Patents

Literature

35 results about "Bundle methods" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

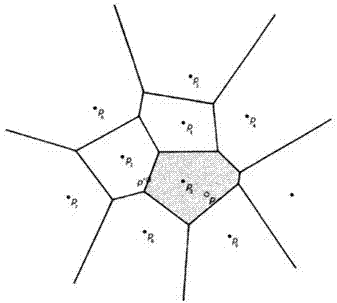

The basic idea of bundle methods is to approximate the subdifferential (that is, the set of subgradients) of the objective function by gathering subgradients from previous iterations into a bundle. In this way, more information about the local behavior of the function is obtained than what an individual arbitrary subgradient can...

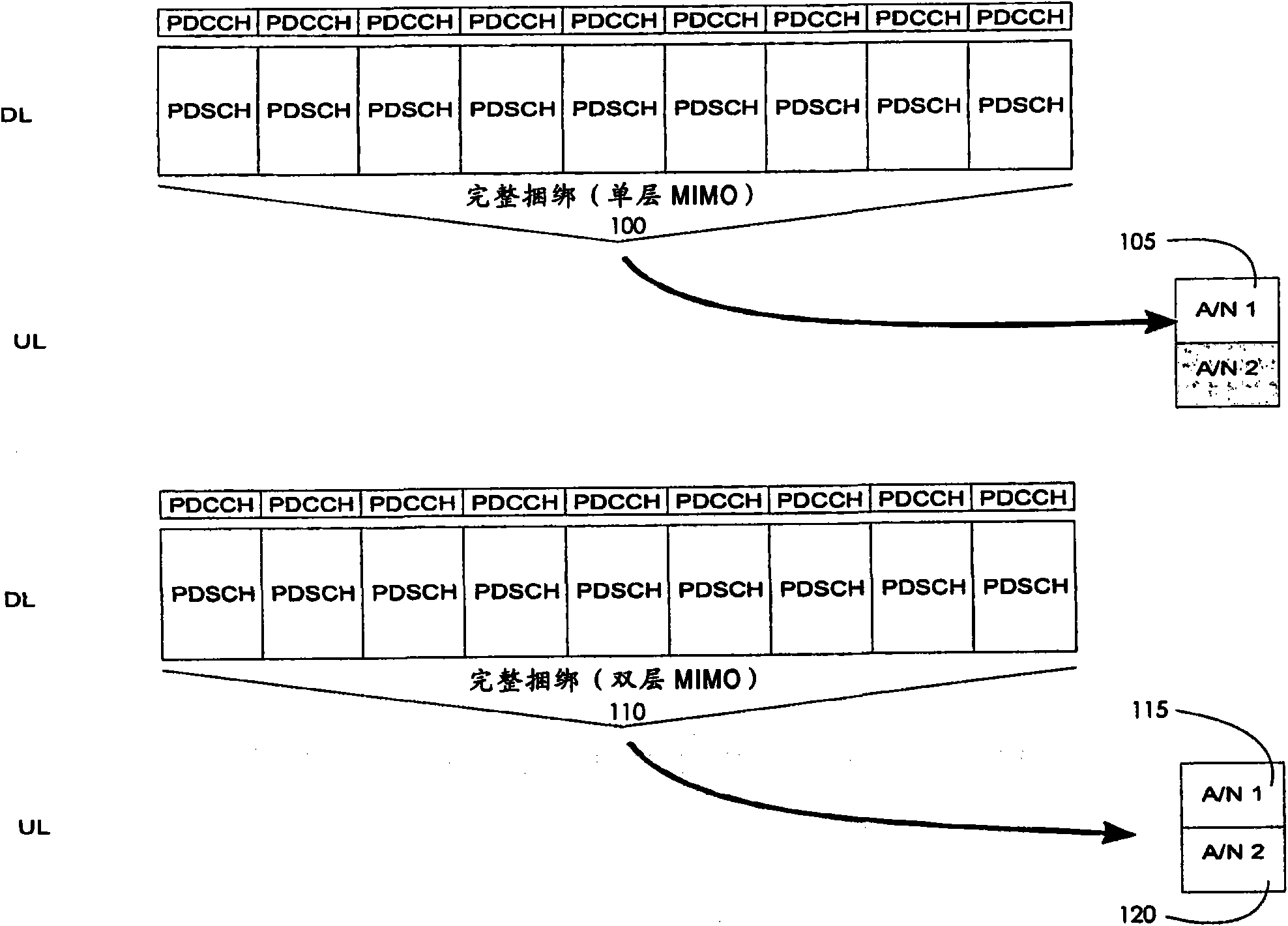

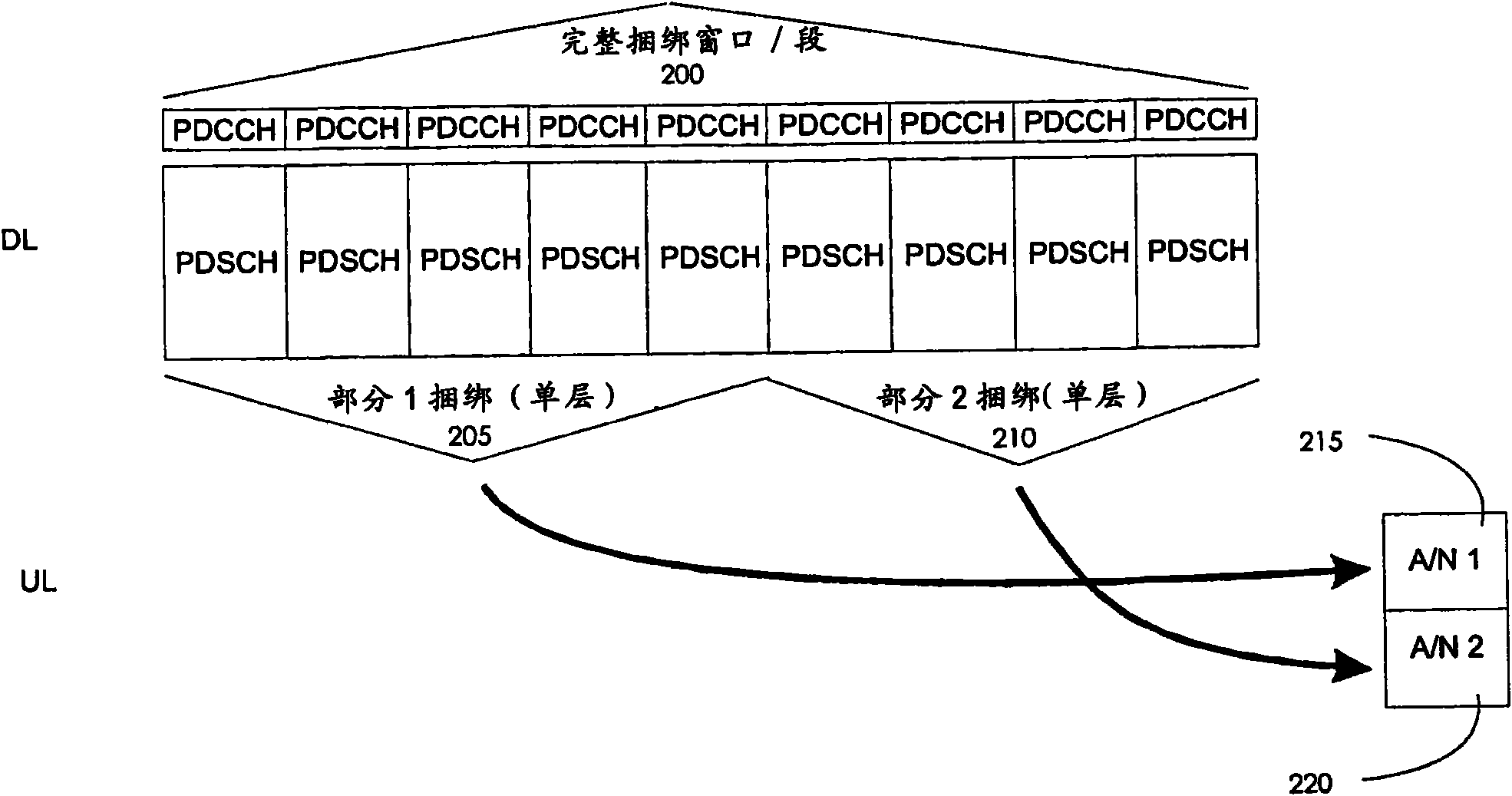

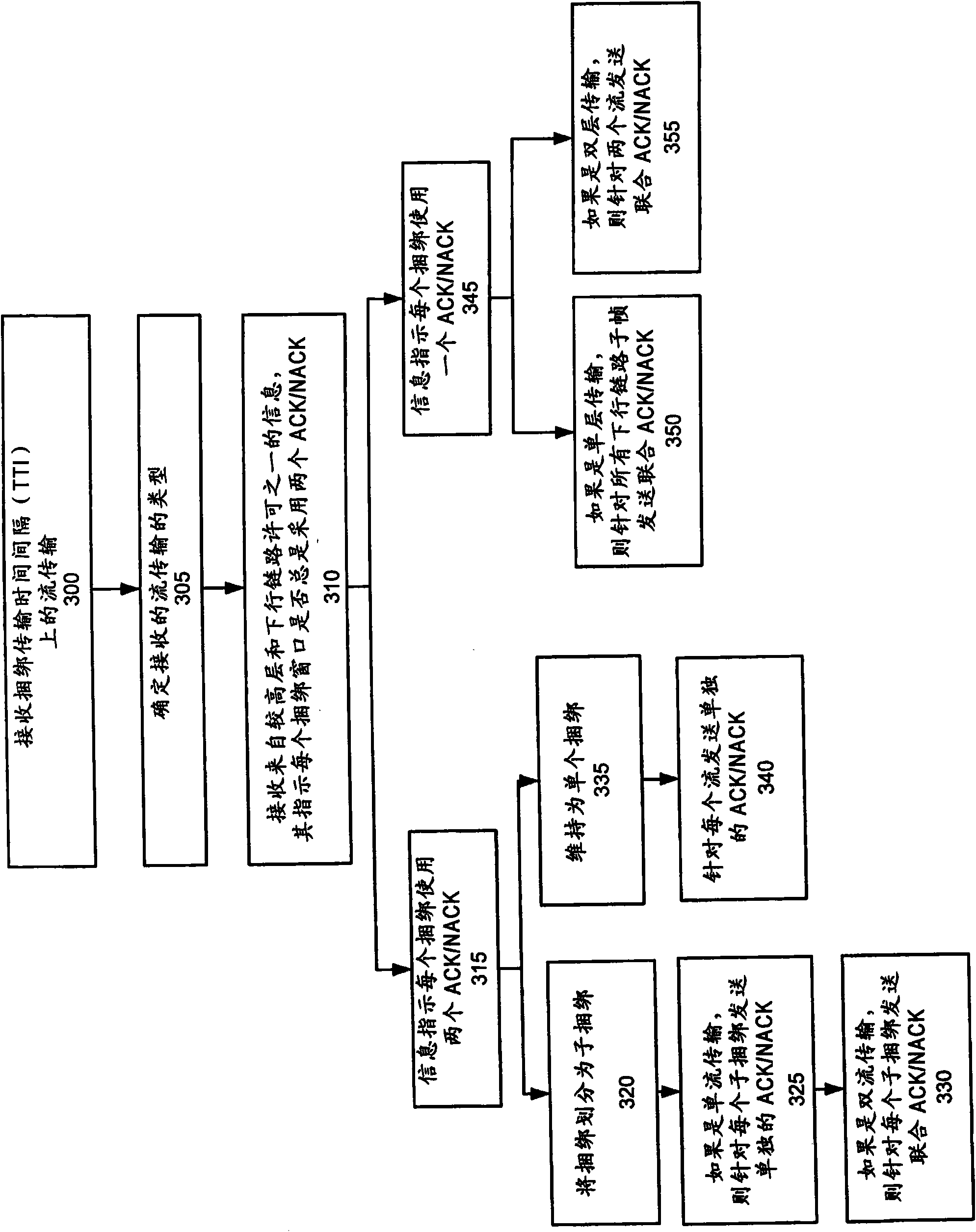

Ack/nack transmission on pucch in lte-atdd with nxpdcch structure

InactiveUS20110141878A1Maximum transmissionImprove reliabilityFrequency-division multiplex detailsTransmission systemsBundle methodTime domain

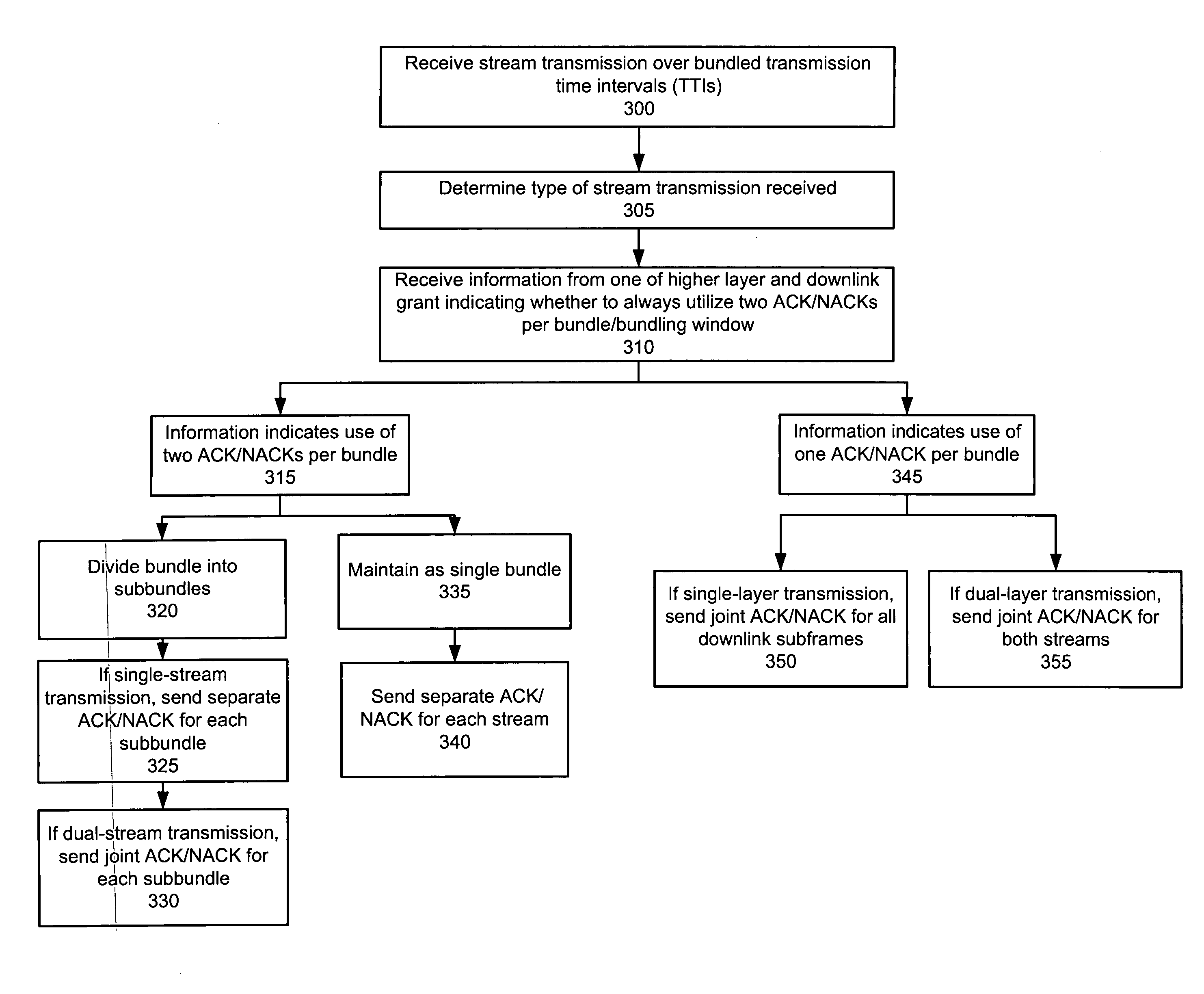

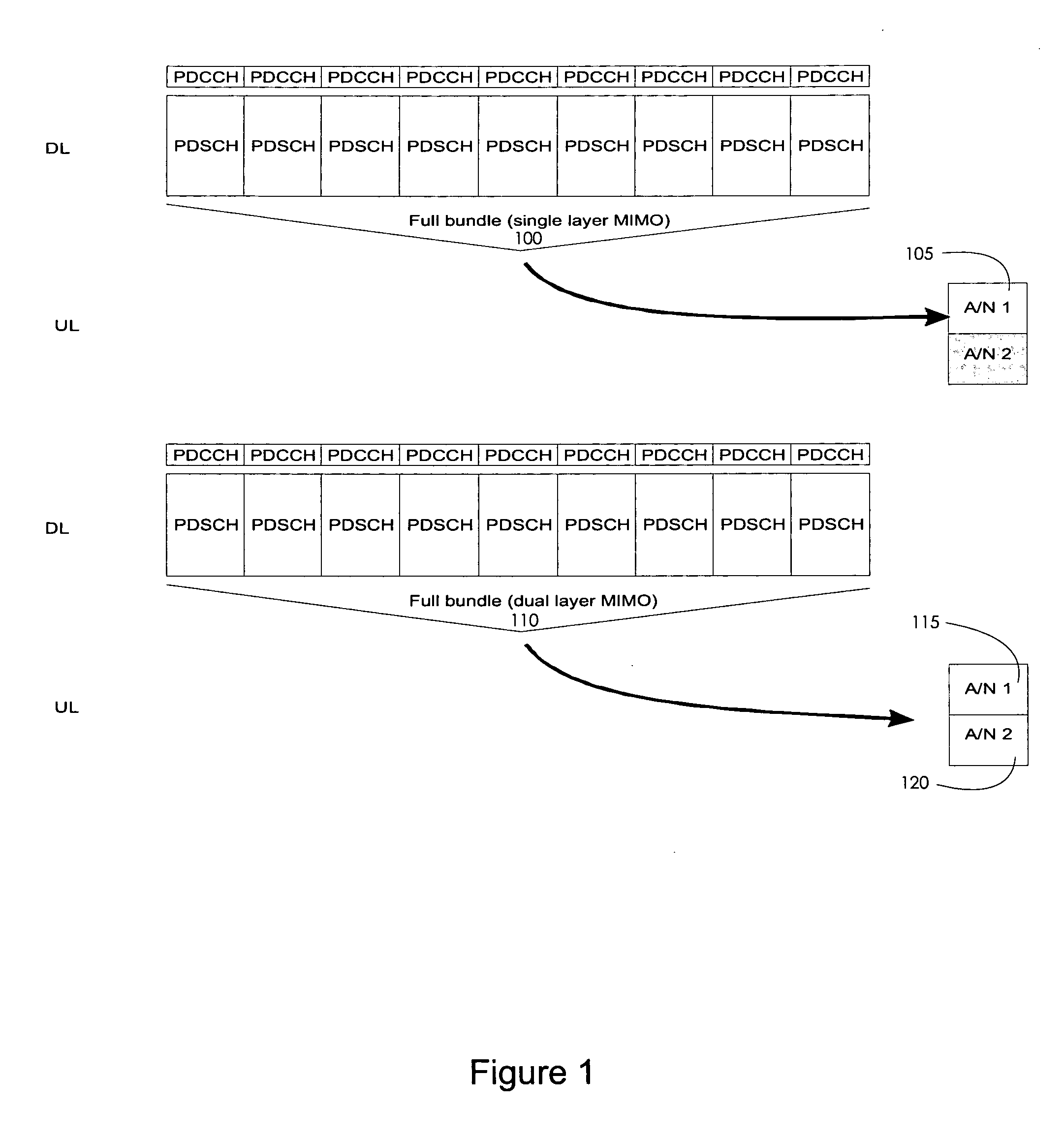

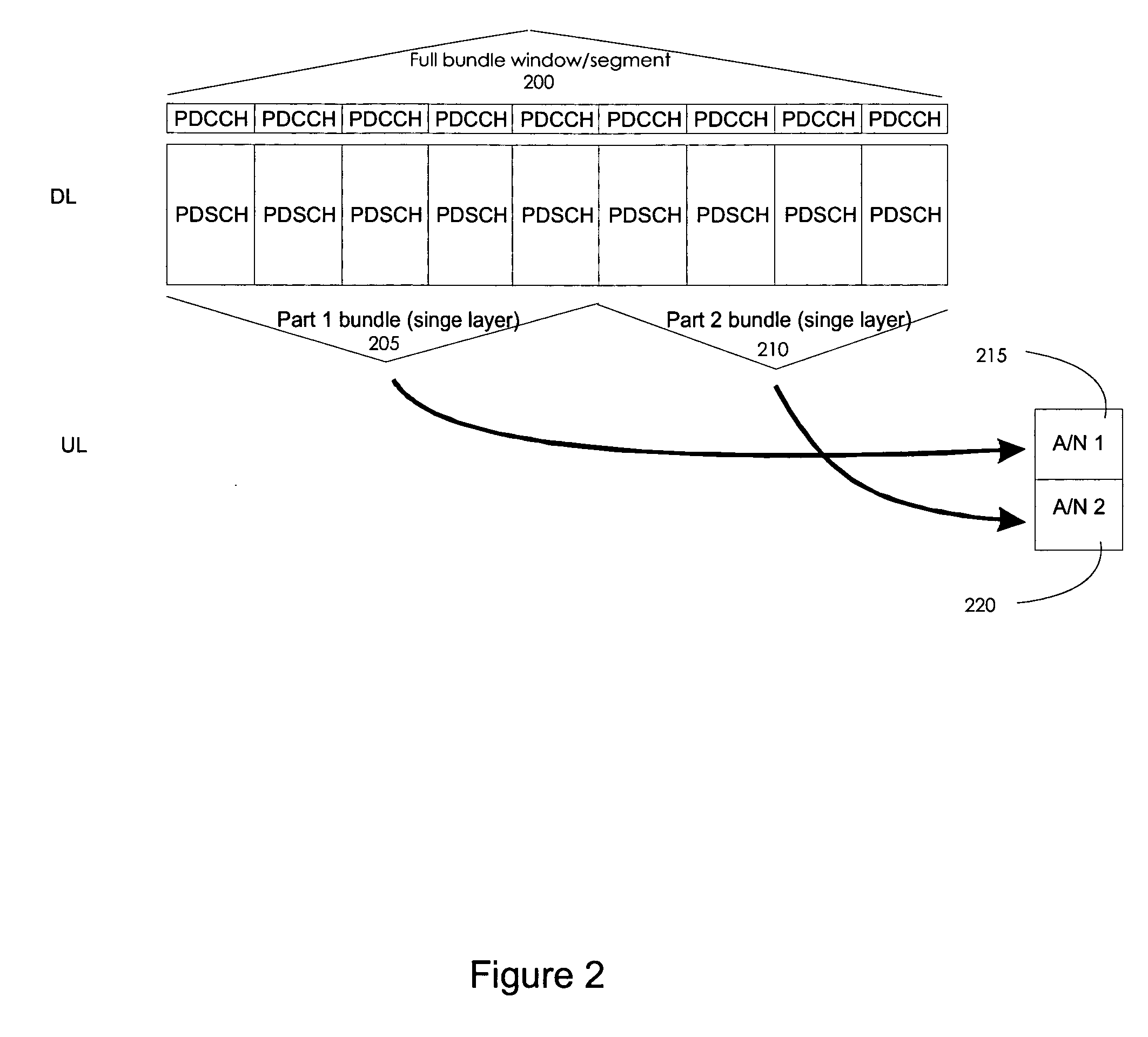

Systems and methods are provided for enabling different “bundling” methods for downlink transmissions and provide different interpretations of the acknowledgement / negative-acknowledgement bit. A user equipment is configured so that it commonly acknowledges all downlink transmission time intervals within a bundle so that if one packet is determined to be erroneous, all packets in that bundle will be retransmitted. Additionally, the systems and methods are implemented by allowing an interpretation to be applied to the uplink acknowledgement / negative-acknowledgement field such that the user equipment is able to divide bundled downlink packets into smaller windows in Long Term Evolution (LTE) Release 8 time division duplex (TDD) mode. In LTE Advanced (LTE-A) TDD mode, various embodiments provide bundling within the time domain, within the frequency domain, and within a hybrid time-frequency domain. Furthermore, enhanced channel selection methods are also provided in support of the above-mentioned bundling methods in accordance with various embodiments.

