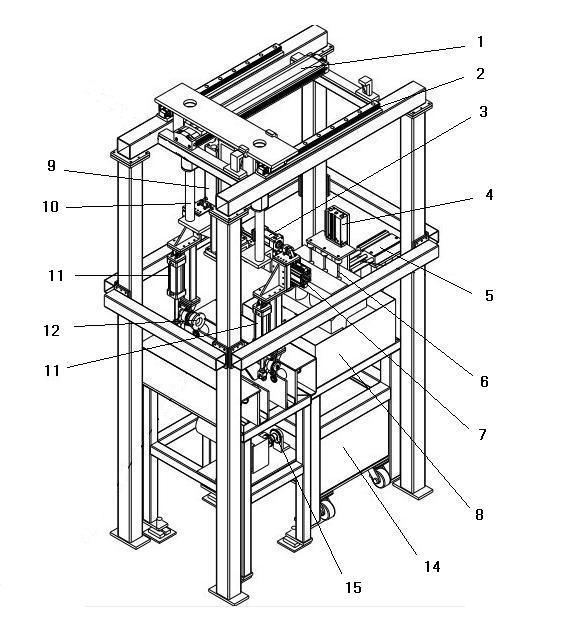

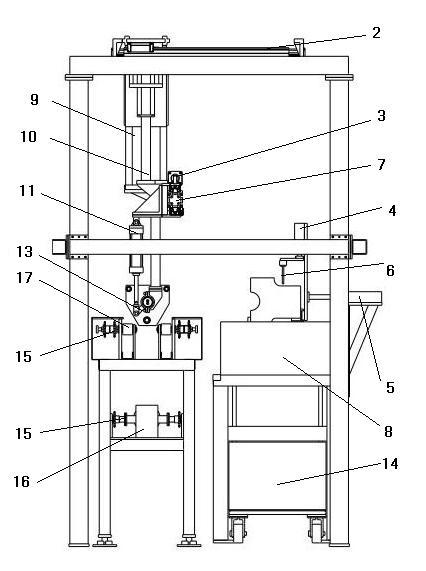

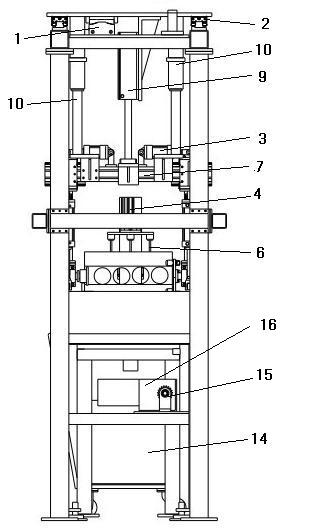

Automatic tooth aligning tool fixture

InactiveCN103878716AGuaranteed Angle RequirementsGuaranteed normal rotationWork holdersMetal working apparatusGear toothEngineering

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Automatic remnants removing device of engine cylinder body

InactiveCN102671895AImprove cleanlinessReduce manual workCleaning using gasesAutomatic controlControl system

The invention relates to the processing field of engine cylinder bodies, and particularly relates to an automatic remnants removing device of an engine cylinder body; the automatic remnants removing device comprises an overturning / moving / locating mechanism, a vibrating mechanism, a high-pressure blowing mechanism, a product transport mechanism, an automatic control system and a remnants collecting trolley, wherein the overturning / moving / locating mechanism comprises a horizontal moving mechanism, an up-down moving mechanism, a clamping mechanism and a rotating mechanism; the high-pressure blowing mechanism comprises an air nozzle and an air nozzle direction adjusting structure; and movements of the horizontal moving mechanism, the up-down moving mechanism, the clamping mechanism, the rotating mechanism, the vibrating mechanism, the air nozzle direction adjusting structure and the product transport mechanism are controlled by the automatic control system. According to the invention, joint action of three methods of vibrating, high-pressure blowing and overturning is used; remnants are removed more cleanly; manual operation is reduced; and production efficiency is increased.

