Digital video monitoring cable for high-speed elevator and its installation and binding method

A digital video, high-speed elevator technology, applied in the direction of cable installation, cable installation device, insulated cables, etc., can solve the problems of damage, reduce the effect of video surveillance, etc., achieve high bending resistance, increased thickness, and ensure long-term reliability and safety The effect of effective use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

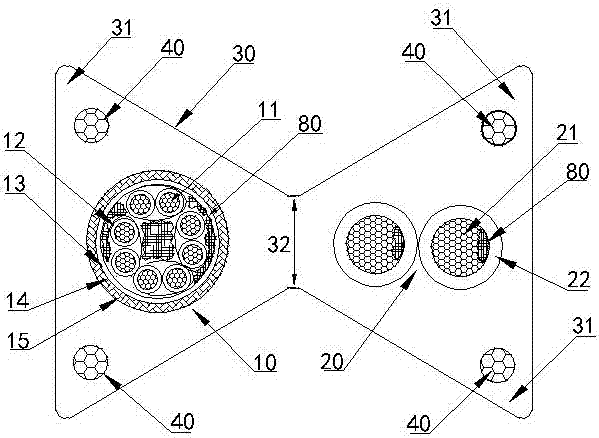

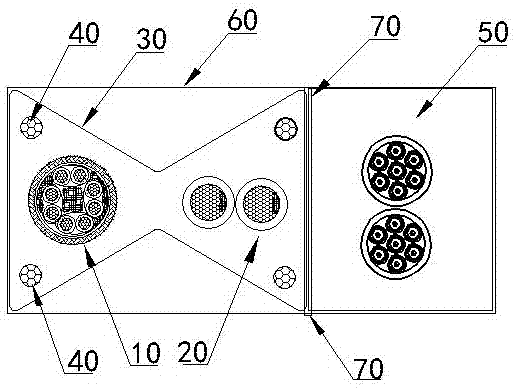

[0026] figure 2 , image 3 In the illustrated embodiment, the present invention provides a method for installing and bundling digital video monitoring cables for high-speed elevators, including the following bundling steps:

[0027] A step of arranging the high-speed elevator digital video monitoring cable described in any one of the above technical solutions in parallel with the elevator accompanying cable 50;

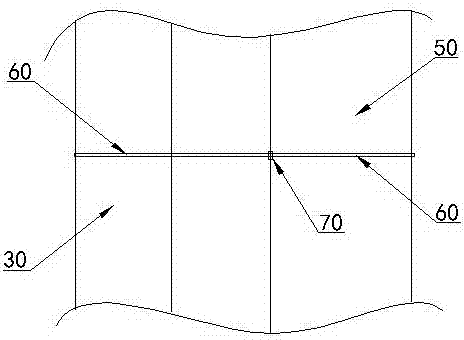

[0028] The horizontal binding step of horizontally binding the parallel-arranged high-speed elevator digital video surveillance cable and the elevator accompanying cable 50 with a binding strap; using the first cable tie 60 to horizontally bind the high-speed elevator digital video surveillance cable and the elevator accompanying cable together.

[0029] On the cable tie after horizontal binding, use the second cable tie 70 to extend into the gap between the digital video surveillance cable for high-speed elevators arranged in parallel and the elevator accompanying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com