Owner:NOKIA CORP

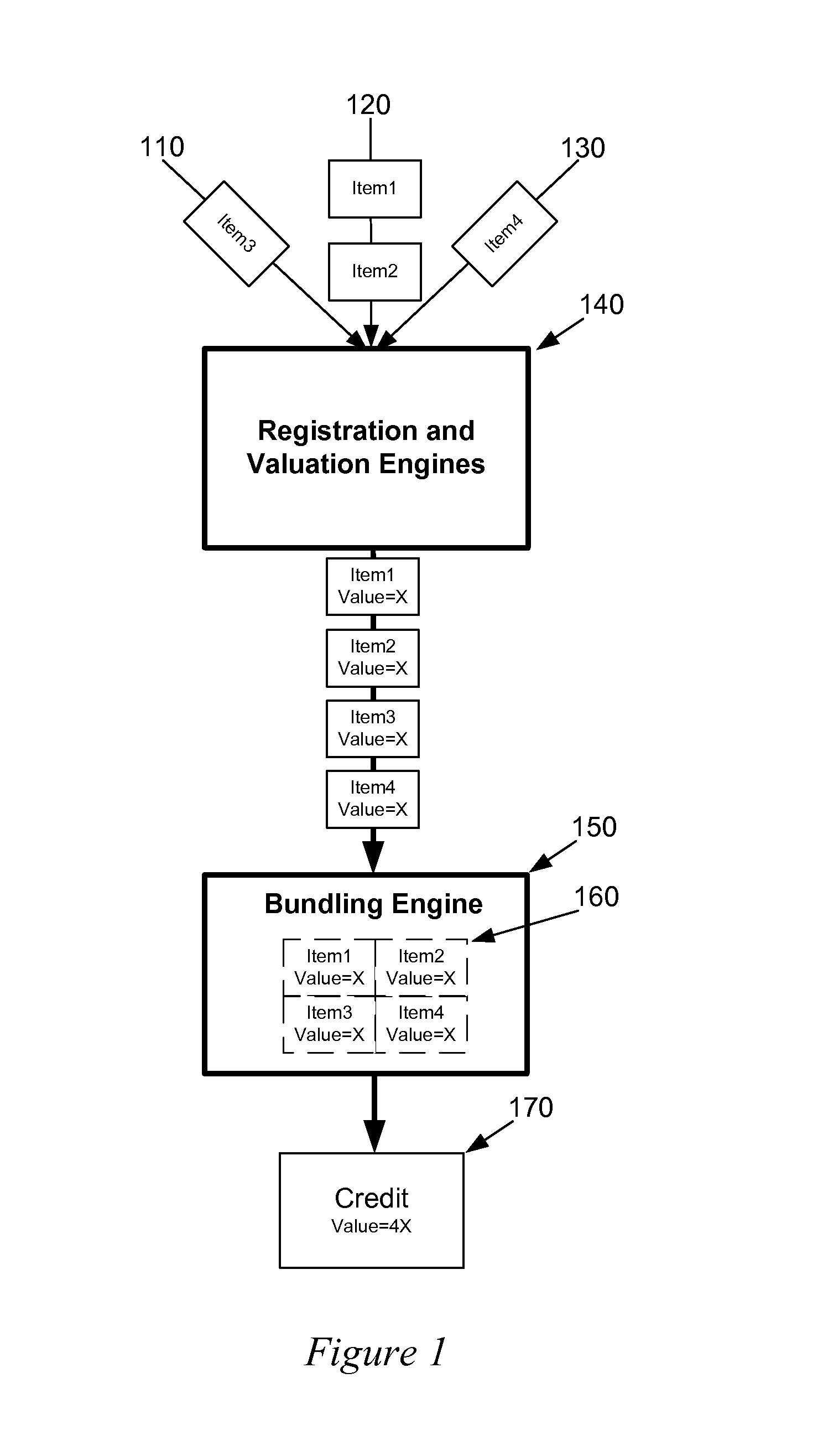

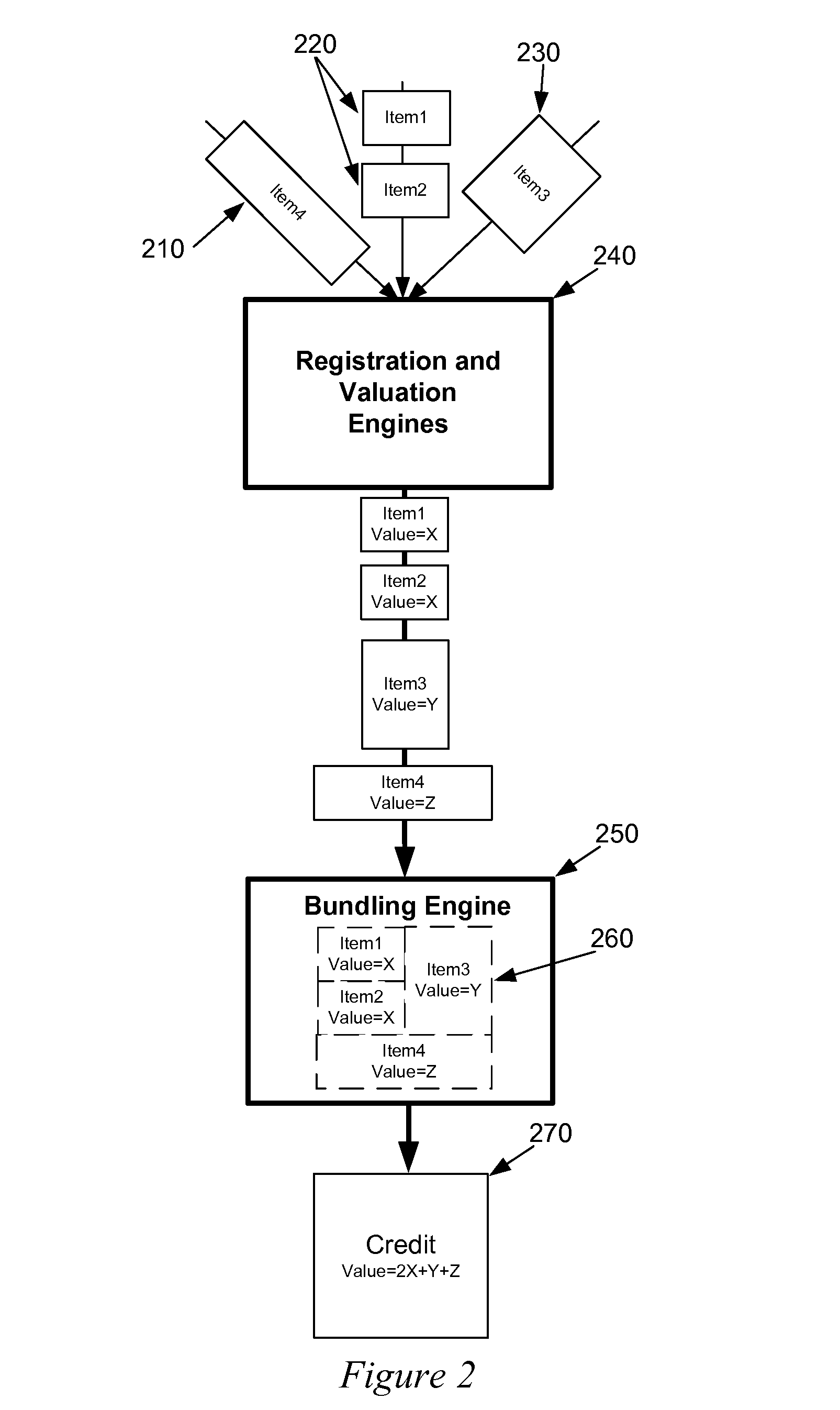

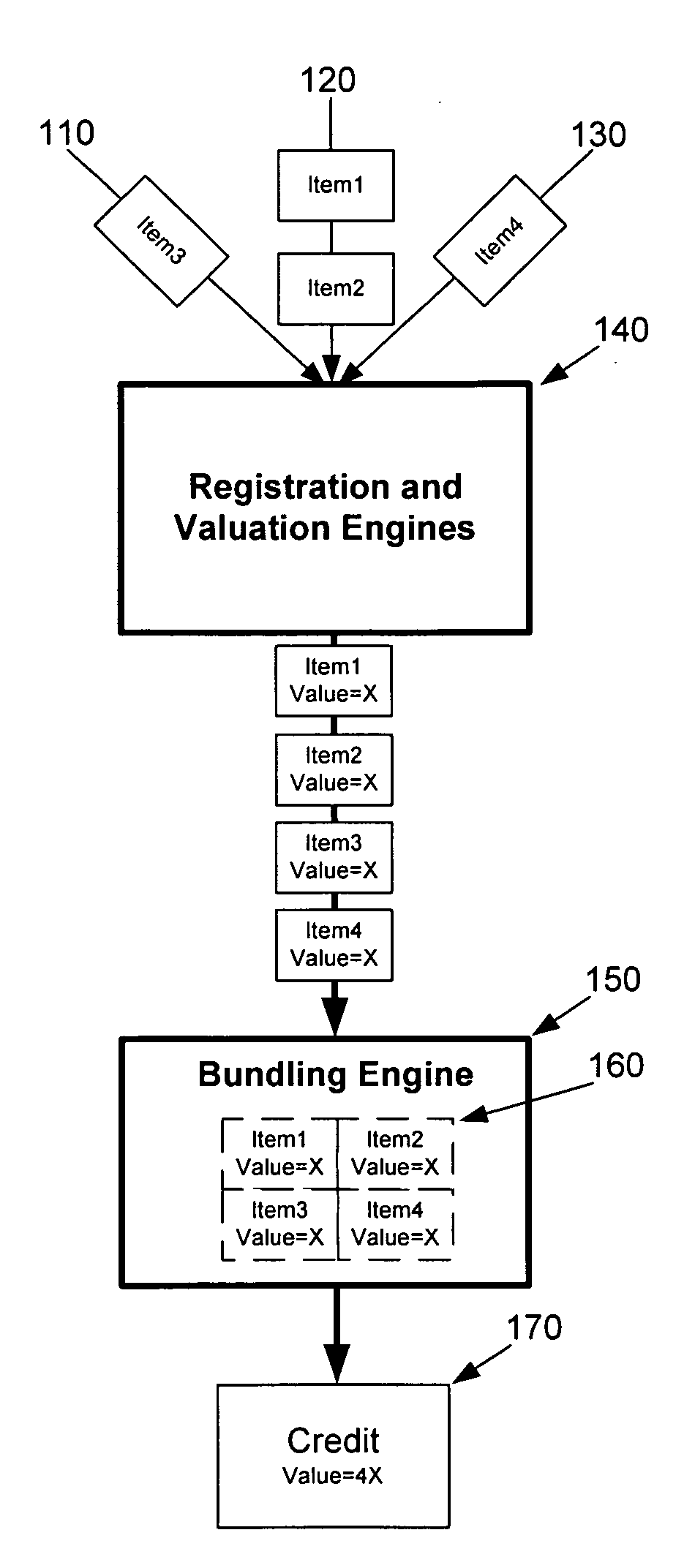

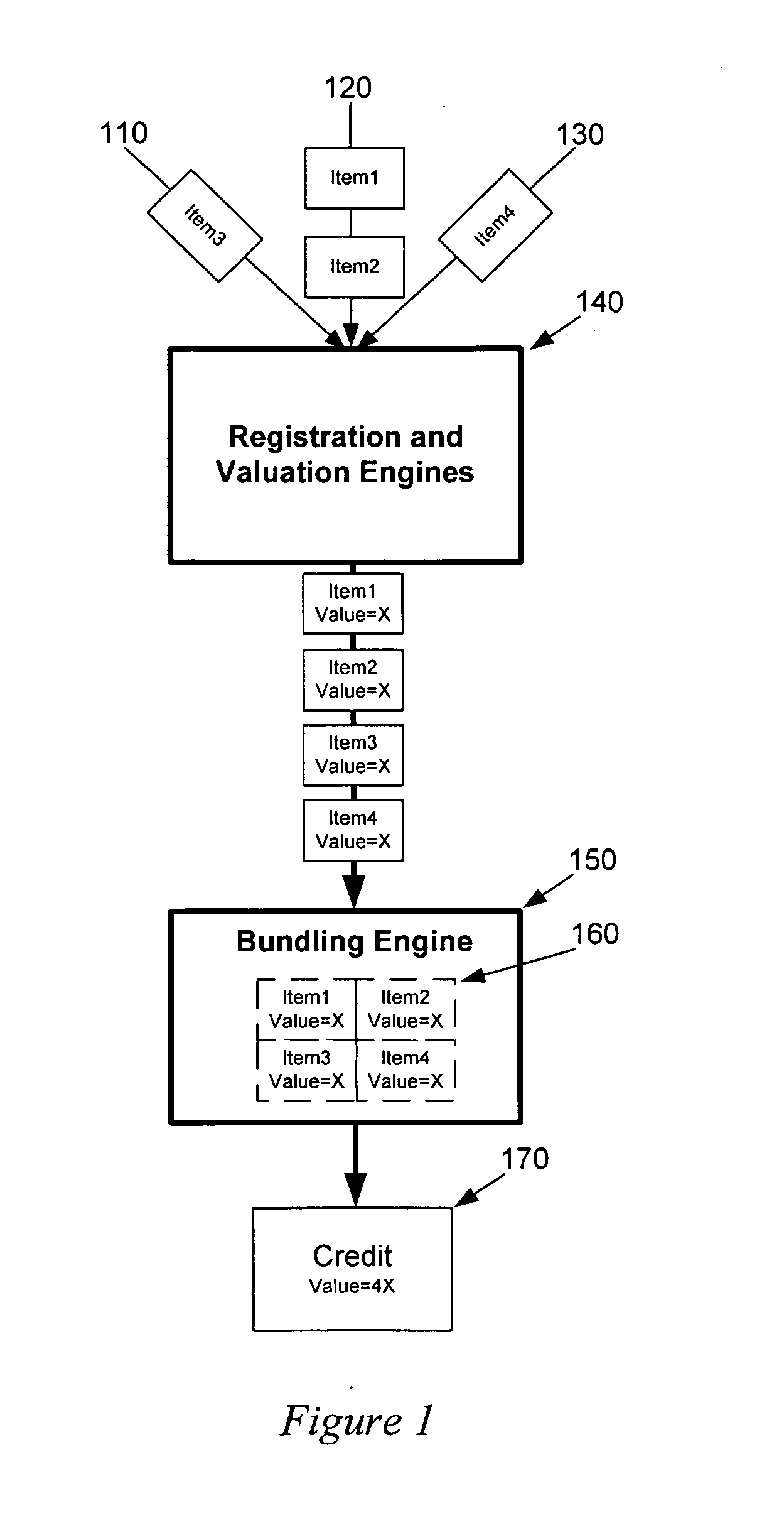

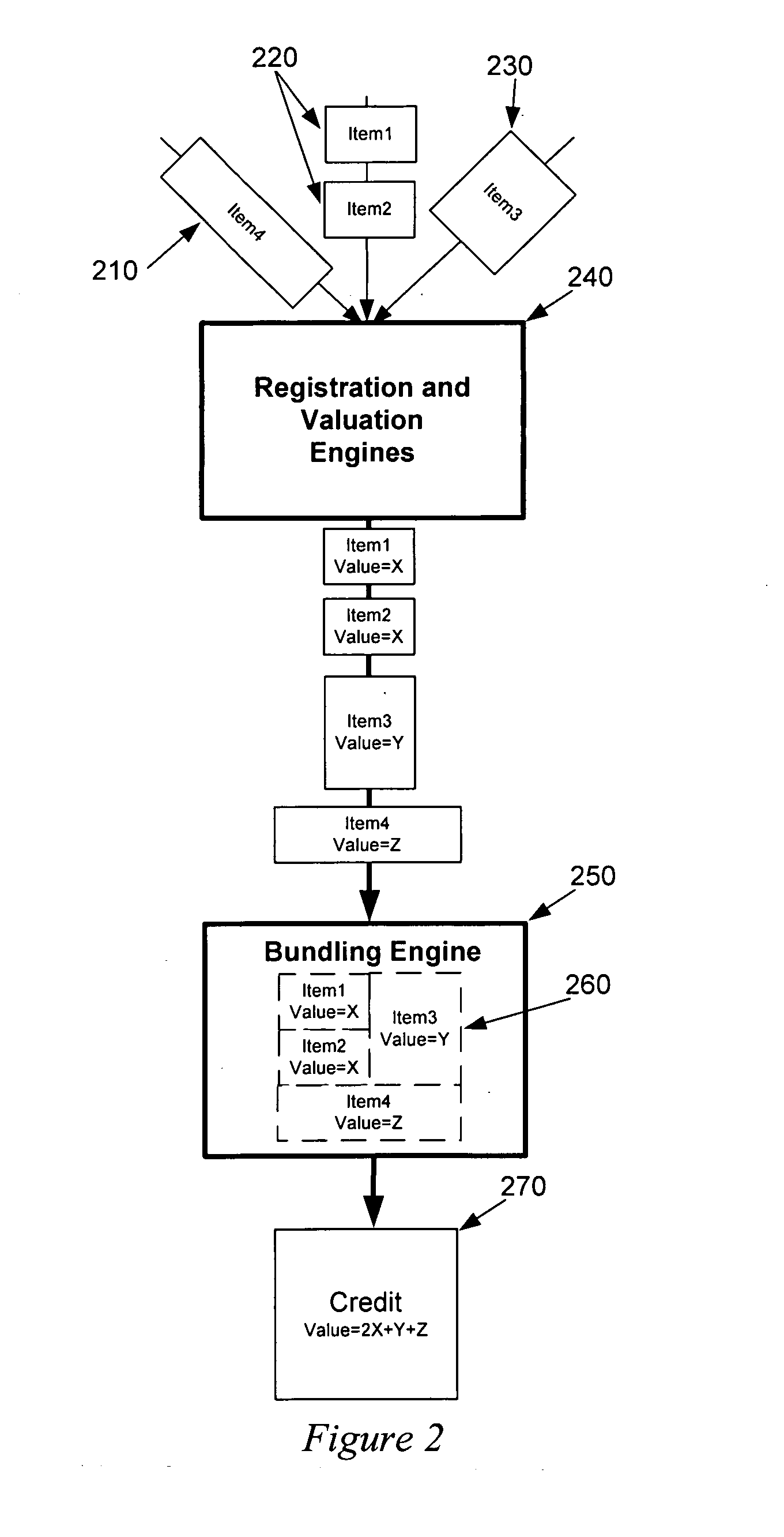

Bundling method and system for credits of an environmental commodities exchange

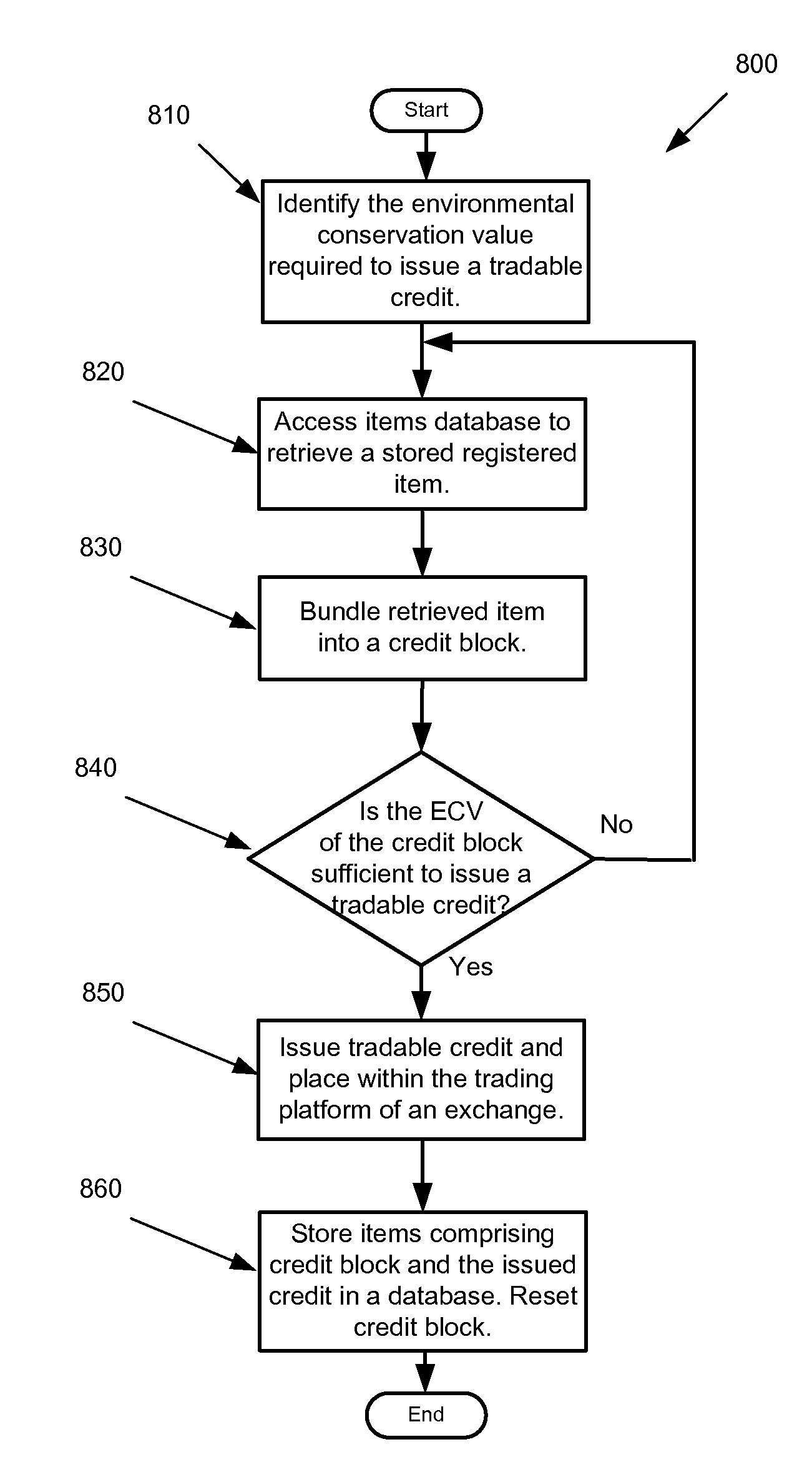

Some embodiments of the invention provide a method of automatically bundling environmental conservation items with computed environmental conservation values into “credit blocks” so that the aggregate sum of the environmental conservation values of the items in a particular block is sufficient to issue a tradable environmental commodity, also referred to as a credit. In some such embodiments the various different items represent items with different forms of environmental conservation such as emissions reductions, energy savings, hazardous waste reductions, or generated renewable energy.In some embodiments, credits with at least one expired item are unbundled and the at least one expired item is removed from the credit block. Some embodiments replace the at least one expired item with at least one valid item having the same or a similar environmental conservation value.

Owner:GOTTHELF PHILIP +1

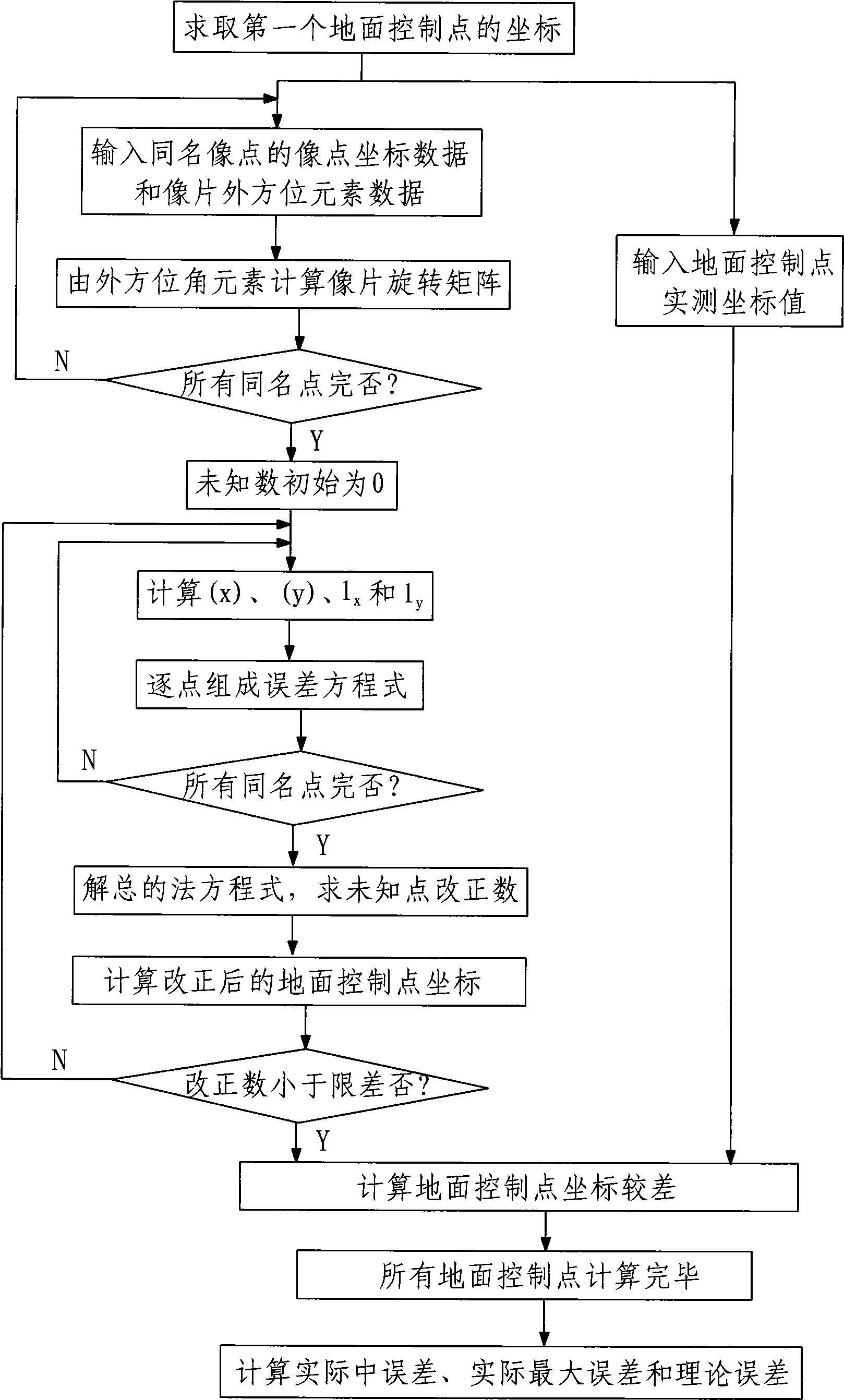

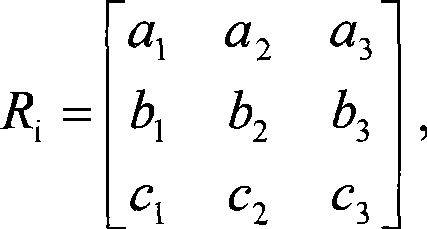

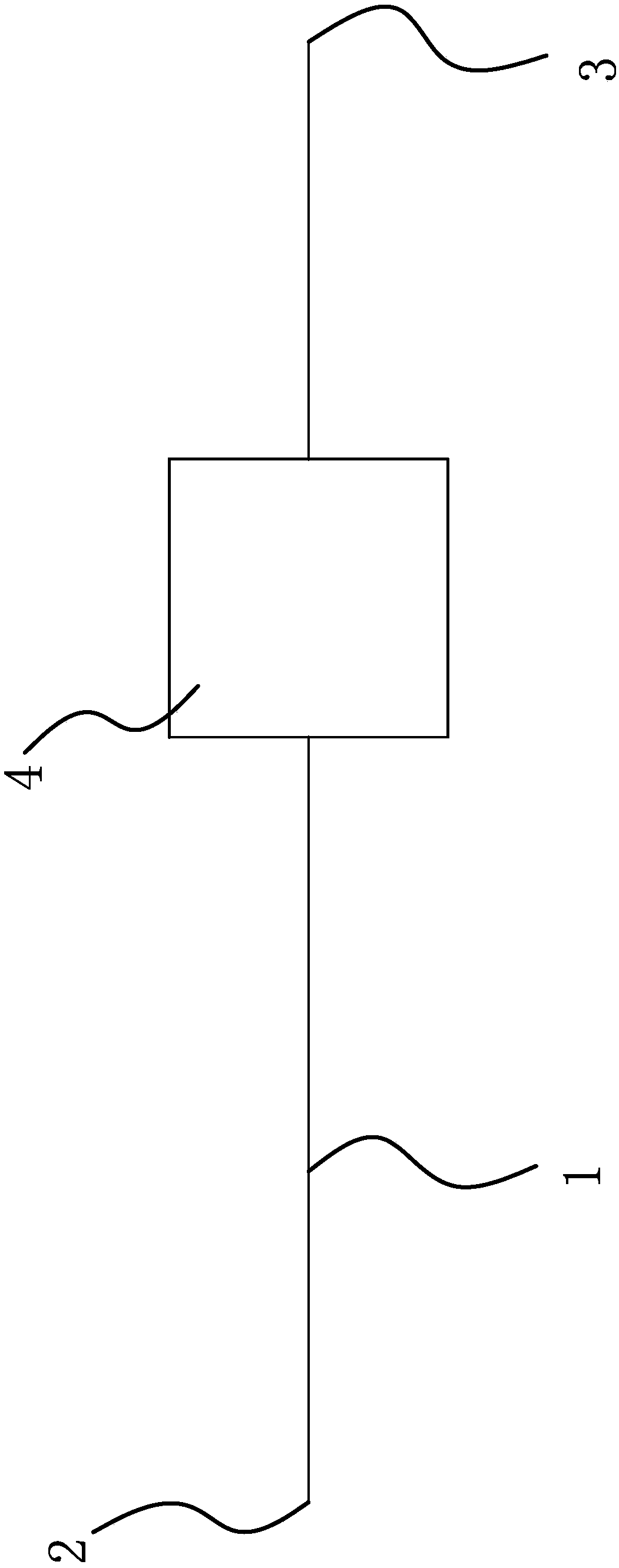

GPS//INS data direct directing precision assessment method

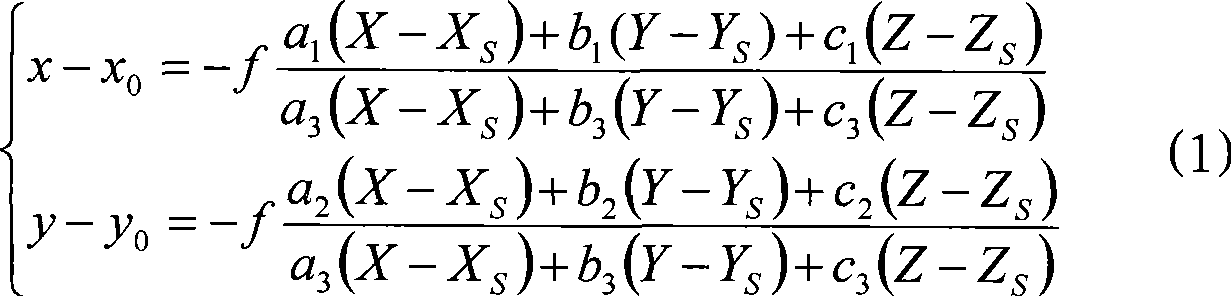

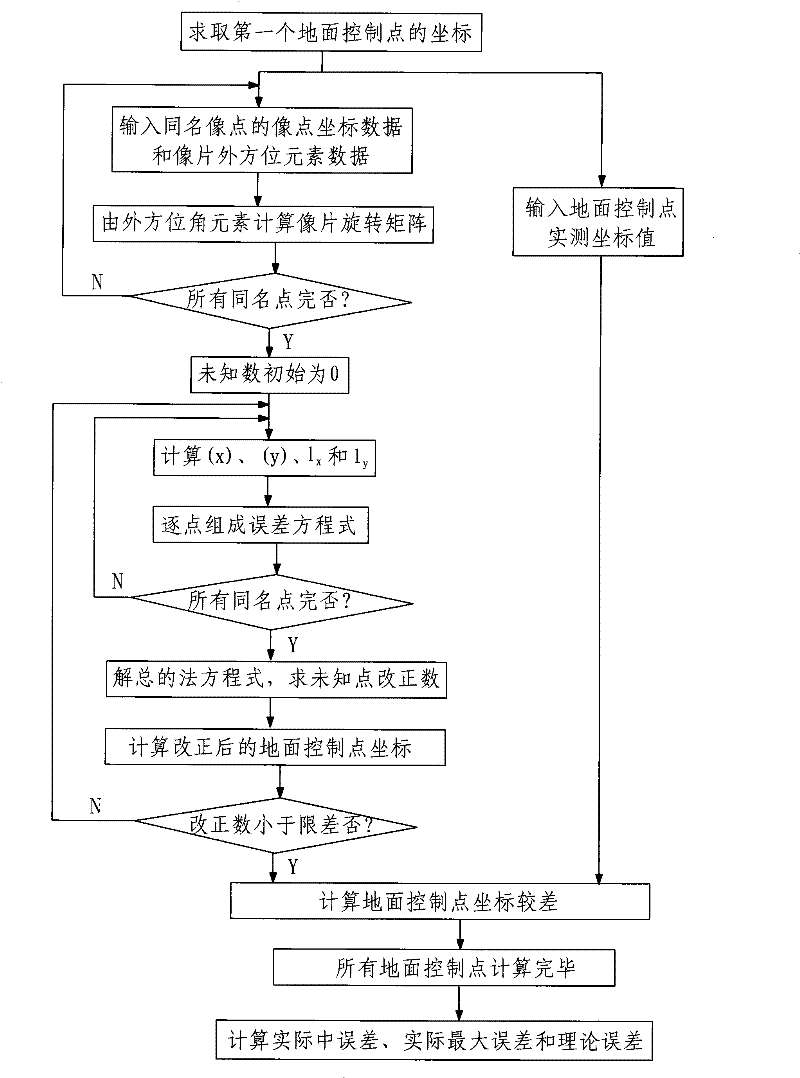

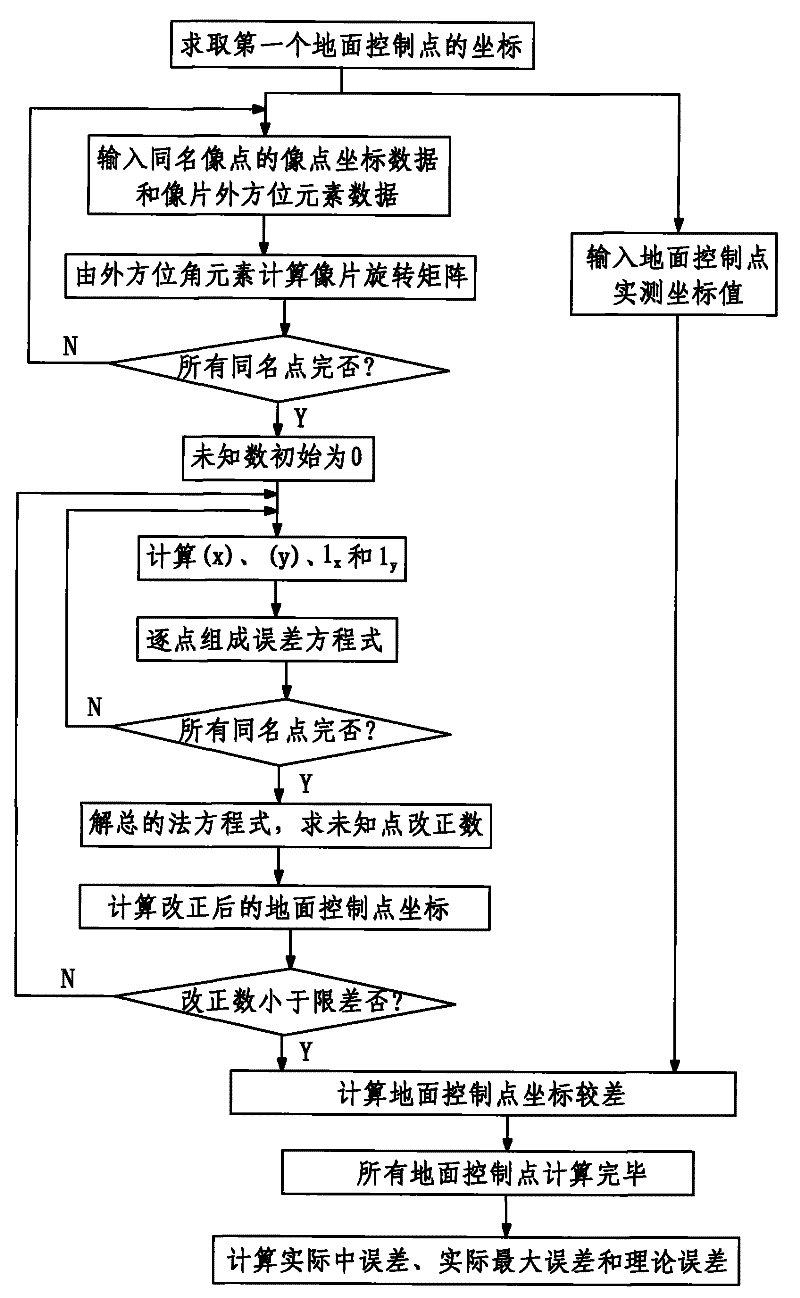

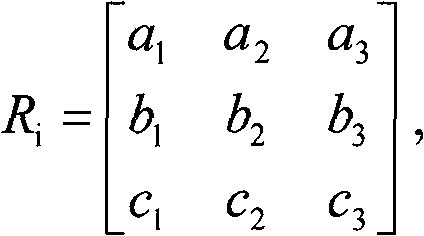

InactiveCN101509784AInnovative designHigh degree of automationInstruments for road network navigationPicture interpretationBundle methodBundle methods

The invention discloses a GPS / INS data direct orientation precision evaluation method, which takes photogrammetric emphasis equation collinearity equation as base and a multi-piece forward intersection of a bundle method as theory basis; the evaluation method is combined with the least square principle for obtaning the coordinate of a ground control point object by compensating calculation; and then a comparison with the actually measured coordinate of the ground control point is carried out for obtaining the error value of the coordinate by the statistics so as to evaluate the direct orientation precision of the outer orientation elements obtained by the GPS / INS system. The method has high evaluation precision and small measurement error, and the evaluation result can be used for manufacture practice directly, thus being capable of effectively avoiding the measurement error of the picpointed coordinate added in manual stereomeasurement; and the algorithm is not limited by image number.