Owner:JIANGLING MOTORS

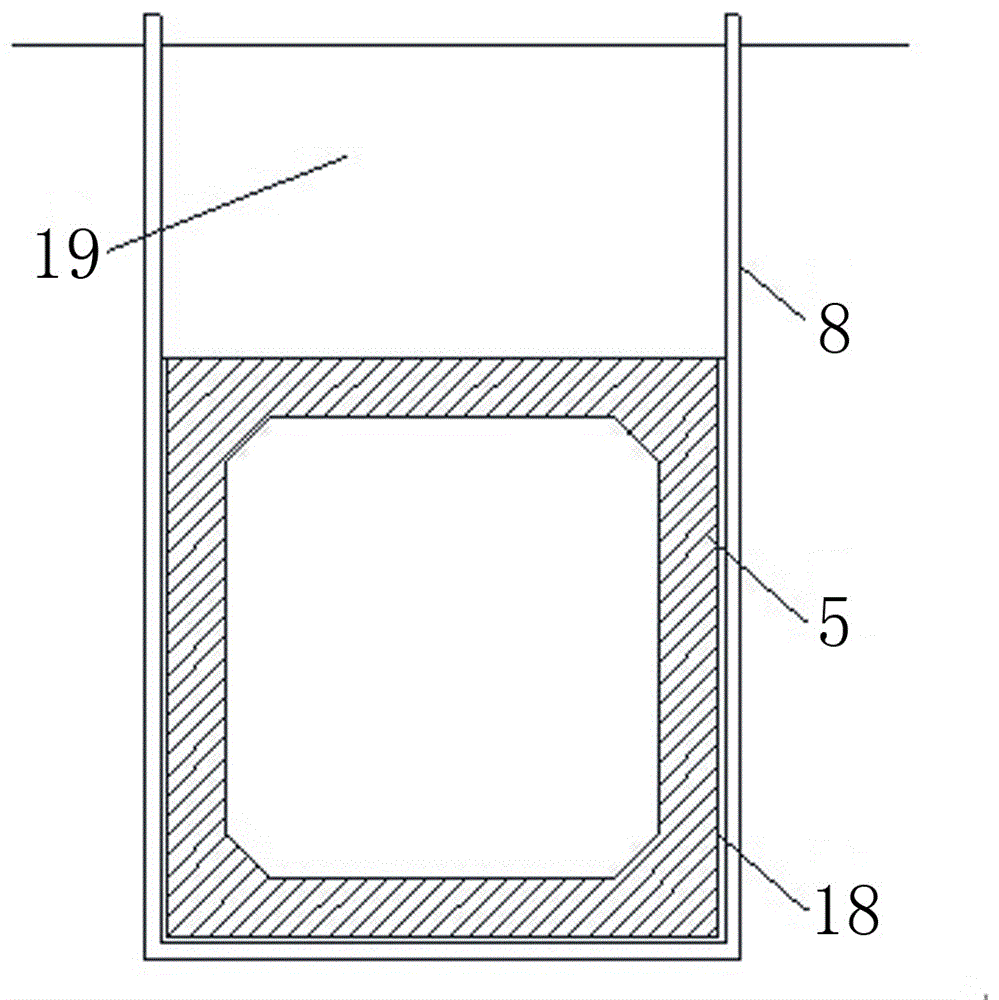

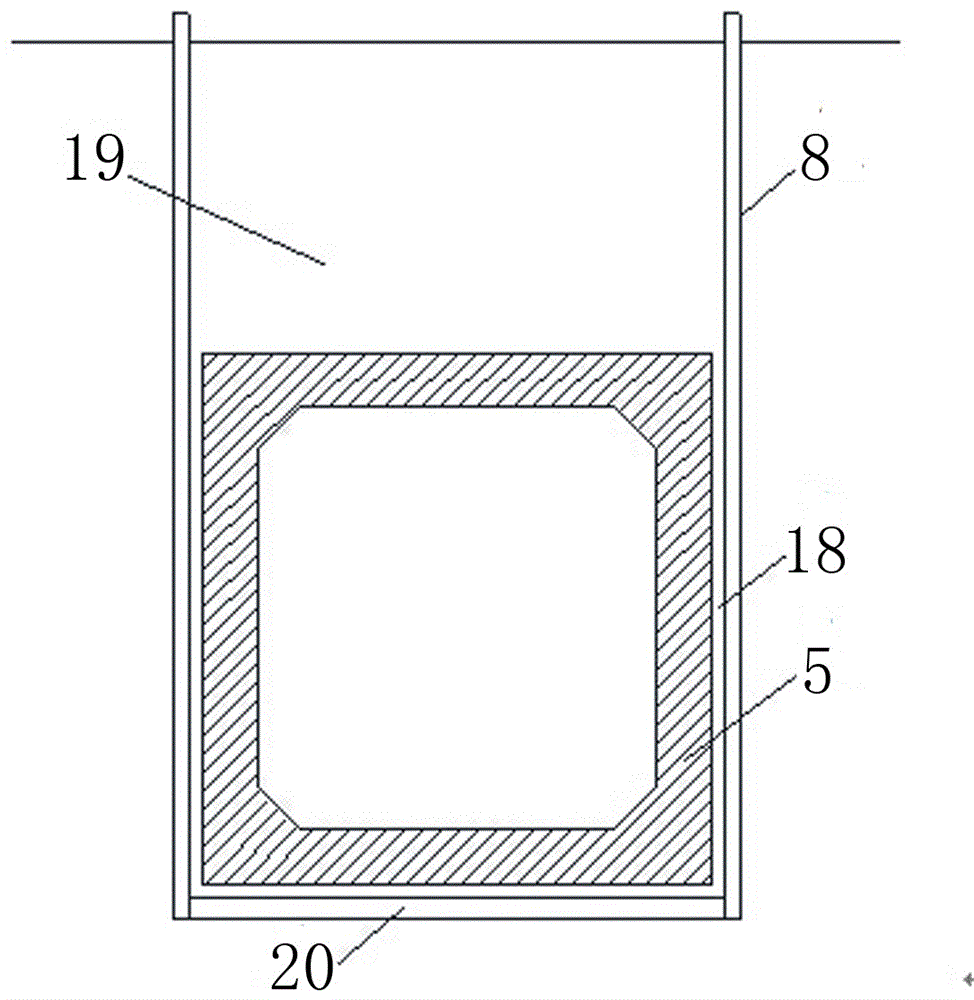

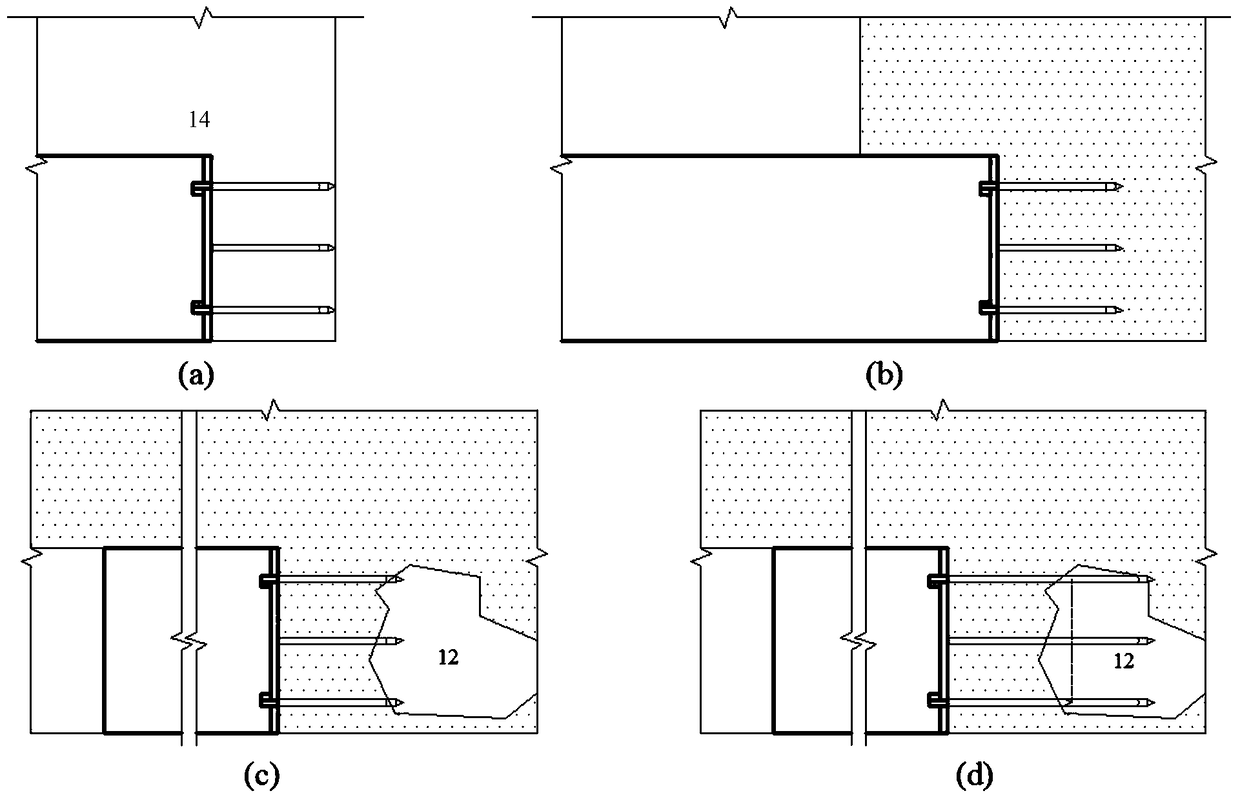

Supporting and retaining device for open excavation construction of comprehensive pipe gallery and construction method thereof

ActiveCN106049532AReduce usageHigh degree of mechanizationArtificial islandsUnderwater structuresEngineeringSheet pile

The invention belongs to the technical field of underground project construction, particularly relates to a supporting and retaining device for open excavation construction of a comprehensive pipe gallery and a construction method thereof, and discloses the movable supporting and retaining device for open excavation construction of the comprehensive pipe gallery and the construction method thereof. The supporting and retaining device for open excavation construction of the comprehensive pipe gallery has the advantages of economization and high efficiency of the open excavation method and does not have to utilize building envelopes such as pile rows and steel sheet piles. The movable supporting and retaining device for construction mainly comprises a front supporting and retaining part, a middle supporting and retaining part and a tail supporting and retaining part, the front supporting and retaining part is composed of expansion blocks on the two sides of the front supporting and retaining part, the middle supporting and retaining part mainly comprises a top plate, side plates and a bottom plate and is connected to the tail supporting and retaining part through hinging oil cylinders, and propelling devices are arranged between the tail supporting and retaining part and the middle supporting and retaining part. According to the supporting and retaining device, the main problems that the construction occupation range is wide and the environmental influence is serious in the construction process of the underground comprehensive pipe gallery and pipelines through the open excavation method are effectively solved. The construction method has the advantages that the mechanization degree is high and the construction speed is high.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

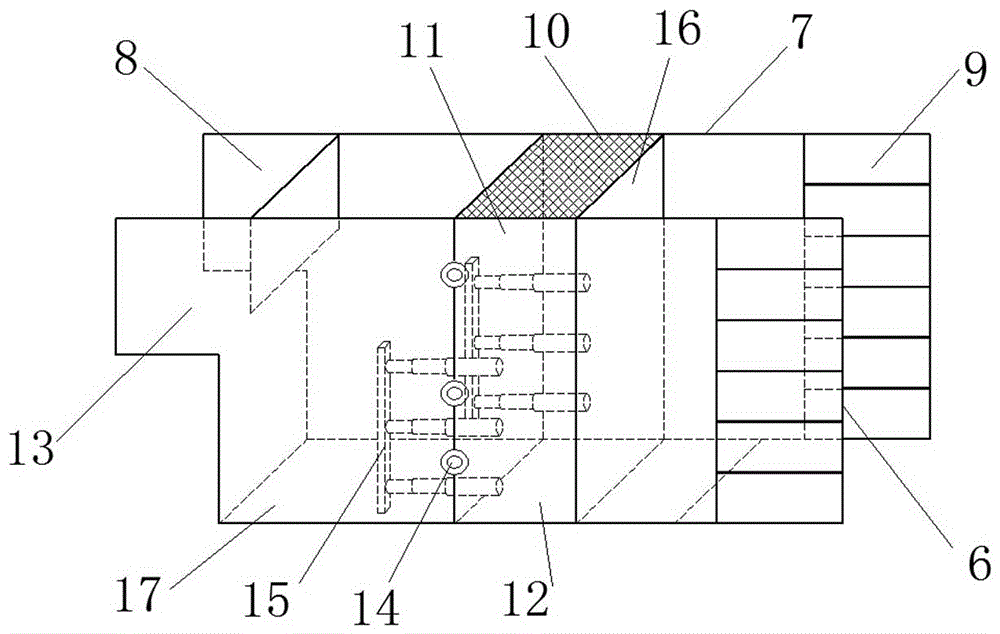

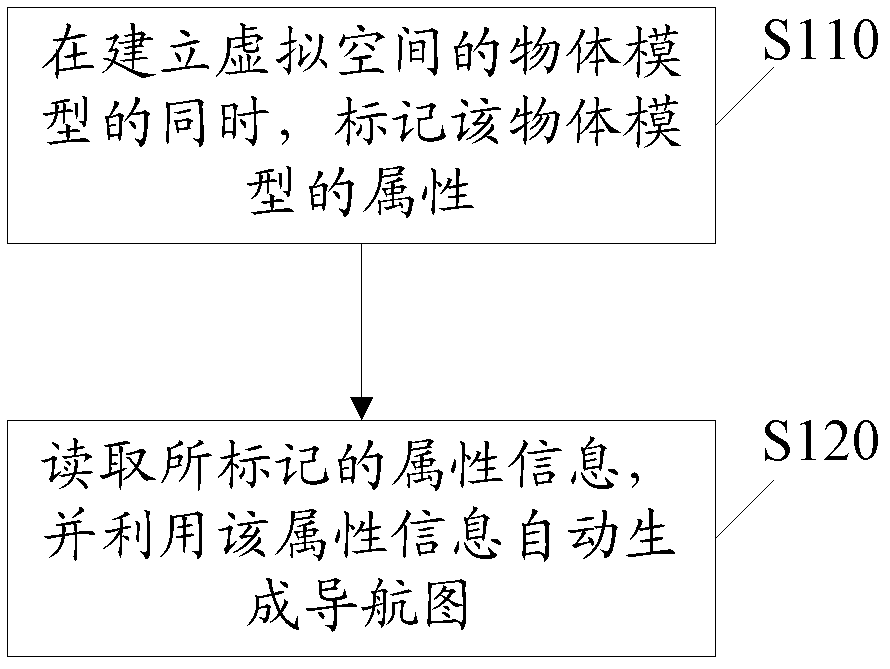

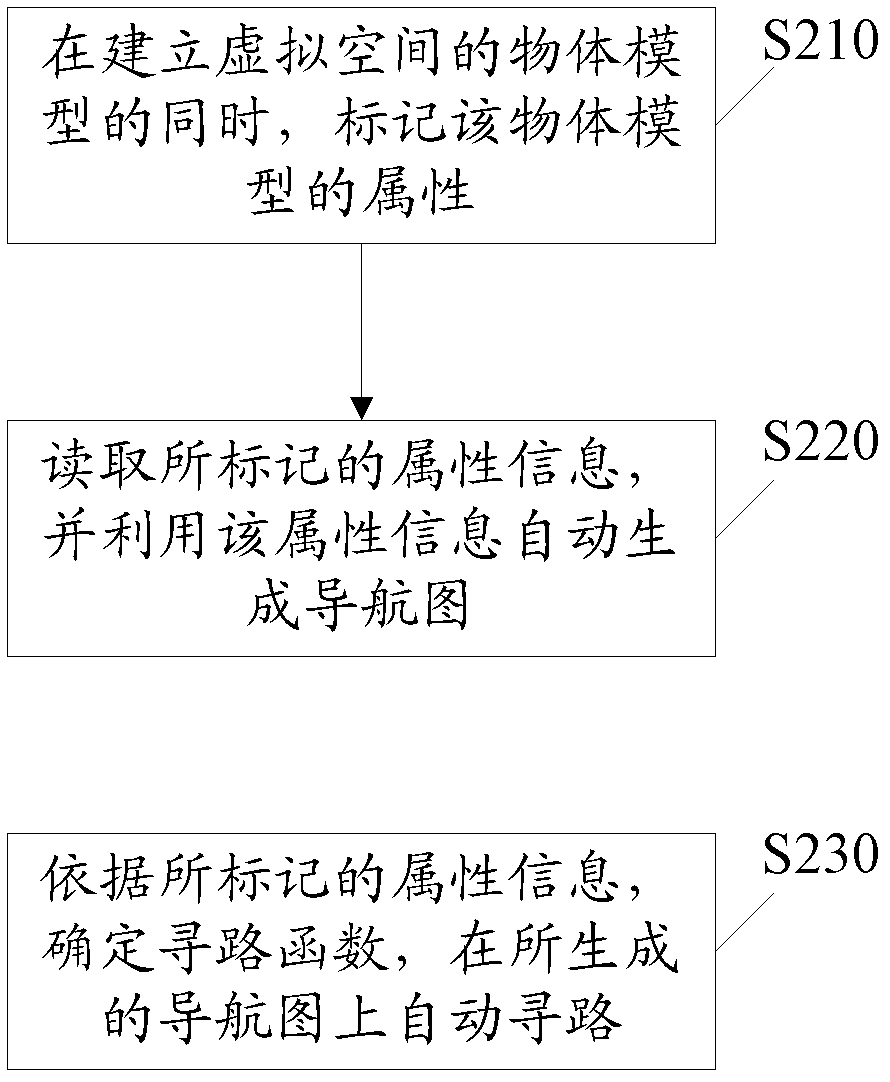

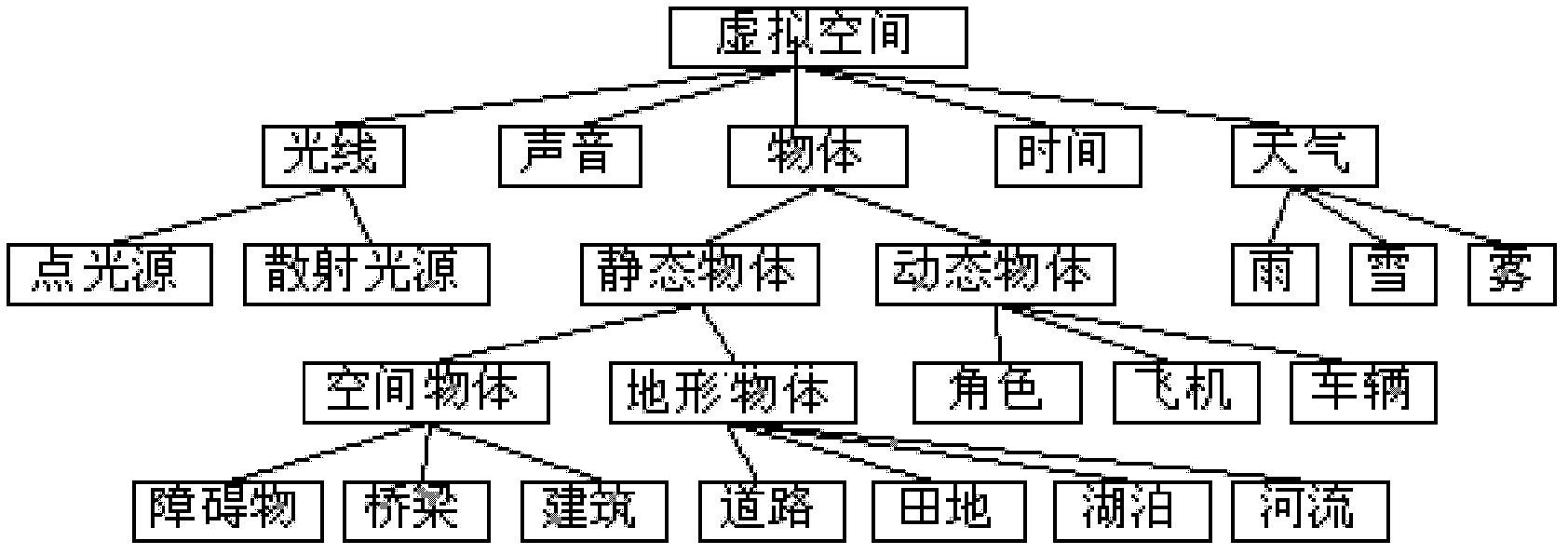

Method and system for automatically generating navigation chart in virtual space, and pathfinding method and system

InactiveCN102306106AImprove reliabilityReduce manual workMaps/plans/chartsSpecific program execution arrangementsVirtual spaceSimulation

The invention discloses a method and a system for automatically generating a navigation chart in a virtual space, and an automatic pathfinding method and an automatic pathfinding system in the virtual space. The automatic pathfinding method in the virtual space comprises the following steps of: marking the attribute of an object model while establishing the object model of the virtual space; automatically generating the navigation chart by using the marked attribute information; and determining a pathfinding function by using the information, and automatically pathfinding on the generated navigation chart. Therefore, the attribute of the object model is marked simultaneously in the scene modeling process, and a computer automatically generates the navigation chart according to the marked attribute, so that manual workload is greatly reduced, and the reliability of the pathfinding system is improved.

Owner:SHENGQU INFORMATION TECH SHANGHAI

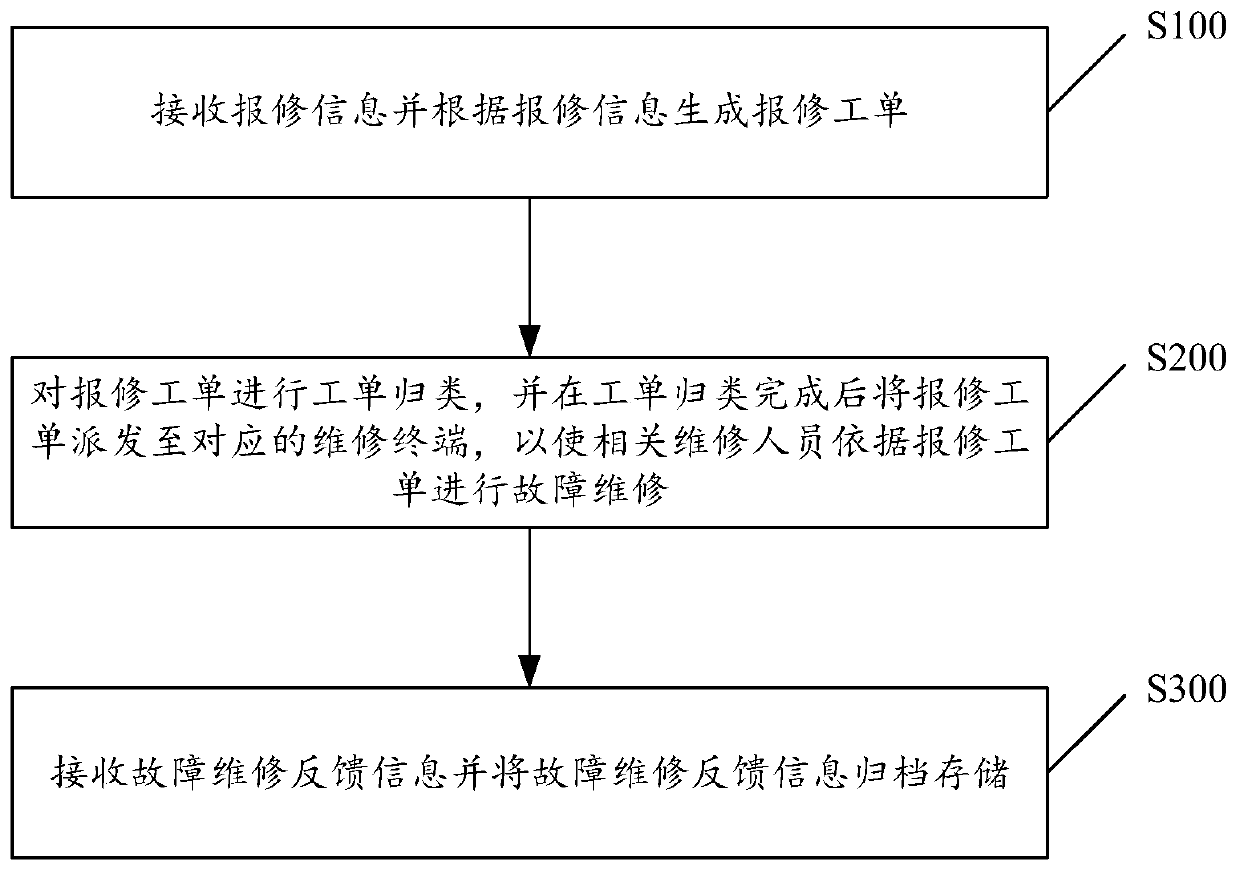

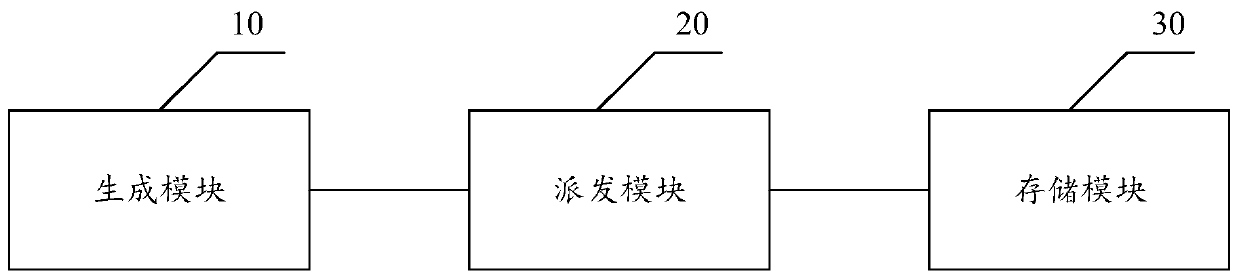

Fault repair management method and system and related device

PendingCN109712036AEffective distributionRealize intelligent automatic managementData processing applicationsManagement systemReliability engineering

The invention discloses a fault repair-reporting management method. The method comprises the following steps: receiving repair-reporting information and generating a repair-reporting work order according to the repair-reporting information; carrying out work order classification on the repair work orders, and after the work order classification is completed, distributing the repair work orders tocorresponding maintenance terminals, so that related maintenance personnel carry out fault maintenance according to the repair work orders; and fault maintenance feedback information is received, andthe fault maintenance feedback information is archived and stored. The fault repair management method can effectively realize intelligent and convenient management of fault repair, improves the faultmaintenance efficiency, and improves the fault repair management level. The invention further discloses a fault repair management system and device and a computer readable storage medium which all have the above technical effects.