Owner:XIAN MEIHANG INFORMATION IND

ACK/NACK transmission on PUCCH in LTE-ATDD with NxPDCCH structure

InactiveCN101981854AError prevention/detection by using return channelSignal allocationBundle methodTime domain

Systems and methods are provided for enabling different ''bundling'' methods for downlink transmissions and provide different interpretations of the acknowledgement / negative- acknowledgement bit. A user equipment is configured so that it commonly acknowledges all downlink transmission time intervals within a bundle so that if one packet is determined to be erroneous, all packets in that bundle will be retransmitted. Additionally, the systems and methods are implemented by allowing an interpretation to be applied to the uplink acknowledgement / negative-acknowledgement field such that the user equipment is able to divide bundled downlink packets into smaller windows in Long Term Evolution (LTE) Release 8 time division duplex (TDD) mode. In LTE Advanced (LTE-A) TDD mode, various embodiments provide bundling within the time domain, within the frequency domain, and within a hybrid time- frequency domain. Furthermore, enhanced channel selection methods are also provided in support of the above-mentioned bundling methods in accordance with various embodiments.

Owner:NOKIA (CHINA) INVESTMENT CO LTD

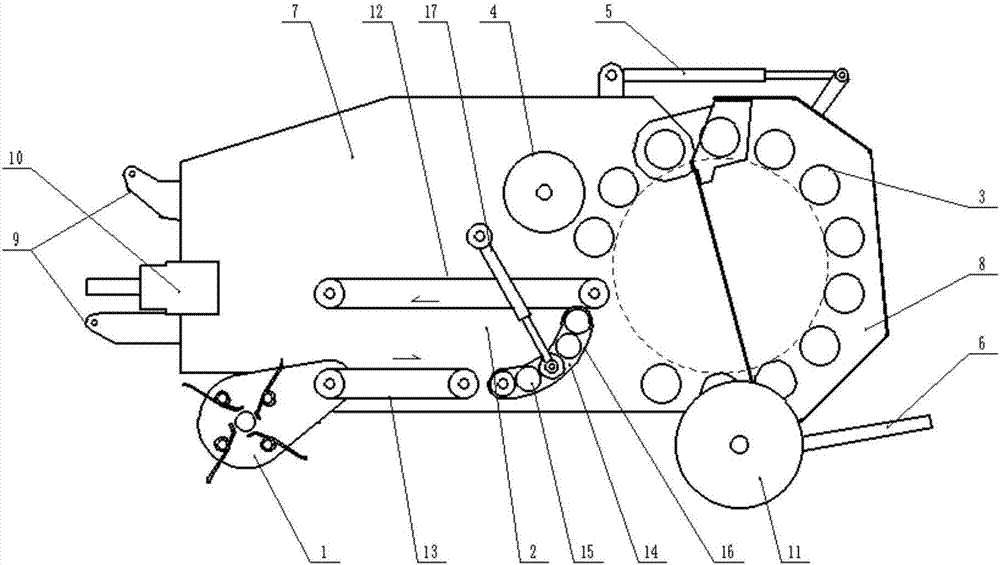

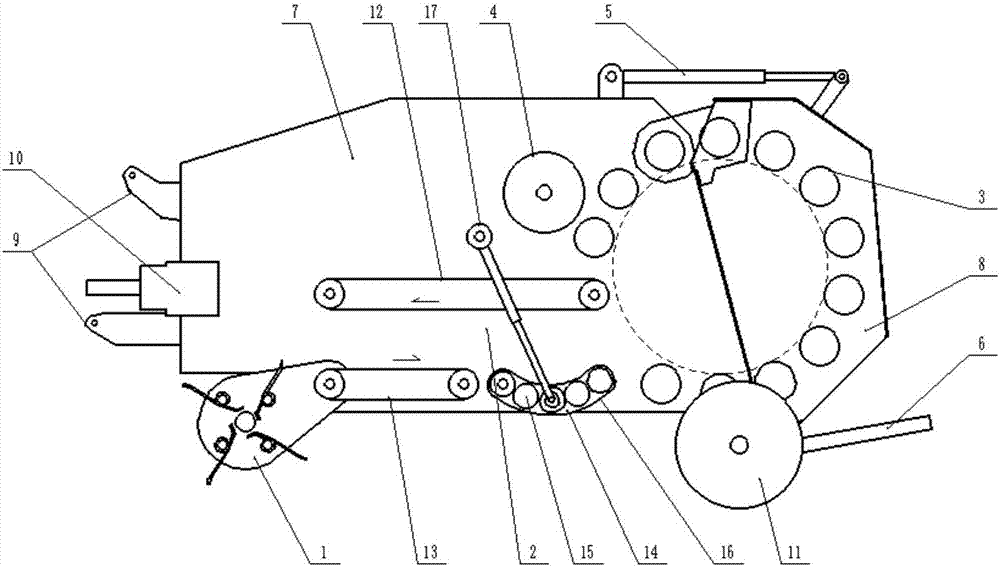

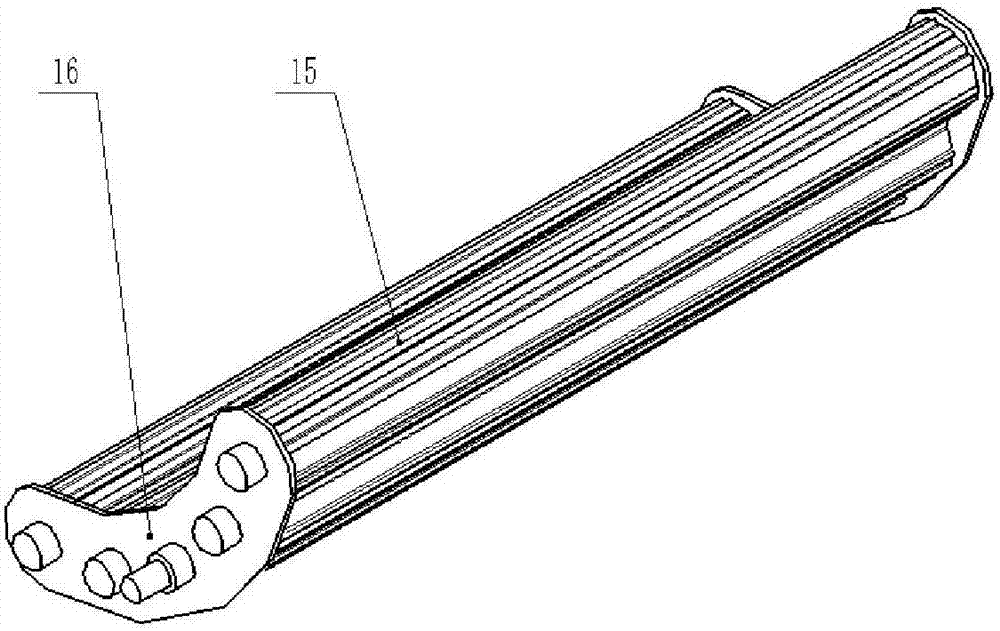

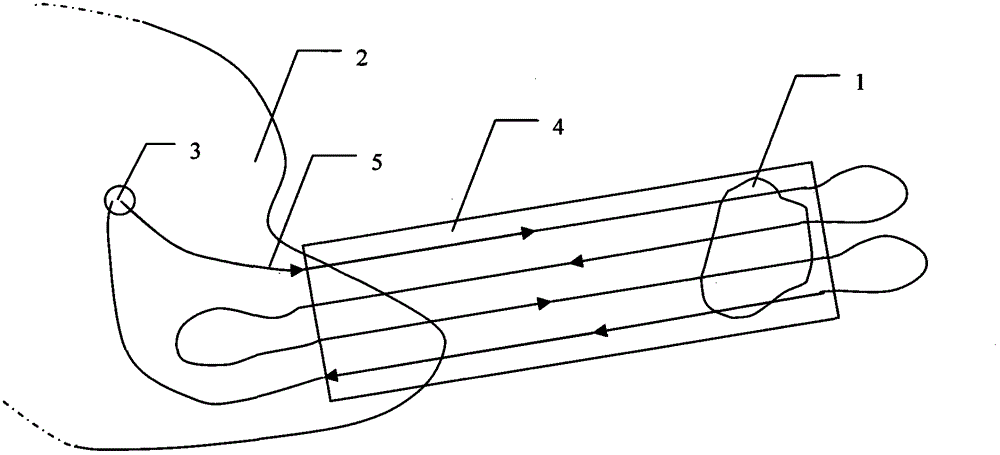

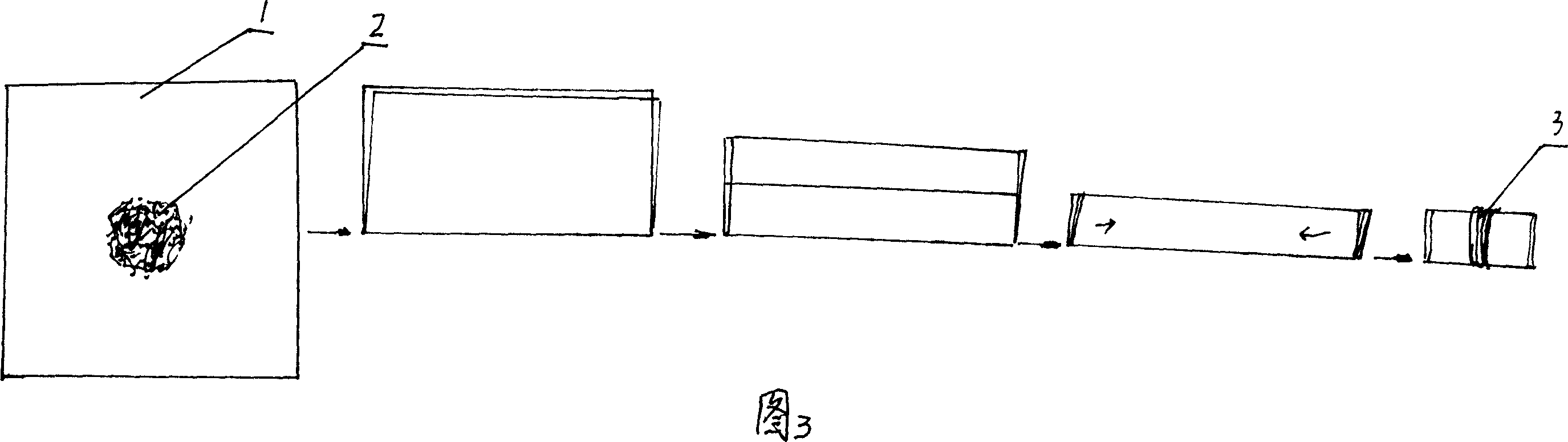

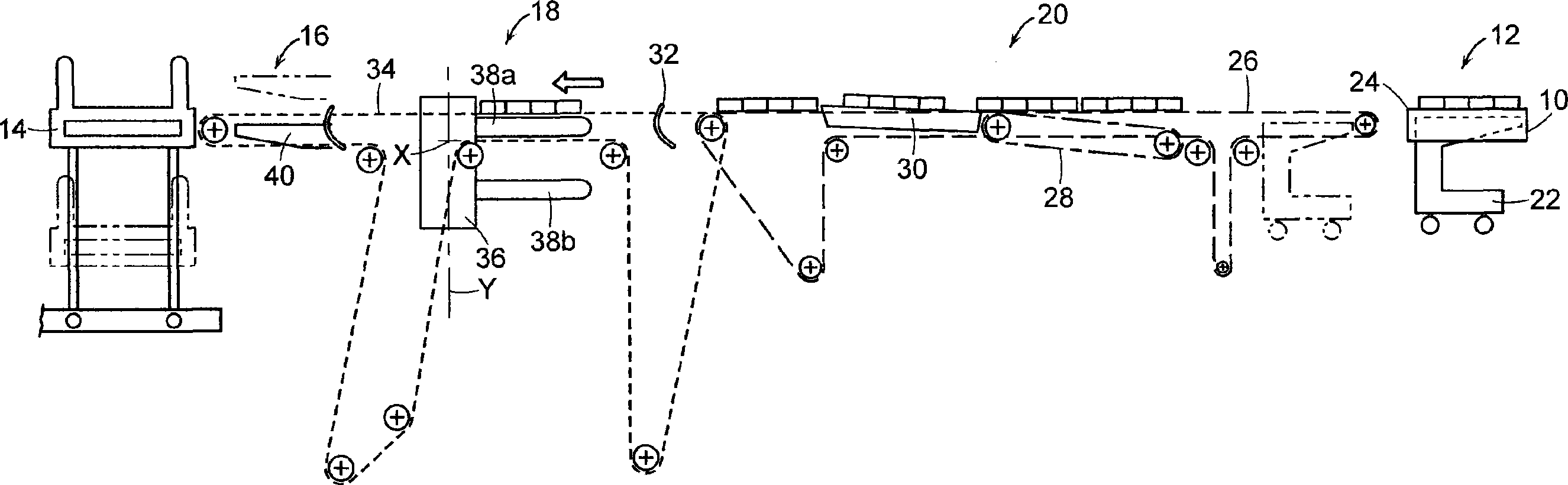

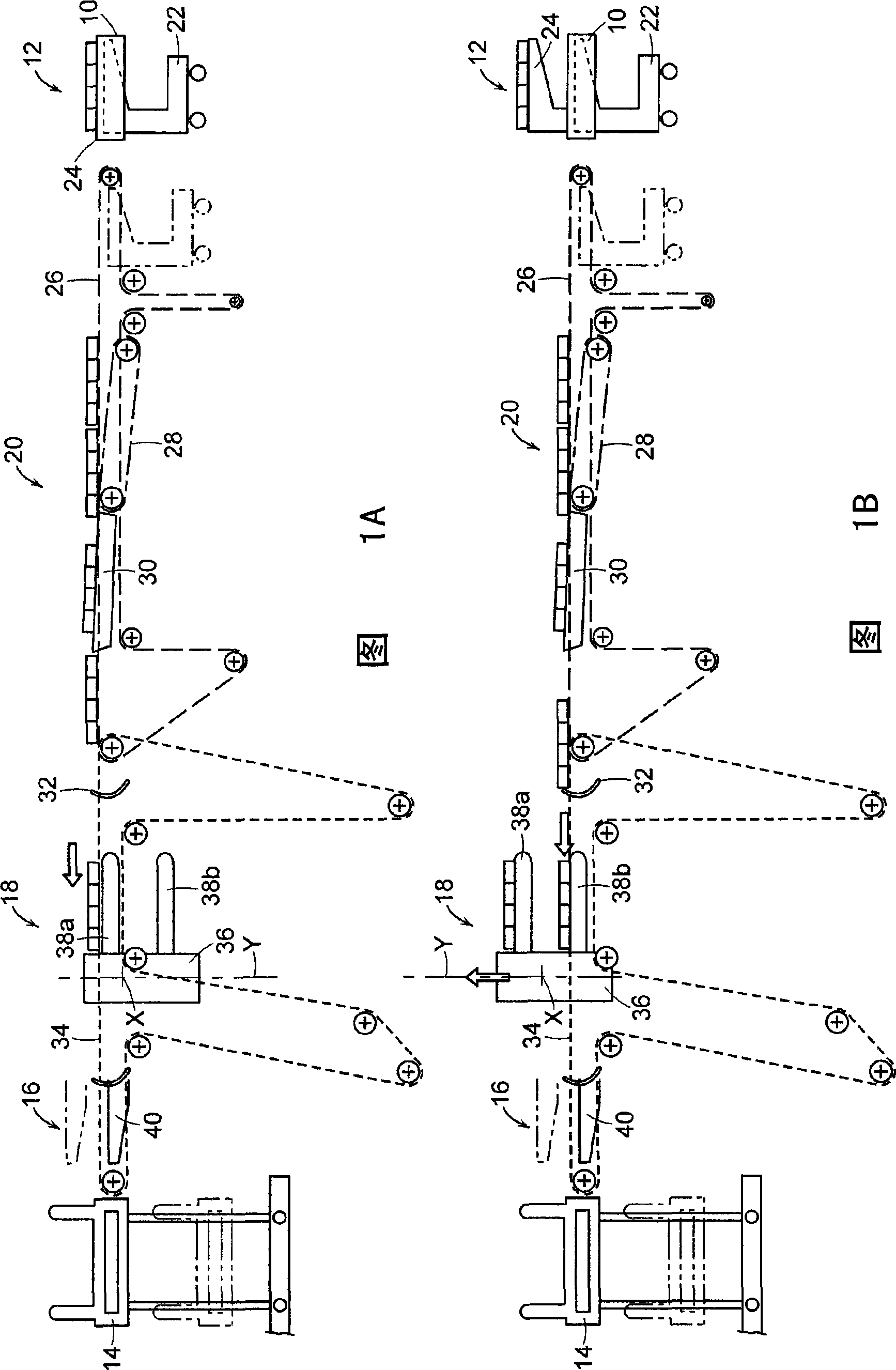

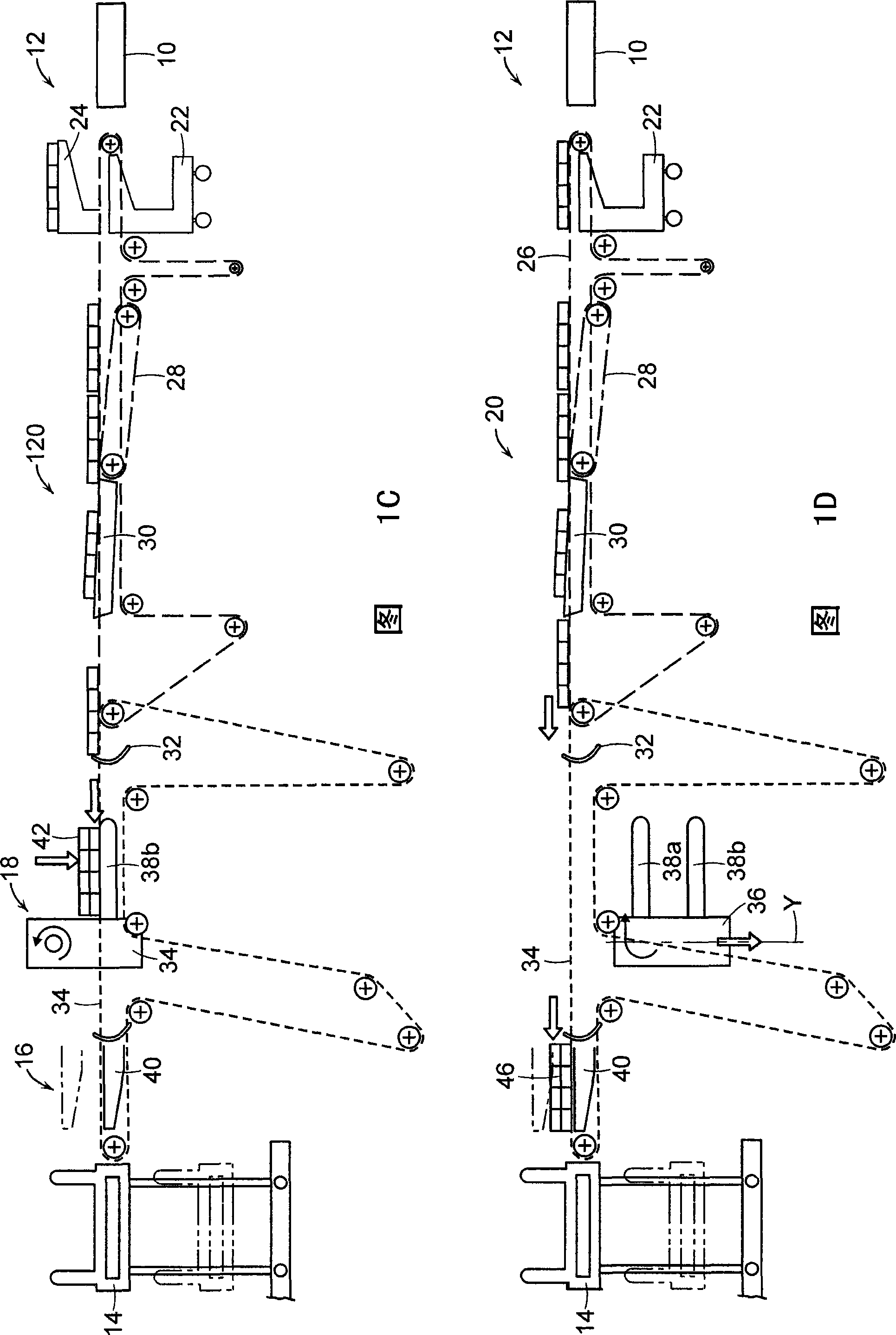

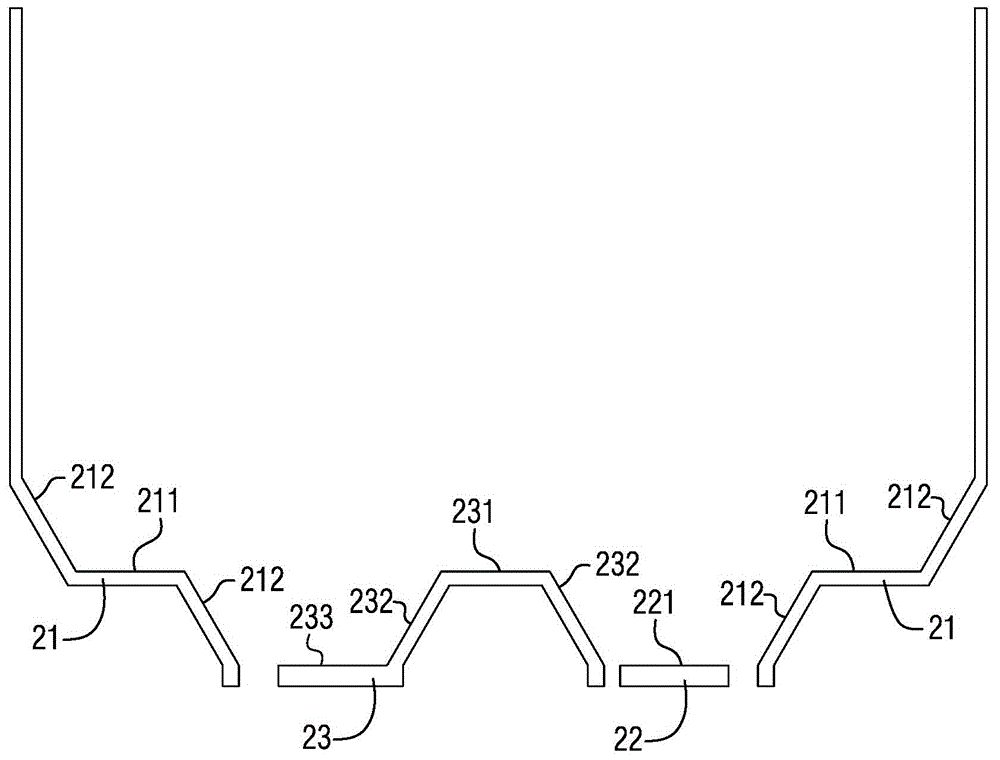

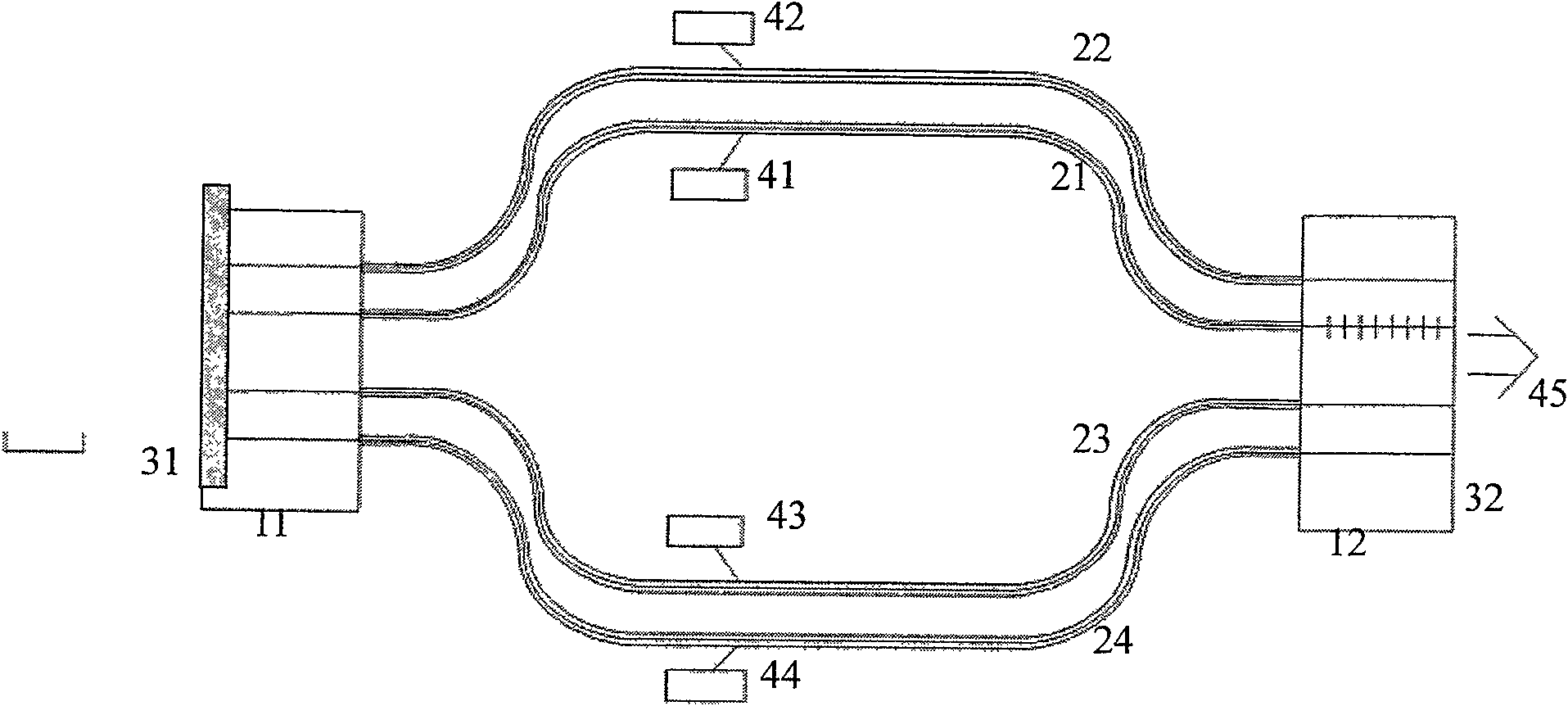

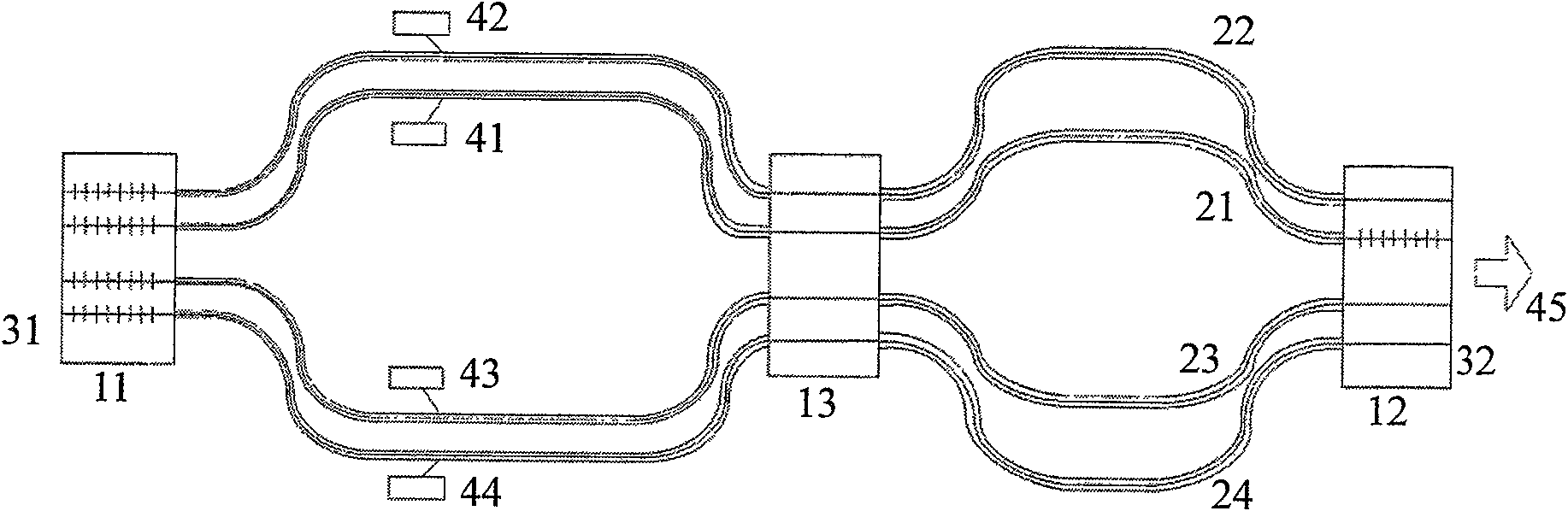

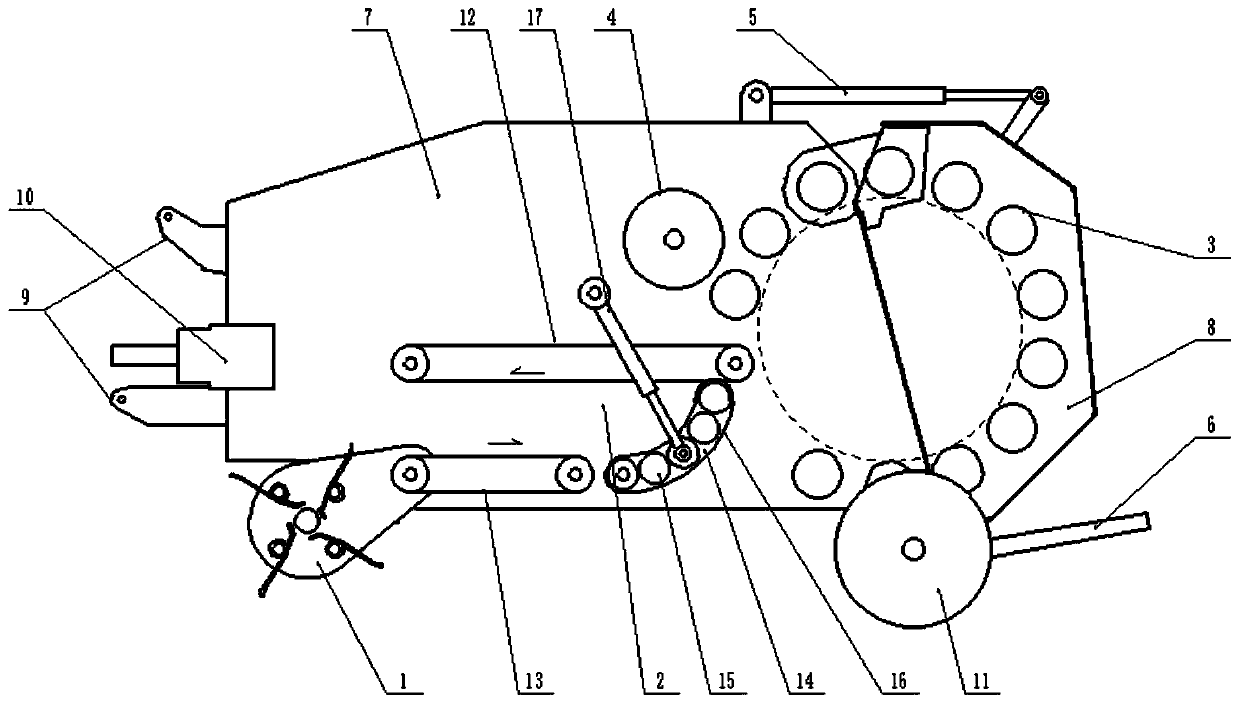

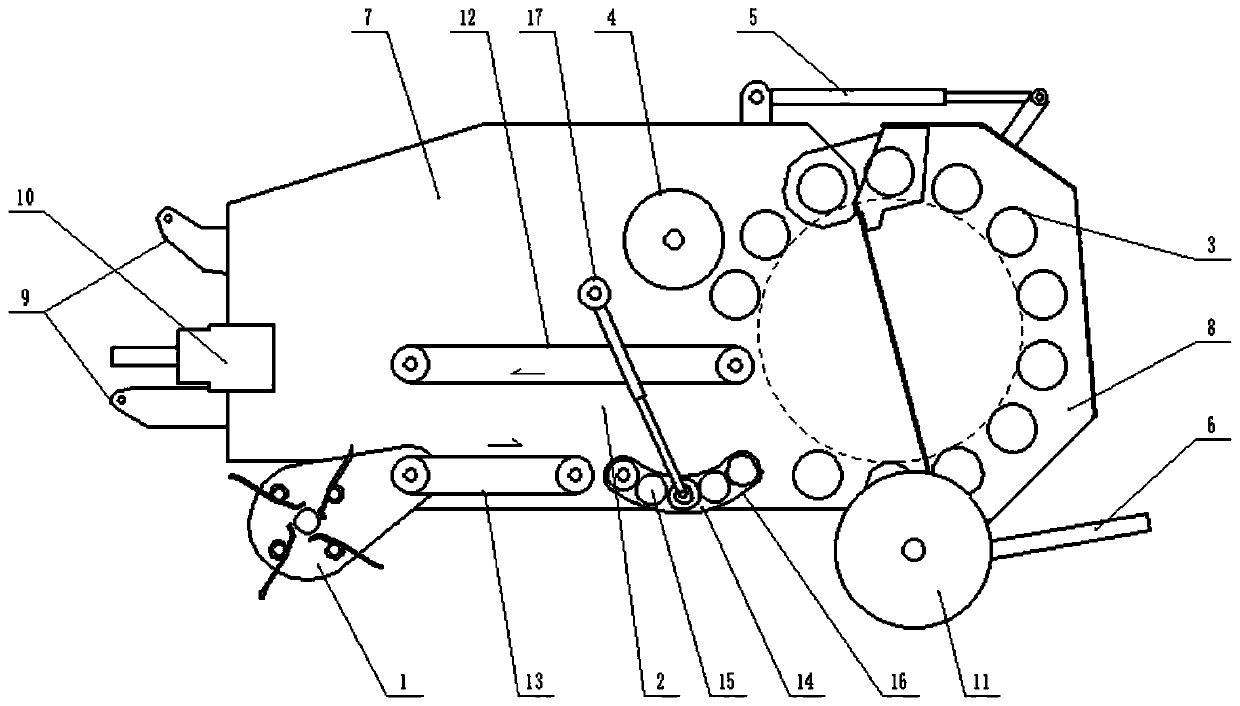

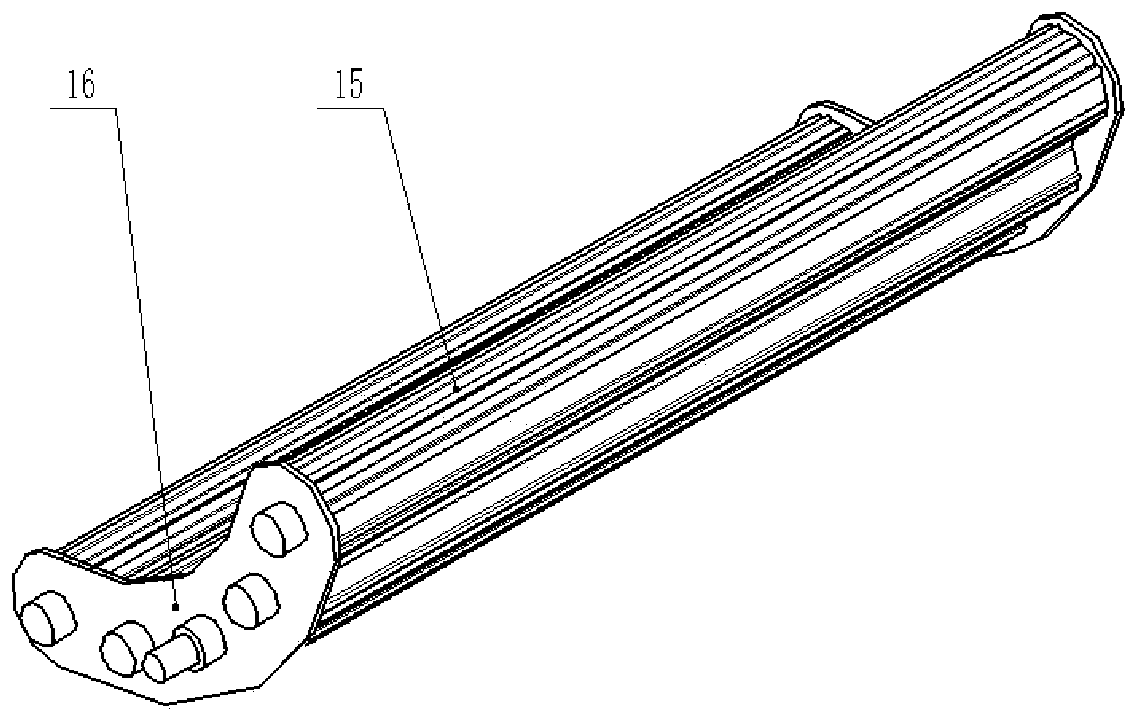

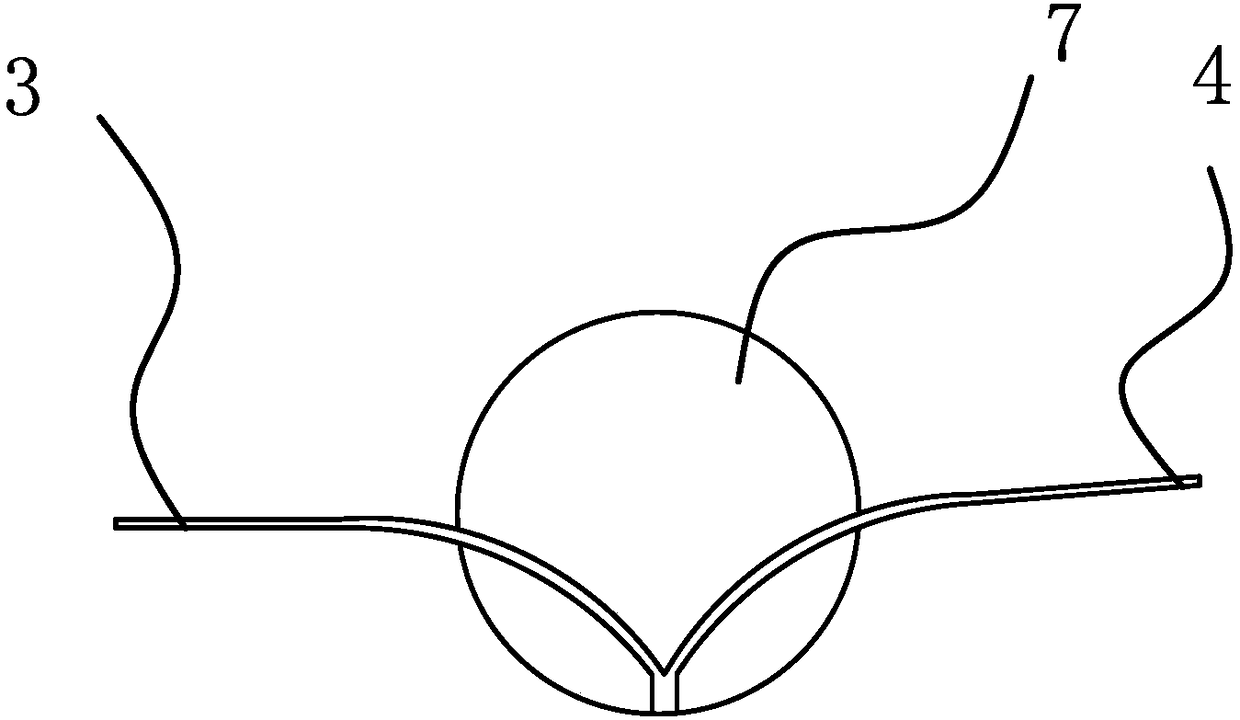

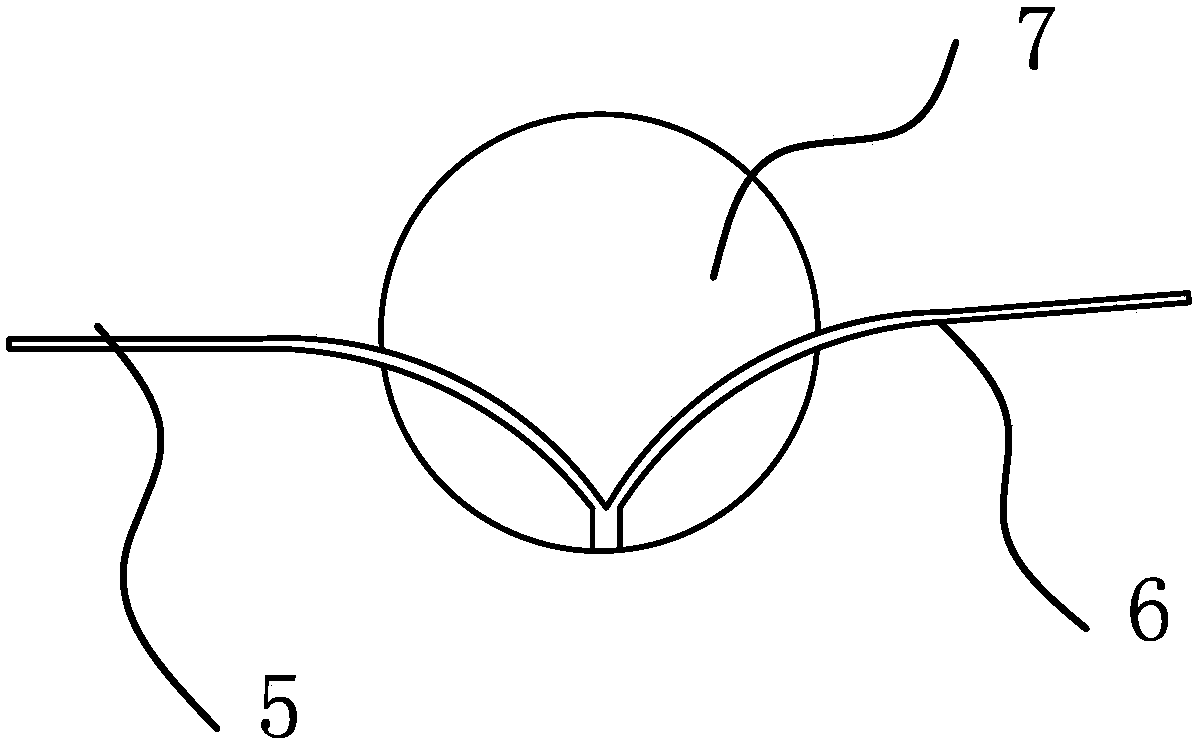

High-density and non-stop bundling method for round bale bundles and bundling machine

The invention relates to a high-density and non-stop bundling method for round bale bundles and a bundling machine used for pasture and crop straws. The method comprises the following steps: firstly forming grass cores in the bundling machine such that grass core and the rest of roll bales are the same in density; then, continuously winding outer layers of grass cores with forage and finally forming final round bale bundles; bundling the round bale bundles and unloading the round bale bundles from the bundling machine; and making next grass cores by the bundling machine in sync during the process such that the bundling machine can continuously bundle round bale bundles in a non-stop manner. The bundling machine most comprises a spring-tooth picker, a steel-roll bundling device, a net-winding mechanism, a hydraulic bale unbundling mechanism, a bale unloading mechanism, a front bin, a back bin door, a hanging mechanism, a driving mechanism, ground wheels and a pre-compressing device. The high-density and non-stop bundling machine for round bale bundles and the bundling machine used for pasture and crop straws have the following beneficial effects: the bundling machine is capable of bundling high-density round bale bundles with uniform density, which is conducive to silage operation and reduction in transport cost in the later period of round bale bundles; and the bundling machine is high in production efficiency, low in production cost and good in bale quality.