Owner:JIAXING HENGCHUANG ELECTRIC POWER GRP CO LTD

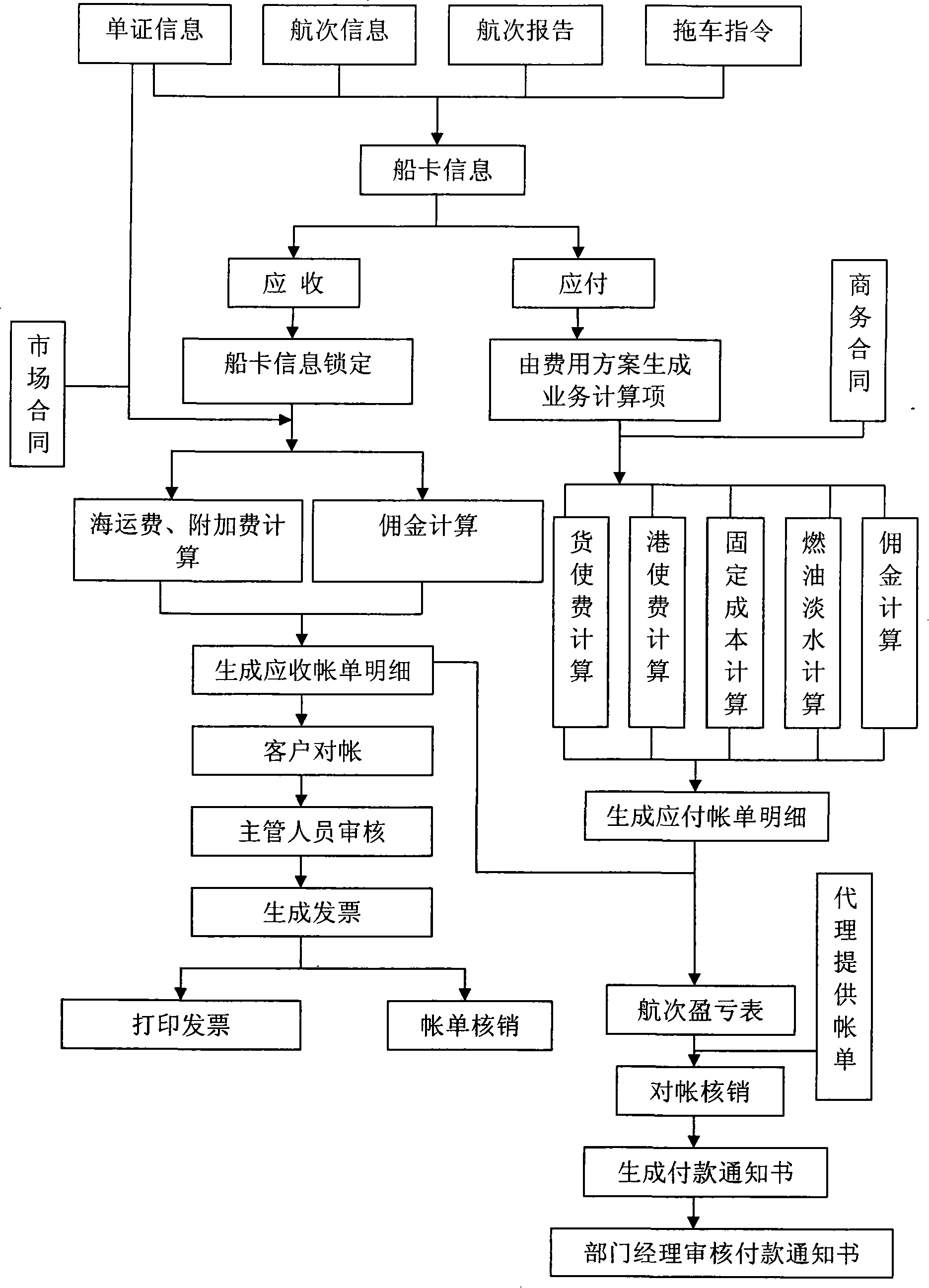

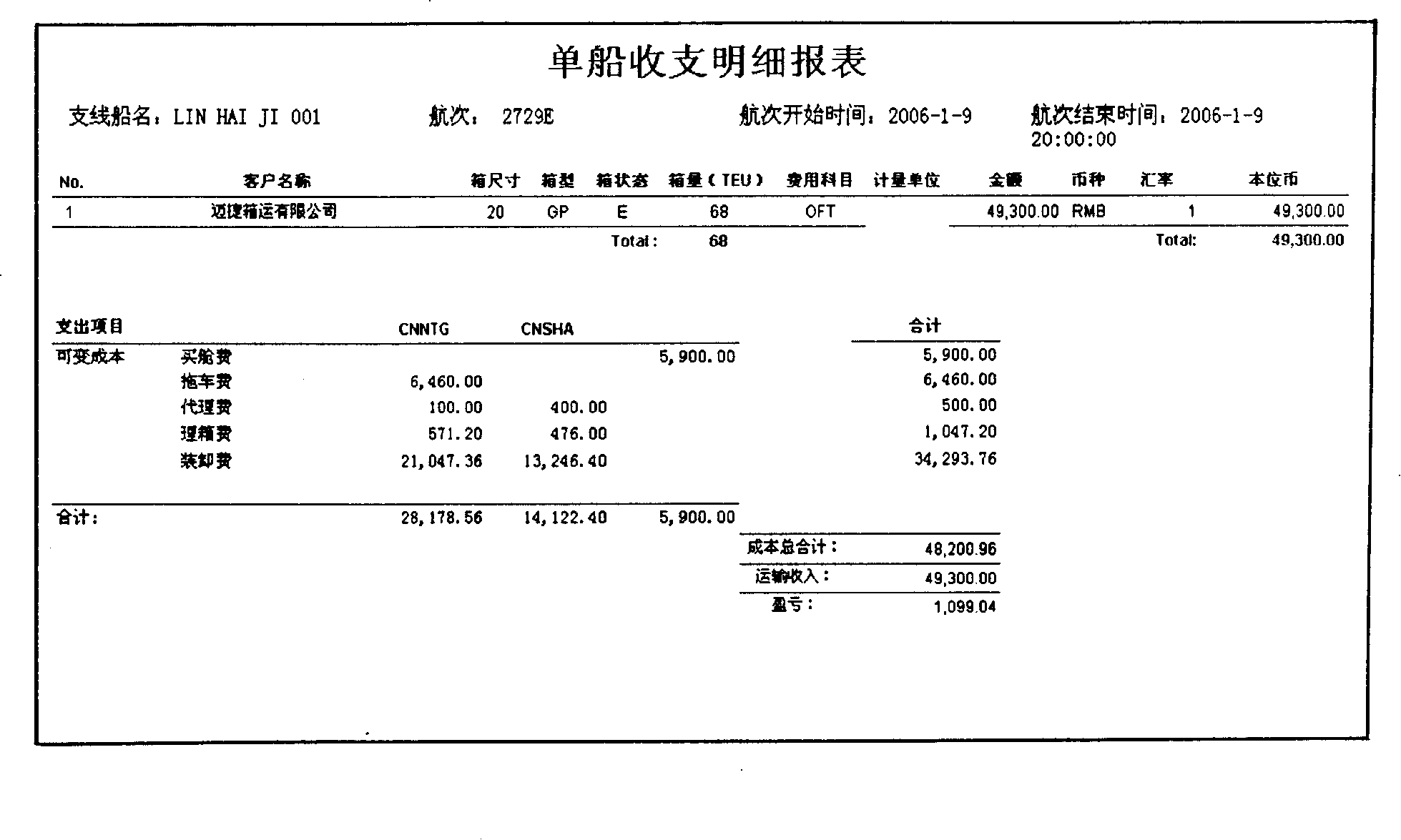

A method for form-auditing and validation information management in branch aviation transport information management system

InactiveCN101187997AAvoid double registrationReduce the phenomenon of staggered leakageData processing applicationsPaymentAviation

The invention relates to a method supporting examination document verification information management in a shipping information management system. The invention is characterized in that the method is run on a computer with C language and programs. The procedures of the method include: for fees to be charged, all fees to be charged for a voyage, i.e. shipping cost, surcharge and commission are calculated, and after calculation completion, an invoice after check and confirmation is made out; and for fees to be paid, fees to be paid in the voyage, i.e. cabin seat fee, ship rent, fuel oil and fresh water fees, ship service fee, freight service fee, commission, surcharge and charging and paying service fee are calculated, a voyage profit-loss table is produced, the pre-estimated paying fee in the system is checked, confirmation or resolution operation is conducted and then a payment notice to be examined by a department manager is generated. The invention has the advantages that the manual labor of the document examiner is reduced, the phenomena of invoicing error and leakage are diminished, and the system is stable, reliable and fast.

Owner:SHANGHAI ZHONGHAI TELECOM INFORMATION SYST

Ultrafine double-sided adhesive tape die cutting technology

InactiveCN106976127AEasy to useAvoid the problem of glue overflow and adhesionMetal working apparatusSurface layerEngineering

The invention provides an ultrafine double-sided adhesive tape die cutting technology. The ultrafine double-sided adhesive tape die cutting technology comprises the following steps that double-sided adhesive tape is provided, a heavy release film is attached to the bottom layer of the double-sided adhesive tape, the surface layer of the double-sided adhesive tape is provided with original release paper in an attached mode, and the whole double-sided adhesive tape is cut into a coil-shaped material strip; partial roller cutting is conducted on one side of the original release paper surface until a cutter arrives at the double-sided adhesive tape, the portion, located at the roller cutting position, of the double-sided adhesive tape and the portion, located at the roller cutting position, of the original release paper are torn away, and the heavy release film region is exposed and serves as a handle portion; the original release paper attached to the double-sided adhesive tape is torn away and replaced by a light release film; the material strip is inverted, the heavy release film surface is upwards placed to be processed through die cutting, cutoff is conducted until the cutter arrives at the double-sided adhesive tape layer, after first-time cutoff of the cutter is accomplished, the double-sided adhesive tape is driven by the material strip to backwards move by the width distance of the needed double-sided adhesive tape, cutting is conducted again, after second-time cutoff of the cutter is accomplished, the double-sided adhesive tape is driven by the material strip to backwards move by the spacing distance, cutting is conducted again, and the step is circularly conducted; and the double-sided adhesive tape width between the first-time cutoff operation and the second-time cutoff operation is reserved, and waste materials are torn away. The ultrafine double-sided adhesive tape die cutting technology achieves complete die cutting of the ultrafine double-sided adhesive tape, and avoids the adhesive overflowing adhesion phenomenon.

Owner:昆山威斯泰电子技术有限公司

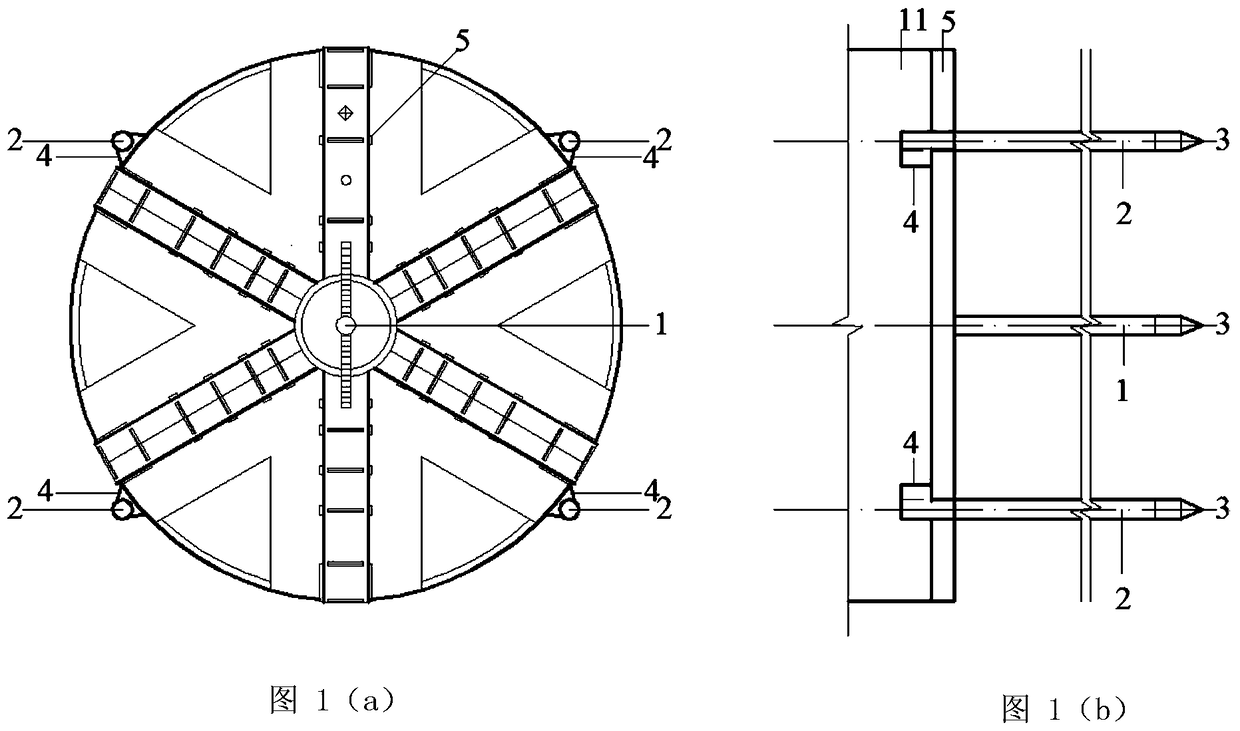

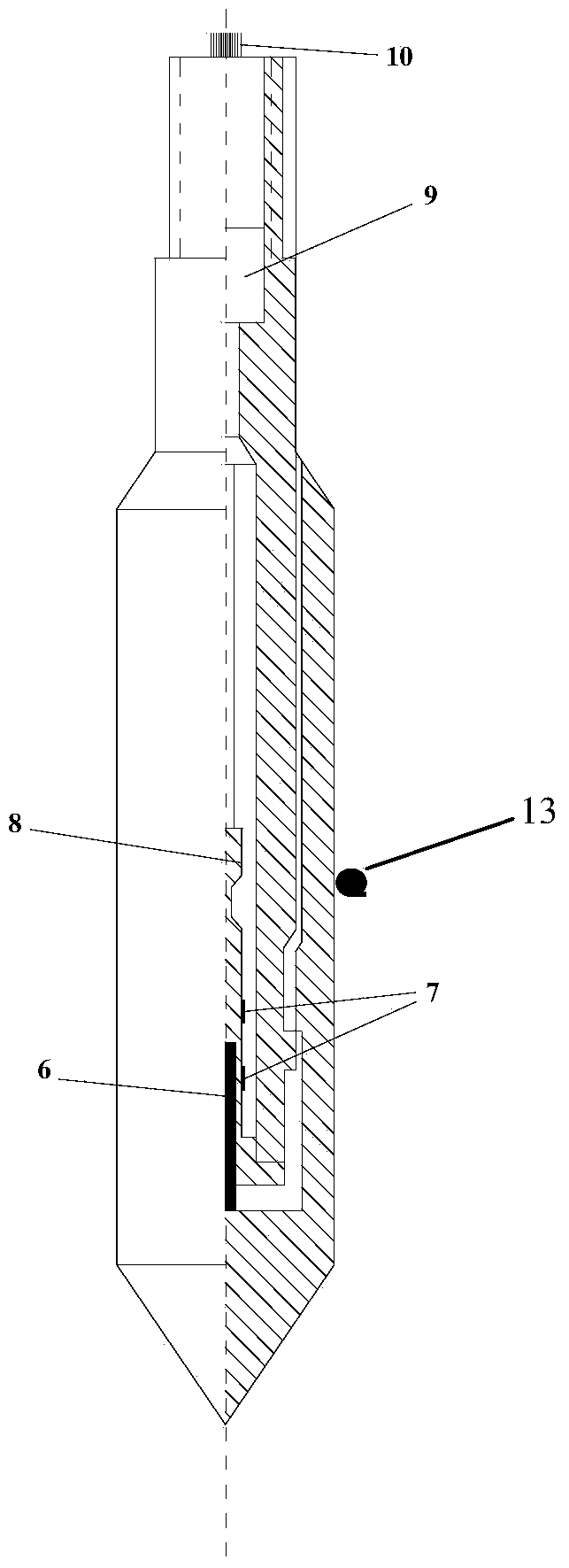

A method for advanced forecasting of soil shield tunnel construction diseases

ActiveCN104863602BSave construction energyShorten the construction periodMining devicesTunnelsSoil sciencePore water pressure

The invention discloses an advanced forecasting method of soil shield tunnel construction disasters. An advanced detecting device is arranged in front of a shield tunneling machine; lateral resistance, end resistance and porewater pressure of a soil layer can be detected by using an advanced probe to determine the property of the soil layer, then the soil layer property determining result is conveyed in a shield tunnel construction control center, a soil layer distribution and property three-dimensional model is formed, and a soil layer distribution and property prediction three-dimensional model corrected continuously within a larger range is automatically generated, so that the front soil body engineering property is judged, the construction scheme is corrected in time, safety measures are taken, the construction cost is reduced, the construction quality is ensured, and major safety accidents are avoided. Through the advanced forecasting method, the construction environment can be predicted, the construction scheme is optimized, safety measures are taken, the advanced forecasting method is safe and convenient, can be suitable for different properties of soil layers, and is economic and accurate in shield tunneling construction, and the material is saved.

Owner:CHONGQING UNIV

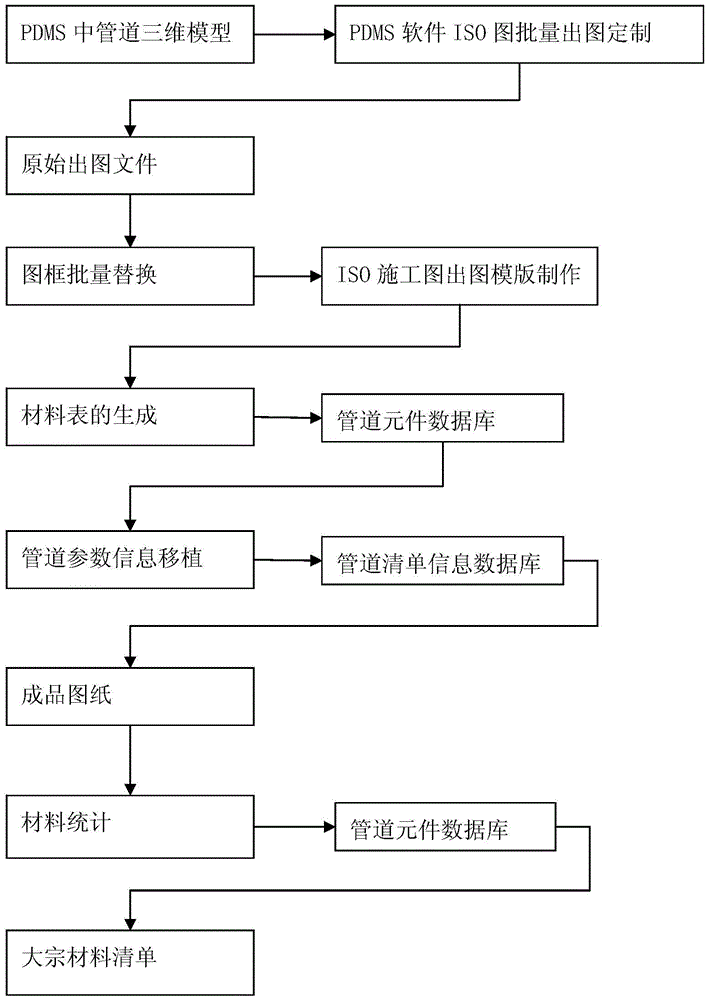

Nuclear power project pipeline ISO drawing customization method

ActiveCN105631113AImprove experienceReduce loadGeometric CADSpecial data processing applicationsNuclear powerQuality by Design

The invention relates to a nuclear power project three-dimension design technology, in particular to a nuclear power project pipeline ISO drawing customization method. The method comprises the steps that deep design is conducted on plotting configuration files for a PDMS software ISO drawing, and then batched plotting, batched replacement and a bill of a large amount of materials are generated and processed by calling an AutoCAD software. Net development interface on the basis of an original construction drawing (in a DXF format) extracted from a PDMS pipeline three-dimension model. By means of the nuclear power project pipeline ISO drawing customization method, a large amount of manual operation work can be decreased, a proofreader and a reviewer can put more energy into nuclear power design and proofreading and reviewing work, the quality of the design is improved, and the design progress is guaranteed.

Owner:CHINA NUCLEAR POWER ENG CO LTD

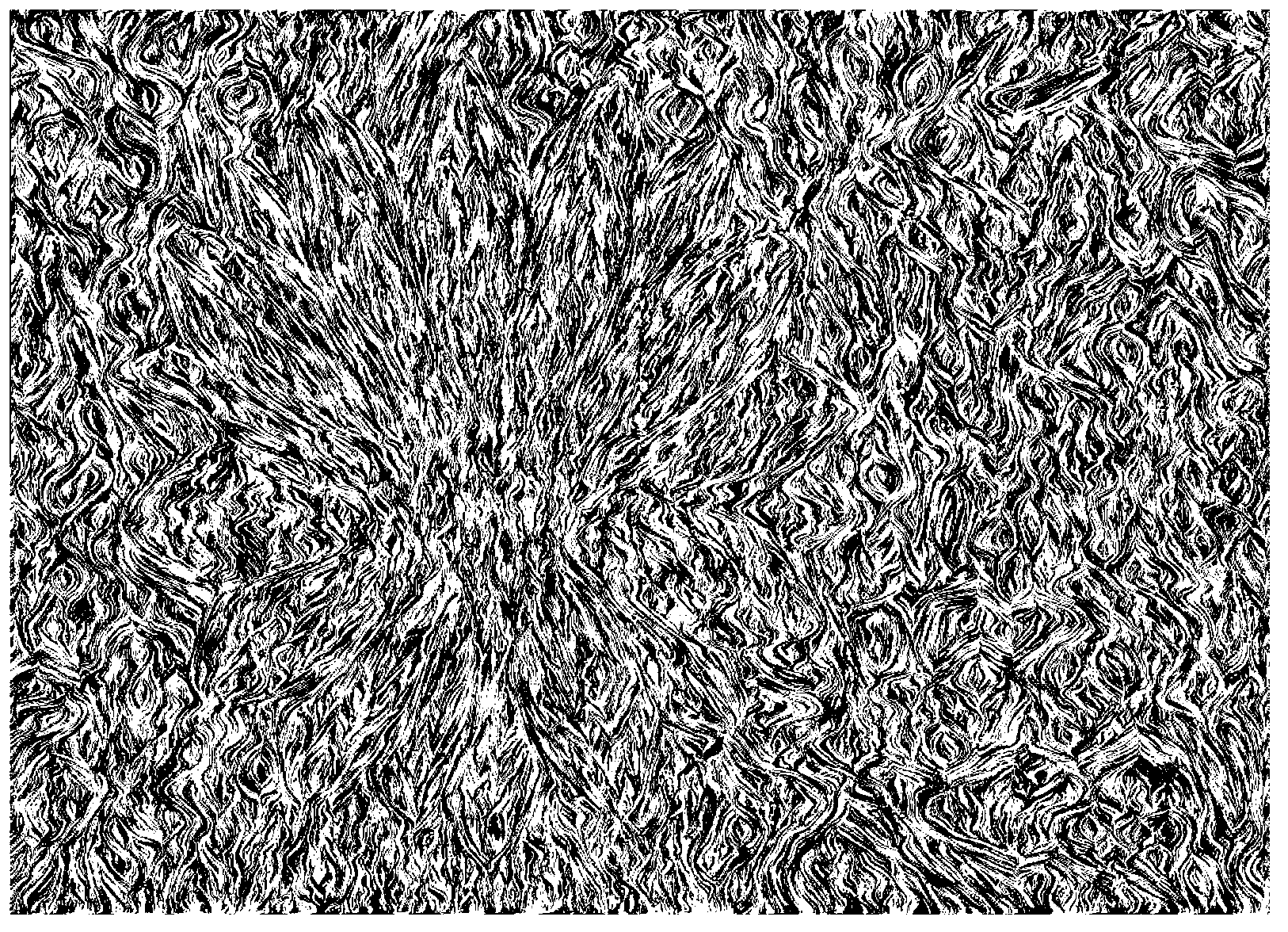

Computer-aided random stitch embroidery producing method adopting fuzzy clustering and random walk

InactiveCN103793549AImprove production efficiencyImprove efficiencyImage analysisCharacter and pattern recognitionColor imageAlgorithm

The invention discloses a computer-aided random stitch embroidery production method adopting fuzzy clustering and random walk. The computer-aided random stitch embroidery producing method includes the steps of 1), defining a parameterized cross needle model suitable for random stitch embroidery stitch features and determining mapping relations between cross needle parameters and image features by the method of an enumeration experiment; 2), taking inputted color images as reference images, generating a cross needle set for given images, clustering the cross needles contained in the cross needle set by adopting a fuzz clustering and random walk algorithm, and adjusting the cross needle parameters according to the mapping relations obtained in the step 1) to obtain a stitch sequence; 3), converting stitch coordinates into coordinates required by a computerized embroidery machine, and inputting the coordinates into the computerized embroidery machine to obtain corresponding disorderly needle embroider products. The computer-aided random stitch embroidery production method is of great significance to mechanized standardization production of the random stitch embroidery.