Owner:CHINA AGRI UNIV

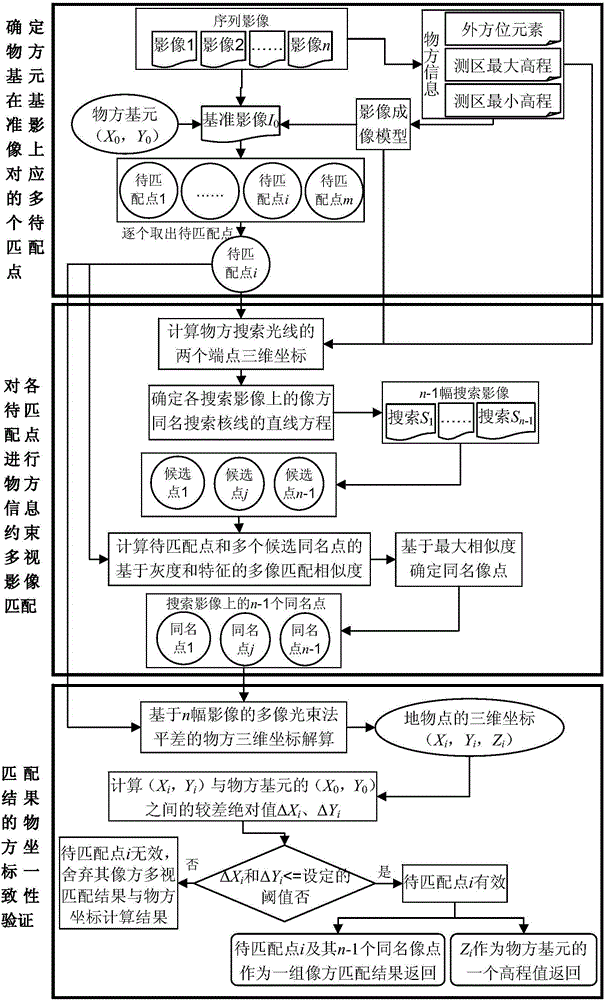

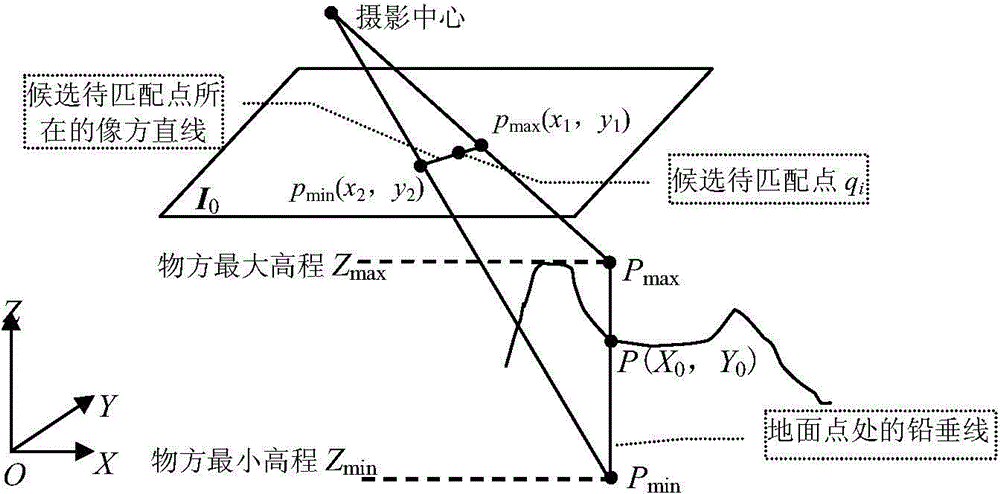

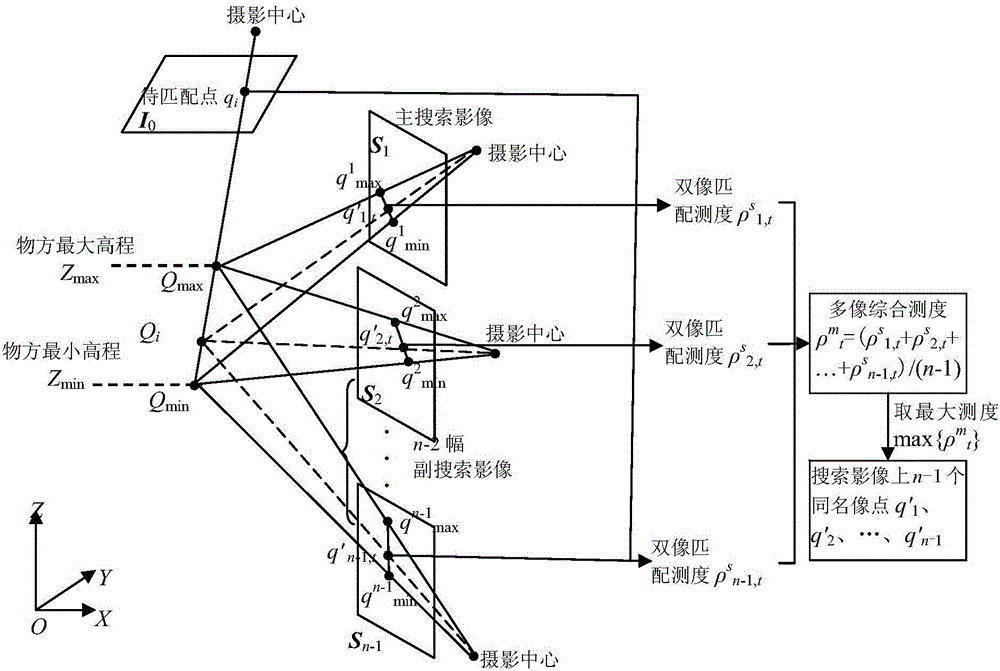

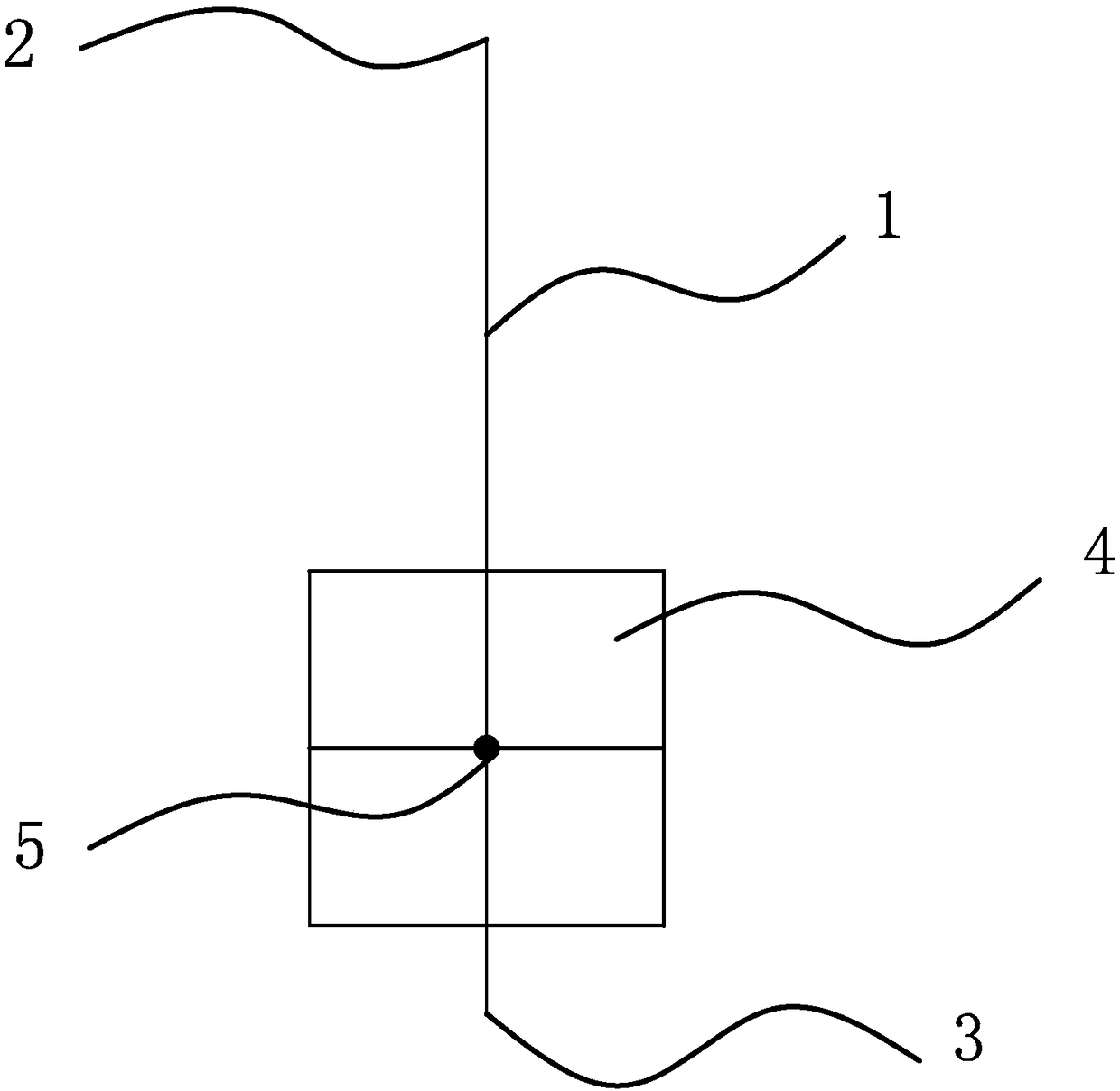

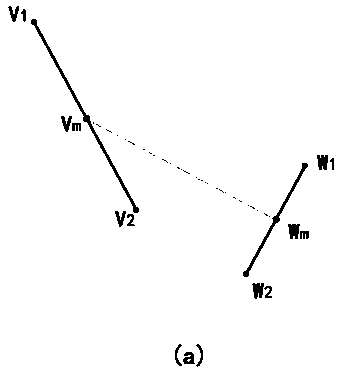

Novel multi-image plumb line track matching method capable of returning multiple elevation values

ActiveCN104318566AEfficient matchingGuaranteed validityImage enhancementImage analysisBundle methodMulti-image

The invention discloses a novel multi-image plumb line track matching method capable of returning multiple elevation values. The method comprises the following steps of: confirming m to-be-matched points of a ground space element (X0, Y0) on a benchmark image by using an image imaging model; matching multiple images restrained by space information to m to-be-matched points; calculating space three-dimensional coordinates (Xi, Yi, Zi) corresponding to the to-be-matched points and an absolute difference (deltaXi and deltaYi) between each coordinate (Xi, Yi) and the space element (X0, Y0) by adopting a multi-image adjustment bundle method, and deciding the returned elevation values according to whether the absolute difference is less than a set threshold. In the multi-image plumb line track matching method, multi-image matching and accuracy test of matching result are together fused to effectively eliminate wrong matching, so that the method can solve the disadvantage that only one elevation value can be returned by the traditional ground image matching method.

Owner:南京泛在地理信息产业研究院有限公司

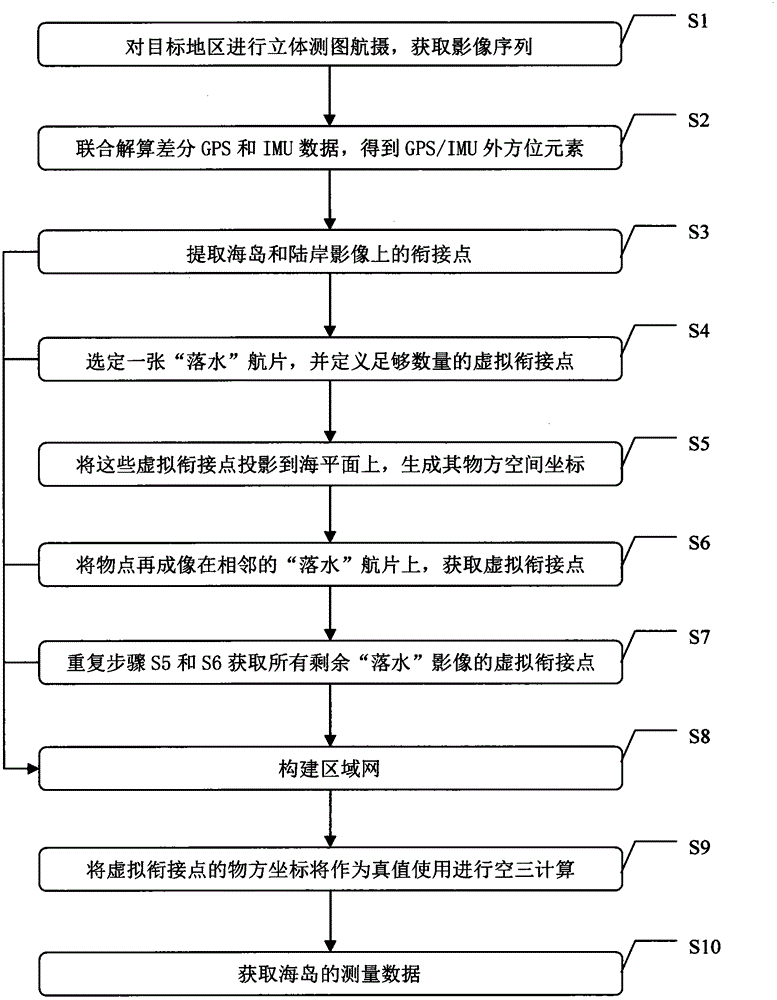

Island-air triangular measuring method based on GPS/IMU positioning and orientating technology

InactiveCN102721410ASolving Measurement ChallengesSolving Aerial Photogrammetry ProblemsPicture interpretationAviationBundle method

The invention relates to the fields of aerial photogrammetry and particularly relates to an island-air triangular measuring method based on a GPS / IMU (Global Position System / Inertial Measurement Unit) positioning and orientating technology. The technical scheme adopted by the invention is that an aerial photography system with high-precision GPS / IMU positioning and orientating equipment is used for carrying out three-dimensional aerial mapping for a target island and sea and a land and shore measuring region with a land control network, extracting joint points of images on the island and the land and shore and directly carrying out virtual joint point generation on fall-water images according to exterior orientation elements solved based on GPS / IMU data, thus realizing the air triangular measurement and calculation by adopting a bundle method and further solving exterior orientation elements of the island, the land and the shore and corresponding object point land coordinates. According to the island-air triangular measuring method disclosed by the invention, the difficult problem that the island measurement cannot be controlled is effectively solved, the foundation for large-medium proportional scale mapping of the island is laid; and meanwhile, the problem of aerial photogrammetry of other measuring regions with poor and single textures (such as deserts, grasslands and snow fields) can be effectively solved.