Owner:NANJING UNIV

Automatic machining device for foundation bolts

PendingCN107598583ARealize the unwinding operationEasy to cutOther manufacturing equipments/toolsEngineeringMachining process

The invention discloses an automatic machining device for foundation bolts. The automatic machining device comprises a storage frame, a base, a feeding mechanism, a cutting and bending mechanism, a conveying mechanism, a thread rolling mechanism, a discharging mechanism and a control mechanism. The storage frame cooperates with the feeding mechanism connected with the cutting and bending mechanism. The conveying mechanism comprises a conveying plate, a conveying table and a first motor. The discharging mechanism comprises a second motor, a conveying belt, a conveying plate, a discharging plateand a receiving cylinder. Through cooperation of the feeding mechanism, the cutting and bending mechanism, the conveying mechanism, the thread rolling mechanism and the discharging mechanism, the foundation bolts can be fully-automatically integrally formed, cutting, bending and thread rolling are conveniently, quickly and accurately finished, manual operation is reduced, the work efficiency is improved, the yielding capacity of the foundation bolts can be increased to six tons every day by four persons, the production efficiency is greatly improved, machining process integration is realized,and machining accuracy is ensured.

Owner:亦宸五金(浙江)股份有限公司

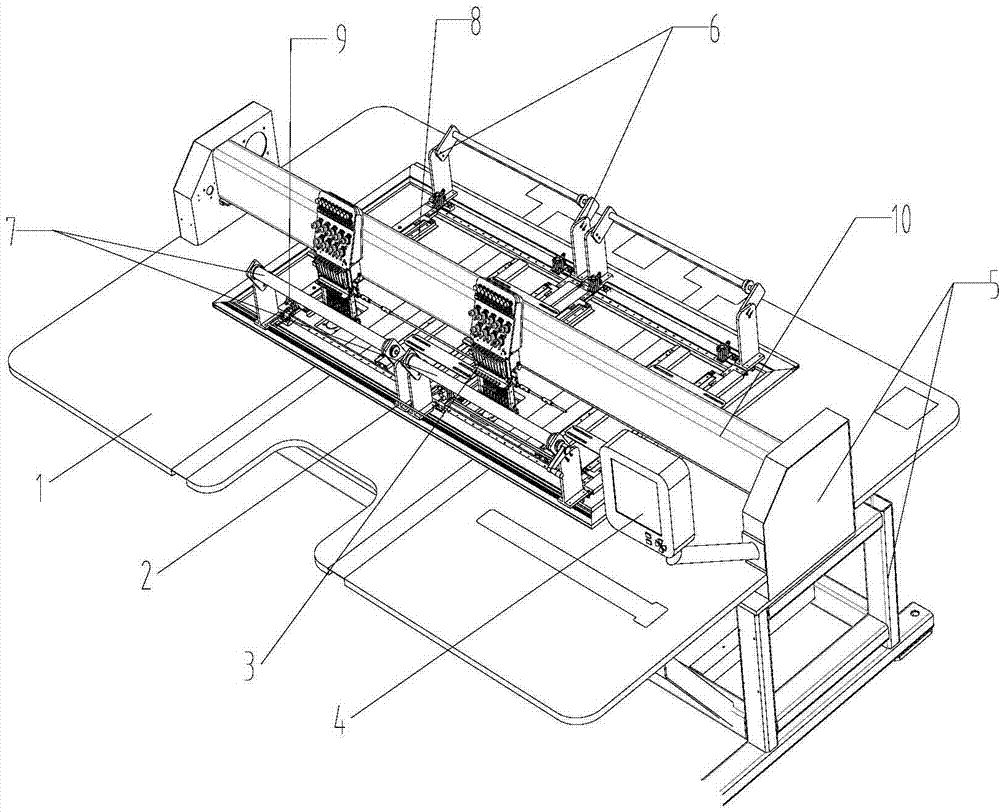

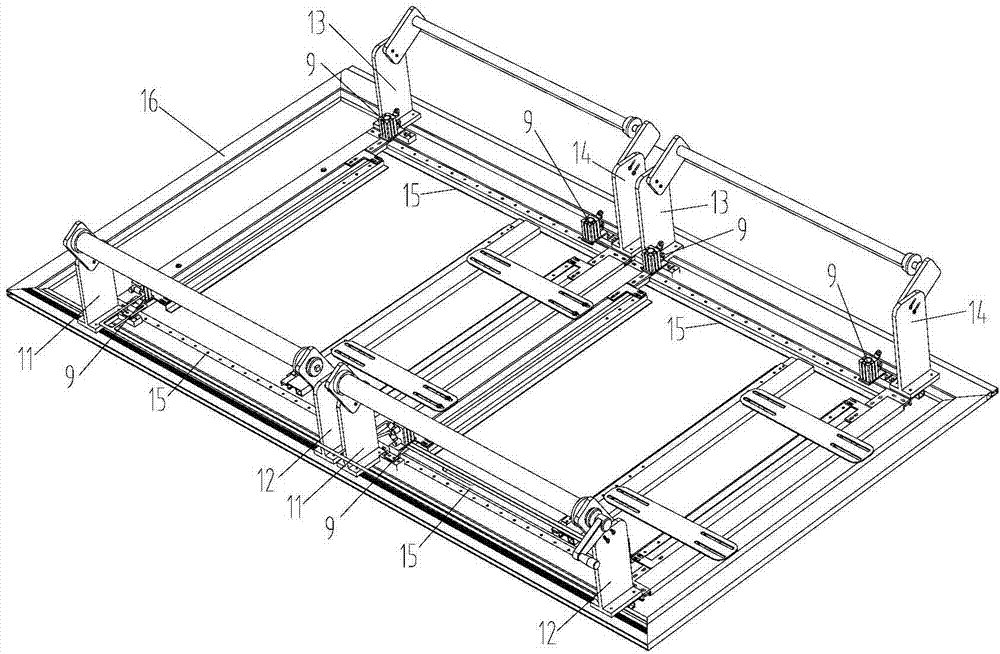

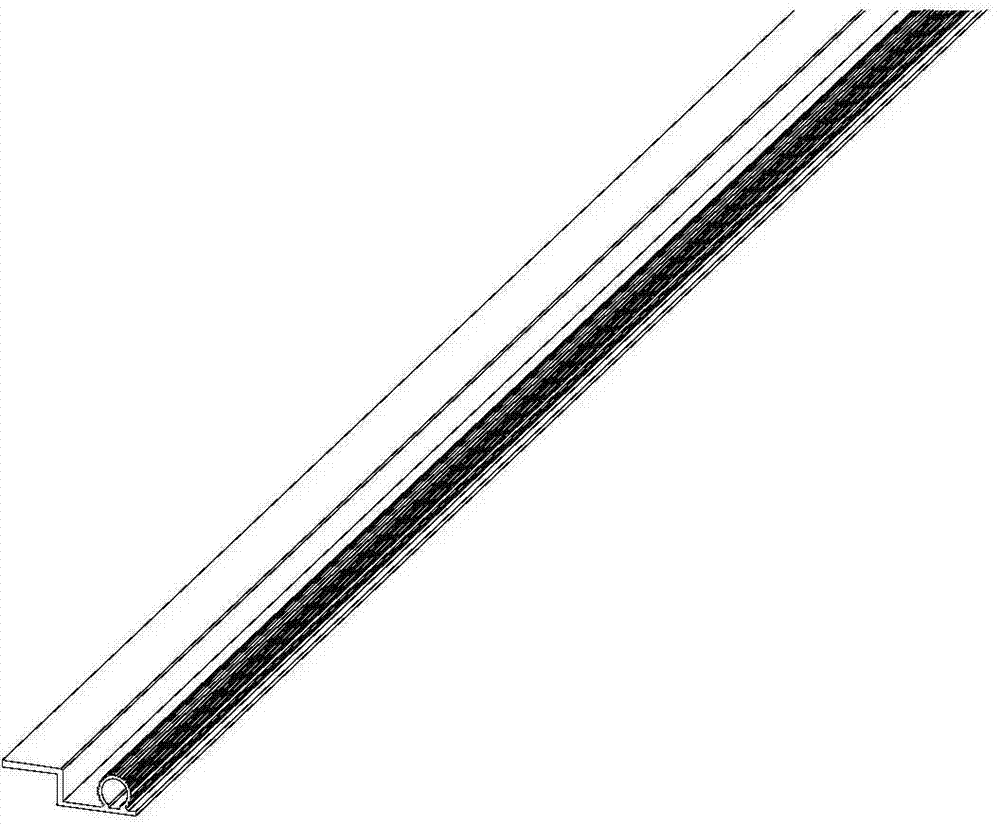

Bedspread embroidery machine

InactiveCN104120564ALow investment costSimple and fast operationAutomatic machinesDual purposeEngineering

The invention discloses a bedspread embroidery machine in the textile industry. The machine is also suitable for performing plain embroidery. The machine structurally comprises a rack and a bedplate, wherein the bedplate is arranged on the rack; a pneumatic tabouret is assembled on the bedplate; the lower part of the pneumatic tabouret is provided with a plain embroidery tabouret; the upper part of the pneumatic tabouret is provided with a feeding device, a material receiving device, a guiding device and a pneumatic press mechanism; during the operation of the bedspread embroidery, the upper part and the lower part of the pneumatic tabouret are fixed together through a connecting plate a, a connecting plate b, a connecting plate c and a connecting plate d by using screws, so that the phenomenon that malposition of the embroidery occurs because the two tabourets are connected loosely during embroidery is avoided; during the operation of the plain embroidery, the screws for connecting the connecting plate a, the connecting plate b, the connecting plate c and the connecting plate d are loosened, and the plain embroidery can be carried out just after taking away the feeding device, the material receiving device, the guiding device and the connecting plates at the upper part; components of a cloth spunlacing mechanism and a thread leading mechanism are arranged on a cross beam of the rack. According to the machine, the products to be embroidered are automatically pressed, so that the working efficiency is improved, and the labor intensity is reduced; with one-machine dual-purpose, the machine can be used for performing both bedspread embroidery and plain embroidery, so that the resources are saved.