Owner:扬州德可达科技有限公司

Aerial triangulation free net building method based on minimum spanning tree for special unmanned aerial vehicle images

ActiveCN107560593AEasy to handleAchieve absolute orientationOptical rangefindersPicture taking arrangementsBundle methodBundle methods

The invention provides an aerial triangulation free net building method based on a minimum spanning tree for special unmanned aerial vehicle images. For such special unmanned aerial vehicle images aswater falling, cloud shielding and overlapping holes, the problems of relative orientation, model connection failures and the like during conventional automatic aerial triangulation are solved; an aerial triangulation free net of the whole area is automatically built under the condition of not providing POS auxiliary data; exterior orientation elements of all images in a detected area and the initial values of object point coordinates are acquired; bundle-method block adjustment is performed; the exterior orientation elements of each image in the whole area and space coordinates of all objectpoints are wholly resolved. If a few of known control point coordinates are provided, the whole area can be incorporated into a control point ground coordinate system to realize absolute orientation.The processing level and the processing capability of the special unmanned aerial vehicle images are greatly improved.

Owner:无锡子可科技有限公司

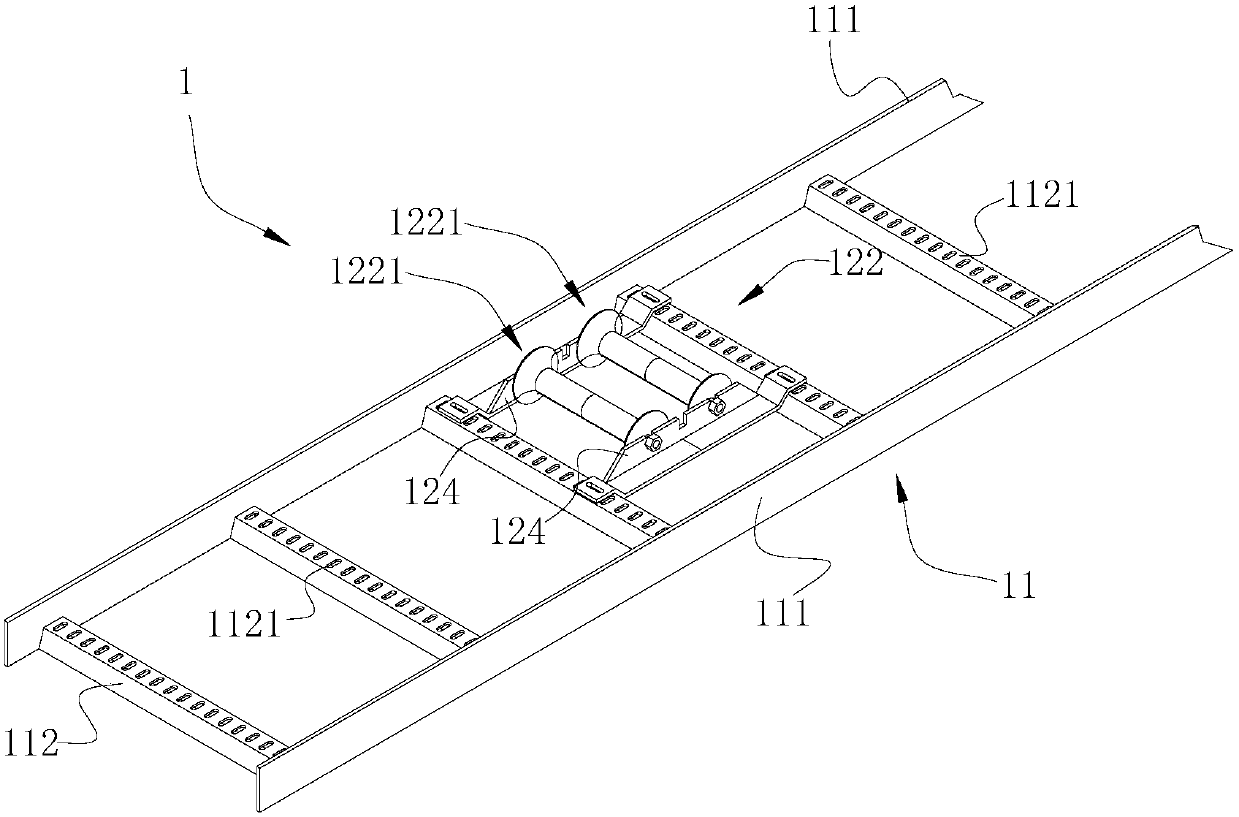

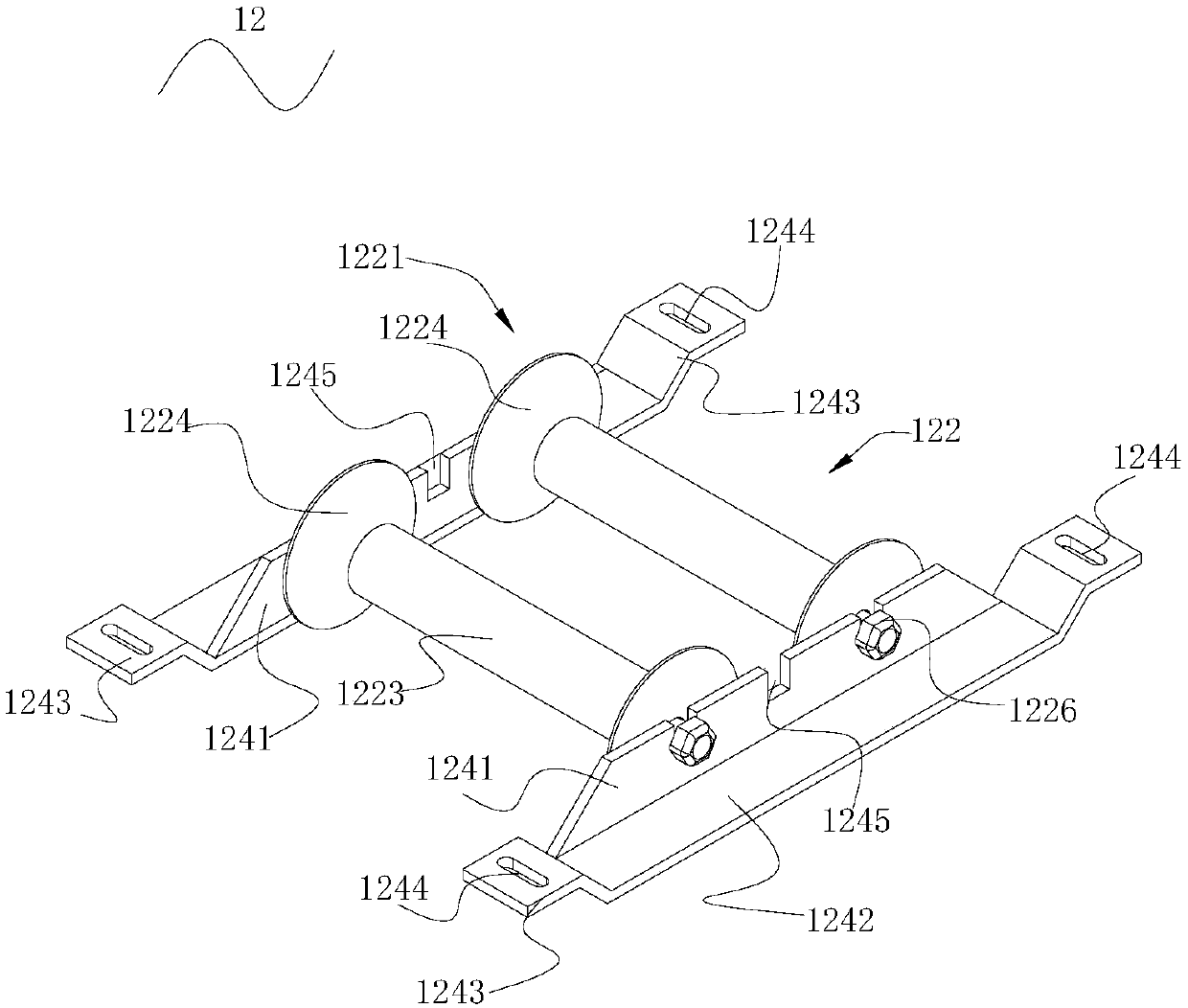

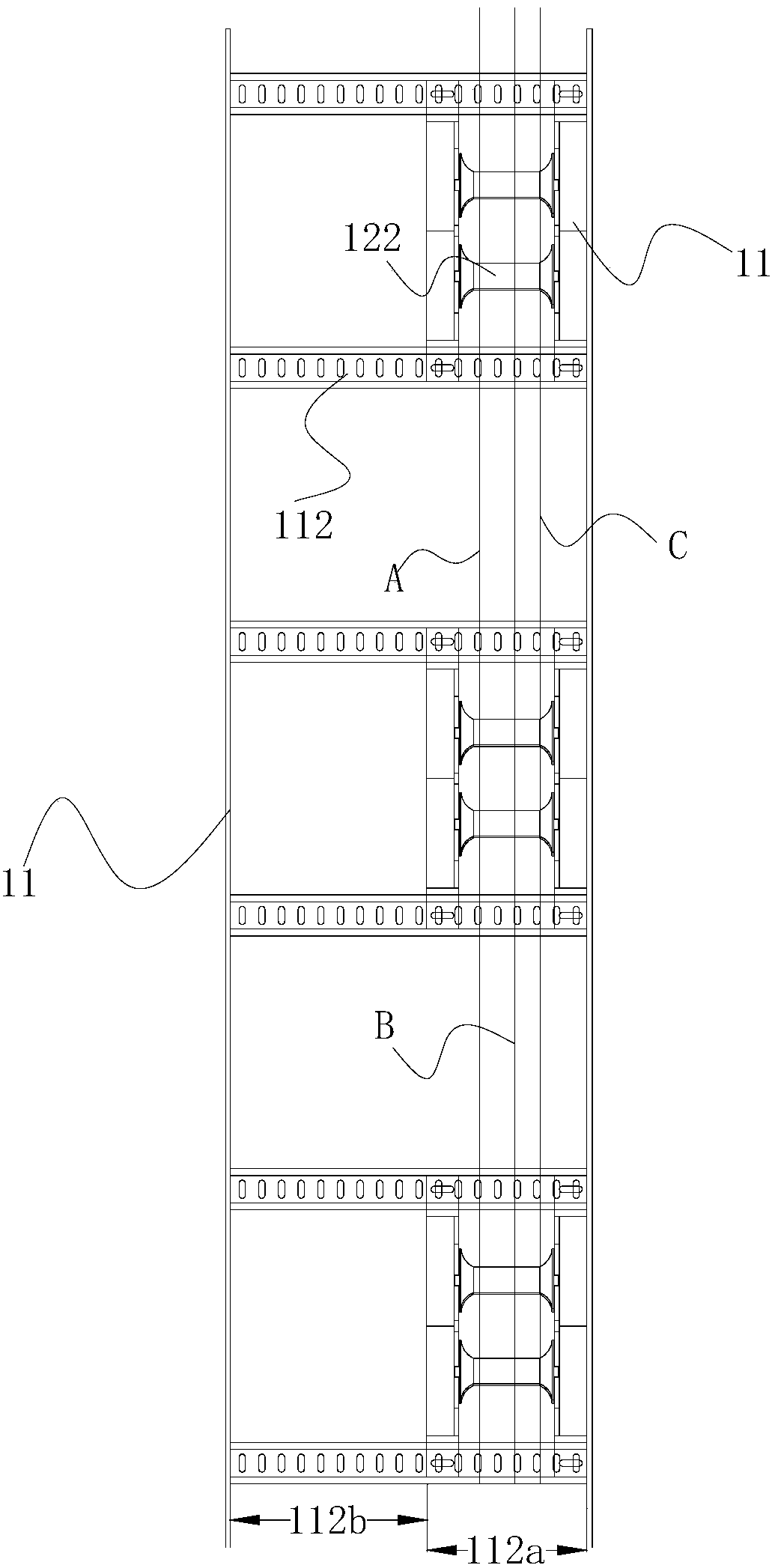

Cable erection assisting device, cable erection device and cable erecting and bundling method

ActiveCN107872028AReduce breakage rateAvoid secondary wearCable installation apparatusBundle methodCable tray

The invention provides a cable erection assisting device, cable erection device and cable erecting and bundling method. In a cable erection device, the cable erection assisting device can be mounted between any two cross supports of a cable tray in a dismountable manner and includes a support and a plurality of rollers. The support includes a pair of support pieces arranged in parallel. Two ends of each support piece are provided with mounting parts used for detachable connection with the cross supports. The interval between the two support pieces is smaller than the width of the cable tray. The rollers are arranged at intervals along the length direction of the support pieces. The two ends of each roller are connected to the two support pieces respectively. The rollers can rotate around their rotary axes which are perpendicular to the length direction of the support pieces. By adopting the devices and the method provided by the invention, simple and convenient operation is achieved, abrasion of cables is reduced and labor strength is reduced greatly, labor power is saved and working efficiency is improved.

Owner:YANTAI RAFFLES SHIPYARD +1

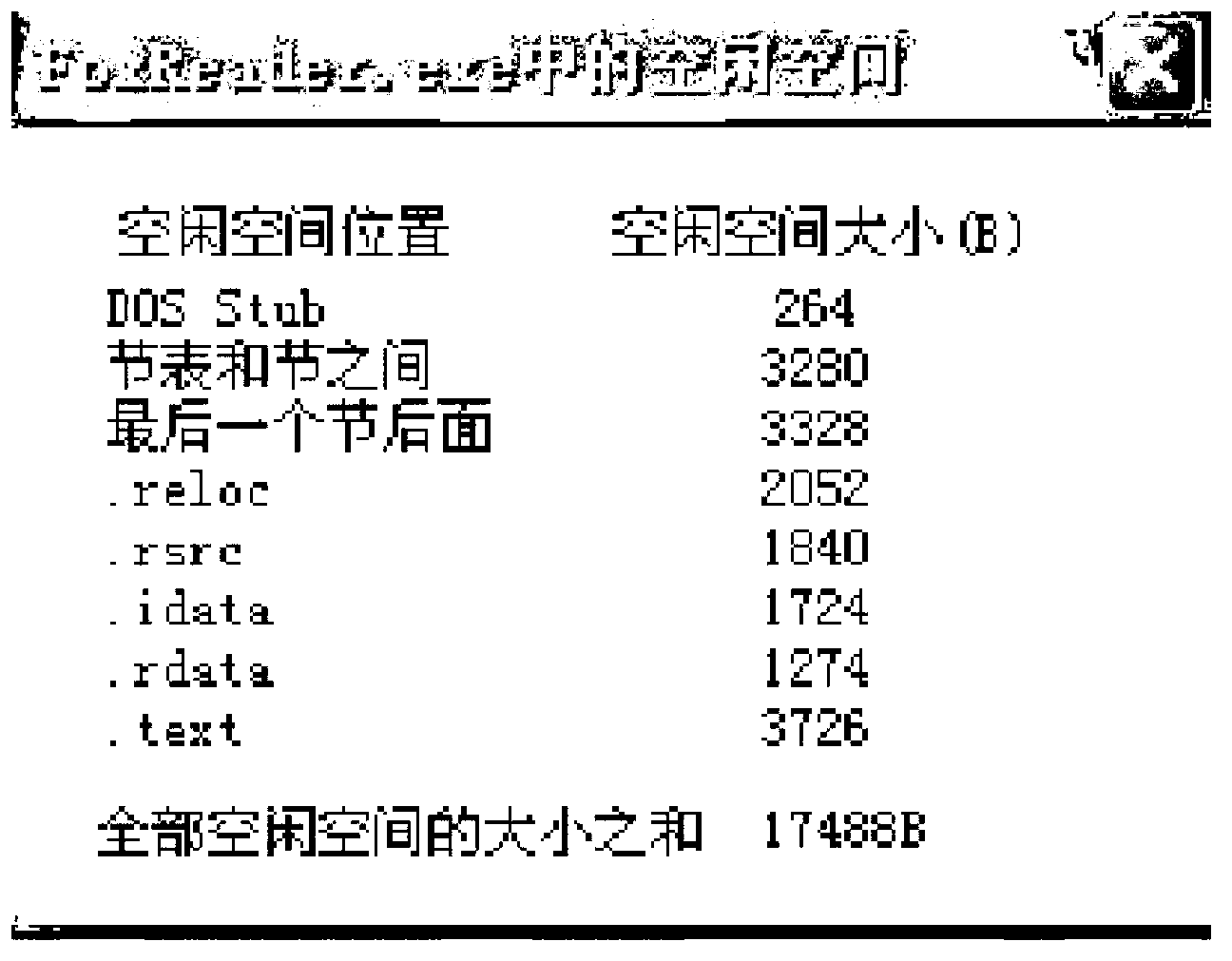

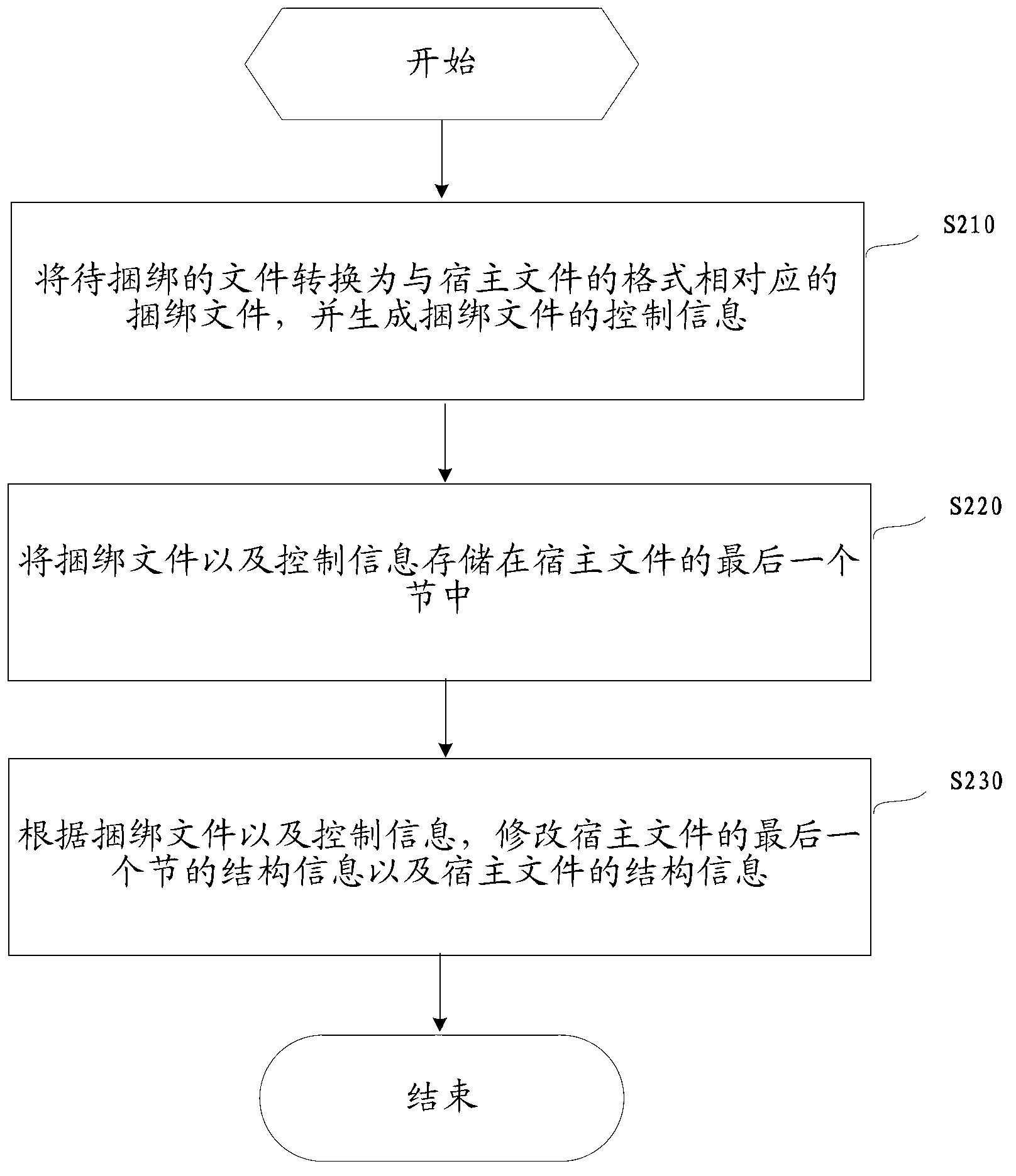

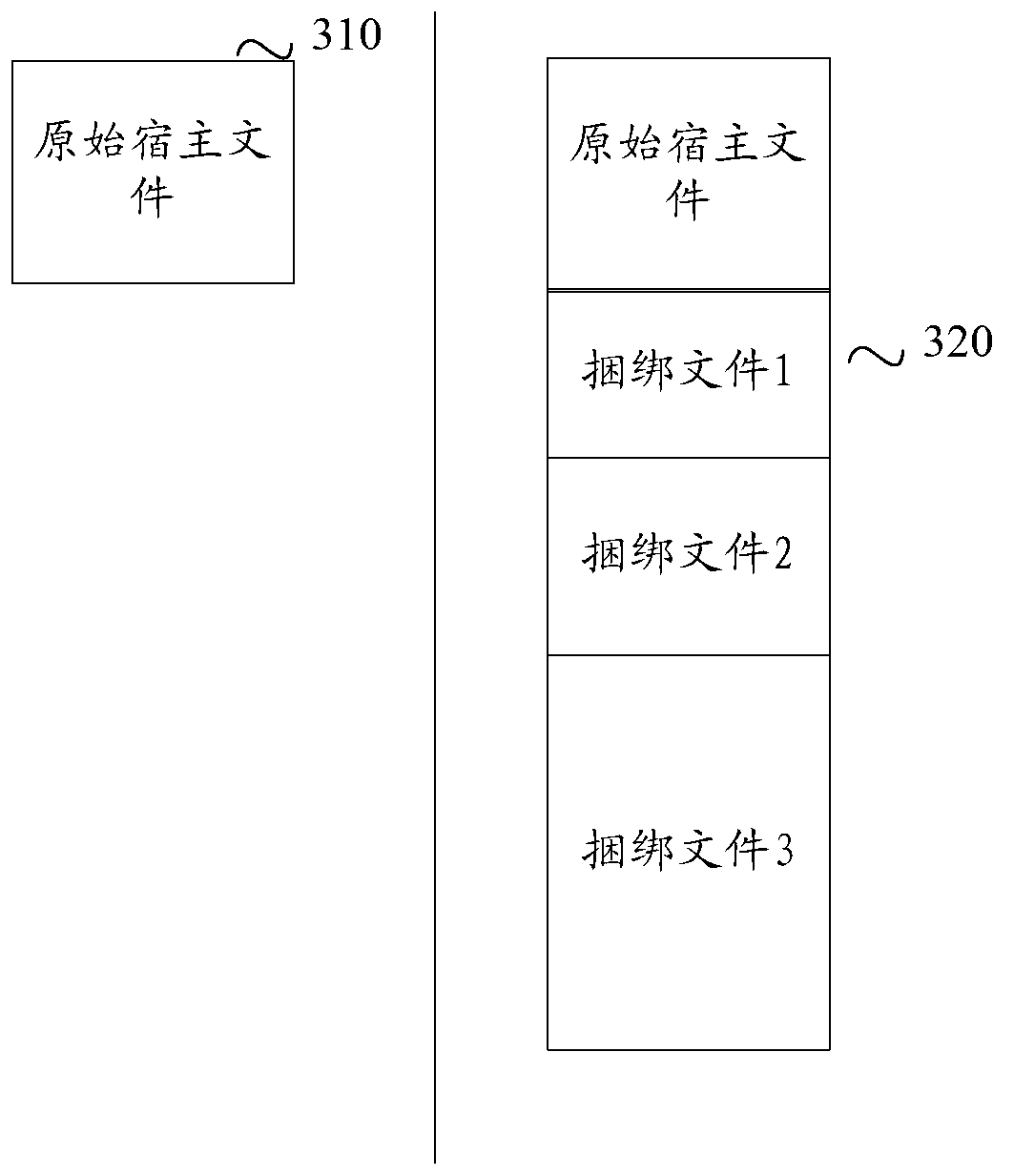

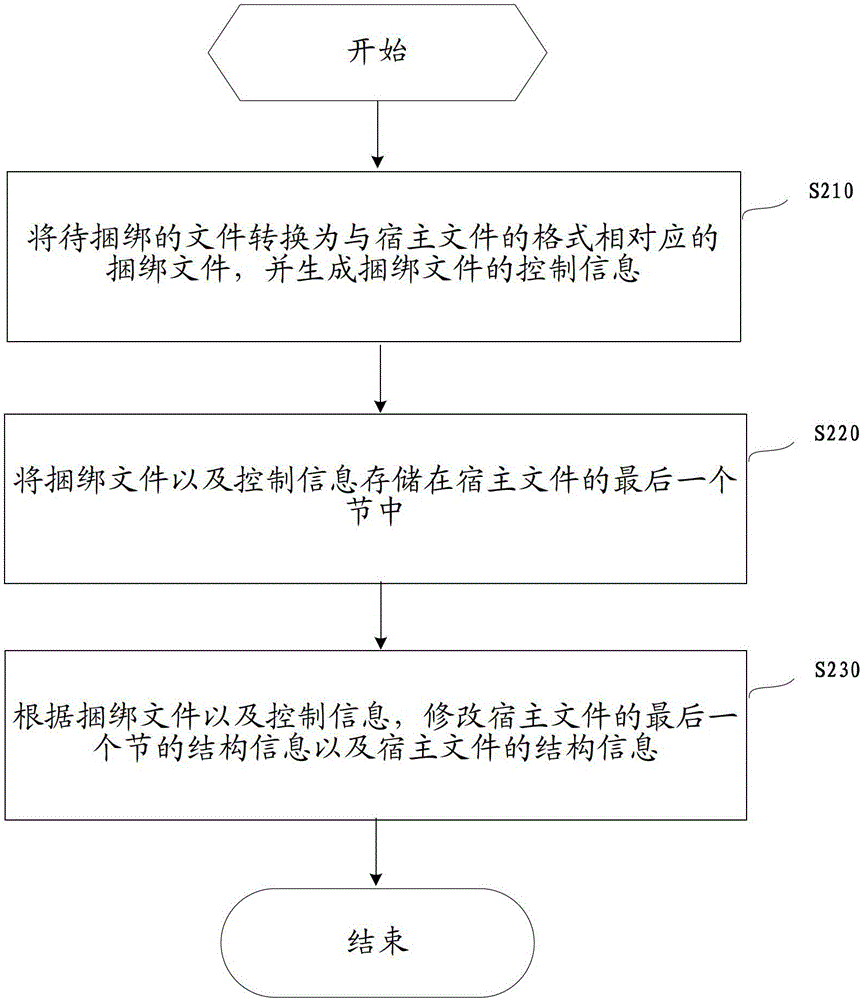

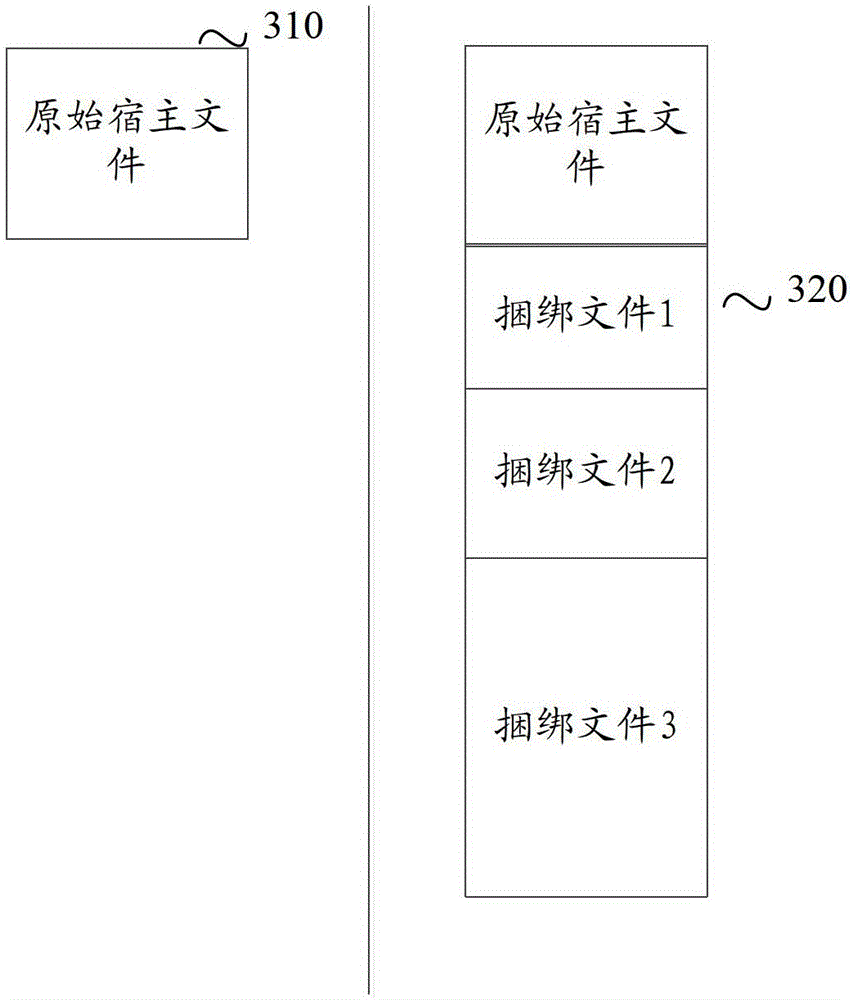

Bundle method and device for file to host file

ActiveCN102982073AIt is not easy to report an errorSpecial data processing applicationsBundle methodBundle methods

The invention discloses a bundle method and a device for a file to a host file. The host file comprises a plurality of bytes which are arrayed in a certain order and used for storing data. The device comprises a converting unit, a bundle unit and a modifying unit. According to the bundle method and the corresponding device for the file to the host file, a last byte of the host file is bundled with a file with an arbitrary length, so that the problems in the prior art that only small files can be bundled, and errors happen caused by the information on the head portion of the host file is too concentrated, large files which can be bundled with arbitrary lengths can be obtained, and the errors can not occur easily.

Owner:三六零数字安全科技集团有限公司

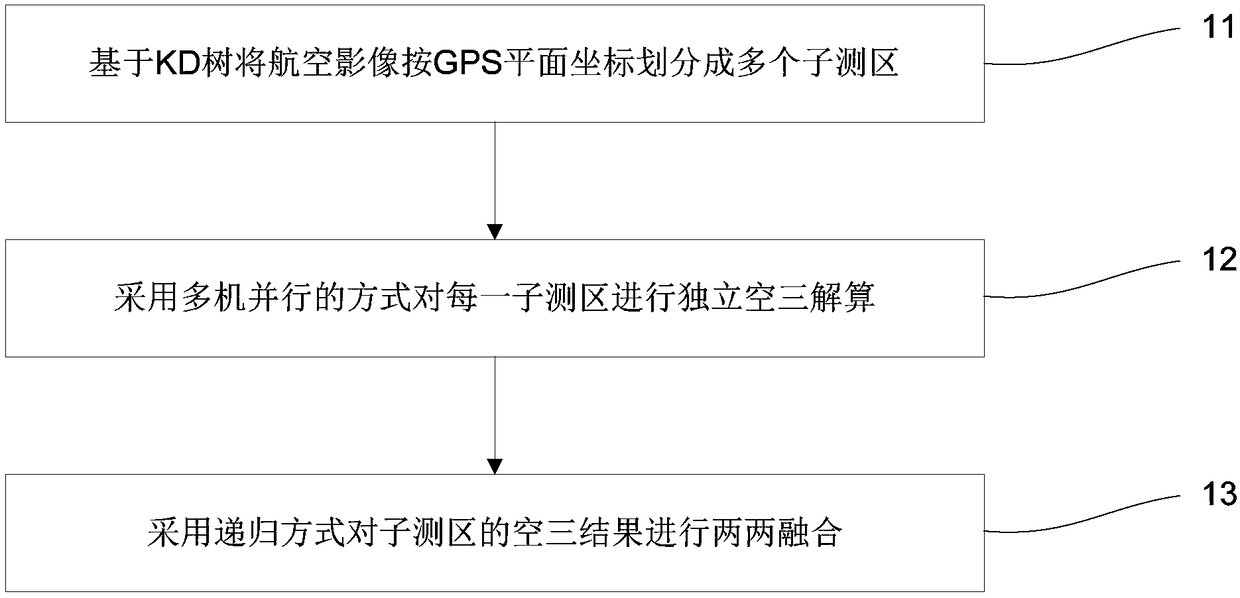

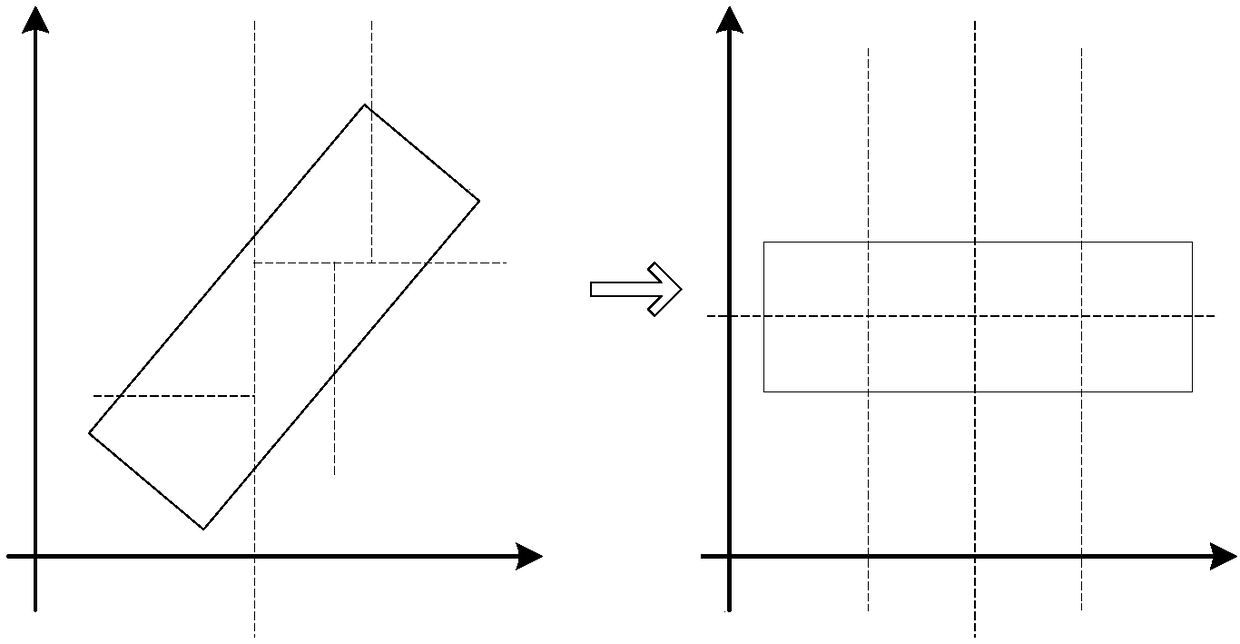

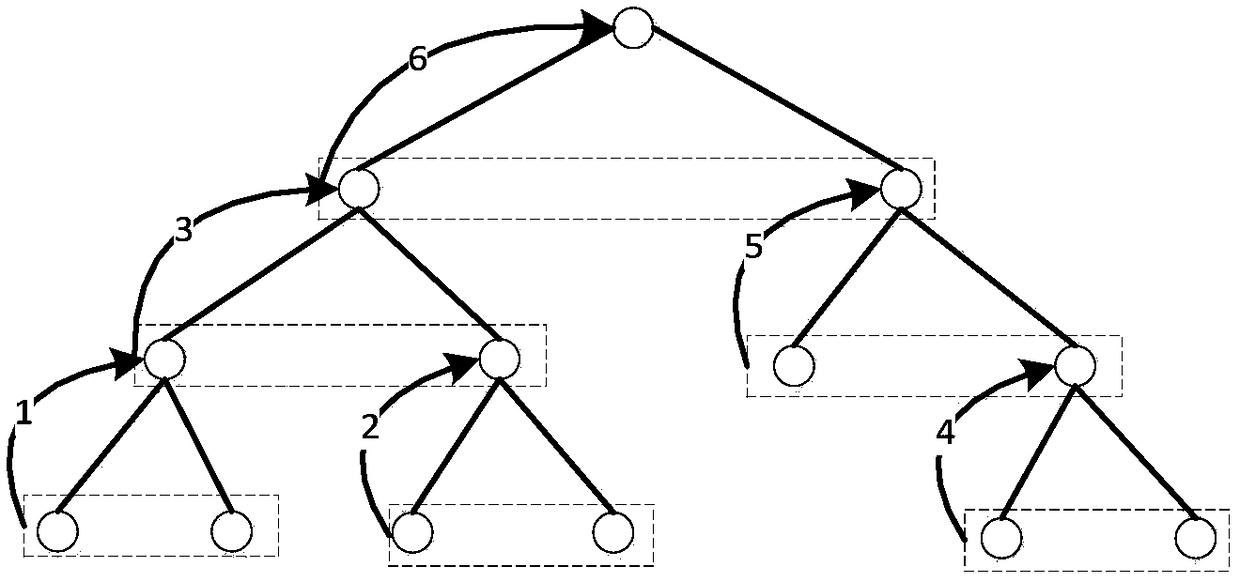

Aerial image parallel aerial-triangulation and recursion fusion method

InactiveCN108332721AImprove efficiencyHigh precisionPicture interpretationBundle methodMulti machine

The invention discloses an aerial image parallel aerial-triangulation and recursion fusion method. The method comprises the following steps: dividing a large-scale testing zone into a plurality of testing sub-zones according to a GPS plane coordinate by utilizing a KD tree algorithm, controlling the number of images of each testing sub-zone, respectively establishing a free network by adopting theexisting SFM algorithm by virtue of a multi-machine parallel way, adjusting by using a GPS-supported light bundle method, finally gradually fusing the aerial-triangulation results of the testing sub-zones by adopting a recursion-type algorithm, and obtaining an aerial-triangulation result of the entire testing zone. The method has the advantages that the segmented SFM way is performed for the large-area testing zone, so that the problems that the massive data SFM is large in error, the speed is low and the success cannot be achieved can be solved; and by adopting the recursion fusion method,each image in the obtained aerial-triangulation result only has one exclusive group of calculation results, and the splicing staggering problem of the testing zone is solved.

Owner:北京中测智绘科技有限公司

Bundling method and auxiliary bundling device for disc-shaped workpiece heat treatment

InactiveCN106947849AGuaranteed to be placed verticallyAvoid deformationFlexible elementsFurnace typesBundle methodBundle methods

The invention belongs to the technical field of machines, and relates to a bundling method and an auxiliary bundling device for disc-shaped workpiece heat treatment. The bundling method and the auxiliary bundling device solve the problems that existing disc-shaped workpieces are not convenient to bundle, and heat treatment is difficult. The bundling method comprises the following steps that firstly, two iron wires the same in length are taken and well twisted to be placed at the bottom of a disc-shaped workpiece to form an iron wire set; secondly, the horizontally-placed iron wire set is bent in the vertical direction; thirdly, a section A and a section C of the iron wire set are bent towards the rear end and twisted into a first rope knot, a section B and a section D are bent towards the front end and twisted into a second rope knot; fourthly, the section A, the section B, the section C and the section D of the iron wires are bent towards the top of the peripheral face of the disc-shaped workpiece; and fifthly, the section A, the section B, the section C and the section D of the iron wire set are twisted into a third rope knot at the top end of the peripheral face of the disc-shaped workpiece, the end portions of the section A, the section B, the section C and the section D of the iron wire set are twisted into a fourth rope knot, and a lantern ring is formed by the third rope knot and the fourth rope knot. The bundling method and the auxiliary bundling device can effectively solve the problem about bundling of the disc-shaped workpiece, and accordingly the disc-shaped workpiece can be conveniently placed in a salt bath furnace.

Owner:ZHEJIANG OCEAN UNIV

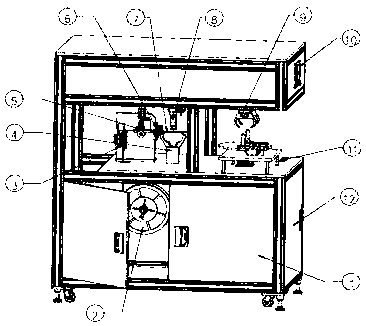

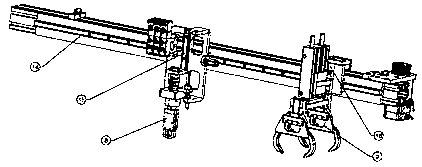

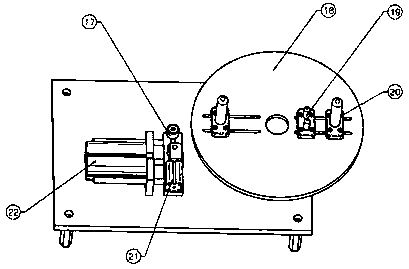

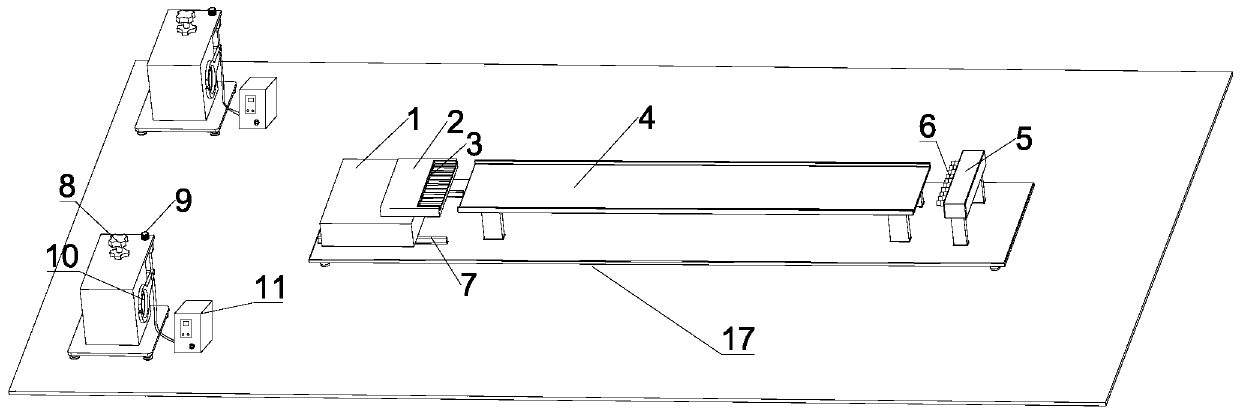

Automatic bundling equipment for power lines and bundling method of equipment

PendingCN108860702ARealize automatic windingRealize the binding actionBinding material applicationBundling machine detailsBundle methodBundle methods

The invention discloses automatic bundling equipment for power lines and a bundling method of the equipment and is used for automatic bundling of the power lines during production and machining of thepower lines. The automatic bundling equipment for the power lines comprises a main body frame; the main body frame is shaped like a lying U; a control cabinet is fixed below the main body frame; a main guide rail is fixed above the main body frame; an operating platform is mounted above the control cabinet; a wire bundling guiding mechanism, a wire bundling feeding mechanism, a wire bundling cutting mechanism, a wire bundling manipulator and a line winding device are sequentially mounted on the operating platform from left to right; rubber strips are mounted on the wire bundling manipulator;and a line bundling manipulator and a line clamping manipulator which can move in a rotating manner are sequentially connected on the main guide rail from left to right. In the manner, by the aid of the equipment, the problem that the efficiency is low in the production and bundling process of the power lines can be effectively solved, the production efficiency can be improved, and the productioncost can be reduced.

Owner:常熟利星光电科技有限公司

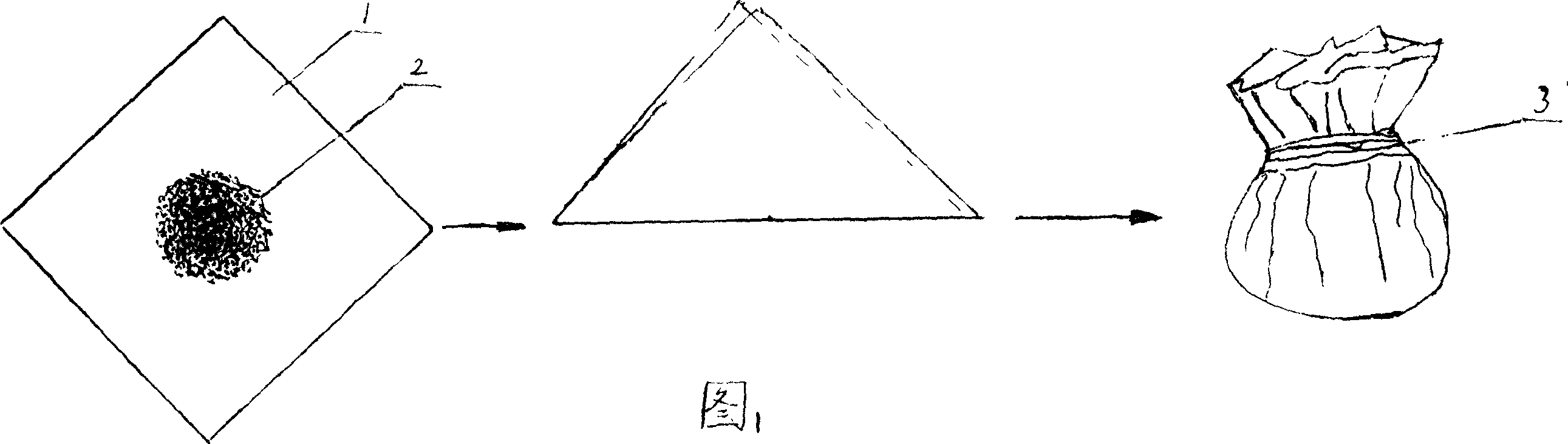

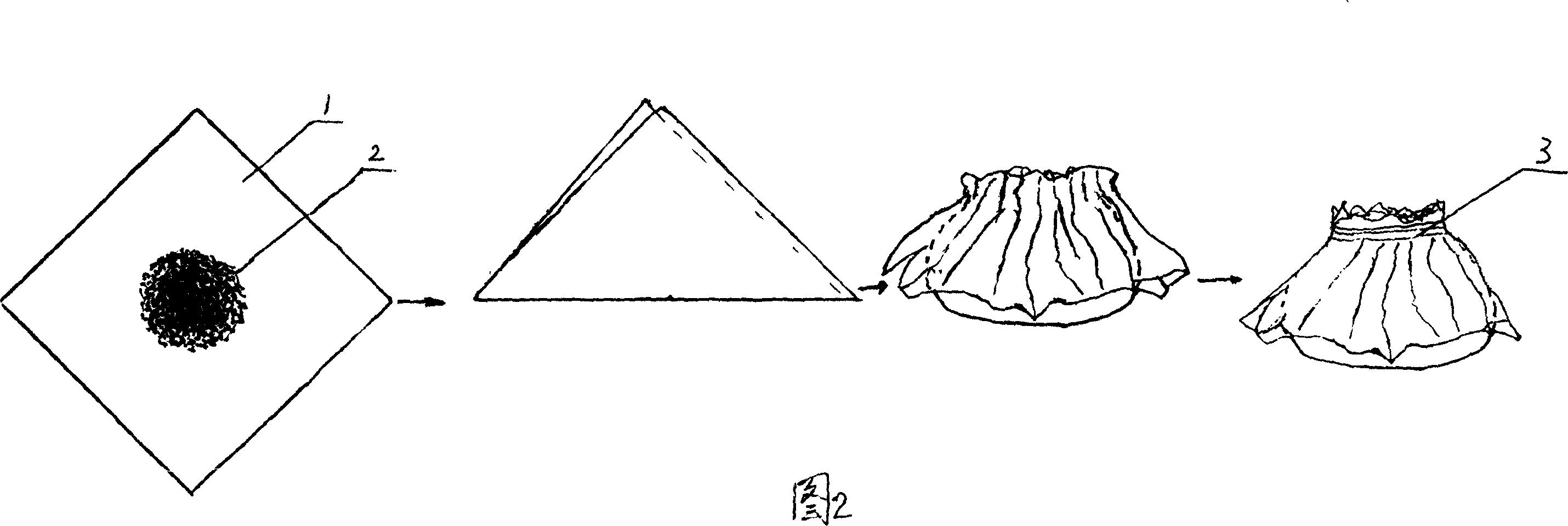

Bundling method for brick blank mixed material heat value measurement

InactiveCN1945262ABurn fullySimple methodMaterial heat developmentPreparing sample for investigationAdobeBundle method

The present invention is mixed adobe material packing method for heat value measurement, and belongs to the field of adobe material heat value measuring technology. The mixed adobe material packing method may be a ball packing method or a reel packing method. The ball packing method includes spreading packing paper, setting mixed adobe material in the center of the paper, folding the paper, tightening the upper part of paper package, and tying with cotton thread. The reel packing method includes transversely rolling the packing paper with mixed adobe material, folding the paper from two ends, and tying with cotton thread in the middle part. The present invention has the advantages of simple packing process and capacity of burning the mixed adobe material fully.

Owner:卜秀侠

Bundling method and system for credits of an environmental commodities exchange

Some embodiments of the invention provide a method of automatically bundling environmental conservation items with computed environmental conservation values into “credit blocks” so that the aggregate sum of the environmental conservation values of the items in a particular block is sufficient to issue a tradable environmental commodity, also referred to as a credit. In some such embodiments the various different items represent items with different forms of environmental conservation such as emissions reductions, energy savings, hazardous waste reductions, or generated renewable energy.In some embodiments, credits with at least one expired item are unbundled and the at least one expired item is removed from the credit block. Some embodiments replace the at least one expired item with at least one valid item having the same or a similar environmental conservation value.

Owner:GOTTHELF PHILIP +1

Bundling method and system for long products

InactiveCN101249901BImprove efficiencyIncrease productionConveyorsBinding material applicationBundle methodTelecommunications

Owner:SIEMENS IND INC

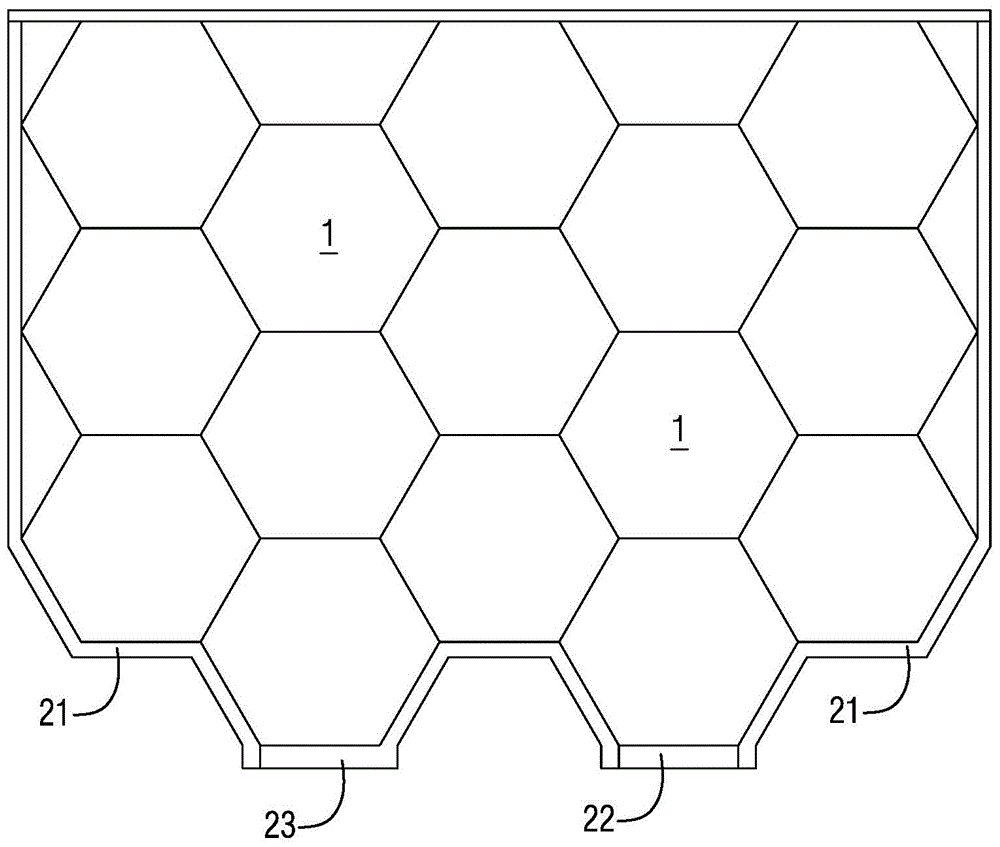

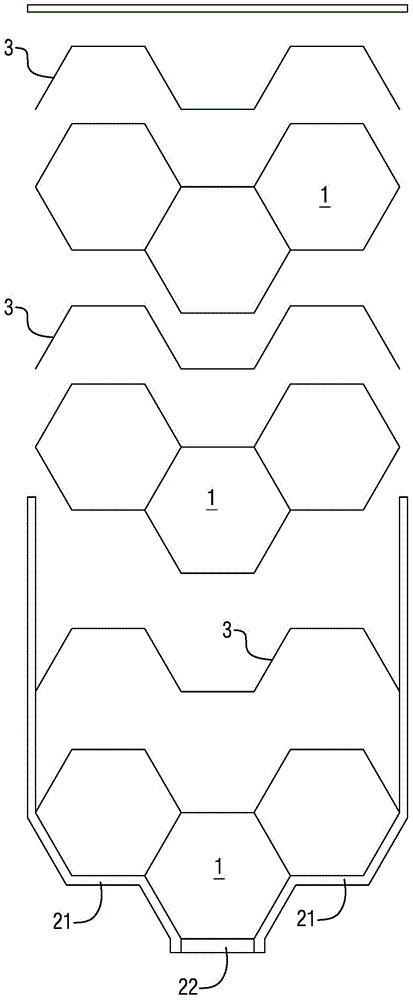

A kind of manufacturing method of honeycomb conductive glass steel pipe bundle

The invention provides a manufacture method of a honeycomb type conductive glass reinforced plastic tube bundle. A plurality of single regular hexagonal conductive glass reinforced plastic tubes are prefabricated into a honeycomb type conductive glass reinforced plastic tube bundle of a defined size according to the design data of an electric demister and the size of each single regular hexagonal conductive glass reinforced plastic tube, thus the honeycomb type conductive glass reinforced plastic tube bundle is conveniently transported to a construction site of the electric demister, the accuracy of the size of the tube bundle can be ensured, and a plurality of honeycomb type conductive glass reinforced plastic tube bundles are combined and installed on the electric demister conveniently.