Owner:上工富怡智能制造(天津)有限公司

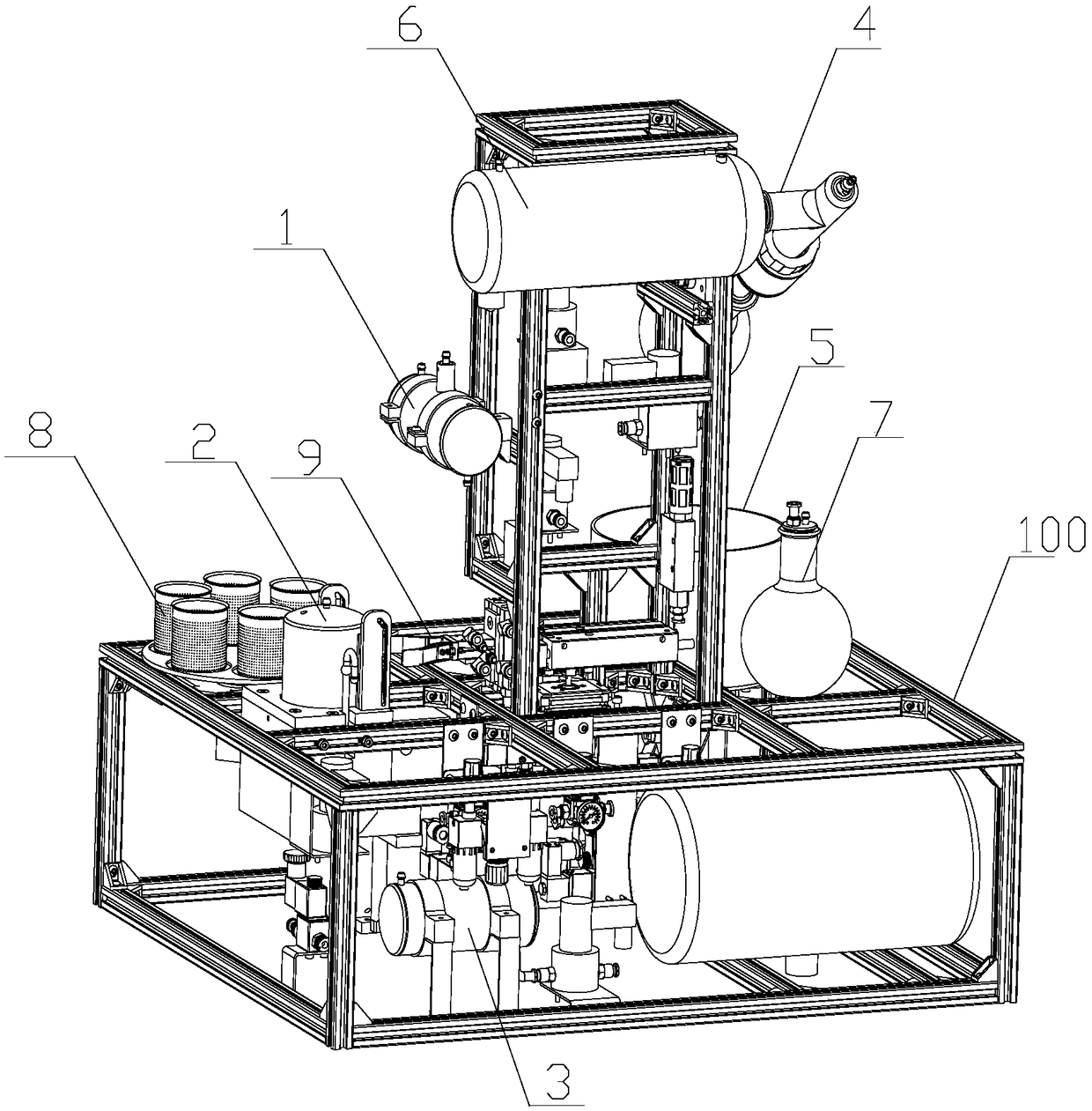

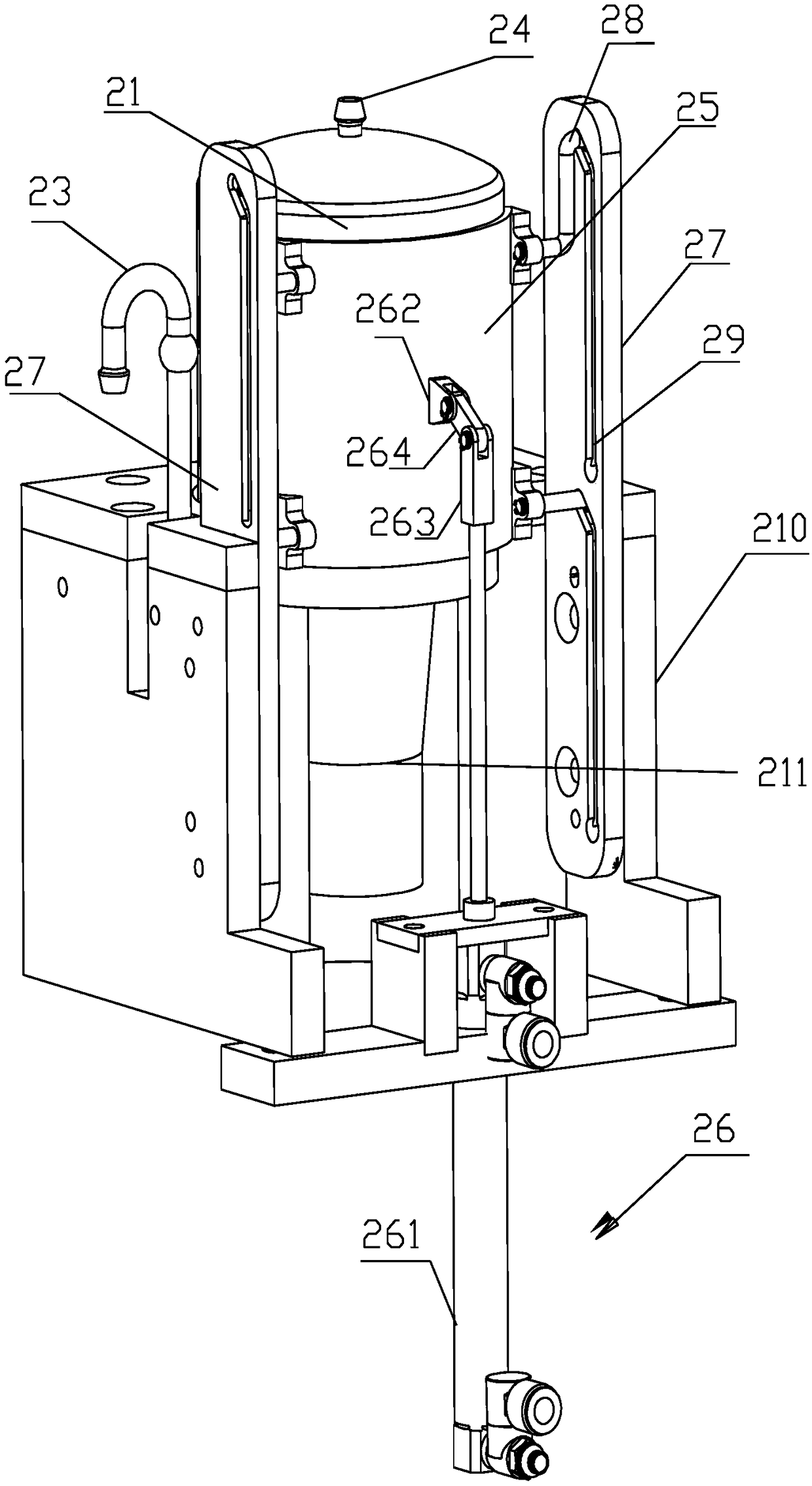

Automatic traditional Chinese medicine extraction concentration integration device

PendingCN108635910ADensity real-time monitoringExtract idealEvaporator accessoriesPharmaceutical product form changeControl systemLiquid storage tank

The invention discloses an automatic traditional Chinese medicine extraction concentration integration device. The automatic traditional Chinese medicine extraction concentration integration device comprises a solvent storage tank, an extraction apparatus, an extraction liquid storage tank, a concentration apparatus, a heating apparatus, a condensation recycler, an extract storage tank and a control system. By adopting the automatic traditional Chinese medicine extraction concentration integration device, the efficiency for extracting and concentrating the traditional Chinese medicine can be greatly improved, the completeness of active ingredient content and the quality of the traditional Chinese medicine can be ensured, the cost can be reduced, the industrialization can be further realized, the technical innovation of energy conservation, environment protection, high efficiency, and environment friendliness can be sufficiently reflected, the traditional rule of the traditional Chinesemedicine can be inherited, and the development requirement in China can be completely met.