Owner:李爱云

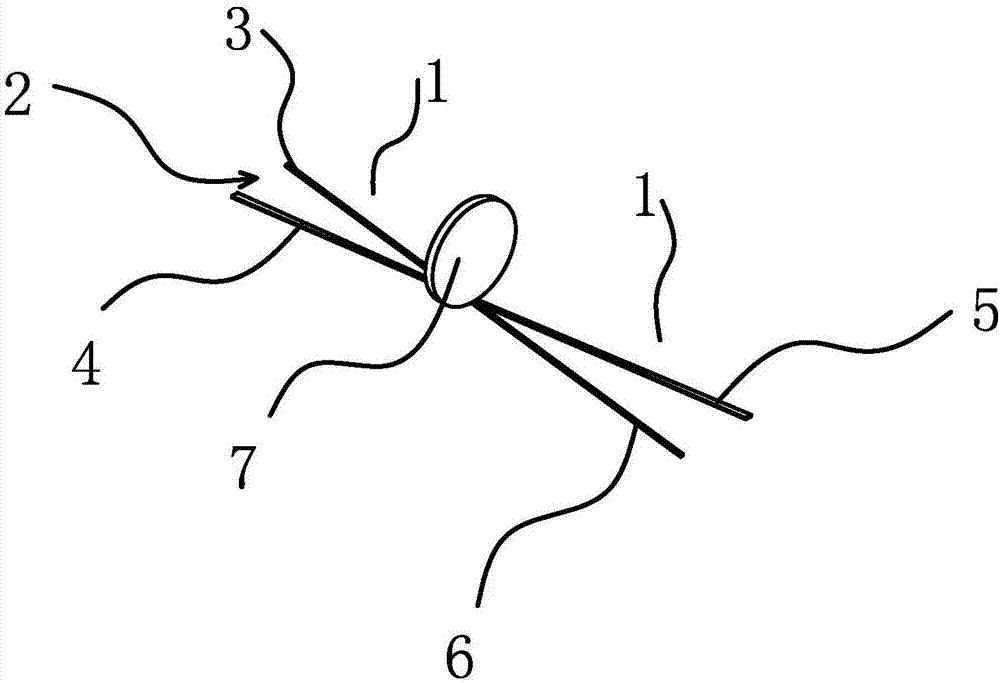

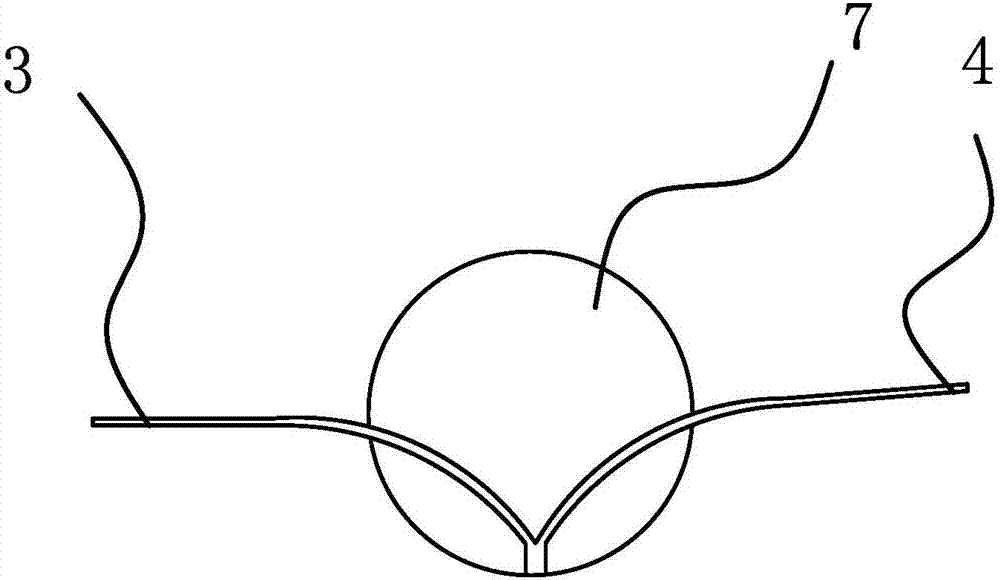

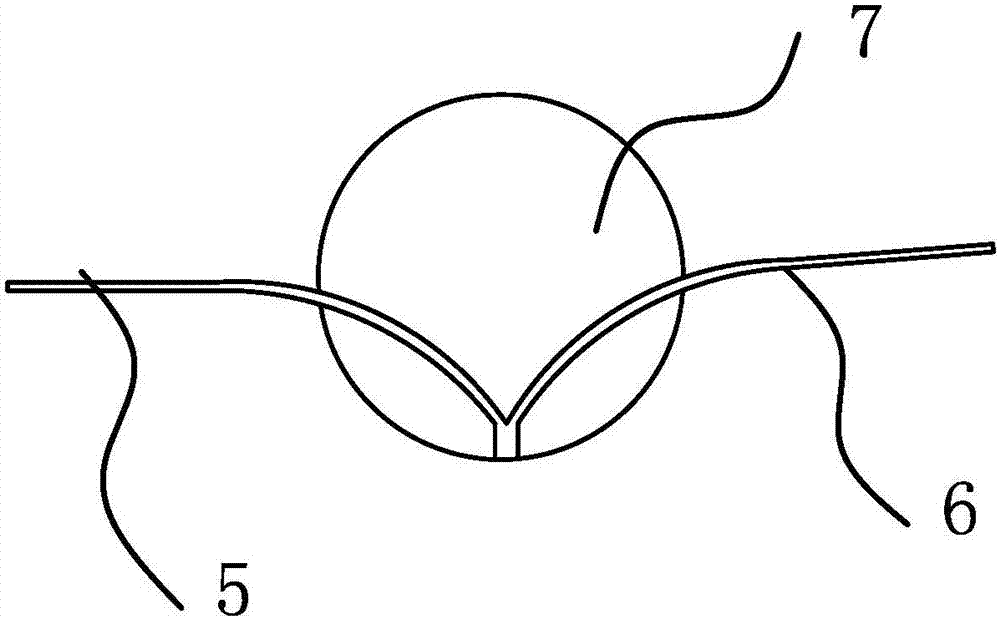

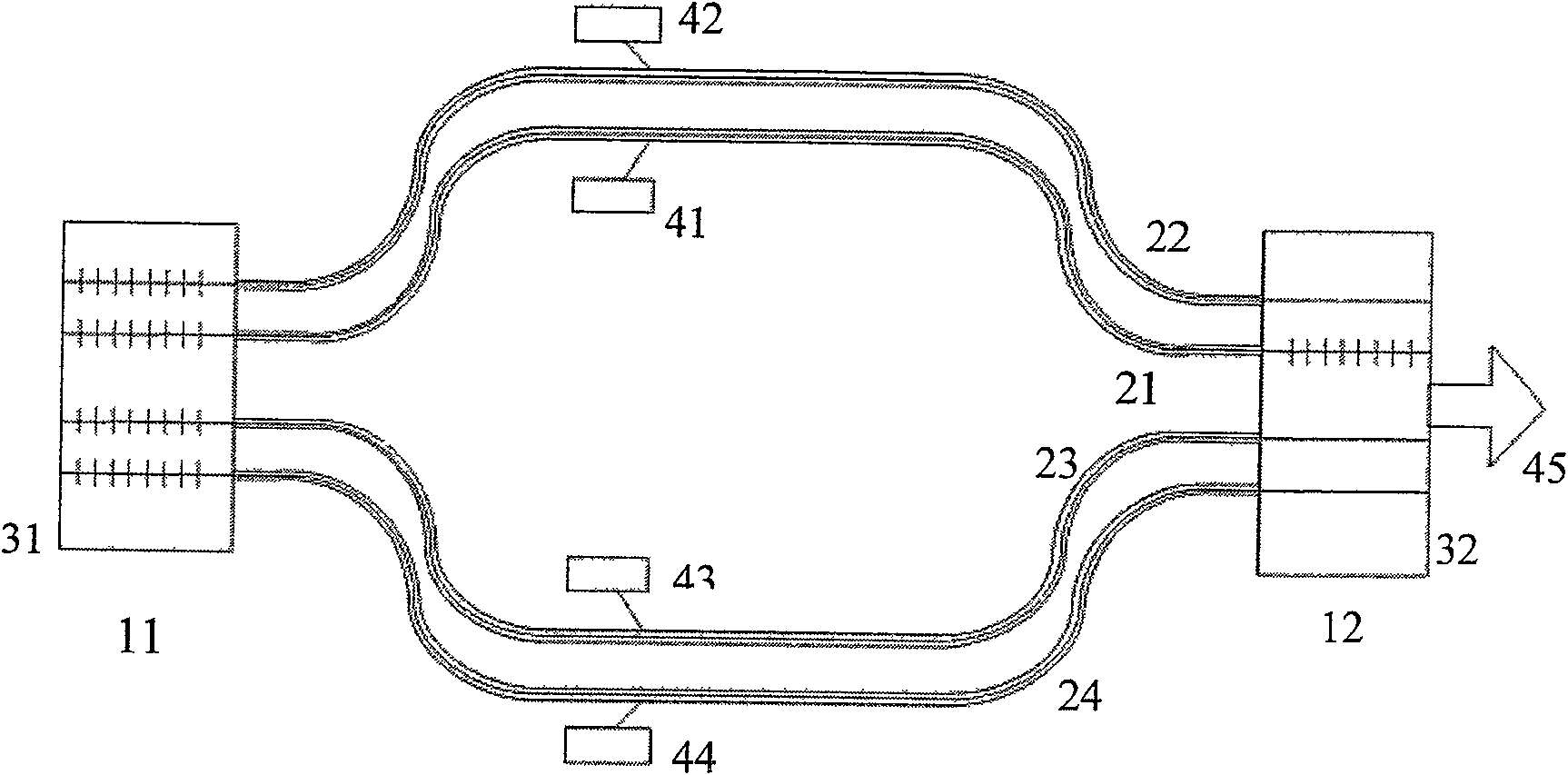

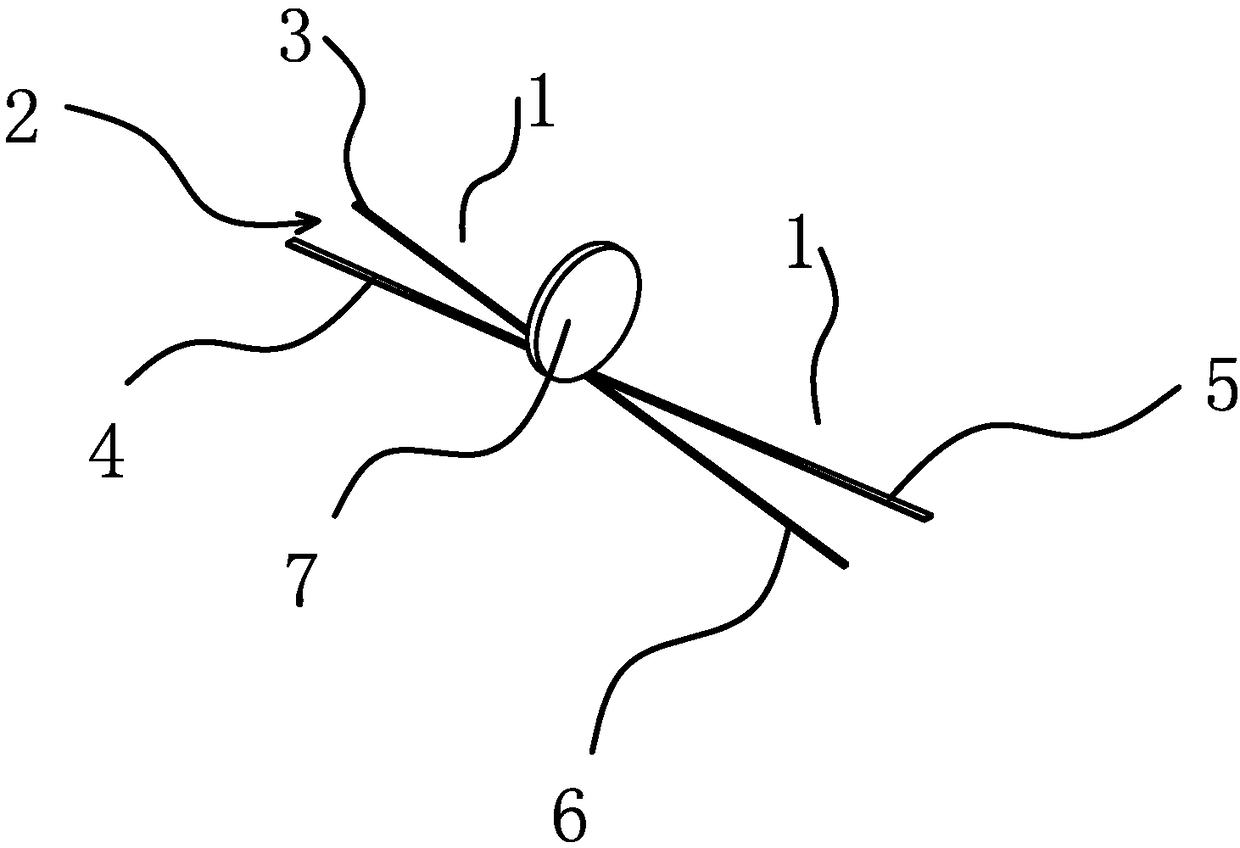

Active lock phase multi-fiber laser without external phase-adjusting part and interference bundle method

InactiveCN100589293CAchieving Active Phase LockActive phase lock reachesCladded optical fibreOptical resonator shape and constructionBundle methodGrating

The present invention relates to an active phase locking multi-optical fiber laser with no external phase modulation device and a coherent beam combination method. Two ends of an active optical fiberare written into a grating; the optical fiber with the maximum gain is used as a main resonant cavity for manufacturing optical fiber lasers; a plurality of active optical fibers with similar length are taken for manufacturing optical fiber lasers. Coating and outer cladding layers at two end parts of the optical fiber of each optical fiber laser are removed, and then a common outer cladding layeris arranged on the place where the outer cladding layers are removed. By utilizing synergistic coupling, the rest active optical fiber lasers are phase-locked on the laser of the main resonant cavitywithout adding any external phase modulation device, which simplifies the complex feedback control system of the prior active phase locking optical fiber laser. According to needs, the number of theoptical fiber lasers can be arbitrarily increased or decreased, so as to increase or decrease beam combination power. In an uncoupling area, the placement of the optical fibers can be arbitrarily arranged. The beam combination method can arbitrarily combine needed optical fiber lasers, can adopt discrete or united pumps, and is easy in heat dissipation and low in requirements on active optical fibers. The active phase locking multi-optical fiber laser is characterized in little influence from environment, compact structure, easy implementation, etc.

Owner:BEIJING JIAOTONG UNIV

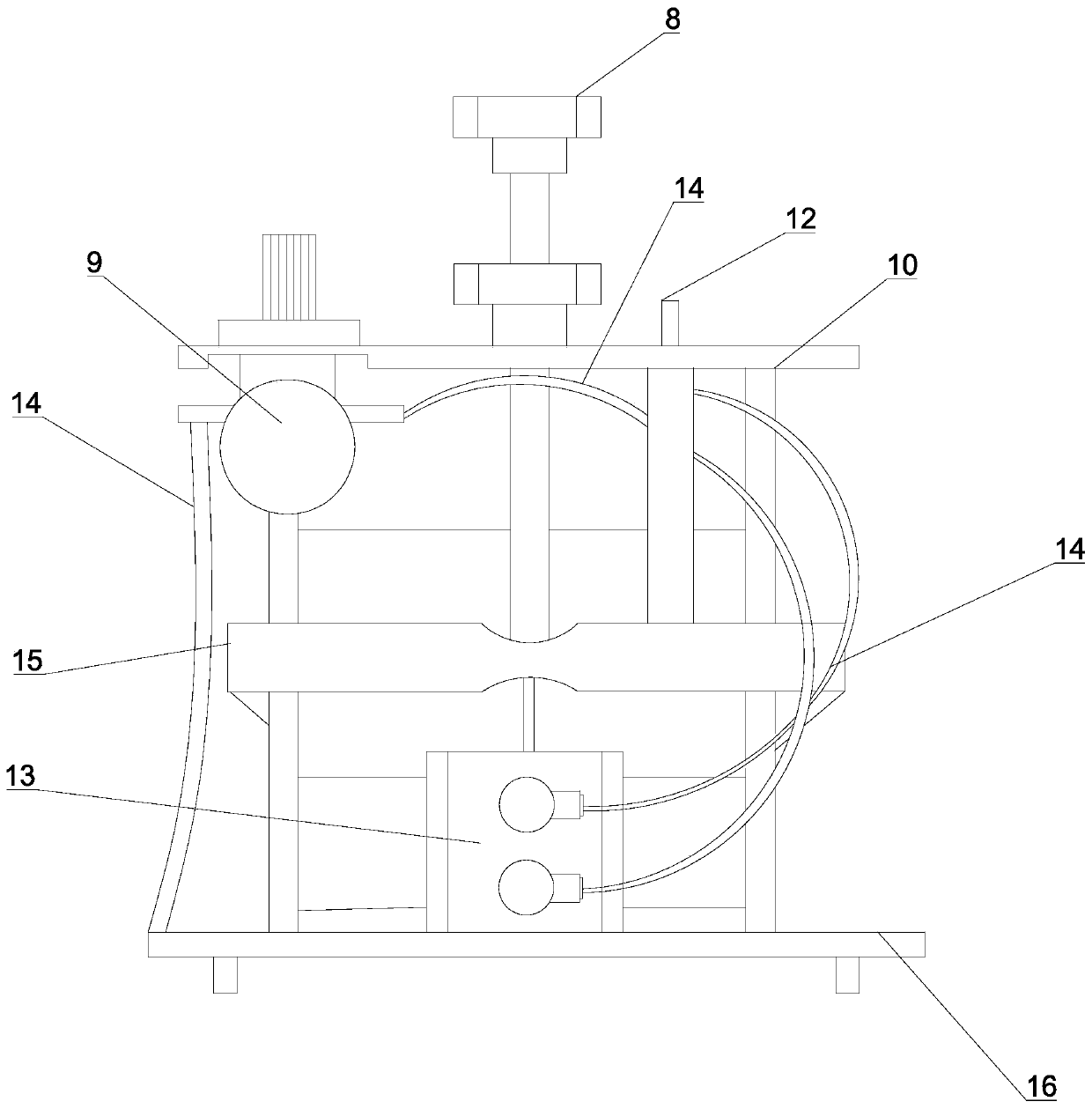

Bundling method and bundling device for reducing risk of stent unloading

ActiveCN110236751AReduced profile outer diameterReduced risk of unloadingStentsBundle methodMedicine

The present invention relates to a bundling method and bundling device for reducing a risk of stent unloading and solves a technical problem that stent unloading is caused due to insecure bundling during use of existing stents. The bundling method comprises the following steps: (1) bundling pressure and time and bundling cavity inner diameter are set, first bundling is conducted, manual rotation for 90 degrees is conducted, then second bundling is conducted, and taking out and heat shaping sleeve are conducted to complete pre-bundling; (2) a stent and a balloon in the step (1) are placed on a material storage tray, one end sleeved with the heat shaping sleeve is placed on a guiding tray, temperature and time are set, the other end is connected with a Luer connector, pressure is applied to the balloon by using nitrogen gas and heat-set shaping is started; and (3) bundling pressure and time and bundling cavity inner diameter are set, the heat shaping sleeve is removed, the stent and balloon are placed in the bundling cavity, after the first bundling, manual rotation for 90 degrees is conducted, and second bundling and taking out are conducted. The present invention also provides the bundling device at the same time. The bundling method and bundling device can be widely applied in technical fields of medical devices.

Owner:JW MEDICAL SYSTEMS LTD

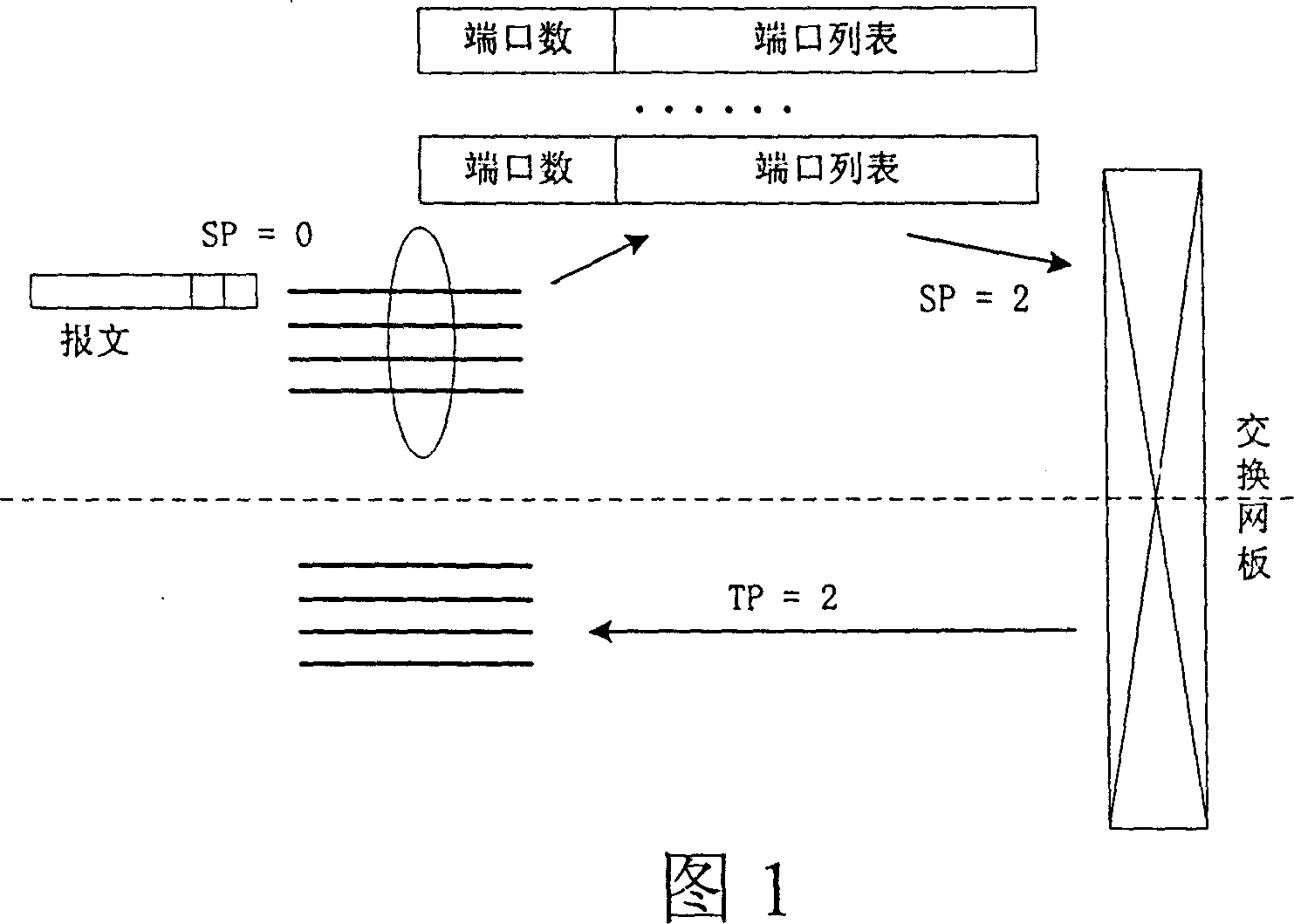

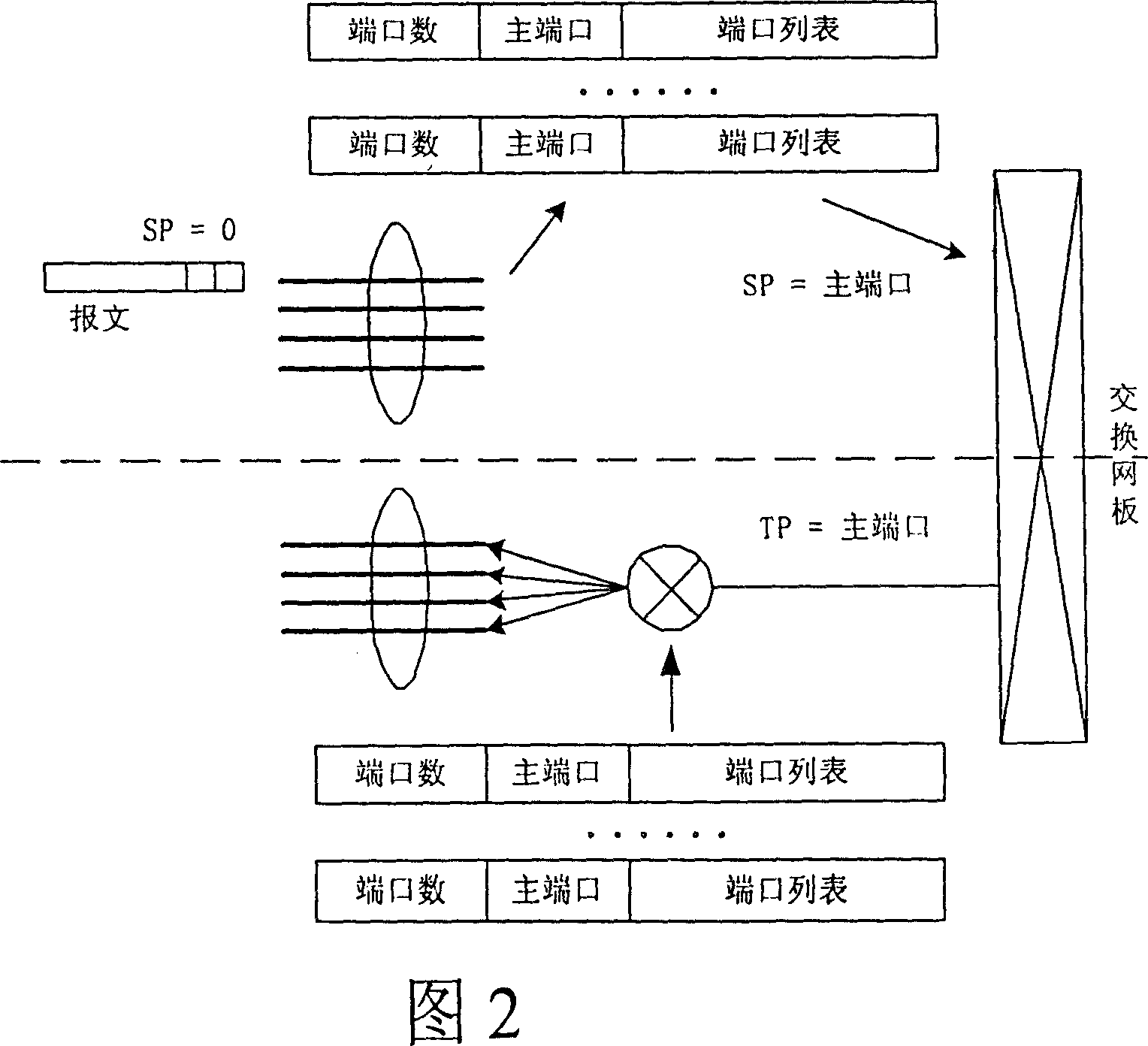

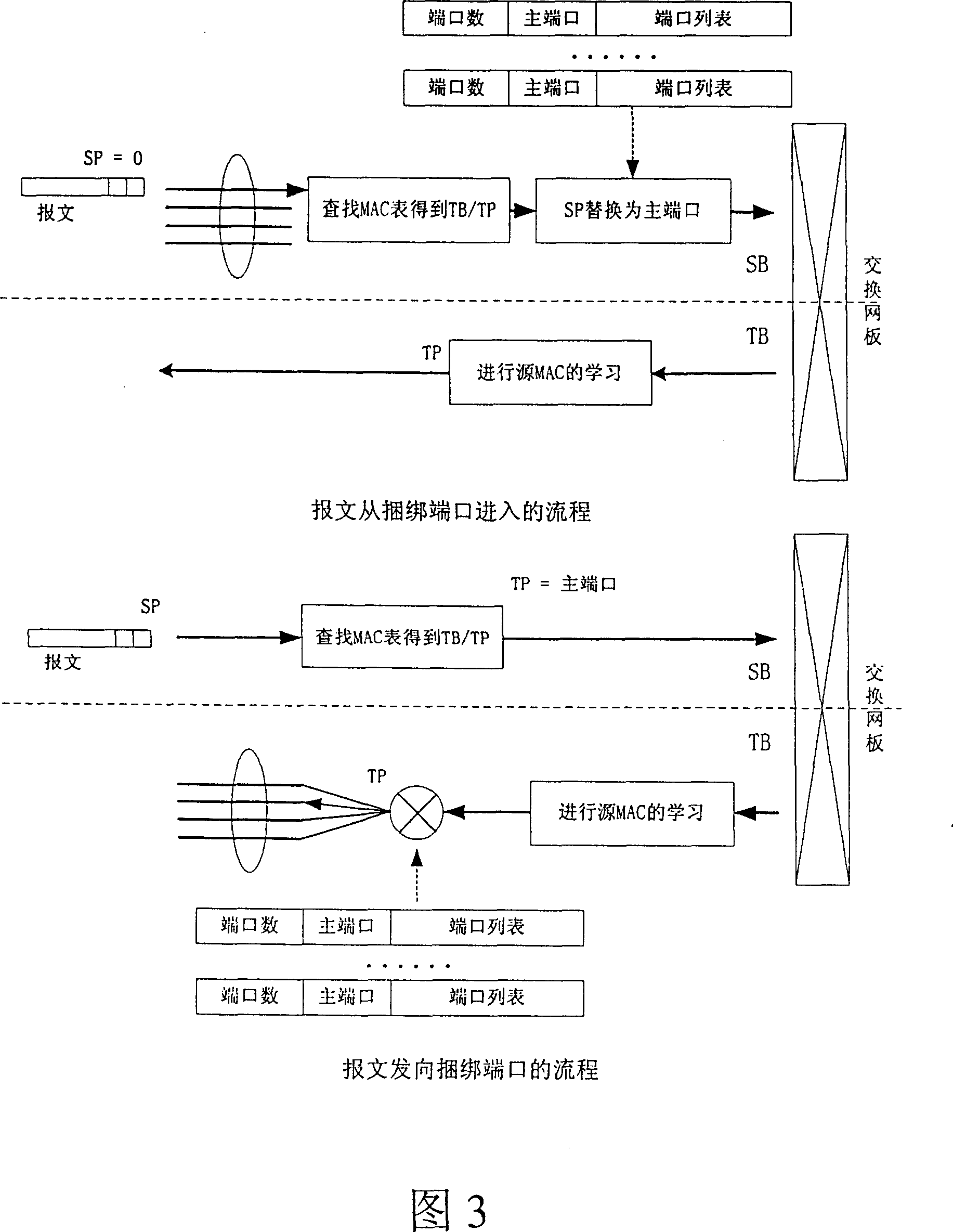

Port bundling method for distributed network exchange system

InactiveCN1311664CEvenly distributedAvoid shockNetworks interconnectionBundle methodTraffic capacity

Owner:HUAWEI TECH CO LTD

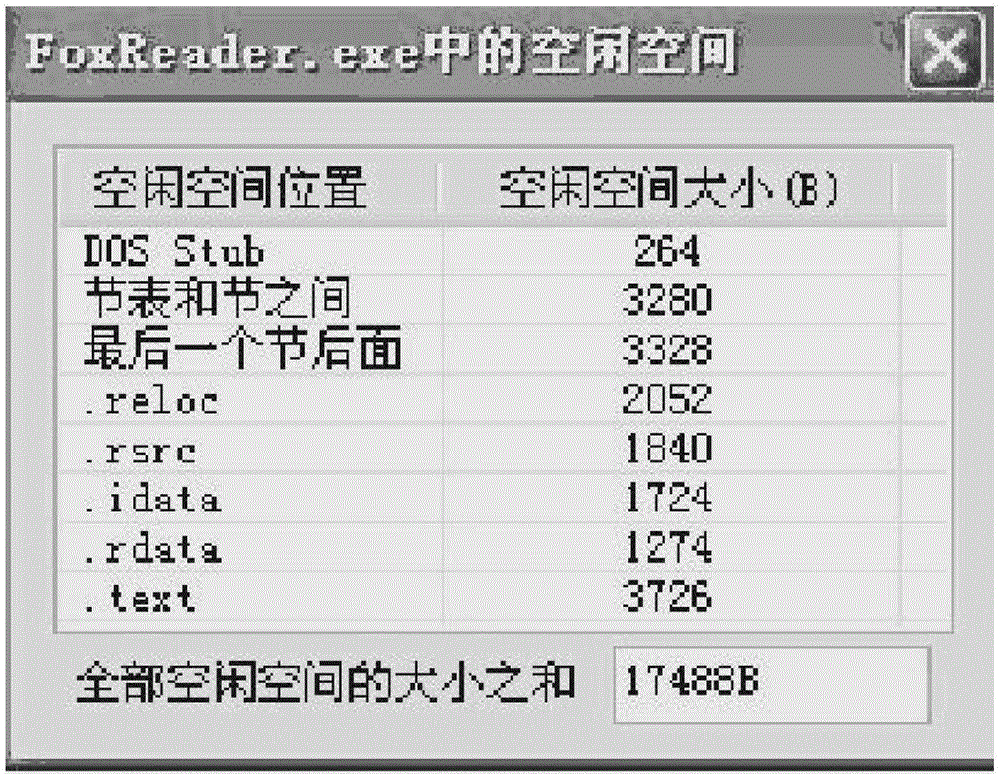

Bundling method and apparatus for files into host files

ActiveCN102982073BIt is not easy to report an errorSpecial data processing applicationsBundle methodBundle methods

The invention discloses a bundle method and a device for a file to a host file. The host file comprises a plurality of bytes which are arrayed in a certain order and used for storing data. The device comprises a converting unit, a bundle unit and a modifying unit. According to the bundle method and the corresponding device for the file to the host file, a last byte of the host file is bundled with a file with an arbitrary length, so that the problems in the prior art that only small files can be bundled, and errors happen caused by the information on the head portion of the host file is too concentrated, large files which can be bundled with arbitrary lengths can be obtained, and the errors can not occur easily.

Owner:三六零数字安全科技集团有限公司

Bundling method of synthetic fiber bundle and synthetic fiber bundle

PURPOSE: To provide a method of packing synthetic fiber bundles wherein curls (cold-setting) occurring during packing and transportation can be minimized to prevent workability and cosmetic characteristics from degrading, and to provide a synthetic fiber bundle for a wig. CONSTITUTION: The method comprises a step of packing the synthetic fiber bundles in a circle with a radius of curvature of 35 mm or more when casing the bundles. The synthetic fiber bundle has an average weaving degree of a single fiber in the bundle of 35 to 85 dtex, and a coefficient of a curl of the fiber when cut for use is 0.25 or less.