Owner:河北鑫民和医药科技开发有限责任公司

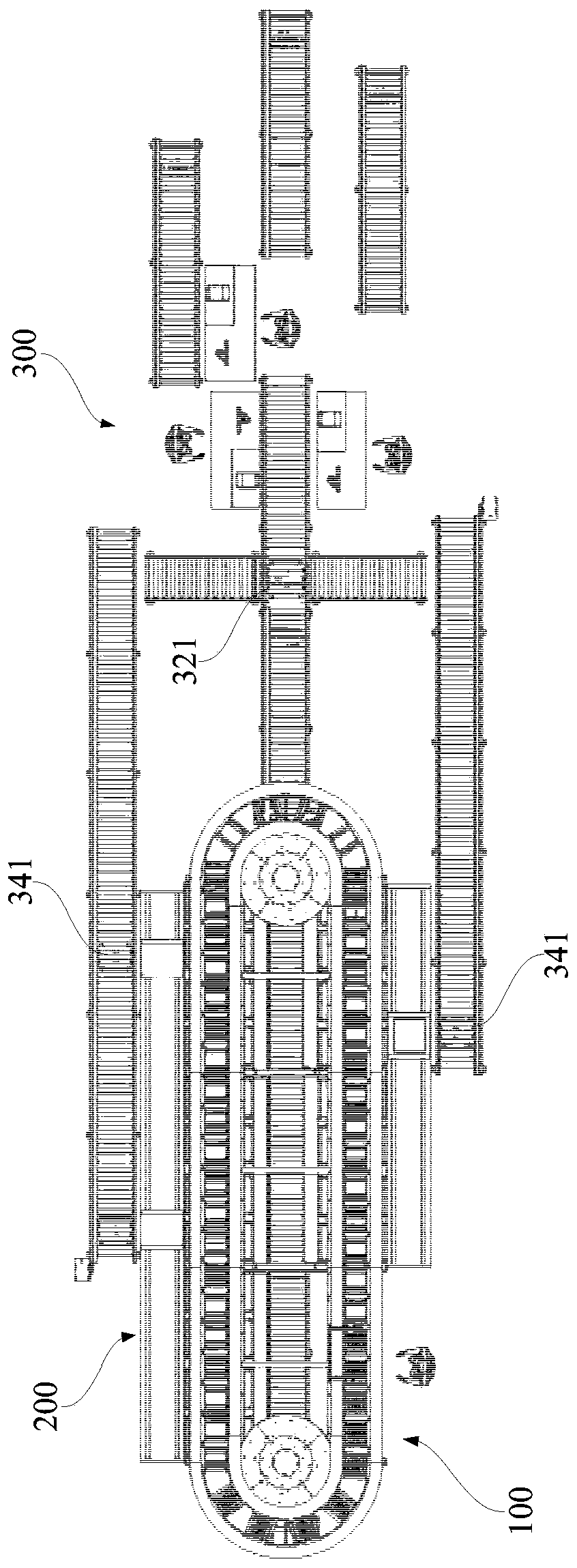

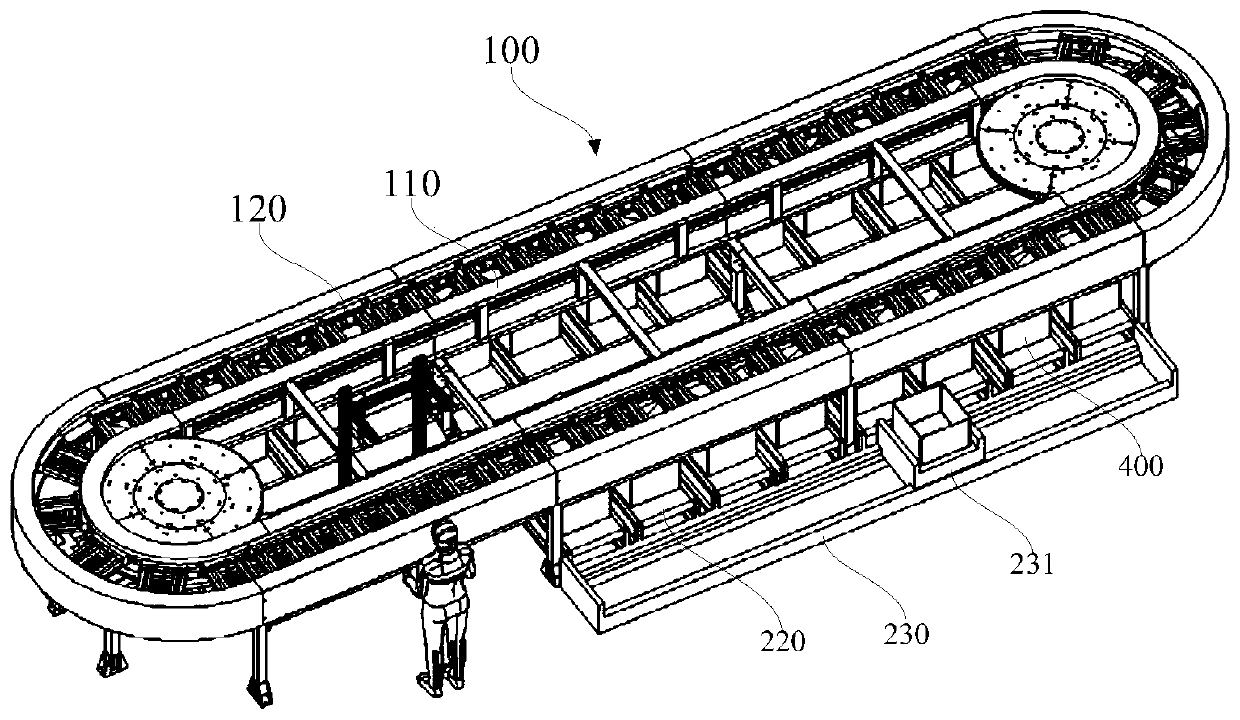

Bag falling type sorting system

PendingCN110090807AConvenient packing workImprove sorting efficiencySortingTransfer systemEngineering

The invention discloses a bag falling type sorting system. The bag falling type sorting system comprises a tray system, a transferring system and a sub-packaging system; the tray system comprises an annular support, a chain transmission mechanism and a plurality of supporting platforms; each supporting platform comprises two openable supporting plates, the first sides of the two supporting platesare connected through a connecting rod mechanism, the second side closing parts of the two supporting plates are lapped on the supporting part of a swinging hook, and the upper end part of the swinging hook is rotationally arranged on a frame of the supporting platforms; the transferring system comprises a goods delivery line, two sides of the goods delivery line are correspondingly provided witha plurality of conveying platforms, and the conveying platforms are provided with a sorting basket for receiving articles falling from the supporting platforms; a transferring platform is arranged onthe outer side of the conveying platforms; the sub-packaging system comprises a goods receiving conveying line and three goods distribution conveying lines, wherein one side of each goods distributionconveying line is correspondingly provided with a box loading operation table, and an empty basket conveying line is arranged between the other side of the goods distribution conveying line and the transferring platform; and a plurality of supporting plate opening mechanisms are arranged on the annular support, and the supporting plate opening mechanisms are positioned above the conveying platforms.

Owner:陈宇

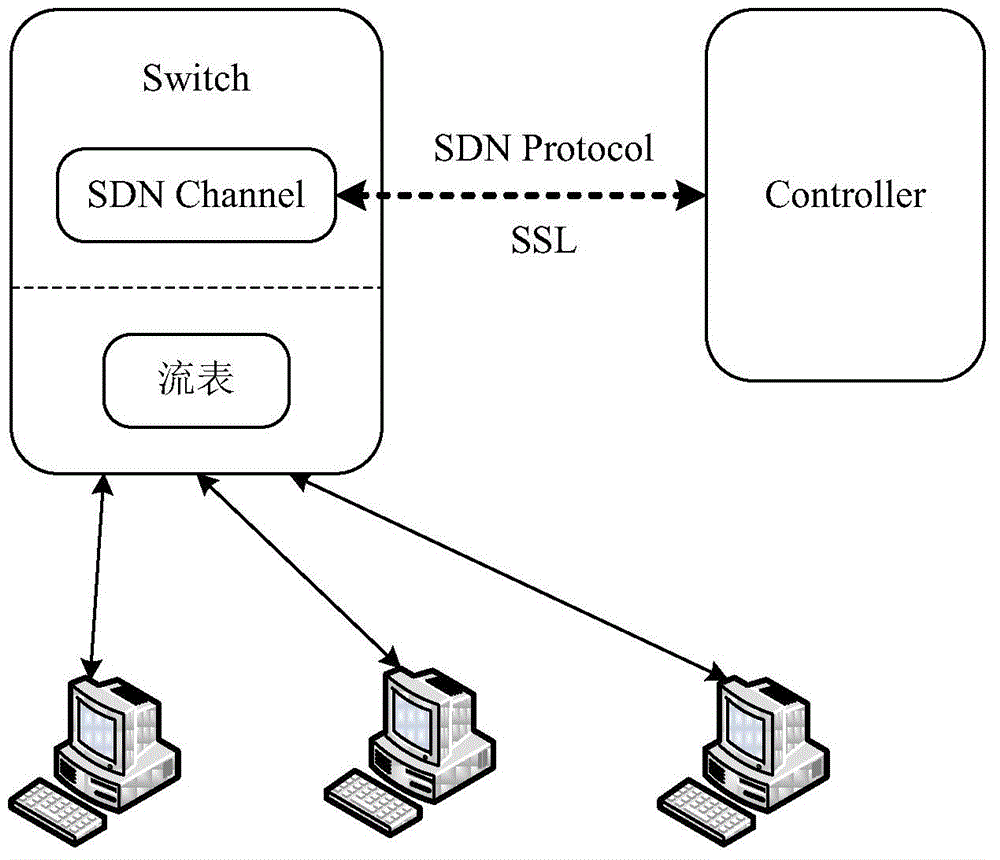

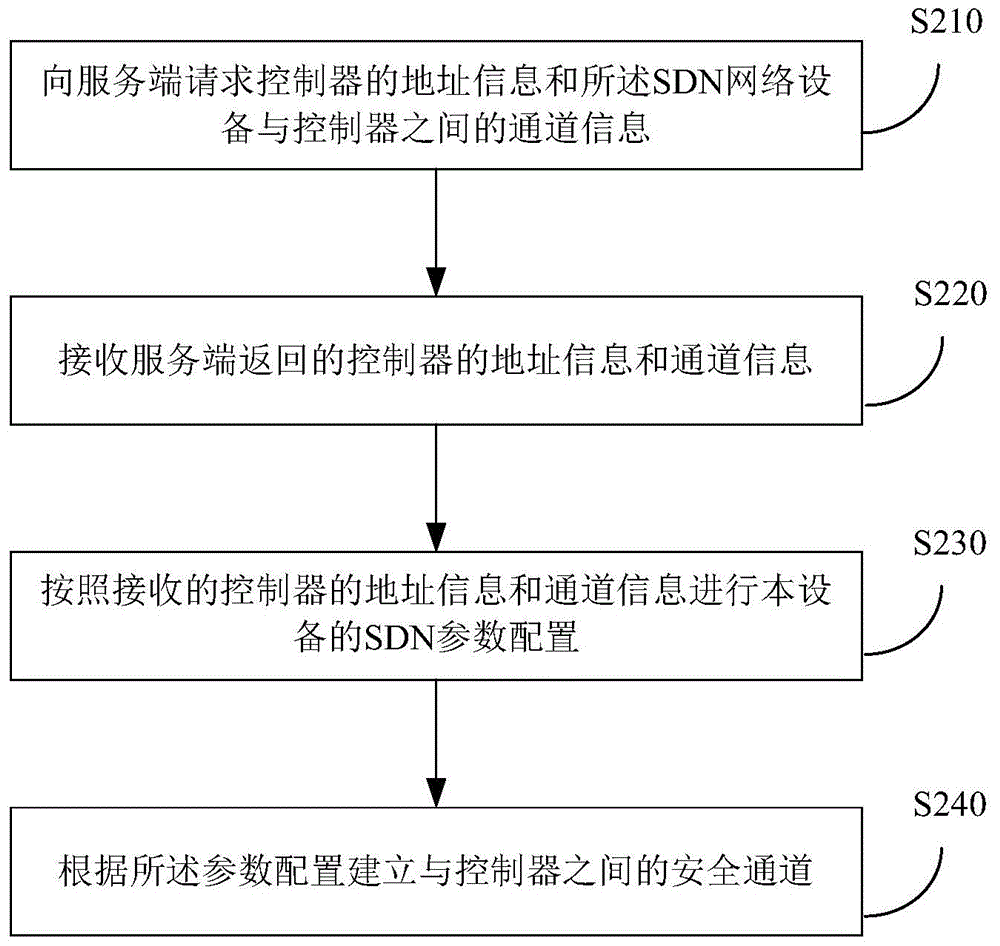

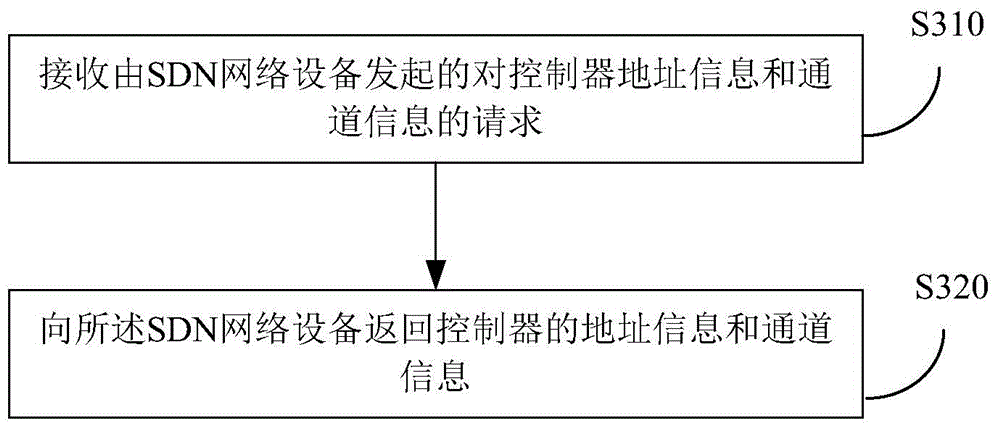

Method and device for realizing zero configuration startup

ActiveCN104901825AReduce manual workImprove accuracyHybrid transportNetwork managementSoftware-defined networking

A startup method is described in which a software defined networking (SDN) network device sends a request to a server to obtain controller address information and channel information and configures SDN parameters in accordance with the controller address information and the channel information and establishes a secure channel with the controller.

Owner:NEW H3C TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com