Owner:KANEKA CORP

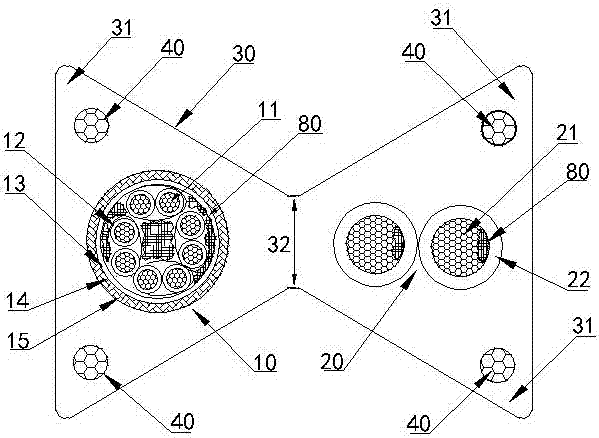

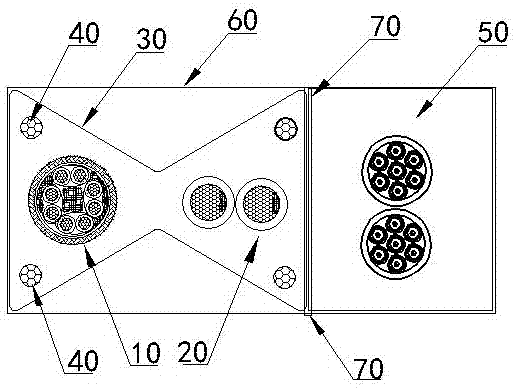

Digital video monitoring cable for high-speed elevator and its installation and binding method

ActiveCN105070371BDaqu ChaoliAvoid accelerated destructionInsulated cablesCable installation apparatusDigital videoBundle method

The invention discloses a digital video monitoring cable for a high-speed elevator and an installing and binding method of the digital video monitoring cable. The digital video monitoring cable comprises a monitoring communication cable, an electrifying cable, four strands of anti-bending wire ropes and a butterfly outer sheath, wherein the butterfly outer sheath is in a butterfly outer sheath structure with two triangular grooves on the cross section; the butterfly outer sheath structure is formed by simultaneously removing an isosceles triangle inwards from each of two opposite sides of a rectangular frame; the monitoring communication cable and the electrifying cable are respectively arranged at the centre positions of two symmetrical triangles; the four strands of anti-bending wire ropes are symmetrically arranged at the positions at the inner sides of four vertex angles of the butterfly outer sheath structure respectively; the butterfly outer sheath and an elevator travelling cable are arranged in parallel and then are transversely bound by a transverse binding tape; and the transverse binding tape at the position of the gap between the butterfly outer sheath and the elevator travelling cable is vertically bound by a binding tape. Therefore, the anti-disturbance force of the cable in the high-speed up and down movement process is improved; damages caused by external force are avoided; and relatively long-term use of the monitoring cable is ensured.

Owner:GUANGZHOU CITY YU HUNG ELECTRIC WIRE & CABLE IND

Construction method of special UAV image aerial three free network based on minimum spanning tree

ActiveCN107560593BEasy to handleTroubleshoot automated build issuesOptical rangefindersPicture taking arrangementsBundle methodAbsolute orientation

Owner:无锡子可科技有限公司

GPS//INS data direct directing precision assessment method

InactiveCN101509784BInnovative designHigh degree of automationInstruments for road network navigationPicture interpretationBundle methodEvaluation result

The invention discloses a GPS / INS data direct orientation precision evaluation method, which takes photogrammetric emphasis equation collinearity equation as base and a multi-piece forward intersection of a bundle method as theory basis; the evaluation method is combined with the least square principle for obtaning the coordinate of a ground control point object by compensating calculation; and then a comparison with the actually measured coordinate of the ground control point is carried out for obtaining the error value of the coordinate by the statistics so as to evaluate the direct orientation precision of the outer orientation elements obtained by the GPS / INS system. The method has high evaluation precision and small measurement error, and the evaluation result can be used for manufacture practice directly, thus being capable of effectively avoiding the measurement error of the picpointed coordinate added in manual stereomeasurement; and the algorithm is not limited by image number.

Owner:XIAN MEIHANG INFORMATION IND

Least square area network color-homogenizing method of aerial remote sensing image

ActiveCN102129669BEasy to specifyHue Difference EliminationImage enhancementTelevision systemsBundle methodArea network

The invention discloses a least square area network color-homogenizing method of an aerial remote sensing image. In the method provided by the invention, the idea of block aerial triangulation of a bundle method is utilized for reference. The method comprises the following steps: firstly counting the pixel hue information of the stacking area of adjacent images of single-phase orthographic correction images; then constructing an equation set of compensation parameters of the pixel hue information of each image; resolving the compensation parameters of the pixel hue information of each image by utilizing a least square adjustment method; and finally adjusting the hue information of each image based on the obtained hue compensation parameters. By utilizing the method, hue difference elimination process can be carried out on the images with relatively large difference in the image content of the large testing zone and the testing zone, and further an arbitrary position in the testing zone and an arbitrary number of images can be conveniently designated as the hue control image to control the basic hue of the entire testing zone in the process of eliminating color difference.

Owner:WUHAN UNIV

A binding method for heat treatment of square workpieces

The invention belongs to the technical field of machinery, relates to a binding method for heat treatment of square workpieces, and solves such technical problems as inconvenience in storage and taking during quenching and tempering of traditional square workpieces. The edge lengths of the square workpieces are assumed as a, and the thicknesses are assumed as b; and the method comprises the following steps: (1) iron wires with lengths of 4a+3b+20 cm are prepared; and two ends of the iron wires are respectively ends A and B; (2) the iron wires are placed on the bottom surfaces of the square workpieces; (3) the ends A and the ends B of the iron wires are bent to the centers of the square workpieces; (4) the ends A and the ends B of the iron wires are respectively bent to the front sides and the back ends; (5) the ends A of the iron wires are bent by bonding with the front end surfaces and the bottom surfaces of the square workpieces; (6) suspension parts of the iron wires are twisted as rope knots 1 on the back end surfaces of the square workpieces; and (7) the ends A and the ends B of the iron wires are twisted together to form rope knots 2; and the rope knots 2 and the rope knots 1 are correspondingly formed to lantern rings. The binding method for heat treatment of the square workpieces has such advantages as convenience in taking and placement during quenching and tempering.

Owner:ZHEJIANG OCEAN UNIV

A high-density non-stop round straw baling method and baler

Owner:CHINA AGRI UNIV

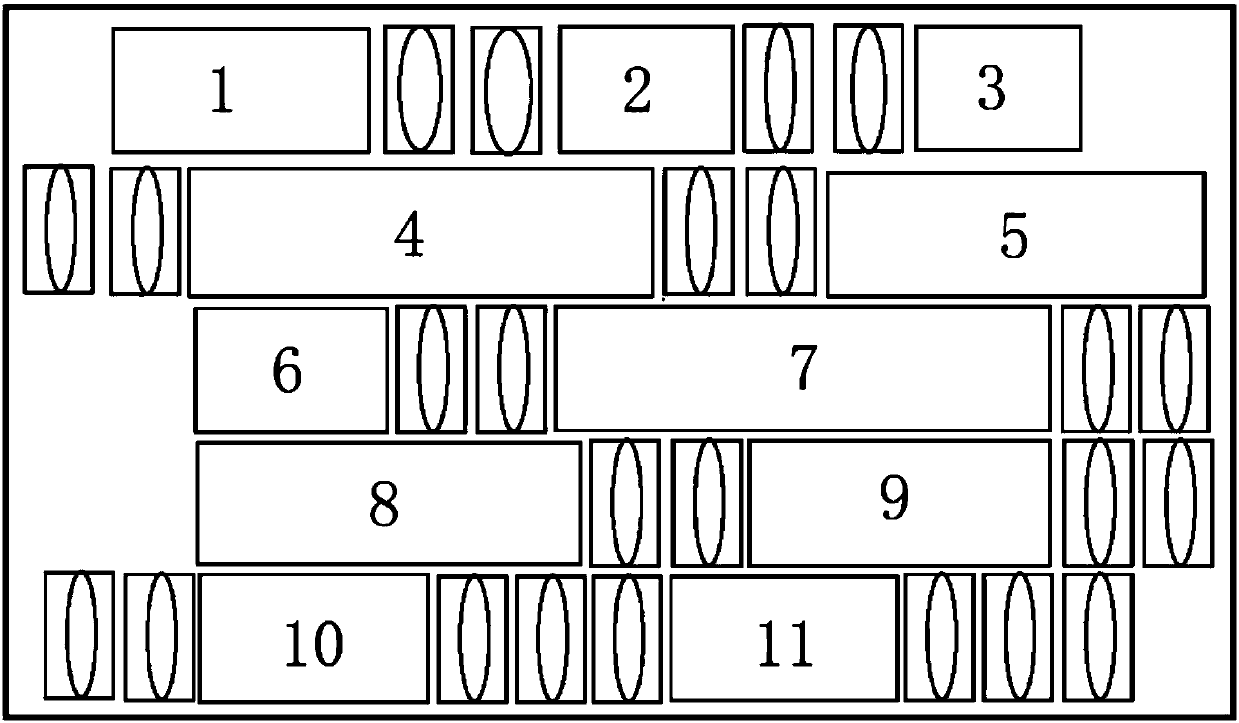

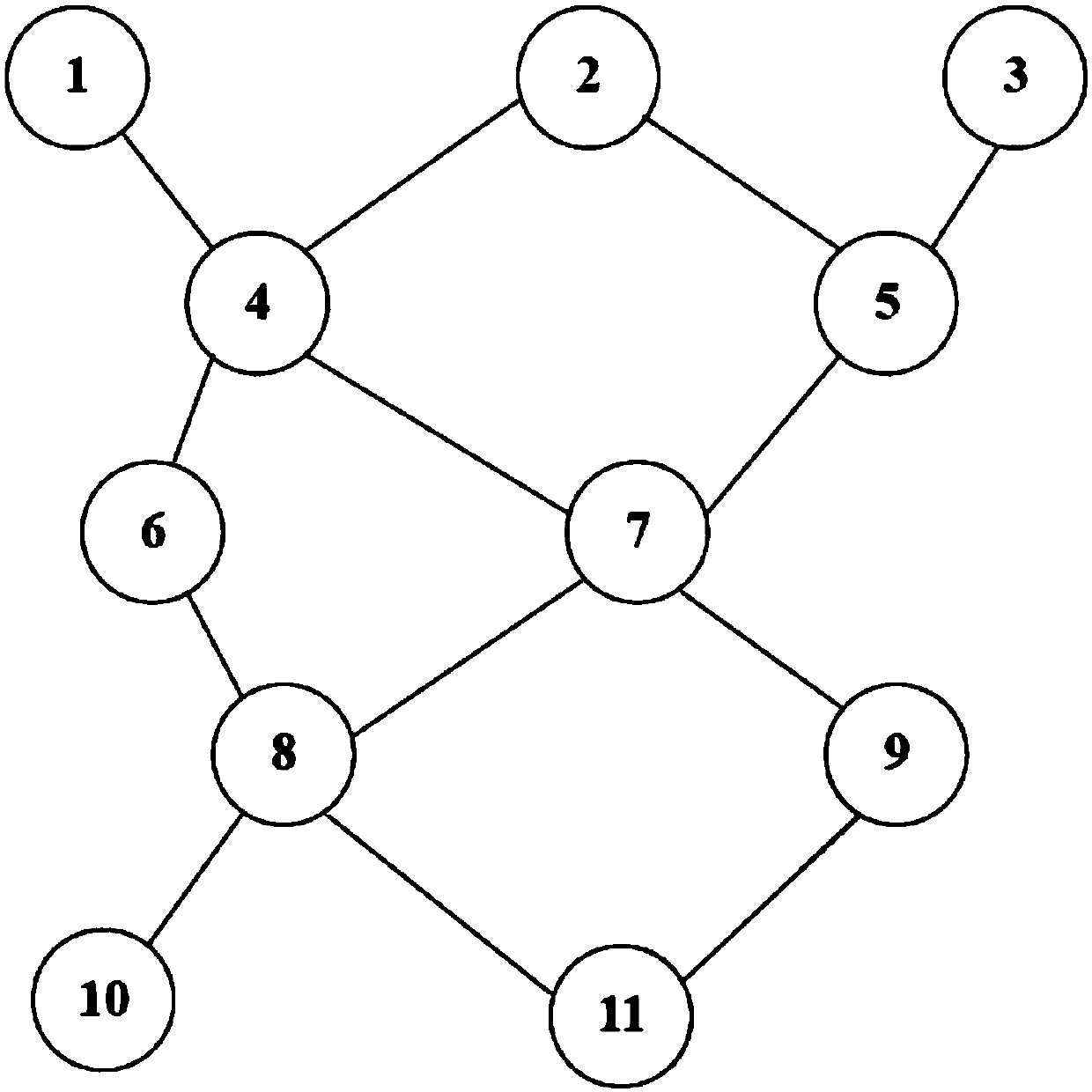

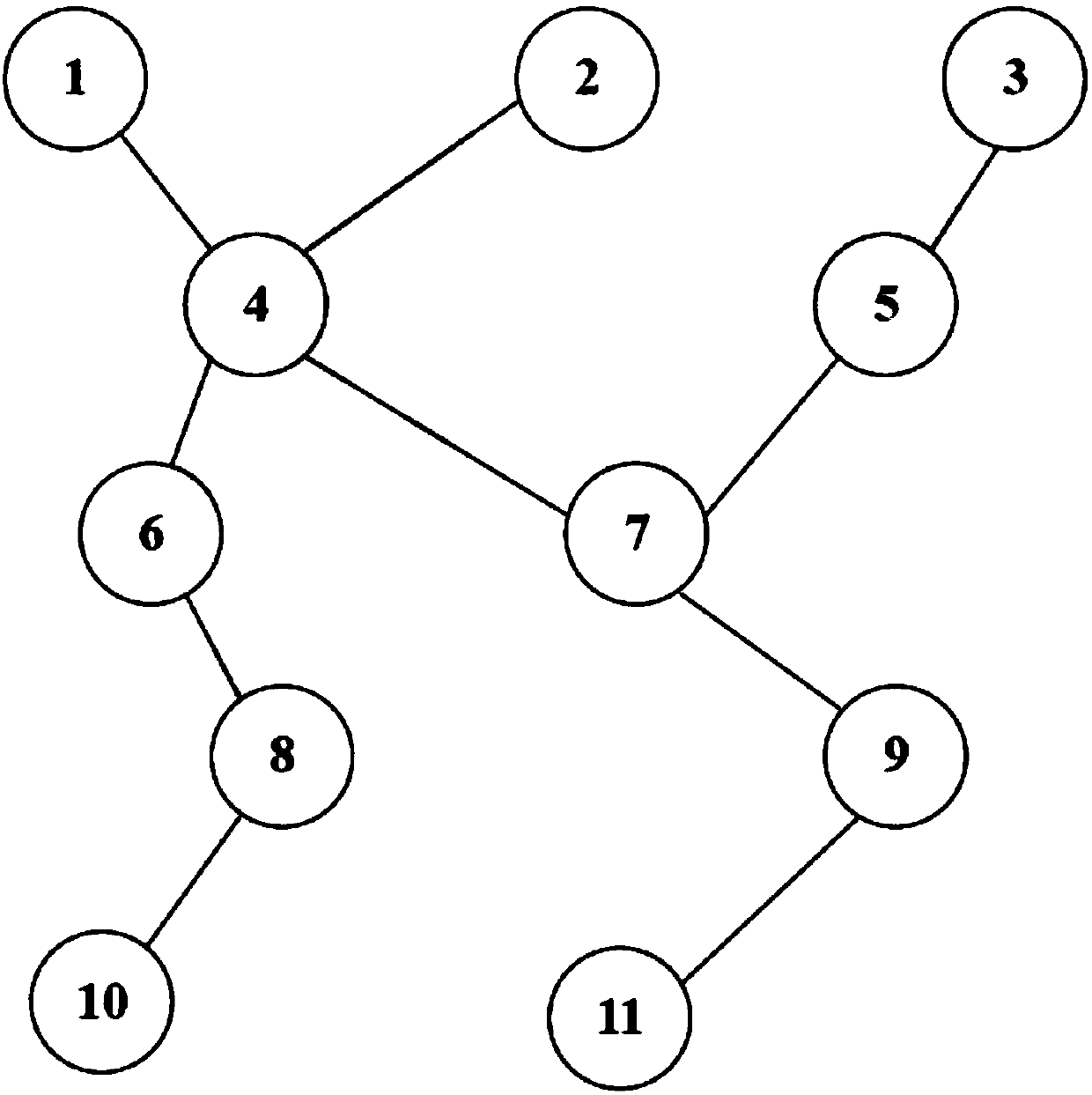

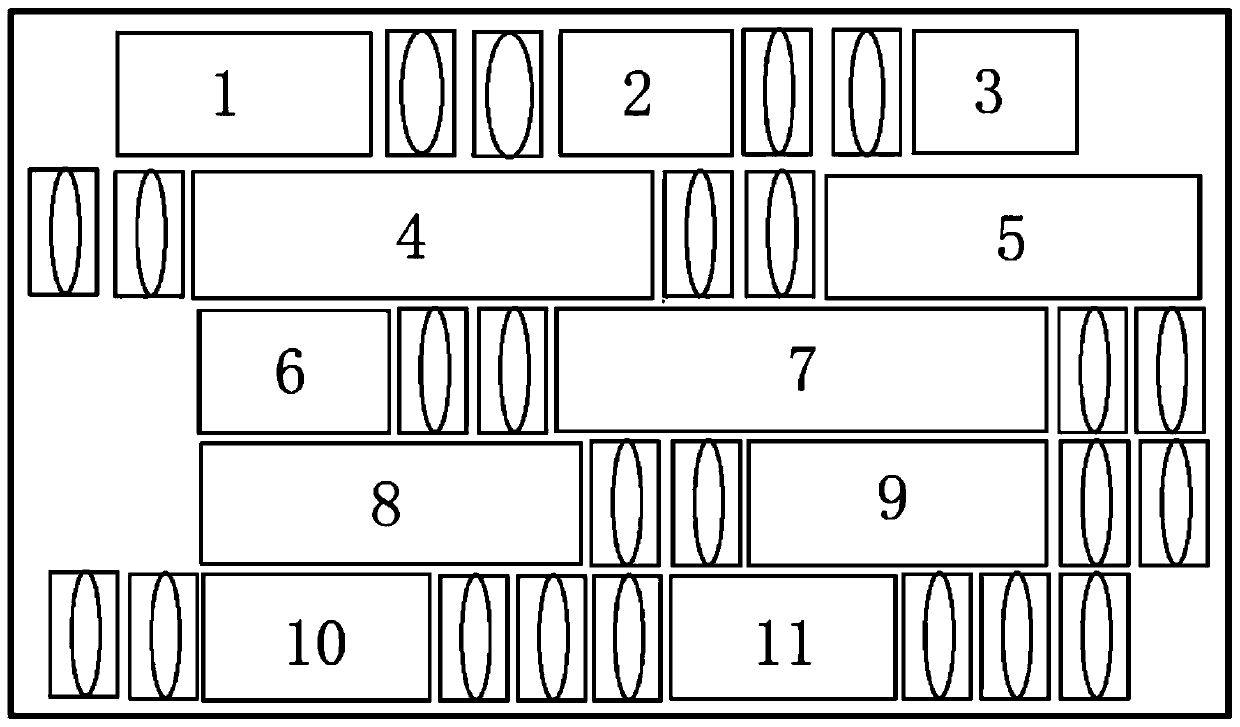

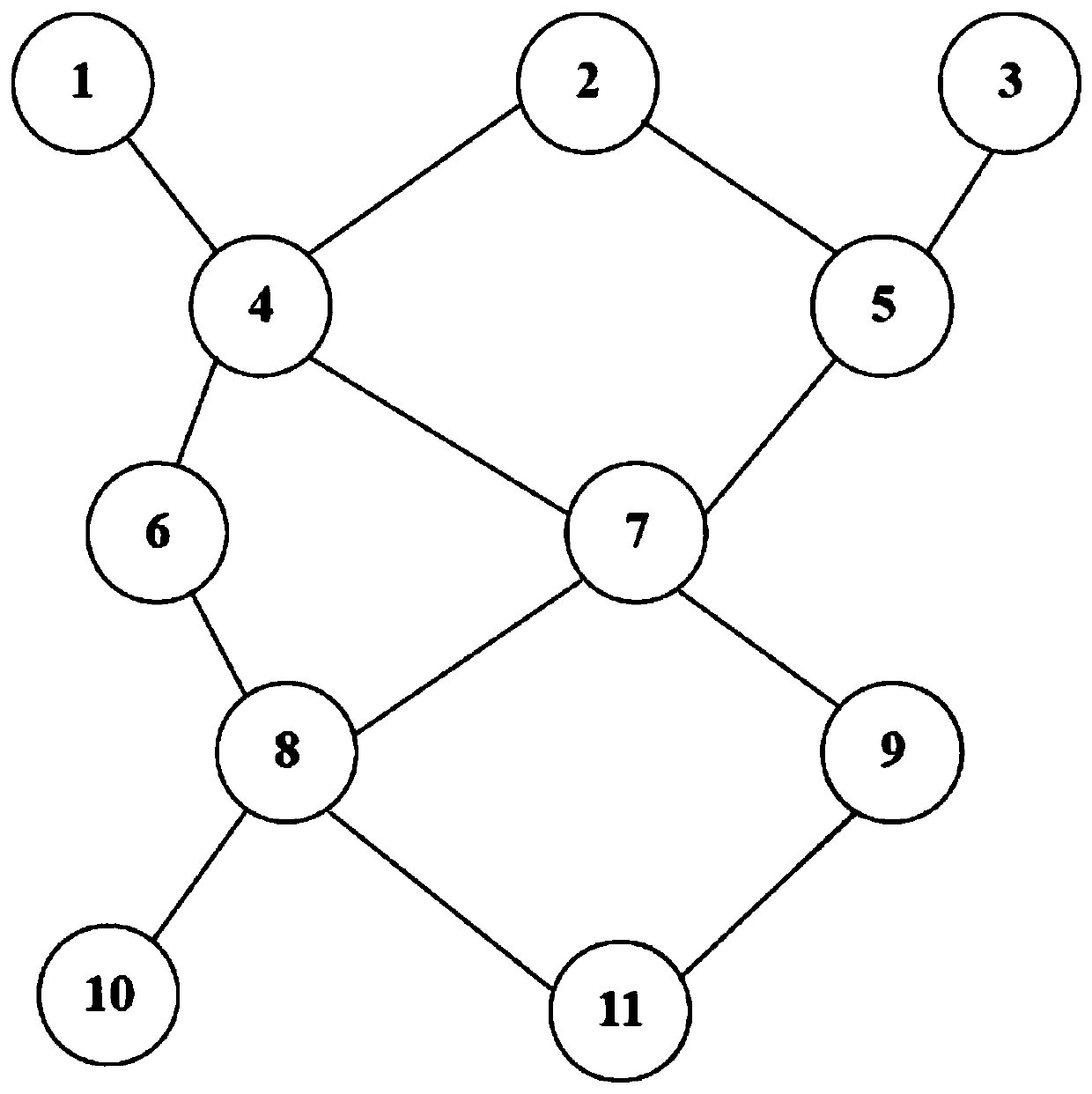

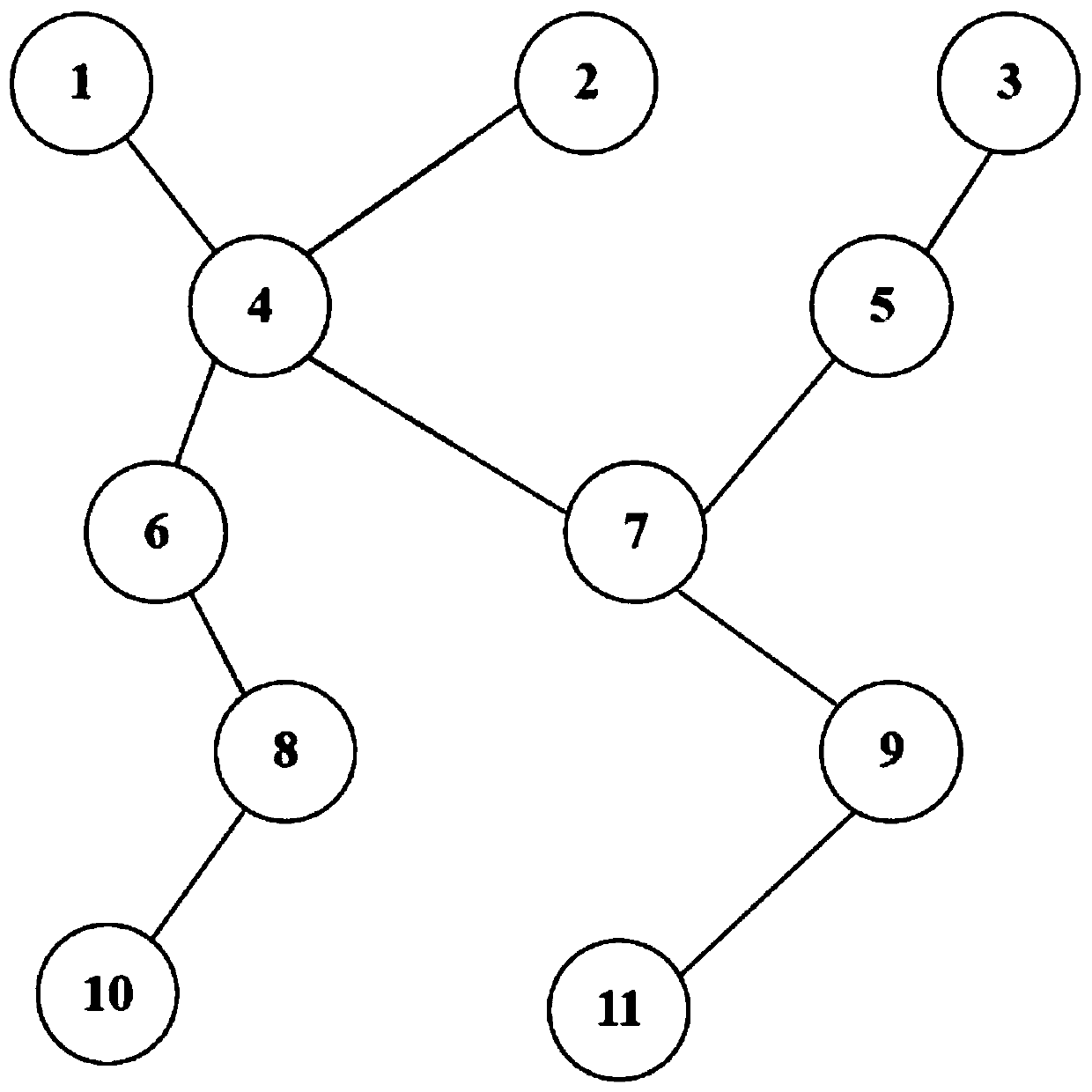

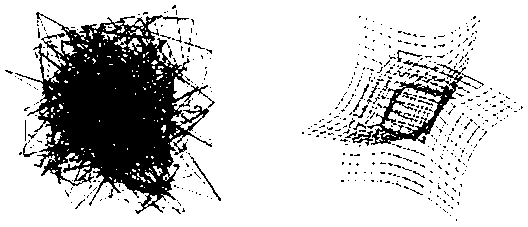

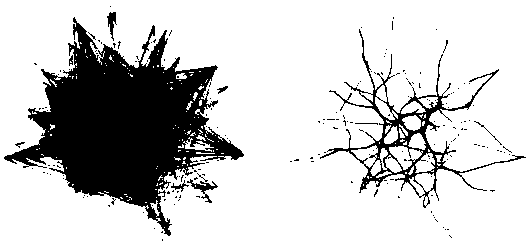

A Simulated Force Field Bundling Method for Complex Node Connection Graphs

InactiveCN106776844BReduce clutterIncrease bundling rateGeographical information databasesSpecial data processing applicationsNODALBundle method

The invention relates to a simulated force field cluster binding method for a complex node connection diagram. The binding method is suitable for being used between connection wires of various angles, distances and proportions based on the local simulated gravitational field between edge wires. The binding scale is optimized and adjusted. Compared with the edge binding of the traditional node-connection view, the efficiency of the binding method is improved.

Owner:HENAN UNIV OF SCI & TECH

A binding method and auxiliary binding device for heat treatment of disc-shaped workpieces

InactiveCN106947849BGuaranteed to be placed verticallyAvoid deformationFlexible elementsFurnace typesBundle methodBundle methods

The invention belongs to the technical field of machines, and relates to a bundling method and an auxiliary bundling device for disc-shaped workpiece heat treatment. The bundling method and the auxiliary bundling device solve the problems that existing disc-shaped workpieces are not convenient to bundle, and heat treatment is difficult. The bundling method comprises the following steps that firstly, two iron wires the same in length are taken and well twisted to be placed at the bottom of a disc-shaped workpiece to form an iron wire set; secondly, the horizontally-placed iron wire set is bent in the vertical direction; thirdly, a section A and a section C of the iron wire set are bent towards the rear end and twisted into a first rope knot, a section B and a section D are bent towards the front end and twisted into a second rope knot; fourthly, the section A, the section B, the section C and the section D of the iron wires are bent towards the top of the peripheral face of the disc-shaped workpiece; and fifthly, the section A, the section B, the section C and the section D of the iron wire set are twisted into a third rope knot at the top end of the peripheral face of the disc-shaped workpiece, the end portions of the section A, the section B, the section C and the section D of the iron wire set are twisted into a fourth rope knot, and a lantern ring is formed by the third rope knot and the fourth rope knot. The bundling method and the auxiliary bundling device can effectively solve the problem about bundling of the disc-shaped workpiece, and accordingly the disc-shaped workpiece can be conveniently placed in a salt bath furnace.

Owner:ZHEJIANG OCEAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com